Patents

Literature

1700 results about "Methyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl acetate, also known as MeOAc, acetic acid methyl ester or methyl ethanoate, is a carboxylate ester with the formula CH₃COOCH₃. It is a flammable liquid with a characteristically pleasant smell reminiscent of some glues and nail polish removers. Methyl acetate is occasionally used as a solvent, being weakly polar and lipophilic, but its close relative ethyl acetate is a more common solvent being less toxic and less soluble in water. Methyl acetate has a solubility of 25% in water at room temperature. At elevated temperature its solubility in water is much higher. Methyl acetate is not stable in the presence of strong aqueous bases or aqueous acids. Methyl acetate is not considered as a VOC in the USA.

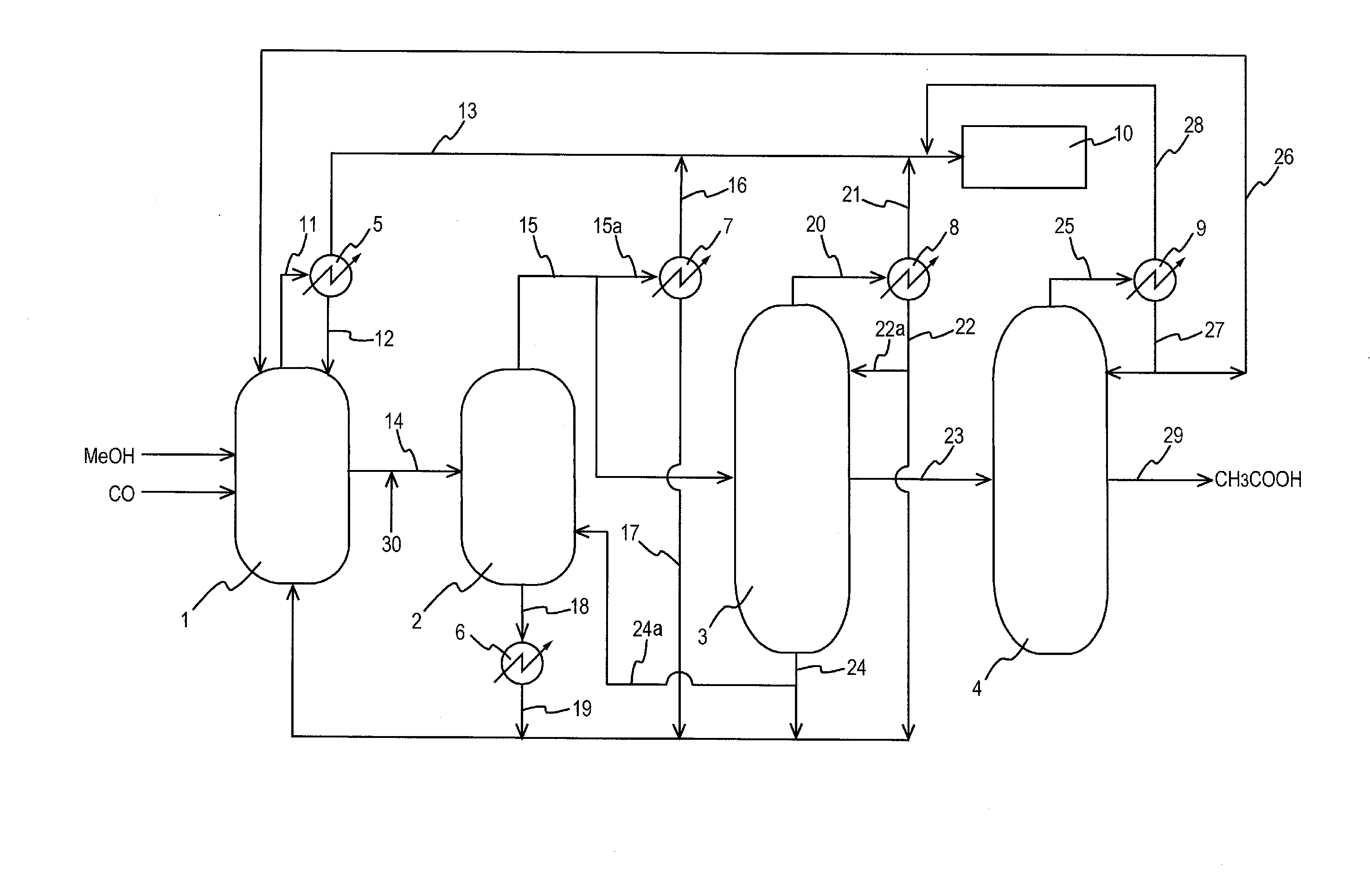

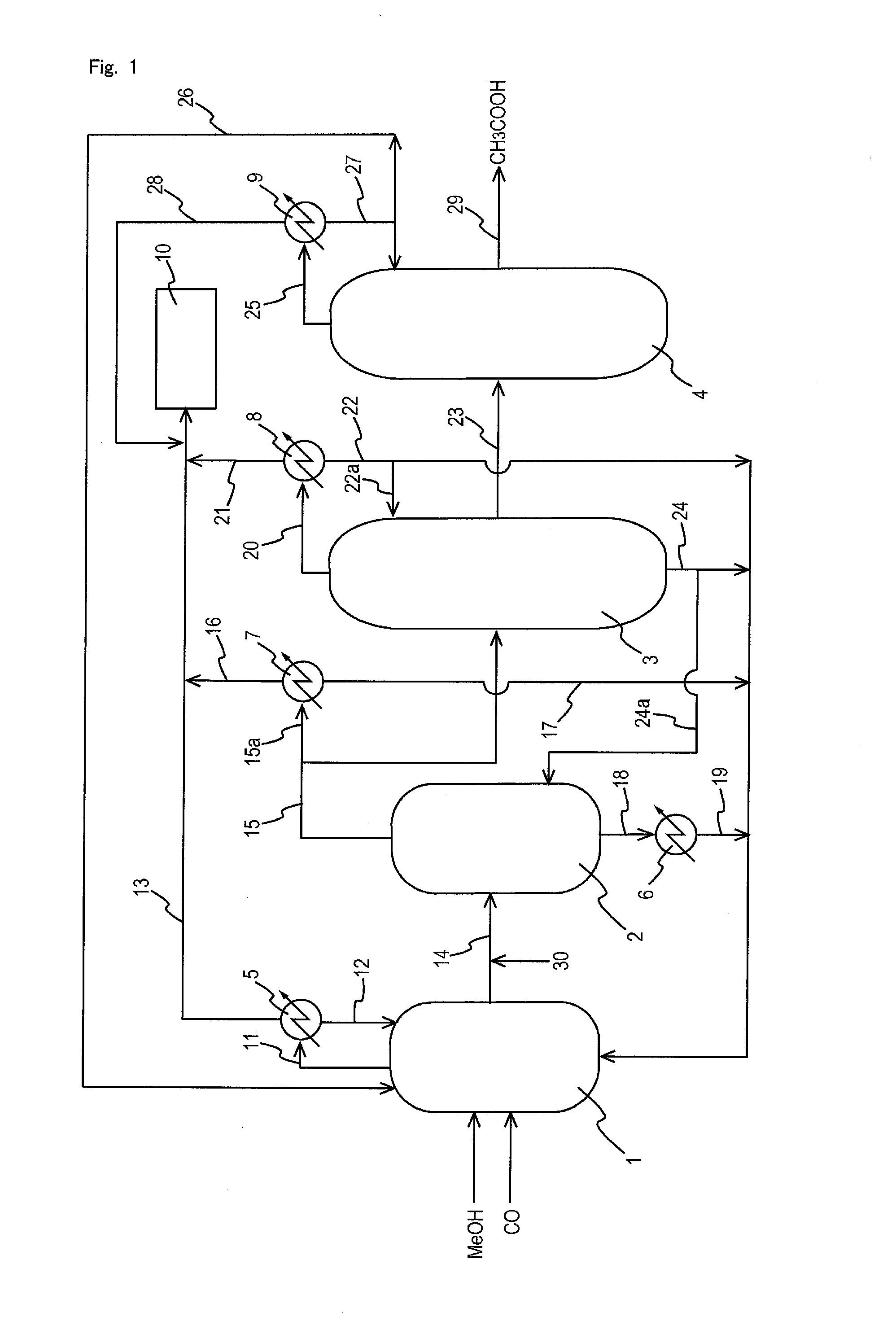

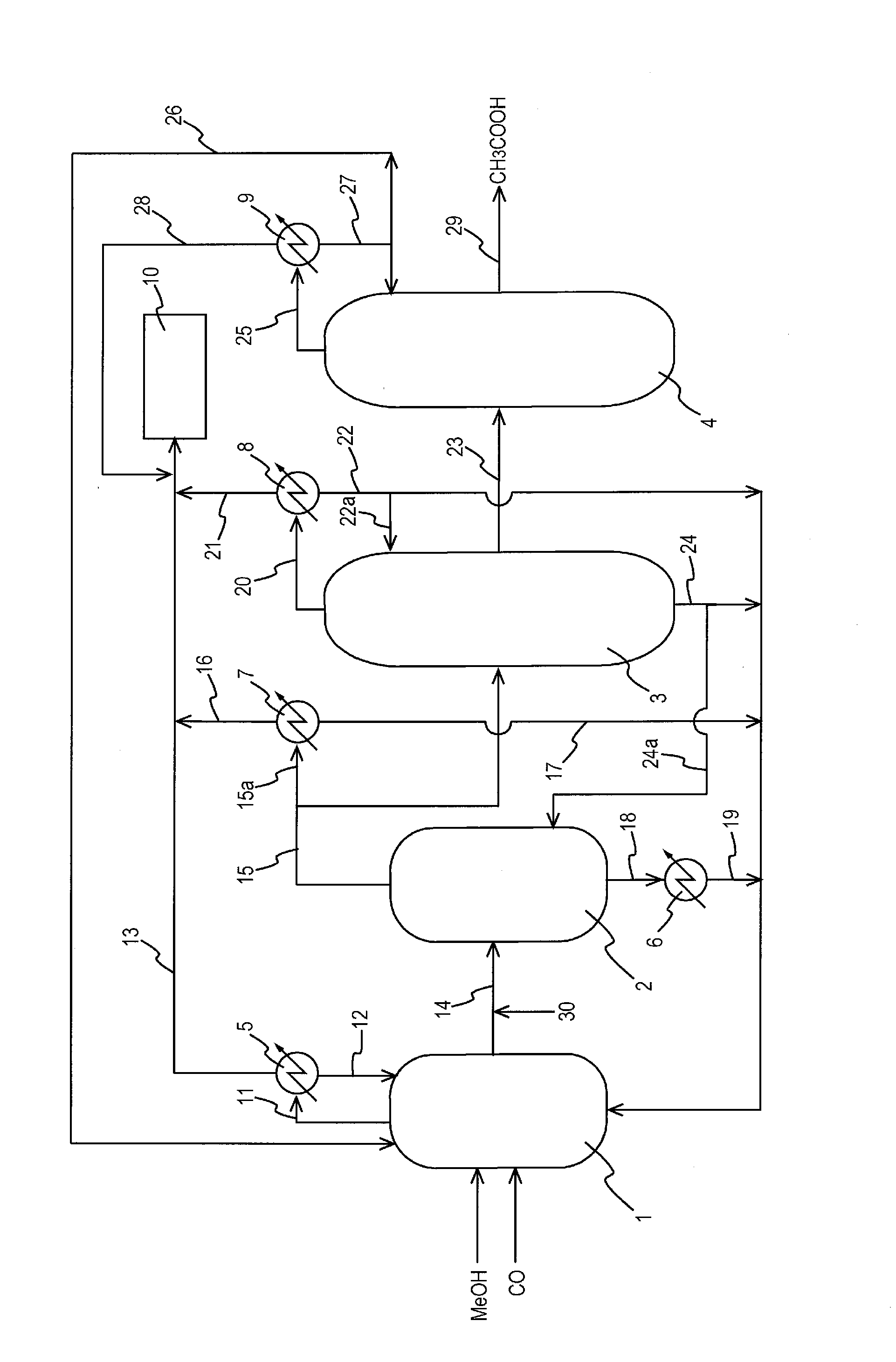

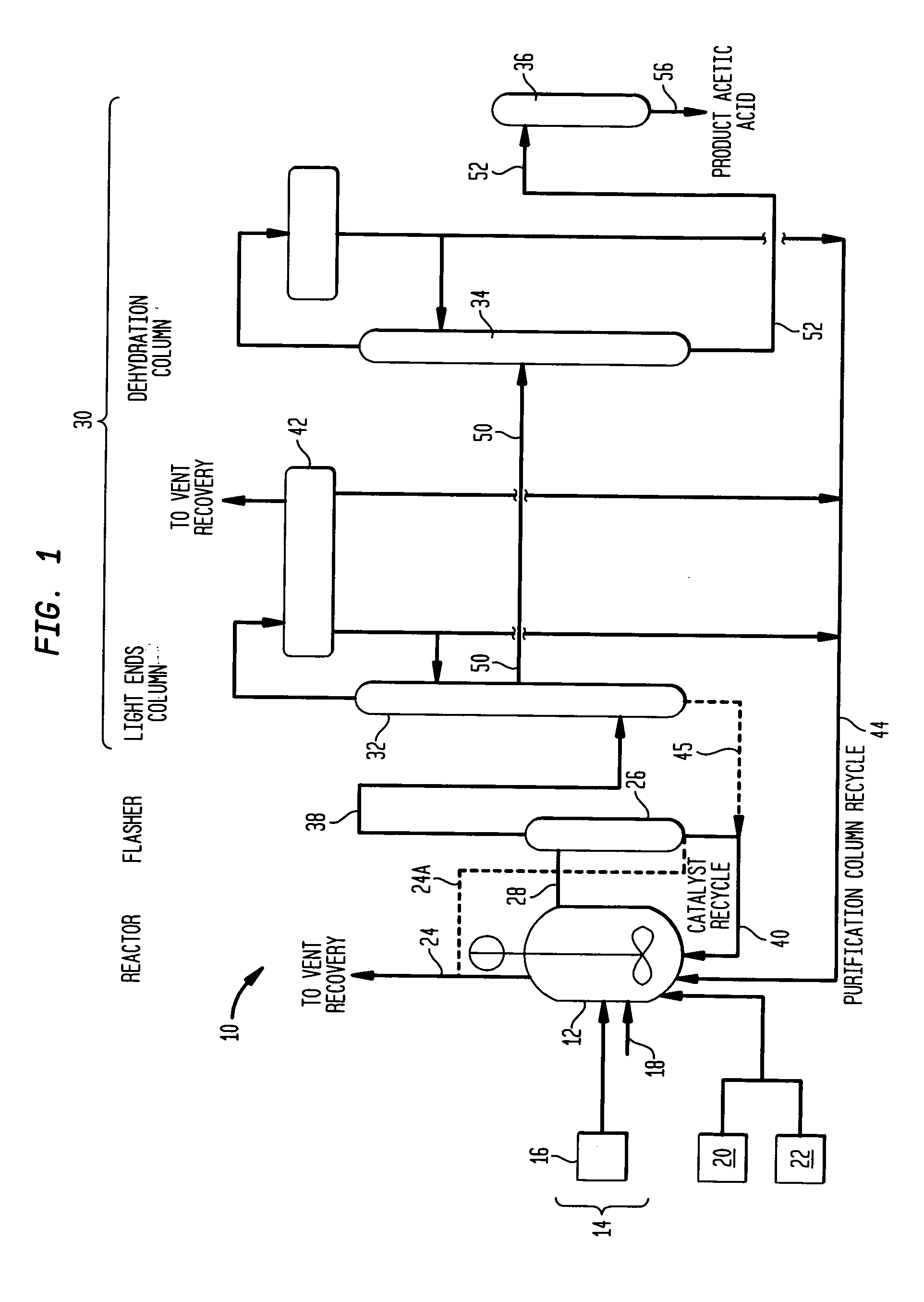

Low water methanol carbonylation process for high acetic acid production and for water balance control

ActiveUS7005541B2High acetic acid production rateIncrease chanceOrganic compound preparationCarboxylic preparation from carbon monoxide reactionWater methanolAcetic anhydride

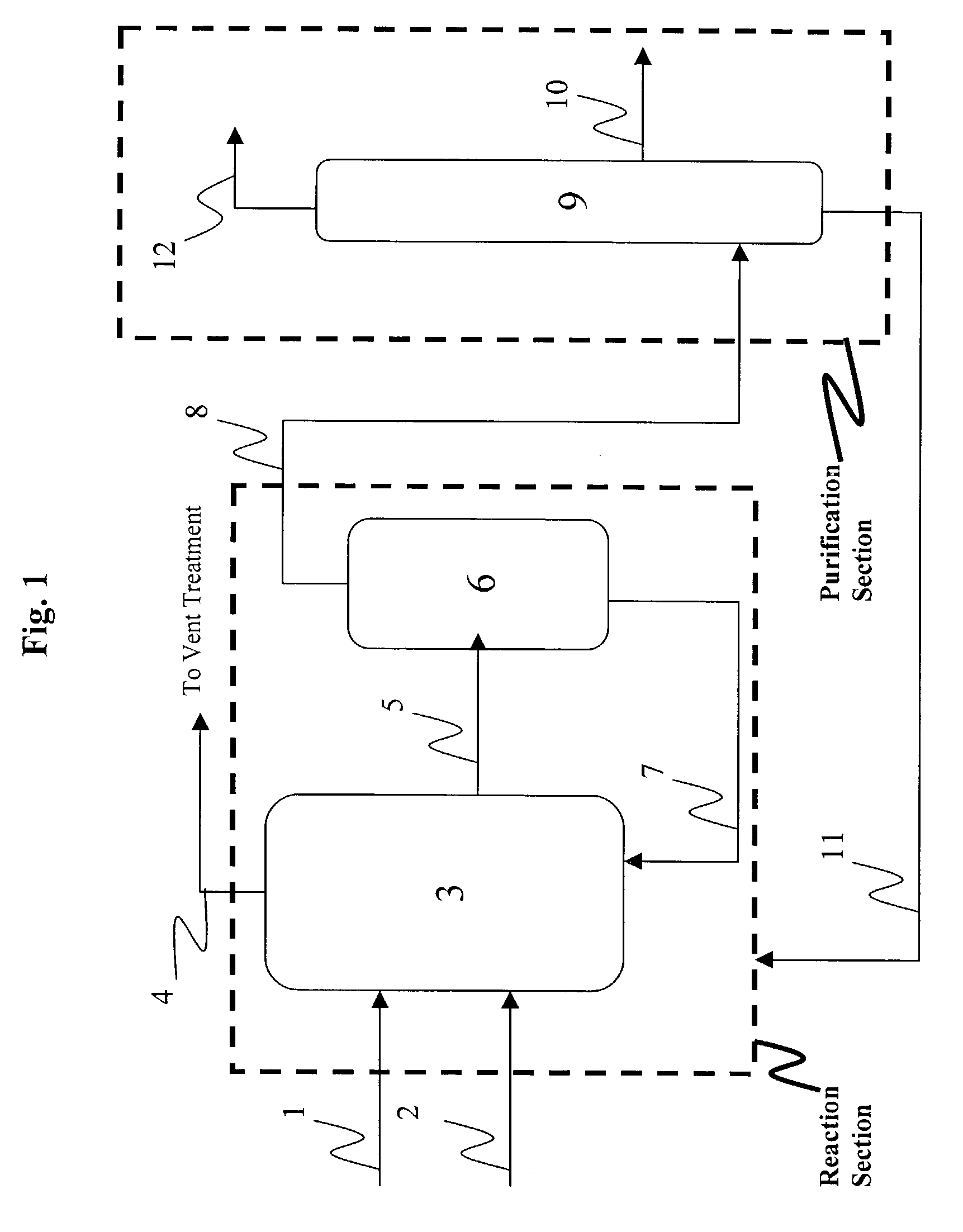

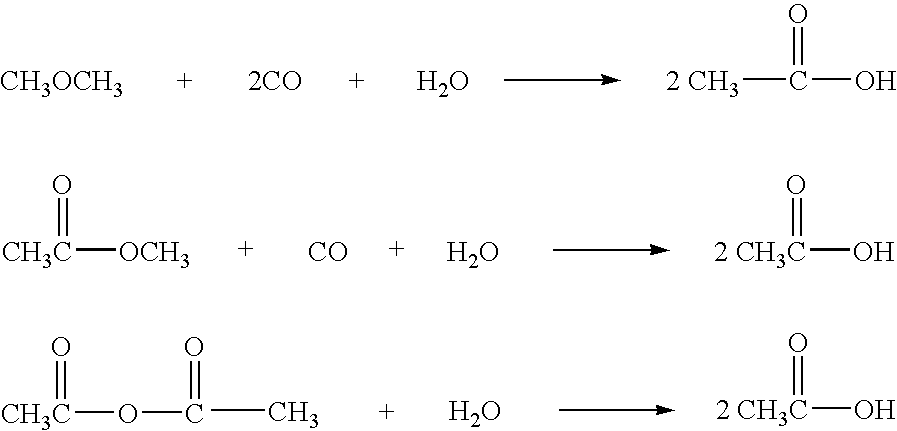

The invention relates to a process for the production of acetic acid by carbonylation of methanol, and reactive derivatives thereof, in a reaction mixture using a rhodium-based catalyst in low water conditions. The process is used to achieve reaction rates of at least 15 g mol / l / hr. The high rate reactions proceed at water concentrations of less than 2.0 wt. %. Under certain conditions, the water concentration in the reaction mixture of the process is maintained at a desired concentration by at least one process step including adding a compound such as methyl acetate, dimethyl ether, acetic anhydride, or mixtures of these compounds to the reaction system. The process step of adding the components to the reaction mixture may be combined with other process steps for controlling water concentrations in reaction mixtures for the carbonylation of methanol.

Owner:CELANESE INT CORP

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

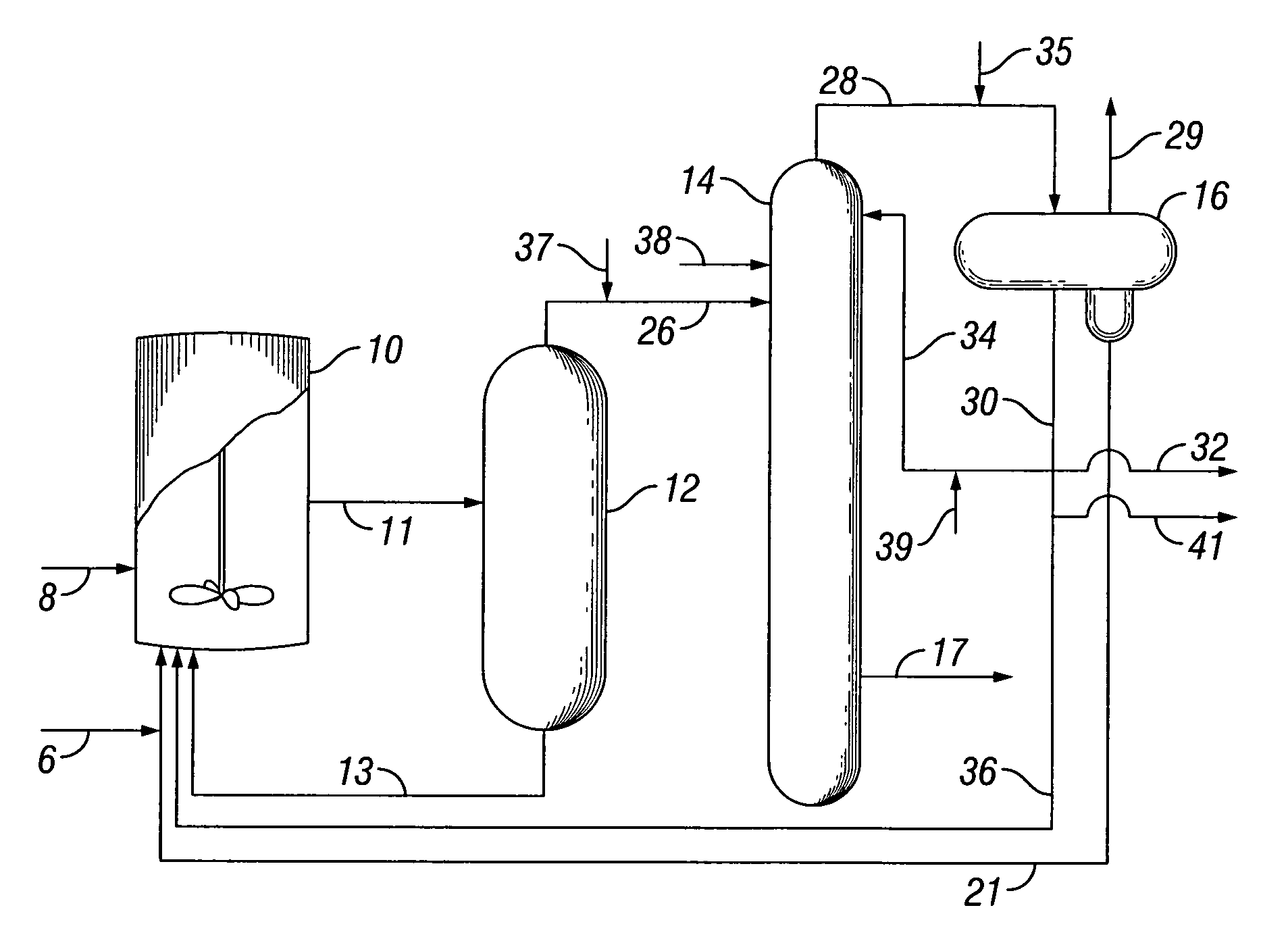

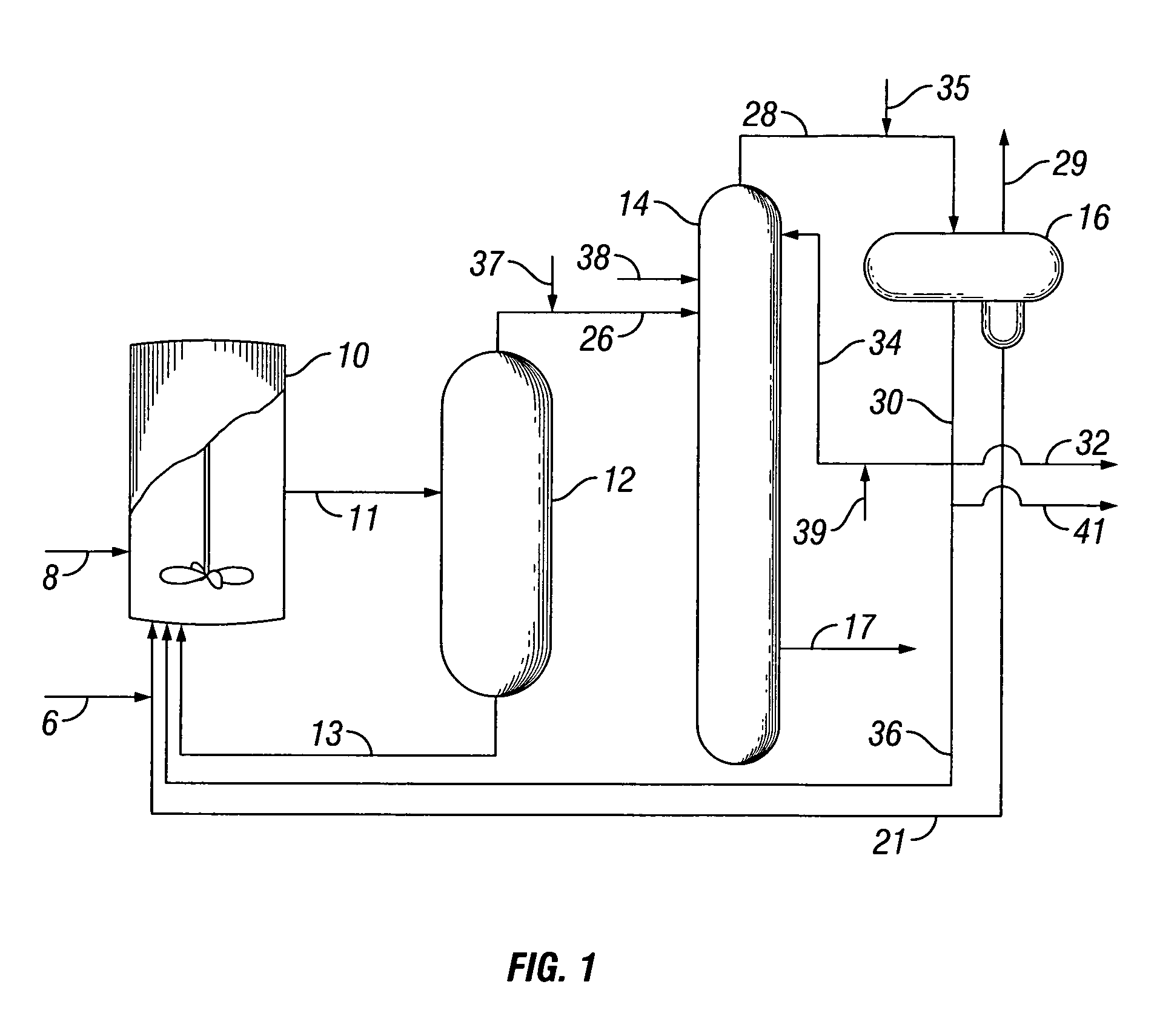

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

Method for preparing methyl acetate by carbonylating dimethyl ether

ActiveCN101613274AImprove stabilityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionMolecular sieveMethyl acetate

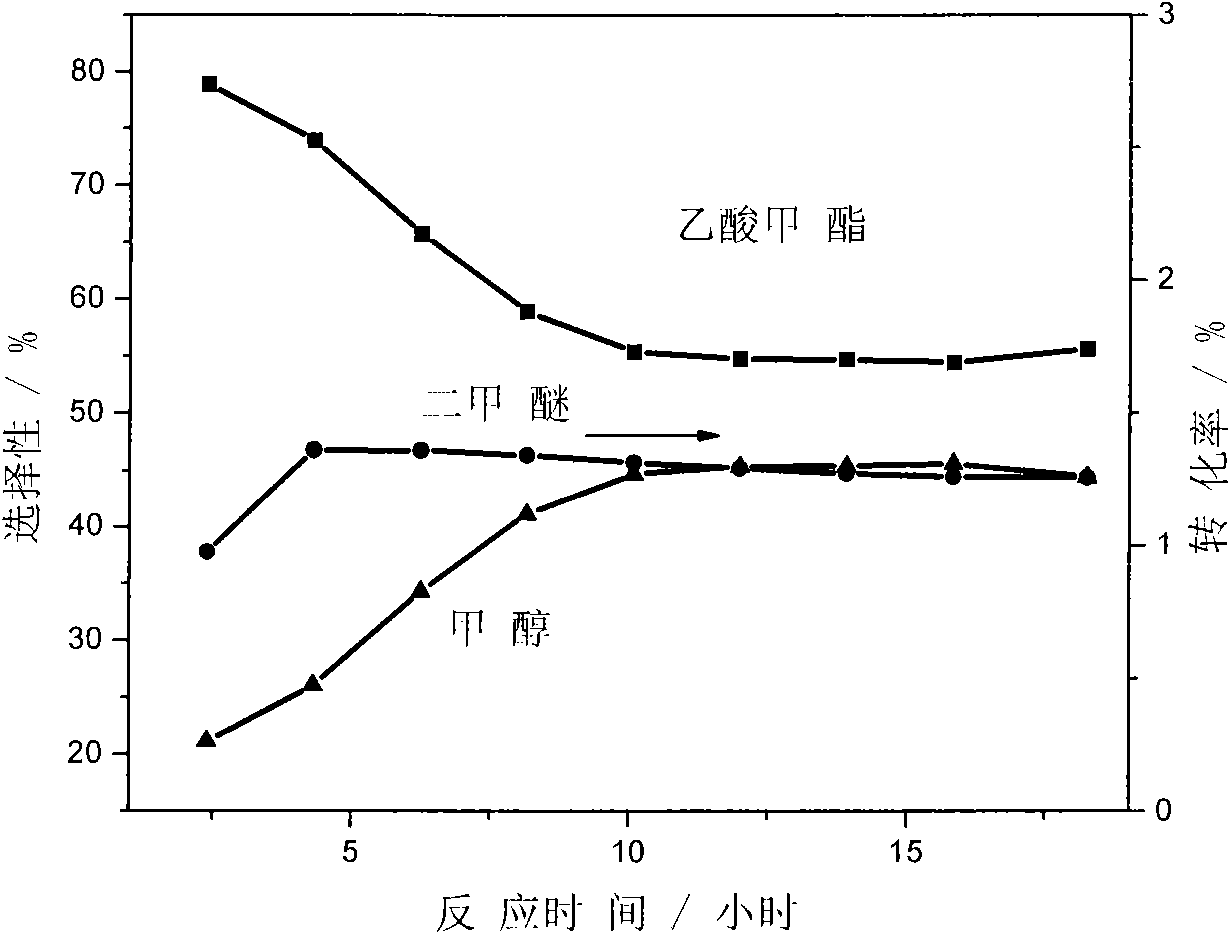

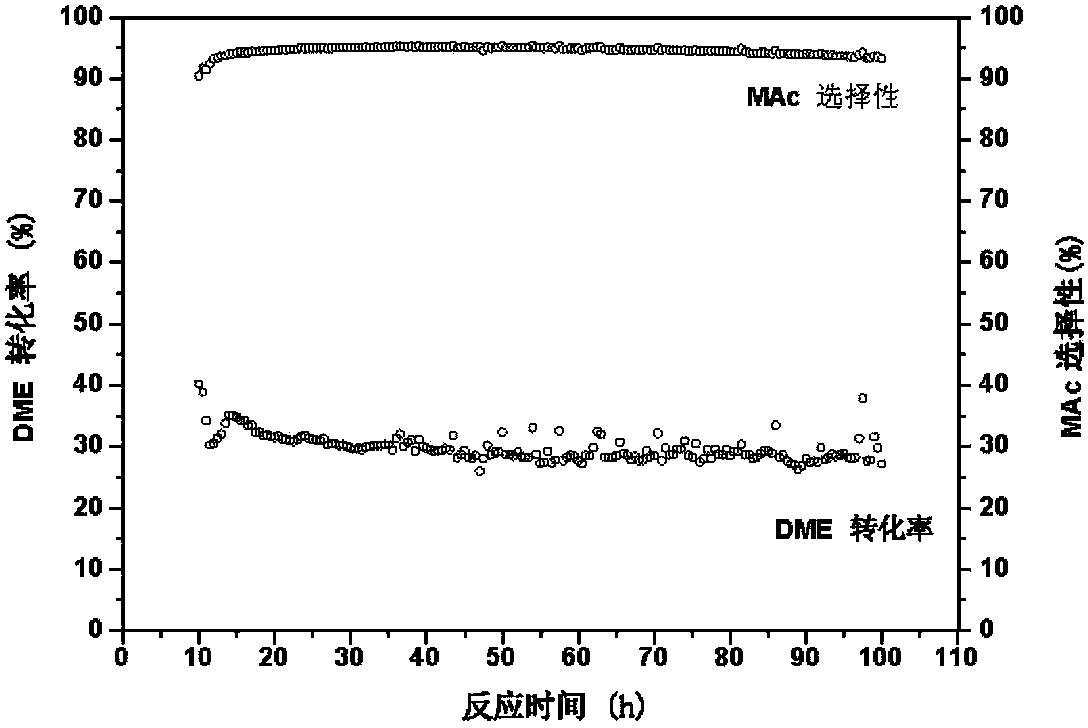

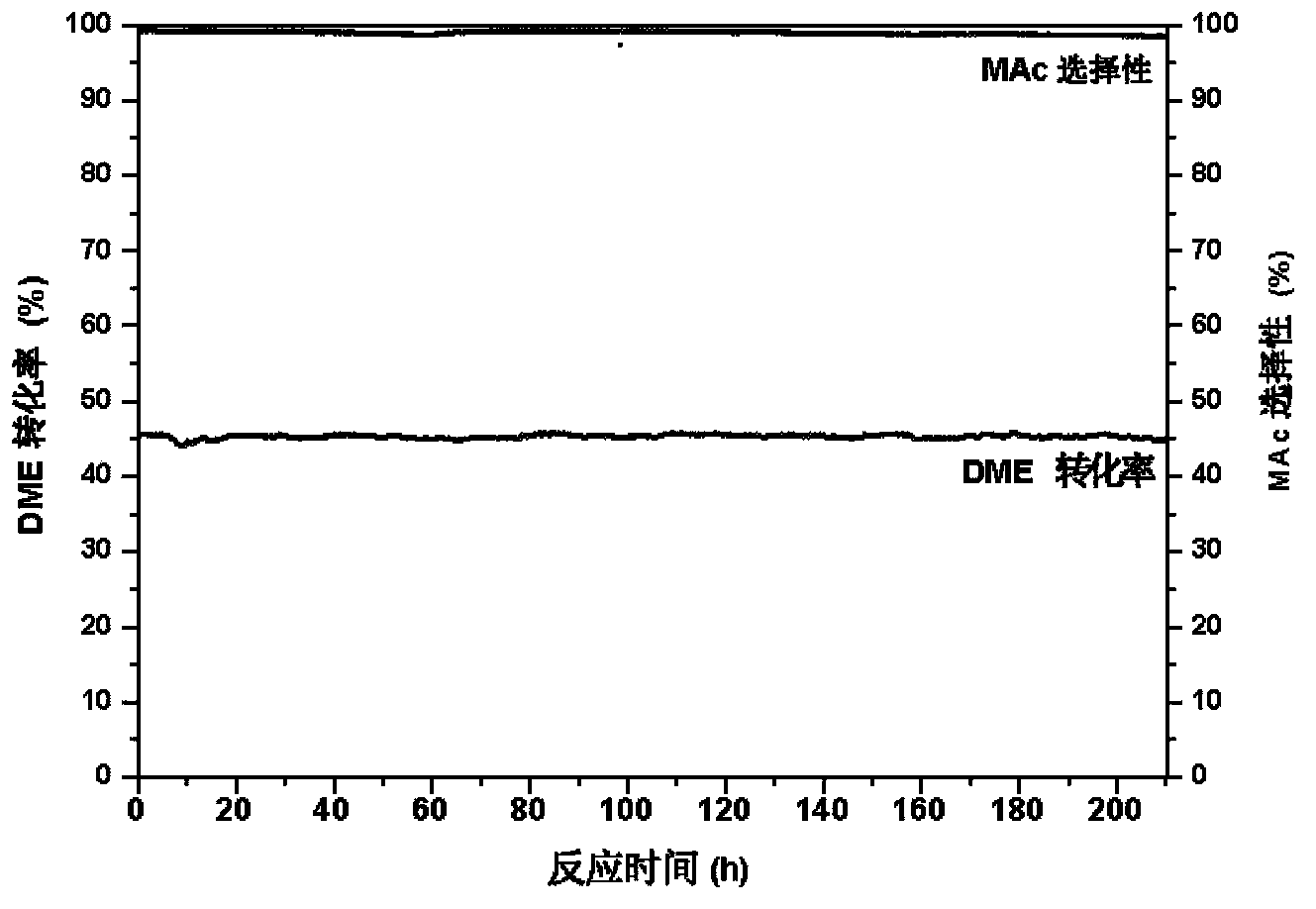

The invention discloses a catalyst modification method for preparing methyl acetate by carbonylating dimethyl ether. The method is applied to the reaction process in which the dimethyl ether reacts with the carbon monoxide to high selectively form methyl acetate in the presence of an acid molecular sieve catalyst, particularly a mordenite molecular sieve. Pyridine organic amines are utilized to modify the mordenite molecular sieve and modify a channel structure and the acidity of the molecular sieve, thereby effectively inhibiting carbon deposition and greatly improving the stability of catalysts. The use of the catalysts by the method can catalyze the carbonylation of dimethyl ether to obtain methyl acetate under mild conditions. The conversion rate of dimethyl ether is between 10 and 60percent, the selectivity of the methyl acetate is over 99 percent, and the activity of the catalysts is kept steady after the reaction is performed for 48 hours.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

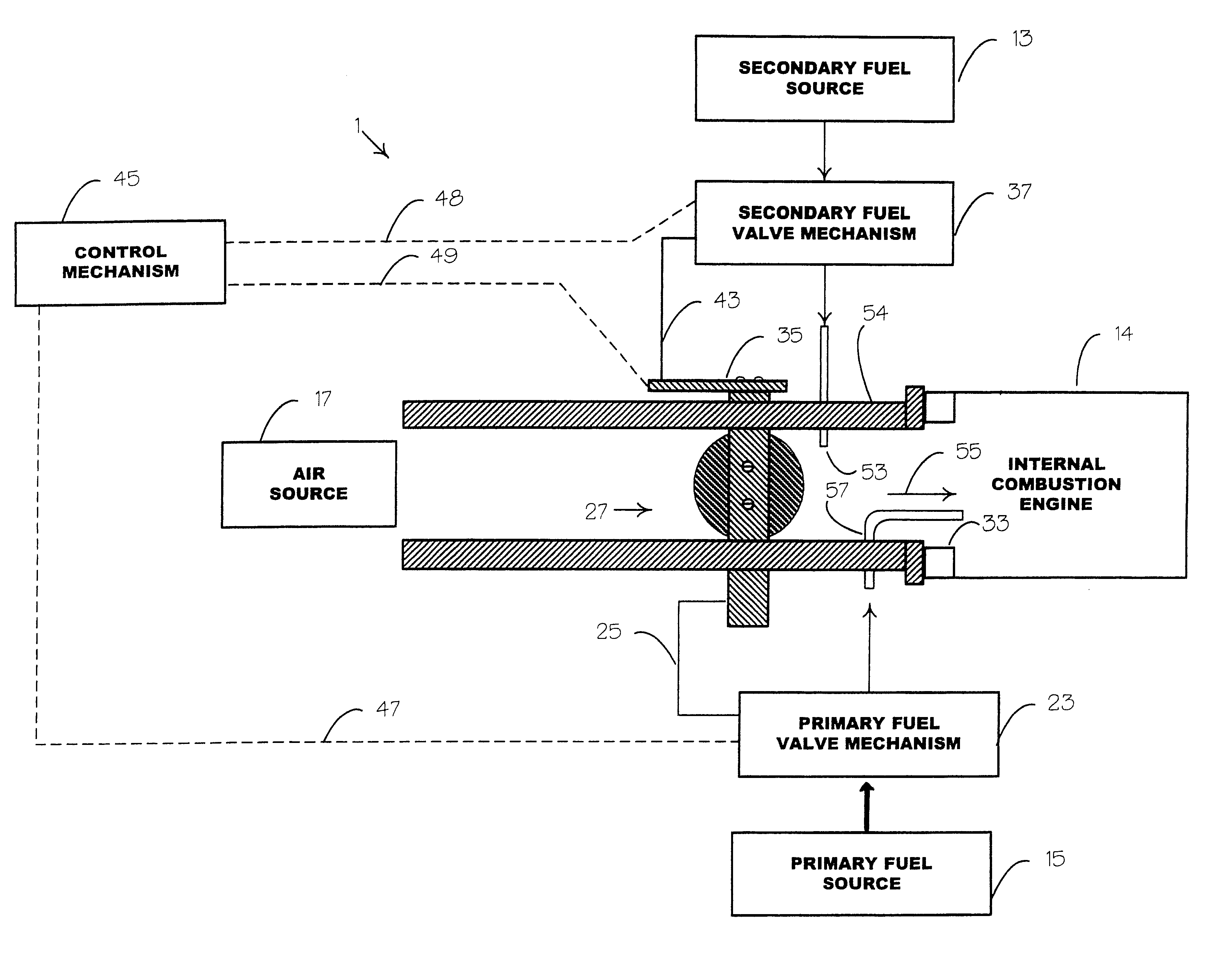

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

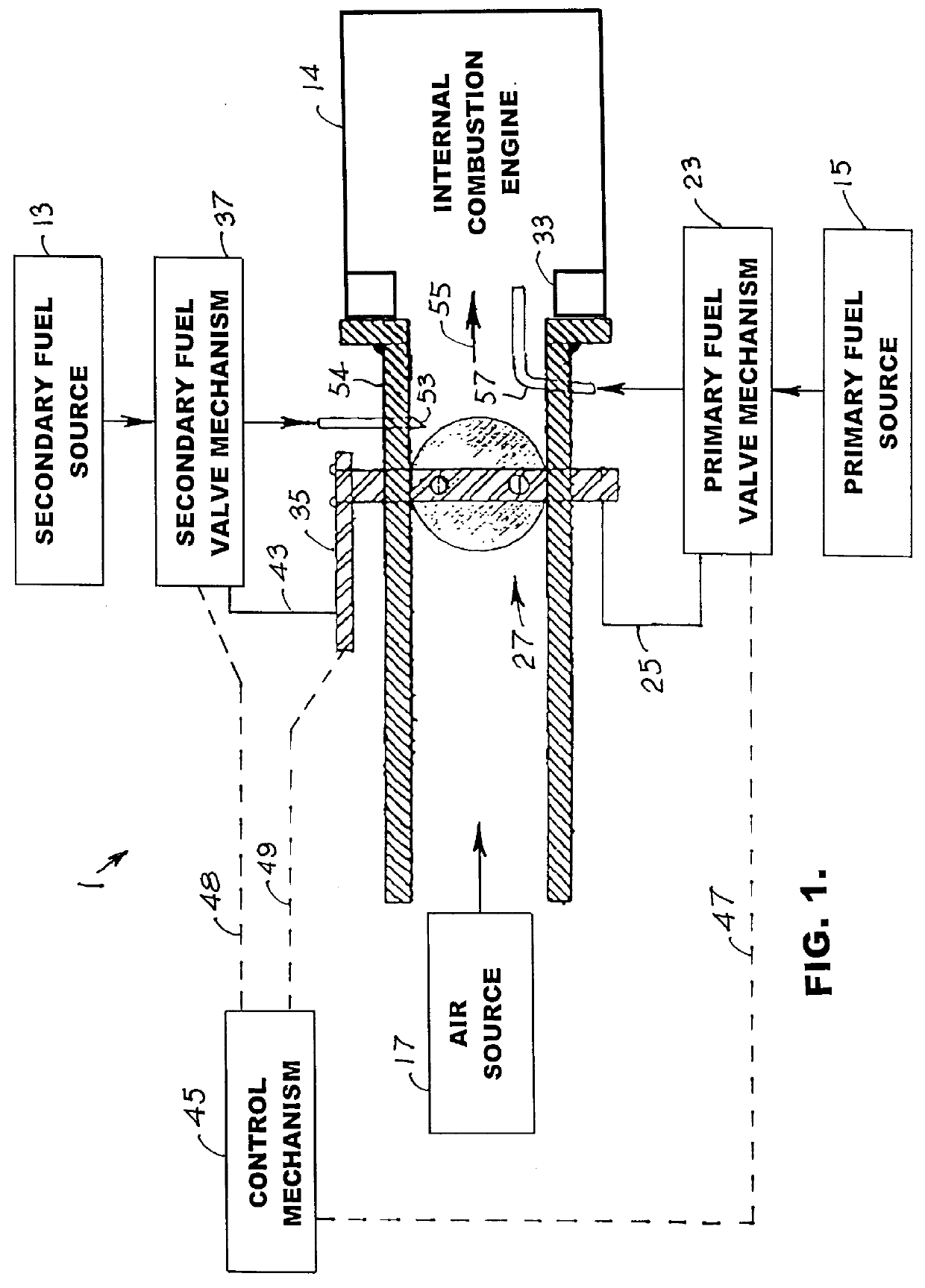

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

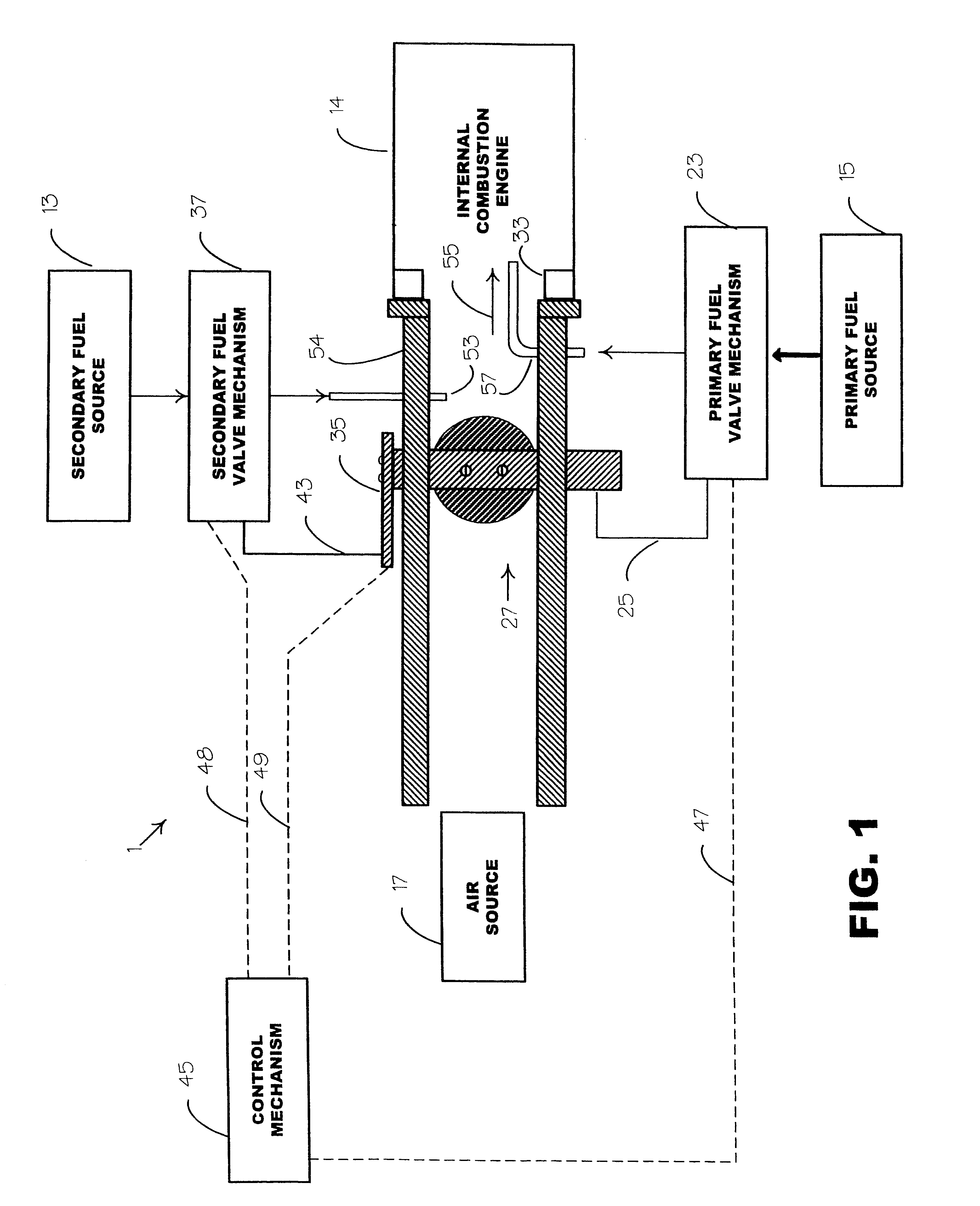

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS6575147B2Easy to operateImprove performanceNon-fuel substance addition to fuelInternal combustion piston enginesCarbon chainMineral spirit

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC INC

Addition of iridium to the rhodium/inorganic iodide catalyst system

InactiveUS6211405B1High rateReduce productionPhysical/chemical process catalystsOrganic compound preparationPtru catalystCarboxylic acid

The present invention provides a process for the carbonylation of an alcohol, ether or ester to products comprising a carboxylic acid, the anhydride thereof or coproduction of the carboxylic acid and anhydride. More particularly, the present invention provides a process for the carbonylation of methanol to produce acetic acid by reacting methanol with carbon monoxide in a liquid reaction medium containing a catalyst comprising rhodium, iridium, iodide ion, and said reaction medium further comprising water, acetic acid, methyl iodide, and methyl acetate and subsequently recovering acetic acid from the resulting reaction product.

Owner:CELANESE INT CORP

Process for producing acetic acid

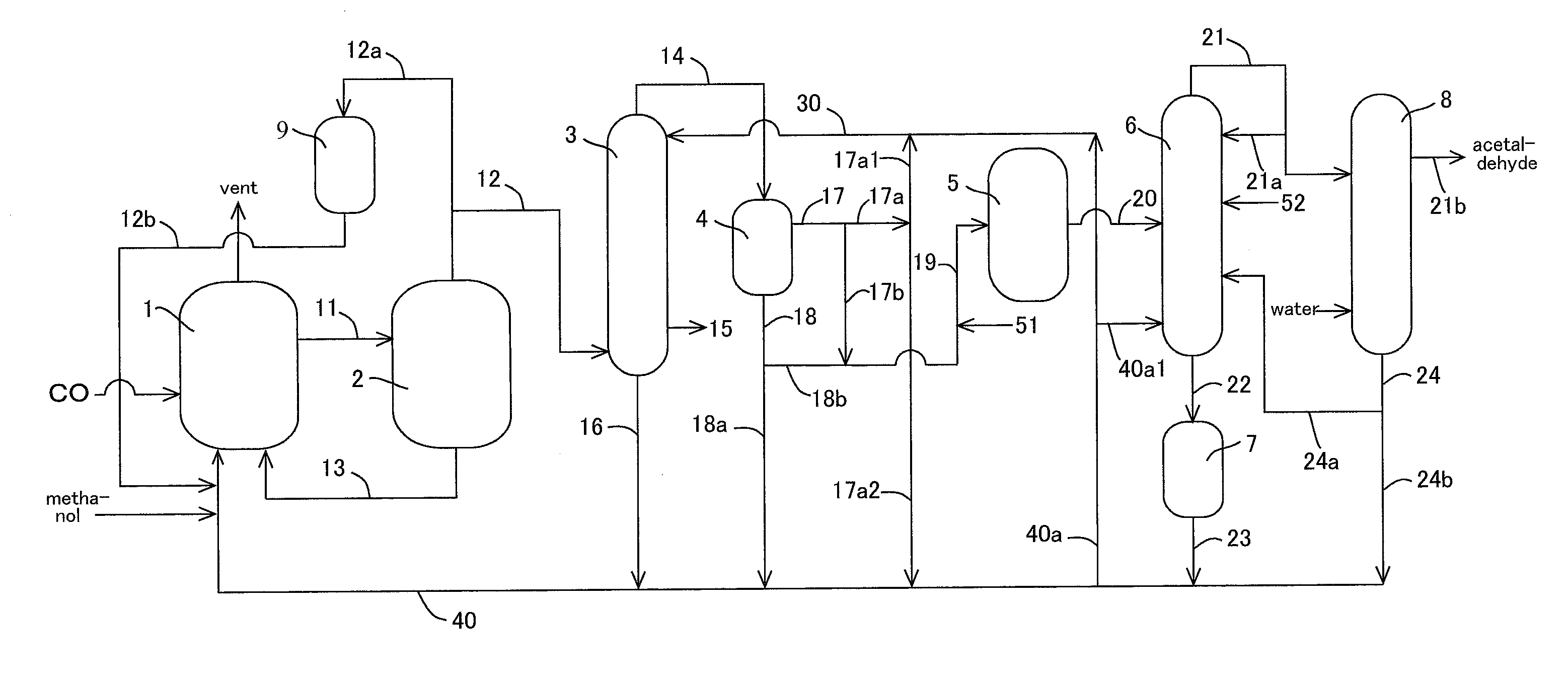

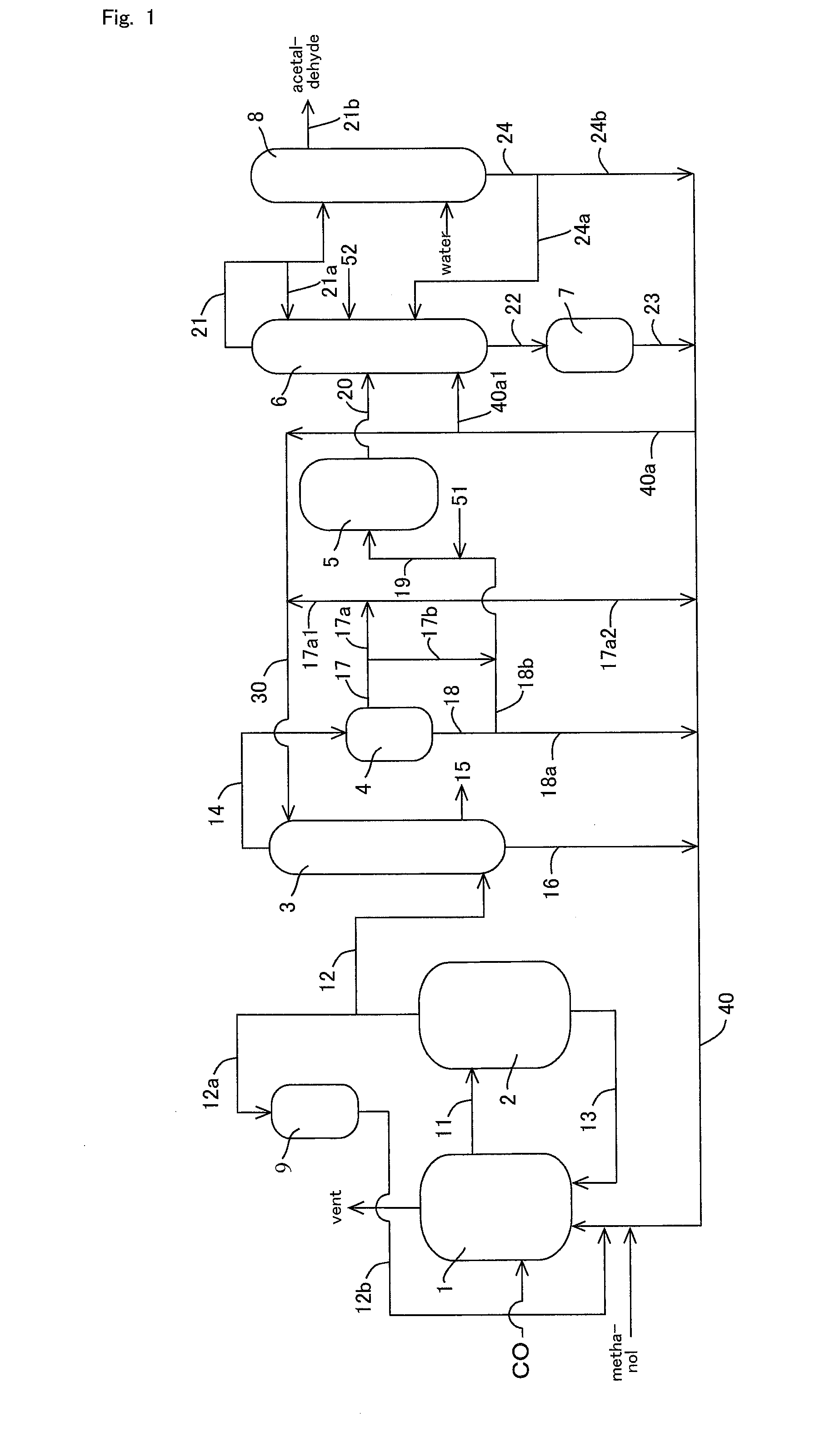

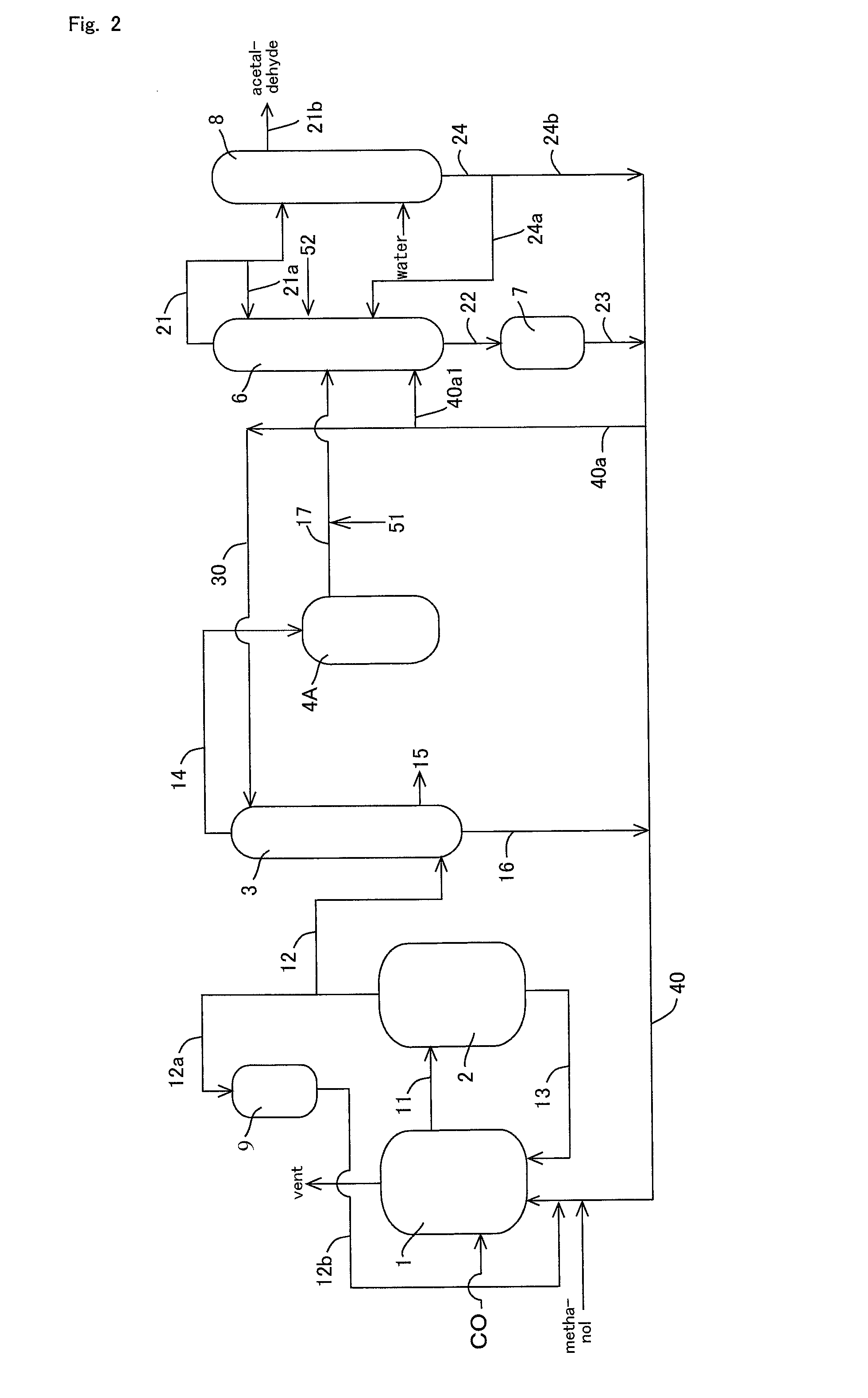

ActiveUS20130264186A1Improve concentrationEfficient executionOrganic chemistry methodsDistillation separationBoiling pointFractionating column

Acetic acid is produced while efficiently inhibiting condensation of hydrogen iodide in a distillation column (second distillation column) for purifying crude acetic acid by further distillation.A process for producing acetic acid comprises an acetic acid collection step for feeding a first distillation column with a volatile component at least containing acetic acid, methyl acetate, methyl iodide, water, and hydrogen iodide, separating a first lower boiling point component as an overhead, and collecting a first liquid stream mainly containing acetic acid, and an acetic acid purification step for feeding a second distillation column with the first liquid stream, further separating a second lower boiling point component as an overhead, and collecting a second liquid stream containing acetic acid, wherein an alkali component is added or mixed to the first liquid stream in the manners (1) and / or (2) for distilling a liquid object to be treated containing the first liquid stream and the alkali component in the second column: (1) the alkali component is added to or mixed with the first liquid stream before the first liquid stream is fed to the second column, (2) in the second column, the alkali component is added or mixed at the same height level as or at a height level upper than a height level at which the first liquid stream is fed.

Owner:DAICEL CHEM IND LTD

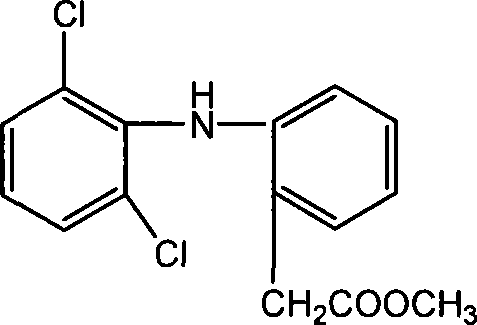

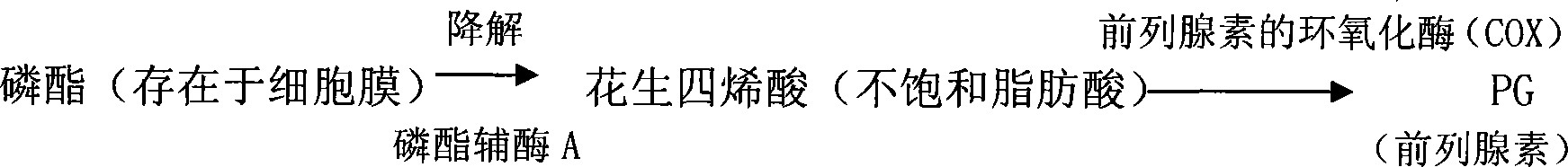

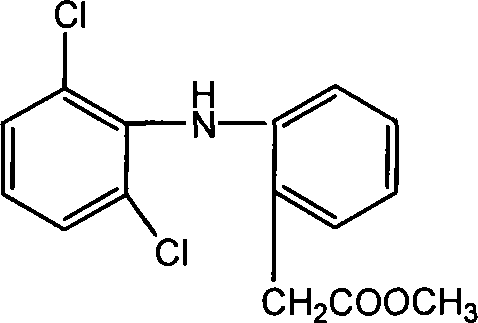

Methyl 2-(2-(2,6-dichlorophenylamino)phenyl)acetate and its synthesizing method and application

InactiveCN101186583AAnti-inflammatory in low dose groupLow analgesic effectOrganic active ingredientsAntipyreticSynthesis methodsChloride

The invention relates to a 2-(2-(2, 6-dichlorophenyl amido) phenyl) methyl acetate, relative synthesis method and application, belonging to the technical field of chemical pharmacy, which comprises that adds acid into diclofenac salt to acidify the salt into diclofenac, reacts diclofenac with methanol, or adds acid into diclofenac salt to acidify the salt into diclofenac, to be reacted with chloracetyl chloride to obtain 2-(2-(2, 6-dichlorophenyl amido) phenyl) methyl acetate. The inventive drug has significant anti-inflammatory and analgesic effects.

Owner:JILIN UNIV

Process for producing acetic acid

ActiveUS20130310603A1Efficient productionEasy to save energyOrganic compound preparationOrganic chemistry methodsIodideReaction step

Acetic acid is produced while inhibiting an increased concentration or production of hydrogen iodide in a carbonylation reactor or corrosion of the carbonylation reactor.A production process of acetic acid comprises a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst (e.g., a rhodium catalyst), an ionic iodide (e.g., lithium iodide), and methyl iodide in a carbonylation reactor; and in the process, (i) the concentration of the metal catalyst is maintained at not less than 860 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 15% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor, and / or (ii) the concentration of the metal catalyst is maintained at not less than 660 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 3.9% by weight, the concentration of the ionic iodide is maintained at not more than 13% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor.

Owner:DAICEL CHEM IND LTD

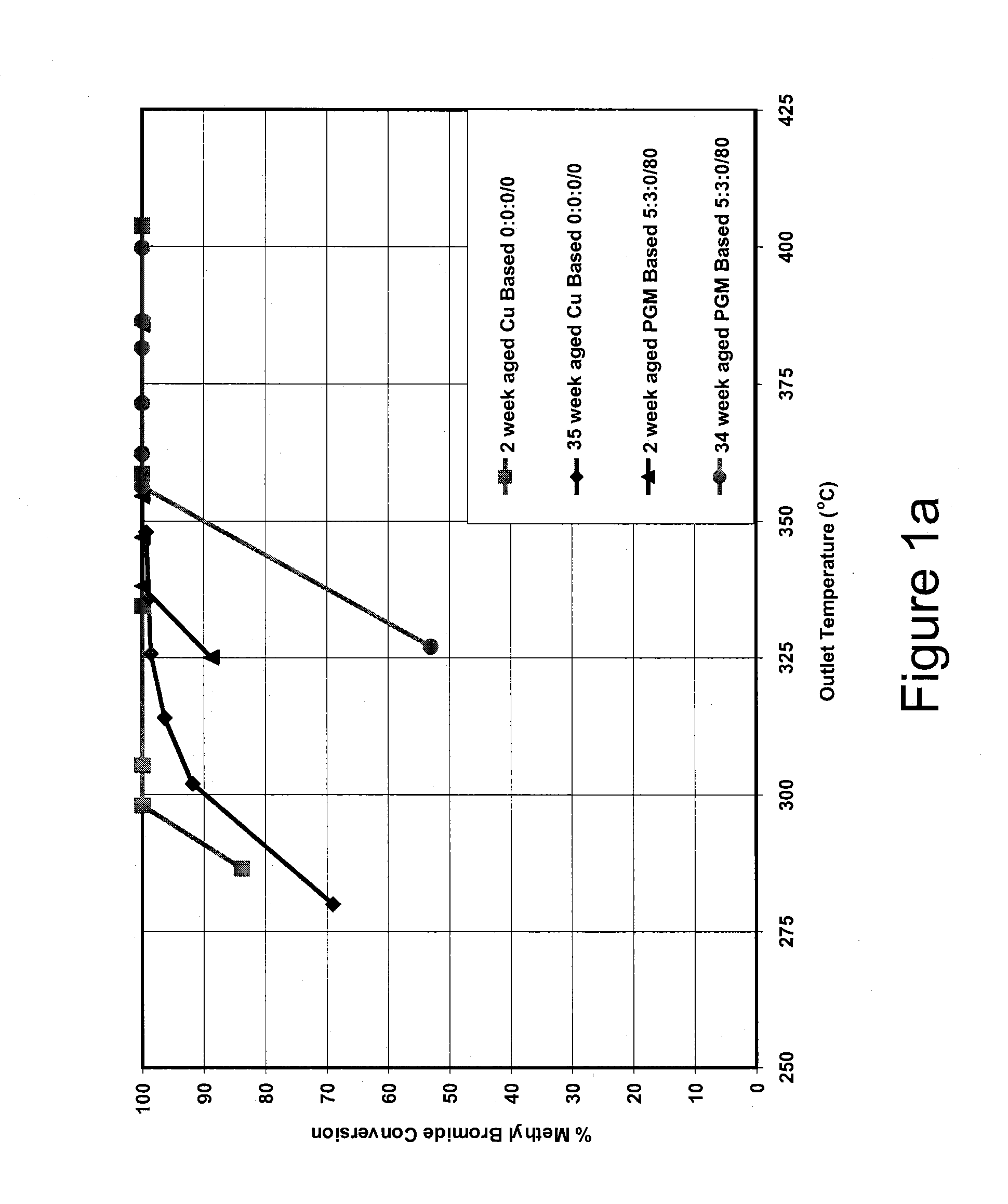

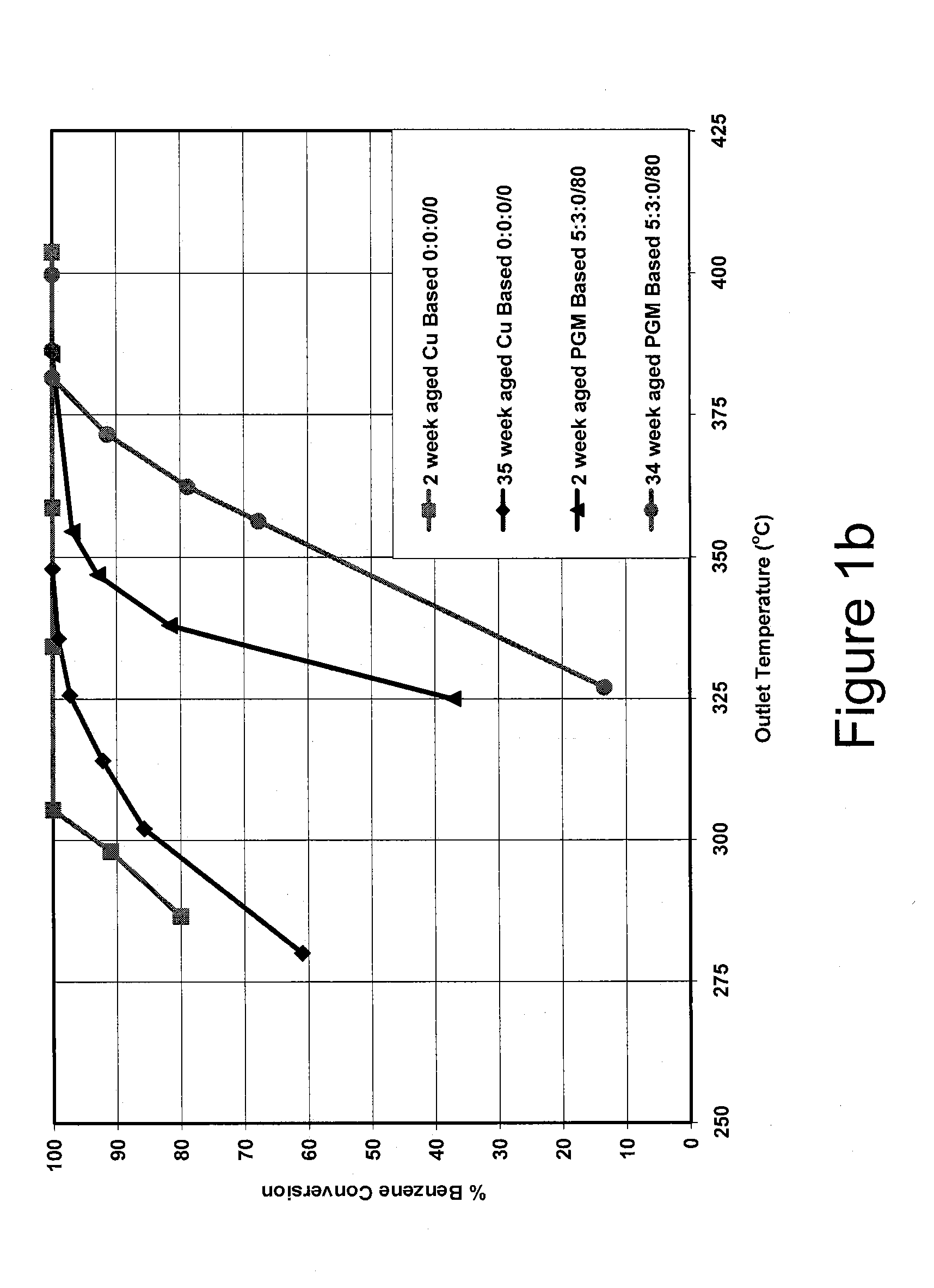

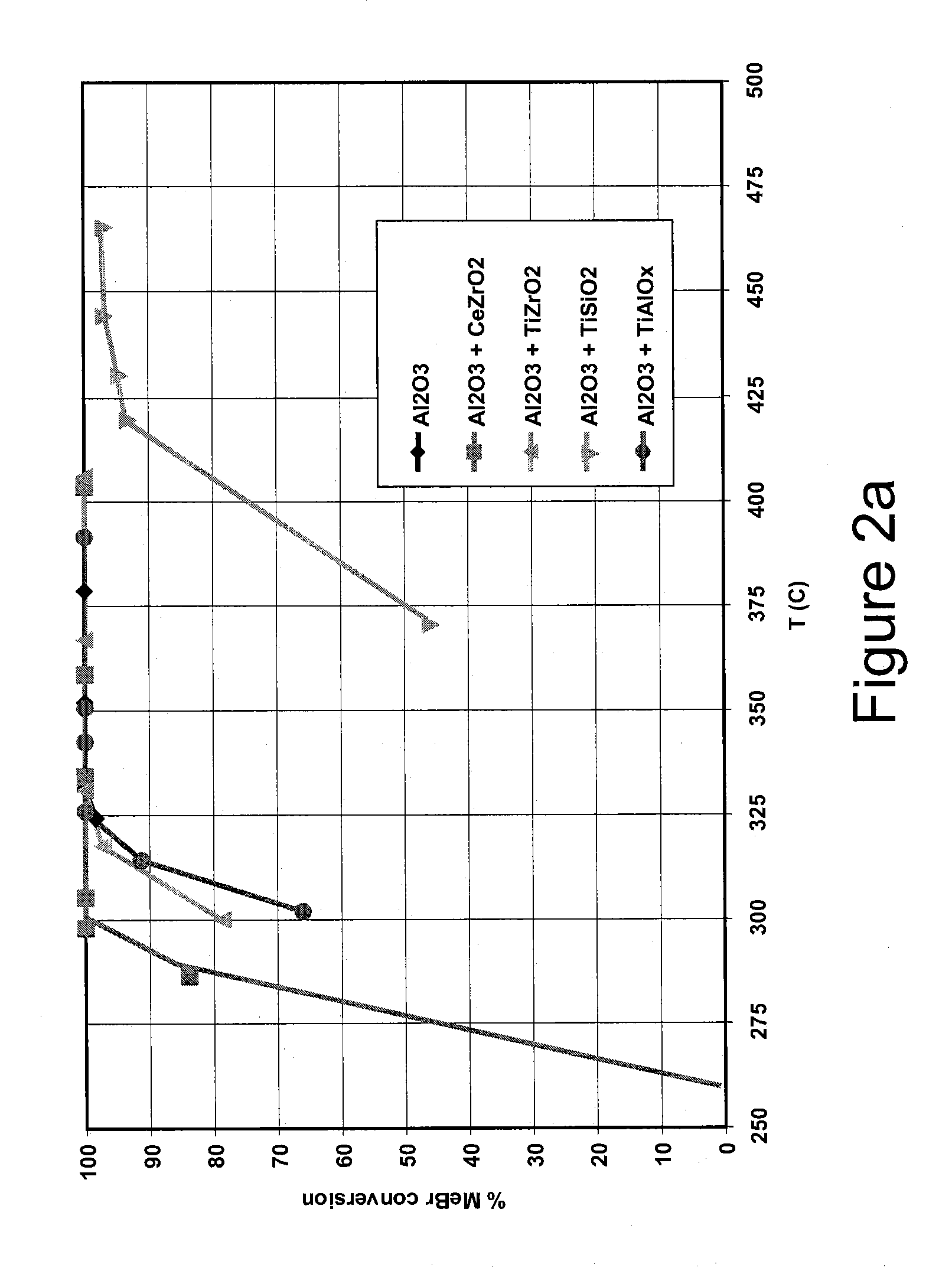

Base metal catalysts for the oxidation of carbon monoxide and volatile organic compounds

A method for oxidizing carbon monoxide (CO) and volatile organic compounds (VOCS) comprises contacting a gas containing water vapor and said CO and VOCs with a catalyst composition comprising at least one base metal promoter and at least one base metal catalyst supported on an oxide support material comprising one or more of alumina, silica, zirconia, ceria, and titania, wherein the VOCs comprise one or more of methyl acetate, methane, methyl bromide, benzene, methanol, methyl ethyl ketone, butane, and butene.

Owner:JOHNSON MATTHEY PLC

Process for producing acetic acid

ActiveUS20130281735A1Efficient removalImprove corrosion resistanceOrganic compound preparationOrganic chemistry methodsDistillationMethyl acetate

Acetic acid is produced while inhibiting increased concentrations of hydrogen iodide and acetic acid in an acetaldehyde distillation column.A production process of acetic acid comprises a step for allowing methanol to react with carbon monoxide; a step for feeding a flasher with the reaction mixture to separate a volatile component (2A) and a low-volatile component (2B); a step for feeding a distillation column with the volatile component (2A), and separating an overhead (3A) containing methyl iodide, acetic acid, methyl acetate, water, acetaldehyde, and hydrogen iodide, and a stream (3B) containing acetic acid to collect acetic acid; and a separation step for feeding an acetaldehyde distillation column with at least part of the overhead (3A) and separating a liquid object to be treated containing the overhead (3A) into a lower boiling point component (4A) containing acetaldehyde and a higher boiling point component (4B); wherein, in the separation step, the liquid object contains methanol and / or dimethyl ether in a concentration of 0.1 to 50% by weight is subjected to distillation.

Owner:DAICEL CHEM IND LTD

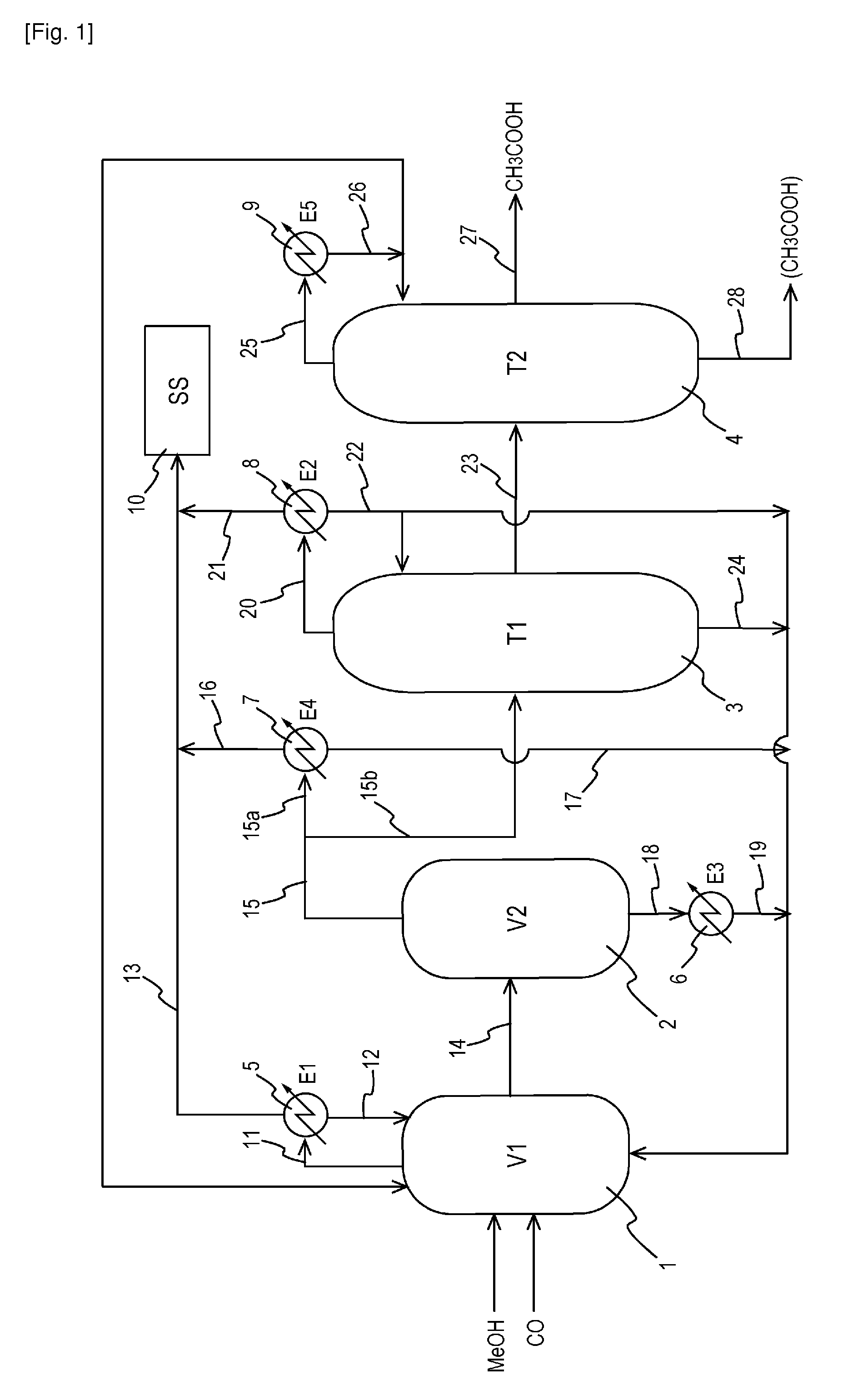

Process for producing acetic acid

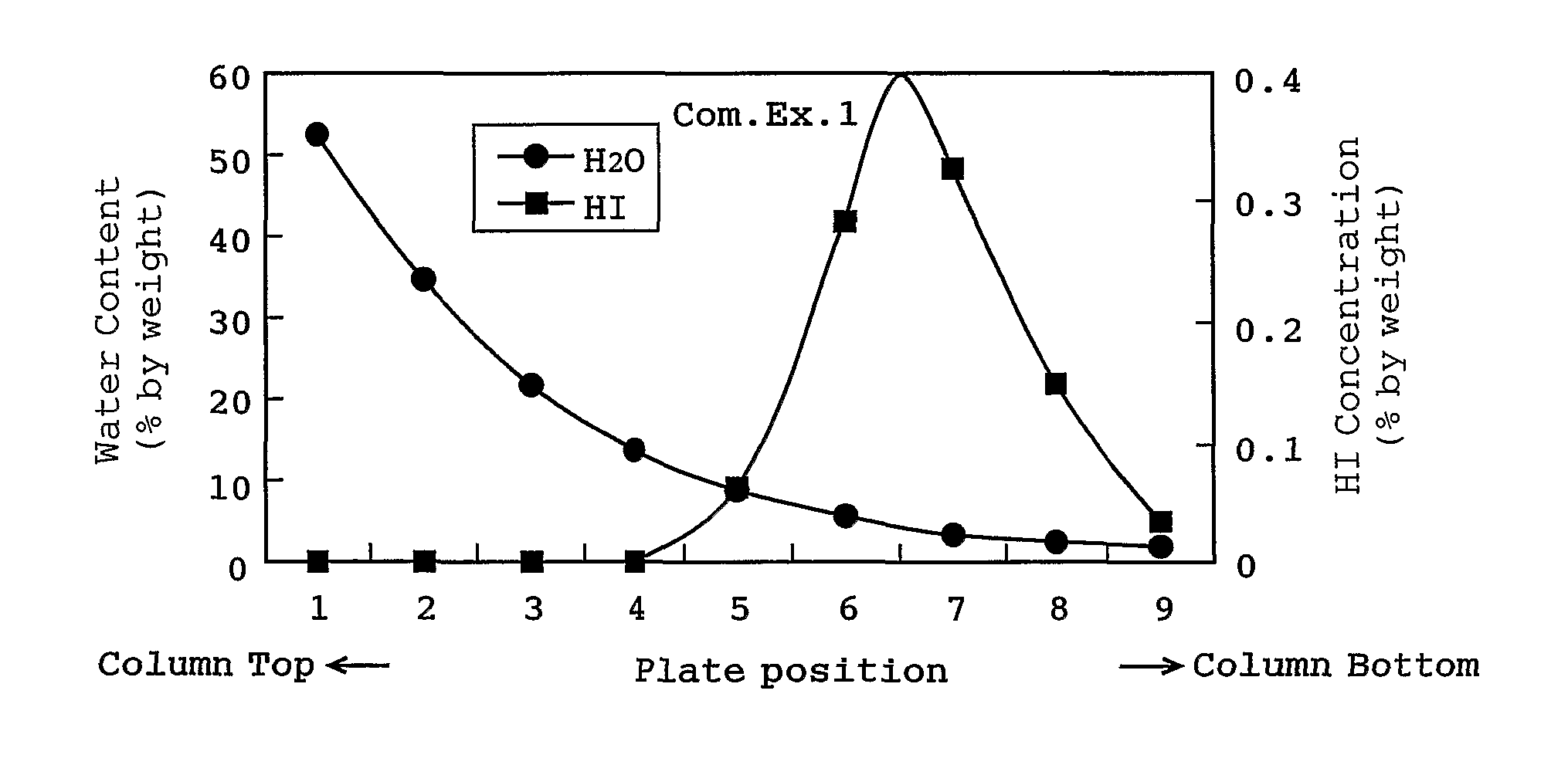

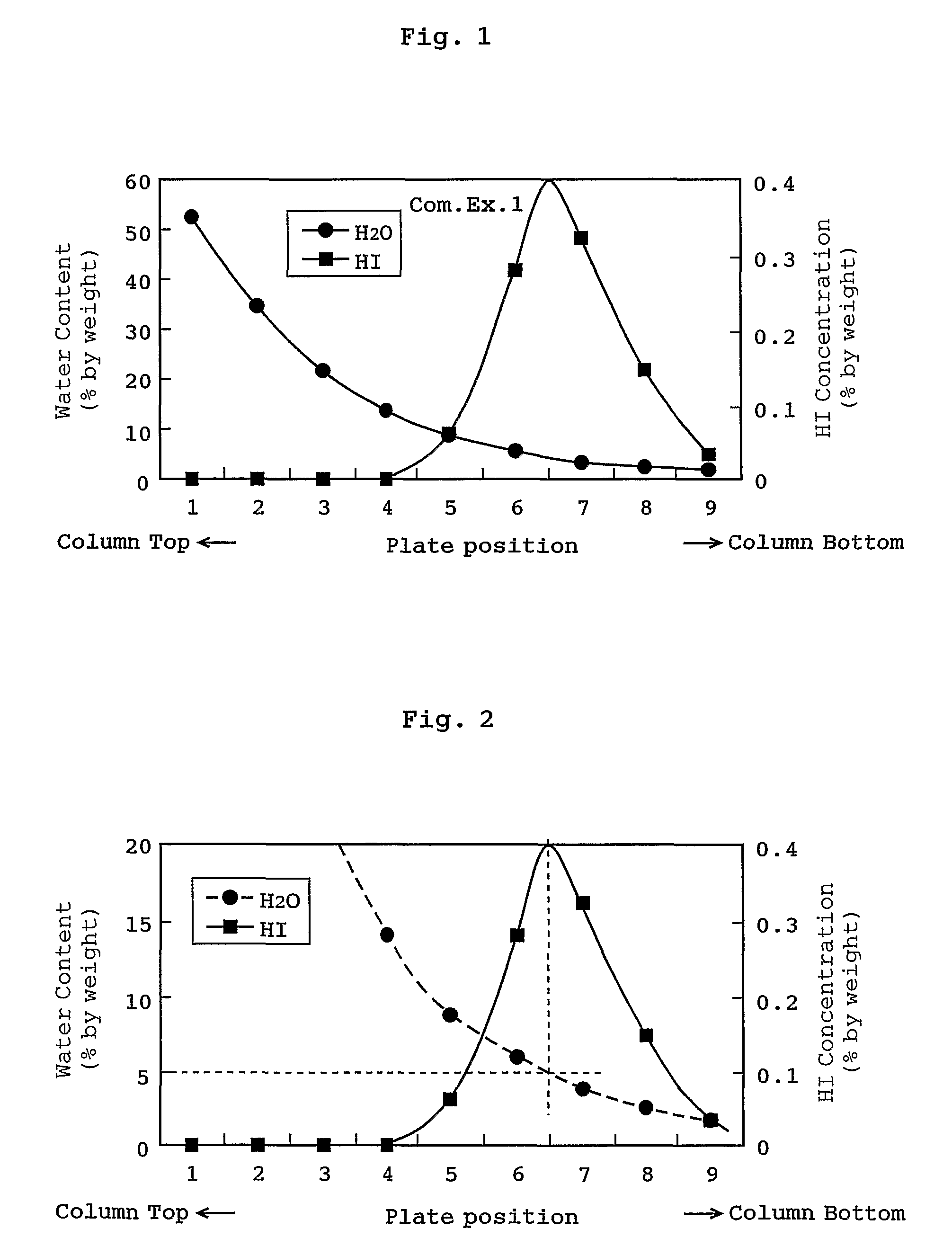

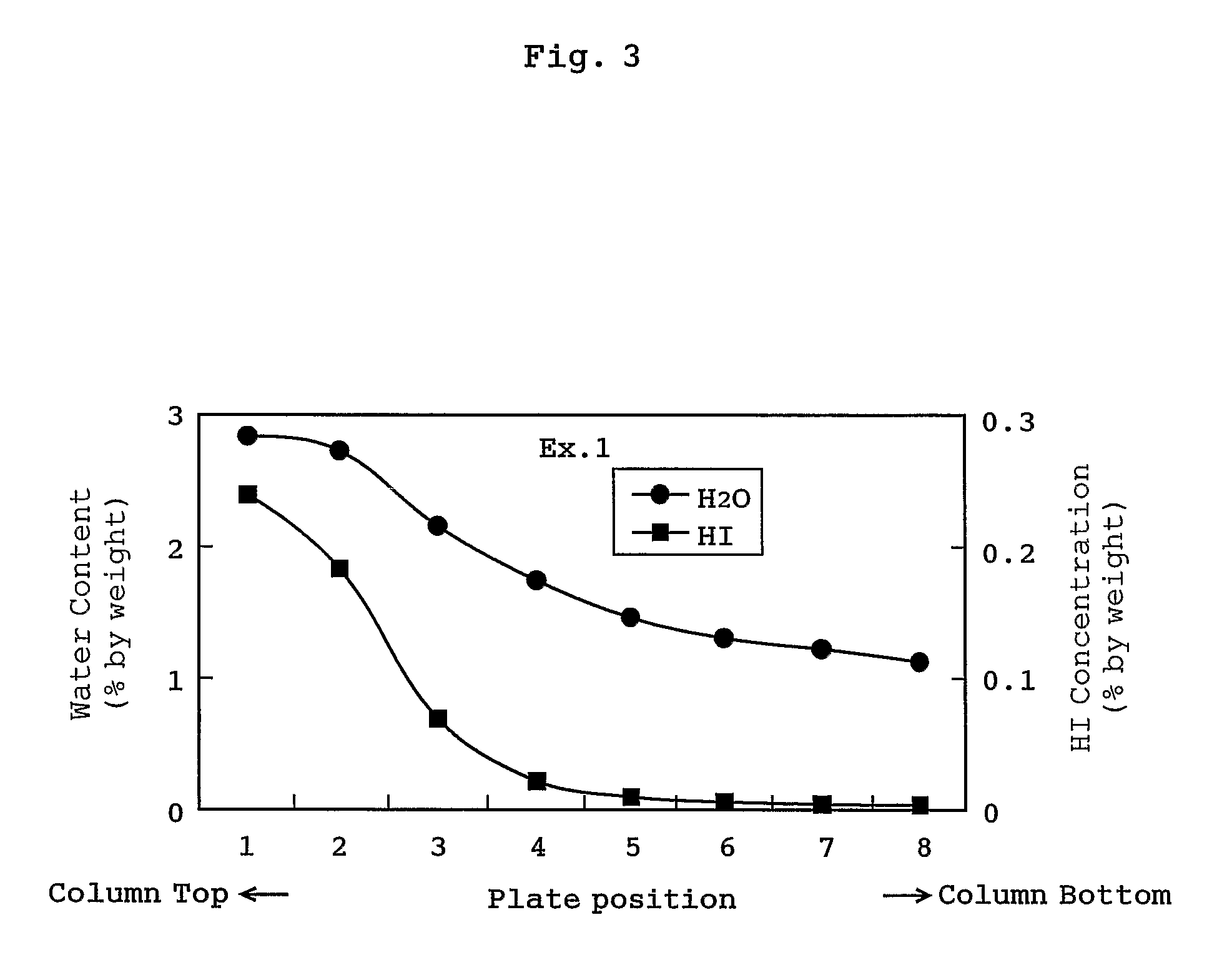

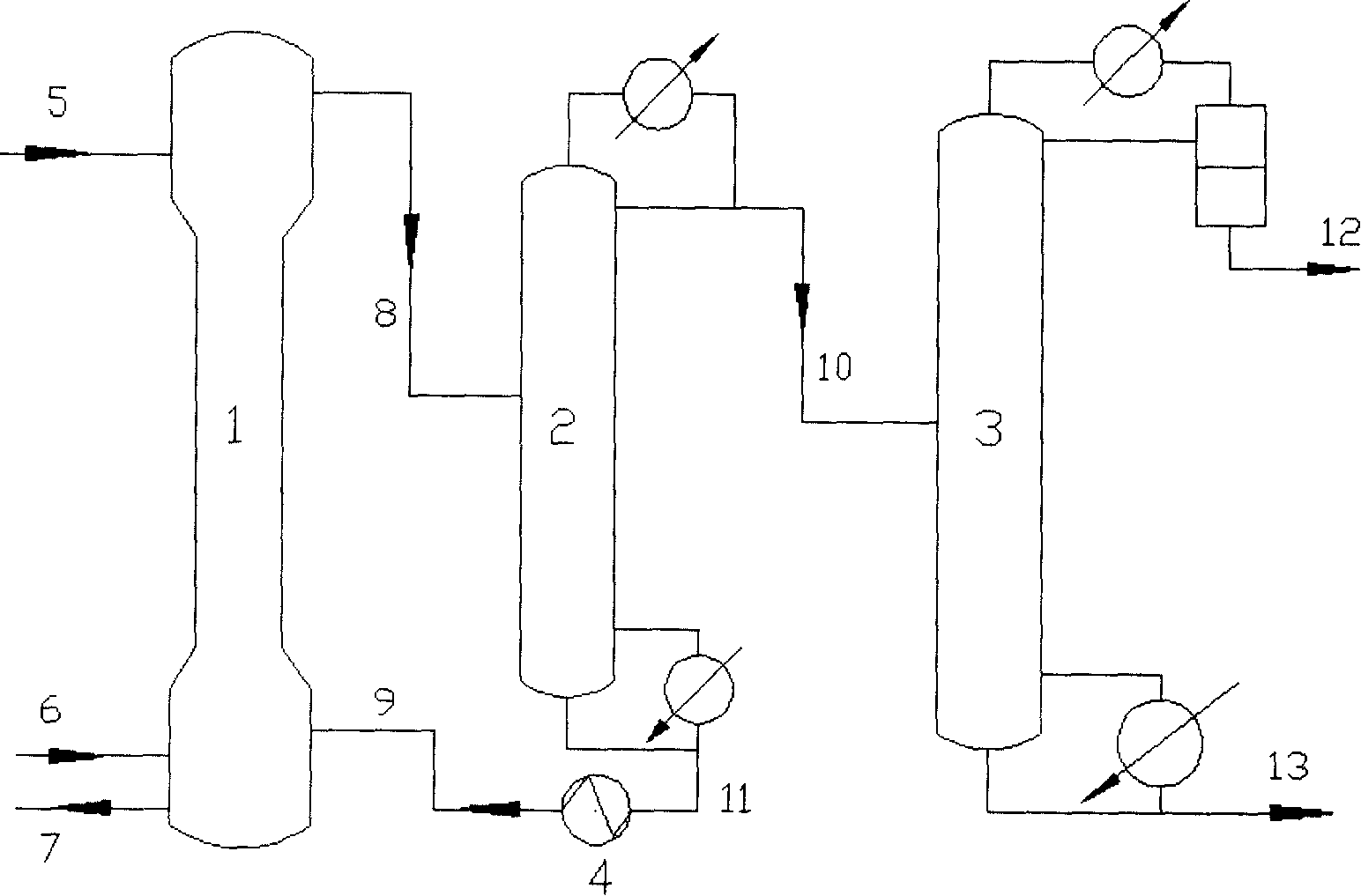

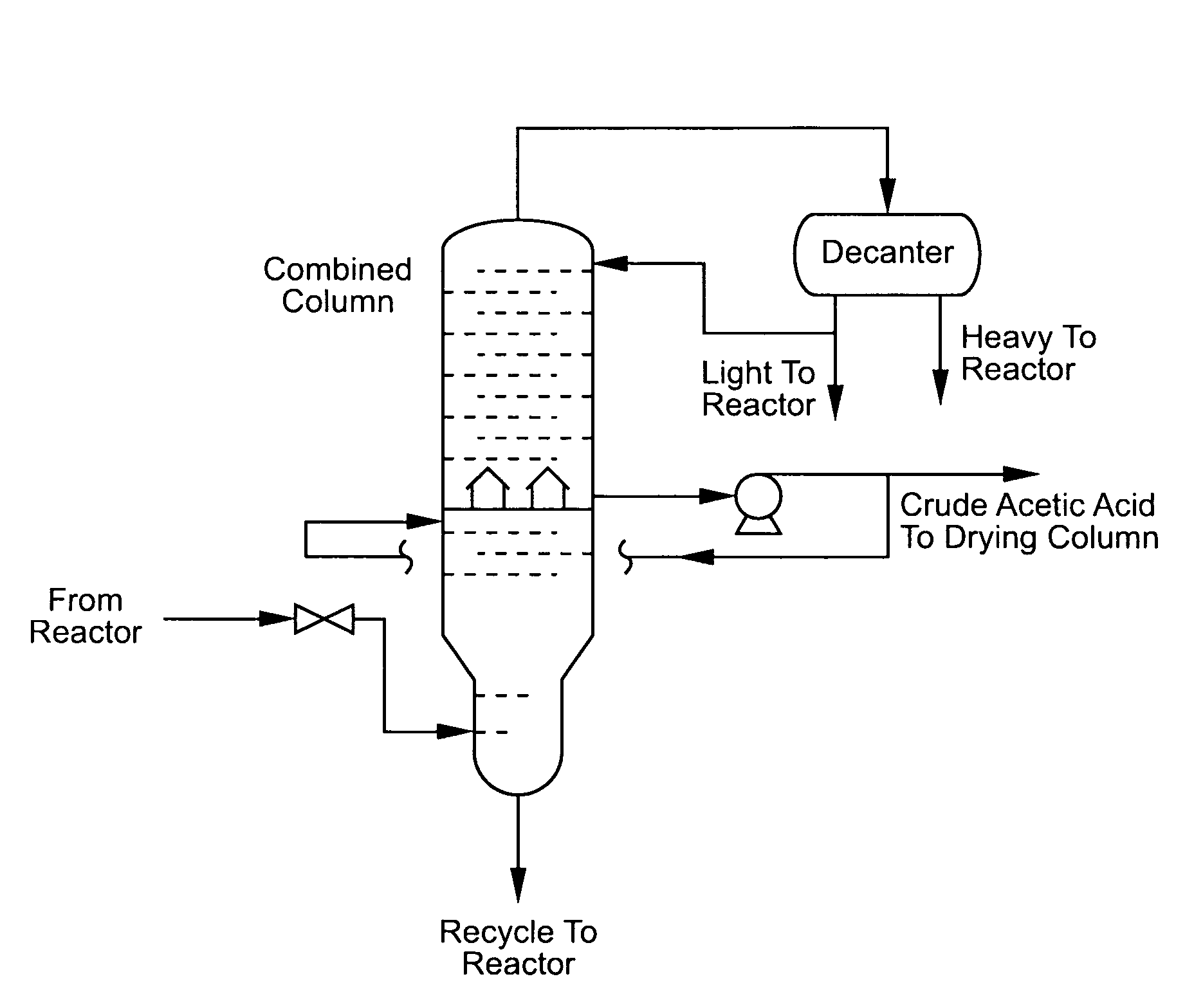

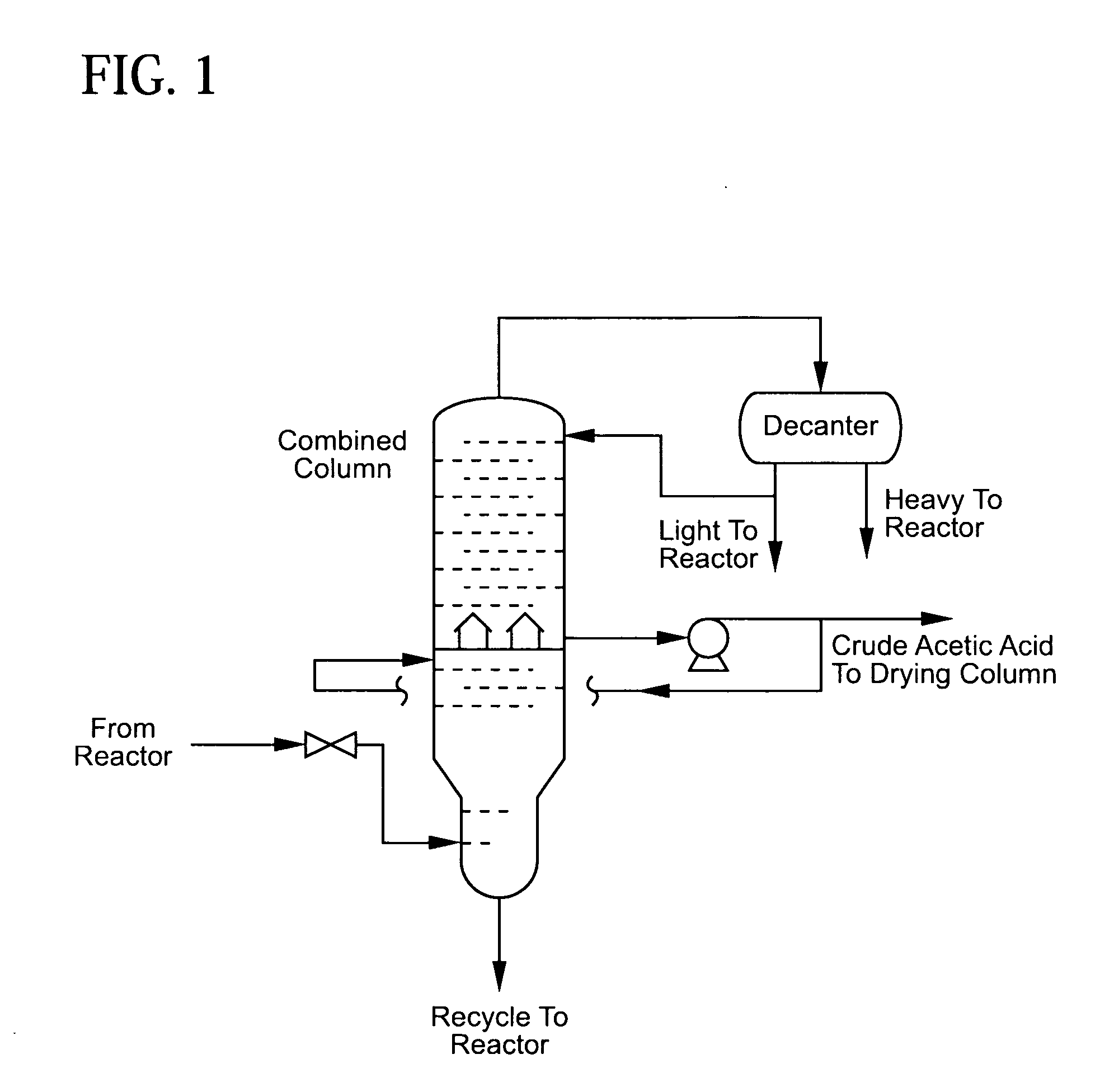

ActiveUS9006483B2Avoid pollutionEnsure stable and continuous operationOrganic compound preparationDistillation separationWater concentrationAcetic acid ear

A production process of acetic acid according to the present invention inhibits concentration of hydrogen iodide and improves a liquid-liquid separation of an overhead from a distillation column. Acetic acid is produced by distilling a mixture containing hydrogen iodide, water, acetic acid and methyl acetate in a first distillation column (3) to form an overhead and a side cut stream or bottom stream containing acetic acid, cooling and condensing the overhead in a condenser (C3) to form separated upper and lower phases in a decanter (4). According to this process, a zone having a high water concentration is formed in the distillation column above the feed position of the mixture by feeding a mixture having a water concentration of not less than an effective amount to not more than 5% by weight (e.g., 0.5 to 4.5% by weight) and a methyl acetate concentration of 0.5 to 9% by weight (e.g., 0.5 to 8% by weight) as the mixture to the distillation column and distilling the mixture. In the zone having a high water concentration, hydrogen iodide is allowed to react with methyl acetate to produce methyl iodide and acetic acid.

Owner:DAICEL CHEM IND LTD

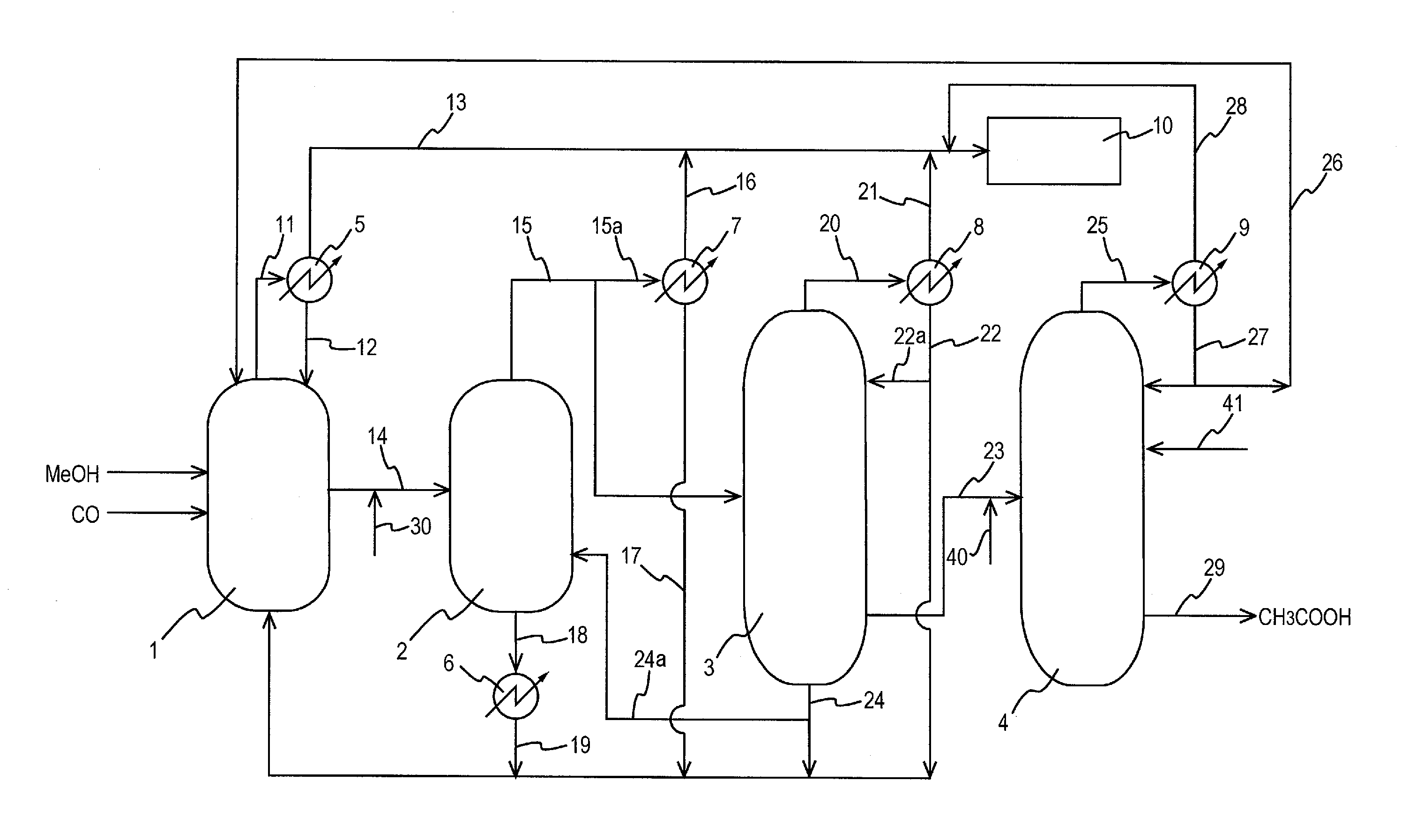

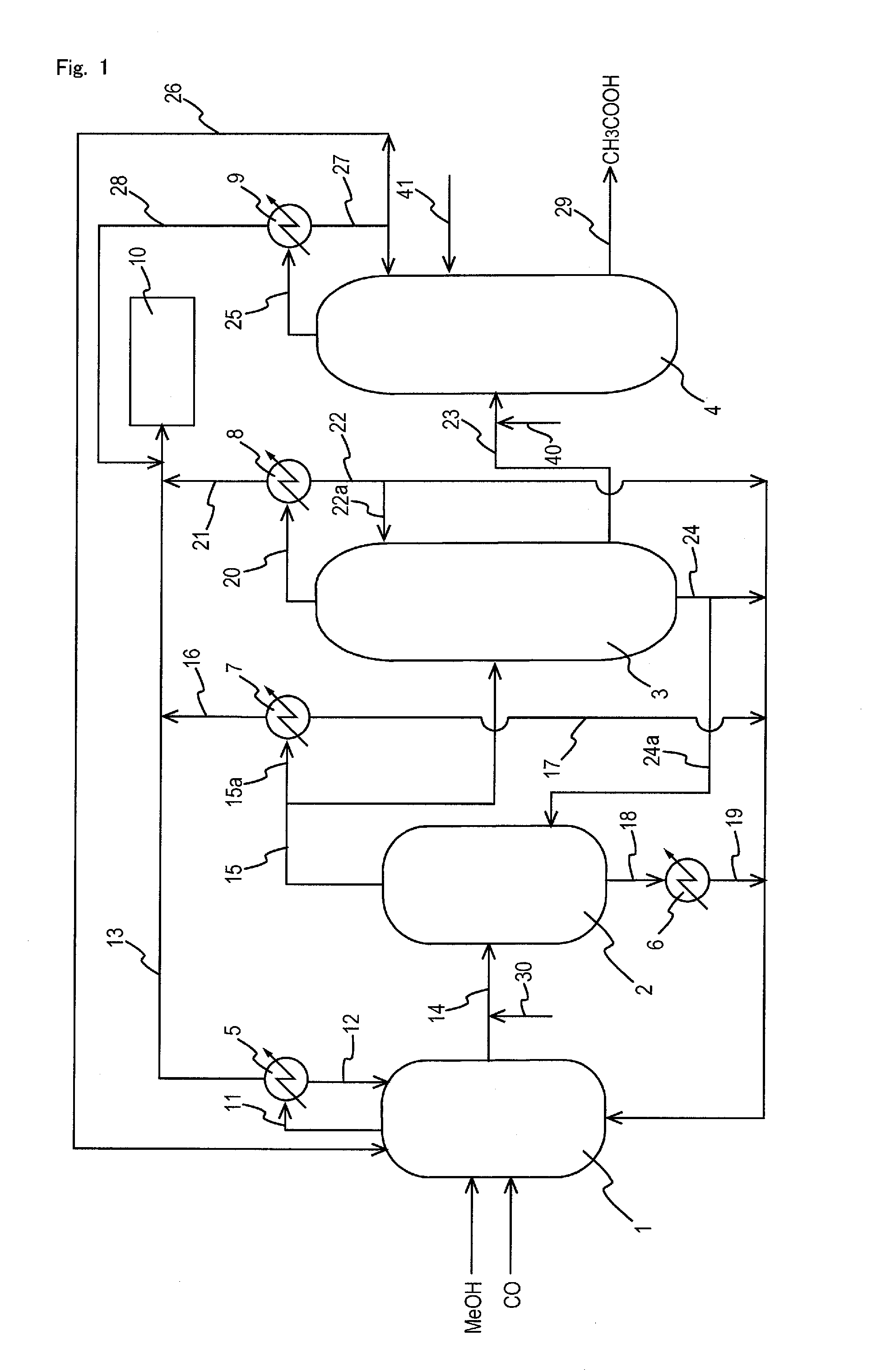

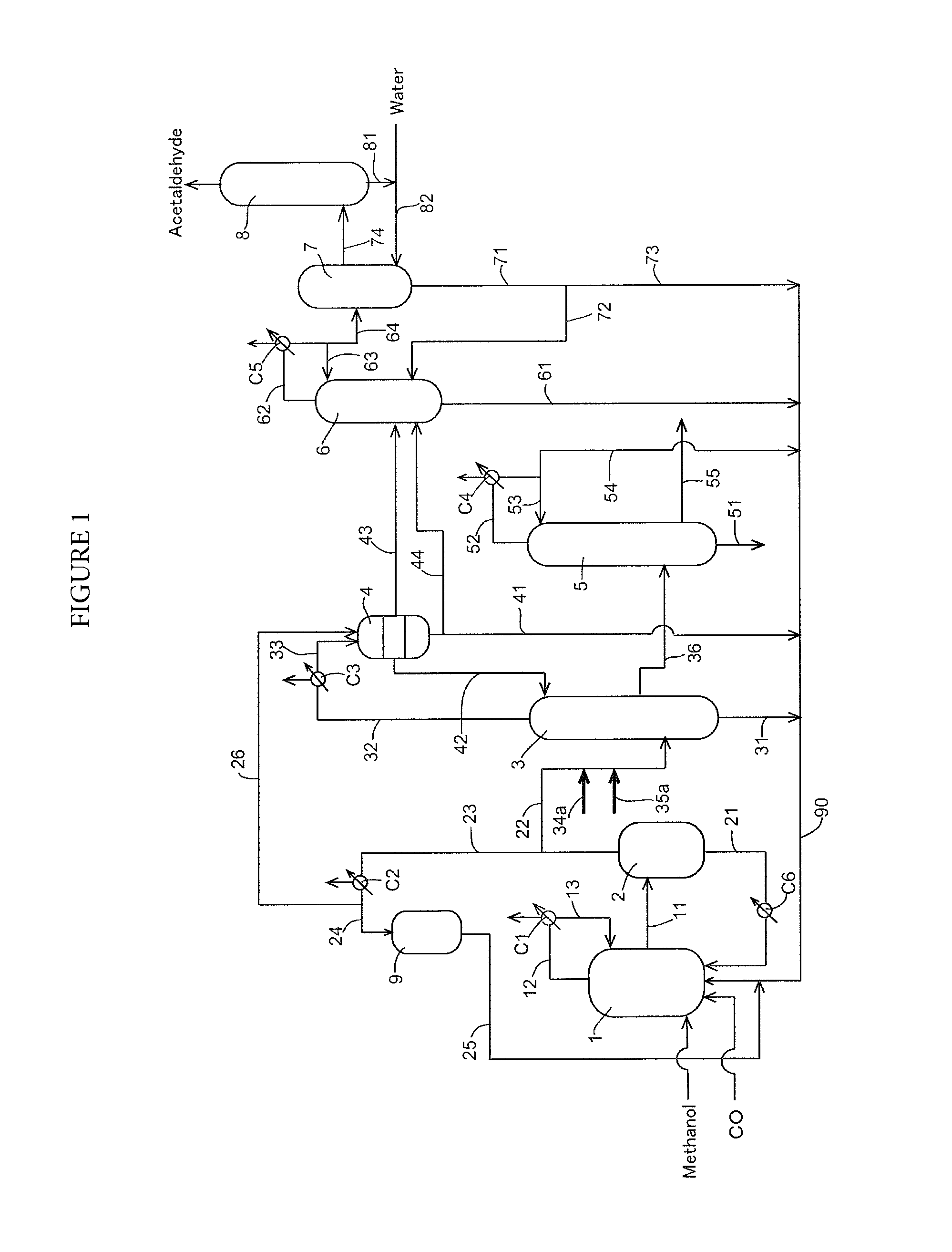

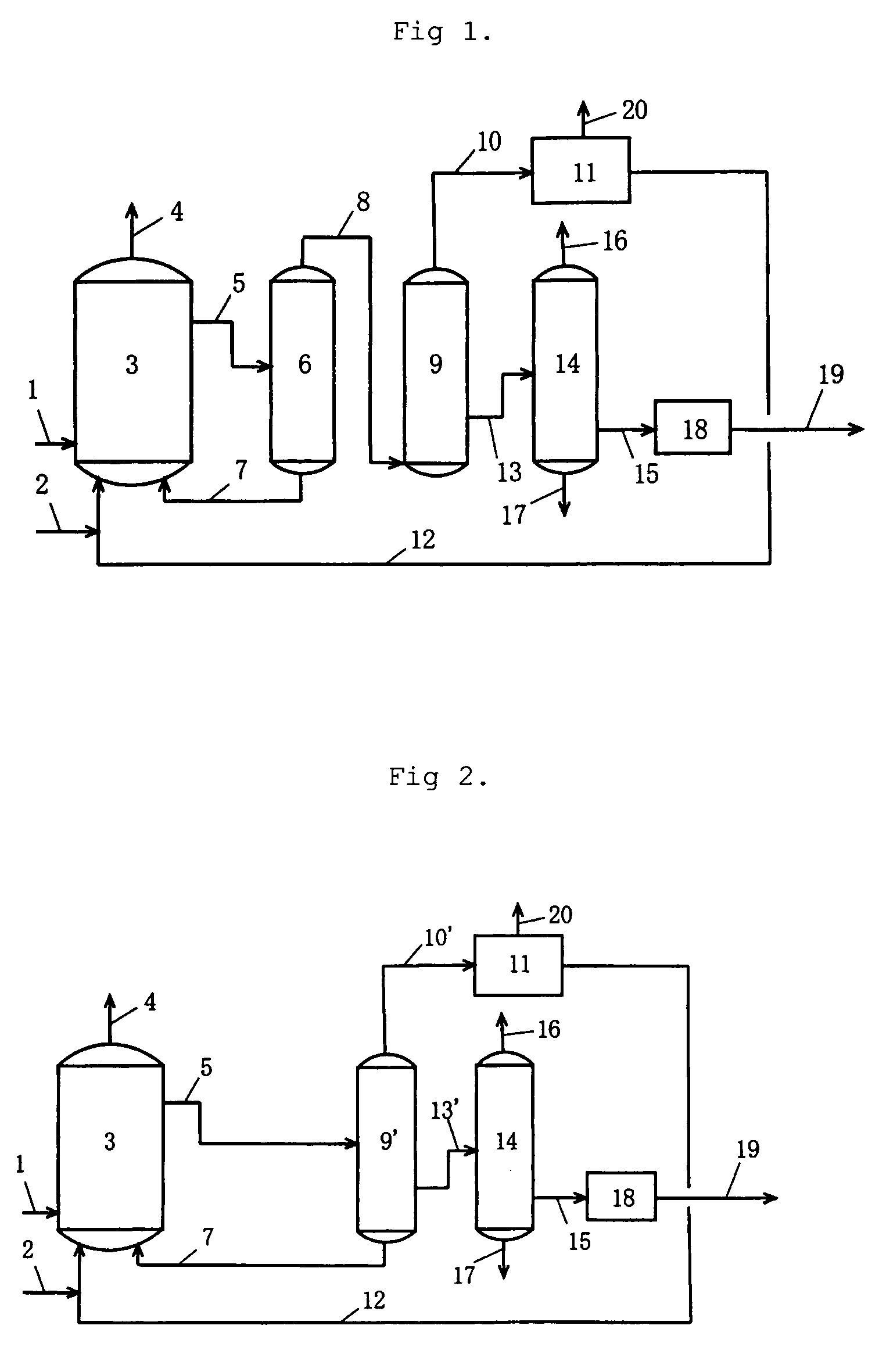

Process for producing acetic acid

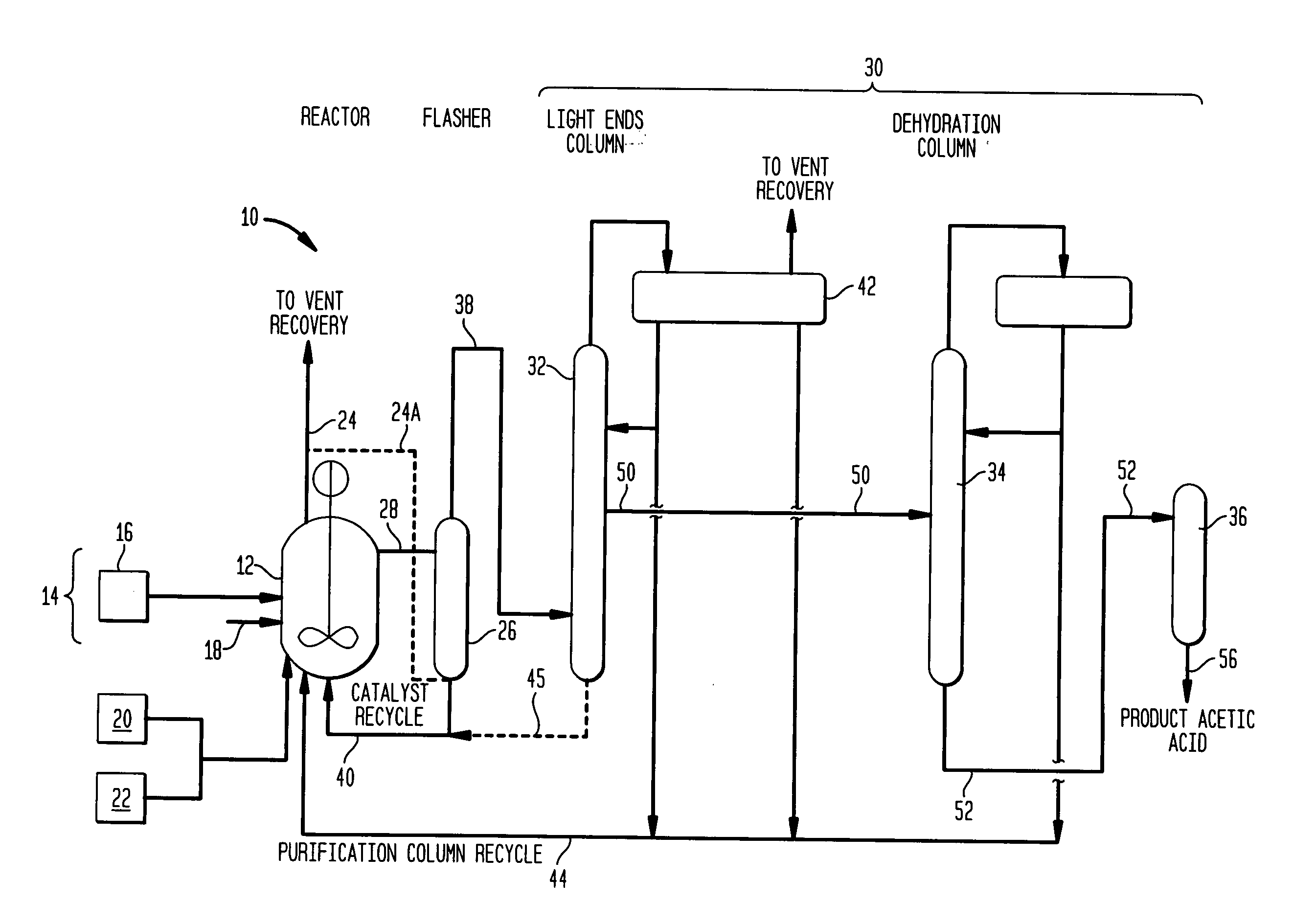

ActiveUS20130116470A1High purityHigh yieldOrganic compound preparationChemical industryDistillationResource saving

A production process of acetic acid comprises a reaction step for continuously allowing at least one member selected from the group consisting of methanol, dimethyl ether, and methyl acetate to react with carbon monoxide in a catalyst system comprising a rhodium catalyst, an iodide salt, and methyl iodide in the presence of acetic acid and water in a plant compromising a reactor 1; a flasher 2; and a distillation column 3; wherein part of the vaporized stream is introduced into a heat exchanger 7. The process achieves a production of acetic acid with a high purity in a resource-saving and energy-saving equipment by efficiently removing a reaction heat even in a large-sized plant.

Owner:DAICEL CHEM IND LTD

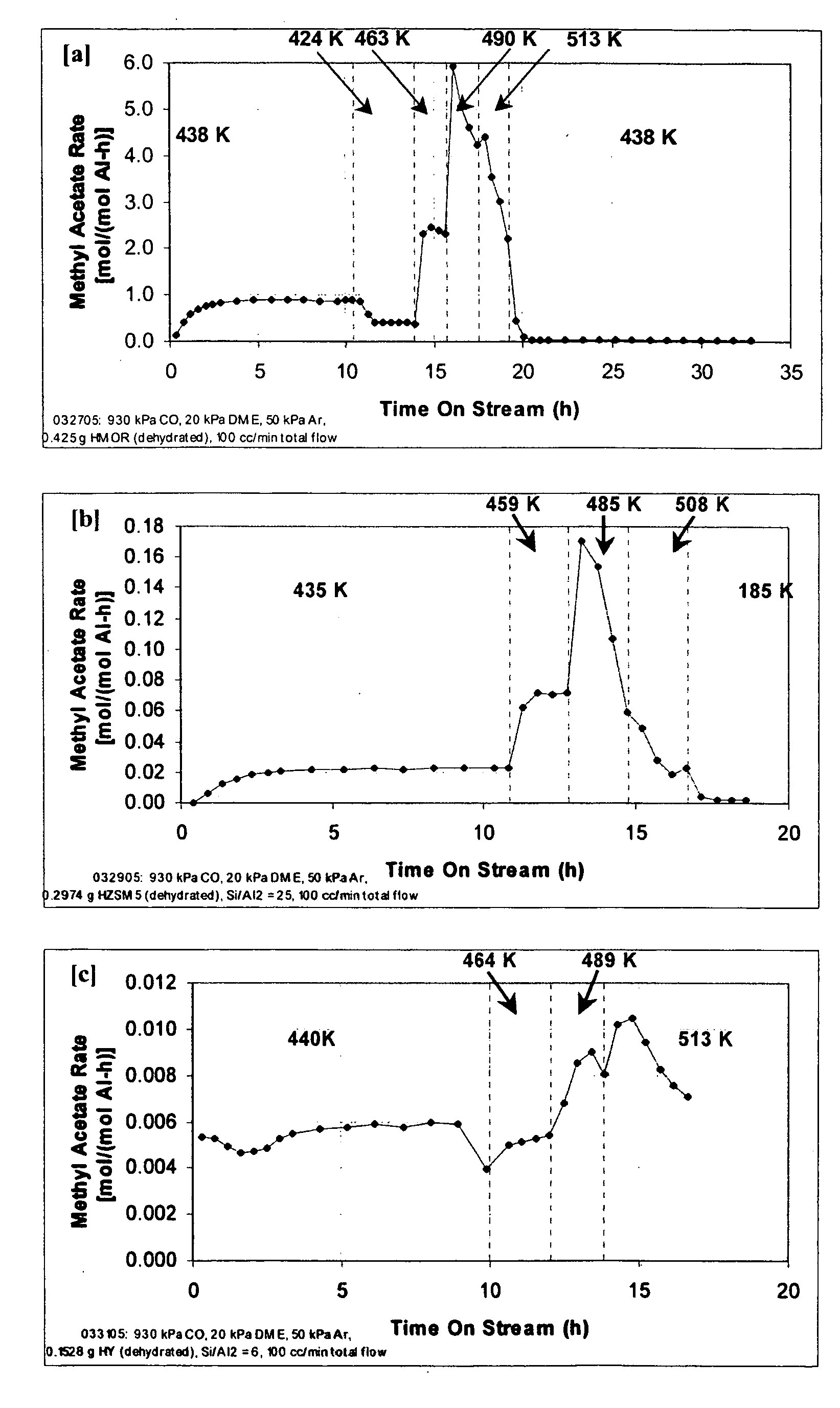

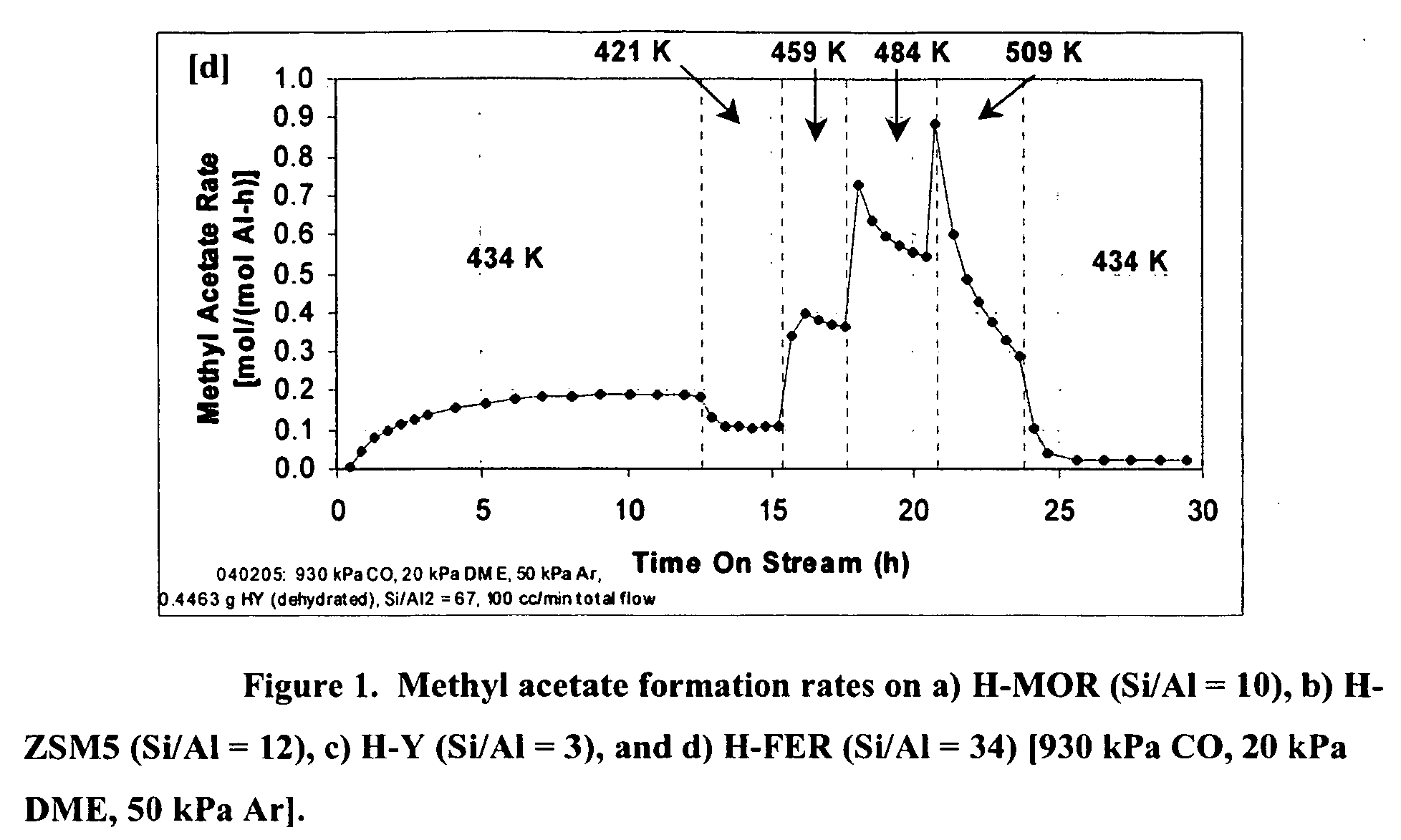

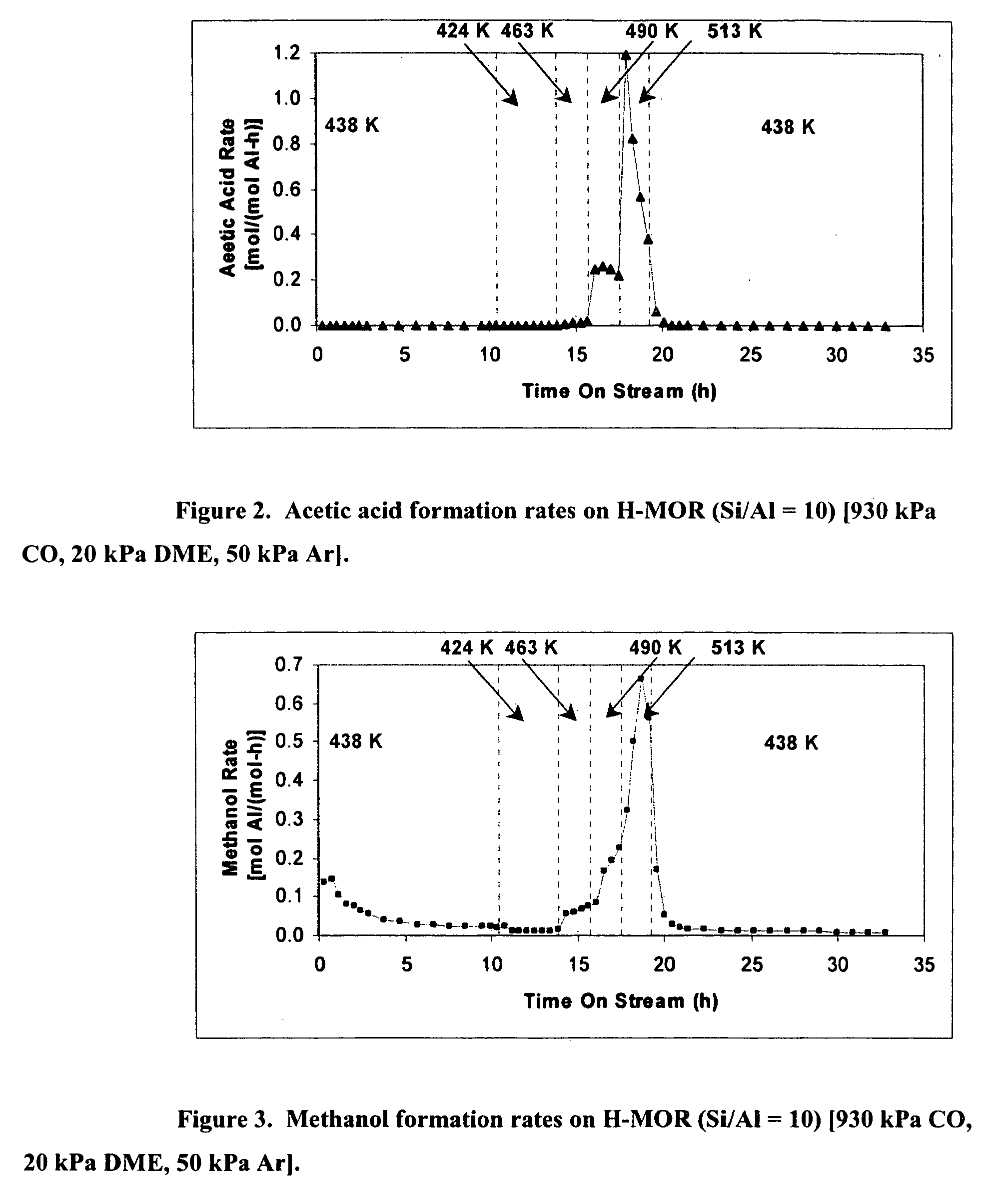

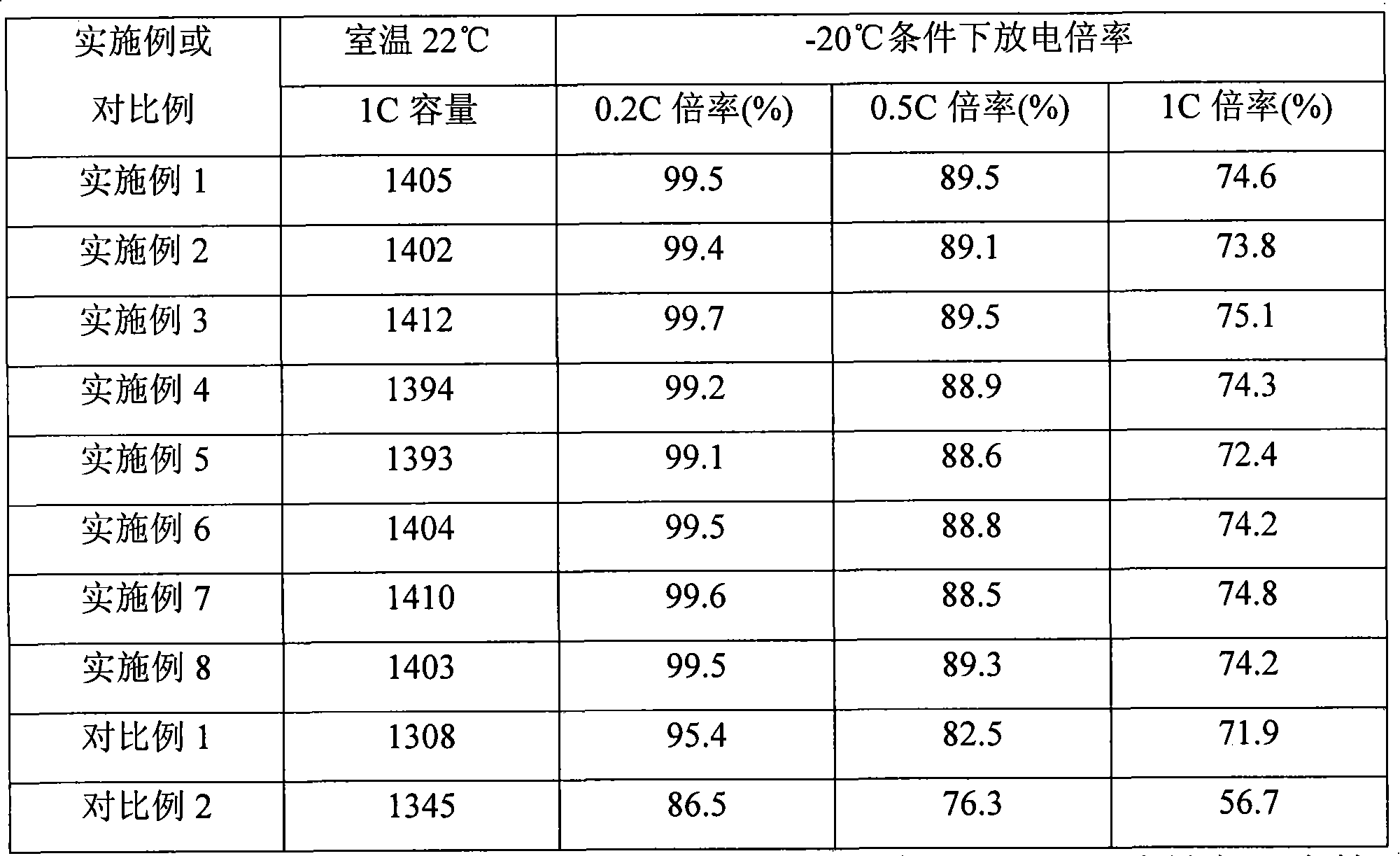

Process for carbonylation of alkyl ethers

InactiveUS20060252959A1Organic compound preparationPreparation from carboxylic acid esters/lactonesMordeniteMethyl acetate

A product comprising a lower alkyl ester of a lower aliphatic carboxylic acid is produced by a process comprising reacting a lower alkyl ether with carbon monoxide in the presence of a catalyst comprising mordenite and / or ferrierite, under substantially anhydrous conditions. More specifically, methyl acetate is selectively produced by reaction of dimethyl ether with carbon monoxide in the presence of a catalyst comprising mordenite or ferrierite, under substantially anhydrous conditions.

Owner:RGT UNIV OF CALIFORNIA +1

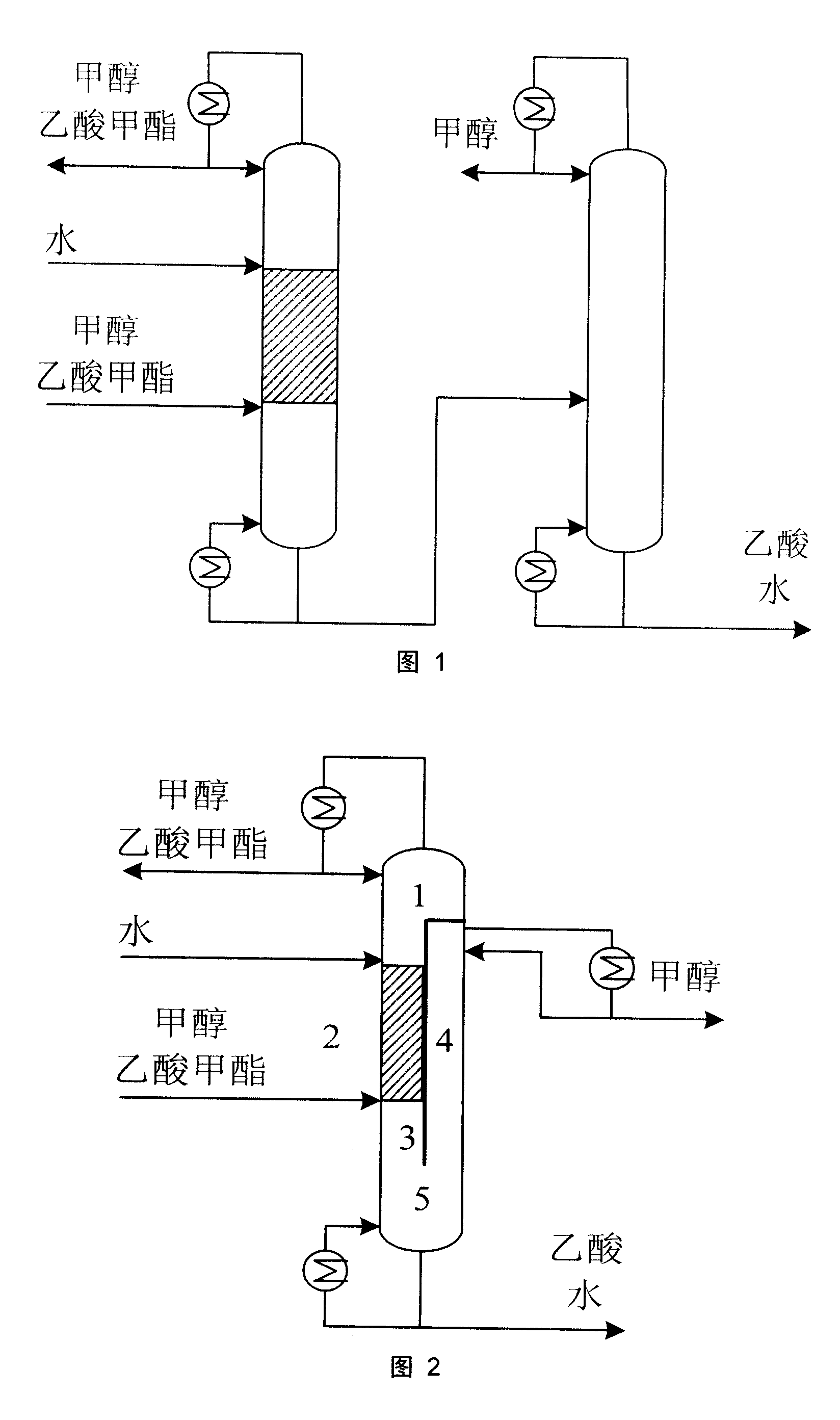

Formation method of lithium ion secondary battery

InactiveCN101640285AImprove electrochemical performanceGood electrical conductivitySecondary cells charging/dischargingMethyl formateMethyl acetate

The invention relates to a formation method of a lithium ion secondary battery. The method comprises the following steps: performing a first formation on a battery containing a first electrolytic solution; and then injecting a second electrolytic solution into a battery container after the first formation to perform a second formation, wherein the first electrolytic solution contains an electrolyte and a first solvent which is mixture of a solvent A and a solvent B; the solvent A is ethylene carbonate, and the solvent B is one or more selected from dimethyl carbonate, diethyl carbonate, methylethyl carbonate, dimethyl sulfite and diethyl sulfite; and the second electrolytic solution contains electrolyte and a second solvent, and the second solvent is one or more selected from propylene carbonate, butylene carbonate, dimethoxyethane, gamma-butyrolactone, methyl formate, ethyl formate, methyl acetate, ethyl acetate, ethyl propionate, ethyl butyrate and propyl butyrate. The lithium ion secondary battery obtained by the method has excellent cycle performance and low-temperature multiplying factor discharge performance.

Owner:SHANGHAI BYD

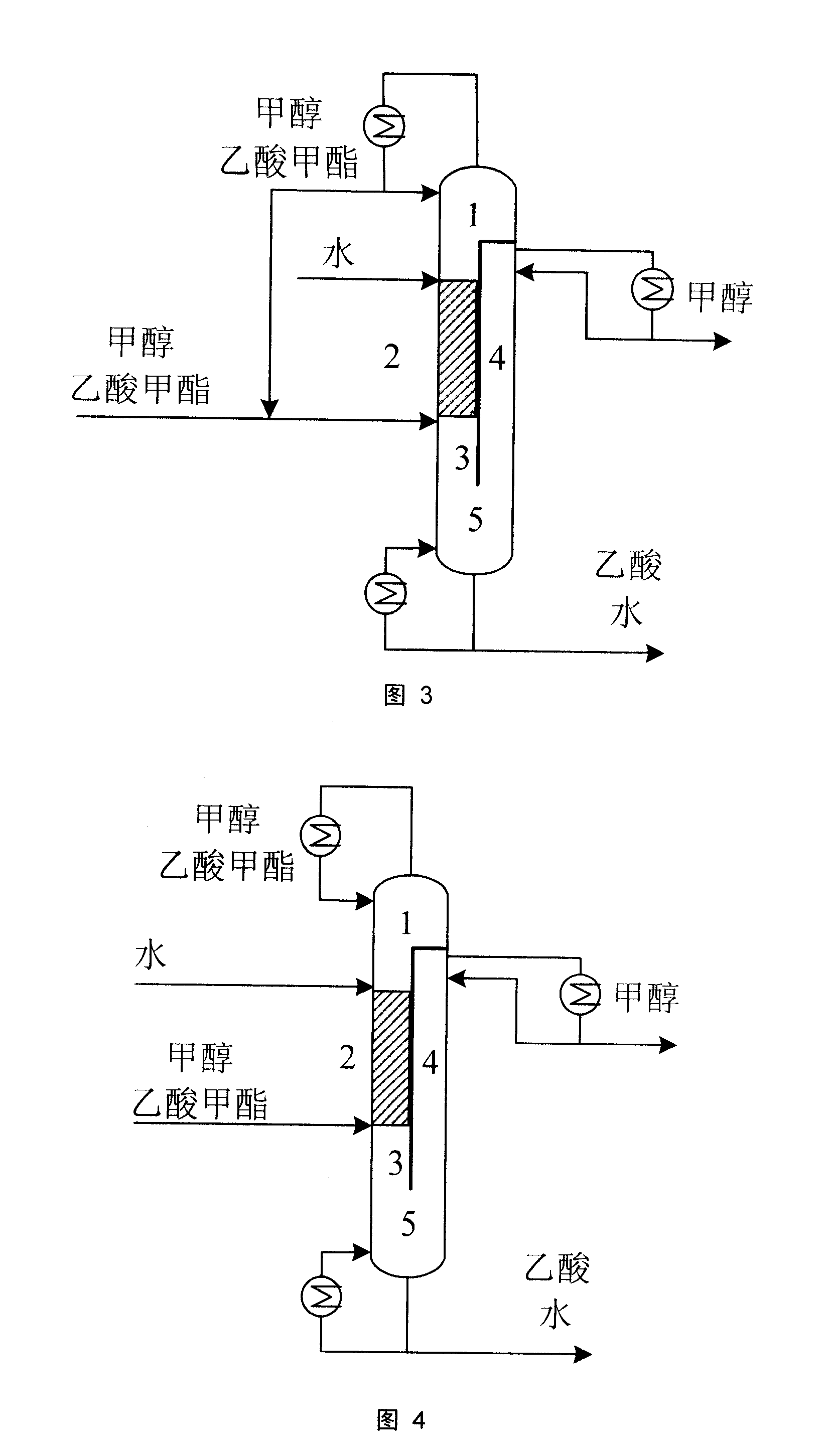

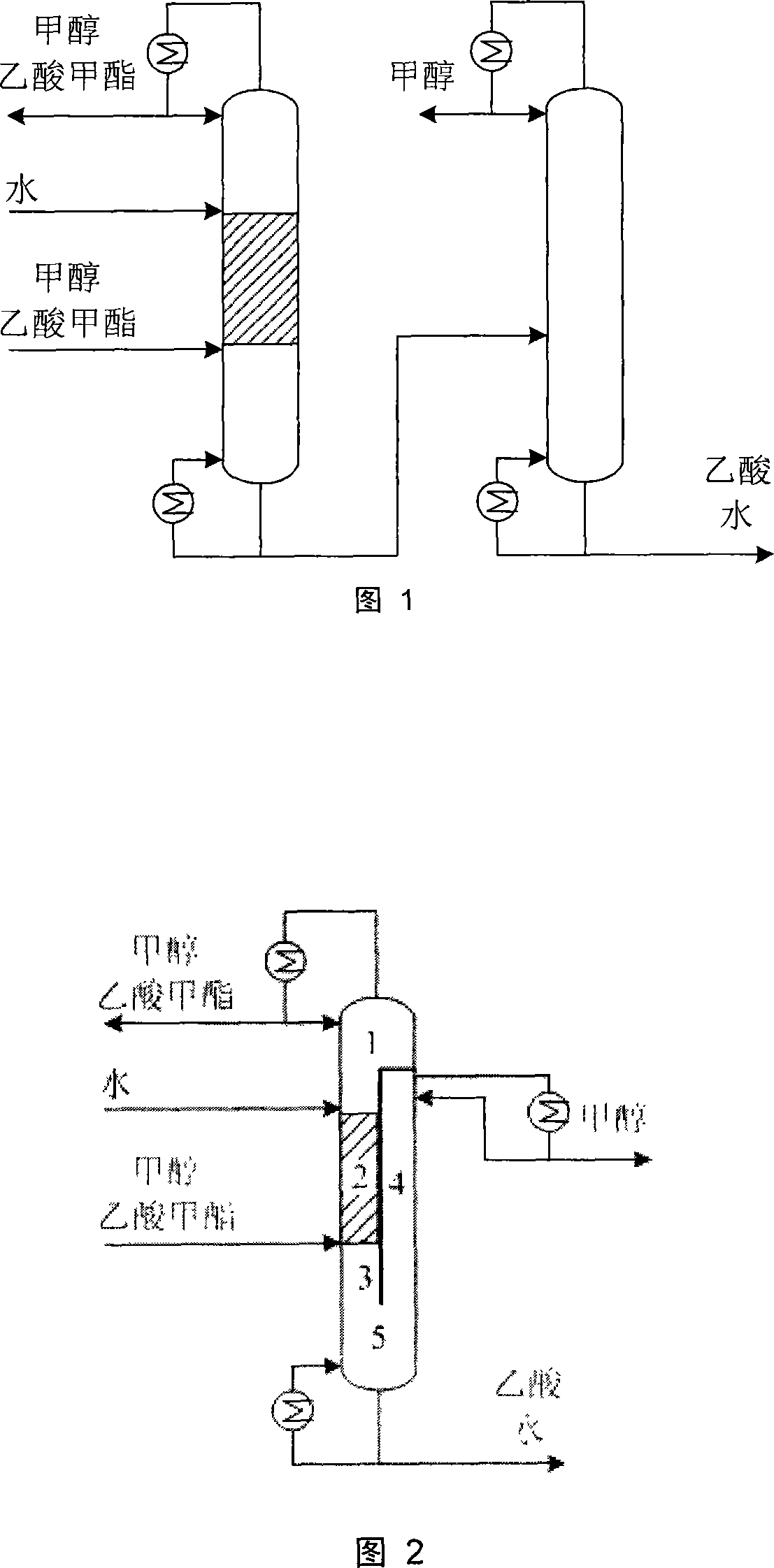

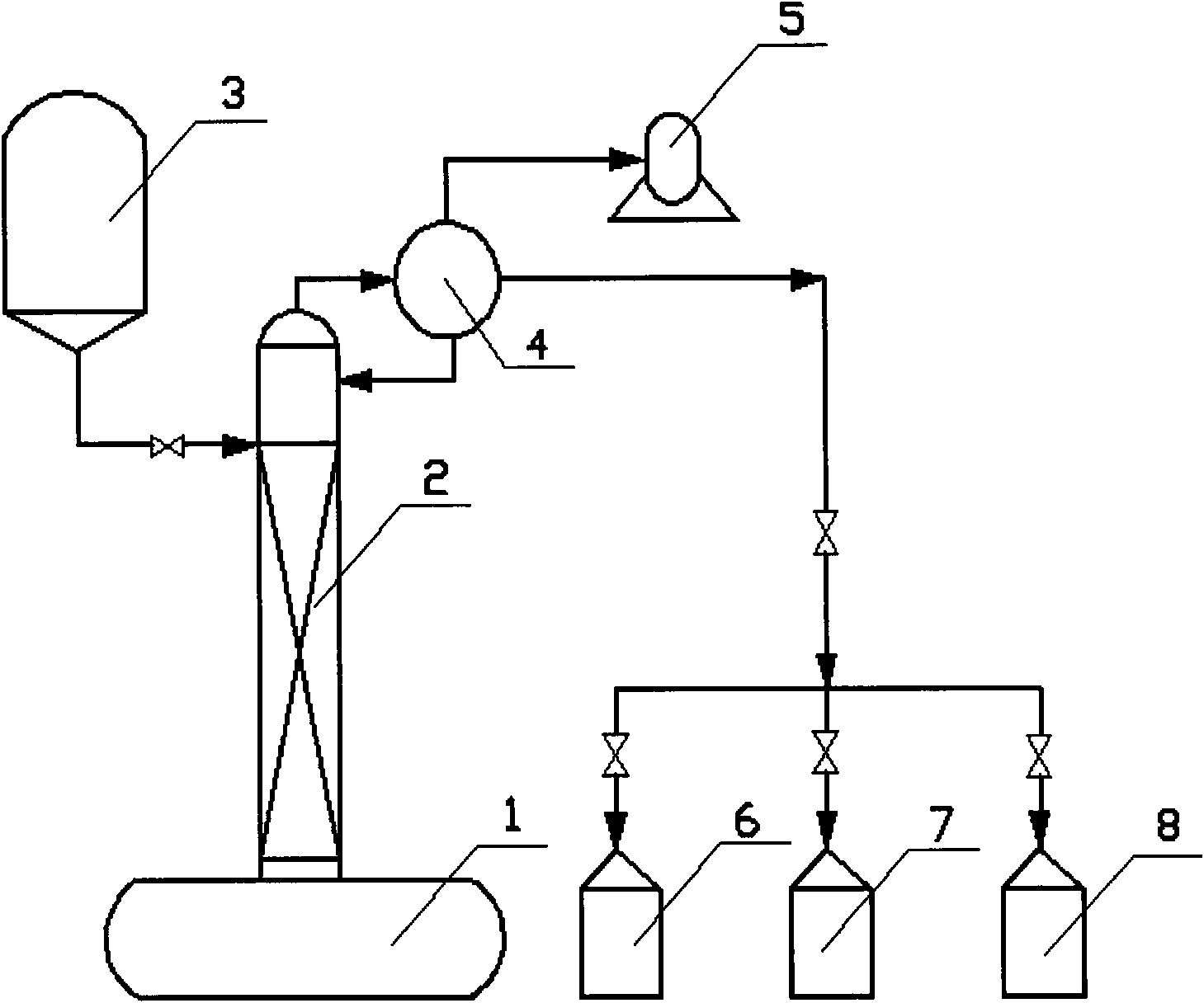

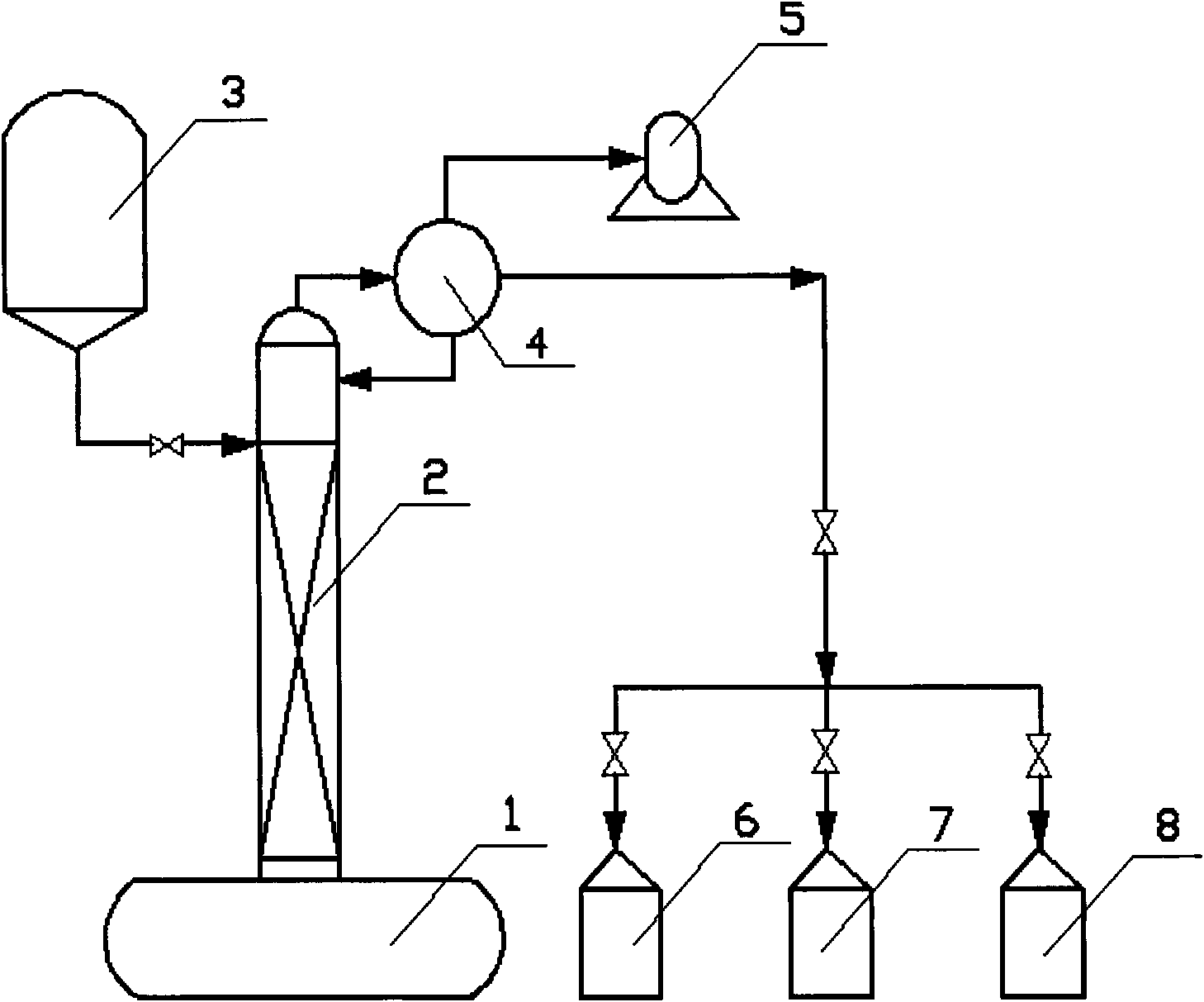

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Methods for producing acetic acid

ActiveUS7683212B2Efficient productionReduce formationHydrogenOrganic compound preparationGas phaseReaction rate

Owner:DAICEL CHEM IND LTD

Universal adhesive and preparation technology thereof

InactiveCN102604588AExtended shelf lifeAvoid serious wasteMineral oil hydrocarbon copolymer adhesivesChemical industryHydrocarbon solventsProduction line

The invention relates o a universal adhesive and a preparation technology thereof. The universal adhesive is prepared by using the following raw materials in parts by weight: rubber, a tackifying resin, a hydrocarbon solvent, an ester solvent and a propellant; the preparation technology comprises the following steps of: firstly adding the barreled hydrocarbon solvent and the ester solvent to the stirred vessel through the compressed air of an air compressor, then successively adding the rubber, the tackifying resin and the other additives one by one to prepare a stock solution; and respectively charging the stock solution to iron tanks on an aerosol filling production line, sealing and then filling the propellant to obtain the product. When in use, the universal adhesive provided by the invention is rapid to operate and convenient to use; in addition, environment-friendly solvents such as methyl acetate and ethyl acetate are mainly adopted in the universal adhesive so that the universal adhesive is safer in use and environment-friendly; finally, the aerosol packaging form of the universal adhesive is firstly put forward; the universal adhesive has good packaging leak tightness and is long in the quality guarantee period; the rest of universal adhesive can be stored for long term after the universal adhesive is used, thereby the serious wasting of the universal adhesive is avoided; and the universal adhesive is in line with and abides by the standard requirements of energy saving, emission reduction and environmental protection.

Owner:FUJIAN NANAN DAYANG AEROSOL MFG

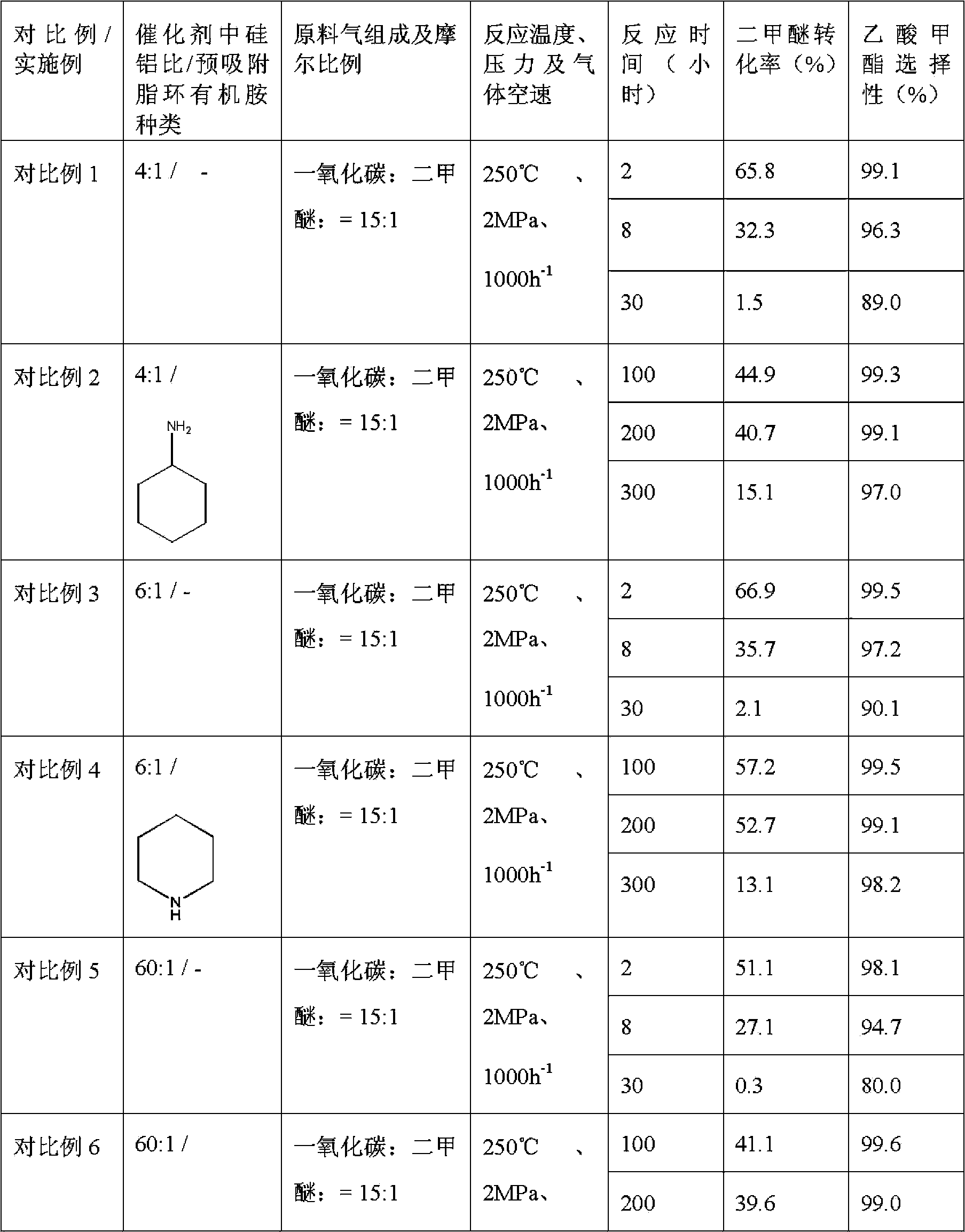

Method used for producing methyl acetate

ActiveCN103896766AStable compensation/inhibition of desorptionCompensate/inhibit desorptionPreparation by carbon monoxide or formate reactionMolecular sieveHydrogen

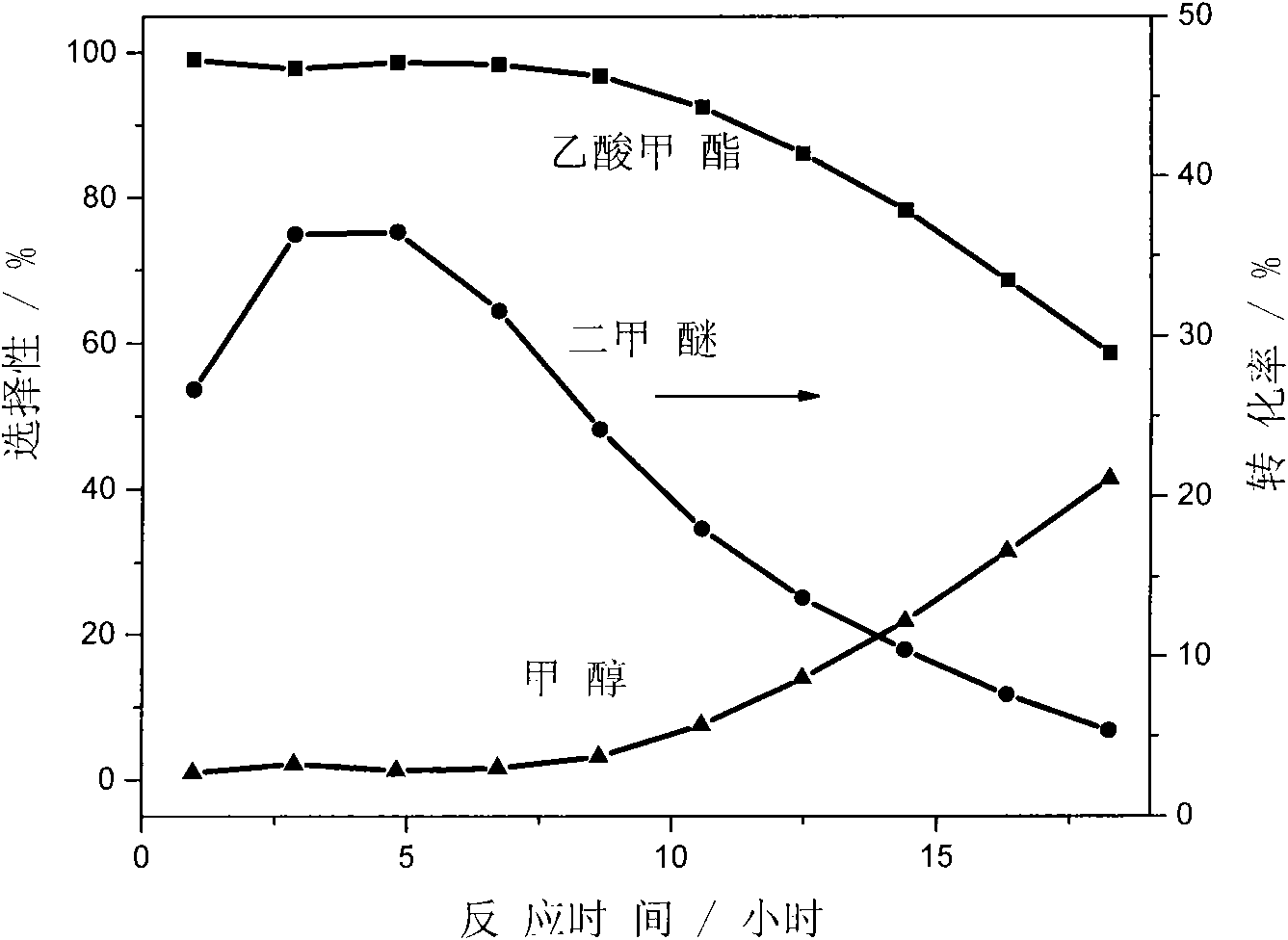

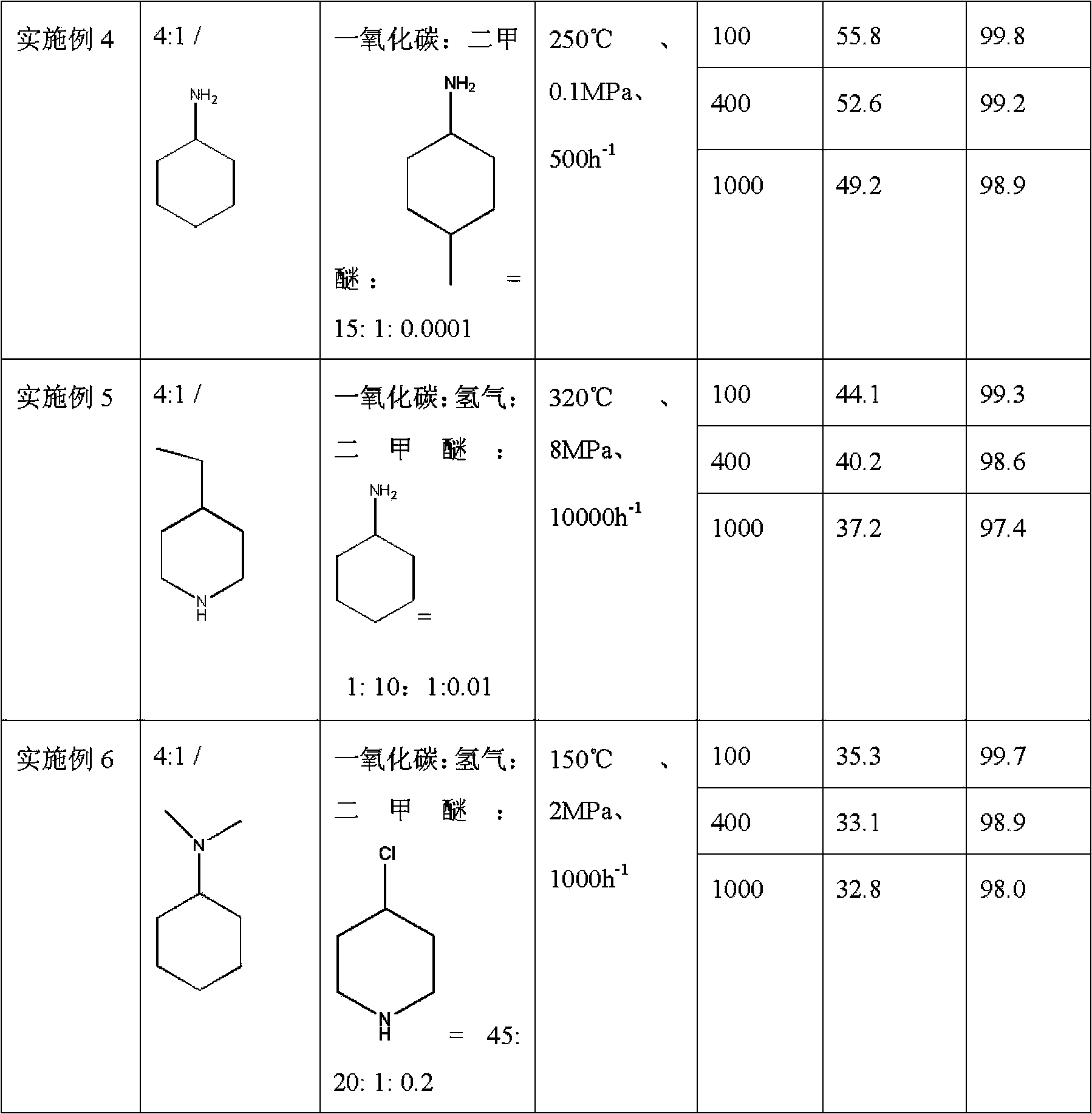

The invention provides a method used for producing methyl acetate. According to the method, raw material gas containing alicyclic organic amine, dimethyl ether, carbonic oxide, and optionally selected hydrogen passes through a reaction reactor filled with a hydrogen-type mordenite molecular sieve catalyst so as to prepare methyl acetate, wherein the hydrogen-type mordenite molecular sieve catalyst is alicyclic organic amine absorbed hydrogen-type mordenite molecular sieve catalyst. According to the method, alicyclic organic amine absorbed hydrogen-type mordenite molecular sieve is taken as the catalyst, and alicyclic organic amine is added into the raw material gas, so that desorption of alicyclic organic amine in reaction processes can be made up stably, stability of the catalyst is increased, and service life of the catalyst is prolonged.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

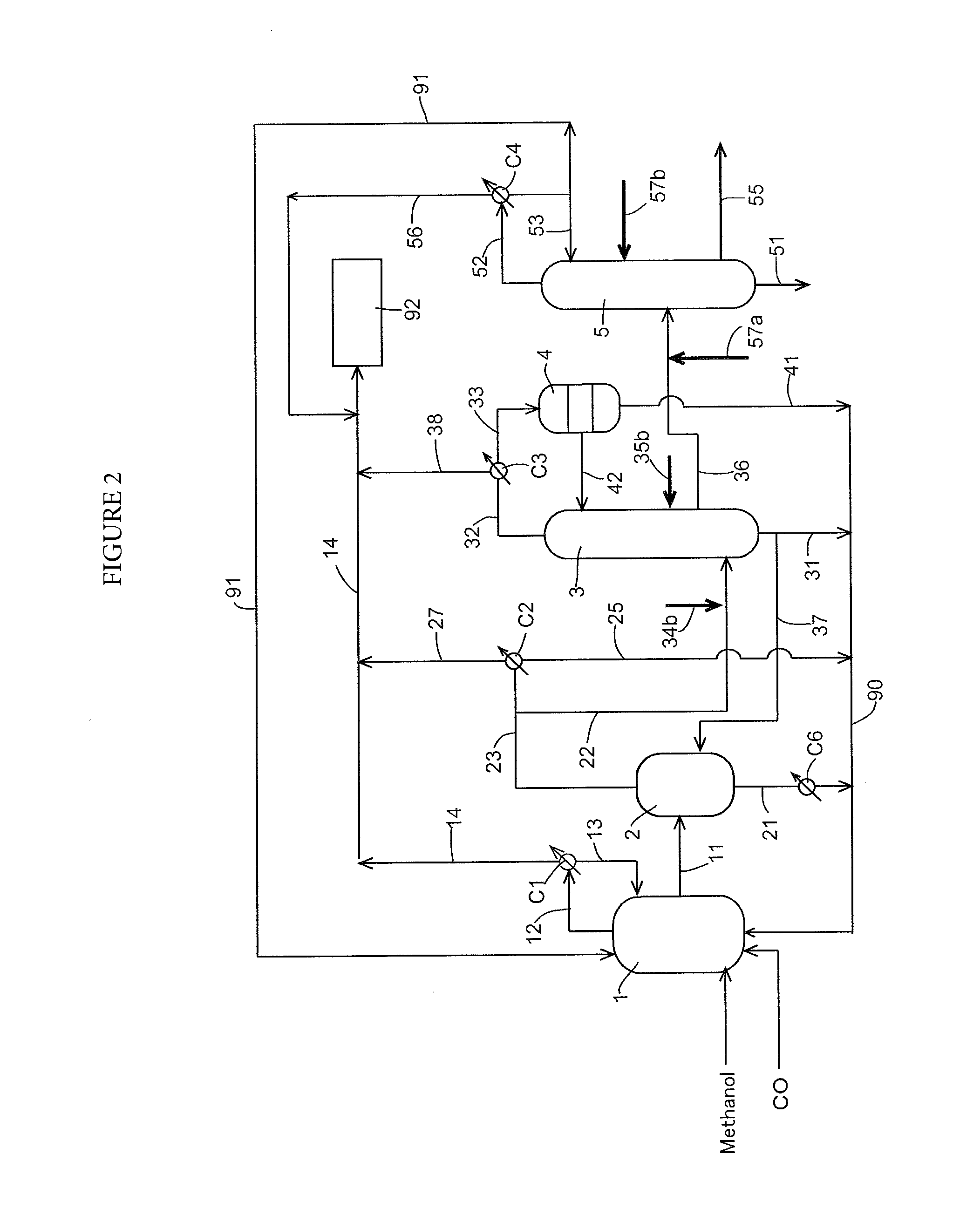

Process for producing acetic acid

ActiveUS20130261334A1Increase concentrationEfficient executionOrganic compound preparationOrganic chemistry methodsIodideDistillation

A process for producing acetic acid by: a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst, an ionic iodide, and methyl iodide in a carbonylation reactor, a flash distillation step for continuously feeding a flasher with a reaction mixture from the reactor and evaporating a volatile component at least containing product acetic acid, methyl acetate, and methyl iodide by flash distillation to separate the volatile component and a liquid catalyst mixture at least containing the metal catalyst and the ionic iodide, and an acetic acid collection step for separating a stream containing acetic acid from the volatile component to collect acetic acid; wherein, in the flash distillation step, the flash distillation is conducted under the condition that the concentration of methyl acetate in the liquid catalyst mixture is not less than 0.6% by weight.

Owner:DAICEL CHEM IND LTD

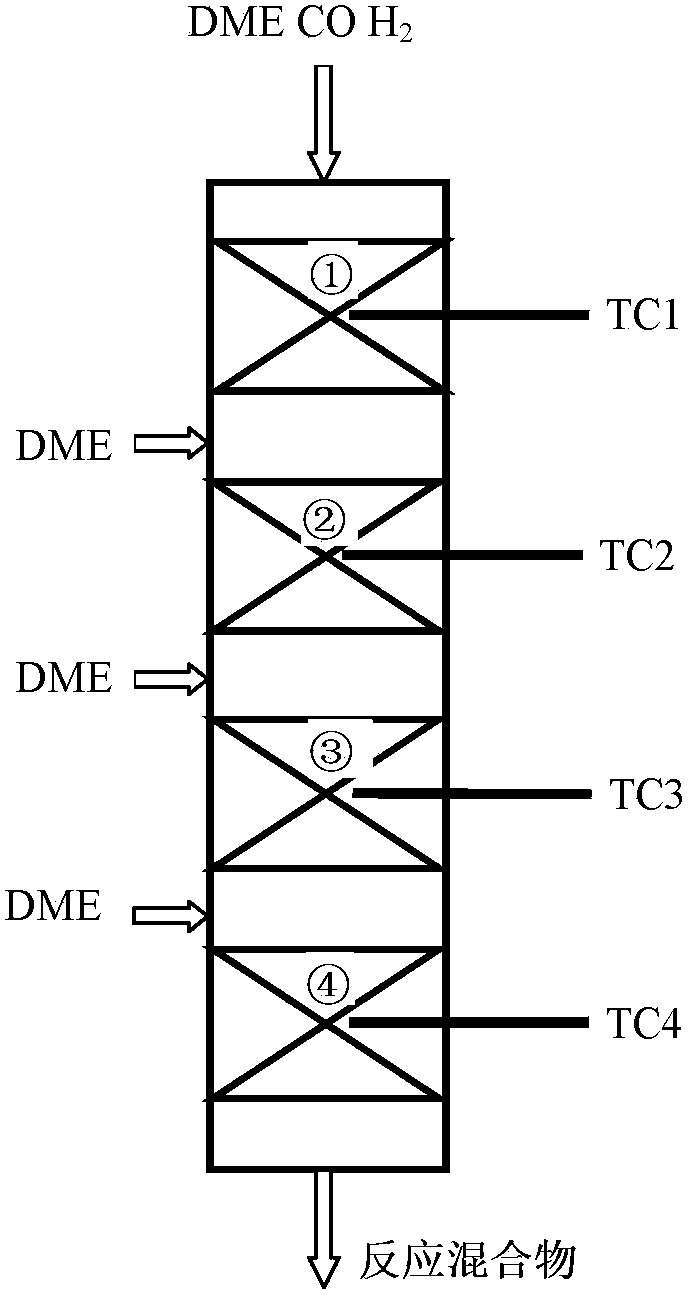

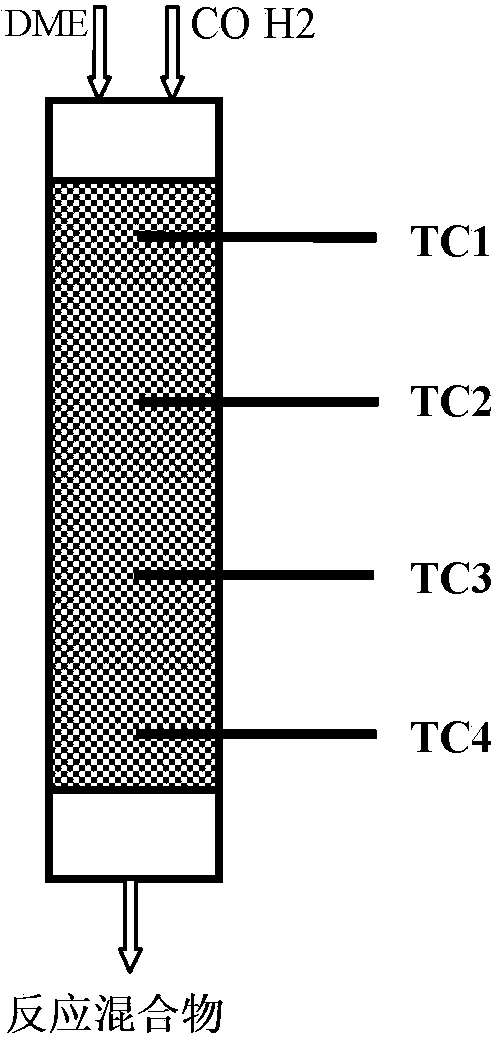

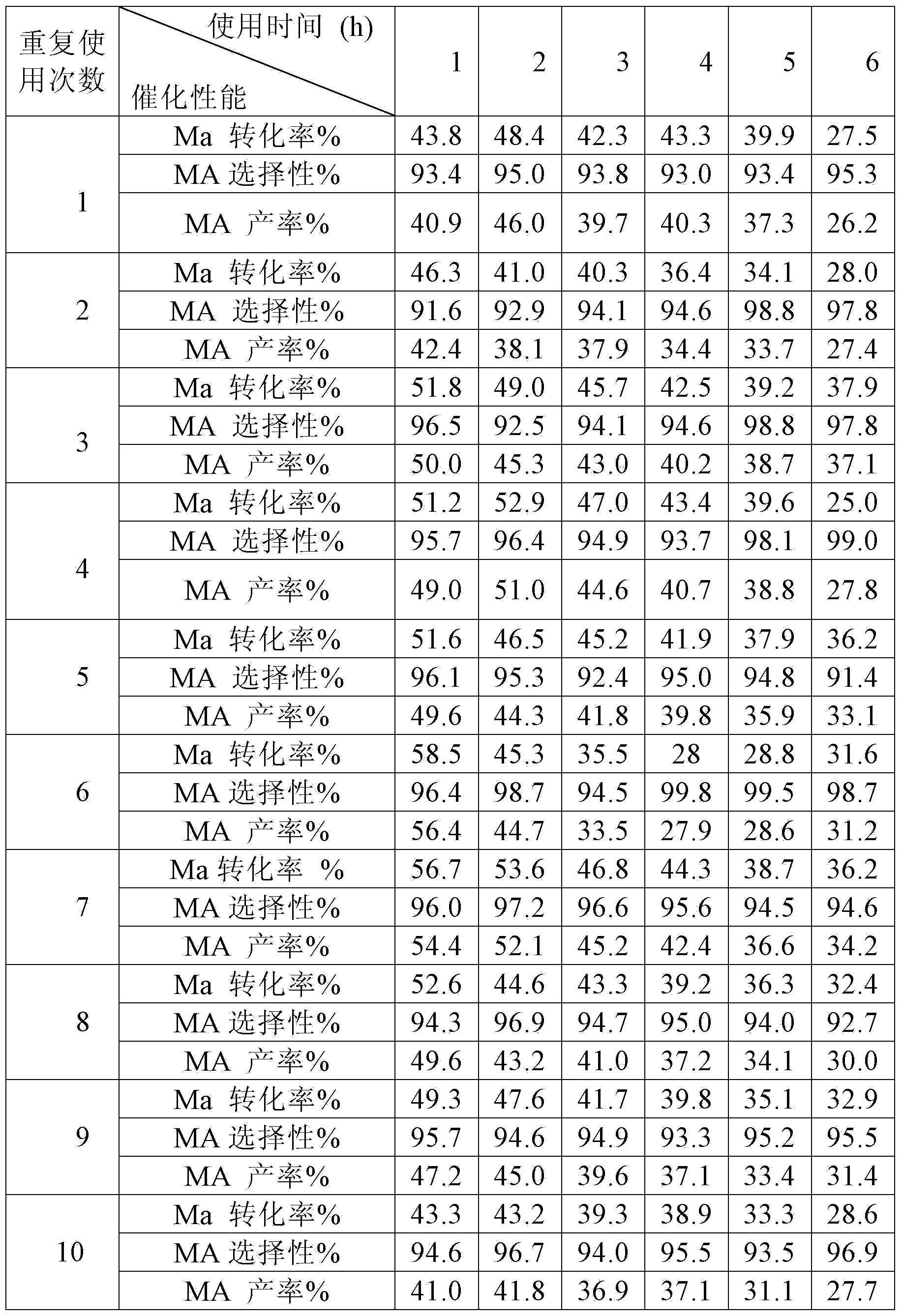

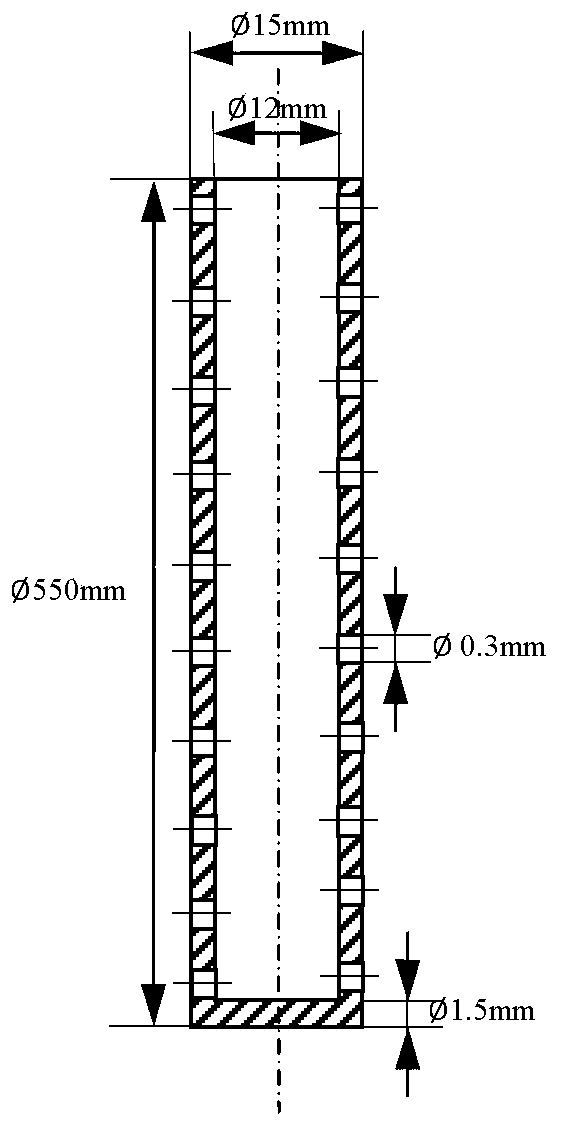

Method used for preparing methyl acetate

ActiveCN103896768AExtend your lifeControl temperature distributionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHydrogen

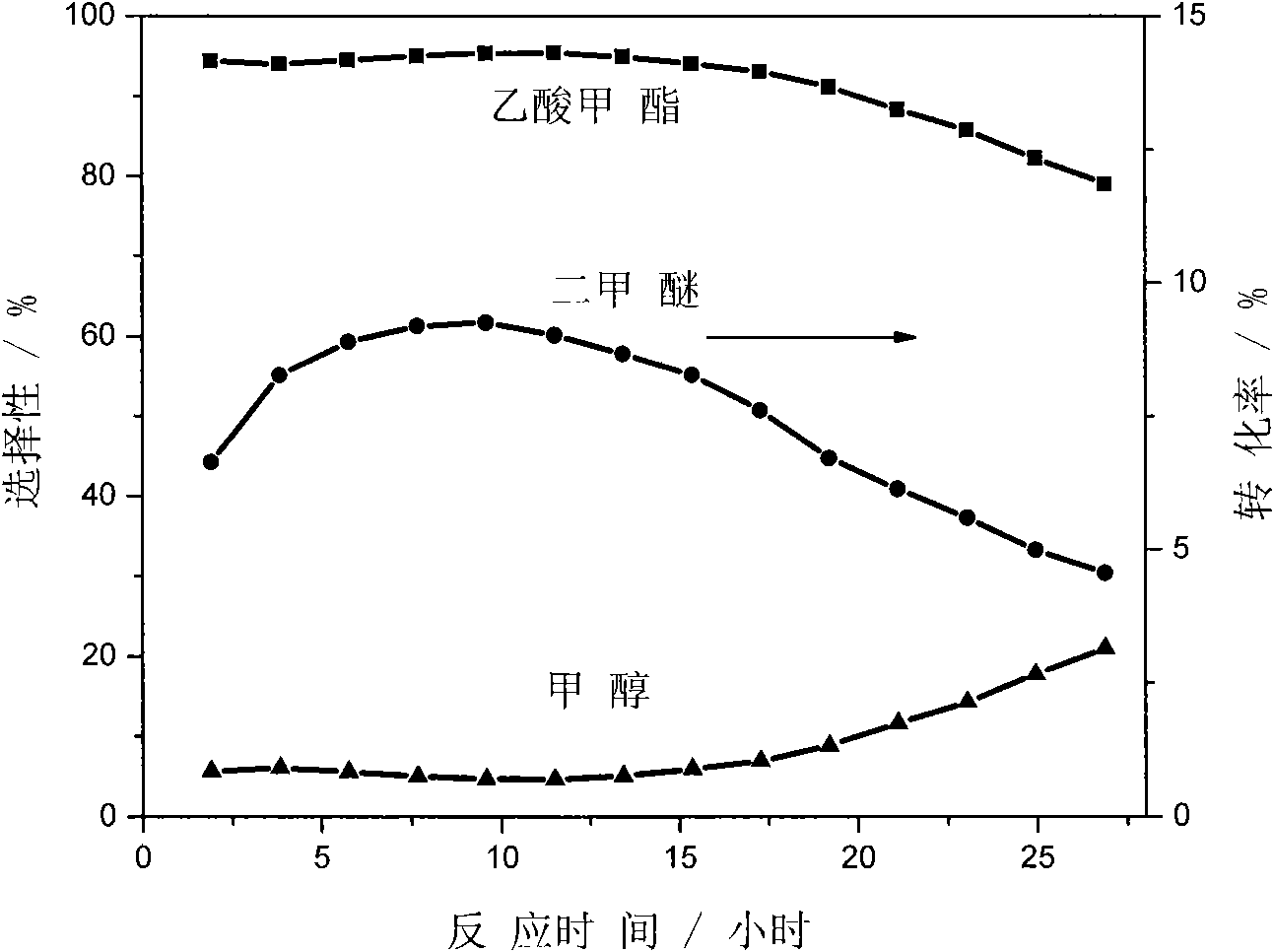

Provided in the present invention is a process for preparing methyl acetate through carbonylation of dimethyl ether, comprising: passing a feed gas containing dimethyl ether, carbon monoxide, and optional hydrogen gas through a reactor loaded with a mordenite molecular sieve catalyst, and preparing methyl acetate by reacting same at a reaction temperature of 19 to 320°C, a reaction pressure of 0.5 to 20.0 Mpa, and a gas volume space velocity of 500 to 5000 h-1; wherein the mordenite molecular sieve catalyst is a hydrogen-type mordenite molecular sieve catalyst with an adsorbed organic amine, the molar ratio of the dimethyl ether to carbon monoxide in the feed gas is DME / CO = 1 / 1 to 1 / 15, the molar ratio of the hydrogen gas to carbon monoxide is H2 / CO = 0 to 10 / 1, and the dimethyl ether in the feed gas is charged into the reactor by means of feeding in stages. The present invention is characterized in that: through treatment by organic amine adsorption, the temperature distribution of catalyst bed can be effectively controlled so as to avoid the occurrence of hot points, and thereby side reactions are reduced, the selectivity of target product is improved, and the lifetime of the catalyst is greatly extended.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

Cs-supported silica-based catalyst and preparation method and application thereof

InactiveCN103801280AImprove stabilityContinuous productionMolecular sieve catalystsOrganic compound preparationGas phaseMethyl acetate

The invention provides a Cs-supported silica-based catalyst. One of SBA-15, SiO2 or silicon dioxide prepared by a silica sol method is used as a carrier, the support is selected from one of Cs salt and a mixture of Cs and modified elements, the catalyst is prepared by a dipping method, the Cs content is 0.1wt%-10wt%, and the content of the modified elements is 0-2wt%. Meanwhile, the invention further provides a preparation method of the Cs-supported silica-based catalyst and application of the Cs-supported silica-based catalyst to the process of preparing methyl acrylate by catalyzing condensation reaction of methyl acetate and a methanal gas phase. The prepared catalyst is capable of realizing the aldol condensation of the methyl acetate and the methanal gas phase under proper conditions so as to prepare the methyl acrylate, wherein the activity of the Cs / SBA-15 catalyst is higher than that of other Cs-supported silica-based catalysts, and the selectivity on the methyl acrylate is good.

Owner:SHANGHAI HUAYI GRP CO

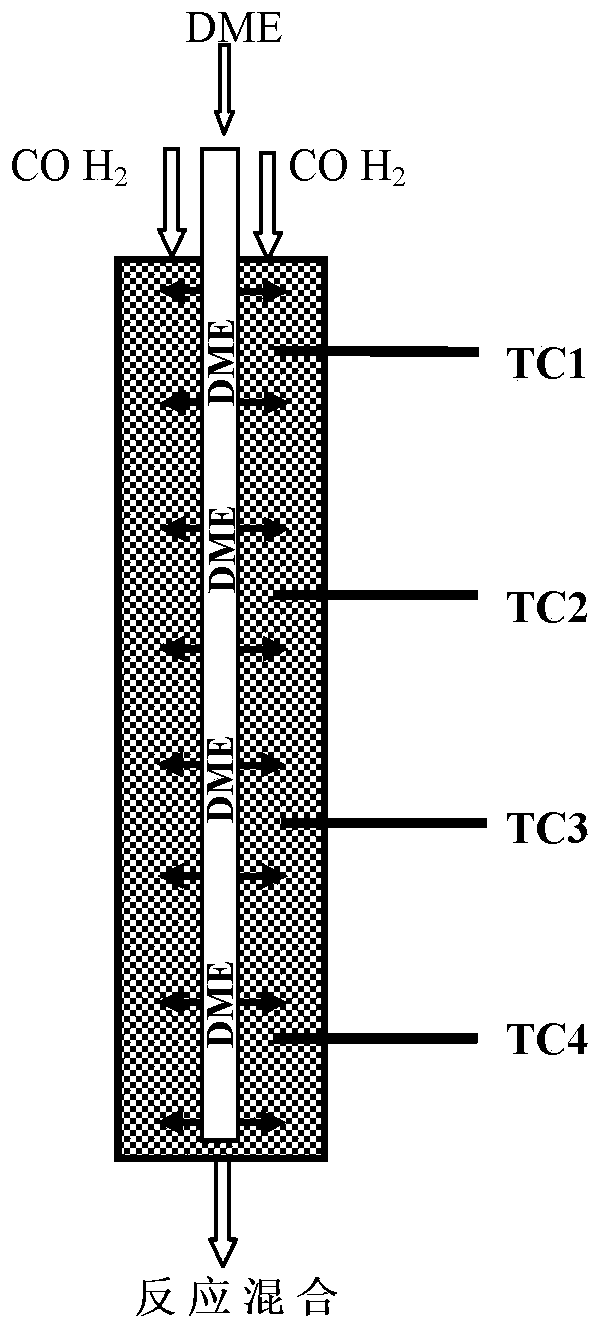

Method used for preparing methyl acetate via carbonylation of dimethyl ether

ActiveCN103896769AExtend your lifeControl temperature distributionPreparation by carbon monoxide or formate reactionHydrogenReaction temperature

Provided is a method for preparing methyl acetate by dimethyl ether carbonylation, comprising passing a feed gas including dimethyl ether, carbon monoxide and optional hydrogen through a reactor filled with a mordenite and / or ferrierite molecular sieve based catalyst and reacting at a reaction temperature of 190-320°C, a reaction pressure of 0.5-20.0 MPa and a gas space velocity of 500-5000 h-1 so as to prepare methyl acetate, wherein the molar ratio of dimethyl ether to carbon monoxide is DME / CO=1 / 1-1 / 15, the molar ratio of hydrogen to carbon monoxide is H2 / CO=0-10 / 1, and the feed gas is distributed into each catalyst bed layer in a segmental feeding manner. A feed gas including dimethyl ether and carbon monoxide is uniformly distributed into each catalyst bed layer via a gas distributor, in a segmental feeding manner, which can remarkably improve the conversion rate of dimethyl ether, effectively control or adjust the temperature distribution of a catalyst bed layer, avoid the appearance of a hot spot, and prolong the service life of a catalyst.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

Process for indirectly producing alcohol with synthetic gas and application of process

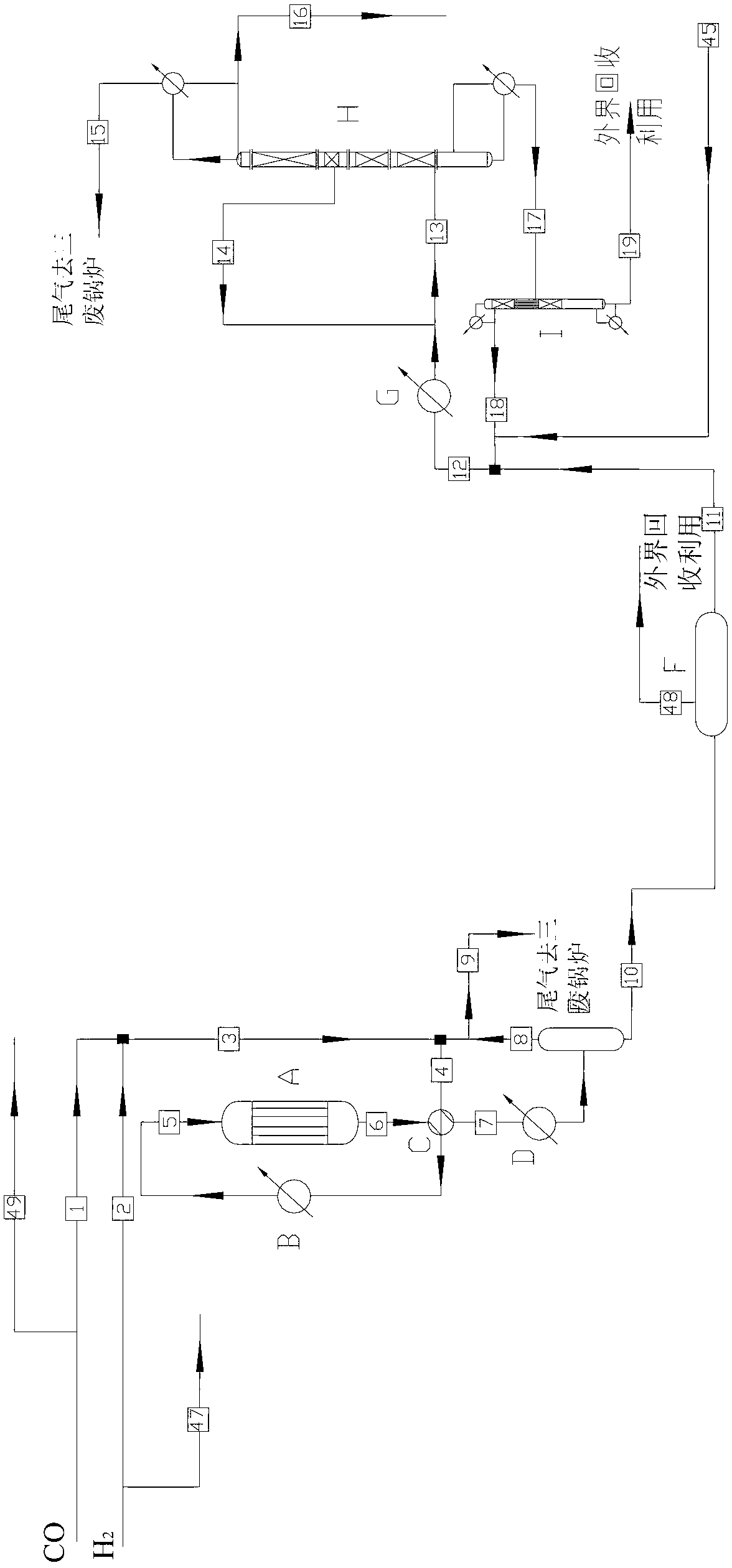

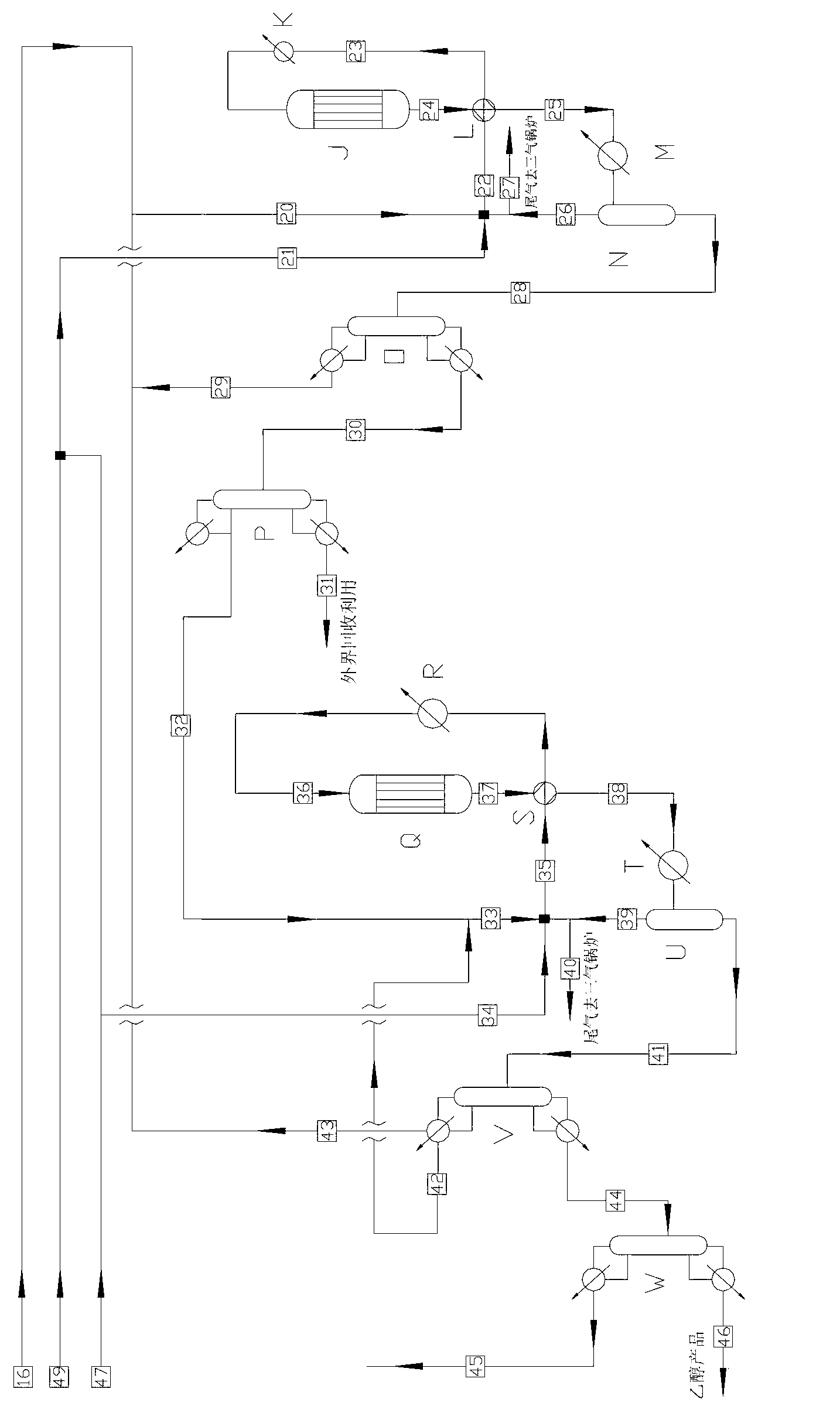

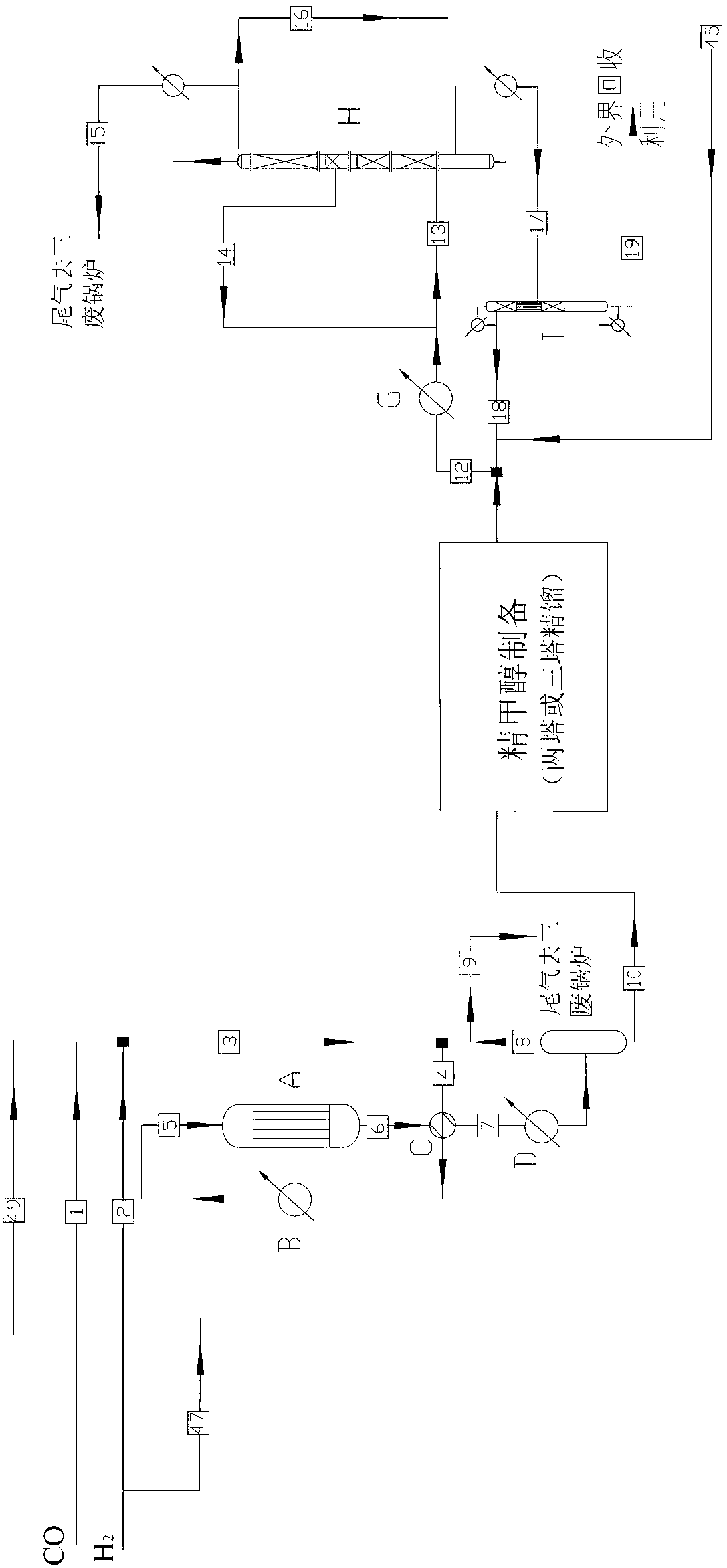

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

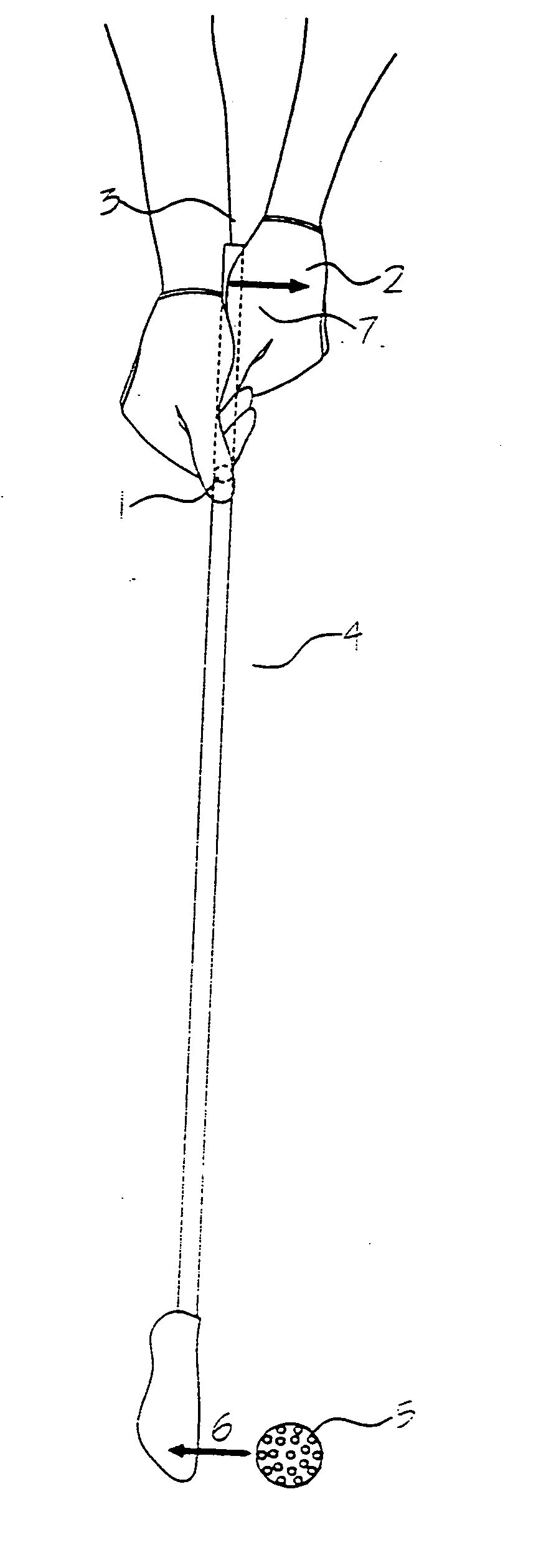

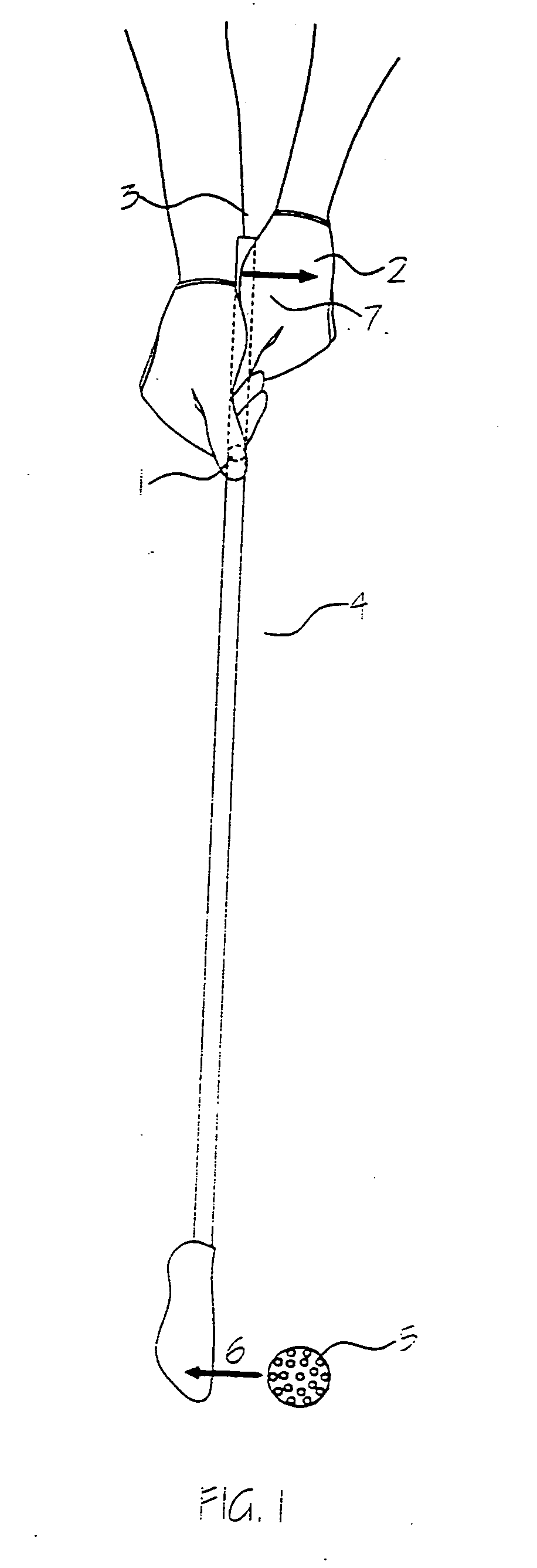

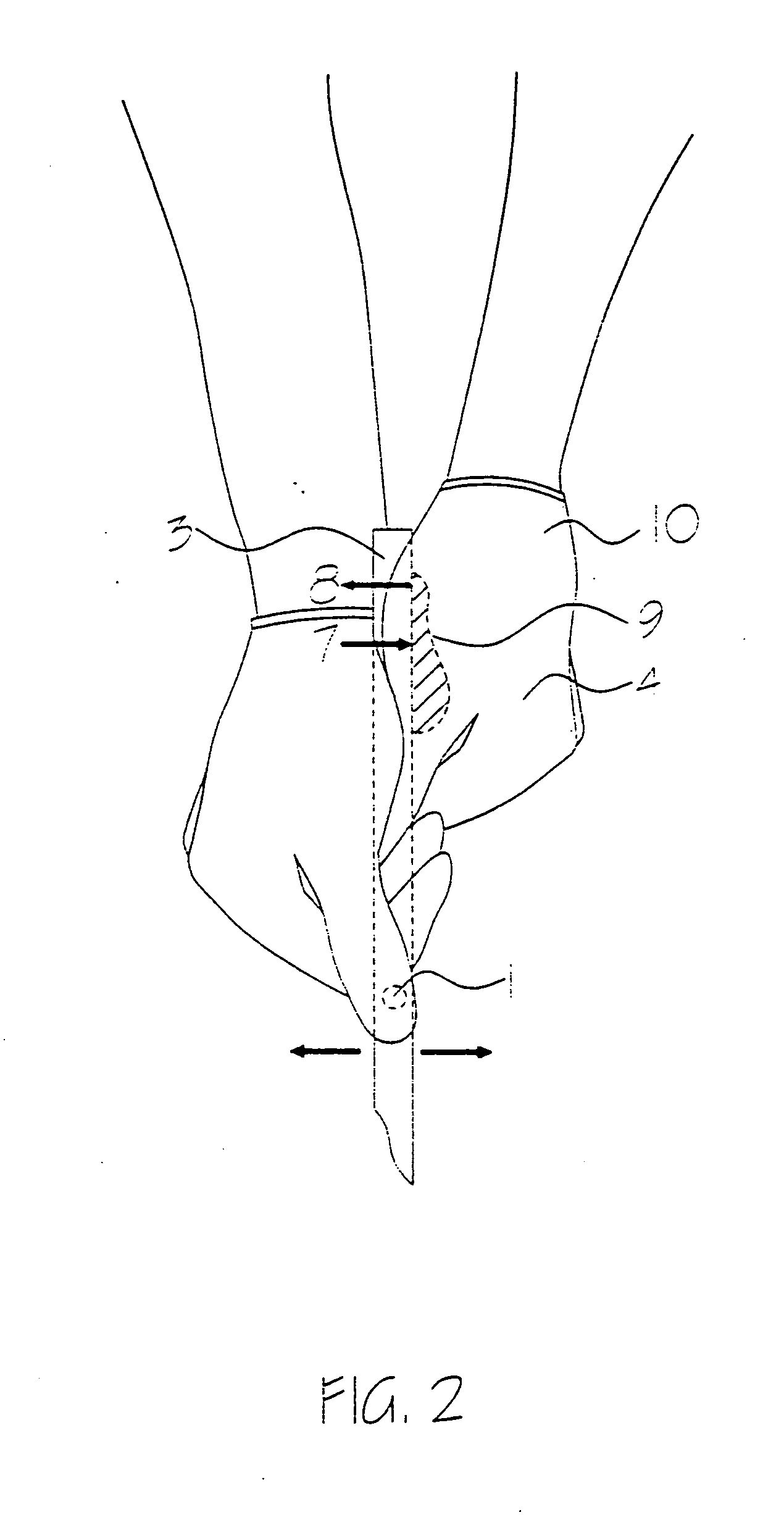

Golf glove with action/anti-action device

InactiveUS20050229285A1Flying distance can be improvedIncrease distanceGlovesSport apparatusElastomerRepulsion force

A golf glove for increasing the flying distance of golf ball has an insert that provide a repulsion forces to the grip of a golf club when the head of the club impacts a golf ball. The insert is made of synthetic elastomer such as polyurethane, silicon rubber, EVA (Ethylene Vinyl Acetate copolymer, EMA (Ethylene Methyl Acetate copolymer), or EAA (Ethylene Acrylic Acetate copolymer). The insert has a planar shape that fits to the concave inner surface of human palm. The insert is firmly attached to the inner surface of the palm side of a golf glove.

Owner:CHUNG PAUL HOON

Distillation process

ActiveUS7884241B2Avoid condensationAvoid corrosionOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateDistillation method

A mixture containing hydrogen iodide and water and having a water content of not more than 5% by weight (particularly not more than 3% by weight) in a distillation system is distilled to prevent condensation of hydrogen iodide in the distillation system. The mixture may comprise hydrogen iodide, water, methanol, methyl iodide, acetic acid, and methyl acetate. Even when the mixture contains hydrogen iodide at a concentration of 1 to 3000 ppm on the basis of weight, an acetic acid product having a concentration of hydrogen iodide of not more than 50 ppm can be obtained by withdrawing a fraction containing hydrogen iodide from the top of the column, and withdrawing acetic acid as a side-cut stream or a stream from the bottom of the column. Such a process (distillation process) effectively inhibits condensation of hydrogen iodide in the distillation system and corrosion in the distillation system.

Owner:DAICEL CHEM IND LTD

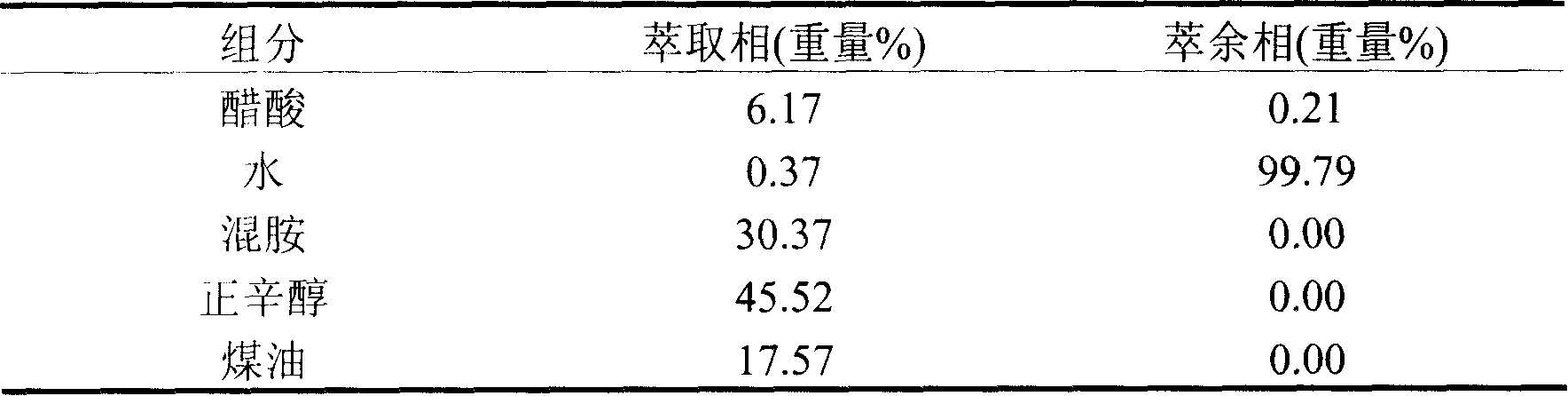

Method for recycling acetic acid in dilute acetic acid

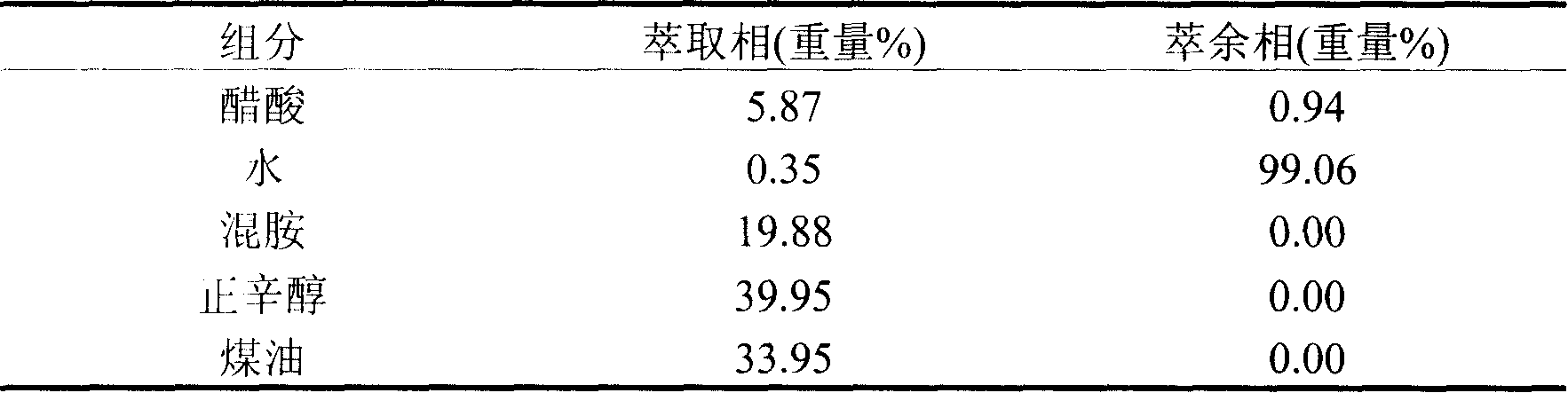

ActiveCN101172941AImprove separation efficiencyIncreased acetic acid contentLiquid solutions solvent extractionCarboxylic compound separation/purificationBenzeneButyl acetate

The invention relates to a method for recycling acetic acid from diluted acetic acid, and aims at solving the problem that the recycling of acetic acid in the hydrolysis of furfural and methyl acetate as well as the Fischer-Tropsch combined production is difficult. The invention comprises the steps as follows: a) diluted acetic acid is extracted by a pulse filling extracting tower, the extractionphase containing extracting agent, the acetic acid and little water for the tower top is acquired, and the residual extraction phase of water containing micro acetic acid from the tower kettle is acquired; b) the extraction phase in an extracting agent recycling tower is conveyed; c) acetic acid 1 is fed into an azeotropic rectifying tower which utilizes one kind of benzene, cyclohexane, ethyl acetate, isopropyl acetate and butyl acetate as the extrainer, two-phase mixture of the extrainer and the water at a phase separator at the top of the tower is acquired, the water is extracted out from the tower top, and the retrainer returns into the tower. The utility model has the technical proposal of producing pure acetic acid at the tower top, solves the problems above, and adapts the industrial productions including recycling of acetic acid from wasted aldehyde water and extracting and refining acetic acid in the methyl acetate hydrolysis technique.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Preparation of acetic acid

InactiveUS20100063319A1Eliminate useOrganic compound preparationCarboxylic preparation from carbon monoxide reactionFractionating columnMethyl acetate

A process for producing acetic acid is disclosed. The process comprises carbonylating methanol to form a reaction mixture comprising a catalyst, catalyst stabilizer, acetic acid, methanol, methyl iodide, methyl acetate, water, and carbon monoxide and introducing at least a portion of the reaction mixture to a distillation column to separate into a bottom steam comprising the catalyst and catalyst stabilizer, a sidedraw stream comprising acetic acid and water, and an overhead stream comprising methanol, methyl acetate, methyl iodide, and water. The process of the invention eliminates the use of flash tank.

Owner:LYONDELLBASELL ACETYLS

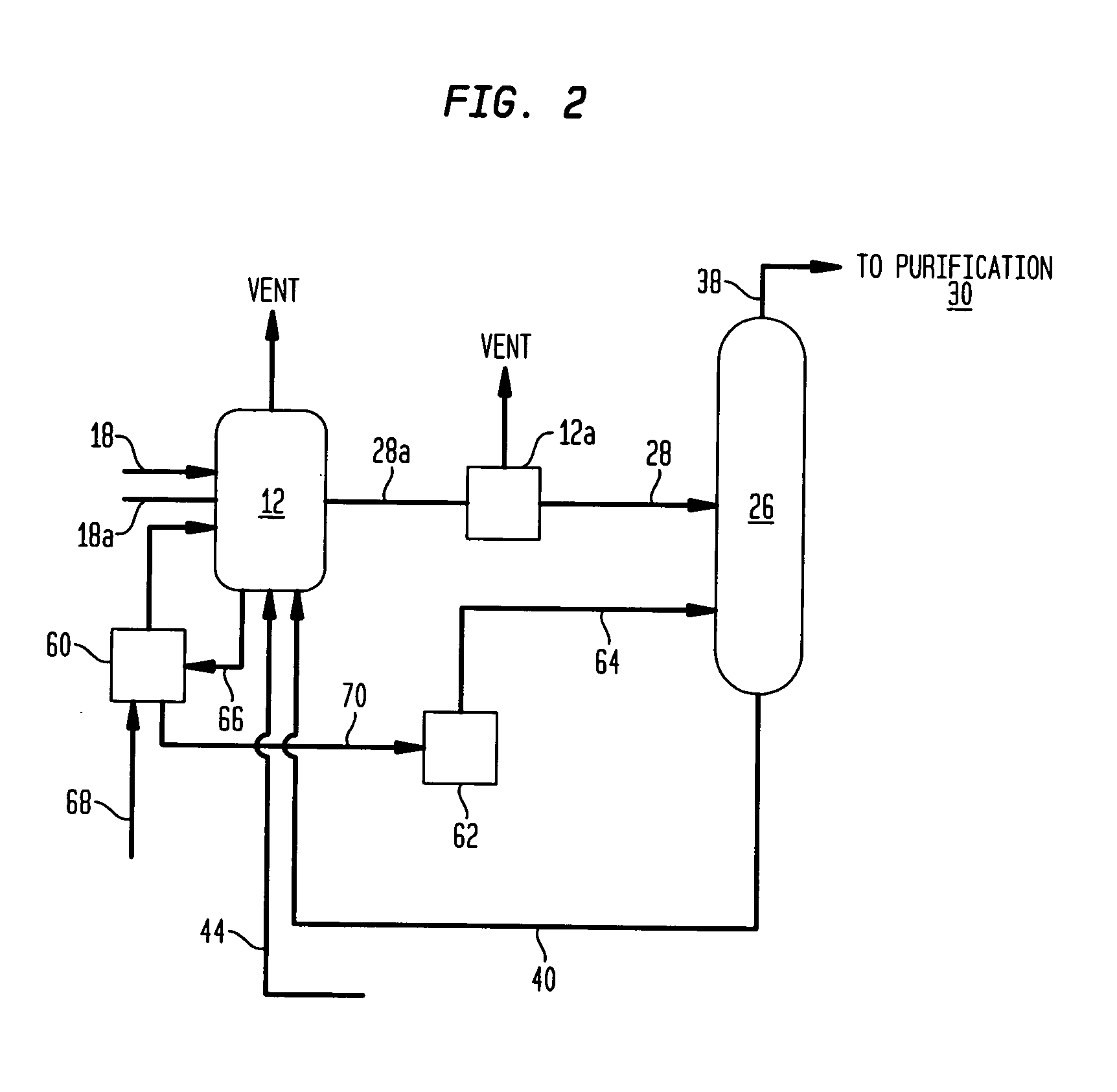

Method and apparatus for carbonylating methanol with acetic acid enriched flash stream

ActiveUS20090270650A1Improve concentrationShorten the purification processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMetal catalystMethyl acetate

A carbonylation process for producing acetic acid including: (a) carbonylating methanol or its reactive derivatives in the presence of a Group VIII metal catalyst and methyl iodide promoter to produce a liquid reaction mixture including acetic acid, water, methyl acetate and methyl iodide; (b) feeding the liquid reaction mixture at a feed temperature to a flash vessel which is maintained at a reduced pressure; (c) heating the flash vessel while concurrently flashing the reaction mixture to produce a crude product vapor stream, wherein the reaction mixture is selected and the flow rate of the reaction mixture fed to the flash vessel as well as the amount of heat supplied to the flash vessel is controlled such that the temperature of the crude product vapor stream is maintained at a temperature less than 90° F. cooler than the feed temperature of the liquid reaction mixture to the flasher and the concentration of acetic acid in the crude product vapor stream is greater than 70% by weight of the crude product vapor stream.

Owner:CELANESE INT CORP

Method for separating methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification

InactiveCN102180791AIncrease relative volatilityNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationMethyl acetateMass content

The invention discloses a method for separating a methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification, which is realized in a way that: a rectifier of an extractive rectification tower is adopted, an ionic liquid 1-ethyl-3-methyl imidazolyl acetate is used as an extractant, and the operation is carried out intermittently, so the top of the extractive rectification tower sequentially produces a methyl acetate product of which the mass content is up to 98-99.9%, a methyl acetate-methanol transitional fraction and methanol of which the mass content is 97-99%; and finally, the extractant of which the mass percent is 99% is left in the heating kettle. The invention has the following advantages: the extractant is adopted to enhance the relative volatility of the methyl acetate-methanol system, the purity of the separated methyl acetate product is high, and the ionic liquid used as the extractant is easy to recover and does not pollute the environment; and only one single tower needs to be operated, so that operation is flexible and the equipment investment is low.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com