Photo-curing silk screen pearly-luster ink applicable to different printing substrates and preparation method thereof

A pearlescent ink, light-curing technology, used in inks, household appliances, applications, etc., can solve problems such as inability to meet and suit different printing substrates, and achieve excellent acid and alkali resistance, and various solvent resistance. Excellent and good performance The effect of flexibility and abrasion and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

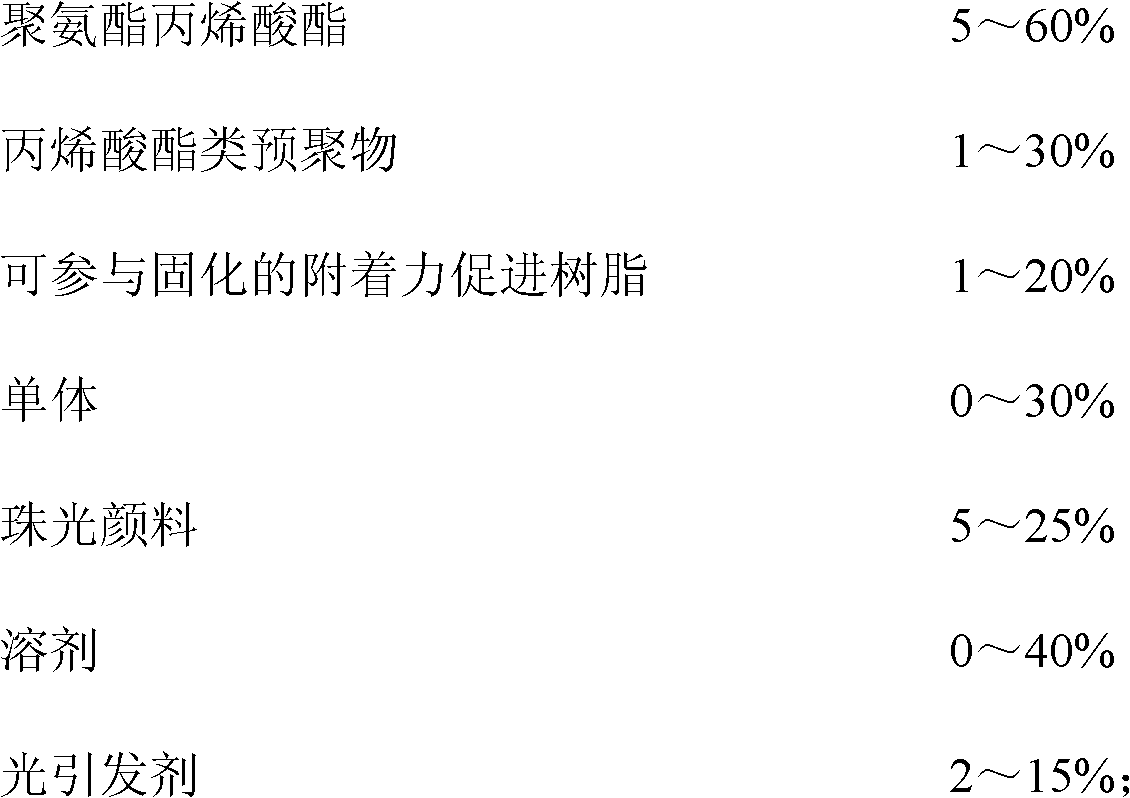

[0030] The formula is shown in Table 1:

[0031] Table 1

[0032]

[0033]

[0034] Preparation:

[0035] (1) mixing each raw material except the pearlescent pigment and the photoinitiator, stirring and dispersing, to obtain the connecting material of the screen ink;

[0036] (2) Add pearlescent pigment, stir and disperse;

[0037] (3) Add a photoinitiator before printing, stir and disperse for 40 minutes, and the photocurable screen pearlescent ink suitable for different printing substrates can be obtained. -1 ).

[0038] Tested by GBT 7707-2008 standard, it has good adhesion to PET, BOPP and other plastic substrates and paper. When printed by KBA-Giori's high-speed rotary screen printing machine, the printing suitability is excellent, and the printing capacity of 10,000 sheets / hour It can dry in time at high speed, the pearlescent effect of the printed matter is obvious, the lines are clear, and the physical and chemical resistances such as acid resistance, alkali ...

Embodiment 2

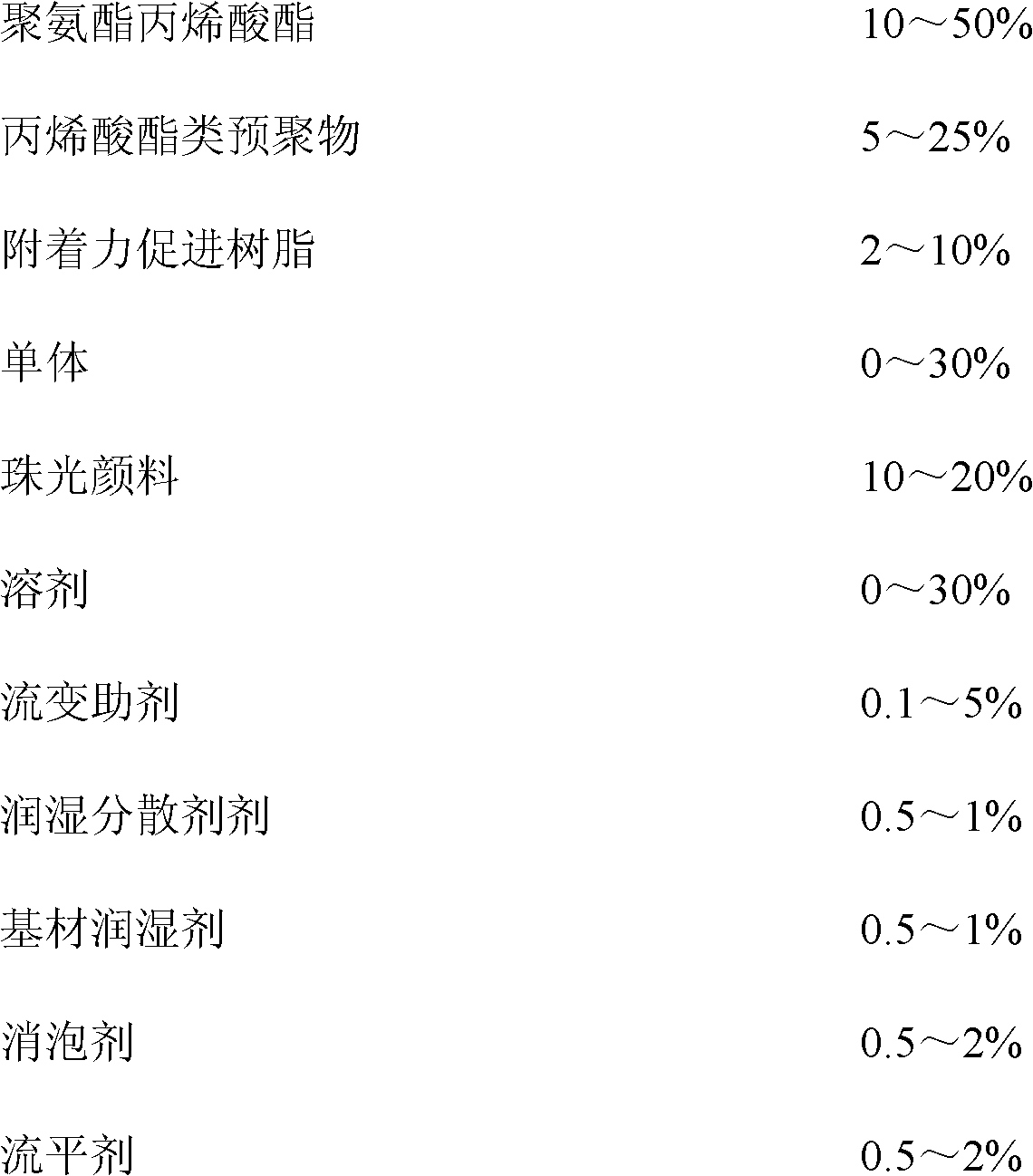

[0040] The formula is shown in Table 2:

[0041] Table 2

[0042]

[0043]

[0044] Preparation:

[0045] (1) Mix other raw materials except the pearlescent pigment, stir and disperse, and obtain the connecting material of screen ink;

[0046] (2) Add pearlescent pigment, stir and disperse;

[0047] (3) Add a photoinitiator before printing, and stir and disperse for 50 minutes to obtain the photocurable screen pearlescent ink suitable for different printing substrates. -1 ).

[0048]Tested by GBT 7707-2008 standard, it has good adhesion to PET, BOPP and other plastic substrates and paper. When printed by KBA-Giori's high-speed rotary screen printing machine, the printing suitability is excellent, and the printing capacity of 10,000 sheets / hour It can dry in time at high speed, the pearlescent effect of the printed matter is obvious, the lines are clear, and the physical and chemical resistances such as acid resistance, alkali resistance, acetone resistance, ethanol r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com