Solid garbage treatment device for constructional engineering

A technology of solid waste and construction engineering, applied in the field of construction engineering, can solve problems such as waste of iron resources, achieve the effects of saving iron resources, improving grinding efficiency, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

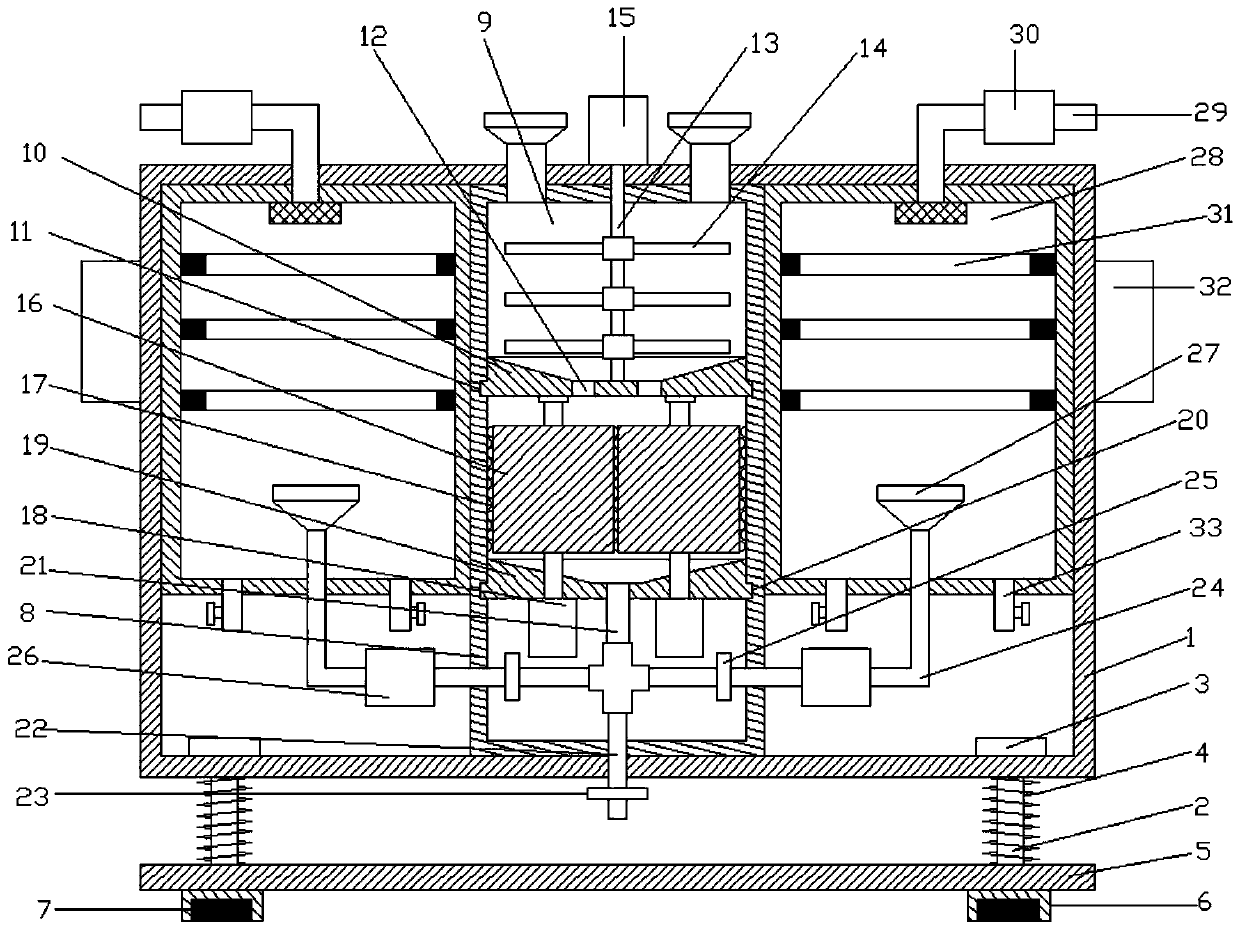

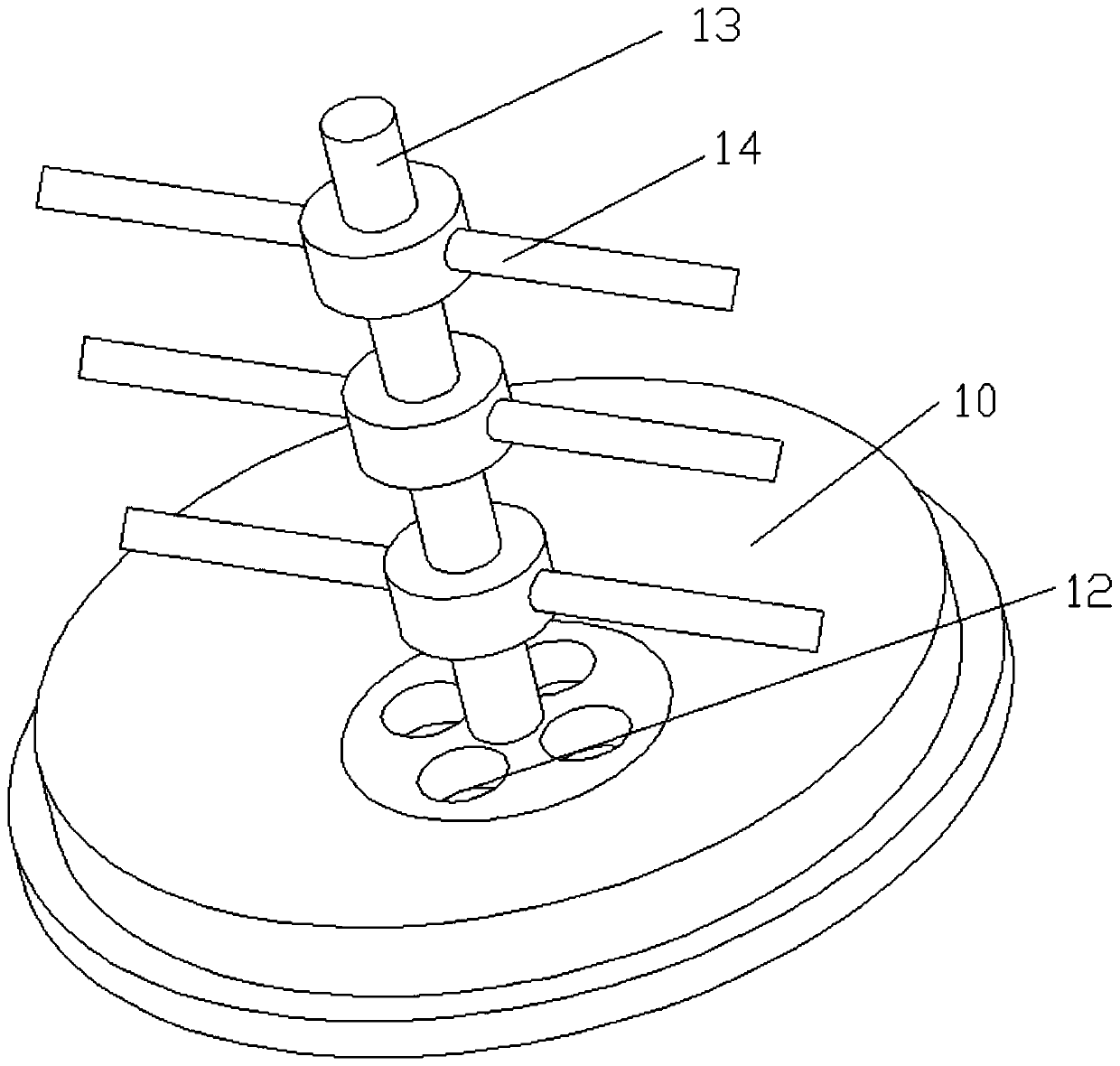

[0025] refer to Figure 1~3 , in an embodiment of the present invention, a solid waste treatment device for construction projects, comprising a support frame 1, a connection chamber 8 is provided in the middle of the support frame 1, a crushing chamber 9 is provided at the upper end of the connection chamber 8, and a crushing chamber 9 is provided at the bottom of the crushing chamber 9 A first rotation guide groove 10 is provided, and the lower end of the first rotation guide groove 10 is inserted into the inside of the first annular limiting groove 11, and the first annular limiting groove 11 is installed on the inner wall of the connecting cavity 8, and the first annular The limit groove 11 can effectively limit the first rotation diversion groove 10, so that the first rotation diversion groove 10 can be rotated smoothly, and the bottom four corners of the first rotation diversion groove 10 are provided with discharge The mouth 12 is convenient for the discharge of the crus...

Embodiment 2

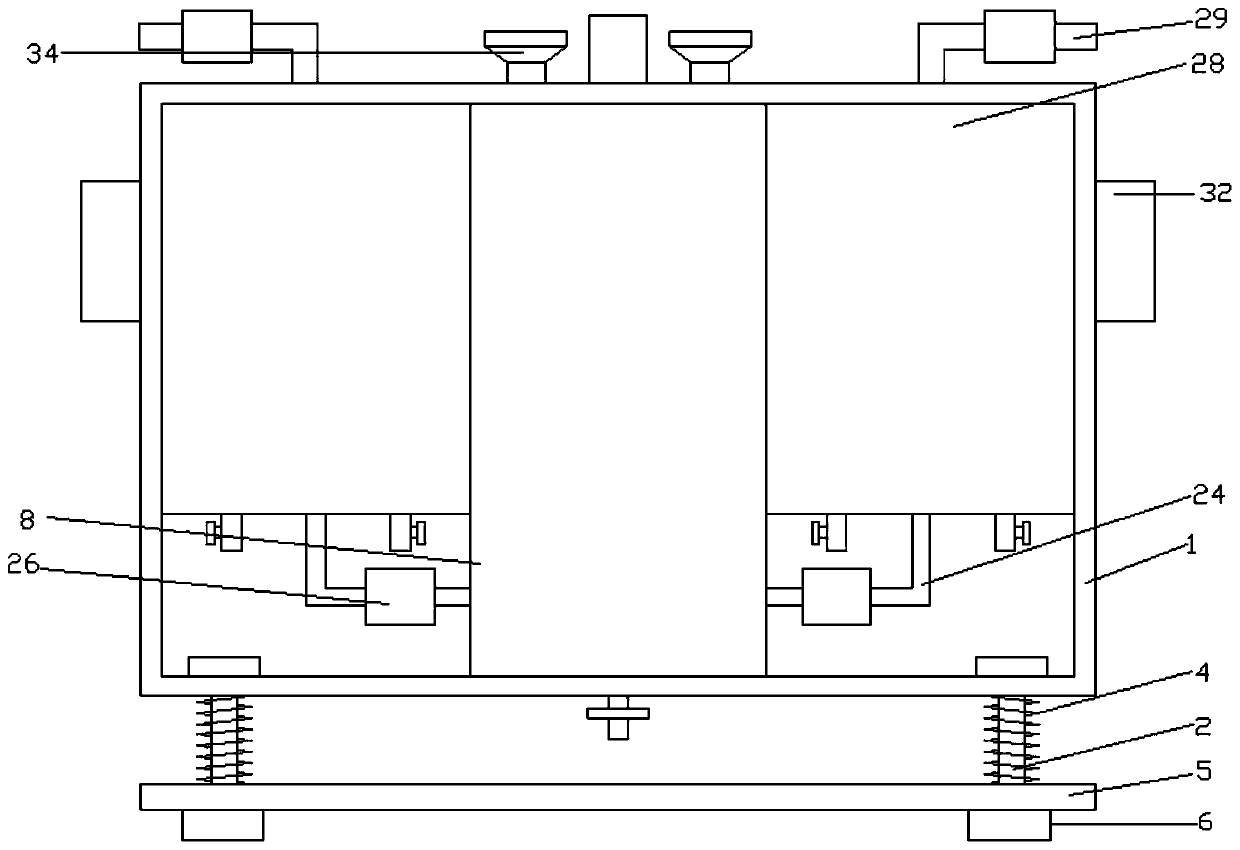

[0030] The difference from Embodiment 1 is that: the four corners of the lower side of the support frame 1 are provided with support columns 2, the upper end of the support column 2 passes through the support frame 1, and the top of the support column 2 is provided with a limit block 3, and the limit block 3 is arranged on the support The bottom of the frame 1 and the lower side of the support column 2 are fixedly equipped with a base plate 5, and a spring 4 is arranged on the support column 2 between the base plate 5 and the support frame 1, which can effectively reduce the vibration of the equipment, so as to ensure the stability of the equipment. The four corners of the lower side of the base plate 5 are fixedly equipped with support blocks 6, and the inner lower end of the support block 6 is inlaid with friction pads 7, which can increase the friction between the support block 6 and the ground, so as to ensure the stability of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com