Mineral fiber-modified flexible rubber concrete

A technology of flexible concrete and mineral fiber, which is applied in the field of rubber flexible concrete and road engineering, which can solve the problems of increased project cost, short service life of road surface, and reduced material homogeneity, and achieve high bending and tensile strength, acid and alkali resistance Excellent, reduce the effect of elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through preferred embodiments, but the protection scope of the present invention is not limited thereto.

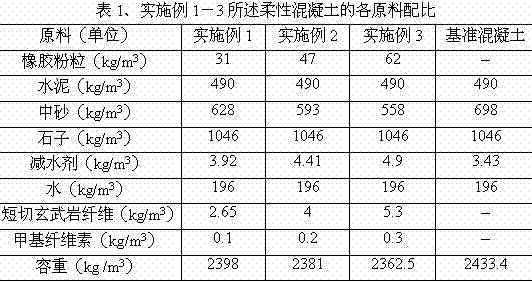

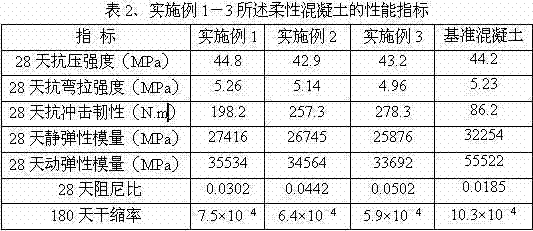

[0020] Embodiment 1-3

[0021] A mineral fiber modified rubber flexible concrete, including rubber cement concrete composed of rubber powder (5-40 mesh), cement (label 42.5), medium sand, stones (maximum particle size 25mm), water reducing agent and water ; also contains chopped basalt fiber and dispersant methylcellulose. The selected chopped basalt fiber has a single fiber diameter of 15 microns, an elastic modulus of 93-110 GPa, an elongation of not less than 3.1%, and a tensile strength of 4150-4800 MPa. The water reducing agent is a polycarboxylate high-performance water reducing agent (purchased from Wuhan Hongkai Building Materials Technology Co., Ltd.), and the water reducing rate is maintained at 10-20%.

[0022] Among them, the volume ratios of rubber silt in Examples 1 to 3 instead of san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com