Electrolyte solution for high-capacity lithium-ion battery, preparation method and lithium-ion battery

A lithium-ion battery and electrolyte technology, which is applied in the field of electrolyte, can solve problems such as poor electrical contact between active materials and current collectors, hidden dangers in battery safety, and shedding of active materials, so as to achieve good shrinkage performance and alleviate battery performance deterioration , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

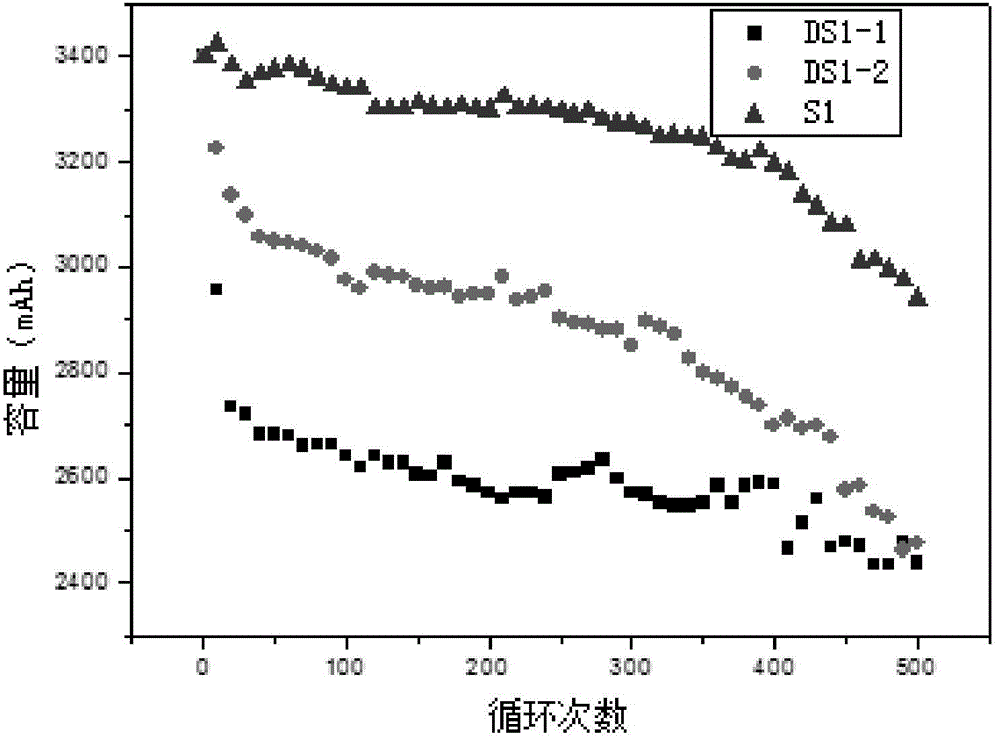

Embodiment 1

[0042] Battery production:

[0043] Positive electrode preparation: The ratio of positive electrode materials is: LiNi 0.8 co 0.15 Al 0.05 o 2 (lithium nickel cobalt aluminum oxide), acetylene black (conductive agent), polyvinylidene fluoride (PVDF, binder) mass ratio is 95:2.5:2.5. Add PVDF to N-methyl-pyrrolidone (NMP), stir evenly at a high speed, add acetylene black to the solution, stir evenly, then add lithium nickel cobalt aluminum oxygen and stir evenly to form a positive electrode slurry, and coat the positive electrode slurry with On the aluminum foil, the positive electrode sheet is baked, compacted, cut, and welded.

[0044] Negative electrode preparation: The ratio of negative electrode materials is silicon-carbon composite material, acetylene black, carboxymethyl cellulose (CMC), and propylene butyl rubber (SBR), with a mass ratio of 95:1.0:1.5:2.5. Add CMC to water, stir at high speed to dissolve completely, then add acetylene black, continue to stir until ...

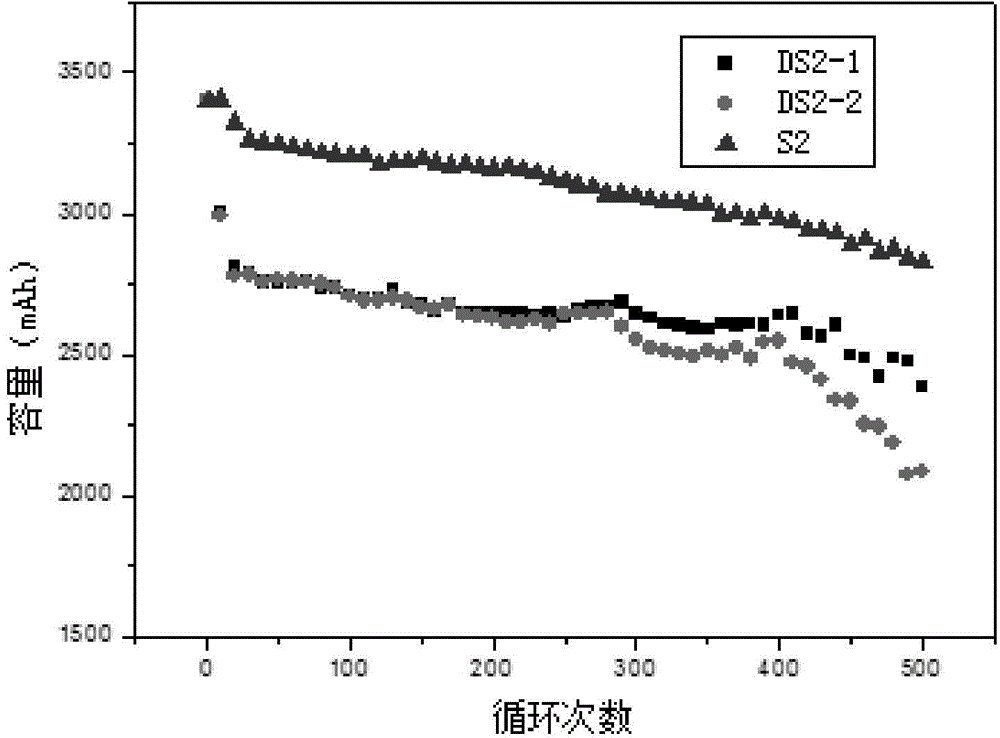

Embodiment 2

[0048] Electrolyte A2 was prepared by using the electrolyte method in Example 1, except that the additives added were fluoroethylene carbonate, lithium tetrafluoroborate, succinonitrile, 1H,1H,5H-octafluoropentyl-1,1,2 , 2-tetrafluoroethyl ether, 18-crown-6, the added amount accounted for 4.0%, 0.5%, 2.0%, 4.0%, 0.5% of the total mass respectively. Among them, lithium hexafluorophosphate accounts for 14.0% (about 1.12mol / L) of the total mass of the electrolyte, and the remaining components are non-aqueous solvents.

[0049] S2 was prepared according to the method of Example 1 using the above electrolyte.

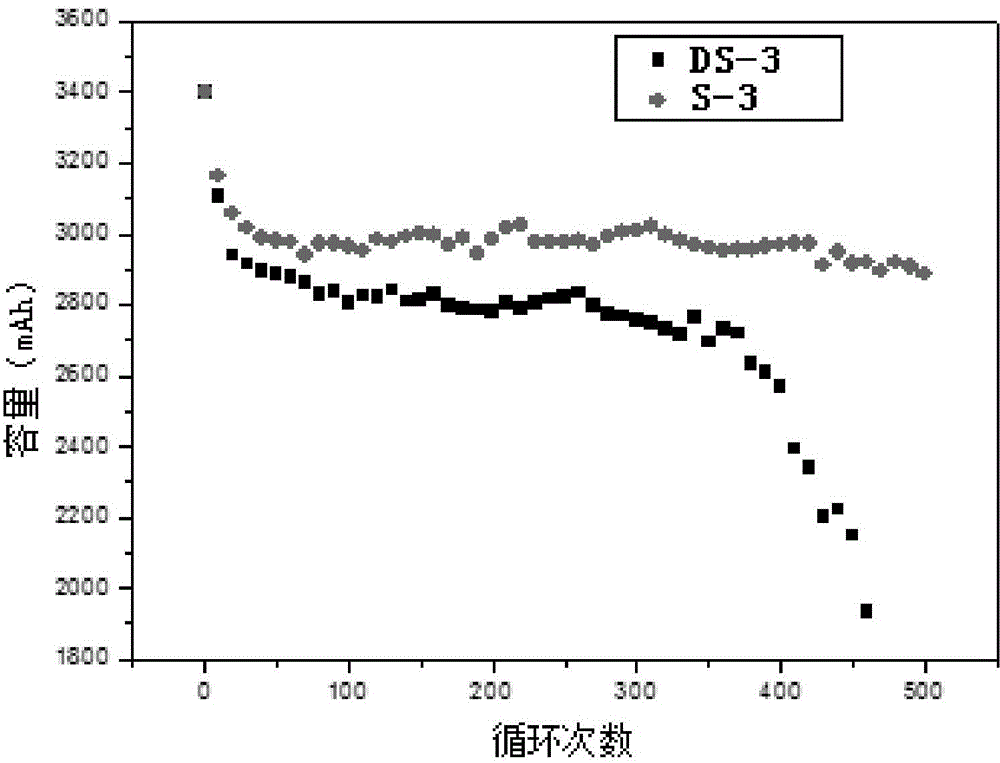

Embodiment 3

[0051] Electrolyte A3 was prepared by using the electrolyte method in Example 1, except that the additives added were fluoroethylene carbonate, lithium bisoxalate borate, adiponitrile, 2H-hexafluoropropyl 2,2,3,3-tetrafluoro Ether and 1-aza-15-crown-5 are added in an amount of 5.0%, 1.0%, 1.0%, 2.0%, and 0.5% of the total mass, respectively. Among them, lithium hexafluorophosphate accounts for 14.0% (about 1.12mol / L) of the total mass of the electrolyte, and the remaining components are non-aqueous solvents.

[0052] S3 was prepared according to the method of Example 1 using the above electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com