Stent Delivery System Having Stent Securement Apparatus

a technology of stent and securement device, which is applied in the field of assembly and method of delivering and deploying an inflation expandable stent, can solve the problems of stent slippage and dislocation from the desired position, and achieve the effect of reducing the diameter of the sten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

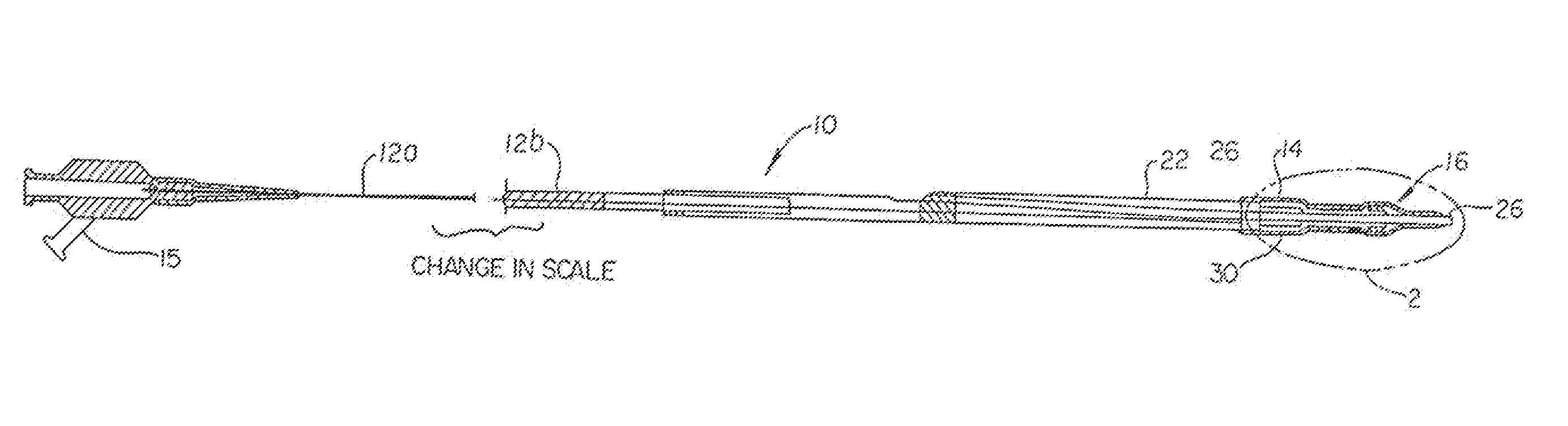

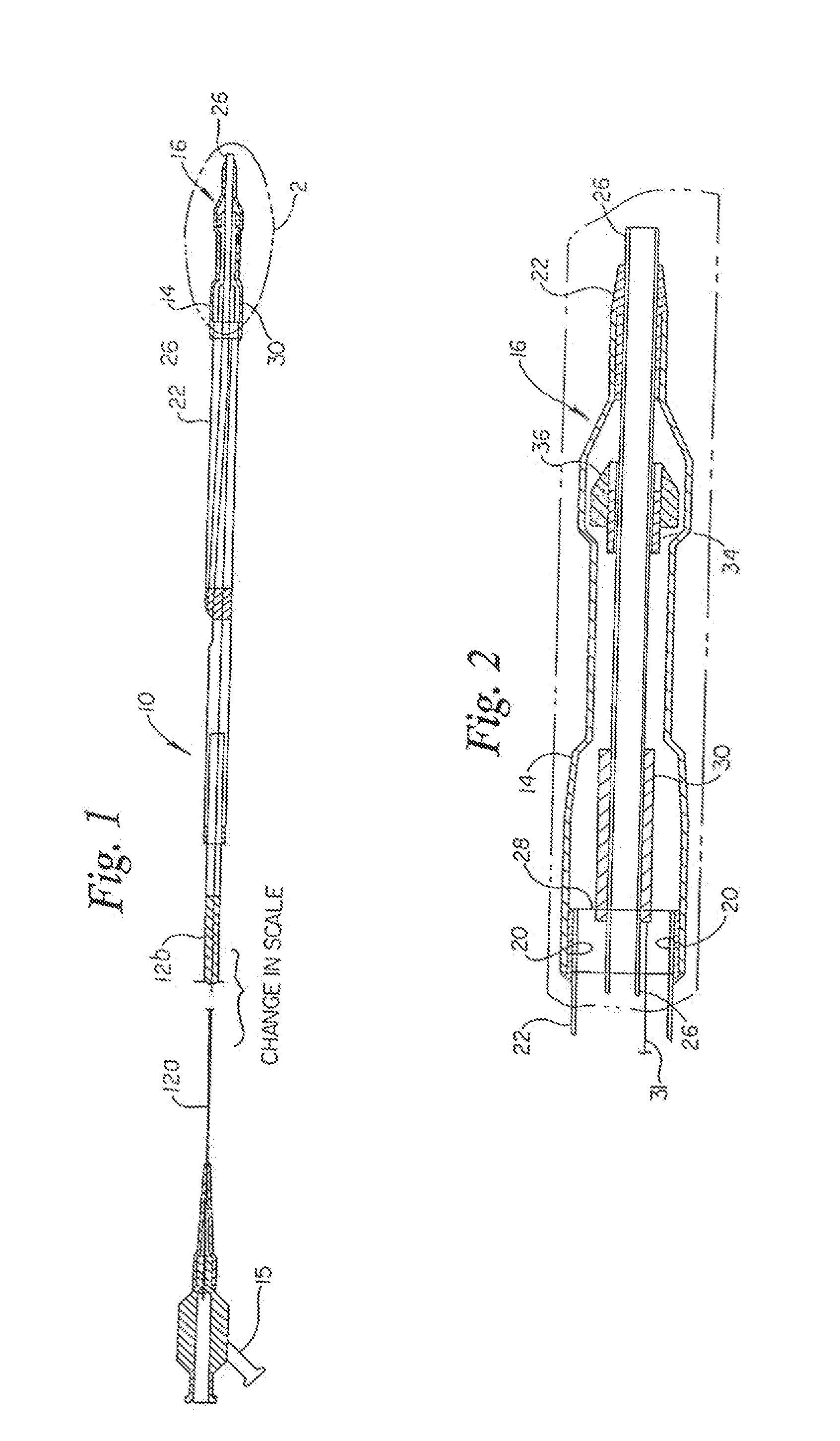

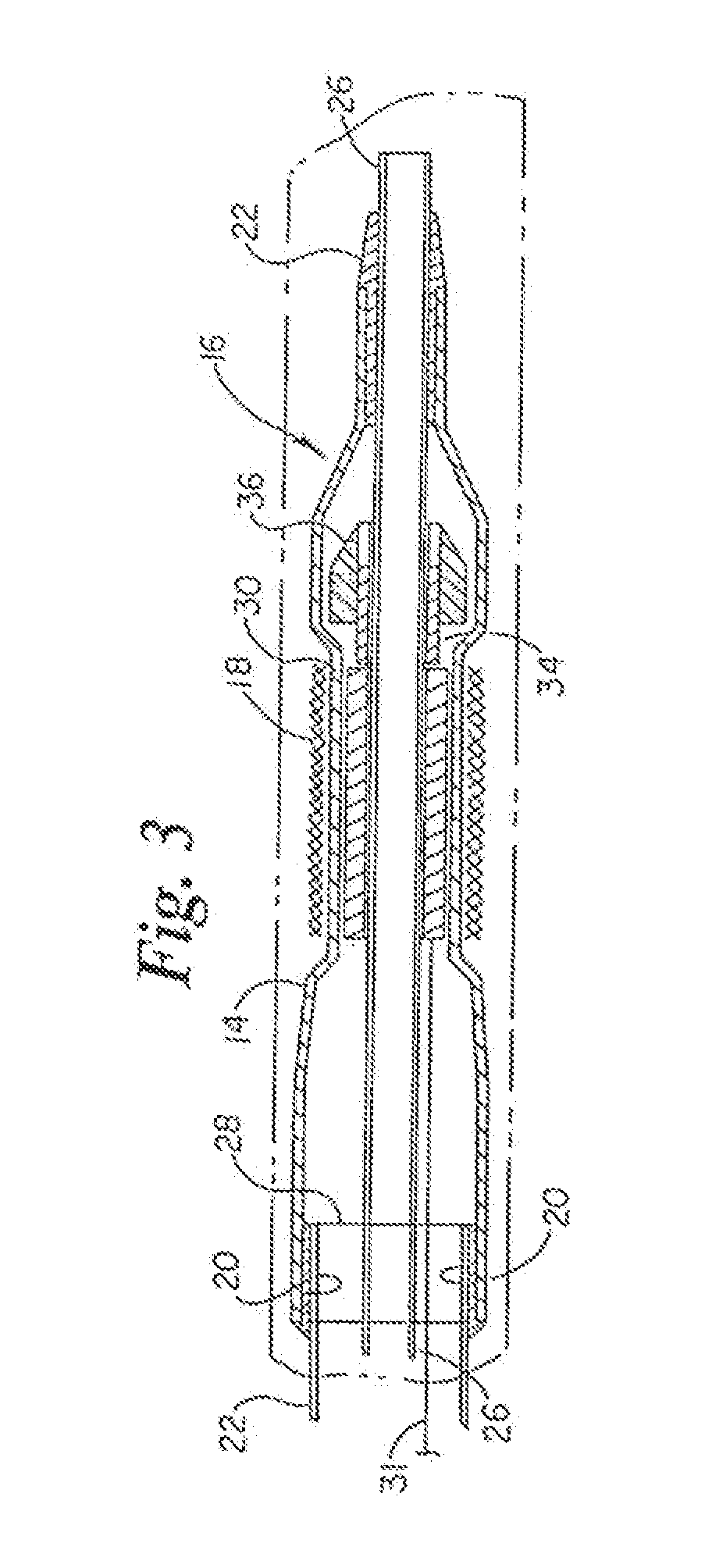

[0063]The present invention relates to stent securement devices, most notably positioned between the balloon and the inner shaft of the catheter. Individual elements of the below disclosed embodiments are generally interchangeable if desired. Referring to FIGS. 1-4 an angioplasty and stent delivery catheter system generally indicated at 10 includes a balloon catheter 12 having a balloon 14 on a distal end portion generally indicated at 16. FIG. 1 shows a proximal portion of the catheter at 12a and a distal portion 12b in enlarged view. FIGS. 2 and 3 show the distal end portion 16 in an even more enlarged view. The illustrative catheter 12 is of the type known as a rapid exchange or single operator catheter. However, other types of catheters may be used, such as over the wire and fixed wire types. The balloon 14 is fixed to the catheter 12 by standard means. The balloon is shown in its contracted state in. A stent 18 is fixed about the balloon by crimping thereto. The stent has a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com