Patents

Literature

140 results about "Sulfate sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium sulfate is the sodium salt of sulfuric acid. When anhydrous, it is a white crystalline solid of formula Na2SO4 known as the mineral thenardite. Sodium sulfate is one of the most important minerals in the chemicals industry.

Method and device for recycling anhydrous sodium sulfate from desulfurization lead plaster filter liquor

ActiveCN101244831AEvaporative crystallizationGuaranteed Concentration RequirementsSulfate/bisulfate preparationAlkali metal sulfite/sulfate purificationFiltrationResource recovery

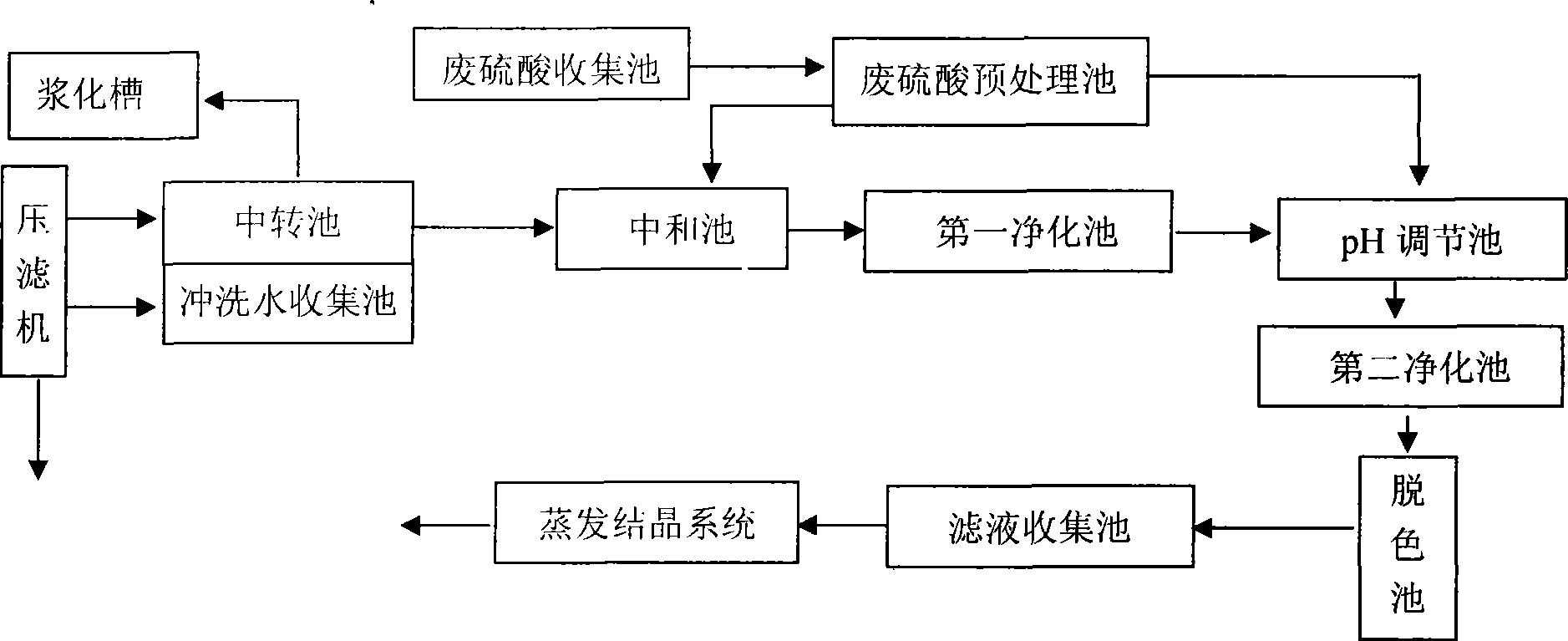

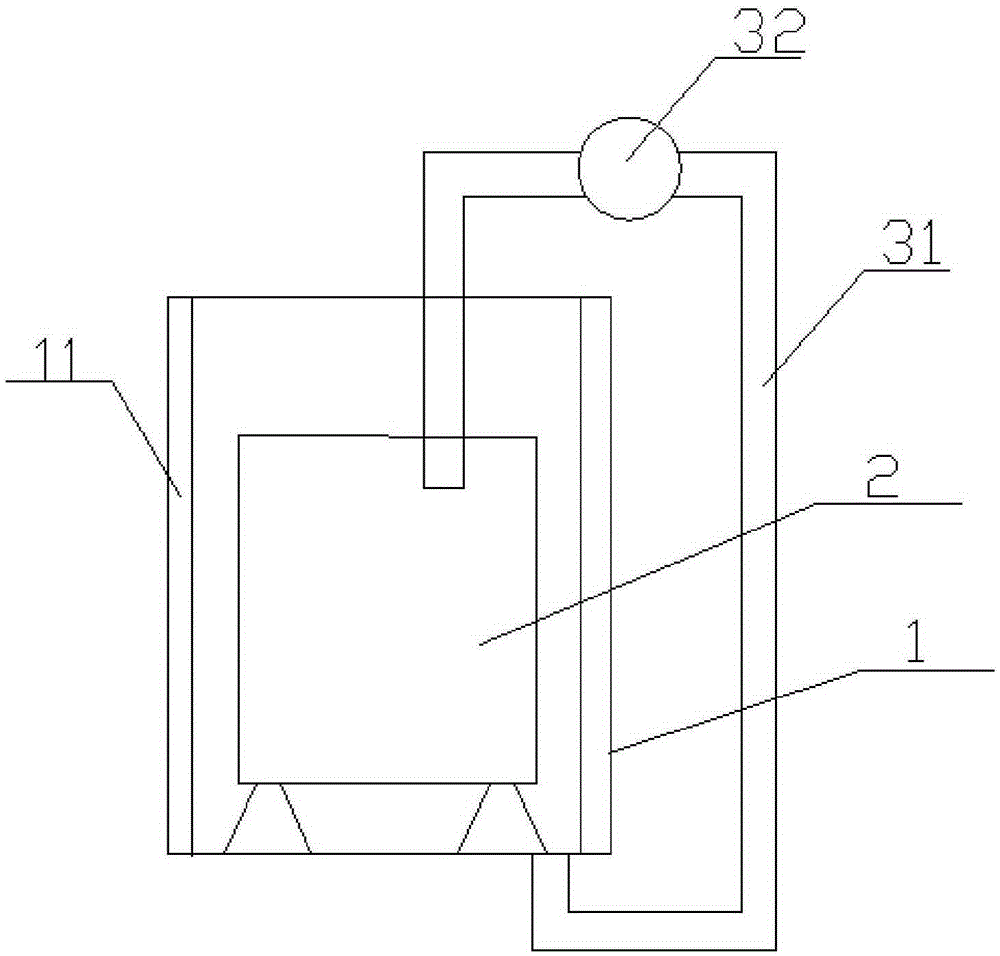

The invention relates to a method of recycling anhydrous sulfate sodium from de-sulfurized lead paste filtration, belonging to a resource recovery and utilization process, which avoids the disadvantages that waste sulfate is used and low concentration sulfate sodium is emitted into the environment. The method of the invention comprises: desulfurized lead paste filtration collection, sodium carbonate neutralization, first time heavy metal removal, filtration PH value adjustment, second-time heavy metal removal, decolorizing step, and vaporization and crystallization step; the device comprises a transfer tank, a neutralization tank, a first-stage purifying tank, a PH adjusting tank, a second-stage purifying tank, a decolorization tank, a filtration collection tank and a vaporization crystallization system; the waste sulfate collection tank is connected with a waste sulfate pre-processing tank, the waste sulfate pre-processing tank is respectively connected with the neutralization tank and the PH adjusting tank. The invention can directly recycle anhydrous sulfate sodium, the waste sulfate is used to neutralize the carbonate sodium remained in the filtration; the heavy metal ions and other ions in the filtration are removed according to two steps, so that the grade of obtained anhydrous sulfate sodium is equal to or larger than industrial grade.

Owner:HUAZHONG UNIV OF SCI & TECH

Coconut oil fruit and vegetable cleaning agent

ActiveCN105255601AReduce intensityReduced Chances of ContaminationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCocamidopropyl betaineCleansing Agents

The invention discloses a coconut oil fruit and vegetable cleaning agent. The coconut oil fruit and vegetable cleaning agent is prepared from, by weight, 58-96 parts of deionized water, 1-15 parts of fatty alcohol polyoxyethylene lauryl ether sulfate sodium, 0.1-0.5 part of caustic soda flakes, 0.1-0.5 part of ethylene diamine tetraacetic acid tetrasodium, 1-10 parts of alkyl polyglucoside, 1-10 parts of calkyl polyglucosides, 1-5 parts of sodium chloride, 0.01-0.5 part of Casson and 0.1-0.5 part of coconut oil essence. The coconut oil fruit and vegetable cleaning agent is high in dirt removing capacity compared with existing detergent, granulate grease dirt and residues dried on and fixed to the surface of utensil can be immediately removed, residues dried on the surface of utensil through air cannot be removed by the existing detergent, soaking needs to be performed for a period of time in clean water, common soaking at least needs to be performed for 10 min, time is wasted, lotus leaf powder is added, and the residues can be removed through clean water without being soaked.

Owner:HUBEI MULAN TONGDA TECH

Pipeline cleaning agent

InactiveCN103740489AEfficient removalKeep clean for a long timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineActive agent

The invention relates to a pipeline cleaning agent which comprises the following components by weight: 15-28 parts of organic acid, 20-35 parts of an asurface active agent, 18-30 parts of a penetrating agent and 0.5-3 parts of an acorrosion inhibitor, wherein the surface active agent comprises one or more ofpolyether, butyl cellosolve, coconut oil fatty acid diethanol amide and fatty alcohol-polyoxyethylene ether sulfate sodium; the penetrating agent comprises one or more of alcohol, sodium dodecyl sulfate, sodium dioctyl sulfosuccinate,dodecyl dimethyl betaine, sodium oleoyl methylamine ethanesulfonate and calcium chloride; the corrosion inhibitor comprises one or more of imidazolinequaternary ammonium salts or imidazoline amides. The pipeline cleaning agent can effectively remove grease and dirt in a pipeline to keep the pipeline unblocked, is safe and non-toxic, cannot corrode equipment, is harmless tohuman skin and conforms to emission standards.

Owner:BEIJING DAISI SCI & TECH

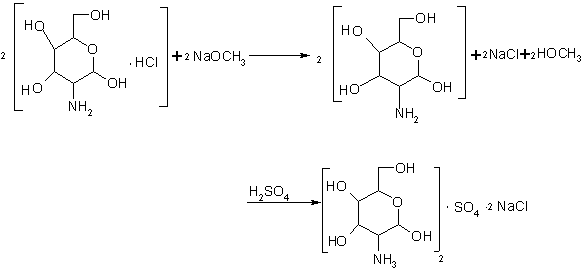

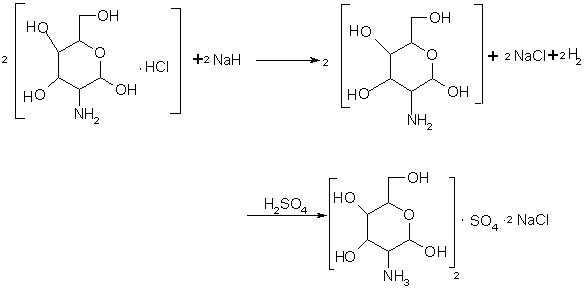

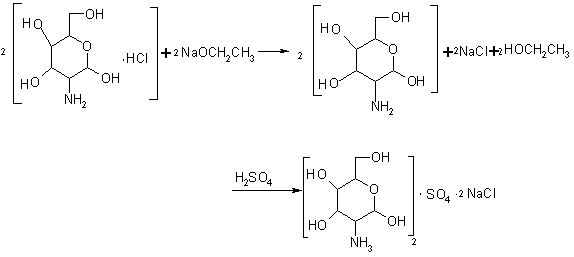

Preparation method of D-glucosamine sulfate sodium chloride salt

ActiveCN102850412AHigh purityNovel methodSugar derivativesSugar derivatives preparationChloride saltNitrogen

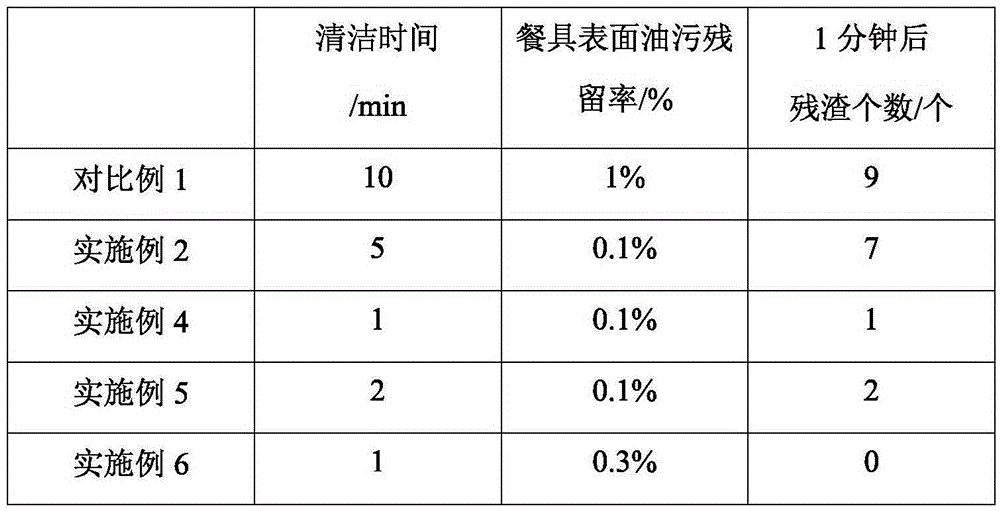

The invention discloses a preparation method of D-glucosamine sulfate sodium chloride salt. The preparation method comprises the following steps of: dissolving D-glucosamine hydrochloride in a solvent; adding a sodium-containing alkaline substance into the obtained solution at the temperature of minus 40-100 DEG C, or adding the sodium-containing alkaline substance into the obtained solution under the protection of one or more protective gas(s) of nitrogen, carbon dioxide and inert gases; adding the sodium-containing alkaline substance into the mixed solution at the maintained temperature of minus 40-90 DEG C; adding sulfuric acid into the obtained solution at the temperature of minus 25 to 90 DEG C for salifying; carrying out complexation reaction to obtain a D-glucosamine sulfate sodium chloride salt complex; and filtering and crystallizing to obtain the D-glucosamine sulfate sodium chloride salt solid. The method is novel and unique and simple and reasonable in technology, product quality is good and purity is high, and completely reaches the standard of United States patent (USP) 34 edition pharmacopeia.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

Rhubarb toothpaste

InactiveCN102058505AImprove immunityEasy to solveCosmetic preparationsToilet preparationsCelluloseToothpaste

The invention relates to rhubarb toothpaste, in particular to rhubarb health-care toothpaste used for cleaning and protecting teeth in daily life. The rhubarb health-care toothpaste comprises the following components in parts by weight: 40-50 parts of calcium carbonate, 15-25 parts of sorbitol, 0.2-1.5 parts of carboxy cellulose, 0.1-1 part of guar gum, 0-0.5 part of saccharin sodium salt, 0.5-2. 5 parts of alcohol sulfate sodium, 0-1 part of sodium pyrophosphate, 1-5 part of silicon dioxide, 0-0.5 part of sodium methyl, 1-3.5 parts of propylene glycol, 15-30 parts of deionized water, 0-0.8 part of essence, 0-1 part of menthol, 0.2-1.5 parts of rhubarb biological extract and 0-0.8 part of sea buckthorn biological extract. The preparation method of the rhubarb health-care toothpaste comprises the following steps of: adding the sorbitol, the carboxy cellulose, the guar gum, the alcohol sulfate sodium, the sodium pyrophosphate, the silicon dioxide, the sodium methyl and the propylene glycol in a vacuum paste machine and mixing uniformly; and then adding the deioned water, and adding the rhubarb biological extract, the sea buckthorn biological extract, the calcium carbonate, the saccharin sodium salt, the menthol and the essence in sequence, and stirring at a high speed in vacuum for sufficiently emulsifying and mixing uniformly.

Owner:孟庆海

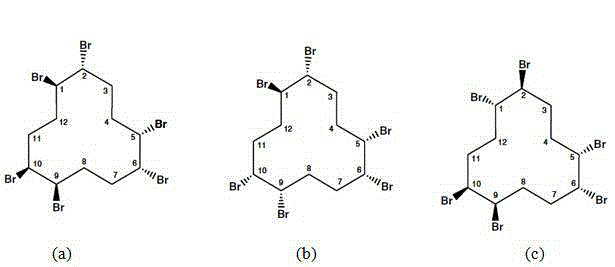

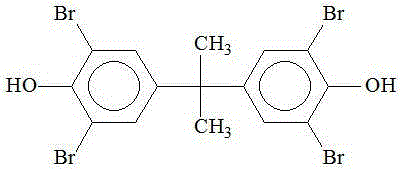

Method for simultaneous determination of hexabromocyclododecane isomer and tetrabromobisphenol A in fat food

InactiveCN105181865AOptimizing pre-processing technologyMeet the requirements for analyzing actual samplesComponent separationTetrabromobisphenol AMicrosphere

The invention provides a method for simultaneous determination of hexabromocyclododecane isomer and tetrabromobisphenol A in fat food. The method is characterized by mainly including sample extraction, extract purification and determination. The extract purification uses mesoporous zirconia hybrid column as a solid phase extraction column containing an anhydrous sodium sulfate layer, a mesoporous zirconia microsphere layer, an acidified silica gel layer, a dielectric hole oxide zirconium microsphere layer and an anhydrous sulfate sodium layer from bottom to top. The recovery rate of hexabromocyclododecane isomer and tetrabromobisphenol A in plant oil, fish, meat, egg, milk and other fat food sample reaches 87.5%-114.4%. The preparation of reusable mesoporous zirconia microsphere optimizes the pretreatment technology, and saves a large amount of solvent; the detection limit, quantification limit, recovery rate and precision can meet the requirements for analysis of real samples; and reliability of the method and result accuracy are verified through the standard substance in international comparison.

Owner:INST OF AGRI QUALITY STANDARDS & TESTING TECH RES HUBEI ACADEMY OF AGRI SCI

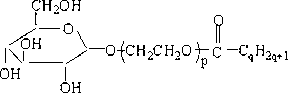

Low-tension foaming agent for improving crude oil extracting rate of high-salinity oil reservoir and preparation method thereof

InactiveCN101717627ACompatibility is not affectedReduce tensionDrilling compositionTemperature resistanceOleic Acid Triglyceride

The invention discloses a low-tension foaming agent for improving crude oil extracting rate of a high-salinity oil reservoir and a preparation method thereof, belonging to the field of foaming agents for oil extraction of the oil reservoir. The foaming agent comprises the following components in percentage by weight: 20-70 percent of alkyl-dimethylamine acetolactone, 10-50 percent of lauryl alcohol polyethenoxy ether sulfate sodium salt, 10-50 percent of coconut oleic acid monoethanol amine and 10-60 percent of water. Compared with the prior art, the low-tension foaming agent has the characteristics of strong foaming ability, high foam stability, temperature resistance, high mineralization resistance, high calcium and magnesium ion resistance, good compatibility with stratum water, and the like, and is suitable for the foam flooding of the high-salinity oil reservoir to improve the crude oil extracting rate.

Owner:RES INST OF PETROLEUM EXPLORATION & DEV SHENGLI OILFIELD CO LTD SINOPEC

Water-based metal cleaner

The invention provides a water-based metal cleaner, relating to a technology of pretreatment of processes of metal coating, electroplating, hot dipping coating and the like, in particular to a technology of cleaning the pretreatment surface of carbon steel. The water-based metal cleaner provided by the method comprises the following components of: 190 to 220 g / L of industrial hydrochloric acid, 1.7 to 8.5 g / L of phosphoric acid, 1 to 5 g / L of oxalic acid or 1 to 5 g / L of tartaric acid, 1 to 2.2 g / L of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES or 1.5 to 2 g / L of sodium dodecyl sulfate, 0.6 to 1.6 g / L of peregal 0-15, and 2 to 2.3 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The cleaner can fast, effectively and synchronously complete two processes of deoiling and derusting on the metal pretreatment surface, can effectively prevent acid mist from volatilizing, prolongs the service life of equipment and improves the working environment of labor workers.

Owner:BEIJING JJRS TECH DEV +1

Liquid detergent

InactiveCN103773622AEfficient removalBright as newAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsAlpha-olefinFatty alcohol

The invention discloses a liquid detergent. The liquid detergent comprises the following components in percentage by weight: 10-20 percent of fatty alcohol-polyoxyethylene ether, 5-8 percent of fatty alcohol polyoxyethylene lauryl ether sulfate sodium, 1-6 percent of alpha-olefin sulfonate, 1-5 percent of sec-alkyl sodium sulfate, 5-10 percent of coconut oil fatty acid diethanolamine, 0.5-1 percent of protease, 1-5 percent of an enzyme stabilizer, 0.1-1 percent of a builder, 0.05-0.5 percent of a fluorescent brightening agent, 0.05-0.5 percent of essence, and the balance of deionized water. The liquid detergent has a good stain removal effect, can effectively remove various intractable dirts on the surface of fabric, meanwhile can prevent secondary sedimentation of the dirt, has a better capacity of modifying the color on the surface of the fabric, and can ensure that the fabric is bright in color as a new one after washing.

Owner:阳紫威

Foaming composite material with high thermal conductivity

ActiveCN103818075AOvercoming thermal conductivityOvercome functionNon-macromolecular adhesive additivesSynthetic resin layered productsAntioxidantPlasticizer

The invention relates to a resin foaming composite material, especially to a foaming composite material with high thermal conductivity. The foaming composite material is prepared by the following steps: primary mixing: 8-12 parts by weight of a heat conduction material is added into 40-100 parts by weight of matrix resin to obtain a primary mixed object; plasticization and granulation: 2-8 parts by weight of a fire retardant, 6-10 parts by weight of a softening plasticizer, 3-7 parts by weight of a flexibilizer, 1-4 parts by weight of a coupling agent and 0.6-1.2 parts by weight of an antioxidant are added into the primary mixed object for blending modification and plasticization, and extrusion and granulation are carried out to obtain a first granule; remixing and foaming: 15-25 parts by weight of one or more selected from fatty alcohol polyoxyethylene lauryl ether sulfate sodium or an azo-compound are mixed with one or more selected from the first granule and 30-70 parts by weight of the matrix resin, extrusion and foaming are conducted to prepare a foaming material, and a full-open foaming material layer is compounded on the foaming material through glue to form the foaming composite material with high thermal conductivity. The material provided by the invention has high thermal conductivity and is waterproof and shock-absorbing.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

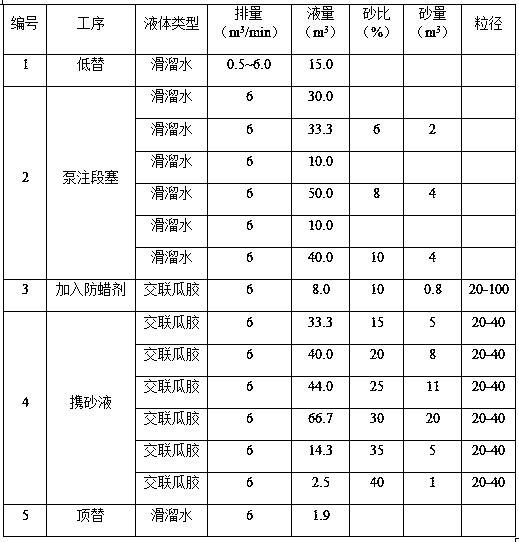

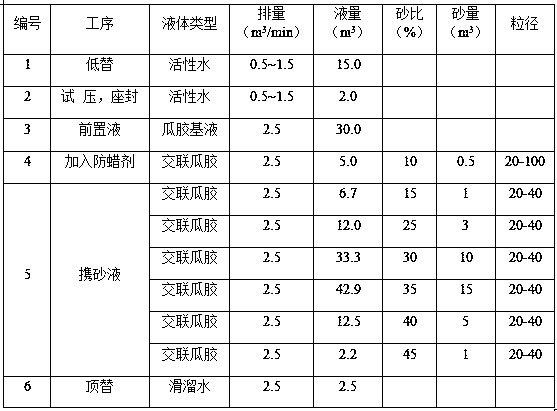

Wax inhibitor added during fracturing construction and preparation method and application thereof

ActiveCN108915637AExpand the scope of actionTo preventCleaning apparatusFluid removalROSIN POWDERSodium stearate

The invention provides a wax inhibitor added during fracturing construction. The wax inhibitor is prepared from the following raw materials in percentage by weight: 10%-20% of sodium stearate, 10%-20%of peregal O-25, 10%-15% of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES, 5%-10% of sodium dodecyl benzene sulfonate ABS, 0.5%-1% of ethylenediamine traacetic acid, 1%-2% of rosin powder, and the balance of quartz sand. Meanwhile, the invention also provides a preparation method and application of the wax inhibitor. The wax inhibitor provided by the invention does not need separate construction, is added during fracturing construction and can penetrate through the distal end of stratum, so that the action range of the wax inhibitor in the stratum is enlarged, the effective time is long, and the wax inhibitor can be slowly released in the stratum at 30 DEG C for about 2 years; wax inhibition is carried out before crude oil production, so that the source of wax production is directly cut off, and the generation of wax is fundamentally prevented; construction is convenient and construction cost is reduced.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

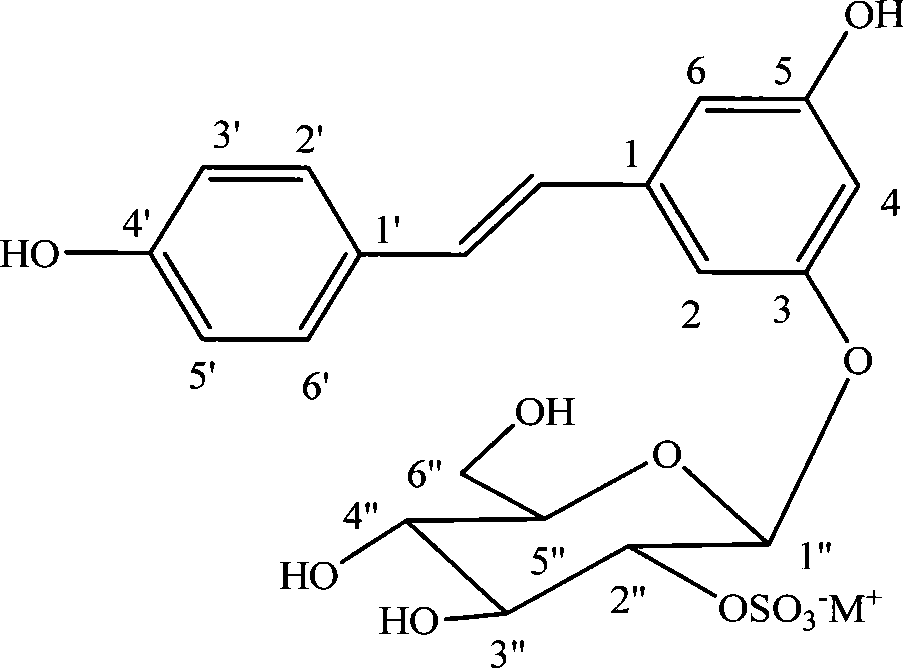

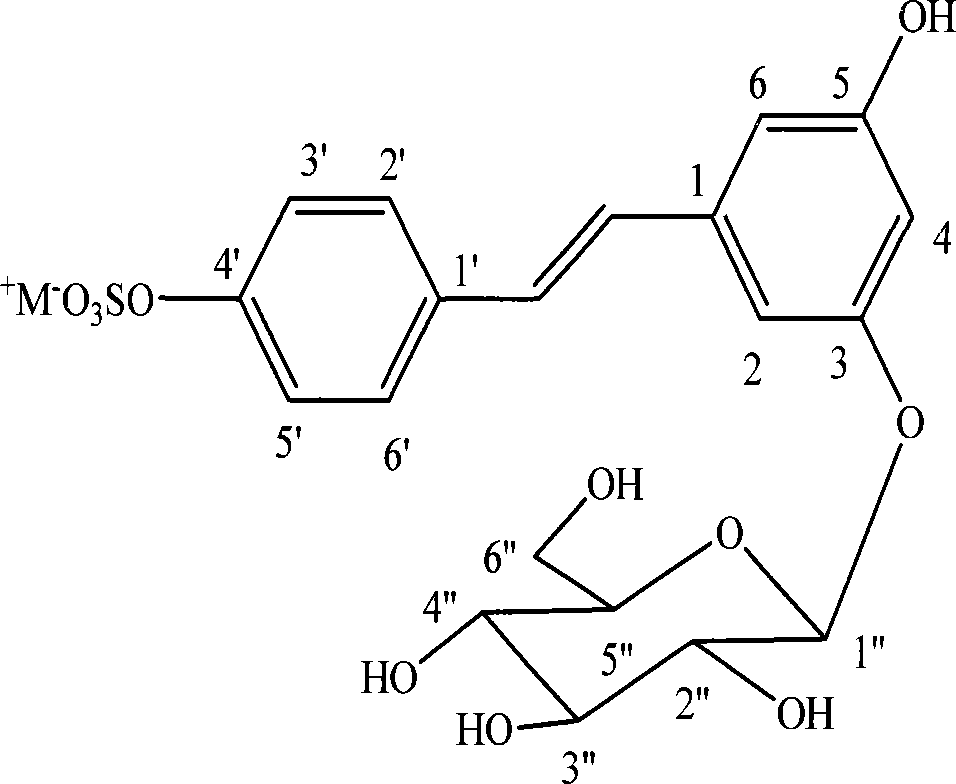

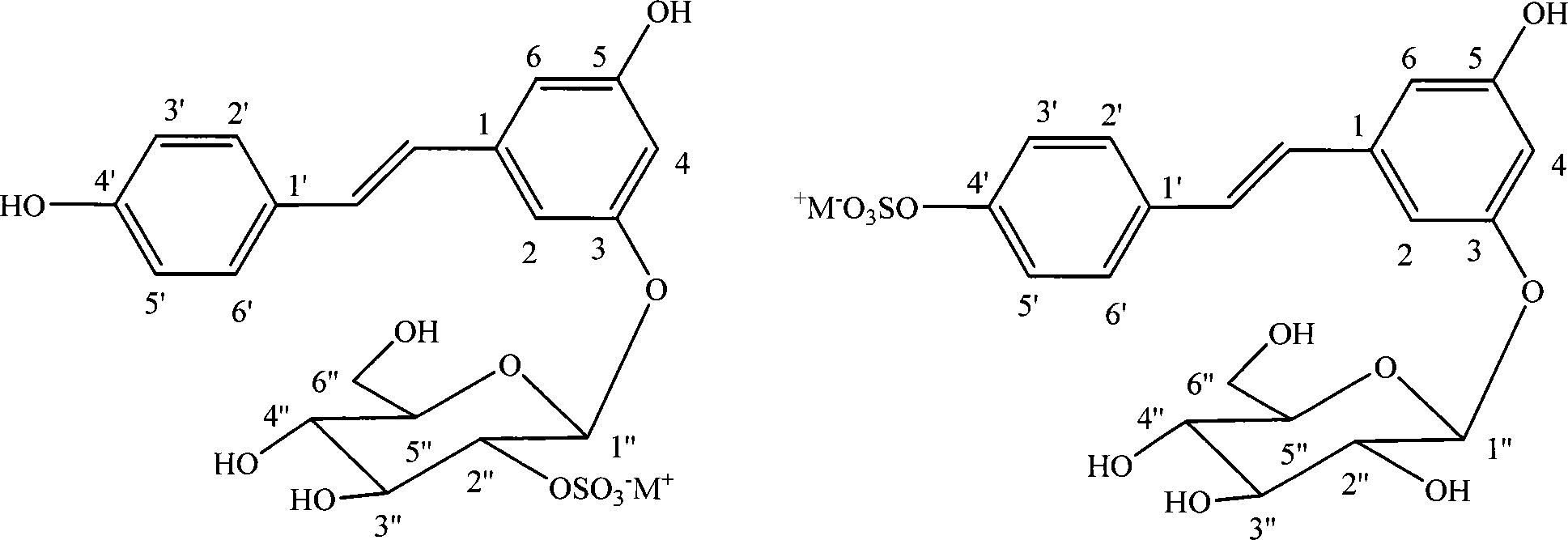

Use of giant knotweed rhizome extract in preparing product for resisting AIDS virus and hepatitis B

InactiveCN101214285ATechnical expertiseEnhance pharmacological effectsOrganic active ingredientsSugar derivativesViral infectious diseaseHepatitis B virus

The present invention relates to purposes of giant knotweed extract. The in vitro anti-HIV experiment shows that resveratrol 3-O-Beta-D- glucoside 2íÕ-sulfate sodium or potash salt and resveratrol 3-O-Beta-D- glucoside 4íÕ-sulfate sodium or potash salt show significant activity of resisting hepatitis B virus; resveratrol 3-O-Beta-D- glucoside 2íÕ-sulfate sodium or potash salt also has significant HIV inhibited effect. The virus infectious diseases such as AIDS and hepatitis B poses a serious threat to human's health and life and hepatitis B is one of the major diseases affecting human's health. The present invention provides a lead compound for doing R&D of novel anti-HIV and hepatitis B virus medicines and also a novel medicine source for clinic application, thus having a significant value to develop and utilize the medical plant resources of our country.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

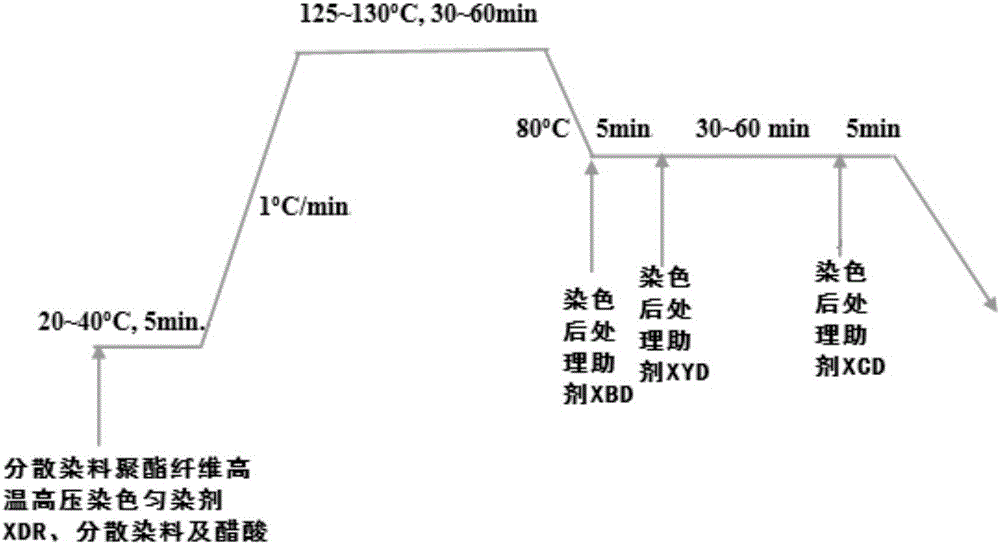

Preparation method and application of leveling agent for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes

The invention discloses a preparation method and application of a leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes. The preparation method is mainly characterized in that fatty alcohol-polyoxyethylene ether, alkyl sodium sulfonate, alkyl sulfate sodium, fatty amine polyoxyethylene ether, urea and purified water are uniformly mixed to obtain the leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes. The invention also discloses a method for dyeing polyester fibers and polyester fiber blended products by use of the leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes. After adoption of the prepared leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes, the oriented adsorption density of surfactant molecules on the surfaces of disperse dyes particles is remarkably improved, the interfacial tension between the dye particles and water and the average grain diameters of the dyes particles are obviously reduced, the solubility of the dyes and the dyeing percentage of the dyes to the fibers are remarkably improved, and agglomeration of the dyes and nonuniform dyeing can be dramatically reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Method for preparing protamine and dextran sulfate sodium microcapsule

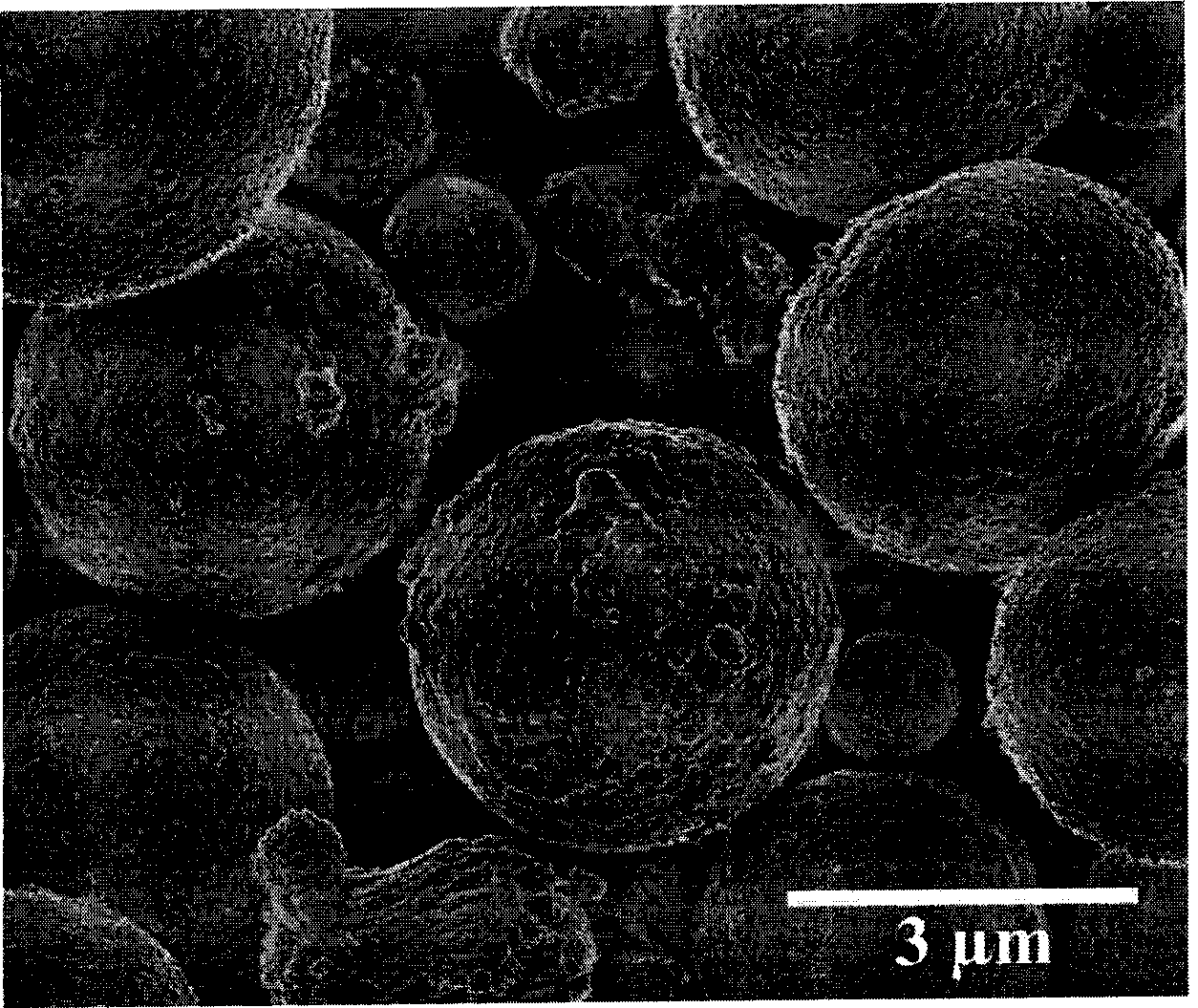

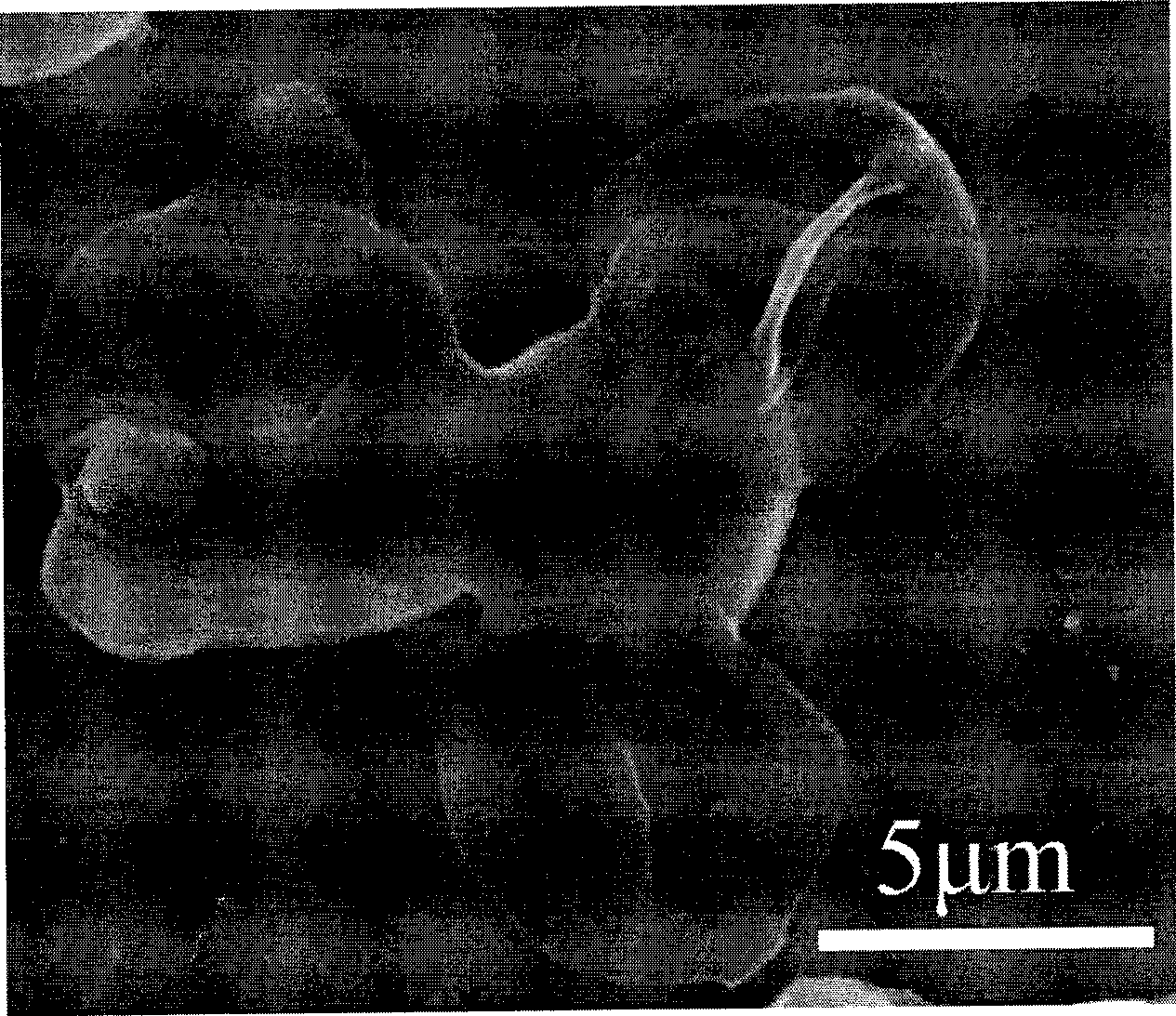

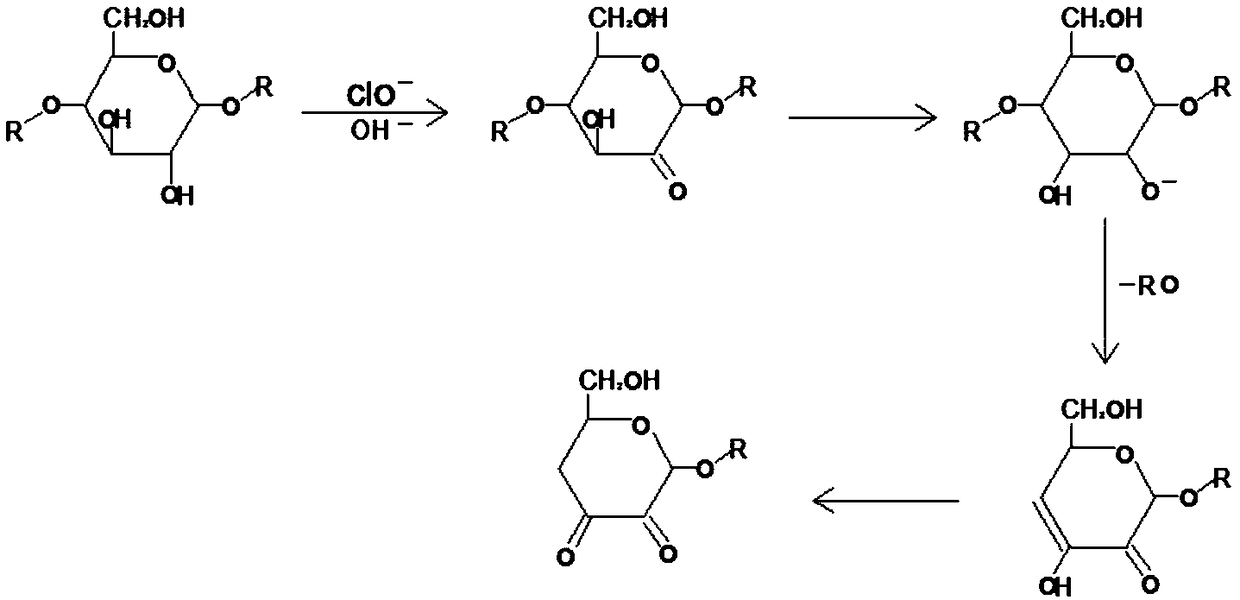

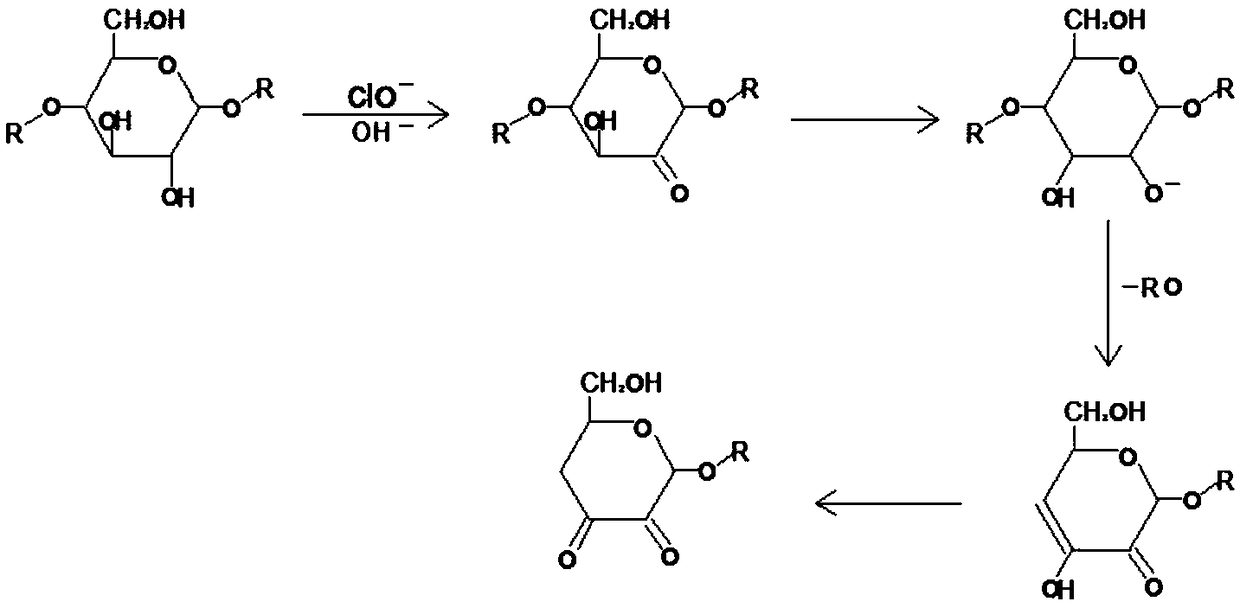

InactiveCN101530767AGood size controlBiocompatibleMicroballoon preparationMicrocapsule preparationMultilayer membraneMicrosphere

The invention relates to a method for preparing the protamine and dextran sulfate sodium microcapsule, comprising the following steps: reacting calcium chloride, sodium carbonate, sodium polystyrene sulfonate or polyallylamine hydrochloride, cetyl trimethyl ammonium bromide, PEO20-PPO70-PEO20 triblock copolymer, polydiallyldimethylamine chloride solution with stirring at the temperature of 10 to 80 DEG C to obtain the calcium carbonate microsphere; fully mixing the obtained calcium carbonate microsphere with the protamine water solution, adsorbing the protamine, removing the protamine not to be adsorbed, fully mixing the calcium carbonate microsphere with the protamine withdextran sulfate sodium containing inorganic salt to adsorb dextran sulfate sodium, removing the dextran sulfate sodium not to be adsorbed; alternately adsorbing to obtain the microcapsule with the protamine and dextran sulfate sodium multilayer membrane core-shell structure; dissolving calcium carbonate in ethylenediaminetetraacetic acid sodiumsalt to obtain the protamine and dextran sulfate sodium microcapsule.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Viscose fiber spinning oiling agent

The invention discloses a viscose fiber spinning oiling agent, comprising sperm whale oil sulfate sodium, fatty acid polyol ester, whale oil sulfate sodium, oleyl alcohol polyoxyethylene (5) ether, and mineral oil. The invention has the advantages of reasonable formula, good effects, and low production cost.

Owner:宋建英

Environment-friendly automobile detergent and preparation method thereof

InactiveCN109266460AHigh glossHigh purityInorganic/elemental detergent compounding agentsCationic surface-active compoundsIonChemistry

The invention discloses an environment-friendly automobile detergent and a preparation method thereof. The environment-friendly automobile detergent is prepared from, by weight, 30-60 parts of sodiumlaureth sulfate, 25-35 parts of modified nanometer microcrystalline cellulose, 25-50 parts of non-ionic surfactant, 15-30 parts of ammonium dodecyl dimethyl benzyl oxide, 10-20 parts of potassium sorbate, 20-30 parts of sodium tripolyphosphate, 15-25 parts of silicone oil emulsion, 5-10 parts of floating agent, 1-5 parts of essence, 10-20 parts of sodium hydrogen ferric diethylenetriamine pentaacetic acid and 50-80 parts of deionized water. According to the environment-friendly automobile detergent, sodium laureth sulfate has high purity and better activation property, and can form a compounded system with the non-ionic surfactant and improve the activation property of the non-ionic surfactant, the surface activity and surface tension of the compounded system are improved after the sodiumlaureth sulfate and the non-ionic surfactant are mixed, and thus the cleaning effect of the automobile detergent can be improved.

Owner:广州市车极速汽车服务有限责任公司 +1

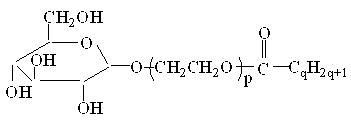

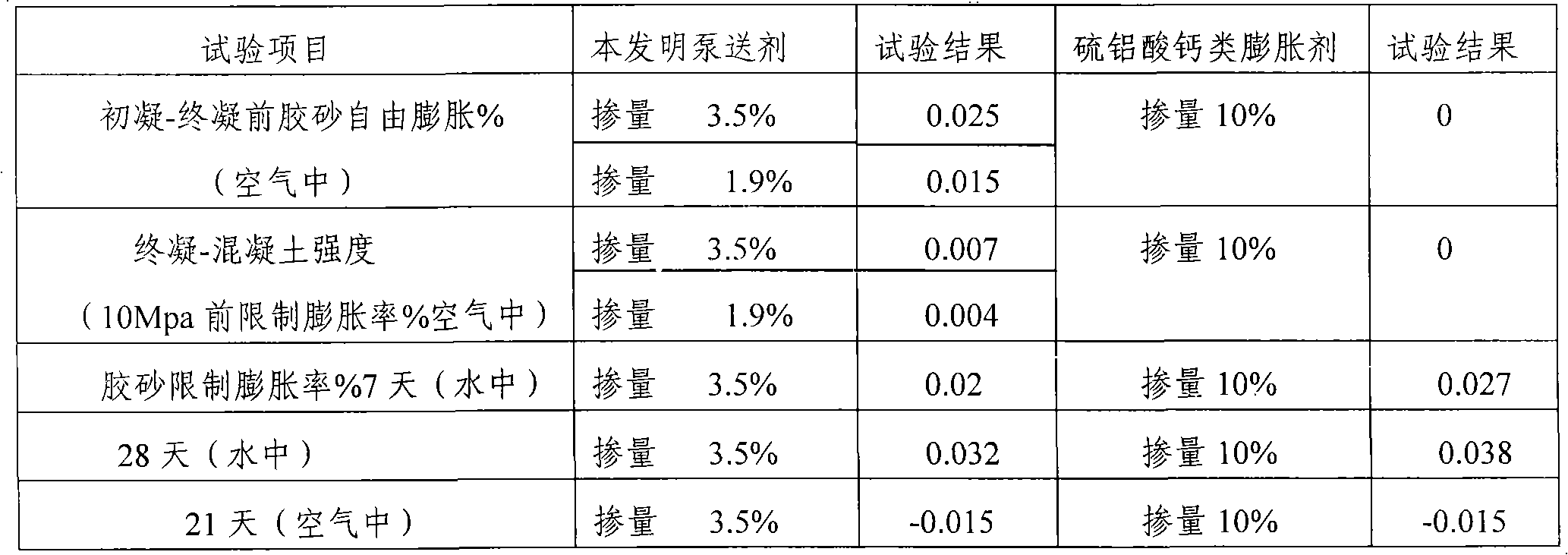

High-efficiency scouring agent containing glucose structural units and preparation method thereof

The invention belongs to the field of textile auxiliaries, relating to a high-efficiency scouring agent containing glucose structural units. The high-efficiency scouring agent is prepared through mixing the following components by weight: 10-15% of alkyl glycoside, 5-10% of polyethylene glycol glucoside aliphatic ester, 15-20% of alkyl glycoside sulfate sodium salt and the balance of water. The invention further provides a preparation method of the scouring agent. The scouring agent and the preparation provided by the invention are featured with reasonable components and simple processes, and the scouring agent s is featured with environmental protection, low-foaming performance and high efficiency so as to meet demands on green environment-friendly high-efficiency scouring agents in the national printing and dyeing industry.

Owner:HANGZHOU MEIGAO HUAYI CHEM

Preparation method of synthesized D-glucosamine sulfate sodium

InactiveCN102417525AHigh purityLess impuritiesSugar derivativesSugar derivatives preparationGlucosamine SulfateCurative effect

The invention provides a preparation method of a synthesized D-glucosamine sulfate sodium. The method comprises the following steps of dissolving, crystallization and drying. The synthesized D-glucosamine sulfate sodium of the present invention has advantages of simple process flow, low cost and benefit for industrialized production; and the synthesized D-glucosamine sulfate sodium prepared by the method of the invention has high purity, little impurity and good curative effect.

Owner:YANGZHOU HONGXIN BIOLOGICAL PRODS

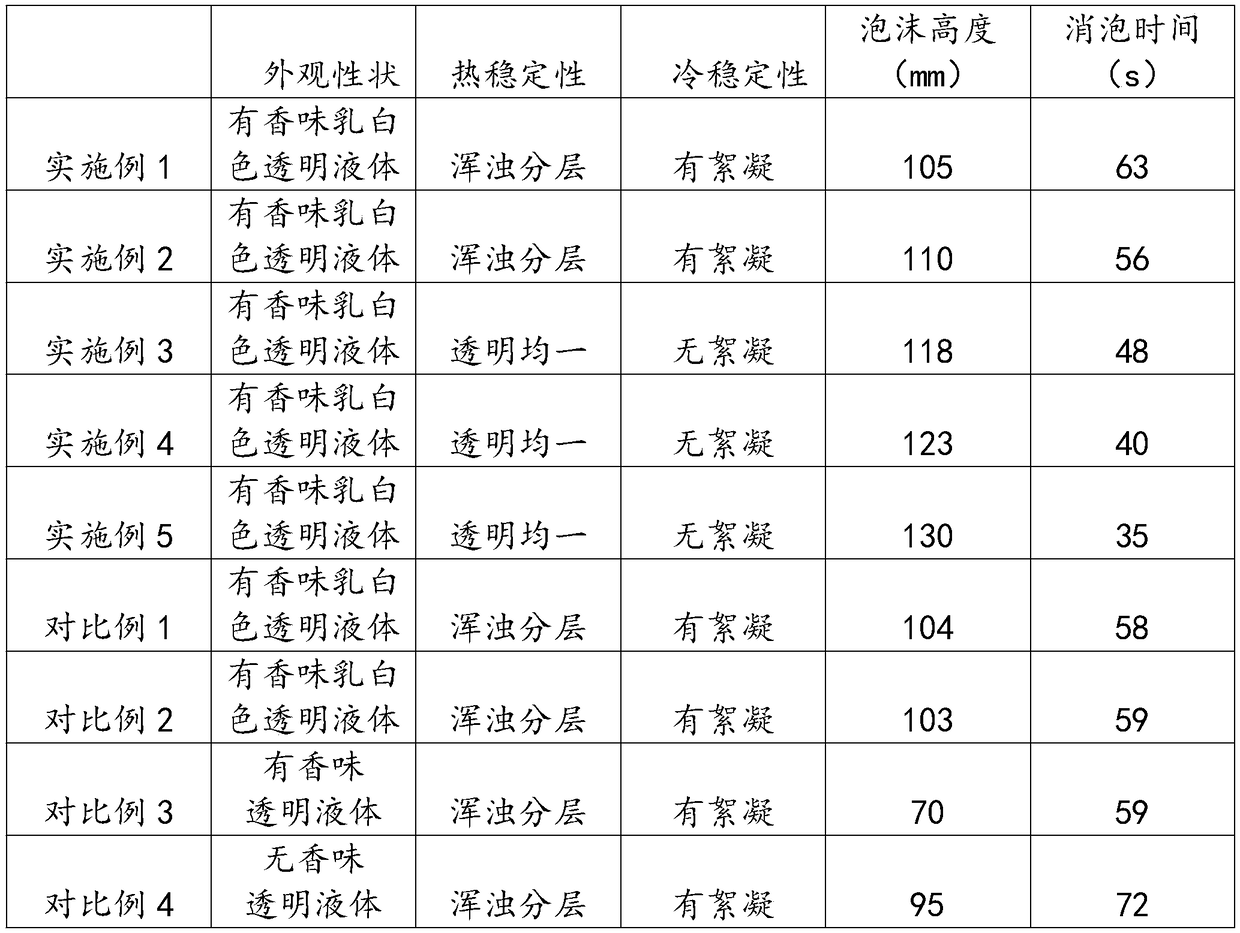

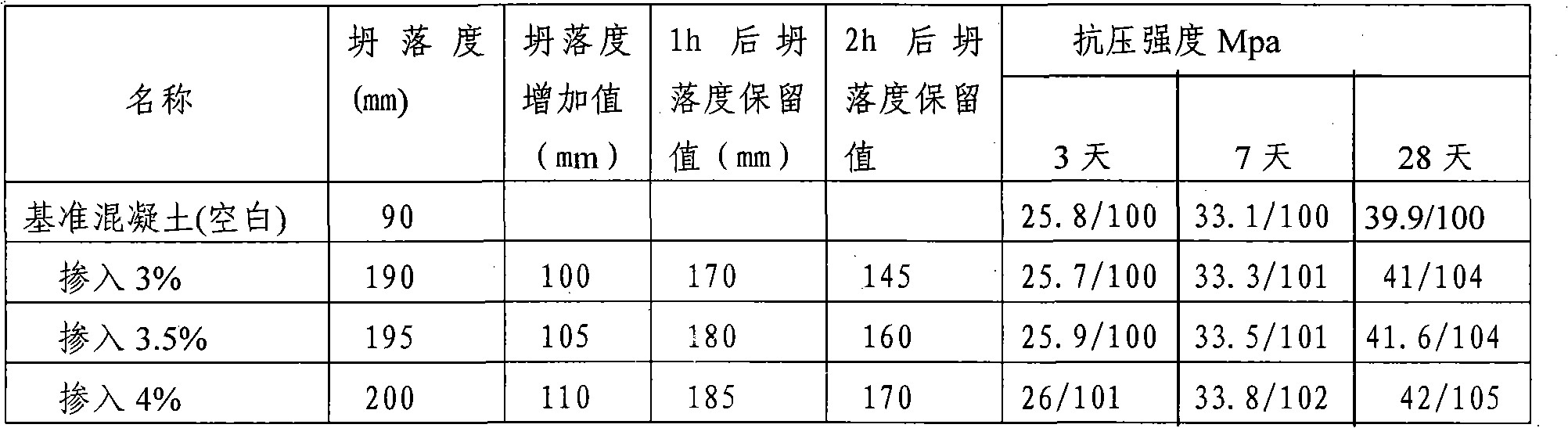

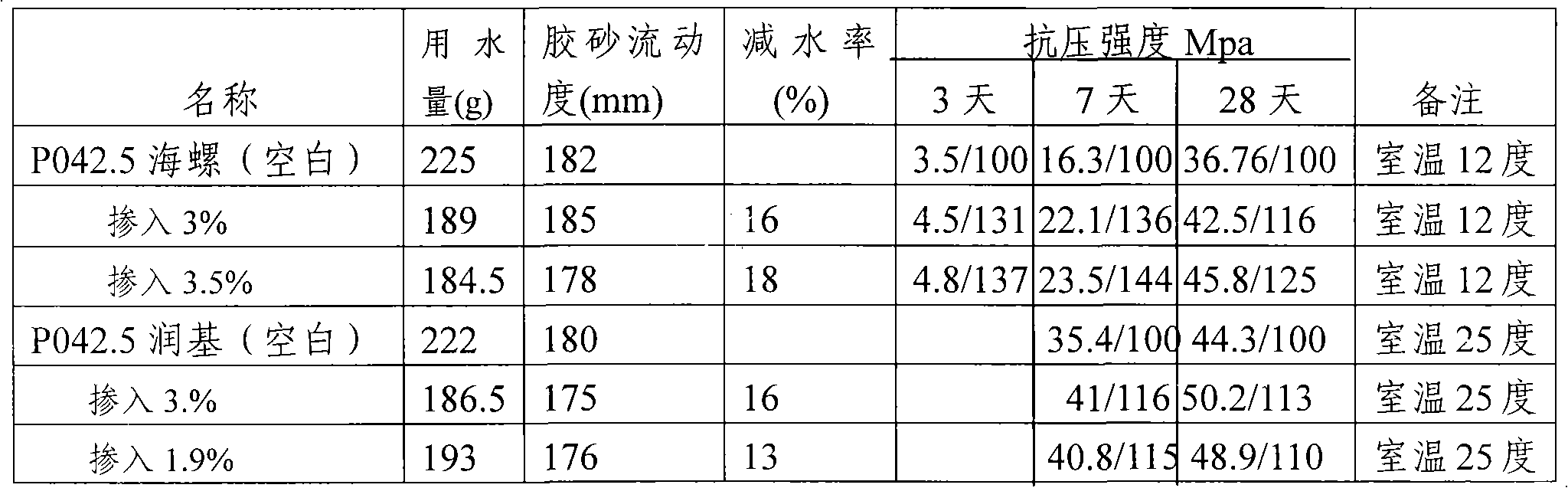

Multifunction shrinking-compensate concrete pump-feed agent

The invention provides a multifunction compensation shrinkage concrete pumping agent, and belongs to the technical field of concrete admixture. The invention is to provide a multifunction compensation and shrinkage concrete pumping agent which can reduce cracks generated early and can reduce cement cracks which are harmful into unharmful cracks in construction when concrete batching plants produce pumping concrete. The multifunction compensation shrinkage concrete pumping agent consists of a naphthalene sulfonic acidformaldehyde condensation product water reducer, aluminum ammonium sulfate, modified lignin sulfonate, lauryl sulfate sodium salt, hydrogen peroxide, aluminum sulfate and water. After the components are mixed and beaten, the mixture is adjusted with sodium hydroxide to the extent that the pH is equal to or more than 5, thus getting aqua. The pumping agent of 1.9 to 4 percent of cement in concrete by weight is added. By adopting the pumping agent, the free expansion coefficient of the pumped concrete ranges from 0.015 to 0.025 percent during the period from initial set to final set; the trace confined expansion coefficient is 0.004 to 0.007 percent before the strength of the concrete becomes 10 MPa from the final set of concrete. Accordingly, by adopting the concrete pumping agent, the early cracks of the pumped concrete are reduced; and the width of the cracks is reduced to the extent that the cracks become unharmful, thus ensuring good economic and social benefits in respect of the quality of pumped concrete.

Owner:金骥

Skid prevention paint for floors

InactiveCN103013271APrevent slippingNo pollution in the processRosin coatingsAlkylphenolPOLYOXYETHYLENE ETHER

The invention discloses skid prevention paint for floors. The skid prevention paint is made from the following raw material components: 30-40 parts of straight-chain alkyl aryl sulfonate, 10-20 parts of phenolic resin, 60-70 parts of alkylphenol polyoxyethylene alcohol sulfate sodium salt, 1-2 parts of sodium chloride, 2-4 parts of rosin, 2-4 parts of ethanol, 2-4 parts of sodium silicate and 1-3 parts of titanium white powder. The skid prevention paint for floors, disclosed by the invention, can prevent skidding, does not pollute the environment, and can make up the deficiencies of the traditional paint, thereby meeting the needs of people.

Owner:QIDONG LONGTENG ELECTRIC

Culture soil for gardenia and preparation method thereof

The invention relates to a culture soil for gardenia flowers. The culture soil is composed of the following components by weight: 200-350 parts of peat, 30-50 parts of pebbles, 30-60 parts of chicken manure, 20-25 parts of goat urine, 40-45 parts of Gardenia stems, 35-50 parts of blue algae, 34-44 parts of tomato branches and leaves, 23-40 parts of sweet potato powder, 20-30 parts of molasses, 25-35 parts of moth, 15-25 parts of pupa, 6-12 parts of Bifidobacterium agent, 8-16 parts of Trichoderma viride agent, 3-7 parts of sodium selenite, 2-6 parts of ammonium sulfate, 7-14 parts of an amino acid chelate liquid, 4-8 parts of manganese sulfate sodium, 2-6 parts of potassium sulfate, 7-12 parts of calcium superphosphate, 9-18 parts of sulfonated lignin and 6-18 of calcium lignin sulphonate.

Owner:合肥科友生物科技有限公司

Organic bacterial manure for loosening soil and improving physical properties of soil and preparing method thereof

InactiveCN105461491ALoss of nutrientsNutrients are not easy to loseExcrement fertilisersBioloigcal waste fertilisersFatty alcoholFermentation

The invention discloses organic bacterial manure for loosening soil and improving physical properties of soil and a preparing method thereof. The organic bacterial manure is prepared from a soil conditioner, dry manure, crop straw, amino acid, organic matter, amino acid chelated microelement fertilizer, a multifunctional biological agent and traditional Chinese medicine residue waste liquid. The soil conditioner is prepared from a soil loosening agent, fatty alcohol-polyoxyethylene ether sulfate sodium salt, slow release boron, slow release zinc, molybdenum, fermentation type humic acid, slow release silicon, a manure synergist and a crop rooting agent. The amino acid chelated microelement fertilizer is prepared from an amino acid chelating agent and a trace metal compound. By the adoption of the organic bacterial manure, nitrogen, phosphorus, potassium, organic acid, amino acid and multiple microelements can be provided, the physical property, chemical property and biological property of soil can be changed, soil is kept loose, and formation of the soil aggregate structure can be promoted, so that the permeability of soil is improved, side effects caused by chemical fertilizer are eliminated, the soil structure is improved, and soil is loose and does not harden.

Owner:GUANGXI WEILIDA BIOTECH CO LTD

Environmentally-friendly water-based cleaner for range hoods

InactiveCN107653089AImprove decontamination abilityMild effectNon-ionic surface-active compoundsPolymeric surface-active compoundsWater basedBetaine

The invention discloses an environmentally-friendly water-based cleaner for range hoods. The cleaner mainly comprises 5.8-7.5 wt% of alkyl glycosides, 0.8-1.5 wt% of a chelating agent, 3.3-5.8 wt% ofsodium sulfosuccinate, 3.3-4.8 wt% of fatty alcohol polyoxyethylene lauryl ether sulfate sodium, 5.8-8.5 wt% of cocoamidopropyl betaine, 3.2-7 wt% of coconutt diethanol amide, and the balance of water. The cleaner prepared in the invention is a water-based cleaner, can be biodegraded and has a good environmental protection performance. The prepared cleaner is weakly acidic or neutral, meets the requirements of the human body health science, and does not corrode skins, and has the characteristics of low toxicity, strong decontamination ability, and great market application potential.

Owner:CHENGDU YUELUN TRADING CO LTD

Environment-friendly circuit board cleaning agent and preparation method thereof

InactiveCN103540463AImprove securityNot dangerous to healthSurface-active non-soap compounds and soap mixture detergentsCoconut diethanolamideActive agent

The invention provides an environment-friendly circuit board cleaning agent. The cleaning agent is prepared from the following raw materials in parts by weight: 2-4 parts of sodium citrate, 5-10 parts of sodium laureth sulfate, 2-3 parts of coconut diethanolamide, 30-40 parts of ethanol, 4-5 parts of polyethylene glycol, 2-3 parts of petroleum sodium sulfonate, 2-3 parts of lignosulfonate, 4-5 parts of auxiliary and 100-120 parts of deionized water. The cleaning agent has the beneficial effects that the cleaning agent does not endanger the health of workers, is environment-friendly, non-combustible and non-explosive and has good safety because of using water and various low-toxicity reagents, is weakly acidic, enables the compatibility effects of various surfactants to be good, greatly improves the decontamination effect and the production efficiency, and reduces the cost; the auxiliary can form a protective film on the surface of the circuit board to isolate air to prevent water and other molecules in the air from corroding the circuit board; the cleaning agent is resistant to oxidation, prevents short circuit and is convenient for operation of the next preparation process.

Owner:合肥市华美光电科技有限公司

Antithrombotic medicament for intravenous injection and preparation method and application thereof

ActiveCN102212148AReduce the degree of polymerizationHigh purityOrganic active ingredientsFermentationPolymannuronic acidAntithrombotic Agent

The invention provides an antithrombotic medicament for intravenous injection. The medicament is a modified acidic polysaccharide consisting of only one monosaccharide and has a structural general formula, wherein R is -CH3 or -CH2-CH(OH)-CH3; R' is -H or -SO3Na; each sugar ring has at least one R' which is -SO3Na; n is equal to 2 to 6; when R is -CH3, the compound represented by the structural general formula is an oligomannuronicacid methyl acetate sulfate sodium salt; and when R is -CH2-CH(OH)-CH3, the compound represented by the structural general formula is an oligomannuronicacid proply acetate sulfate sodium salt. The medicament for intravenous injection has obvious anticoagulation, wherein the anticoagulation titer is 17 to 23; rabbit collagen induced platelet aggregation and platelet adhesion are obviously inhibited; and local ischemic brain damage caused by formation of cerebral thrombosis is lessened by inhibiting the formation of cerebral thrombosis and ischemic brain tissues are obviously protected.

Owner:OCEAN UNIV OF CHINA

Heavy dirt dry-cleaning agent

InactiveCN102864620AEasy to useEffective dissolutionDry-cleaning apparatus for textilesTetrachloroethyleneAlcohol

The invention discloses a heavy dirt dry-cleaning agent which is prepared by using alkyl sulfate sodium salt, tetrachloroethylene, octadecanol, methyl p-hydroxybenzoate, tallow sulphonic p-monoethanolamine, ethanolamine oleate and alcohol. The components by weight part are as follows: 20-40 parts of alkyl sulfate sodium salt, 6-8 parts of tetrachloroethylene, 5-10 parts of octadecanol, 8-12 parts of methyl p-hydroxybenzoate, 10-15 parts of tallow sulphonic p-monoethanolamine, 4-6 parts of ethanolamine oleate and 15-25 parts of alcohol. The heavy dirt dry-cleaning agent provided by the invention is convenient to use and can effectively dissolve oil soluble dirt attached to textile and can simultaneously disperse the solid dirt so as to effectively remove the dirt.

Owner:LINKCONN ELECTRONICS

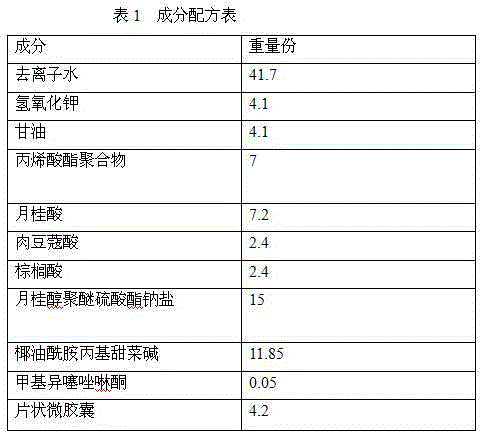

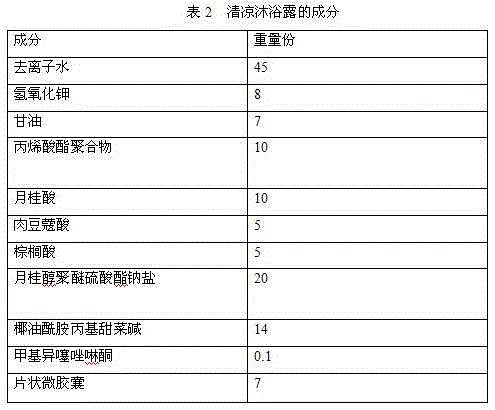

Cool and refreshing body wash with flaky microcapsules

InactiveCN105342890AEasy to push and wipeGood spreadabilityCosmetic preparationsToilet preparationsBetaineMethylisothiazolinone

The invention discloses cool and refreshing body wash with flaky microcapsules. The cool and refreshing body wash is prepared from, by weight, 40-45 parts of deionized water, 4-8 parts of potassium hydroxide, 4-7 parts of glycerin, 7-10 parts of an acrylate polymer, 7-10 parts of lauric acid, 2-5 parts of myristic acid, 2-5 parts of palmitic acid, 15-20 parts of sodium laureth sulfate, 11-14 parts of cocamidopropyl betaine, 0.05-0.1 part of methylisothiazolinone and 4-7 parts of the flaky microcapsules. When the cool and refreshing body wash with the flaky microcapsules is adopted, the flaky microcapsules can be softened in a cool and refreshing body wash substrate and easy to push and smear.

Owner:CHONGQING PELLETS TECHN & TRADE

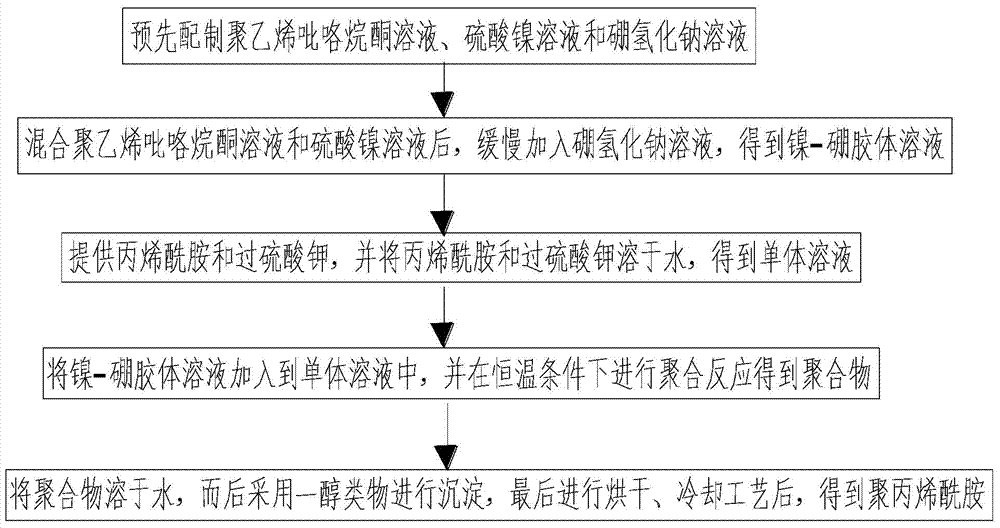

Polyacrylamide as well as preparation method and application thereof

InactiveCN103788269ASimple process conditionsReduce energy consumptionPolymer sciencePotassium peroxodisulfate

The invention discloses polyacrylamide as well as a preparation method and application thereof, belonging to the technical field of high polymer compounds and preparation methods and application thereof. In the preparation method, nickel sulfate-sodium borohydride is taken as an oxidation reduction system, Ni<2+> is reduced into a Ni(0)-B colloidal solution under the protection of polyvinylpyrrolidone, and potassium peroxodisulfate is added as an initiator for initiating the polymerization of acrylamide (AM) to prepare the polyacrylamide. The method is carried out at the normal temperature without heating to a high temperature, so that the energy consumption is lowered. Moreover, nitrogen is not introduced for deoxygenizing, so that the phenomenon of implosion is avoided, the preparation process condition of polyacrylamide is simplified, and energy needed in preparation is saved. Meanwhile, the molecular weight of the polyacrylamide prepared by using the method can be controlled between 350,000 and 1,600,000, the polydispersity index D of the molecular weight is more than or equal to 1.20 and less than or equal to 1.62, and the polyacrylamide can be suitable for different applications.

Owner:SHAOXING UNIVERSITY

Normal-temperature phosphorus-free water-based cleaning compound

The invention relates to a normal-temperature phosphorus-free water-based cleaning compound. Each liter of water contains the following components: 0.2-1.5 g of fatty alcohol polyoxyethylene ether, 1.0-3.0 g of iso-tridecanol polyoxyethylene ether, 0.5-3.0 g of fatty alcohol EO / PO polyether, 0.3-2.0 g of 2-sodium 2-ethylhexyl sulfate, 10 g of sodium silicate, 5 g of sodium carbonate, 0.1-0.5 g ofsodium citrate, and 0.2-0.8 g of EDTA2Na. The cleaning compound has rust-protection and corrosion inhibition effect for metal, corrosion and damage are little, and the cleaned cold rolling plate surface is clean and shine.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

Environment-friendly tableware detergent

InactiveCN102827705ASimple preparation processLow costInorganic/elemental detergent compounding agentsAmpholytes/electroneutral surface-active compoundsAlkyl polyglycosideFatty alcohol

The invention relates to a detergent, especially to an environment-friendly tableware detergent. The environment-friendly tableware detergent is prepared from the following raw materials according to the following weight part ratio: alkyl polyglucoside: fatty alcohol polyoxyethylene lauryl ether sulfate sodium: dimethyl dodecyl amine oxide: ascorbic acid: sodium hexametaphosphate: coral powder: citric acid: deionized water =6-20:1-10:1-10:15-35:2-10:20-30:10-20:80-100. The detergent is suitable for both hand washing and tableware machinery washing. During hand washing, the detergent is not irritating to skin and is nontoxic. A preparation technology of the detergent is simple and requires low cost. The detergent is quickly biodegradable, will not cause pollution after being used and entering the natural environment, produces rich foam, has strong decontamination capacity and good stability, and has good social benefits.

Owner:赵万吉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com