Patents

Literature

318 results about "Oil water emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

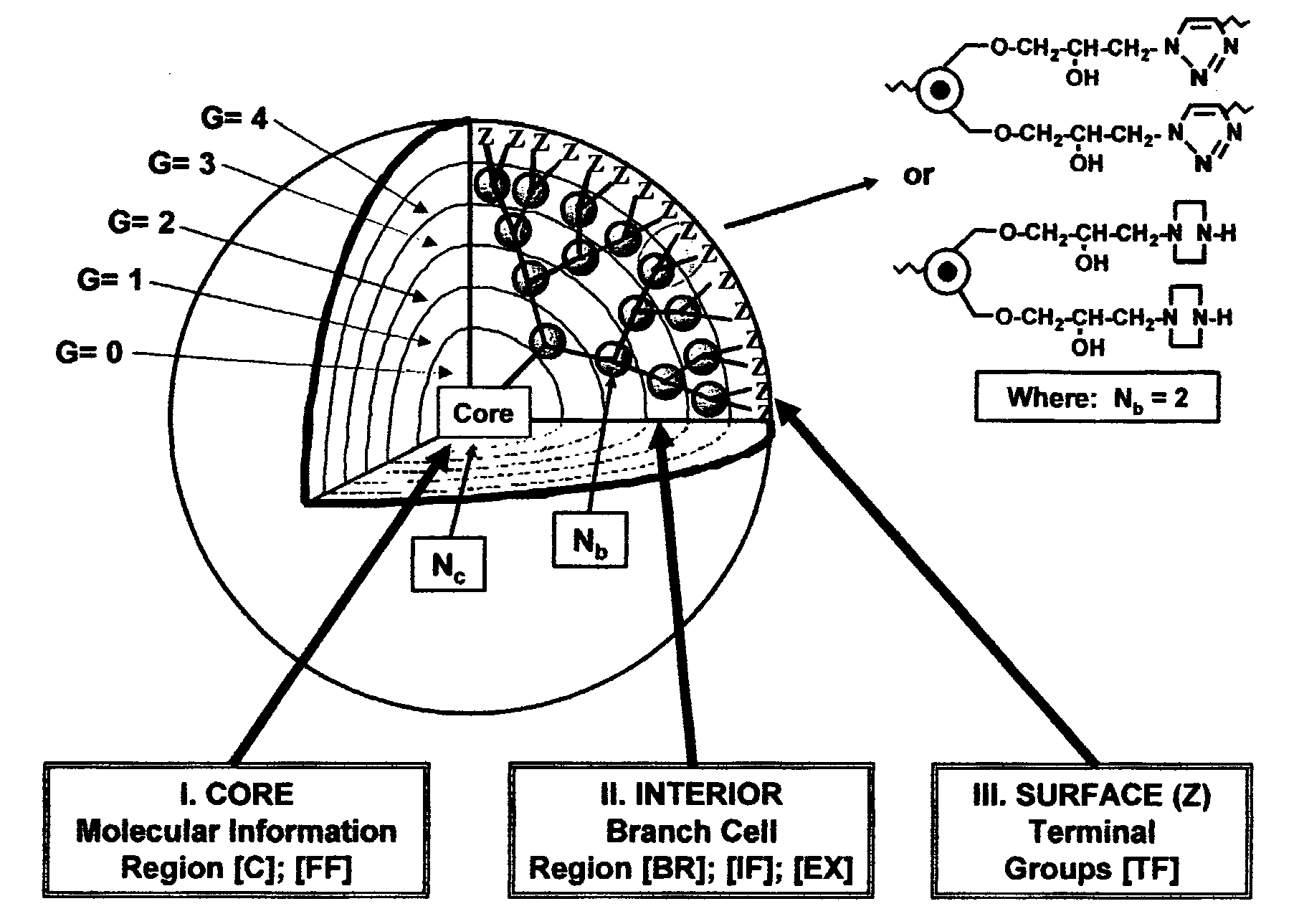

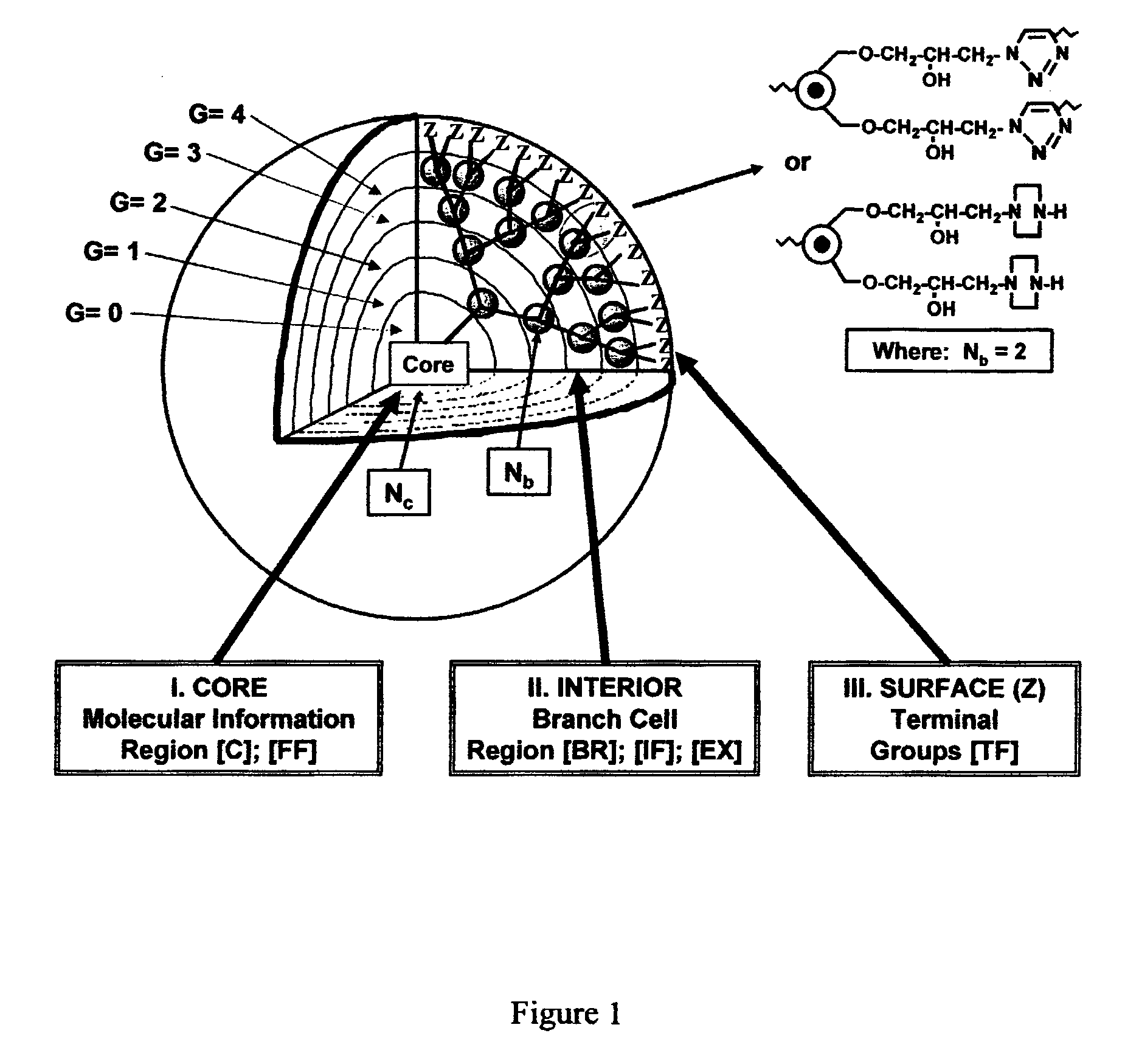

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

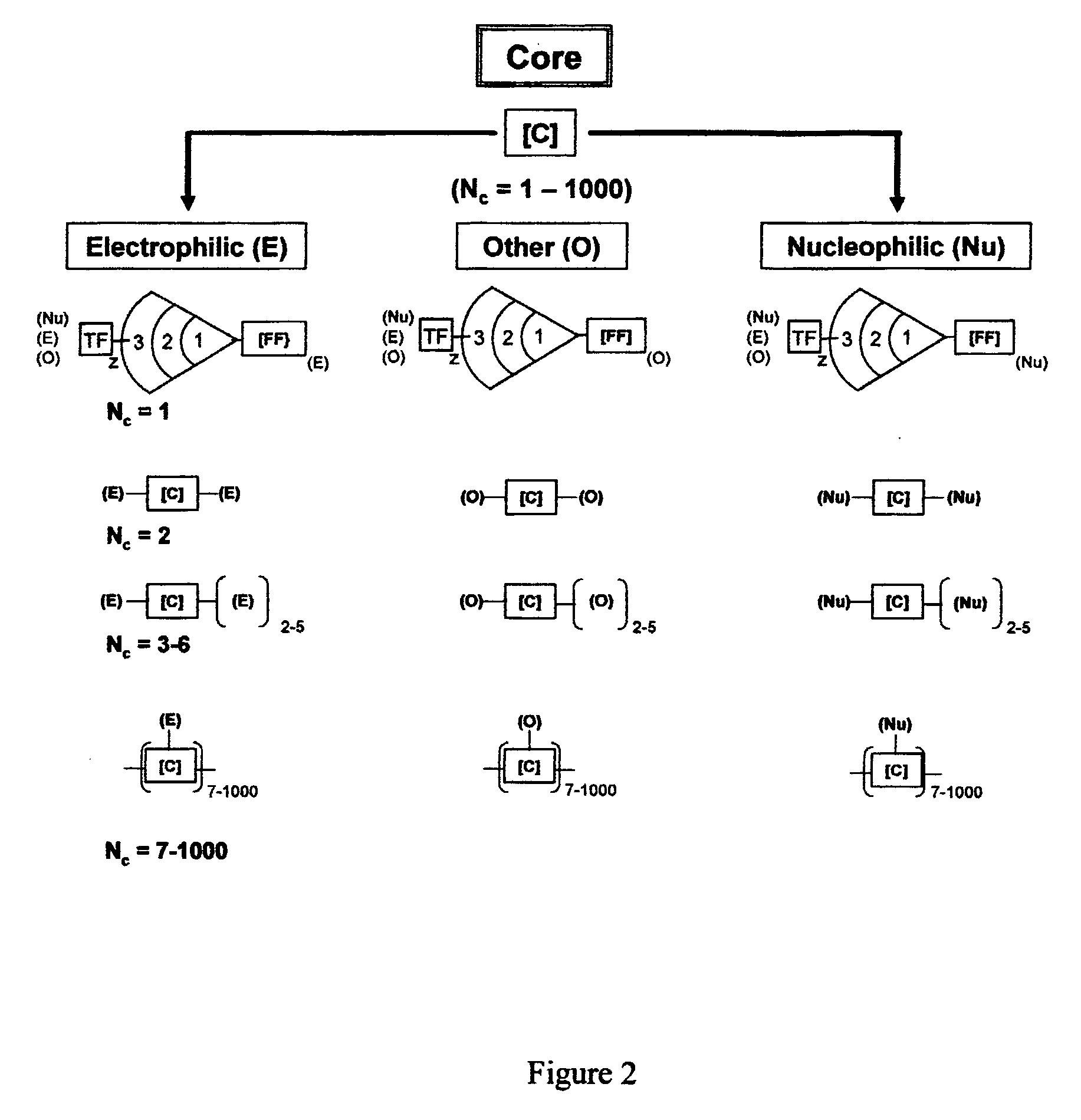

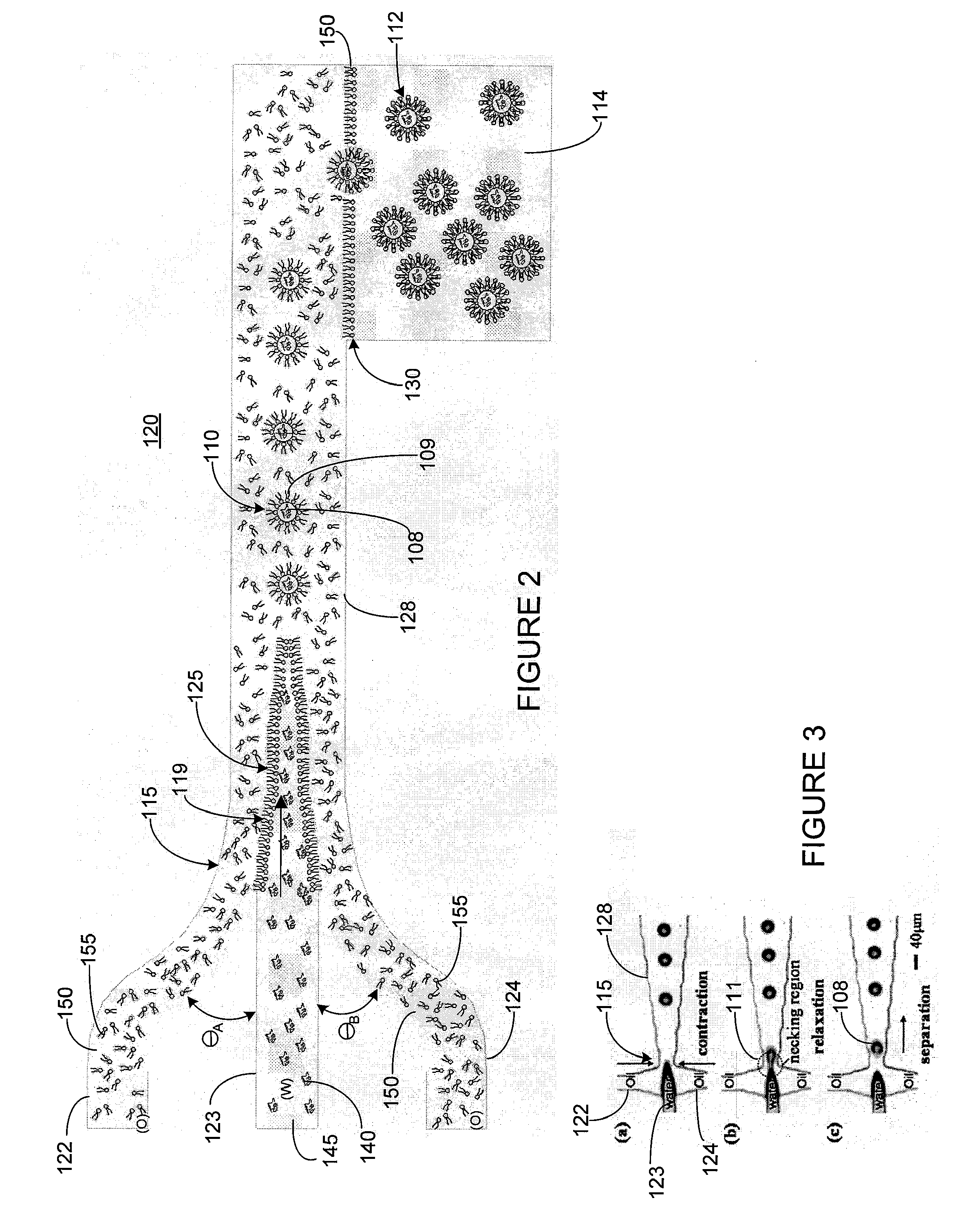

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS20050032240A1Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

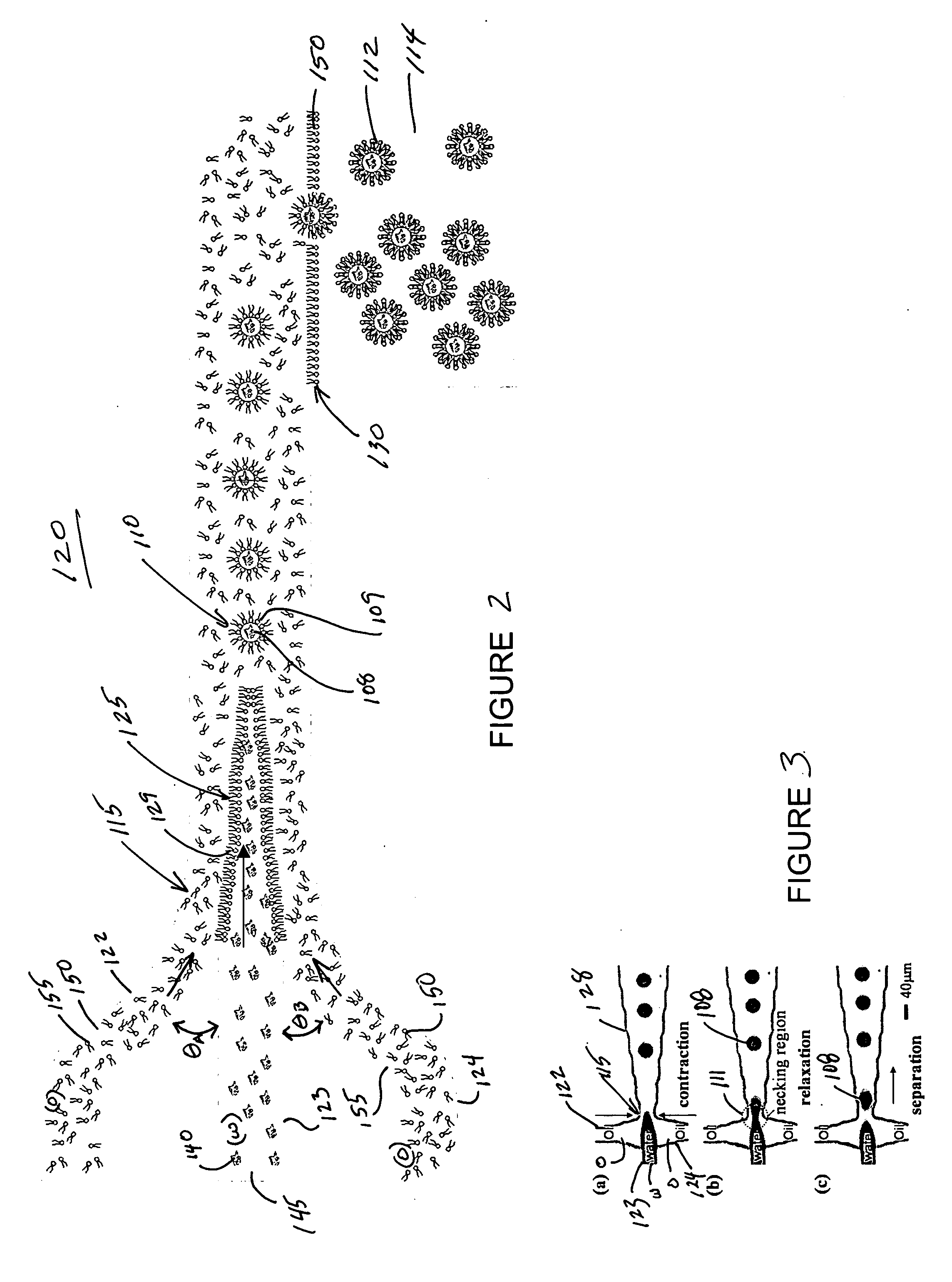

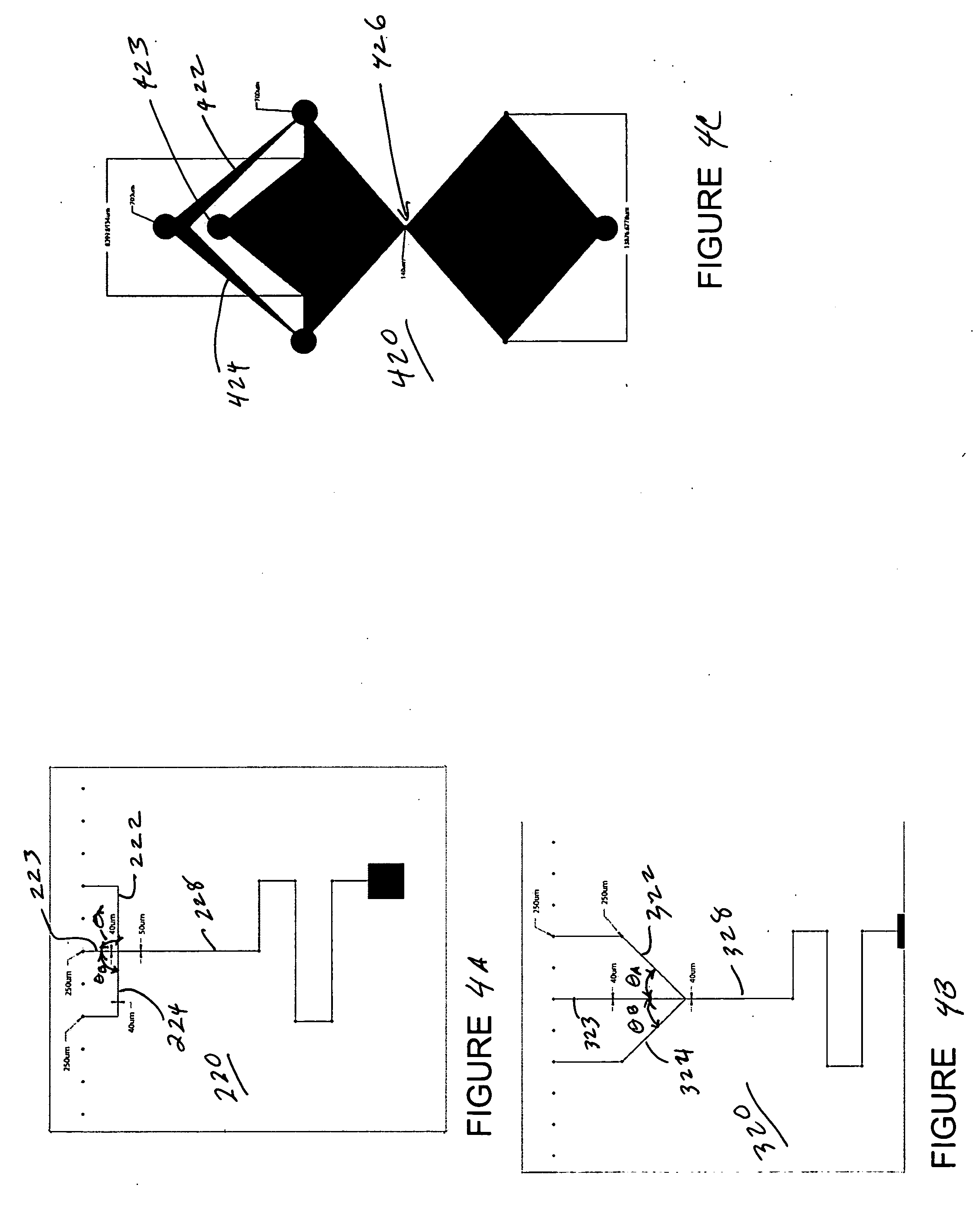

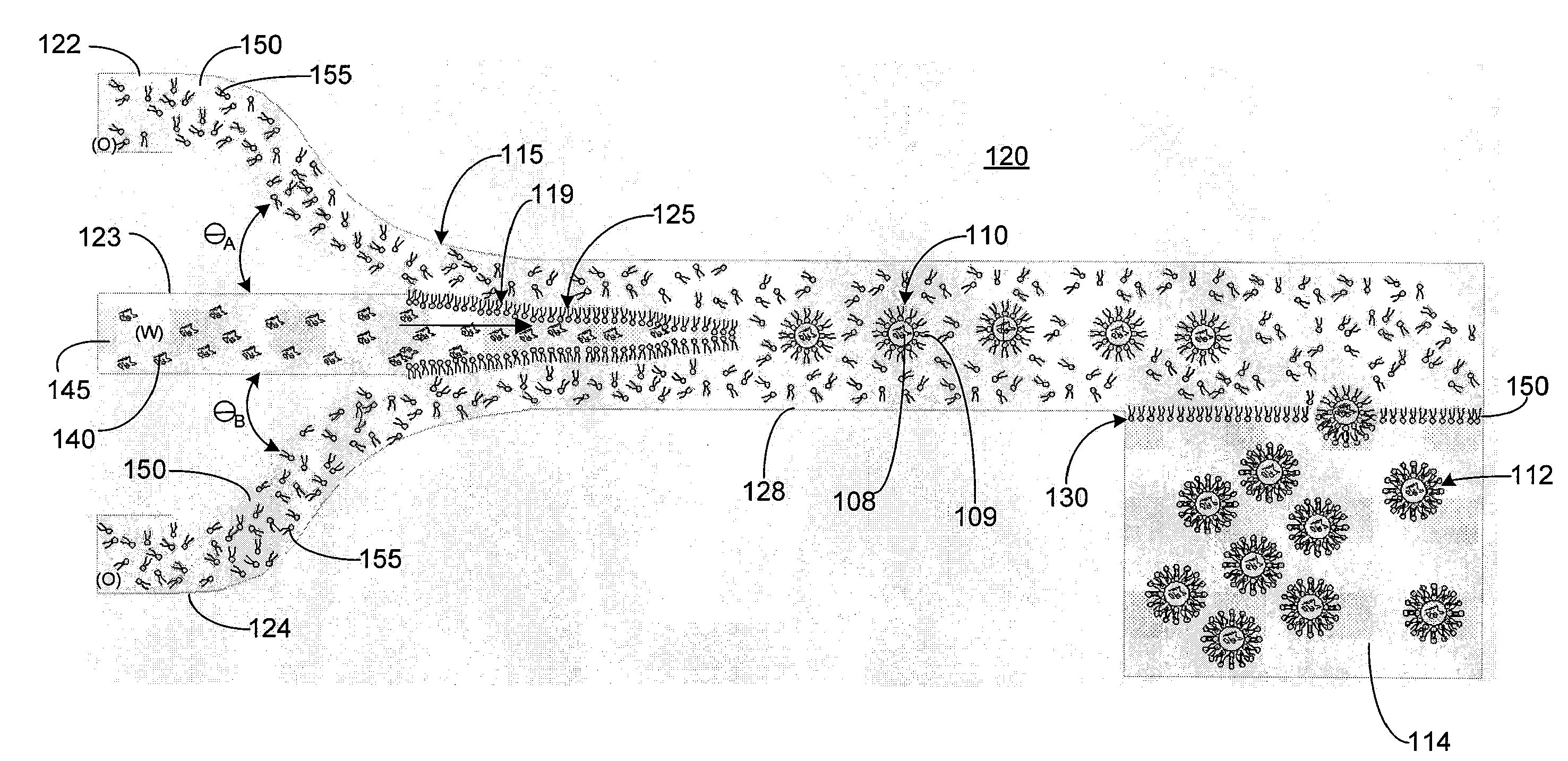

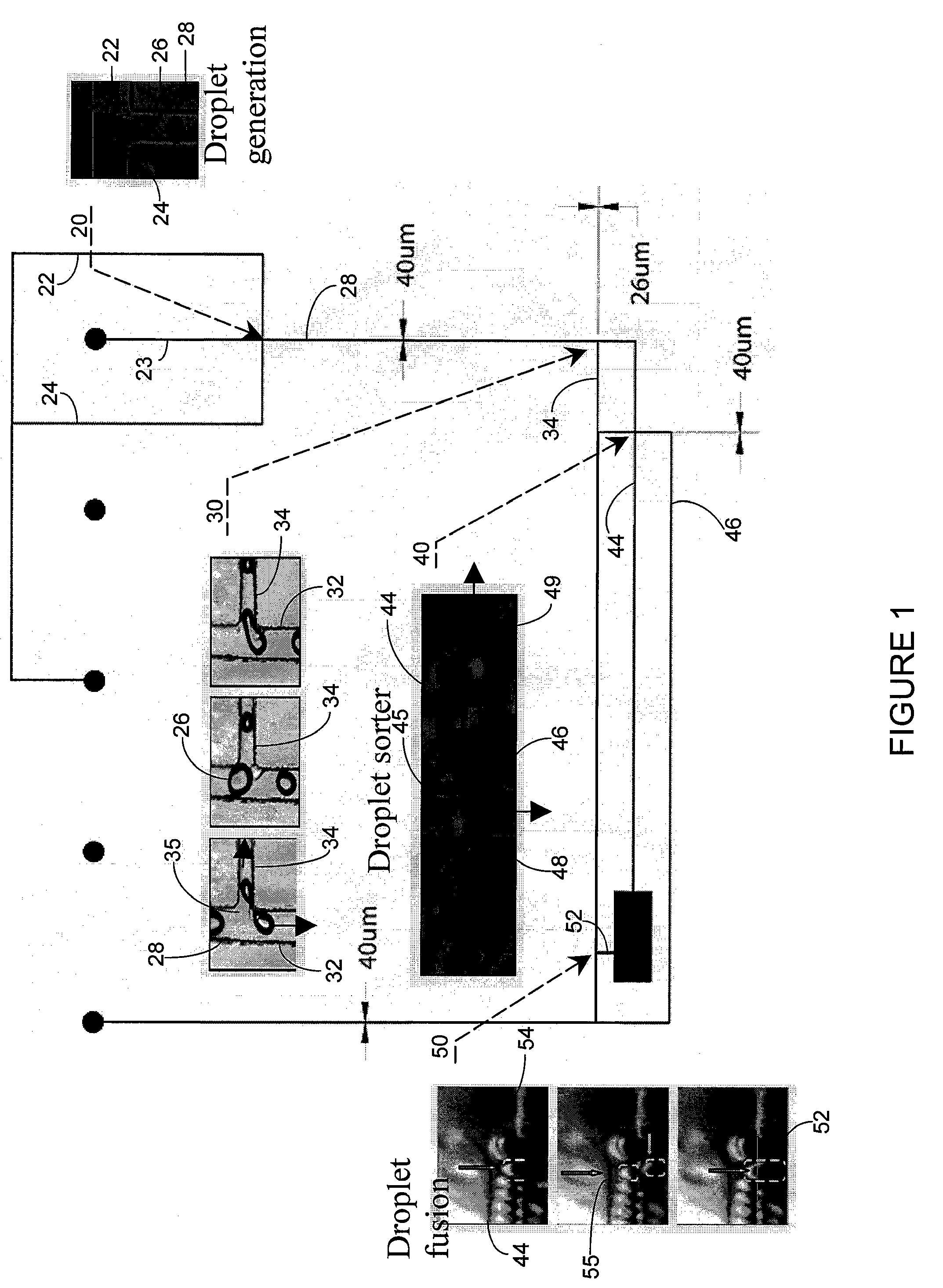

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS7595195B2Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

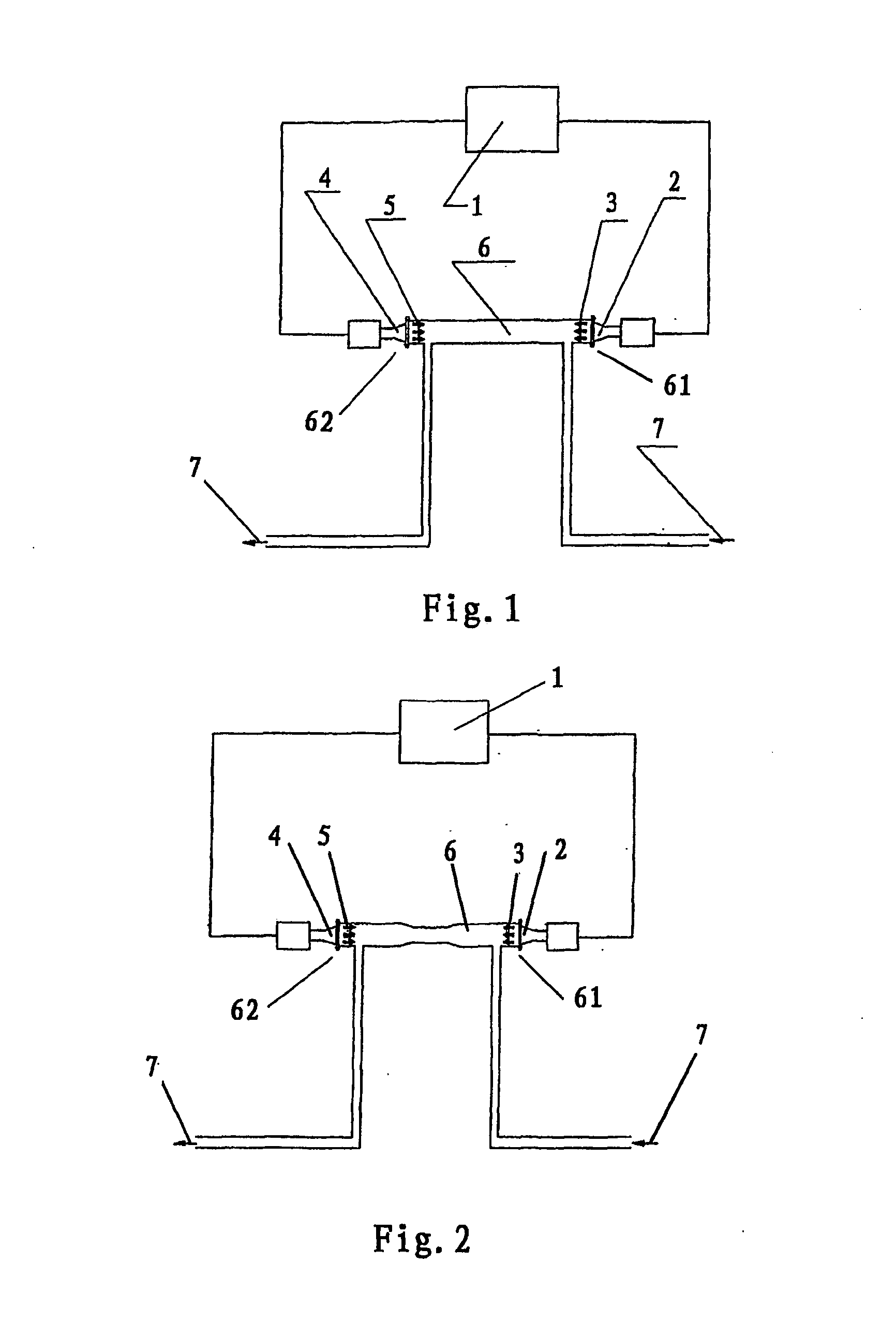

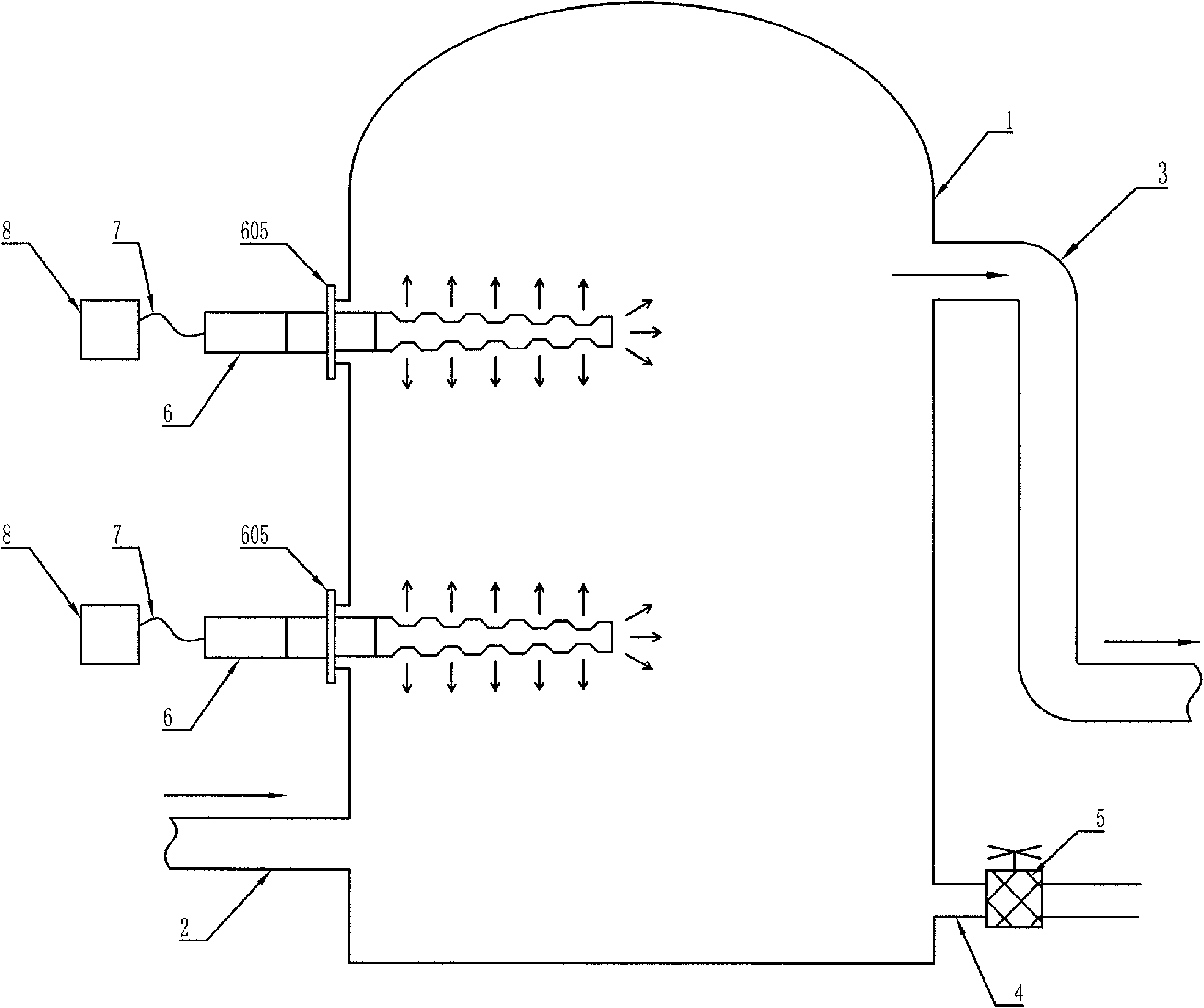

Method and Apparatus for Demulsifying an Oil-Water Emulsion Via Ultrasonic

ActiveUS20070272618A1Good effectExtension of timeDewatering/demulsification with mechanical meansLiquid separation by electricityUltrasound - actionOil water emulsion

A method for demulsifying water-oil emulsions through ultrasonic action, comprises a step of making the water-oil emulsions flow through at least one ultrasonic acting region in a flow direction, wherein: within the ultrasonic acting region, a concurrent ultrasonic wave whose traveling direction is the same as the flow direction of the water-oil emulsions is generated by at least a one first ultrasonic transducer provided at the upstream end of the ultrasonic acting region, and at same time, a countercurrent ultrasonic wave whose traveling direction is opposite to the flow direction of the water-oil emulsions is generated by at least a one second ultrasonic transducer provided at the downstream end of the ultrasonic acting region; and the concurrent ultrasonic wave and the countercurrent ultrasonic wave act simultaneously on the water-oil emulsions which flow through the ultrasonic acting region, so as to demulsify the water-oil emulsions. After being demulsified, the water-oil emulsions gravity settle and separate, or settle and separate under an electric field, so as to be dewatered. The present invention can apply to various water-oil separating technologies in the procedures from mining to processing of crude oil.

Owner:CHINA PETROCHEMICAL CORP

Preparation method and application of ultra-hydrophobic and ultra-lipophilic paper-based separating material

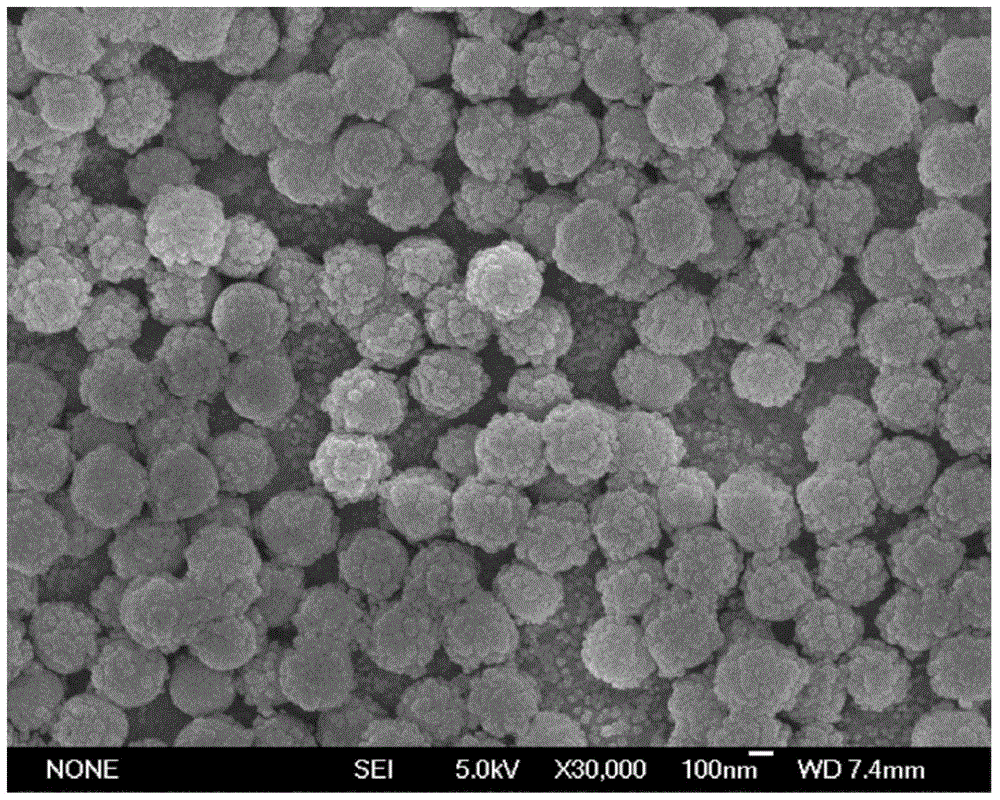

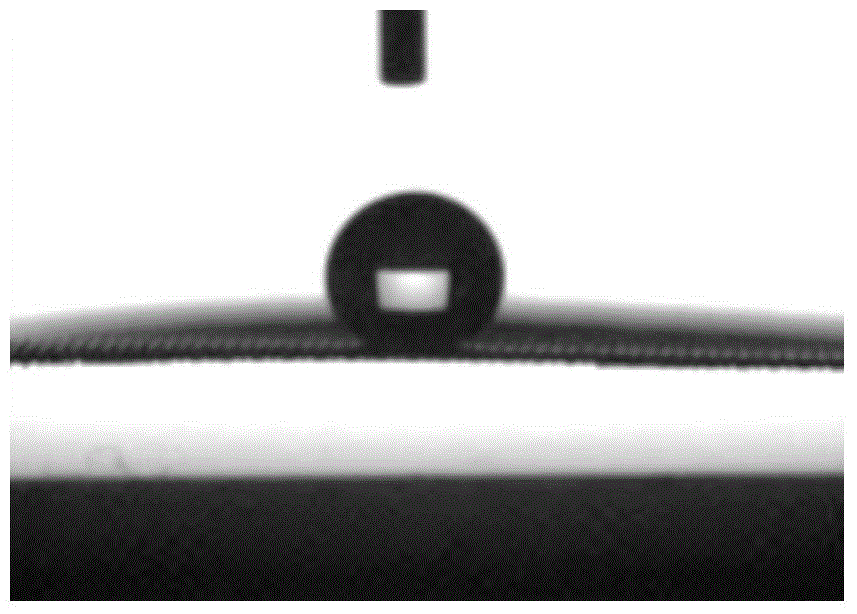

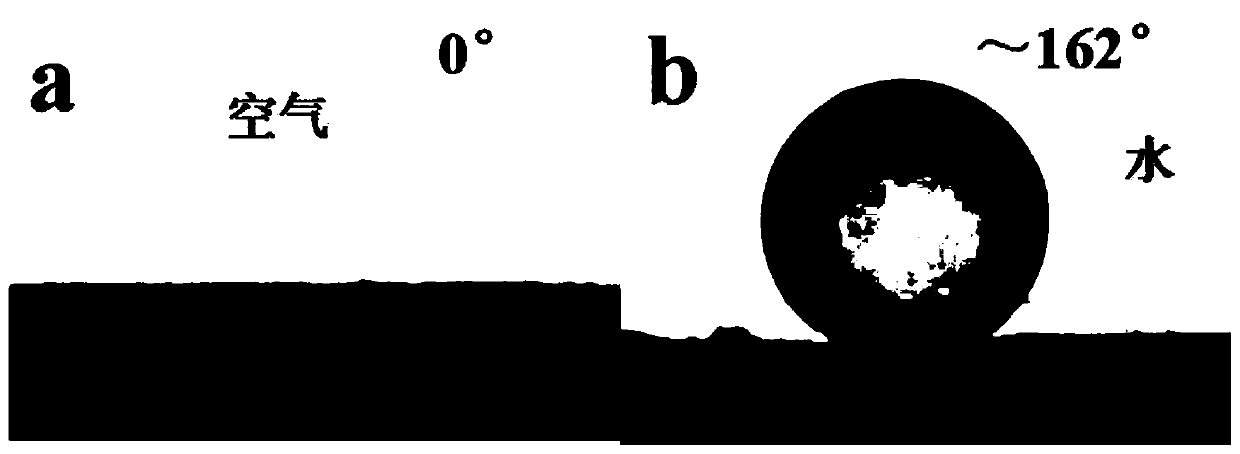

InactiveCN102225273AImprove permeabilityReduce pollutionFiltration separationLiquid separationOil water emulsionSilicon dioxide

The invention relates to a preparation method and an application of an ultra-hydrophobic and ultra-lipophilic paper-based separating material. The preparation method comprises that: (1) a sol solution of silicon dioxide nano-particles with a particle size of 24 to 36nm is prepared with existing technologies; (2) the solution is modified with a silanizing reagent; (3) a piece of filter paper is immersed in the modified nano-particle solution for 10 to 20 seconds, and is naturally dried, such that an ultra-hydrophobic and ultra-lipophilic paper-based separating material is obtained. The surfaceof the material possesses micron-sized apertures. The contact angle between the separating material and the water surface is larger than 150 DEG. The material has a good ultra-hydrophobic performance, and is acid resistant and organic solvent resistant. The material can be used repeatedly, and can be used for absorbing oil stains floated on water surfaces. The material brings an excellent separating effect to oil-water mixtures, especially oil-water emulsion with high viscosity, and has wide application prospect in industrial oil-water separation and water area oil stain cleaning. According to the present invention, the preparation technology is simple, the requirement for equipment is low, the preparation condition is not restricted by region differences, and mass industrial production can be realized easily.

Owner:HUNAN NORMAL UNIVERSITY

Ethylene device quench oil viscosity reductant

InactiveCN101062880AEasy to useDoes not cause emulsificationHydrocarbon purification/separationHydrocarbonsVisbreakerLiquid viscosity

The invention discloses an ethylene device quench oil viscosity reductant in inhibiting liquid viscosity intensification technical domain, which is characterized by the following: comprising with inhibitor, disperser and metal deactivator; possessing the function of aggregation inhibition, aggregation prevention and metallic surface deactivation; decreasing erosion and incrustation of quench system device; possessing little adding quantity and good stability; non-generating side effect of oil water emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

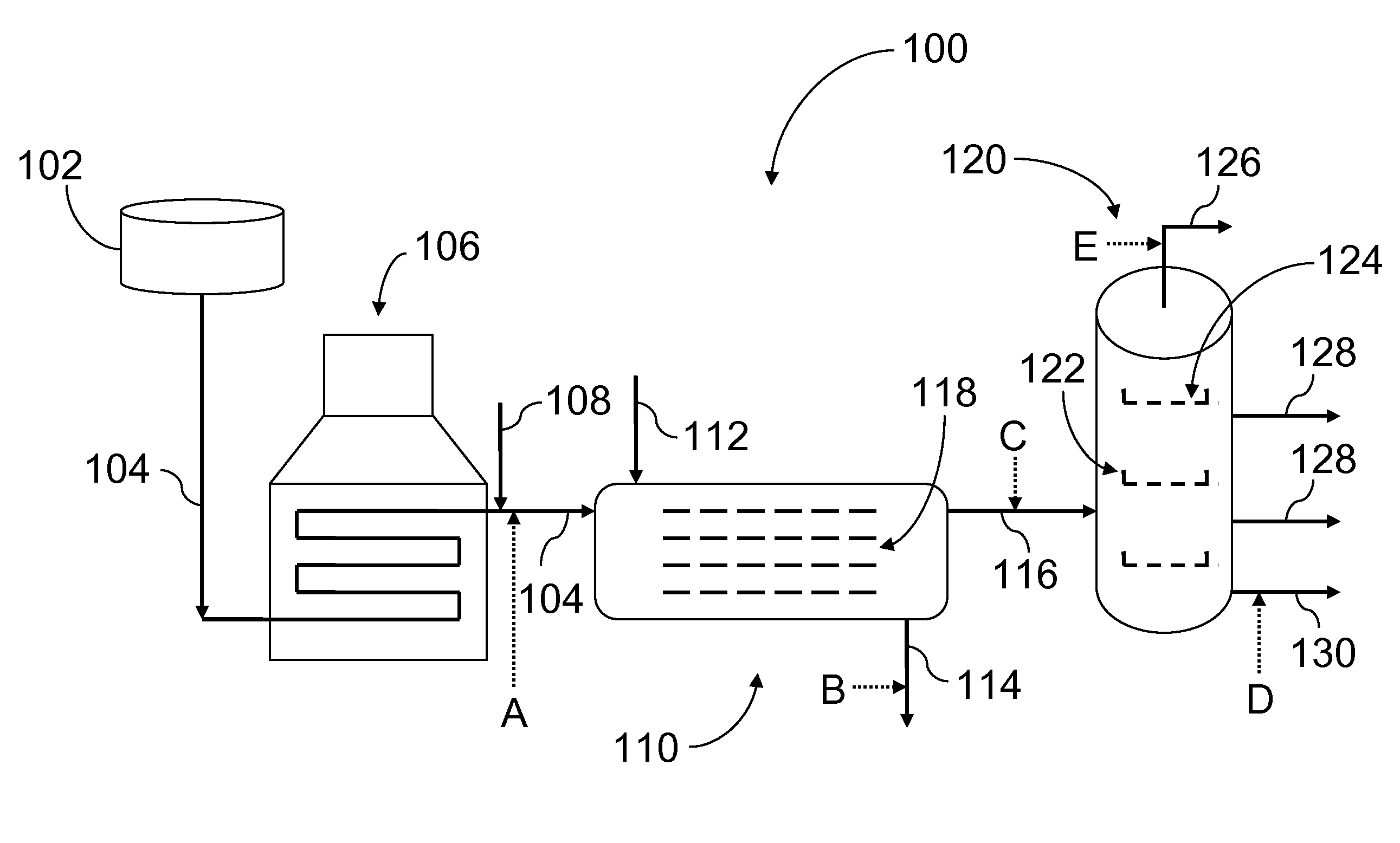

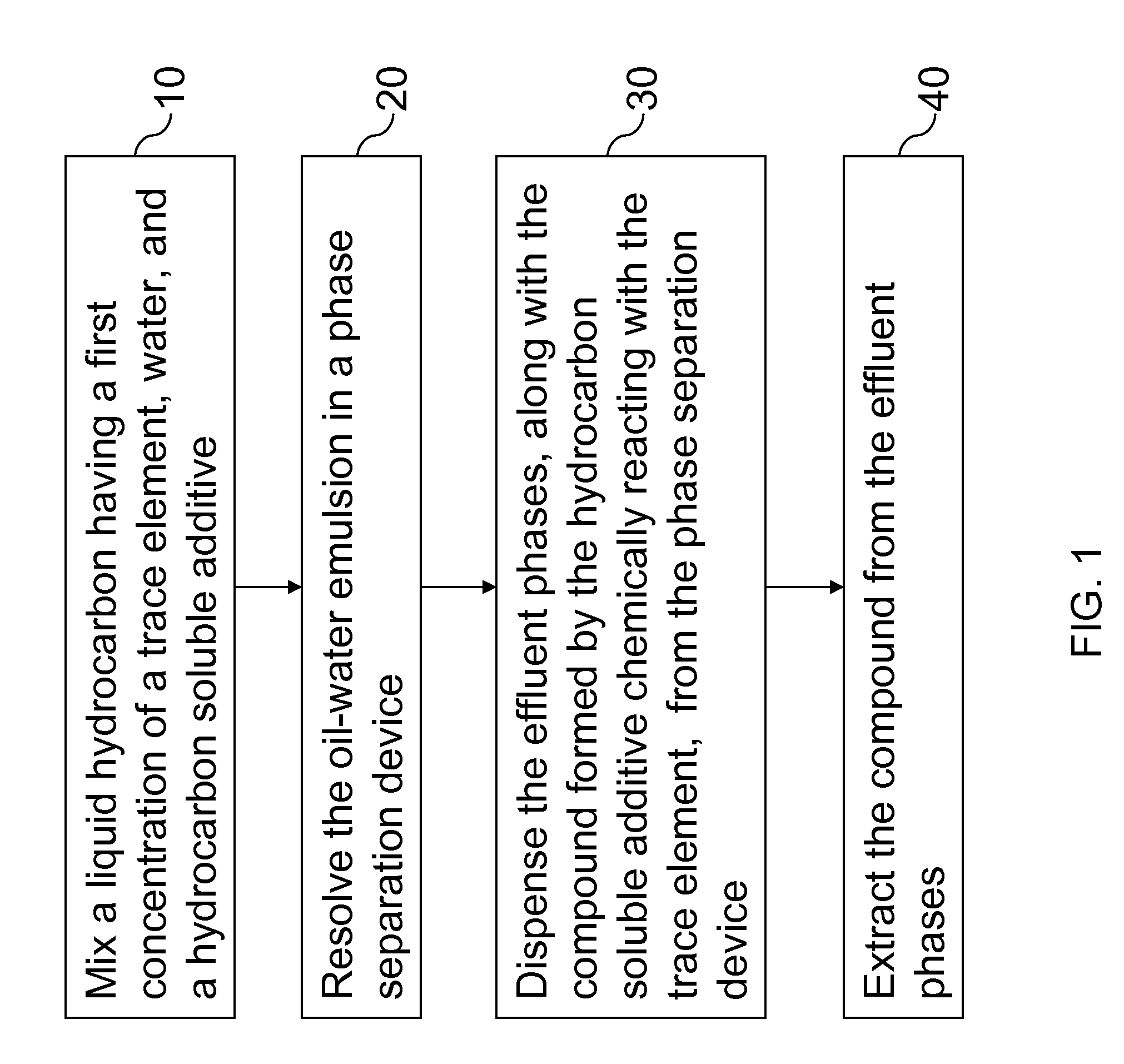

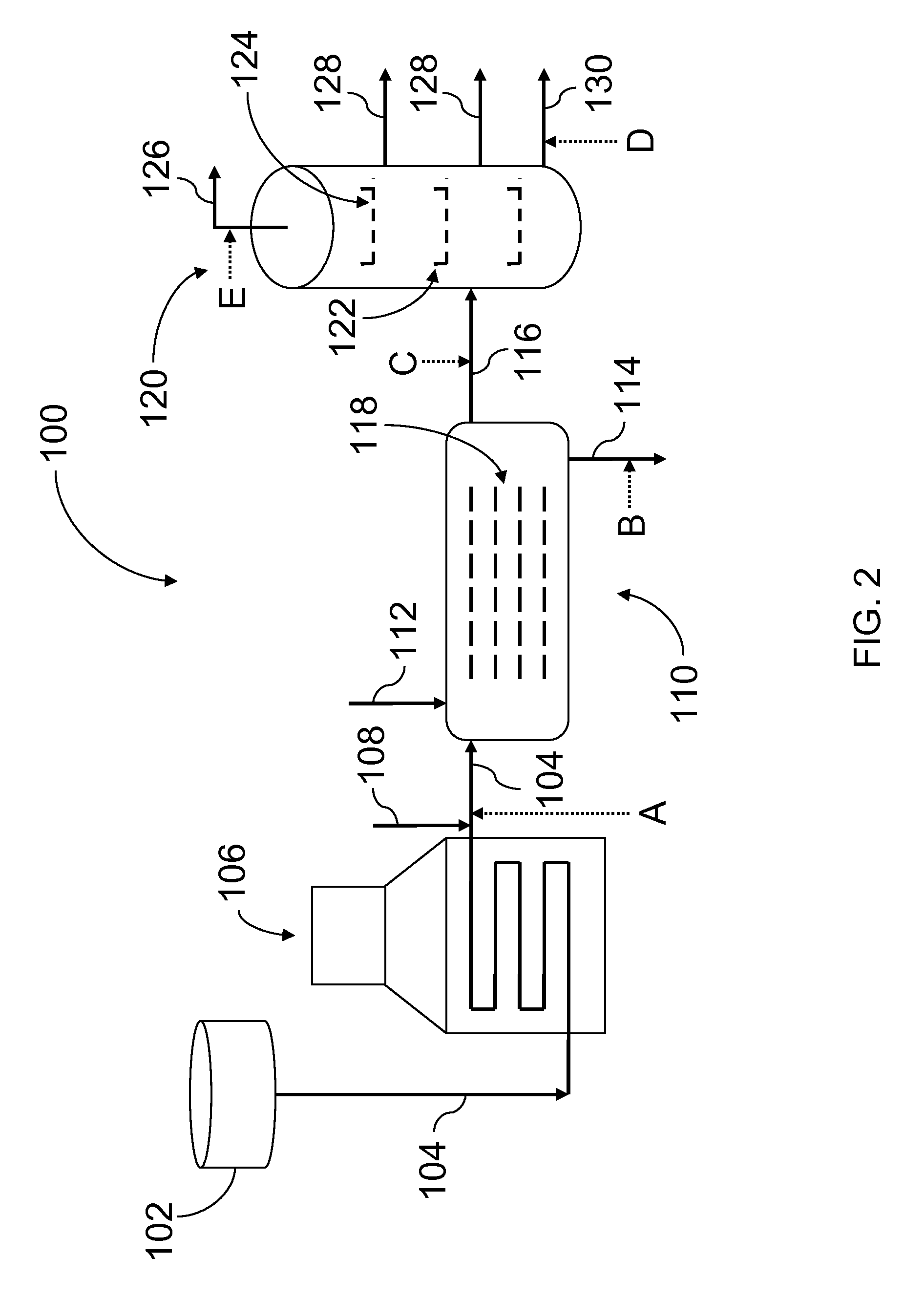

System and method for separating a trace element from a liquid hydrocarbon feed

InactiveUS20100000910A1Easy to removeEasy to separateTransportation and packagingRefining by water treatmentChemical reactionTrace element

The present invention is generally directed to removing a trace element from a liquid hydrocarbon feed. The liquid hydrocarbon feed, containing the trace element, is mixed with the water along with a hydrocarbon-soluble additive. While being mixed, a compound, which in some cases is preferably insoluble, is formed by the hydrocarbon-soluble additive chemically reacting with the trace element. A phase separation device, such as a desalter or an oil-water separator, receives the oil-water emulsion containing the compound and resolves the mixture to produce the compound, effluent brine, and effluent liquid hydrocarbon with a reduced concentration of the trace element as compared to the liquid hydrocarbon feed. In some embodiments, the present invention is directed to removing elemental mercury from a liquid hydrocarbon feed. A hydrocarbon-soluble sulfur-containing additive, typically an organic polysulfide, is mixed with the liquid hydrocarbon feed and water. The hydrocarbon-soluble, sulfur-containing additive reacts with the mercury, rapidly forming an agglomeration of mercuric sulfide which is then dispensed with the effluent brine or the effluent liquid hydrocarbon.

Owner:CHEVROU USA INC

Preparation method for microporous membrane having multi-scale gradient micro-structure surface

ActiveCN103611437APlay the role of inner support reinforcementControllable areaSemi-permeable membranesMicro structureUltrafiltration

The present invention relates to a preparation method for a microporous membrane having a multi-scale gradient micro-structure surface. The method comprises: fixing a screen mesh on the upper surface of a rough flexible substrate, coating a polymer solution layer with a thickness of 50-500 mum on the upper surface of the screen mesh at a constant speed, curing, washing, and carrying out simple mechanical peeling to remove the rough flexible substrate to obtain the microporous membrane having the multi-scale gradient micro-structure surface. According to the present invention, the process of the method is simple, the membrane area can be controlled, continuous production can be achieved, mechanical properties of the membrane are high, and the membrane has super-hydrophobic or super-hydrophilic property, wherein the super-hydrophobic membrane has super-lipophilic property, and the super-hydrophilic membrane has super-oleophobic property under water and has super-hydrophobic property under oil; and the obtained membrane can be adopted to effectively separate various oil and water mixtures including nano-scale oil water emulsions, and can further be used in fields of self-cleaning ultrafiltration / microfiltration membrane sewage treatments, medical sterilization, food turbidity removal, sterilization, material separation, membrane distillation, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for demulsifying

InactiveUS20070299143A1Easy to separateDemulsifying emulsionDewatering/demulsification with chemical meansOther chemical processesPolymer scienceOil water emulsion

The invention relates to a method for separating emulsions of oil and water, the method comprising incorporating a demulsifying-effective amount of a silicone demulsifier into an emulsion comprising an oil phase and an aqueous phase, the silicone demulsifier having a molecular structure comprising a polysiloxane backbone of at least two siloxane units covalently bound to (i) one or more alkylene oxide groups comprising one or more alkylene oxide units independently having one to five carbon atoms, and (ii) one or more oxirane-containing and / or oxetane-containing groups, wherein said oxirane or oxetane is optionally ring-opened by reaction with a chemical or group capable of ring-opening an oxirane or oxetane ring, respectively, and wherein a solid filler is substantially excluded from the silicone demulsifier and emulsion. The invention also relates to compositions containing the above-described demulsifier and the water and oil phases of an emulsion.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

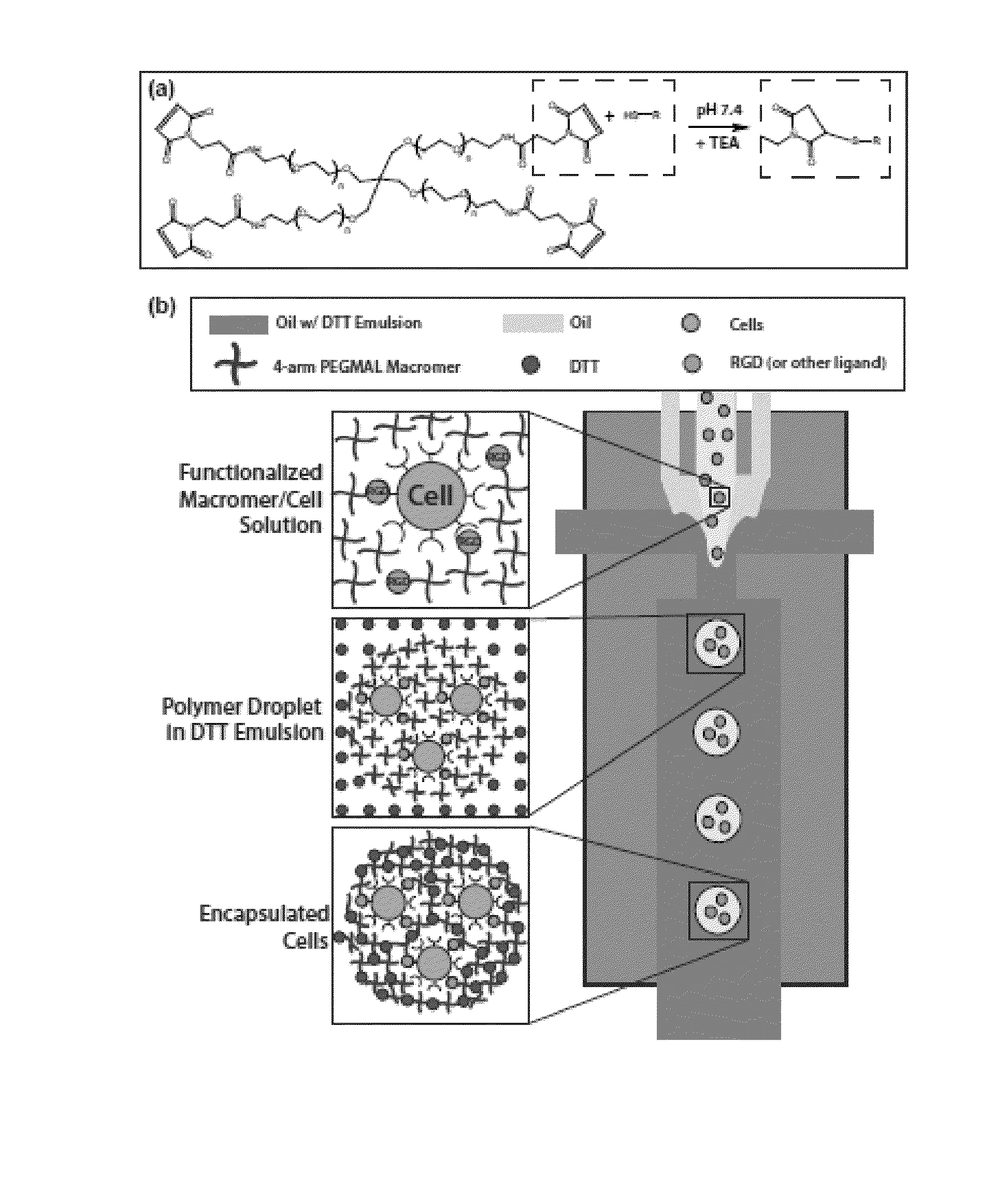

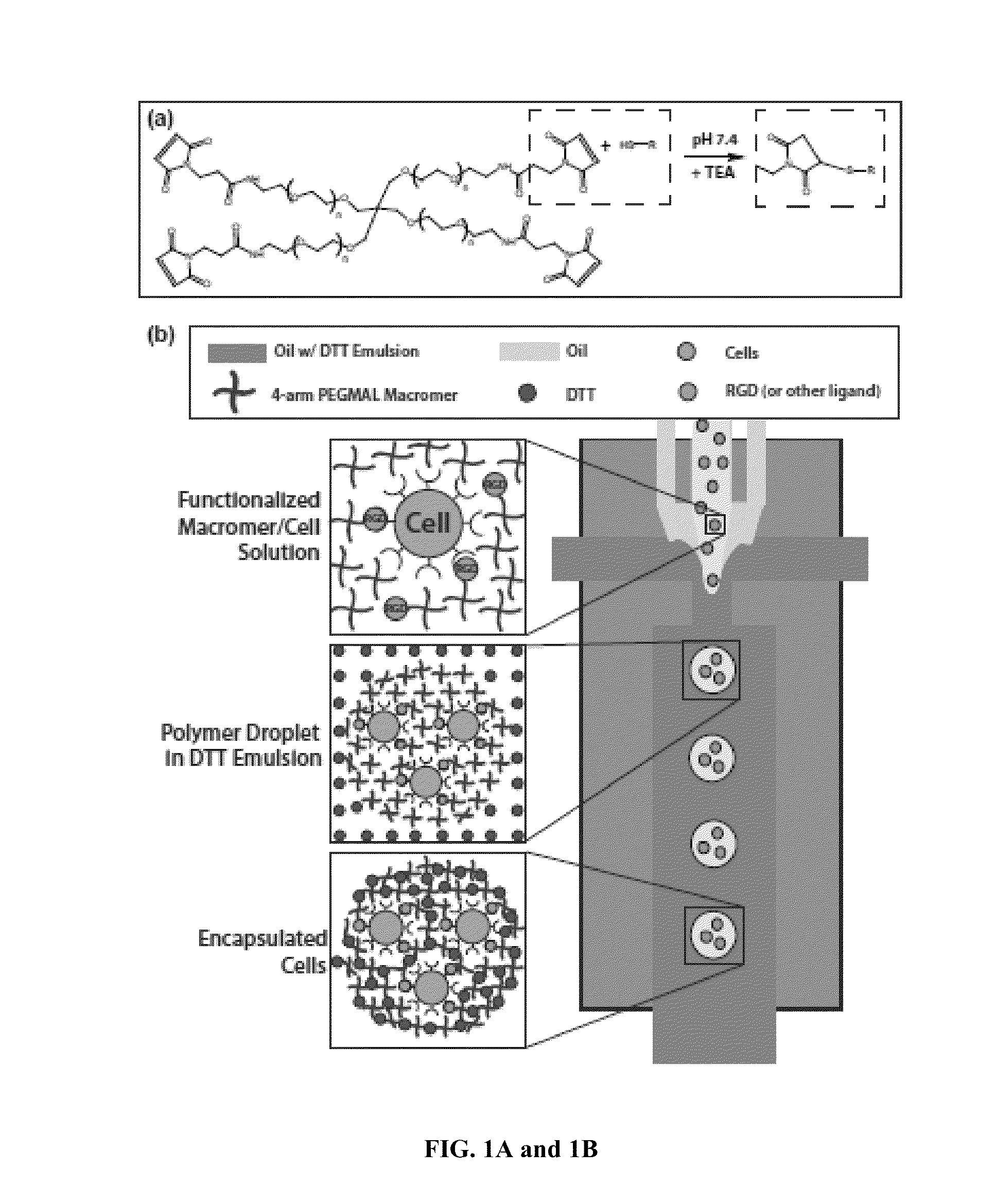

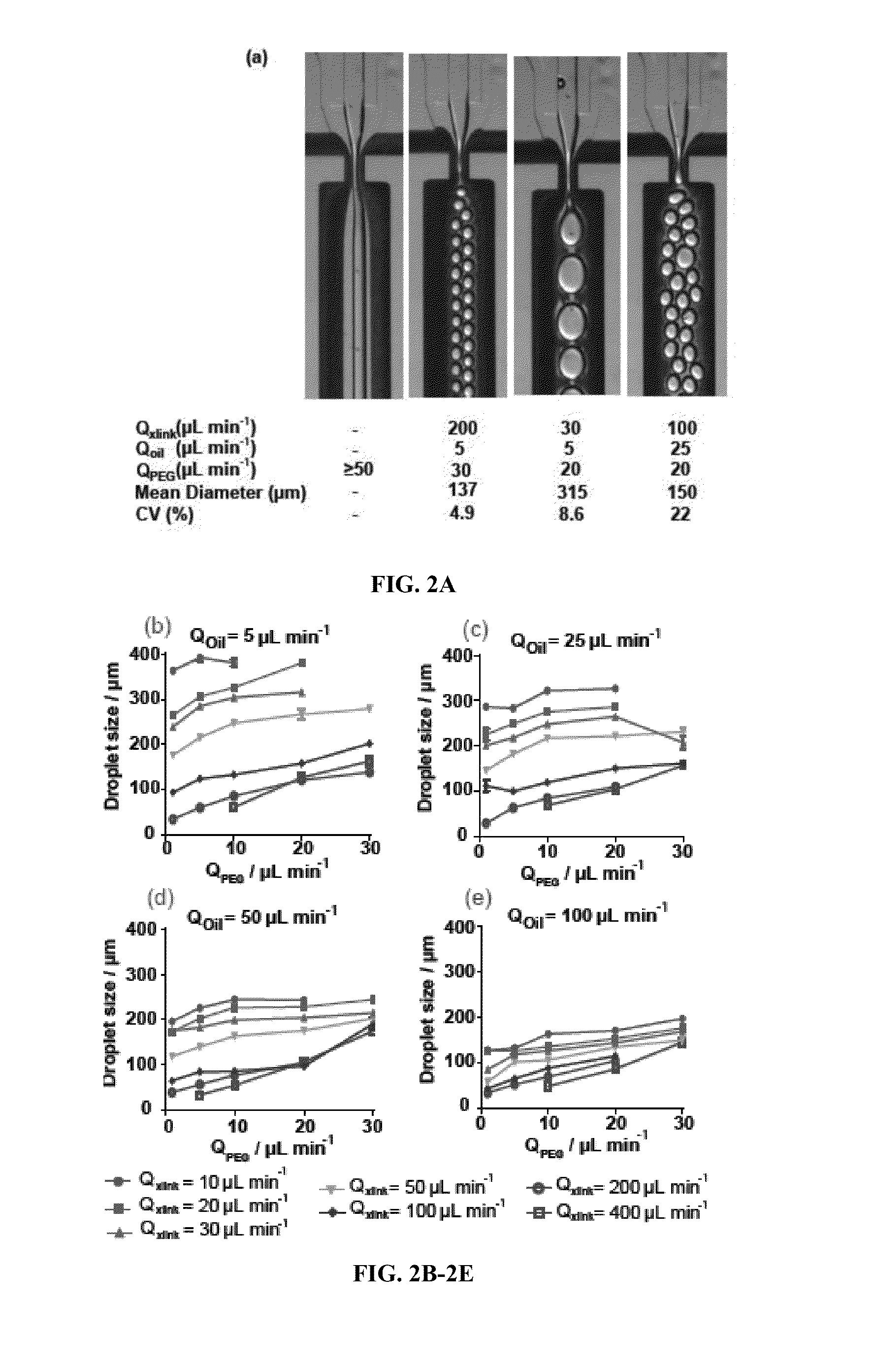

Microgels for Encapsulation of Cells and Other Biologic Agents

ActiveUS20150071997A1Increase cell adhesionConducive to survivalBiocidePeptide/protein ingredientsOil water emulsionOil phase

Methods of encapsulating cargo in a microgel droplet, microgel droplets prepared according the provided methods, and methods of use thereof are disclosed. The methods of preparing cargo-encapsulated microgels generally include flowing through a flow-focusing nozzle of a microfluidic device a macromer phase, an oil phase, and a crosslinker phase to form microgel droplets by oil-water emulsion. The phases are pumped, injected, or flowed through the microfluidic device such that as the macromer phase approaches the flow focusing nozzle, the co-flowing oil phase shields the macromer from contact with the crosslinker phase until flow instability occurs and macromer phase droplets form. After flow instability occurs, the crosslinker diffuses from the crosslinker phase into the droplets in an effective amount to covalently crosslink the macromer into a microgel network encapsulating the cargo in the crosslinked macromer. Microgels prepared according to the disclosed methods and methods of use thereof are also provided.

Owner:GEORGIA TECH RES CORP

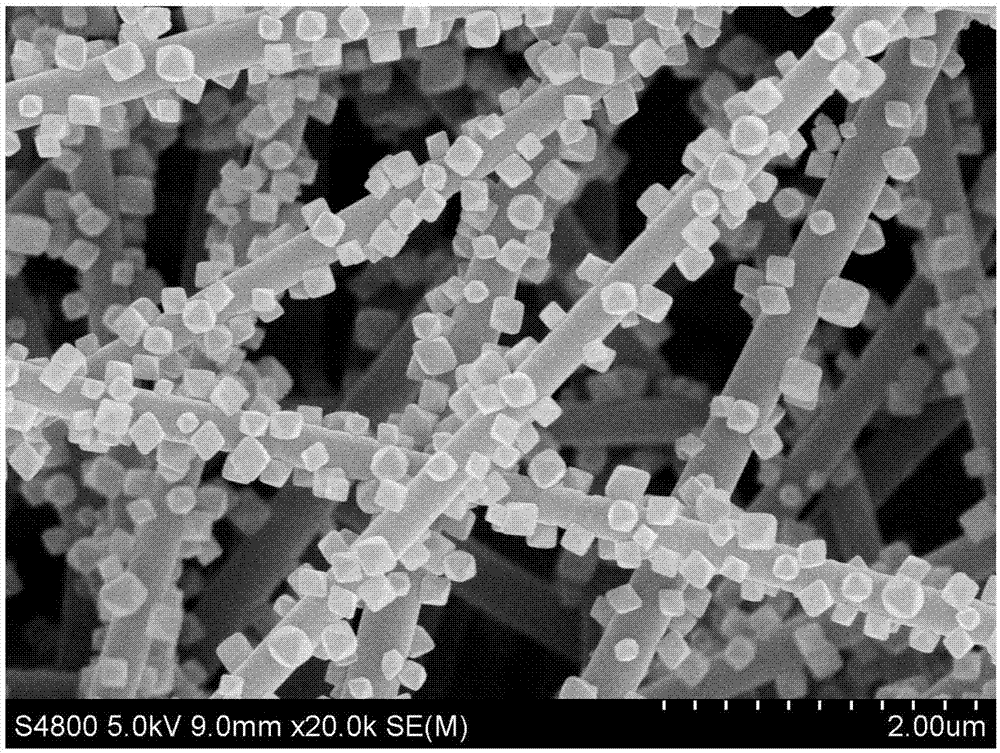

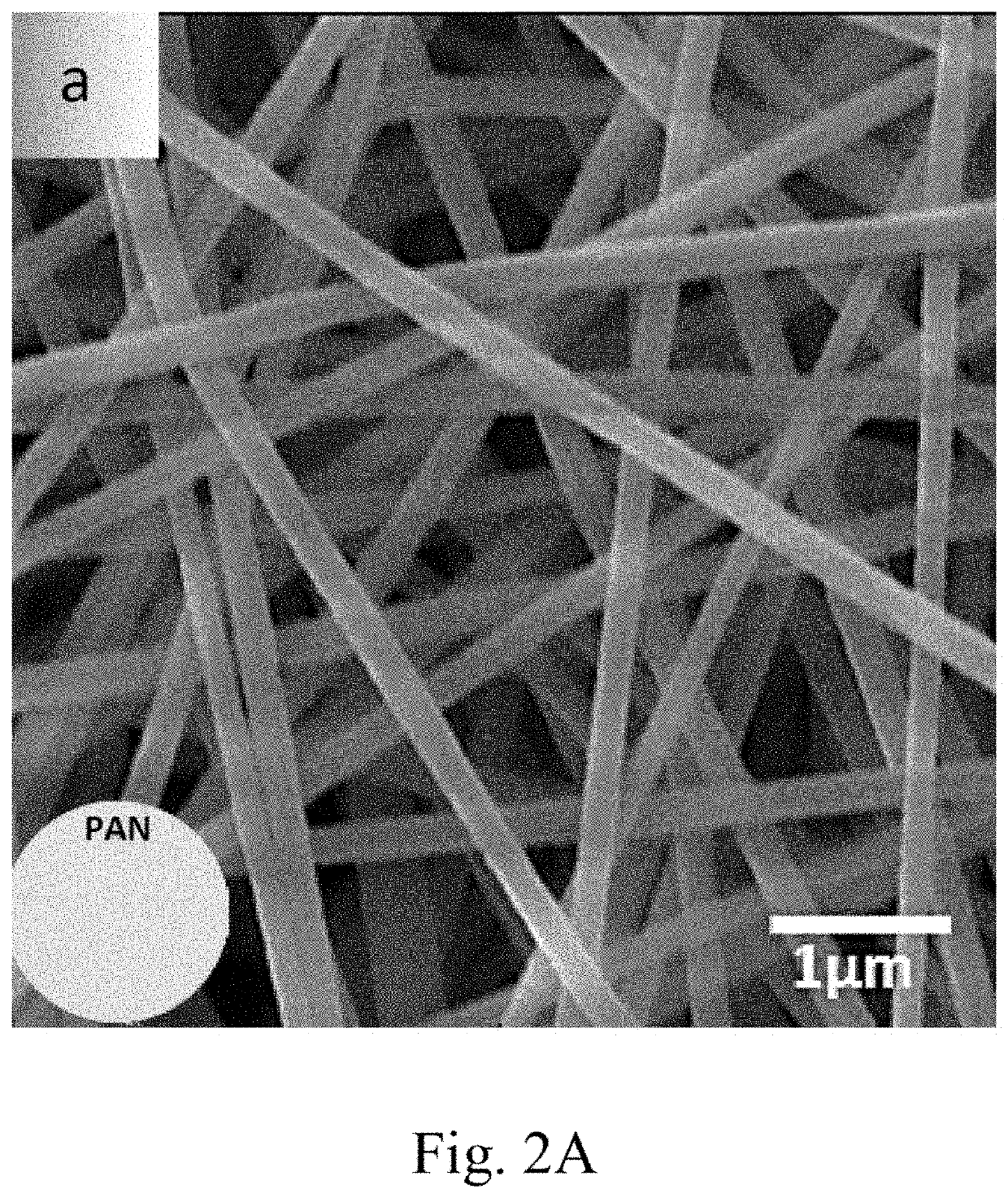

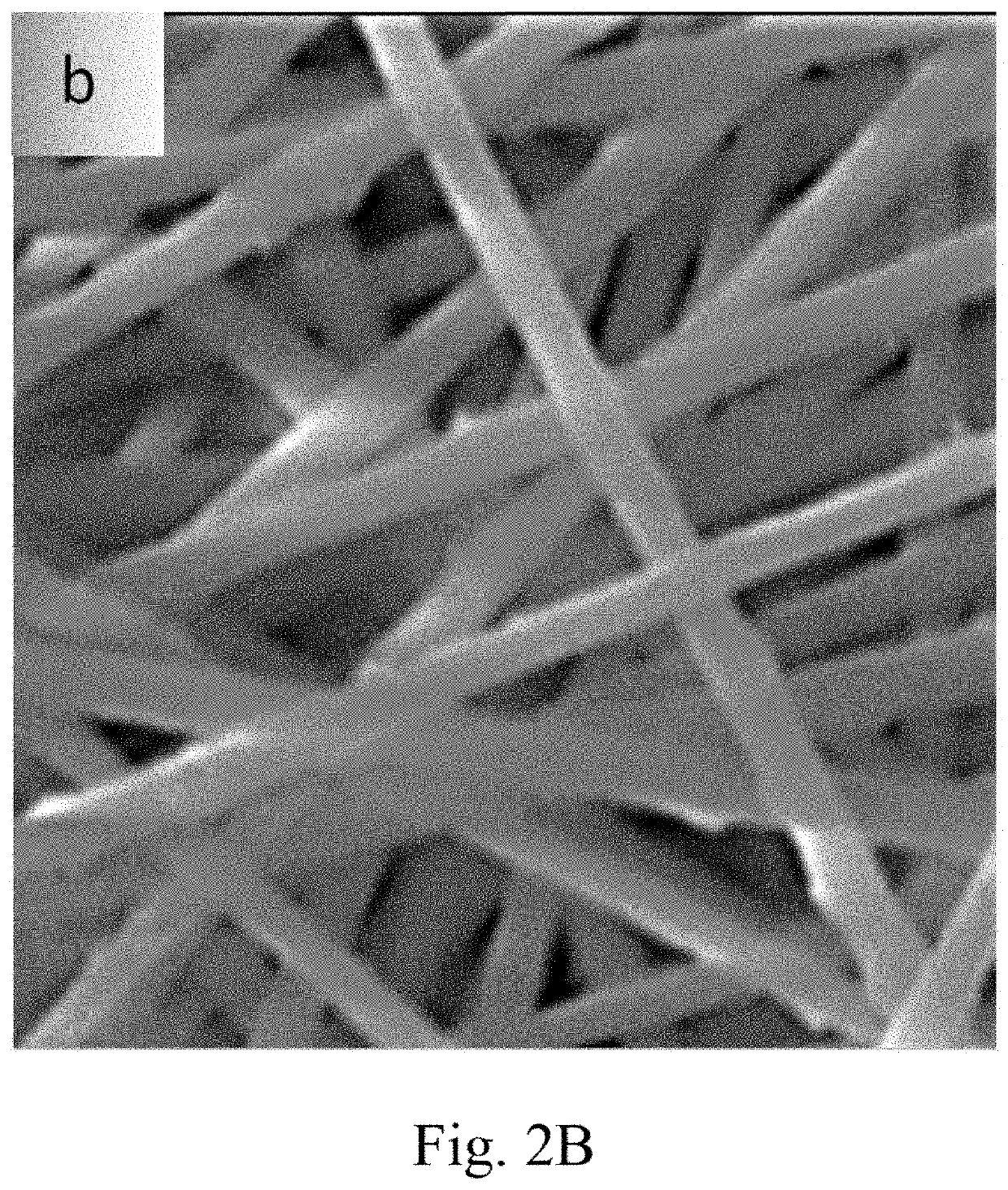

Oil-water emulsion separation membrane of metal organic framework compound/polyacrylonitrile

InactiveCN107983180AImprove oil stain resistanceEasy to separateSemi-permeable membranesMembranesYarnMetal-organic framework

The invention relates to an oil-water emulsion separation membrane of a metal organic framework compound / polyacrylonitrile. According to the oil-water emulsion separation membrane, polyacrylonitrile is used as a raw material and is prepared into a fiber membrane with the yarn diameter of about 300 nanometers and extremely high porosity by utilizing an electrostatic spinning technology; then the fiber membrane is subjected to a hydrolytic action so that functional groups including hydroxyl, carboxyl and the like are formed on surfaces of fibers; furthermore, the fiber membrane and amino on hydrophilic UIO-66-NH2 can form hydrogen bonding and electrostatic adsorption; finally, a porous fiber membrane with a hydrophilic multi-grade structure is prepared. The porous fiber membrane can be usedfor carrying out efficient separation on oil-water emulsion and has extremely low oil adhesion and relatively high oil stain resistance; furthermore, a preparation method of the oil-water emulsion separation membrane is simple and feasible, is safe and environmentally friendly and has very good application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

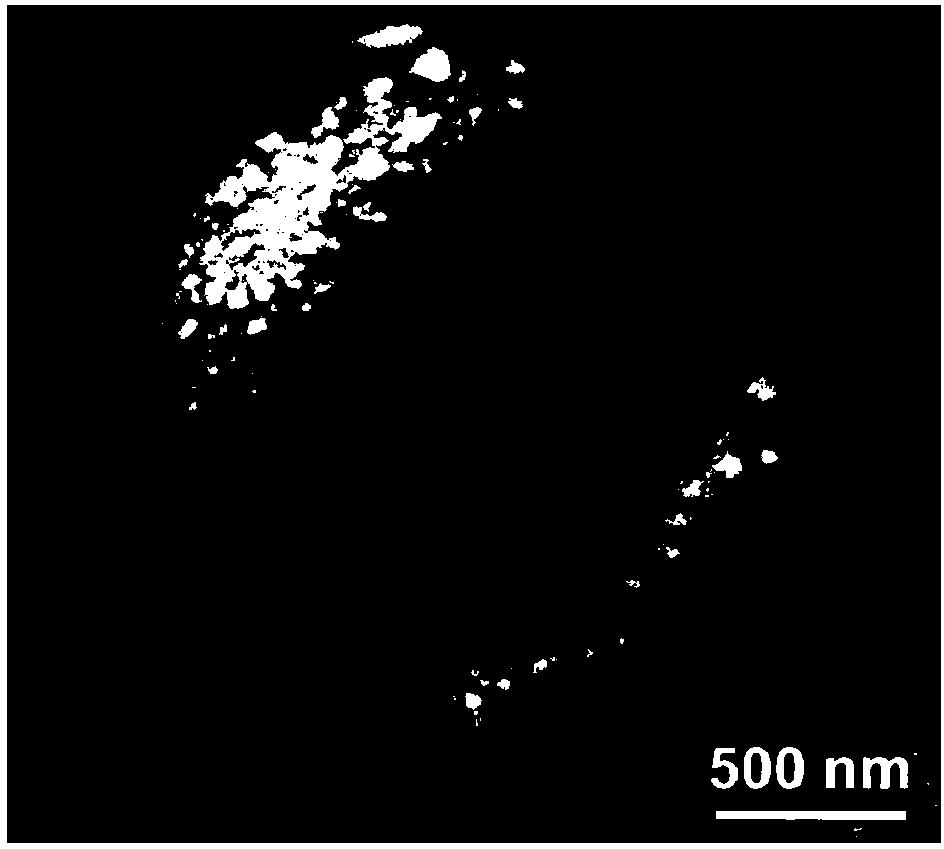

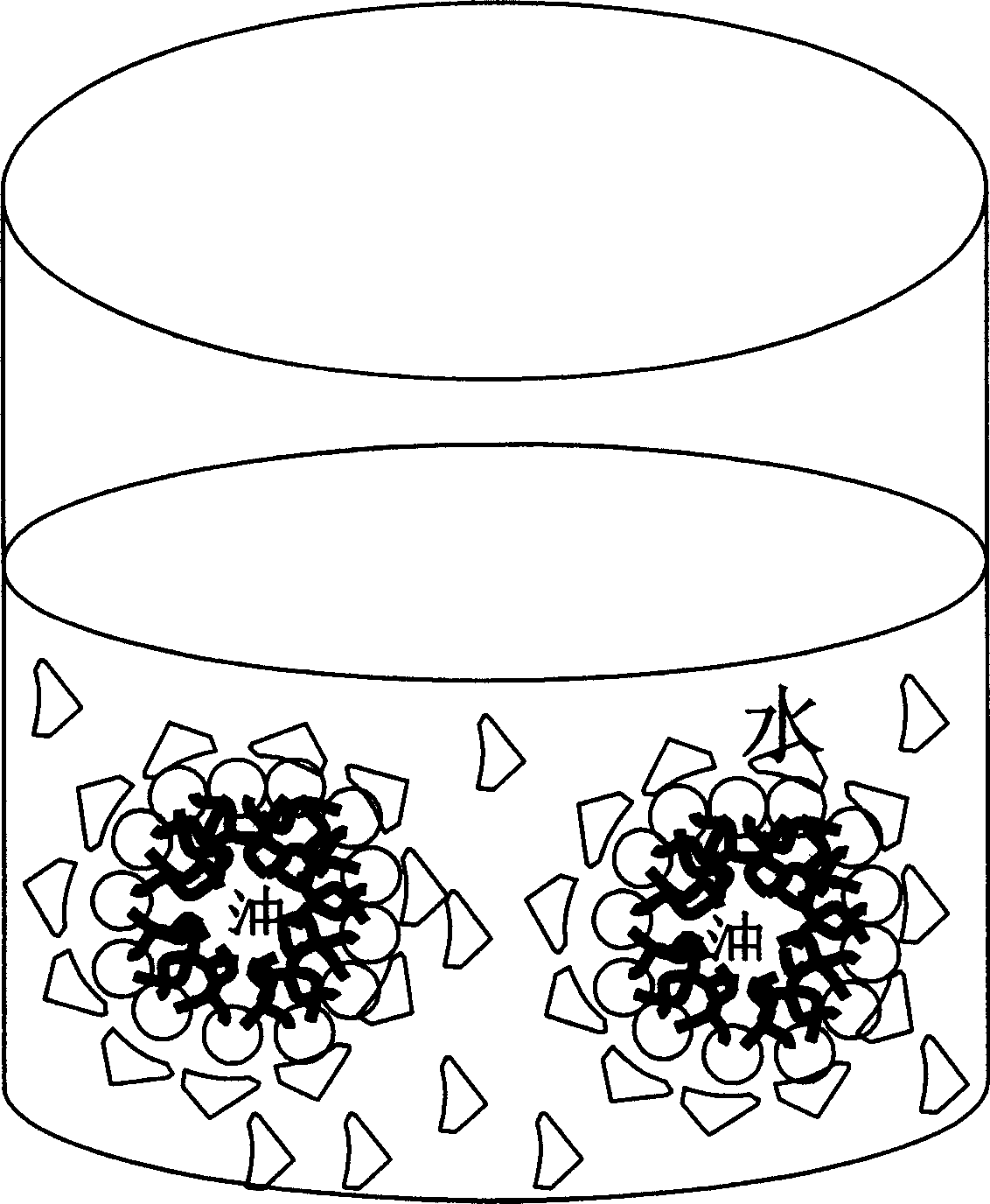

Composite janus microspheres based oil-water micro-emulsion separation method

ActiveCN108311067AEfficient separationEasy to separateFatty/oily/floating substances removal devicesWater treatment compoundsChemical compositionMicrosphere

The invention discloses a composite janus microspheres based oil-water micro-emulsion separation method. With the polymers Janus microspheres with different structures and different chemical compositions as a base material, the method comprises the following steps: adsorbing magnetic nano particles on the surfaces of the microspheres through electrostatic interaction, to obtain composite Janus microspheres with magnetic responsiveness; mixing and stirring the composite Janus microspheres and an oil-water emulsion; realizing demulsification and layering of the oil-water emulsion; after the layering, applying a magnetic field to realize efficient and quick oil-water separation. According to the method disclosed by the invention, the composite Janus microspheres serve as a particle surfactanton the oil-water interface to realize the demulsification and layering of the oil-water emulsion; by applying the magnetic field, efficient and quick separation of oil and water can be realized. Theoil-water micro-emulsion separation method disclosed by the invention has the advantages of simplicity, quick process and easiness in condition control, and is applicable to efficient separation of oil water formed by different types of large-area oil.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

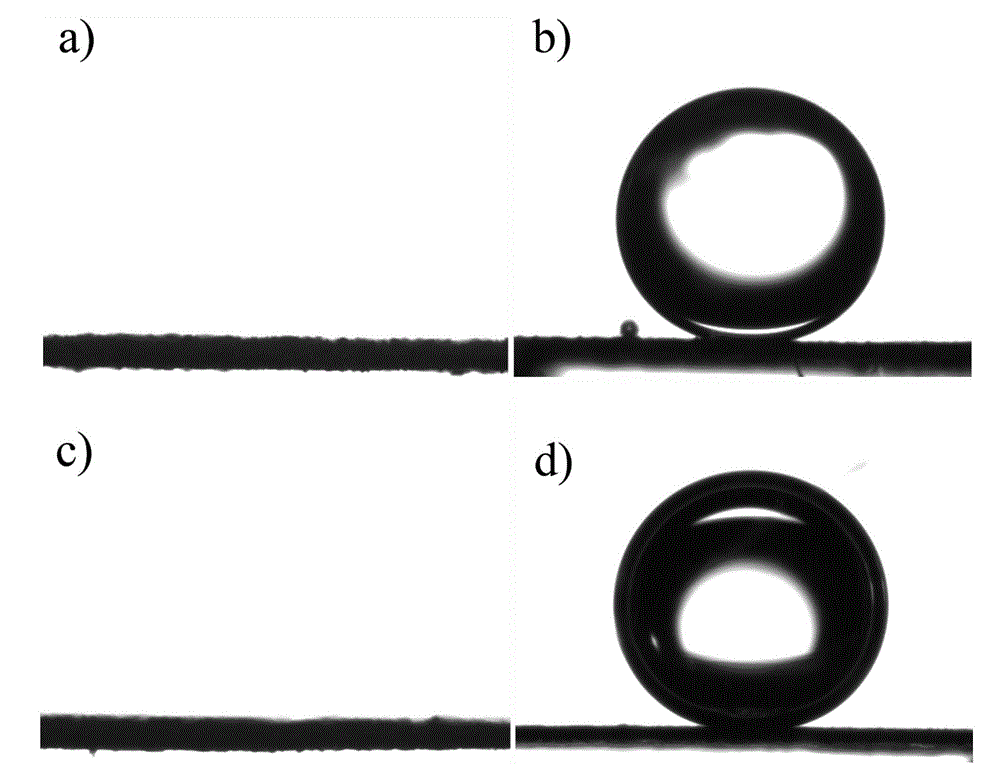

Super-hydrophobic coating layer used for oil-water separation and having hierarchical structure, super-hydrophobic material thereof, and preparation method of material

ActiveCN104802488AEasy to separateSimple processLayered productsCoatingsChemical industryOil water emulsion

The invention belongs to the technical field of preparation of nano-materials, and relates to a super-hydrophobic oil-water separation material containing a hierarchical structure coating layer. The hierarchical structure coating layer is formed by a layer of solid spherical SiO2 nano-particles with the particle size of 10-50nm and the particle size of 70-500nm, and the surface of the coating layer is provided with a layer of a low surface energy substance. The coating layer is obtained through layer-by-layer electrostatic in situ self-assembling, and can be used on stainless steel wire nets, stainless steel fiber sintered felts and other metal net products. The water contact angle of the stainless steel sintered nets coated with the hierarchical structure coating layer can exceed 150DEG. The material is simple to prepare, can be used to process filter core materials in coalescence separators, can be repeatedly used in oil-water separation, especially has a good separation effect on an oil-water emulsion, and can be widely used in oil-containing sewage treatment in the petroleum chemical industry, the metallurgy industry, the chemical engineering industry, the beverage industry, the food industry and the pharmacy industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

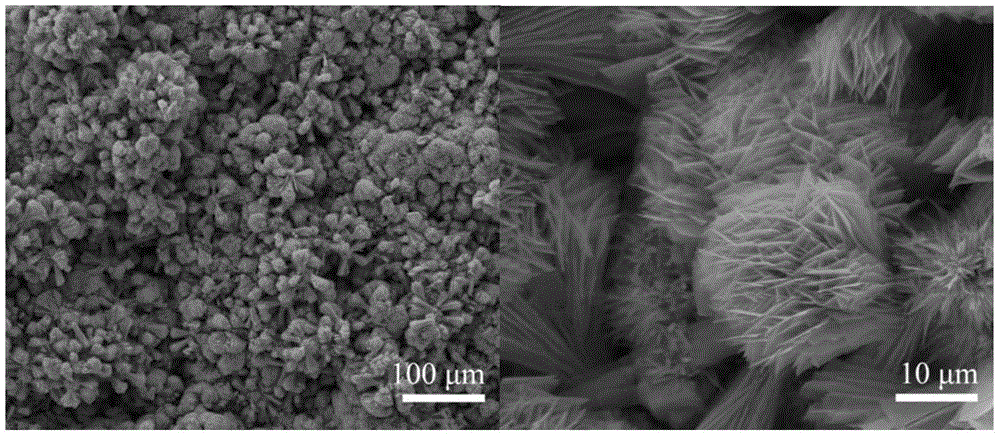

Net film applied to oil-in-water emulsion separation, preparation method and application of net film

ActiveCN104548667ARaw materials are easy to getLow costMembrane filtersFiltration separationMicro nanoCobalt salt

The invention relates to a net film applied to oil-in-water emulsion separation, a preparation method and application of the net film. The net film is a composite net film formed by loading metal oxide layers of micro-nano composite structures on net holes and net wires of a metal net, wherein the metal oxide layers of the micro-nano composite structures are formed by clustering nano-zinc oxide and nano-cobalt oxide. The preparation method of the net film comprises the following steps: (1) dissolving an alkaline medium and dissolvable zinc salt in water and uniformly stirring to prepare a mixed solution A; (2) dipping a metal net in the mixed solution A and carrying out hydrothermal reaction to prepare a nano-zinc oxide loaded metal net; (3) dissolving carbamide and dissolvable cobalt salt in water and uniformly stirring the mixture to prepare a mixed solution B; and (4) taking out the metal net in the step (2), washing the metal net and dipping the metal net in the mixed solution B, carrying out hydrothermal reaction, and burning the metal net to prepare the net film. The net film can be widely applied to oil-water separation.

Owner:TSINGHUA UNIV

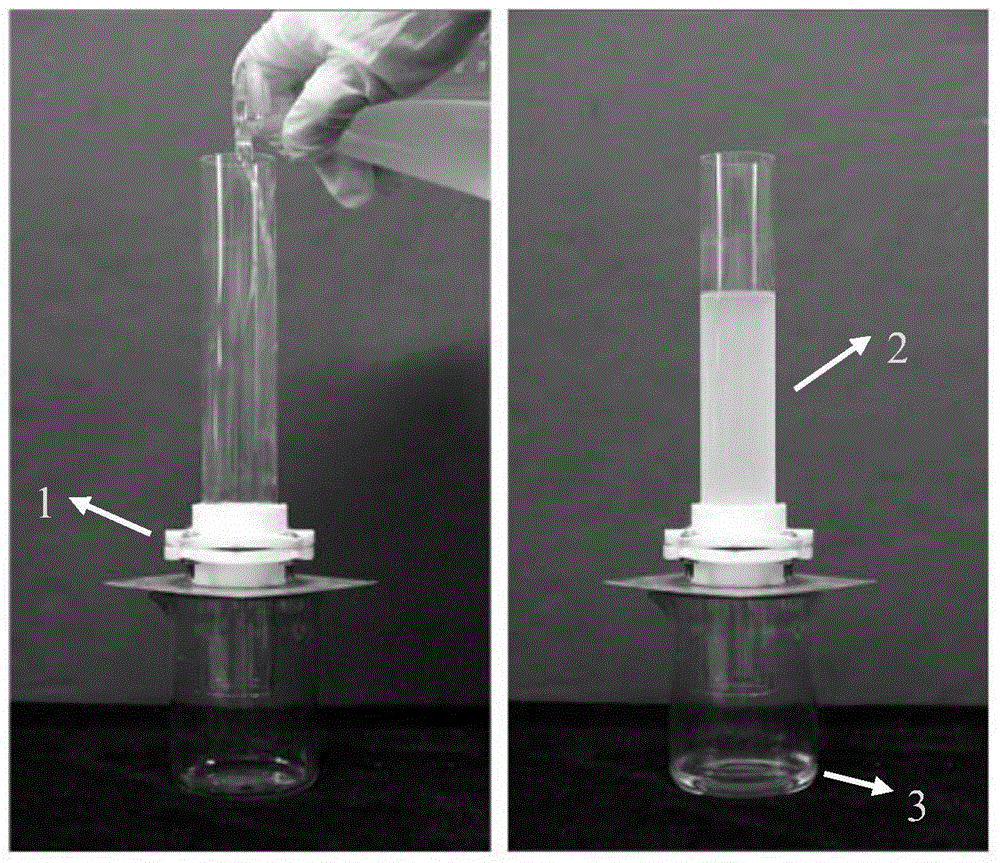

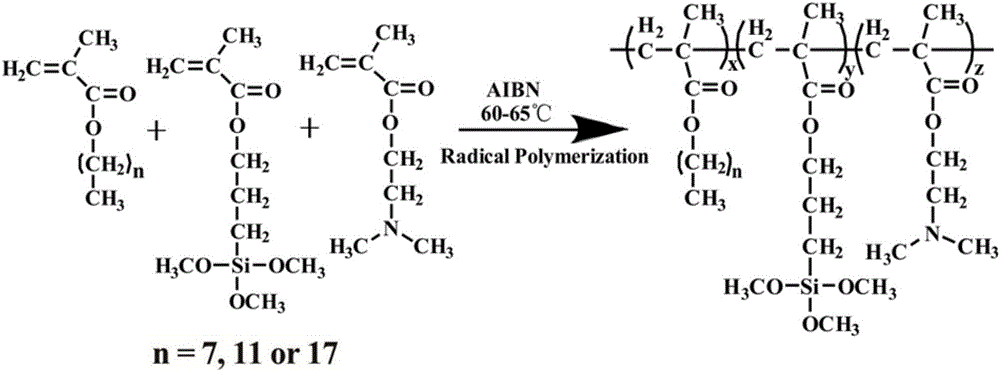

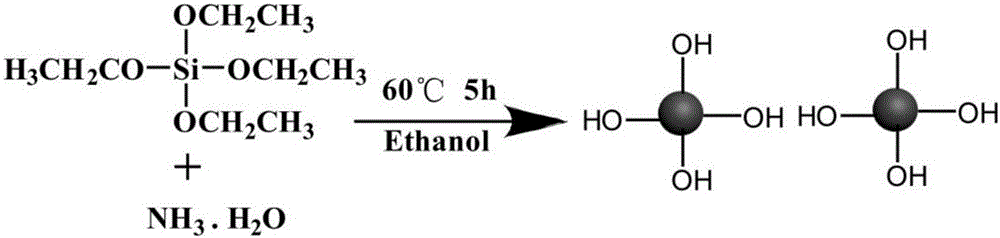

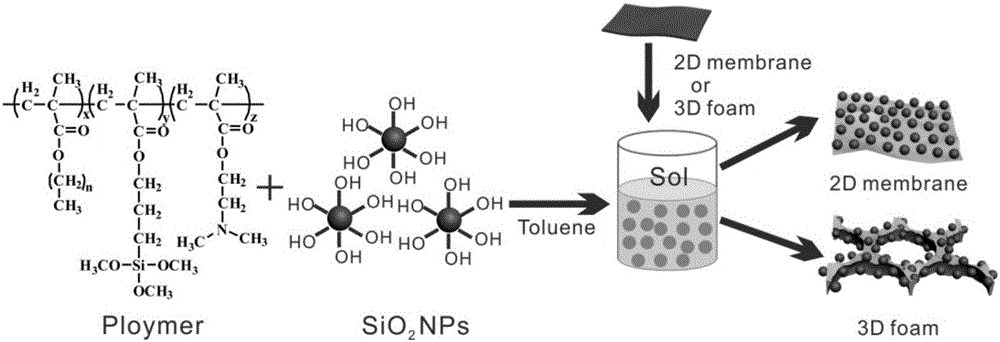

Preparation of pH responsive two-dimensional thin film and three-dimensional sponge oil-water separation materials and oil-water separation application

ActiveCN106243271AEasy to separateEasy to prepareFatty/oily/floating substances removal devicesOther chemical processesOil water emulsionDip-coating

The invention provides a copolymer having pH responsiveness; then a mixed solution (sol) is formed from the copolymer and silica nanoparticles, and then pH-responsive two-dimensional thin film material (cotton and filter paper) and a pH-responsive three-dimensional sponge material (polyurethane sponge) are prepared by a simple dip-coating way. The oil-water separation performance of the prepared two-dimensional thin film material and the prepared three-dimensional sponge material can be controlled by adjusting change of the pH. At the pH of 2, the materials show superhydrophilic / underwater superoleophobic performance; at the pH of 12, the materials can have the superhydrophilic / underwater superoleophobic performance converted into superhydrophobic / superoleophilic performance. In addition, the wettability of the materials can be changed in situ under adjustment of the pH. More importantly, the materials not only can separate an oil / water / oil three-phase oil-water mixture, but also can separate water-in-oil, oil-in-water and acid oil-in-water oil-water emulsion, and also can absorb all kinds of oil products.

Owner:海安腾昱智能科技有限公司

Fluorizated cellulose acetate film and preparation method

ActiveCN101716471AEasy to synthesizeEasy to makeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCeriumSulfanilamide

The invention relates to a fluorizated cellulose acetate film and a preparation method. The fluorizated cellulose acetate film is prepared by taking cerium salt as an initiator and grafting hydrophobic and oleophobic fluoroester methacrylic acid (FMA, such as methacrylic acid-12-fluorine heptyl ester G04, methacrylic acid hexafluoro-butyl ester G02 and the like) and hydrophilic polyglycol ester methacrylic acid (PEGMA) or methacrylic acid MAA and sulfanilamide MPDSAH sequentially onto cellulose acetate by a water-phase free-radical interfacial polymerization method; and then, taking the synthesized fluorizated cellulose acetate as a film material and preparing an asymmetrical oil-water separation film with pollution resistance and ultra-low flux depression by a non-solvent initiating phase conversion method. When the fluorizated cellulose acetate film is used for processing oil-water emulsion, the detention rate is as high as 99.8%, the rate of flux depression can be lowered to 3.4%, the water flux can be kept at 247.1L / m2h, and the rate of flux recovery is as high as 100%. The fluorizated cellulose acetate oil-water separation film has superior anti-pollution performance and strong recycle property.

Owner:南通诚恩机械有限公司

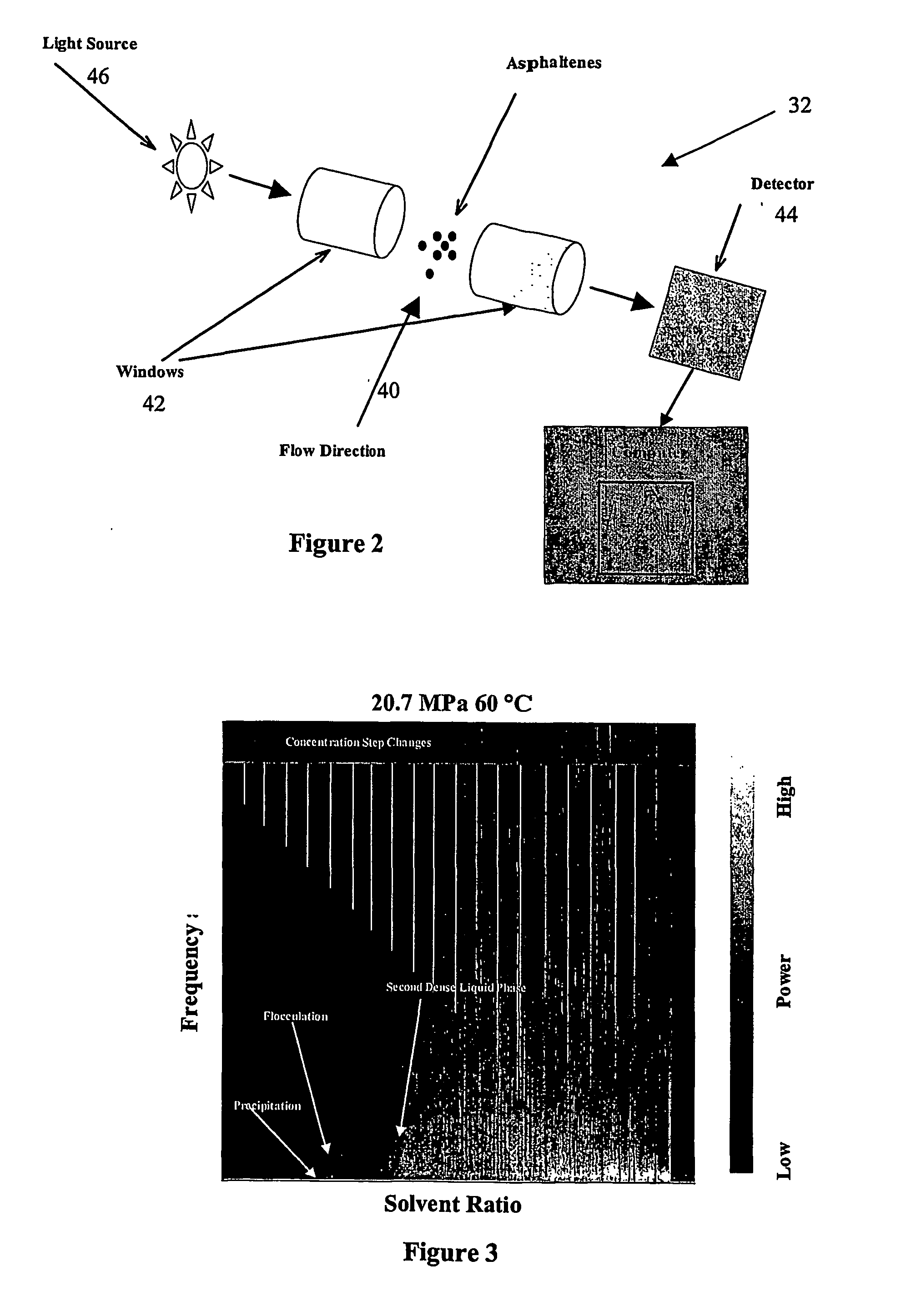

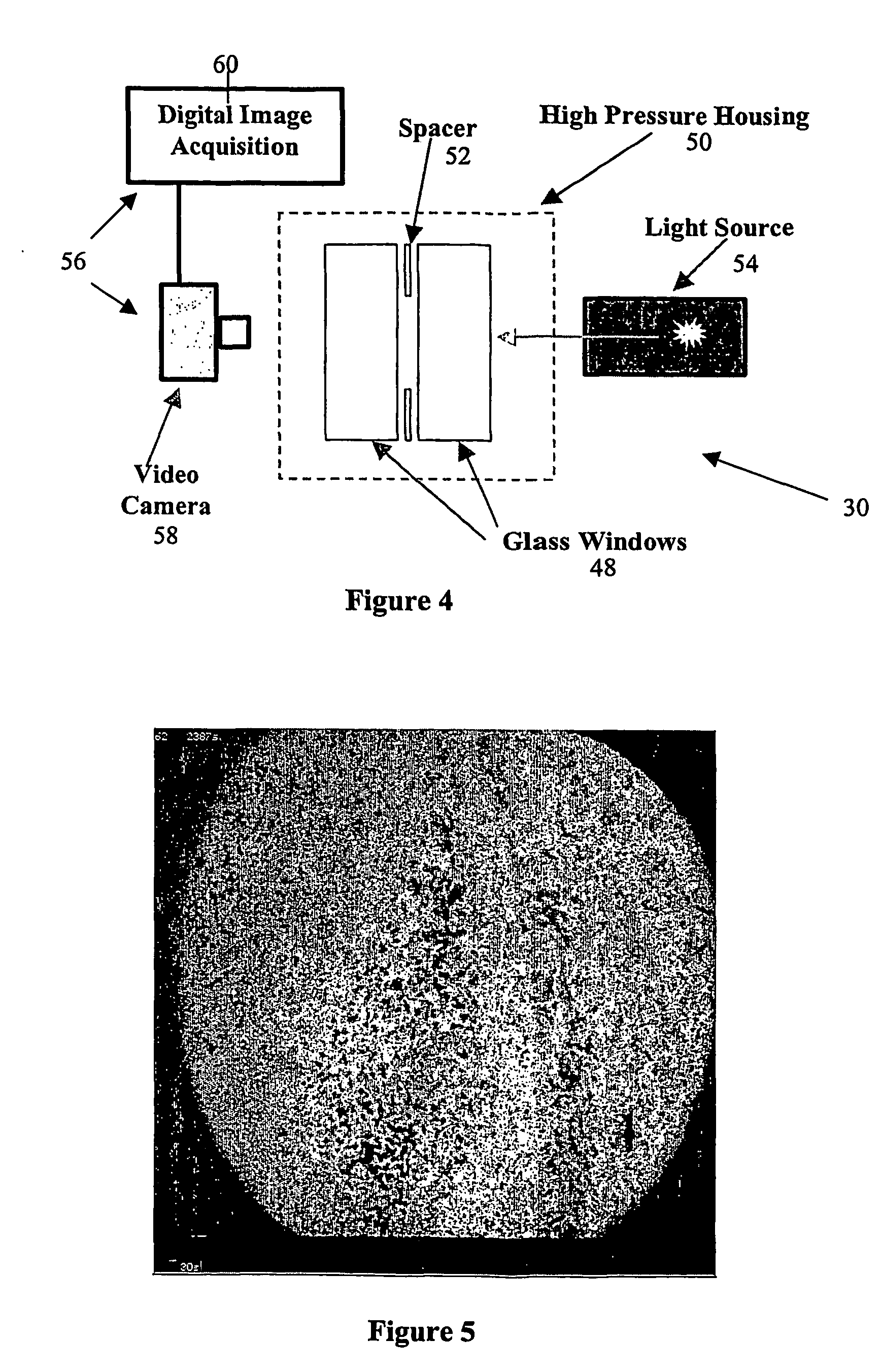

Method of characterizing a dispersion using transformation techniques

InactiveUS20070134804A1Well representedEasy to useTransmissivity measurementsAnalysis by subjecting material to chemical reactionFast Fourier transformFrequency spectrum

A method for analyzing a dispersion such as an oil / solid suspension or an oil / water emulsion. A set of original domain data is collected relating to an attribute of the dispersion, such as light transmittance therethrough. The set of original domain data is then transformed into a transformed set of original domain data which is in the frequency domain. Any transformation technique, such as a fast Fourier transform, may be used to transform the original domain data from a first domain, such as a time or spatial domain, into the frequency domain. The dispersion is then characterized using the transformed set of original domain data. One or more frequency domain spectra may be generated from the transformed set of original domain data, which frequency domain spectra express a parameter relating to the attribute of the dispersion as a function of frequency, in which case the characterizing step may be performed using the frequency domain spectra.

Owner:ALBERTA RES COUNCIL INC

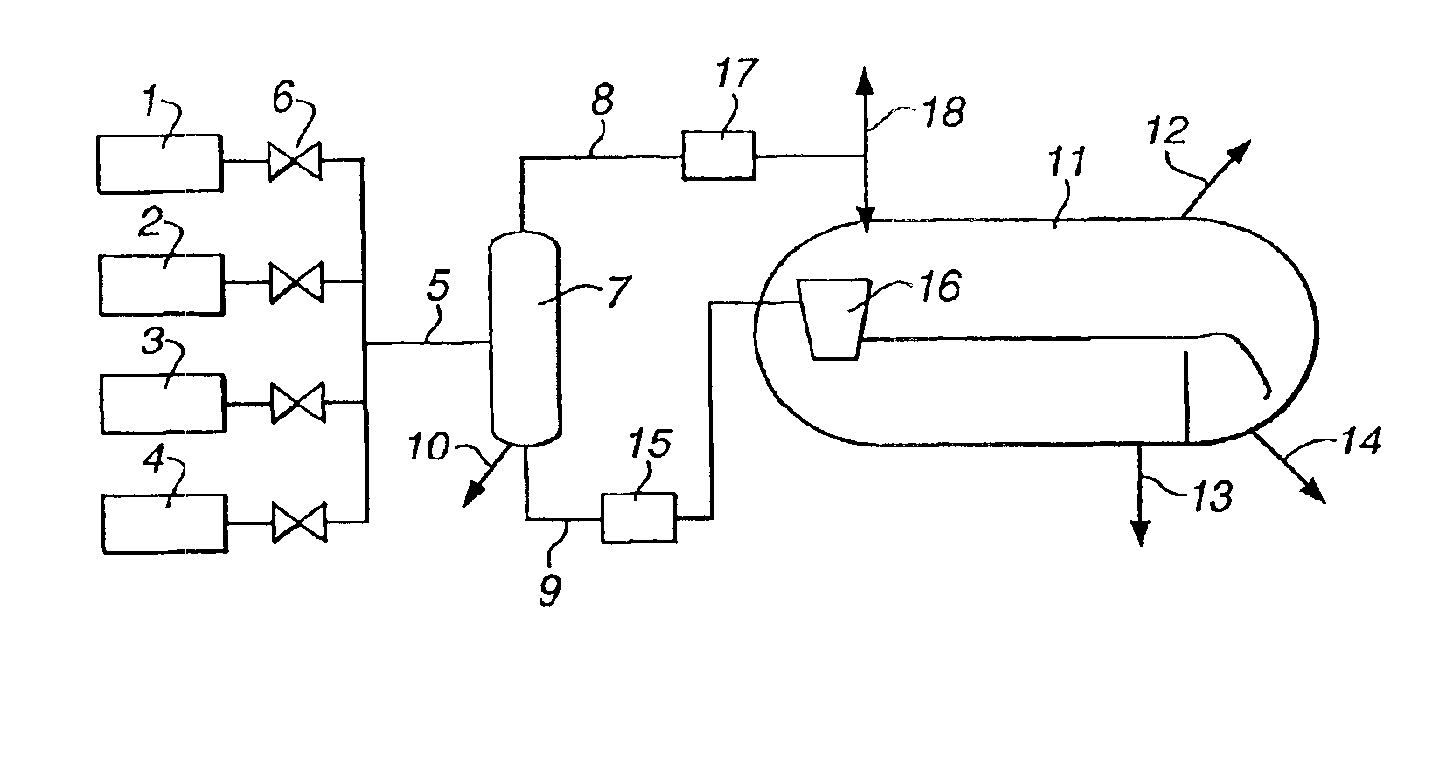

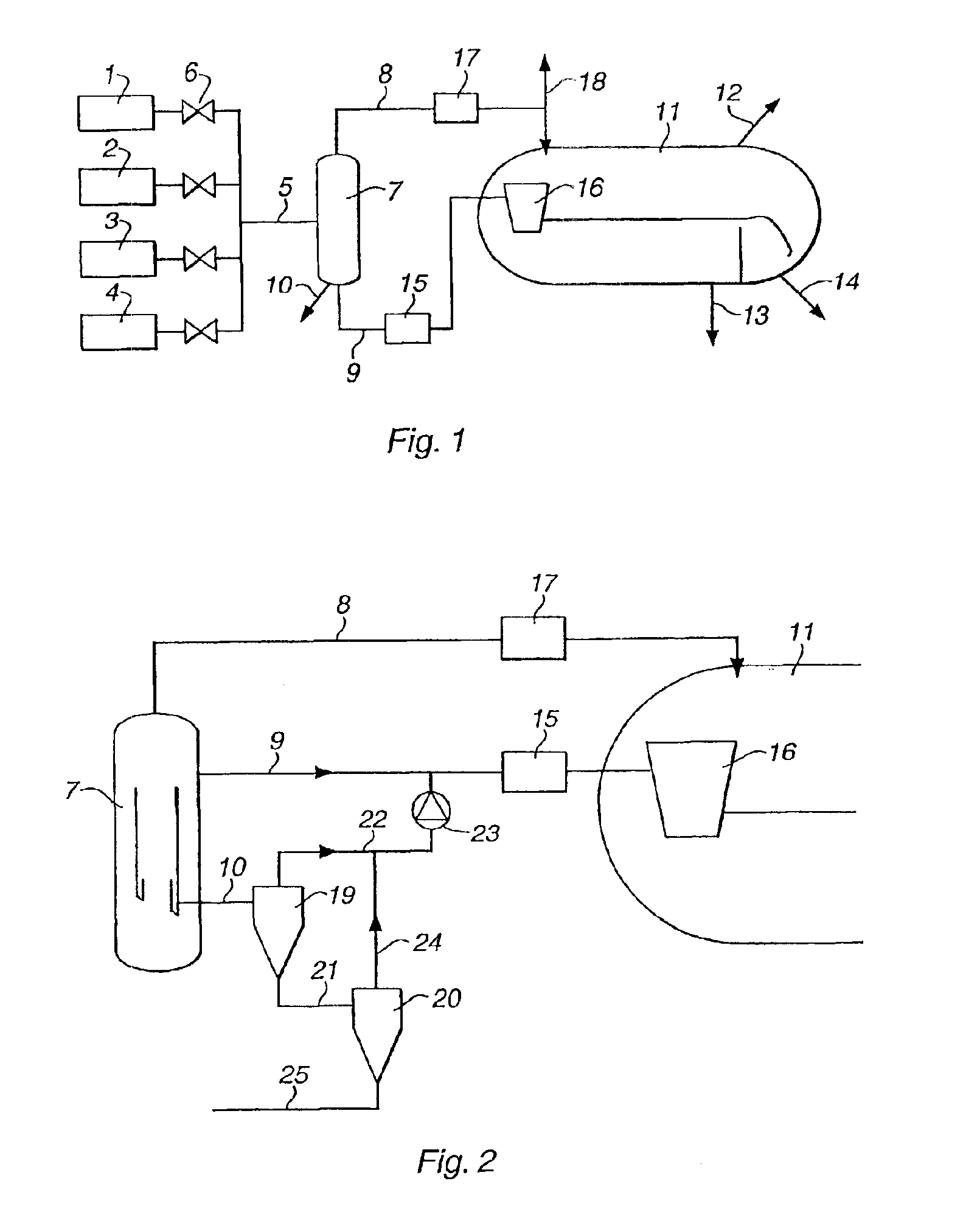

Method and a system for separating a mixture

InactiveUS6872239B2Good flexibilityEasy to controlWater/sewage treatment by centrifugal separationCentrifugal force sediment separationCycloneOil water emulsion

A method for separating phases of a mixture comprising and oil-water together with gas. At least a substantial part of the gas is separated from the emulsion before the emulsion is introduced into a separator tank. The oil-water emulsion from which the gas has been separated is conducted to a liquid-liquid cyclone for further separating the phases of the emulsion. The liquid-liquid cyclone is located inside the separator tank. The emulsion is conducted to the separator tank for separating the oil from the water.

Owner:SULZER MANAGEMENT AG

Preparation method of magnetic graphene oxide demulsifying agent

ActiveCN106219669AExpand application scaleExpand the scope ofFatty/oily/floating substances removal devicesWater treatment compoundsOil water emulsionPollution

The invention discloses a preparation method of a magnetic graphene oxide demulsifying agent. The magnetic graphene oxide demulsifying agent is prepared by taking magnet powder as a carrier and loading graphene oxide on the surface of the carrier; the use amount ratio of the magnet powder to ethanol to water to a silane coupling agent to the graphene oxide is (1g to 5g) to (70mLto 95mL) to (5mL to 30mL) to (0.2g to 1g) to (1g to 5g). In preparation and application of the magnetic graphene oxide demulsifying agent provided by the invention, a magnetic separation method can be used, and high efficiency, time saving, energy saving and environment protection are realized; the application scale and range of the graphene oxide in an oil-water emulsion separation process can be easily expanded. The raw materials for preparing the demulsifying agent are easy to obtain, low in cost, stable in physical and chemical properties and capable of being repeatedly used and secondary pollution is avoided; the demulsifying agent has huge social and economic value and a wide application prospect.

Owner:SHANDONG JIAOTONG UNIV

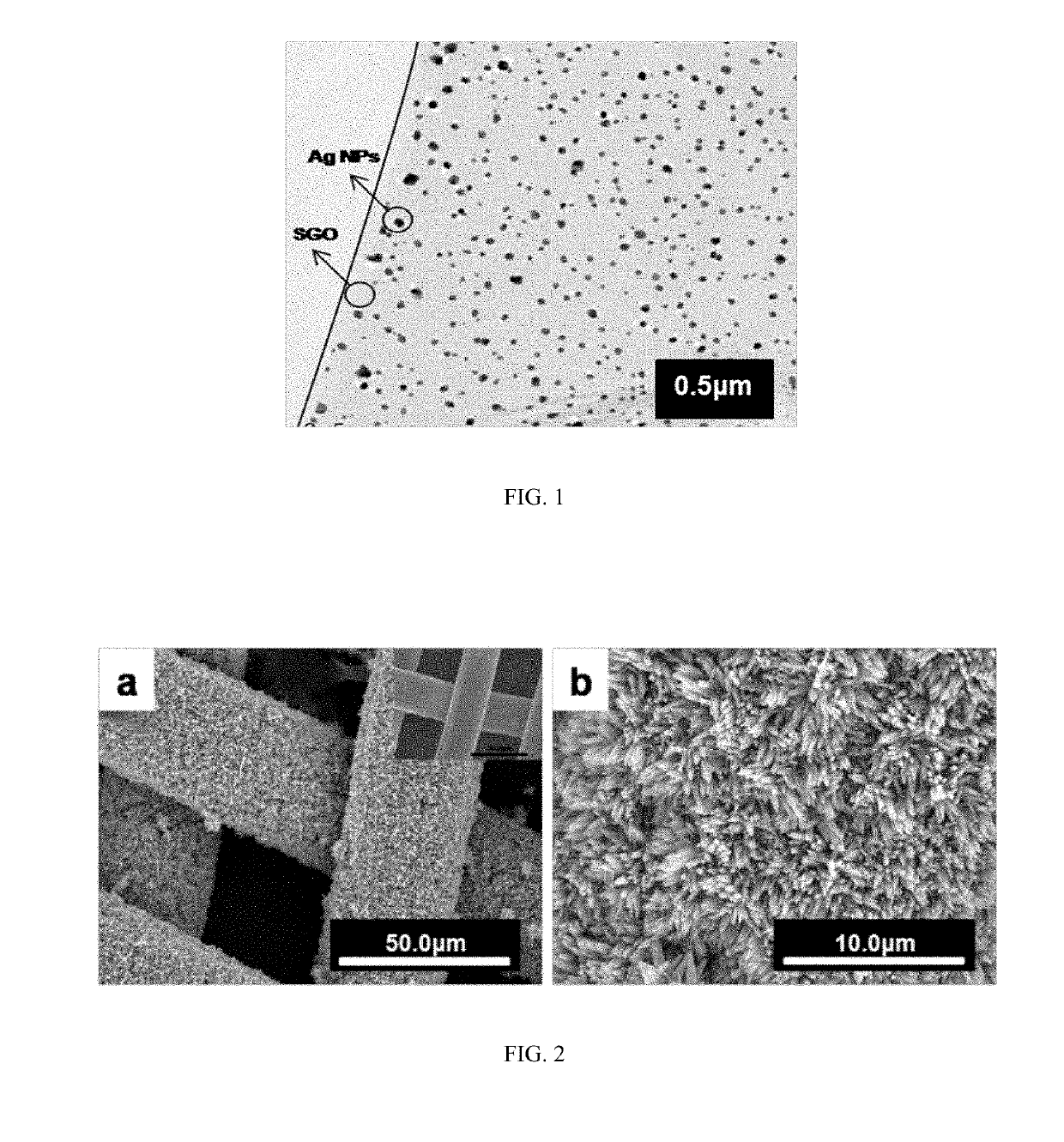

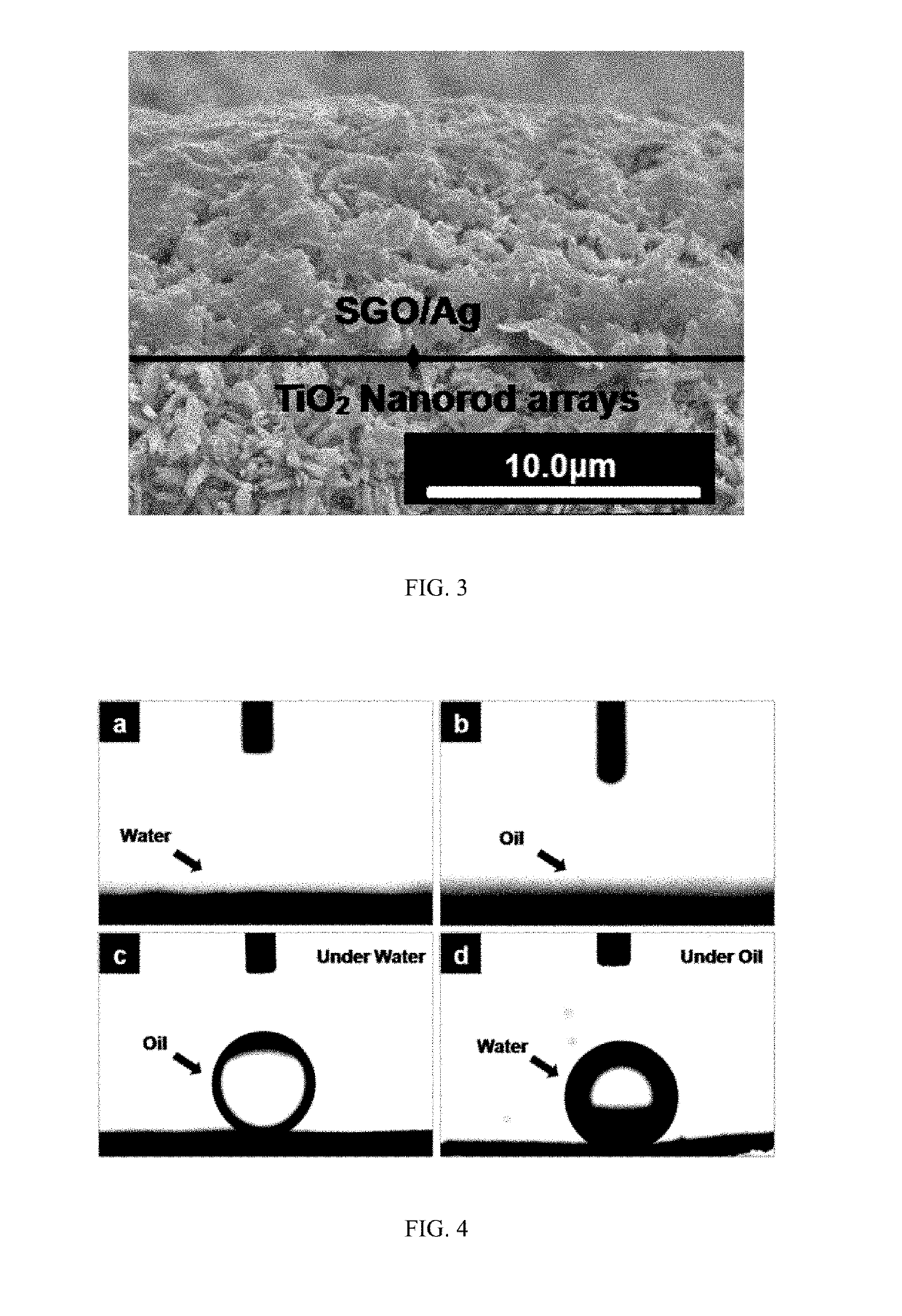

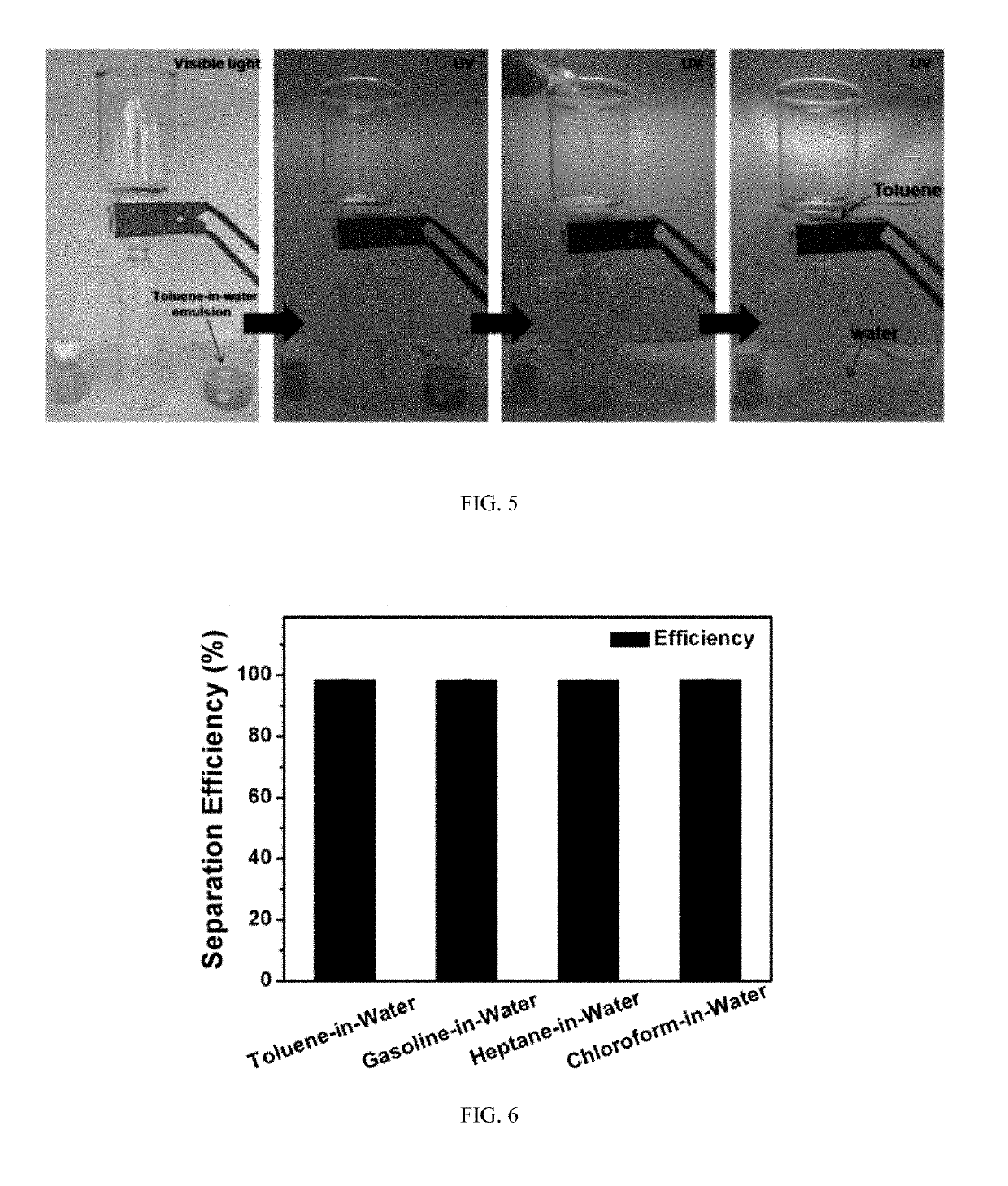

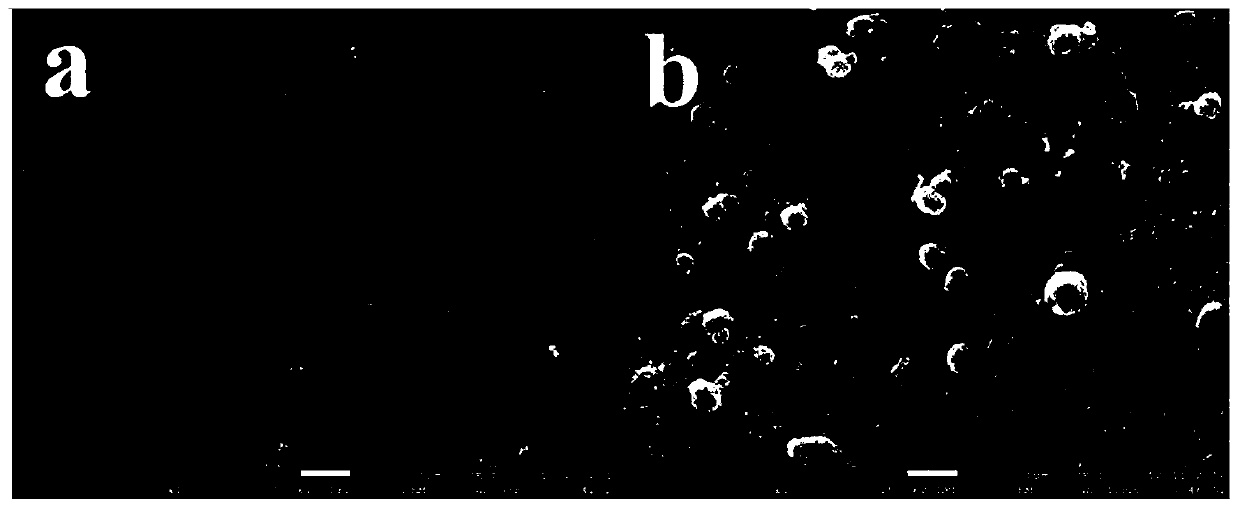

Titanium dioxide / sulfonated graphene oxide / ag nanoparticle composite membrane and preparation and application thereof

ActiveUS20190126211A1Low costEasy to getMaterial nanotechnologyCarbon compoundsOxide compositeEngineering

Titanium dioxide / sulfonated graphene oxide / silver nanoparticle composite membrane and its preparation method and application are disclosed. Mixing graphene oxide, sodium chloroethanesulfonate, and sodium hydroxide uniformly in the water, and then adding concentrated nitric acid to obtain sulfonated graphene oxide; mixing the aqueous solution of said sulfonated graphene oxide with the aqueous solution of silver nitrate, stirring in the dark, then adding ascorbic acid, and continuing to stir to obtain a silver nanoparticle / sulfonated graphene oxide composite material; dispersing said silver nanoparticle / sulfonated graphene oxide composite material in water, and then deposited on said titanium dioxide nanorods arrays by vacuum deposition, and vacuum dried to obtain titanium dioxide / sulfonated graphene oxide / silver nanoparticle composite membrane. The membrane possessed photocatalytic effect under UV light and special wettability: super-hydrophobic oil under water / super-hydrophobic under oil, which could in situ separation and degradation of oil / water emulsion.

Owner:SUZHOU UNIV

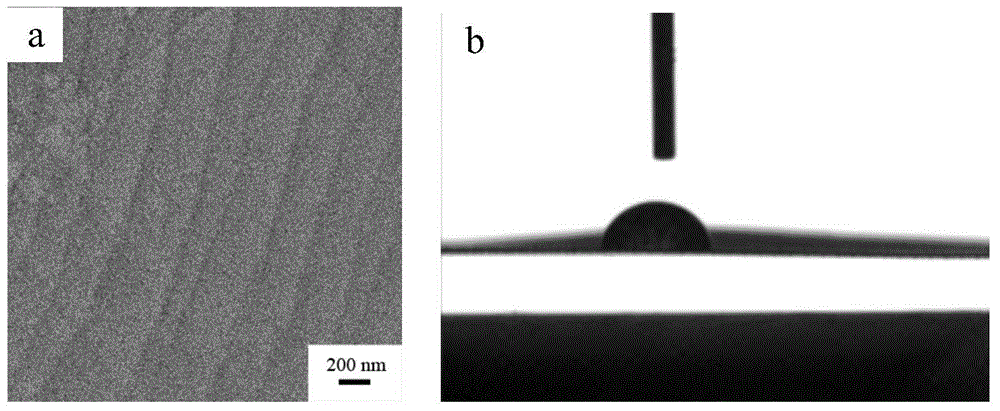

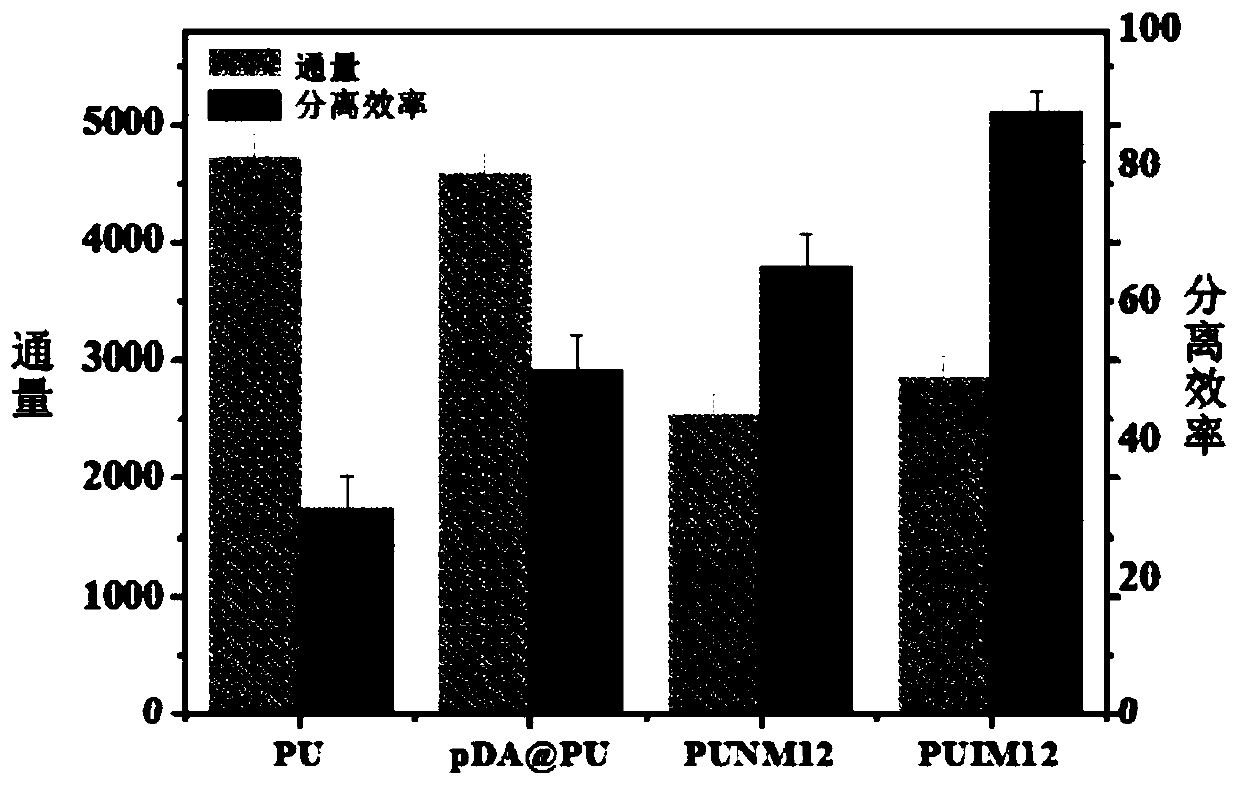

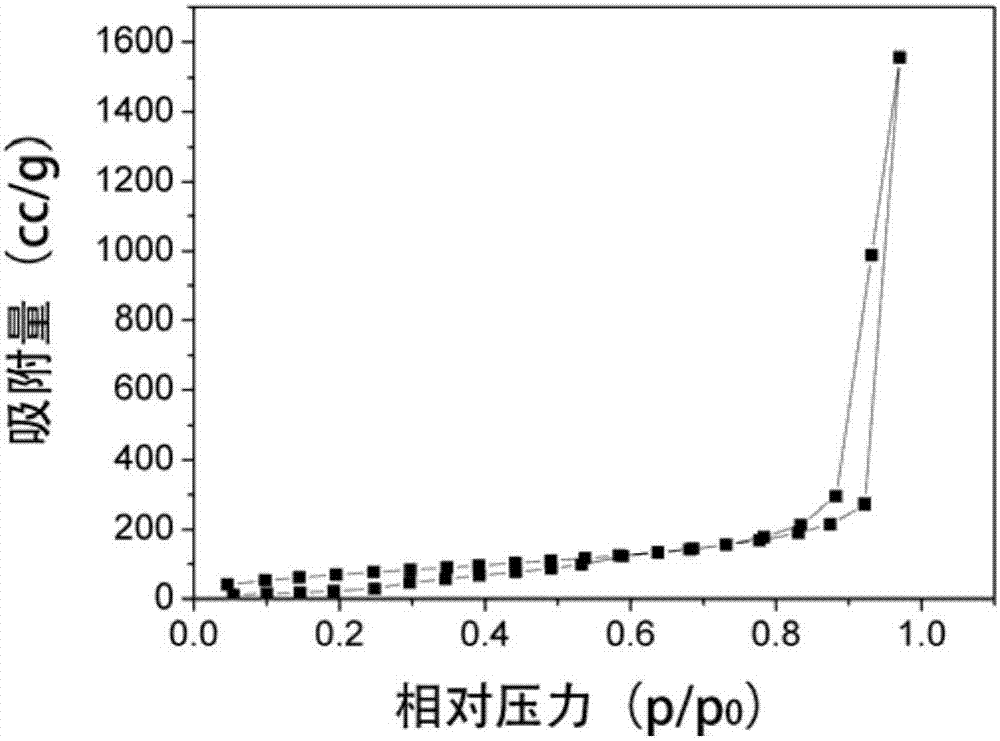

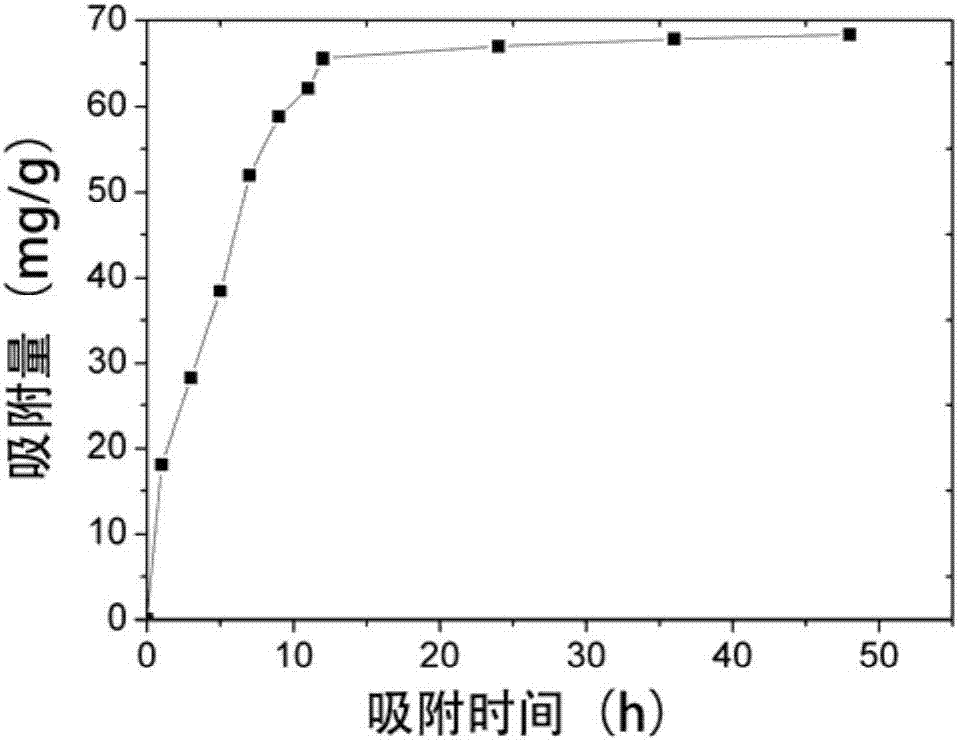

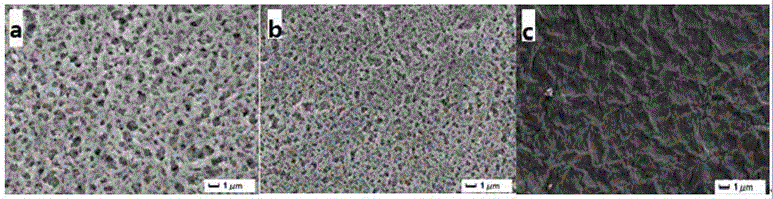

Preparation method and application of PVDF/UiO-66-NH2 imprinted composite membrane

ActiveCN110711499AIncrease roughnessLow priceMembranesSemi-permeable membranesNanoparticleOil water emulsion

The invention belongs to the field of environmental functional materials, and particularly relates to a preparation method and an application of a PVDF / UiO-66-NH2 imprinted composite membrane. According to the preparation method, UiO-66-NH2 nanoparticles are modified to the surface of the PVDF membrane through a delayed phase inversion one-step method by utilizing the viscosity of PVDF, so that the roughness of the surface of the PVDF membrane is improved, and the problems that blending is easy to embed, the surface modification process is complex and the like are solved. The wettability and the molecular imprinting membrane technology are combined for the first time, so that the prepared PVDF / UiO-66-NH2 imprinting composite membrane has super-hydrophilicity / underwater super-oleophobicity,can effectively separate / adsorb antibiotics in emulsion, synergistically and selectively adsorb / separate antibiotics and separate oil-water emulsion, and has excellent anti-pollution performance. ThePVDF material used in the preparation method is low in price, the preparation method is simple, easy to control, low in energy consumption and free of secondary pollution, accords with the concept ofgreen chemistry, can be produced on a large scale and can be applied to the field of separation of antibiotics in emulsion.

Owner:JIANGSU UNIV

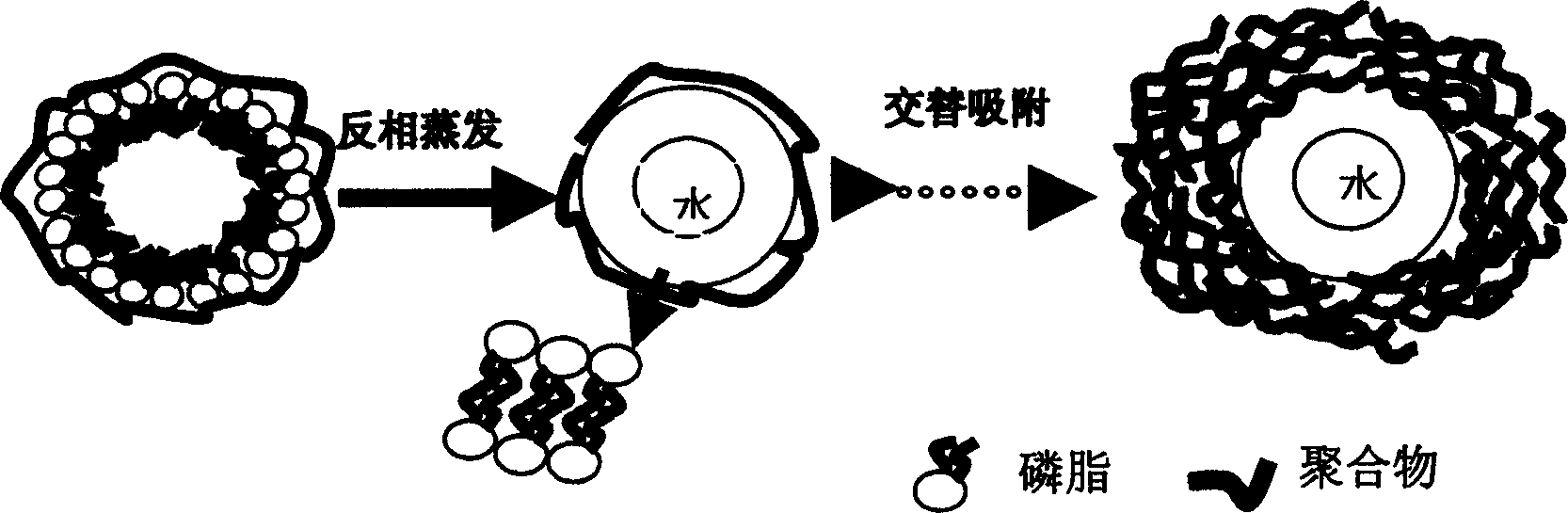

Multilayer phospholipid protein microcapsule for drug slow release wall material and its preparation method

InactiveCN1839804ASimple methodIncrease percentageMacromolecular non-active ingredientsMicrocapsulesCrystallographyOrganic solvent

The invention relates to a process for preparing self-assembled multilayer microcapsule by utilizing oil-water emulsion, wherein multilayer phosphatide / protein microcapsule can be used as the pharmaceutical slow release wall material, the microcapsule comprises liposoluble phosphatide and protein, the concentration of the liposoluble phosphatide is 0.1-1.0mg / ml, the concentration of protein is 0.1-1.0mg / ml, the volumetric ratio of phosphatide and protein is 1-10:10. The preparing process comprises dissolving the liposoluble phosphatide into organic solvent, the dispersing it into protein-containing aqueous solution.

Owner:SOUTHEAST UNIV

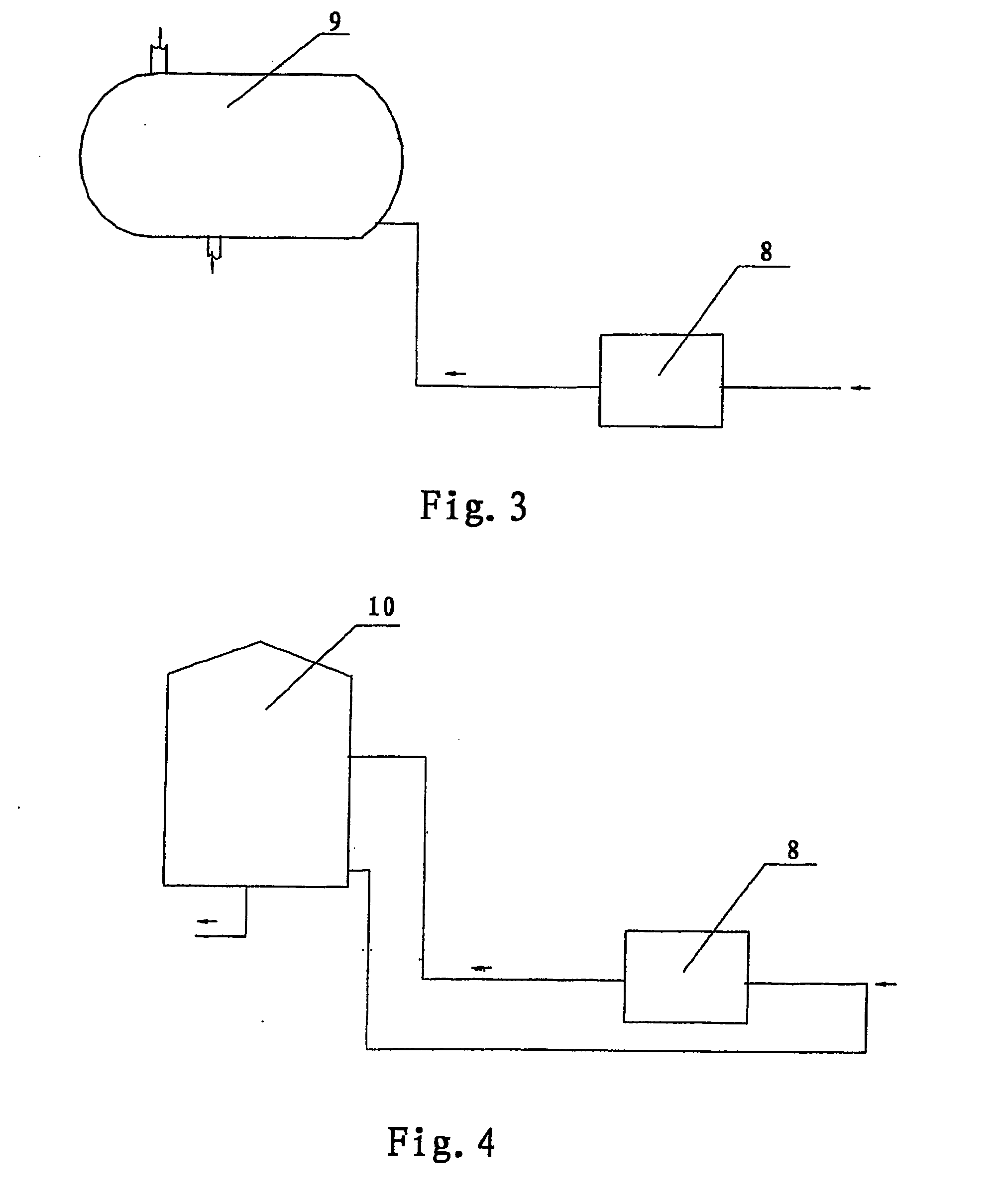

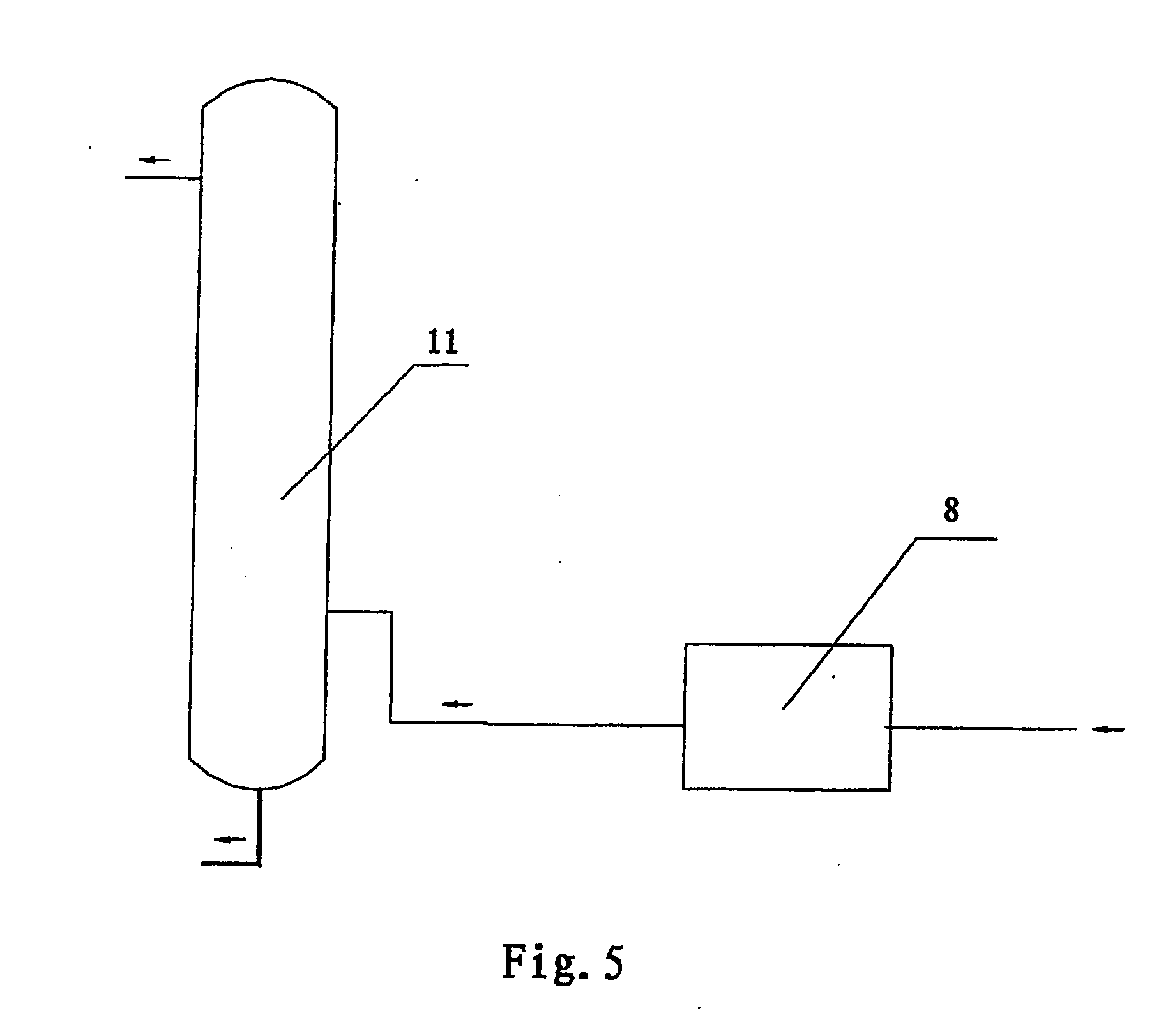

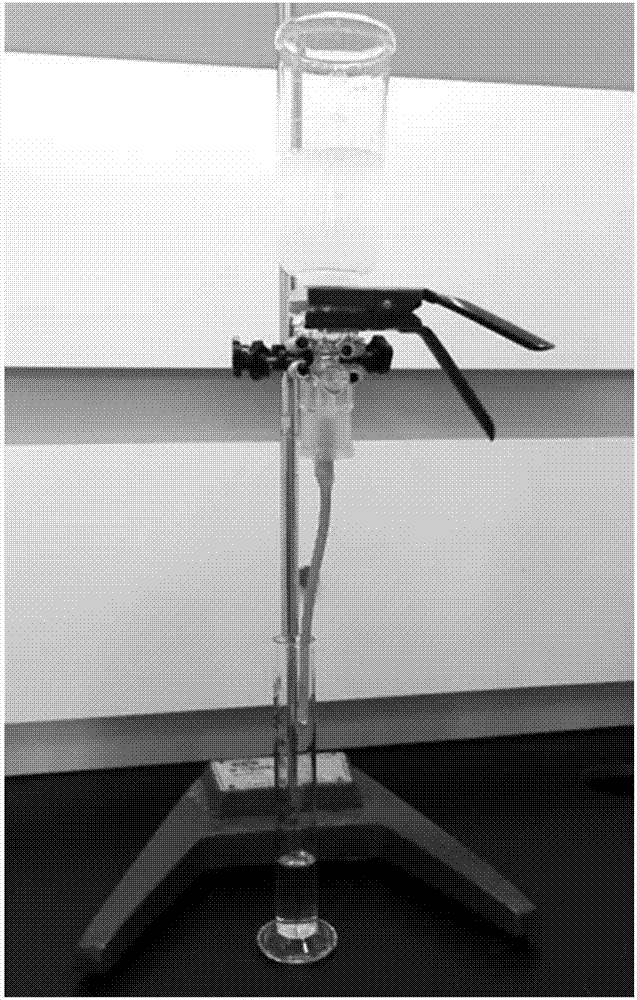

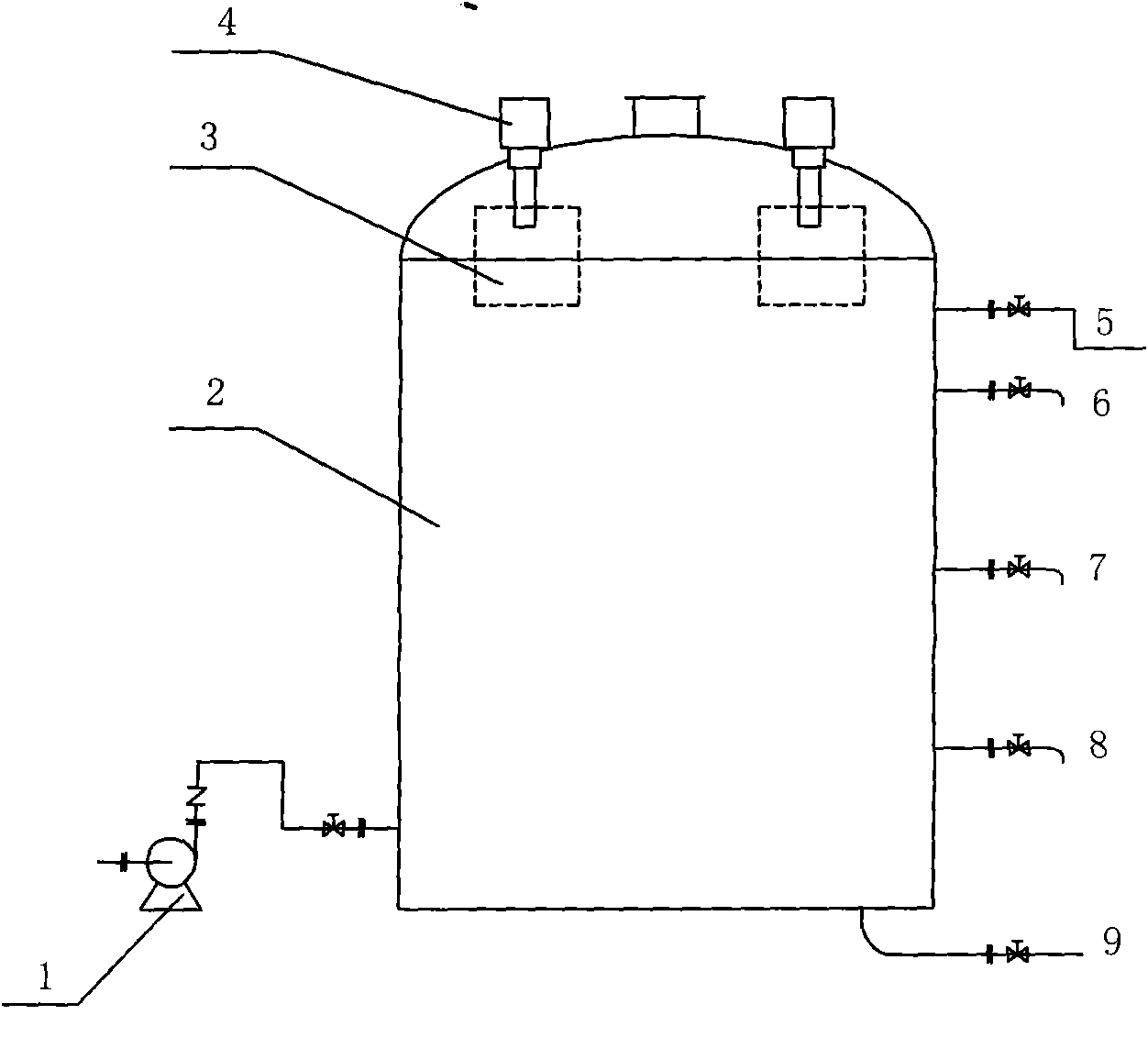

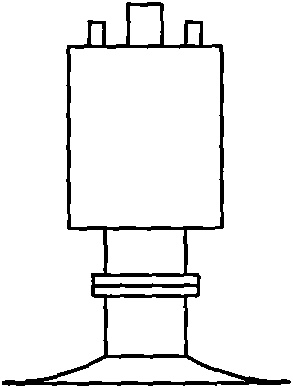

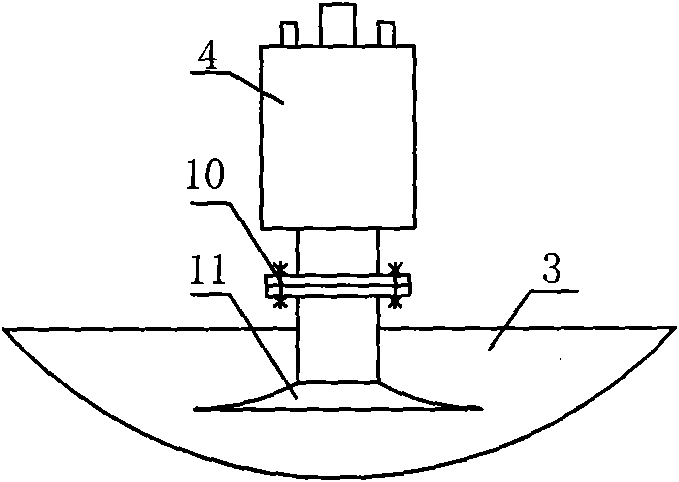

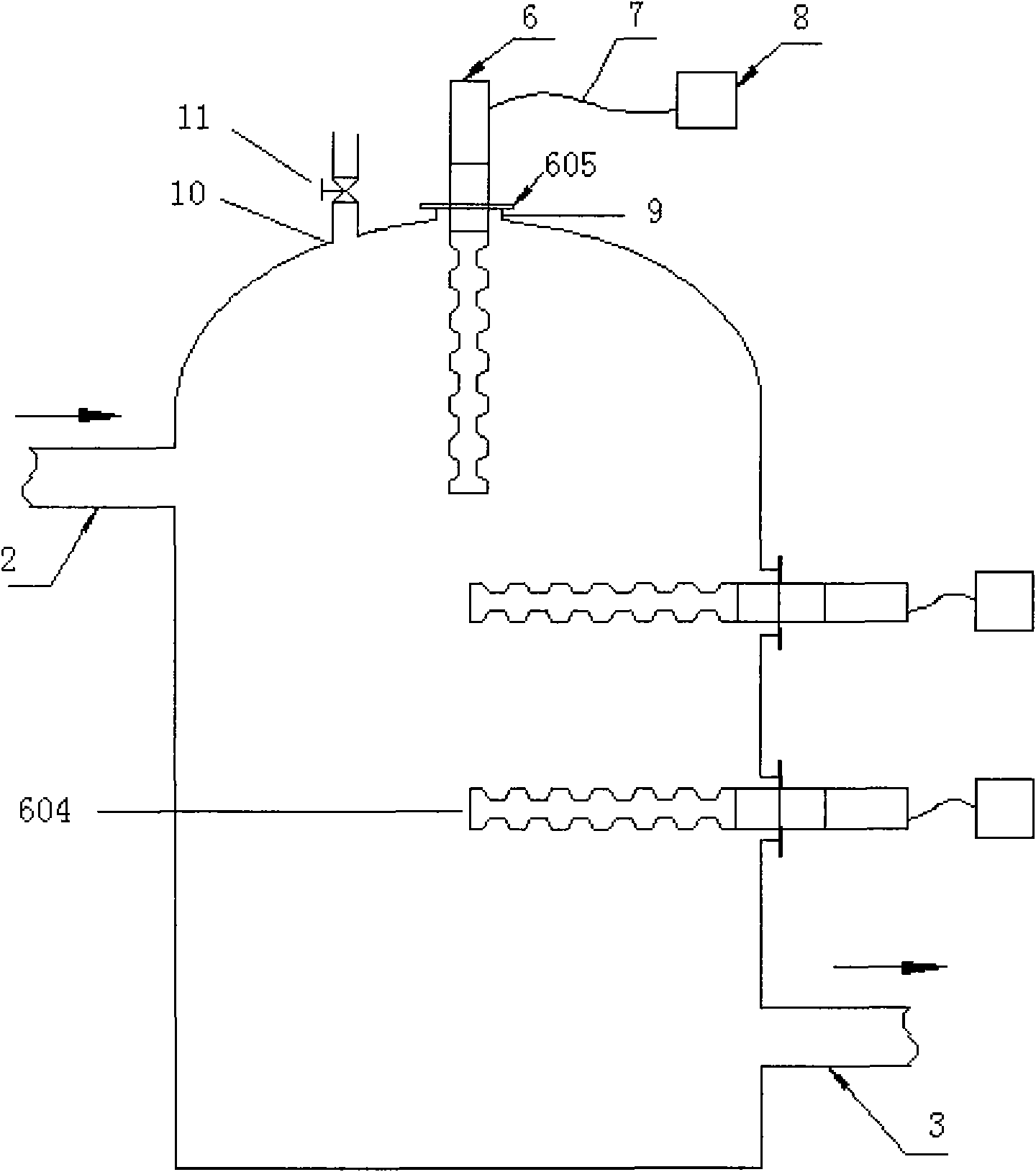

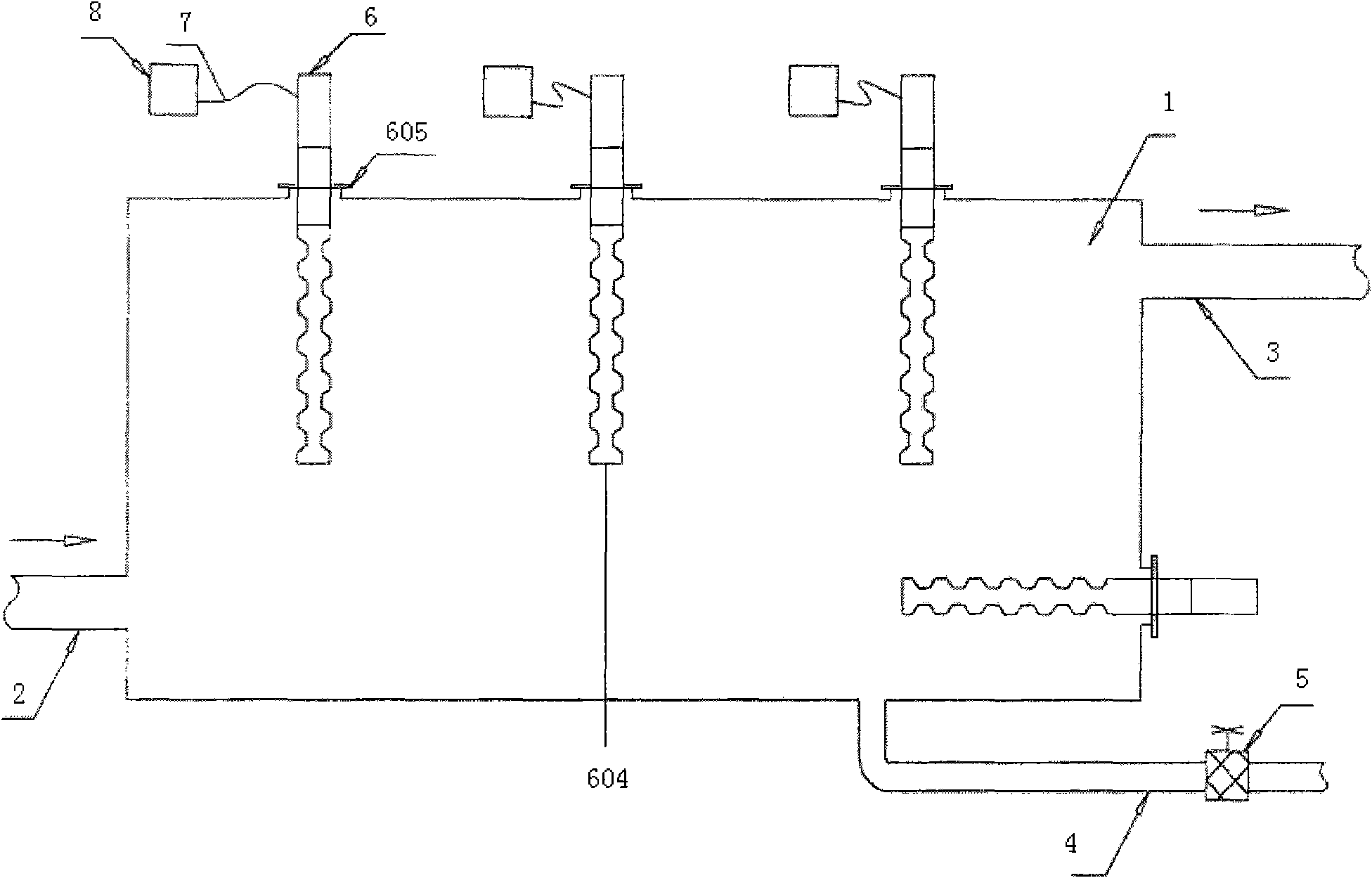

Method and device for performing emulsion breaking on oil-water emulsion by ultrasonic wave

InactiveCN102051201ASimple structureSettling fastDewatering/demulsification with electric/magnetic meansUltrasonic radiationOil water

The invention relates to a method for performing emulsion breaking on an oil-water emulsion by an ultrasonic wave. In the method, one or more ultrasonic generators are arranged in a raw material storage tank or a settlement tank in the gravity settling direction, only one ultrasonic generator acts in the direction of the same vertical line. An emulsion breaking device for implementing the method comprises the raw material storage tank or the settlement tank, and one or more ultrasonic generators are arranged at the bottom or / and top of the raw material storage tank or the settlement tank. The ultrasonic generators are distributed reasonably according to structural size and ultrasonic radiation areas, so that the ultrasonic generators cover comprehensively, and are prevented from being overlapped. The ultrasonic generators are connected with ultrasonic distributors, and one ultrasonic generator is arranged in one ultrasonic distributor. The action direction of the ultrasonic wave is the vertical direction and is consistent with the gravity settling direction, so the driving force is added in the oil-water settling direction, and the oil-water settling speed is accelerated. The device is uniform in ultrasonic wave energy distribution, excellent in emulsion breaking effect, simple in operation, convenient to run and maintain and low in running cost.

Owner:CHINA PETROLEUM & CHEM CORP

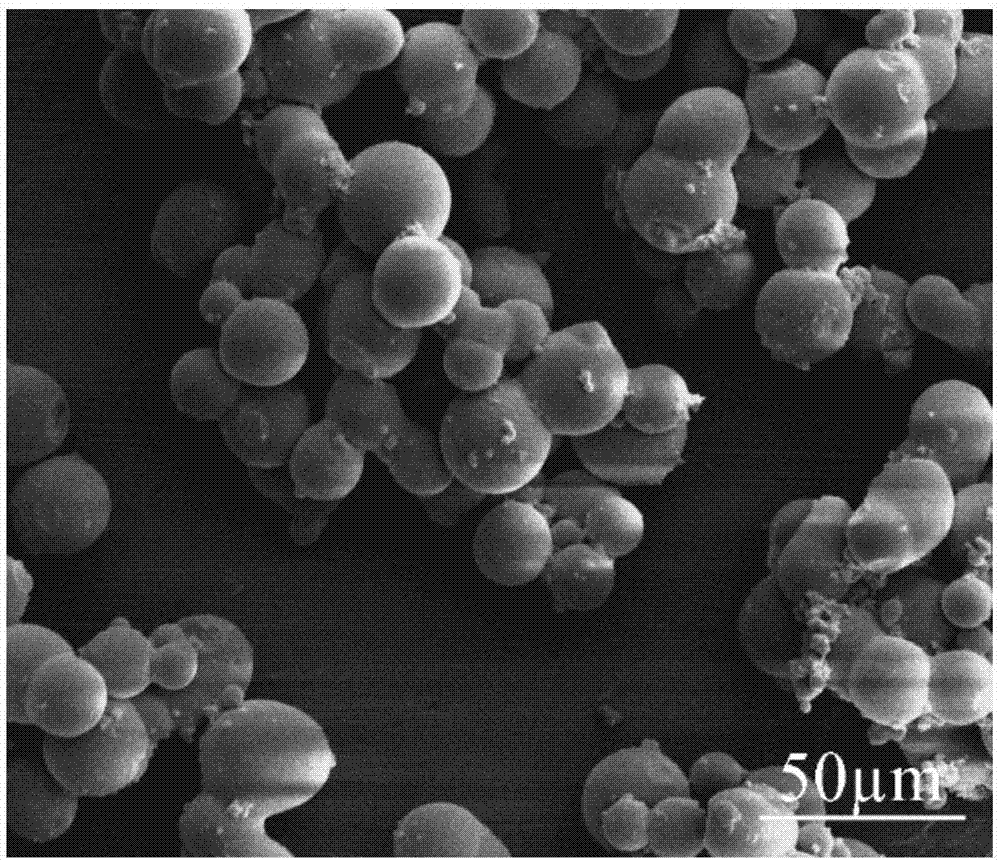

Modified silica aerogel microsphere, and preparation method and application thereof

InactiveCN107043112AStrong acid and alkali resistanceHigh mechanical strengthWater contaminantsAlkali metal oxides/hydroxidesMicrosphereOil phase

The invention belongs to the technical field of adsorption materials, and discloses a modified silica airgel microsphere, a preparation method and an application thereof. The preparation method is as follows: use an acid solution to adjust the pH value of the alkaline silica sol to 2-3, then add a cyano-containing alkoxysilane compound, and add absolute ethanol under stirring conditions to obtain a mixed precursor; The mixed precursor is added to the oil phase under stirring conditions to obtain a water-in-oil emulsion, and then ammonia water is added, stirred and mixed evenly, and then allowed to stand for layering, and the lower layer of sediment is removed, washed and dried to obtain a cyano-modified silicon dioxide aerosol Glue microspheres; then added to the hydroxylamine hydrochloride solution dissolved with anhydrous sodium carbonate for reaction, the product was washed and dried to obtain the modified silica airgel microspheres. The invention prepares silica airgel microspheres and performs amidoxime modification on them, and has the advantages of high specific surface area and good adsorption performance.

Owner:SOUTH CHINA UNIV OF TECH

Graphene oxide film based on dopamine biomimetic modification as well as preparation method and application thereof

InactiveCN106823825AReduce porositySmall apertureSemi-permeable membranesCellulose ester membraneReusability

The invention relates to a graphene oxide film based on dopamine biomimetic modification as well as a preparation method and application thereof, and belongs to the field of film material preparation. The preparation method comprises the following steps of: firstly preparing a mixed cellulose ester film modified by dopamine by using a mussel biomimetic method; and then carrying out vacuum drawing and filtering of a graphene oxide solution on the surface of the film, and drying to obtain the film. The film is capable of filtering stable oil-water emulsion of a surface active agent and has the advantages of high separation efficiency, good stability and reusability. The preparation method has the beneficial effects that the film is prepared by vacuum drawing and filtering, the preparation method is simple, needed raw materials are mild without toxicity and are easily available, and the film is suitable for large-scale production and application.

Owner:JIANGSU UNIV

Dendritic reverse demulsifier

InactiveCN102234526AImprove demulsification efficiencyImprove water qualityDewatering/demulsification with chemical meansDemulsifierEpoxy

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Emulsion ultrasonic emulsion breaking device

InactiveCN101564604ARealize three-dimensional illuminationSpeed up the flowDewatering/demulsification with mechanical meansNon-miscible liquid separationMatched pairBalanced flow

The invention relates to an emulsion ultrasonic emulsion breaking device, which comprises a cavity provided with an input port and an output port, wherein the input port and the output port are arranged on the cavity in an upper-lower matched pair or a lower-upper matched pair, namely the input port is arranged close to the lower end of the cavity, the corresponding output port is arranged close to the upper end of the cavity, and vice versa; and the wall of the cavity is provided with at least one ultrasonic wave generating device through flanges, and a tool head of the ultrasonic wave generating device has a candied gourd shape and is arranged in the cavity. Under the action of the gravity, the emulsion ultrasonic emulsion breaking device achieves balanced flow of an emulsion in an acting cavity, adopts an ultrasonic vibration system, makes full use of ultrasonic waves sent to the circumference from a lateral surface of a rod by the ultrasonic tool head immerged into the emulsion to enlarge the action zone of the ultrasonic waves in the cavity as large as possible, and improves the efficiency and the effect of ultrasonic emulsion breaking. The emulsion ultrasonic emulsion breaking device is adaptable to oil-water emulsion breaking separation.

Owner:WEIHAI HAIHER TECH

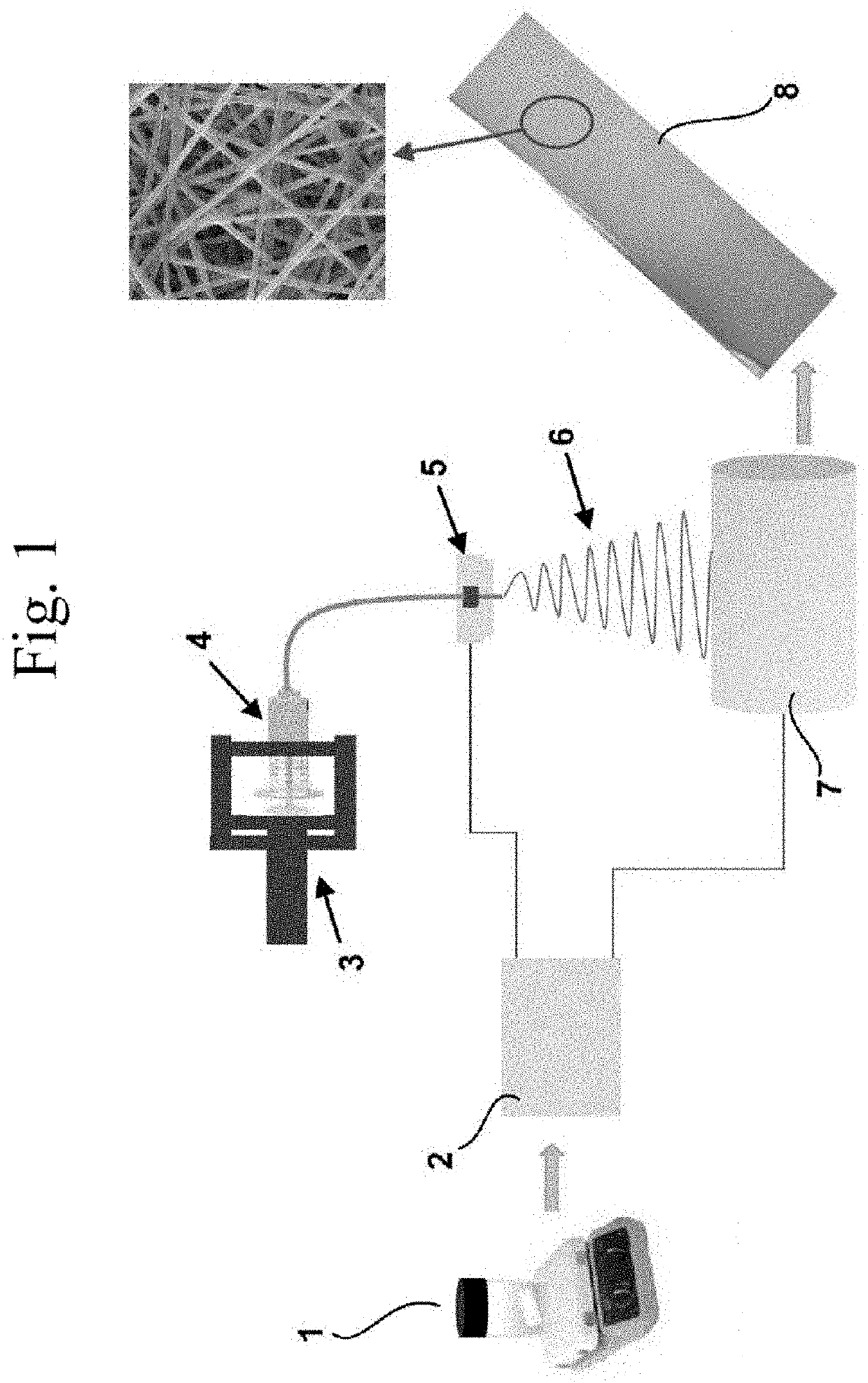

Hybrid membrane and method for separating oil and water

ActiveUS20200197878A1MembranesFatty/oily/floating substances removal devicesPolymer scienceElectrospinning

A hybrid membrane, particularly of polyacrylonitrile (PAN) / graphene oxide (GO) / SiO2, separates oil and water even from emulsions. The membrane can be made by one-step electrospinning, adding GO and SiO2 nanofillers in PAN in various concentrations. The nanofillers may be uniformly embedded in the nanofibrous structure of the electrospun hybrid membrane, with GO mainly embedded inside the PAN nanofibers and may cause knots, and / or SiO2 nanoparticles embedded on the nanofiber surface and may form micro-nano fiber surface protrusions. Hierarchical structures formed can have enhanced hydrophilicity due to oxygen-containing groups on both SiO2 and GO, and have >99% oil rejection from oil-water emulsions. Separation flux and phase rejection of gravity separation may be enhanced by incorporation of nanofillers, which may also enhance membrane mechanical properties. Separated water flux may be enhanced from 2600 (pure PAN) to 3151 Lm−2h−1 for the hybrid.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Preparation method for functional film capable of simultaneously realizing oil-water emulsion separation and dye removal

PendingCN108905651ANo secondary pollutionPost-processing is simpleSemi-permeable membranesMembranesMatrix solutionOrganic dye

The invention discloses a preparation method for a functional film capable of simultaneously realizing oil-water emulsion separation and dye removal. The method comprises the following steps: (1) preparing a polymer matrix solution; and (2) combining a hydroxyl-containing substrate with the polymer matrix solution, and enabling acceleration of gelation and introduction of charged functional groupsto be realized in one step to obtain the functional film capable of simultaneously realizing the oil-water emulsion separation and the dye removal. According to the method disclosed by the invention,the polymer matrix solution gives high specific surface energy to the hydroxyl-containing substrate, so that super-hydrophilic underwater super-oleophobic performance is obtained, and high-efficiencyseparation of oil and water can be realized; and the charged functional groups are introduced, organic dye is adsorbed through electrostatic interaction, so that the organic dye is removed, and finally dye pollutants are removed while an oil-water emulsion is separated only by gravity.

Owner:石狮市川大先进高分子材料研究中心

Super-hydrophilic polymer microporous membrane, and preparation method and application thereof

InactiveCN110280149AImprove separation efficiencyEfficient separationSemi-permeable membranesLiquid separationHydrophilic polymersPolymer science

The invention discloses a super-hydrophilic polymer microporous membrane, and a preparation method and application thereof. The preparation method comprises the following steps: impregnating a pretreated polymer microfiltration membrane in impregnation liquid, then dissolving dopamine hydrochloride and tannic acid in the impregnation liquid, oscillating at a suitable temperature, then taking the polymer microfiltration membrane out from the impregnation liquid, and washing and drying to obtain the super-hydrophilic polymer microporous membrane. The super-hydrophilic polymer microporous membrane provided by the invention has super hydrophilicity and underwater super oleophobic property, and is good in stability; the oil-water separation efficiency is high; an oil-water emulsion can be effectively separated; meanwhile, the preparation process is simple, raw materials adopted can be derived from biomass, safe and environment-friendly effects are achieved, the price is low, large-scale preparation can be realized, and a very good industrial application prospect is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com