Patents

Literature

32results about How to "Effective length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

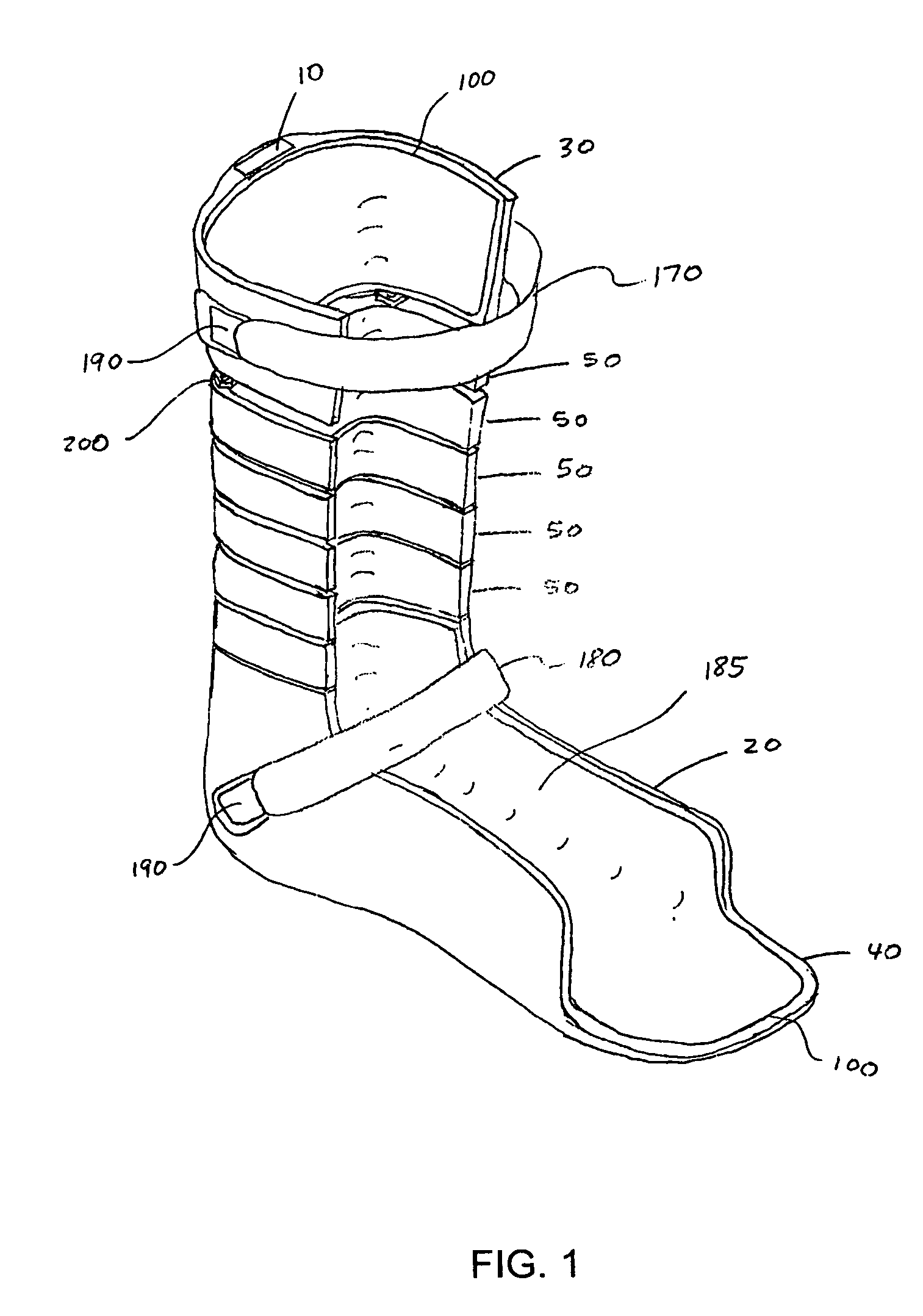

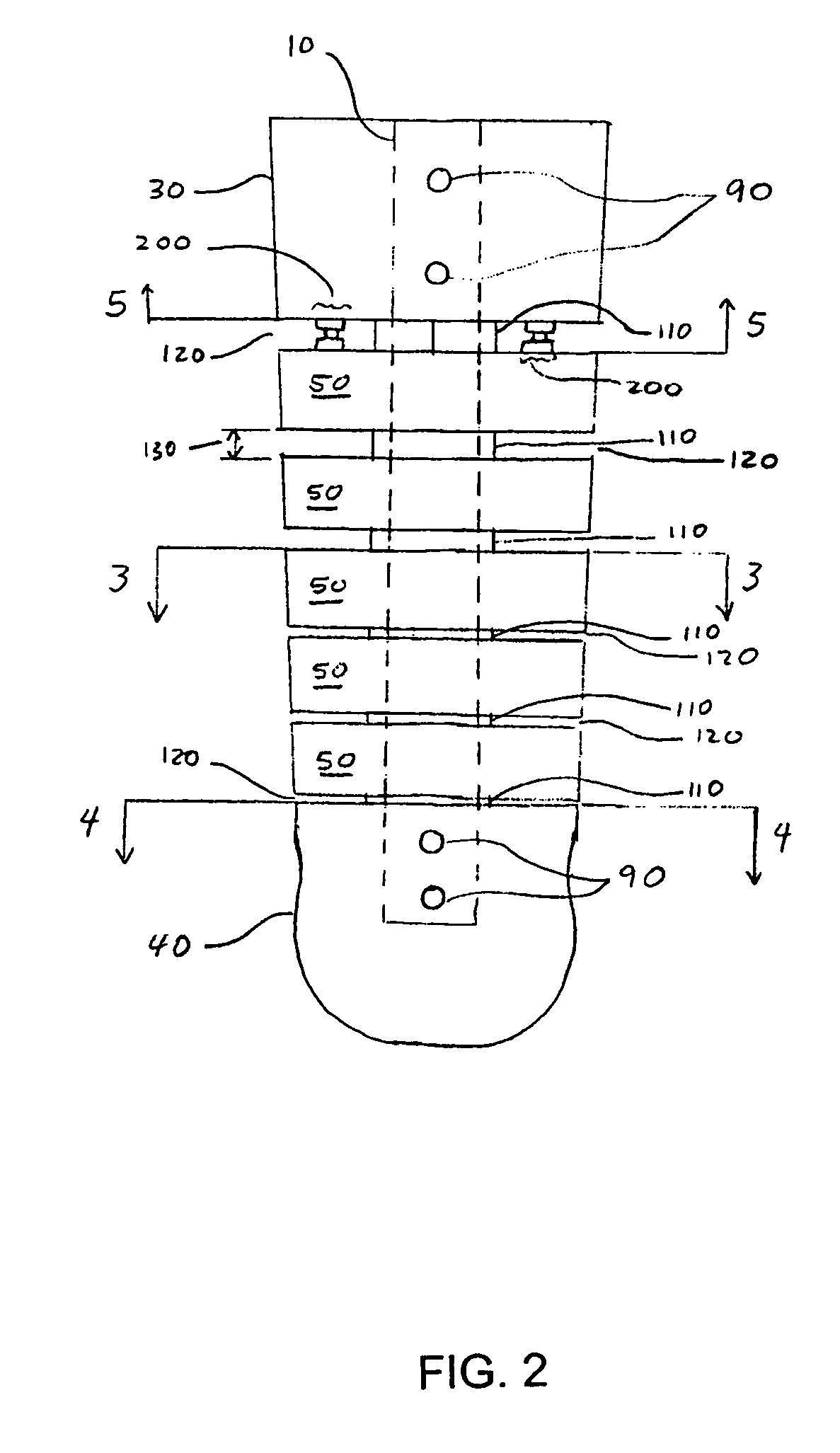

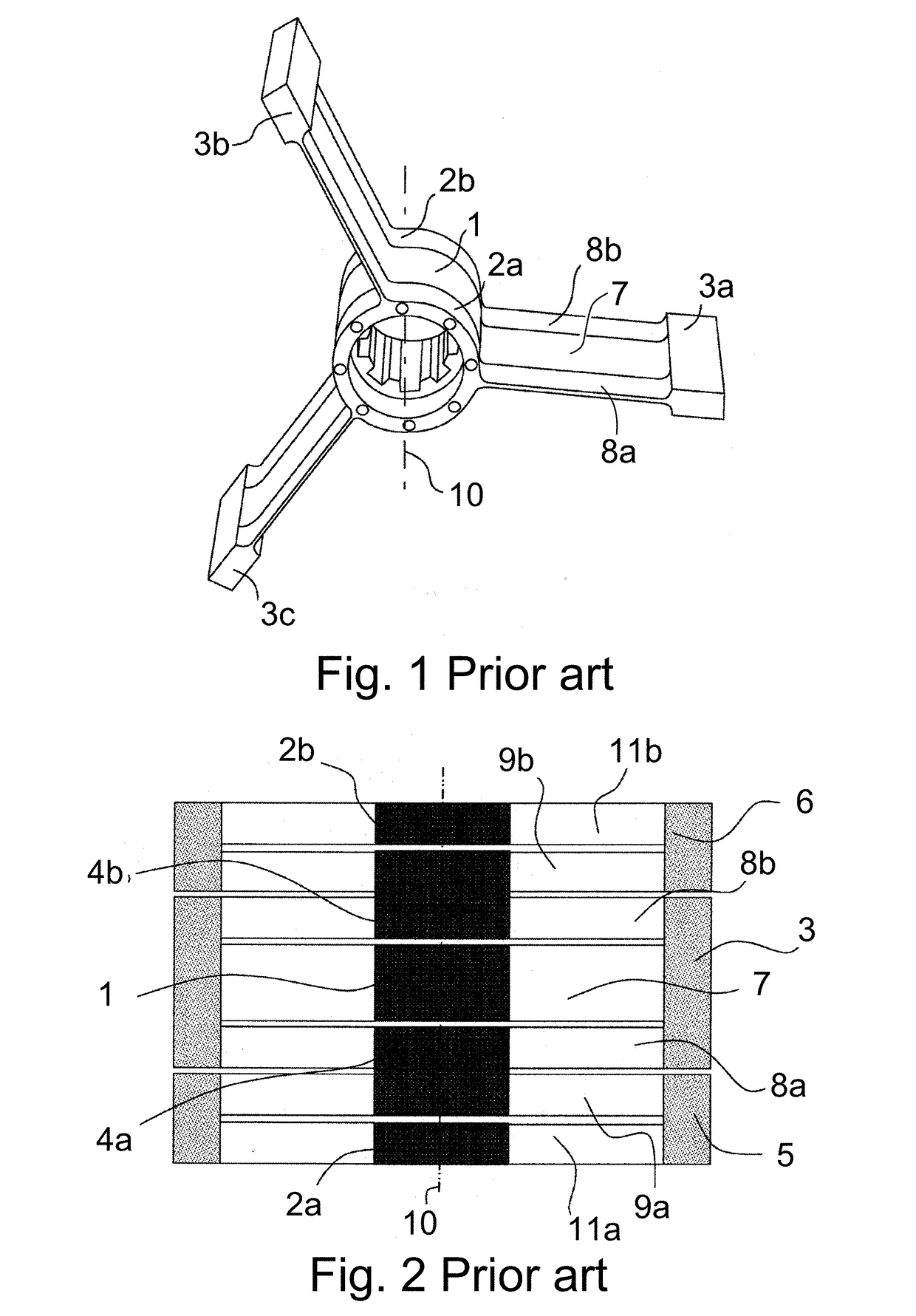

Ankle-foot orthosis

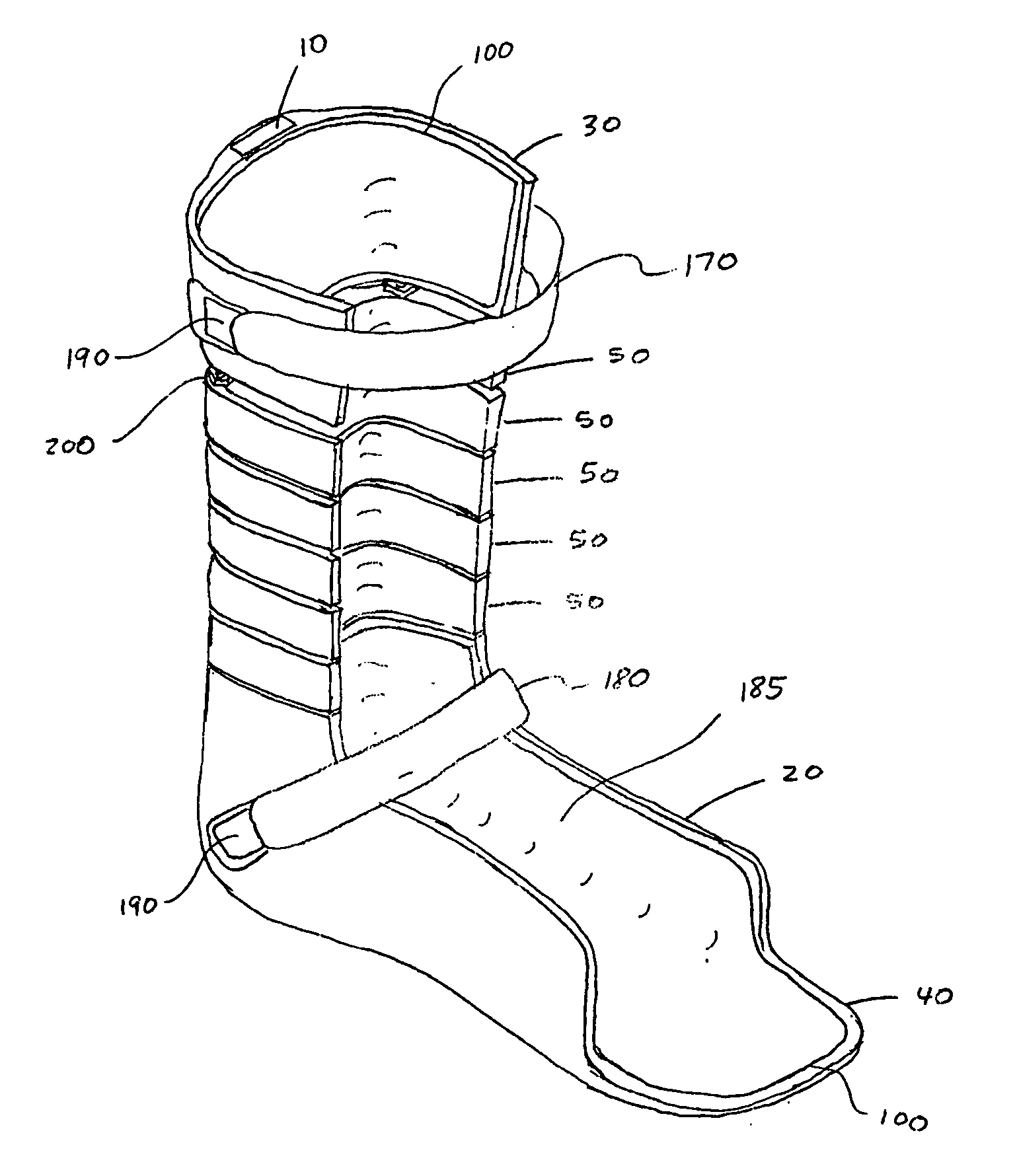

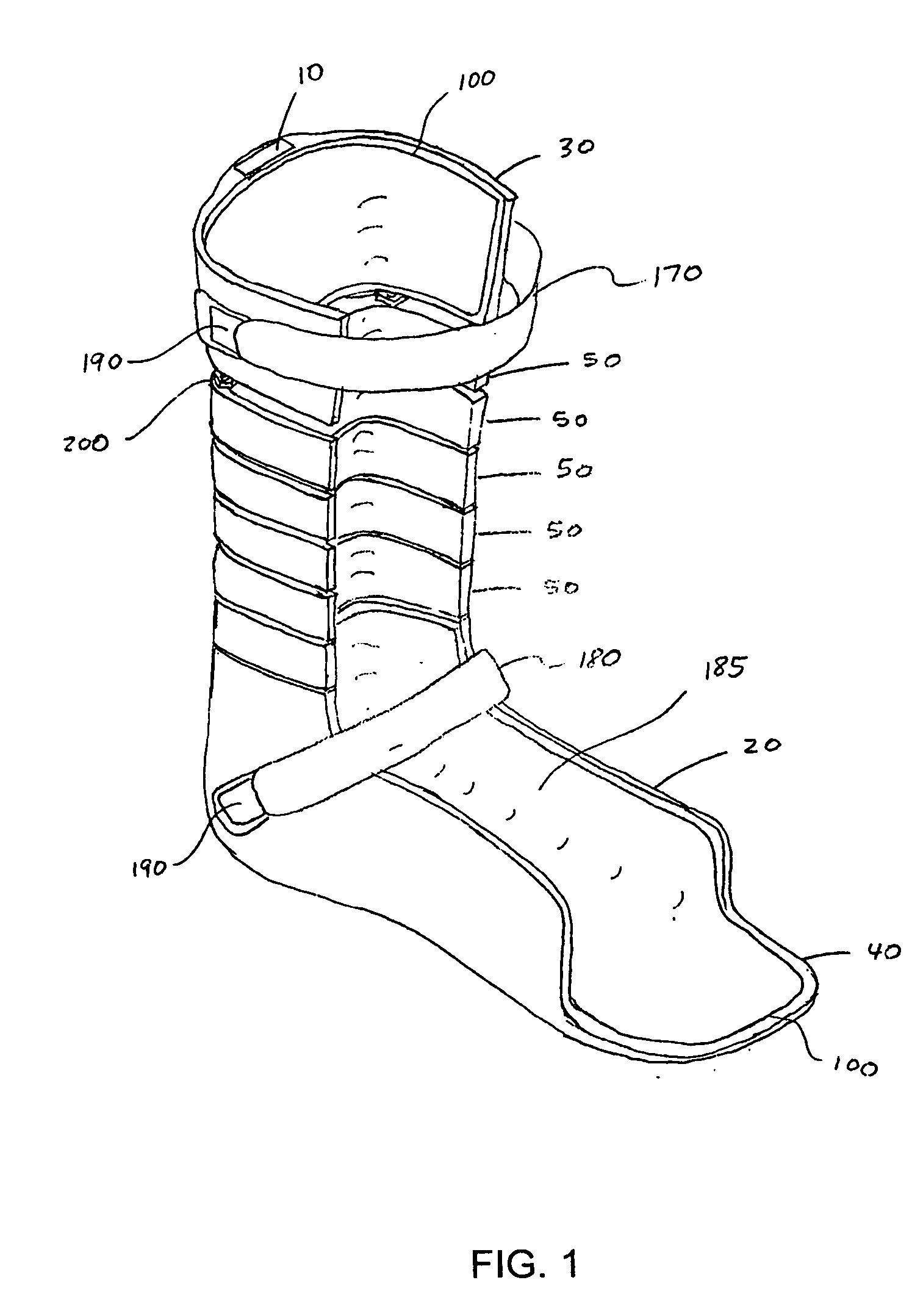

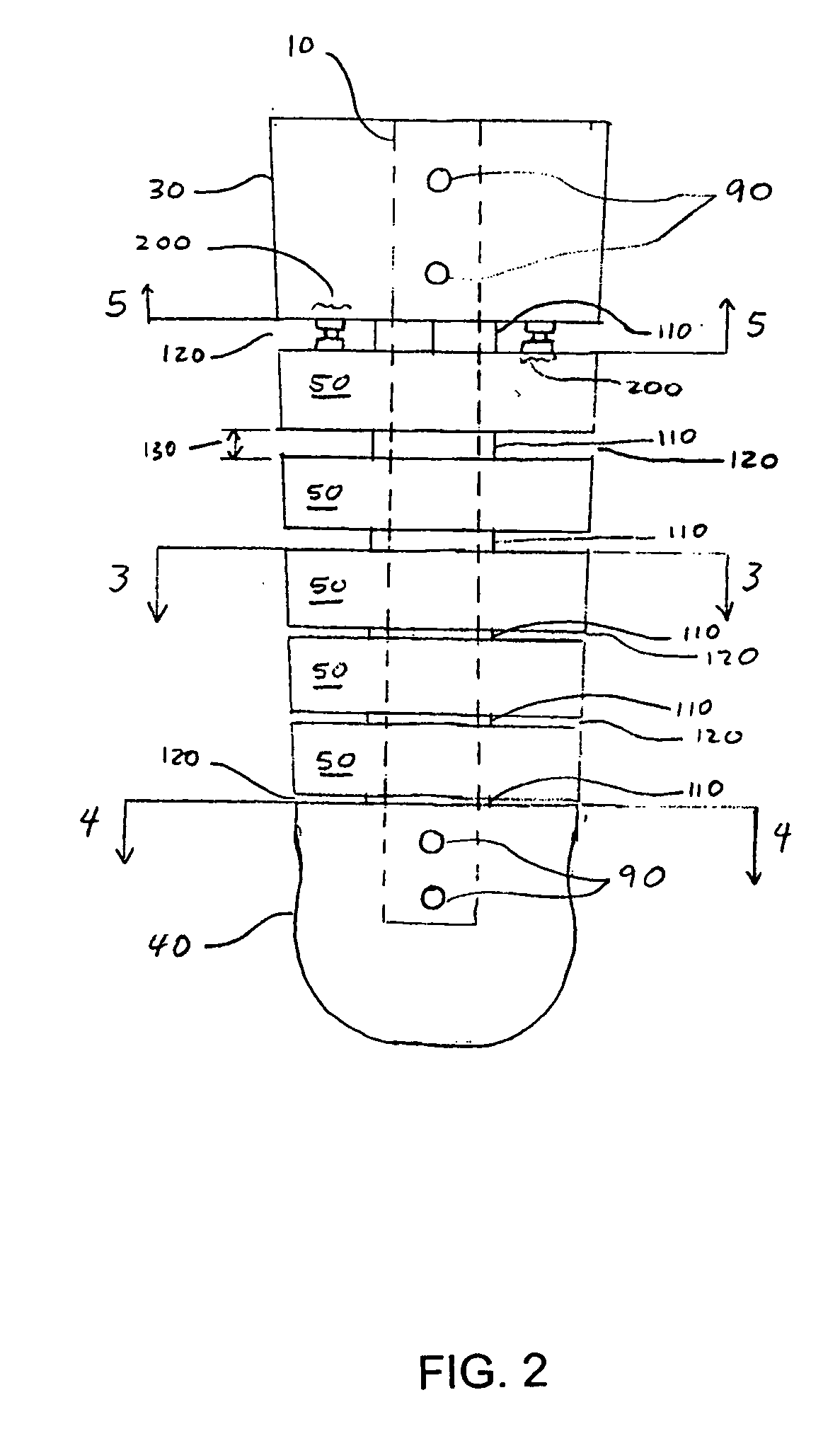

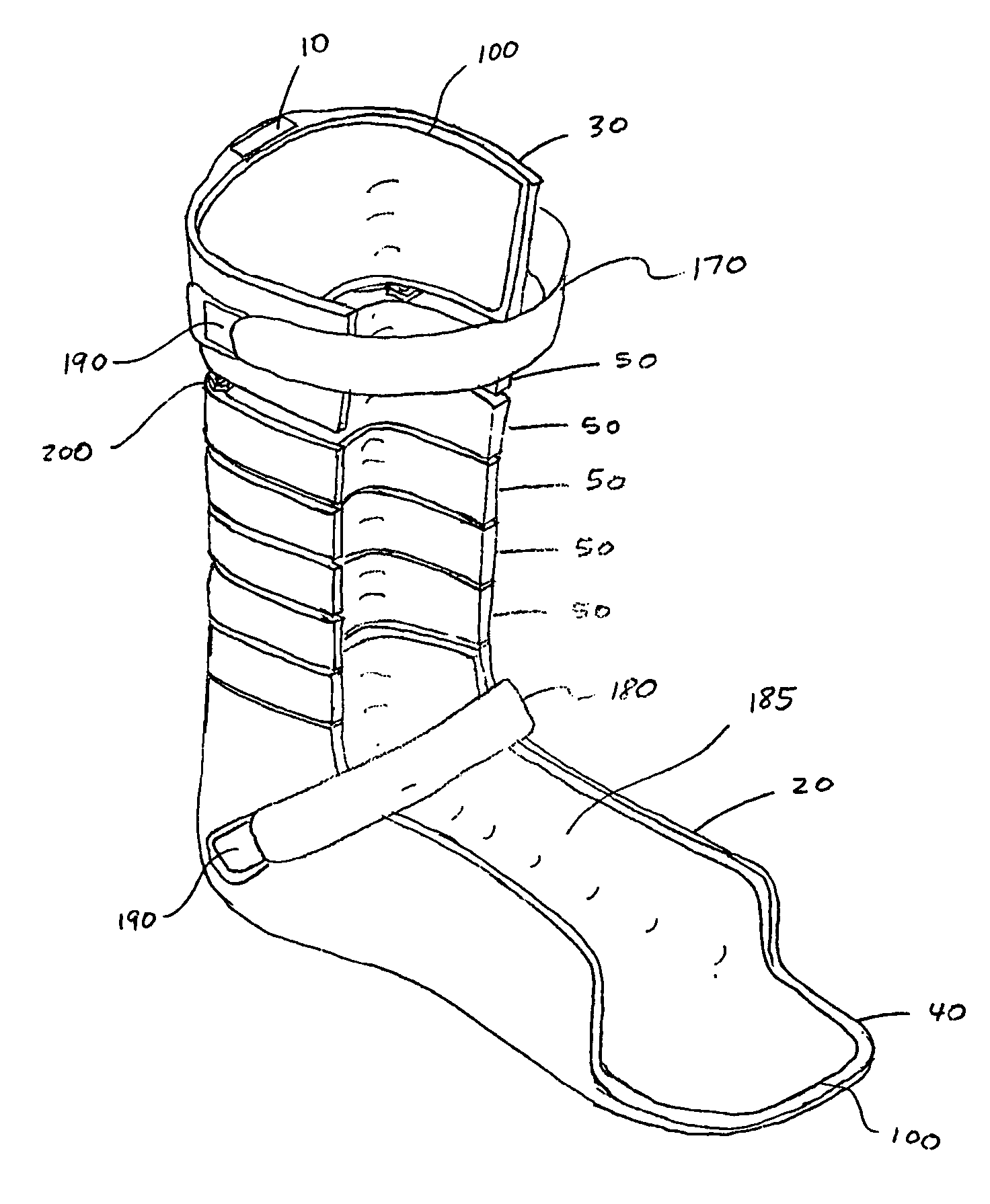

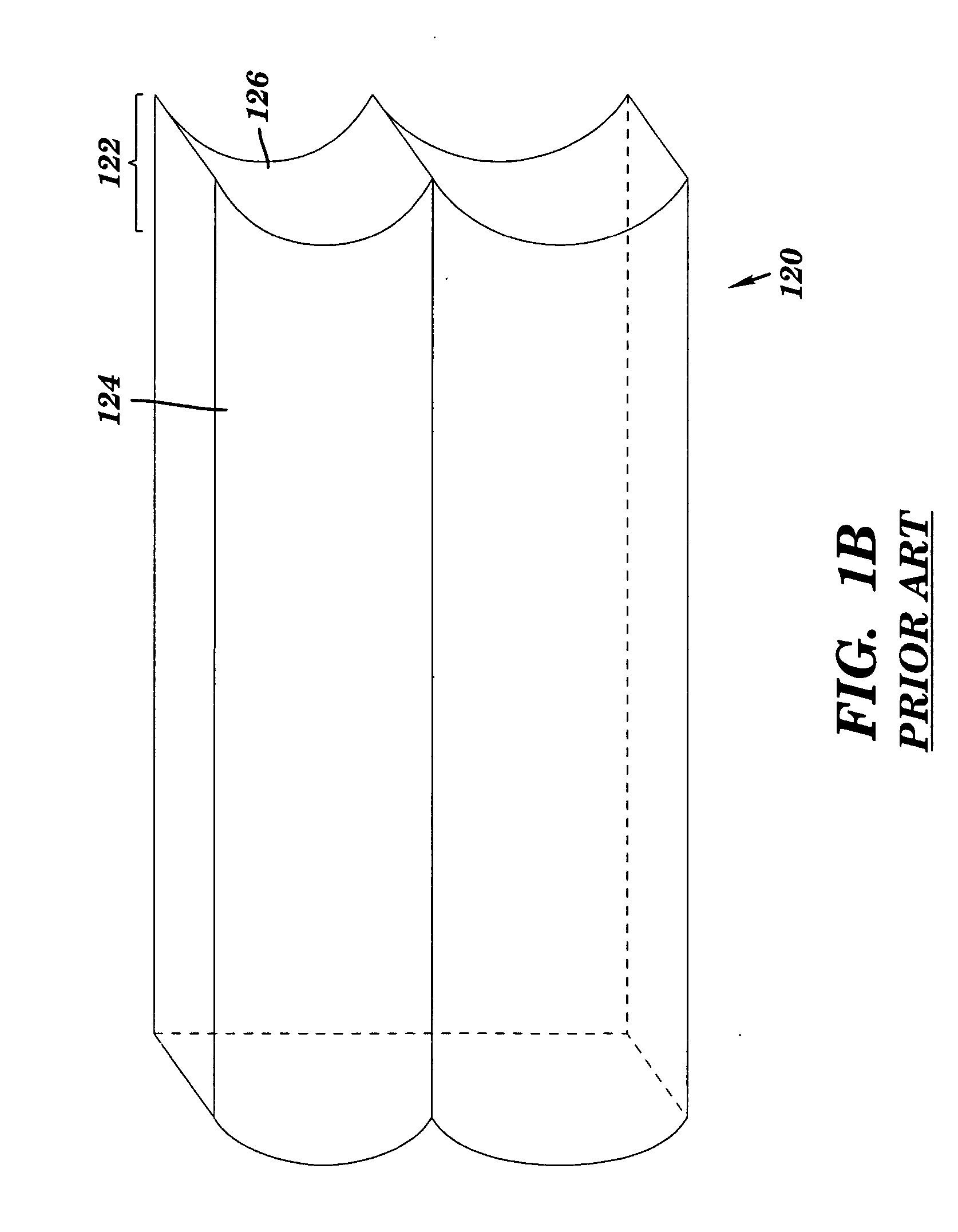

ActiveUS20050273028A1Expanding and narrowing width of gapIncrease stiffnessNon-surgical orthopedic devicesFoot dorsiflexionCattle calf

An ankle-foot orthosis for aiding or enhancing a user's foot and ankle movement, wherein the orthosis comprises at least one strut member, a calf shell, a foot shell, and a plurality of segments. Gaps formed between adjacent segments, an uppermost segment and the calf shell, and a lowermost segment and the foot shell have gap widths, wherein gaps at a higher location have larger gap widths than those at a lower location. Therefore, in dorsiflexion, the gaps close in series from bottom to top, gradually increasing the orthosis stiffness, creating a progressive dorsiflexion stop, and decreasing the magnitude of loads transferred into the user. In plantar flexion, the gaps similarly decrease in series from bottom to top, gradually increasing the orthosis stiffness, creating a progressive plantar flexion stop, and decreasing the magnitude of loads transferred into the user.

Owner:RONAN REYNOLDS +2

Ankle-foot orthosis

ActiveUS7335177B2Effective lengthIncrease stiffnessNon-surgical orthopedic devicesKnee orthosisOrthotic device

An ankle-foot orthosis for aiding or enhancing a user's foot and ankle movement, wherein the orthosis comprises at least one strut member, a calf shell, a foot shell, and a plurality of segments. Gaps formed between adjacent segments, an uppermost segment and the calf shell, and a lowermost segment and the foot shell have gap widths, wherein gaps at a higher location have larger gap widths than those at a lower location. Therefore, in dorsiflexion, the gaps close in series from bottom to top, gradually increasing the orthosis stiffness, creating a progressive dorsiflexion stop, and decreasing the magnitude of loads transferred into the user. In plantar flexion, the gaps similarly decrease in series from bottom to top, gradually increasing the orthosis stiffness, creating a progressive plantar flexion stop, and decreasing the magnitude of loads transferred into the user.

Owner:RONAN REYNOLDS +2

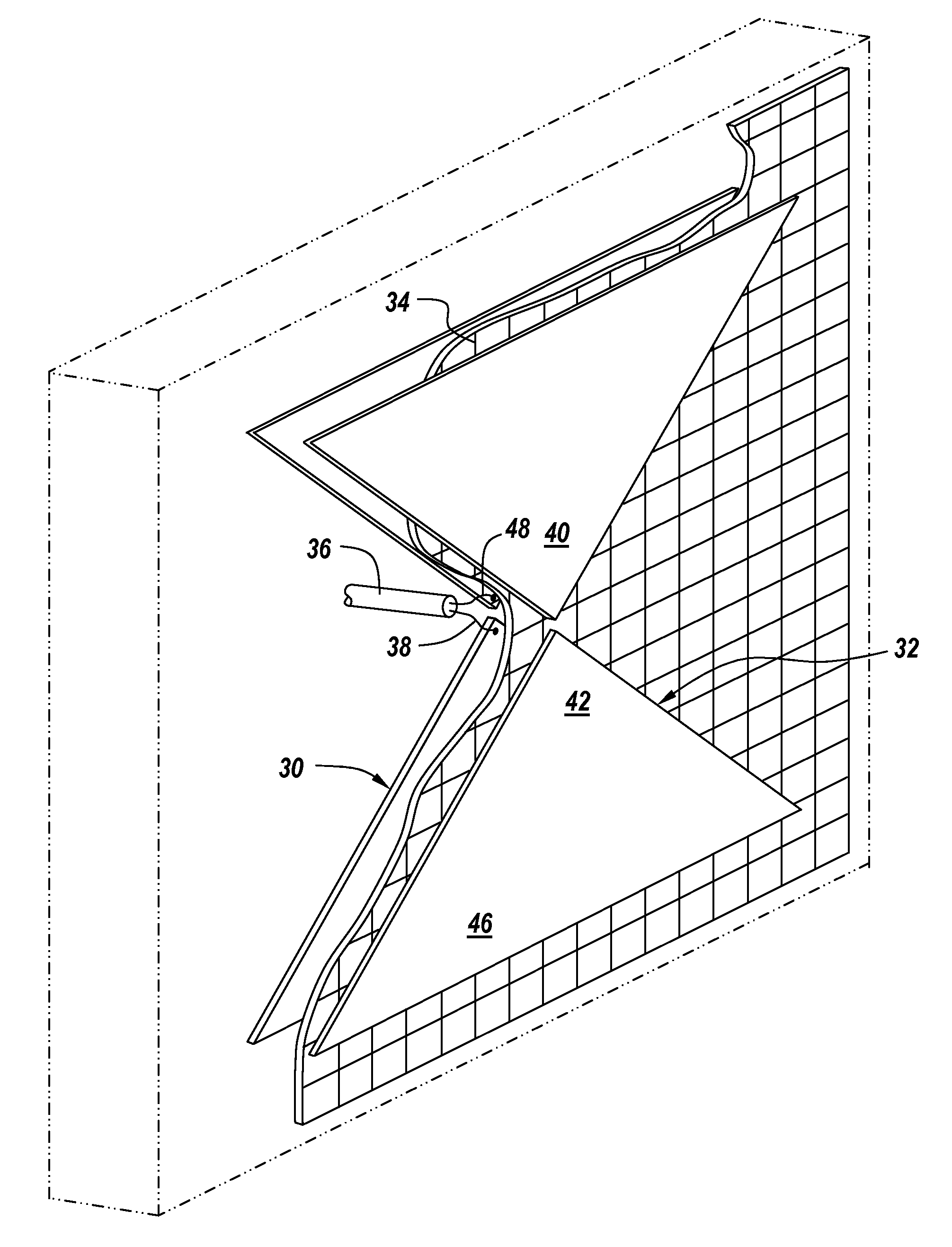

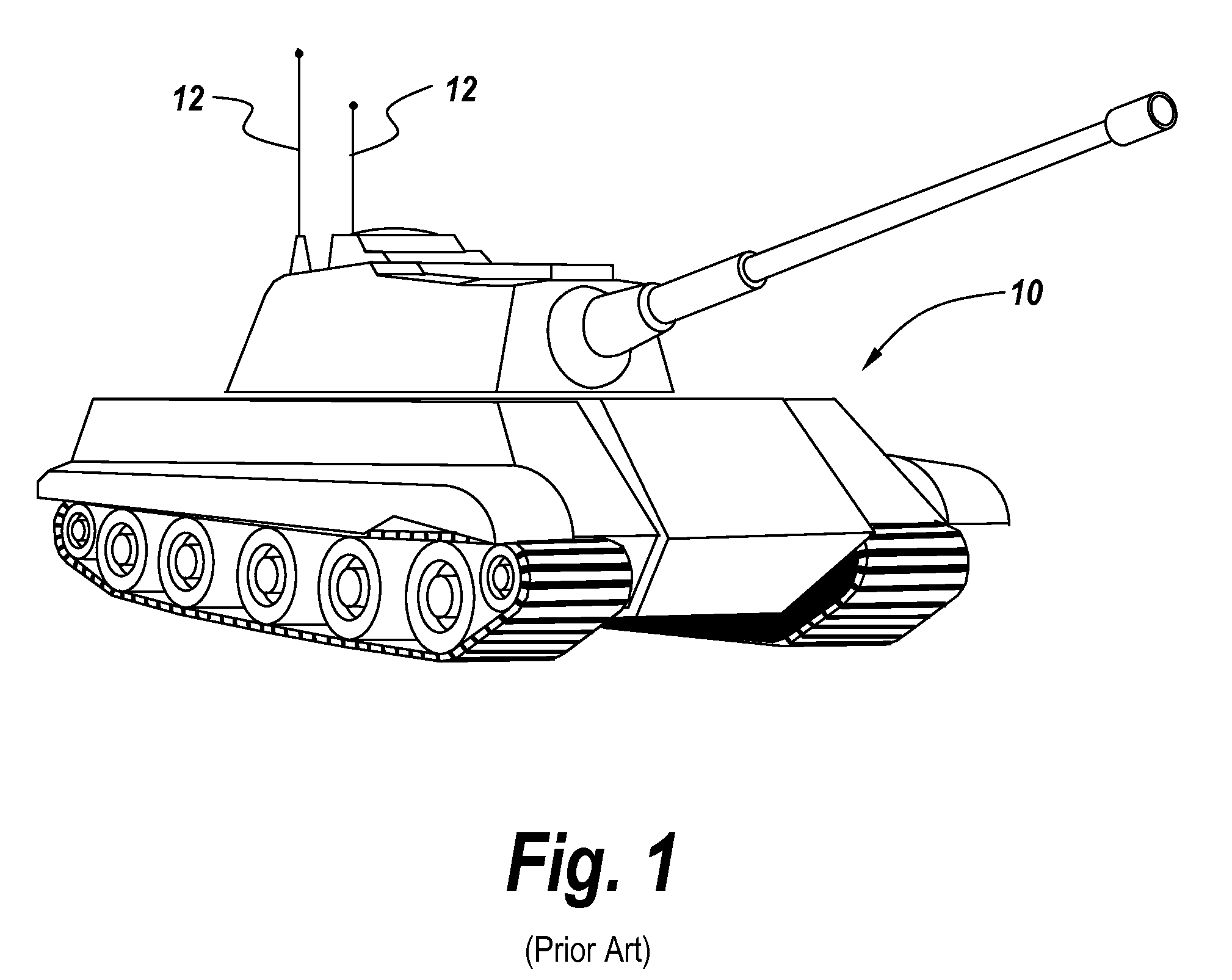

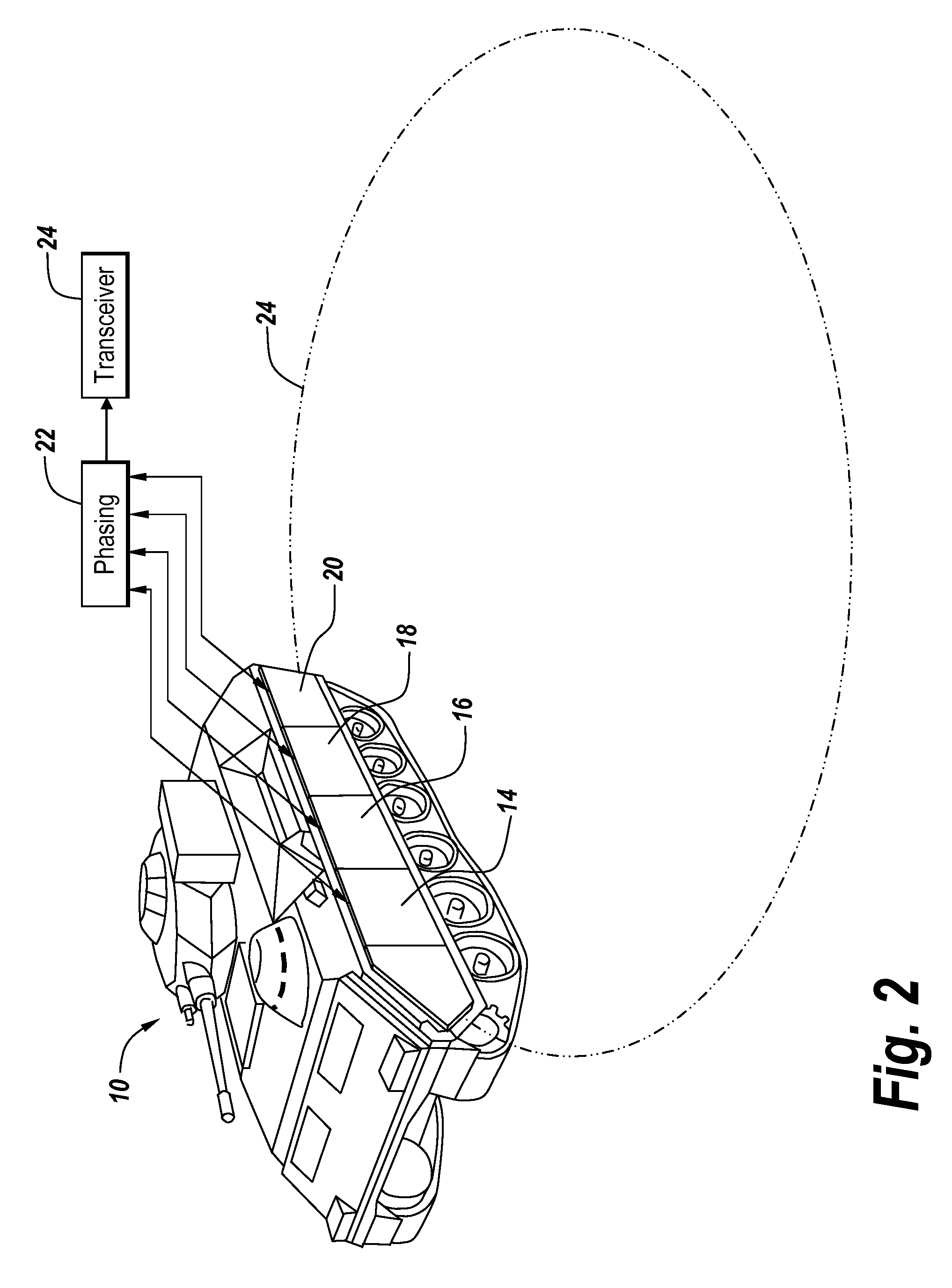

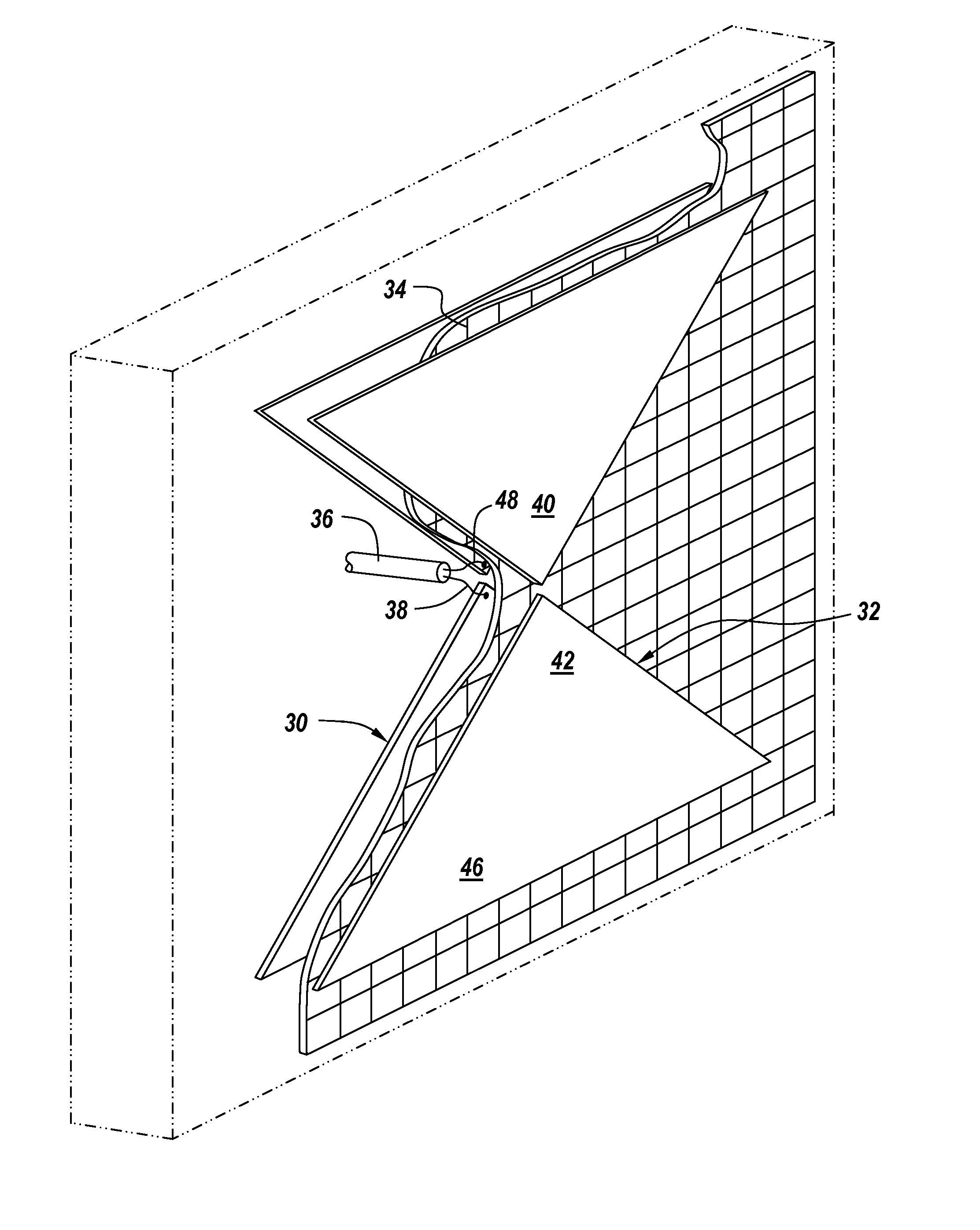

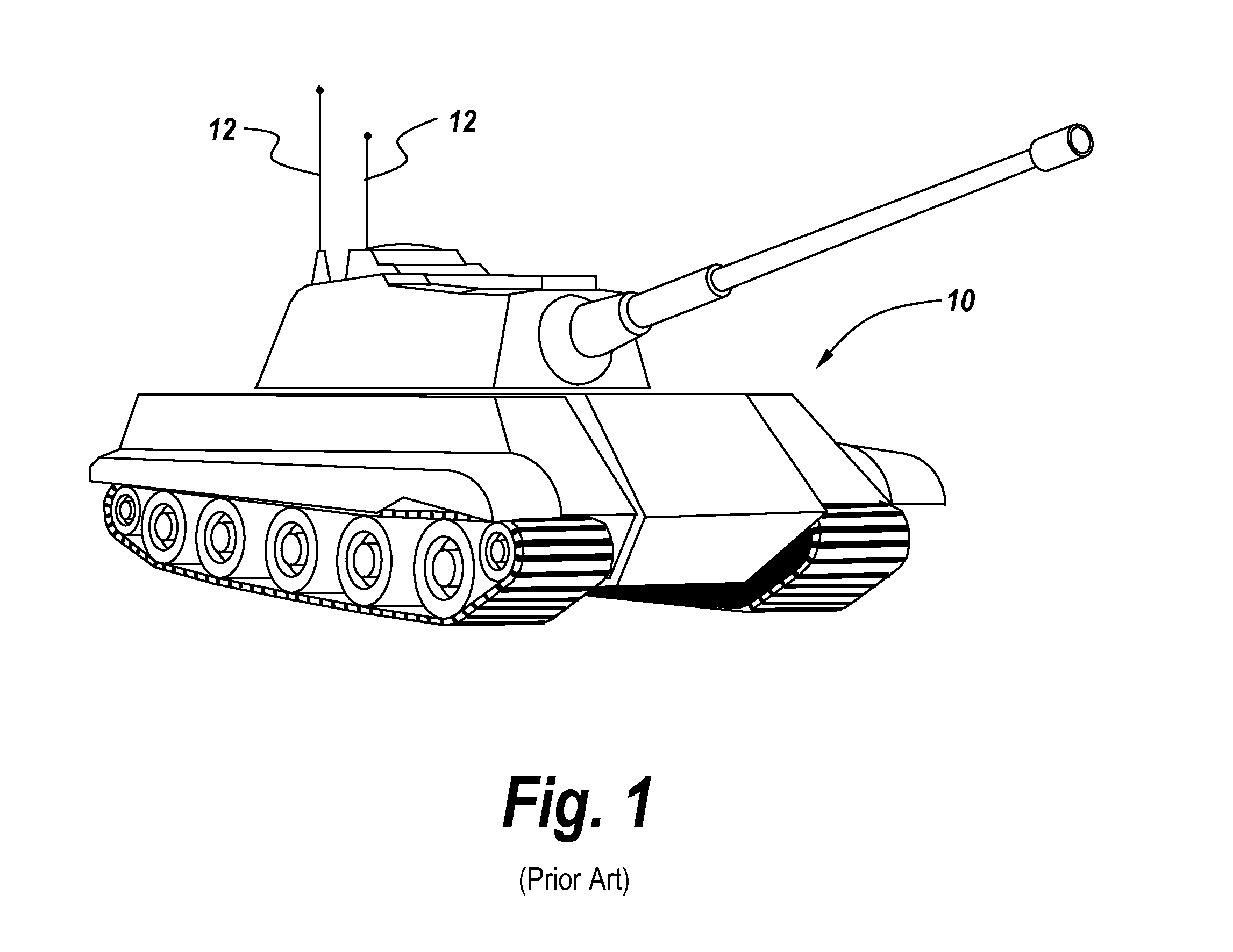

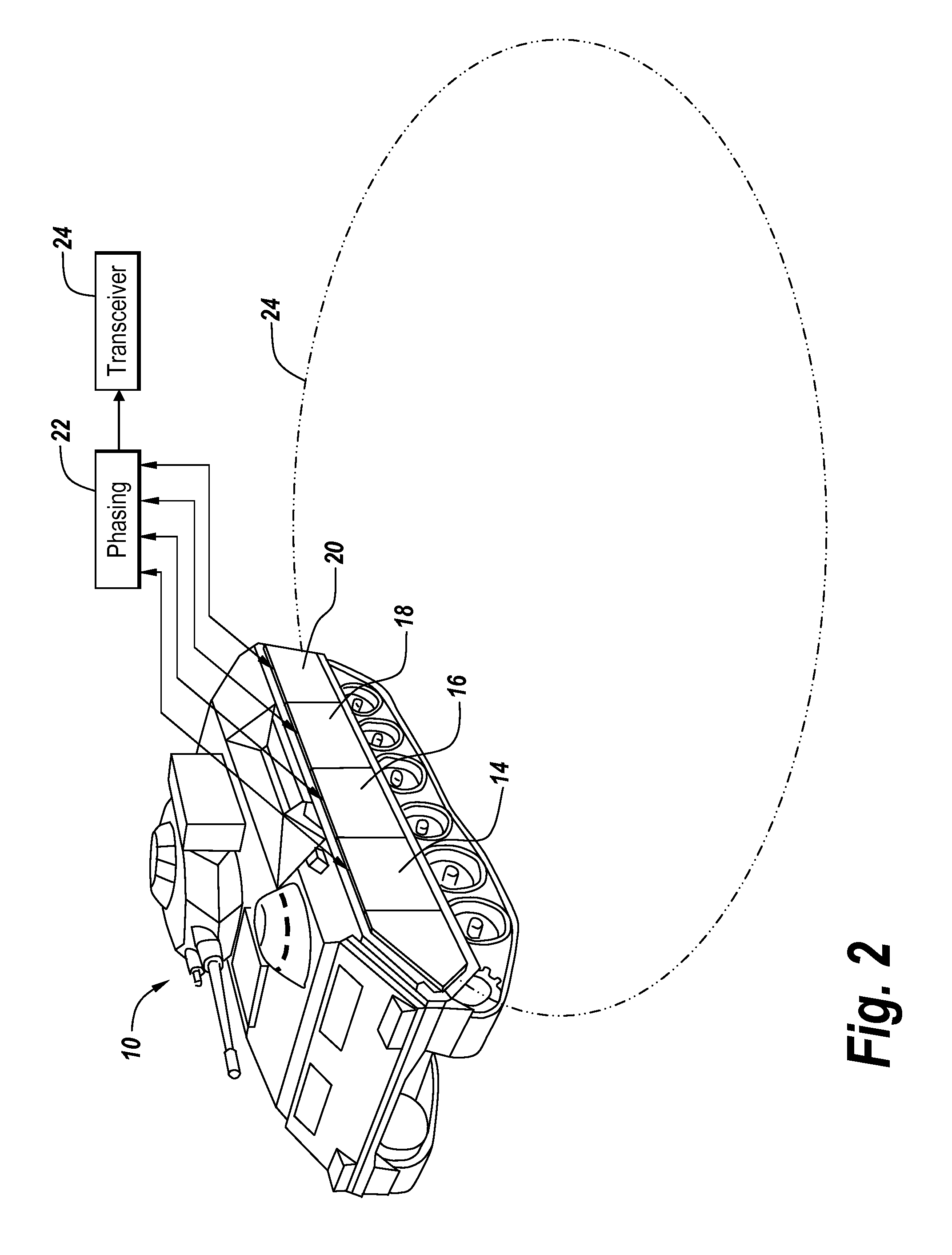

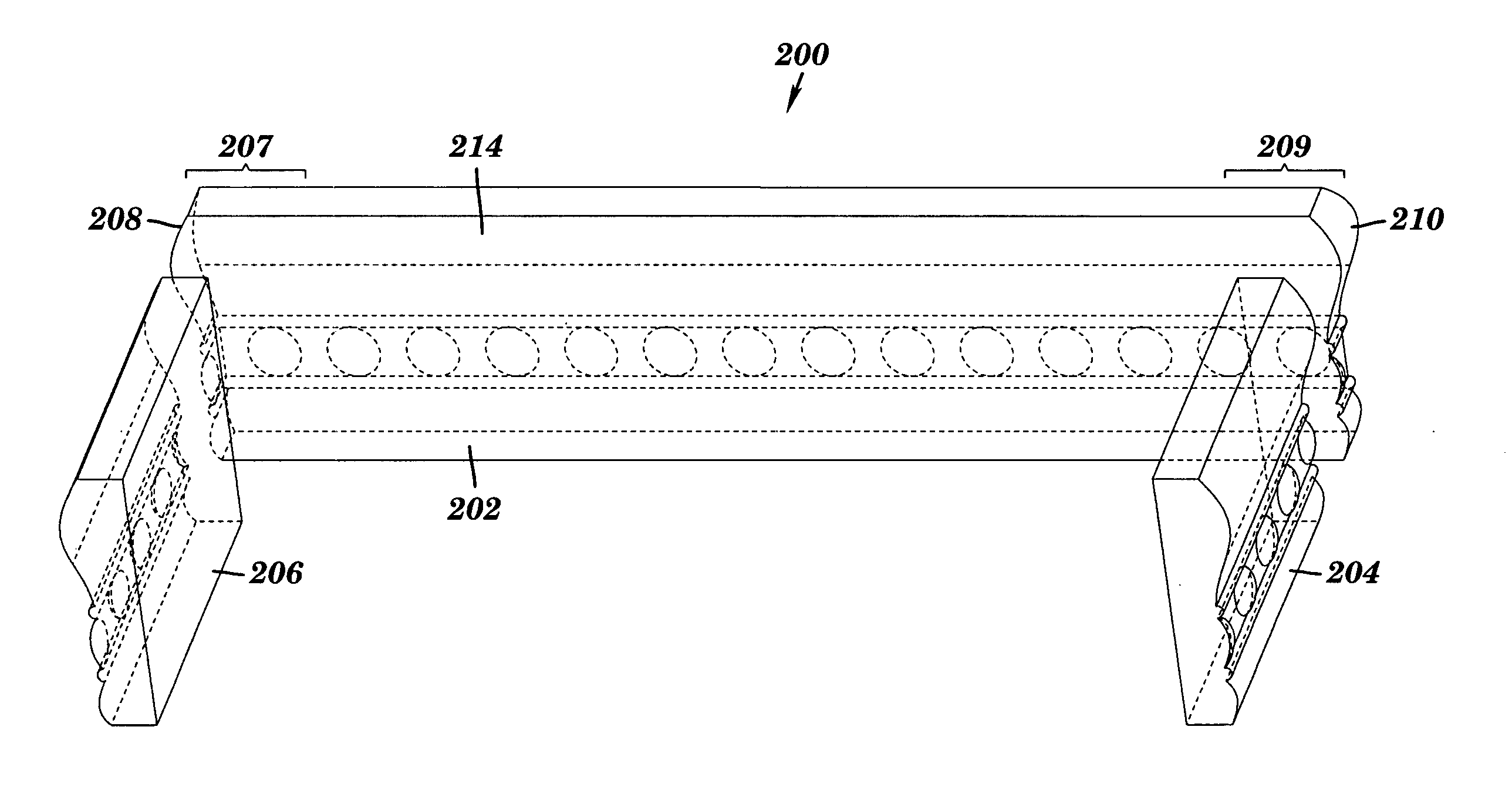

Wide band embedded armor antenna

ActiveUS8599080B2Effective efficiencyEffective lengthSimultaneous aerial operationsAntenna adaptation in movable bodiesBroadbandEngineering

An extremely thin embedded antenna for an armor-carrying vehicle utilizes a dipole driven element to the inside of the armor plate and a parasitically-driven dipole element on top of the armor plate, with the parasitic element providing appropriate forward gain and antenna matching characteristics such that there need be no aperturing of the armor plate in order to feed the antenna. In one embodiment, the bowtie antenna elements are elongated, extended or expanded by outboard antenna sections which are spaced from the distal ends of the corresponding bowties, with a meanderline choke bridging the gap between a bowtie element and its extended portion.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

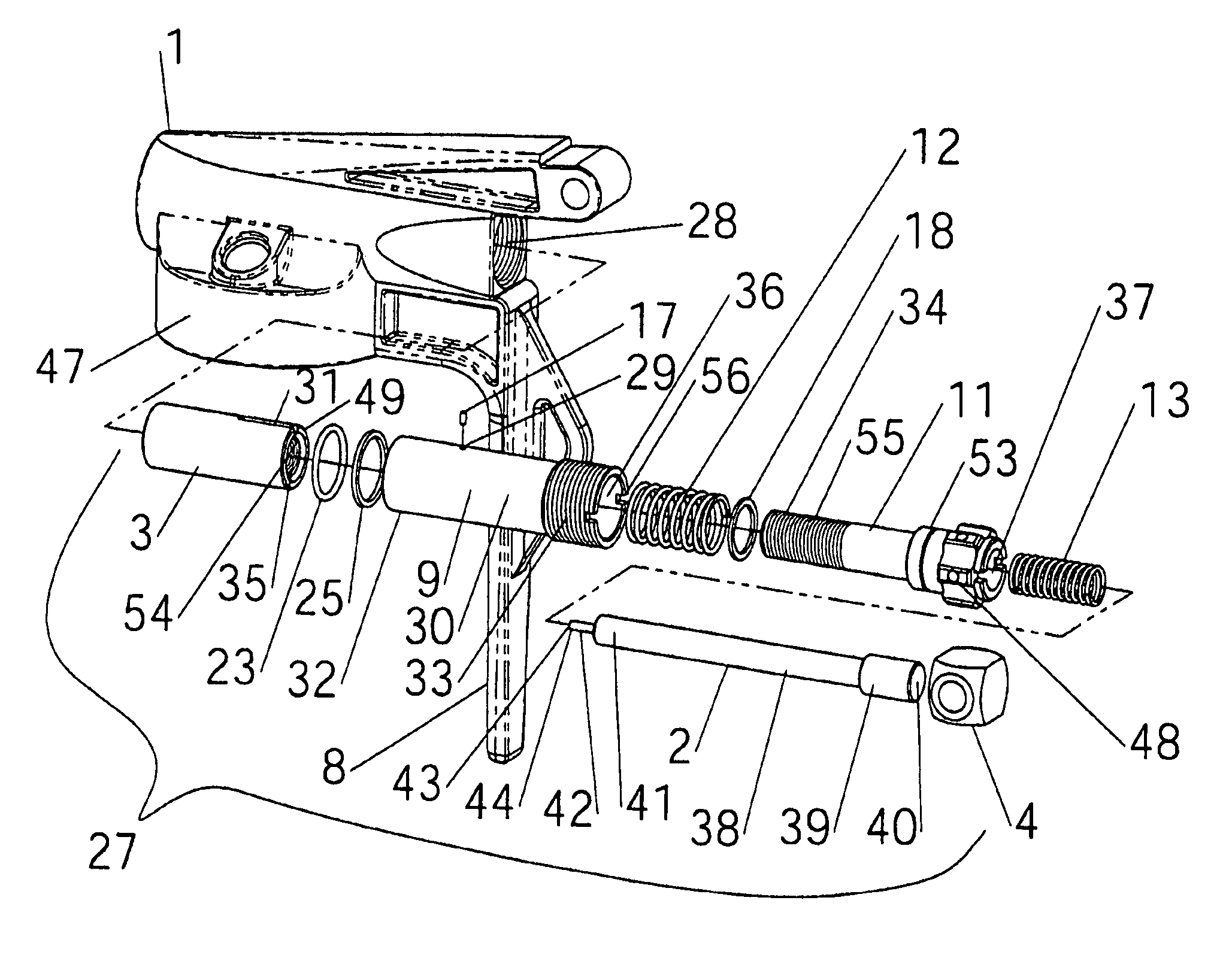

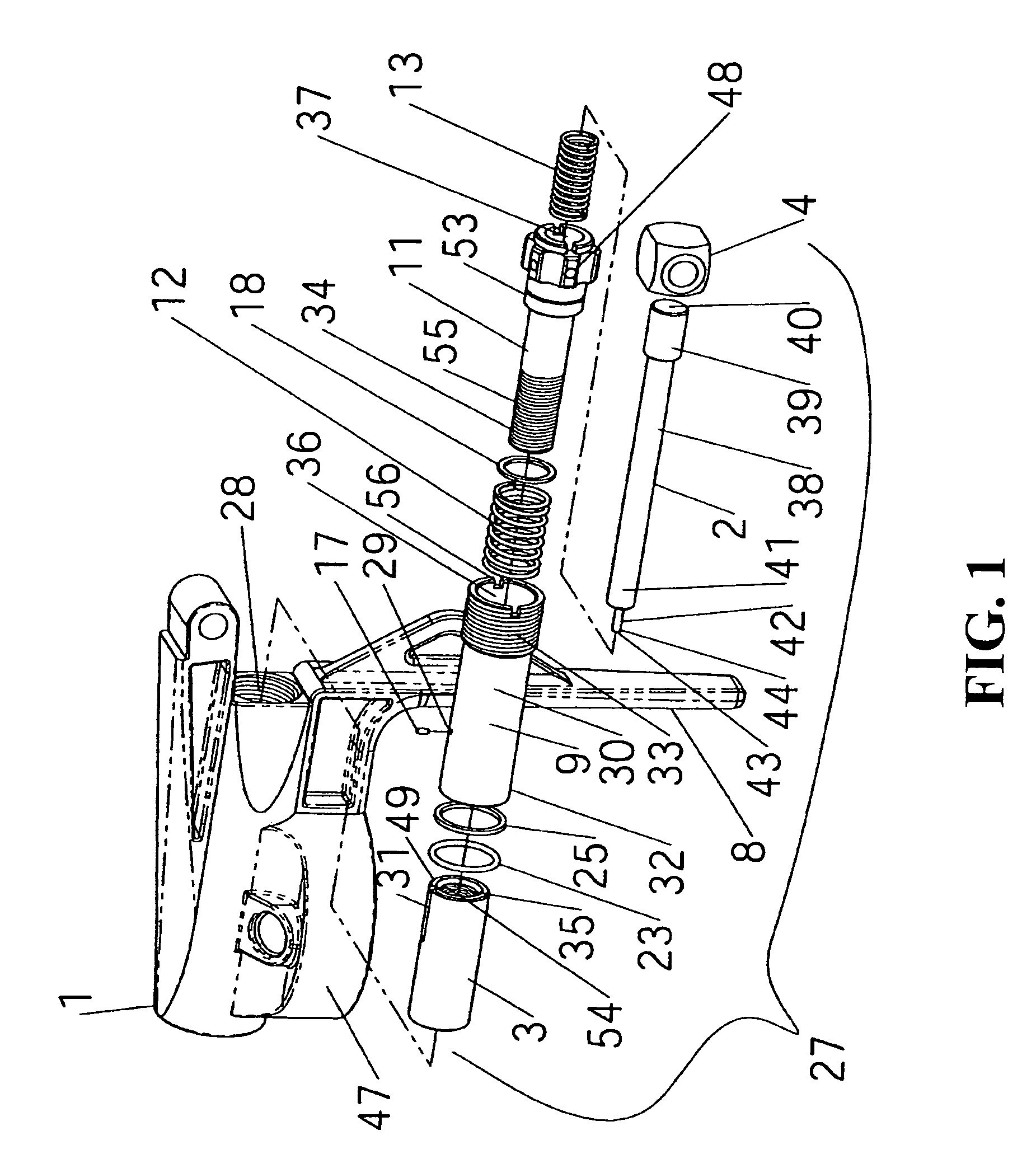

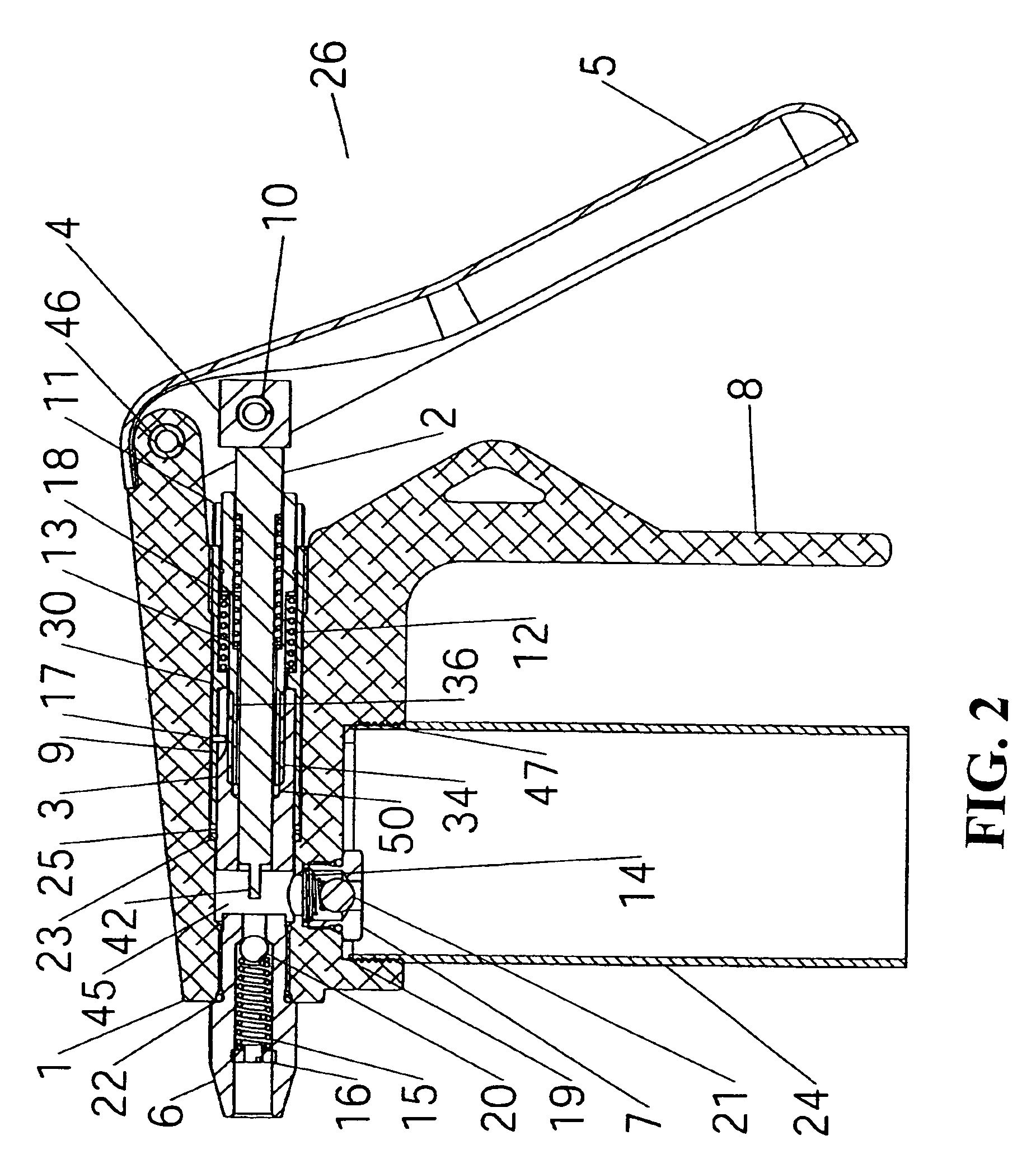

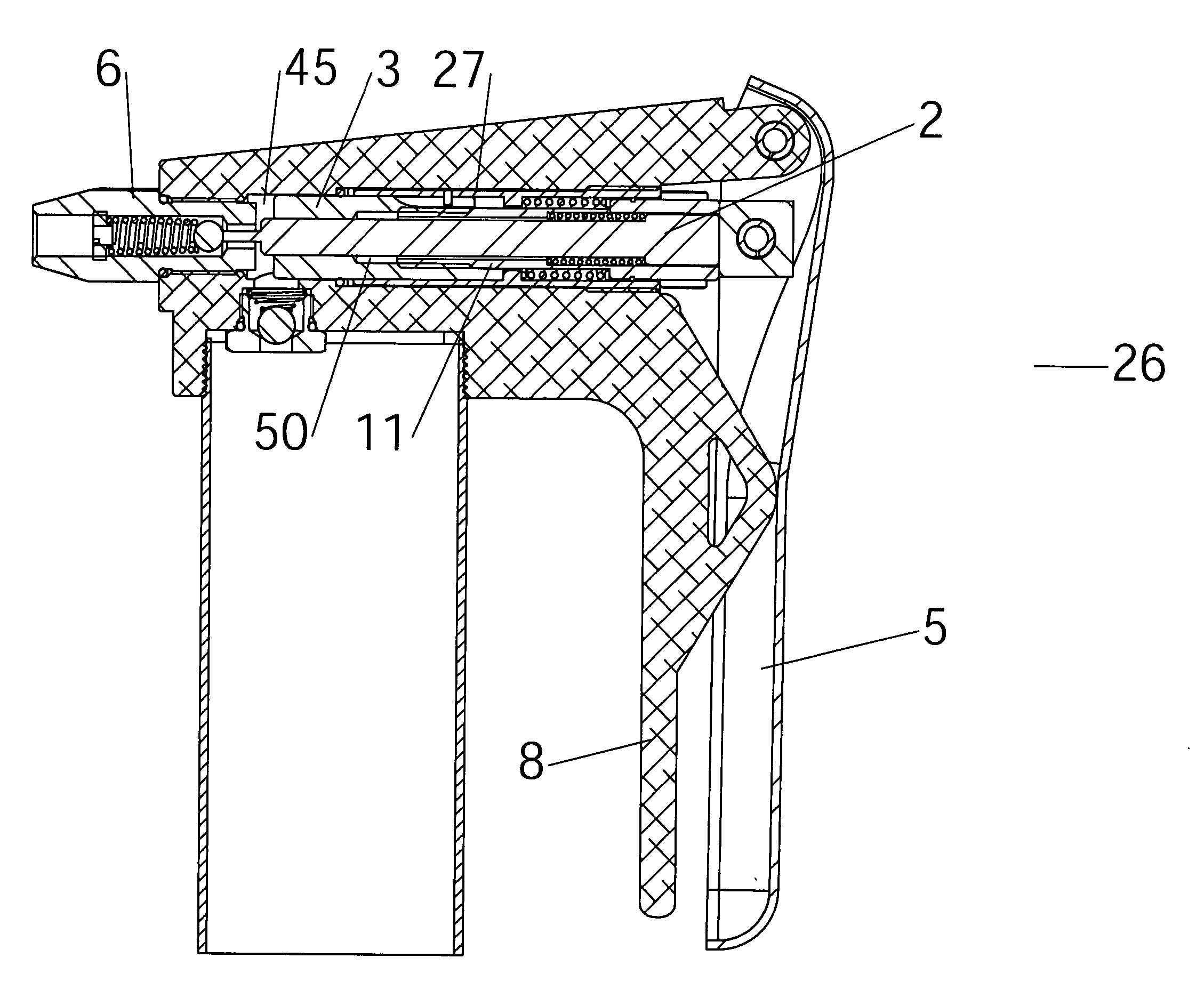

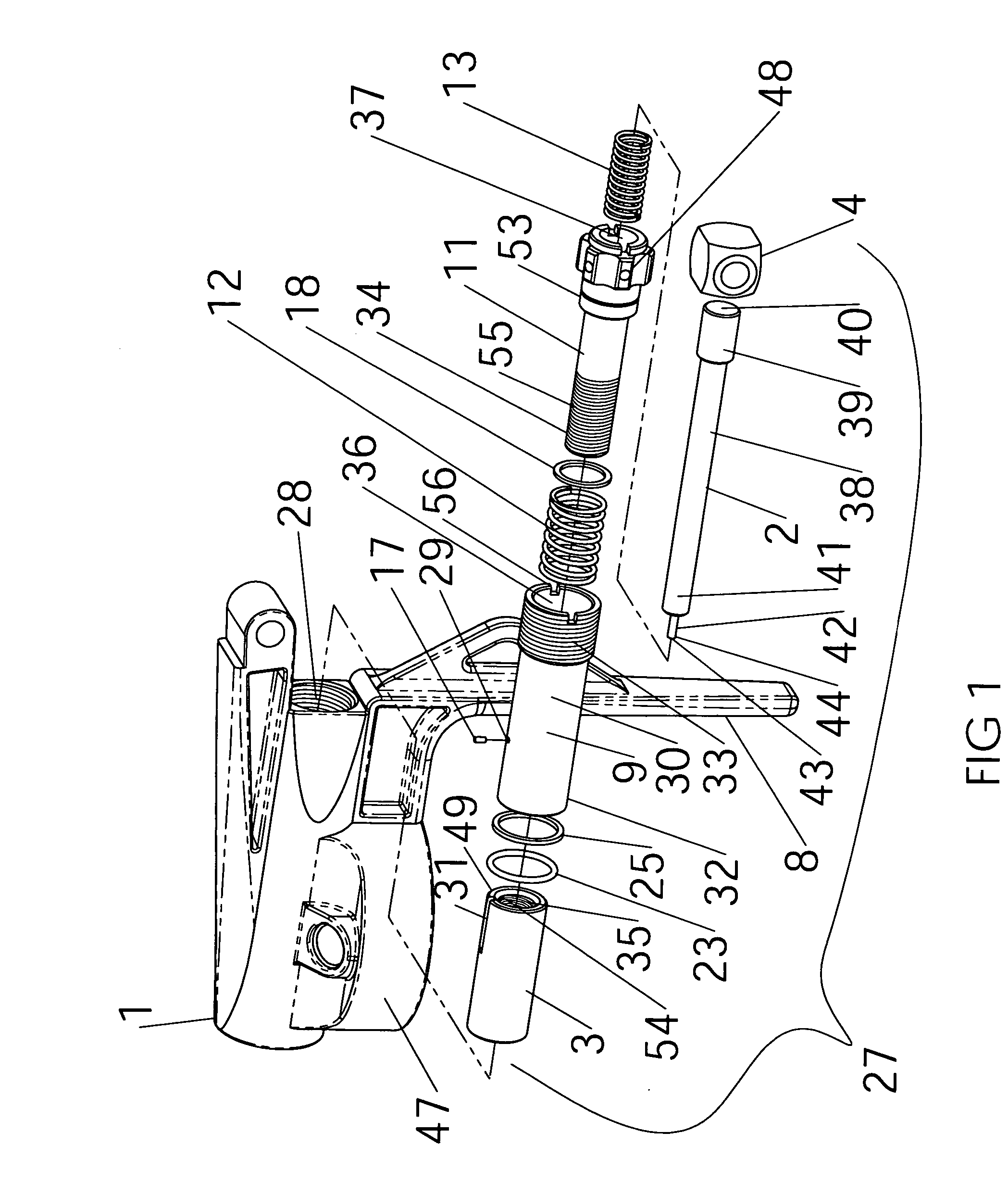

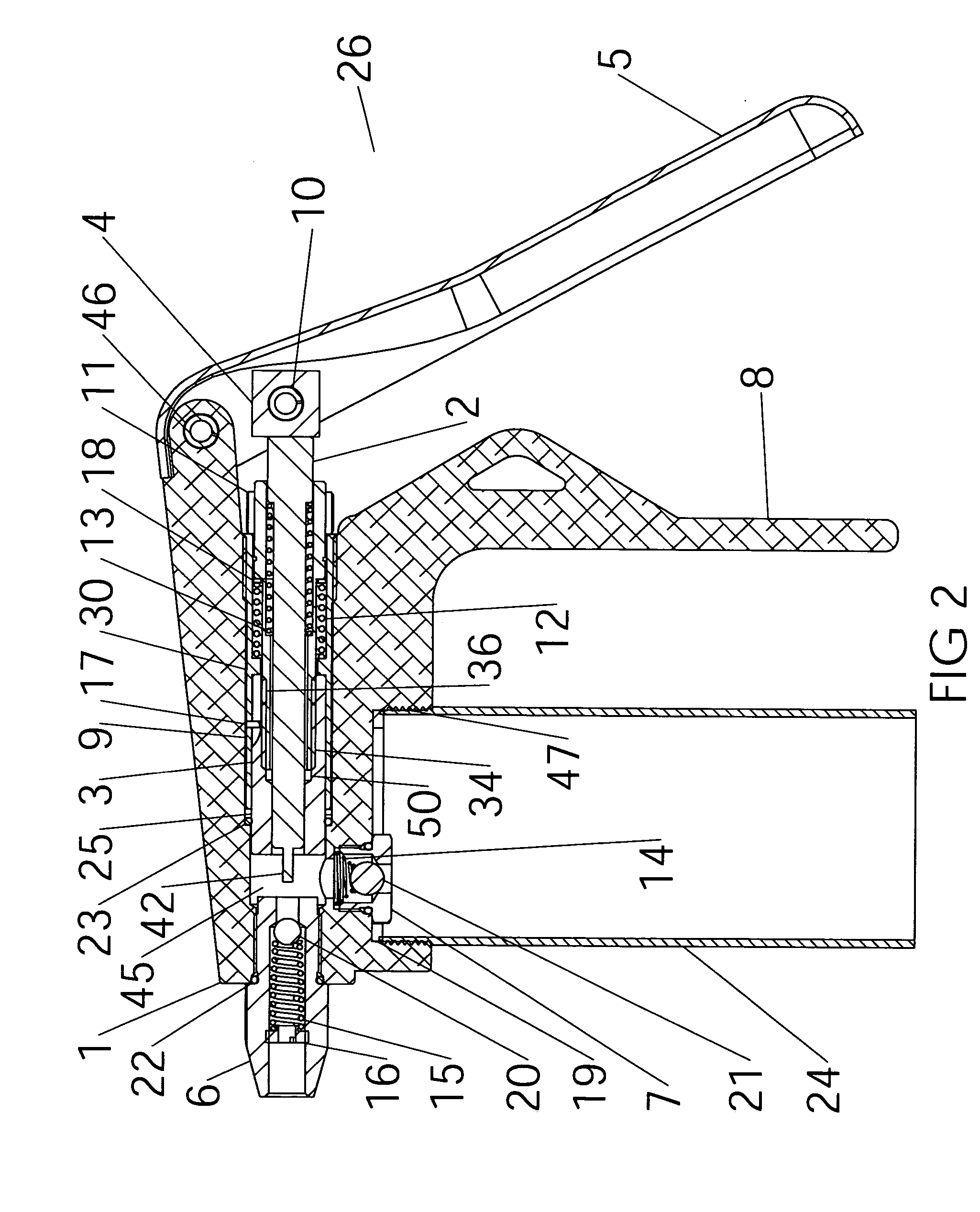

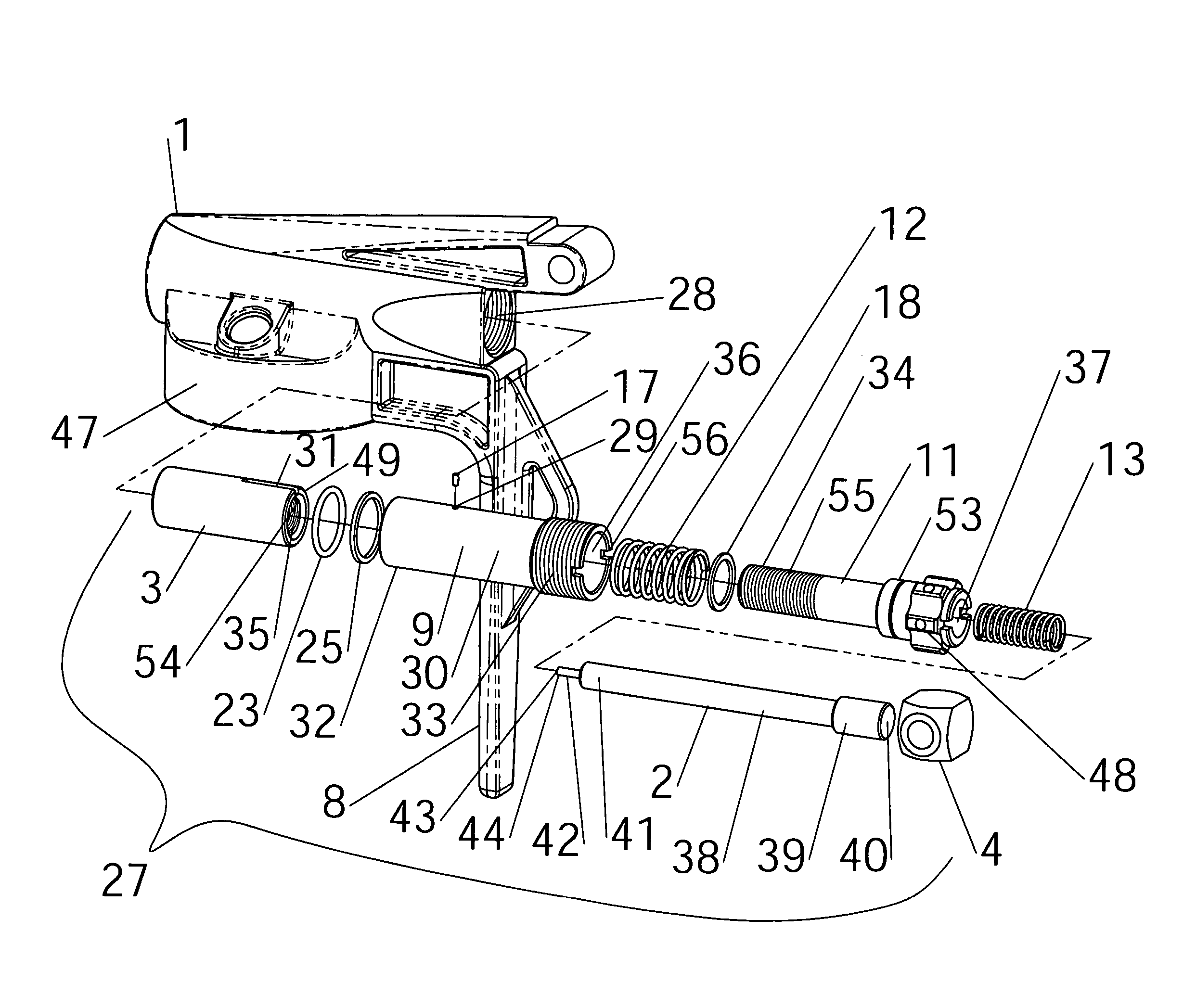

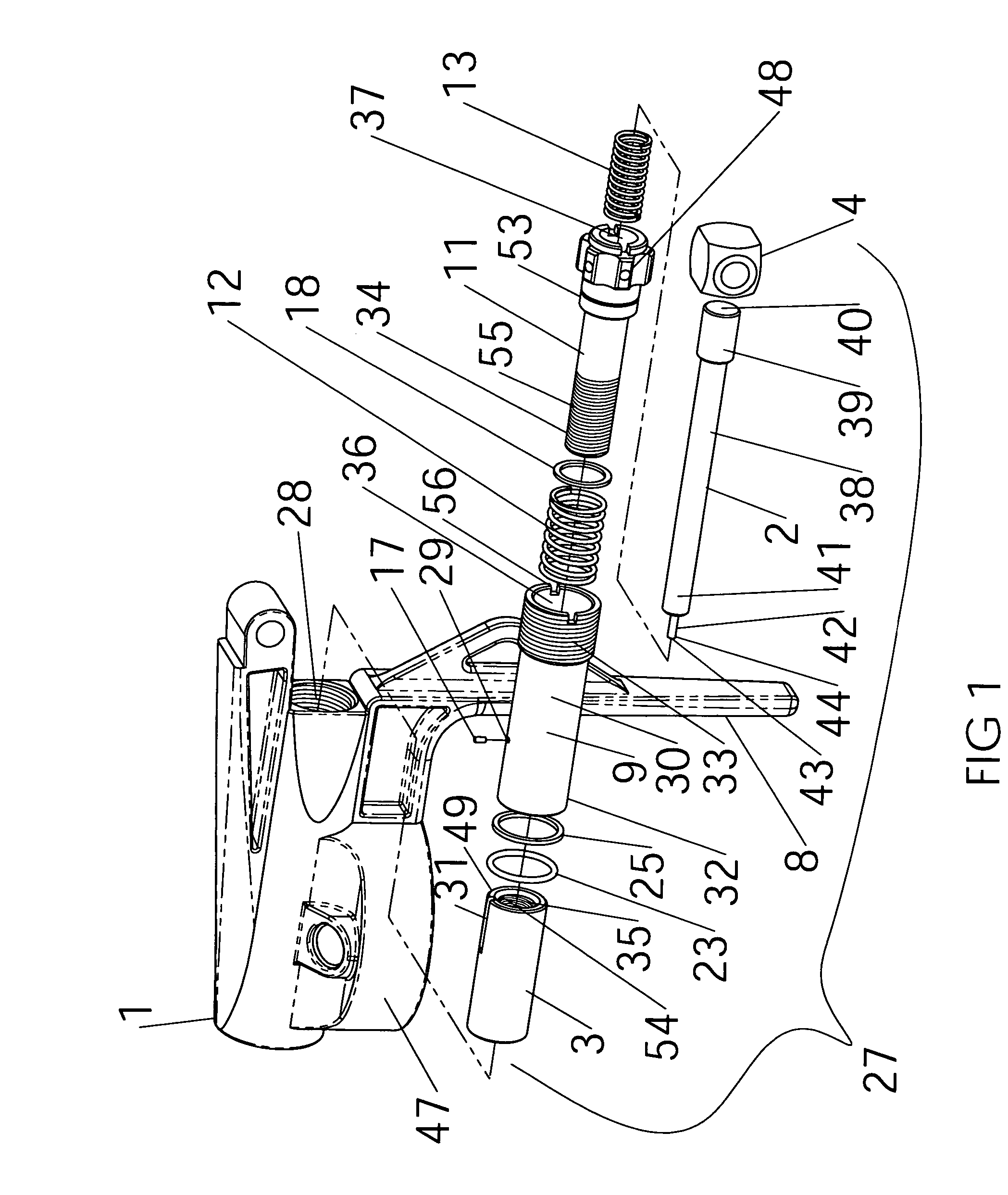

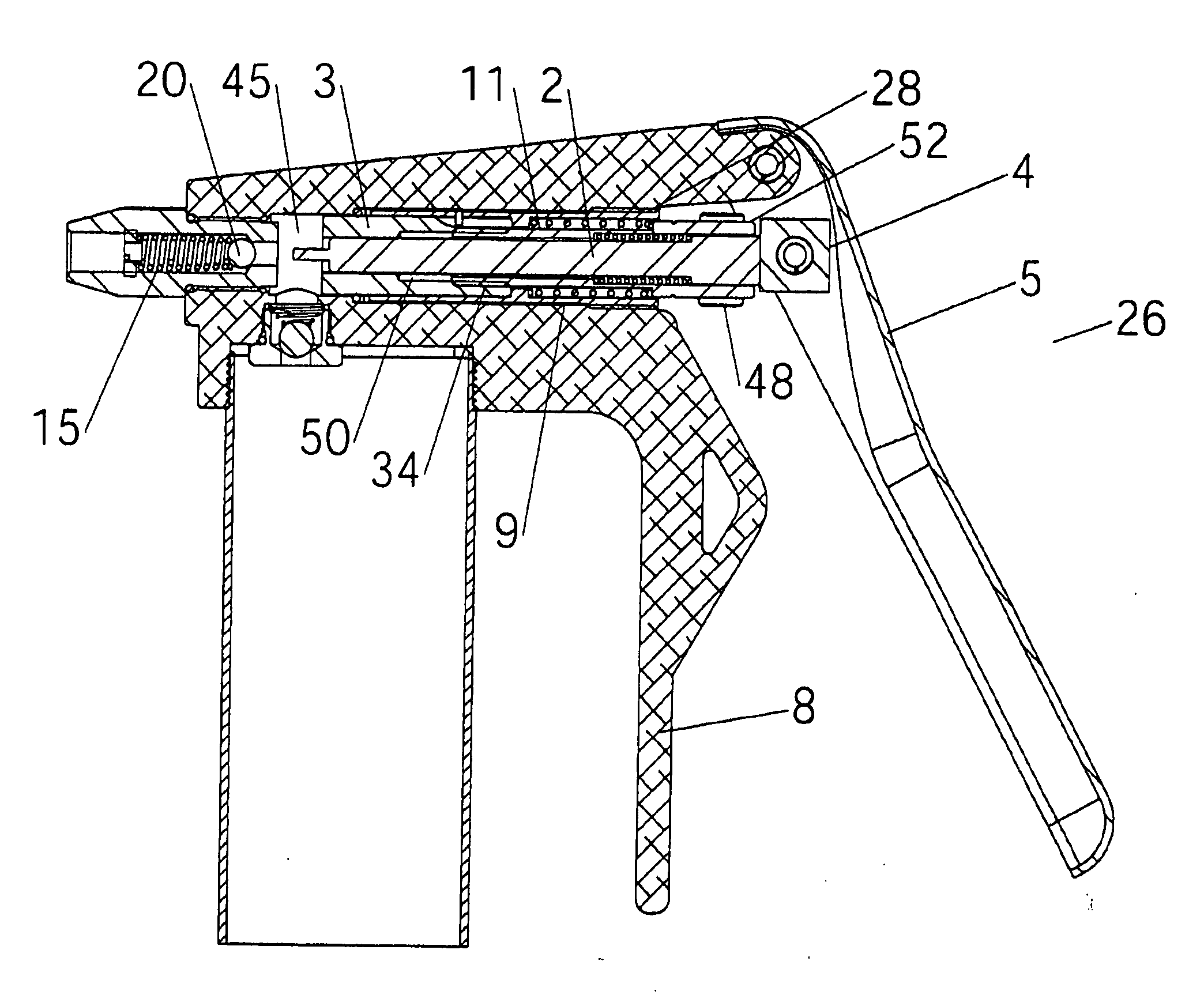

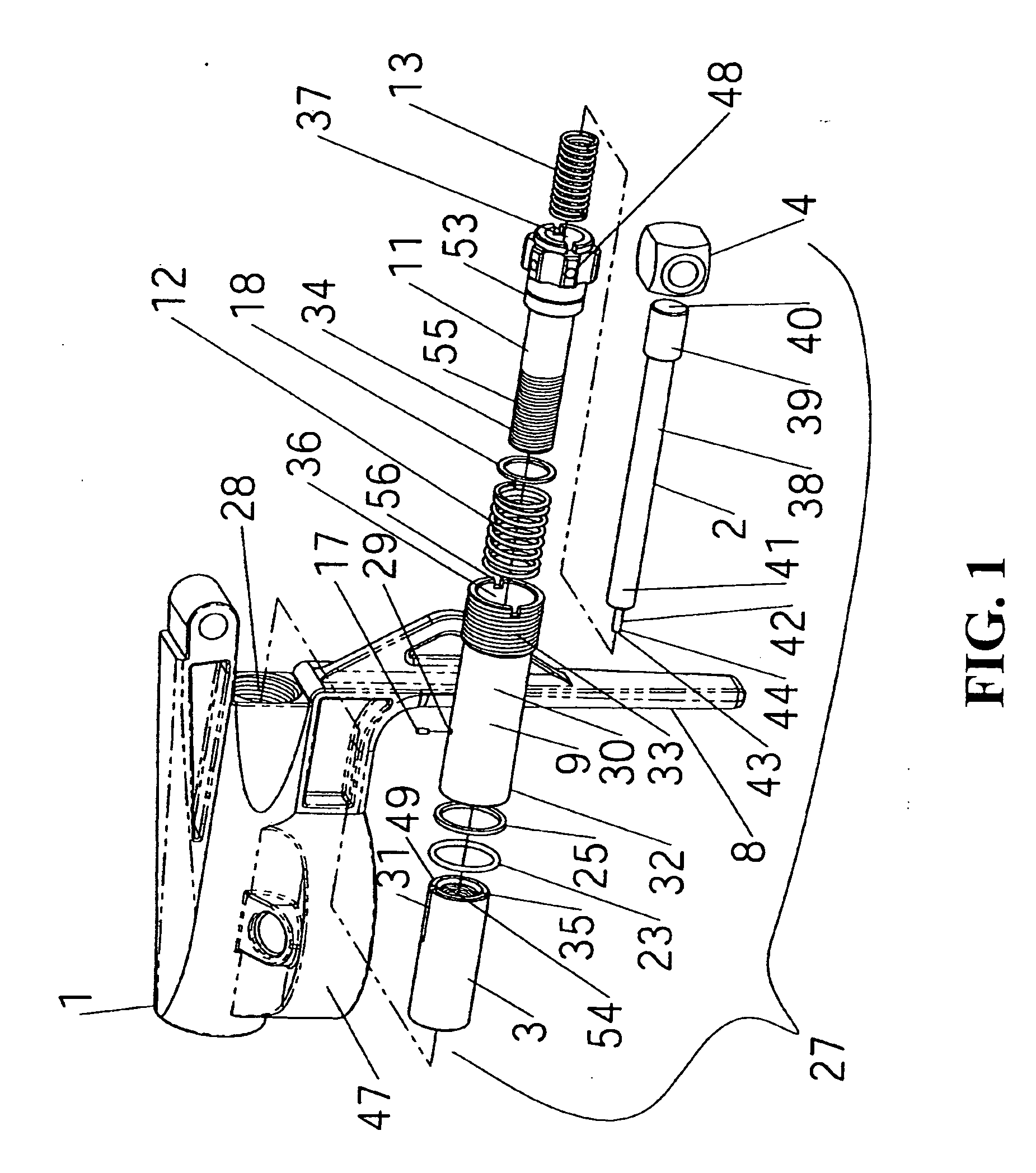

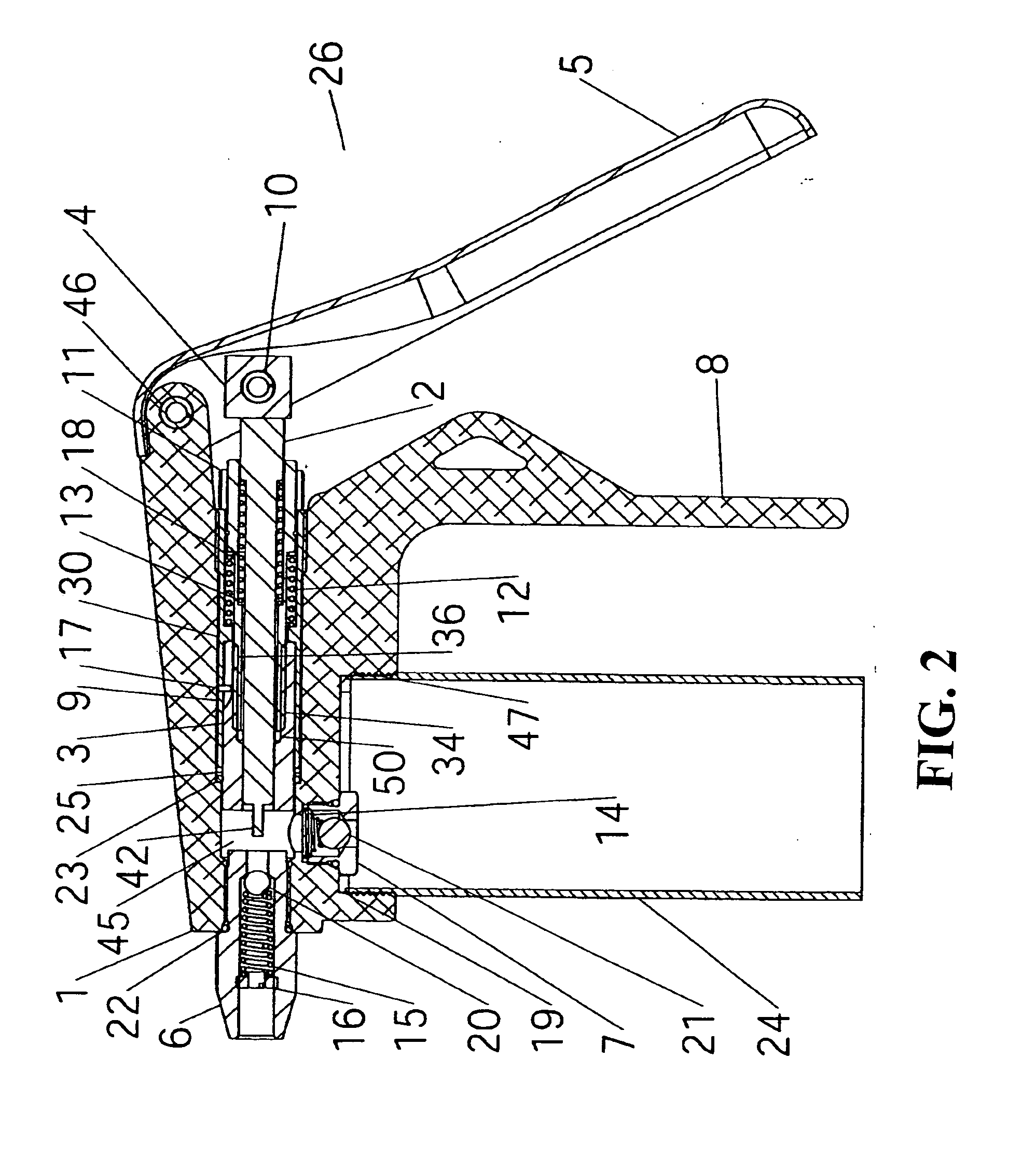

Two stage grease gun

InactiveUS7377406B2Little effortLimit longitudinal movementManual lubricationLarge containersEngineeringHigh pressure

A portable grease gun with a dual pressure output capability which can be selectively changed by the user with little effort. The larger diameter plunger is slidable within a plunger retainer. The larger diameter plunger has a bore through them in which a smaller diameter plunger is slidable. The smaller diameter plunger moves when an actuating lever is operated to compress grease in the grease gun. The larger diameter plunger may be adjusted to remain static during operation of the actuating lever or it may be adjusted to move during all or part of the compression stroke of the actuating lever. A high pressure can be generated by movement of the smaller diameter plunger alone, or a high flow volume can be generated by movement of the smaller and larger diameter plungers in unison.

Owner:WEEMS IND INC

Two stage grease gun

InactiveUS20050230430A1Little effortLimit longitudinal movementManual lubricationLarge containersEngineeringMechanical engineering

A portable grease gun with a dual pressure output capability which can be selectively changed by the user with little effort. A larger diameter plunger is longitudinally coupled to an extension. The larger diameter plunger and its extension are variable in length by manual rotation of the extension relative to the larger diameter plunger. The larger diameter plunger is slidable within a plunger retainer over a limited range and is not free to rotate within the plunger retainer. The larger diameter plunger and the plunger extension have aligned bores through them in which a smaller diameter plunger is slidable. The smaller diameter plunger moves when an actuating lever is operated to compress grease in the grease gun. The larger diameter plunger may be adjusted to remain static during operation of the actuating lever or it may be adjusted to move during all or part of the compression stroke of the actuating lever.

Owner:WEEMS IND INC

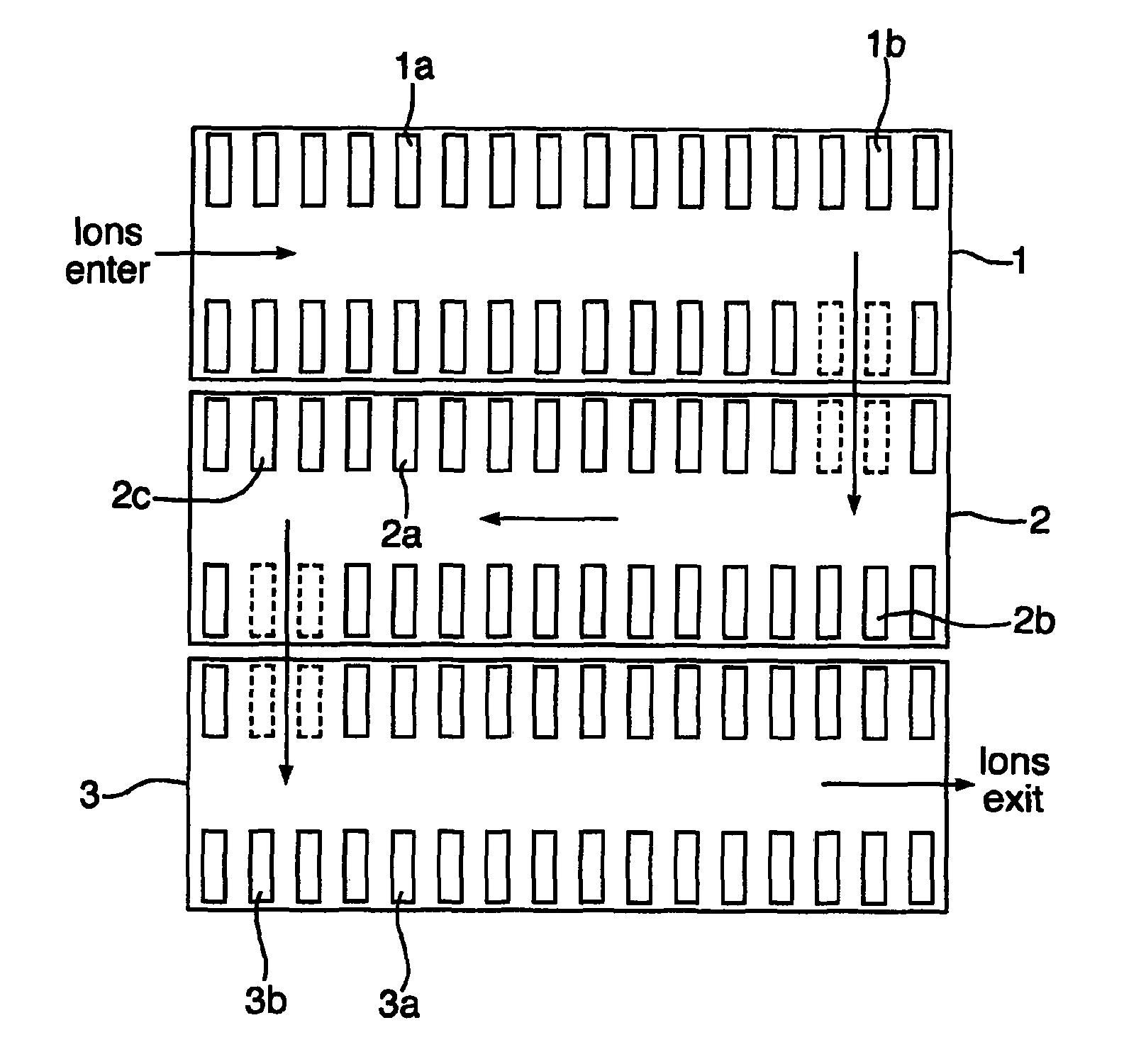

Ion guide array

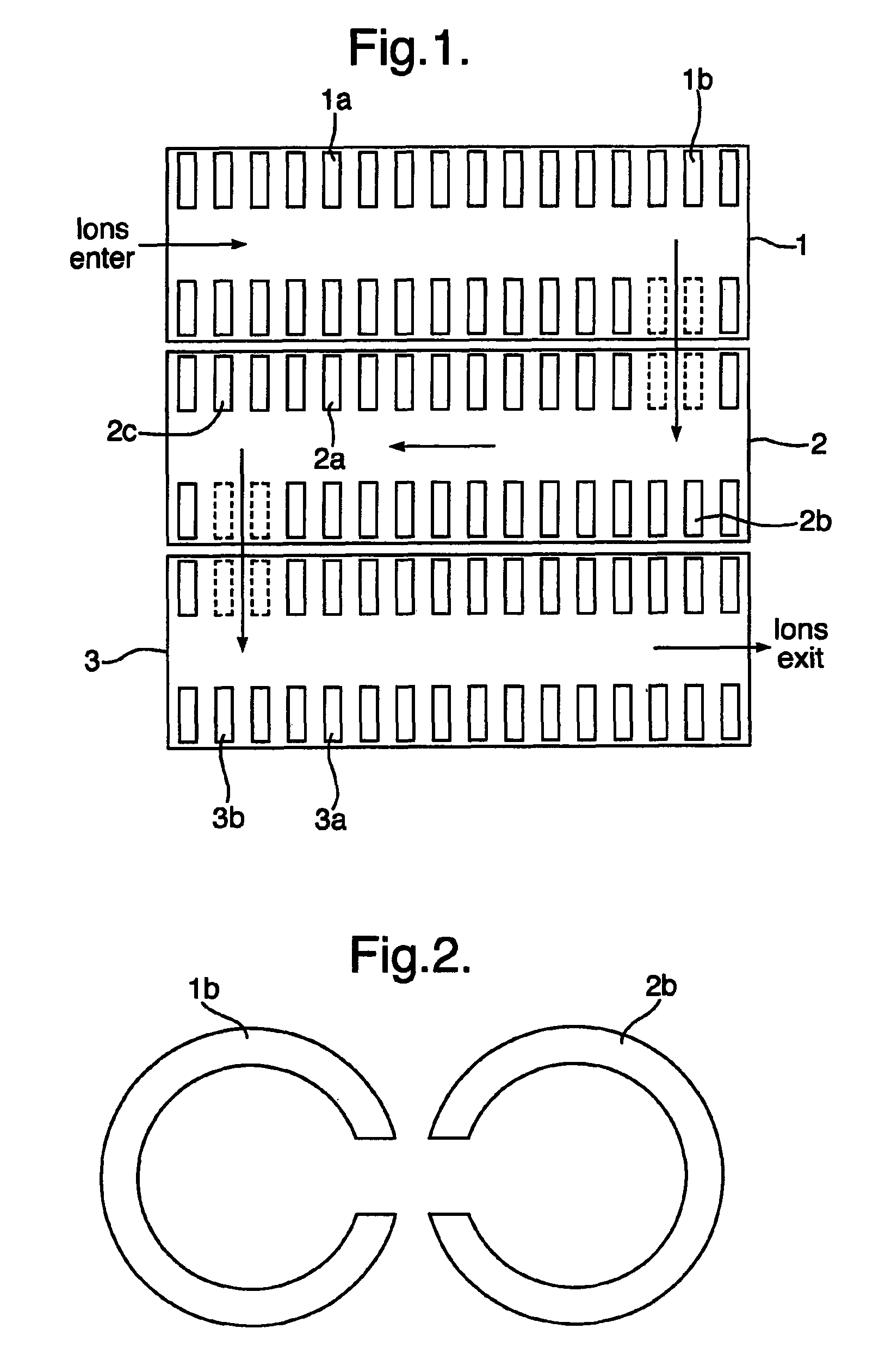

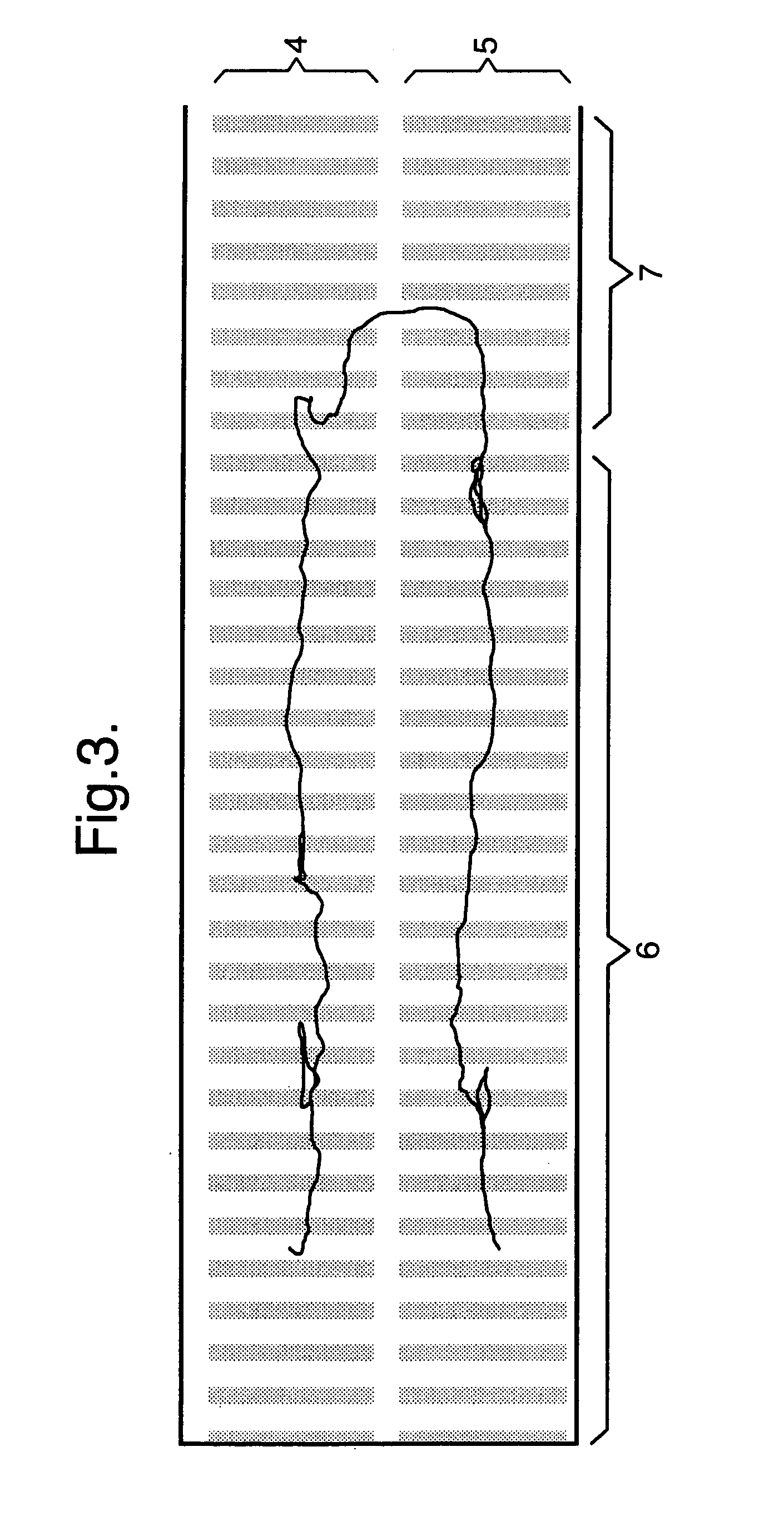

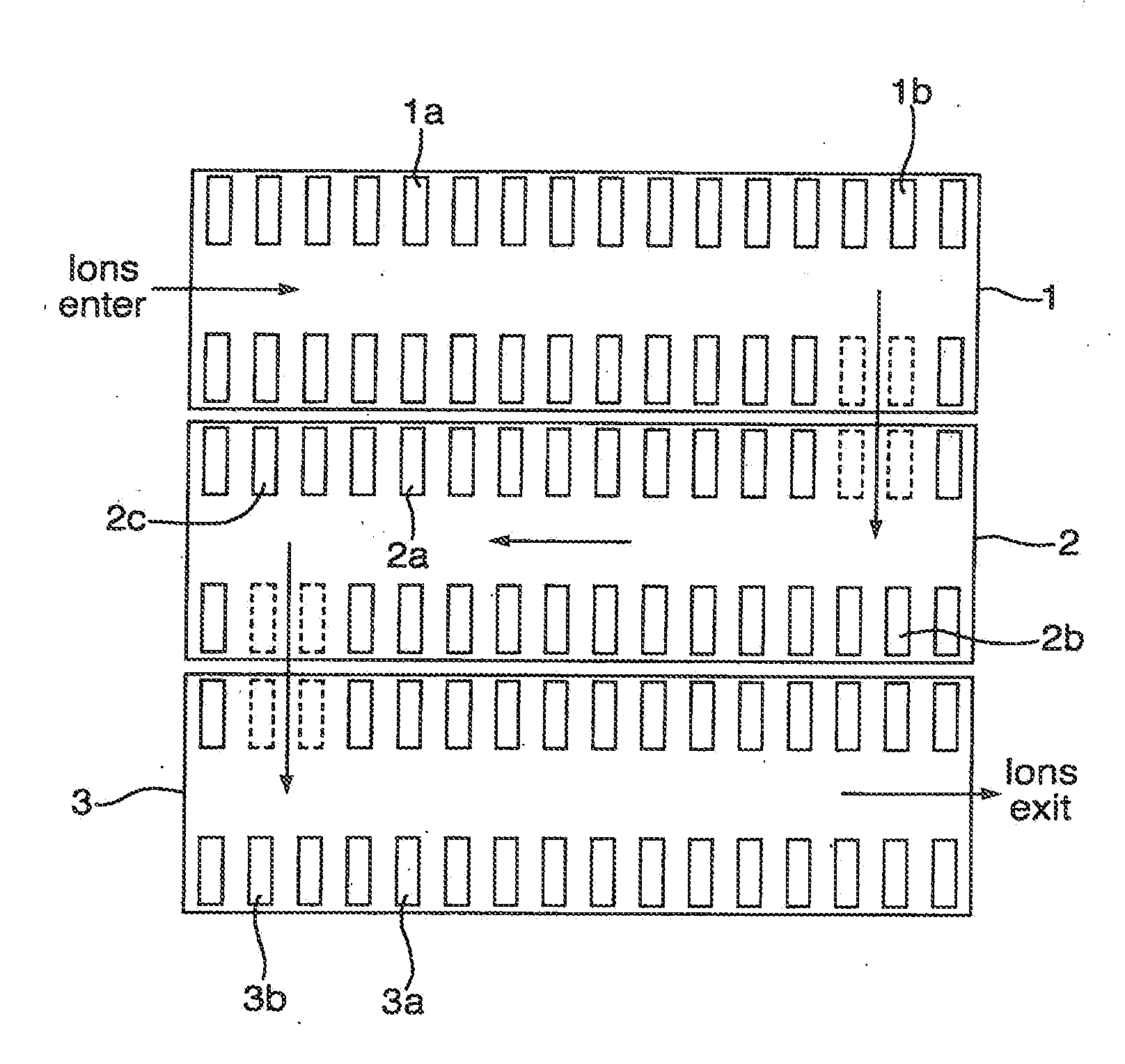

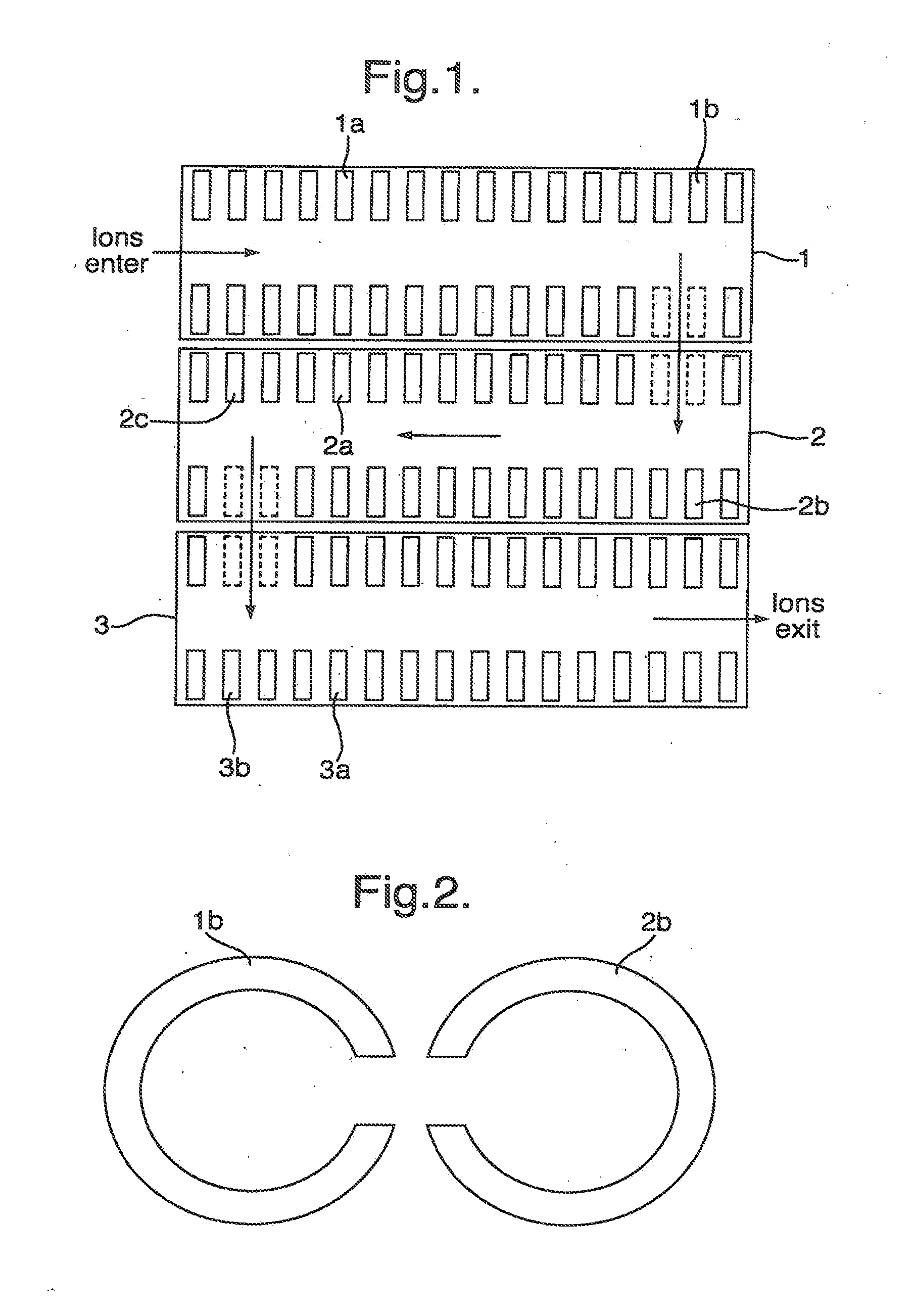

ActiveUS8384027B2High resolutionHigh transmission low field ion mobility separatorStability-of-path spectrometersTime-of-flight spectrometersIonAtomic physics

An ion guide array is disclosed comprising a first ion guide section and a second ion guide section and optionally further ion guide sections. Each ion guide section may comprise a plurality of electrodes having an aperture through which ions are transmitted in use. A transfer section is arranged at the exit of the first ion guide section and ions are transmitted radially from the first ion guide section into the second ion guide section. The electrodes in the transfer section may have a radial aperture enabling ions to be transmitted radially from the first ion guide section to the second ion guide section.

Owner:MICROMASS UK LTD

Wide band embedded armor antenna

ActiveUS20120293381A1Reduce VSWRMaximize gainSimultaneous aerial operationsAntenna adaptation in movable bodiesDriven elementDipole

An extremely thin embedded antenna for an armor-carrying vehicle utilizes a dipole driven element to the inside of the armor plate and a parasitically-driven dipole element on top of the armor plate, with the parasitic element providing appropriate forward gain and antenna matching characteristics such that there need be no aperturing of the armor plate in order to feed the antenna. In one embodiment, the bowtie antenna elements are elongated, extended or expanded by outboard antenna sections which are spaced from the distal ends of the corresponding bowties, with a meanderline choke bridging the gap between a bowtie element and its extended portion.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

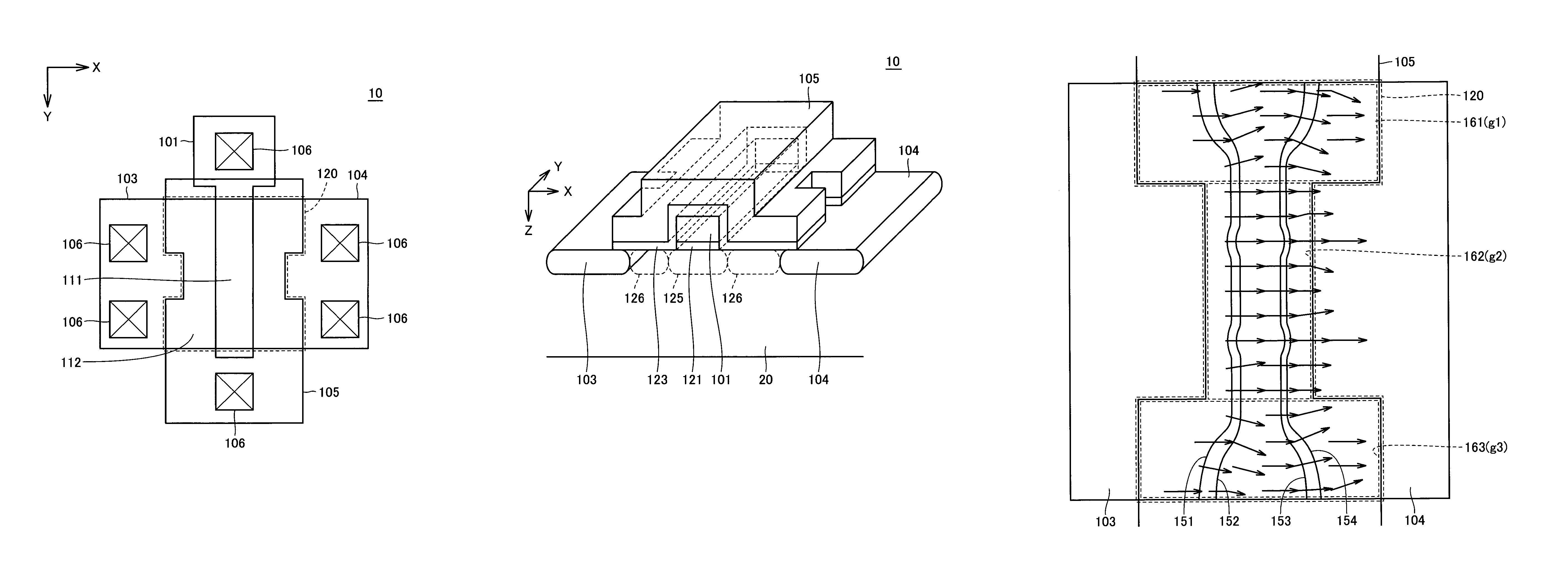

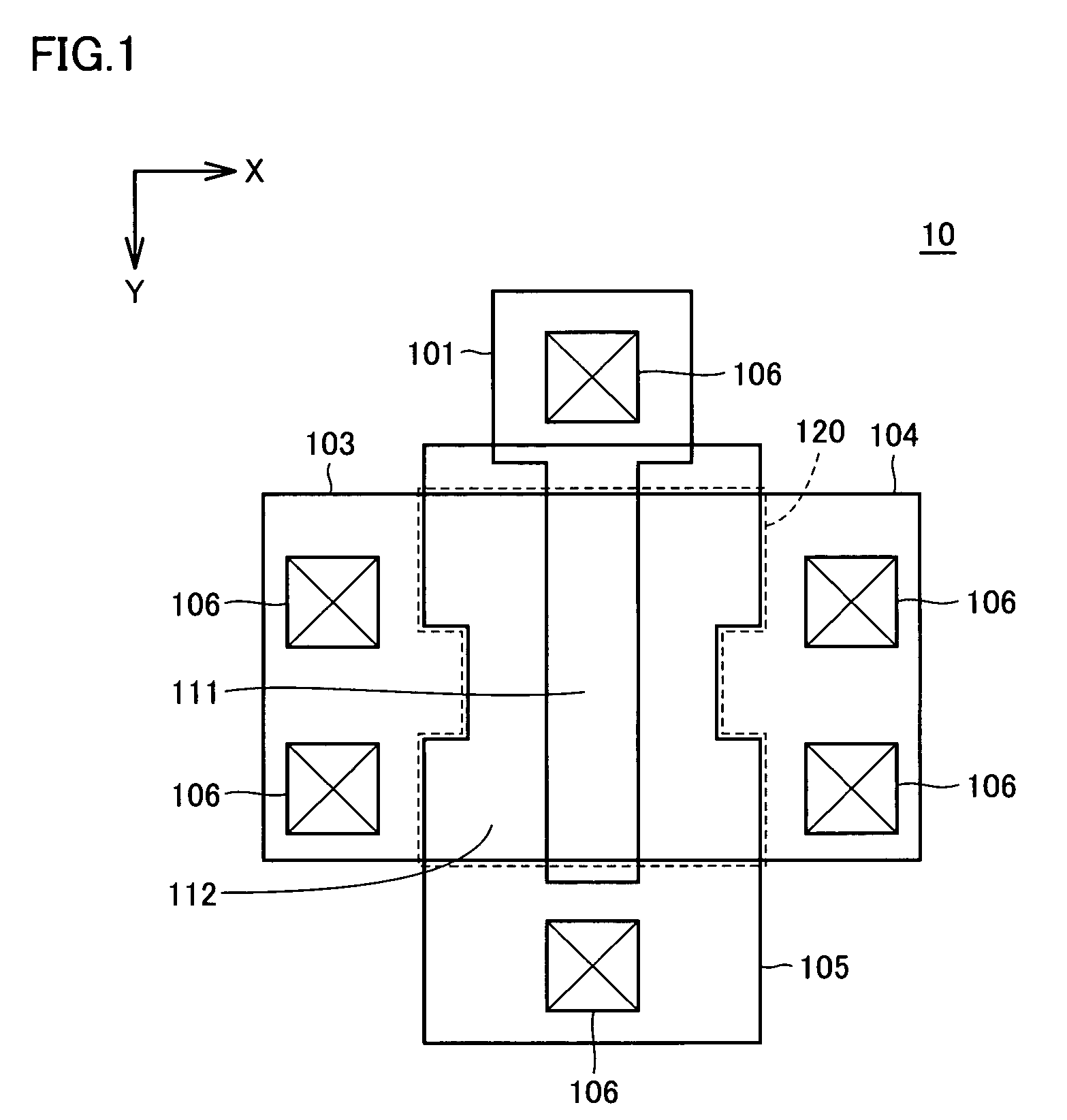

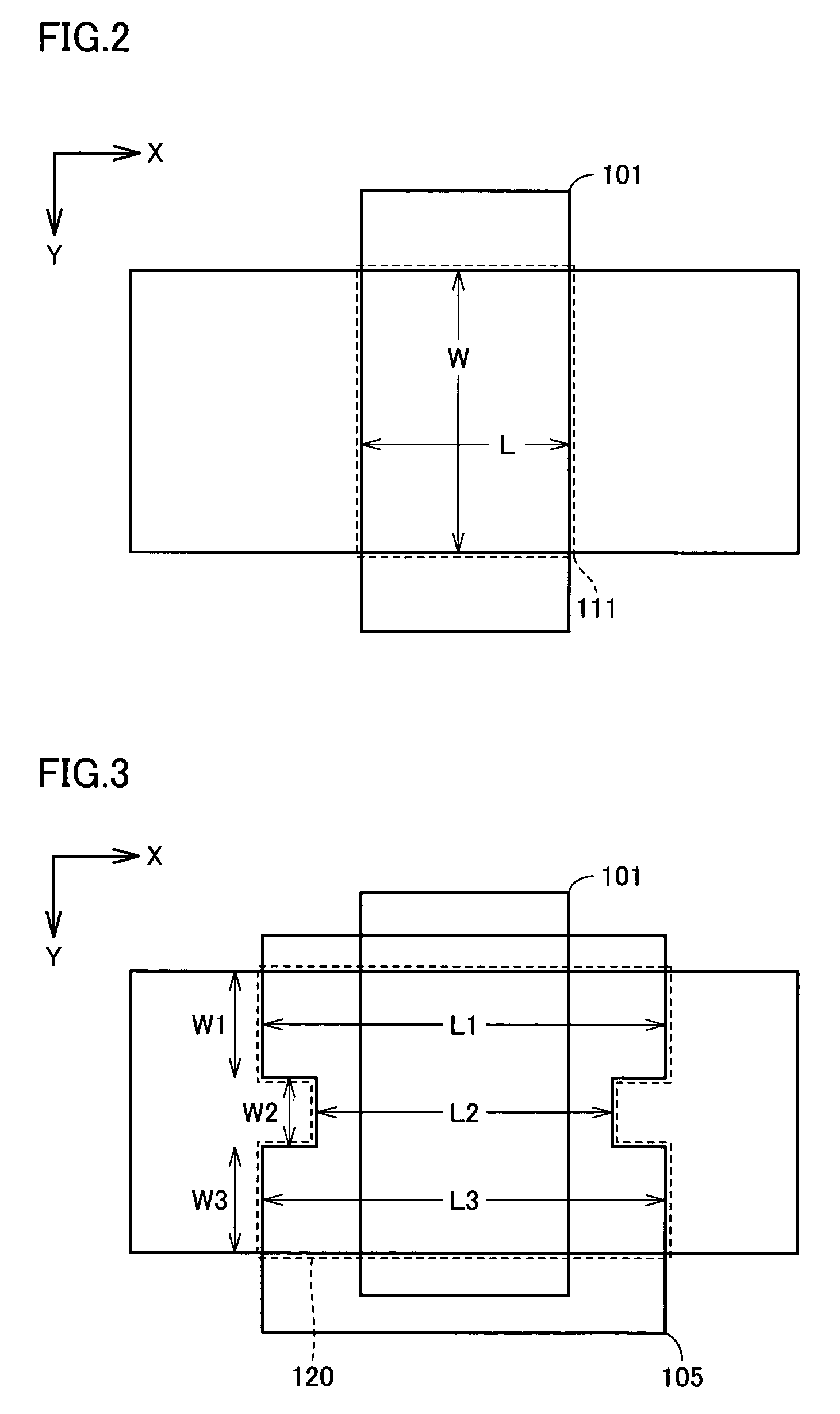

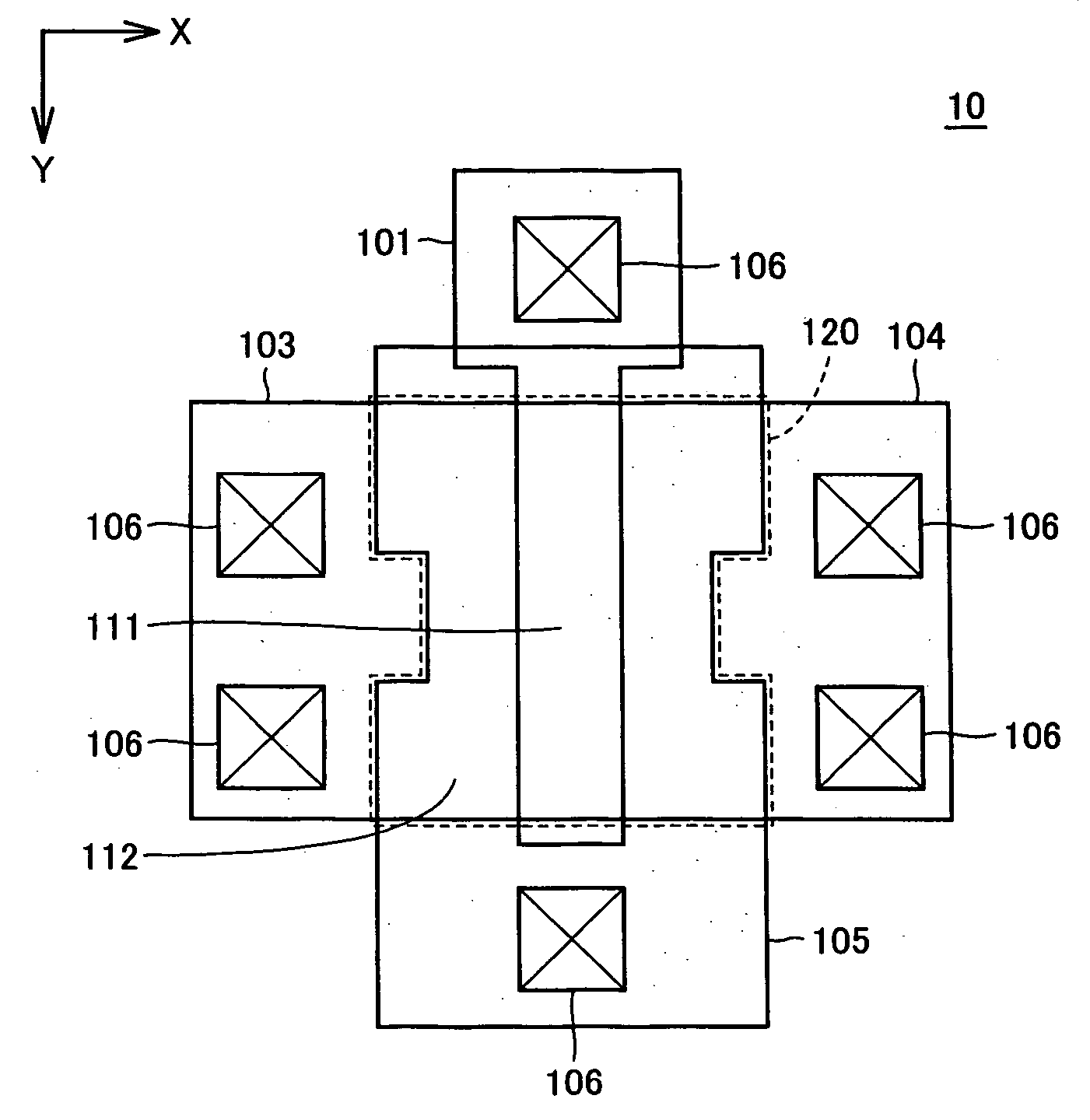

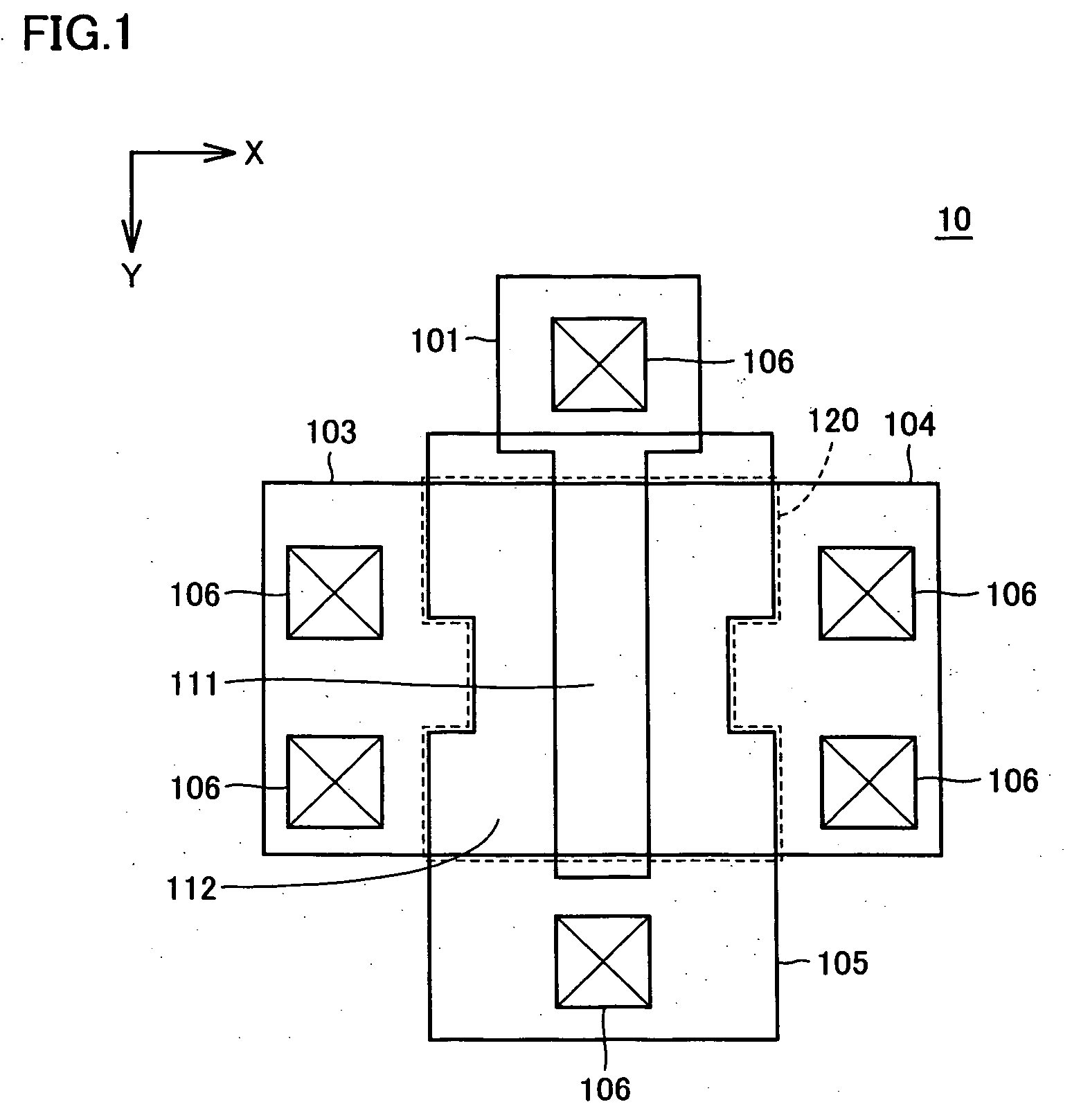

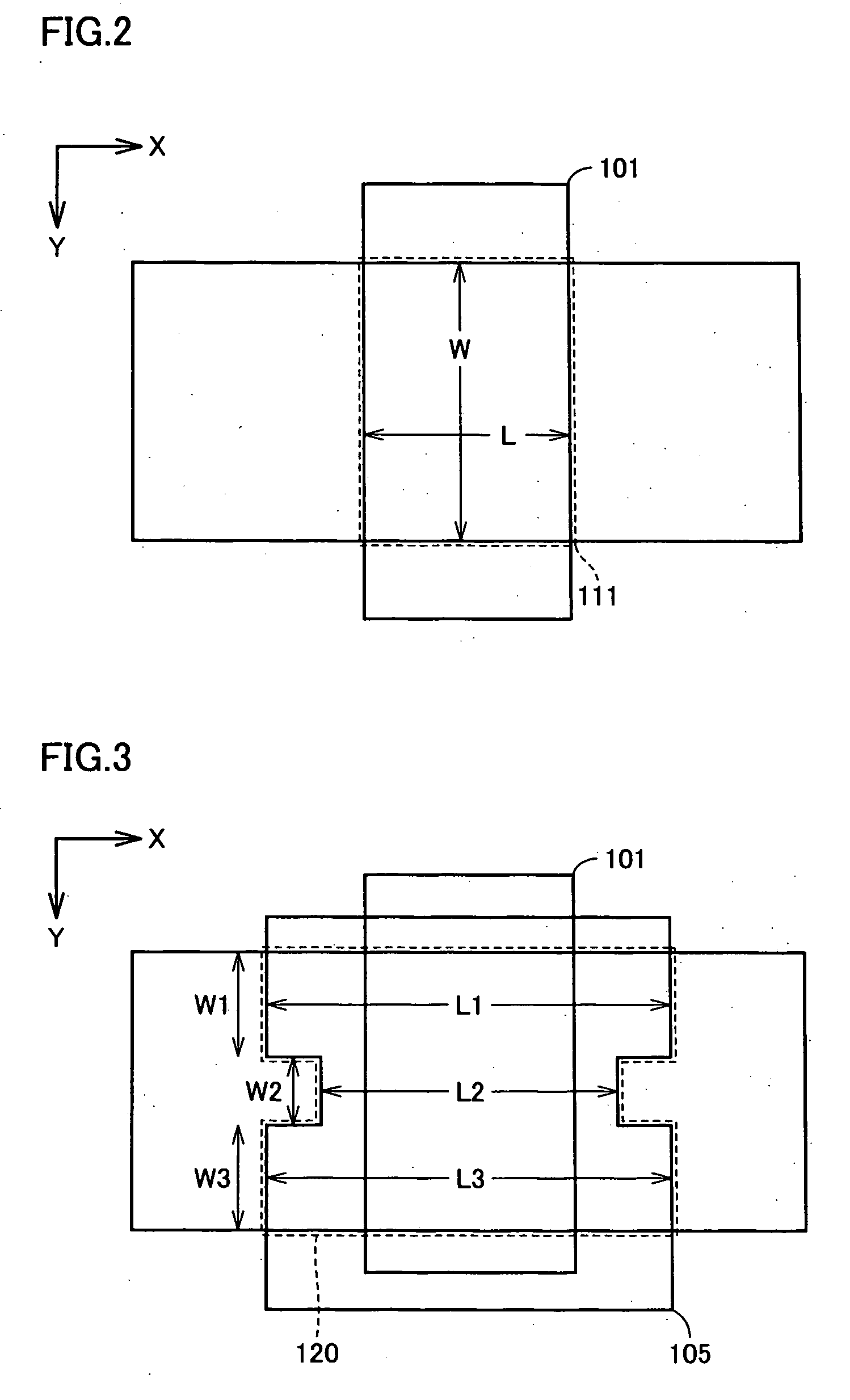

Semiconductor device allowing modulation of a gain coefficient and a logic circuit provided with the same

InactiveUS7057239B2Improve accuracyEasy to produceTransistorSemiconductor/solid-state device manufacturingGain coefficientEngineering

In addition to ordinary MOS gate, drain and source, a semiconductor element includes a control gate having geometry, which is defined only by a group of straight lines along a rectangular form of the MOS gate, is not defined by an oblique line and provides a nonuniform gate length at least in one of regions aligned in a direction of a gate width. A channel region formed by the control gate provides a region of strong electric fields and a region of weak electric fields. Consequently, a conductance of a whole channel region formed by the MOS gate and the control gate, i.e., a gain coefficient β of the semiconductor element can be modulated in accordance with voltages applied to the MOS gate and the control gate.

Owner:FUSAYOSHI HIROTSU +1

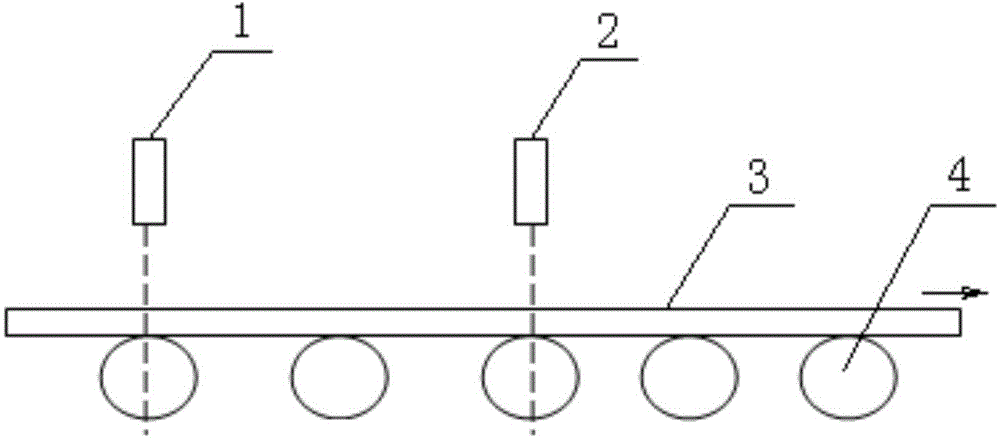

Online length measuring method for thermal-state steel pipe

InactiveCN106140830AEffective lengthHigh yieldLength control deviceMeasuring devicesThermal stateShortest distance

The invention provides an online length measuring method for a thermal-state steel pipe. The online length measuring method is characterized in that an optical fiber type hot metal detector with response time being 5ms is separately above each of a roller way with a distance of 1.5-2m from an outlet of a tandem mill and a roller way with a distance of 12-14m from the outlet of the tandem mill. After the thermal-state steel pipe is rolled by the tandem mill, the head part of the thermal-state steel pipe firstly passes through the first hot meal detector with a shorter distance, the first hot metal detector is used for converting a detected value into an electric signal which is input into a PLC, and the PLC starts timing; when the head part of the thermal-state steel pipe passes through the second hot metal detector, the PLC reads a first timing interval; and when the tail end of the steel pipe deviates from the first hot metal detector, timing of PLC is ended, and the PLC calculates length Y of the steel pipe by setting procedures. The online length measuring method is simple and reliable, can completely meet technological requirements, can operate on an HMI of a computer and can display effective steel pipe length, wherein detected length is 12-35m, and detection errors are + / -10mm; and the length of the steel pipe is detected, so that tandem-rolling regulating precision is improved and unit yield is increased.

Owner:ANGANG STEEL CO LTD

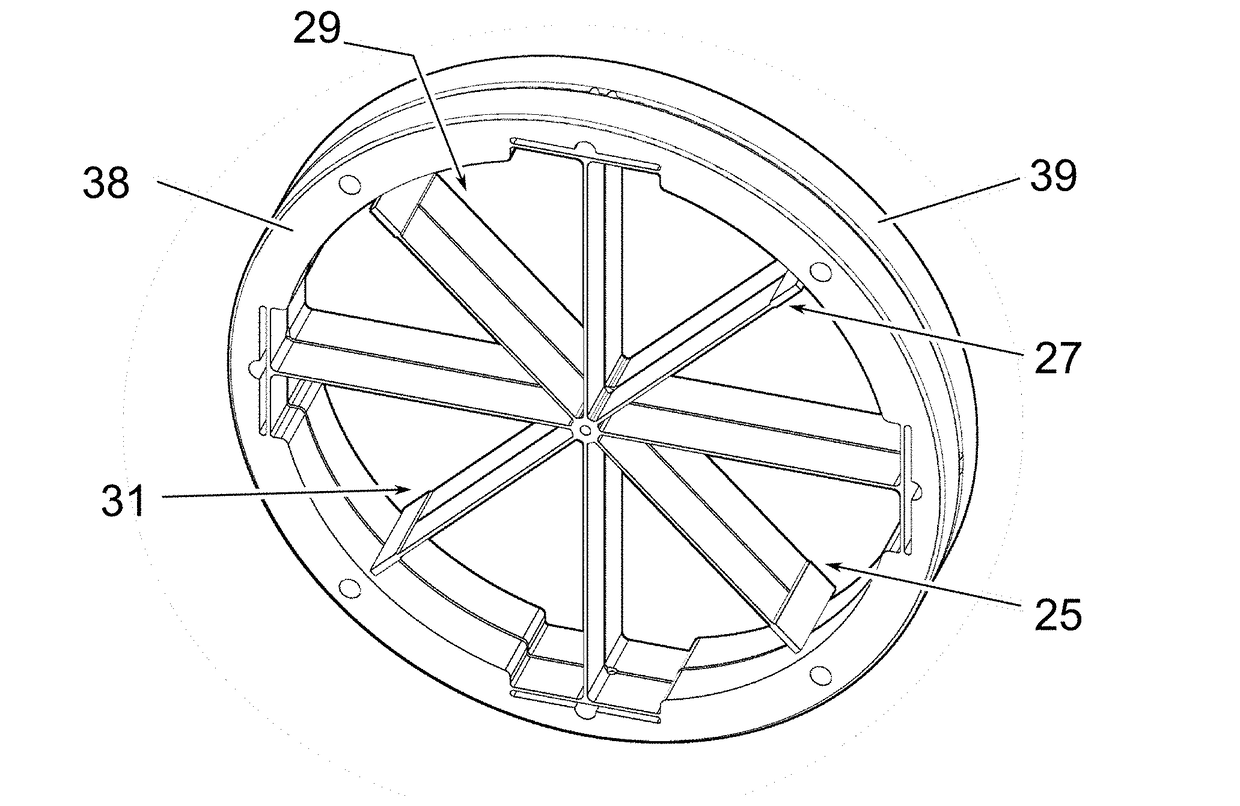

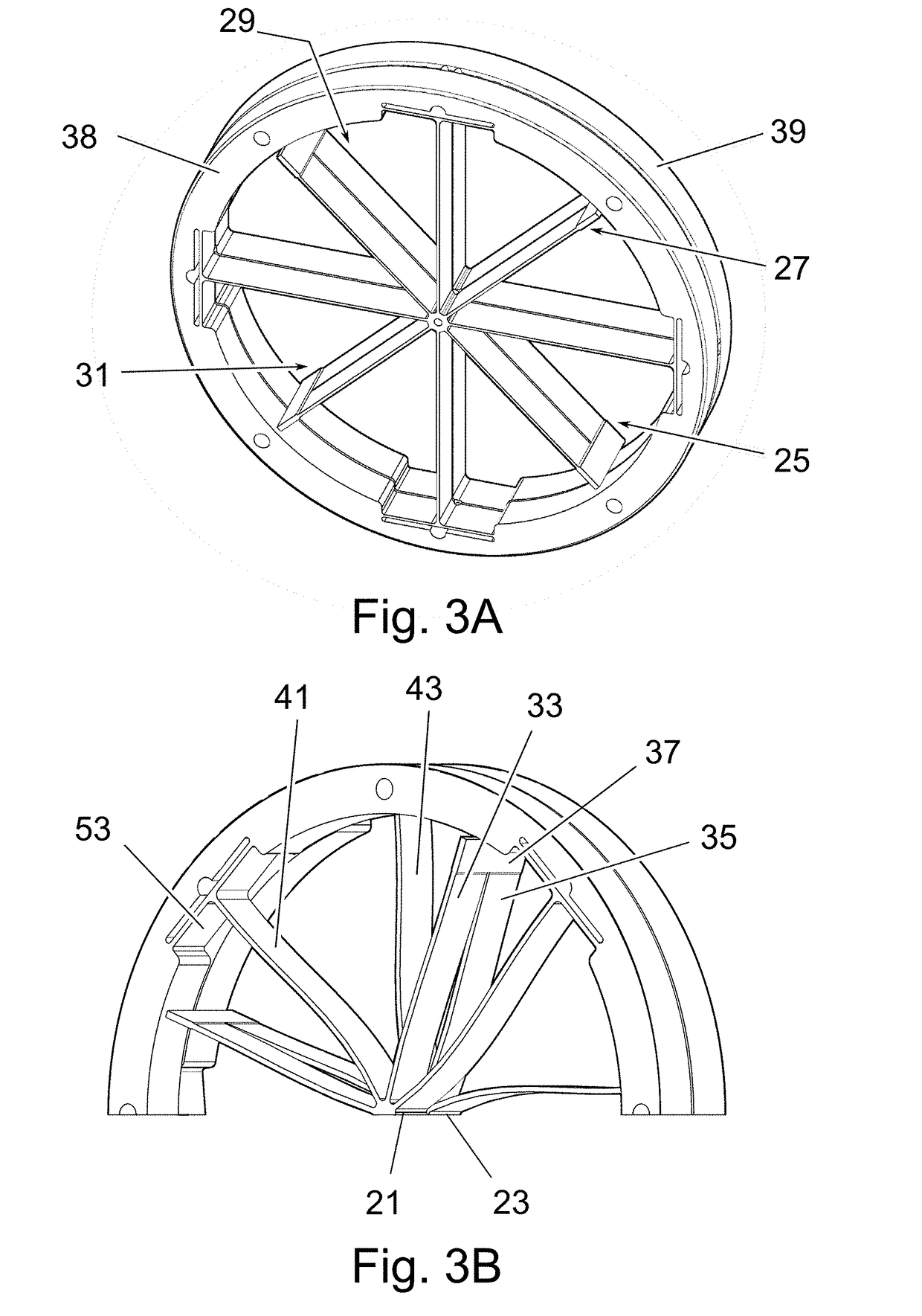

Large angle flexible pivot

PendingUS20180319517A1Improve centeringEffective lengthCosmonautic vehiclesFrequency stabilisation mechanismSpokeEngineering

A flexible pivot includes a first stage including a first cylinder and interface structure and a second stage including a second cylinder and interface structure in axial alignment with those of the first stage. Flexible connecting members are arranged for connecting the first and the second stages. Each flexible connecting member includes a pair of legs and a cross member joining the legs, each leg extending in a direction transverse to the axis of the cylinders, the legs being attached to the first and the second cylinders respectively. The first cylinder and the first interface structure are concentric. Flexible spokes are attached to the first cylinder by one end and to the first interface structure by the other. Each spoke extends in a direction transverse to the axis of the cylinders. Finally, the second stage includes flexible connection unit arranged to connect the second cylinder to the second interface structure.

Owner:ALMATECH SA

Two stage grease gun

InactiveUS7337927B2Little effortLimit longitudinal movementManual lubricationLarge containersEngineeringMechanical engineering

A portable grease gun with a dual pressure output capability which can be selectively changed by the user with little effort. A larger diameter plunger is longitudinally coupled to an extension. The larger diameter plunger and its extension are variable in length by manual rotation of the extension relative to the larger diameter plunger. The larger diameter plunger is slidable within a plunger retainer over a limited range and is not free to rotate within the plunger retainer. The larger diameter plunger and the plunger extension have aligned bores through them in which a smaller diameter plunger is slidable. The smaller diameter plunger moves when an actuating lever is operated to compress grease in the grease gun. The larger diameter plunger may be adjusted to remain static during operation of the actuating lever or it may be adjusted to move during all or part of the compression stroke of the actuating lever.

Owner:WEEMS IND INC

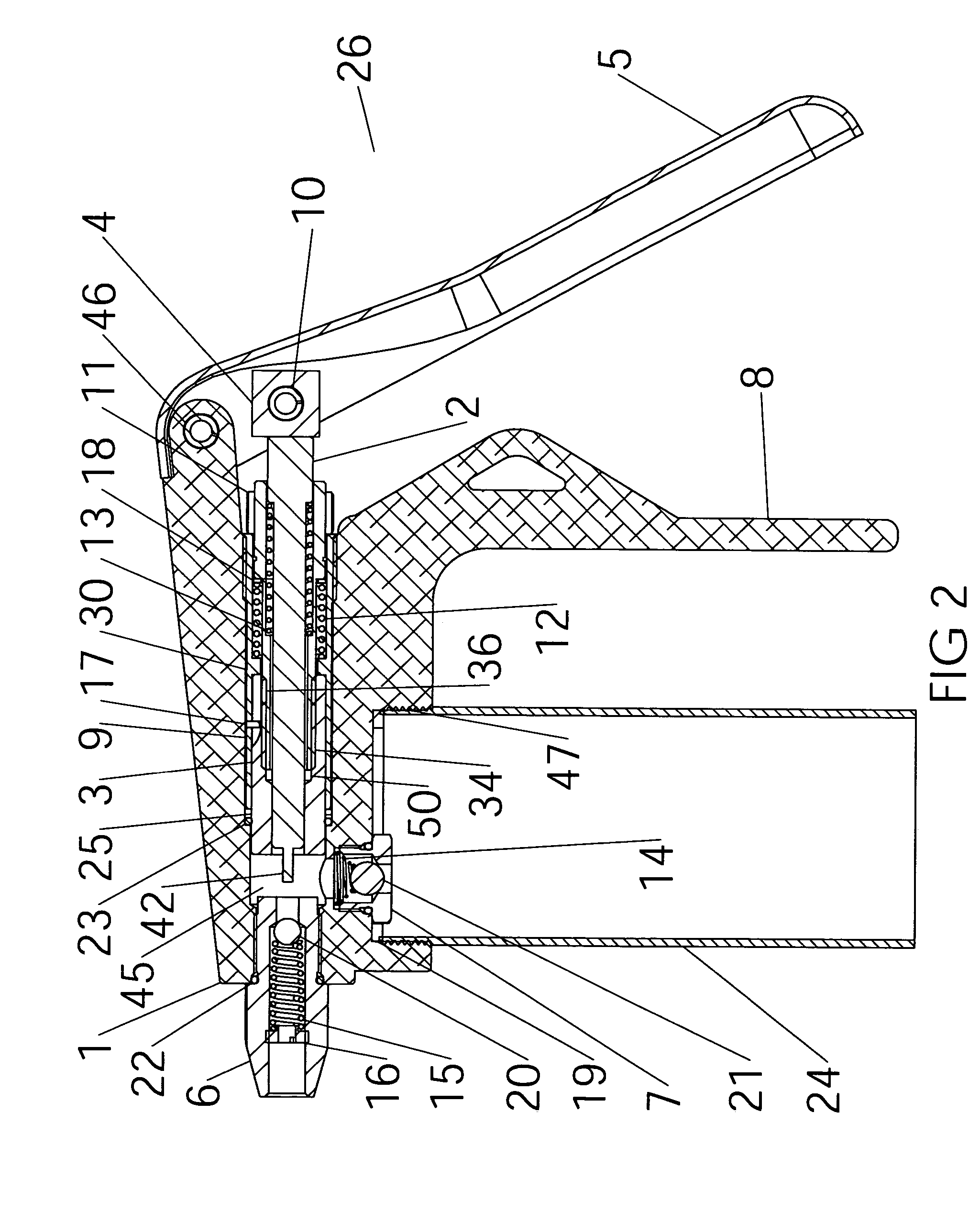

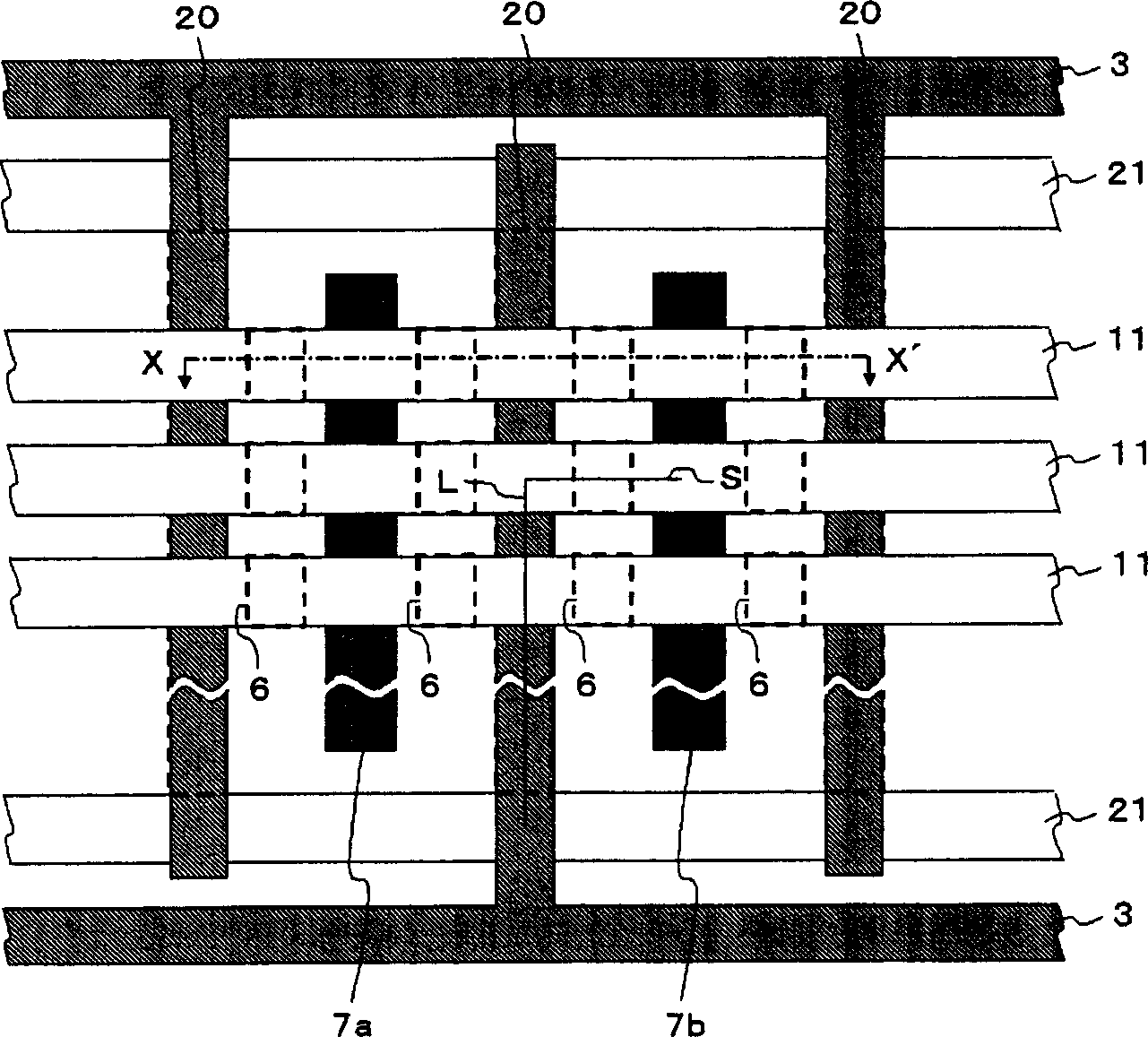

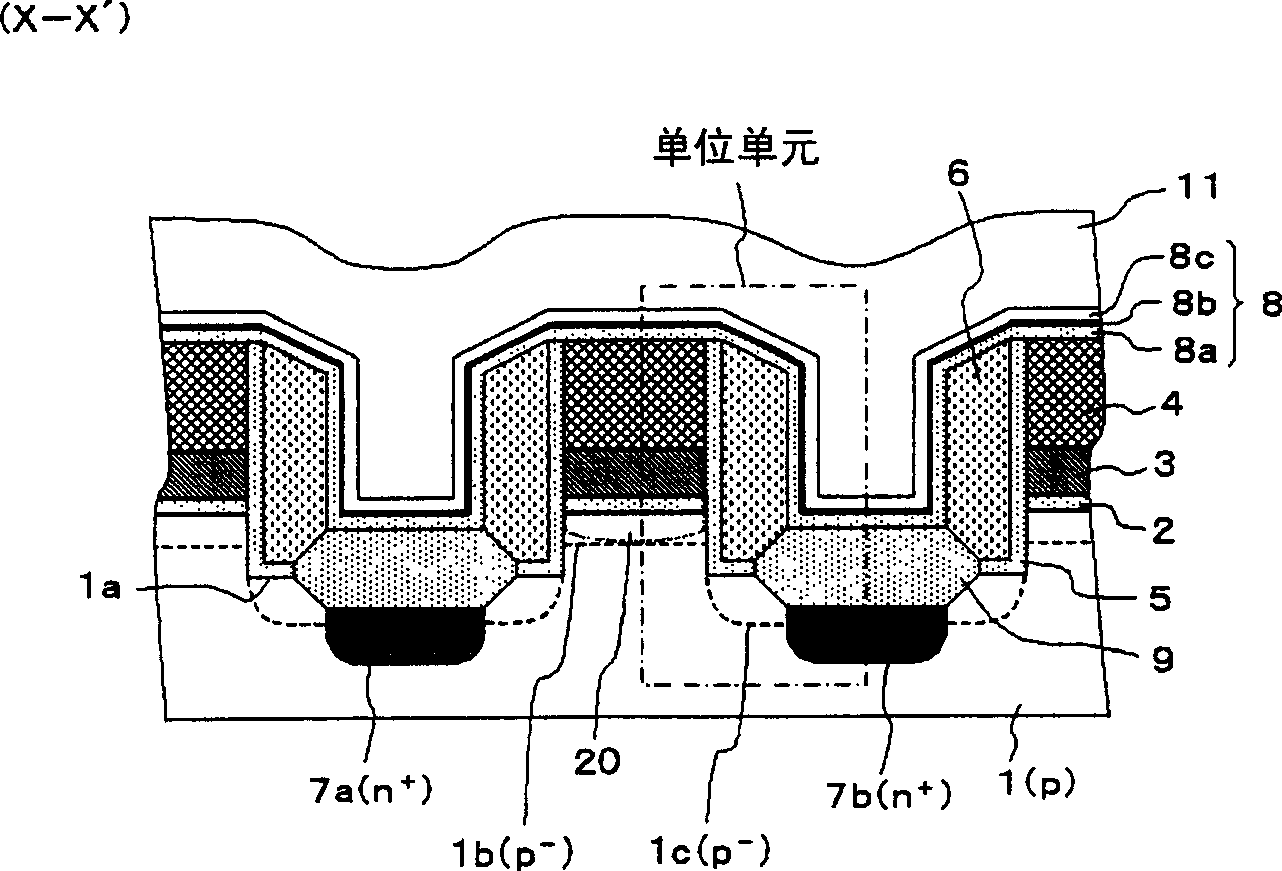

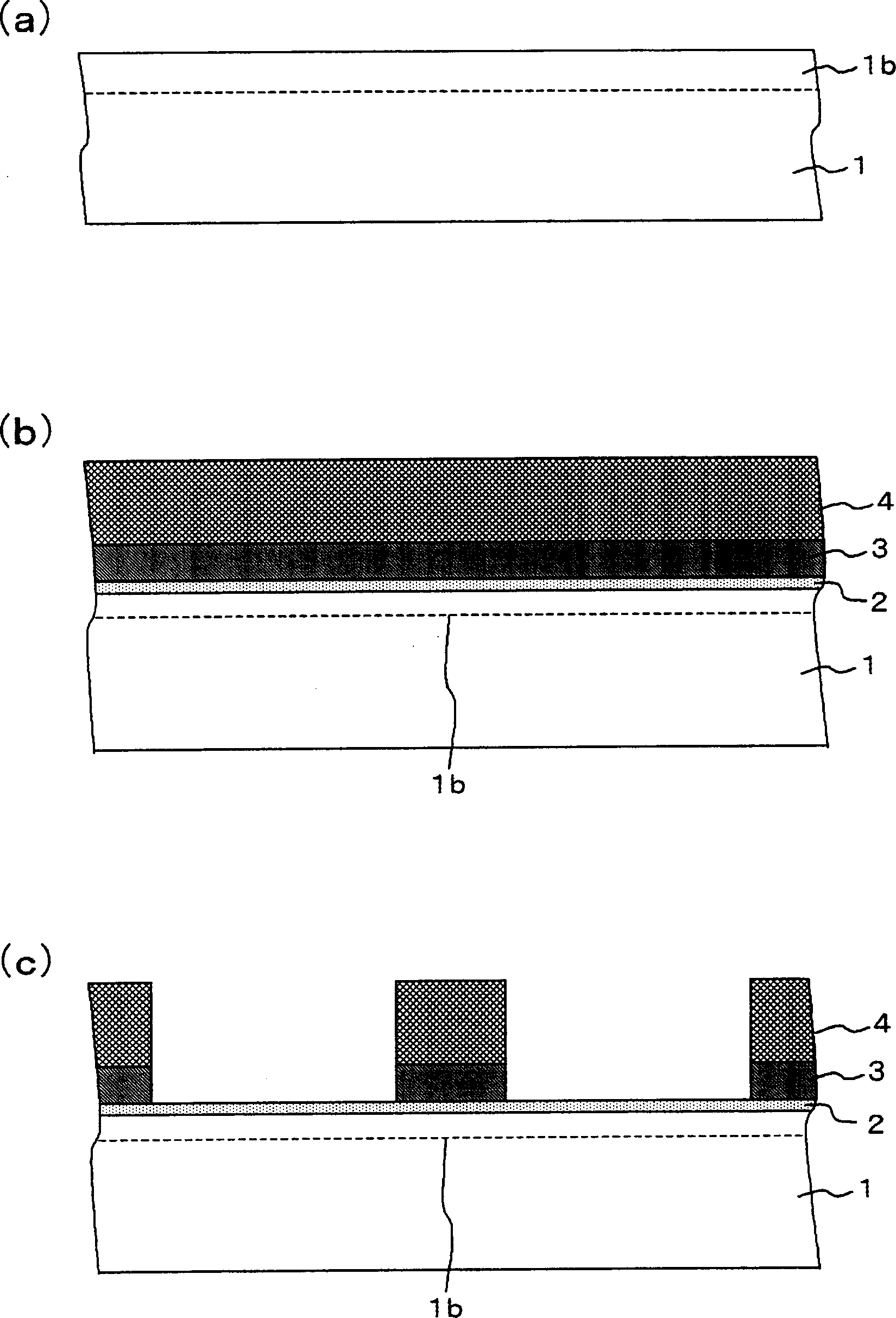

Semiconductor storage device and method for manufacturing same

InactiveCN1855513AReduce cut-off leakageEffective lengthTransistorSolid-state devicesSemiconductor storage devicesMiniaturization

A semiconductor-memory device that reduces leak off due to miniaturization of memory cells, and comprises as a single unit cell: a substrate 1 having a trench section 1 a; a selector gate 3 that is located via an insulating film 2 on the substrate adjacent to the trench section 1 a; a first well 1 b that is formed on the surface of the substrate 1 below the selector gate 3 ; a floating gate 6 that is located via an insulating film 8 a on the surface of the bottom section and sidewall section of the trench section 1 a; a second well 1 c that is formed on the surface of the bottom section of the trench section 1 a below the floating gate 6 ; a first diffusion area 7 a that is formed on the surface of the bottom section of the trench section 1 a; and a control gate 11 located via an insulating film 8 on top of the floating gate 6 ; and where the area near the sidewall surface and bottom surface of the trench section 1 a forms a channel in the selector gate 3 ; and the impurity density of the first well 1 b is not more than the impurity density of the second well 1 c.

Owner:NEC ELECTRONICS CORP

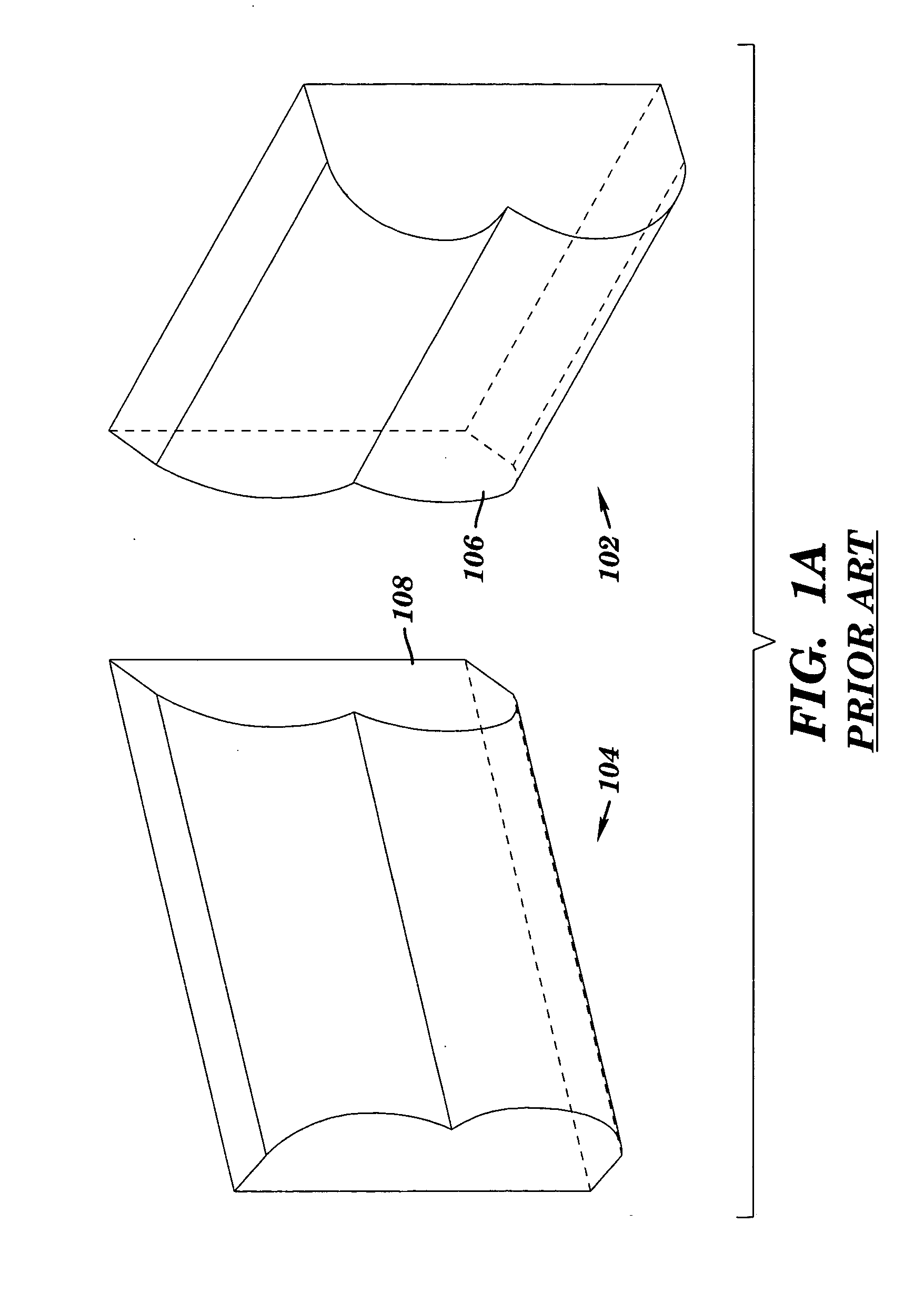

Trim paneling with miterless corner joints and related methods

Disclosed herein is a paneling system including a first and a second span element each possessing a substantially non-rectangular lateral cross-section and at least one butt end having a surface substantially perpendicular to a longitudinal axis of the span element. The paneling system also includes a transition element having a first end defining a first coping profile, the first coping profile being mateable to the butt end of a first span element at substantially a right angle, and a second end defining a second coping profile, the second coping profile being mateable to the butt end of a second span element at substantially a right angle. Also disclosed is a method of installing a paneling system that includes arranging transition and span elements to mate and form miterless corners.

Owner:QUESTECH CORP

Two stage grease gun

InactiveUS20060231576A1Little effortLimit longitudinal movementManual lubricationLarge containersHigh pressureUnison

A portable grease gun with a dual pressure output capability which can be selectively changed by the user with little effort. The larger diameter plunger is slidable within a plunger retainer. The larger diameter plunger has a bore through them in which a smaller diameter plunger is slidable. The smaller diameter plunger moves when an actuating lever is operated to compress grease in the grease gun. The larger diameter plunger may be adjusted to remain static during operation of the actuating lever or it may be adjusted to move during all or part of the compression stroke of the actuating lever. A high pressure can be generated by movement of the smaller diameter plunger alone, or a high flow volume can be generated by movement of the smaller and larger diameter plungers in unison.

Owner:WEEMS IND INC

Ion Guide Array

ActiveUS20130140469A1Reduced footprintSmall sizeStability-of-path spectrometersTime-of-flight spectrometersAtomic physicsIon

An ion guide array is disclosed comprising a first ion guide section and a second ion guide section. Each ion guide section may comprise a plurality of electrodes having an aperture through which ions are transmitted in use. A transfer section is arranged at the exit of the first ion guide section and ions are transmitted radially from the first ion guide section into the second ion guide section. Electrodes in the transfer section may have a radial aperture enabling ions to be transmitted radially from the first ion guide section to the second ion guide section.

Owner:MICROMASS UK LTD

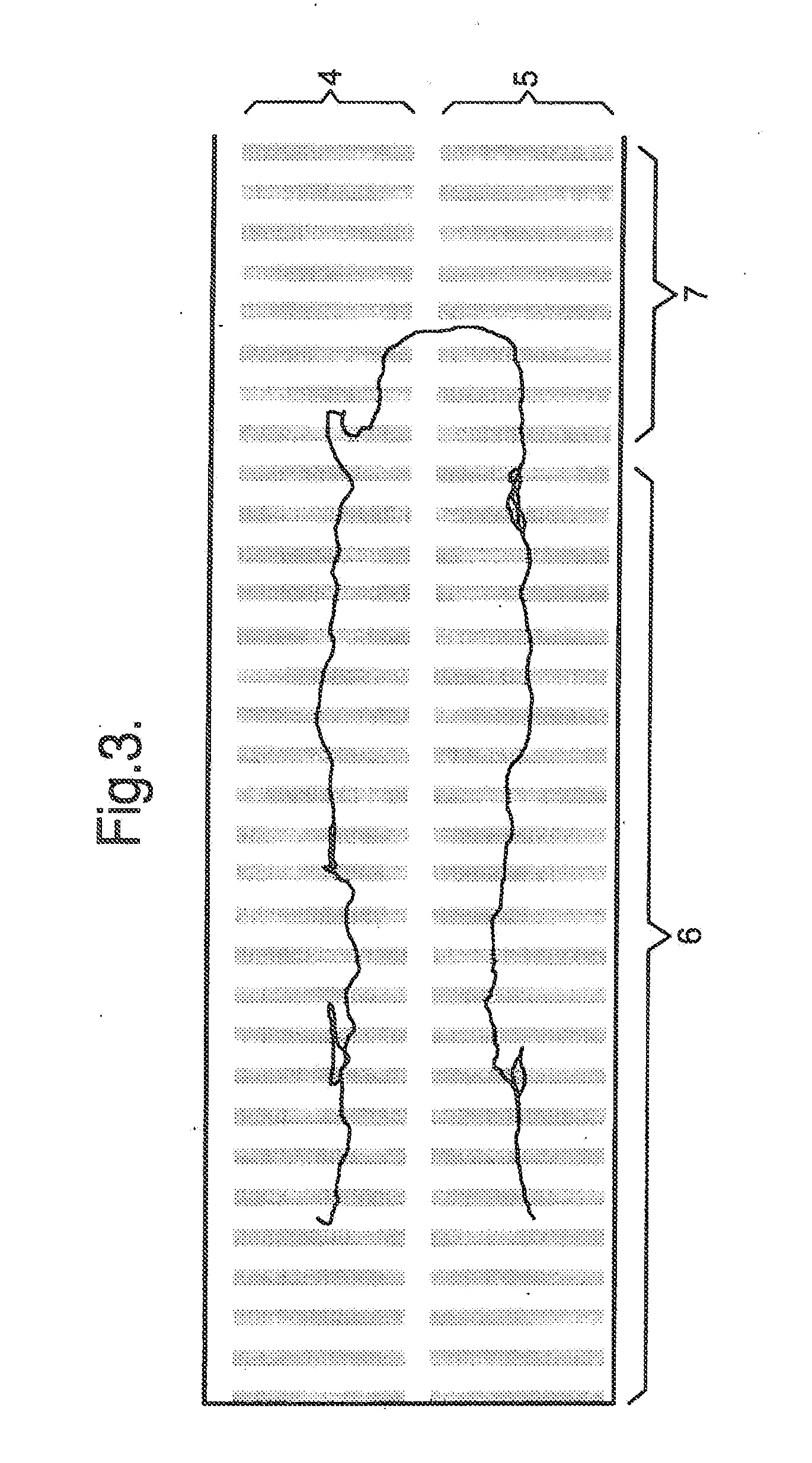

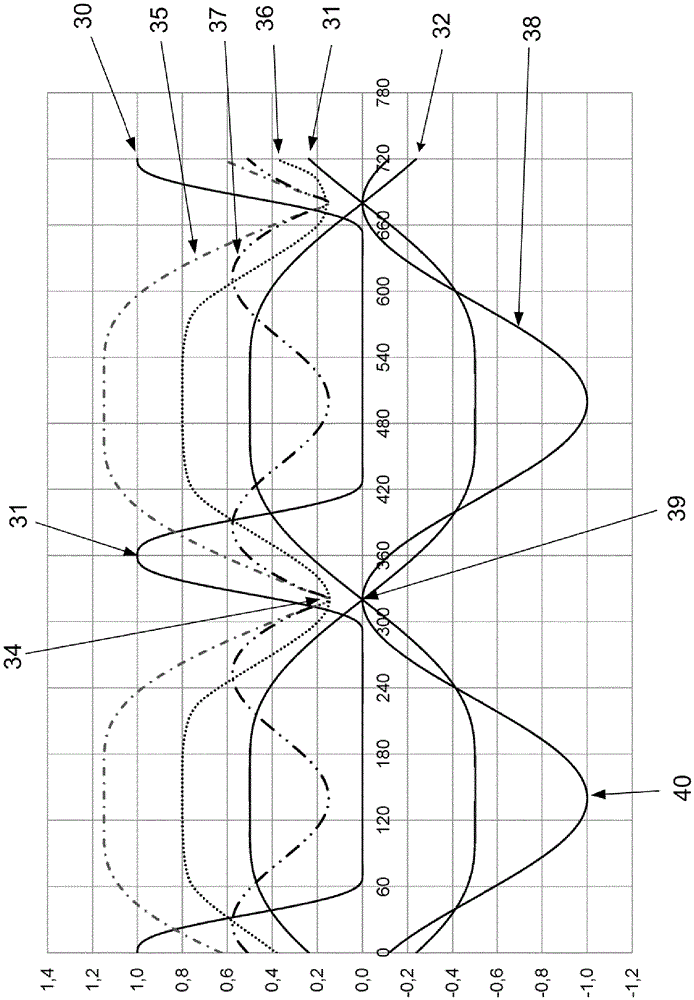

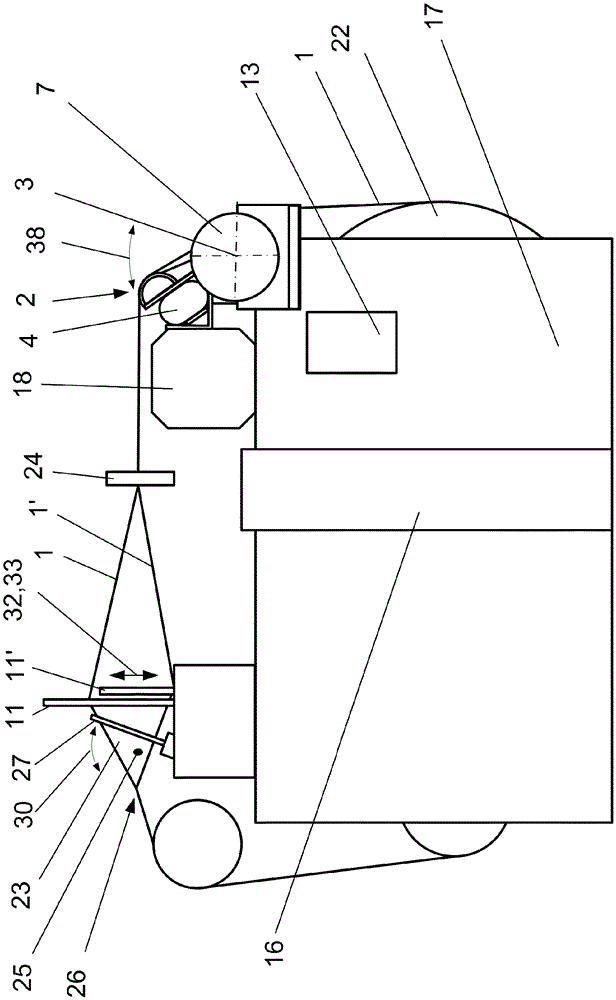

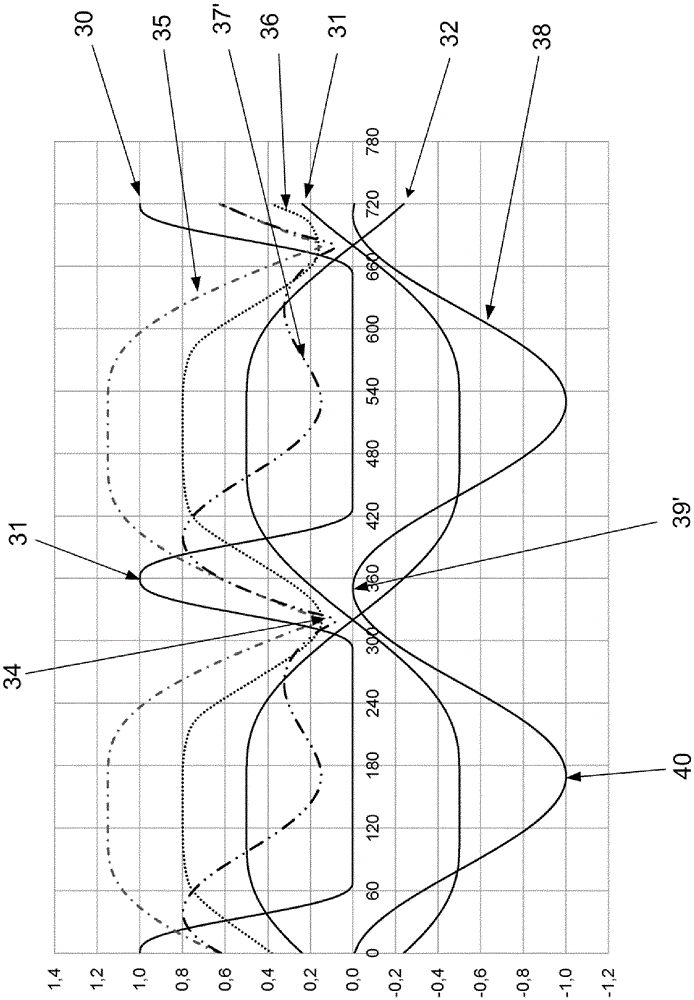

Method and device for applying forces and motions to warp threads of weaving machine

The invention relates to a method for applying forces and motions to warp threads (1, 1 ') of a weaving machine, comprising the following steps: deflecting the warp threads (1, 1 ') via a thread-deflecting element (2), which is supported in such a way that the thread-deflecting element can be pivoted about a pivot axis (3); applying spring forces to the thread-deflecting element (2) by means of more than three force application points (5) along a first line (6), which extends parallel to the pivot axis (3), wherein the spring forces are applied by at least one spring element (4); applying a specified forced-oscillation motion (38) to the thread-deflecting element (2), wherein said motion (38) is applied by a drive means (7) via a drive element (8), wherein the forces on the thread-deflecting element (2) are supported partially on at least one spring element (4) by means of the thread-deflecting element (2) and partially on the drive means (7) by means of the drive element (8). The invention further relates to a corresponding device.

Owner:LINDAUER DORNIER GMBH

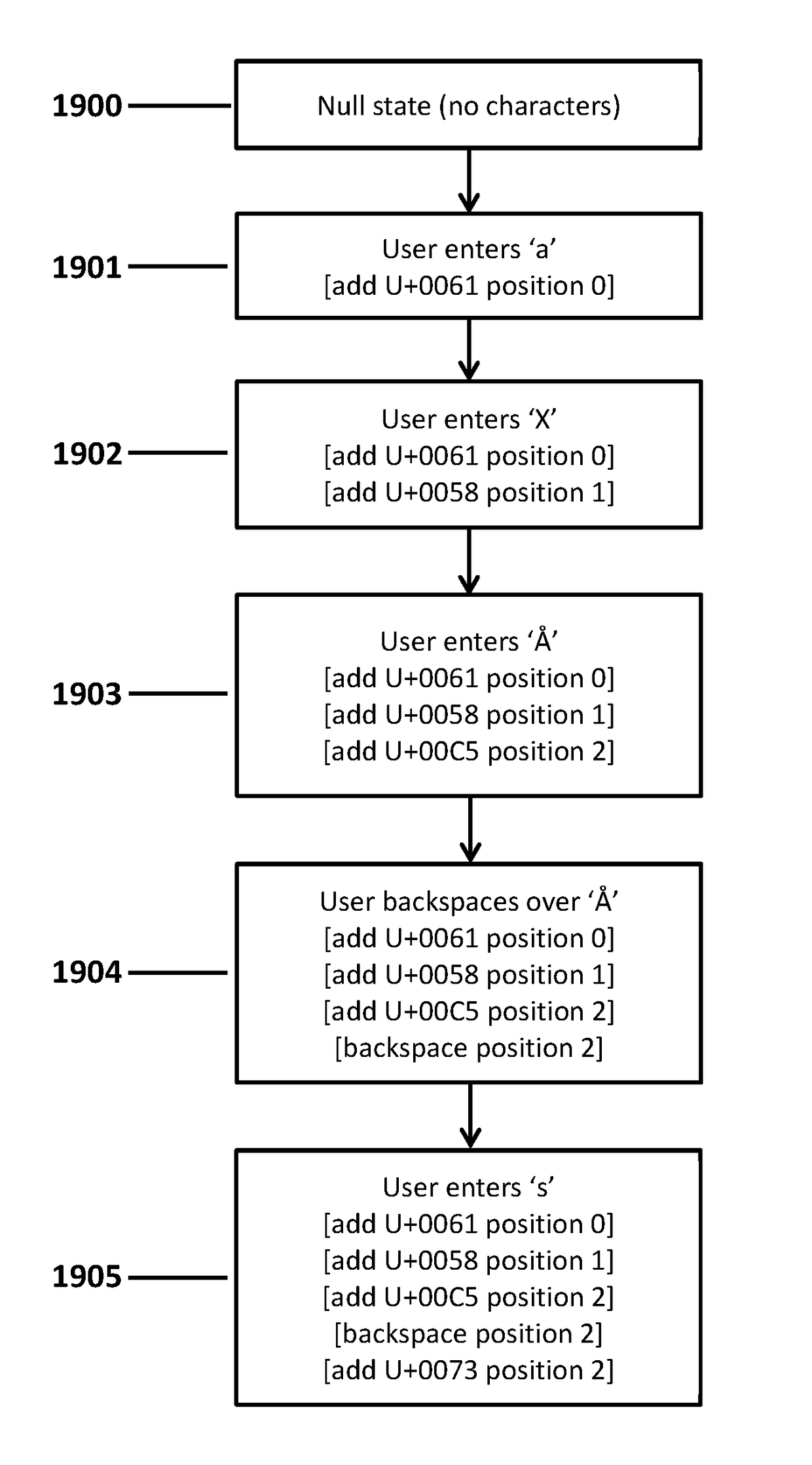

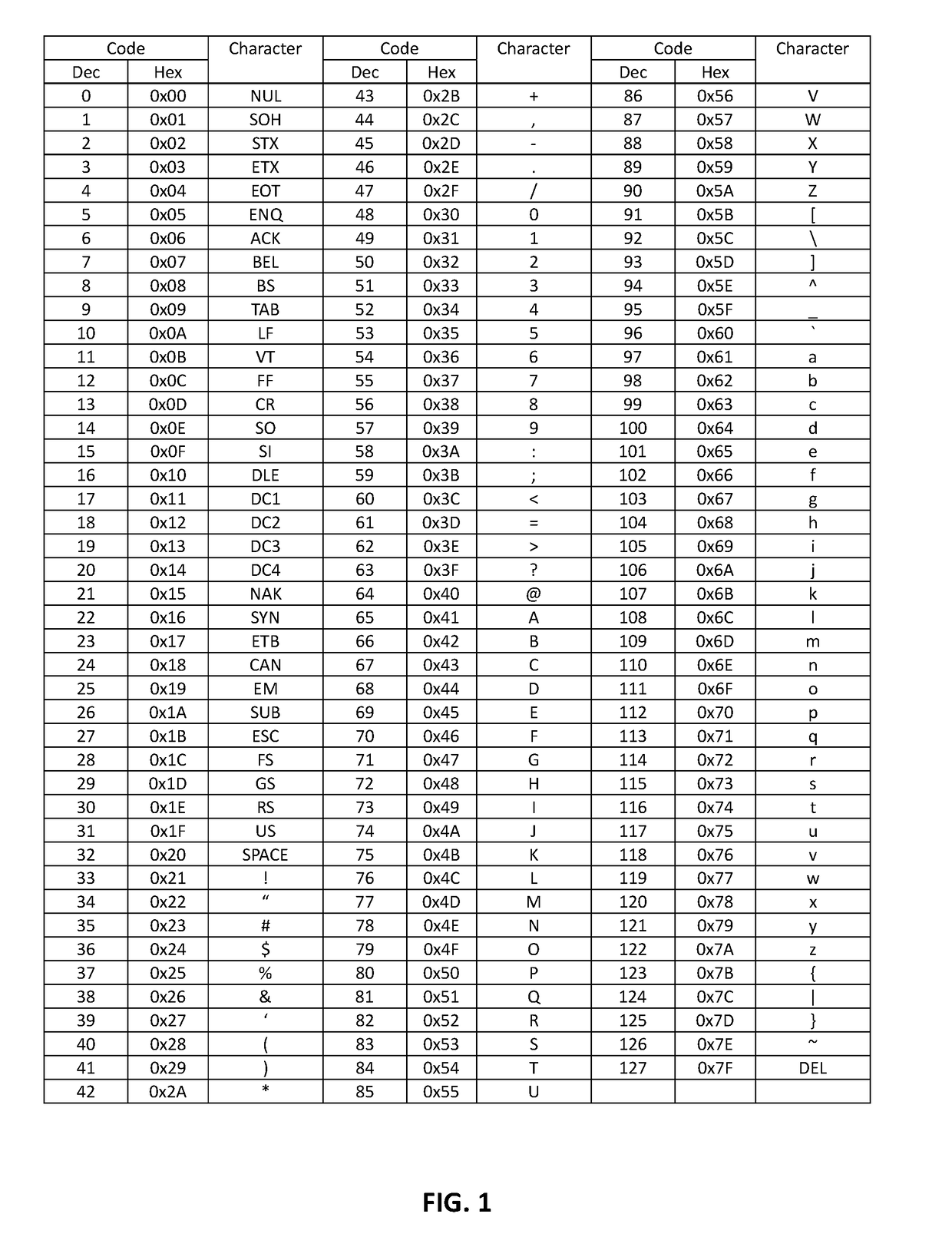

Apparatus and method for cryptographic operations using enhanced knowledge factor credentials

InactiveUS10015163B2Easy to rememberMemorable credentialCode conversionDigital data authenticationUser inputCryptographic protocol

Owner:UNIVAULTAGE

Apparatus and method for cryptographic operations using enhanced knowledge factor credentials

ActiveUS9516015B1Easy to rememberMemorable credentialCode conversionDigital data authenticationAlgorithmTheoretical computer science

Owner:UNIVAULTAGE

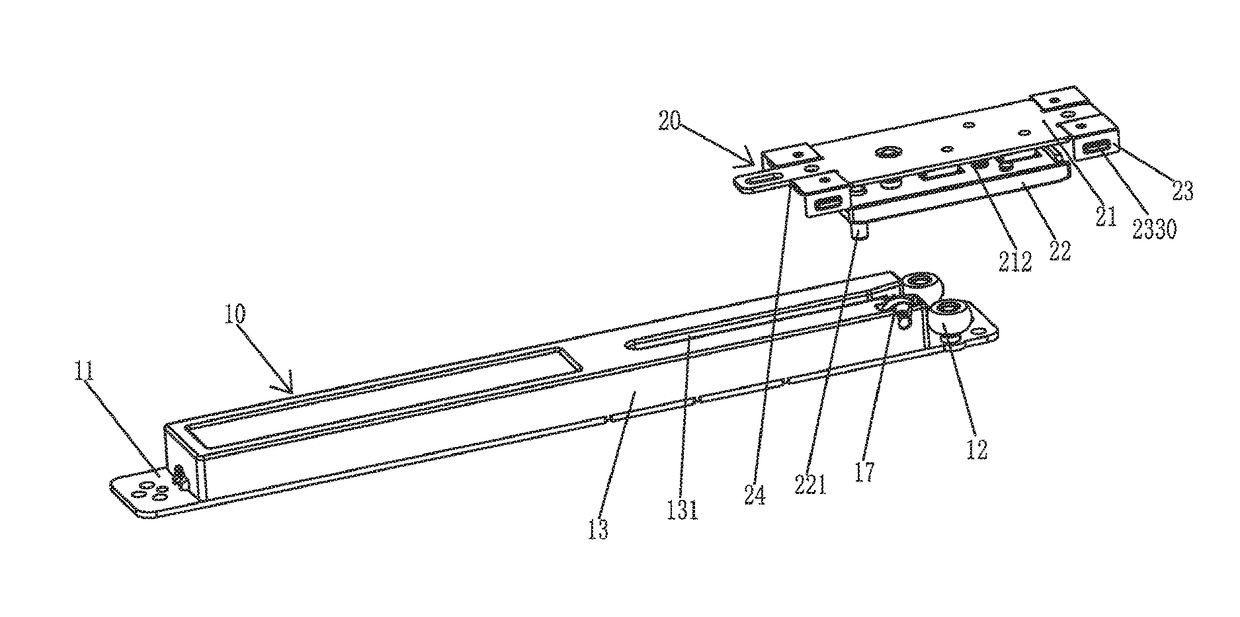

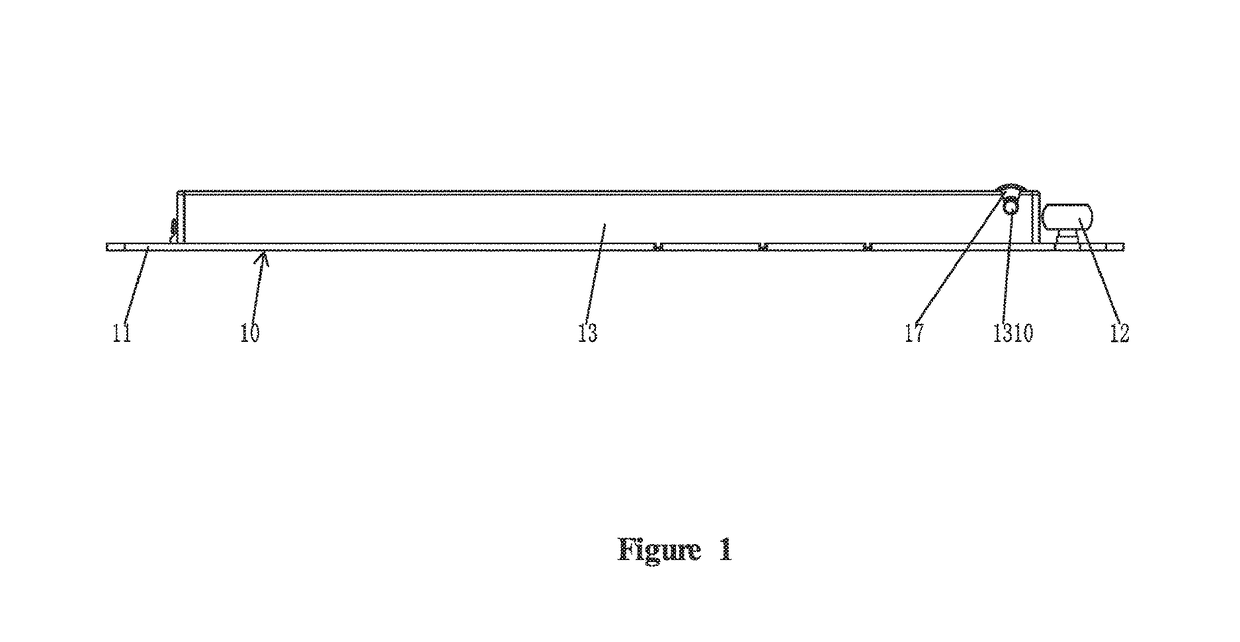

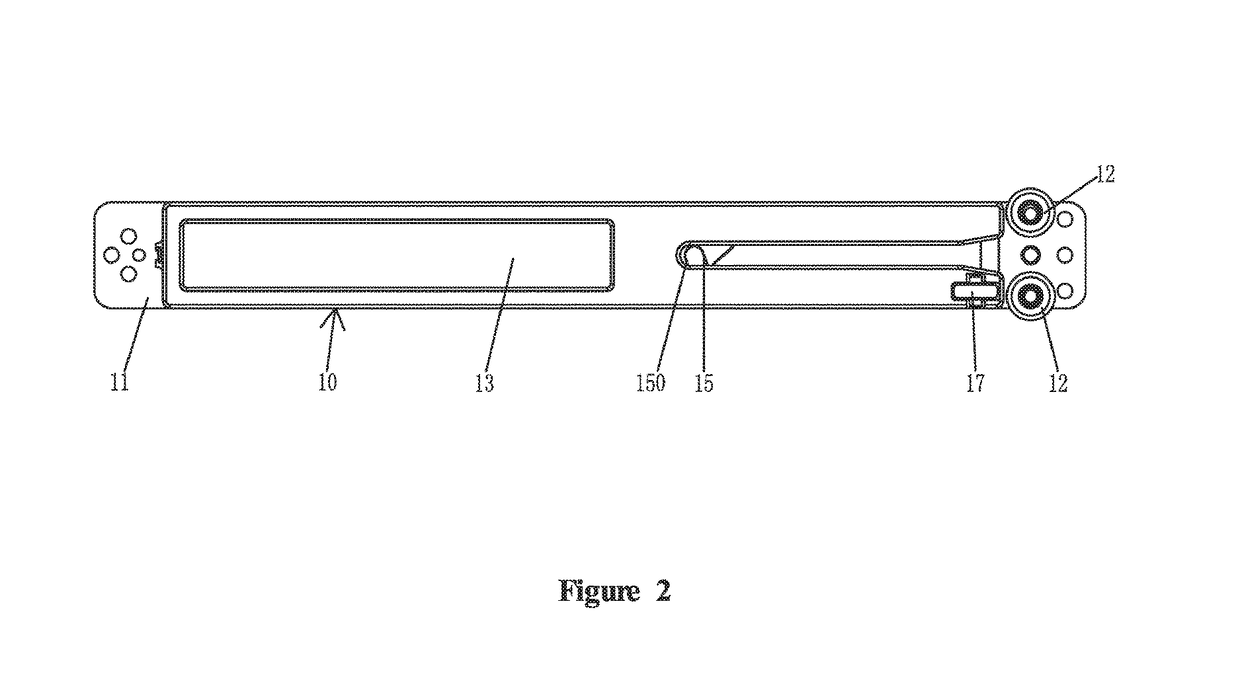

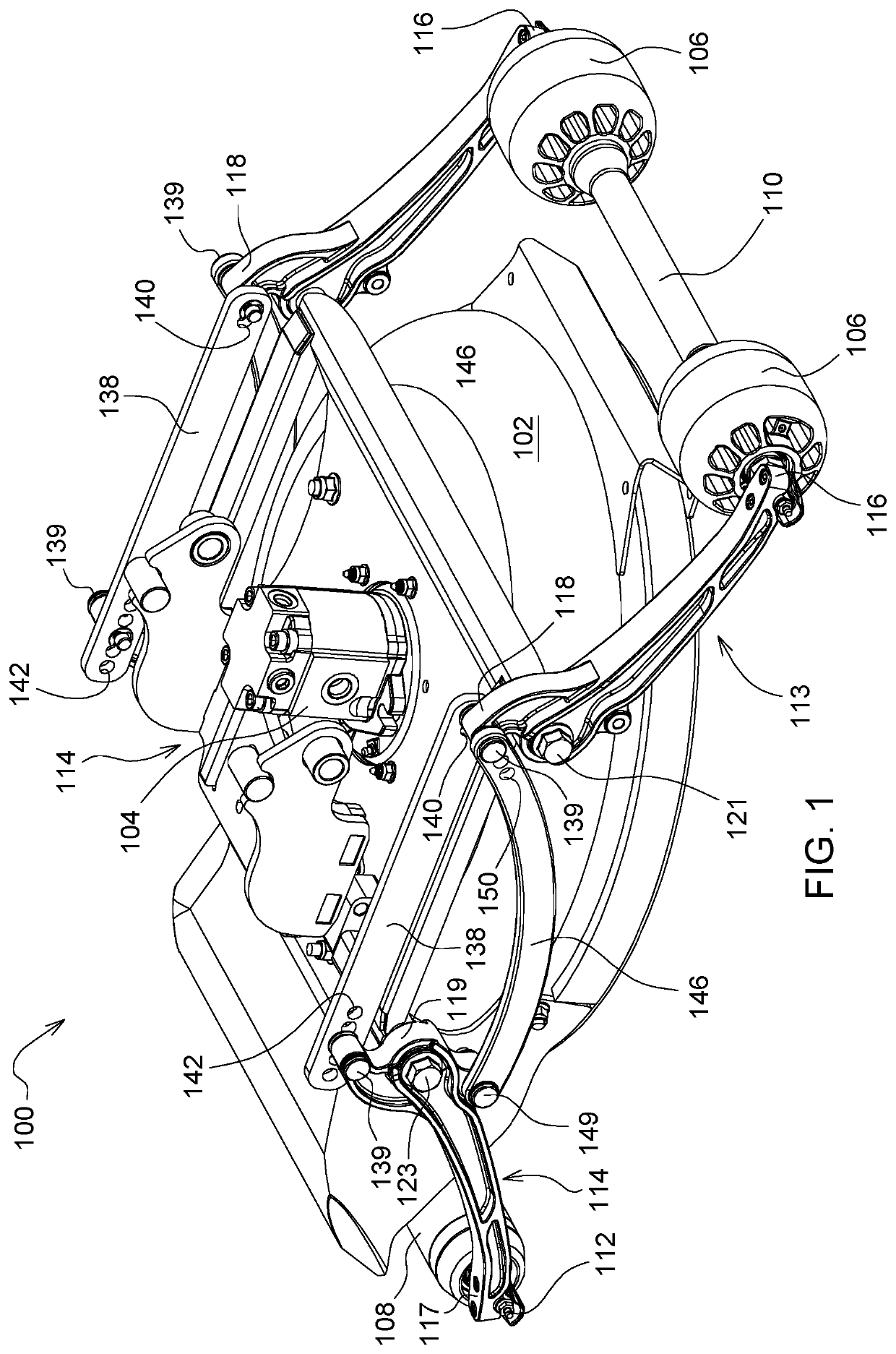

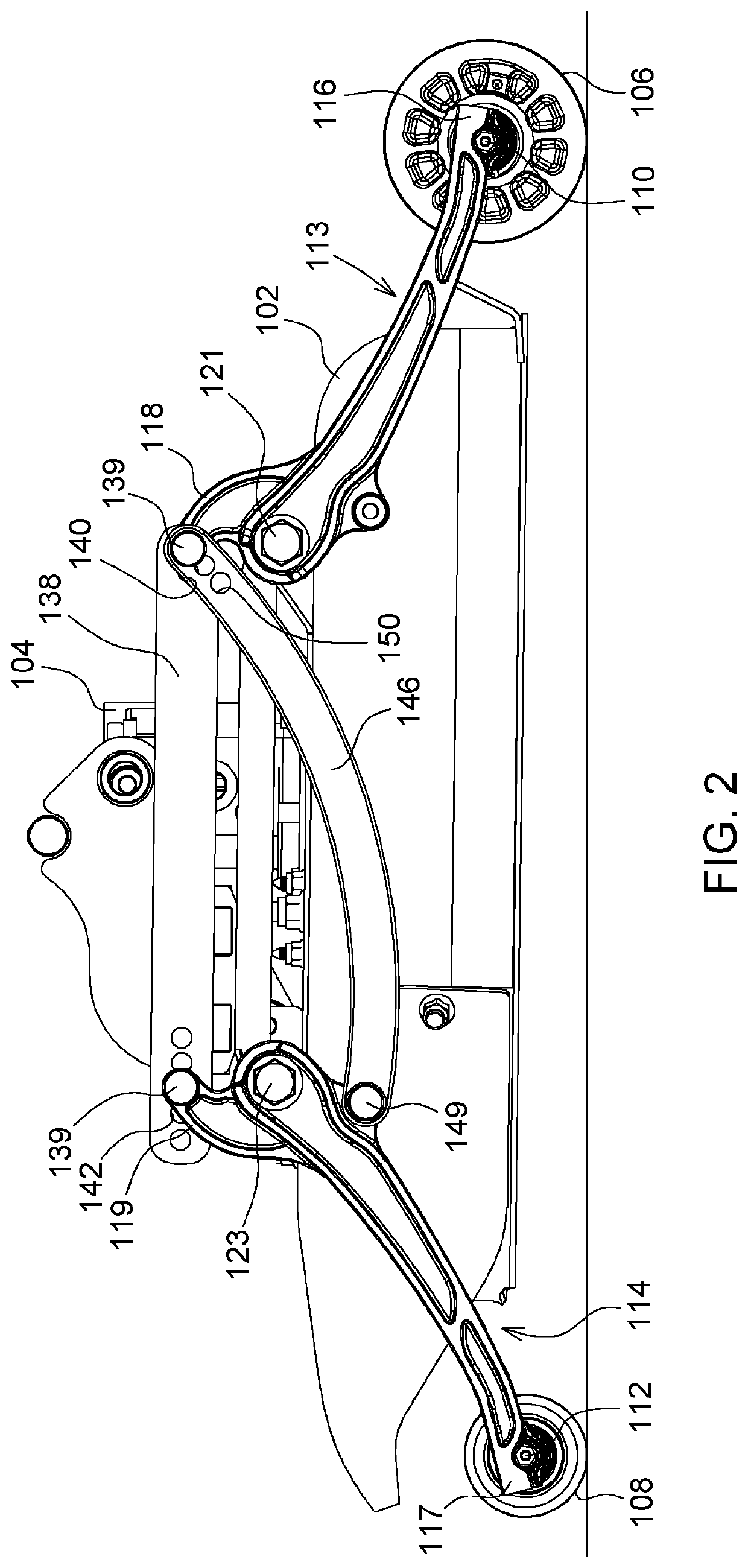

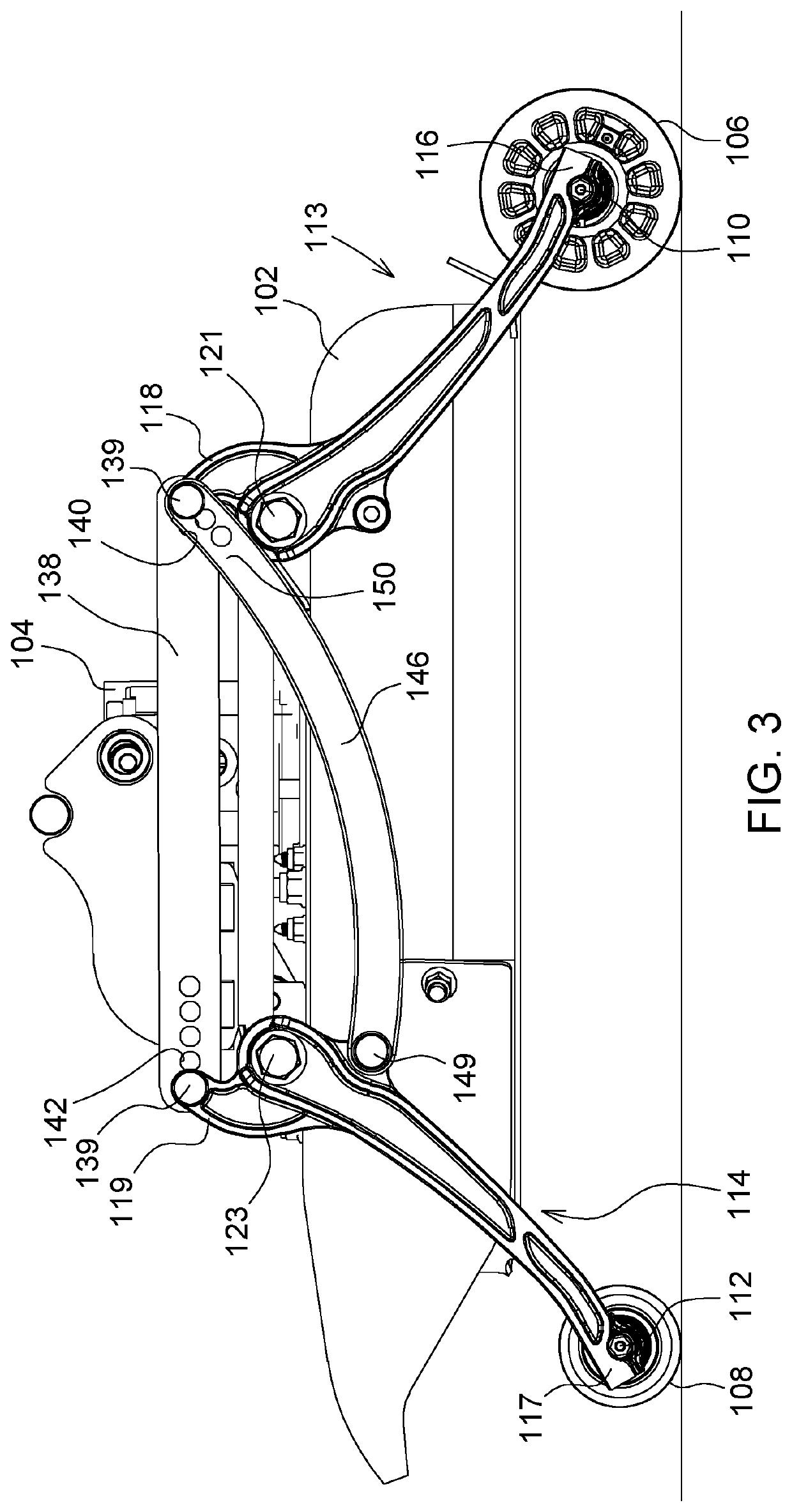

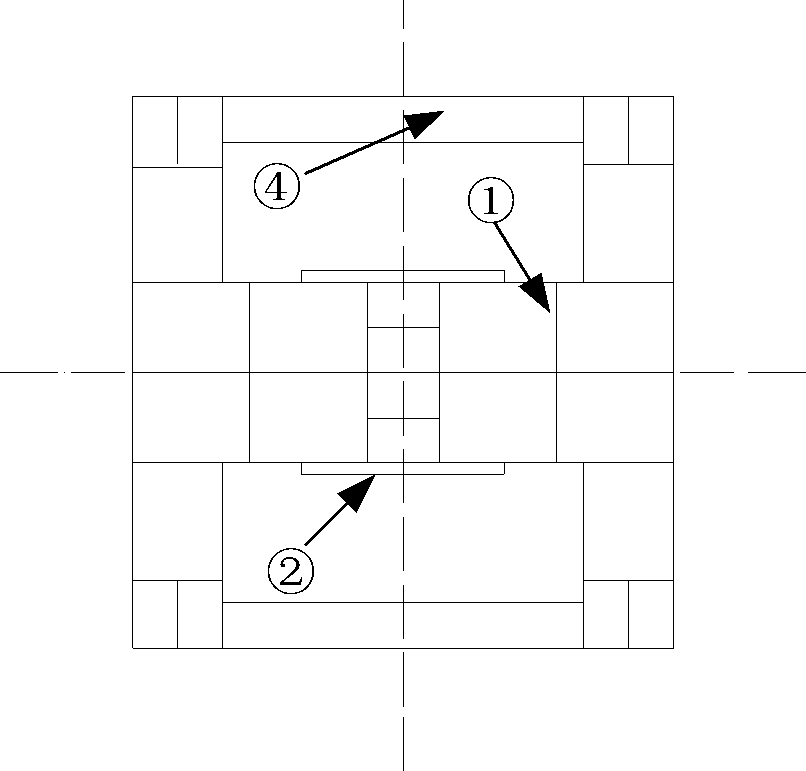

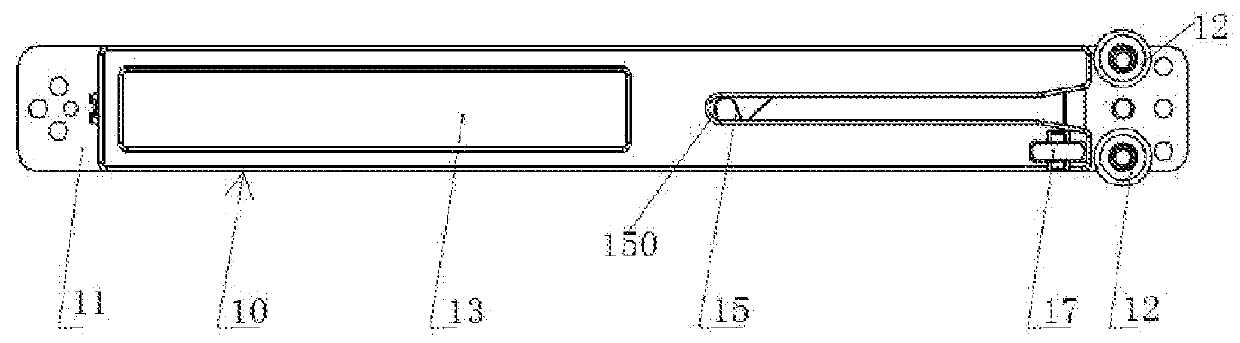

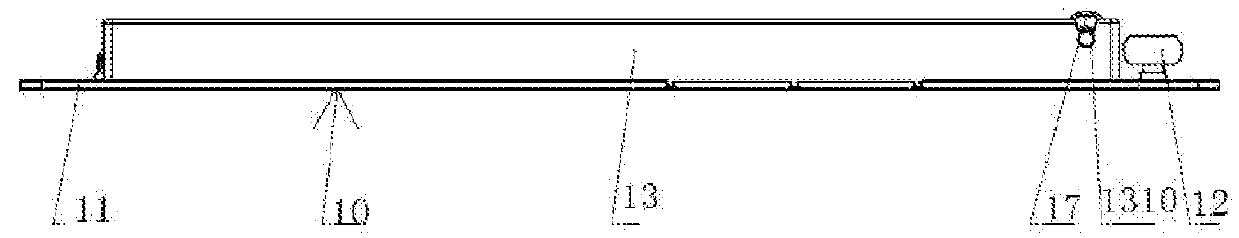

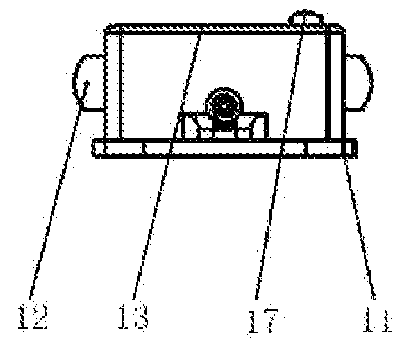

Anti-jumping upper wheel device with double dampers

ActiveUS9834972B2Effective lengthEasy to assembleLinear bearingsBuilding braking devicesEngineeringMechanical engineering

An anti-jumping upper wheel device with double dampers comprises of an anti-jumping upper wheel assembly with double damper (10) being comprised of an upper wheel plate (11), an upper wheel (12), an upper wheel cover (13) and double dampers (14) and a pulling unit (20); wherein, an anti-jumping roller (17) is mounted to the upper wheel cover (13); the pulling unit (20) is a double-plate pulling unit which is comprised of a baseplate of pulling unit (21) and a pillar plate of pulling unit (22) mounted above it; a pulling pillar (221) is fixed vertically on the pillar plate of pulling unit (22); wherein, connecting elastic units (23, 24) are overlapped and connected in parallel to three branch plates (2131, 2132, 2133, 2141, 2142, 2143) mounted on longitudinal direction in parallel of both ends on longitudinal direction of the baseplate of pulling unit (21).

Owner:ZHONGSHAN OPIKE HARDWARE PROD CO LTD

Semiconductor device allowing modulation of a gain coefficient and a logic circuit provided with the same

InactiveUS20060192252A1Effective lengthEffective widthTransistorSemiconductor/solid-state device manufacturingDevice materialGain coefficient

In addition to ordinary MOS gate, drain and source, a semiconductor element includes a control gate having geometry, which is defined only by a group of straight lines along a rectangular form of the MOS gate, is not defined by an oblique line and provides a nonuniform gate length at least in one of regions aligned in a direction of a gate width. A channel region formed by the control gate provides a region of strong electric fields and a region of weak electric fields. Consequently, a conductance of a whole channel region formed by the MOS gate and the control gate, i.e., a gain coefficient β of the semiconductor element can be modulated in accordance with voltages applied to the MOS gate and the control gate.

Owner:KENZAN

Height of cut and rake adjustment system

A height of cut and rake adjustment system for a rough, trim and surround mower deck with a pair of front height of cut arms and a pair of rear height of cut arms. Each height of cut arm is pivotably mounted to the mower deck on a pivot axis below an upper end of each height of cut arm. An adjustable height of cut linkage extends between the upper end of each front height of cut arm and the upper end of each rear height of cut arm. An adjustable rake linkage extends between the upper end of each front height of cut arm and an intermediate portion of each rear height of cut arm below the pivot axis.

Owner:DEERE & CO

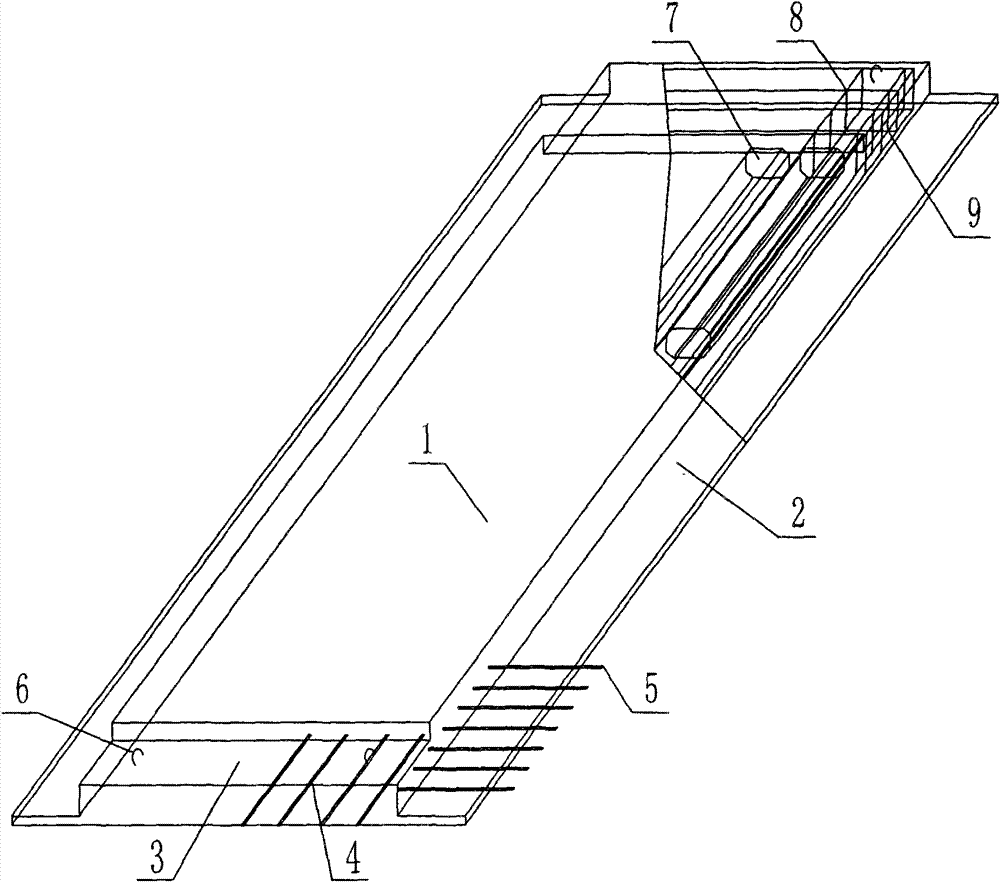

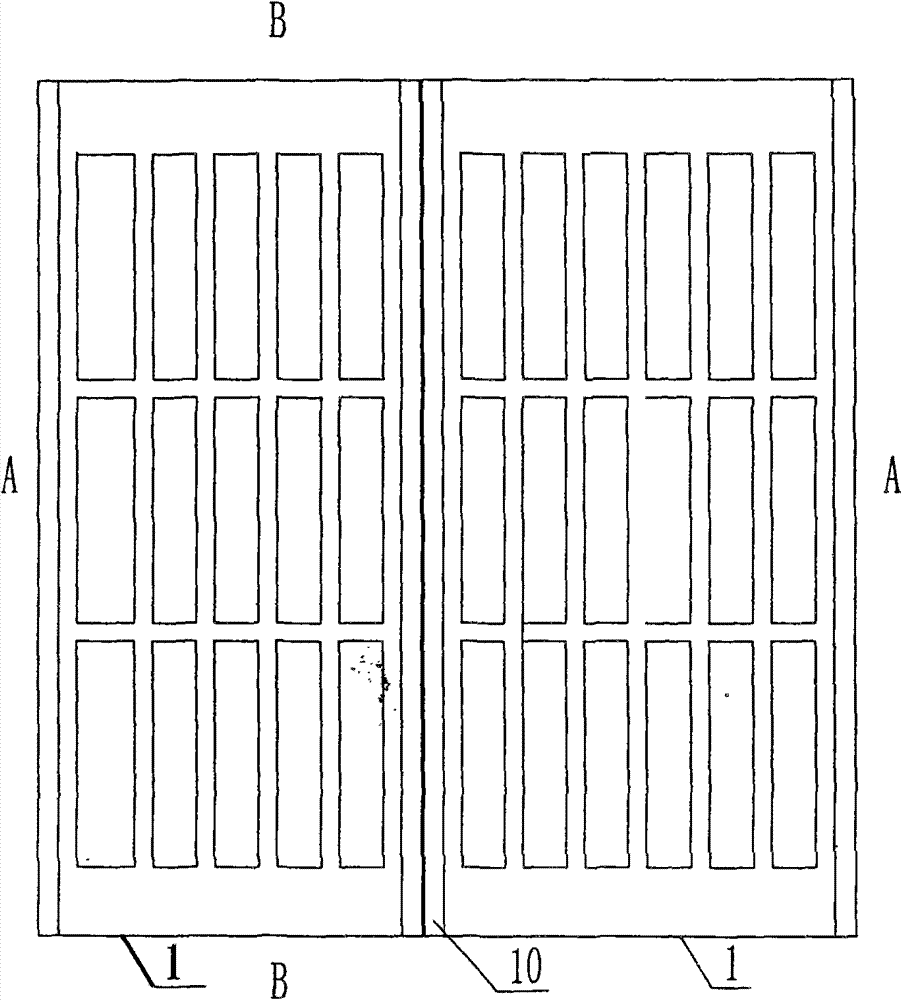

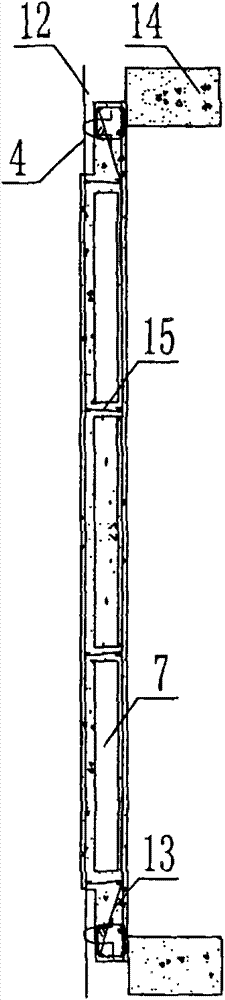

Steel bar concrete precast floor slab

InactiveCN101787760BImprove seismic performanceImprove anti-seepage performanceFloorsEarthquake resistanceSurface layer

The invention relates to improvement of the traditional steel bar concrete precast floor slab, which is characterized in that the upper surface layer and the lower surface layer of a precast concrete hollow floor slab are internally provided with a two-way steel bar framework, an upper and lower layer connecting steel bar concrete ribs consisting of a vertical steel bar connecting steel bars of the upper surface layer and the lower surface layer and wrapping concrete is arranged between the upper surface layer and the lower surface layer; heat insulation and sound insulation materials are filled between the two steel bar concrete ribs; two sides and two ends of the floor slab in an axial direction are both provided with connecting steel bars and side wings of the extending thickness less than the thickness of the floor slab; and shelf beams at two end parts of the floor slab are internally provided with transverse steel bar frameworks forming beam structures and anti-shearing diagonalsteel bars connecting the steel bars at the lower surface layer. The precast floor slab integrates the advantages of the precast floor slab and the cast-in-place floor slab, overcomes all defects of the precast floor slab and the cast-in-place floor slab, especially has small cast-in-place construction workload and high construction speed, can meet requirements of the construction for rapid operation, materials saving and no pollution in an assembled building, accords with the development direction of the building industrialization production, and has high earthquake resistance of the cast-in-place floor slab.

Owner:张吉华 +1

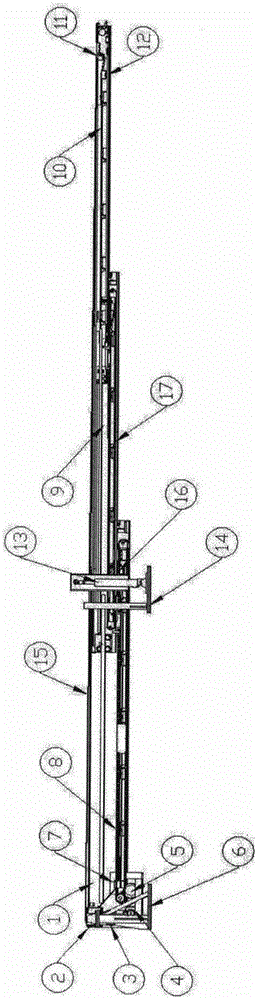

Telescopic belt conveyer

InactiveCN105752638AGuaranteed tensionEffective lengthSupporting framesClassical mechanicsEngineering

The invention relates to conveying machines, in particular to a telescopic belt conveyer which aims at achieving the effects that the length of a belt conveying face can be effectively enlarged or reduced, inclined conveying can be achieved, and the tensioning degree of a belt is maintained all the time.The telescopic belt conveyer is characterized by being composed of two telescopic racks, a fixed rack, a belt, hydraulic lifting mechanisms, an overturn frame, a control table, a driving roller, a first driven roller, direction changing rollers, second driven rollers and the like, wherein the driving roller, the first driven roller and the corresponding three direction changing rollers are arranged in the fixed rack, and the corresponding five direction changing rollers and the corresponding second driven roller are arranged in each telescopic rack used for drawing the belt back.The telescopic belt conveyer comprises the two lifting mechanisms which are located at the two ends of the fixed rack (1) respectively, and the two lifting mechanisms are used for enabling the belt conveyer to achieve inclined conveying.Thus, carrying personnel can carry out carrying conveniently, labor is reduced, and the working efficiency is improved.

Owner:HANGZHOU JINJU TECH

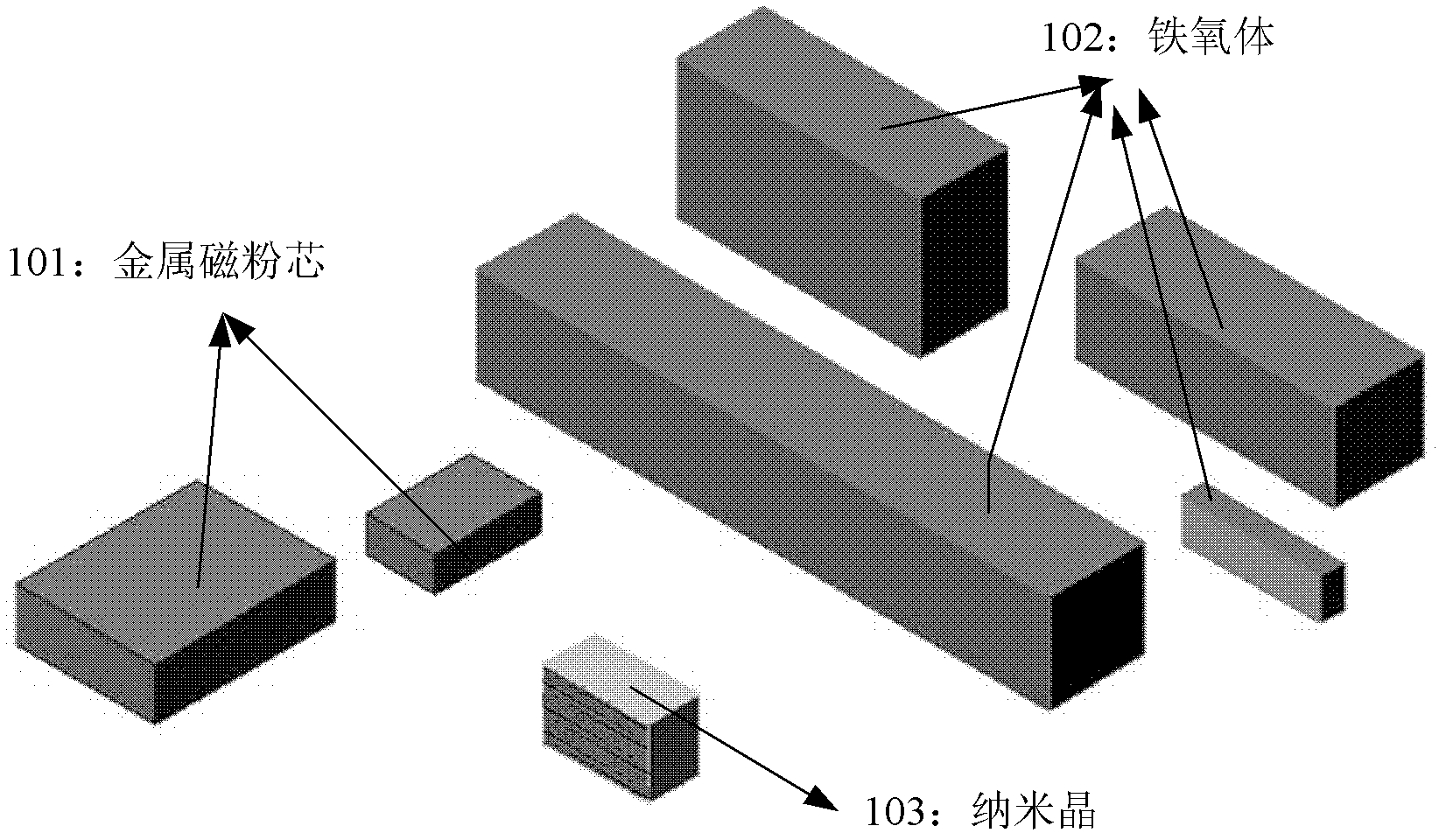

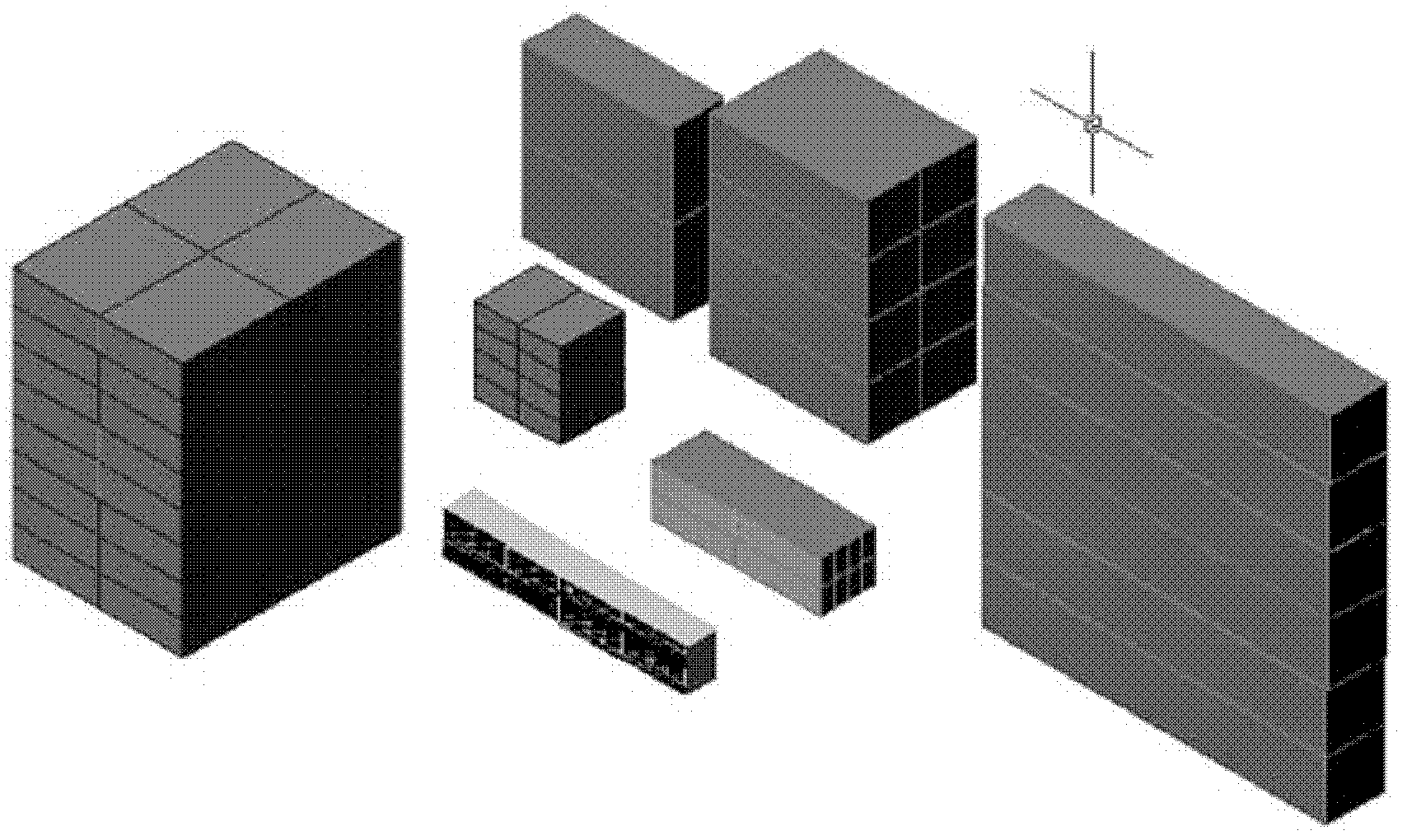

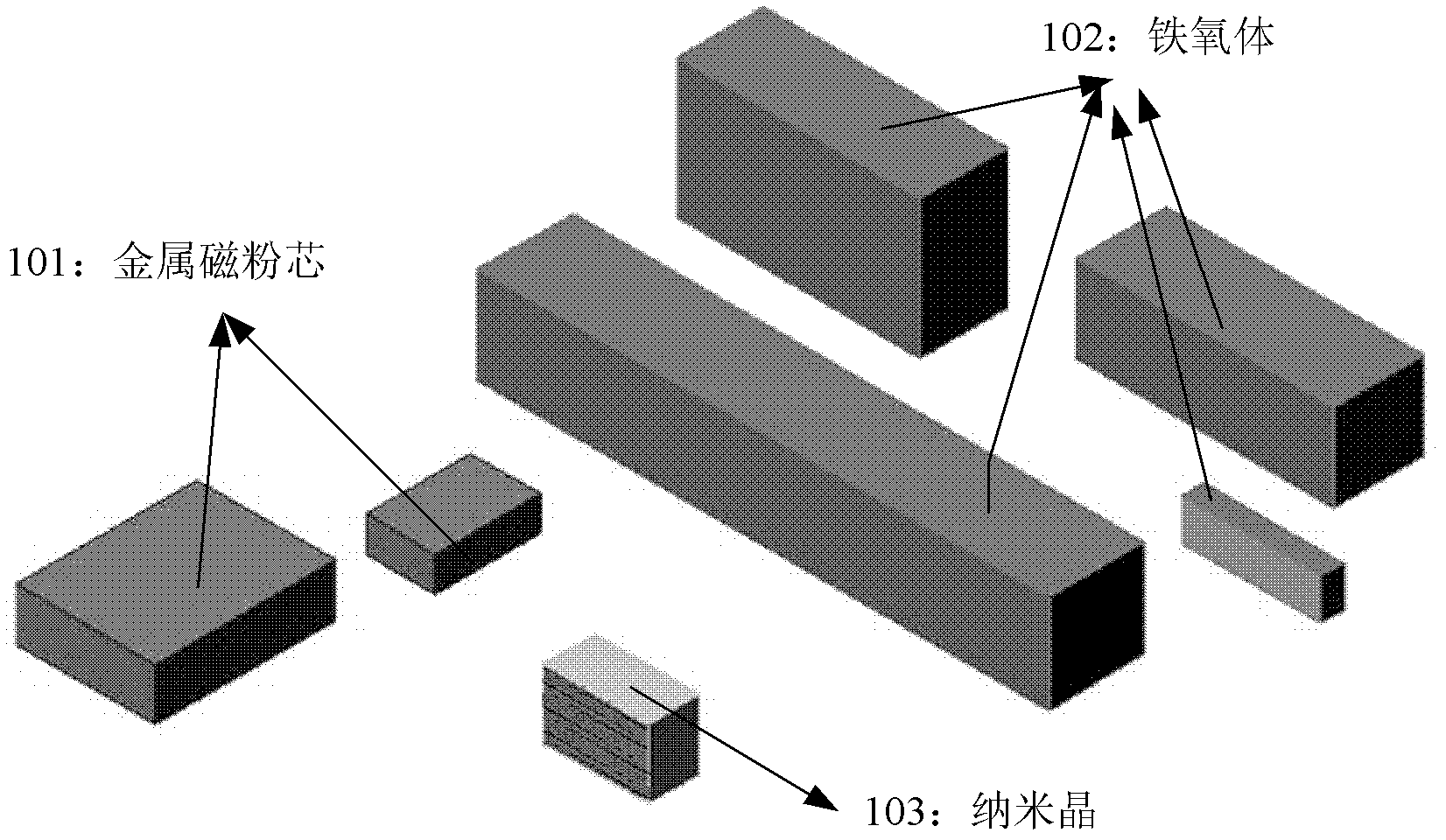

Choking coil and manufacture method thereof

ActiveCN102592782AEvenly distributed air gapEffective lengthTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectromagnetic interferenceConductor Coil

The invention relates to a choking coil and a manufacture method of the choke coil, and discloses a choking coil including a magnetic core and a winding. The magnetic core comprises a bottom, a center column arranged on the bottom and wound by the winding, at least two lateral sides keeping contact with the periphery of the bottom in a manner of being substantially parallel to the center column, and a neck arranged on the upper end in a manner of contacting the lateral sides. In addition, the saturation magnetic flux density of the magnetic material adopted by the center column is larger thanthat of the magnetic material adopted by the lateral sides, and the cross section area of the center column is correspondingly smaller than that of the lateral sides. A closed magnetic core structureis formed by reasonably splicing the magnetic cores with different magnetic materials based on the material properties. Accordingly, the choking coil provided by the invention breaks through the conventional choking coil having a magnetic core made of a single magnetic material, and has the advantages of uniform air gap distribution, high flexibility in regulating length and area of an effective magnetic path, low external electromagnetic interference, and so on.

Owner:北京七星飞行电子有限公司

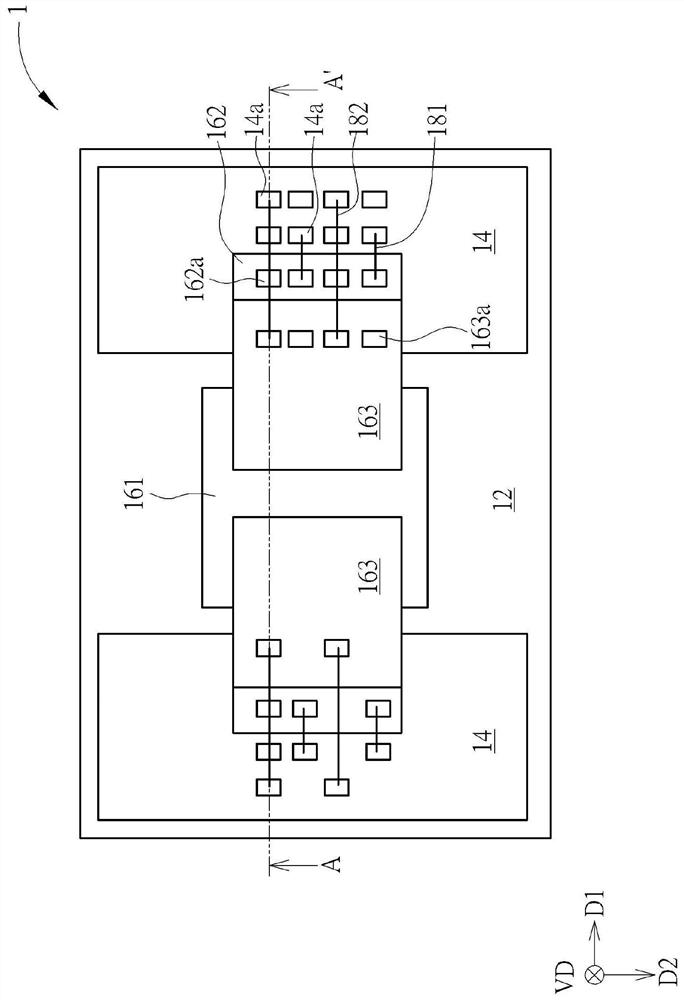

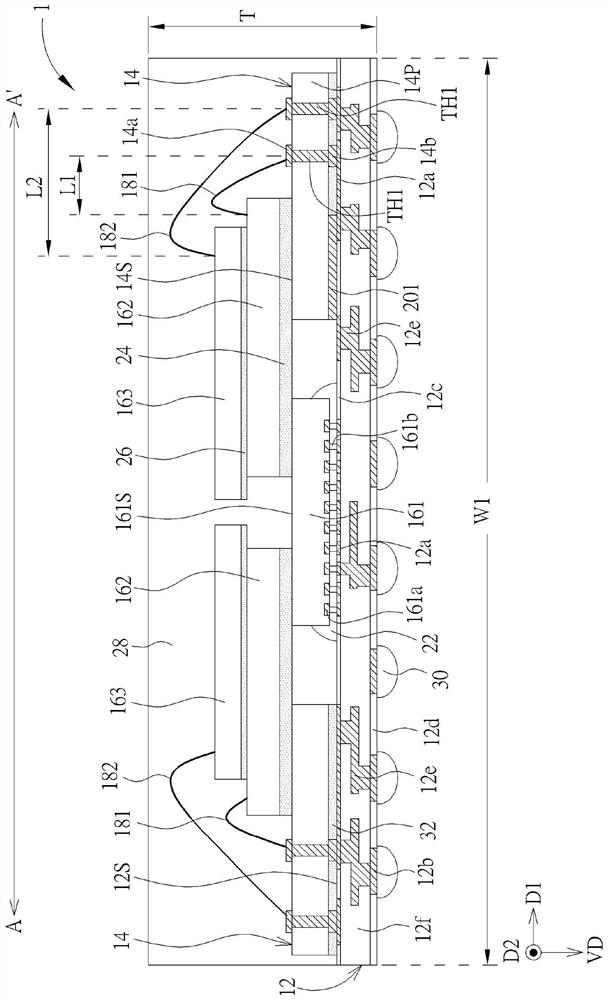

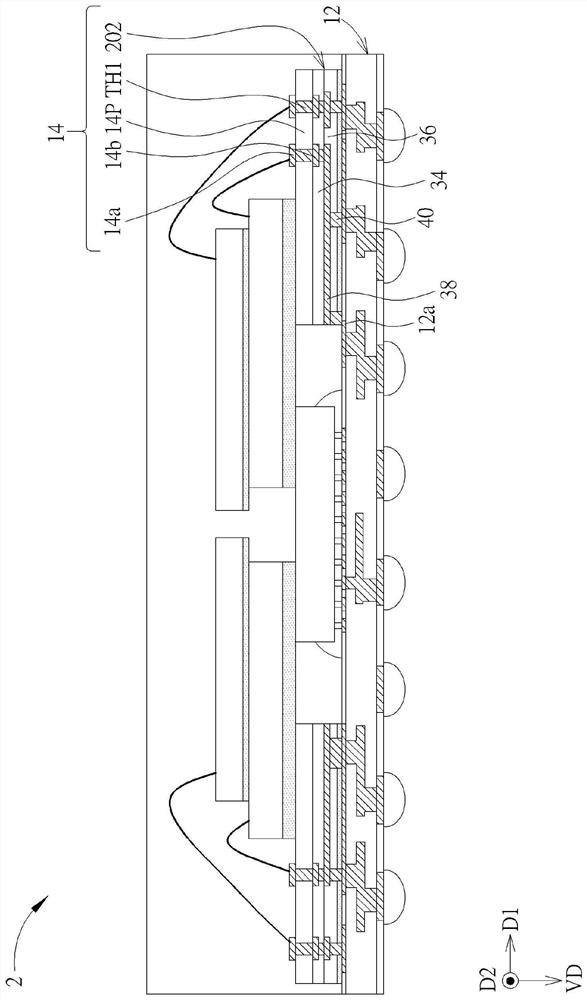

Chip package structure

PendingCN113130473AEffective lengthLower the resistance valueSemiconductor/solid-state device detailsSolid-state devicesElectrical connection

Owner:POWERTECH TECHNOLOGY INC

Choking coil and manufacture method thereof

ActiveCN102592782BEvenly distributed air gapEffective lengthTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectromagnetic interferenceEngineering

The invention relates to a choking coil and a manufacture method of the choke coil, and discloses a choking coil including a magnetic core and a winding. The magnetic core comprises a bottom, a center column arranged on the bottom and wound by the winding, at least two lateral sides keeping contact with the periphery of the bottom in a manner of being substantially parallel to the center column, and a neck arranged on the upper end in a manner of contacting the lateral sides. In addition, the saturation magnetic flux density of the magnetic material adopted by the center column is larger than that of the magnetic material adopted by the lateral sides, and the cross section area of the center column is correspondingly smaller than that of the lateral sides. A closed magnetic core structure is formed by reasonably splicing the magnetic cores with different magnetic materials based on the material properties. Accordingly, the choking coil provided by the invention breaks through the conventional choking coil having a magnetic core made of a single magnetic material, and has the advantages of uniform air gap distribution, high flexibility in regulating length and area of an effective magnetic path, low external electromagnetic interference, and so on.

Owner:北京七星飞行电子有限公司

Anti-jumping upper wheel device with double dampers

ActiveUS20160032967A1Compact structureLow costRolling contact bearingsLinear bearingsMechanical engineeringJumping

An anti-jumping upper wheel device with double dampers comprises of an anti-jumping upper wheel assembly with double damper (10) being comprised of an upper wheel plate (11), an upper wheel (12), an upper wheel cover (13) and double dampers (14) and a pulling unit (20); wherein, an anti-jumping roller (17) is mounted to the upper wheel cover (13); the pulling unit (20) is a double-plate pulling unit which is comprised of a baseplate of pulling unit (21) and a pillar plate of pulling unit (22) mounted above it; a pulling pillar (221) is fixed vertically on the pillar plate of pulling unit (22); wherein, connecting elastic units (23, 24) are overlapped and connected in parallel to three branch plates (2131, 2132, 2133, 2141, 2142, 2143) mounted on longitudinal direction in parallel of both ends on longitudinal direction of the baseplate of pulling unit (21).

Owner:ZHONGSHAN OPIKE HARDWARE PROD CO LTD

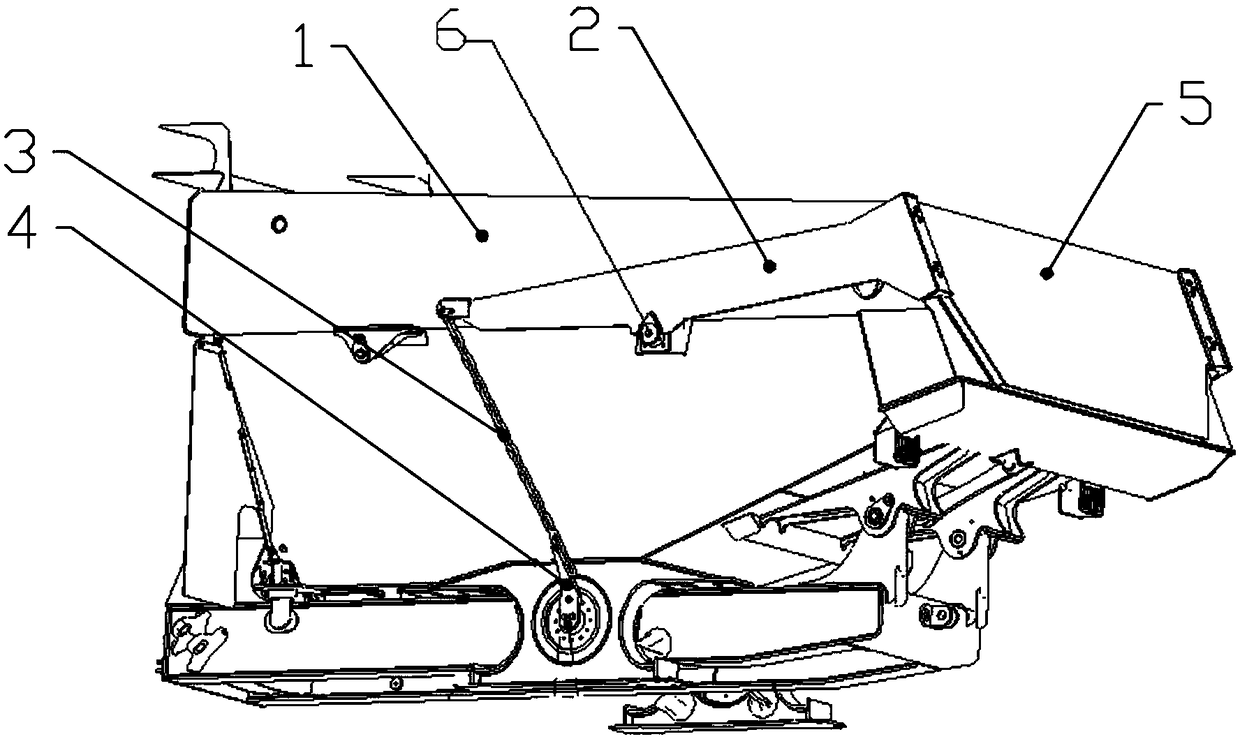

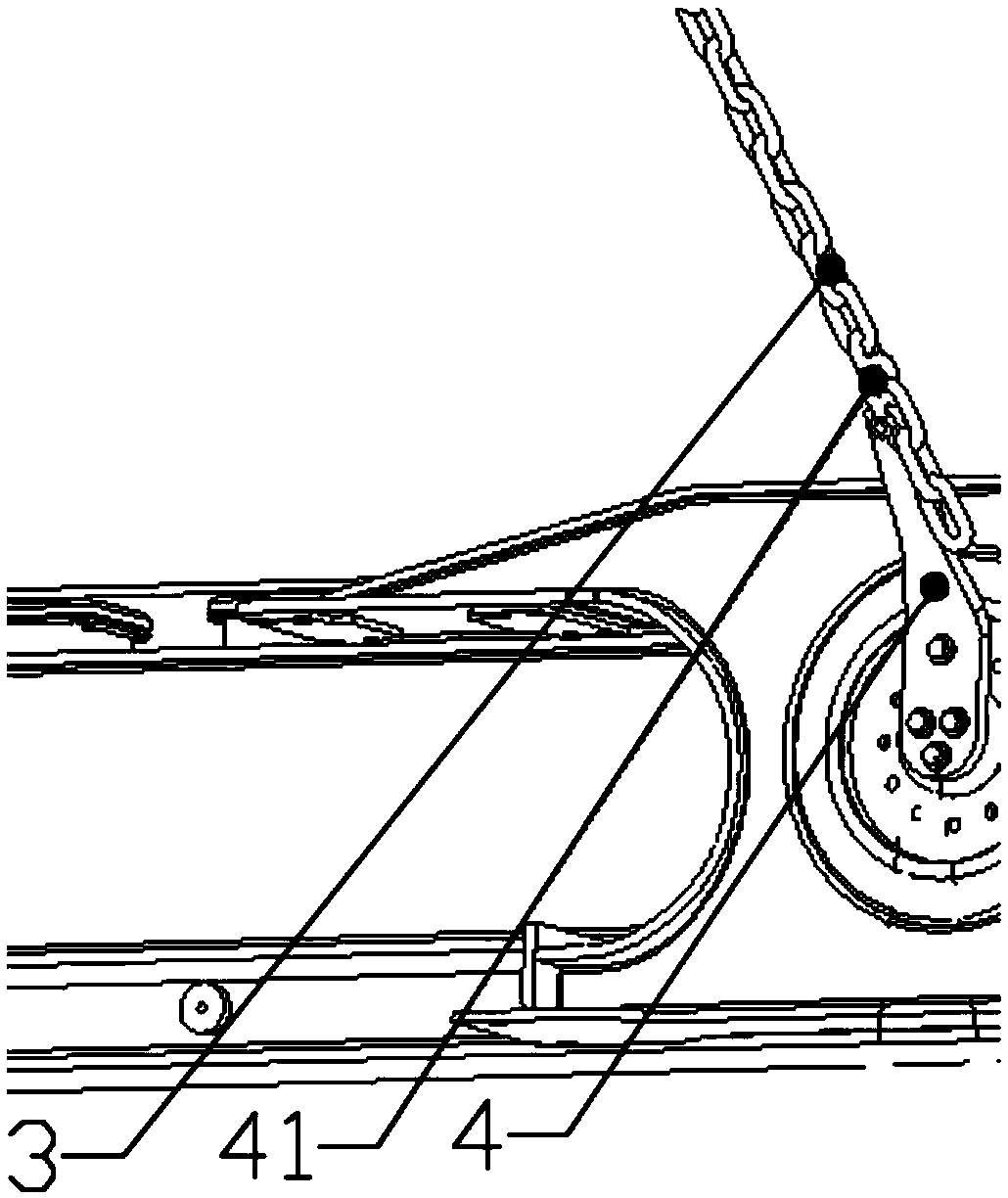

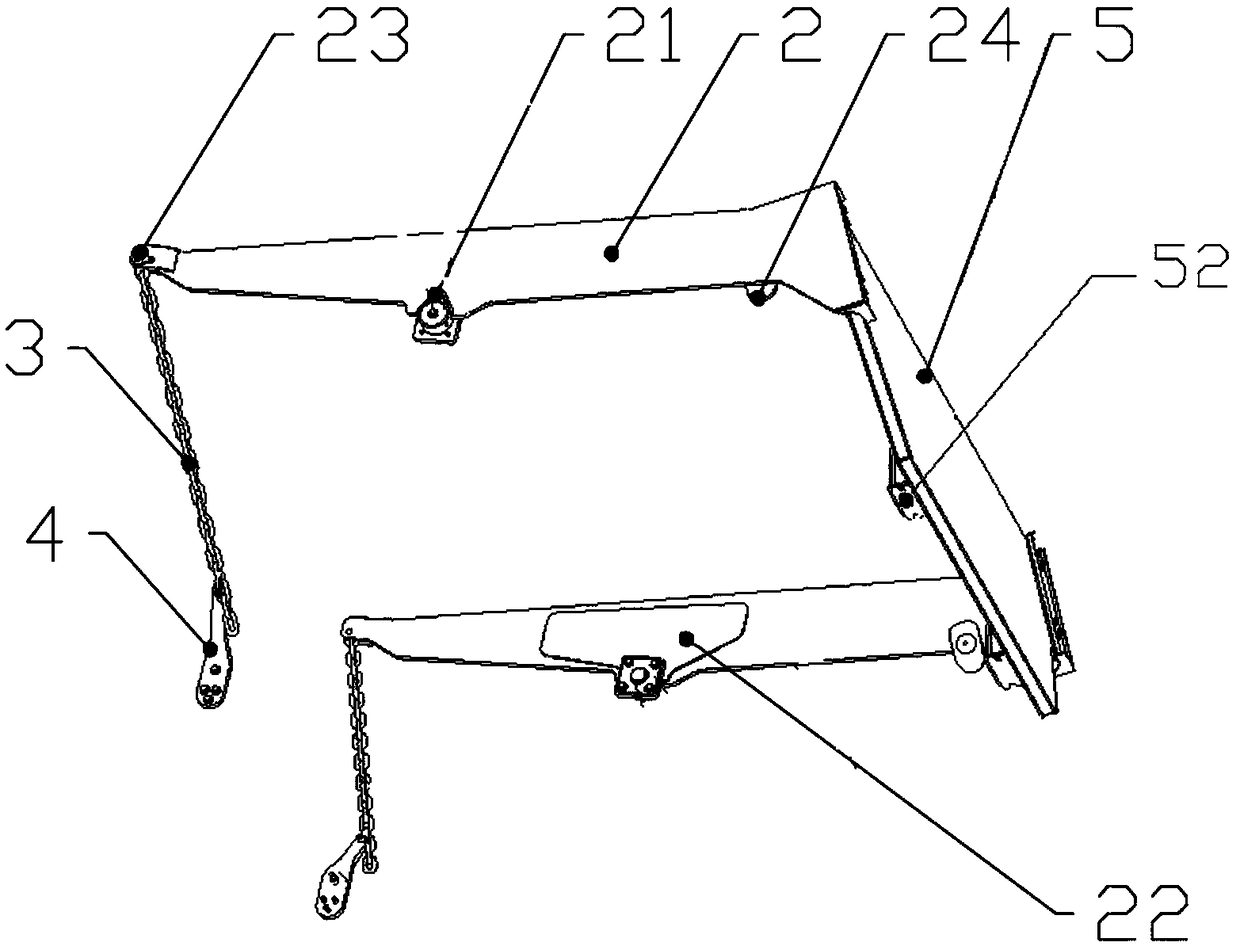

Hinging-type dump truck container rear baffle and hinging-type dump truck

The invention discloses a hinging-type dump truck container rear baffle and a hinging-type dump truck. The hinging-type dump truck container rear baffle comprises a side arm, a chain, a rear baffle body, a mounting seat and a mounting plate arranged on the side portion of a truck frame; a lug plate is arranged at one end of the side arm, a side arm baffle is arranged at the other end of the side arm, a mounting block is further arranged between the lug plate and the side arm baffle of the side arm, the mounting seat is connected to the side portion of a container, and extending ends are arranged at the two ends of the rear baffle body; and the lug plate is connected with the chain, the side arm baffle is connected with the two ends of the rear baffle body, the mounting block is connected with the mounting seat, the mounting plate is provided with an unloading buckle, and the unloading buckle is connected with the chain. During unloading, the container is turned up rearwards, the mounting seat is overturned rearwards along with the container, the distance between the mounting seat and the mounting plate is increased along with overturning of the container, the chain pulls the side arm to rotate with the mounting seat as the axis, and thus the rear baffle body is opened. Manual operation is not needed in the whole process, and the rear baffle body synchronously moves along with the container. After unloading is completed, the side arm, the rear baffle body and the rear end of the container are covered under the action of gravity.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

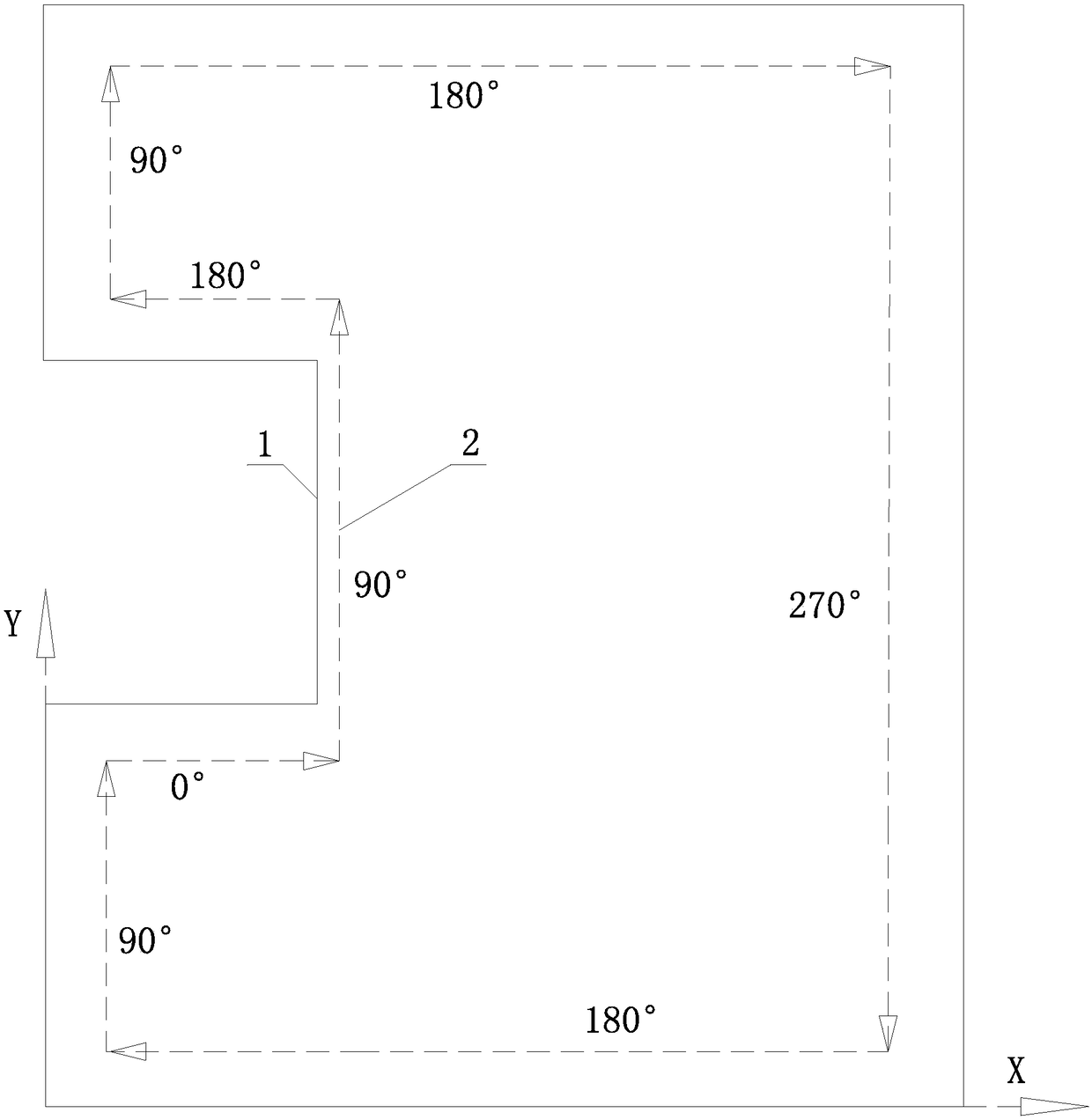

A method for generating length scale of architectural decorative board

ActiveCN109190230AGood technical effectCalculate processing sizeGeometric CADCovering/liningsEffective lengthEngineering

A method for generating length scale of architectural decorative board relates to size processing of decorative boards and features that one wall is selected as reference wall, a decorative board on it is used as reference board, and the decorative board adjacent to the reference board in clockwise direction is a front group, and the thickness of the front group is D before; the decorative board adjacent to the reference board in the counterclockwise direction is the back group, the thickness of the back group is D after, and the length of the decorative board without inserting groups in frontof and behind the same is the actual length L actual; the internal and external angles between adjacent decorative boards are judged, and the machining dimensions of the decorative boards are calculated according to L have = L actual + eD before + fD after and L + =L have + mD before + nD after. At first, the invention determines the quantity and thickness of the decorative board on the wall surface, and measures the size of the wall surface to calculate the effective length and the machining length of the decorative board after decoration, the calculation is convenient and quick, and the effective length and the machining length of the decorative board can be obtained through simple calculation.

Owner:QUZHOU COLLEGE OF TECH

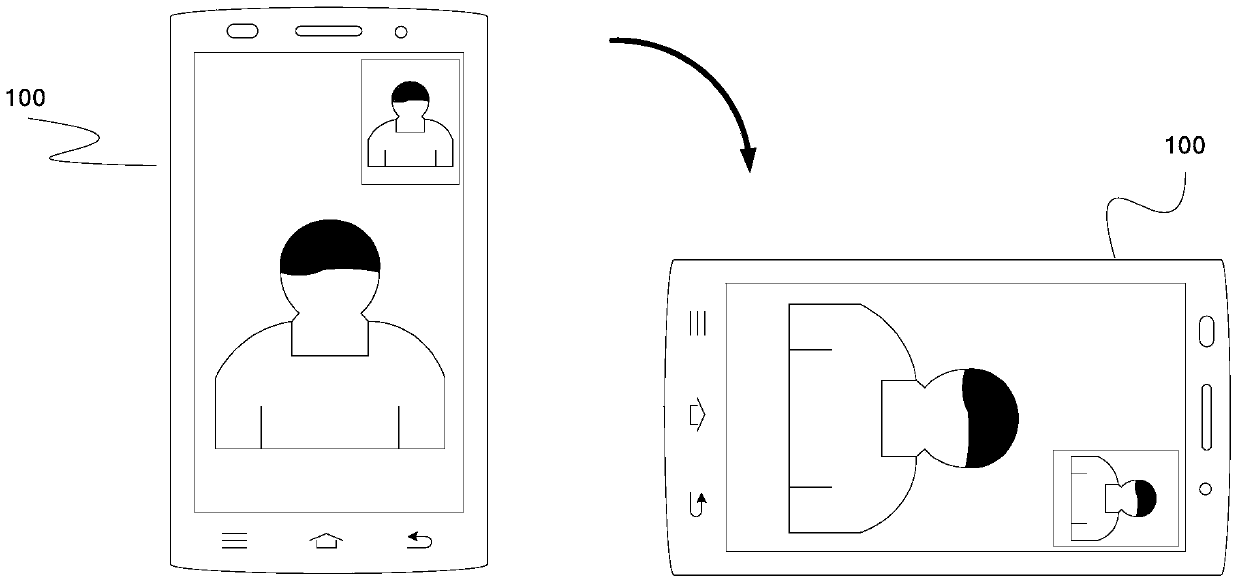

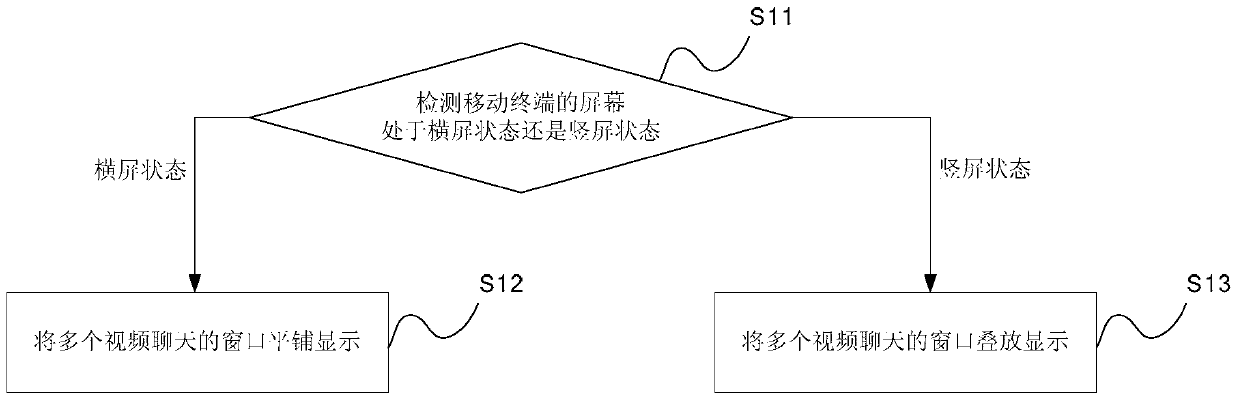

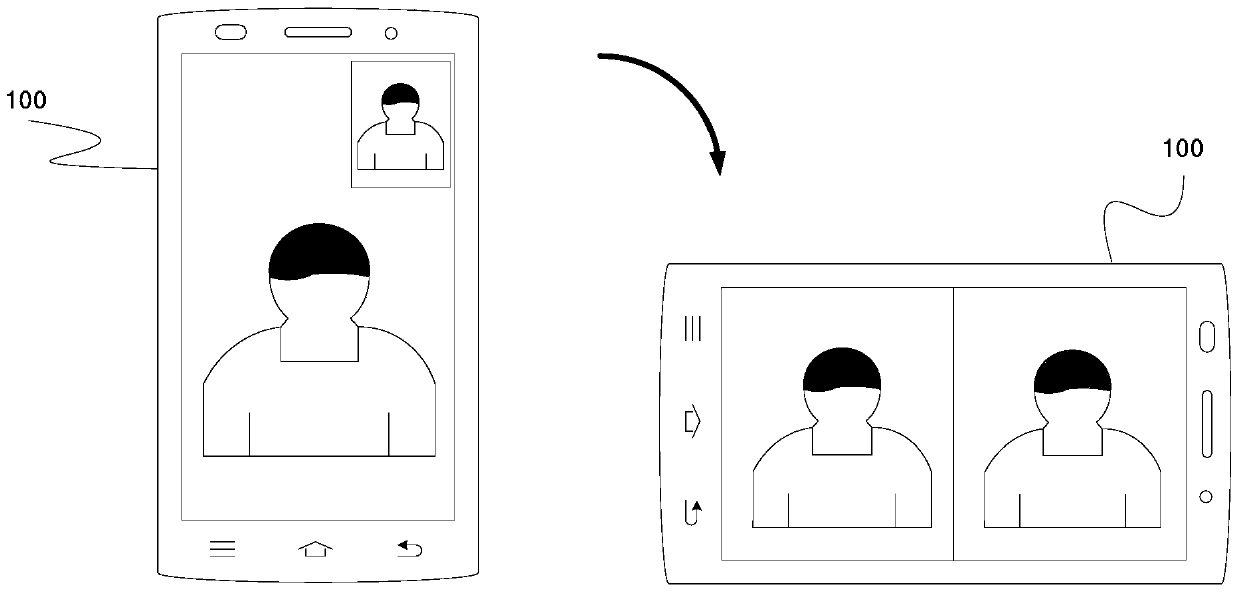

Method and device for displaying video chat window

ActiveCN105204733BEffective lengthImprove experienceInput/output processes for data processingVideo chatComputer graphics (images)

The invention discloses a video chat window display method and device. The method is applied to a mobile terminal and comprises the following steps: detecting whether the screen of the mobile terminal is in a horizontal state or a vertical state; displaying a plurality of video chat windows in a tiled manner when the screen is in a horizontal state; displaying the plurality of video chat windows in a stacked manner when the screen is in a vertical state. According to the video chat window display method and device, the video chat windows are displayed in the tiled manner when the screen is in the horizontal state, so that the horizontal length of the screen can be used effectively, and the user experience in video chat can be improved.

Owner:XIAOMI INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com