Acid-and-alkali-resistant environment-friendly ink for automotive windscreen and preparing method thereof

A windshield, acid and alkali resistant technology, which is applied in the field of ink, can solve the problems of unretrieved patent documents of acid and alkali resistant environmental protection ink, etc., and achieve the effect of low UV resistance, simple process and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An acid and alkali-resistant environmental protection ink for automobile windshield, which is prepared from lead-free cadmium composite glass powder, inorganic pigment, varnish, dispersant, leveling agent and thixotropic agent, and the mass percentage of each raw material is :

[0045] Lead-free cadmium composite glass powder 50%

[0046] Inorganic Pigment 20%

[0047] Varnish 28.5%

[0048] Dispersant 0.6%

[0049] Leveling agent 0.6%

[0050] Thixotropic agent 0.3%.

[0051] The inorganic pigment is mainly copper chrome black, the dispersant is DA302N dispersant, the leveling agent is silicone leveling agent, and the thixotropic agent is fumed silica.

[0052] The varnish is a mixture of organic solvent and resin. The resin accounts for 2% of the mass of the varnish. The organic solvent is a mixed solvent composed of terpineol and diacetone alcohol at a mass ratio of 3:1. The resin is silicone resin.

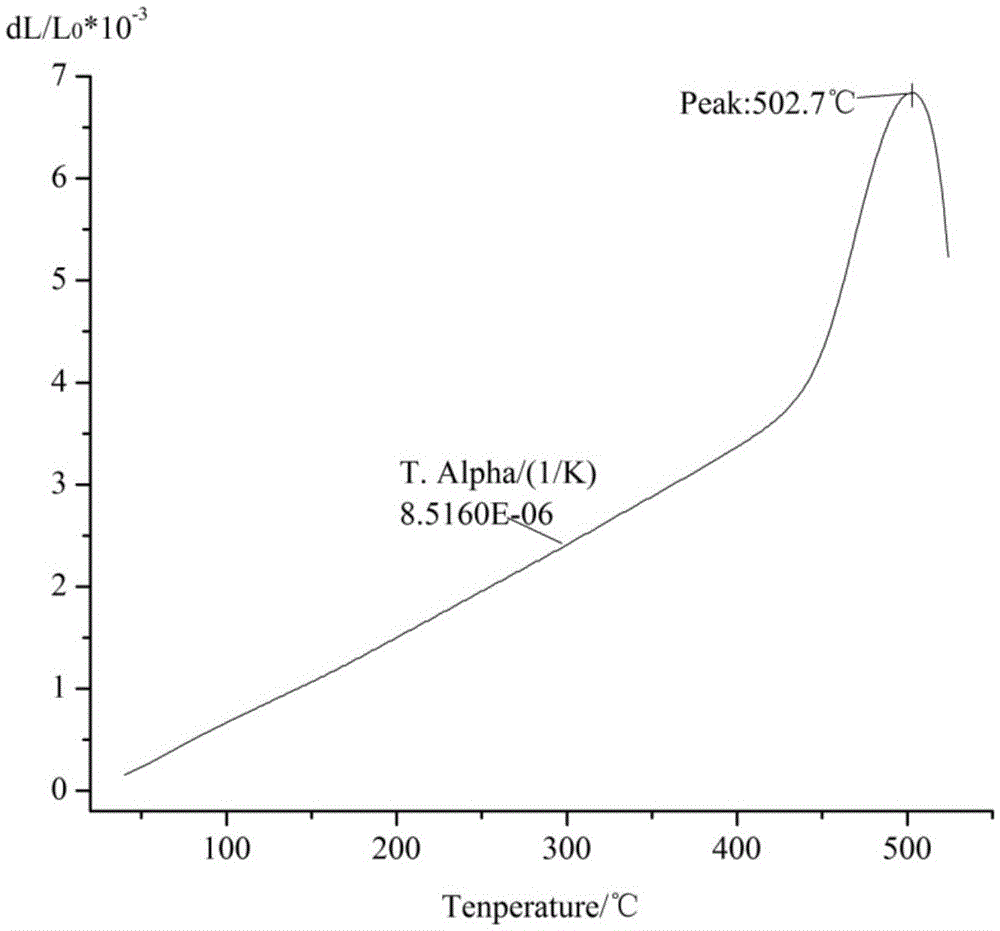

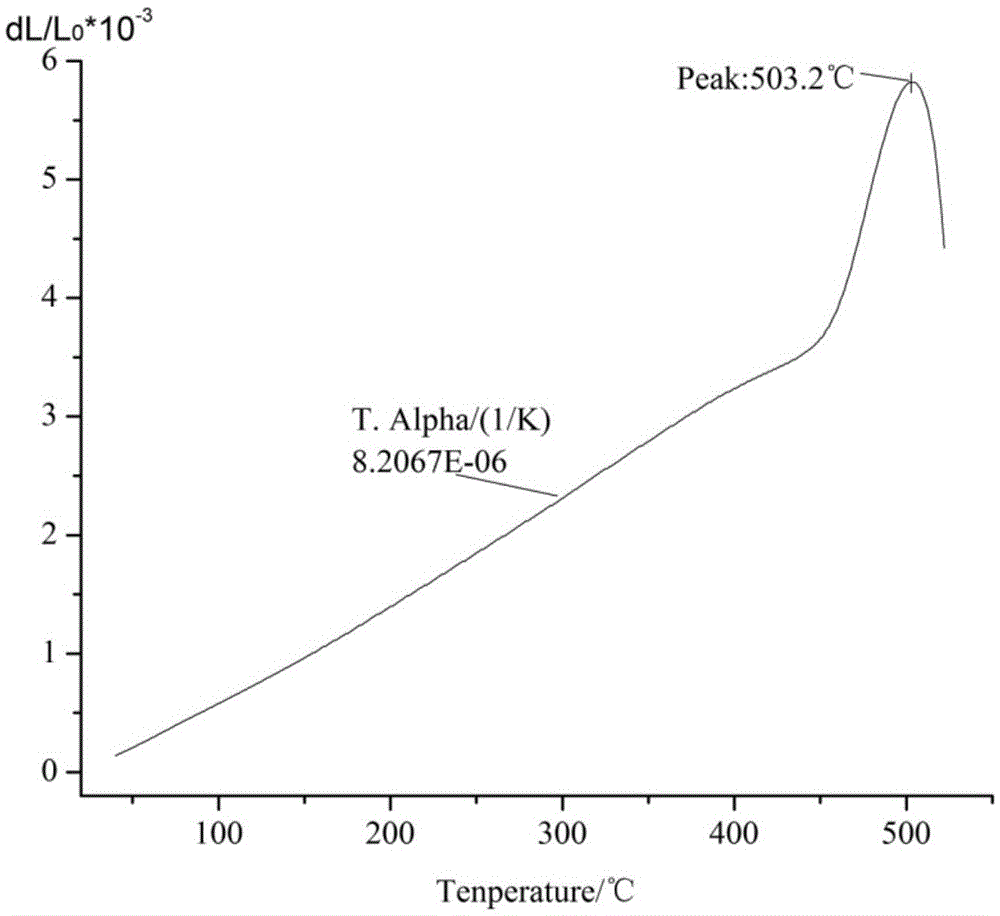

[0053] Lead-free cadmium composite glass powder is made of B...

Embodiment 2

[0065] An acid and alkali-resistant environmental protection ink for automobile windshield, which is prepared from lead-free cadmium composite glass powder, inorganic pigment, varnish, dispersant, leveling agent and thixotropic agent, and the mass percentage of each raw material is :

[0066] Lead-free cadmium composite glass powder 50%

[0067] Inorganic Pigment 8%

[0068] Varnish 40%

[0069] Dispersant 1%

[0070] Leveling agent 0.6%

[0071] Thixotropic agent 0.4%.

[0072] The inorganic pigment is mainly copper chrome black, the dispersant is DA302N dispersant, the leveling agent is silicone leveling agent, and the thixotropic agent is fumed silica.

[0073] The varnish is a mixture of organic solvent and resin, the resin accounts for 3% of the varnish mass, the organic solvent is diacetone alcohol, and the resin is silicone resin.

[0074] Lead-free cadmium composite glass powder is made of Bi with a particle size of 2-5 μm 2 o 3 -B 2 o 3 -SiO 2 Glass powder ...

Embodiment 3

[0085] An acid and alkali-resistant environmental protection ink for automobile windshield, which is prepared from lead-free cadmium composite glass powder, inorganic pigment, varnish, dispersant, leveling agent and thixotropic agent, and the mass percentage of each raw material is :

[0086] Lead-free cadmium composite glass powder 69.4%

[0087] Inorganic Pigment 8%

[0088] Varnish 20%

[0089] Dispersant 1%

[0090] Leveling agent 1%

[0091] Thixotropic agent 0.6%.

[0092] The inorganic pigment is mainly copper chrome black, the dispersant is DA302N dispersant, the leveling agent is silicone leveling agent, and the thixotropic agent is fumed silica.

[0093] The varnish is a mixture of organic solvent and resin, the resin accounts for 4% of the varnish mass, the organic solvent is diacetone alcohol, and the resin is polyketone high hydroxyl resin.

[0094] Lead-free cadmium composite glass powder is made of Bi with a particle size of 2-5 μm 2 o 3 -B 2 o 3 -SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com