Patents

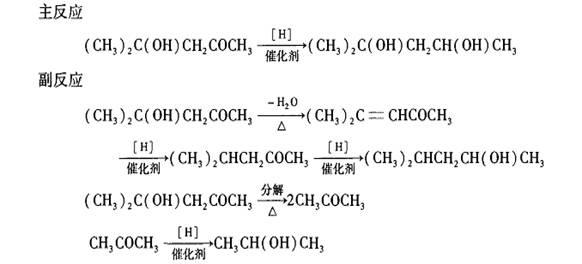

Literature

490 results about "Diacetone alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diacetone alcohol is a chemical compound with the formula CH₃C(O)CH₂C(OH)(CH₃)₂, sometimes called DAA. This liquid is a common synthetic intermediate used for the preparation of other compounds, and is also used as a solvent.

Liquid crystal alignment agent and liquid crystal display unit

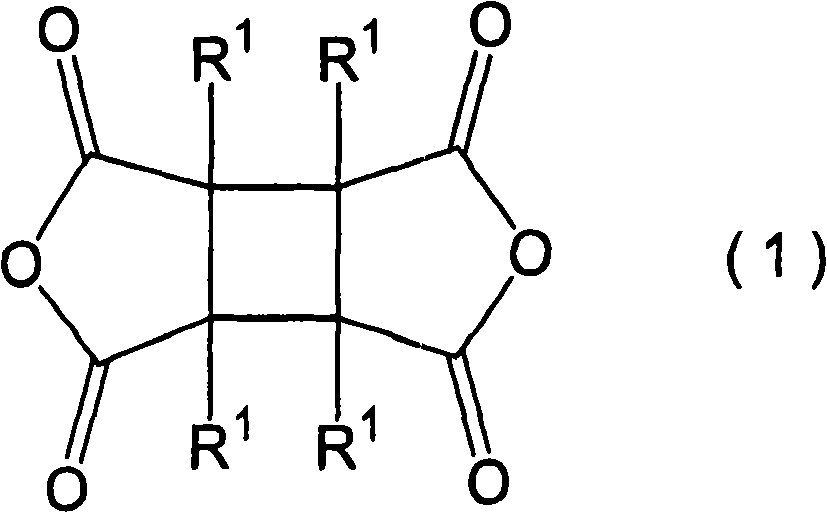

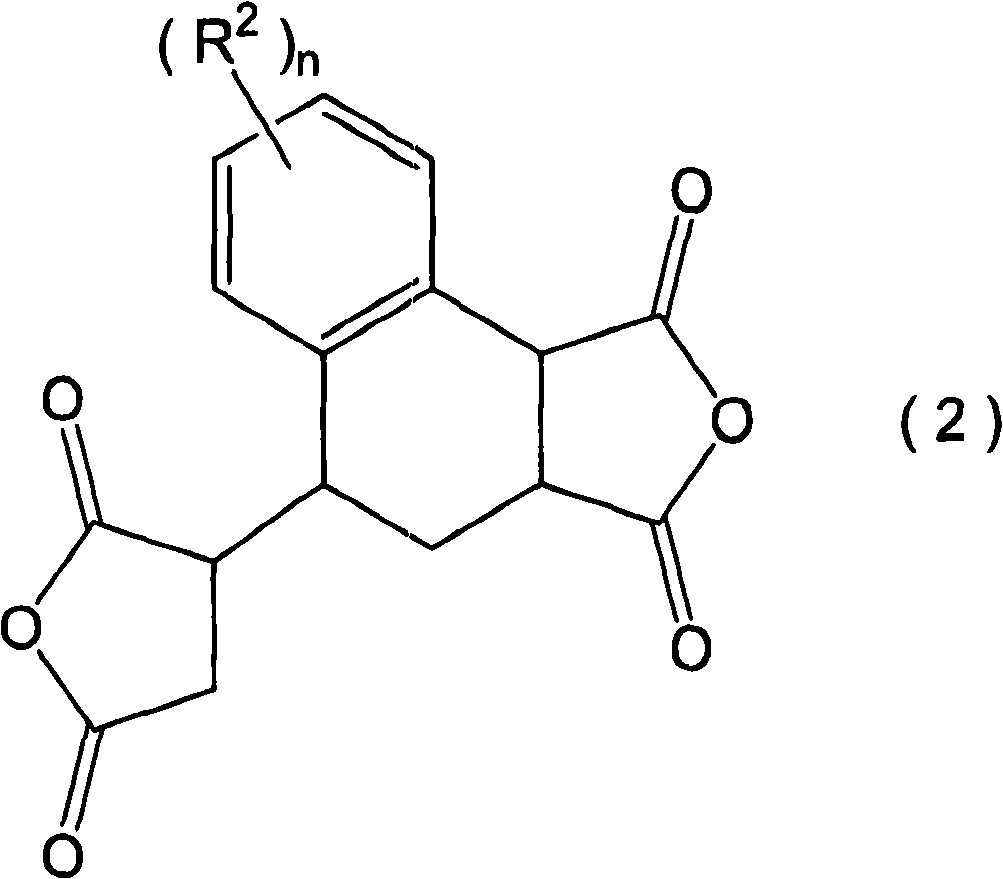

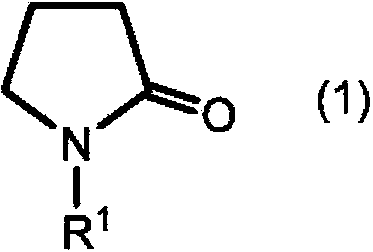

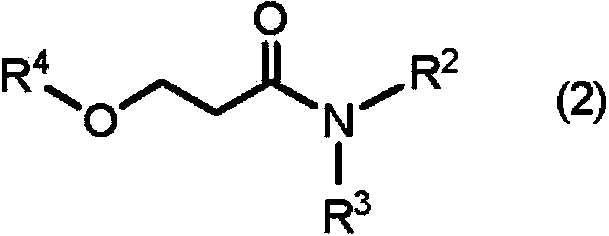

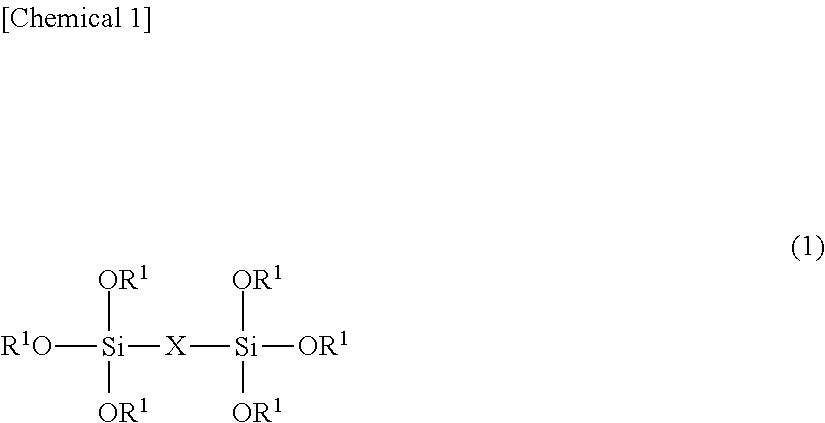

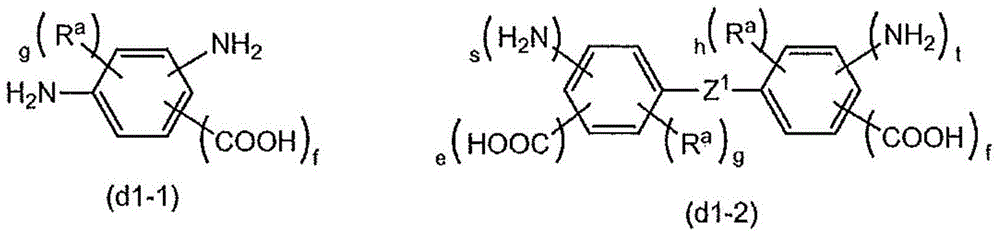

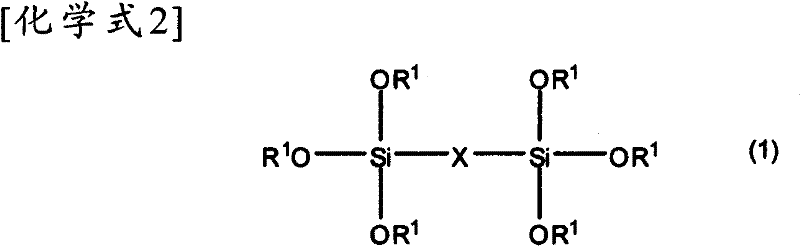

The present invention relates to an aligning agent for liquid crystal containing at least a polymer and solvent selected from polyamic acid and polyimide gained by dewatering closed-loop, the solvent contains: (A) a first solvent containing compound with formula (I); (B) a second solvent selected from at least one of N-methyl-2-pyrrolidone, gamma-butyrolactone, 1,3-dimethyl-2-imidazolone, N, N-dimethylformamide and N, N- dimethylacetylamide; and (C) a third solvent selected from at least one of butyl cellosolve, diacetone alcohol, carbonic sub-propyl ester, diethylene glycol diethyl aether and ethyl-3- oxethyl propionic ether. (In formula (I) the R respectively represents alkyl with 3 to 10 carbon atoms).

Owner:JSR CORPORATIOON

BPA and polycarbonate made from renewable materials

Owner:SHPP GLOBAL TECH BV

Removable adhesive for adhering an image to a surface and a method for removing the image

InactiveUS20070110966A1Easy to removeDecorative surface effectsDuplicating/marking methodsDiacetone alcoholTetrahydrofuranol

A removable adhesive of a combination of acrylic and urethane polymers is provided for securing, among other things, a transfer image to a hard surface. A removable top coat is provided. A top coat comprising a cellulose acetate butyrate alcohol and a diacetone alcohol is provided. A remover for removing the transferred image is provided which is a combination of tetrahydrofuryl alcohol and a dibasic ester and a surfactant.

Owner:WARREN DONALD

Anticorrosive coating

InactiveCN102964967AStrong resistance to salt waterGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyDiacetone alcohol

The invention discloses an anticorrosive coating, which is prepared from the following raw materials in parts by weight: 20-35 parts of epoxy resin 618, 10-18 parts of etherified amino resin, 5-10 parts of flaky graphite, 3-6 parts of grey mica iron oxide, 5-8 parts of aluminium oxide, 3-7 parts of tertiary amine curing accelerator, 2-6 parts of silane coupling agent, 8-15 parts of ethanol ethyl ether acetate, 3-6 parts of diluent and 7-11 parts of cellulose acetate. The diluent is one or a plurality of diacetone alcohol, cyclohexanone, ethanol, methanol, ethylene glycol or ethyl ether. The anticorrosive coating provided by the invention is strong in salt water resistance, good in weather resistance and anticorrosive property, and stronger in adhesive force and wear resistance.

Owner:QINGDAO XUANWEI COATING MATERIAL

Polyurethane elastic process paint formula and preparation method

InactiveCN101597438AShorten drying timeWith energy savingPolyurea/polyurethane coatingsPolyurethane elastomerCyclohexanone

The invention discloses a paint technology, in particular to a 'polyurethane elastic process paint' formula and a preparation method; the formula of polyurethane elastomer is used in the paint formula and each component is measured and prepared to produce paint according to a certain proportion. The 'paint' comprises the following components: component A: 30 parts of diacetone alcohol, 30 parts of butyl acetate, 30 parts of xylene, 10 parts of cyclohexanone, 28-35% of elastic resin, 0.9-8.1% of elasticator, 5-6% of OK520 matt powder, 0.9-3.1% of flatting agent, 1.8-2.2% of feel agent, 1-2.2% of drier and 0-5.5% of elastic powder 5070 D; component B: 100% of firming agent 3390; component C: 50 parts of toluene and 50 parts of butyrin. The 'paint' is characterized in that when the 'paint' is coated on the workpiece, after air drying or baking, the 'paint' can turn up with a magical effect that the paint film has the springy feel like human skin and fine hairs. The 'paint' has mild texture, is a modern innovative paint and fills the technology gap in China and abroad.

Owner:孔赟荣

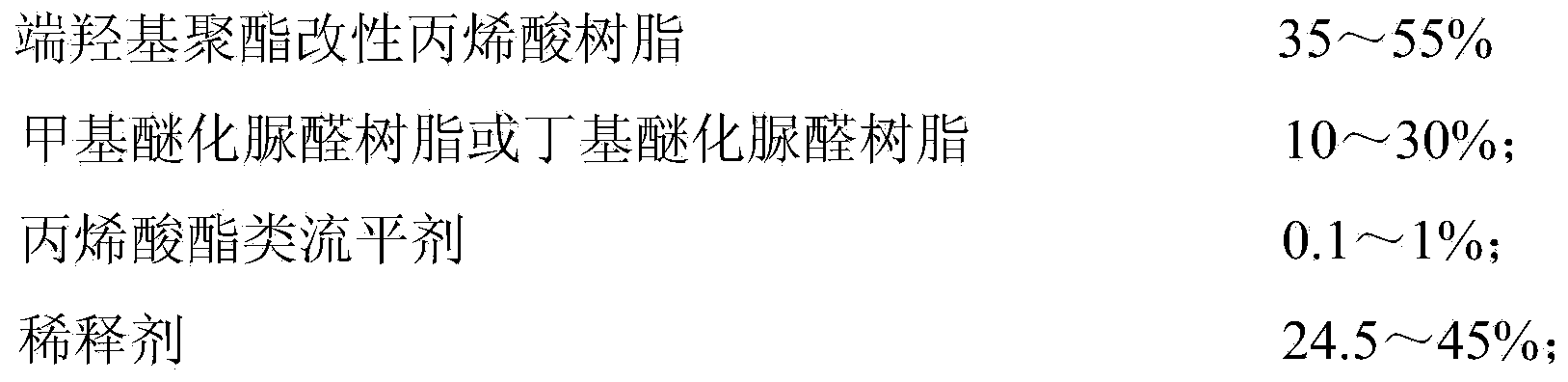

Thermal sublimation transferring-printing coating pulp and method for carrying out thermal sublimation transferring-printing by using same

ActiveCN104073103AGood light fastnessExcellent outdoor aging resistanceDuplicating/marking methodsEpoxy resin coatingsCross-linkPolyester

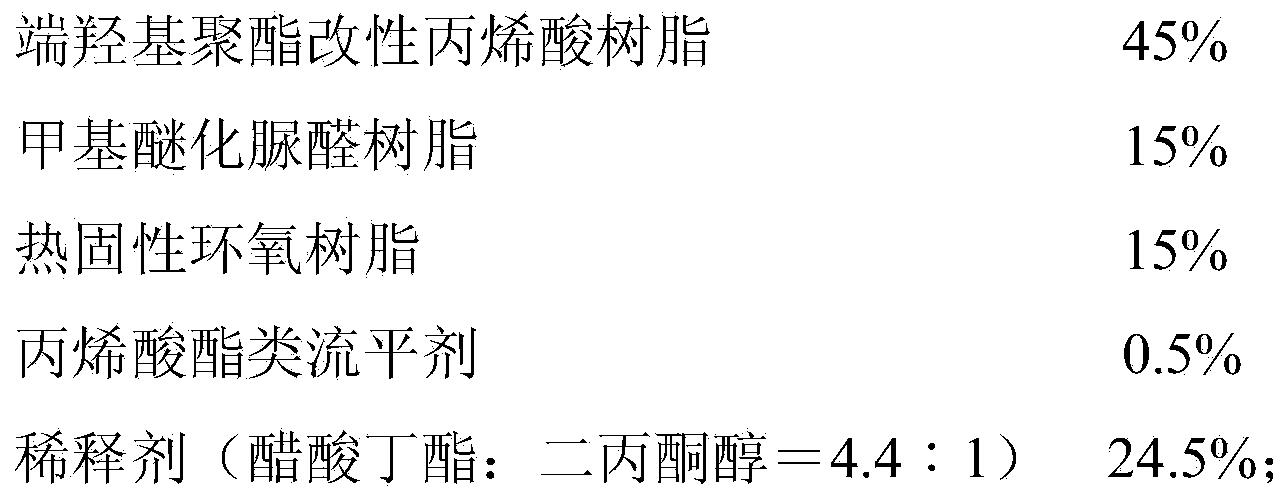

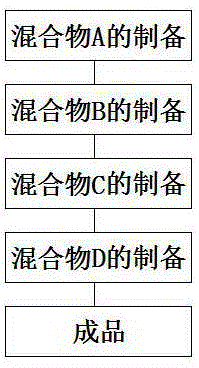

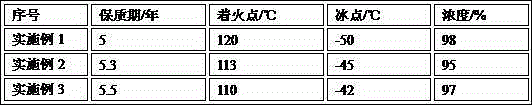

The invention discloses thermal sublimation transferring-printing coating pulp which comprises the following components in percentage by mass: 35-55% of hydroxyl-terminated polyester modified crylic acid resin, 10-30% of methyl etherified urea resin or butyl etherified urea resin, 0.1-1% of acrylic leveling agent and 24.5-45% of diluent, wherein the solid content of the hydroxyl-terminated polyester modified crylic acid resin is 60%+ / -2%, and the acid value is 3-5mgKOH / g; the solid content of methyl etherified urea resin or butyl etherified urea resin is 75%+ / -2%, the acid value is less than 1mgKOH / g; the diluent is a mixture of n-butyl acetate and diacetone alcohol. When the coating pulp is coated on the surface of a printed article and is heated, the hydroxyl-terminated polyester modified crylic acid resin has cross-linking reaction with methyl etherified urea resin or butyl etherified urea resin to form a net-shaped structure, and thus the pattern generated after transferring-printing is clear, full, high in color fastness, long-lasting without fading, and high in glossiness.

Owner:东莞隽思印刷有限公司

Anticorrosive environment-friendly spray paint formula

InactiveCN105199580ABright colorGood light fastnessAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholChemical industry

The invention discloses an anticorrosive environment-friendly spray paint formula, and relates to the field of chemical industries. The anticorrosive environment-friendly spray paint formula comprises the following components in parts by weight: 28 to 35 parts of glacial acetic acid, 3 to 7 parts of organic fluorine epoxy resin, 7 to 12 parts of epoxy modified organic silicon resin, 2 to 6 parts of glycol monomethyl ether, 6 to 9 parts of dimethyl sulfoxide, 8 to 13 parts of zinc phosphate, 8 to 13 parts of barium chromate, 1 to 4 parts of ethanol, 2 to 7 parts of polyacrylate, 1 to 4 parts of alcohol soluble resin, 7 to 13 parts of diacetone alcohol, 6 to 9 parts of zinc oxide, 8 to 13 parts of toluene diisocynate, 3 to 7 parts of n-butyl acetate, 12 to 16 parts of benzophenone, 9 to 13 parts of triethanolamine and 3 to 7 parts of diphenyl polysiloxane. The paint is bright in color and good in air-curing resisting effect, can substitute medium chrome yellow in inorganic pigment, is applicable to the outer wall paint, and has no harm of heavy metals, no harmful substances, good environment protection effect, little odor, no peculiar smell after being smeared on the wall, good mechanical performance, excellent electric insulation performance, dampness and water resistance, rust and cold resistance and ozone aging resistance.

Owner:王海平

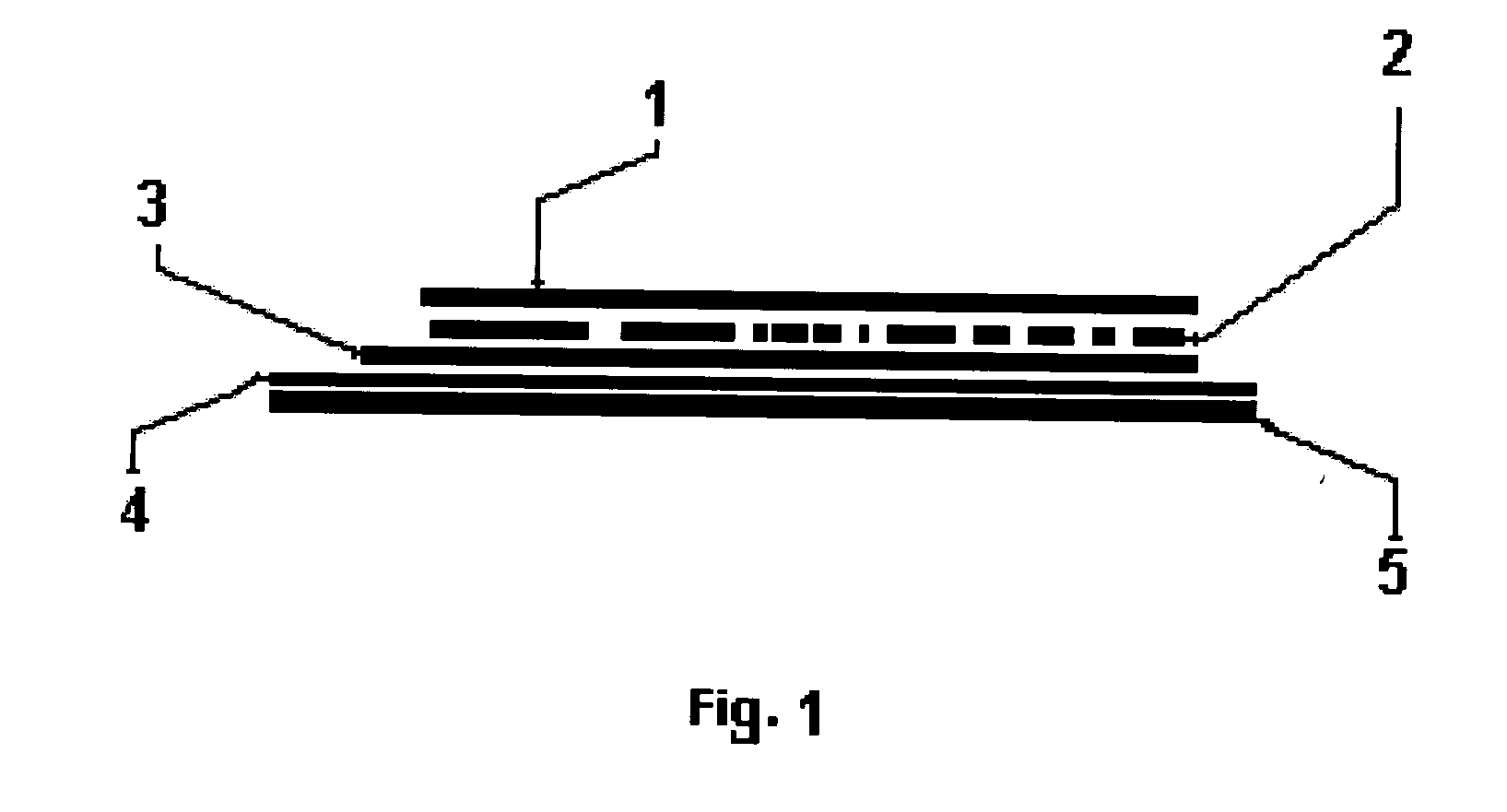

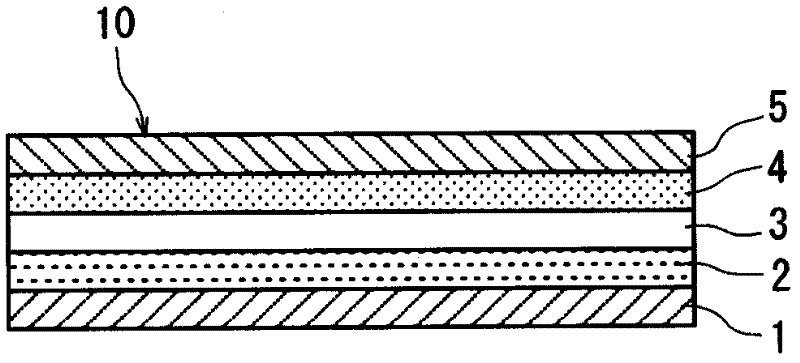

Liquid crystal orientation agent, liquid crystal orientation film, manufacturing method of liquid crystal orientation film, and liquid crystal display element

InactiveCN103666486AImprove yieldUniform coatingLiquid crystal compositionsNon-linear opticsDiacetone alcoholDiethylene glycol diethyl ether

The invention relates to a liquid crystal orientation agent, a liquid crystal orientation film, a manufacturing method of the liquid crystal orientation film, and a liquid crystal display element. The liquid crystal orientation agent has good printing performance with respect to a substrate and good continuous printing performance and prevents swelling of printing plates. The liquid crystal orientation agent contains at last one polymer (A) selected from the group formed by polyamide acid, polyimide, polyamide acid ester and polysiloxane, a first solvent containing more than one of N-ethyl-2-pyrrolidone, 1,3-dimethyl-2-imidazolone, 3-methoxy-N, N-dimethylpropionamide and so on, and a second solvent containing more than one of propylene glycol diacetate, diethylene glycol diethyl ether, diisoamyl ether diacetone alcohol and so on.

Owner:JSR CORPORATIOON

Strong acid resistant and inner corrosion-resistant paint and its manufacturing method

InactiveCN1621464AGood acid corrosion resistanceGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The present invention relates to one kind of strong acid resistant inner anticorrosive paint and its production process. The paint is produced through adding epoxy resin into mixed solvent one xylene, diacetone alcohol and cyclohexanone; adding phenolic resin, chrome green, precipitated barium sulfate, graphite, PTFE, polyacrylate copolymer solution, polymethyl alkyl siloxane solution and polyamdie wax via mixing; and grinding. The paint may be coated to inner wall of acid gas pipeline and high sulfur matter conveying pipeline for preventing corrosion.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

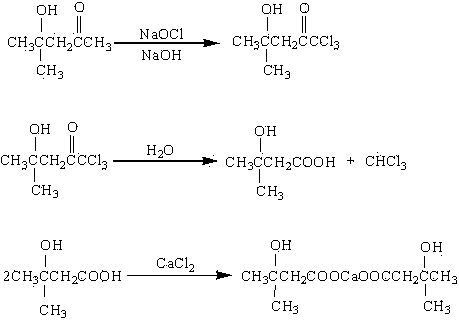

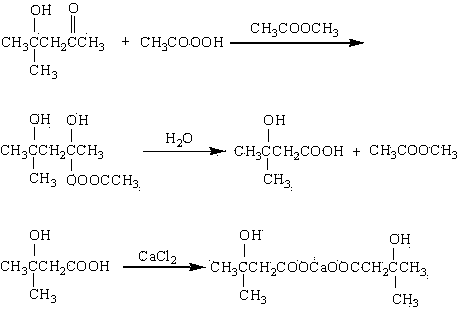

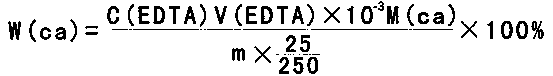

Preparation method of feed additive calcium beta-hydroxy-beta-methylbutyrate

ActiveCN103694107ASimple preparation processRaw materials can be recycledOrganic compound preparationCarboxylic acid salt preparationDiacetone alcoholDistillation

The invention provides a preparation method of a feed additive calcium beta-hydroxy-beta-methylbutyrate. The preparation method comprises the following steps: 1) performing reaction on glacial acetic acid, sulfuric acid and H2O2 and performing reduced-pressure distillation after the reaction to obtain a peracetic acid solution; 2) mixing the product obtained in the step 1) and diacetone alcohol, adding methyl acetate serving as a solvent, reacting, and distilling and collecting 70-DEG C fraction after the reaction, wherein the residuum after distillation is a beta-hydroxy-beta methylbutyric acid solution; 3) adding water into the distillation residuum obtained in the step 2), adding a sodium hydroxide solution, adjusting the pH value to be 6.0 to 7.0, separating out calcium beta-hydroxy-beta-methylbutyrate, filtering and drying to obtain the product. The preparation process of the calcium beta-hydroxy-beta-methylbutyrate is simple and avoids environmental pollution. The prepared product has high quality, is stable and reliable, and is convenient to popularize.

Owner:CHANGSHA POWERLIFE BIOTECH

Process for producing diacetone alcohol

ActiveCN1787986AOrganic compound preparationOrganic chemistry methodsDiacetone alcoholAlkaline earth metal

An object of the present invention is to provide a method for producing diacetone alcohol capable of long-term operation. The present invention relates to a method for producing diacetone alcohol, which in the presence of a solid alkaline catalyst containing at least (i) a metal hydroxide selected from alkali metal hydroxides and alkaline earth metal hydroxides and (ii) a binding agent, Producing diacetone alcohol from acetone is characterized by using a solid basic catalyst having a pore diameter of 0.01 μm to 1 μm and a pore volume of 1.8 ml / g as a solid basic catalyst.

Owner:MITSUBISHI RAYON CO LTD

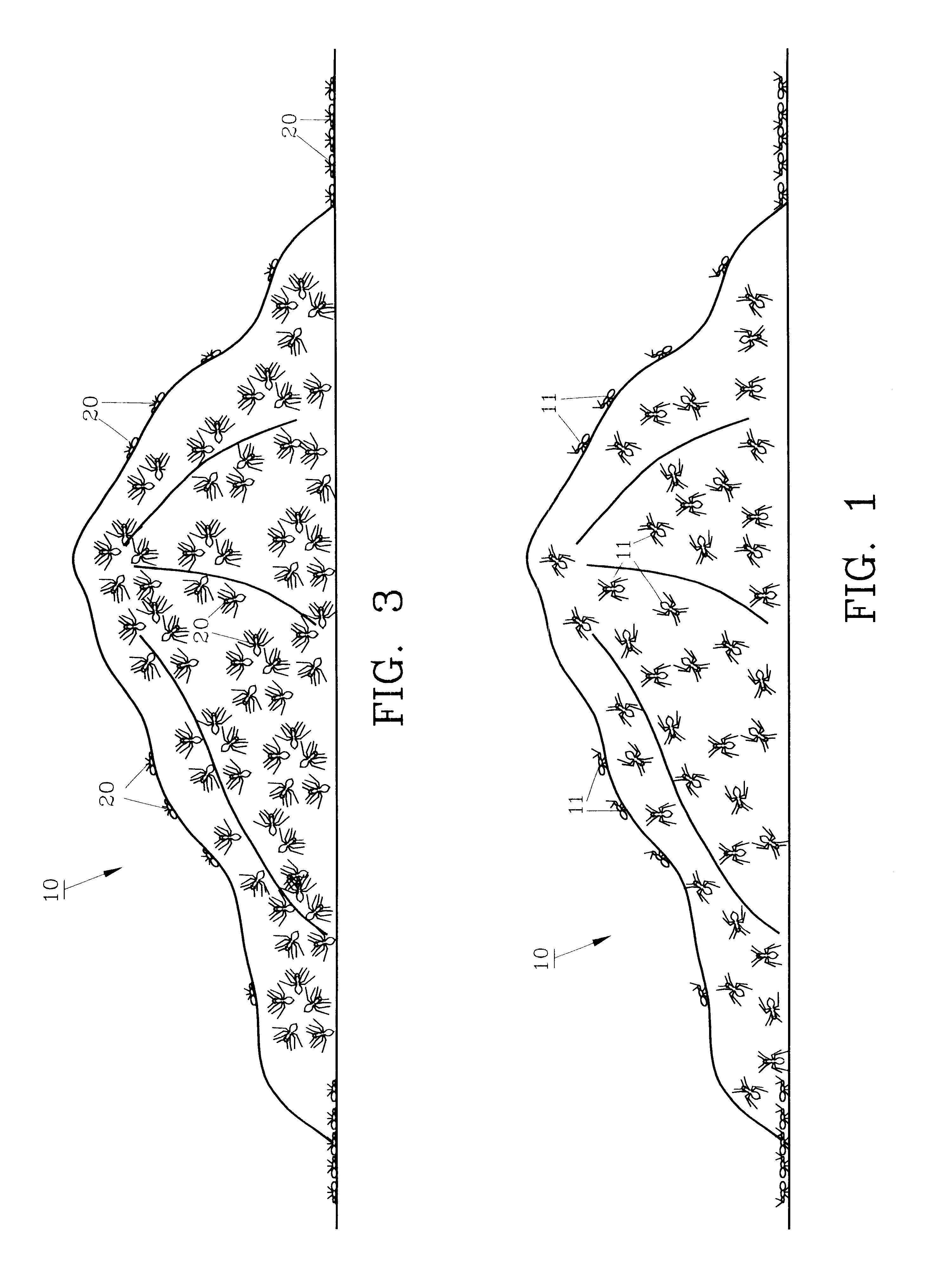

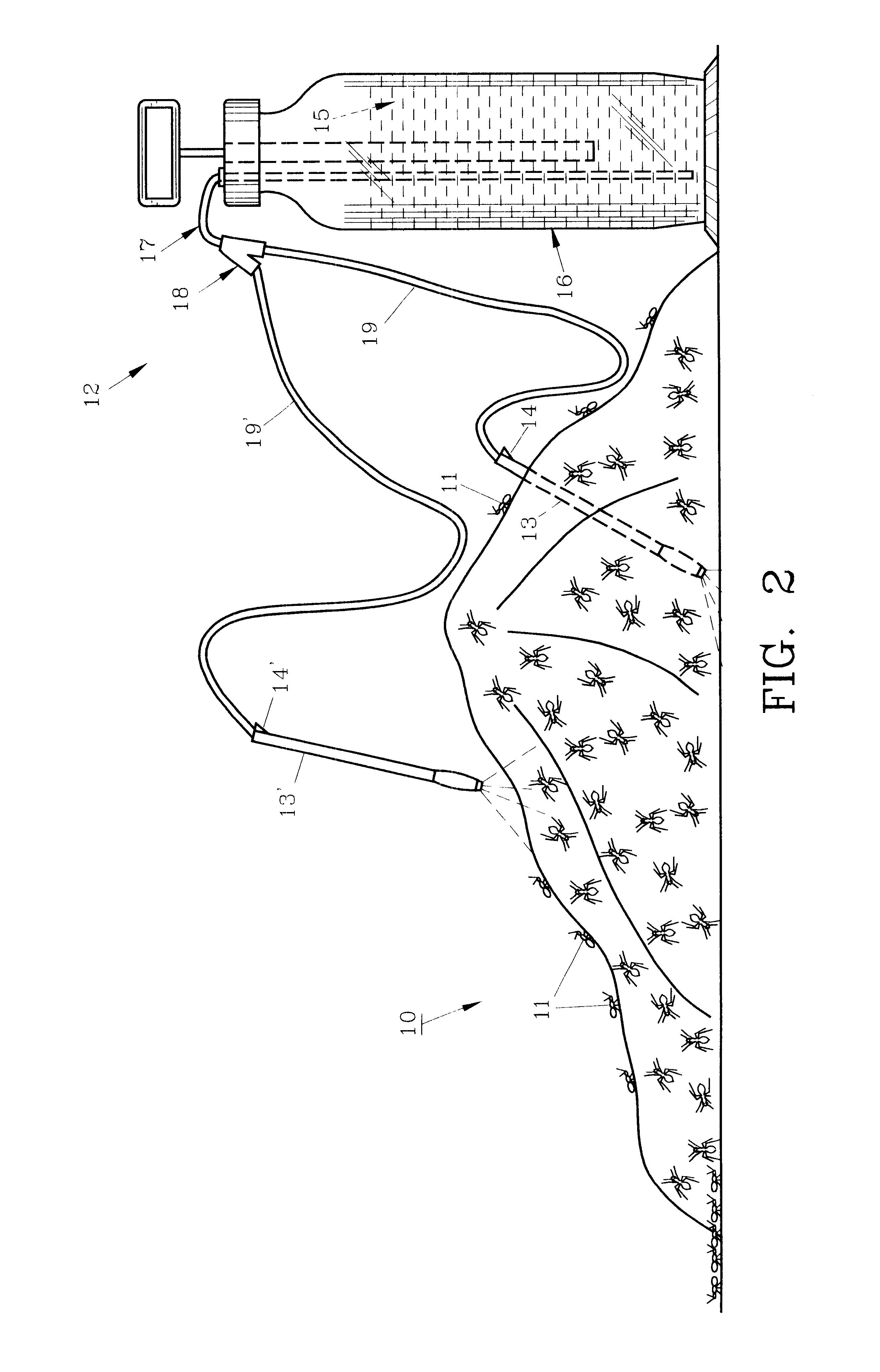

Insect eradicator and method

InactiveUS6441051B1Safe handlingEfficient use ofBiocideDead animal preservationDiacetone alcoholMETHYL SOYATE

An effective, environmentally, friendly insecticide and method of application are described herein. The conventional insecticide d-limonene is combined with diacetone alcohol to enhance its lethal properties. An emulsion concentrate is first prepared using d-limonene, diacetone alcohol, polyglycol ether and methyl soyate. This concentrated emulsion mixture can then be stored for use as needed. When needed this concentrated emulsion is mixed at a ratio of 10 parts by weight emulsion and 90 parts by weight of water to form an effective mixture for spraying in a modified manual garden sprayer having two spray wands.

Owner:WHEELER WILLIAM B

Antistatic paint

InactiveCN104371503AGood ability to eliminate static electricityImprove scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsDiacetone alcoholEpoxy

The invention discloses antistatic paint. The antistatic paint comprises 25-30% of polyurethane resin, 20-26% of conductive diacetone alcohol, 2-5% of titanium dioxide powder, 8-12% of conductive assistants, 30-45% of epoxy resin, 2-8% of conductive zinc oxide, 3-6% of ultra-fine aluminum silicate and 15-22% of water. Owing to the mode, the antistatic paint has the advantages of good static electricity elimination capacity, excellent scratch resistance, ultra-high impact resistance and outstanding high-temperature-resistant performance.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

Process for synthesizing 2-methyl-2,4-pentendiol through hydrogenation reduction of diacetone alcohol

InactiveCN102329193AReduce generationHigh quality yieldOrganic compound preparationHydroxy compound preparationNickel catalystDiacetone alcohol

The invention relates to a process for synthesizing 2-methyl-2,4-pentendiol through hydrogenation reduction of diacetone alcohol, and belongs to the technical field of production processes of the 2-methyl-2,4-pentendiol. In the process, the diacetone alcohol is used as a raw material and is mixed with an aid, and then hydrogen is aerated under pressure under the action of a nickel catalyst to synthesize the 2-methyl-2,4-pentendiol through reduction replacement; and the aid is an alkaline compound, and the alkaline compound can be an alkaline inorganic compound or an alkaline organic compound which does not have a negative effect on hydrogenation reactions. By adding the aid, the disadvantages that the yield of products is low, more other byproducts are produced, the production cost is high, the process is difficult to operate, the separation of the products is difficult and the like existing in the conventional process are overcome, and other byproducts in the reduction process are reduced, so that the product yield of the synthesis of the 2-methyl-2,4-pentendiol is improved; and the purity of the 2-methyl-2,4-pentendiol is 99.5 percent, and the mass yield is improved to 99 percent. The process has the characteristics of simplicity, stable reaction, no pollution and the like, and is easy to operate.

Owner:荆州市宇鹏科技有限公司

Removable solvent based paint formulation and system

A removable lacquer coating or paint of approximately 20 to 30% by weight of cellulose acetate butyrate, 50 to 80% by weight of alcohol and 10 to 30% by weight of diacetone alcohol is provided. It may also contain from 1 to 7% sucrose acetate isobutyrate. This removable paint can be removed by a formulation of diacetone alcohol, ethyl alcohol, hydroxypropylcellulose and a surfactant.

Owner:WARREN DONALD

Wear-resistant, high-temperature resistant and anti-corrosion coating for sand-containing heavy oil gathering pipelines and preparation method thereof

ActiveCN101691473AGood high temperature corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneDiacetone alcohol

The invention relates to a wear-resistant, high-temperature resistant and anti-corrosion coating for sand-containing heavy oil gathering pipelines and a preparation method thereof. Methylphenyl silicone resin and bisphenol A epoxy resin E-44 are added into mixed solution of dimethylbenzene, diacetone alcohol, cyclohexanone and dimethyl dicarboxylic acid; the mixture is added with gamma-methacryloxypropyltrimethoxysilane and polyether modified methyl alkyl polyorganosiloxane, and then is mixed evenly; the mixture is added with 1,250-mesh titanium dioxide, 800-mesh precipitated barium sulfate, 800-mesh grey ferro titanium powder, 1,250-mesh gas-phase silicon dioxide, 1,250-mesh wollastonite in powder, 2,500-mesh nano-alumina powder and 2,500-mesh molybdenum disulfide, and is stirred and ground into the wear-resistant, high-temperature resistant and anti-corrosion coating for the sand-containing heavy oil gathering pipelines; and after curing, the wear-resistant, high-temperature resistant and anti-corrosion coating forms a wear-resistant, high-temperature resistant and anti-corrosion coat for the sand-containing heavy oil gathering pipelines. The wear-resistant, high-temperature resistant and anti-corrosion coating can be used for corrosion resistance of inner walls of high temperature sand-containing oil gathering pipelines in the development of sand-containing heavy oil fileds.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Finishing coat for button, skin-texture stone-like button and preparation method thereof

ActiveCN107556898AHas a stone-like appearanceWith skin texturePretreated surfacesClothes buttonsDiacetone alcoholCyclohexanone

The invention provides finishing coat for a button, a skin-texture stone-like button and a preparation method thereof. The finishing coat comprises a material A, a material B and a material C in a mass ratio of (8-10):1:(2.5-3.5), wherein the material A comprises colorless saturated polyester resin, 80-150 microns of colorful polyurethane elastic particles, 5-10 microns of polyurethane elastic powder, 80-150 microns of plant fiber powder, a flatting agent, matt powder, a feeling agent, a drier, n-butyl acetate, diacetone alcohol and cyclohexanone; the material B is an isocyanate curing agent;and the material C is n-butyl acetate. The components of the finishing coat for the button are compatible with each other, and the finishing coat is sprayed to the button surface, so that the button has a stone-like appearance, skin texture and relatively high color fastness. The button coated with the finishing coat has a color fastness being 4-5 grade, and after five times of washing, color variety is 4-5 grade, and the surface does not have remarkable defect.

Owner:ZHEJIANG WEIXING IND DEV

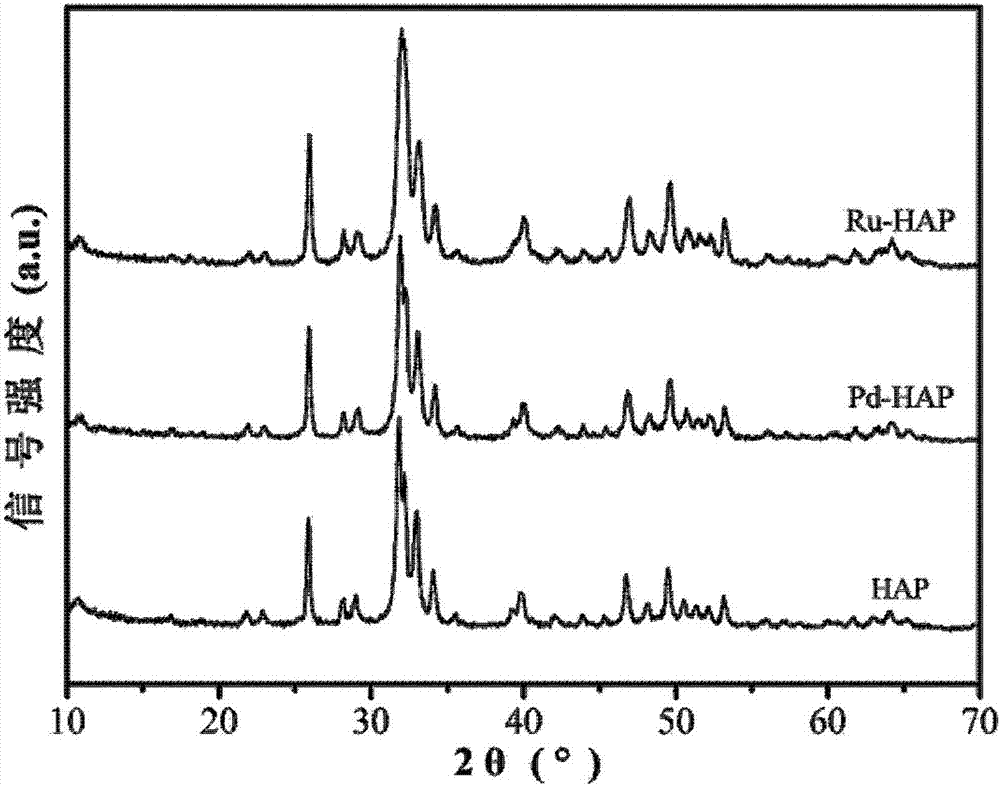

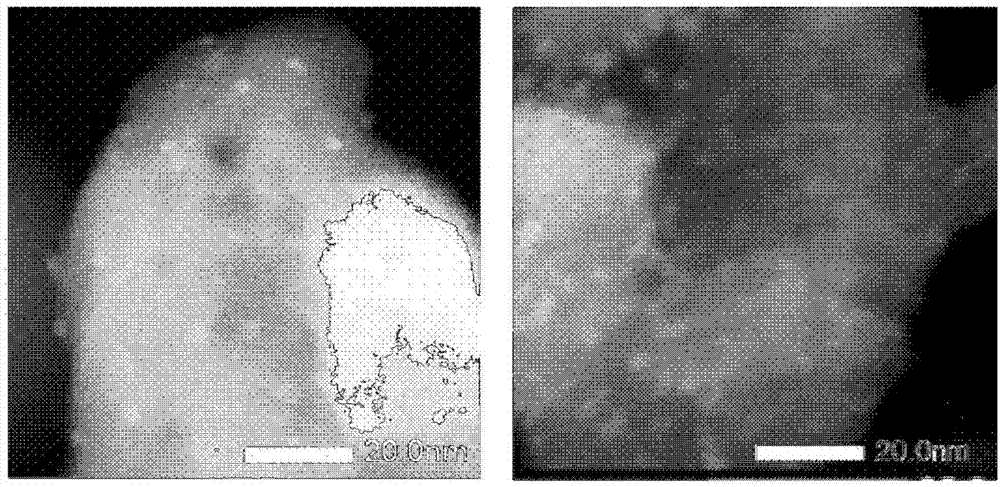

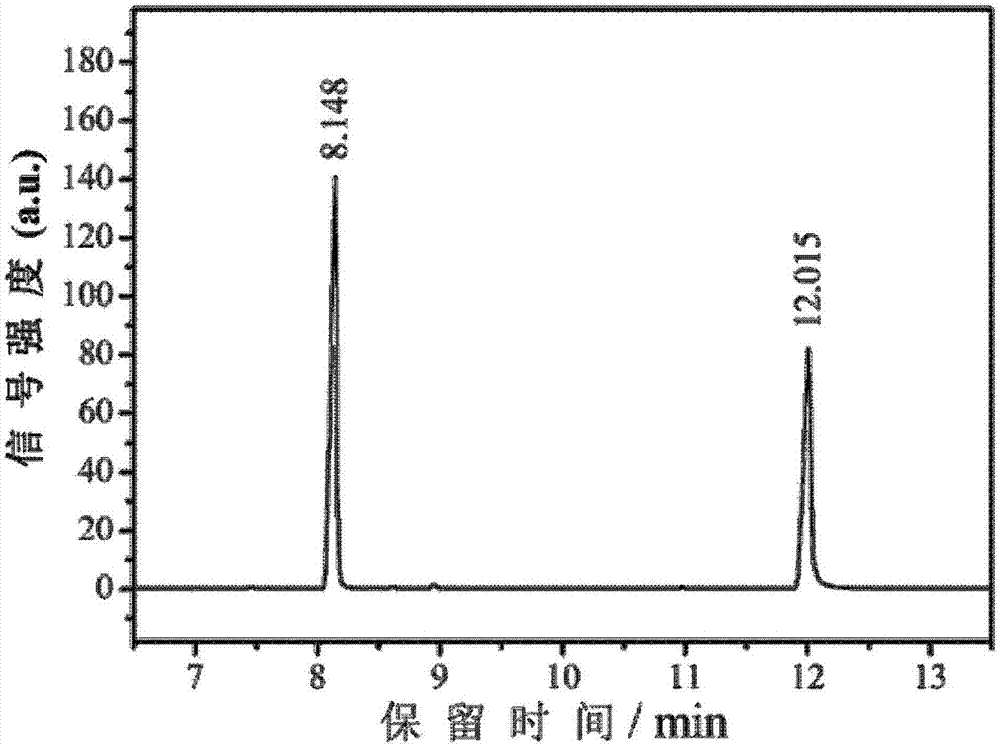

Catalyst and method for preparing 2-methyl-2,4-pentanediol by diacetone alcohol hydrogenation

ActiveCN107235825AEasy to useHigh hydrothermal stabilityPhysical/chemical process catalystsOrganic compound preparationDiacetone alcoholHydrogen

The invention provides a catalyst and a method for preparing 2-methyl-2,4-pentanediol by diacetone alcohol hydrogenation. The method includes that diacetone alcohol and hydrogen are subjected to reaction in the presence of a catalyst to generate 2-methyl-2,4-pentanediol, wherein the catalyst is a supported metal catalyst formed by loading of an active metal component on a hydroxyapatite carrier. The method can be implemented in an environment-friendly solvent as well as under a solvent-free condition, and the conversion rate of diacetone alcohol in preparation of 2-methyl-2,4-pentanediol is up to 100%; a reaction process for preparing 2-methyl-2,4-pentanediol from diacetone alcohol is simple, and simple equipment, simplicity and convenience in operation and mild reaction conditions are realized; the catalyst is simple in preparation and low in cost, large-scale production can be realized, and the catalyst prepared according to an ion exchange method is high in hydrothermal stability and recyclability; reaction products can be easily separated from the catalyst and a solvent system, and short reaction period, suitableness for industrial production and a promising application prospect are realized.

Owner:UNIV OF SCI & TECH OF CHINA

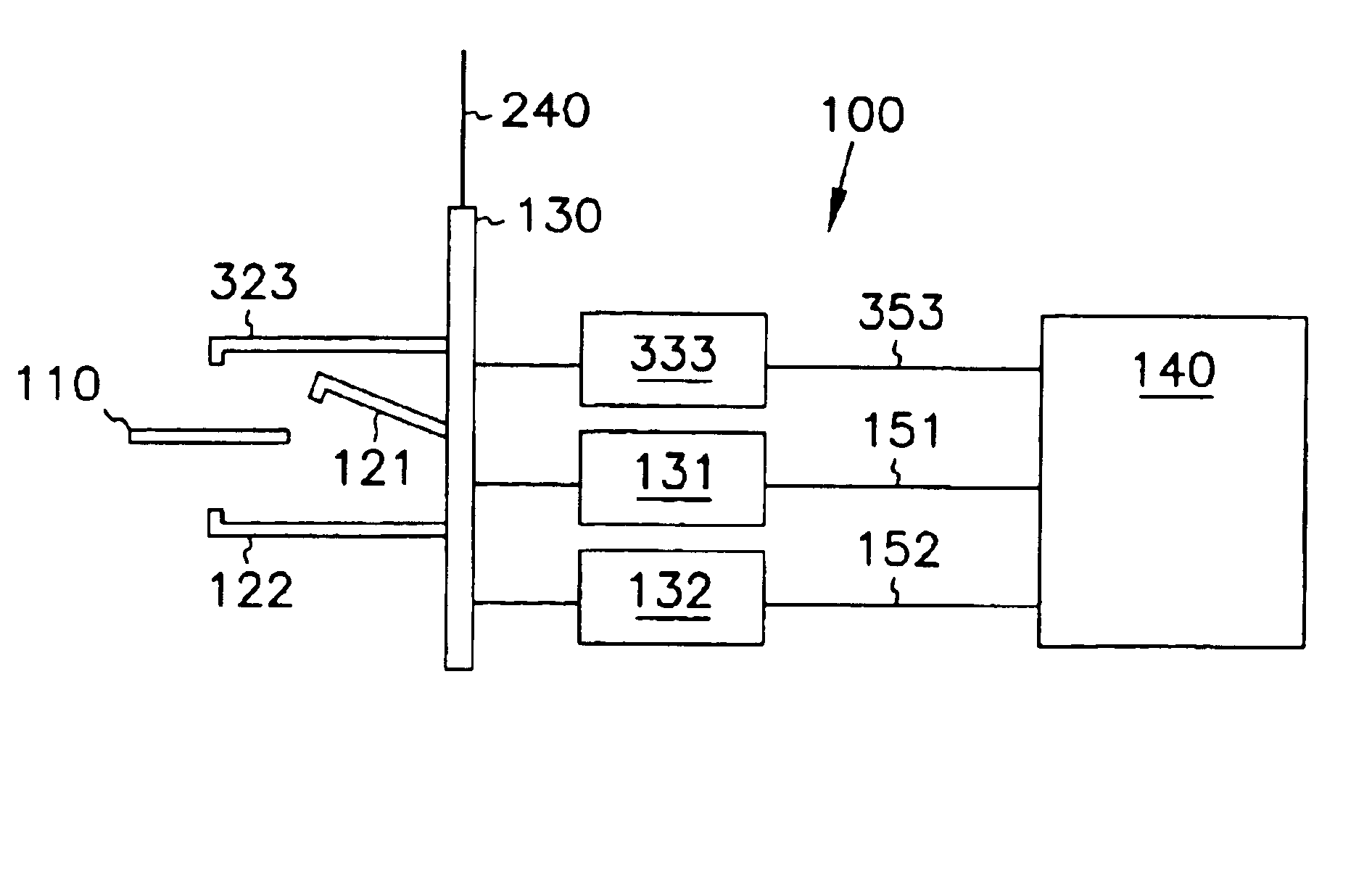

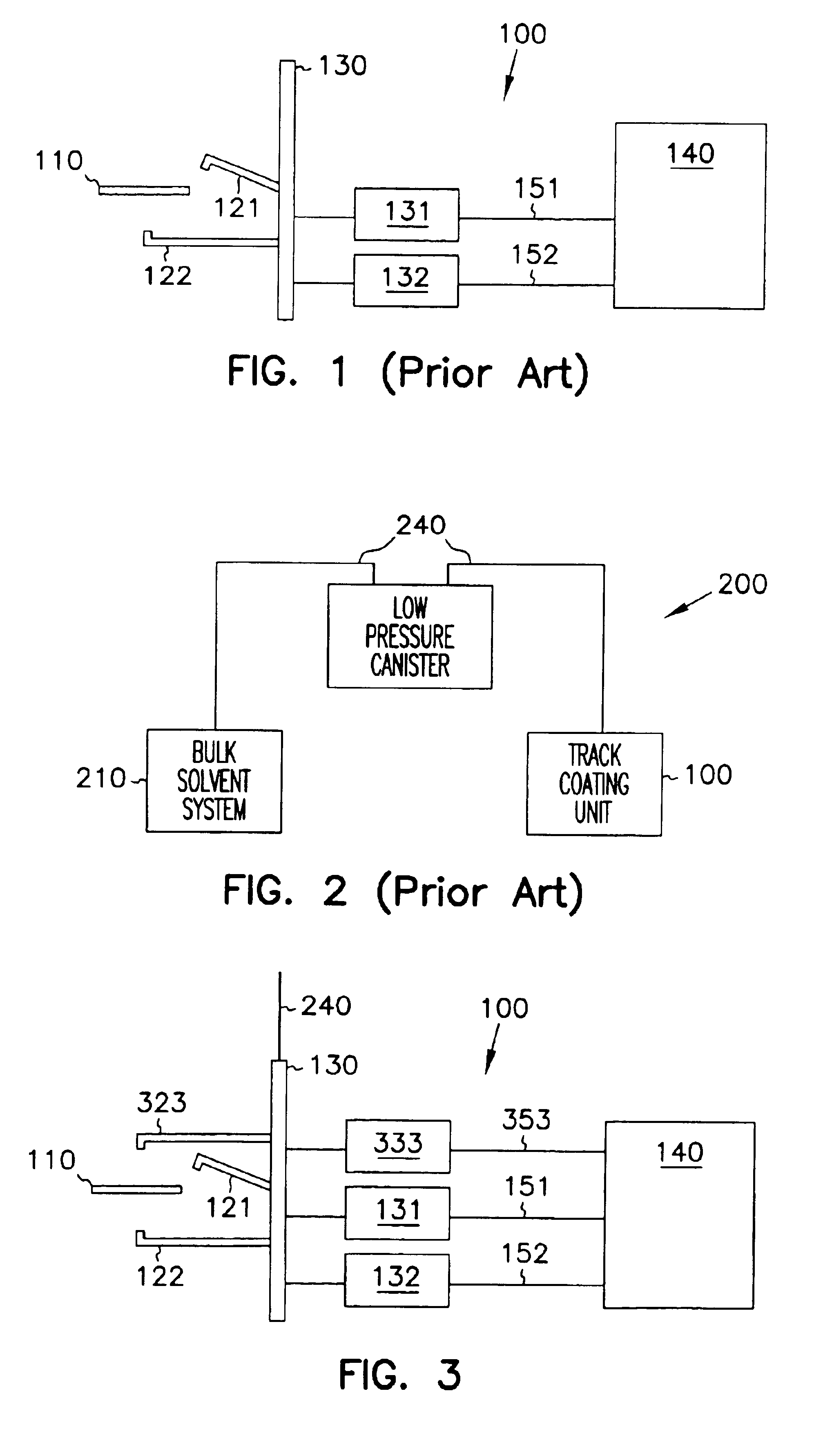

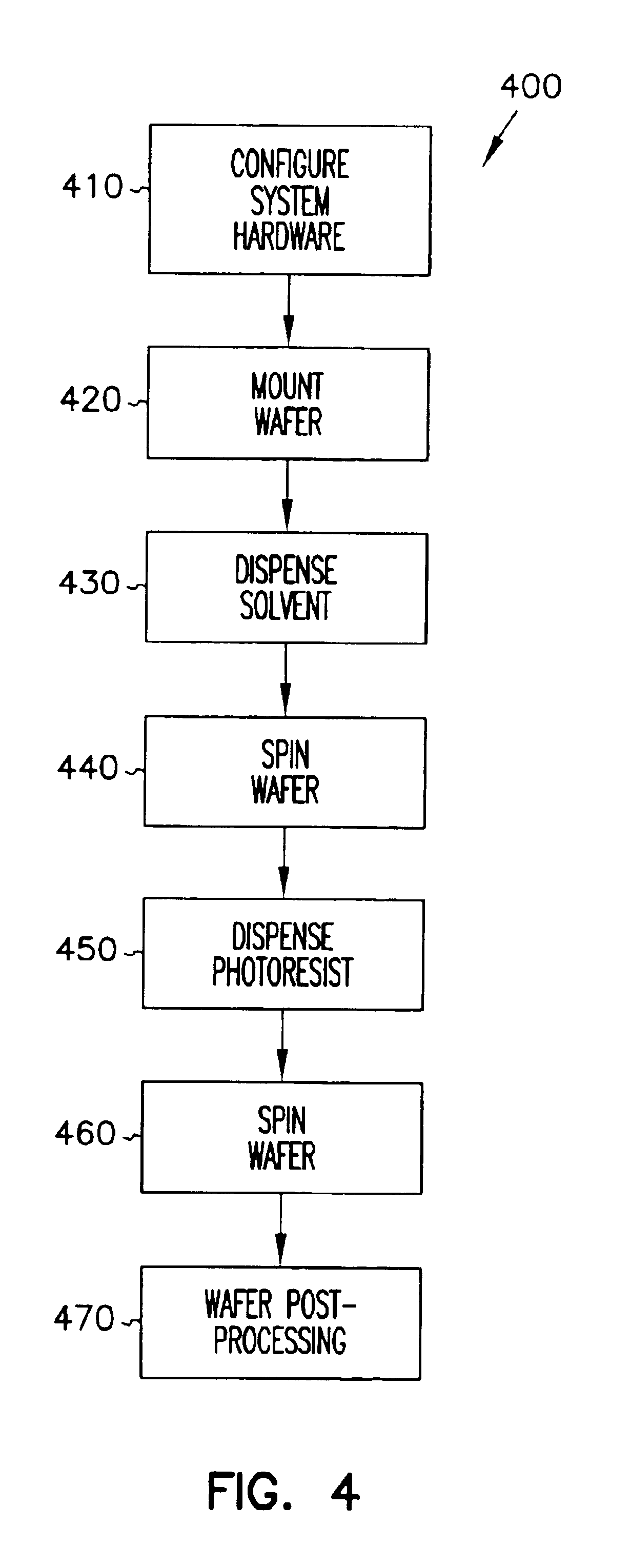

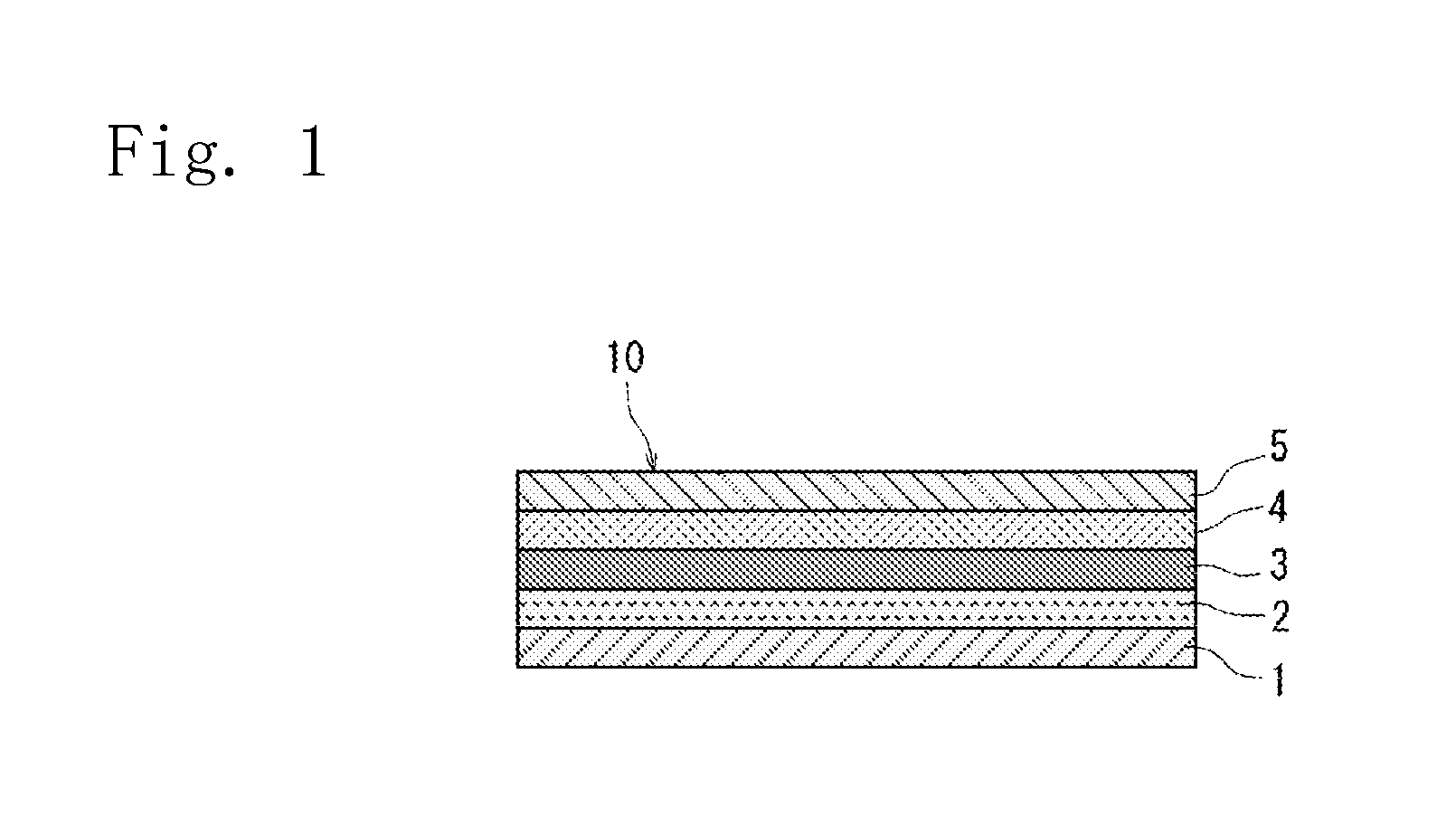

Solvent prewet and method to dispense the solvent prewet

InactiveUS6884462B2Less materialQuality improvementPretreated surfacesSemiconductor/solid-state device manufacturingResistDiacetone alcohol

Owner:CONVERSANT INTPROP MANAGEMENT INC

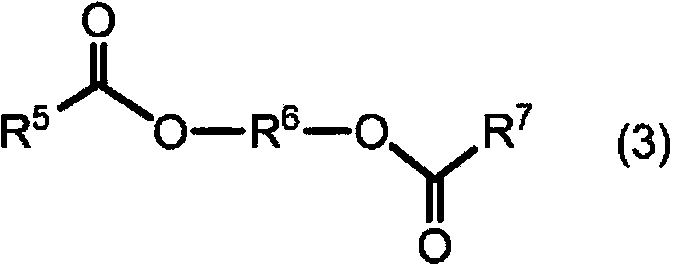

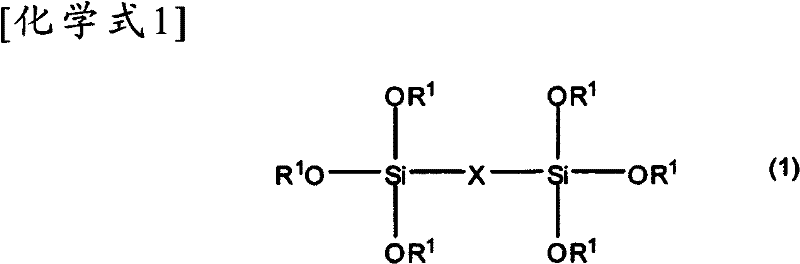

Coating composition, process for producing the composition, and laminate having a hard coat layer

InactiveUS20110244244A1Good effectWell formedLiquid surface applicatorsSynthetic resin layered productsDiacetone alcoholMass ratio

To provide a coating composition capable of forming a hard coat layer having excellent transparency and scratch resistance on the surface of an optical resin substrate such as a plastic lens, and exhibiting long-term storage stability.[Means for Solution] The coating composition comprises (A) a fine particulate composite metal oxide, (B′) a hydrolyzed product obtained by the hydrolysis of (B) a hydrolyzable organosilicon compound containing (B1) an organosilicon compound that has an epoxy group, such as γ-glycidoxypropyltrimethoxysilane, (C) water, (D1) a low-boiling lowly viscous alcohol having not more than 3 carbon atoms, such as methanol or ethanol, (D2) a low-boiling highly viscous alcohol such as t-butanol, (D3) a high-boiling organic solvent having a boiling point of 150° C. to 200° C., such as diacetone alcohol, and (E) a curing catalyst such as tris(2,4-pentanedionato)aluminum(III), the mass ratio (D1 / C) of the component (D1) and the component (C) being in a range of 1.80 to 7.00, the mass ratio (D2 / C) of the component (D2) and the component (C) being in a range of 0.24 to 2.50, and the mass ratio (D3 / C) of the component (D3) and the component (C) being in a range of 1.10 to 4.40.

Owner:TOKUYAMA CORP

Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

ActiveCN105001881AReduce non-display areaAchieve narrow frameLiquid crystal compositionsNon-linear opticsDiethylene glycol diethyl etherDiacetone alcohol

The invention provides a liquid crystal aligning agent, a liquid crystal aligning film and a liquid crystal display element. The liquid crystal aligning agent contains at least one polymer (A) selected from the group consisting of polyamic acid, polyamic acid ester and polyimide, and solvents. The solvents contain a specific solvent (X) and a specific solvent (Y). The specific solvent (X) is 1-butoxy-2-propanol; and the specific solvent (Y) contains at least one of the group consisting of diethylene glycol diethyl ether, diacetone alcohol, propylene glycol diacetate and dipropylene glycol monomethyl ether. According to the invention, undesirable film thickness of the end of the coating area of the liquid crystal aligning agent is limited.

Owner:JSR CORPORATIOON

Antistatic coating

InactiveCN105219223AGood ability to eliminate static electricityImprove scratch resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyDiacetone alcohol

The invention relates to an antistatic coating comprising the following components in parts by weight: 22-28 parts of epoxy resin, 16-20 parts of conductive diacetone alcohol, 3-8 parts of titanium dioxide, 6-14 parts of an antistatic agent, 3-9 parts of conductive mica powder, 2-6 parts of silicon micro powder and 55-65 parts of deionized water. Therefore, the antistatic coating disclosed by the invention is smoother after film forming, and is good in static elimination capability, good in scratch resistance, super strong in impact resistanc and outstanding in high temperature resistance and corrosion resistance.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

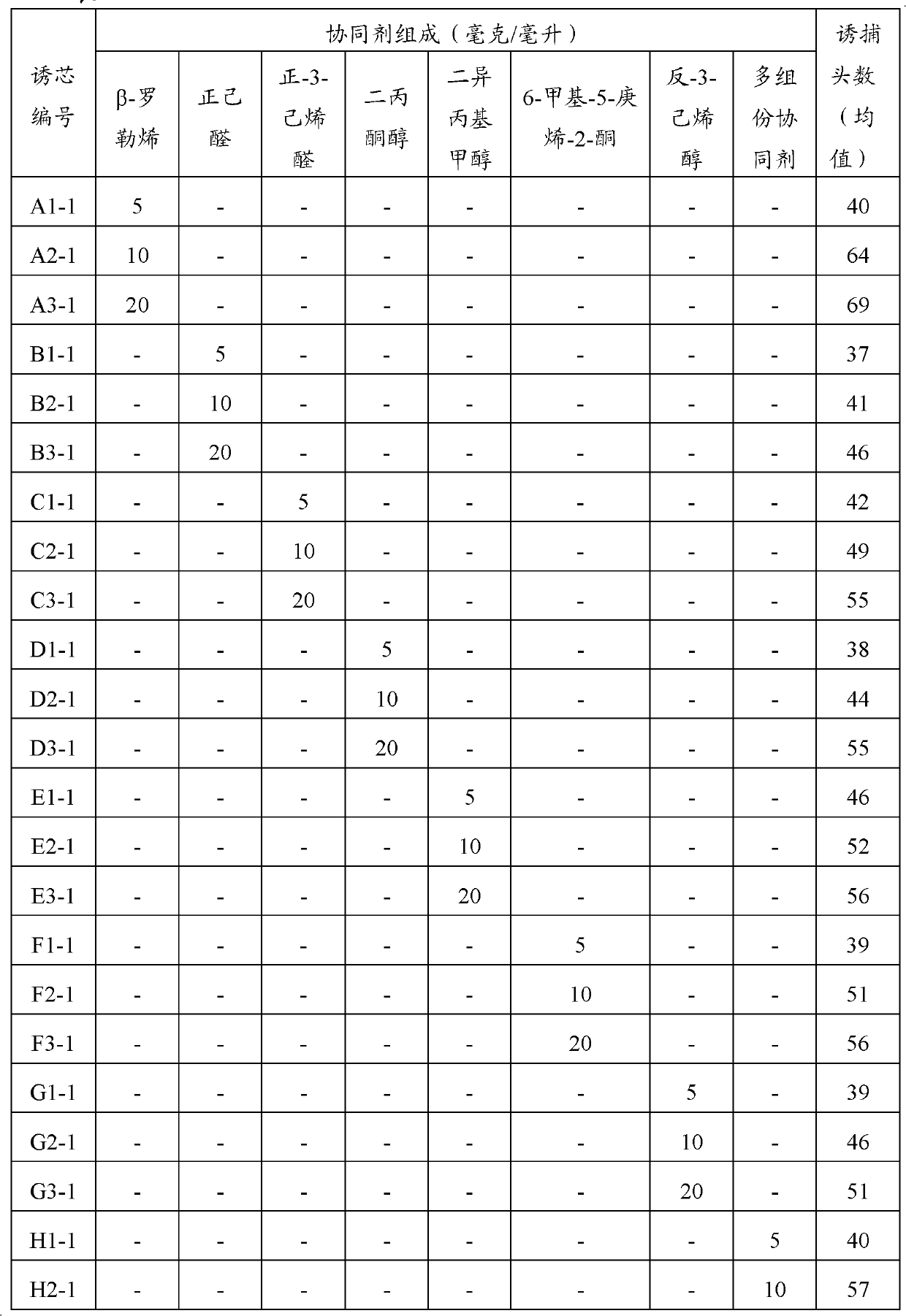

Hyphantria cunea Drury attractant composition, its application and attracting core

InactiveCN103315002AFlexible usageStrong autonomyBiocidePest attractantsDiacetone alcoholCis-3-Hexenal

The invention provides a Hyphantria cunea Drury attractant composition, its application and attracting core. The Hyphantria cunea Drury attractant composition includes Hyphantria cunea Drury sex pheromone and its synergistic agent. The synergistic agent contains one or more of the following plant source smell components: beta-ocimene, hexanal, cis-3-hexenal, diacetone alcohol, diisopropylcarbinol, 6-methyl-5-heptene-2-one, trans-3-hexenol, o-xylene, hemimellitene, trans-2-hexenal, and limonene. The attractant composition provided in the invention can be prepared into an attracting core so as to be used cooperatively with the existing Hyphantria cunea Drury sex pheromone. The invention provides the attracting core containing the Hyphantria cunea Drury attractant composition to prevent, control and detect Hyphantria cunea Drury, so that the defects of high cost and difficult popularization of imported and domestic Hyphantria cunea Drury sex pheromone attracting cores in the prior art are solved. The attracting core provided in the invention has the advantages of low cost, flexible use, and higher trapping efficiency.

Owner:INST OF ZOOLOGY CHINESE ACAD OF SCI

Seawater corrosion-resistant epoxy paint and manufacturing method thereof

InactiveCN102786865AStrong adhesionImprove impact resistanceAntifouling/underwater paintsPaints with biocidesDiacetone alcoholFatty amine

The invention relates to a seawater corrosion-resistant epoxy paint and a manufacturing method thereof. The manufacturing method comprises the following steps of adding modified phenolic epoxy resin and bisphenol-F-epoxy resin into a mixed solvent of dimethylbenzene, diacetone alcohol and n-butyl alcohol; adding titanium dioxide, aluminium triphosphate, alumina powder, silica micropowder, sericite powder, carbon black, an aluminate coupling agent, polymethyl alkyl siloxane solution and polyamide wax into the mixture; blending, stirring and grinding the materials to prepare A liquid of the seawater corrosion-resistant paint; adding aliphatic amine and modified phenolic amine into mixed solution of absolute ethyl alcohol and dimethylbenzene to prepare B liquid; and mixing the A liquid and the B liquid to prepare the seawater corrosion-resistant epoxy paint. The paint can be used for curing at 0 DEG C, has excellent storage stability and very good adhesion, abrasion resistance, flushing resistance and seawater resistance, and can be applied to splashing areas and underwater corrosion resistance of ships, marine platforms, marine work steel structures and the like.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

Strong-acid-resistant high-strength anticorrosive paint and preparation method thereof

InactiveCN104629588APlay the role of anti-corrosion protectionStrong scrub resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholEpoxy

The invention discloses a strong-acid-resistant high-strength anticorrosive paint which comprises the following components in parts by mass: 25-28 parts of epoxy resin, 22-26 parts of polyurethane, 9-13 parts of silicon dioxide, 5-7 parts of titanium dioxide, 3-6 parts of zinc powder, 2-5 parts of barium sulfate, 4-6 parts of graphite, 7-9 parts of diacetone alcohol, 5-9 parts of polytetrafluoroethylene, 7-11 parts of polydimethylsiloxane, 4-8 parts of carboxymethyl cellulose, 1-3 parts of tributyl phenol polyethenoxy ether and 33-45 parts of deionized water. The invention also discloses a preparation method of the strong-acid-resistant high-strength anticorrosive paint. The product can resist corrosion of strong acid and strong alkali, performs the protective and anticorrosive functions on equipment in extreme weather, and has the advantages of excellent mechanical properties, high scrub resistance, high aging resistance, high powdering resistance, higher weather resistance, higher wear resistance, better high-temperature resistance, high safety and environment friendliness.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Germicidal negative-radical waterproof coating and preparation method thereof

InactiveCN104277680AImprove adhesionImprove aging resistanceAntifouling/underwater paintsPaints with biocidesDiacetone alcoholCellulose

The invention discloses a germicidal negative-radical waterproof coating, which is characterized by being prepared from the following raw materials in parts by weight: 0.2-0.4 part of a dispersant EFKA4010, 0.1-0.2 part of a defoaming agent BYK-390, 0.2-0.3 part of a defoaming agent BYK-057, 0.1-0.3 part of a dodecylbenzene sulfonic acid, 40-50 parts of an organosilicone modified polyester resin, 10-15 parts of an acrylic resin, 6-8 parts of a hexamethoxymethyl melamine resin, 4-6 parts of rutile titania, 2-4 parts of silicon sol, 0.3-0.5 part of methyl cellulose, 0.3-0.5 part of palm wax, 3-6 parts of barium sulfate, 4-5 parts of mica powder, 1-2 parts of a matting agent, 0.2-0.4 part of an anti-scratch agent BYK-980, 7-9 parts of S-150, 3-5 parts of diacetone alcohol, 5-7 parts of butyl acetate, 0.5-1.0 part of quizalofop-p-ethyl, and 5-7 parts of a negative-radical additive. According to the coating disclosed by the invention, the added silicon sol is used for enhancing the hardness and wear resistance of a coated film, the added anti-scratch agent is used for improving the scratch resistance of the coated film, the added rutile titania achieves good bacteriostatic and germicidal effects and the like on the soil, and the added negative-radical additive has a good negative-radical effect and has no adverse effect on plants.

Owner:ANHUI LENCAQI BUILDING MATERIAL

Process for preparing 3-hydroxy-3-methylbutyrate (HMB) amino acid salt

InactiveCN1434025AMuscle strengtheningReduce fatOrganic compound preparationAmino-carboxyl compound preparationDiacetone alcoholHaloform reaction

The method for preparing 3-hydroxy-3-methylbutyric acid (HMB) amino acid salt uses diacetone alcohol as raw material and includes the following steps: making haloform reaction in water, adopting isobutanol to extract the produced HMB acid, then making the isobutanol layer and amino acid form salt in alcohol-water mixed liquor so as to obtain the invented product. Its product purity is high, and environment pollution is less, after said product is taken in, it can be completely fed into blood plasma and can be absorbed by human body. Said product can be used for promoting growth of musculus ofhuman body, reducing fat and raising immunological function of human body.

Owner:EAST CHINA NORMAL UNIVERSITY

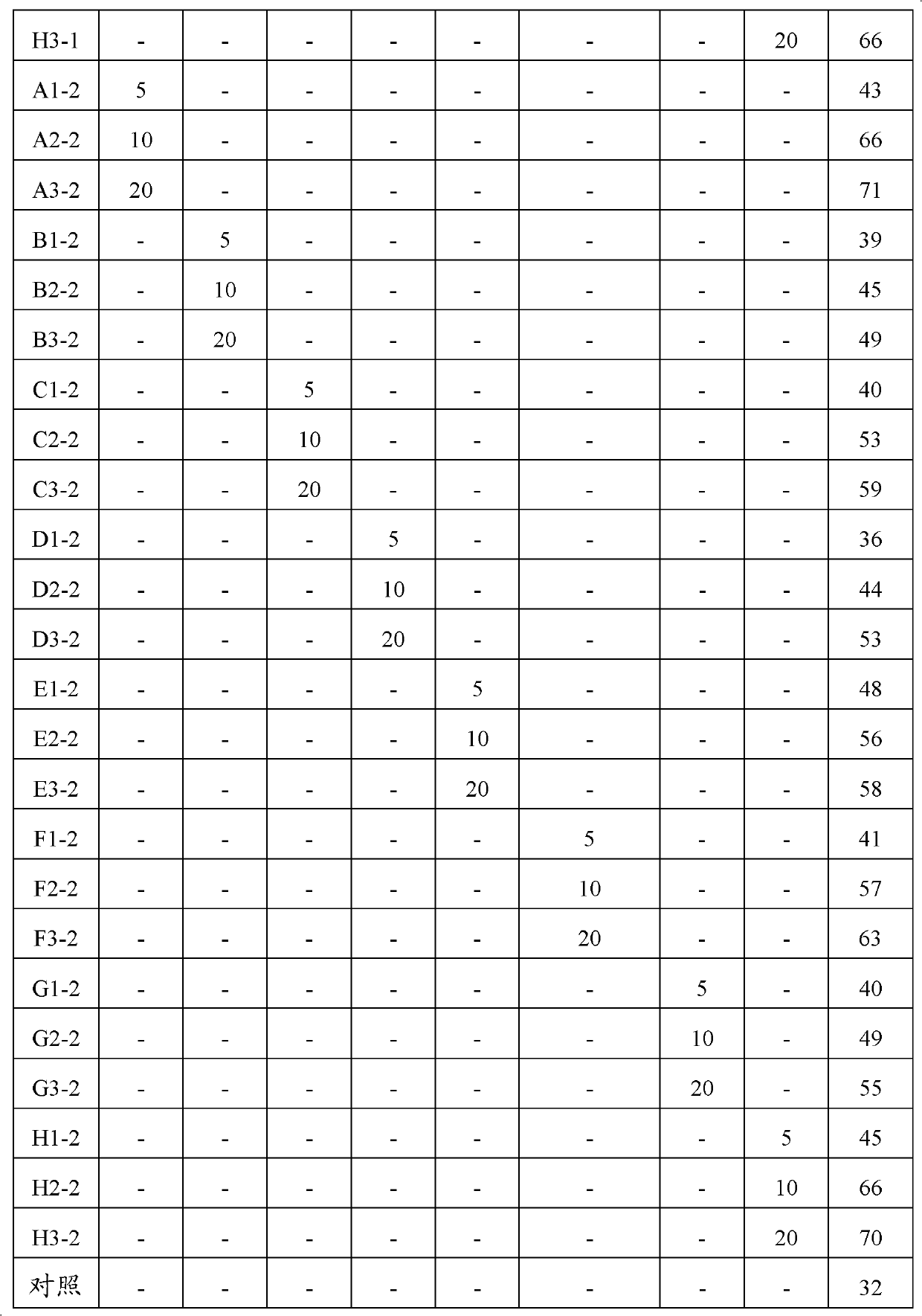

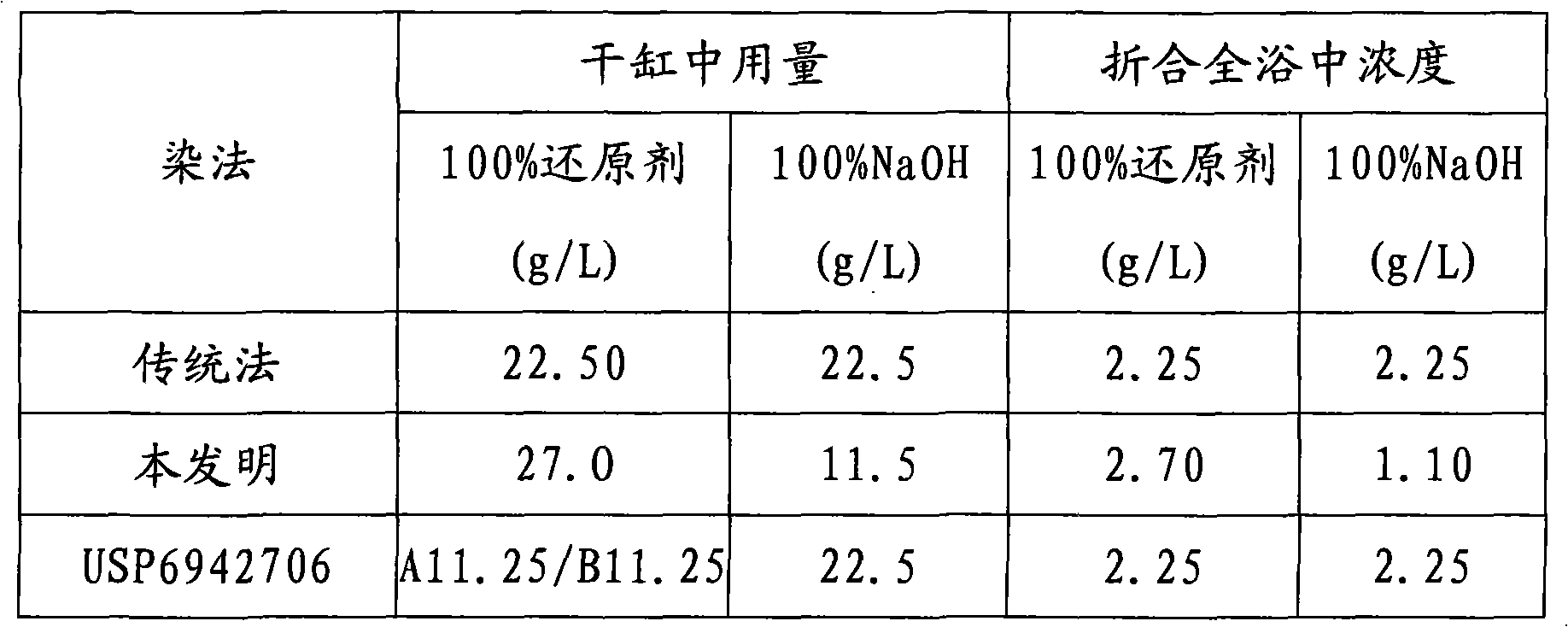

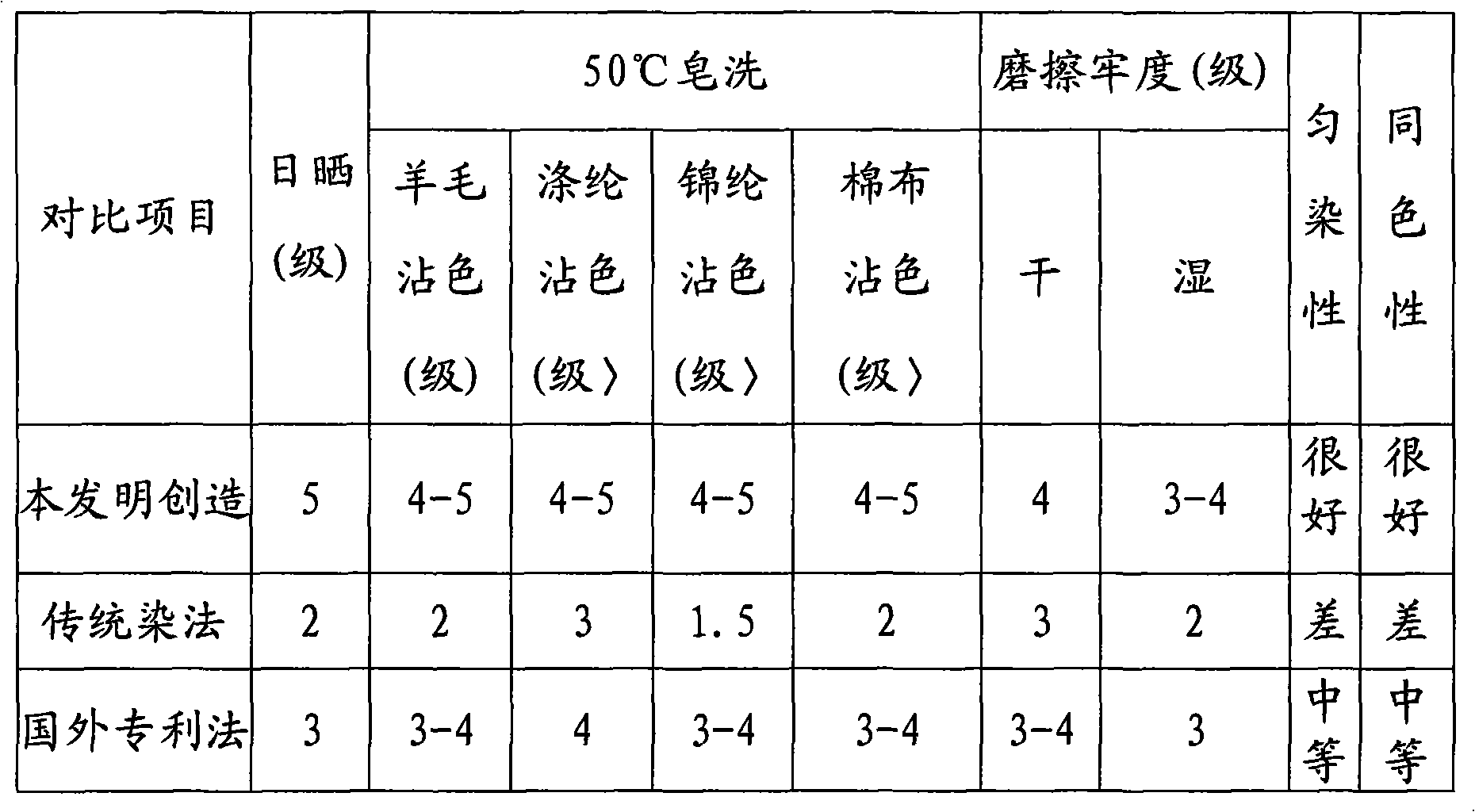

Fiber pervasion swelling agent and method for dyeing the same

ActiveCN101349009AUniform dyeingGood same colorFibre treatmentDyeing processDiacetone alcoholEthyl salicylate

The invention discloses a fiber penetrating swelling agent which comprises the compositions in weight portion: 0.00016 to 0.0006 portion of laurocapram, 1 to 5 portions of N-methyl pyrrolidone, 5 to 10 portions of diacetone alcohol, 5 to 15 portions of ethyl salicylate, and 5 to 10 portions of isopropyl salicylate. The invention also discloses a method for dyeing by the fiber penetrating swelling agent, comprising the following steps that: a reducing agent and sodium hydrate are used for reducing the dye by a vatting method; the weight ratio of a reducing solution to the dye is 37.5: 0.8 to 2.0; a leveling agent and the fiber penetrating swelling agent are added to dye or a buffering agent is added to adjust the pH value and is dyed by vat acid, the temperature is reduced and the mixture is washed; the mixture is subjected to oxidizing to develop color, fixing, reducing temperature and washing; the fresh water bath is performed, the fiber penetrating swelling agent is reduced and washed, and the temperature is reduced and the fiber penetrating swelling agent is produced. The fiber penetrating swelling agent ensures that the dye insoluble in water is effectively moistened and penetrated, and the fiber crystallizing area is effectively swelled to receive the dye; the fiber penetrating swelling agent ensures that a suspended solid is dyed evenly, has good homochromatism, improves the degree of dyeing, and solves the 'white core' problem of fiber.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

Technical manufacturing process for low-temperature curing amino baking finish

InactiveCN102161853AExtended drying timeOptimize drying temperatureCoatingsDiacetone alcoholTest performance

The invention discloses a technical manufacturing process for low-temperature curing amino baking finish, which is characterized in that the formula of the low-temperature curing amino baking finish comprises the following raw materials in percentage by weight: 62 to 68 percent of acrylic resin, 20 to 22 percent of amino resin, 0 to 5 percent of dye, 1 to 2 percent of adhesive force promoter, 0.1 to 0.3 percent of leveling agent, 4 to 7 percent of butyl acetate, 2 to 4 percent of diacetone alcohol. The technical manufacturing process comprises the steps of filling the raw materials which are verified to be qualified into a stirring kettle according to a ratio, uniformly dispersing the raw materials by the stirring of a dispersing machine, regulating color, testing performance indexes after color is regulated, filtering if the mixture passes the test, and packaging, wherein when the used amount of the dye is zero, varnish is made, so performance index test can be performed immediately after uniformly stirring and dispersing without regulating color, and the vanish passing the test can be filtered and packaged. When the technical manufacturing process is used, the drying time of the conventional amino baking finish can be reduced greatly, energy cost can be reduced considerably, and the production process is environment-friendly and safe.

Owner:HANGZHOU LIWEI CHEM INDAL PAINT

Coating composition, method for producing same, and laminate having hard coat layer

InactiveCN102272254AIncrease film thicknessGood dispersionCoatingsSpecial surfacesDiacetone alcoholHydrolysis

Provided is a coating composition which can form a hard coat layer with excellent transparency and excellent scratch resistance on the surface of an optical resin substrate such as a plastic lens, and which exhibits long-term storage stability. The coating composition comprises (A) composite metal oxide fine particles, (B') a hydrolyzate obtained by hydrolysis of (B) a hydrolyzable organosilicon component containing (B1) an epoxy-containing organosilicon compound such as gamma-glycidoxy-propyltrimethoxysilane, (C) water, (D1) a low-boiling and low-viscosity alcohol having three or fewer carbon atoms (such as methanol or ethanol), (D2) a low-boiling and high-viscosity alcohol (such as t-butanol), (D3) a high-boiling organic solvent having a boiling point of 150 DEG C or above and below 200 DEG C (such as diacetone alcohol), and (E) a curing catalyst such as tris(2, 4-pentanedionato)aluminum (III), wherein the (D1) / (C) mass ratio is 1.80 to 7.00; the (D2) / (C) mass ratio is 0.24 to 2.50; and the (D3) / (C) mass ratio is 1.10 to 4.40.

Owner:TOKUYAMA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com