Patents

Literature

103 results about "Dimethyl sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl sulfite is a sulfite ester with the chemical formula (CH₃O)₂SO. Dimethyl sulfite is used as an additive in some polymers to prevent oxidation. It is also a potentially useful high energy battery electrolyte solvent.

Modified chlorinated polypropylene adhesive

InactiveCN1715352AHigh grafting rateReduce the degree of degradationAdhesivesPolymer scienceAdhesive

The modified chlorinated polypropylene adhesive consists of chlorinated polypropylene 100 weight portions, glycidol acrylate 0.05-0.2 weight portions, additive 0.05-0.4 weight portions, initiator 0.1-0.5 weight portions, and tackifier 5-15 weight portions. The chlorinated polypropylene has chlorine content of 25-45 wt%; the additive is styrene, dimethyl acetamide or dimethyl sulfoxide; the initiator is bibenzoyl peroxide or diisopropyl benzene peroxide; and the tackifier is petroleum resin, rosin ester or terpene. The adhesive is ropy, and may be painted or extruded into film of 0.1-0.5 mm thickness when used. It has excellent adhering performance on metal, non-polar polymer, etc. and may be used widely.

Owner:HUBEI UNIV

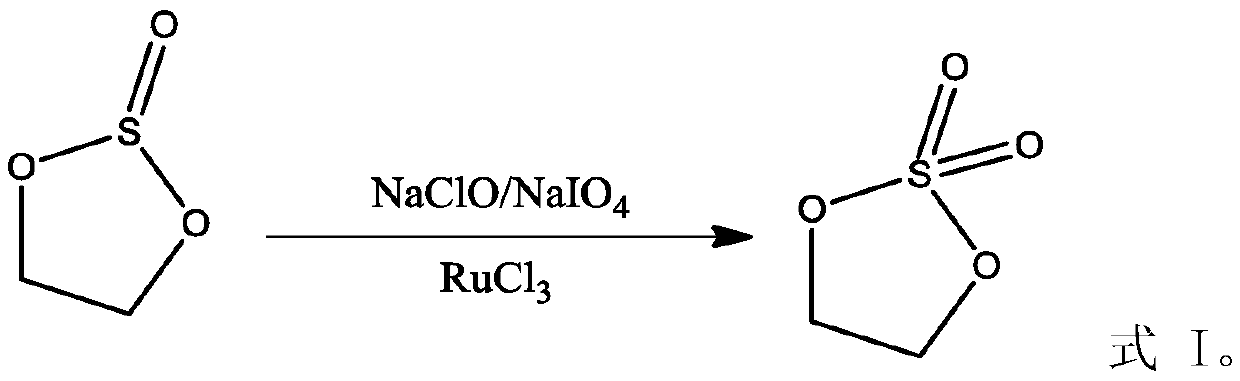

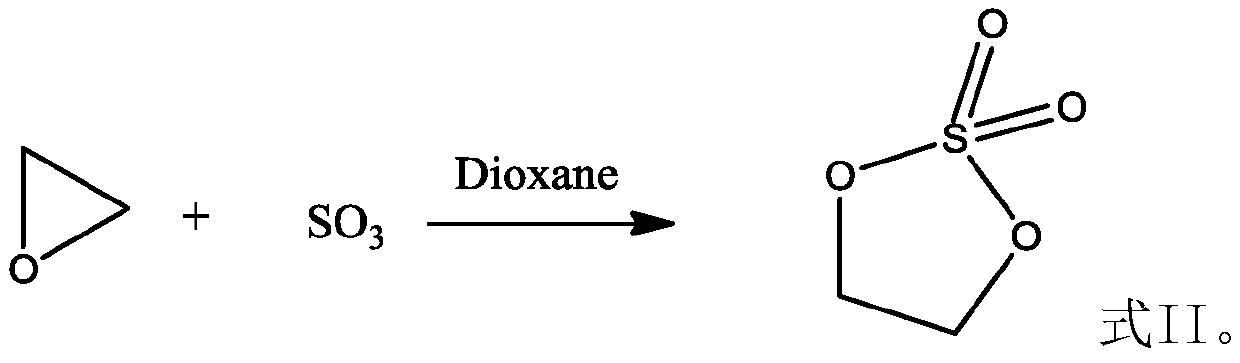

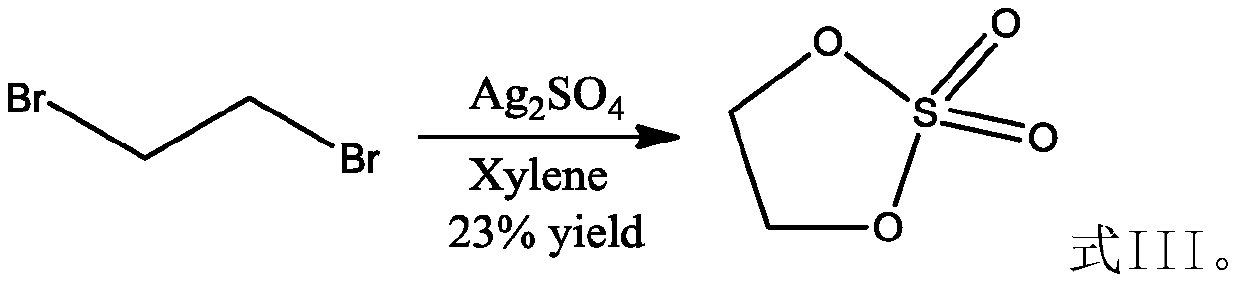

Preparation method of ethylene sulfate

The invention discloses a preparation method of ethylene sulfate. The method comprises the following steps: firstly, ethylene glycol and thionyl chloride are used as raw materials to synthesize ethylene sulfite, the ethylene sulfite and air or oxygen are subjected to a direct oxidation reaction under the action of a catalyst to form ethylene sulfate, filtration is performed, washing is performed by using water, concentration is performed, crystallization is performed, and therefore the finished-product ethylene sulfate is obtained. The method provided by the invention adopts the novel catalystand uses the air or the oxygen as an oxidant, thereby effectively reducing use costs of the catalyst and the oxidant; and the method has less waste water, thereby being more in line with concepts ofenergy saving, greenness and environmental protection.

Owner:福建博鸿新能源科技有限公司

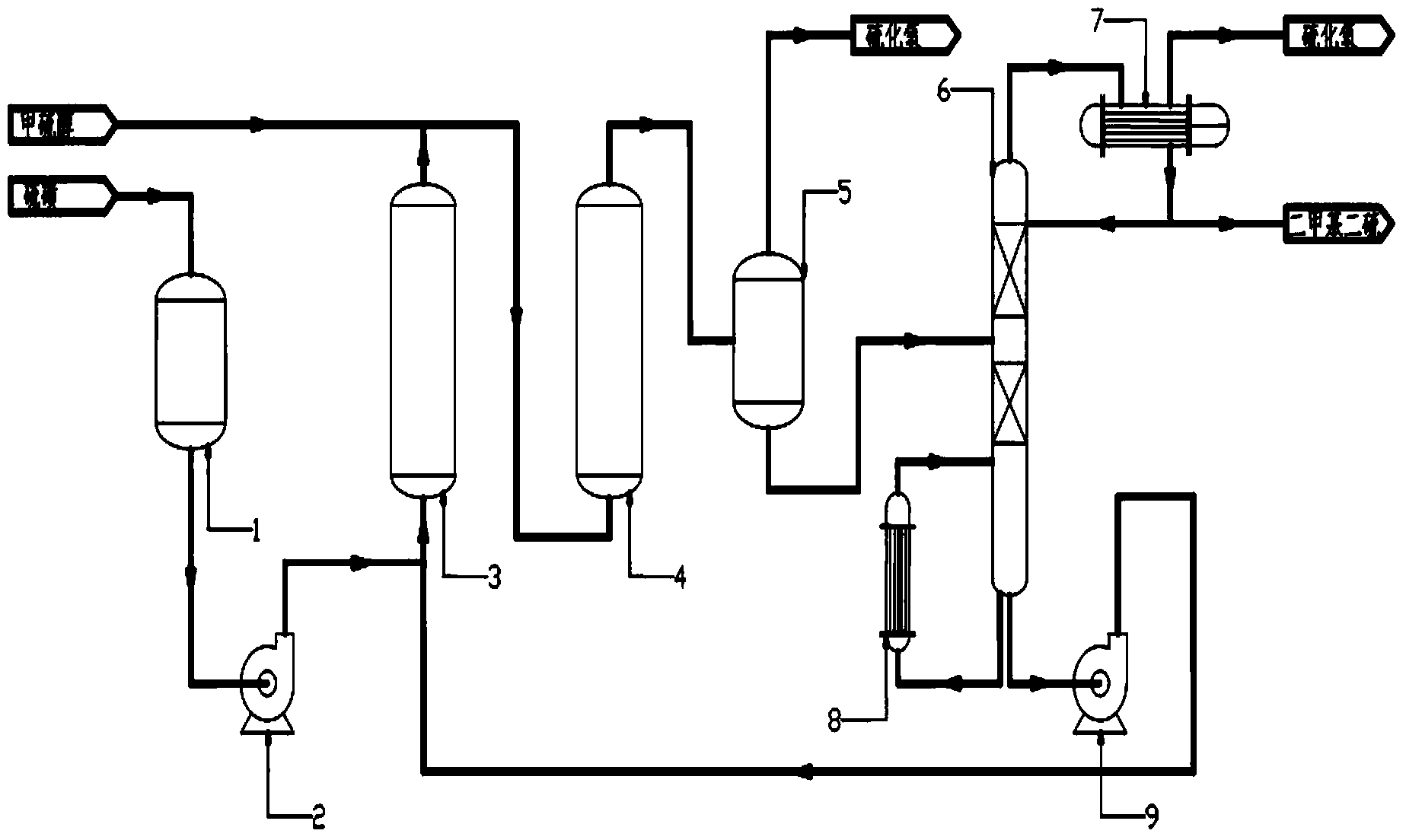

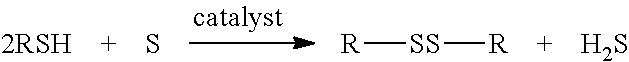

Method for continuously producing dimethyl disulfide

ActiveCN103864650ASolve recycling difficultiesGuaranteed conversionOrganic compound preparationHydropoly/poly sulfide preparationDiallyl disulfideMethyl disulfide

The invention discloses a method for continuously producing dimethyl disulfide. The method is characterized in that after being molten, a material sulfur is fed into a dimethyl trisulfide reactor by virtue of a feeding pump so as to react with recycled dimethyl disulfide to generate dimethyl trisulfide; dimethyl trisulfide and methyl mercaptan are feed into a dimethyl disulfide reactor so as to react to generate dimethyl disulfide; a dimethyl disulfide crude product is fed into a separating tank, so that most of hydrogen sulfide is separated out, a liquid-phase product is fed into a rectifying tower, a dimethyl disulfide product is condensed and recycled at a tower top, hydrogen sulfide is exhausted as a non-condensable gas, and the dimethyl disulfide and dimethyl trisulfide in a tower kettle are returned and recycled. A method of enabling dimethyl trisulfide to be excessive is adopted, so that methyl mercaptan is completely converted, separating requirements are lowered and a separating process is simplified, and therefore, not only can the dimethyl disulfide yield be improved to 90%, but also the product purity is up to 99wt%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Preparation method of polyether diol

ActiveCN103193972AMaintain stabilityLow temperature stabilityCosmetic preparationsTransportation and packagingMethyl carbonateKetone

The invention relates to a preparation method of a polyether diol. The polyether diol has a structure shown in the formula 1. The preparation method can design products having different molecular weights according to demands. The preparation method comprises the following steps that trimethylolpropane and an aldehyde or a ketone undergo an aldolization (ketalation) reaction to produce a compound (3); ethylene oxide is polymerized into a polyether monoalcohol in the presence of the compound (3) as an initiator; the polyether monoalcohol and dimethyl sulfate or dimethyl carbonate or a haloalkane undergo a Williamson reaction to produce a methyl-terminated polyether product; and the methyl-terminated polyether product undergoes a ring-opening reaction to produce polyether diol. The preparation method has the advantages of simple processes, high efficiency, low raw material cost, wide raw material sources and good industrialization prospect.

Owner:WANHUA CHEM GRP CO LTD +1

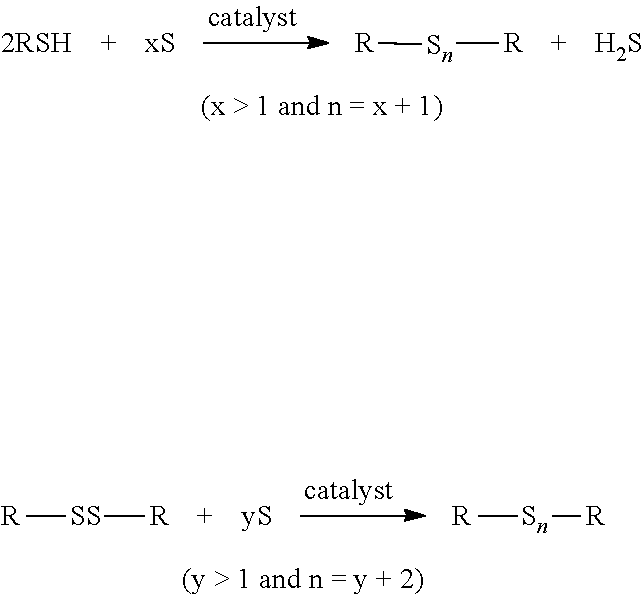

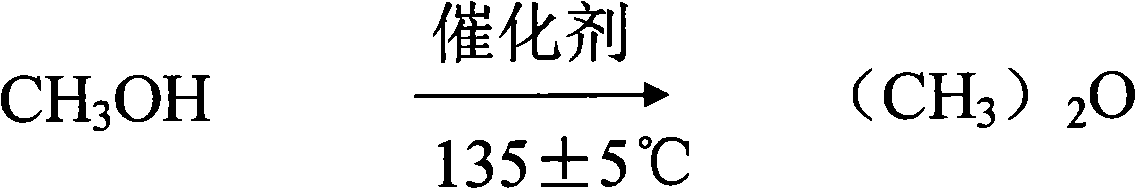

Method for converting dimethyl sulfate waste residue into dimethyl sulfate product

InactiveCN102249953AZero emissionEliminate pollutionSulfur compoundsSulfonic acid esters preparationDistillationSulfate

The invention discloses a method for converting dimethyl sulfate waste residue into a dimethyl sulfate product, belongs to a method for preparing sulfate, and in particular relates to a method for recycling waste residue generated by a dimethyl sulfate device in the production running process. The method is characterized by comprising the following steps of: hydrolyzing and etherifying dimethyl sulfate in the dimethyl sulfate waste residue to convert the dimethyl sulfate into dimethyl ether; and performing esterification on the generated dimethyl ether and sulfur trioxide to obtain the dimethyl sulfate product. The method comprises the following process steps of: hydrolysis, etherification, separation of distillates, esterification, and distillation. The invention provides a method for converting the dimethyl sulfate waste residue into the dimethyl sulfate product; and the dimethyl ether is recycled from the dimethyl sulfate waste residue and is further converted into the dimethyl sulfate product. The waste residue generated by the dimethyl sulfate device is recycled, and the environmental pollution of the dimethyl sulfate waste residue is eliminated. The purity of the recycled dimethyl ether gas is 99.0 to 99.75 percent; the dimethyl sulfate product has the dimethyl sulfate content of more than or equal to 99.5 percent and the acidity of less than or equal to 0.6 percent; and the content of a byproduct of sulfuric acid is 50 to 70 percent.

Owner:SHANDONG XINGHUI CHEM

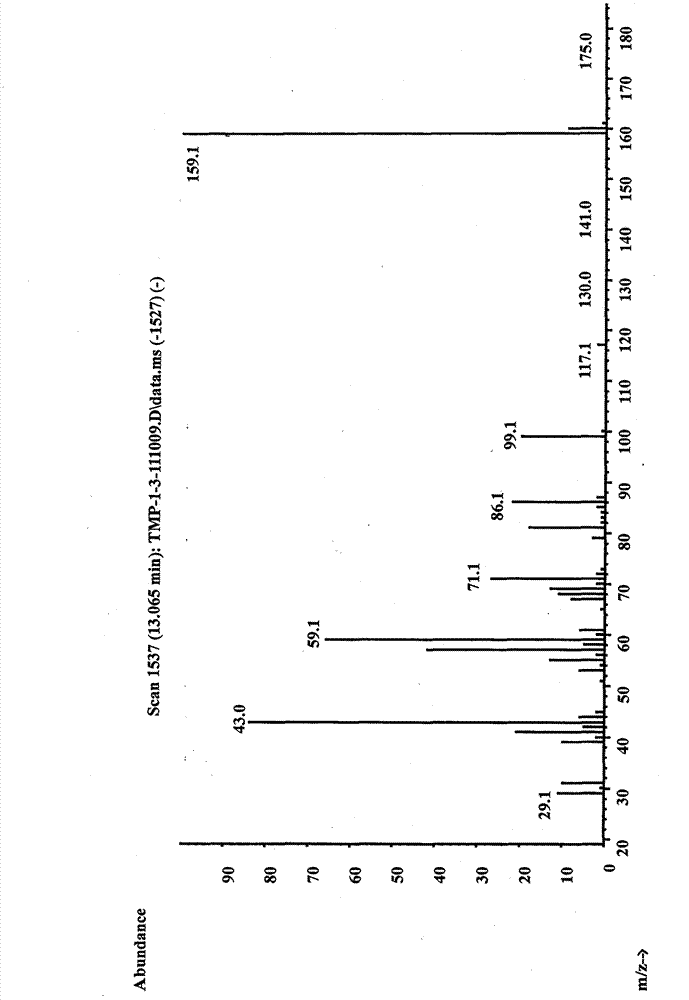

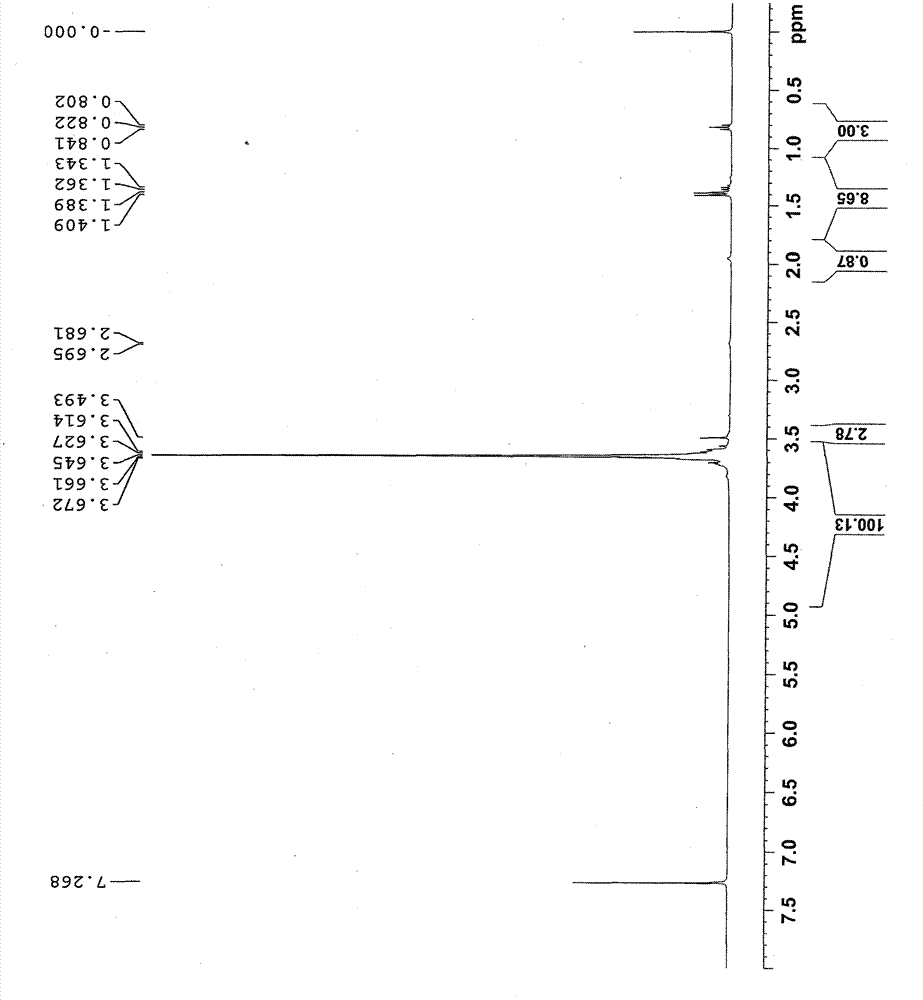

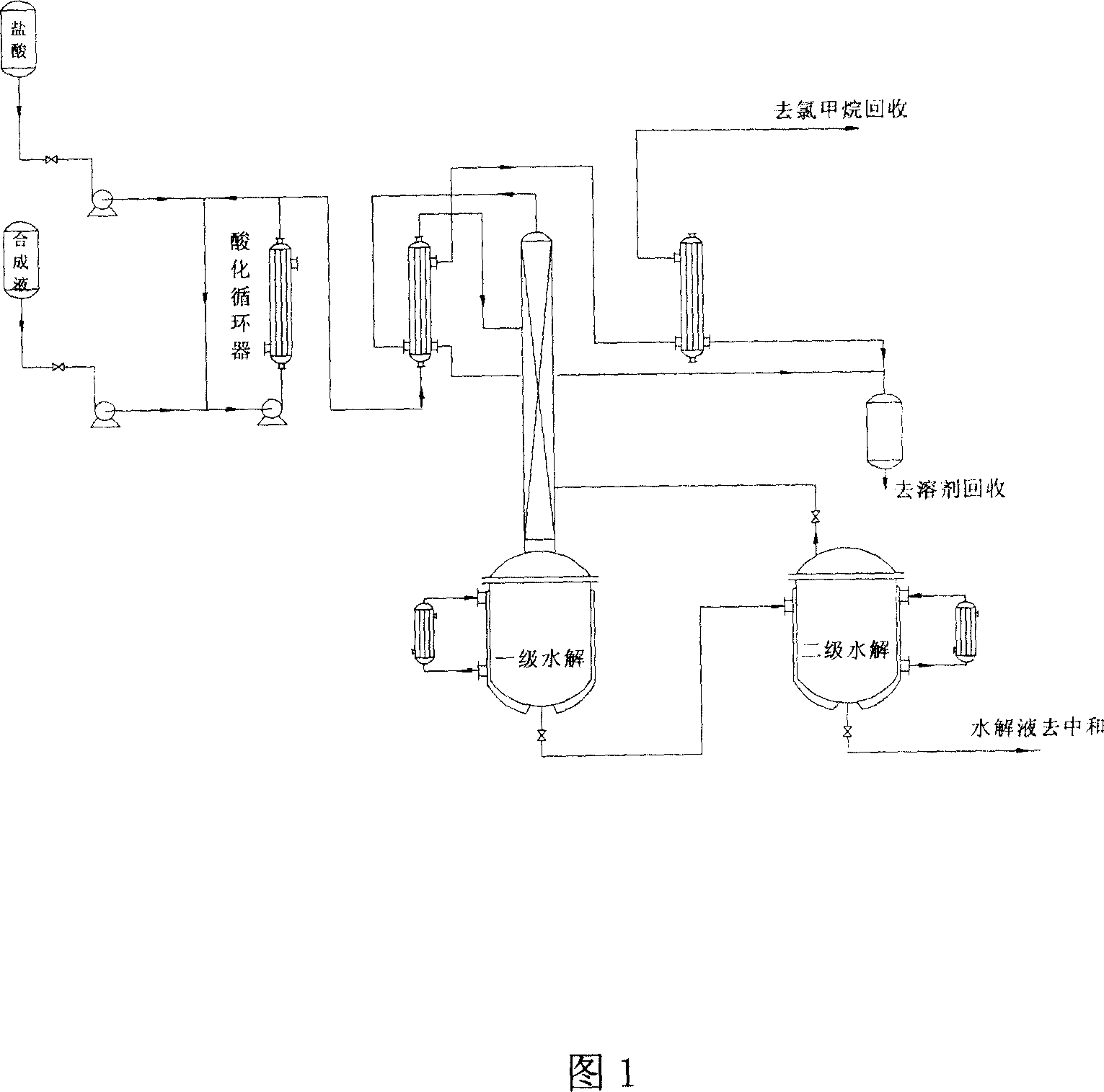

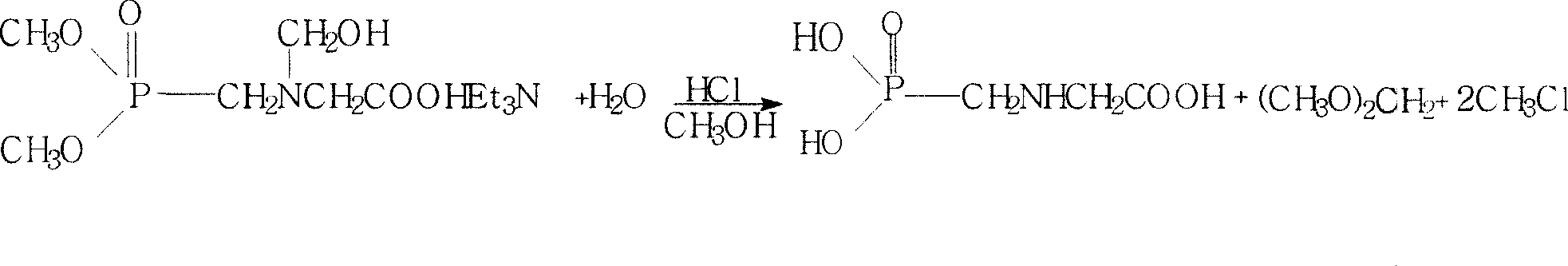

Continuous synthesis of glyphosate by dimethyl ester

Continuous synthesis of glyphosate by dimethyl ester is carried out by taking paraformaldehyde, amino acetic acid and dimethyl ester as raw materials to obtain synthetic liquid, acidizing it with hydrochloric acid, mixing, entering into hydrolytic reactive zone, reacting in hydrolytic reactor continuously, acidizing synthetic liquid, hydrolyzing in hydrolytic reactive zone continuously, forming into glyphosate salt, batching continuously and neutralization crystallizing to obtain the final product. It realizes continuous hydrolysis and simplifies process and can be used in large-scale production.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

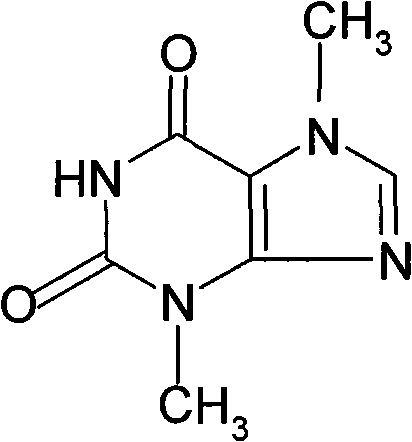

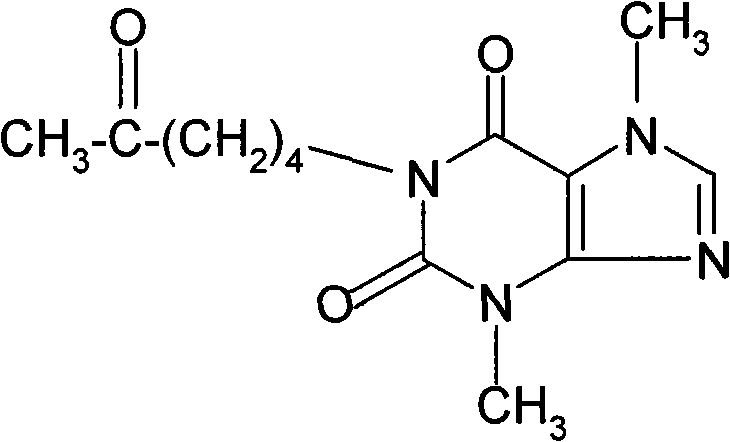

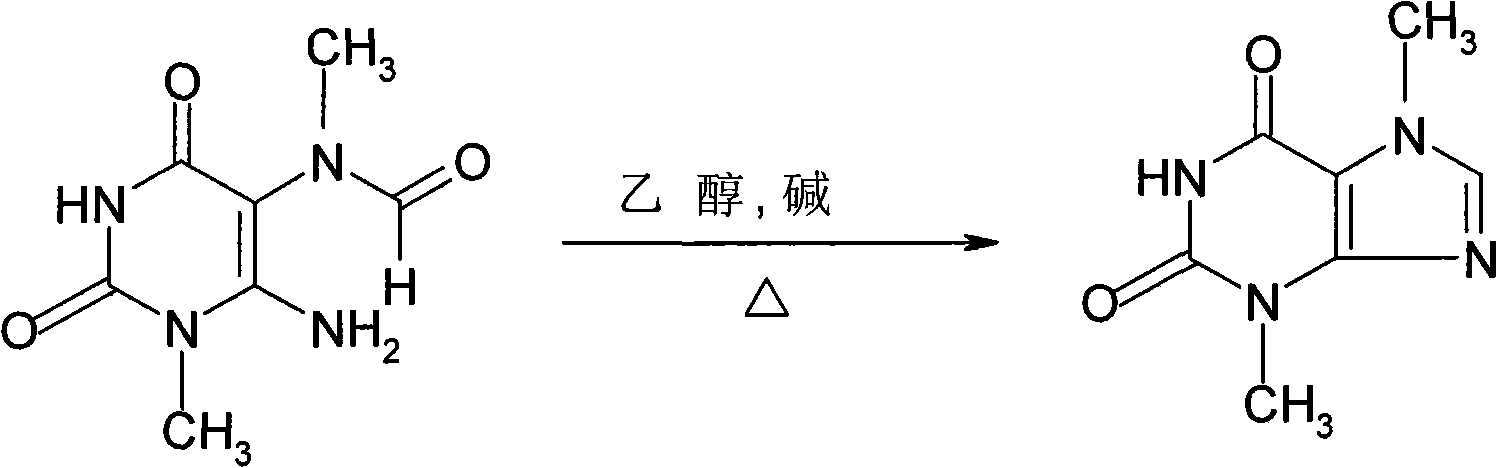

Theobromine production process

The invention provides a new method for preparing a theobromine by a 3-methyl xanthine disodium salt methylation with more production value. The theobromine is prepared by using acetone as a solvent to react with a dimethyl sulfate under the existence of a sodium carbonate and then acidified. The invention uses the acetone as the solvent and decreases the hydrolysis loss of the dimethyl sulfate; the sodium carbonate provides an alkaline condition for the methylation reaction and the Ph value is intermediate. The dimethyl sulfate is dropped to carry out the methylation reaction with the advantages of good selectivity and a yield higher than other methylation technique by more than 10 percent. The acetone is recycled and reused, the reaction is relatively complete and has little caffeine by-product, and the acquired analysis content of theobromine crude product HPLC is larger than 90 percent. The invention is extremely applicable to industrial production.The invention relates to a refining method of santheose, which is characterized in that dissolves liquid alkali into crude santheose solution, decolourizes, fitlers, and adds reduction agent into filter liquor, acidifies at 60-80 DEG C until pH=5-6, filters and dries to obtain santheose final product. The inventive method has refining yield of 90%, standard product color, high product quality, low cost and industrialization suitability.

Owner:PERRIGO TRADING (SHANGHAI) CO LTD

Health white spirit containing beneficial functional component

ActiveCN101007992ADoes not change colorDoes not affect the tasteOrganic active ingredientsMetabolism disorderBisulfideDaidzein

The invention discloses a health- caring wine containing good effective element. The wine with alcohol degree being 15- 75 (V / V %) comprises maltol, borneo camphor, cedrol, dimethyl trisulfide, dimethyl bisulfide, ligustrazine, daidzein, crust and puerarin, which not only changes wine color, but aslo does not influence waste, no toxic action. The health- care wine can improve bloos circulation, reduce blood pressure, reduce blood fat and promote circulation of qi and relieve pain, resist tumor and cause head pain after excessive drink.

Owner:SICHUAN TUOPAI SHEDE WINE

Dimethyl Disulphide Derived at least partially from Renewable Materials

ActiveUS20110172138A1Cosmetic preparationsOrganic compound preparationRenewable materialsDimethyl disulphide

Owner:ARKEMA FRANCE SA

Method for preparing glycol sulfite

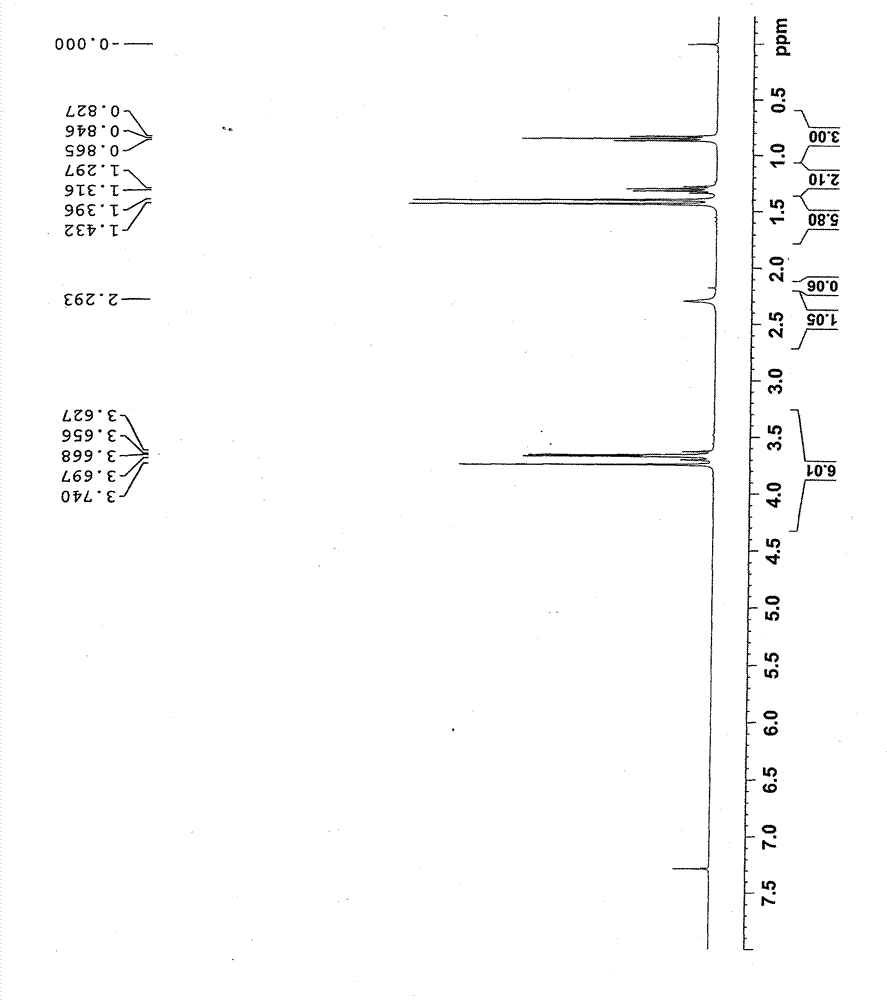

The preparation method for ethylene sulfite comprises: with dimethyl sulfite and glycol as material without ratio limit and 0.01-5wt% p-toluenesulfonic acid as catalyst, heating from 60-70Deg to 160-180Deg gradually while removing continually the generated methanol to promote the reaction tend to completeness; finally, fractionating and purifying to obtain the product. This invention has high yield and purification with no corrosion to device.

Owner:福建邵武创鑫新材料有限公司

Production process for preparing dimethyl sulfate by composite acid through catalytic dehydration

InactiveCN101654420AReduce pollutionImprove efficiencySulfuric acid esters preparationDistillationSulfur trioxide

The invention relates to a production process for preparing dimethyl sulfate by composite acid through catalytic dehydration, which solves the problems of high consumption of sulphuric acid and methanol during production and more serious production pollution in the prior domestic production of dimethyl sulfate due to the adoption of conventional sulphuric acid-methanol method. The production process is characterized in that composite acid catalyst is adopted to carry out dehydrated etherealization of vaporized methanol to generate dimethyl ether gas; after purification, dimethyl ether gas reacts with dimethyl sulfate rich solution absorbing sulfur trioxide to generate a crude product of dimethyl sulfate; and an eligible finished product of dimethyl sulfate is obtained through reduced pressure distillation. The production process is suitable to be used in small and medium-sized methanol production enterprises or sulphuric acid production enterprises taking dimethyl sulfate as a downstream product.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

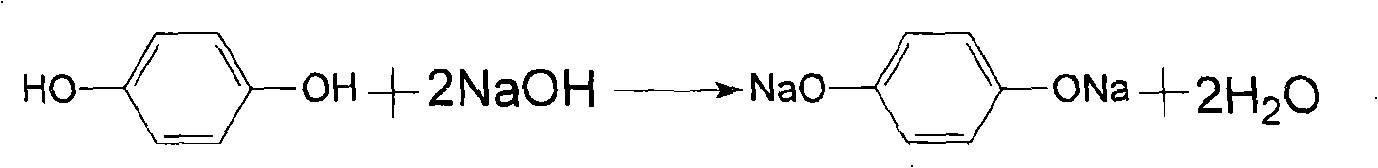

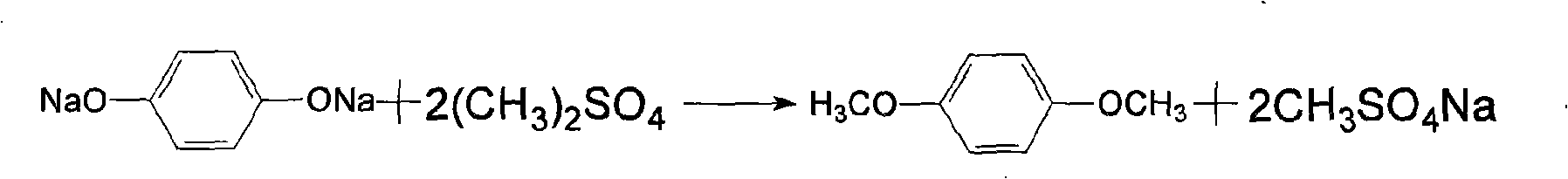

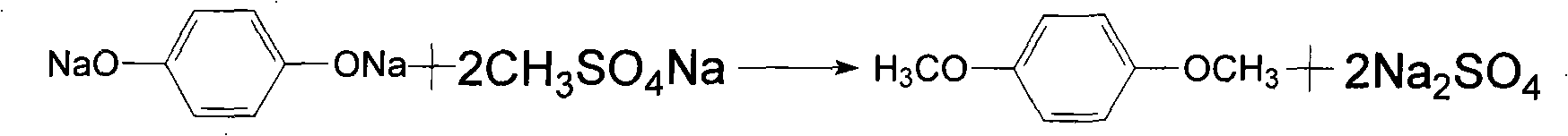

Novel synthetic process of p-phenylene dimethyl ether

InactiveCN101348422AReduce dosageHigh reaction yieldEther preparation by ester reactionsHydroxybenzoate EthersWater vapor

The invention relates to a novel process for synthesizing p-xylene glycol dimethyl ether. The synthesis method takes hydrochinone and dimethyl sulfate as raw materials, and obtains the product through substitution inside an alkaline medium. Moreover, the synthesis method has the technological characteristics that by means of the principle of equilibrium shifting, the product is moved out of a reaction system during reaction, thereby accelerating reaction and ensuring complete reaction; in the prior synthesis process, the auxiliary raw material dimethyl sulfate no longer participates in reaction when reacted to generate monomethyl sodium sulfate, and the theoretical utilization rate of dimethyl sulfate is only 50 percent; therefore, the method greatly increases the utilization rate of dimethyl sulfate, and reduces the consumption of dimethyl sulfate by 40 percent; meanwhile, reaction yield is also increased to a certain extent; moreover, because the process makes use of the special characteristics of azeotropic distillation of the product and water, the product obtained during reaction can be moved out in time, while the reaction raw materials and intermediate product para hydroxyanisole are stored in a reactor in the form of sodium salts in the alkaline medium and do not enter the product when distilled out along with water vapor; therefore, the product has extremely high purity and can be obtained without adopting the prior alcohol refining; and the novel process ensures greatly simplified production process, higher production safety, lower production cost and labor intensity and better operating environment for workers, thereby having significant social benefit and economic benefit.

Owner:舒景林

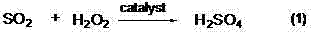

Method for removing residues out of dimethyl sulfate

ActiveCN103570591AIncrease contentGood removal effectOrganic chemistryOrganic compound preparationCopper sulfateDimethyl sulfate

The embodiment of the invention provides a method for removing residues out of dimethyl sulfate, belonging to the technical field of chemical purification. The method comprises the steps: adding a catalyst and a hydrogen peroxide solution with the mass concentration of 30-70%, reacting at the temperature of 35-55 DEG C, removing residues, and separating the catalyst and water to obtain high-purity dimethyl sulfate after the reaction is finished, wherein the usage amount of the hydrogen peroxide solution is 0.15-0.35% of that of the dimethyl sulfate, the usage amount of the catalyst is 0.05-0.2% of weight of the dimethyl sulfate, and the catalyst comprises manganese dioxide, calcium oxide, cobalt sulfate or copper sulfate. The method for removing residues, provided by the invention, can be used for effectively removing the residues such as CHOSO3H, SO2 and (CH3O)2SO out of the dimethyl sulfate, and a treated dimethyl sulfate product contains more than or equal to 99.5% of DMS, less than or equal to 20ppm of SO2 and less than or equal to 30ppm of (CH3O)2SO, so that the removing effect is very remarkable.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

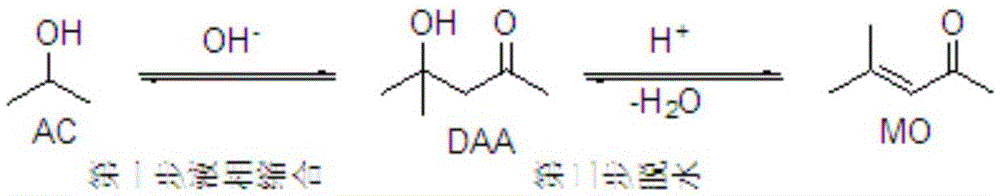

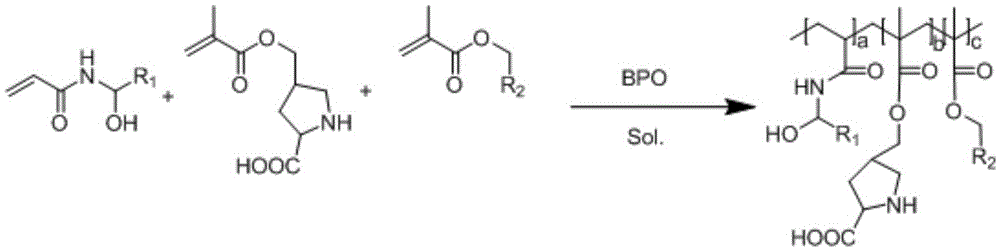

Preparation method of polymer catalyst for acetone condensation

ActiveCN105728040APromote formationImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOxygenMethyl group

The invention relates to a preparation method and applications of a polymer catalyst. The catalyst is applied to acetone condensation and dehydration for preparing mesityl oxide and is capable of improving the conversion rate of acetone. The preparation method comprises the following steps: adding N-hydroxymethyl acrylamide, 2-methyl-2-acrylic acid-4-L-methyl proline ester, 2-methyl-2-acrylic acid-4-methyl piperidine ester, an initiator namely benzoperoxide (BPO), and a solvent into a pressure resistant reaction flask in sequence, wherein the solvent can be methanol (MA), N,N-dimethyl formamide (DMF), dimethyl sulfoxide (DMSO), or N,N-dimethyl acetamide (DMA), stirring to dissolve the components mentioned above, removing oxygen; carrying out reactions at a certain polymerization temperature, after reaction, precipitating the reaction product, subjecting the reaction production to centrifugation, and drying the reaction product to obtain the catalyst (PNL).

Owner:NANJING UNIV +1

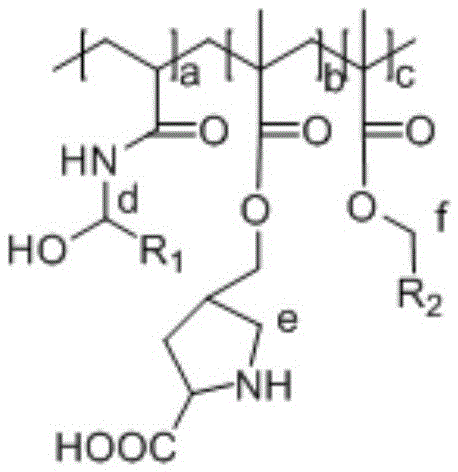

Preparation method of chitosan quaternary ammonium salt

ActiveCN106167532AGood choiceOvercoming Situations That Require PressurizationMethyl carbonateIonic liquid

The invention relates to a preparation method of a chitosan quaternary ammonium salt, and belongs to the technical field of high molecule modification. The preparation method comprises following steps: firstly, chitosan is subjected to Eschweiler-Clarke reaction so as to obtain N, N-dimethyl chitosan; at an ionic liquid environment, quaternization reagent dimethyl carbonate is added for quaternization of N, N-dimethyl chitosan; and at last, an obtained reaction product solution is washed with an organic solvent and is dried so as to obtain N, N, N-trimethyl chitosan. According to the preparation method, the quaternization reagent dimethyl carbonate is nontoxic, the reaction products are carbon dioxide and methyl alcohol, and methyl alcohol can be recycled to prepare dimethyl carbonate, so that the preparation method is green, and is friendly to the environment. In addition, compared with dimethyl sulfate, selectivity of methylation reaction of dimethyl carbonate with amines is higher.

Owner:JIANGNAN UNIV

Microcapsule of dimethyl ester fumarate and preparation method

InactiveCN1600100ADoes not affect the antibacterial effectEliminate usage restrictionsBiocideAnimal repellantsParaffin waxSoftgel

A dimethyl fumarate (DMF) softgel is composed of the core prepared from DMF particles and the wall layer prepared from refined paraffin wax, animal wax, plant wax, or synthetic high-molecular material. Its advantages are no irritation to people, and high output rate and effect.

Owner:王立峰

Combinational preparation method of nano zinc oxide and toluene dicarbamate

ActiveCN101012177AImprove economyReduce adverse effectsOrganic compound preparationZinc oxides/hydroxidesMethyl carbonateToluenediamine

The invention discloses a making method of toluenediamine methyl formate of nanometer zinc oxide, which comprises the following steps: adding diaminotoluene, zinc acetate and dimethyl ester carbonate in the autoclave with molar rate at 1:0.01-0.7:15-30; sealing the autoclave; stirring; reacting under 100-200 deg.c for 1-10h; filtering; decompressing to rectify under 30-70 deg.c at 5-30Kpa; obtaining the solid product (toluenediamine methyl formate); washing filter pie; drying in the vacuum; obtaining the nanometer zinc oxide.

Owner:HEBEI UNIV OF TECH

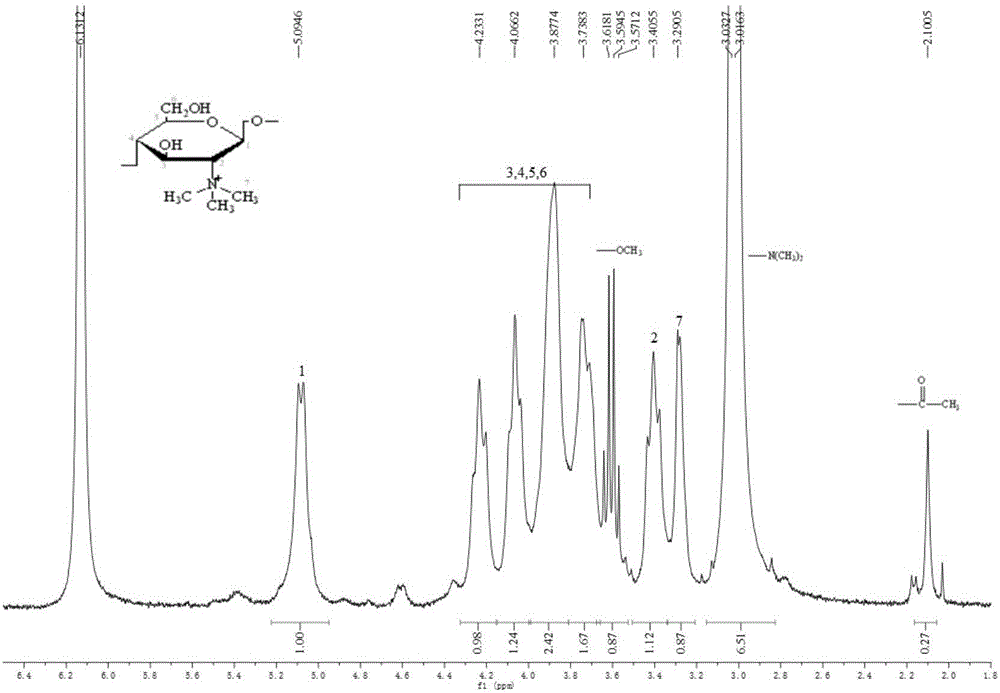

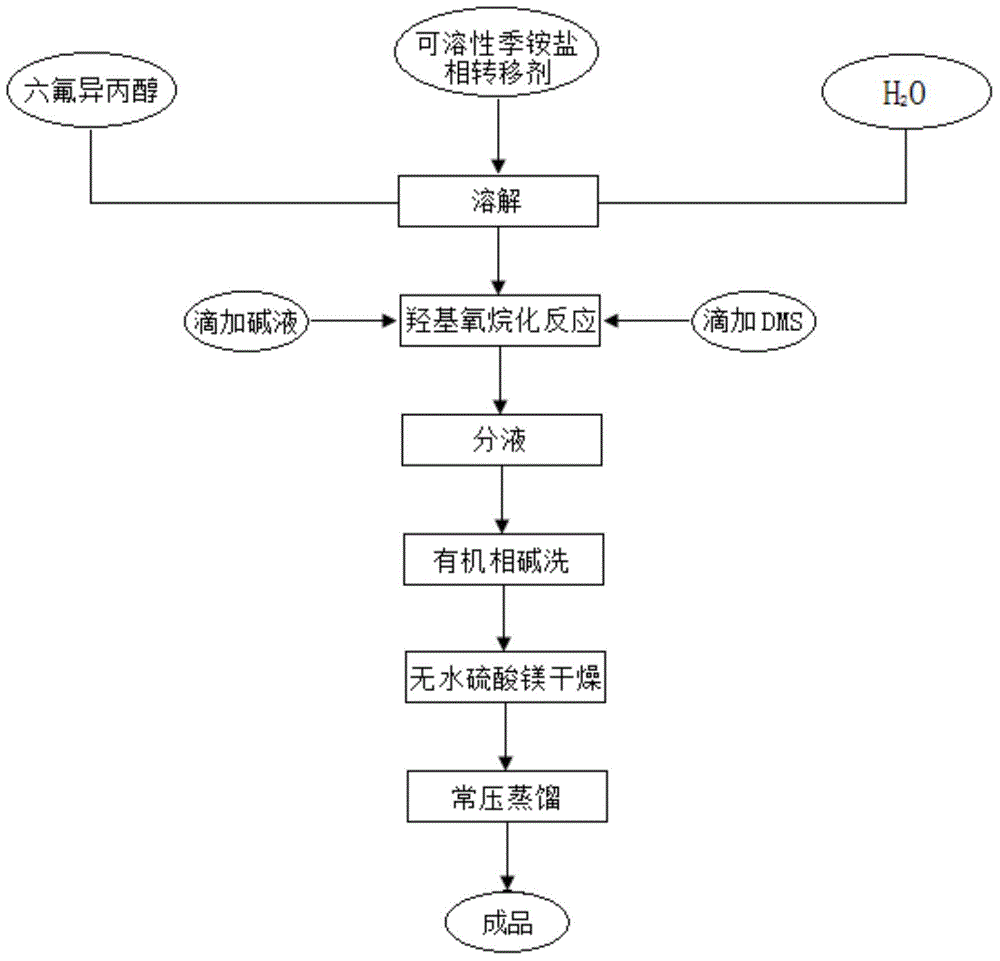

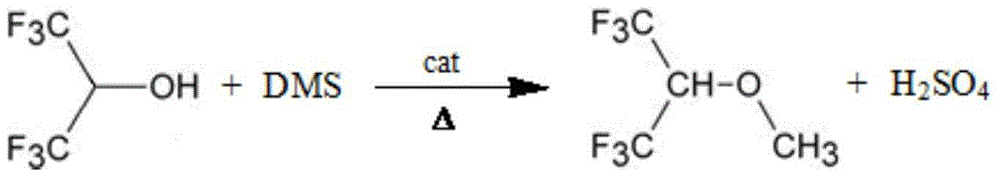

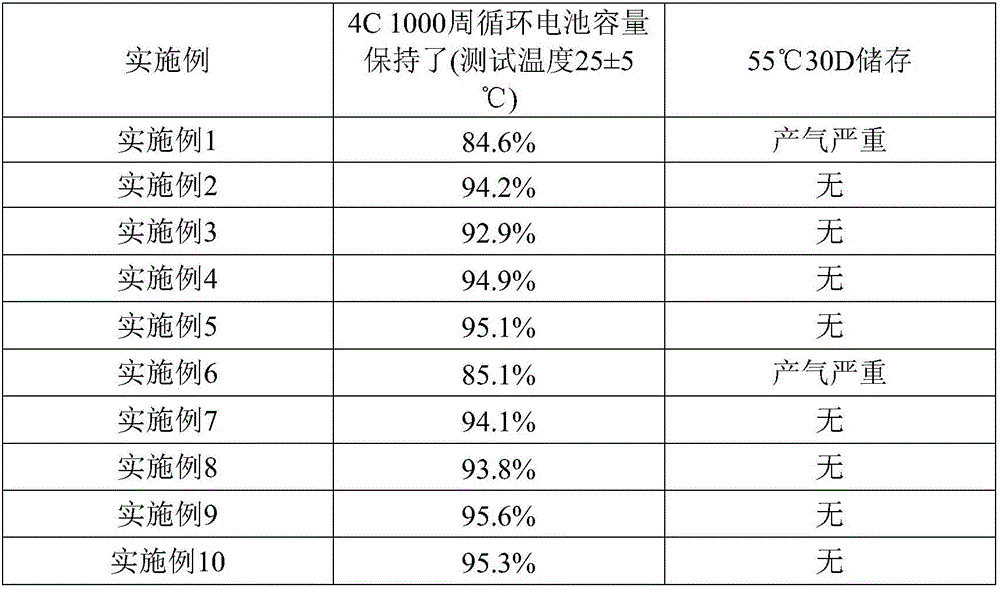

Process method for catalytic synthesis of 1,1,1,3,3,3-hexafluoro isopropyl methyl ether

The present invention relates to a process method for catalytic synthesis of 1,1,1,3,3,3-hexafluoro isopropyl methyl ether, and the method includes the steps of preparation of an alkaline hexafluoroisopropanol solution containing a phase transfer catalyst, preparation of hexafluoro isopropyl methyl ether, distillation and purification and the like. The 1,1,1,3,3,3-hexafluoro isopropyl methyl ether is prepared from dimethyl sulfate and hexafluoroisopropanol as raw materials in an alkaline environment under the effect of a soluble quaternary ammonium salt phase transfer catalyst, and product yield and purity are greatly improved.

Owner:LIANYUNGANG TETRAFLUOR NEW MATERIALS

Method for determining dimethyl sulfate and diethyl sulfate in electronic and electric products

InactiveCN103592377AEasy to separateAccurate measurementComponent separationInjection volumeHplc method

The invention discloses a method for determining dimethyl sulfate and diethyl sulfate in electronic and electric products. The method comprises the following steps: adding a certain amount of acetone into a prepared sample, carrying out ultrasonic extraction to obtain the target compounds, deriving the target compounds with p-nitrophenol under alkaline conditions, extracting the derivation products with diethyl ether, and separating and detecting the ethyl ether extraction solution with a high performance liquid chromatography (HPLC) system. The chromatographic column uses an octadecyl bonded silica gel as the filler; the detector is a diode array detector; the mobile phase is a mixed solvent composed of 40-60 vol% of methanol and 60-40 vol% of water; the detection wavelength is 305nm; the column temperature is 40-60 DEG C; and the sample injection volume is 5-20 muL. After the systemic comparative studies, the invention establishes an HPLC method for determining contents of dimethyl sulfate and diethyl sulfate in electronic and electric products for the first time; and the method has the technical characteristics of favorable separating effect, high determination accuracy, high sensitivity, high specificity, simple and quick analysis and the like.

Owner:青岛谱尼测试有限公司

Electrolyte for storage battery

InactiveCN105958119AImprove performanceImprove stabilitySecondary cellsOrganic electrolytesHigh temperature storageSolvent molecule

The invention provides electrolyte for a storage battery. The electrolyte comprises lithium salt, a solvent and an additive. The additive is one of or the combination of many kinds of vinylene carbonate, 1,3-propanesulfonate, 1,3-propanesultone, glycol sulfite, dimethyl sulfite and lithium bis(oxalate)borate. The usage amount of the additive is 0.5%-5% of the total mass of the lithium salt and the organic solvent. According to the electrolyte, the additive forms a passivation layer on the surface of a graphene-based lithium titanate electrode when the battery is charged for the first time. The passivation layer coats on the surface of an electrode material stably. The solvent molecules are effectively prevented from passing through and prolapsing from the material through adoption of the formed passivation film, therefore, the flatulence phenomenon resulting from side reaction of the electrolyte and the graphene-based lithium titanate is prevented, while the Li<+> can freely intercalate and prolapse through the passivation layer. Through adoption of the method, the stability of the graphene-based lithium titanate battery in the circulation and high temperature storage processes can be greatly improved, and the performance of the battery can be greatly improved.

Owner:天津普兰能源科技有限公司

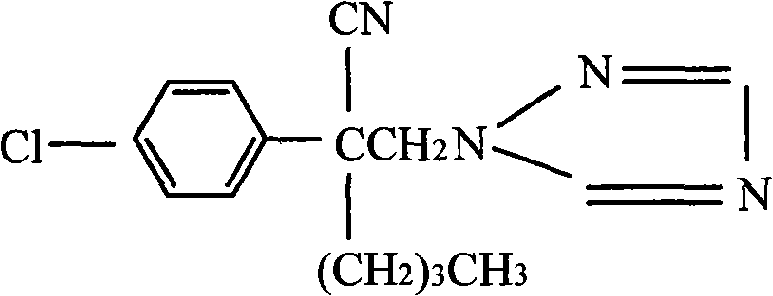

Preparation method of bulk myclobutanil

InactiveCN101538250AReduce manufacturing costQuality improvementBiocideOrganic chemistrySodium hydroxideDimethyl sulfite

The invention discloses a preparation method of bulk myclobutanil. A production method comprises the following steps: A, transferring p-chlorobenzonitrile, n-chlorobutane and tetrapropyl ammonium bromide into a reaction kettle, slowly adding a sodiumhydroxide solution with mass concentration of 50% dropwise to obtain 2-(4-chlorphenyl)hexanenitrile; B, sequentially transferring the 2-(4-chlorphenyl)hexanenitrile, dichloromethane and the tetrapropyl ammonium bromide into the reaction kettle, and slowly adding the sodiumhydroxide solution with mass concentration of 50% dropwise to obtain 1-chloro-2-nitrile-2-(4-chlorphenyl)hexane; and C, sequentially adding dimethyl sulphoxide, the sodiumhydroxide solution with mass concentration of 50% and 1,2,4-triazole to the reaction kettle to obtain a finished product of the bulk myclobutanil. Measurement shows that the bulk myclobutanil prepared by the preparation method has a white appearance and high purity above 98%.

Owner:HUBEI XIANLONG CHEM IND

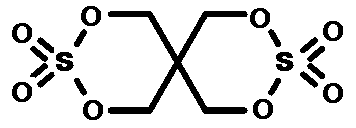

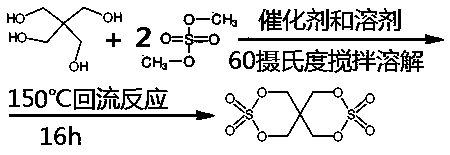

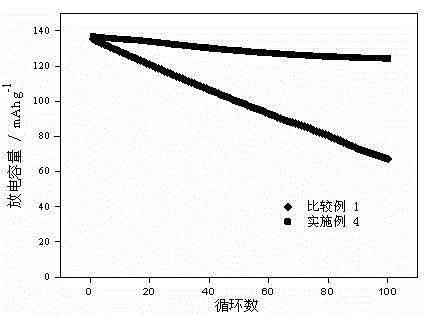

Preparation method for synthesizing pentaerythritol bicyclic sulfate

The invention discloses a preparation method for synthesizing pentaerythritol bicyclic sulfate from dimethyl sulfate and pentaerythritol by a one-step synthesis process under the action of a catalyst.The method which adopts the pentaerythritol and dimethyl sulfate as raw materials comprises the following steps: heating a solvent, the dimethyl sulfate and the catalyst to 60-65 DEG C under the protection of nitrogen to achieve full dissolving, adding the pentaerythritol in batches while refluxing at 70 DEG C to start a reaction, continuously reacting and heating to 150 DEG C, carrying out condensation refluxing to separate a reactant methanol in order to obtain crude pentaerythritol bicyclic sulfate, filtering and distilling the crude product obtained by the reaction, washing and purifyingthe distilled crude product with a solvent, and performing vacuum drying to obtain the target product that is purified pentaerythritol bicyclic sulfate. The compound prepared by the method has the advantages of novel structure, high product purity, low raw material cost, simplicity and high efficiency in one-step synthesis, easiness in disposal of wastes, and high economical property of the reaction process, and can be used for lithium ion battery electrolyte additives to improve the comprehensive performances of batteries.

Owner:杨记

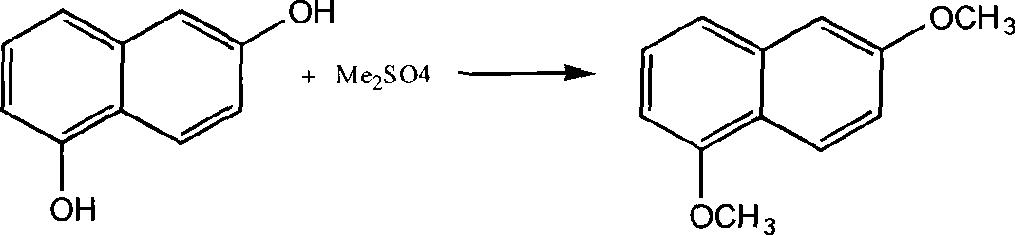

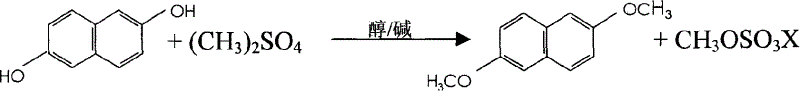

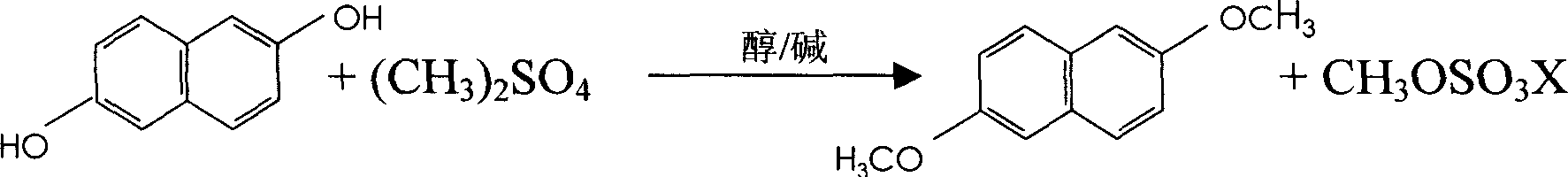

Preparation technique of 1,6-dimethoxynaphthalene

The invention puts forward a novel process for synthesizing 1,6-dimethoxynaphthalene. The process comprises the steps of adding sodium hydrosulfite for preventing oxidation to a medium of petroleum ether and NaOH aqueous solution, adding quaternary ammonium salt as a phase transition catalyst, using dimethyl sulfate to methylate 1,6-dihydroxynaphthlene, adding NaOH aqueous solution and dimethyl sulfate by stages, performing reaction at a temperature between 50 and 60 DEG C and preparing the 1,6-dimethoxynaphthalene. In a first stage, the weight ratio of petroleum ether, the NaOH aqueous solution, the sodium hydrosulfite, the quaternary ammonium salt and the dimethyl sulfate to the 1,6-dimethoxynaphthalene is 4.5-8:1, 4.6-6:1, 0.02-0.06:1, 0.02-0.05:1 and 1.2-1.8:1 respectively; the time of dripping the dimethyl sulfate is 10 to 60 minutes; and in a second stage, the weight ratio of the added NaOH aqueous solution and the dimethyl sulfate to the 1,6-dimethoxynaphthalene is 2.3-3:1 and 0.88-1.2:1 respectively. The method has the advantages that reaction conditions are easy to control; the petroleum ether can be recovered and indiscriminately used; and the 1,6-dimethoxynaphthalene is high in purity and does not need to be refined by use of solvents.

Owner:NANTONG BAISHENG CHEM

Preparation method of dimethyl disulfide

InactiveCN104592070ALong-term cycle useLong-term useHydropoly/poly sulfide preparationDimethyl sulfiteSulfuric acid

The invention provides a preparation method of dimethyl disulfide, which comprises the following steps: adding powder sulfur into a reactor under pressurized reaction conditions, and reacting the sulfur with a liquid catalyst sodium sulfide in the reactor to generate a sodium persulfide solution; introducing impure methyl mercaptan gas to react with sodium persulfate, wherein the reaction solution is divided into an organic layer dimethyl disulfide and byproducts (dimethyl trisulfide and dimethyl polysulfide); and rectifying the dimethyl disulfide and byproducts (dimethyl trisulfide and dimethyl polysulfide) to obtain dimethyl disulfide, wherein the mixed solution of the byproducts (dimethyl trisulfide and dimethyl polysulfide) returns to the reactor to complete the circular reaction. The reaction conditions are mild, the product is insoluble in the liquid catalyst and can be easily separated, and the catalyst can be circularly used for a long time.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Method for preparing methane chloride by dimethyl sulfate

InactiveCN101633598ARealize harmless treatmentHigh purityHalogenated hydrocarbon preparationEconomic benefitsChloride

The invention discloses a method for preparing methane chloride by dimethyl sulfate, dimethyl sulfate is taken as a raw material, hydrogen chloride gas is led into dimethyl sulfate solution, and methane chloride is generated by reacting for 0.5-10h at 60-180 DEG C; and the amount of substance of hydrogen chloride gas led into dimethyl sulfate solution per hour is 1-10 times that of substance of dimethyl sulfate. The invention has the advantages of mild reaction condition, simple technical process, capability of carrying out effective harmless treatment on dimethyl sulfate and higher economic benefit, belonging to the field of preparation of methane chloride.

Owner:HANERGY TECH

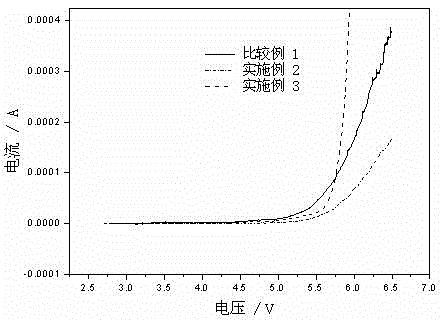

Wide-temperature efficient anti-flaming electrolyte for lithium ion battery and preparation method thereof

InactiveCN107256983AImprove low temperature voltage plateau phenomenonLow conductivitySecondary cellsOrganic electrolytesMethyl carbonateMass ratio

The invention discloses wide-temperature efficient anti-flaming electrolyte for a lithium ion battery. The wide-temperature efficient anti-flaming electrolyte for the lithium ion battery is prepared by the following raw materials by mass percentage: 80-85% of a non-aqueous organic solvent, 10-13% of lithium salt, 1-5% of a function additive, and 1-5% of an anti-flaming assistant, wherein the non-aqueous organic solvent is formed by mixing cyclic carbonate, dimethyl sulfite, dimethyl carbonate and Gamma-butyrolactone, wherein the mass ratio is 2-5:1-3:1-3:1; the lithium salt is lithium oxalyldifluroborate (LiODFB) and lithium bisoxalatoborate (LiBOB), wherein the mole ratio is 25-40:75-60; the function additive is ethylene carbonate ec and ethylene sulfate, wherein the mass ratio is 1:1-3; and the anti-flaming assistant is a fluoro-phosphonitrile compound. The wide-temperature efficient anti-flaming electrolyte has the better electrochemical stability within the working voltage range of the battery, the usability of the lithium ion battery containing the electrolyte from the low-temperature to the high-temperature is effectively improved, and the application range of the battery is more effectively widened.

Owner:无锡九宇宝新能源科技有限公司

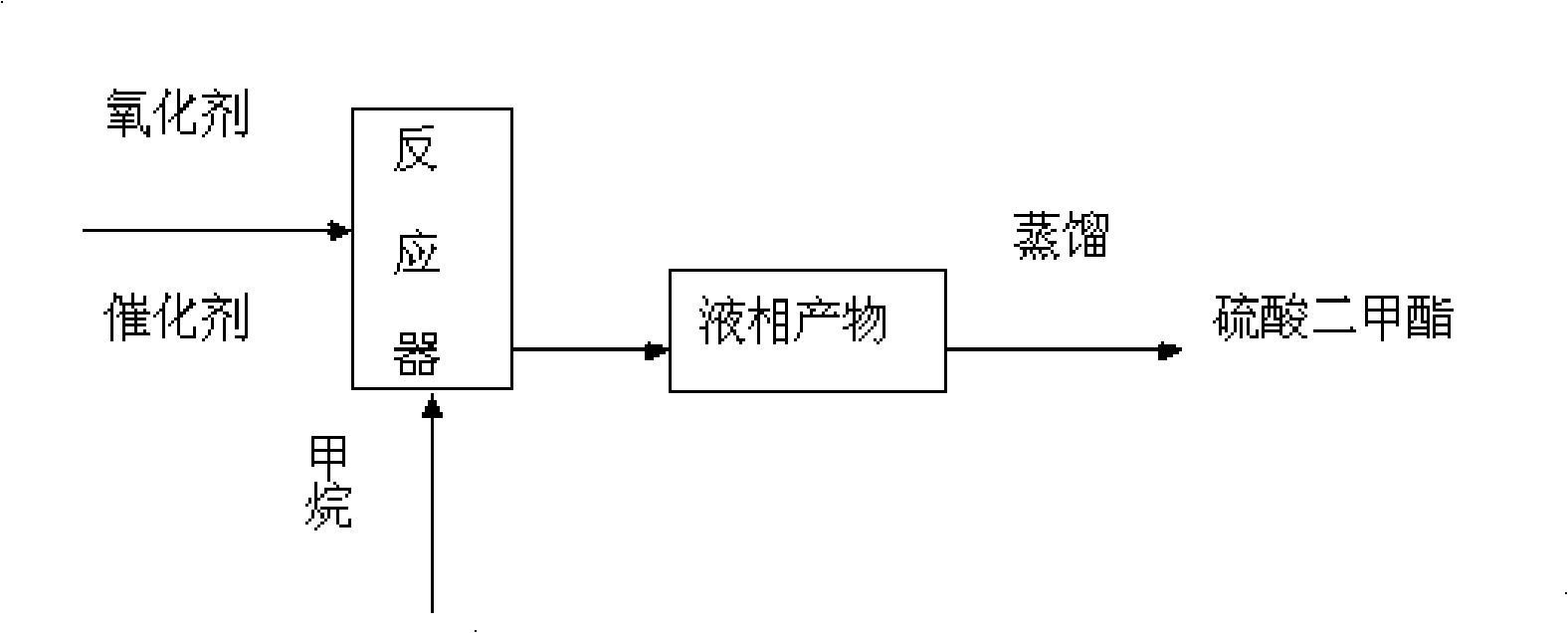

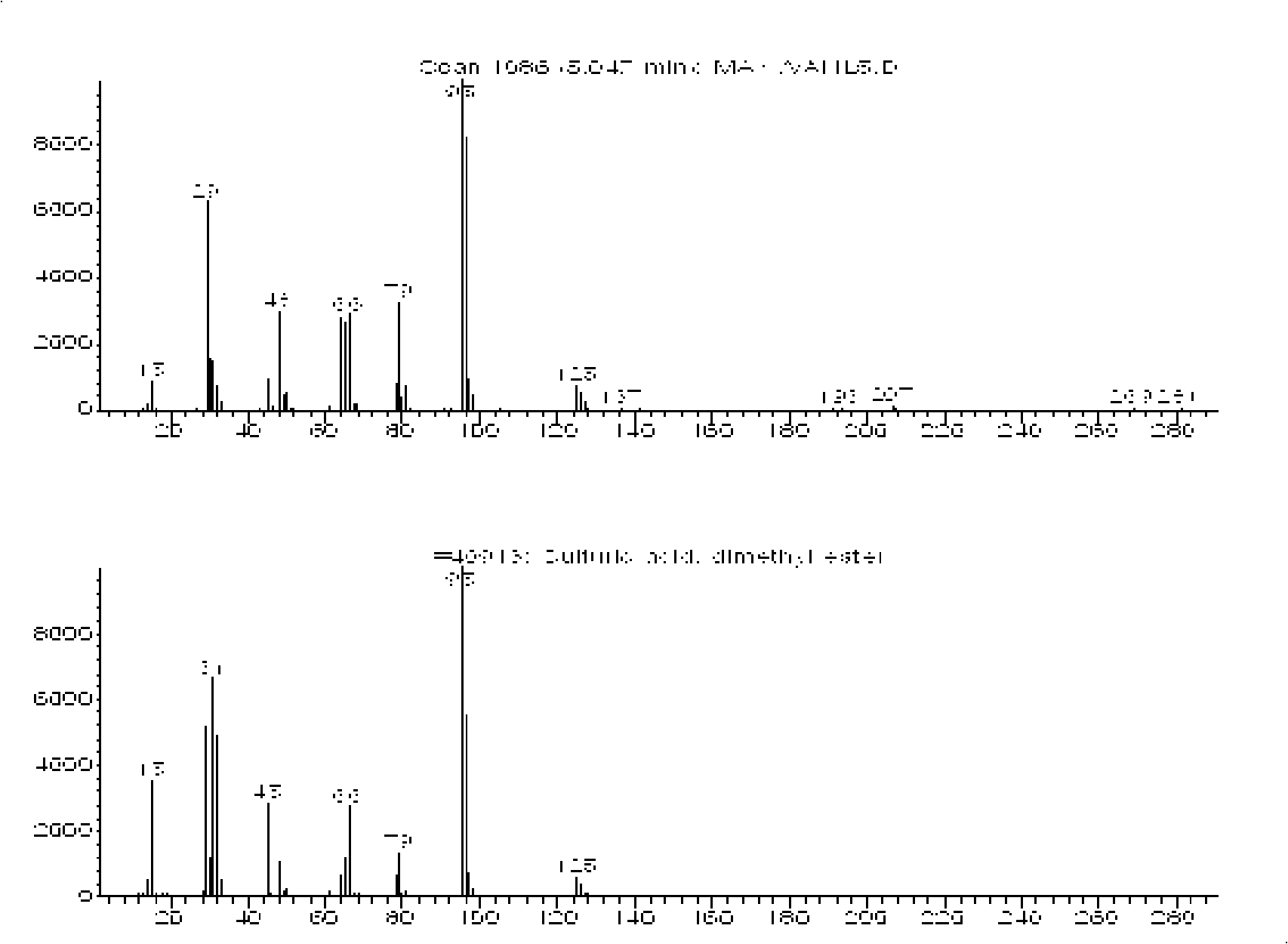

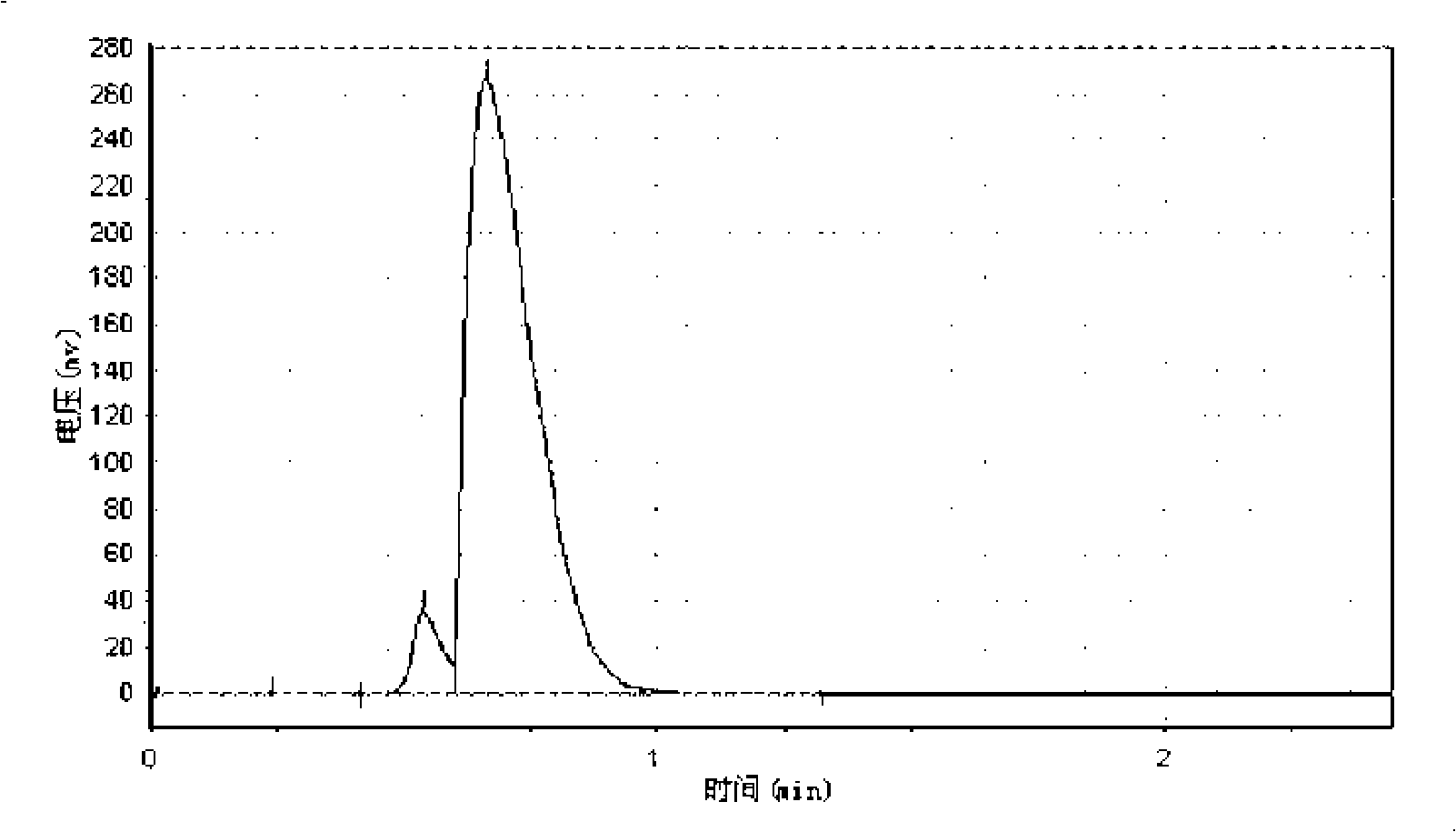

Process for preparing dimethyl sulfate by discontinuous process

InactiveCN101407481AReduce consumptionReduce lossSulfuric acid esters preparationIodineSulfur trioxide

The invention discloses a process for preparing dimethyl sulfate by using a batch process, which belongs to the field of preparing dimethyl sulfate. According to a molar raio of I: SO3 of 1:86-430, catalyst iodine or iodine compound and sulfur trioxide or compound containing dissociative sulfur trioxide are put into a high pressure reaction kettle; then gas containing methane of about 1-3MPa is led into the high pressure reaction kettle; at the temperature of 130-175 DEG C, the reaction lasts for 3-480min; and then the obtained mixture from the reaction is distilled in liquid phase to get the product dimethyl sulfate. The process has the reaction process which is easy to be controlled, the reaction condition is moderate, the safety is high, and the process is simple and efficient and is applicable to industrial production.

Owner:HANERGY TECH

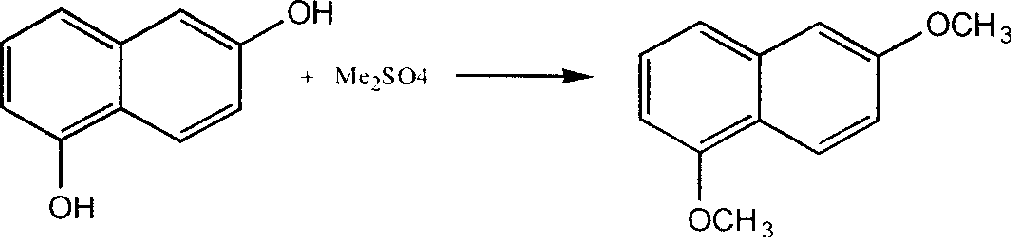

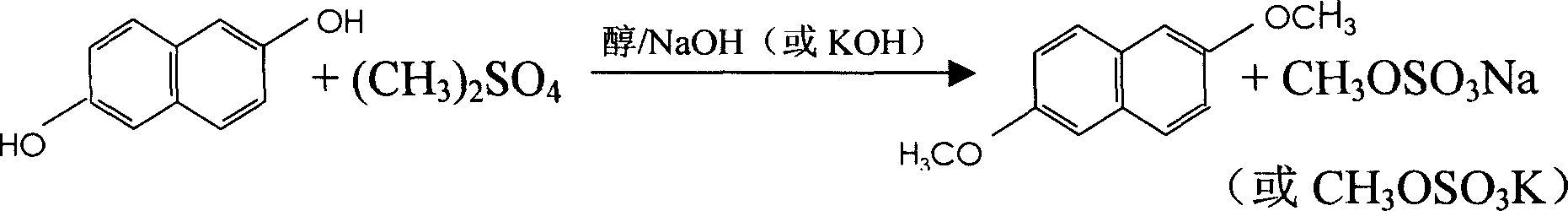

Production method of 2,6-dimethoxynaphthalene

InactiveCN1724498ASimple process routeLow reaction conditionsEther preparation by ester reactionsAlcoholPotassium hydroxide

The invention discloses a process for producing 2,6-dimethoxynaphthalene, which comprises dissolving 2,6-dihydroxy naphthalene into alcohol dissolvent, reacting with dimethyl sulfate for 3-6 hours under alkaline condition at 20-70 deg. C, thus obtaining 2,6-dimethoxynaphthalene, the alkaline solution used in the reaction is selected from sodium hydroxide and potassium hydroxide, the concentration is between 15-45%, the mol ratio of 2,6-dimethoxynaphthalene and dimethyl sulfate is between 1:2.8-4.5, the purity of the 2,6-dimethoxynaphthalene is greater then 98%. The production process has the advantages of short reaction time and high yield.

Owner:南通莱嘉利化工有限公司

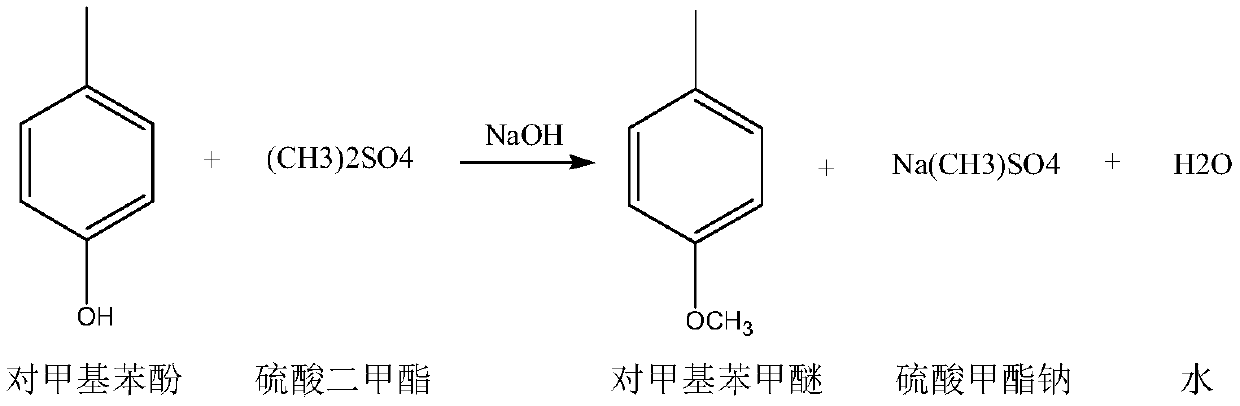

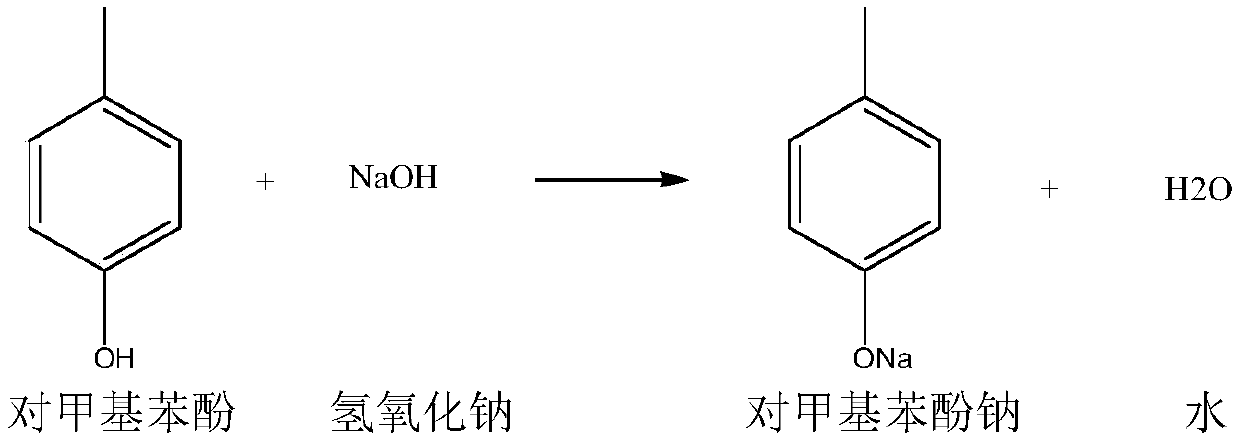

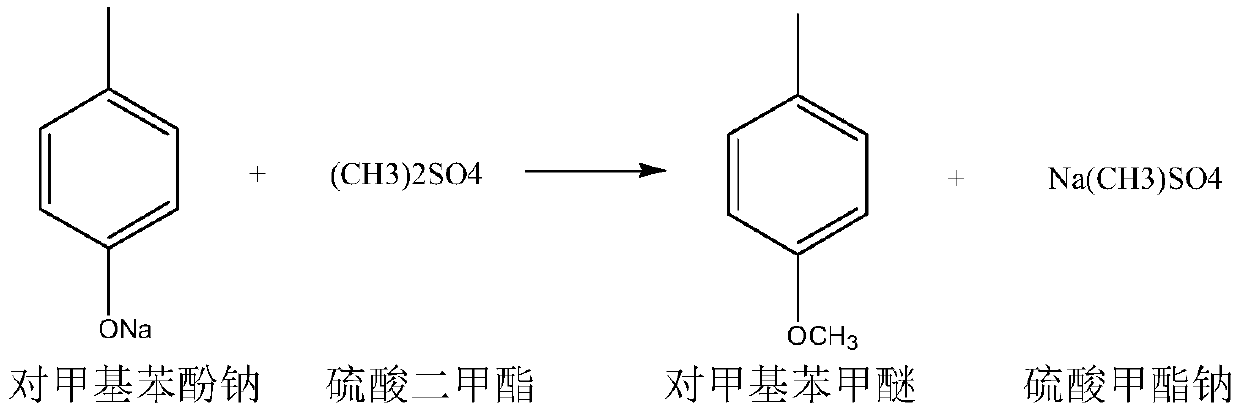

Preparation method of 4-methylanisole

InactiveCN110054549AIncrease profitOrganic compound preparationEther preparation by ester reactionsSolventP-methyl anisole

The invention discloses a preparation method of 4-methylanisole. The method includes: using p-cresol and sodium hydroxide as the raw materials to prepare p-methylphenol sodium; allowing the p-methylphenol sodium and dimethyl sulfate to have methylation in a nonpolar solvent to prepare the 4-methylanisole and byproduct sodium methylsulfate; allowing the p-methylphenol sodium and the byproduct sodium methylsulfate to have reaction in a polar solvent to prepare the 4-methylanisole and sodium sulfate. The method has the advantages that the 4-methylanisole is prepared through the three-step reaction, the utilization rate of the dimethyl sulfate is increased, and wastewater zero discharge is achieved.

Owner:XINCHANG COUNTY TAIRU TECH CO LTD

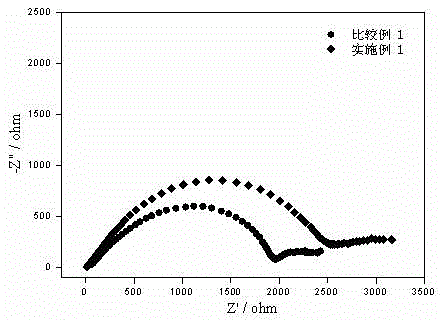

Electrolyte of lithium ion battery

InactiveCN102881941ASolve the large impedanceImprove thermal stabilitySecondary cellsElectrolytic agentOXALIC ACID DIHYDRATE

Electrolyte of a lithium ion battery consists of lithium salt and an organic solvent, wherein the lithium salt is one of bis-oxalic acid lithium borate and lithium difluoroborate or a mixture of the bis-oxalic acid lithium borate and the lithium difluoroborate, the organic solvent consists of a component A, a component B and a component C, the component A is sulfolane, the component B is a linear carbonic ester compound or a linear sulfite compound or a mixture of the linear carbonic ester compound and the linear sulfite compound, and the component C is a cyclic carbonate compound. The molar concentration of the electrolyte lithium salt is 0.4-1.5 mol / L. The volume percentage of the sulfolane SL in the electrolyte is 11%-70%. The linear carbonic ester compound is one or more of dimethyl carbonate, diethyl carbonate and methyl ethyl carbonate, and the volume percentage of the linear carbonic ester compound in the electrolyte is 0%-70%. The linear sulfite compound is one or more of sulphurous acid dimethyl ester and sulphurous acid diethyl ester, and the volume percentage of the linear sulfite compound in the electrolyte is 0%-70%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com