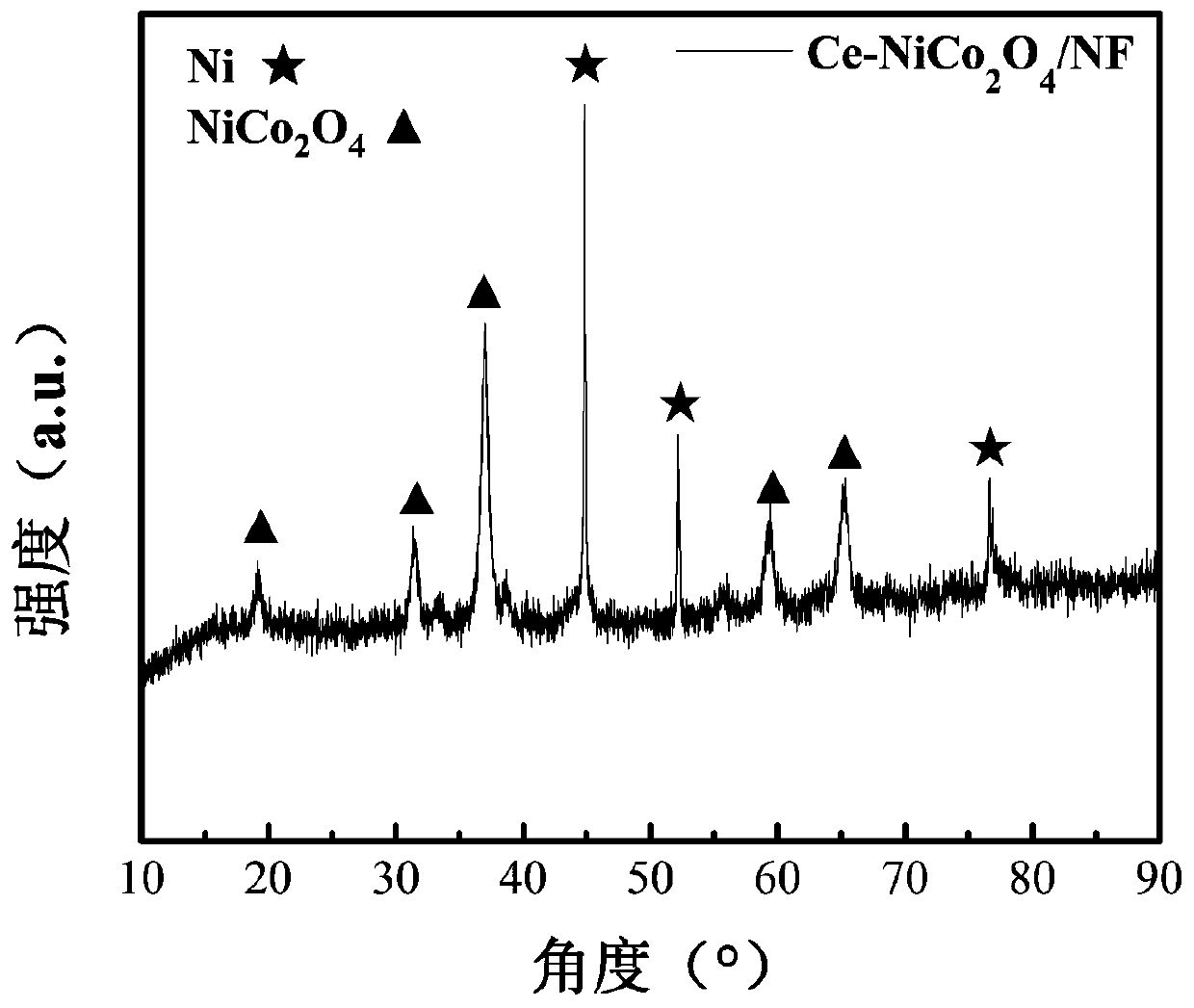

CeO2-NiCo2O4/NF composite electrocatalytic material and preparation method and application thereof

A technology of ceo2-nico2o4 and electrocatalytic materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor stability and low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

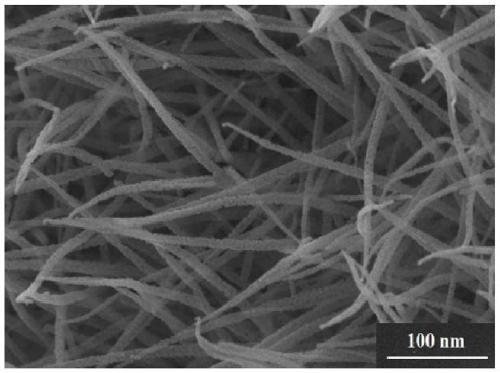

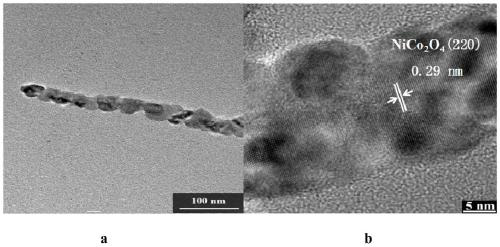

Embodiment 1

[0036] Pretreatment of foamed nickel: Cut commercially available nickel foam into 1cm×2cm size, soak in 20mL of acetone, ultrasonically treat for 10min, remove surface oil, wash 3 times with water, wash off acetone; soak in 3mol / L HCl for 5min , remove the nickel oxide layer on the surface of the nickel foam, and then wash it with water for 3 times, each time for 5 minutes, to wash off the Cl - , dried under vacuum conditions for later use.

[0037] Prepare 80mL mixed metal salt solution of cobalt nitrate and nickel nitrate, the total metal ion concentration is 0.085mol / L, vertically immerse the treated foam nickel into the mixed metal salt solution for 5min; add 0.8mmol hexadecyl trimethyl Ammonium bromide, ultrasonic treatment for 5 minutes, then add 6 mmol urea as a precipitant, ultrasonic treatment for 5 minutes; react at 180 ° C for 4 hours in a reactor lined with polytetrafluoroethylene liner, rinse with deionized water for 5 times, at 70 °C to obtain a one-dimensional ...

Embodiment 2

[0040] Commercially available nickel foam was pretreated according to Example 1.

[0041] Prepare 80mL mixed metal salt solution of cobalt nitrate and nickel nitrate, the total metal ion concentration is 0.085mol / L, vertically immerse the treated foam nickel into the mixed metal salt solution for 5min; then add 0.5mol hexadecyl trimethyl ammonium bromide, ultrasonically treated for 5 minutes, then 12 mmol of urea was added as a precipitant, and ultrasonically treated for 5 minutes; reacted at 160°C for 4 hours in a reactor lined with a polytetrafluoroethylene liner, rinsed with deionized water for 5 times, and then Dry at 70°C to obtain a one-dimensional nickel-cobalt composite hydroxide NiCo grown on the foamed nickel skeleton. 2 -OH / NF. Will get NiCo 2 -OH / NF was placed in a muffle furnace, baked under air atmosphere, raised to 500°C at a heating rate of 5°C / min, and kept at this temperature for 4 hours, and cooled naturally to room temperature to obtain a foam growing on ...

Embodiment 3

[0044] Commercially available nickel foam was pretreated according to Example 1.

[0045] Use cobalt nitrate and nickel nitrate to prepare 80 mL of mixed metal salt solution with a total metal ion concentration of 0.085 mol / L, and vertically immerse the treated foam nickel into the above solution for 5 minutes to sonicate; then add 0.6 mol cetyl trimethyl bromide Ammonium, ultrasonic treatment for 5 minutes, then add 18mmol urea as a precipitant, ultrasonic treatment for 5 minutes; react at 160°C for 4h in a reactor lined with polytetrafluoroethylene liner, rinse with deionized water for 5 times, at 70°C Dry to obtain a one-dimensional nickel-cobalt composite hydroxide NiCo that grows on the foamed nickel skeleton. 2 -OH / NF. Will get NiCo 2 -OH / NF was placed in a muffle furnace, baked under air atmosphere, raised to 500°C at a heating rate of 5°C / min, and kept at this temperature for 4 hours, and cooled naturally to room temperature to obtain a foam growing on the nickel foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com