Novel synthetic process of p-phenylene dimethyl ether

A technology of terephthalic ether and a new process, which is applied in the field of new synthesizing terephthalic ether, can solve the problems of high total production cost, high price, increased production cost and the like, and achieves improvement of reaction yield and reduction of production cost. , the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

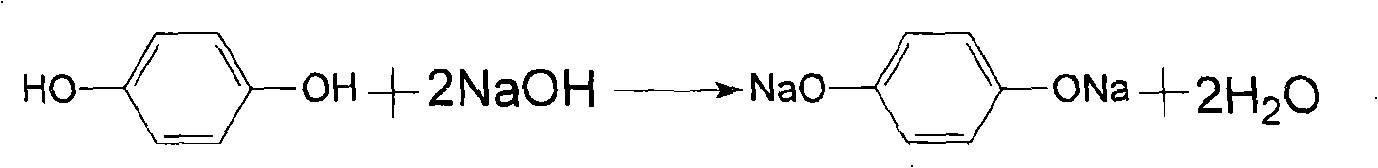

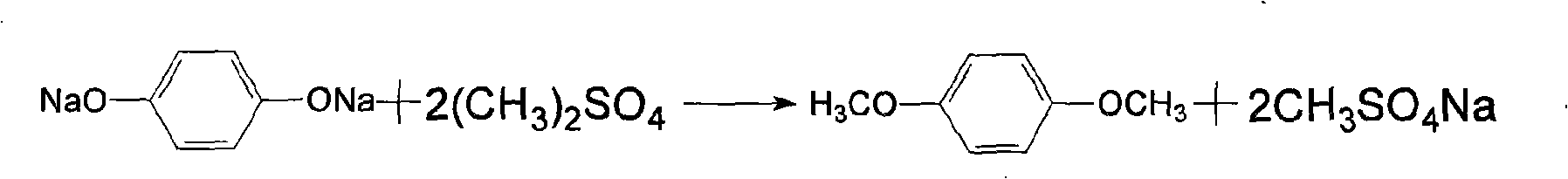

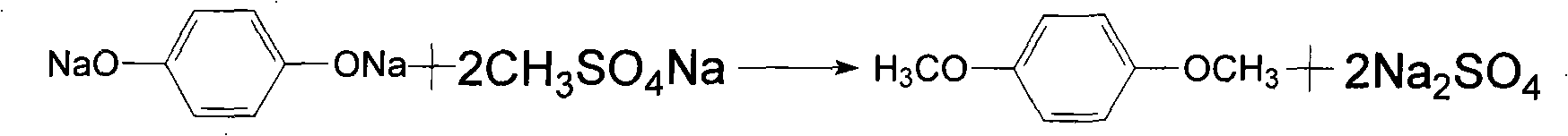

Method used

Image

Examples

Embodiment 1

[0022] Add 300ml of water, 30g of hydroquinone, and 55g of sodium hydroxide with a concentration of 30% into a 500ml four-neck flask, stir and raise the temperature to 55°C in a water bath, and slowly add 45g of dimethyl sulfate dropwise at this temperature for about half an hour , after the dropwise addition, keep warm for one hour, slowly add 25g of 30% sodium hydroxide solution about 15-20 minutes after the finish of the keep warm, then continue to heat up to 102-103°C for 5 hours, after the reflux, turn the reflux device Change it to a distillation device, and feed direct steam to carry out distillation at the same time. After the distillate is clarified and no product is distilled out, the reaction is over. Collect the distillate, filter and dry after cooling, and obtain 31g of the product, with a yield of 90.2%. It is 55.3°C.

Embodiment 2

[0024] Add 300ml of water, 30g of hydroquinone, and 65g of sodium hydroxide with a concentration of 30% into a 500ml four-neck flask, stir and raise the temperature to 55°C in a water bath, and slowly add 45g of dimethyl sulfate dropwise at this temperature for about half an hour After the dropwise addition, keep the temperature for one hour, slowly add 15g of 30% sodium hydroxide solution about 15-20 minutes after the heat preservation, then continue to heat up to 102-103°C for 5 hours, after the reflux, turn the reflux device Change it to a distillation unit, and feed direct steam to carry out distillation simultaneously. After the distillate is clarified and no product is distilled out, the reaction is finished. The distillate is collected, filtered and dried after cooling to obtain 29.8g of product, and the yield is 86.7%. The freezing point is 54.8°C.

Embodiment 3

[0026] Add 300ml of water, 30g of hydroquinone, and 55g of sodium hydroxide with a concentration of 30% into a 500ml four-neck flask, stir and raise the temperature to 55°C in a water bath, and slowly add 50g of dimethyl sulfate dropwise at this temperature for about half an hour , after the dropwise addition, keep warm for one hour, slowly add 25g of 30% sodium hydroxide solution about 15-20 minutes after the finish of the keep warm, then continue to heat up to 102-103°C for 5 hours, after the reflux, turn the reflux device Change it to a distillation unit, and feed direct steam to carry out distillation simultaneously. After the distillate is clarified and no product is distilled out, the reaction is finished. Collect the distillate, filter and dry after cooling, and obtain 30.7g of product, with a yield of 89.3%. The freezing point is 55.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com