Silicon-fluorine-containing styrene-acrylic emulsion and preparation method thereof

A styrene-acrylic emulsion and silicon-fluorine technology, applied in the direction of coating, can solve the problems of easy hydrolysis and flocculation of organic silicon, poor compatibility of organic fluorine, few patents, etc., which is beneficial to market competition, inhibits hydrolysis, and fully reacts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

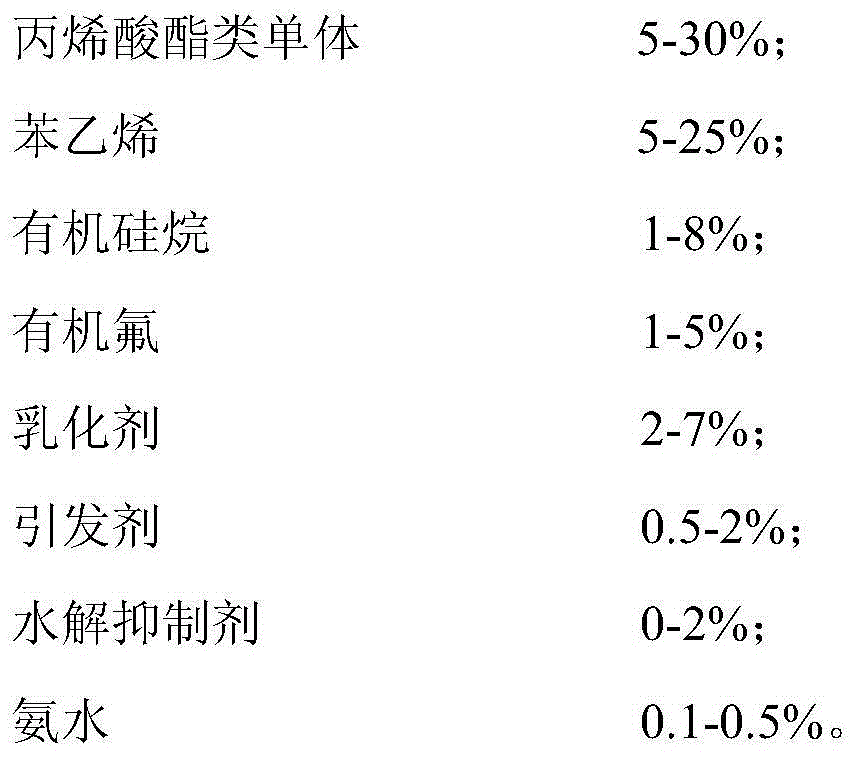

Method used

Image

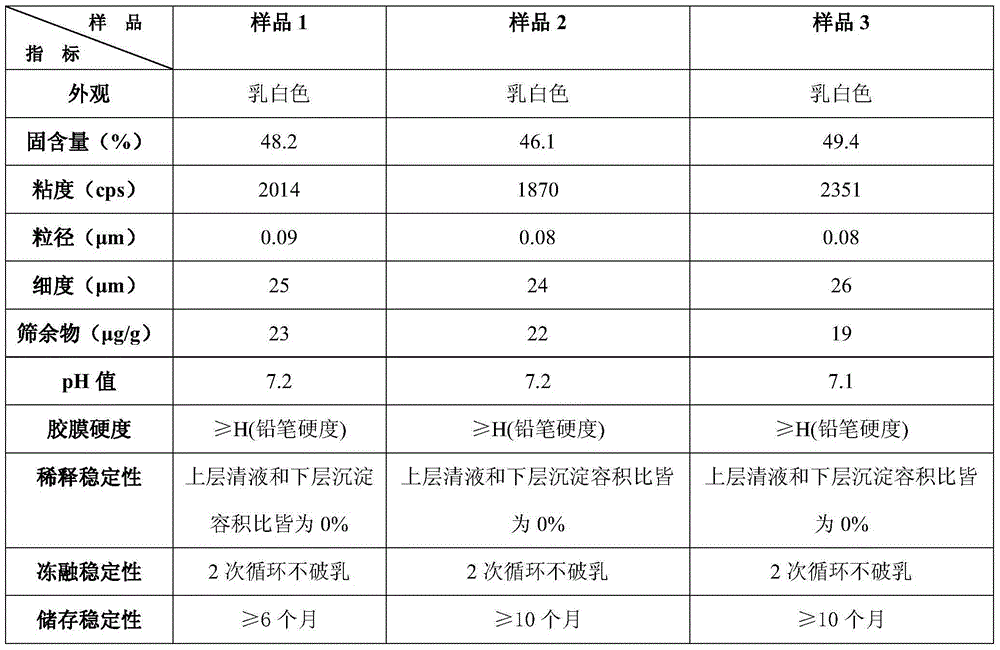

Examples

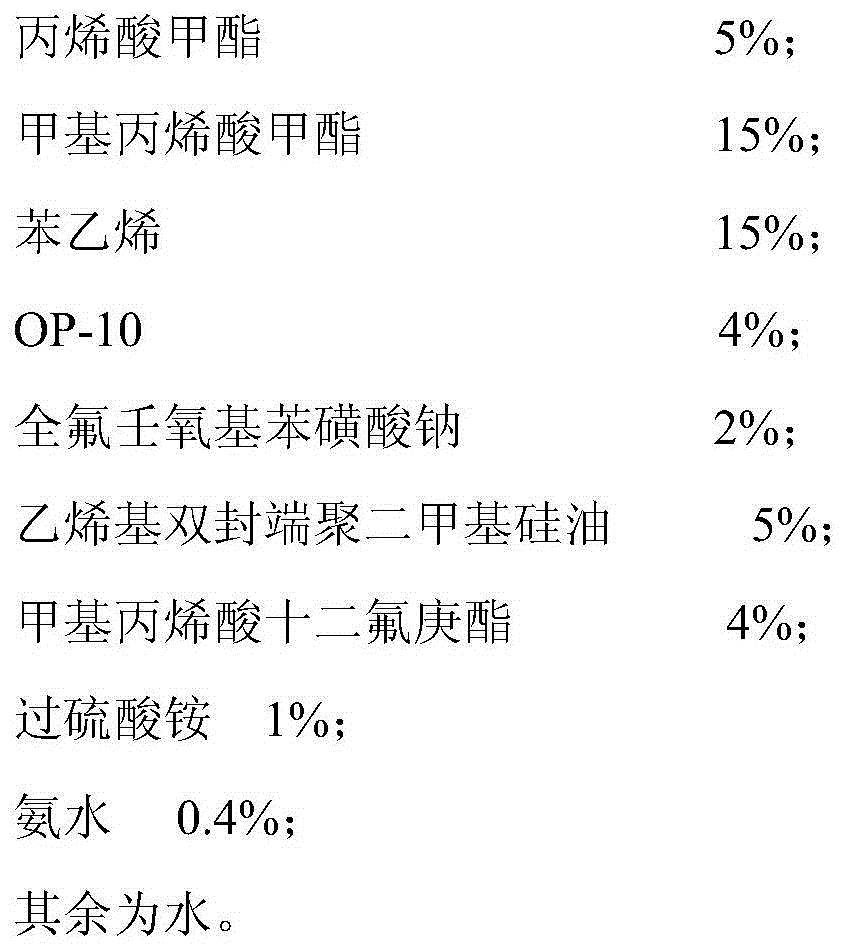

Embodiment 1

[0032] Prepare the styrene-acrylic emulsion containing silicon fluorine according to the following steps:

[0033] 1) Prepare a compound emulsifier solution in advance, specifically mix 6g Tween-60 and 3g sodium perfluorononoxybenzenesulfonate, measure 5ml deionized water, and stir well with a glass rod to obtain a compound Type emulsifier solution, spare.

[0034] Mix 20g of methyl acrylate, 20g of methyl methacrylate, 30g of styrene and 87ml of deionized water; in the emulsifier, add dropwise an emulsifier that accounts for 40% of the total amount of the compound emulsifier solution while emulsifying solution, continue to emulsify for 15 minutes after the dropwise addition, and obtain the pre-emulsion;

[0035] 2) Prepare the initiator solution in advance, specifically, add 3 g of ammonium persulfate to 10 ml of deionized water to fully dissolve, add 3 drops of acetic acid solution to adjust its pH to about 5, and set aside.

[0036] Add about one-third of the pre-emulsion...

Embodiment 2

[0040] Prepare the styrene-acrylic emulsion containing silicon fluorine according to the following steps:

[0041] 1) Pre-prepared compound emulsifier solution, specifically mixing 6g of sodium dodecylbenzenesulfonate and 2g of perfluorononoxybenzenesulfonate, and taking 6ml of deionized water, stirring with a glass rod Evenly obtain the compound emulsifier solution, set aside.

[0042] Mix 10g methyl acrylate, 30g methyl methacrylate, 30g styrene and 90ml deionized water, add dropwise the emulsifier solution that accounts for 40% of the total amount of the compound emulsifier solution while emulsifying in the emulsifier, drop Continue to emulsify for 15 minutes after adding to obtain the pre-emulsion;

[0043] 2) Prepare the initiator solution in advance, specifically, add 2 g of ammonium persulfate to 10 ml of deionized water to fully dissolve, add 3 drops of acetic acid solution to adjust the pH of the initiator to about 5, and set aside.

[0044] Add about one-third of t...

Embodiment 3

[0048] Prepare the styrene-acrylic emulsion containing silicon fluorine according to the following steps:

[0049] 1) Pre-prepared compound emulsifier solution, specifically mix 8g OP-10 and 4g sodium perfluorononyloxybenzene sulfonate, and measure 5ml deionized water, stir with a glass rod to get the compound type Emulsifier solution, set aside.

[0050] Mix 10g butyl acrylate, 30g ethyl methacrylate, 30g styrene and 83ml deionized water, add dropwise the emulsifier solution that accounts for 40% of the total amount of the compound emulsifier solution while emulsifying in the emulsifier, add dropwise Continue to emulsify for 15 minutes after completion to obtain the pre-emulsion;

[0051] 2) Prepare the initiator solution in advance, specifically, add 2 g of potassium persulfate to 10 ml of deionized water to fully dissolve, add 3 drops of acetic acid solution to adjust the pH value of the initiator to about 5, and set aside.

[0052] Add about one-third of the pre-emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com