Integral type casing centralizer and manufacturing method thereof

A centralizer and integral technology, which is applied in the field of oil and gas well cementing, can solve the problems that are difficult to satisfy high-inclination directional wells and horizontal wells, the reset force of elastic casing centralizers is low, and the danger of obstruction in the necking section of the wellbore, etc. problems, to achieve the effect of good adaptability, high yield and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

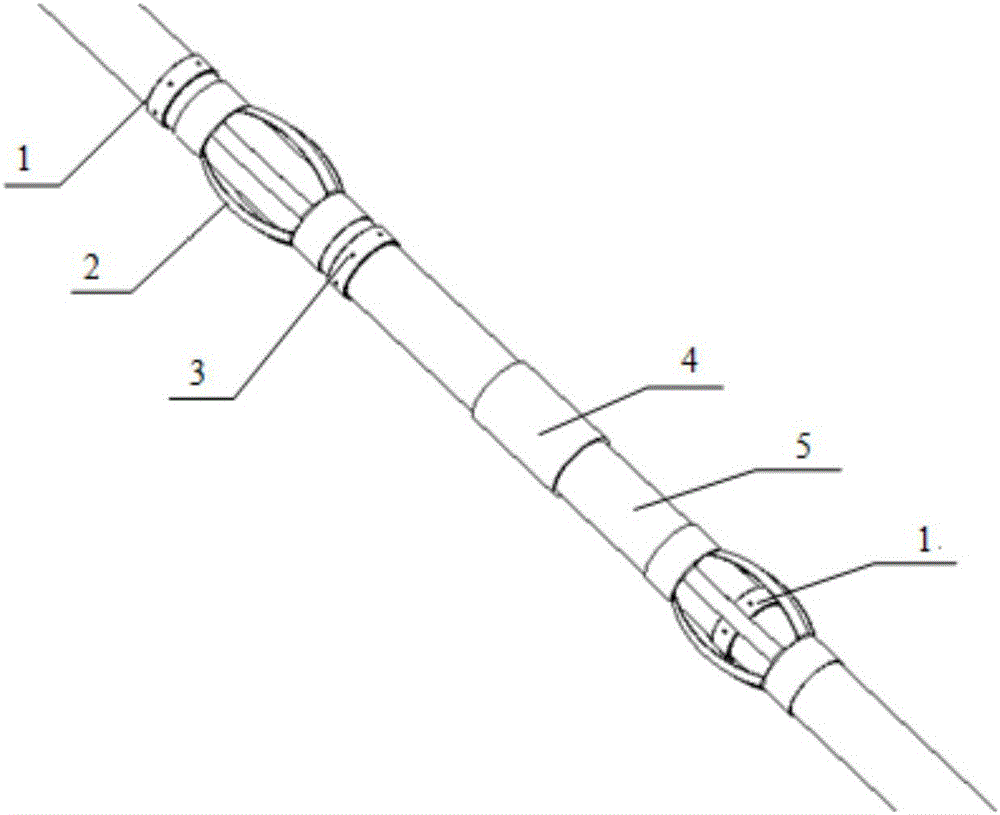

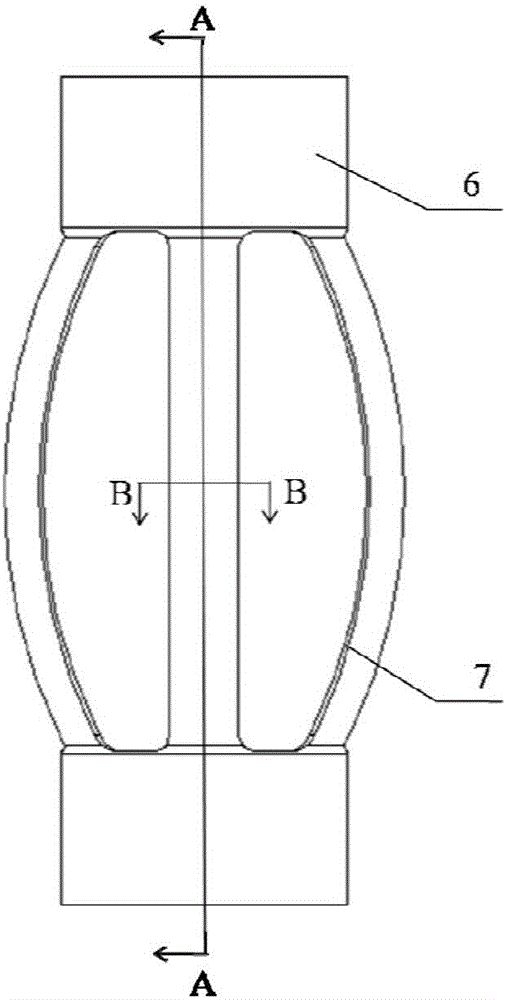

[0067] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0068] In order to solve the deficiencies of existing casing centralizers, the present invention adopts the following technical solutions: the integral centralizer is processed by blanking of uniform wall thickness material pipes or plates, and the two ends of the body are cylindrical circles. hoop; between the hoops at both ends, there are limbs for supporting and centralizing evenly distributed in the circumferential direction, and the outer diameter of the centralizer formed by the limbs is smaller than or equal to the inner diameter of the upper casing; the shape and cross-sectional shape of the limbs have various changes according to the use function Structure: the shape of the limbs is drum-shaped, isosceles trapezoidal, spiral, etc., and the cross-sectional shape is arc-shaped, bent, and rectangular; The circular arc is transitioned, and the centralizer bow and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com