Patents

Literature

67results about How to "Reduce closing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

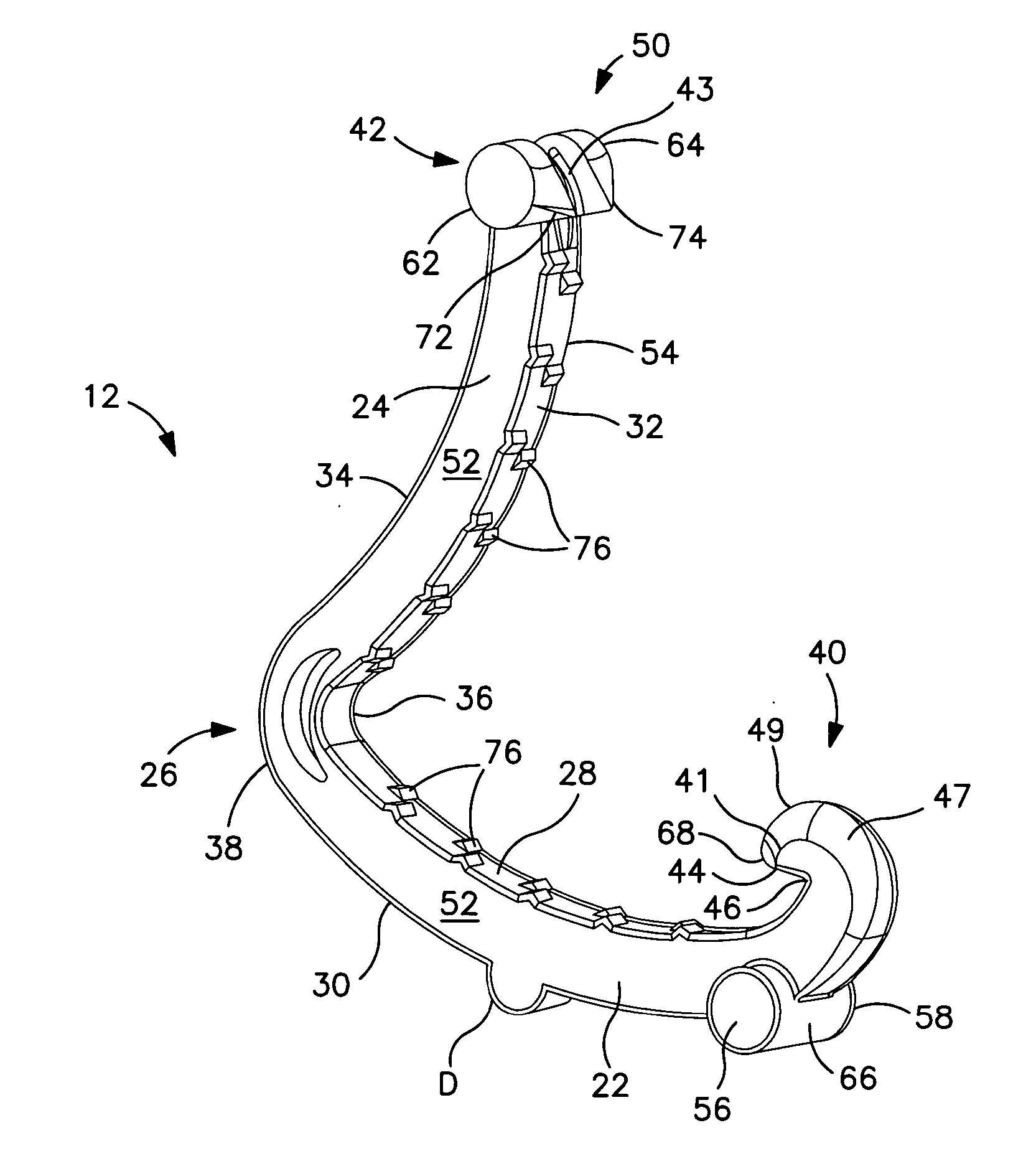

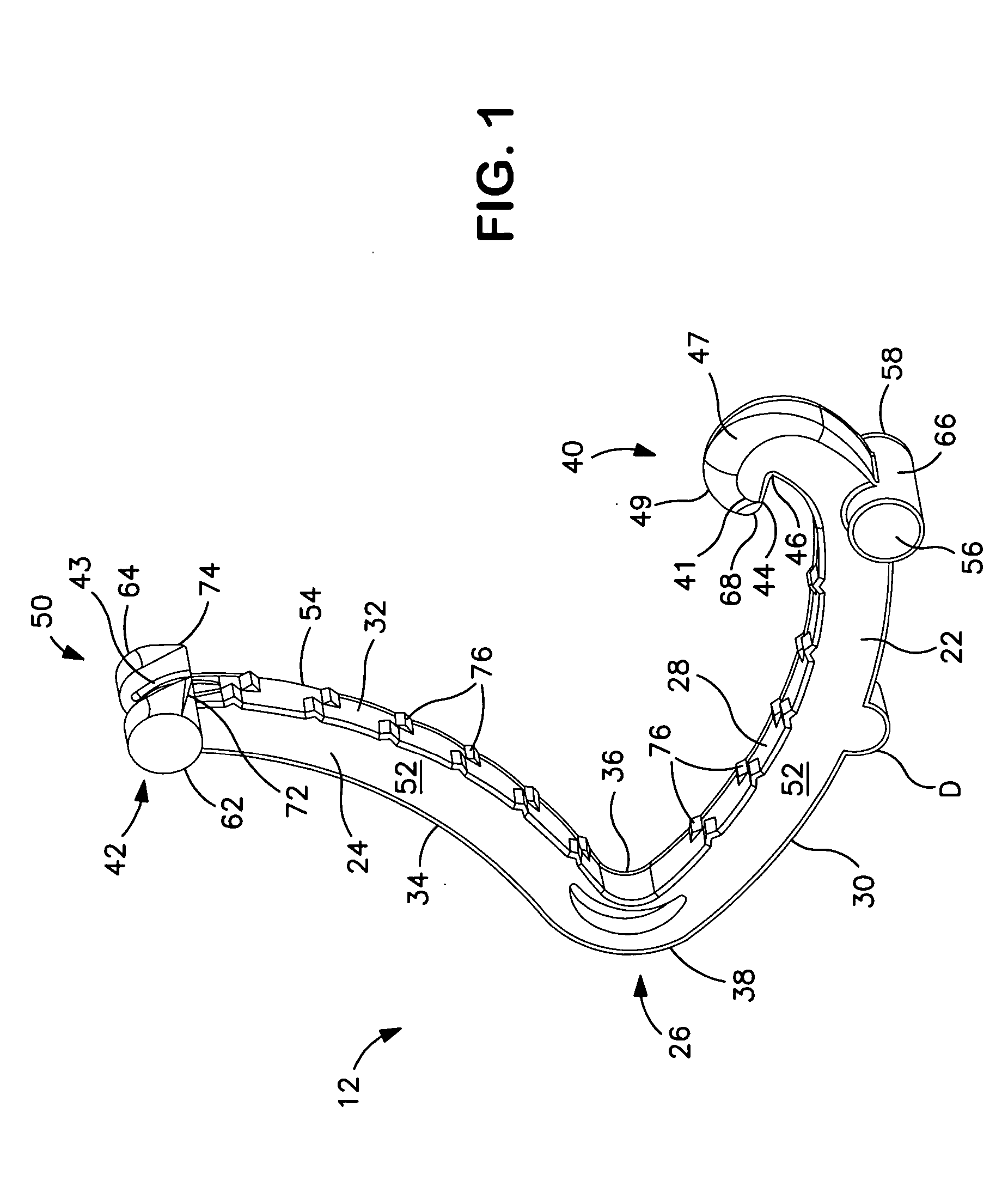

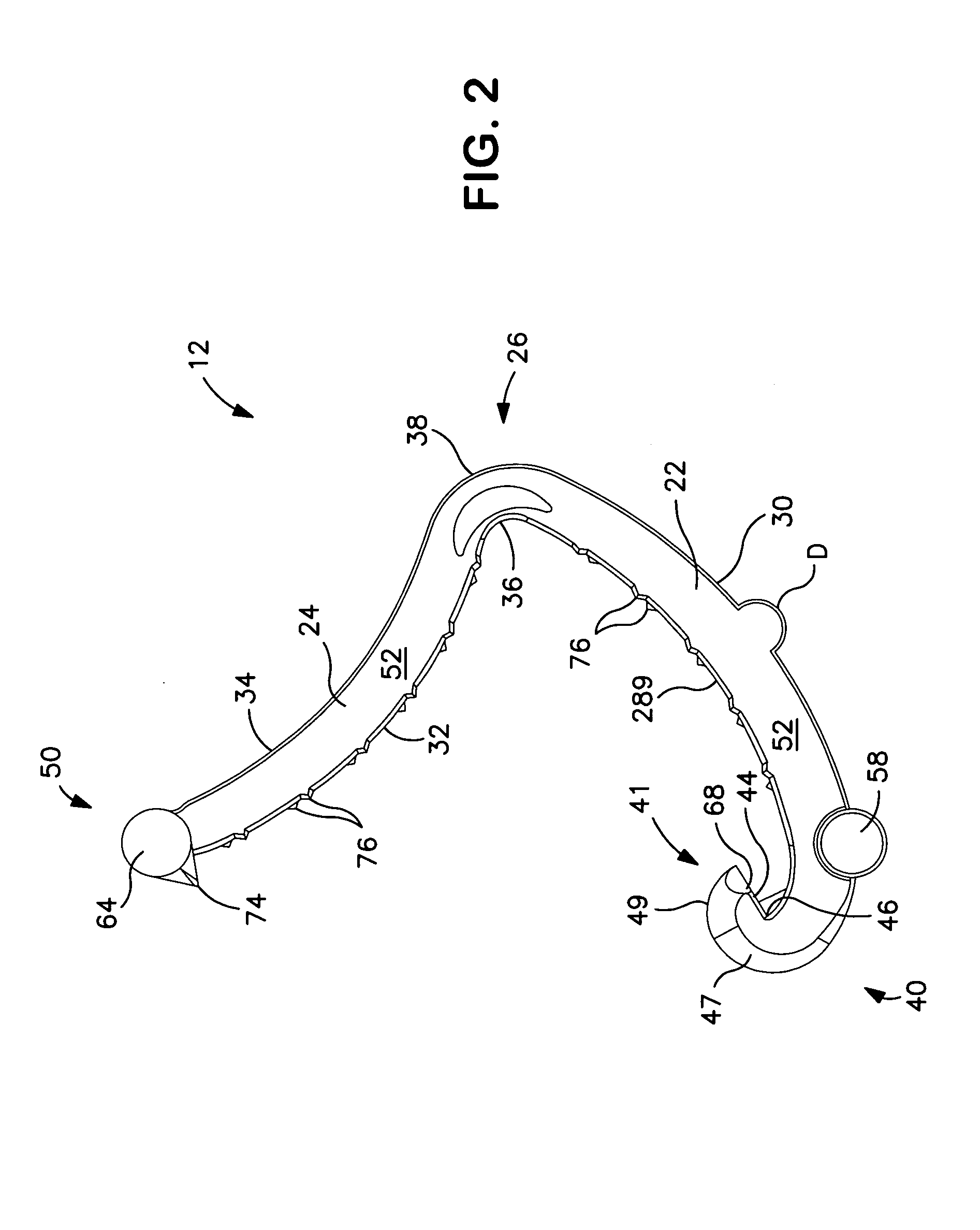

Reduced closure force ligating clip

InactiveUS20060217749A1Removably lock the clipFacilitate closure and lockingWound clampsLigating clipsEngineering

Owner:TELEFLEX MEDICAL INC

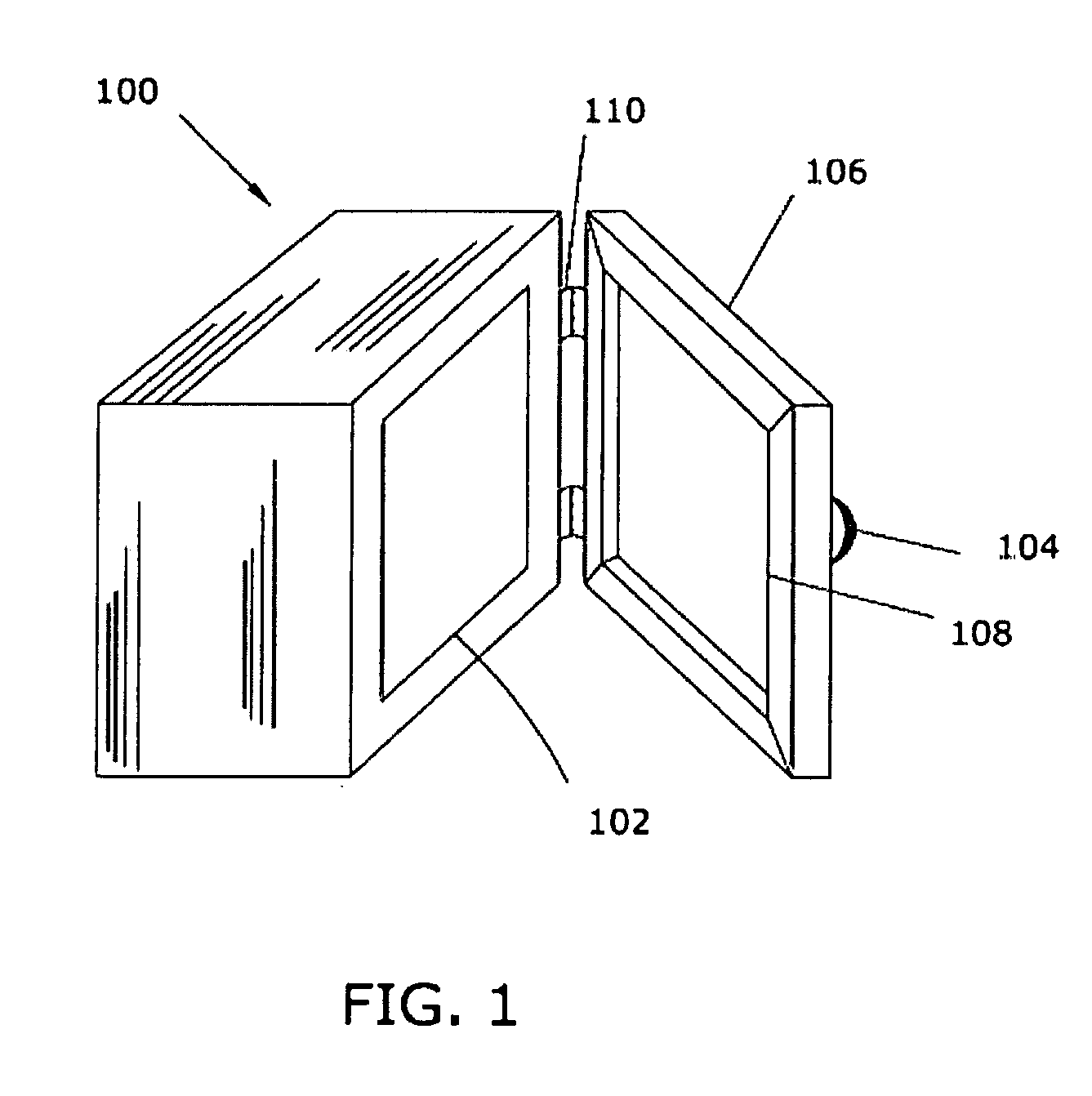

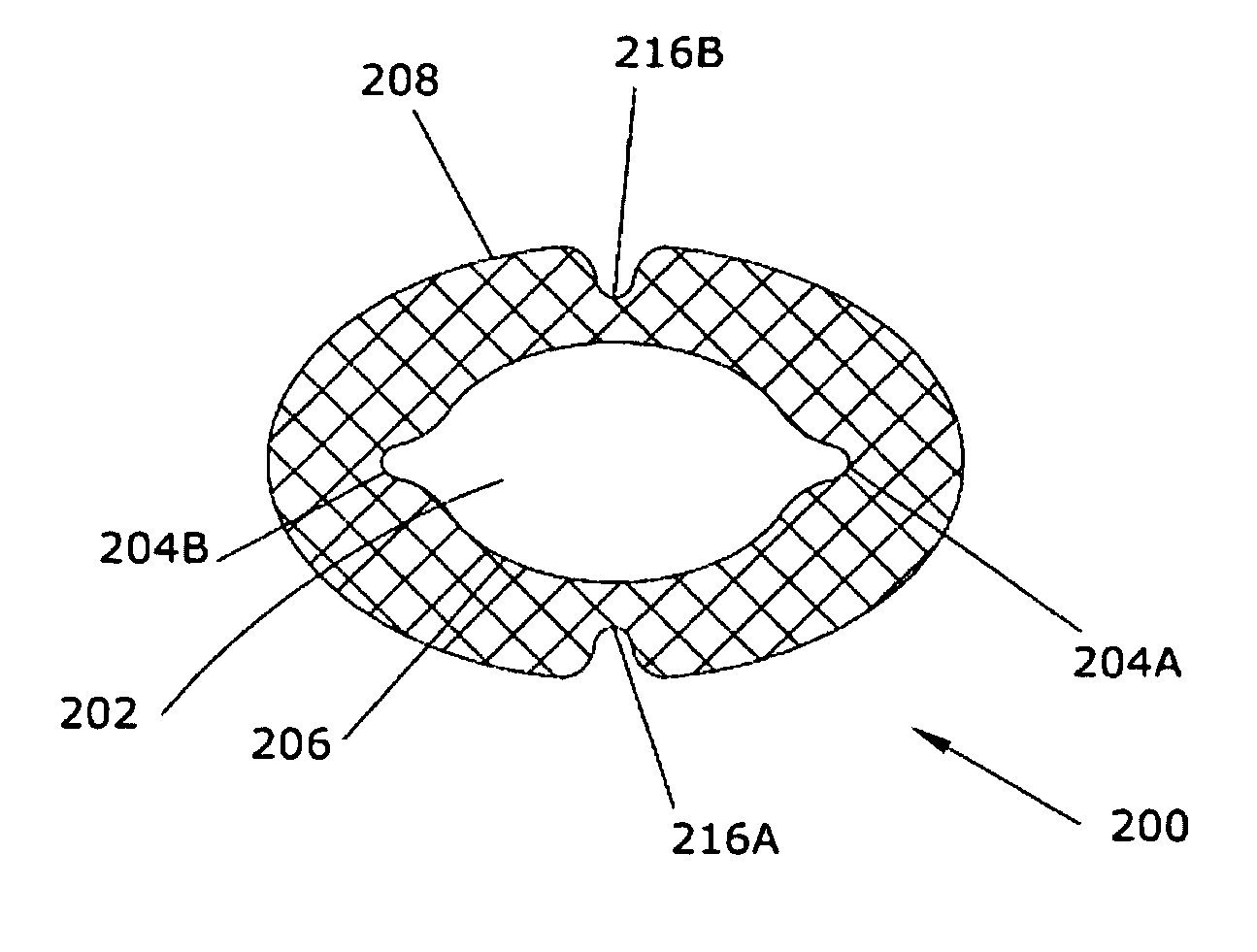

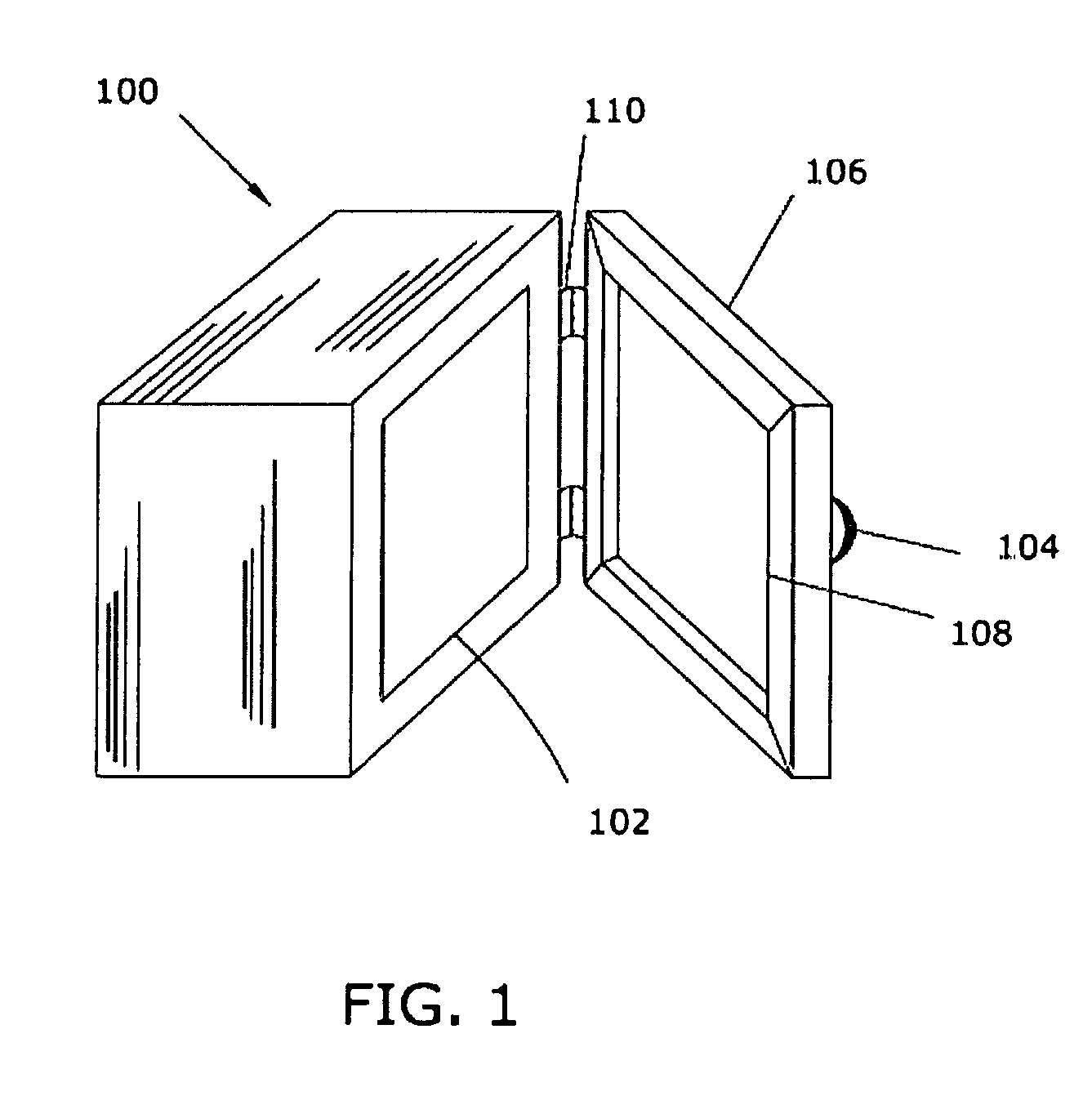

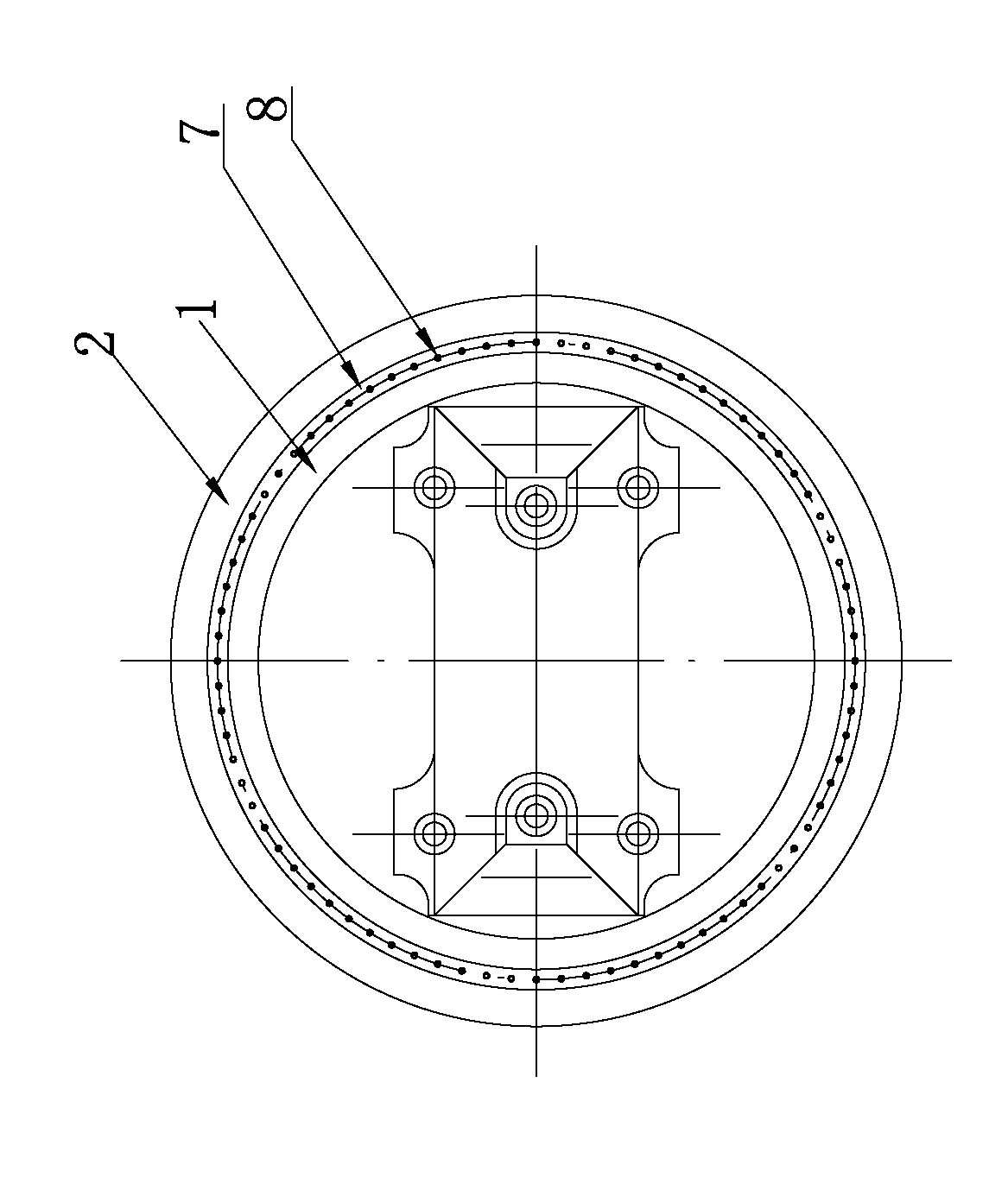

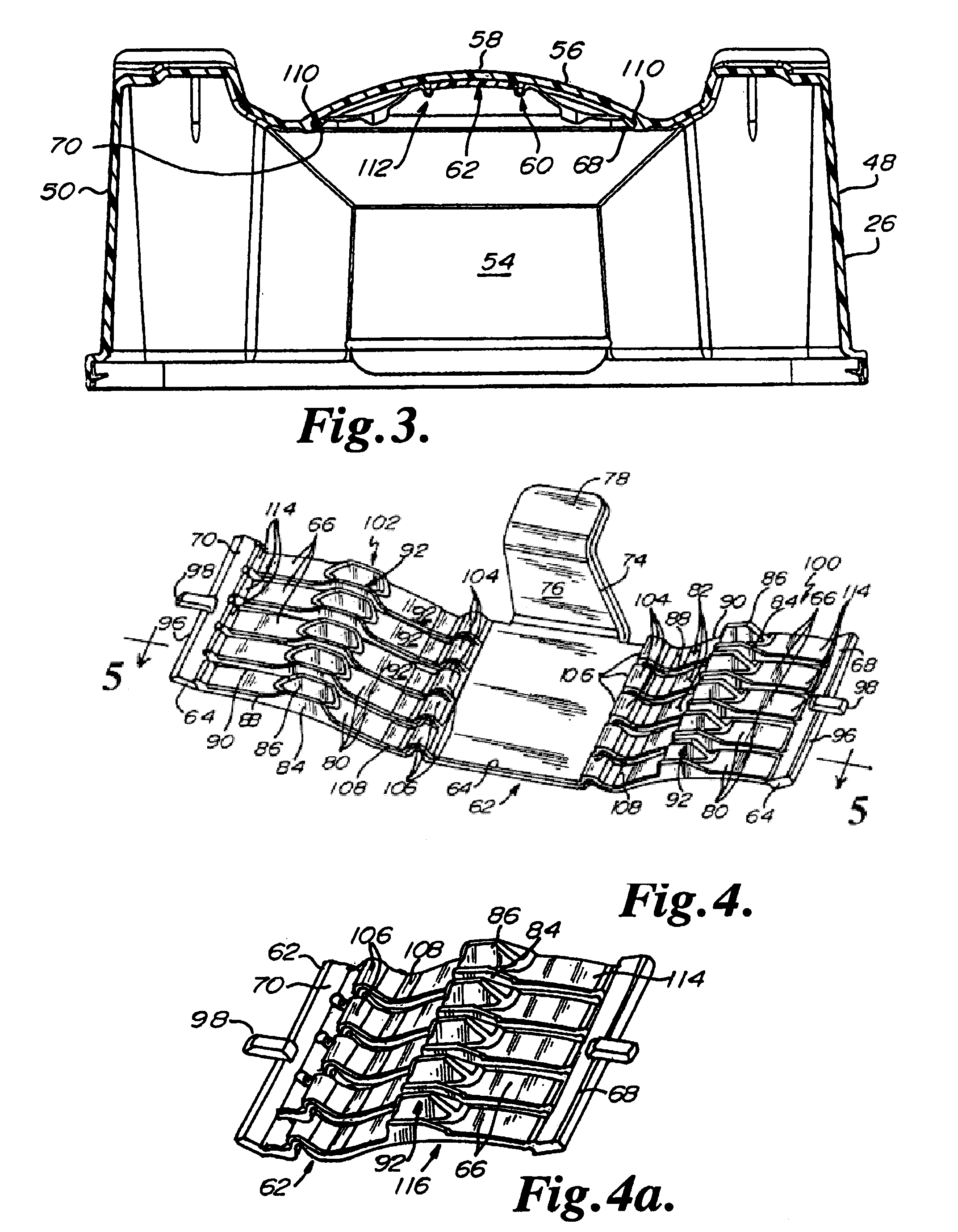

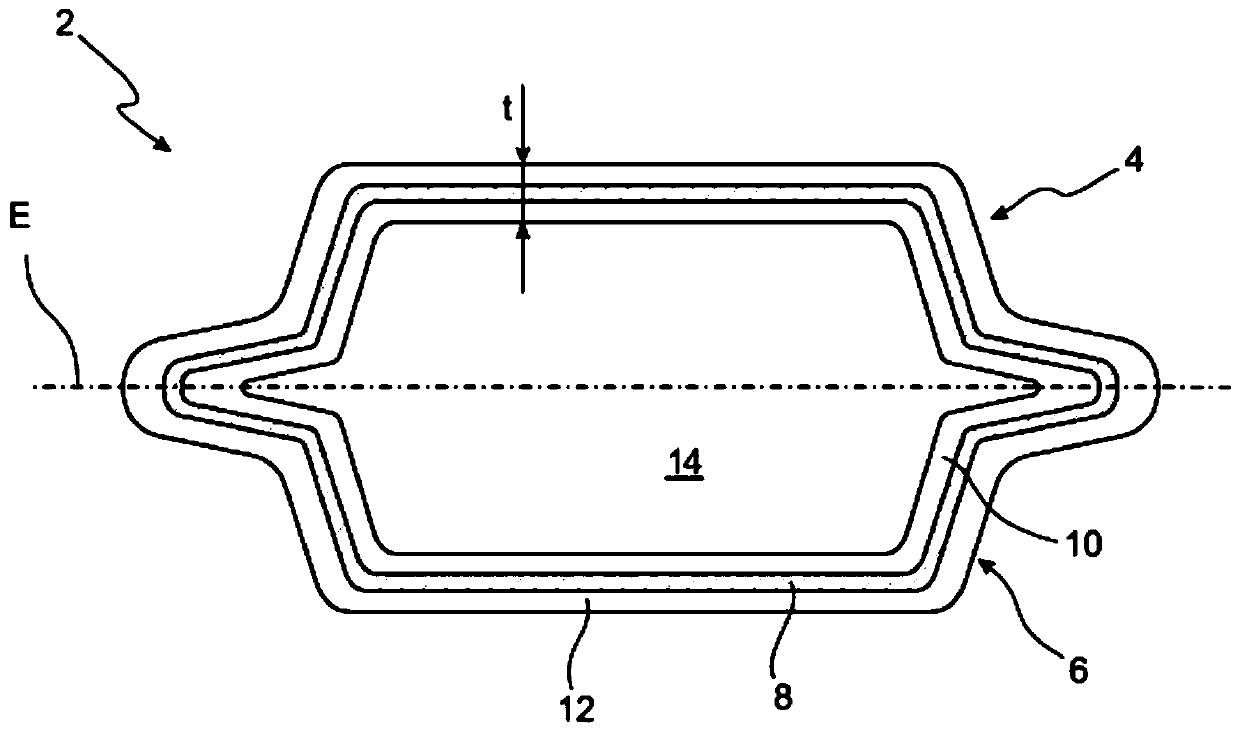

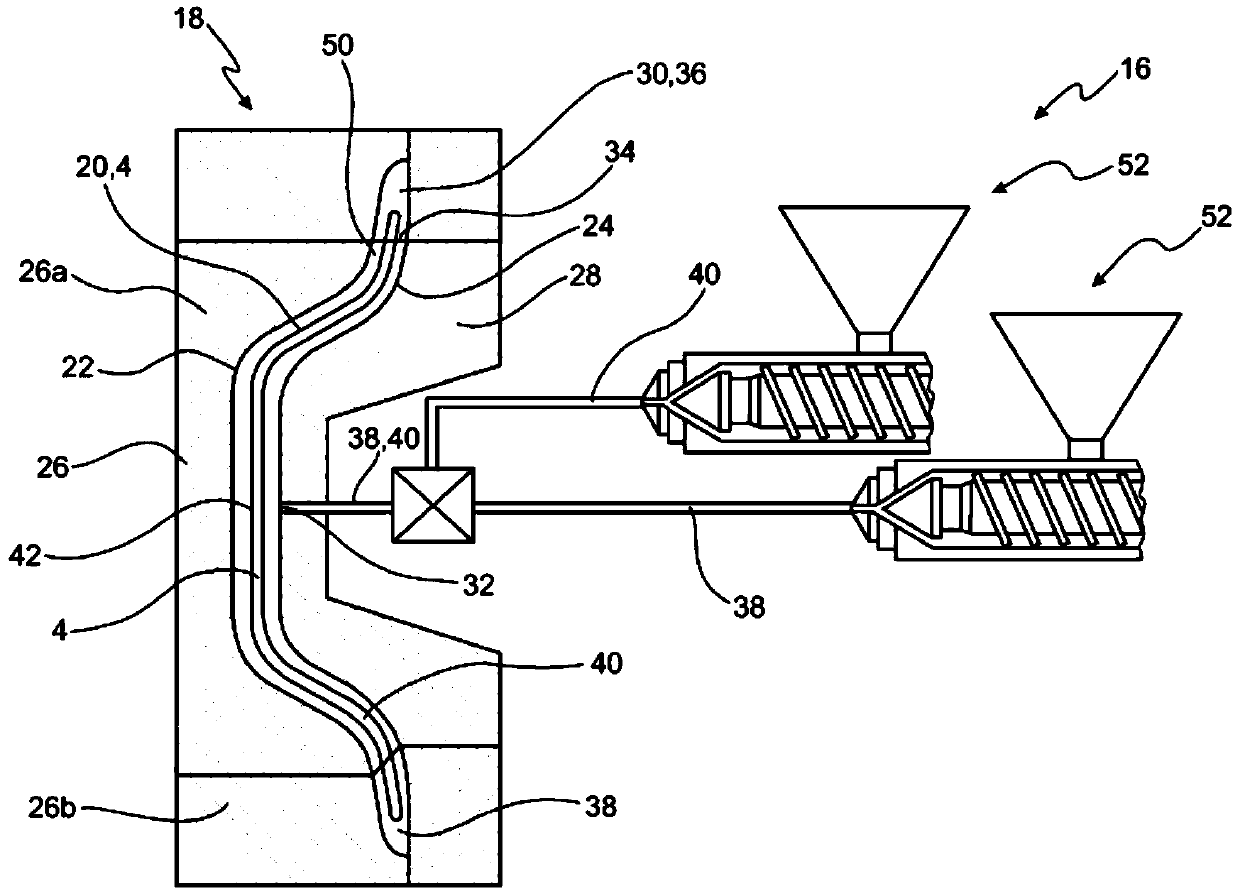

Strip gaskets for EMI shielding

ActiveUS20060260838A1Low closure forceLow resistanceElectrically conductive connectionsScreening gaskets/sealsBending momentEngineering

A strip gasket utilizing a low closure force on an enclosing face for shielding electromagnetic interference is disclosed. The strip gasket includes an outer surface and an inner surface. The inner surface provides a hollow cross section region. Bending moments are created on surface peripheries of the inner surface and the outer surface, or both, to provide a low closure force on an enclosing face. The bending moment results in an increased surface area of the strip gasket providing a low resistance. Cauchy's stress analysis reveals that a lower force is required to compress the strip gasket as compared to conventional strip gaskets.

Owner:PARKER INTANGIBLES LLC

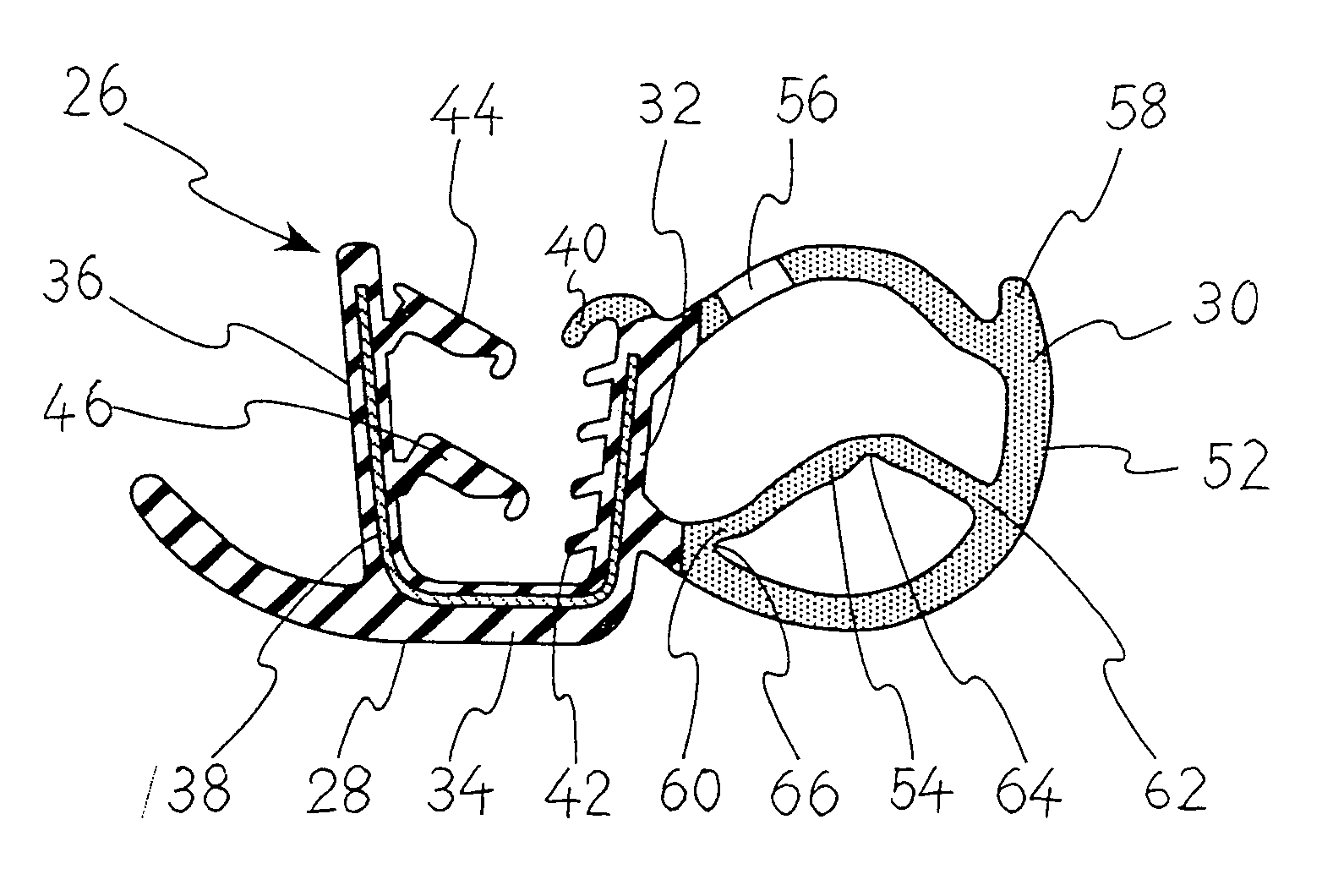

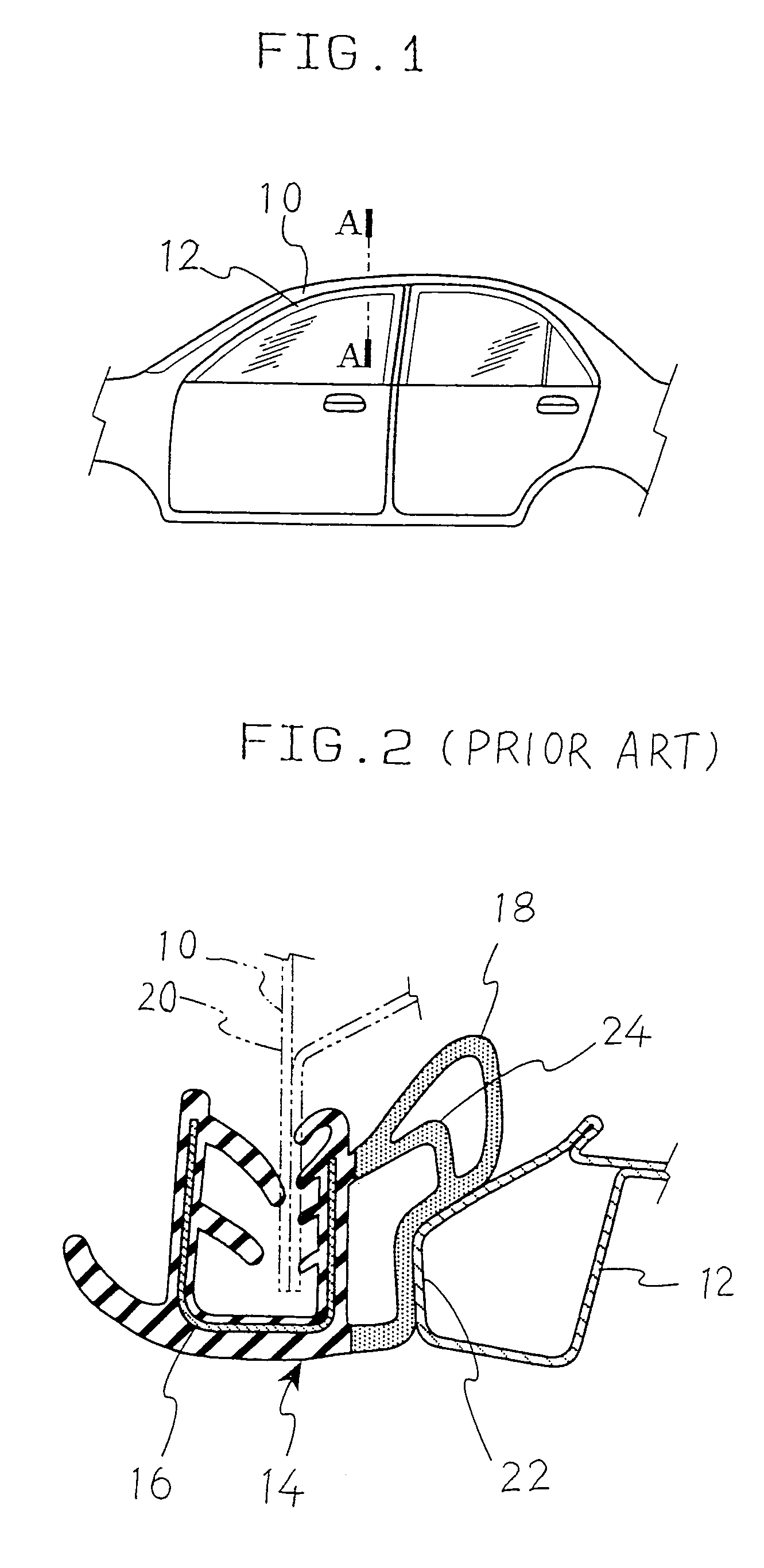

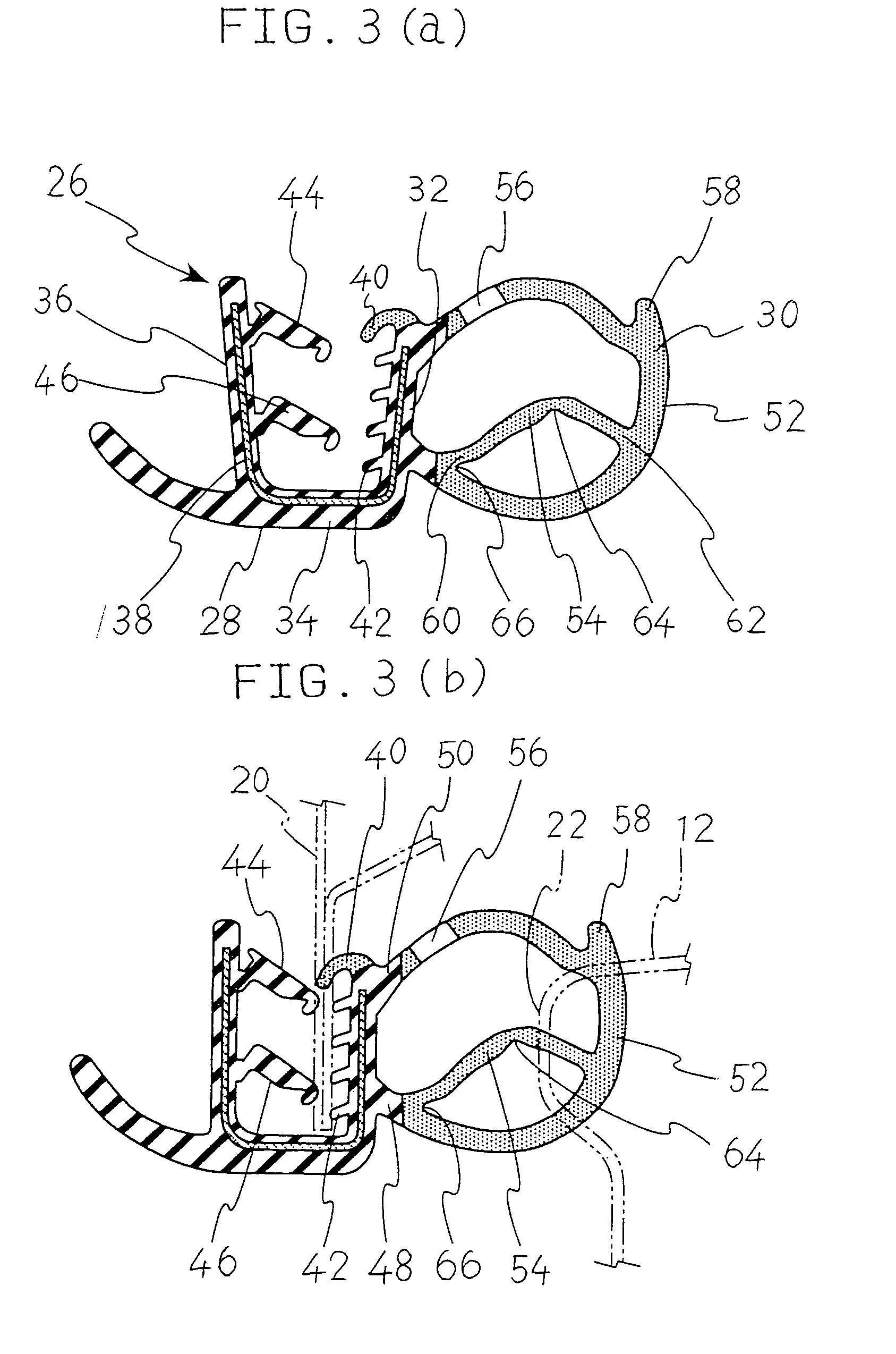

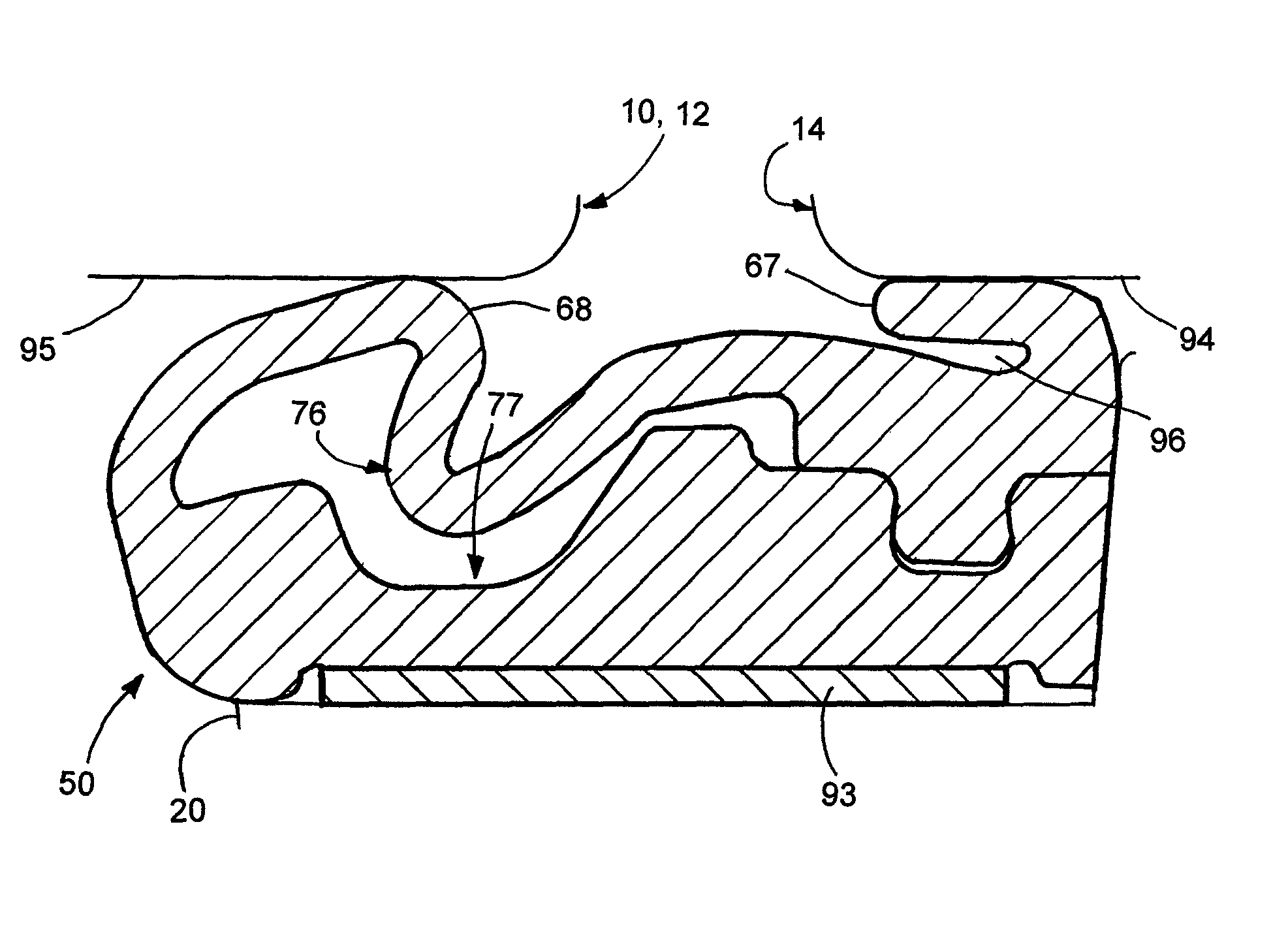

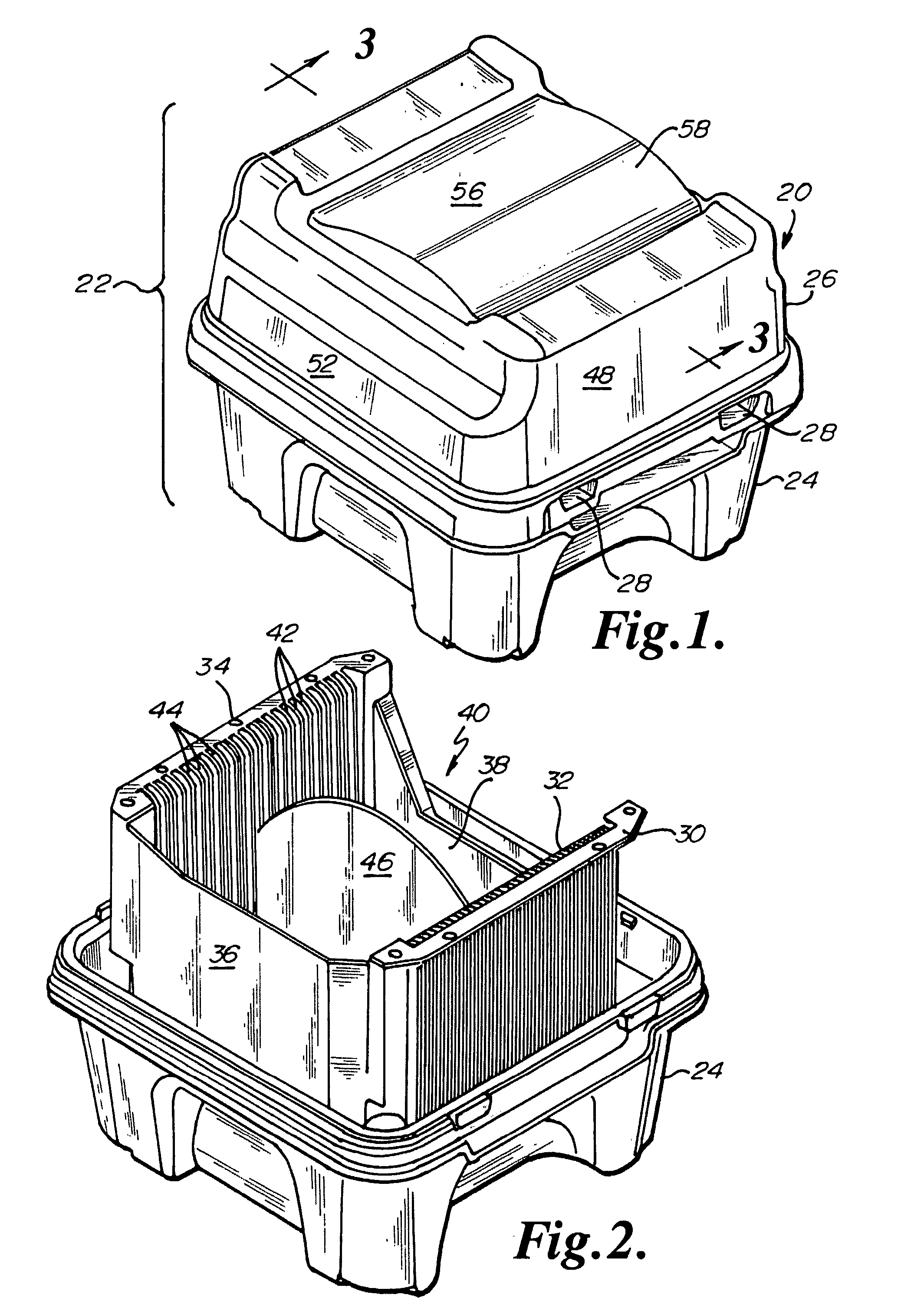

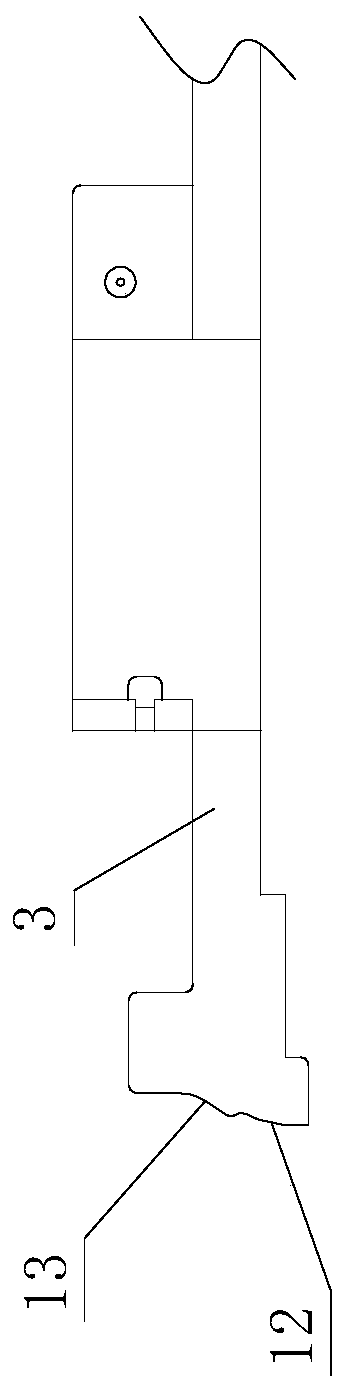

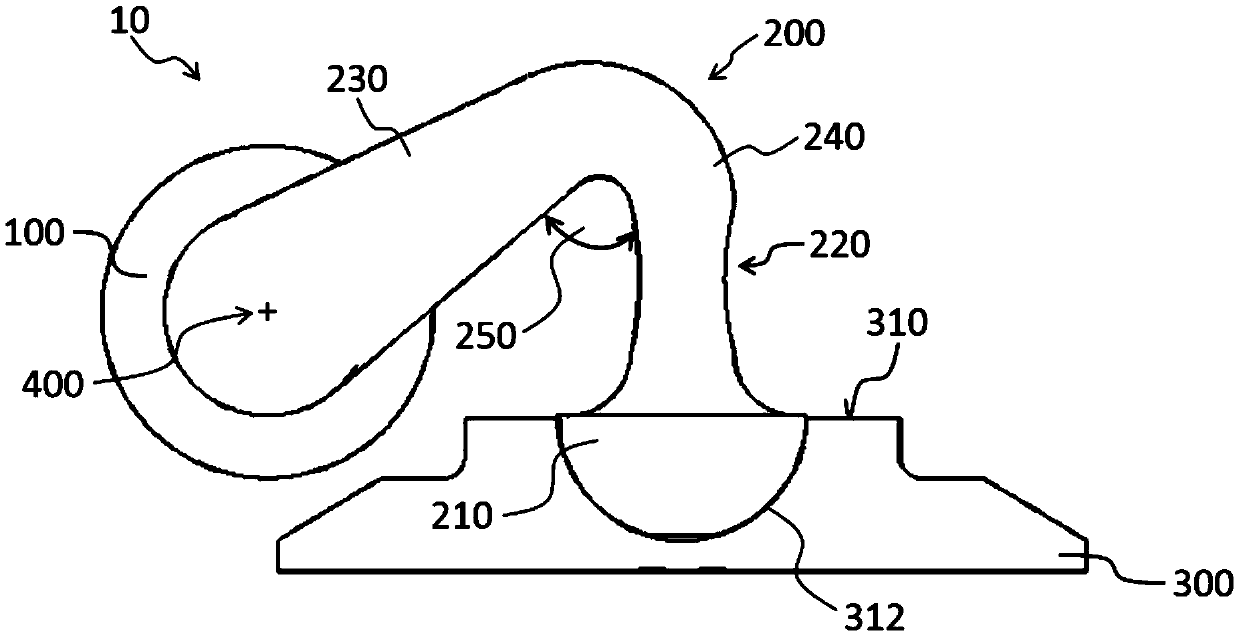

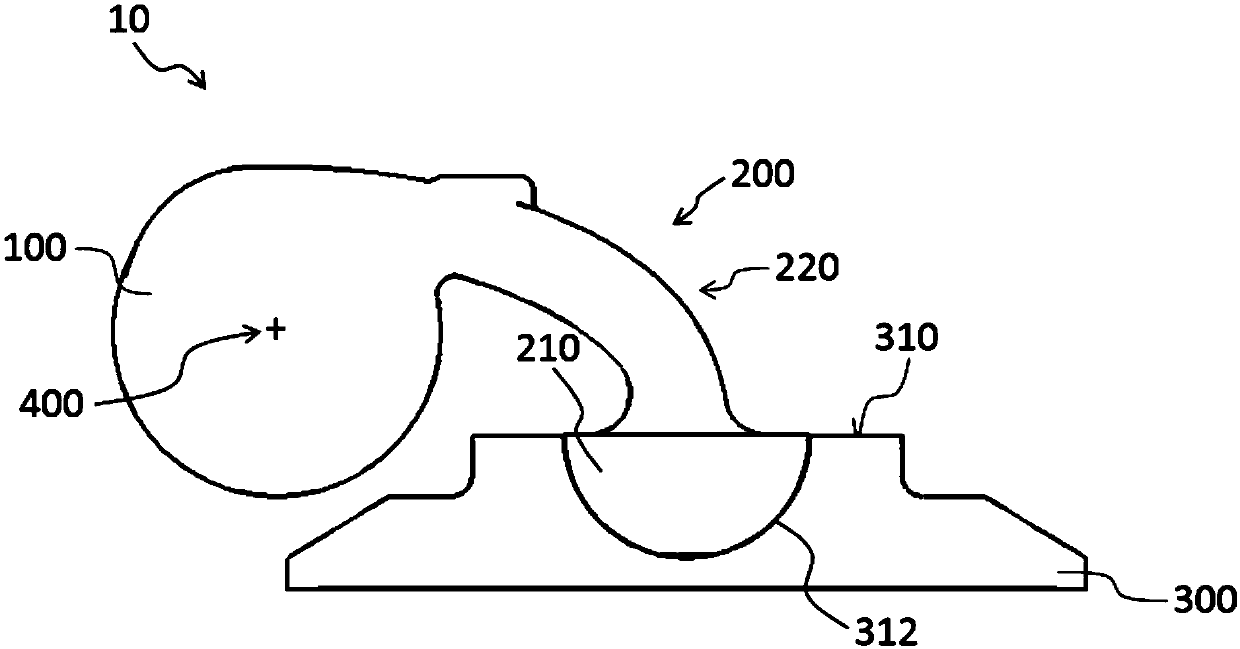

Door opening trim weather strip for motor vehicle

InactiveUS6972140B2Improve sound insulationReduce closing forceEngine sealsLayered productsMobile vehicleEngineering

A door opening trim weather strip for a motor vehicle, which exhibits excellent noise insulating properties between a door opening portion of a vehicle body and a door of a motor vehicle, and requires a small force for closing the door, thereby improving feelings in closing the door. The door opening trim weather strip includes a trim portion in which a flange provided in the door opening portion is adapted to be inserted, and a tubular seal portion for sealing between the door opening portion and the door. The tubular seal portion includes two base parts which are respectively composed of a solid rubber and project from an outside surface of an outer side wall of the trim portion integrally therewith, an arc-shaped part which is composed of a sponge rubber and of which ends are respectively connected to the two base parts to form a generally arc-shaped cross-section, and a noise insulating wall which is composed of a sponge rubber and is formed in a space defined by the outer side wall, the two base parts and the arc-shaped part into a generally inverted v-shaped cross-section. The noise insulating wall has a bending part at about a widthwise center thereof. Ends of the noise insulating wall are respectively connected to an inside surface of the arc-shaped part such that at least one portion of the noise insulating wall is foldable between the two base parts.

Owner:TOYODA GOSEI CO LTD

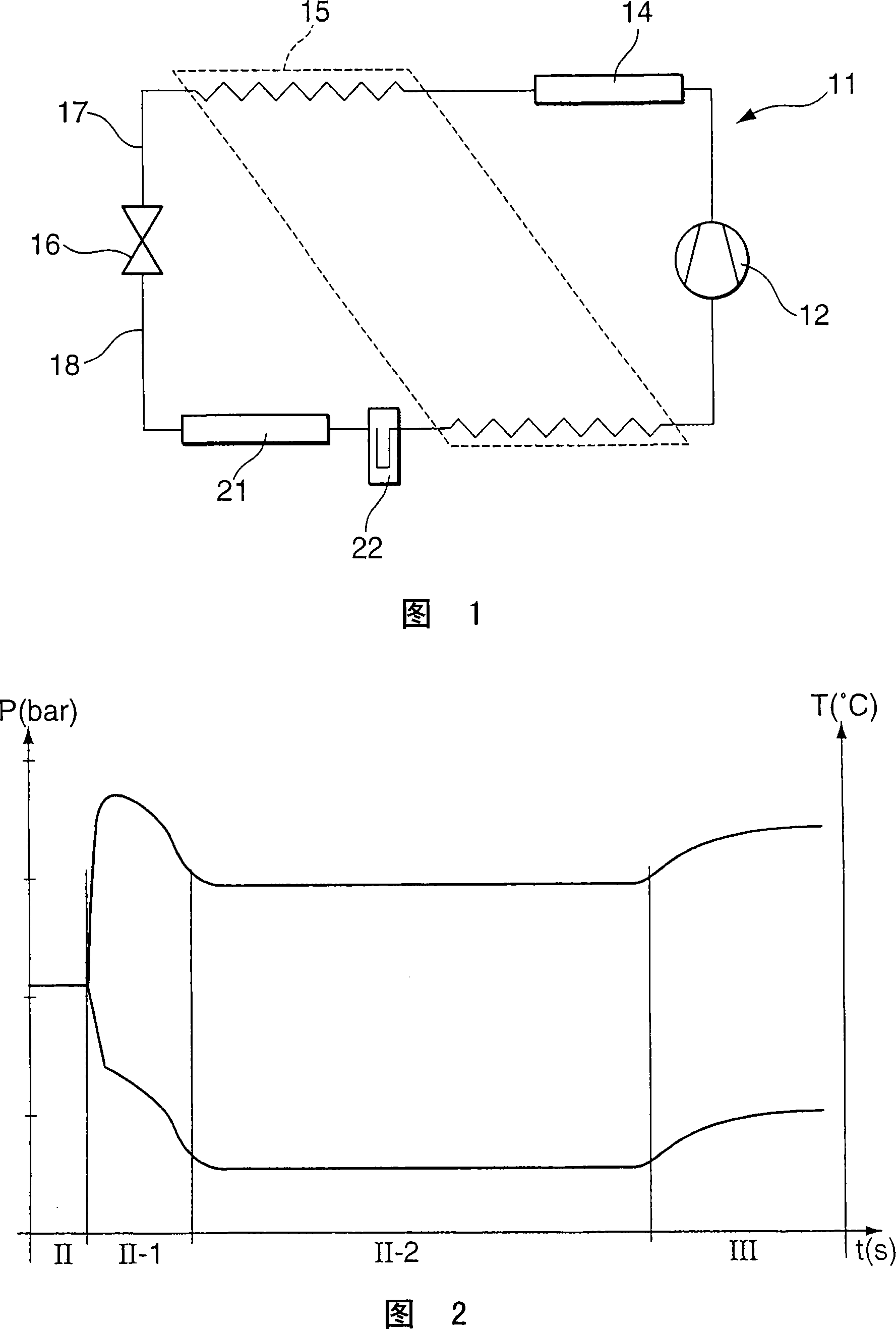

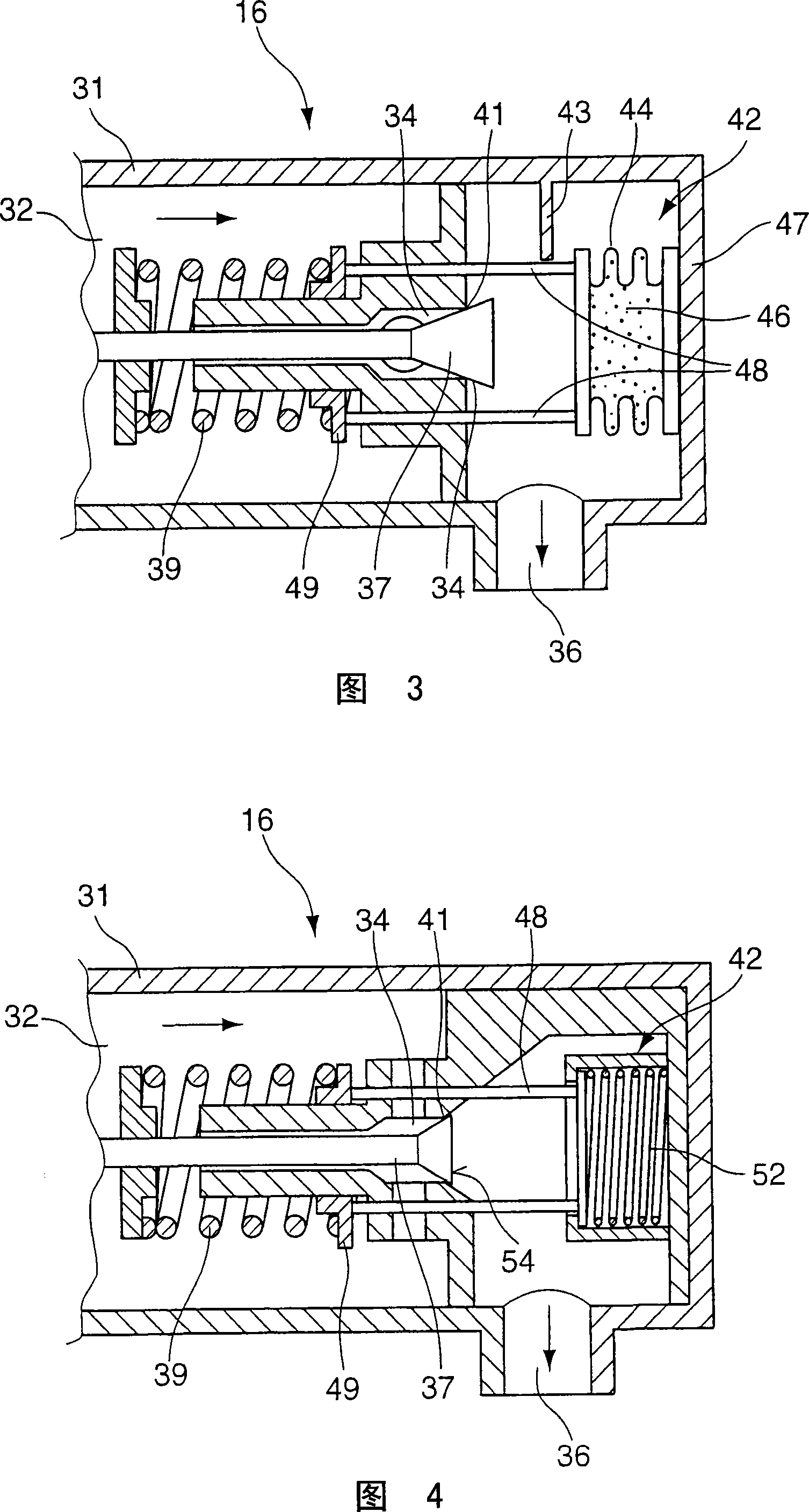

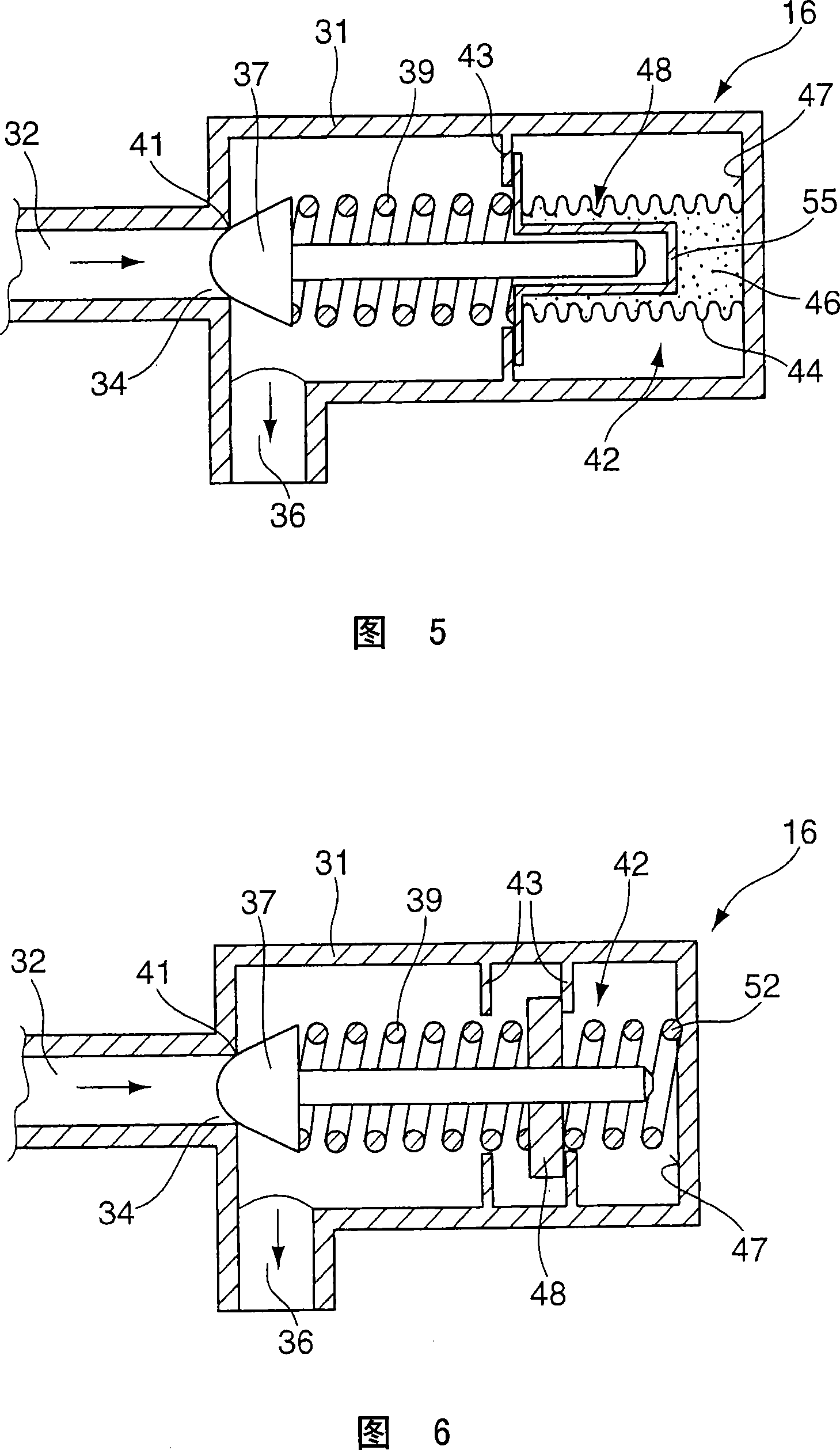

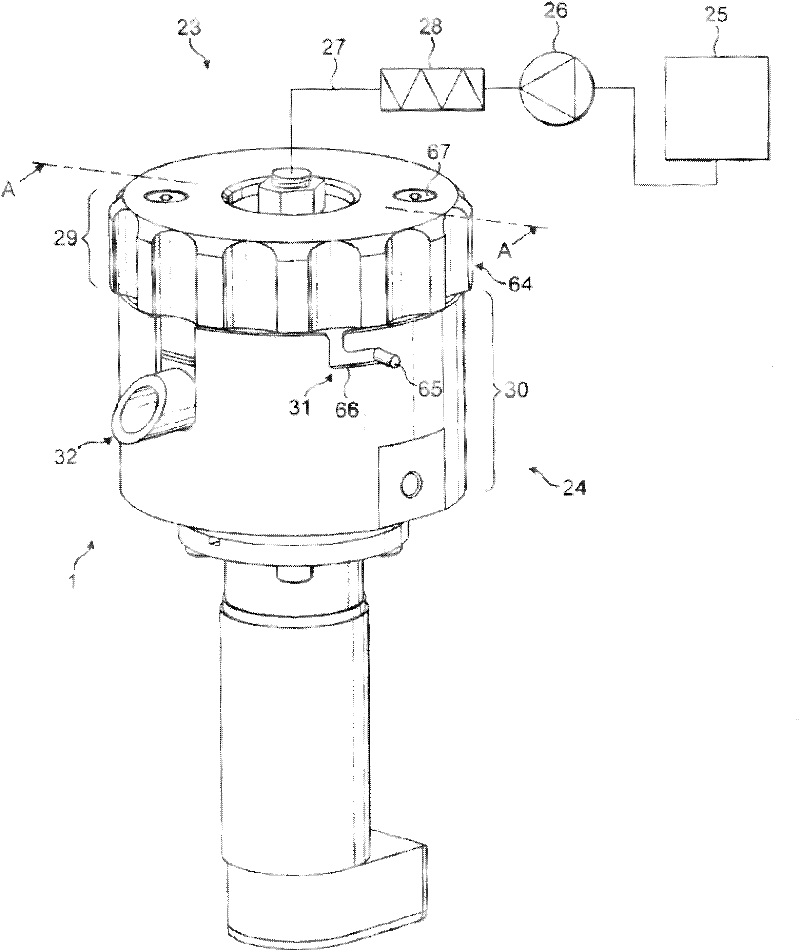

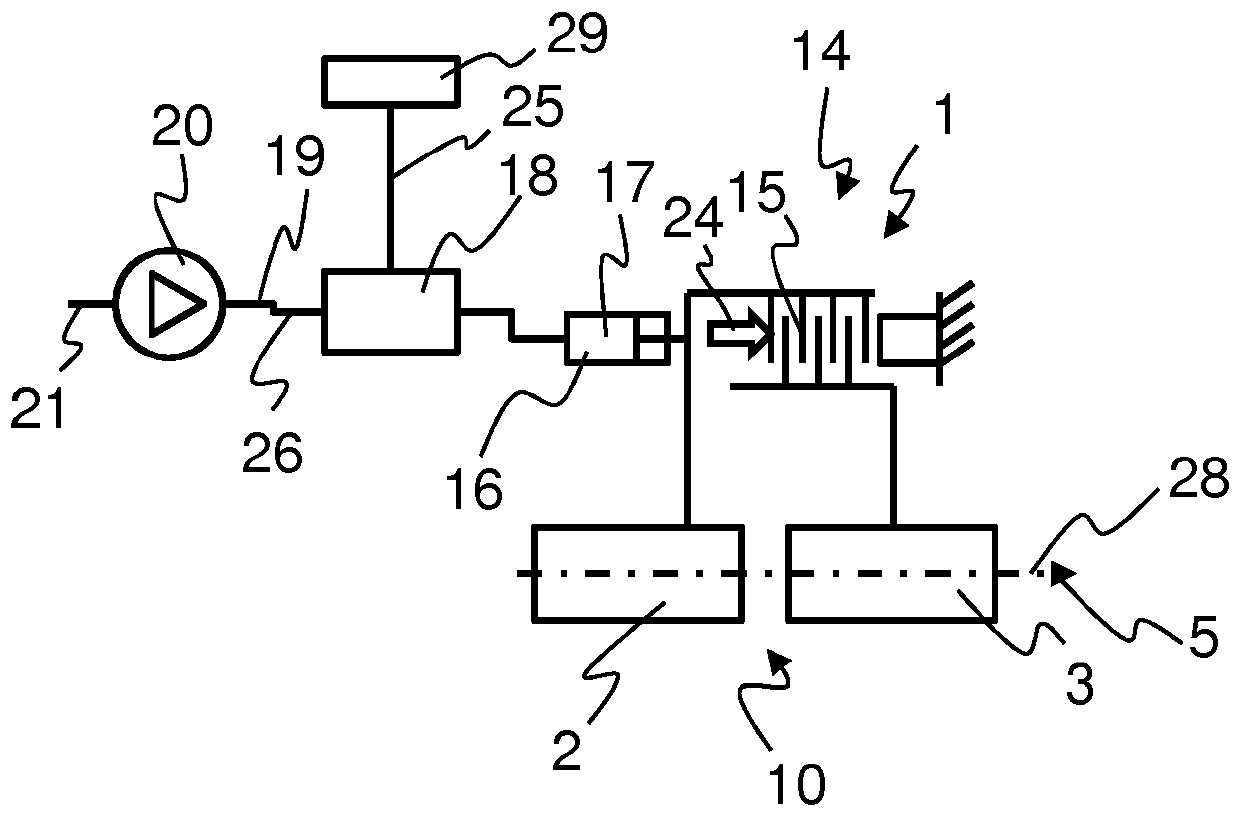

Expansion valve control method, and expansion valve

InactiveCN101135387AImprove responsivenessLow mass flowOperating means/releasing devices for valvesCompression machinesPressure riseEngineering

The invention relates to a method for controlling an expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant, with a valve housing which has a feed opening and a removal opening, with a valve-closing member which closes a valve seat of a passage opening arranged between the feed and removal openings, and with a resetting device which acts in the closing direction of the valve-closing member, an adjusting element, which is assigned to the valve-closing member, on the low-pressure side being activated via a predetermined threshold value as the low pressure rises or as the temperature on the low-pressure side rises and actuates at least one actuating element by means of which a closing force of the resetting device acting on the valve-closing member is reduced such that a passage opening is enlarged or a passage of a bypass valve arranged on the low-pressure side, which passage is arranged parallel to the passage opening, is opened.

Owner:OTTO EGELHOF GMBH & CO KG

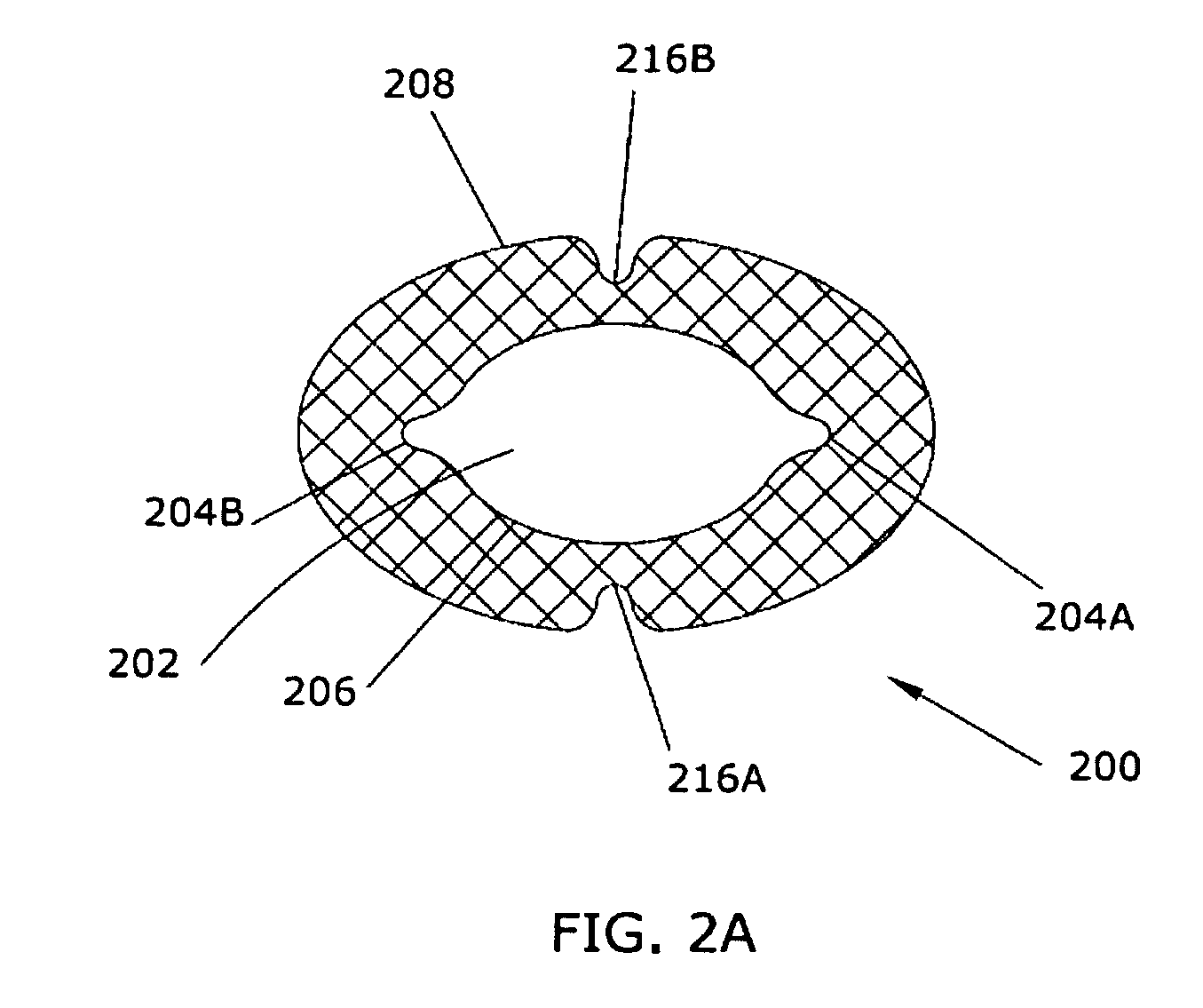

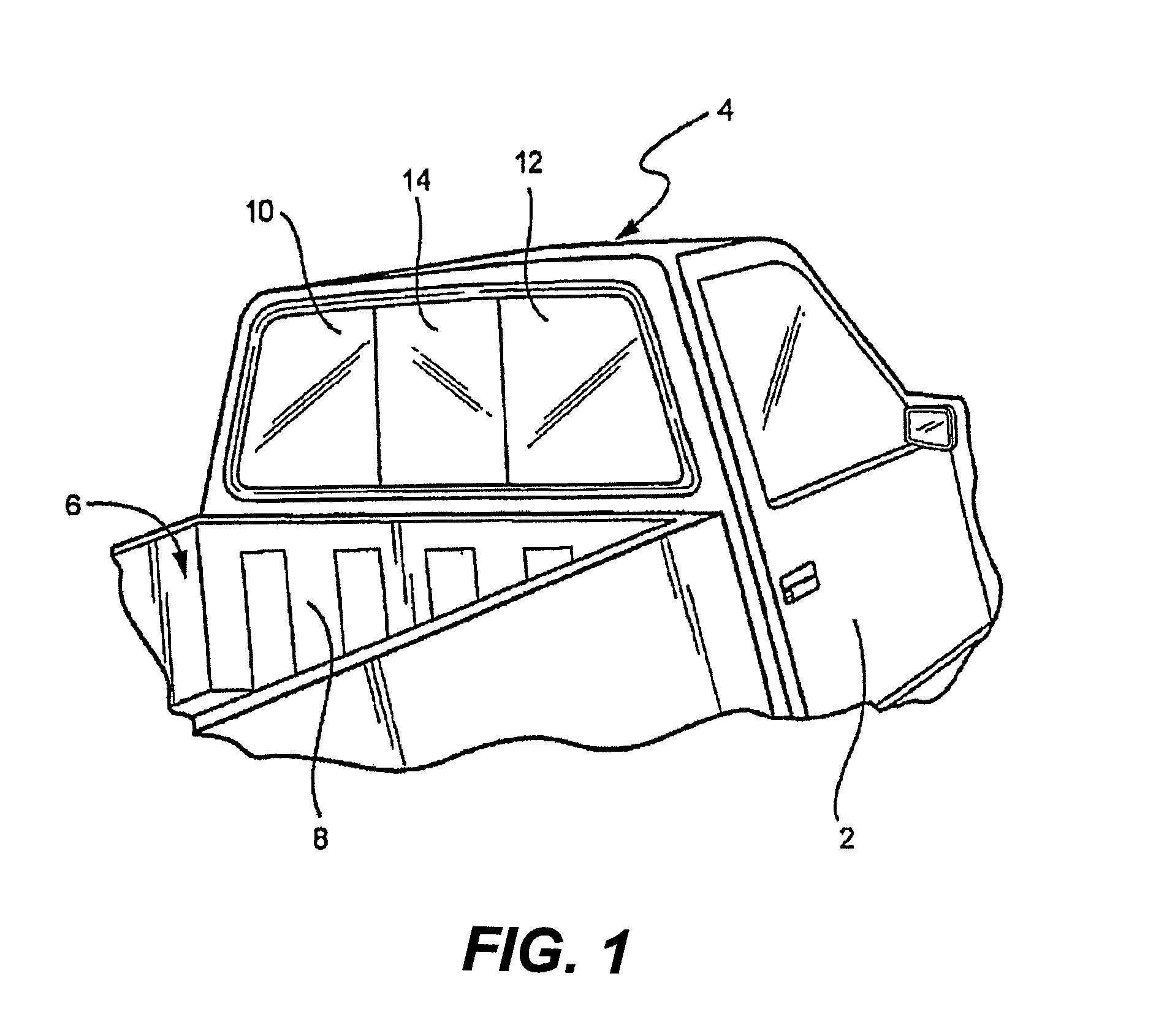

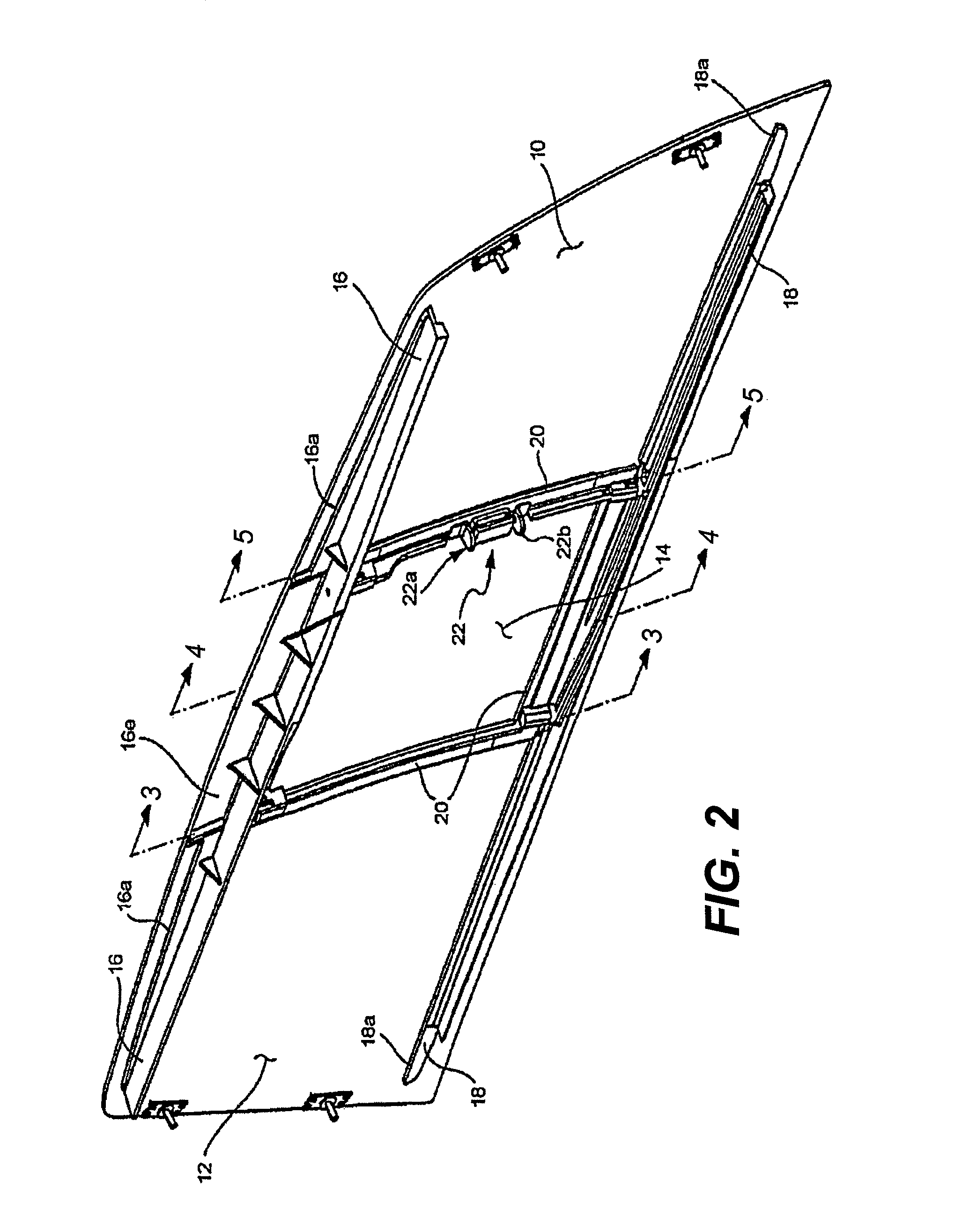

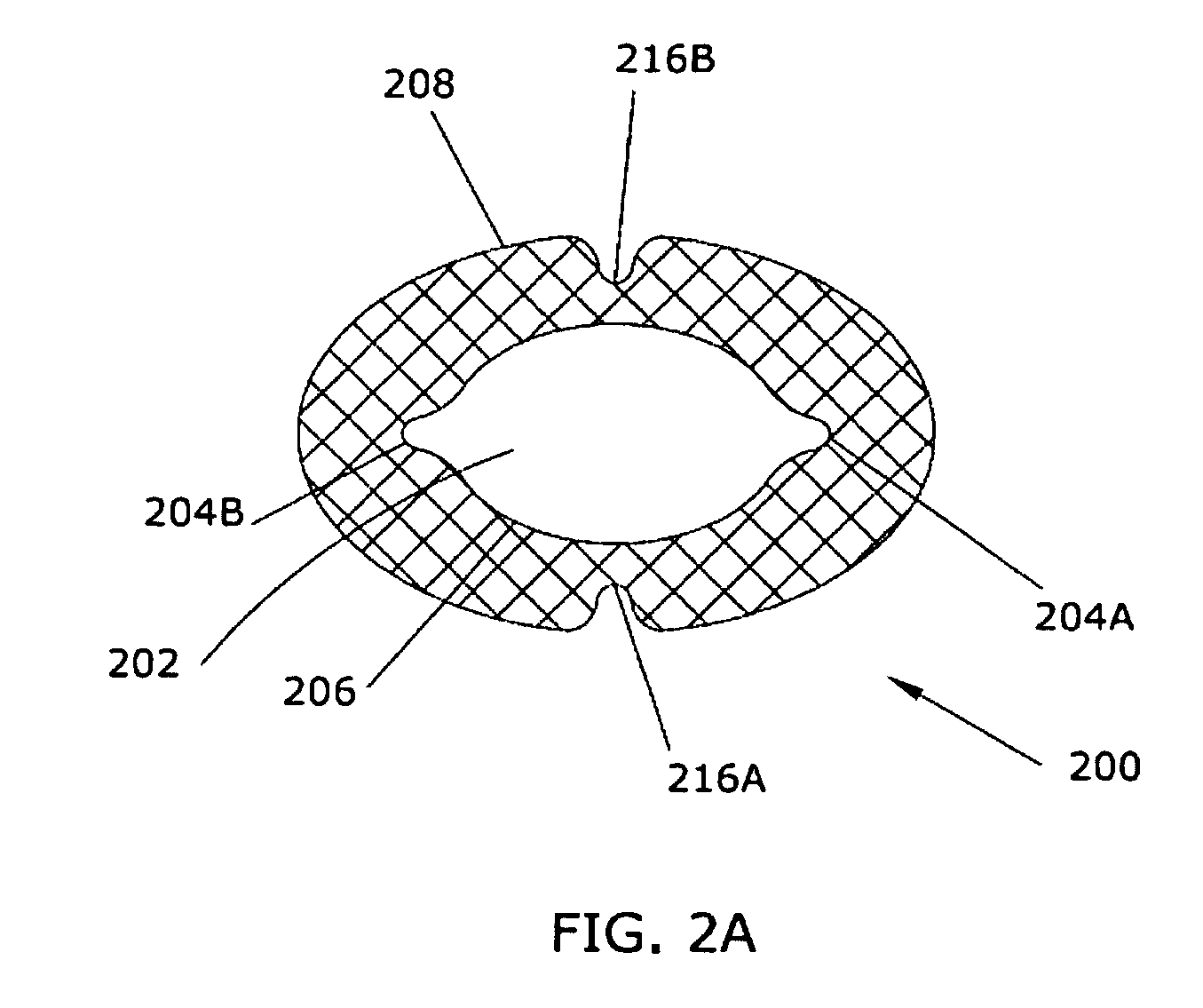

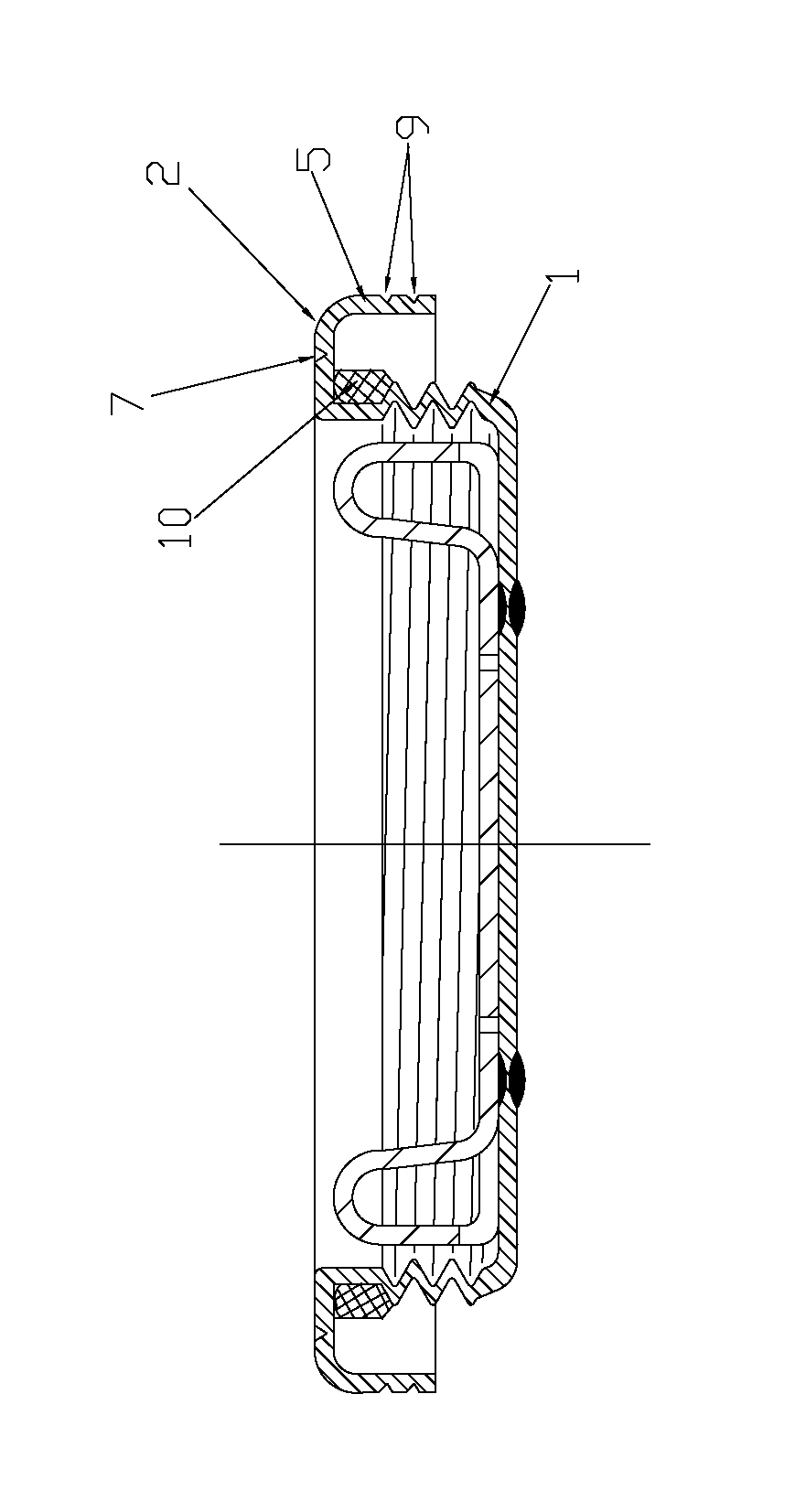

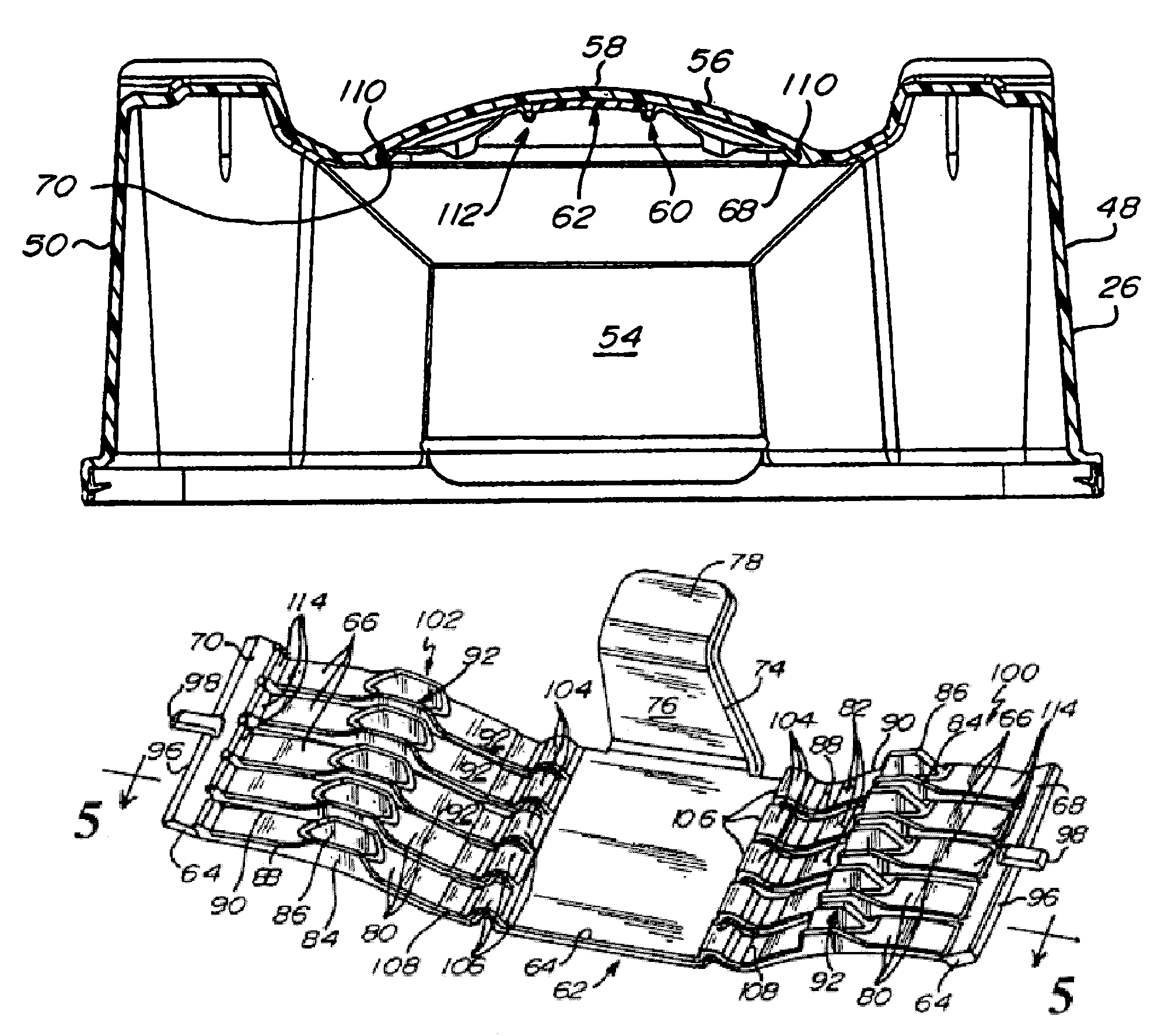

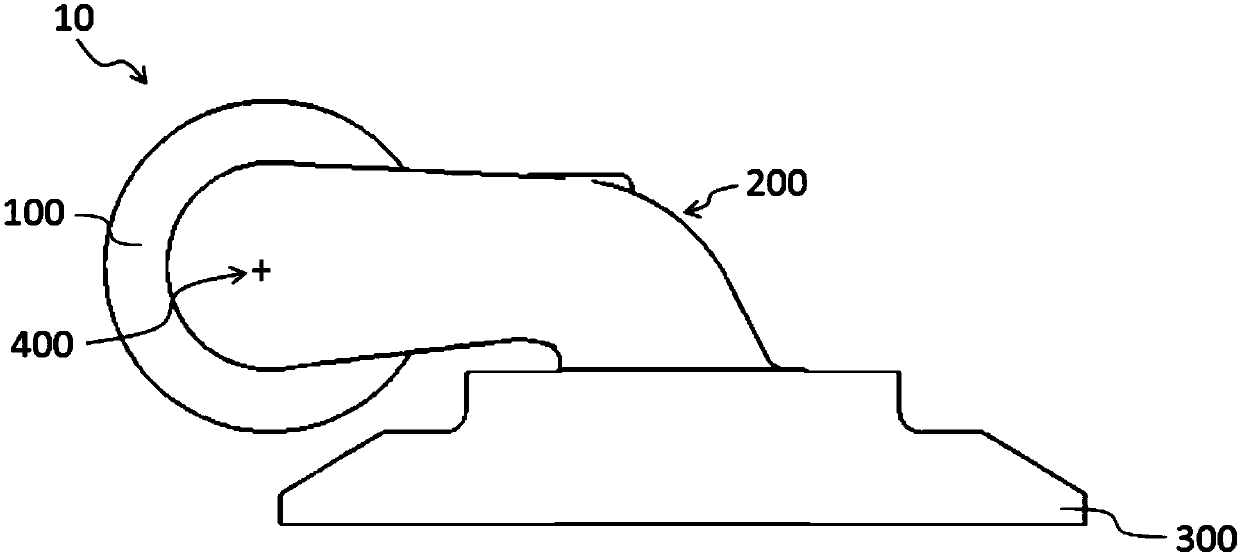

Supported hollow seal

InactiveUS8069615B2Prevent leakageAvoid sealing effectSealing arrangementsVehicle sealing arrangementsPick-up truckEngineering

A hollow seal for use in sealing between relatively movable first and second panels, such as between a fixed window panel and a slidable window panel of a rear window of a pick-up truck or the like. The hollow seal has an internal geometry that supports an outside layer or portion of the seal under pressurization to prevent leakage and seal blowout. The outside portion is shaped to provide a pair of laterally spaced-apart sealing lips that have a pressure-activated sealing geometry for tight sealing against the panels when under pressurization.

Owner:PARKER HANNIFIN CORP

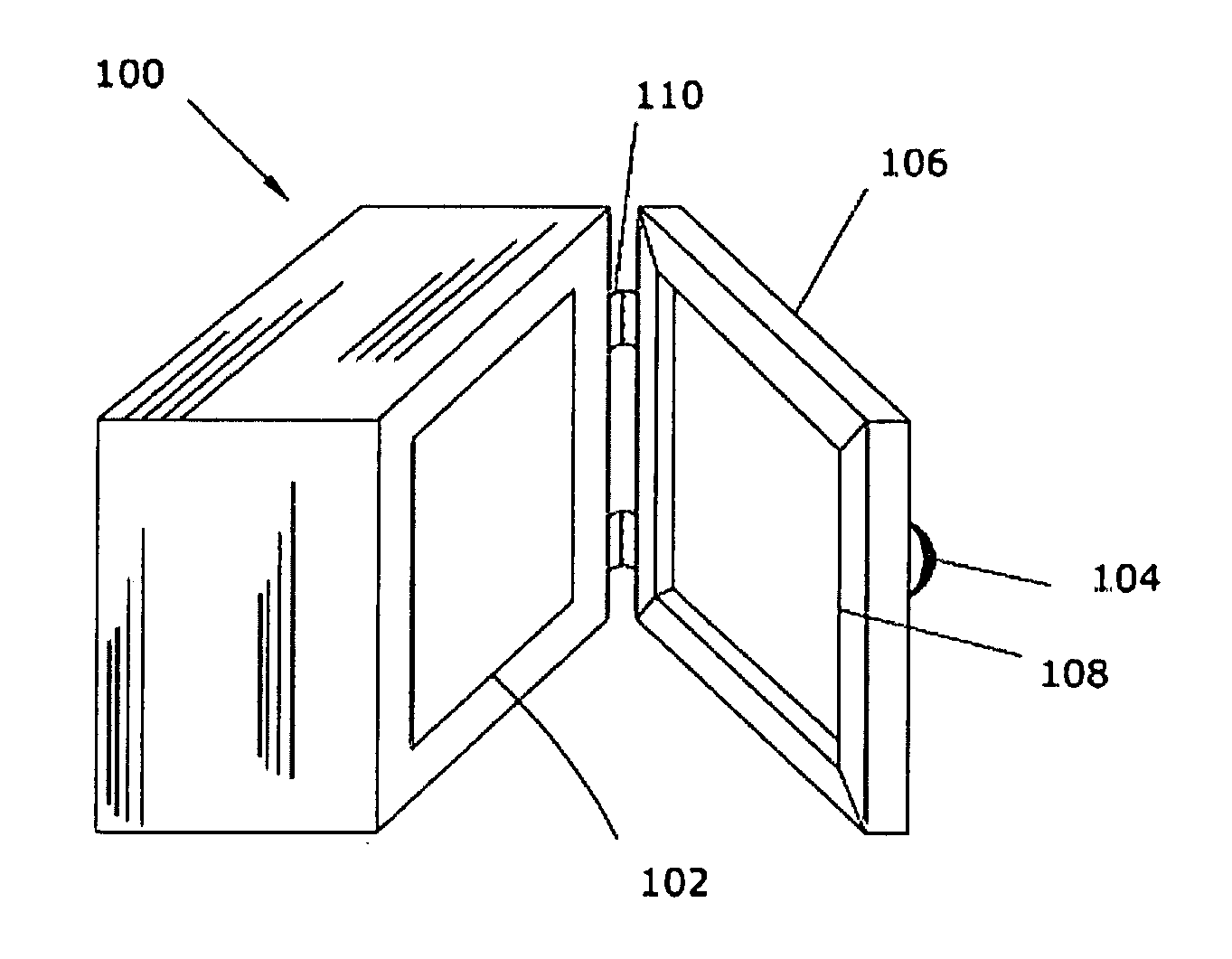

Strip gaskets for EMI shielding

ActiveUS7375291B2Reduce closing forceLower resistanceElectrically conductive connectionsScreening gaskets/sealsBand shapeElectromagnetic interference

A strip gasket utilizing a low closure force on an enclosing face for shielding electromagnetic interference is disclosed. The strip gasket includes an outer surface and an inner surface. The inner surface provides a hollow cross section region. Bending moments are created on surface peripheries of the inner surface and the outer surface, or both, to provide a low closure force on an enclosing face. The bending moment results in an increased surface area of the strip gasket providing a low resistance. Cauchy's stress analysis reveals that a lower force is required to compress the strip gasket as compared to conventional strip gaskets.

Owner:PARKER INTANGIBLES LLC

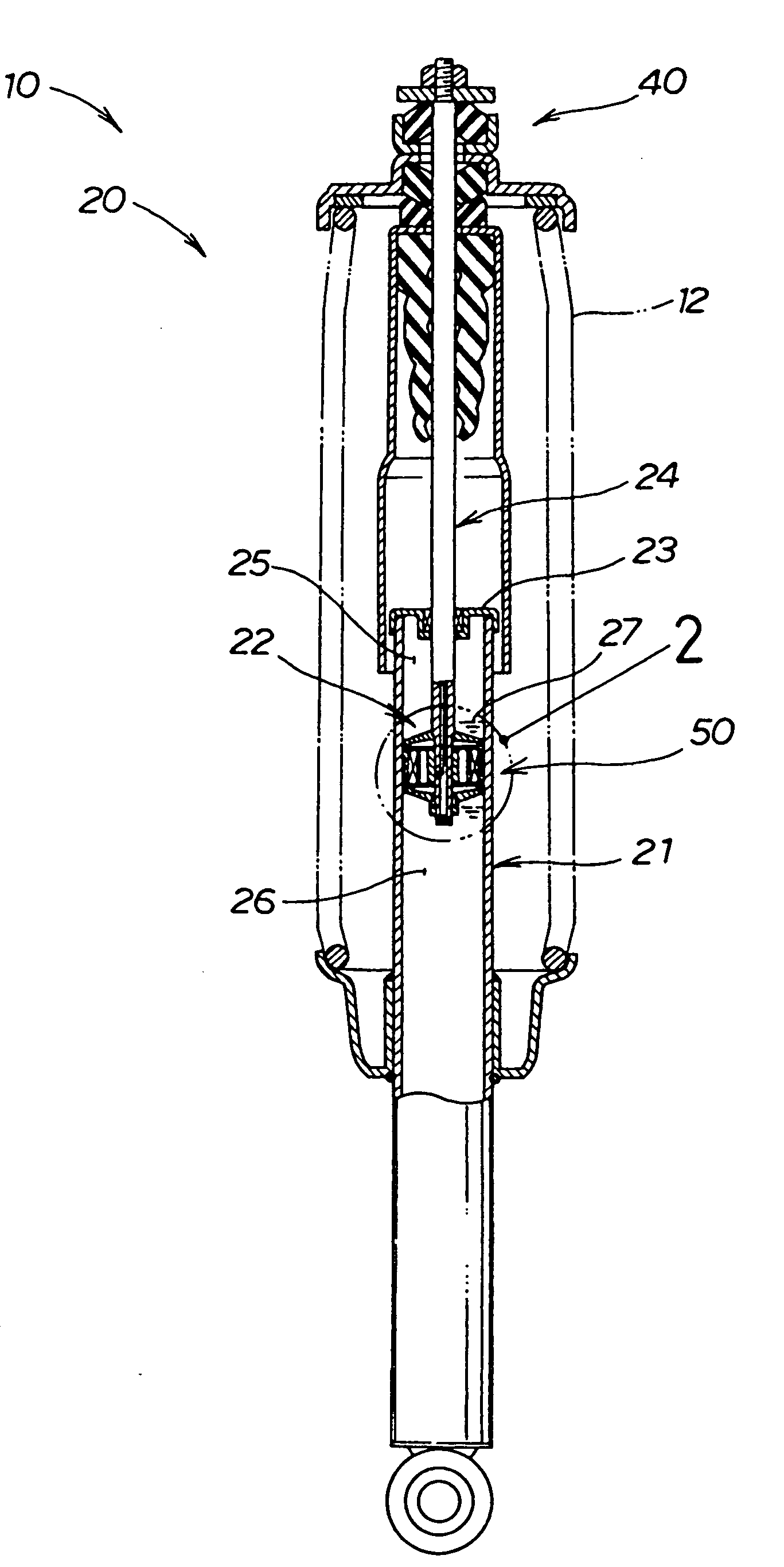

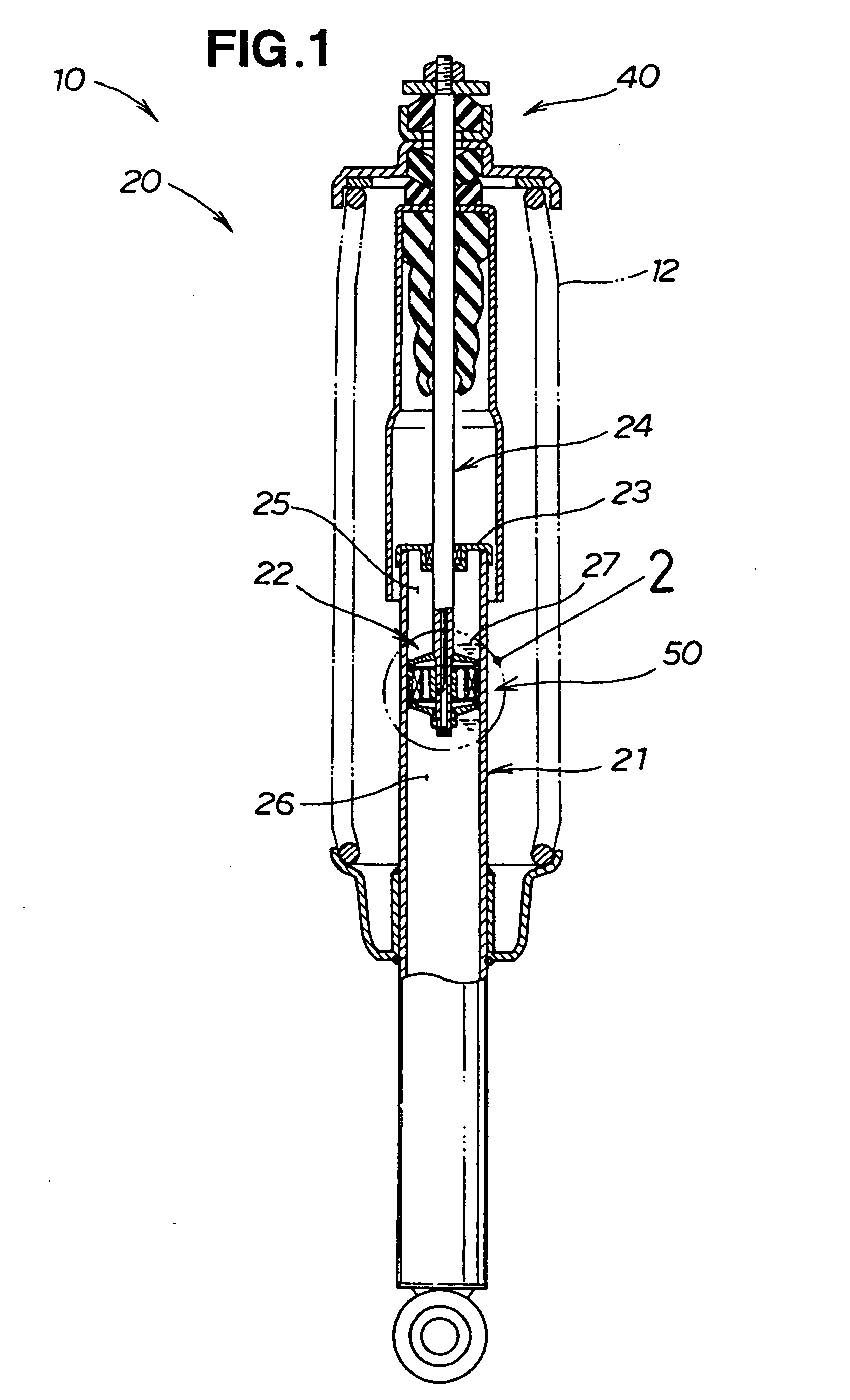

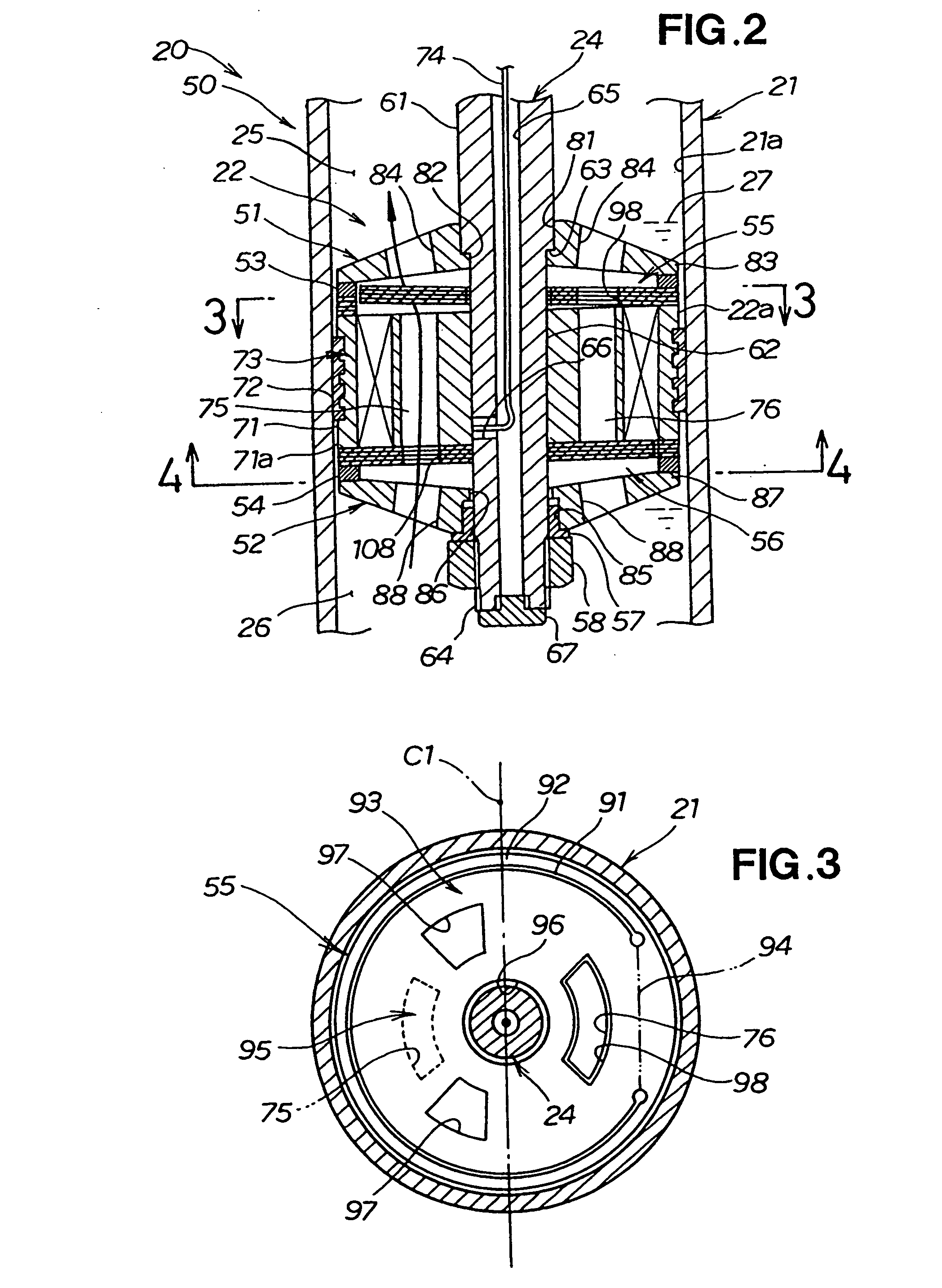

Vehicle damper of variable damping force

InactiveUS20080277217A1Improve responsivenessHighly responsive valve controlSpringsLiquid based dampersEngineeringControl theory

A vehicle damper of variable damping force including a cylinder, a piston and valves is disclosed. The valves have opening / closing parts and supporting parts. The opening / closing parts and the supporting parts are positioned separately so that a sufficient distance is obtained. Lengthening the distance from the supporting parts to the opening / closing parts makes it possible to reduce the opening and closing force of the opening / closing parts and to obtain highly responsive valves.

Owner:HONDA MOTOR CO LTD

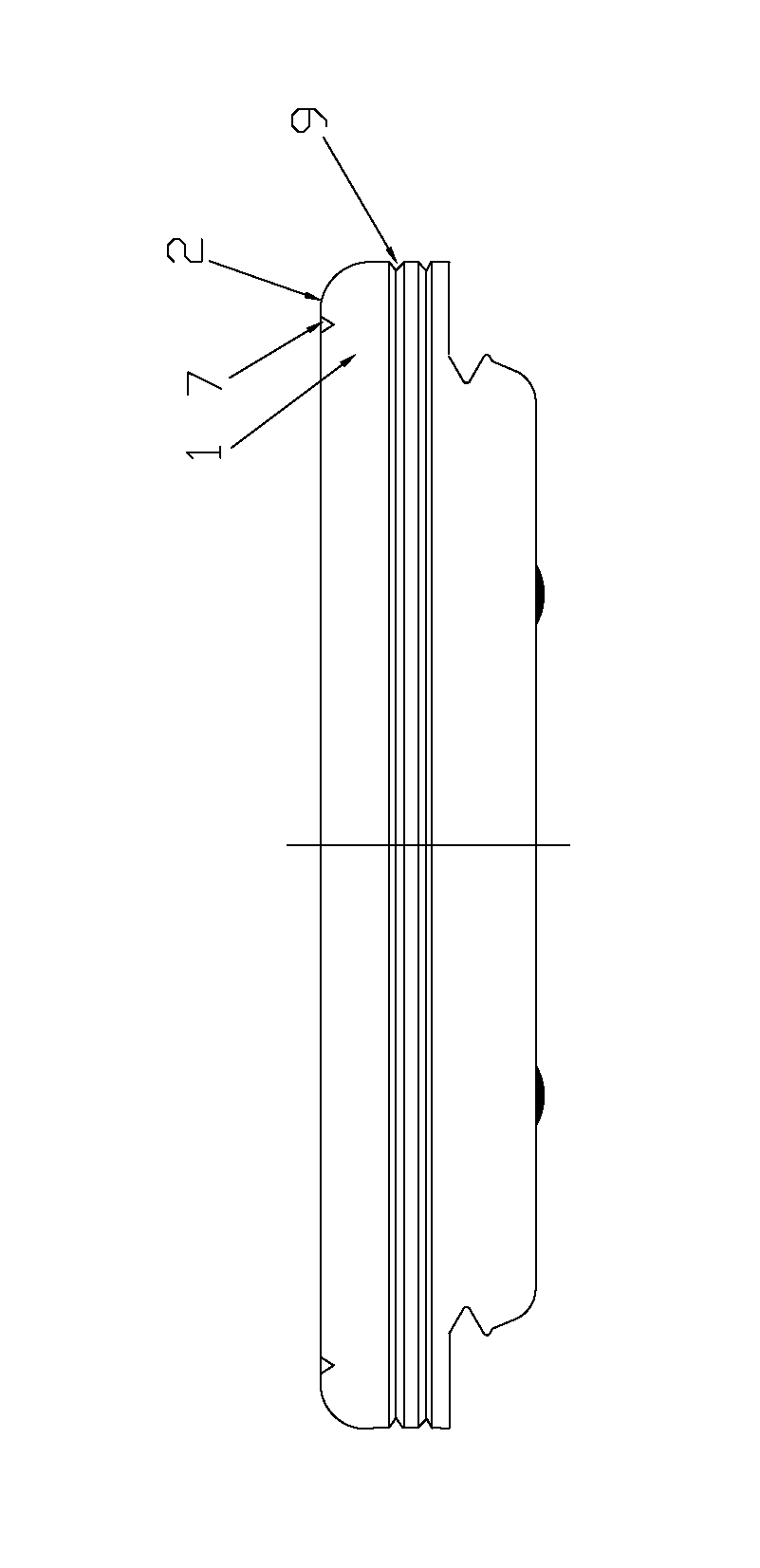

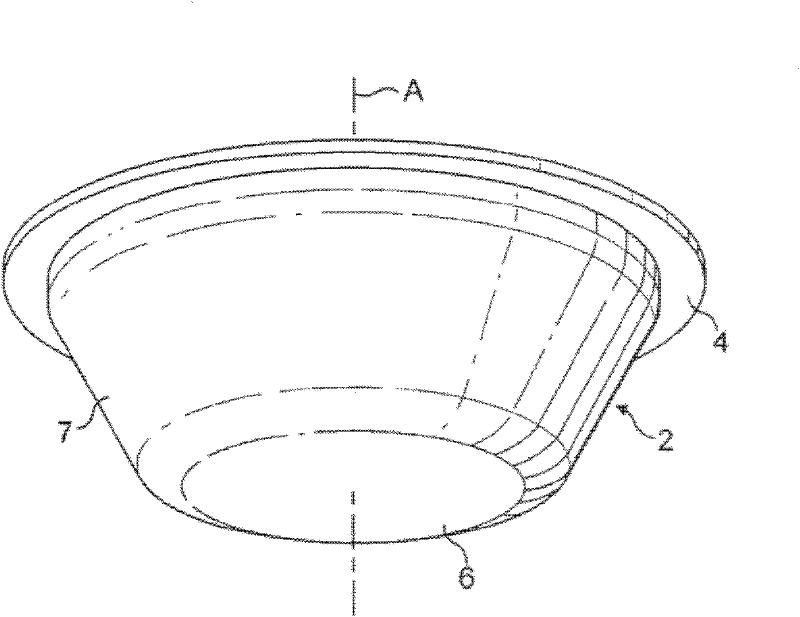

Anti-counterfeiting and anti-theft disposable barrel bung

The invention discloses an anti-counterfeiting and anti-theft disposable barrel bung. The barrel bung comprises a barrel bung body (1) and is characterized in that the outer circle of the upper end of the barrel bung body (1) is connected with an anti-counterfeiting and anti-theft ring (2) which can be torn down under the opening force of the barrel bung and can be left on a helicoidal flange (3) connected with a barrel body (4) after being separated from the barrel bung body (1); a breaking groove (7) or a breaking line which facilitates separation is formed at the connection part of the anti-counterfeiting and anti-theft ring (2) and the barrel bung body (1); the anti-counterfeiting and anti-theft ring (2) is provided with an opening contracting edge (5); and the minimum inner diameter of the opening contracting edge (5) after assembly and contraction can ensure that the anti-counterfeiting and anti-theft ring (2) can not be separated from the helicoidal flange (3) on the barrel body (4) on the non-destruction premise after being separated from the barrel bung body (1). The disposable barrel bung is simple in structure, convenient to manufacture, and good in anti-counterfeiting and anti-theft effects.

Owner:张有龙

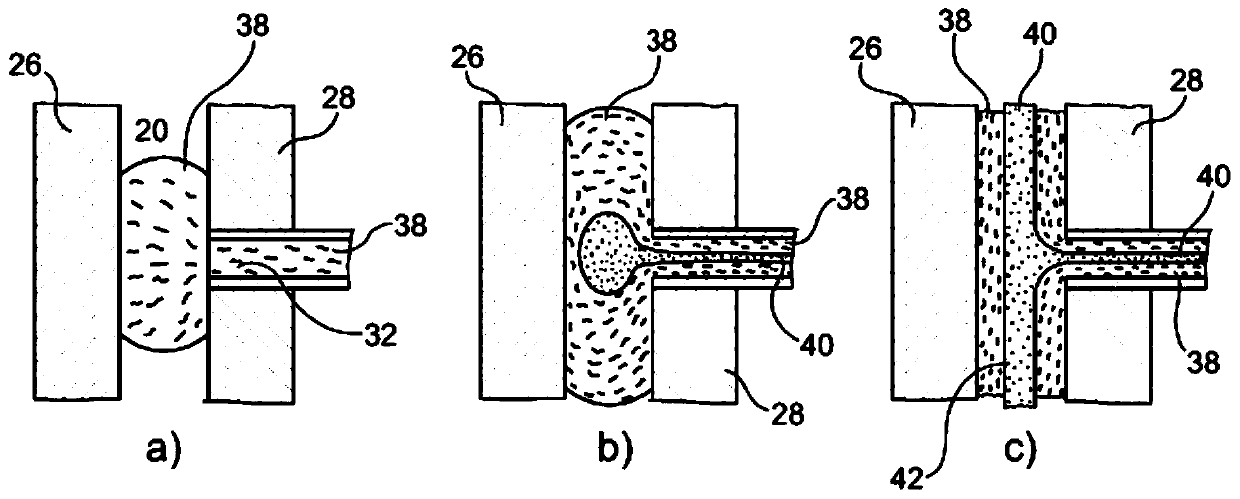

Casting device and casting method

InactiveCN104001860AFlow velocity increases or decreasesDoes not require complex controlsFoundry mouldsFoundry coresElectromagnetic castingElectromagnetic field

The invention relates to a direct electromagnetic casting driving apparatus (1) and a method of manufacturing a cast component through a plurality of casting channels (10, 11, 12). Different solution channels (20, 21, 22) in the casting channels (10, 11, 12) are heated, braked or accelerated in different degrees by means of the electromagnetic fields of electrified coils (30, 31, 32, 33). A non-contact feed is also provided. Required casting driving force is reduced. The invention ensures controllable starting of a second casting step and reverse action on edge layer solification. Meanwhile, the running material is reduced and the injection weight is minimized.

Owner:舒乐绞扭机有限责任公司

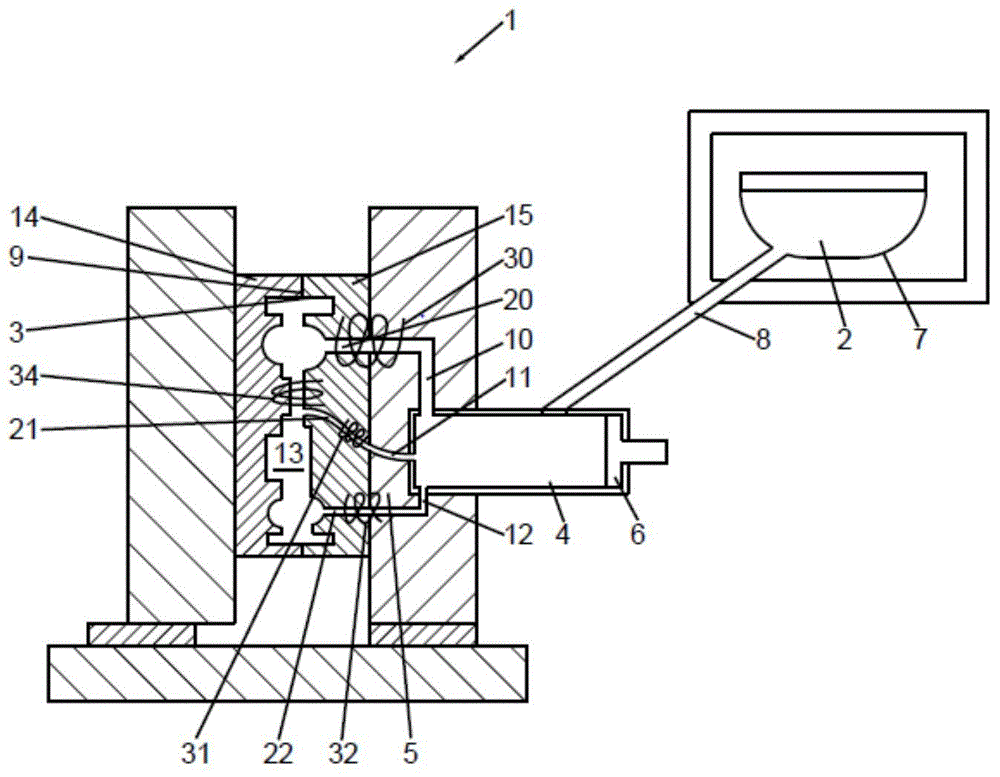

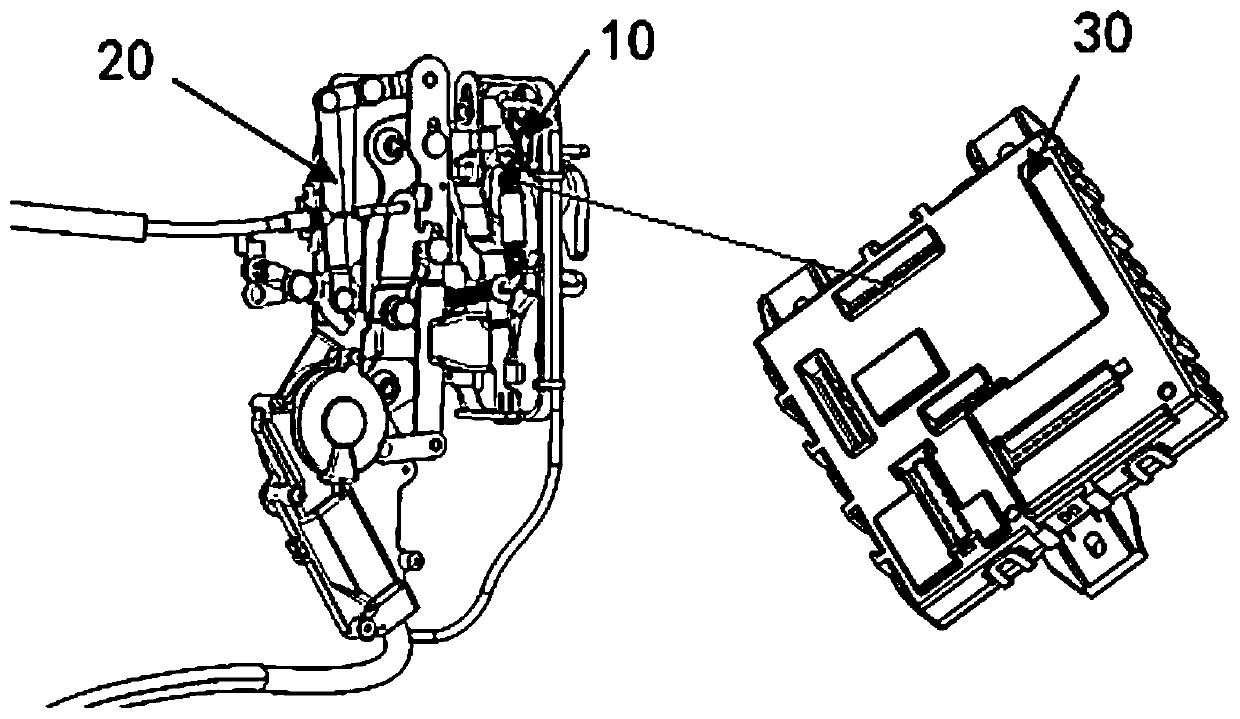

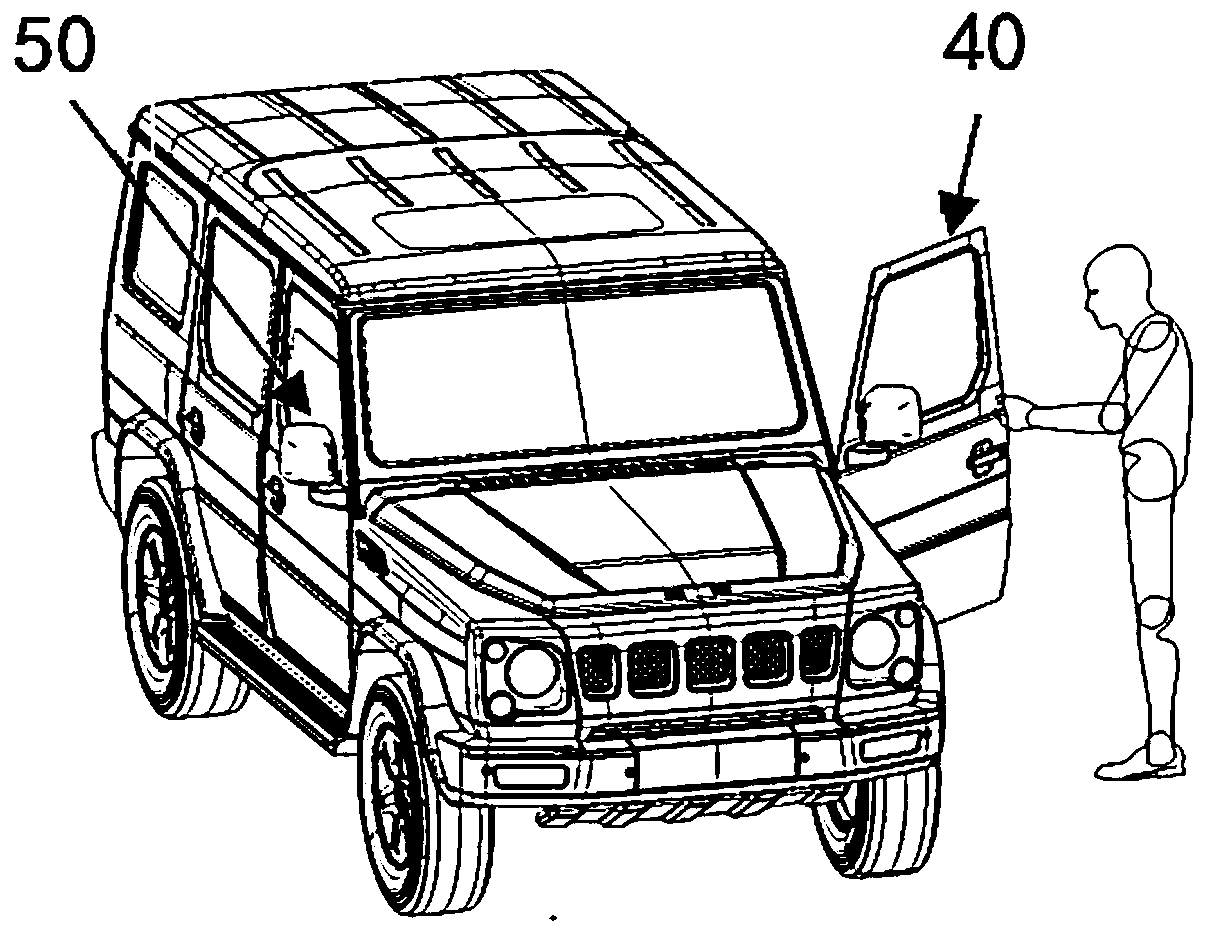

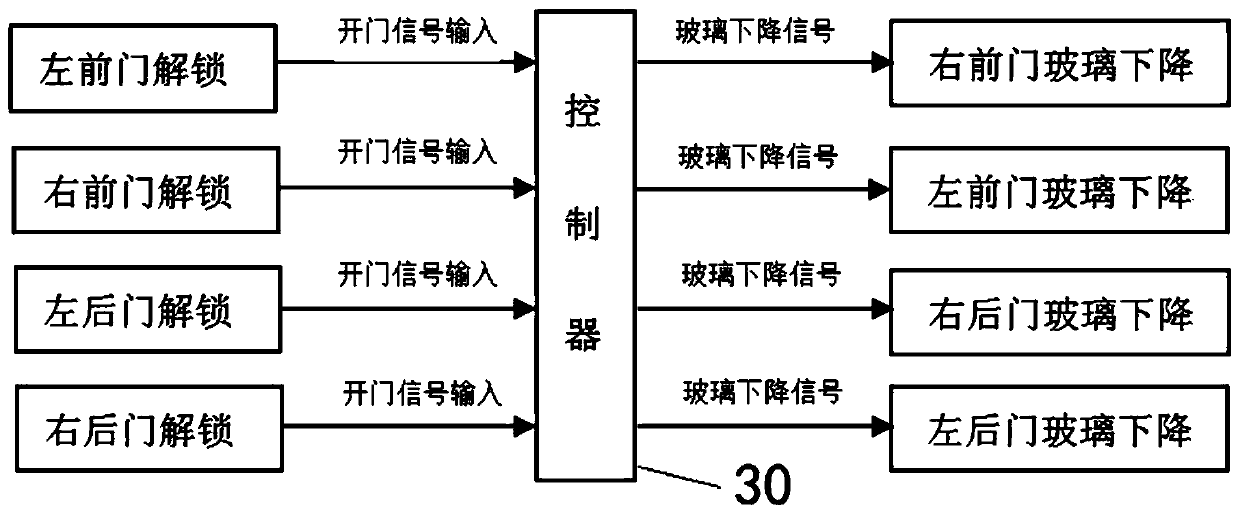

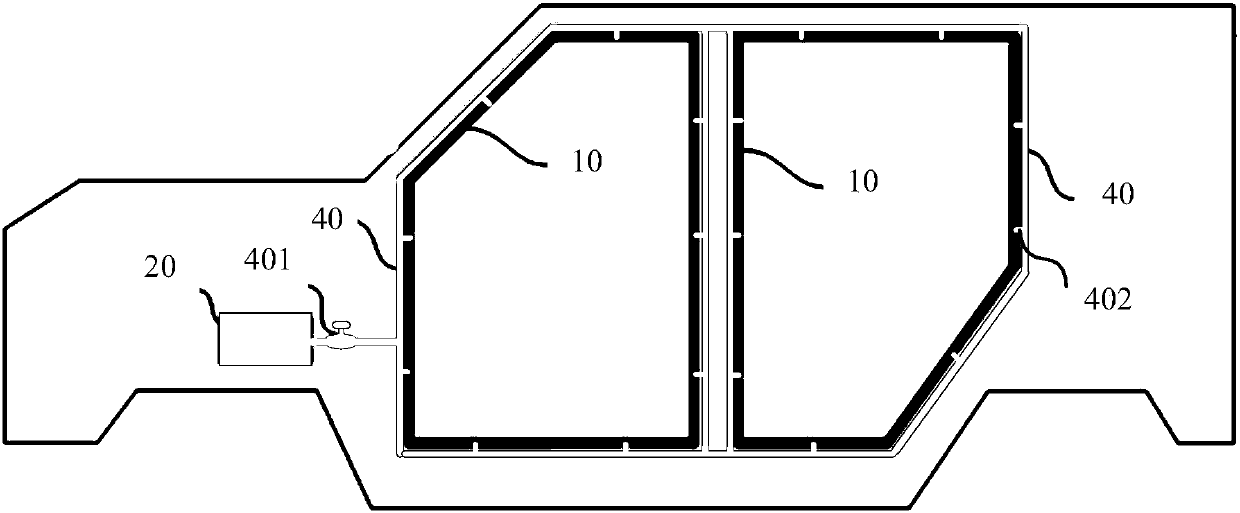

Device capable of reducing automobile door closing force and ear pressure sense and automobile

PendingCN110656842AReduce closing forceEliminate ear pressurePower-operated mechanismElectrical locking circuitsCar doorControl engineering

The invention provides a device capable of reducing automobile door closing force and an ear pressure sense and an automobile. The device capable of reducing the automobile door closing force and theear pressure sense includes a door lock sensor and a controller; the door lock sensor is connected with a door lock of an automobile door to detect states of the automobile door and send state signals; and the controller is connected with a lifter of window glass of the automobile, and the controller receives the state signals to control lifting up or down of the window glass. According to the device capable of reducing the automobile door closing force and the ear pressure sense, in the process of using, when the automobile door is opened, the window glass is controlled to automatically descend for a certain distance to generate a gap, in the process of closing the automobile door, the air squeezed into a passenger cabin is discharged from a window, air is discharged in time to eliminatethe impact of air pressure resistance on the door closing force, so as to effectively reduce the door closing force and to eliminate the ear pressure sense, the rectification period of the door closing force is shortened, the design change cost is lowered, and the quality of the automobile is improved.

Owner:BAIC GRP ORV CO LTD

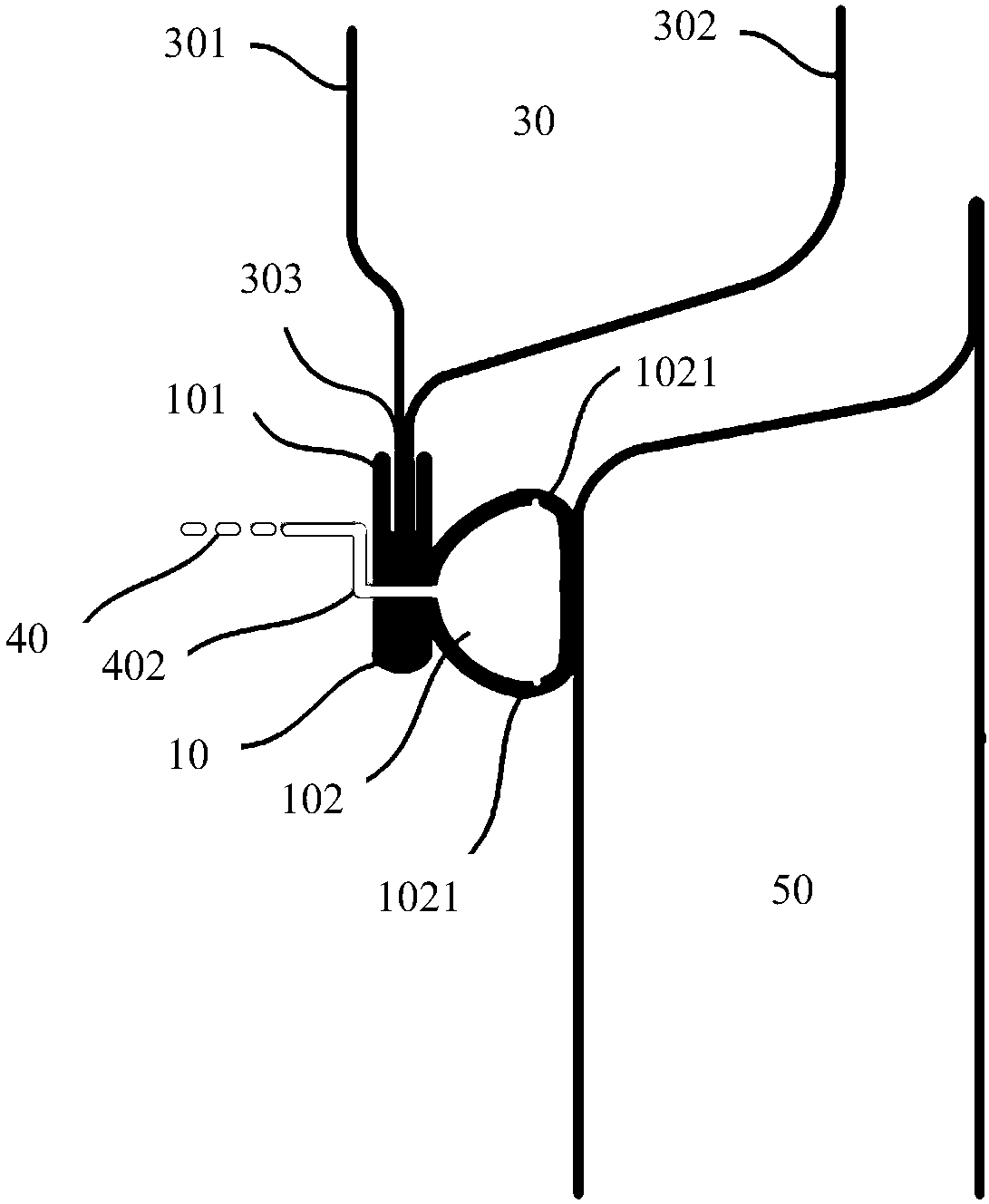

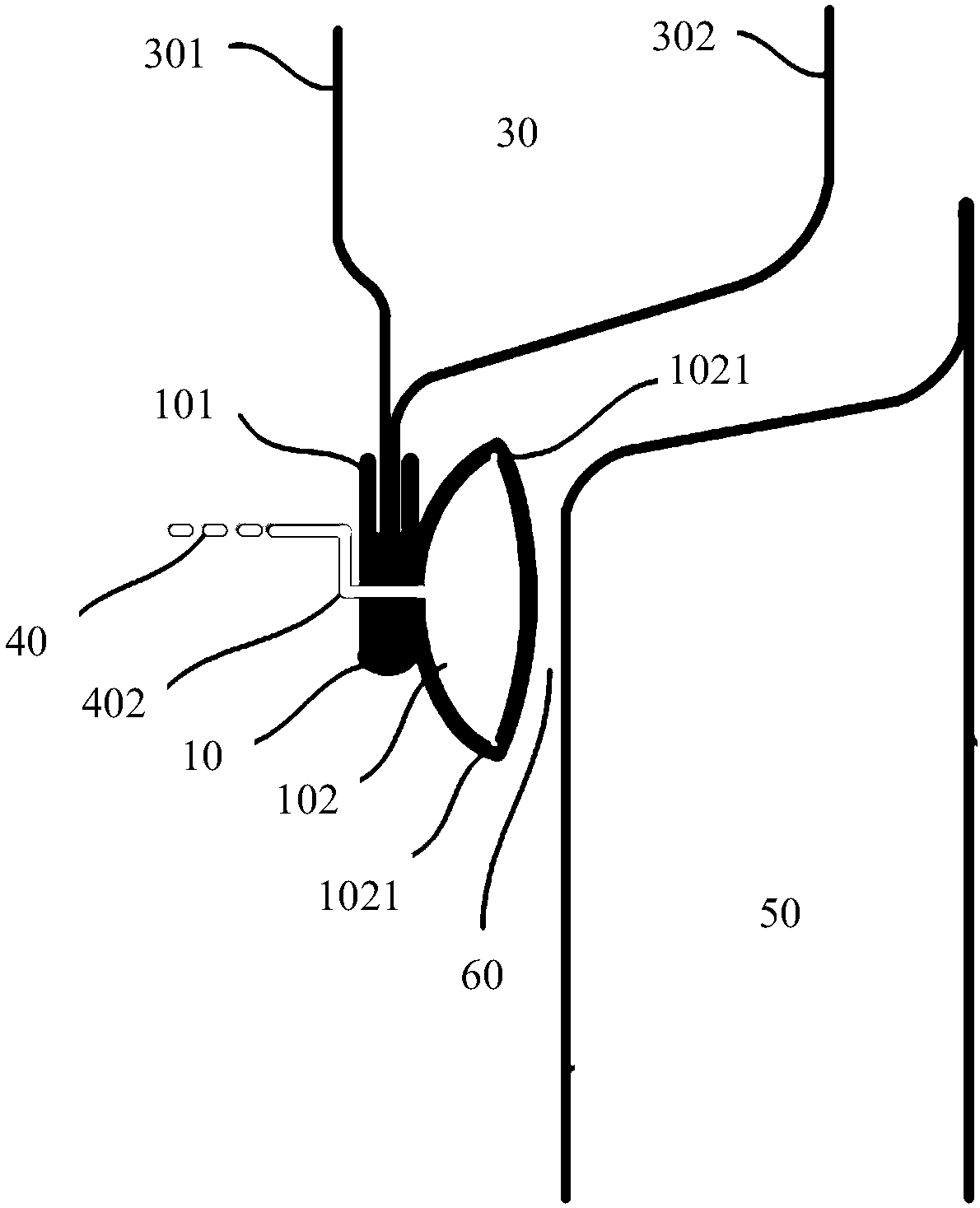

Vehicle sealing assembly and method and vehicle

PendingCN107804146AAchieve sealingSmall changes in air pressureEngine sealsVehicle sealing arrangementsIn vehicleEngineering

The invention provides a vehicle sealing assembly and method and a vehicle. The vehicle sealing assembly comprises a sealing strip and an air pump, wherein the sealing strip comprises a sealing stripclamping groove and a sealing strip foaming pipe which is arranged on a coaming of the vehicle through the sealing strip clamping groove; the air pump is communicated with the sealing strip foaming pipe through an air guide pipe and used for extracting air in the sealing strip foaming pipe when a vehicle door is in an open state and filling air into the sealing strip foaming pipe when the vehicledoor is in a close state. By means of the vehicle sealing assembly, compared with the prior art, the in-vehicle air pressure changes little in the vehicle door closing process, the situation that thein-vehicle pressure is quickly increased, so that the strength for closing the door is high can be avoided, the strength for closing the door can be effectively reduced, and meanwhile, vehicle sealingcan be achieved after the door is closed.

Owner:BAIC GRP ORV CO LTD

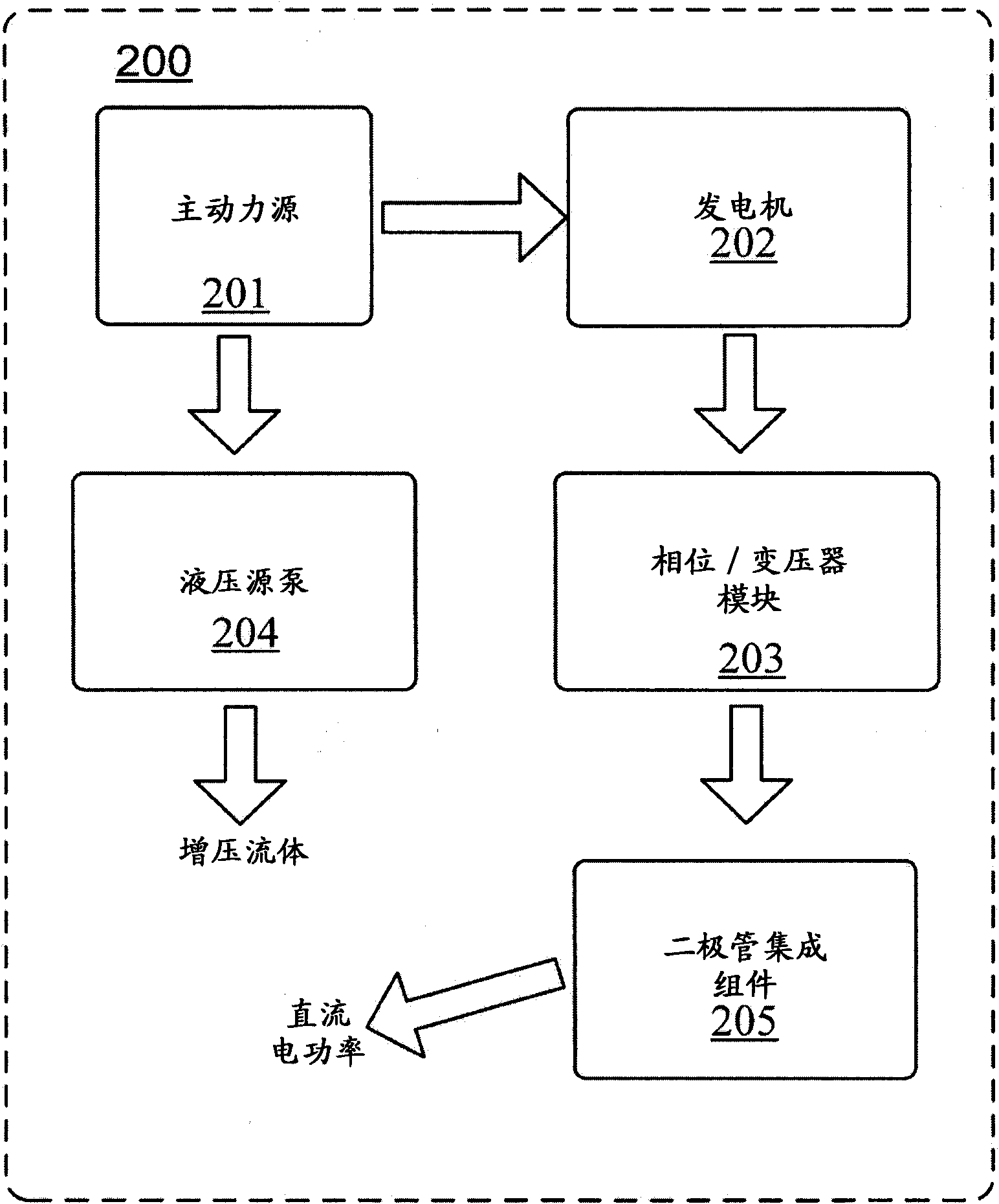

Liquid food preparation system for preparing a liquid food by centrifugation

ActiveCN102245066AReduce the perforation forceReduce closing forceBeverage vesselsMedicineCentrifugation

The present invention relates to a liquid food preparation system for preparing a liquid food from a food substance comprising a device and a capsule removably insertable in the device, by passing water through the substance in the capsule, comprising a water injection head for injecting water in the capsule and a capsule holder for holding the capsule in the device, means for driving the capsule in centrifugation, perforating means which are configured relative to the capsule in the device to open outlets at the periphery of the capsule, a capsule comprising a delivery pierceable membrane, wherein said perforating means, are suited to be engaged through the membrane for forming with the perforated membrane a filtering means for retaining solid particles in the capsule and orifices in the membrane for enabling the centrifuged liquid to leave the capsule.

Owner:SOC DES PROD NESTLE SA

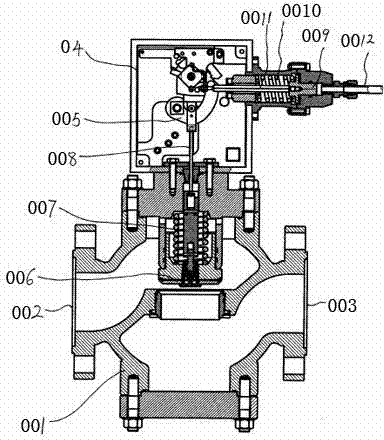

Safety shut-off valve

InactiveCN104763827AImprove securityImprove organizational structureOperating means/releasing devices for valvesEqualizing valvesEngineeringShock resistance

The invention discloses a safety shut-off valve. The safety shut-off valve comprises a valve body, an upper valve body and a shut-off mechanism. The valve body is provided with a first channel and a second channel, the upper valve body is connected with the upper end of the valve body through a screw and used for sealing the valve body, and the shut-off mechanism is arranged in the middle of the valve body and used for connecting or disconnecting the first channel and the second channel. The safety shut-off valve is characterized in that the shut-off mechanism comprises a shut-off part and a cam connecting device which are separated from each other; the valve body is integrally formed by forged steel in a turn milling mode. The independent cam connecting device is adopted, so that separated repair is facilitated, and the situation that the shut-off valve cannot work normally due to maintenance assembly errors is avoided; the internal structure of the valve body is simple, the forged steel integration valve body is adopted, the internal organizational structure of the valve body is improved, grains are refined, the mechanical properties, such as shock resistance, plasticity and toughness, of the forged steel integration valve body are superior to those of a cast steel valve body, and the safety performance of the valve is improved.

Owner:北京润凡电子制造有限公司

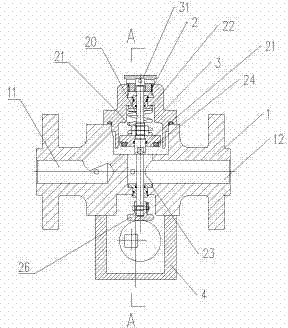

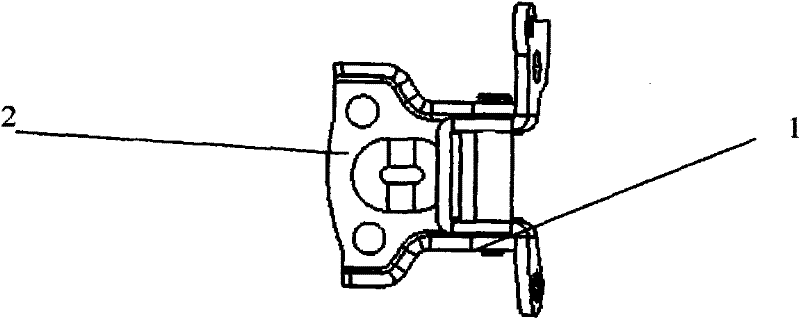

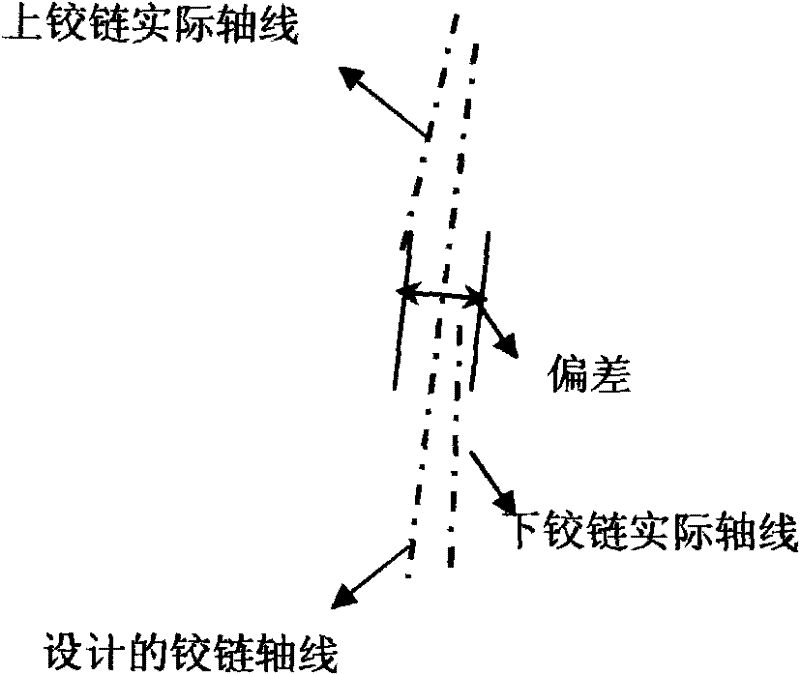

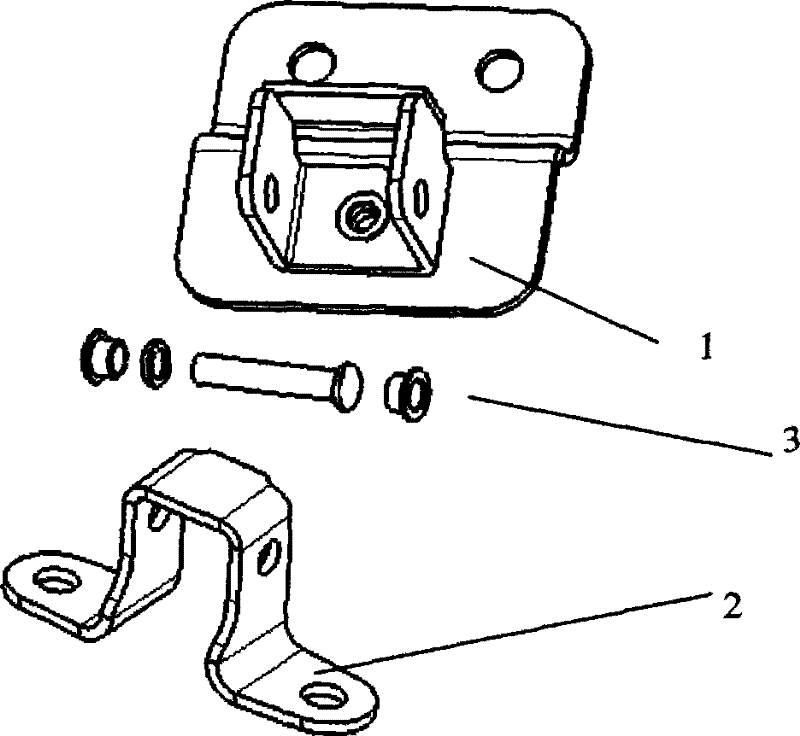

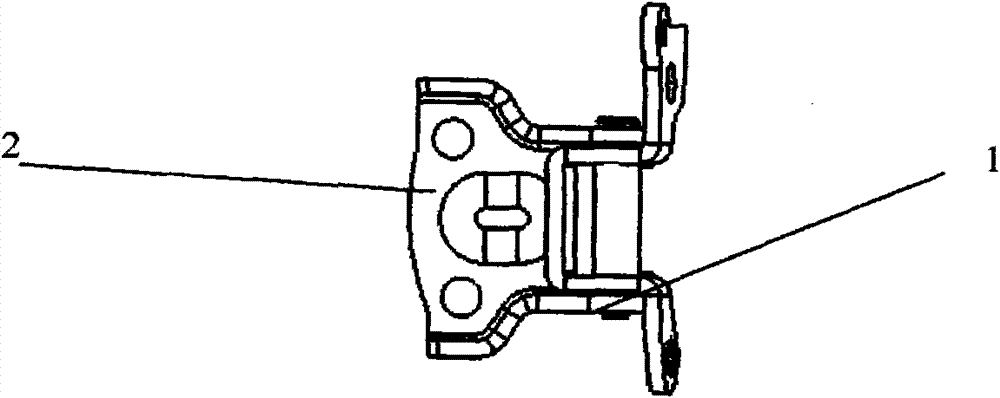

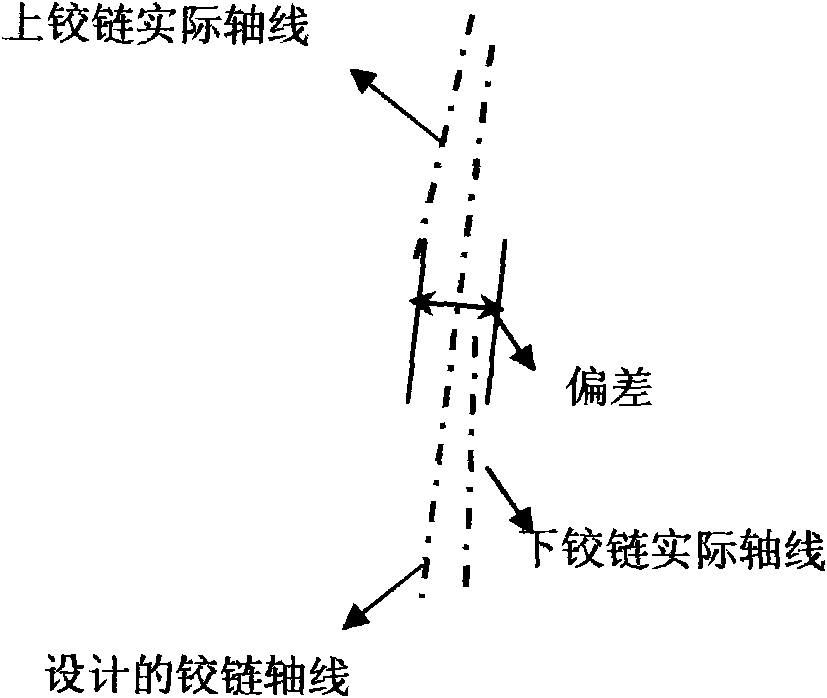

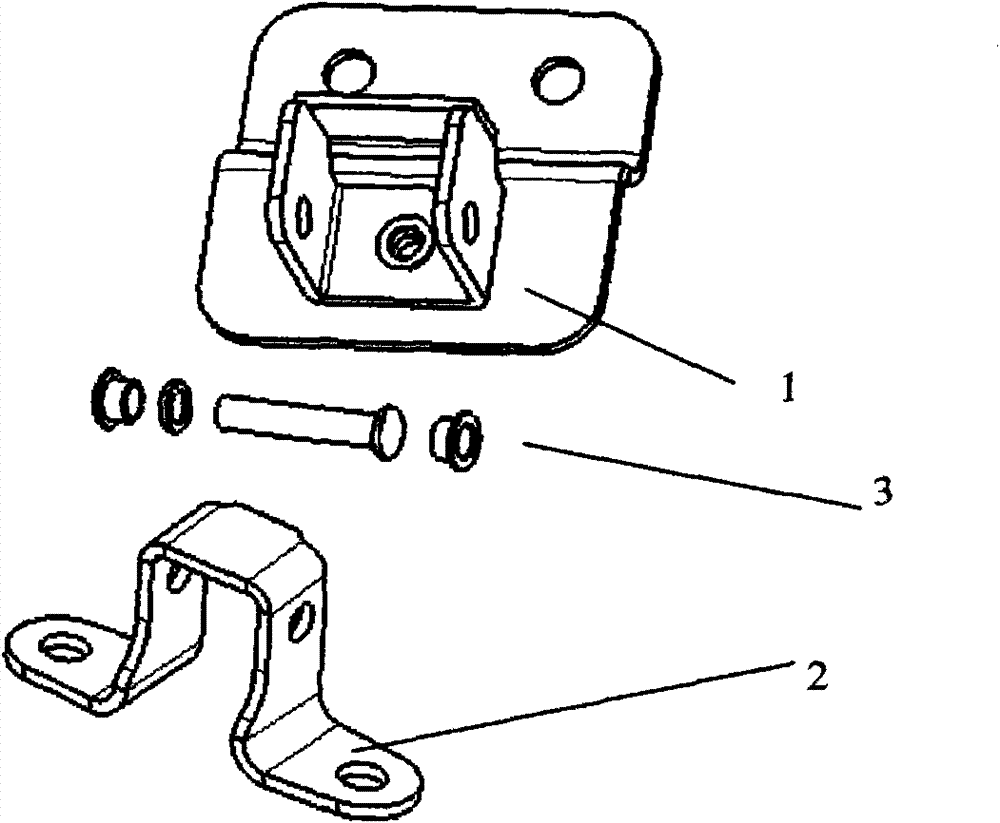

Car door hinge

The invention discloses a car door hinge. The car door hinge comprises a fixed piece, a movable piece and a connecting piece, wherein the fixed piece and the movable piece are connected with each other through the connecting piece; the fixed piece comprises an installation part and a rotor; the installation part is installed on the car body structure; and the rotor is connected with the installation part through a rivet and can rotate on the installation plane of the installation part around the rivet, thereby adjusting the rotation axis of the hinge. The hinge of the invention can automatically adjust the coaxiality of the upper part and the lower part, overcome the bound force and effectively reduce the possibility of abnormal sound and vibration when the user opens or closes the car door. The hinge greatly reduces the closing force of the door and ensures that the car door can be easily opened and closed, thereby relieving the abrasion, prolonging the service life and saving the manufacturing cost.

Owner:CHERY AUTOMOBILE CO LTD

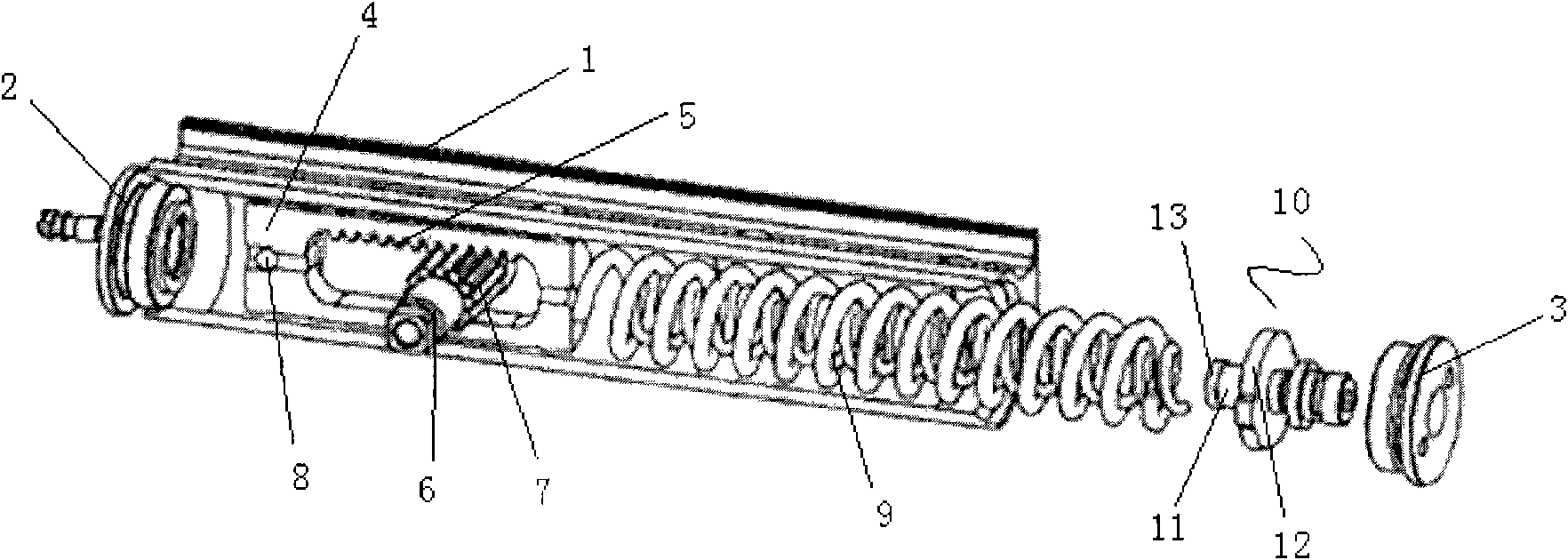

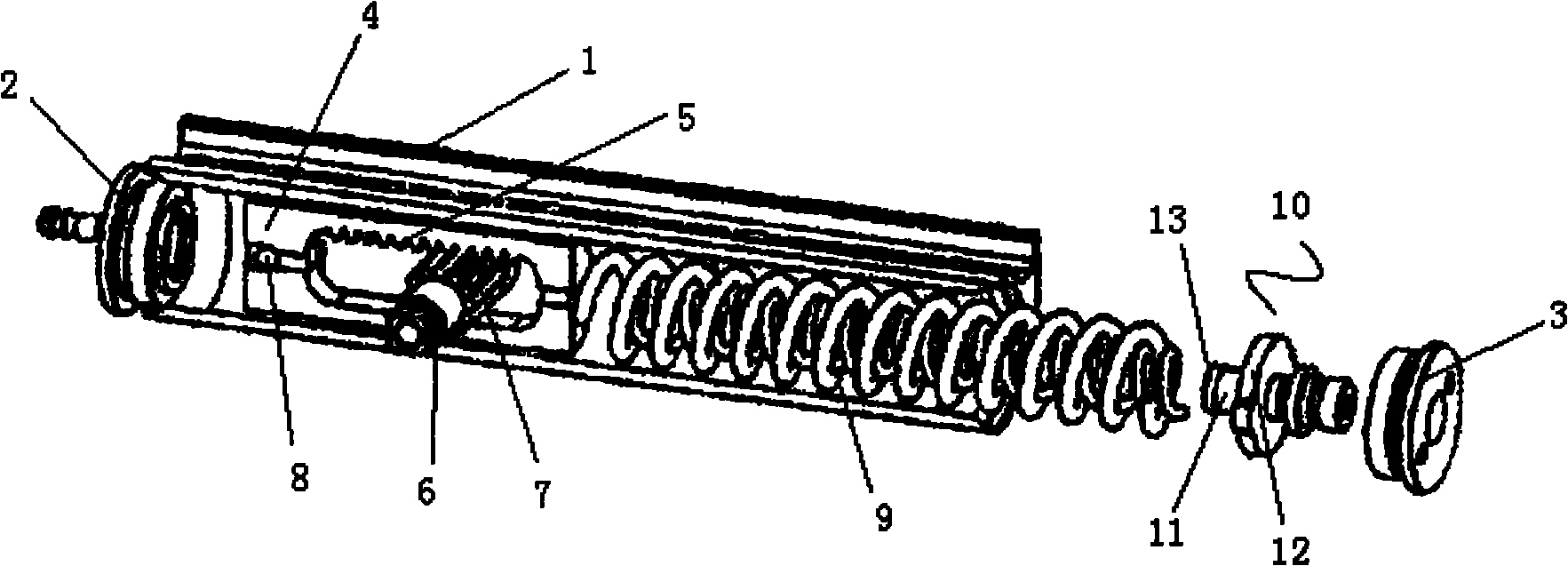

Door closer hydraulic mechanism for fine regulating door-closing power

InactiveCN102182377ASmall amount of compressionReduce closing forceBuilding braking devicesEngineeringSteel ball

The invention discloses a hydraulic mechanism of a door closer. The hydraulic mechanism comprises a cylindrical valve body. Two ends of the valve body are provided with a front end cover and a rear end cover respectively; a rack piston is arranged in a valve chamber of the valve body; the inner wall of the rack piston is provided with a rack; a gear shaft is arranged in a through hole passing through walls of the valve body and the rack piston; the gear shaft is provided with a transmission gear, and the transmission gear is meshed with the rack; the left end of the rack piston is provided with a check valve steel ball; the right end of the rack piston is connected with a compression spring arranged in the right chamber of the valve body; and a power regulator for fine door-closing power is arranged between the rear end cover at the right end of the valve body and the compression spring. The hydraulic mechanism has a function of finely regulating completely satisfactory door-closing power of a user with no limit, so the same door closer can be applicable to different door widths and door weights.

Owner:ZHAOQING CITY ZHISHENG DOOR CONTROL HARDWARE CO LTD

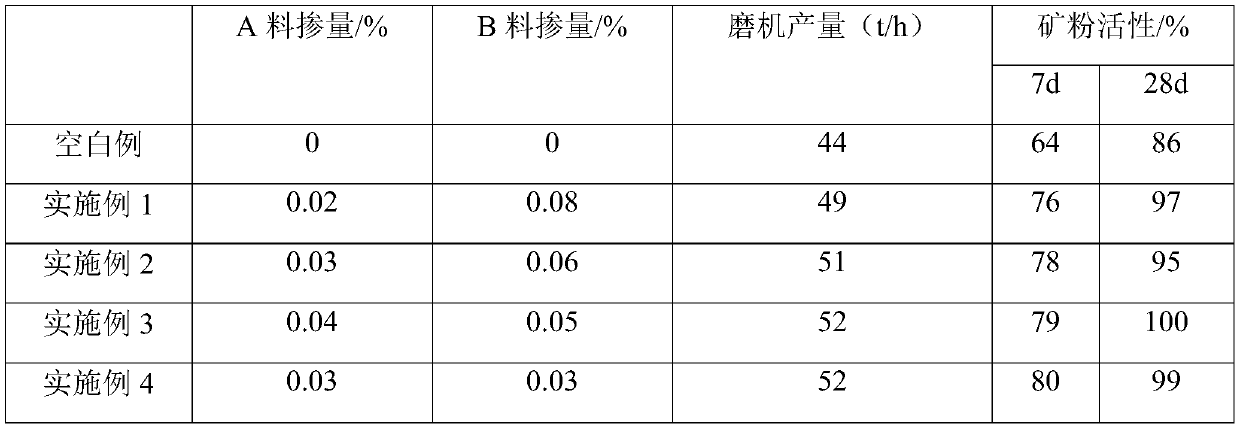

Activity excitation type grinding aid used for vertical mill grinding mineral slag

The invention discloses an activity excitation type grinding aid used for vertical mill grinding mineral slag, and belongs to the technical field of mineral slag additive. The activity excitation typegrinding aid used for vertical mill grinding mineral slag is composed of a material A and a material B; the material A is composed of, by weight, 15-30 parts of polypropylene-based amine salt, 10-15parts of diisopropylethanolamine, 5-10 parts of triglycol, 3-10 parts of ethylene glycol butyl ether acetate, and 50-75 parts of water; the material B is composed of, by weight, 5 to 8 parts of redispersible latex powder, 10 to 20 parts of ultrafine aluminum silicate, 10 to 20 parts of an activator, and 40 to 70 parts of limestone powder. According to the invention, a plurality of chlorine-free components are adopted, optimization of design composition is adopted so as to obtain the activity excitation type grinding aid used for vertical mill grinding mineral slag; in the activity excitation type grinding aid used for vertical mill grinding mineral slag, the synthetic effect of the components is achieved, so that problems of conventional grinding aid such as poor grinding air effect on vertical mill grinding mineral slag are solved, and at the same time, mineral powder activity is excited effectively.

Owner:安徽海螺材料科技股份有限公司 +1

Reusable resilient cushion for wafer container

ActiveUS8528738B2Avoid stickingEliminates potentially catastrophic resultSemiconductor/solid-state device manufacturingOther accessoriesInterior spaceEngineering

Owner:ENTEGRIS INC

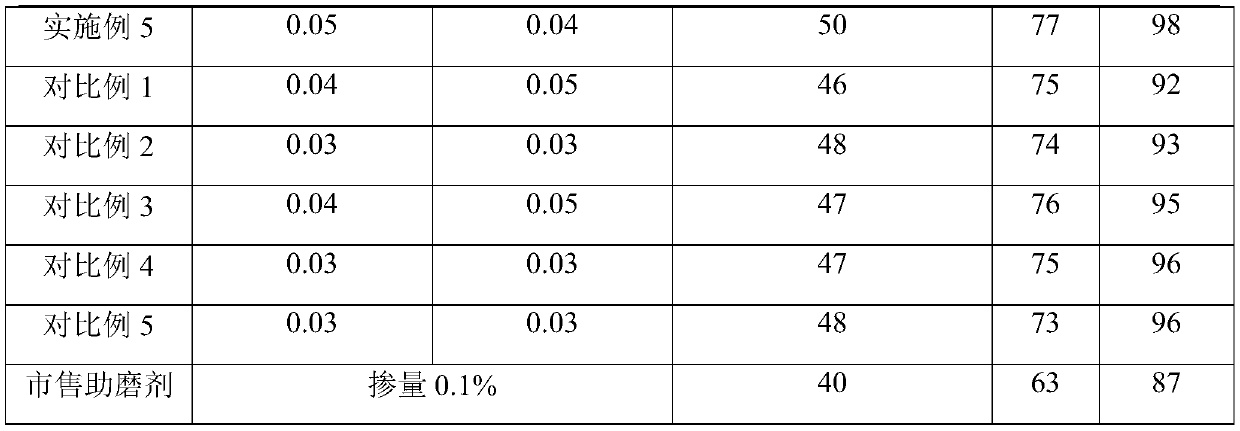

Active grinding aid for vertical mill ground steel slag

The invention discloses an active grinding aid for vertical mill ground steel slag, and belongs to the technical field of steel slag admixtures. The active grinding aid comprises an active excitation component and a composite grinding aid component, wherein the active excitation component comprises the following raw materials in parts by weight: 5-10 parts of molasses, 5-10 parts of triethylene glycol, 3-7 parts of aluminum sulfate and 2-6 parts of calcium formate; the composite grinding aid component comprises the following raw materials in parts by weight: 10-20 parts of an alcamine component, 5-10 parts of citric acid, 3-5 parts of an exciting agent and 1-5 parts of an activating agent. The use of the alcamines grinding aid is greatly reduced, the mixing amount is small, the grinding efficiency is high, the obtained steel slag is high in specific surface area and good in activity, efficient resource utilization of the waste steel slag is achieved, and the active grinding aid has wide economic benefits and social benefits.

Owner:金明寓建设集团有限公司

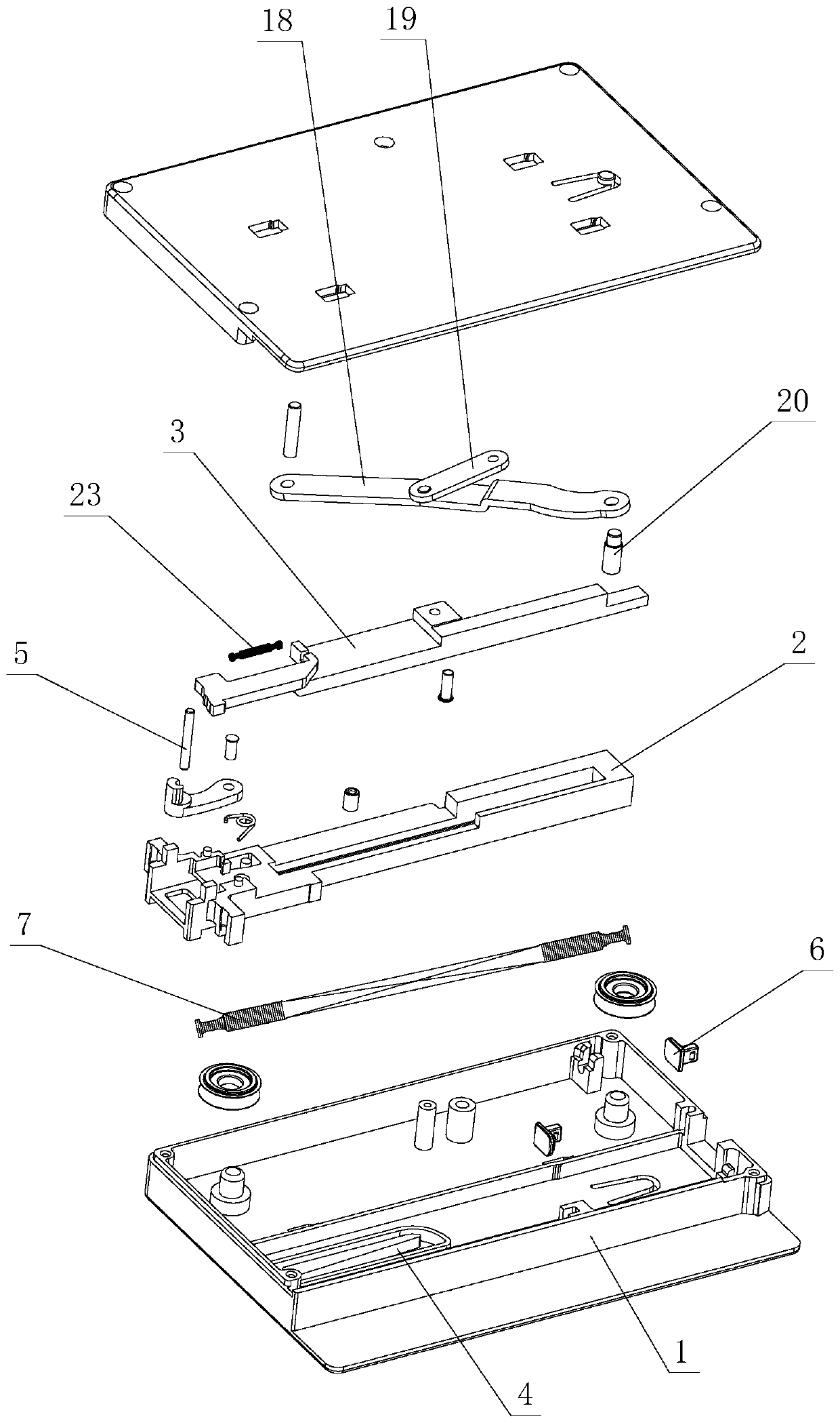

Furniture mutelabor-savingpressingand reboundingopening-closing structure

PendingCN110269415AImprove user experienceAvoid collisionBuilding braking devicesWing openersEngineeringDriving mode

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

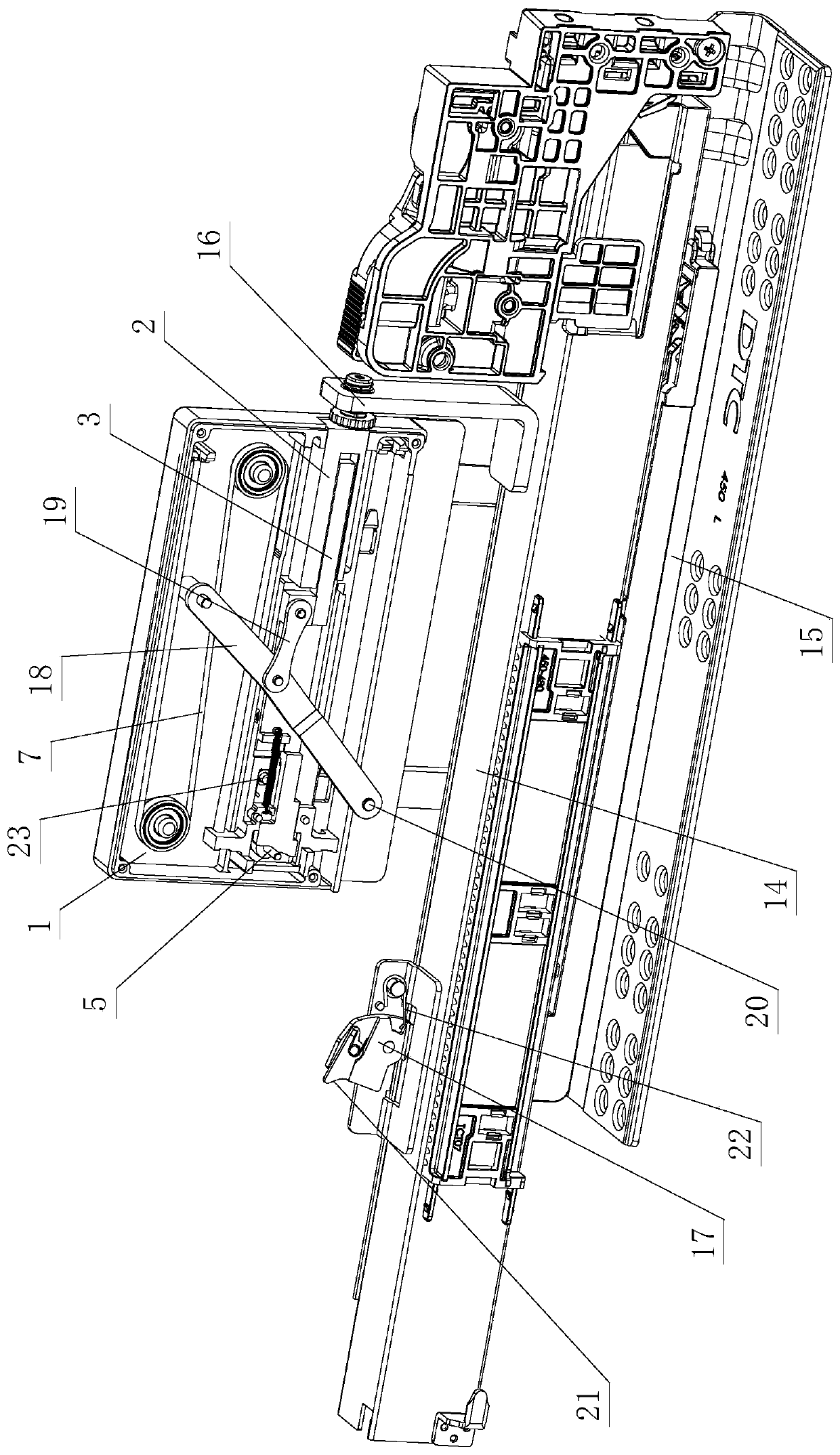

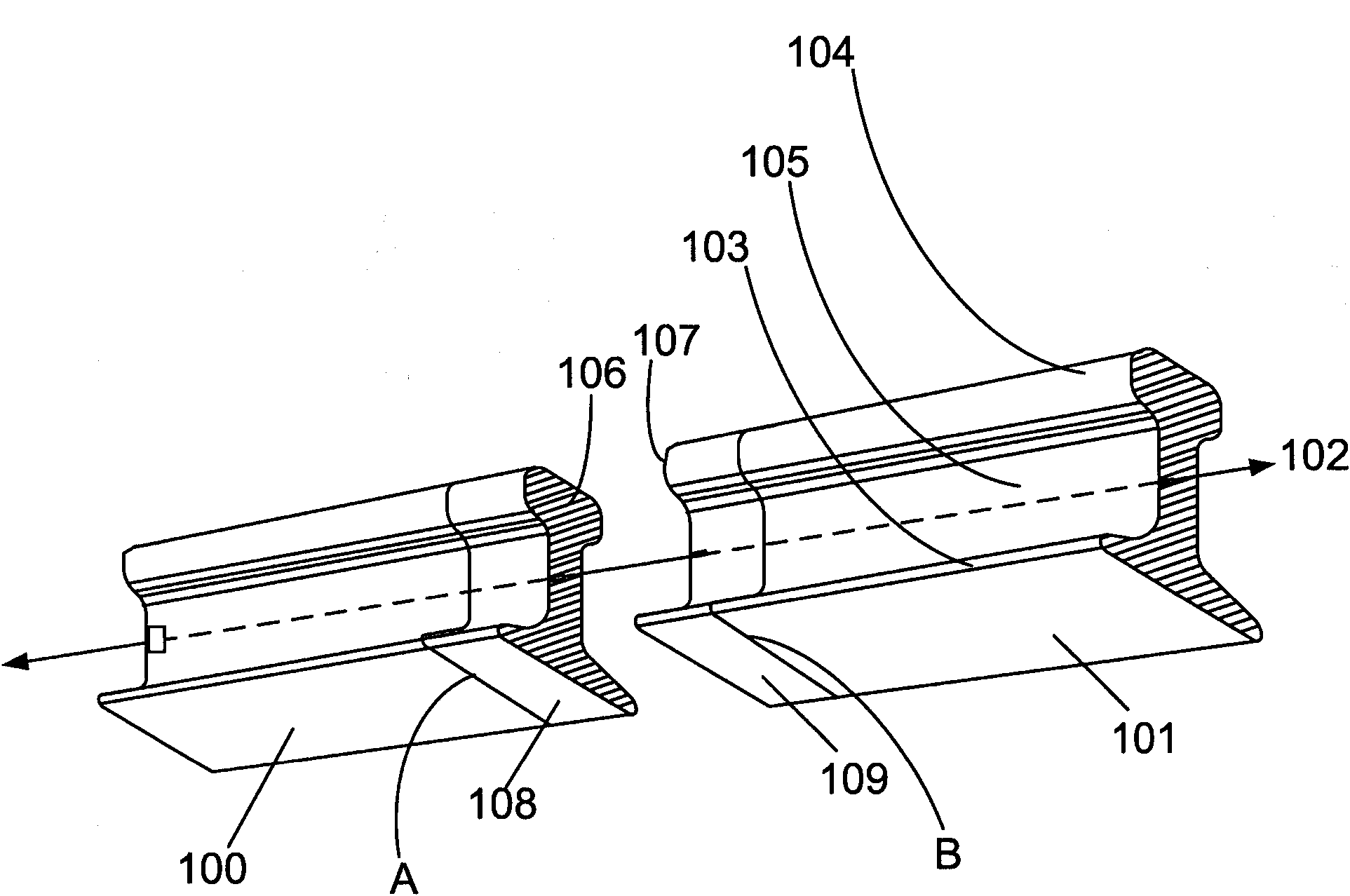

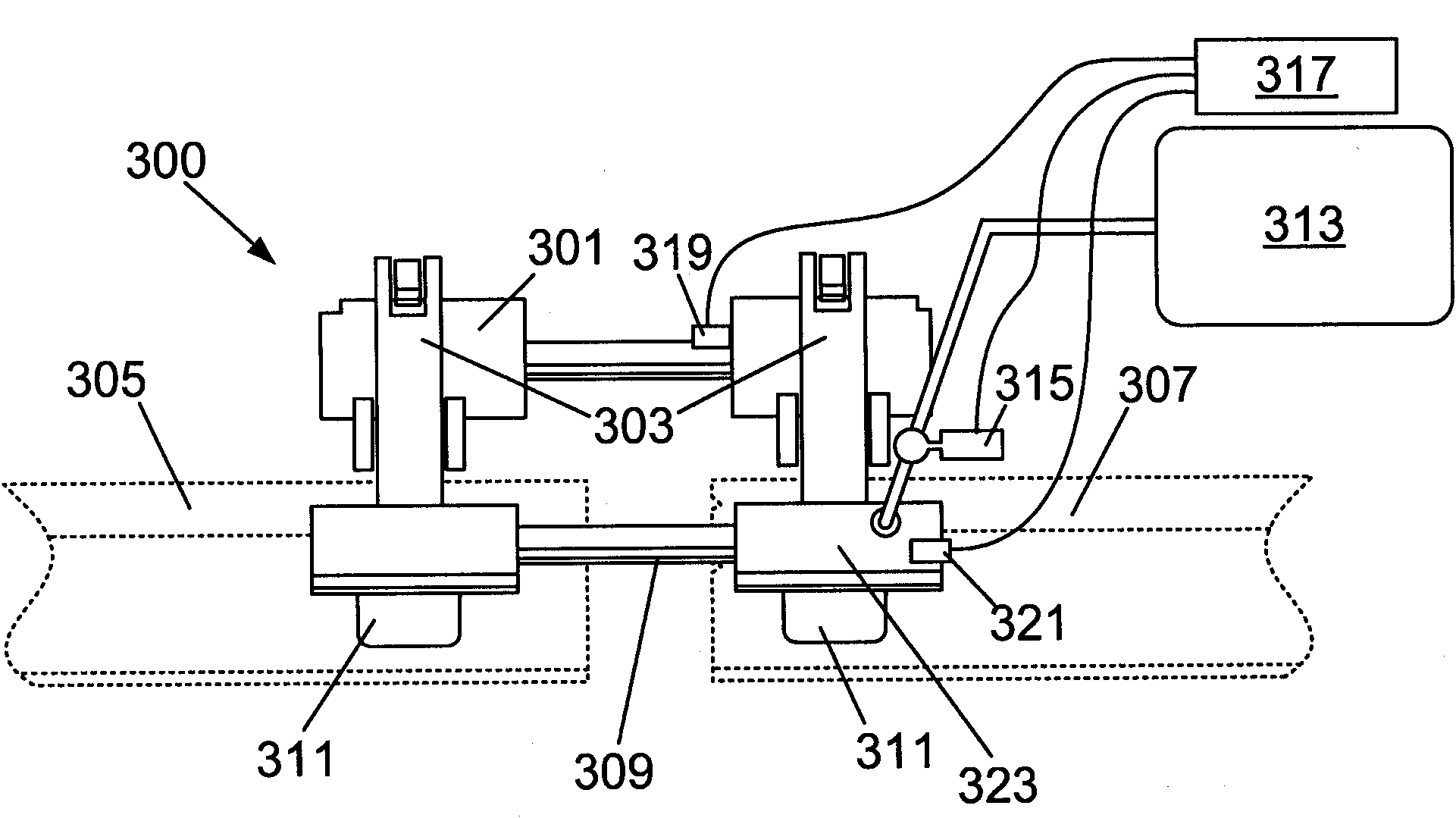

Welding process with jerk compensation

ActiveCN101780600AKeep closing speedReduce closing forceRailway track constructionResistance welding apparatusHydraulic cylinderPower flow

An improved welding head for creating an in-track weld between a first rail segment and a second rail segment includes a controller having computer-readable instructions read by the controller. The computer-readable instructions include instructions for compensating for rail jerk during in-track welding. The welding head includes a closing force actuator, such as a hydraulic cylinder, for moving the rail segments toward one another. A pressure transducer is monitored during welding to determine a closing force. An impending jerk of the rail movement is detected if an abnormal closing force change is observed, and in response the flow of hydraulic fluid into or out of the hydraulic cylinder is restricted to prevent or minimize the jerk. In addition, when an impending jerk is detected the weld current may be temporarily increased to burn or prevent the formation of short circuit paths between the rails.

Owner:CHEMETRON RAILWAY PROD

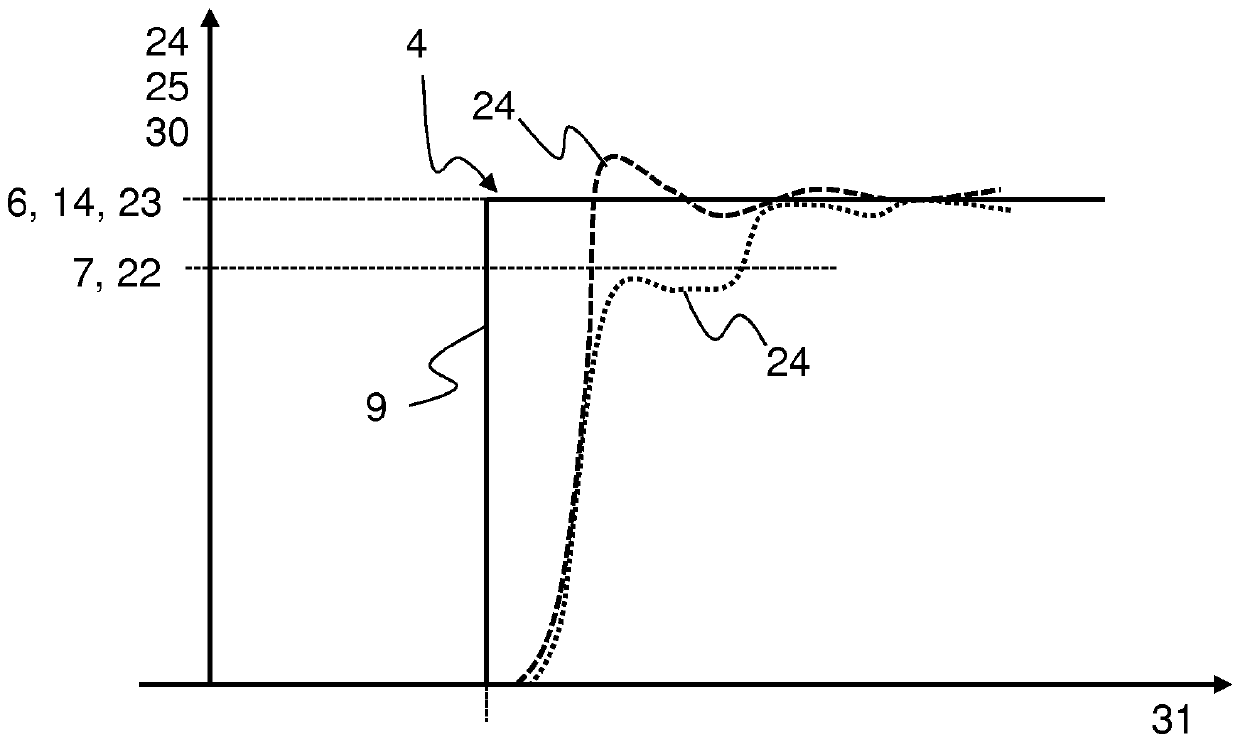

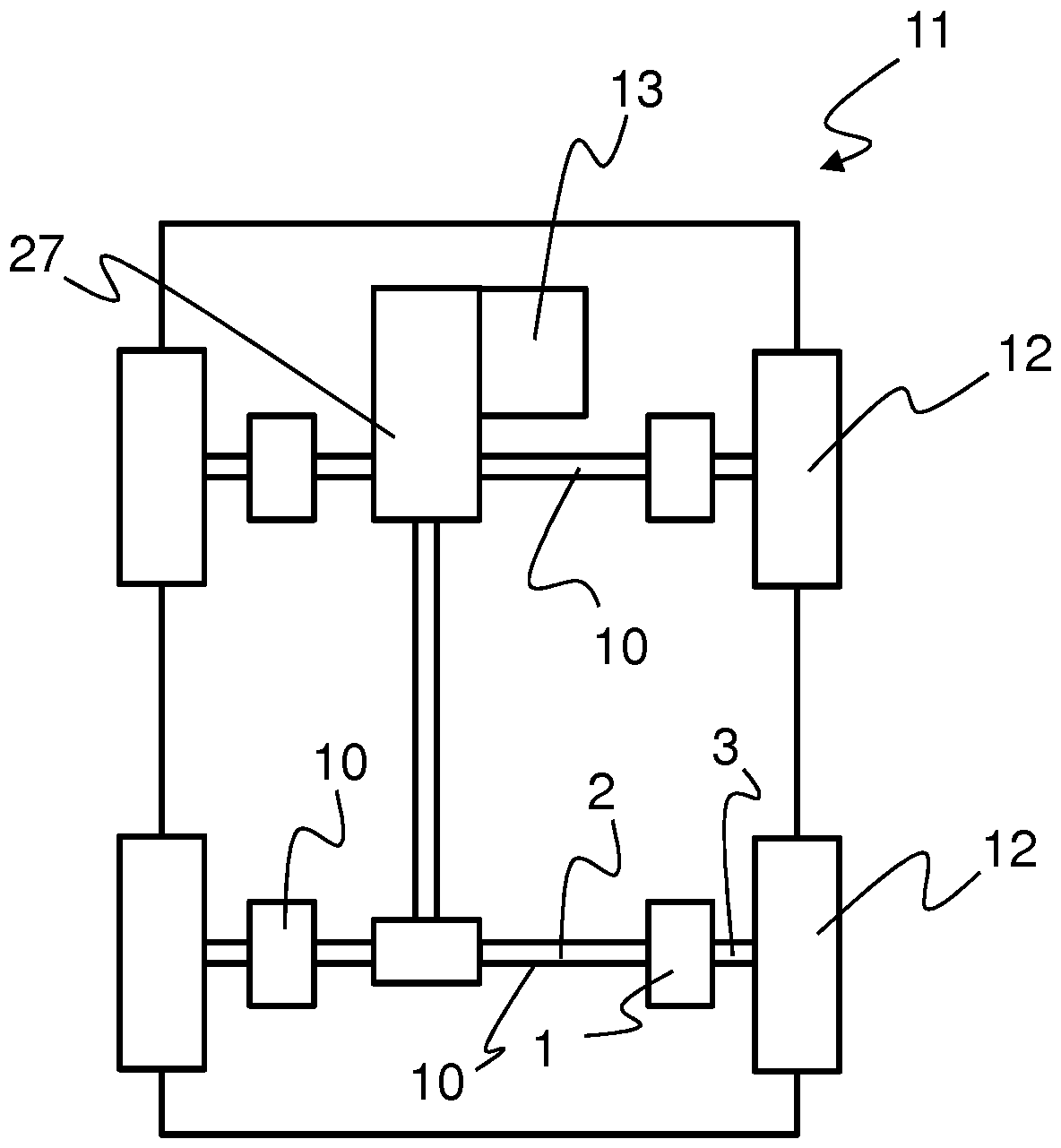

Method for actuating a multi-plate clutch

ActiveCN110249151AReach lifeReduce closing forceFriction clutchesControl devicesTarget engagementControl theory

The invention relates to a method for actuating a multi-plate clutch 1 between an input shaft 2 and an output shaft 3 for the switchable transmission of torques, wherein, when there is a torque requirement 4 and a subsequent engagement of the multi-plate clutch 1, at least the following steps are carried out: a) determining a target engagement force 6, effective in an axial direction 5, of the multi-plate clutch 1 for the transmission of a target torque 9 to the output shaft 3; b) determining and setting a limit engagement force 7 which is smaller than the target engagement force 6; and c) setting the target engagement force 6 in a delayed manner. The limitation of the target engagement force 6 to the limit engagement force 7 means that a transmission of an actual torque 8 is realised, wherein a maximum actual torque 8 transmitted when the multi-plate clutch 1 is engaged exceeds a target torque 9 to be transmitted by at most 5%.

Owner:GKN AUTOMOTIVE INC

Car door hinge

The invention discloses a car door hinge. The car door hinge comprises a fixed piece, a movable piece and a connecting piece, wherein the fixed piece and the movable piece are connected with each other through the connecting piece; the fixed piece comprises an installation part and a rotor; the installation part is installed on the car body structure; and the rotor is connected with the installation part through a rivet and can rotate on the installation plane of the installation part around the rivet, thereby adjusting the rotation axis of the hinge. The hinge of the invention can automatically adjust the coaxiality of the upper part and the lower part, overcome the bound force and effectively reduce the possibility of abnormal sound and vibration when the user opens or closes the car door. The hinge greatly reduces the closing force of the door and ensures that the car door can be easily opened and closed, thereby relieving the abrasion, prolonging the service life and saving the manufacturing cost.

Owner:CHERY AUTOMOBILE CO LTD

Method for producing a liquid container, liquid container for a motor vehicle and injection molding tool

ActiveCN109843538AReduce volumeSmall sizeDomestic articlesFuel supplyEngineeringMechanical engineering

Owner:KAUTEX TEXTRON

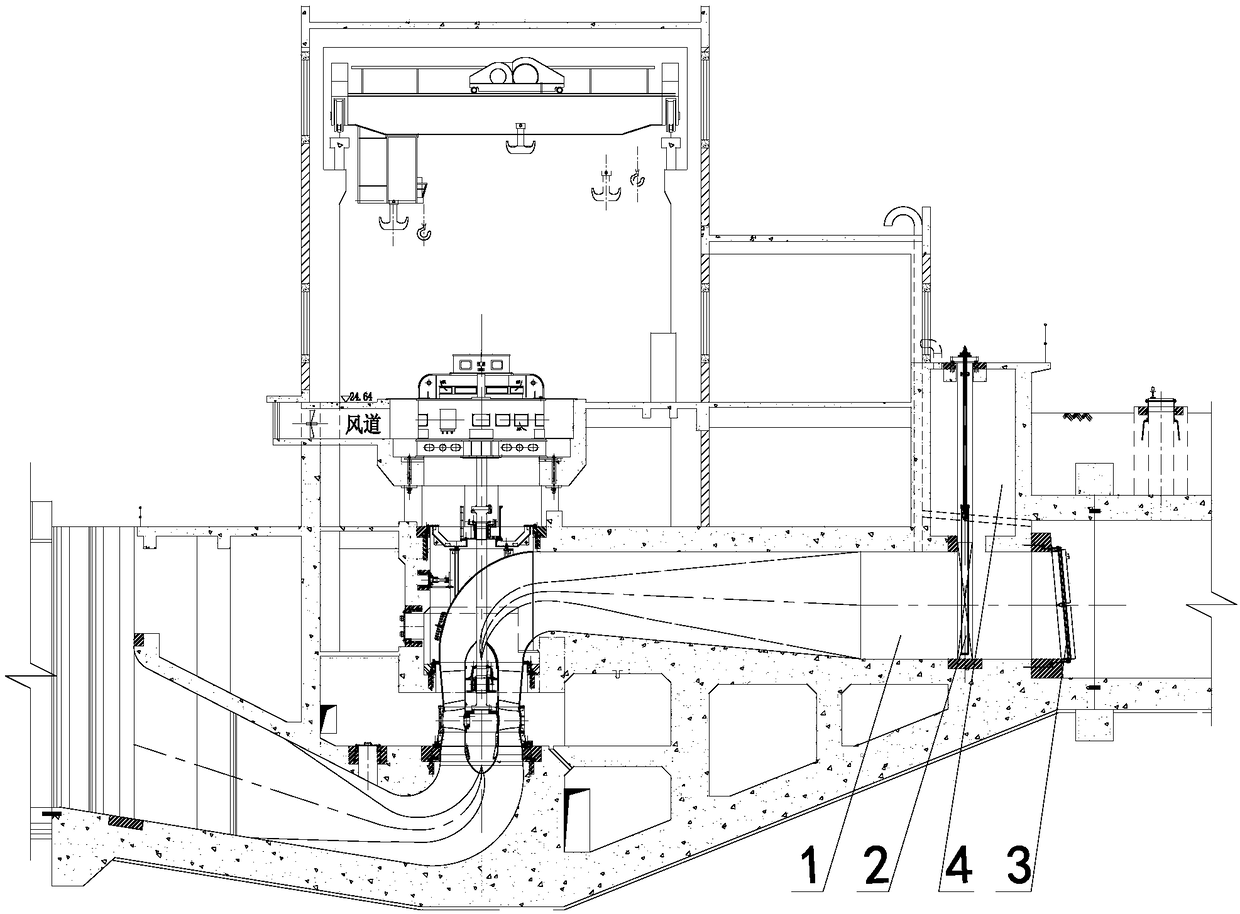

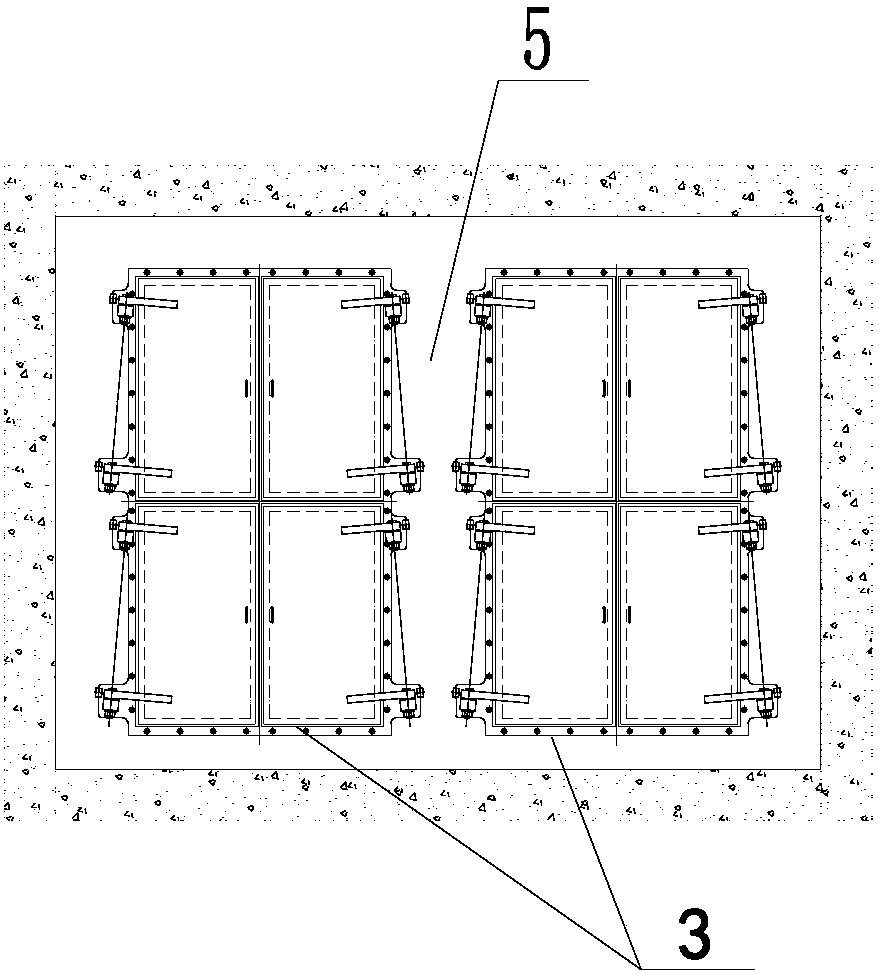

Combined cutoff device for large axial flow pump

InactiveCN108331077AReduce working capacityEffective partitionPumping plantsDrinking water installationAxial-flow pumpDevice form

The invention discloses a combined cutoff device for a large axial flow pump. A straight water outlet flow passage of each water pump is uniformly partitioned into two parts by a concrete partition pier on the plane, the combined cutoff device formed by a rapid gate and a co-seat multi-leaf side-turning flap valve is arranged on each part of the water outlet flow passage of each water pump, and each rapid gate is arranged on one side, close to the corresponding water pump, of the corresponding side-turning flap valve. Each rapid gate is controlled by a hydraulic host, and closed gate shafts are adopted. By cooperation of the rapid gates and the side-turning flap valves, the requirement of valve-opening starting of the axial flow pump can be met, startup-shutdown procedures are simple, cutoff reliability is achieved, and safety of units and pump stations is guaranteed.

Owner:ANHUI SURVEY & DESIGN INST OF WATER CONSERVANCY & HYDROPOWER

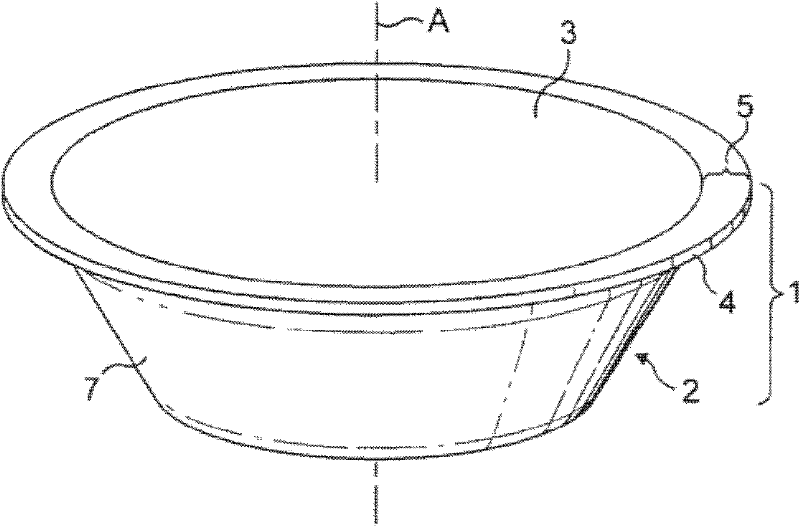

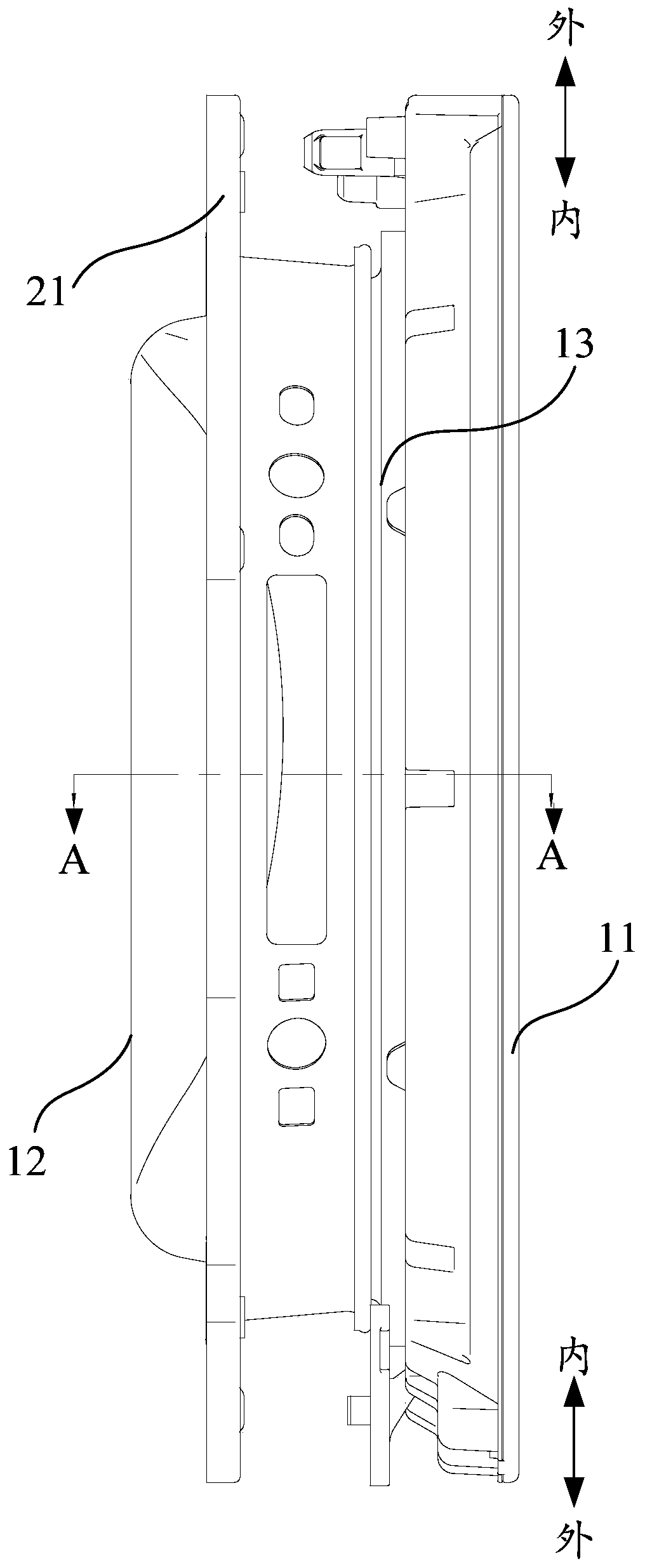

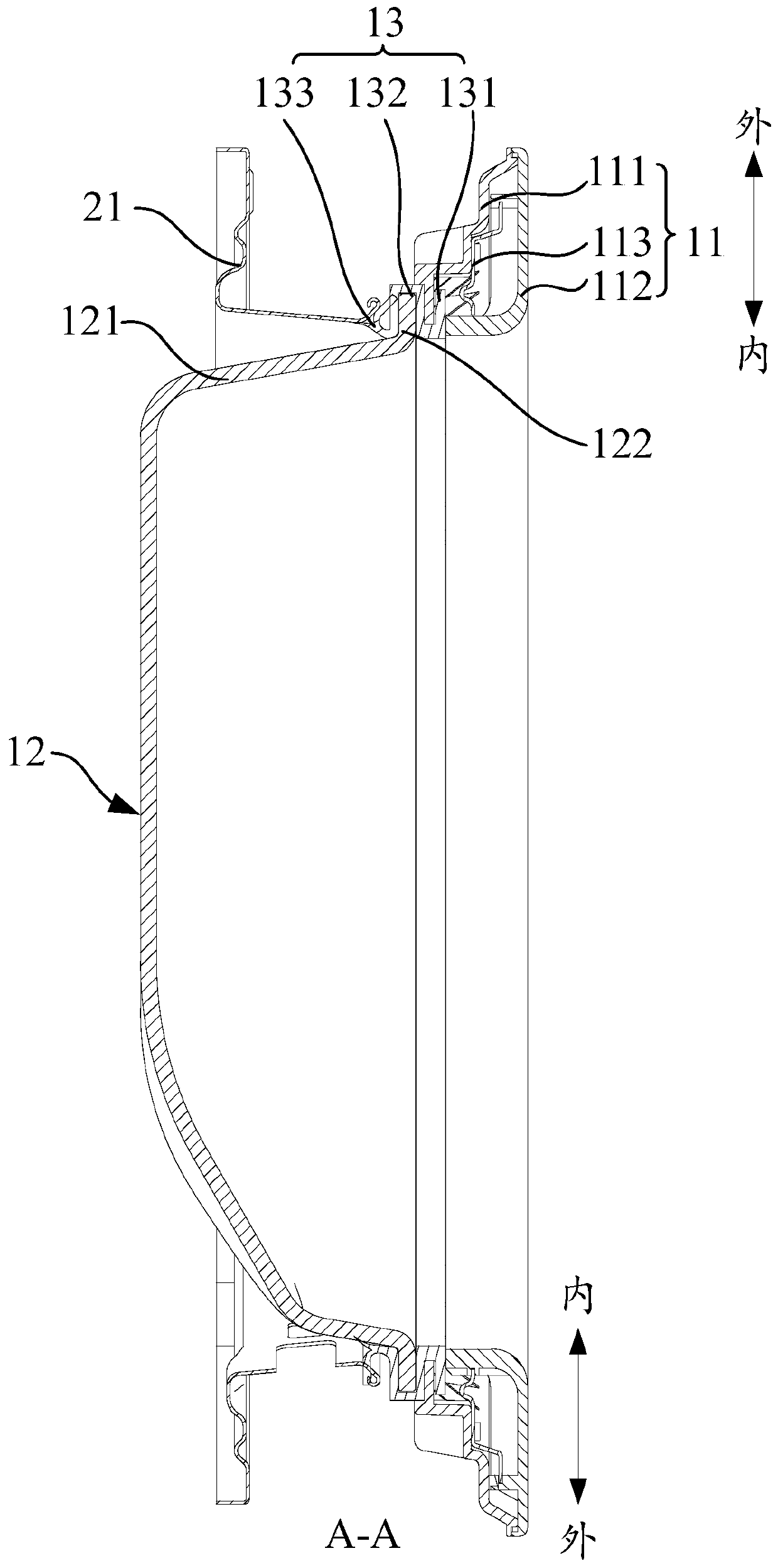

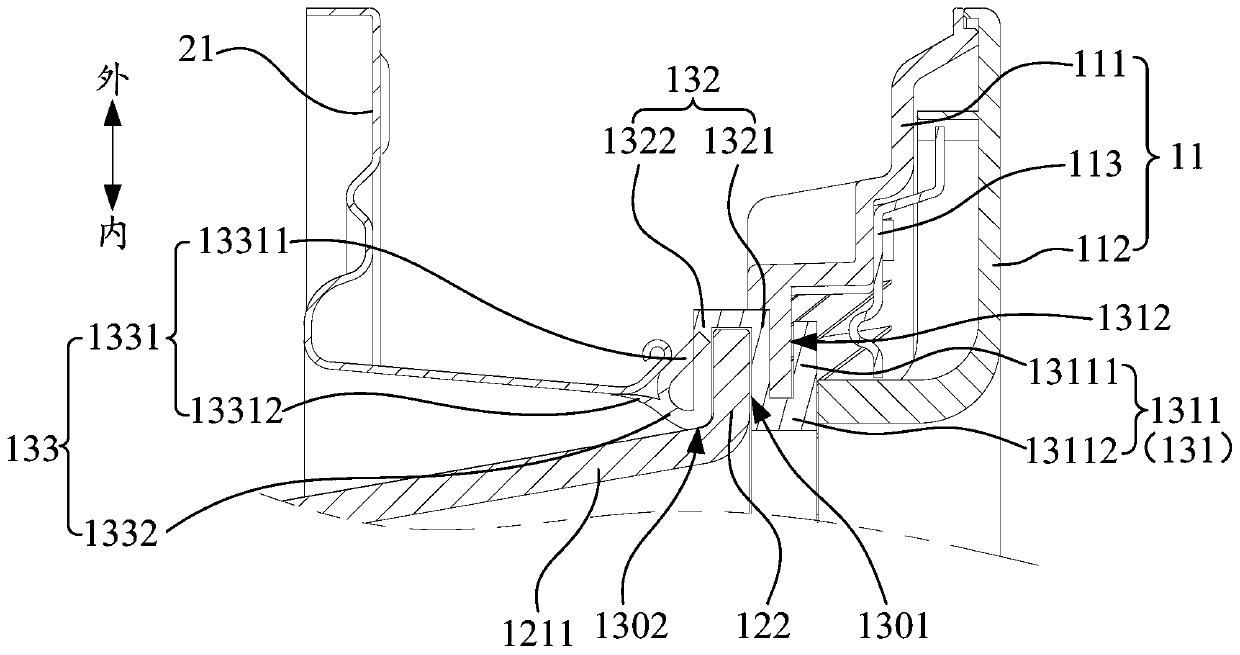

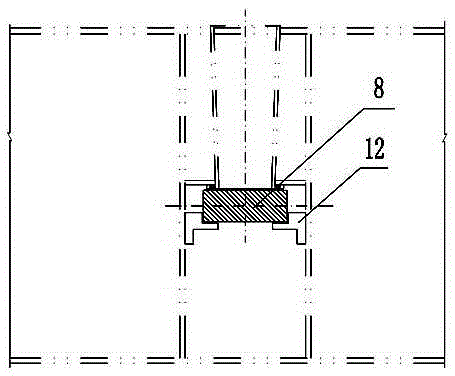

Door assembly and clothes treating apparatus

ActiveCN110791927AReliable assemblyEasy to assembleOther washing machinesSealing arrangementsStructural engineeringStructural deformation

The invention provides a door assembly and a clothes treating apparatus; the door assembly comprises: a door ring assembly; door glass; and a door sealing ring connected with the door ring assembly, agroove being formed in the door sealing ring, the door glass penetrating the door sealing ring, and part of the door glass being embedded in the groove, so that the door glass is mounted on the doorsealing ring. The door assembly provided by the scheme of the invention provides stable and reliable fitting of door glass; the door glass is locked by the door sealing ring, so that compared with theprior art, the door assembly allows the door glass to be separated from the door ring assembly, and the door glass is more convenient to fit; floatable displacement of the door glass is not limited by the door ring assembly, elastic structural deformation of the door sealing ring can provide more elastic floating displacement for the door glass, and the door glass can better buffer and adapt to internal pressure fluctuations in a washing tub; in addition, overall vibration of the door assembly can be reduced, the reliability of the door assembly to seal the sealing the washing tub is improved, and the risk of leakage is lessened.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

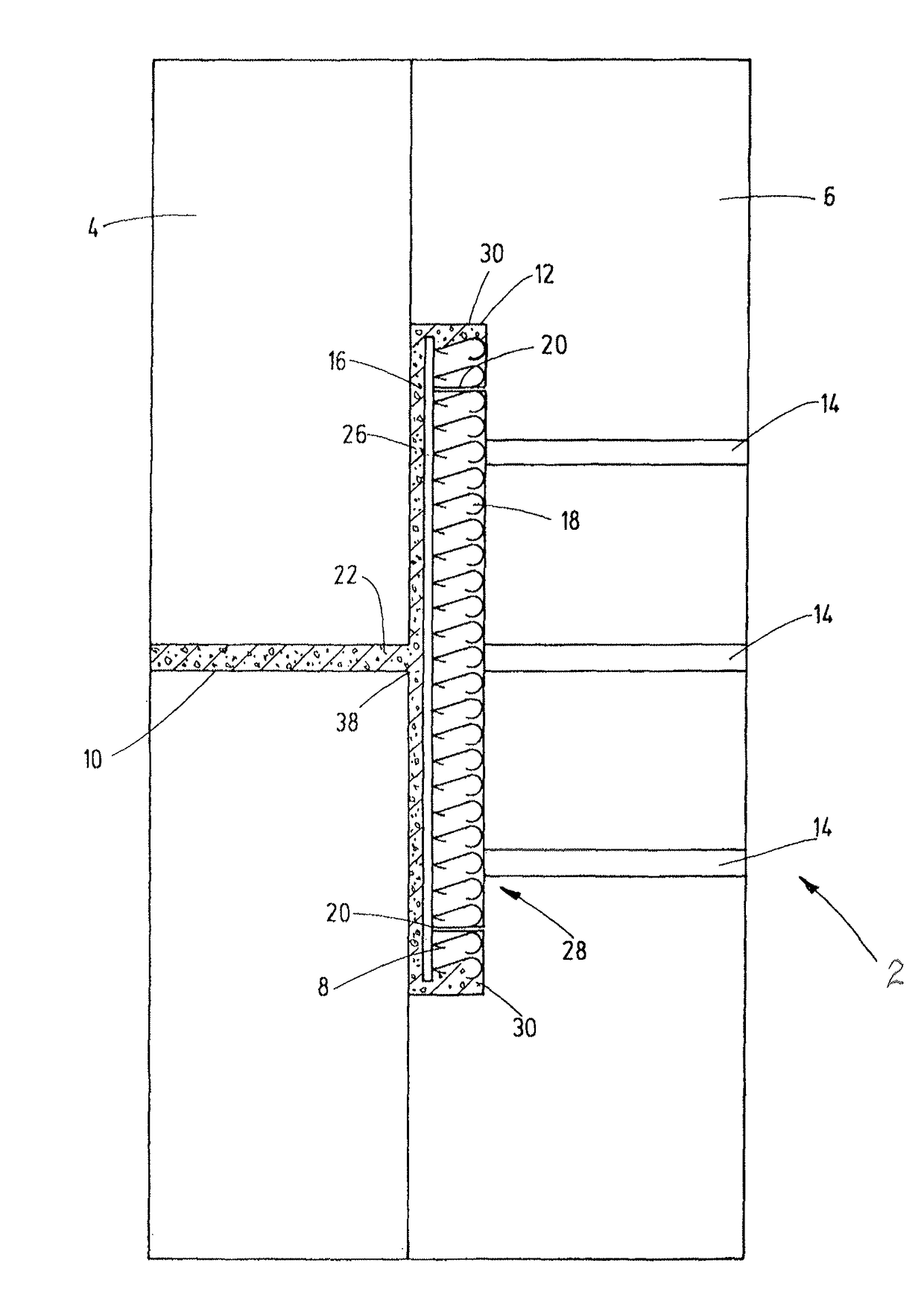

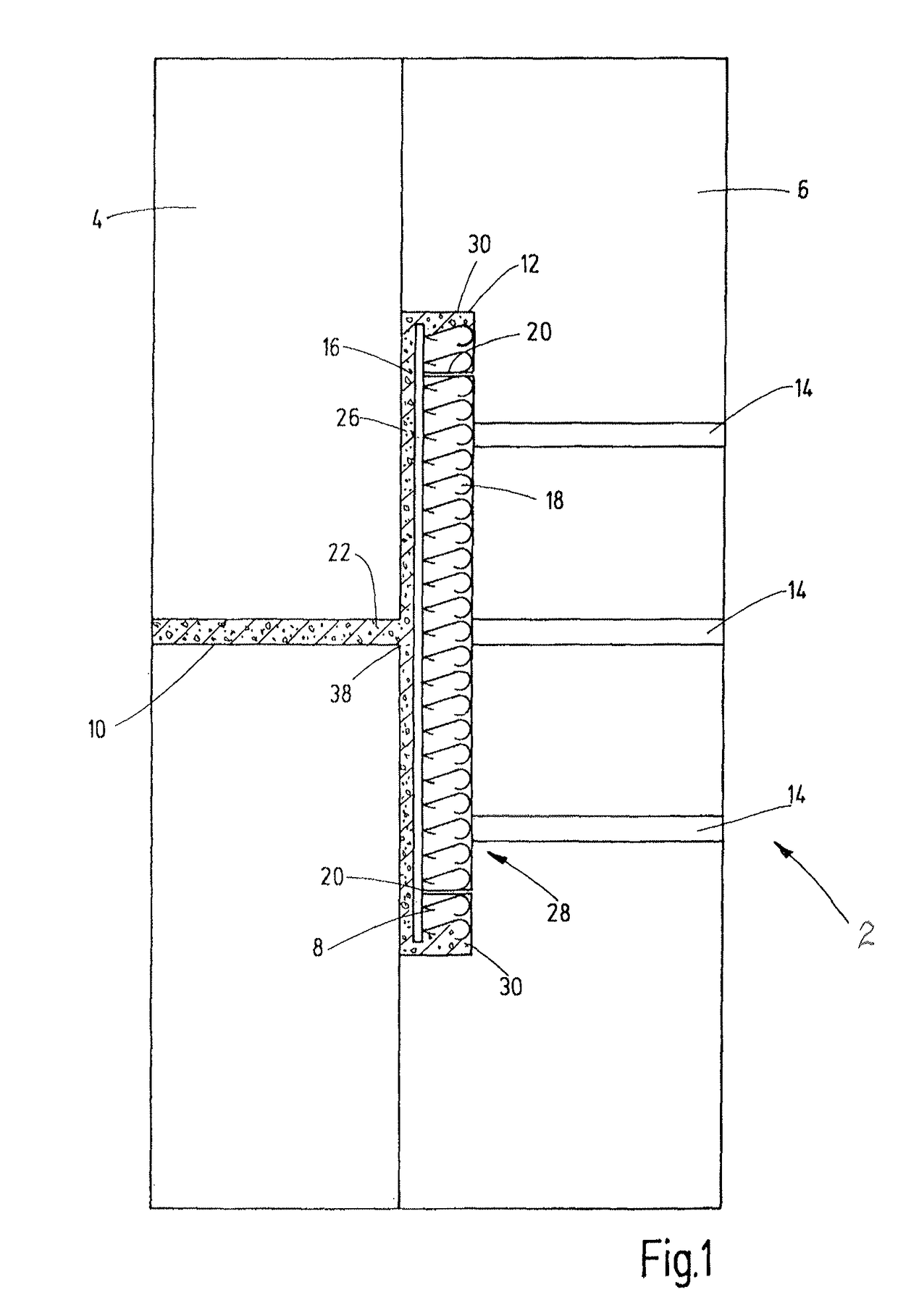

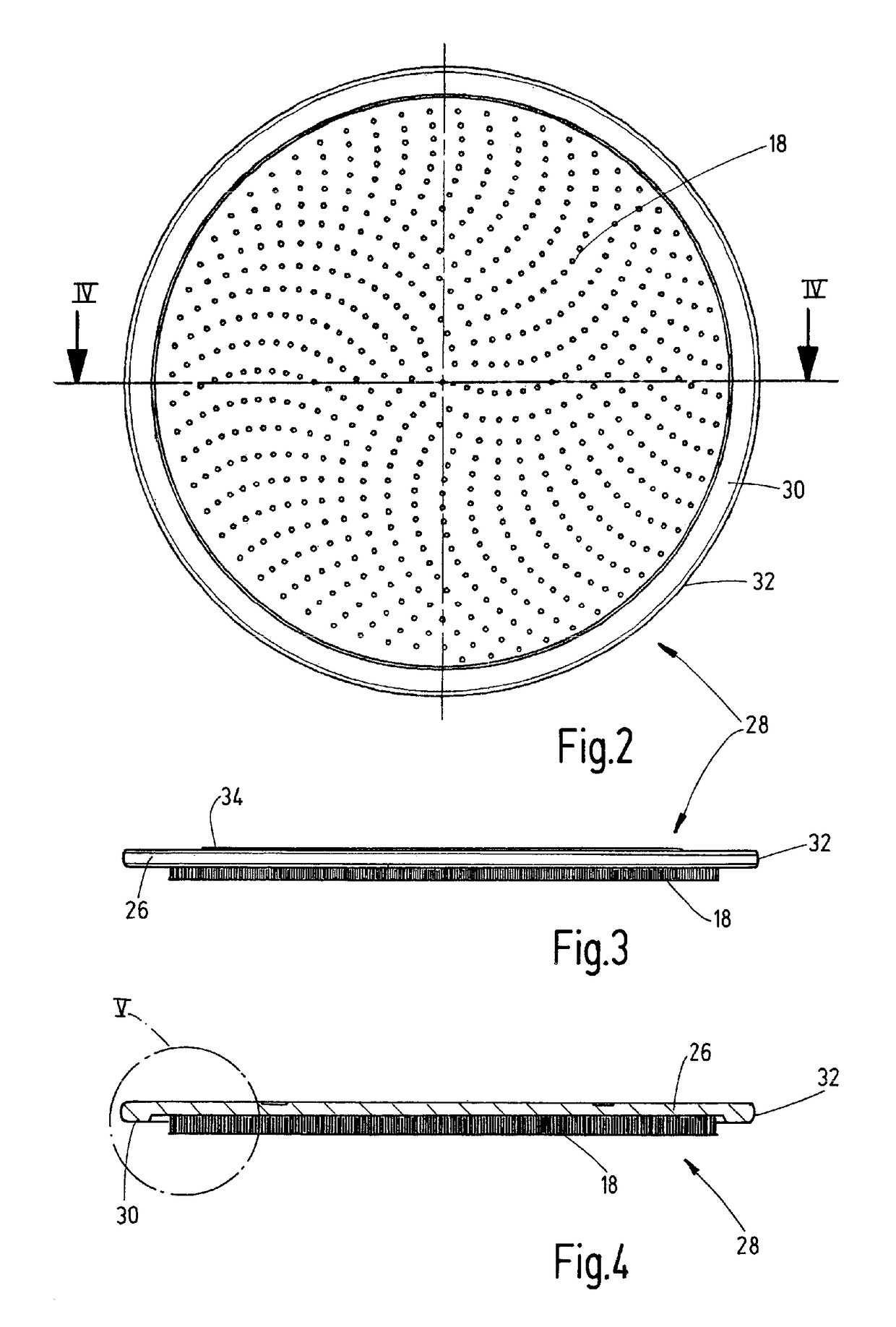

Method for producing a connecting part using an injection foam molding process

ActiveUS9849616B2Efficiently and reliably producedLow equipment complexityVehicle arrangementsMaterial gluingSynthetic materialsEngineering

A method for producing a connecting part (28) uses an injection foam molding process. In a first step, a fastening part with adhesive and / or hooking elements (18), forming a component of a contact fastener, is produced and introduced into an injection mold (2) as an insert part (16). A support part (26) is formed in the mold in a second step using a foamed synthetic material (22). The support part is connected to the insert part to form the connecting part (28).

Owner:GOTTLIEB BINDER

Flap arrangement for turbine, turbine, and exhaust gas turbocharger

ActiveCN109653812AReduce sealImprove sealingInternal combustion piston enginesLift valveWastegateRelative motion

Owner:BORGWARNER INC

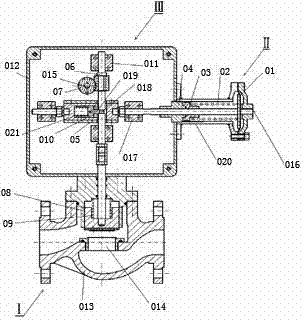

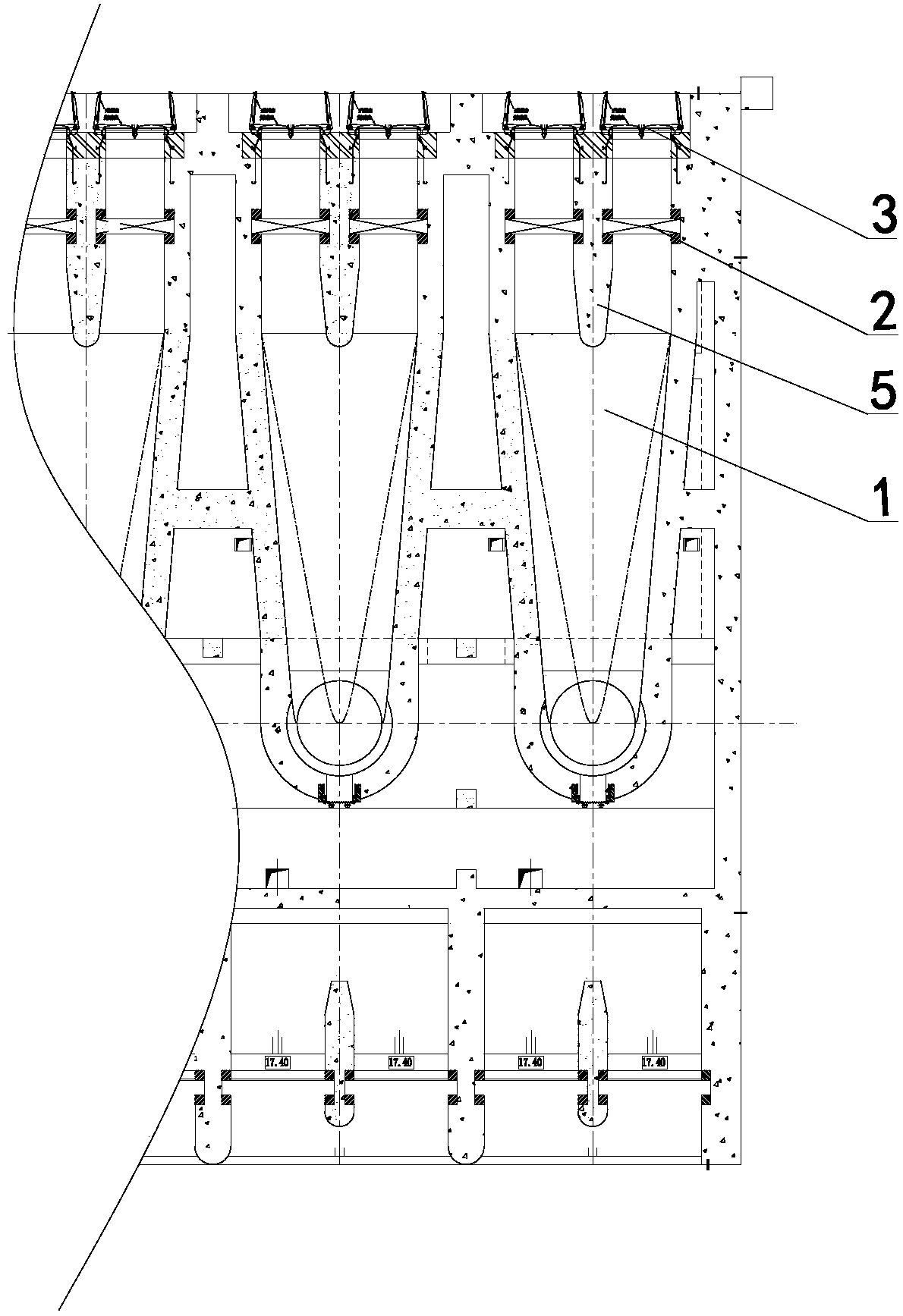

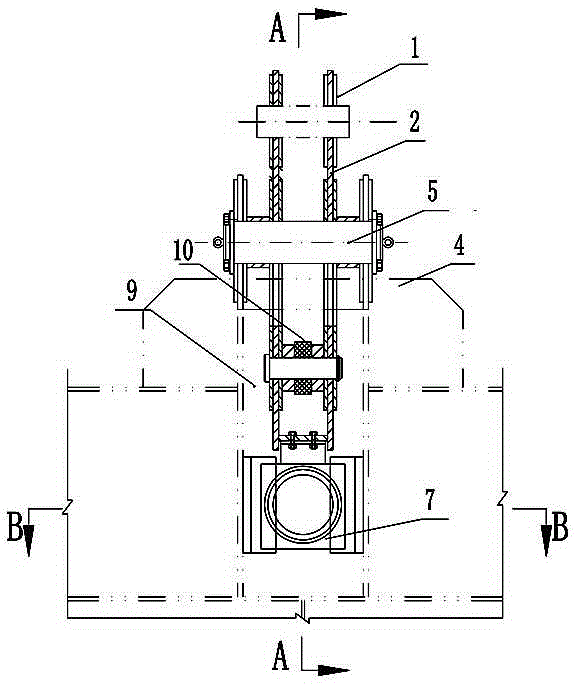

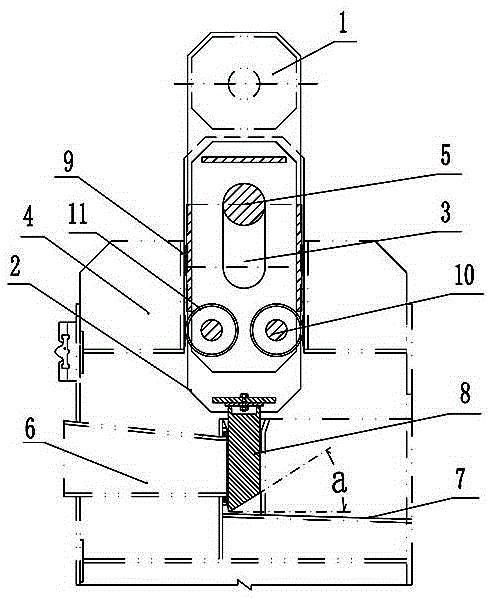

Knife-type water filling valves for flat gates in rivers with heavy sediment

ActiveCN103867738BReduce closing forceImprove opening and closing effectBarrages/weirsSlide valveHermetic sealEdge structure

The invention discloses a cutter-shaped filling valve for a much-sediment river plane gate. The cutter-shaped filling valve comprises a hoisting rod, a hole groove, a bearing shaft and a valve plate, wherein the top of the hoisting rod is hinged to a hoisting head of a hoist, the hole groove is formed in the middle of the hoisting rod in the longitudinal direction, the bearing shaft penetrates through the hole groove and is fixedly connected with the plane gate, the valve plate of a valve chamber is arranged between a plane gate water inlet and a sluice channel, and the upper end of the valve plate is connected with the lower end of the hoisting rod. The lower end face of the valve plate is of a cutting edge structure upwards inclining towards the downstream side, and the inclined angle alpha is larger than 30 degrees. The longitudinal section of the hoisting rod is of a U-shaped structure, and the position, located below the hole groove, in the hoisting rod of the U-shaped structure is provided with a guiding wheel matched with a gate groove in a rolling mode. The valve chamber is internally provided with a rubber hermetic seal which is sealed with the valve plate plane and surrounds the water inlet. The two side walls, located on the downstream, in the valve chamber are provided with a cantilever type supporting main rail and a lateral guide rail. The cutter-shaped filling valve has the advantages that the cutter-shaped filling valve is designed for much-sediment rivers, the door closing force of the plane gate is reduced, and the problem of the water-equalizing pressure of a water stopping plane gate on the upstream of the much-sediment rivers is solved.

Owner:YELLOW RIVER ENG CONSULTING

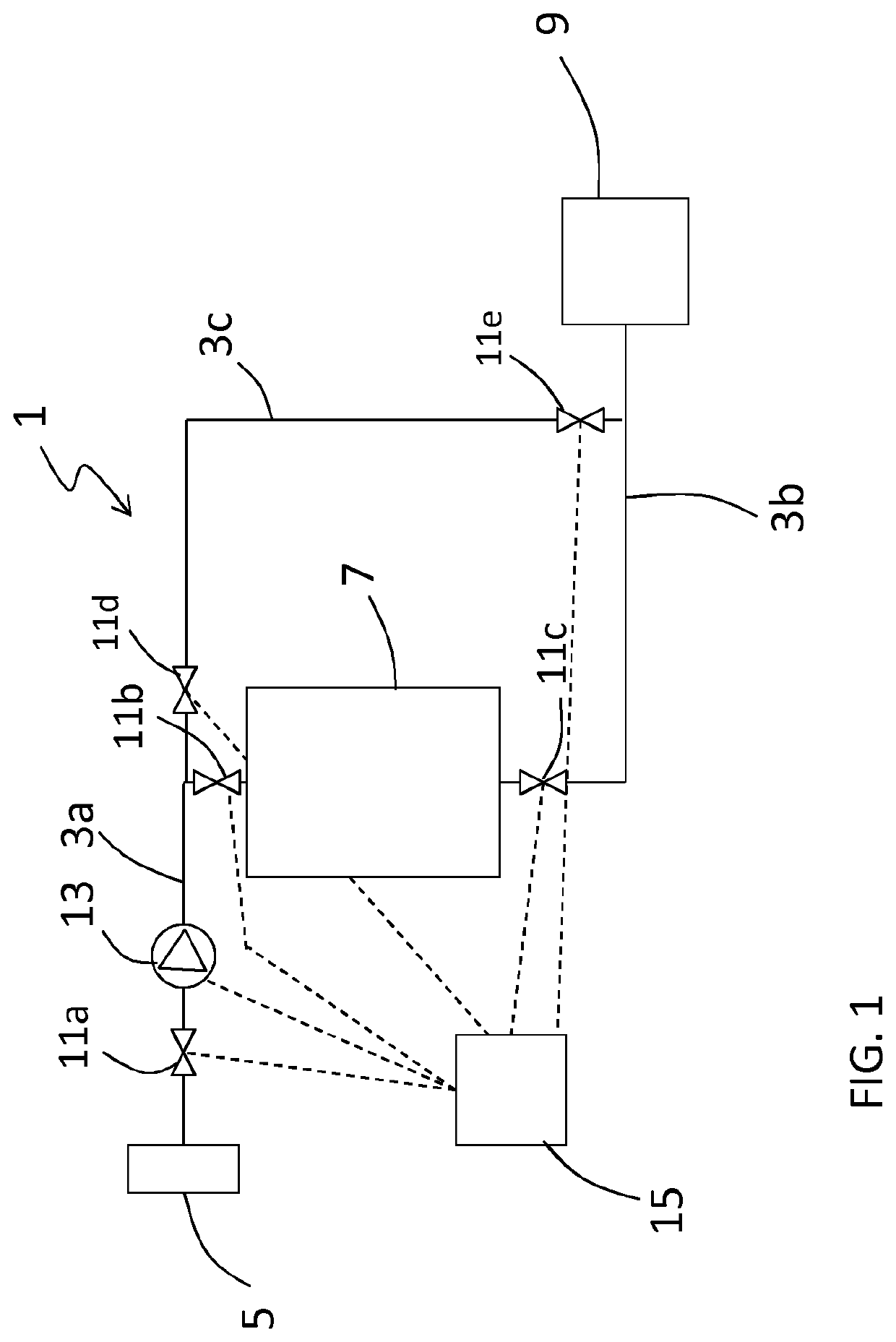

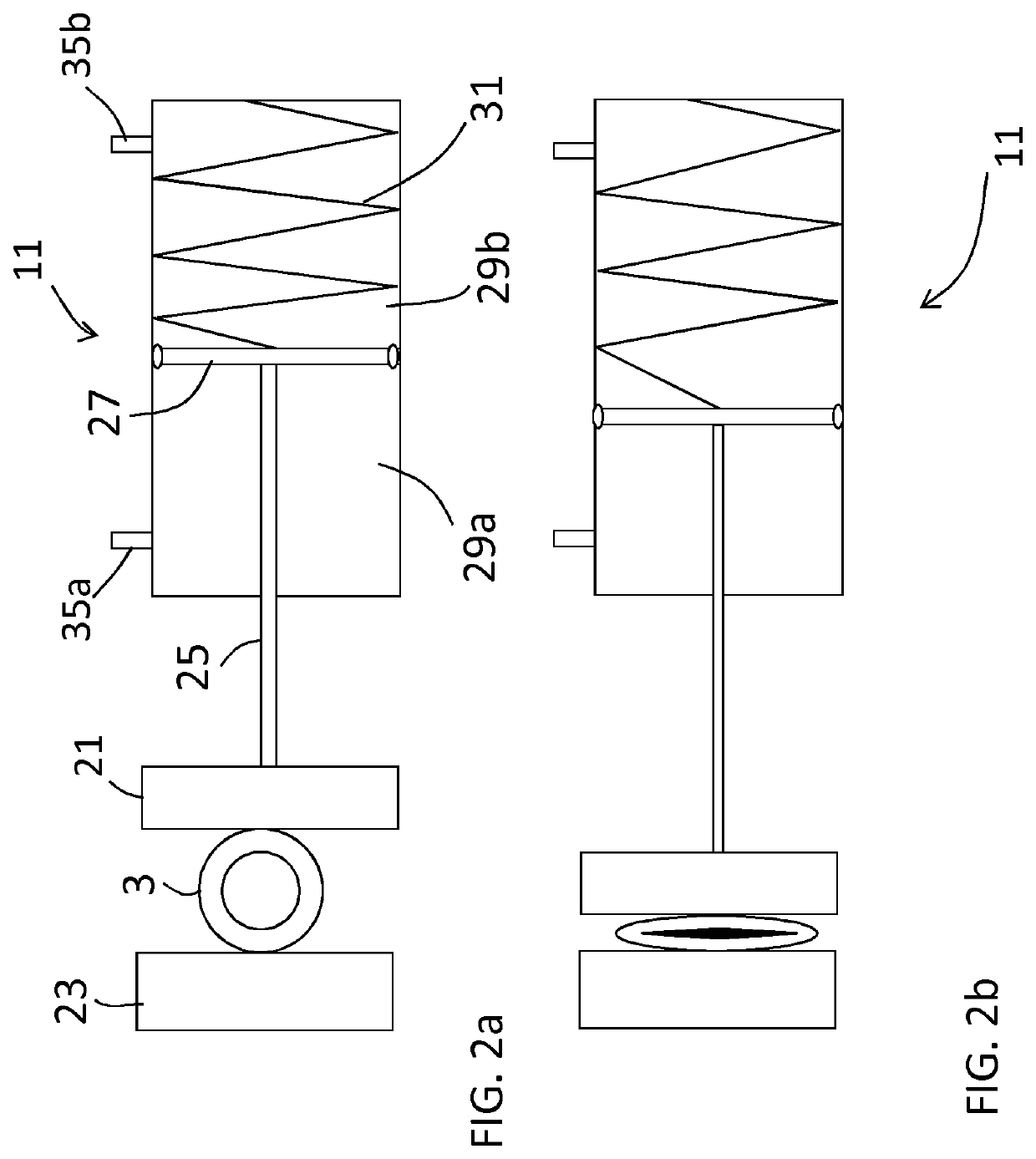

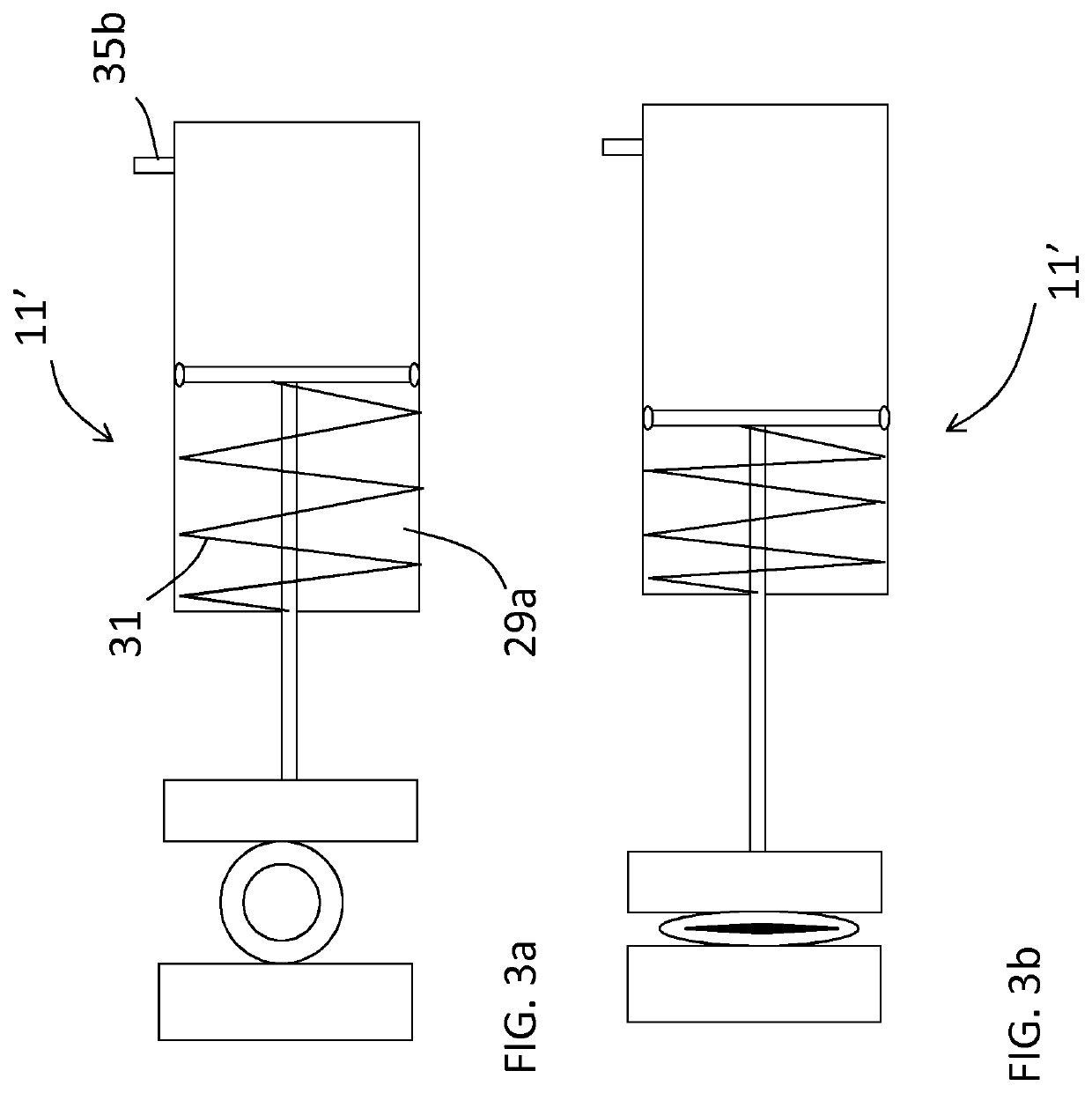

A Bioprocess Flow System

PendingUS20210062923A1Reliable controlAvoiding high closing forceDiaphragm valvesOperating means/releasing devices for valvesEngineeringVALVE PORT

A method for controlling at least one valve provided to a tube in a bioprocess flow system, said method comprising the steps of: —controlling the at least one valve to be in a first state, which is an open state when a flow through the tube should be allowed; —controlling the at least one valve to be in a second state during some parts of a process run in the system, said second state is a closed state were a first closing force is provided; and—controlling the at least one valve to be in a third state during some parts of a process run in the system, said third state is a closed state were a second closing force is provided which is a higher force than the first closing force.

Owner:CYTIVA SWEDEN AB

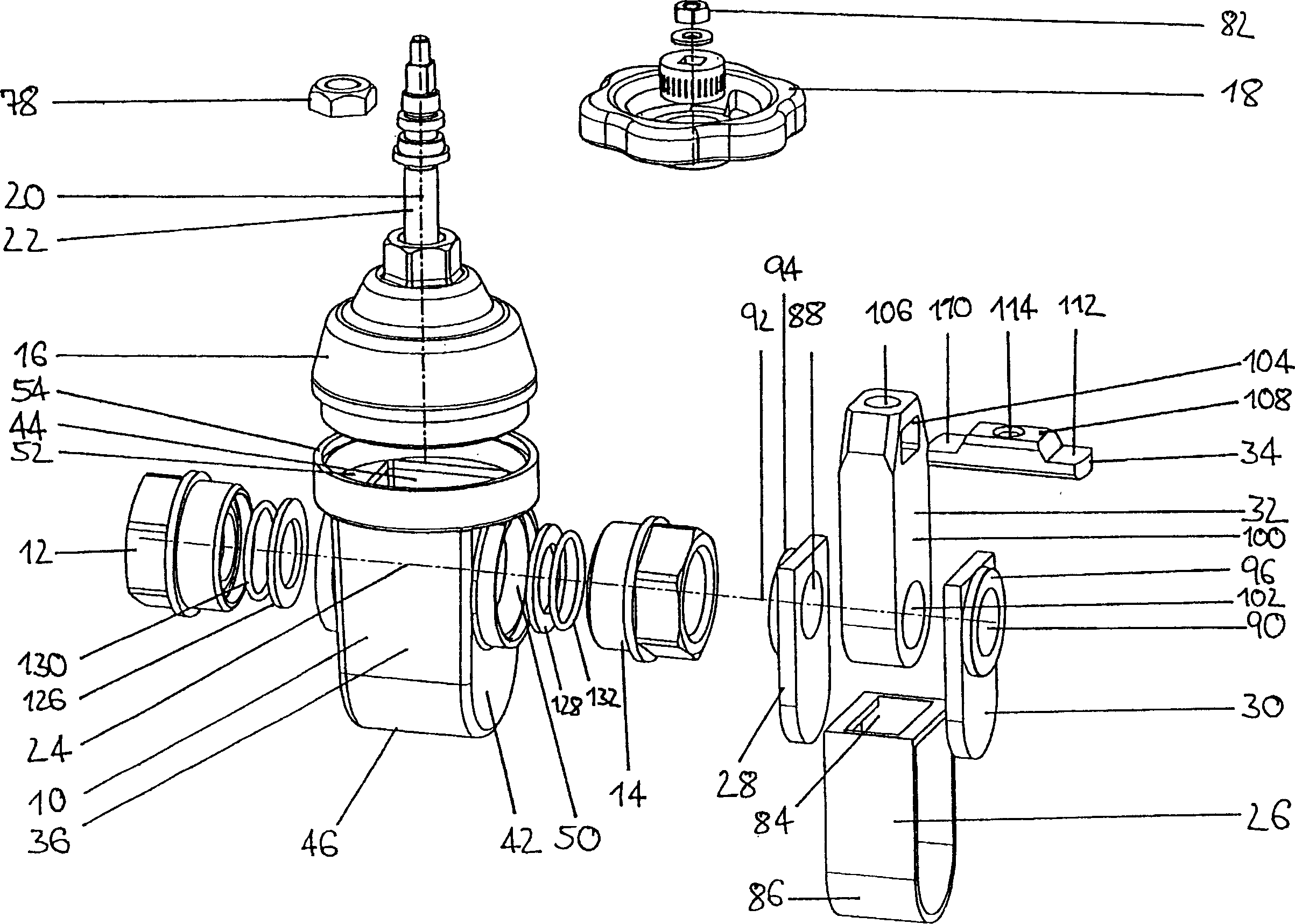

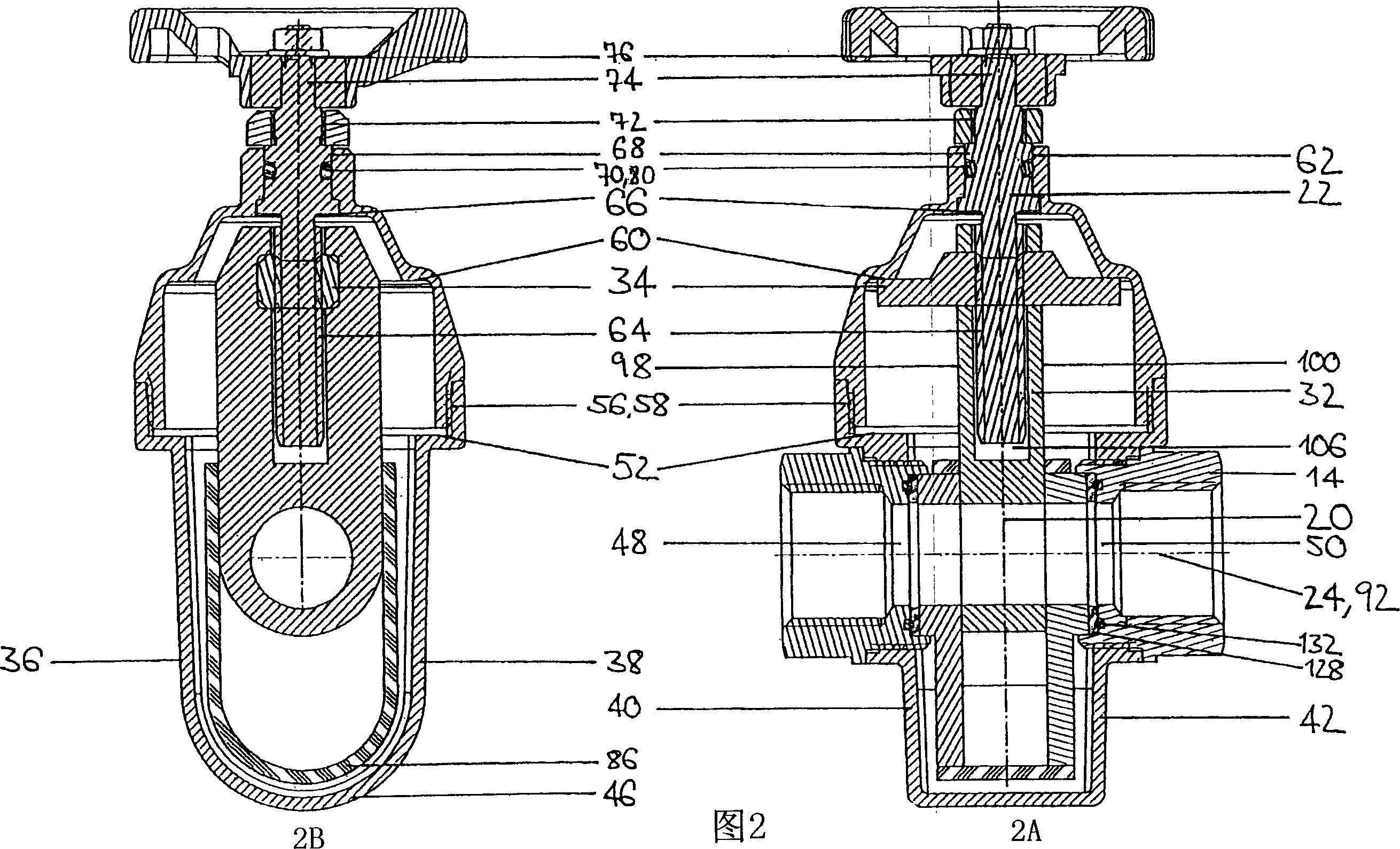

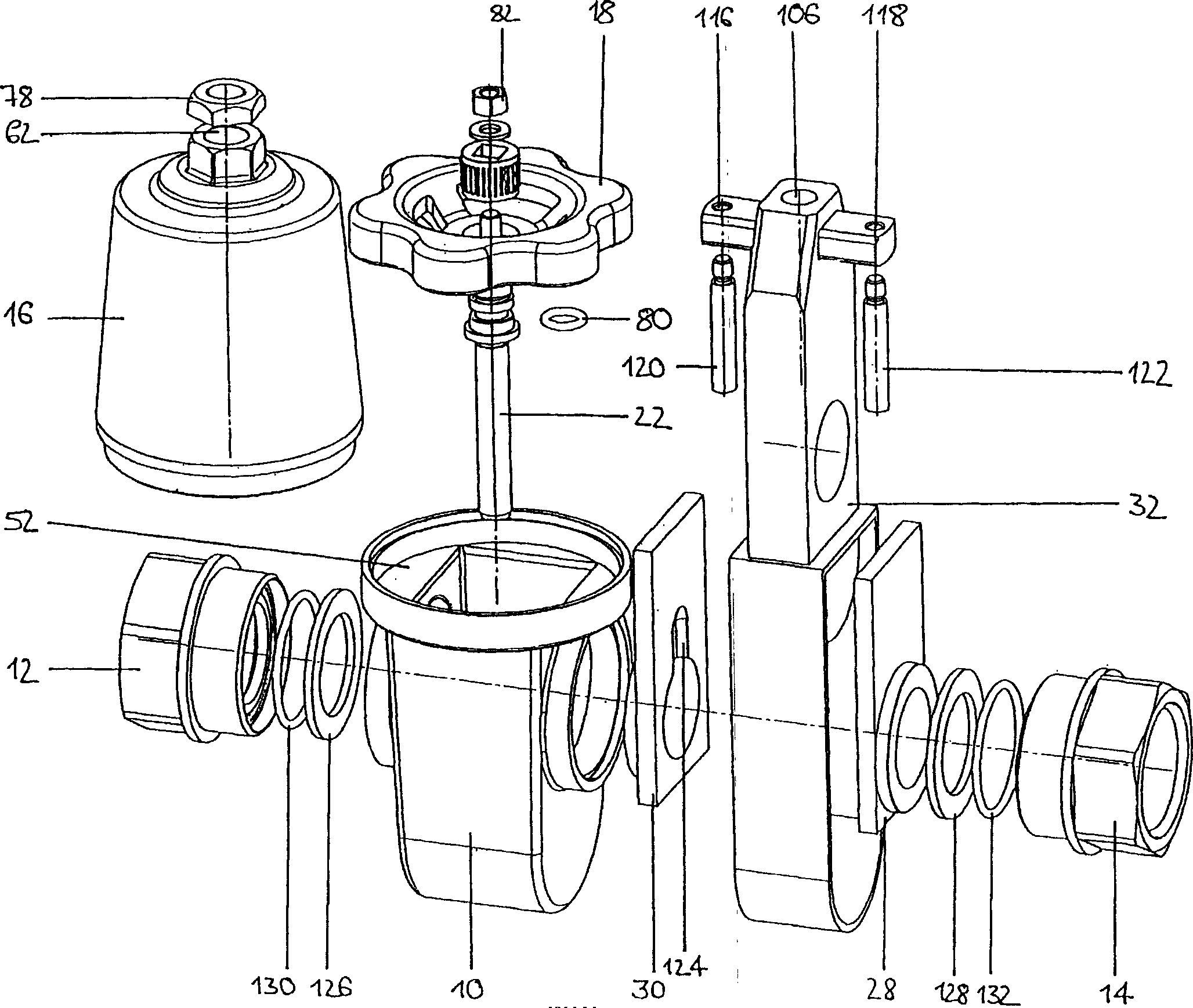

Gate valve

InactiveCN1824979AEasy to produceImprove sealingOperating means/releasing devices for valvesSlide valveEngineeringGate valve

A gate valve comprising a valve housing with connection openings disposed in mutually opposite relationship on a first common axis, and also connection elements for the inlet and outlet of a fluid, a cap on the valve housing and a valve actuation means coupled to a sliding gate. It is provided therein that arranged in the valve housing are: a hollow cage having a first and a second end face of which the first end face has an insertion opening, further with two mutually oppositely disposed fixed side walls and two parallel mutually oppositely disposed free side walls which are formed by two separate side plates with through bores which in the installed condition are on a second common axis, the sliding gate which has a through-flow opening is introduced through the insertion opening of the cage and is guided sealingly in the cage and between the side plates and the side plates bear with their respective inward side in surface contact against the sliding gate, the sliding gate has two end positions so that in a first opened end position the through-flow opening of the sliding gate coincides completely with the diameter of the through bores of the side plates in the installed condition and in a second closed end position the through-flow opening of the sliding gate is completely outside the diameter of the through bores of the side plates.

Owner:INTERFORGE KLEE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com