Nanofiber membrane for water-oil emulsion separation and preparing method thereof

A nanofiber membrane and oil-water emulsion technology, which is applied in the field of preparation of nanofiber membrane materials, can solve the problems of less involvement in membrane filtration, and achieve the effects of easy industrial production, mild reaction conditions and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

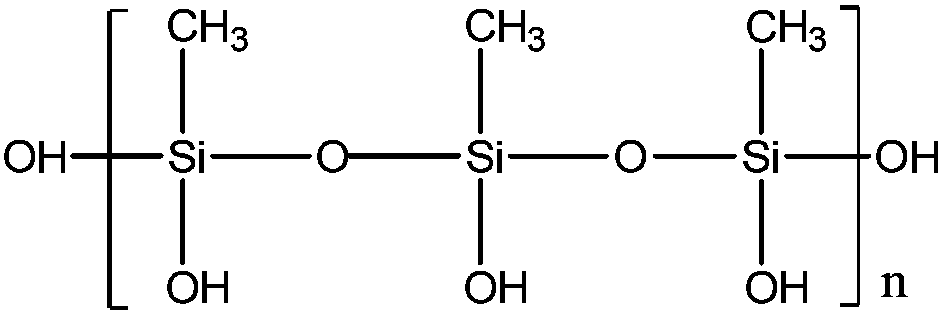

[0028] Preparation of polymethylsilicol-coated nanofiber membranes by soaking polyacrylonitrile fiber membranes in 20% potassium methylsilicate solution

[0029] (1) dissolving polyacrylonitrile in N,N-dimethylformamide solution is configured into spinning solution, the mass fraction of spinning material accounting for the total system is 12.5%, and under magnetic stirring until the solution is clear and uniform, then Let stand for 24 hours.

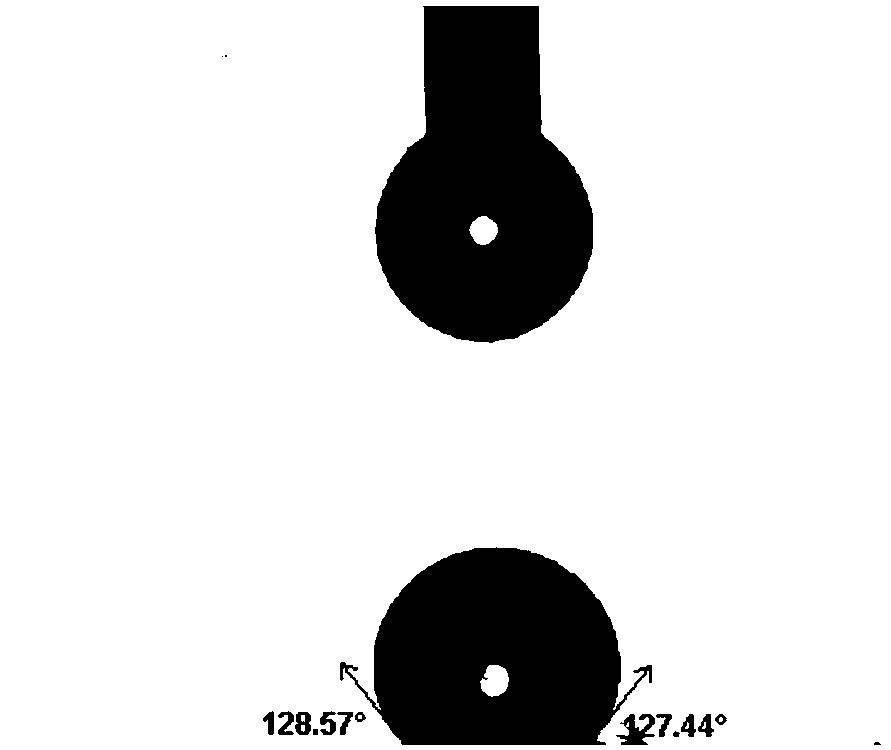

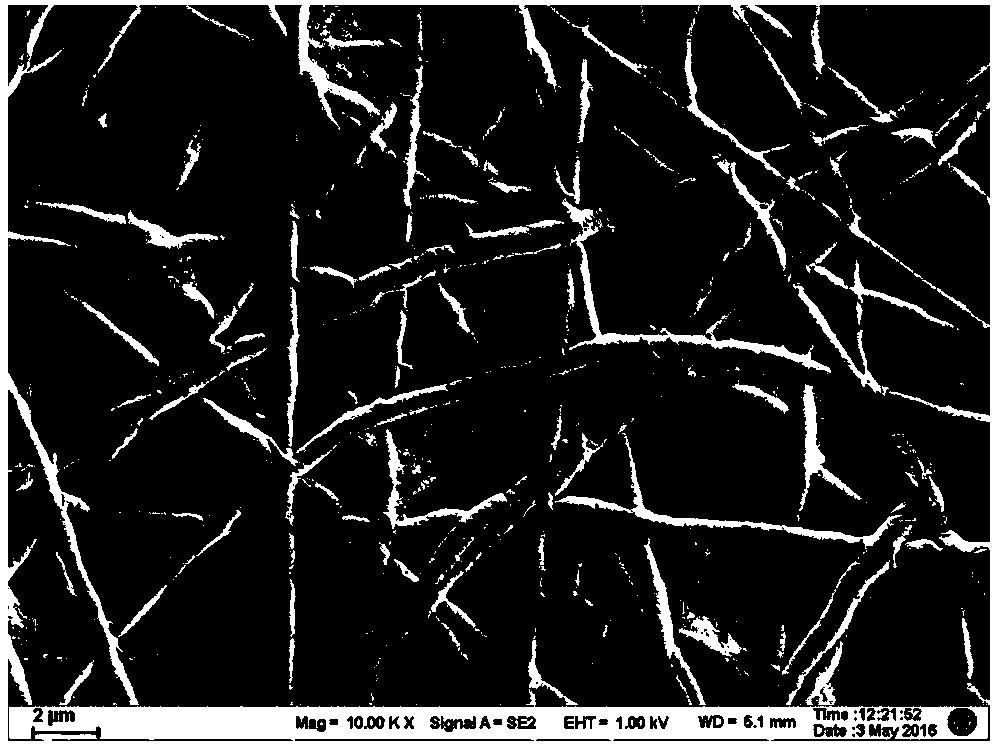

[0030] (2) Electrospinning is carried out in a self-assembled electrospinning device, electrospinning parameters: the diameter of the spinneret is 0.8mm, at a voltage of 15kV, the receiving distance is 15cm, and the electrospinning is carried out at a propulsion speed of 0.8mL / h, tin foil Paper is used for receiving, and the volume of each fiber membrane spinning solution is 0.5 mL. The collected electrospun nanofibrous membranes were dried for later use. The prepared electrospun nanofiber membrane exhibits a monodisperse state between...

Embodiment 2

[0034] Preparation of polymethylsilicic alcohol-coated nanofiber membranes by soaking polylactic acid nanofiber membranes in 10% potassium methylsilicate solution

[0035] (1) Polylactic acid is dissolved in N, N-dimethylformamide solution and is configured into a spinning solution, the mass fraction of the spinning material in the total system is 12.5%, and the solution is clear and uniform under magnetic stirring, and then statically Set for 24 hours.

[0036] (2) Electrospinning is carried out in a self-assembled electrospinning device, electrospinning parameters: the diameter of the spinneret is 0.5mm, at a voltage of 16kV, the receiving distance is 12cm, electrospinning is performed at a propulsion speed of 0.8mL / h, tin foil Paper is used for receiving, and the volume of each fiber membrane spinning solution is 0.5 mL. The collected electrospun nanofibrous membranes were dried for later use. The prepared electrospun nanofibrous membrane exhibits a monodisperse state bet...

Embodiment 3

[0040] Preparation of Polymethicon-coated Nanofiber Membrane by Soaking Chitosan Nanofiber Membrane in 30% Potassium Methylsilicate Solution

[0041] (1) dissolving chitosan in N,N-dimethylformamide solution is configured into a spinning solution, the mass fraction of the spinning material accounting for the total system is 12.5%, and under magnetic stirring until the solution is clarified and uniform, then Let stand for 24h.

[0042] (2) Electrospinning was carried out in a self-made electrospinning device, electrospinning parameters: the diameter of the spinneret needle was 0.5 mm, the receiving distance was 15 cm at a voltage of 12 kV, and the electrospinning was carried out at a propulsion speed of 1.0 mL / h. The fibers were spun onto tin foil paper, and the volume of each fiber membrane spinning solution was 0.5 mL. The collected electrospun nanofibrous membranes were dried for later use. The prepared electrospun nanofibrous membrane exhibits a monodisperse state between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com