A centralizer with self-adaptive variable diameter

An adaptive and centralizer technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of high frictional resistance of the drill string and poor centering of the drill string, and achieve small axial friction, good centering, and Bring in the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

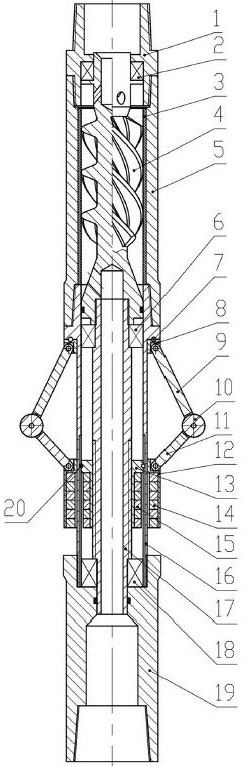

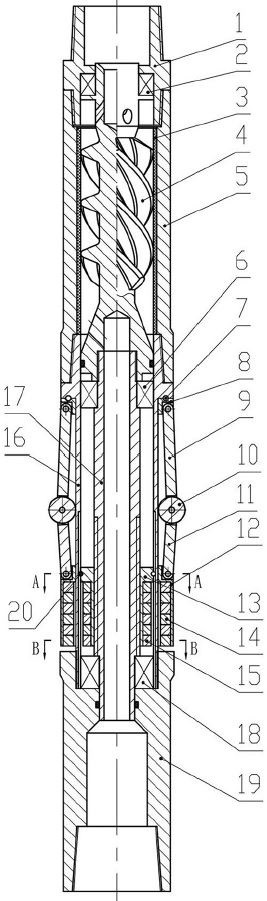

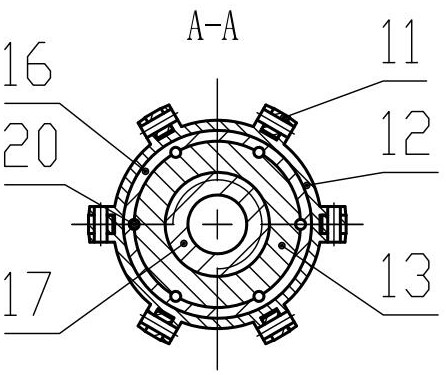

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a centralizer with self-adaptive variable diameter of the present invention is composed of upper joint 1, bearing a2, rubber stator 3, screw rotor 4, stator shell 5, bearing b6, steel ball a7, support ring 8, support arm a9, roller 10, support arm b11, thrust cylinder 12, nut cylinder 13, outer magnetic ring 14, inner magnetic ring 15, connecting cylinder 16, transmission screw 17, bearing c18, lower joint 19 and steel ball b20; The structural features are: the upper joint 1 is connected to the upper drill string with threads, the lower joint 19 is connected to the lower drill string with threads; the upper end of the stator shell 5 is connected with the lower end of the upper joint 1 with threads, and the lower end of the stator shell 5 is threaded with the upper end of the connecting cylinder 16 connection; the rubber stator 3 is fixed in the inner cavity of the stator housing 5; the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com