Patents

Literature

44results about How to "Efficient rinse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

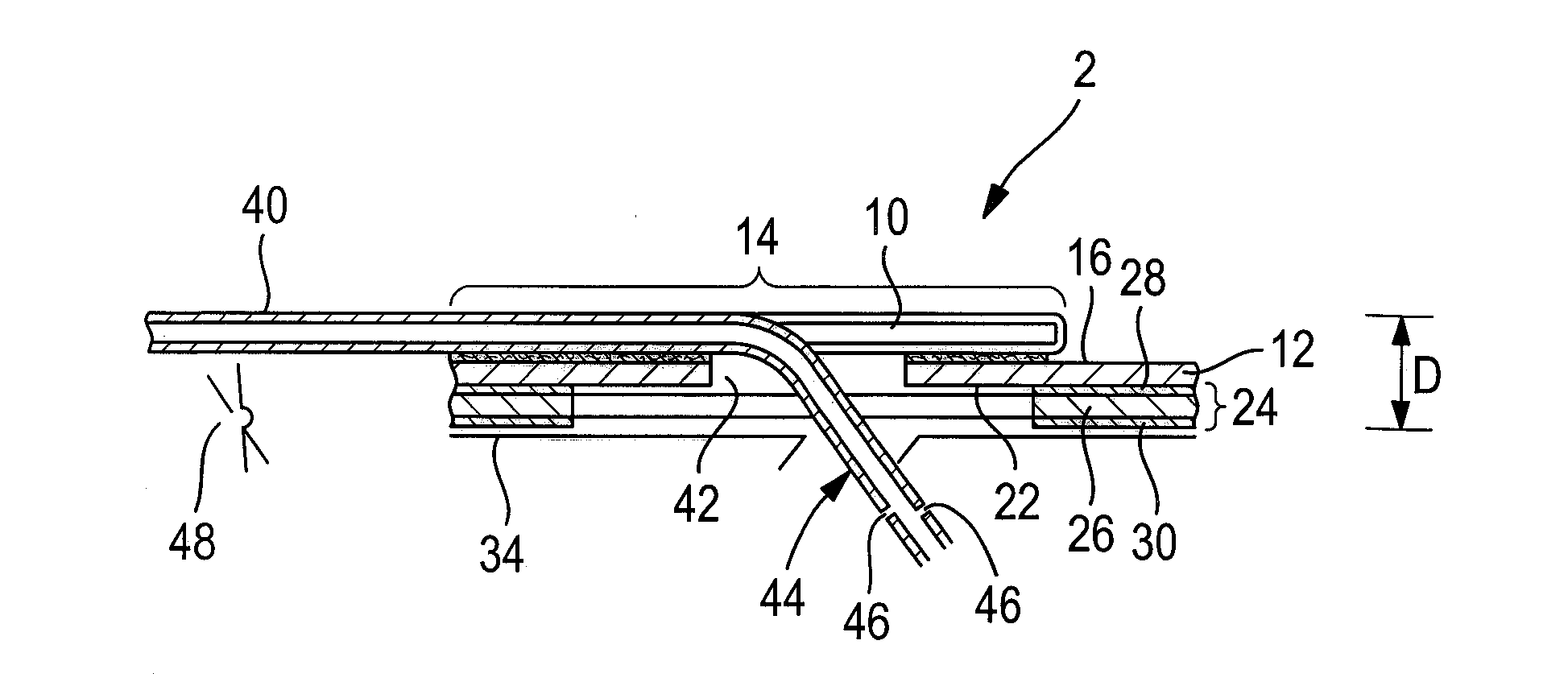

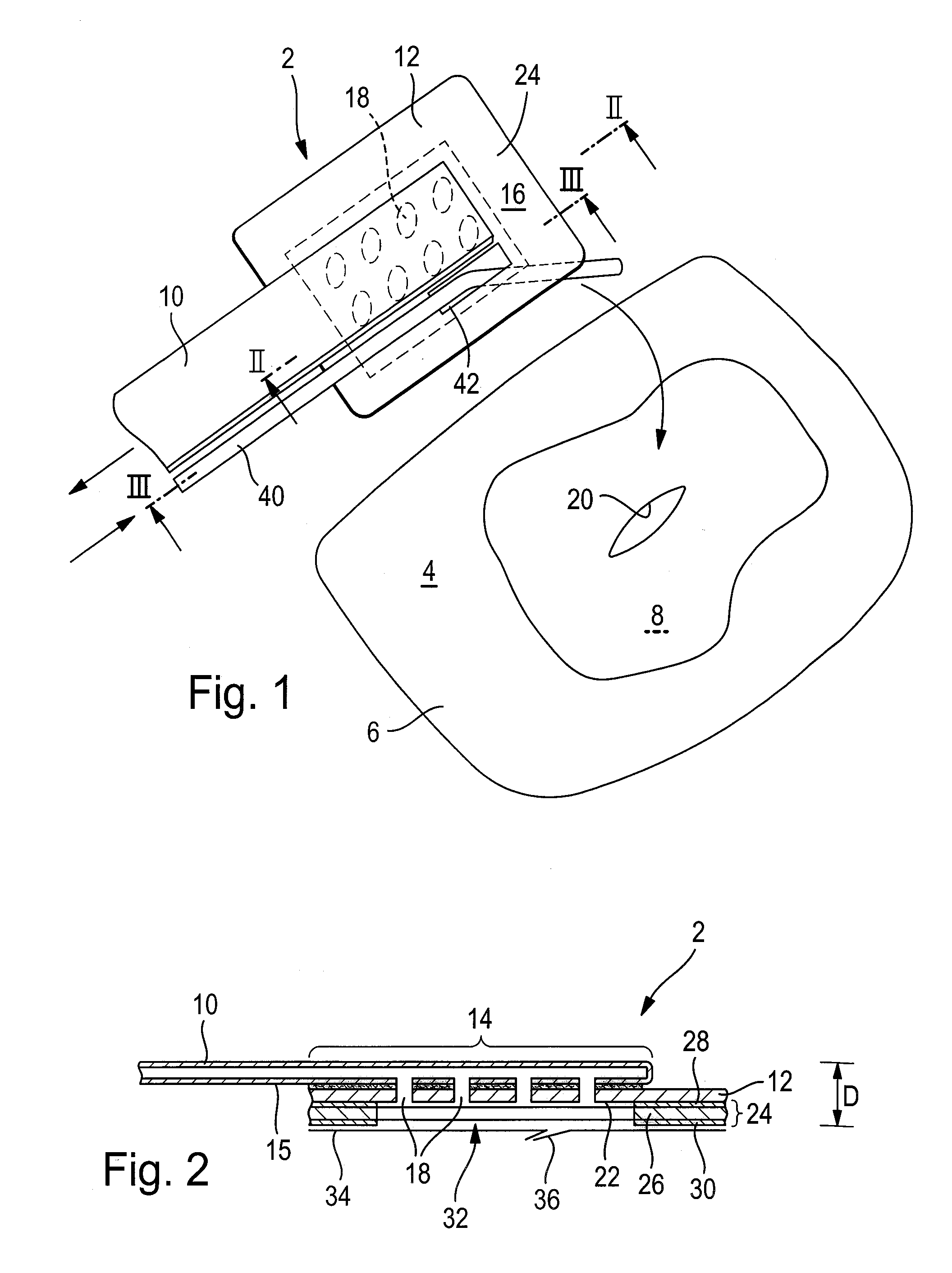

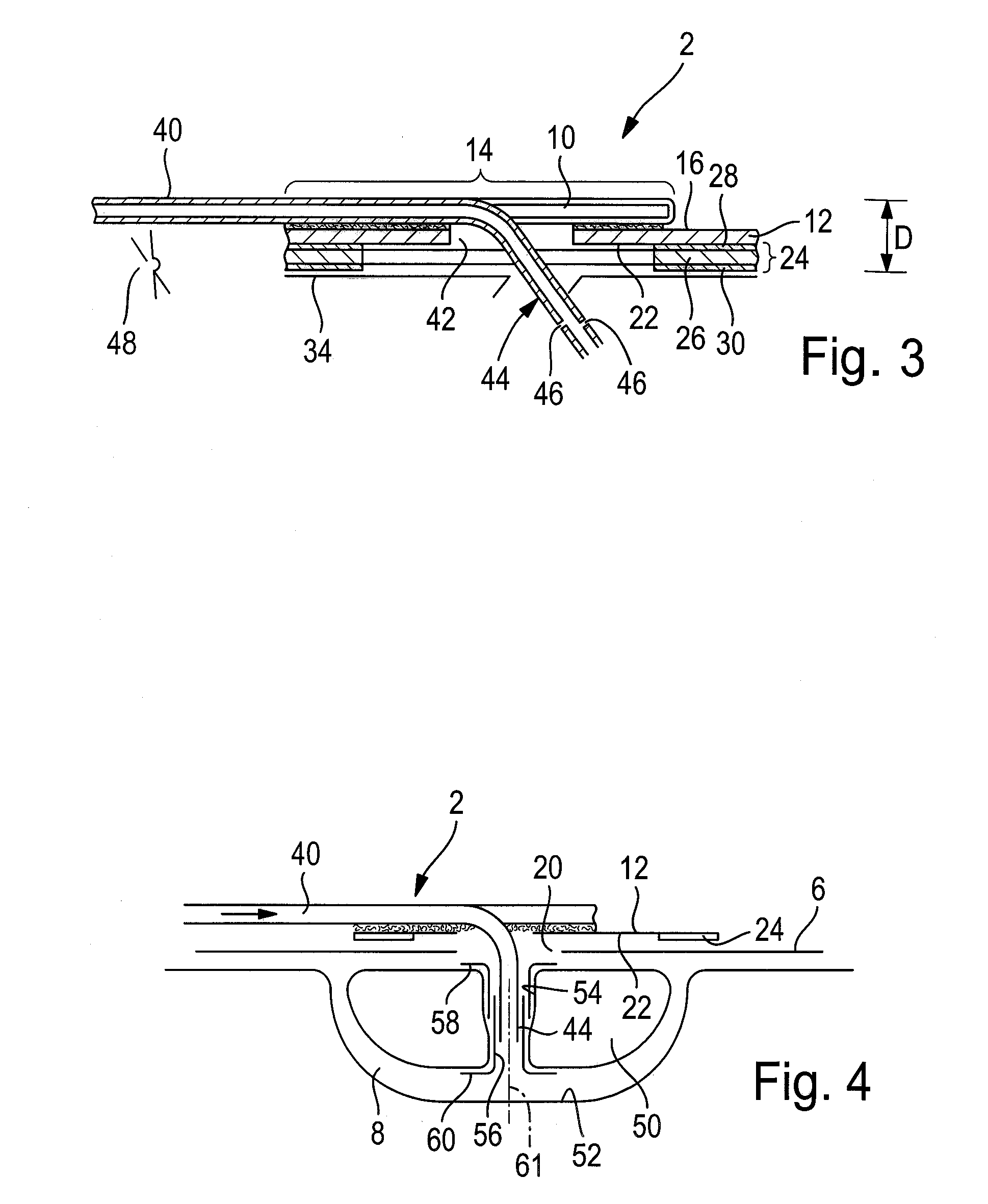

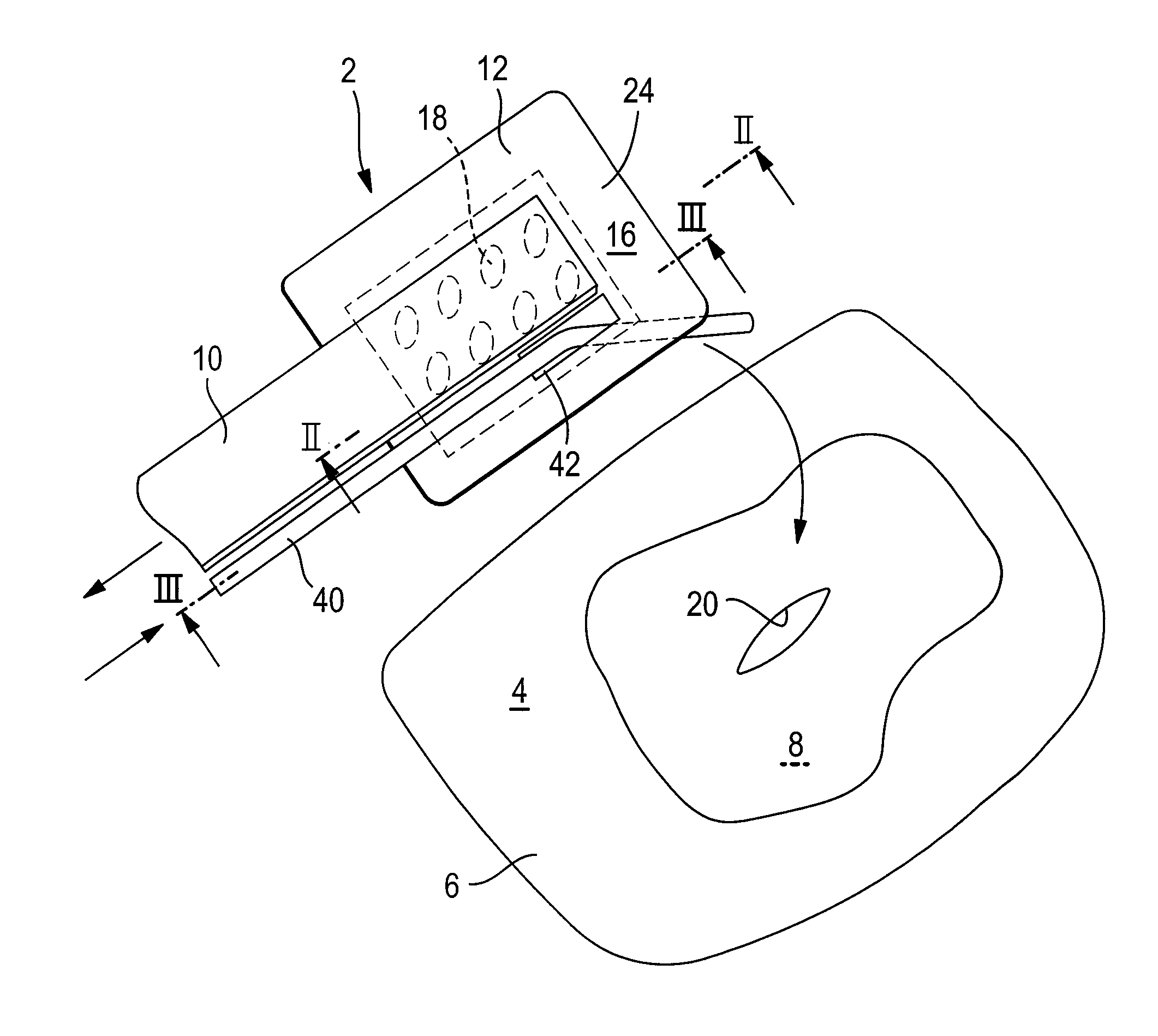

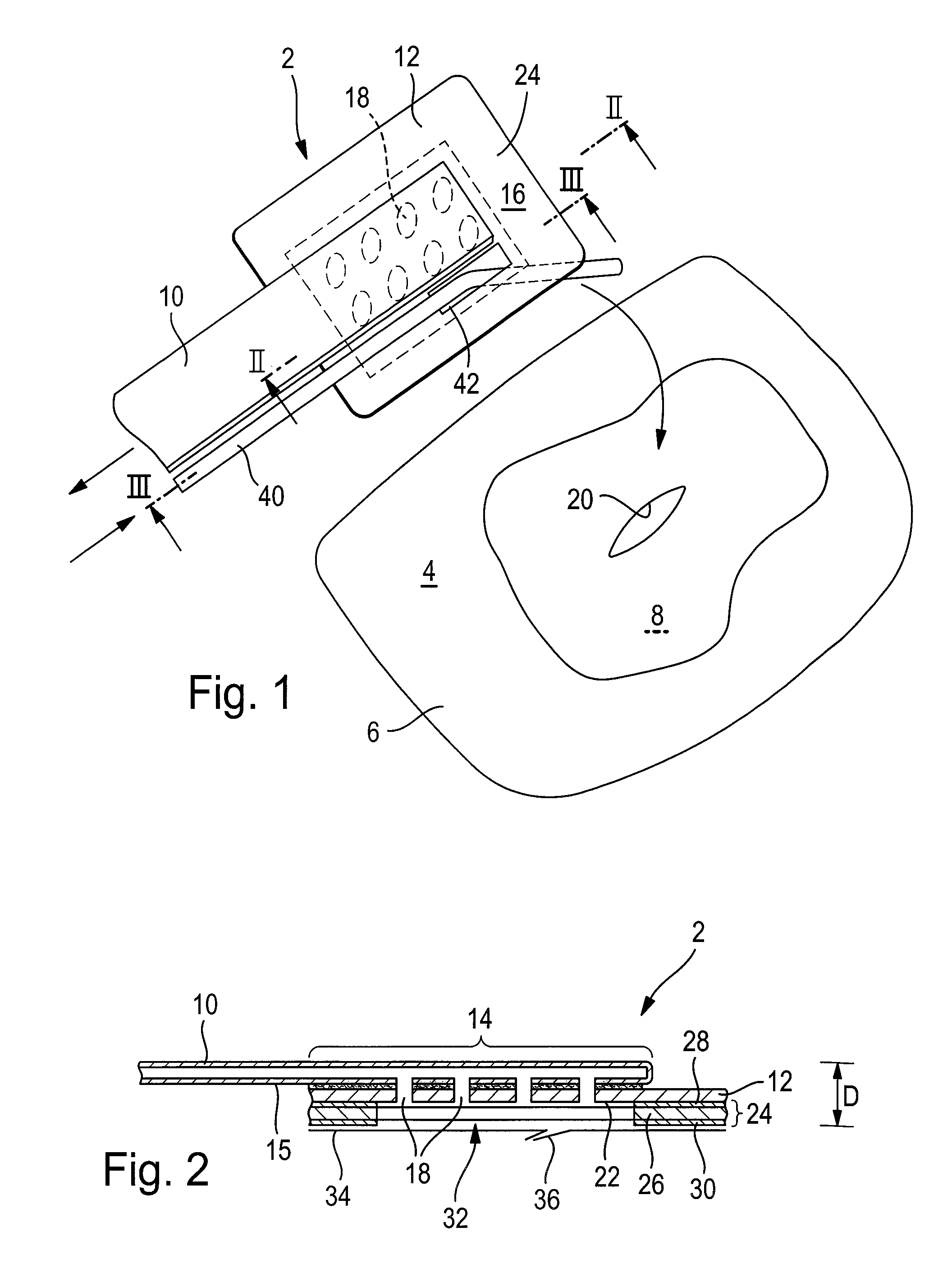

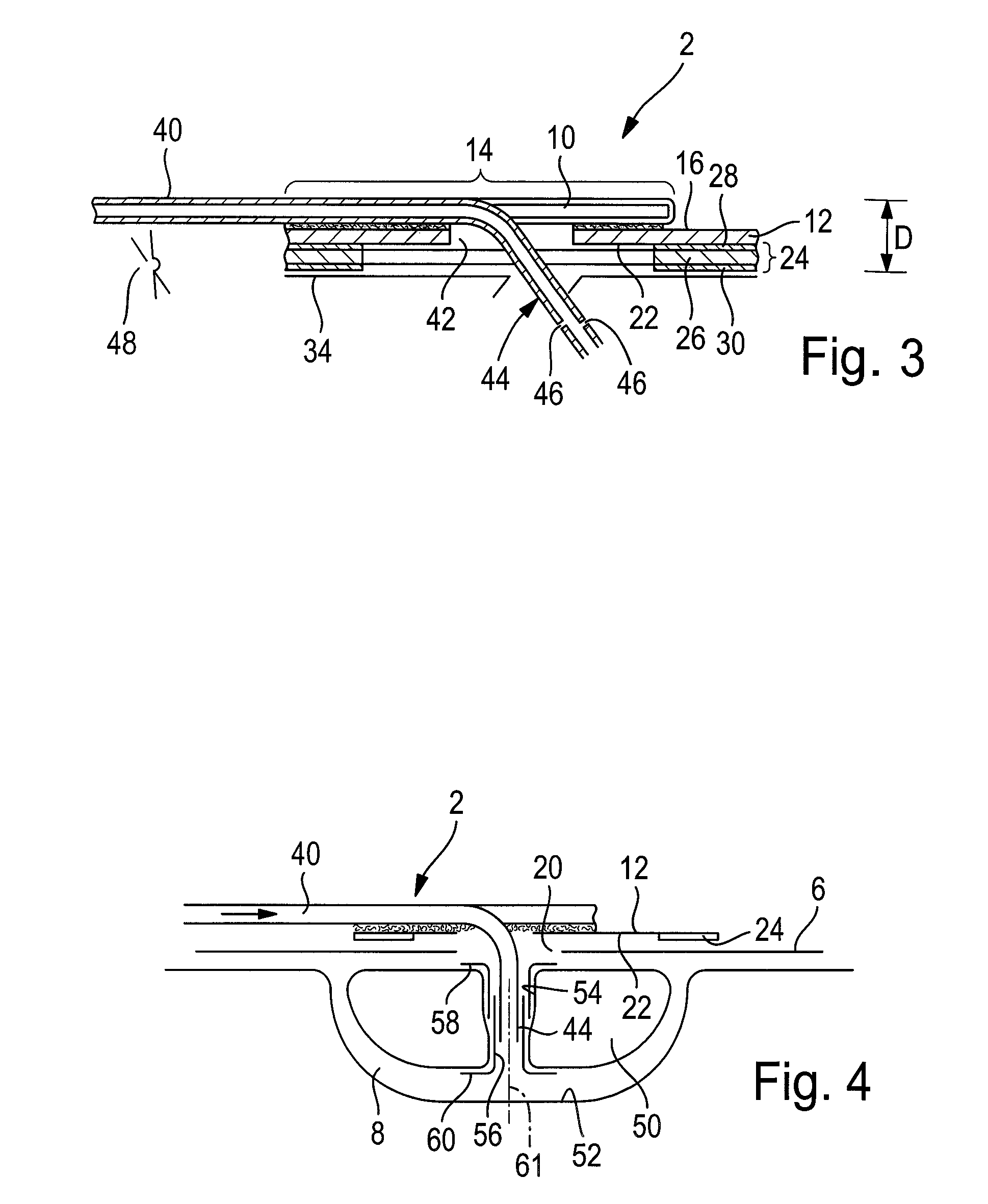

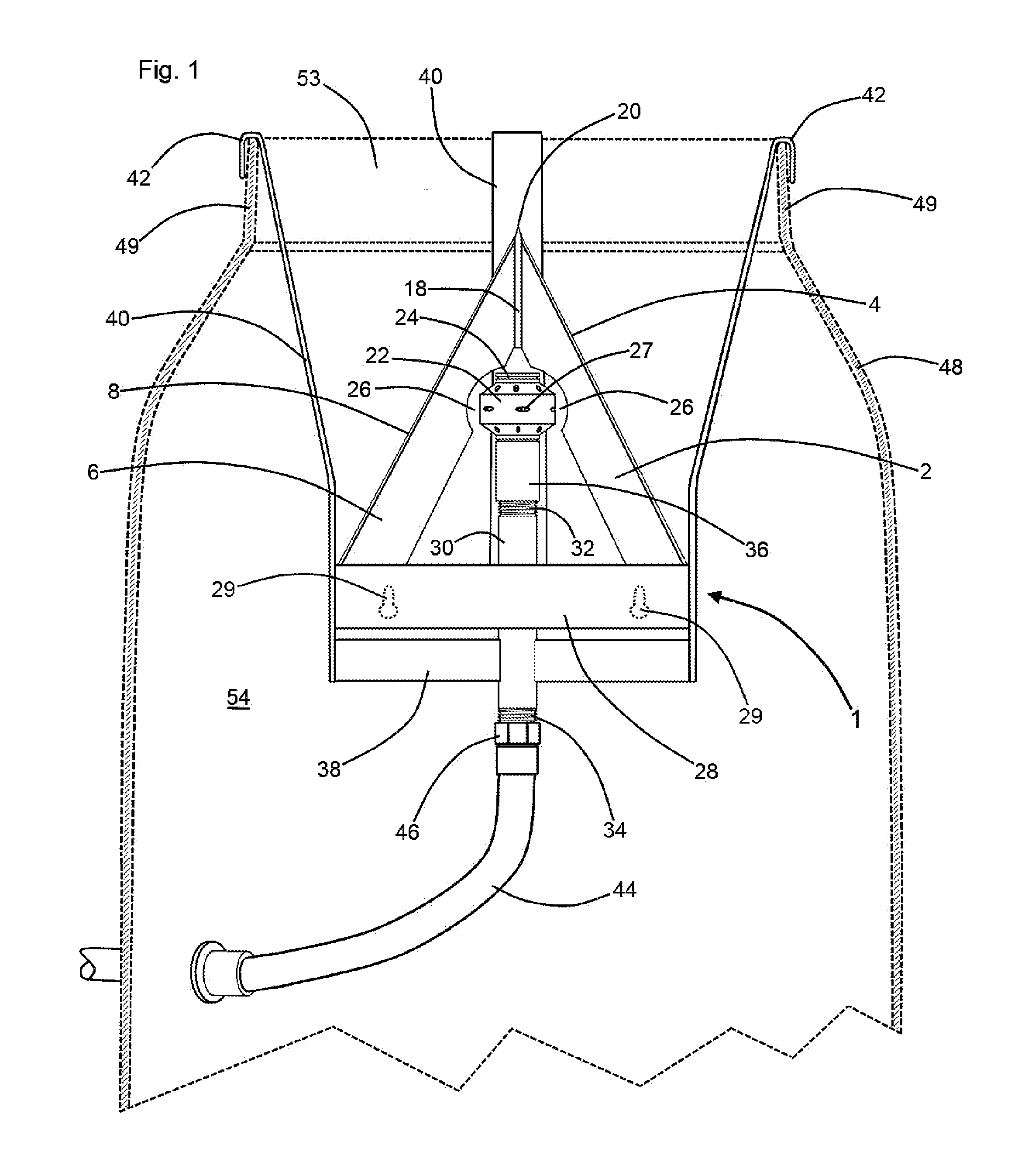

Wound support for use in vacuum therapy of wounds

InactiveUS20130066286A1Easy to closeChange lengthAdhesive dressingsIntravenous devicesFeeding tubeAtmosphere

A wound support (50) for use in the vacuum therapy of wounds, can be disposed in its intended use in a wound space underneath a vacuum dressing (6) sealing the wound space with respect to the atmosphere in an essentially vacuum-tight manner, wherein the wound space can communicate with a suction tube (10) to which a vacuum can be applied through an opening (20) in the vacuum dressing (6). The wound support (50) comprises a flexibly compliant foamed material and has a through-hole (54) that extends in the direction of the wound depth, which is used to insert or pass through a wound-side end section (44) of a fluid feed tube (40). A sleeve (56) is disposed in the through-hole (54) into which this end section (44) can be inserted.

Owner:PAUL HARTMANN AG

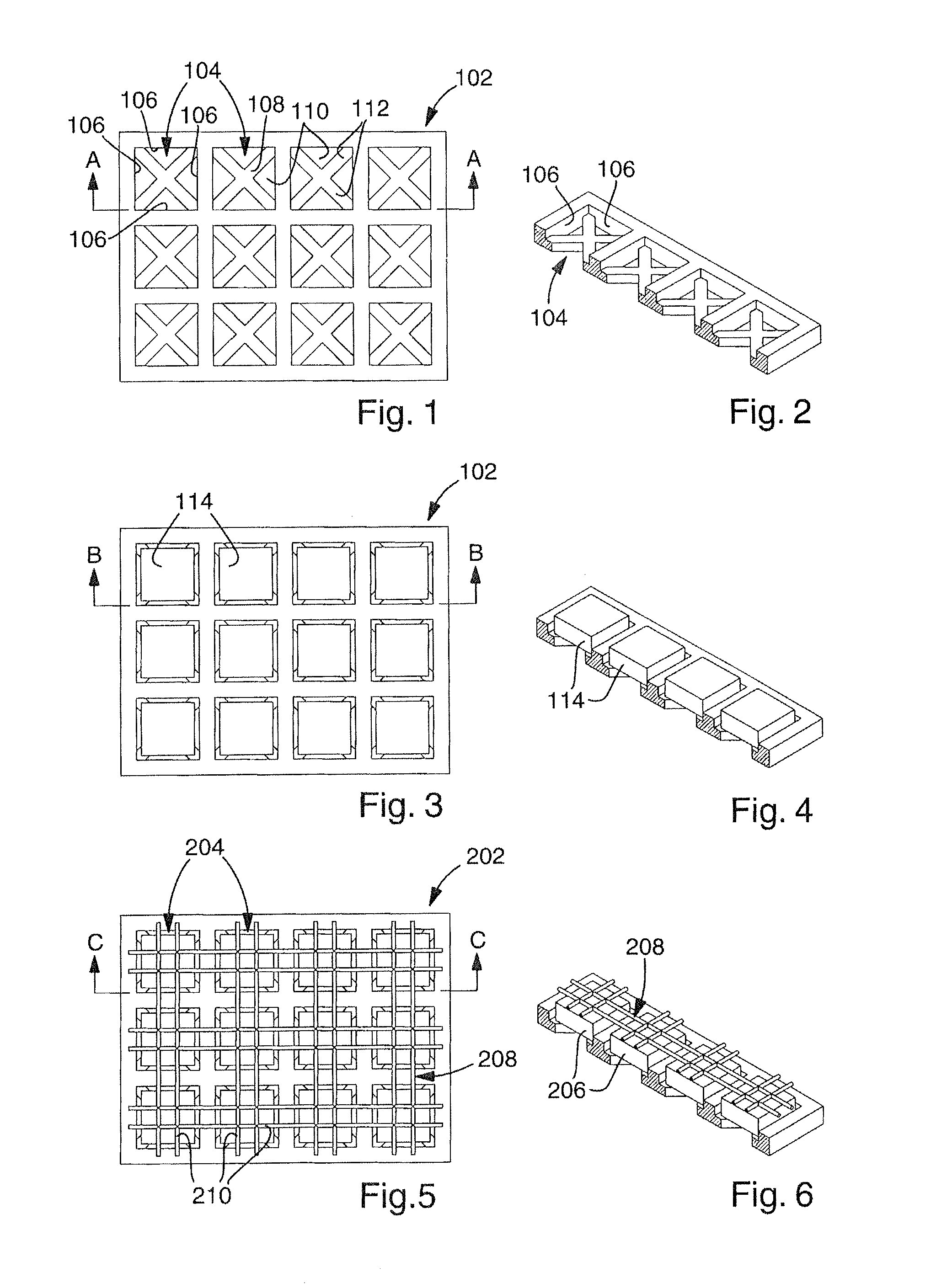

Method and an apparatus for treating at least one workpiece

InactiveUS20120315827A1Efficiently and quickly driedEfficient dryingAgriculture tools and machinesDrying solid materials with heatEngineeringElectronic component

Apparatus for treating a workpiece has first and second regions at least partially enclosed by a casing and in communication via a passage, and support means for a carrier holding the workpiece in the first region for treatment. Pressure difference between the regions forces the workpiece toward the carrier and guides a flow of media from the first to the second region through the passage, at least partly, to create said pressure difference. Method for treating at least one workpiece holds the workpiece by forcing it toward the carrier with a created pressure difference between two regions. Holding also guides a flow of media from the first region to the second region through the passage in order to, at least partly, create said pressure difference. The treatment may comprise blasting, rinsing or drying. The workpiece may comprise cutting inserts, electronic components, small sized machined or formed components or parts.

Owner:VAPORMATT LTD +1

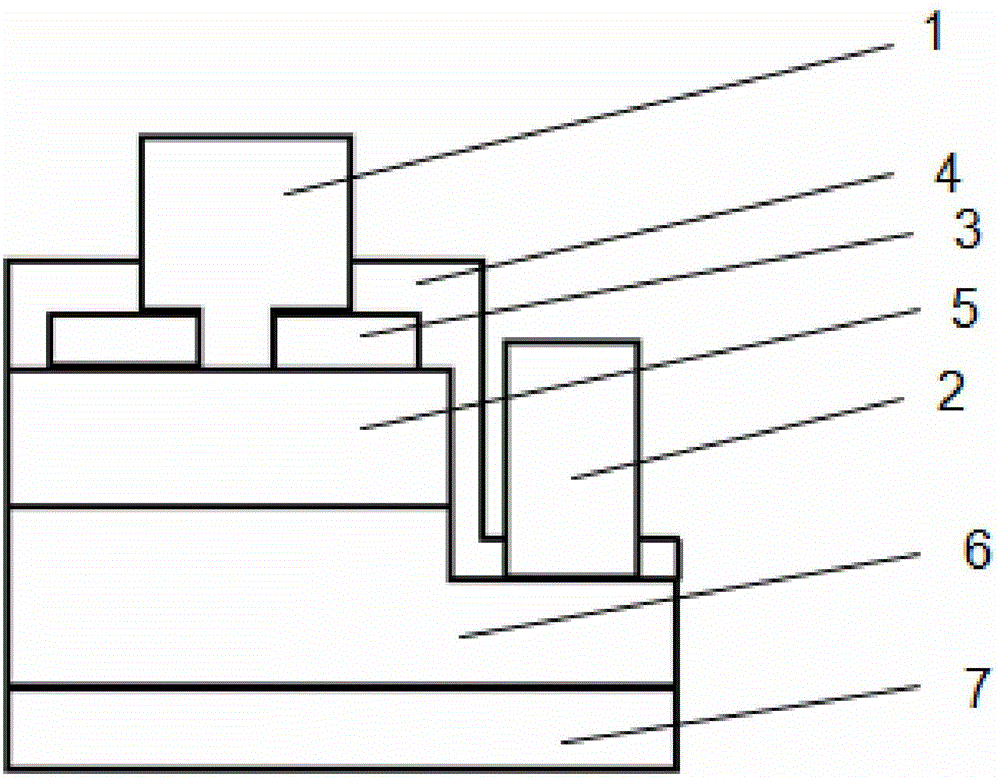

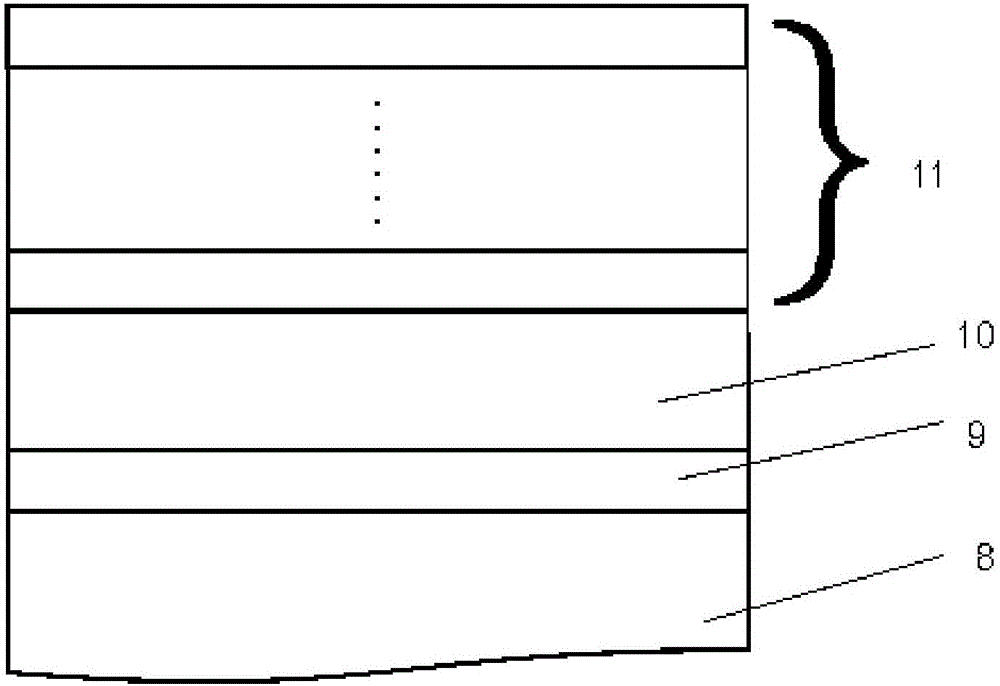

Removal method of LED electrode structure

The invention relates to a removal method of an LED electrode structure. The removal method comprises the following steps of firstly, initially reducing adhesion between a metal electrode layer and a P-GaN layer through physical ultrasound; secondly, corroding a surface protection layer with hydrofluoric acid; and finally, removing all metal (comprising titanium, gold beryllium, gold, platinum, silver, nickel and germanium) in which metal chromium and aluminum are taken as a bottom layer in the metal electrode layer by a mixed solution of hydrochloric acid and hydrogen peroxide. According to the removal method, a relatively thin strip of chromium at the bottommost layer is removed in a specific environment and metal arranged at an aluminum top layer can also drop off with aluminum mainly through reaction of metal aluminum and dilute acid. The removal method has the advantages of simple steps and simplicity in operation, the whole metal electrode layer is completely and effectively corroded and remade on the condition that a special chromium corrosion liquid, a gold corrosion liquid and the like is not used and on the premise that no damage is completely ensured, the LED electrode structure after being corroded and cleaned is clean in surface, and no any metal residue and bottom membrane residue at a chromium layer are generated.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Wound support for use in vacuum therapy of wounds

InactiveUS8926593B2Painful discomfort of the patientAvoid injuryWound drainsAdhesive dressingsFeeding tubeAtmosphere

A wound support (50) for use in the vacuum therapy of wounds, can be disposed in its intended use in a wound space underneath a vacuum dressing (6) sealing the wound space with respect to the atmosphere in an essentially vacuum-tight manner, wherein the wound space can communicate with a suction tube (10) to which a vacuum can be applied through an opening (20) in the vacuum dressing (6). The wound support (50) comprises a flexibly compliant foamed material and has a through-hole (54) that extends in the direction of the wound depth, which is used to insert or pass through a wound-side end section (44) of a fluid feed tube (40). A sleeve (56) is disposed in the through-hole (54) into which this end section (44) can be inserted.

Owner:PAUL HARTMANN AG

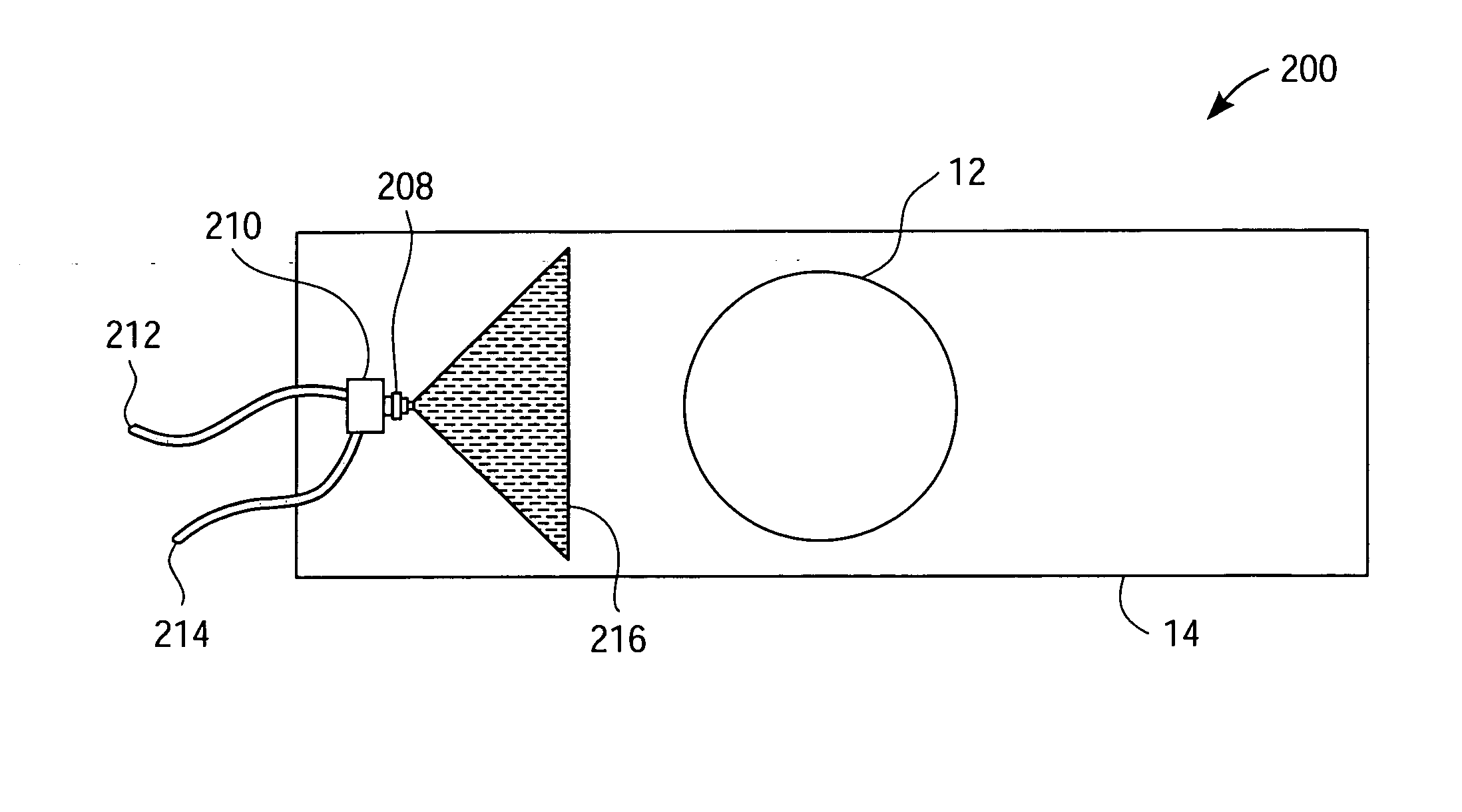

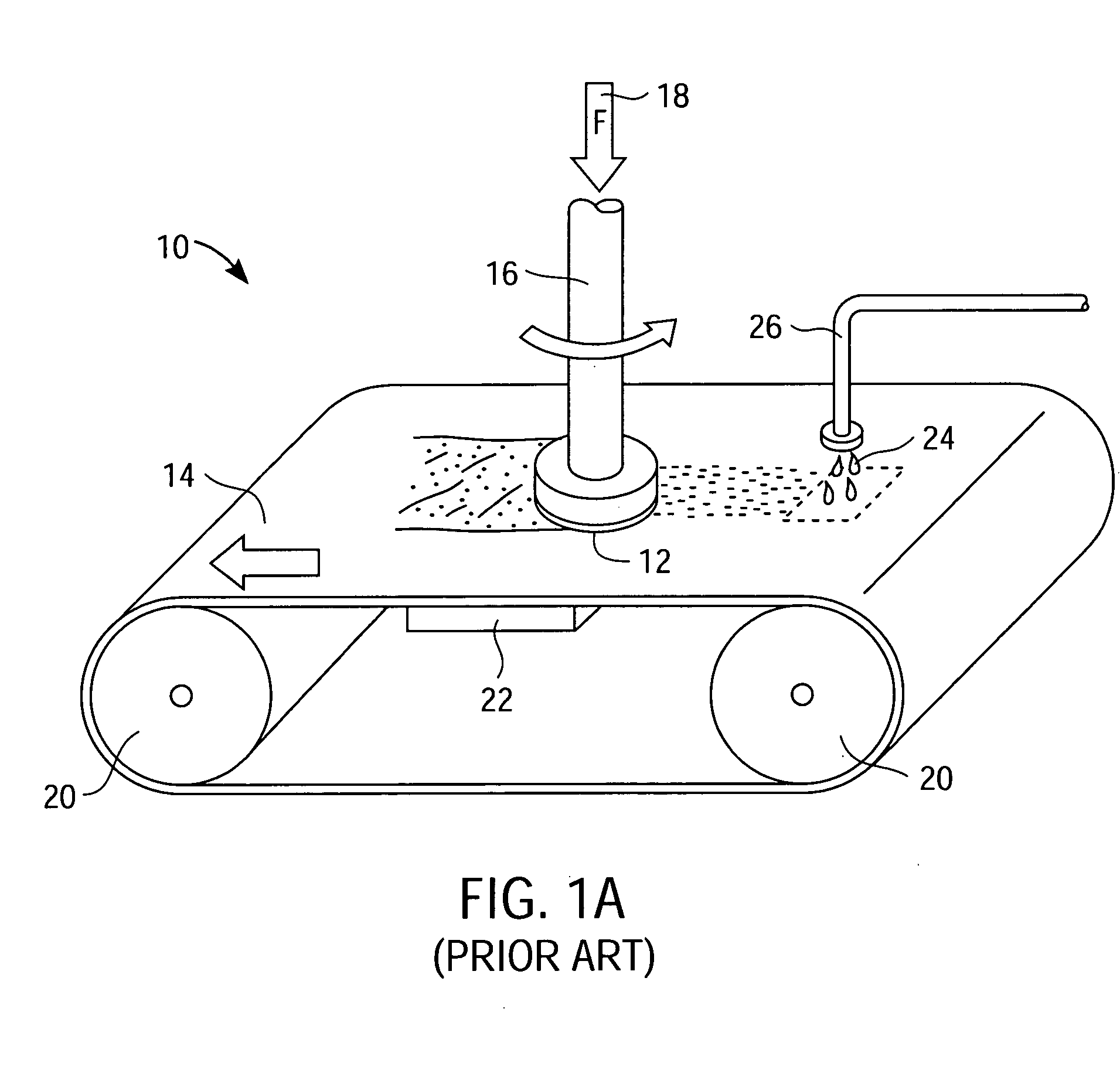

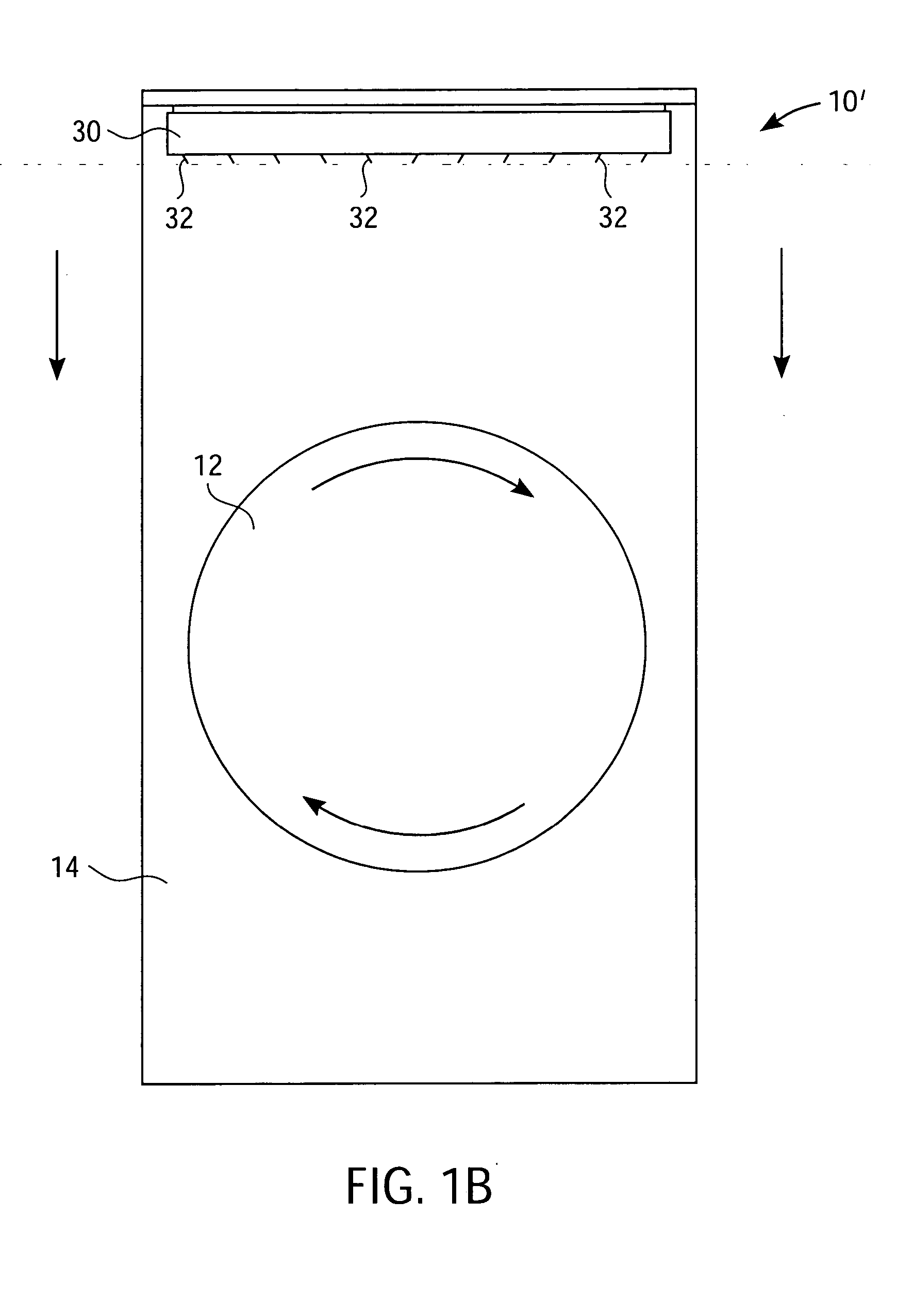

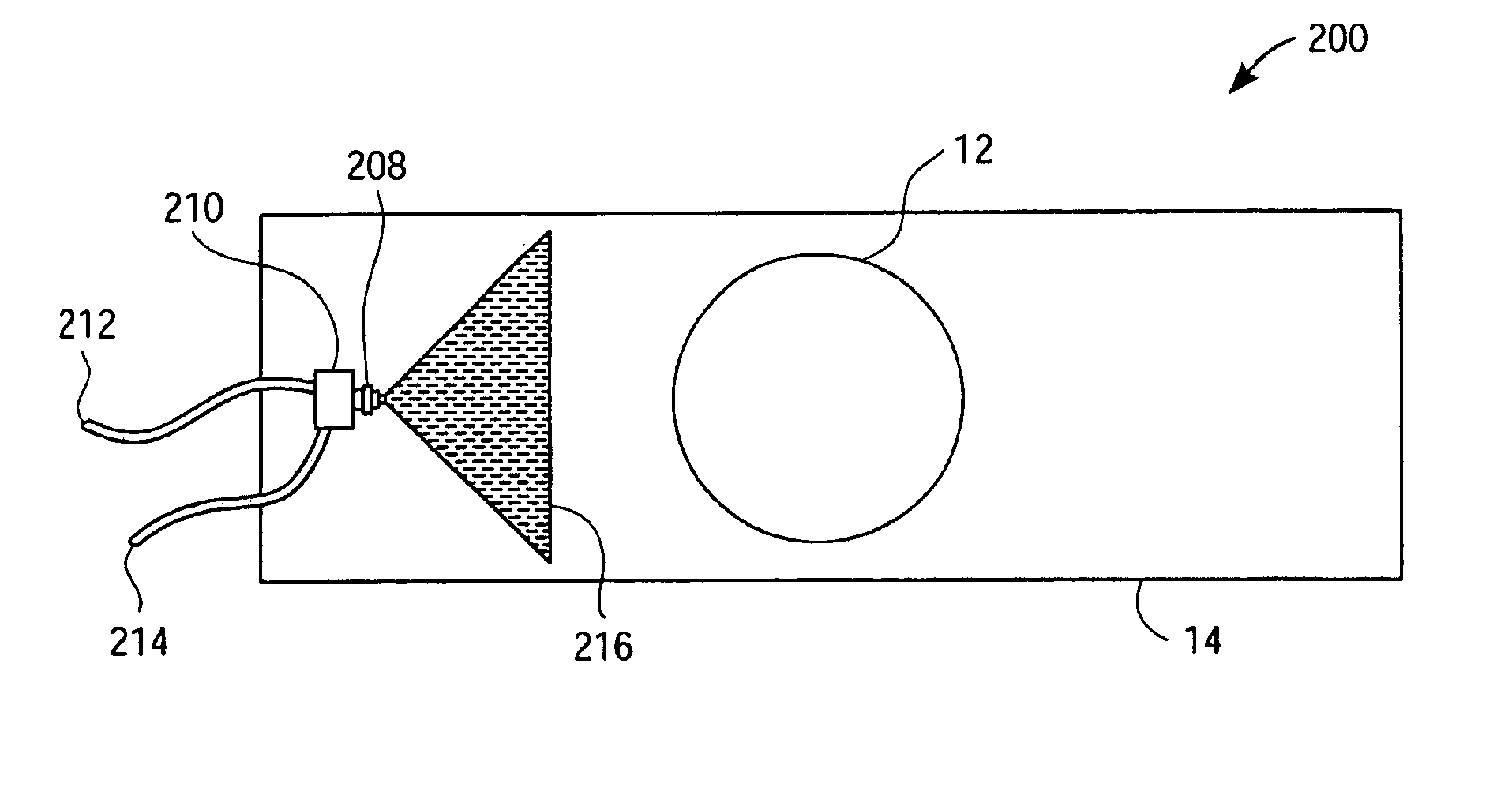

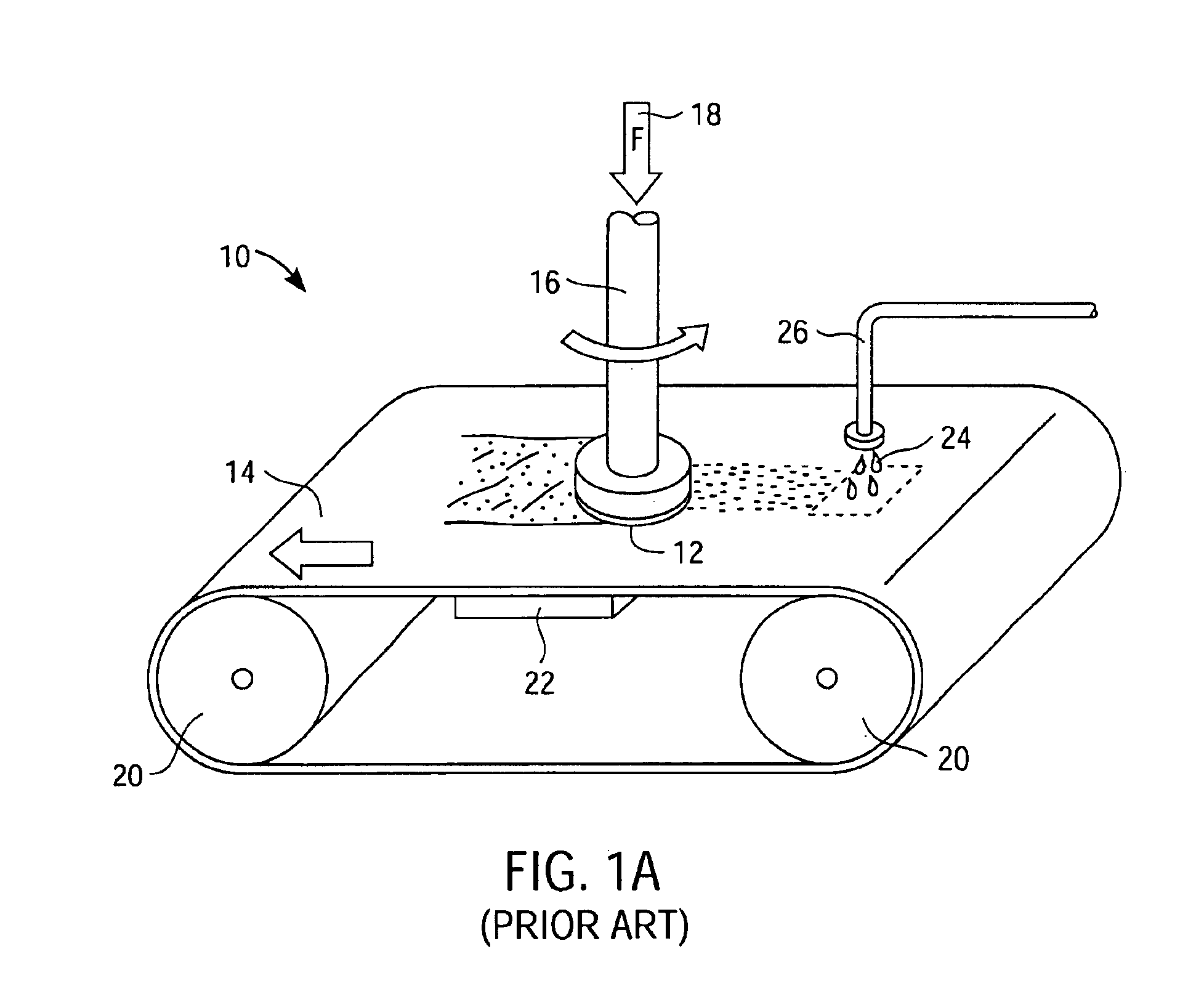

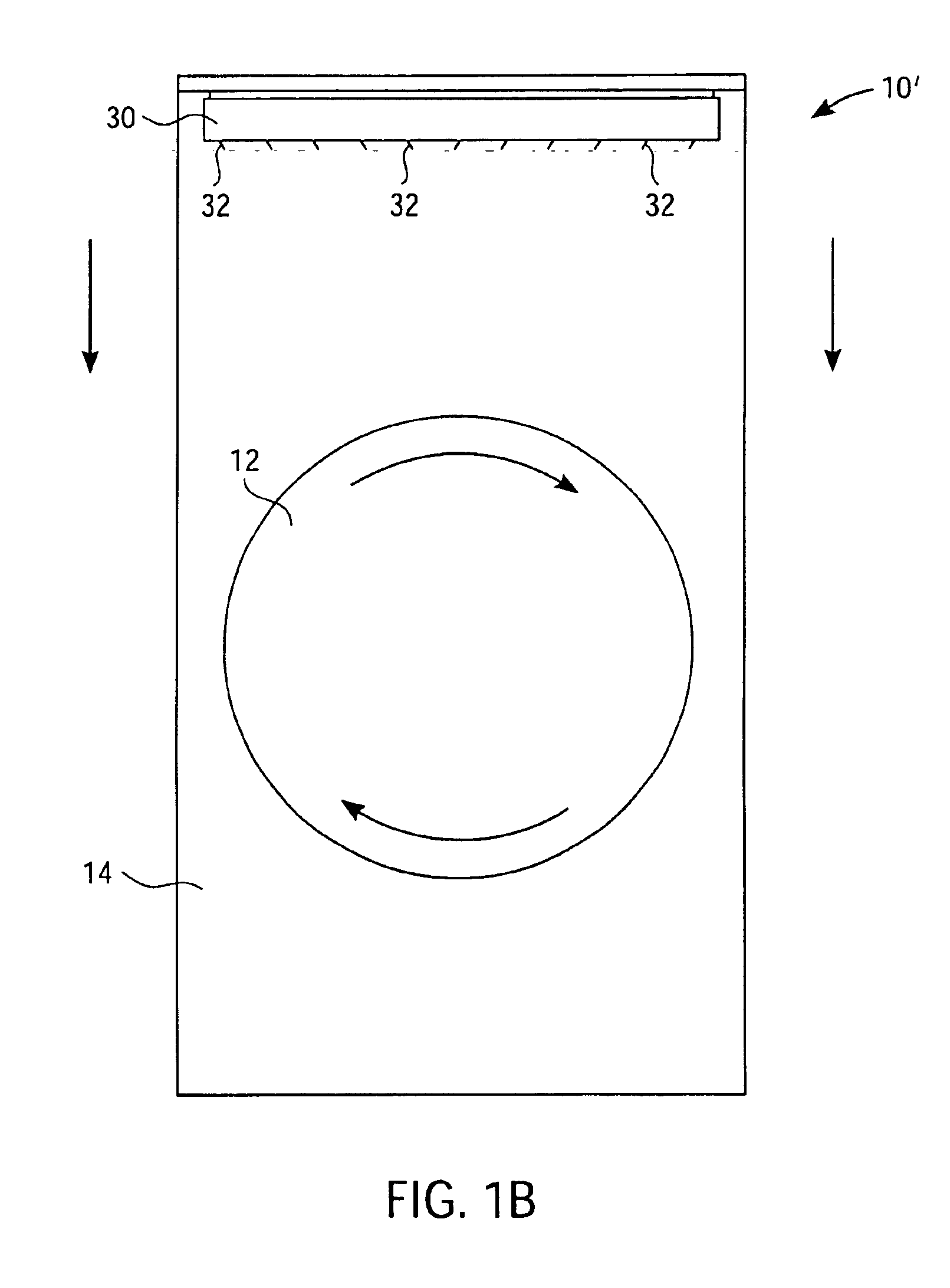

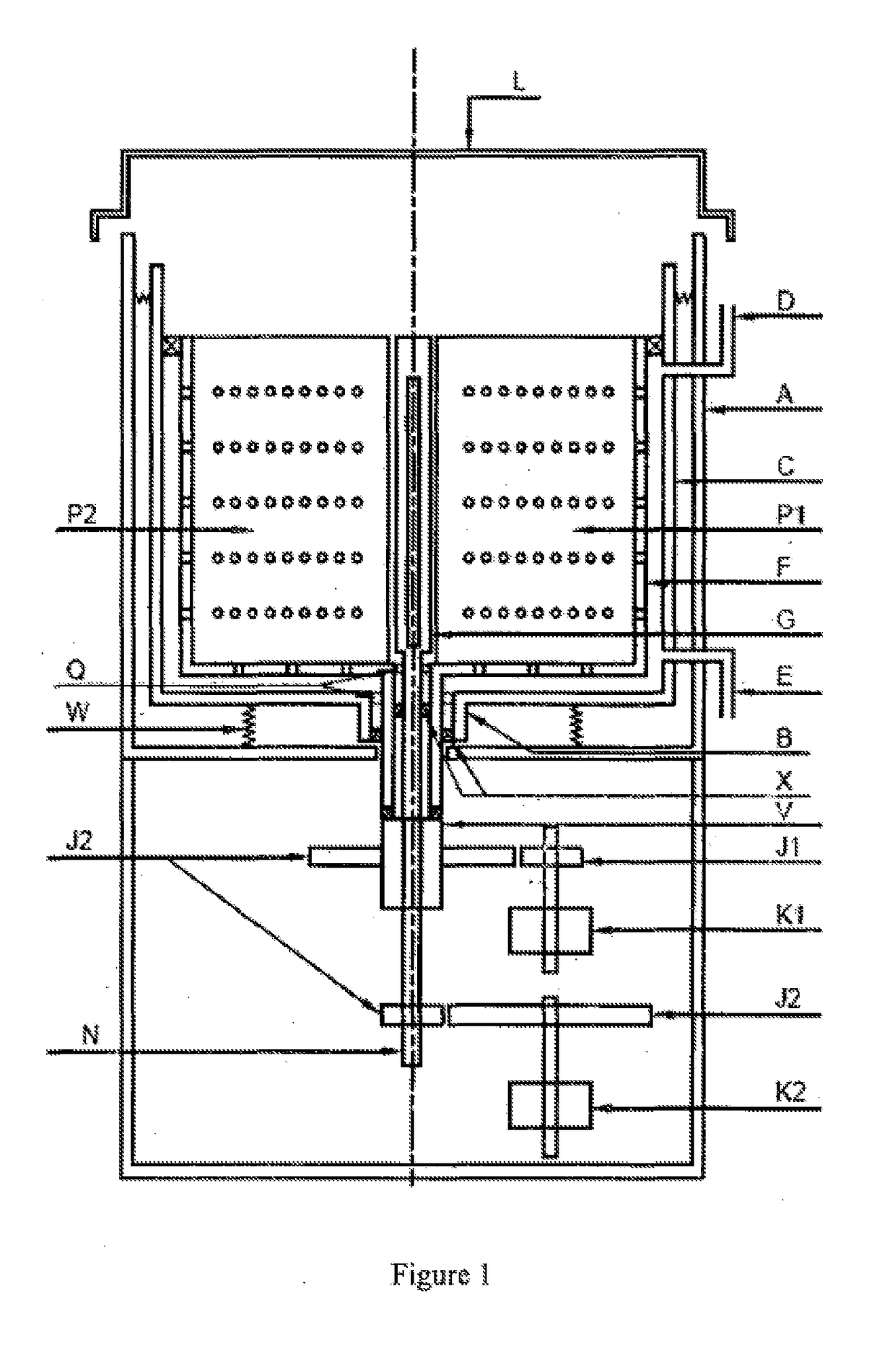

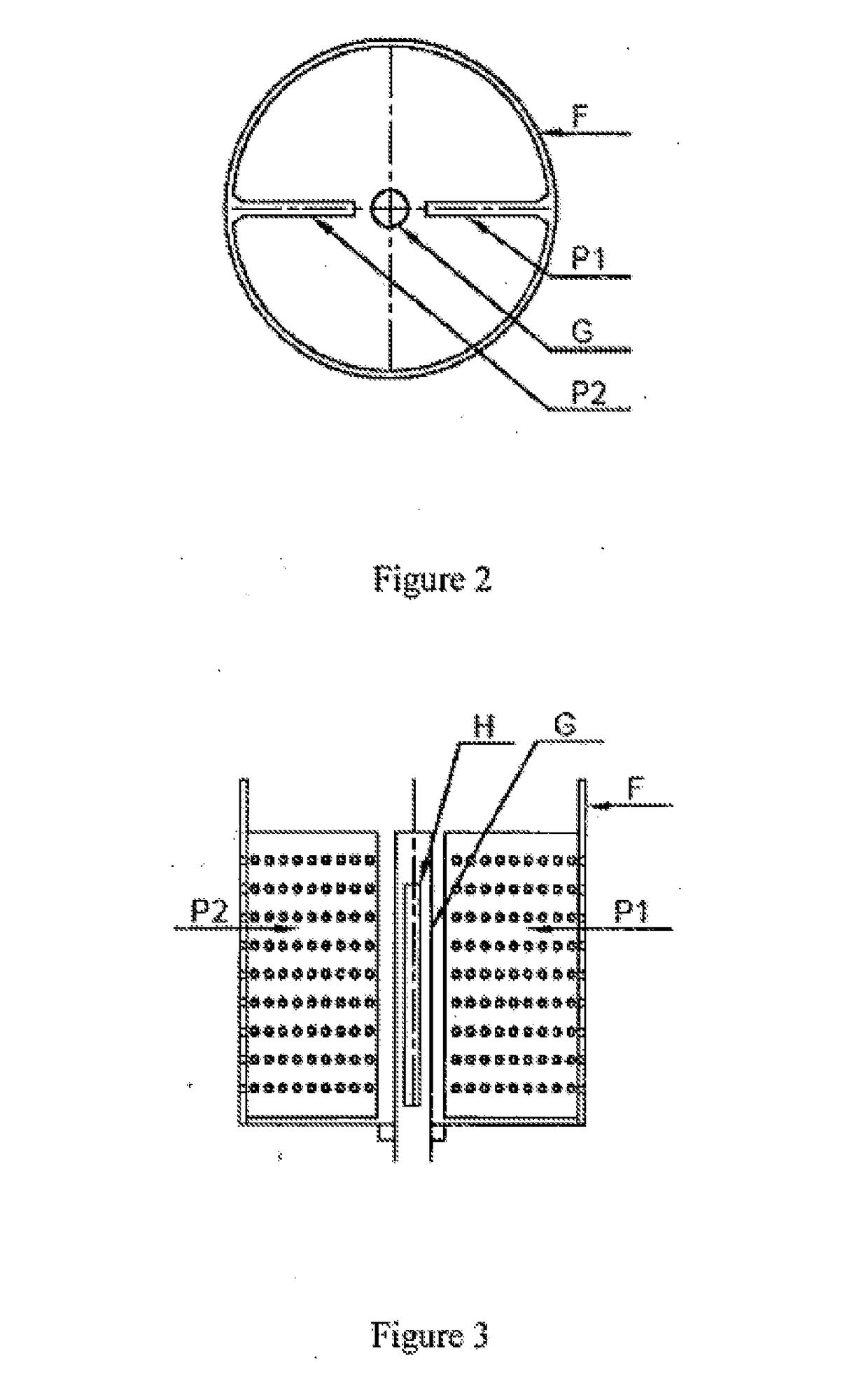

System, method and apparatus for applying liquid to a cmp polishing pad

InactiveUS20050070212A1Reduce flow rateEqually distributedPolishing machinesRevolution surface grinding machinesSpray nozzleEngineering

Owner:APPLIED MATERIALS INC

System, method and apparatus for applying liquid to a CMP polishing pad

InactiveUS6872128B1Equally distributedReduce flow ratePolishing machinesRevolution surface grinding machinesSpray nozzleEngineering

A system and method of delivering a liquid to a CMP polishing pad includes supplying the liquid to a nozzle, the nozzle being oriented toward a polishing surface of the CMP polishing pad. The liquid flows at a rate of less than or equal to about 100 cc per minute. A pressurized carrier gas is also supplied to the nozzle. The liquid is substantially evenly sprayed from the nozzle onto the CMP polishing pad.

Owner:APPLIED MATERIALS INC

Tube section piece

InactiveUS20050073146A1High trafficEasy to installAdjustable jointsPisciculture and aquariaWater organismDriven element

Owner:DAEHNE PHILIPP

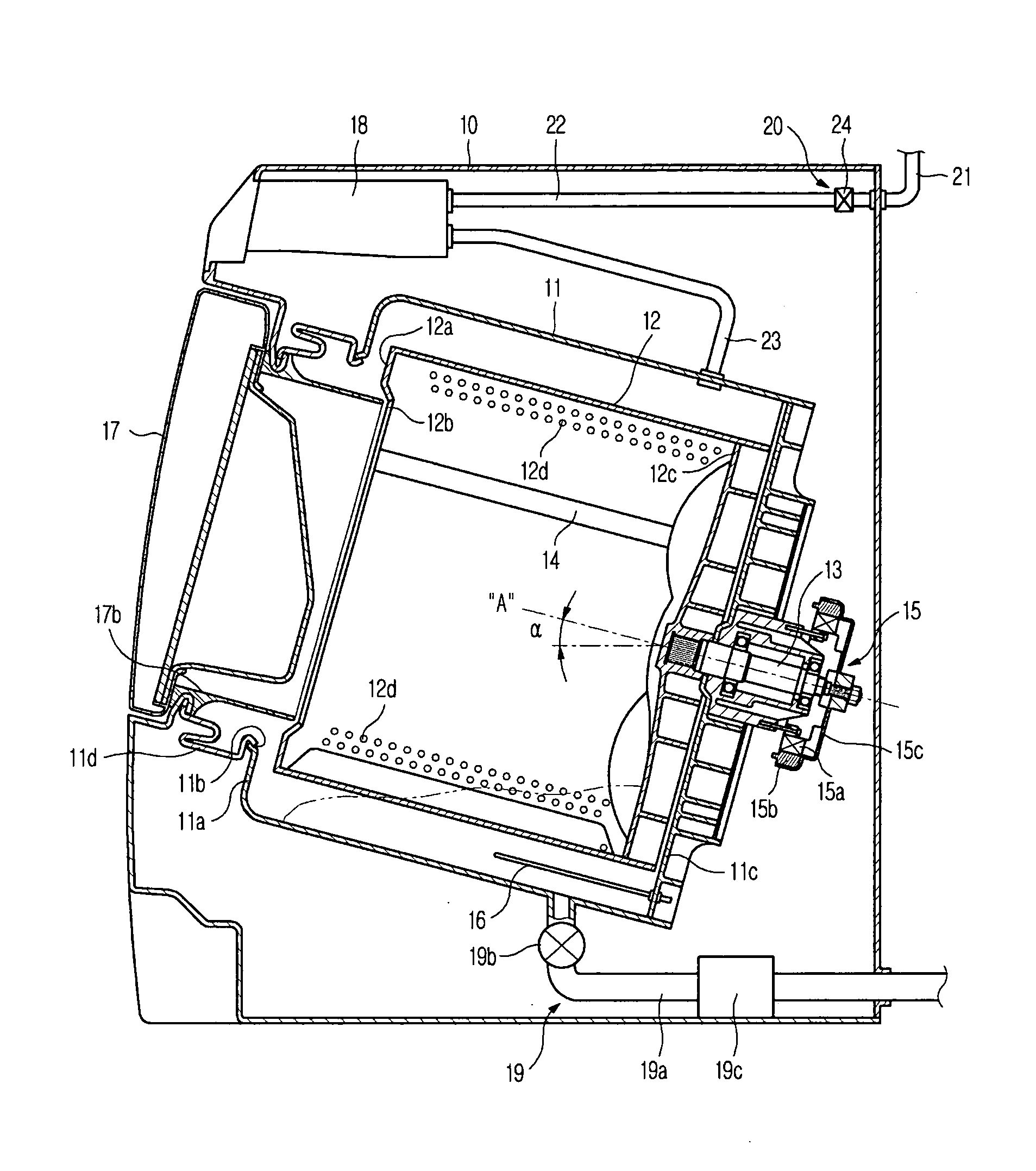

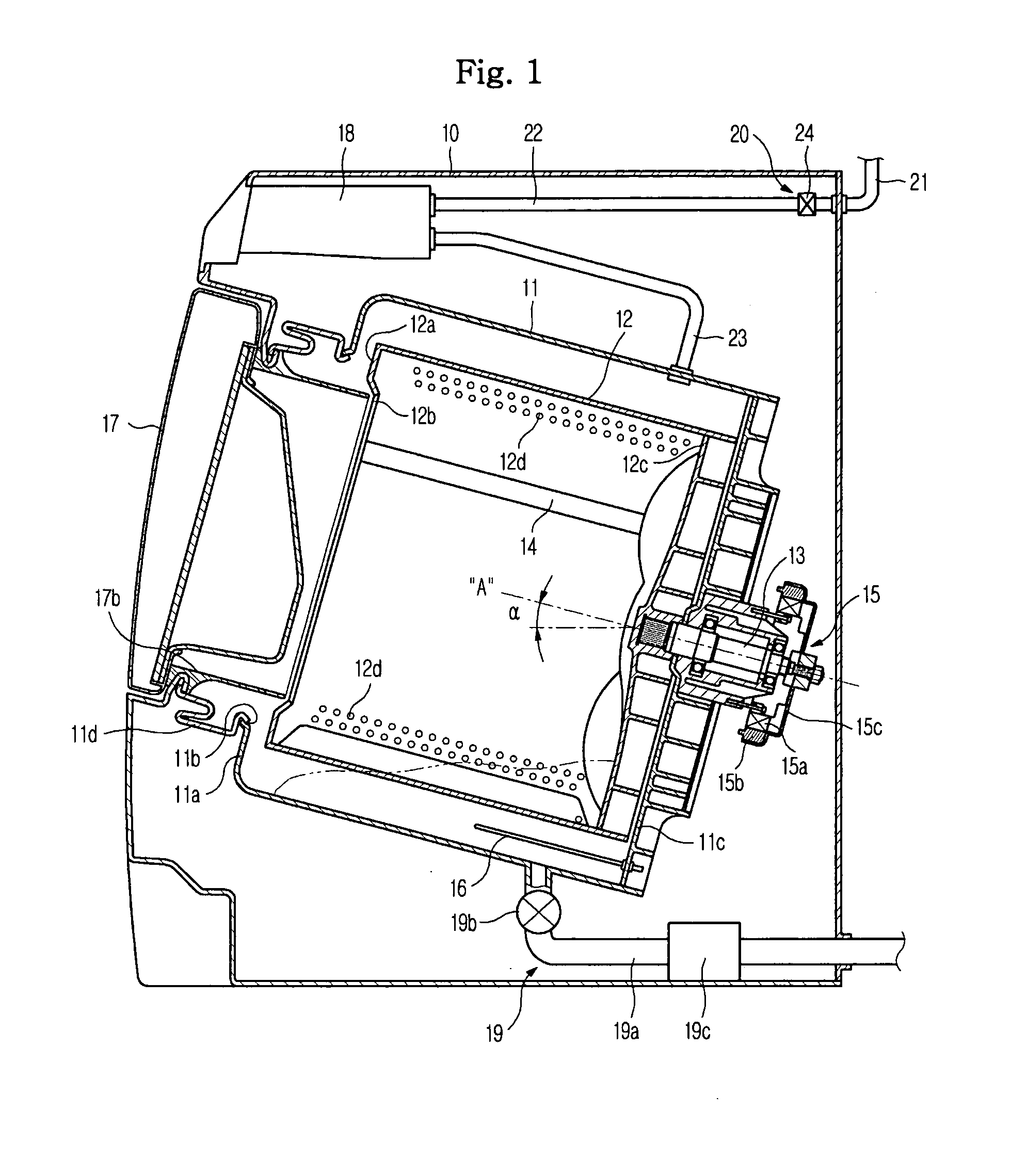

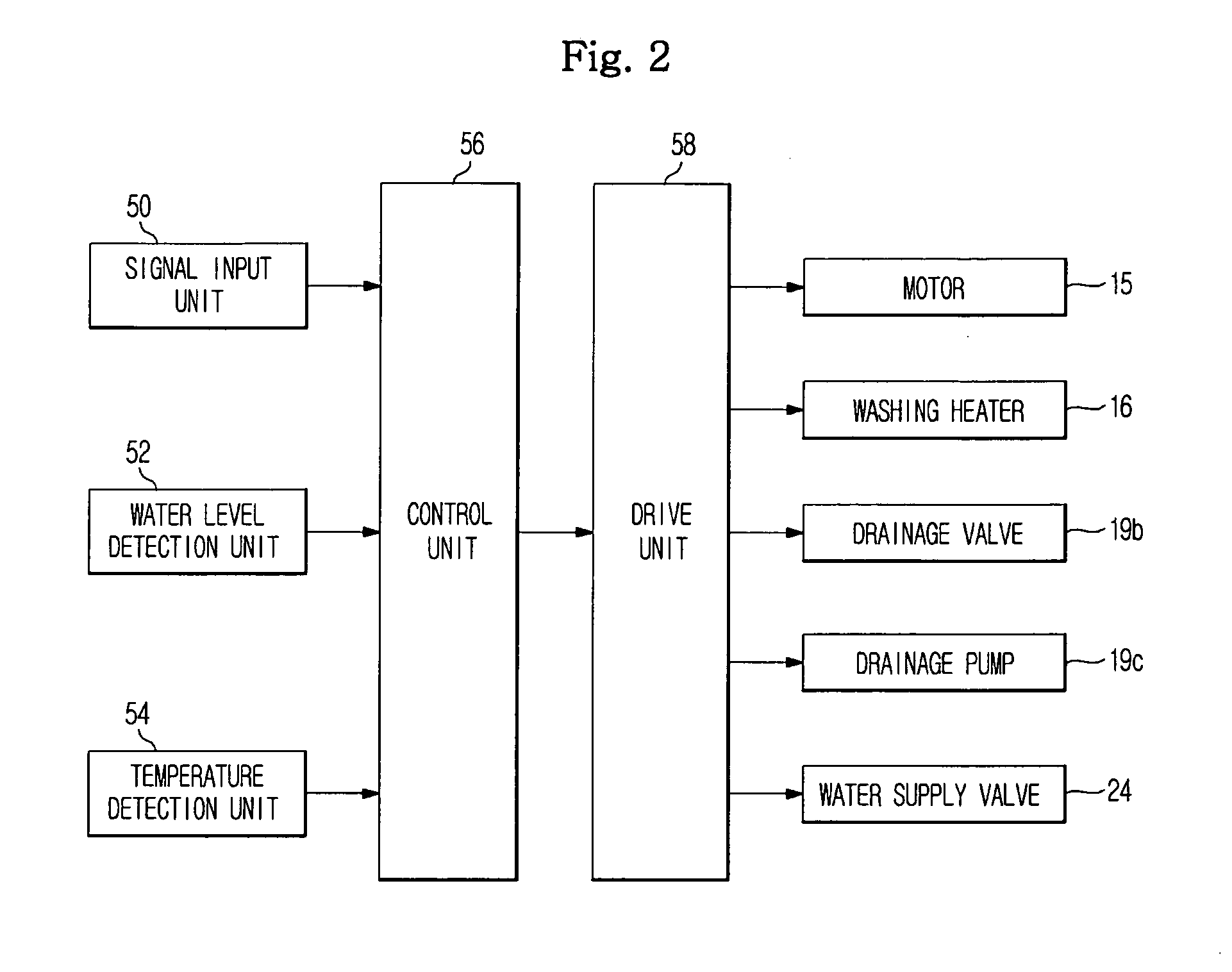

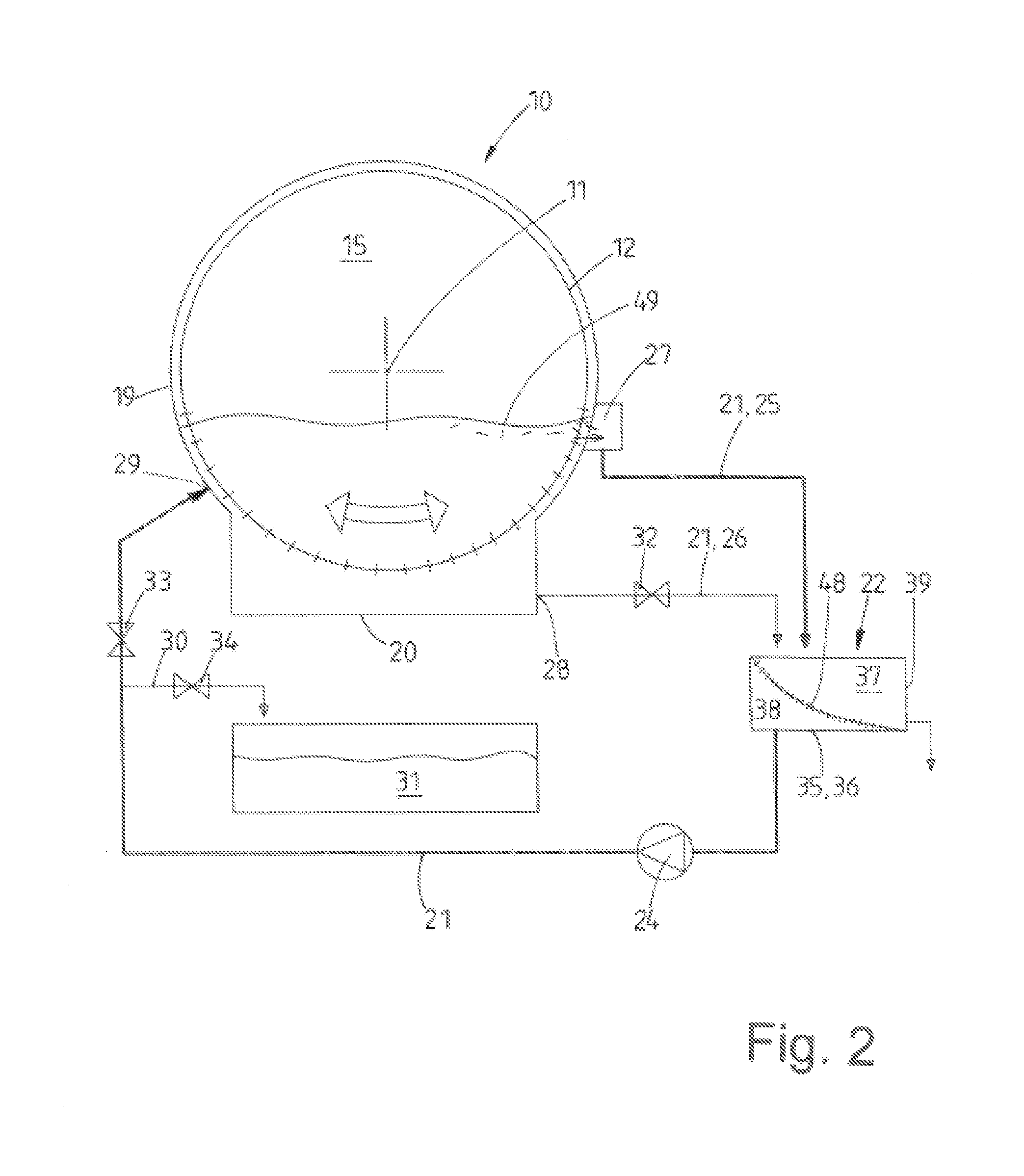

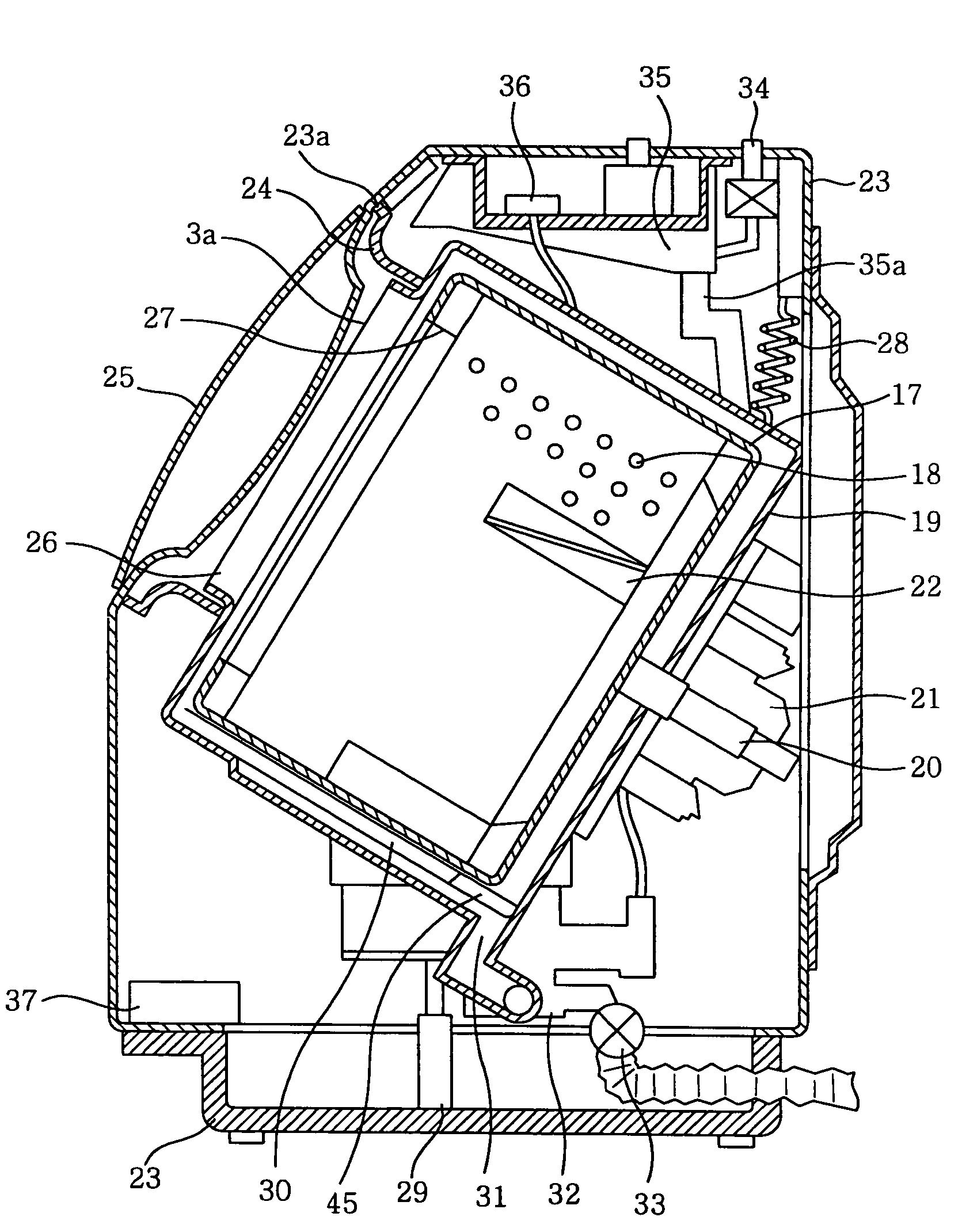

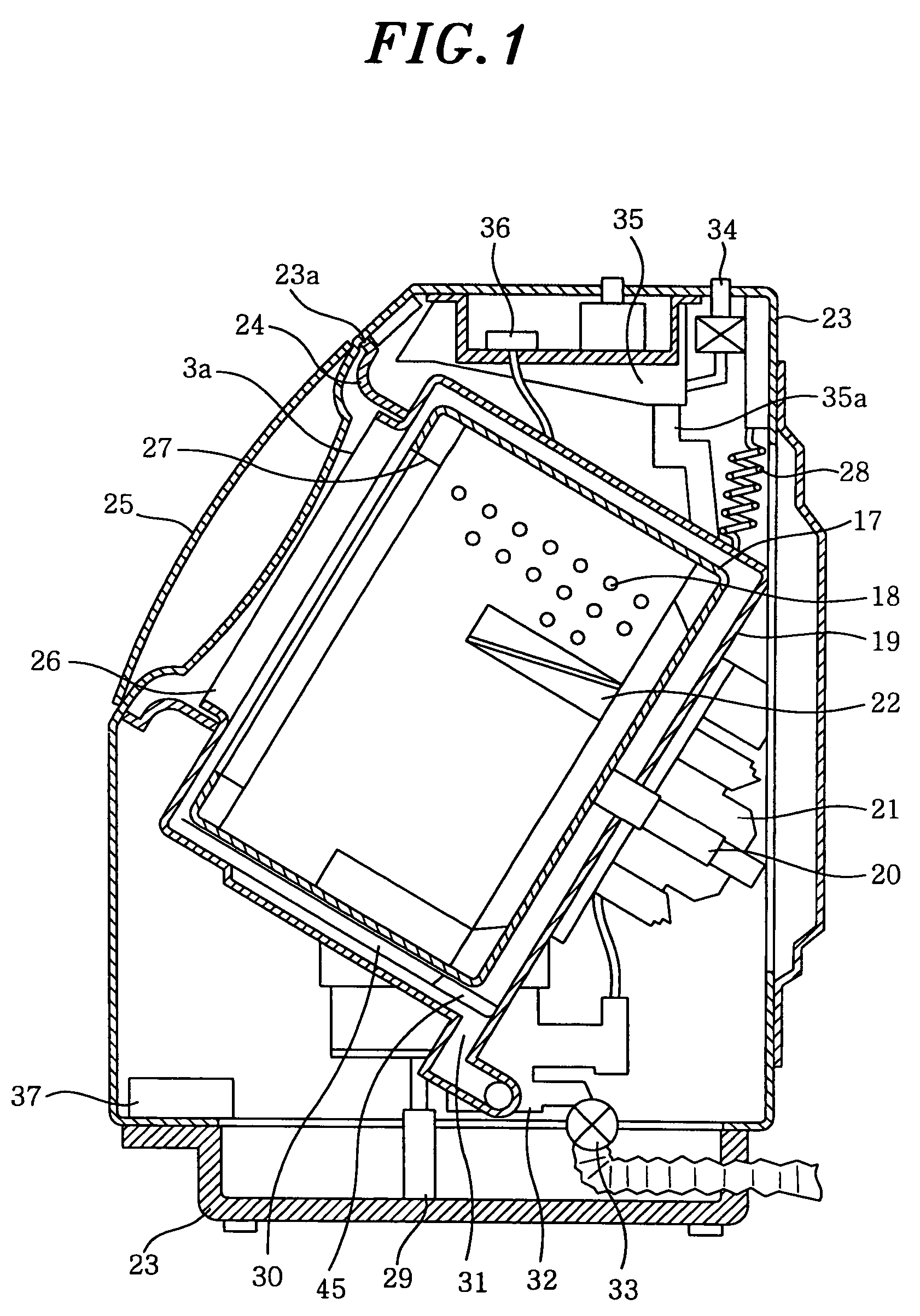

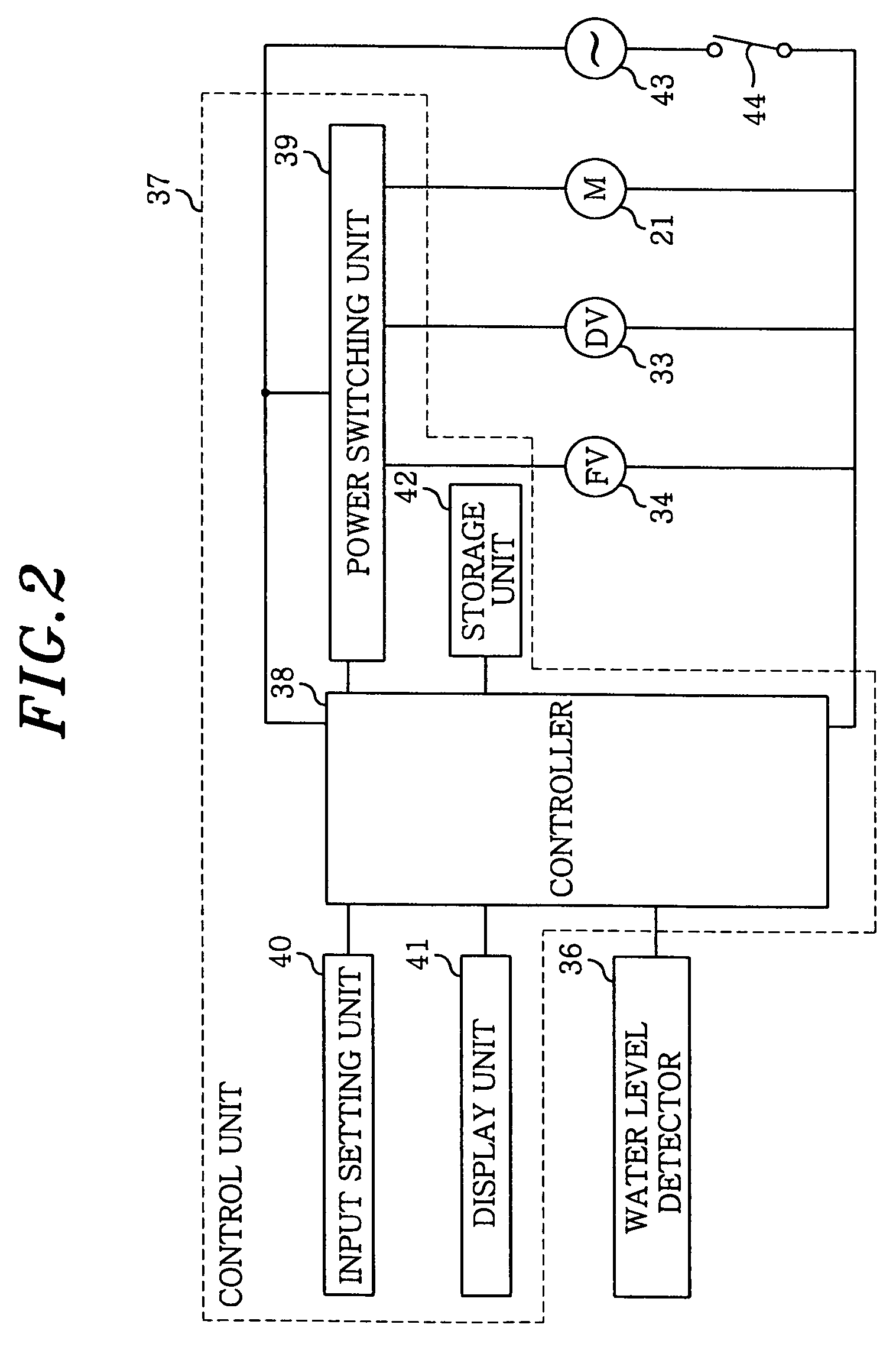

Drum type washing machine

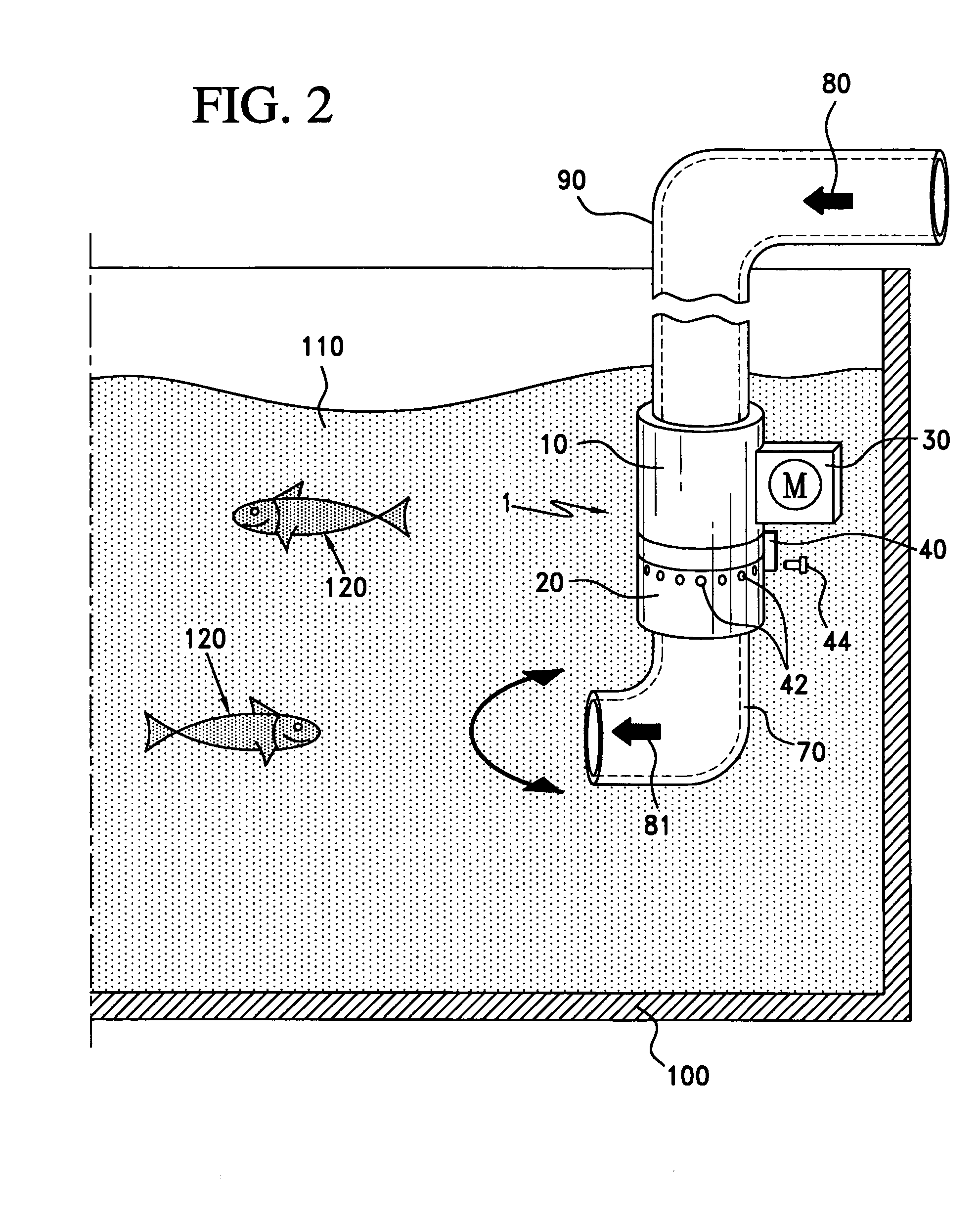

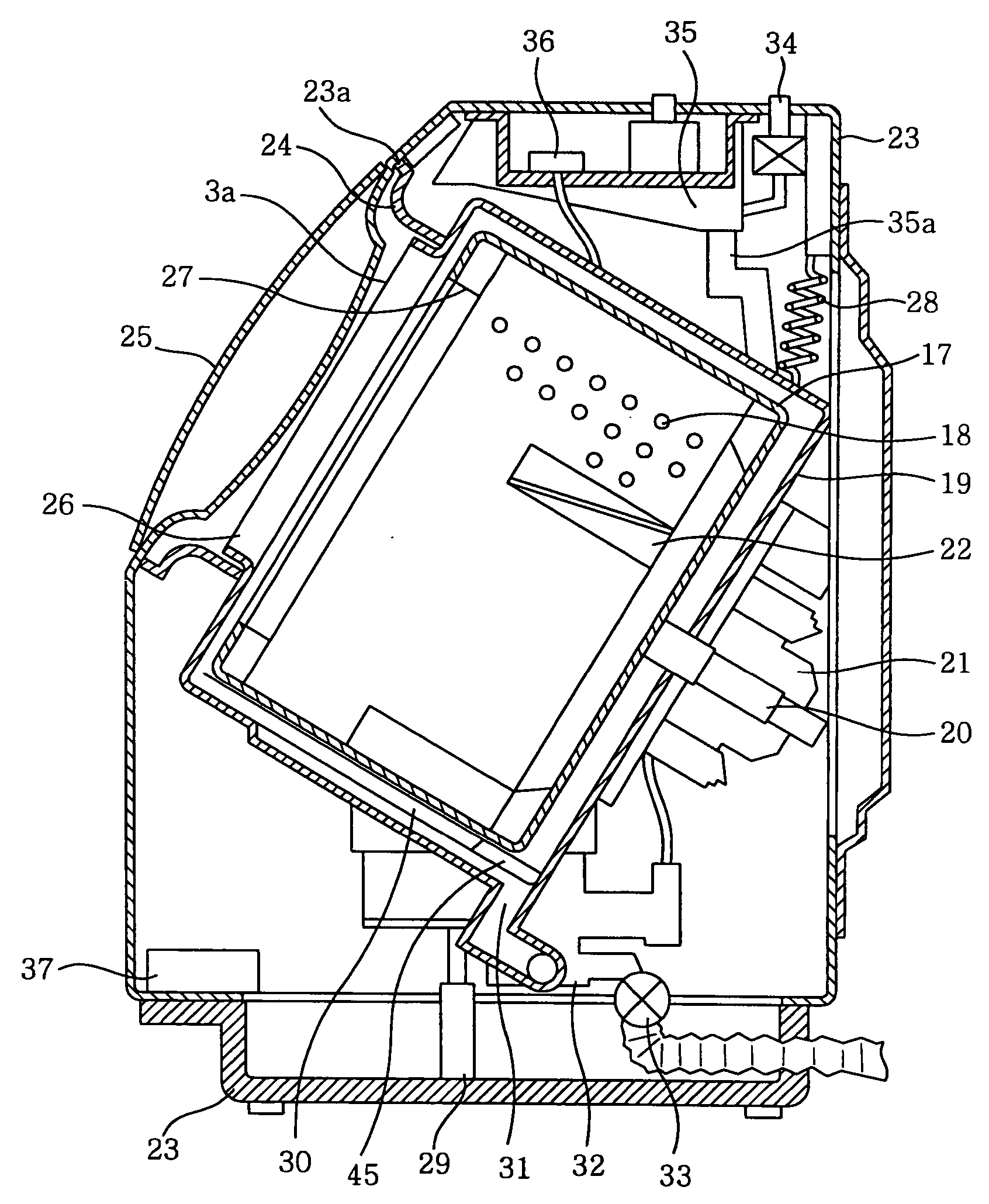

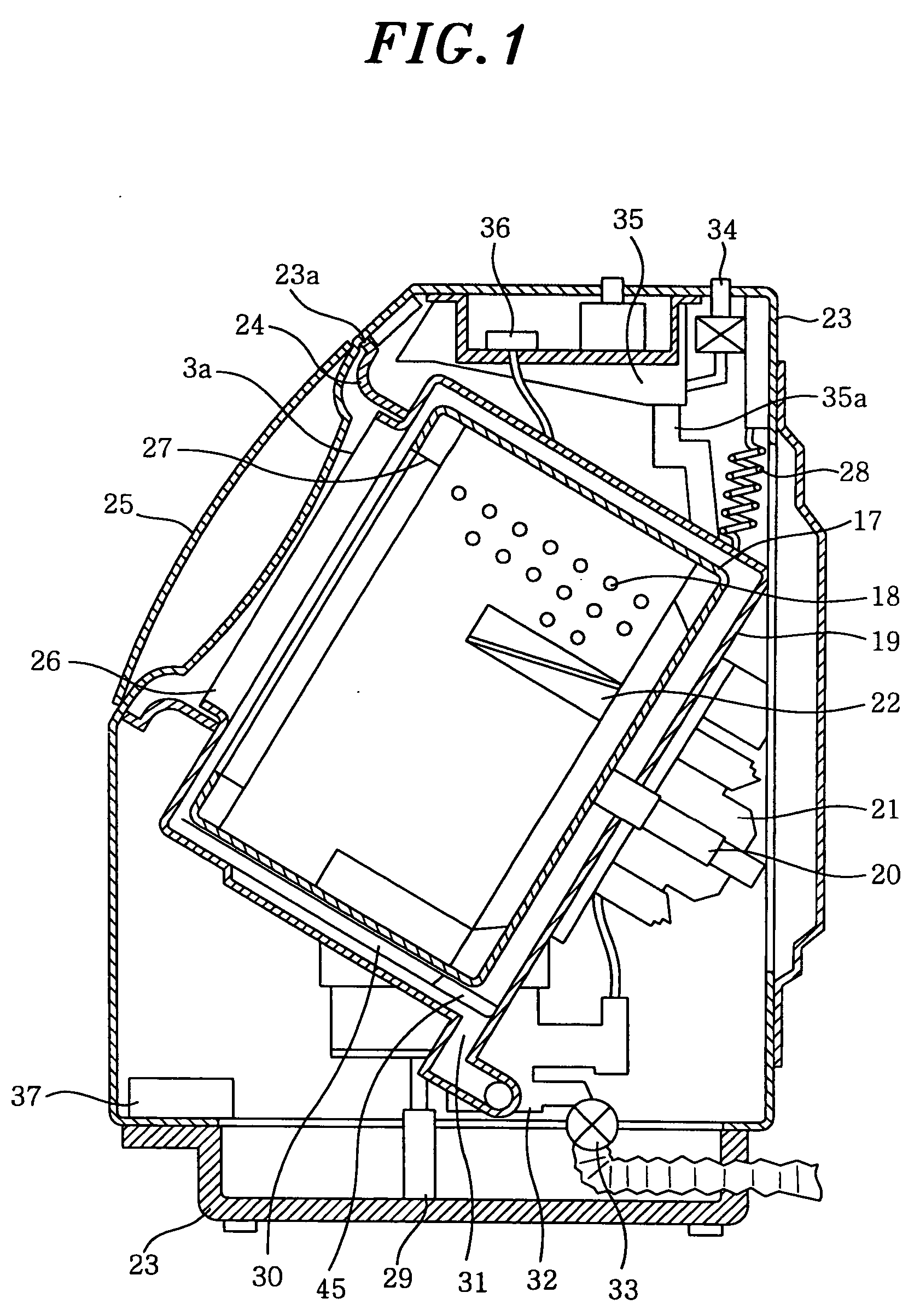

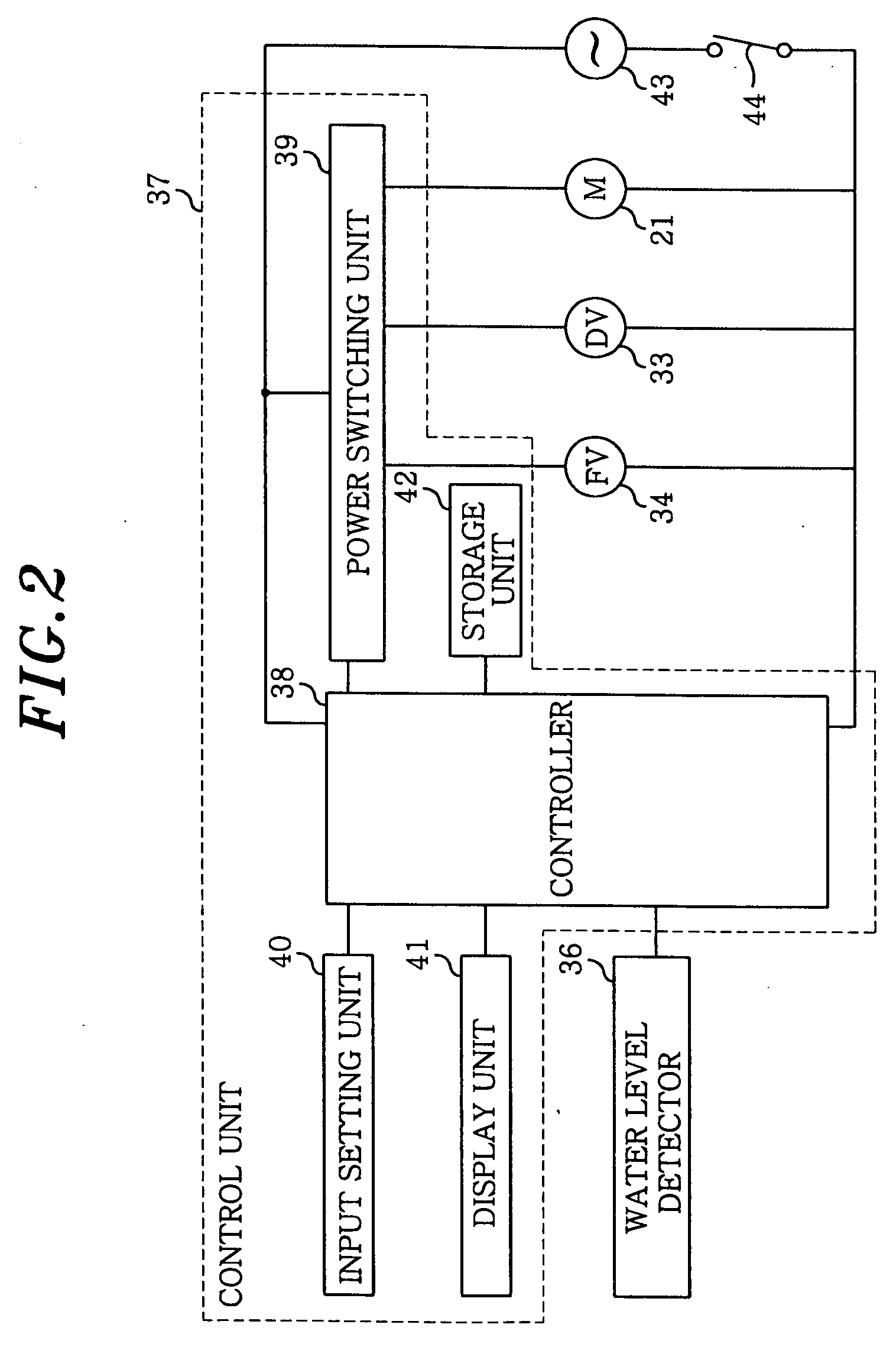

InactiveUS20060096336A1Reducing water-extracting timeDesired rinsing efficiencyOther washing machinesControl devices for washing apparatusWash waterWater supply

A drum type washing machine includes a water tub; a cylindrical rotary drum rotatably installed in the water tub such that a central axis of rotation of the rotary drum is horizontal or slanted; a water outlet provided on a bottom portion of the water tub; a motor for rotating the rotary drum; a water supplying unit for supplying wash water into the water tub; a water draining unit for draining the wash water from the water tub; and a controller for controlling the motor, the water supplying unit and the water draining unit to thereby perform a washing, a rinsing and a water-extracting process. A guiding member with a guiding surface is installed on an inner bottom portion of the water tub to facilitate collection of the wash water and guide the collected wash water toward the water outlet during the water-extracting process.

Owner:PANASONIC CORP

Washing machine and rinsing control method of the same

InactiveUS20080216251A1Extend rinse timeImprove rinsing efficiencyOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

Disclosed herein are a washing machine and a rinsing control method of the same that is capable of increasing spin-drying RPM before the final rinsing, such that the spin-drying RPM before the final rinsing is higher by a specific percentage than a predetermined RPM, to strongly squeeze out residual detergent, contained in laundry, from the laundry, and adding soaked rinsing time, during the final rinsing, to completely dissolve residual detergent contained in laundry, thereby improving the rinsing efficiency. The washing machine includes a rotary drum to receive laundry and a motor to rotate the rotary drum. The rinsing control method includes determining whether a current operation is a rinsing operation, and, when the current operation is the rinsing operation, controlling intermediate spin-drying RPM and rinsing time to remove residual detergent from the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

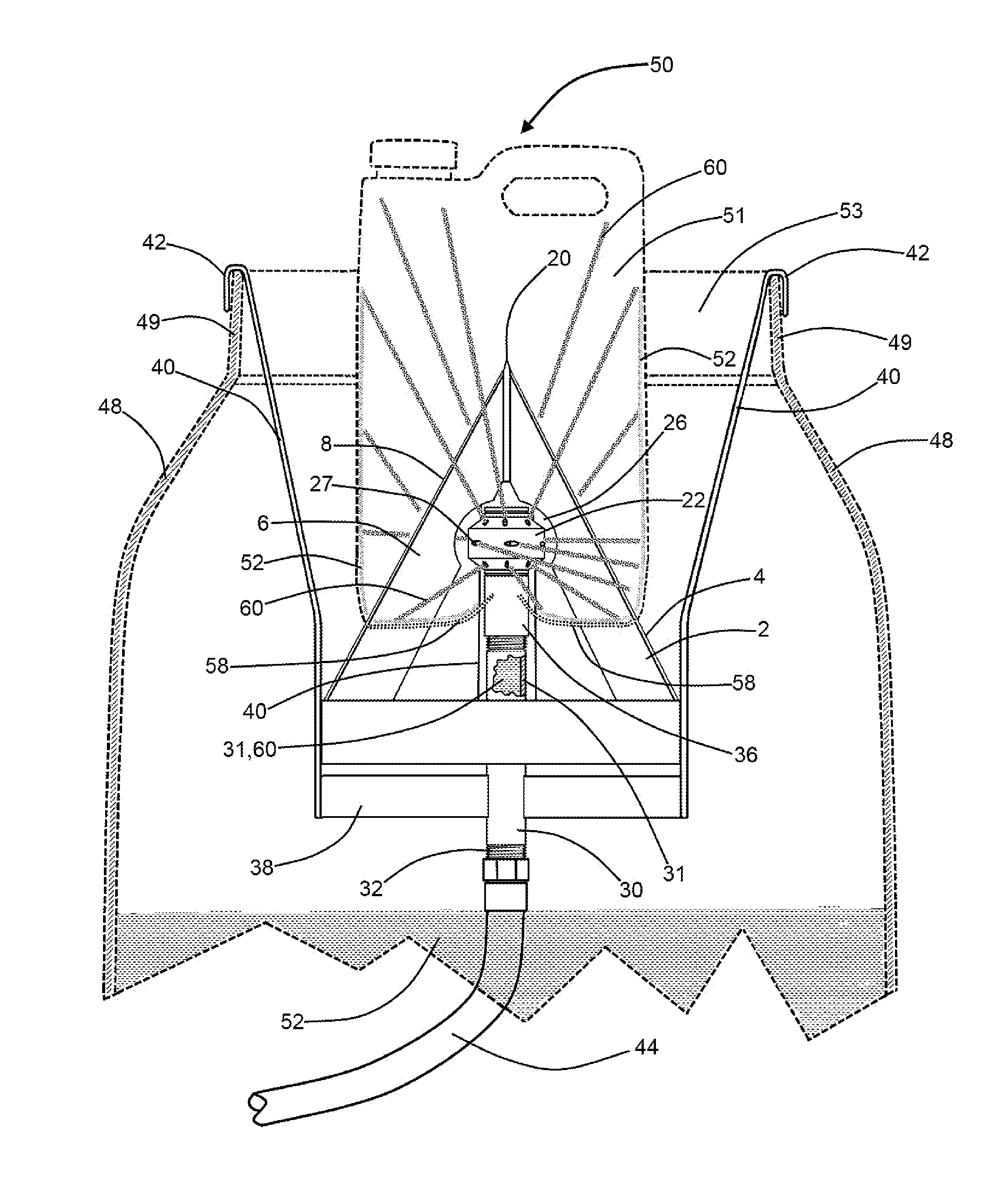

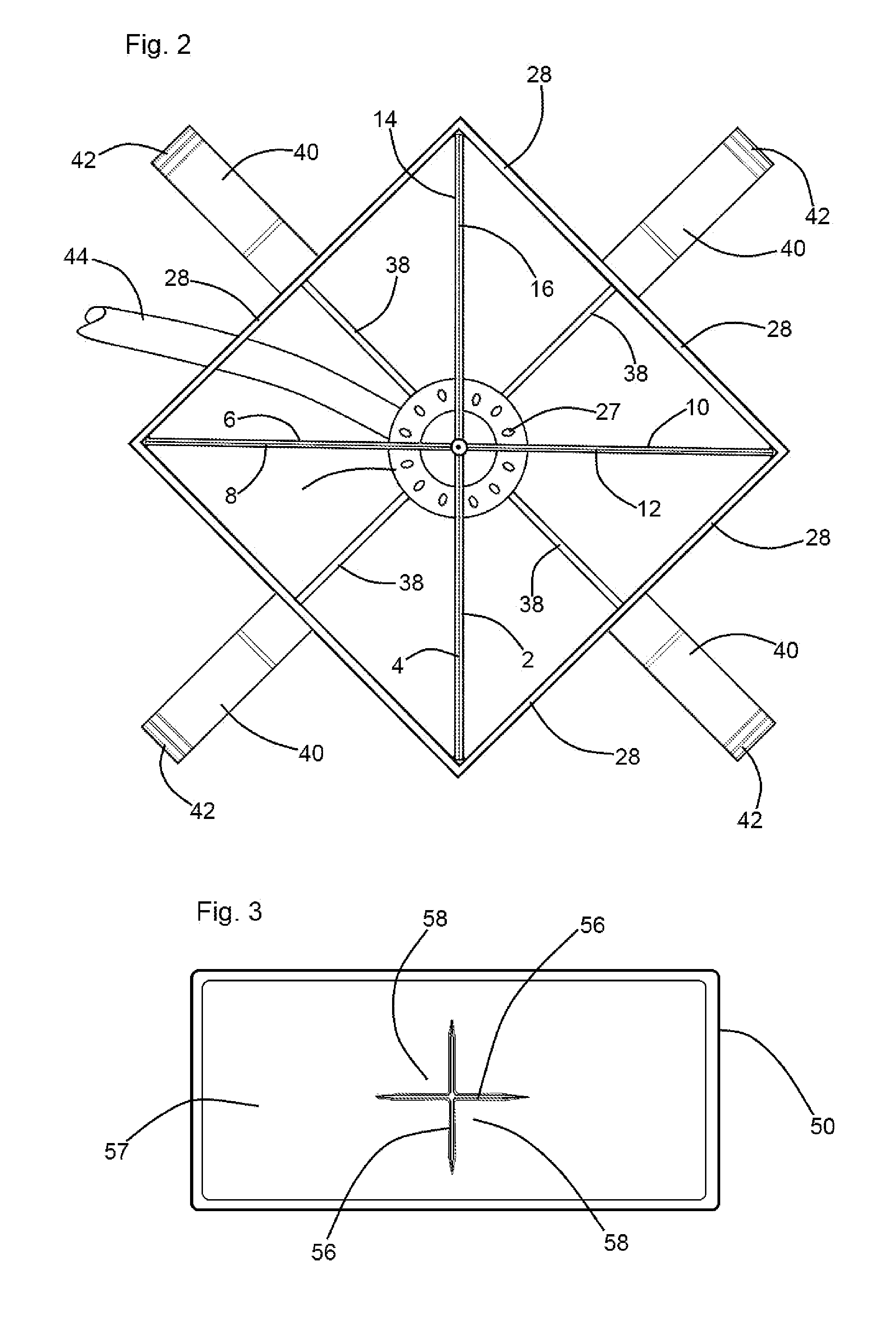

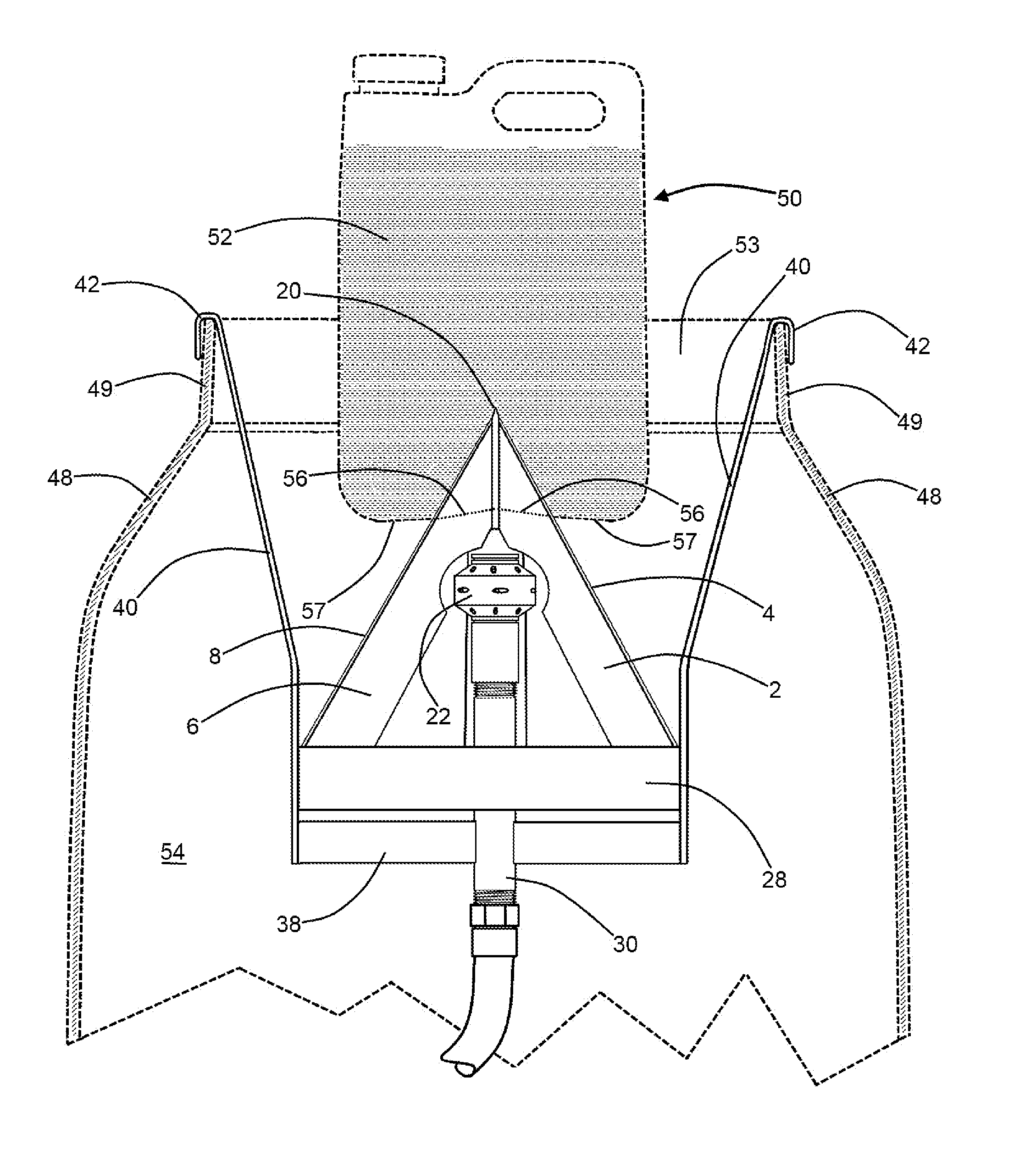

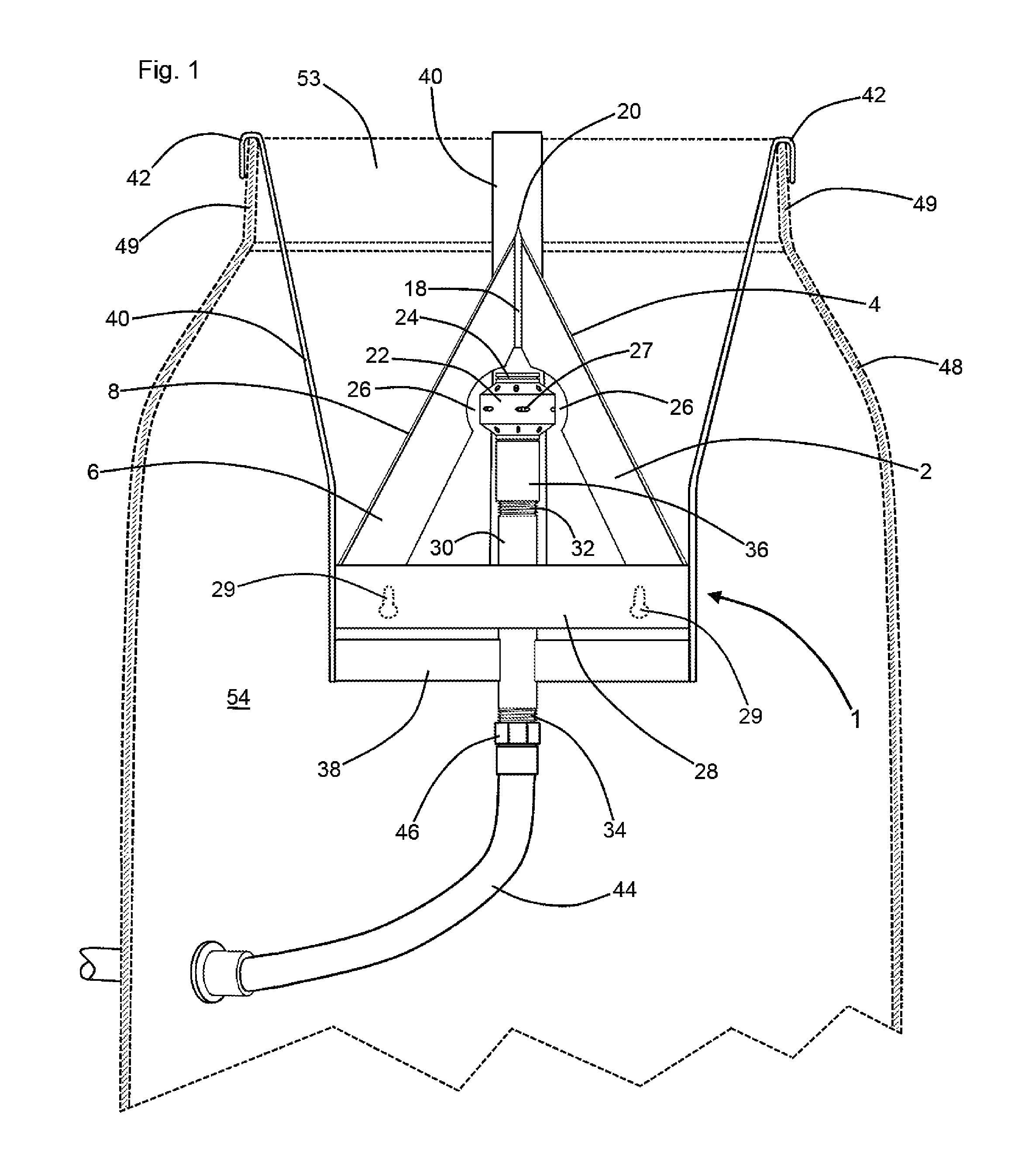

Assembly for Dispensing a Canister's Liquid Contents Into a Vessel and for Rinsing a Residue of the Liquid Contents

ActiveUS20140090749A1Improve rinsing performanceEfficient rinseLiquid fillingHollow article cleaningEngineeringMechanical engineering

An assembly for purging a canister into a tank and for rinsing the canister, the canister having a floor, the assembly including a “A” configured lance having a plurality of legs and a bar, each leg among the plurality of legs forming a blade having an upper end and an outer edge, the blades' upper ends and outer edges being sharpened for, upon upward impingement against the canisters' floor, dividing the floor into a plurality of sections, each section among the plurality of sections being configured as a flexible leaf, the bar member forming and functioning both as a leaf deflecting mandrel, and as a rotatable sprinkler head, the “A” configured lance and associated sprinkler head configured mandrel being mountable within the tank by suspension hooks.

Owner:ECK ETHAN

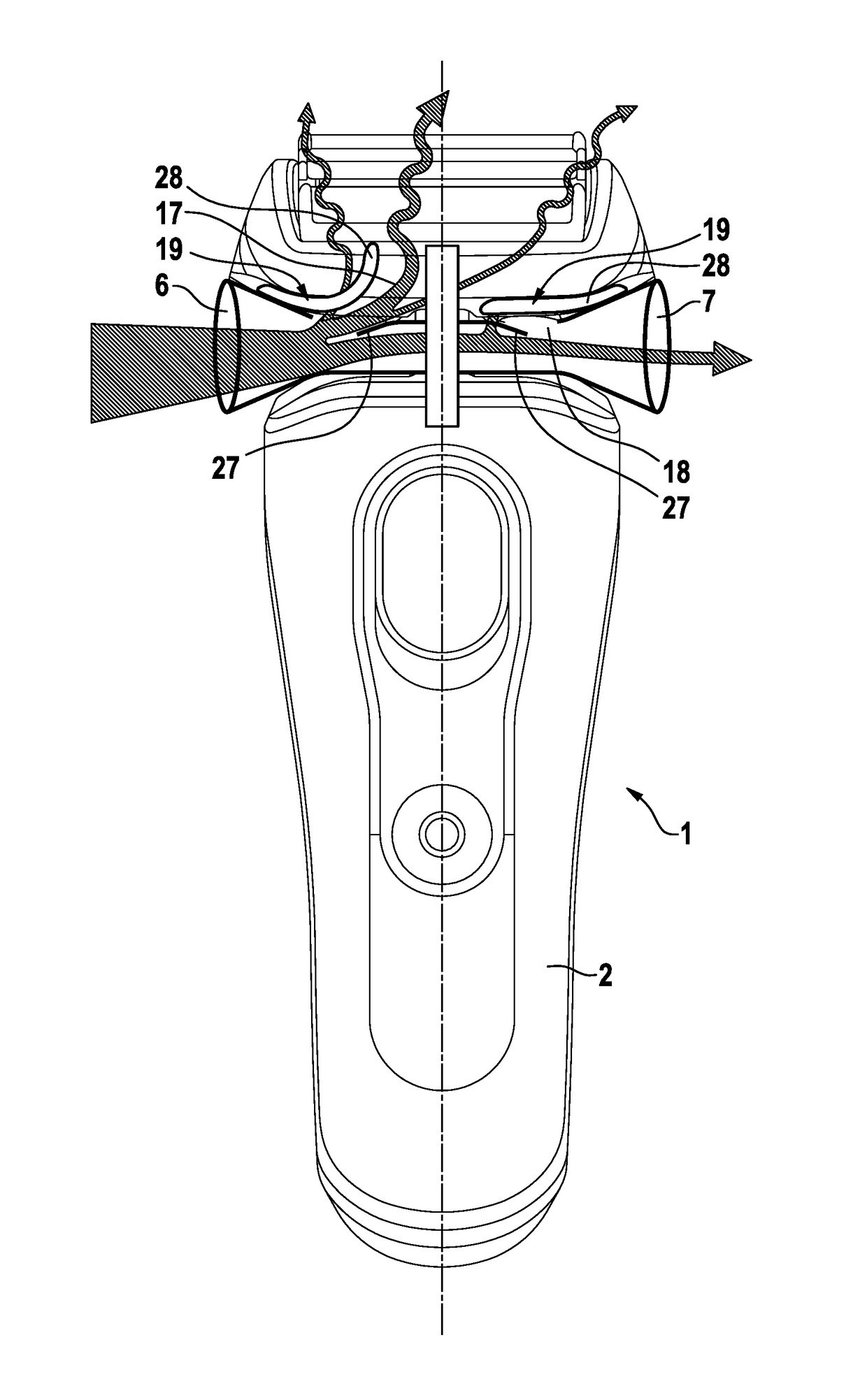

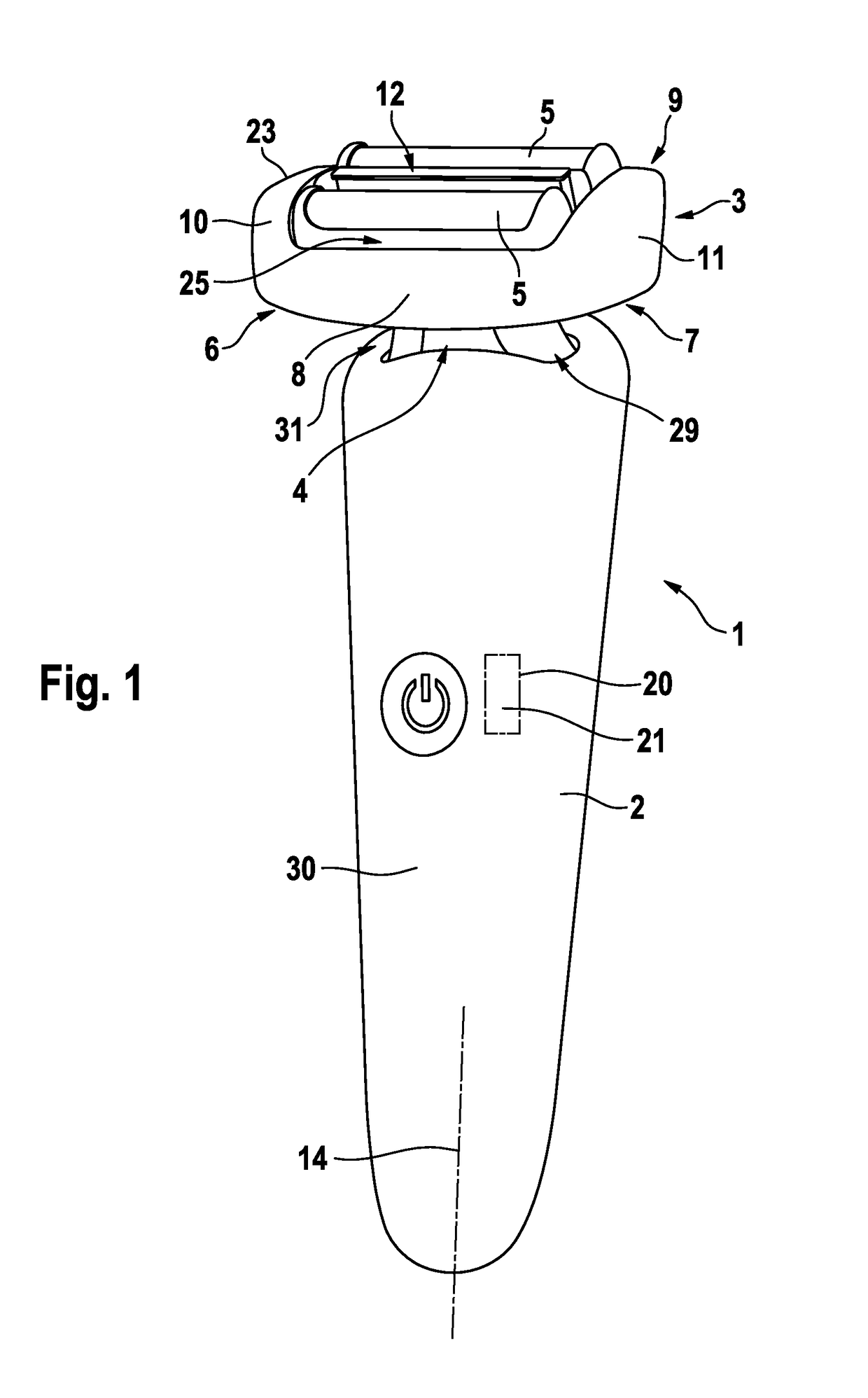

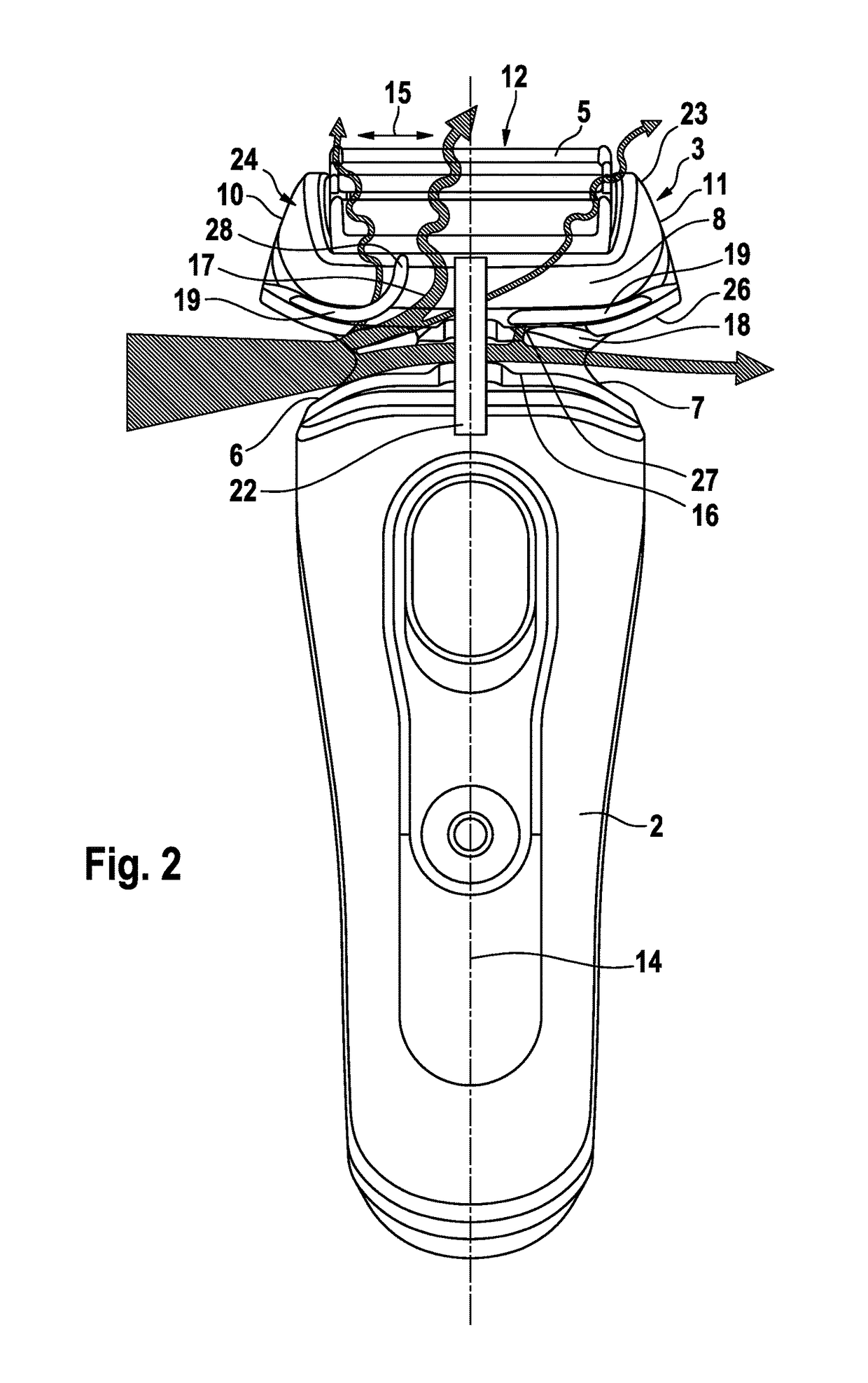

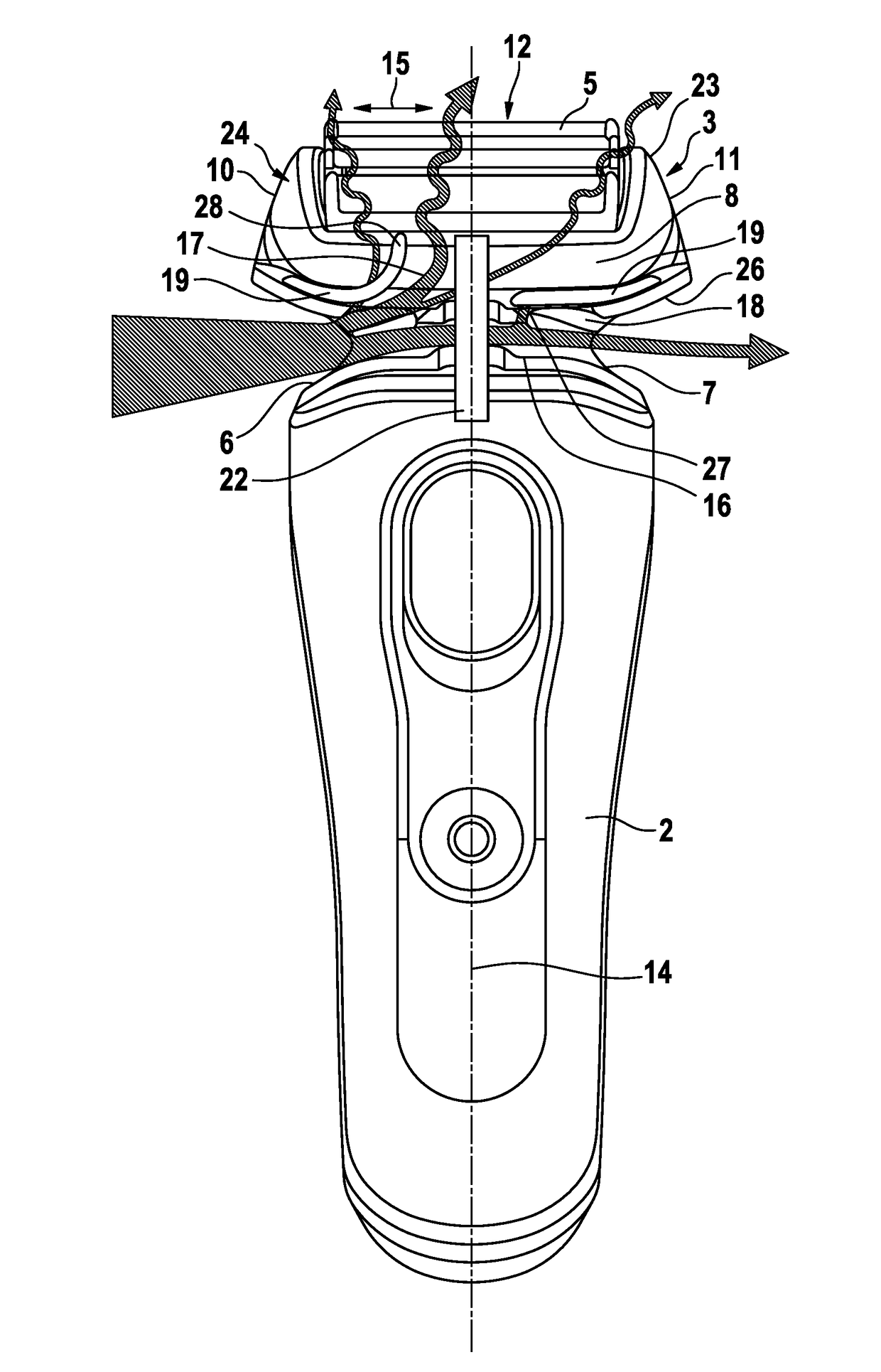

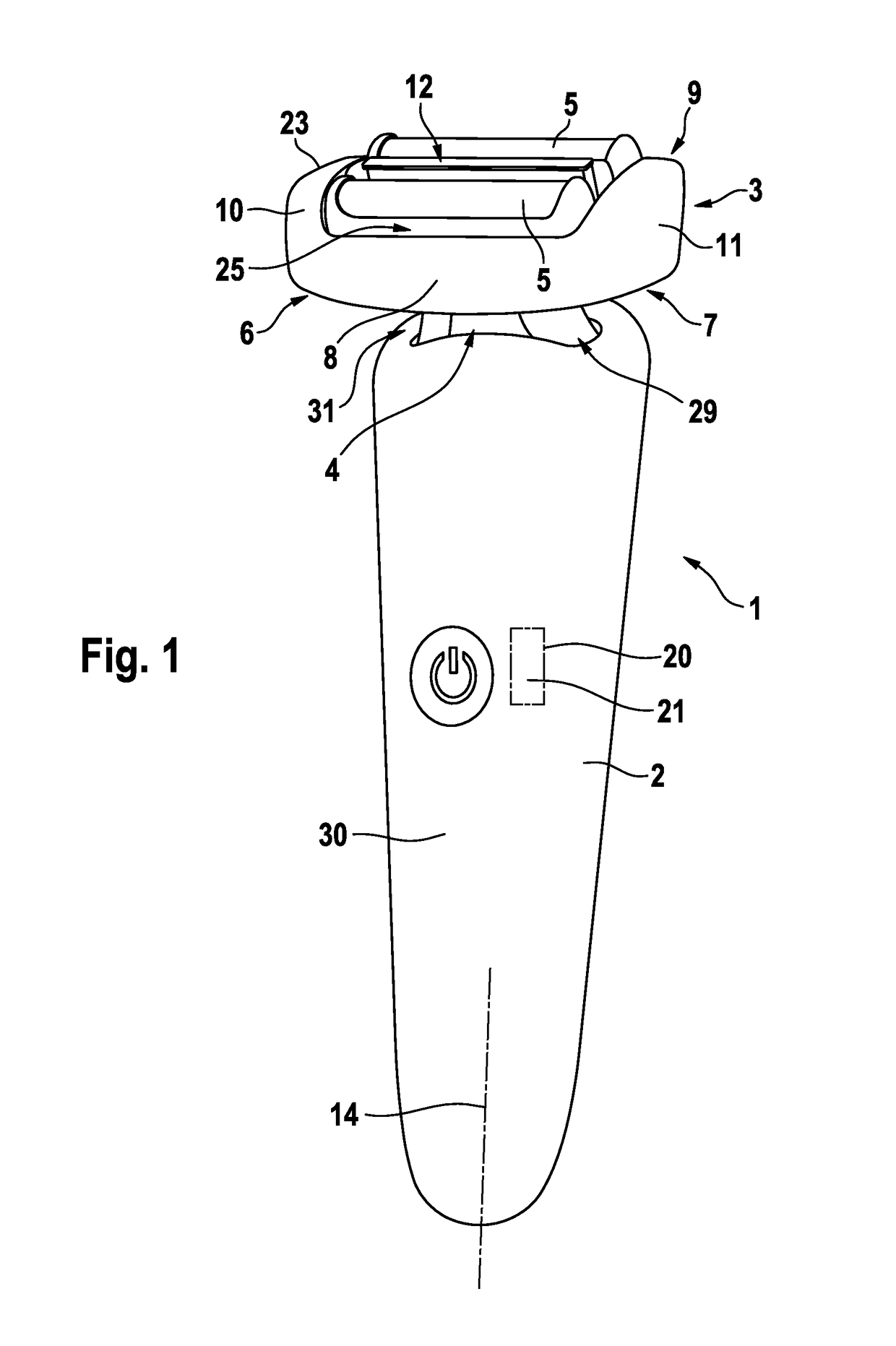

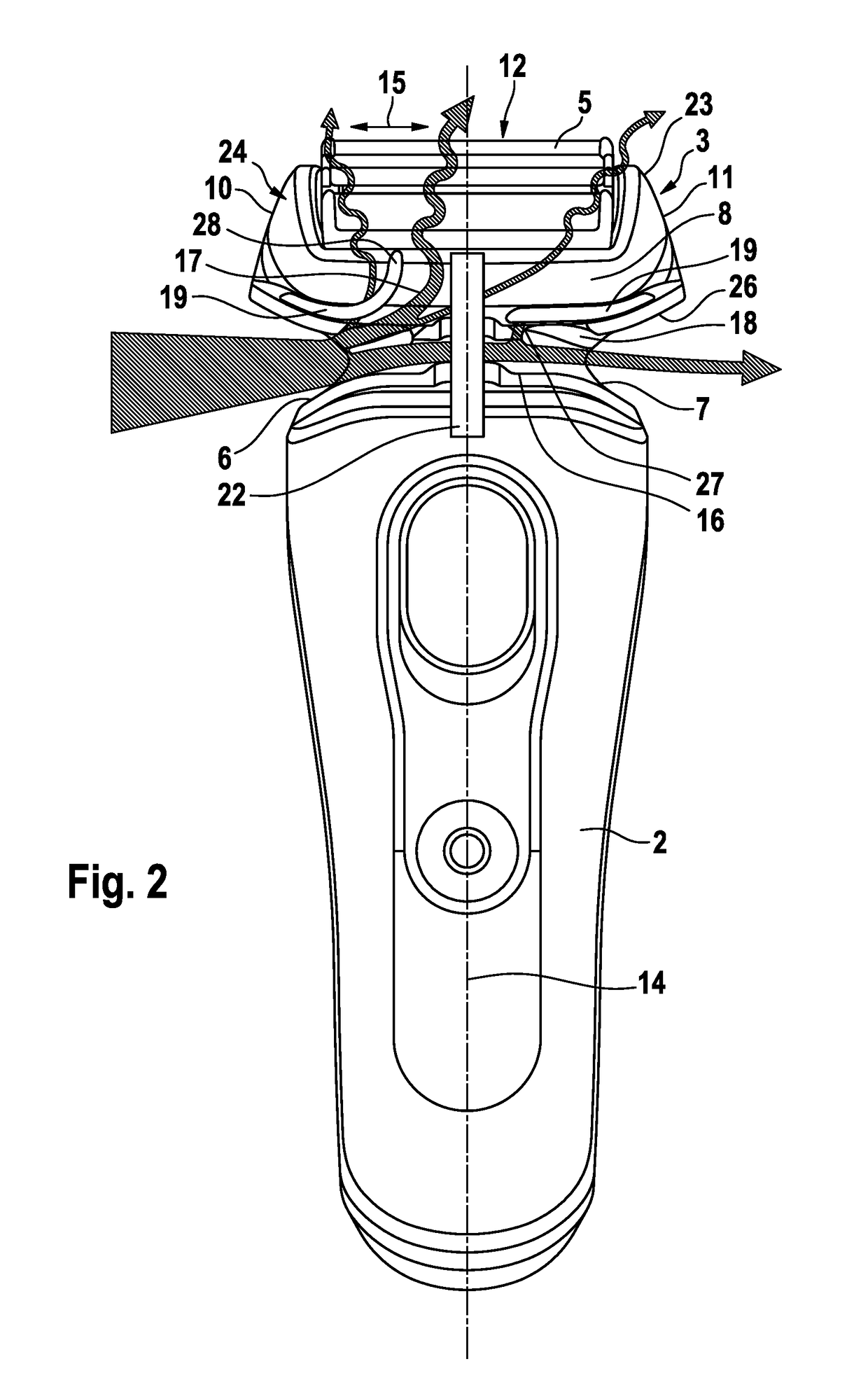

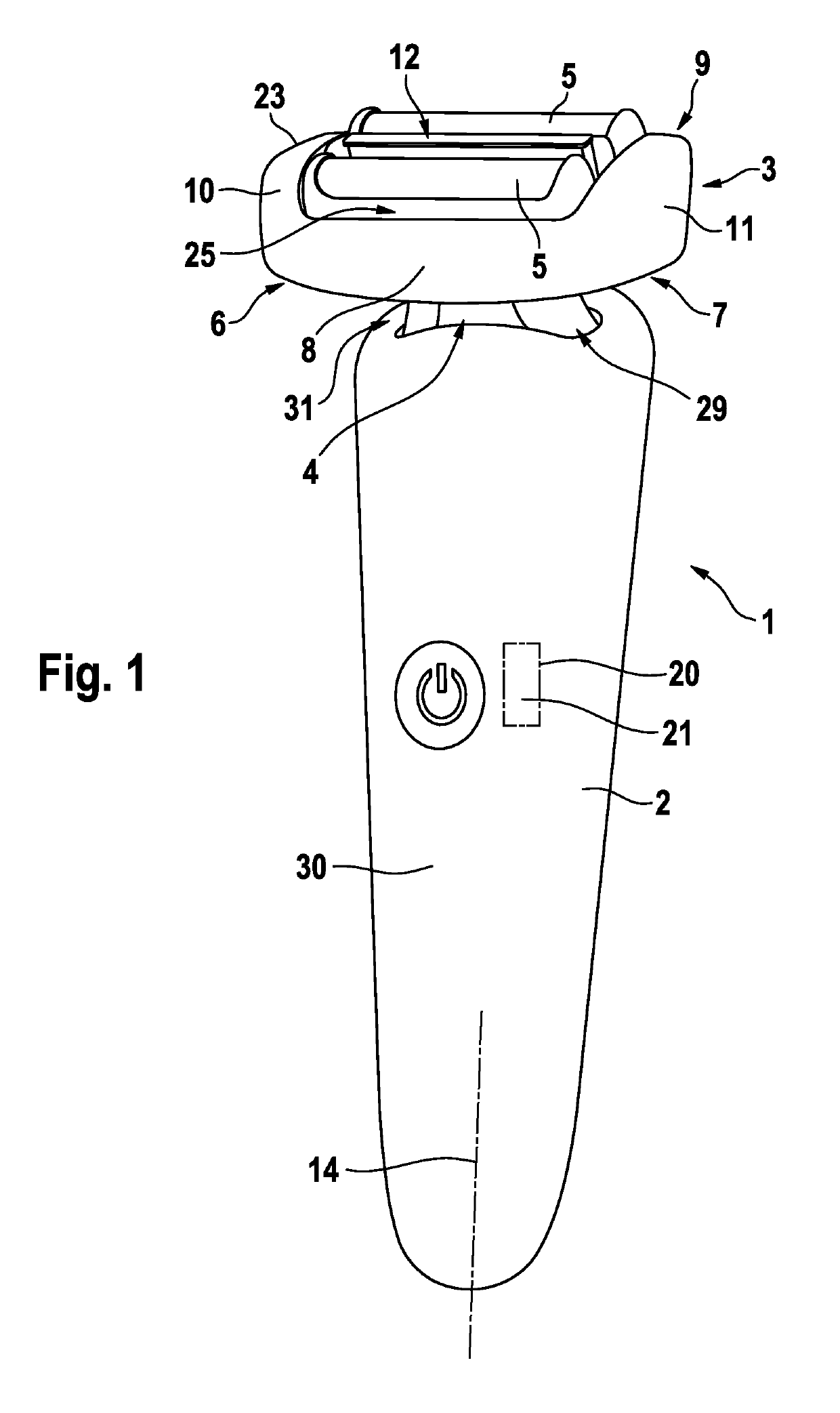

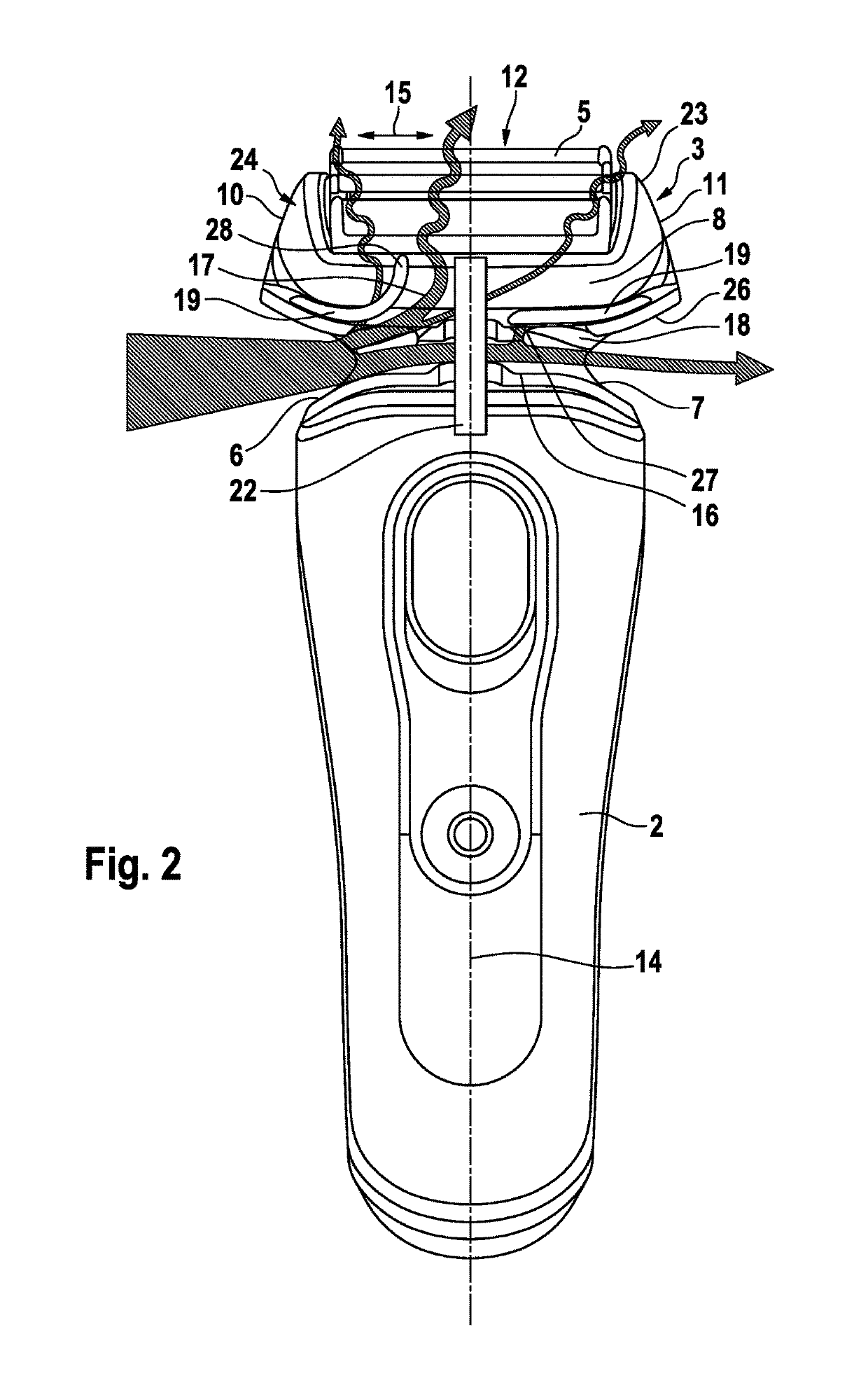

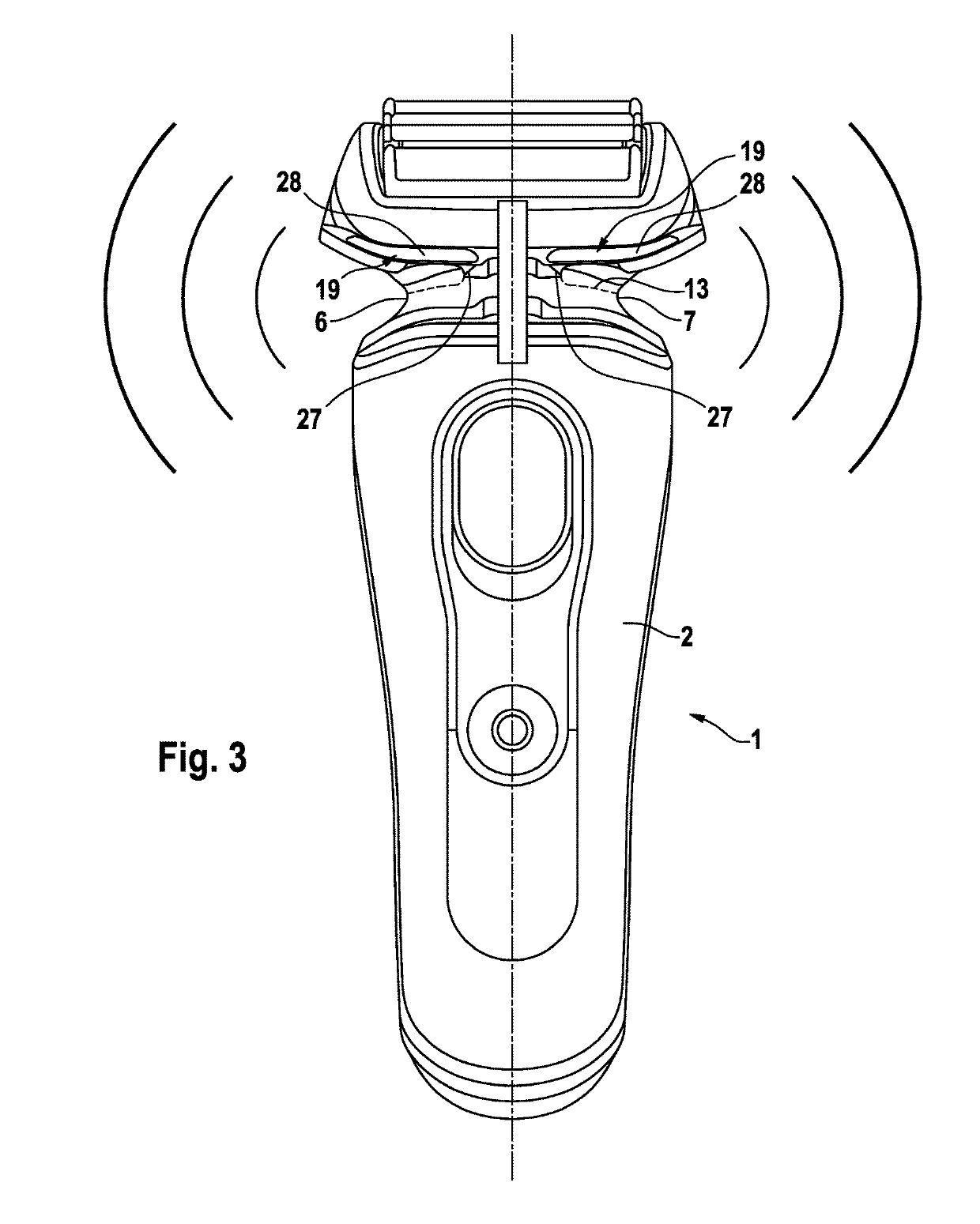

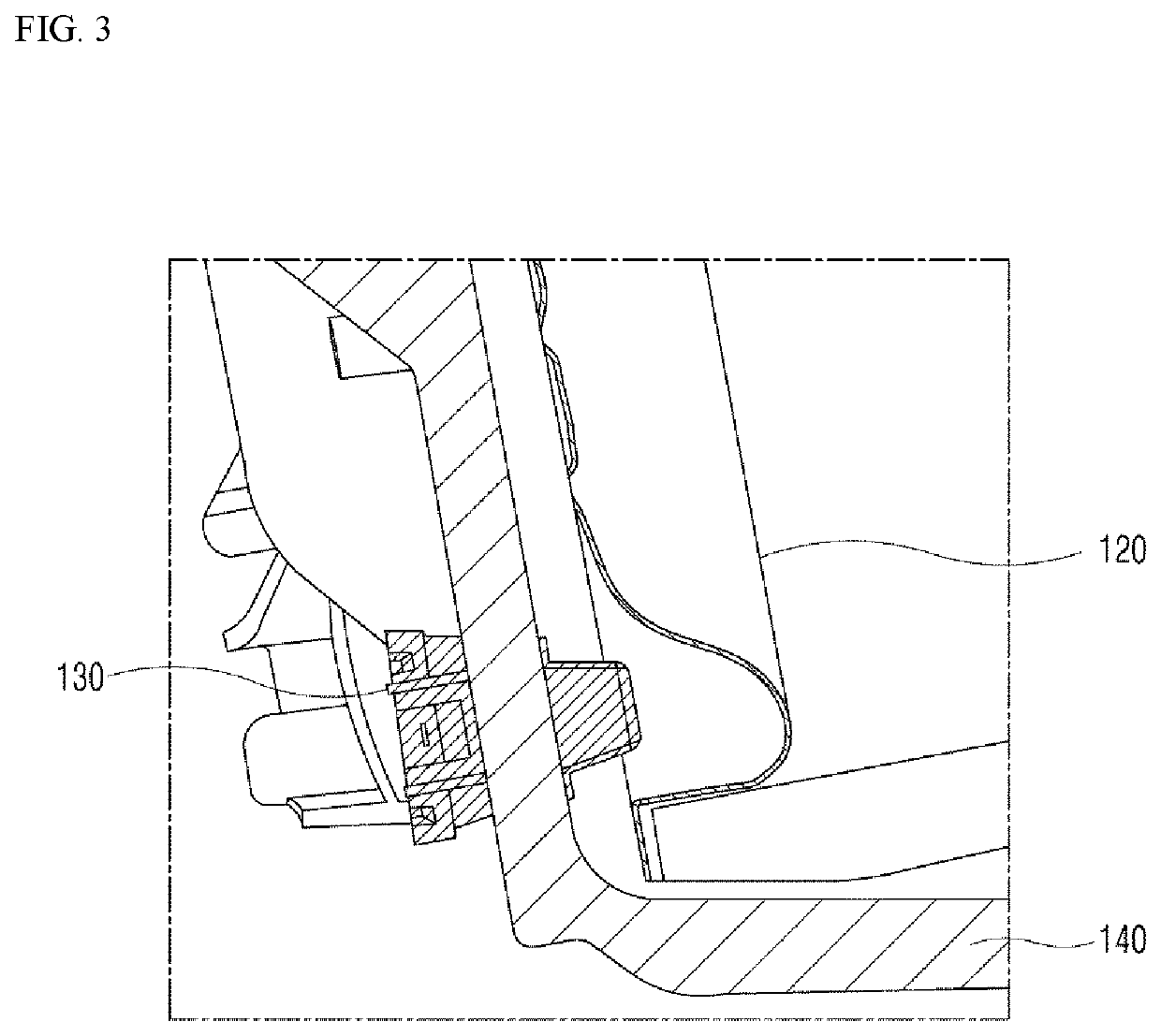

Electric shaver

ActiveUS20180085954A1Easy and self-explaining handlingAvoid misleadingMetal working apparatusRinse waterEngineering

The present invention generally relates to cleaning and washing shavers with water or other fluids. More particularly, the present invention relates to electric shavers comprising a handle portion, a shaver head supported by said handle portion and including at least one drivable cutter element, and at least one rinse opening for rinsing water through the interior of said shaver head. In accordance with one aspect, said rinse opening has a horn-shaped contour with a cross-section continuously expanding towards the ambience of the shaver.

Owner:BRAUN GMBH

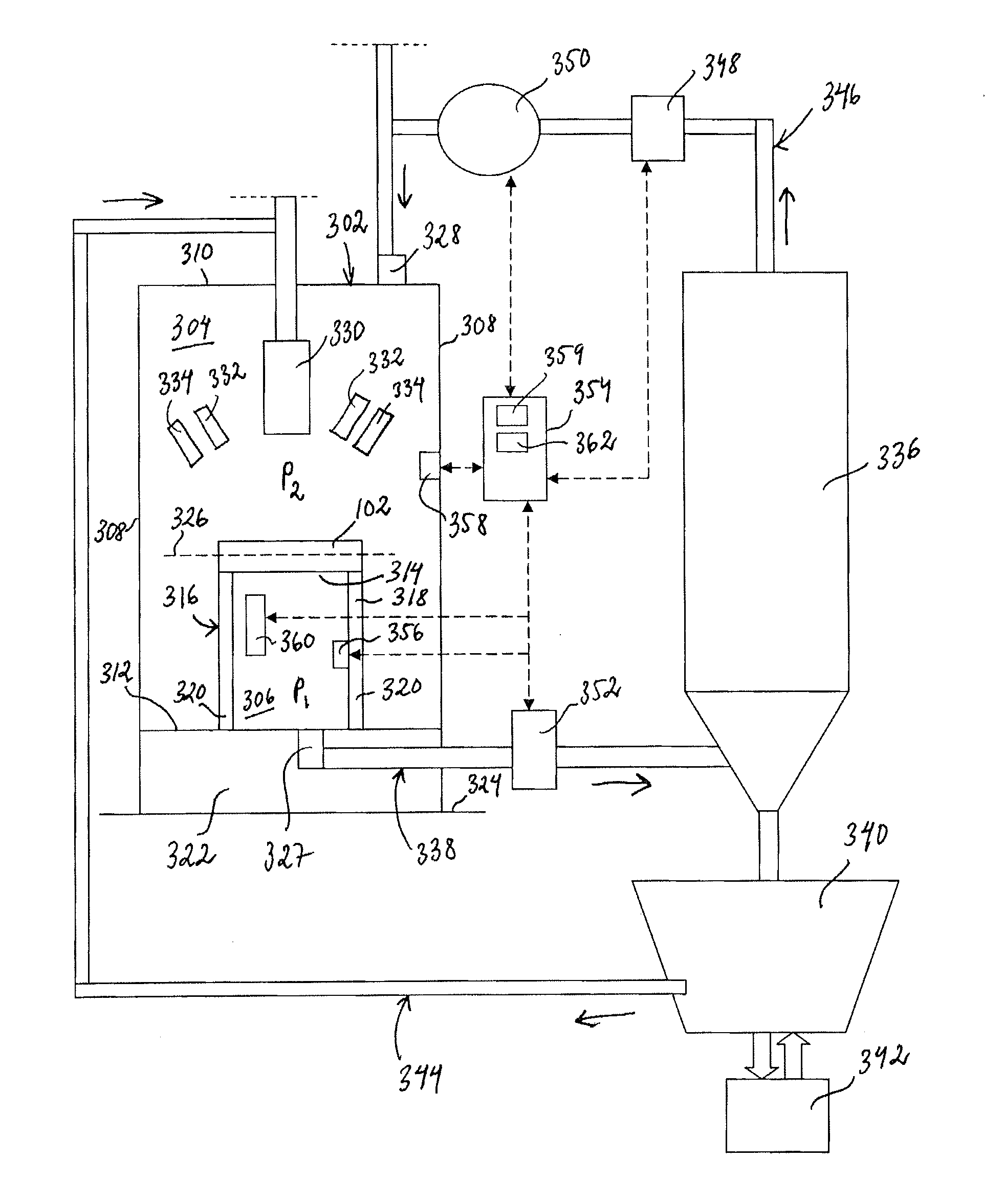

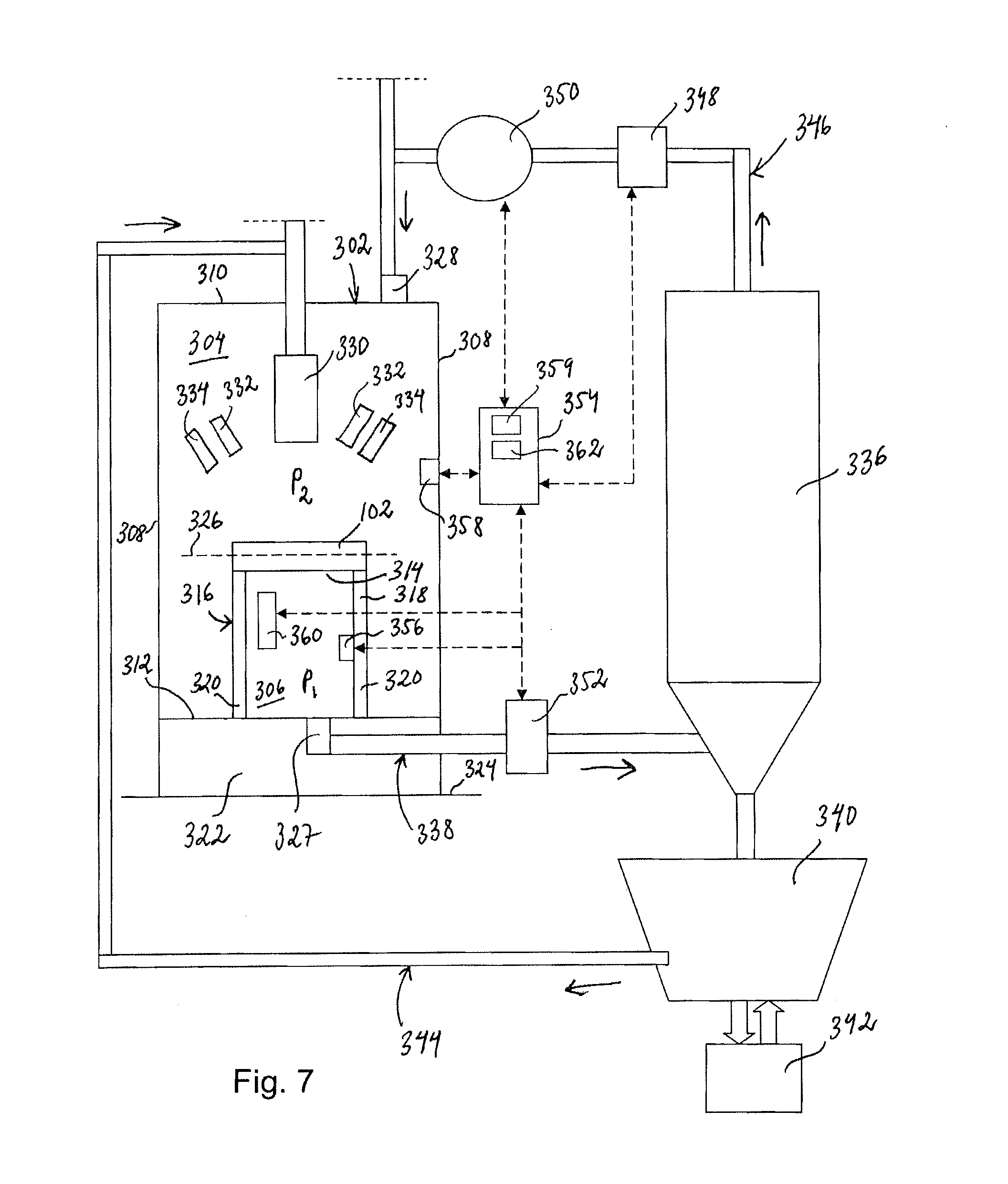

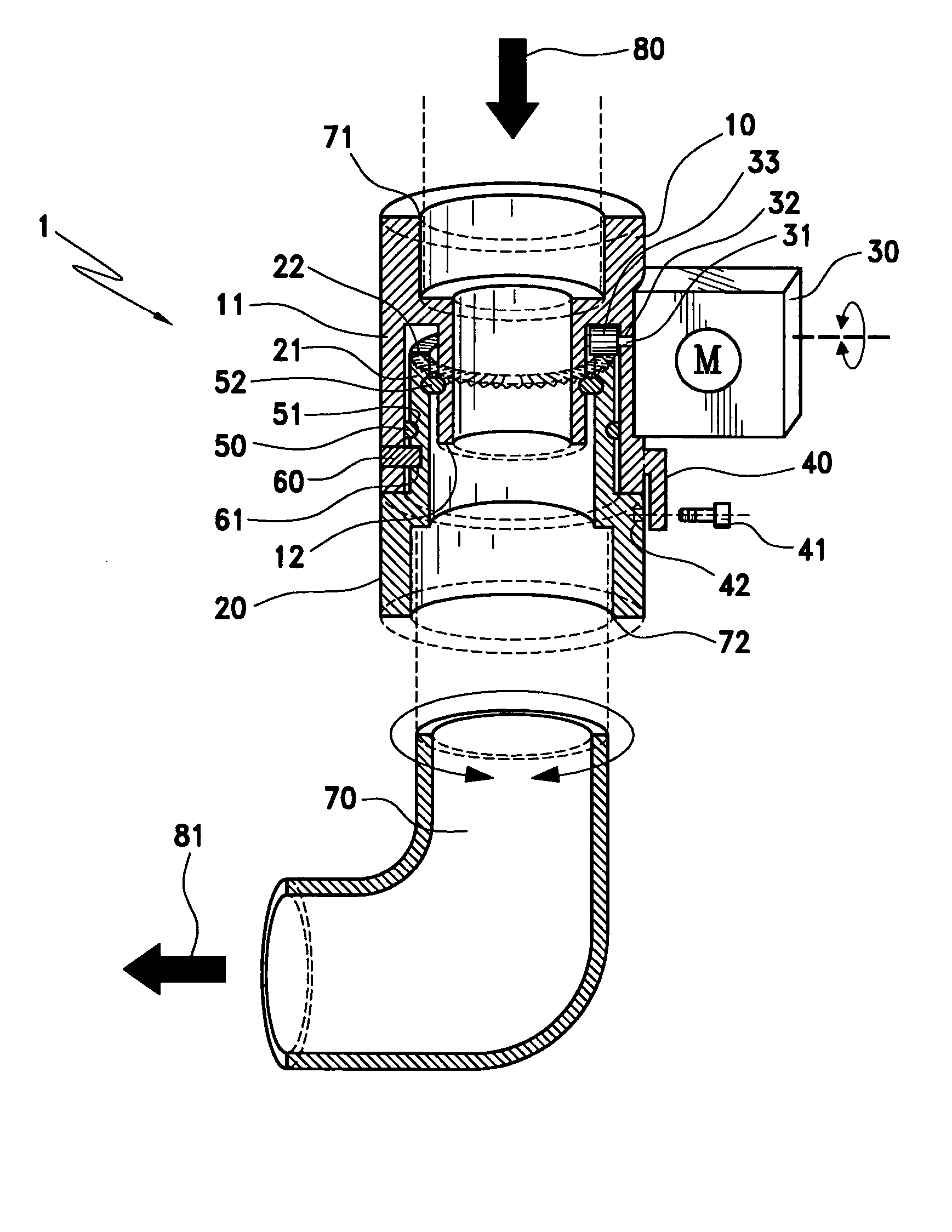

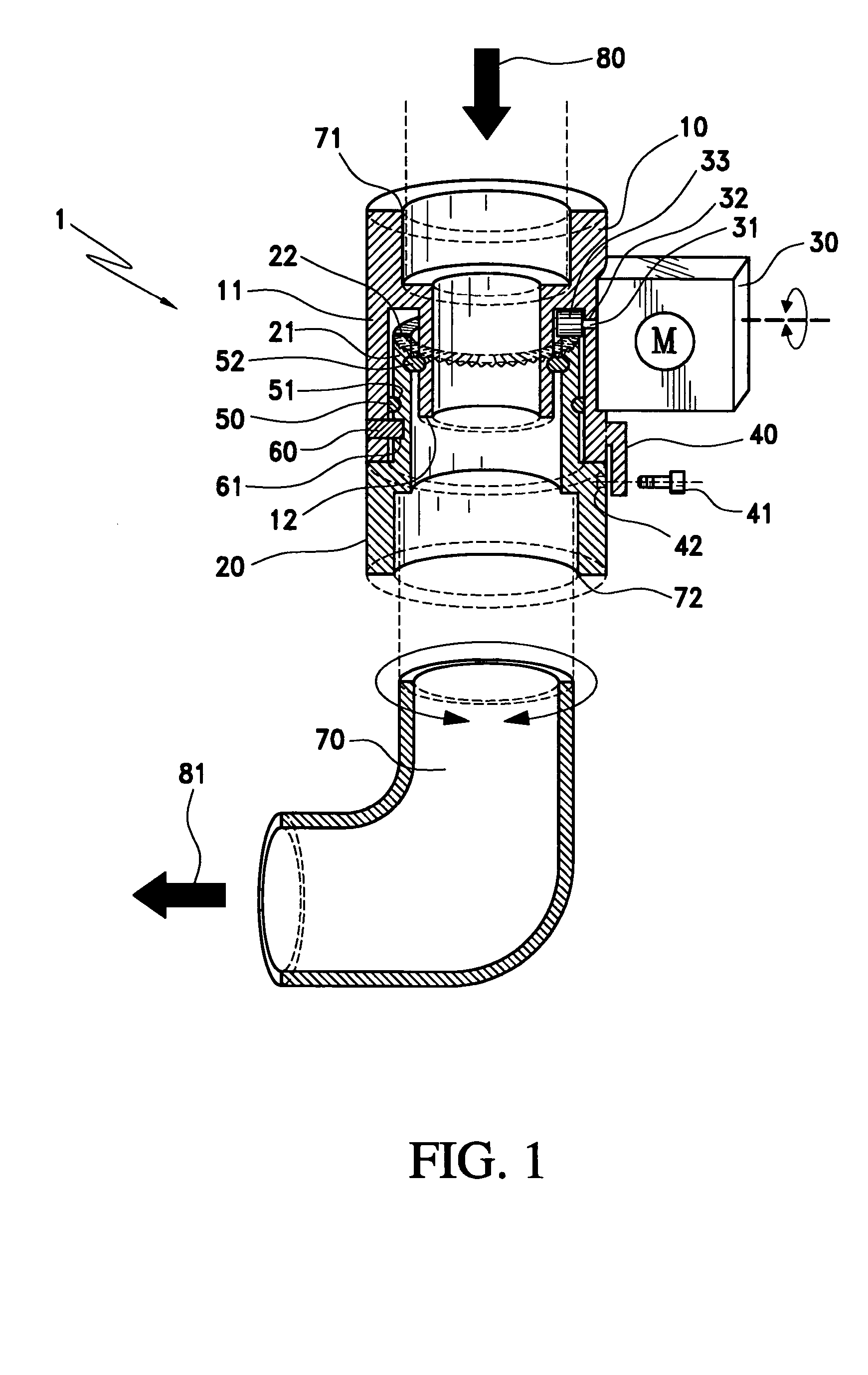

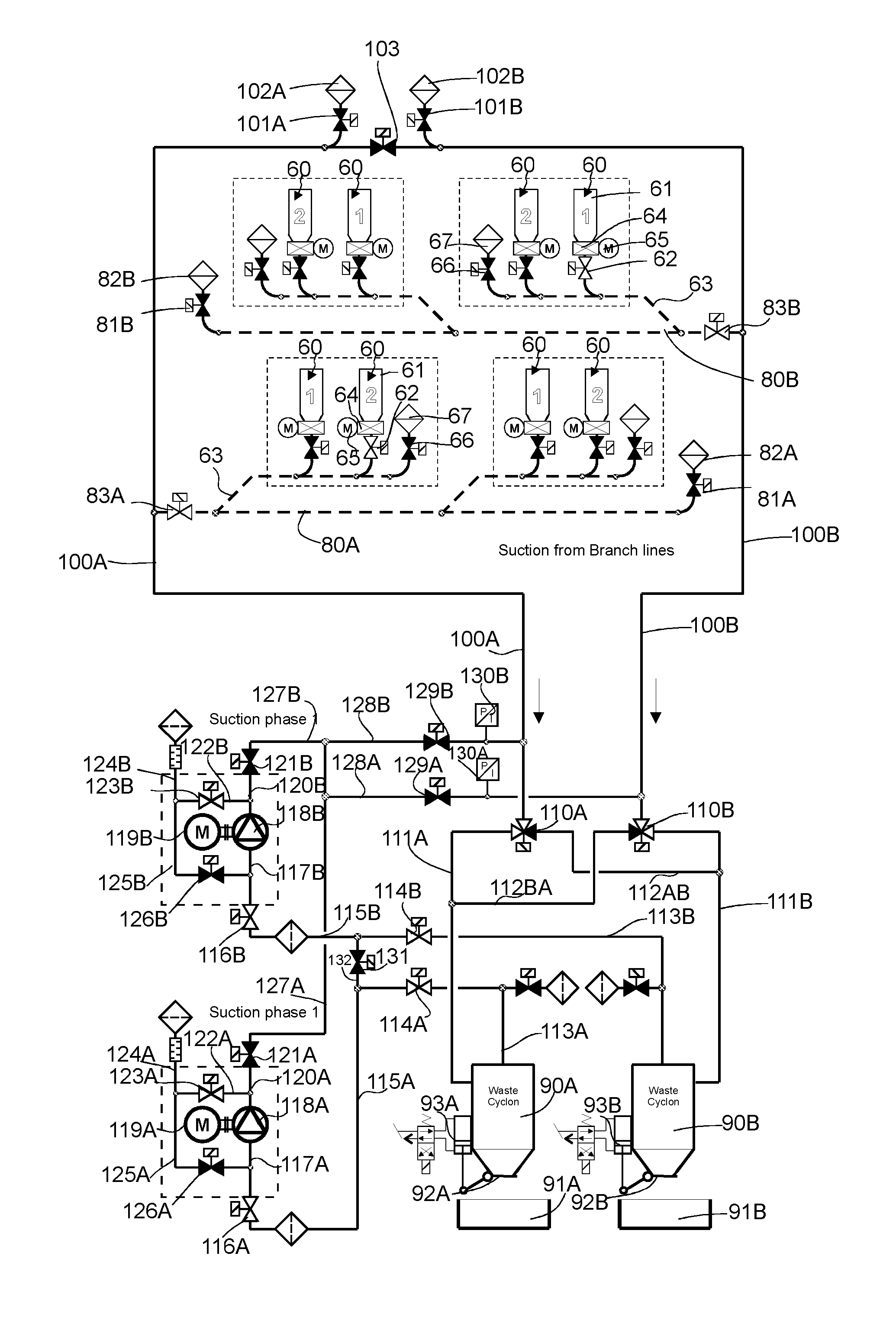

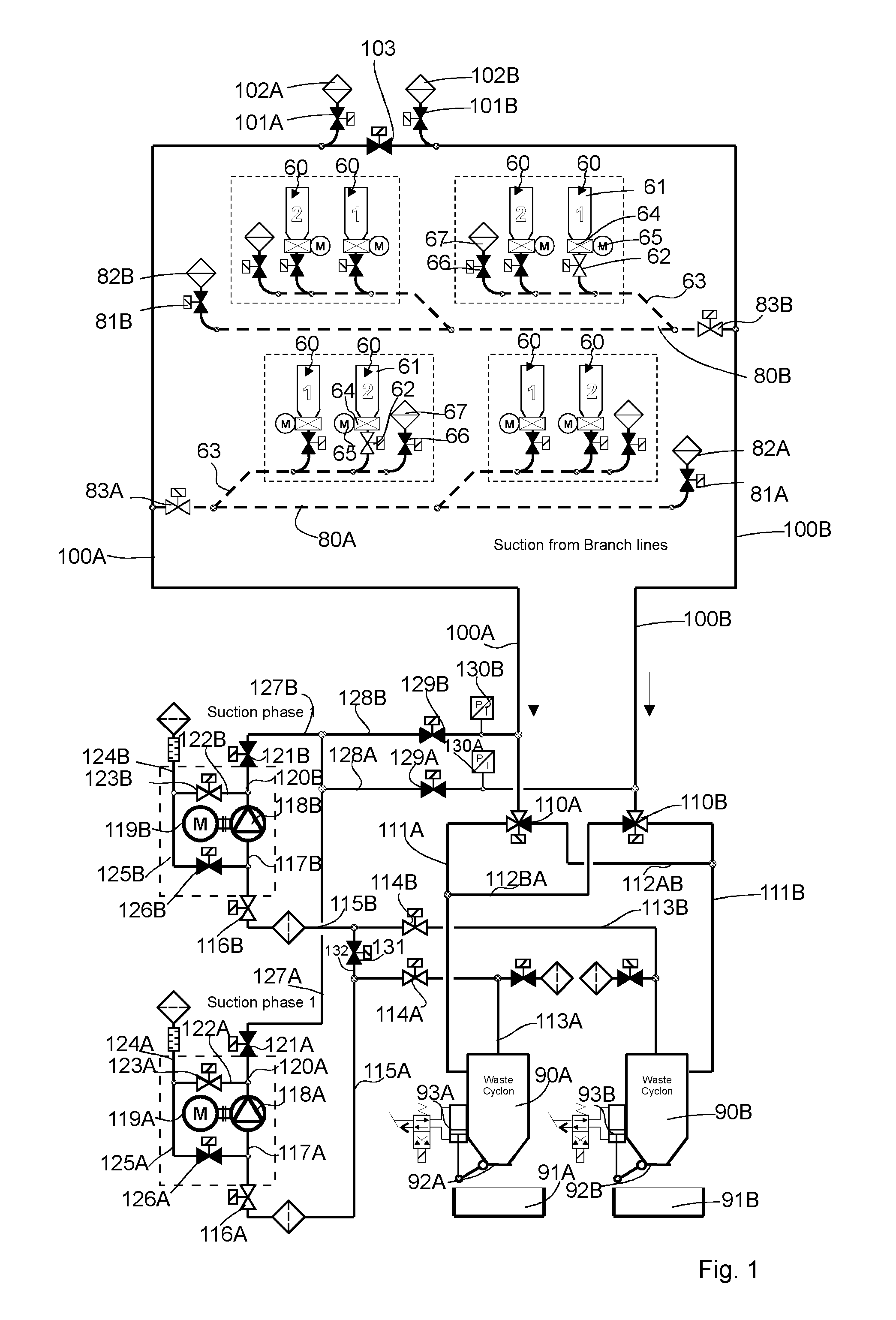

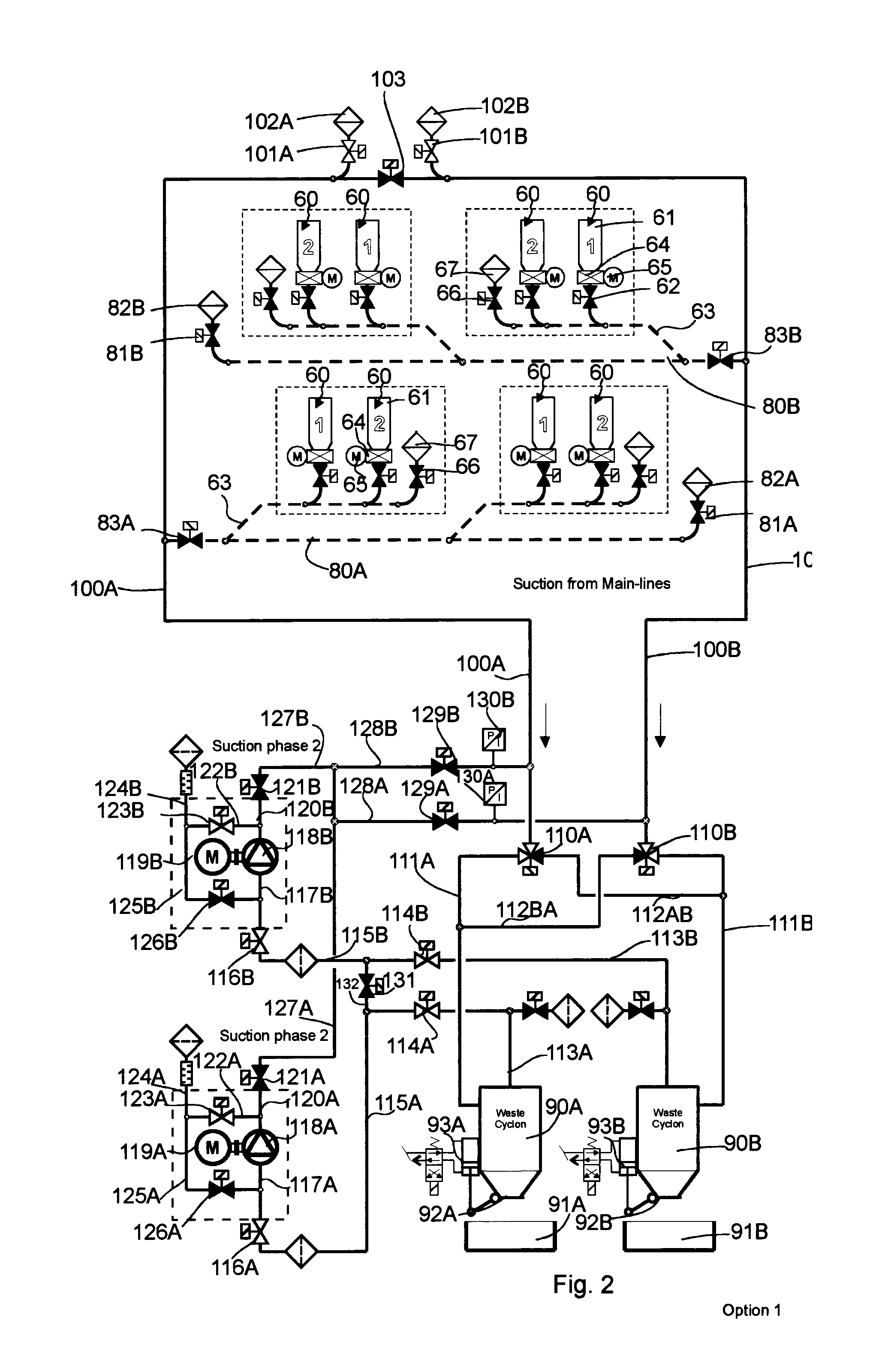

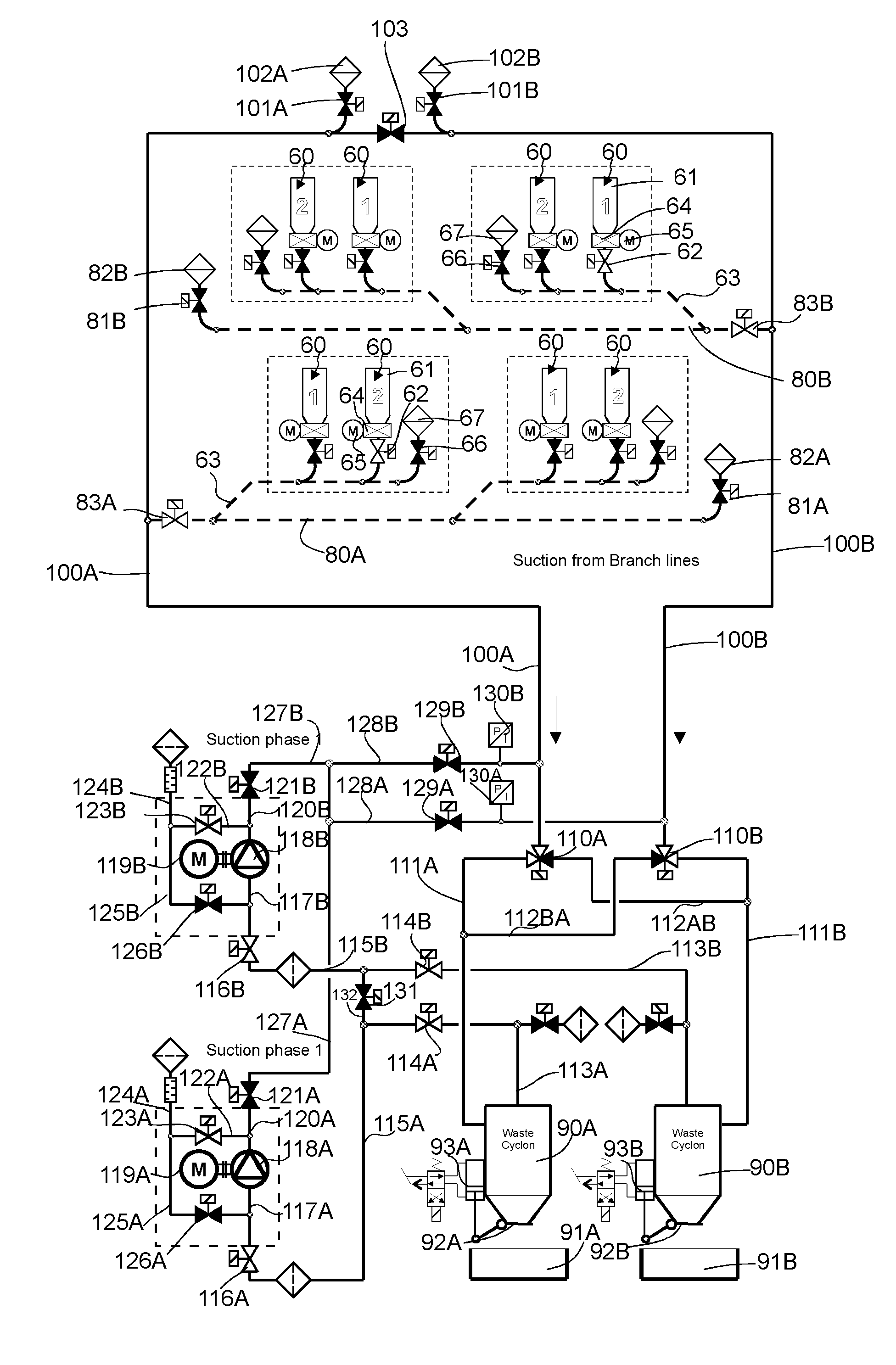

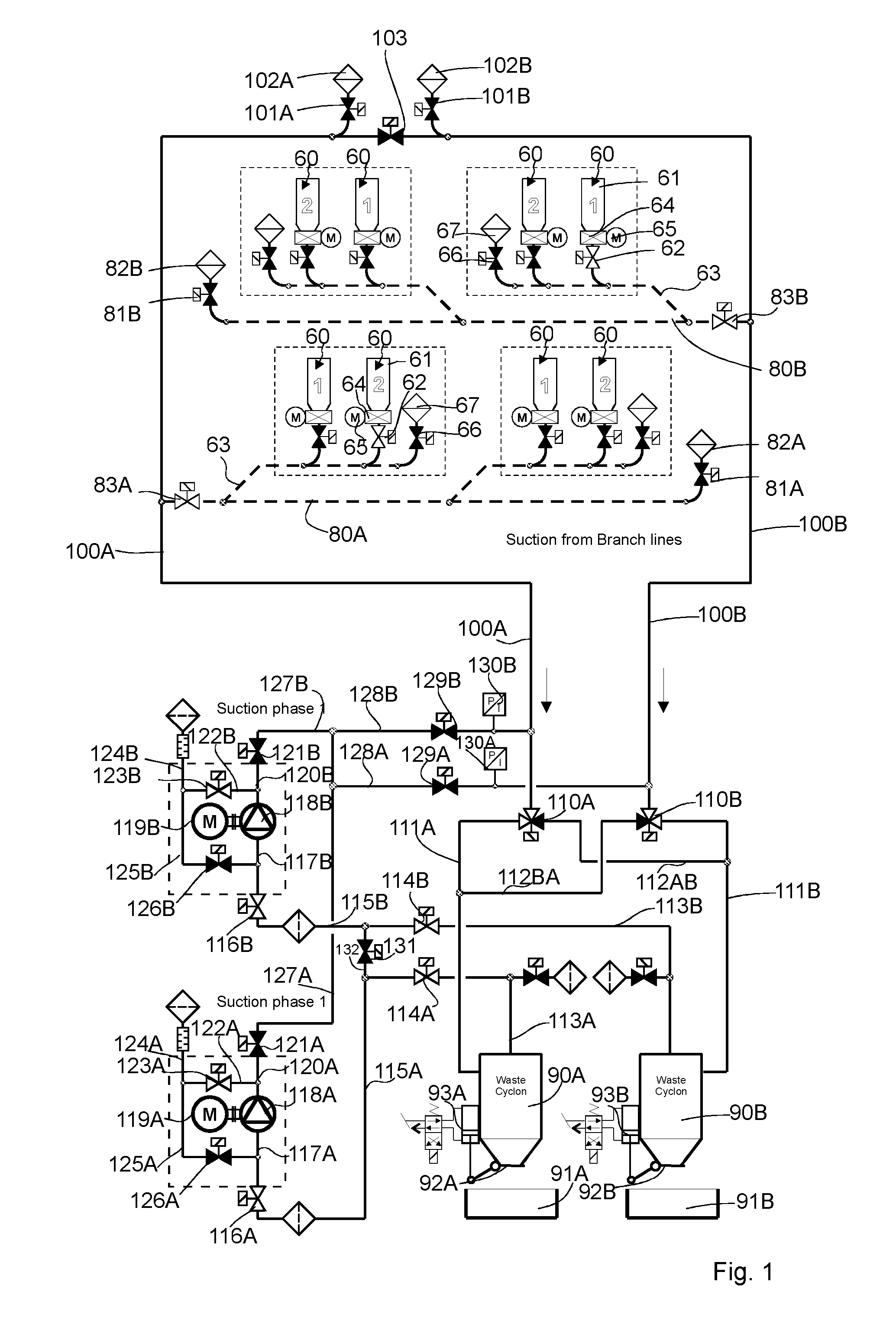

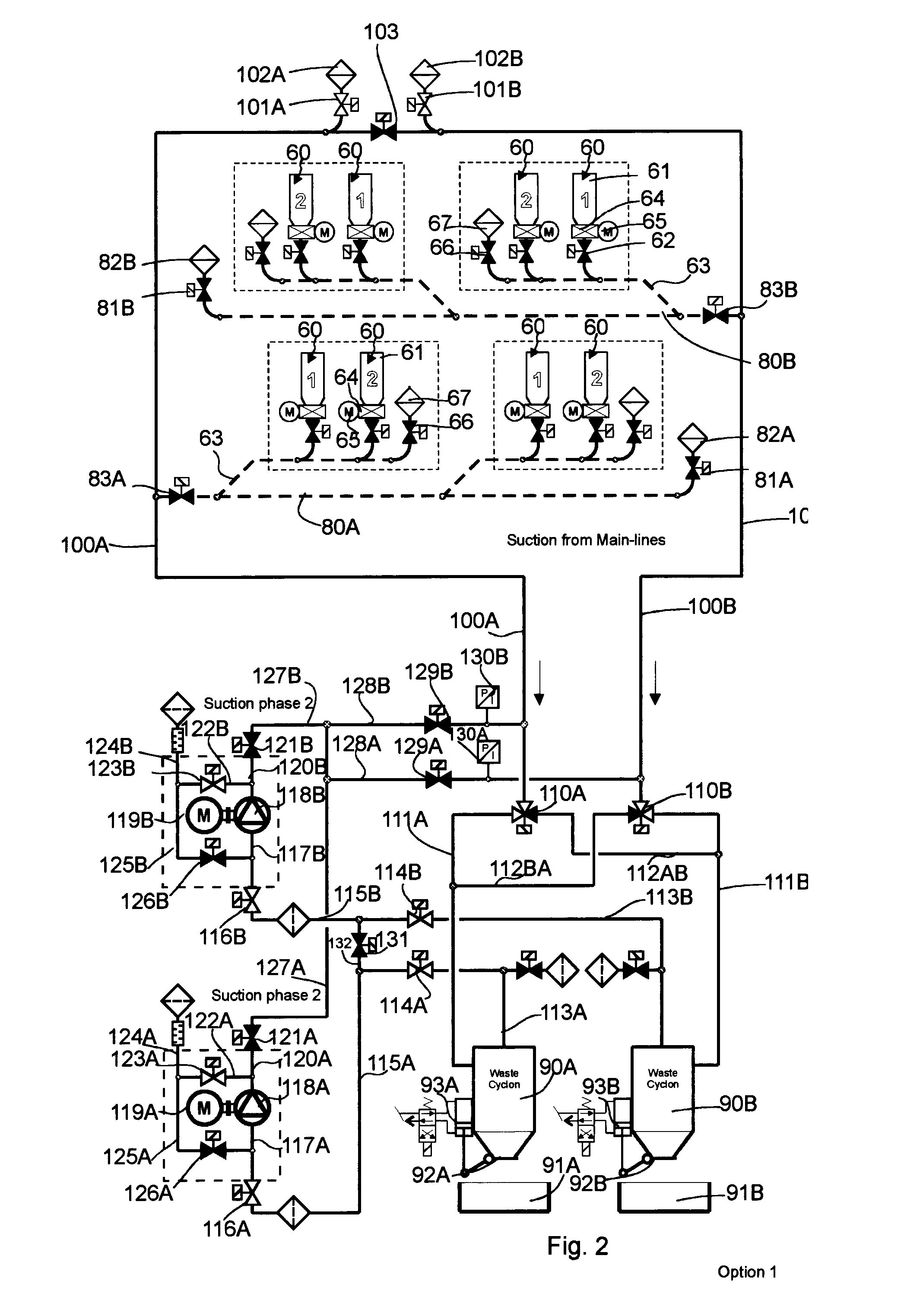

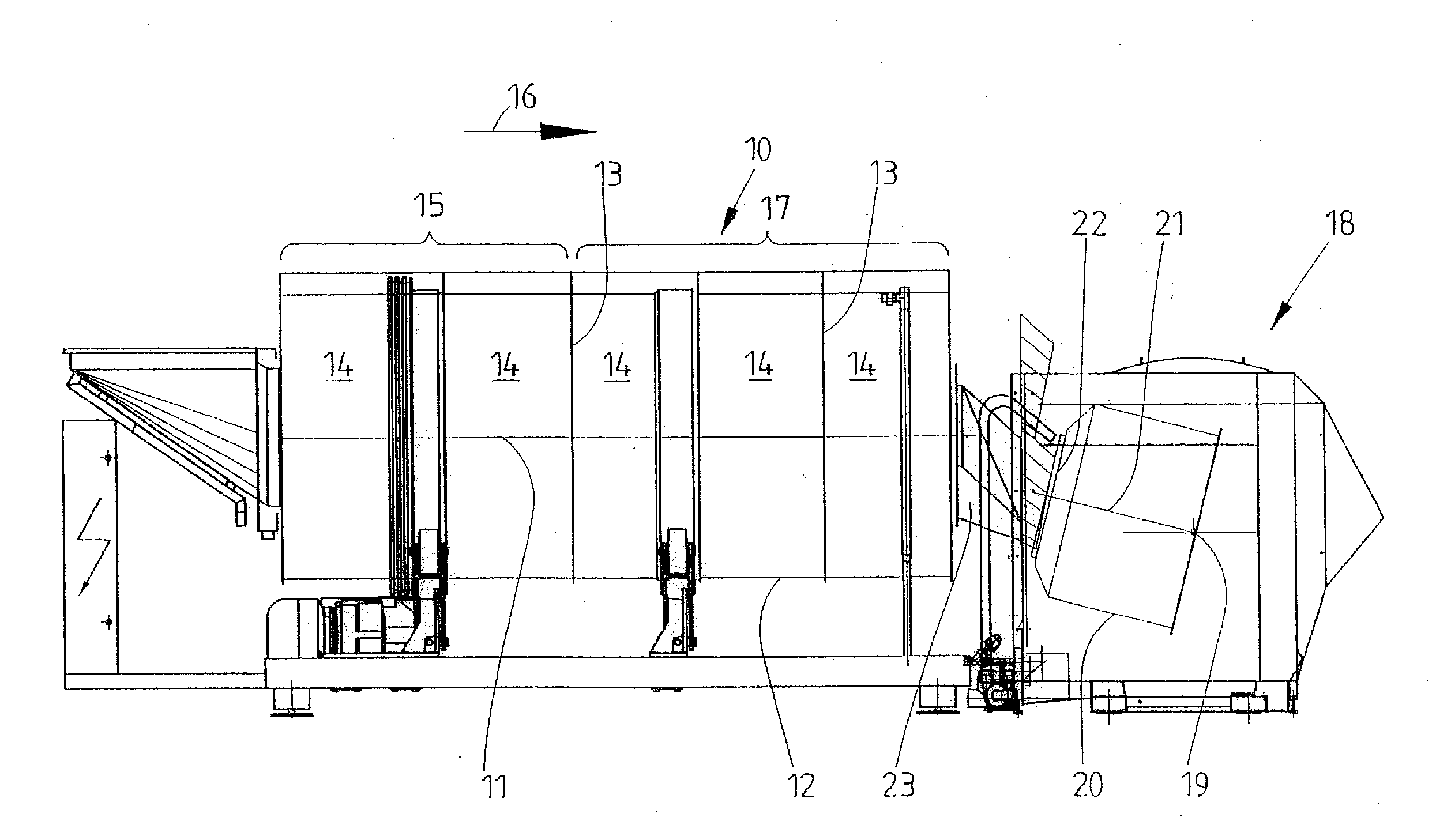

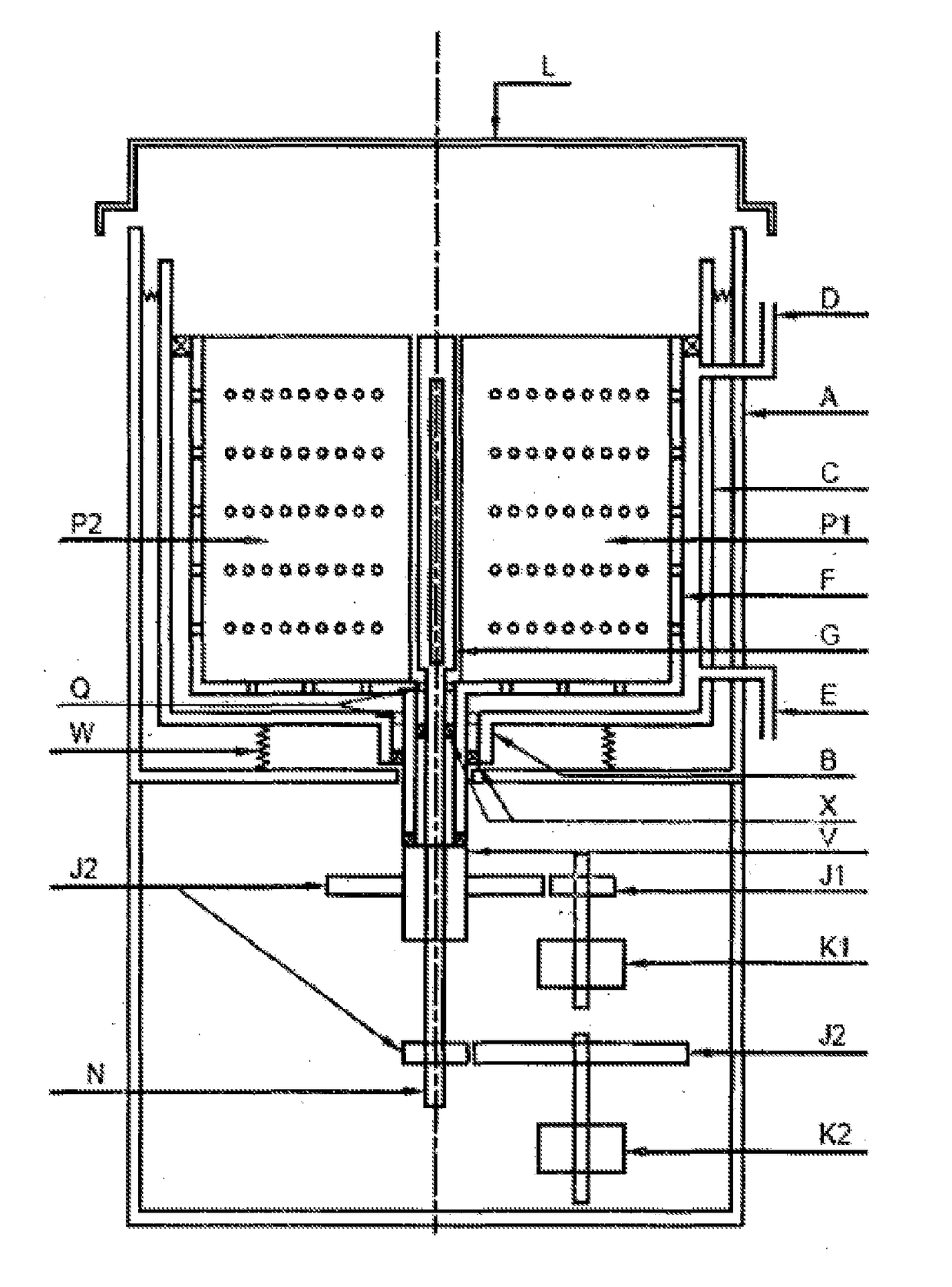

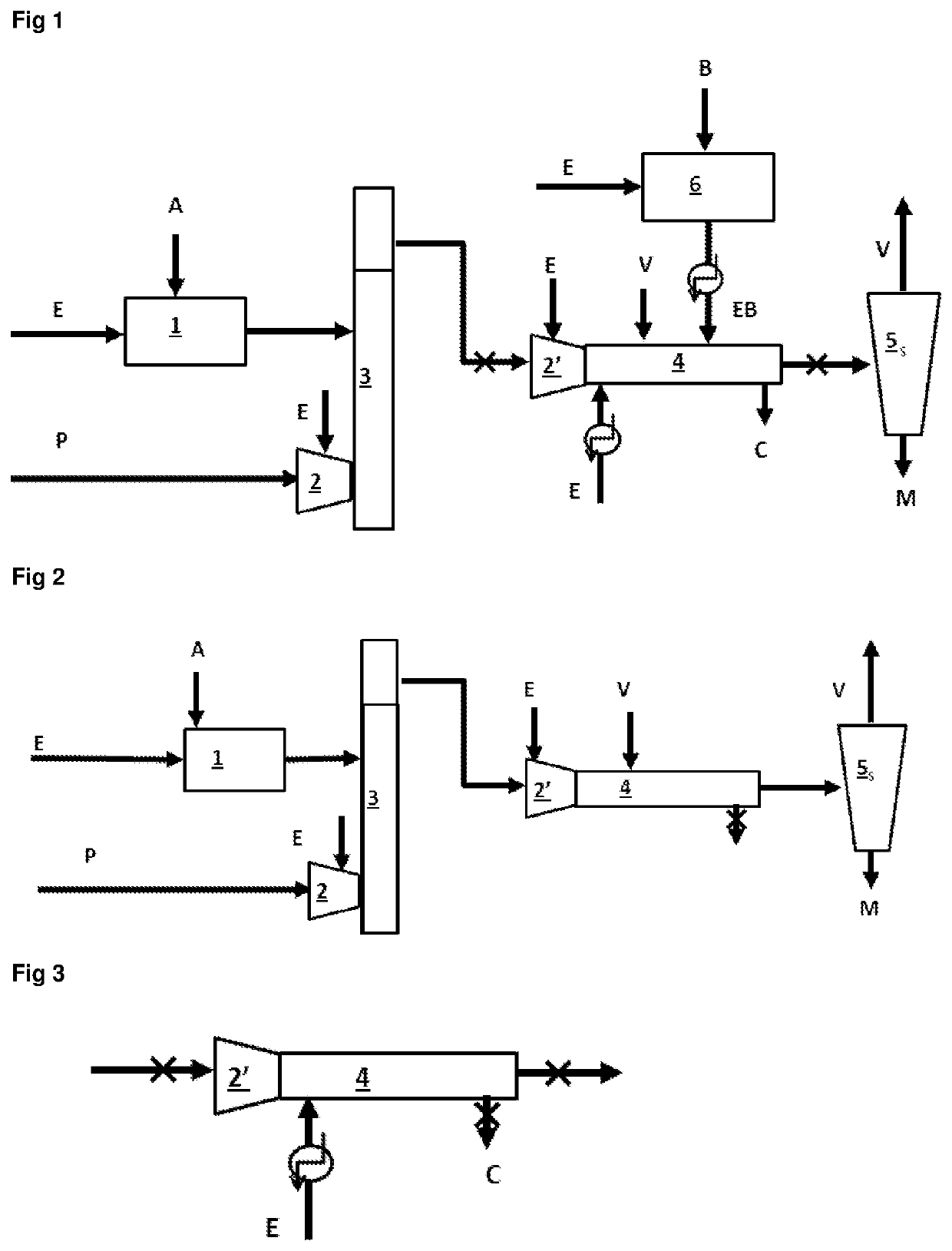

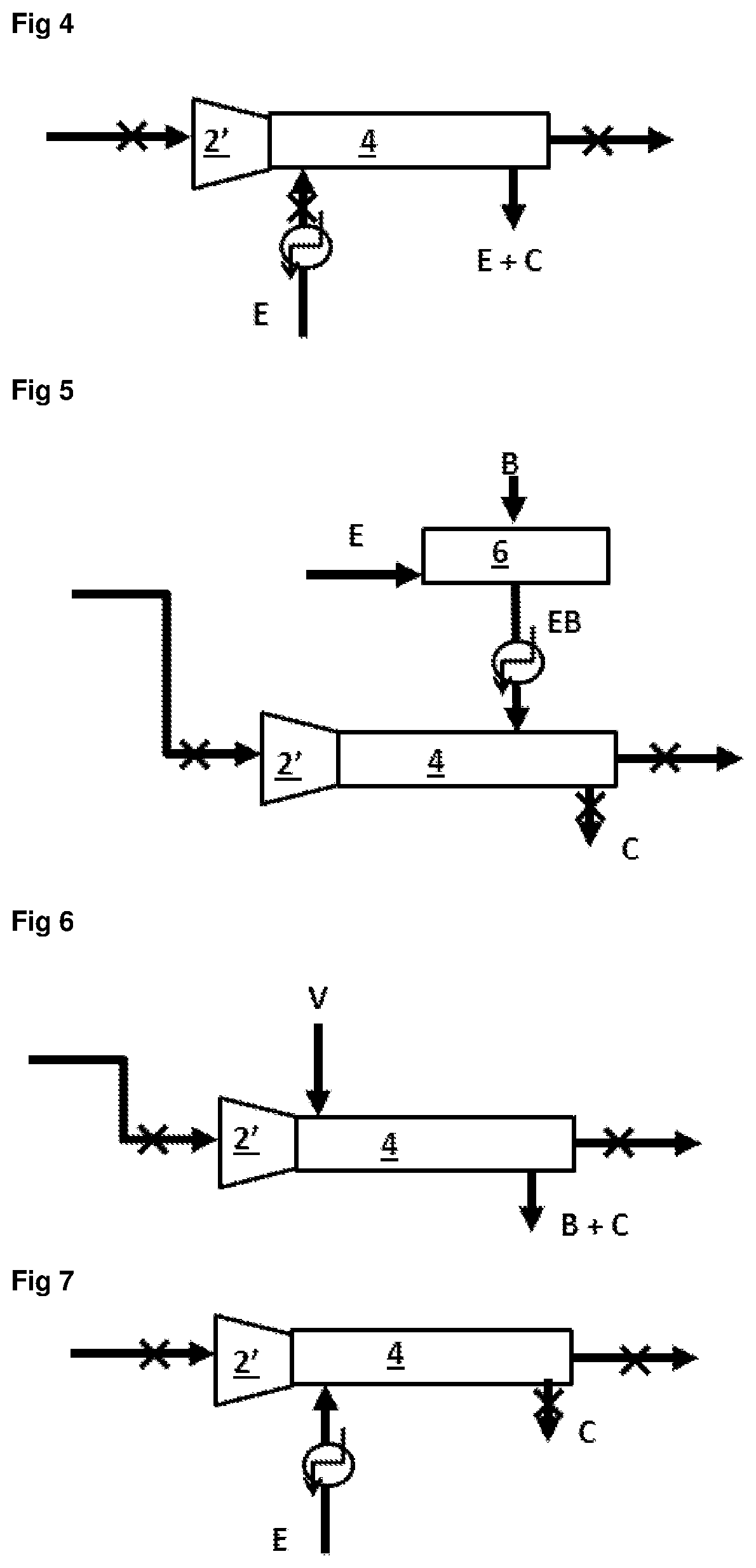

Method and pneumatic material conveying system

ActiveUS20130195563A1Efficient dryingEfficient rinseRefuse gatheringBulk conveyorsEngineeringPressure difference

Method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one input point (60) of material, more particularly of waste material, a material conveying pipe, which can be connected to the input point (60), and at least one separating device (90, 90A, 90B), in which the material to be conveyed is separated from the conveying air, and also means for achieving a pressure difference and / or a conveying air current in the conveying pipe at least during conveyance of the material, which means for achieving a pressure difference and / or a conveying air current comprise at least one pump unit, which comprises at least one pump device (118A, 118B). In the method the conveying piping comprises at least one main conveying pipe section (100A, 100B) and also at least one branch conveying pipe section (80A, 80B), which can be connected to the main conveying pipe section (100A, 100B), and in that an input point (60) can be connected to a branch conveying pipe section (80A, 80B), in which method material is transferred initially from an input point (60) via a branch conveying pipe (80A, 80B) into a main conveying pipe section (100A, 100B) by means of the suction / pressure difference and / or the conveying air flow achieved by at least one pump device (118A, 118B) and in which method a main conveying pipe section (100A, 100B) is used as a material reservoir and in that in a second phase the material transferred into a main conveying pipe section is transferred by means of the suction / pressure difference and / or the conveying air flow achieved by at least one pump device into a separating means (90A,

Owner:MARICAP OY

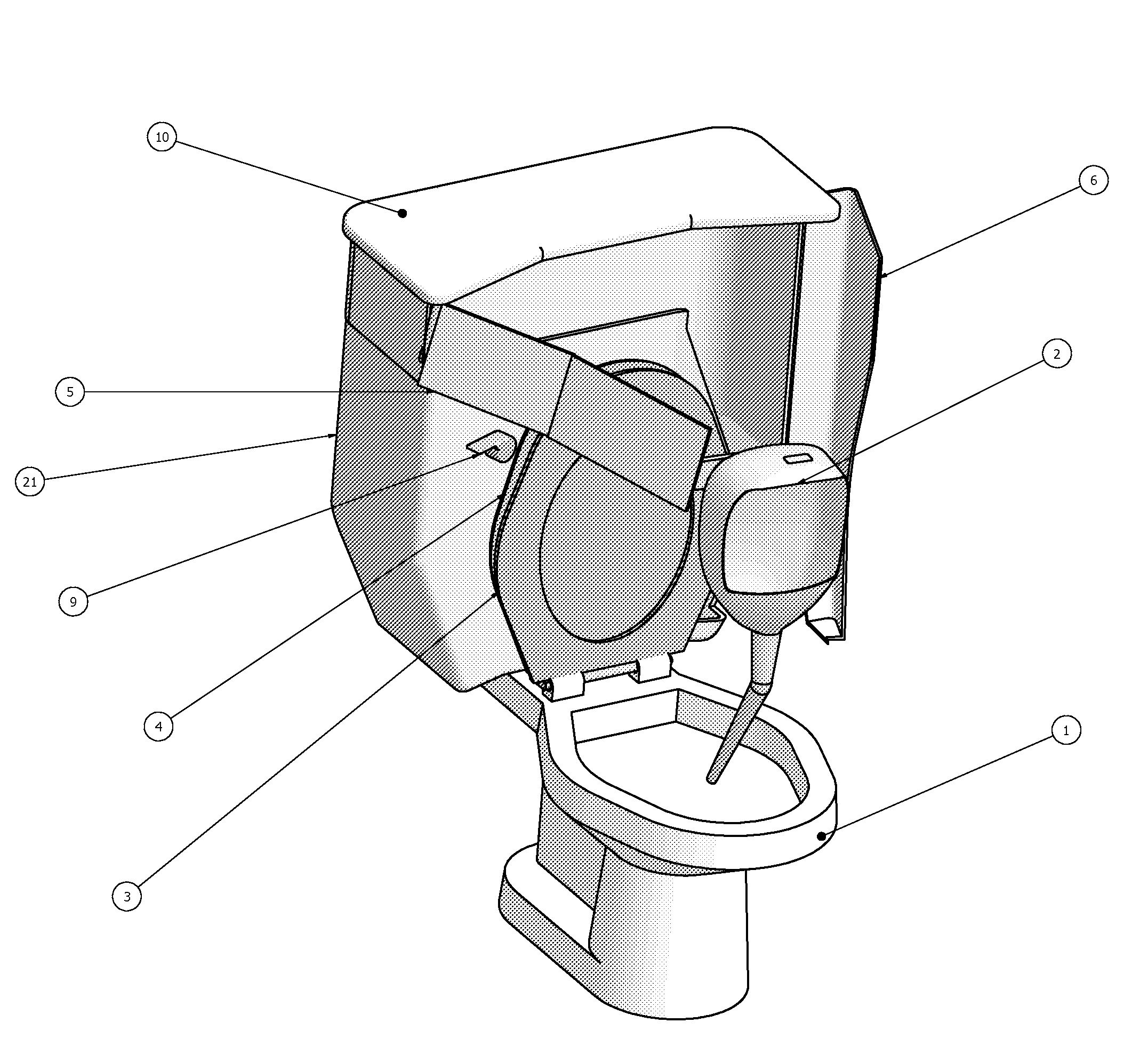

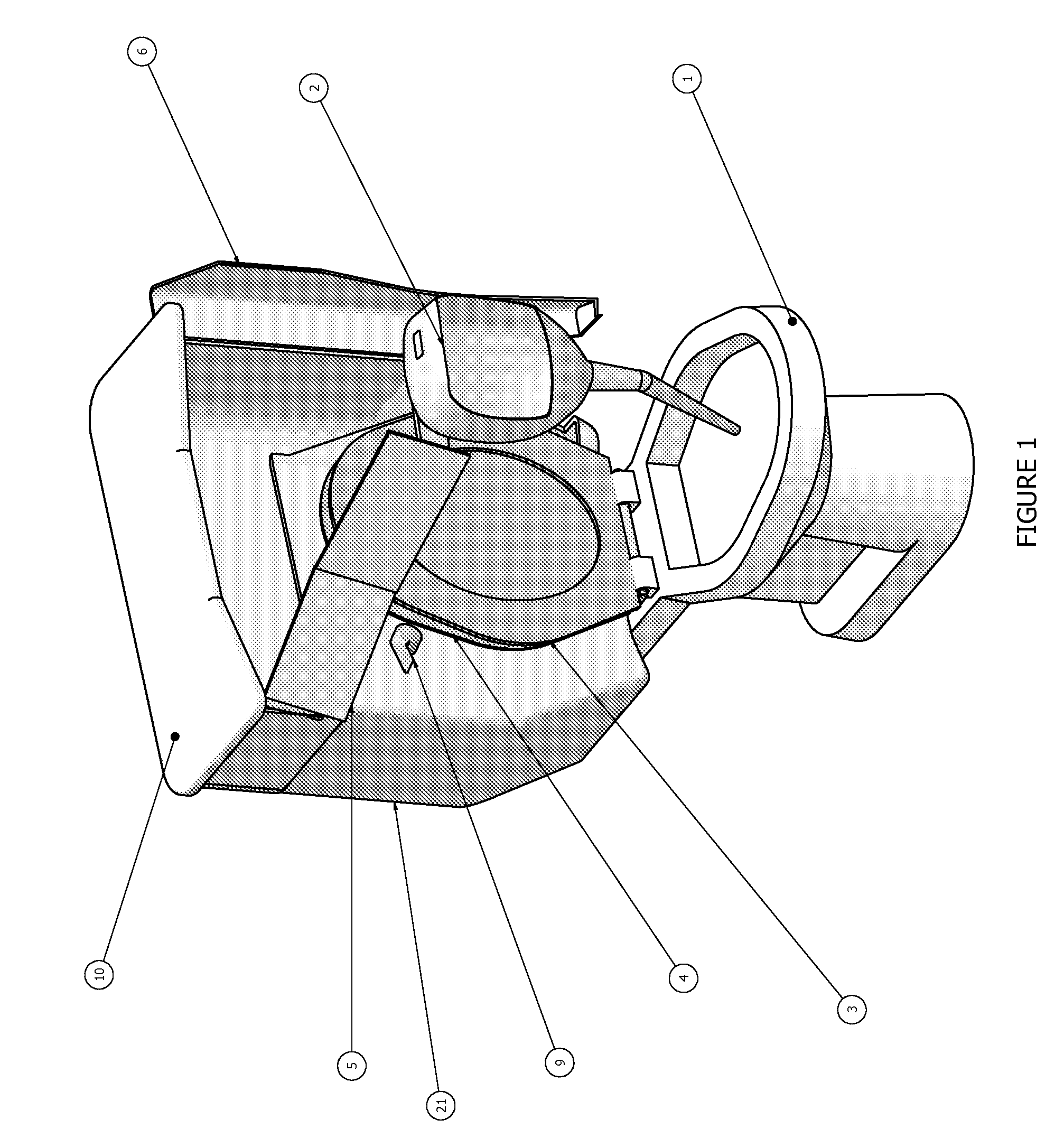

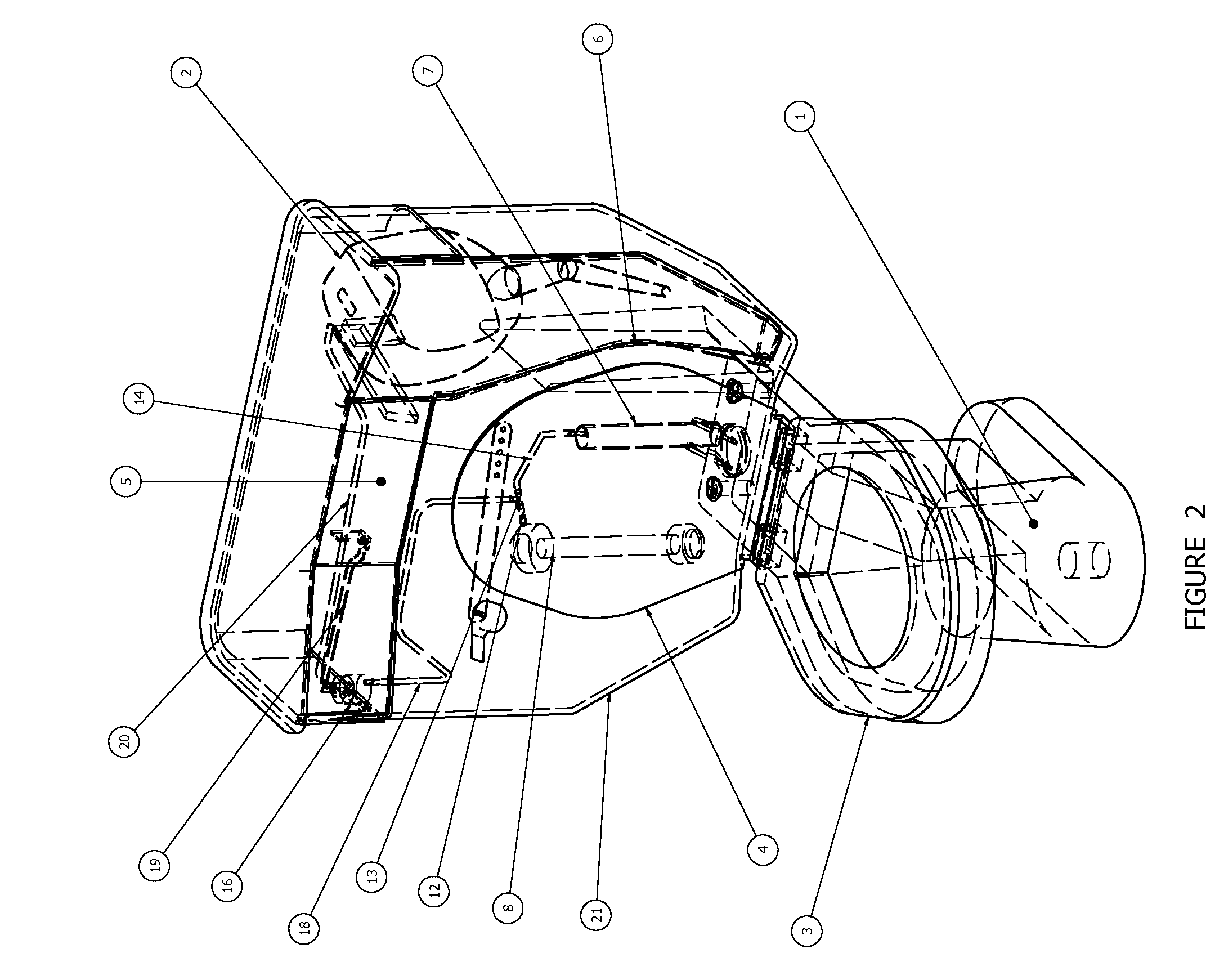

Interchangeable toilet tank with urinal

InactiveUS20100037379A1Easy to installEliminate requirementsLavatory sanitoryRinse waterFlush toilet

A special toilet tank equipped with a pivoting urinal, to facilitate the collection of urine from a standing male person. This will protect surrounding floors, walls and structure, from urine spray. The folding urinal is moveable from a stored position in the special tank enclosure to a position above the toilet bowl. The urine drops directly into the toilet bowl eliminating the need for a separate drain line. A water line passes through a position valve, to provide rinse water inside the urinal to flush the urine from the inside surfaces. The rinse water also drops into the bowl during flushing. When the urinal is in the stored position, the position valve prevents flow of water to the urinal during normal flushing.

Owner:HANSON RICHARD BRIAN +1

Method and pneumatic material conveying system

ActiveUS9242808B2Efficient dryingEfficient rinseRefuse gatheringBulk conveyorsEngineeringPressure difference

A method and system for pneumatically conveying waste material through a conveying system which includes an input point for introducing waste material, at least one main conveying pipe section, at least one branch conveying pipe section, at least one separating device, and at least one pump unit for producing a pressure differential and air current within the operating system, whereby in a first phase, the main conveying pipe section functions as a material reservoir and in a second phase, the waste material is transferred to the separating device by the suction / pressure difference and / or conveying air flow produced by the pump device.

Owner:MARICAP OY

Method and apparatus for washing in particular items of laundry

InactiveUS20120233785A1Efficient washingEfficient rinseOther washing machinesDry-cleaning apparatus for textilesEngineeringLaundry

A method and apparatus for washing items of laundry that makes provision to continuously filter the treatment liquid during the washing operation. As a result, interfering attendant materials in and on the treatment liquid are successively removed during the washing operation, which increases the efficacy of the washing operation. Provision is preferably made to remove both lighter constituents, such as foam and lint, from the treatment liquid and also to filter heavier constituents, such as impurities washed out of the items of laundry, from the treatment liquid using the same filter. The same filter can also be used, after the end of the washing operation, to filter the treatment liquid to be let out and to temporarily store the treatment liquid in a collecting tank before the filtered treatment liquid is reused. The invention thus permits multiple functions of the filter.

Owner:KANNEGIESSER GMBH CO HERBERT

Chamber cleaning when using acid chemistries to fabricate microelectronic devices and precursors thereof

InactiveUS20150128993A1Reduce pollutionQuick and effective removalHollow article cleaningDetergent mixture composition preparationTreatment strategyNuclear chemistry

The present invention provides treatment strategies that reduce contamination on wafer surfaces that are treated with acid chemistries. The strategies are suitable for use with a wide variety of wafers, including those including sensitive microelectronic features or precursors thereof. These strategies involve a combination of neutralizing and rinsing strategies that quickly and effectively remove residual acid and acid by-products from both the front side of workpiece(s) as well as from other processing chamber surfaces that can be causes of contamination.

Owner:TEL FSI

Assembly for dispensing a canister's liquid contents into a vessel and for rinsing a residue of the liquid contents

ActiveUS9216888B2Improve rinsing performanceEfficient rinseHollow article cleaningLiquid flow controllersEngineeringMechanical engineering

An assembly for purging a canister into a tank and for rinsing the canister, the canister having a floor, the assembly including a “A” configured lance having a plurality of legs and a bar, each leg among the plurality of legs forming a blade having an upper end and an outer edge, the blades' upper ends and outer edges being sharpened for, upon upward impingement against the canisters' floor, dividing the floor into a plurality of sections, each section among the plurality of sections being configured as a flexible leaf, the bar member forming and functioning both as a leaf deflecting mandrel, and as a rotatable sprinkler head, the “A” configured lance and associated sprinkler head configured mandrel being mountable within the tank by suspension hooks.

Owner:ECK ETHAN

Electric shaver

ActiveUS20180085955A1Easy and self-explaining handlingEasy to cleanMetal working apparatusRinse waterEngineering

The present invention generally relates to cleaning and washing shavers with water or other fluids. More particularly, the present invention relates to electric shavers comprising a handle portion, a shaver head supported by said handle portion and including at least one drivable cutter element, and at least one rinse opening for rinsing water through the interior of said shaver head.

Owner:BRAUN GMBH

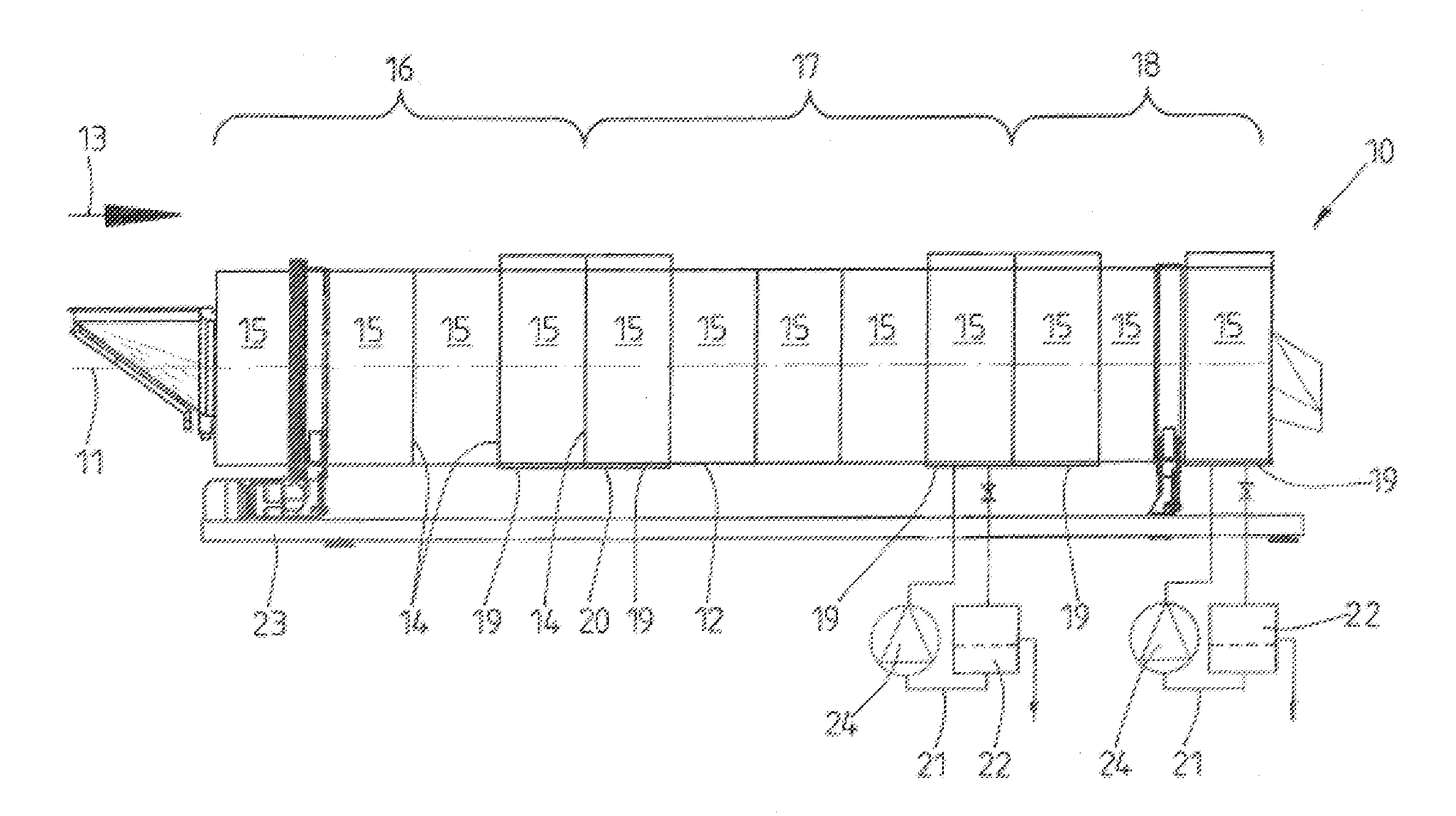

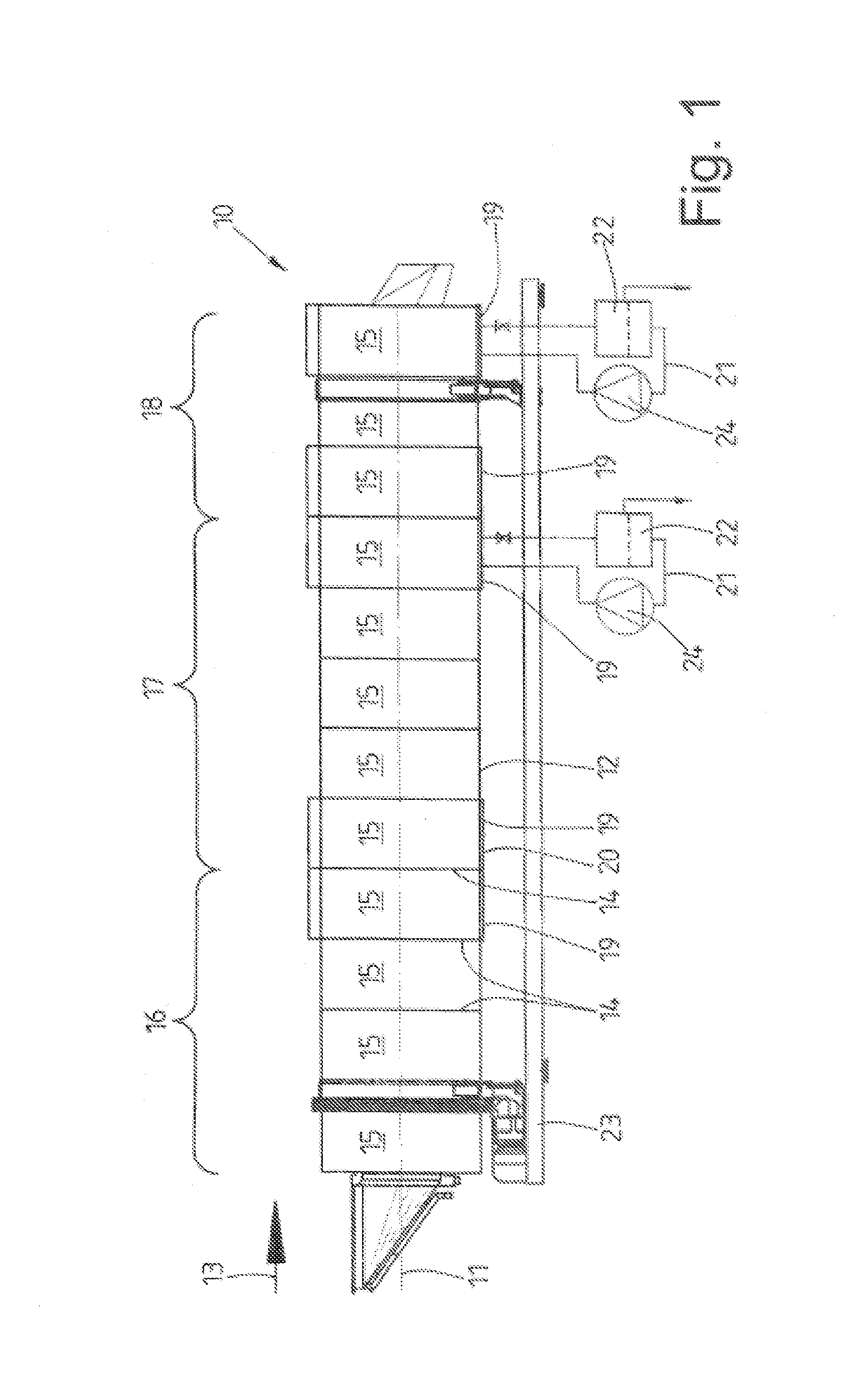

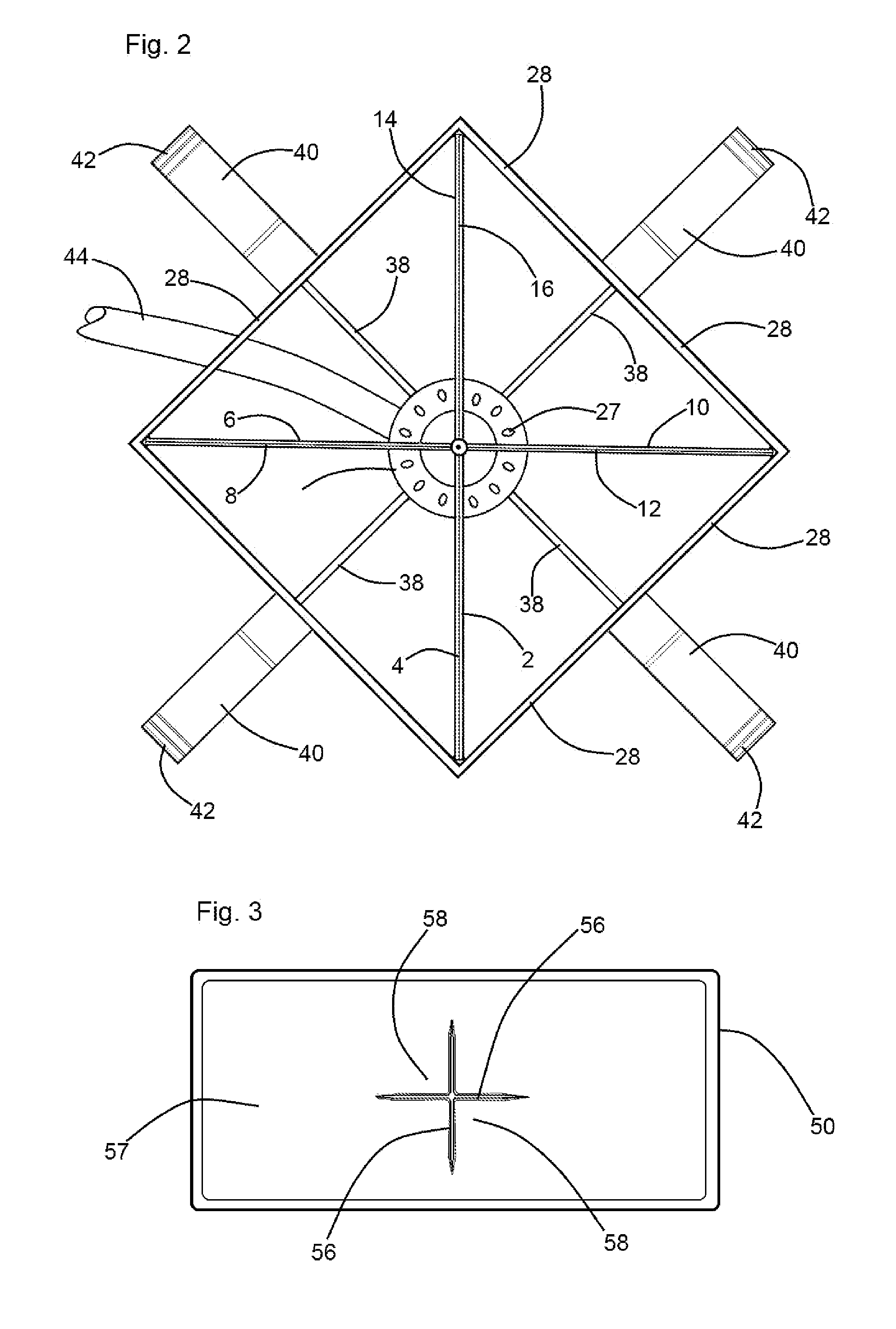

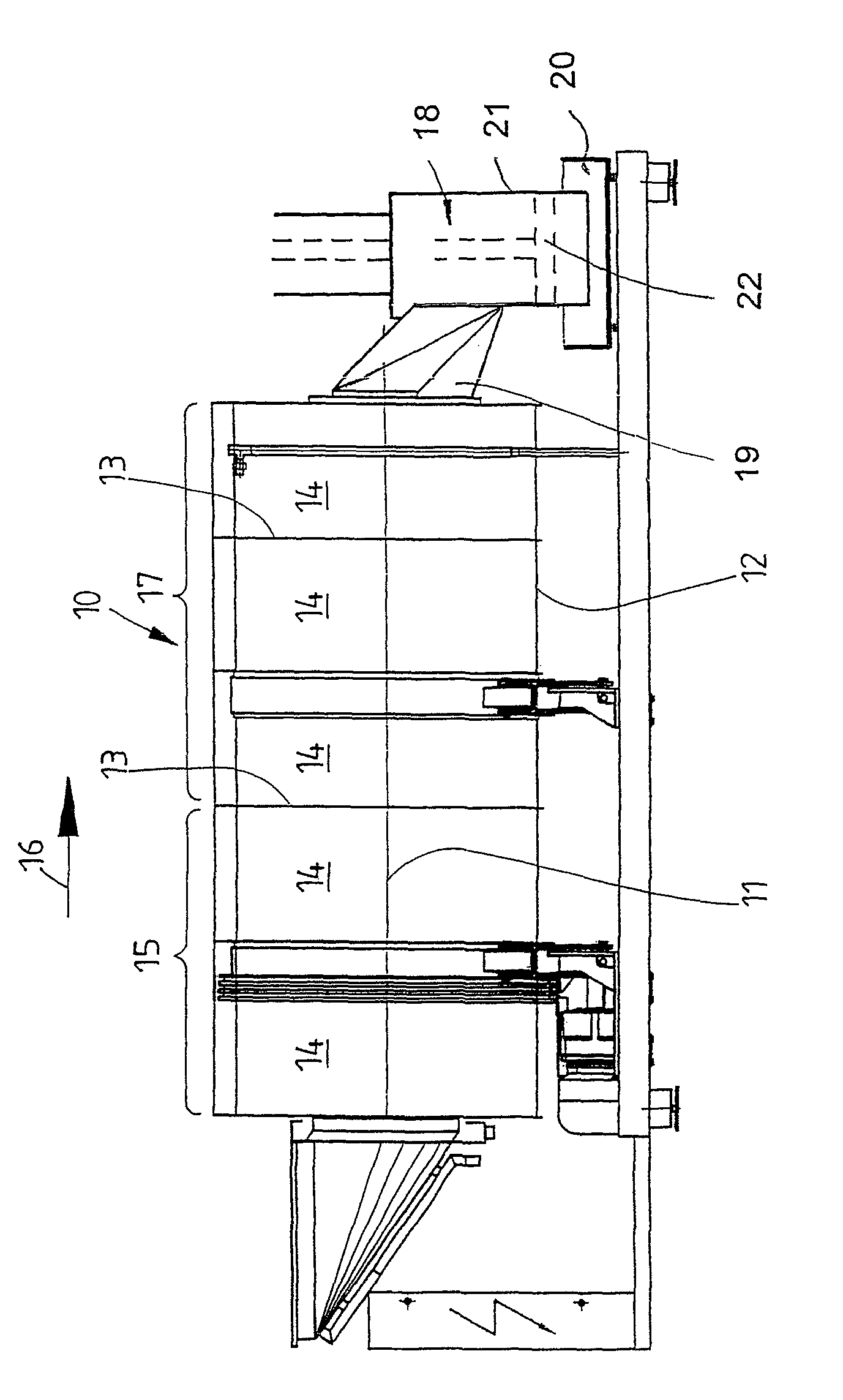

Method and device for wet treating laundry items

InactiveUS20140216111A1Inexpensive mannerEasy constructionOther washing machinesTextiles and paperLaundry washing machineEnvironmental engineering

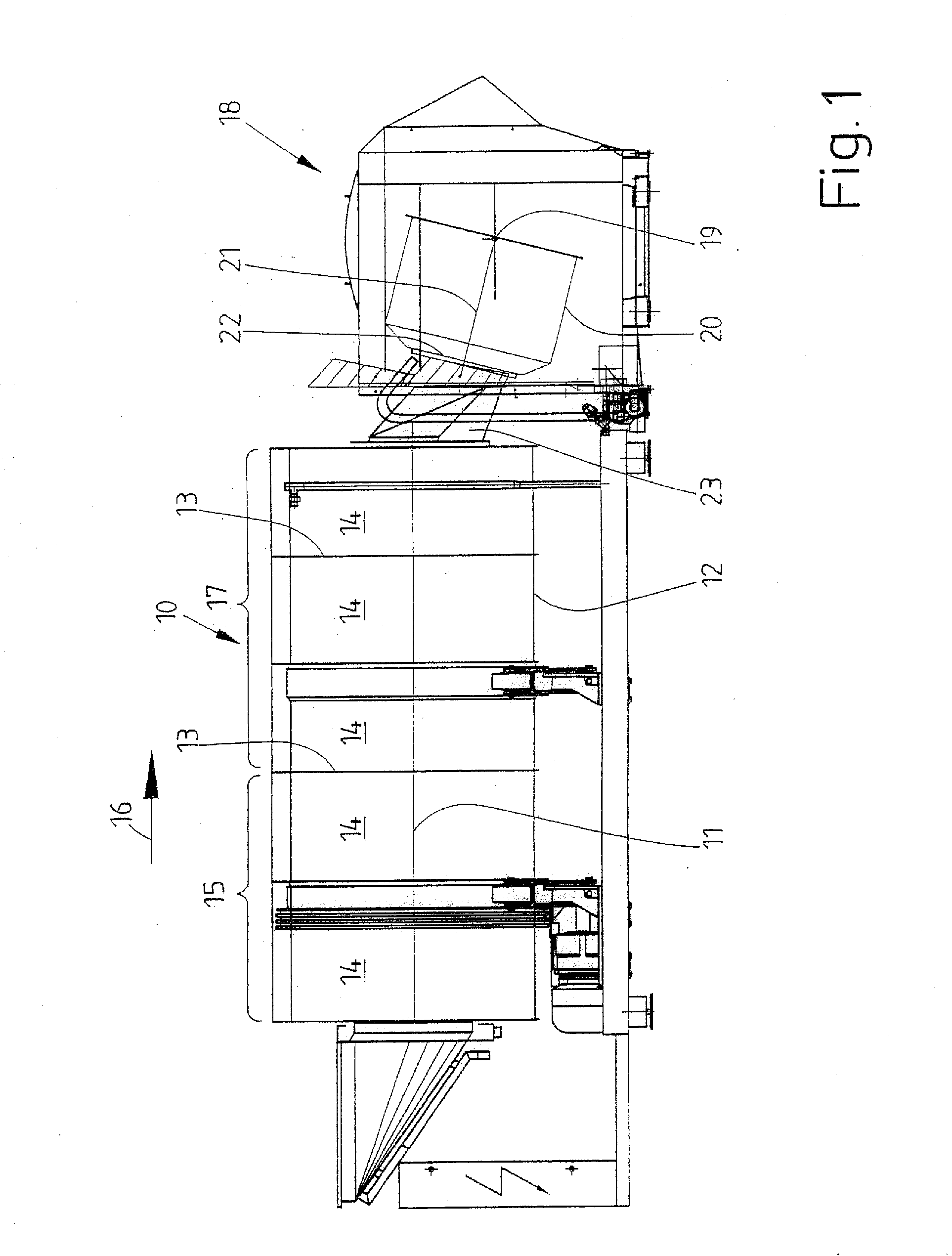

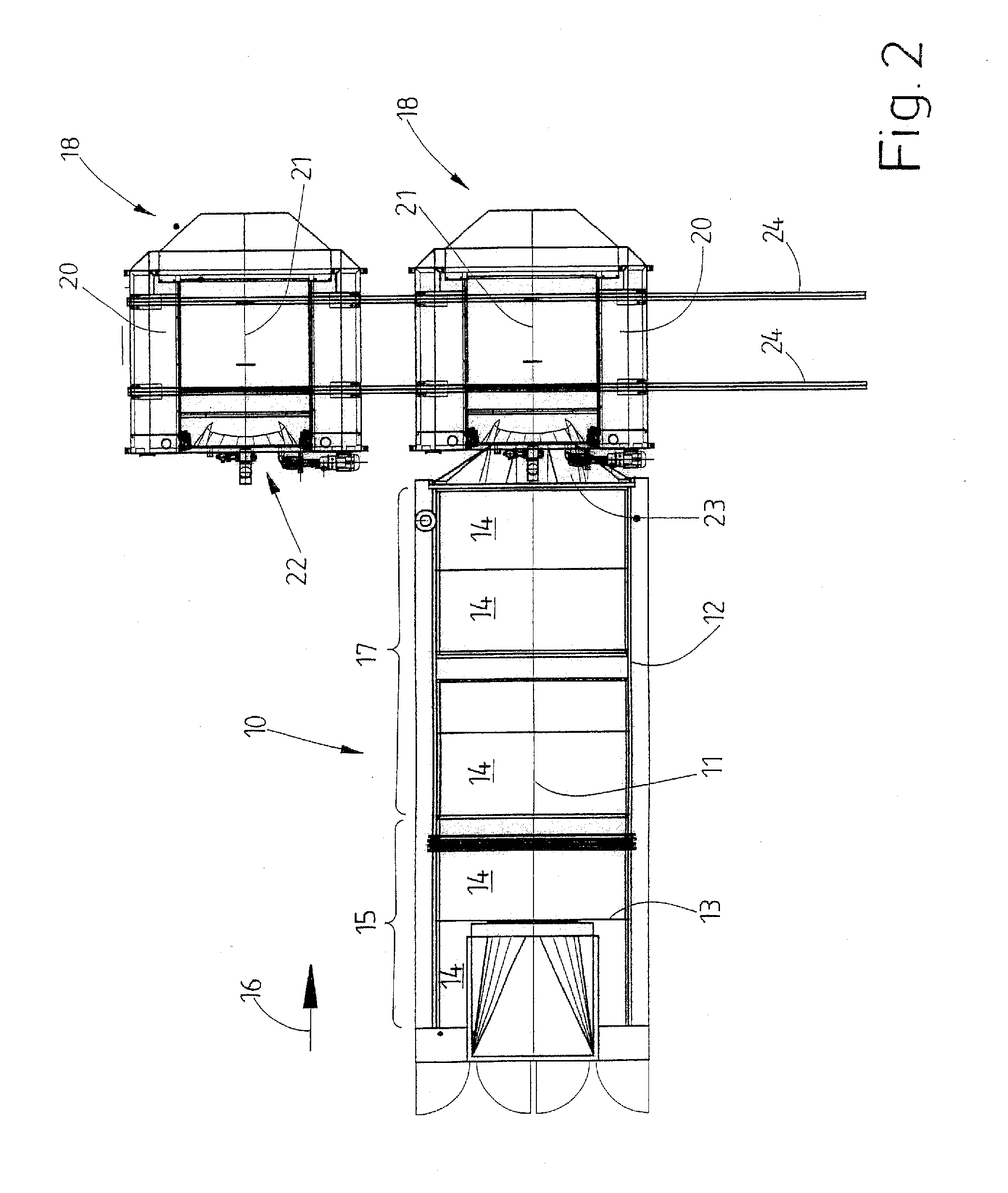

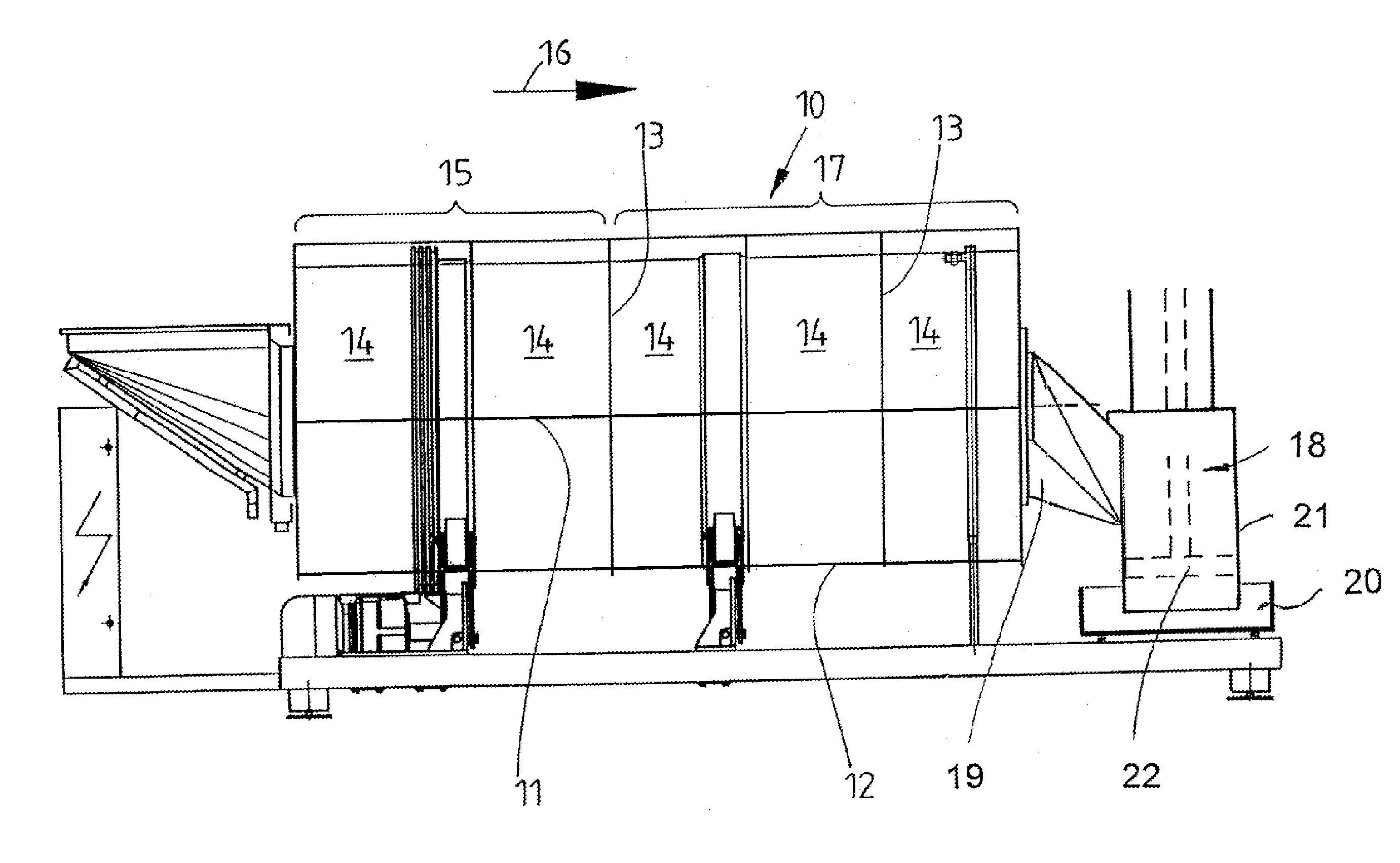

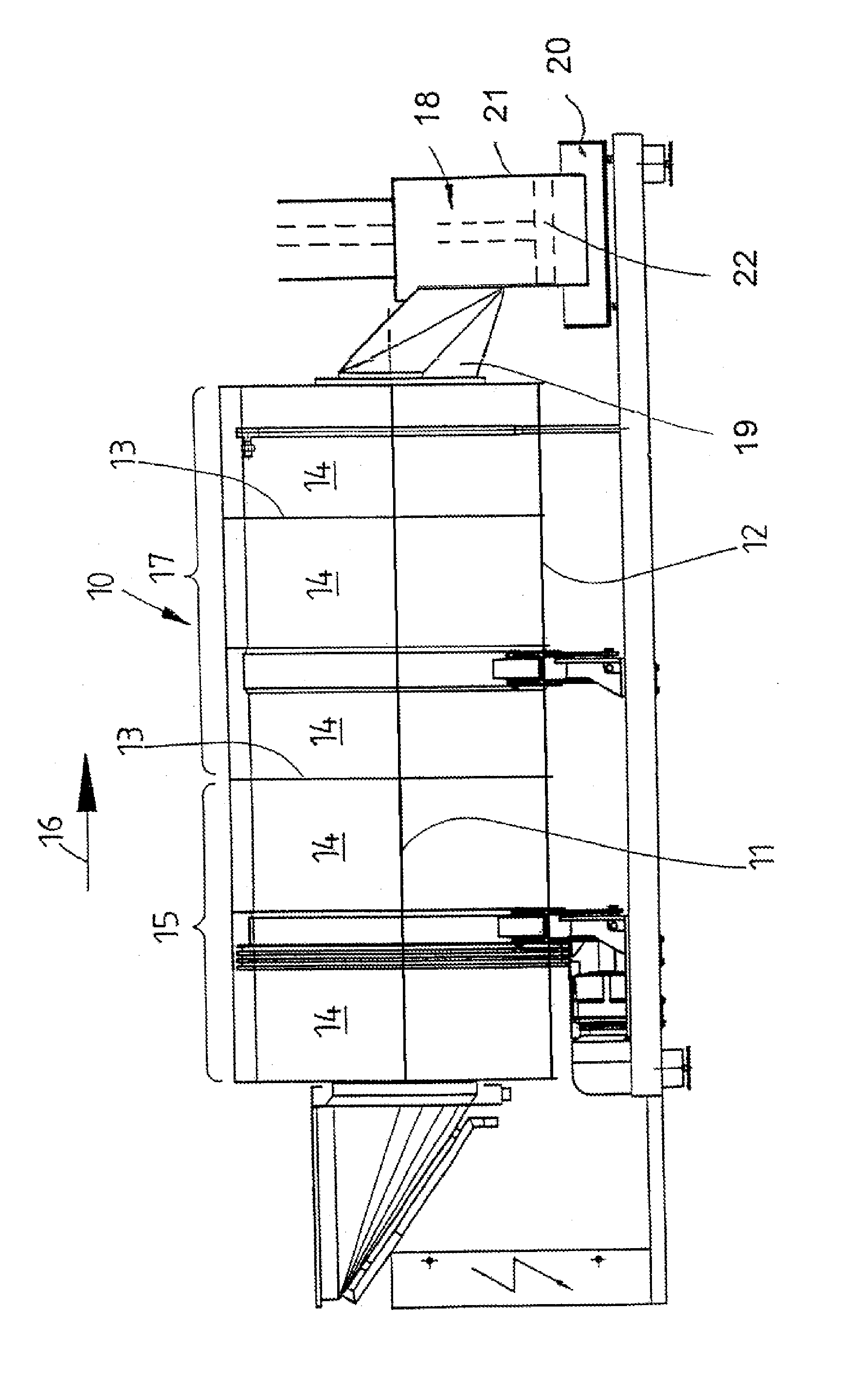

An inline washing system to be formed from a tunnel-type washing machine (10) which both rinses and removes water from the items of laundry. However, rinsing and simultaneously also water removal can also be performed in the downstream spin-dryer (18) or water-removal press. It has been found that the rinsing performance is better and fresh water can be saved on account of the invention. By virtue of the invention, it is possible to wash relatively small amounts of laundry using a tunnel-type washing machine (10) in an economical manner. The tunnel-type washing machine (10) can be designed to be shorter and also simpler if it is designed without a rinse zone.

Owner:KANNEGIESSER GMBH CO HERBERT

Device for the wet treatment of items to be washed

InactiveUS20120060564A1Economical wet-treatmentInexpensive mannerOther washing machinesTextiles and paperPulp and paper industryFresh water

An inline washing system to be formed from a tunnel-type washing machine (10) which only washes the items of laundry. Rinsing and also water removal are then performed in the downstream water-removal press (18). It has been found that the rinsing performance is better and fresh water can be saved as a result of this. It is therefore also possible to wash relatively small amounts of laundry using a tunnel-type washing machine (10) in an economical manner because the tunnel-type washing machine (10) can be designed without a rinse zone.

Owner:KANNEGIESSER GMBH CO HERBERT

Electric shaver

ActiveUS10478981B2Easy and self-explaining handlingAvoid misleadingMetal working apparatusRinse waterElectric razors

Owner:BRAUN GMBH

Automatic washing machine which simultaneously agitates, squeezes and spins water soaked clothes to wash and dehydrate

InactiveUS20180305852A1Minimise imbalanceEfficient washingOther washing machinesControl devices for washing apparatusEngineeringDrive motor

An automatic washing machine which can compress and decompress clothes during washing process comprises an enclosed support frame, a water tub mounted in the support frame, a cylindrical basket rotatably mounted in the water tub, a central shaft rotatably mounted in the cylindrical basket, variable speed drive motors connected to central shaft and cylindrical basket, shaft fins projecting radially outward from the central shaft and basket fins projecting radially inward towards the central shaft interposed between each other and a control panel equipped to rotate the interposed fins of the shaft and cylindrical basket independently or together at uniform or different speeds in the same or different directions in order to compress, decompress, agitate, hold and spin water soaked clothes to wash, rinse and dehydrate.

Owner:VARGHESE WILSON

Method and device for the wet treatment of items to be washed

ActiveUS8075636B2Cycle timeEconomical wet-treatmentDetergent compounding agentsWashing machine with receptaclesFresh waterPulp and paper industry

An inline washing system to be formed from a tunnel-type washing machine (10) which only washes the items of laundry is described. Rinsing and also water removal are then performed in the downstream water-removal press (18). It has been found that the rinsing performance is better and fresh water can be saved as a result of this. It is therefore also possible to wash relatively small amounts of laundry using a tunnel-type washing machine (10) in an economical manner because the tunnel-type washing machine (10) can be designed without a rinse zone.

Owner:KANNEGIESSER GMBH CO HERBERT

Drum type washing machine

InactiveUS7607327B2Shorten the timeEfficient rinseOther washing machinesTextiles and paperWash waterWater supply

Owner:PANASONIC CORP

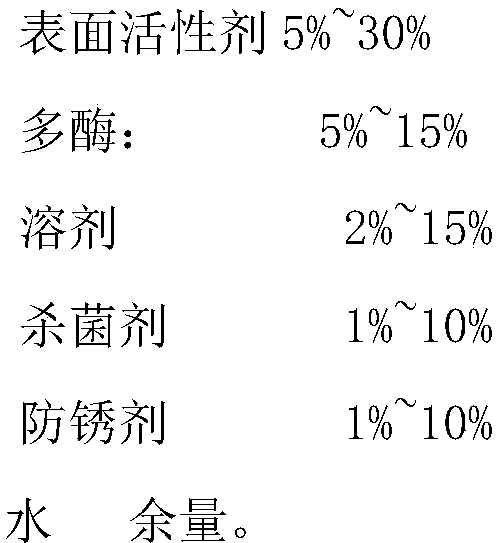

Medical equipment cleaning agent and preparation method thereof as well as preparation method of dispersed scale inhibitor

InactiveCN108219988ASuitable for cleaningEasy to prepareOrganic detergent compounding agentsNon-ionic surface-active compoundsMedical equipmentPolyethylene glycol

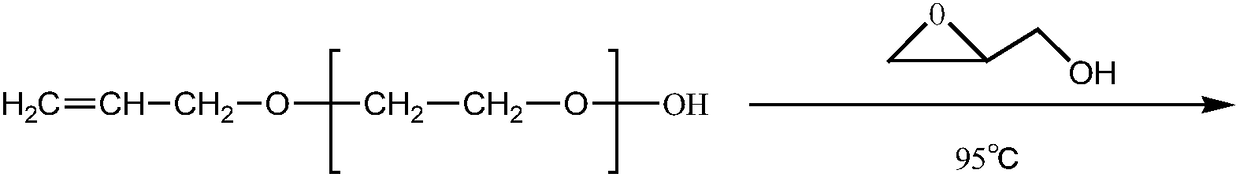

The invention relates to a medical equipment cleaning agent, which is prepared from the following components by mass percent: 1-10% of a dispersed scale inhibitor, 5-30% of a surface active agent, 5-15% of polymerase, 2-15% of a solvent, 1-10% of a bactericide, 1-10% of an anti-rust agent and the balance of water. A preparation method of the dispersed scale inhibitor comprises the steps of enabling allyloxy polyethylene glycol and glycidol, which are taken as raw materials, to be subjected to an anionic ring-opening reaction so as to synthesize a dendritic polyether monomer; enabling the obtained dendritic polyether monomer and acrylic acid to be subjected to a free radical polymerization reaction in a water phase to obtain the dispersed scale inhibitor. The medical equipment cleaning agent provided by the invention is simple and convenient to prepare, safe and non-toxic, thus being suitable for cleaning medical equipment.

Owner:NANJING JUSHA DISPLAY TECH +2

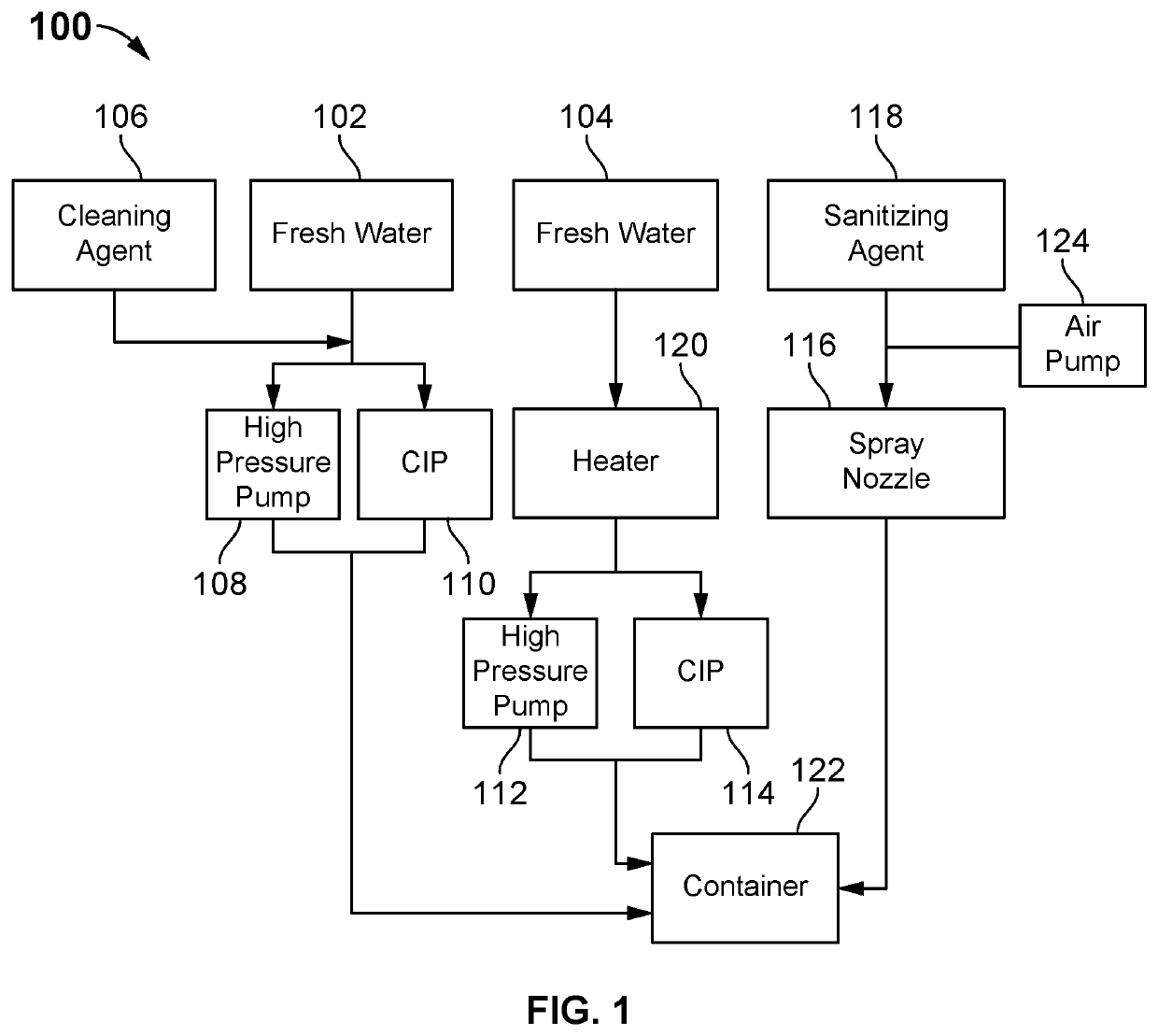

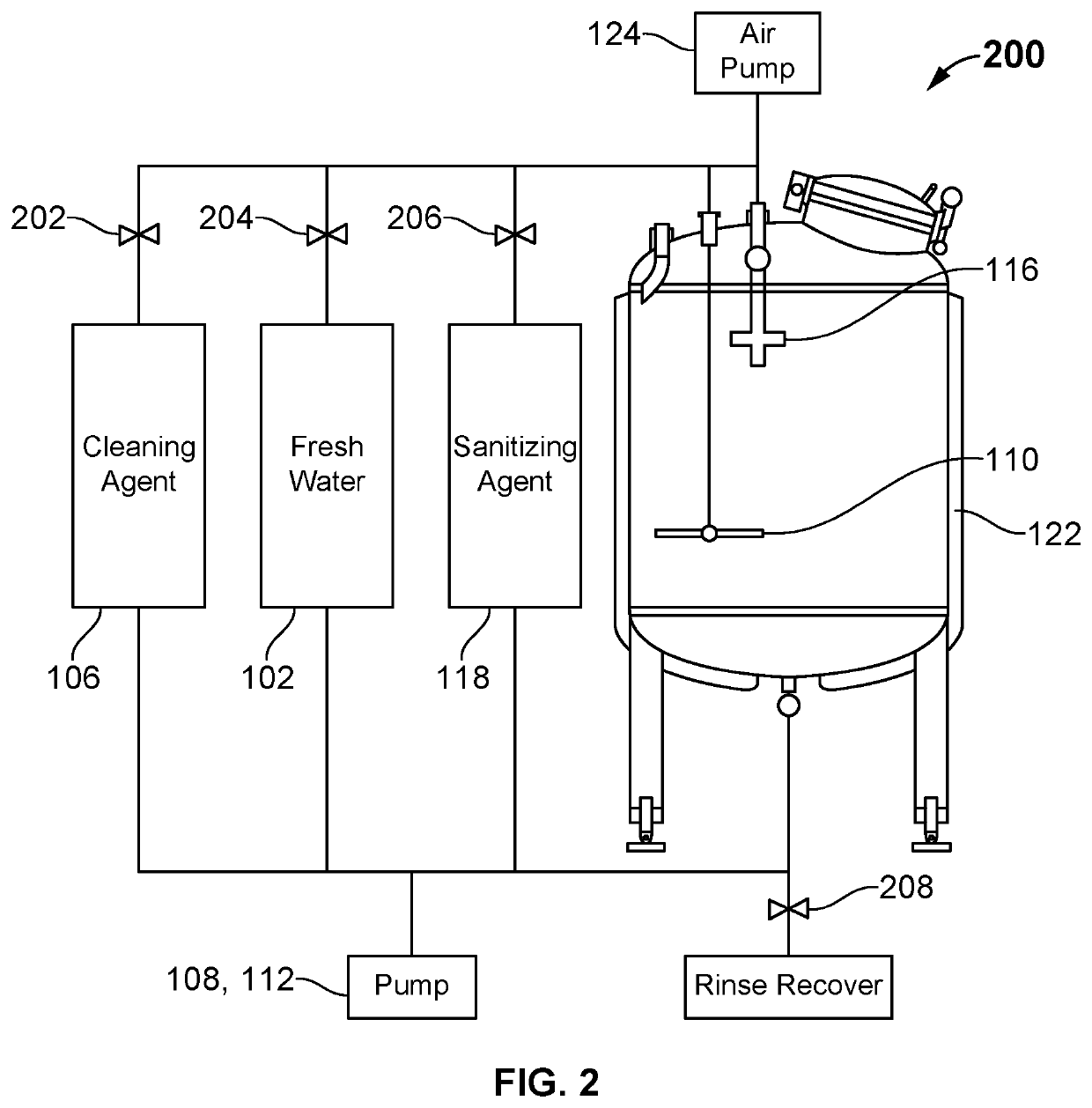

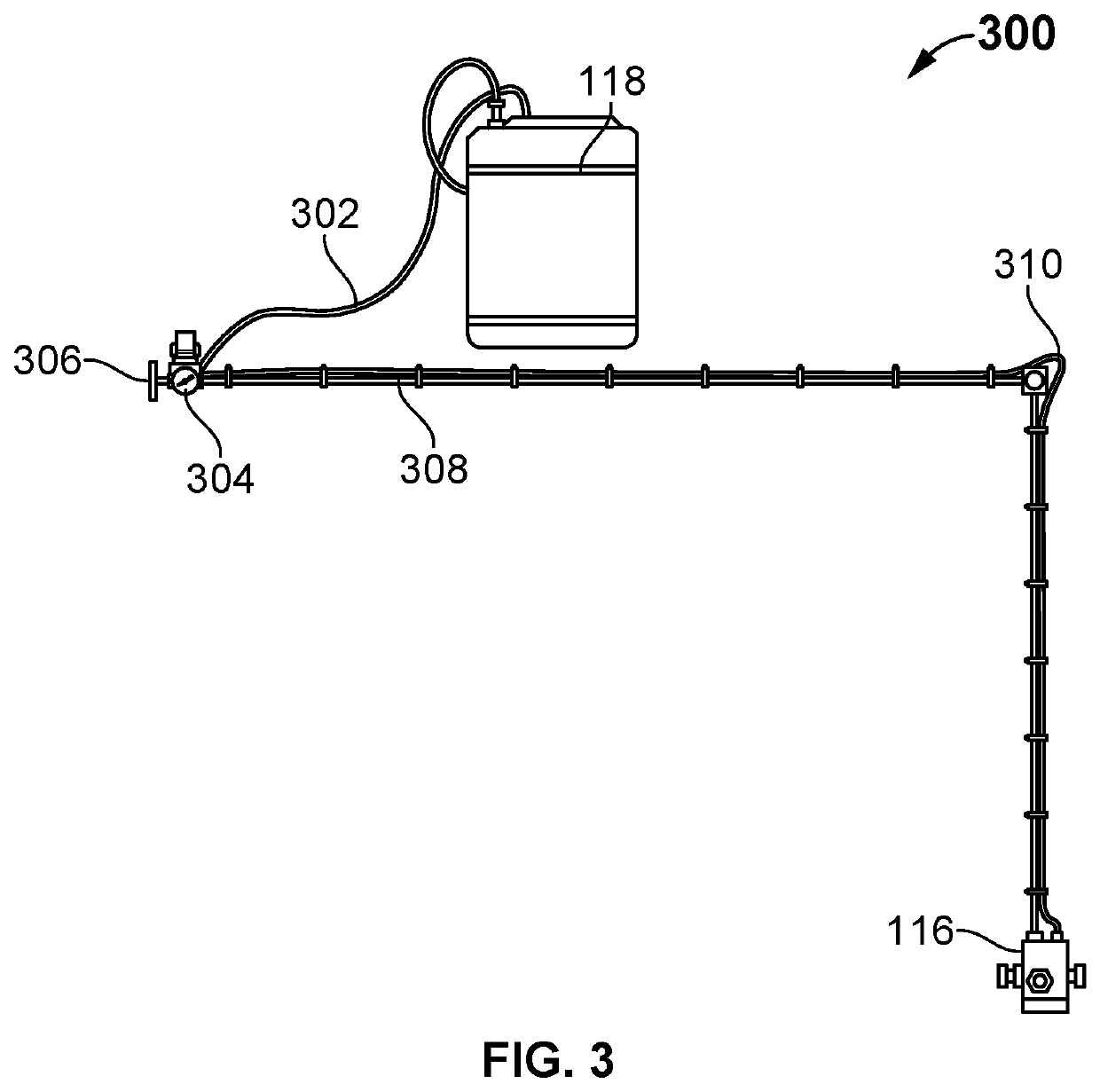

System and method for cleaning and sanitizing foodstuff tanks

PendingUS20210197240A1Effective disinfectionReduce water consumptionHollow article cleaningLavatory sanitorySpray nozzleEngineering

A system and method for cleaning, rinsing, and sanitizing a container is disclosed. The system has a modular trolley having a dolly having at least one wheel, at least one tube coupled to the dolly, wherein the tube has a hollow interior and an inlet end, and wherein the tube has a vertical section located on a back side of the dolly, a chassis coupled to the at least one tube and posited downstream of the dolly, wherein the chassis comprises at least one chassis wheel, a spray nozzle fluidly coupled to an end of the tube on the vertical section, a sanitizing container for storing a sanitizing agent, wherein the sanitization container is supported by the dolly, a sanitization feed hose fluidly coupled to the spray nozzle, a gas source coupled to the inlet end of the tube, a pump in fluid commination with the sanitizing agent chamber, wherein the pump is in fluid communication with a gas; and wherein the gas source, via the tube, introduces the gas to the spray nozzle to mix the sanitizing agent, at pressure, with the gas to disperse the sanitizing agent and gas mixture in the container for sanitizing the container.

Owner:HINCK RONALD

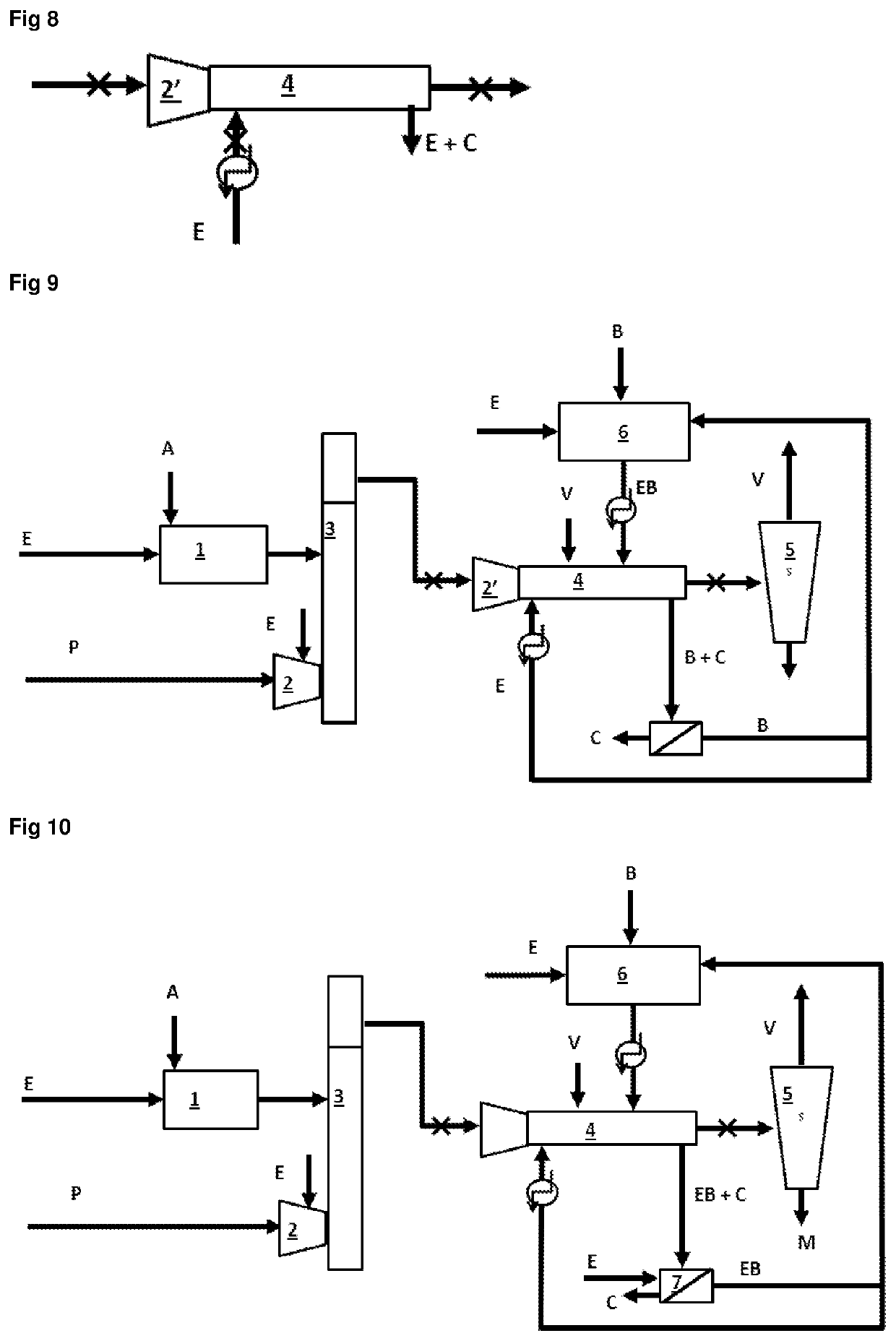

Method for cleaning a reactor for processing a lignocellulosic biomass

PendingUS20220056395A1Less energyEasy to implementBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseAlkaline water

The present invention concerns a method for cleaning a reactor (4) for treating a lignocellulosic biomass (P), said method comprising the following steps:a) draining the reactor of the reaction mixture containing the biomass,b) filling the reactor with a basic aqueous solution (EB),c) draining the reactor,d) injecting steam (V) into the reactor,e) filling the reactor with an aqueous solution (E),f) draining the reactor.

Owner:INST FR DU PETROLE +2

Composite cleaning agent for medical apparatuses and preparation method thereof

InactiveCN107937164AEasy to cleanImprove permeabilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsVegetable oilAdjuvant

The invention relates to a composite cleaning agent. Firstly, compound enzyme serving as the main agent composes a multi-enzyme cleaning component of the cleaning agent, and can achieve targeted cleaning of residual protein, organic matters and the like on medical apparatuses; secondly, a scale inhibitor serving as the adjuvant composes an organic cleaning component of the cleaning agent, and canachieve effective cleaning of mineral oil, animal and vegetable oil spot and the like on medical apparatuses; at the same time, inorganic base serving as the adjuvant on the one hand can provide an alkaline cleaning environment, and on the other hand, weak base composes an inorganic cleaning component in the cleaning agent, can achieve effective cleaning of inorganic matters on medical apparatuses, therefore, the multi-component compounded cleaning agent can realize efficient cleaning of medical apparatuses.

Owner:付一辰

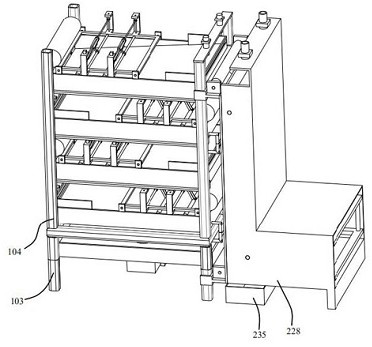

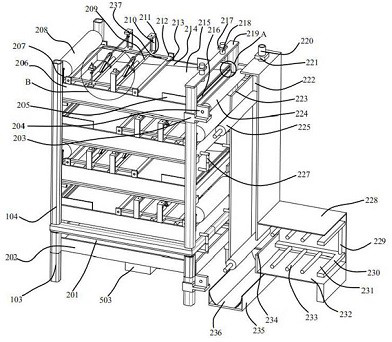

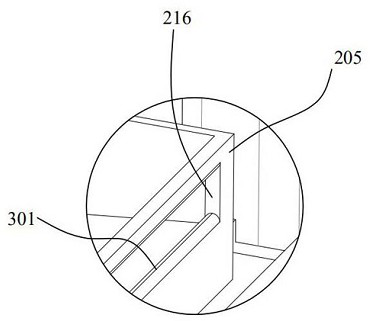

Washing and drying equipment for textile cloth

InactiveCN111676621APrevent splashEfficient rinseTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentPolymer scienceEngineering

The invention discloses washing and drying equipment for a textile cloth. The washing and drying equipment for the textile cloth structurally comprises a supporting bracket which is of a frame-type structure, wherein support legs abutted against the ground are fixedly arranged on the lower end surface of the supporting bracket; a drying device vertically hanging the textile cloth and carrying outdrying dehydration is arranged at the right side of the support legs; a plurality of rinsing devices used for rinsing the textile cloth are arranged in the supporting bracket in a staggered manner; and a water drainage device used for draining water out of the equipment is arranged below the rinsing devices. According to the equipment, rinsing and drying functions of the equipment are realized byvirtue of the drying device, the rinsing devices, the water drainage device and a water guide-in device; the textile cloth is vertically hung by virtue of the drying device, water in the textile clothis separated from the textile cloth by virtue of the impulsion of high-pressure air while freely falling; and moreover, the textile cloth is further dried in a manner of electric heating, and water is enabled to flow from top to bottom by virtue of the rinsing devices.

Owner:上海梓庆五金制品有限公司

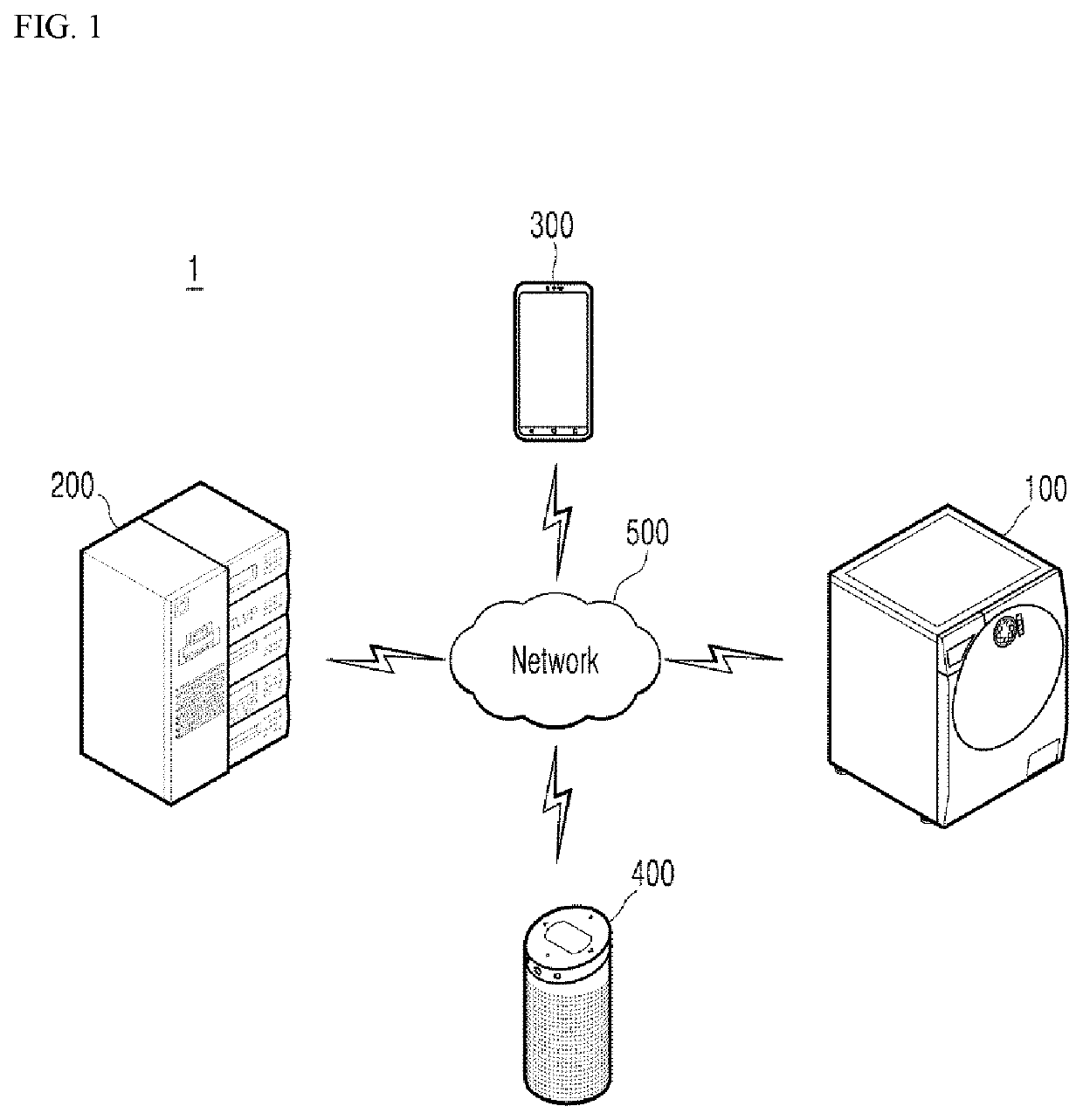

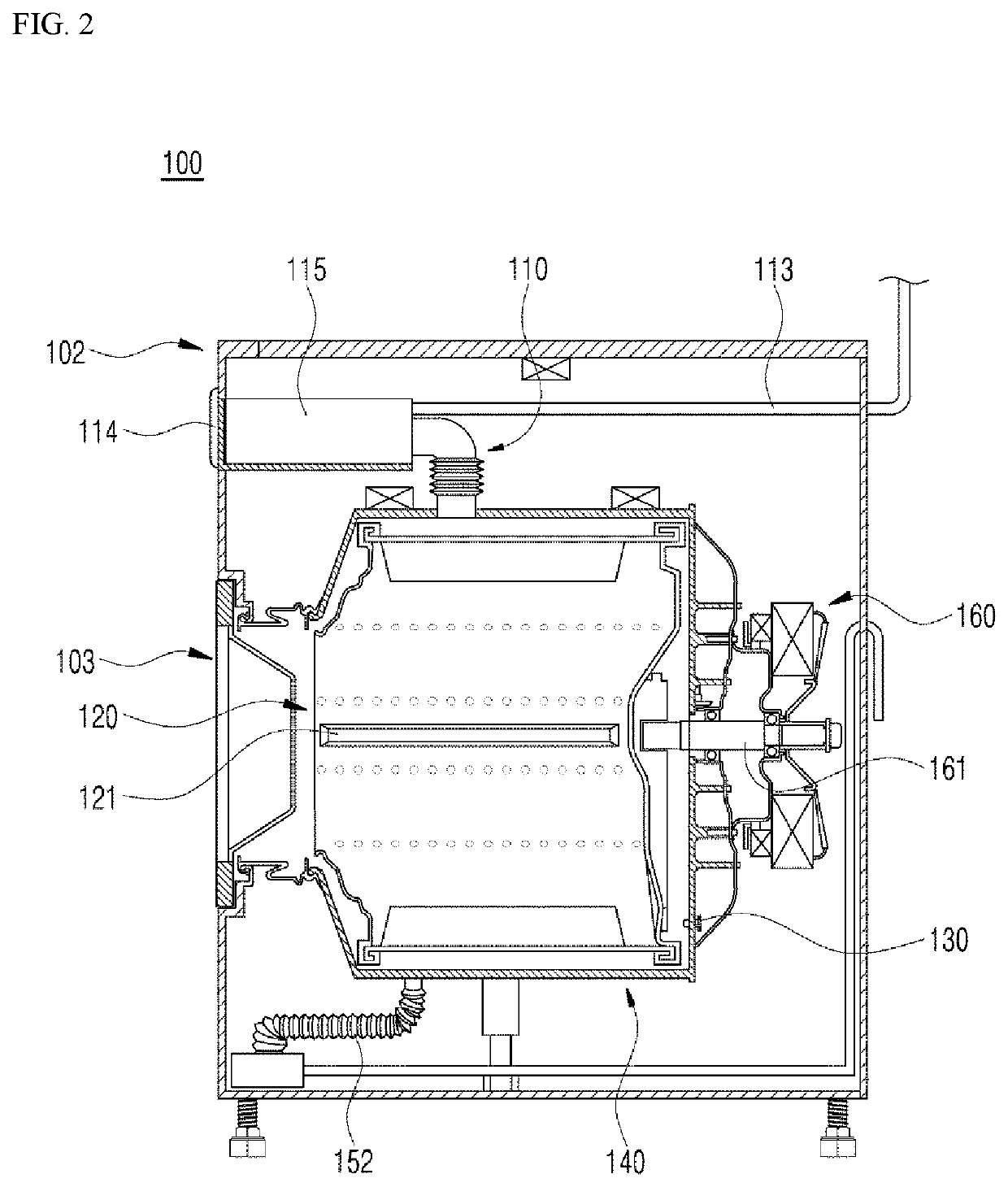

Washing machine for adjusting operation based on injected detergent and method for controlling the same

ActiveUS20210062397A1Accurate signalEfficient rinseOther washing machinesControl devices for washing apparatusLaundry washing machineProcess engineering

A washing machine capable of operating in an IoT environment through a 5G communication network and estimating the type and amount of injected detergent through a neural network model created according to machine learning, and a method of controlling the washing machine, are provided. The washing machine may include a first tub into which laundry is loaded, a water supplier configured to supply washing water to the first tub, a detergent detection sensor configured to detect first conductivity and first turbidity of the washing water, and a processor configured to determine a washing cycle of the washing machine based on detected information.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com