High-efficiency scouring agent containing glucose structural units and preparation method thereof

A structural unit, glucose technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of unsatisfactory scouring agent scouring effect, adverse environmental impact, etc., to meet the needs of green and environmentally friendly high-efficiency scouring agents, good scouring Effects, effects with reasonable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

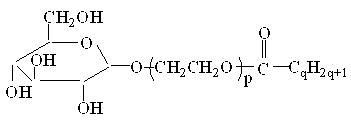

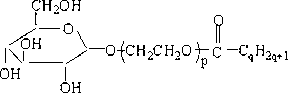

Image

Examples

Embodiment 1

[0031] A high-efficiency scouring agent containing glucose structural units, which is made by mixing the following components in weight percentage: dodecyl glucoside (average degree of polymerization is 3) 15%, polyethylene glycol (average degree of polymerization is 4) glucose Glycoside laurate 10%, lauryl glucoside (average degree of polymerization 3) sulfate sodium salt 15%, water 60%.

[0032] The preparation method of the above-mentioned high-efficiency scouring agent containing glucose structural units comprises:

[0033] (1) After measuring the components according to the above weight percentages, add lauryl glucoside and sodium lauryl glycoside sulfate into water, stir and mix evenly;

[0034] (2) Add polyethylene glycol glucoside laurate to the mixture in step (1), then stir and mix evenly to obtain the product.

Embodiment 2

[0036] A high-efficiency scouring agent containing glucose structural units, which is made by mixing the following components in weight percentage: tetradecyl glucoside (average degree of polymerization is 5) 15%, polyethylene glycol (average degree of polymerization is 9) glucose Glycoside palmitate 5%, myristyl glucoside (average degree of polymerization 5) sulfate sodium salt 20%, water 60%.

[0037] The preparation method of the above-mentioned high-efficiency scouring agent containing glucose structural units comprises:

[0038] (1) After measuring the components according to the above weight percentages, add tetradecyl glucoside and sodium tetradecyl glycoside sulfate into water, stir and mix evenly;

[0039] (2) Add polyethylene glycol glucoside palmitate to the mixture in step (1), then stir and mix evenly to obtain the product.

Embodiment 3

[0041] A high-efficiency scouring agent containing glucose structural units, which is made by mixing the following components in weight percentage: hexadecyl glucoside (average degree of polymerization is 6) 10%, polyethylene glycol (average degree of polymerization is 13) glucose Glycoside stearate 10%, cetyl glucoside (average degree of polymerization 6) sulfate sodium salt 20%, water 60%.

[0042] The preparation method of the above-mentioned high-efficiency scouring agent containing glucose structural units comprises:

[0043] (1) After measuring the components according to the above weight percentages, add cetyl glucoside and cetyl glucoside sulfate sodium salt into water, stir and mix evenly;

[0044] (2) Add polyethylene glycol glucoside stearate to the mixture in step (1), then stir and mix evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com