Preparation method of feed additive calcium beta-hydroxy-beta-methylbutyrate

A technology of calcium methylbutyrate and feed additives, which is applied in the preparation of carboxylate, carboxylate, and organic compounds, etc. It can solve the problem of decreased feed intake, digestive disorders, and drug resistance of original microorganisms in piglets, etc. problem, to achieve the effect of stable and reliable product quality, simple preparation process and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

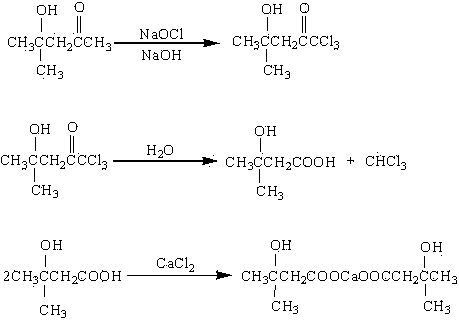

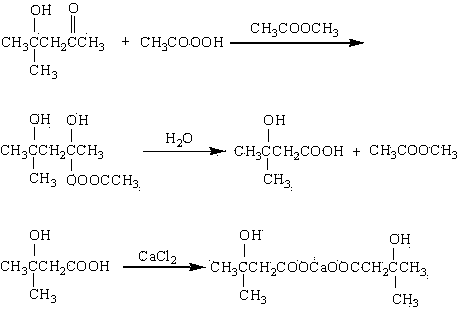

Method used

Image

Examples

Embodiment 1

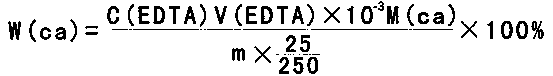

[0016] The preparation method of the feed additive β-hydroxyl-β-methylbutyrate calcium of the present embodiment may further comprise the steps:

[0017] 1) Preparation of peracetic acid: 100ml of glacial acetic acid, 10ml of 10% sulfuric acid solution, 300ml of 30%H 2 o 2 Add it into the reaction vessel, control the reaction temperature at 45°C, and react for 10 minutes. After the reaction, it will be distilled under reduced pressure, and the fraction at 60°C will be collected to obtain 125ml of peracetic acid aqueous solution;

[0018] 2) Preparation of β-hydroxy-β-methylbutyric acid: In a reaction vessel, mix 125ml of peracetic acid aqueous solution obtained in step 1) with 62.5ml of diacetone alcohol, add 100ml of methyl acetate as a solvent, and control the temperature at 30 ℃ reaction, after reacting for 1 hour, the mixture was transferred to a distillation device, and the fraction at 70 ℃ was collected by distillation to obtain methyl acetate, and the residue after dis...

Embodiment 2

[0021] The preparation method of the feed additive β-hydroxyl-β-methylbutyrate calcium of the present embodiment may further comprise the steps:

[0022] 1) Preparation of peracetic acid: mix 200ml glacial acetic acid, 20ml 10% sulfuric acid solution, 650ml 30%H 2 o 2 Add it into the reaction vessel, control the reaction temperature at 50°C, and react for 15 minutes. After the reaction, it will be distilled under reduced pressure, and the fraction at 60°C will be collected to obtain 252.5ml of peracetic acid aqueous solution;

[0023] 2) Preparation of β-hydroxy-β-methylbutyric acid: In a reaction vessel, mix 252.5ml of peracetic acid aqueous solution obtained in step 1) with 125ml of diacetone alcohol, add 200ml of methyl acetate as a solvent, and control the temperature at 35 ℃ reaction, after 1.2 hours of reaction, the mixture was transferred to a distillation device, and the fraction at 70 ℃ was collected by distillation to obtain methyl acetate, and the residue after dis...

Embodiment 3

[0026] The preparation method of the feed additive β-hydroxyl-β-methylbutyrate calcium of the present embodiment may further comprise the steps:

[0027] 1) Preparation of peracetic acid: mix 150ml glacial acetic acid, 15ml 10% sulfuric acid solution, 500ml 30%H 2 o 2 Add it into the reaction vessel, control the reaction temperature at 55°C, and react for 20 minutes. After the reaction, it will be distilled under reduced pressure, and the fraction at 60°C will be collected to obtain 187ml of peracetic acid aqueous solution;

[0028] 2) Preparation of β-hydroxy-β-methylbutyric acid: In a reaction vessel, mix 187ml of peracetic acid aqueous solution obtained in step 1) with 75ml of diacetone alcohol, add 150ml of methyl acetate as a solvent, and control the temperature at 37°C Reaction, after reacting for 1.5 hours, the mixture was transferred to a distillation device, and the fraction at 70°C was collected by distillation to obtain methyl acetate, and the residue after distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com