Device and method of rotating slotting magnetic pole polishing of inner surface of pipe fitting

A technology for slotting magnetic poles and inner surfaces, which is applied in the direction of grinding drive devices, grinding/polishing equipment, surface polishing machine tools, etc., and can solve the problems of single and single movement track of magnetic abrasive grains and the inability to continue to improve surface quality, etc. Achieve the effects of promoting tumbling and renewal, improving surface roughness, and increasing grinding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

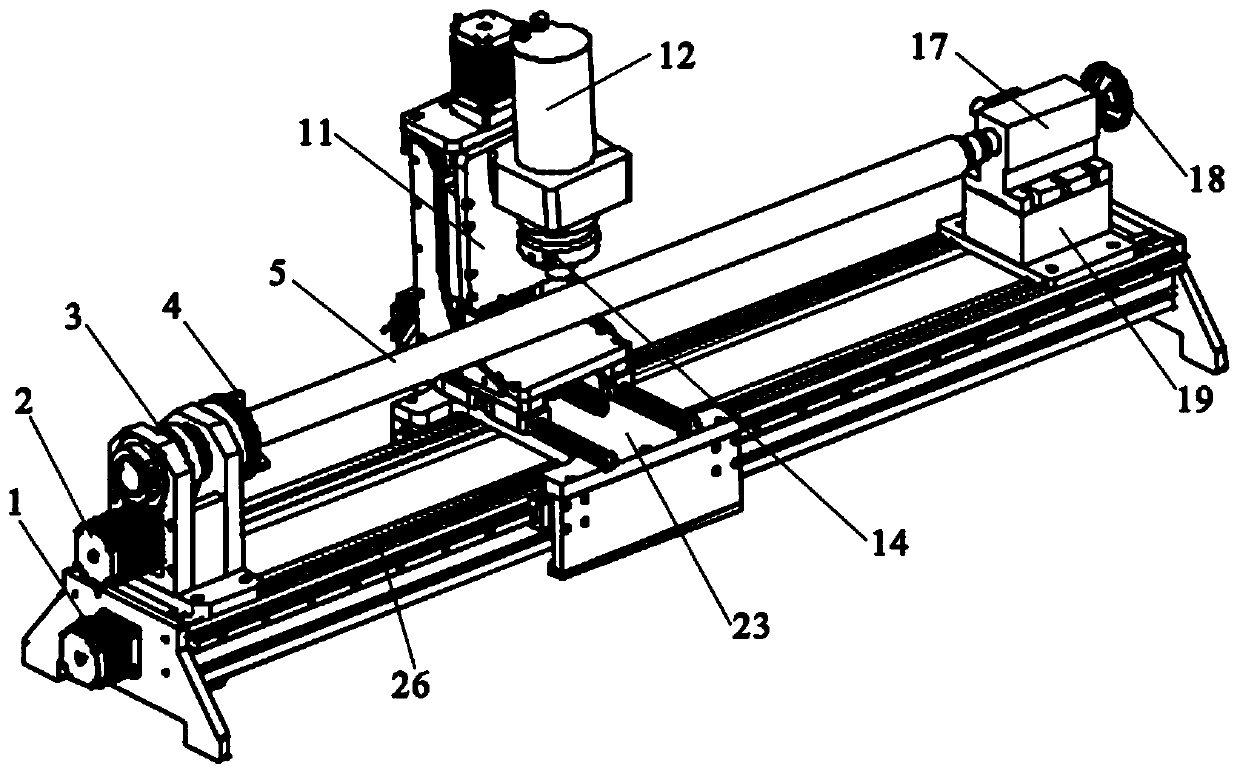

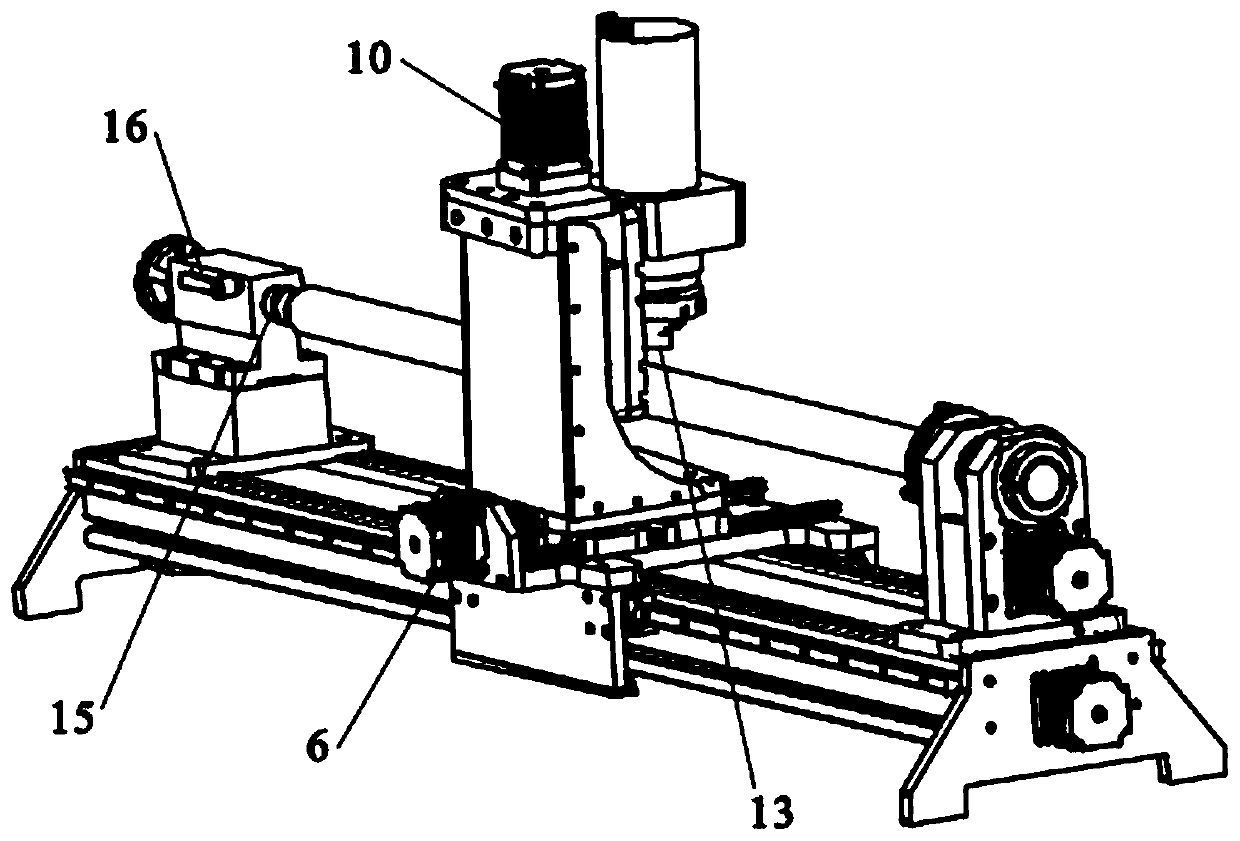

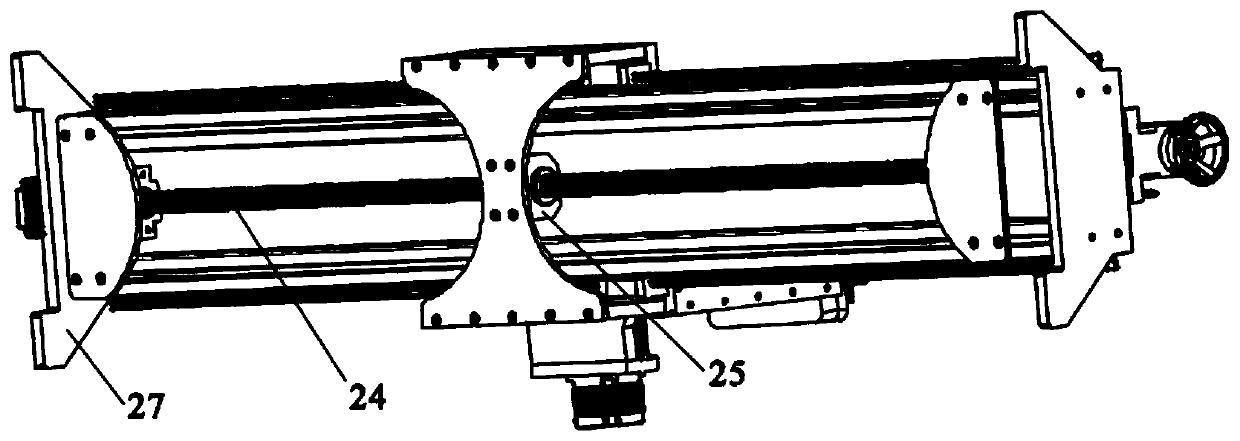

[0031] See Figure 1-Figure 6 , a device for polishing the inner surface of a rotary slotted magnetic pole, including a horizontal drive mechanism, a vertical drive mechanism, a rotating motor 12, a rotating motor support plate 11, a slotted magnetic pole 14, a magnetic pole chuck 13, a main motor 2, and a triangular chuck 4. The base 19; the horizontal drive mechanism is connected with the vertical drive mechanism to drive the vertical drive mechanism to move in the horizontal direction; the vertical drive mechanism is connected with the rotary motor 12 through the rotary motor pallet 11; the rotary motor 12 drives the magnetic pole chuck 13 to rotate The magnetic pole chuck 13 is equipped with a slotted magnetic pole 14; the base 19 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com