Casting device and casting method

A sprue and melt technology, applied in the direction of casting molds, casting mold components, casting equipment, etc., can solve problems such as inability to ensure, unfavorable operating material ratio or pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

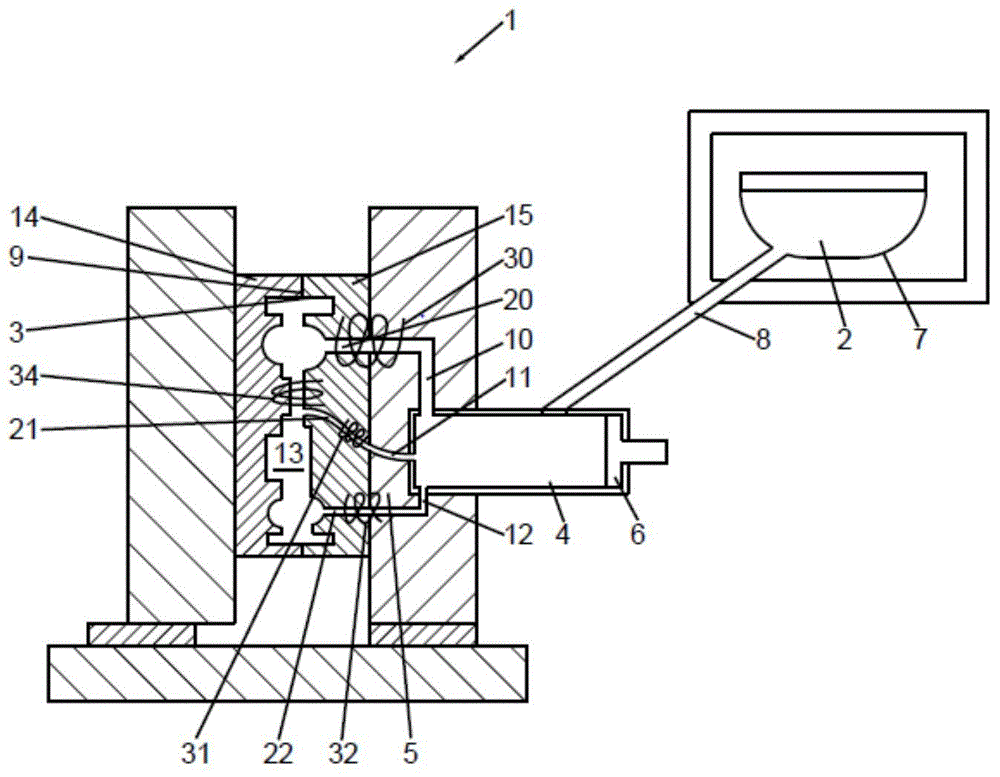

[0033] figure 1 A casting device 1 for injection casting of molten magnesium or aluminum is shown. The melt 2 is conducted from the melting furnace as storage container 7 via a feed line 8 into a filling chamber 4 . The filling chamber 4 forms a store for a predetermined quantity of melt 2 . The melt 2 can leave the filling chamber 4 via a plurality of sprues 11 , 12 , 13 and flow into a mold cavity 3 . The mold cavity 3 is formed by the two casting mold half-shells 14 , 15 as a hollow space 13 and forms, in a known manner, a negative mold enlarged with shrinkage (Schwindma β) of the die-cast product to be produced. The two casting mold half-shells 14 , 15 have a vertical parting face 9 for later removal of the casting.

[0034] Filling chamber 4 is filled with a metered quantity of melt 2 in the first casting phase. Precise metering ensures that the mold cavity 3 is later completely filled and that the resulting casting waste is not broken.

[0035] The casting piston 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com