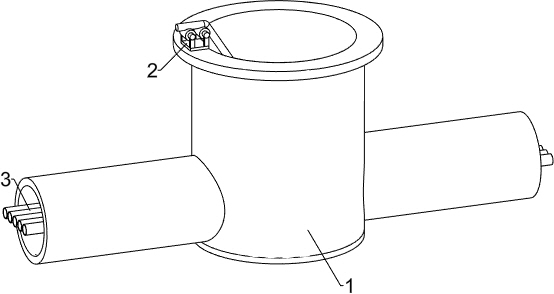

Electric traction device with positioning function

An electric traction and functional technology, applied in transportation and packaging, cable laying equipment, thin material handling, etc., can solve the problems of inconvenient fixing and center positioning, cumbersome operation process, right-angle bending of cables, etc., and achieve good cable traction effect , increase the contact area, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

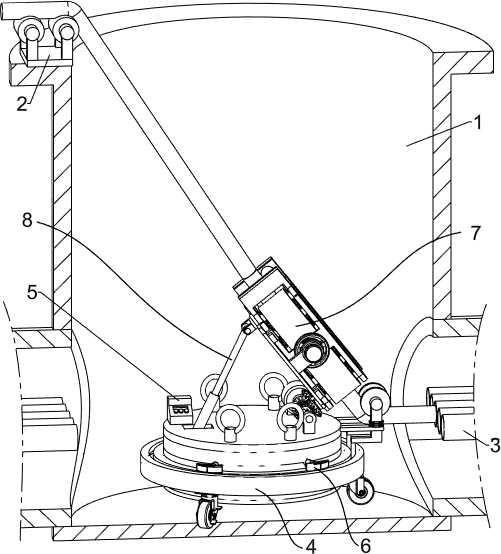

[0029] When this device needs to be used, one situation: when it is necessary to perform threading operation from the cable shaft 1 to the underground pipe on one side, the operator passes the right end of the cable through the traction mechanism 7, and then the operator starts the traction mechanism 7 to clamp the cable After the cable clamping is completed, the operator places the guide assembly 2 on the right side of the upper part of the cable well 1, and places the cable above the guide assembly 2, and then the operator uses one end of the rope to place the four ends on the directional locking mechanism 4. The operator puts the device into the cable well 1 through the rope, and at the same time the right part of the clamped cable is pulled into the cable well 1. When the device is placed in the cable well 1, the operator puts the rope in his hand Place it at the wellhead of the cable well 1, then the operator enters the cable well 1 and passes one end of the cable through ...

Embodiment 2

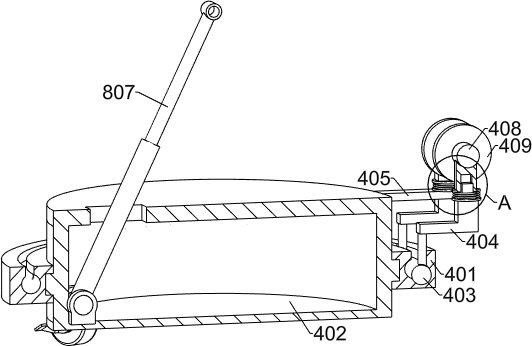

[0033] like Figure 7 As shown, the fixed assembly includes a sealing sleeve 612, and the sealing sleeve 612 is welded on the right part of the slide bar 611, and the right end of the slide bar 611 is fixedly connected with an air pressure sensor, and the air pressure sensor is electrically connected with the console 5, and the outer end of the slide bar 611 The air pressure sensor is located in the sealing sleeve 612, and the right part of the sealing sleeve 612 is slidably provided with a second limiting sleeve 613, and a first spring 614 is welded between the second limiting sleeve 613 and the sealing sleeve 612. The spring 614 is located in the sealing sleeve 612, and the right part of the second limiting sleeve 613 is fixedly connected with a clamping block 615. The clamping block 615 is set as a cavity, and the cavity of the clamping block 615 and the second limiting sleeve 613 Connected, the outer surfaces of the four clamping blocks 615 are all set to be arc-shaped, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com