Patents

Literature

82results about How to "Effective shredding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

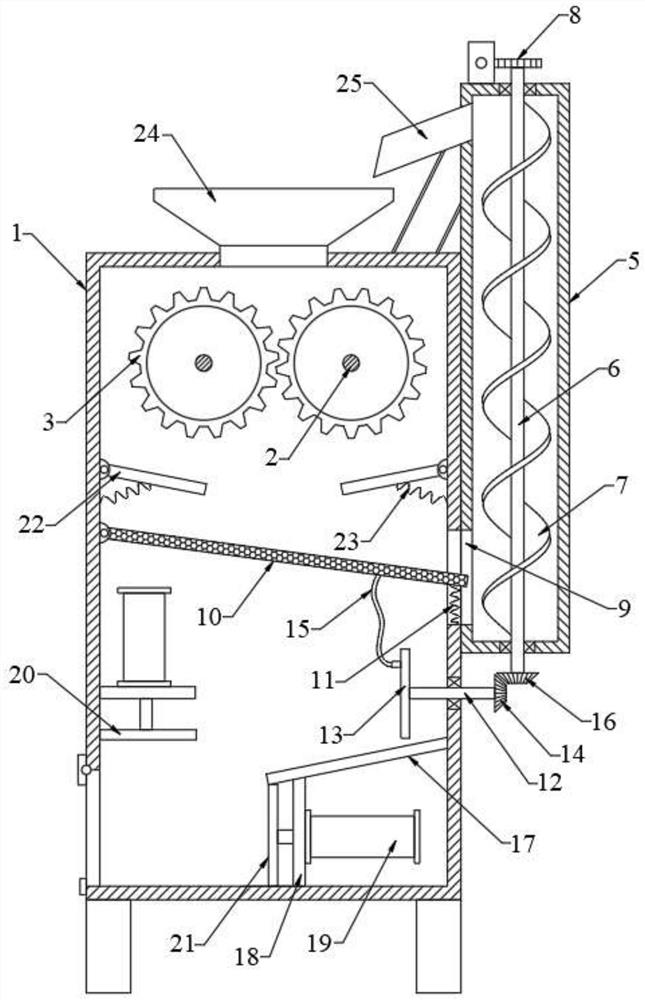

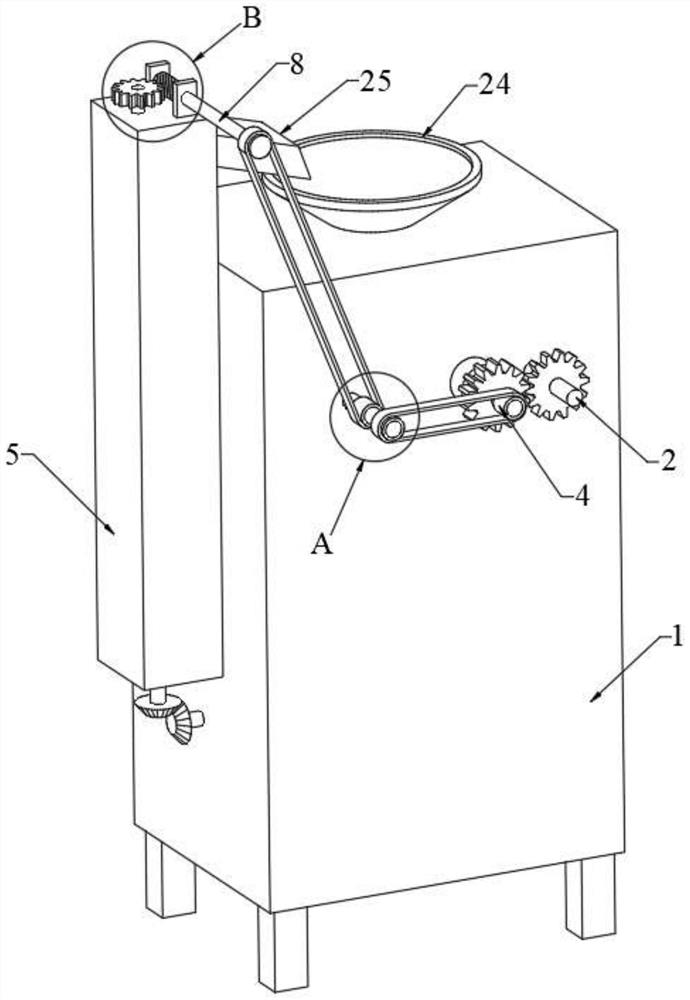

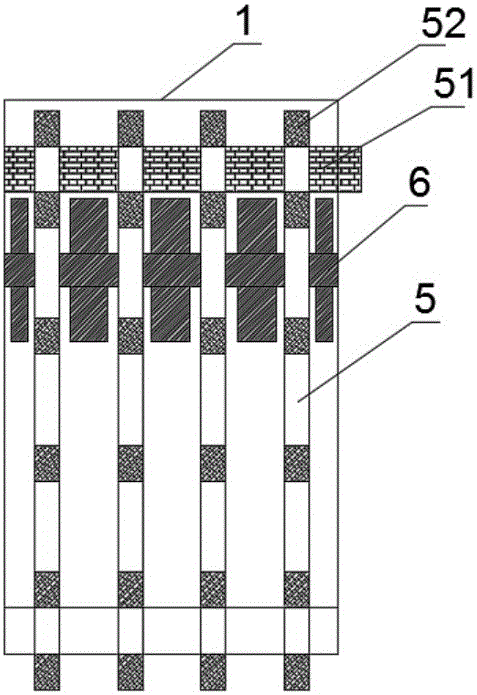

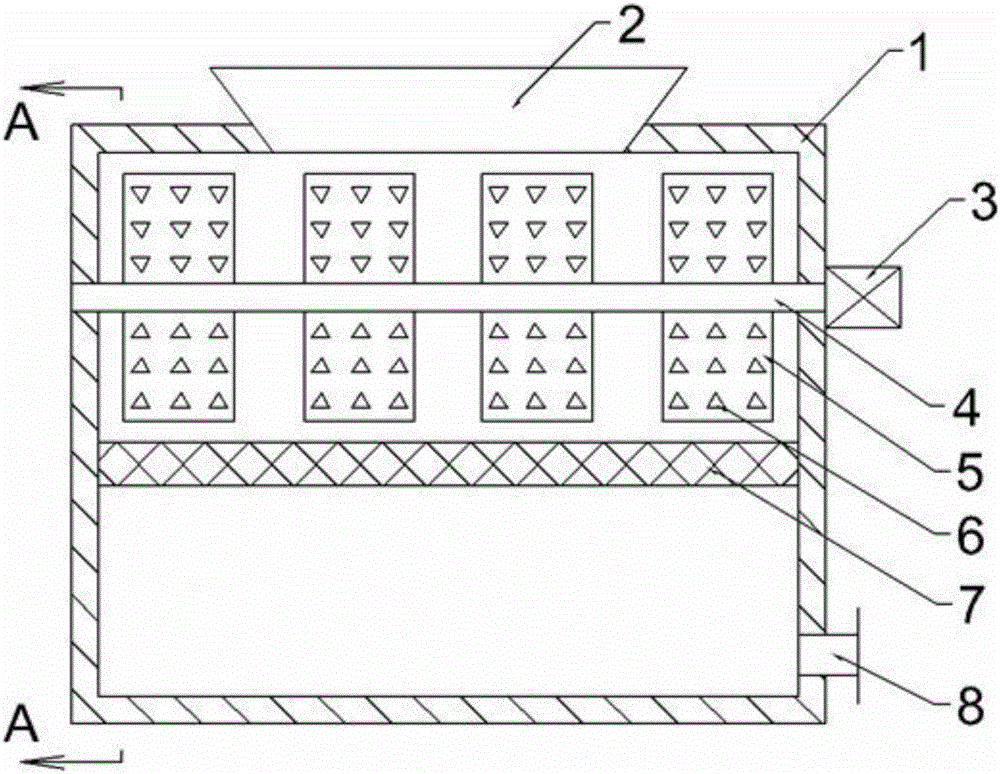

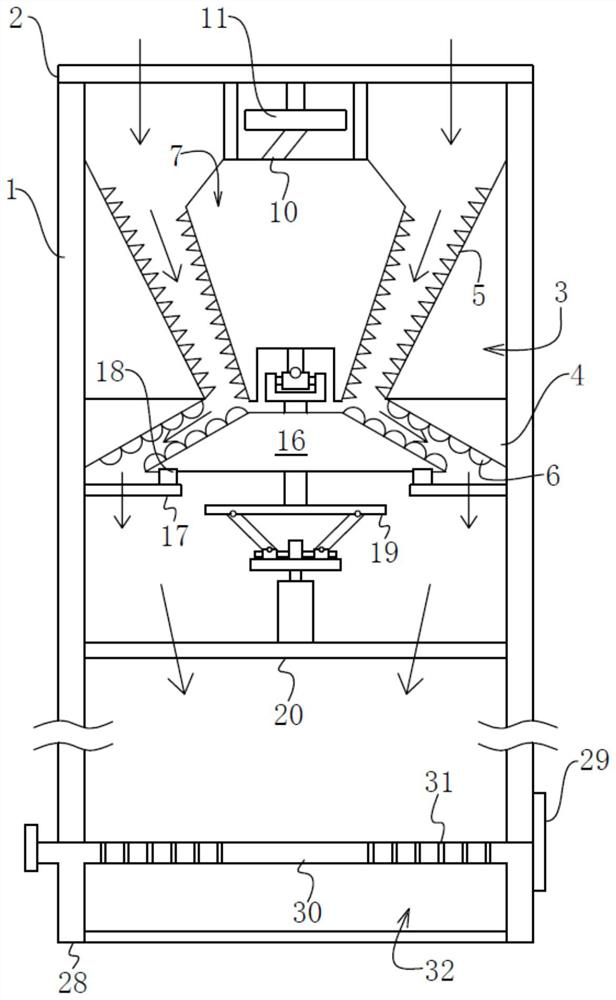

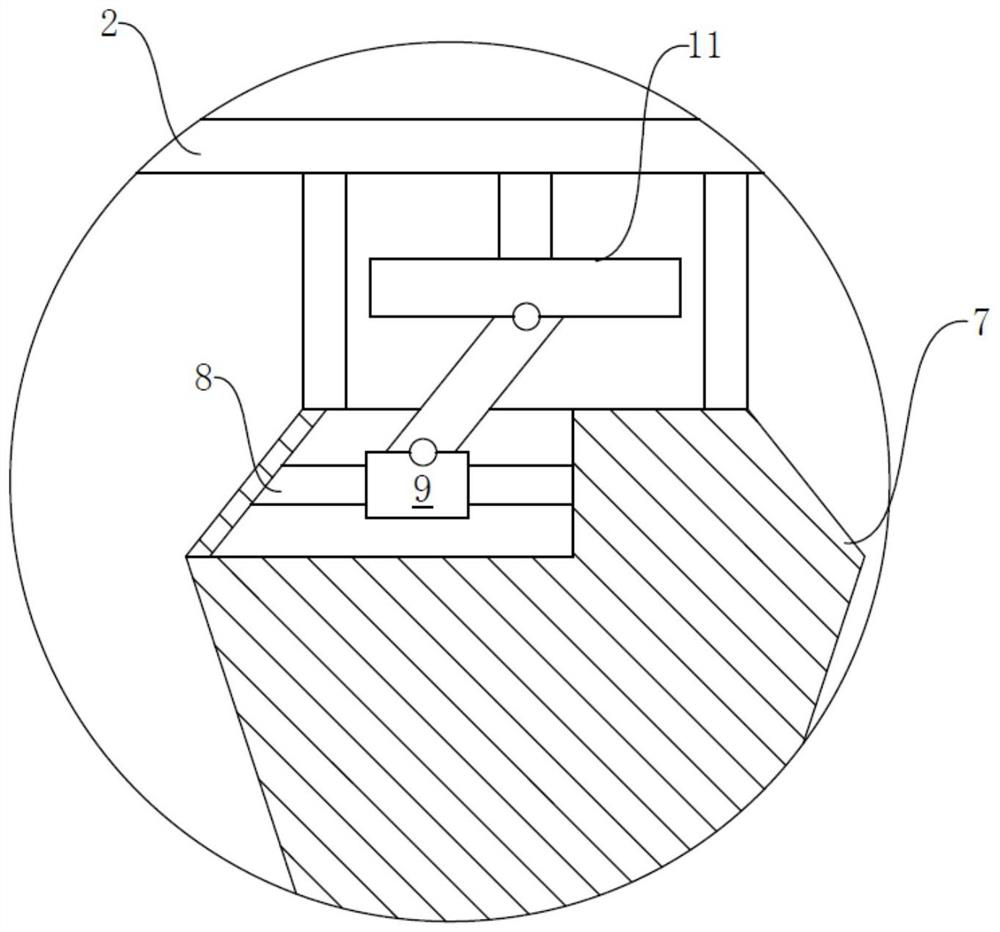

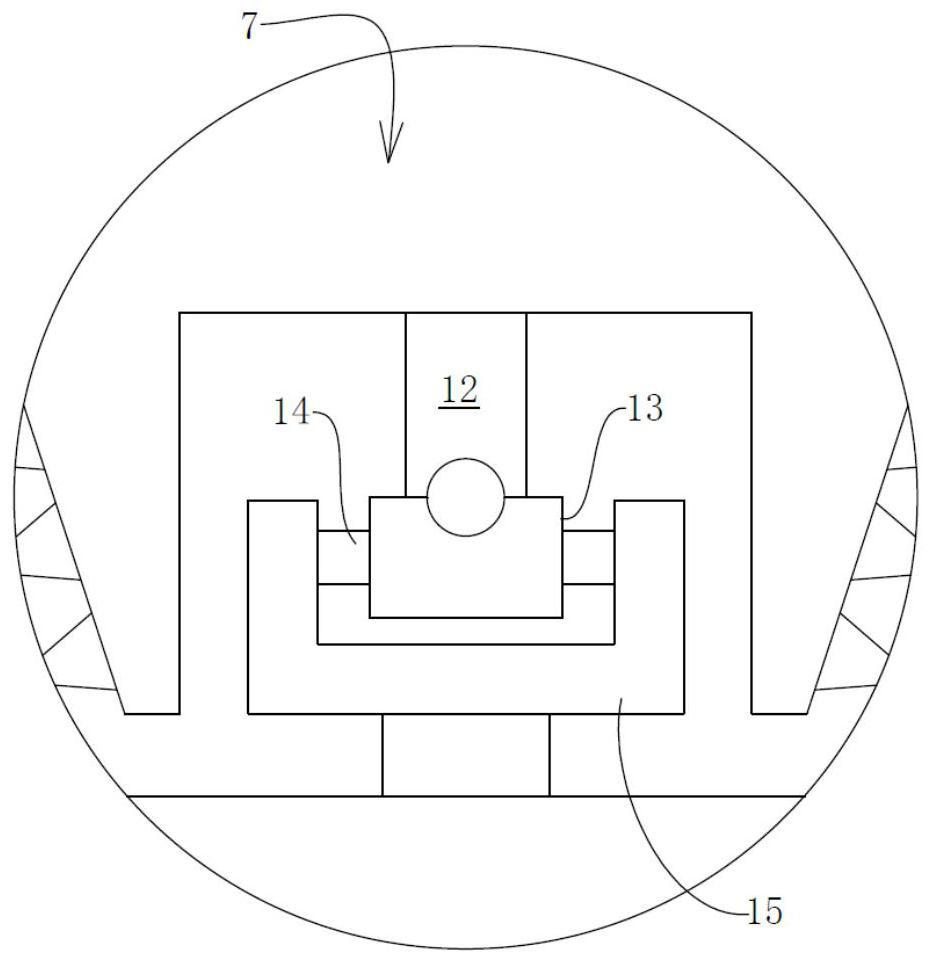

Anti-corrosive intelligent kitchen garbage barrel and manufacturing method thereof

ActiveCN106335723AEffective absorption and filtrationEffective shreddingRefuse receptaclesWastewaterSewage

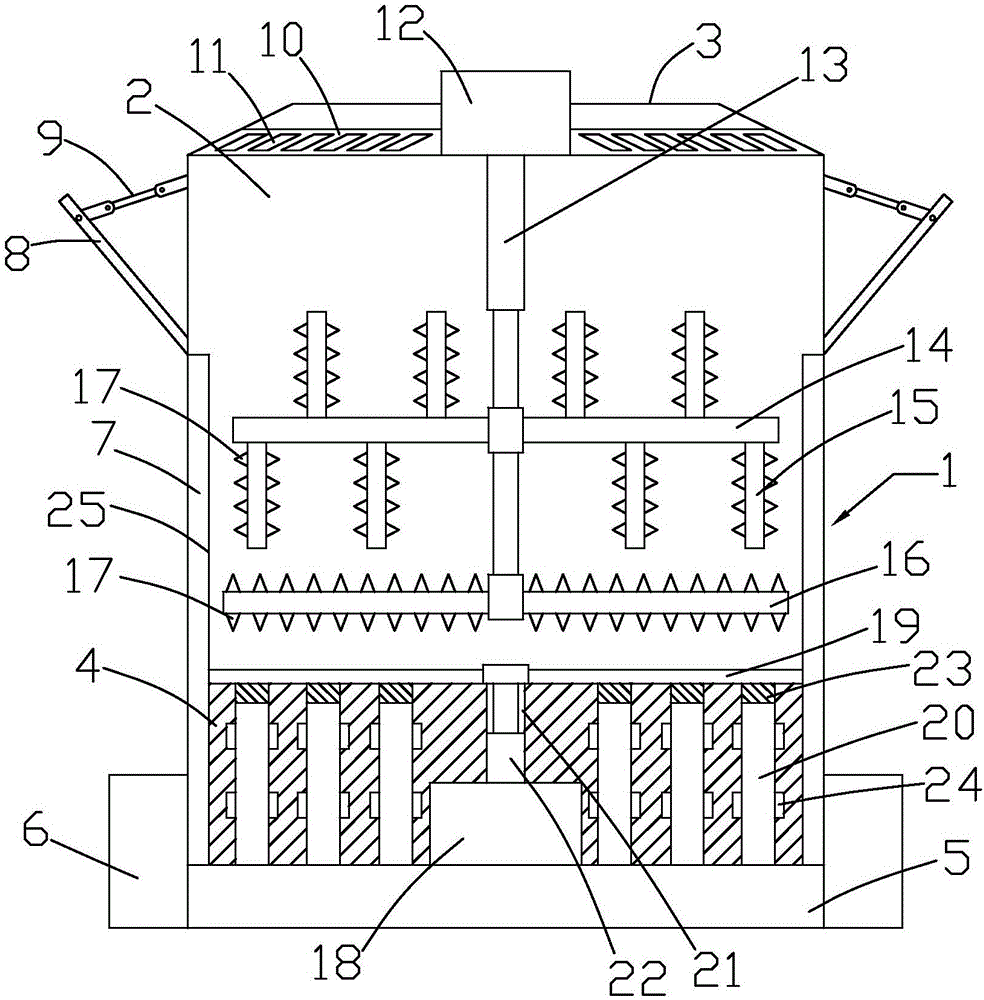

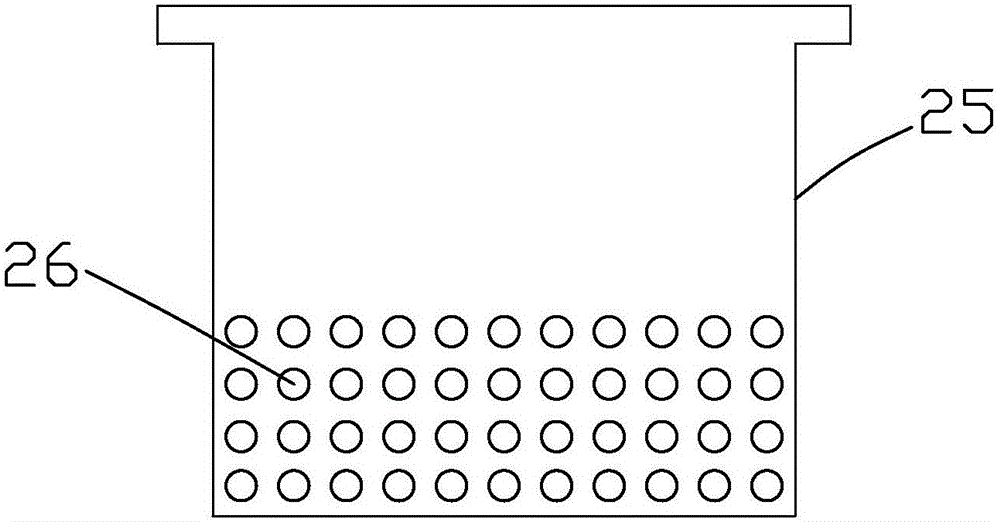

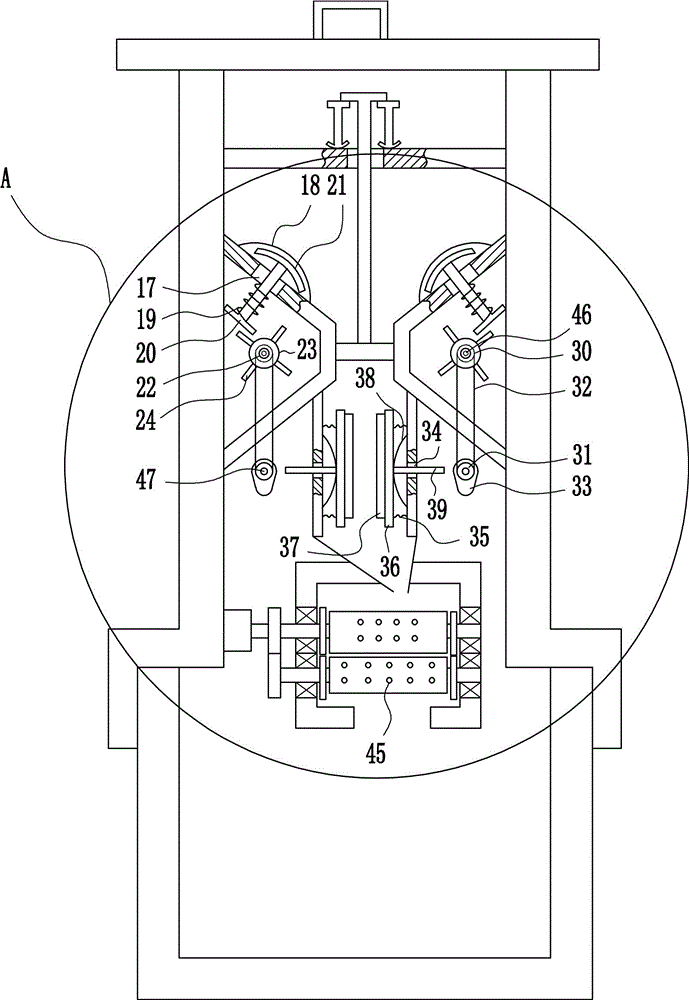

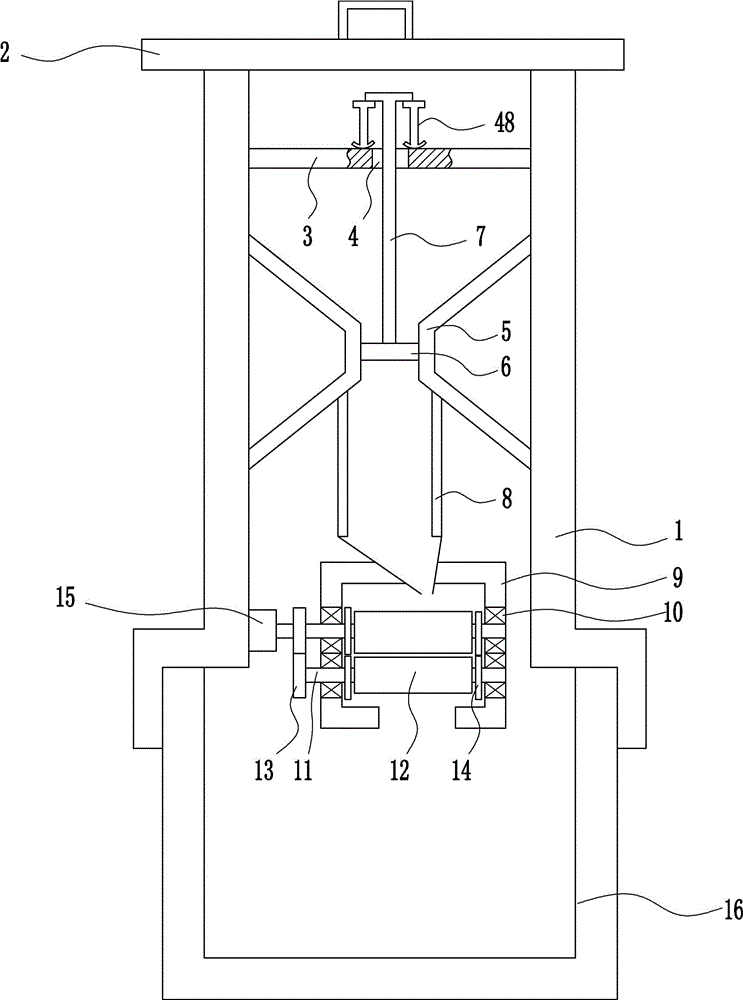

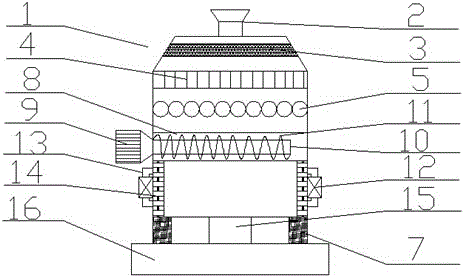

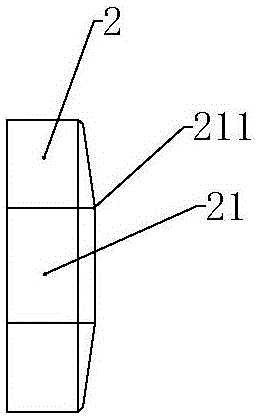

The invention discloses an anti-corrosive intelligent kitchen garbage barrel and a manufacturing method thereof. The anti-corrosive intelligent kitchen garbage barrel comprises a barrel box, an end cover and a wastewater purifying device, wherein a stirring cavity, a cylinder body, a forming plate and a storage cavity are arranged inside the barrel body; a crushing mechanism is arranged in the stirring cavity; feeding mechanisms are symmetrically arranged on the outer side surface of the barrel boxy; the forming plate is positioned between the cylinder body and the storage cavity; a forming extrusion mechanism is arranged above the forming plate; and the wastewater purifying device is positioned on the bottom side surface of the barrel body. The manufacturing method comprises the following steps: (1) mounting of the storage cavity; (2) mounting of the forming plate and the forming extrusion mechanism; (3) mounting of the crushing mechanism; (4) mounting of the wastewater purifying device; (5) mounting of the feeding mechanisms; and (6) preliminary running debugging. The anti-corrosive intelligent kitchen garbage barrel disclosed by the invention is simple in structure and high in practicability; not only can kitchen garbage be crushed, but also the crushed kitchen garbage can be used for fish and poultry feeding; the garbage recovery efficiency is improved; and the environmental pollution caused by corrosion of the kitchen garbage is effectively prevented.

Owner:浙江融家科技有限公司

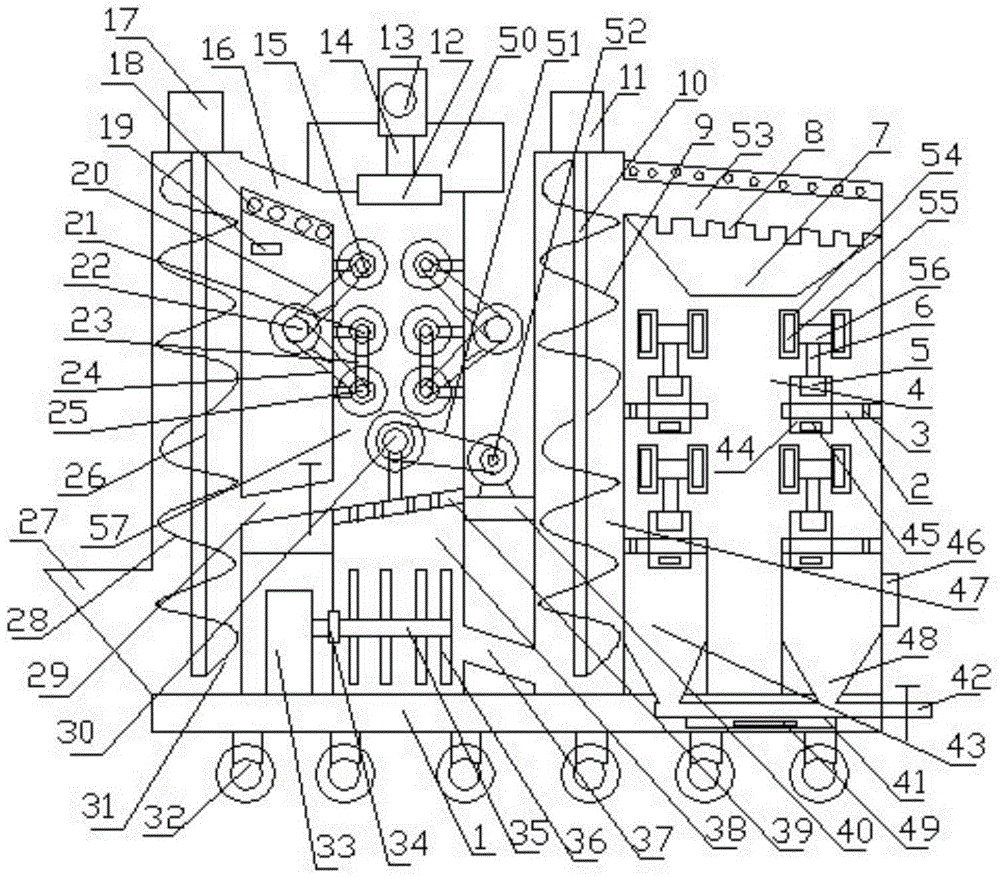

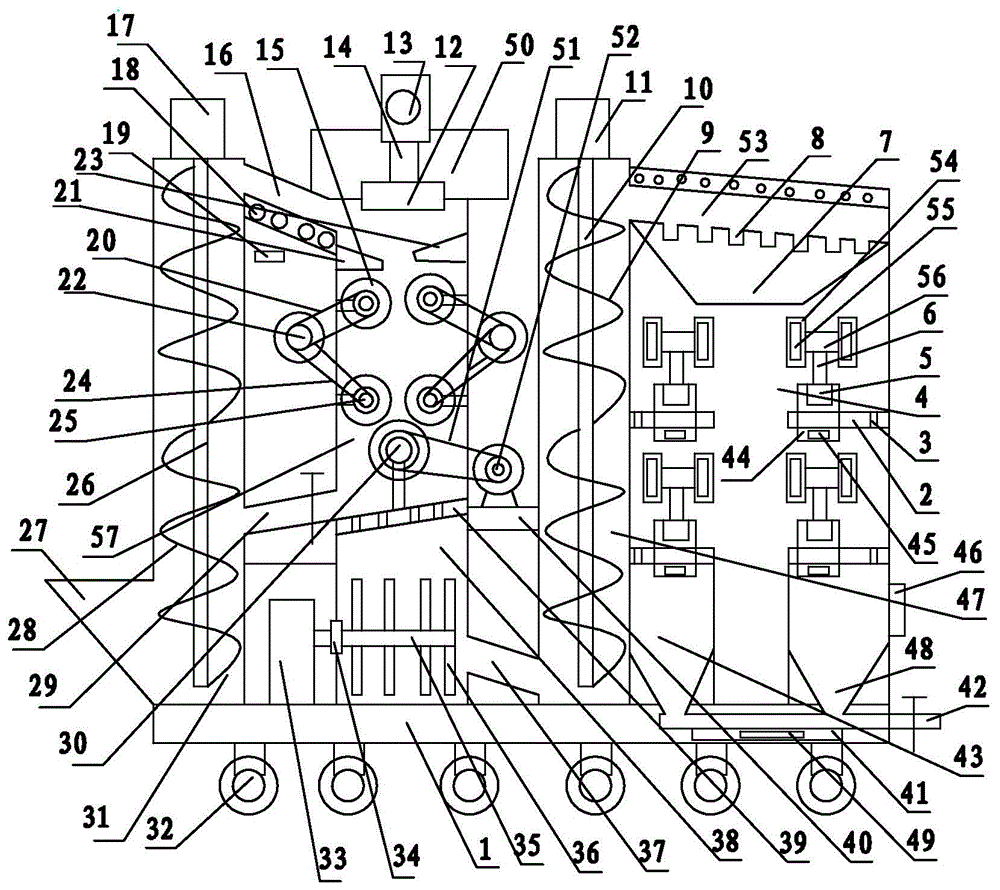

Automatic cigarette making machine

InactiveCN101986903AShorten the timeEffectively adjust the tightnessCigarette manufactureEngineeringMechanical engineering

The invention relates to an automatic cigarette making machine, which is characterized in that a container with an upper opening is arranged in a housing, and a feeding assembly is used to push tobacco shreds in the container to export outside from a tobacco shred pipe in the front part of the container, a rotary disk is connected with one end of a linkage assembly, a plurality of sleeves arrayed in a circle are arranged on the rotary disk, and a piece of cigarette paper is filled in each sleeve. Thus, when the linkage assembly drives the rotary disk to move opposite to the container backward, one sleeve is sleeved on the tobacco shred pipe to fill in tobacco shreds, when the rotary disk moves opposite to the container forward, a piece of cigarette paper can be filled in, and while the rotary disk moves opposite to the container forward and backward for one time, the rotary disk rotates for a fixed angle to sleeve the sleeves of the rotary disk on the tobacco shred pipe in sequence, therefore tobacco shreds are filled in each piece of cigarette paper in sequence.

Owner:LAING BAN INT

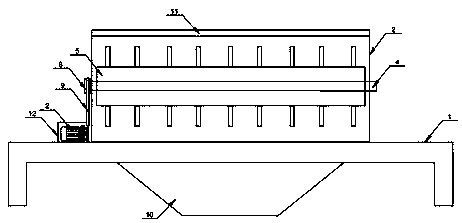

Reinforced concrete pile crusher

The invention discloses a reinforced concrete pile crusher, and mainly relates to the field of building machinery. The reinforced concrete pile crusher comprises a plurality of crushing devices, wherein each crushing device comprises a top steel plate, a bottom steel plate, a device housing welded between the top steel plate and the bottom steel plate, a servo hydraulic cylinder, a slide motor base and a servo motor; the crushing devices are fixed with one another end to end; a device cavity is arranged on the inner part of the device housing; the slide motor bases are in horizontal sliding connection in the device cavity; the output shafts of the servo motors are connected with power rotary shafts; the tail ends of the power rotary shafts get out of the device housing, and are equipped with drill bits; and each crushing device is fixedly arranged at the top end of a big arm of an excavator through a chain, and the corresponding servo hydraulic cylinder works through a hydraulic systemon an excavator. The reinforced concrete pile crusher has the beneficial effects that a reinforced concrete pile can be effectively cut off and cut up, so that reinforcement can be separated from a concrete pile to the greatest extent for recycling the reinforcement.

Owner:宋忠辉 +3

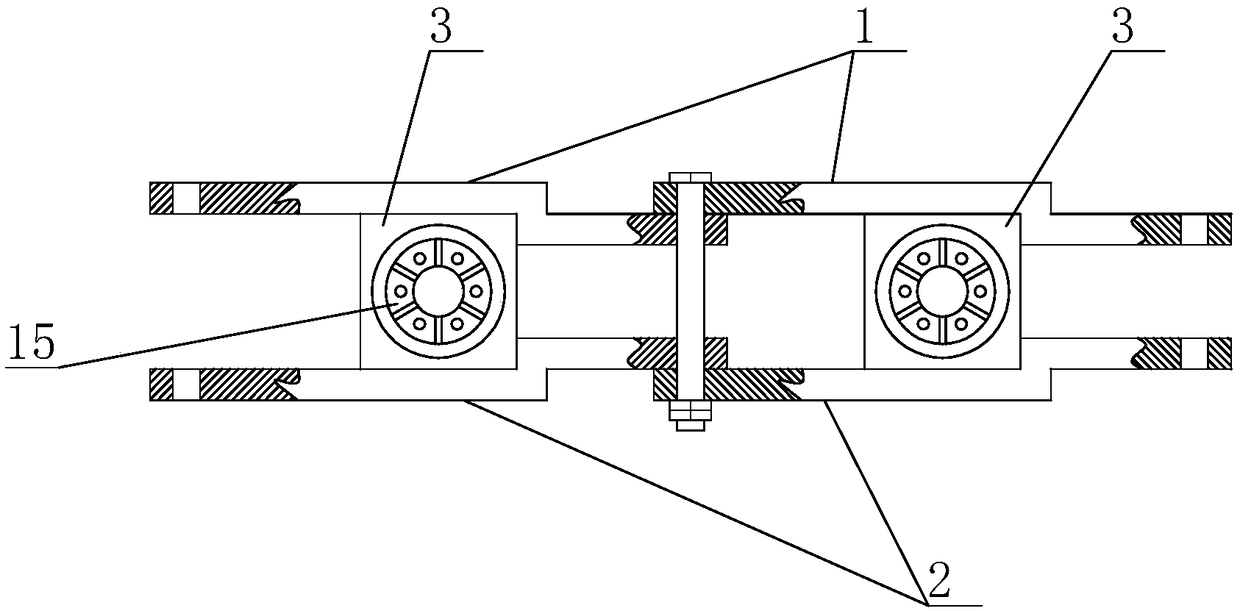

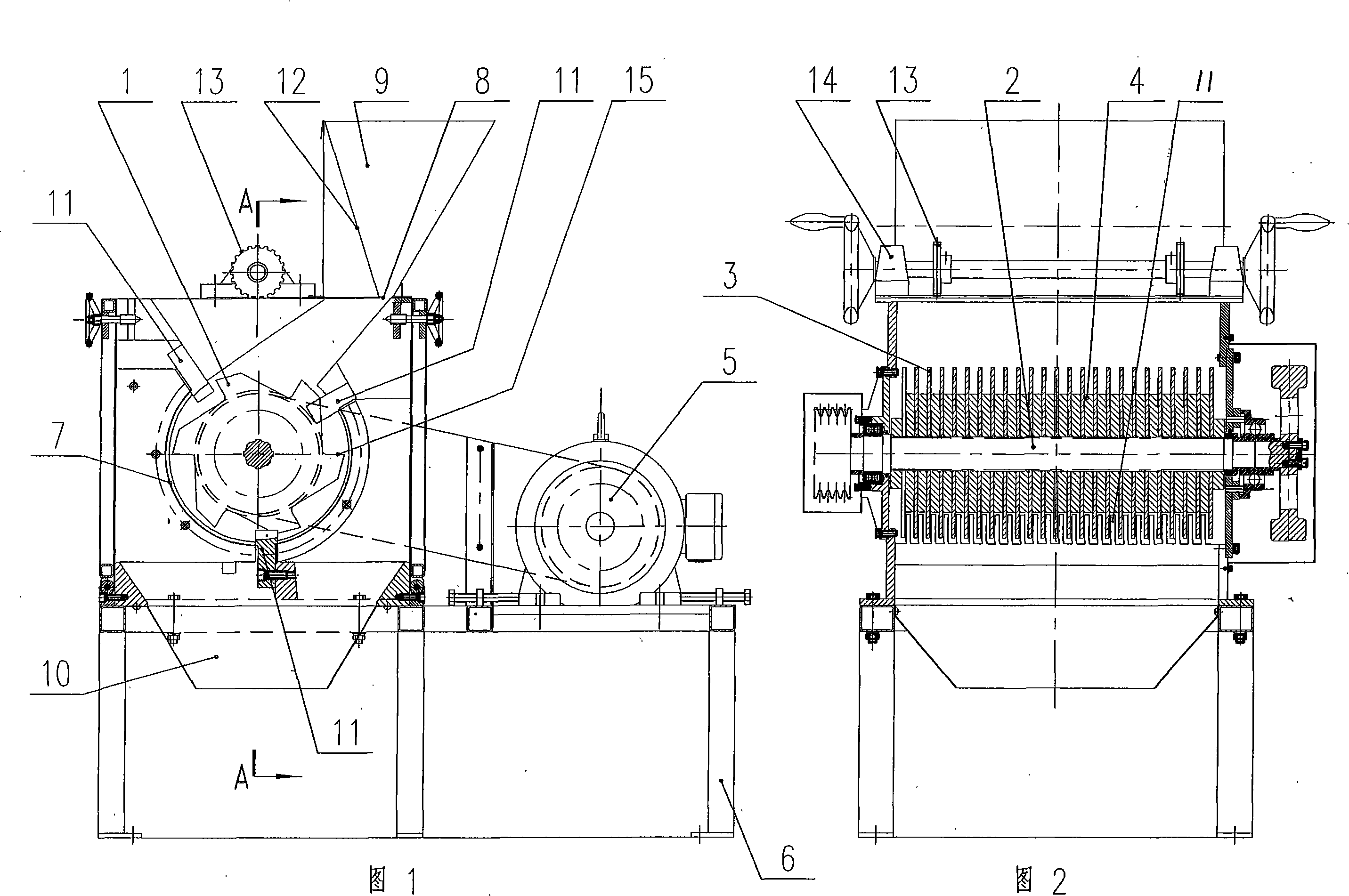

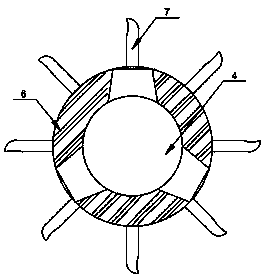

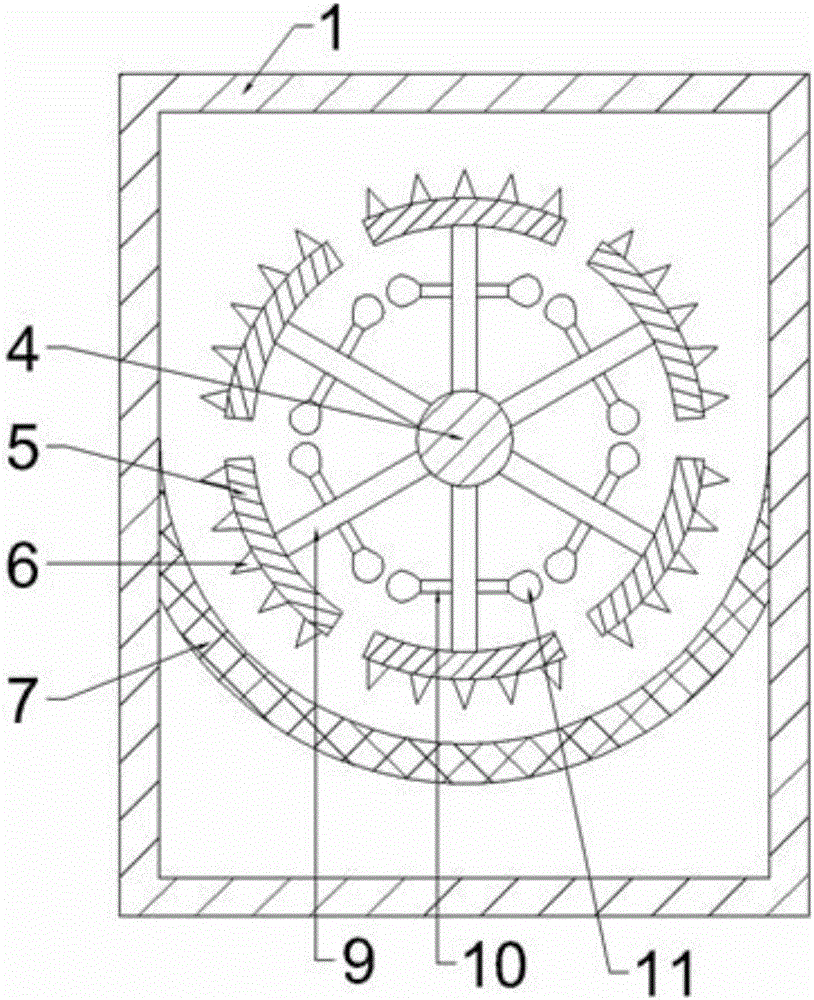

Rolling cutter grinder

InactiveCN101214458AEffective shreddingAvoid cloggingTobacco treatmentGrain treatmentsEngineeringKnife blades

A hob pulverizing machine comprises a stander (6) and a hob mounted on the stander. The hob comprises a horizontal rotating shaft (2) and a moveable knife tackle (1) installed on the rotating shaft. The moveable knife tackle has a subassembly of blades with cutting edge (15). The blades are separated by a range spacer (4). The rotating shaft of the moveable knife tackle is connected with a gear (5). A meshed cylinder (7) is arranged outside the moveable knife tackle. One or more than one comb-shape stationary knives (11) are arranged on the inner wall of the cylinder along the direction of circumference. The comb of the stationary knife and the blades of the moveable knife tackle alternate with each other and match. The top of the cylinder is provided with a feed opening (8). The bottom of the cylinder is provided with a discharge opening (10). The utility model provides the hob pulverizing machines that can pulverize wet and cellulosic materials. The particle size of the wet and cellulosic materials is consistent. The utility model has high efficiency and simple structure. And caulking materials do not stick easily and inlet amount can be adjusted.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

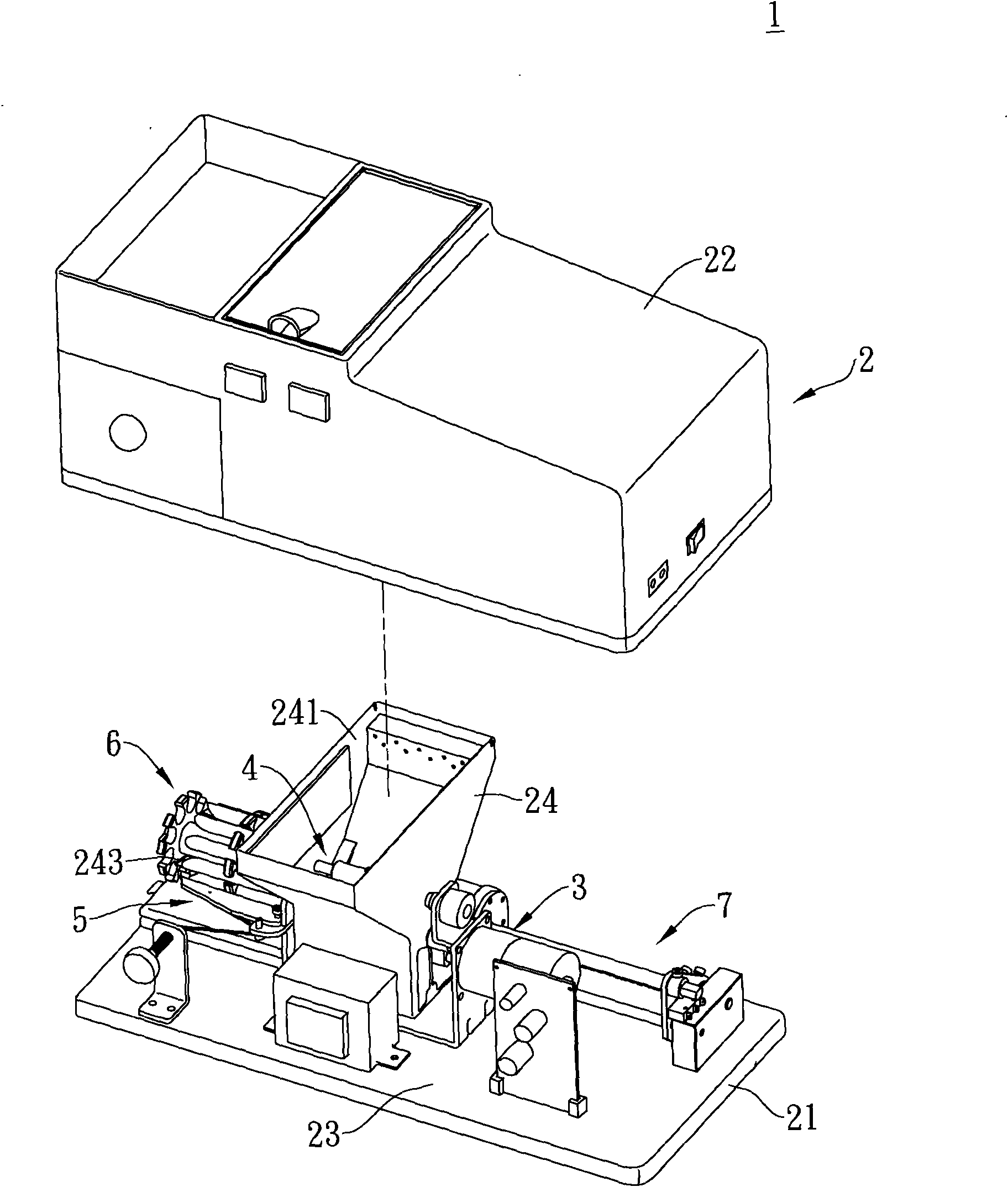

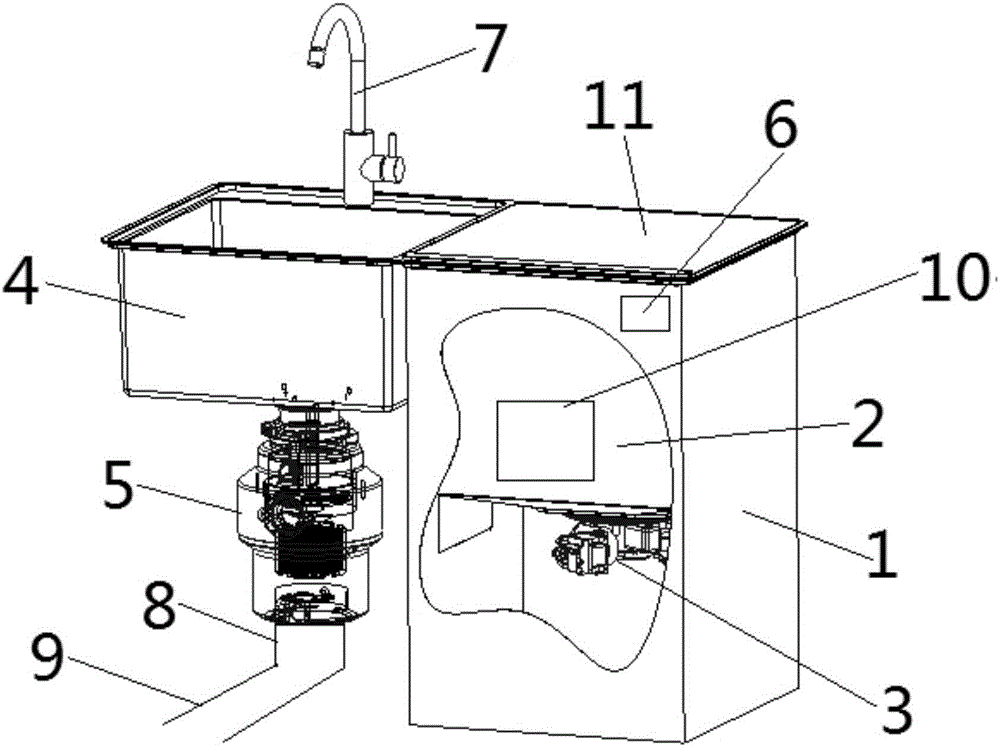

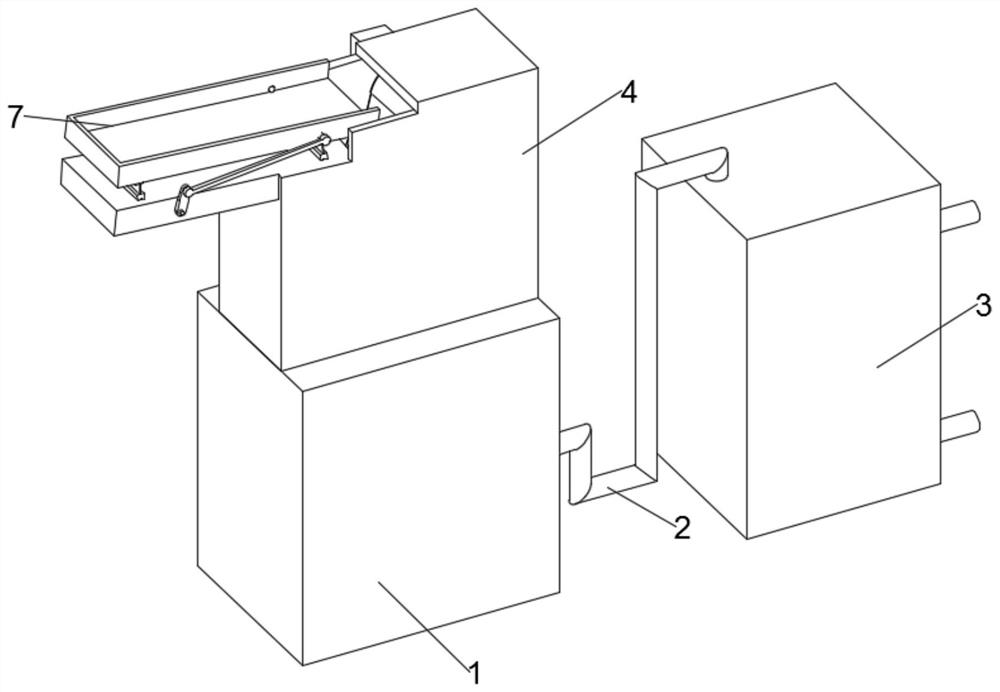

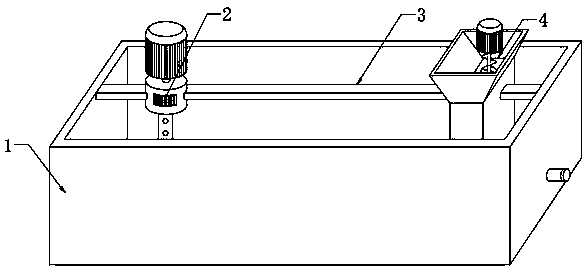

Water tank-type bowl-washing machine

InactiveCN106175634ASmall footprintSimple structureWashing controlling processesTableware washing/rinsing machine detailsEngineeringWater tanks

The invention provides a water tank-type bowl-washing machine, relating to the field of goods in daily life. The machine comprises an outer shell (1) of the bowl-washing machine. An inner container (2) of the bowl-washing machine is arranged in the outer shell (1). A washing part (3) is connected with the inner container (2) of the bowl-washing machine. The water tank-type bowl-washing machine further comprises a water pool (4), below which a food garbage crusher (5) is arranged. The washing part (3) and the food garbage crusher (5) are respectively connected with a control part (6). The water tank-type bowl-washing machine has following beneficial effects: a simple structure is obtained; manufacture cost is low; the machine is capable of conveniently and rapidly washing dishes after application and effectively and rapidly crushing food barrage such that life convenience and processing and washing efficiency are improved.

Owner:WUHU GUANGYING IND CO LTD

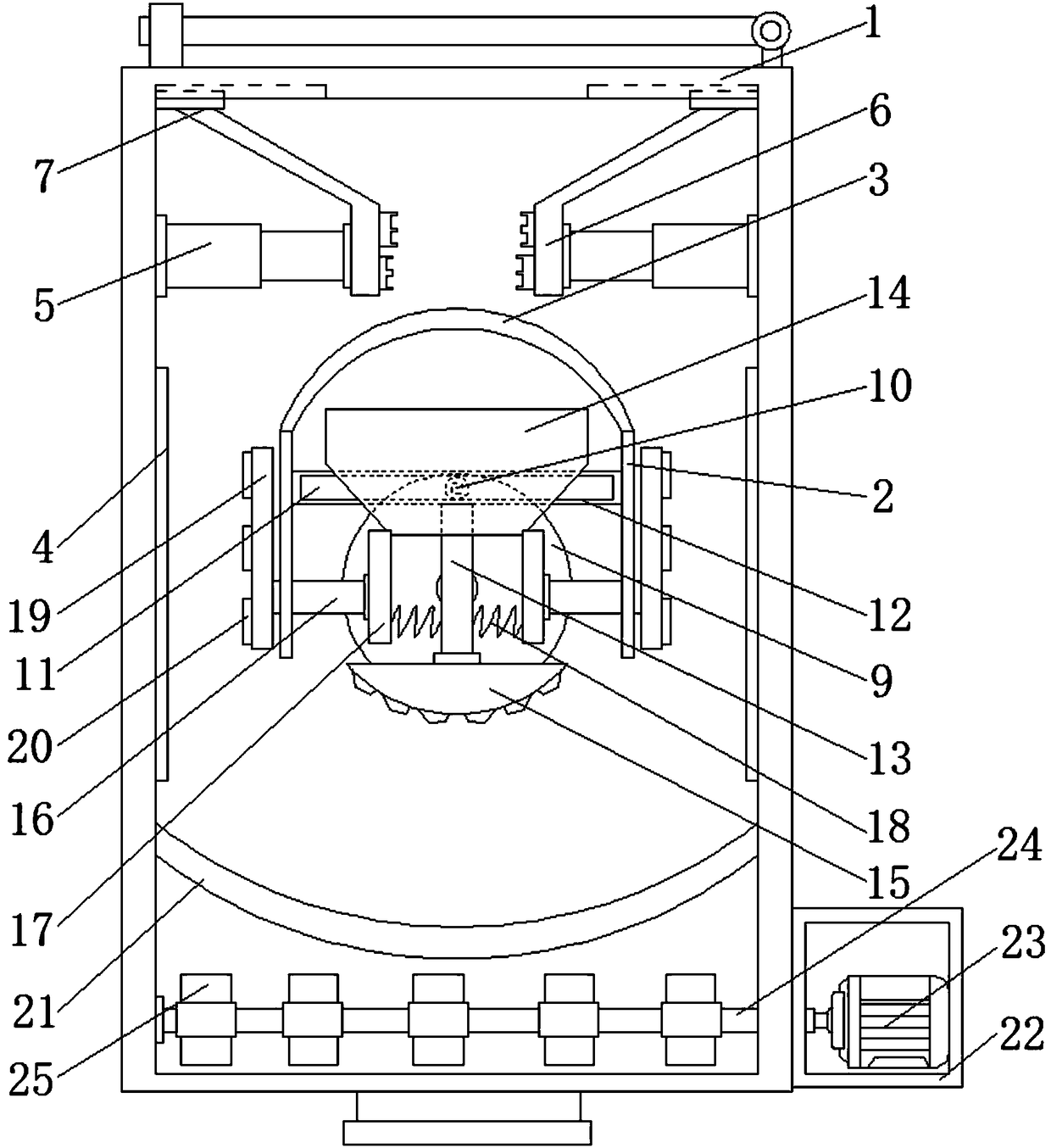

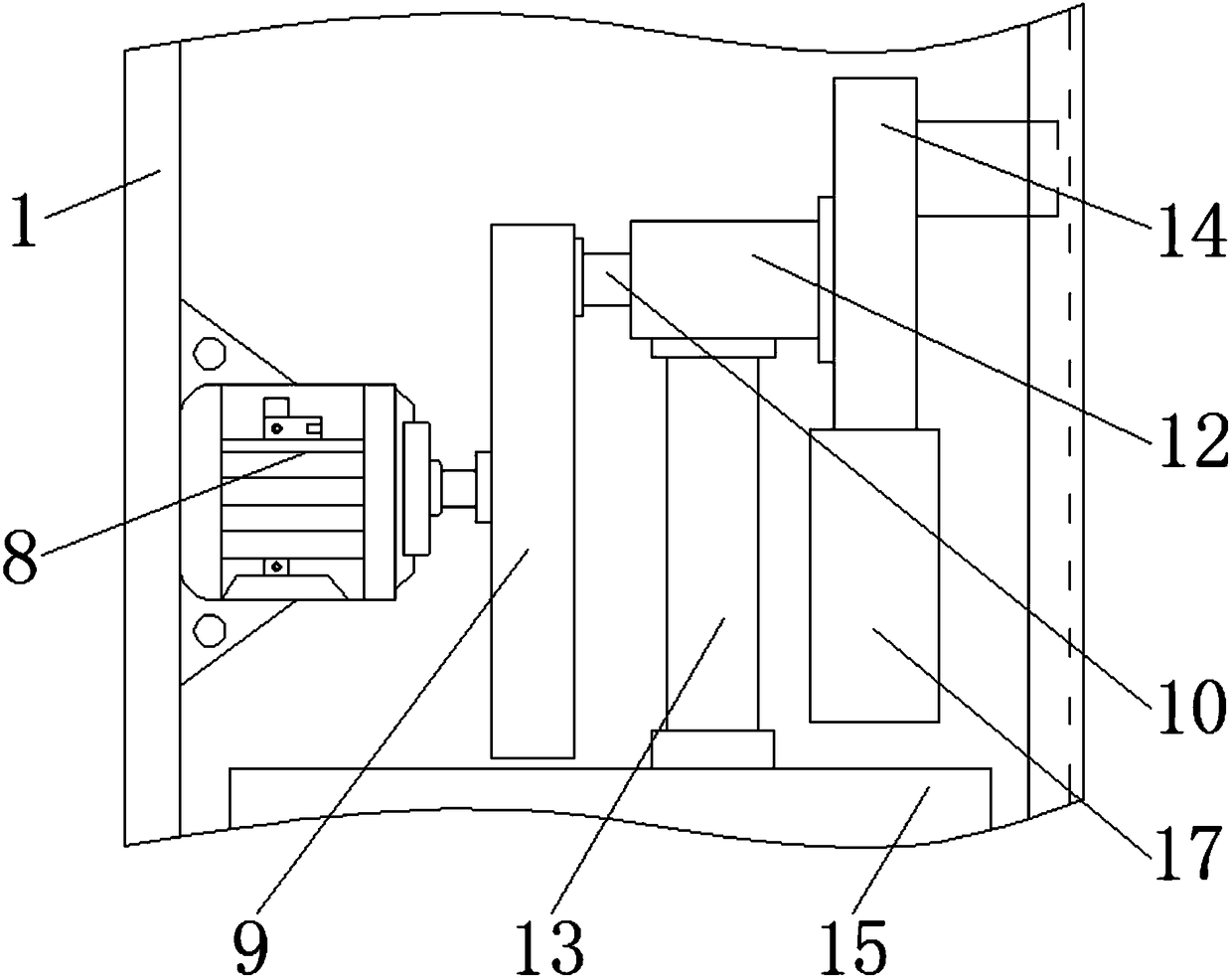

High-efficient wheat grinding equipment

The invention relates to wheat grinding equipment, in particular to high-efficient wheat grinding equipment. The invention aims to solve the technical problems so as to provide the high-efficient wheat grinding equipment integrating soaking and grinding for dehulling. In order to solve the technical problems, the invention provides the high-efficient wheat grinding equipment, which comprises a work tank, a tank cover, a guide rod, a placement tank, a rubber baffle, a lifting rod, a pipeline, a grinding tank, bearing seats, first rotating rods, a grinding roller, first gears and the like. The tank cover is arranged on the top part of the work tank and can be detached from the work tank; the guide rod is welded to the upper part in the work tank; a guide hole is formed in the guide rod; the placement tank is welded to the middle part in the work tank; and the rubber baffle is arranged in the middle part in the placement tank. The high-efficient wheat grinding equipment provided by the invention integrates wheat soaking, wheat grinding and wheat dehulling so as to be multifunctional, the practicability is improved, and a device capable of stirring wheat during wheat soaking is arranged.

Owner:WUHE SHUNPENG AGRI & SIDELINE PROD CO LTD

Agricultural and sideline product grinding device

The invention discloses an agricultural and sideline product grinding device comprising a body, and the body includes a feed port, a storage warehouse, a variable frequency motor and a squeezing roller. The feed port is arranged on the upper part of the body, a filter layer is arranged on the top position in the body, a plurality of equally arranged feed tubes are arranged below the filter layer, a plurality of squeezing rollers are arranged in the body, the variable frequency motor is arranged on the outer wall of the body, a grinding storehouses is arranged in the body, the output part of the variable frequency motor is connected with a stirring shaft; the stirring shaft extends to the grinding storehouses arranged in the body, a spiral stirring shaft is arranged on the surface of the stirring shaft, a fan is arranged on the outer wall of the body, a gas predistributor is arranged in the body, the storage warehouse is arranged below the body, and a buffer device is arranged between the body and the storage warehouse. The agricultural and sideline product grinding device has the advantages of reasonable structure design, good crushing effect, and long service life and the like.

Owner:ANHUI XINQIAO IND & TRADE

Rubber block chopping machine

InactiveCN102716791AEffective shreddingMutual adhesion does not occurGrain treatmentsGranularityEngineering

The invention discloses a rubber block chopping machine, which comprises a material feeding hopper, a chopping device, a material discharging device and an isolation agent spraying device which can respectively spray isolation agents into the material feeding hopper and the material discharging device, wherein the chopping device comprises a chopping chamber, a main shaft which is arranged in the chopping chamber in a rotatable manner, a plurality of movable cutters fixedly arranged on the main shaft, fixed cutters which are fixedly arranged in the chopping chamber, positioned on the two sides of the main shaft and spaced from the movable cutter group at a preset distance and a cambered screen arranged on the lower part of the chopping device. According to the chopping machine, the movable cutters and the fixed cutters are matched to chop rubber blocks; under the screening of the screen, large rubber blocks can be chopped, and the granularity of the chopped rubber granules are uniform; furthermore, the isolation agents are filled in the chopping chamber, so that the chopped granules cannot be adhered; and the subsequent processing smoothness can be guaranteed.

Owner:TIANJIN SAIXIANG TECH

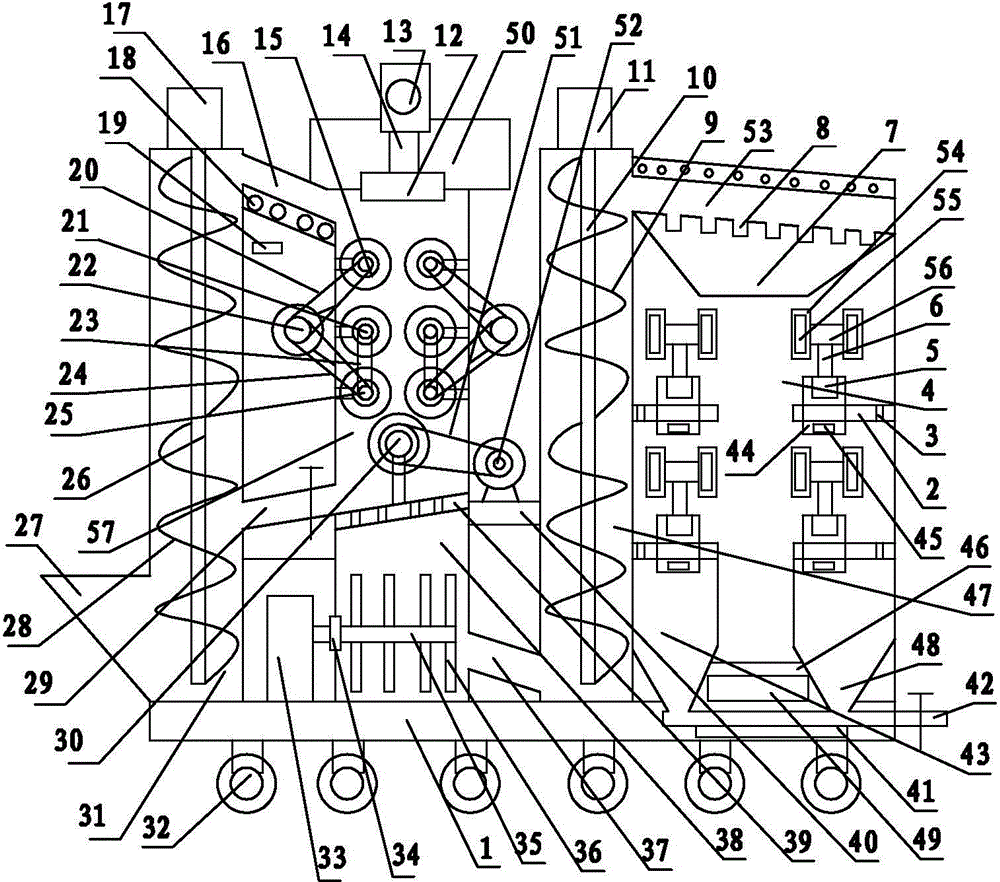

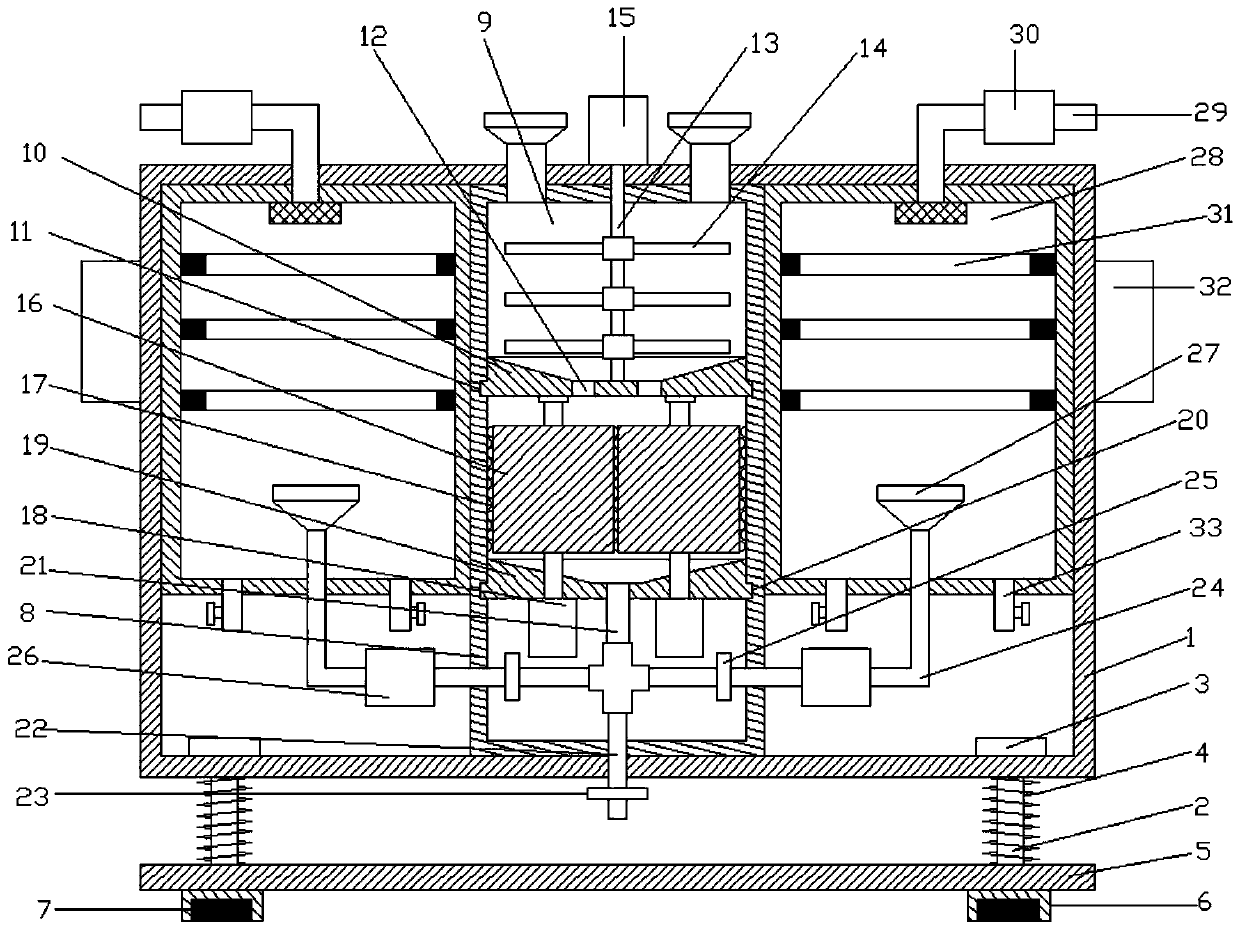

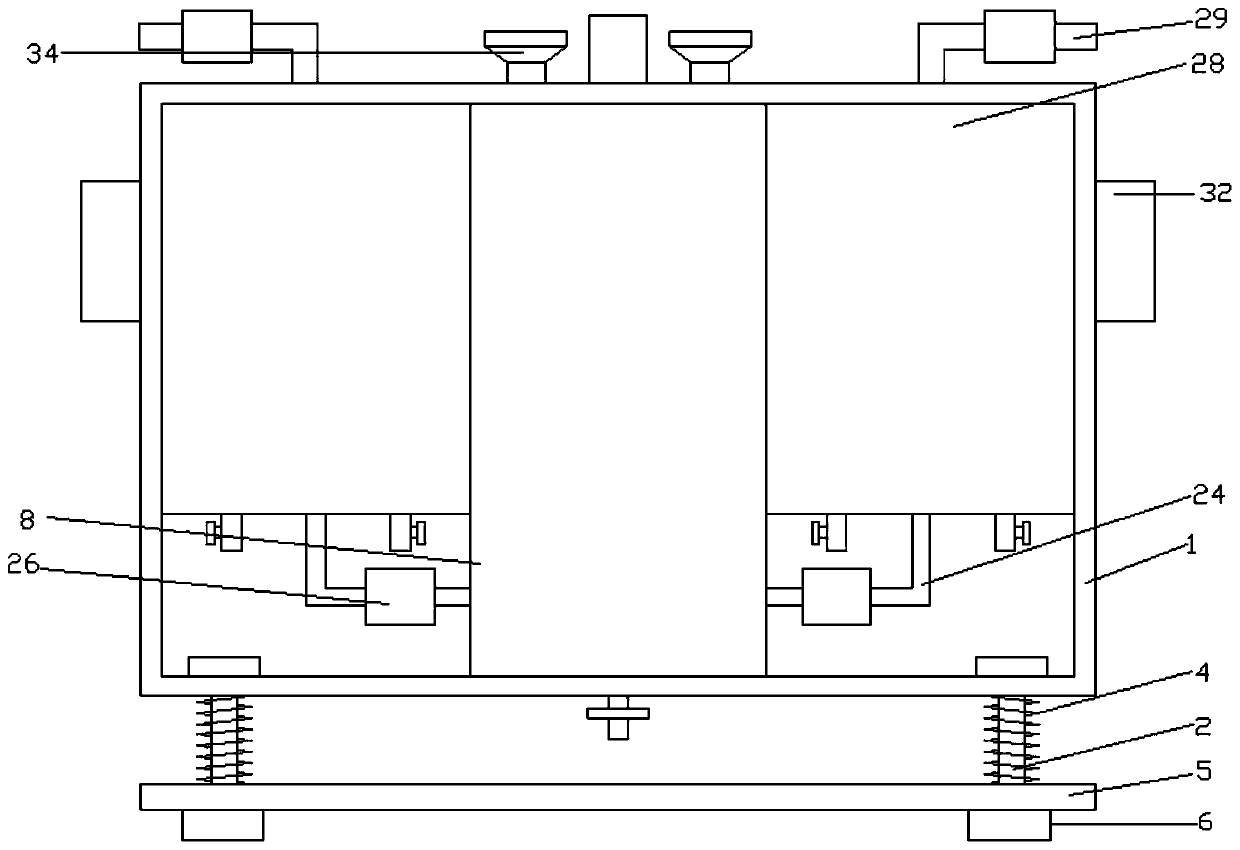

Material crushing magnetic separator

InactiveCN104907126AImprove the crushing effectEasy to separateSievingScreeningMagnetic separatorTherapeutic effect

The invention relates to a material crushing magnetic separator. The material crushing magnetic separator comprises a bottom seat, wherein a feeding cavity is formed in the left side of the upper portion of the bottom seat, a left lifting cavity is connected with the right side of the feeding cavity, a feeding pipe is connected with the upper portion of the right side of the left lifting cavity, a crushing cavity is connected with the right side of the feeding cavity, a return pipe is connected with the lower portion of the left side of the crushing cavity, a filter plate is arranged on the lower portion of the crushing cavity, a stirring cavity is formed in the lower portion of the filter plate, a blanking pipe is connected with the right side of the stirring cavity, a right lifting cavity is connected with the right side of the blanking pipe, a discharging cavity is connected with the upper portion of the right side of the right lifting cavity, a plurality of discharging holes are formed in the lower portion of the discharging cavity, a feeding cavity is located on the lower portion of each discharging hole, and separation cavities are arranged on the lower portions of the feeding cavities. The material crushing magnetic separator can effectively perform crushing treatment on materials, facilities lifting treatment after the materials are crushed, improves crushing treatment effects of the materials, facilitates drying treatment, performs magnetic separation after the materials are crushed more than once, conveniently separates out impurities, facilitates counting of the quantity of the impurities, improves separation treatment effects of the impurities, and is convenient to use.

Owner:陈守树

Cement block breaking machine with uniform breaking function

PendingCN108212473AUniform breaking functionAvoid blockageGrain treatmentsArchitectural engineeringCement

The invention discloses a cement block breaking machine with a uniform breaking function. The cement block breaking machine comprises a box body, wherein vertical plates are fixedly connected betweenthe front side and the back side of the inner wall of the box body; two vertical plates are arranged; an arc-shaped plate is fixedly connected between the tops of the two vertical plates; two sides ofthe inner wall of the box body are fixedly connected with baffles; the two sides of the inner wall of the box body are fixedly connected with electric hydraulic rods; the electric hydraulic rods arelocated at the tops of the baffles; one end of each electric hydraulic rod is fixedly connected with a breaking plate; the top of each breaking plate is fixedly connected with an oblique plate; one side away from the breaking plate of each oblique plate is in sliding connection with the top of the inner wall of the box body. The invention relates to the technical field of breaking of the cement blocks. The cement block breaking machine with the uniform breaking function is capable of effectively breaking the cement blocks and simultaneously driving left-and-right breaking and carrying out secondary breaking through a power device; the cost is greatly reduced; the cement can be uniformly broken; the operating efficiency is greatly improved.

Owner:湖州双林森达地板厂

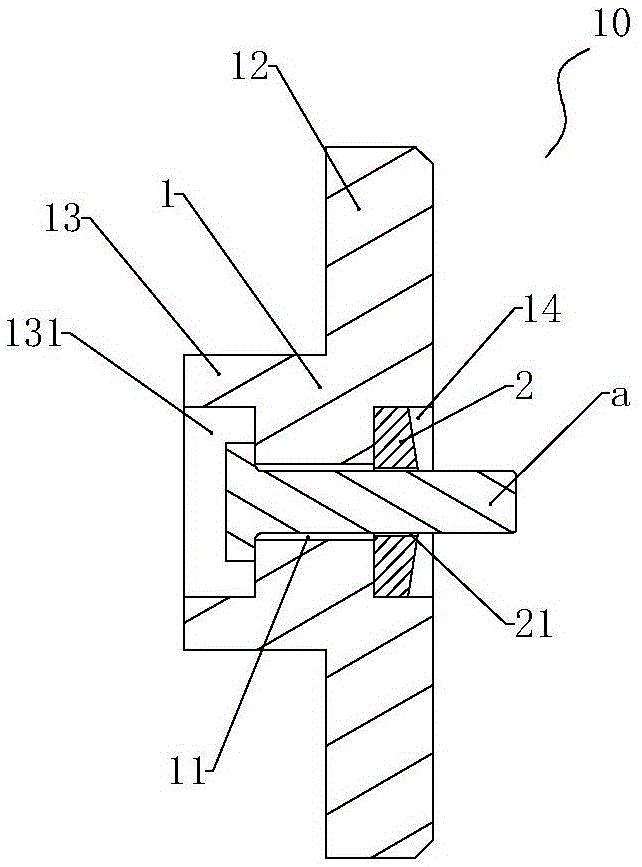

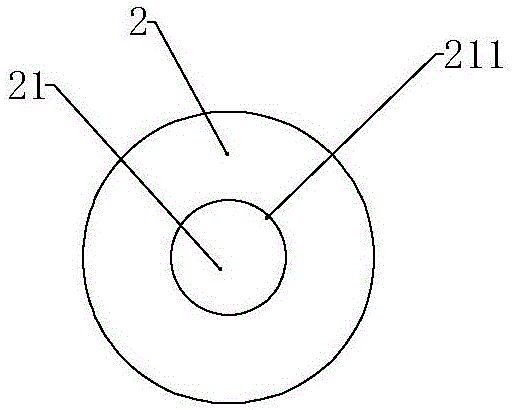

Clamping punching clamp for inertia friction welding

ActiveCN105127587AEasy to replaceExtended service lifeNon-electric welding apparatusFriction weldingPunching

The invention provides a clamping punching clamp for inertia friction welding. The clamping punching clamp comprises a clamp base and a punching core, wherein a communicated first passage for penetrating a workpiepe is arranged on the clamp base; the punching core is fixed to the clamp base in a demountable manner, and positioned on the outer side at one end of the first passage; a second passage which has the same axis with the first passage and allows the workpiepe to penetrate is arranged on the punching core; the inner diameter of the first passage is larger than that of the second passage. The punching core of the clamping punching clamp is easy to replace after being worn, while replacing the whole clamp is not required, so that the service life of the clamp is prolonged, and the cost is reduced. The clamp adopts a split-type different inner diameter structure, and the size of an inner hole where punched scraps are likely to accumulate is increased, so that the problem that part clamping is difficult is avoided. The punching core adopts a semi-spiral or raised structure, so that welding burrs can be cut into pieces effectively, and are prevented from sticking to the inner hole of the punching core, and the service life of the punching hole is prolonged accordingly.

Owner:北京航为高科连接技术有限公司

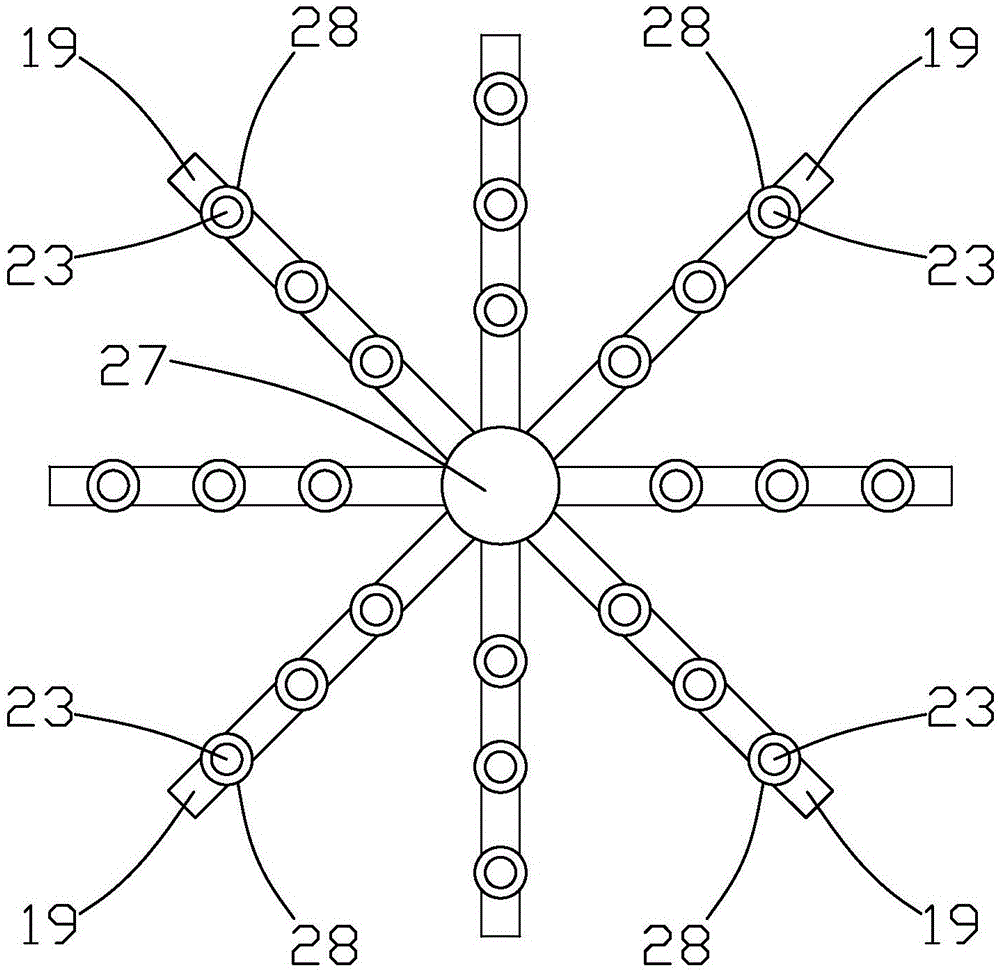

Municipal wastewater efficient recovery, purification and utilization device

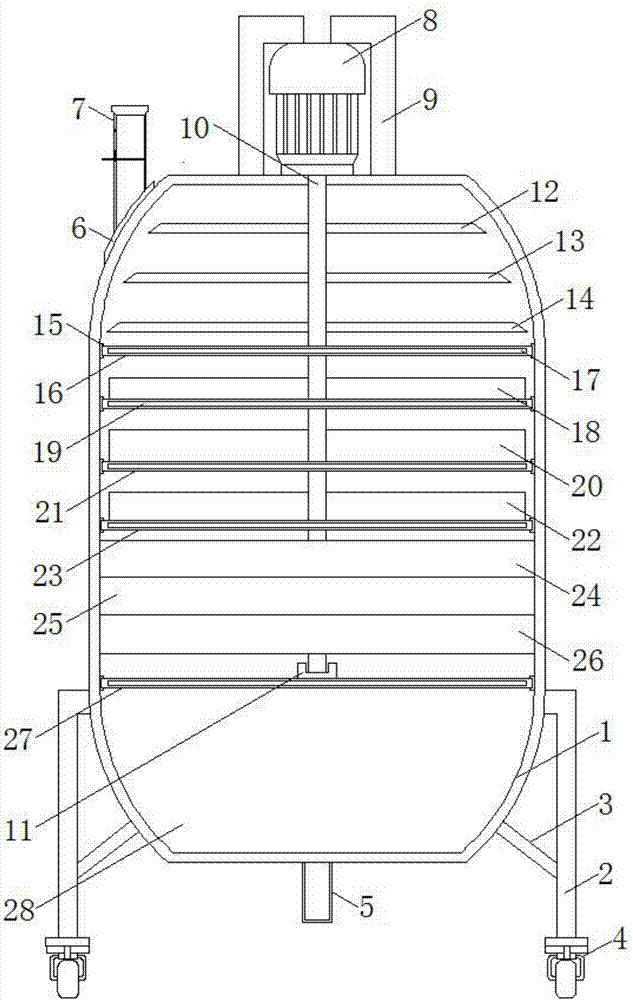

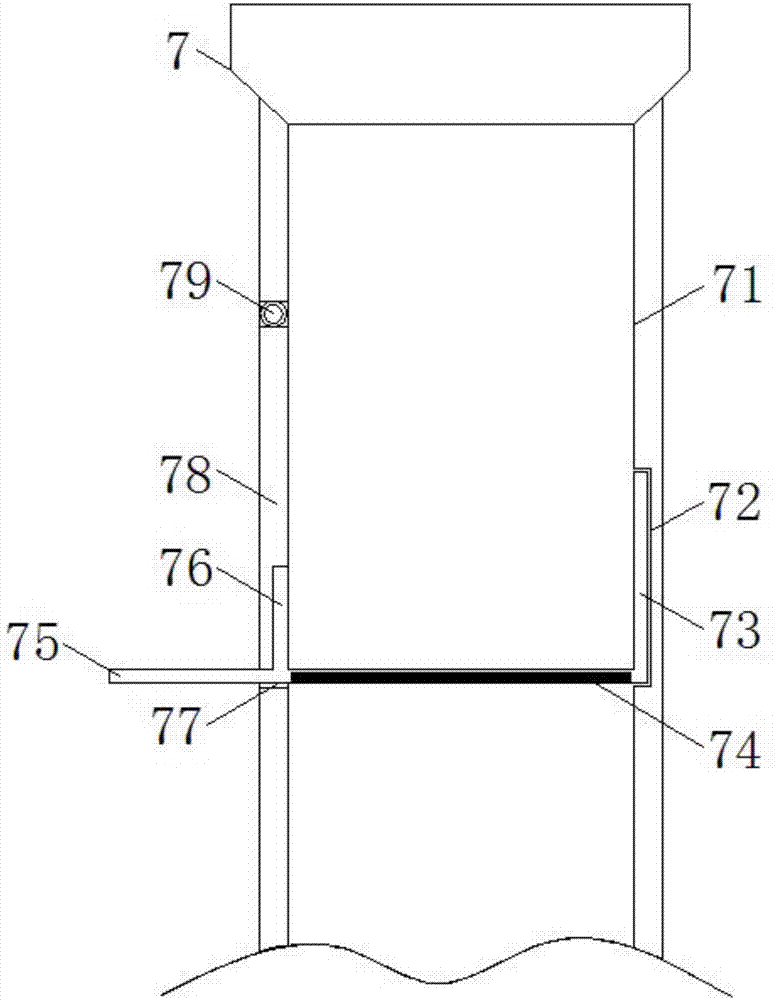

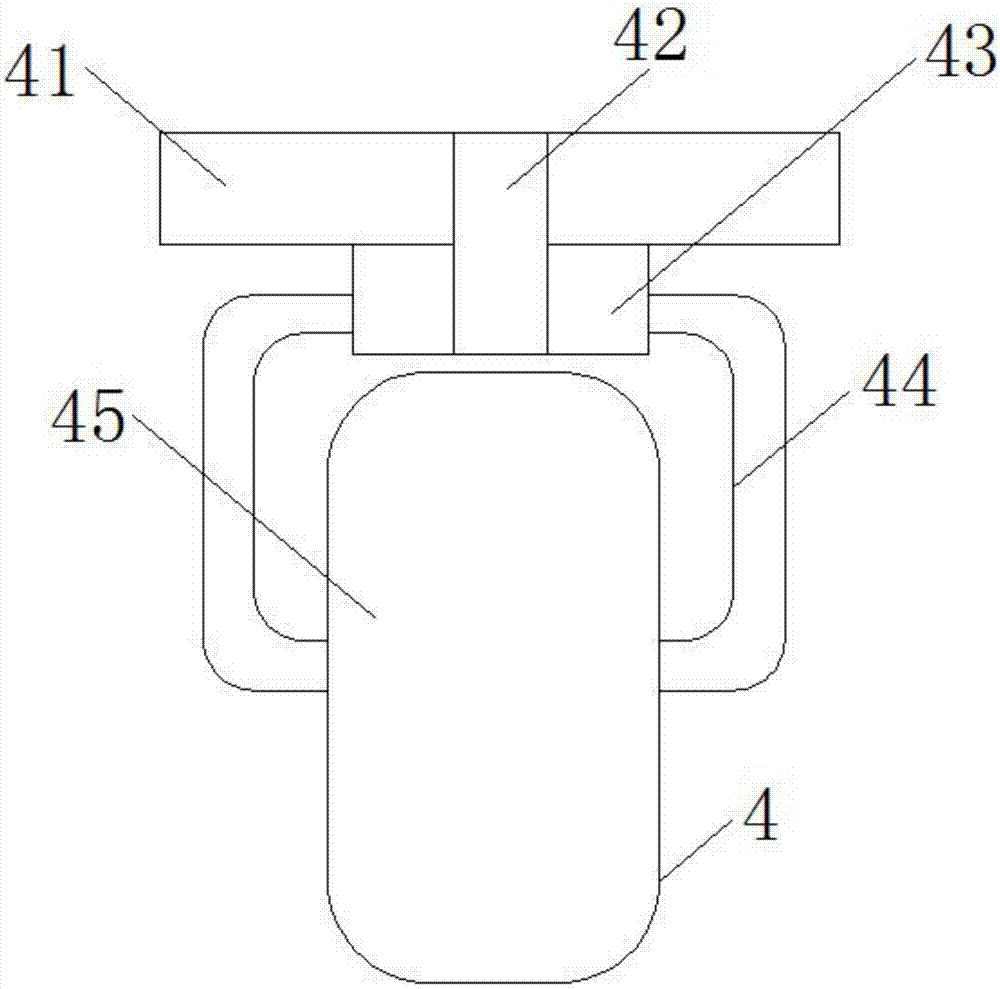

The invention discloses a municipal wastewater efficient recovery, purification and utilization device including a purifying cylinder, on both sides of the purifying cylinder are fixedly provided with supporting feet, the inner side of the supporting feet are fixedly provided with diagonal supporting rods located on the outer side of the purifying cylinder, the bottom of the supporting feet are fixedly provided with universal wheels, the bottom of the purifying cylinder is communicated with a water outlet, the left side of the purifying cylinder is fixedly provided with an installation ring, the top of the installation ring is communicated with a water inlet pipe located on the left side of the purifying cylinder, the top of the purifying cylinder is fixedly provided with a drive motor, both sides of the drive motor are fixedly provided with motor mounting seats located on the top of the purifying cylinder. The municipal wastewater efficient recovery, purification and utilization device can effectively guarantee the municipal wastewater is inputted from the water inlet pipe to the purifying cylinder, can effectively filter out waste slag directly, can facilitate the cleaning of a slag filter plate, effectively ensures the whole purification device may not be blocked because of the waste slag, and solves the problem of bad purification efficiency.

Owner:嵊州市晟祥盈净水设备有限公司

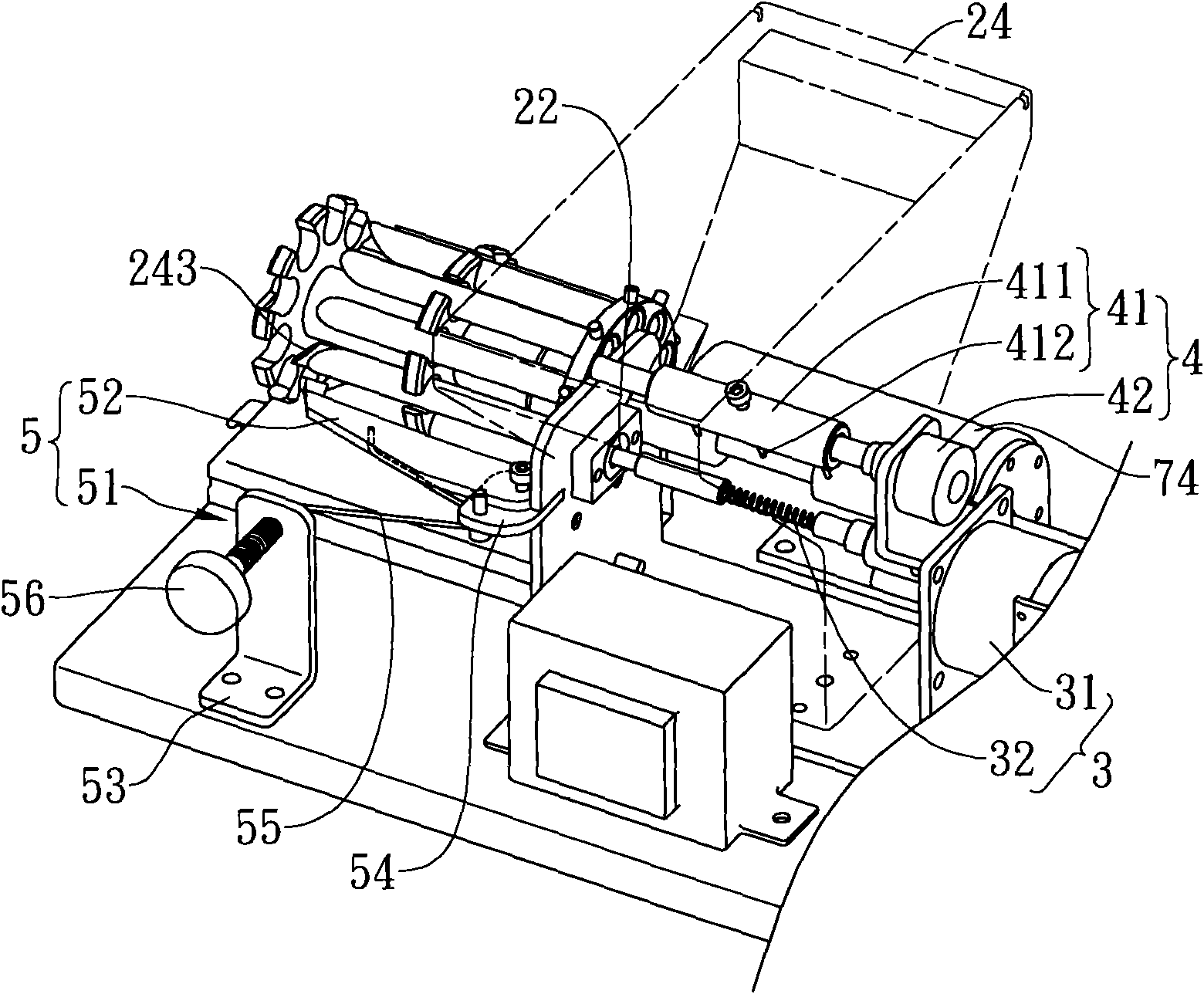

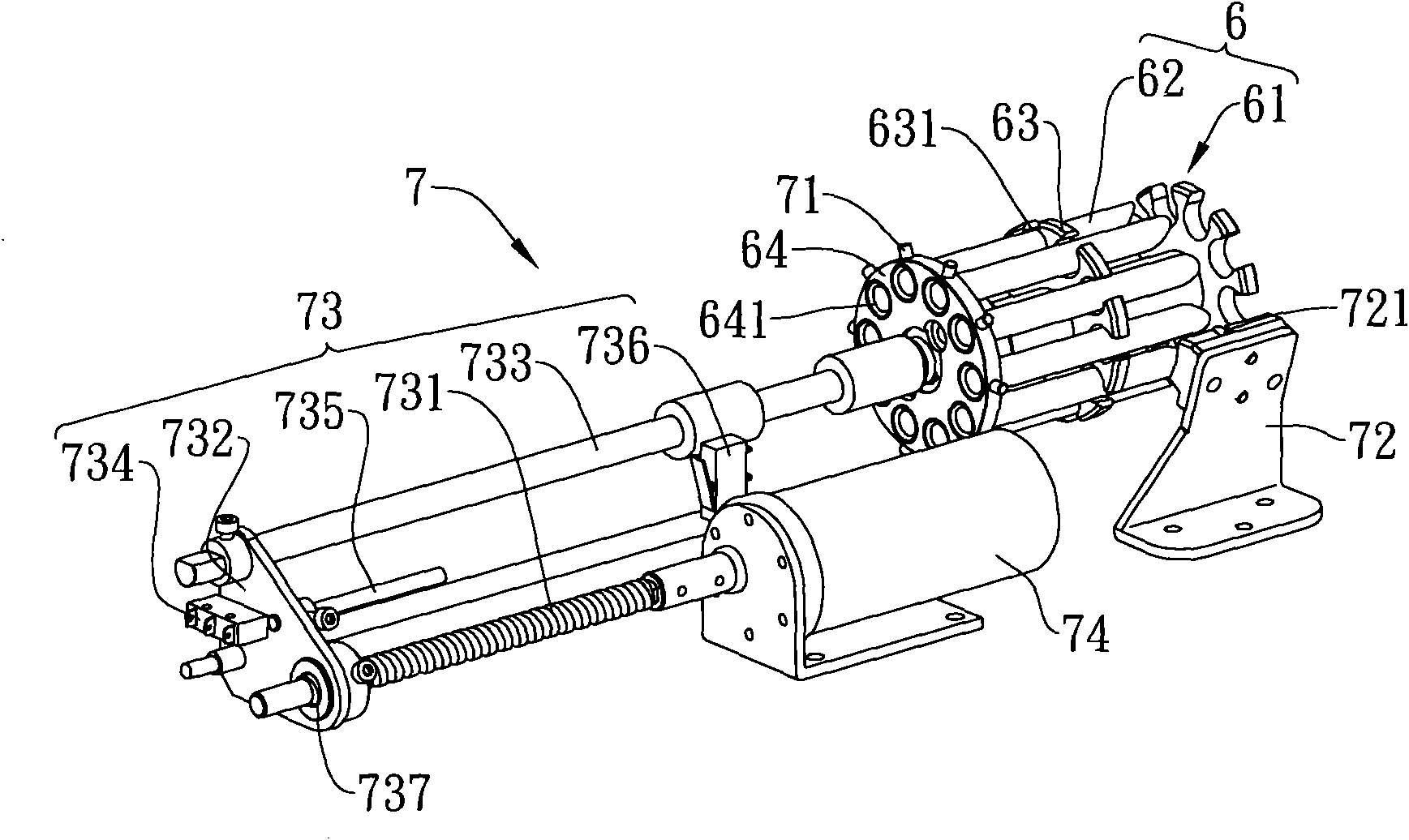

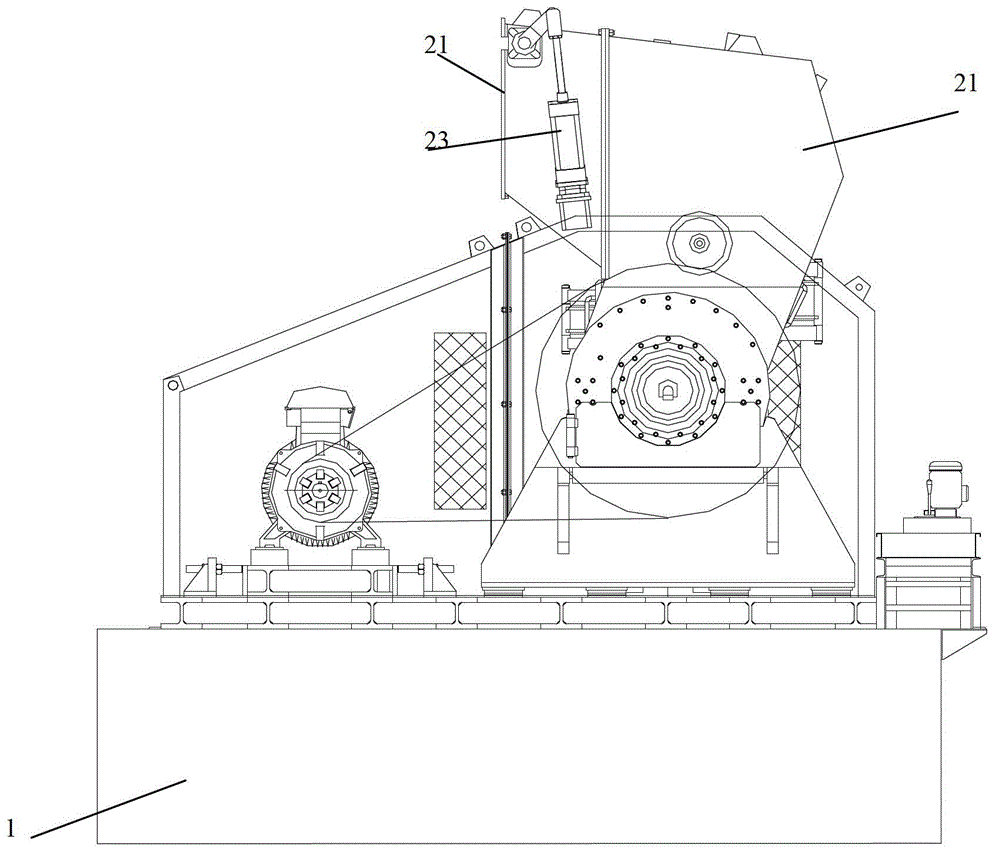

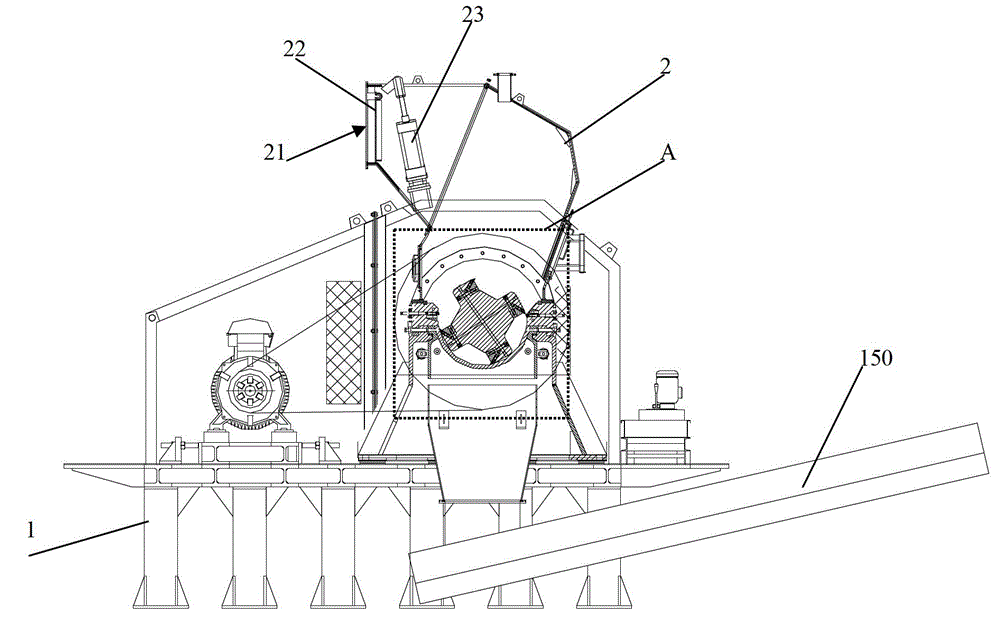

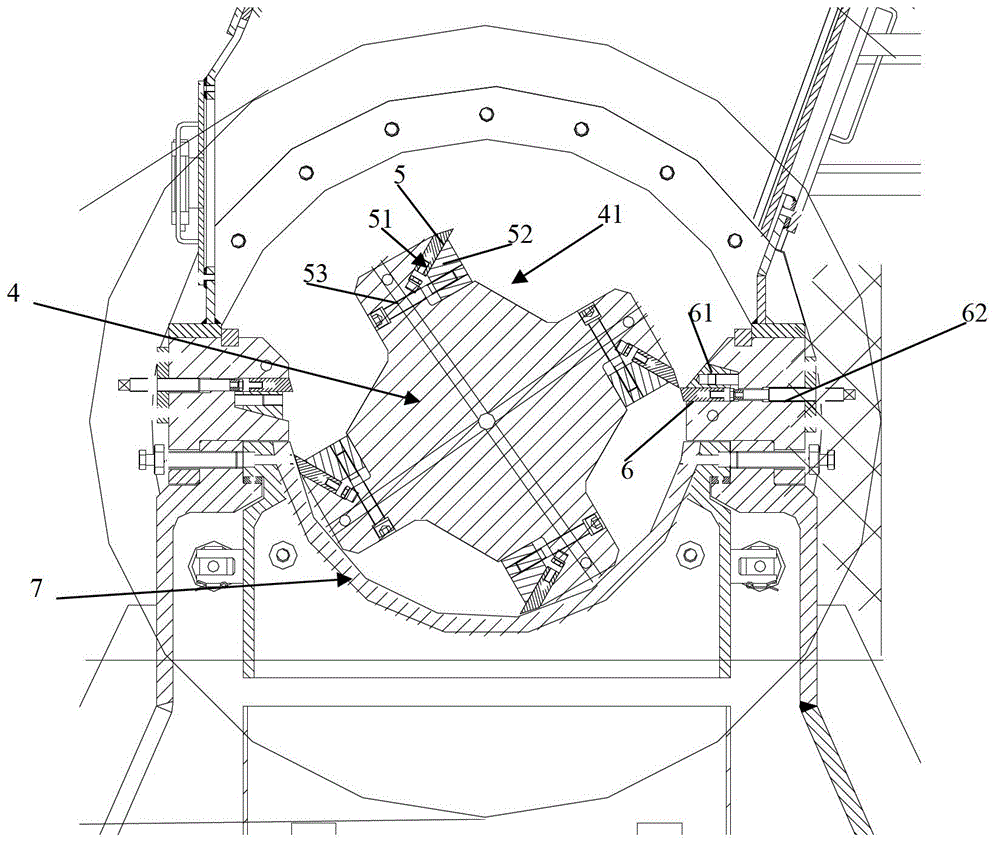

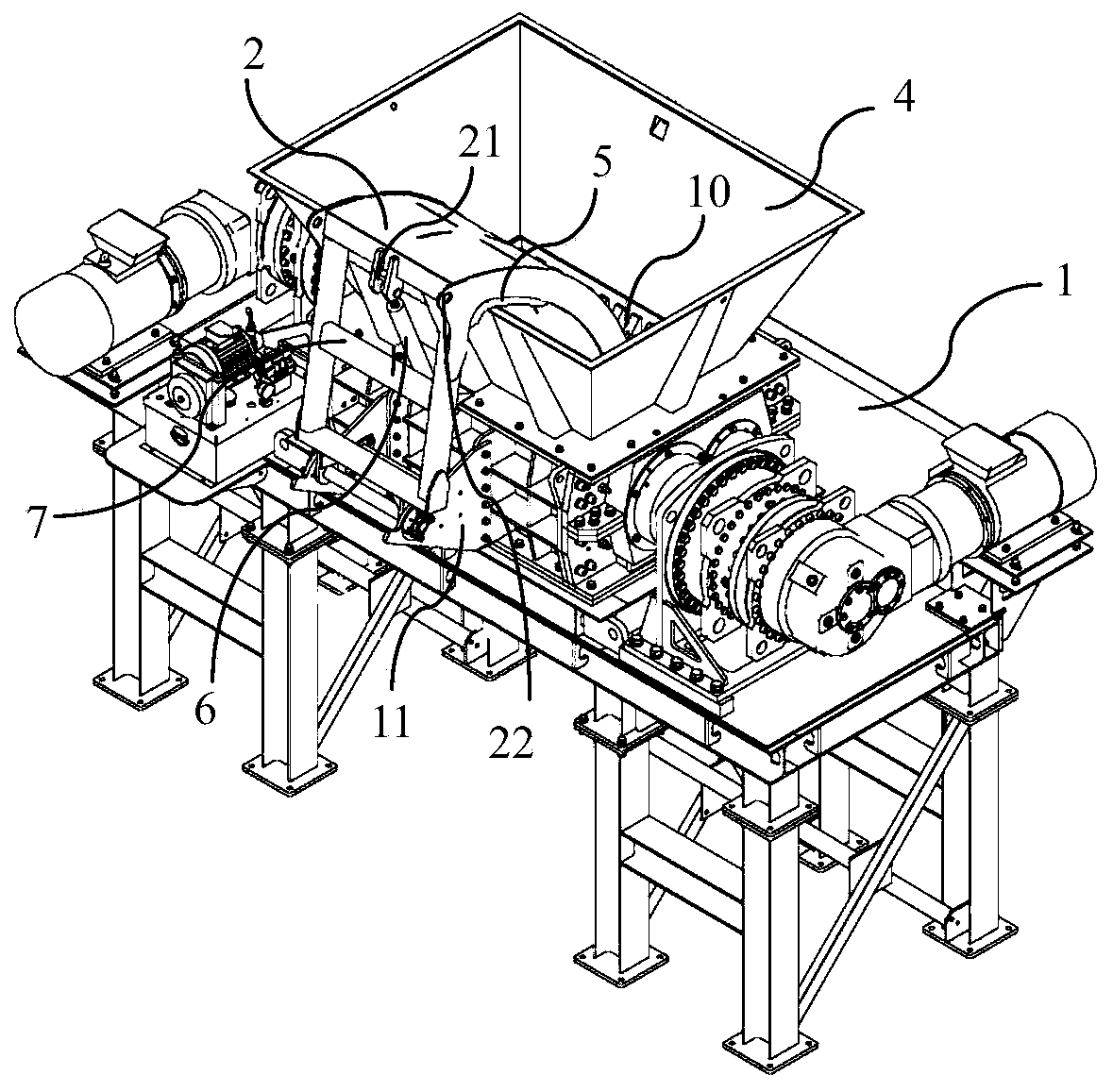

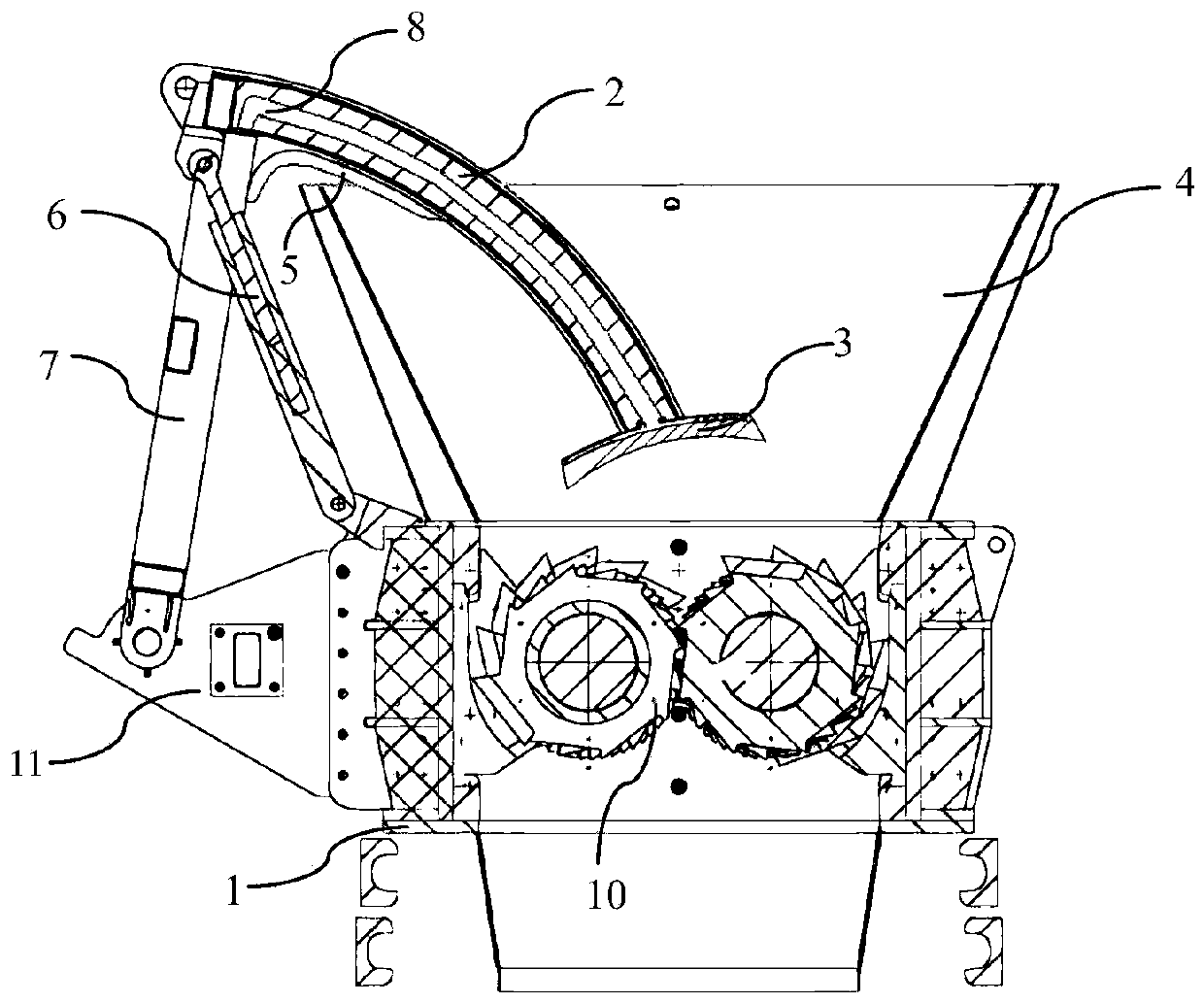

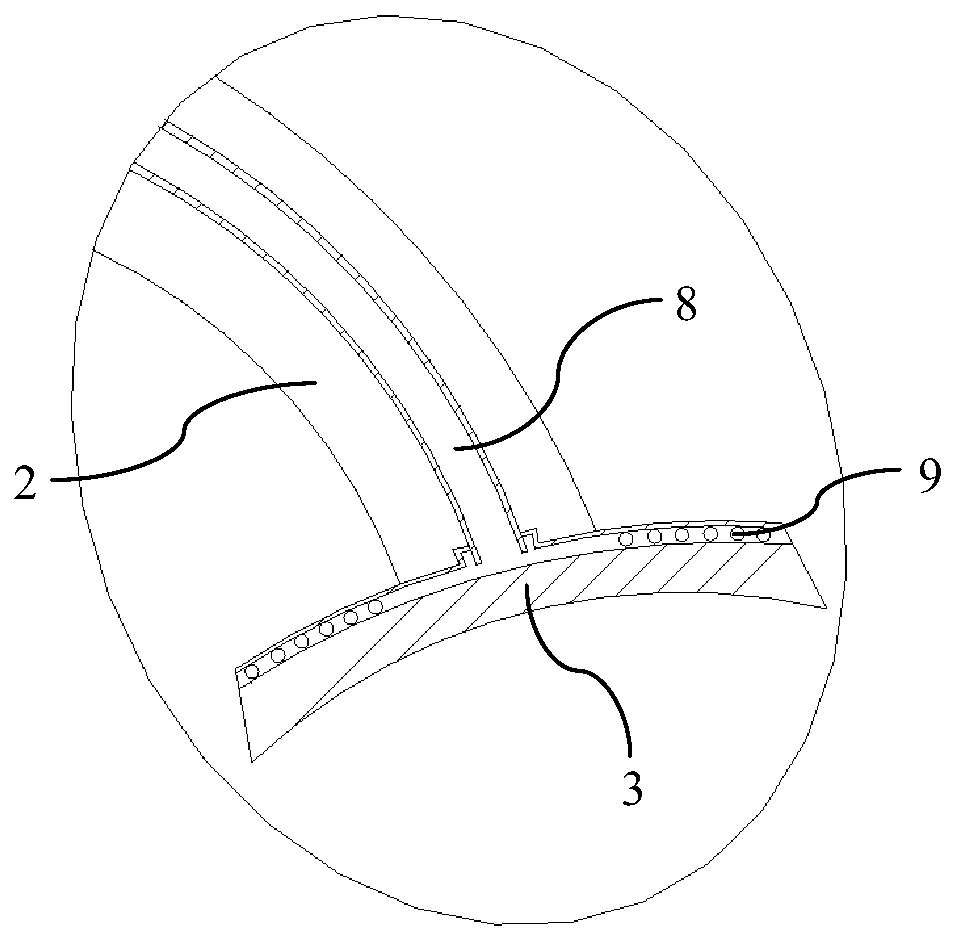

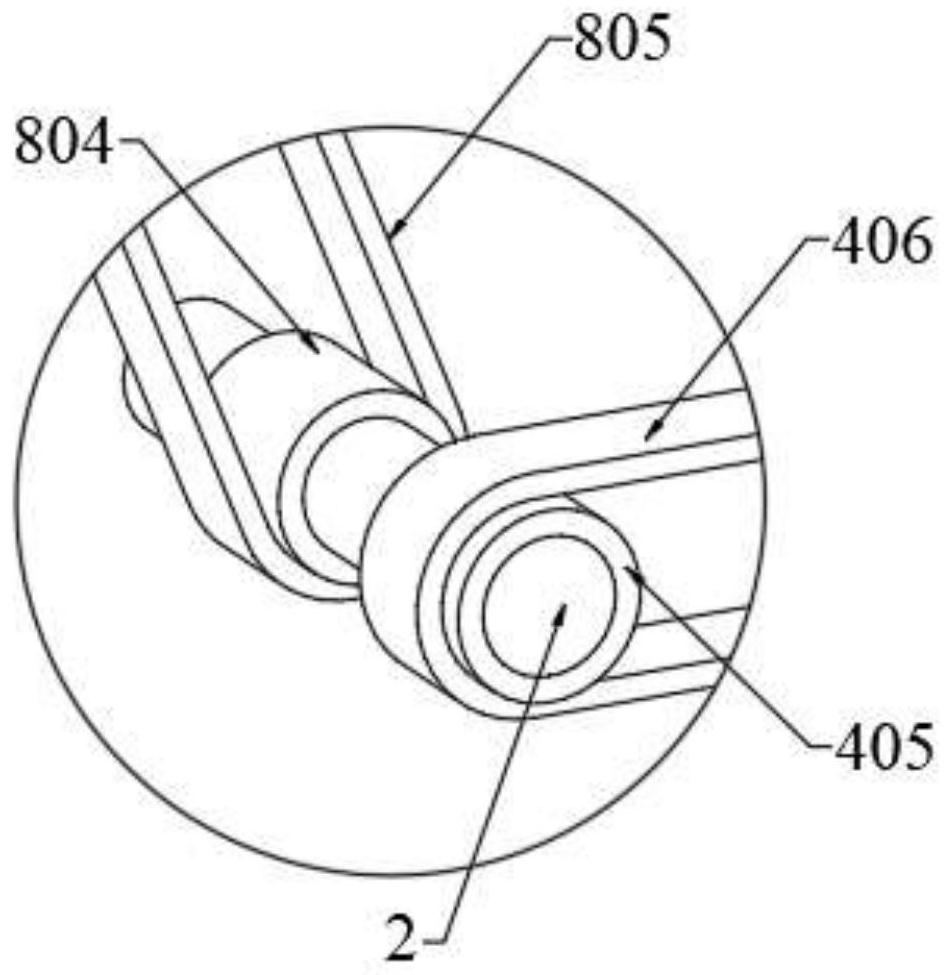

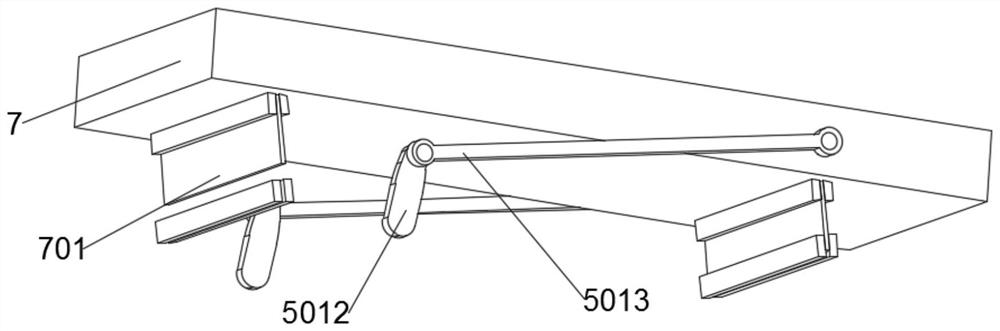

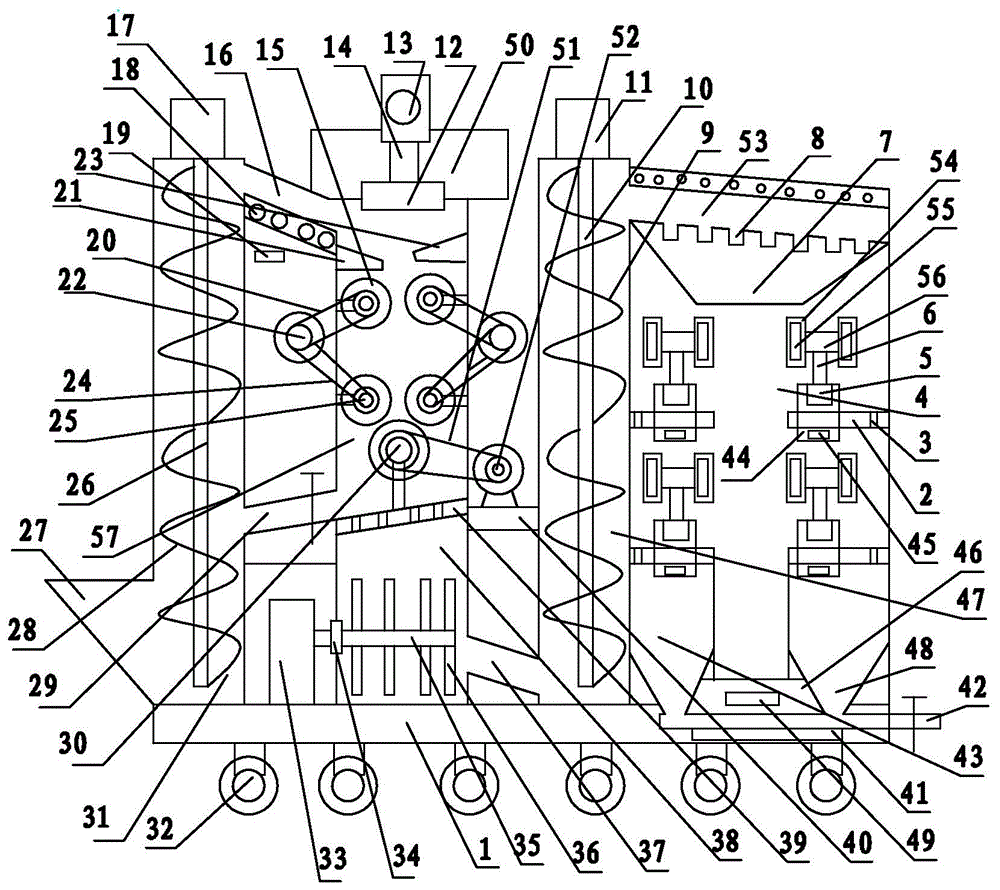

Double-shaft shredding machine for shredding cylinders

ActiveCN110142112AEffective shreddingThe material is stable when the contact is pressed downGrain treatmentsHydraulic cylinderEngineering

The invention discloses a double-shaft shredding machine for shredding cylinders, and belongs to the technical field of material treatment equipment. The double-shaft shredding machine comprises a stand, a pressure plate, a contact, a hydraulic cylinder, a supporting rod, knife rolls and a supporting plate, and further comprises a guide pipe, wherein a connecting block and a lug are arranged on the pressure plate; the connecting block of the pressure plate is hinged to a piston rod of the hydraulic cylinder; the end, facing the knife rolls, of the pressure plate is connected with the contact in a threaded manner; one end of a cylinder body of the hydraulic cylinder is hinged to the stand; one end of the supporting rod is fixed to the pressure plate through the lug; the other end of the supporting rod is hinged to the supporting plate; the supporting plate is fixed to the stand; and the guide pipe stretches from the top end in the pressure plate to the bottom end and is connected with the contact in a threaded manner. According to the double-shaft shredding machine, on one hand, utilization is simple, operation is convenient to achieve, and disassembly and change are relatively convenient to achieve; and on the other hand, when the double-shaft shredding machine is utilized to shred materials, the spherical or cylindrical materials are pressed more stably, and the knife rolls shred the materials effectively.

Owner:马鞍山恒隆机械科技有限公司

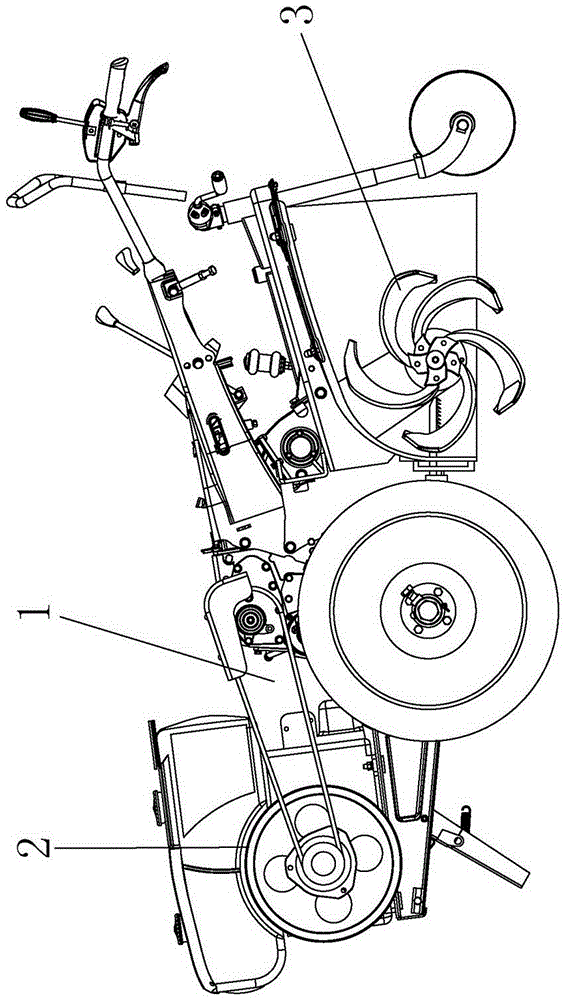

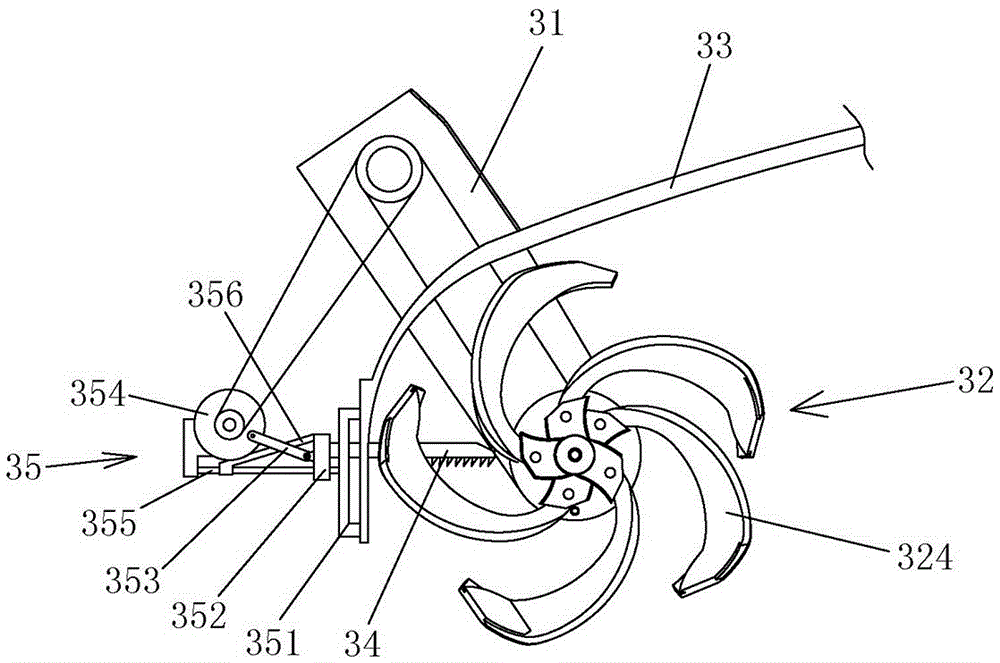

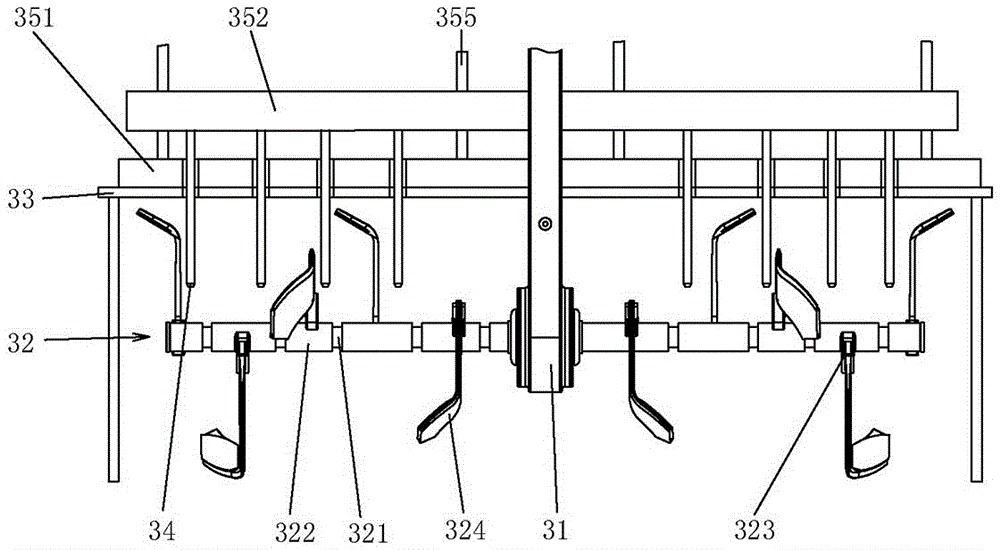

Rotary tiller

ActiveCN105917764AImprove cutting effectLarge effective cutting sectionTilling equipmentsVehicle frameRotary engine

The invention relates to the technical field of agricultural machinery and particularly relates to a rotary tiller. The rotary tiller comprises a vehicle frame, a power traction device and a rotary tillage device, wherein the power traction device is arranged in the front of the vehicle frame, and the rotary tillage device is arranged in the back of the vehicle frame; and the rotary tillage device comprises a transmission frame, a transmission mechanism, a rotary knife assembly and a protective hood, the transmission frame is fixedly connected onto the vehicle frame, the transmission mechanism is arranged in the transmission frame and drives the rotary knife assembly to rotate, the rotary knife assembly comprises a knife shaft and rotary knives rotating along with the knife shaft, cutting knives are arranged in the protective hood, each cutting knife is arranged between every two adjacent rotary knives, one end of each cutting knife is connected with a reciprocating push mechanism, the other end of each cutting knife is pointed to the axis of the knife shaft, and the reciprocating push mechanisms are arranged at the outer side of the protective hood and drive the cutting knives to reciprocate along the radial direction of the knife shaft. According to the rotary tiller, soil blocks or weeds attached to the rotary knives can be effectively stripped or chopped, so that the hacking performance and rotary tillage effect are improved; and the depth of soil piercing of the rotary knives can be adjusted, so that the resistance to the soil piercing of the rotary knives is low, and the power consumption of cutting and soil crushing of the rotary knives is lowered.

Owner:GUANGDE COUNTY SHIJIE TOWN WENCAI RICE PLANTING FAMILY FARM

Straw smashing device

PendingCN114210403AEffective shreddingAvoid mixingCrop conditionersMowersDraft animalsAgricultural engineering

The invention discloses a straw smashing device, and belongs to the technical field of straw treatment.The straw smashing device comprises a smashing box, two first rotating shafts are rotationally connected between the front wall and the rear wall of the smashing box, smashing rollers are fixedly connected to the outer walls of the first rotating shafts, and a conveying cylinder is fixedly connected to the right wall of the smashing box; the right wall of the smashing box and the left wall of the conveying cylinder are provided with communicated material returning openings, and the left wall of the smashing box is hinged to a filtering screen plate extending to the material returning openings. According to the scheme, smashed straw can be screened through the filtering sieve plate, the follow-up straw smashing effect and quality are improved, the straw which is not smashed completely above the filtering sieve plate can enter the conveying cylinder, the driving mechanism and the linkage mechanism are matched to drive the spiral conveying blade to rotate so that the straw can be conveyed upwards, and therefore the straw smashing effect is improved. And finally, the straw falls into the smashing box again to be smashed, complete smashing of the straw can be achieved, the situation that the straw which is completely smashed is doped in the finally-smashed straw is greatly avoided, and meanwhile subsequent livestock can eat the straw conveniently.

Owner:王秀丹

Automatic material smashing and magnetic separation separator

InactiveCN104923338AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsEngineeringMaterial supply

The invention relates to an automatic material smashing and magnetic separation separator comprising a base. A feeding cavity is formed in the left side of the upper portion of the base. The right side of the feeding cavity is connected with a left lifting cavity. The upper portion of the right side of the left lifting cavity is connected with a feeding pipe. The right side of the feeding pipe is connected with a smashing cavity. The lower portion of the left side of the smashing cavity is connected with a material return pipe. The lower portion of the smashing cavity is provided with a filtering plate. The lower portion of the filtering plate is provided with a stirring cavity. The right side of the stirring cavity is connected with a discharging pipe. The right side of the discharging pipe is connected with a right lifting cavity. The upper portion of the right side of the right lifting cavity is connected with a discharging cavity. The lower portion of the discharging cavity is provided with multiple discharging holes. A material supplying cavity is formed below the discharging holes. A separation cavity is arranged below the material supplying cavity. The automatic material smashing and magnetic separation separator can effectively smash materials, conveniently lift smashed materials, improves the material smashing effect and facilitates drying, magnetic separation is conducted after repeated smashing, impurities can be conveniently separated from the materials, statistics of the weight of the impurities can be conveniently conducted, the impurity separation effect is improved, and the automatic material smashing and magnetic separation separator is convenient to use.

Owner:郑小燕

Intelligent treatment equipment for livestock breeding waste

ActiveCN113664016AThe crushing effect is guaranteed throughout the processEffective shreddingBio-organic fraction processingSolid waste disposalAnimal scienceCrop livestock

The invention discloses intelligent treatment equipment for livestock breeding waste, and belongs to the technical field of livestock breeding waste treatment equipment. The intelligent treatment equipment for livestock breeding waste comprises a mixing treatment box, wherein a particle treatment box is arranged on the upper side of the mixing treatment box, a treatment plate is fixedly arranged on the left side of a treatment block, a plurality of cutting grooves are linearly formed in the surface of the treatment plate at equal intervals, an arc-shaped groove A is formed in the lower end of the right side of the treatment block, a balancing weight is arranged on the left side of the particle treatment box, and a fixed plate is fixedly arranged on the right side of the balancing weight. According to the intelligent treatment equipment, the structures are in close fit, so that when the device is used, firstly, large fixed waste passes through the treatment plate, and the qualified fixed waste after treatment can smoothly pass through the space between the two plates through extrusion of the fixed plate and the treatment plate, so that the fixed waste is effectively crushed, and therefore, sufficient decomposition and utilization can be realized in the later period, and the treatment efficiency and effect are improved.

Owner:梁梦颖

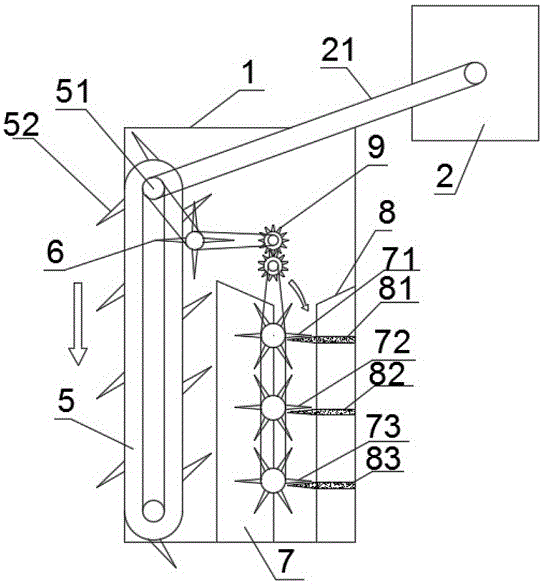

Agricultural soil crusher

InactiveCN106342421ASoil volume remains constantEffective shreddingClod-crushersAgricultural engineeringAgriculture

The invention discloses an agricultural soil crusher, comprising a machine case, wherein rolling wheels are fixedly arranged at the bottom part of the machine case; a handle is respectively fixedly arranged at two sides of the machine case in an upwards inclined rightward manner through bolts; a power device is fixedly arranged on the lower face of the top part of the machine case; the left side of the machine case is an opening; a rotary shaft is respectively fixedly arranged on the upper end and the lower end at the left side of the machine case; the rotary shafts are electrically connected with the power device; the rotary shafts are connected with each other through a caterpillar track; digging hooks are fixedly arranged on the outer surface of the caterpillar track; a soil removing wheel is fixedly arranged at the upper right side of the caterpillar track; a crushing wheel fixing block is fixedly arranged at the right side of the caterpillar track. The agricultural soil crusher has the advantages that massive soil can be effectively crushed through the cooperation between crushing wheels and rakes; the soil can be further crushed due to the fact that the density of the crushing wheel and the rake is smaller and smaller from top to bottom; for soil volume required by different crops, unnecessary rakes can be drawn out, so that the soil volume is unchanged.

Owner:施秉县富民高新农业发展有限公司

Waste paper shredding device

The invention discloses a waste paper shredding device, comprising a frame, wherein the top of the frame is provided with a shredded paper carton, a gear shaft penetrates through the inside of the shredded paper carton, and the gear shaft is externally sleeved with a roller; the inner wall of the roller is fixedly provided with gear teeth, the gear teeth mesh with the gear shaft, the circumferential side of the roller is fixedly provided with a blade, one end of the gear shaft is provided with a transmission wheel, and the top of the shredded paper carton is provided with a motor; the transmission wheel and the end of a motor output shaft are connected to a transmission chain, a discharge port is arranged in the bottom of the shredded paper carton, and a cover is arranged at the top of theshredded paper carton. The invention can effectively cut the waste paper by providing the blade and setting one end of the blade into an arc structure, and the blade can be affixed to the inner sidewall of the shredded paper carton, and the waste paper can be picked up. The waste paper is shredded repeatedly and the effect of shredding paper is increased, which is beneficial to improvement of the efficiency of shredding paper.

Owner:江苏美华包装有限公司

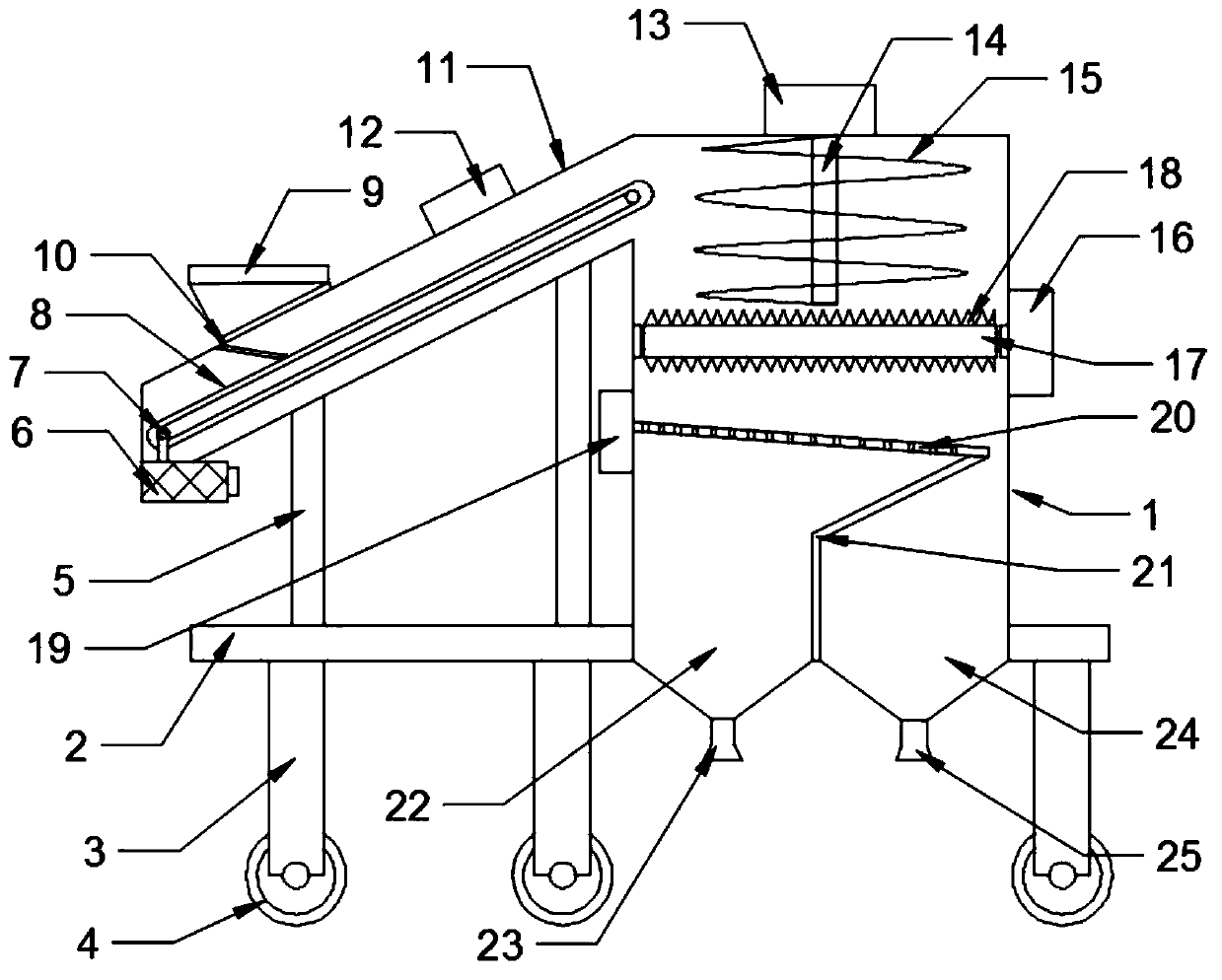

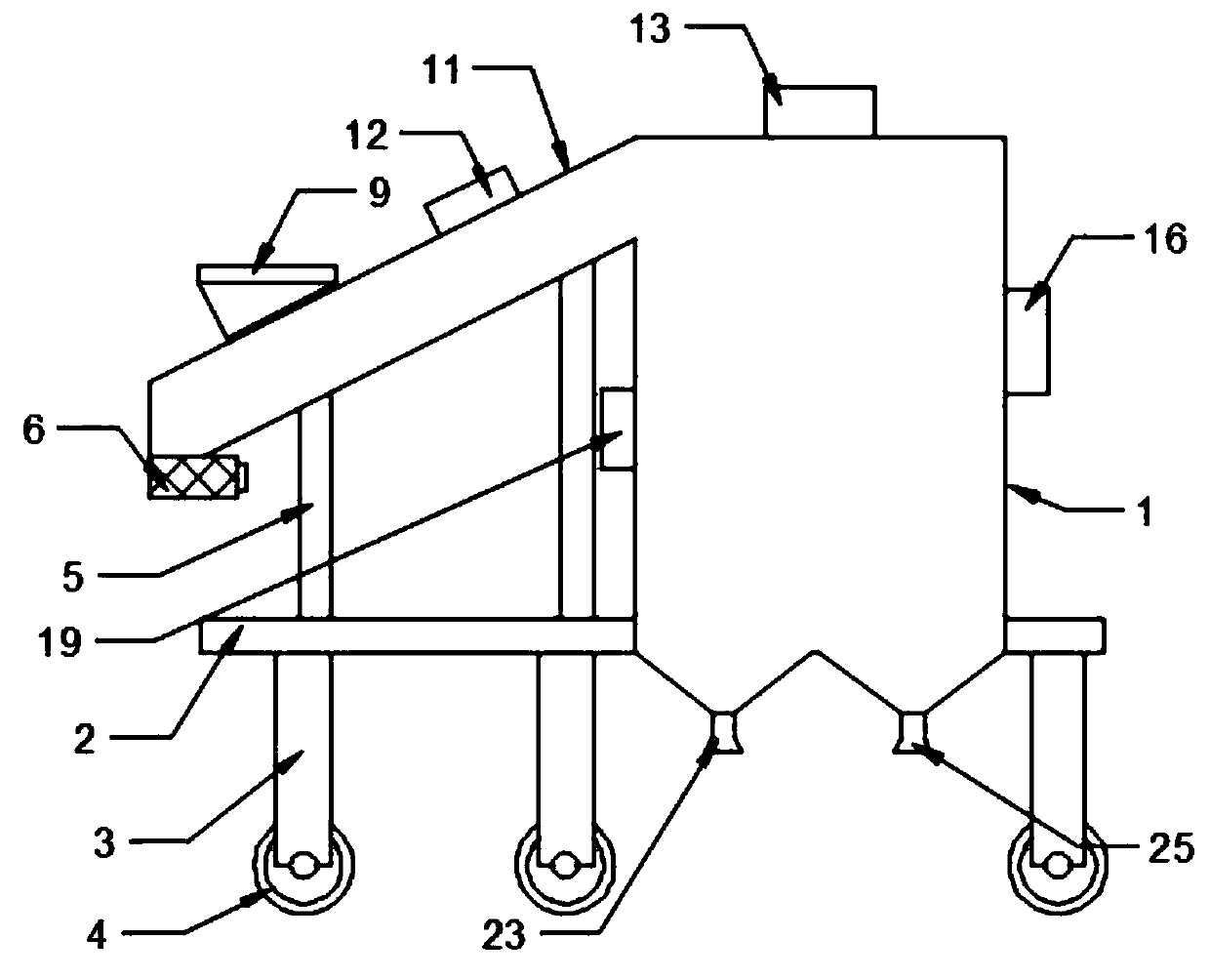

Chicken feed preparation device and chicken feed preparation method

InactiveCN111111532AWell mixedEasy to useFeeding-stuffRotary stirring mixersMotor vibrationElectric machine

The invention discloses a chicken feed preparation device and a chicken feed preparation method. The invention belongs to the technical field of feed processing equipment. The device comprising a shell, a conveying device shell fixedly connected thereto, and a powder residue outlet and a feed outlet that are formed in the bottom end of the shell. A motor A is fixedly arranged at the bottom end ofthe conveying device shell; a rotating roller is connected with the motor A through a belt is arranged in the conveying device shell; a conveying belt is arranged on the outer sides of the rotating rollers, a vibrating screen plate is arranged in the shell, a vibrating motor is arranged on the outer side of the shell and corresponds to the vibrating screen plate, and a partition plate is arrangedbelow the vibrating screen plate and divides the lower end of the shell into a powder residue collecting bin and a feed collecting bin. The vibrating motor drives the vibrating screen plate to vibrateto effectively distinguish large and small particles of feed, and the large and small particles of feed are collected separately, so that the purposes of improving the screening efficiency and quality of the feed and facilitating sufficient and uniform mixing and proportioning of the feed are achieved.

Owner:宿州市富家饲料有限公司

Anti-blocking artificial fish reef and using method thereof

ActiveCN109874717AEfficient removalEffective shreddingClimate change adaptationPisciculture and aquariaSludgeArtificial reef

The invention discloses an anti-blocking artificial fish reef and a using method thereof. The anti-blocking artificial fish reef comprises a fish reef seat, a fish reef cover, a floating plate, a vertical plate and a first transmission mechanism, wherein the interior of the fish reef seat is of a hollow structure; the fish reef cover is rotatably arranged on the upper part of the fish reef seat; the floating plate is directly or indirectly arranged on the sidewall of the fish reel cover; the vertical plate capable of sliding vertically is arranged in a vertical hole in the bottom of the fish reel seat; the first transmission mechanism is connected to the fish reel cover and the vertical plate and can convert the rotation of the fish reef cover into the vertical movement of the vertical plate; a residue discharge hole is formed in the vertical plate; and the sidewall of the vertical hole is provided with a resetting mechanism used for limiting and resetting the vertical plate. Accordingto the anti-blocking artificial fish reef and the using method thereof, the first transmission mechanism can convert the rotation of the fish reef cover into the vertical movement of the vertical plate, so that residues such as fish excrement and sludge deposited on the vertical plate are shaken; and the residue discharge hole on the vertical plate can efficiently discharge the residues out of the fish reef seat, so that the structure is ingenious.

Owner:蔡以恒

Automatic magnetic separator for materials

InactiveCN104959206AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsMagnetic separatorTherapeutic effect

The invention relates to an automatic magnetic separator for materials. The automatic magnetic separator comprises a base, wherein a feeding cavity is formed in the left side of the upper part of the base; a left lifting cavity is connected to the right side of the feeding cavity; a material supplying pipe is connected to the upper part of the right side of the left lifting cavity; a crushing cavity is connected to the right side of the material supplying pipe; a material returning pipe is connected to the lower part of the left side of the crushing cavity; a filtering plate is arranged at the lower part of the crushing cavity; a stirring cavity is formed at the lower part of the filtering plate; a discharging pipe is connected to the right side of the stirring cavity; a right lifting cavity is connected to the right side of the discharging pipe; a discharging cavity is connected to the upper part of the right side of the right lifting cavity; a plurality of discharging holes are formed in the lower part of the discharging cavity; a material supplying cavity is formed below the discharging holes; a separating cavity is formed below the material supplying cavity. The automatic magnetic separator disclosed by the invention can be used for crushing materials and favorably lifting the crushed materials, so that the crushing treatment effect of the materials is improved; in addition, the drying treatment is facilitated, magnetic separation is carried out after crushing for multiple times, and impurities are conveniently separated; besides, the mass of the impurities is conveniently counted, the separating treatment effect of the impurities is improved, and the convenience in use is realized.

Owner:陈少军

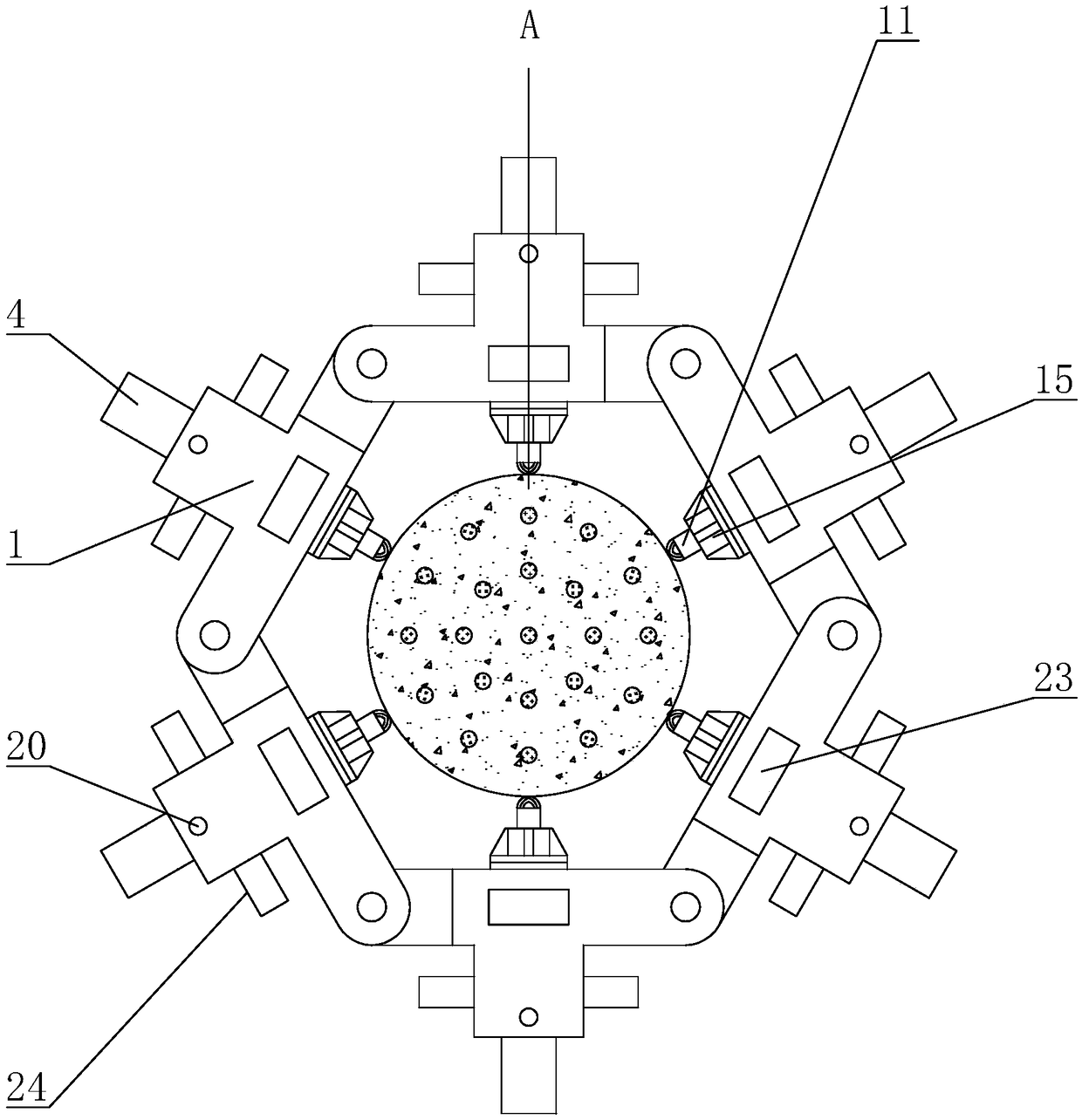

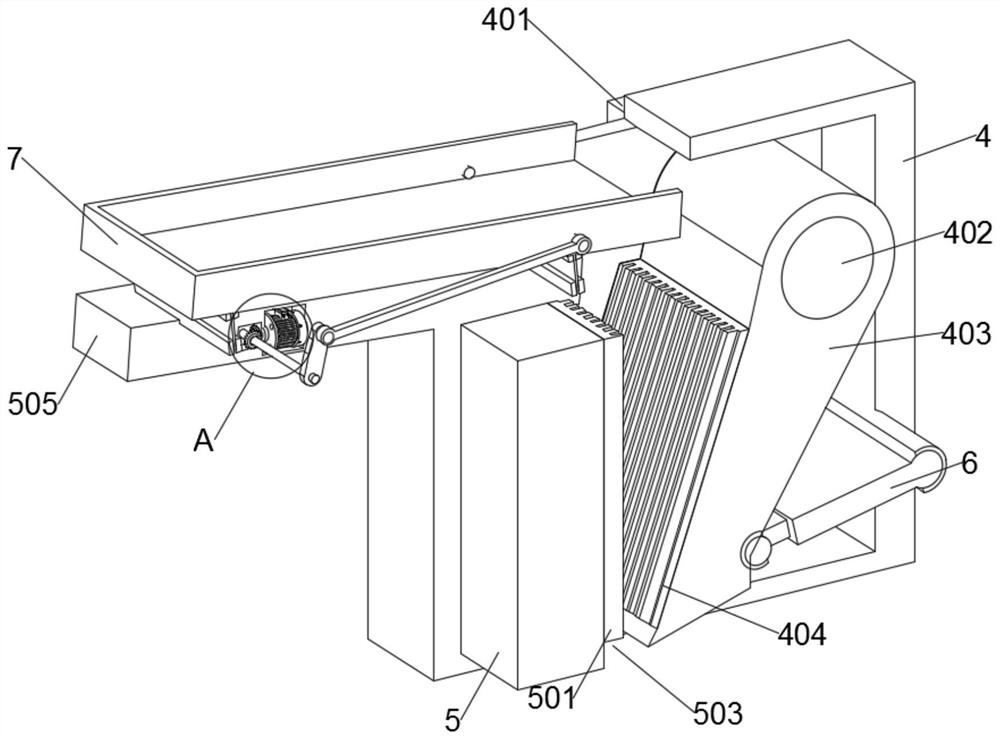

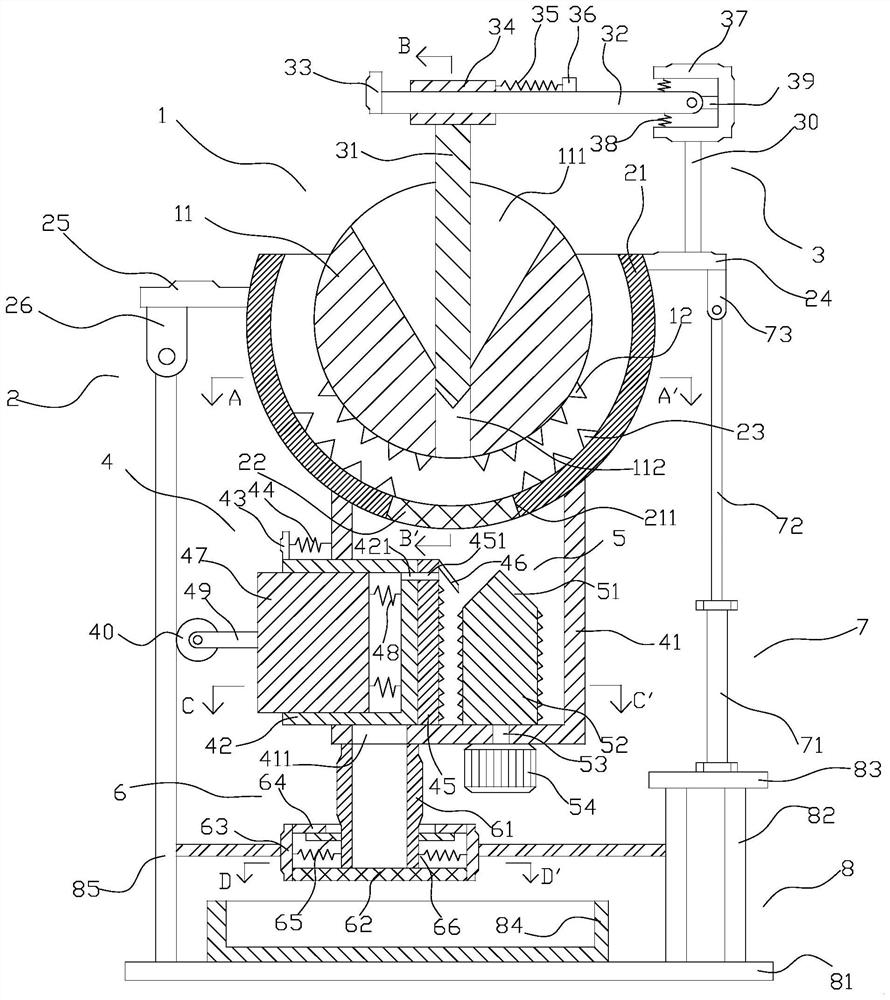

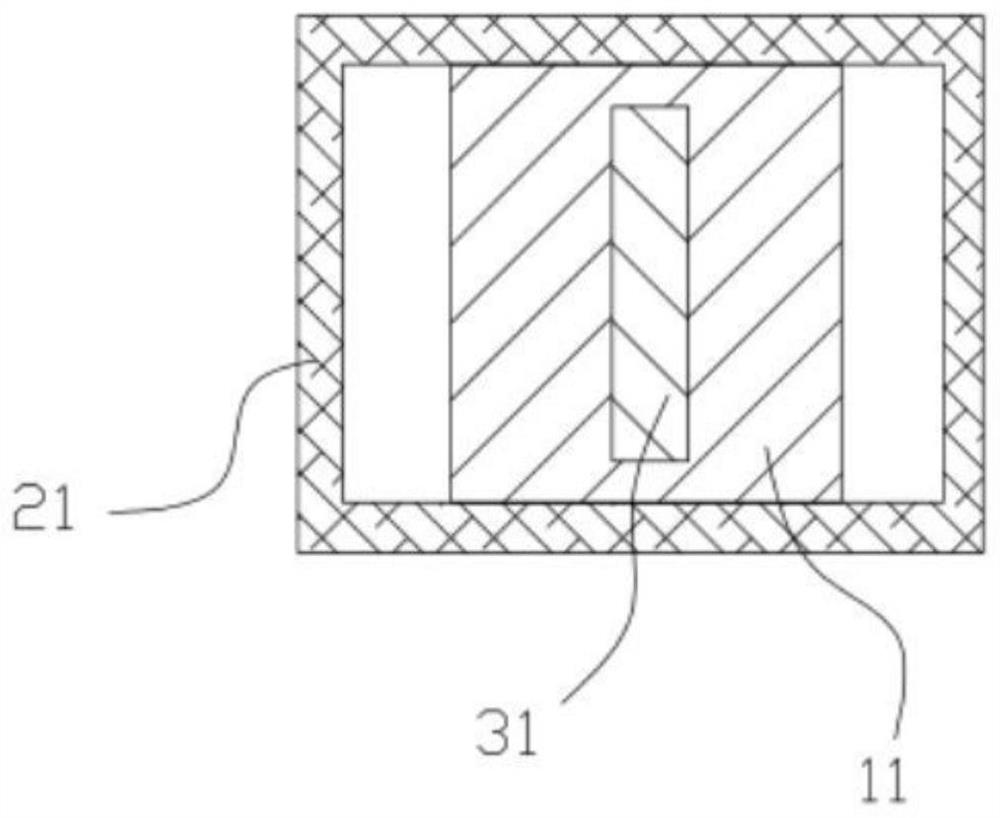

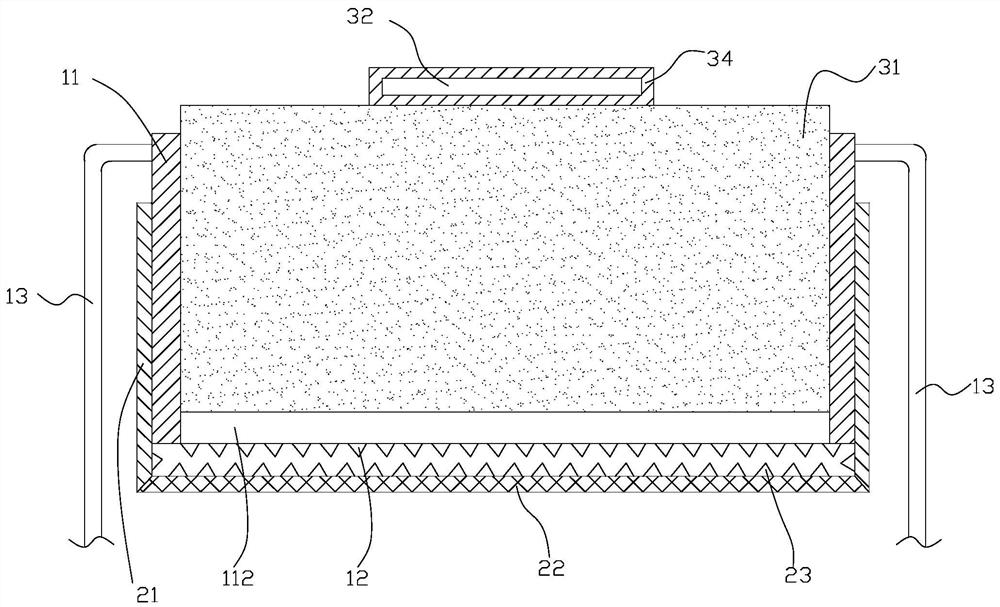

Crushing and refining device for environmental-friendly compound farmyard manure for agriculture and forestry and application method

ActiveCN112156829AImprove crushing effectAvoid cloggingClimate change adaptationExcrement fertilisersAgricultural scienceAgricultural engineering

The invention relates to a crushing and refining device for environmental-friendly compound farmyard manure for agriculture and forestry. The crushing and refining device comprises a feeding mechanism(1), a crushing mechanism (2), a centralizing mechanism (4), a refining mechanism (5), a screening mechanism (6) and a driving mechanism (7). The feeding mechanism (1) comprises a feeding wheel (11)and a first crushing tooth (12), the first crushing tooth (12) is fixedly connected to the outer surface of the feeding wheel (11), and a collecting cavity (111) located in the upper end and a feedingcavity (112) located below the collecting cavity (111) are formed in the feeding wheel (11). By arranging a plugging plate capable of moving up and down to plug the feeding cavity periodically, fertilizer particles enter a crushing frame periodically, so that each batch of fertilizer particles can be crushed fully and effectively, and therefore, an effect of crushing the fertilizer particles is improved and the structure is prevented from being damaged.

Owner:宿州长林生态农业发展有限公司

Material magnetic separating machine

ActiveCN104941799AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsTherapeutic effectEngineering

The invention relates to a material magnetic separating machine which comprises a base, wherein a feeding cavity is formed on the left side of the upper part of the base; the right side of the feeding cavity is connected with a left lifting cavity; the upper part of the right side of the left lifting cavity is connected with a material supply pipe; the right side of the material supply pipe is connected with a crushing cavity; the lower part of the left side of the crushing cavity is connected with a material return pipe; a filter plate is arranged at the lower part of the crushing cavity; a mixing cavity is formed at the lower part of the filter plate; the right side of the mixing cavity is connected with a material unloading pipe; the right side of the material unloading pipe is connected with a right lifting cavity; the upper part of the right side of the right lifting cavity is connected with a discharge cavity; a plurality of discharge holes are formed at the lower part of the discharge cavity; a material supply cavity is formed at the lower parts of the discharge holes; and a separating cavity is formed at the lower part of the material supply cavity. The material magnetic separating machine can effectively performs crushing treatment on a material specifically, facilitates lifting treatment on the material after crushing, improves the crushing treatment effect of the material, and facilitates drying treatment; magnetic separation is performed after crushing for multiple times, so that the separation of impurity matters can be separated out conveniently; the quantity of the impurity matters can be counted conveniently; the impurity separation treatment effect is improved; and the material magnetic separating machine is convenient to use.

Owner:重庆先隆电力设备制造有限公司

Improved natural substance fermentation extraction device

The invention relates to an improved natural substance fermentation extraction device, which comprises a processing frame body, wherein a rotating cavity is arranged in the top end surface of the processing frame body; a mincing disc is arranged in the rotating cavity in a rotatable and matched way; a mincing cavity is arranged in the top end surface of the mincing disc; a plurality of groups of external mincing blades are fixedly arranged in the circumferential direction of the inner surface of the mincing cavity; an annular cavity is formed in the processing frame body at the bottom of the rotating cavity in a communicating way; convex blocks are fixedly arranged at the inner walls of the left side and the right side of the annular cavity; a driving seat is fixedly arranged between the convex blocks arranged between the left side and the right side; the driving seat is positioned right under the mincing disc; the top end surface of the driving seat and the bottom end surface of the mincing disc are connected through a rotating round table in a rotatable and matched way; an accommodating cavity is formed in the top end surface of the driving seat; a driving motor is fixedly arranged in the inner bottom wall of the accommodating cavity.

Owner:何胜利

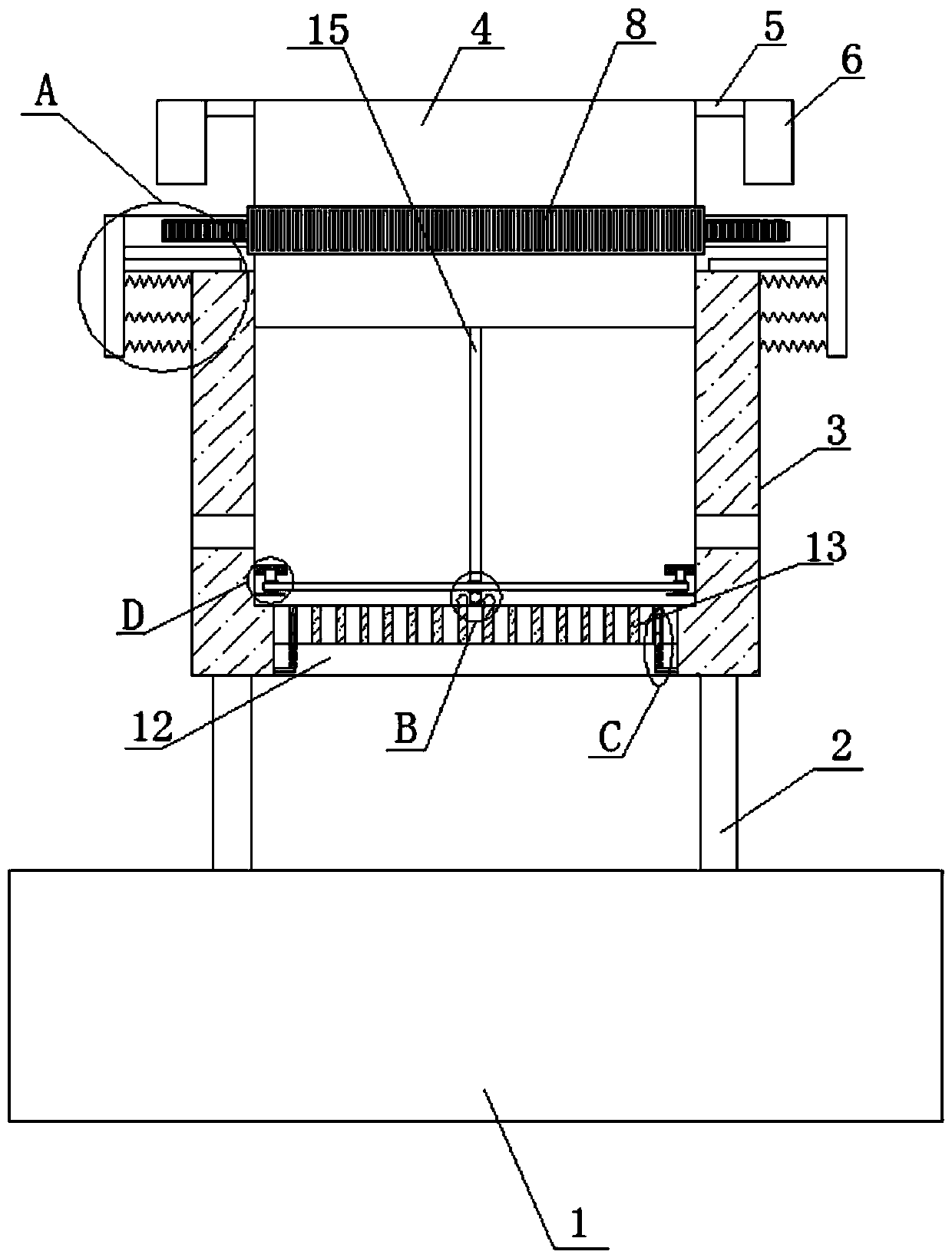

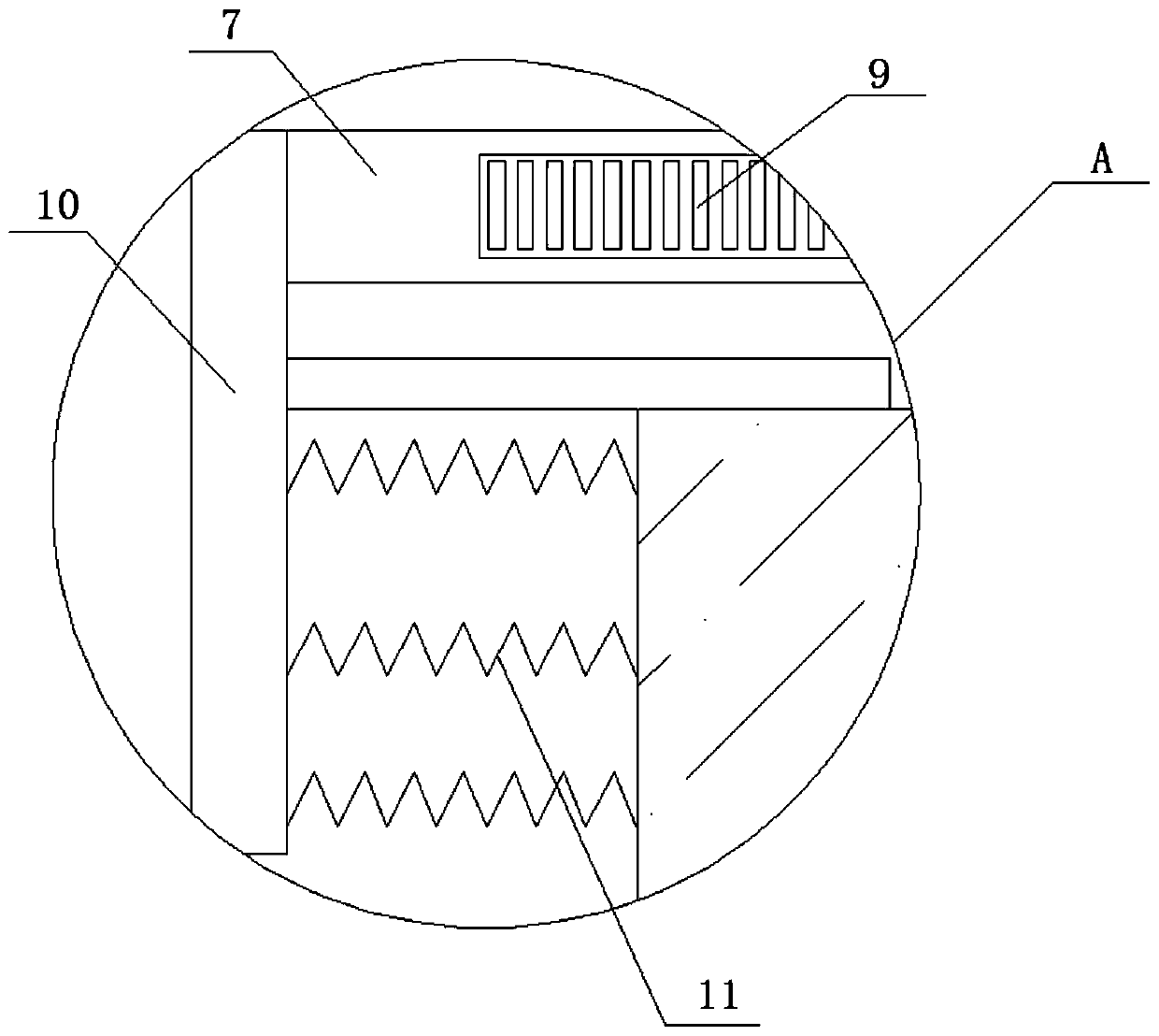

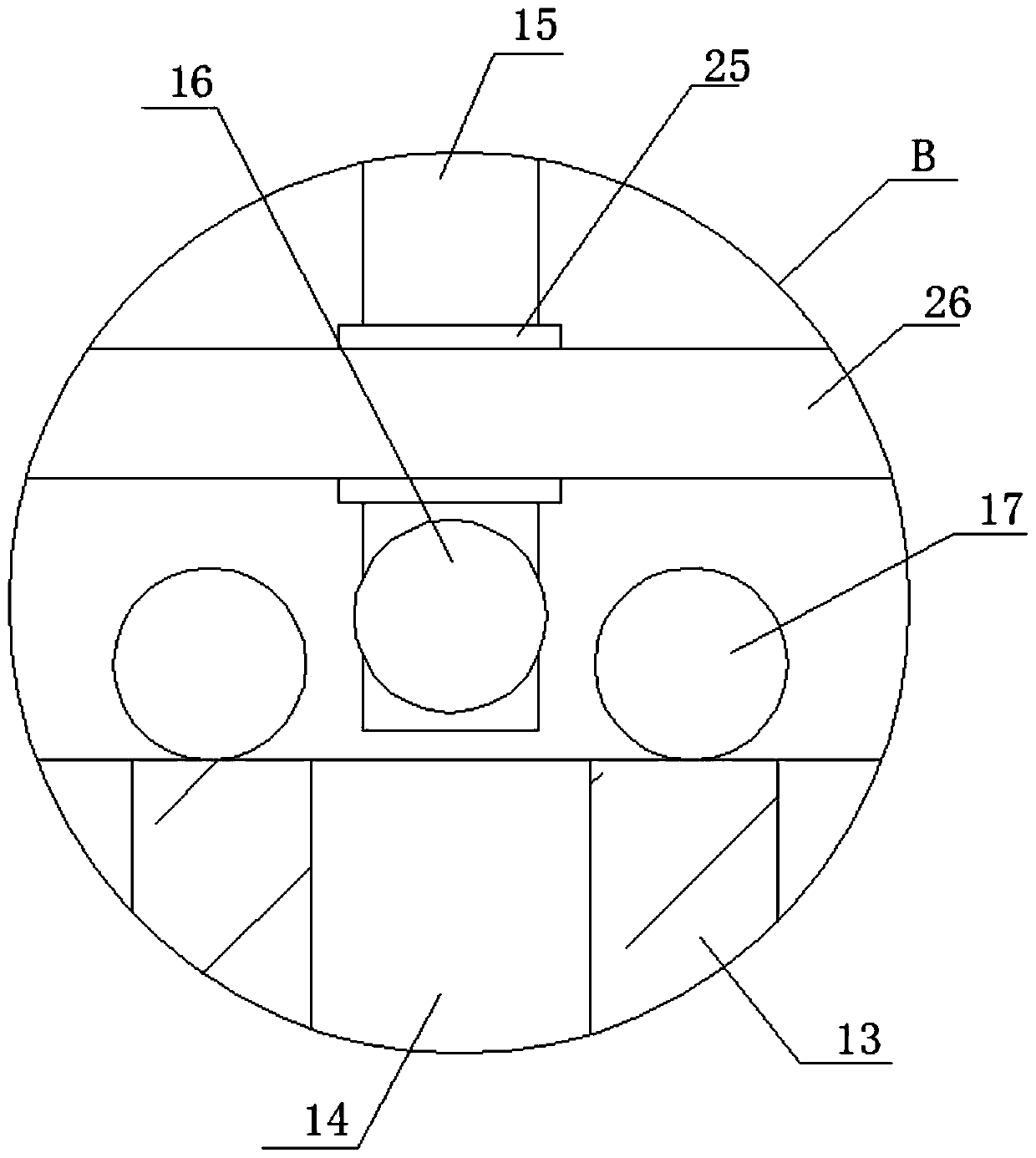

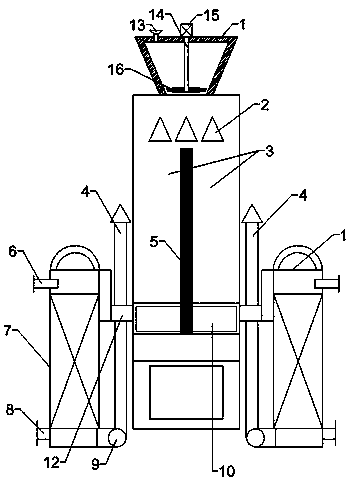

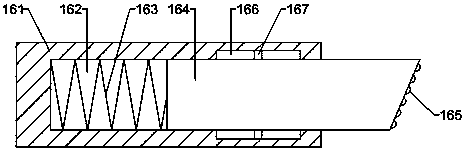

Semi-coke furnace capable of processing raw materials of pulverized coal

InactiveCN107723010AEffective shreddingDirect heating destructive distillationSpecial form destructive distillationMotor driveCarbonization

A semi-coke furnace capable of processing pulverized coal raw materials, comprising a semi-coke furnace, the interior of the semi-coke furnace is provided with a carbonization chamber, the bottom of the carbonization chamber is provided with a flower wall, the middle of the carbonization chamber is provided with a partition wall, and the top of the semi-coke furnace is A silo is provided, the silo is in the shape of an inverted circular platform, and a coal block crushing device is installed in the silo, the coal block crushing device includes a rotating shaft, the top of the rotating shaft is rotatably connected with the silo, and the top of the rotating shaft is fixedly connected with the output shaft of the motor, the rotating shaft The bottom end is fixedly connected with a disc, and the disc is provided with an annular groove with an opening facing outward, and a plurality of springs are arranged in the annular groove. The beneficial effects of the present invention are: the motor drives the rotating shaft to rotate, the disc on the rotating shaft rotates, and the crushing plate inside the disc protrudes from the annular groove for a certain length under the action of centrifugal force, so that the other end of the crushing plate is in contact with the inner side wall of the silo contact with each other, and the pulverizing protrusions provided at the outer end of the pulverizing plate effectively pulverize the coal block.

Owner:王峰

Material smashing device

Owner:WUHU HENGHAO MACHINERY MFG

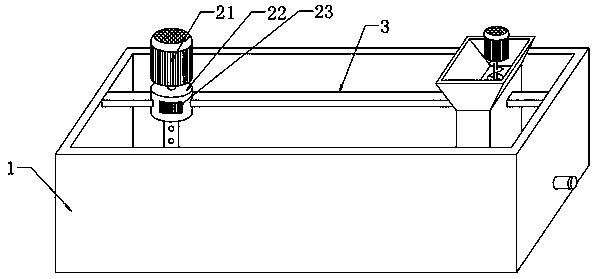

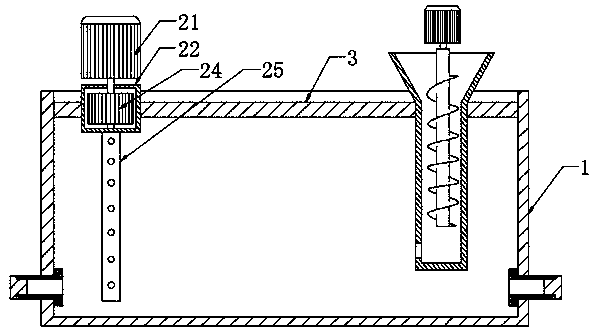

Fry breeding device and method of lateolabrax japonicus

InactiveCN110235820AEven and efficient oxygen supplySolve the problem of insufficient uniform and effective oxygen supplyClimate change adaptationPisciculture and aquariaSebastesTurbine blade

The invention provides a fry breeding device and method of lateolabrax japonicus. The device comprises an oxygen supply motor, a turbine chamber, an air inlet grid, a turbine blade, a jet rod, an auger motor, an auger shaft, a sliding groove, a squeezing groove and a discharge port, wherein the turbine chamber is formed in the left side of a transverse rod, the upper side of the turbine chamber is provided with the oxygen supply motor, the front end face of the turbine chamber is provided with the air inlet grid, the inner portion of the turbine chamber is assembled with the turbine blade, and the lower side of the turbine chamber is connected with the jet rod. The fry breeding device and method of the lateolabrax japonicus solve the problem that an existing lateolabrax japonicus fry oxygen supply device is not even and effective enough in oxygen supply; the right side of the transverse rod is provided with the sliding groove, the upper side of the inner portion of the sliding groove is provided with the auger motor, the lower side of the auger motor is connected with the auger shaft, the lower side of the sliding groove is provided with the squeezing groove, and the left side of the squeezing groove is provided with the discharge port, so that the fry breeding device and method of the lateolabrax japonicus solve the problem that the digestion of lateolabrax japonicus fry is not facilitated due to the fact that original fry breeding feeding particles are larger. The fry breeding device and method of the lateolabrax japonicus has the advantages that the structure is reasonable, and the increase of the survival rate of the lateolabrax japonicus fry breeding is facilitated.

Owner:NANJING SHUAIFENG FEED

Solid garbage treatment device for constructional engineering

InactiveCN111013758AImprove grinding efficiencyEasy to useMagnetic separationGrain treatmentsElectric machineryScrap

The invention relates to the field of constructional engineering, in particular to a solid garbage treatment device for constructional engineering. The solid garbage treatment device comprises a supporting framework, wherein a connecting cavity is arranged on the middle part of the supporting framework; a crushing cavity is arranged at the upper end of the connecting cavity; a first rotary guide slot is formed in the bottom of the crushing cavity; discharge holes are formed in the bottom of the first rotary guide slot; a crushing shaft is mounted at the upper side of the first rotary guide slot between the discharge holes; a crushing motor is mounted at the upper side of the crushing shaft; the lower side of the first rotary guide slot is equipped with a grinding roller through a bearing base; the lower side of the grinding roller is equipped with a grinding motor; a discharge tube is arranged on the middle part of the lower side of the second rotary guide slot; left and right ends ofthe discharge tube are connected with a first air exhaust tube through four-way tubes; the other end of the first air exhaust tube is provided with an air-blowing cover; an air exhaust cover is mounted on the bottom of a scrap iron recycling cavity; and a plurality of electromagnet rings are arranged at the upper end of the scrap iron recycling cavity. The solid garbage treatment device can effectively separate scrap iron in solid garbage, so that waste of iron resources is reduced.

Owner:赵文鹏

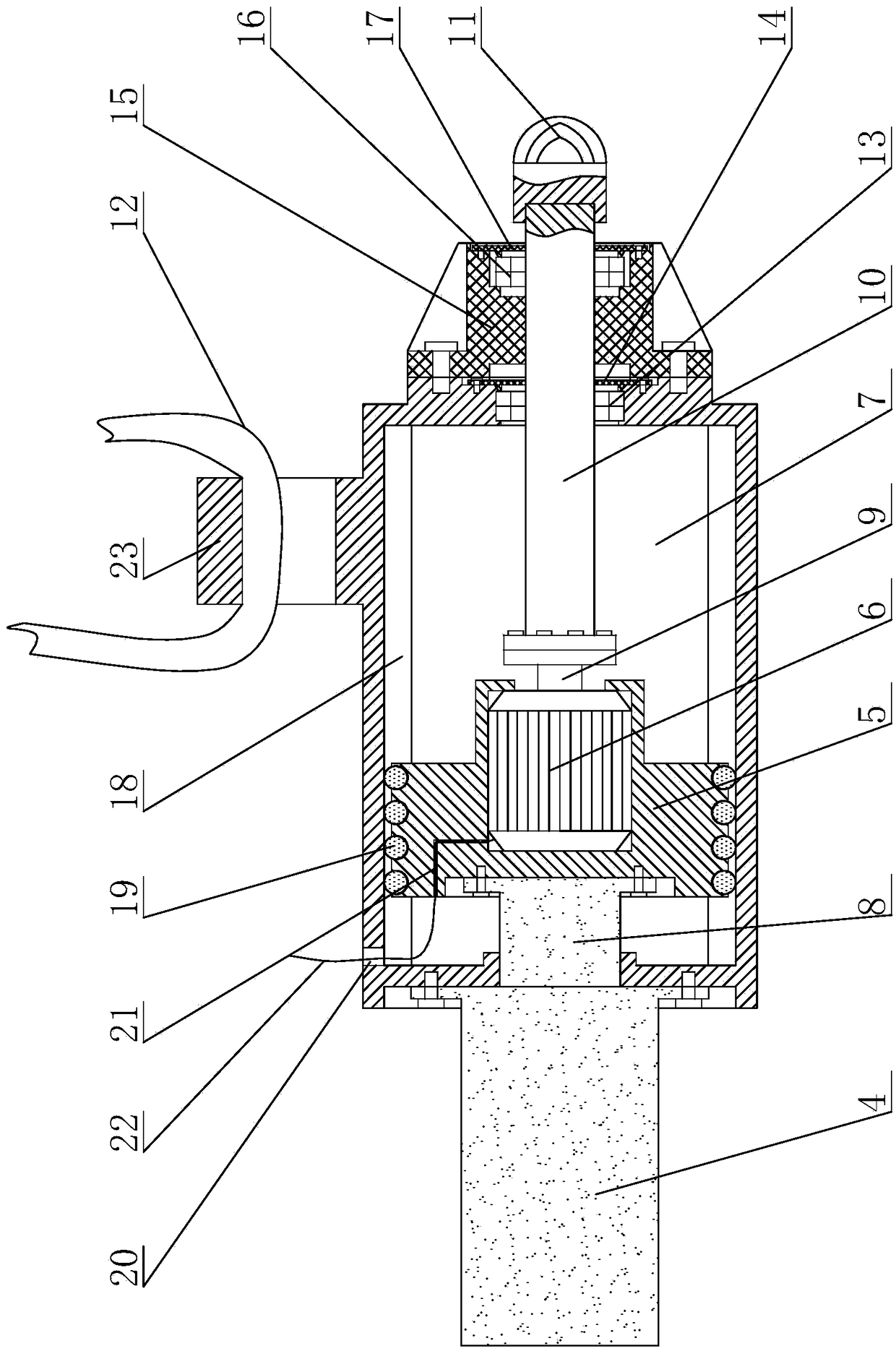

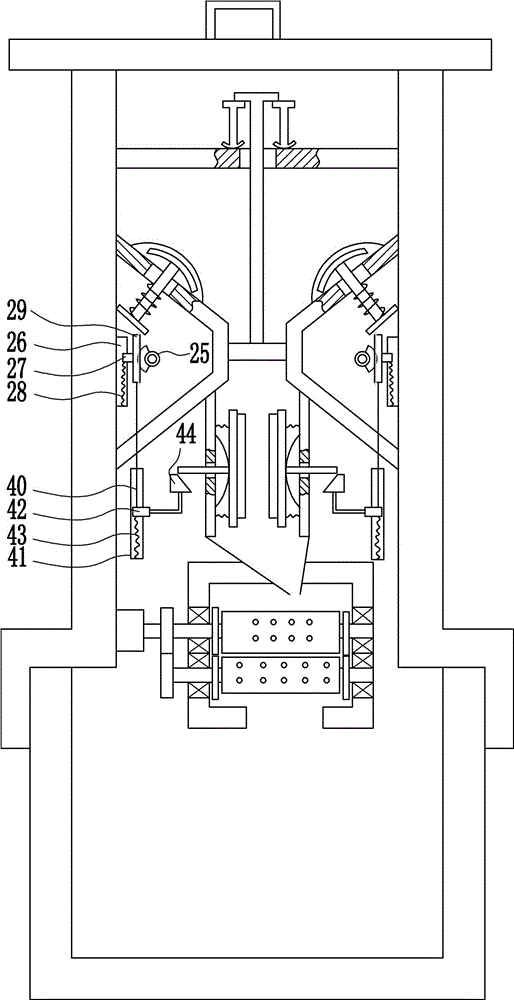

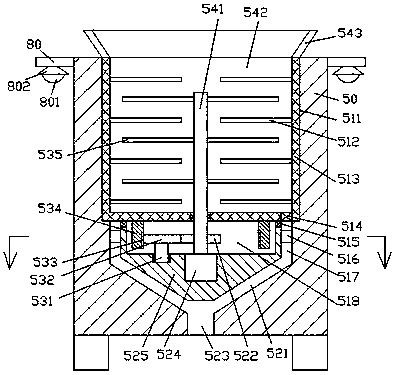

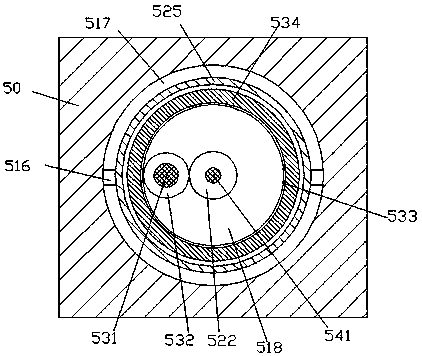

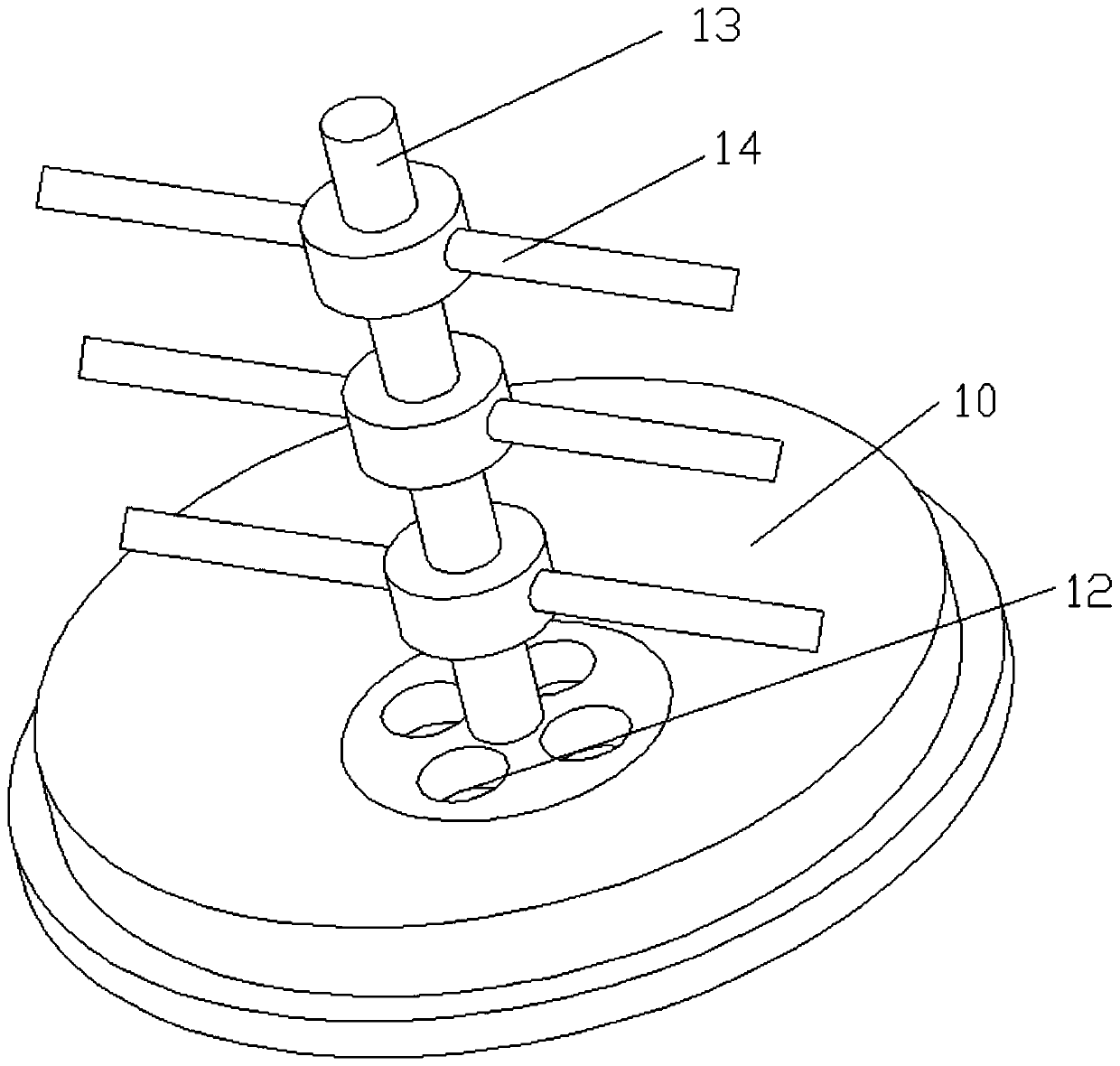

Crushing device for kitchen garbage recycling system and system with same

ActiveCN112619779ACrushed fullyFacilitate harmless treatment and utilizationGrain treatmentsGarbage collectionGrinding

The invention discloses a crushing device for a kitchen garbage recycling system and the system with the same. The crushing device comprises a barrel body, crushing blocks, a crushing roller and a grinding disc, wherein an upper cover is arranged at the upper part of the barrel body; the crushing blocks are arranged around the inner wall of the barrel body, and crushing teeth used for crushing kitchen garbage are arranged on the crushing blocks; the crushing roller is rotatably arranged on a central shaft of the barrel body, and has the function of reciprocating in the up-down direction and the left-right direction; and the grinding disc is rotatably arranged on the central shaft of the barrel body and positioned at the lower part of the crushing roller. According to the crushing device, the crushing roller and the grinding disc which have a rotating function are arranged in the central axis direction of the barrel body, under cooperation with the crushing blocks and grinding blocks on the inner wall of the barrel body, hard kitchen garbage such as bones is subjected to rotary grinding and then subjected to grinding crushing, the kitchen garbage is effectively crushed and even reaches a powder state, crushing is sufficient, and later harmless treatment and utilization are facilitated.

Owner:南宁市广厨厨房设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com