Method and device for applying forces and motions to warp threads of weaving machine

A movement and loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as low warp tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

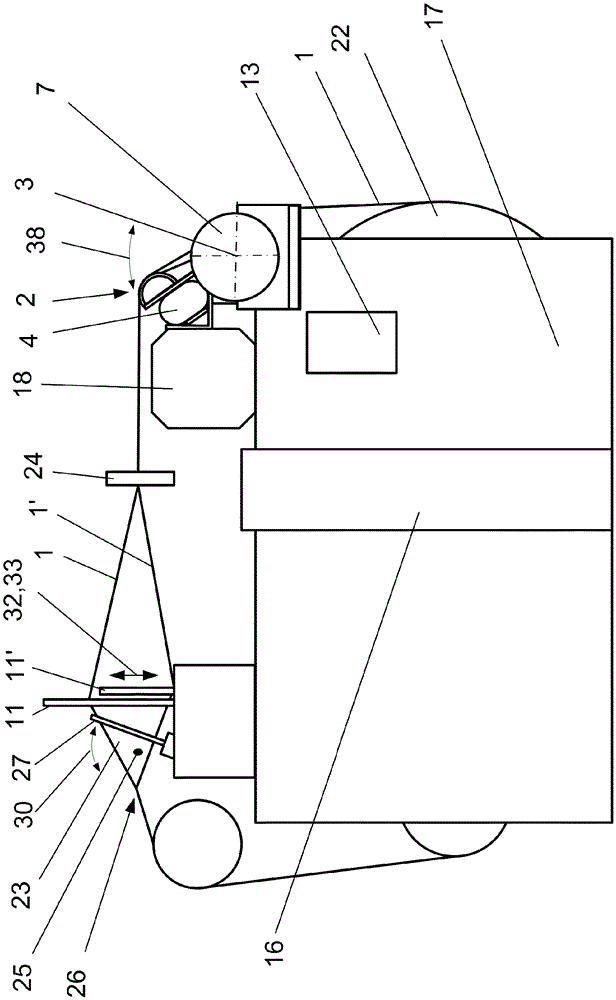

[0069] figure 1 shows a side view of a weaving machine with an embodiment of the device according to the invention; figure 2 An excerpt of it is shown.

[0070] On the rear side of the loom, the loom has a warp beam 22 from which the warp threads 1 are drawn. The warp threads 1 are supplied to the thread deflecting elements 2 in the present example via deflecting tubes 28 . The warp yarn 1 is deflected from the drawing direction to the weaving plane by means of the yarn deflecting element 2 . In order to monitor the warp thread 1, a warp thread monitor 24 is provided in the present example, which limits the vertical movement of the warp thread in the rear shed (ie between the shed former 11 and the warp beam 22), but does not impede Horizontal movement of the warp.

[0071] In the weaving plane, the warp threads 1 , 1 ′ are guided via the shed formers 11 , 11 ′ and the reed 27 into the front region of the weaving machine. The warp threads 1 , 1 ′ run vertically through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com