Method for removing residues out of dimethyl sulfate

A technology for dimethyl sulfate and residues, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of poor removal effect, ester quaternary ammonium salt odor, and ineffective improvement of dimethyl sulfate Purity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

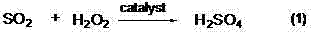

[0028] Weigh the acidity as 0.32%, SO 2 The content is 207ppm, (CH 3 O) 2 SO content is the dimethyl sulfate 400g of 462ppm in the 500ml there-necked flask with stirring, then add the H of 0.9g mass concentration 30% 2 o 2 . Start stirring, and then put 0.4g of MnO into the system 2 , heating up, when the system temperature rises to 35 0 Start timing at C, and at this temperature (35±2 0 C) Insulation reaction for 3.5h. End the reaction, and add 10g molecular sieve to the system, let stand for 36h, filter out molecular sieve and MnO 2 , the obtained dimethyl sulfate has an acidity of 0.25%, SO 2 8.9ppm, (CH 3 O) 2 SO 18.7ppm, the product appearance is colorless, clear and transparent.

Embodiment 2

[0030] Weigh the acidity as 0.32%, SO 2 The content is 207ppm, (CH 3 O) 2 SO content is the dimethyl sulfate 400g of 462ppm in the 500ml there-necked flask with stirring, then add the H of 0.5g mass concentration 50% 2 o 2 . Start stirring, and then put 0.4g of MnO into the system 2 , heating up, when the system temperature rises to 35 0 Start timing at C, and at this temperature (35±2 0 C) Insulation reaction for 3.5h. Finish the reaction, and add 6g of silica gel to the system, let stand for 40h, filter out silica gel and MnO 2 , the acidity of the obtained dimethyl sulfate is 0.24%, SO 2 9.8ppm, (CH 3 O)2 SO 20.6ppm, the product appearance is colorless, clear and transparent.

Embodiment 3

[0032] Weigh the acidity as 0.32%, SO 2 The content is 207ppm, (CH 3 O) 2 SO content is the dimethyl sulfate 400g of 462ppm in the 500ml there-necked flask with stirring, then add the H of 0.9g mass concentration 30% 2 o 2 , start stirring. Drop into the CaO of 0.35g in the system again, heat up, when the system temperature rises to 48 0 Start timing at C, and at this temperature (48±2 0 C) Insulation reaction for 4.0h. Finish reaction, and add 10g calcium chloride in the system, filter out calcium chloride and CaO after leaving standstill 38h, gained dimethyl sulfate acidity 0.22%, SO 2 11.5ppm, (CH 3 O) 2 SO 17.9ppm, the product appearance is colorless, clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com