Medical equipment cleaning agent and preparation method thereof as well as preparation method of dispersed scale inhibitor

A technology for medical devices and cleaning agents, applied in the field of cleaning agents, can solve problems such as incomplete cleaning of enzyme cleaning agents, and achieve the effects of increasing cleaning performance, good anti-corrosion effect, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

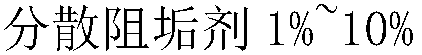

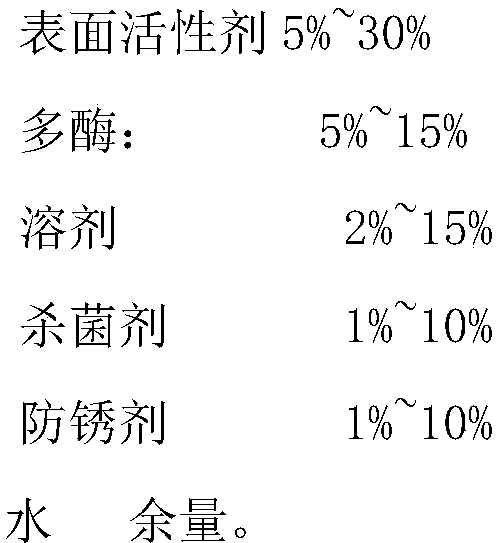

[0034] (1) Synthesis of dispersed scale inhibitor: Add allyl alcohol polyoxyethylene ether and potassium methylate to the reactor, the ratio is 1:0.2 by mass, vacuumize and replace 3 times, then fill the reactor with nitrogen, slowly drop ring Oxypropanol, the reaction temperature was raised to 95°C and the stirring reaction was continued for 2.0h. After the reaction, vacuumize for 0.5h, filter, cool down and keep the kettle for use. Reaction equation and product structure are shown in the following formula:

[0035]

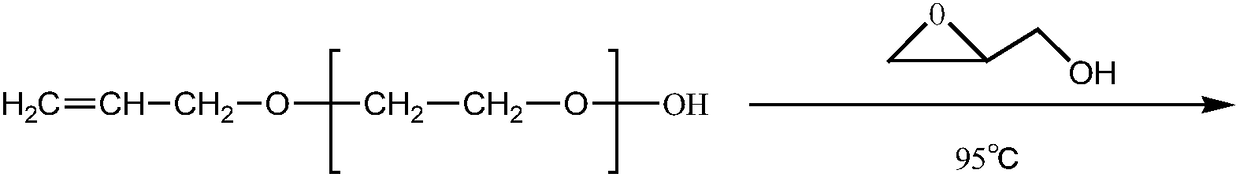

[0036] Add deionized water to the product left in the still for use, the mass ratio is 3:5, under the protection of nitrogen, the polymerization temperature is raised to 70°C, and then ammonium persulfate solution is slowly added dropwise, and AA (the product left in the still and The mass ratio of AA is 1:1), after 1.5h, the dropwise addition is completed, and the temperature is raised to 80°C to continue the reaction for 1.5h to obtain a dispersed scale in...

Embodiment 2

[0040] (1) Synthesis of dispersed scale inhibitor: Add allyl alcohol polyoxyethylene ether and potassium methylate to the reactor, the ratio is 1:0.2 by mass, vacuumize and replace 3 times, then fill the reactor with nitrogen, slowly drop ring Oxypropanol, the reaction temperature was raised to 95°C and the stirring reaction was continued for 2.0h. After the reaction, vacuumize for 0.5h, filter, cool down and keep the kettle for use. Reaction equation and product structure are shown in the following formula:

[0041]

[0042] Add deionized water to the product left in the still, and the mass ratio is 3:5. Under nitrogen protection, the polymerization temperature is raised to 70 ° C, and then ammonium persulfate solution is slowly added dropwise, and AA (the product left in the still and The mass ratio of AA is 1:1), after 1.5h, the dropwise addition is completed, and the temperature is raised to 80°C to continue the reaction for 1.5h to obtain a dispersed scale inhibitor. ...

Embodiment 3

[0046] (1) Synthesis of dispersed scale inhibitor: Add allyl alcohol polyoxyethylene ether and potassium methylate to the reactor, the ratio is 1:0.2 by mass, vacuumize and replace 3 times, then fill the reactor with nitrogen, slowly drop ring Oxypropanol, the reaction temperature was raised to 95°C and the stirring reaction was continued for 2.0h. After the reaction, vacuumize for 0.5h, filter, cool down and keep the kettle for use. Reaction equation and product structure are shown in the following formula:

[0047]

[0048]Add deionized water to the product left in the still, and the mass ratio is 3:5. Under nitrogen protection, the polymerization temperature is raised to 70 ° C, and then ammonium persulfate solution is slowly added dropwise, and AA (the product left in the still and The mass ratio of AA is 1:1), after 1.5h, the dropwise addition is completed, and the temperature is raised to 80°C to continue the reaction for 1.5h to obtain a dispersed scale inhibitor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com