Patents

Literature

208results about How to "Effective holding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

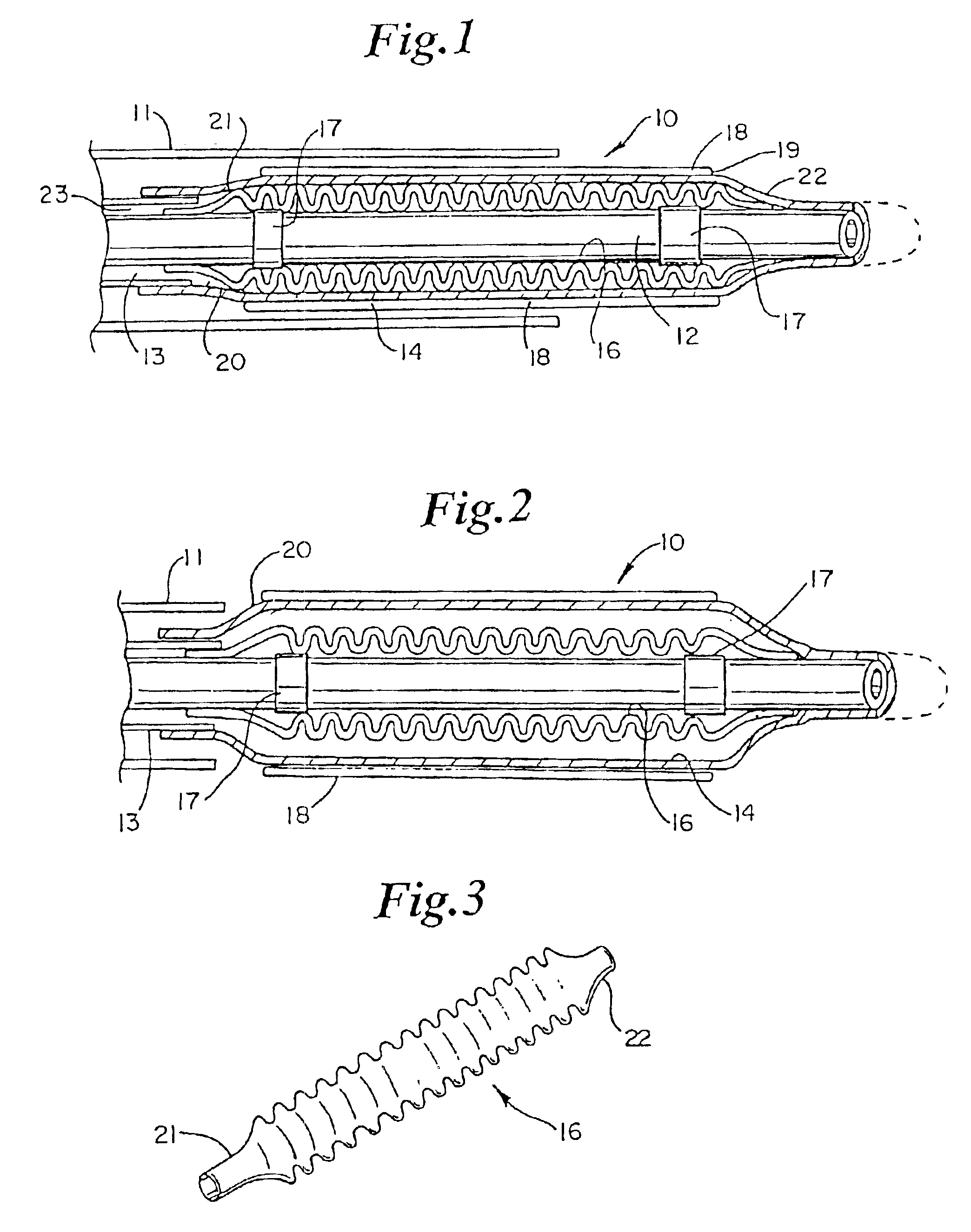

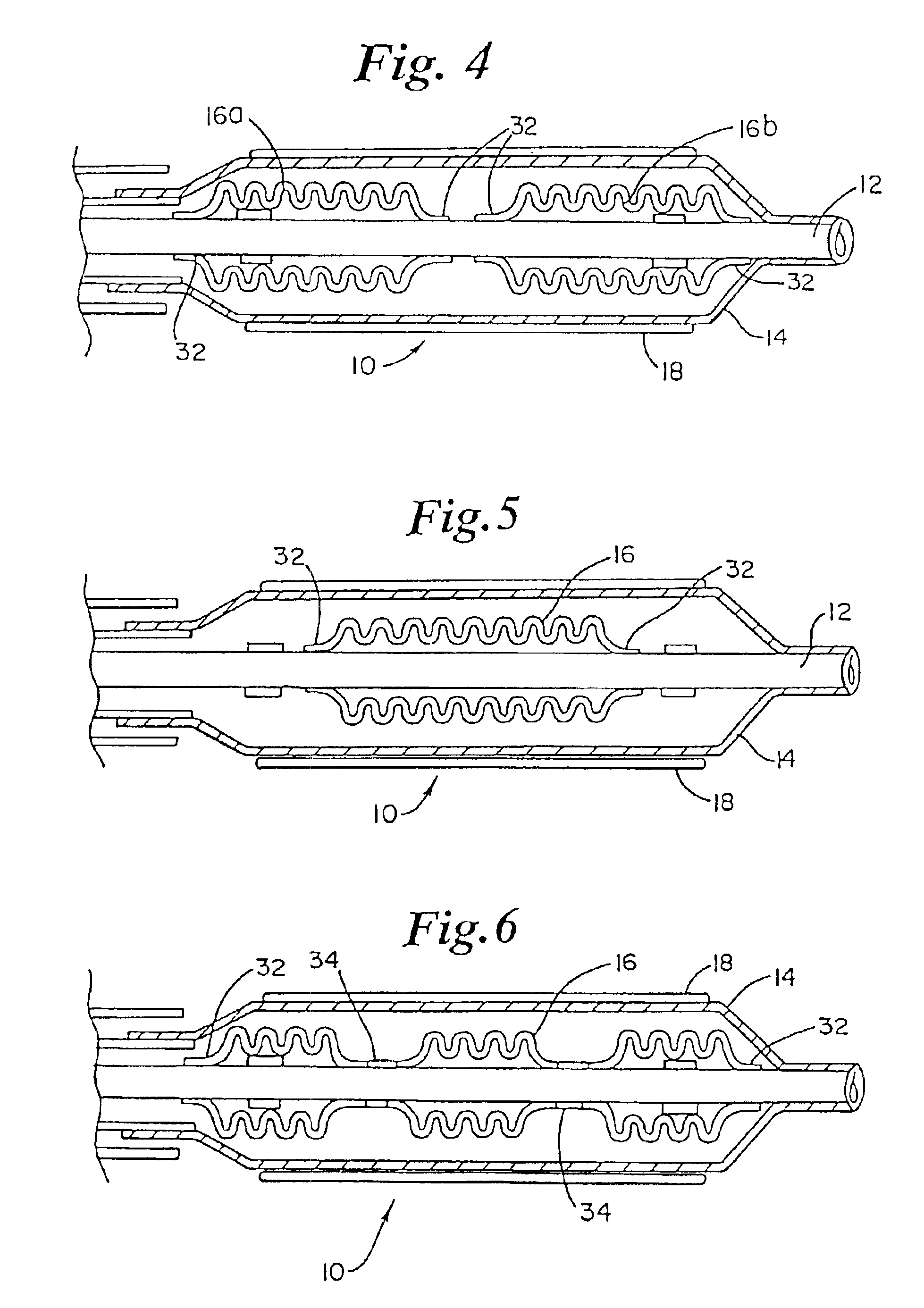

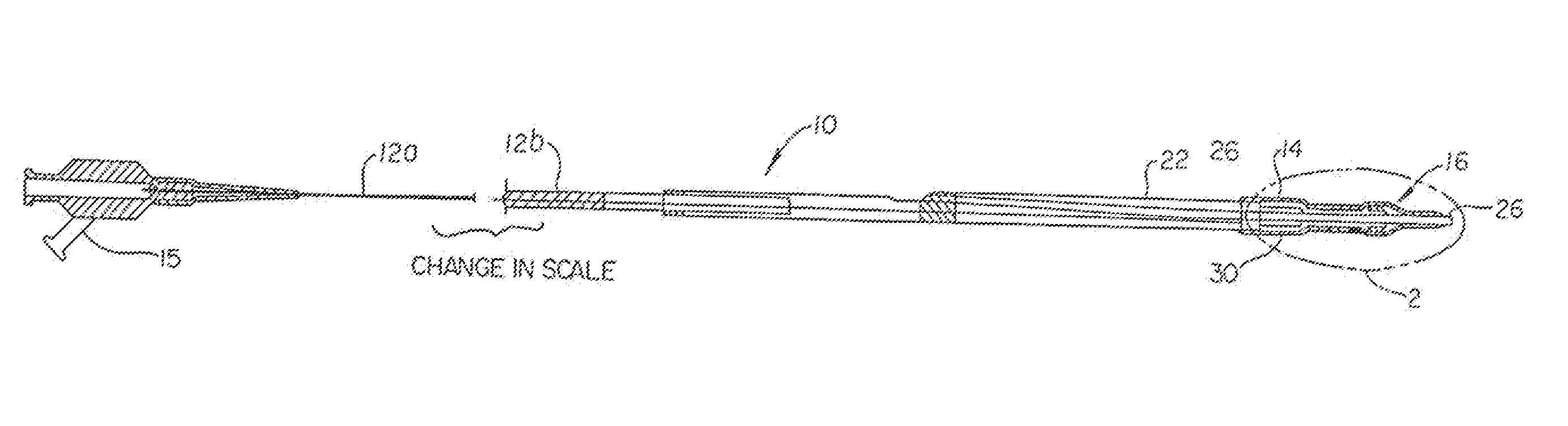

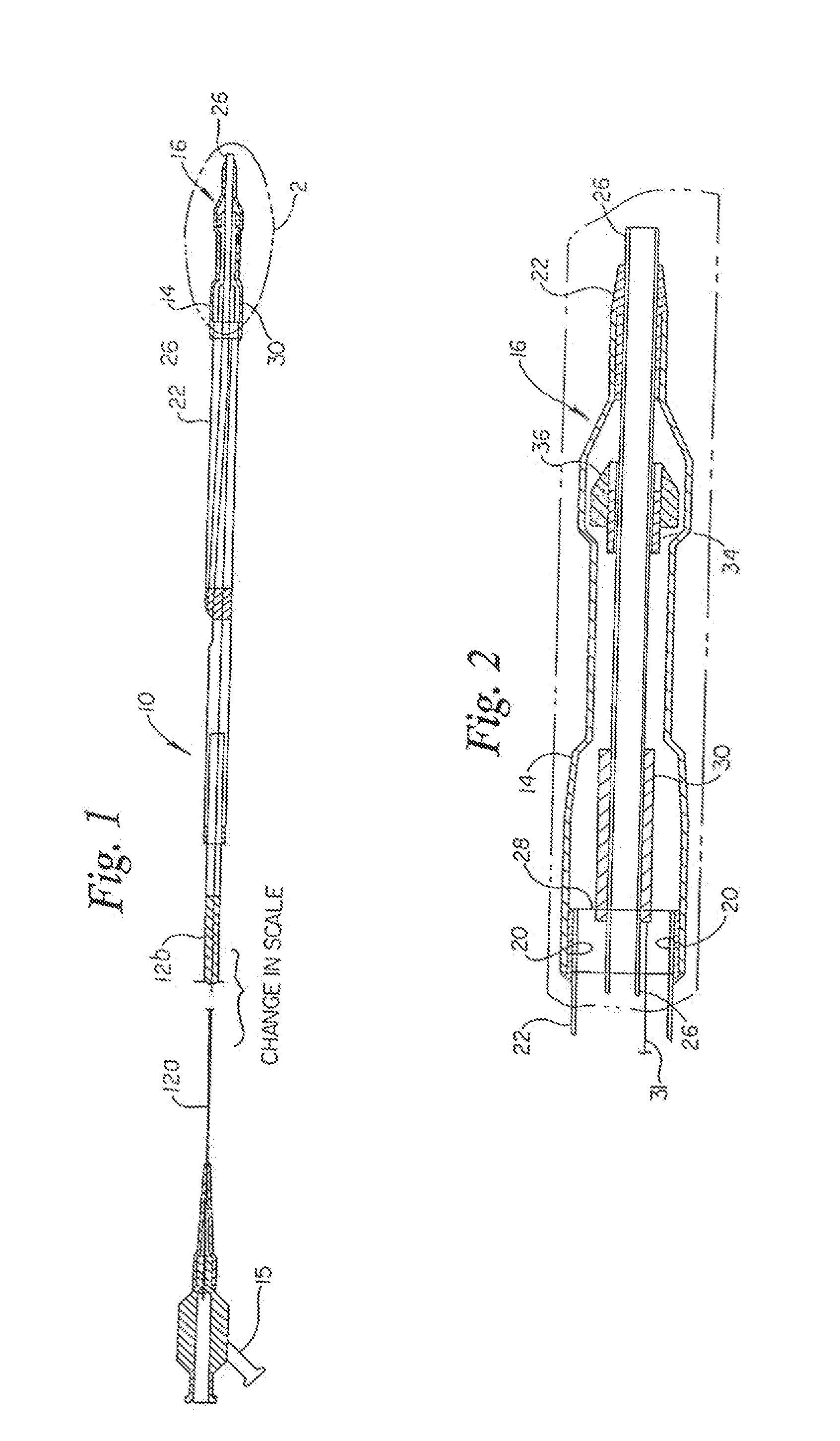

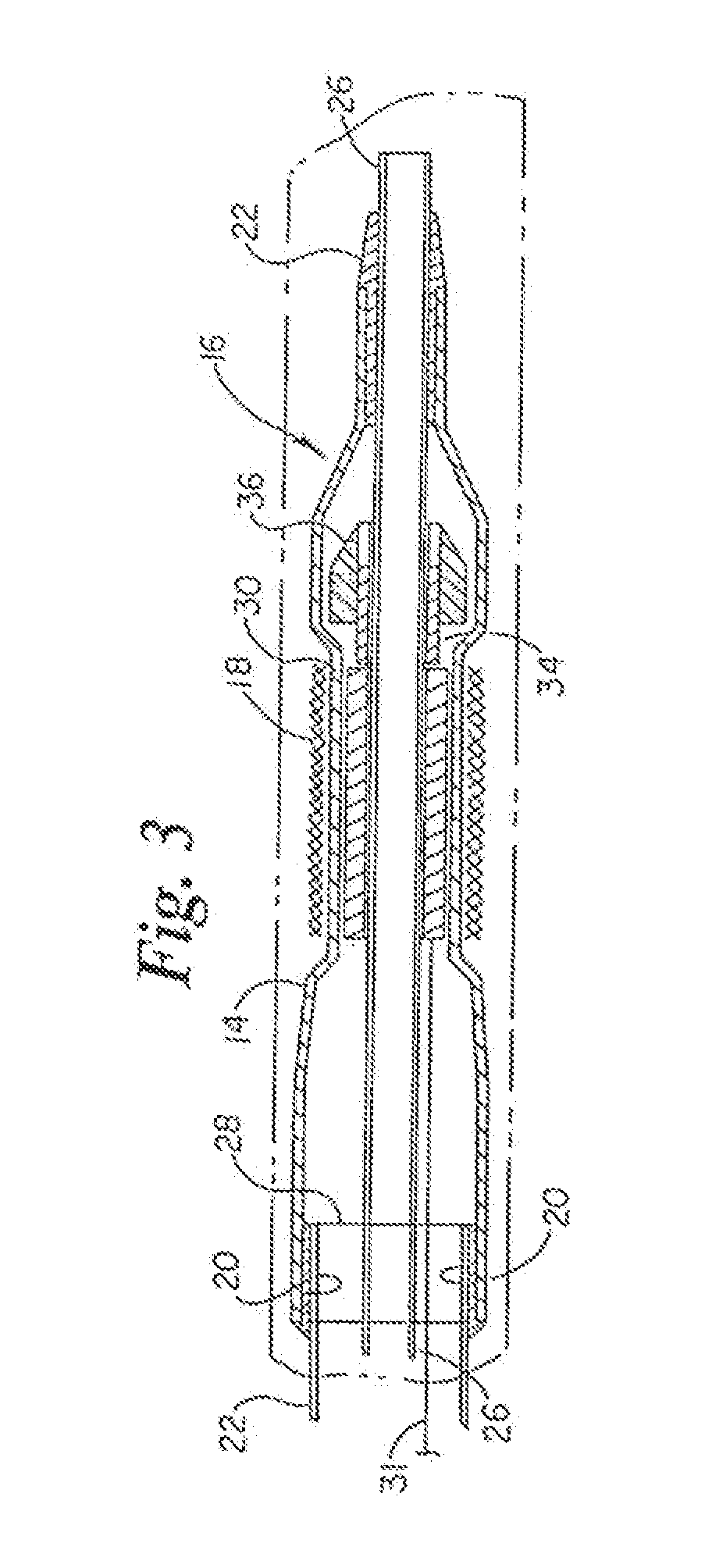

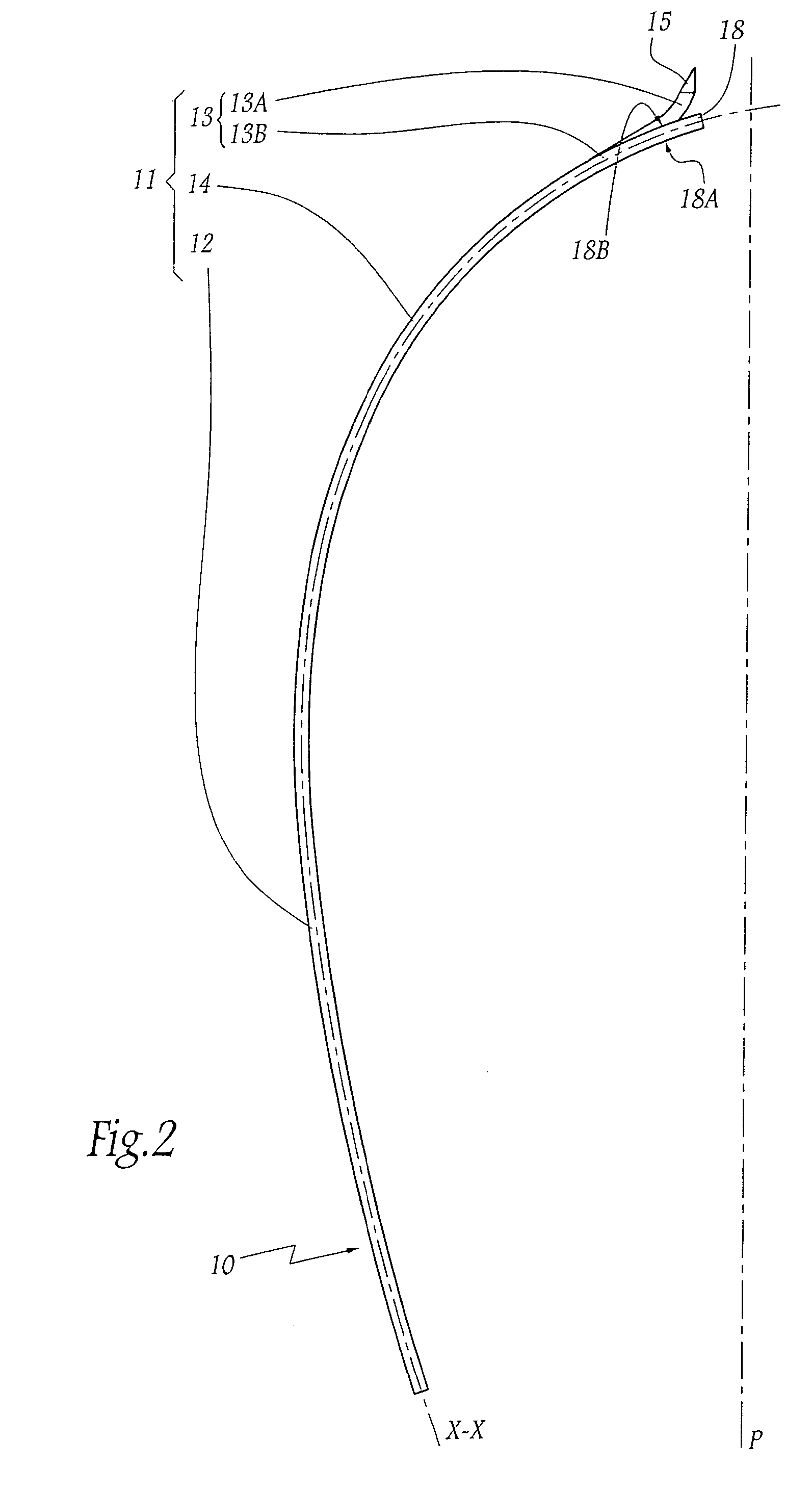

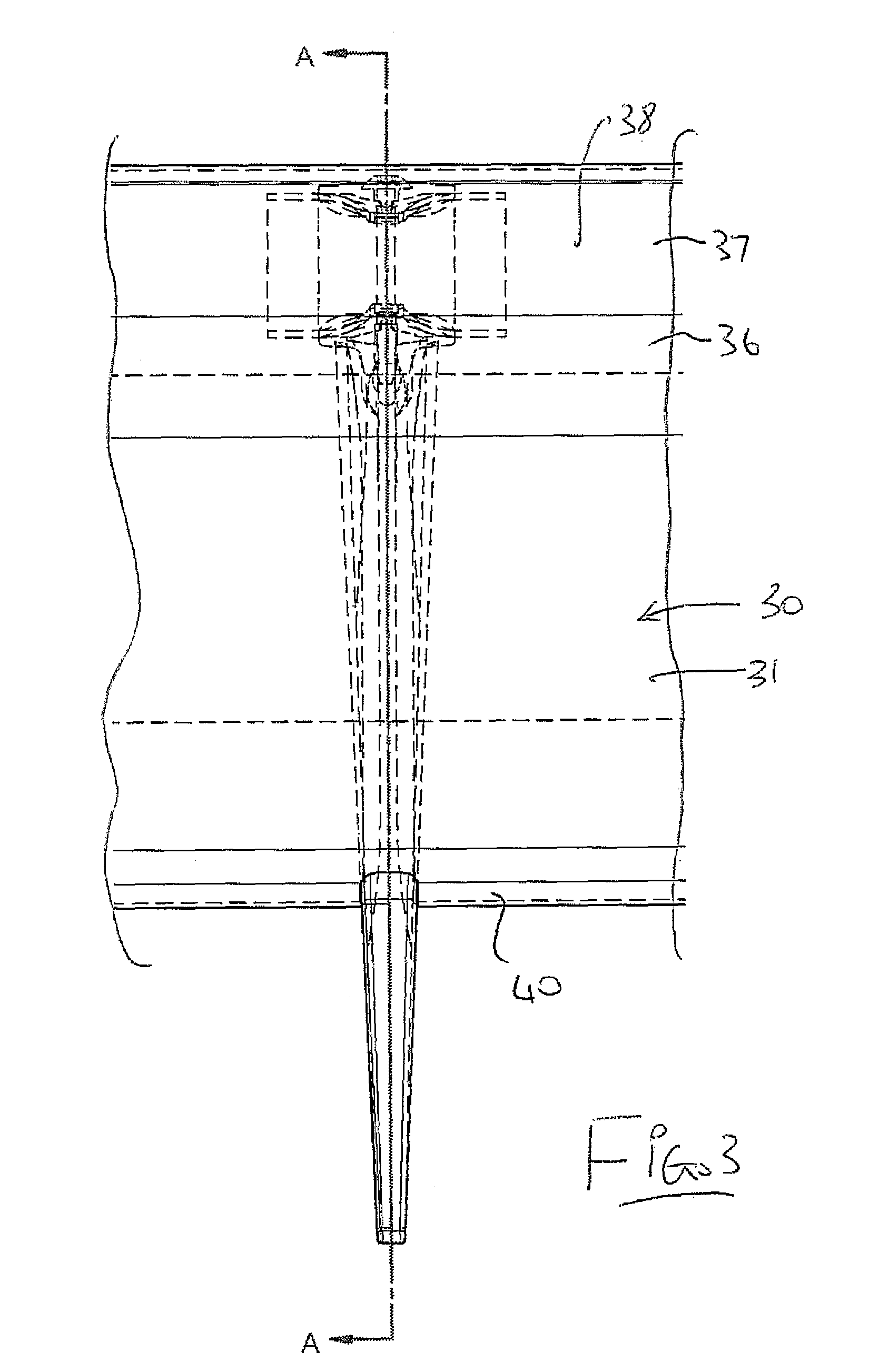

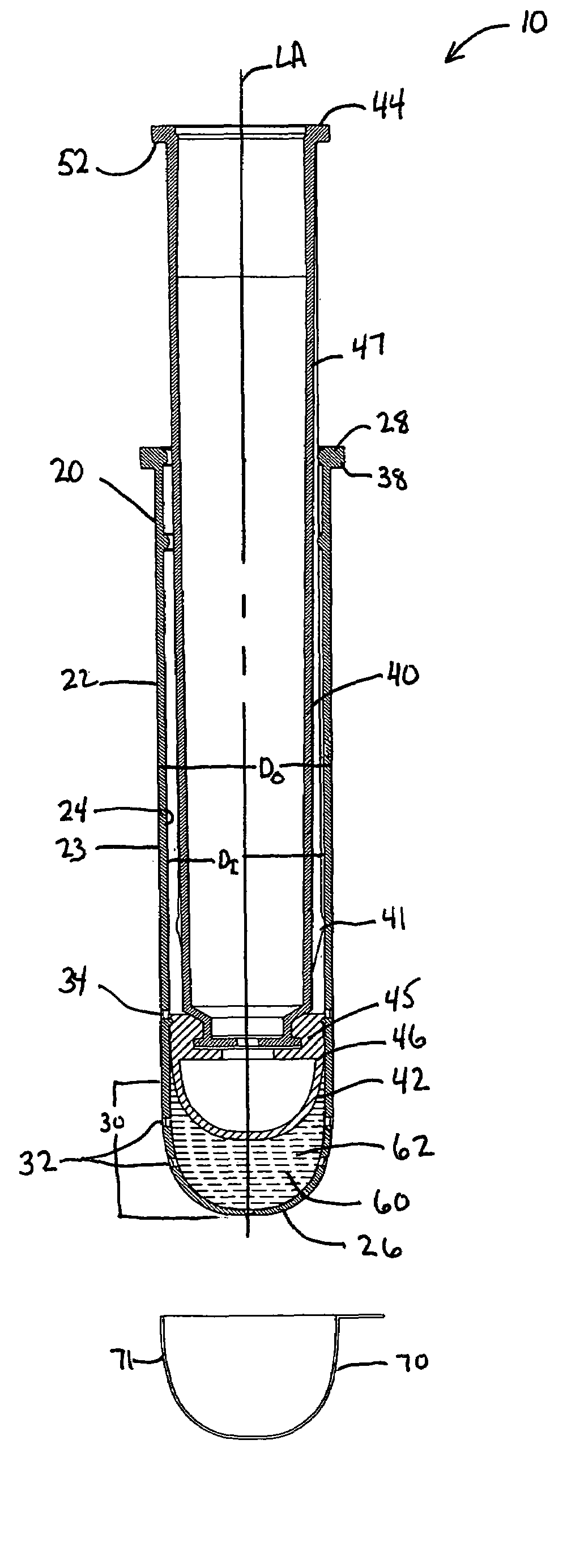

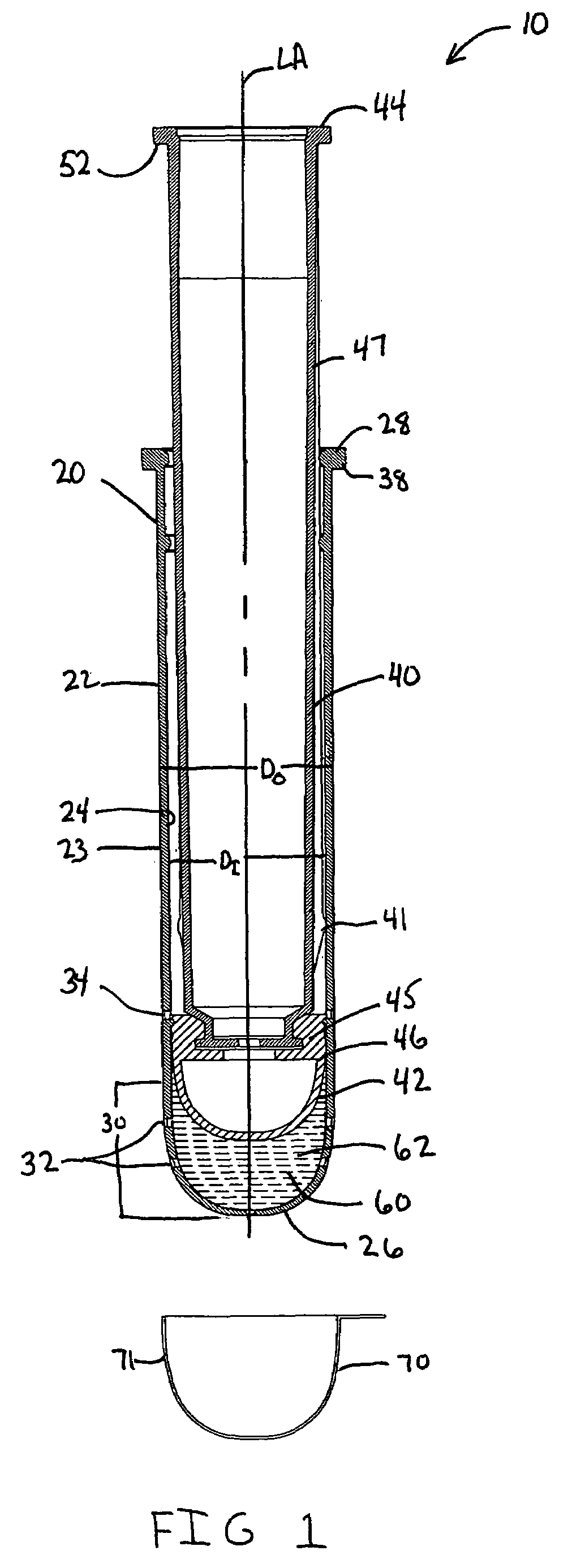

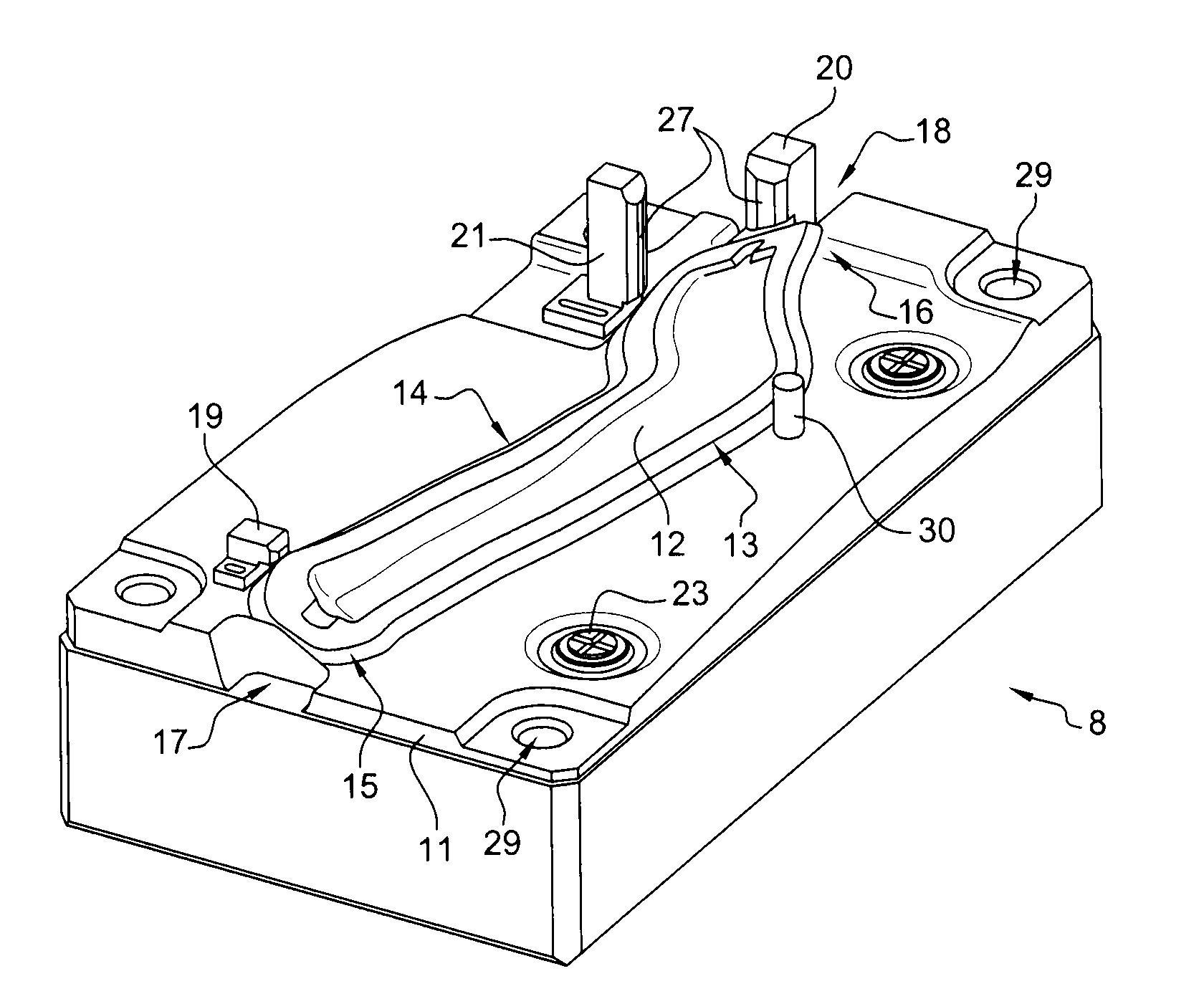

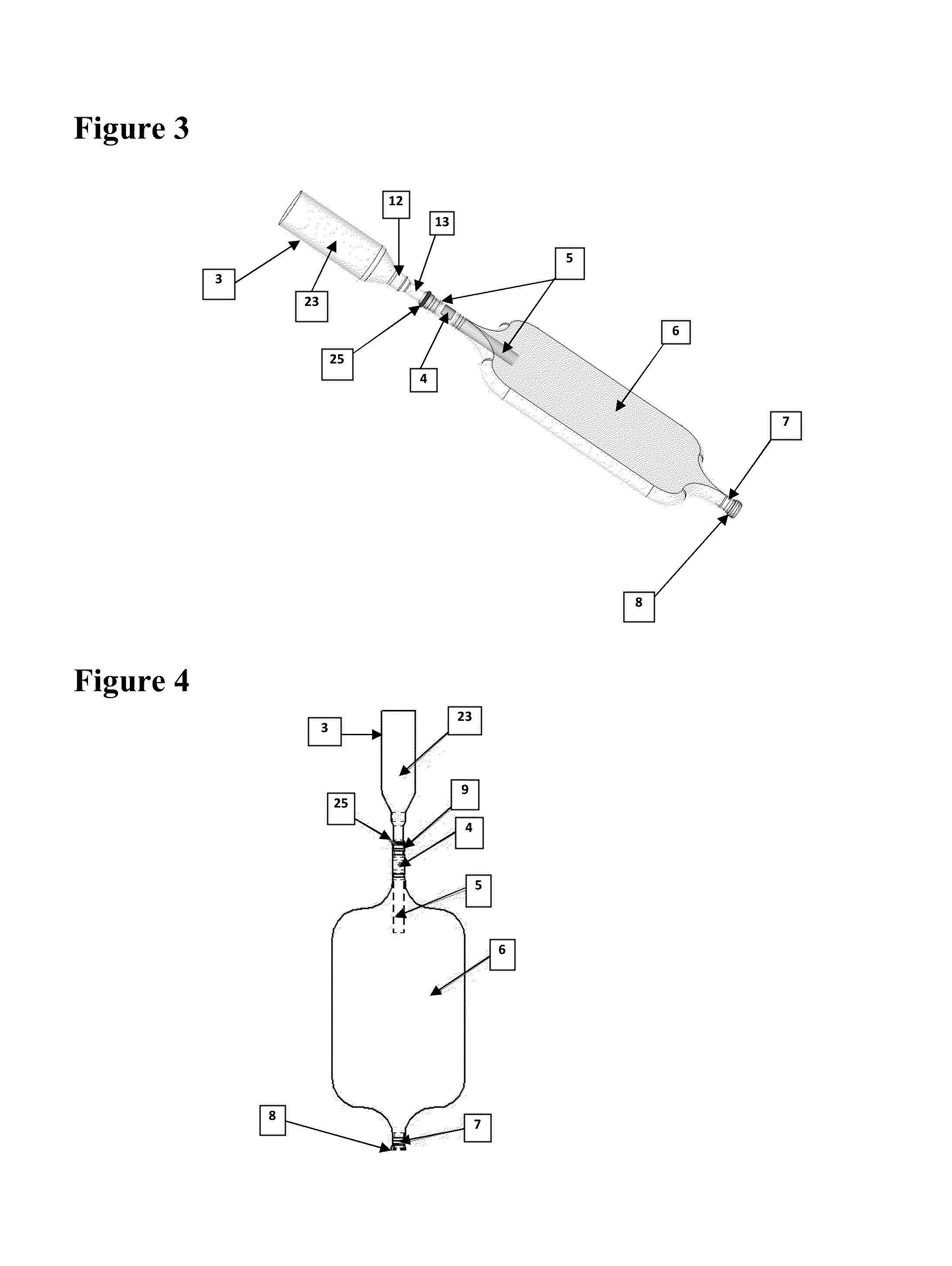

Balloon catheter with stent securement means

InactiveUS6881216B2Reduce deliveryReduce delivery diameterStentsBalloon catheterInsertion stentBalloon catheter

An assembly for delivery and deployment of an inflation expandable stent within a vessel is comprised of a catheter, an inflation expandable stent, an expandable balloon, and a securement means such as a corrugated tube component or an expandable tube component. The tube component is mounted on the inner shaft beneath the balloon and provides increased securement to the stent in a reduced delivery diameter to maintain the stent on the catheter during delivery to the deployment site. The tube component is adhered to the inner shaft and has a plurality of ribs or is fluid expandable to no more than the delivery diameter and may be comprised of more than one separately inflatable pouch expandable to provide the stent with a substrate seat with increased friction and to decrease the slack in stent recoil crimping. The assembly is used in a method for delivering and deploying a stent, and also adds safety when loading / crimping the stent onto a balloon.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

Aircraft fuselage shell component with crack propagation resistance

InactiveUS6595467B2Increasing weight and costEasy to crackFuselage bulkheadsWelding apparatusResidual strengthFiber-reinforced composite

Owner:AIRBUS OPERATIONS GMBH

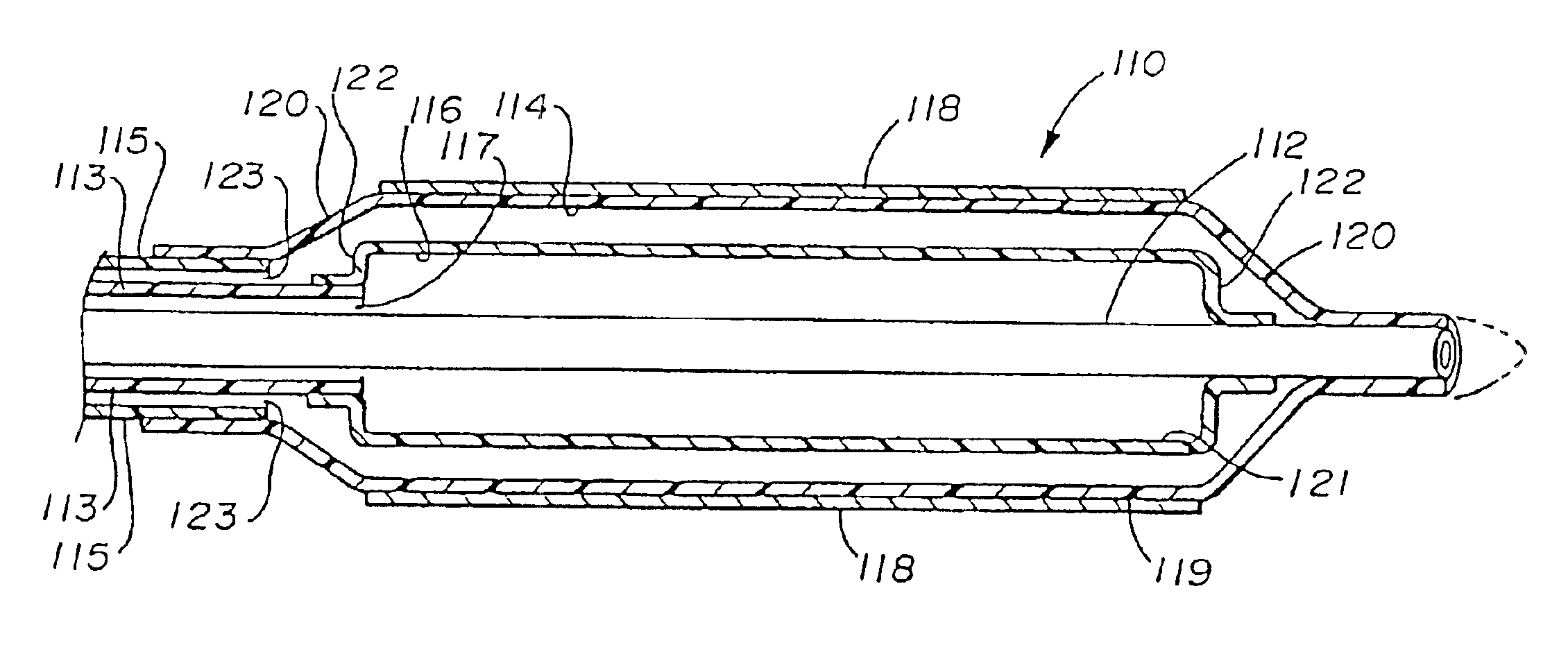

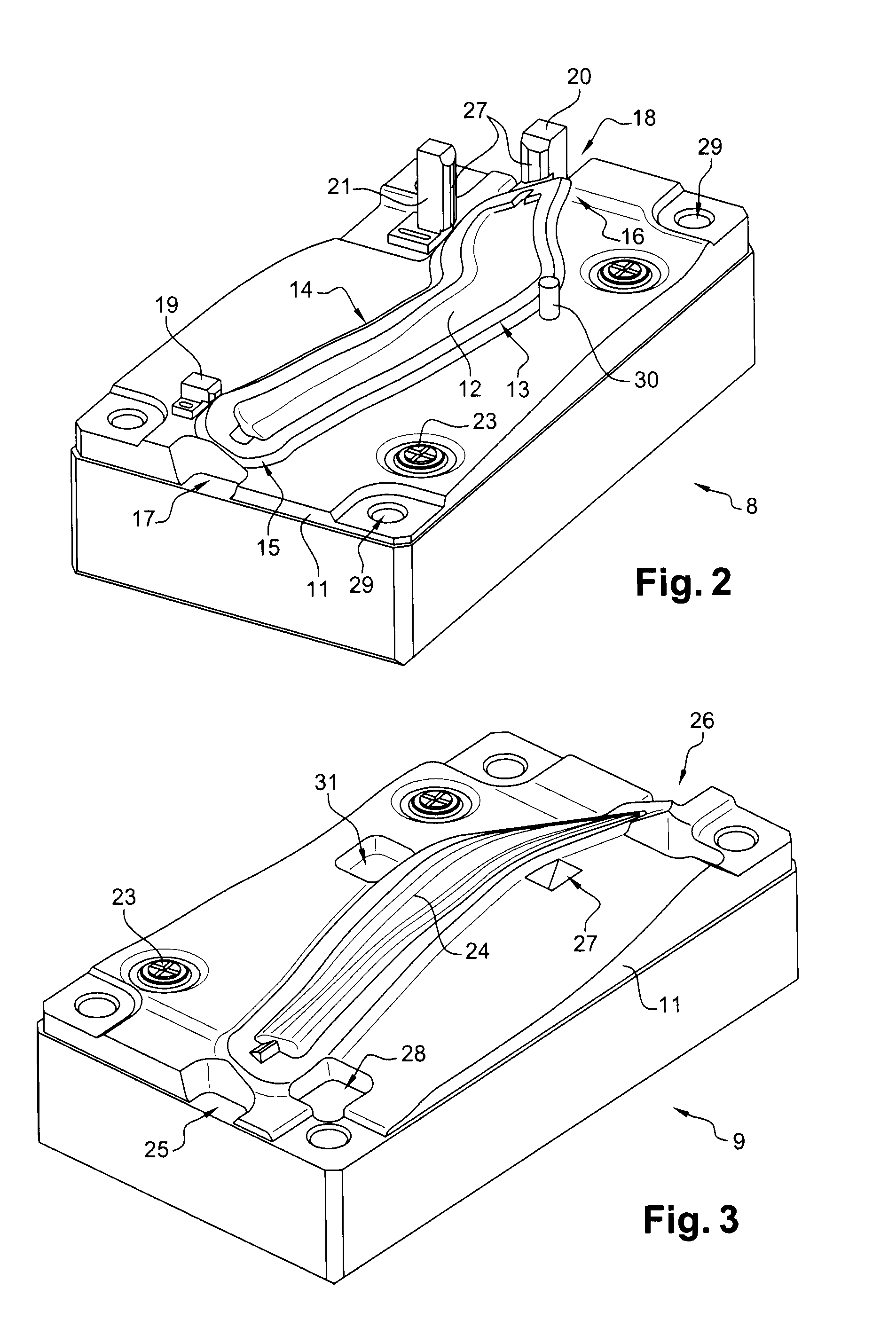

Stent Delivery System Having Stent Securement Apparatus

InactiveUS20100274344A1Reduce the overall diameterEffective holdingStentsBalloon catheterDelivery systemCatheter device

A system / assembly for delivery and deployment of an inflation expandable stent within a vessel, comprising a catheter having proximal and distal ends; a stent, inflation expandable from a delivery diameter to a deployment diameter, such that the delivery diameter is reduced from the deployment diameter for conforming the stent to the catheter, such that the stent, in its delivery diameter, is coaxially mounted on the catheter near the catheter distal end; an expandable inflation means coaxially mounted on the catheter axially within the stent, for expansion of the stent from the delivery diameter to the deployment diameter upon application of fluid deployment pressure to the inflation means; and a securement component coaxially mounted on the catheter, axially within the expandable inflation means, the securement component designed and adapted to provide a securement pressure to the stent in the delivery diameter to maintain the stent in position on the catheter during delivery to the deployment site.

Owner:BOSTON SCI SCIMED INC

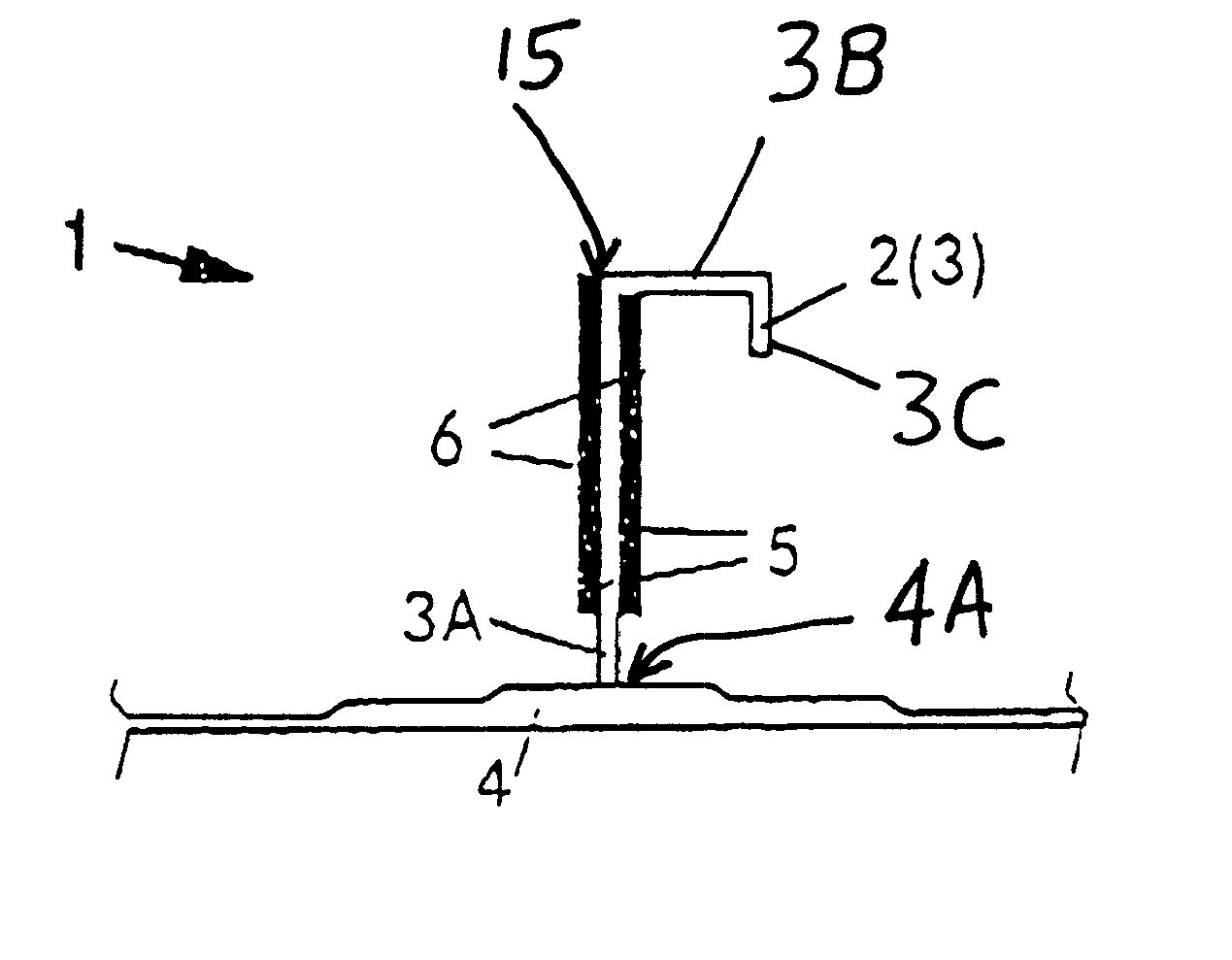

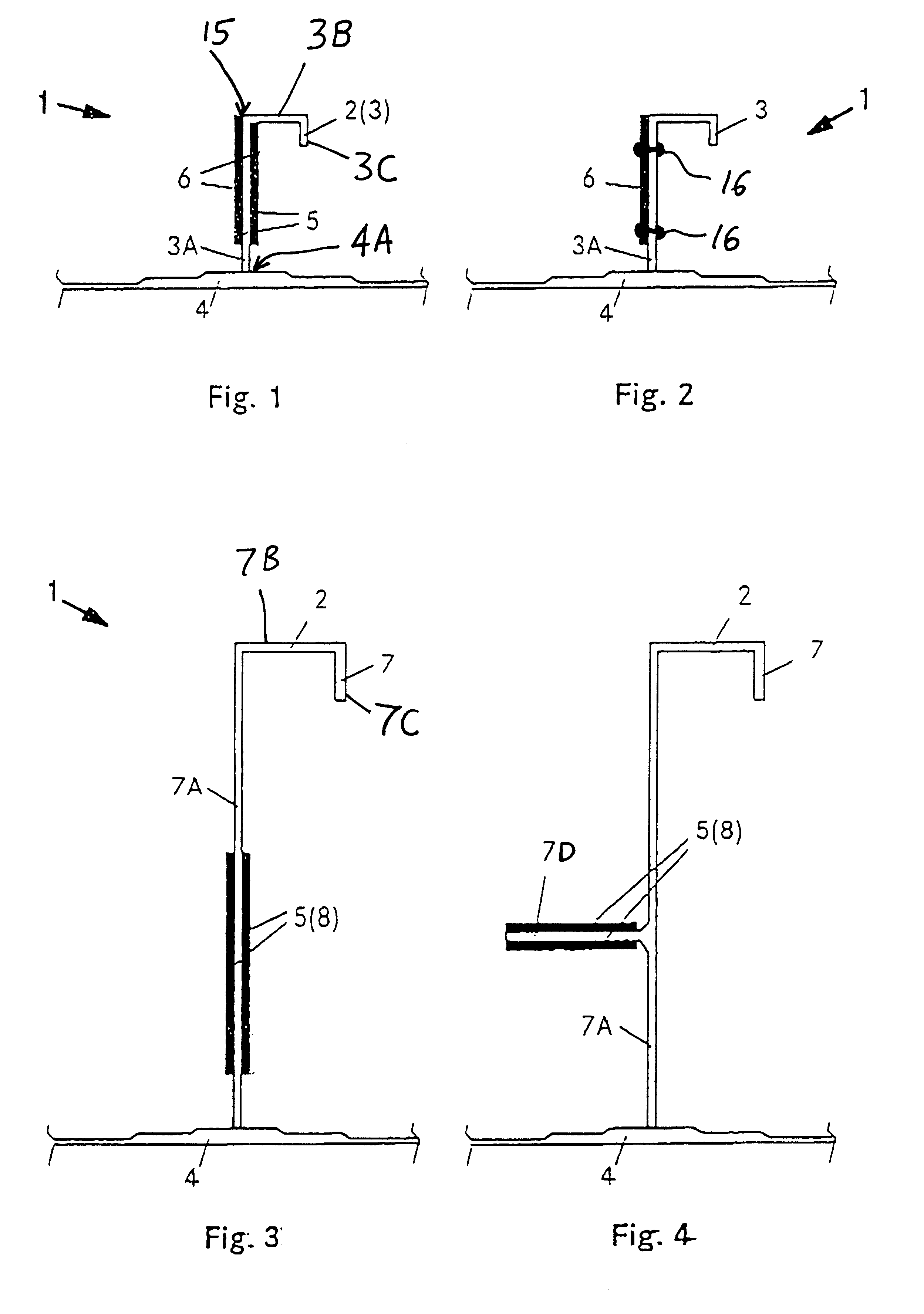

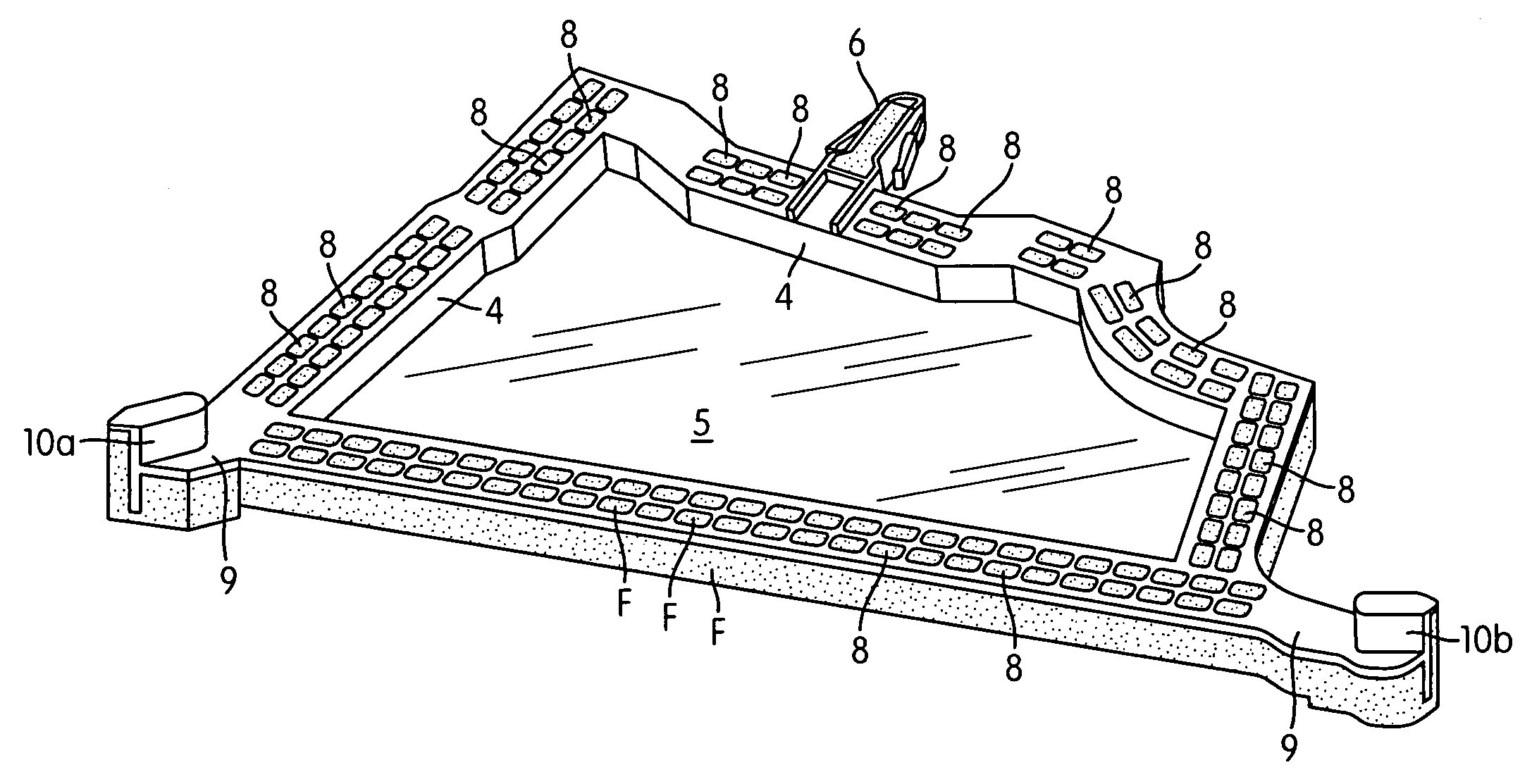

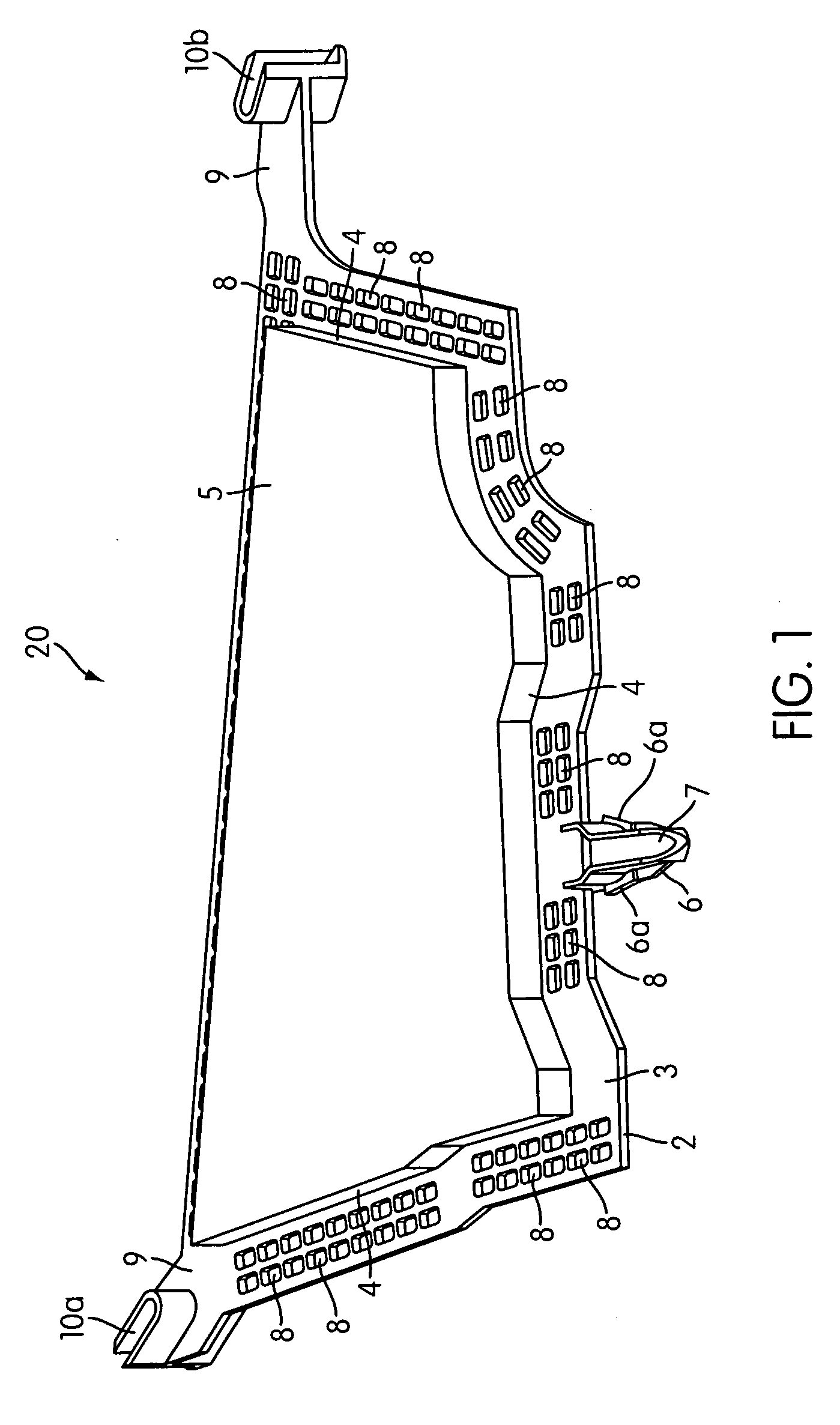

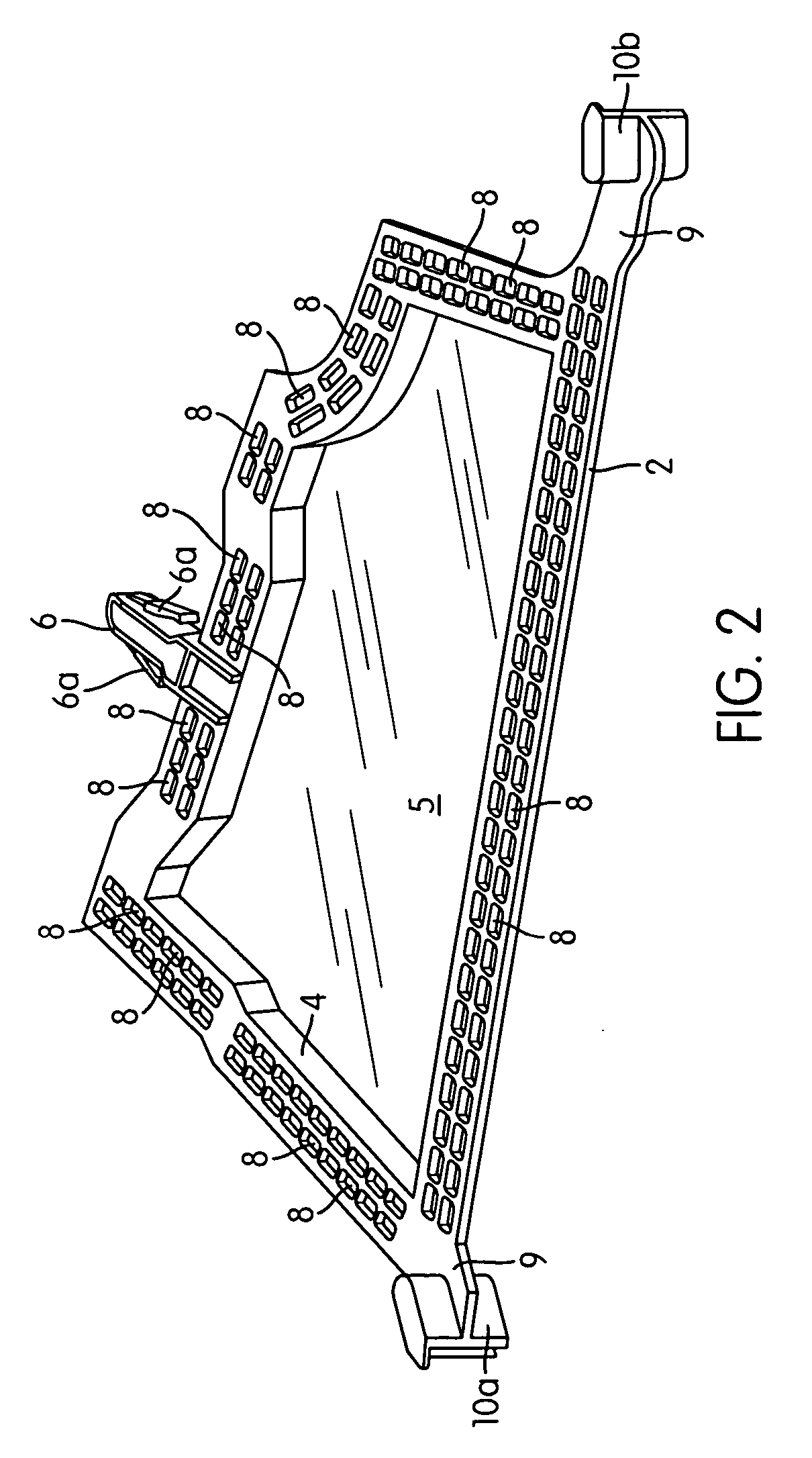

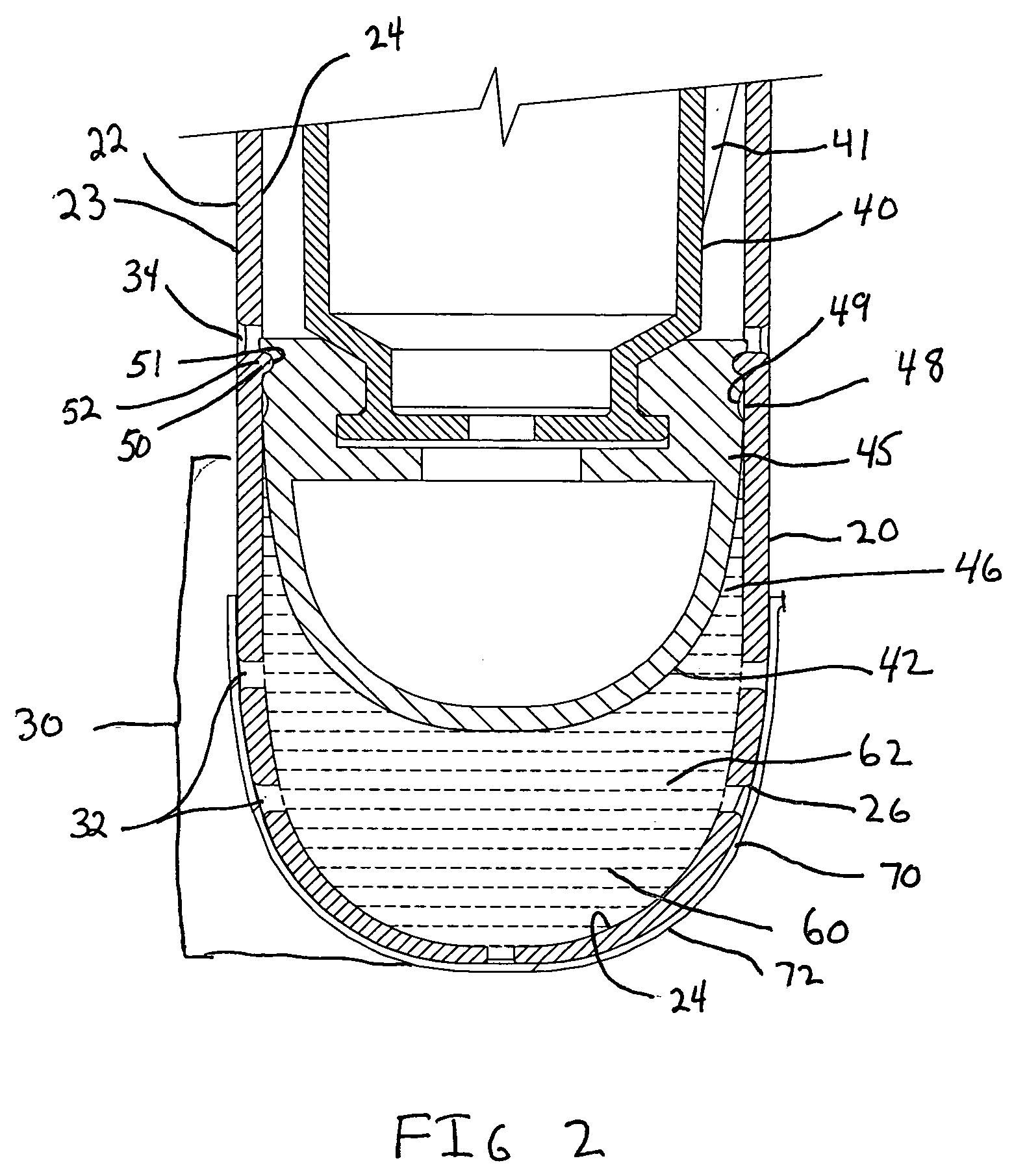

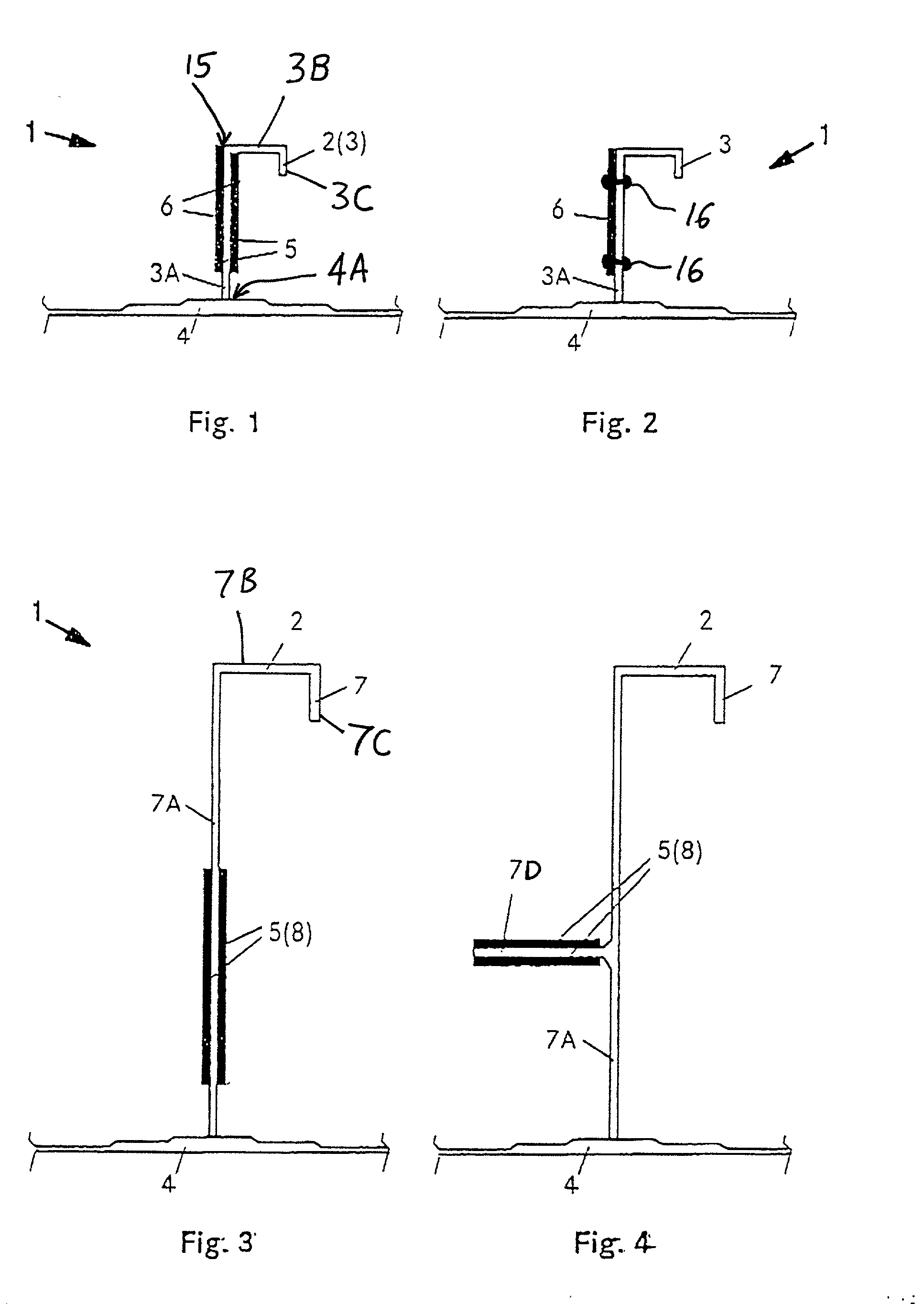

Holding jig for a foamable material

ActiveUS20070138683A1Small diameterEffective holdingPig casting plantsConfectioneryEngineeringFOAM CONTROL

The invention provides a holding jig for supporting and fixing a solid material capable of being foamed by application of heat in a cavity of a hollow structure. The holding jig may be provided with a plate-like base body made smaller in diameter than the cavity of the hollow structure, a holding part that is provided in a predetermined width in the form of a ring on the periphery of one side of said base body and supports one side of the foamable material, a step part with predetermined height, which is projected in the form of a ring at the inner peripheral end of said holding part and supports the inner peripheral surface of the foamable material, and an attaching means with which the base body can be freely attached to or detached from the hollow structure. The holding part can be provided with a plurality of small holes that open from one side to the other side of the base body, preferably in a net or lattice pattern. The holding jig may have one or more extensions containing approximately U-shaped foaming control walls that assist in directing expansion of the foaming material towards corners of the hollow structure.

Owner:CEMEDINE HENKEL

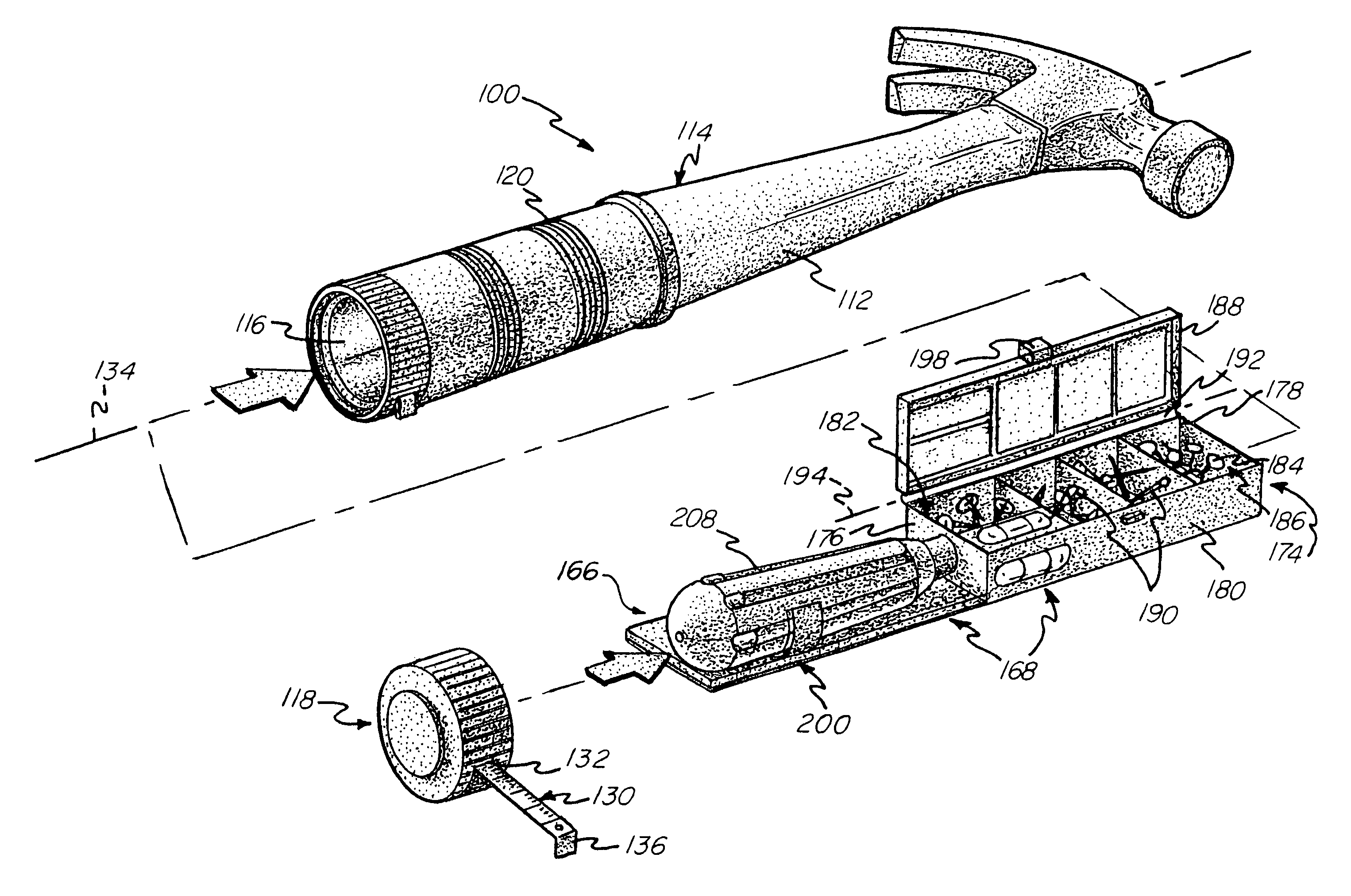

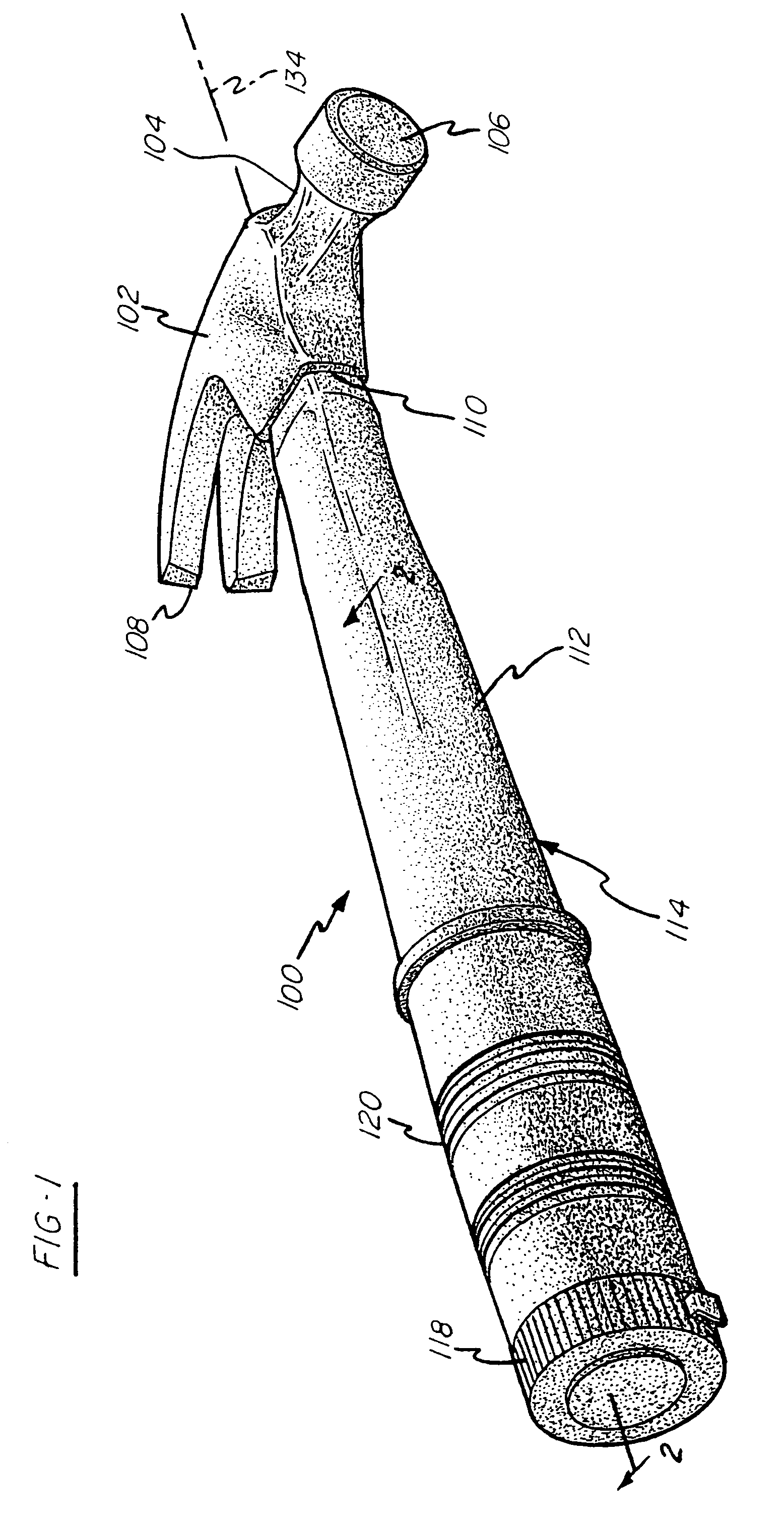

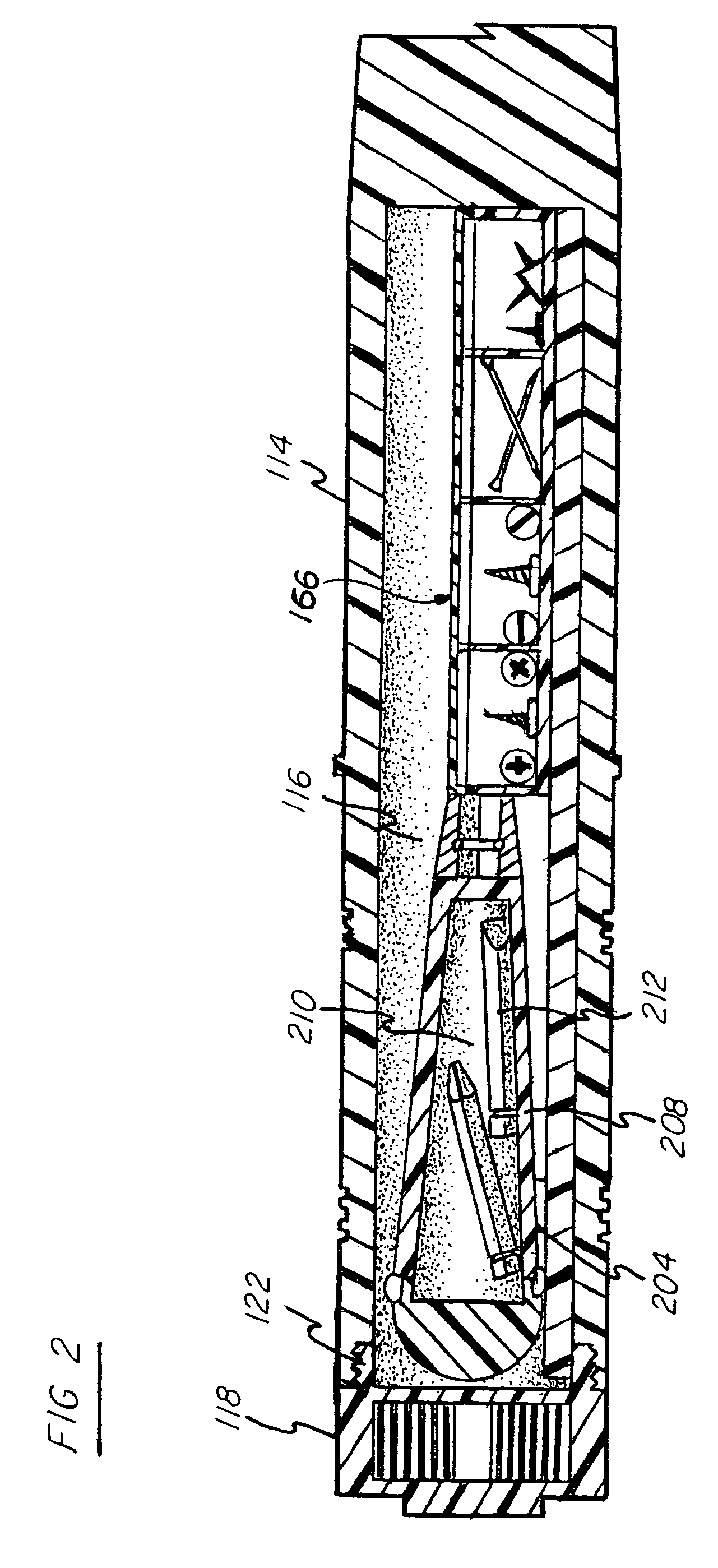

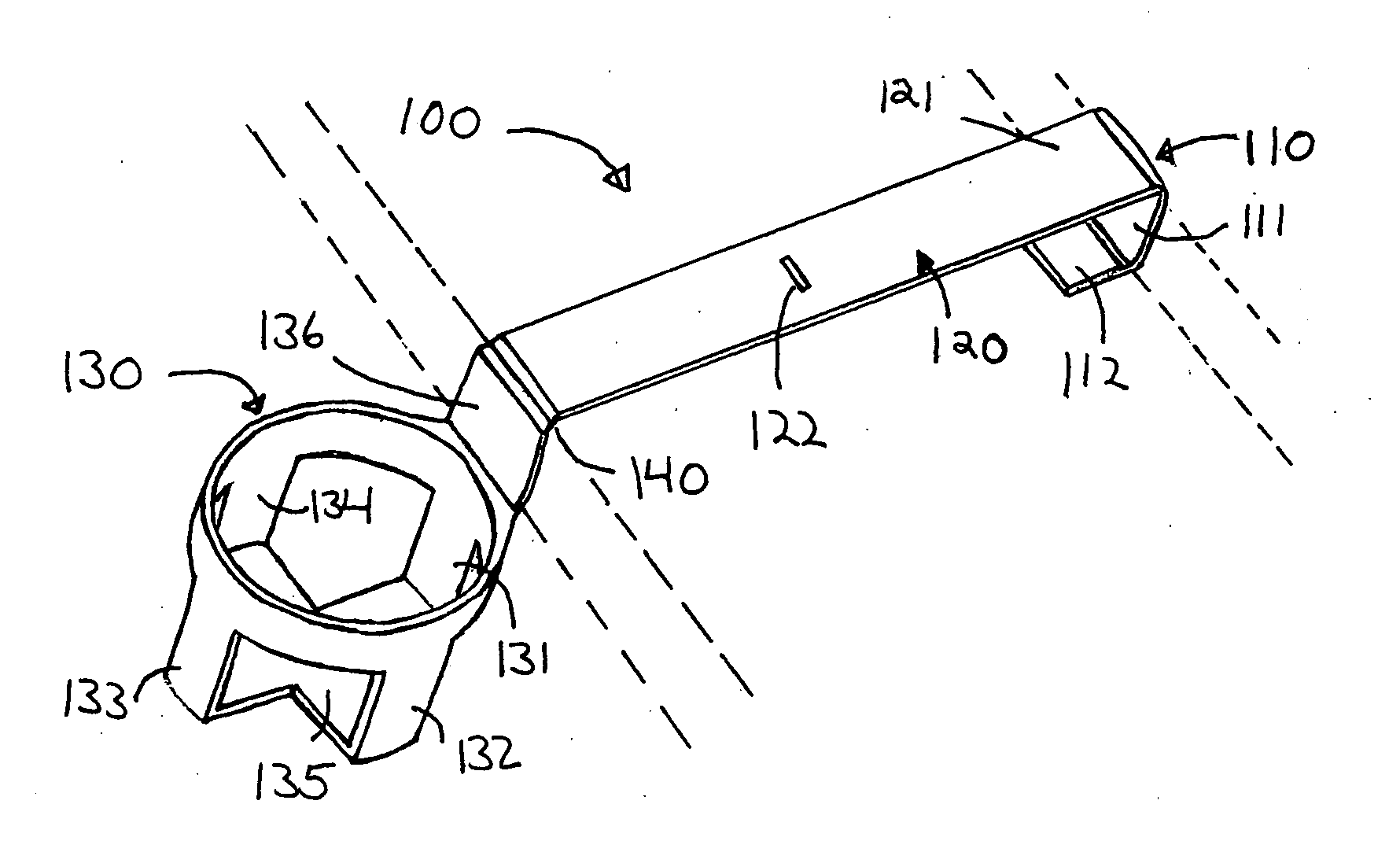

Hammer

InactiveUS7013516B1Easy to useEfficiently and conveniently holdsSpannersWrenchesEngineeringMechanical engineering

The present invention is directed to a hammer having a number of accessories including a storage cavity adapted to efficiently and conveniently hold tools, supplies, and the like and / or an additional number of accessories. The hammer comprises a hammer head having a front portion adapted for striking a nail or a tack, and a handle having a longitudinal extending cavity therein. A tray tailored to fit and slide within the longitudinal extending cavity is provided and is adapted to support a plurality of accessories.

Owner:READY TOOLS

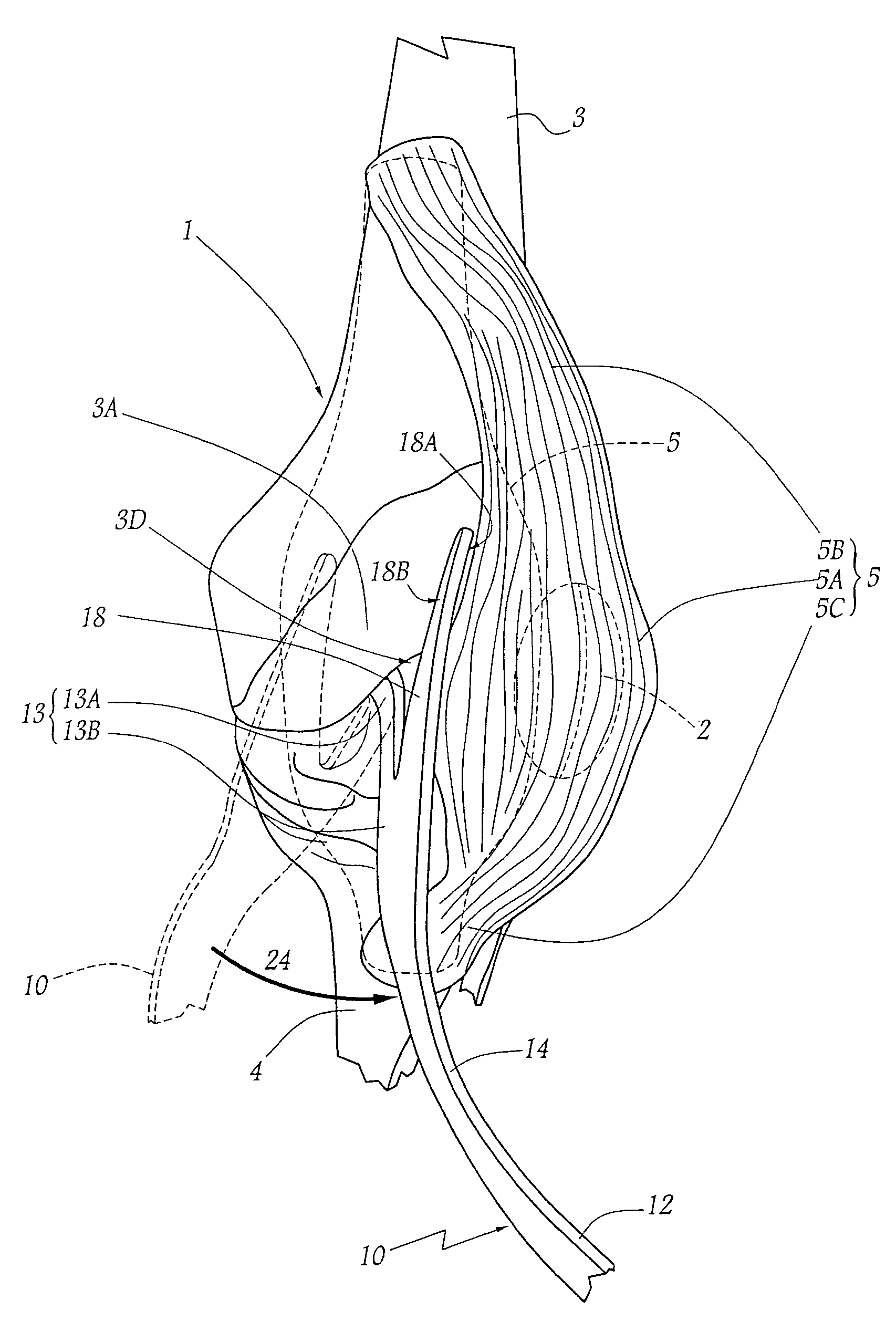

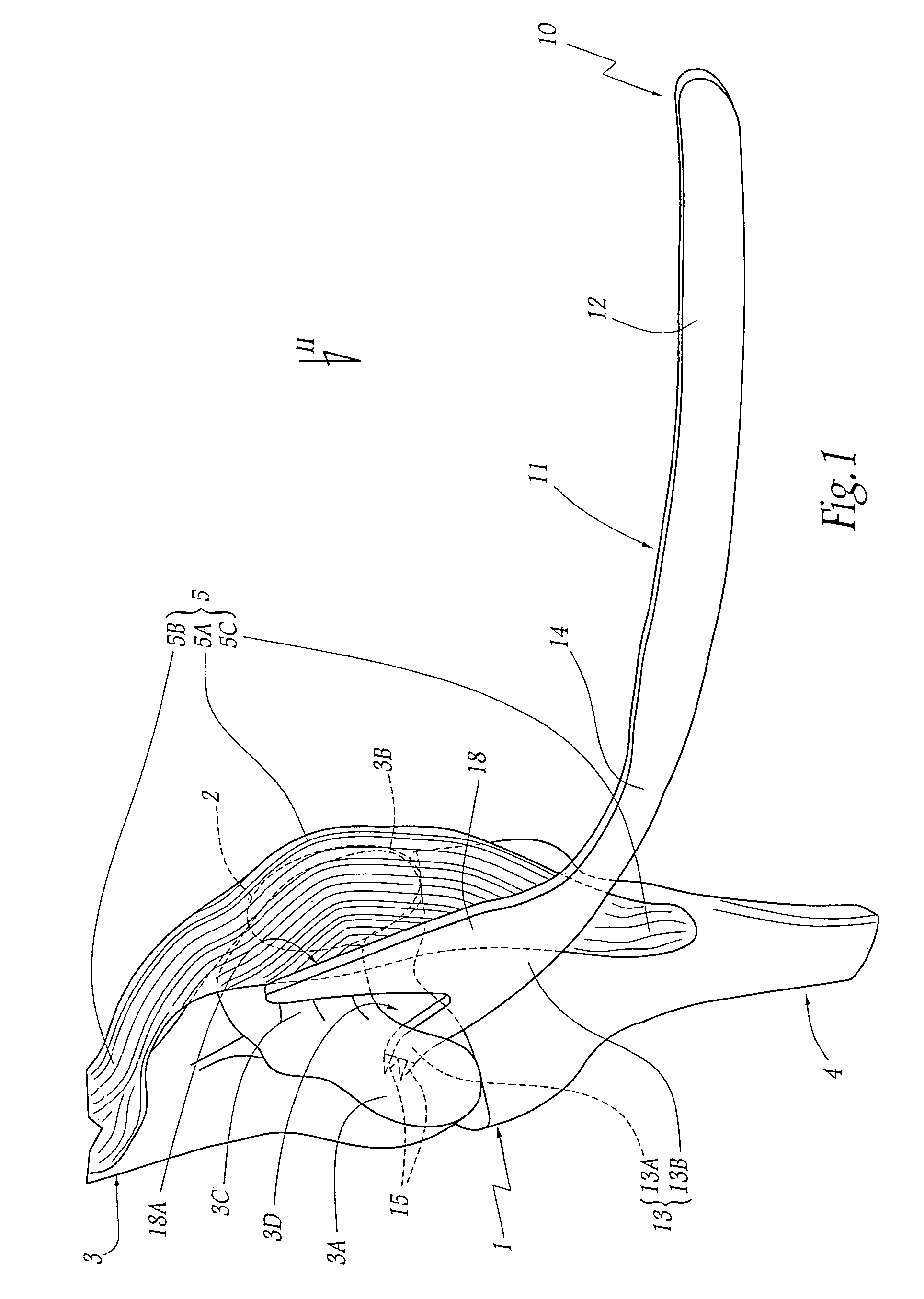

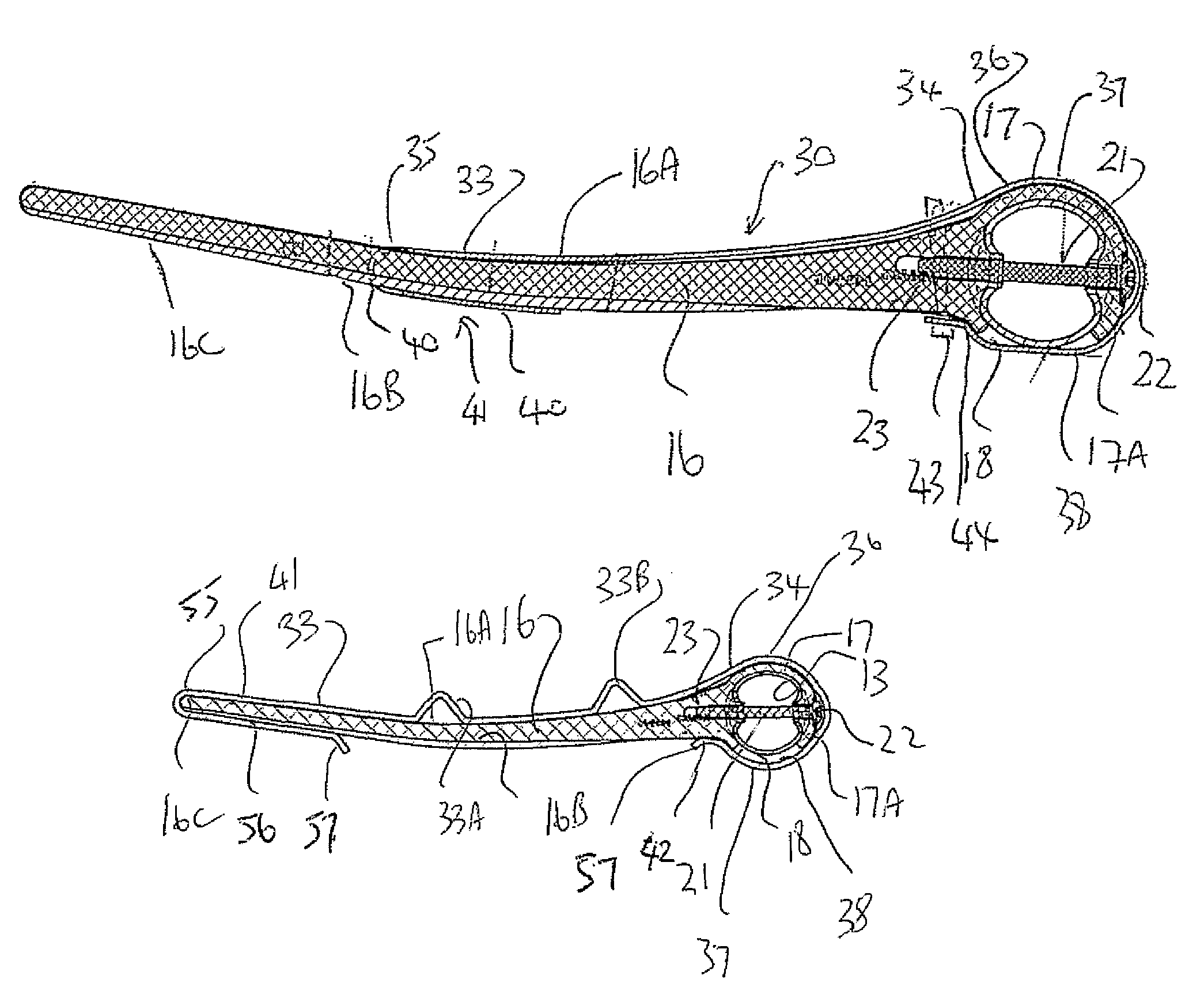

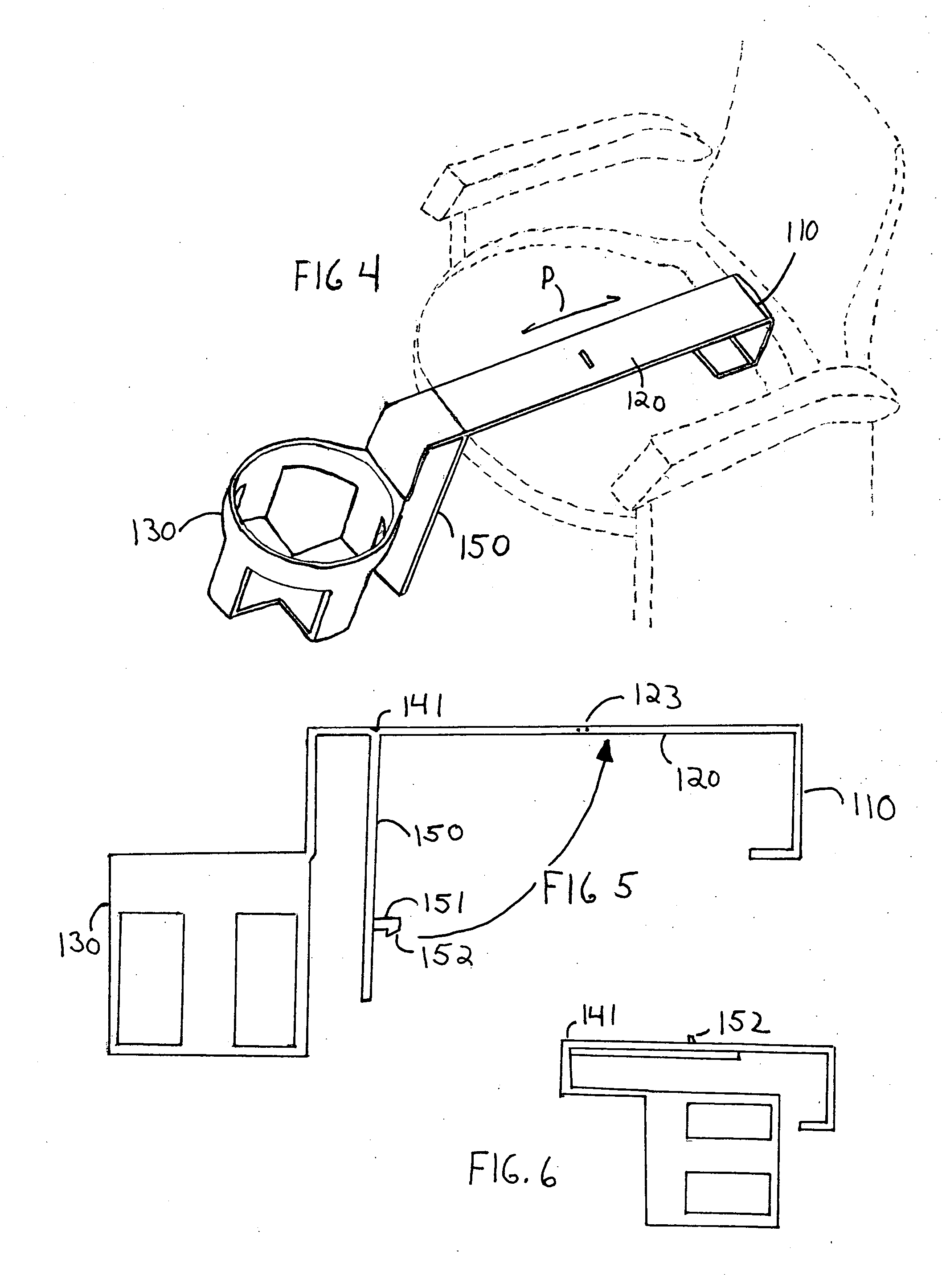

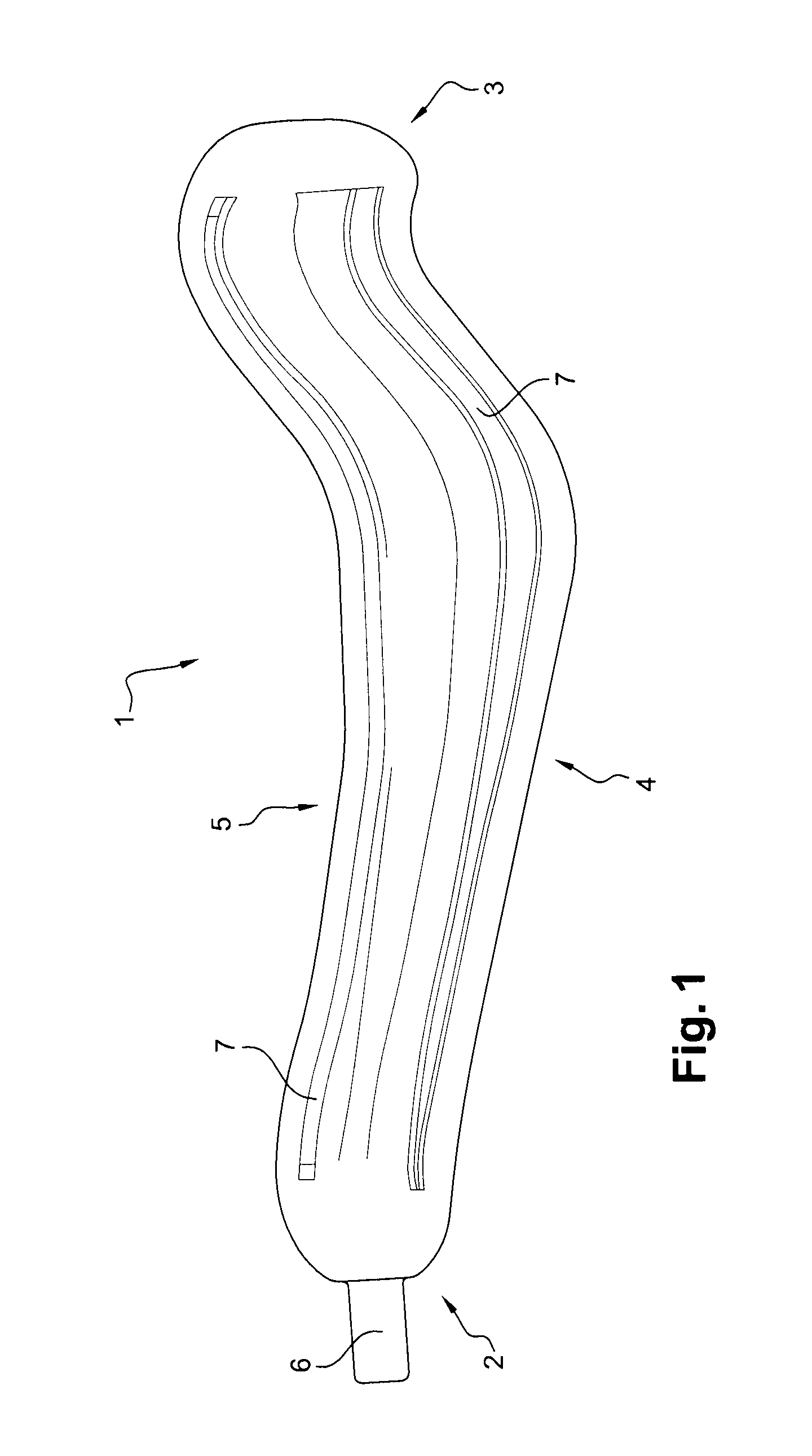

Patellar retractor and method of surgical procedure on knee

InactiveUS7468077B2Easy to processSimple to useSurgeryJoint implantsQuadriceps muscleFEMORAL CONDYLE

The distal end part of the retractor according to the invention is provided both with terminal tips for abutment on one of the femoral condylar walls which define therebetween the intercondylar space, and with a wing extending laterally in projection from this end part in order to form a frontal surface for thrust, in a medial-lateral direction, of that part of the quadriceps muscle tendon containing the patella when the tips are in abutment in the intercondylar space. By using this retractor as a lever, the wing efficiently reclines the patella, without turning it completely on itself, entirely exposing one of the femoral condyles. This invention is more particularly applicable to a surgical procedure for implanting a unicompartmental knee prosthesis.

Owner:CORIN

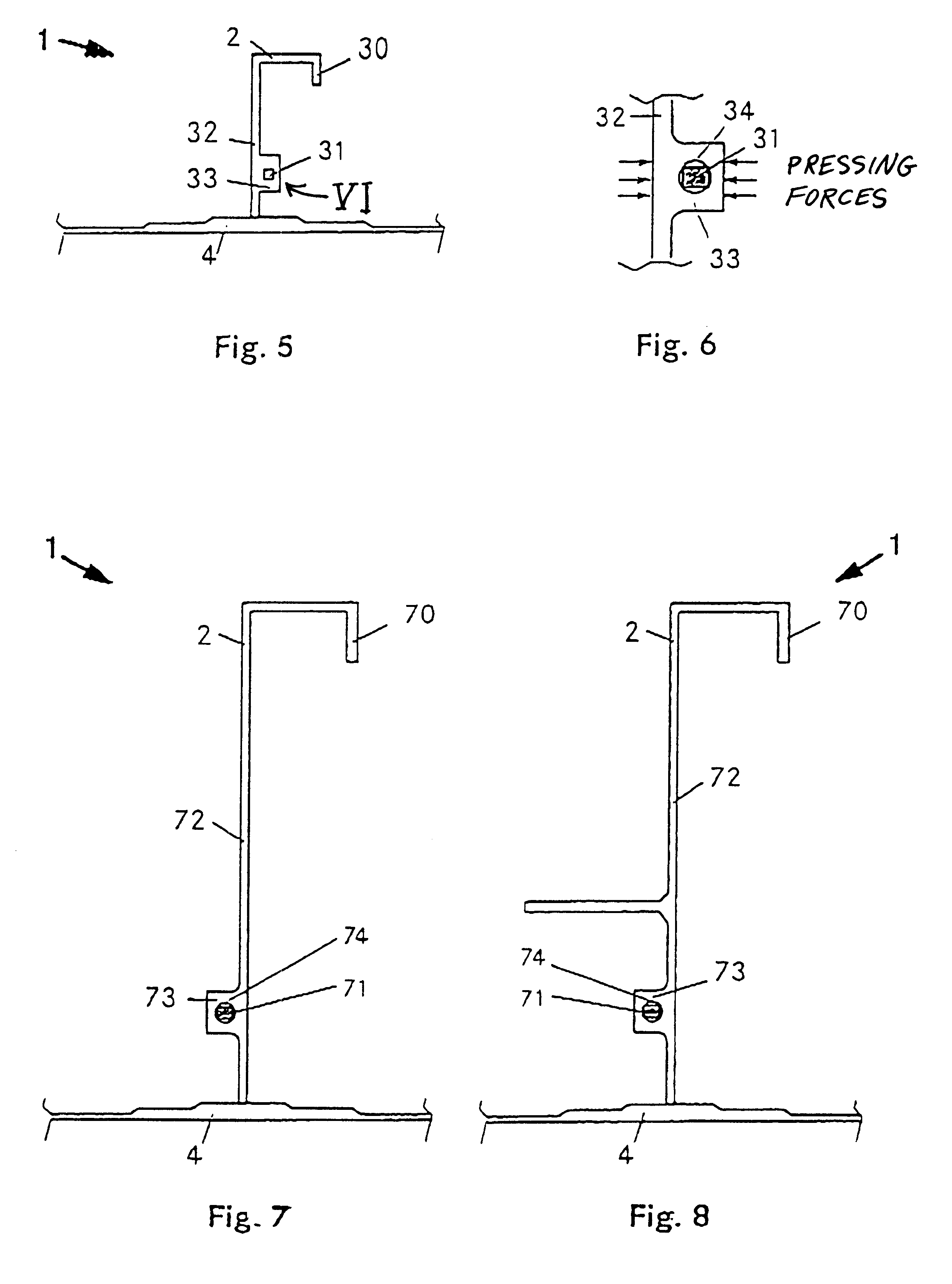

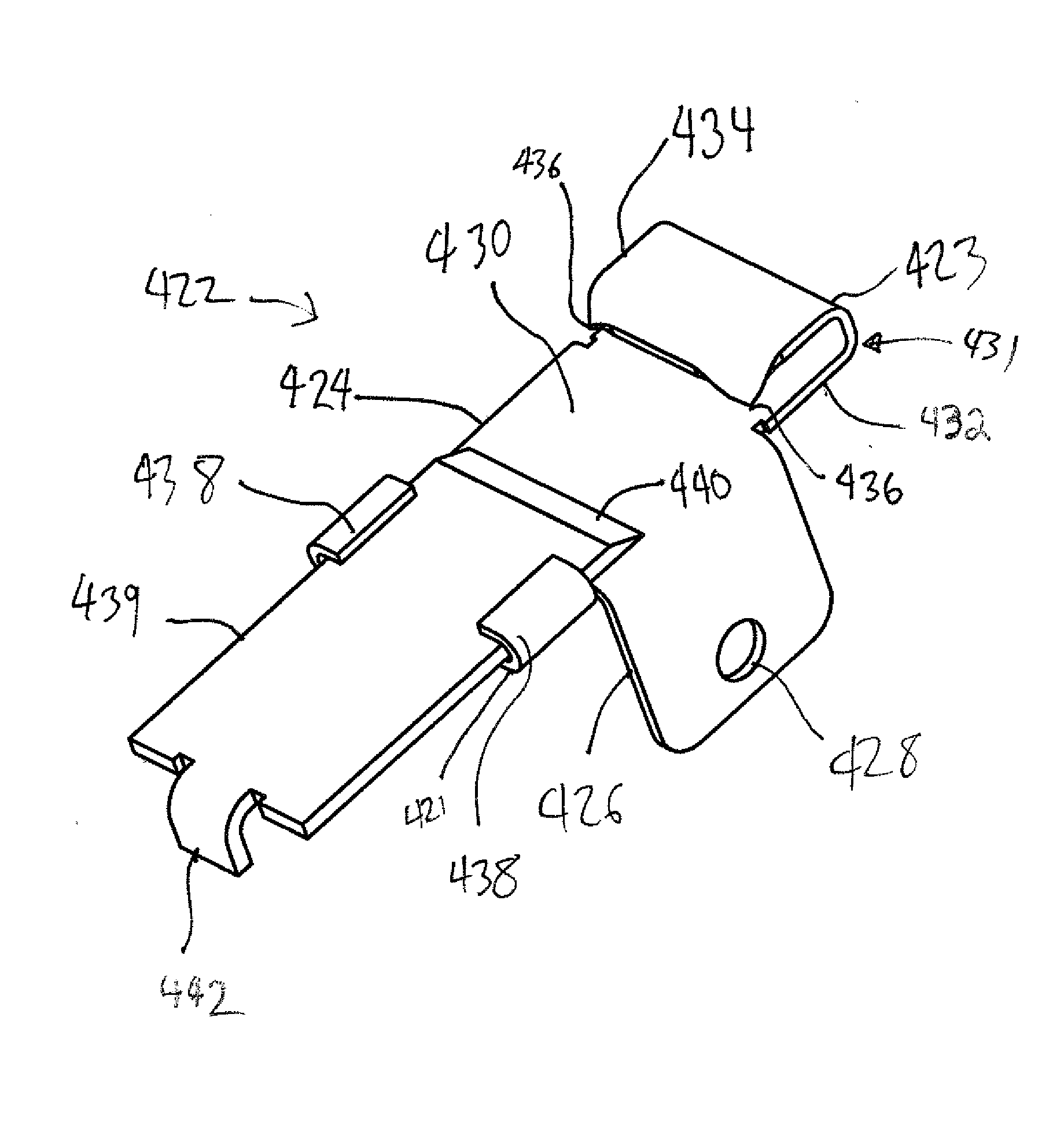

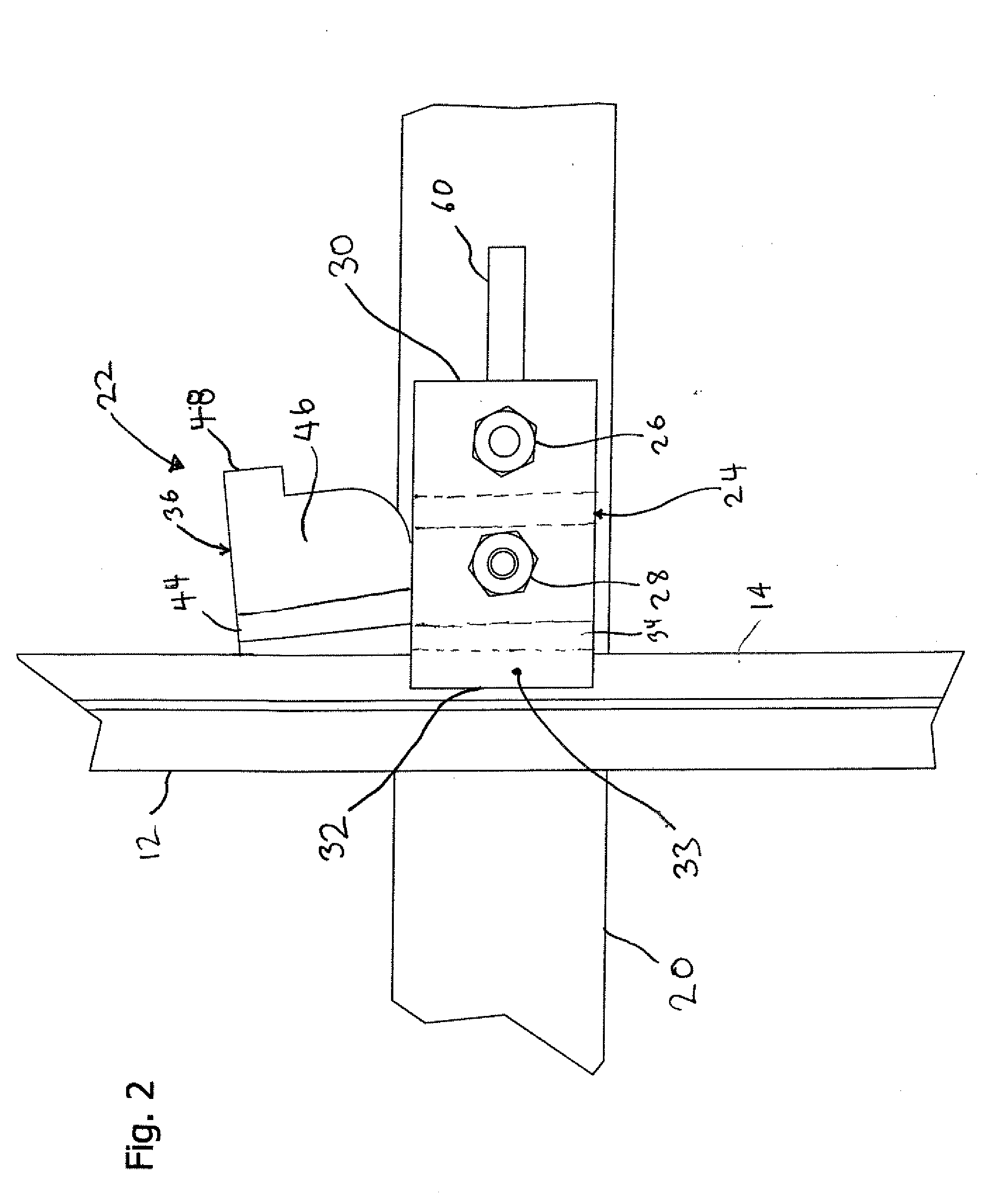

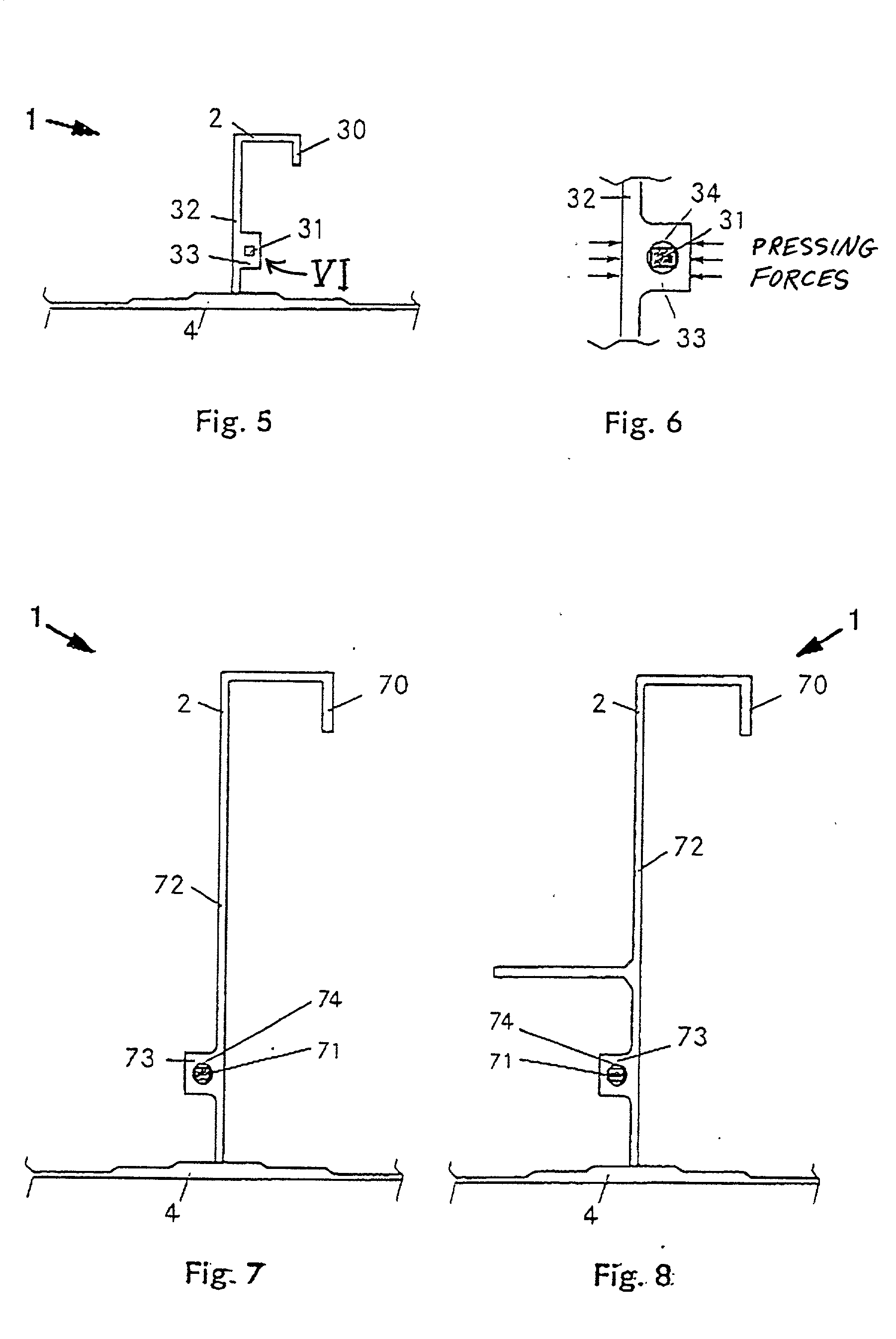

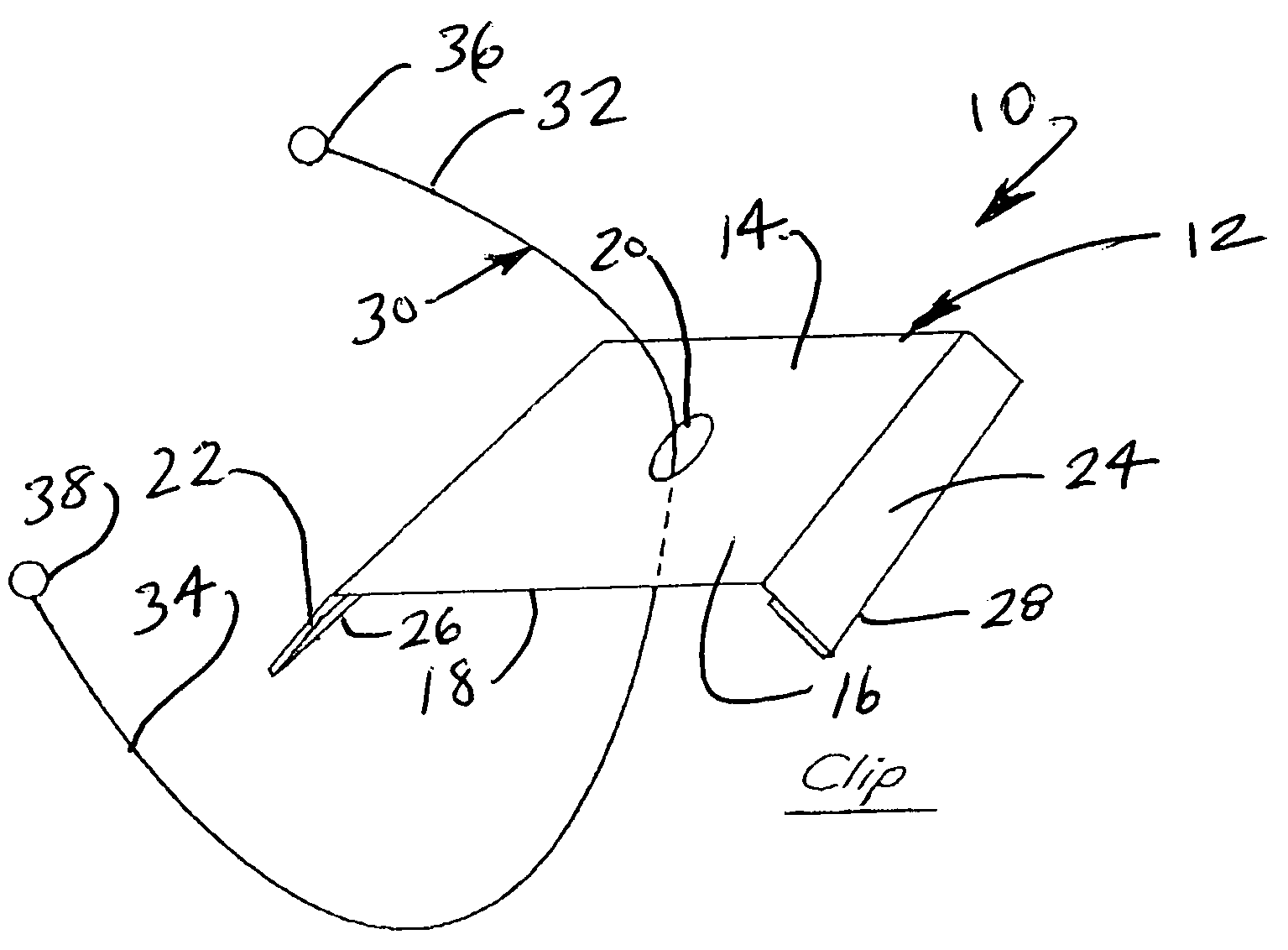

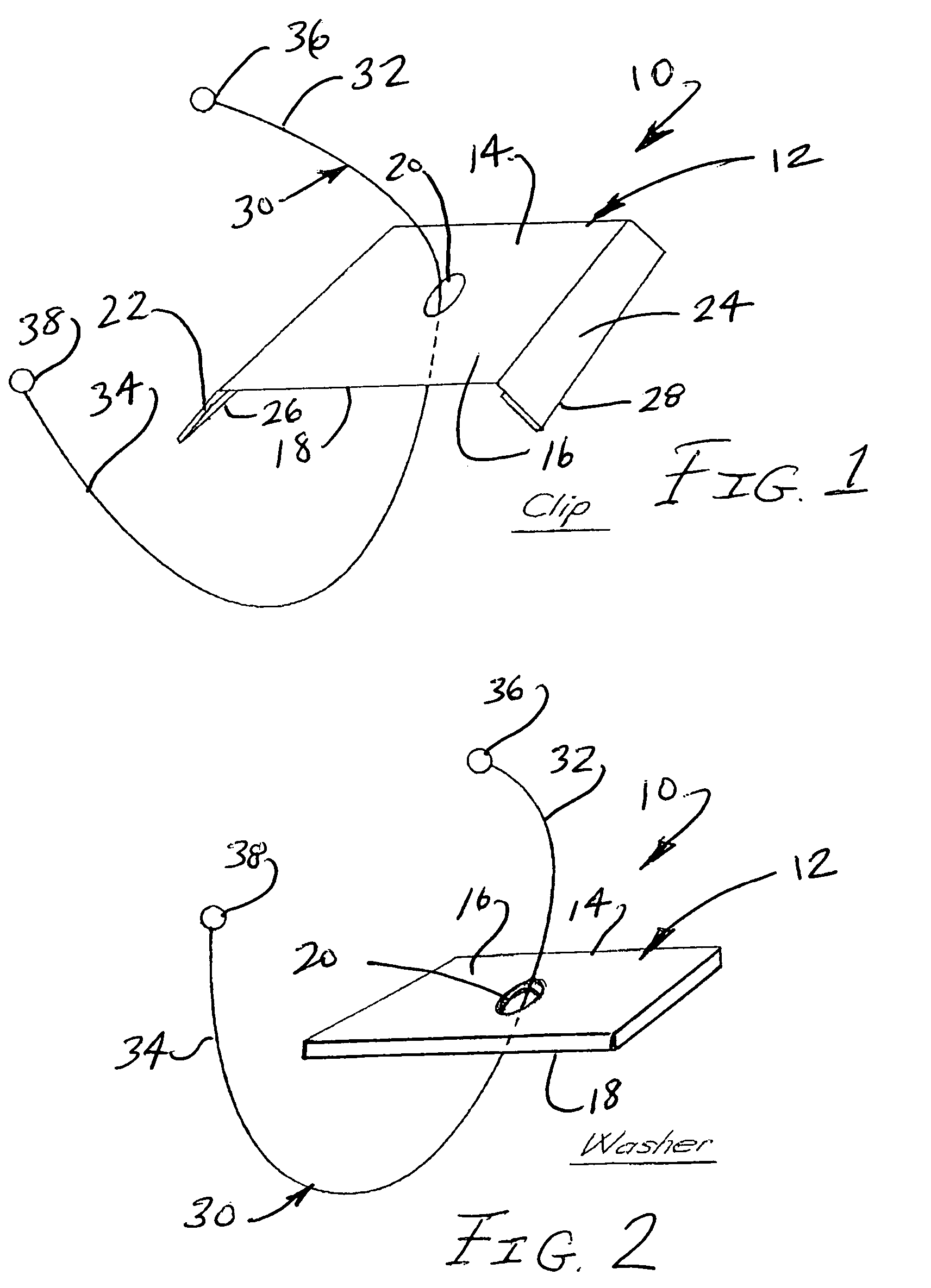

Sandwich wedge clamp for fastening a solar panel

InactiveUS20120201601A1Careful quality controlEffective lengthSolar heating energySolar heat devicesEngineeringFlange

The present invention includes a solar panel mount. The solar panel mount comprises a mounting surface such as a base or a rail. The rail has a generally elongated clamp plate attached to the rail proximal to a first end and having a clamp pad proximal to a second end. There is a wedge plate pivotally connected to the rail proximal to a first end of the wedge plate. The wedge plate is attached between the rail and the generally elongated clamp plate. The wedge plate is pivotal from a disengaged position to a clamping position. The clamping position is the position of the wedge where the wedge head is between the clamp plate and the rail. In another embodiment, the mount is configured to support a solar panel having a flange that is clamped between the clamp pad and the rail.

Owner:DYNORAXX

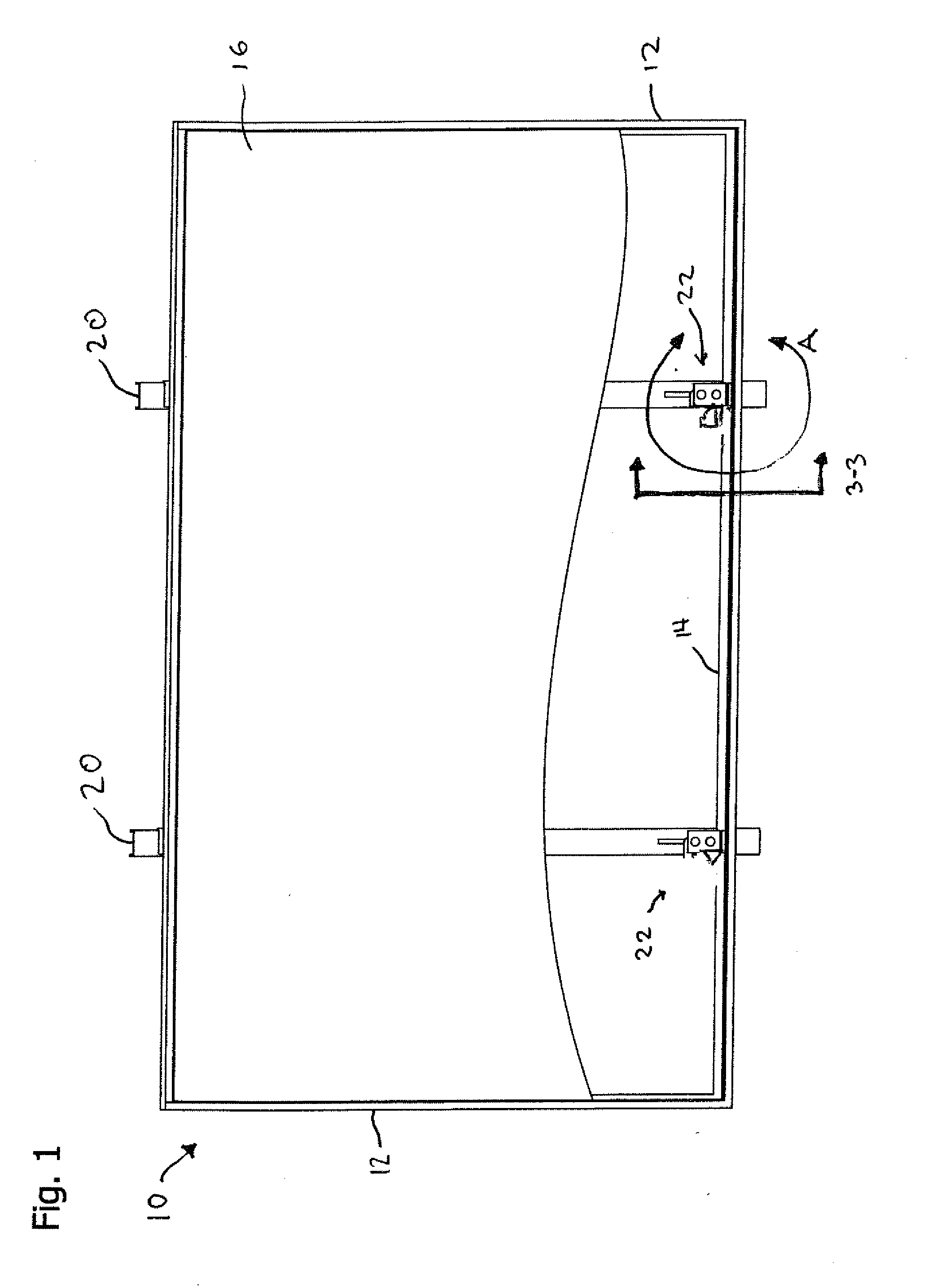

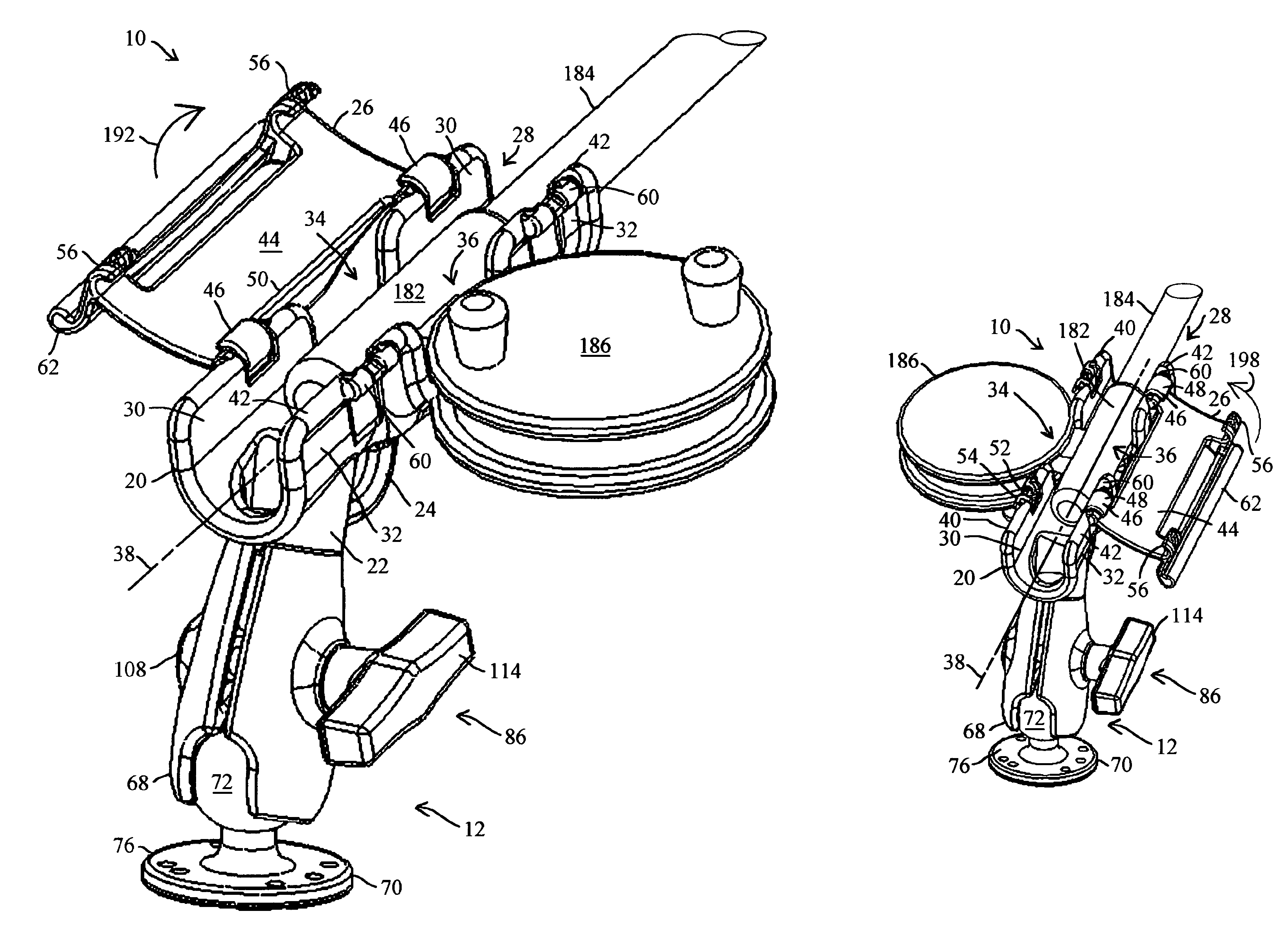

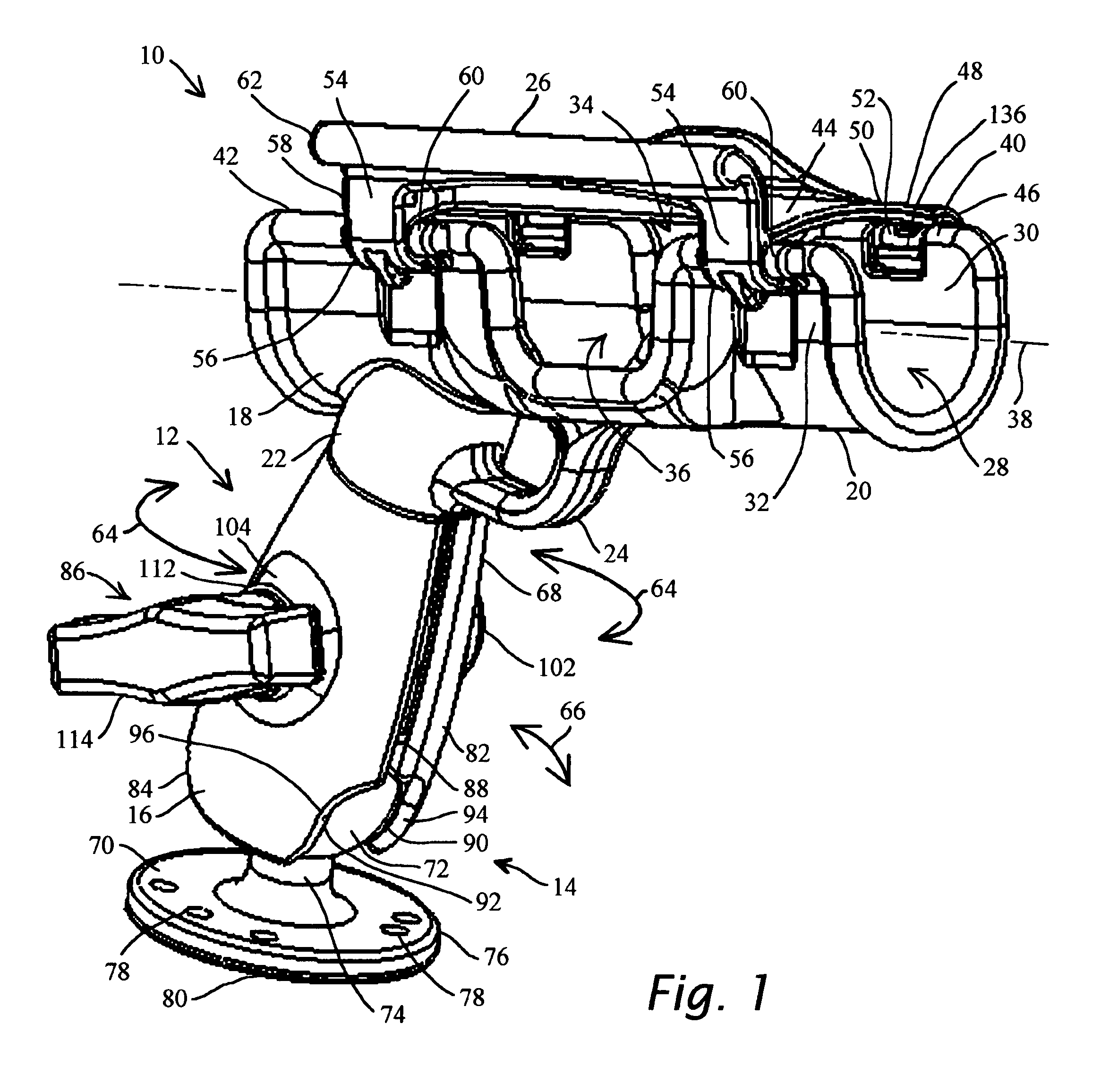

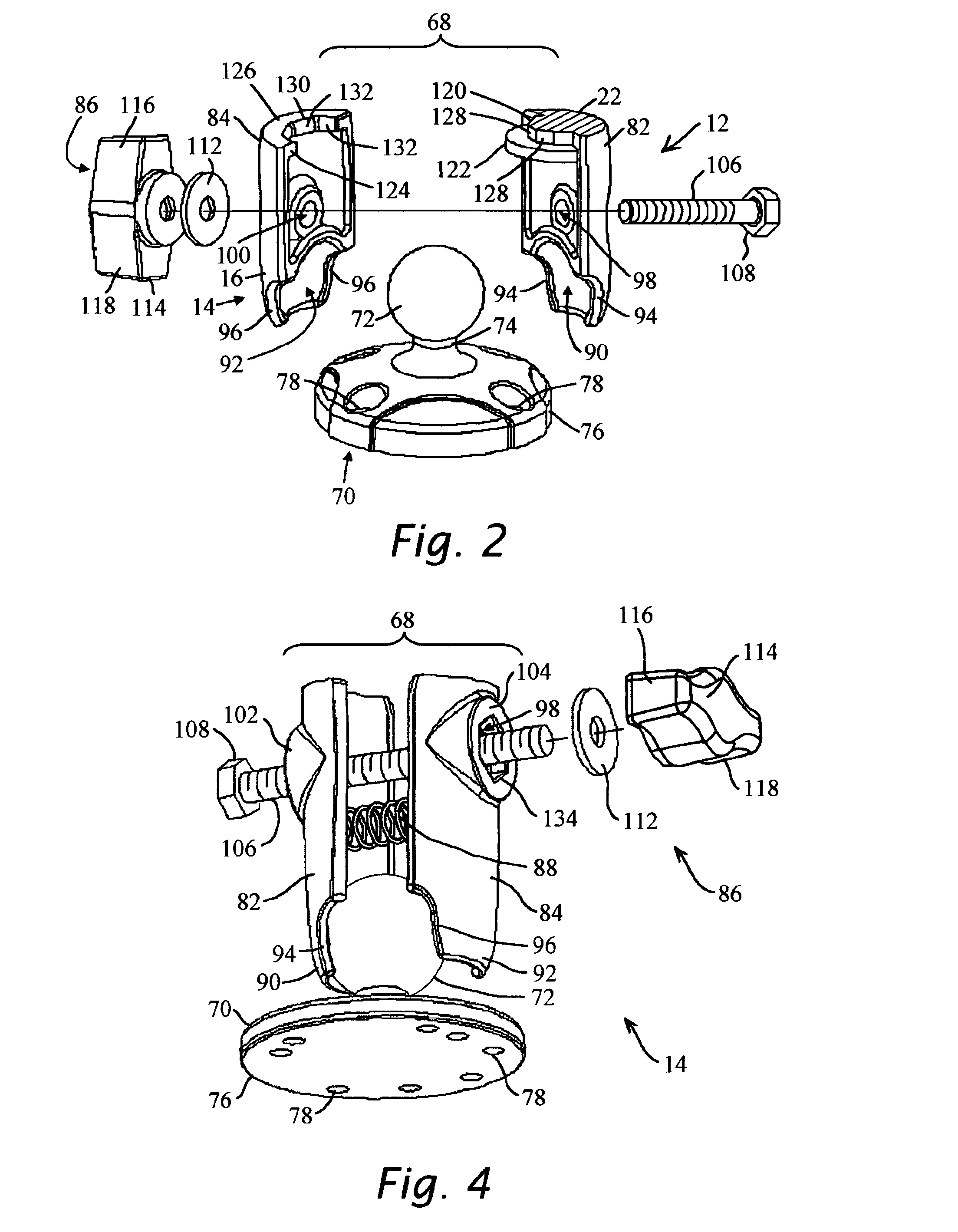

Fishing rod holder

ActiveUS7849630B2Rapid and efficient mannerEffective holdingOther angling devicesLocking mechanismEngineering

A fishing rod holding device having a long U-shaped barrel with a longitudinal opening between a pair of opposing longitudinal walls, and a notch formed through an outer edge of each of the opposing longitudinal walls. A is bail structured to fit over the longitudinal opening between the pair of opposing longitudinal walls of the U-shaped barrel at least covering the wall notches and portions of the barrel on either side of the wall notches. A hinge mechanism is provided between the bail and the outer edge of a first one of the opposing longitudinal walls of the semi-tubular barrel for swinging the bail over the longitudinal opening thereof, and a locking mechanism is provided between the bail and the outer edge of a second one of the opposing longitudinal walls for securing the bail relative to the semi-tubular barrel.

Owner:CARNEVALI JEFFREY D

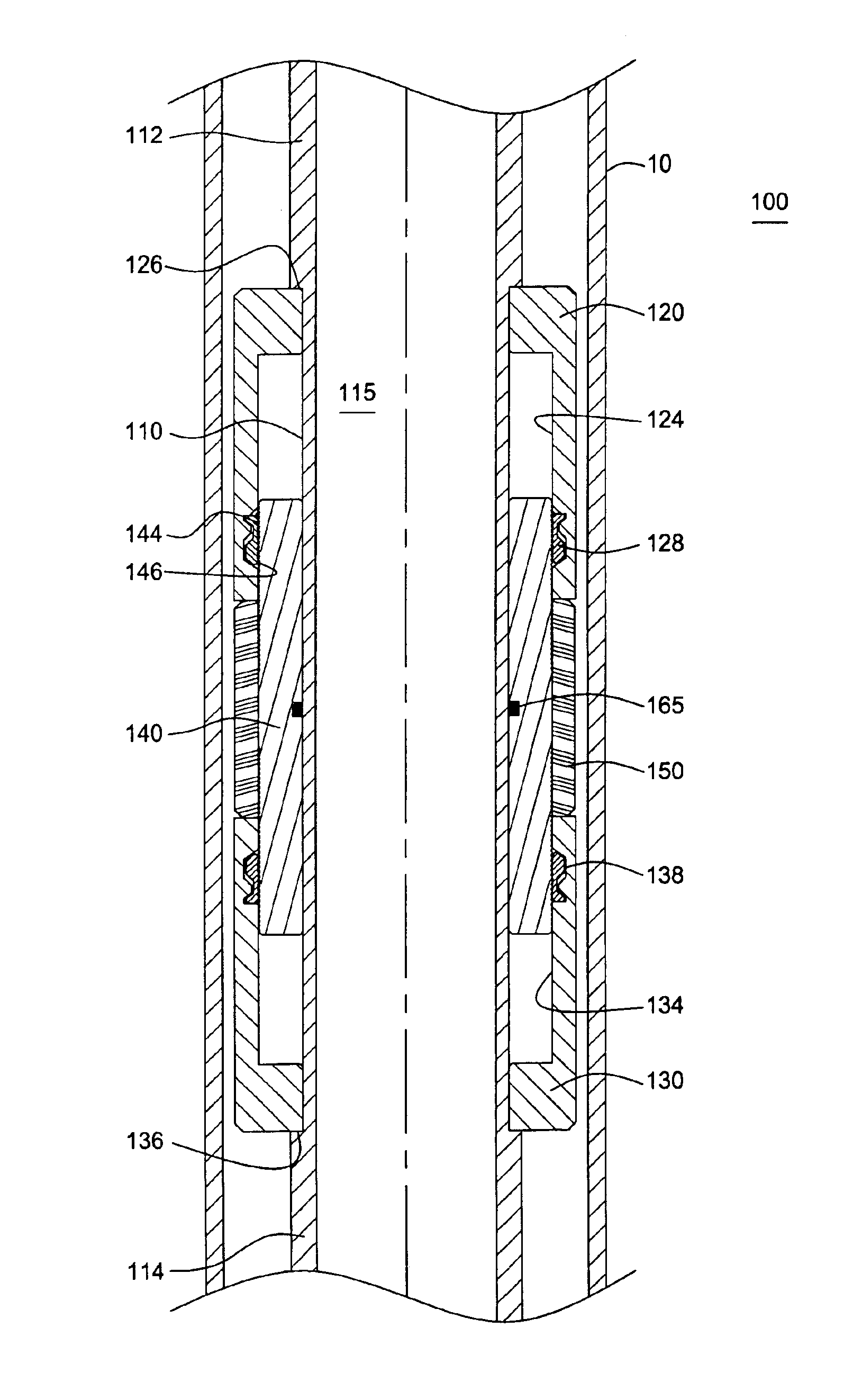

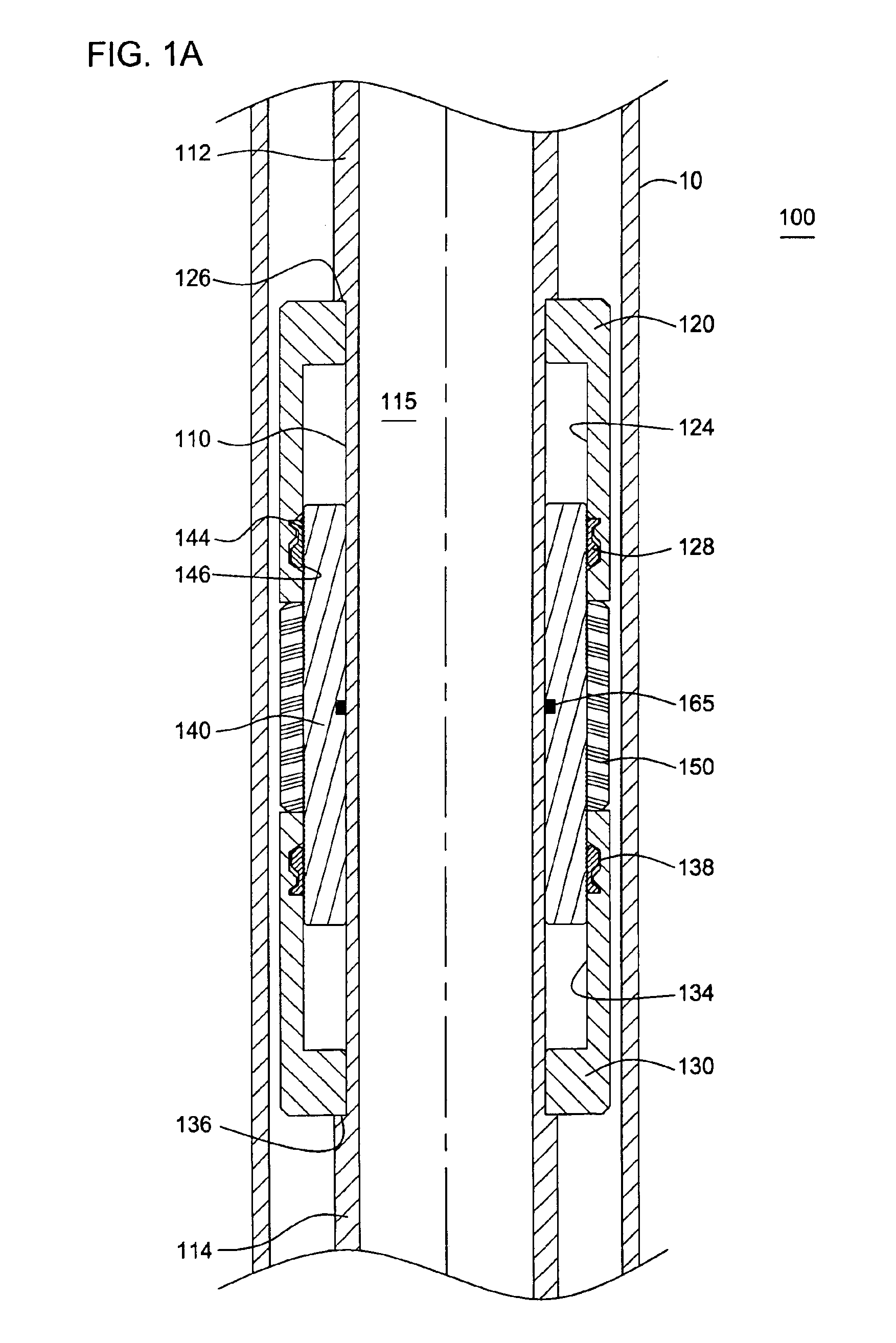

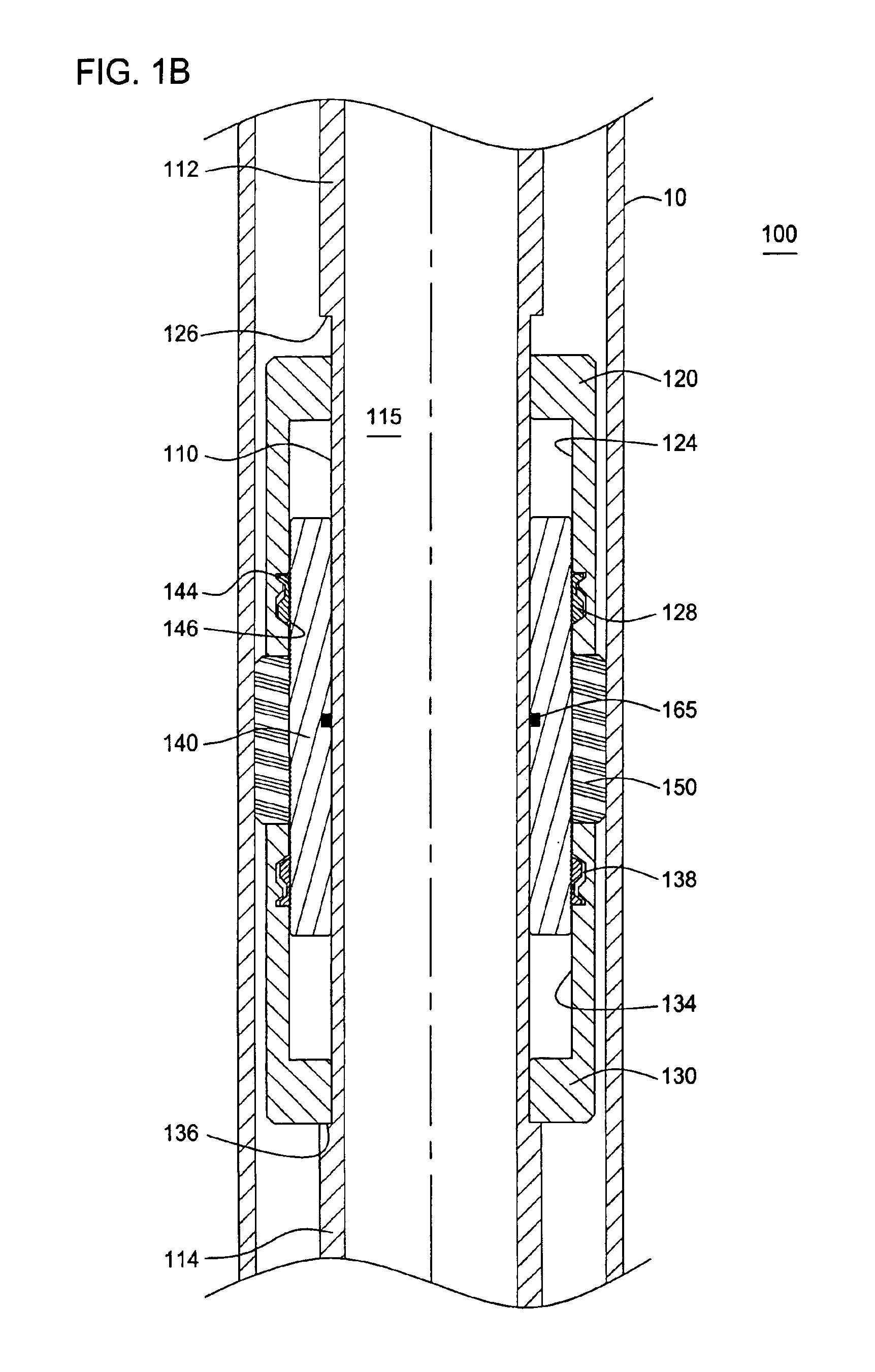

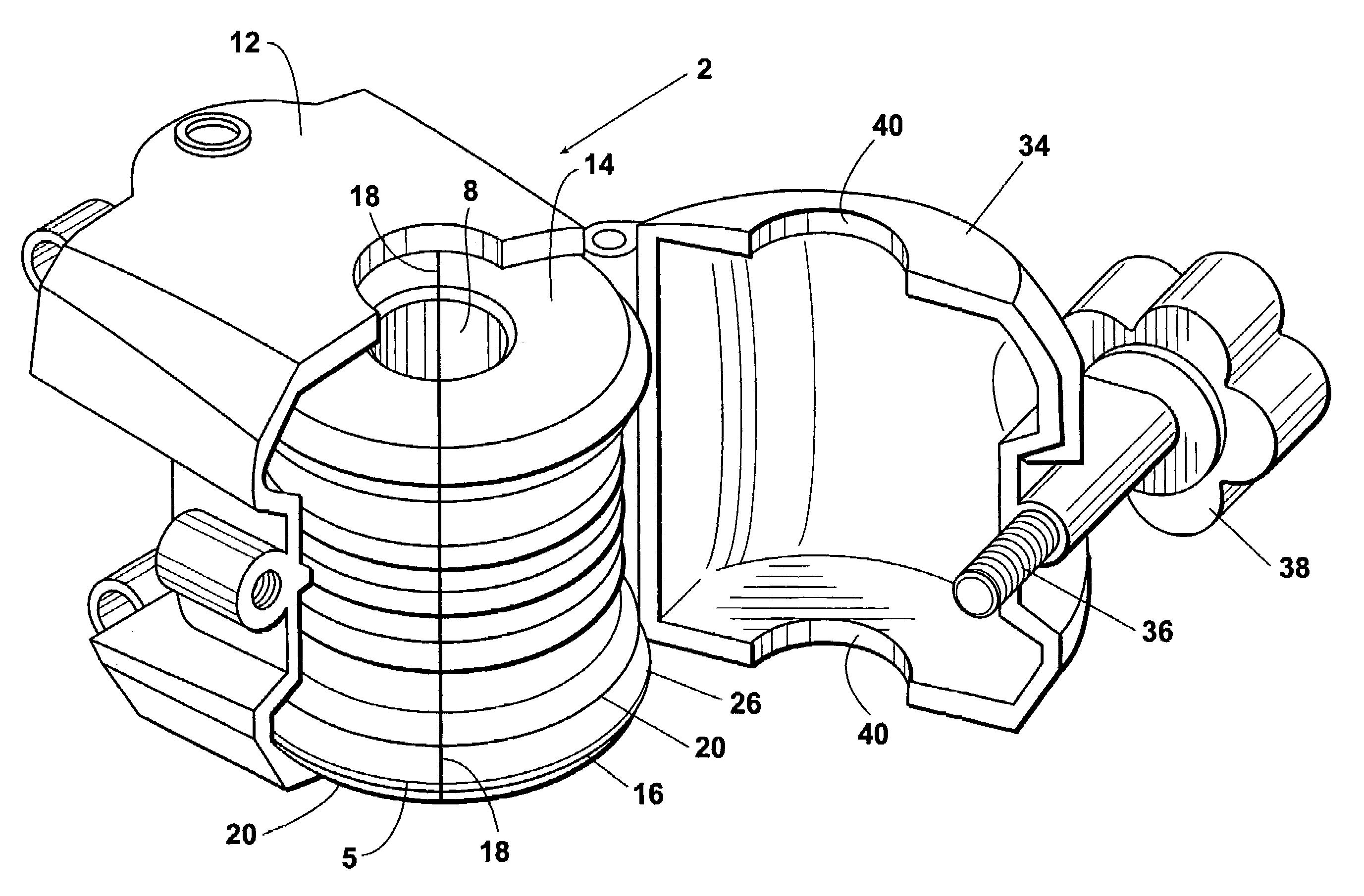

Bi-directionally boosting and internal pressure trapping packing element system

Present invention is a packer for sealing an annular region in a wellbore. The packer includes a packing element which is held through bi-directional forces. The packer first comprises an inner mandrel. Disposed around the inner mandrel are three tubulars: (1) a top sleeve; (2) a bottom sleeve; and (3) a booster sleeve. A packing element is disposed circumferentially around the outer surface of the booster sleeve. The top sleeve and bottom sleeve each include an upper compression member which rides across the booster sleeve in order to compress the packing element. The packing element is expanded outward from the packer to engage a surrounding string of casing through compressive forces provided by the top and bottom sleeves. Thereafter, differential pressure applied above or below the packer acting on the packer element and booster sleeve may provide additional compression of the packer element.

Owner:WEATHERFORD TECH HLDG LLC

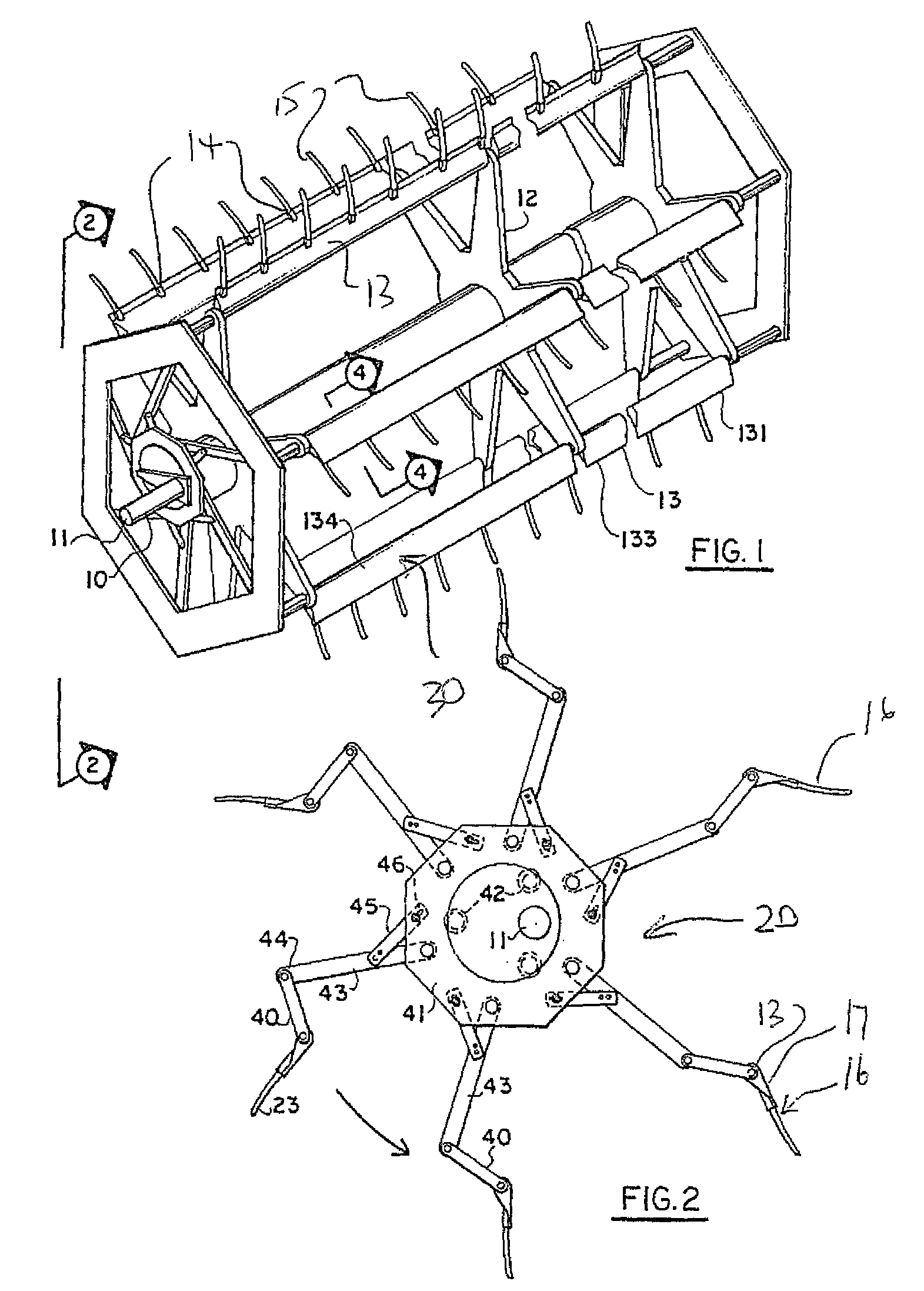

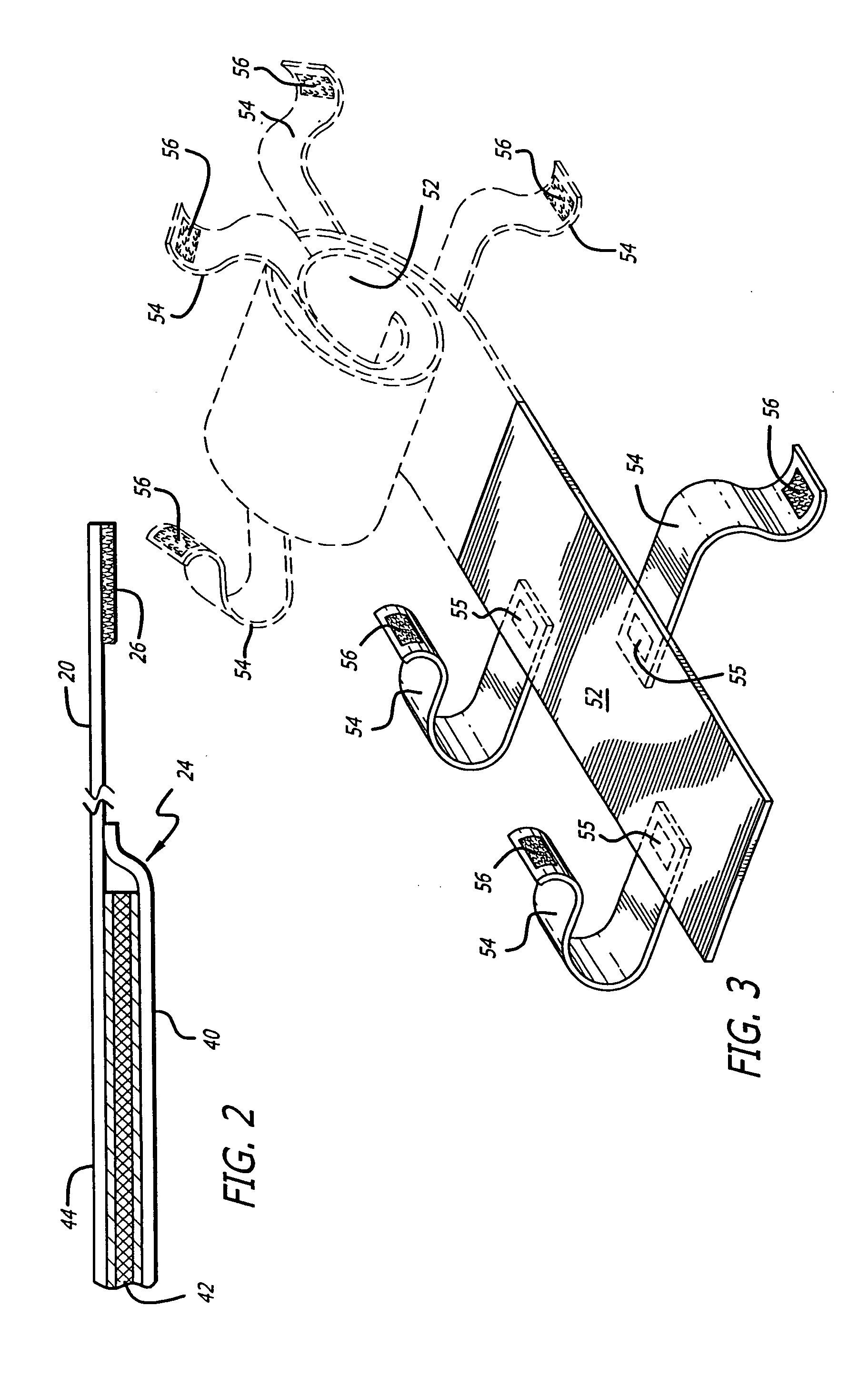

Extruded bat for the reel of a crop harvesting header

A removable bat attachment to be applied when required over the tine tubes and fingers of reel of a harvesting machine is formed by an elongate flexible plastic extruded member having a first wall lying against the leading face of the plurality of fingers, a second wall at the inner edge of the first wall wrapping around the tine tube to define a generally cylindrical channel shaped receptacle to receive the tine tube therein and a third wall at the outer edge. In one arrangement the outer edge wraps around an outer end of the fingers and is snap fit onto the outer ends of the fingers and on to the tine tube so as to be held in place thereon by the snap fit. In another arrangement the outer edge has an end wall with a series of holes one for each finger so that the fingers project outwardly from the outer edge.

Owner:MACDON INDS

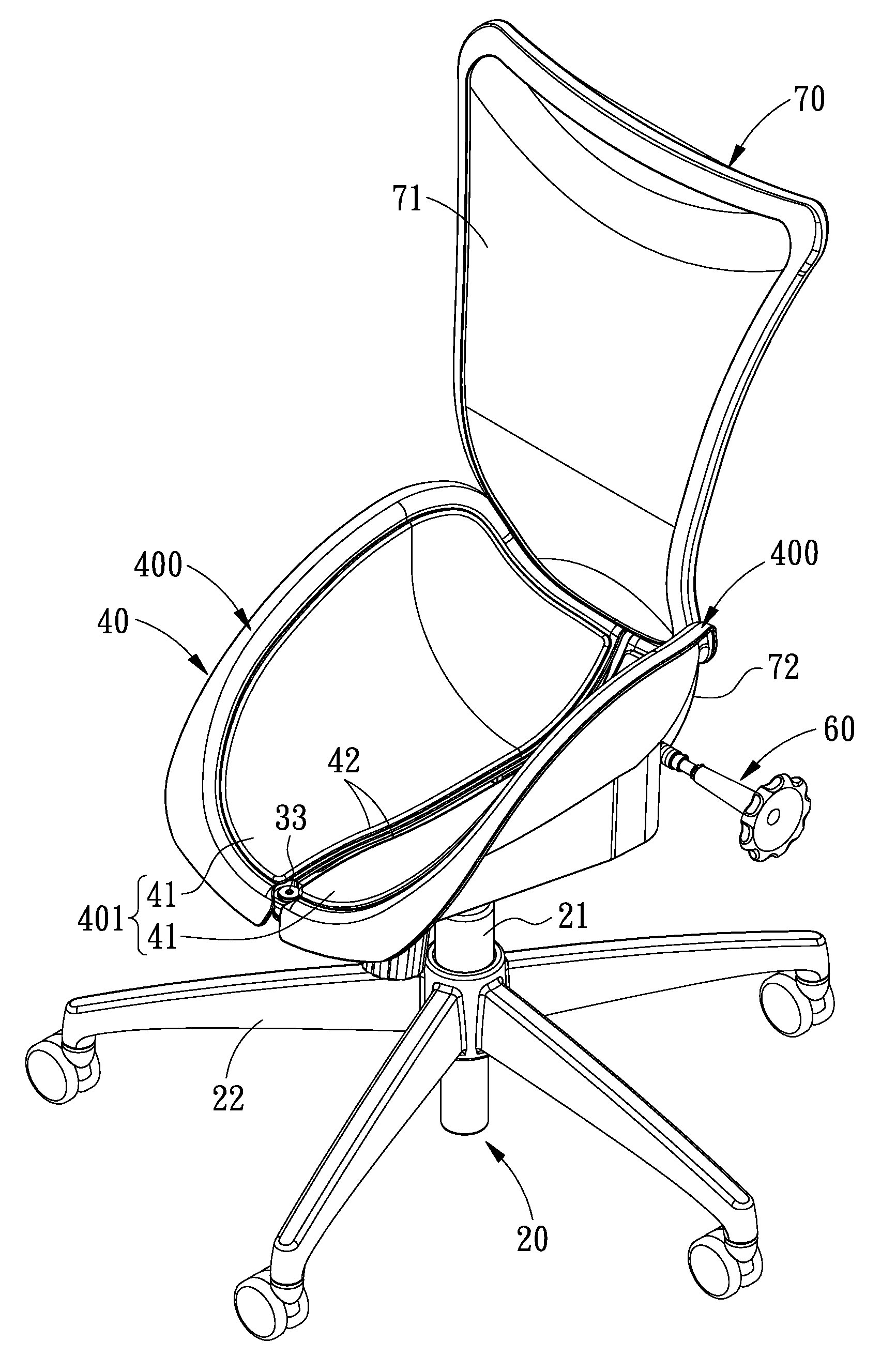

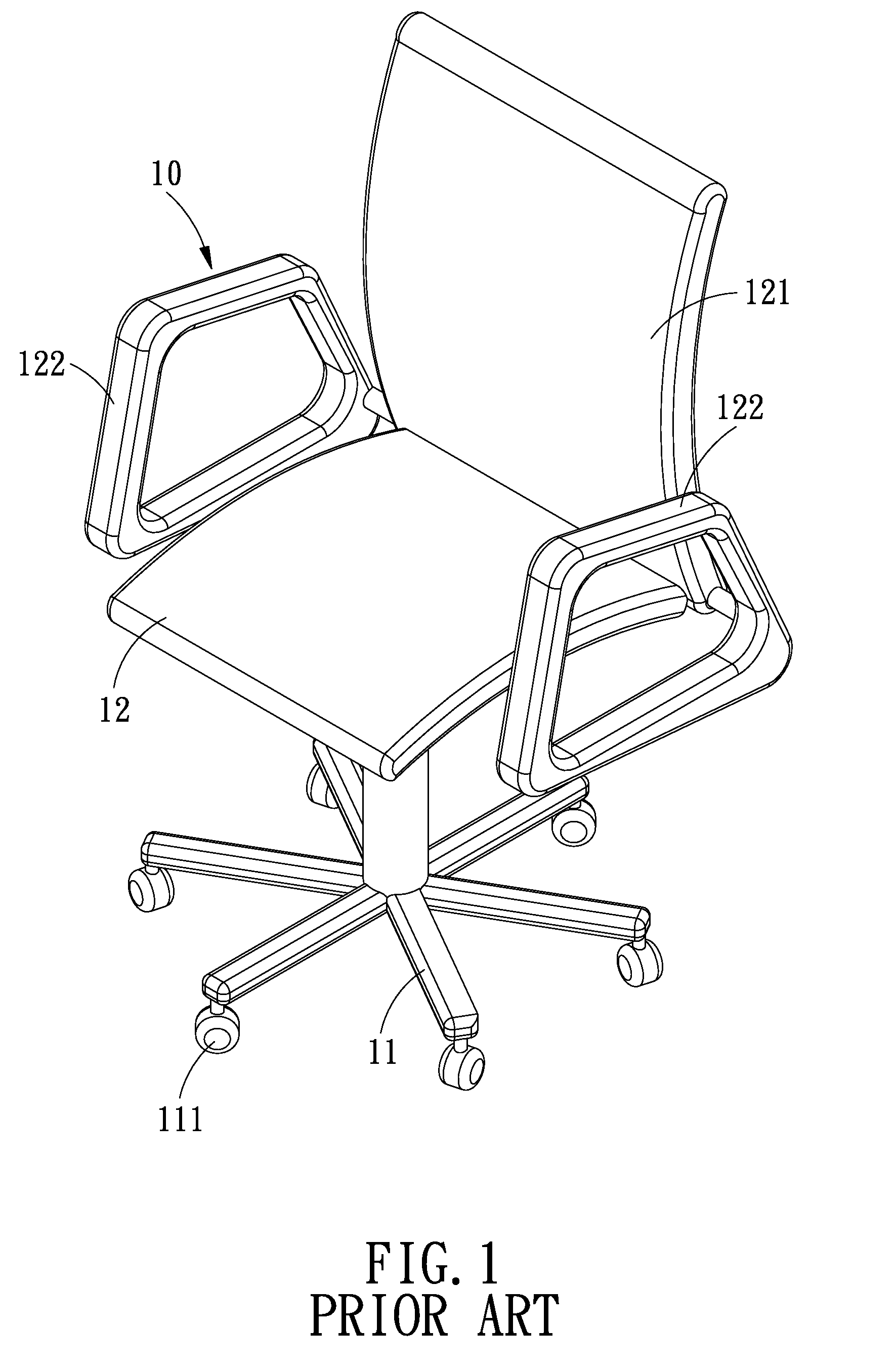

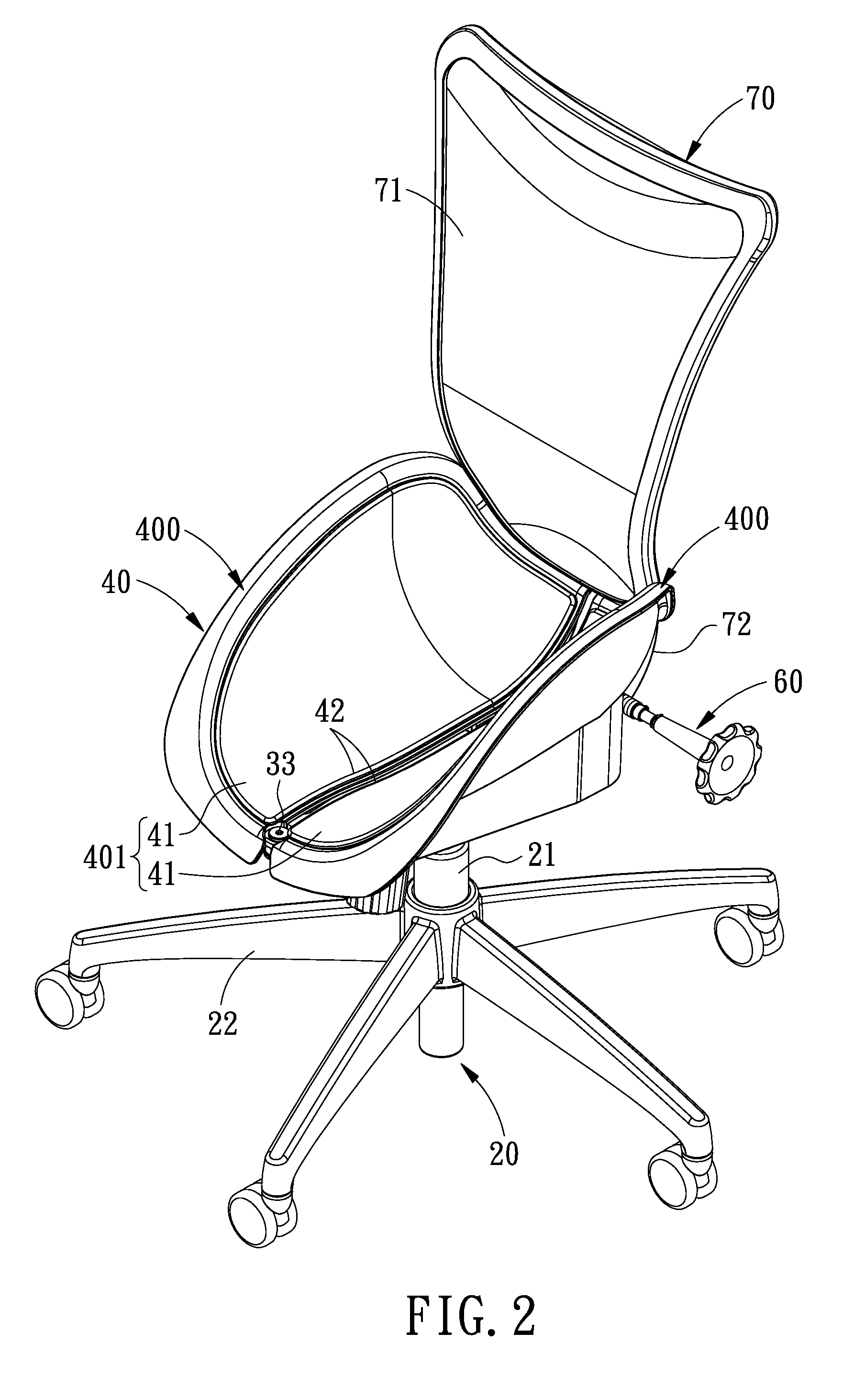

Chair with a hip-shaping seat

InactiveUS8602493B1Effective holdingAdjustable widthStoolsAdjustable chairsEngineeringMechanical engineering

Owner:CHEN YUNG KUN

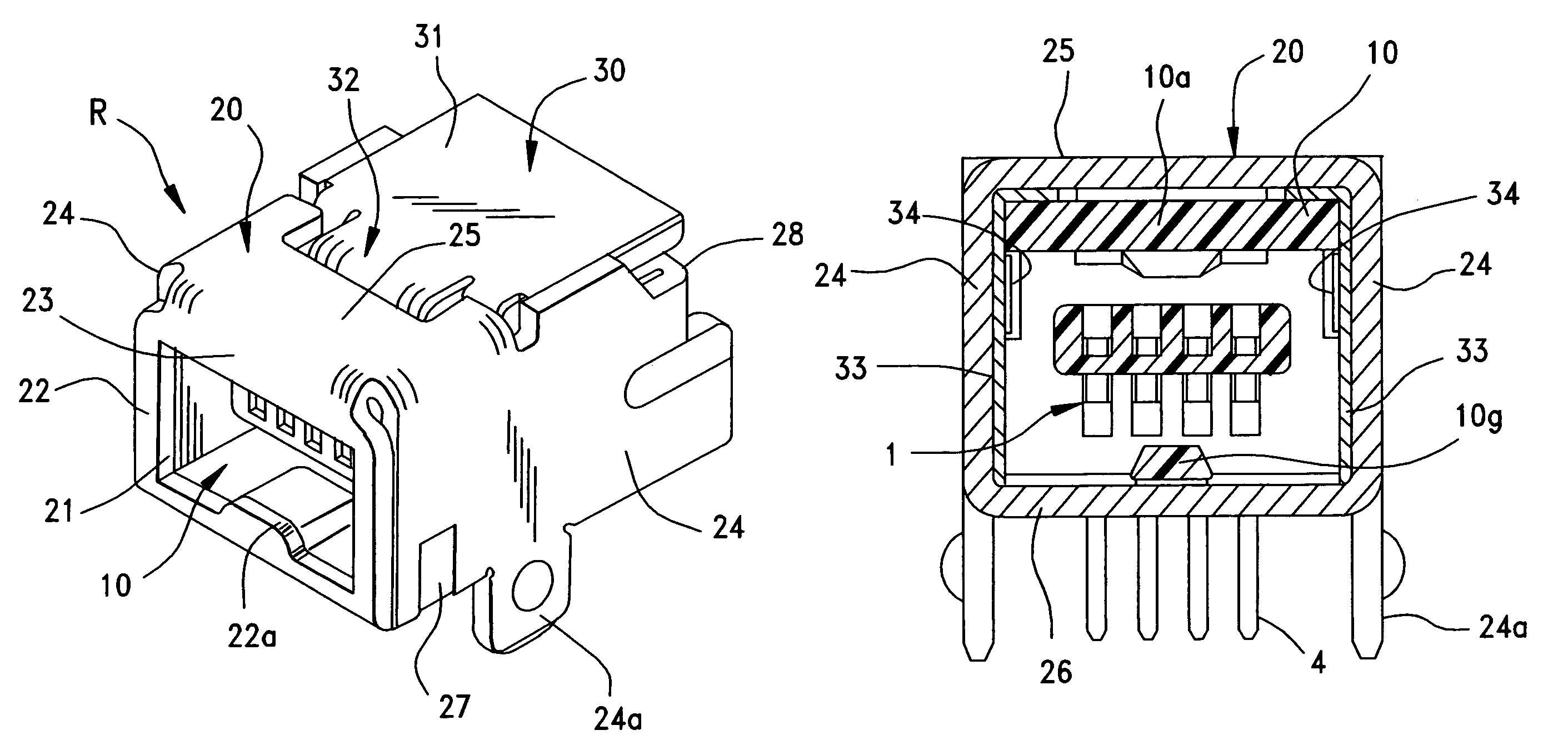

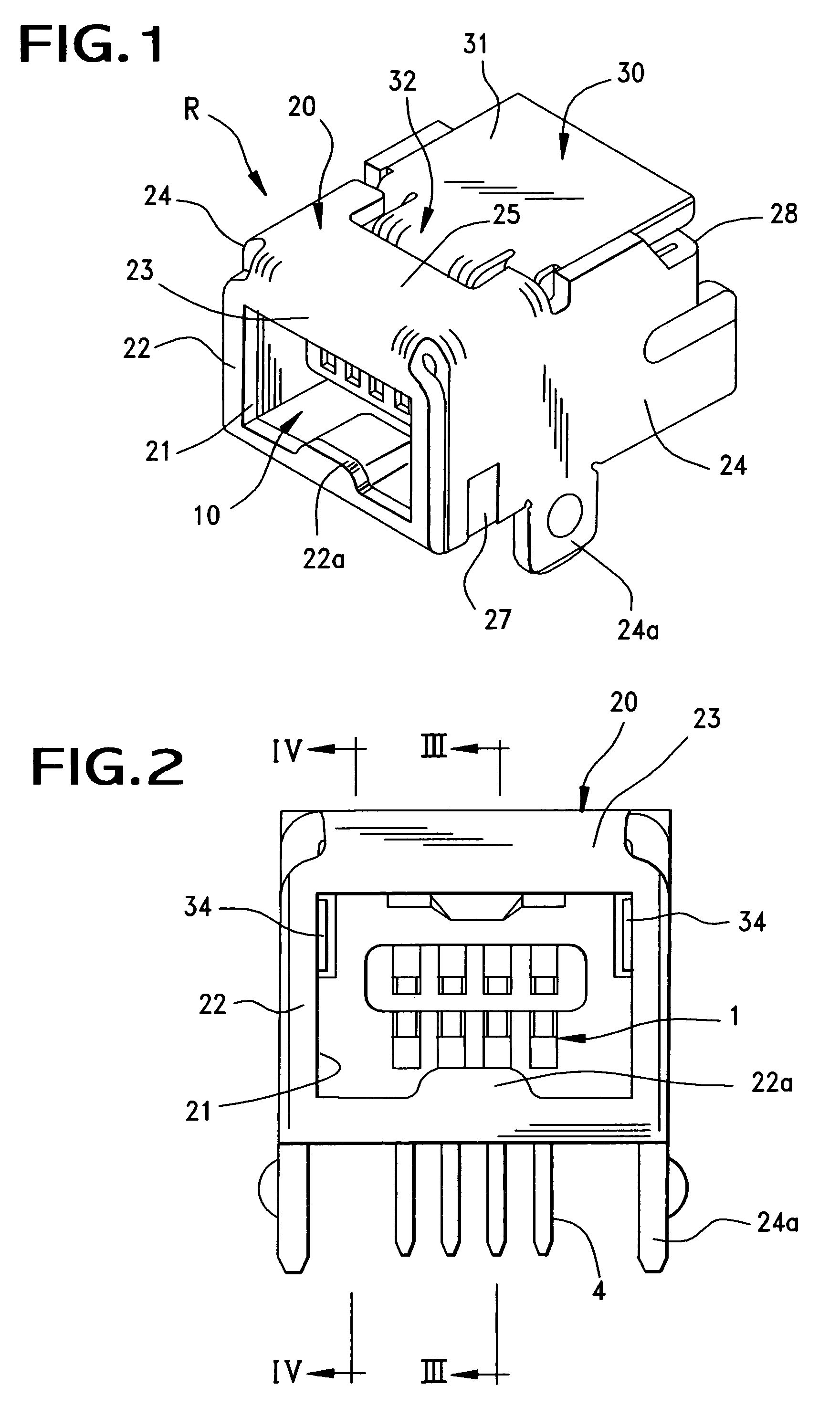

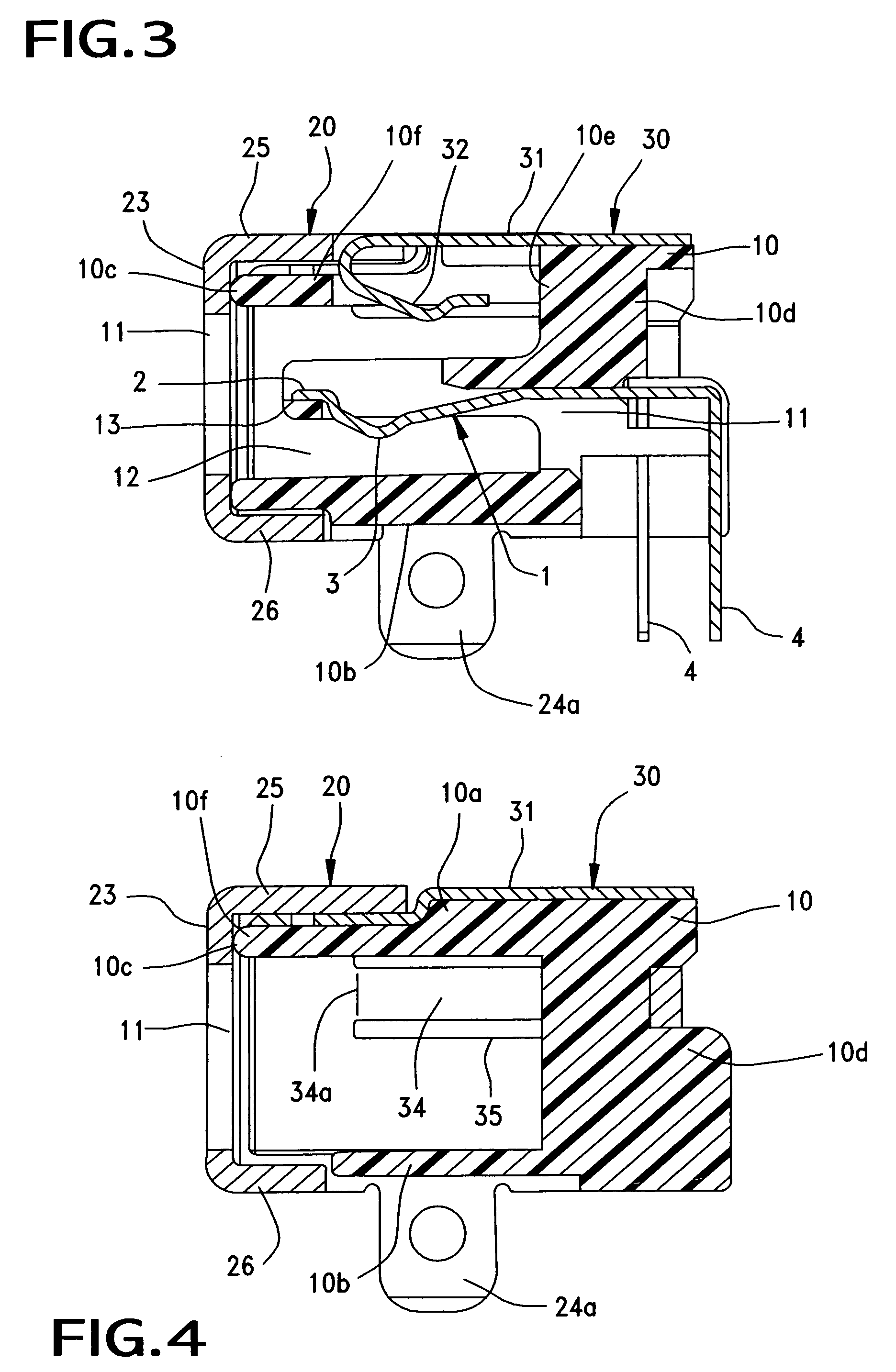

Shielded connector of reduced-size with improved retention characteristics

InactiveUS6926557B1Small sizeReduce weightElectrically conductive connectionsCoupling protective earth/shielding arrangementsReduced sizeElectrical and Electronics engineering

A reduced weight and size shielded receptacle connector includes an internal insulative connector housing having top and bottom walls, without any sidewalls interconnecting the top and bottom walls together. A plurality of conductive terminals are supported within the connector. A receptacle portion of the connector is formed in cooperation with the top and bottom walls of the connector housing and with a pair of metal sidewalls formed by bending a shield member around parts of the connector housing. A metal retaining shield is provided that also overlies a portion of the connector housing and which is partially retained on the connector housing by the metal shell. The shield not only provides shielding, but also serves to retain the opposing connector in mating engagement with receptacle connector by way of three retention members that extend in and engaged the opposing connector in three different directions.

Owner:MOLEX INC

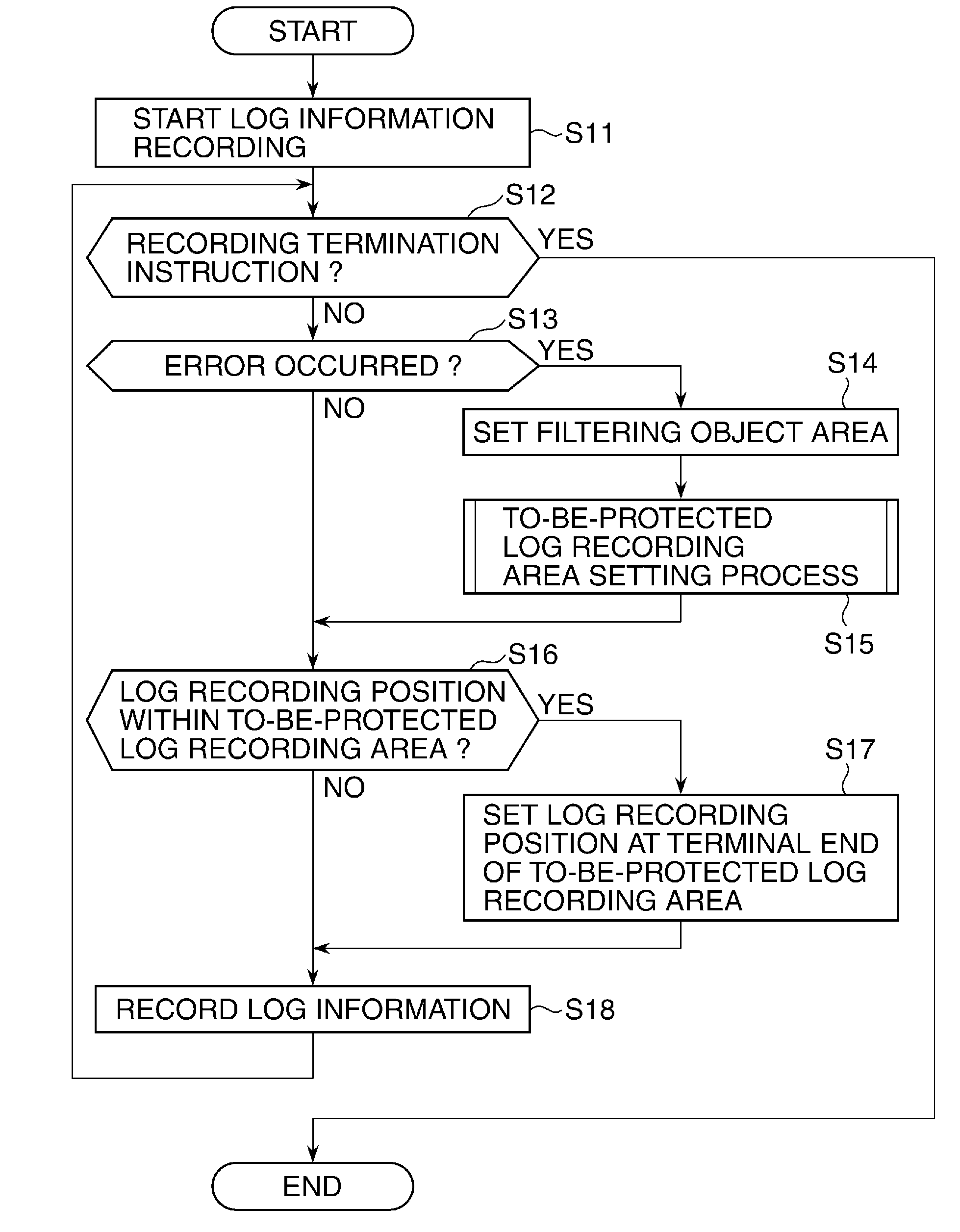

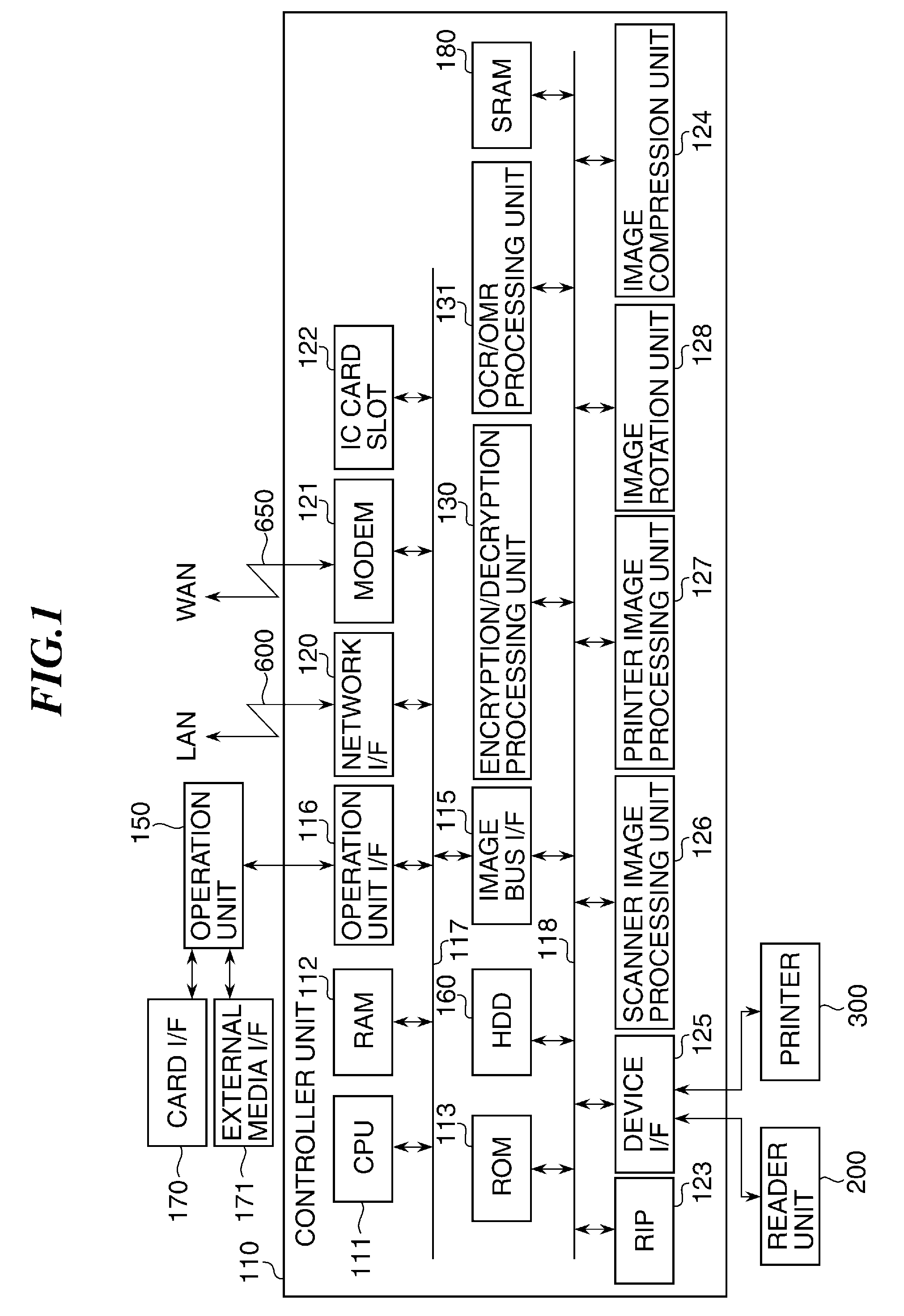

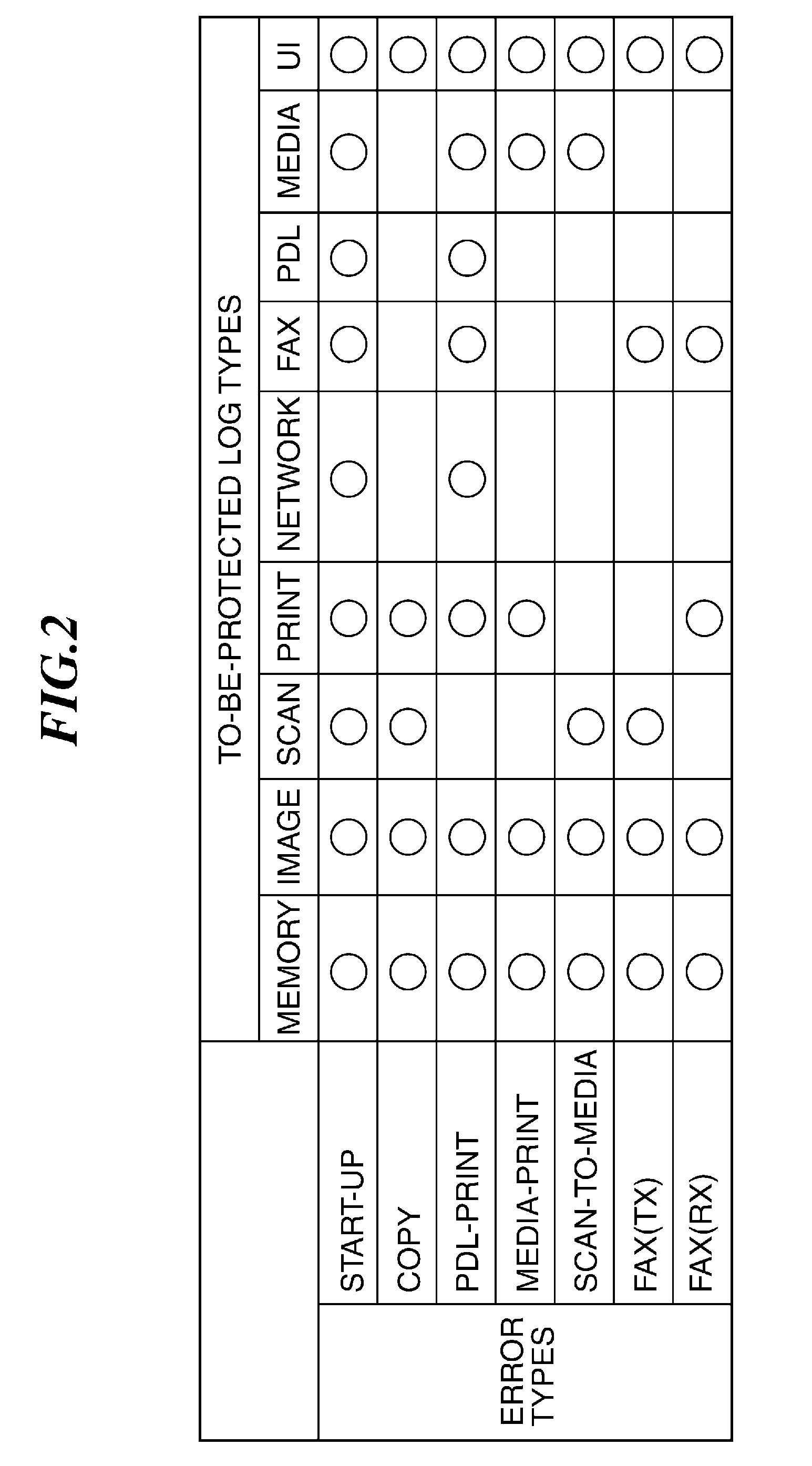

Information processing apparatus that records logs, and control method and storage medium therefor

An information processing apparatus capable of overwrite-recording time-series logs indicating an operation history and efficiently holding log information on operations relating to an occurring error. When an error is detected, a filtering object area is set that contains log information for a predetermined time period immediately before the error detection. Then, a type of the occurring error is identified, and log types to be protected are decided based on the identified error type. Among the filtering object area, log recording areas for the decided log types are decided as a to-be-protected log recording area. Subsequently, further log information is recorded so as to avoid the to-be-protected log recording area.

Owner:CANON KK

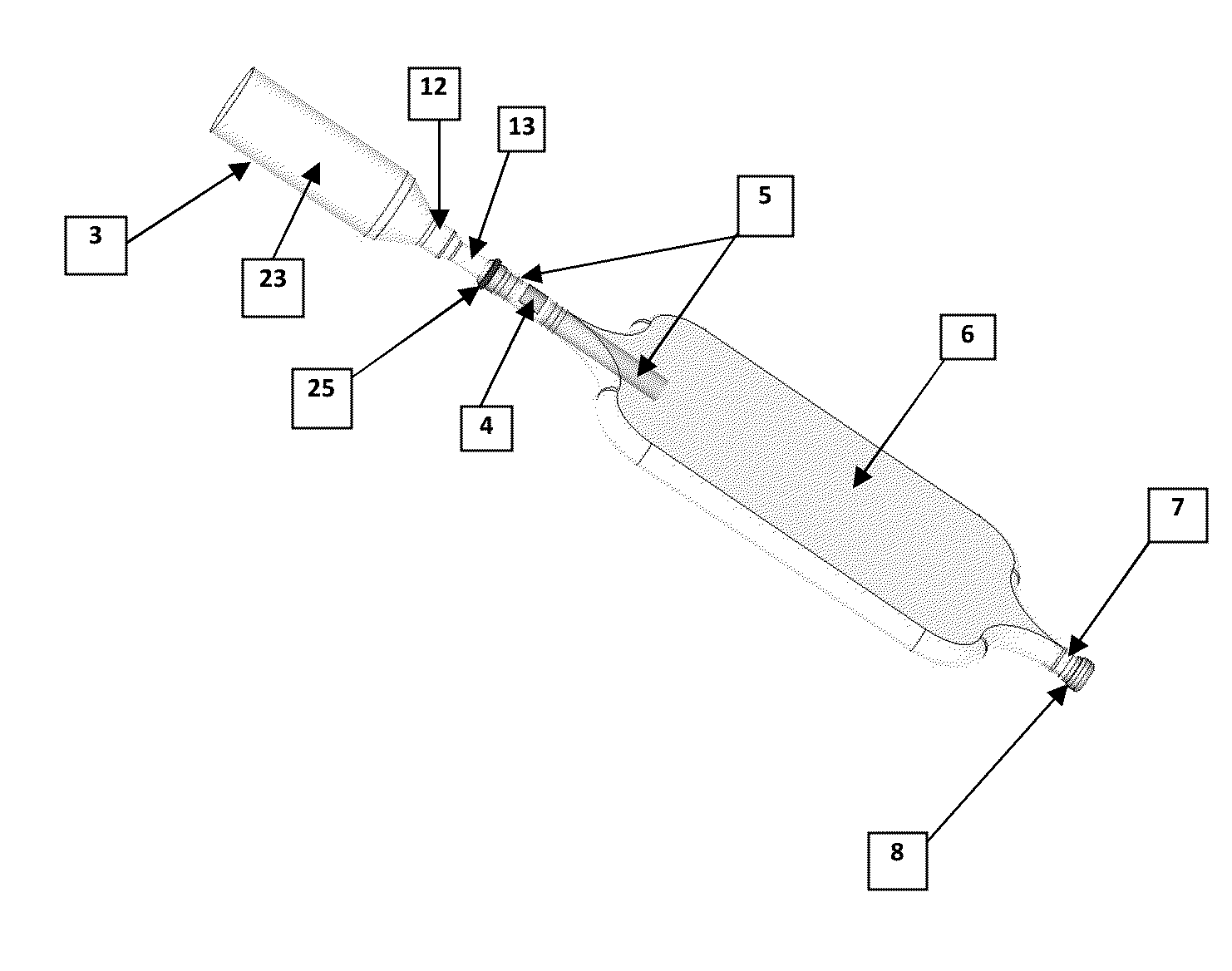

Delivery device

An applicator for introducing a therapeutic substance into a body cavity of a subject in need of the therapeutic substance is provided. The applicator has the look and feel of a conventional tampon applicator but delivers a therapeutic substance. Generally, the applicator has a first outer member having a shape suitable for insertion into a body cavity of a mammal and has a dispensing end and a second end distal to the dispensing end. A second inner member is coaxially and slidably housed within the first member such that one end of the second inner member is within the first member. The applicator of the present invention also has at least one aperture located in a side wall of the outer member. The aperture is located on the side wall of the outer member between the dispensing end and the second end of the outer member.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Cup holder

InactiveUS20050051690A1Effective holdingPrevent disengagementWash-standsStoolsEngineeringPublic Venue

A cup holder for holding a container or drink on seats in arenas, stadiums and other public venues. The holder has an engagement portion that holds the rear side of the seat, a basket for holding a container therein and a strip extending therebetween. The holder is provided with a hinge between the basket and the strip to allow the holder to be collapsed. The holder further is provided with a flange for preventing rearward movement of the holder when it is attached to a seat. The strip may be a set length or may comprise a pair of telescoping members to allow for the holder to fit over varying seat widths.

Owner:PHILLIPS JOHN O +1

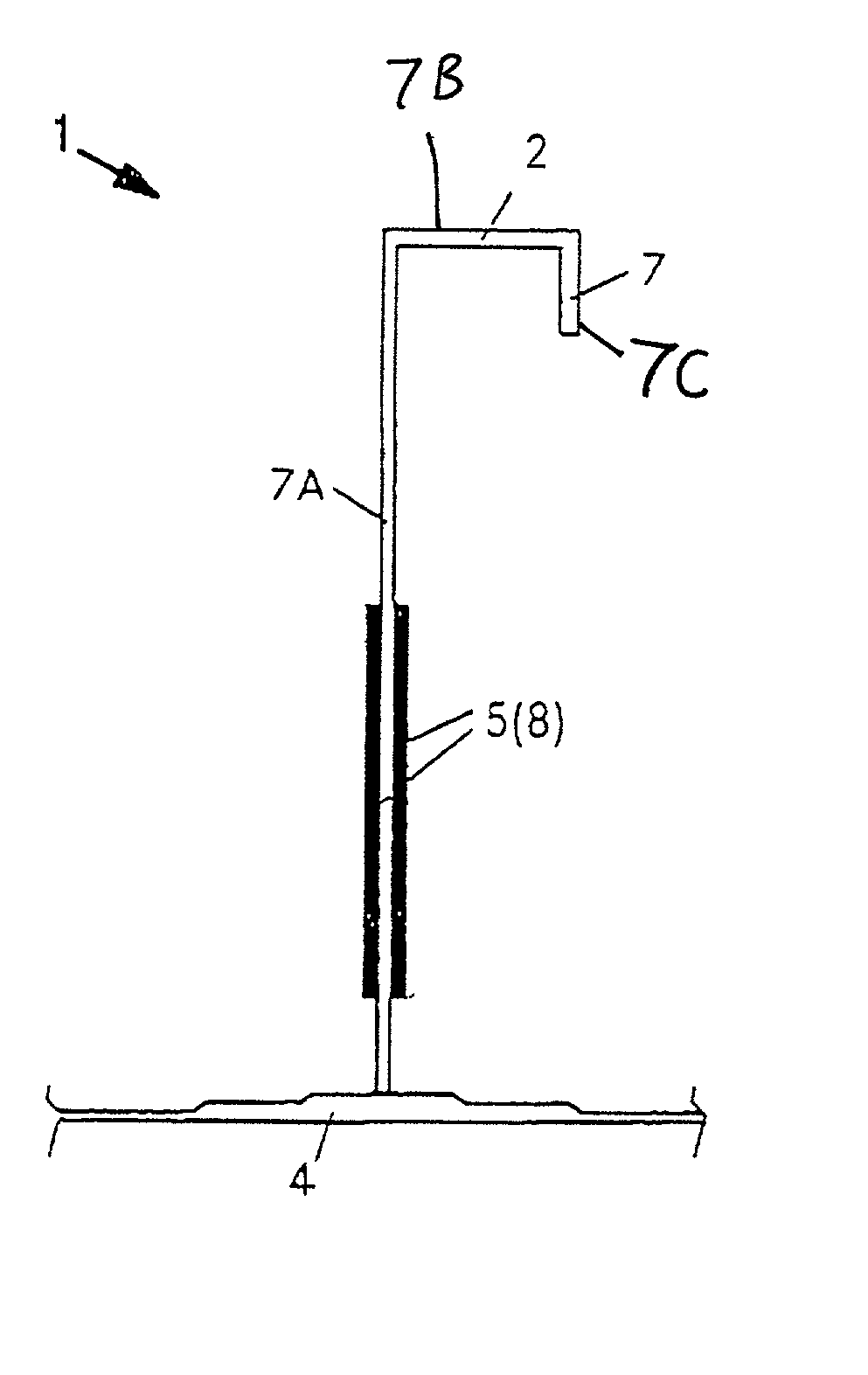

Aircraft fuselage shell component with crack propagation resistance

InactiveUS20020000492A1Increasing weight and costEasy to crackFuselage bulkheadsNon-rigid airshipsResidual strengthEngineering

When stiffening members, such as stringers and frame members, are welded onto a skin sheet to form an aircraft fuselage shell, a crack originating in the skin sheet tends to propagate through the weld joints into the stiffening members. In order to prevent crack propagation into a stiffening member, the stiffening member is reinforced with a web doubler plate or a tension band made of high strength steel or titanium alloys or fiber-reinforced composites. The doubler plate is riveted or adhesively bonded onto a stiffening member web, or the tension band is crimped into the stiffening member web. The resulting fuselage shell structure has crack stopping properties and thus an increased residual strength, so it can be used with welded joints at all areas of the fuselage shell, including the top and sides as well as the bottom of the fuselage.

Owner:AIRBUS OPERATIONS GMBH

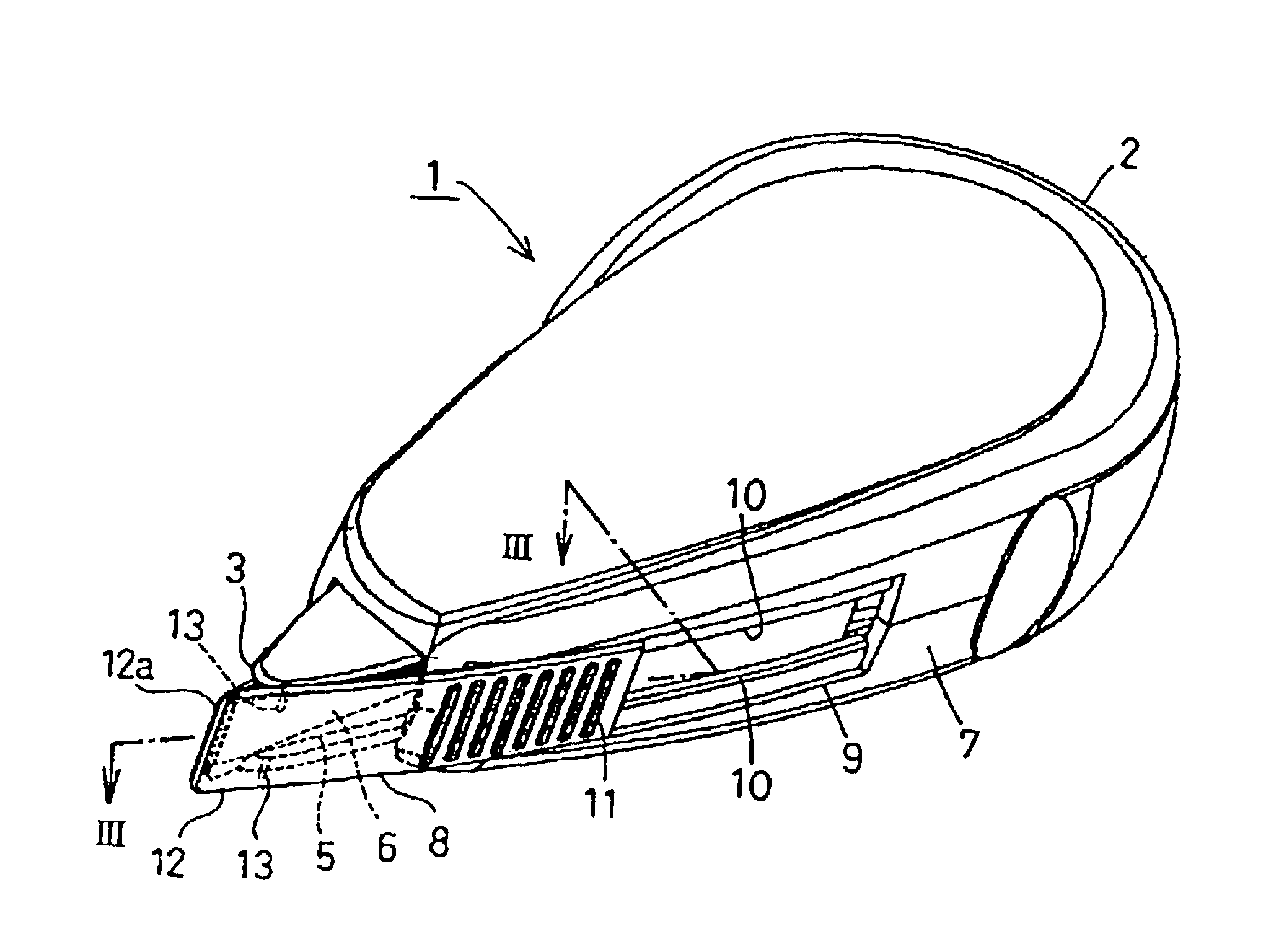

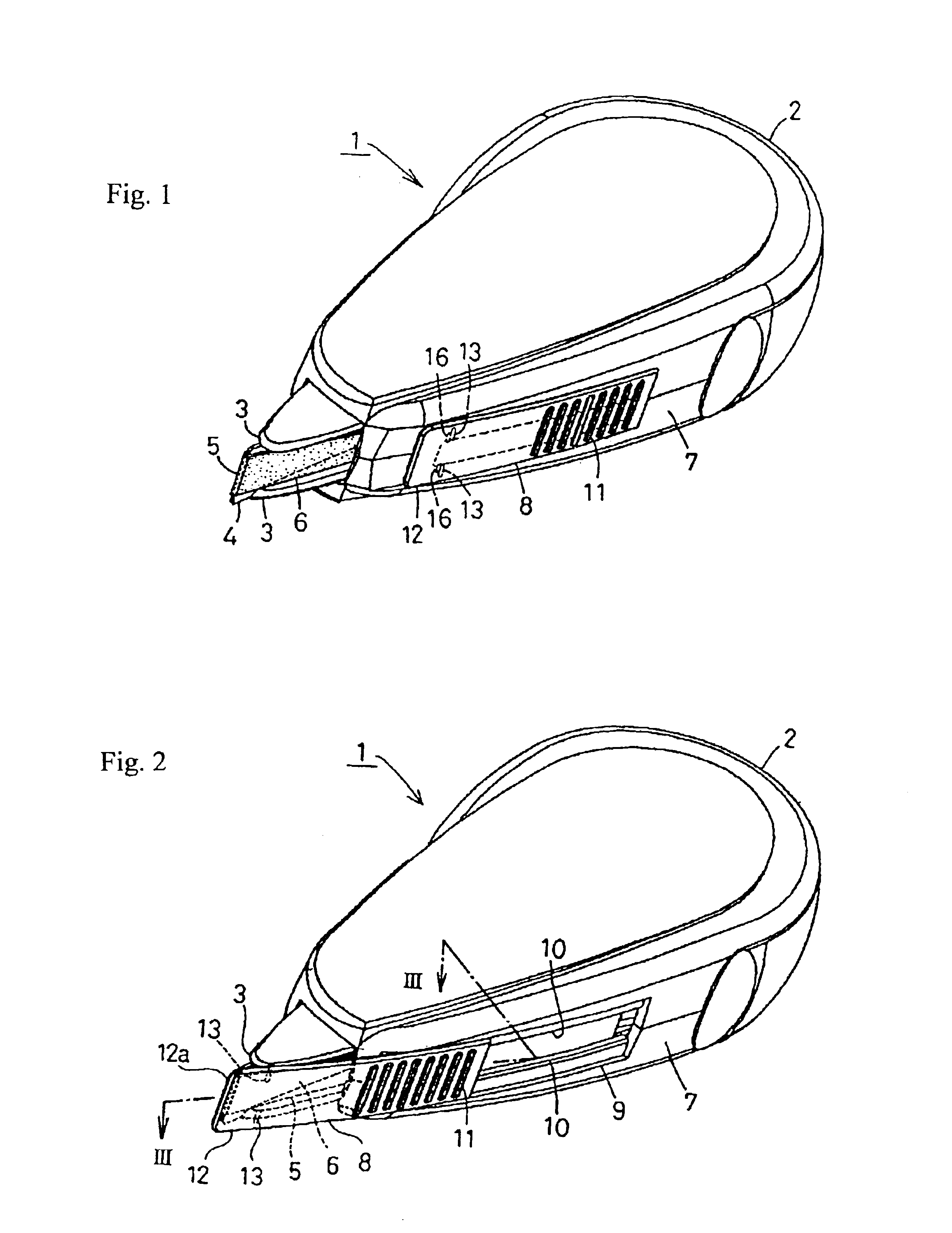

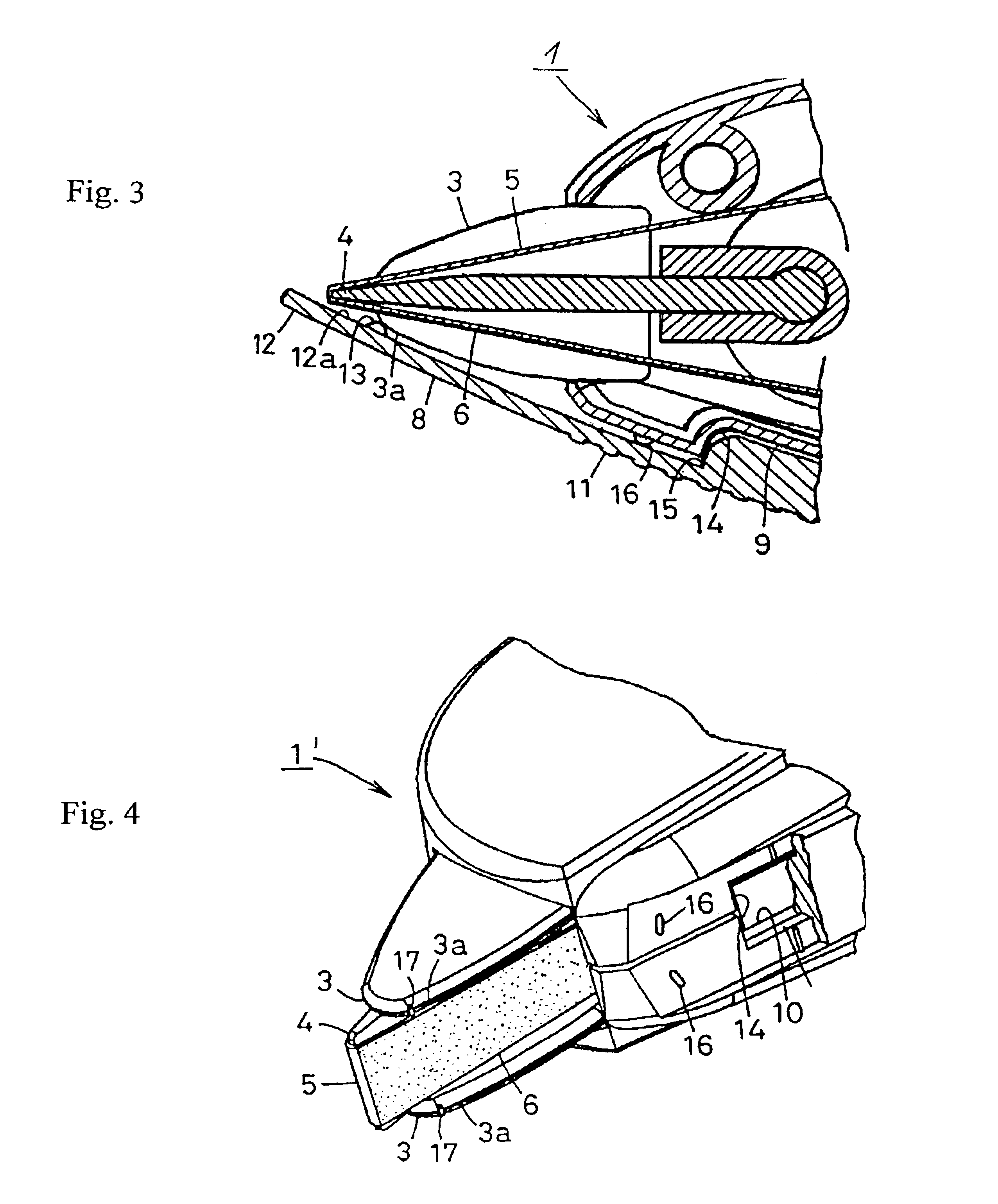

Coating transfer device

InactiveUS6761200B2Reduce manufacturing costLess-expensive to manufactureLiquid surface applicatorsFilament handlingEngineeringMechanical engineering

Owner:TOMBOW PENCIL CO LTD

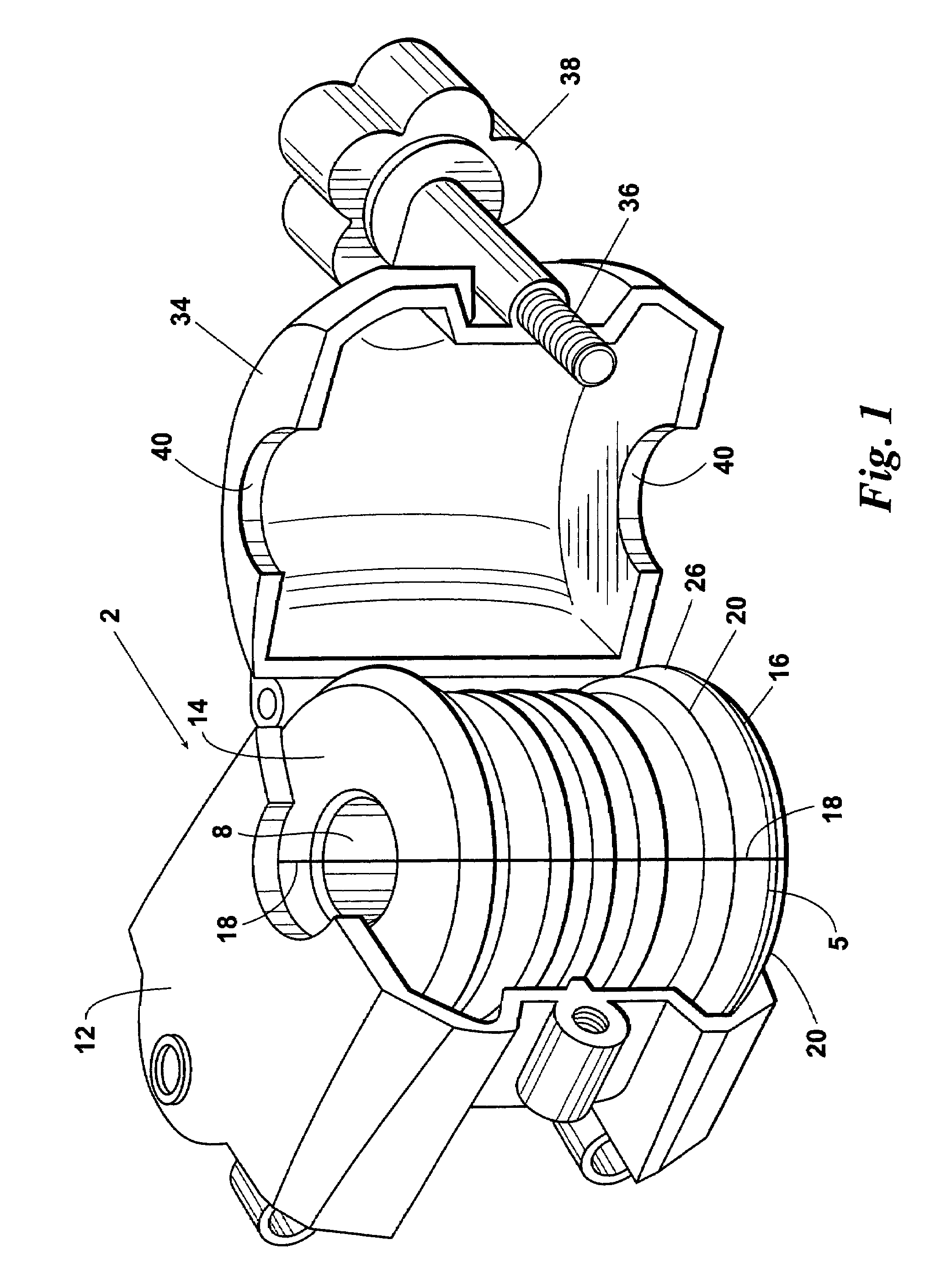

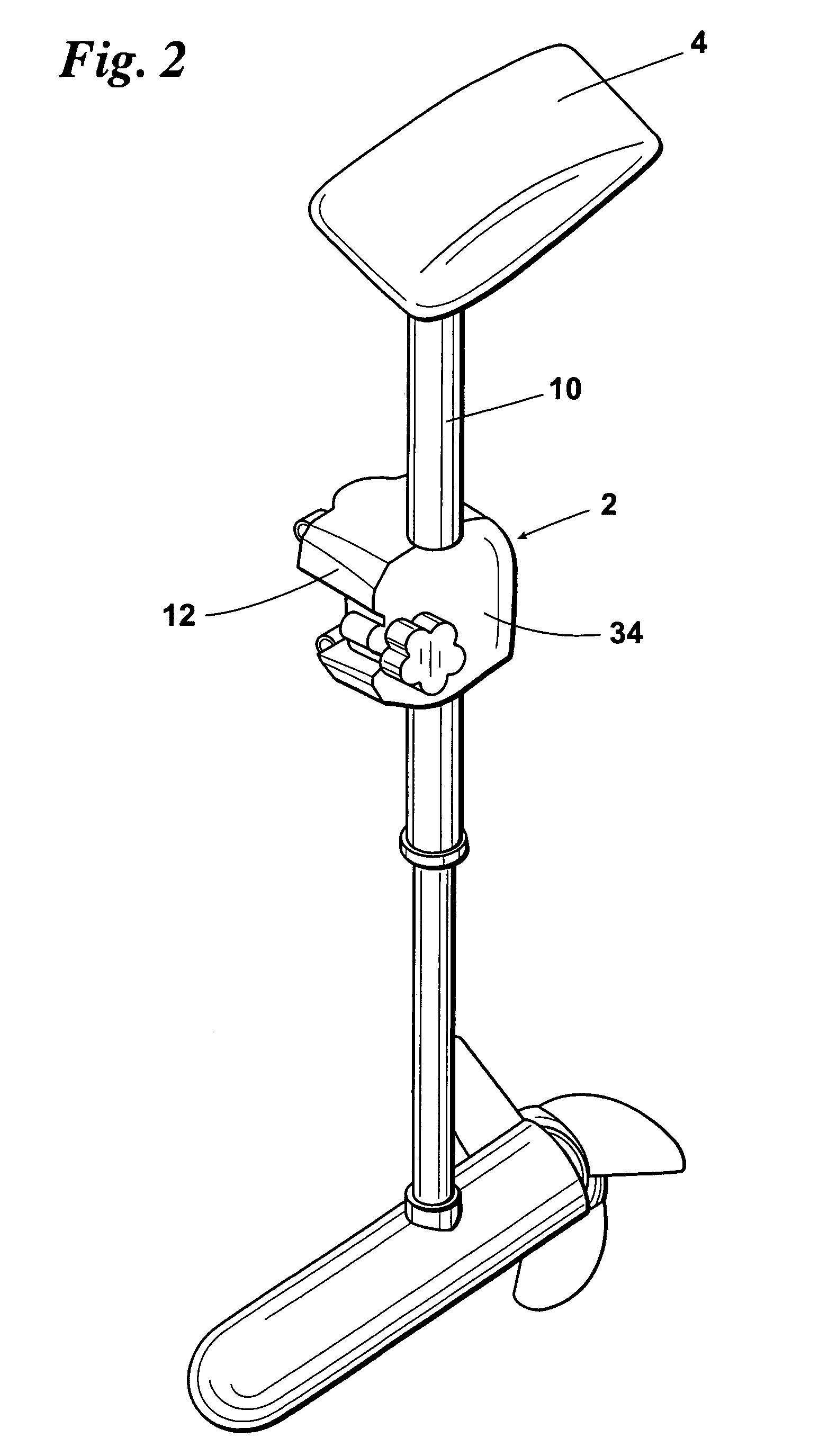

Impact absorbing isolator sleeve and assembly for mounting a trolling motor

ActiveUS7303595B1Easy and convenient installation and replacementEffective energy absorptionRotary propellersPropulsion power plantsTrolling motorMechanical engineering

An assembly for mounting a trolling motor comprising an inventive flexible gripping isolator sleeve positionable around the trolling motor column and a retainer which receives and retains the gripping isolator sleeve in a manner effective for holding the trolling motor column in an operating position. The gripping isolator sleeve is formed and configured in a manner effective for flexing sufficiently to allow the trolling motor to deflect in any direction when impacted and for then automatically returning the trolling motor to its operating position.

Owner:BRUNSWICK CORPORATION

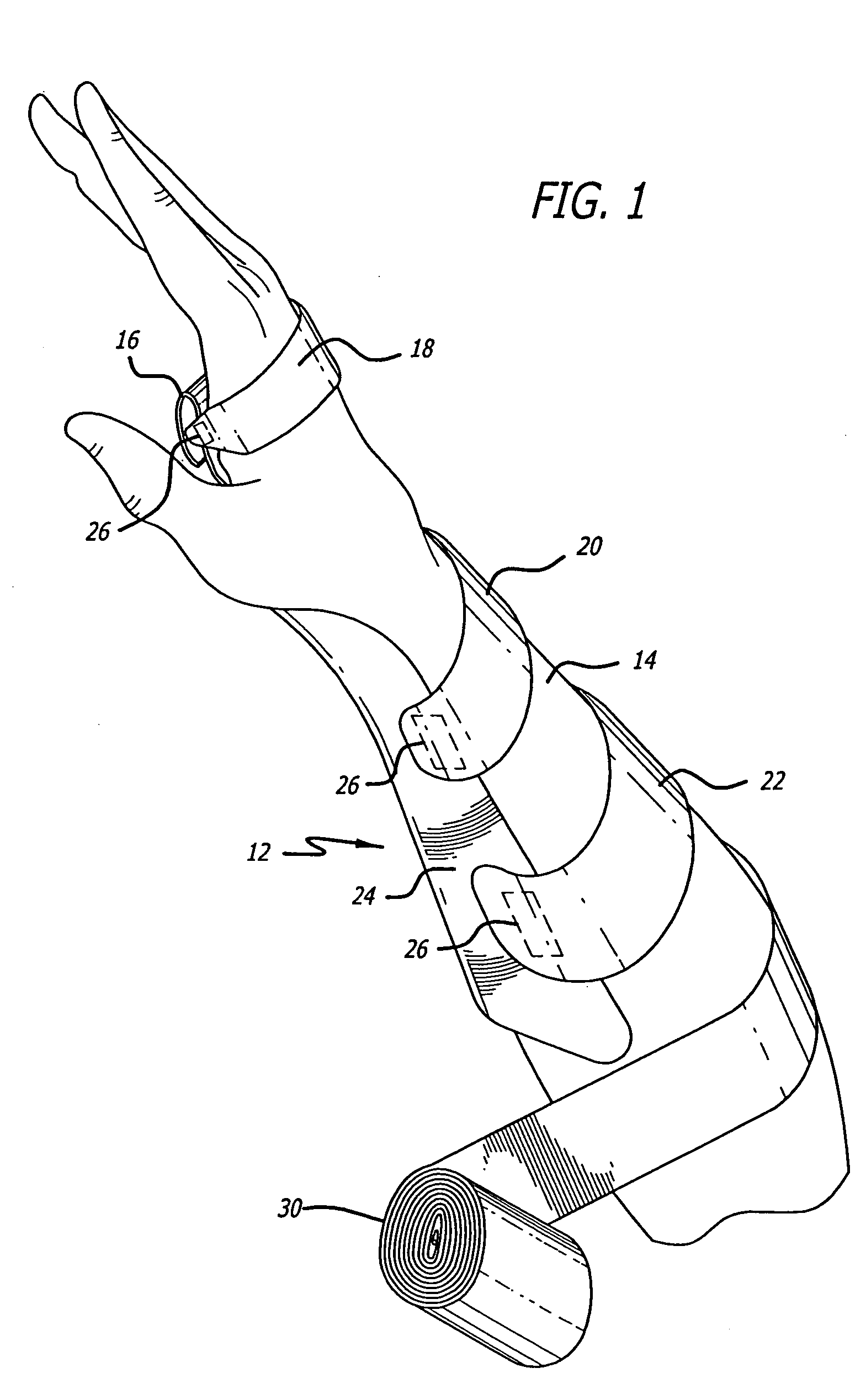

Splint or support with quick location technique

An orthopaedic splint apparatus and technique involving the use of a water hardenable blank with (1) primary tacking arrangements for adjustably holding the splint or support in place after it has been activated and placed on the injured part of the anatomy, and may also include (2) secondary, functional arrangements for holding the splint firmly in place following accurate mounting and location of the splint on the injured part of the anatomy. The tacking arrangements may involve the use of lateral extensions from the main body of the splint with hook and loop type fasteners or adhesive associated with the extensions for holding the splint onto the injured part of the anatomy.

Owner:KAUPTHING BANK

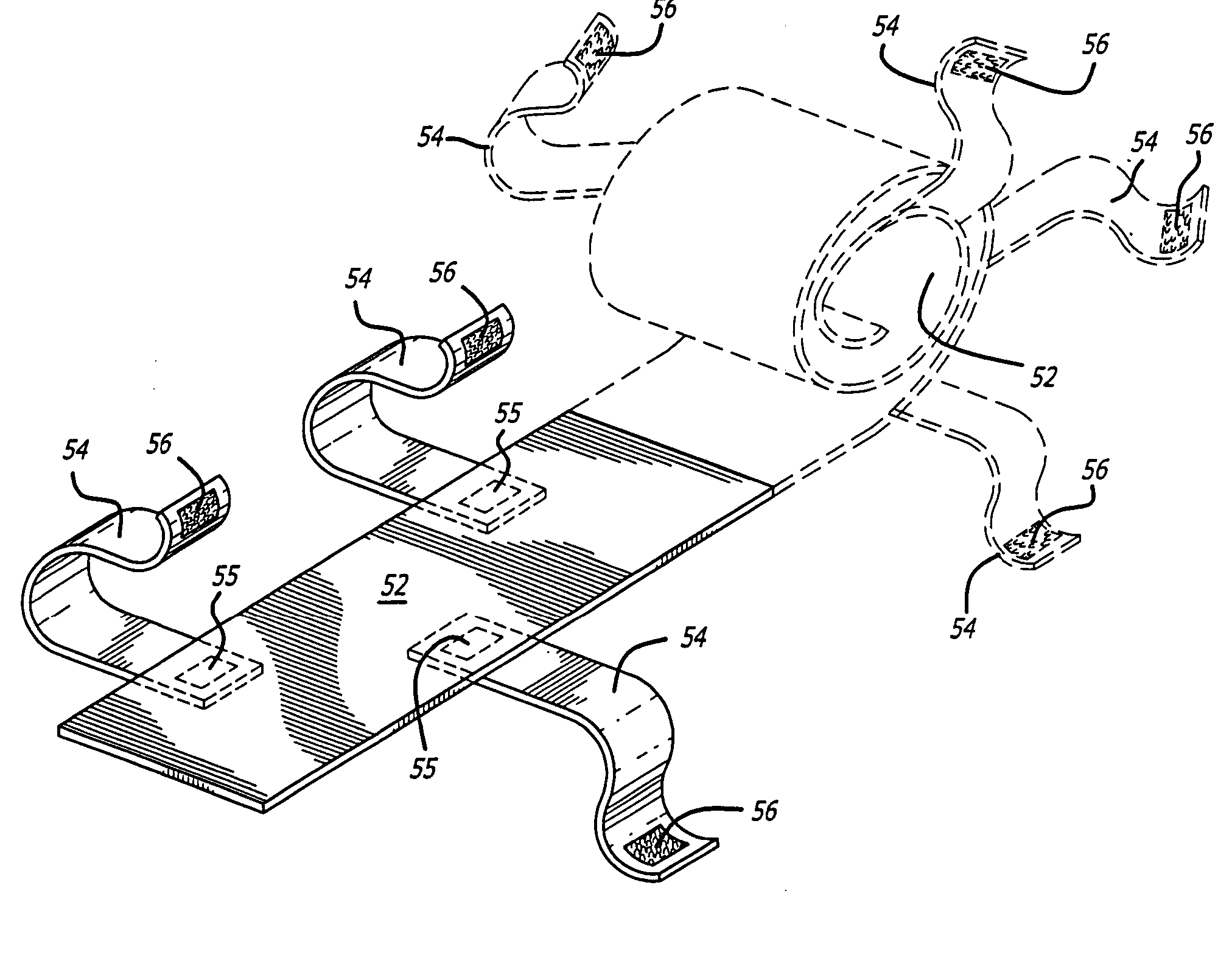

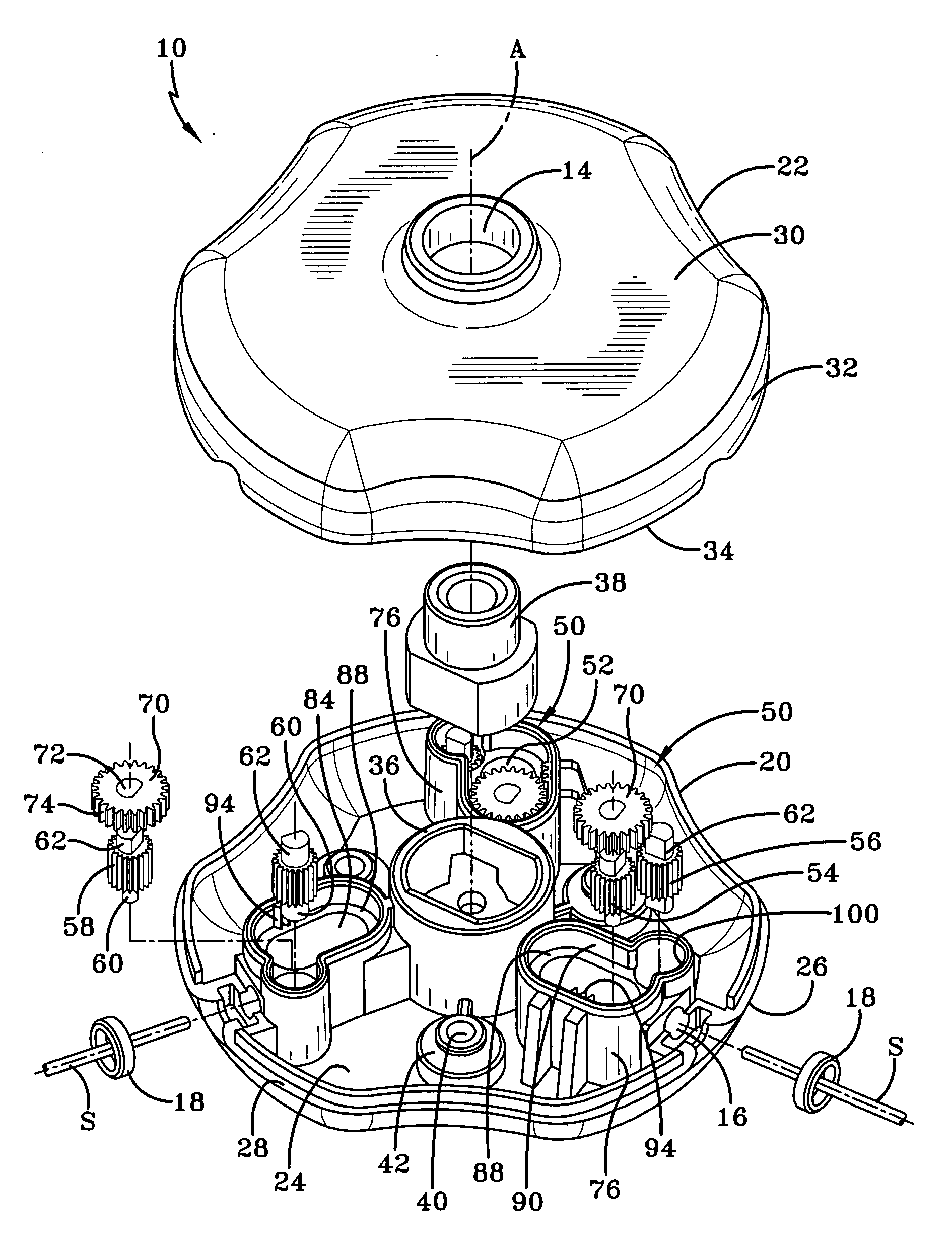

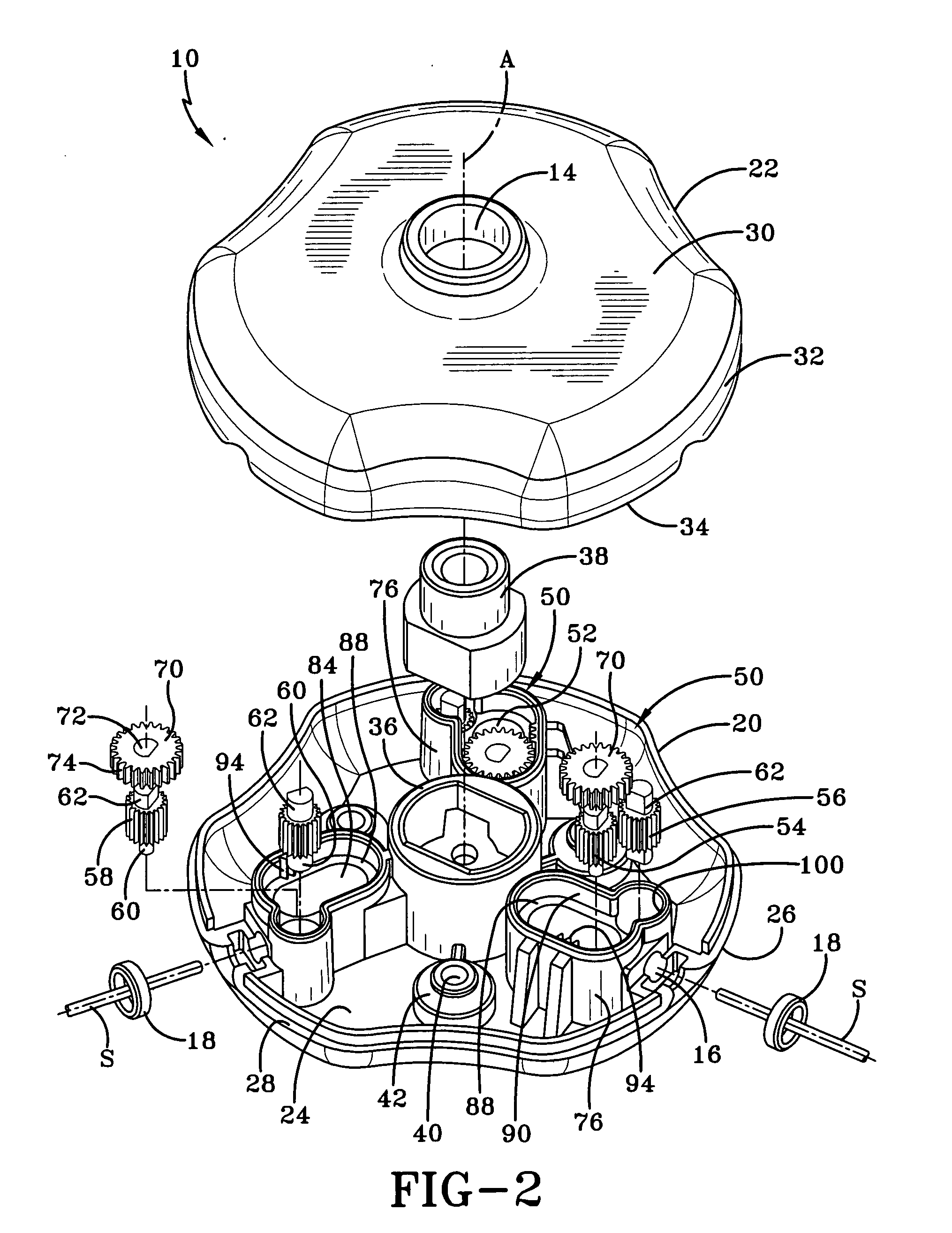

Mechanism for attaching trimmer line strips to a head of a trimming apparatus

InactiveUS20070084061A1Quickly and easily insert one endEffective holdingMowersMetal working apparatusEngineeringMechanical engineering

A trimmer head includes a housing encasing one or more impinging gear mechanisms. Each impinging gear mechanism includes at least one guide chamber disposed in the housing of trimmer head, and a pair of gripping gears located on opposed sides of an opening through which the trimmer line strip is received. The gripping gears engage the trimmer line strip upon insertion of the strip into the housing. At least one of the pair of gripping gears is located within the guide chamber and is movable linearly with respect to guide chamber, to permit securing of the trimmer line strip between the pair of gripping gears.

Owner:SHAKESPEARE CO

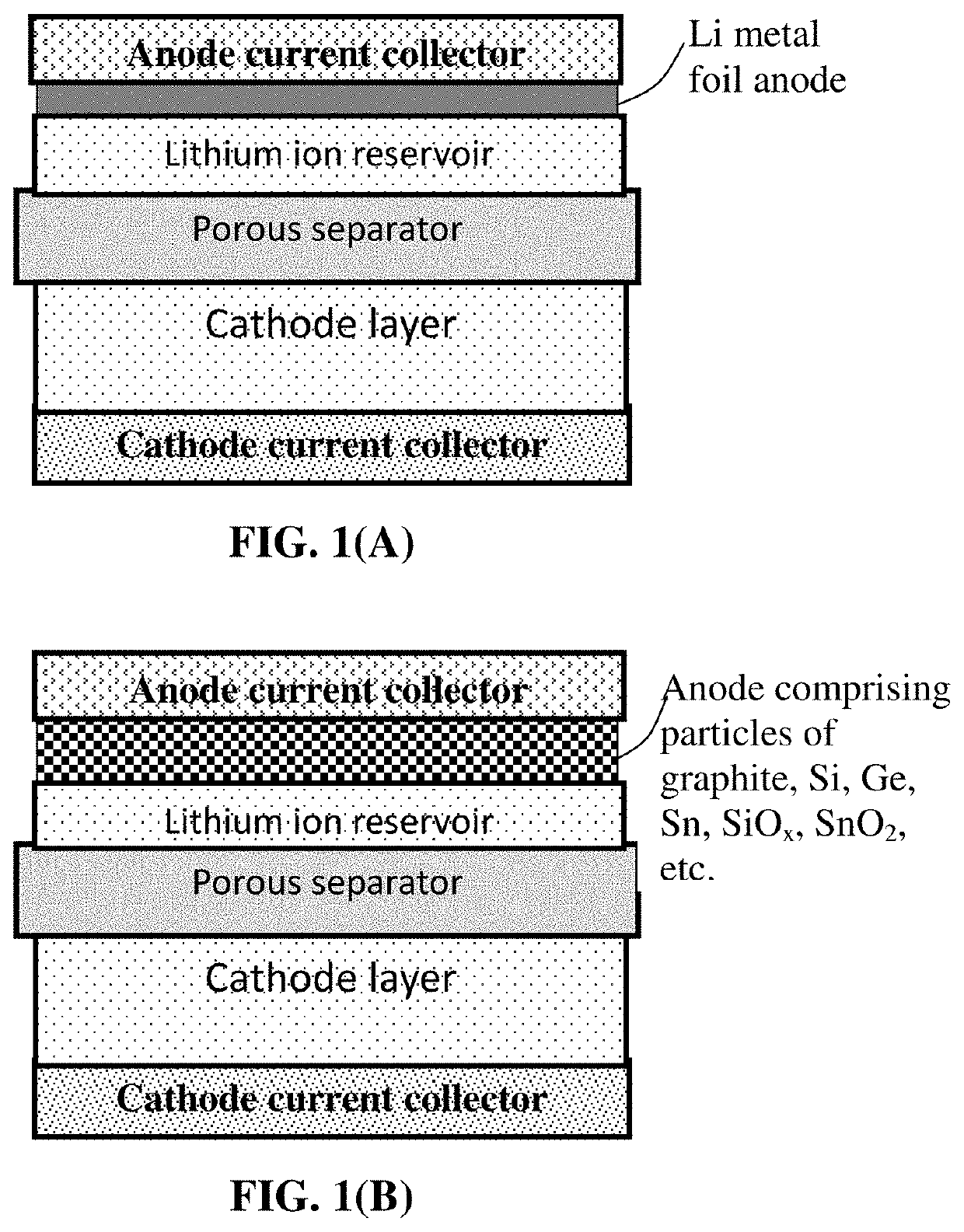

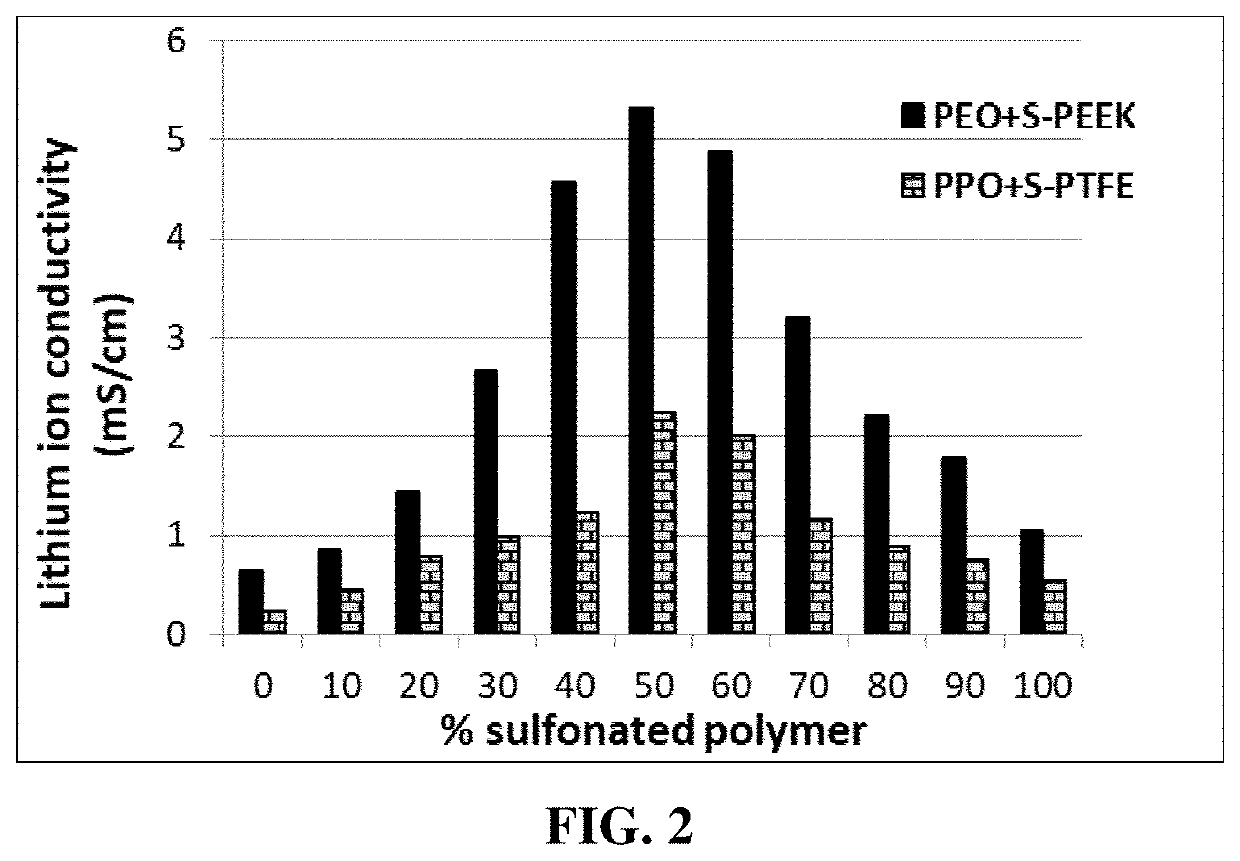

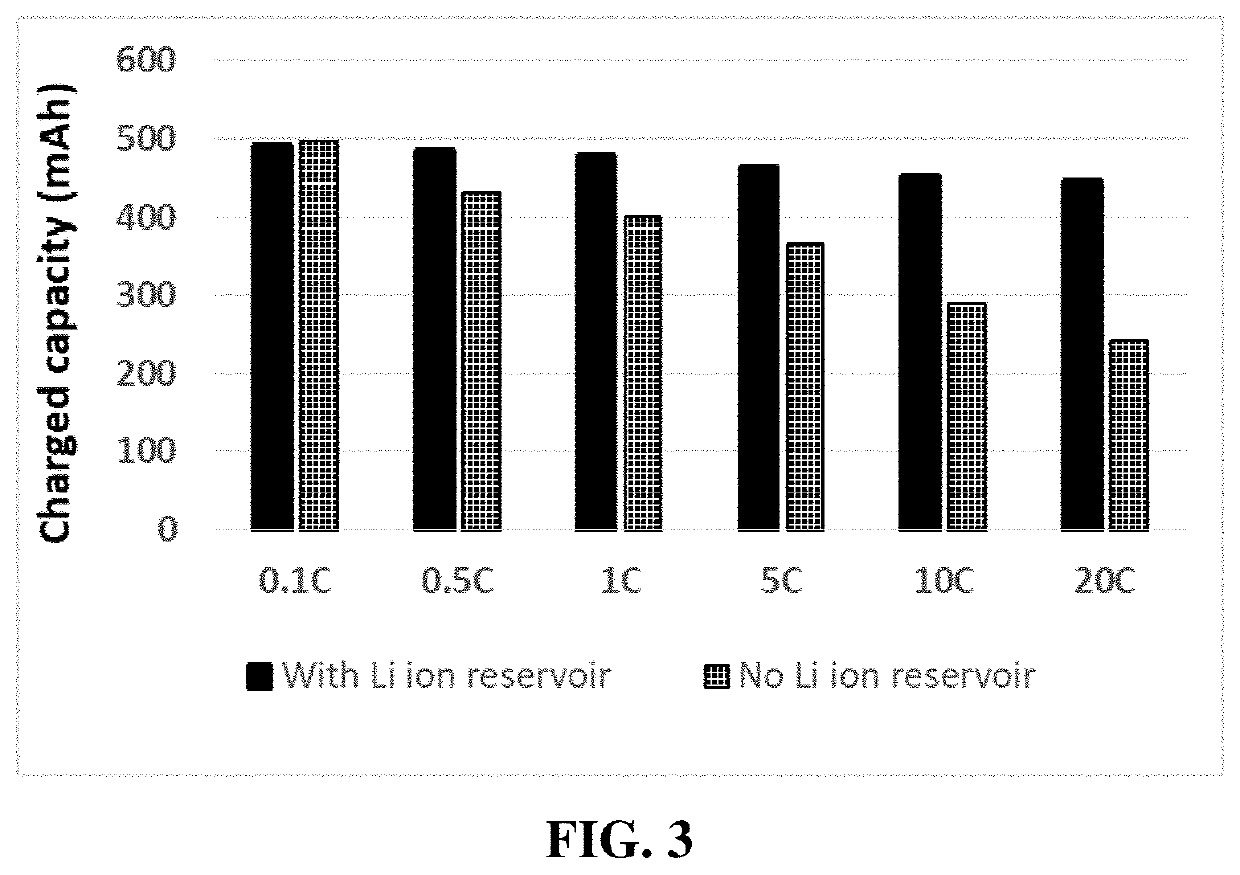

Fast-chargeable lithium battery

ActiveUS20190379045A1Effective holdingImproves Structural IntegrityElectrode carriers/collectorsNegative electrodesRedoxElectron

Provided is a lithium secondary battery containing an anode, a cathode, a porous separator disposed between the anode and the cathode, an electrolyte, and a lithium ion reservoir disposed between the anode and the porous separator and configured to receive lithium ions from the cathode when the battery is charged and enable the lithium ions to enter the anode in a time-delayed manner, wherein the reservoir comprises a conducting porous framework structure having pores (pore size from 1 nm to 500 μm) and lithium-capturing groups residing in the pores, wherein the lithium-capturing groups are selected from (a) redox forming species that reversibly form a redox pair with a lithium ion; (b) electron-donating groups interspaced between non-electron-donating groups; (c) anions and cations wherein the anions are more mobile than the cations; or (d) chemical reducing groups that partially reduce lithium ions from Li+1 to Li+δ, wherein 0<δ<1.

Owner:GLOBAL GRAPHENE GRP INC

Tooling and a method for hot forging pieces of sheet metal

ActiveUS20120174384A1Simple and effective and inexpensiveEasy to controlShaping toolsTool carrier control devicesLeading edgeEngineering

The invention provides tooling and a method for hot forging pieces of sheet metal that are to form metal reinforcement mounted on the leading or trailing edge of a turbine engine blade, by means of bottom and top matrices each presenting a twisted elongate surface for use in shaping an initially plane piece of sheet metal, the shaping surface of the bottom matrix presenting a high portion, a low portion, and two end zones. The bottom matrix includes studs for positioning and guiding the piece, the studs being situated at the periphery of the corresponding shaping surface.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Hydro-block air vent condom catheter and method of use

ActiveUS20150320583A1Reduction in macerationReduction in skinMedical devicesCatheterPenisCondom catheters

This invention is a device that utilizes hydro-block venting material in various condom catheter configurations to permit adequate airflow into the catheter thereby permitting efficient and complete drainage of urine away from the user following urination by means od gravity, siphoning or pumping. In one embodiment the condom that fits on the penis is itself made of hydro-block venting material. In another embodiment the hydro-block material is placed on the proximal end of a storage bag. In yet another embodiment a retro-fit assembly containing the hydro-block venting material can be retrofitted for use with any condom catheter. Both adhesive and inflatable rings are disclosed as attachment means to secure the condom catheter to the user and prevent leakage.

Owner:HARVIE MARK R

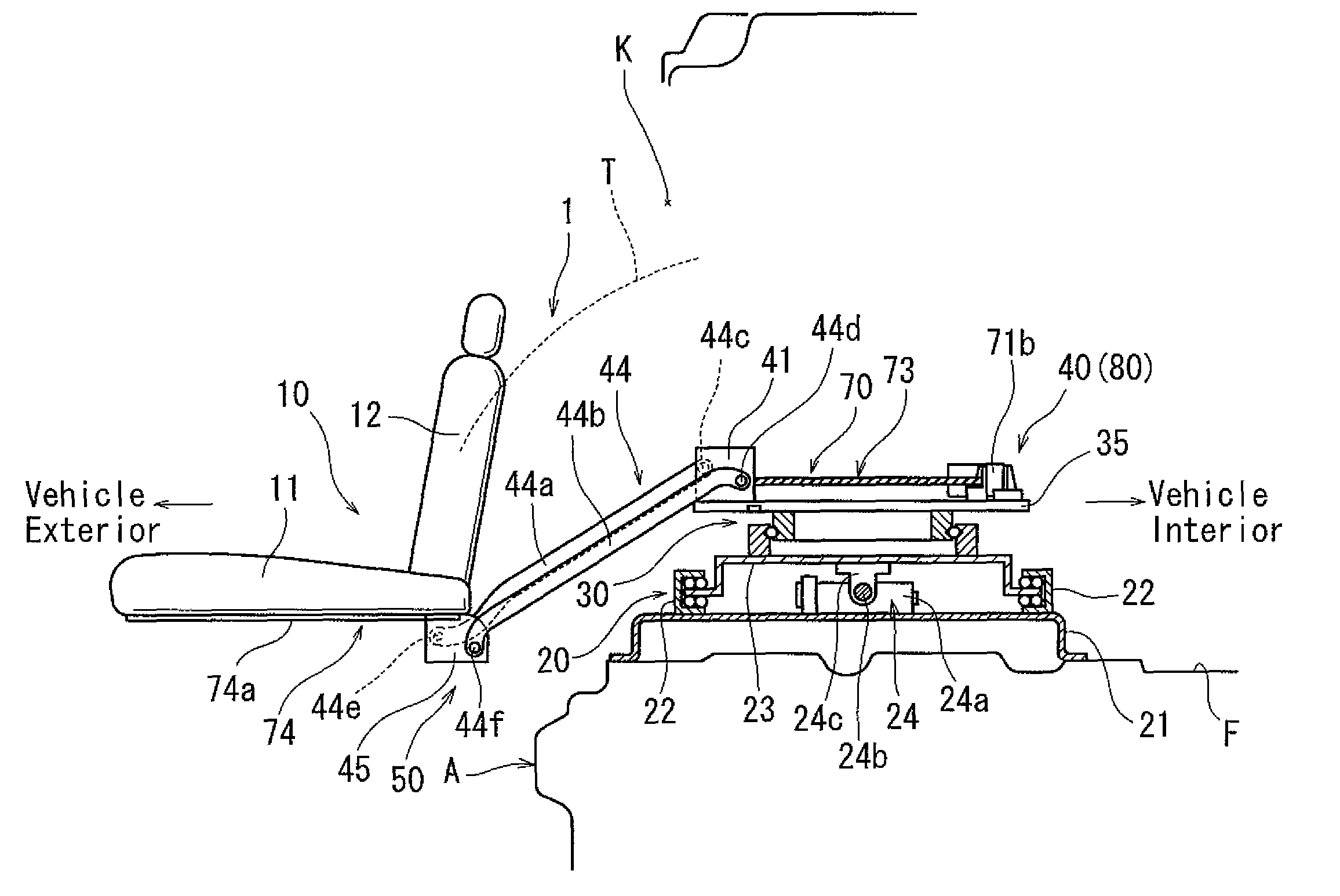

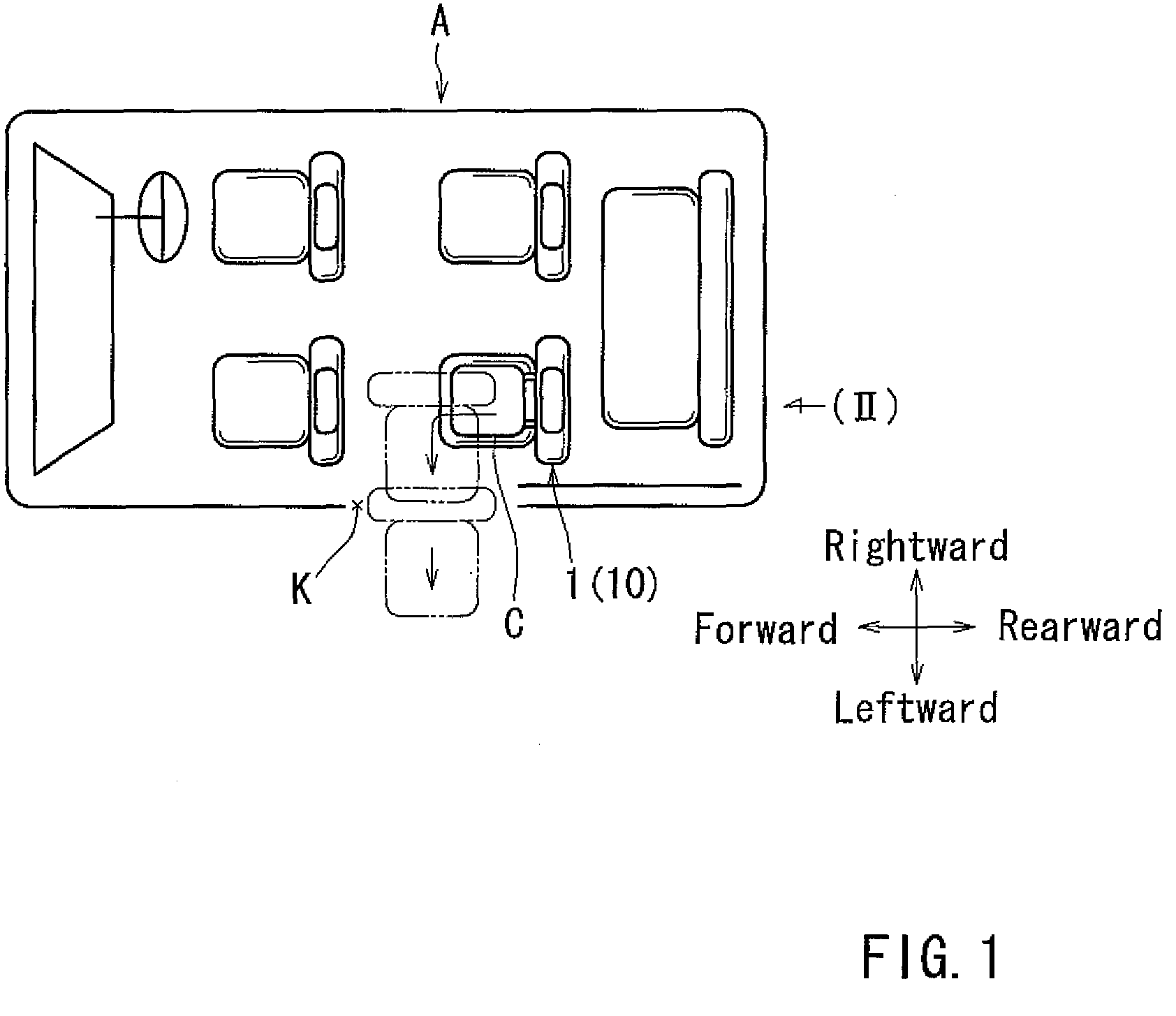

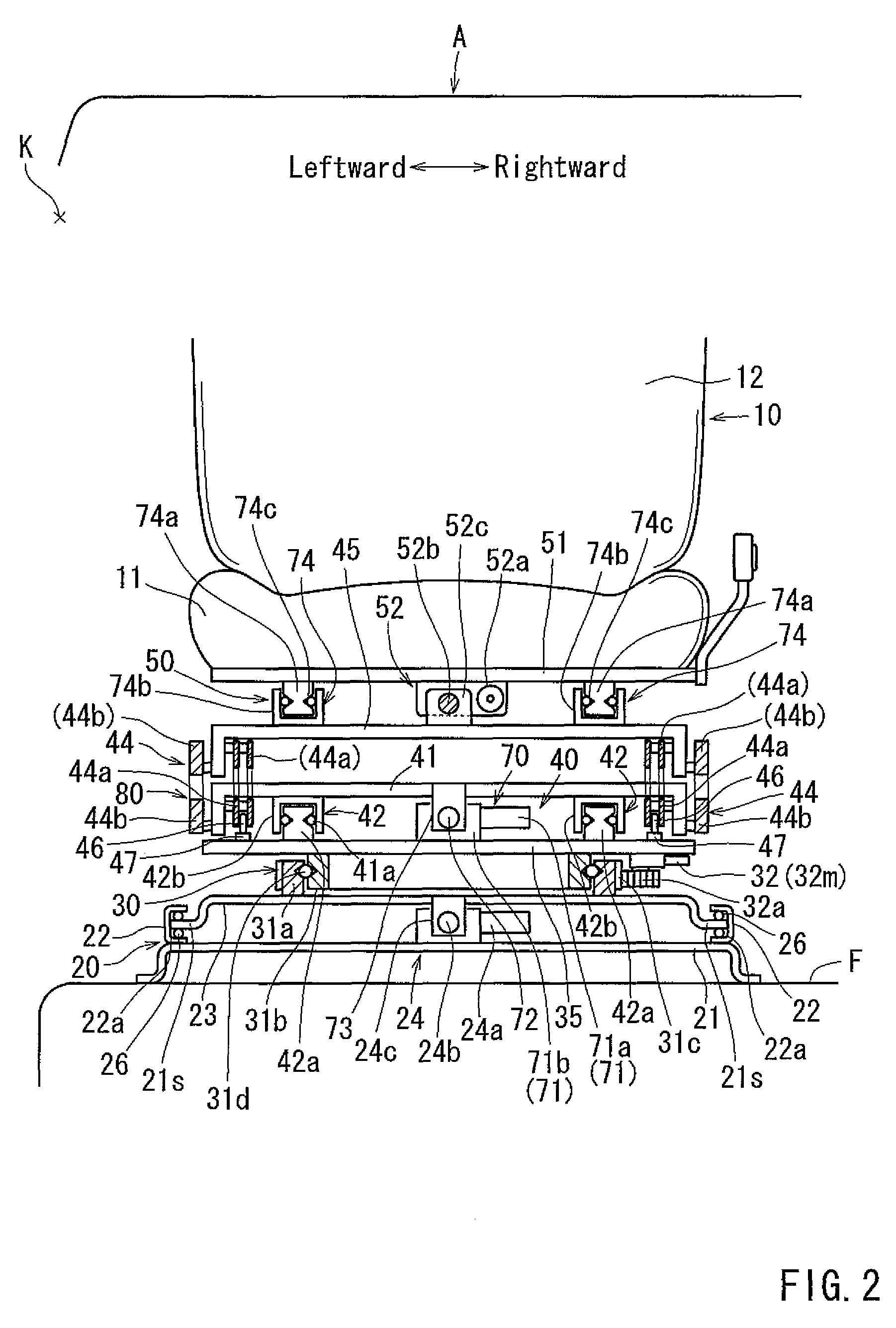

Vehicle seats

InactiveUS8033605B2Avoid damageGuaranteed normal transmissionMovable seatsKids chairsEngineeringCushion

A vehicle seat may include a seat main body having a seat cushion, a rotation mechanism that is arranged and constructed to horizontally rotate the seat main body with respect to a vehicle floor, a vertically moving mechanism that is arranged and constructed to vertically move the seat main body while moving the seat main body between vehicle interior and vehicle exterior, and a seat support that is capable of attaching the seat main body to the vertically moving mechanism. A cushion frame of the seat cushion is composed of a pair of longitudinal side frame elements, an anchor frame positioned between the side frame elements and anchor members attached to the anchor frame. The anchor frame is connected to the seat support via reinforcement members.

Owner:TOYOTA SHATAI KK

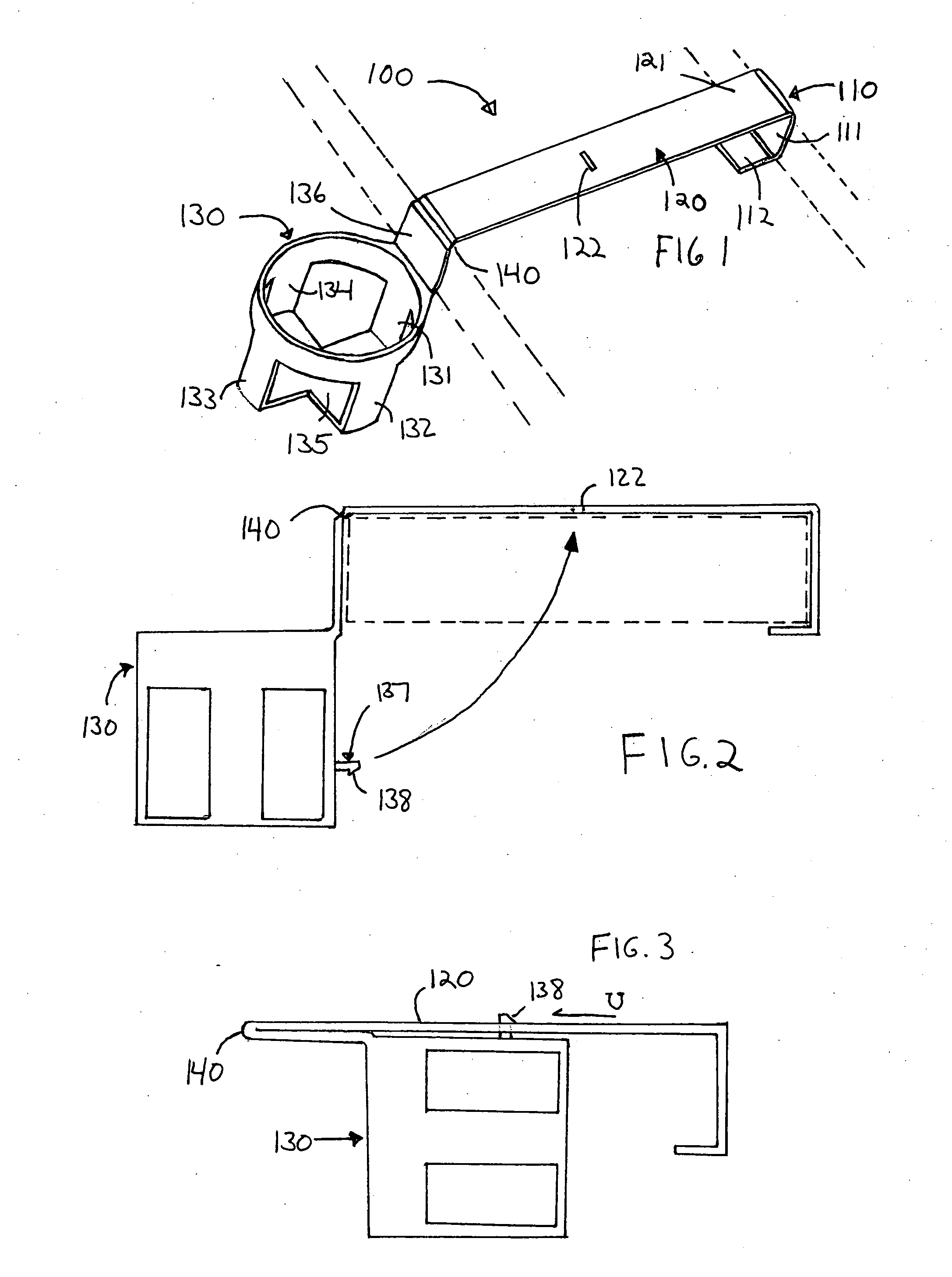

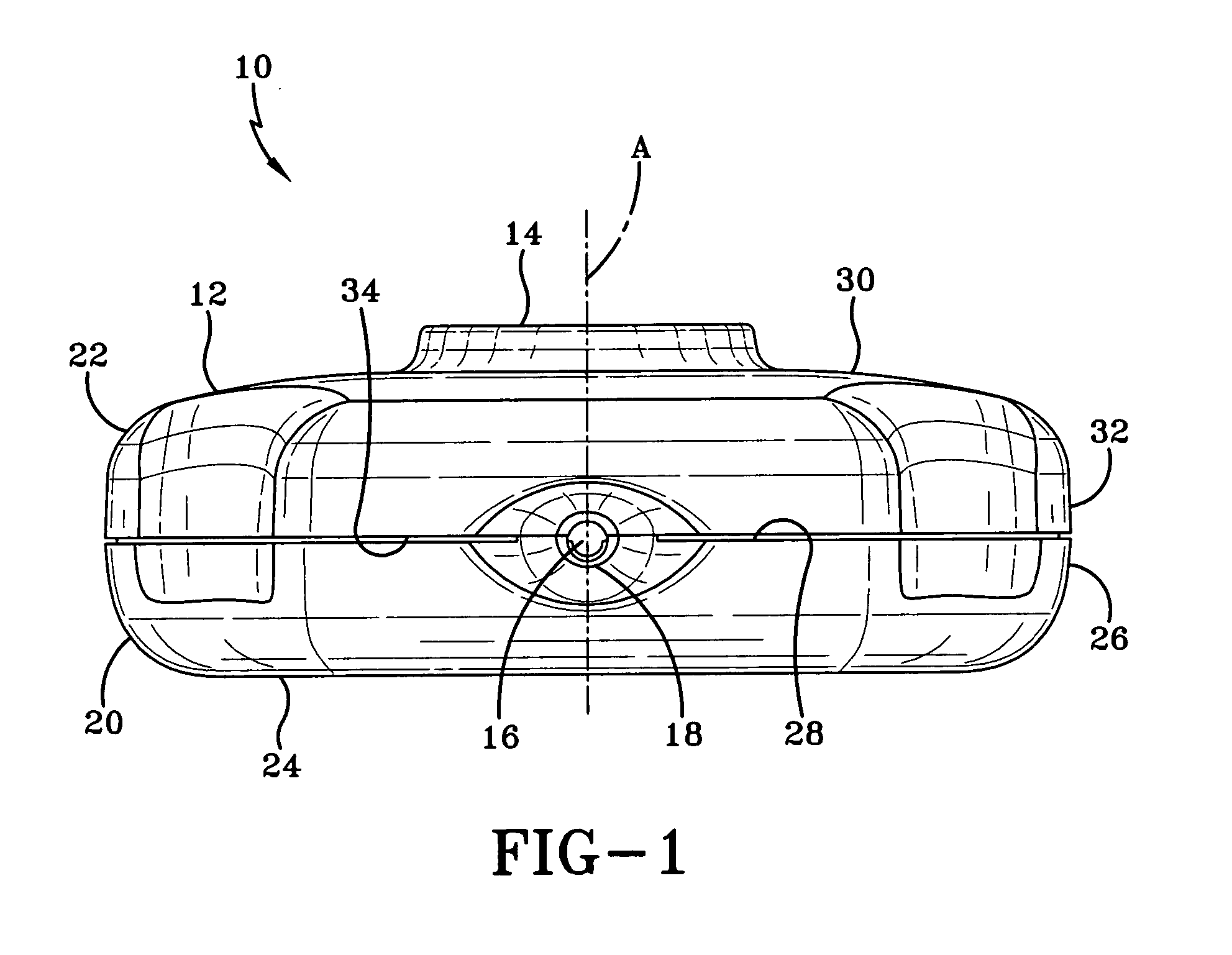

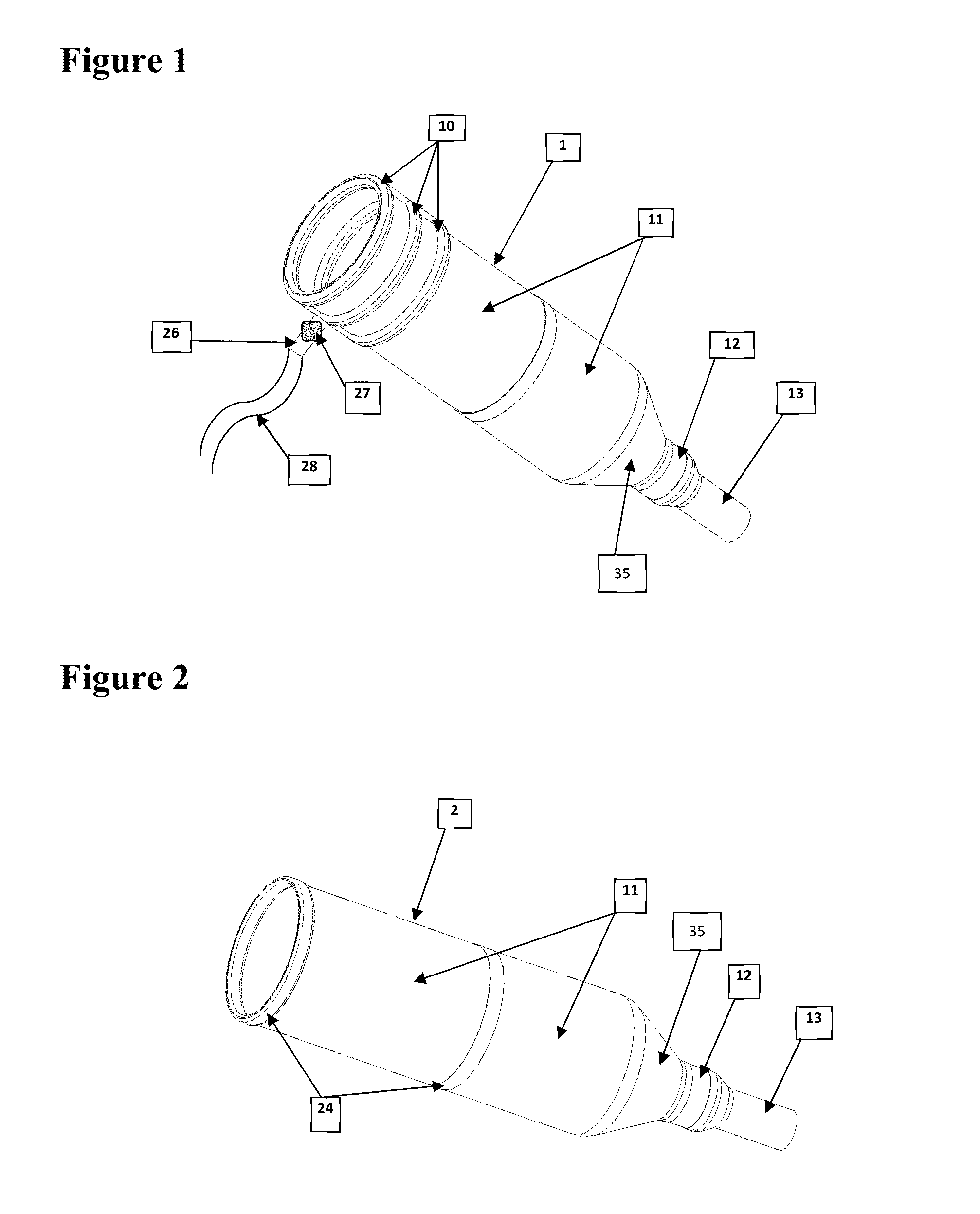

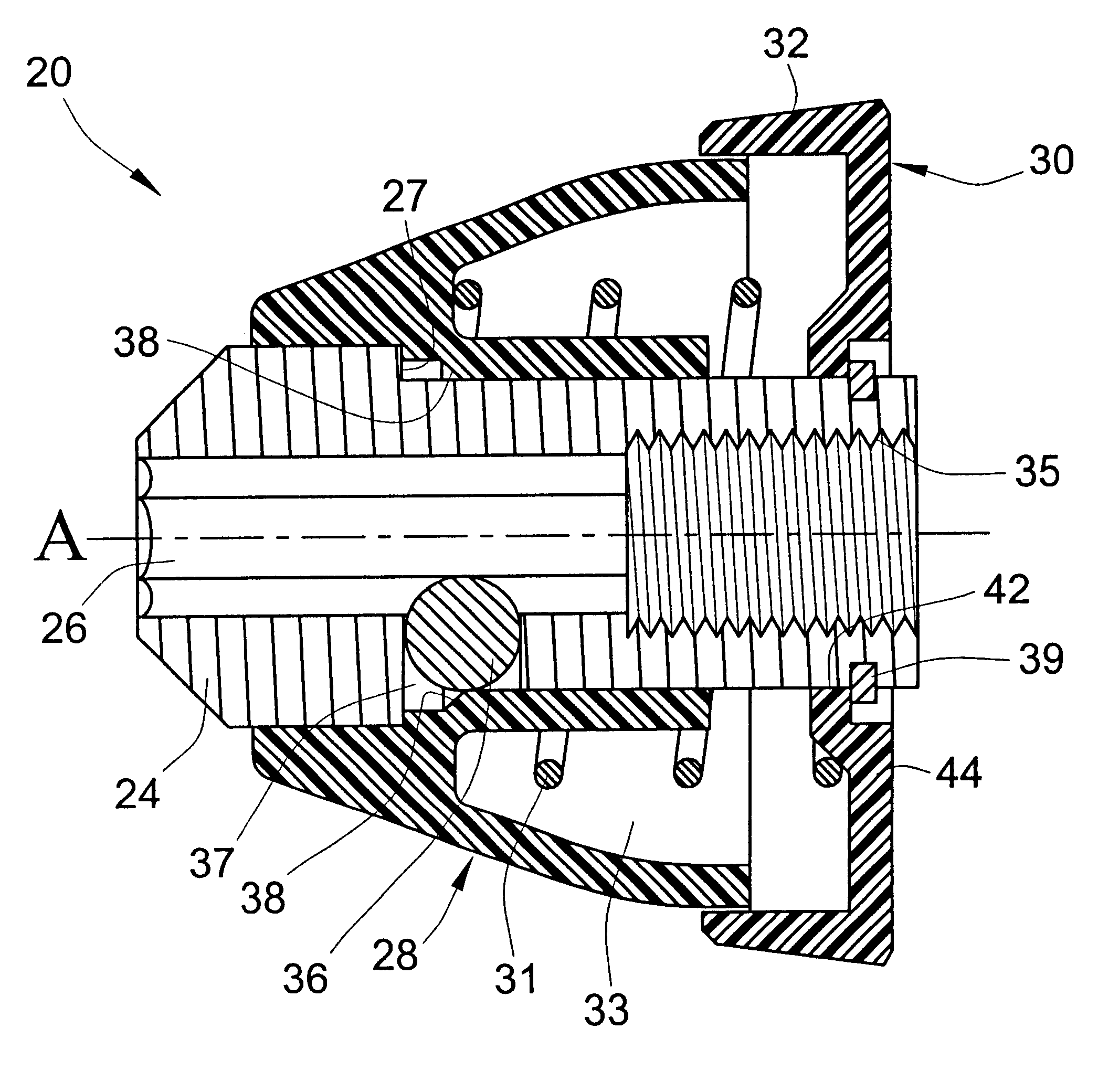

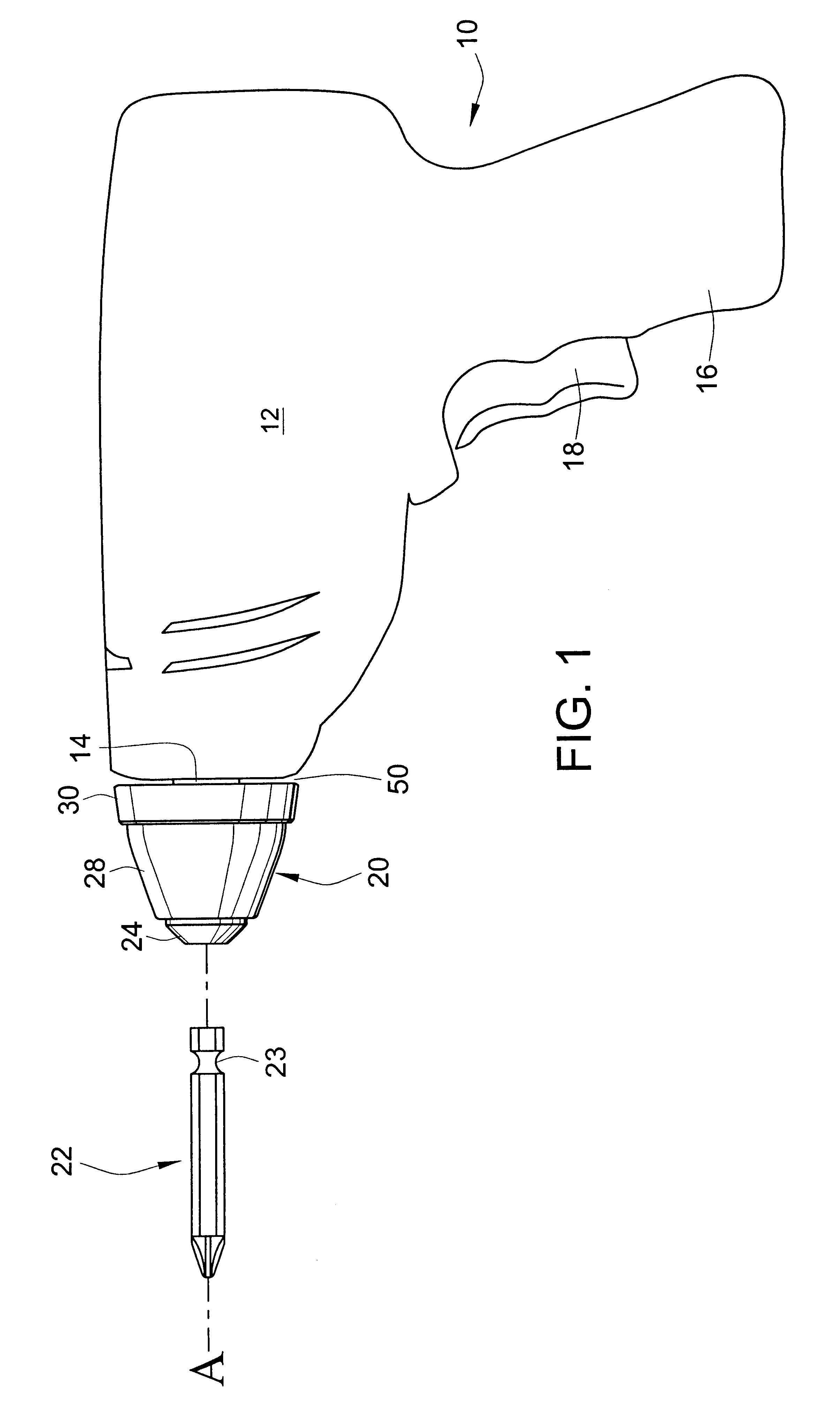

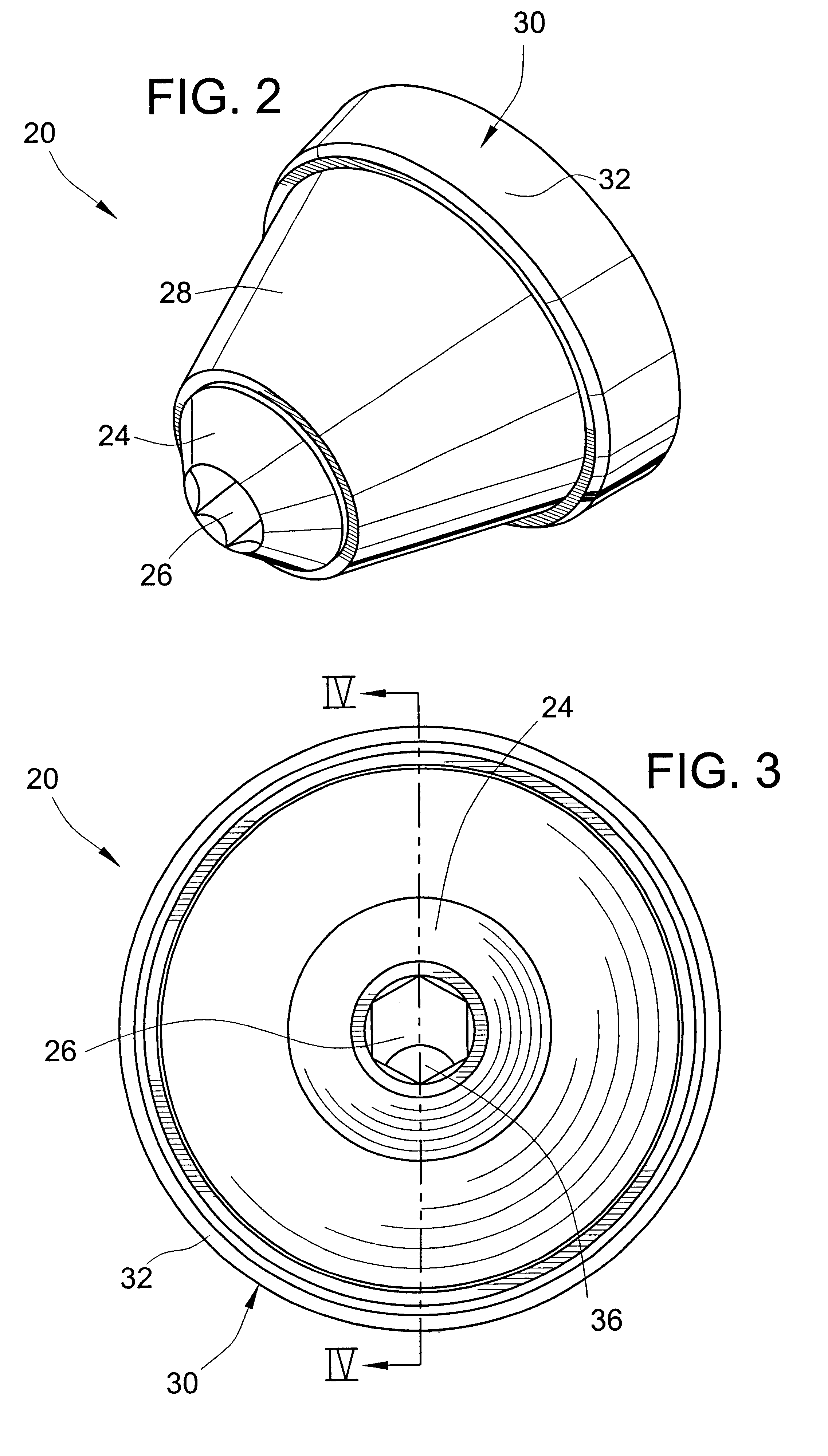

Quick-release chuck having compact collar

The quick-release chuck for a rotary power tool is provided for holding a tool bit. The chuck includes a barrel having an axial bore to receive the tool bit and an axially movable sleeve operable to position a locking member to selectively lock or release the tool bit. A proximal end of the chuck near the housing of the power tool includes a low-profile collar which holds a spring in compression against the sleeve, biasing the sleeve in a distal, locked position. The components of the chuck may advantageously be assembled in a stacked manner. The low-profile collar permits the chuck to occupy a minimal length and to be positioned with a minimal separation from the housing of the power tool for enhanced safety.

Owner:CREDO TECH CORP

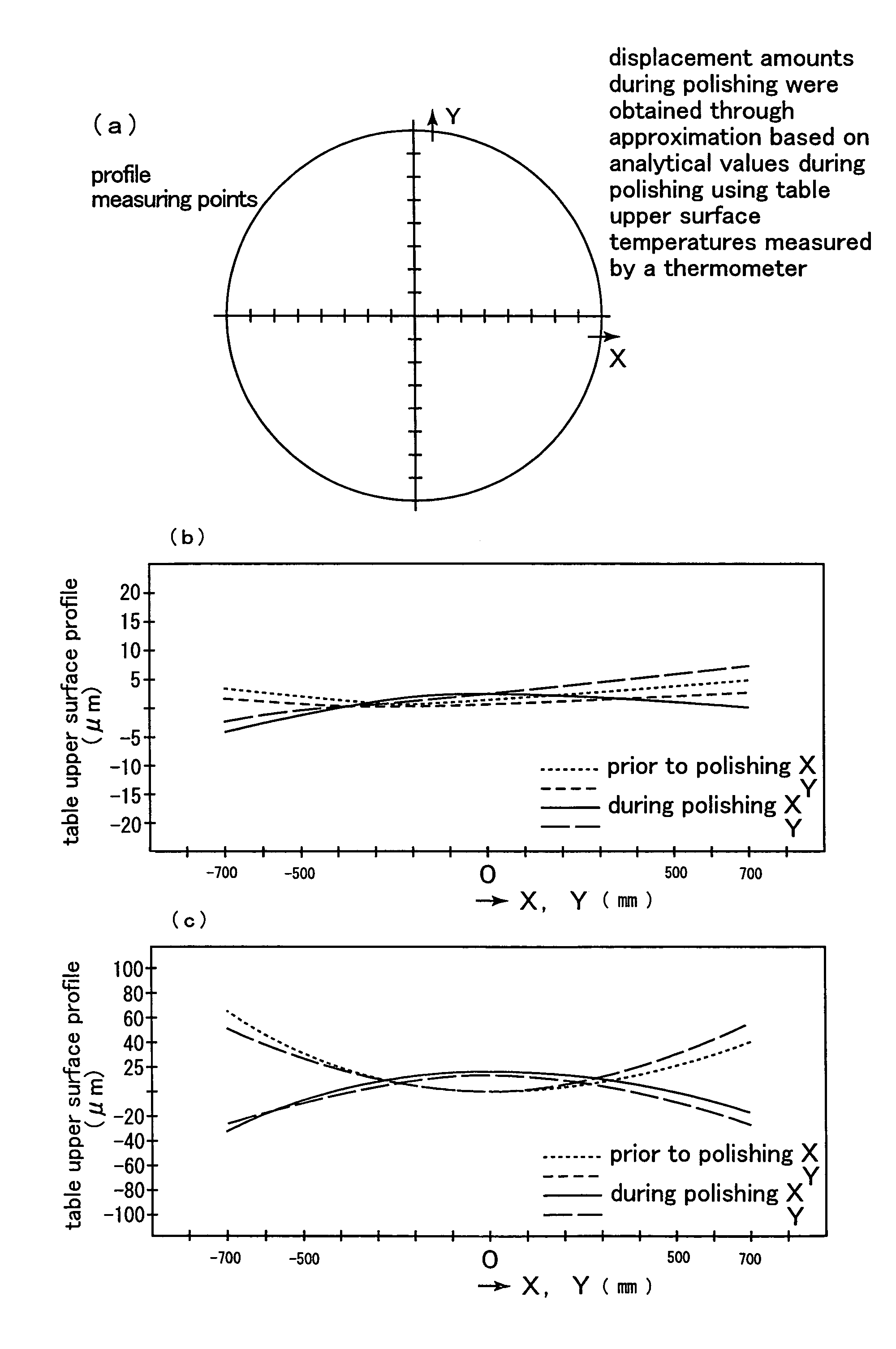

Polishing apparatus and method

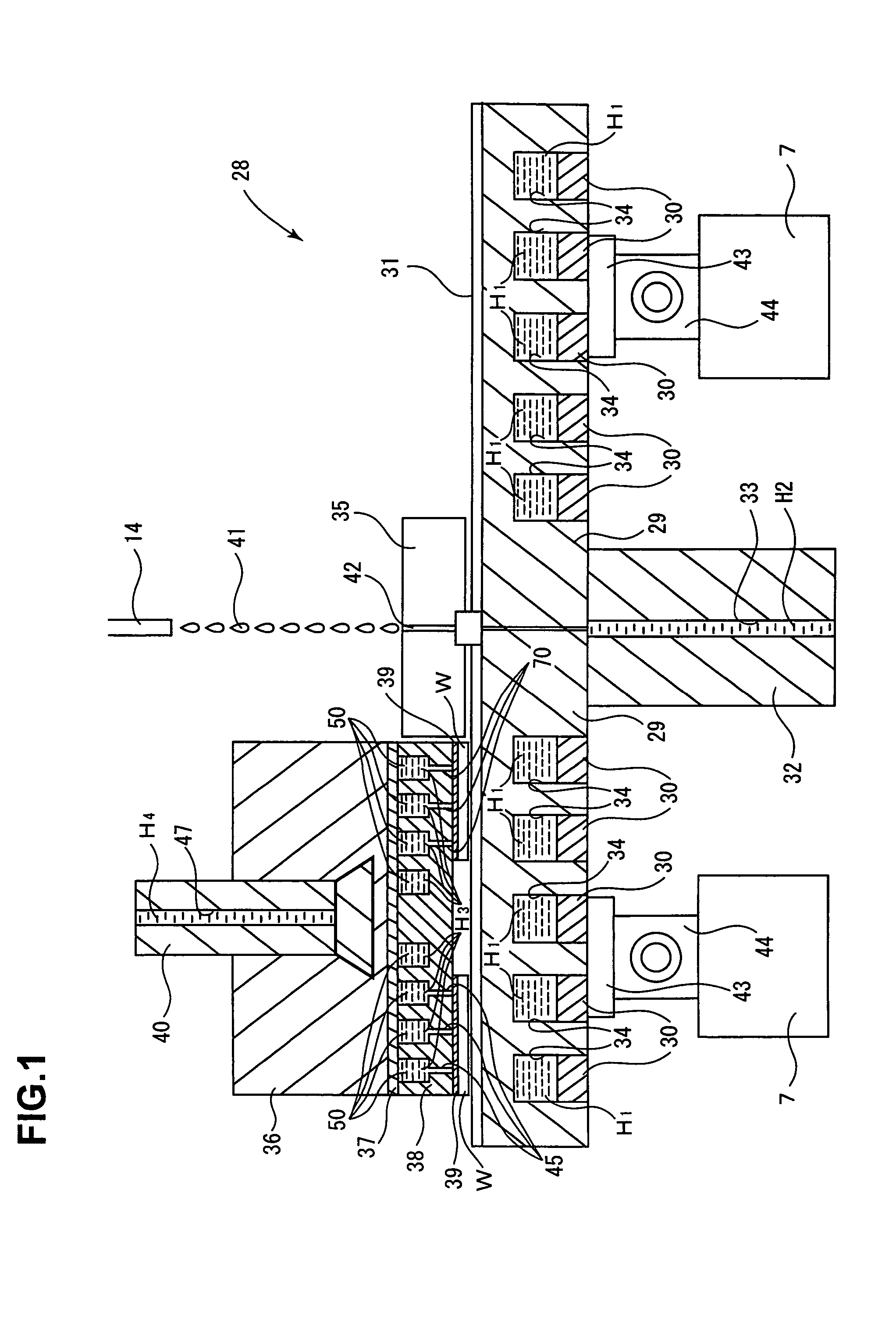

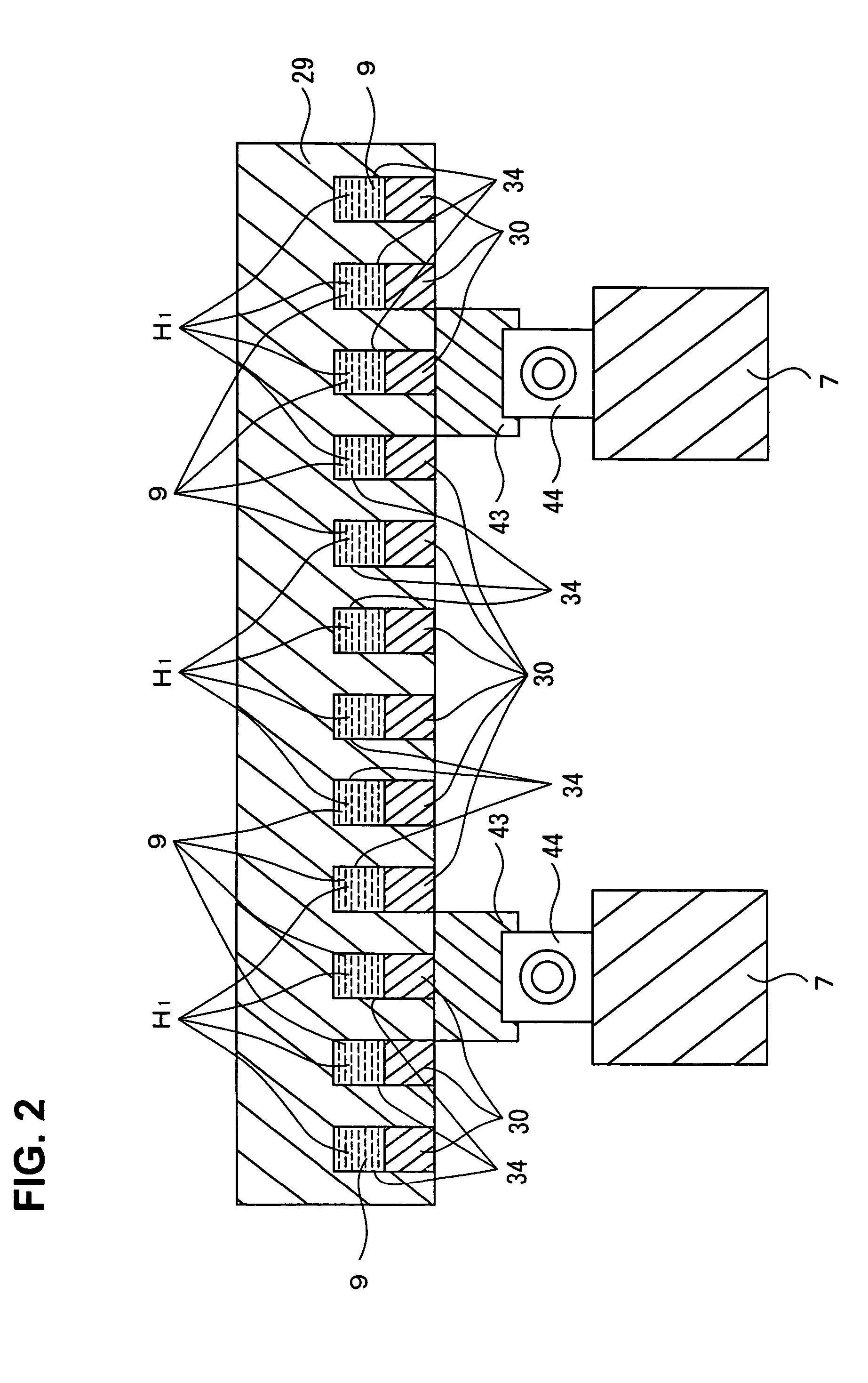

InactiveUS7513819B2Improve efficiencyImprove accuracyPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

There are provided a polishing apparatus and a polishing method capable of performing polishing a work (such as a wafer) with high efficiency and high precision, a novel work holding plate effectively holding a work and an adhering method for a work capable of adhering the work on the work holding plate with high precision. The polishing apparatus comprises: a polishing table(29); and a work holding plate(38), wherein a work held on the work holding plate(38) is polished supplying a polishing agent solution(41) in the apparatus, and in polishing action, an amount of deformation of the polishing table(29) in a direction normal to an upper surface thereof with respect to the upper surface thereof and / or an amount of deformation of the work holding plate(38) in a direction normal to a work holding surface thereof is restricted to 100 m or less by forming the polishing table(29) in one-piece, contriving flow paths of cooling water and others.

Owner:SHIN-ETSU HANDOTAI CO LTD

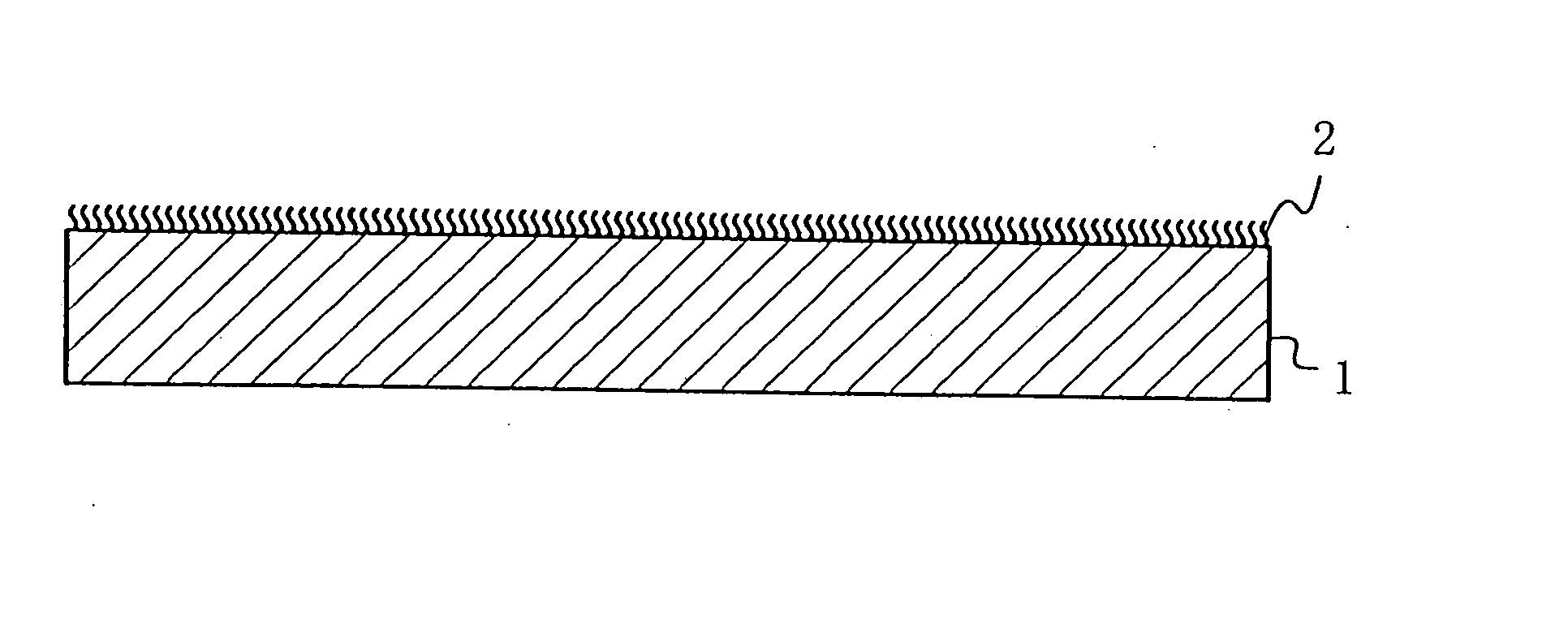

Polishing pad for cmp, method for polishing substrate using it and method for producing polishing pad for cmp

InactiveUS20040224623A1InhibitionHigh frequencySemiconductor/solid-state device manufacturingFlexible-parts wheelsFiberSilicon oxide

In CMP technology for planarizing an interlayer insulation film, a BPSG film, an insulation film for shallow trench isolation, or the like, in the production process of a semiconductor element, irregularities of a matter being polished, e.g. a silicon oxide film, are planarized efficiently at a high speed while suppressing the occurrence of polishing flaws on the substrate by employing a polishing pad having organic fibers exposed on the surface thereof abutting against the matter being polished.

Owner:HITACHI CHEM CO LTD +1

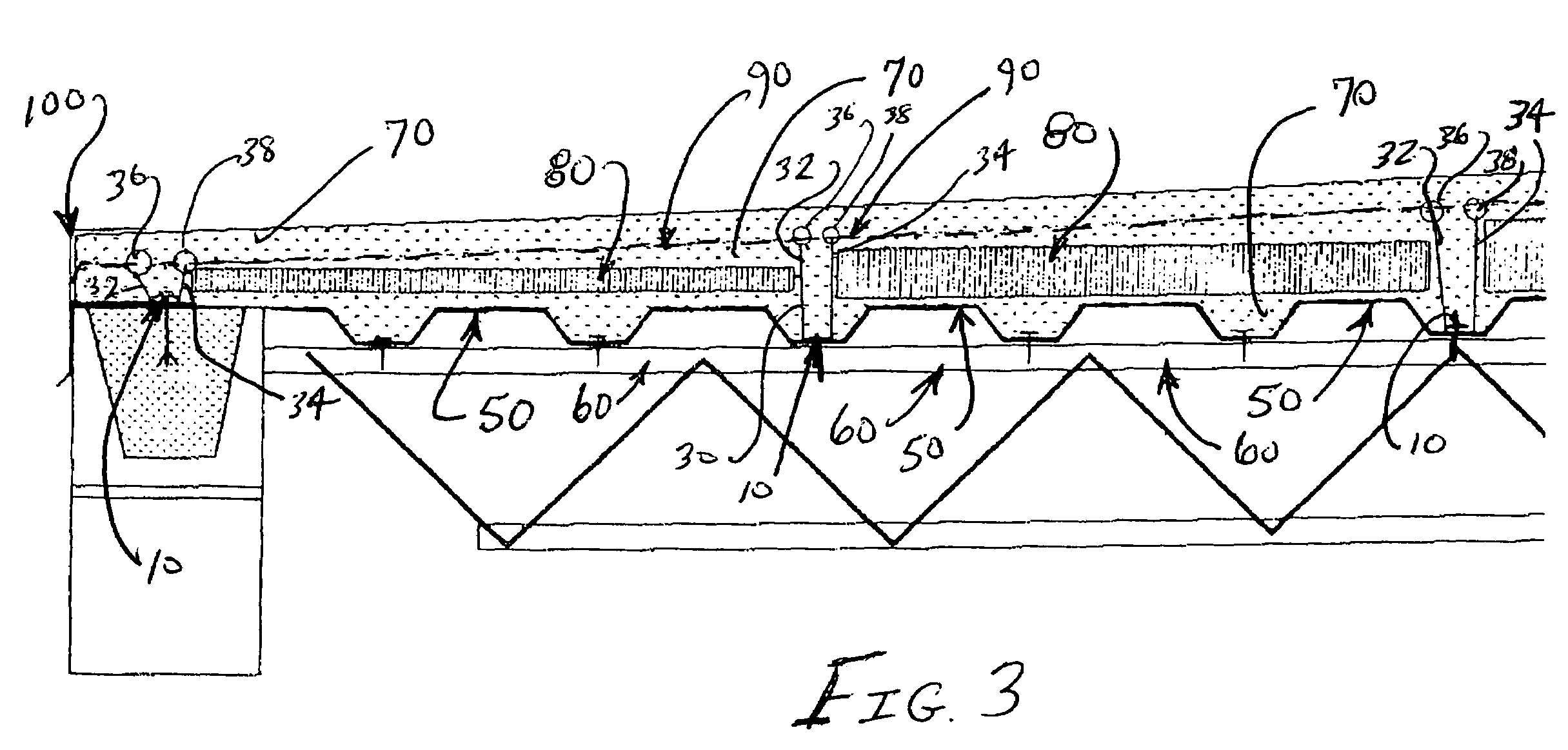

Fastener for lightweight concrete roof systems

A device for use in the installation of lightweight concrete roof systems includes a base element having a substantially flat portion and a wire tie. The wire tie extends from the base element and terminates at opposite ends which may be formed in a ring or loop. In use, the base element is mechanically fastened to the bar joist, through the steel deck, of the roof system. The terminal ends of the wire tie are secured to steel-welded wire reinforcement fabric overlying a layer of lightweight concrete, thereby securing the lightweight concrete to the steel deck of the roof system and preventing separation of the lightweight concrete due to external forces such as wind sheer.

Owner:GEMBALA HENRY +2

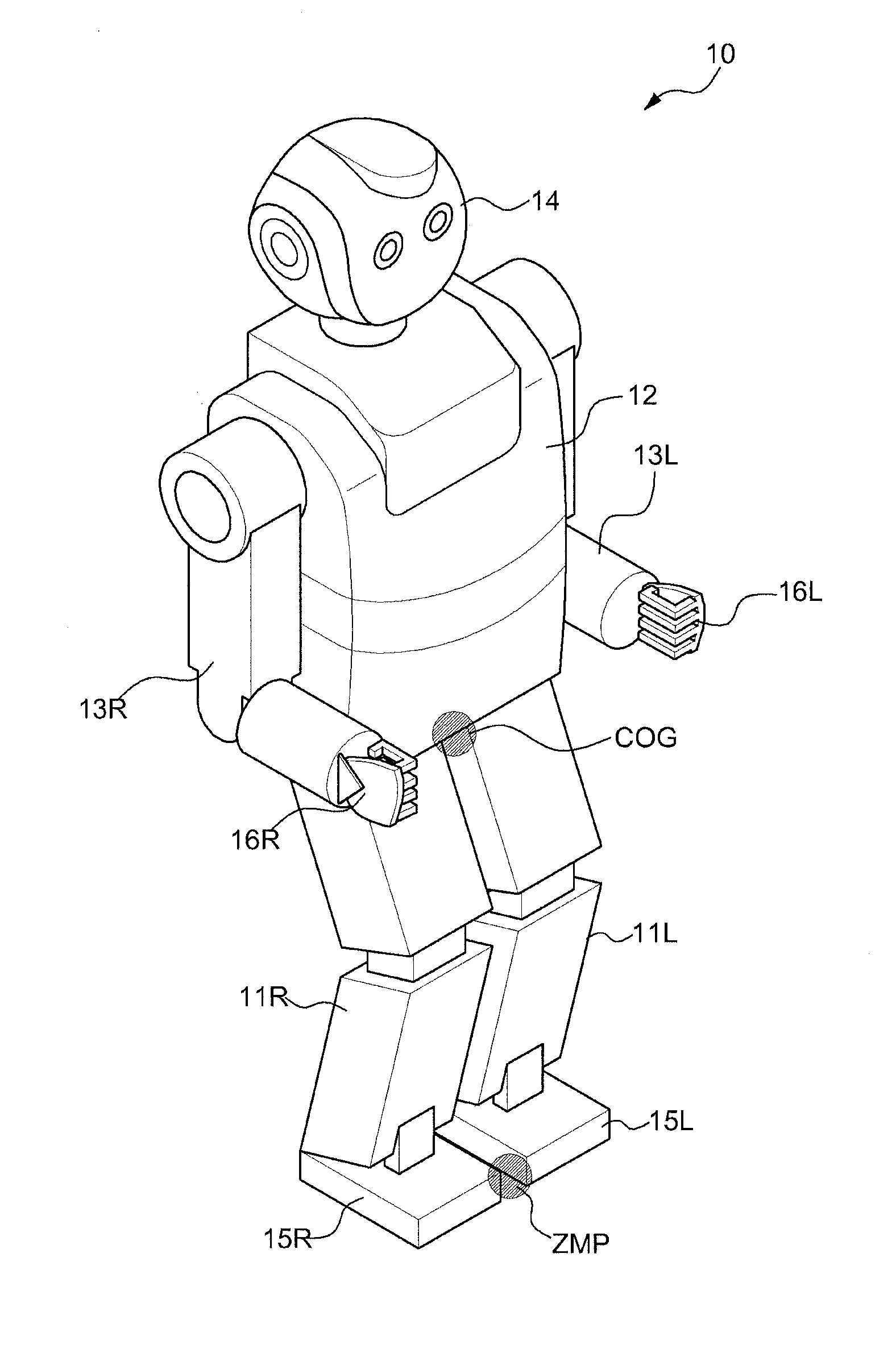

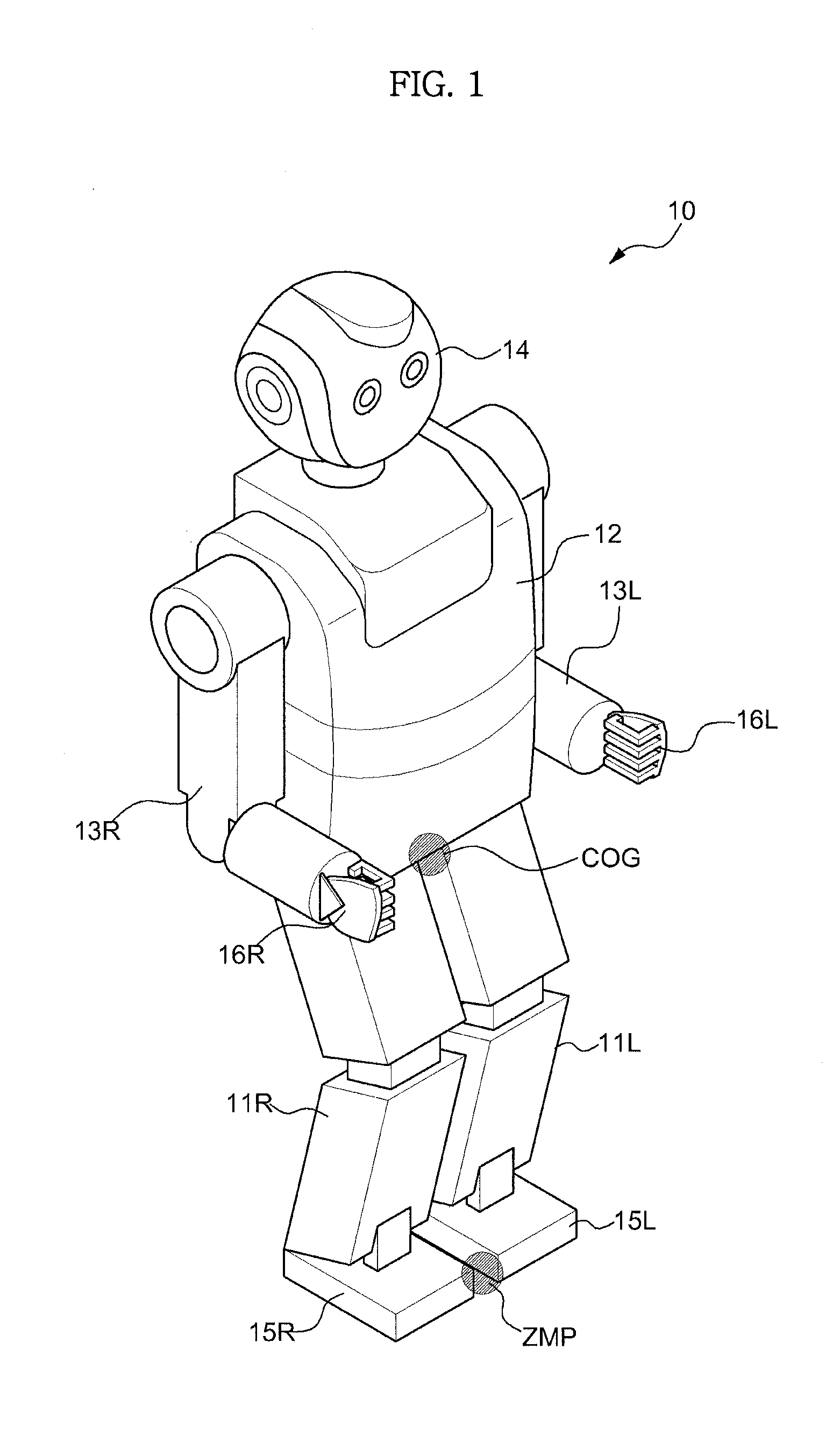

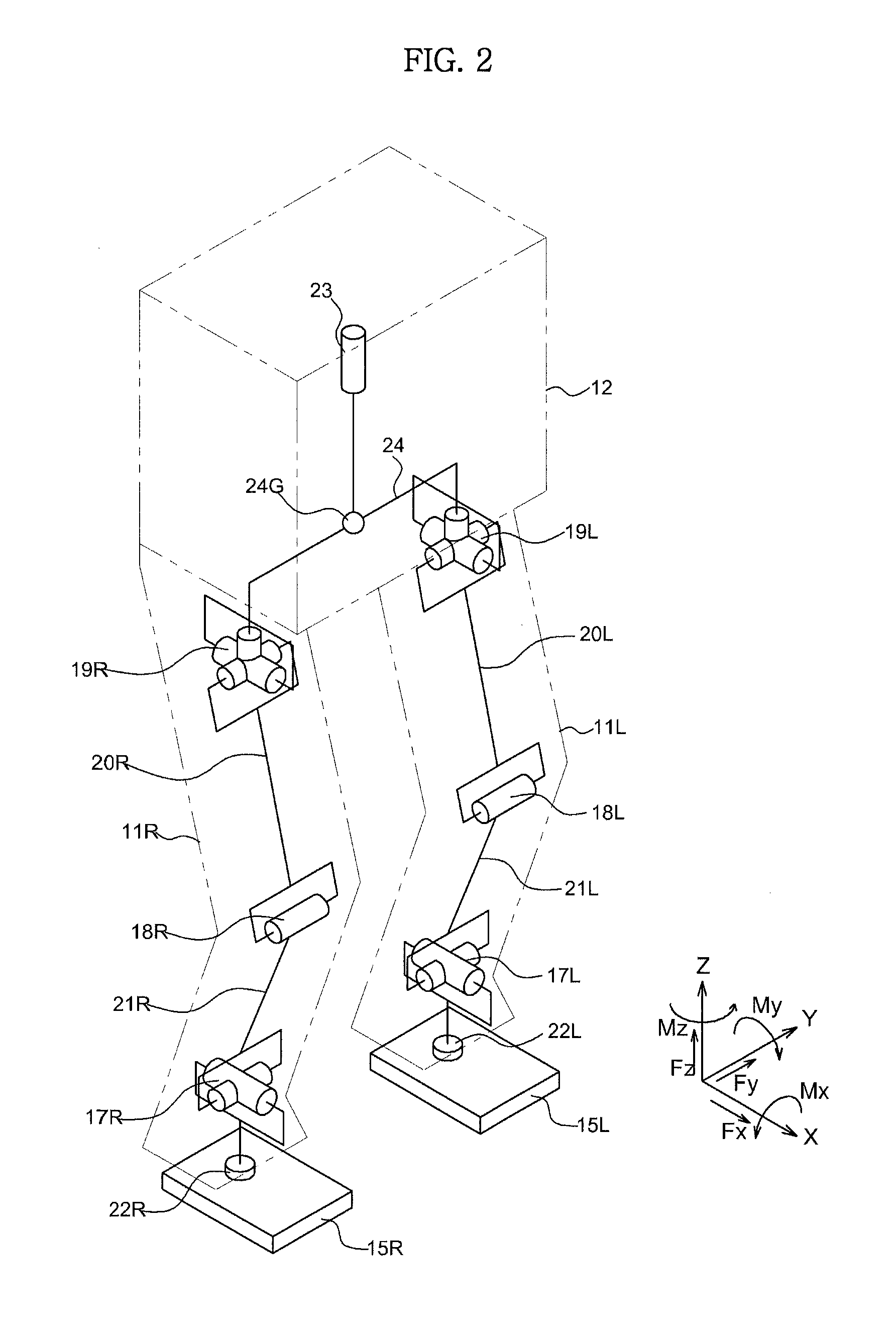

Apparatus and method controlling legged mobile robot

InactiveUS20110040410A1Effective balancePrevent fallingProgramme controlProgramme-controlled manipulatorEngineeringControl theory

Disclosed is an apparatus and method adjusting motion of each joint of a robot to compensate for friction force of each joint such that the sole of the foot of the robot clings to the ground. The motion of each joint is adjusted as if gravity acts on each joint of the robot in a direction opposite to gravity and the robot is held in an erect state. Therefore, the robot can stand while keeping its balance without falling.

Owner:SAMSUNG ELECTRONICS CO LTD

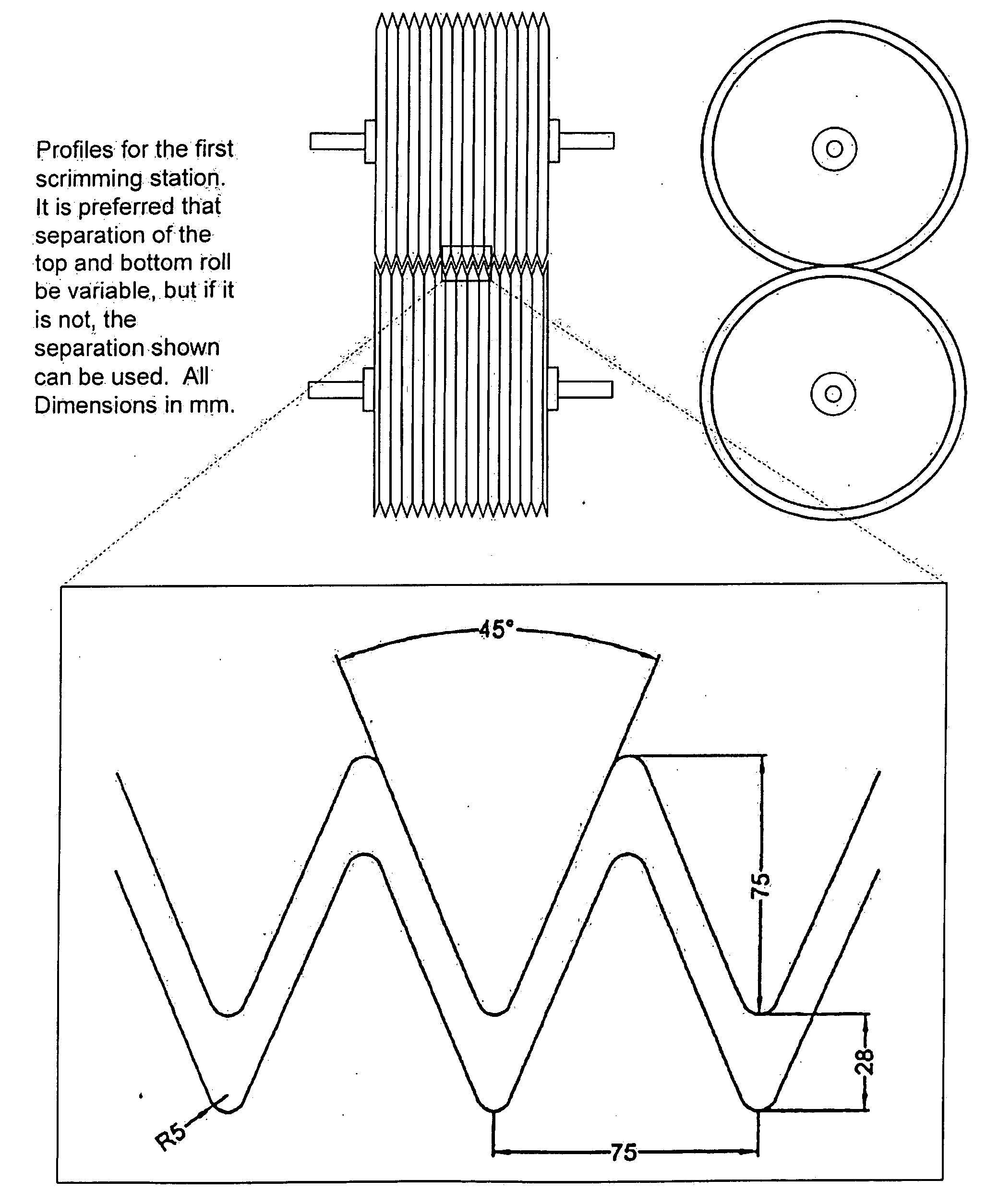

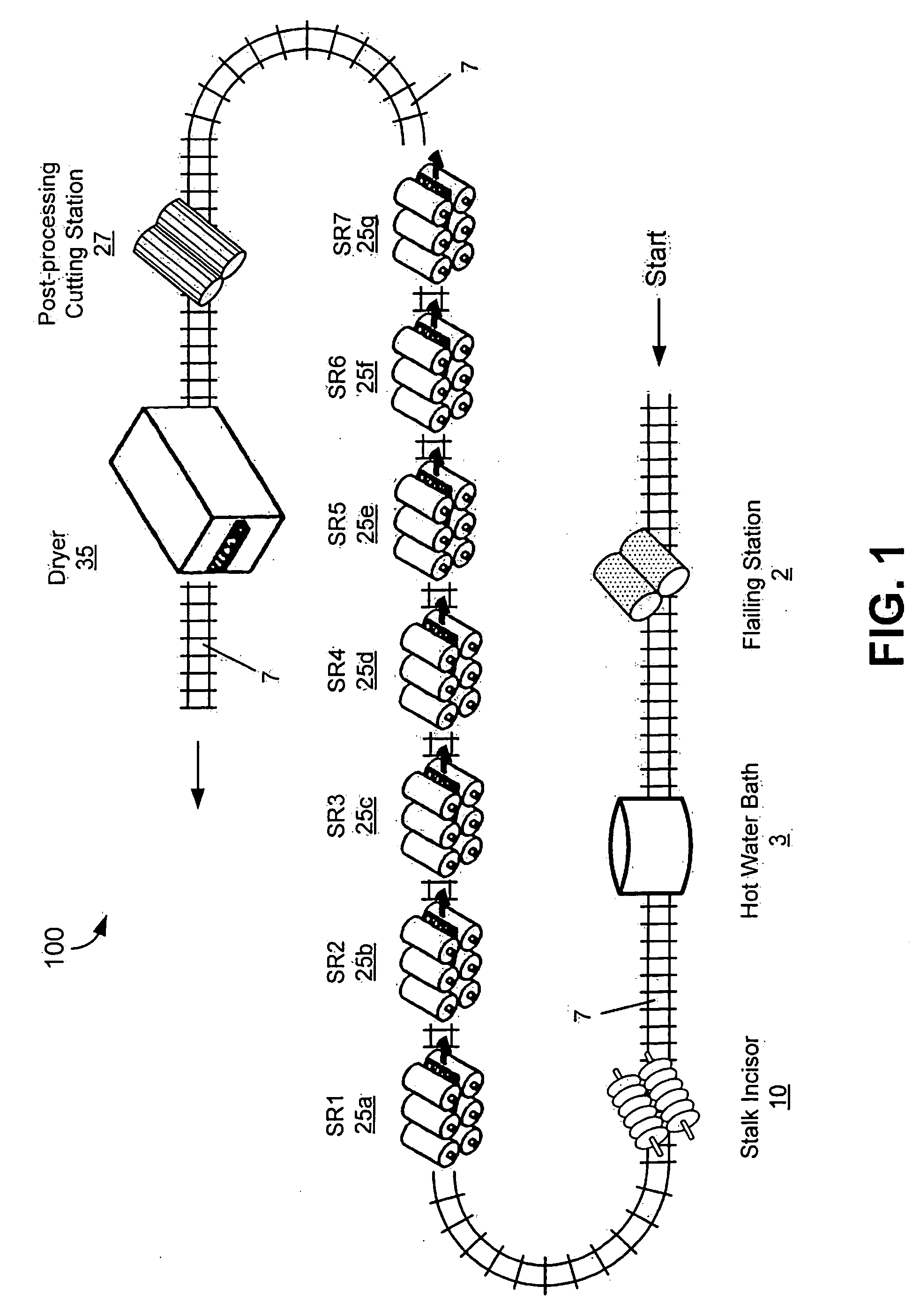

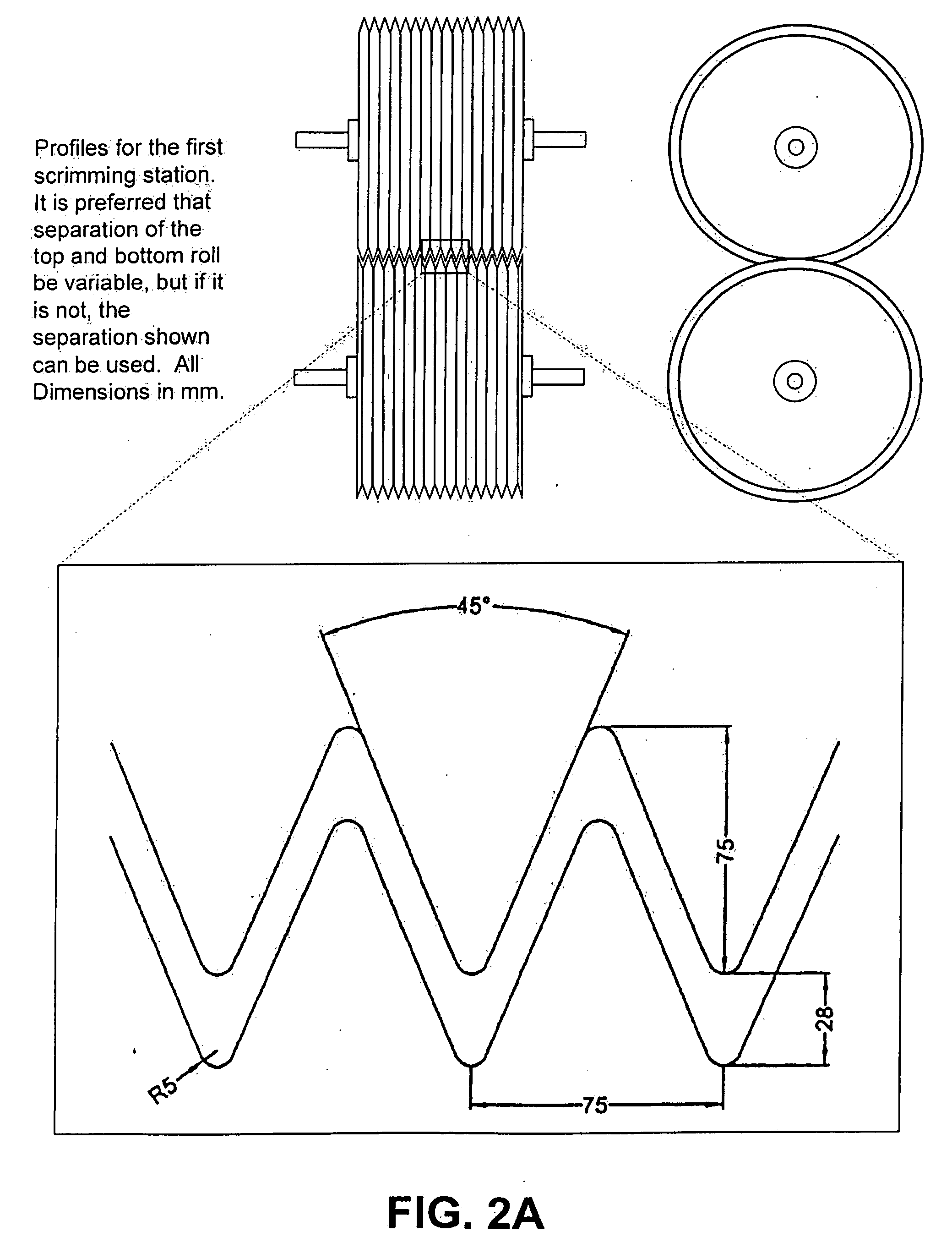

System and method for the separation of bast fibers

InactiveUS20090145563A1Quality improvementEfficient separationFibre cleaning/opening by toothed membersWood working apparatusEngineeringBast fibre

The present invention relates generally to the timber products industry, and particularly to methods and apparatus for the separation of bast fibers. More particularly, the present invention relates to methods and apparatus for use in the separation of inner core from outer bast of bast plants using soaking, cutting, and scrimming methods and apparatuses.

Owner:TIMTEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com