Concrete mixer

A technology for concrete mixers and mixing blades, which is applied in the direction of mixers, cement mixing devices, mixers with rotating containers, etc., and can solve problems such as limited collection, high moisture content, and increased environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

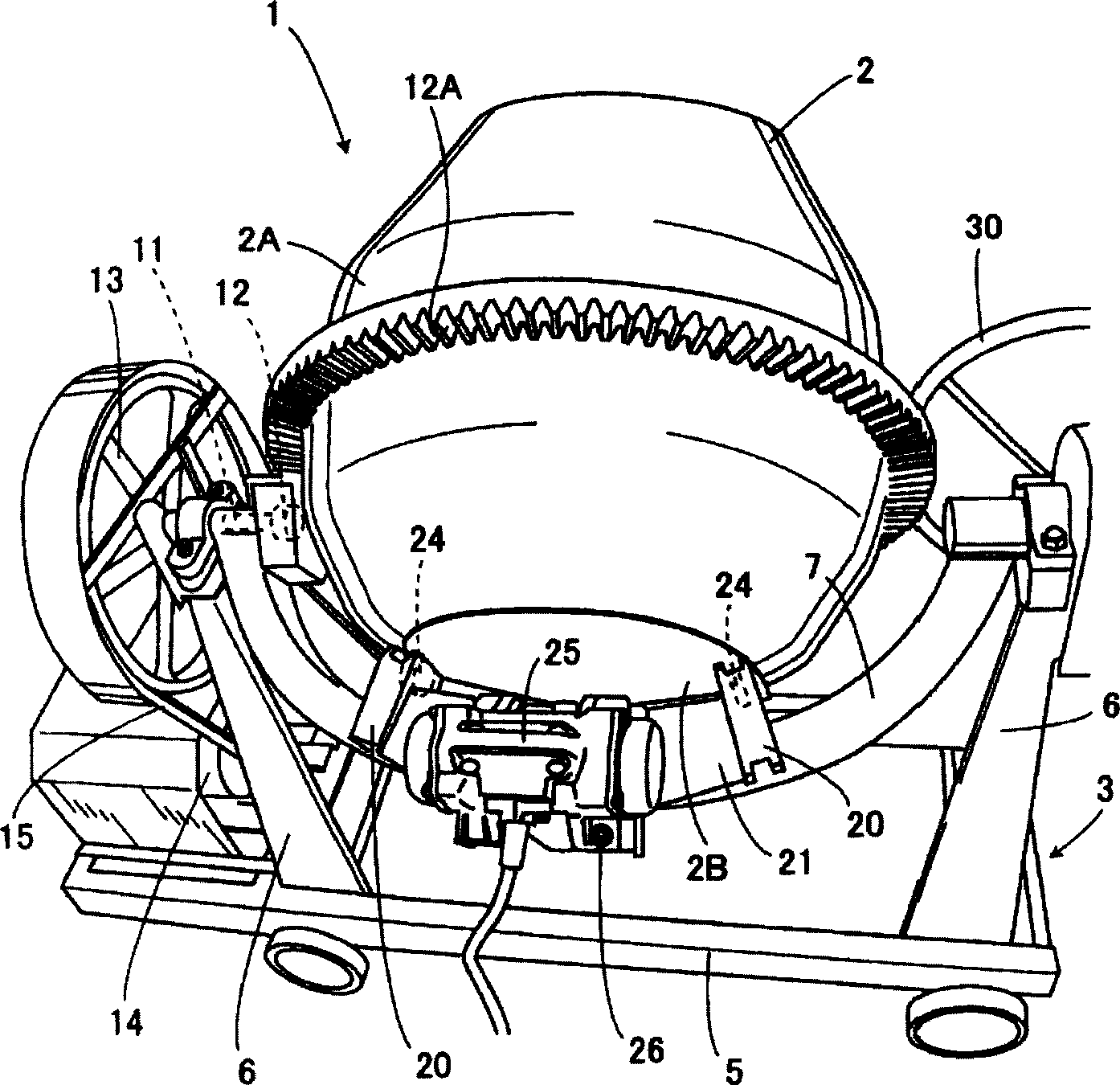

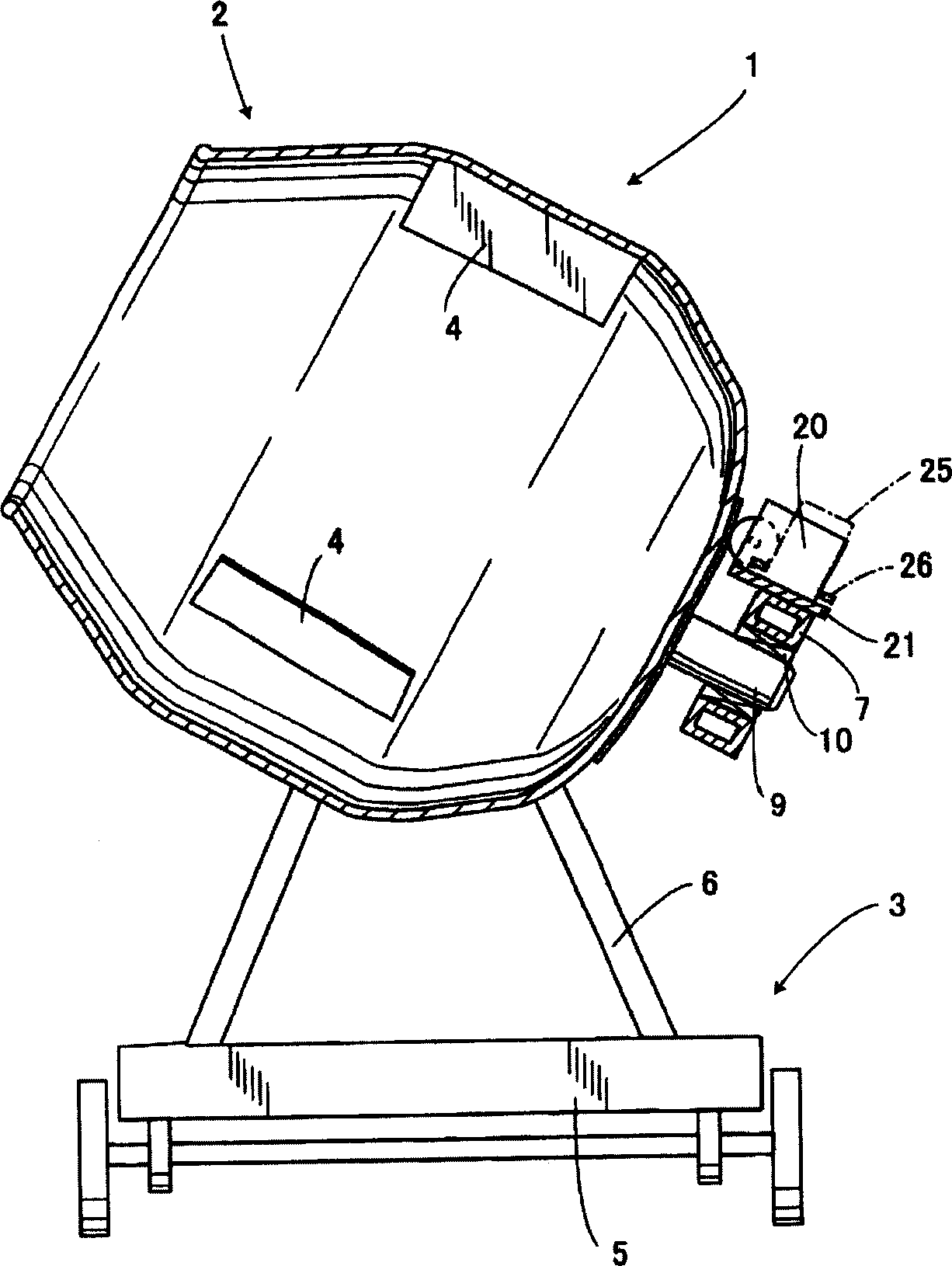

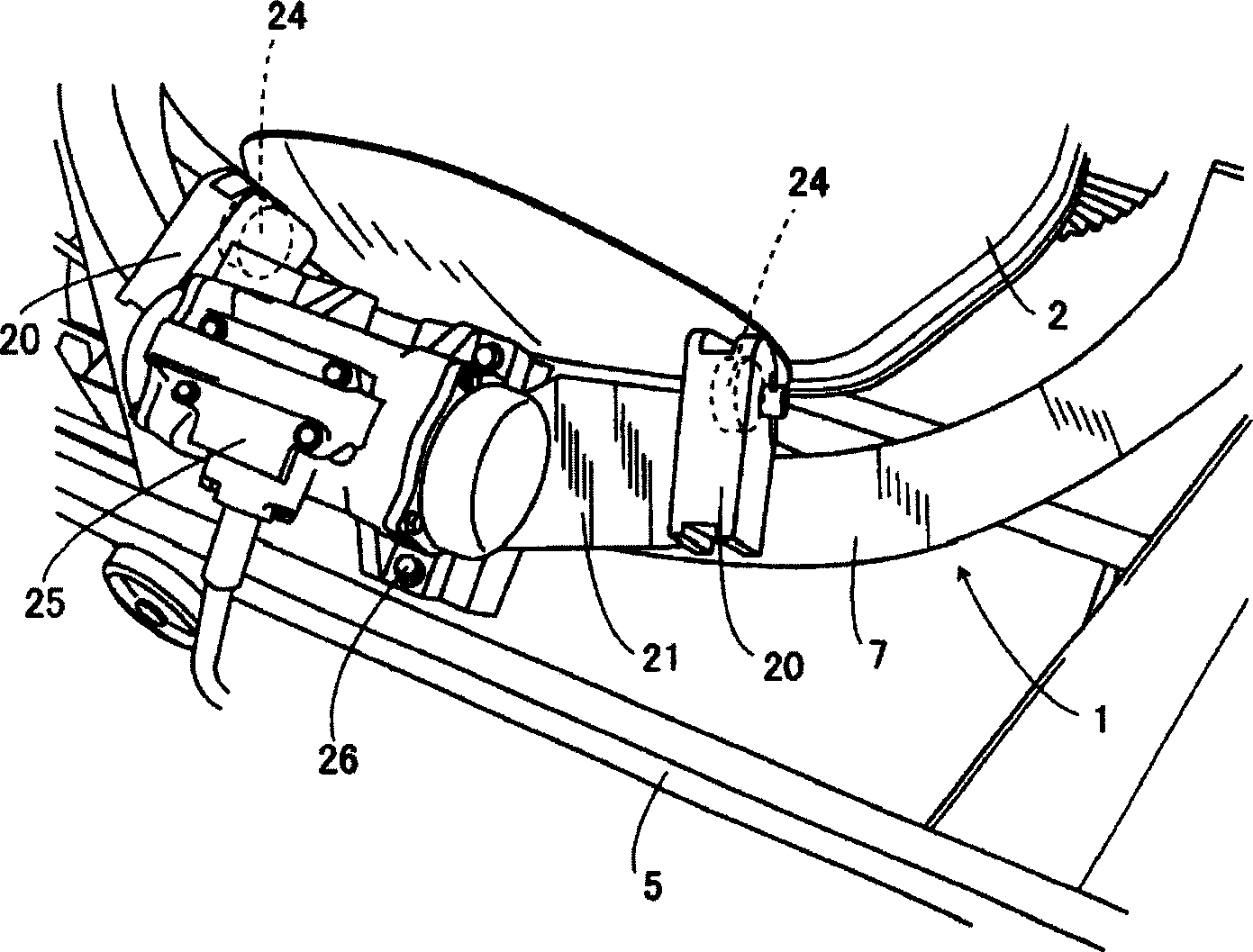

[0028] Embodiments of the present invention will be described below with reference to the drawings. Figure 1 ~ Figure 3 Represent the first embodiment of the present invention, above-mentioned figure, sign 1 represents rotary concrete mixer, mixes materials such as gravel, sand, cement, water and admixture, manufactures concrete; The opening is used to inject the aforementioned materials; 3 represents the frame of the base, which supports the drum 2 . The above-mentioned middle part 2A of the rotating drum 2 expands toward the bottom 2B of the rotating drum 2 to form a trumpet shape, and at the same time, bends and smoothly hangs on the bottom 2B from the lower part of the middle part 2A. Also, the stirring blade 4 is fixed inside the drum 2 .

[0029] The aforementioned base 3 includes a frame-shaped base 5 equipped with casters that can move freely, a pair of left and right support frames 6,6 erected on the base 5, and an installation frame 7 erected between the pair of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com