Production method and production line for pre-printed surface paper corrugated paperboards

A technology for corrugated board and production method, which is applied in the field of pre-printed corrugated board production and production line, can solve problems such as inability to adapt to the production of pre-printed color corrugated board, shorten bonding time, save structural cost, and ensure bonding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

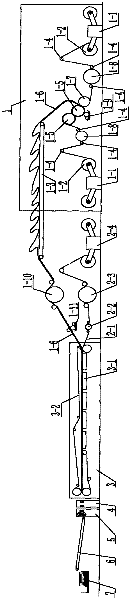

[0029] see figure 2 , a pre-printed surface paper corrugated board production line, comprising a single facer corrugator 1, four corrugated paper guide rolls 3, a face paper guide roll 16, base paper support 4, reel paper 5, gluing device 7 and pressing The device 8 is a corrugated cardboard conveying device composed of four corrugated paper guide rollers, so as to realize the conveyance of single-sided corrugated cardboard 2 from the stand-alone corrugating machine 1 to the pressing device 8 . The corrugated cardboard conveying device has a section of lower conveying device 17 , and the lower conveying device 17 is located below the base paper support 4 .

[0030] As far as the specific technical solution is concerned, an underground passage 18 is dug below the base paper support 4 , the lower conveying device 17 is arranged in the underground passage 18 , and the single-sided corrugated cardboard 2 passes through the underground passage 18 . The length spanned by the lower...

Embodiment 2

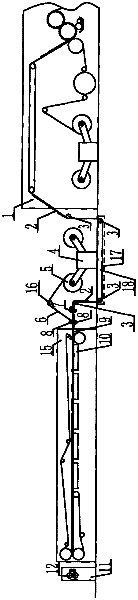

[0033] Another variation to the above-mentioned technical scheme: as image 3As shown, the double-sided corrugated cardboard 9 can not be dried through the drying device 15, but directly enters the cutting device 11, and the continuous double-sided corrugated cardboard 9 is cut into a single double-sided sheet of a predetermined size by a cutting knife 12. Surface corrugated cardboard can completely avoid the influence of high temperature on the pre-printed surface paper of corrugated cardboard.

Embodiment 3

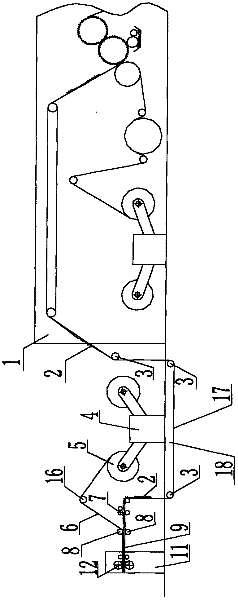

[0035] Another variation to the technical solution of embodiment 1: as Figure 4 As shown, the single-sided corrugated cardboard 2 is first dried by two heating rollers 13 and then enters the lower conveying device 17, and then bonded with the pre-printed face paper 6. The drying treatment of the single-sided corrugated cardboard 2 can improve the double-sided corrugated cardboard 9 Adhesive effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com