Patents

Literature

62results about How to "Improve centering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

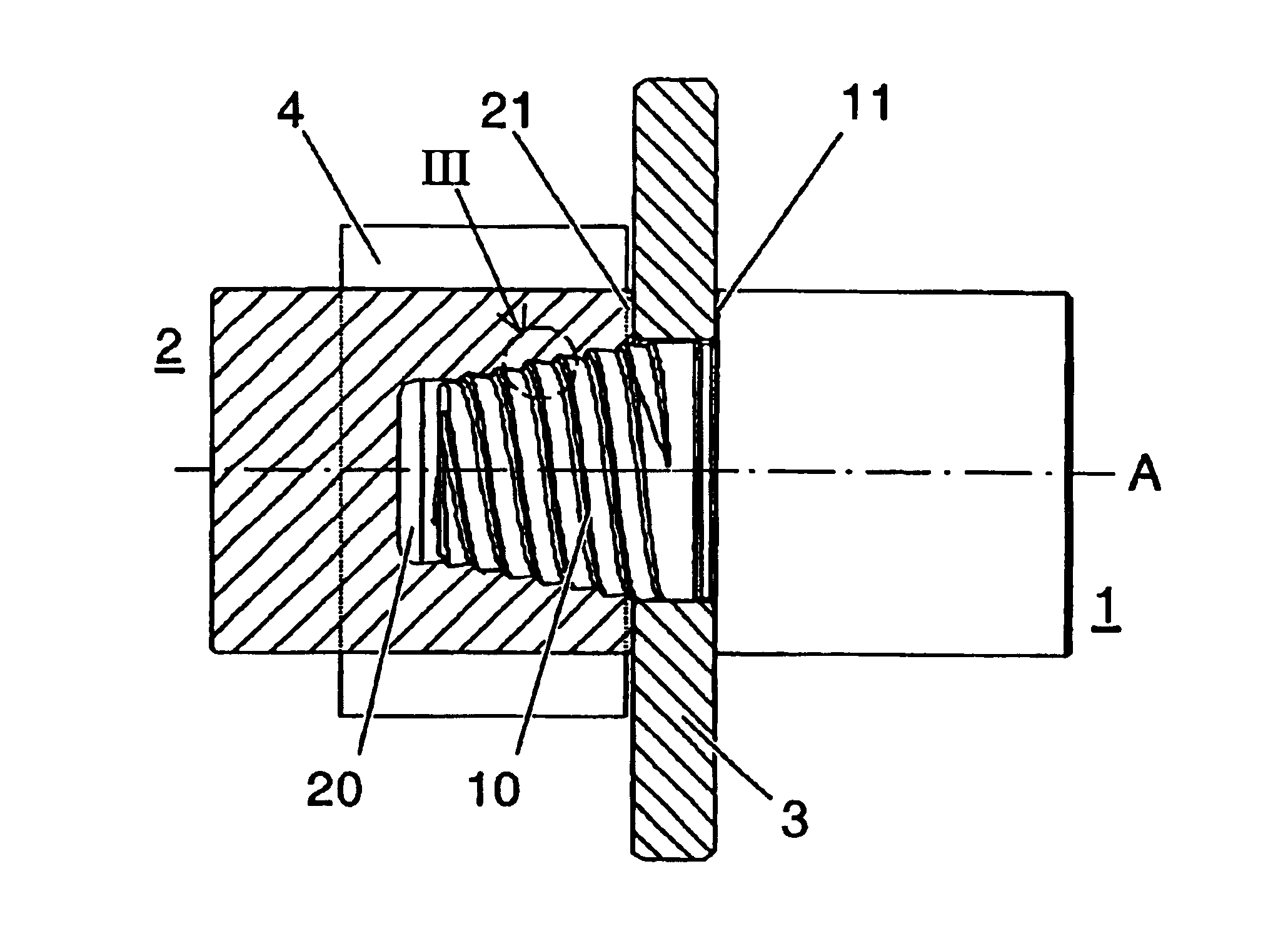

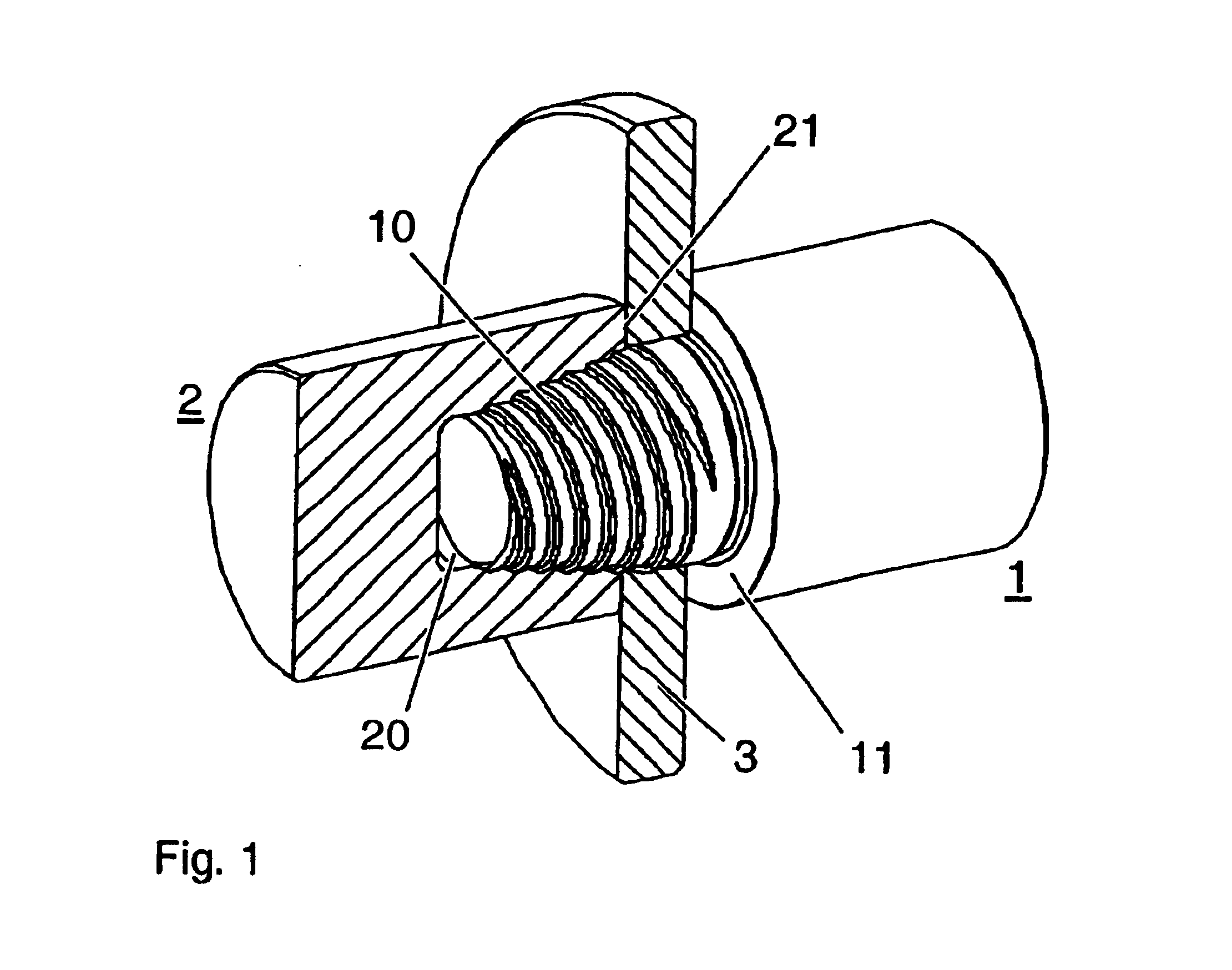

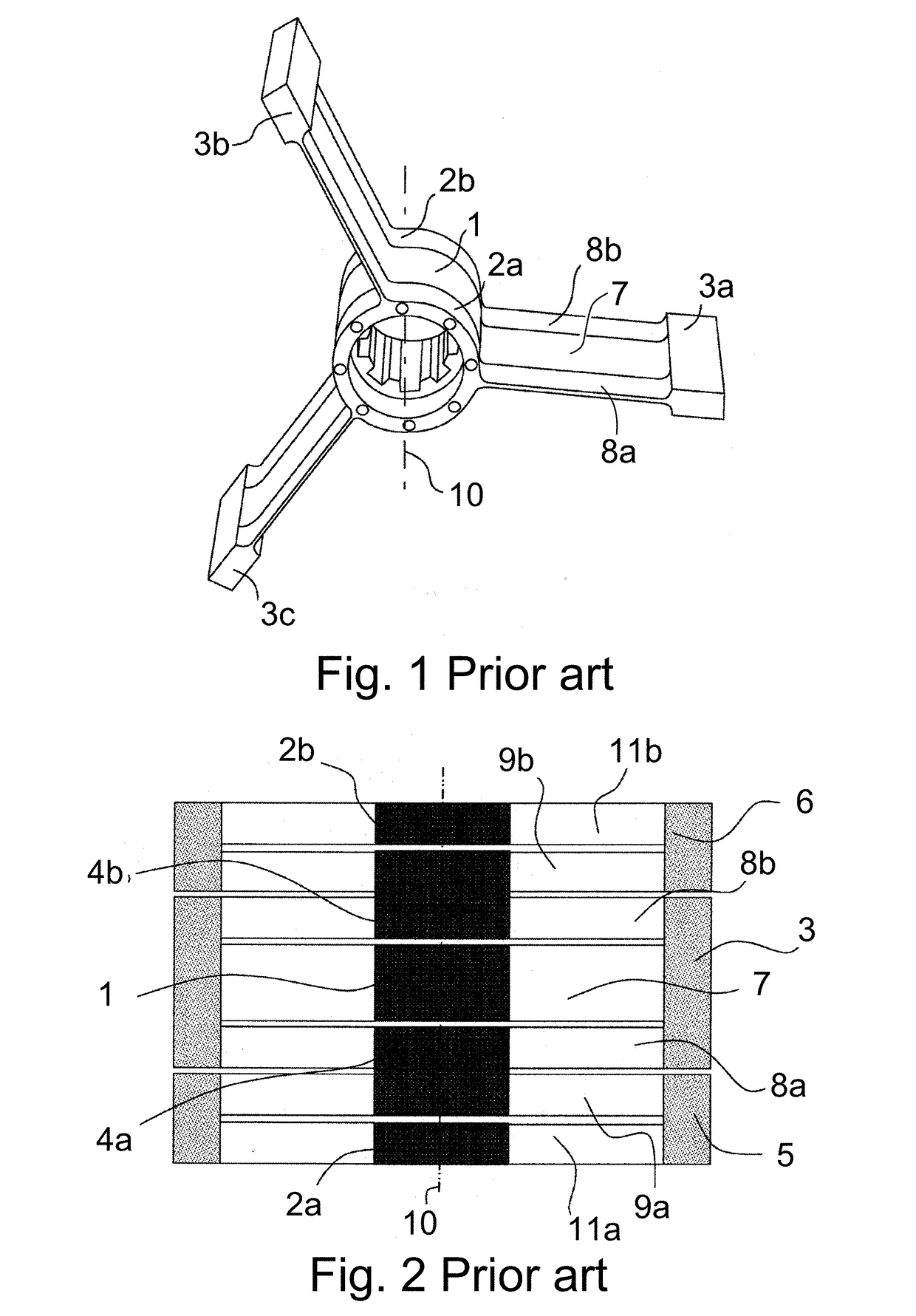

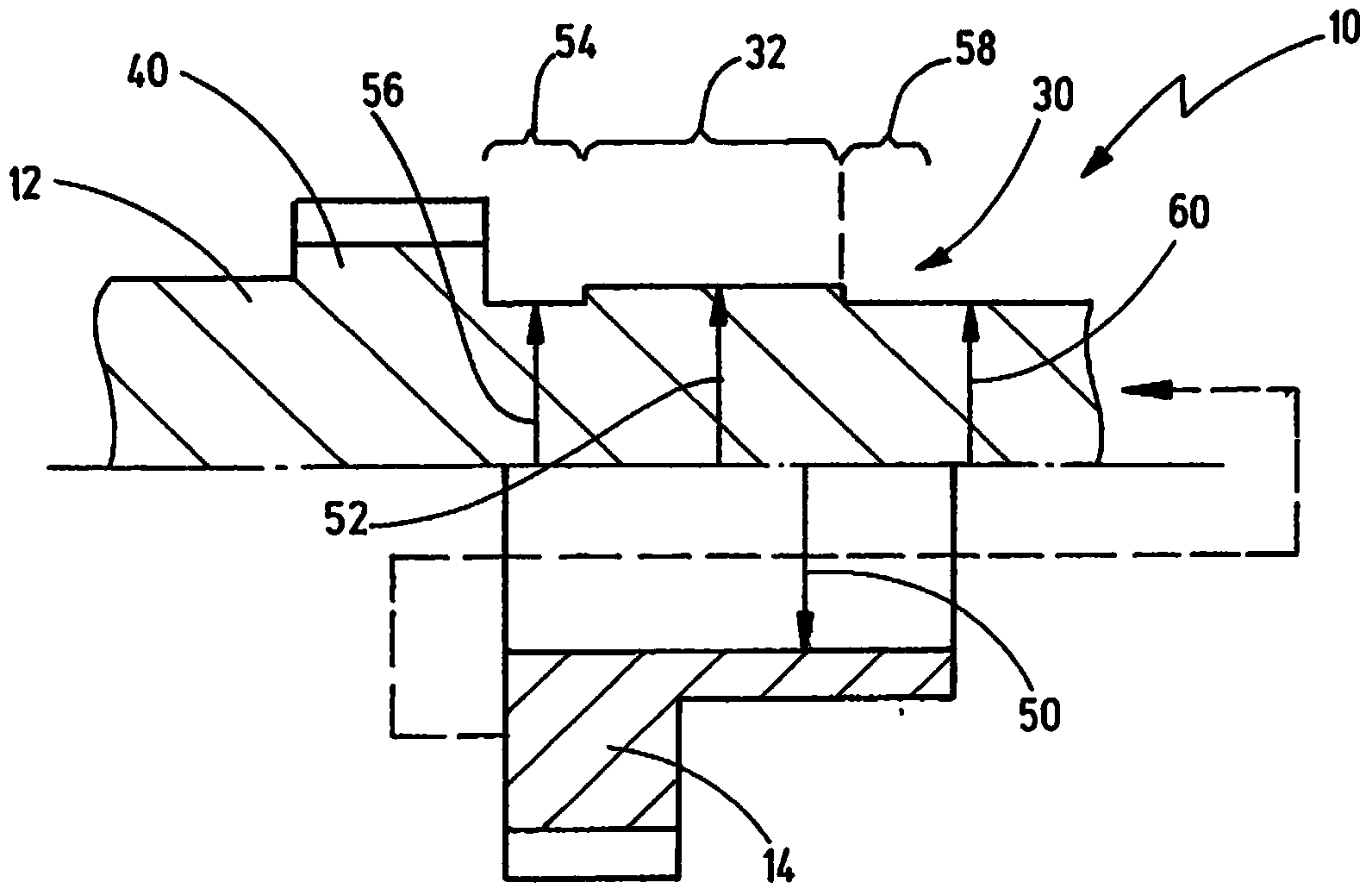

Shaft/hub connection

InactiveUS6918723B2Improve centeringAxial prestressing force between the two parts to be connected can be correspondingly reducedEngine manufactureWashersEngineeringTorque transmission

Owner:ABB TURBO SYST

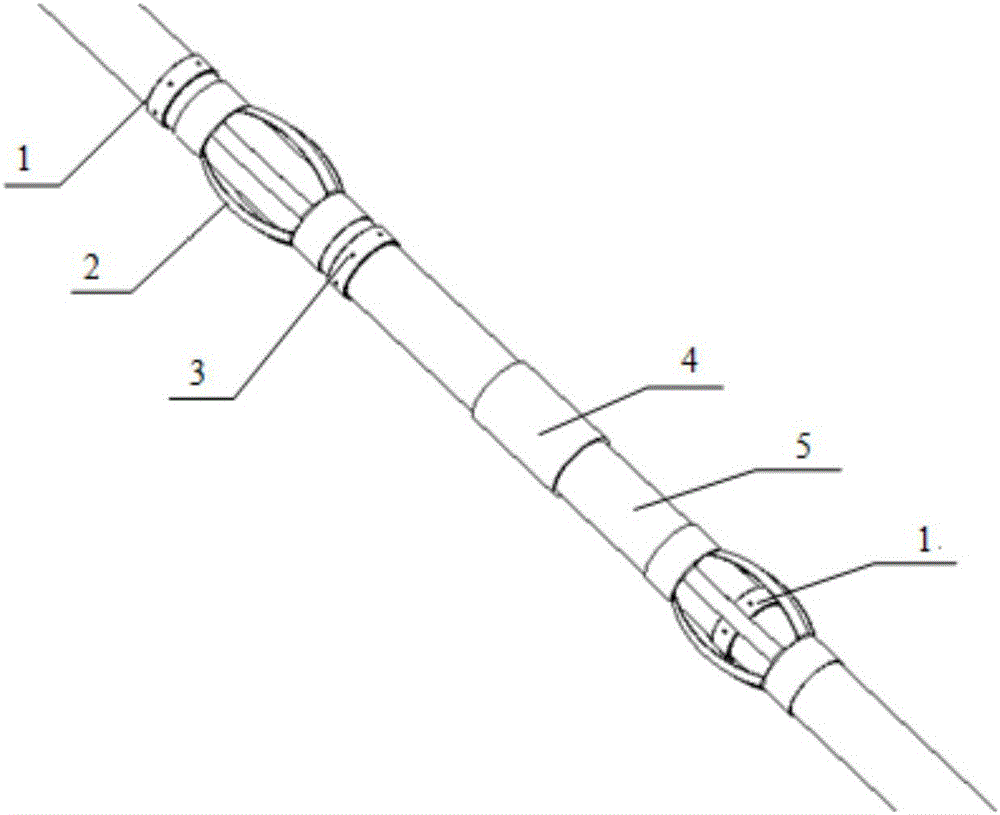

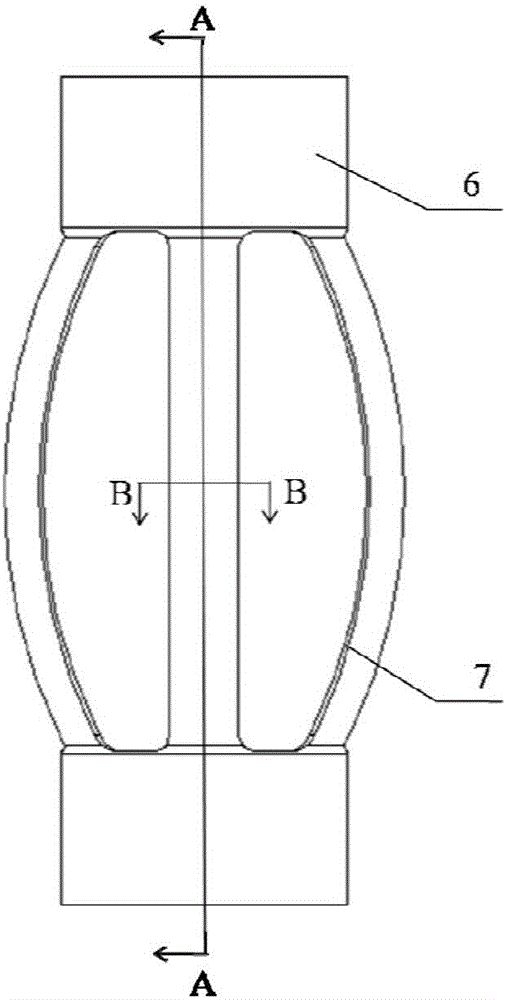

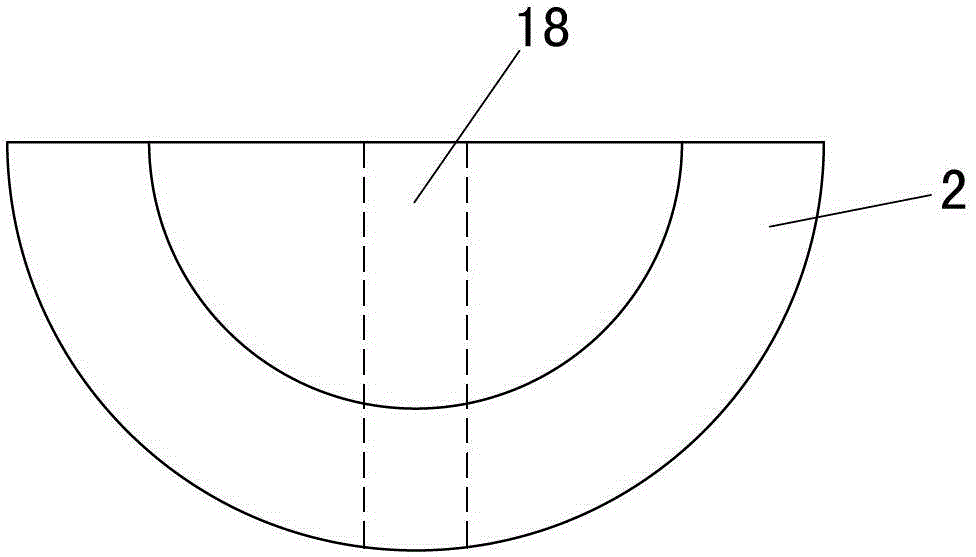

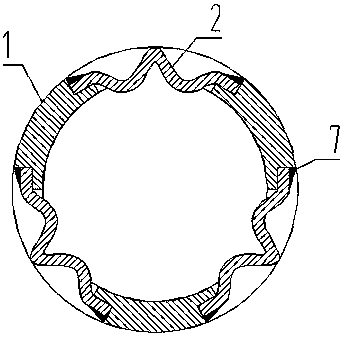

Integral type casing centralizer and manufacturing method thereof

The invention provides an integral casing centralizer and a manufacturing method thereof, belonging to the field of oil and gas well cementing. The integral casing centralizer is processed by uniform wall thickness material pipe or plate, including hoops at both ends, and limbs located between the hoops at both ends; the limbs are evenly distributed on the circumference, and each The two ends of each limb are respectively connected with the hoops at both ends; each limb is arched outward; the outer diameter of the centralizer formed by all the limbs is smaller than or equal to the inner diameter of the upper casing.

Owner:CHINA PETROLEUM & CHEM CORP +1

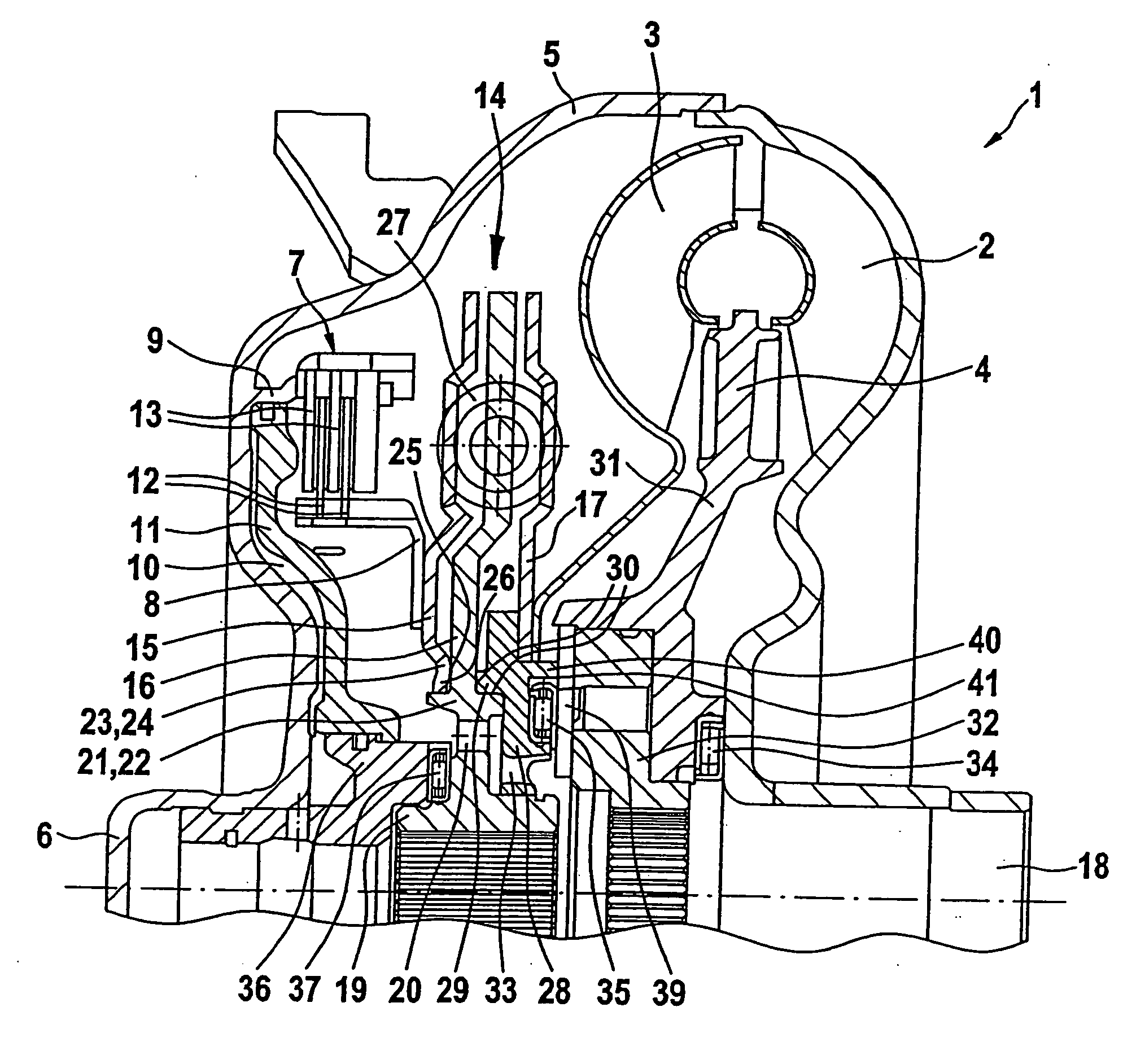

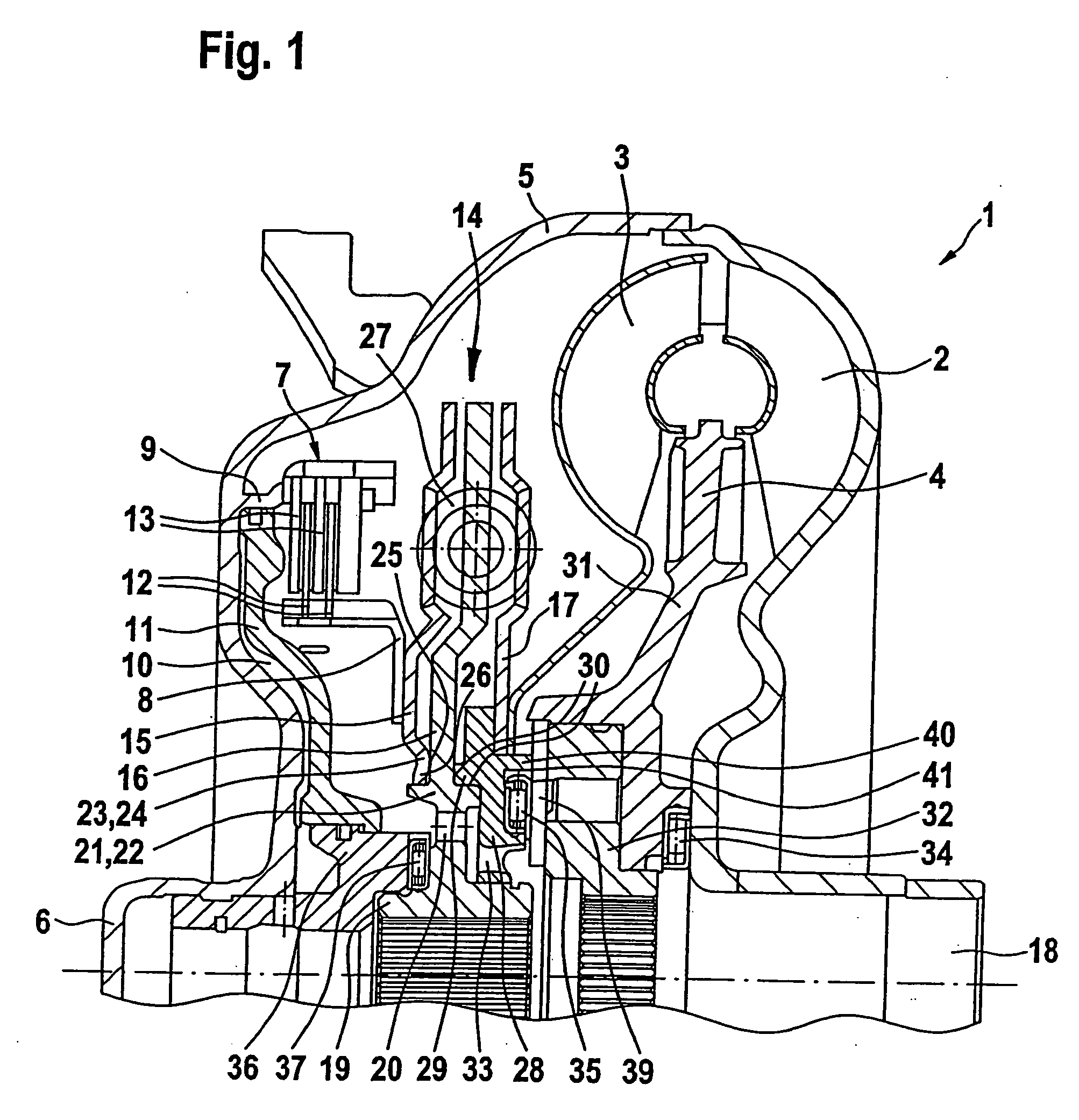

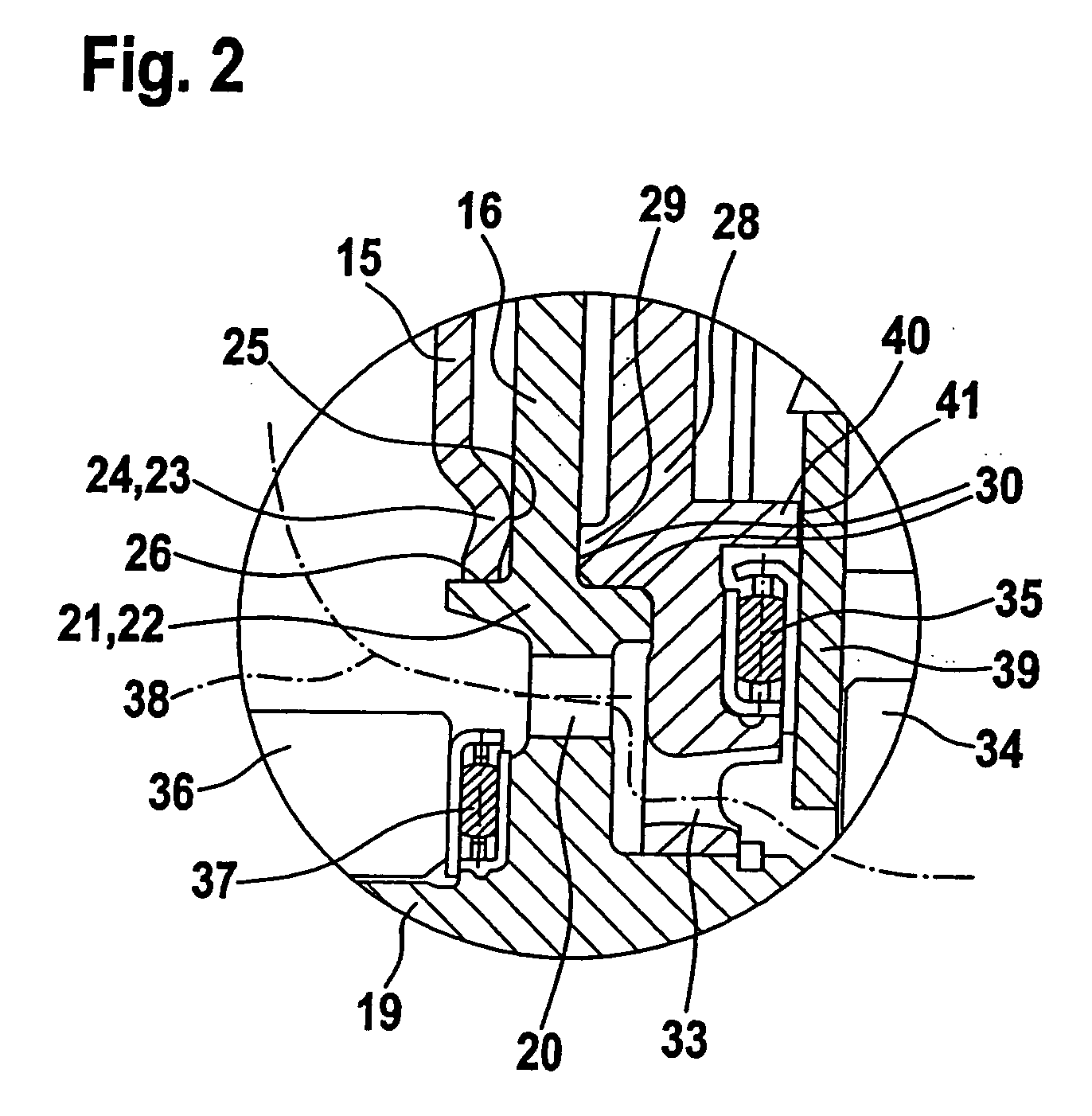

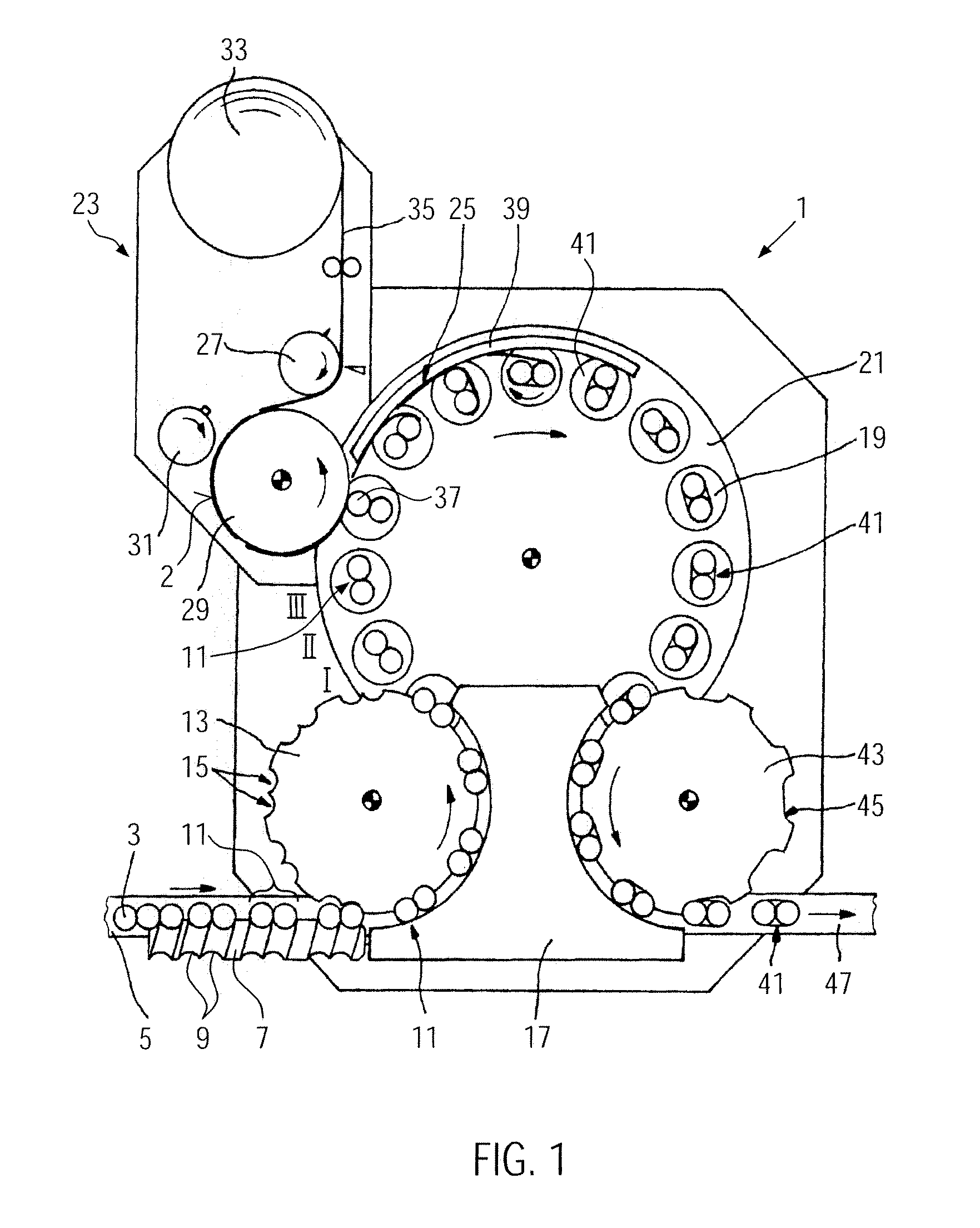

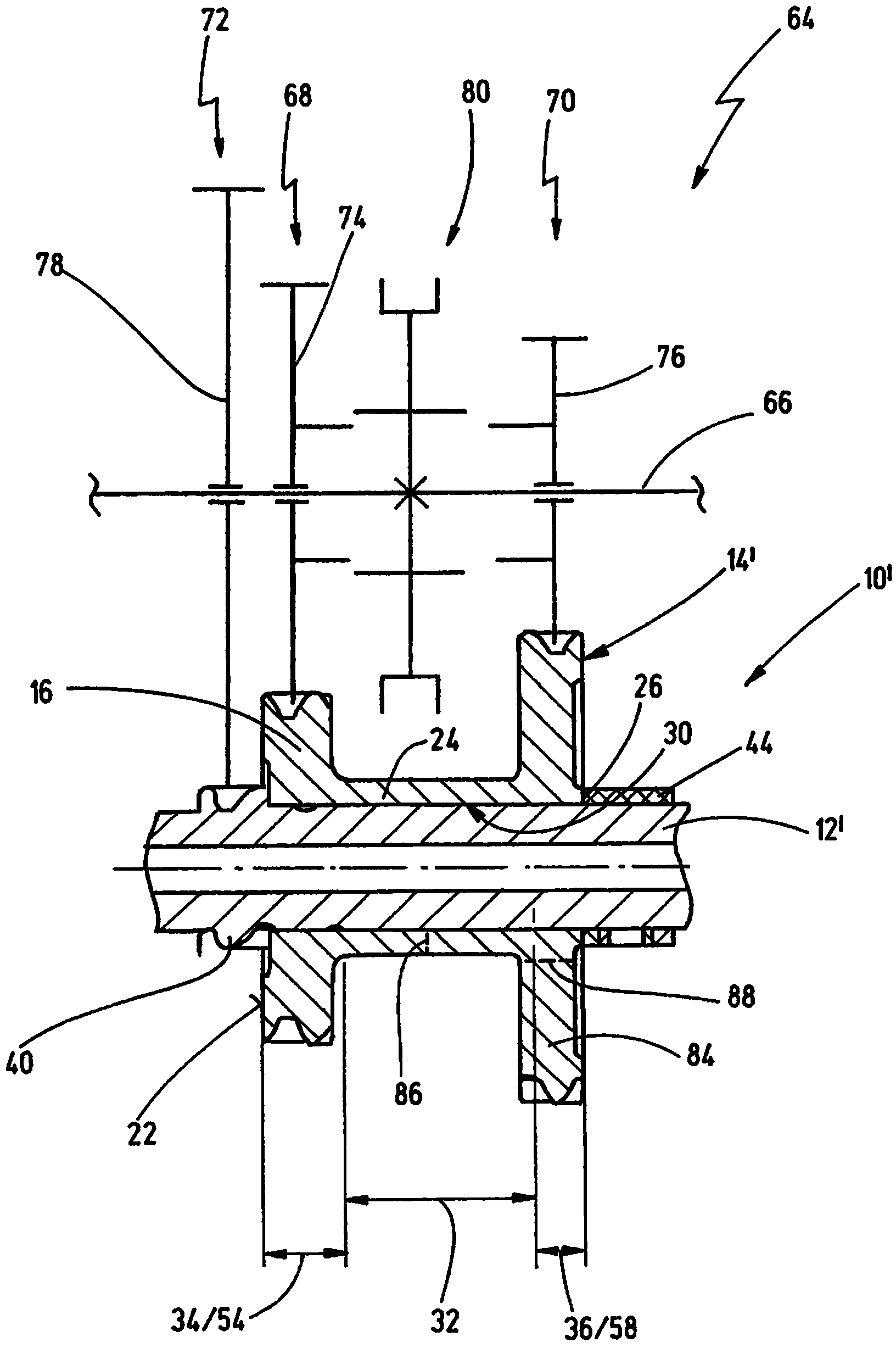

Hydrodynamic torque converter

InactiveUS20070068759A1Easy to assembleLower assembly costsYielding couplingRotary clutchesImpellerTurbine wheel

In a hydrodynamic torque converter including a working fluid for the transmission of a torque from an engine to an output shaft, a pump impeller, a stator with guide vanes, a turbine wheel connected to the output shaft via a hub-like support, a converter lock-up clutch for locking the pump impeller to the turbine wheel and a torsional vibration damper connected between the turbine wheel and the output shaft and including disk-shaped support elements, annular axially and radially extending gap seals are provided between two adjacent disk-shaped support elements of the vibration damper so as to form a labyrinth seal structure for controlling the flow of fluid through the converter lock-up clutch for cooling the clutch.

Owner:DAIMLER AG

Insertion combination type recyclable expanding body anchor rod of high-bearing inner cabin and construction method

ActiveCN102943474APrecise positioningEasy to installBulkheads/pilesStructural engineeringHigh intensity

The invention relates to an insertion combination type recyclable expanding body anchor rod of a high-bearing inner cabin and a construction method and belongs to the technical field of civil engineering. An unbonded steel strand is rewound through a smooth arc-shaped top bearing anchor end to form a double number of steel strands, and after forming through a specially-made steel strand locking device, the steel strands, a locking body and a binding lacing strip are commonly locked to form an insertion locking assembly, and the assembly is connected with a cabin type assembly composed of a bottom fixed pedestal and the like and is fastened through a locking screw and a nut. After the insertion combination type recyclable expanding body anchor rod of the high-bearing inner cabin is sent into a stratum, the high-pressure grouting cabin is unfolded in an expanded mode, a large-diameter high-strength anchor body is formed, and after a supporting function with high anchoring safety is finished, the unbonded steel strand can be recycled efficiently and rapidly and is simple to construct and simple in structure.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

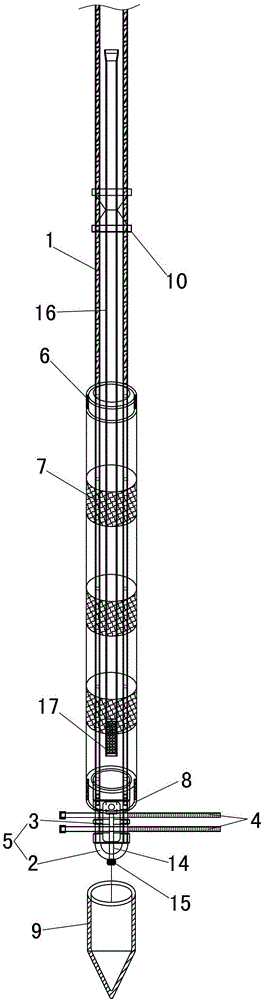

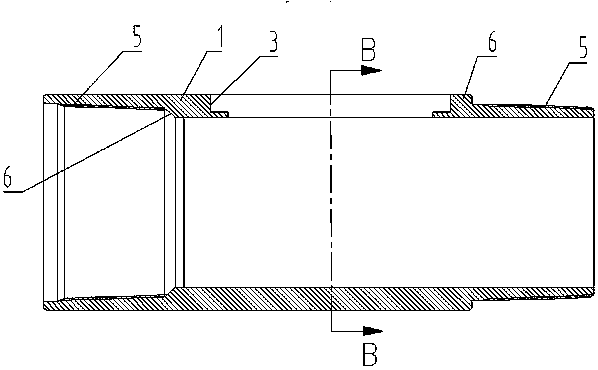

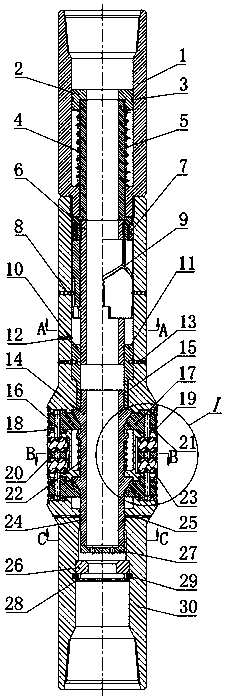

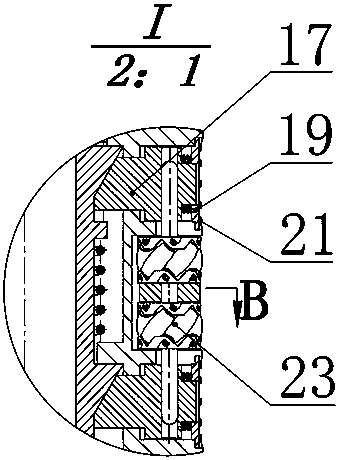

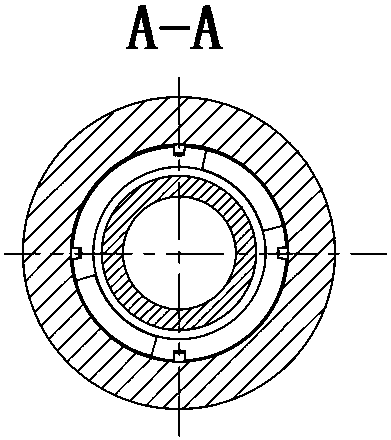

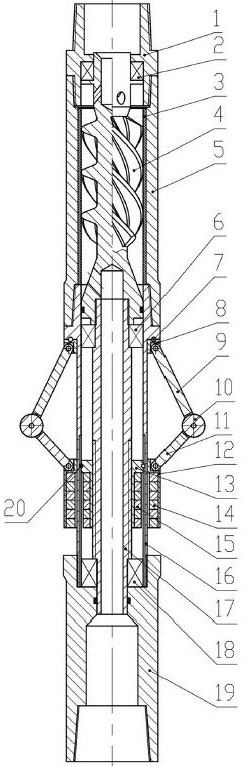

Diameter-changing and friction-reducing drill column centralizer

InactiveCN102943635AImprove centeringQuality improvementDrilling rodsDrilling casingsCircular coneEngineering

The invention relates to a diameter-changing and friction-reducing drill column centralizer which comprises an upper connector, a lower connector, an inner tubular column and an outer tubular column. The inner tubular column is internally connected between the upper connector and the lower connector, and the outer tubular column is externally connected between the upper connector and the lower connector; a tapered barrel is sleeved between the upper connector and the lower connector in a sliding and sealing mode, the tapered barrel is formed by integrating a cylinder section and a circular cone section, and the outer diameter of the lower portion of the circular cone section is tapered; a tension spring is sleeved on the inner tubular column on the upper side of the tapered barrel, and the tapered barrel is connected to the lower portion of the upper connector through the tension spring; a through hole is arranged on the tubular wall of the inner tubular column on the upper portion of the tapered barrel; a plurality of punched holes are circumferentially arranged on the tubular wall of the outer tubular column in a ring mode, a centralizing column is arranged in each punched hole in a sealing and sliding mode, an inner end surface of the centralizing column contacts with an outer surface of the circular cone section of the tapered barrel and is provided with a contact surface which is matched with the outer surface of the circular cone section; and a flange is arranged on the outer wall of the centralizing column in a ring mode, and a compressed spring is sleeved between the flange and the inner wall of the outer tubular column. By means of the centralizer, outer diameters can be real-timely attached to a well wall, centering degrees, drilling qualities and efficiencies of a drilling rod in a drilling well can be improved, and the centralizer is provided with a friction-reducing function.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

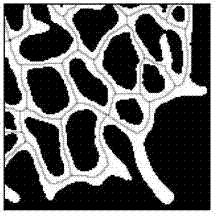

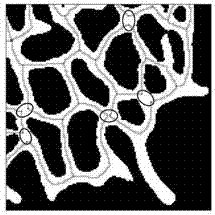

Pore throat recognition method with consideration of pore throat tail end

ActiveCN104778678AImprove centeringRelatively small errorImage analysisCharacter and pattern recognitionWavelet noiseThroat

The invention relates to a pore throat recognition method with consideration of a pore throat tail end and in particular to a method for recognizing pores and throats in microscopic visualization model oil displacement experiment images in the field of oilfield development. The method comprises the following steps: carrying out binaryzation treatment on images; carrying out length transformation on space of pores and throats; extracting a center line by using a turning point algorithm; cancelling inner paths in the pores to obtain path curves of the rest of paths; carrying out wavelet noise reduction on the path curves; finding bottleneck positions of the pores and the throats and carrying out pore throat recognition without consideration of the tail end; extracting a center line by using a combustion algorithm and finding the pore throat tail end; extracting a center line of the tail end by using the turning point algorithm by means of an endpoint of a combustion center line of the tail end; and combining the center line of the turning point algorithm and carrying out the pore throat recognition method with consideration of the pore throat tail end. With combination of the combustion algorithm and the turning point algorithm, the tail end part can be independently recognized; the extracted center line is good in centering effect; the relative errors of recognition of the pore throat length are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

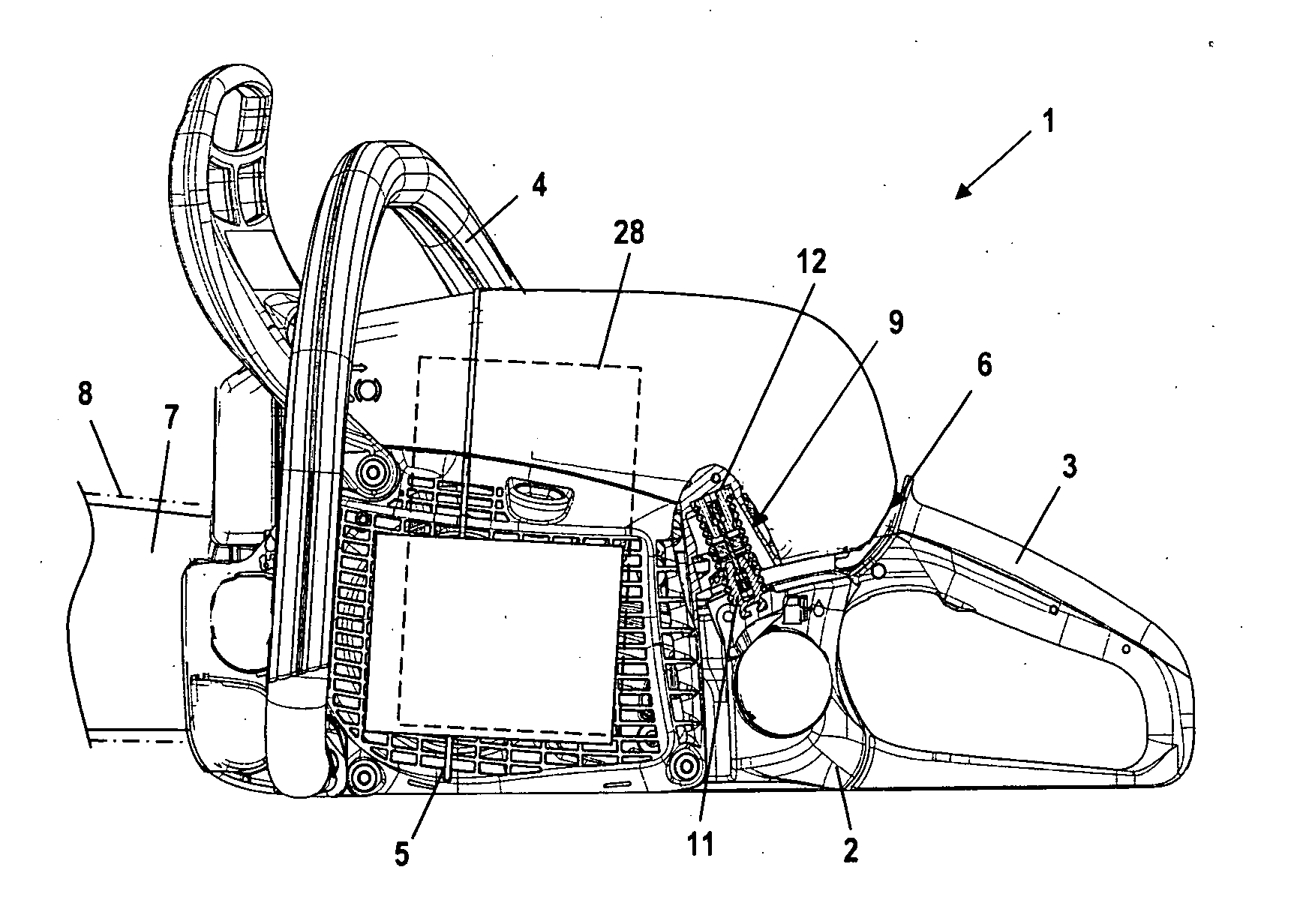

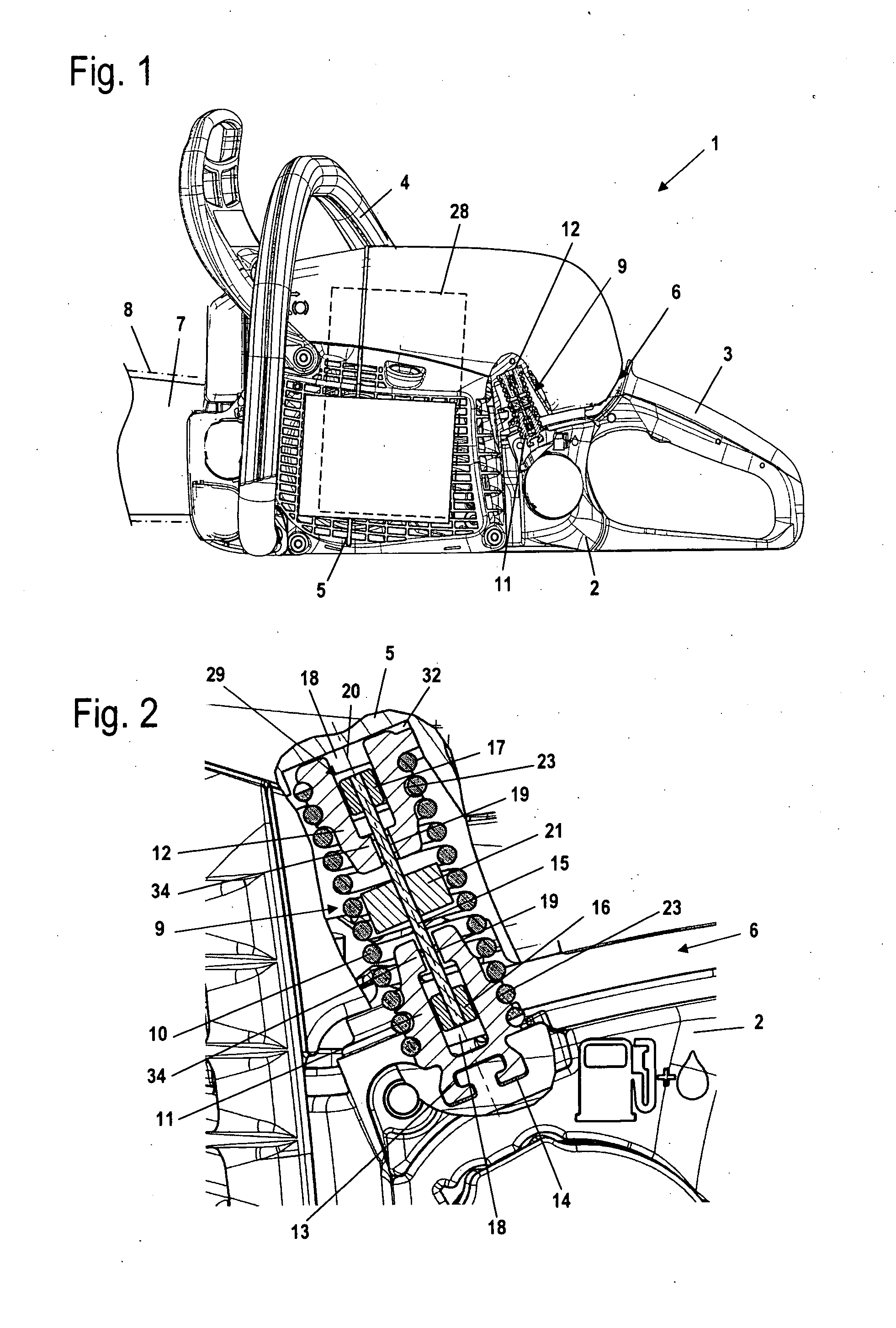

Handheld work apparatus

ActiveUS20110226501A1Simple configurationEasy to installMetal sawing devicesPortable percussive toolsHand heldCoil spring

A handheld work apparatus includes a drive motor (28) to drive a tool and at least one handle (3) as well as at least one anti-vibration element (9) that includes a coil spring (10). The coil spring (10) is operatively connected to the handle (3) at one end and with the drive motor (28) at the other end. The anti-vibration element has a tear-off guard (29) which extends through the anti-vibration element (9). A centering element (21) is arranged on the tear-off guard (29) to avoid, in a simple manner, that the tear-off guard moves radially outwards.

Owner:ANDREAS STIHL AG & CO KG

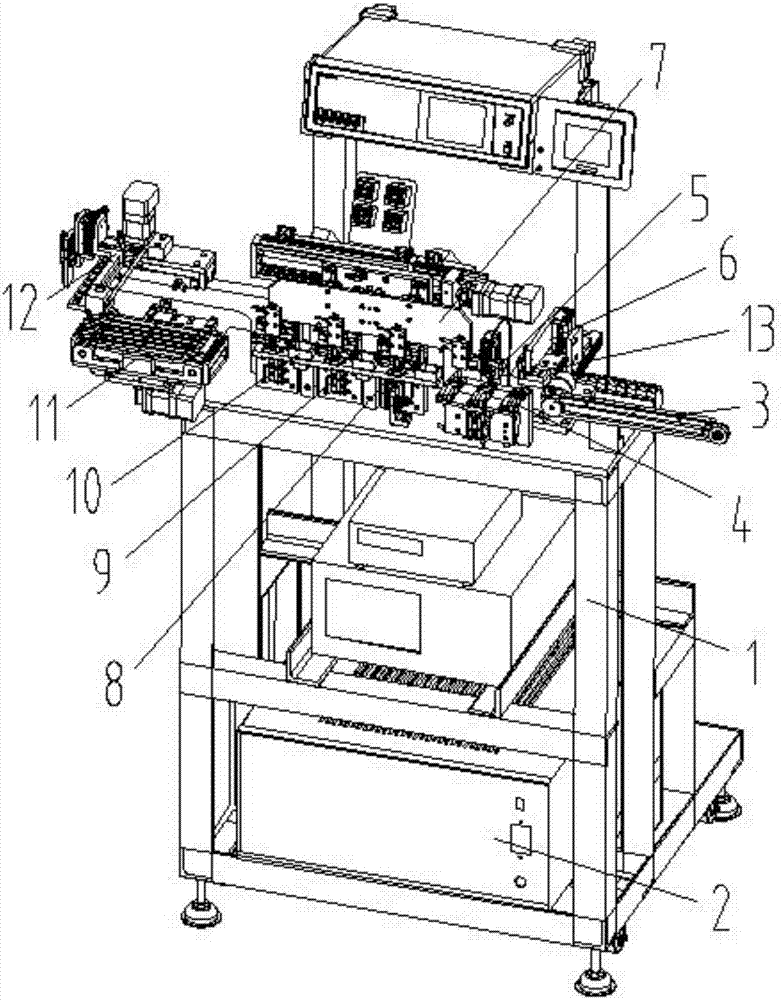

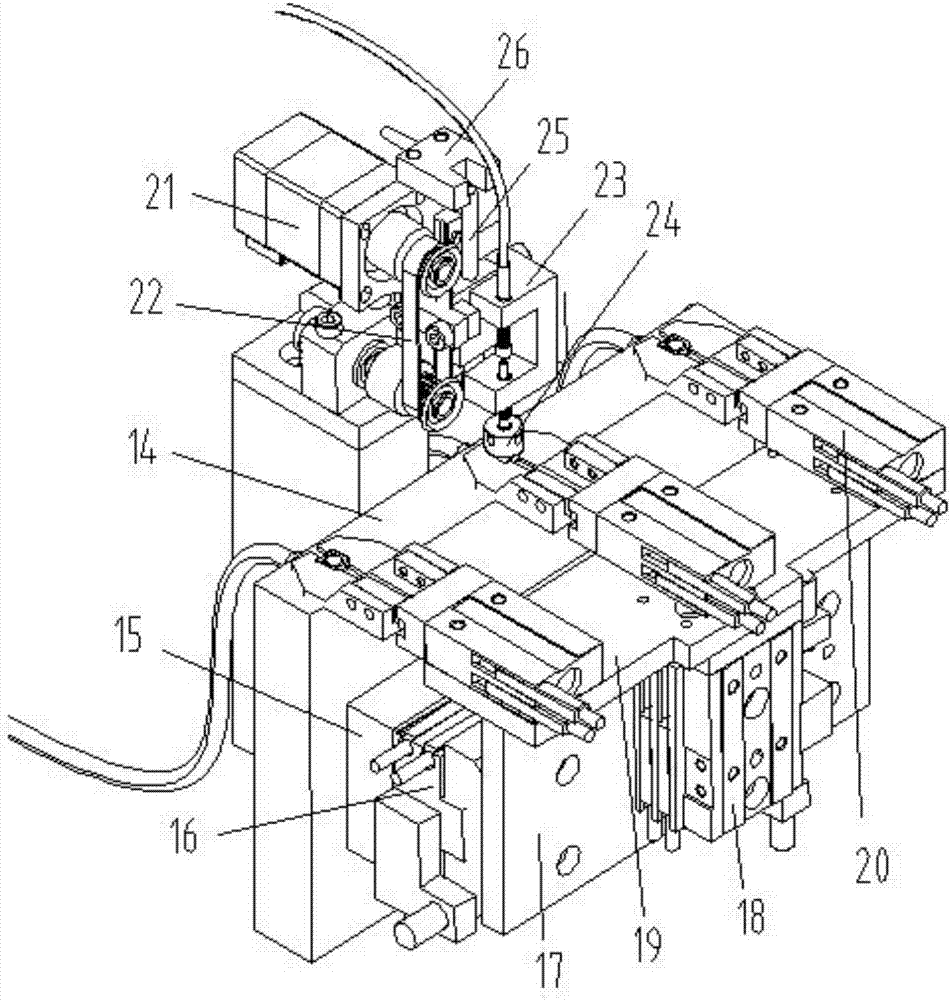

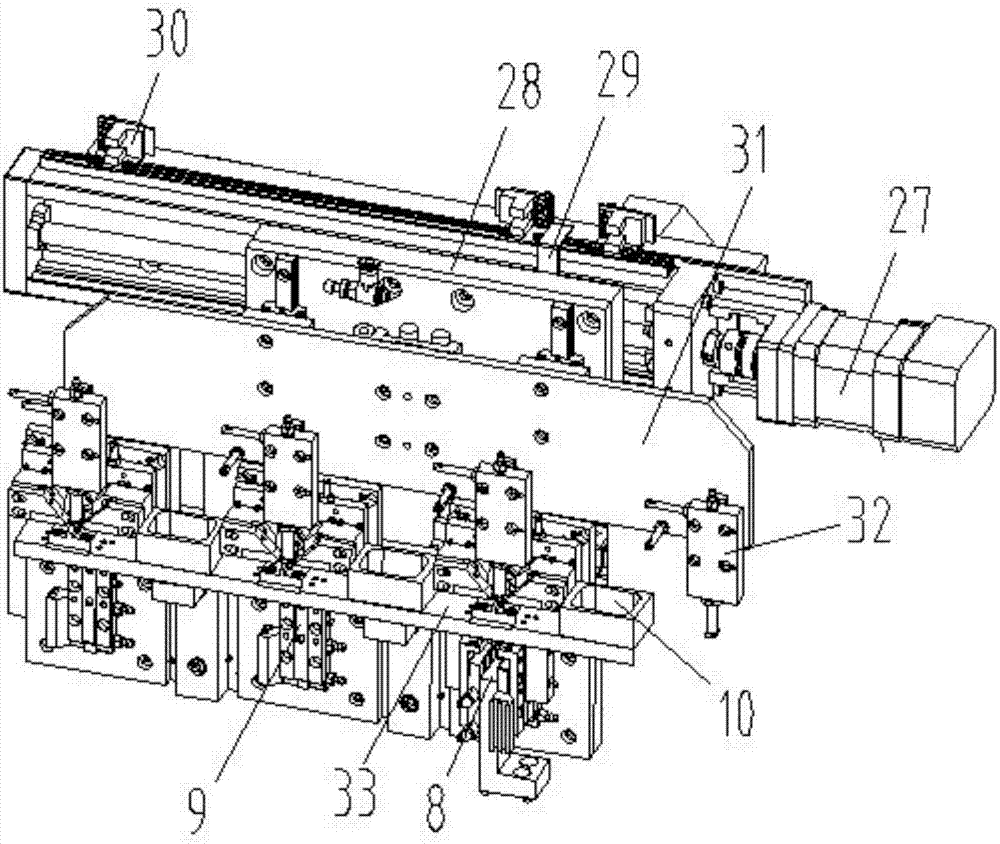

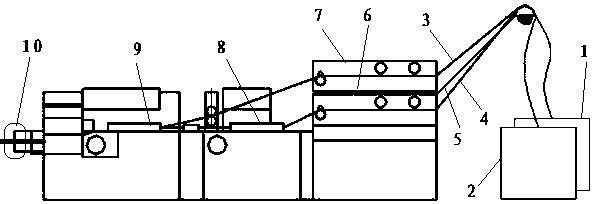

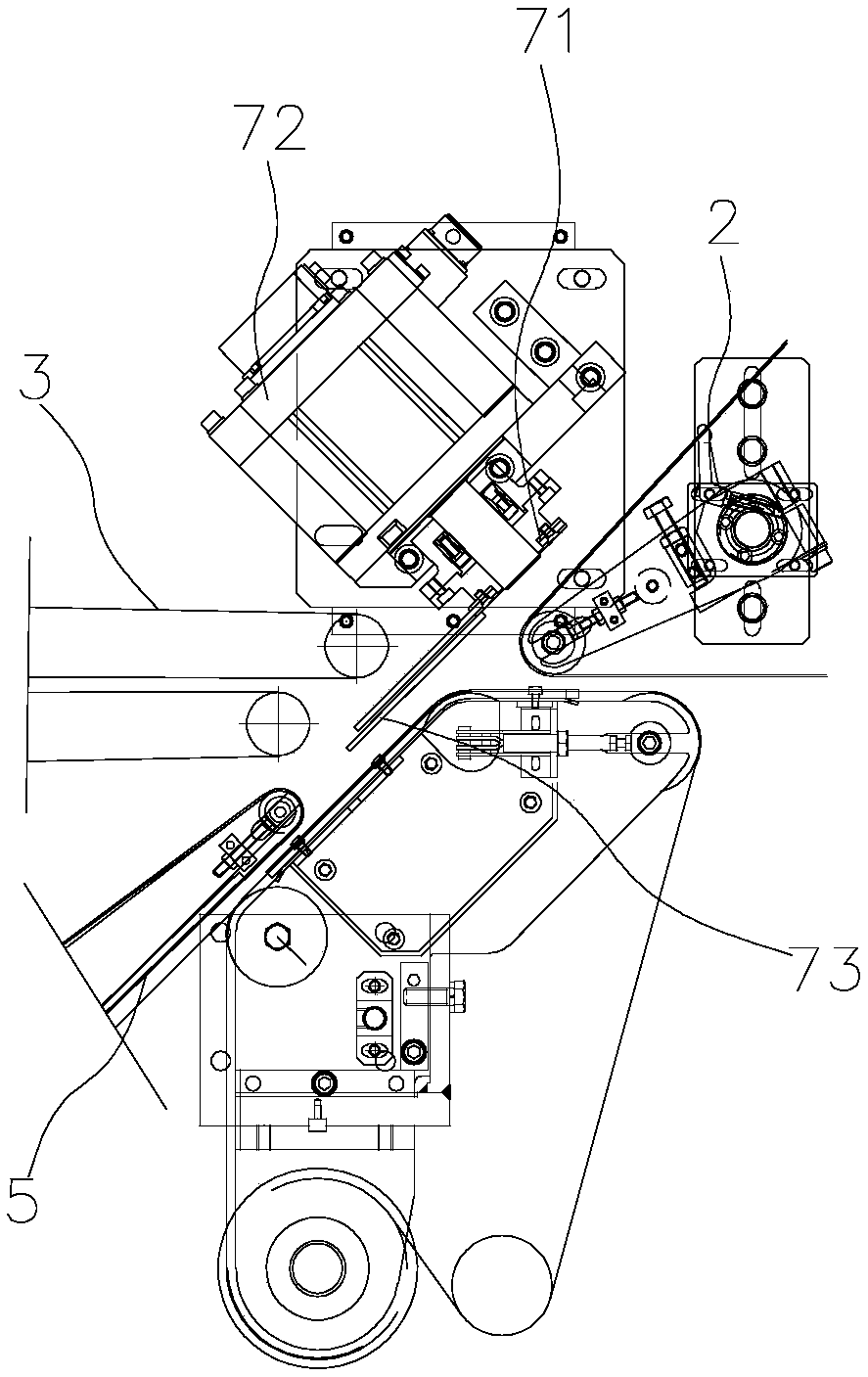

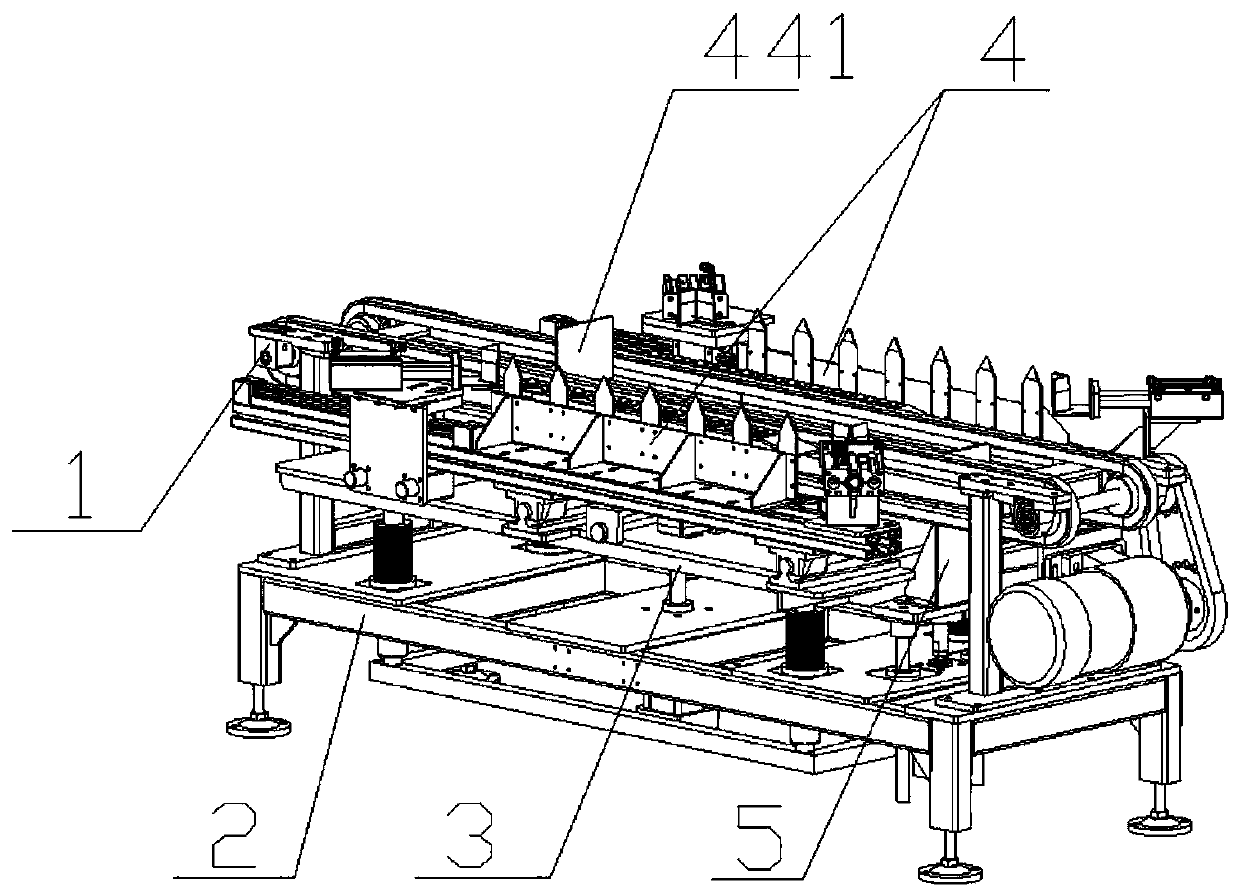

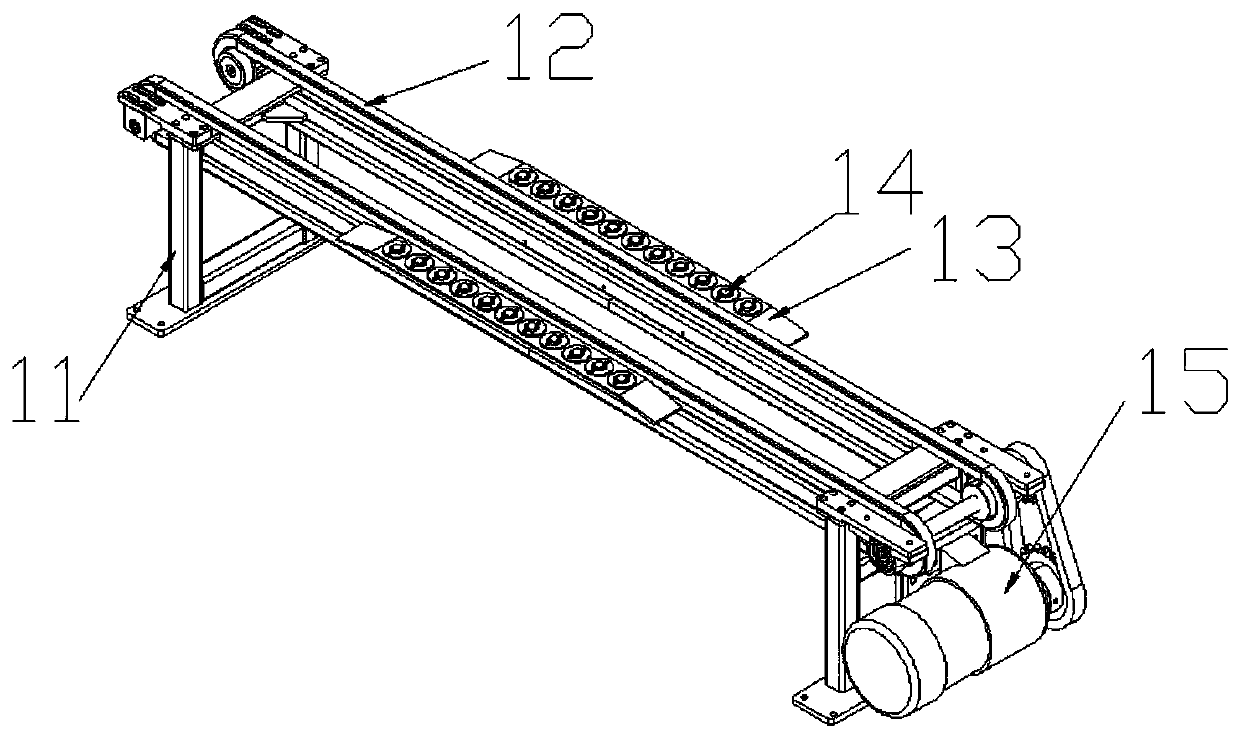

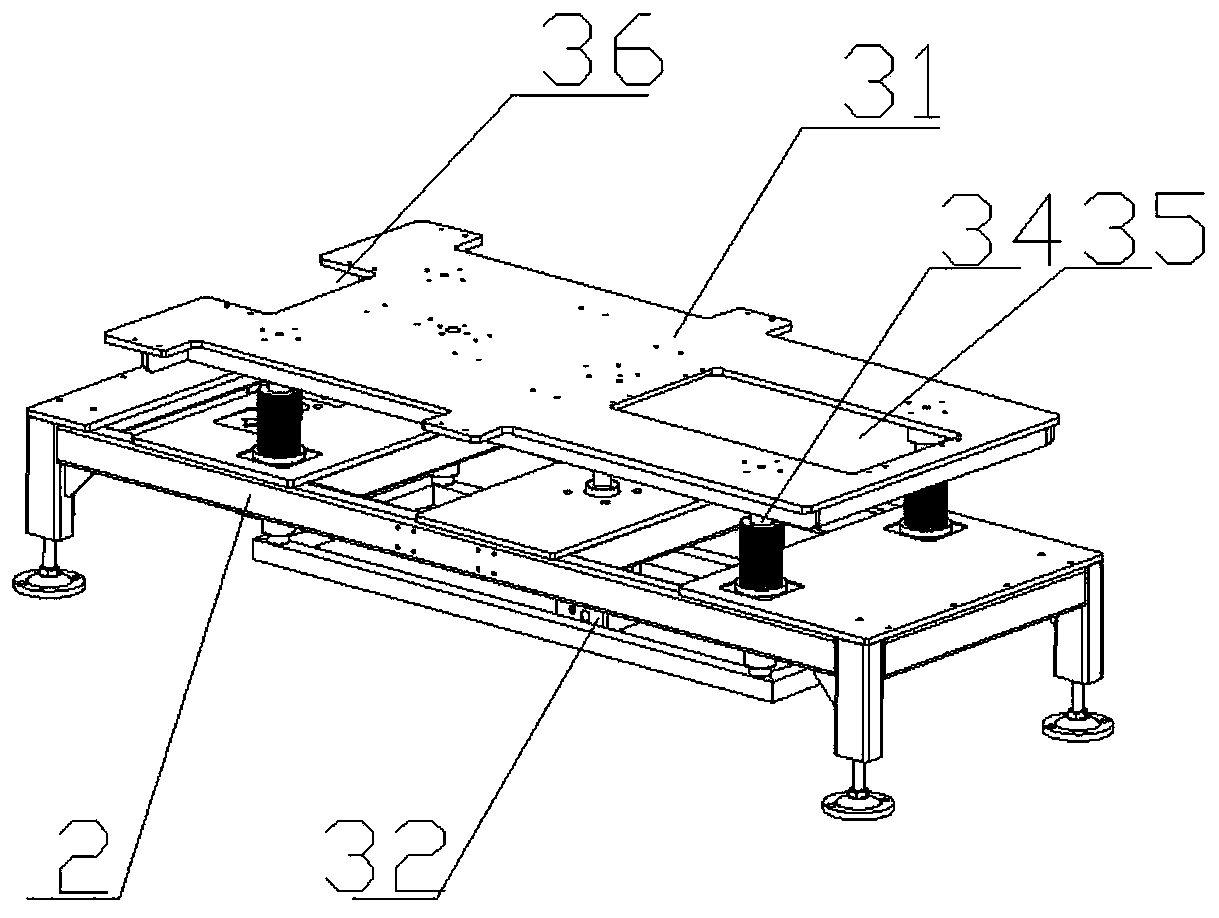

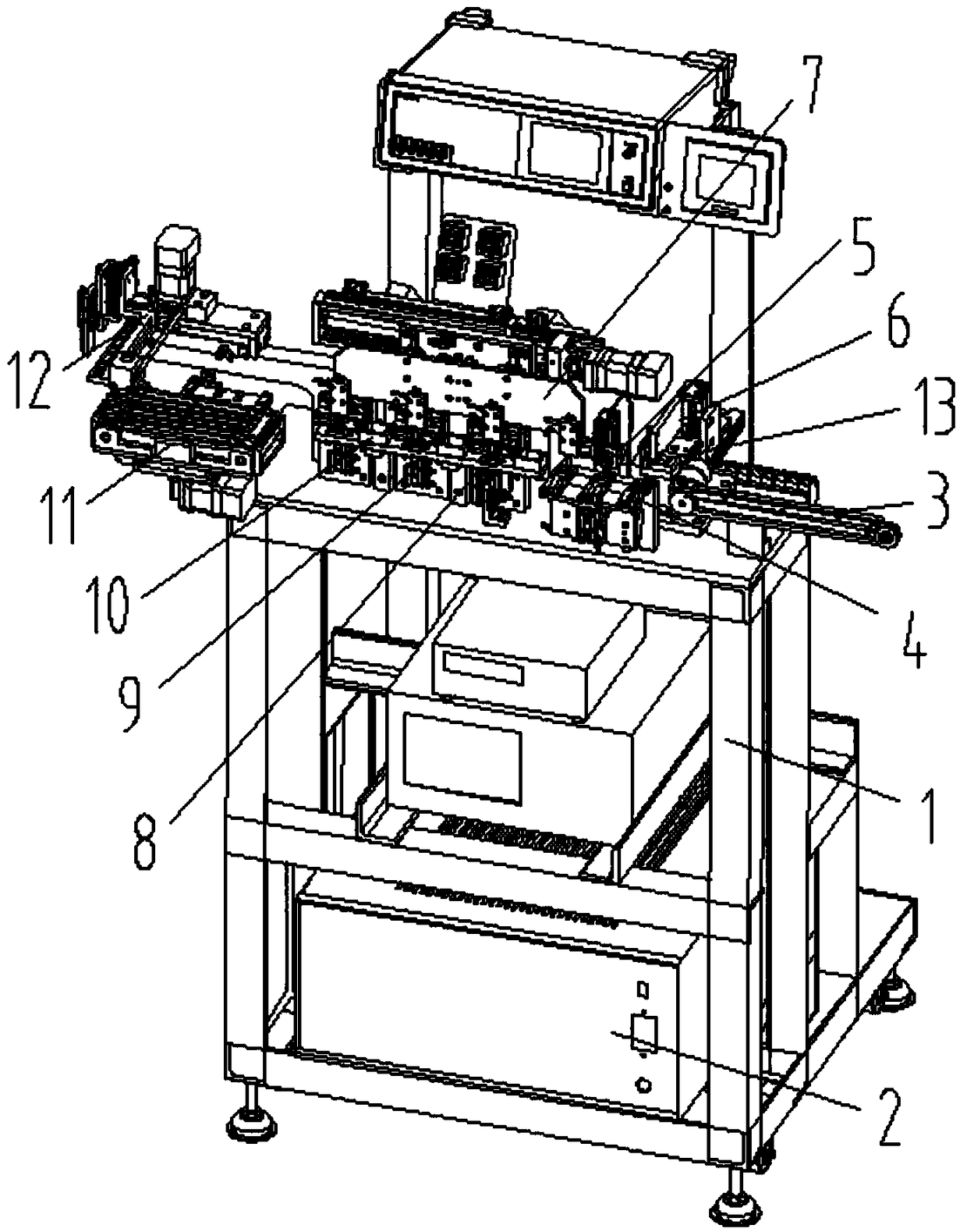

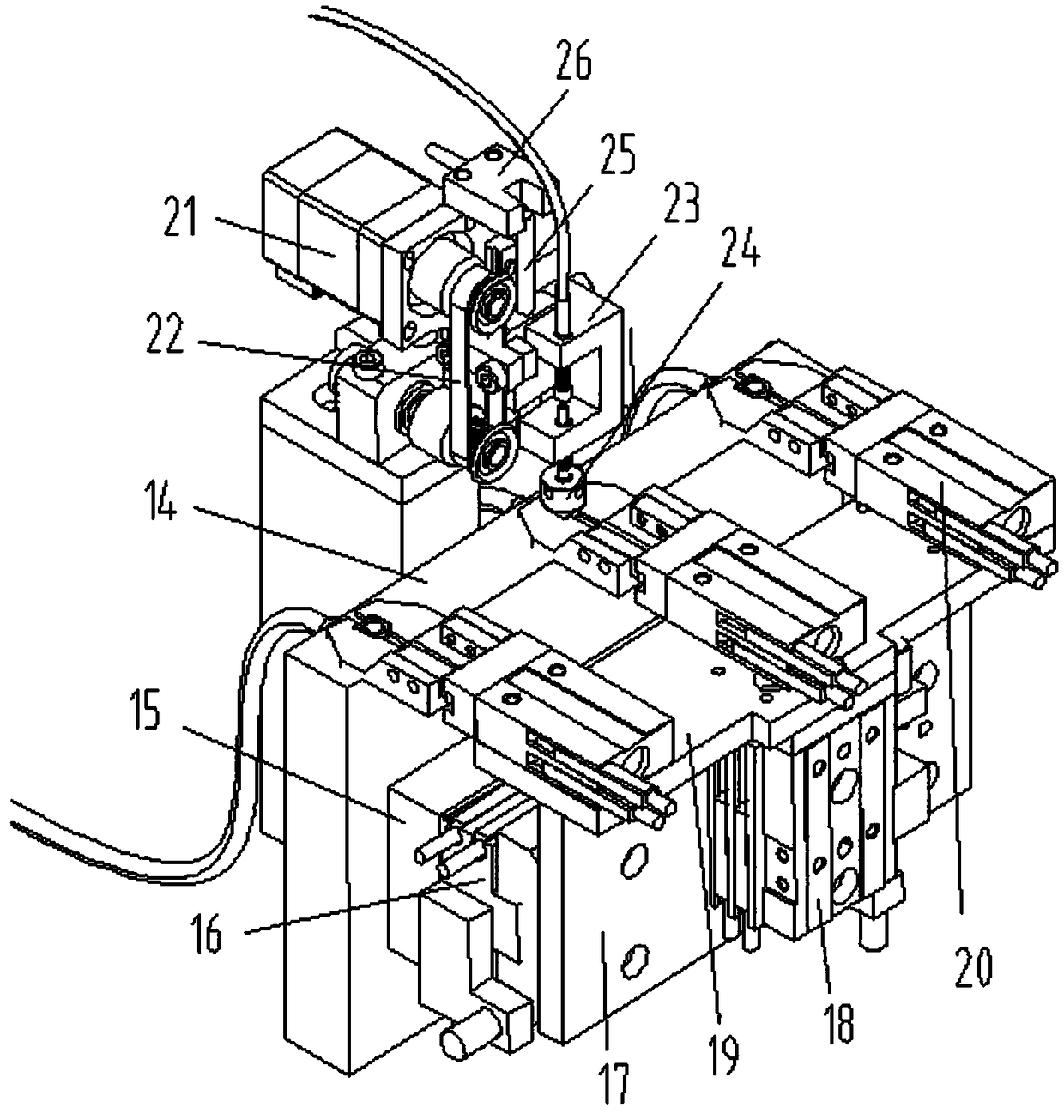

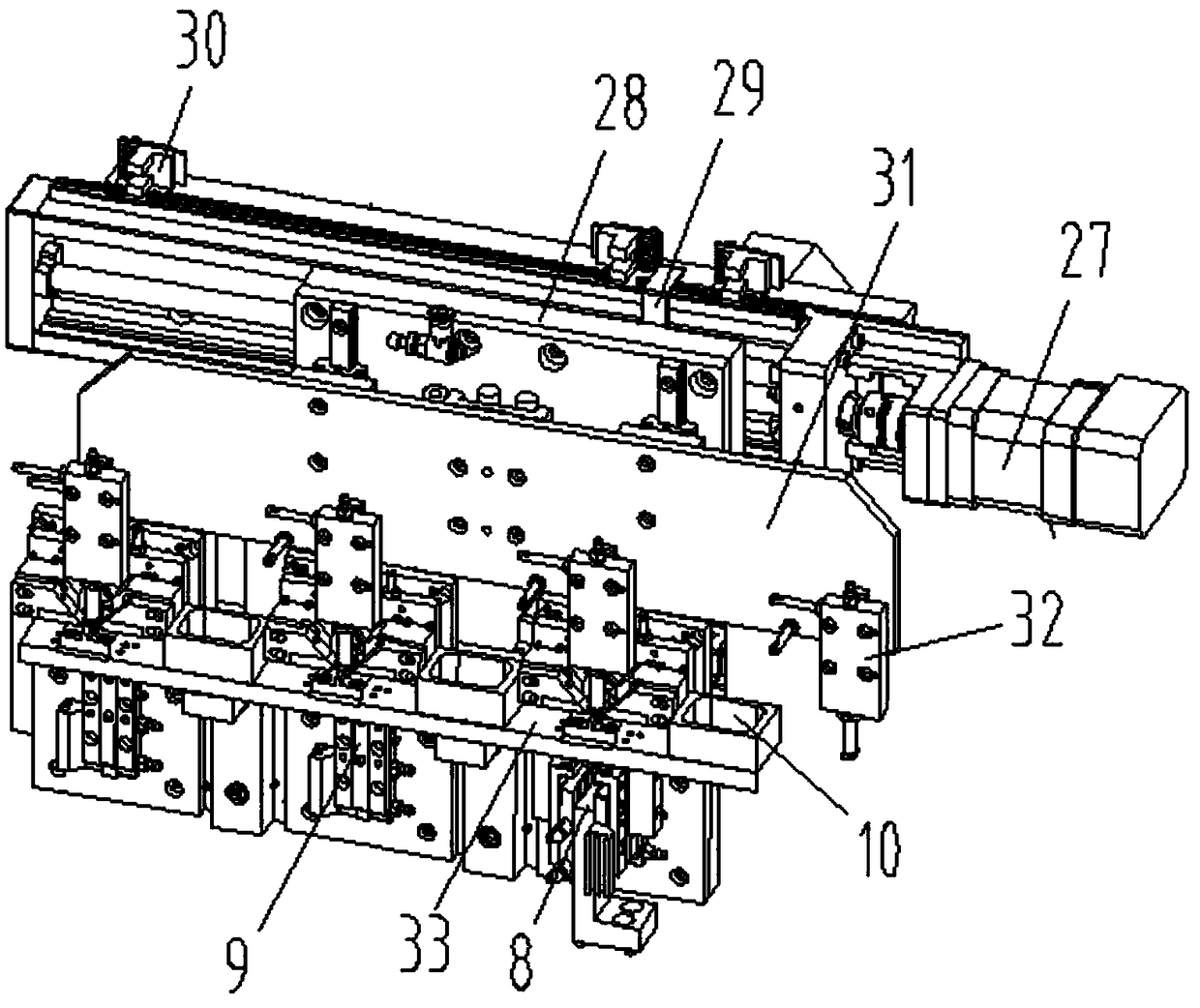

Chip resistor detecting sorting machine

ActiveCN106862101AGuaranteed accuracyGuarantee qualityElectrical testingSortingDistribution controlChip resistor

The invention relates to a chip resistor detecting sorting machine. The chip resistor detecting sorting machine comprises a machine frame and a power distribution control cabinet, wherein a feeding conveying device, an upper part detecting seat and a lower part detecting seat are sequentially arranged on the machine frame from right to left; the feeding conveying device and the upper part detecting seat are matched through an upper part detecting and taking device; the upper part detecting seat and the lower part detecting seat are matched through a lower part detecting and taking device; an upper part detecting device which is matched with products is arranged on the upper part detecting seat, wherein a CCD detecting head is used as a detecting component of the upper part detecting device; a lower part detecting device matched with the lower parts of the products is arranged on the lower part detecting seat; the lower part detecting device comprises a detecting and discharging seat arranged on the lower part detecting seat; an LCR detecting probe penetrating through the lower part of the detecting and discharging seat is arranged at the lower part of the detecting and discharging seat; and a first unqualified product collecting box is arranged at the lower part detecting seat. According to the chip resistor detecting sorting machine disclosed by the invention, automatic and integral detection for two sides of chip resistors is realized, so that the detecting accuracy is guaranteed, and the quality of subsequent finished products is guaranteed; and besides, the detecting efficiency is improved.

Owner:SHENZHEN MESTEK ELECTRONICS CO LTD

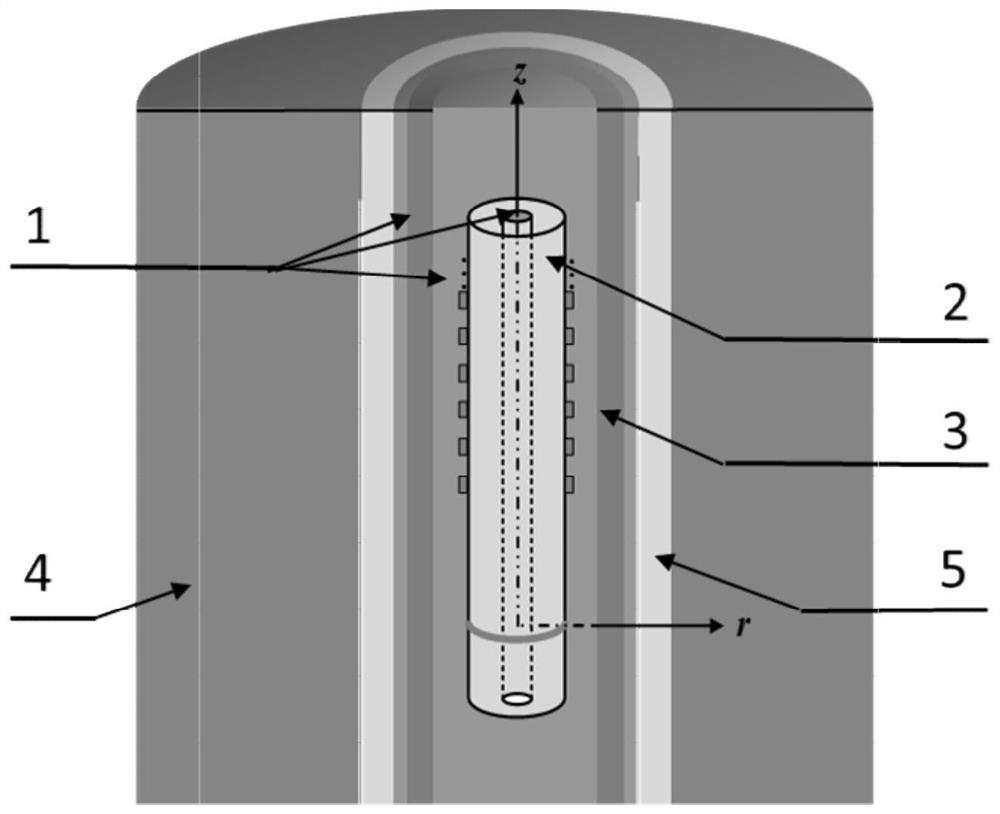

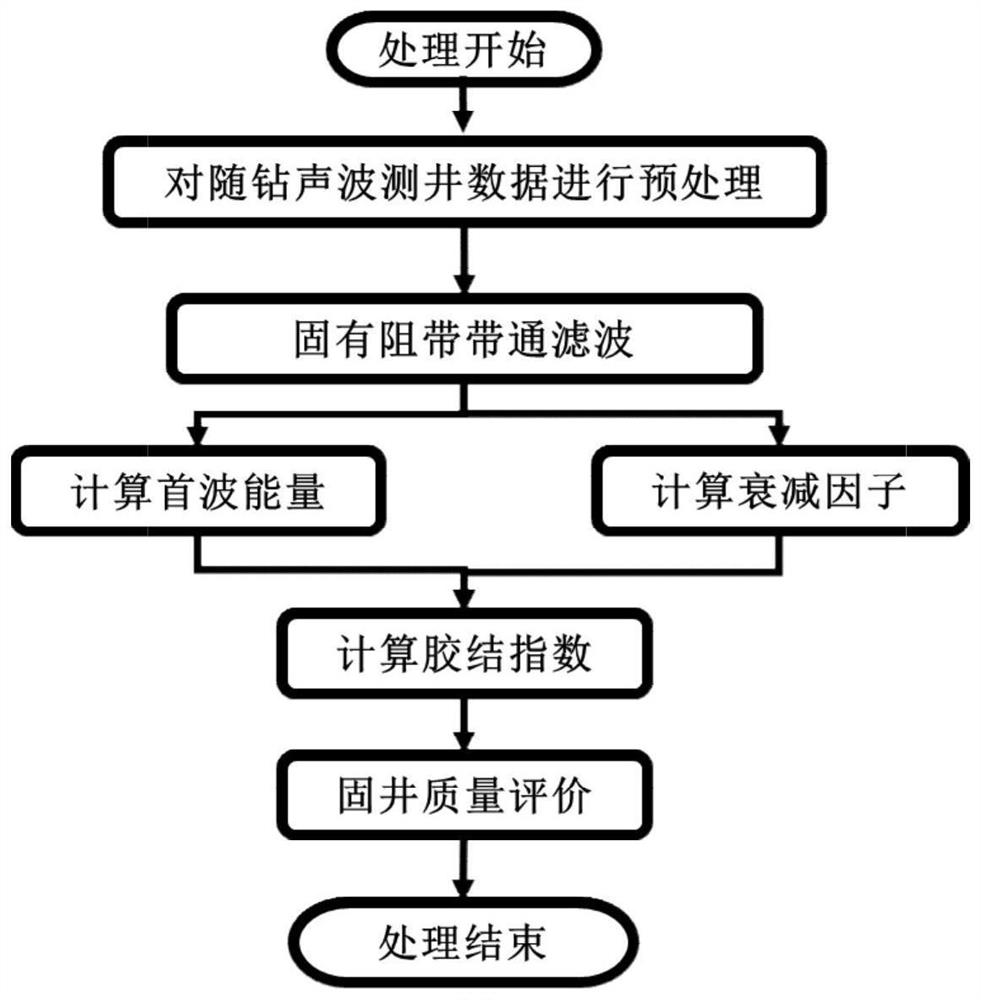

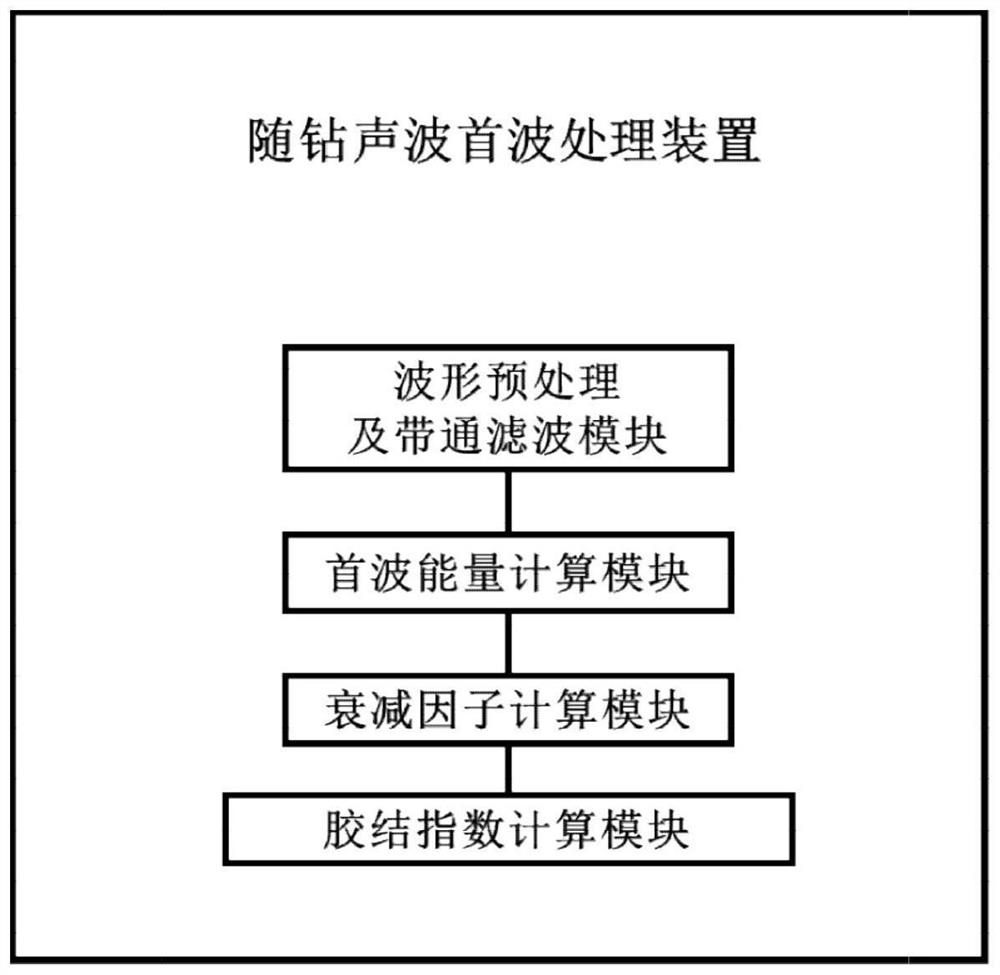

While-drilling sound wave well cementation quality evaluation method and processing device

The invention discloses a while-drilling sound wave well cementation quality evaluation method and a processing device. The while-drilling sound wave well cementation quality evaluation method comprises the steps that 1, while-drilling data are pre-processed, and full-wave train data of array sound waves are obtained; 2, the influence of drill collar waves in the head waves is eliminated; 3, the energy of a head wave is calculated, and the wave energy of a sleeve in a window is calculated according to the length of the window; 4, a head wave array attenuation factor is calculated, and a corresponding array attenuation factor is calculated according to the obtained head wave energy; 5, a cementation index is calculated, and the cementation index is calculated by using a cementation index calculation formula according to a fitting formula of the attenuation factor of the block and the CBL; 6, the well cementation quality is comprehensively evaluated by using a cementation index curve; and 7, whether all the depth points are processed or not is judged, if so, processing is ended, and if not, the steps are repeated until all the depth points are processed. According to the while-drilling sound wave well cementation quality evaluation method, the problems of long time consumption and high cost during well cementation quality evaluation of highly-deviated wells and horizontal wells in cable logging can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

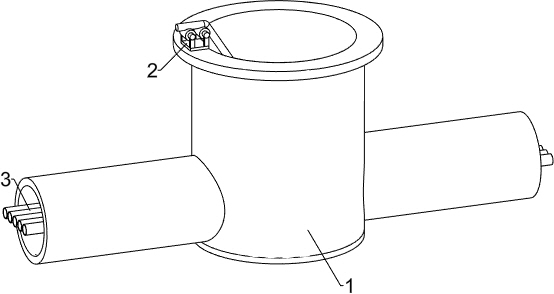

Plasma cutting device and method for underground oil casing

PendingCN112443286AReal-timeRealize regulationDrilling rodsDrilling casingsEngineeringElectric cables

The invention discloses a plasma cutting device and method for an underground oil casing. The plasma cutting device comprises an electrode, an electrode feeding mechanism and a guide shoe, the electrode is fixed to the electrode feeding mechanism, the electrode is arranged outwards in the radial direction, the guide shoe is connected to the axial lower end of the electrode feeding mechanism, and the electrode and the electrode feeding mechanism are both connected with a cable; the upper end of the electrode feeding mechanism is connected with a rotating mechanism; the upper end of the rotatingmechanism is connected with an upper centering mechanism; and a lower centering mechanism is further connected between the guide shoe and the electrode feeding mechanism. Strings are cut, the cuttingefficiency is high, and the success rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

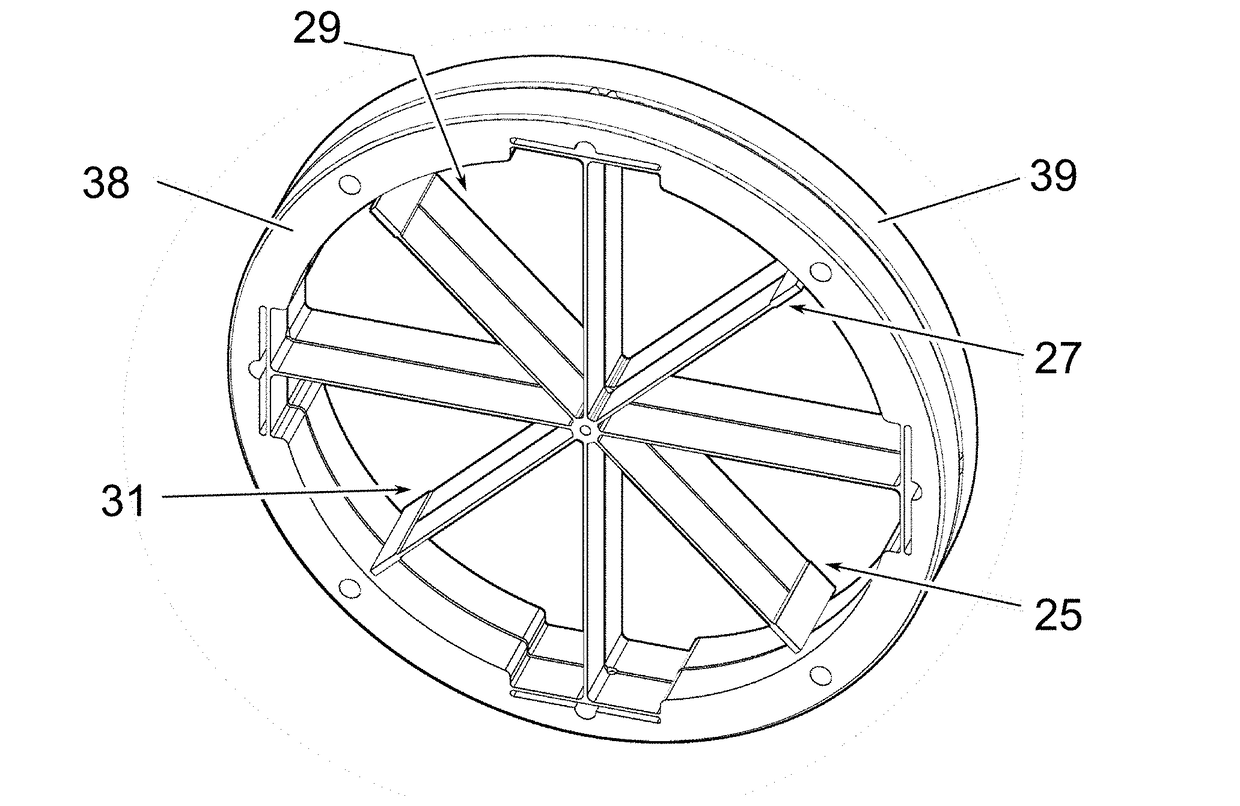

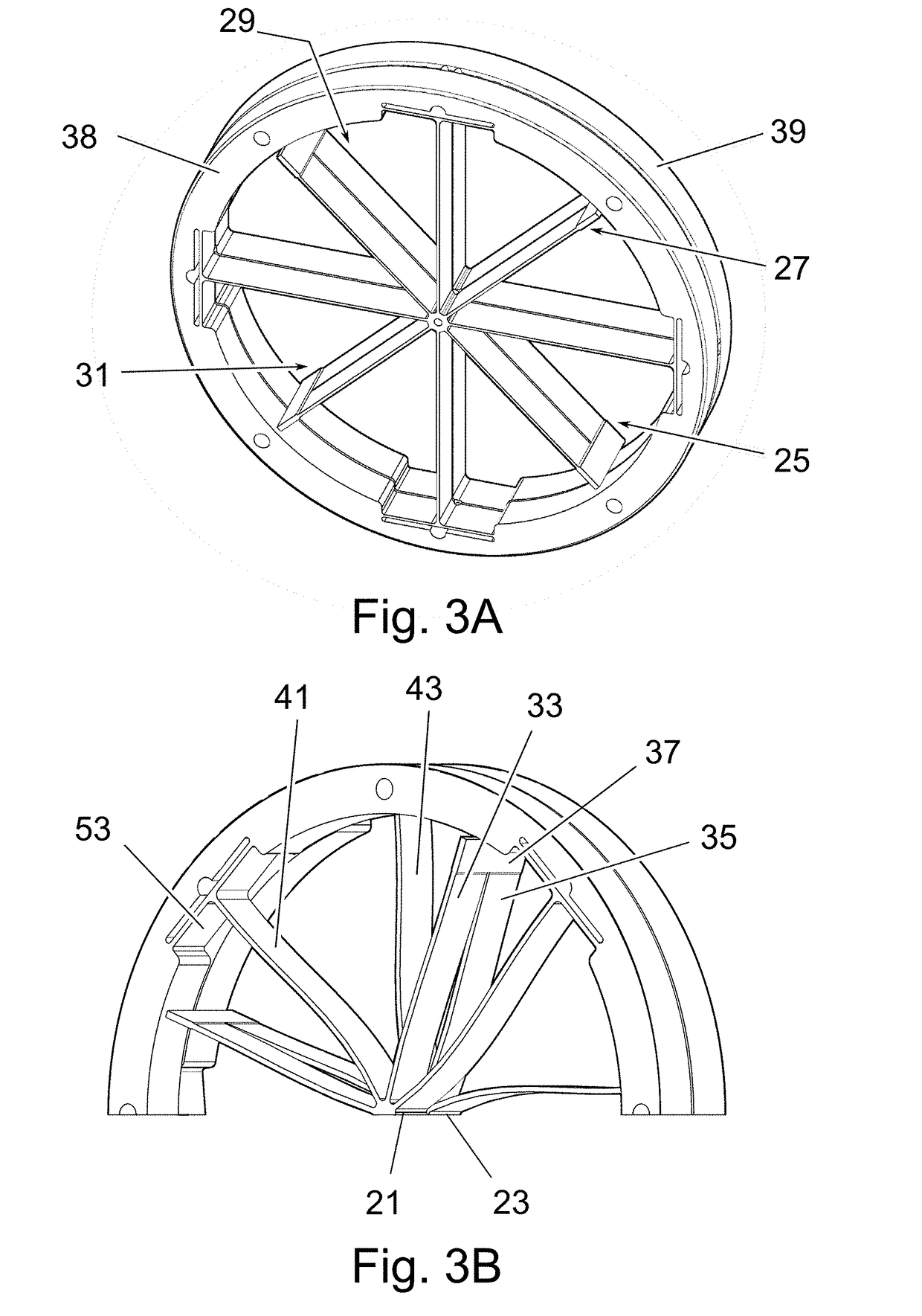

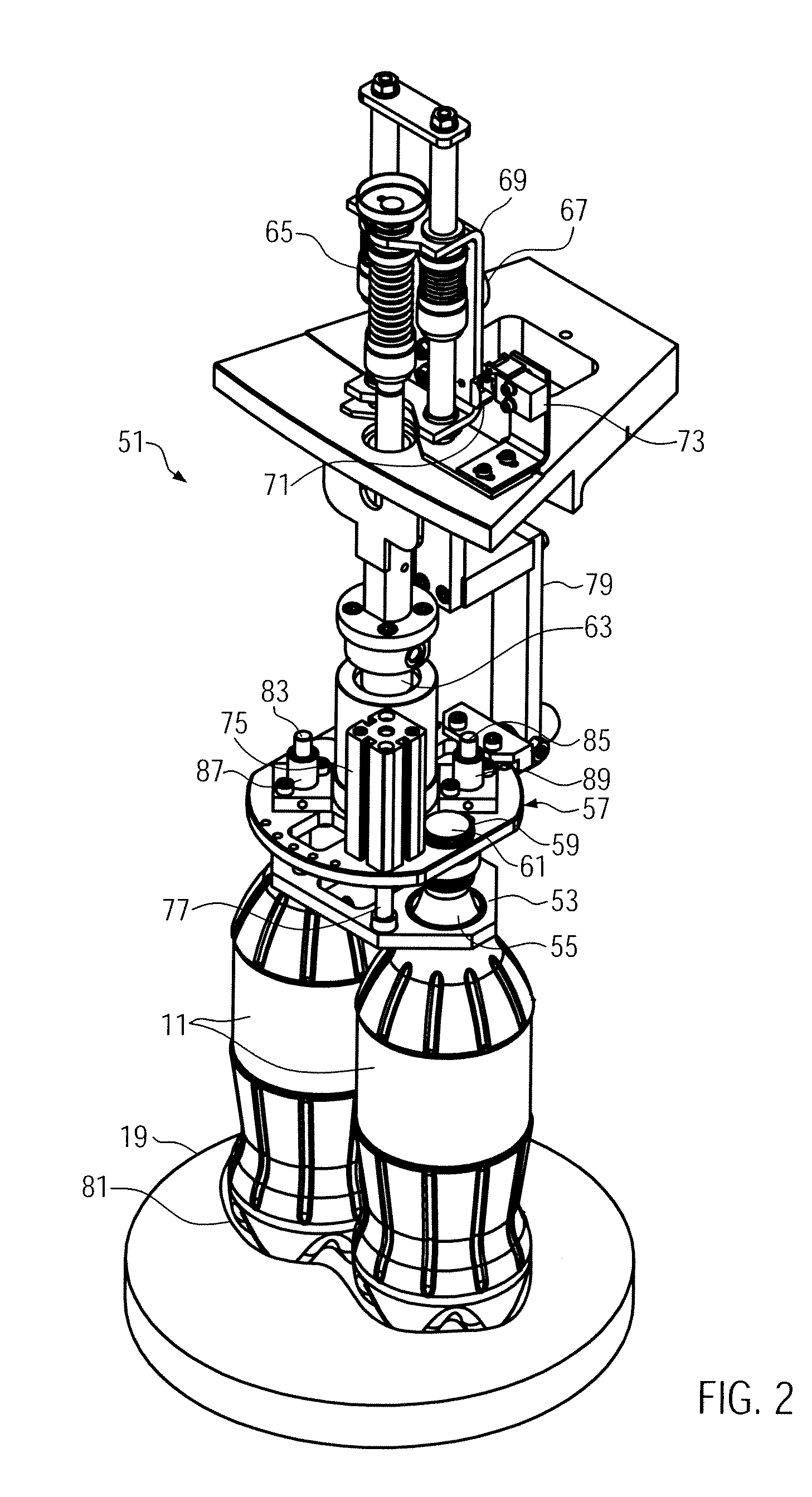

Large angle flexible pivot

PendingUS20180319517A1Improve centeringEffective lengthCosmonautic vehiclesFrequency stabilisation mechanismSpokeEngineering

A flexible pivot includes a first stage including a first cylinder and interface structure and a second stage including a second cylinder and interface structure in axial alignment with those of the first stage. Flexible connecting members are arranged for connecting the first and the second stages. Each flexible connecting member includes a pair of legs and a cross member joining the legs, each leg extending in a direction transverse to the axis of the cylinders, the legs being attached to the first and the second cylinders respectively. The first cylinder and the first interface structure are concentric. Flexible spokes are attached to the first cylinder by one end and to the first interface structure by the other. Each spoke extends in a direction transverse to the axis of the cylinders. Finally, the second stage includes flexible connection unit arranged to connect the second cylinder to the second interface structure.

Owner:ALMATECH SA

Forming equipment of paper-parcel-free coaxial core filter stick and running process of forming equipment

PendingCN108477673ALow input costSave operating spaceTobacco smoke filtersManufacturing efficiencyTwo layer

The invention discloses forming equipment of a paper-parcel-free coaxial core filter stick. The forming equipment is provided with two filament tow conveying mechanisms arranged in parallel, a combined opening mechanism, an inner-layer paper-parcel-free filter stick solidifying and shaping mechanism, an outer-layer paper-parcel-free filter stick solidifying and shaping and composite forming mechanism and a guiding-out mechanism. The inner-layer paper-parcel-free filter stick solidifying and shaping mechanism heats inner-layer filament tows by steam, and paper-parcel-free inner core filter sticks are made at first; and then an outer layer is shaped by heating through steam. According to the forming equipment, the inner layer and the outer layer are sequentially formed, the two layers are spaced clearly, a forming production line is short, and the manufacturing efficiency is high.

Owner:NANTONG CIGARETTE FILTER

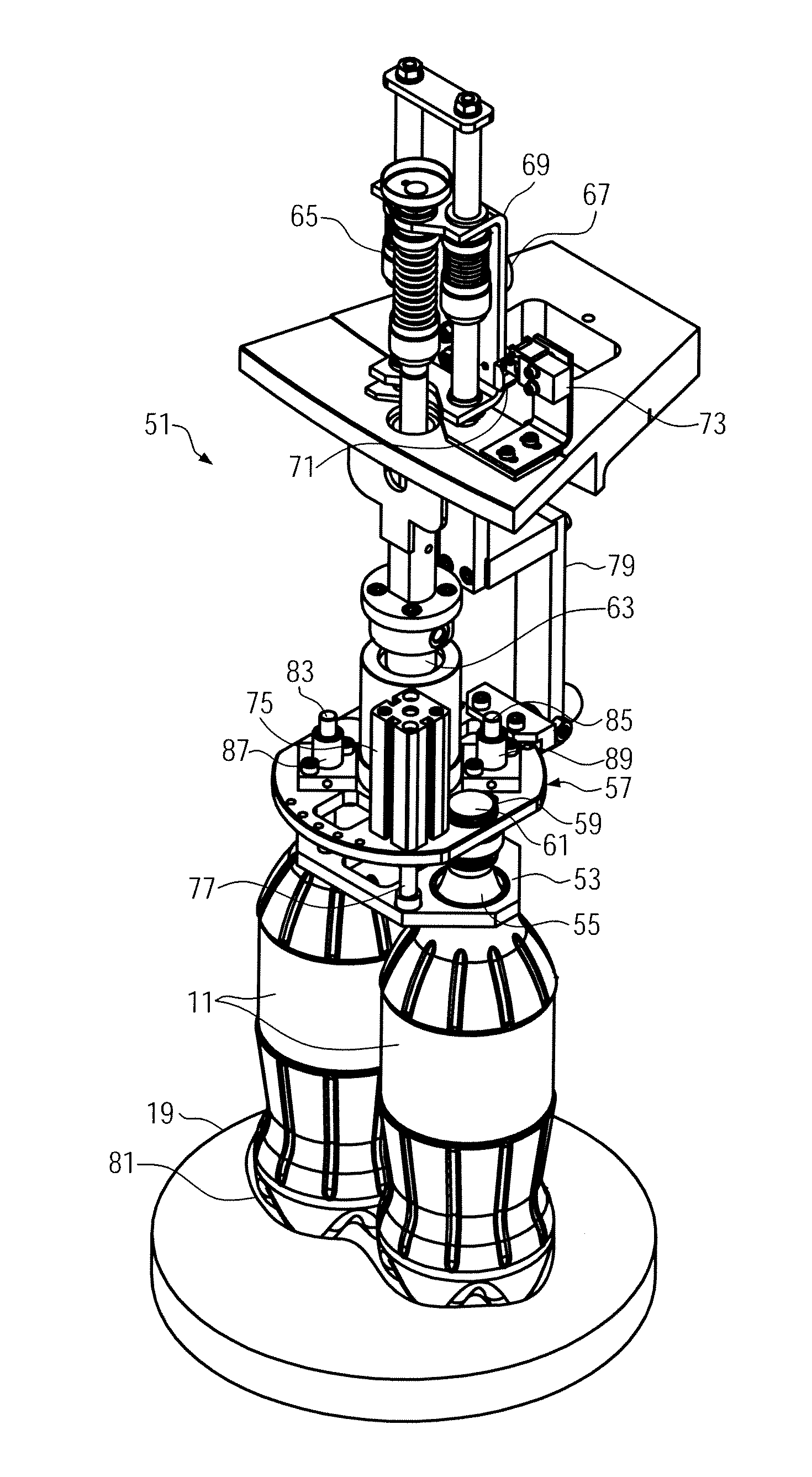

Centering unit for aligning at least two grouped vessels and method for aligning two grouped vessels

InactiveUS8935903B2Improve convenienceImprove alignment stabilityRotary pressesButter manufactureEngineeringStructural engineering

Owner:KRONES AG

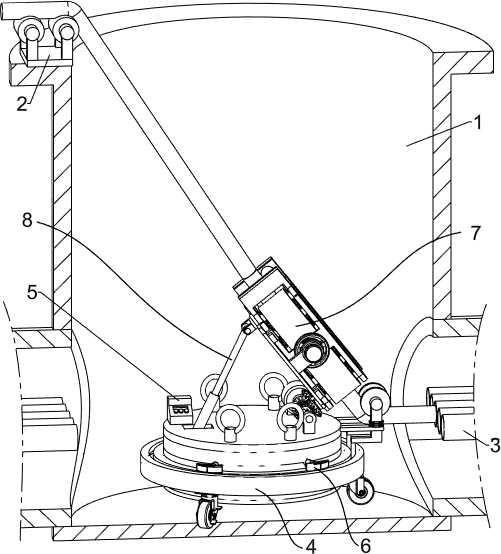

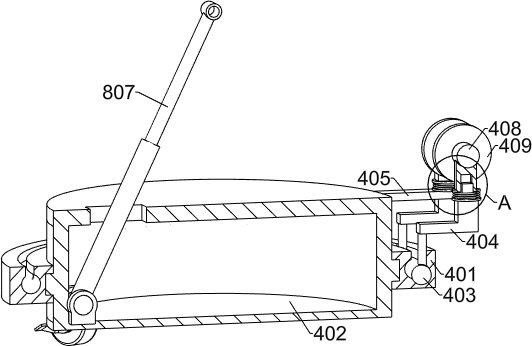

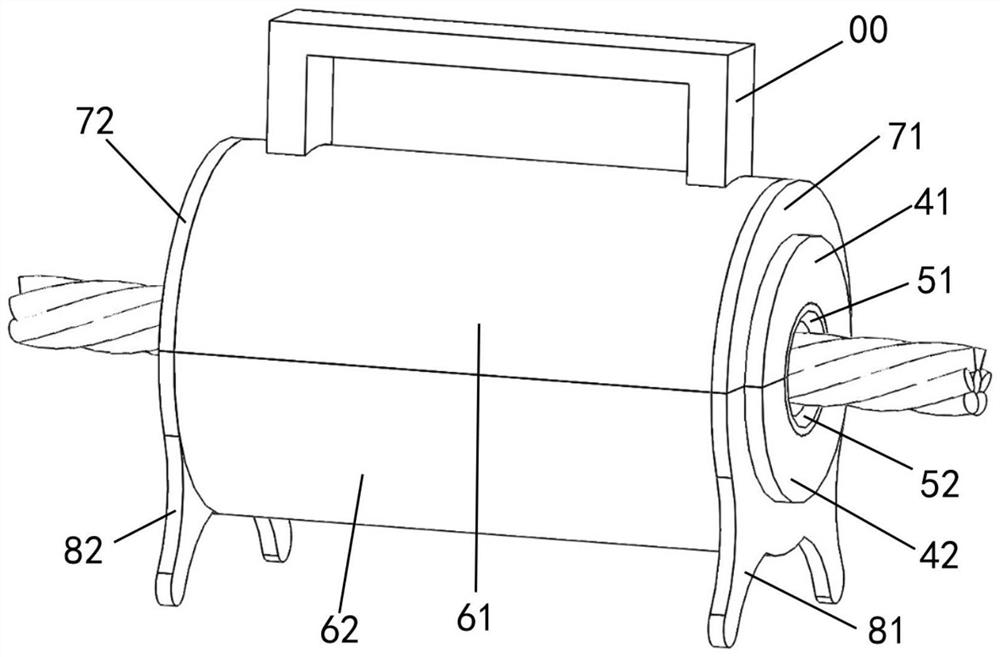

Electric traction device with positioning function

ActiveCN114649780AEasy to operateReduce work intensityFilament handlingApparatus for laying cablesControl theoryElectric traction

The invention relates to the technical field of cable installation, in particular to an electric traction device with a positioning function. The technical problems that when cable traction needs to be carried out on a plurality of protection pipes, an operator needs to install a plurality of guide wheels, the operation process is tedious, a cable is bent in a right-angle mode when a cable traction machine is placed under a cable well, so that the cable is prone to being damaged, and the traction machine placed at the bottom of the cable well is inconvenient to fix and carry out center positioning are solved. An electric traction device with a positioning function comprises a directional locking mechanism. A fixing mechanism is arranged on the directional locking mechanism, a traction mechanism is arranged on the upper portion of the fixing mechanism, and an angle adjusting mechanism is arranged on the traction mechanism. Through cooperation of the directional locking mechanism and the fixing mechanism, the directional locking mechanism is fixed and centered, cable angle adjustment is completed through the angle adjusting mechanism, the situation that the cable at the position of the positioning sleeve is extruded and deformed is avoided, installation of a guide wheel is reduced, and the working intensity of operators is relieved.

Owner:山东五洲电力工程有限公司

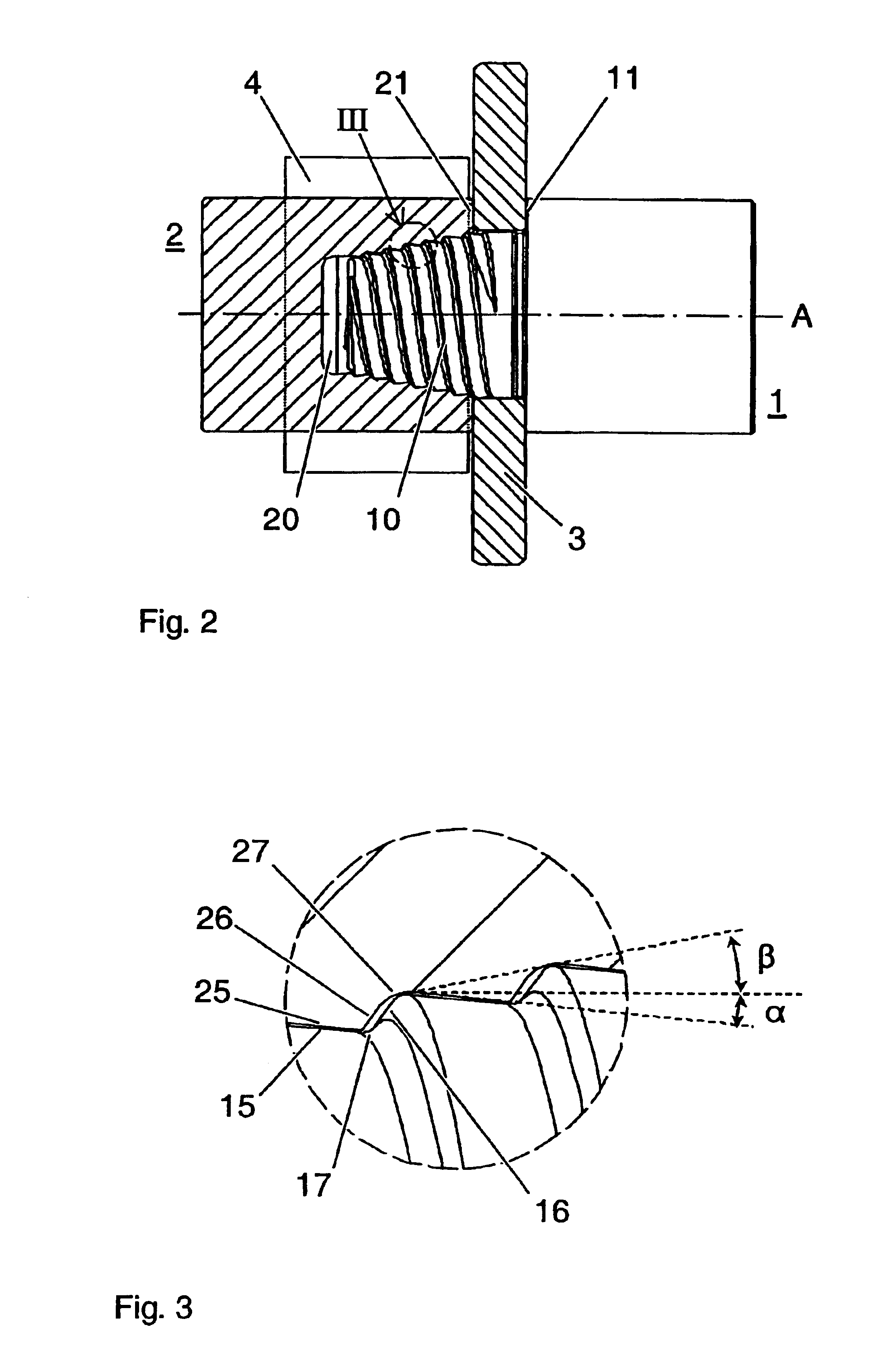

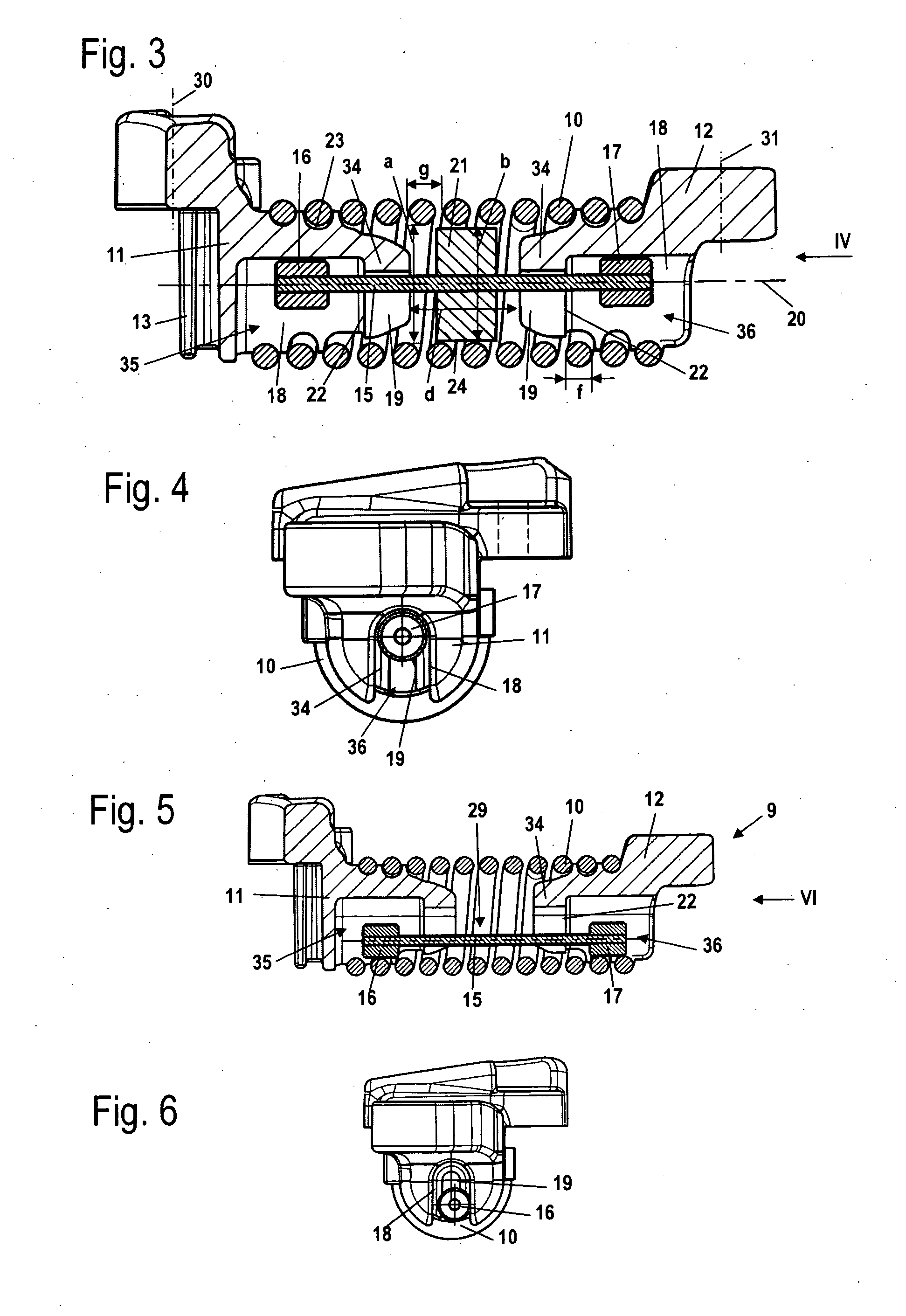

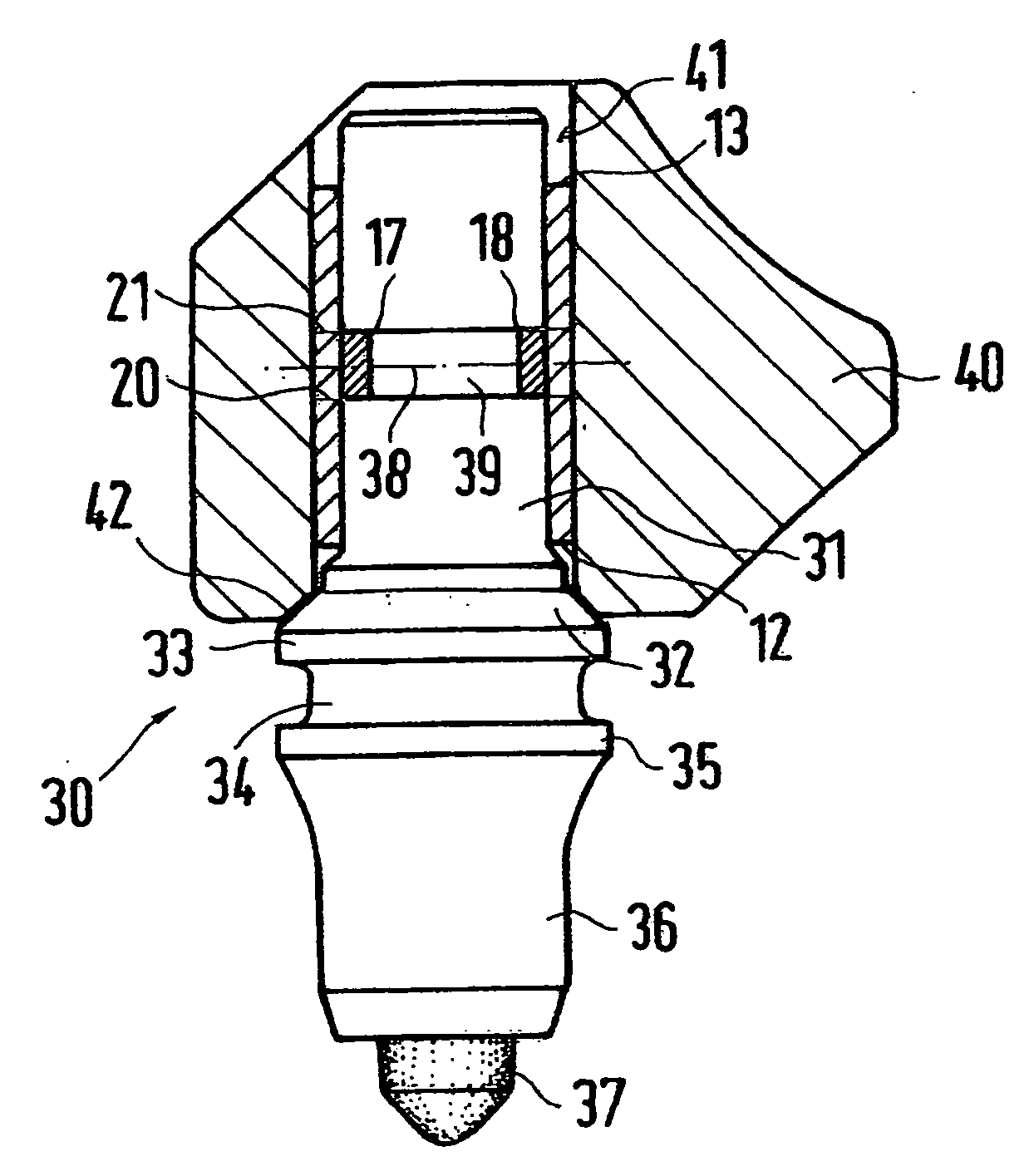

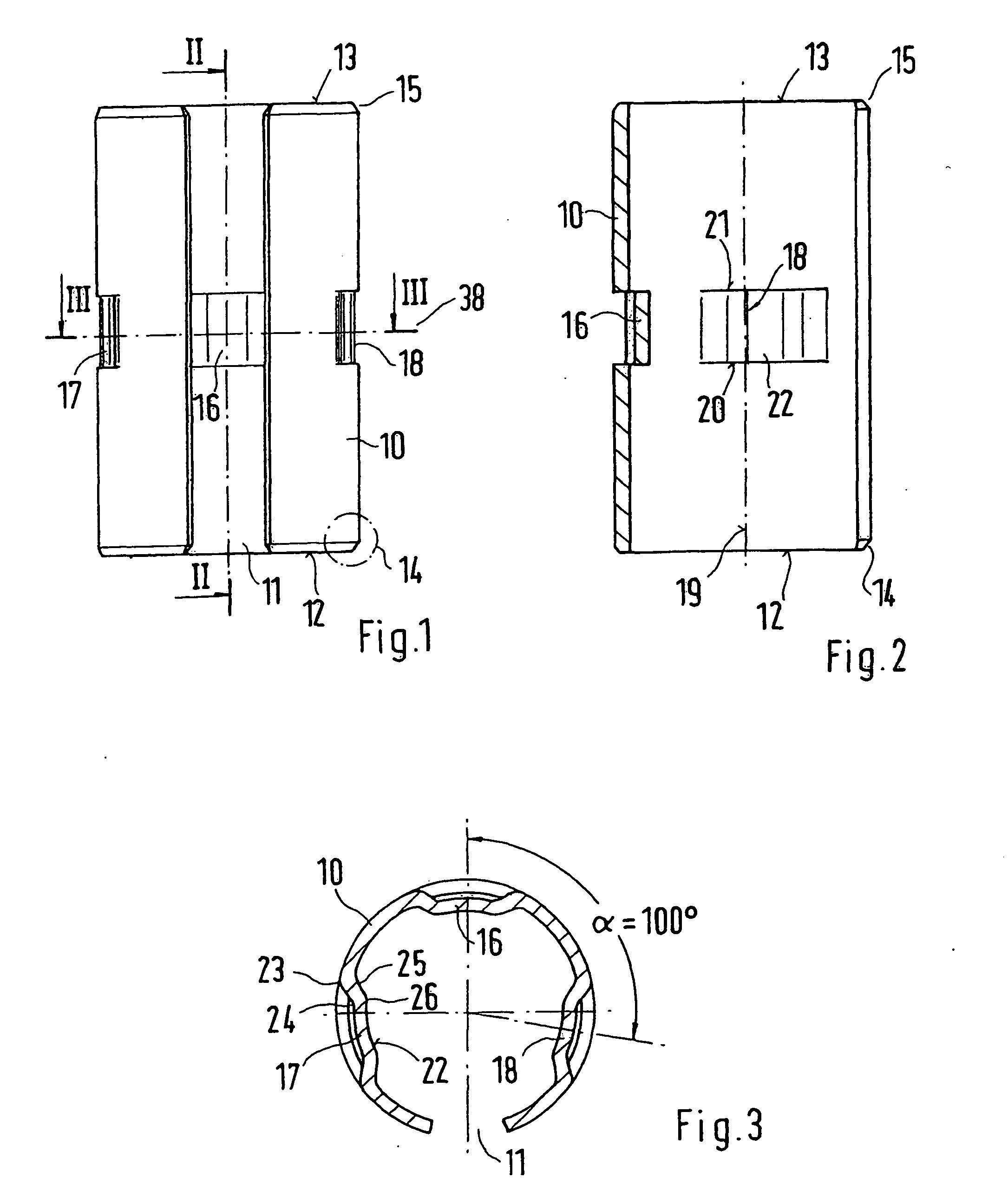

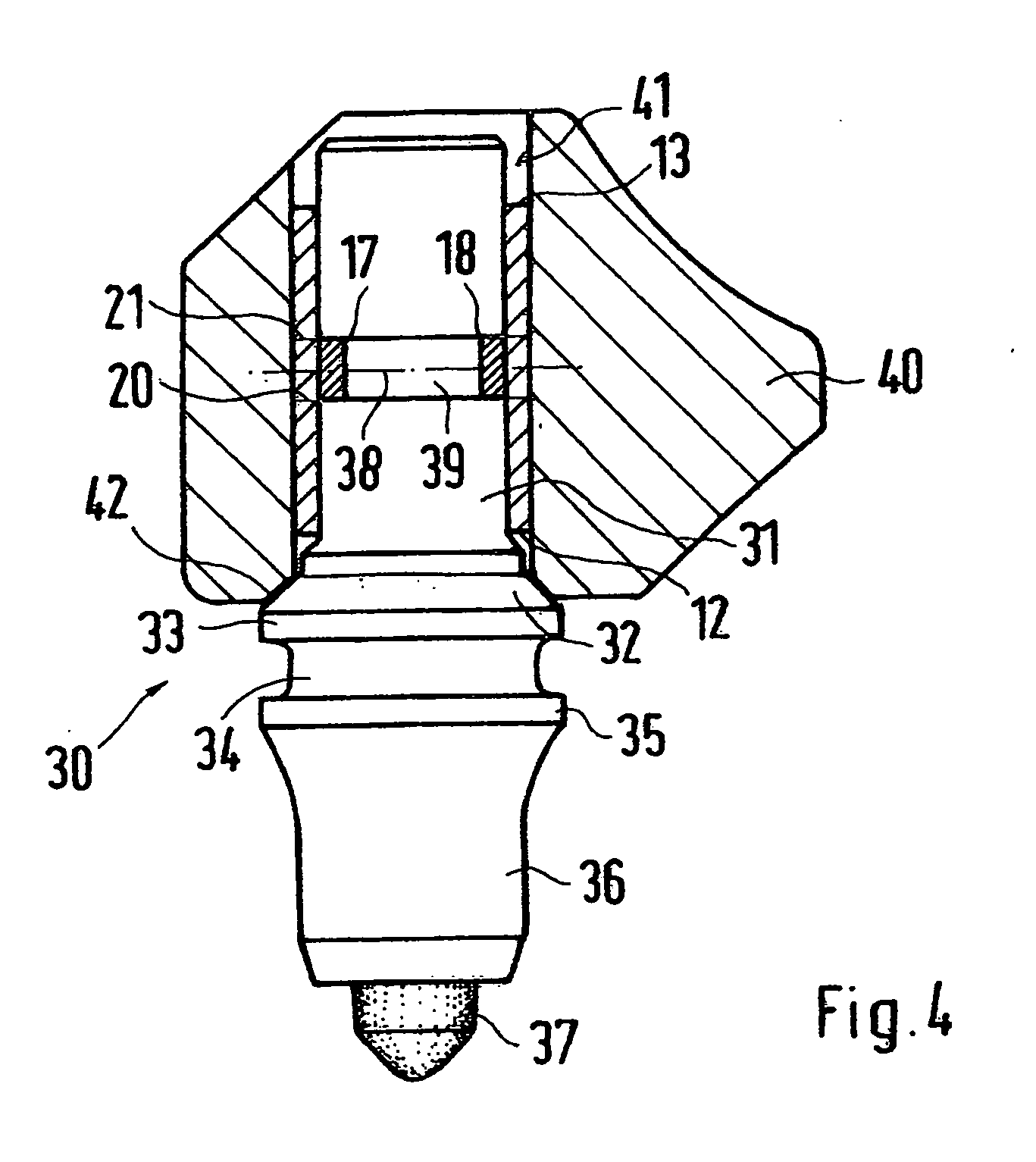

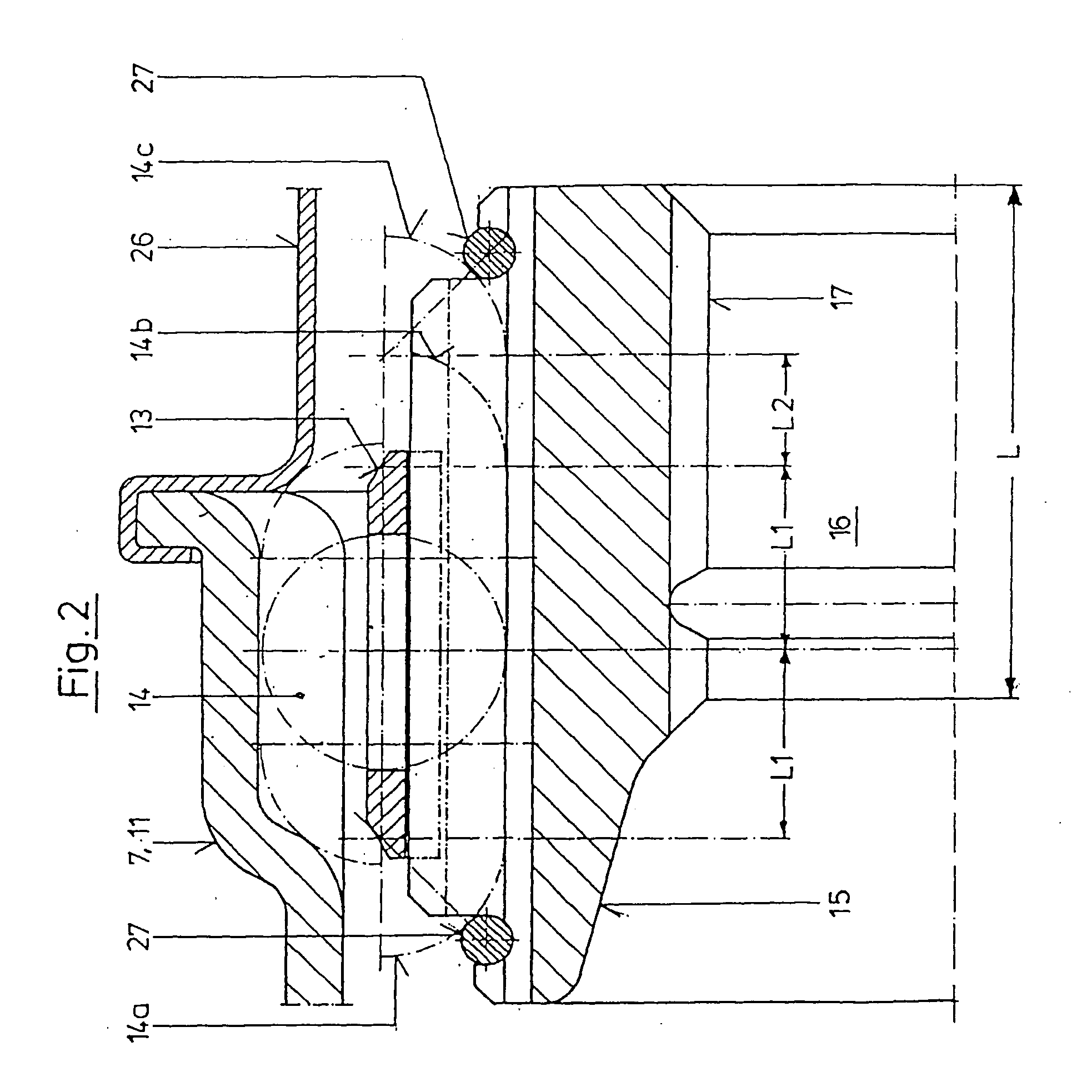

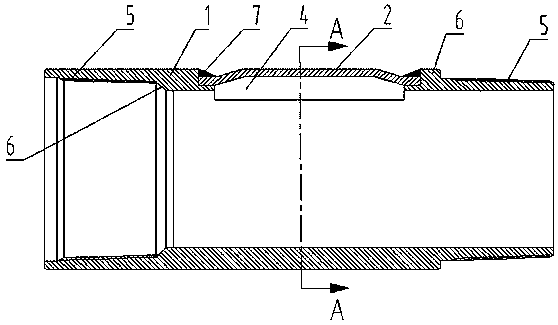

Circular-Shank Tool Comprising a Tool Holder

A circular-shank tool including a tool holder for improving the centering of the shank of the circular-shank tool in the locking sleeve by a configuration of the retaining elements and to improve an ability of the shank to rotate in the sleeve. To achieve this, the retaining elements are distributed between two stamped edges that lie transversely with respect to a longitudinal axis of the locking sleeve and are stamped inwards or indented, the stamped edges extend over part of the circumference of the locking sleeve and are interspaced at a distance that corresponds to the width of the peripheral groove in the shank of the circular-shank tool and the retaining elements form a coaxial concave centering section facing the convex groove base of the peripheral groove.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

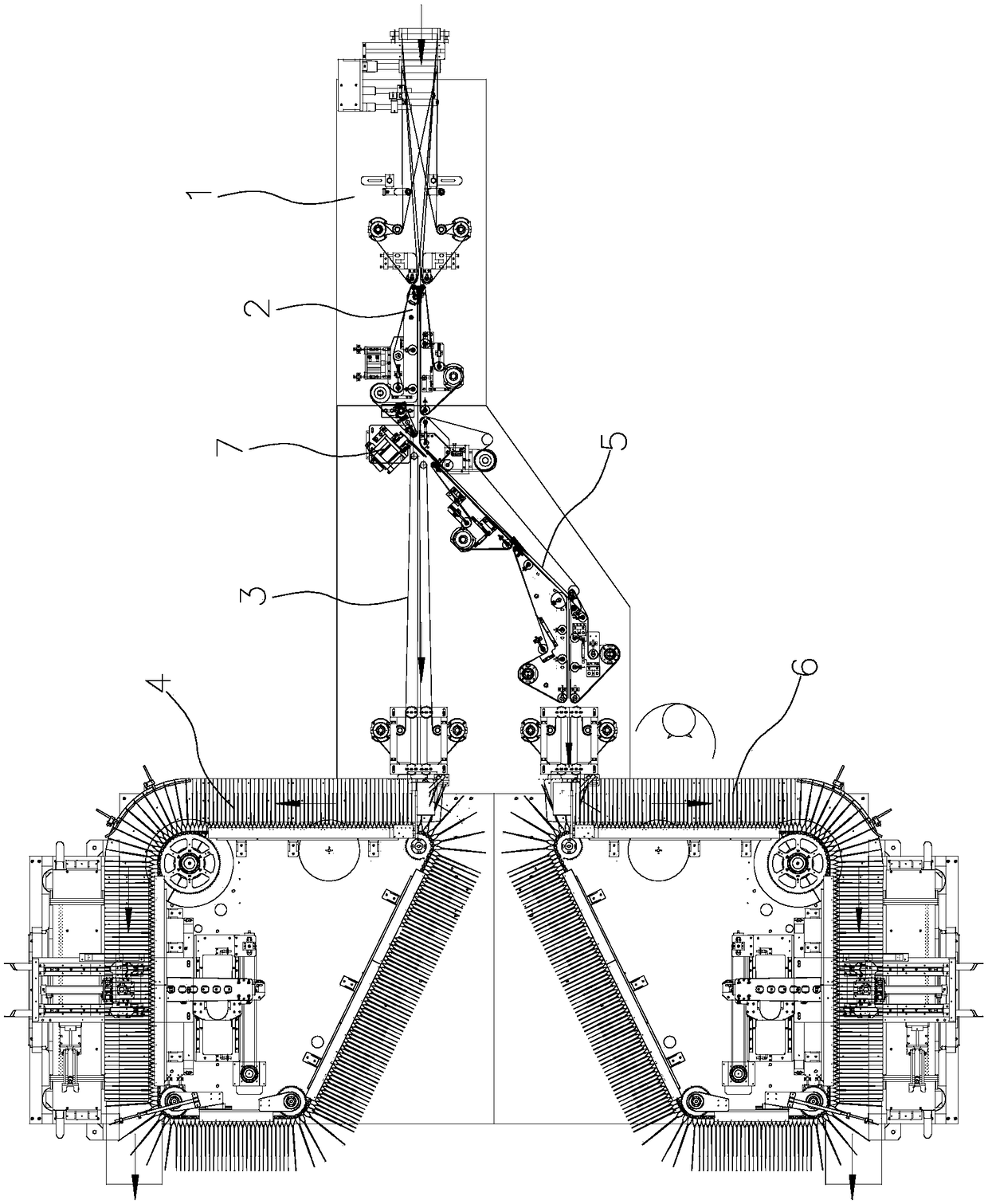

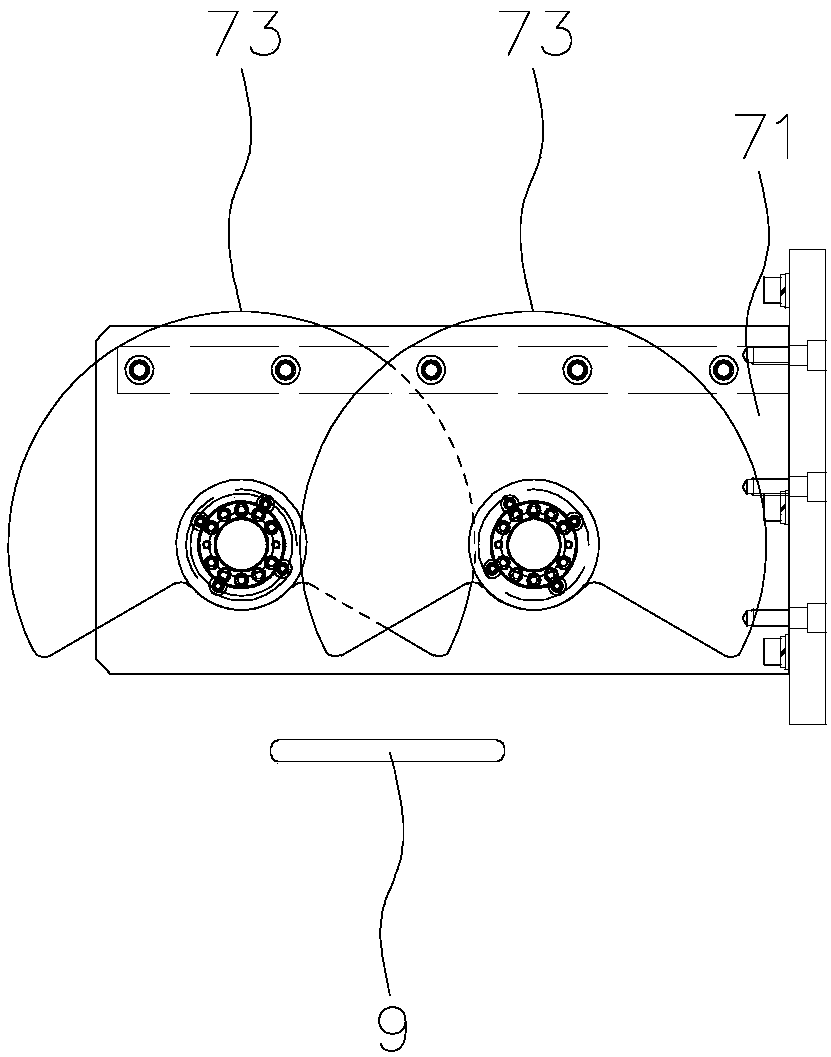

Double-way stacking machine

The invention relates to the field of disposable sanitary product equipment, in particular to a double-way stacking machine. The double-way stacking machine comprises a machine frame, an input mechanism, a first conveying mechanism, a first stacking apparatus, a second conveying mechanism and a second stacking apparatus, and the input mechanism, the first conveying mechanism, the first stacking apparatus, the second conveying mechanism and the second stacking apparatus are arranged on the machine frame according to the production line; a flow-distribution shifting piece mechanism is disposed on the machine frame and comprises a support disposed on the machine frame, a servo motor disposed on the support and two impellers which are rotationally disposed on the support; the two impellers arein transmission connection with the servo motor; when the impellers swing, the advancing path of product inputting of the input mechanism can be blocked or non-blocked. When the path is non-blocked,the input mechanism communicates with the first conveying mechanism so as to convey products; and when the path is blocked, the products of the input mechanism move downwards to enter the second conveying mechanism. The technical problems that in existing stacking procedures, the products are input only in one way, and the working efficiency is low are solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

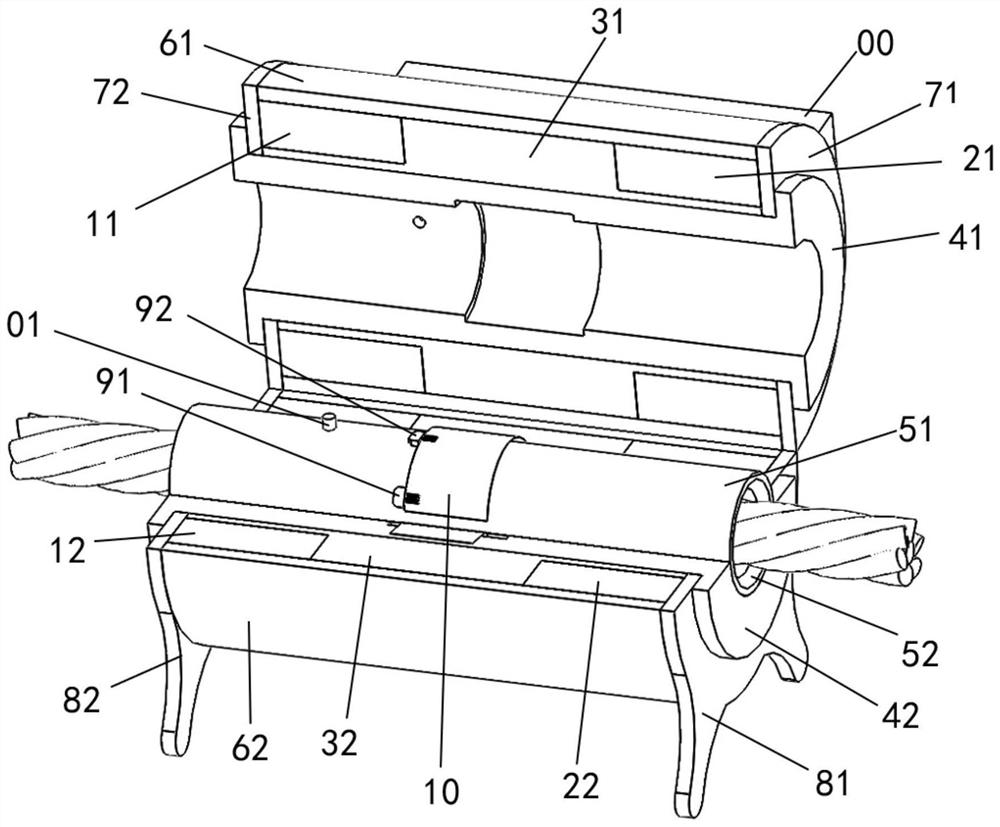

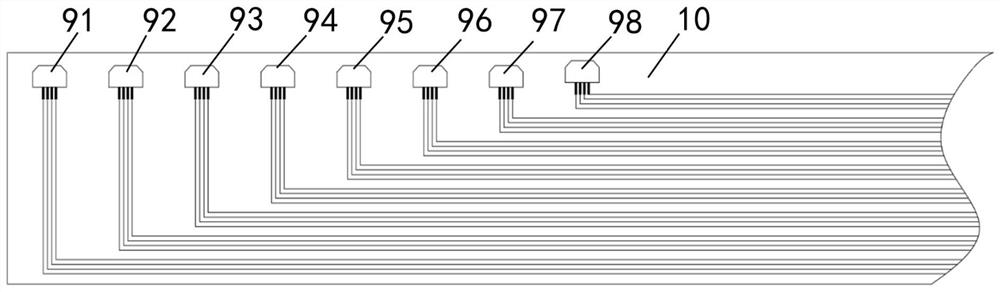

Lining replaceable type steel wire rope detector

ActiveCN112378991AImprove centeringOvercome the disadvantages of farNuclear energy generationMaterial magnetic variablesMagnetic signalWire rope

The invention relates to the technical field of steel wire rope detection, and discloses a detection method and an internal structure of a detector. The lining replaceable type steel wire rope detector is characterized in that a lining slightly larger than the diameter of a steel wire rope is arranged, so that the instrument achieves good centering performance; a plurality of matched inner liningsand outer linings are provided for detecting steel wire ropes with different rope diameters, so that the universality of the instrument is improved; a concave platform is arranged at the outer lining, and an installation space for a flexible flat cable board is reserved in cooperation with the inner lining, so that the defect that a steel wire rope in a roller type steel wire rope detector is faraway from a detection element can be overcome, and high detection precision is achieved; and the installation space for the of the flexible flat cable board is reserved in cooperation, so that installation is convenient, and all-phase arrangement of detection elements can be achieved. According to the invention, the radial vector of the magnetic flux leakage signal of the steel wire rope is detected, the value of the radial vector of the signal is zero when the steel wire rope is not damaged, and the radial vector of the magnetic flux leakage signal exists only when the damage exists, so thatthe problem that the axial vector collected in the past exceeds the measuring range of a detection element is solved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

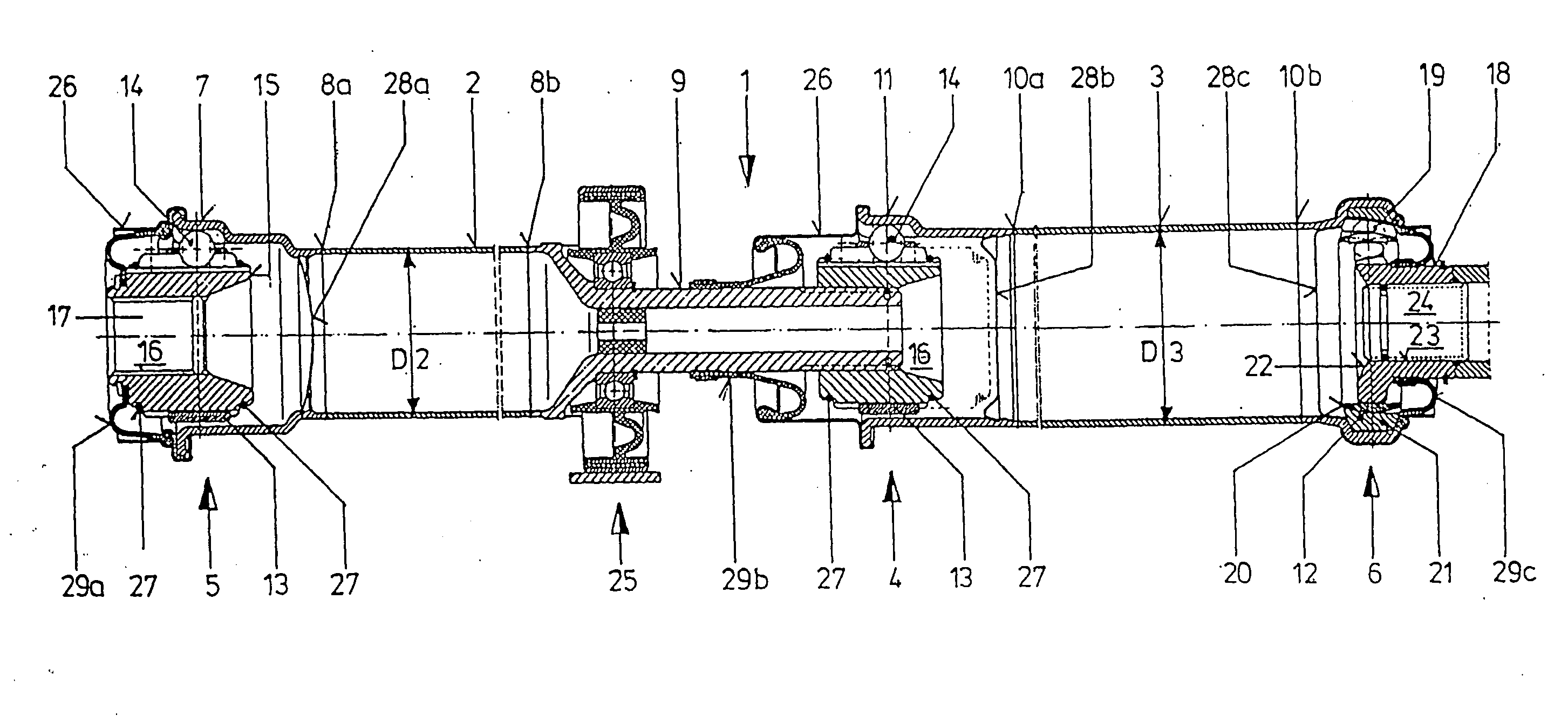

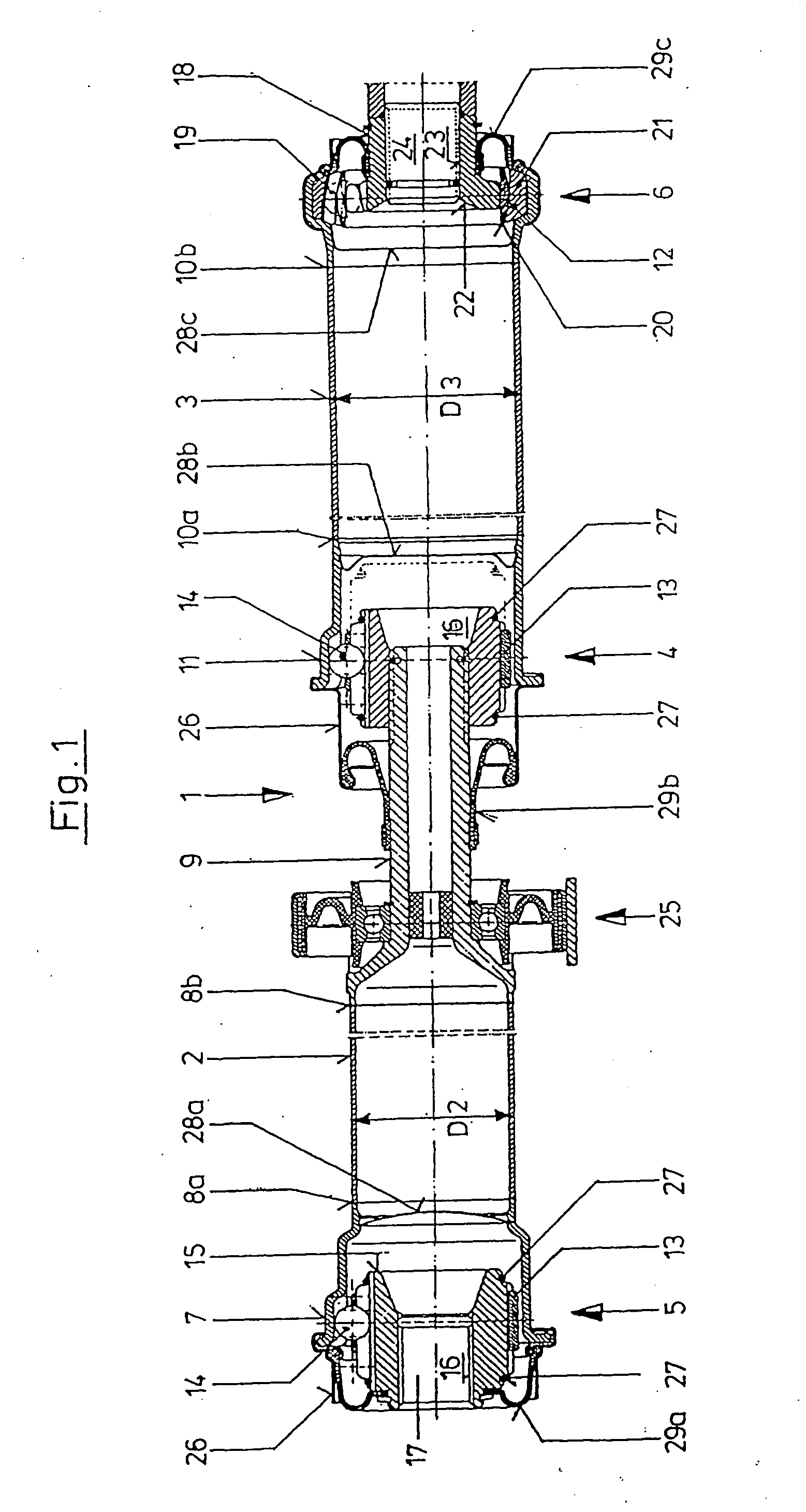

Longitudinal shaft

InactiveUS20090305795A1Centering of the two segments of the longitudinal shaft by wayImprove pronunciationYielding couplingRotary machine partsMobile vehicleEngineering

Owner:SHAFT FORM ENG GMBH

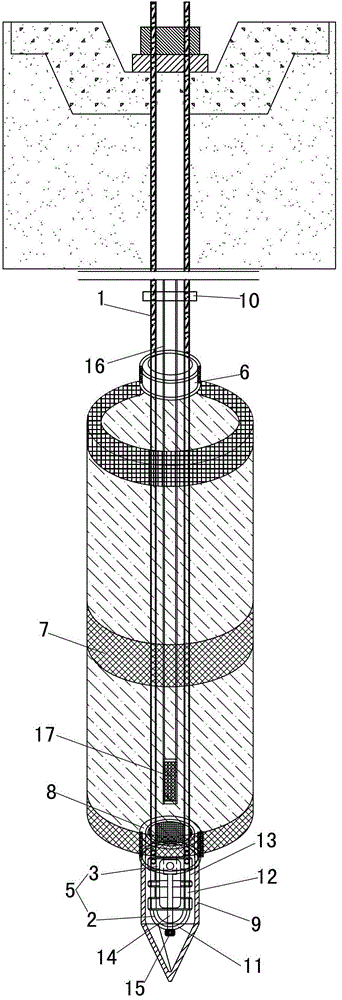

Self-adaptive casing centralizer and righting method

PendingCN110566138AEasy to operateConvenient rightingDrilling rodsSealing/packingWell cementingSelf adaptive

The invention discloses a self-adaptive casing centralizer and a righting method. The self-adaptive casing centralizer comprises a body. A plurality of self-adaptive expansion assemblies capable of being automatically expanded by pressure to automatically adapt to the diameter of a well to right and fix a casing are arranged on the body. Each self-adaptive expansion assembly comprises a bellows arranged in a stepped through-hole slot. The cross section of each bellows is in a wavy shape. The self-adaptive casing centralizer is simple in whole structure and convenient to operate and can adapt to different well diameters, the casing is effectively righted and fixed, and the well cementing quality is improved; the overall outer diameter of the body of the self-adaptive casing centralizer is smaller than the well diameter of a wellbore when the body of the self-adaptive casing centralizer is in an initial state, the centralizer can smoothly enter the well, the risk of encountering resistance is reduced, the well wall is not damaged, the bellows can uniformly expand, the supporting force is improved, the casing is effectively righted, and the centering degree of a casing column is increased; and after centering of the casing is completed, the wellbore annular clearance is uniform, the well cementing quality can be effectively improved, and the whole construction is easy and convenient.

Owner:潍坊市宇宏石油机械有限公司

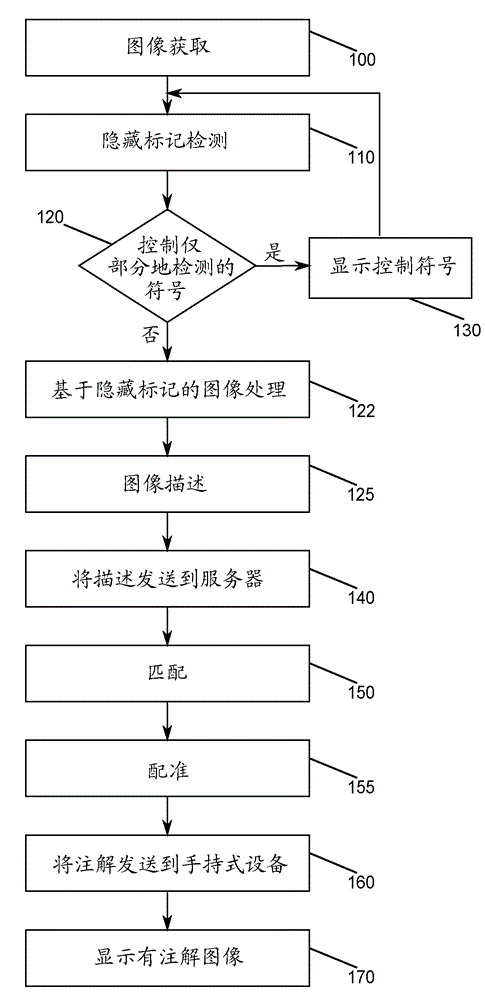

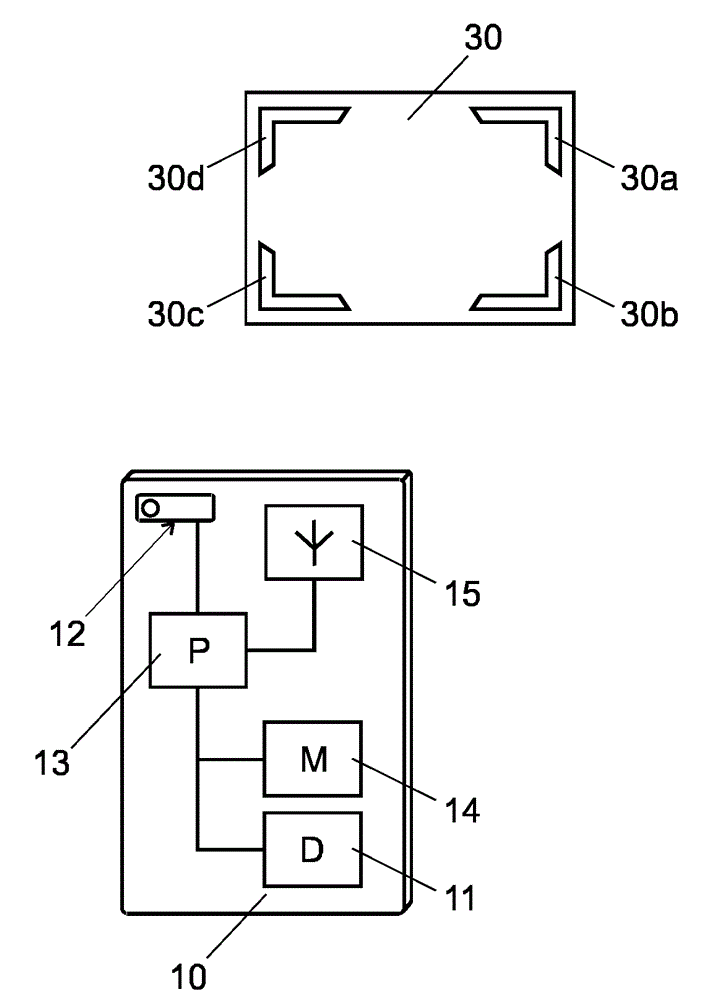

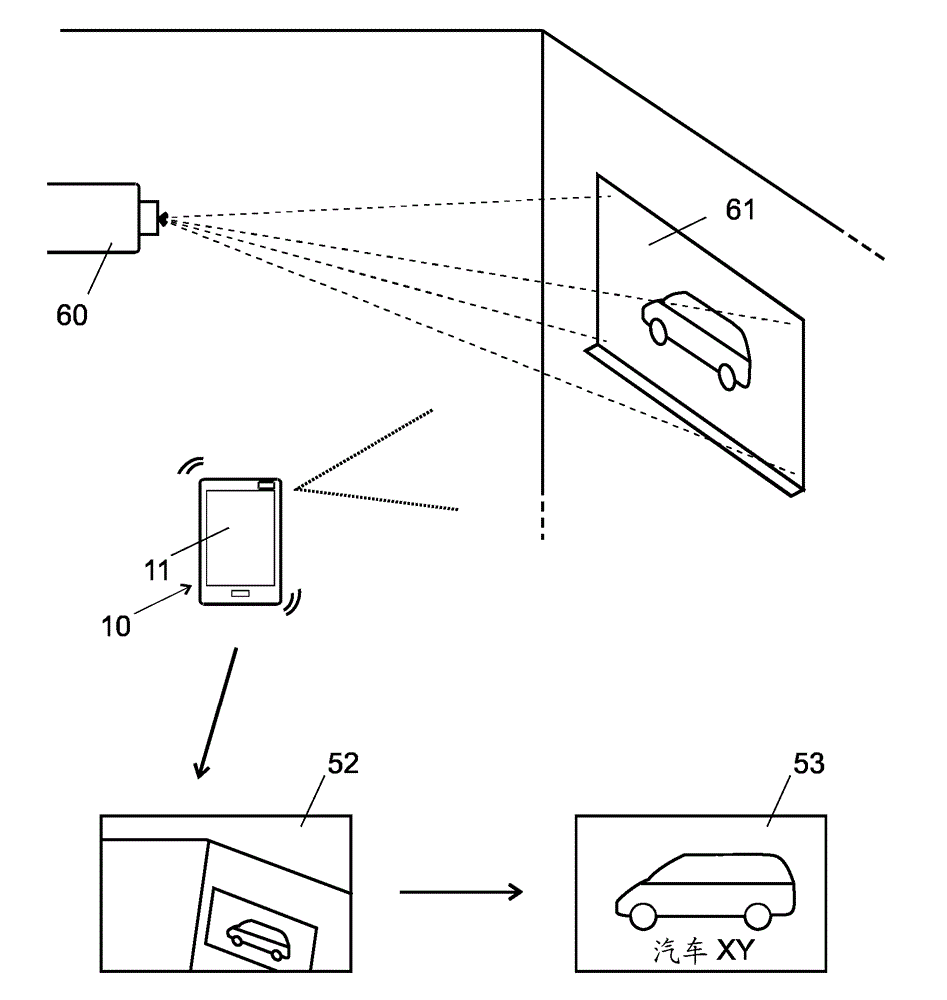

Method and system for image capture and facilitated annotation

InactiveCN104871179AImprove matchImprove capture qualityCharacter and pattern recognitionImage data processing detailsUser deviceReference image

A method for capturing and processing an image, comprising: capturing a captured image with an image sensor; retrieving steganographic marks hidden in said captured image; processing said captured image based on said hidden marks, so as to generate a processed image; matching the processed image with a reference image from a set of reference images and superimposing elements on the captured image, depending on said reference image. A user device, comprising an image sensor suitable for capturing at least one image and a processor configured to at retrieve hidden marks in said captured image and generating a processed image based on said hidden marks retrieval and annotations processed remotely; the user device is part of a system with a remote server matching the image.

Owner:VIDINOTI

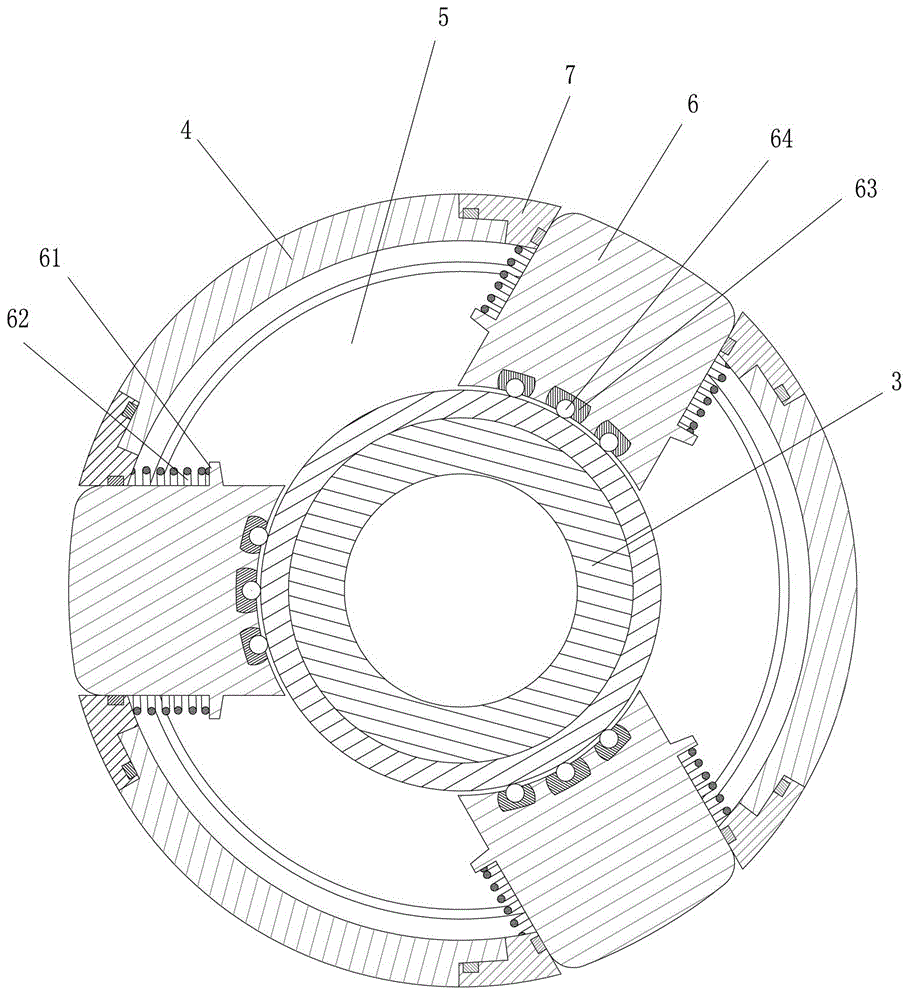

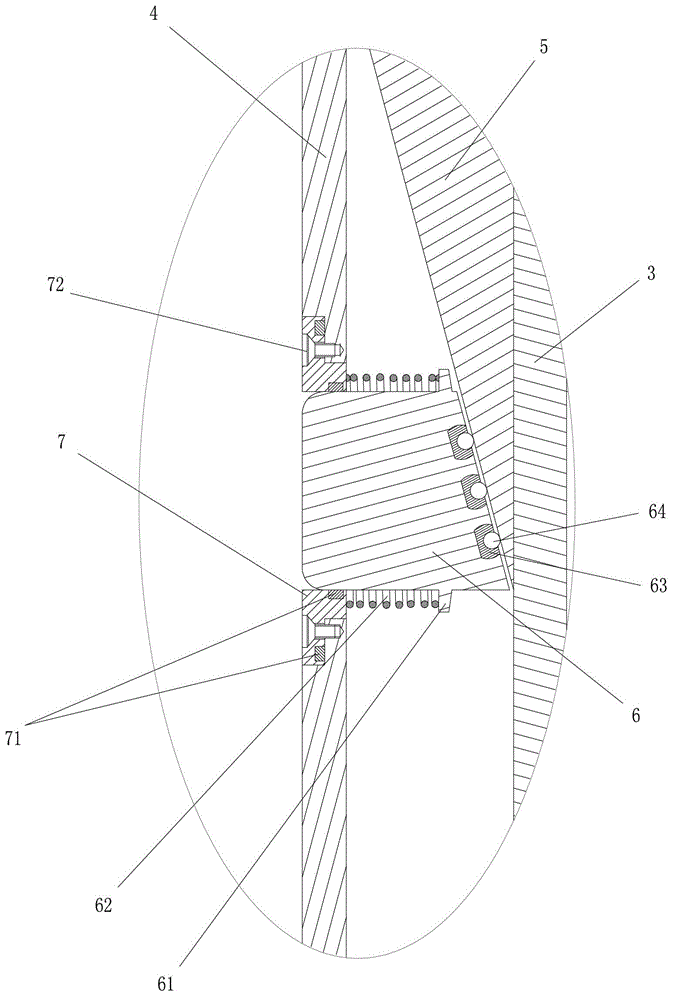

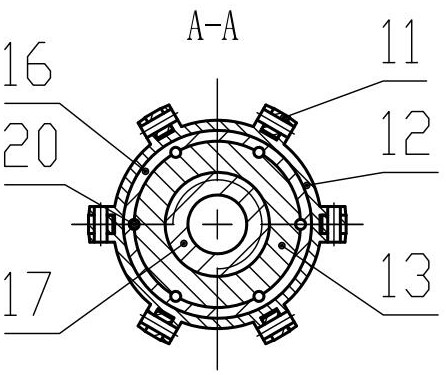

Universal roller type variable diameter centralizer

ActiveCN106907116BConvenient hydraulic driveSimple mechanical structureDrilling rodsDrilling casingsFriction effectUpper joint

The invention relates to a universal roller reducing centralizer. The centralizer comprises a body, an upper joint, a reducing mechanism and a universal roller mechanism. The reducing mechanism is located inside the body and the upper joint, a piston and a piston rod of the reducing mechanism are located inside the upper joint, a guide block is pushed by the piston under the effect of a reset spring and a drilling fluid, the universal roller mechanism is placed in grooves evenly distributed in the peripheral direction, outside the body, a core pin can move back and forth under the effect of hydraulic pressure and spring force, a universal roller is mounted on a plunger through an axle, cone steps are formed in the outer surface of the core pin and can drive the plunger to move outwards, and therefore the working outer diameter of the centralizer is changed, when the hydraulic pressure is reduced to the minimum, the outer diameter of the centralizer is the minimum, and it is convenient for a drill string to trip in and trip out. The situations can be achieved that the outer diameter of the centralizer is tightly close to well wall in real time and has the anti-friction effect, and the centering degree of the drill string, the well wall quality and the drilling efficiency are improved.

Owner:DAQING TIANDEZHONG PETROLEUM SCI & TECH CO LTD

Automatic pouring jacket paper tray center positioning clamping device and paper carton clamping forming method

The invention relates to an automatic pouring jacket paper tray center positioning clamping device which comprises a speed-fold chain mechanism for conveying paper cartons and a support base. A lifting mechanism is arranged on the support base. A clamping positioning shaping mechanism and a front blocking mechanism matched with the speed-mold chain mechanism are arranged on the lifting mechanism.The lifting mechanism, the clamping positioning shaping mechanism and the front blocking mechanism are each provided with an air cylinder. The front blocking mechanism comprises a second forward pressing piece and a photoelectric sensor. An air cylinder on the lifting mechanism controls the lifting mechanism to ascend to the corresponding position of the speed-fold chain mechanism. When paper cartons are moved to the front blocking mechanism on the speed-fold chain mechanism, the second forward pressing piece blocks the paper cartons from continuing moving forwards, the photoelectric sensor senses that the paper cartons are reached, and the clamping positioning shaping mechanism clamps and shapes the paper cartons. Due to the design of the centered clamping shaping mechanism with the combination of the air cylinder and a gear rack, the centering performance is good, and the clamping speed is high.

Owner:NINGBO AUX ELECTRIC +1

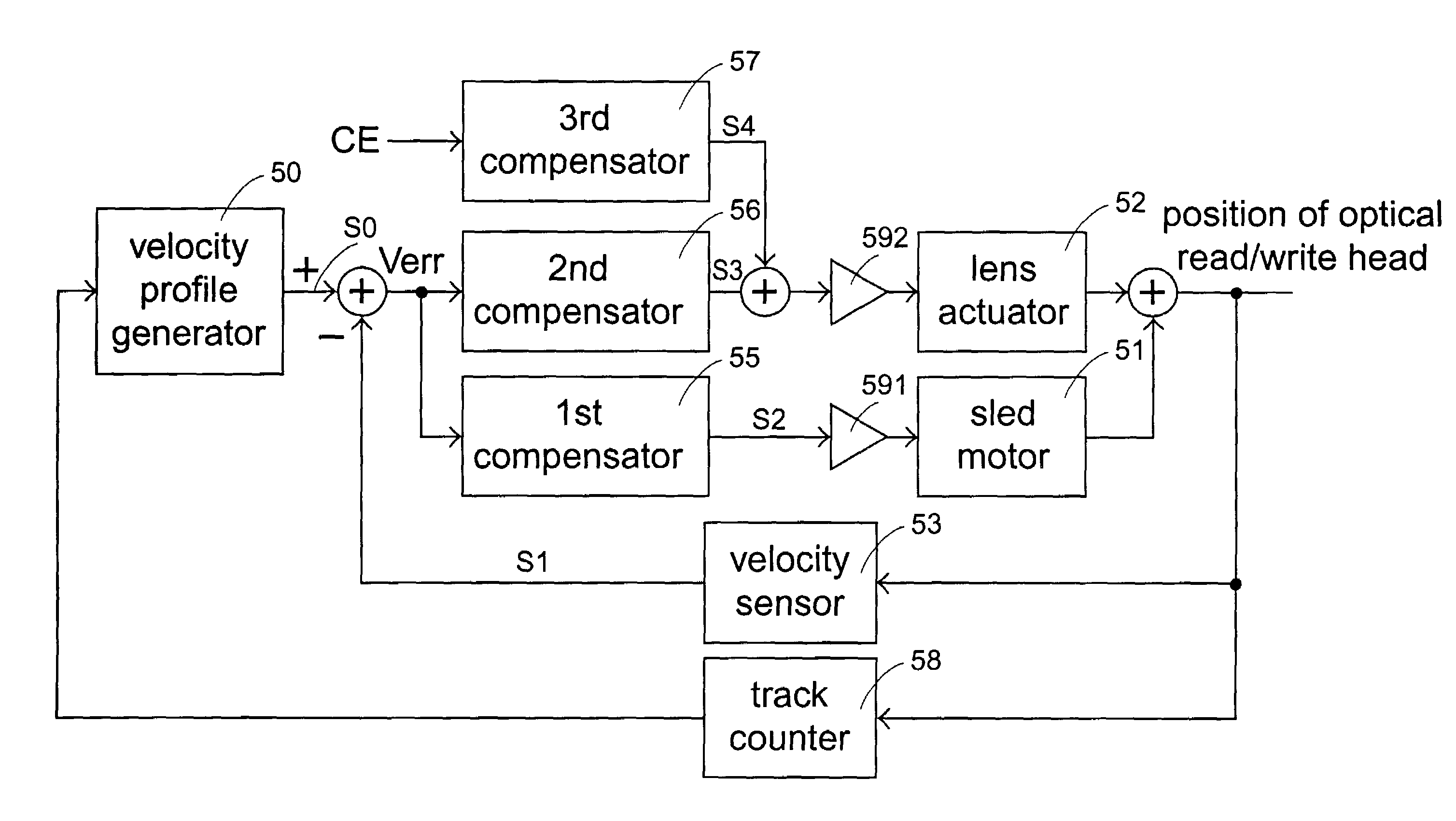

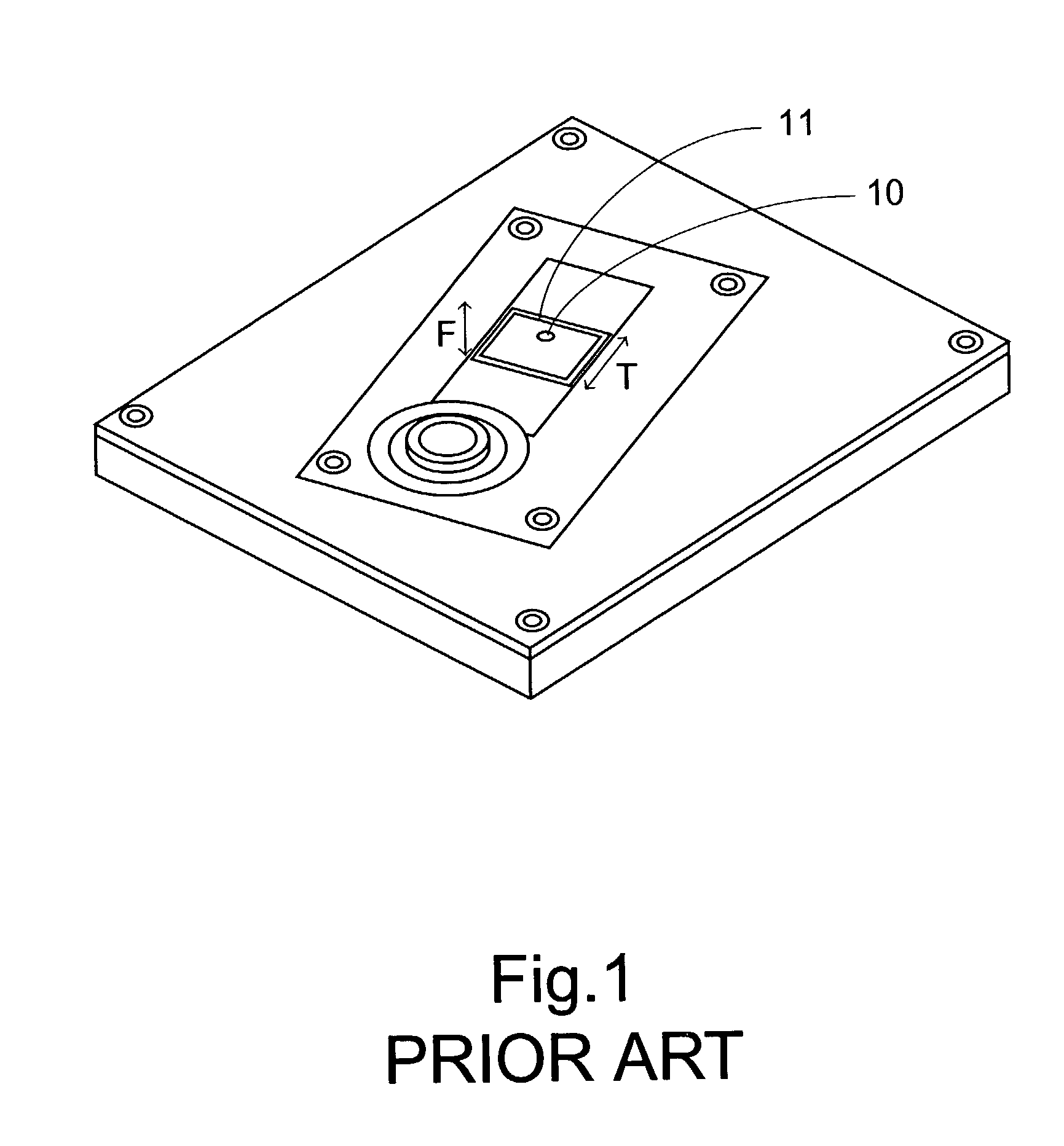

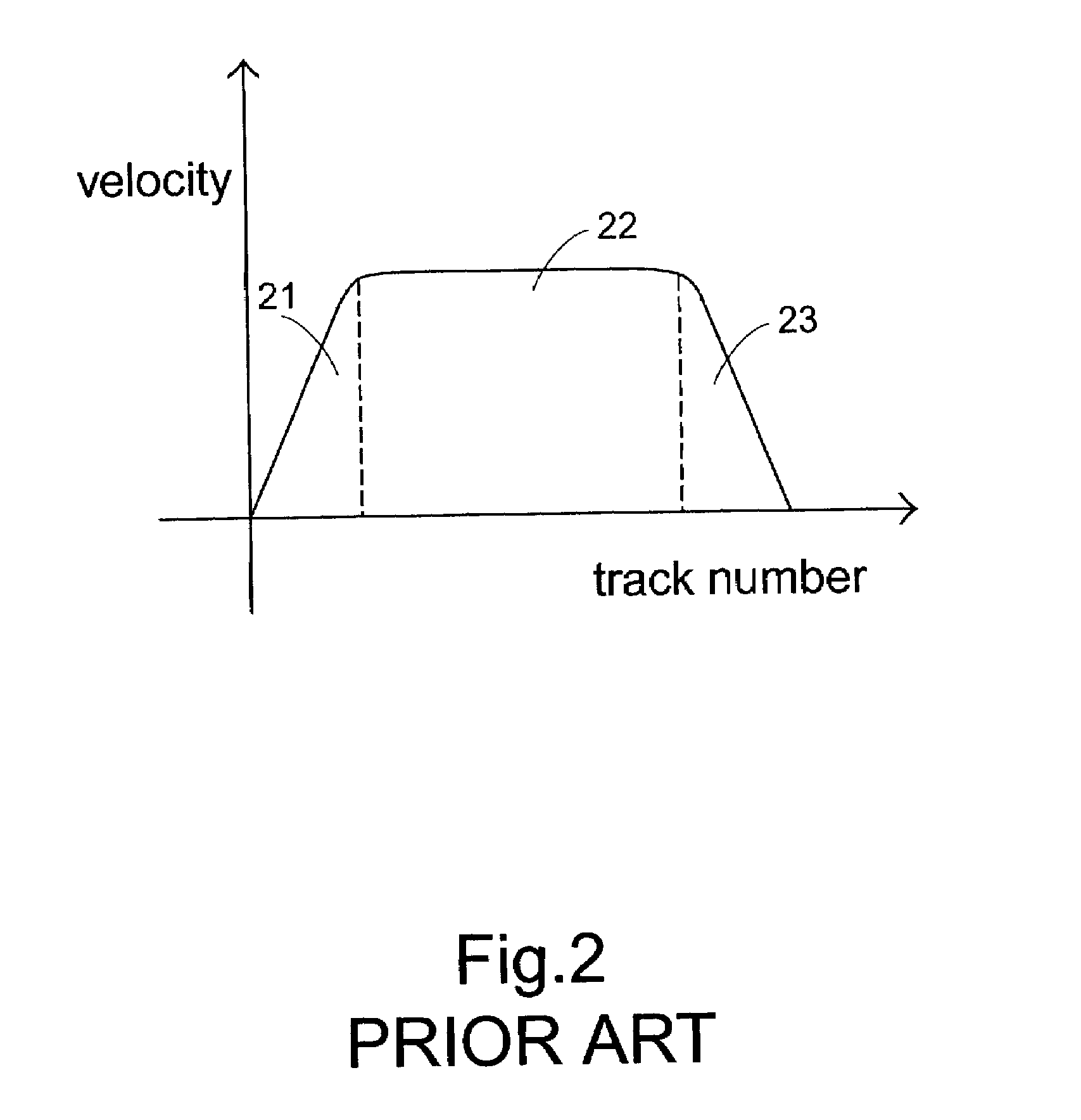

Method and apparatus for long seeking control of pickup head

InactiveUS7106670B2Improve convenienceOptimizationRecord information storageCarrier monitoringClassical mechanicsActuator

A method for long seeking control of an optical read / write head is disclosed. The optical read / write head includes a sled moved by a sled motor, and a lens mounted on the sled and moved by a lens actuator, and said method includes steps of determining a velocity profile according to a desired travel distance of the optical read / write head; detecting an instant velocity and an instantaneous position of the optical read / write head at a certain time spot; comparing the instant velocity with a target velocity corresponding to the instantaneous position according to the velocity profile; modifying velocities of the sled and the lens according to the comparing result; and dynamically adjusting a position of the lens in the sled. An apparatus for long seeking control of an optical read / write head is also disclosed.

Owner:TIAN HLDG

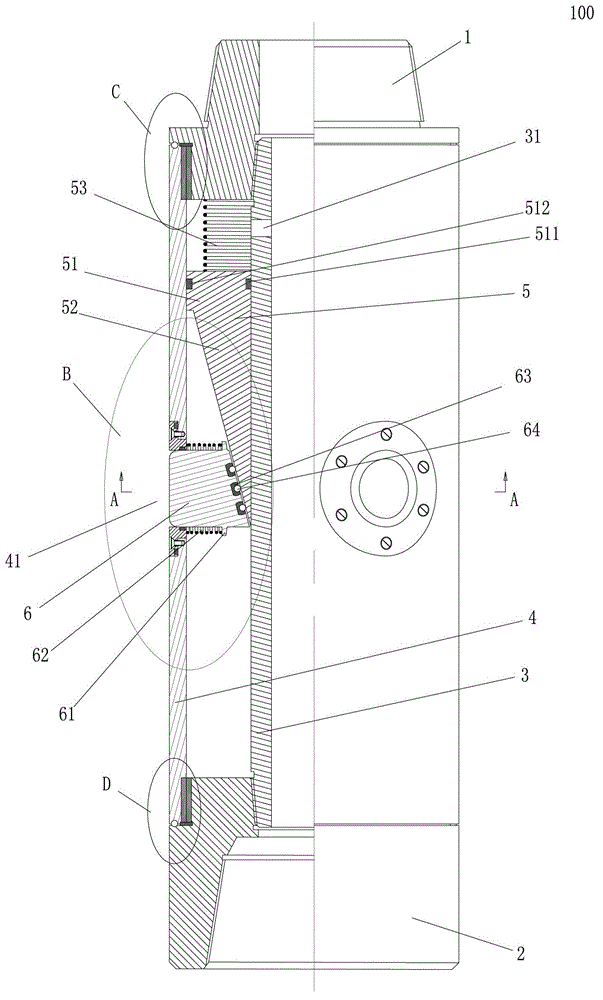

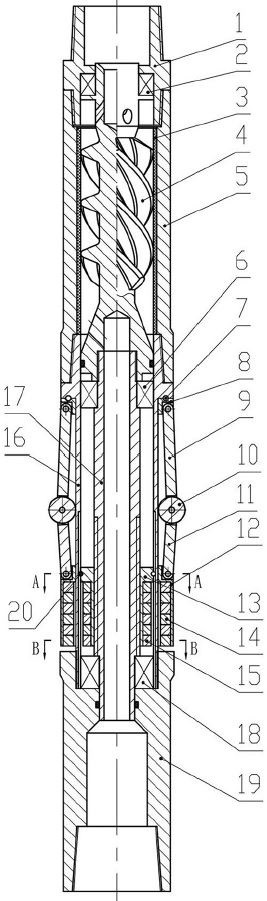

A centralizer with self-adaptive variable diameter

ActiveCN112593869BEasy to sendAvoid risk of leakageDrilling rodsDrilling casingsUpper jointEngineering

The invention relates to a centralizer with self-adaptive variable diameter used in the field of oil and gas well engineering. It solves the problems of poor centering of the drill string and high frictional resistance of the drill string. The technical solution is: the upper end of the stator shell is connected with the lower end of the upper joint with screws, and the lower end of the stator shell is connected with the upper end of the connecting cylinder with a thread; the rubber stator is fixed in the inner cavity of the stator shell; the screw rotor is placed in the inner cavity of the rubber stator, and the bearing a is installed in the screw. The upper end of the outer circle of the rotor; the transmission screw is placed in the inner cavity of the connecting cylinder, and the transmission screw rotates flexibly in the inner cavity of the connecting cylinder; the upper end of the lower joint is connected with the lower end of the connecting cylinder with screws; the lower end of the roller and the support arm a is hinged, and the roller and the support arm b The lower end is hinged. The present invention can realize the function of effectively changing the diameter in the downhole, the roller and the well wall are fully attached, and the drill string is well centered; the roller and the well wall are purely rolling, the axial friction between the drill string and the well wall is small, and the drill string is fed convenient.

Owner:SOUTHWEST PETROLEUM UNIV

A chip resistor detection and sorting machine

ActiveCN106862101BQuality assuranceGuaranteed accuracyElectrical testingSortingElectrical resistance and conductanceDistribution control

The invention relates to a chip resistance detection and sorting machine, which includes a frame and a power distribution control box. The frame is provided with a feeding conveying device, an upper detection seat and a lower detection seat in sequence from right to left, and the feeding and conveying device Cooperate with the upper detection seat through the upper detection and reclaiming device, and cooperate with the upper detection seat and the lower detection seat through the lower detection and reclaiming device. The upper detection device that cooperates with the product and uses the CCD detection head as the detection part is arranged above the upper detection seat. The lower detection seat is provided with a lower detection device that cooperates with the lower part of the product. The lower detection device includes a detection discharge seat arranged on the lower detection seat. The lower part of the detection discharge seat is provided with an LCR detection probe that passes through it. The first unqualified product collection box is set on the top, and the invention realizes the automatic and integrated detection of both sides of the chip resistor, which ensures the accuracy of the detection, ensures the quality of the subsequent finished products, and improves the efficiency of detection at the same time.

Owner:SHENZHEN MESTEK ELECTRONICS CO LTD

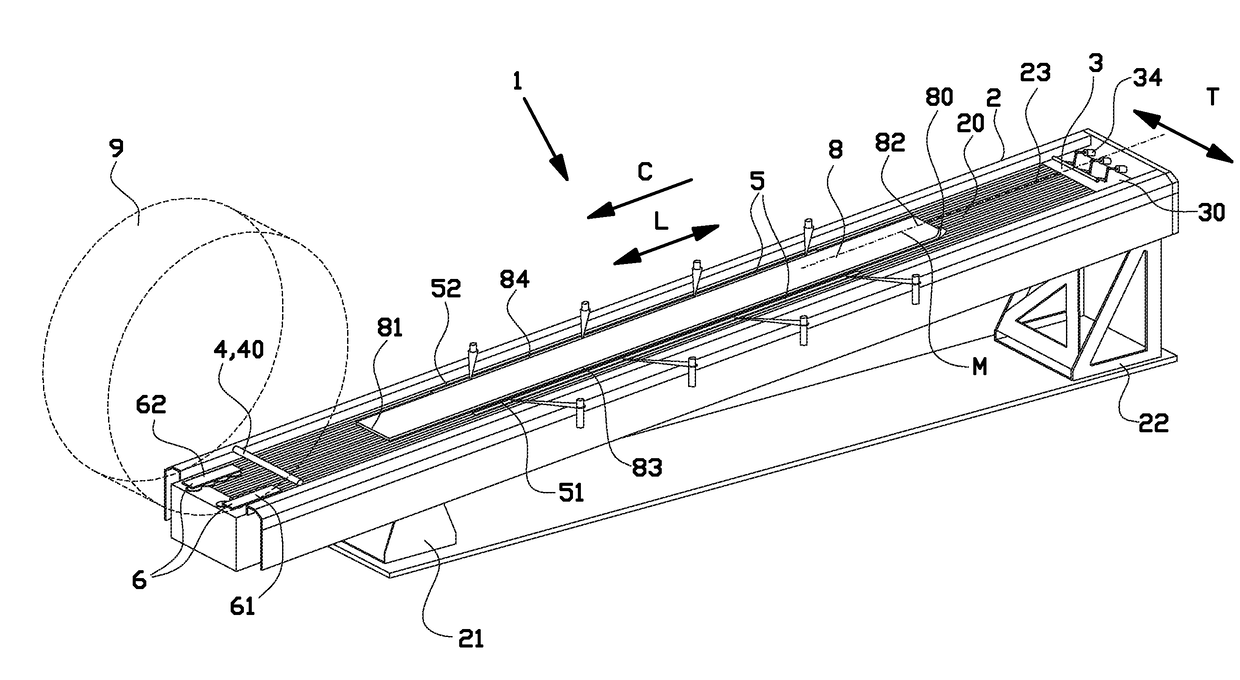

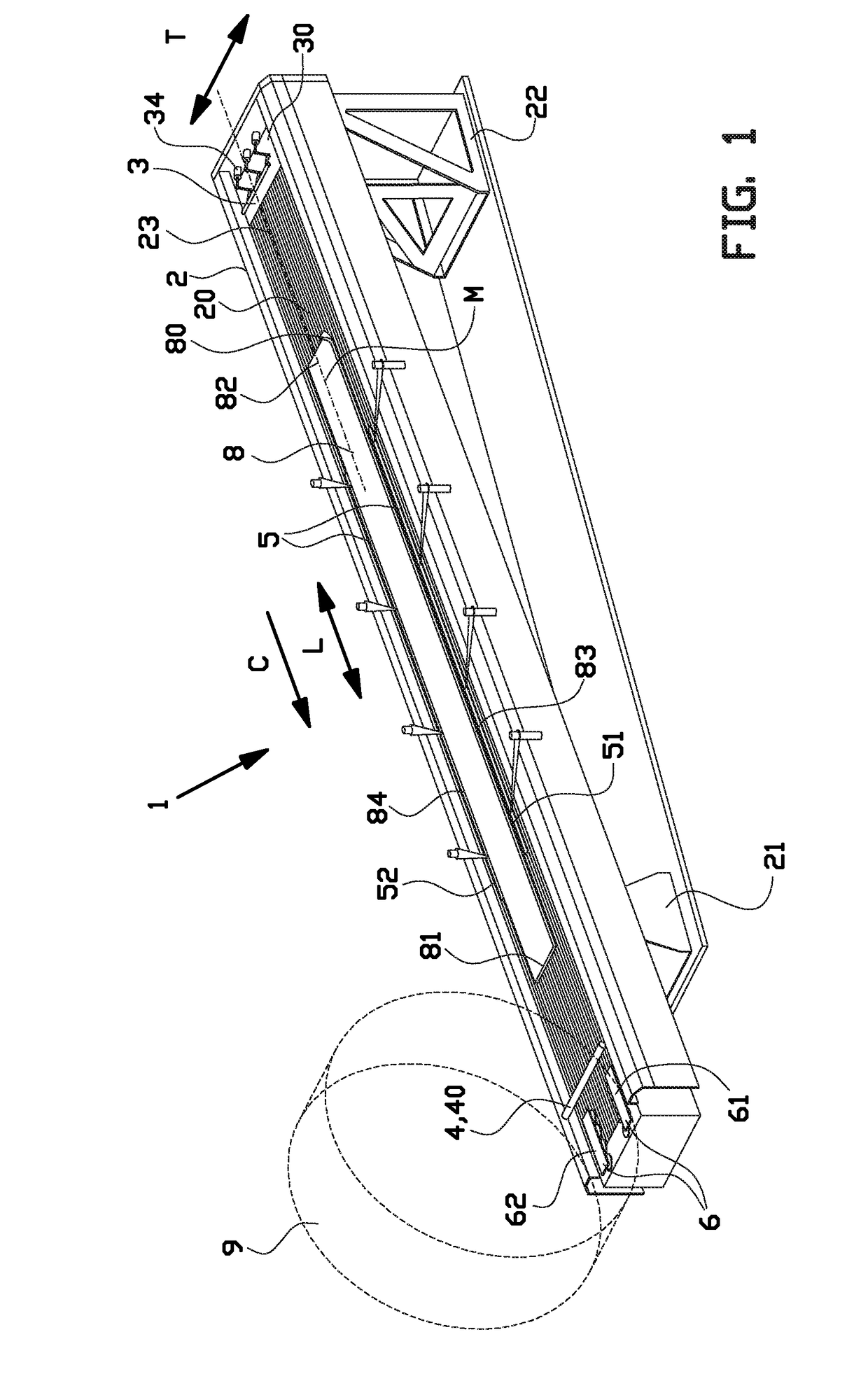

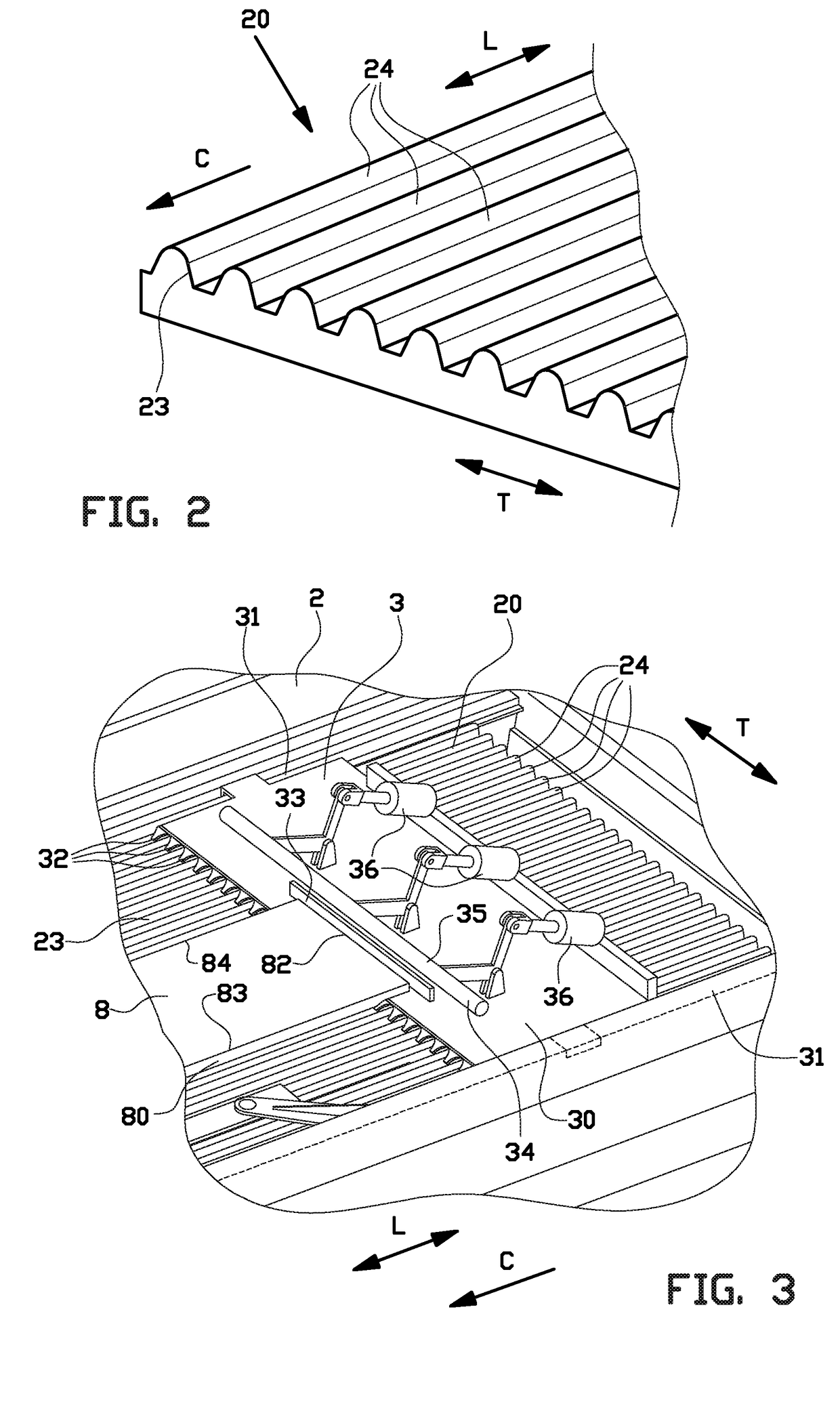

Conveyor and method for conveying a tire component

Provided is a conveyor for conveying a tire component, in particular a tread for retreading, wherein the conveyor includes a support surface that extends in a direction of conveyance to support the tire component during conveyance in the direction of conveyance, wherein the support surface is provided with a surface structure that is arranged to contact seventy-five percent or less than seventy-five percent of the downwardly facing surface area of the tire component, wherein the support surface is arranged to be held stationary during conveyance of the tire component and wherein the conveyor is provided with one or more manipulators to manipulate the position of the tire component on the stationary support surface by sliding the tire component over the stationary support surface.

Owner:VMI HOLLAND BV

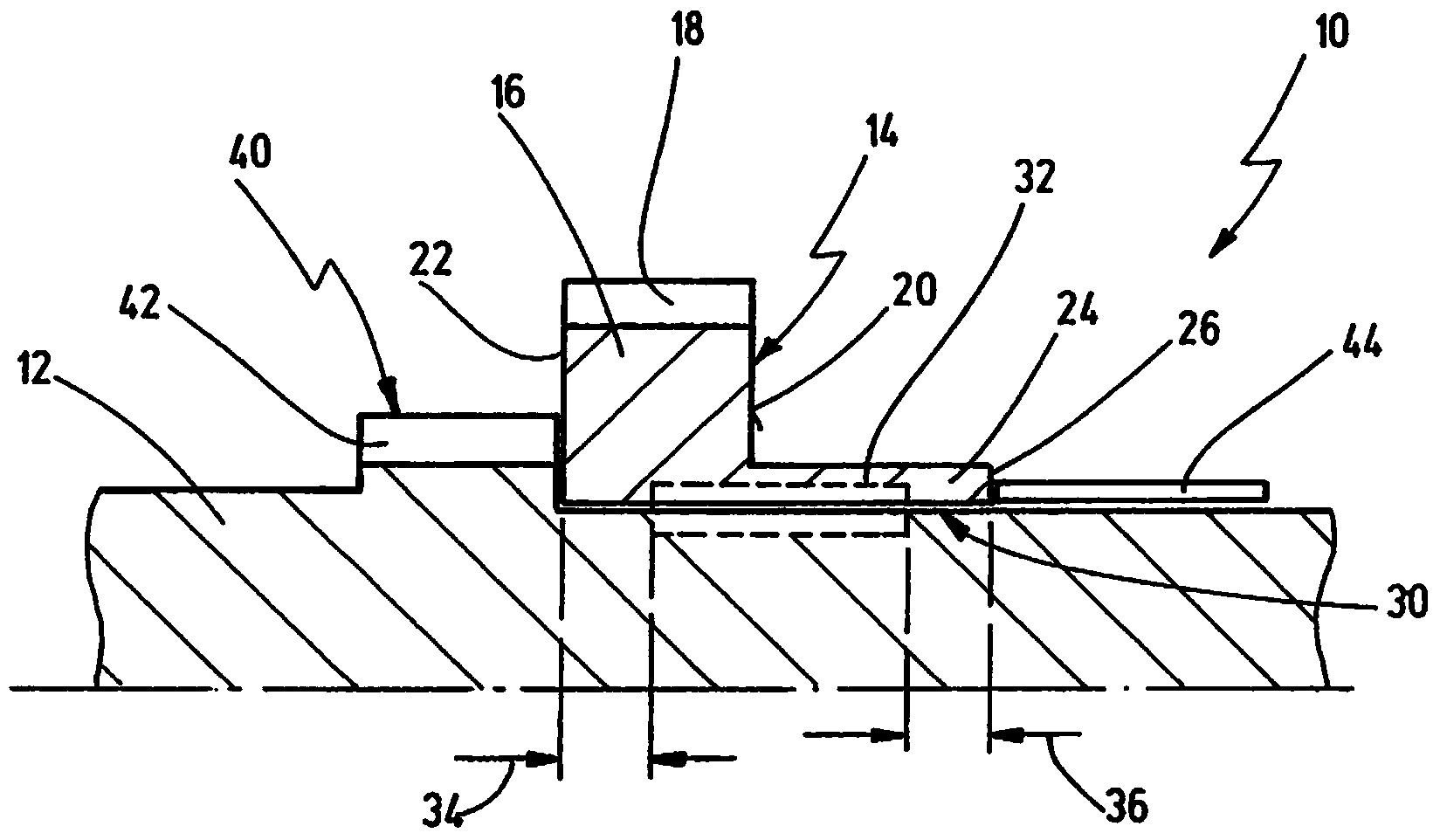

Shaft device for a transmission

ActiveCN104235322AReduce the impactExtended service lifeShaftsCouplings for rigid shaftsEngineeringMechanical engineering

A shaft devcice (10) for a transmission (64) is disclosed, and is provided with a shaft (12) and a fixed gear unit (14). The fixed gear unit (14) is fixed on the shaft (12) through a shaft / hub joint part (30) and is provided with a fixed gear (16) and a hollow shaft portion (24), wherein the fixed gear (16) has a first axial side (20), a second axial side (22) and a tooth system (18), and the hollow shaft portion (24) surrounds the shaft (12) and extends from said first axial side (20) of the fixed gear (16). In the device, the shaft / hub joint part (30) comprises a main connecting portion (32), and the main connecting portion (32) is separated from the second axial side (22) of the fixed gear (16) in an axial direction.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Manufacturing method for composite cast segment for dry-type waste heat recovery for blast furnace slag

InactiveCN109079123AHigh thermal conductivityRapid heat exchange and heat storageIncreasing energy efficiencyRecycling and recovery technologiesContinuous useCopper

The invention discloses a manufacturing method for a composite cast segment for dry-type waste heat recovery for blast furnace slag. The manufacturing method comprises the following steps: a copper ball is adopted as an inner core of the composite cast segment, and the inner core copper ball and an outer shell material are enabled to form the composite cast segment in a manner of steel die casting, ferrite steel is adopted as the outer shell steel material of the composite cast segment, and the volume ratio of the copper ball to the outer shell material is 1: 4 to 1: 15; and a casting temperature is 1510 DEG C to 1380 DEG C. The copper core in the composite cast segment has a high heat conductivity coefficient, and is capable of realizing rapid heat exchange and heat storage after making contact with the liquid-state blast furnace slag; and the outer ferrite steel is long in service life, and capable of meeting the continuous use requirement of a dry-type waste heat recovery process for the blast furnace slag. Due to the outer steel shell body of the composite cast segment, recovery and reuse for the cast segment can be realized through a magnetic separation process. The compositecast segment has an inner-copper and outer-steel structure, and the copper core is high in heat exchange speed, and higher in high-temperature-impact-resistant capacity. The composite cast segment isproduced through a steel die; the casting process is low in exhaust process difficulty; and the copper ball wrapped by molten steel is high in centering degree.

Owner:ANGANG STEEL CO LTD

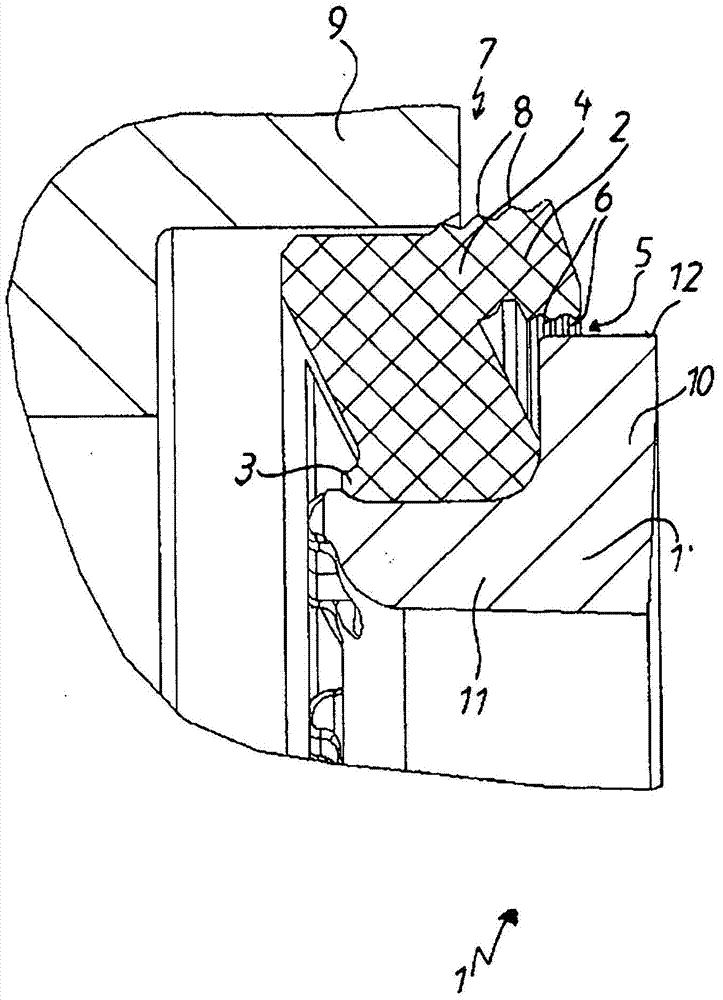

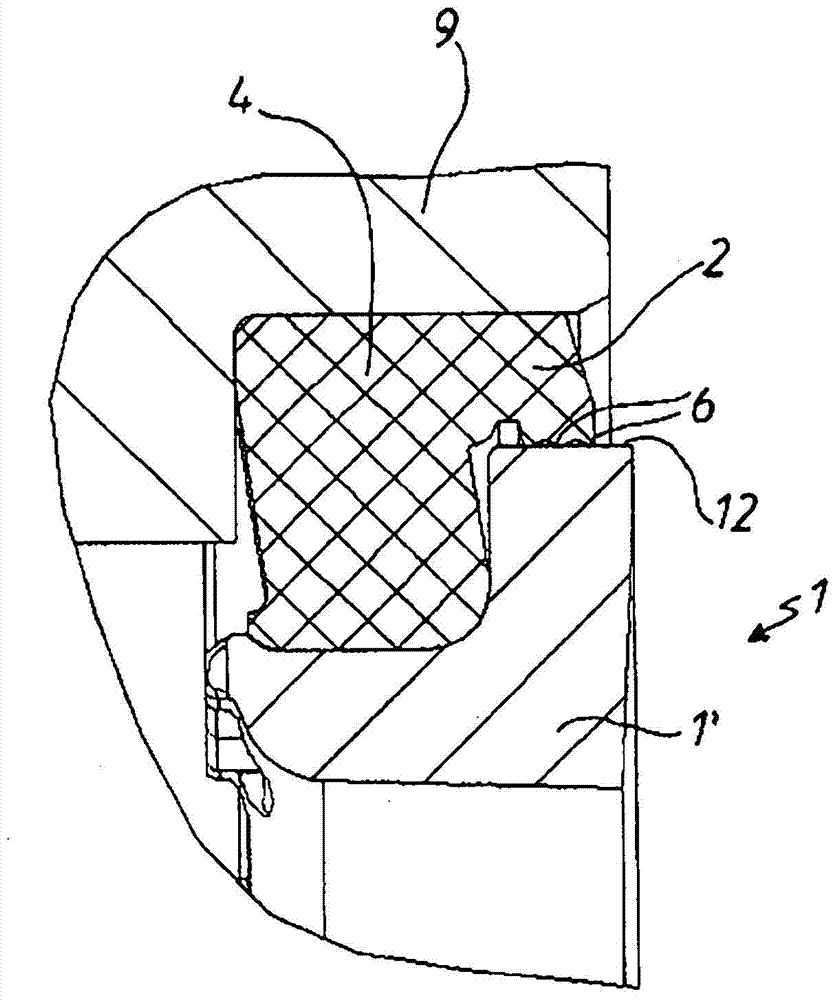

Slide ring seal

The invention relates to a slide ring seal, in particular a running gear seal (1), at least comprising an angular slide ring and / or counter ring, the radial limb of which forms a sliding region and the axial limb of which forms a receiving area for a trapezoidal sealing element, which is provided, radially outside the sliding region, with a shoulder engaging at least partially over the radial limb and forming a secondary seal, characterised in that at least in the region of the radial limb the shoulder is provided with a dirt lip-forming contour that in the installed state of the slide ring seal, in particular a running gear seal, is supported on the outer circumferential surface of the radial limb, viewed in the axial direction.

Owner:FEDERAL MOGUL BURSCHEID

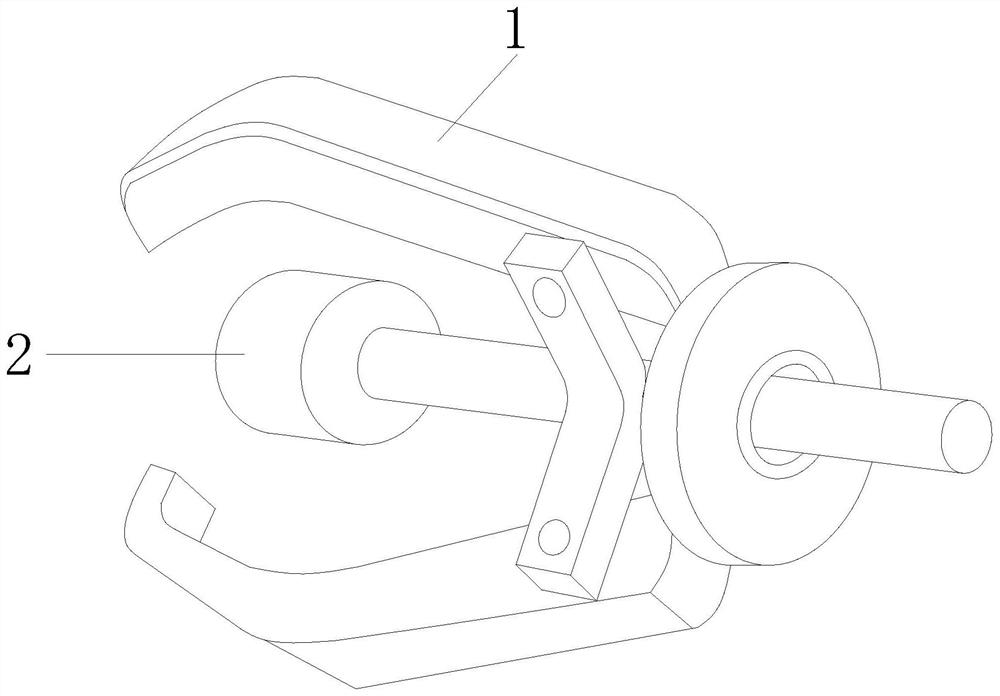

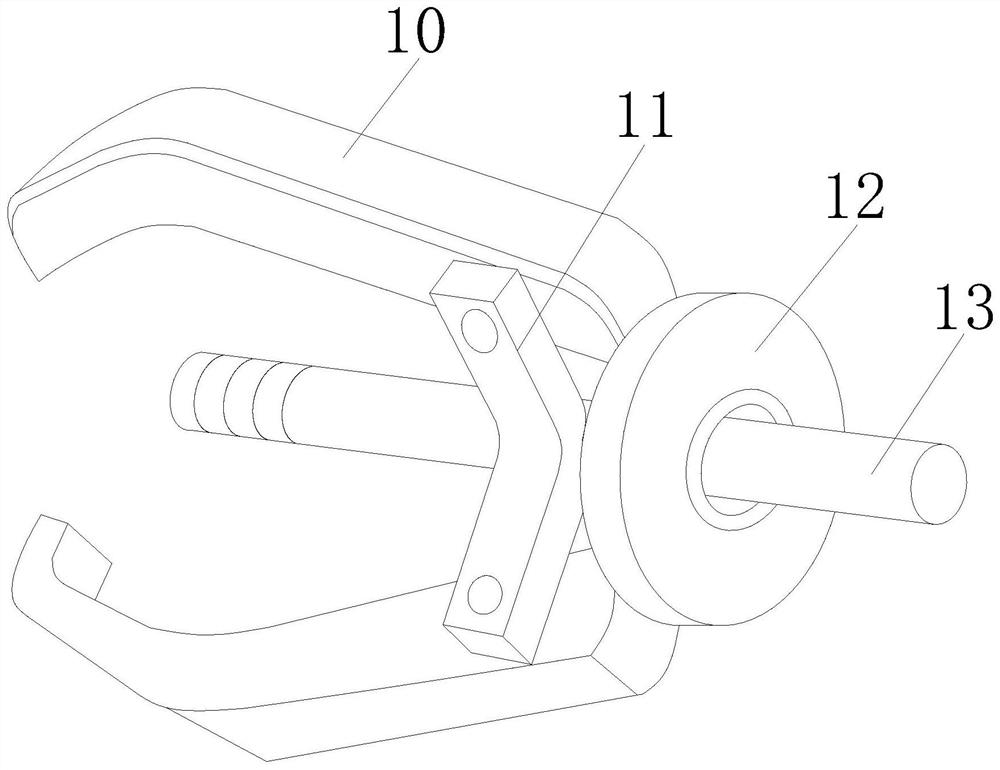

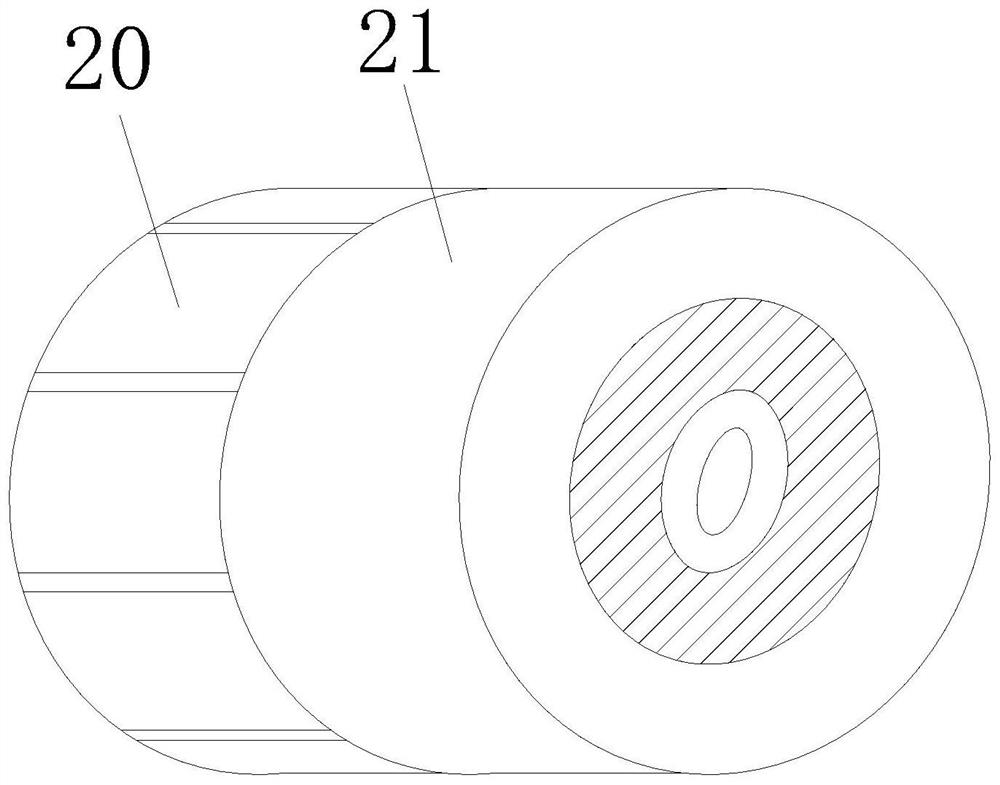

A bearing loading and unloading tool with improved centering degree and reduced friction rate

ActiveCN109434753BReduce frictionEasy to fixMetal-working hand toolsClassical mechanicsStructural engineering

The invention discloses a bearing loading and unloading tool which improves the centering degree and reduces the friction rate. Its structure includes a clamping frame and a bearing clamping column. The clamping frame is assembled and connected with the bearing clamping column. plate, adjusting rotary plate, and adjusting rotary rod. The clamping arm is connected to the fixed shaft plate of the clamping arm through a shaft bolt. The clamping arm is connected to the shaft of the adjusting rotary plate. The bearing clamping column includes a backing ring mechanism and a column shaft. When the bearing is fixed on the shaft seat in the present invention, the bearing and the bearing clamping column are spliced in the way of placing them horizontally, which improves the centering degree of the bearing and the bearing clamping column, and also reduces the bearing internal pressure. The friction between the ring and the outer ring of the cross bar of the shaft seat; when separating, the pads of the bearing clamp column are used to protect the inner ring surface of the bearing, which avoids the friction between the inner ring of the bearing and the outer ring of the cross bar of the shaft seat, and ensures the quality of the bearing. It also prolongs the service life of the shaft seat.

Owner:山东普丰园林科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com