Patents

Literature

454results about How to "Increase magnetic induction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

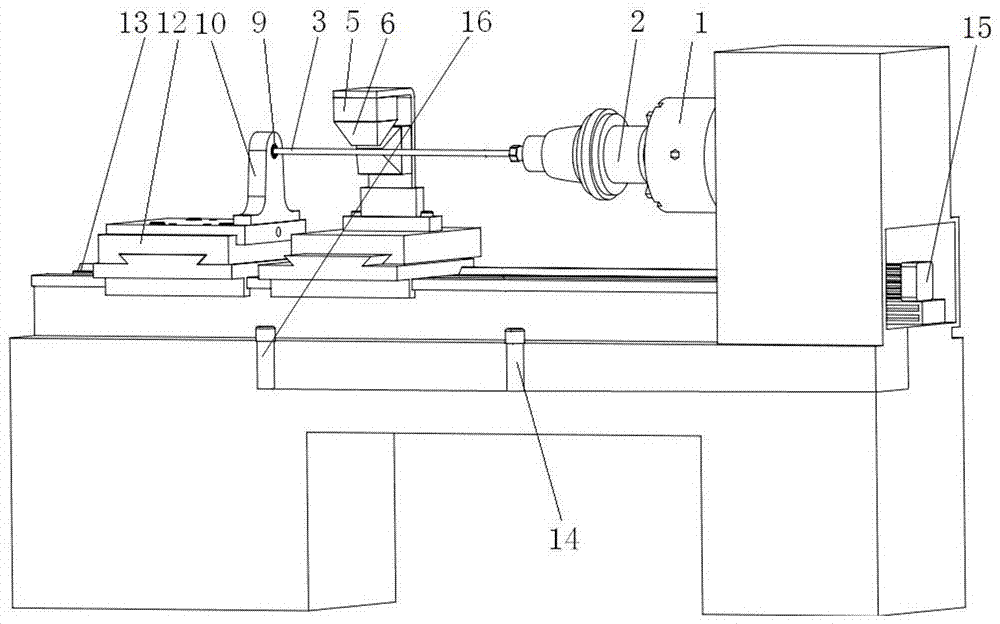

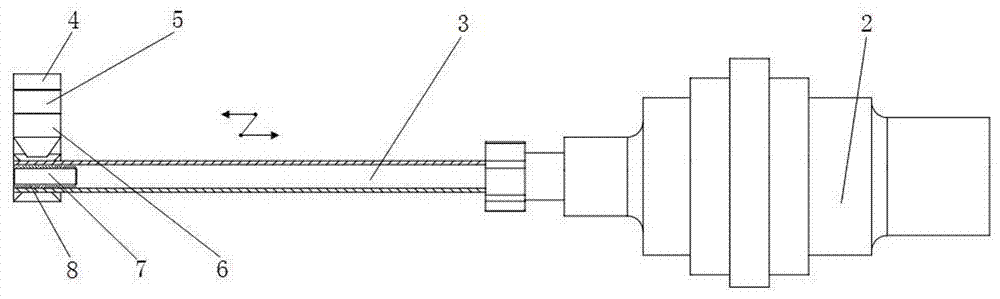

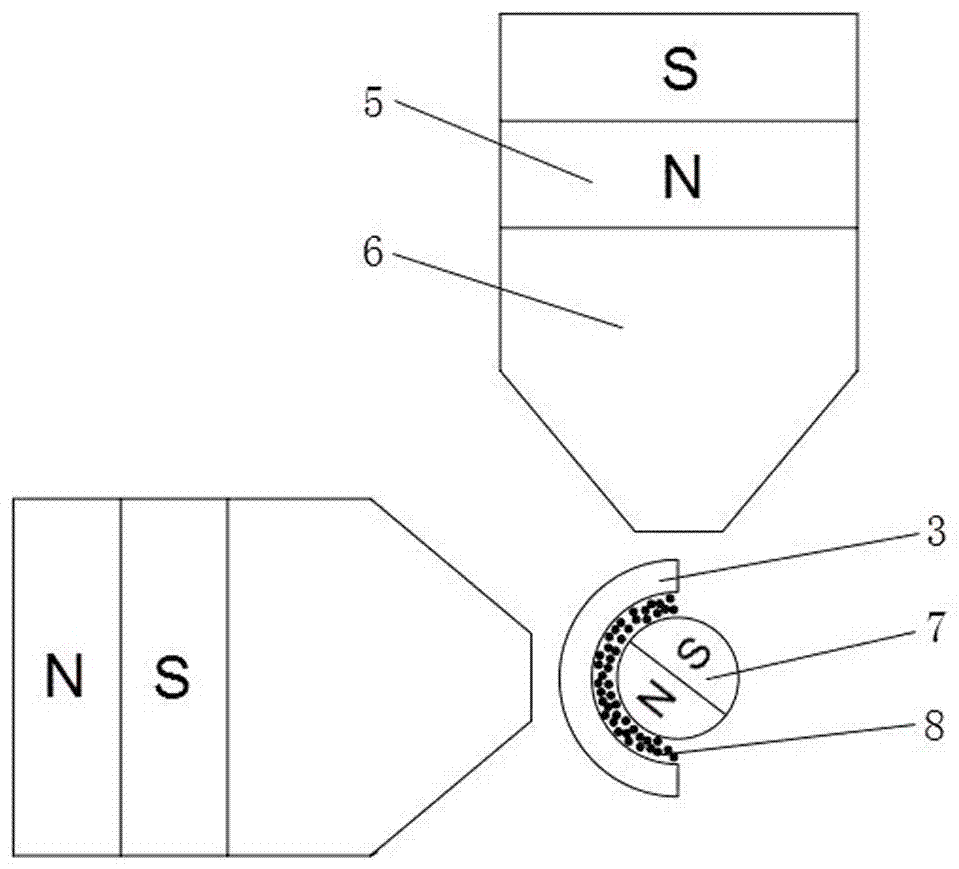

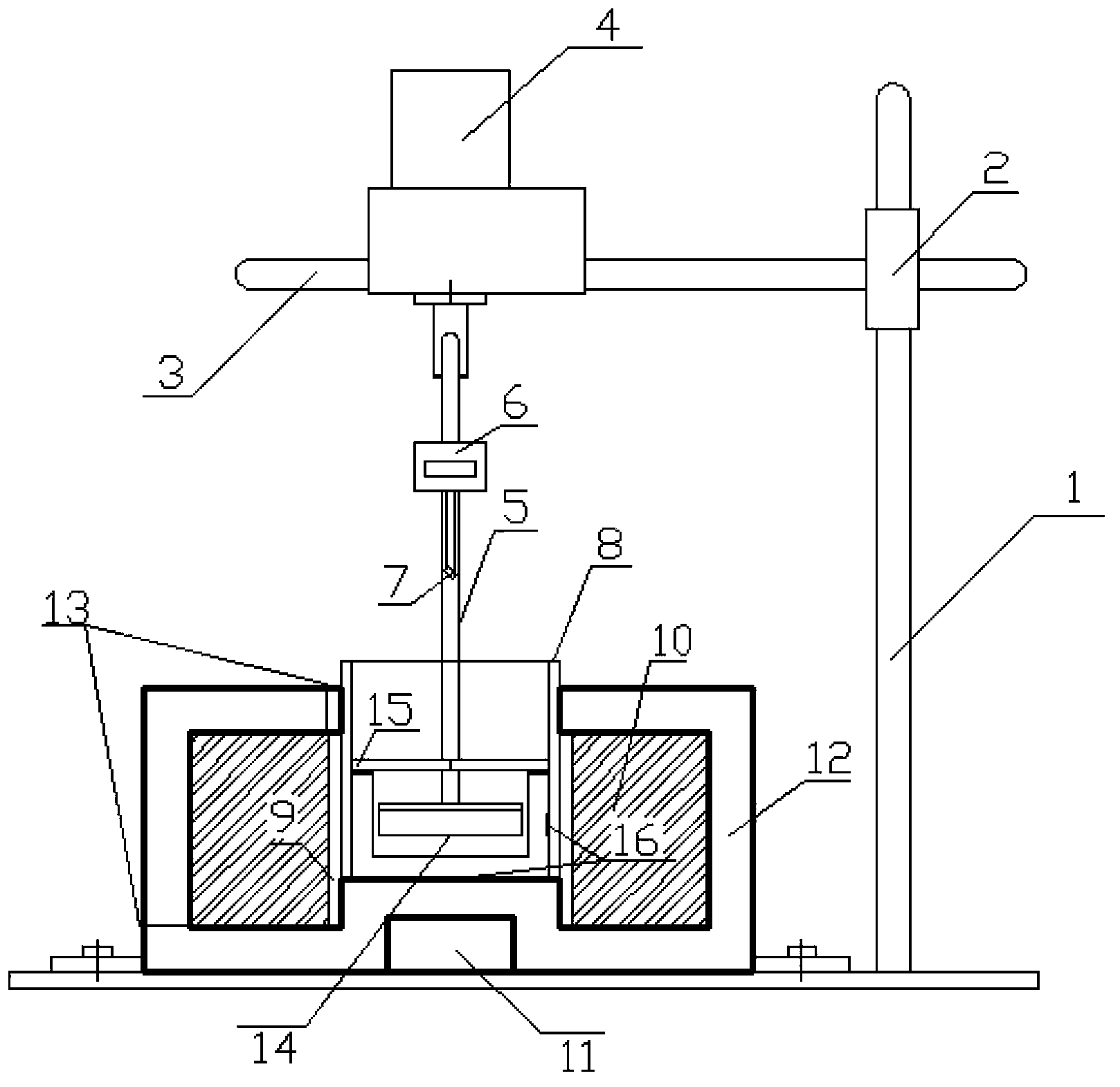

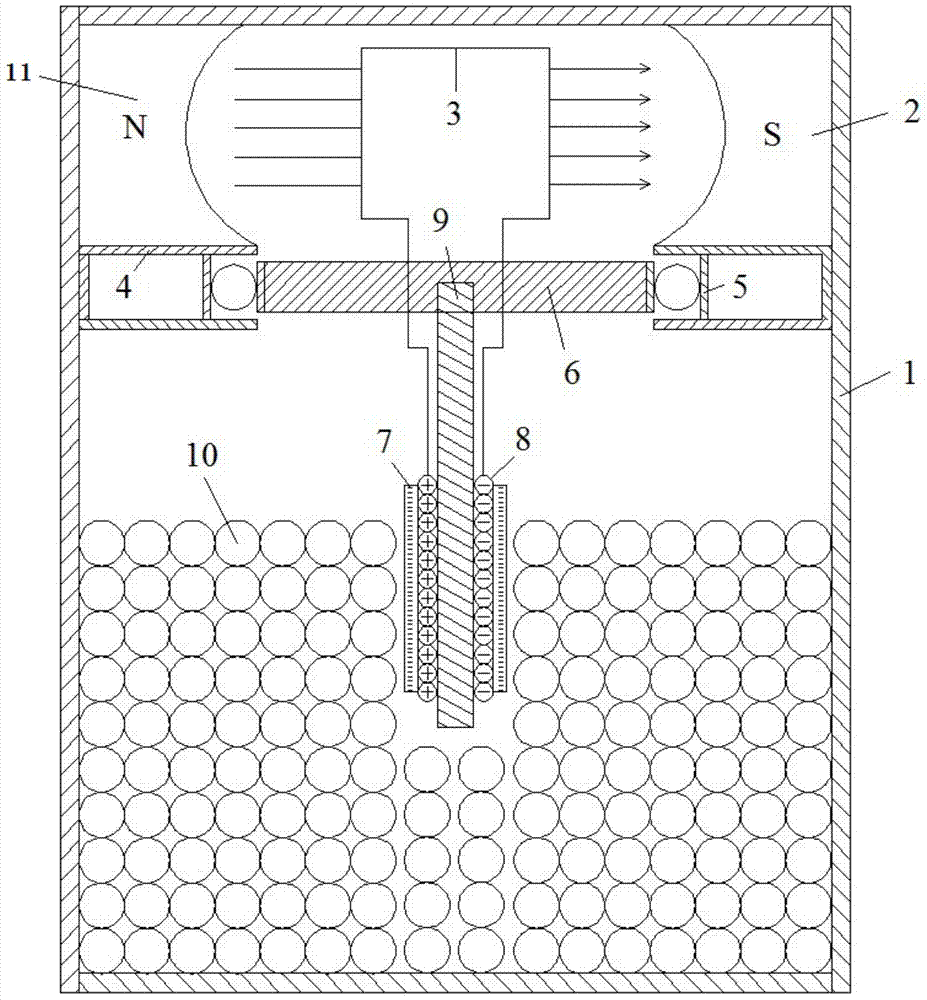

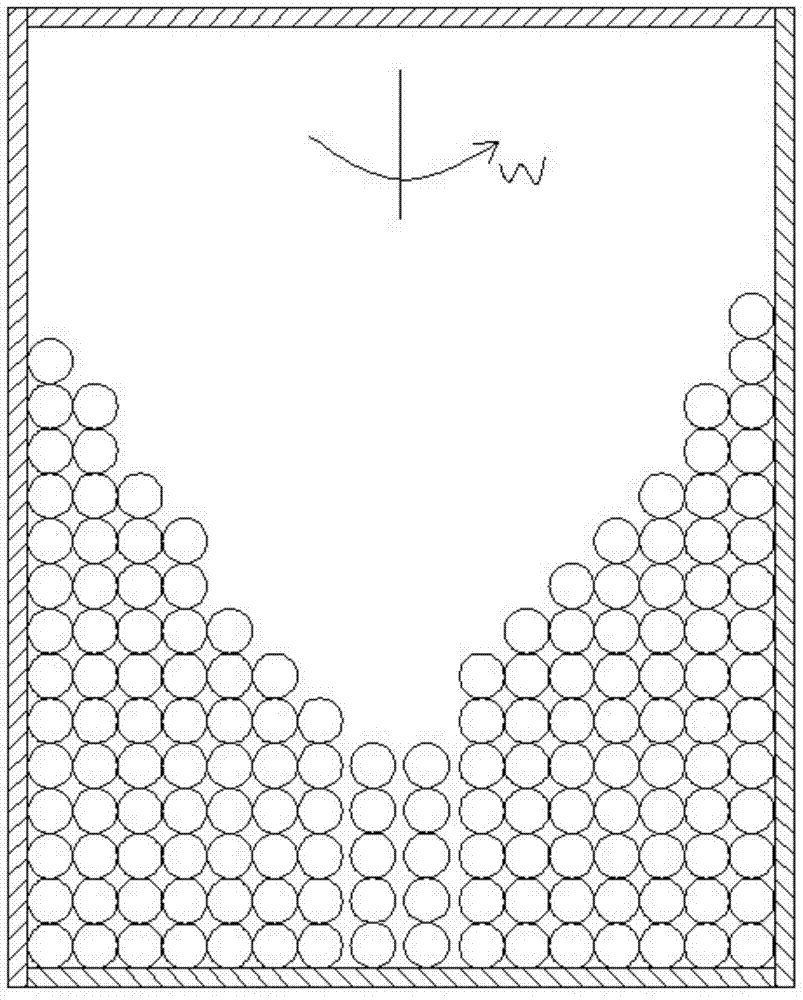

Inner surface polishing device of large-length-diameter-ratio slender pipe and method thereof

InactiveCN106938410AIncrease magnetic inductionIncrease grinding pressureGrinding work supportsMaterial removalDiameter ratio

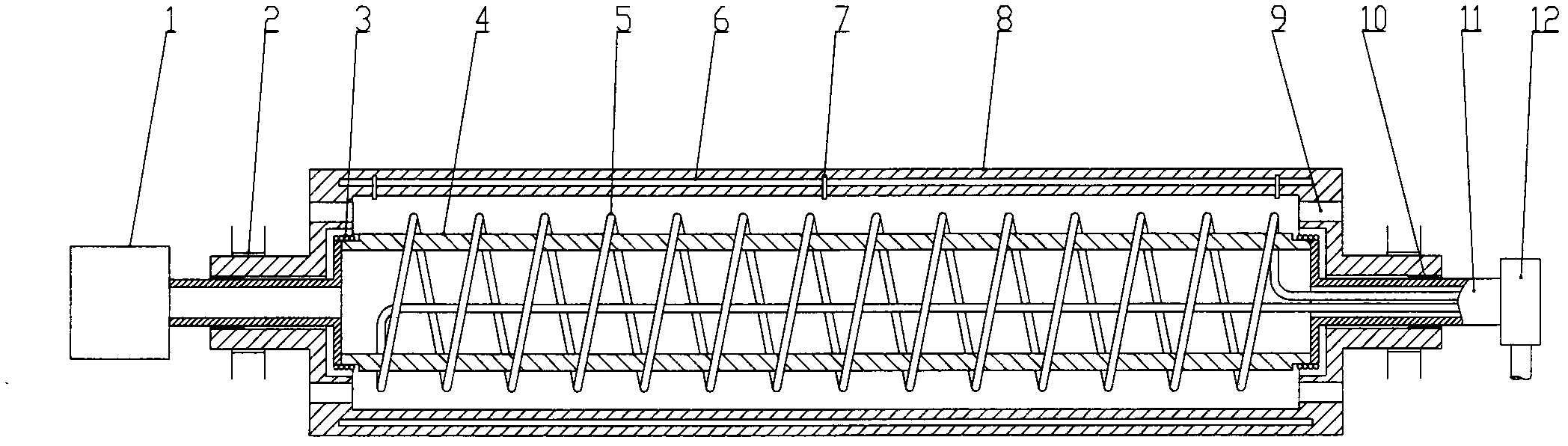

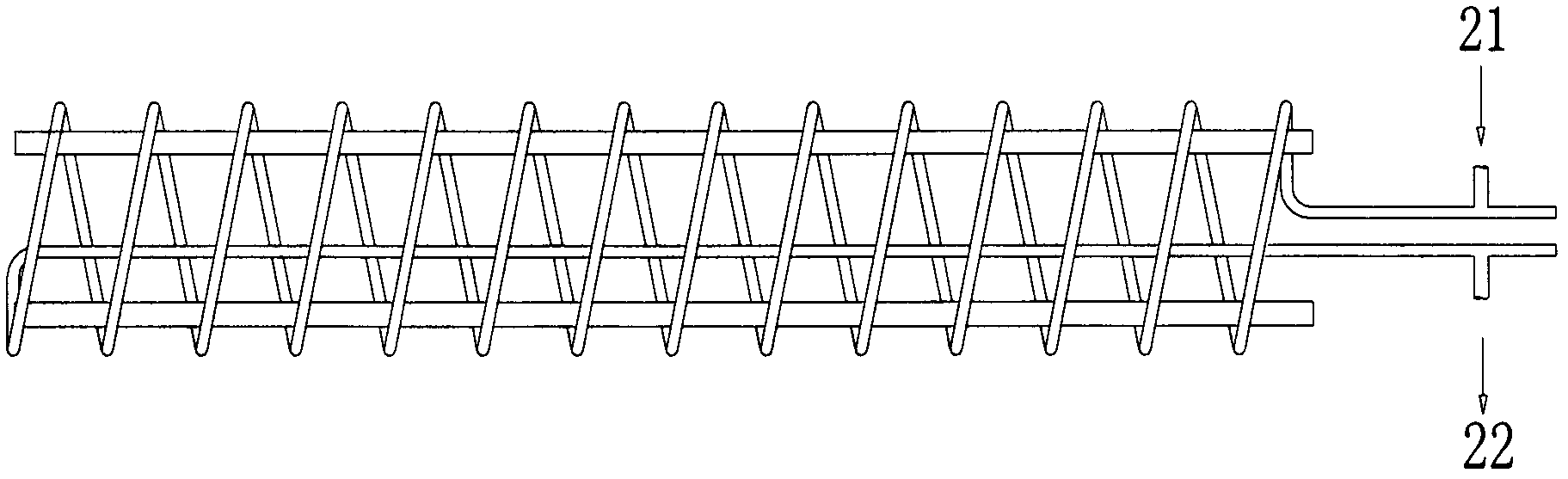

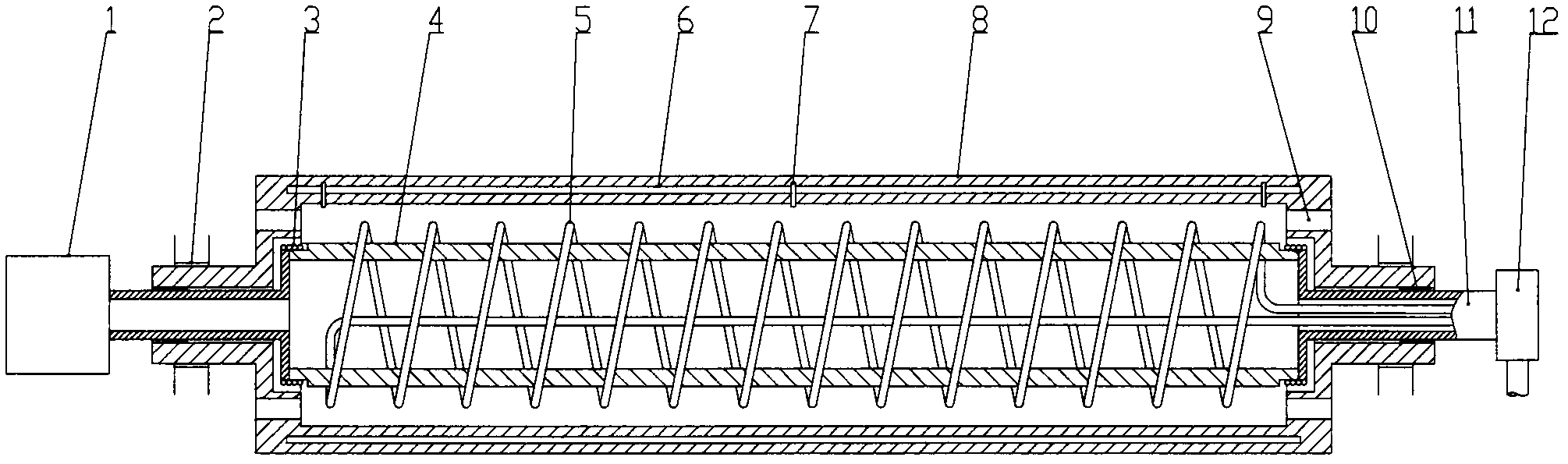

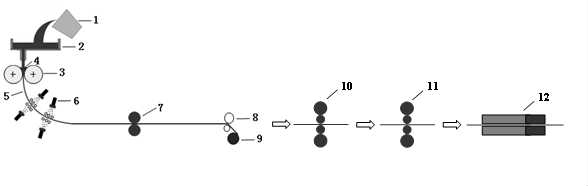

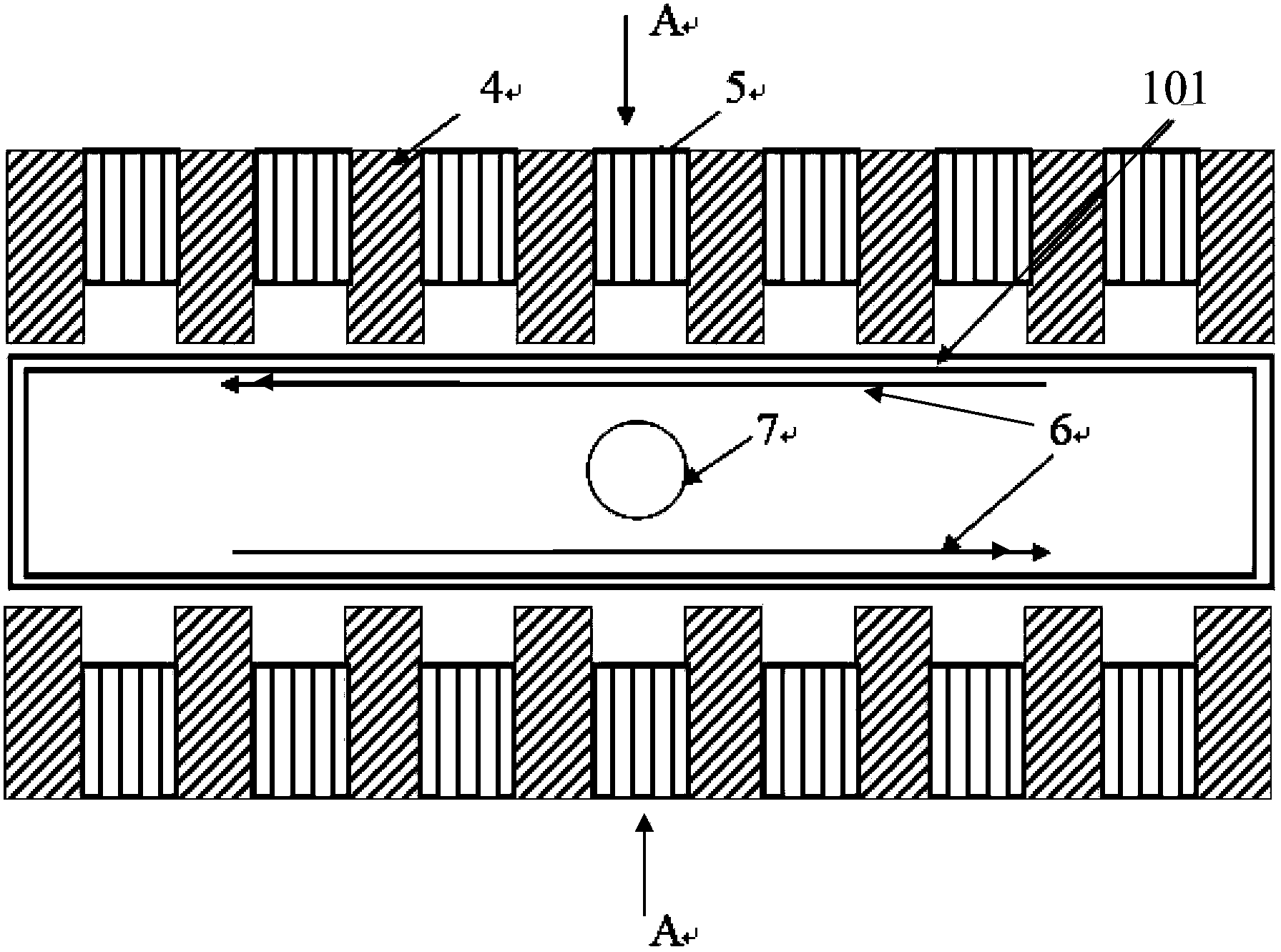

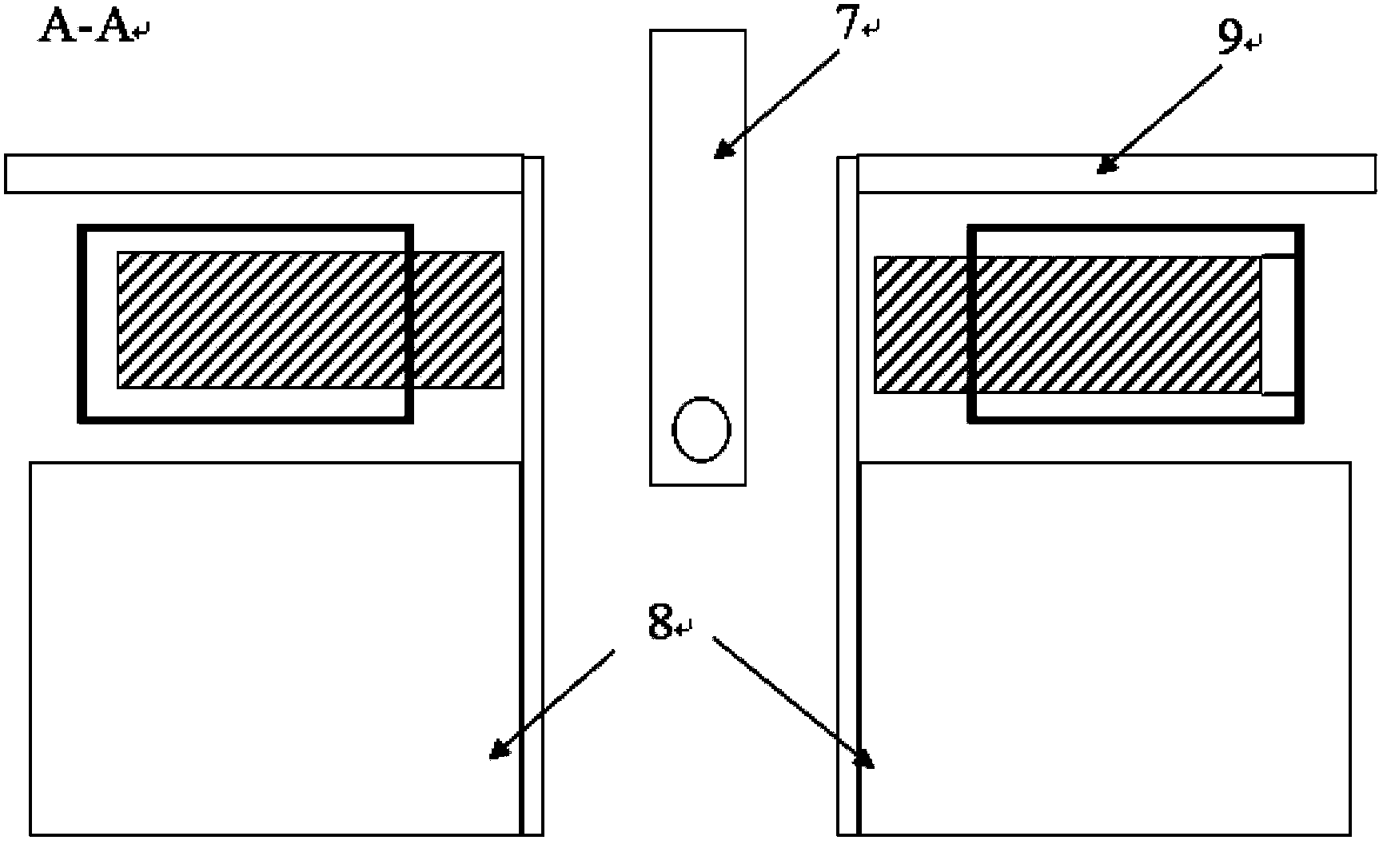

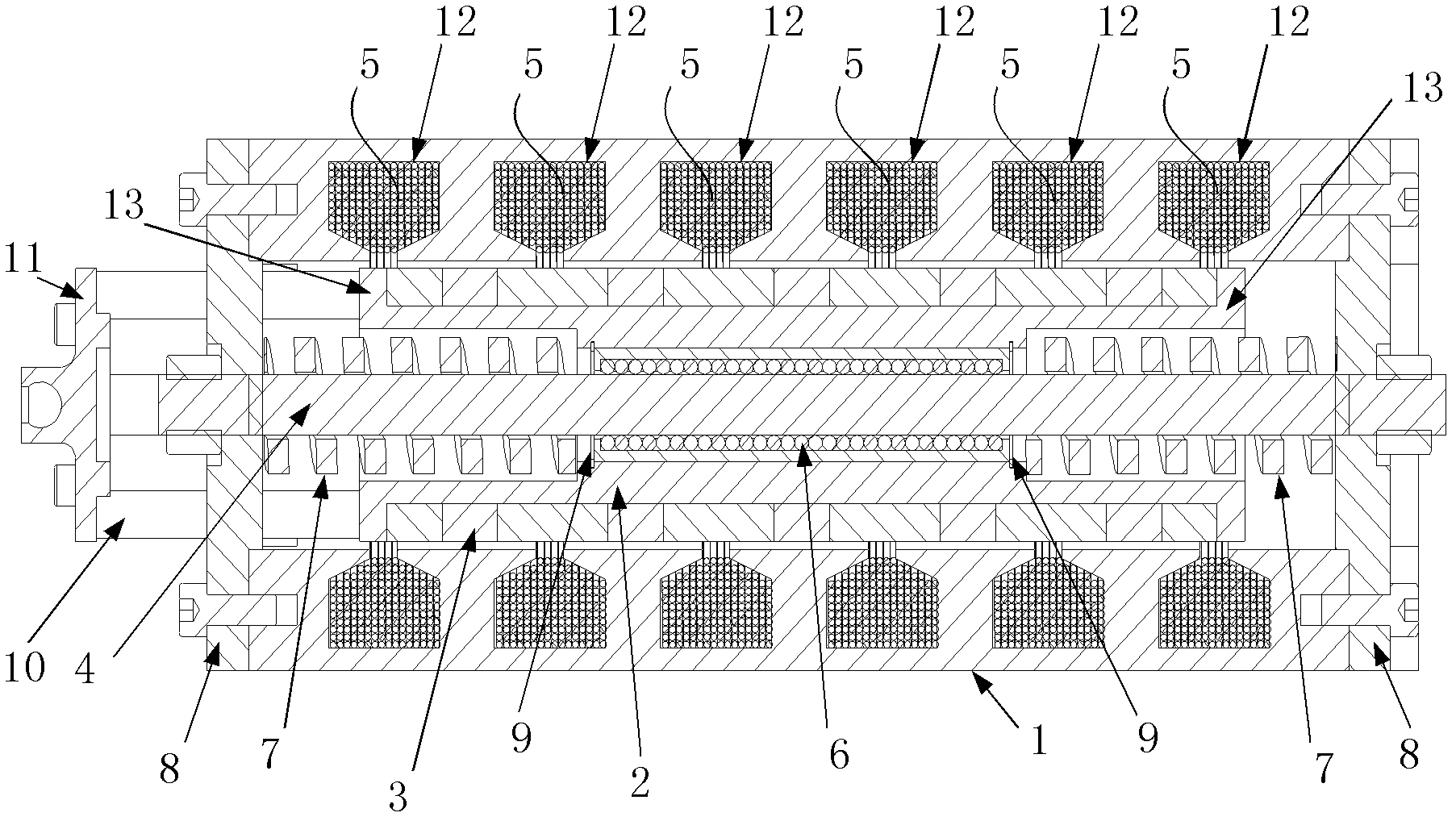

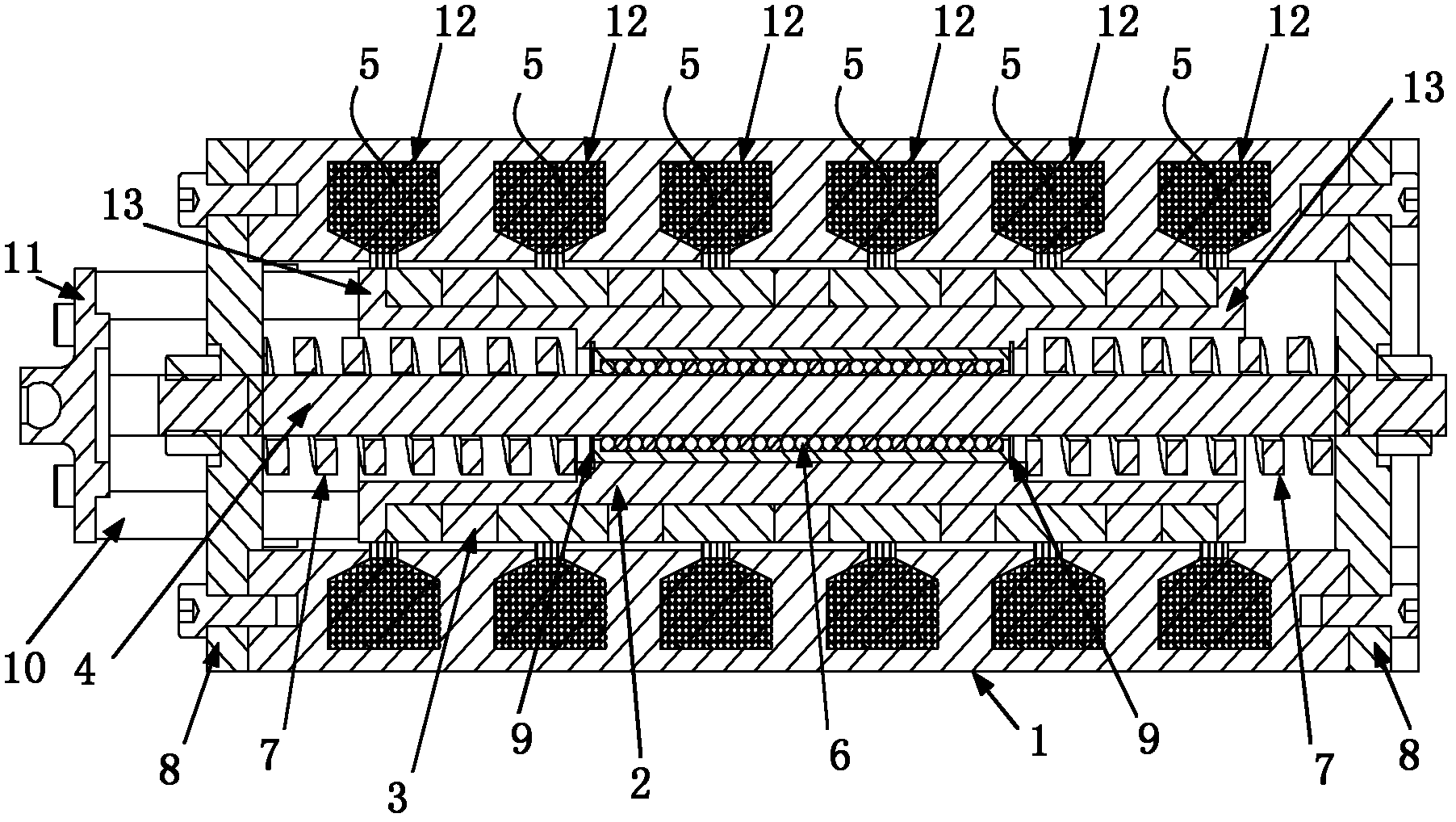

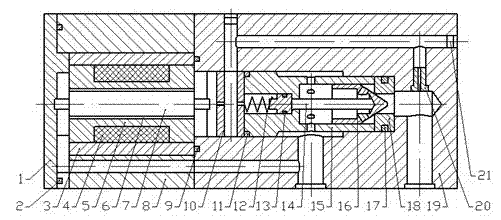

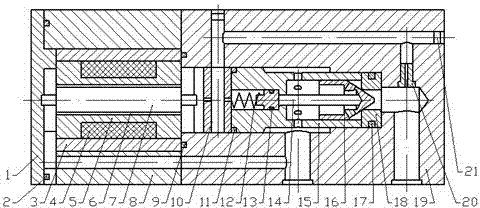

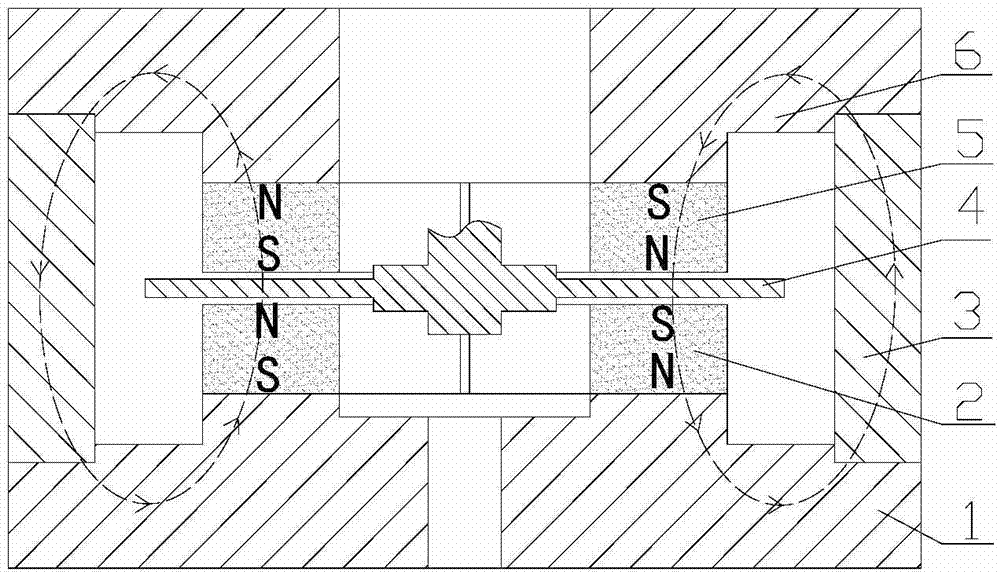

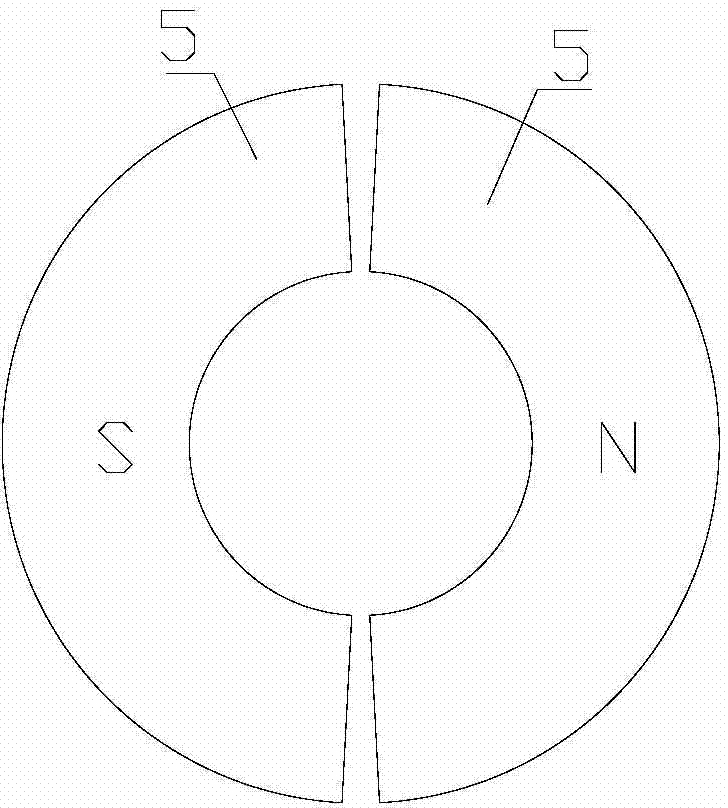

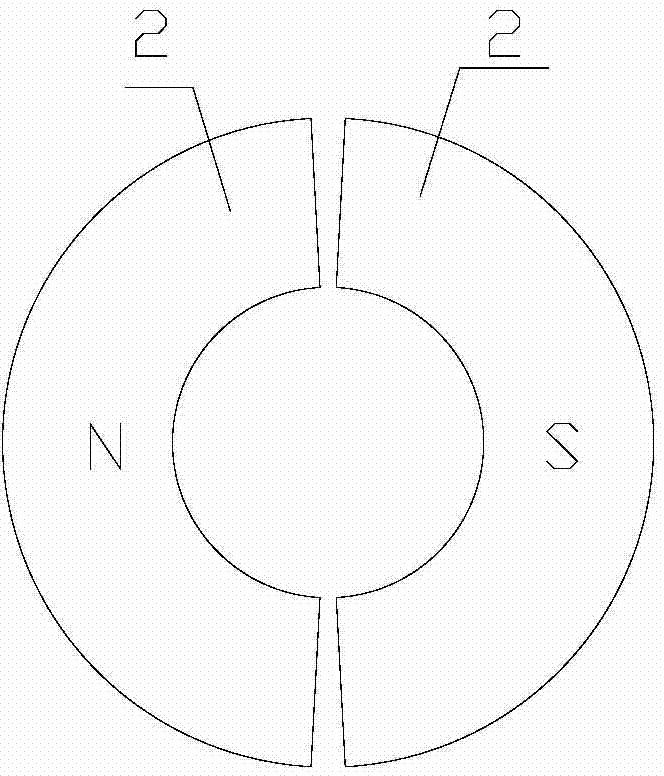

The invention belongs to the technical field of magnetic grinding, and in particular, relates to an inner surface polishing device of a large-length-diameter-ratio slender pipe and a method thereof. The polishing device is characterized by comprising a machine tool body, a moving mechanism arranged on the machine tool body, a workpiece clamping mechanism arranged on the machine tool body and a grinding mechanism arranged on the machine tool body; the grinding mechanism includes an ultrasonic generator and a magnetic grinding device; and the magnetic grinding device includes an external grinding device and an internal grinding device. The polishing device adds ultrasonic vibration into the traditional magnetic grinding process, so that magnetic grinding particles generate a high-frequency impact effect on the inner surface of the slender pipe; an auxiliary magnetic pole is added in an inner cavity of the slender pipe for forming a magnetic loop with an external magnetic pole, so that the magnetic induction strength of unit space is improved, and the grinding pressure is also increased; and the material removing quantity is 1.5 times of that in traditional magnetic grinding.

Owner:UNIV OF SCI & TECH LIAONING

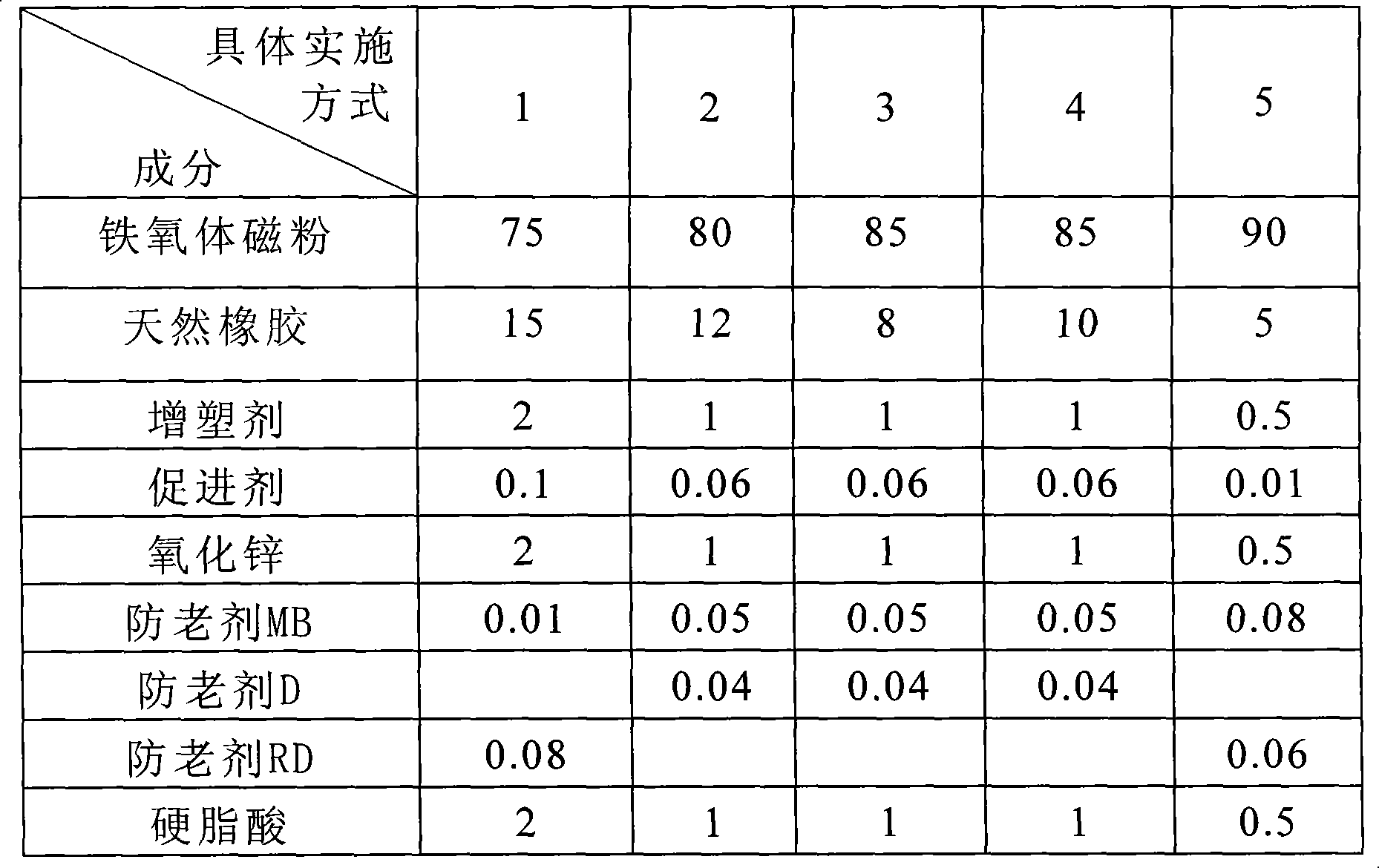

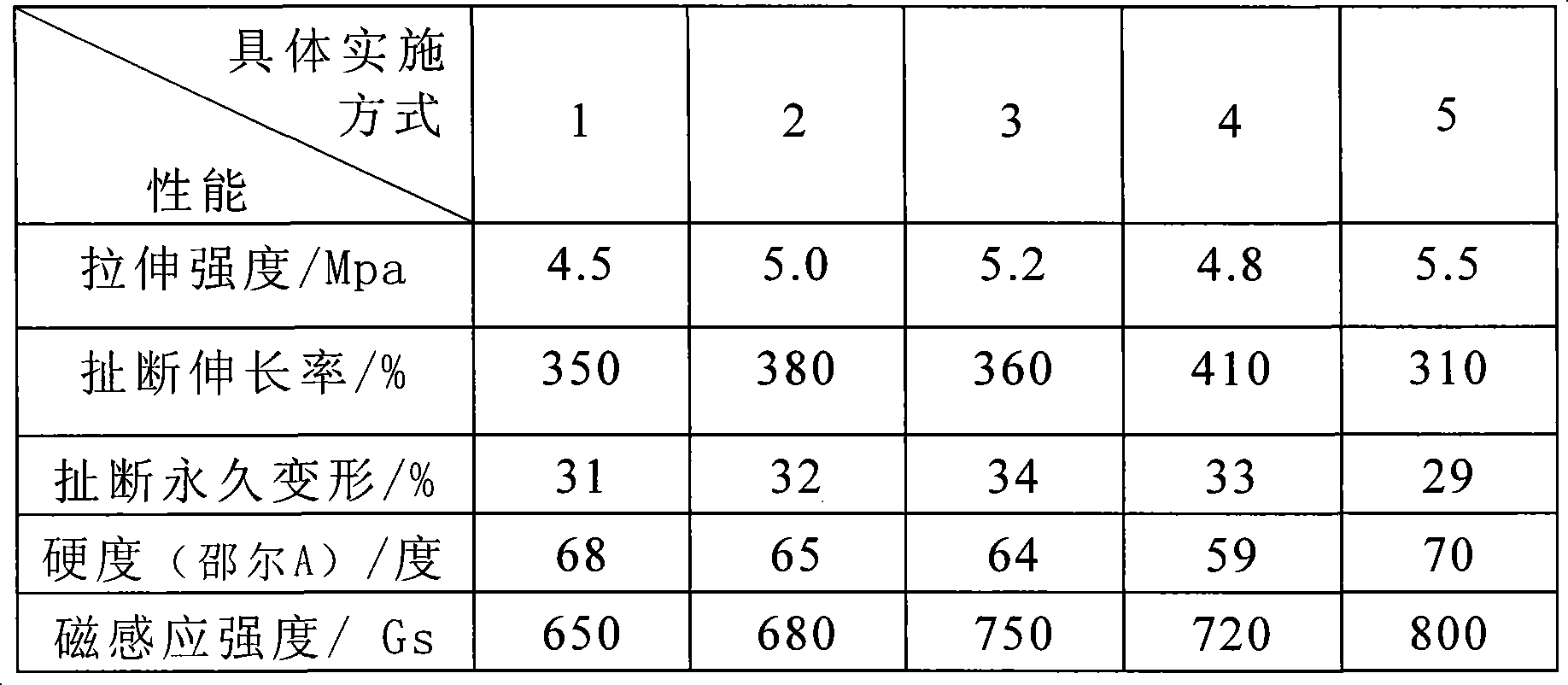

Magnetic rubber having high magnetic flux density and preparation method thereof

InactiveCN101230156ACompatibility is reasonableIncrease magnetic inductionOrganic/organic-metallic materials magnetismPlasticizerVolumetric Mass Density

The invention provides magnetic rubber with high magnetic induction intensity and the preparation method thereof, which belongs to the composite material technology field. The invention solves the problems in the prior production process that the production cost is high, the magnetic induction intensity of the produced special magnetic rubber product is low, and the elasticity performance is poor. The magnetic rubber with high magnetic induction intensity is made of ferromagnetic oxide powder, natural rubber, plasticizer, accelerator, activator, antioxidant and stearic acid which are prepared. The preparation method comprises the following steps: step A, grinding and blending; step B, rubber refining; step C, moulding, and step D, charging magnetism. The magnetic induction intensity of the magnetic rubber special product reaches above 600 gauss, and the elasticity performance is good; the preparation method and process is simple, and the production cost is low.

Owner:杨中联

Testing device for magneto-rheological fluid shear yield stress

ActiveCN103512690AAvoid wall slipEasy to pass through verticallyFlow propertiesApparatus for force/torque/work measurementFluid shearClosing wound

The invention relates to a device used for testing magneto-rheological fluid shear yield stress. The testing device mainly comprises an adjustable uniform magnetic field generating device, a steel barrel, a rotary shaft, a seal ring cover plate, a support, a motor, a torque sensor, a Hall piece, a data demodulation single-chip microcomputer and a testing display instrument. The testing device has the advantages that the magnetic field generating device can generate a large adjustable uniform magnetic field; wall face sliding can be prevented from occurring to magneto-rheological fluid under the condition that the magnetic field exists; a testing and displaying device enables weak voltage difference signals to be output onto the testing display instrument accurately in real time through a torque sensor, the PWM theory, a signal amplifying circuit and A / D conversion; a low-reluctance closed loop is formed on the outer side of a close-wound coil through industrial pure iron, and a coil fixing frame on the inner side of the close-wound coil is made of nylon materials so that more magnetic lines can pass through the magneto-rheological fluid. The magneto-rheological fluid is arranged in the center of the magnetic field generating device, so that the magnetic induction strength generated by the detected magneto-rheological fluid is distributed evenly and perpendicularly.

Owner:东南大学常州研究院

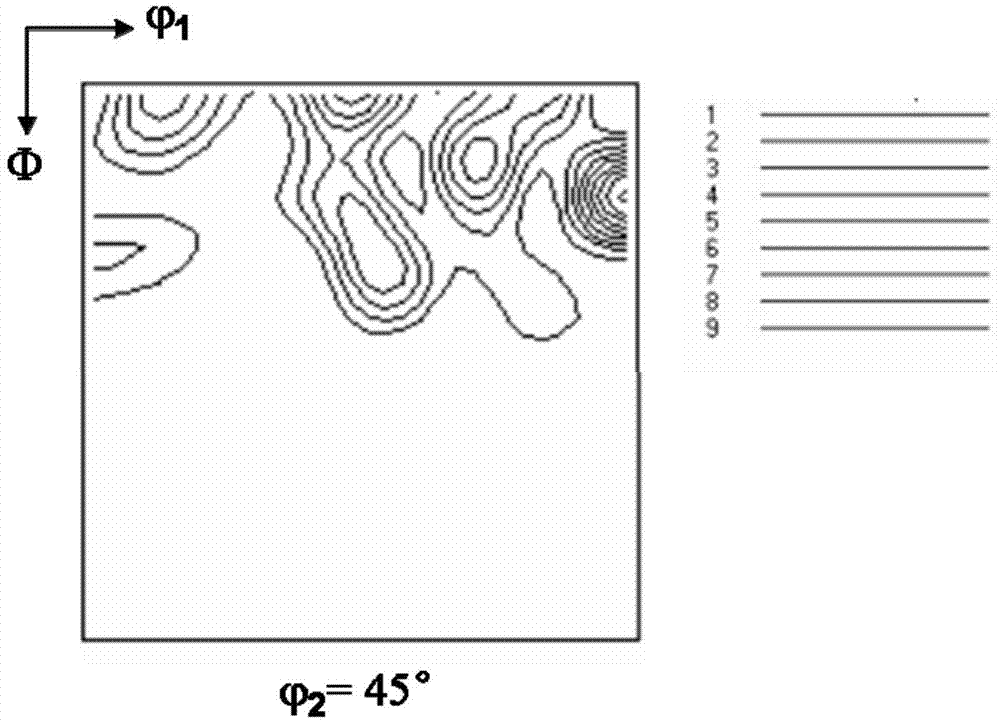

Non-oriented high-silicon electrical steel ribbon and its making method

InactiveCN103060701ASolve the characteristics of poor processing performanceImprove magnetismElectrical steelUltimate tensile strength

The invention relates to a non-oriented high-silicon electrical steel ribbon and its making method, and belongs to the fields of the metallurgical technology and the material science. The chemical components of the ribbon comprise 4.5-7.0wt% of Si, 2.0-5.0wt% of Cr, 0.06-1.0wt% of Al, 0.3-0.8wt% of Mn, 0.005wt% or less of N, 0.004wt% or less of S, 0.02wt% or less of P, 0.003wt% or less of O, 0.005wt% or less of C, and the balance Fe, and the thickness of the ribbon is 0.35-0.5mm. The making method comprises the following steps: smelting non-oriented high-silicon steel in a vacuum smelting furnace; carrying out double-roller ribbon roll-casting at a casting temperature of 1420-1460DEG C to the ribbon thickness of 1.0-1.5mm; carrying out hot rolling of the ribbon at 800-1100DEG C to the hot rolled ribbon thickness of 0.8-1.0mm; pickling, and preheating the ribbon, and carrying out warm rolling at 400-700DEG C; and annealing. The addition of the Cr element in the high-silicon electrical steel ribbon obviously improves the processing performance of the high-silicon steel ribbon, the iron loss value is same to the iron losses of present high-silicon steel products, and the magnetic induction intensity is above 0.03T higher than that of the present products. The making method has the advantages of simple technology, low energy consumption, high yield, and excellent product magnetic property.

Owner:NORTHEASTERN UNIV

Electromagnetic induction heating roller

InactiveCN102325395AReduce pollutionReduce fireCoil arrangementsInduction heating apparatusElectricityKerosene

The invention discloses an electromagnetic induction heating roller in which high-frequency electromagnetic induction coils are arranged. The main body is a hollow roller body; a magnetism conductive iron core is arranged in the roller body; one end of the magnetism conductive iron core is connected with a cable connector through a half shaft; a heating coil wound on the magnetism conductive iron core is led into the roller body via the cable connector; a compensative heating coil wound on both ends of the magnetism conductive iron core is led into the roller body via the cable connector; a layer of water-filled isolating cavity is arranged in the wall of the roller body; and the surfaces of both ends of the roller body are respectively provided with a plurality of air holes for exhausting heat. The heating roller which is produced by utilizing the electromagnetic induction heating principle can replace various other heating rollers which are still used in a large quantity at present. Compared with the currently used steam heating, resistance wires, electric heating tubes or method for heating the surface of the heating roller with hot kerosene, the electromagnetic induction heating roller can save more electricity consumption and increase the temperature stability and precision of the roller surface.

Owner:张家港市弘扬机械设备有限公司

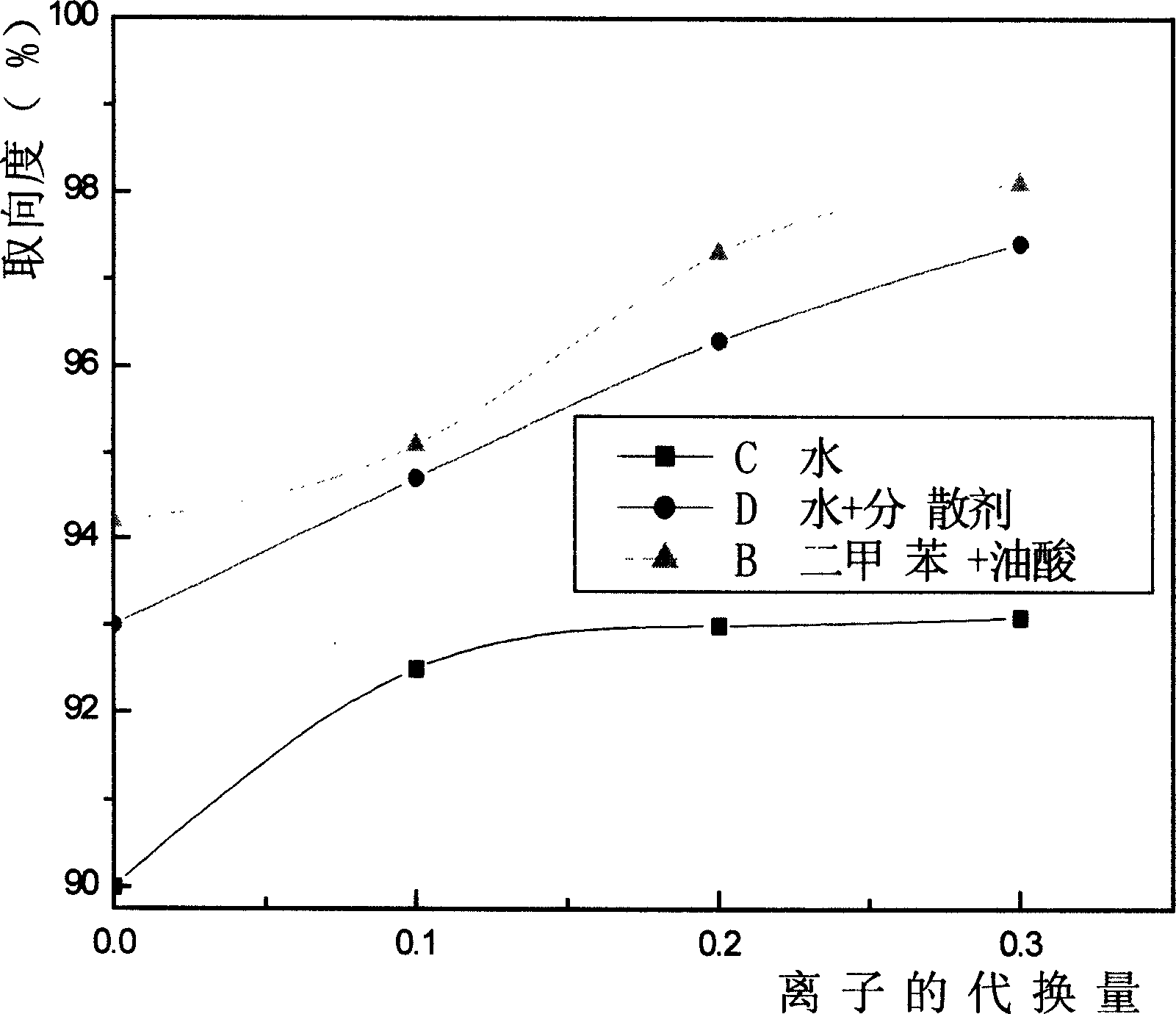

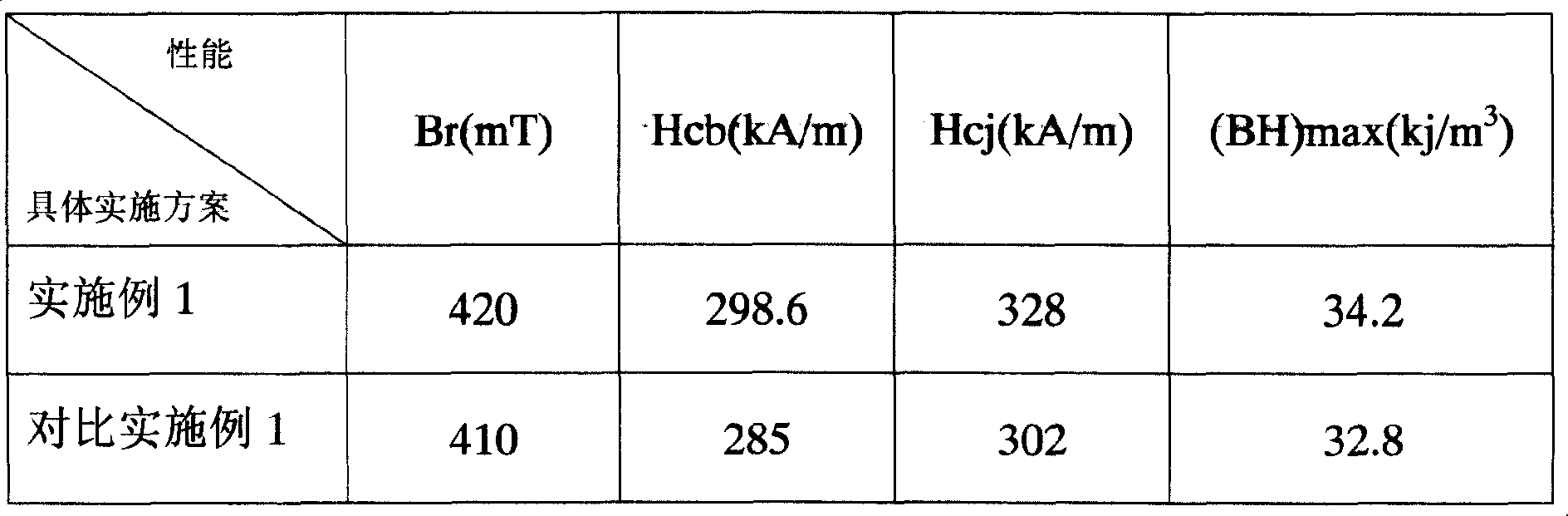

Process for preparing magnetic powder and sintered magnet and product produced thereby

ActiveCN1655295AIncrease the anisotropy constantImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyFerrite powder

This invention relates to magnetic material field and especially to a process method improvement and its formula to hexagonal magnetic lead ferrite powder and sinter magnetism, wherein the said magnetism or magnetic powder has one-Curie temperature with A,R, B and Fe hexagonal ferrite main phase and the following molecular formula: A1-XRx[(Fe3+aFe2+b)12-yBy]zO19, through adding positive three Co and optimizing the formula and improving the magnetism crystal aeolotropism constant K1.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

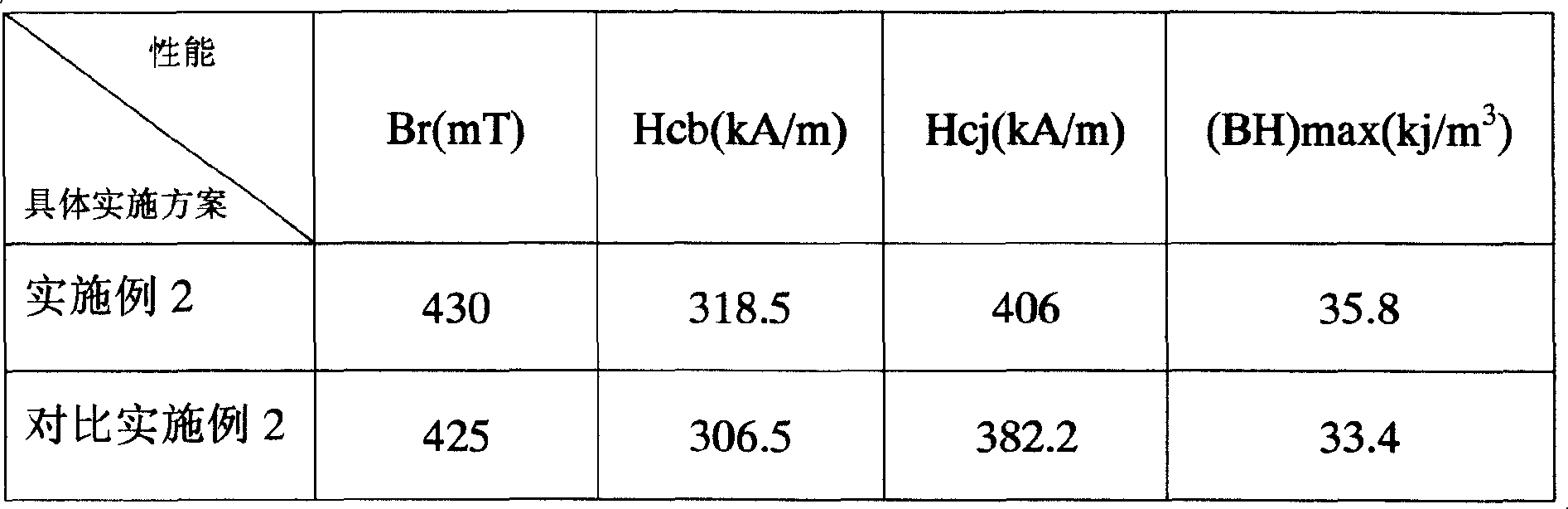

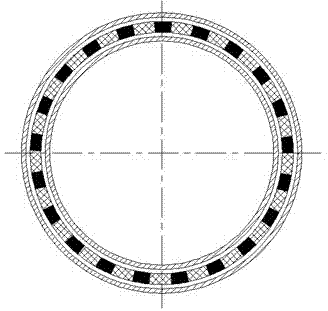

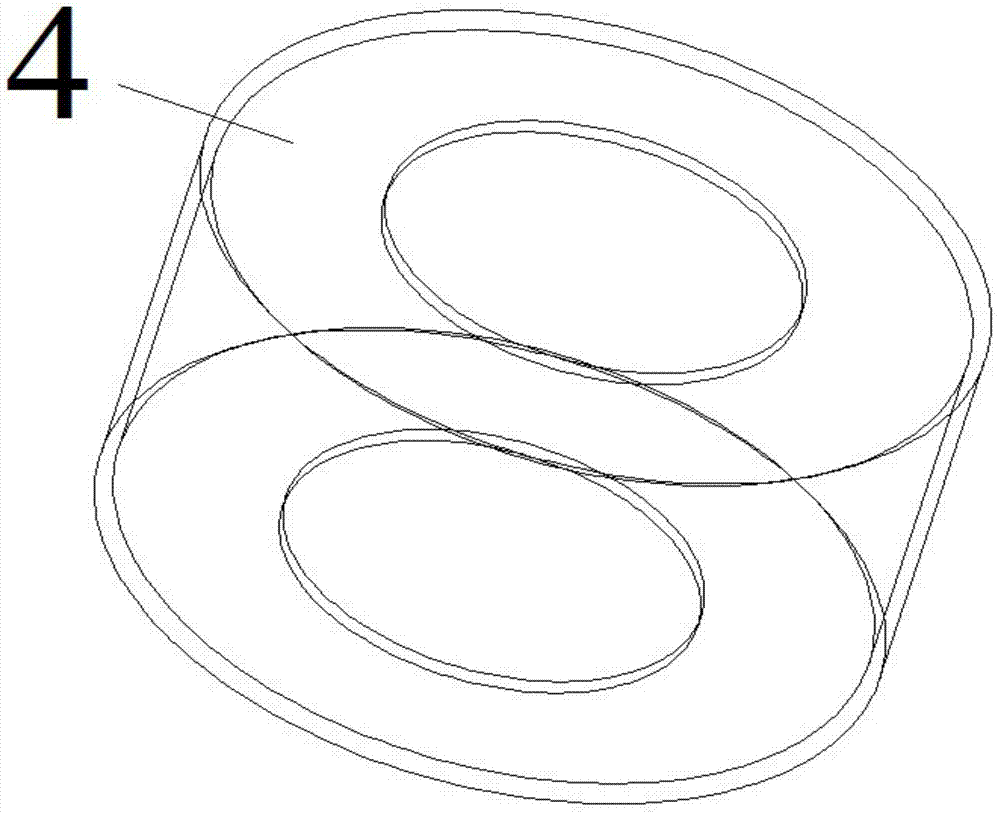

Cable tunnel inspection robot equipped with wireless charging equipment and charging method for robot

InactiveCN106787233AFast wireless chargingIncrease magnetic inductionCircuit arrangementsEngineeringElectron

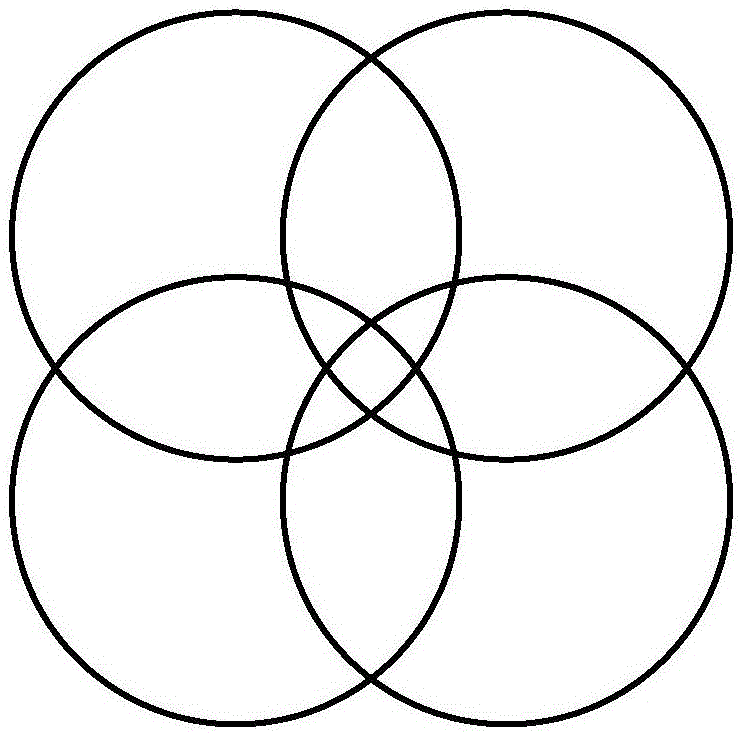

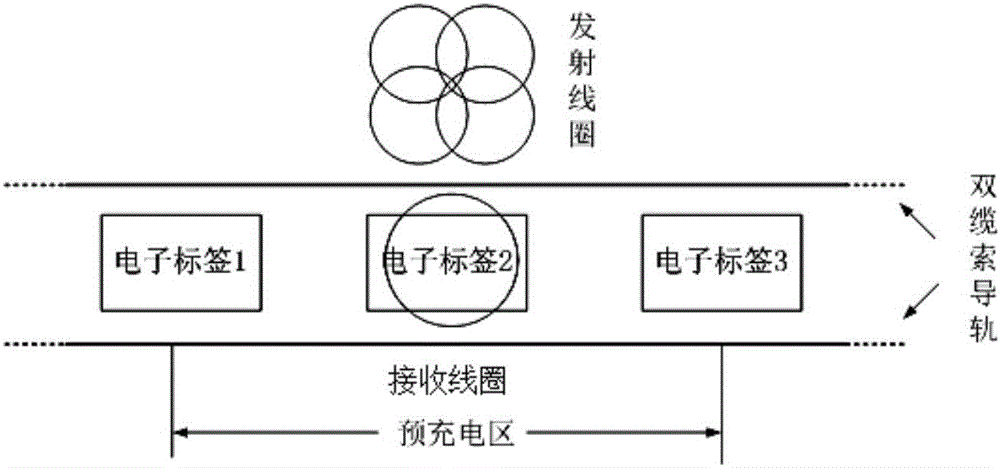

The invention discloses a cable tunnel inspection robot equipped with wireless charging equipment and a charging method for the robot. The wireless charging equipment comprises a transmitting unit, a receiving unit and a ZigBee communication module, wherein the receiving unit is mounted on the cable tunnel inspection robot; the transmitting coils in the transmitting unit are four equal-size circular coils which are arranged on the same plane and are connected in series mutually; a square is formed by the centers of the circular coils in a surrounding manner, and the circular coils are partially overlapped mutually; a charging battery in the receiving unit is used for supplying electric energy for the cable tunnel inspection robot; and a first controller in the transmitting unit and a second controller in the receiving unit are in wireless connection through the ZigBee communication module. According to the charging method disclosed by the invention, an RFID electronic tag is adopted to realize accurate positioning of the cable tunnel inspection robot, so that quick wireless charging of a dual-cable-rope guiding rail type cable tunnel inspection robot is realized.

Owner:WUHAN UNIV

High-magnetic strength oriented silicon steel and production method thereof

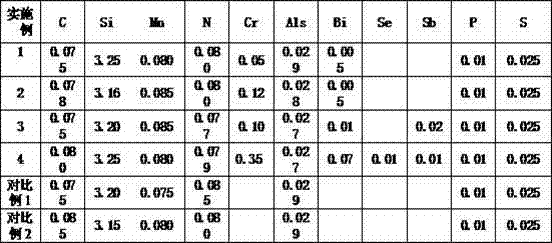

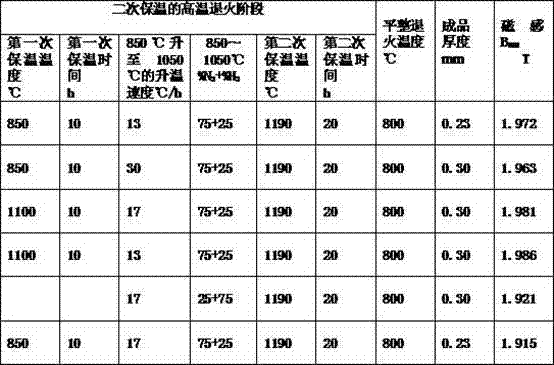

The invention discloses high-magnetic strength oriented silicon steel, comprising the following components by weight percent: 0.055-0.095% of C, 2.95-3.25% of Si, 0.050-0.090% of Mn, no more than 0.01% of P, 0.010-0.025% of S, 0.006-0.010% of N, 0.05-0.5% of Cr, 0.020-0.030% of Als, 0.002-0.1% of Bi, 0.01-0.06% of Se and 0.01-0.06% of Sb. The production method comprises the following production steps: heating a casting blank; rolling, processing at normal temperature; conventionally rolling into the product by adopting a primary cold rolling method or a secondary rolling method containing intermediate annealing; decarbonizing and annealing; coating a parting compound of taking magnesium oxide as a main ingredient; annealing at high temperature by adopting secondary heat preservation, carrying out heat preservation at 800-1100 DEG C for 5-20 hours, and at 1170-1220 DEG C for 5-25 hours in a full-hydrogen atmosphere; stretching and flatly annealing; coating an insulating layer on the surface of a steel plate. The magnetic induction strength B800 of the oriented silicon steel is not lower than 1.95T by independently adding or compositely adding Sb, Se and Bi grain-boundary segregation elements, and the magnetic property is stable.

Owner:武汉钢铁有限公司

Low temperature superconductivity ferromagnetic deironing device

ActiveCN101195108AReduce heat leakageImprove stabilityOpen gradient mangetic separatorsSuperconducting magnets/coilsSuperconducting CoilsSuperconductivity

The invention discloses a strong magnetic iron remover with low temperature superconductivity, a cryostat is arranged on an outer cover of the invention, and the cryostat is hoisted on an inner wall of the outer cover through a pull-rod. The cryostat is provided with an indoor temperature Dewar, a 4.2K Dewar is arranged in the indoor temperature Dewar, a heat radiation screen is arranged between the indoor temperature Dewar and the 4.2K Dewar, gaps are arranged in perimeters between the indoor temperature Dewar and the heat radiation screen and between the heat radiation screen and the 4.2K Dewar, a superconducting coil can be coiled in insulation on an inner cylinder of the 4.2K Dewar, and power can be provided for the superconducting coil by a pair of two-dimensional electric currents lead-in wires. A vacuum state is between the indoor temperature Dewar and the 4.2K Dewar, and the 4.2K Dewar is filled with liquid helium20. The invention has great magnetic induction intensity, and can suck out tiny iron magnetic substances from materials, and has high working stability.

Owner:SHANDONG HUATE MAGNET TECH +1

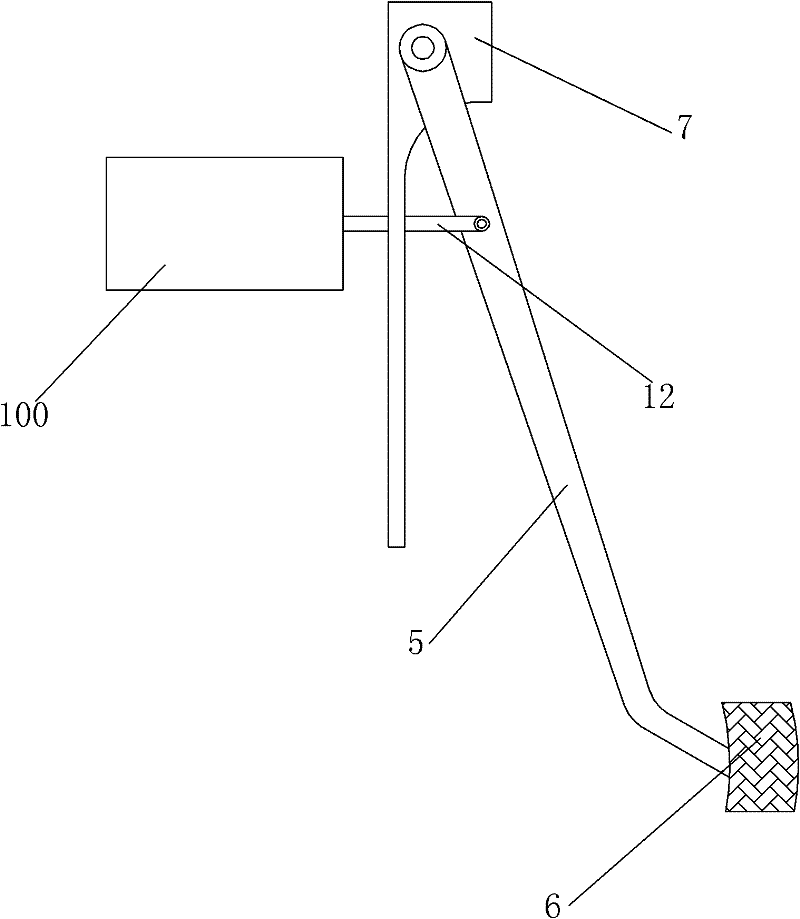

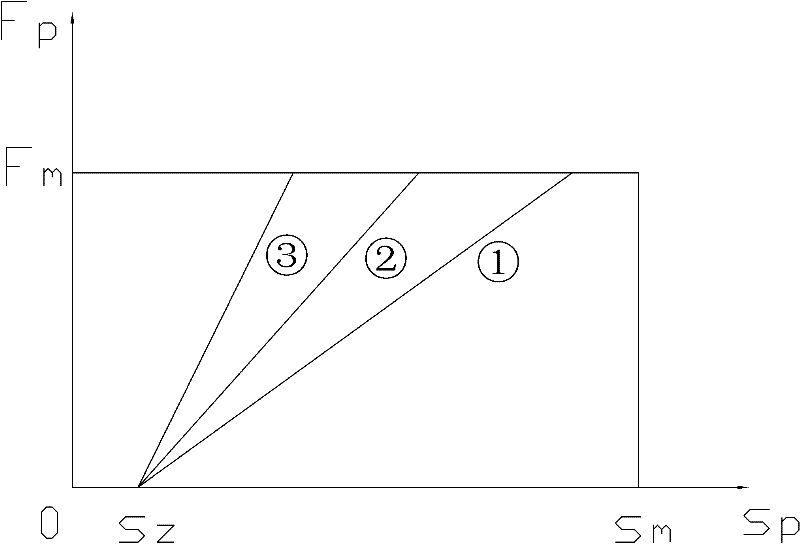

Automobile brake pedal mechanism and pedal feel simulator thereof

The invention relates to an automobile brake pedal mechanism and a pedal feel simulator thereof. The brake pedal mechanism comprises a brake pedal, a pedal displacement sensor, the pedal feel simulator, a microwave distance-measuring radar, a central processing unit and the like, wherein the pedal displacement sensor adopts two variable resistors for identifying the brake intention of a driver; the pedal feel simulator is based on a magnetorheological fluid principle; the central processing unit can controls the voltage volume of a coil and adjusts the damp of the simulator according to the pedal speed or distance information of front vehicles, people or barriers provided by the microwave distance-measuring radar, so that the driver has excellent operation feel, and the stability, comfortand safety of brake can be improved. Meanwhile, by changing the set value in the central processing unit, the damp output curve of the pedal feel simulator can be adjusted to meet requirements of different vehicle models or drivers. The automobile brake pedal mechanism and the pedal feel simulator thereof have the advantages of simple structure, quick response, good adaptability and the like, andis convenient in operation,.

Owner:南通特力锻压机床有限公司 +1

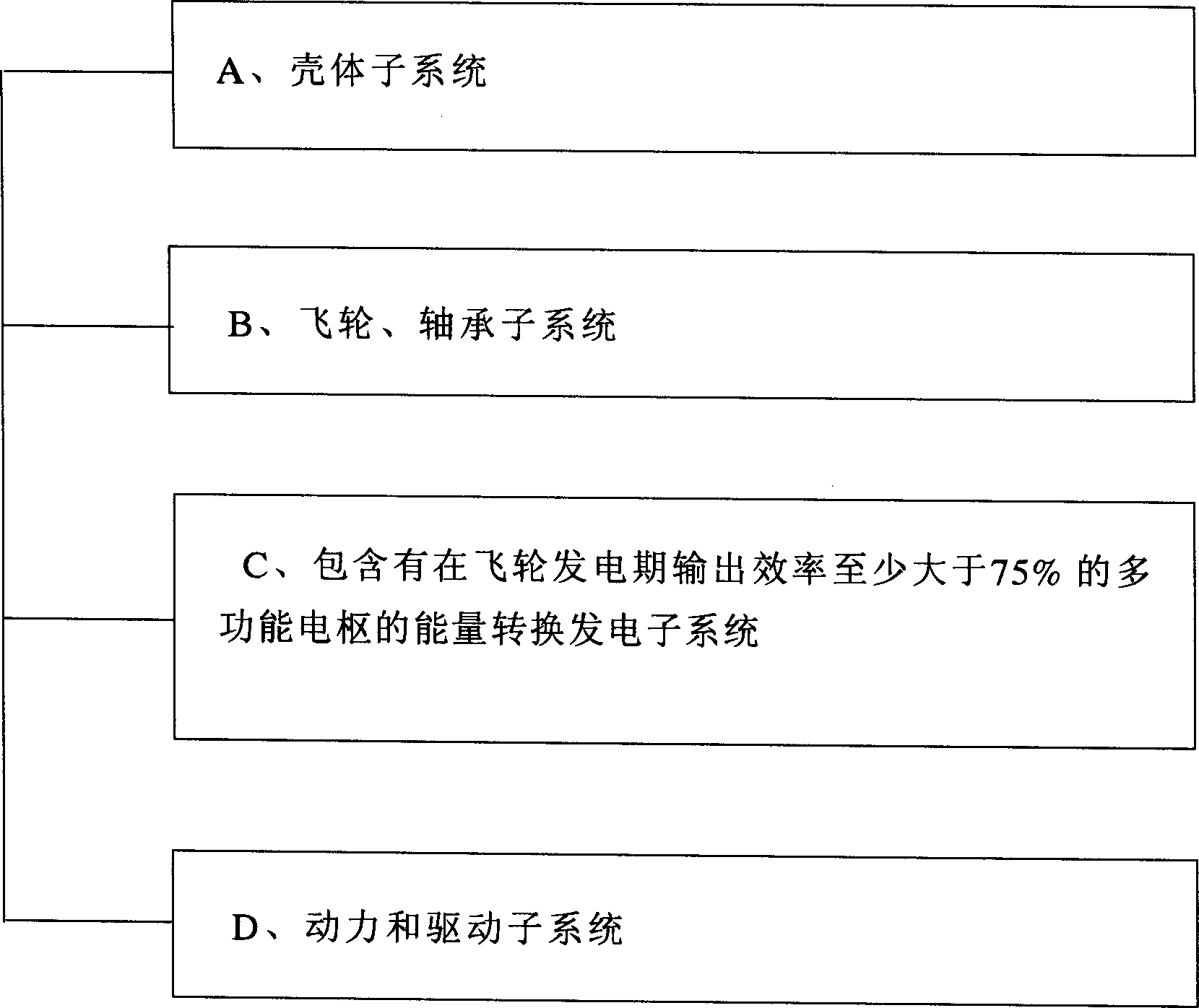

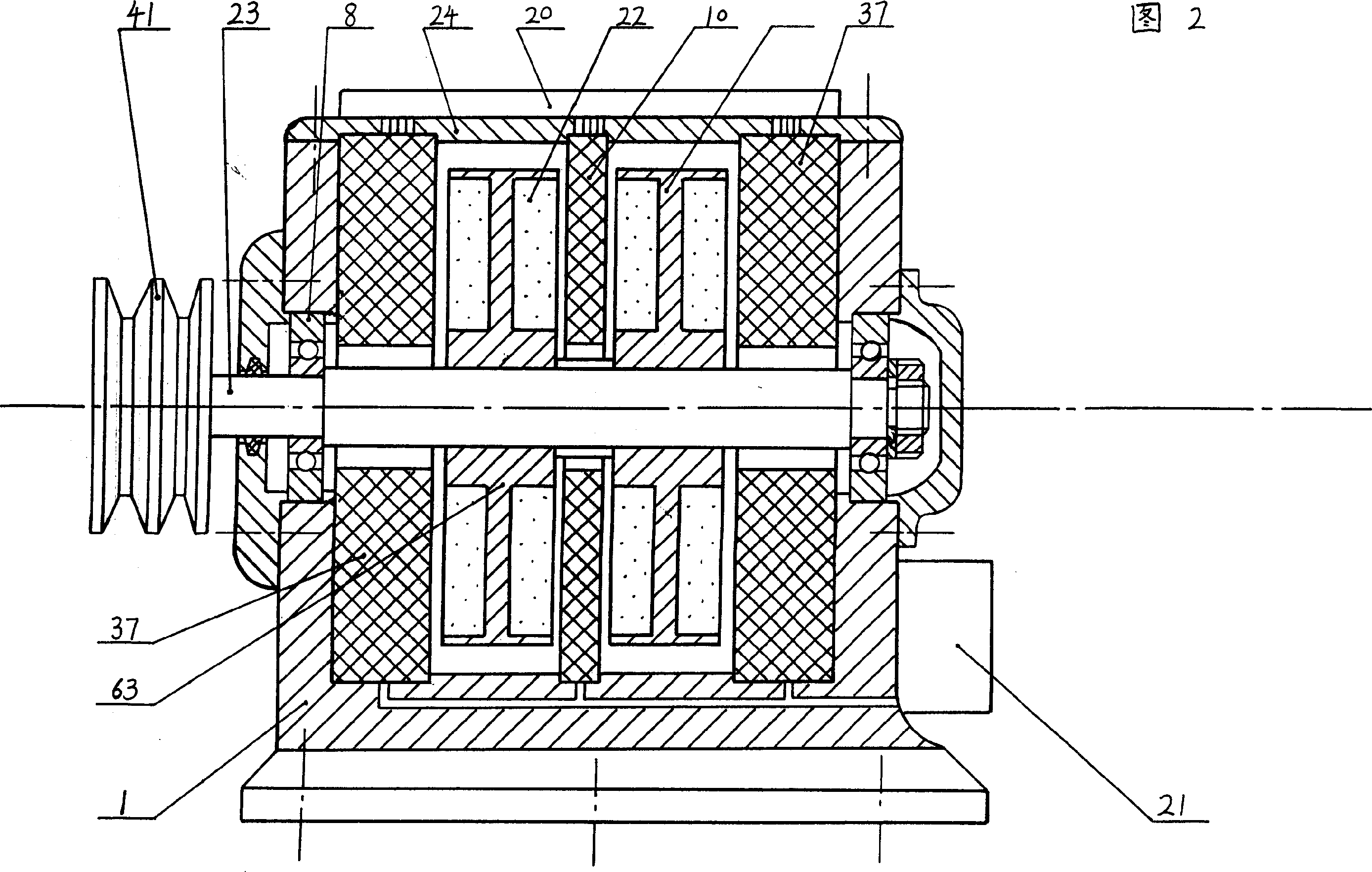

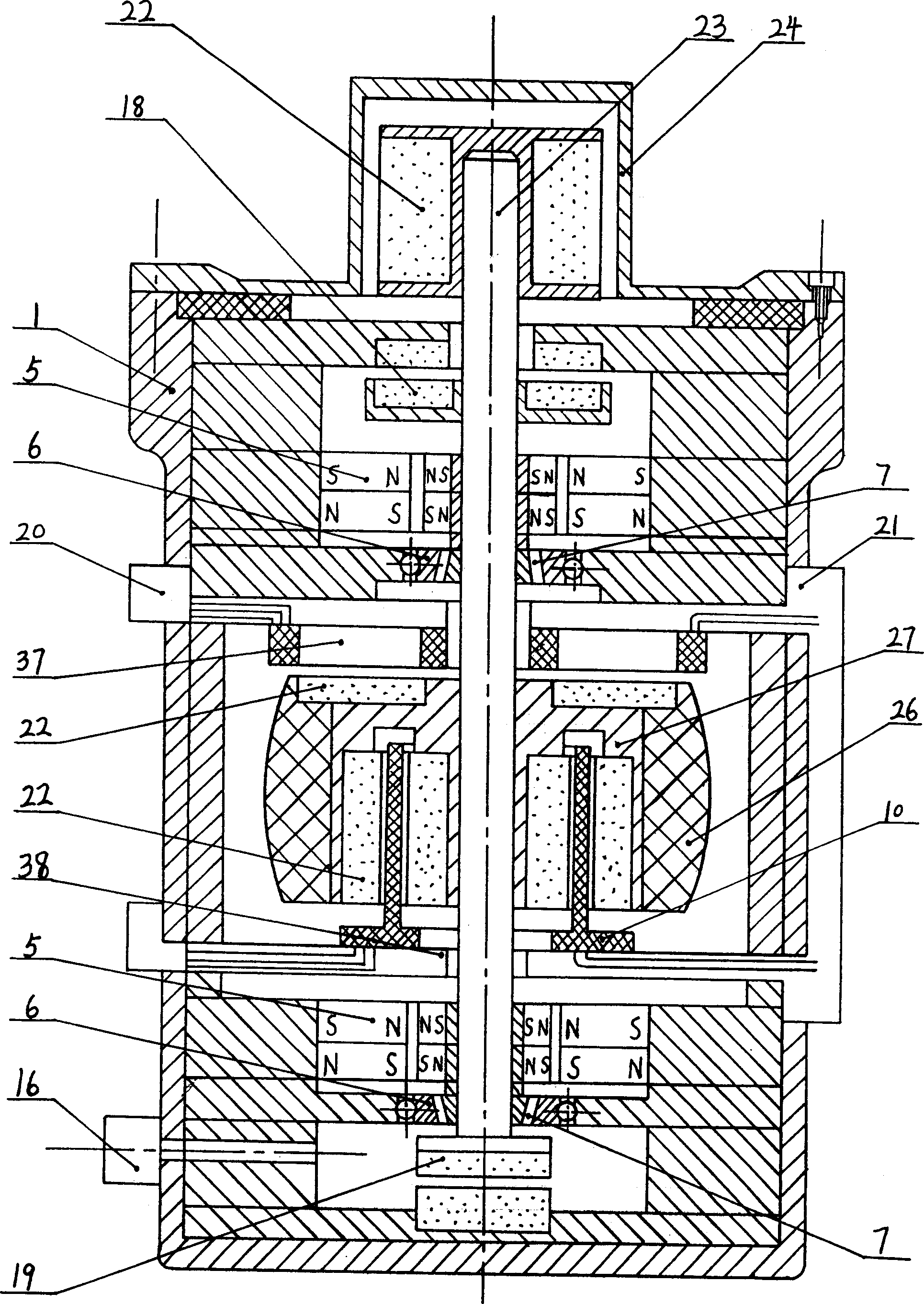

Flywheel generating, multifunctional system and manufacturing method and important component included in this system

InactiveCN1467901AImprove output efficiency during power generationImprove output efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsAviationElectronic systems

Flywheel generating multifunctional system comprising, a case subsystem, flywheel-bearing subsystem, energy conversion generating subsystem containing a multifunctional armature, power and propulsion subsystem. In the system, at least one of the following components is used, a flywheel including more than one pair of magnetic poles at the axial and radial positions respectively, a combination flywheel with enlarged magnetic pole excitation operating area, annular magnetic suspension bearing possessing constraining force of more than two two-dimensions, eccentric type ring shape magnetic suspension bearing, more than two multifunctional armatures using weak magnetic material as armature core, controllable movable armature winding with iron core made of soft magnetic material.

Owner:吴震宇

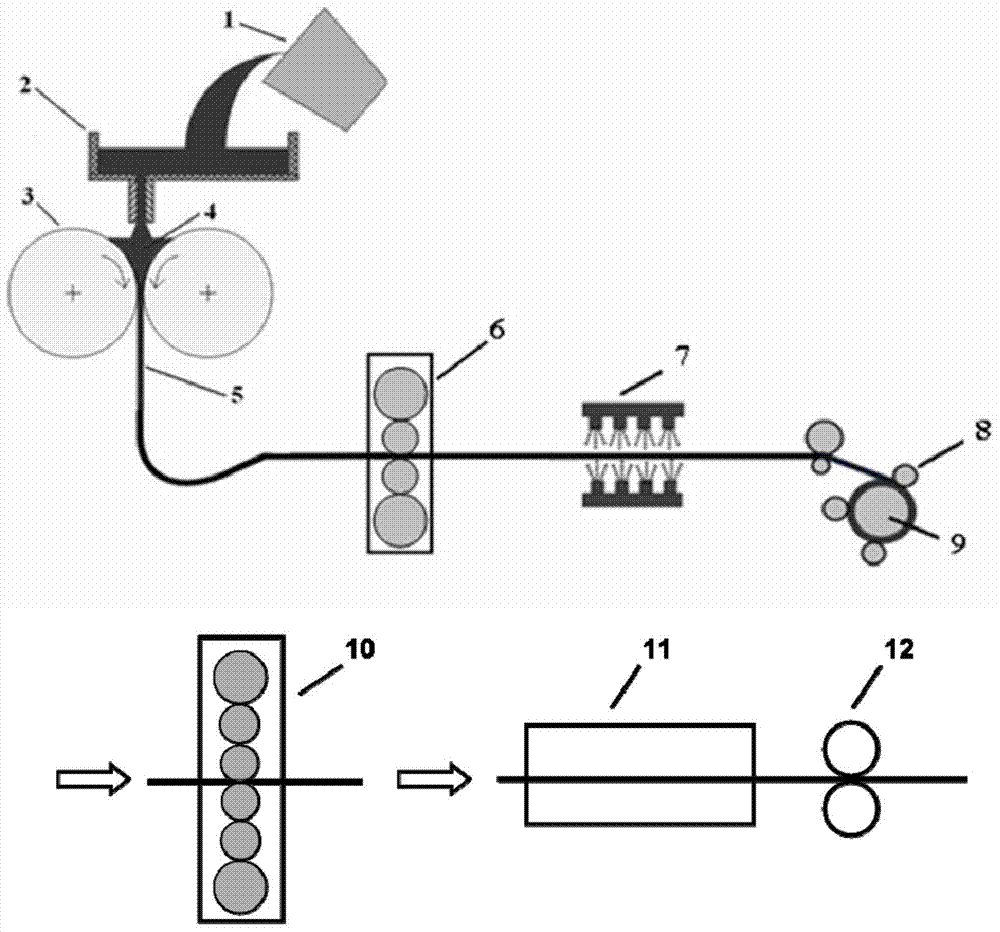

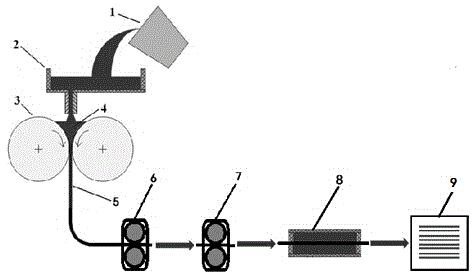

A manufacturing method of non-oriented silicon steel sheet based on twin-roll strip continuous casting technology

The invention relates to the technical field of metallurgical technology, in particular to a method for manufacturing a non-oriented silicon steel plate based on a twin-roll thin strip continuous casting technology. The method comprises the steps of: smelting molten steel with the silicon content of 2.9-3.5wt% at a temperature of 1610-1720 DEG C; pouring the molten steel in a tundish, wherein themolten steel flows into a cavity formed by two crystallizing rolls which rotate at a linear velocity of 20-60m / min and a side-closing plate through the tundish, and is in contact with the crystallizing rolls to generate a solidified shell, and a cast band is led out of the crystallizing rolls; obtaining a cast band coil after the cast band is subjected to the online side-shearing treatment and coiling; warm-rolling the cast band coil after the cast band coil is cooled down to 200-600 DEG C in air, wherein the amount of deformation in warm-rolling is 5-30 percent; and cold-rolling, annealing and coating the warm-rolled cast band coil to prepare a non-oriented silicon steel plate. The method provided by the invention has the advantages that the process is simple and compact, energy is saved, consumption is reduced, microscopic structures of the cast band can be effectively controlled, the drawability, the plate shape and the surface quality of the cast band can be improved, and the magnetic induction intensity of the non-oriented silicon steel plate can be effectively increased.

Owner:NORTHEASTERN UNIV

Semi-process cold-rolling non-oriented electrical steel and production process thereof

The invention discloses a semi-process cold-rolling non-oriented electrical steel and a production process thereof, which mainly solves the technical problems that the prior art is high in energy consumption, large in pollution and high in cost. According to the technical scheme, the semi-process cold-rolling non-oriented electrical steel is a special steel which comprises the following ingredients by mass: not more than 0.01% of C, not more than 0.015% of P, not more than 0.012% of S, not less than 0.4% and not more than 0.60% of Si, not less than 0.6% and not more than 0.8% of Mn, not less than 0.15% and not more than 0.25% of Al, and the balance of Fe. The production process comprises the following steps: smelting molten steel, continuous casting, hot-rolling, punching and annealing, and specifically comprises the following steps: pretreating molten iron, smelting in a rotary furnace, blowing argon over the whole process, conducting RH (Rockwell Hardness) fine smelting, conducting CSP (Cast Steel Plate) continuous casting, putting in a CSP heating furnace, conducting CSP hot-continuous-casting, pickling and cold-rolling and annealing, wherein in the smelting process in the rotary furnace, silicon iron, ferromanganese iron and an aluminum alloy are added to conduct alloying so as to manufacture an alloy steel. The semi-process cold-rolling non-oriented electrical steel is mainly used in a production process of a motor iron core.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

Rare earth permanent magnetic material and method for preparing same

The invention provides a rare earth permanent magnetic material. The rare earth permanent magnetic material comprises a primary phase and a secondary phase, and the secondary phase is isolated from the primary phase or the secondary phase covers the periphery of the primary phase. The primary phase is composed of R1x1R2y1Fe(100-x1-y1-z1-w1)Coz1Bw1N1g1; R1 is selected from Pr or / and Nd, R2 is selected from at least one of Dy, Tb and Ho, 26wt%<=x1+y1<=36wt% and 0.01wt%<=y1<=10wt%; the secondary phase is composed of R3x2R4y2Fe(100-a-b-c-v-u)Coz2Bw2N2g2, R3 is selected from at least one of Pr, Nd, Dy and Tb, R4 is Ho, 35wt%<=x2+y2<=65wt% and 0.01wt%<=y2<=20wt%. The rare earth permanent magnetic material is prepared in a dual-alloy mode, is low in cost, strong in coercive force and high in magnetic induction, and a magnet of a smaller size can be used when the rare earth permanent magnetic material is applied to a motor,.

Owner:BYD CO LTD

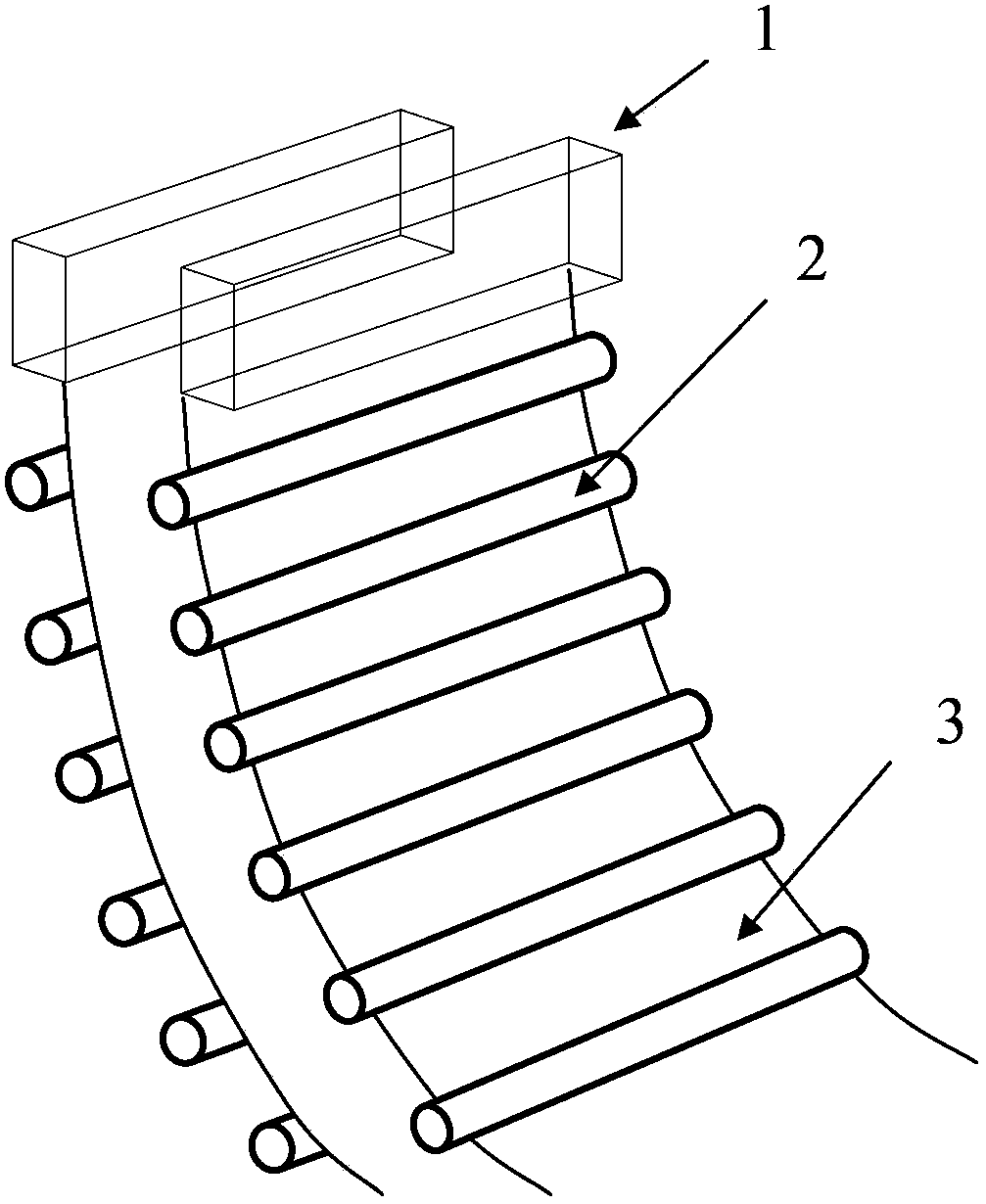

Electromagnetic sensor of electromagnetic stirring device of slab continuous-casting crystallizer

The invention discloses an electromagnetic sensor of an electromagnetic stirring device of a slab continuous-casting crystallizer and belongs to the electromagnetic stirring device of the slab continuous-casting device with an aim to solve the problem of flux leakage of an iron core. The electromagnetic sensor comprises the iron core, multiple sets of coils and a magnetic shield, the iron core is a columnar iron core composed by stringing and stacking multiple E-shaped iron core bodies together, and each E-shaped iron core is composed of highly-permeable E-shaped silicon steel sheets; the coils identical in the number of windings are respectively wound on the outer side of the columnar iron core, and each coil is conducted with alternating current with a certain phase position, frequency and current intensity; the magnetic shield is an opening shield and is arranged on the rear side of the iron core, and the opening side of the magnetic shield faces a crystallizer copper plate. By the aid of the electromagnetic sensor with the magnetic shield structure, trend of a magnetic line of force in space is changed, higher magnetic sensing intensity can be generated under the condition of the same input current, electromagnetic force can be enhanced, efficiency of the system is improved, and interference of the magnetic field of the stirring device upon peripheral equipment instruments is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Blueing treatment process for semi-processed electrical steel rotor or stator

InactiveCN103060822AReduce iron lossIncrease magnetic inductionSolid state diffusion coatingElectrical steelHigh energy

The invention relates to a blueing treatment process for a semi-processed electrical steel rotor or stator, which is mainly used for solving the technical problems of high energy consumption, great pollution, high cost and the like of the prior art. The key points of the technical scheme are as follows: semi-processed electric steel is adopted for preparing a rotor or stator punched sheet, then oil firing, decarbonization, distressing and annealing are performed on the rotor or stator punched sheet, and blueing treatment is finally performed to prepare a finished product. The blueing treatment process is mainly used in production processes of rotor or stator iron cores of motors.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

Production method of 350 MPa grade cold rolled magnetic pole steel

InactiveCN1904114ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionUltimate tensile strength

This invention relates to a process of producing 350MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production method of 250 MPa grade cold rolled magnetic pole steel

InactiveCN1904113ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionMetallurgy

This invention relates to a process of producing 250MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot rolling steps: the start rolling temperature 1050-1100DEG C,end rolling temperature 840-880DEG C,cooling to 640-700DEG C for coiling. (3)cooling to 70DEG C below for acid picking. (4)cold rolling steps; (5) bell furnace anneal; controlling temperature 660-680DEG C (6) temper rolling, then the products. Account to weight the main chemical composition is: C 0.03-0.09%,Si 0.10-0.30%,Mn 0.30-0.70%,Nb 0.015-0.025 %,Als 0.01-0.07%,P <=0.025%,S <=0.010%, Fe the rest.

Owner:WUHAN IRON & STEEL (GROUP) CORP

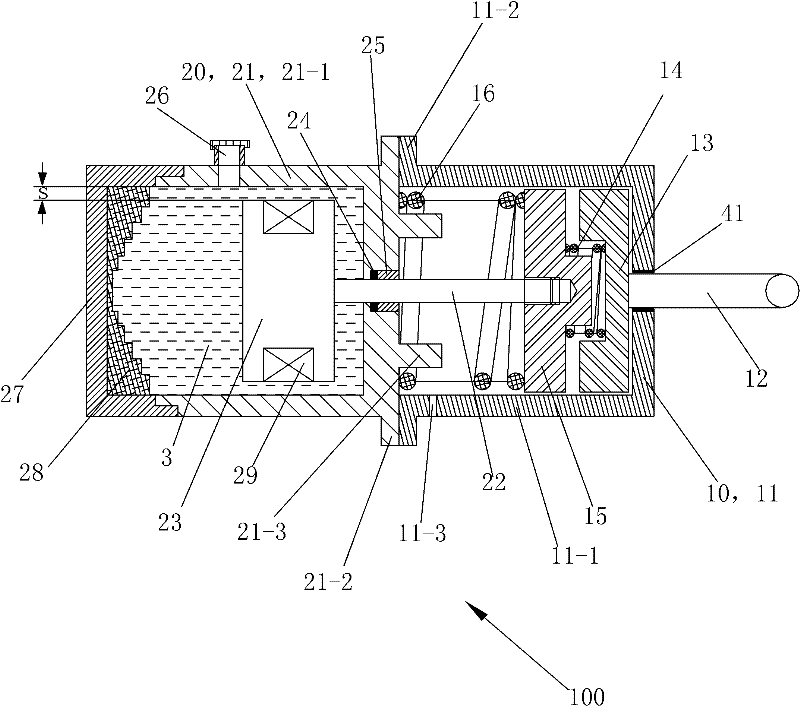

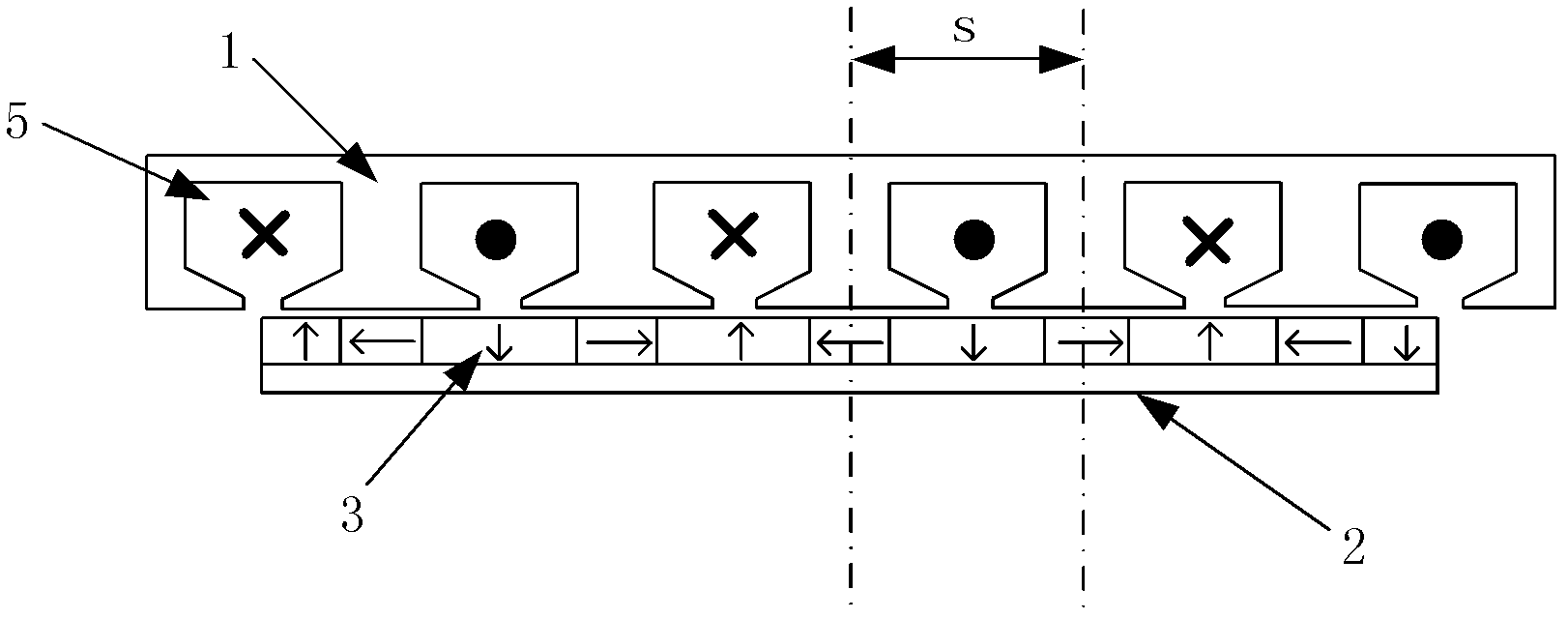

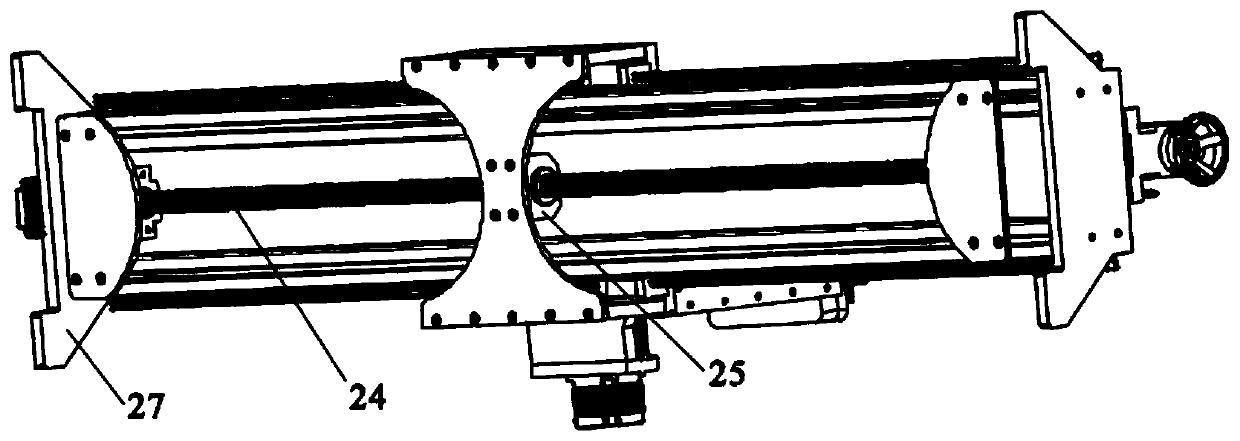

Linear oscillation motor for direct drive pump based on selfshield characteristic of Halbach array

ActiveCN102594079ALarge outputIncrease magnetic inductionMagnetic circuit rotating partsResonanceConductor Coil

The present invention discloses a linear oscillation motor for a direct drive pump based on selfshield characteristic of Halbach array, which comprises the following components: a cylindrical outer stator, an inner rotor, permanent magnets, a supporting shaft, a coil winding, a linear bearing, resonance springs and an end cap. The inner rotor is provided in the outer stator. The inner wall of theouter stator is circumferentially provided with coil winding grooves. The inner rotor can perform oscillation motion in the outer stator. The outer wall of the inner rotor is provided with permanent magnets which are arranged according to a Halbach array arrangement mode. The inner part of the inner rotor is provided with the supporting shaft. Two ends of the supporting shaft are fixed with two ends of the outer stator through end caps. The linear bearing and two resonance springs are sleeved on the supporting shaft. The two resonance springs are provided at two ends of the linear bearing. The resonance springs and the linear bearing are relatively fixed with the inner rotor. After one end of the inner rotor passes through the end cap at the same end, connection with an outer executing mechanism through a spherical hinge joint. The linear oscillation motor has the following advantages: large output force in an axial direction, high utilization rate and compact integral structure.

Owner:BEIHANG UNIV

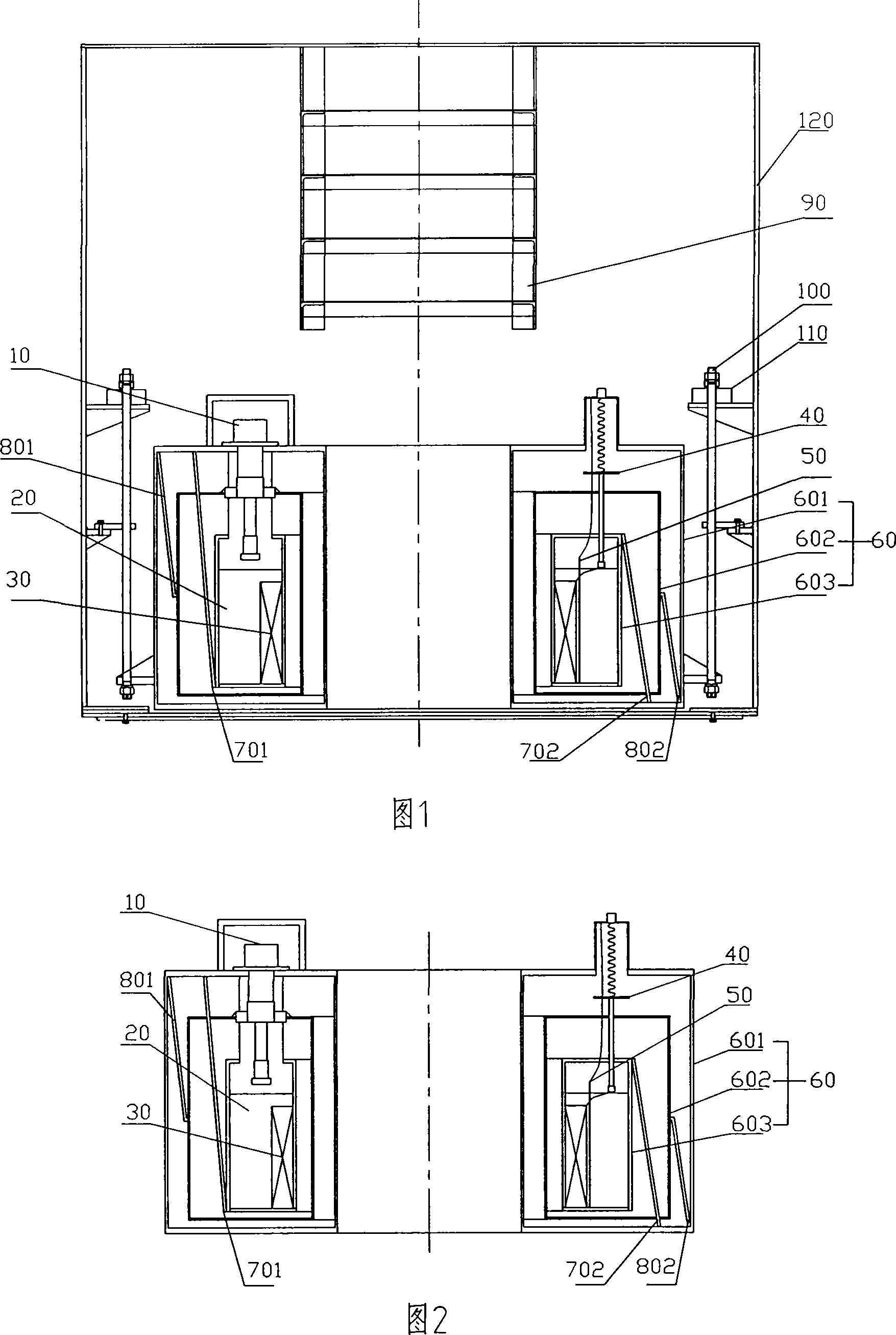

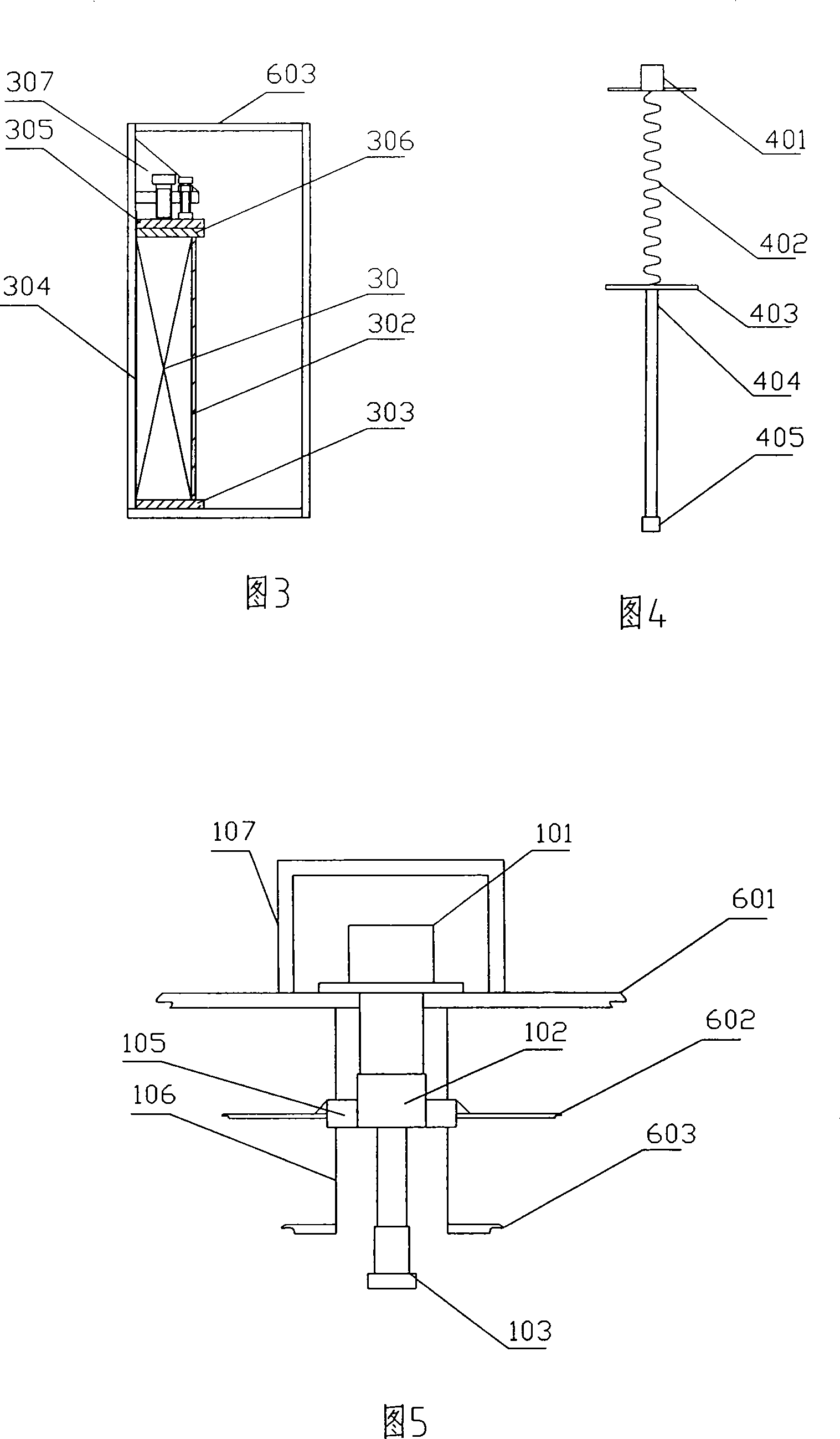

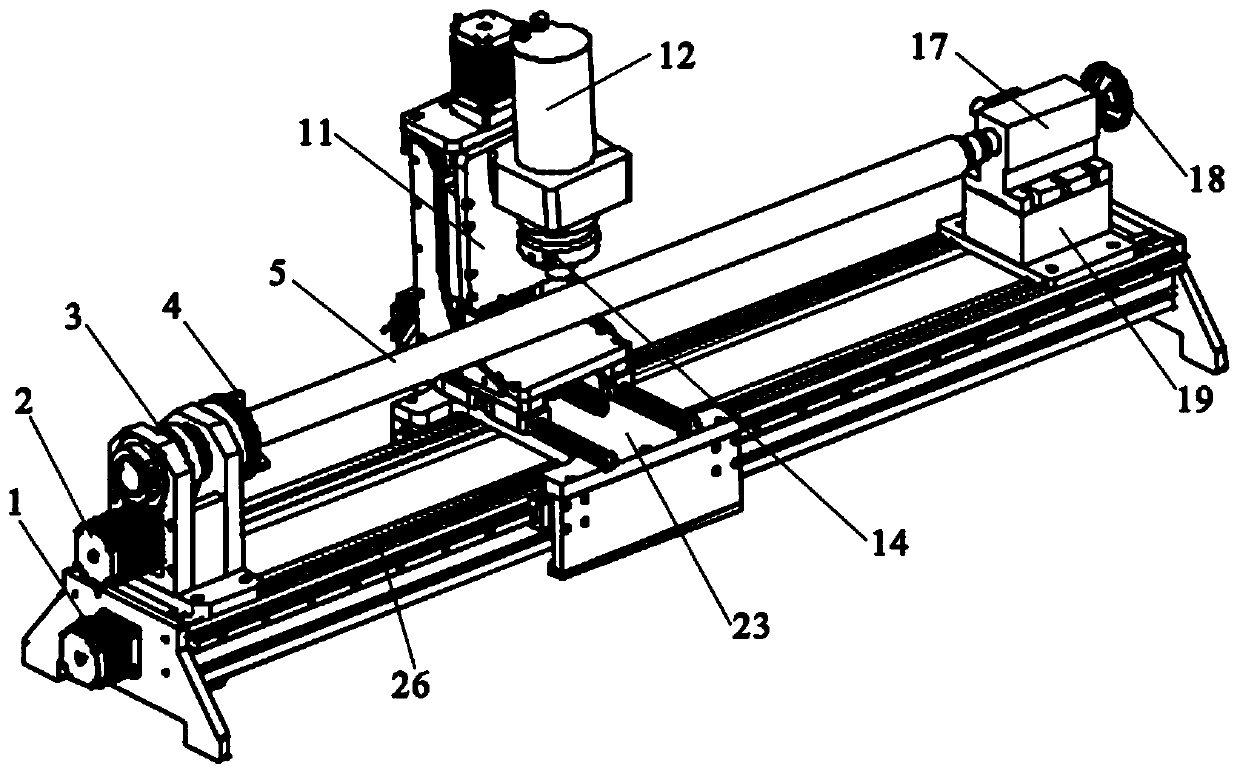

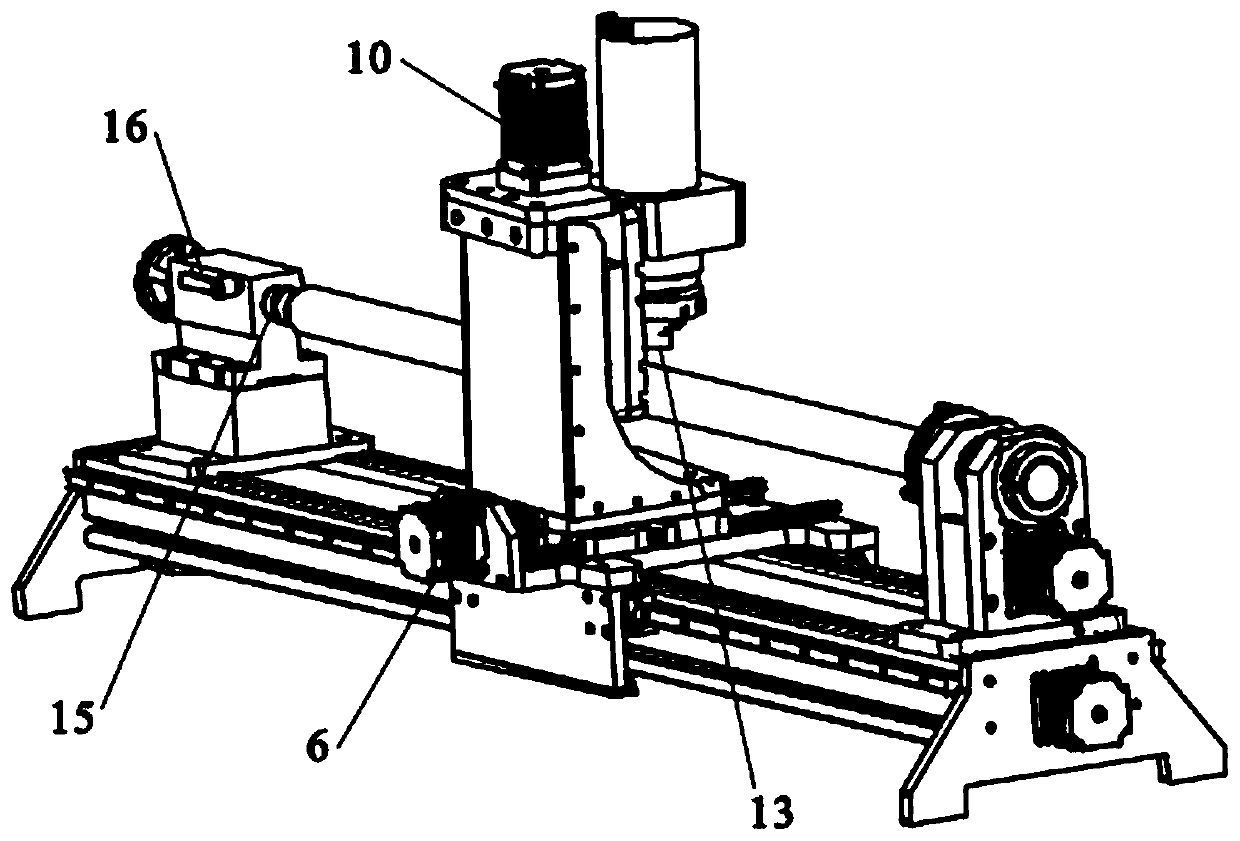

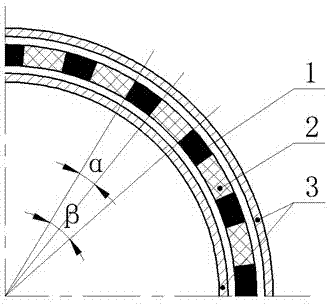

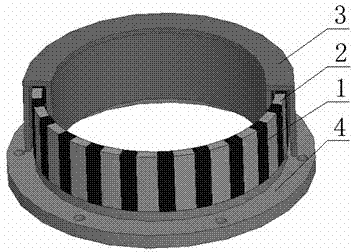

Device and method of rotating slotting magnetic pole polishing of inner surface of pipe fitting

PendingCN110253346AImprove surface roughnessComplicated trajectoryEdge grinding machinesPolishing machinesMotor drivePipe fitting

The invention relates to a device and method of rotating slotting magnetic pole polishing of the inner surface of a pipe fitting. The device comprises a horizontal driving mechanism, a vertical driving mechanism, a rotating motor, a rotating motor supporting plate, a slotting magnetic pole, a magnetic pole chuck, a main motor, a triangular chuck and a base. The horizontal driving mechanism is connected with the vertical driving mechanism and drives the vertical driving mechanism to move in the horizontal direction, and the vertical driving mechanism is connected with the rotating motor through the rotating motor supporting plate. The rotating motor drives the magnetic pole chuck to rotate, and the slotting magnetic pole is clamped on the magnetic pole chuck. The base is fixed to the horizontal driving mechanism, and the main motor drives the triangular chuck. One end of a workpiece is clamped on the triangular chuck, and the other end of the workpiece is limited by a tail base. The workpiece is arranged below the slotting magnetic pole. The device and method have the advantages that the inner surface of the pipe fitting can be processed, the rotating magnetic pole drives magnetic abrasive particles, the movement trail is more complex, the impact scratch caused by the magnetic abrasive particles on the pipe fitting which needs to be processed is more complex, and therefore the surface roughness of the pipe fitting which needs to be processed can be improved.

Owner:UNIV OF SCI & TECH LIAONING

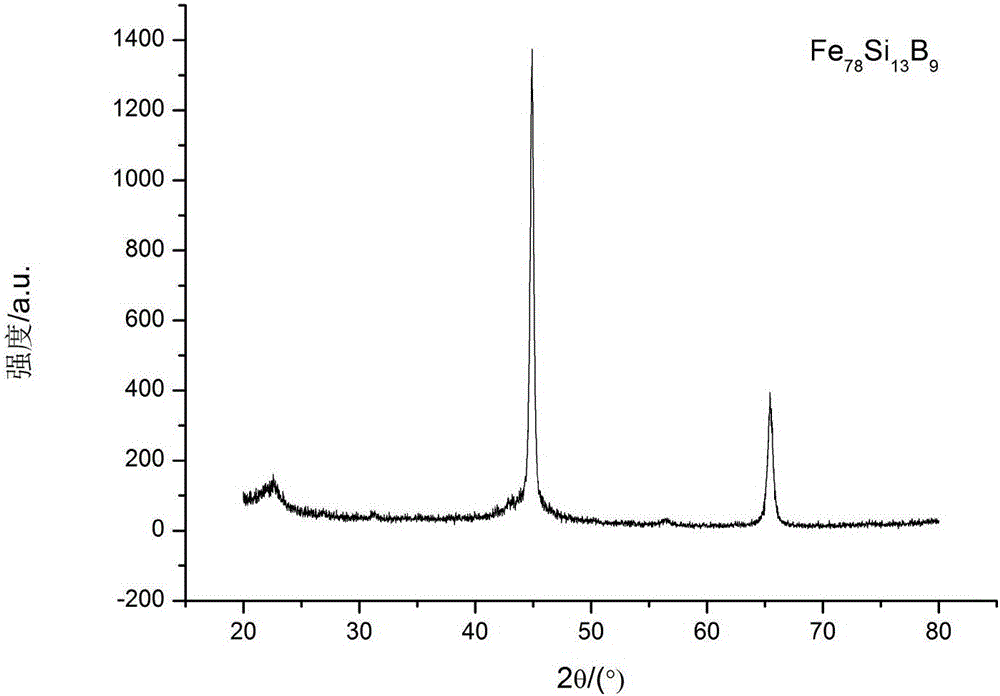

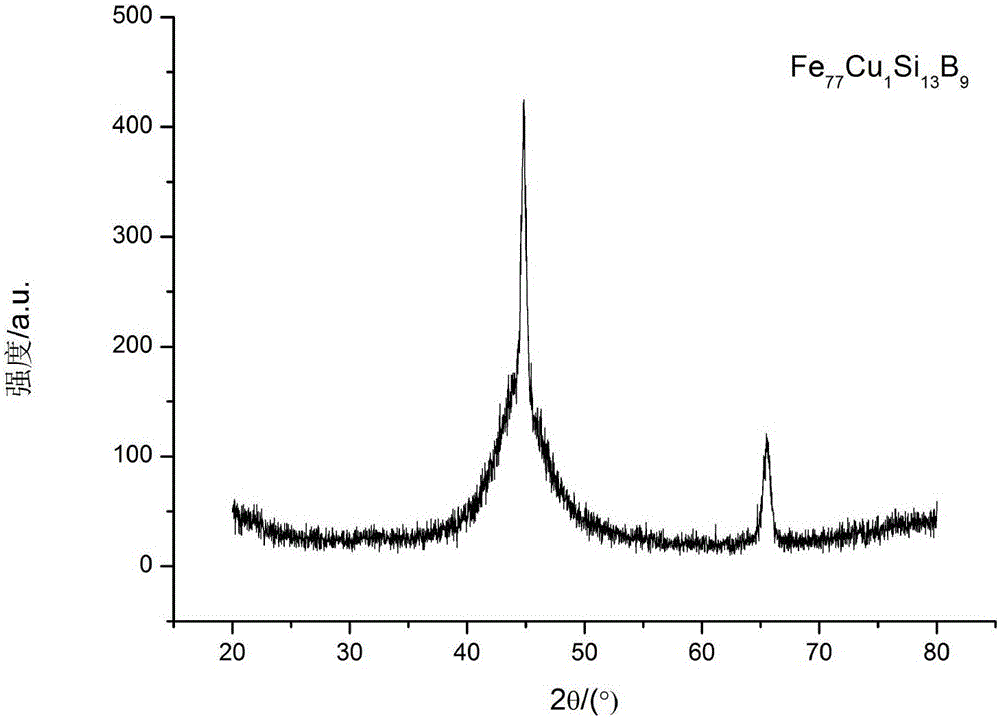

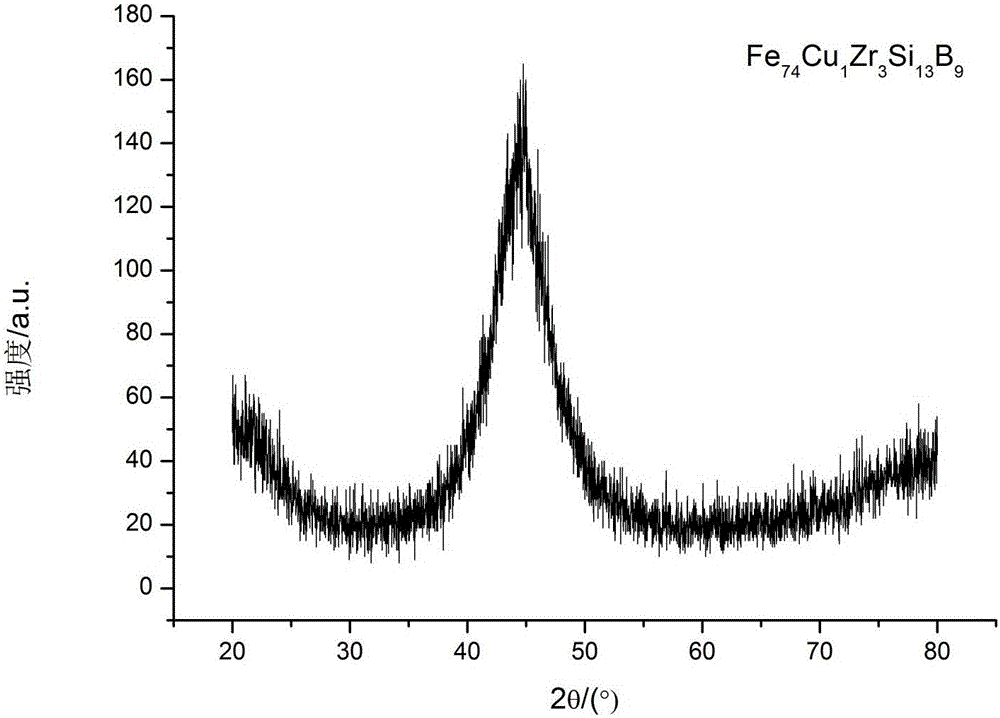

Fe-based amorphous/nanocrystalline soft magnetic alloy thin belt and preparation method thereof

The invention relates to a Fe-based amorphous / nanocrystalline soft magnetic alloy thin belt. A chemical expression formed by elements of the alloy thin belt is FeaSibBaCudMee, wherein the atomic percent of the elements is shown as follows: a is equal to 80-85, b is equal to 2-13, c is equal to 5-13, d is equal to 0.5-2, e is equal to 0.5-5, a+b+c+d+e is equal to 100; Me is Zr, Nb or Mo. The alloy thin belt has a thickness of 15-40 [mu]m and a width of 1-5 mm. Through adding the Me element in the method, the nucleation rate of super-cooled liquid is effectively improved, and the precipitation of a BCC nanocrystalline iron phase is promoted, Fe-based nano alloy is prepared, and the magnetostriction coefficients of a material are reduced, so that the initial magnetic conductivity is improved, and the saturated magnetic induction intensity is obviously improved.

Owner:HEBEI UNIV OF TECH

Transmission line lead anti-icing compound coil based on ferrite and preparation method thereof

InactiveCN103435893AIncrease magnetic inductionImprove hydrophobicityInsulated cablesInsulated conductorsMagnetic heatingAntioxidant

The invention discloses a transmission line lead anti-icing compound coil based on ferrite and a preparation method thereof, and relates to the fields of a magnetic heating material and safe operation of a power grid, in order to solve the problems of low heat productivity, high cost, large load and fixed form of the anti-icing material of a transmission conductor. The product is prepared from ferrite magnetic material powder and polymer base stock. The method comprises the following steps: weighing the ferrite magnetic material powder, the polymer base stock, a plasticizer, a lubricating agent and an antioxidant; and extruding and drying by an extruder after stirring, so as to obtain the compound coil of which the thickness is 2-10mm, wherein the loss at normal temperature is less than 5 W / kg, the saturation flux density when the temperature is lower than 0 DEG C can be up to 0.85T, and the single calorific value at -5 DEG C to 0 DEG C can be up to 32 W / kg under an alternating magnetic field of 50Hz. Thus, the anti-icing compound coil can be applied to the fields of the magnetic heating material and safe operation of the power grid.

Owner:STATE GRID CORP OF CHINA +1

Superconductive magnetism-isolation-type magnetism adjusting device

ActiveCN103795224AIncrease magnetic inductionReduce displacementDynamo-electric gearsSuperconducting magnets/coilsMagnetic lineElectrical conductor

The invention relates to a superconductive magnetism-isolation-type magnetism adjusting device, and belongs to the technical field of mechanical engineering transmission. The device is characterized by comprising a magnetism adjusting iron block, a superconductive substrate, a heat insulation layer, a supporting frame, a cold conveying pipe, a loop pipe and a refrigerator. The meissner effect of a superconductive material is utilized, when the temperature of the superconductive material is lower than a critical temperature and a superconductive state is formed, the superconductive material repels magnetic lines of force completely out of the superconductive material so that magnetic lines of force of an external magnetic field cannot penetrate through the superconductive material, the direction of the magnetic lines of force is changed and all the magnetic lines of force pass through the magnetism adjusting iron block. An adjustment magnetic field formed after the external magnetic field is adjusted through the magnetism adjusting iron block is different in rotation speed and distribution from an original magnetic field, and accordingly a magnetism transmission device has a speed adjustment function.

Owner:JIANGSU UNIV

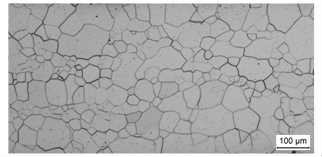

Manufacturing method of thin-strip continuous casting high magnetic induction non-oriented silicon steel

The application discloses a manufacturing method of thin-strip continuous casting high magnetic induction non-oriented silicon steel. The manufacturing method comprises the following steps: (1) smelting molten steel and performing thin-strip continuous casting to obtain a cast strip, wherein the degree of superheat for thin-strip continuous casting is 30-55 DEG C; (2) cooling the cast strip and directly performing hot rolling and coiling to obtain hot-rolled strip steel, wherein the hot-rolling reduction is 30%-50%; (3) performing cold rolling with the reduction of not more than 60% on the hot-rolled strip steel; and (4) performing annealing treatment to obtain a non-oriented silicon steel finished plate. The manufacturing method disclosed by the invention has the advantages of short process flow, low production cost and obvious energy-saving and emission-reducing effects. By eliminating an abnormally coarse columnar crystal structure through the appropriate hot-rolling reduction, a corrugated defect of a cold-rolled product is avoided; meanwhile, (100) plane texture in an as-cast microstructure is inherited; the cold-rolling reduction is reduced, so that the formation of cold-rolled (111) texture is avoided, the proportion of annealing plate (100) texture is increased, a high magnetic induction non-oriented silicon steel product is obtained, and the magnetic induction of the high magnetic induction non-oriented silicon steel is above 1.81T.

Owner:SHAGANG GROUP +2

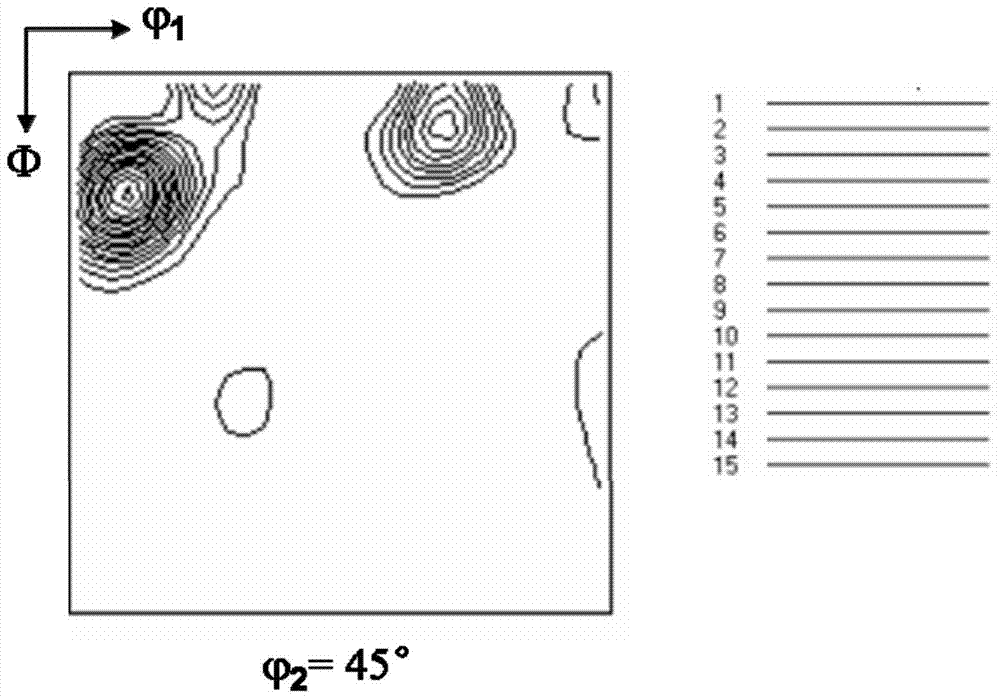

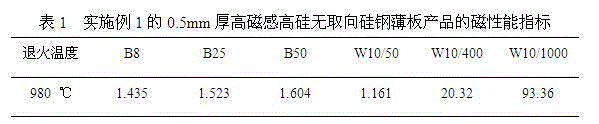

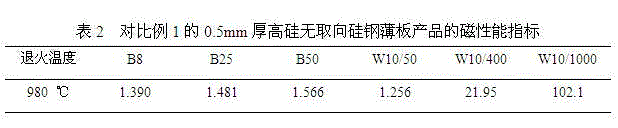

High-magnetic-induction high-silicon non-oriented silicon steel plate and preparation method thereof

ActiveCN104451372AIncrease productivityReduce manufacturing costChemical compositionManufacturing technology

The invention belongs to the field of electrical steel plate manufacture, particularly relates to a high-magnetic-induction high-silicon non-oriented silicon steel plate and a preparation method thereof. The high-magnetic-induction high-silicon non-oriented silicon steel plate comprises chemical components in percentage by weight as follows: 6.4%-6.6% of Si, 0.005%-0.02% of Ce, smaller than or equal to 0.005% of N, smaller than or equal to 0.003% of S, smaller than or equal to 0.02% of P, larger than or equal to 0.003% of O, smaller than or equal to 0.005% of C and the balance of Fe. The preparation method comprises steps as follows: firstly, molten steel is smelt, cast rolling is performed under protection of argon atmosphere, a high-silicon non-oriented steel strip is obtained and cooled to the temperature of 900-1,100 DEG C, then hot rolling is performed, a hot rolled plate with the thickness of 1.0-1.3 mm is obtained and cooled to the temperature of 150-500 DEG C, warm rolling is performed, then, acid pickling and annealing are performed, and the high-magnetic-induction high-silicon non-oriented silicon steel plate is obtained. According to the technical scheme, a microalloying element Ce is added, matched manufacture technologies combining cast rolling, hot rolling and warm rolling are adopted, and accordingly, the magnetic induction strength of the high-silicon non-oriented silicon steel plate is remarkably improved.

Owner:NORTHEASTERN UNIV

Vibration reduction device of high-speed rotating shaft system

InactiveCN104500635AImprove damping performanceTo achieve the purpose of vibration reductionMagnetic springsShock absorbersElectrical polarityCentrifugal force

The invention discloses a vibration reduction device of a high-speed rotating shaft system. The device comprises a particle damper shell, wherein particles are filled in the particle damper shell; a first magnet and a second magnet which is reverse to the first magnet in polarity are arranged on the two sides of the top of the particle damper shell respectively; a hollow shell is fixedly arranged on the lower side of the first magnet and the second magnet; a bearing is arranged in the hollow shell; an inner ring of the bearing is connected with a supporting cylinder; an iron core is fixedly arranged in the supporting cylinder; an electrified coil is wound on the iron core and is connected with a metal coil in the middle of the first magnet and the second magnet. According to the vibration reduction device of the high-speed rotating shaft system, a magnetic field is generated by flowing current produced by an electromagnetic induction system through the electrified coil, and centrifugal force stressed by the particles is counteracted by magnetic field force to eliminate the phenomenon of marginalized squeezing of the particles, so a best vibration reduction state is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

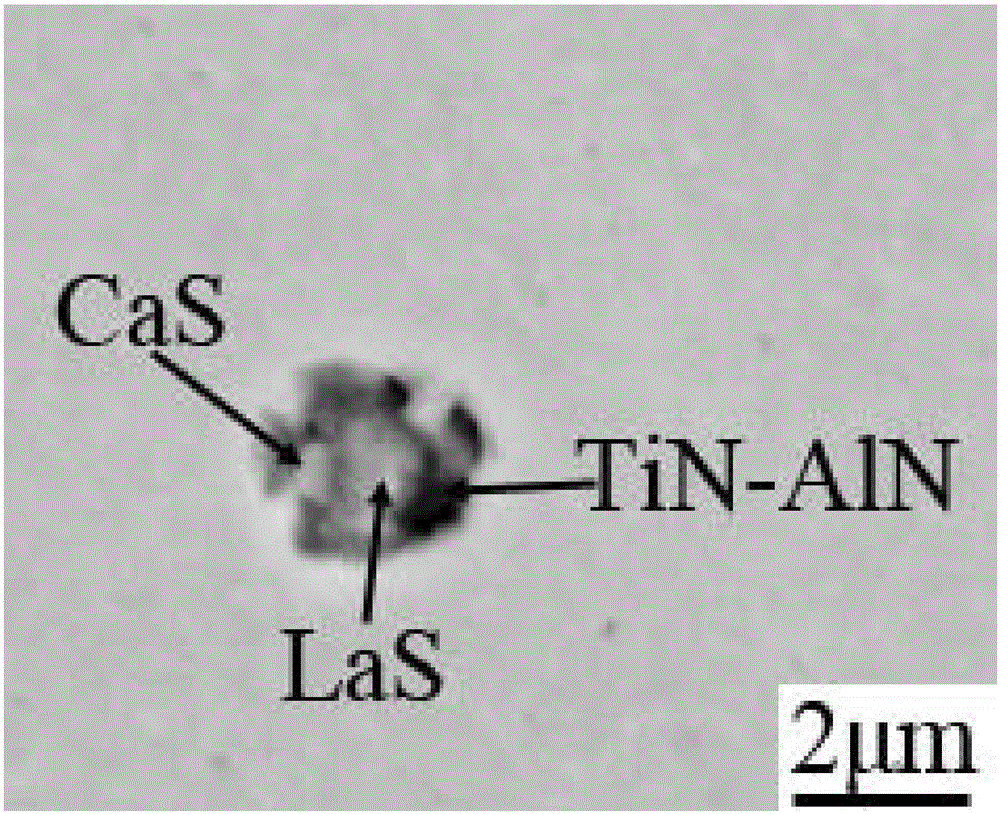

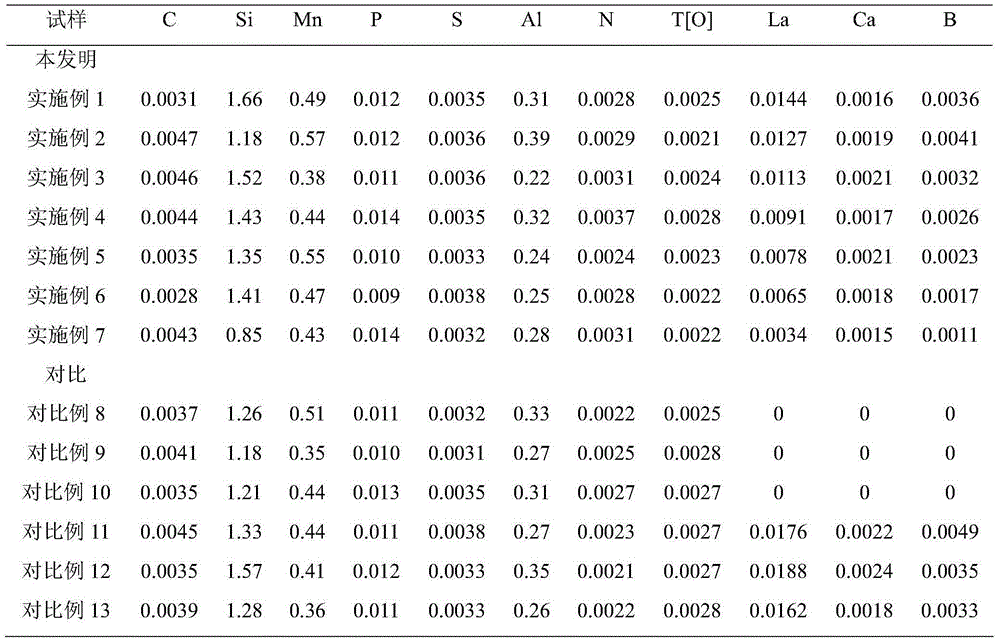

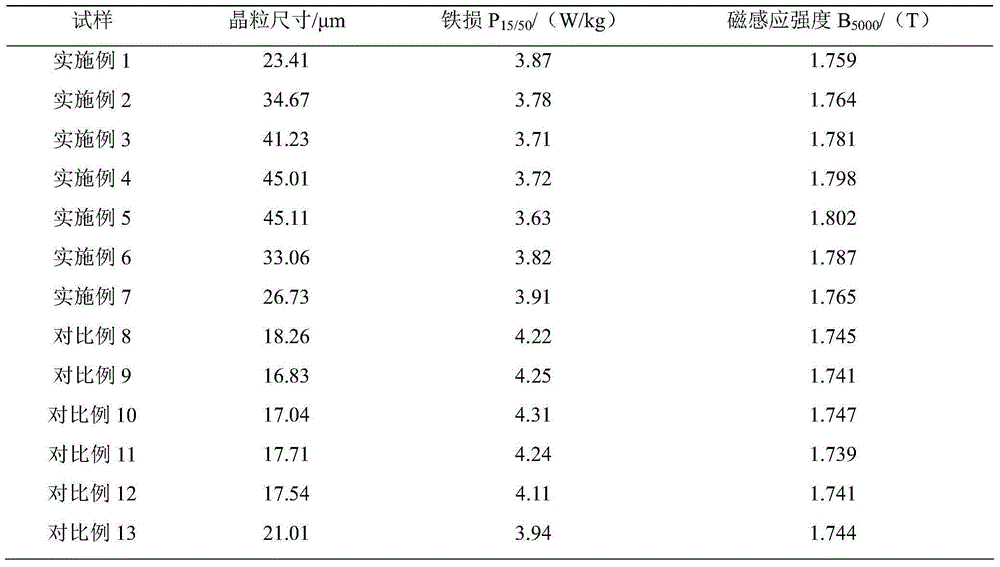

Method for preparing compound element processed non-oriented silicon steel for high-efficiency motor

The invention discloses a method for preparing compound element processed non-oriented silicon steel for a high-efficiency motor and belongs to the technical field of electrical steel. A non-oriented electrical steel casting blank into which a certain amount of Ca, a certain amount of La and a certain amount of B are added serves as the raw material, smelting, forging, hot rolling, normalizing, acid pickling, primary cold rolling, intermediate annealing, secondary cold rolling and finished product annealing are conducted in sequence, the temperature and time of finished product annealing are controlled to be 900-940 DEG C and 3-5 min respectively, and the non-oriented silicon steel product, which is low in iron loss and high in magnetic strength, for the high-efficiency motor is obtained finally. The final magnetic performance of the product is that when a steel plate is 0.5 mm thick, P15 / 50=3.6-3.9 W / kg, and B5000=1.76-1.80 T. The steel belt finished product can be widely applied to large and medium motor manufacturing as well as variable-frequency air conditioner compressor manufacturing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Magnetorheological pilot-operated overflow valve

InactiveCN102374204ALarge damping forceIncrease magnetic inductionServomotor componentsEngineeringPressure difference

The invention provides a magnetorheological pilot-operated overflow valve belonging to the technical field of hydraulic drive. The magnetorheological pilot-operated overflow valve comprises an end cover, an end cover seal ring, a magnetorheological valve housing, a coil, an iron core, a valve core, a pilot-operated valve body, a pilot-operated seal ring, a damp piece, a main valve housing seal ring, a spring, a guide rod seal ring, a guide rod, a main valve housing, a main valve core, a main valve seat insert, a main valve seat, a main valve body and a damper. The main valve core is in a parabolic ball shape, and the half cone angle of the valve core is larger than that of the valve seat, thus, the pressure difference between an inlet and an outlet of a cone valve can be effectively reduced; the minimum negative pressure moves backwards along a liquid flow direction, appears at the back of the valve core and is avoided appearing in the valve seat, thus, the possibility of gas etching is reduced, noise is reduced, key parts of the valve core and the valve seat are protected, and the service life of the magnetorheological pilot-operated overflow valve is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

Double-magnetic-source magnetic circuit structure of permanent-magnet angle vibration table

A double-magnetic-source magnetic circuit structure of a permanent-magnet angle vibration table comprises an upper magnetic steel, a lower magnetic steel, a top cover, an outer wall, a base and an air gap between the upper magnetic steel and the lower magnetic steel, wherein the top cover is arranged on the outer wall in an erected mode, the outer wall is fixed on the base, the upper magnetic steel is fixed at the bottom of the top cover, and the lower magnetic steel is fixed at the top of the base; a moving coil is of a disc-type structure and is located between the upper magnetic steel and the lower magnetic steel, and the upper magnetic steel and the lower magnetic steel are respectively in clearance fit with the moving coil; the moving coil comprises at least one moving coil unit; each moving coil unit includes a base body and a coil assembly; each coil assembly includes a first coil and a second coil, wherein the first coil and the second coil are formed by winding one wire; each coil includes an effective wire assembly and a connection wire assembly; every two adjacent effective wire assemblies form one Ampere force generating portion; each Ampere force generating portion corresponds to a magnetic field, and the directions of the currents in every two adjacent Ampere force generating portions are opposite. The double-magnetic-source magnetic circuit structure of the permanent-magnet angle vibration table has the advantages of being simple and compact in structure, high and even in magnetic induction intensity and stable in air-gap magnetic field.

Owner:ZHEJIANG UNIV

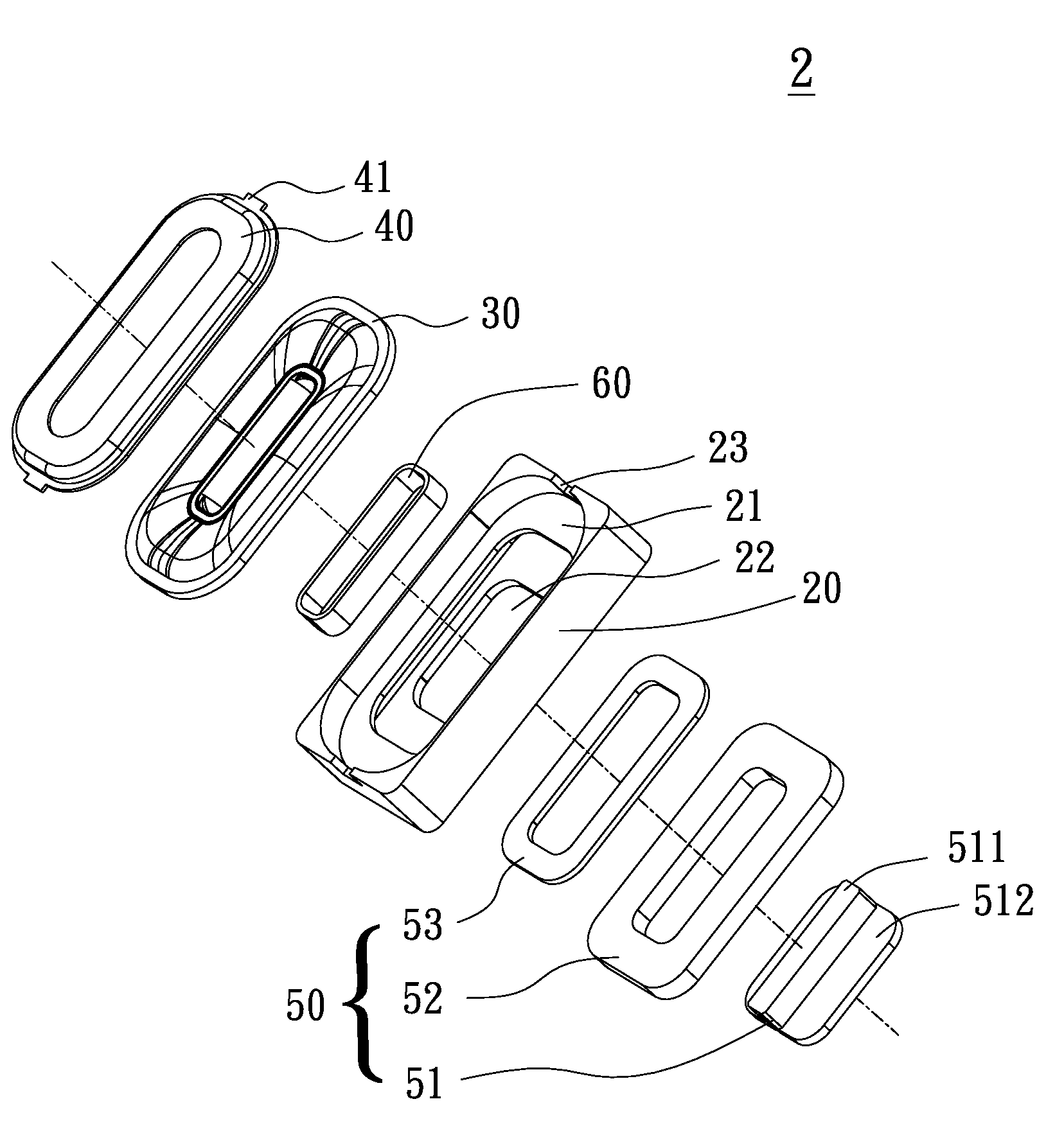

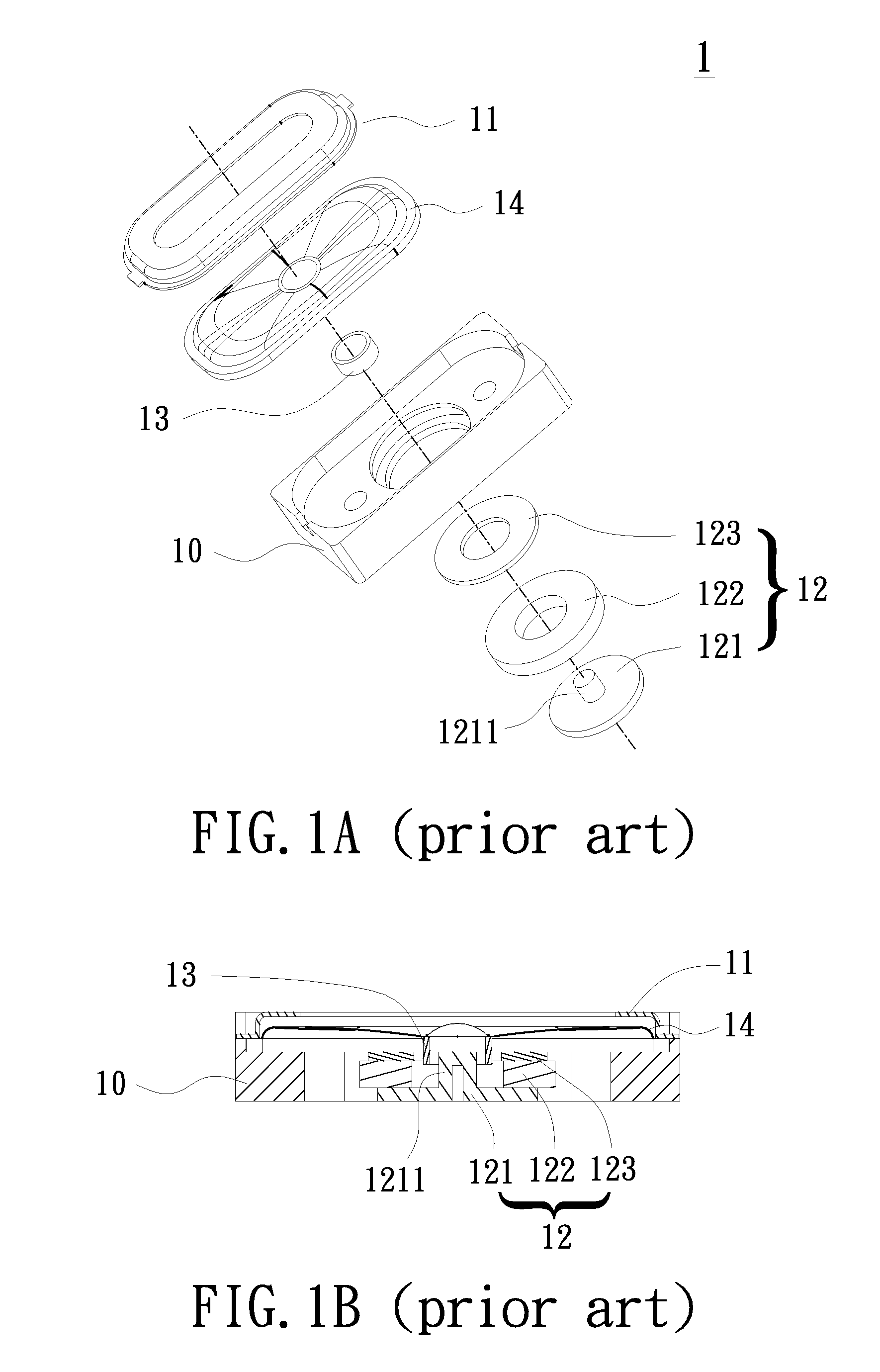

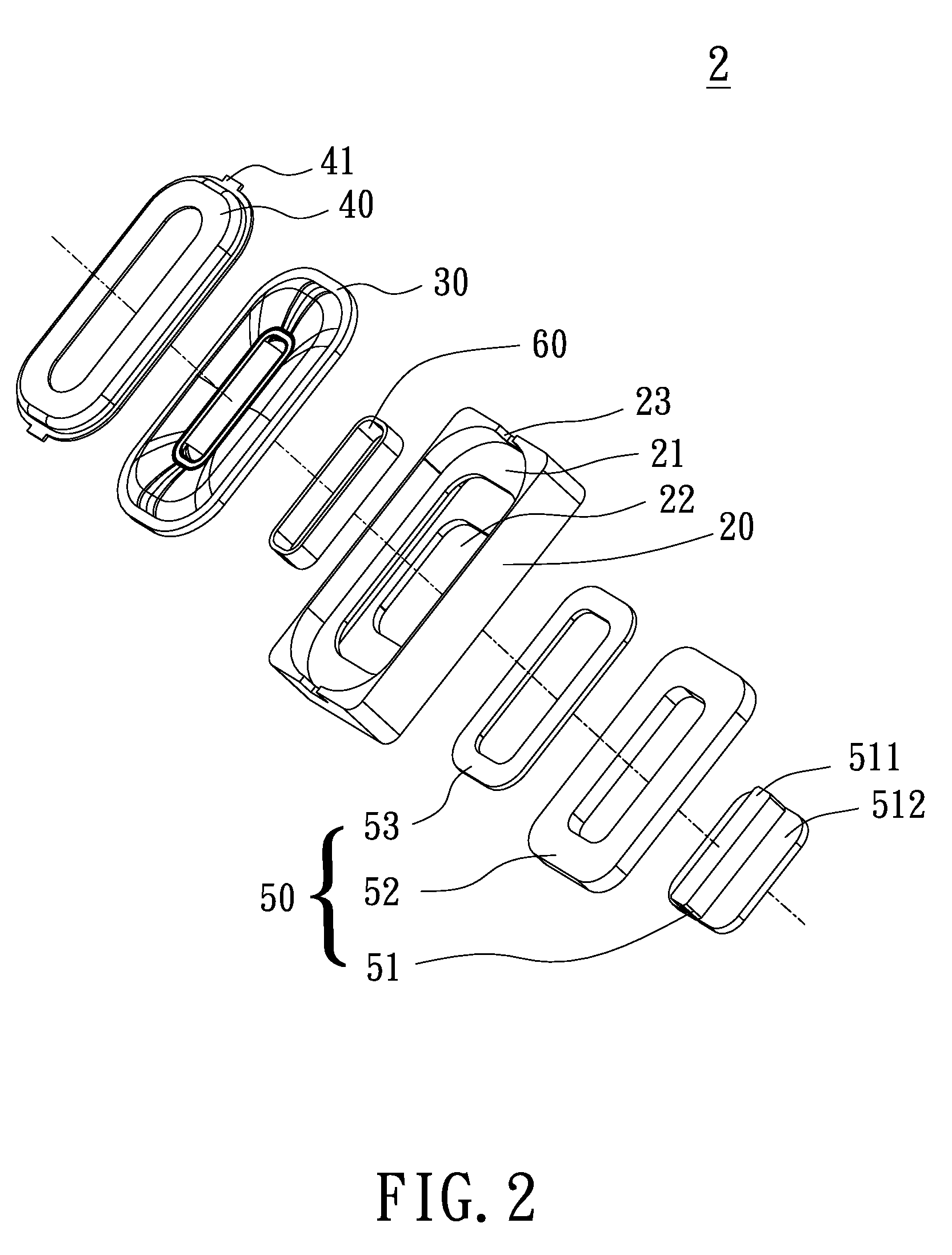

Speaker, Yoke thereof and Method for Manufacturing Yoke

InactiveUS20090304223A1Increase magnetic flux magneticIncreased magnetic sensitivityTransducer detailsPole pieceLoudspeaker

Owner:MERRY ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com