Patents

Literature

689results about How to "Strong acid and alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photo-curing silk screen pearly-luster ink applicable to different printing substrates and preparation method thereof

ActiveCN102634251AGood flexibility and abrasion and scratch resistanceGood acid and alkali resistanceInksSolventPrepolymer

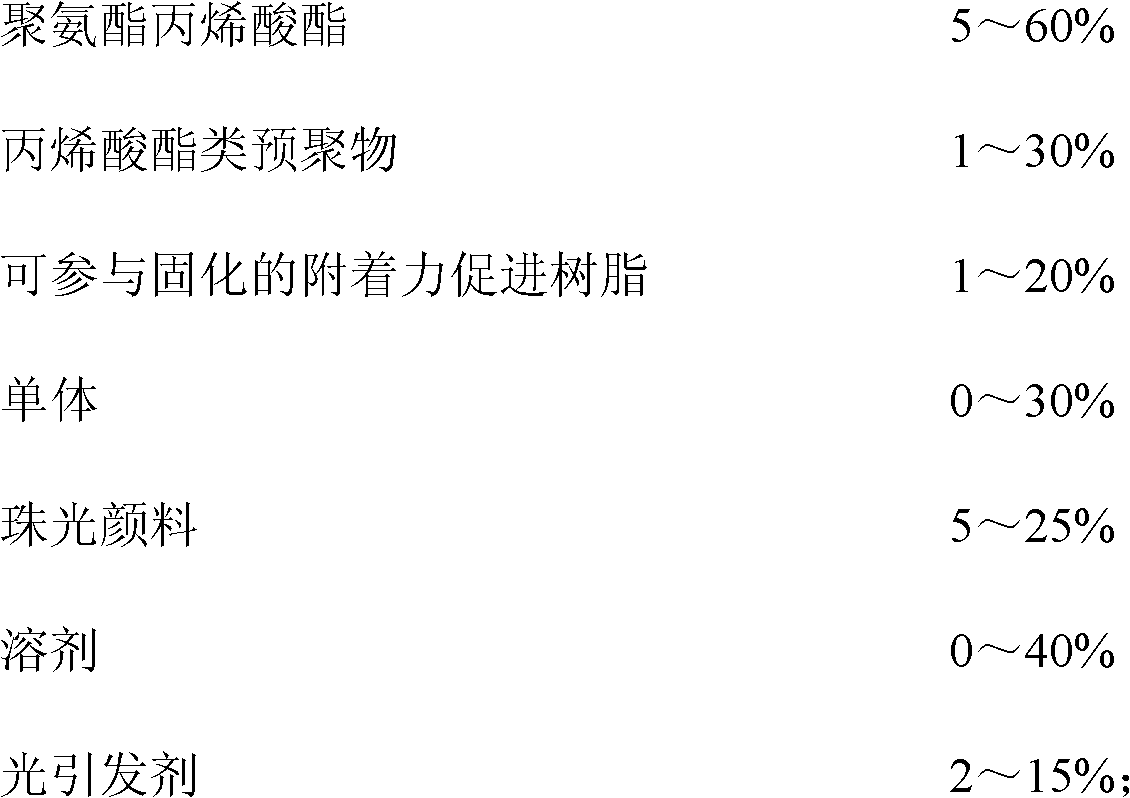

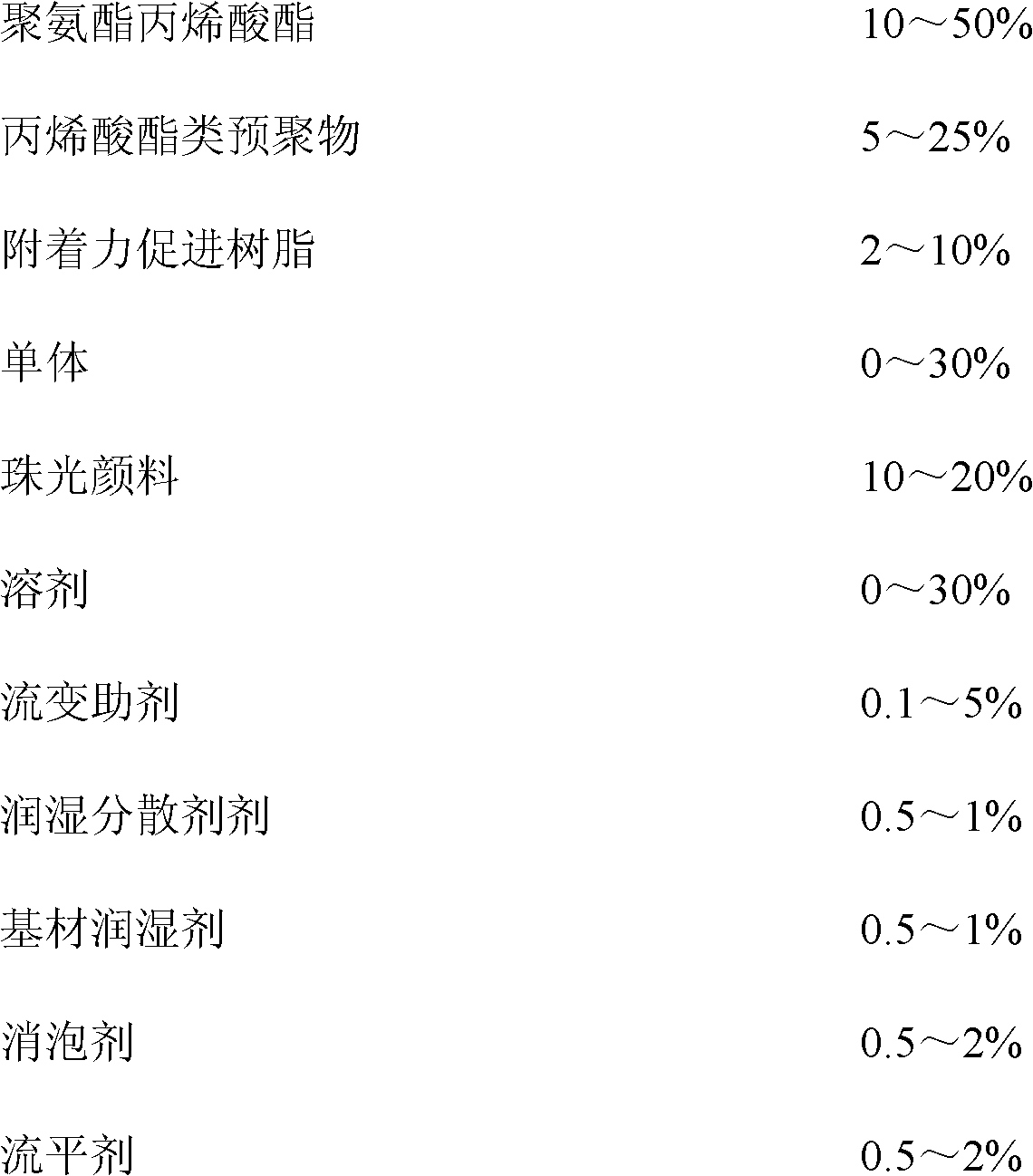

The invention provides a photo-curing silk screen pearly-luster ink applicable to different printing substrates and a preparation method of the photo-curing silk screen pearly-luster ink. The ink is prepared from the following components in percentage by weight: 5-60% of polyurethane acrylate, 1-30% of acrylates pre-polymer, 1-20% of adhesive force accelerating resin capable of participating curing, 0-30% of monomer, 5-25% of pearly-luster pigment, 0-40% of a solvent and 2-15% of a light initiator. The photo-curing silk screen pearly-luster ink applicable to the different printing substrate disclosed by the invention can be suitable for the different printing substrates at the same time and comprises plastic substrates including paper, PET (Poly Ethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), PP (Propene Polymer), PE (Poly Ethylene) and the like, and metal substrates; an adhesive force between the photo-curing silk screen pearly-luster ink and the printed materials is good and the photo-curing silk screen pearly-luster ink has good flexibility and wear-resisting and scrape-resisting strength; the acid-resisting and alkali-resisting performance is excellent and the performance for resisting each type of solvent is good, so that the requirements on silk-screen printing can be met.

Owner:CHINA BANKNOTE INK +1

Nonionic waterborne polyurethane dispersoid and preparation method thereof

InactiveCN102690404AWide range of usesGood acid and alkali resistancePolyurethane dispersionPolymer science

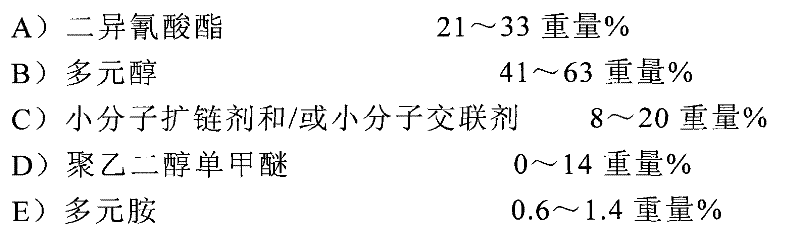

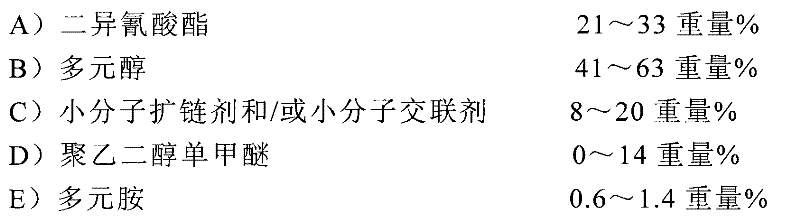

The invention discloses a nonionic waterborne polyurethane dispersoid and a preparation method thereof. The dispersoid is mainly made from raw materials of A) diisocyanate, B) one or more than two polyols containing at least two hydroxy groups, wherein number average molecular weight of the polyols is 1000-4000, C) a small molecule chain extender and / or a small molecule cross-linking agent, D) methoxy polyethylene glycol with medium-low molecular weight, and E) one or more than one polyamines with number average molecular weight smaller than 500. According to the invention, the prepared dispersoid is with a small particle size, has long storage time and has great stabilities of acid tolerance, alkali tolerance and salt tolerance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

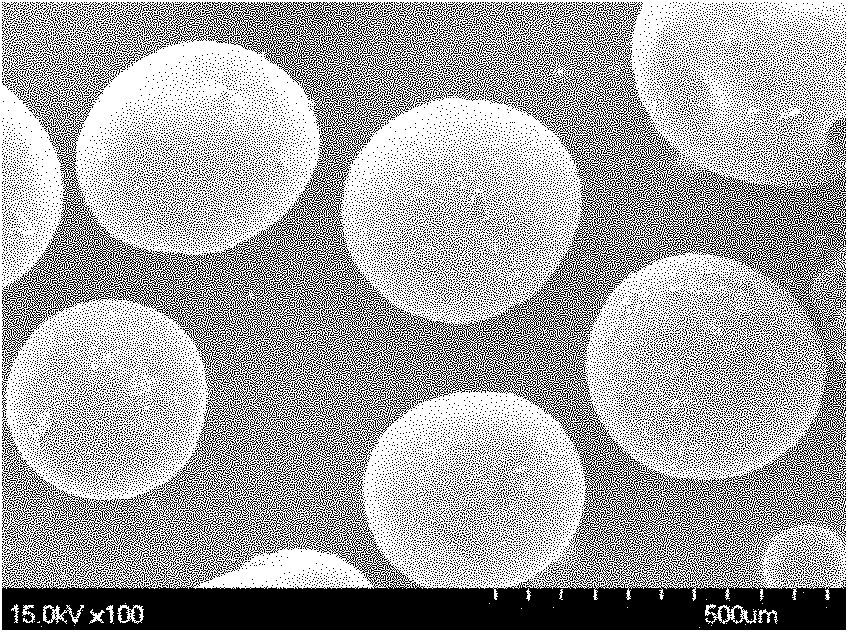

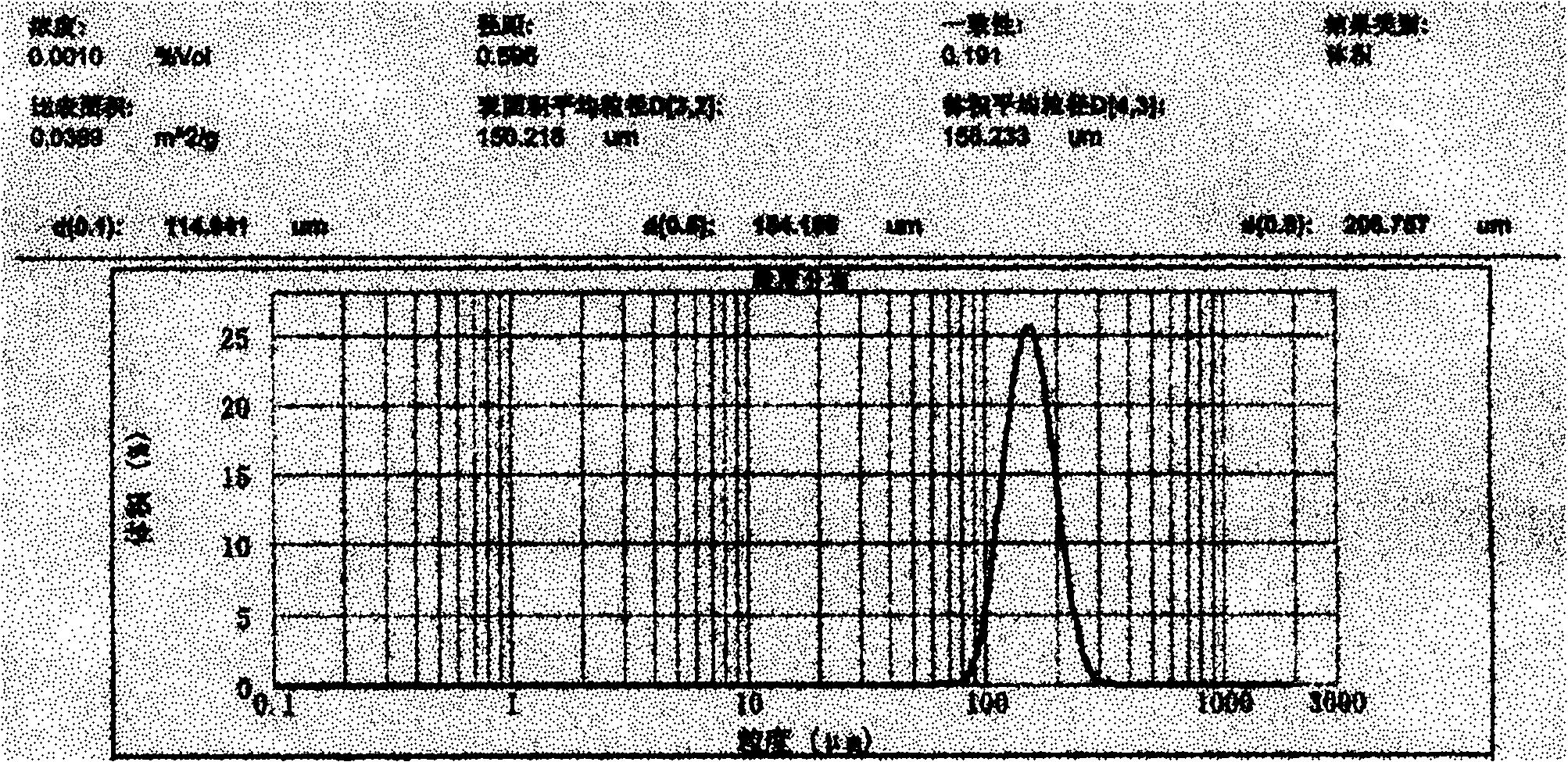

Polymer hollow microsphere and preparation method thereof

The invention relates to a polymer hollow microsphere and a relative preparation method. The preparation method comprises using emulsion polymerization method to prepare water absorbing polymer, using core-shell polymerization to prepare the polymer microsphre coated by water absorbing polymer, using the reaction character of functional monomer at the surface of the polymer microsphere and atomization drying to obtain the polymer hollow microsphere with ideal size, many internal hollow microspheres and negative pressure in the hollow microsphere. The preparation method has low energy consumption, controllable preparation, various products, controllable grain size of hollow microsphere, better size adaptability, high stability, high production efficiency, no generation of waste water, waste gas and waste slag, low pollution and environment protection, whose polymer hollow microspheres have better acie and alkali resistnace. The invention is suitable for construction material and paint, with wide application and practical value.

Owner:金小刚

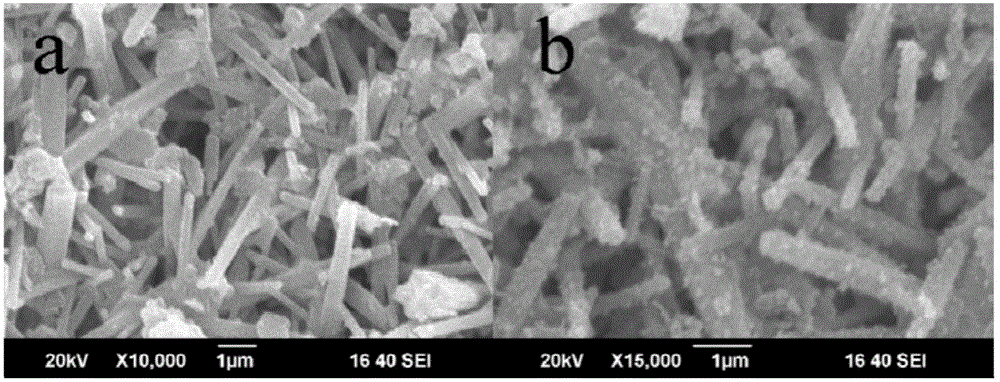

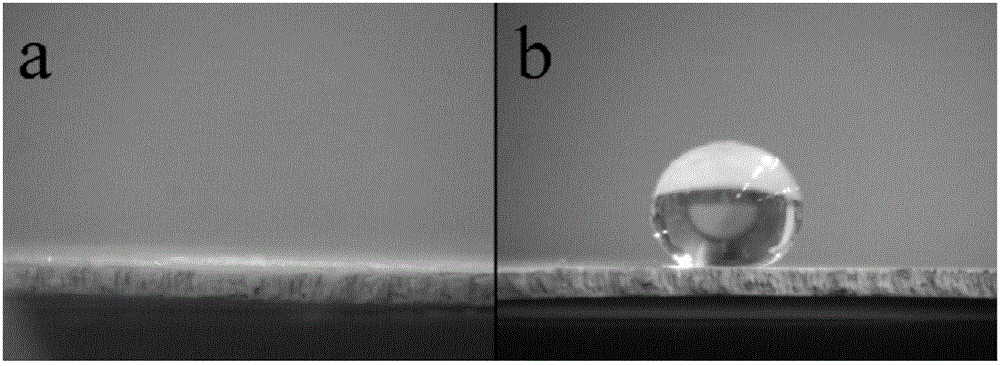

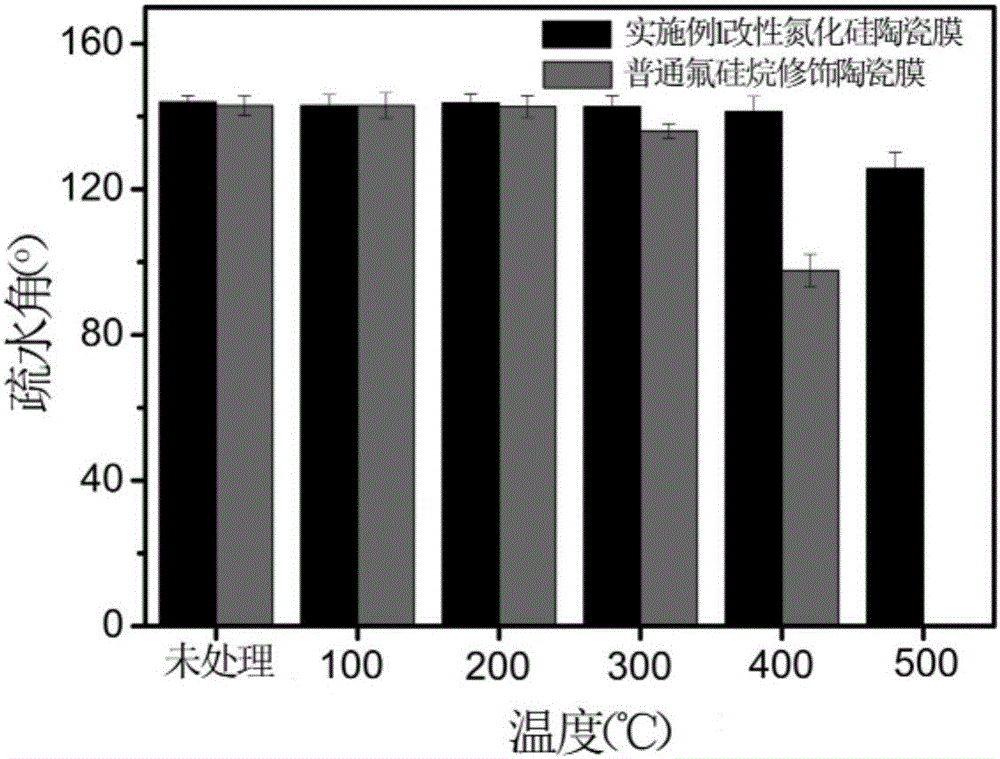

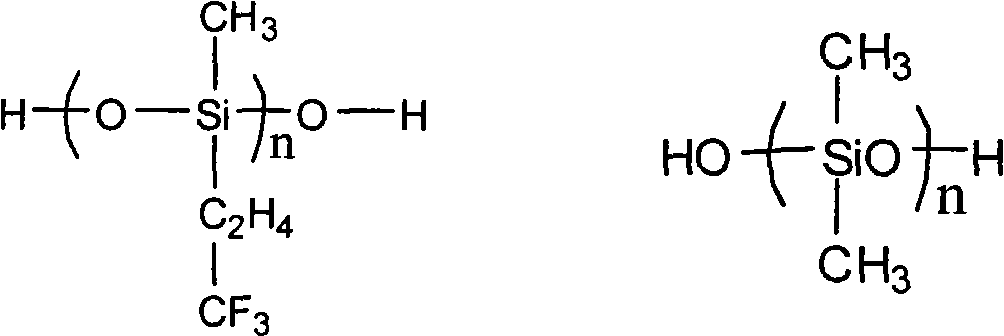

Modification method of ceramic membrane and modified ceramic membrane

ActiveCN106669440AGood chemical stabilityExtended service lifeSemi-permeable membranesSilane compoundsDesalination

The invention provides a modification method of a ceramic membrane and a modified ceramic membrane. The modification method of the ceramic membrane comprises the following steps: performing surface treatment on the ceramic membrane to obtain a fresh ceramic membrane; coating the surface of the ceramic membrane with a silane compound through an impregnation method or a sedimentation method; performing thermal treatment on the coated ceramic membrane under a protective atmosphere, naturally cooling to obtain the modified ceramic membrane after the modification. The modification method of the ceramic membrane provided by the invention has advantages that the modification process is simple, the raw material cost is low, and secondary pollution on the environment can be avoided in the modification process; compared with the common organic modification material, the modified ceramic membrane prepared through modification has the features of high long-term stability, strong acid-base resistance, and strong hydrophobic property; and the modified ceramic membrane can be extensively applied to sea water desalinization, oil-water separation, wastewater treatment and other fields.

Owner:PETROCHINA CO LTD +1

Super-hydrophobic/super-oleophilic oil-water separating net

Super hydrophobic / super oleophylic oil-water separation net has meshes 300-1500 covered thin perfluoroalkyl siloxane copolymer membrane with thickness 20~50nm, which can be metal fiber fabric of stainless steel or cupper, or fabric or terylene and nylon. Its preparation method is: 1. degrease, clean with acid and bath to the fabric net and dry; 2. for the weight share, mix the liquid with perfluoroalkyl siloxane 0.1-5%, water 1-10%, hydrochloric acid or 1N 0.1-2% and other is alcohol for 30-120 minutes, form gel-sol; 3. dip the net into gel-sol for 3-30 seconds, take out, dry naturally, repeat for 2-8 times; 4. take hot curing for the fabric net at 80-250Deg for 10-120 minutes, obtain the membrane and oil-water separation net.

Owner:NANJING UNIV

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and preparation method thereof

ActiveCN101597463ALower surface energyReduce adhesionCoatingsDecabromobiphenyl etherAluminium hydroxide

The invention provides a fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and a preparation method thereof; the fluorinated silicone rubber anti-pollution flashover coating (short for FRTV) has the following compositions by mass percent: 5-30 percent of fluorinated silicone rubber, 10-30 percent of silicon rubber, 4-8 percent of nanometer grade gas-phase white carbon black, 0.5-8 percent of compound fire retardants, 0.2-0.5 percent of firming agent, 0.01-0.05 percent of catalyst, 0.02-0.08 percent of antioxidant, 2-8 percent of flatting agents, 0.2-0.4 percent of de-foaming agent, 0.1-0.5 percent of paint and 30-60 percent of solvent. The compound fire retardant is composed of inorganic aluminium hydroxide and organic decabromodiphenyl oxide, wherein comprising 1-6 percent of the inorganic aluminium hydroxide and 0.5-3 percent of the organic decabromodiphenyl oxide. The preparing process of the coating is simple, and the coating has good weather ability, oil resistance and longer service life.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

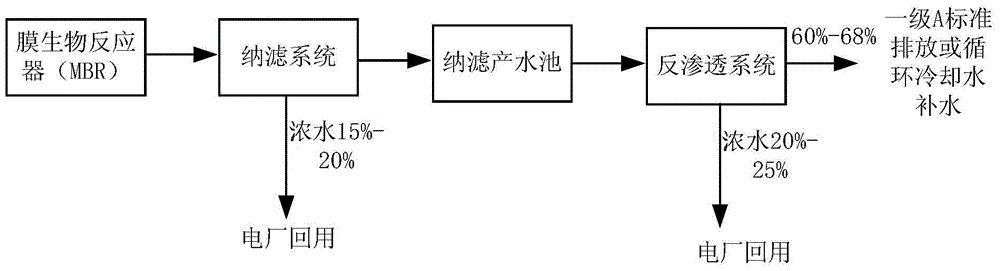

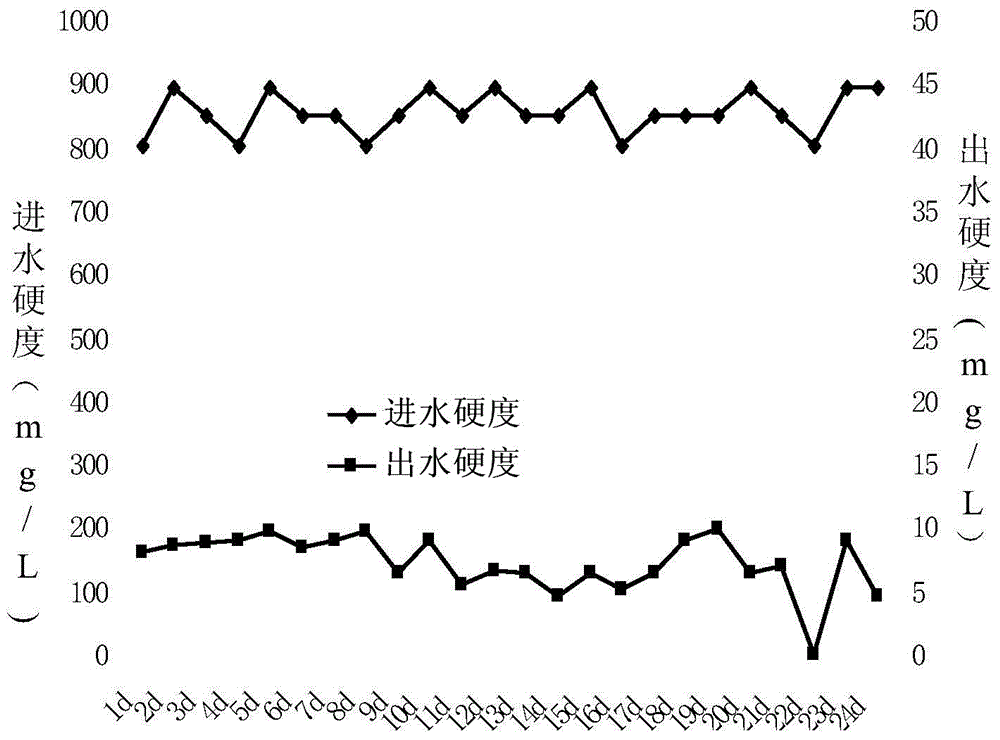

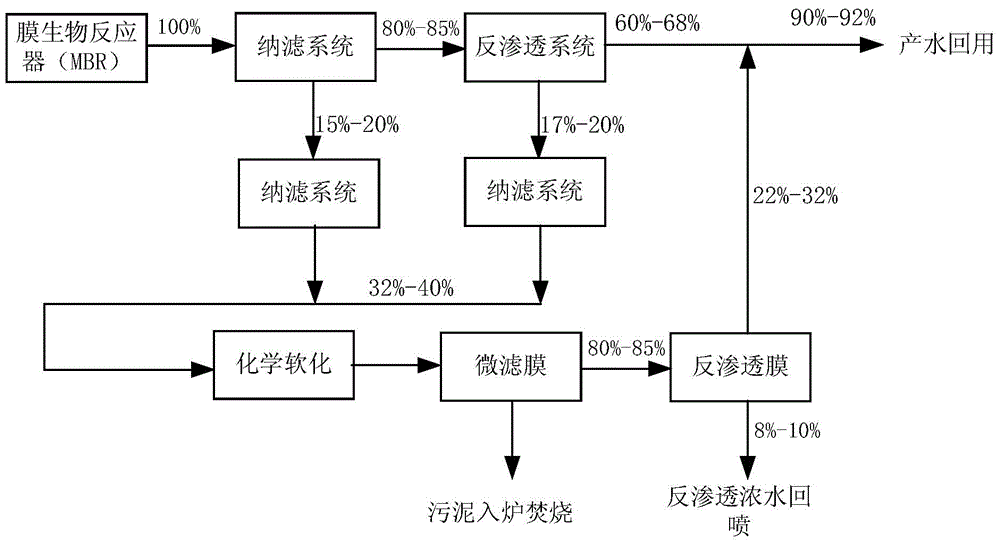

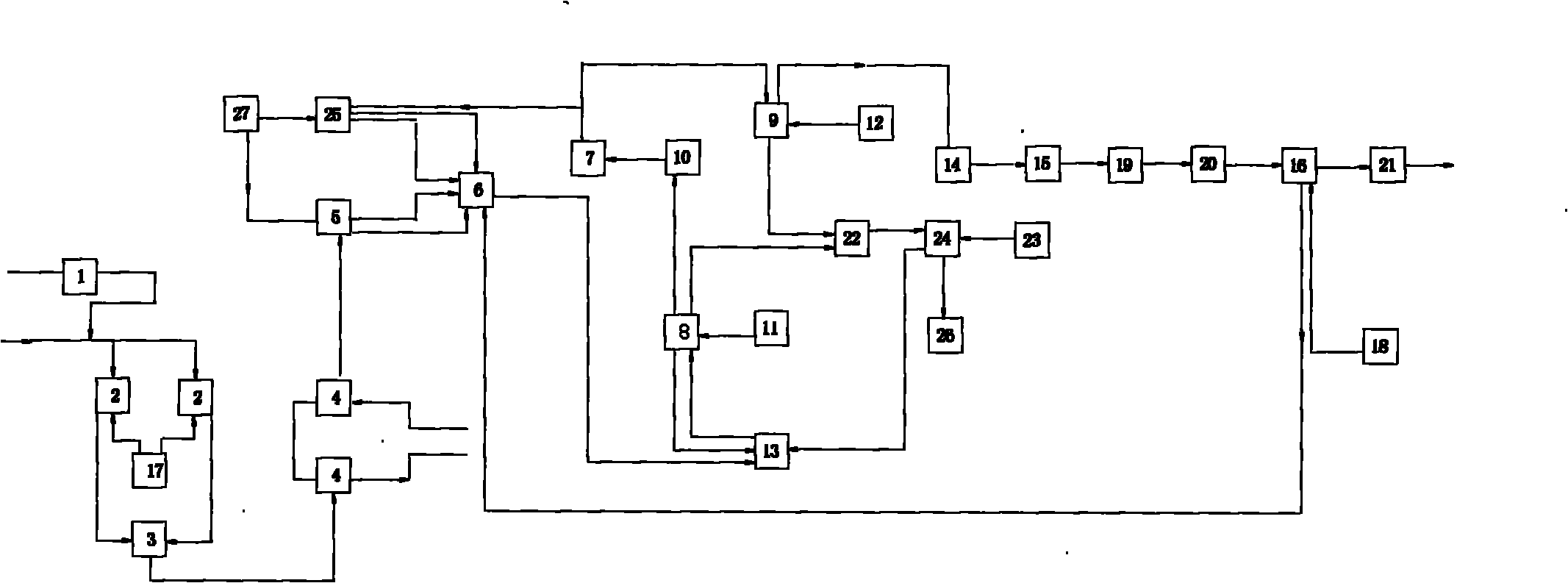

Treatment method and device of landfill leachate concentrate

InactiveCN104787929AIncrease productionAchieve recyclingUltrafiltrationMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to a treatment method and a device of landfill leachate concentrate. The method comprises the following steps: Step S1: carrying out chemical softening treatment on the concentrate to reduce hardness of the concentrate, Step S2: filtering effluent of Step S1 with a microfiltration membrane to remove suspended solids from the concentrate, and Step S3: carrying out reverse osmosis treatment on effluent of Step S2 with a disc tubular reverse osmosis membrane to form recycled effluent. The method and the device have the following advantages: 1, a 'chemical softening, microfiltration membrane and DTRO (Disk Tubular Reverse Osmosis)' technology is employed for treating the nanofiltration and reverse osmosis concentrate, the fresh water yield of a whole system is increased, the recycling of water resources is achieved, and operating cost of a power plant is saved; and 2, the 'chemical softening, microfiltration membrane and DTRO' technology is employed for treating the nanofiltration and reverse osmosis concentrate, so that the concentrate is reduced, and the predicament that the yield of the concentrate is high, and the power plant cannot eliminate the concentrate is solved.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD

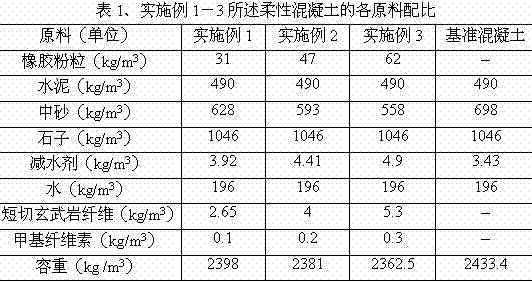

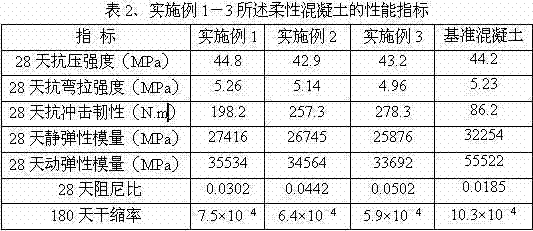

Mineral fiber-modified flexible rubber concrete

InactiveCN102557555AImprove stress resistanceImprove flexural strengthSolid waste managementCelluloseRoad engineering

The invention relates to mineral fiber-modified flexible rubber concrete. The mineral fiber-modified flexible rubber concrete comprises rubber cement concrete, chopped basalt fiber and a dispersant methylcellulose, wherein the rubber cement concrete consists of rubber particles, cement, sand, stones, a water reducing agent and water; and the chopped basalt fiber is 0.1 to 0.5 percent of the volume of the rubber cement concrete, and the dispersant is 0.05 to 0.2 percent of the weight of the water. The concrete is applicable to road engineering, and has high compressive strength, bending tensile strength and deformability, and low modulus of elasticity.

Owner:HENAN UNIVERSITY

Composite acupuncture filter bag used for smoke treatment of ceramic kiln

ActiveCN101695615AShort production processHigh porosityDispersed particle filtrationFiltration separationYarnAlkali free

The invention discloses a composite acupuncture filter bag used for smoke treatment of a ceramic kiln. Short fibers and base fabrics are acupunctured by adopting non-woven acupuncture technology to form a composite acupuncture plain felt, the plain felt is soaked and coated by adopting a surface chemical treatment agent, and then the plain felt is dried and cured at a high temperature and is tailored and sewn to form the filter bag, wherein the base fabrics adopt 30-count alkali-free glass fiber woven fabrics; the short fibers for acupuncture comprise polypropylene fibers, polyphenylene sulfide fibers and 80-count short glass fiber yarns; and the surface chemical treatment agent comprises polytetrafluoroethylene emulsion, polyacrylic ester emulsion, coupling agent, antistatic agent and water. The invention provides the composite acupuncture filter bag used for the smoke treatment of the ceramic kiln, which has the advantages of moisture resistance, good acid corrosion resistance, long service life, high strength of the base fabrics and lower production cost. The problems of poor moisture resistance, poor corrosion resistance, low strength, short service life and high production cost of the filter bag in the prior art are solved. The filter bag is suitable for dust removal and purification treatment for the smoke of the ceramic kiln.

Owner:山东兴国新力环保科技股份有限公司

Polymer phase-change microsphere and preparation method thereof

InactiveCN101250245AAdjustable sizeStrong acid and alkali resistanceHeat-exchange elementsPhase-change materialEmulsion polymerization

The invention relates to a polymer phase transformation microsphere and a relative preparation method. The preparation method comprises using emulsion polymerization method or suspension polymerization method to synthesize oil absorbing type resin, absorbing organic phase transformation material in the presence of water, coating outer layer, atomizing and drying to obtain the heat capacity microsphere with phase transformation function. The invention has low energy consumption, controllable preparation, various products, better acid and alkali resistance, better heat insulation, better size adaptability, high stability, adjustable grain size of microsphere, high production efficiency, low pollution and simple operation, which is suitable for construction material and paint, with wide application and practical value.

Owner:金小刚

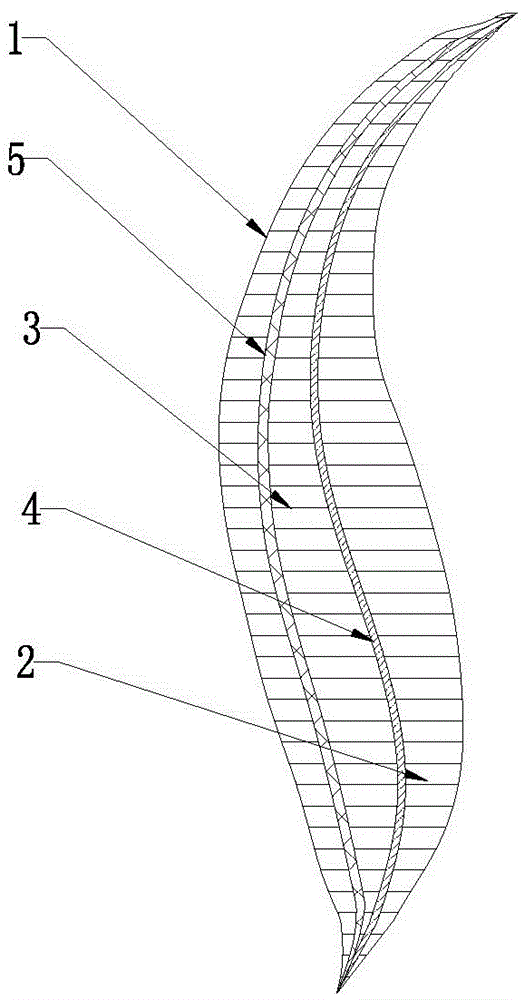

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

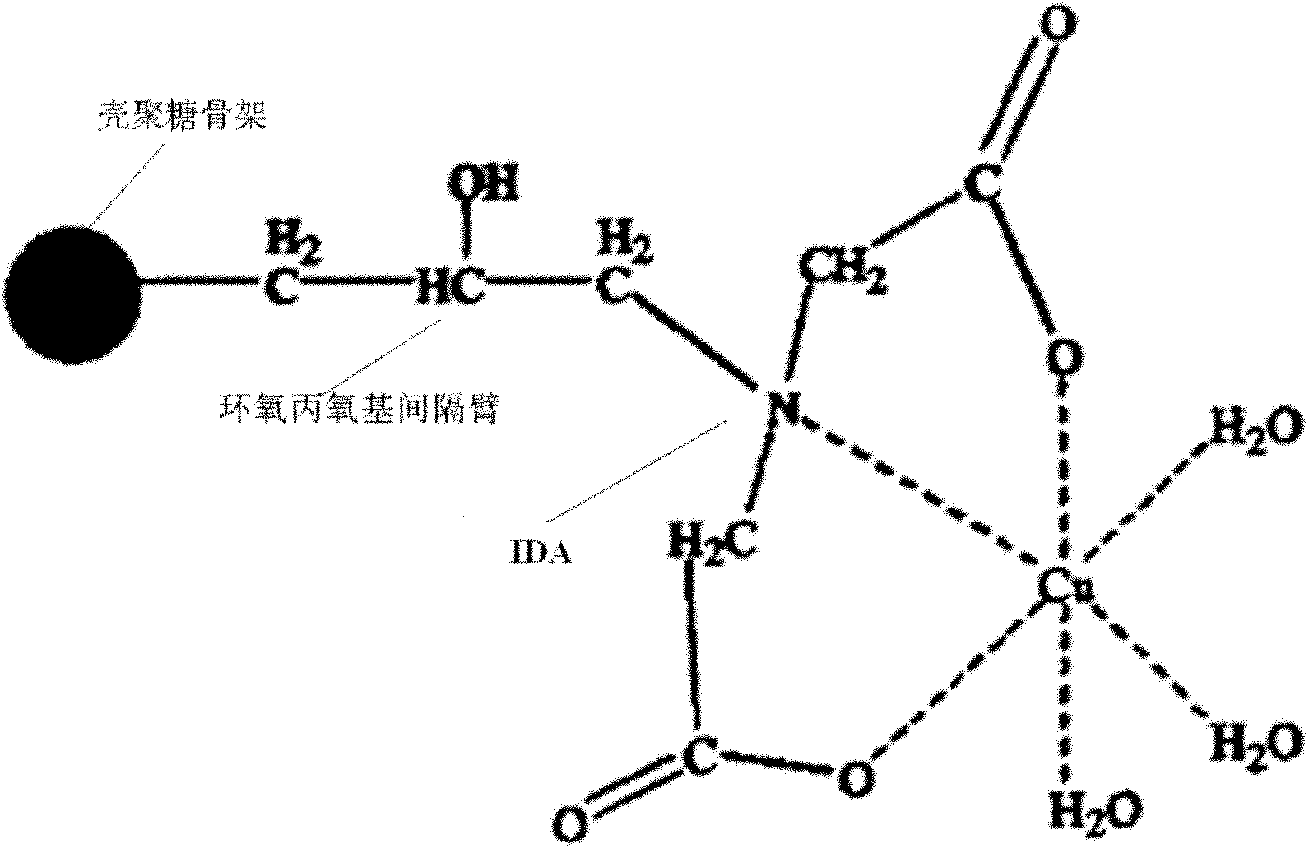

Method for preparing chitosan separation medium suitable for protein purification

ActiveCN102068965AEasy to operateGood particle size uniformityOther chemical processesPeptide preparation methodsCross-linkEpoxy

The invention relates to a method for preparing a chitosan separation medium suitable for protein purification, which comprises the following steps of: (1) dispersing acetic acid solution of chitosan into liquid paraffin with stirring to form chitosan particles in the presence of cyclohexane serving as a porogen and a small amount of span80, and further cross-linking the chitosan particles to form a chitosan skeleton under the action of glutaraldehyde serving as a cross-linking agent; (2) swelling the chitosan skeleton, and reacting a hydroxyl group on the chitosan skeleton with epoxy chloropropane in dimethyl sulfoxide (DMSO) / NaOH mixed solution to introduce an epoxy group into the chitosan skeleton so as to obtain a grafted chitosan skeleton; and (3) adding iminodiacetic acid (IDA) / NaOHmixed solution into the grafted chitosan skeleton, reacting at the temperature of between 20 and 80 DEG C for 1 to 10 hours, and performing suction-filtration to obtain the chitosan separation medium. The chitosan separation medium solves the leakage problem of metal ions to a large extent, has the advantages of process stability, high repeatability and the like, and is suitable for mass production.

Owner:ZHEJIANG UNIV OF TECH

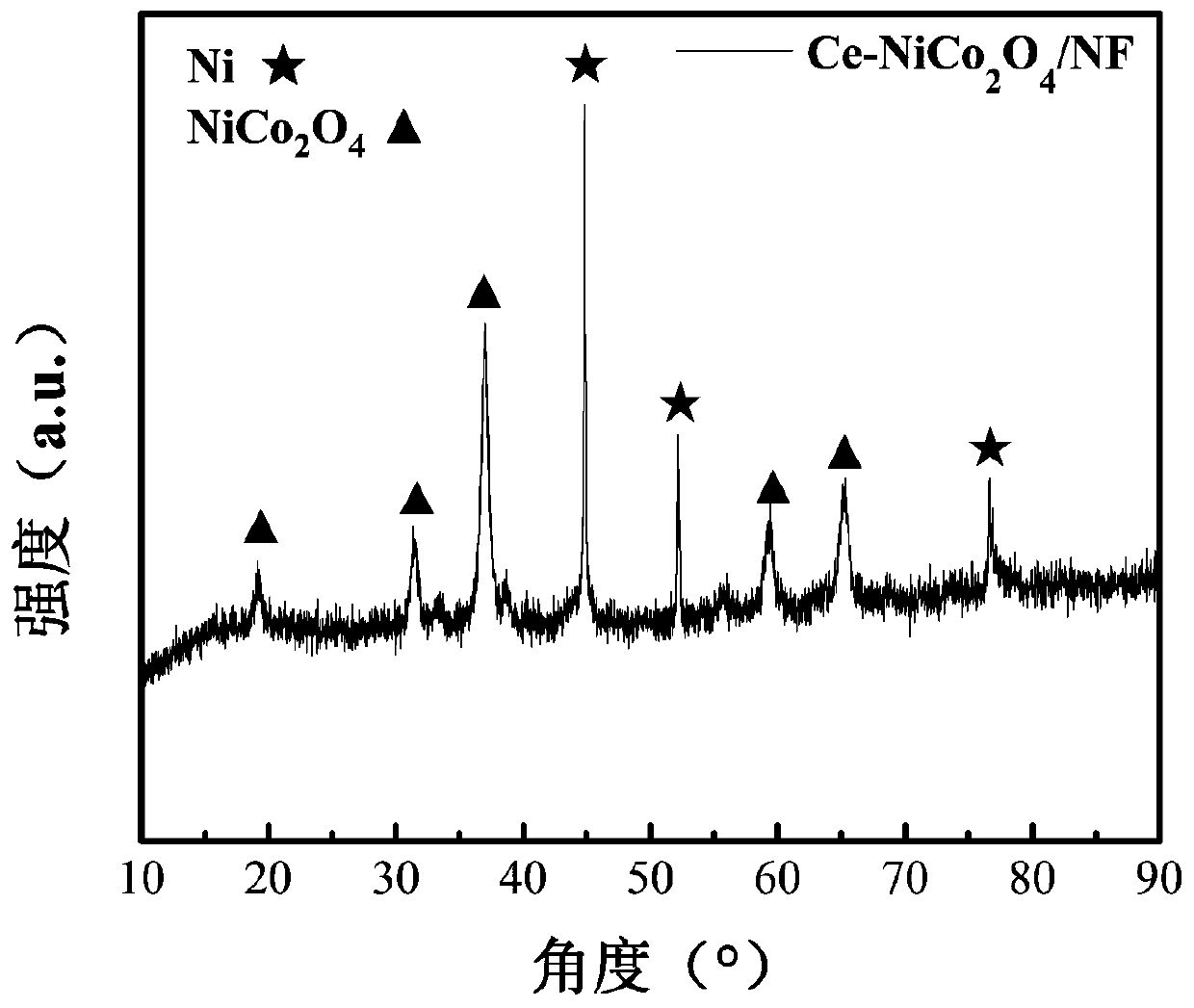

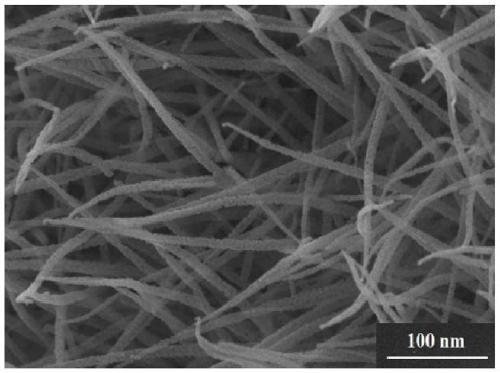

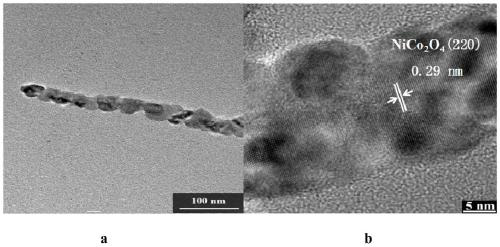

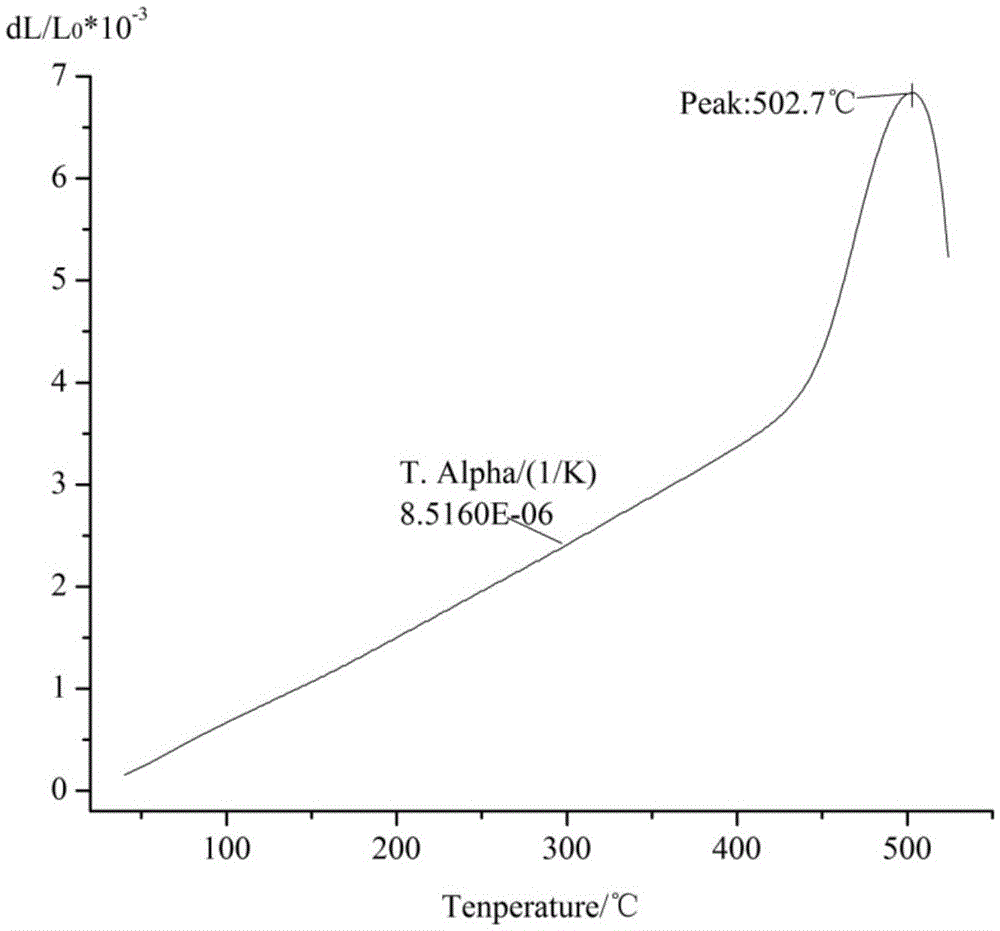

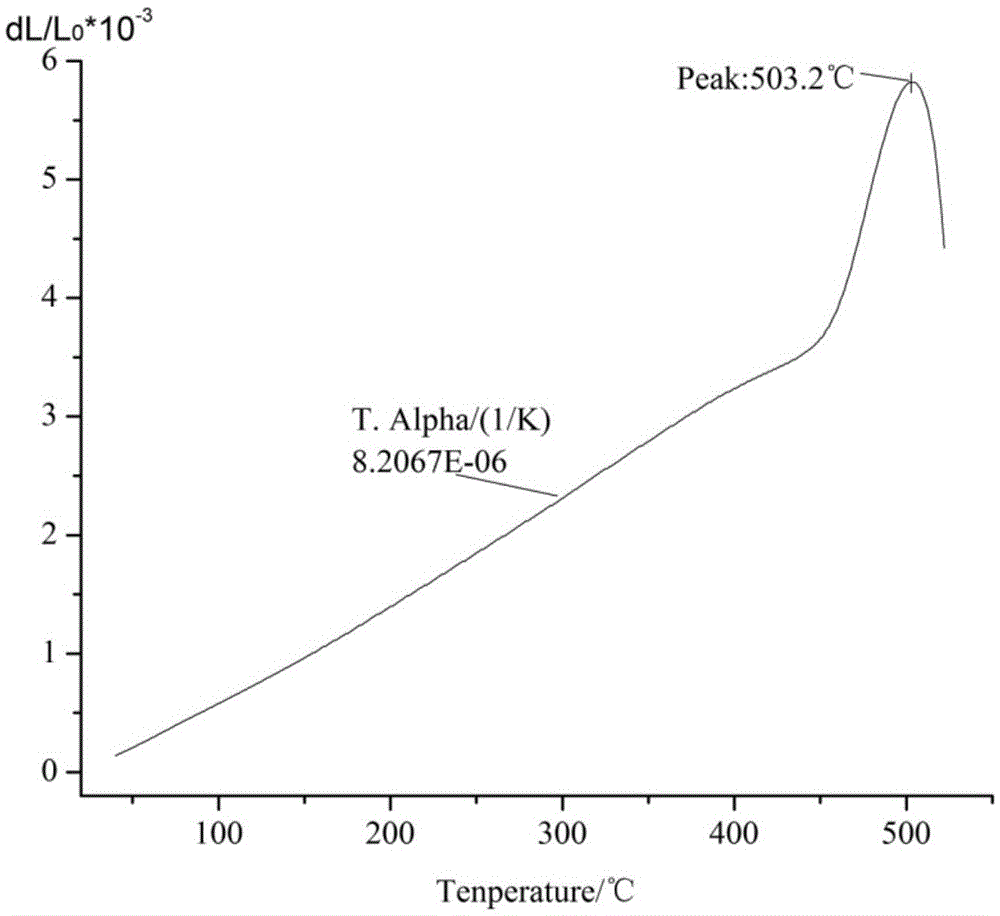

CeO2-NiCo2O4/NF composite electrocatalytic material and preparation method and application thereof

InactiveCN109806879AImprove structural stabilityImprove permeabilityCatalyst activation/preparationElectrode shape/formsNanowireOxygen

The invention provides a CeO2-NiCo2O4 / NFcomposite electrocatalytic material and a preparation method and application thereof. The method includes the steps that a nickel-cobalt hydroxide precursor (NiCo2-OH / NF) is grown in situ on the surface of foamed nickel through a hydrothermal method, a one-dimensional NiCo2O4 nanowire is constructed on the surface of the foamed nickel through roasting treatment, finally, CeO2 are uniformly deposited on the surface of the NiCo2O4 nanowire through an electro-deposition method to obtain the CeO2-NiCo2O4 / NF composite electrocatalytic material, wherein NiCo2O4 is of a spinel structure, NiCo2O4 is oriented to form the nanowire growing vertically on the surface of a foamed nickel sheet substrate, and the CeO2 are uniformly deposited on the surface of NiCo2O4. The composite electrocatalytic material has excellent electrocatalytic oxygen evolution activity and stability, when the current density is 10 mA.cm<-2>, in the alkaline electrolyte environment, the oxygen evolution overpotential of CeO2-NiCo2O4 / NF is 261-217 mV, and the oxygen evolution overpotential is 401-334 mV in the acidic electrolyte environment; and the catalytic material is used for anelectrocatalytic oxygen evolution reaction of water.

Owner:BEIJING UNIV OF CHEM TECH

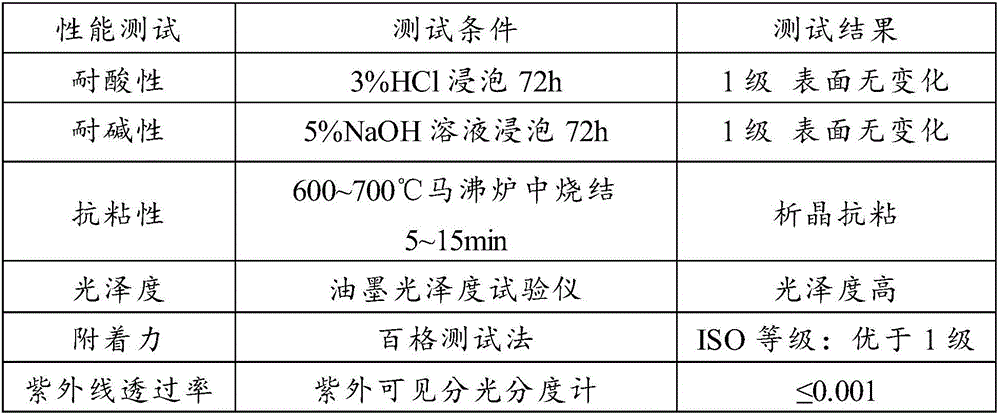

Acid-and-alkali-resistant environment-friendly ink for automotive windscreen and preparing method thereof

The invention relates to the technical field of ink, in particular to an acid-and-alkali-resistant environment-friendly ink for an automotive windscreen.The acid-and-alkali-resistant environment-friendly ink is characterized by being prepared from, by mass, 50%-70% of lead-and-cadmium-free composite glass powder, 8%-20% of inorganic pigment, 20%-40% of varnish, 0.6%-1% of dispersing agent, 0.6%-1% of flatting agent and 0.3%-0.6% of thixotropic agent.The acid-and-alkali-resistant environment-friendly ink for the automotive windscreen is efficient and environmentally friendly, has excellent acid and alkali resistance and suitable sintering temperature, is good in water resistance, high in adhesive force and good in ultraviolet resistance, and has the quite low light transmissivity, and foreign-automobile-windscreen ink products can be replaced with the ink.

Owner:湖南衡义材料科技有限公司

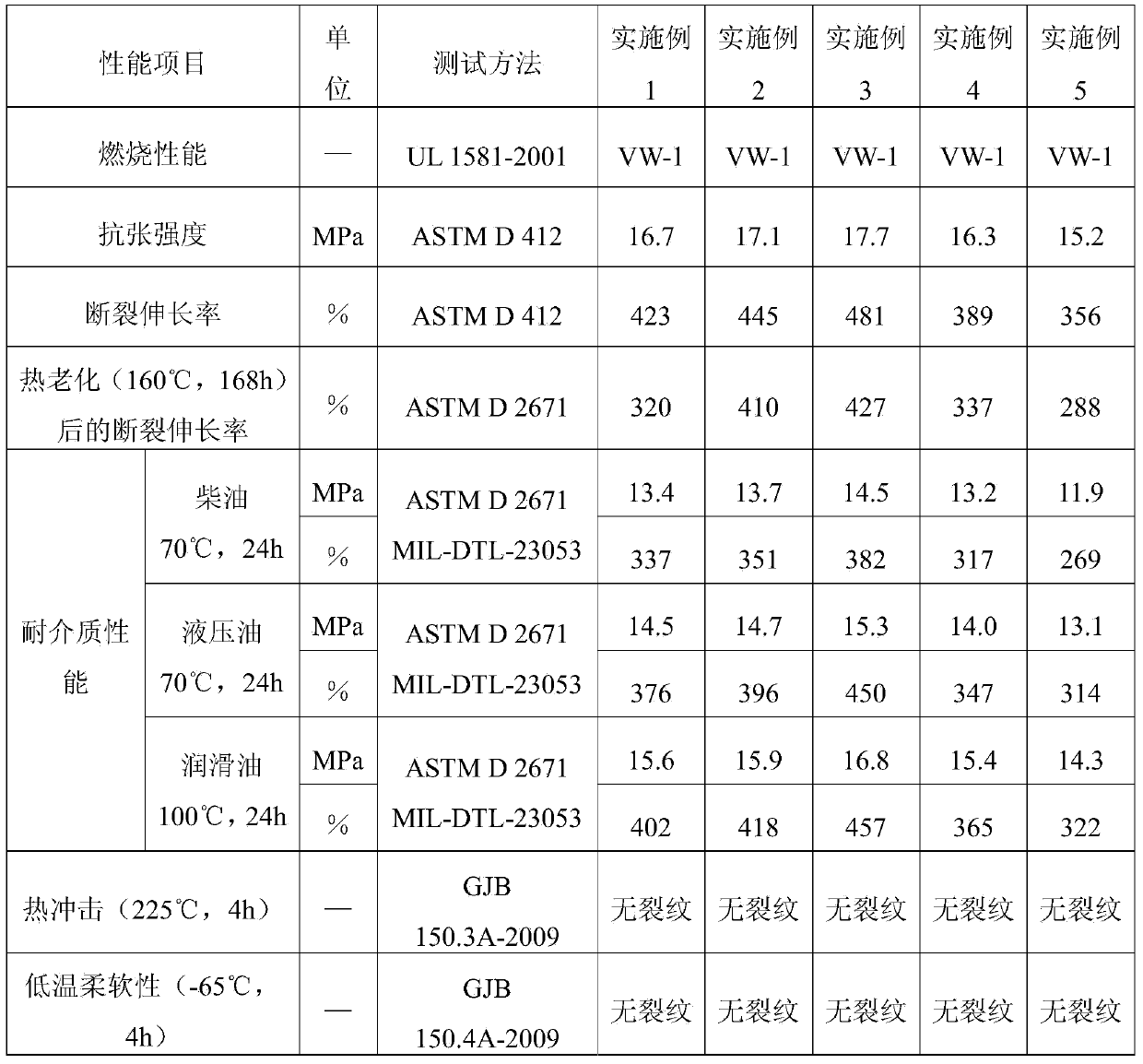

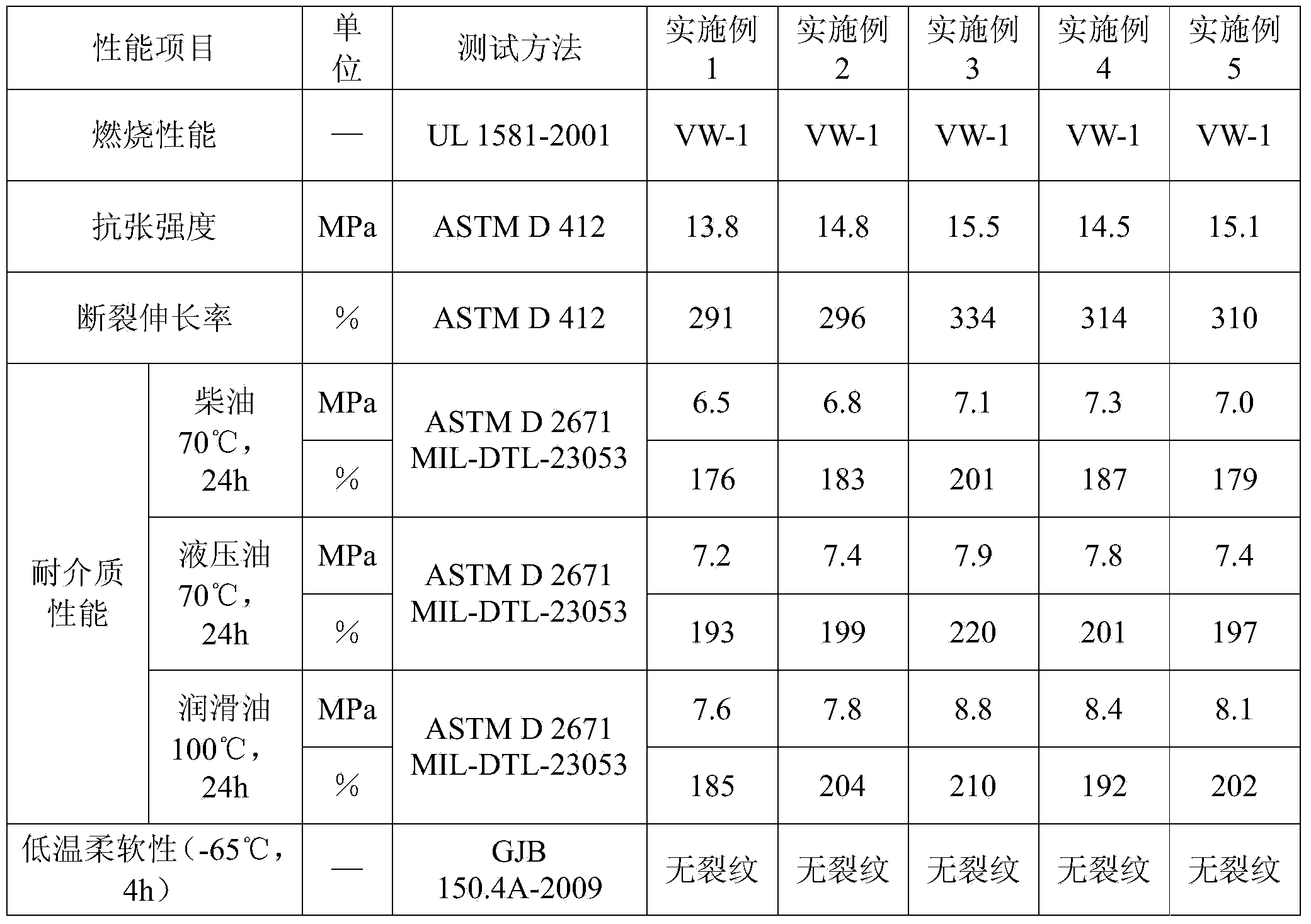

Thermoplastic polyester elastomer heat-shrinkable casing tube for automobile wire harness as well as preparation method and application of heat-shrinkable casing tube

The invention discloses a thermoplastic polyester elastomer heat-shrinkable casing tube for an automobile wire harness as well as a preparation method and an application of the heat-shrinkable casing tube. The heat-shrinkable casing tube comprises the following components in parts by weight: 50-80 parts of a thermoplastic polyester elastomer, 30-60 parts of halogen-containing resin, 5-15 parts of black masterbatch, 5-30 parts of diantimony trioxide, 0-100 parts of a flame retardant, 3-15 parts of a flame retardant synergist, 1-4 parts of a thermal stabilizer, 0.5-4 parts of an antioxidant, 0.5-2 parts of a silicone aid and 1-2.5 parts of a sensitizer. The preparation method comprises the following steps: mixing the thermoplastic polyester elastomer, the halogen-containing resin, the black masterbatch, diantimony trioxide, the flame retardant, the flame retardant synergist, the thermal stabilizer, the antioxidant and the silicone aid, adding the sensitizer, mixing, granulating, extruding to form a tube, performing irradiation crosslinking, stretching by expanding, shaping by cooling, flattening, and marking. The heat-shrinkable casing tube has the advantages of relatively low price, high-efficiency flame retardance, excellent mechanical property, low pollution, high-temperature oil resistance, acid-base corrosion resistance and capability of being applied in a severe working environment.

Owner:广州凯恒科塑有限公司

Environment-friendly water-based bi-component polyurethane steel-structure anti-corrosion finish paint and preparation method

InactiveCN102604530AStrong acid and alkali resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryEmulsion

The invention provides environment-friendly water-based bi-component polyurethane steel-structure anti-corrosion finish paint and a preparation method. The anti-corrosion finish paint comprises a component A and a component B, wherein the component A comprises, by weight, 55-58 parts of hydroxyl water-based resin emulsion, 27-33 parts of titanium oxide, 0-2 parts of Prussian blue, 0-3 parts of carbon black, 1-2 parts of defoamer, 0.5-1 part of dispersing agent, 0.5-1 part of wetting agent and 10-17 parts of water; the component B comprises, by weight, 80-82 parts of curing agent and 18-20 parts of cosolvent; and the two components are mixed in the weight proportion of 4.4:1. The anti-corrosion finish paint is highly waterproof, high in hardness and glossiness and full in color, has the advantages of good leveling property, high covering power, firmness in adhesion, acid-resistant and alkali-resistant coatings, safety in construction and the like, and can be widely used for steel structures of all walks of life, such as mechanical equipment, rolling stock, constructions such as departure halls, stadiums, railway station rooms, convention centers, commercial buildings, bridges and the like of steel structures, thereby having a huge market prospect.

Owner:SHANGHAI MAMPLE NEW MATERIAL

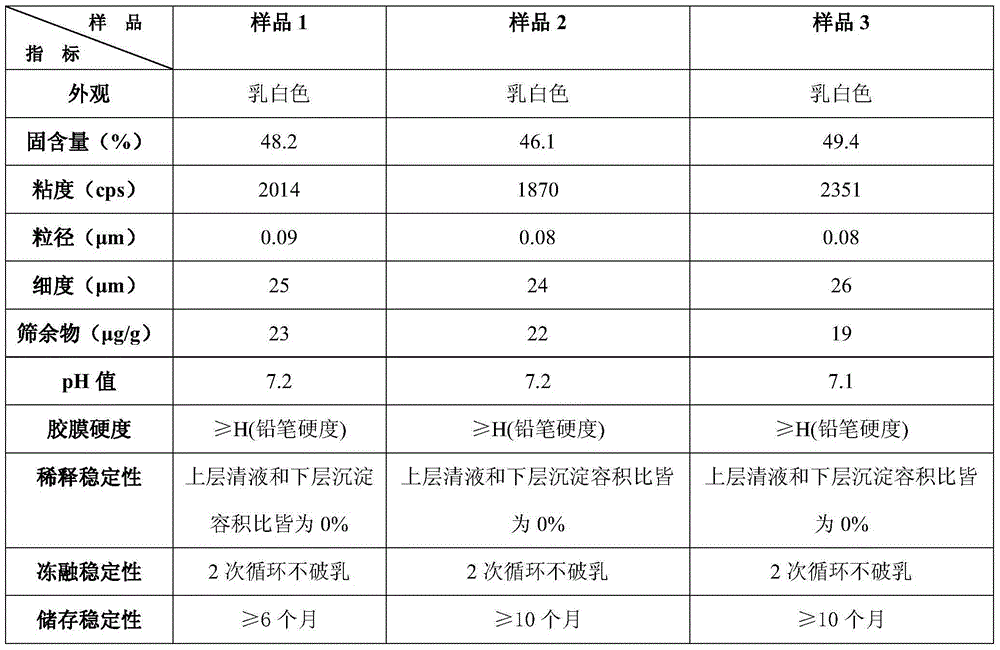

Preparation method of high-performance waterborne acrylic resin

ActiveCN109796555AImprove performanceHigh glossPolyurea/polyurethane coatingsAcrylic resinCarboxylic acid

The invention discloses a preparation method of high-performance waterborne acrylic resin. The waterborne acrylic resin is prepared from the raw materials of, by mass, 25-35 parts of unsaturated monomers containing hydroxyls, 20-40 parts of hard monomers, 20-40 parts of soft monomers, 8-15 parts of unsaturated carboxylic acid, 3-5 parts of an initiator, 0.5-2 parts of an organic silicone modifier,0.5-1.5 parts of a chain transfer agent and 80-90 parts of a solvent. The preparation method comprises the steps that colorless and transparent acrylate prepolymers with the hydroxyl content of 2.5 mmol / g and the solid content of 60+ / -1% is synthesized by solution copolymerization, and the high-performance waterborne acrylic resin is obtained through a 'salt forming method'. According to the preparation method, the organic silicone modifier is introduced to the acrylic resin to improve the water resistance, heat resistance and chemical resistance performance of the acrylic resin, a simple method, cheap raw materials which are convenient to obtain and conventional equipment are used for preparing the waterborne acrylic resin with good performance, the glossiness of a product is high, the drying speed is fast, the mechanical performance is excellent, water resistance, weather resistance and solvent resistance are good, and the coating demands of the majority of workpieces are met.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

Automobile toughened glass ink and preparation method thereof

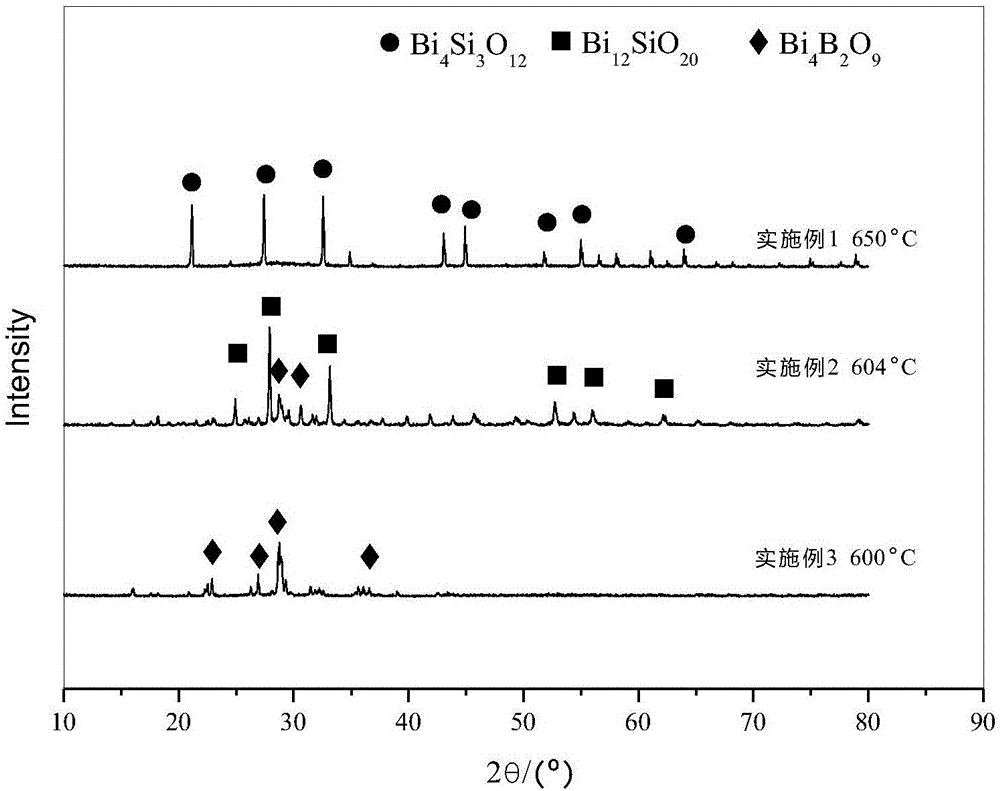

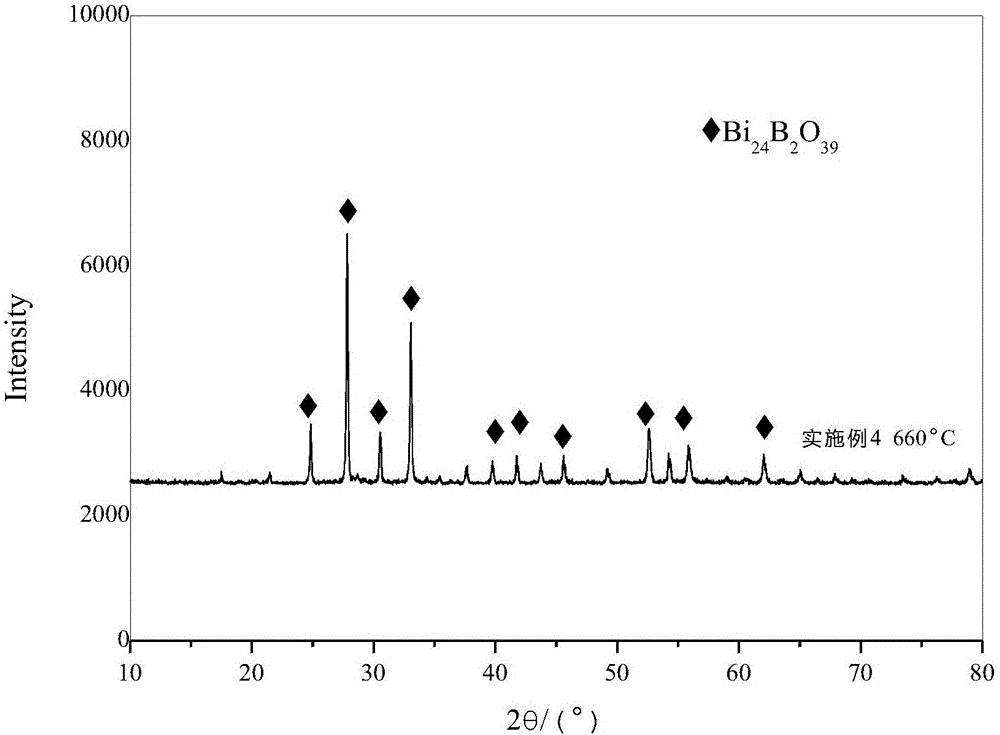

InactiveCN107523117AGood anti-stick and non-stick moldImprove adhesionInksCoatingsSilver pasteUltraviolet

The invention provides automobile toughened glass ink, which is prepared from glass powder, inorganic pigment, varnish, a dispersing agent, a flatting agent and a thixotropic agent, wherein the glass powder is prepared from 74-85wt% of Bi2O3, 2-11wt% of SiO2, 2-11wt% of B2O3, 2-5wt% of Al2O3 and 2-5wt% of ZnO. The application also provides a preparation method and application of the automobile toughened glass ink. When the glass powder in the automobile toughened glass ink provided by the invention is sintered at the temperature of 600-700 DEG C, one or a plurality of silicate or borate crystal phases are easy to separate out; a dense crystallization layer enables the ink to have a good anti-sticking property and not to adhere to a mould, and enables the ink to have the advantages of being high in adhesive force and high in acid and alkali resistance, shielding conductive silver paste, resisting ultraviolet radiation, and the like.

Owner:GUANGDONG UNIV OF TECH

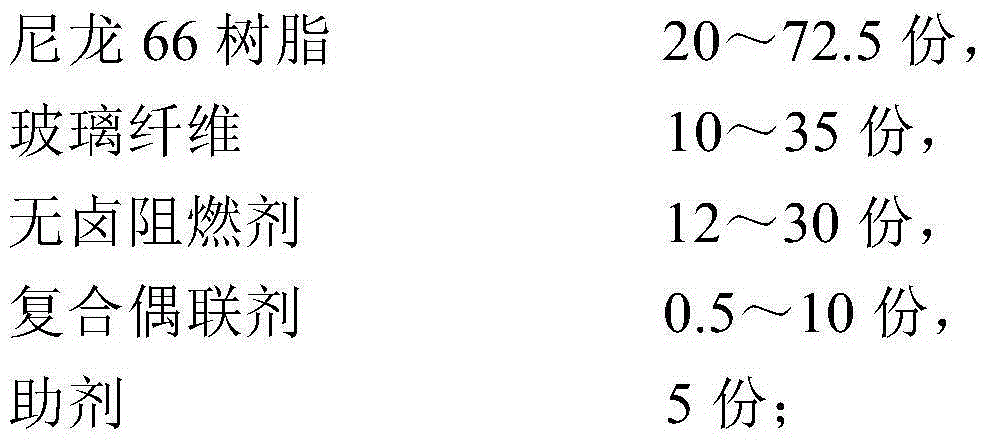

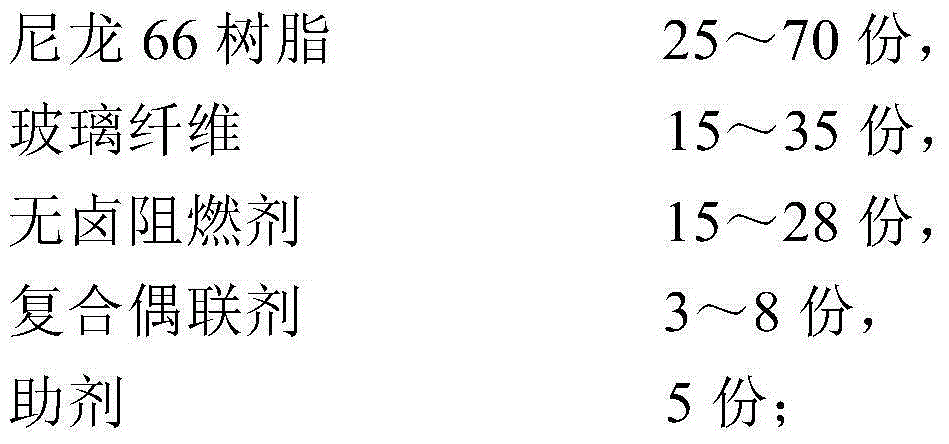

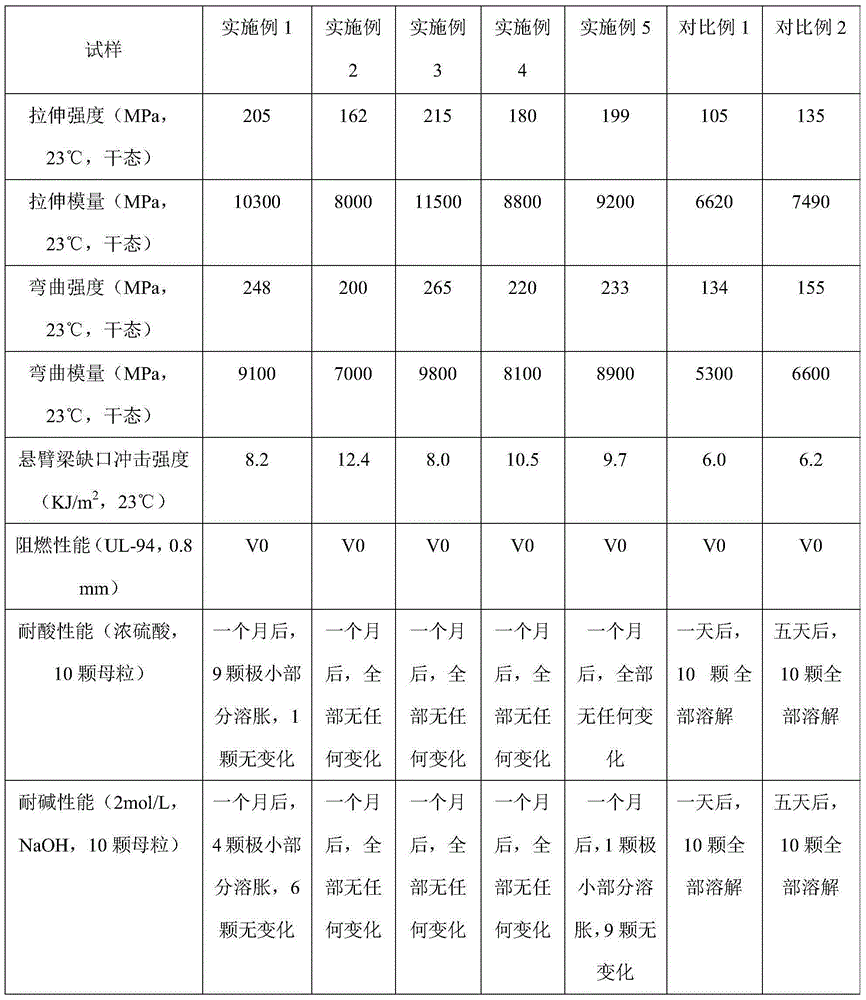

Halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance and preparation method of PA66 composite material

InactiveCN105062050AGood acid and alkali resistanceStrong acid and alkali resistanceEpoxyGlass fiber

The invention discloses a halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance. The PA66 composite material comprises raw materials in parts by weight as follows: 20-72.5 parts of PA66 resin, 10-35 parts of glass fiber, 12-30 parts of a halogen-free flame retardant, 0.5-10 parts of a composite coupling agent and 5 parts of an auxiliary, wherein the composite coupling agent is selected from a mixture formed by mixing gamma-aminopropyl triethoxysilane with gamma-epoxy propoxy propyl trimethoxysilane or epoxy resin in the weight ratio being 1: (1-50). The composite material has higher acid and alkali resistance, good processing fluidity as well as excellent mechanical properties, heat resistance and flame retardation, the problem of insufficient acid and alkali resistance of PA products in the prior art is particularly solved, the acid and alkali resistance is improved remarkably, and the composite material has broad market prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

High-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing as well as preparation method and application thereof

The invention discloses high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing as well as a preparation method and an application thereof. The heat-shrinkable tubing comprises the following components: chlorinated polyethylene, resin A, resin B, a polymer compatibilizer, black masterbatch, antimonous oxide, a flame retardant synergist, a halogen-free flame retardant, a thermal stabilizer, hydrotalcite, an antioxidant, a sensitizer and a silicone additive. The method comprises the following steps: firstly, banburying the antimonous oxide, the flame retardant synergist, the halogen-free flame retardant and hydrotalcite; adding and banburying the chlorinated polyethylene, the resin A, the resin B, the polymer compatibilizer, the black masterbatch, the thermal stabilizer, the antioxidant and the silicone additive; finally adding a sensitizer and banburying, and then palatalizing, and extruding to form the tubing; and carrying out irradiation crosslinking, expanding drawing, cooling sizing, and marking, so as to obtain the high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing. The high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing has the advantages of being low in price, efficient, flame-retardant, excellent in mechanical property, low in pollution, high in high-temperature oil resistance, and good in resistance to acid and alkali corrosion, and can be applied to a bad working condition.

Owner:广州凯恒科塑有限公司

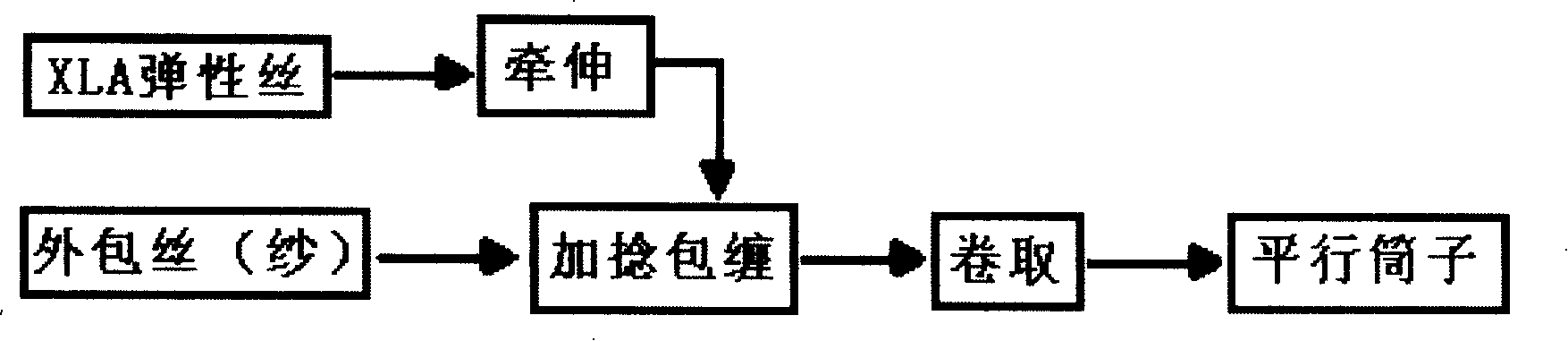

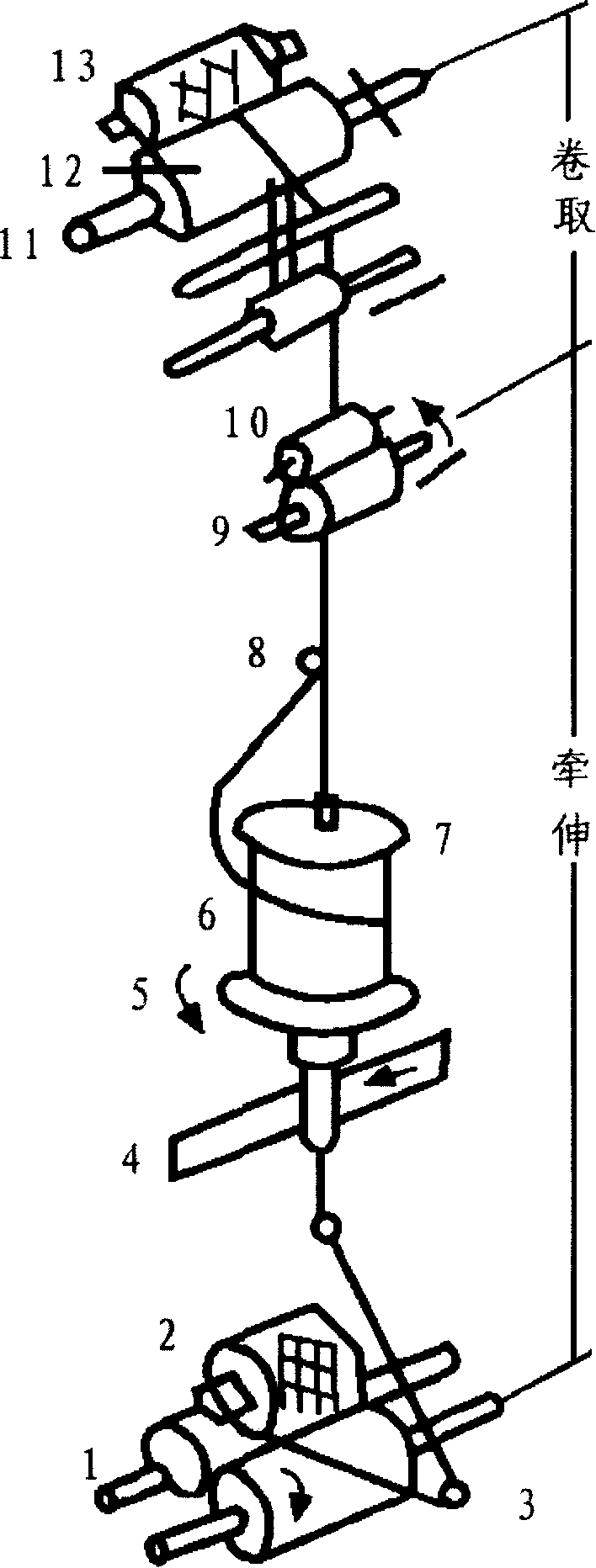

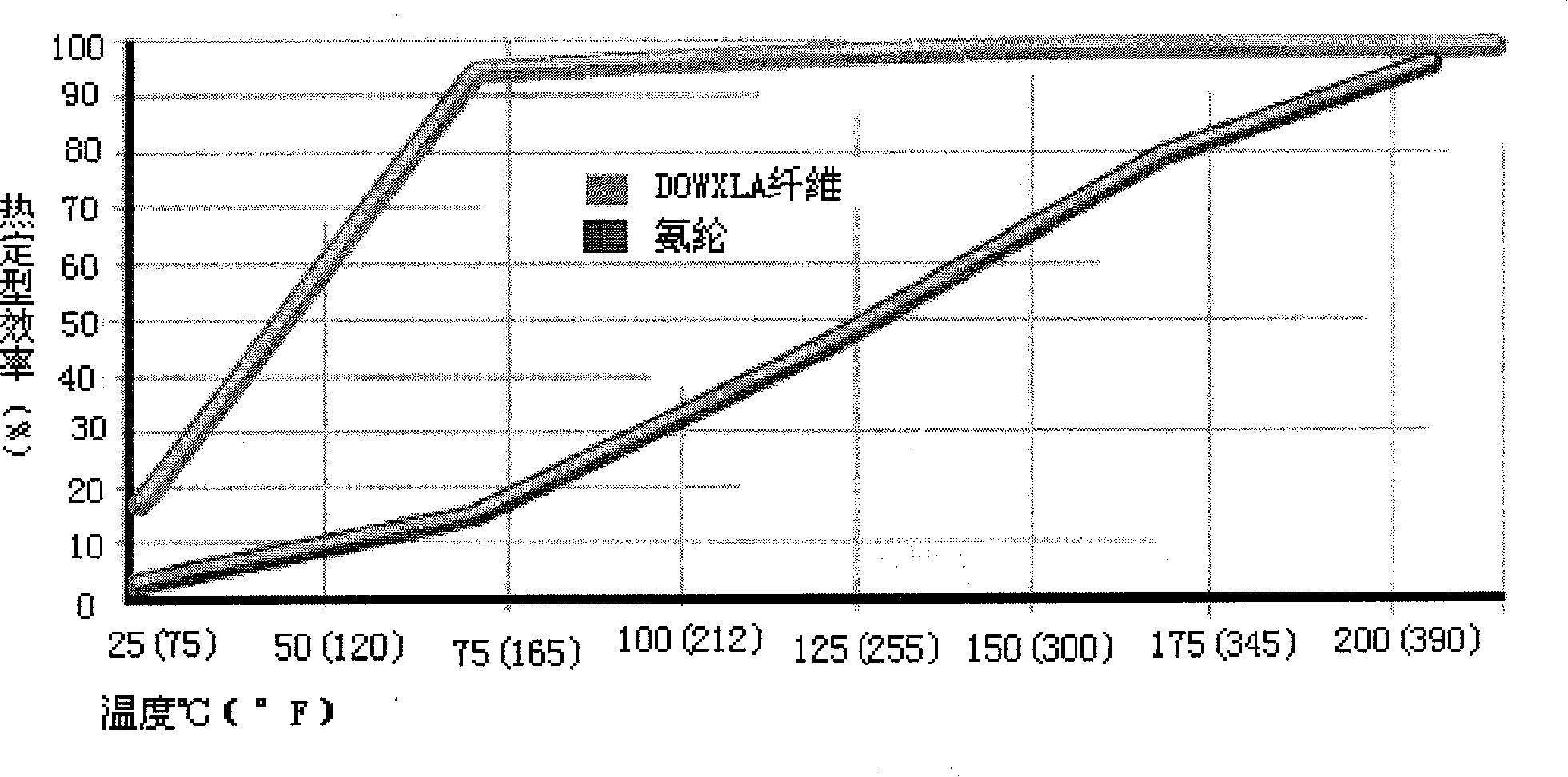

Manufacturing process for low-temperature shaped elastic coating yarn

InactiveCN101200825AImprove physicsGood chemical propertiesHeating/cooling textile fabricsYarnYarnPolyolefin

The invention discloses a low temperature setting elastic coating wire manufacturing process, in particular relates to a coating manufacturing process which implements the low temperature setting on polyolefin elastic filament fiber. The technological process of the invention is mainly divided into four parts of elastic wire feeding, tensile covering, relaxation coiling and the last lower temperature setting of textile. In every process step, specific process conditions are selected. Especially when the low temperature setting condition is selected, such as 60 or 70 DEG C, the setting of the elastic long fiber textile can be realized. At the same time, proper traction force, traction multiple, coating twist, winding speed, etc. are matched in the coating wire manufacturing process. The invention has the advantage that wearing fabrics with high quality can be produced under the effective energy saving condition. Fabric strength, heat setting property, etc. are well guaranteed. And the operation is more convenient. The invention can be widely applied to the preparation process of various high-grade fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

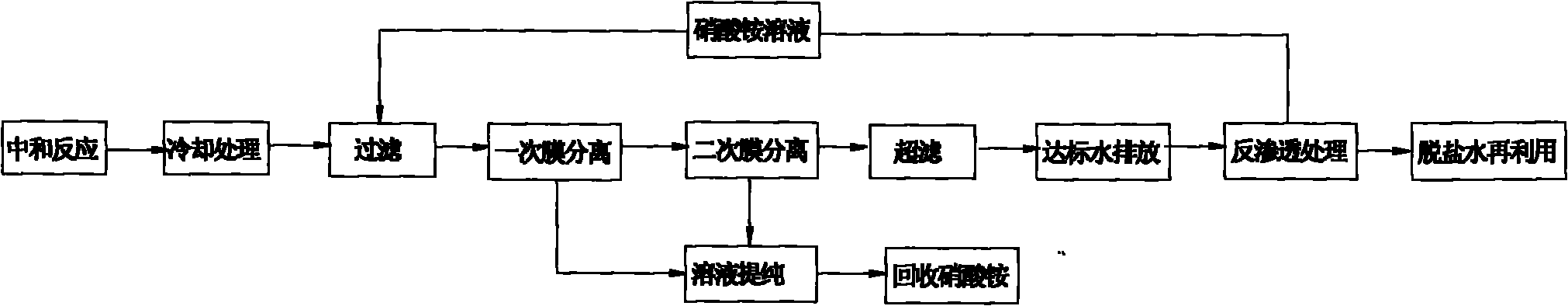

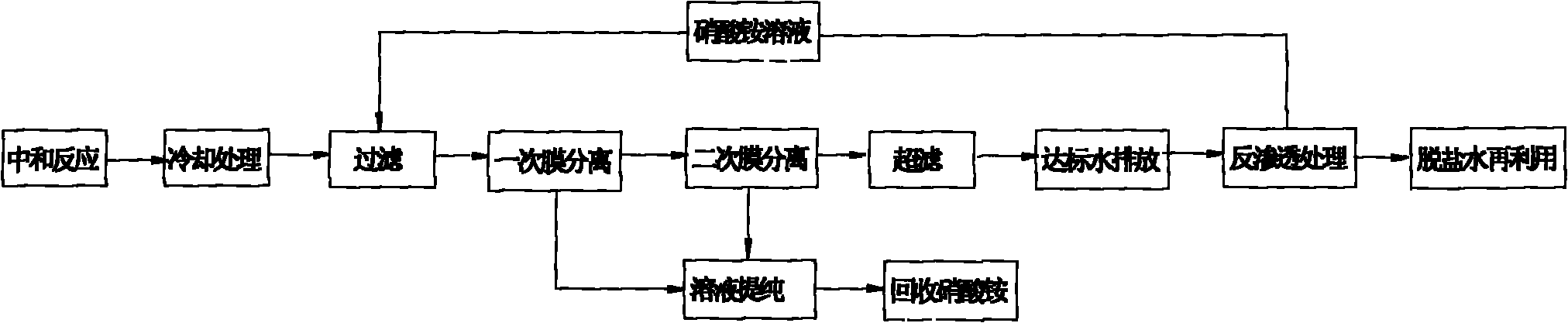

Method for treating waste water containing ammonia and nitrogen

InactiveCN101844845AImplementation of zero emission effectIncrease contentAmmonium nitratesWater/sewage treatment bu osmosis/dialysisElectricityWastewater

The invention discloses a method for treating waste water containing ammonia and nitrogen, comprising the steps of: firstly, separating and recycling high content substances in ammonium nitrate waste water and enabling the discharged water to reach the national discharge standard through employing that electrodialysis has operation capacity under the working conditions of sparingly soluble salt and over-saturation; and secondly, deeply treating the discharged water meeting the standard by utilizing reverse osmosis to enable the discharged water to totally meet the indexes of desalted soft water used in ammonium nitrate industry, and simultaneously carrying out electrodialysis separation circulating treatment and recycling to achieve the effect of zero discharge of waste water in an entire system.

Owner:YANCHENG HONGSHEN ENVIRONMENTAL PROTECTION ENG

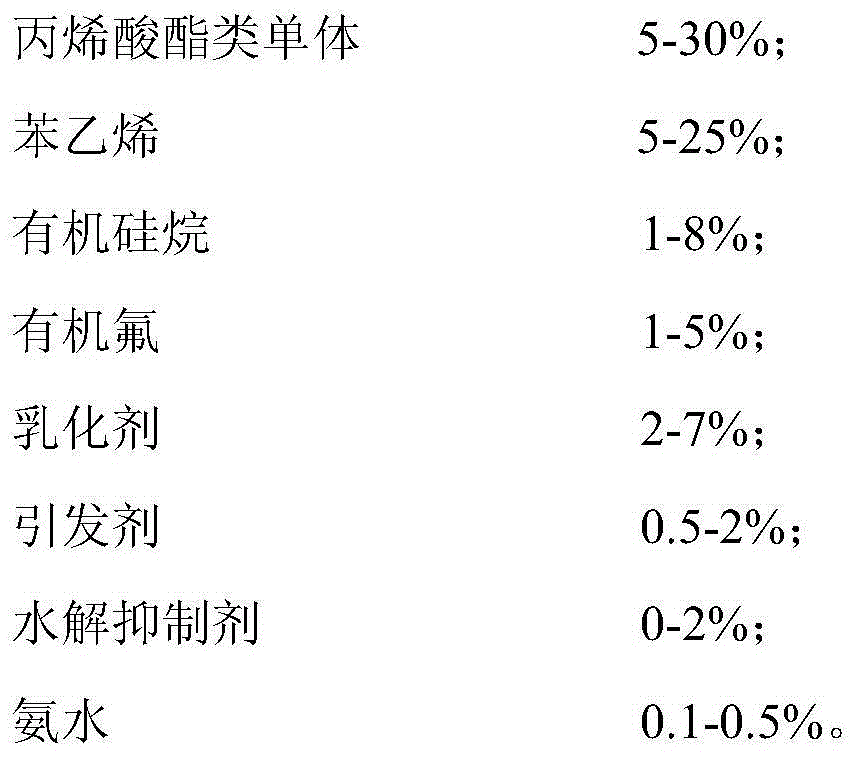

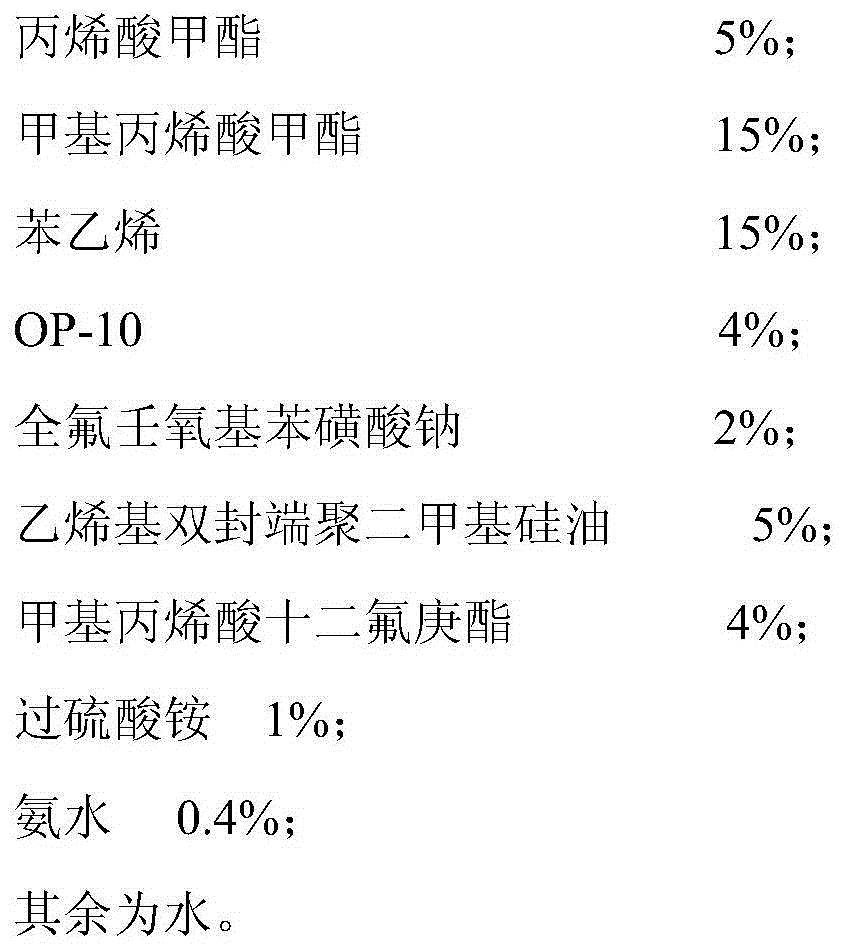

Silicon-fluorine-containing styrene-acrylic emulsion and preparation method thereof

The invention provides a silicon-fluorine-containing styrene-acrylic emulsion and a preparation method thereof. The silicon-fluorine-containing styrene-acrylic emulsion mainly comprises the following components in percentage by mass: 5-30% of acrylate monomer, 5-25% of styrene, 1-8% of organosilane, 1-5% of organic fluorine, 2-7% of emulsifier, 0.5-2% of initiator, 0-2% of hydrolysis inhibitor and 0.1-0.5% of ammonia water. The styrene-acrylic emulsion provided by the invention has the advantages of the organosilicon and organic fluorine, can effectively lower the emulsion cost, and has better water resistance and oil resistance.

Owner:GUANGZHOU GLORYSTAR CHEM

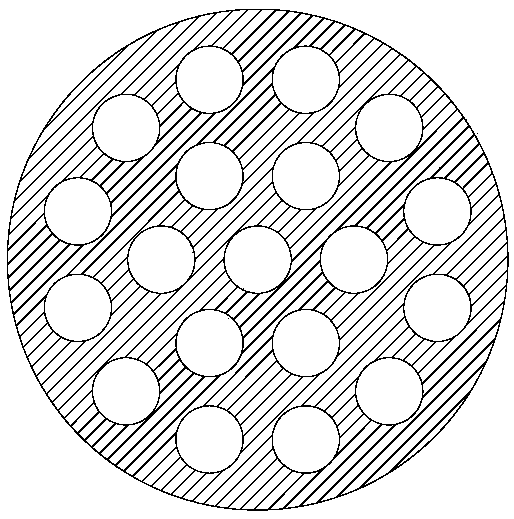

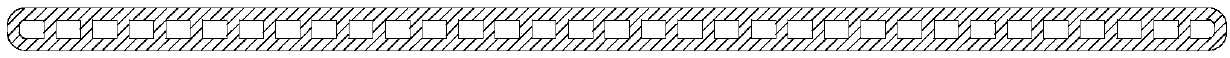

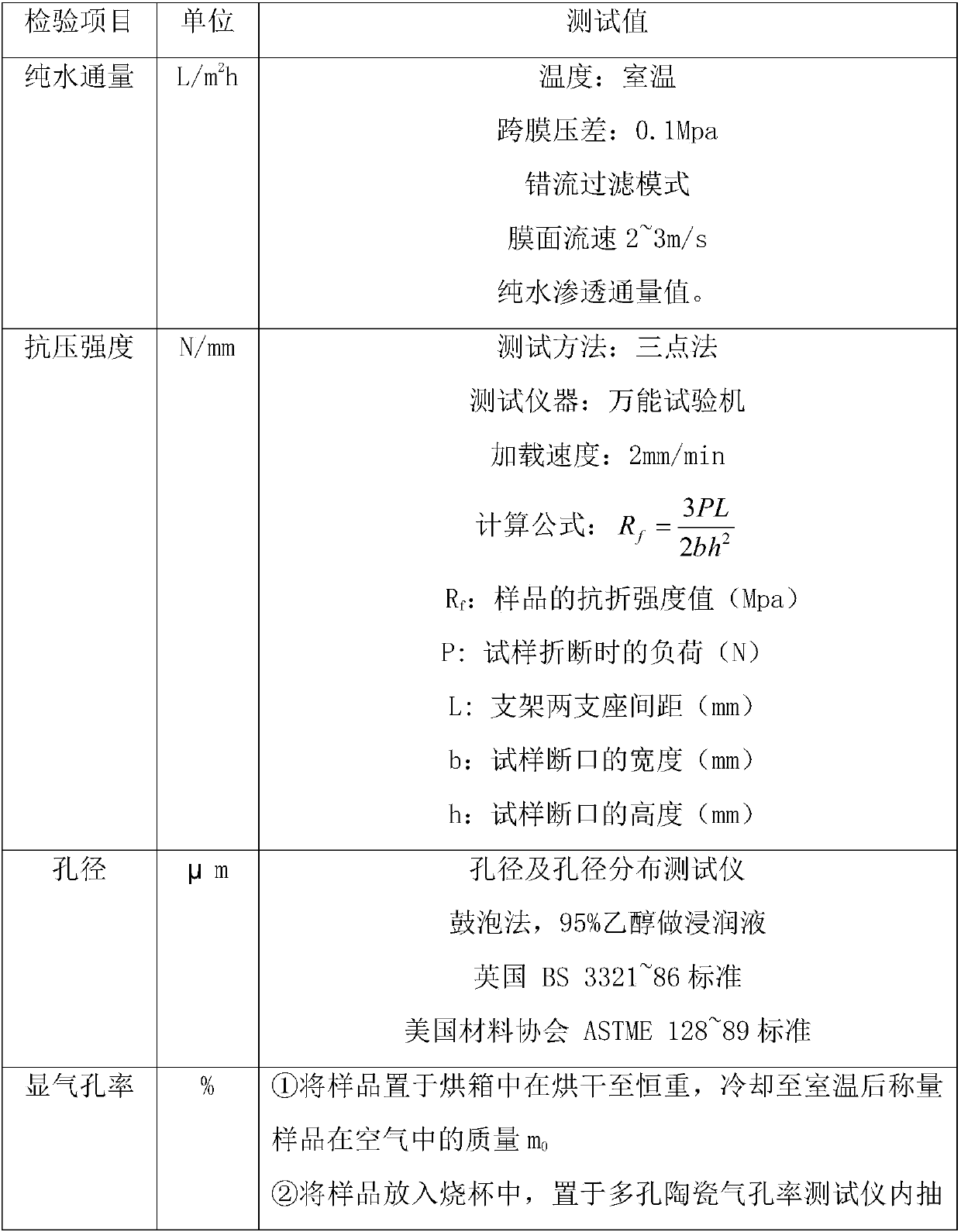

Preparation method of low-temperature sintered acid-and-alkali-resistant porous silicon carbide ceramic supporting body

ActiveCN107619281AImprove hydrophilicityImprove pollutionSemi-permeable membranesCeramicwareSlurrySolvent

The invention relates to the technical field of porous ceramic material and film separation, in particular to a low-temperature sintered acid-and-alkali-resistant porous silicon carbide ceramic supporting body and a method for preparing the same. The method comprises the following steps: slurry preparation, extrusion forming, low-temperature drying and high-temperature sintering. Raw materials used in slurry preparation comprise silicon carbide powder, a sintering aid, a forming agent, a pore-forming agent, a lubricating agent and a solvent. The low-temperature sintered acid-and-alkali-resistant porous silicon carbide ceramic supporting body is mainly characterized in that the porous silicon carbide ceramic supporting body which is high in mechanical strength and high in porosity and resists acid and alkali can be fired with the sintering aid capable of resisting acid and alkali at the temperature of 1,400 DEG C. The low-temperature sintered acid-and-alkali-resistant porous silicon carbide ceramic supporting body has the advantages of low sintering temperature, low production energy consumption, simple technological method, low equipment requirements, low production cost and investment cost, flexible control, easiness in forming, suitability for industrial customization, and capability of meeting large-scale production.

Owner:ZHEJIANG SCI-TECH UNIV

Low-alkali composite multi-functional cement grinding aid and preparation method thereof

The invention relates to a low-alkali composite multi-functional cement grinding aid and a preparation method thereof. The cement grinding aid contains 5-25 percent of trolamine, 5-20 percent of triisopropanolamine, 3-10 percent of xylitol, 3-10 percent of dodecyl sodium sulfate, 3-15 percent of hyposulphite, 1-5 percent of calcium lignosulphonate, 3-11 percent of anhydrous calcium chloride and 25-50 percent of water. The grinding aid has multiple functions under the action of the effective mechanism of the grinding aid components. Compared with the prior art, the invention can greatly reduce the wrought material dosage, increase the addition of industrial slag, lower the product cost, stabilize the product quality, improve the workability of cement and enable the cement to have higher corrosion resistance and acid and alkaline resistance. The production process is simple, and the products have long preservation period.

Owner:湖北统领科技有限公司

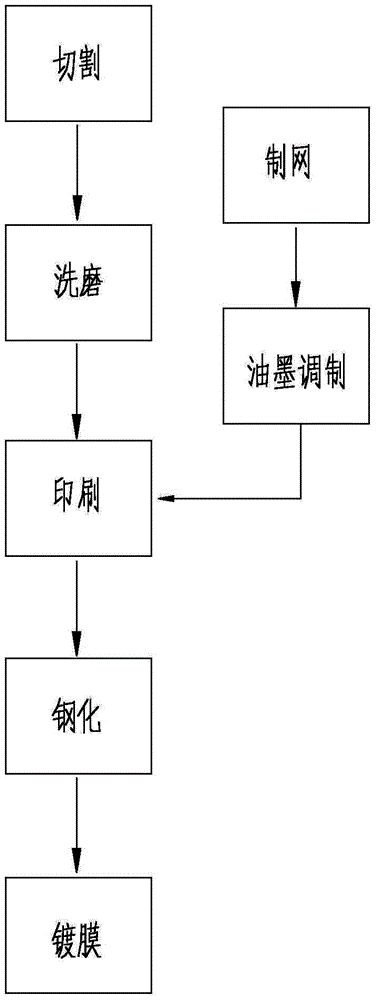

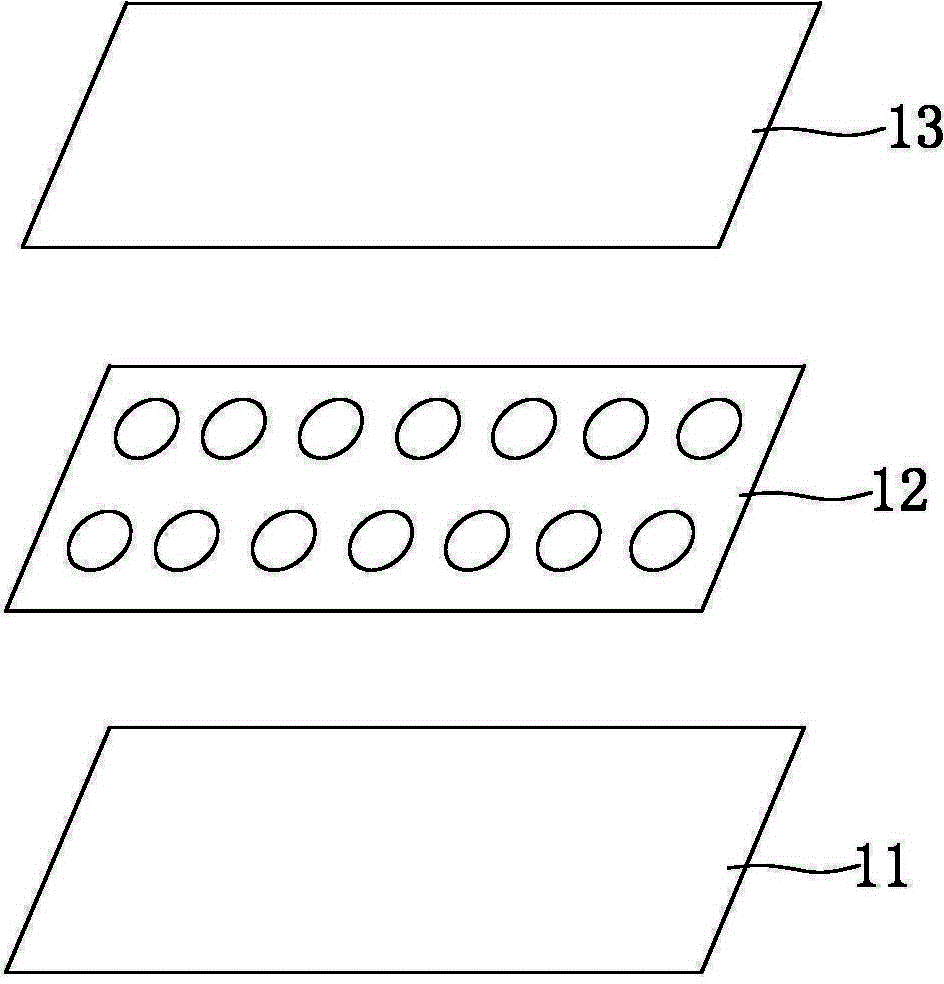

Manufacturing method for color glaze coated glass and color glaze coated glass

ActiveCN105271808AIncrease tightnessSimple processGlass tempering apparatusGlass productionScreen printingWear resistant

The invention belongs to the glass manufacturing technology field, and discloses a manufacturing method for color glaze coated glass and color glaze coated glass. The manufacturing method comprises steps: a cutting procedure is carried out, namely, a glass original sheet is selected and cut; a washing and grinding procedure is carried out, namely, the glass original sheet is ground and washed; a printing procedure is carried out, namely, a screen printing plate is selected and washed, printing oil is blended, and a pattern is printed on the surface of the glass original sheet; a toughening procedure is carried out, namely, the surface of the glass original sheet is cleaned, the glass original sheet is conveyed to a toughening furnace and heated, then is outputted after heating and cooled rapidly to a normal temperature, and glaze layer is formed; a coating procedure is carried out, namely, coating layers with different colors are plated on the glaze layer according to needs. The color glaze coated glass is manufactured through the above manufacturing method. The manufacturing method is simple, and the production efficiency is high. The color glaze coated glass manufactured through the method has good acid-base resistance, has a good adhesive force, and is durable and wear-resistant. The color is changeable, the sunshade effect is raised, and usage requirement of the coated glass are met.

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

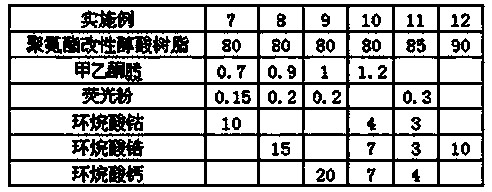

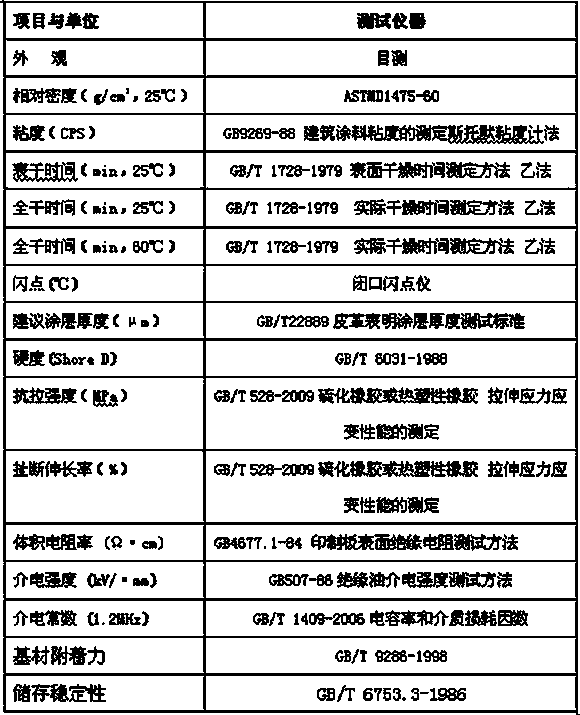

Polyurethane three-proofing coating

InactiveCN103756544AStrong acid and alkali resistanceStrong adhesionPolyurea/polyurethane coatingsAlcoholPolyol

The invention relates to a polyurethane three-proofing coating which is blended from the following components according to weight percentage: 80-90 polyurethane modified alkyd resin, 3-4 cobalt drier, 6-7 zirconiumdrier, 3-9 calcium drier, 0.7-1.2 methyl ethyl ketoxime, and 0.15-0.30 fluorescent powder, wherein the polyurethane modified alkyd resin is blended from the following components according to weight percentage: 45-55 alkyd resin, 2-6polyisocyanates, 4-8 micromoleculepolyhydric alcohols, 2-4 micromolecule mono-alcohol, and 40-50 solvent. The polyurethane three-proofing coating does not contain aromatic hydrocarbon solvents or lead matters, and meets the environmental requirement of RoHS (restriction of hazardous substances) of the European Union.

Owner:YIYUAN ELECTRONICS TECH

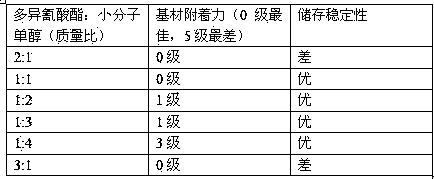

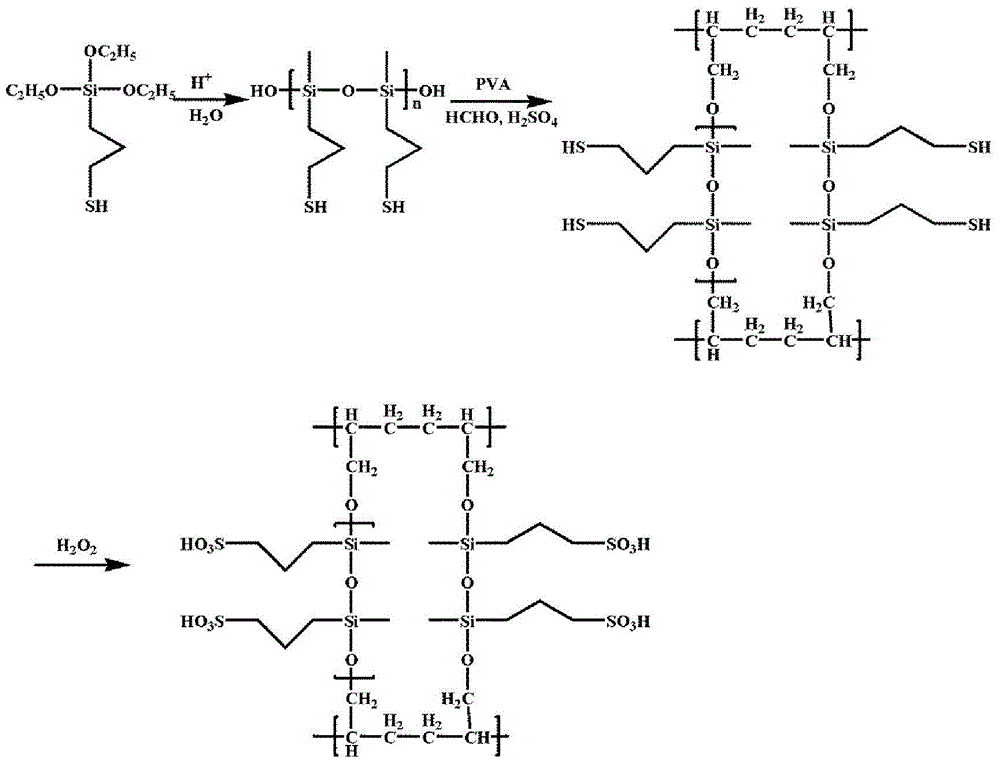

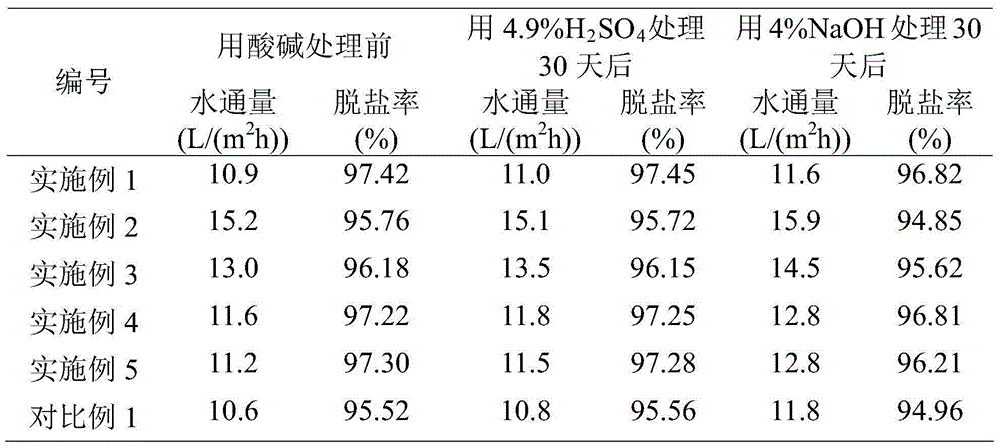

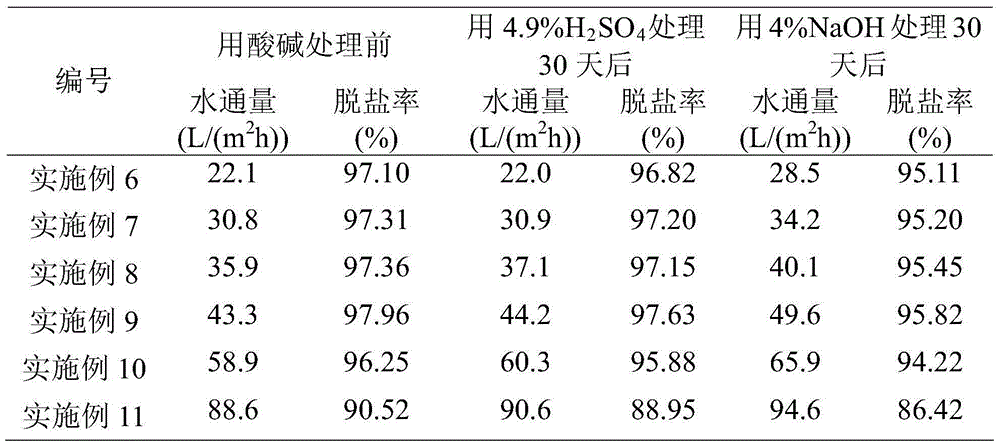

Composite nanofiltration membrane and preparation method thereof

ActiveCN105435656AStrong acid and alkali resistanceGuaranteed uptimeSemi-permeable membranesMembranesPolymer scienceNanofiltration

The present invention discloses a composite nanofiltration membrane and a preparation method thereof and application of the composite nanofiltration membrane prepared by the preparation method in the field of water treatment. The composite nanofiltration membrane comprises a support layer and a separation layer which are stacked together, wherein the separation layer is obtained by forming of an initial composite nanofiltration membrane by sol-gel and thermal crosslinking reaction of a polymer containing a hydroxyl group and a silane coupling agent containing a mercapto group and then post-treatment of the initial composite nanofiltration membrane by use of a water solution containing an oxidizing agent, wherein the initial composite nanofiltration membrane is located on the surface of the support layer and is in a crosslinking net structure. The composite nanofiltration membrane may be stable to operate in a water solution of pH = 0-14, has a high salt removing rate and water permeability (water flux), also has strong acid and base resistance, is simple in preparation method, and has great prospects for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

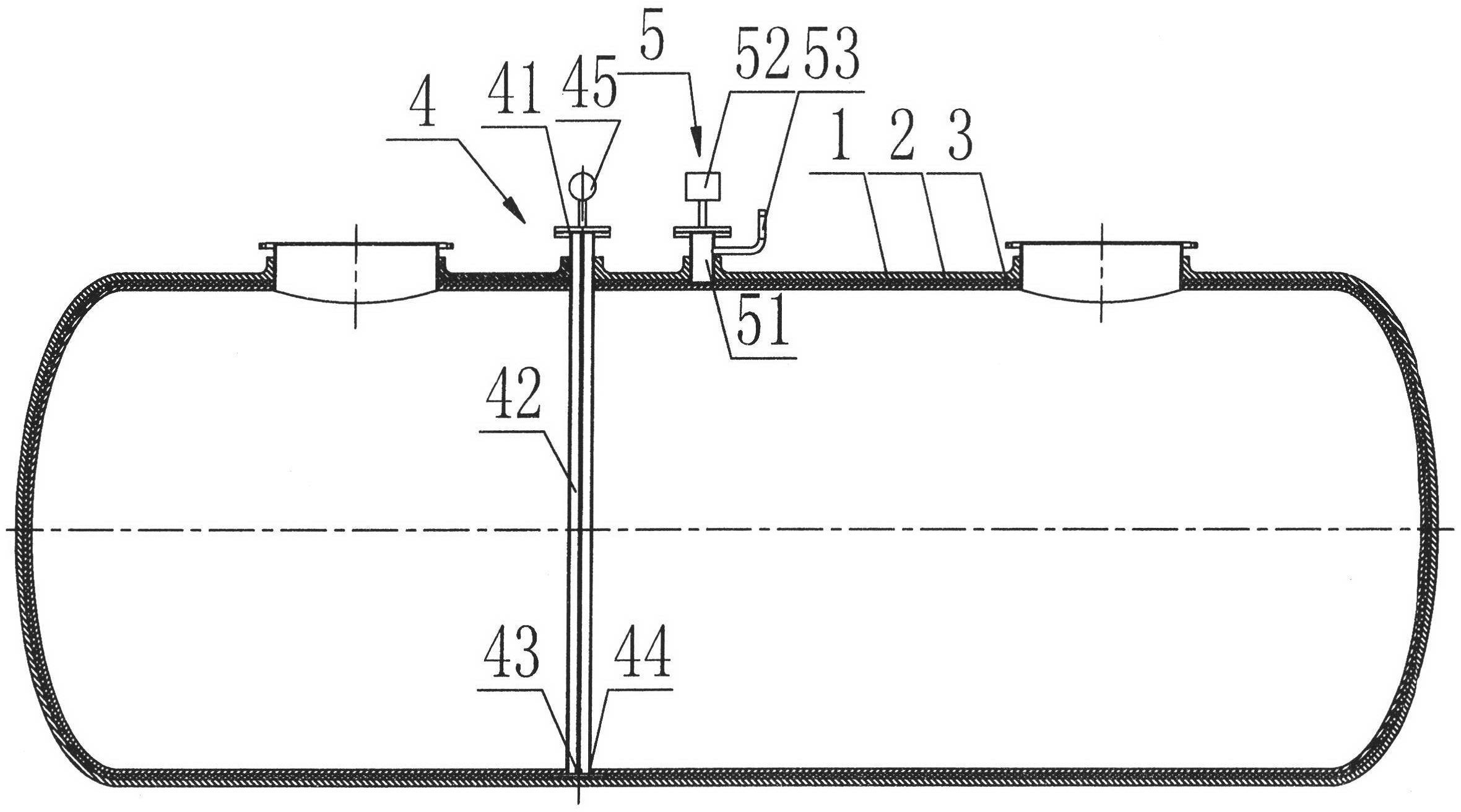

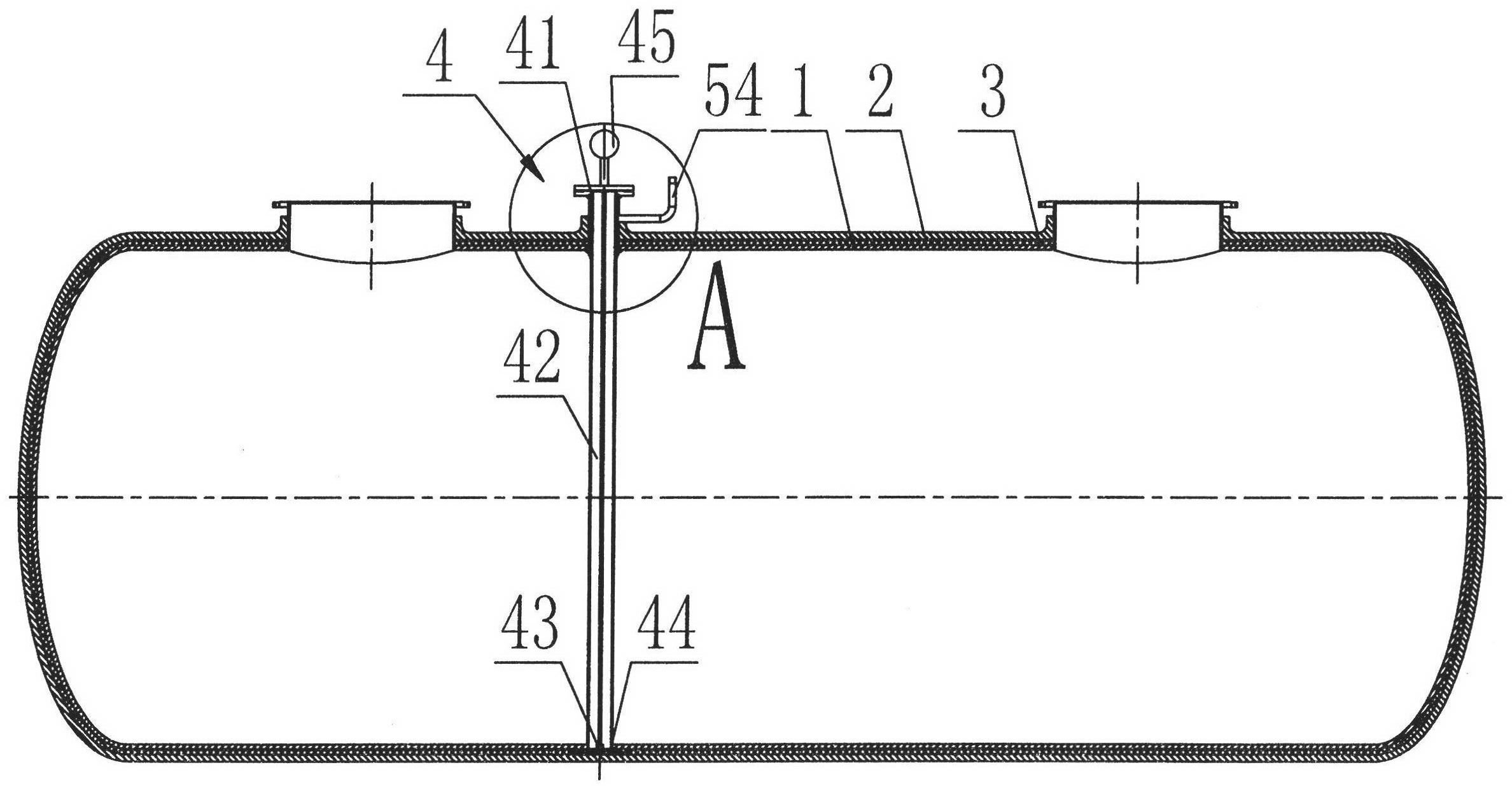

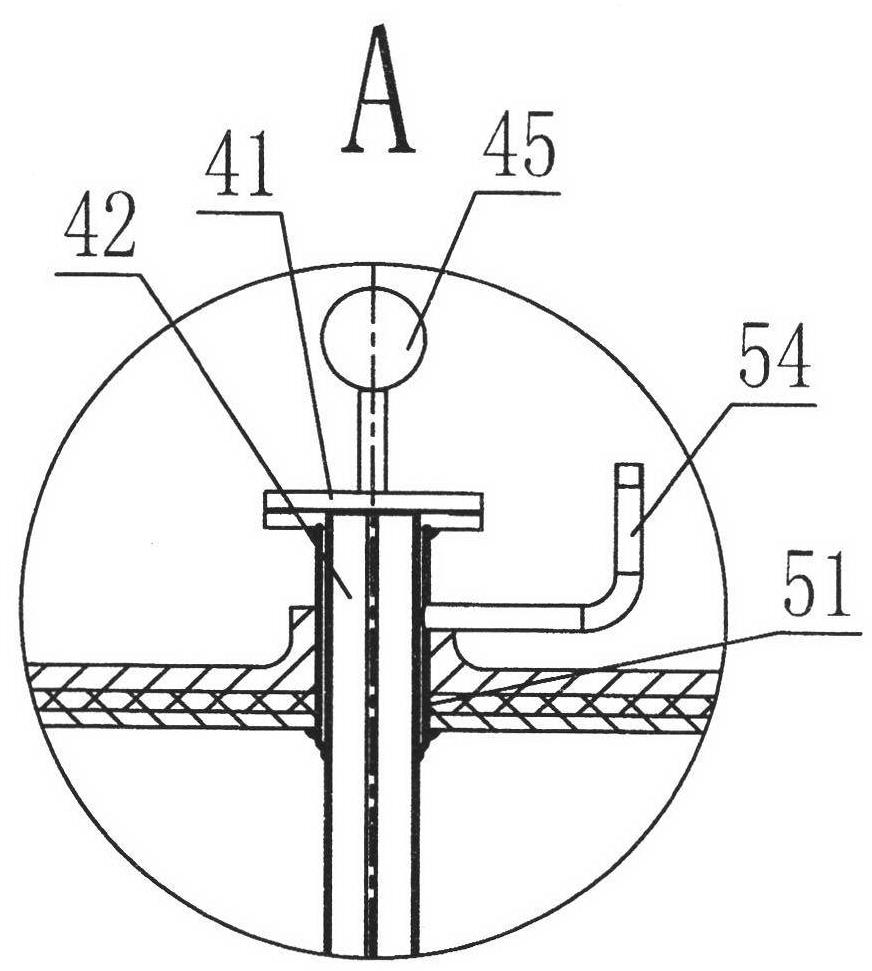

Glass fiber stereoscopic reinforced double-layer oil tank

The invention relates to a glass fiber stereoscopic reinforced double-layer oil tank, which sequentially comprises a steel tank body and a glass steel tank body from the inside to the outside, wherein a glass fiber stereoscopic reinforced hollow layer is arranged between the steel tank body and the glass steel tank body and comprises glass fiber stereoscopic reinforced cloth which is wound on the steel tank body and a hollow layer which is formed by coating resin on the glass fiber stereoscopic reinforced cloth and then performing expansion and solidification. The glass fiber stereoscopic reinforced double-layer oil tank has the advantages that: with a unique leakage detection system, leakage of oil gas or underground water can be identified, leakage of the steel tank body or the glass steel tank body can be detected, a user can stop using the oil tank immediately and can repair the leakage timely, outflowing of flammable and explosive or toxic substances is fundamentally eliminated, and hidden danger of the underground water and soil is timely eliminated.

Owner:徐云祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com