Modified silica aerogel microsphere, and preparation method and application thereof

A silica and aerogel technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as fragility, strong pH influence, and poor stability, and achieve Strong acid and alkali resistance, improved chelating performance, and high filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

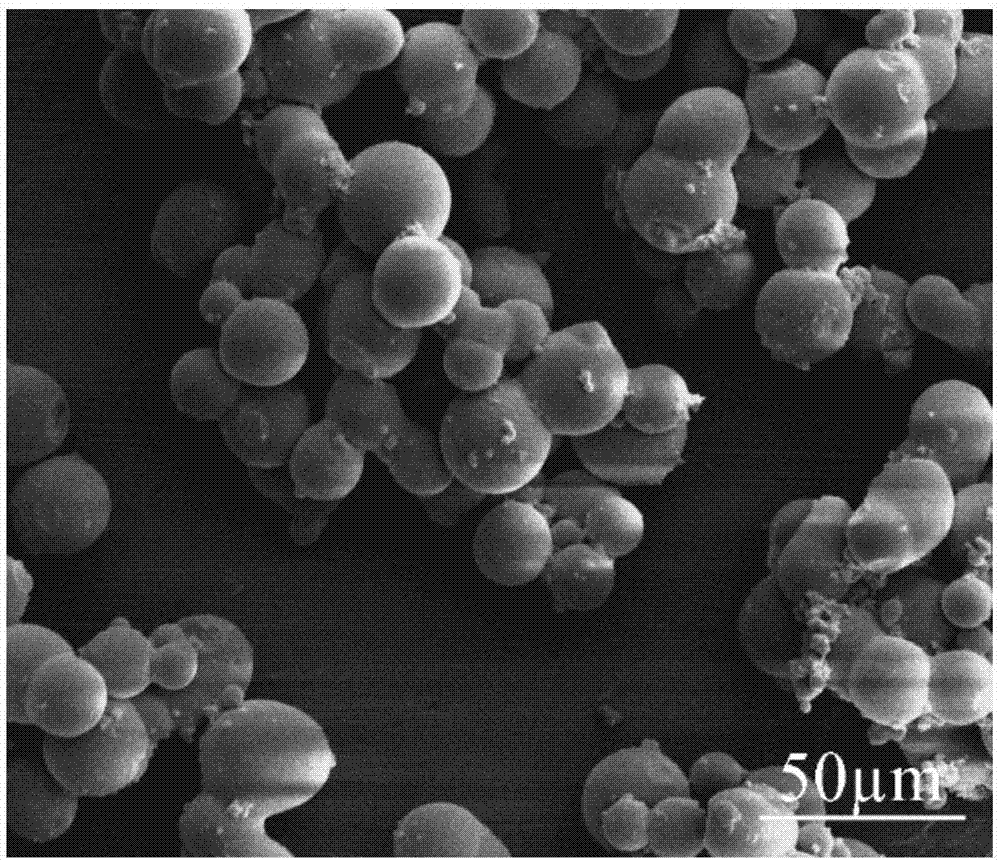

[0030] (1) Measure 10ml alkaline silica sol, use the nitric acid solution that mass fraction is 10% to adjust its pH value to be 3, then add CETS, silica sol (with SiO 2 The molar ratio of ) to CETS is 1:0.4, and then adding anhydrous ethanol with a volume ratio of 1:1.5 to the above mixed solution under stirring conditions to prepare a mixed precursor;

[0031] (2) Take 67ml of n-heptane, 3ml of n-butanol, 9ml of Span 80, and 1ml of Tween 80 and stir at 40°C for 30 minutes to obtain an oil phase, and then add the mixed precursor obtained in step (1) to the oil phase In, the stirring speed is 400r. min -1 , the volume ratio of the added mixed precursor to the oil phase is 0.4:1, so that it forms a uniform water-in-oil emulsion, then after stirring for 30 minutes, adding ammonia water with a concentration of 2mol / L, and continuing to stir for 20 minutes to stop, Let it stand to separate layers, then wash the lower sediment with absolute ethanol three times, and finally freeze...

Embodiment 2

[0038] (1) Measure 10ml alkaline silica sol, use the nitric acid solution that mass fraction is 10% to adjust its pH value to be 3, then add CETS, silica sol (with SiO 2 The molar ratio of 1) to CETS is 1:1, and then adding anhydrous ethanol with a volume ratio of 1:1.5 to the above mixed solution under stirring conditions to prepare a mixed precursor;

[0039](2) Take 67ml of n-octane, 3ml of n-butanol, 8ml of Span 80, and 2ml of Tween 80 and stir at 40°C for 30 minutes to obtain an oil phase, and then add the mixed precursor obtained in step (1) to the oil phase In, the stirring speed is 500r. min -1 , the volume ratio of the added mixed precursor to the oil phase is 0.1:1, so that it forms a uniform water-in-oil emulsion, and then after stirring for 30 minutes, adding ammonia water with a concentration of 2mol / L, and continuing to stir for 20 minutes to stop, Let it stand to separate layers, then wash the lower sediment with absolute ethanol three times, and finally freez...

Embodiment 3

[0045] (1) Measure 10ml alkaline silica sol, use the nitric acid solution that mass fraction is 10% to adjust its pH value to be 3, then add CETS, silica sol (with SiO 2 The molar ratio of ) to CETS is 1:0.4, and then adding anhydrous ethanol with a volume ratio of 1:1 to the above mixed solution under stirring conditions to prepare a mixed precursor;

[0046] (2) Take 67ml of n-octane, 3ml of n-butanol, 8.5ml of Span 85, and 1.3ml of Tween 65 and stir for 30min at 40°C to obtain an oil phase, and then add the mixed precursor obtained in step (1) to In the oil phase, the stirring speed is 300r. min -1 , the volume ratio of the added mixed precursor to the oil phase is 0.3:1, so that it forms a uniform water-in-oil emulsion, and then after stirring for 30 minutes, adding ammonia water with a concentration of 2mol / L, and continuing to stir for 20 minutes to stop, Let it stand to separate layers, then wash the lower precipitate with absolute ethanol three times, and finally obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com