Automatic cigarette making machine

A cigarette machine and automatic technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of time-consuming, uneven taste, labor-consuming, etc., and achieve the effect of ensuring quality, smooth filling operation, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

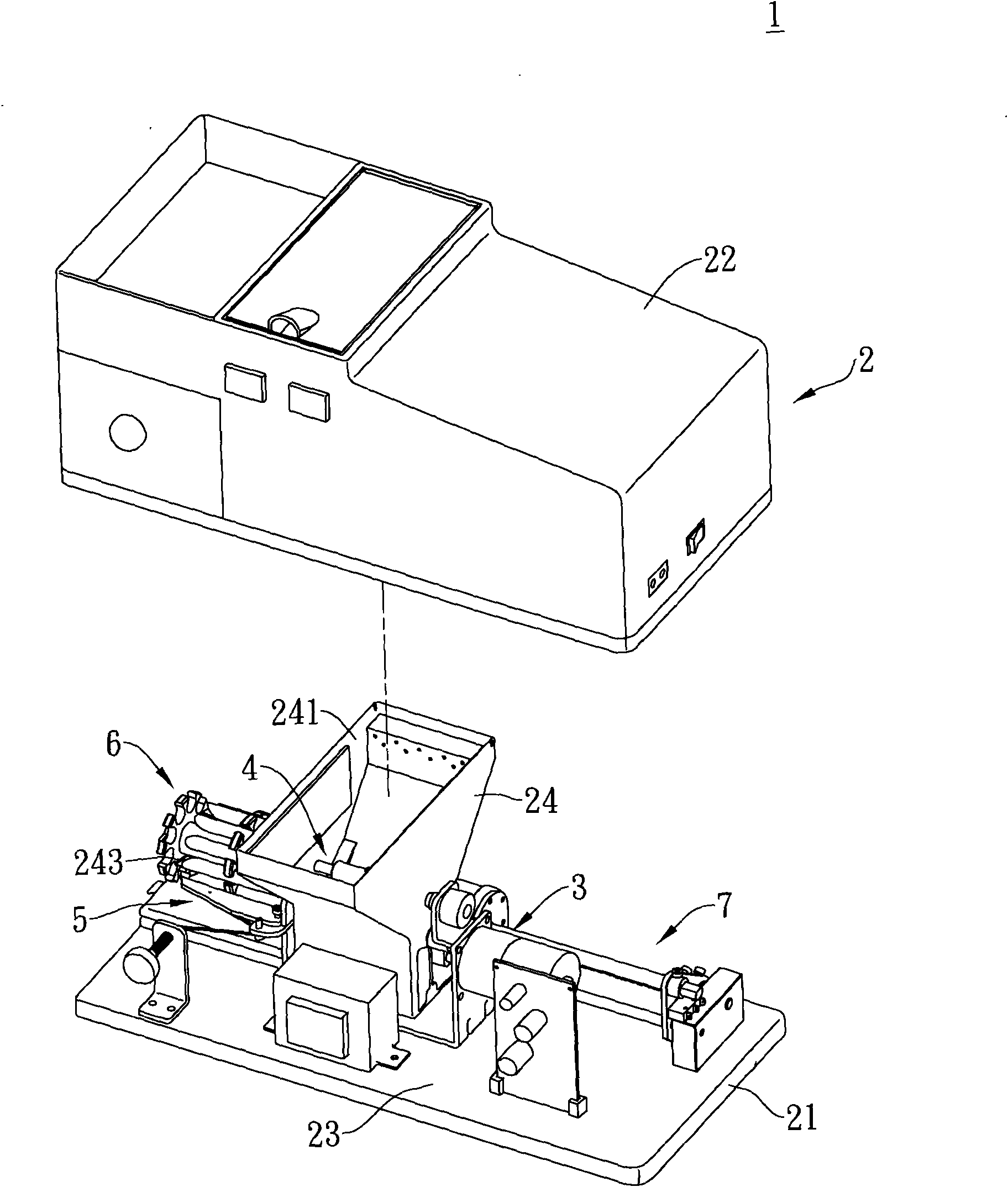

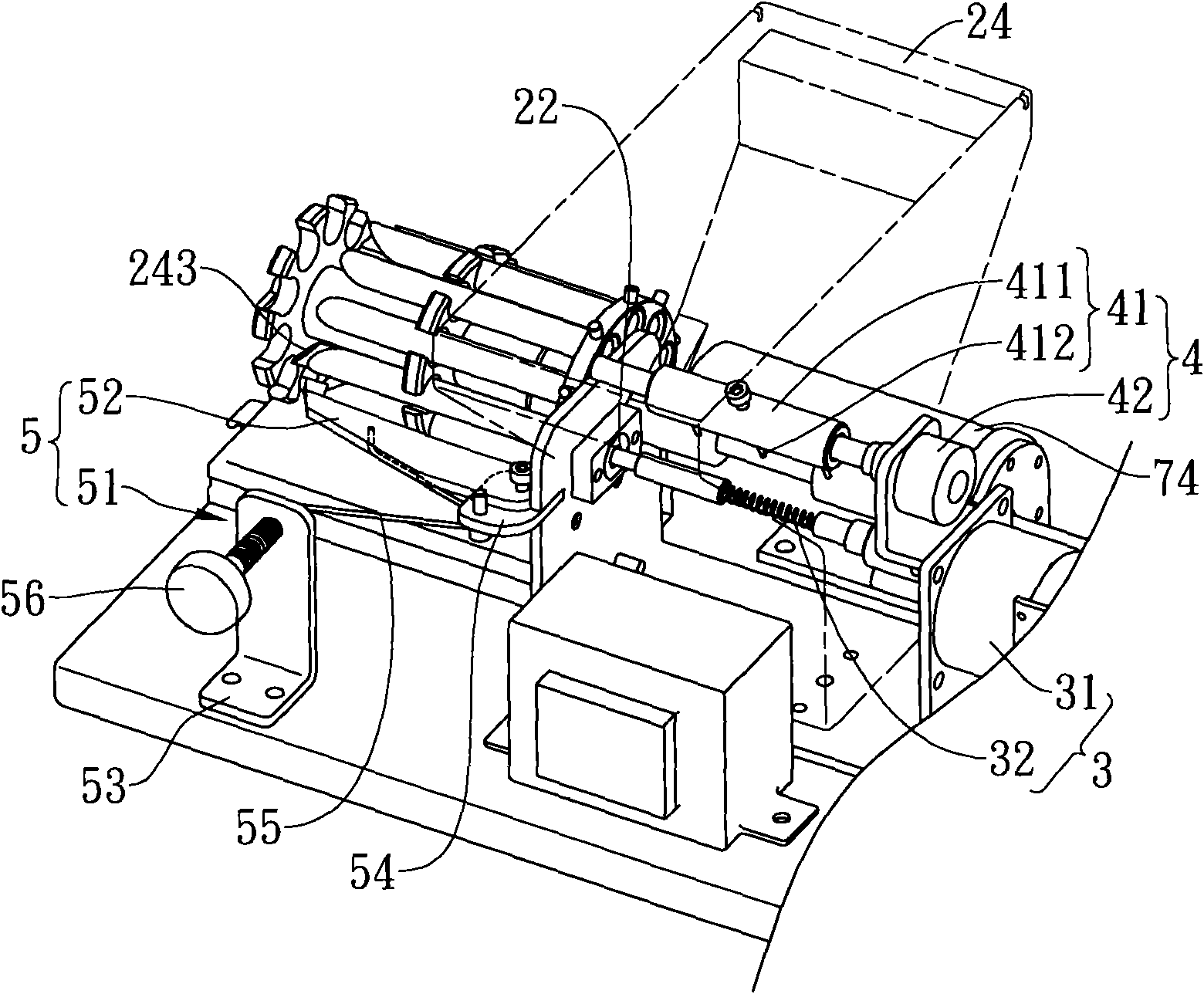

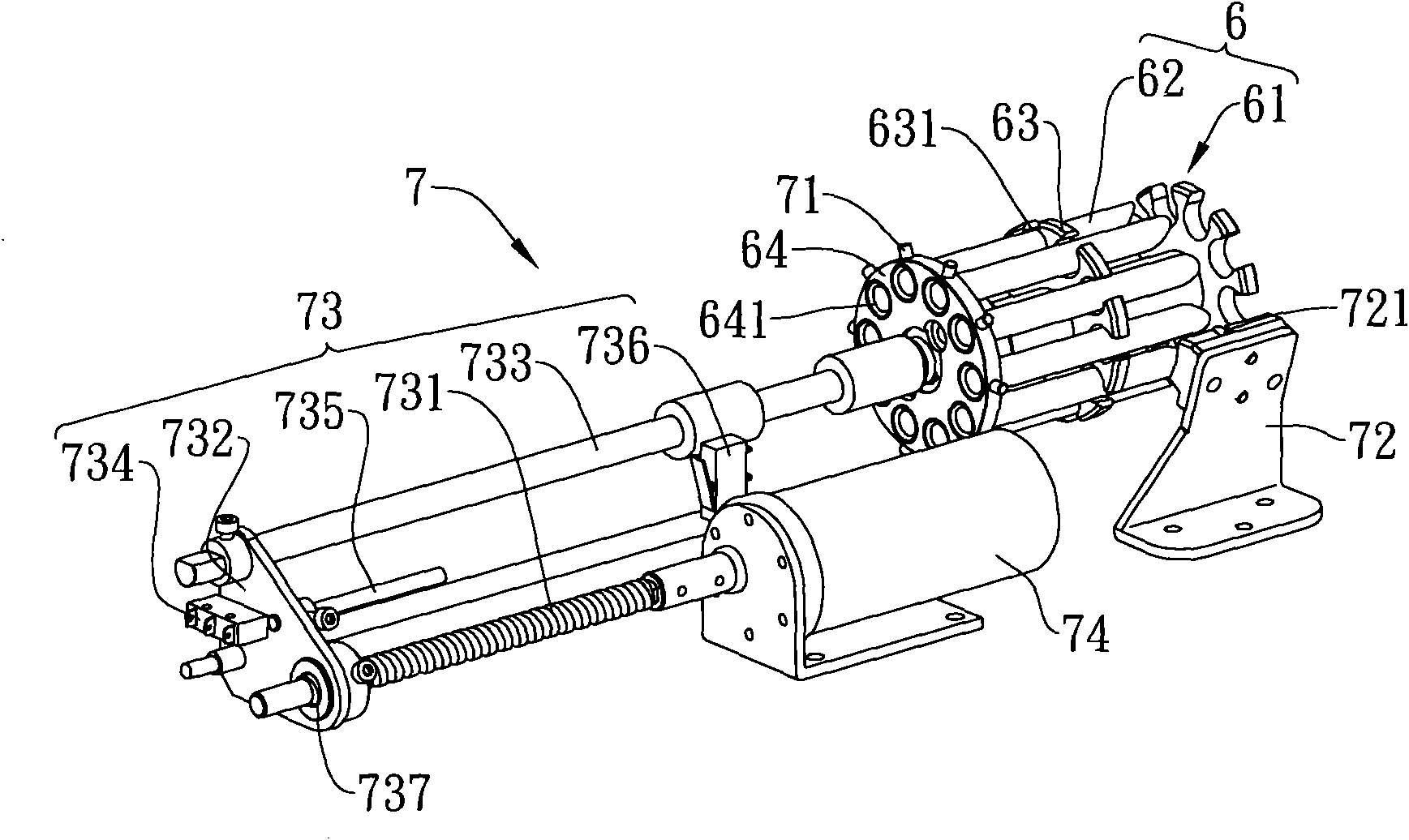

[0023] see figure 1 As shown, it is a preferred embodiment of the automatic cigarette rolling machine 1 of the present invention, including a housing 2 , a feeding component 3 , a stirring component 4 , a pressure regulating device 5 , a turntable 6 and a linkage component 7 . Wherein, the housing 2 is roughly in the shape of a cuboid, and includes a base 21 and an upper cover 22 covering the base 21. An accommodating space 23 is formed between the base 21 and the upper cover 22, and a The containing box 24 with the opening 241 is fixed in the accommodating space 23 for containing shredded tobacco. The front side of described containing box 24 is provided with an outlet 242, and described outlet 242 communicates with a smoke inlet conduit 243 that is connected to containing box 24 front sides (as figure 2 shown).

[0024] see figure 2 As shown, the feeding assembly 3 includes a motor 31 and a propelling rod 32, the motor 31 is fixed on the rear side of the container 24, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com