Patents

Literature

525results about How to "Effective stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

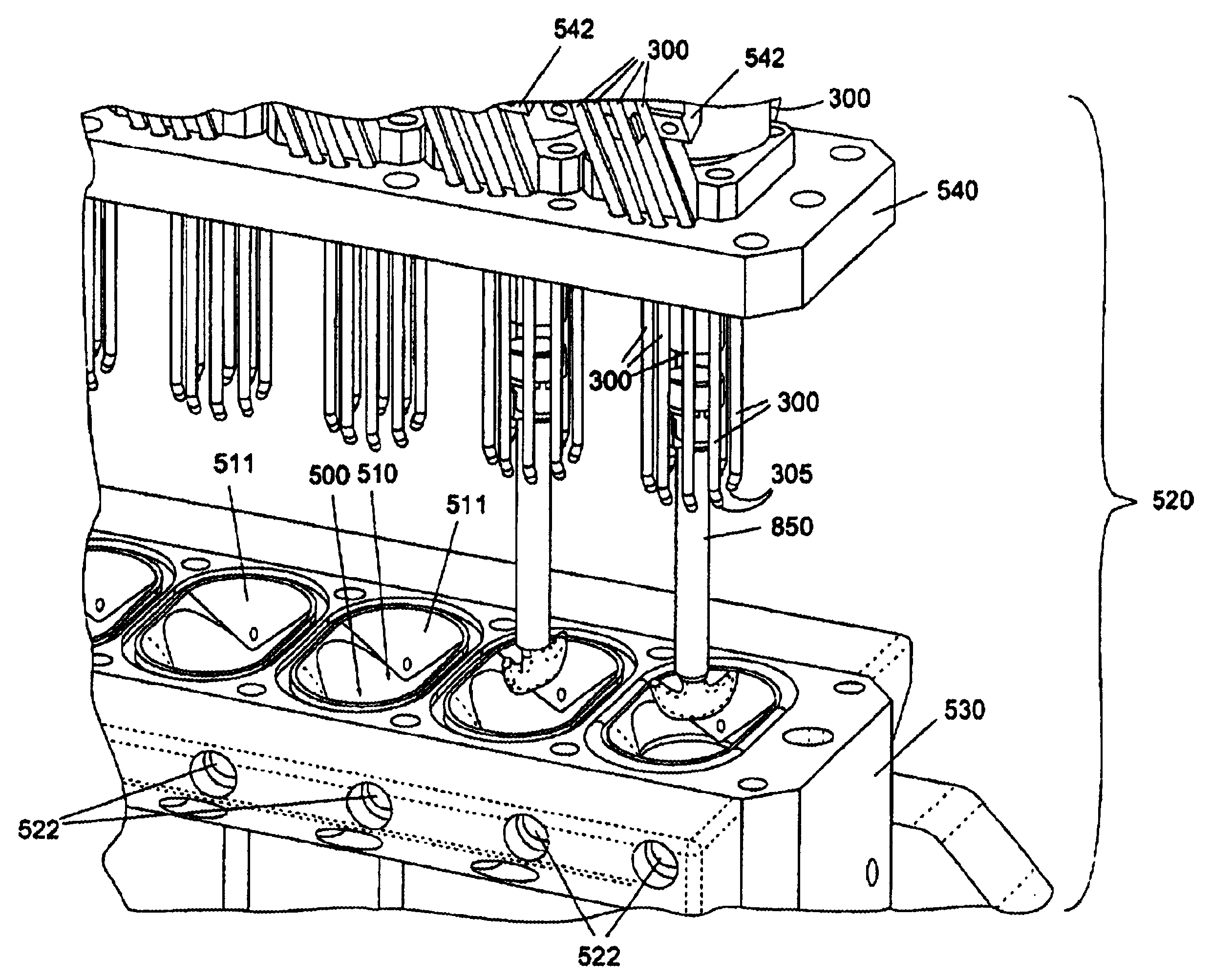

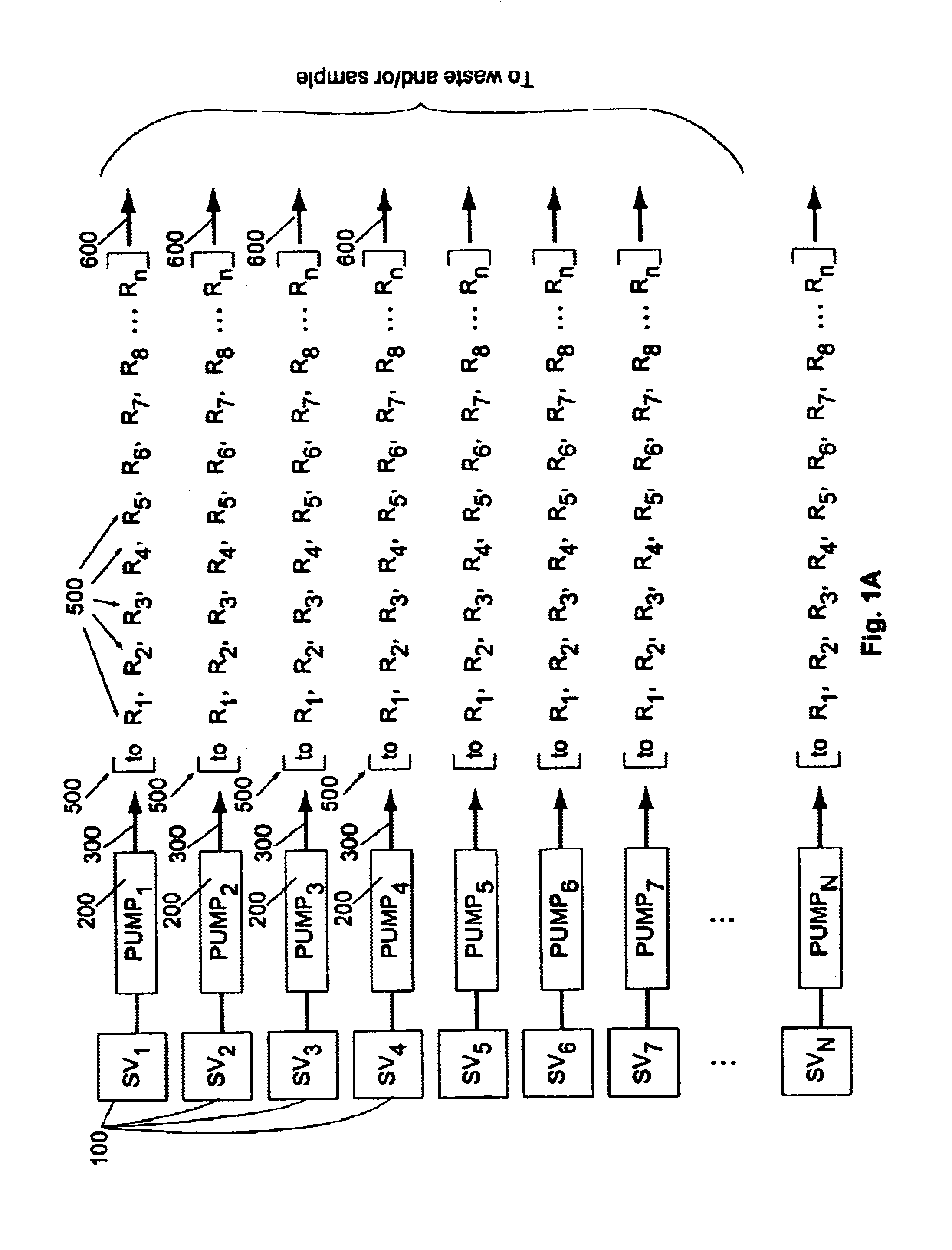

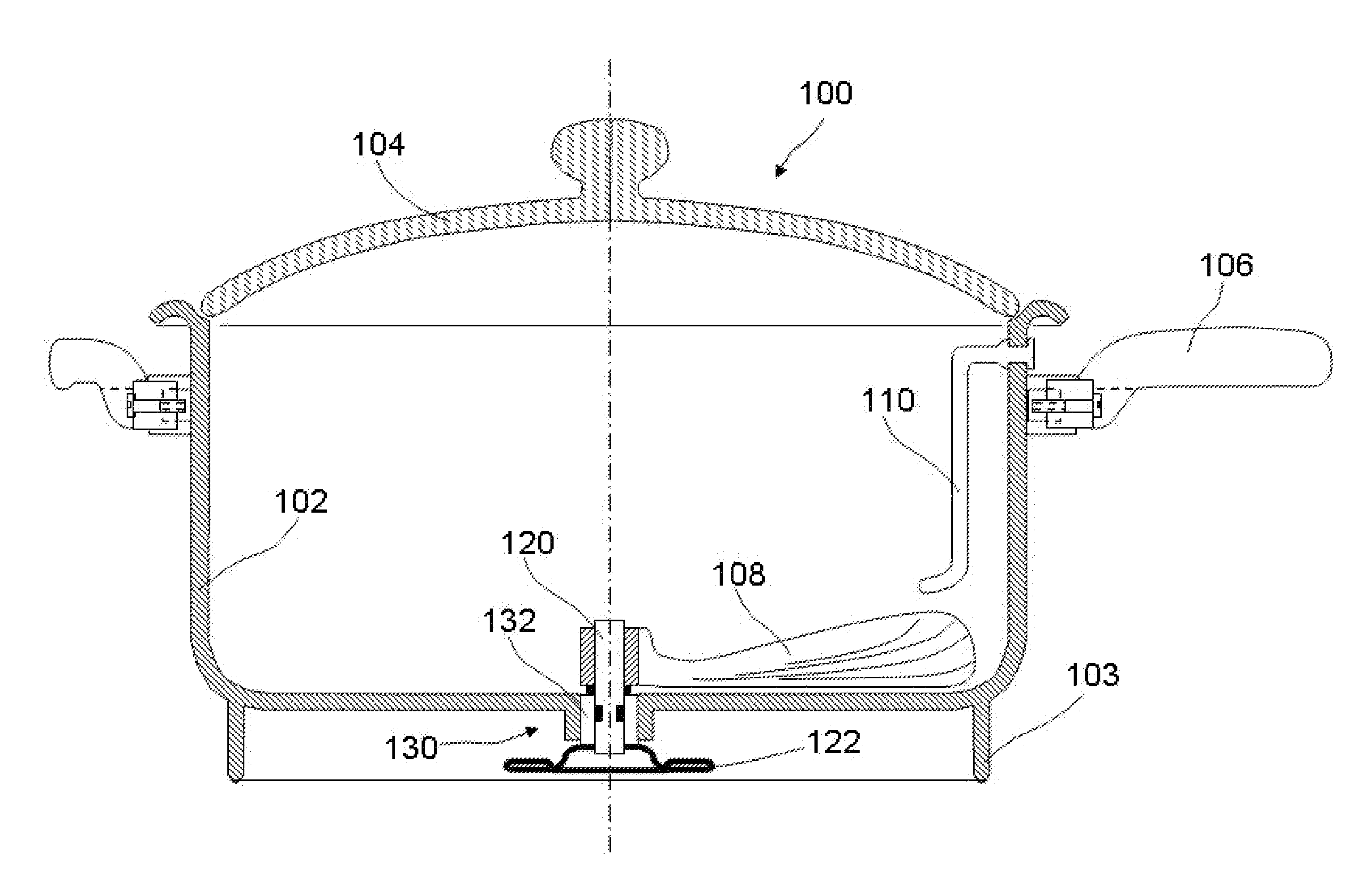

Parallel semicontinuous or continuous reactors

InactiveUS6994827B2Substantial flexibilityMaximum flexibilitySequential/parallel process reactionsMacromolecular librariesPressure responsePhotochemistry

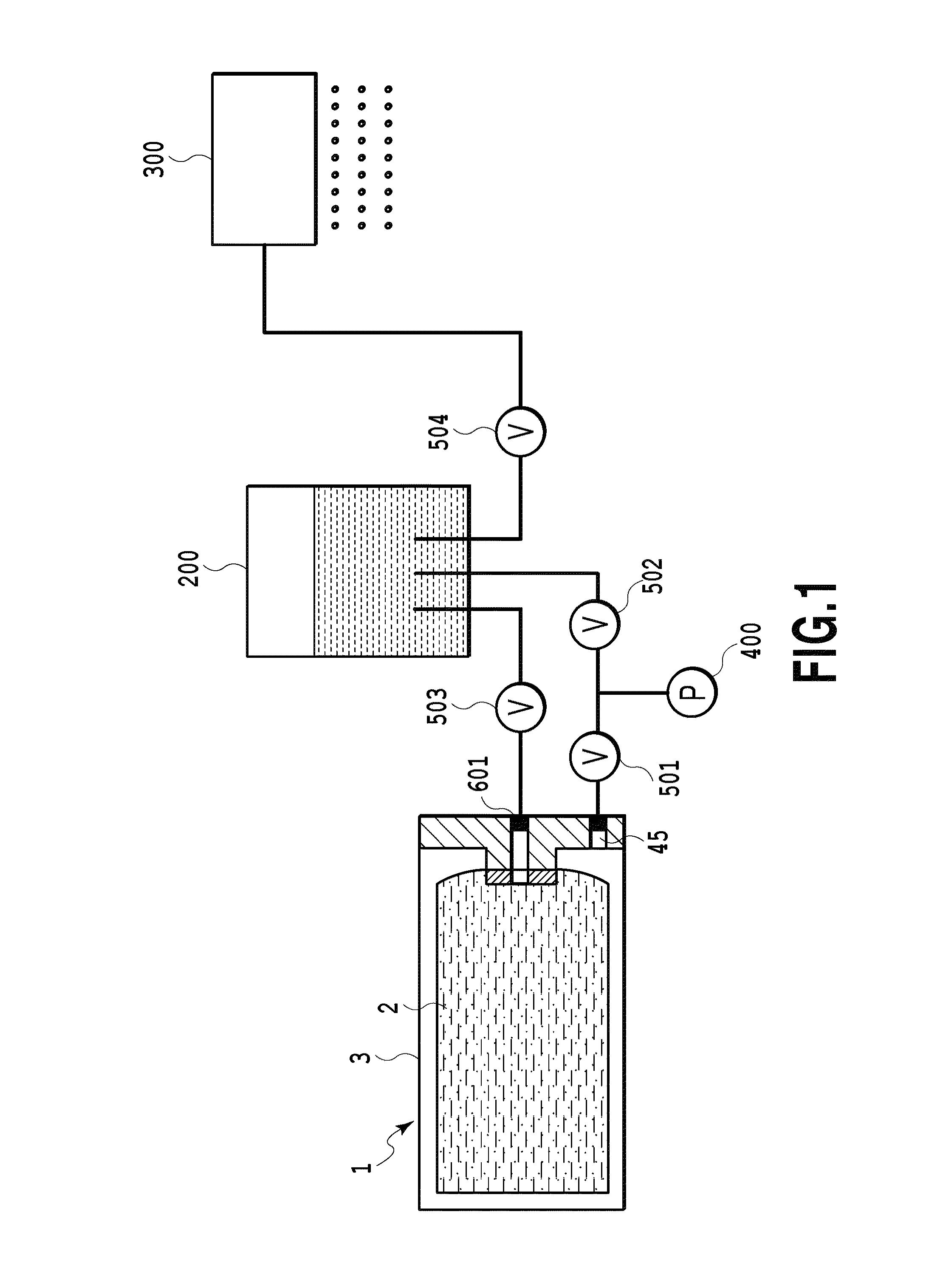

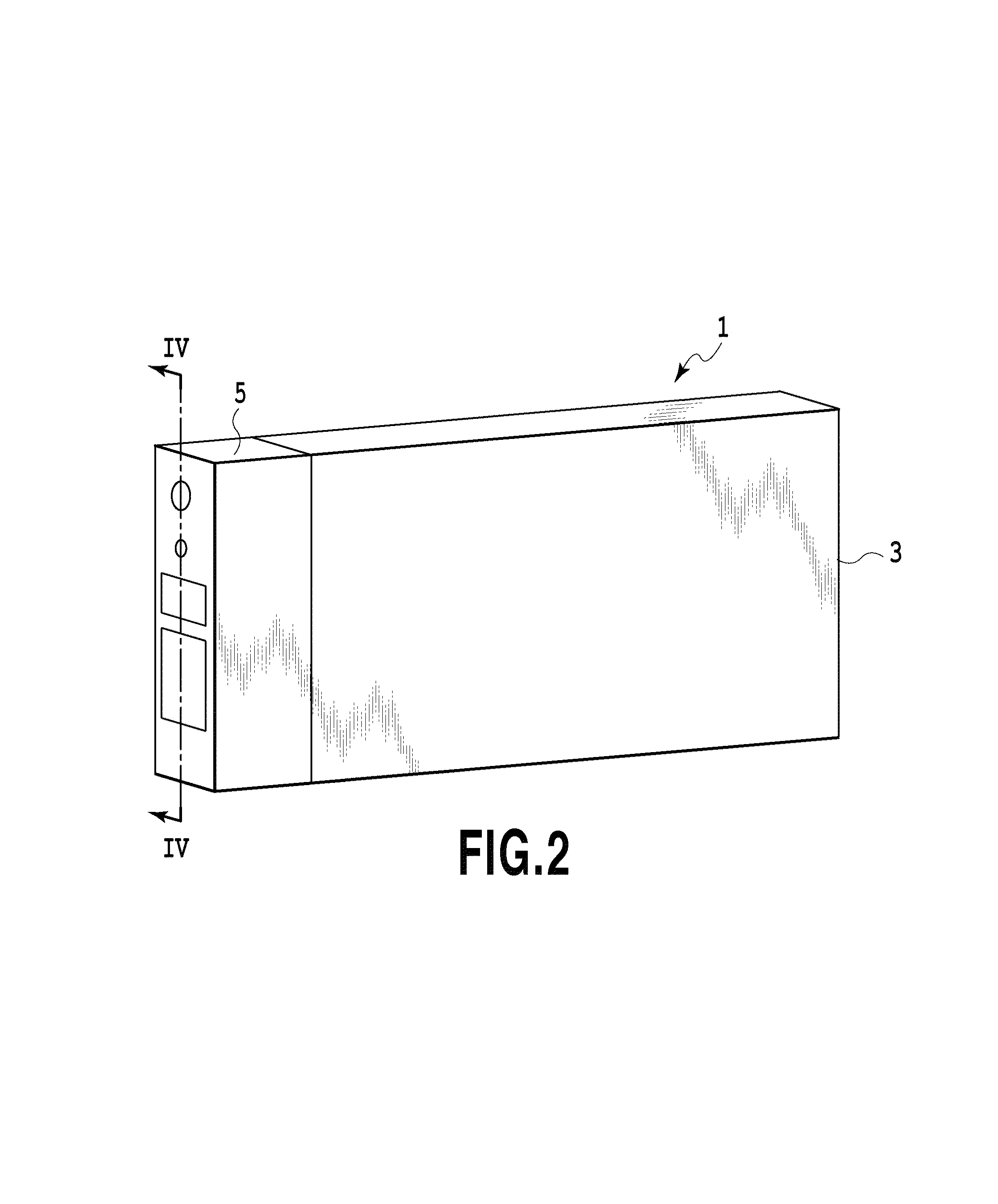

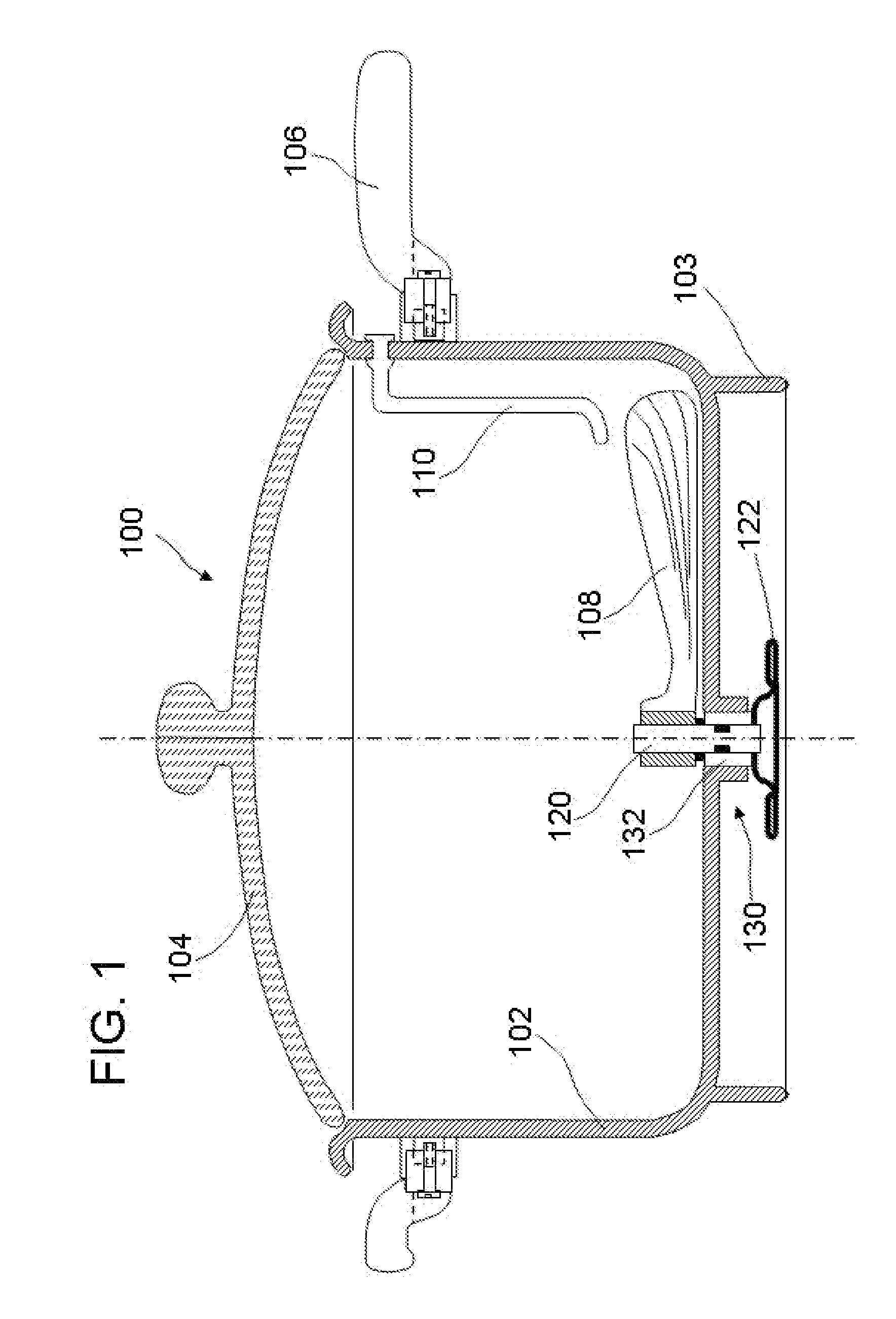

Parallel semi-continuous or continuous reactors are disclosed. The parallel reactors preferably comprise four or more reaction vessels. The reaction vessels are preferably small volume reaction vessels, preferably pressure reaction vessels, and / or preferably integral with a common reactor block. The reaction vessels can comprise shaft-driven stirrers. At least two, preferably at least three or at least four liquid feed lines can provide selective fluid communication between each of the reaction vessels and one or more liquid reagent sources. Additional features, suitable in connection with parallel reactors or with single reaction vessels are also disclosed.

Owner:UNCHAINED LABS

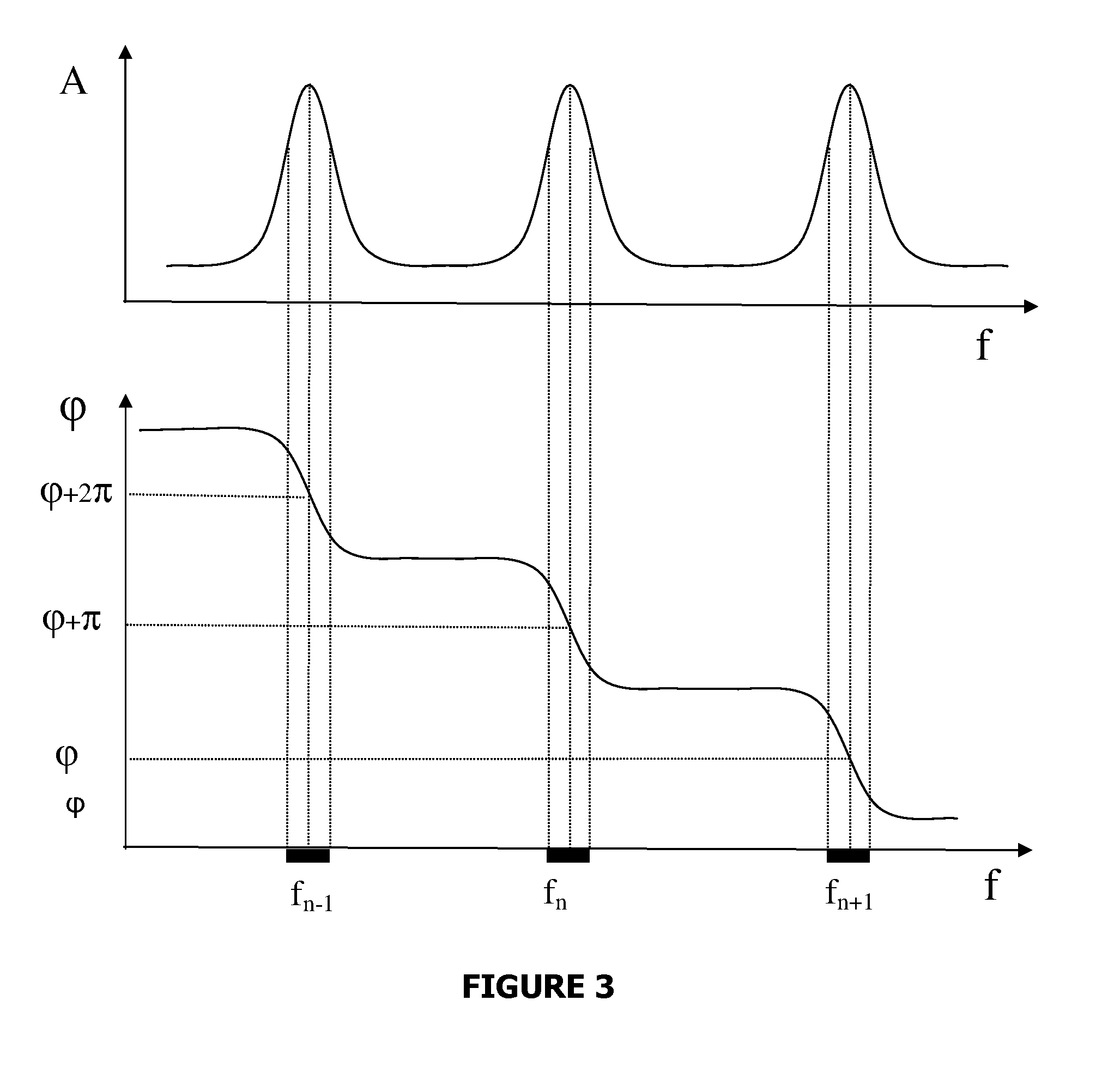

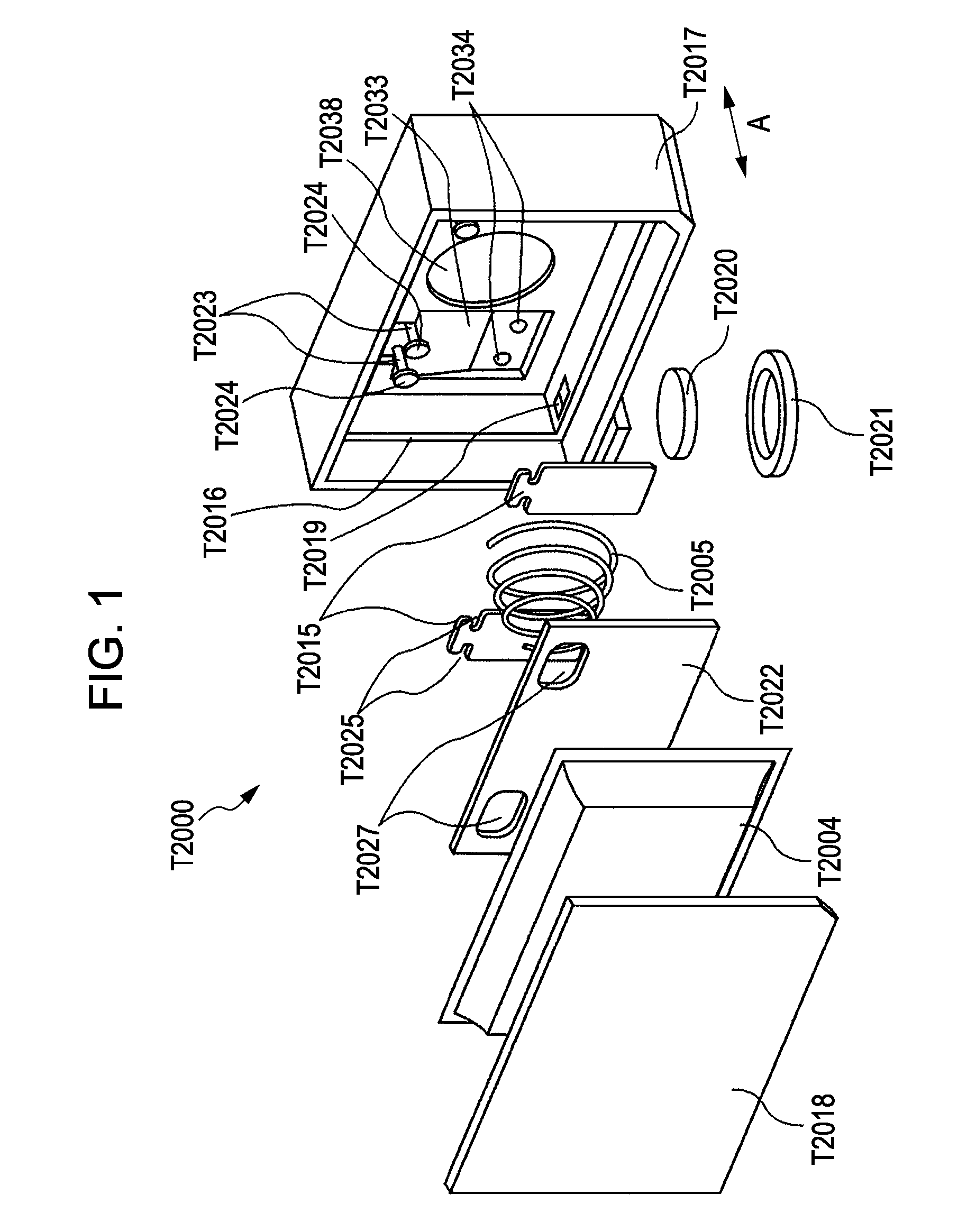

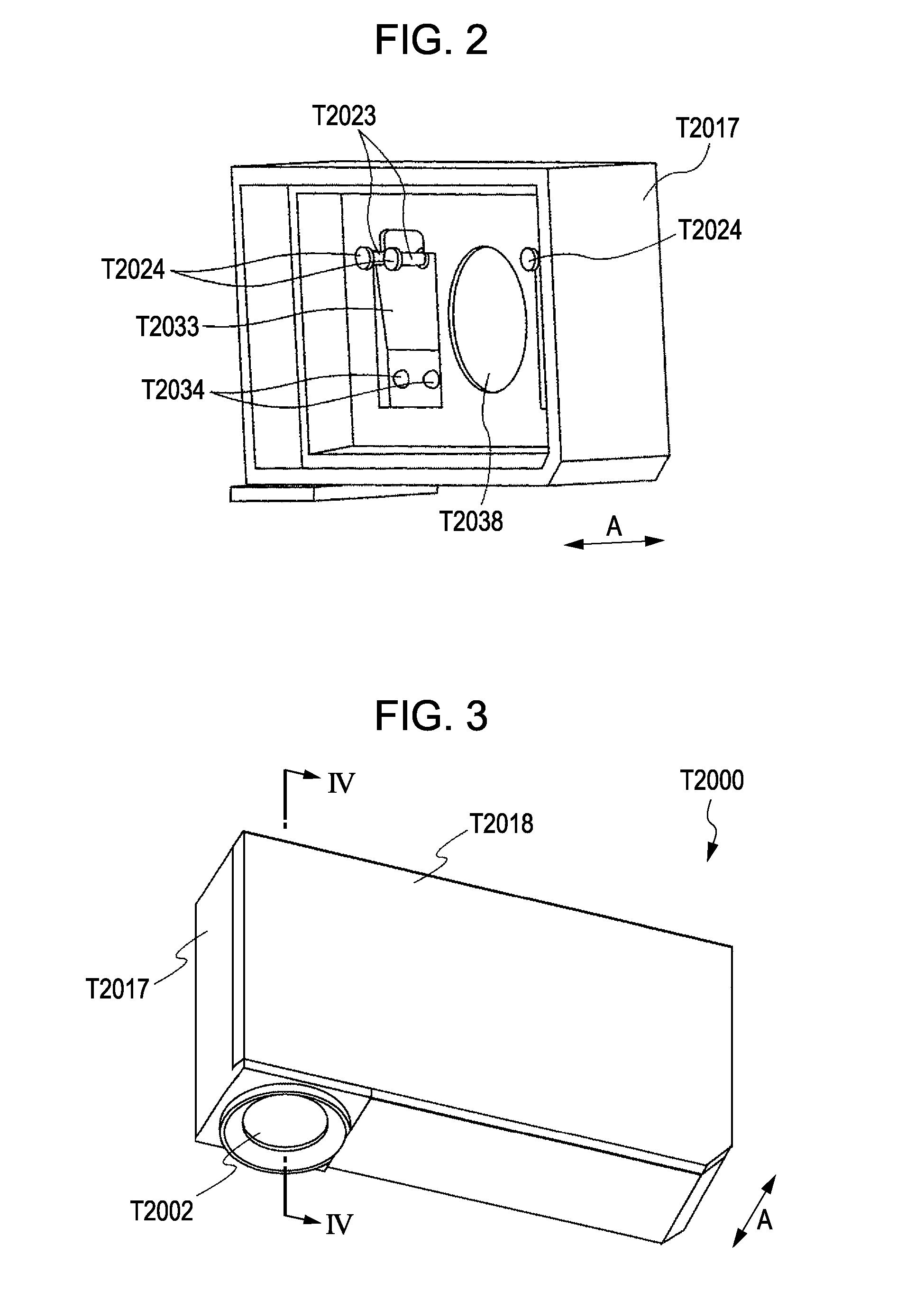

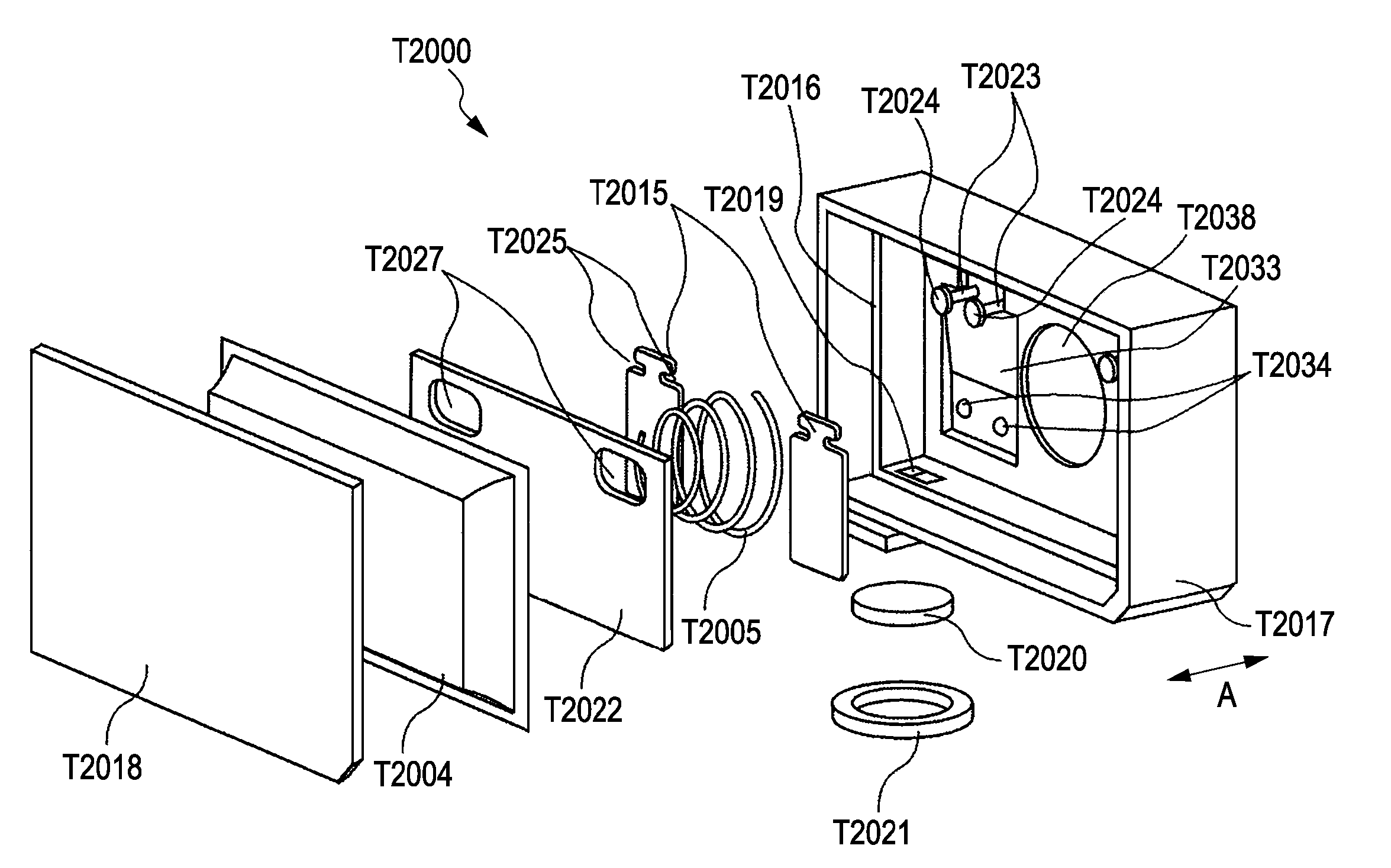

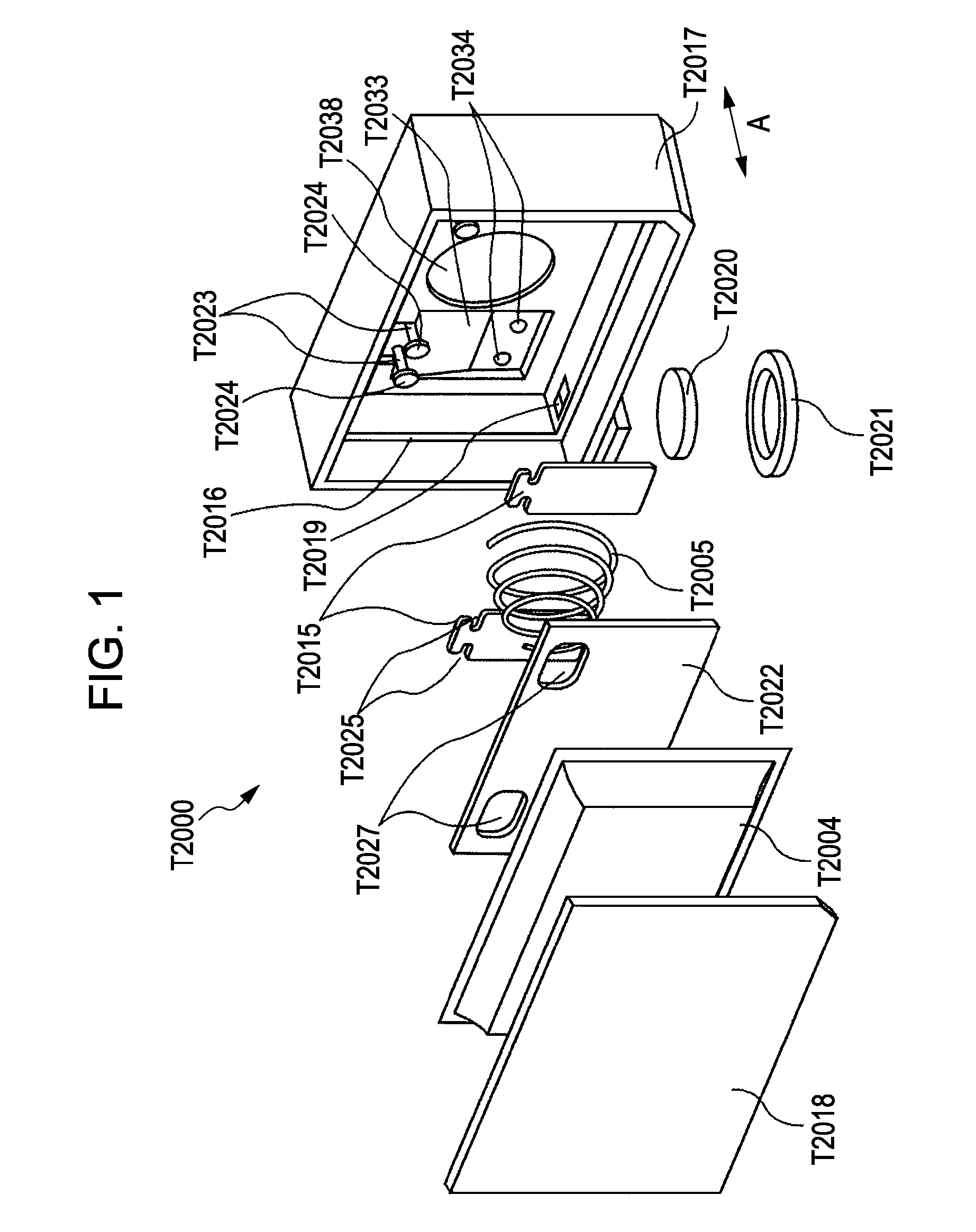

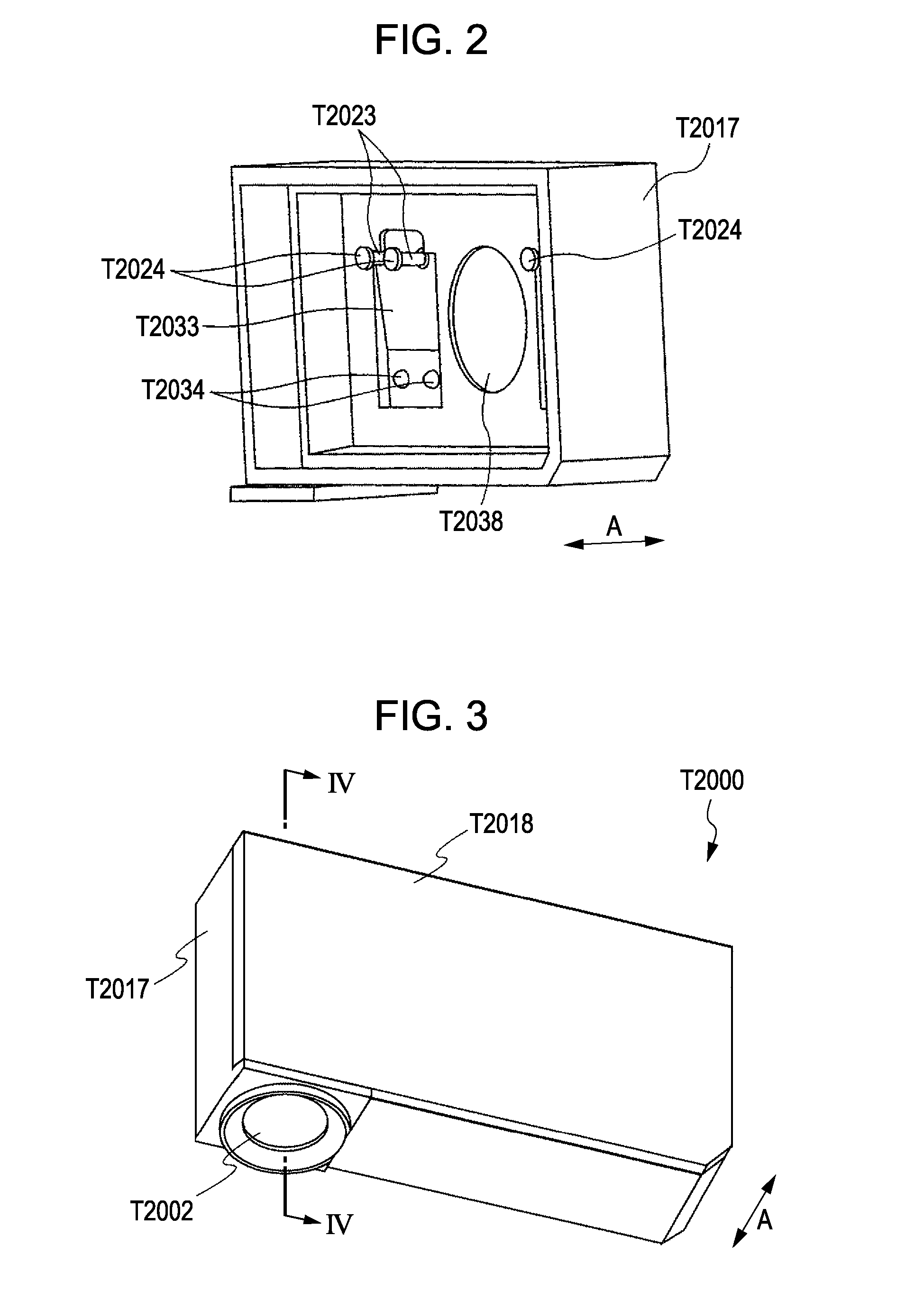

Liquid container and apparatus in which liquid container is mountable

A liquid container enables a liquid contained in a liquid containing chamber to be supplied to an exterior through a supply port. The liquid container includes a first channel, a second channel, and a communication path. The first channel is in communication with a first opening which opens into the liquid containing chamber. The second channel is in communication with a second opening which opens into the liquid containing chamber, the second opening being positioned above the first opening in a direction of gravitational force. The communication path allows the first channel and the second channel to communicate with each other outside the liquid containing chamber to permit a flow of the liquid.

Owner:CANON KK

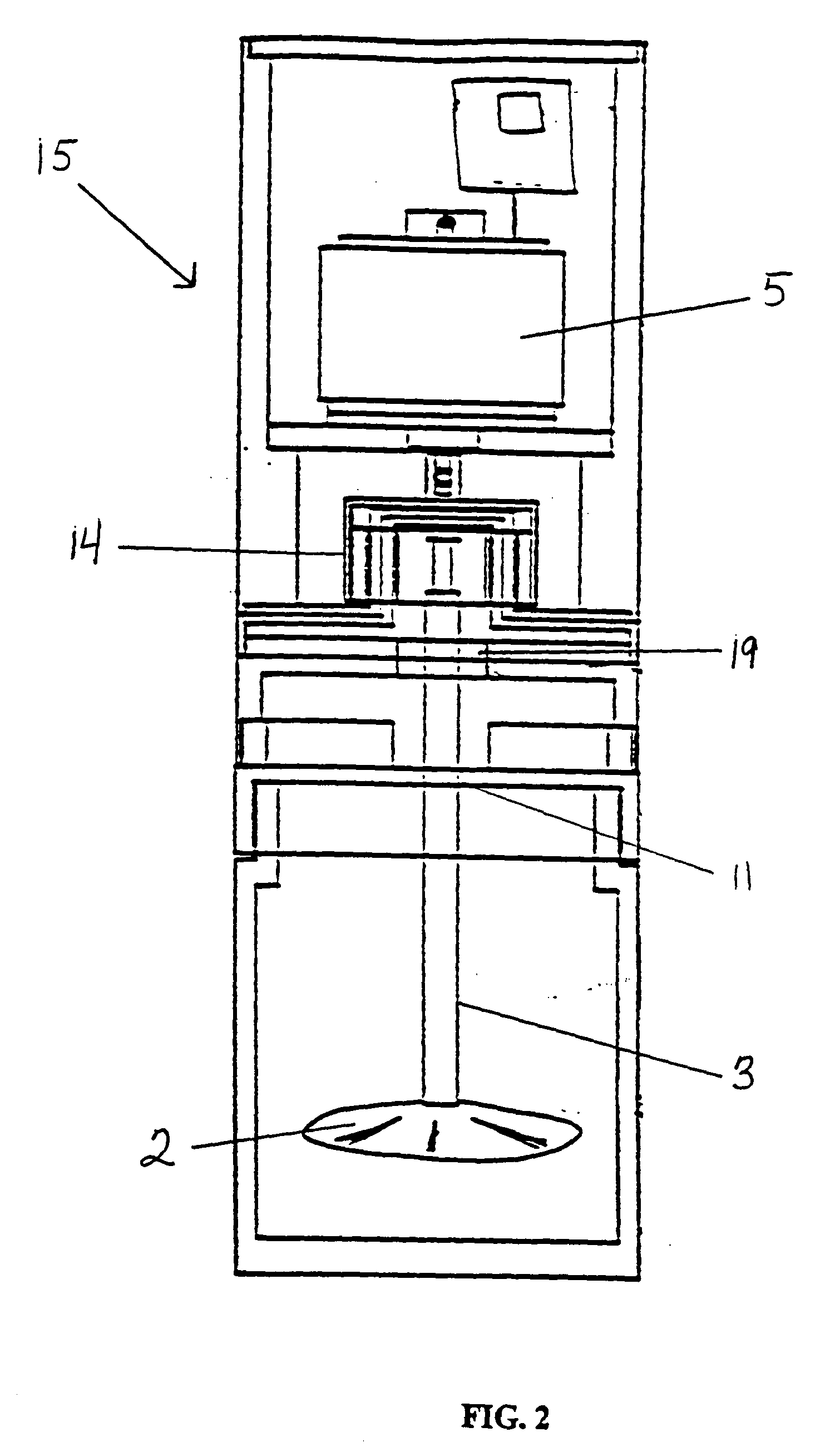

Organic contaminant soil extraction system

InactiveUS20040009610A1Effective stirringReduce usageTransportation and packagingRotary stirring mixersSolventPhysics

A device and method for testing a soil sample for organic contaminants, including stirring soil samples and solvent for subsequent testing of an extracted phase with a plurality of interchangeable rotationally configured stir implements for testing of a variety of soils.

Owner:UNIV OF WYOMING RES THE

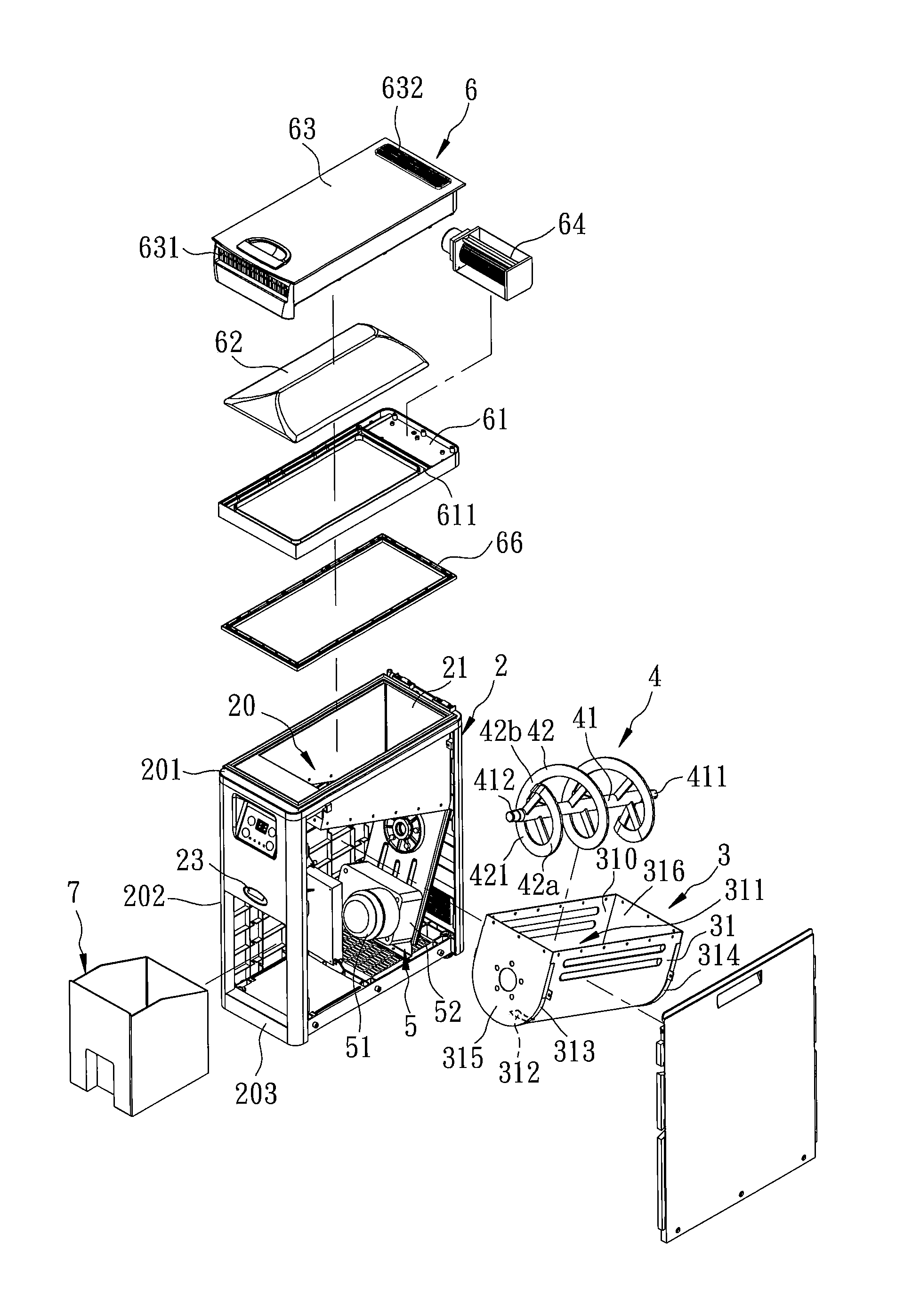

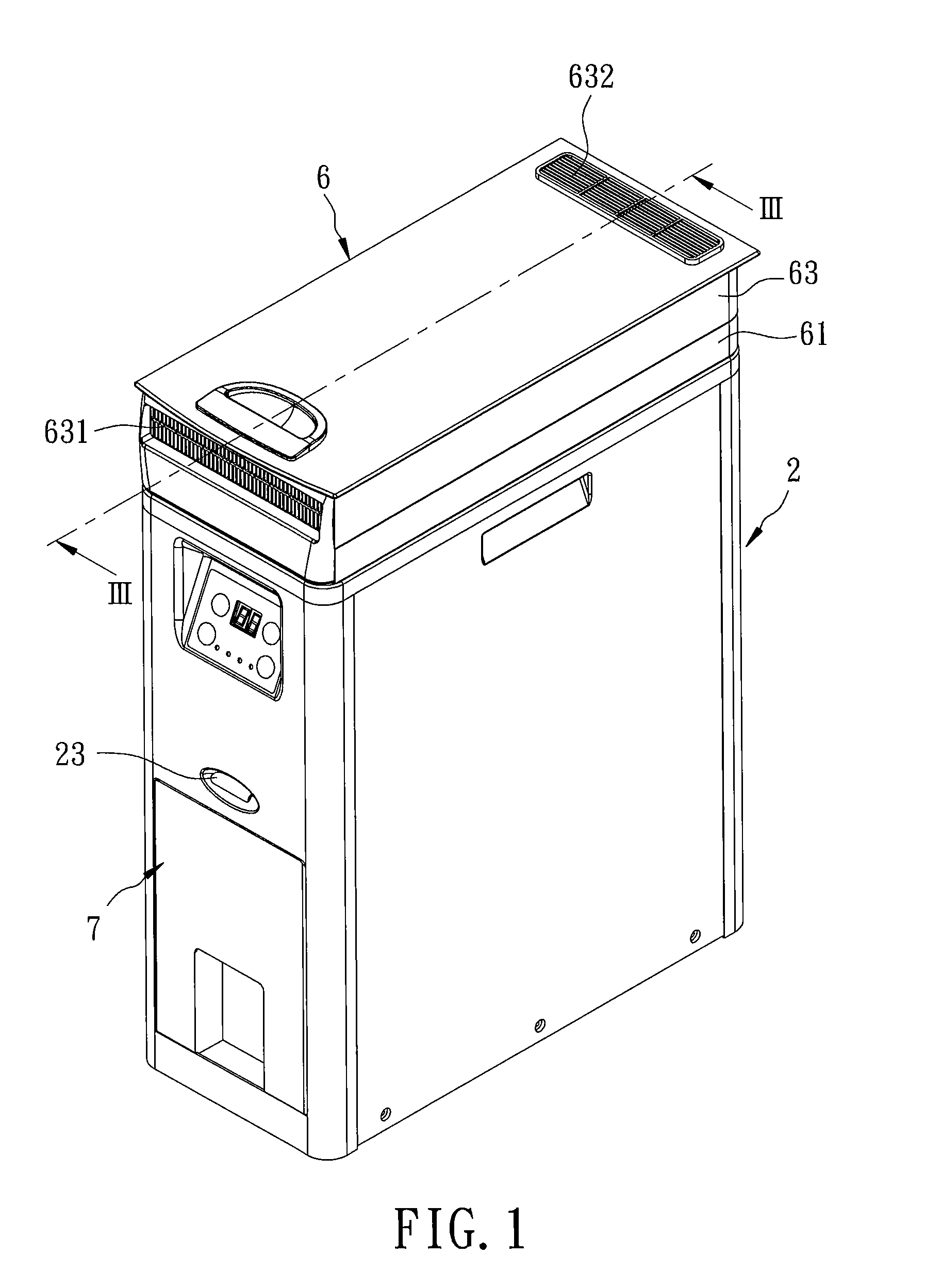

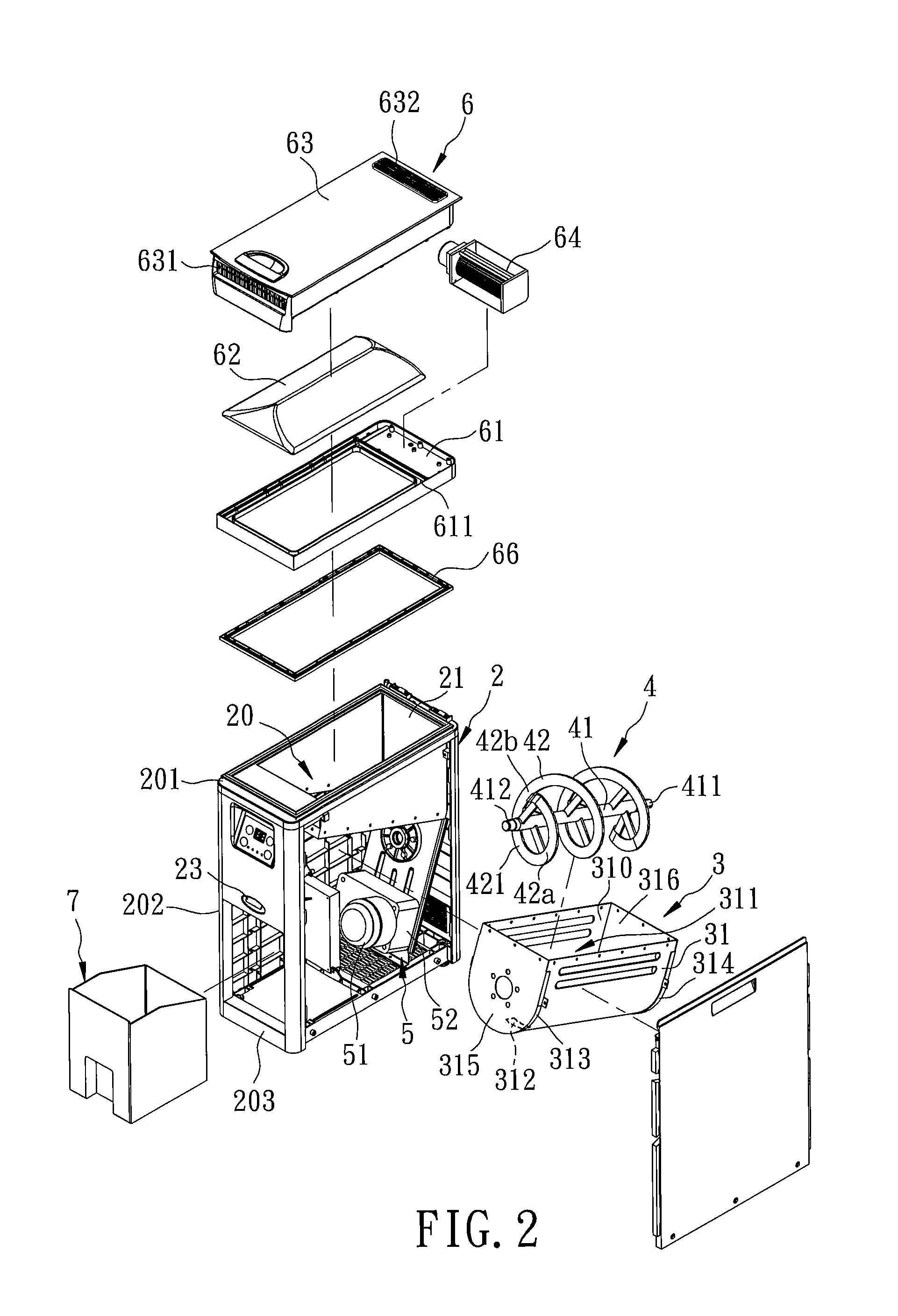

Waste Disposal Device

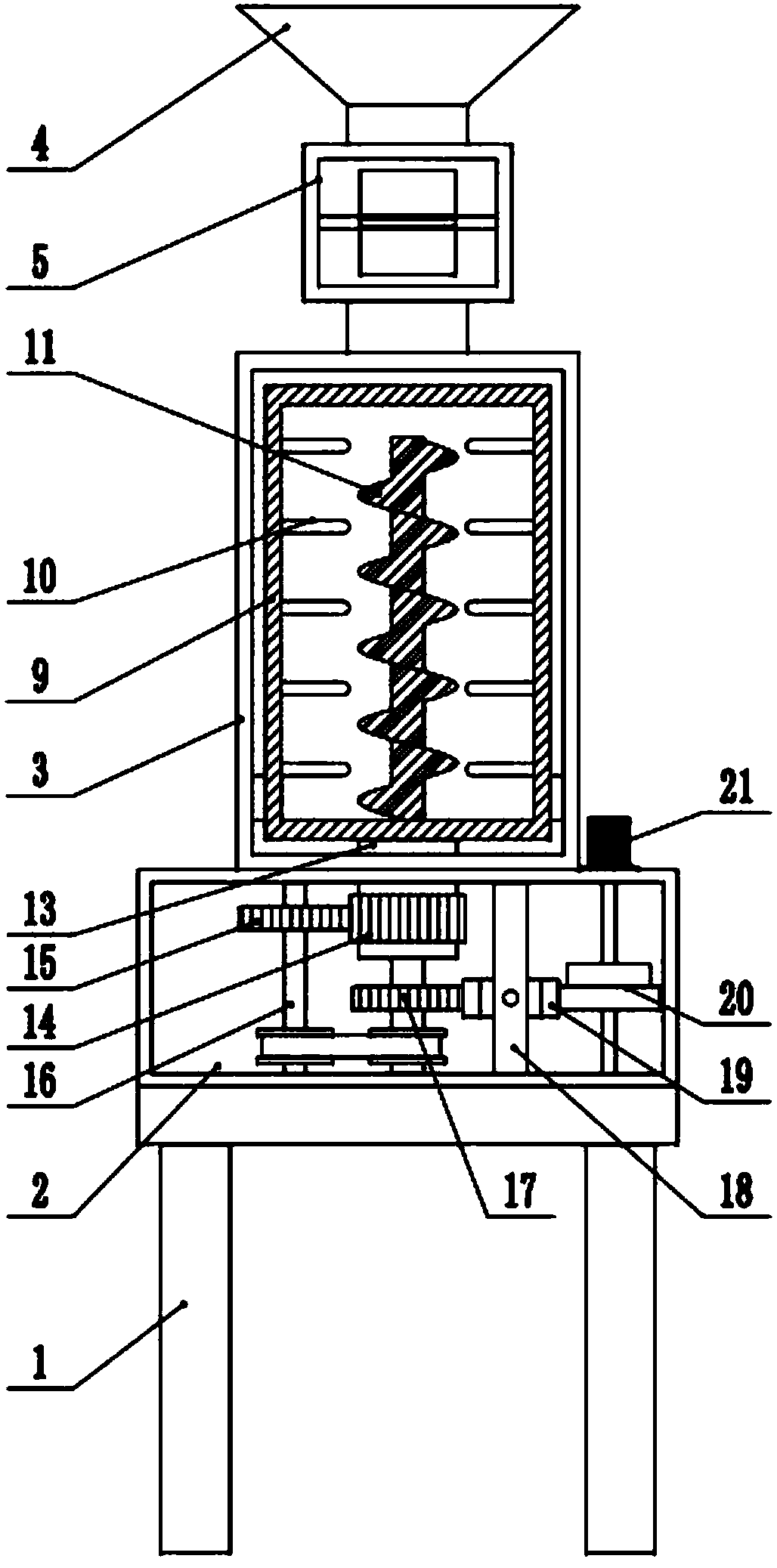

InactiveUS20130217111A1Effective stirringEfficient shreddingBioreactor/fermenter combinationsBiological substance pretreatmentsWaste disposal

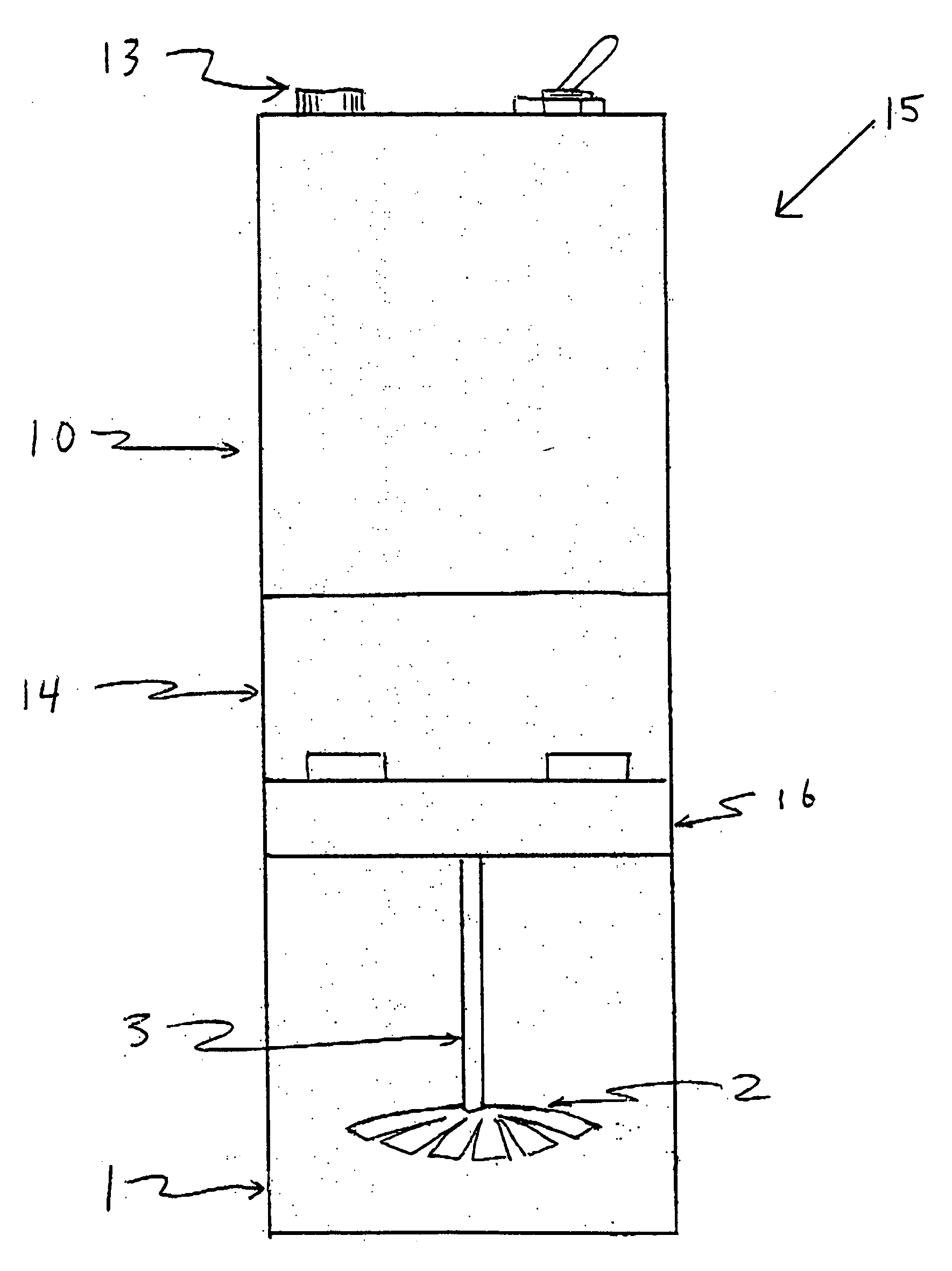

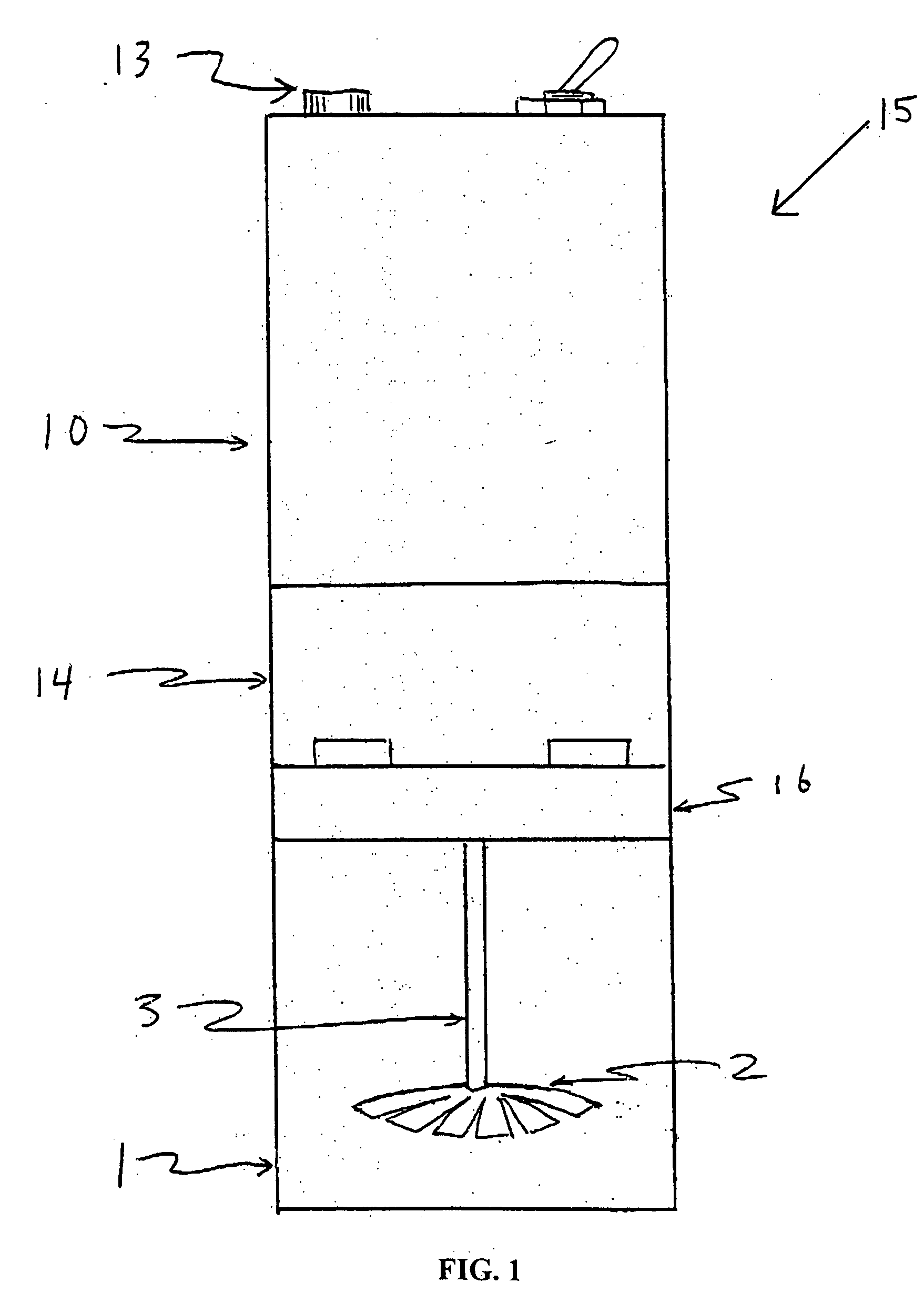

A waste disposal device includes a grinder tank disposed within a housing and having an inner rounded surface angularly extending about an axis for loading of kitchen waste therein, and a grinder assembly rotatably mounted in the tank about the axis to stir and shred the waste and configured to force the waste to advance forward so that the shredding and drying process can be carried out efficiently. A condensing unit is disposed to cool and condense hot air in the housing into water which is drained through a drain port to thereby reduce leakage of unpleasant odor through an access opening of the housing.

Owner:KITCHEN UTENSIL

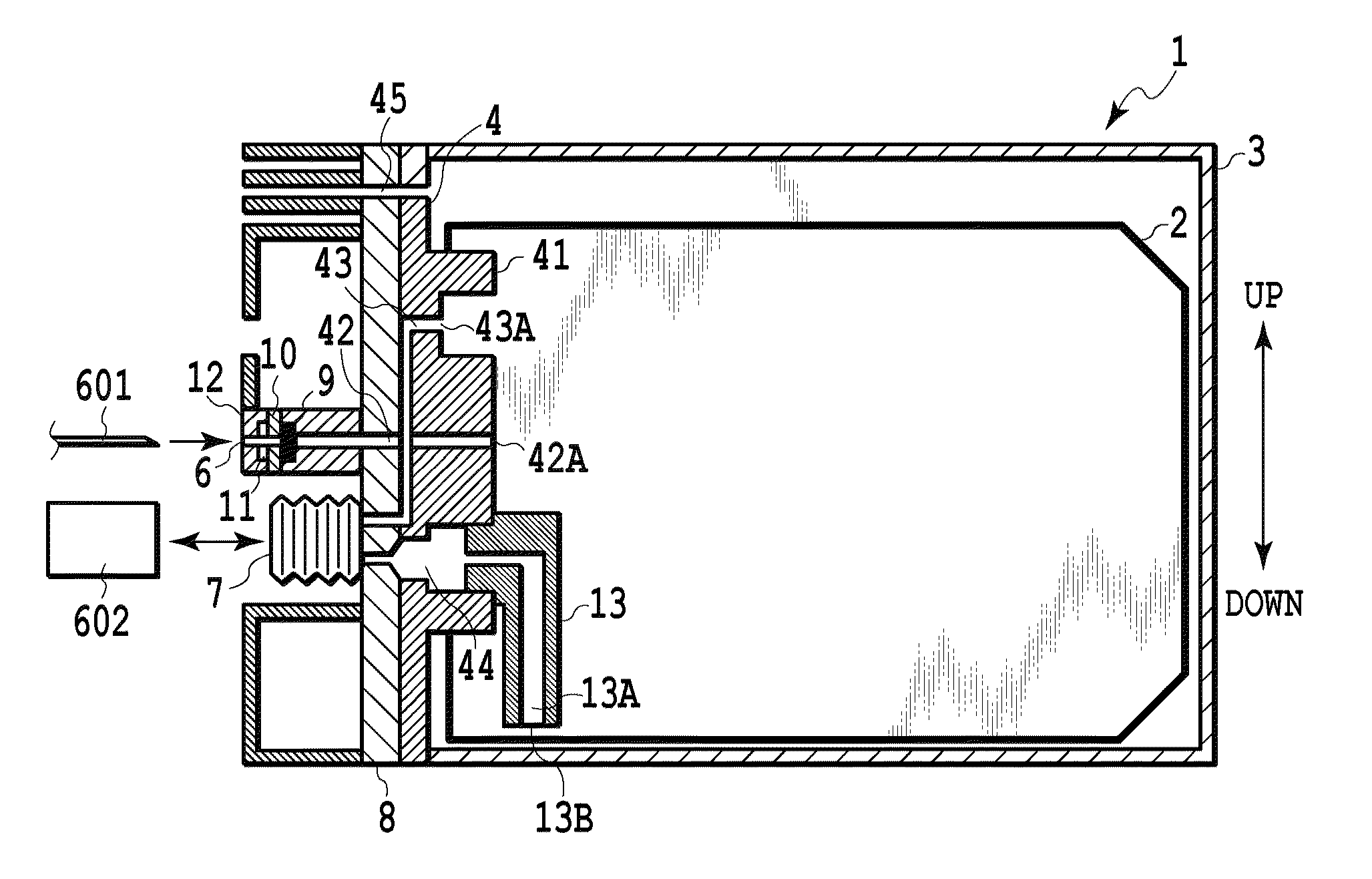

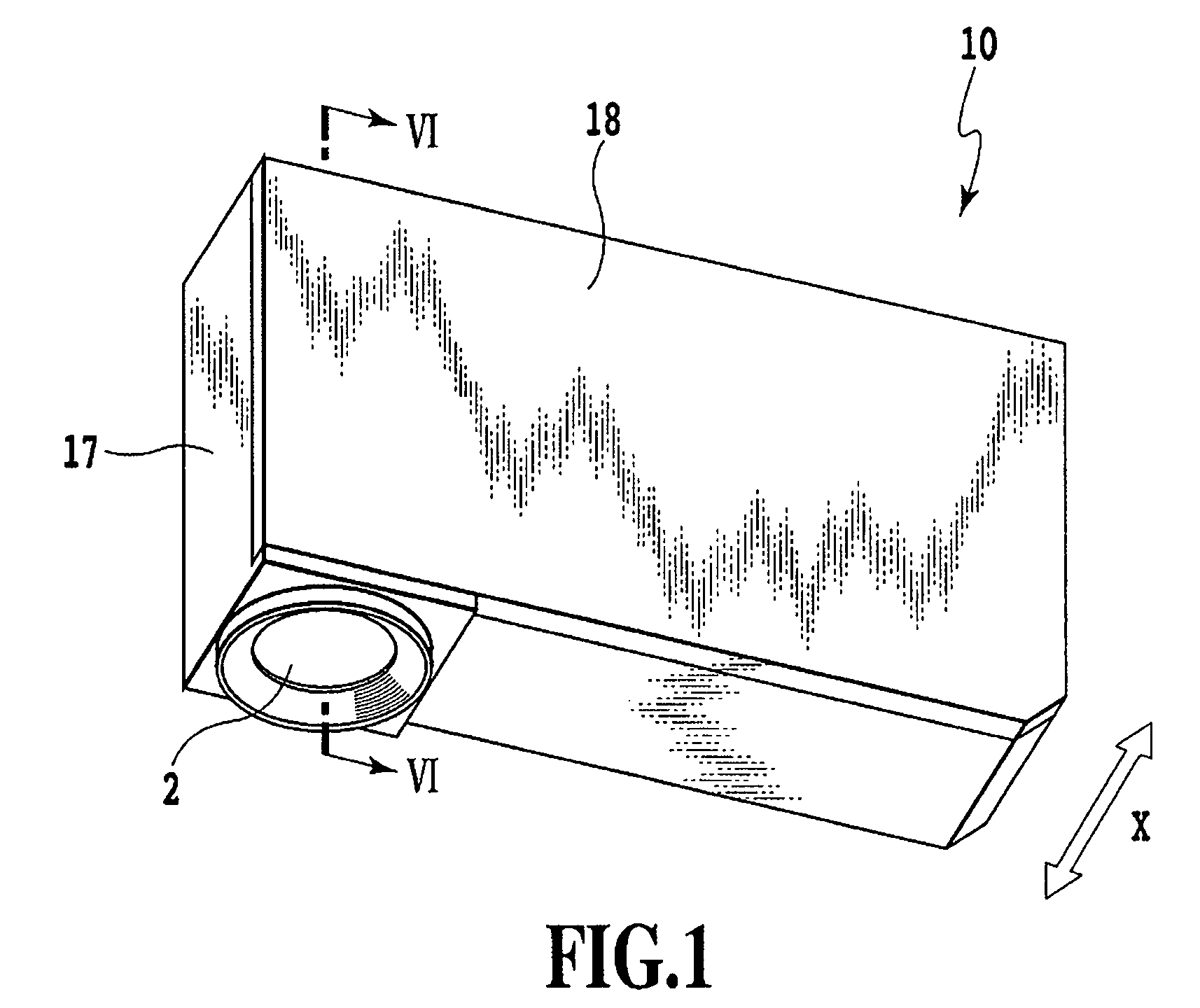

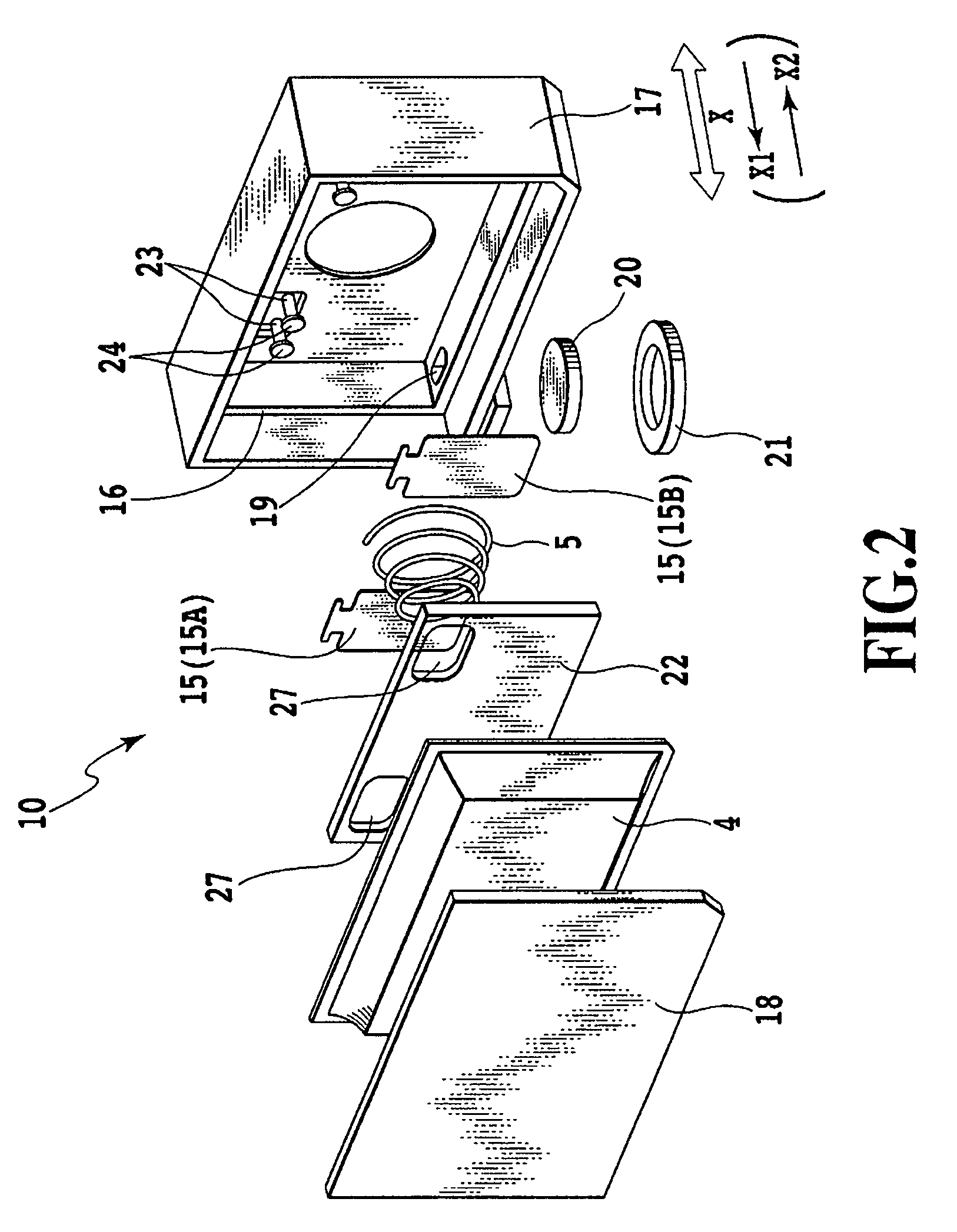

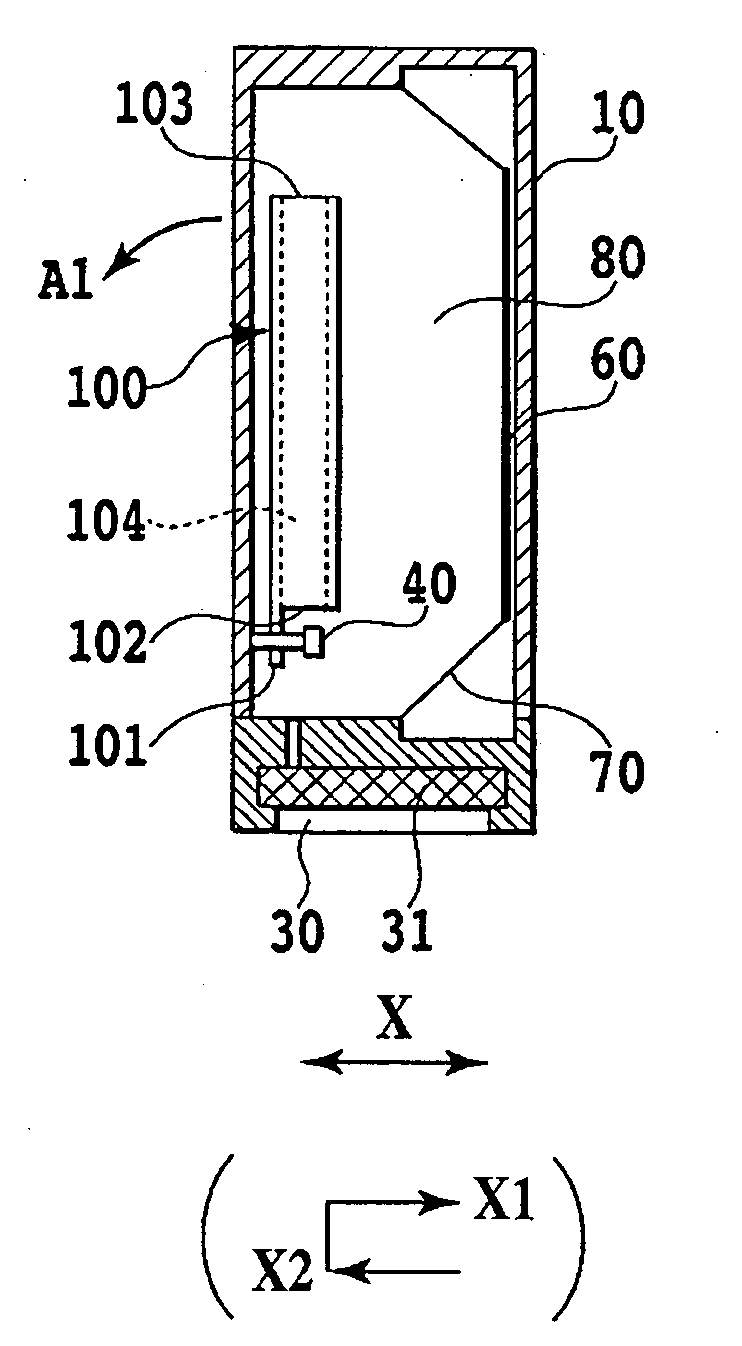

Liquid container

InactiveUS7735984B2Effective stirringIncrease the differenceShaking/oscillating/vibrating mixersTransportation and packagingStart timeMechanical engineering

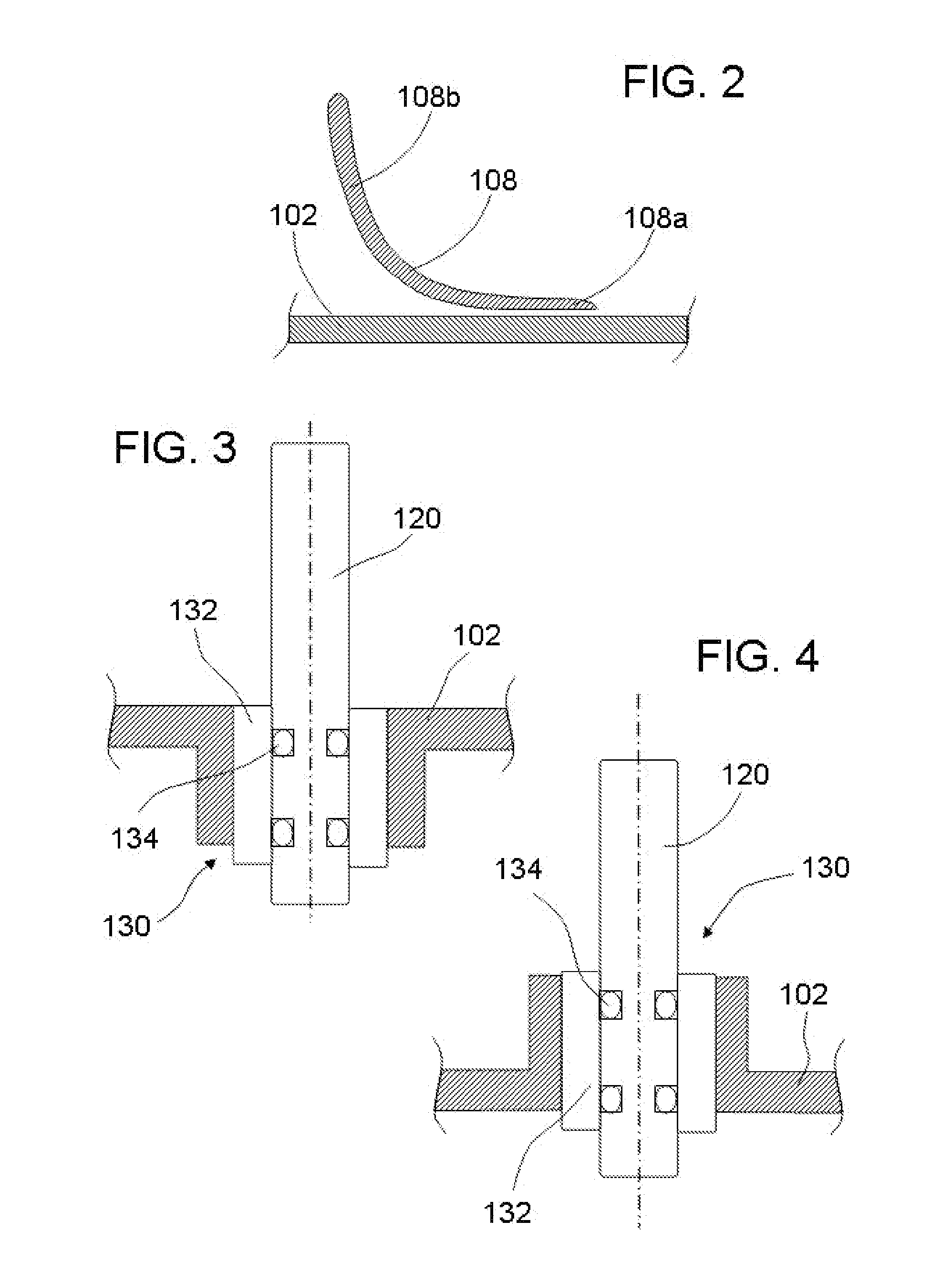

An ink tank includes two stirring members having different masses in an ink containing chamber. The two stirring members are moved by an inertial force according to movement of a carriage and stir ink. The two stirring members have different movement start times and movement speeds.

Owner:CANON KK

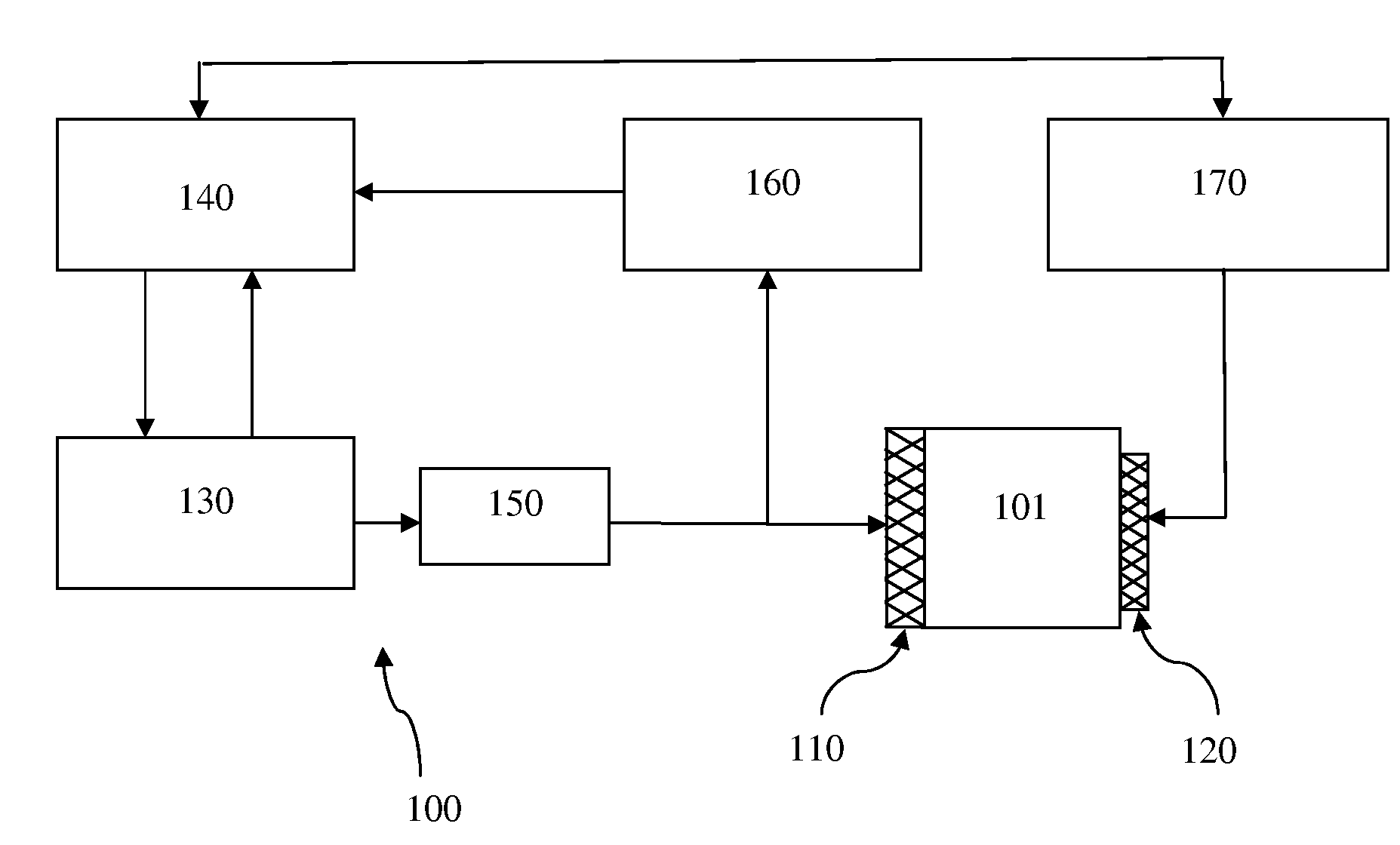

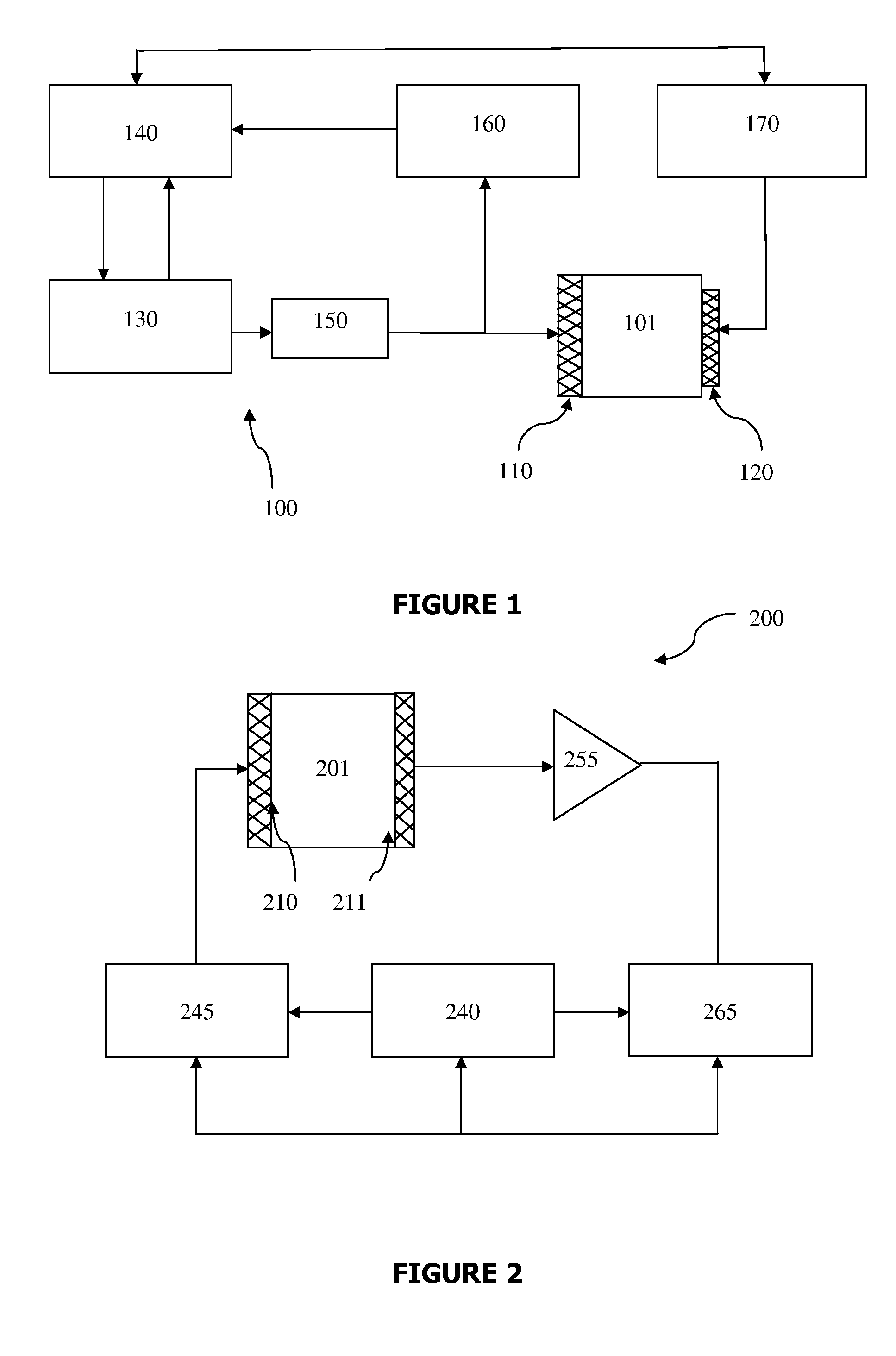

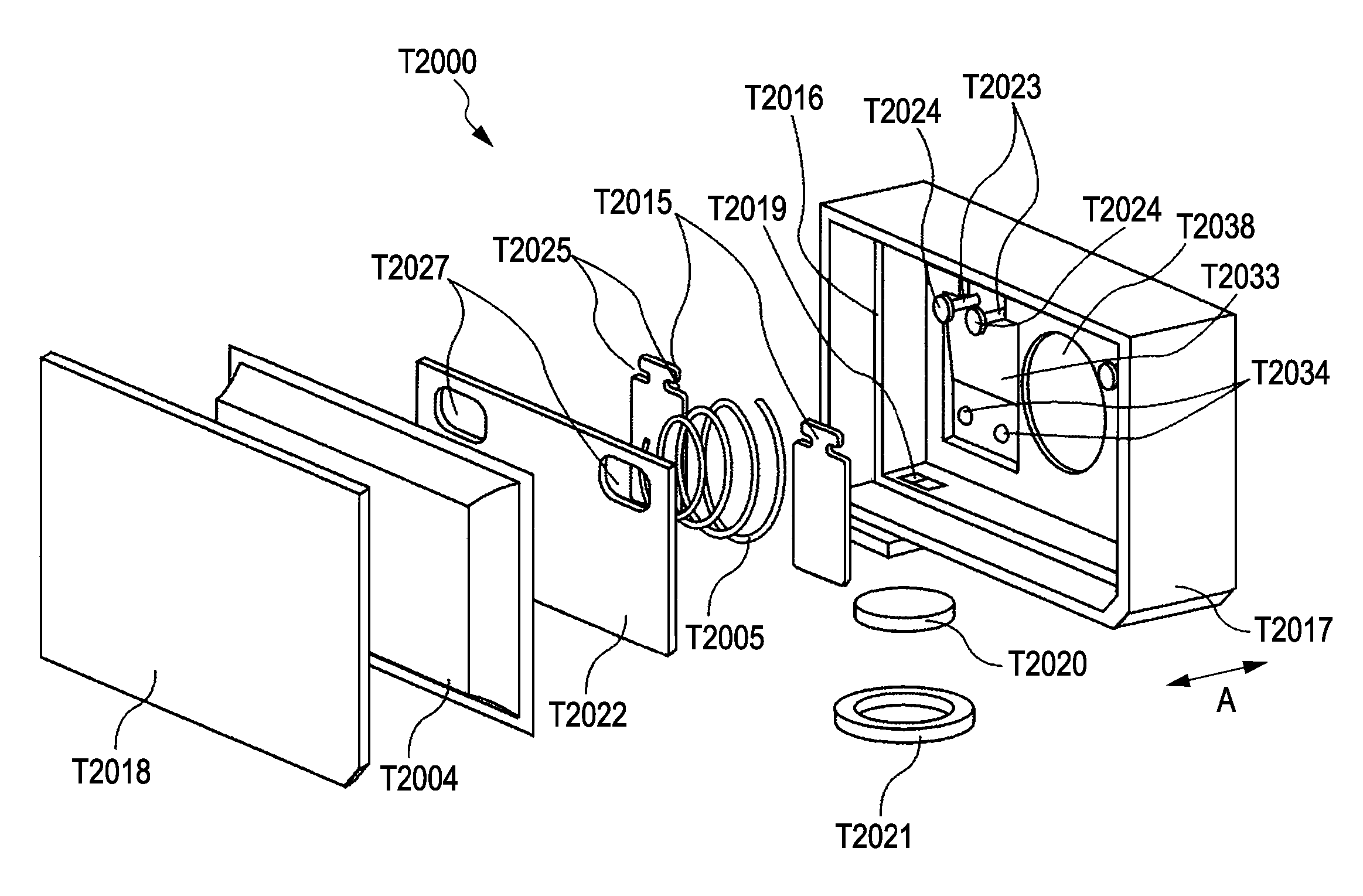

Method and device for ultrasound assisted particle agglutination assay

InactiveUS20090053688A1Accurate assessmentSensitive detectionBioreactor/fermenter combinationsBiological substance pretreatmentsActive matterAgglutination assay

Ultrasound-assisted particle agglutination assay methods and apparatuses are described based on first providing a standing wave ultrasound field at a resonance frequency of a test liquid in a resonator cell containing microparticles covered with a binding agent with high affinity to an analyte sought to be detected by the assay test. Formation of the specifically-bound and nonspecifically-bound aggregates of these microparticles is then followed by effective stirring of the liquid with swept-frequency sonication causing disintegration of nonspecifically-bound aggregates and leaving specifically-bound aggregates in place for further detection and measurement. The methods and devices of the invention allow significant improvement in the sensitivity and specificity of agglutination tests and are advantageously applicable to detecting various proteins, DNA, RNA and other biologically active substances. Specific examples are provided.

Owner:ALLIED INNOVATIVE SYST

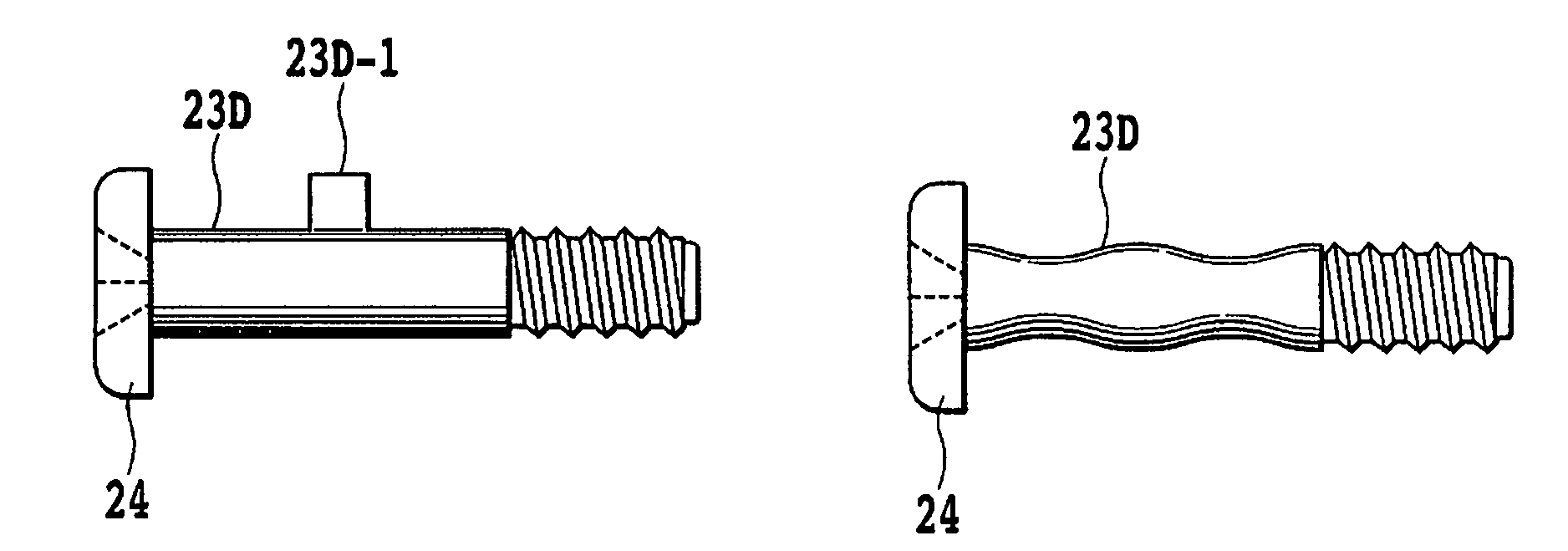

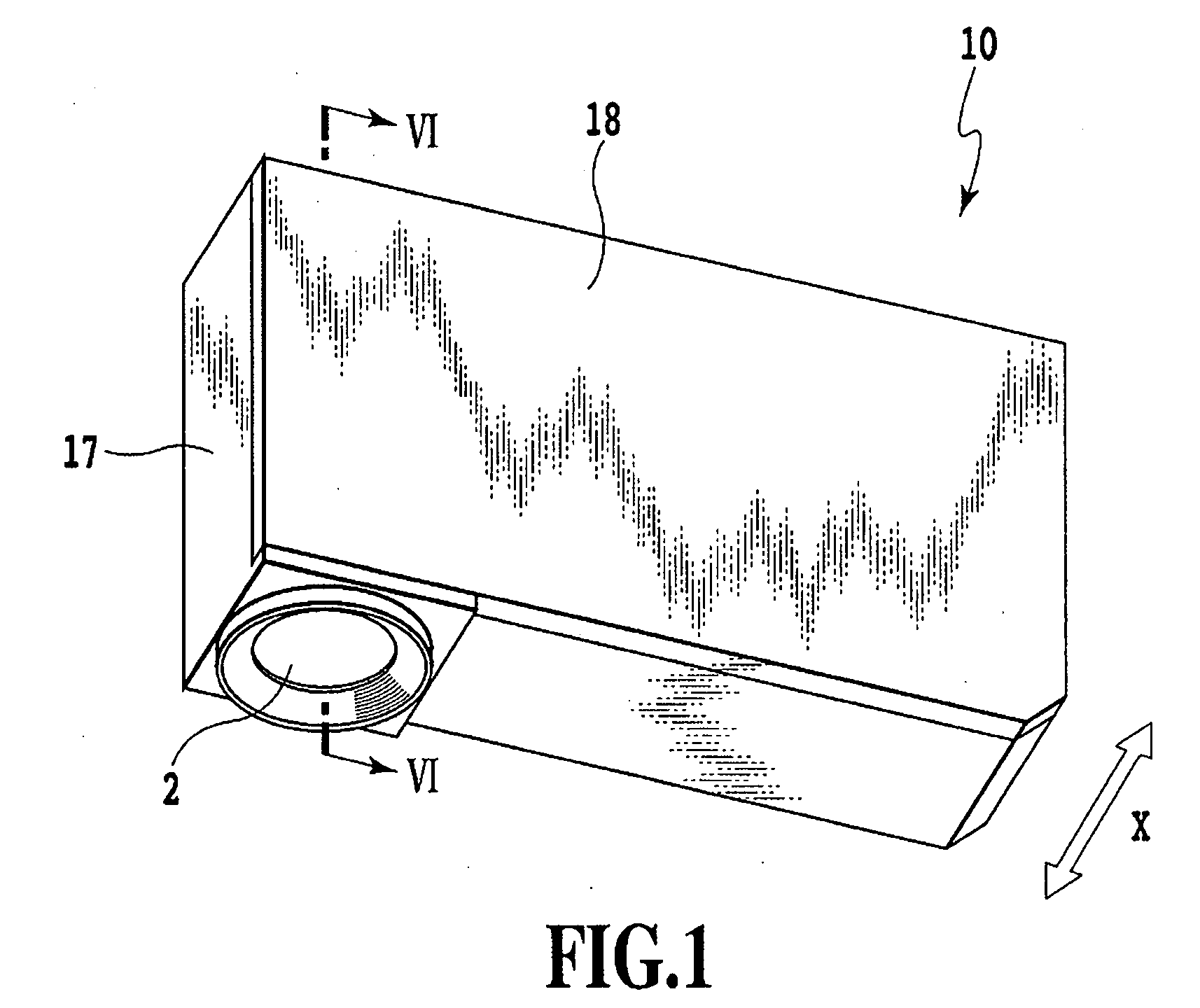

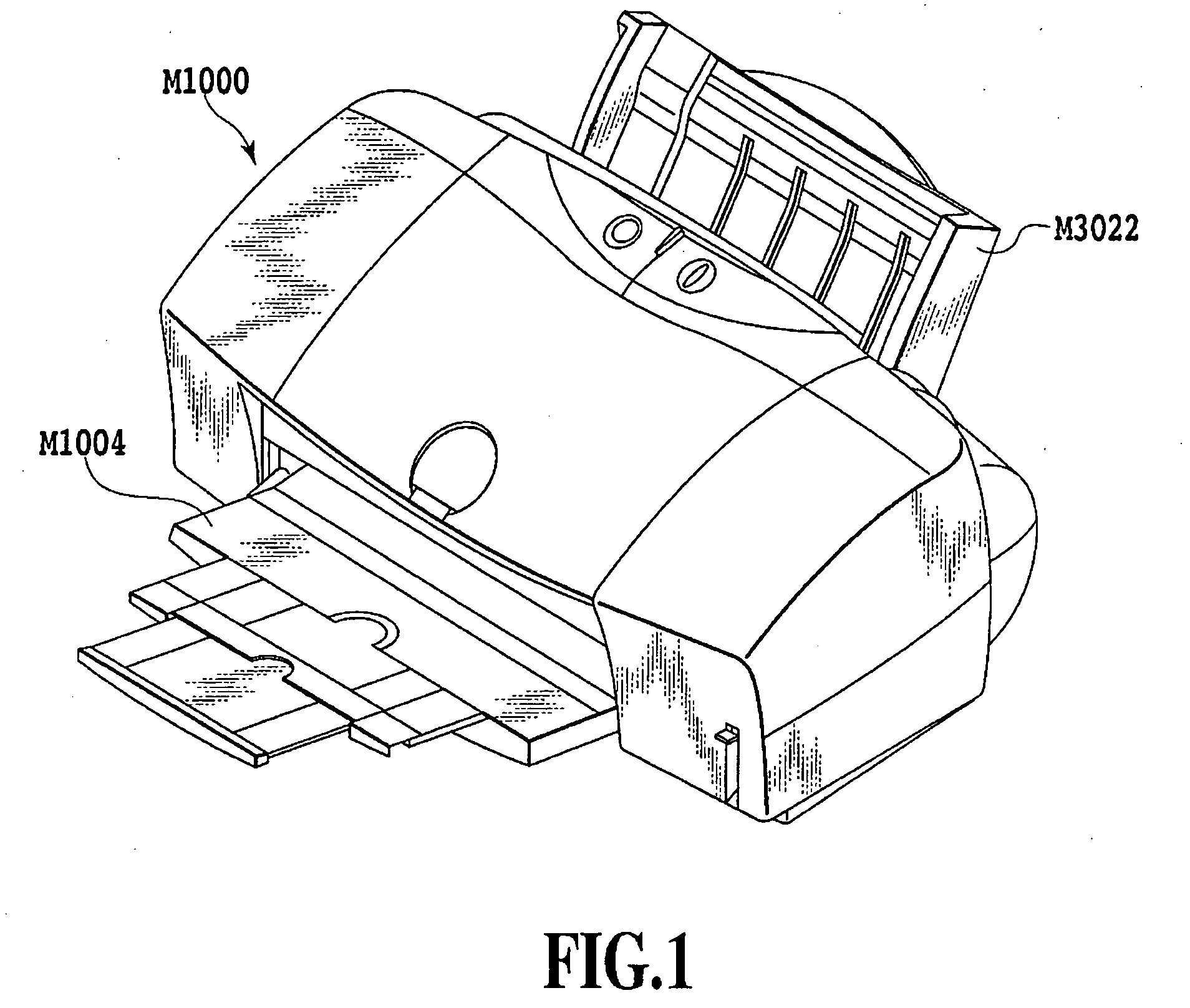

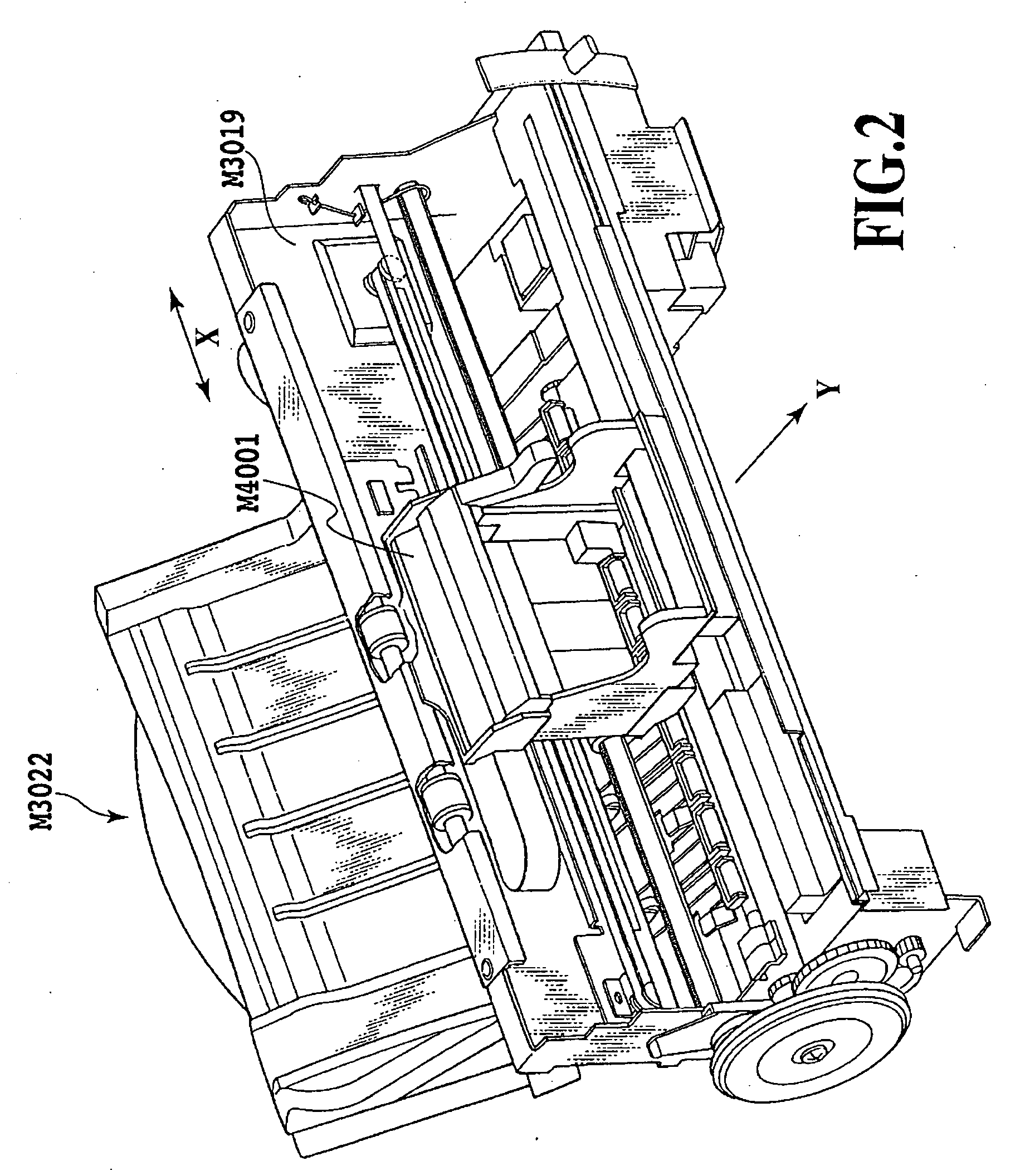

Ink tank and recording apparatus

ActiveUS7618133B2Effective stirringQuality improvementPrintingElectrical and Electronics engineering

Owner:CANON KK

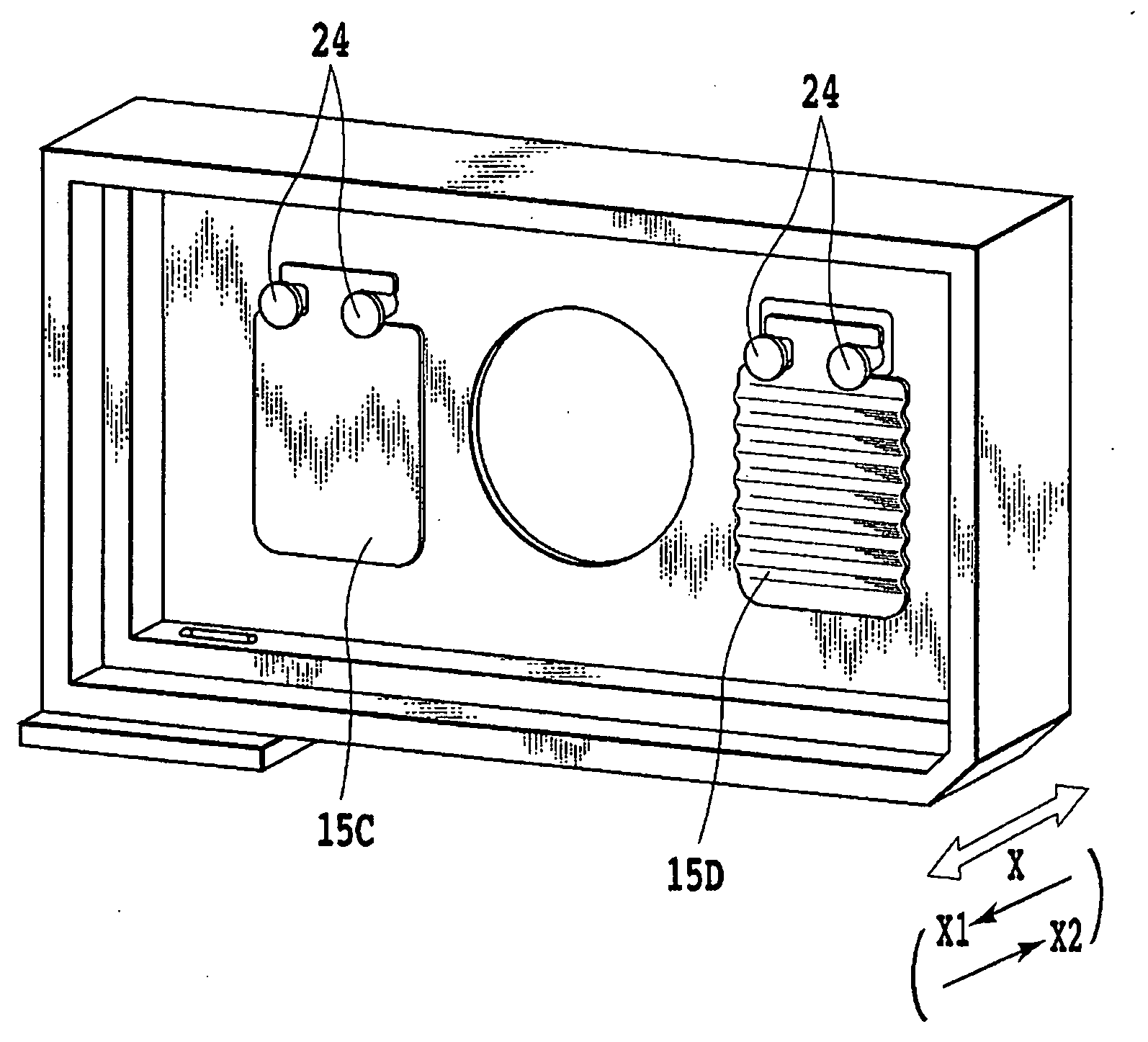

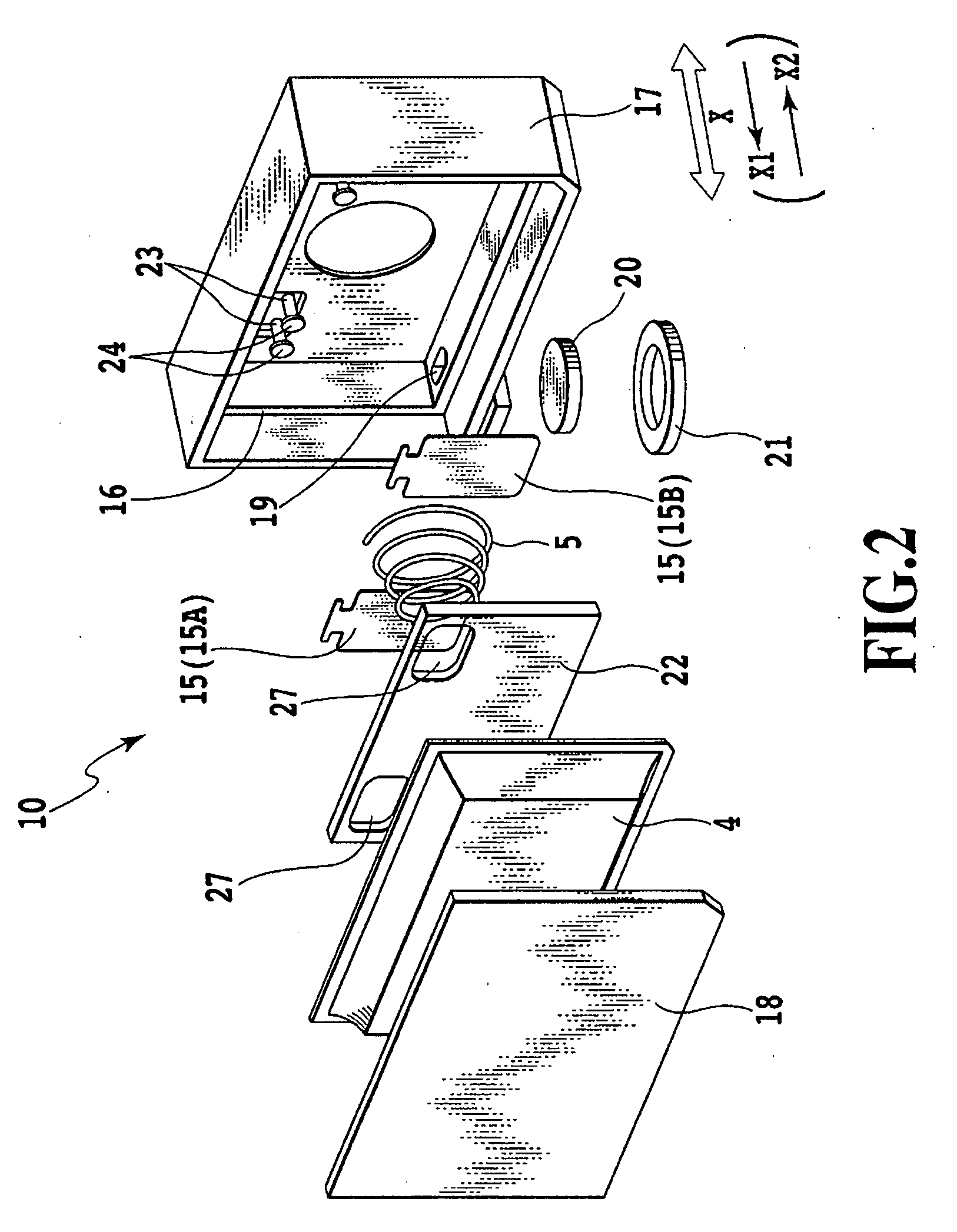

Liquid container

InactiveUS20070263052A1Effective stirringIncrease the differenceShaking/oscillating/vibrating mixersTransportation and packagingStart timeMechanical engineering

An ink tank includes two stirring members having different masses in an ink containing chamber. The two stirring members are moved by an inertial force according to movement of a carriage and stir ink. The two stirring members have different movement start times and movement speeds.

Owner:CANON KK

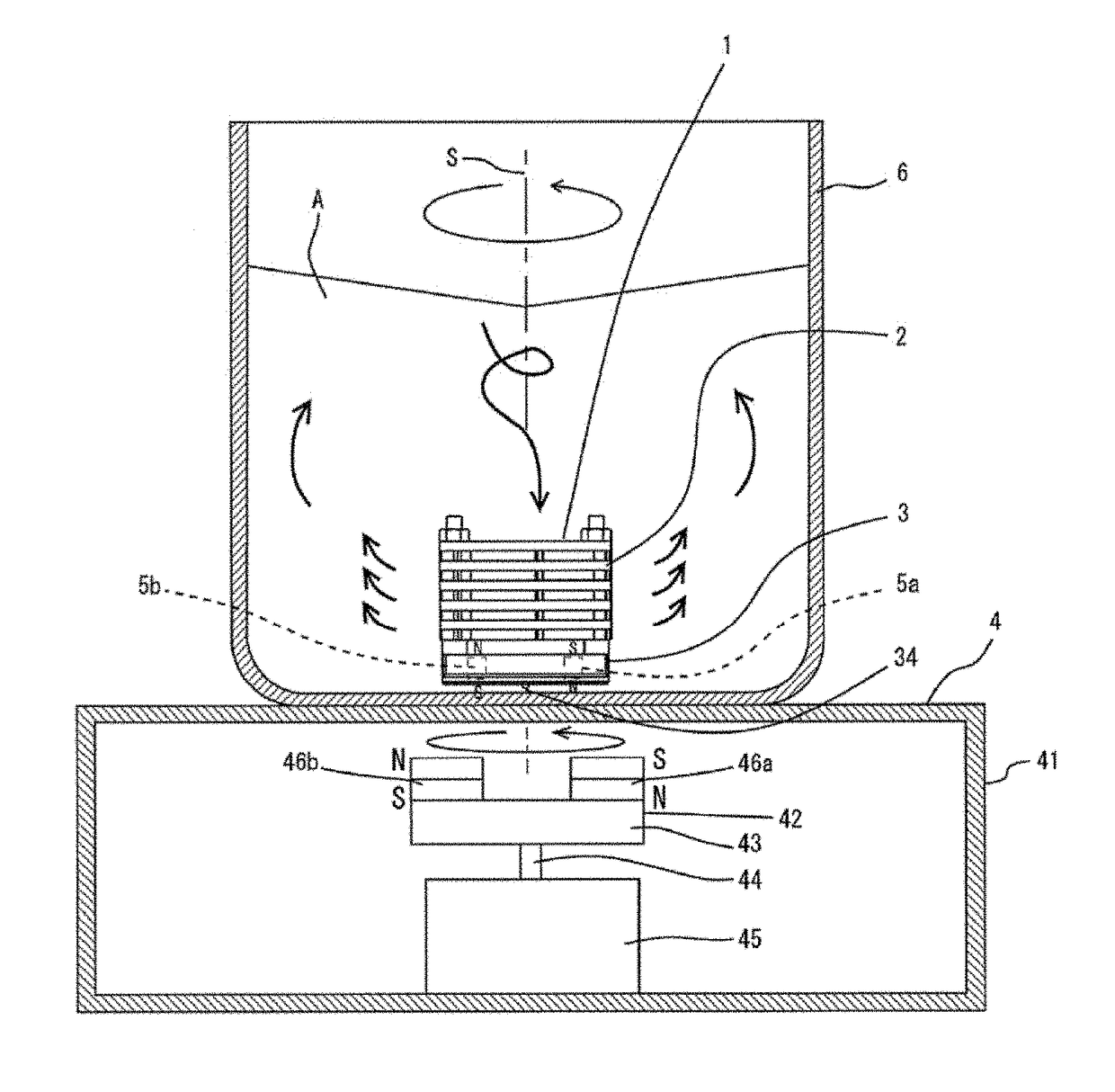

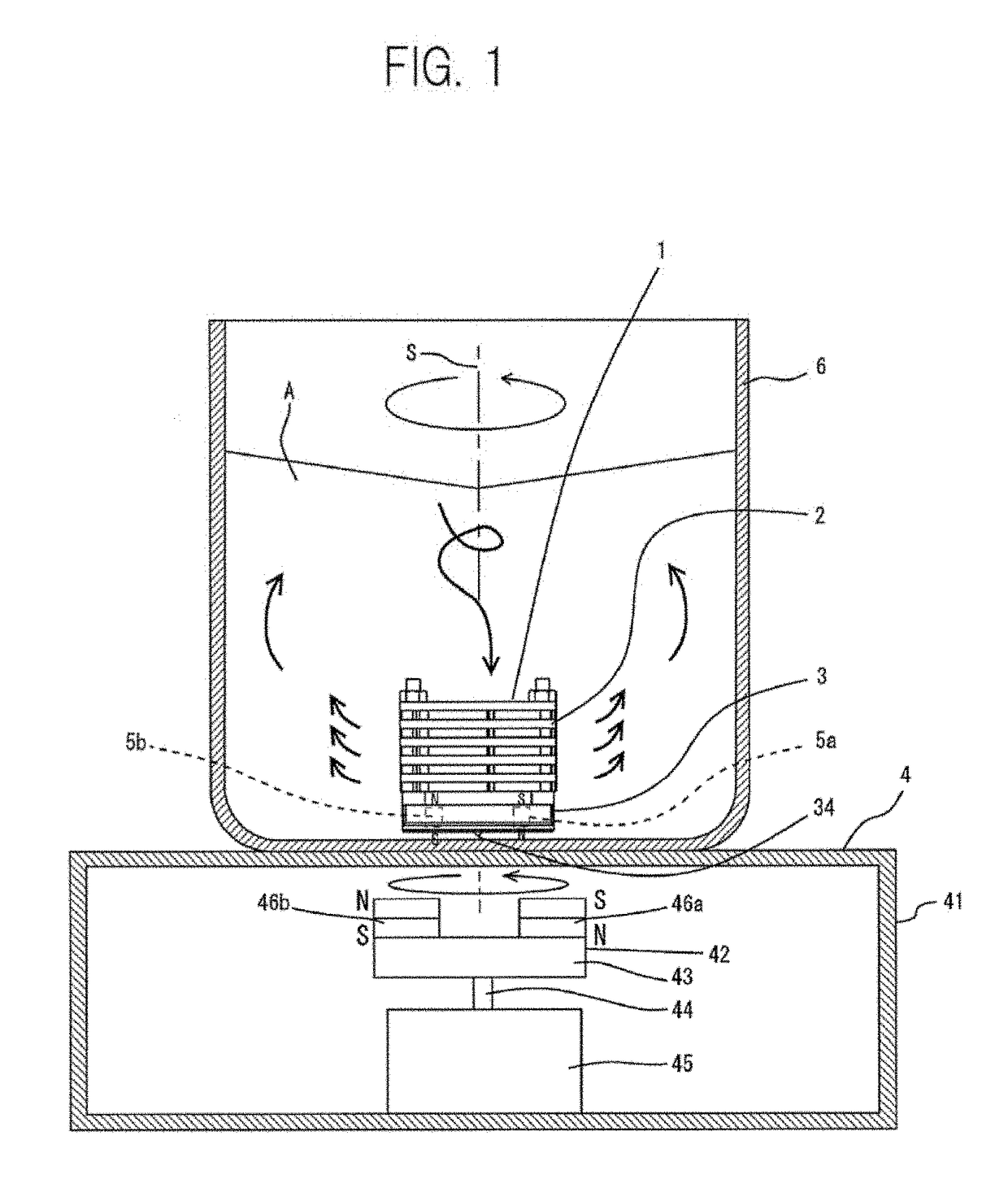

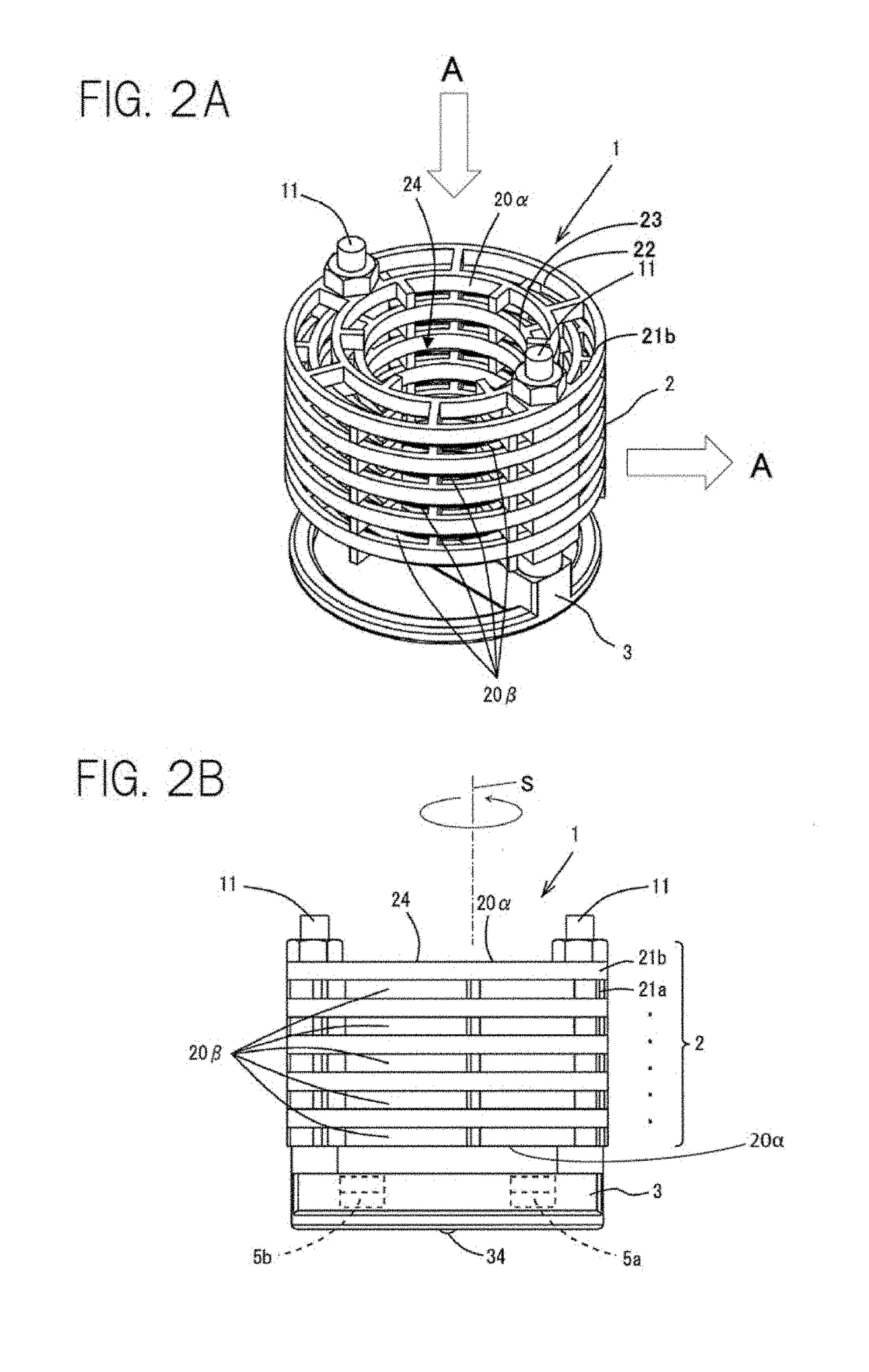

Mixing unit and method for stirring fluid

InactiveUS20180043321A1Shorten mixing timeQuick mixRotary stirring mixersTransportation and packagingRotational axisEngineering

A stirring unit for stirring a fluid contained in a vessel includes a mixing body for stirring the fluid by rotating around a rotation axis, and a magnet or a magnetic substance for receiving a rotating magnetic field for rotating the mixing body, in which a suction port and a discharge port for the fluid are provided on a surface of the mixing body, a plurality of flow paths connecting the suction port and the discharge port are provided inside the mixture, the suction port is disposed at a position on the rotation axis or at a position closer to the rotation axis than the discharge port, and the discharge port is disposed at a position outside the rotation axis than the suction port.

Owner:ISEL CO LTD

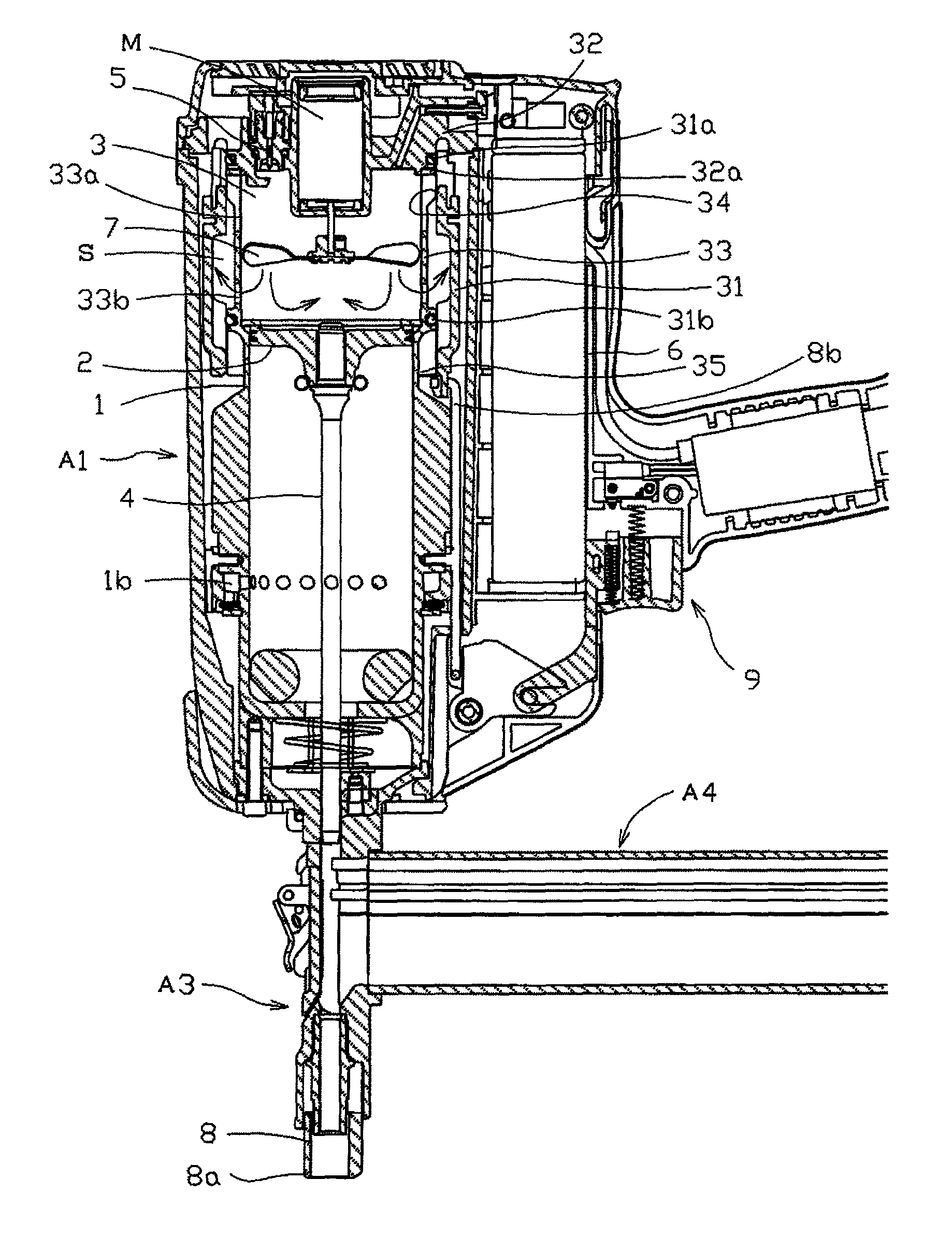

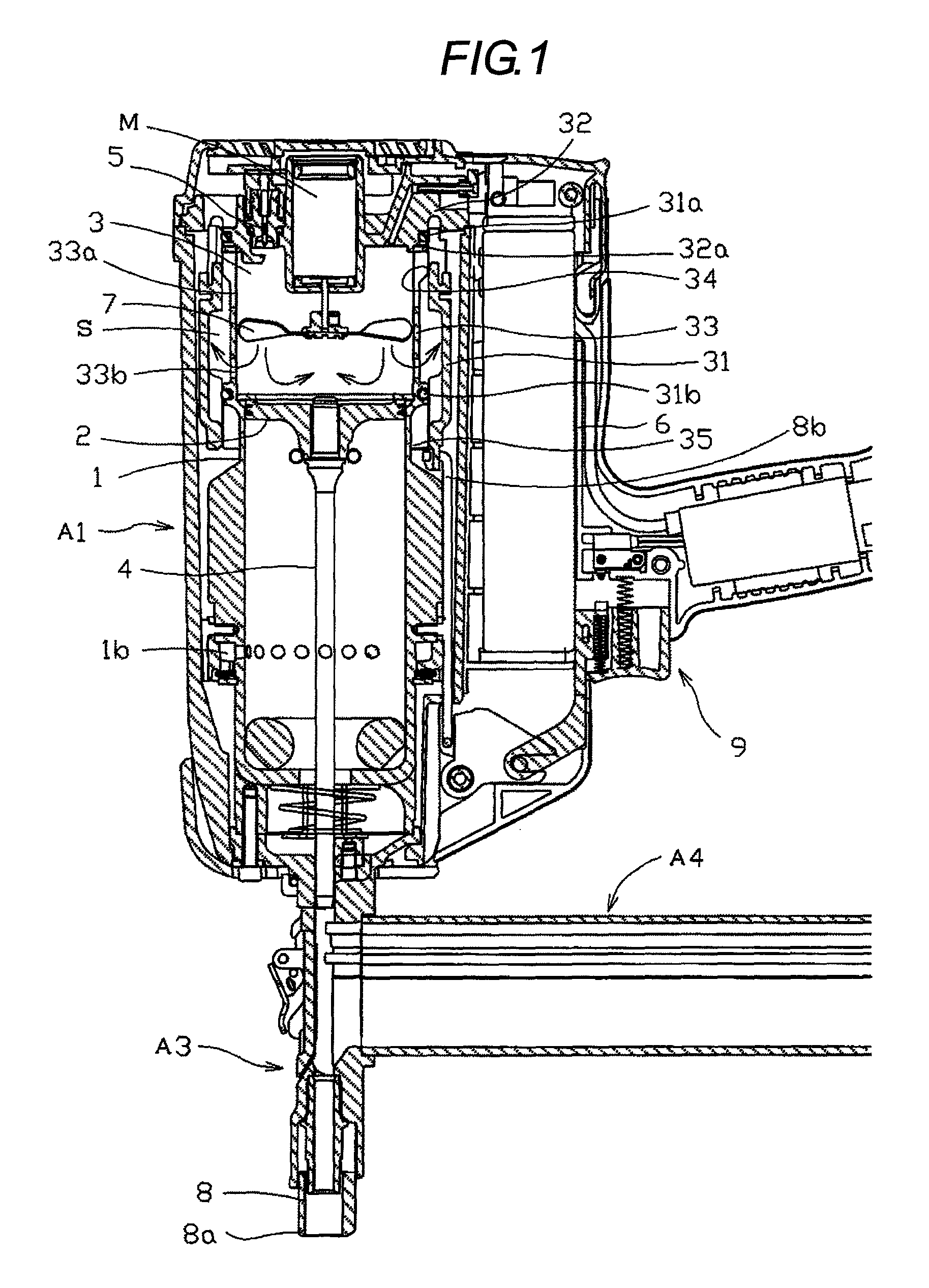

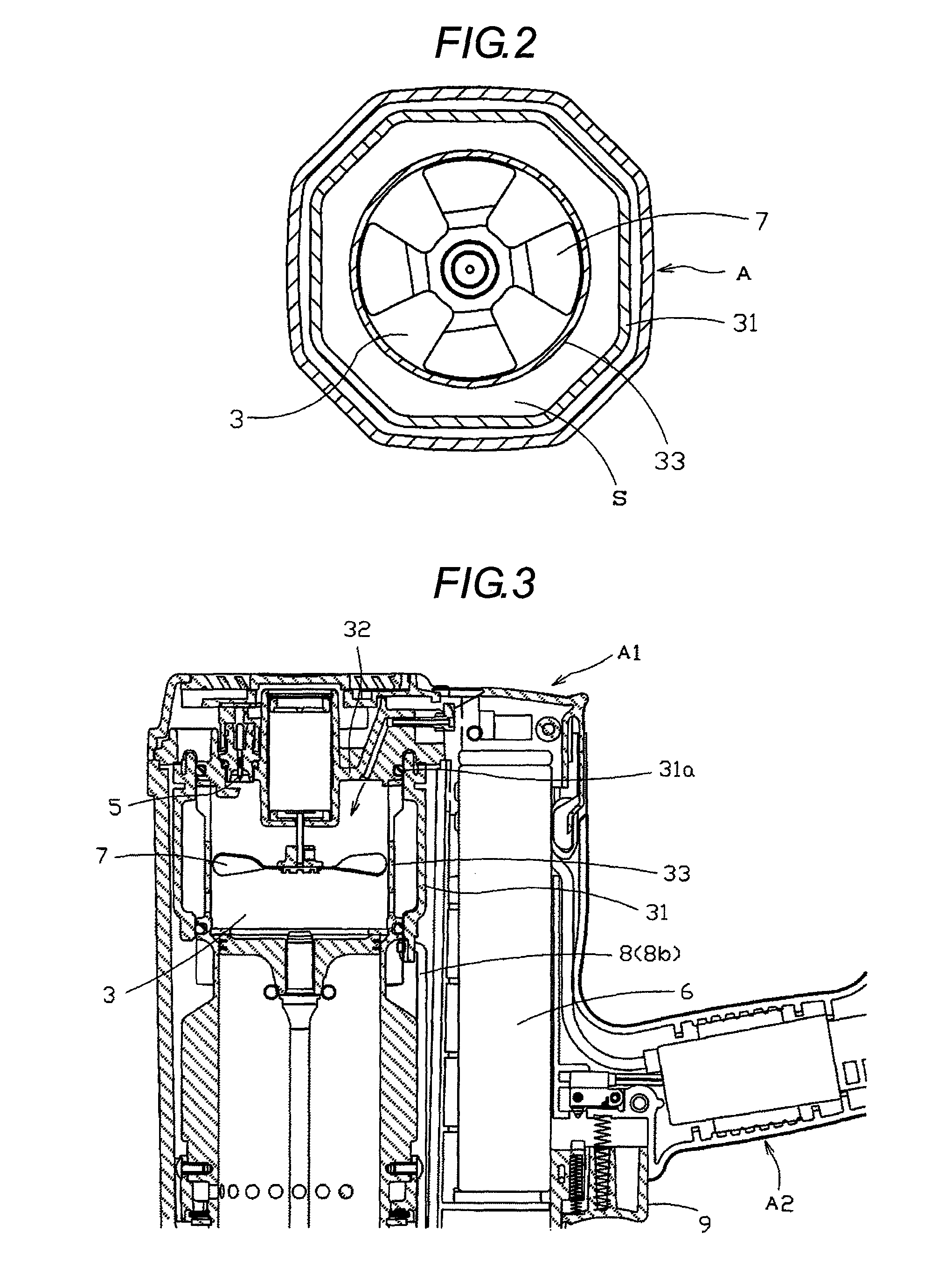

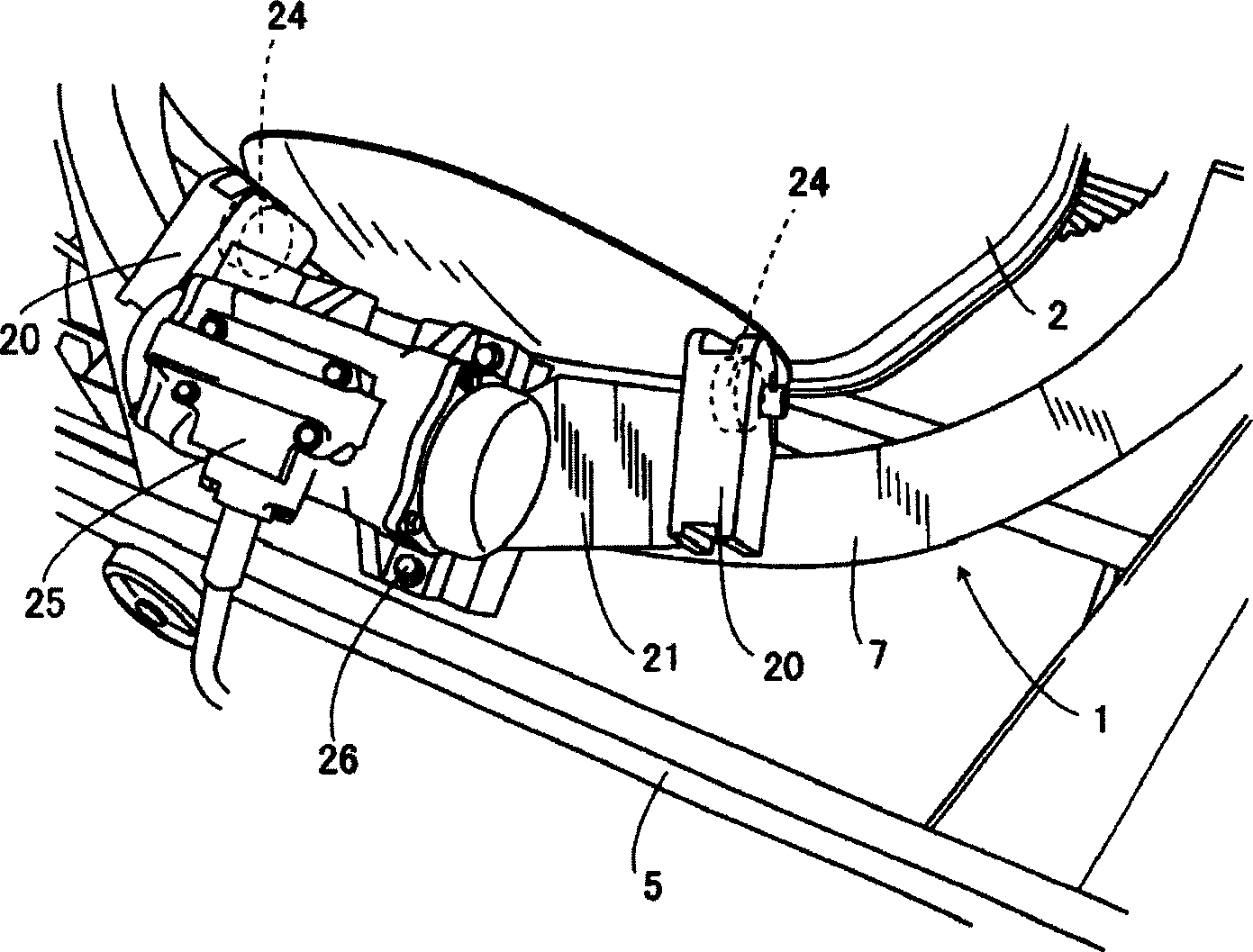

Gas internal combustion type nailing machine

InactiveUS8113403B2Effective stirringEngine componentsFree piston enginesCombustion chamberEngineering

In a gas internal combustion type nailing machine, a tubular-shaped sleeve is fixed between a movable housing and a fan. Between the movable housing and sleeve, an annular space portion is formed. In such portions of the sleeve as existing respectively upwardly and downwardly of the fan, there are formed communication holes and in communication with the annular space portion. Mixed gas blown out by the fan flows through the lower communication hole and returns from the annular space portion to the combustion chamber through the upper communication hole.

Owner:MAX CO LTD

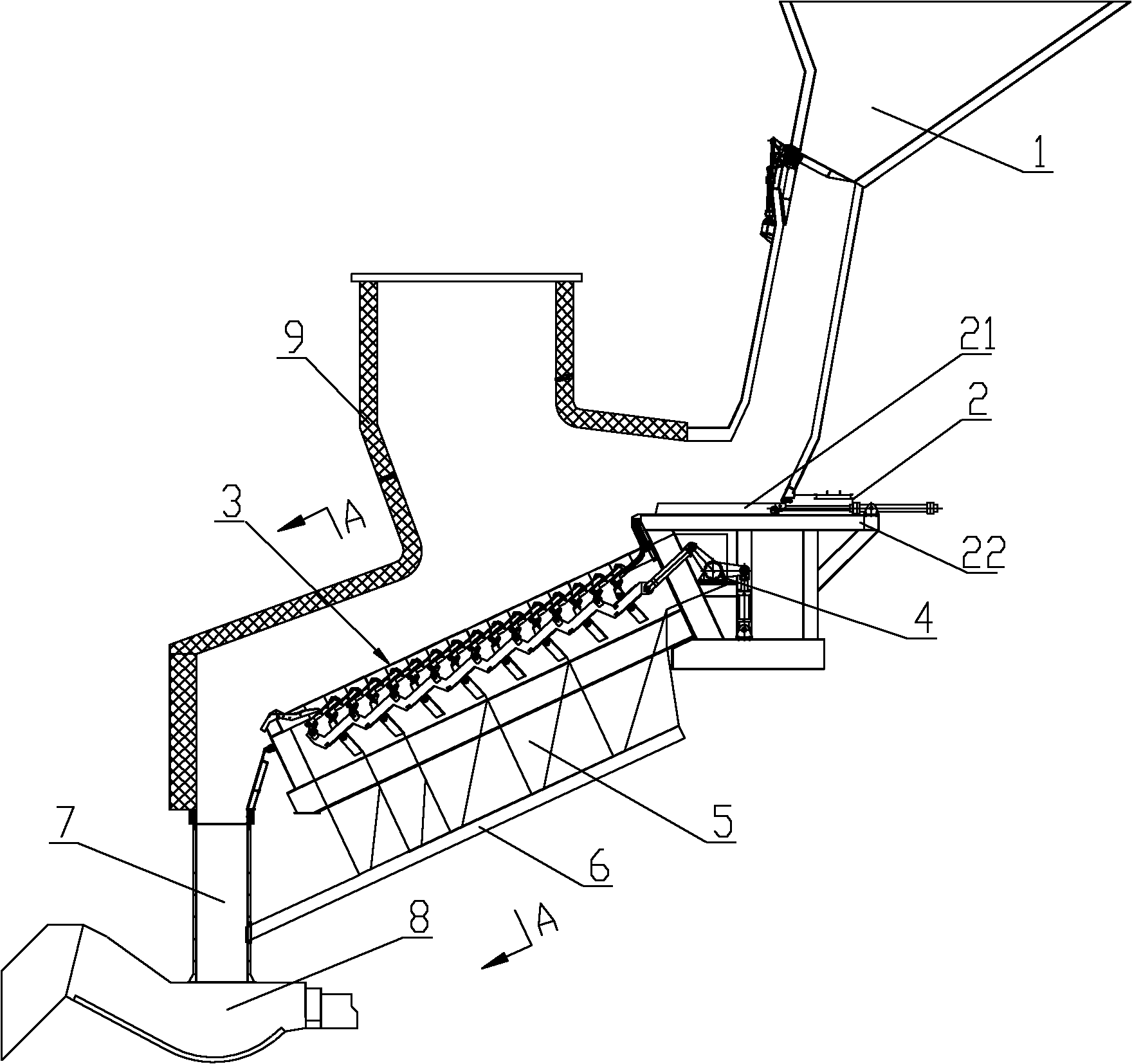

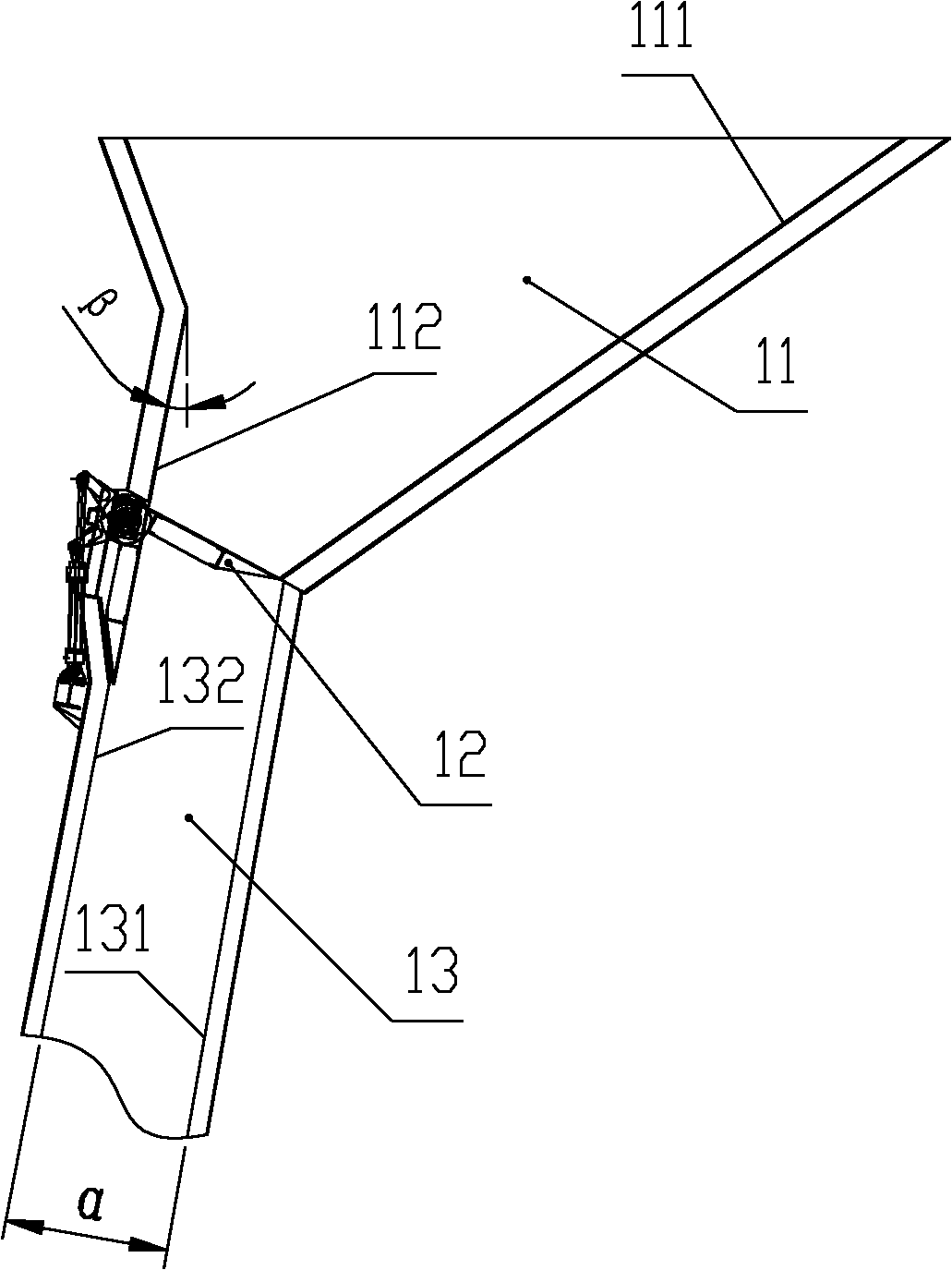

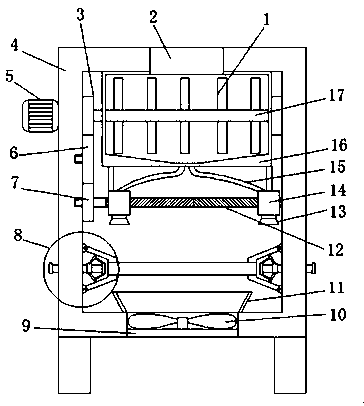

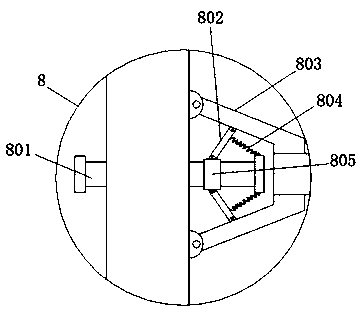

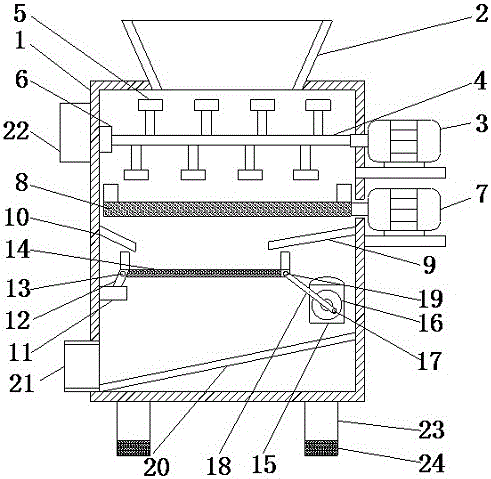

Reciprocating inverse-pushing type garbage incinerator

The invention discloses a reciprocating inverse-pushing type garbage incinerator which comprises a hearth wall body, a hopper device arranged on an upper port of the hearth wall body, a residue falling groove arranged at a lower port of the hearth wall body and a residue discharging machine positioned below the residue falling groove, wherein a reciprocating inverse-pushing type fire grate is arranged in the hearth wall body, a primary air chamber and an ash discharging device are sequentially arranged below the fire grate, a closed rotating shaft fire grate drive device is arranged below thefeeding device; the fire grate comprises a fire grate frame, a plurality of fixed beams used for supporting and fixing fire grate sheets, and a plurality of movable beams used for driving movable fire grate sheets; the fixed beams and the movable beams are arranged on the fire grate frame at intervals laterally, the corresponding fixed fire grate sheets and the movable fire grate sheets are arranged and overlapped at intervals laterally, the fire grate is inclined downwards along the advancing direction of rubbish, the fire grate is divided into 2-6 lines of fire grate units along the direction vertical to the advancing direction of rubbish, and the movable beam of each line of fire grate units is driven by the corresponding primary closed rotating shaft drive device through a movable beam frame. The reciprocating inverse-pushing type garbage incinerator ensures that the rubbish can be effectively conveyed, stirred, loosened, crushed and fully combusted in a process of incinerating the rubbish, and has the advantages of good sealing property, and no air and ash leakage and dropping and permeating phenomena.

Owner:SHENZHEN DINGZHU ENVIRONMENTAL PROTECTION TECH

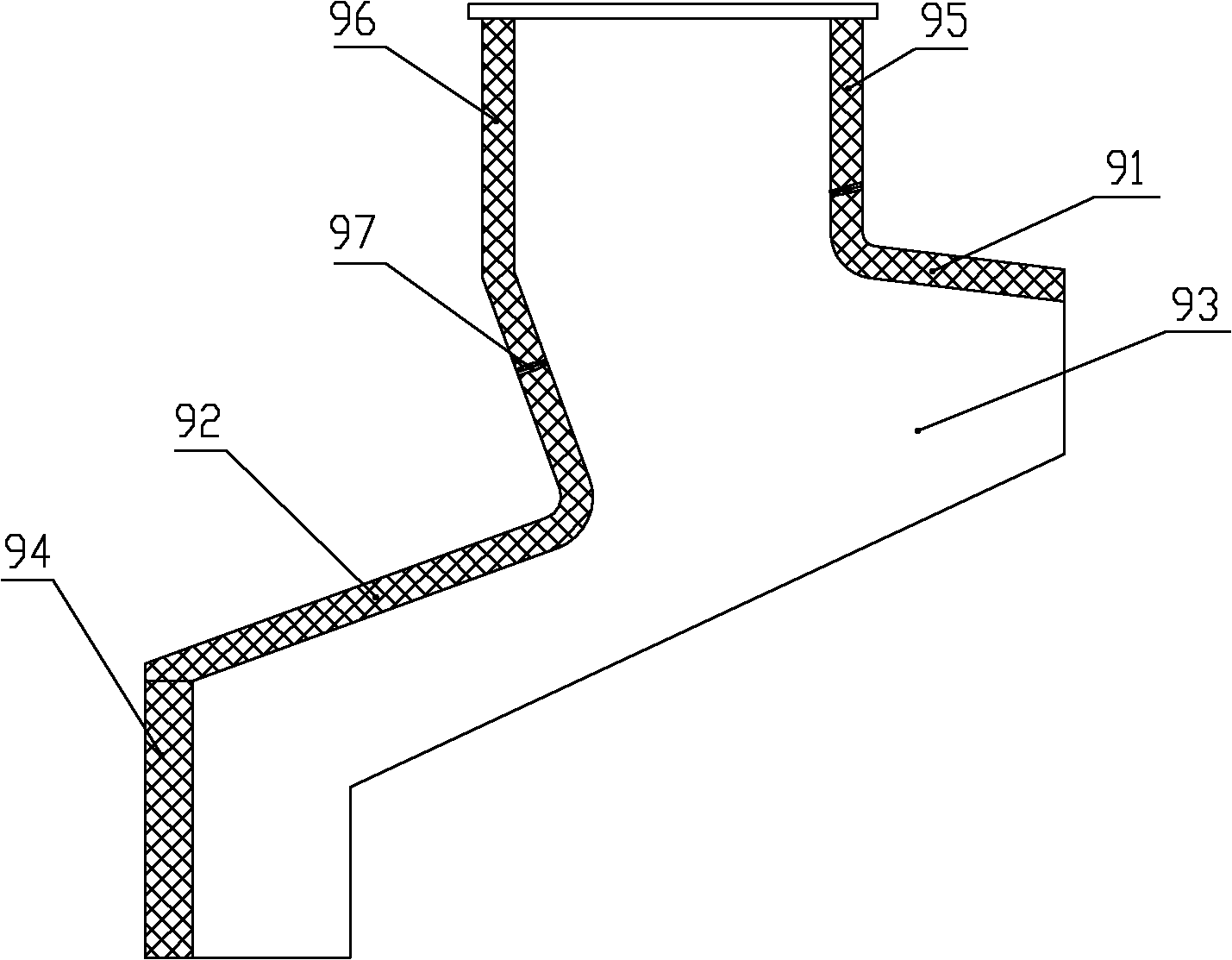

Liquid container, head cartridge, ink jet printing apparatus, and stirring method for liquid container

InactiveUS20070263048A1Easily and reliably raisedEffective stirringShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical engineering

A swing member that is provided in an ink containing chamber is swung according to movement of a carriage of a printing apparatus. Accordingly, an ink flow occurs in a hollow portion of the swing member from one of openings to the other opening, such that ink in an ink tank is stirred.

Owner:CANON KK

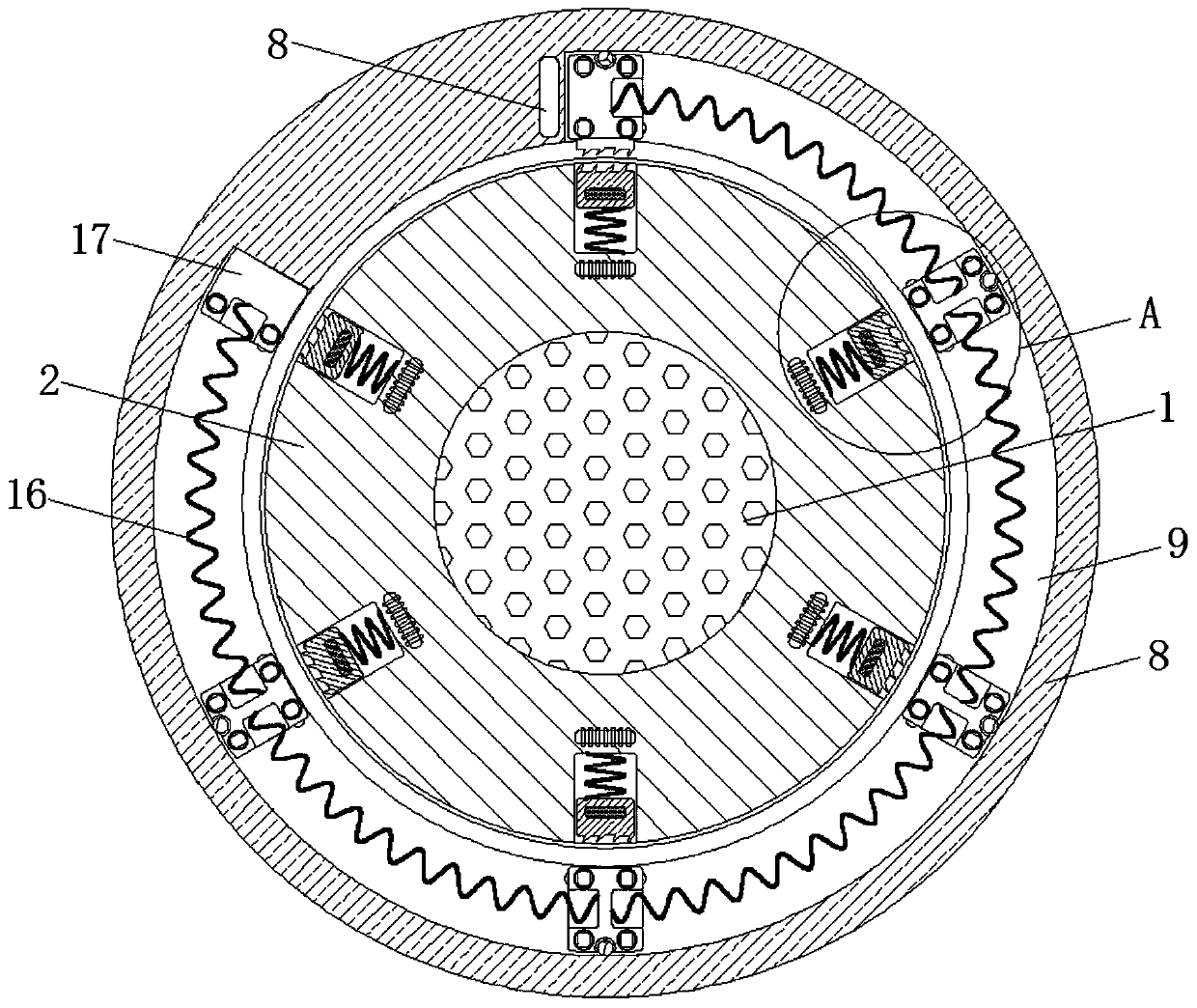

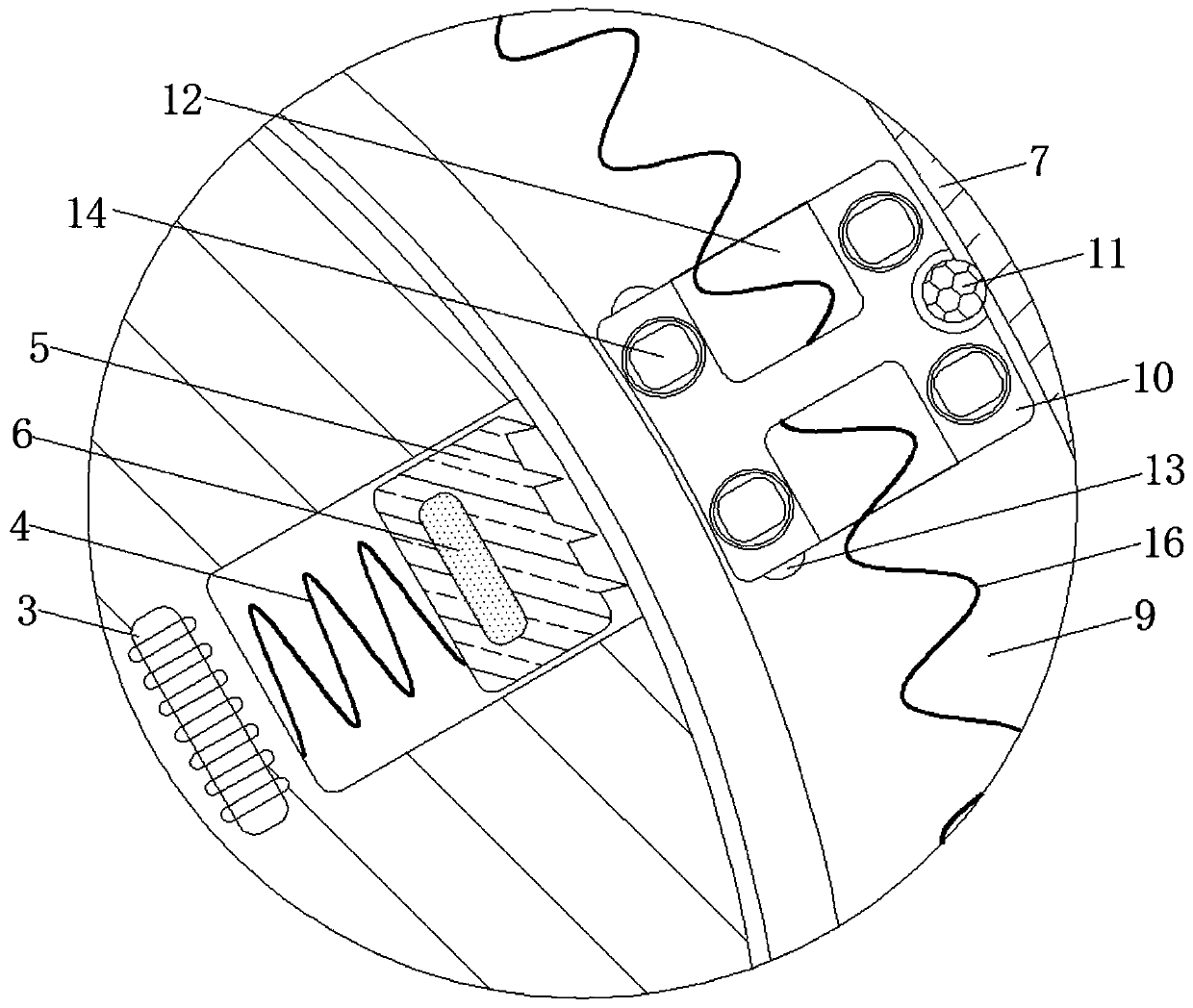

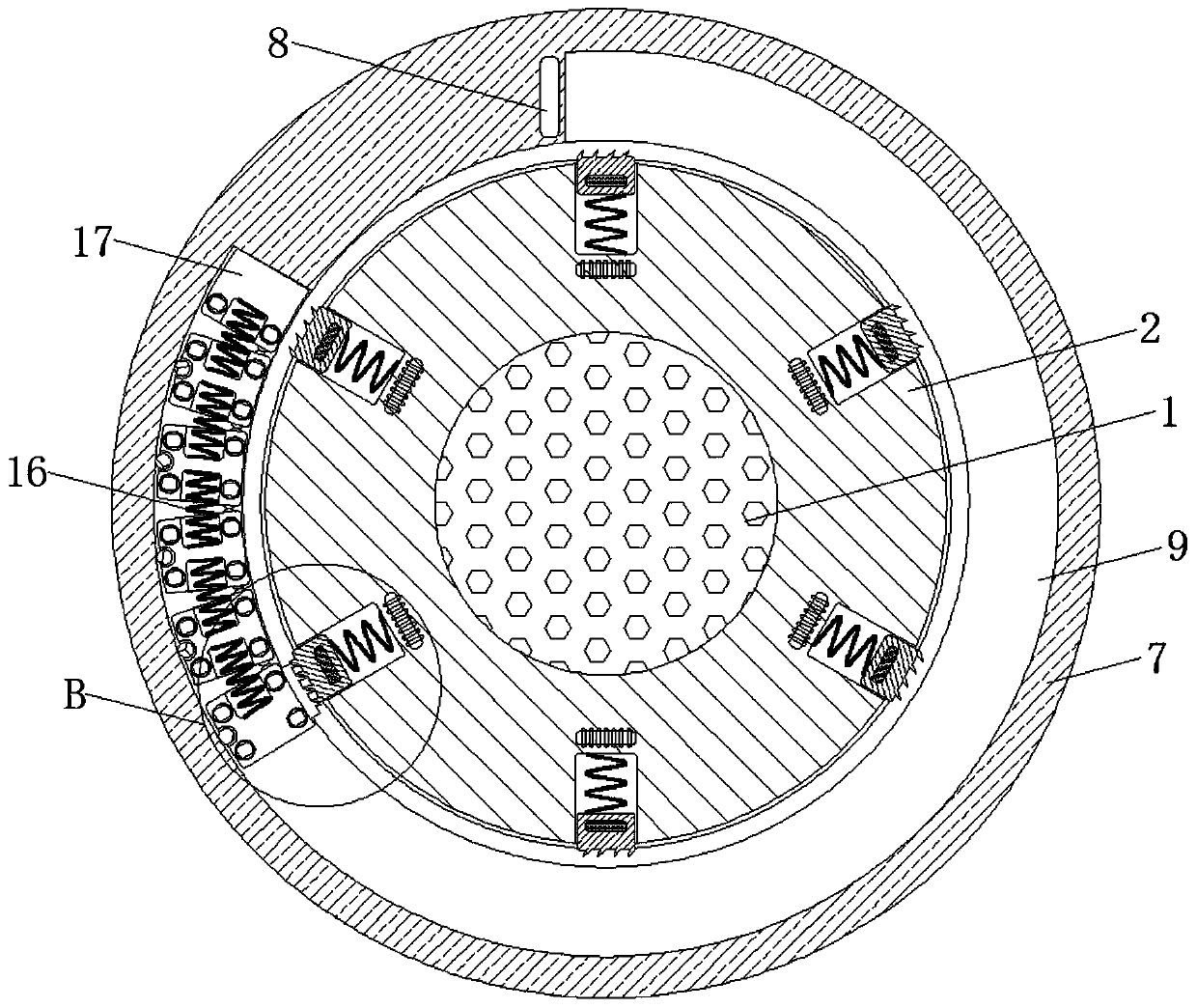

Centrifugal force change-based device for preventing stirring device from stalling

InactiveCN111495264APrevent splashSave paintTransportation and packagingMixer accessoriesElectrical resistance and conductanceEngineering

A centrifugal force change-based device for preventing a stirring device from stalling relates to the technical field of furniture, and comprises a rotating shaft, a turntable is fixedly connected tothe outer side of the rotating shaft, uniformly distributed electromagnets I are fixedly connected to the inner wall of the turntable, and uniformly distributed springs I are fixedly connected to theouter side of the turntable. According to the centrifugal force change-based device for preventing the stirring device from stalling, a clamping block is matched with a movable resistor for use, whenthe rotating shaft rotates and stalls, the clamping block can move outwards under the action of release force, and is clamped to the limiting block to increase the resistance, if stall is too large, the clamping block can drive the movable resistor at the top to gradually rotate rightwards, the larger the stall is, the more the finally electrically connected resistors are, the lower the circuit voltage is, and the lower the rotating speed is, and when the stall reaches the maximum value, all the movable resistors are electrically connected and finally electrically connected with the power-offblock, so that the whole circuit of the stirring device is disconnected, splashing of a coating is effectively avoided, and the coating is effectively saved.

Owner:山东鑫联胜运输有限公司

Self-stirring cookware

Owner:PENG ZHENG

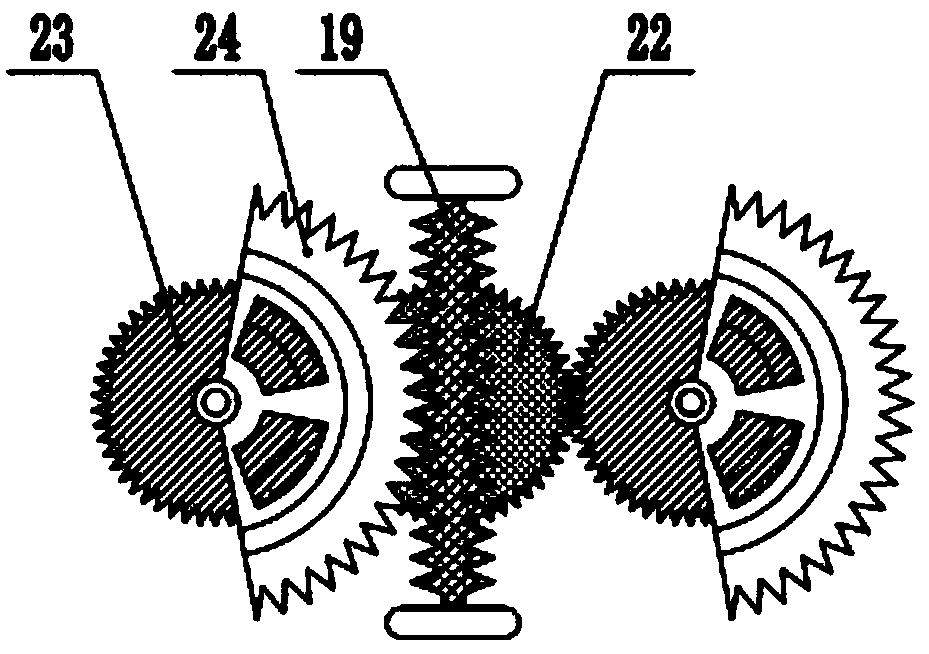

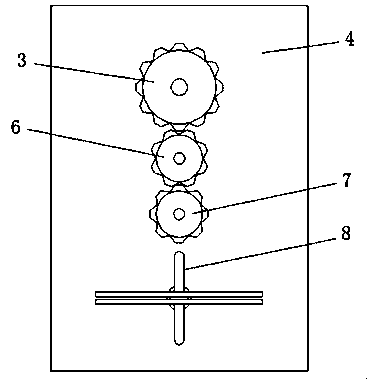

Fodder stirring device based on gear assembly driver

InactiveCN108187539ASimple structureEasy to useFeeding-stuffTransportation and packagingFodderBiochemical engineering

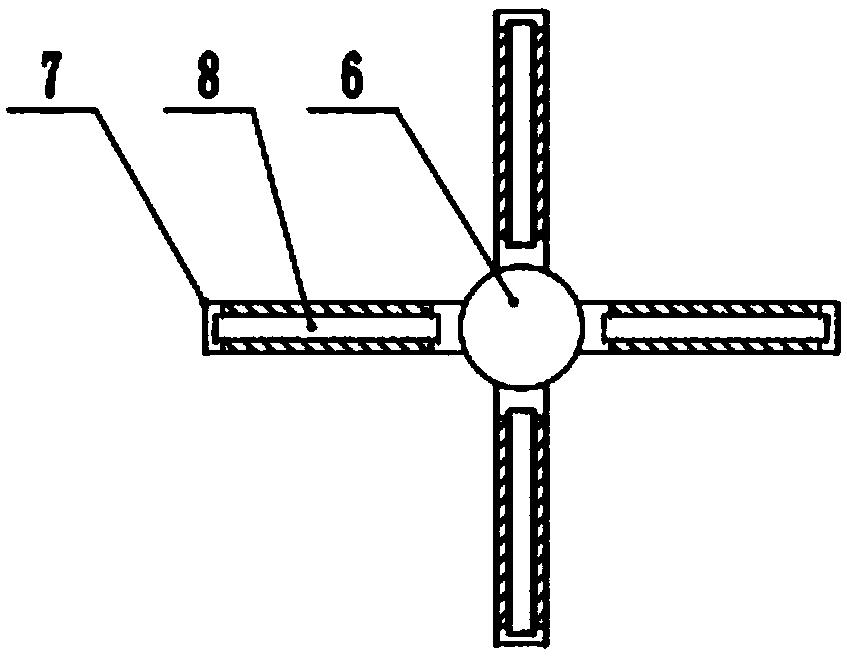

The invention discloses a fodder stirring device based on a gear assembly driver. The fodder stirring device comprises a device body, wherein the device body is provided with a support frame; a powercabin is arranged on the support frame; a stirring bin is arranged on the power cabin; a feeding bin is arranged on the top of the stirring bin; a preheating mechanism is arranged at the joint of thefeeding bin and the stirring bin; a rotating box is arranged inside the stirring bin; a fixed sleeve is arranged at the bottom of the rotating box; a second gear is arranged inside the power cabin; afixed mount is arranged inside the power cabin; a rack is arranged on the inner side of the fixed mount; and a power assembly is arranged on the right side of the rack. The fodder stirring device is simple in structure, fodder can be stirred effectively, and the effect for stirring fodder is good by rotating paddles and the inner layer and the outer layer of the rotating box during stirring, and periodic power is provided for the device body through the gear assembly during operation, so that the stirring structure inside the device body rotates positively and negatively, the fodder mixing efficiency is improved, and the device is convenient to use and high in practicability.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

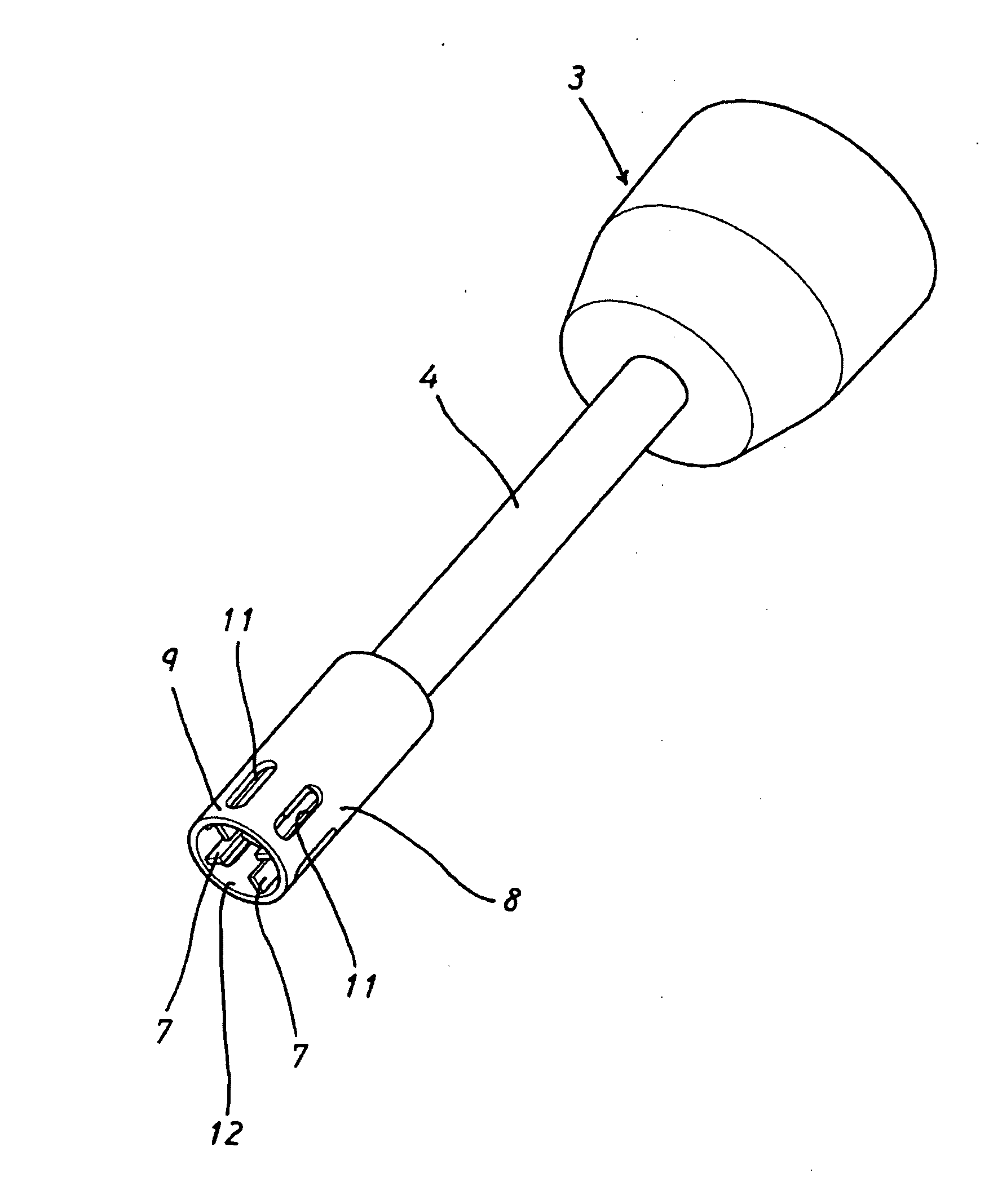

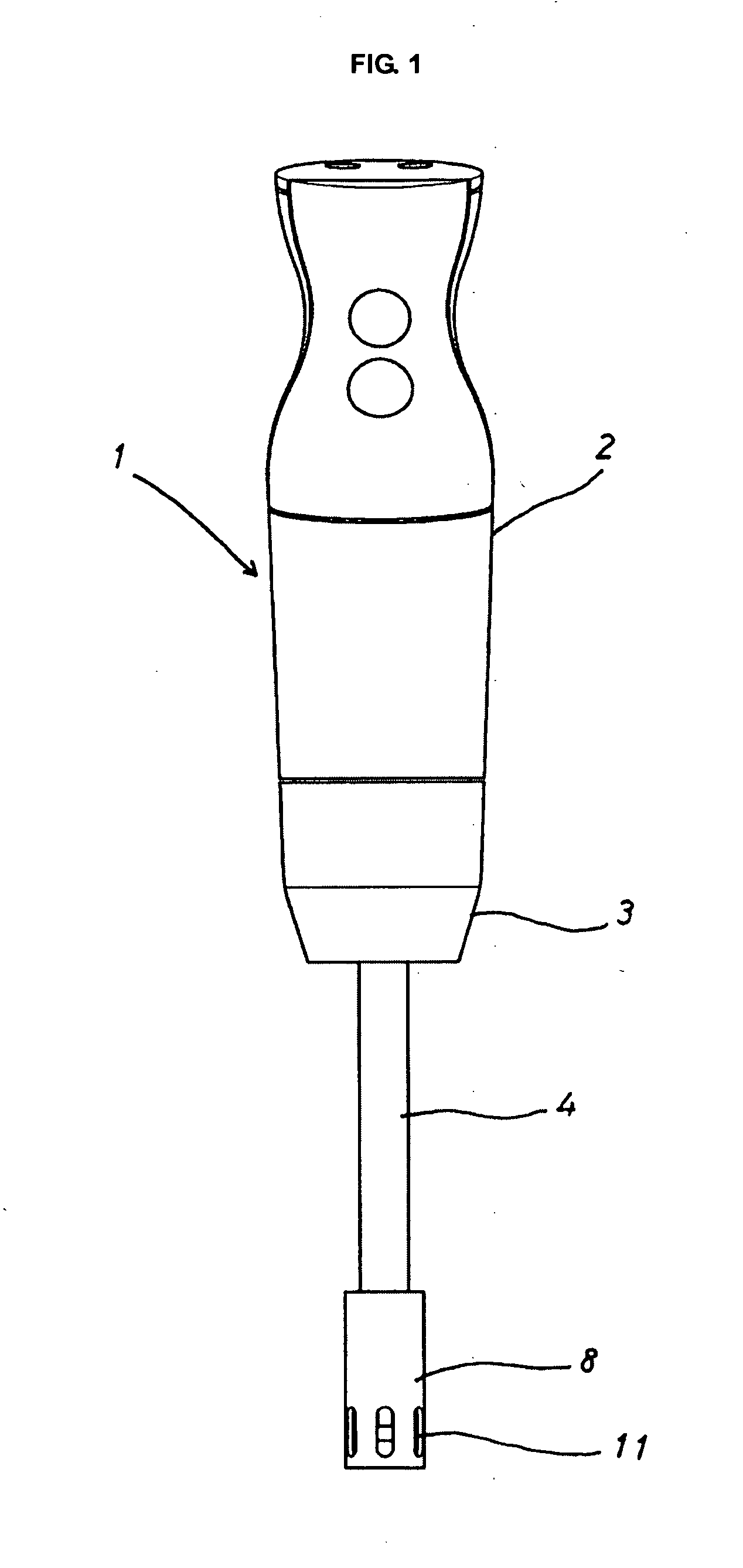

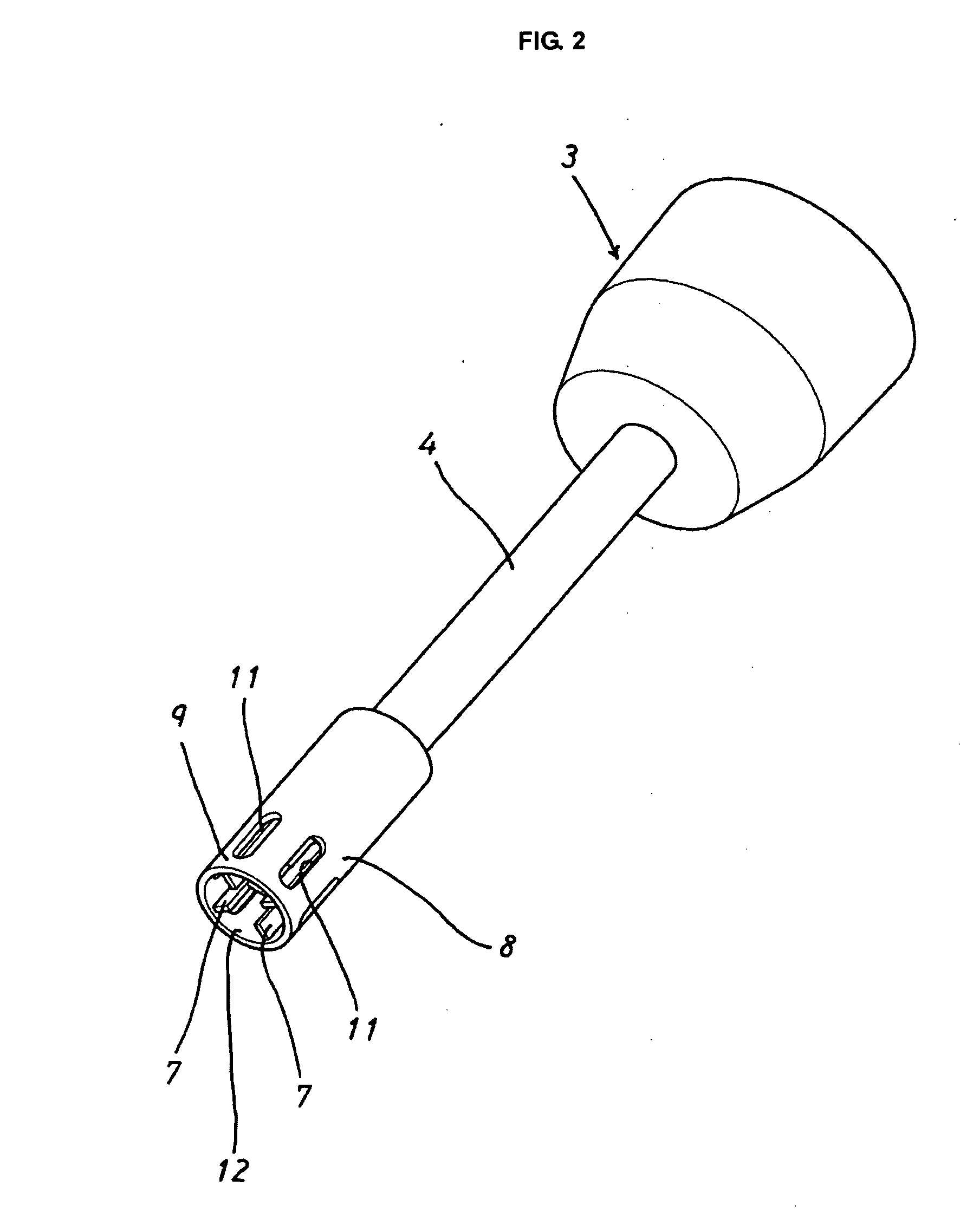

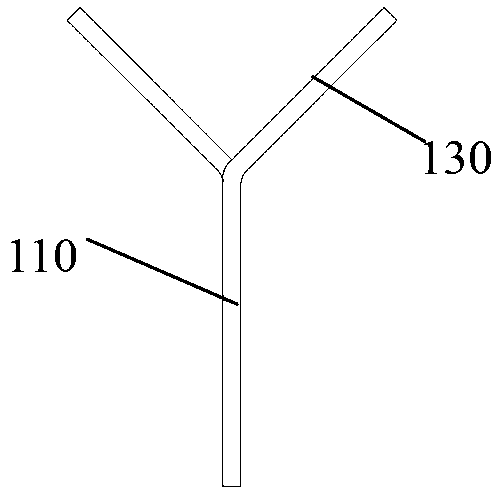

Stirring tool

InactiveUS20100300304A1Mixed together efficientlyStirring efficiency can be somewhat inferiorRotary stirring mixersMixer accessoriesKnife bladesEngineering

Disclosed is a stirring tool which is capable of fully and efficiently mixing ingredients such as mayonnaise even in relatively small amounts. A stirring blade is mounted on a rotating shaft which is rotated by a driving force. A hollow blade cover is provided which covers the periphery of the rotating stirring blade and a portion of the edge of the stirring blade constitutes a long edge which is an edge part that faces the inner circumferential face and which extends along the inner circumferential face of the blade cover. Openings which are holes and an opening are provided at the end of the blade cover and in a peripheral wall of the blade cover for circulation of the stirred ingredients. The long edge can be seen through the holes in the peripheral wall when the rotating blade rotates.

Owner:KAI R&D CENT CO LTD

Process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves

ActiveCN102727538AQuick contactAccelerated leaching extractionNervous disorderGinkgophyta medical ingredientsAfter treatmentBULK ACTIVE INGREDIENT

The present invention discloses a process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves. The process comprises the following steps: (1) carrying out a pretreatment on ginkgo biloba leaves; (2) carrying out extraction by an ultrasonic device; (3) carrying out reduced pressure concentration; (4) loading the resulting solution on a macroporous resin to carry out a treatment; (5) collecting the resulting eluate; (6) carrying out reduced pressure concentration; (7) detecting the resulting extract; and (8) carrying out drying and storing on the extract. With the process of the present invention, the ginkgo biloba flavone content and the ginkgo biloba lactone content in the extract prepared by the process of the present invention are high, the loss of active ingredients are avoided, the production process is simplified, the production cycle is shortened, and the ginkgo biloba phenolic acid content after treatment is substantially reduced.

Owner:JIANGSU EHAI PHARMA CORP

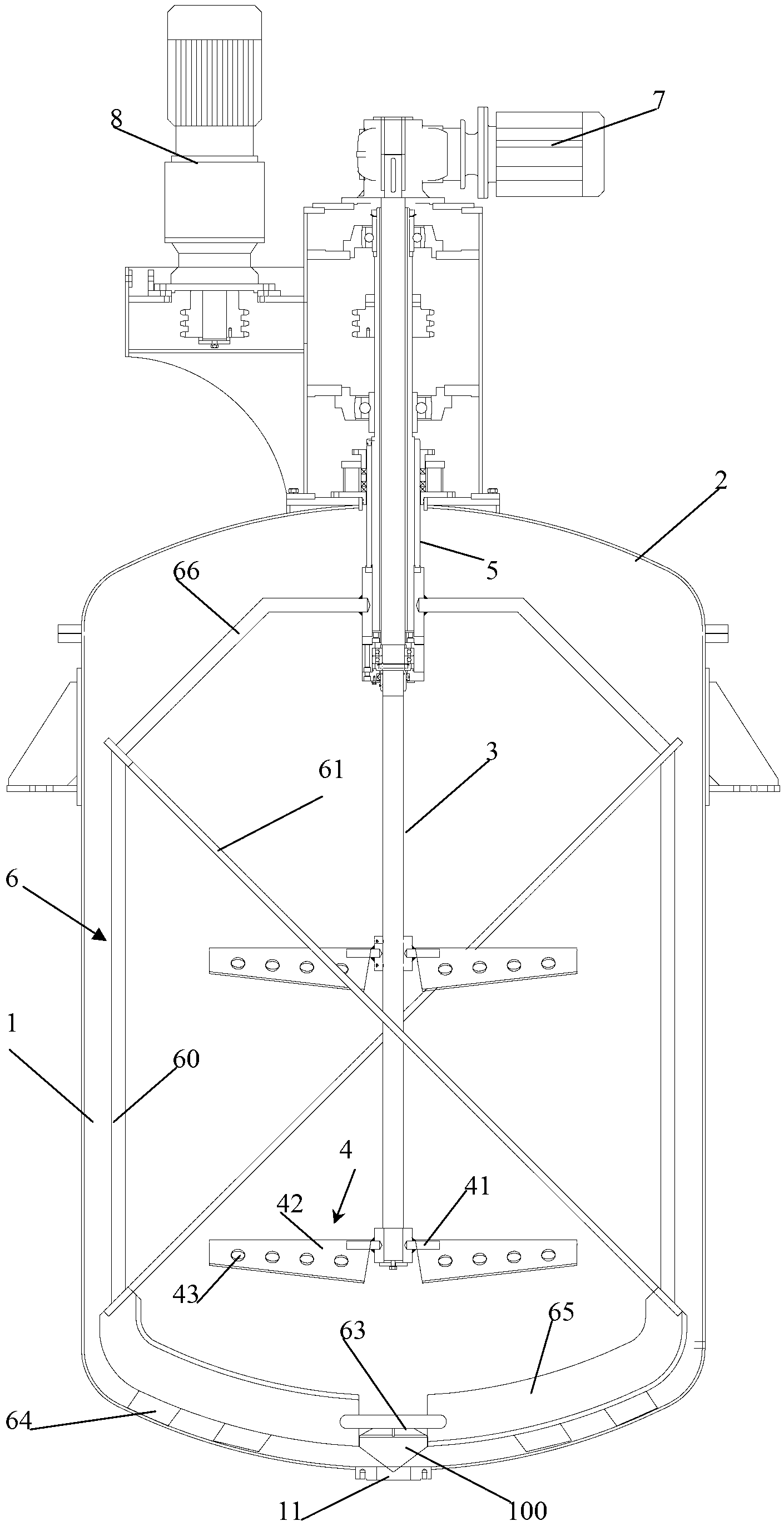

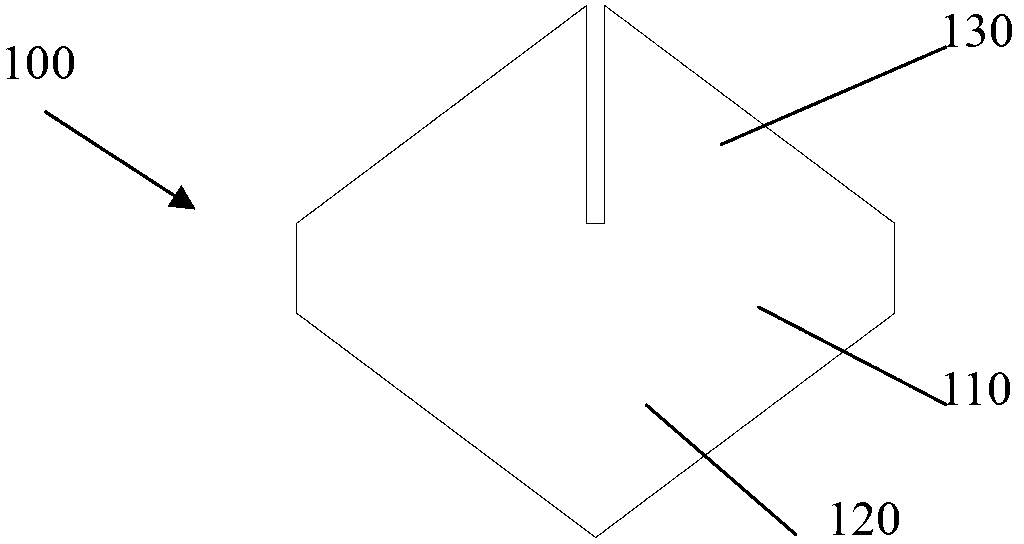

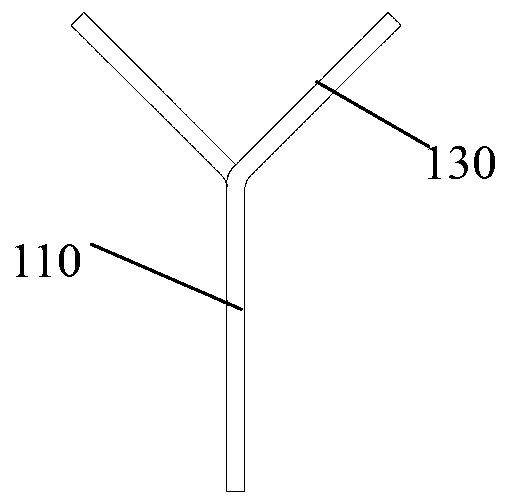

Double-stirring type stirring tank capable of smoothly discharging materials

InactiveCN103301768AEffective stirringWell mixedRotary stirring mixersMixer accessoriesRaw materialBiochemical engineering

The invention discloses a double-stirring type stirring tank capable of smoothly discharging materials. The double-stirrer type stirring tank comprises a tank body, a tank cover, a stirring rod, at least one group of stirring blades, a transmission cylinder, a peripheral stirring mechanism, an inner driving motor and an outer driving motor, wherein a material discharging hole is formed in the bottom center of the tank body; the tank cover is arranged on the top of the tank body; the stirring rod is rotatably and fixedly connected with the tank cover; the at least one group of stirring blades is arranged in the tank body and is fixedly connected with the stirring rod; the transmission cylinder is rotatably sleeved outside the stirring rod; the peripheral stirring mechanism is arranged inside the tank body and is fixedly connected with the transmission cylinder; the inner driving motor and the outer driving motor are arranged outside the stirring tank and are in transmission connection with the stirring rod and the transmission cylinder respectively. The stirring tank adopts coaxial inner and outer stirring s; the inner stirring can effectively stir central materials in a blade type design; peripheral materials can be stirred and mixed by the arc-shaped stirring blades supported by a square bracket; meanwhile, the problem that raw materials in the center of the tank cannot be effectively mixed and discharged in the later period of material discharging can be solved through a central stirring blade.

Owner:PROVENCAL TOMATO PROD TIANJIN

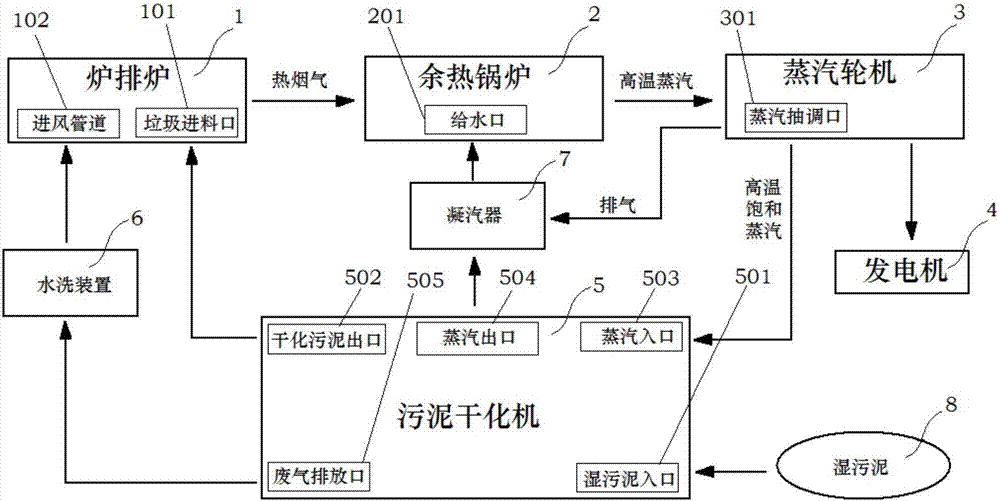

Method and system for cooperatively treating sludge through grate furnace waste incineration

PendingCN107013928AEasy to handleTechnically feasibleSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention discloses a method and system for cooperatively treating sludge through grate furnace waste incineration, and belongs to the field of sludge treatment. Steam generated by grate furnace waste incineration is firstly utilized for carrying out indirect heat exchange drying on the sludge, and then the sludge dried to a certain degree and in-furnace waste are mixed and incinerated in a grate furnace according to a certain proportion. According to the method and system, the existing and mature grate furnace waste incineration technology is utilized for achieving effective drying and cooperative incineration on the sludge, the sludge independent drying cost and the building and operating cost of an incineration treatment project can be greatly reduced, and harmlessness, reduction and recycling of sludge treatment are achieved.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

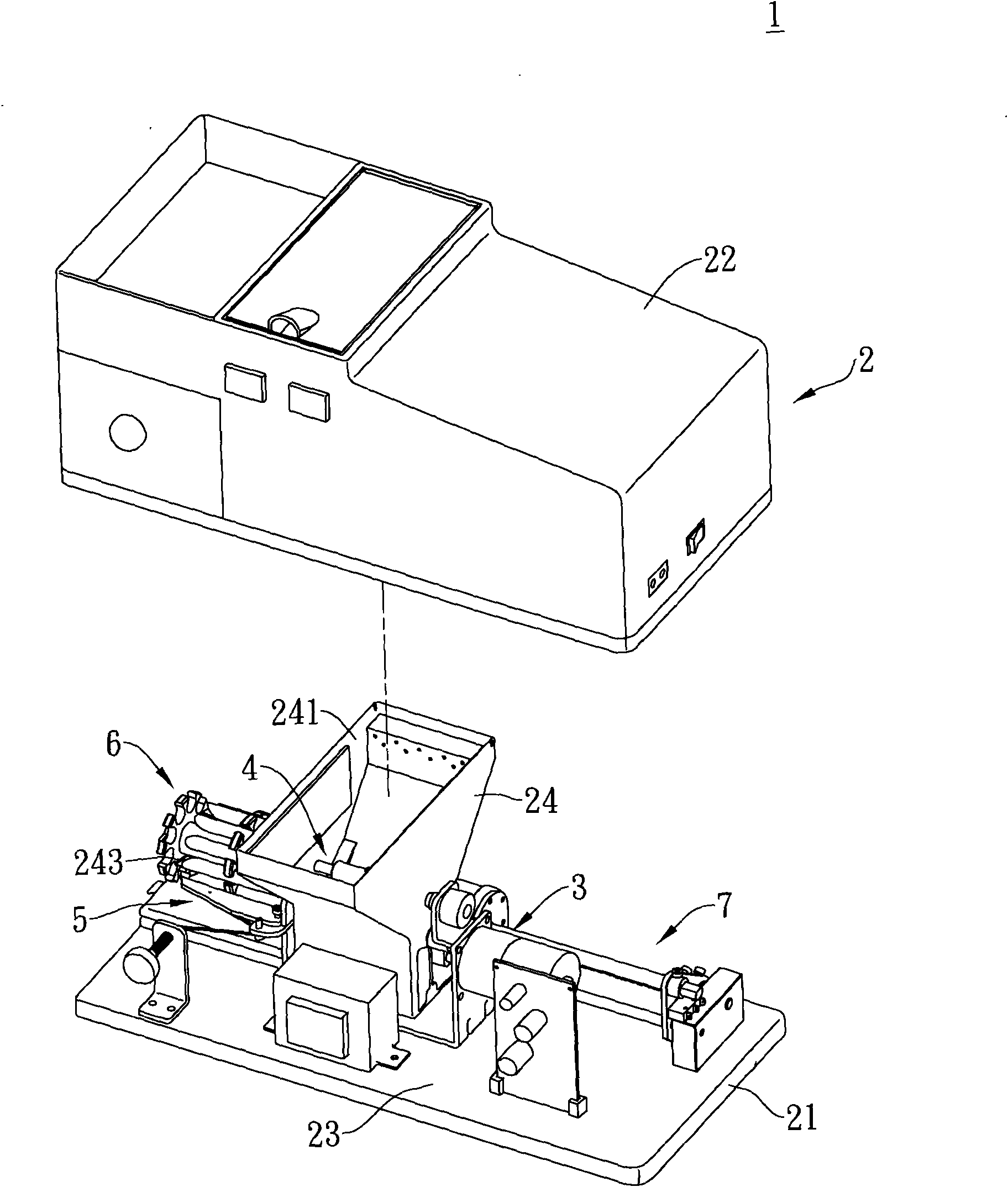

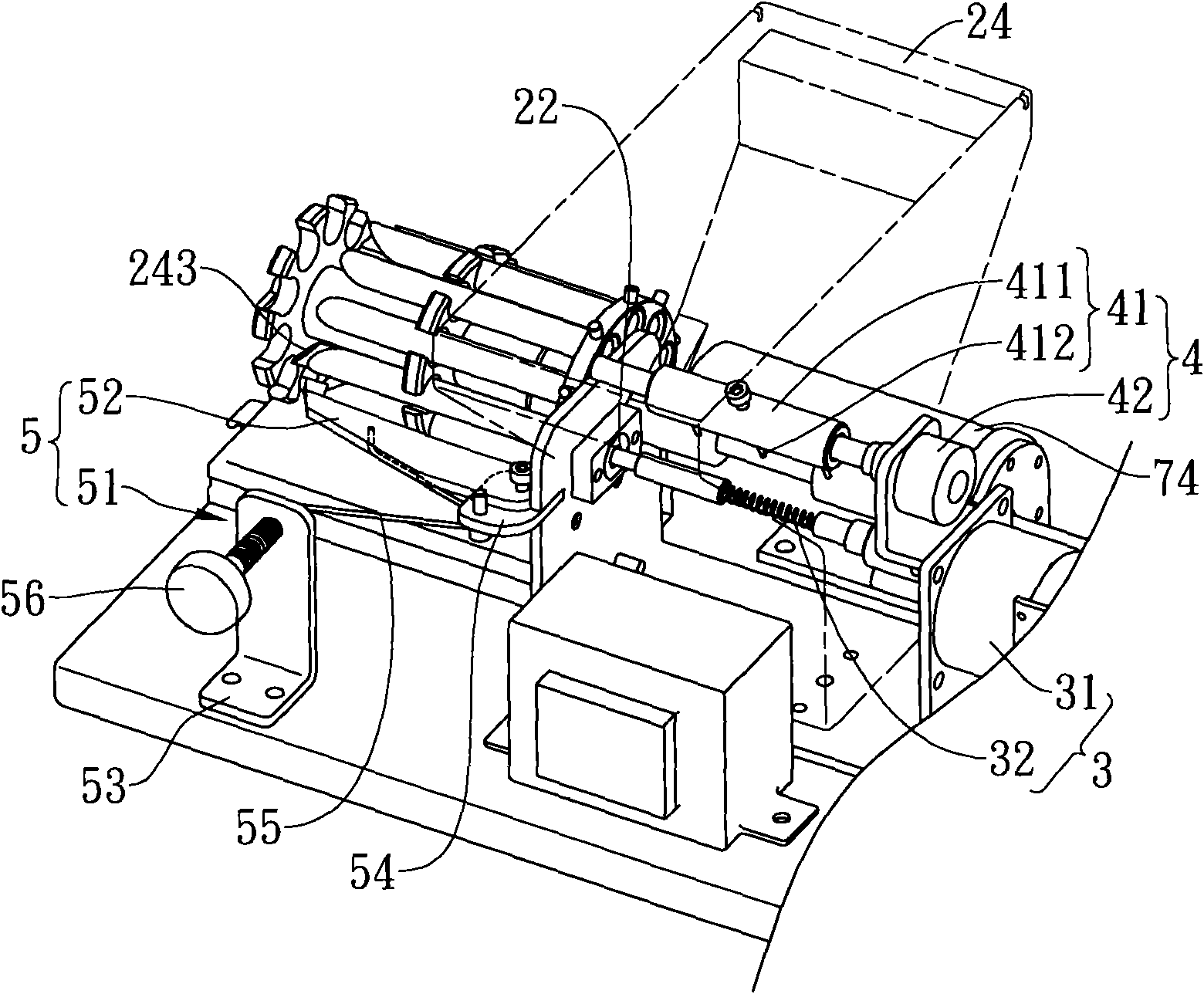

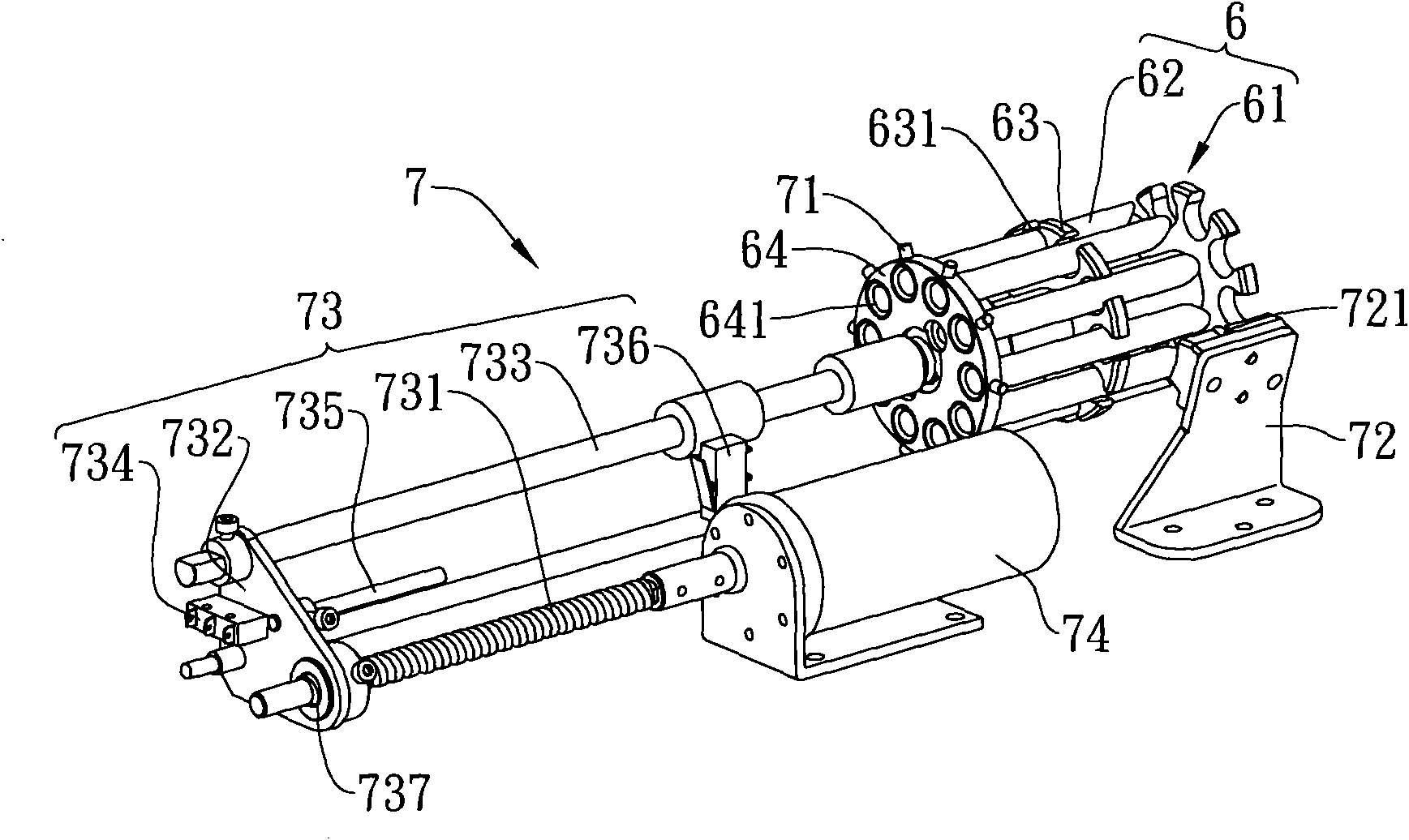

Automatic cigarette making machine

InactiveCN101986903AShorten the timeEffectively adjust the tightnessCigarette manufactureEngineeringMechanical engineering

The invention relates to an automatic cigarette making machine, which is characterized in that a container with an upper opening is arranged in a housing, and a feeding assembly is used to push tobacco shreds in the container to export outside from a tobacco shred pipe in the front part of the container, a rotary disk is connected with one end of a linkage assembly, a plurality of sleeves arrayed in a circle are arranged on the rotary disk, and a piece of cigarette paper is filled in each sleeve. Thus, when the linkage assembly drives the rotary disk to move opposite to the container backward, one sleeve is sleeved on the tobacco shred pipe to fill in tobacco shreds, when the rotary disk moves opposite to the container forward, a piece of cigarette paper can be filled in, and while the rotary disk moves opposite to the container forward and backward for one time, the rotary disk rotates for a fixed angle to sleeve the sleeves of the rotary disk on the tobacco shred pipe in sequence, therefore tobacco shreds are filled in each piece of cigarette paper in sequence.

Owner:LAING BAN INT

Ink tank and recording apparatus

ActiveUS20070052769A1Effective stirringQuality improvementPrintingElectrical and Electronics engineeringEngineering

Owner:CANON KK

Energy-saving type double-stirring mixing tank and control method thereof

InactiveCN103301770AExpand the mixing rangeEffective stirringRotary stirring mixersMixer accessoriesEngineeringLiquid level sensor

The invention discloses an energy-saving type double-stirring mixing tank which comprises a controller, a tank body, a tank cover, a stirring rod, at least one pair of mixing blades, a transmission barrel and a peripheral mixing mechanism, wherein the a discharge hole is formed in the center of the bottom of the tank body; the tank cover is arranged on the top of the tank body; the stirring rod is rotatablely and fixedly connected with the tank cover; the least one pair of mixing blades are arranged in the tank body and fixedly connected with the stirring rod; the transmission barrel is rotatablely sheathed at the outer side of the stirring rod; the peripheral mixing mechanism is arranged in the tank body and is fixedly connected with the transmission barrel; the bottom of the tank body is provided with a liquid level sensor connected with the controller by a signal; and the controller is used for controlling an internal driving motor and an external driving motor according to the signal of the liquid level sensor. The energy-saving type double-stirring mixing tank can be used for stirring and mixing the peripheral material by the arc-shaped mixing blades supported by a square bracket, and the mixing blades can be started and stopped in real time according to the actual condition of the liquid level in the tank since the liquid level sensor is additionally arranged in the mixing tank, so that the aim of saving energy can be effectively achieved.

Owner:PROVENCAL TOMATO PROD TIANJIN

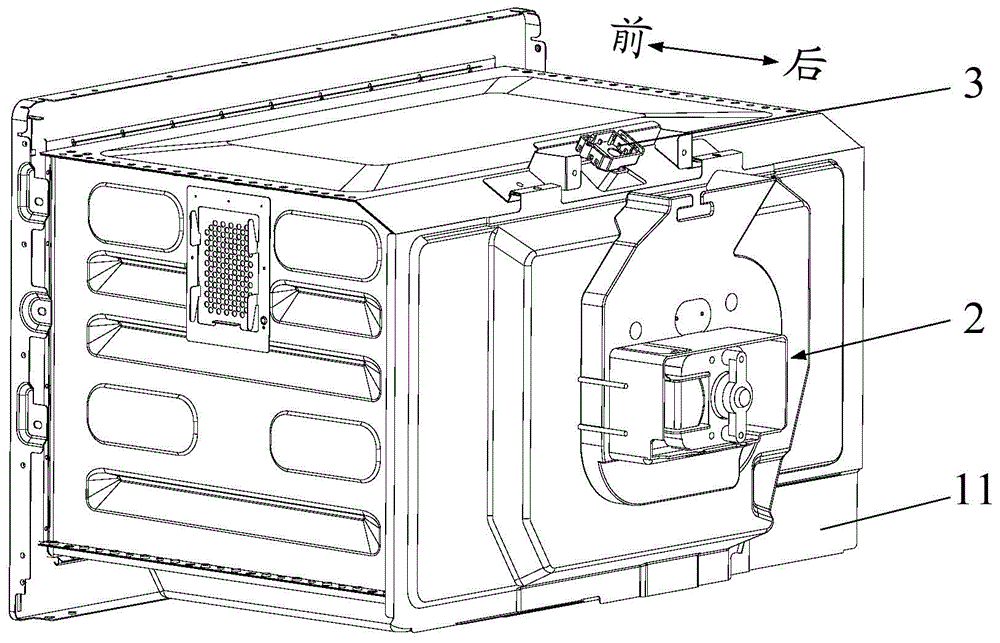

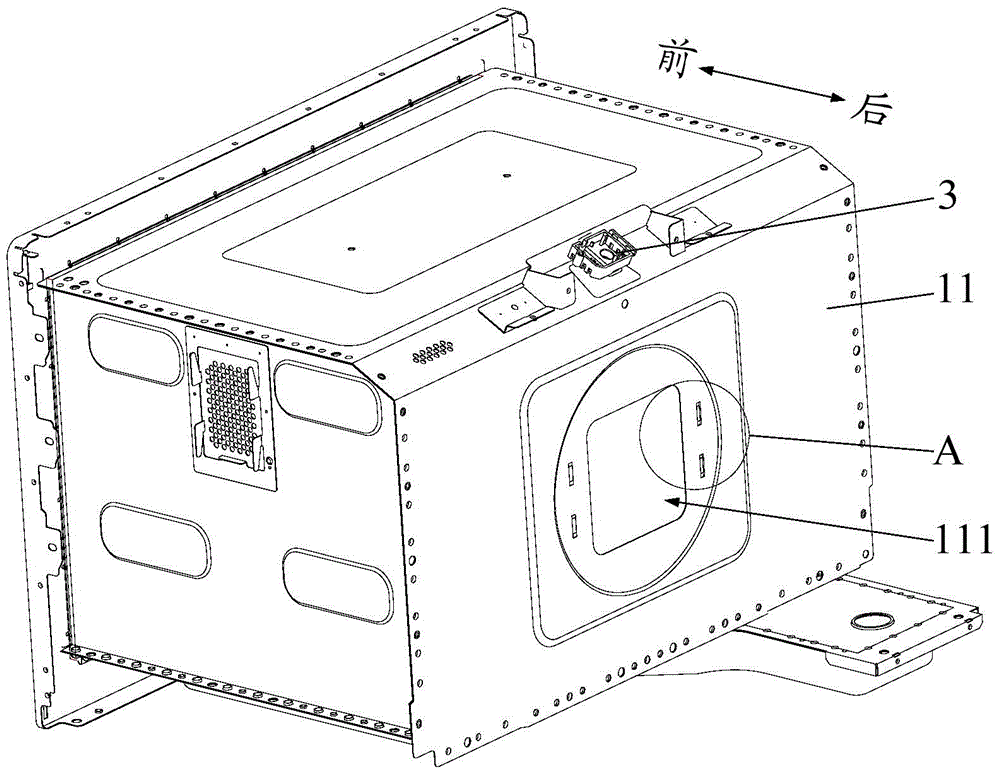

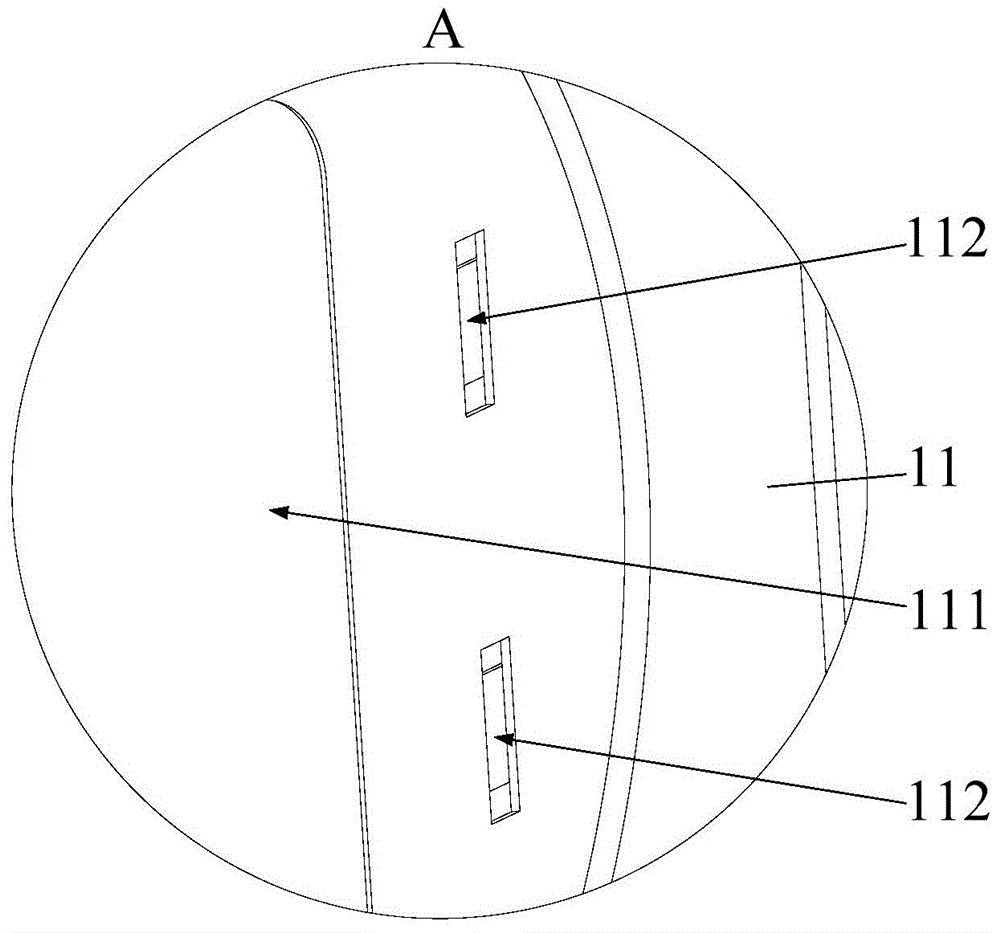

Microwave oven

ActiveCN104456648AEffective stirringEffective reflectionDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention provides a microwave oven which comprises an oven cavity, a first stirring device and a second stirring device, wherein a microwave-transmitting hole is formed in a rear plate of the oven cavity; the first stirring device is fixed below the bottom plate of the oven cavity; microwaves enter the oven cavity after being stirred by the first stirring device; the second stirring device is fixed on the rear plate and positioned on the rear side of the rear plate; stirring blades of the second stirring device are made of microwave-proof materials; turbulent microwave holes are formed in the stirring blades; microwaves can penetrate through the microwave-transmitting hole and are reflected back into the oven cavity after being stirred by the stirring blades. According to the microwave oven provided by the invention, microwaves can be effectively stirred and reflected through rotating stirring blades, when passing through the wave-transmitting hole, the microwaves in the oven irradiate to the second stirring device to be stirred by stirring blades and then reflected back into the oven cavity, so that microwaves in the oven cavity can be distributed more uniformly, the heating efficiency and the heating quality of food in the microwave oven can be improved, the usage performance of the product can be improved, and the microwave oven is more competitive in market.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Automatic washing machine sheet metal production device

The invention belongs to the field of sheet metal processing, in particular to an automatic washing machine sheet metal production device. The device includes a paint spray box, the inner wall of thetop of the paint spray box is connected with a storage box, one side wall of the paint spray box is connected with a rotary motor through bolts, an output shaft of the rotary motor is horizontally connected with a rotating rod, the rotating rod passes through the side walls of the paint spray box and the storage box, the inner wall of the other side, extending to the storage box, of the rotating rod is rotatably connected with the storage box, and the circumferential side wall of the rotating rod is sleeved with a driving wheel the driving wheel is located on the outer portion of the storage box. The device can effectively fix sheet metal parts different in size and can carry out uniform paint spraying operation. During the paint spraying operation, paint raw materials can be effectively stirred, the precipitation of the paint raw materials can be prevented, the purity of paint can be improved, the drying operation of the sheet metal parts after paint spraying can be assisted, the drying time of the sheet metal parts can be reduced, and the production efficiency of the sheet metal parts is improved, and the device is suitable for popularization.

Owner:NINGBO KINGSUN GRP

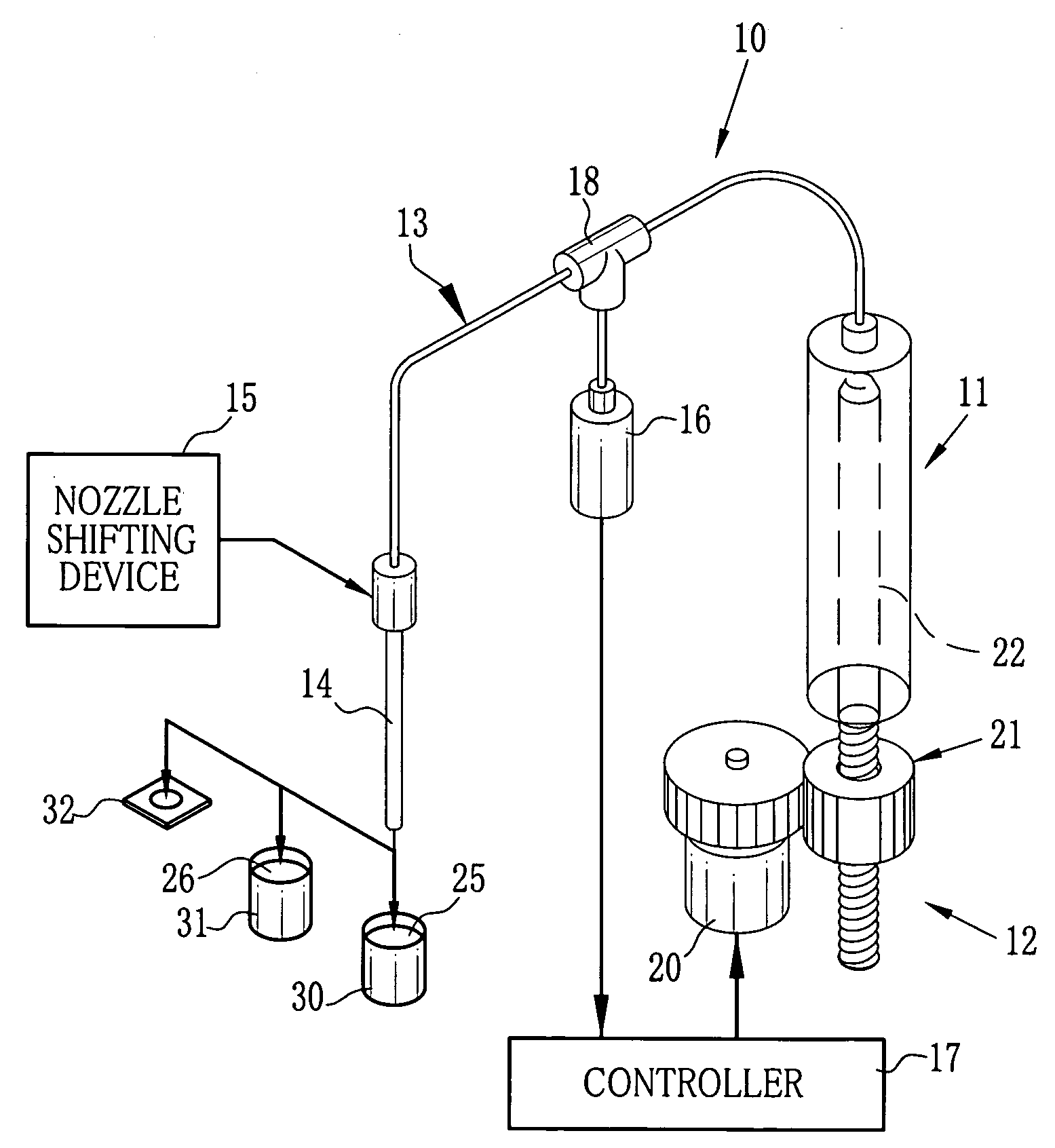

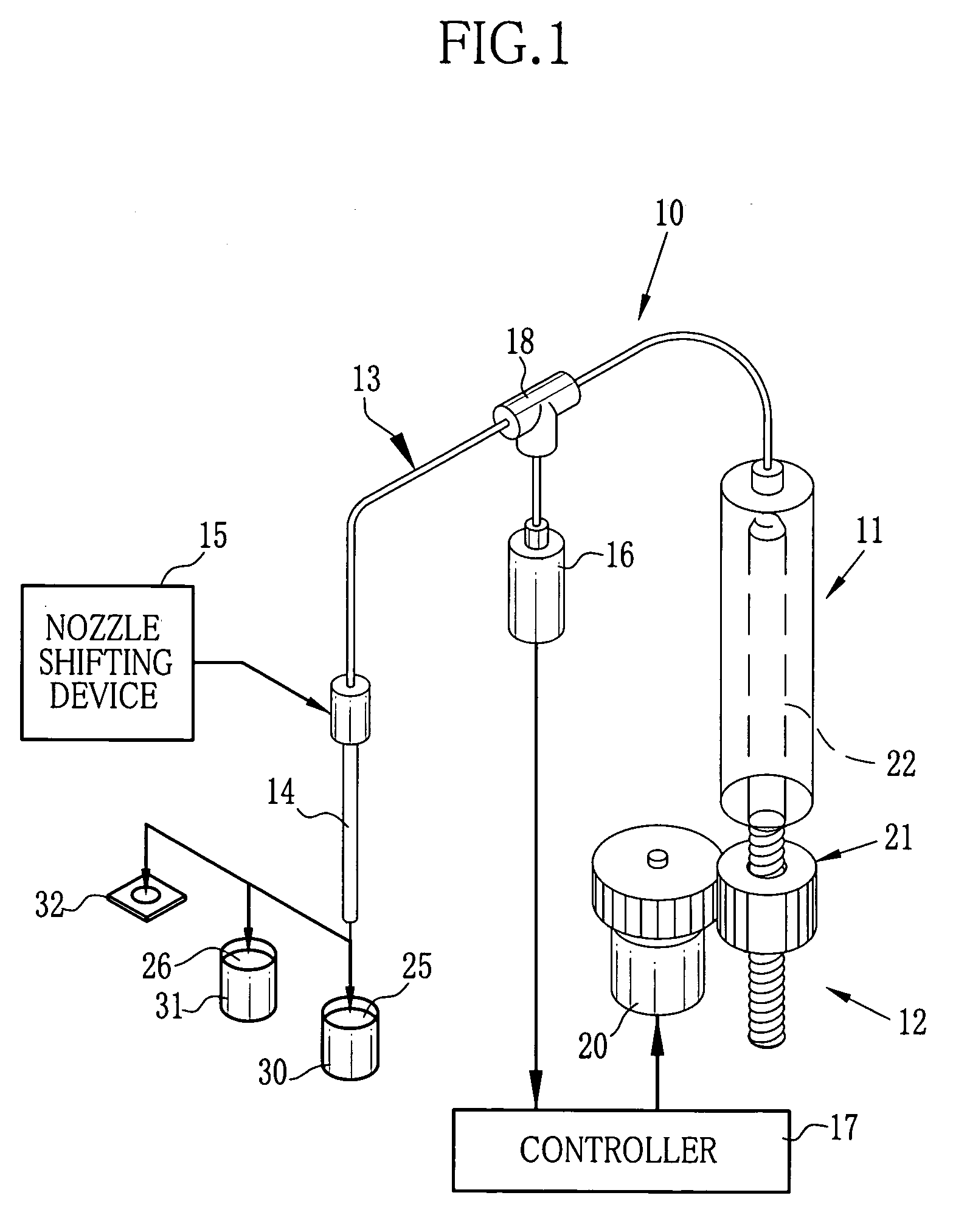

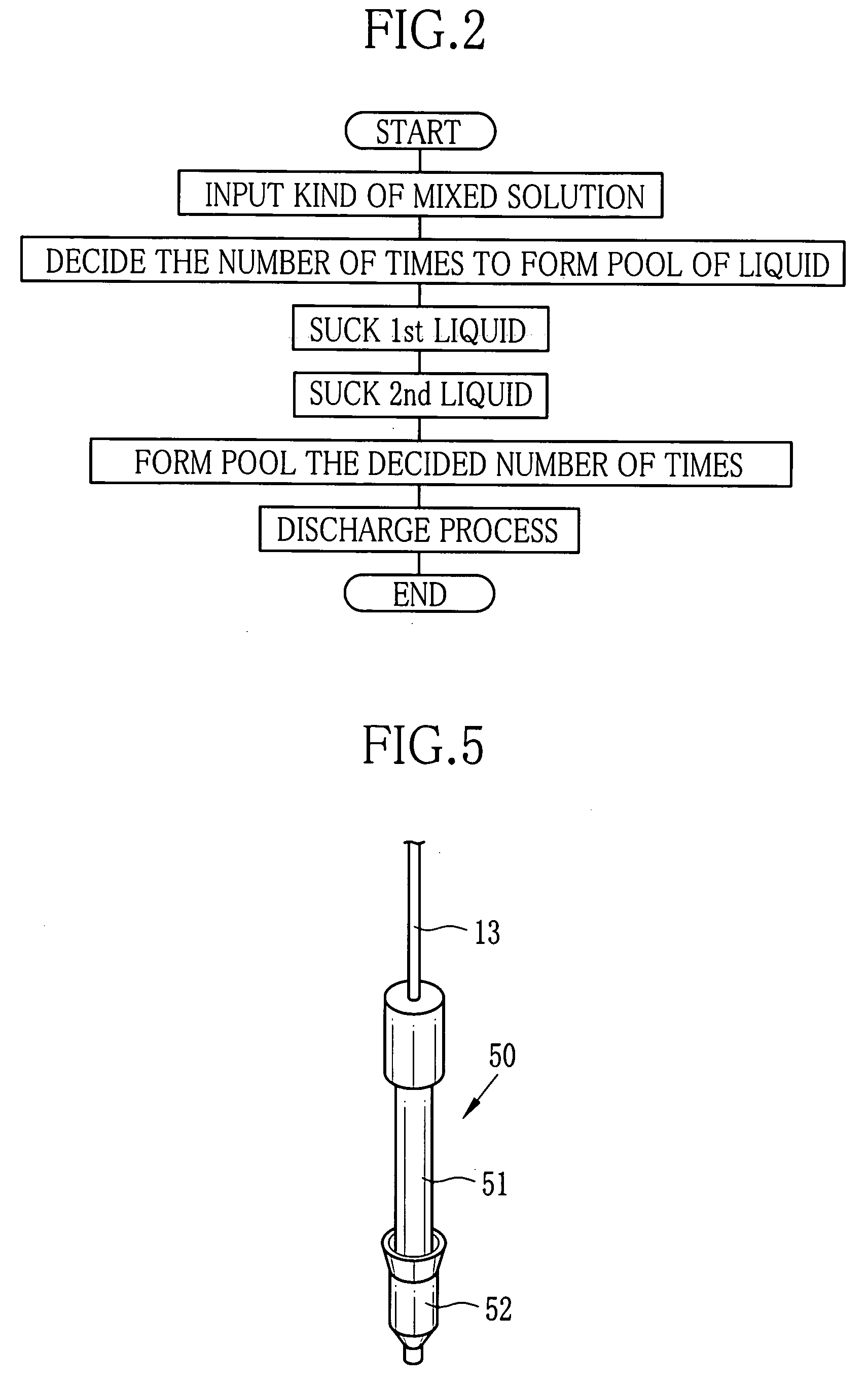

Method of homogenizing microvolume liquid and apparatus therefor

InactiveUS20060285430A1Promote homogenize effectQuick and efficientShaking/oscillating/vibrating mixersFlow mixersFluid cellEngineering

In a method of homogenizing micro-volume liquid, a first liquid and then a second liquid is sucked into the suction nozzle. The sucked first and second liquids are sent to a nozzle end, to form a pool of a mixed liquid of the first and second liquids at the nozzle end. According to the inertia, the mixed liquid gets so fluid in the pool that the first and second liquids are stirred in the pool. Thereafter, the pool of the mixed liquid is sucked into a liquid channel. According to the kinds of liquids to be mixed, the number of times to form the pool is predetermined. The steps of forming the pool at the nozzle end and sucking it into the liquid channel are repeated by the decided number of times, to homogenize the mixed liquid quickly.

Owner:FUJIFILM CORP +1

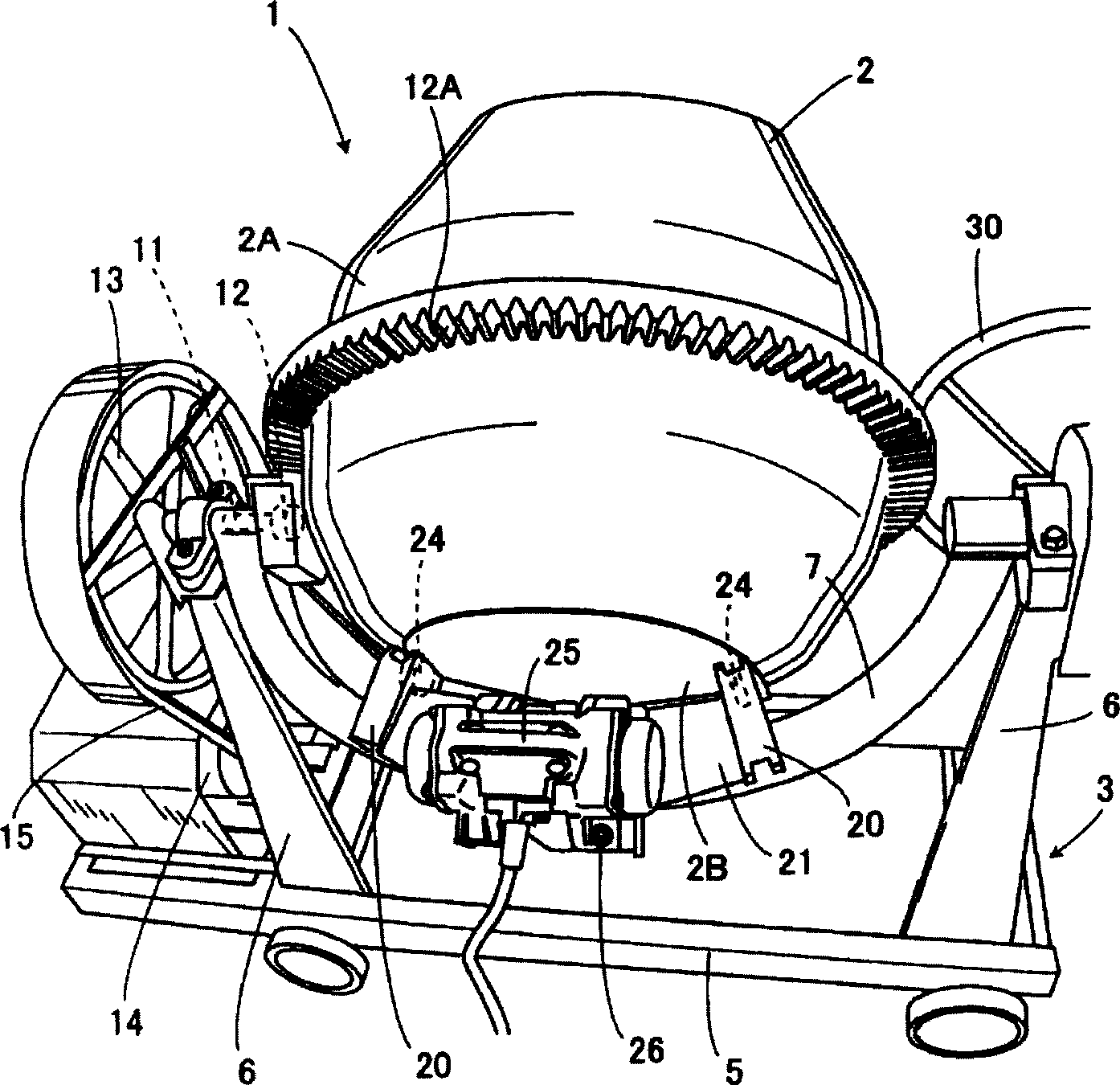

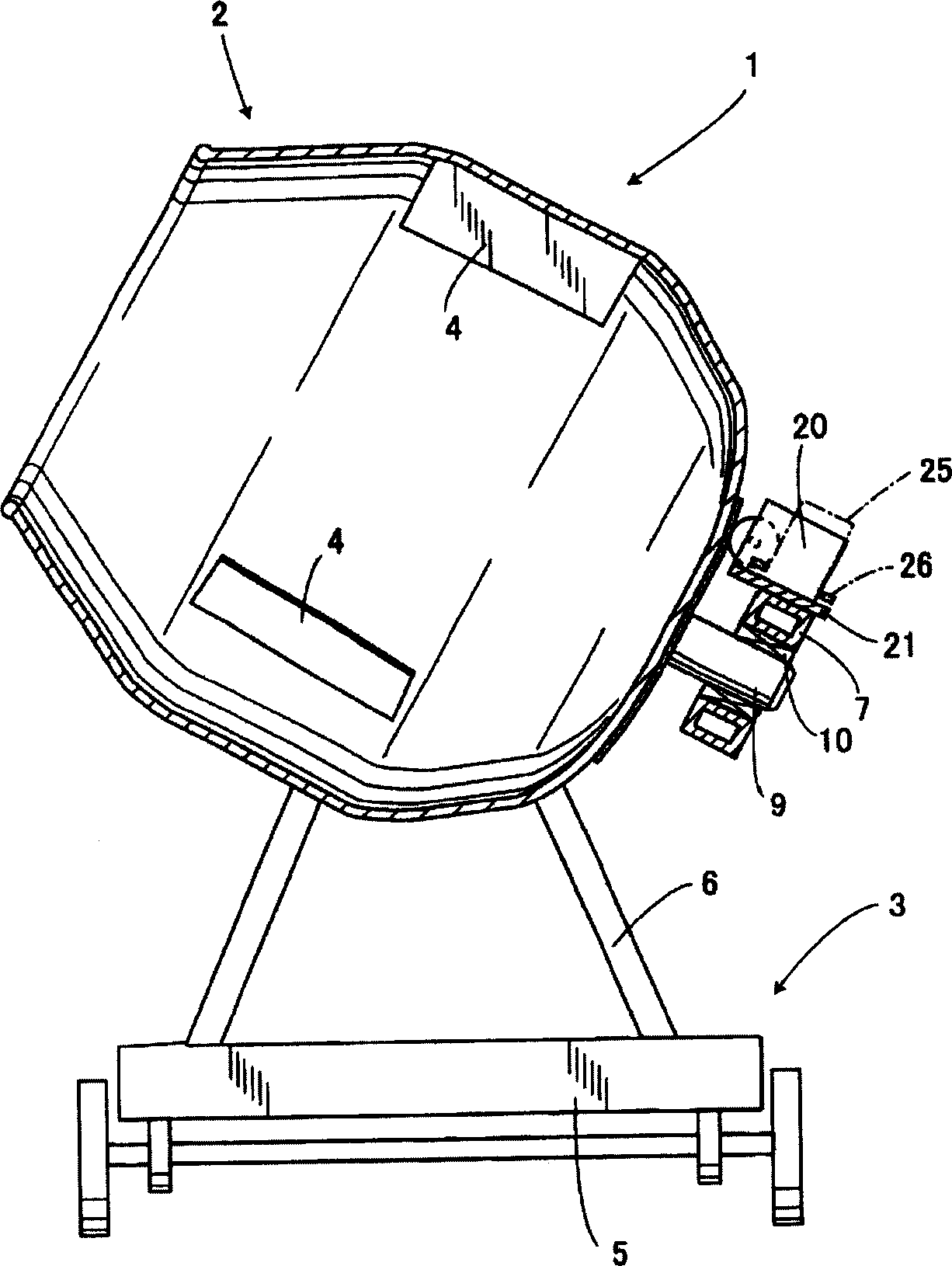

Concrete mixer

InactiveCN1538900AEffective stirringRotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringMechanical engineering

Owner:ASAMI SEISAKUSHO

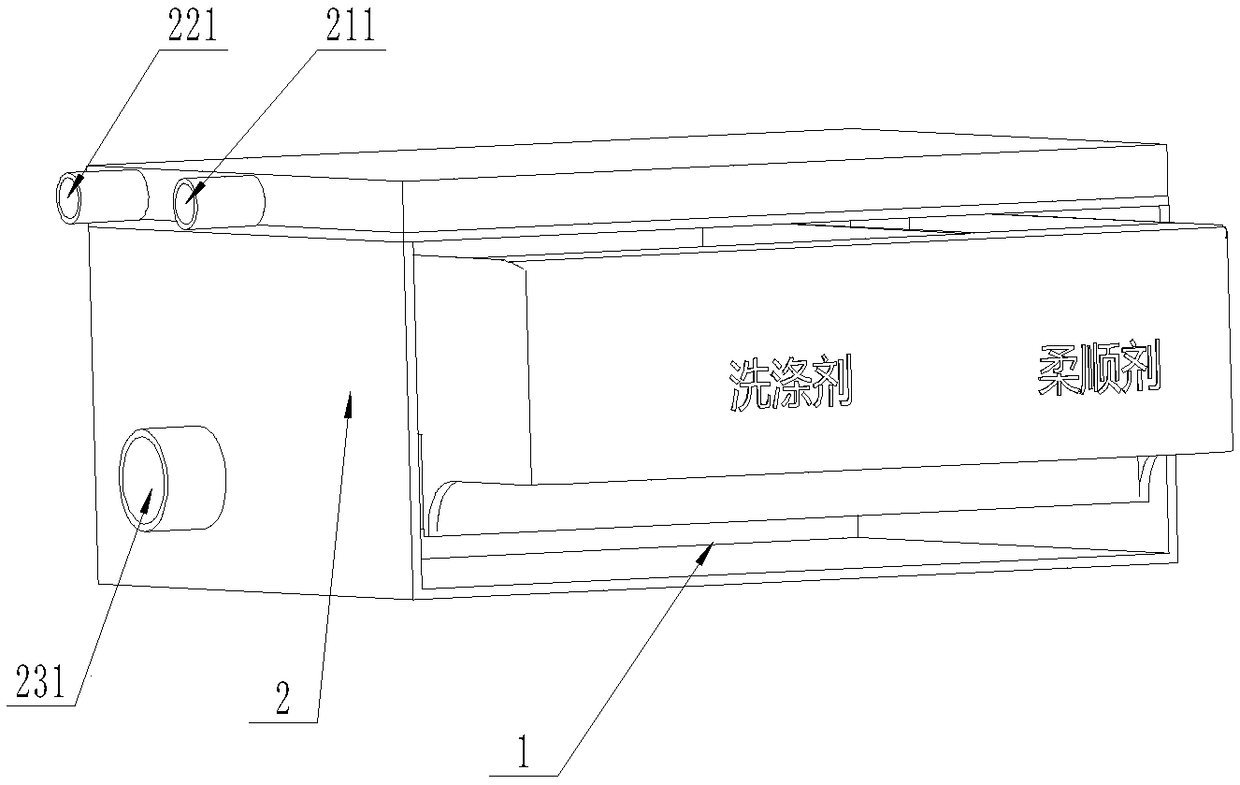

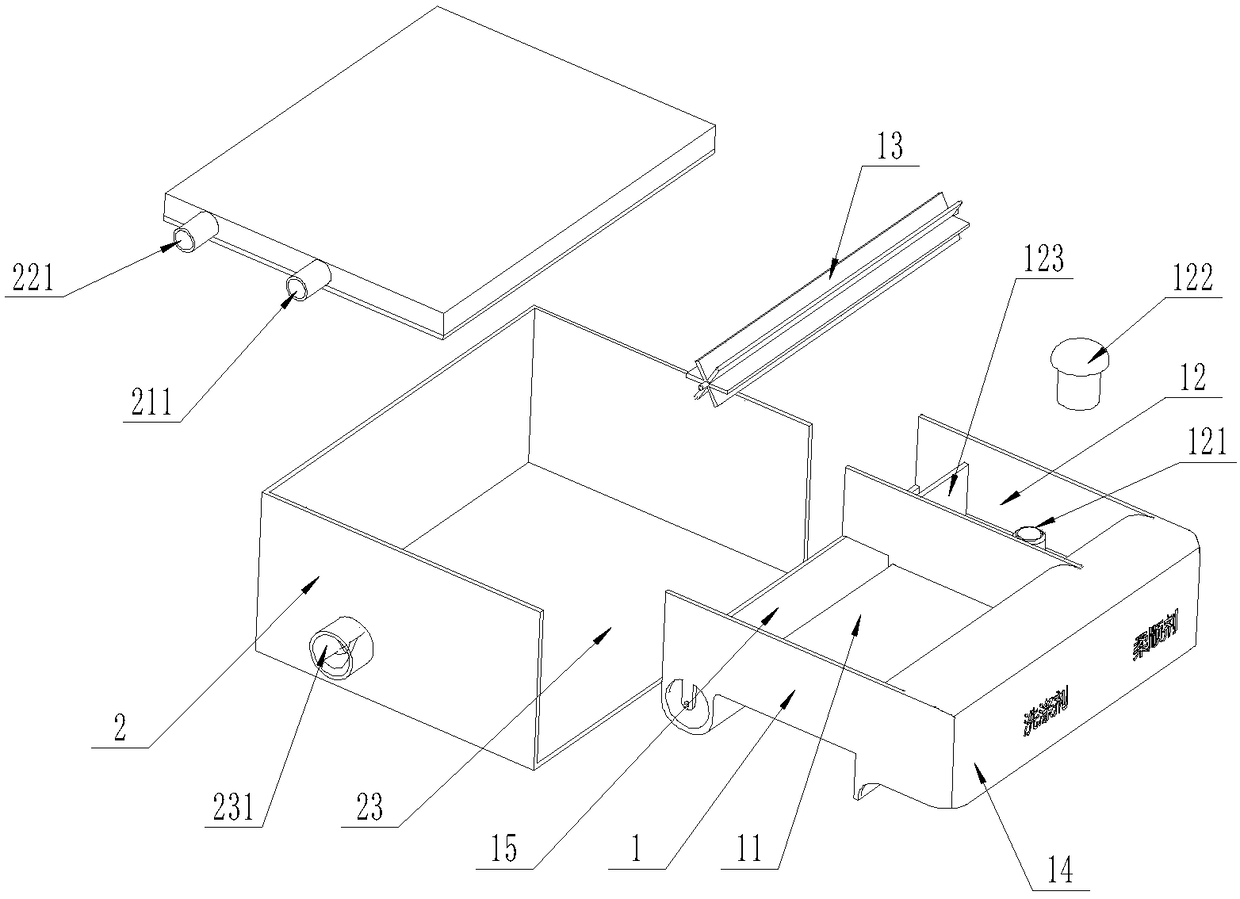

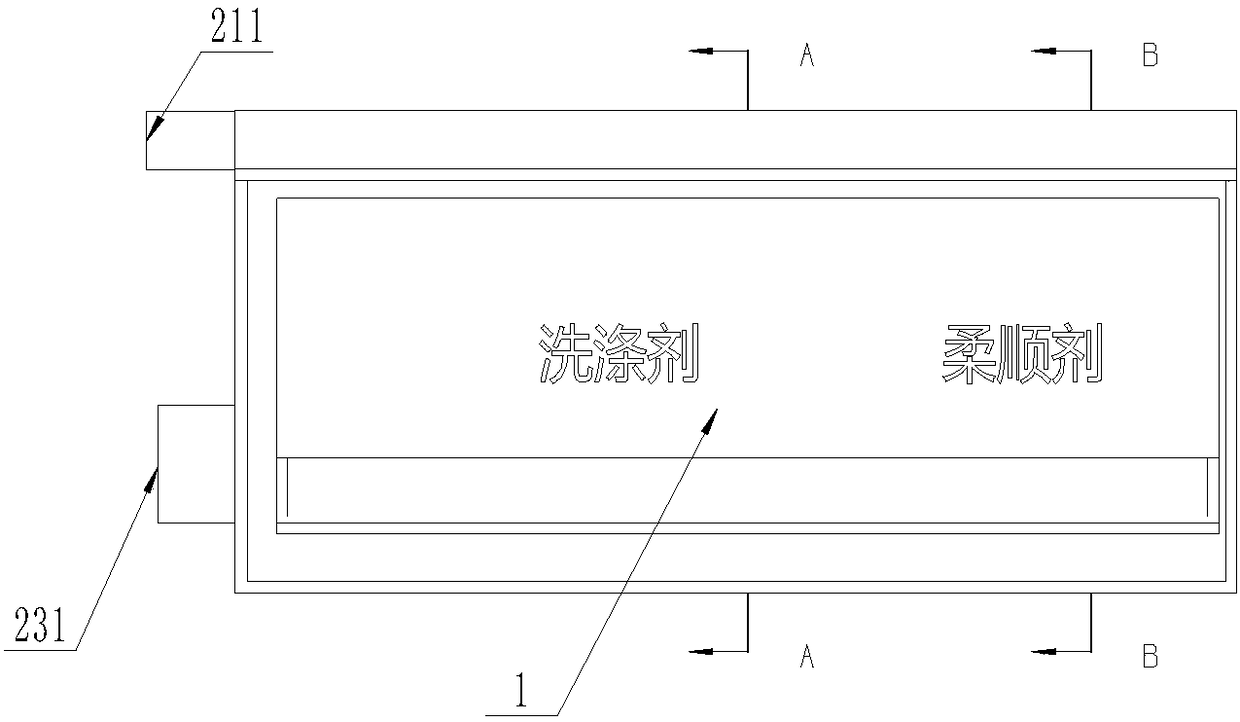

Washing machine and washing agent device thereof

ActiveCN108866957AIncrease speedEffective stirringOther washing machinesTextiles and paperImpellerEngineering

The invention belongs to the field of household electrical appliance and specifically provides a washing machine and a washing agent device thereof. The present invention is directed to solving the problem that the conventional detergent box cannot sufficiently dissolve the detergent including the washing powder in water. For this purpose, the detergent device of the present invention comprises adetergent box and a water storage module; the detergent box is provided with a water outlet, and the water outlet is provided with an impeller; the water storage module comprises a water inlet chamber, a water outlet chamber, and a partition plate disposed therebetween; a through hole is provided in the partition for connecting the water inlet chamber and the water outlet chamber. When the detergent box is inserted into the water outlet chamber, the impeller has a through hole at the projected position of the partition so that the water falling from the through hole and the detergent solutionflowing out from the outlet of the detergent box can simultaneously drive the impeller to rotate in one direction and therefore stirring the detergent solution. Therefore, the detergent device of thepresent invention can sufficiently dissolve the detergent in water to prevent the washing powder from agglomerating.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

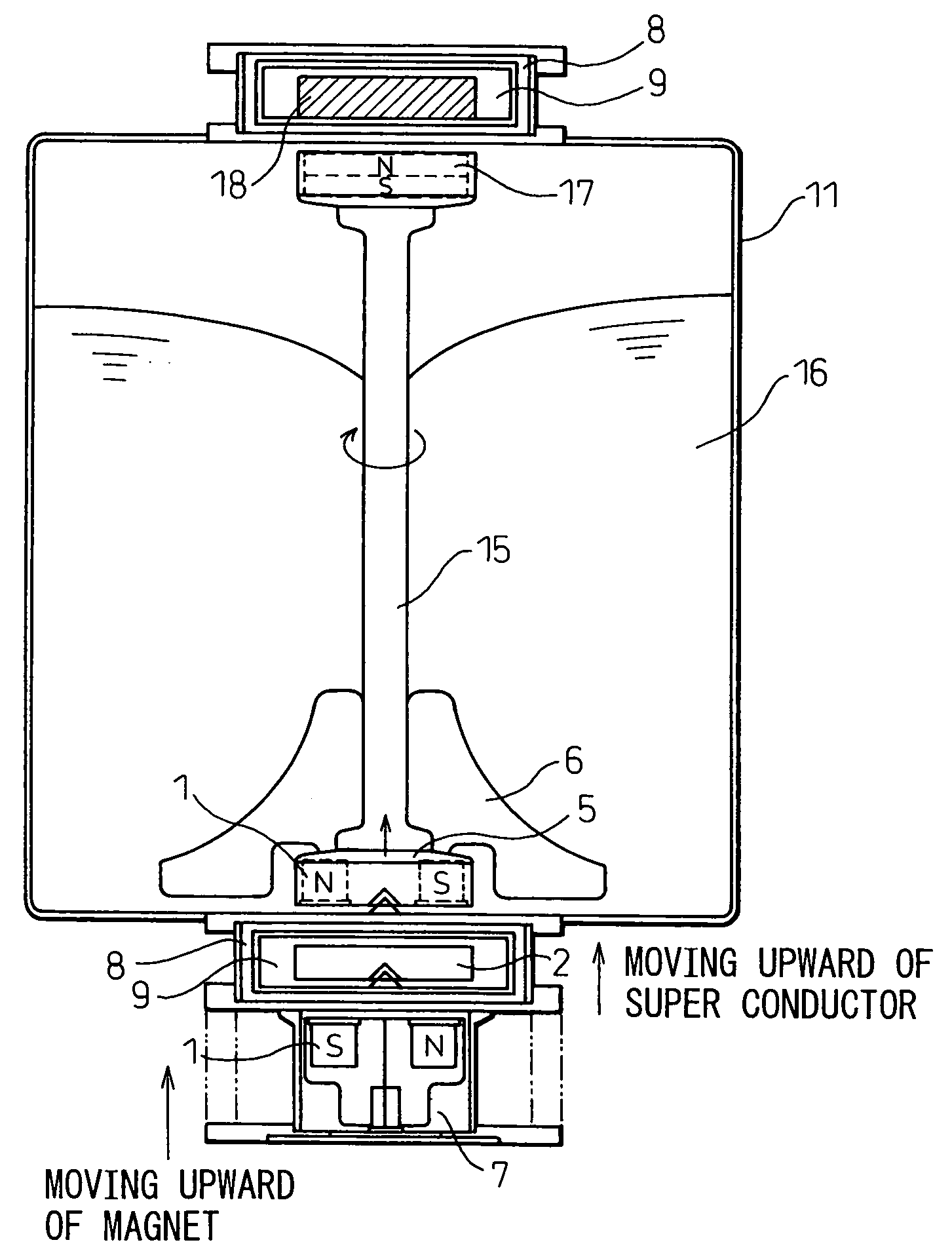

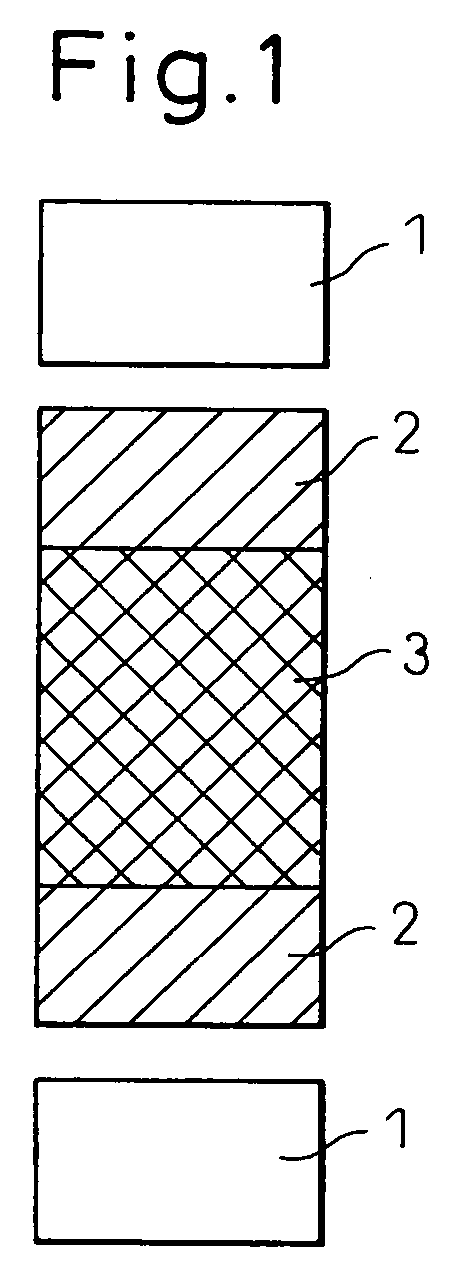

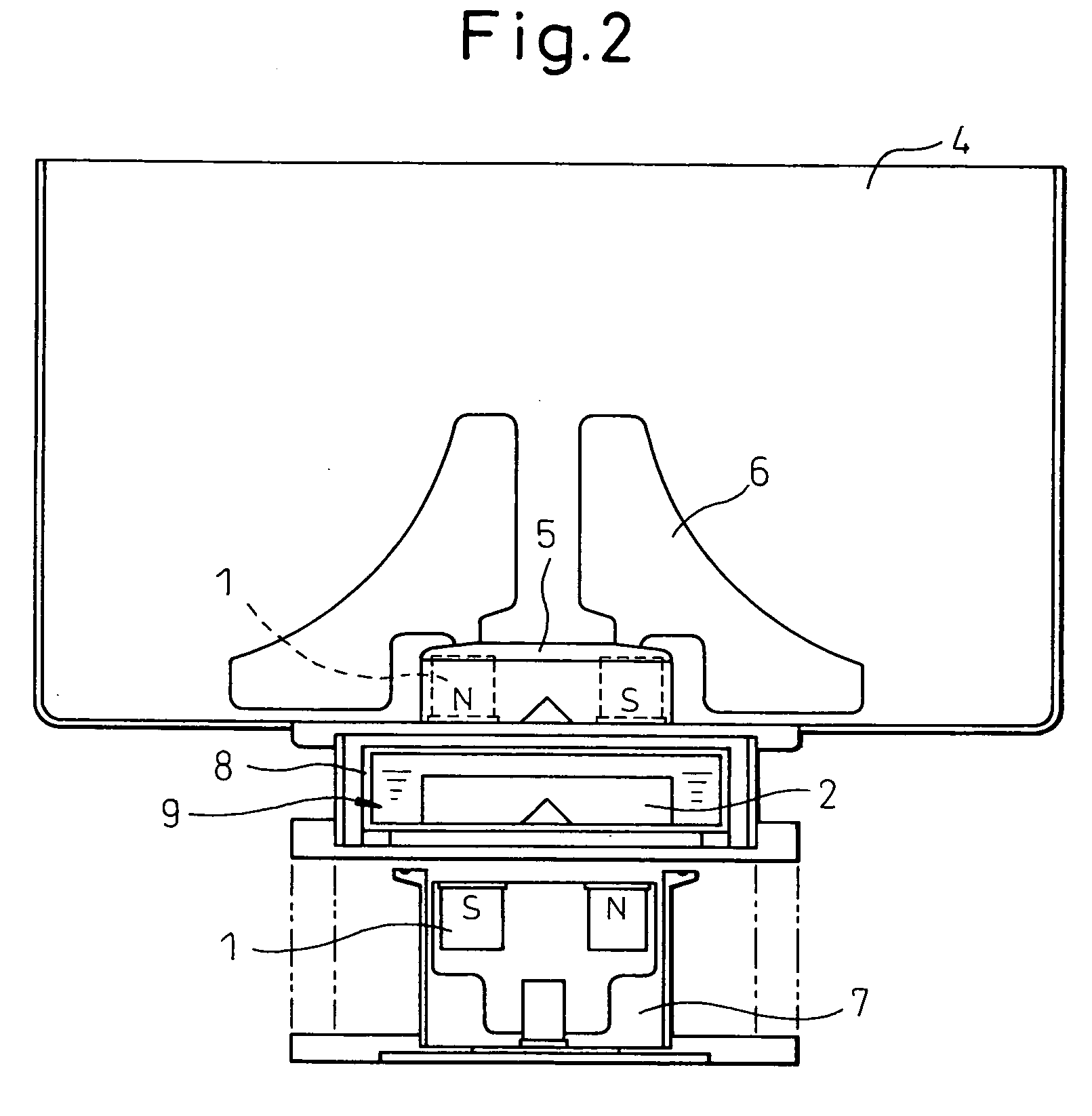

Superconductive non-contact rotary device

InactiveUS20070080595A1Avoid pollutionEffective stirringDynamo-electric brakes/clutchesRotary stirring mixersElectrical conductorMagnet

A superconductive non-contact rotary device comprising; a bulk superconductor having a pinning effect arranged in a heat insulating cryogenic vessel, a permanent magnet arranged at one side of the vessel so as to face one surface of the bulk superconductor across a wall, and a permanent magnet arranged at the other side of the vessel facing the other surface of the bulk superconductor across a wall, one permanent magnet being rotated to make the other permanent magnet rotate in a non-contact state.

Owner:MAGUNEO

Construction sand screening machine

InactiveCN106540782ASolve the inefficiency of screeningPrevent leakageGrain treatmentsSieveScreening effect

The invention discloses a construction sand screening machine which comprises a machine body. The top of the machine body communicates with a feed hopper. A first motor is fixedly mounted at the top of the right side of the machine body. The output end of the first motor penetrates through the machine body and extends into the machine body to be fixedly connected with a rotary shaft. Stirring rods are fixedly mounted on the surface of the rotary shaft. A bearing is movably connected with the left side of the rotary shaft. The left side of the bearing is fixedly connected with the left side of the inner wall of the machine body. A second motor is fixedly mounted on the portion, under the first motor, of the right side of the machine body. According to the construction sand screening machine, the leakage problem when sand falls to a secondary sieve from a primary sieve can be effectively avoided through a first baffle and a second baffle, screening can be effectively conducted through cooperation of the secondary sieve, a disc and a third motor, the screening effect of the coarse sand and the fine sand can be better through arrangement of the primary sieve and the secondary sieve, and therefore the problem of low screening efficiency is solved.

Owner:林志城

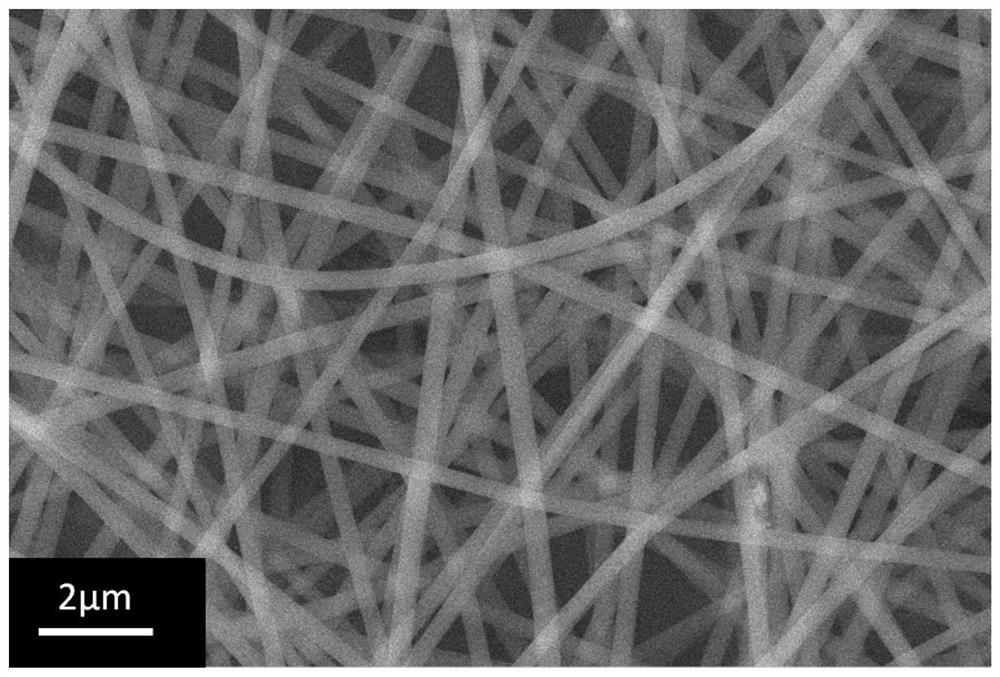

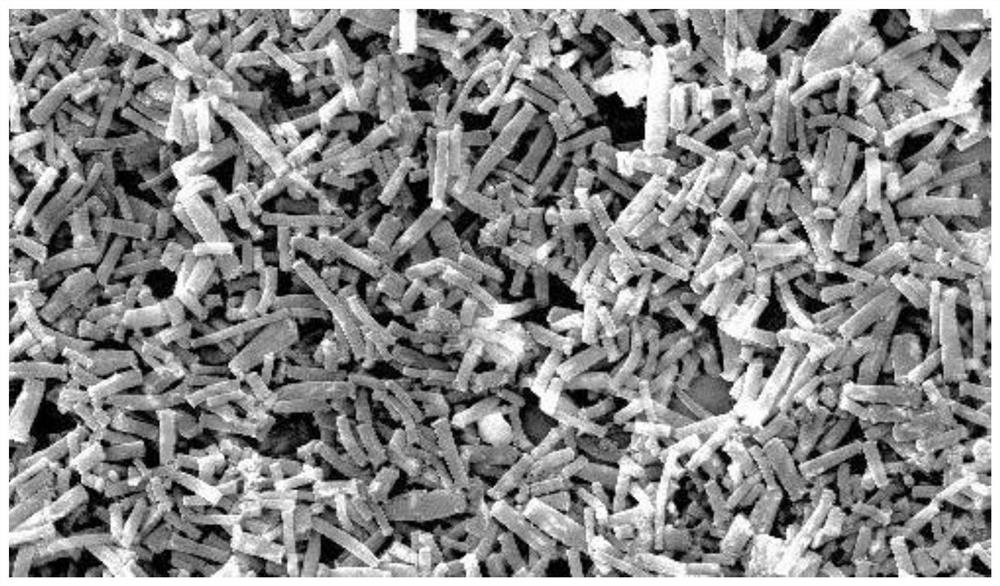

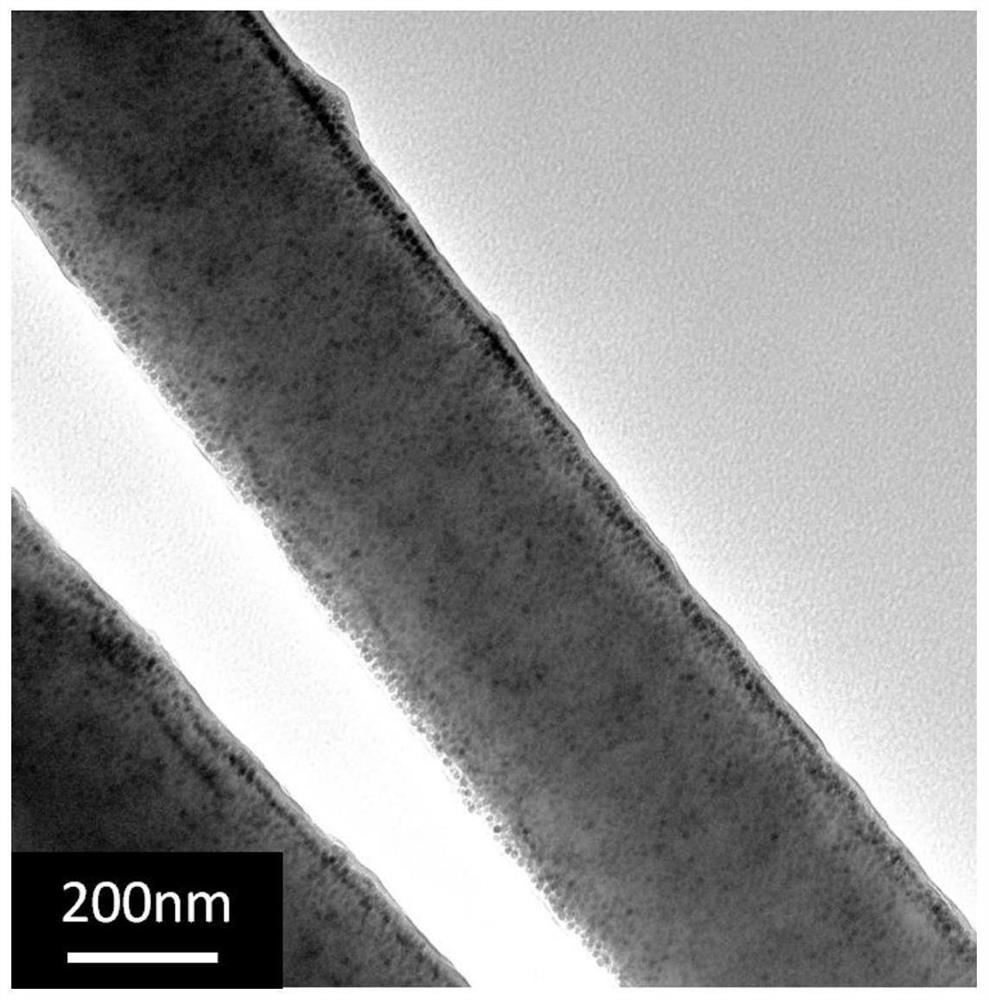

Magnetic nano stirrer prepared through electrostatic spinning technology and preparation method and application thereof

ActiveCN111690999AWide range of optionsEfficient methodMaterial nanotechnologyTransportation and packagingPolymer scienceSpinning

The invention relates to a magnetic nano stirrer prepared by using an electrostatic spinning technology and a preparation method and application thereof and belongs to the field of preparation of functional nano materials. An oleic acid cracking method is adopted for synthesis of different particle diameters and sizes of Fe3O4 magnetic nano particles, through a series of pretreatment, the particles are transferred to a PAN high-molecular polymer solution, after even stirring and mixing are performed, the mixture is sprayed into a water bath cylinder through electrostatic spinning, and an ultrasonic probe is inserted into the water bath cylinder for breaking nano filters, thereby obtaining the nano stirrer. The method uses the electrostatic spinning to array and wrap the magnetic nano particles at one step, is easy to implement and short in production cycle, and easily achieves continuous production. The prepared stirrer has good magnetic property and stirring performance. The magneticnano stirrer is adjustable in size, suitable for stirring in microfluidic pipes different in diameter and micro-droplets and thus has good application prospects in the fields such as micro reactions.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com