Patents

Literature

141results about How to "Promote tumbling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow-through media

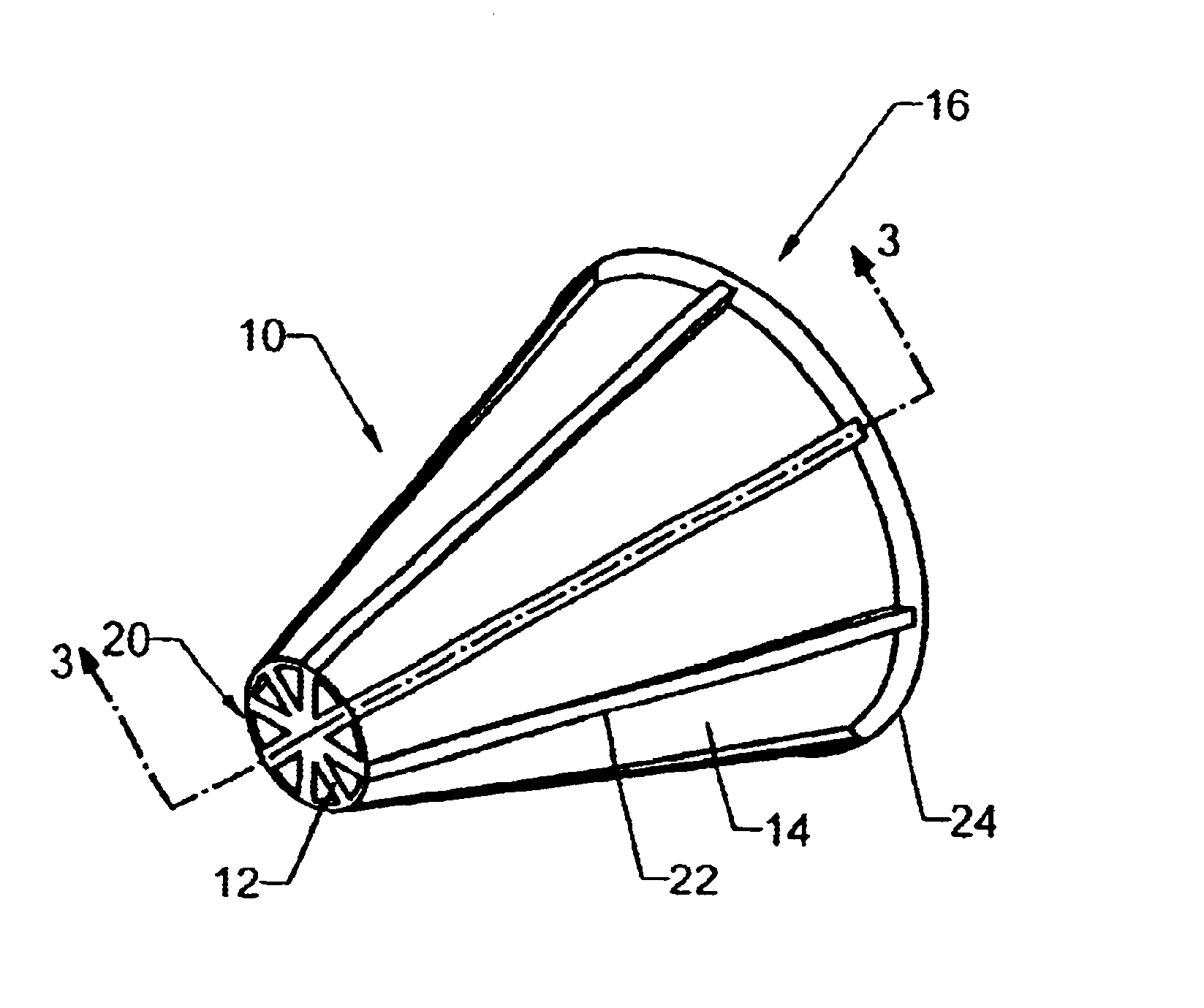

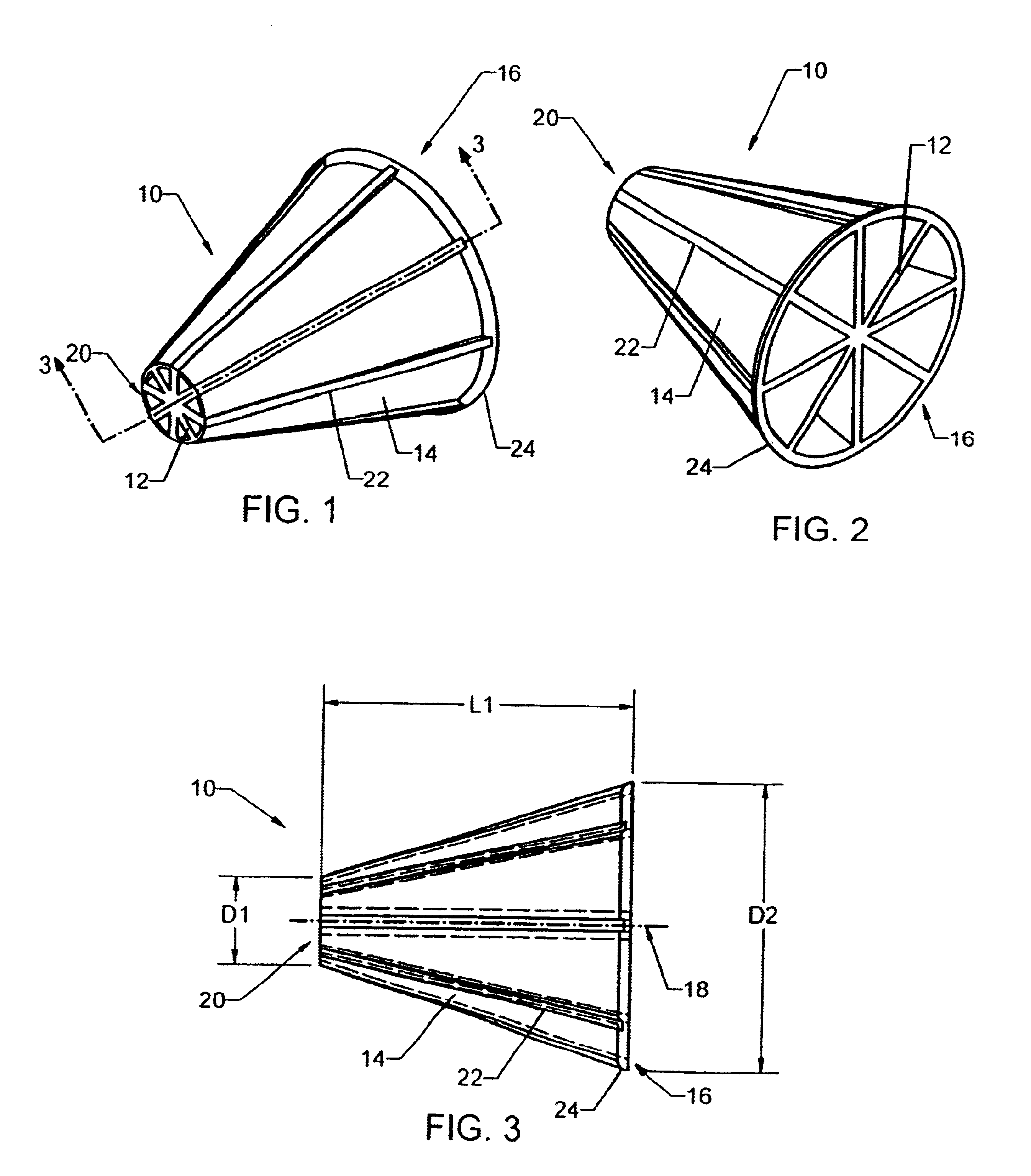

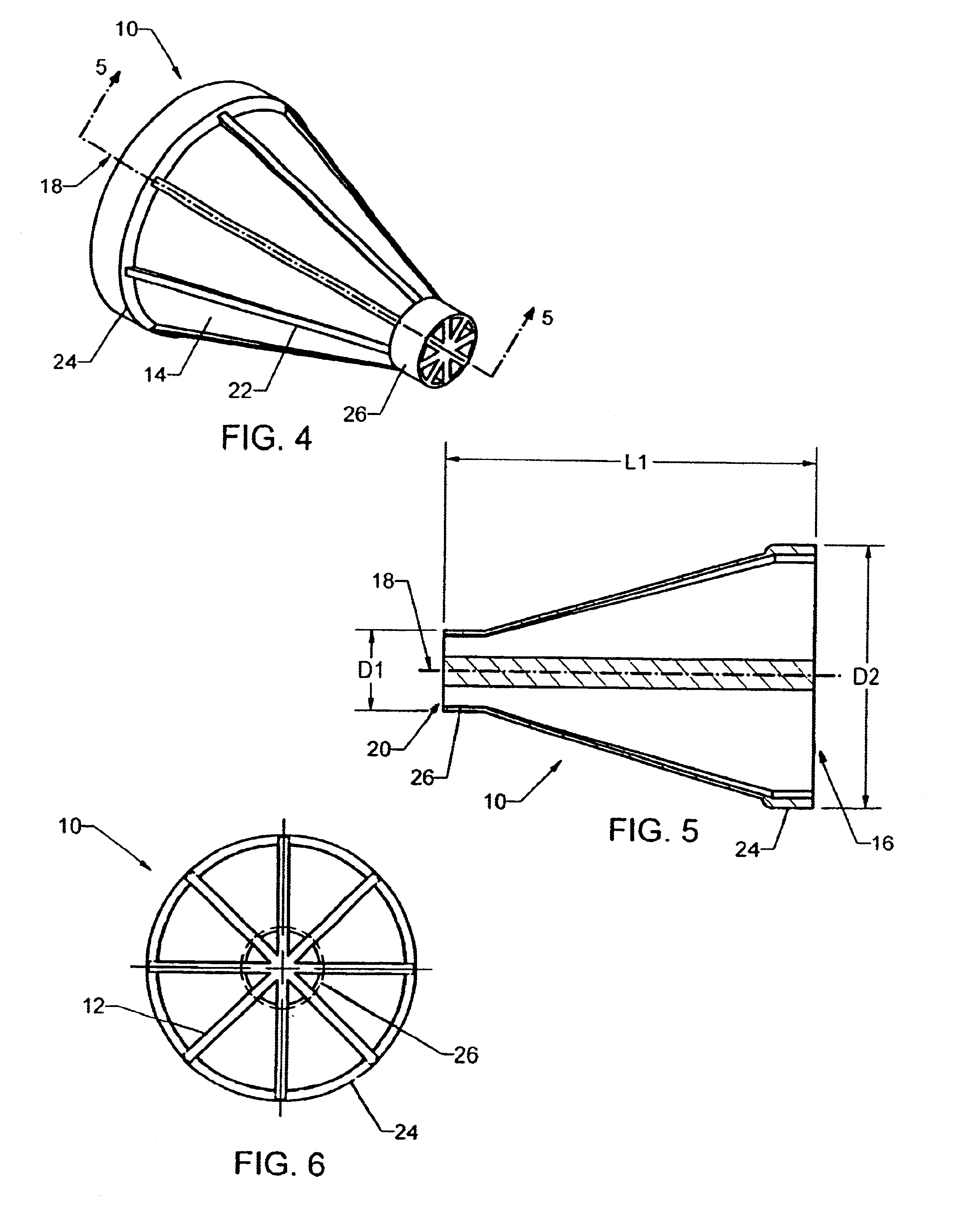

InactiveUS6852227B1Promote tumblingEfficient removalBioreactor/fermenter combinationsBiological substance pretreatmentsSewageEffluent

A flow-through medium for use in a biological digester has a truncated conical shape, a plurality of internal ribs, and optional external ribs. The conical shape of the media creates a venturi-like action for fluid flowing through the media, which increases the tumbling of the media elements against each other and against the wall of the enclosure in which they are contained. Moreover, the conical shape and venturi-like action prevents slough from accumulating within the media elements, allowing it to be washed through the media.A method of treating sewage effluent includes placing the media elements in an enclosure partially submersed in the effluent and rotating the enclosure to expose the media to the effluent and to a source of oxygen.

Owner:JRJ HLDG

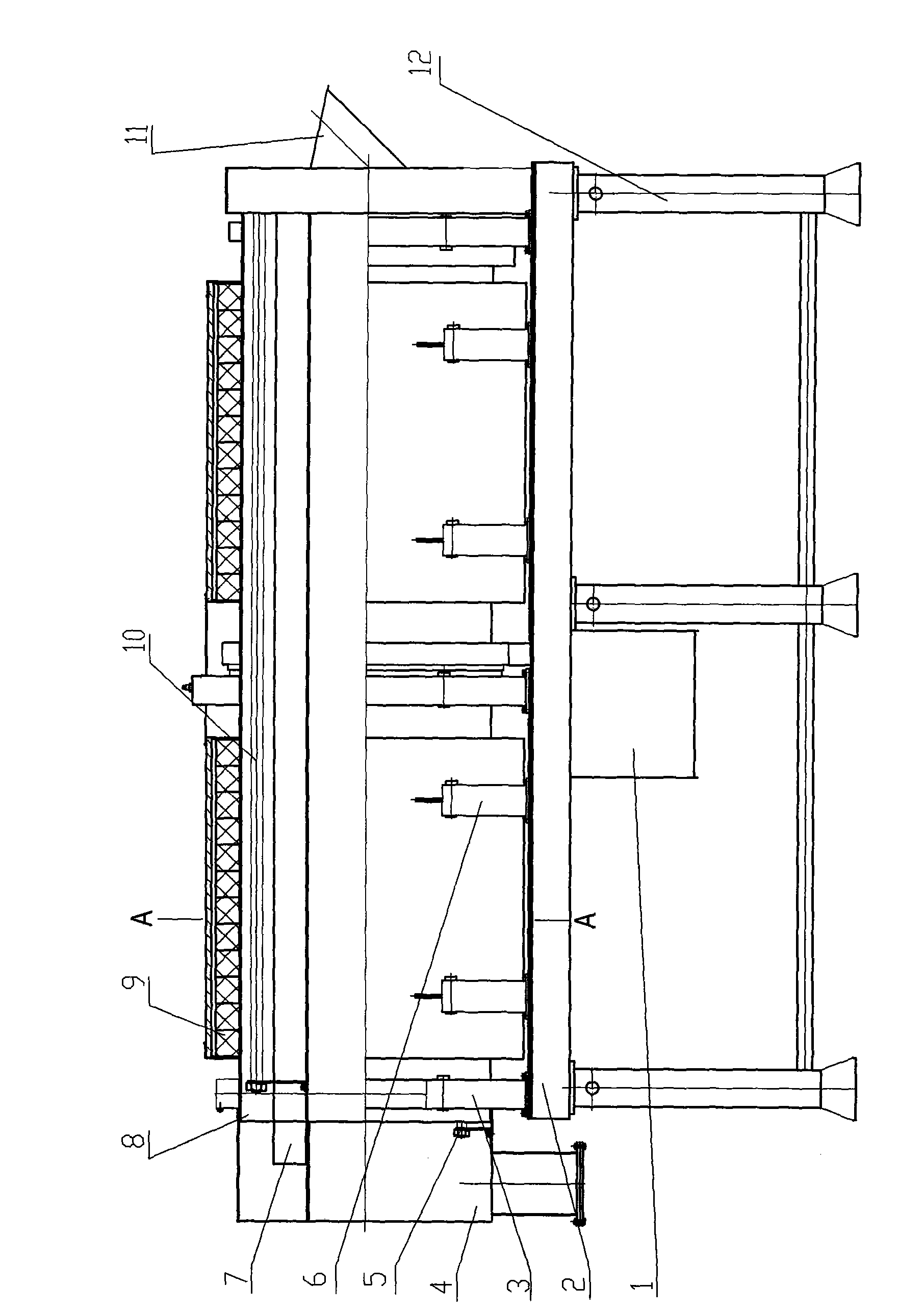

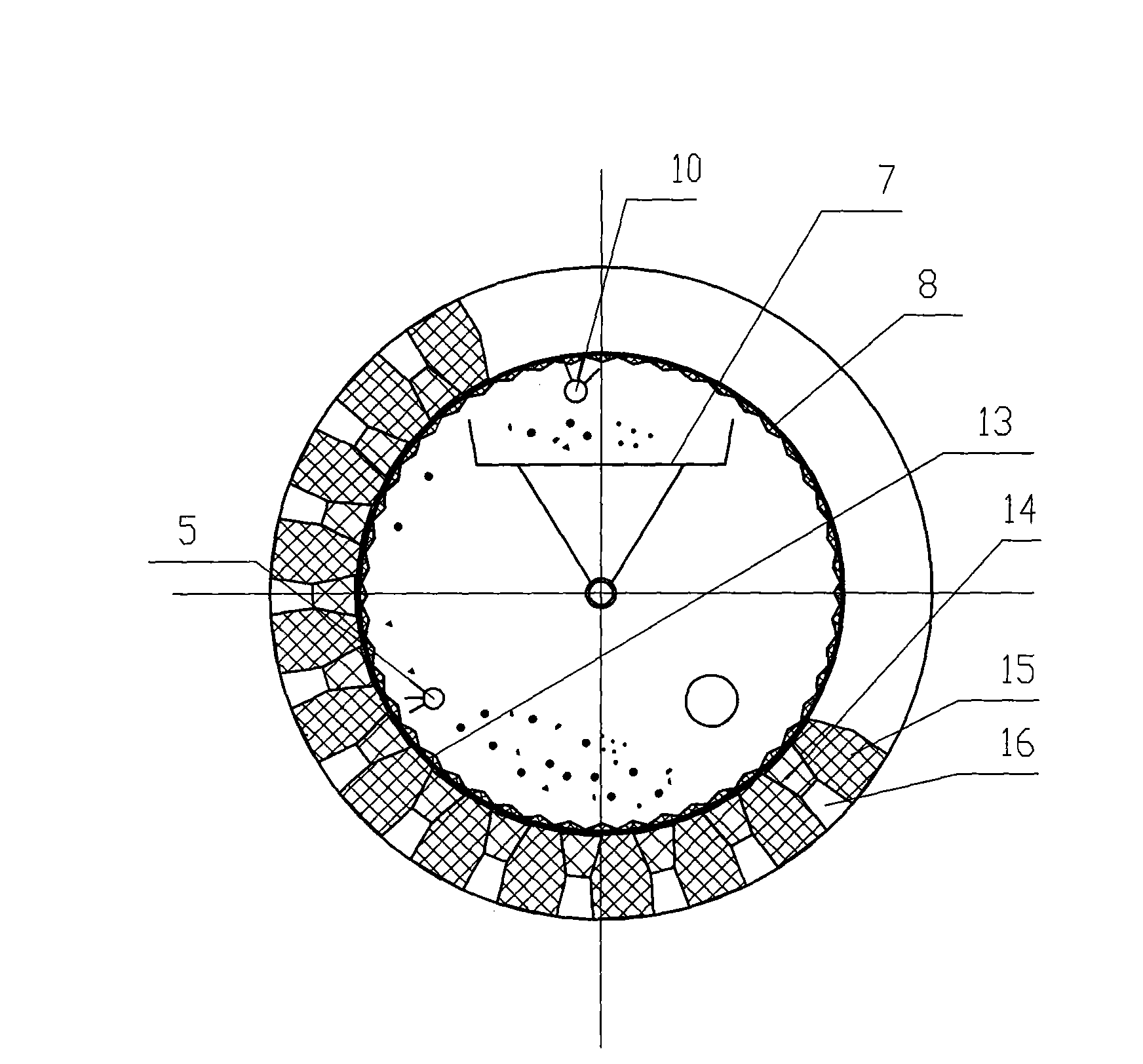

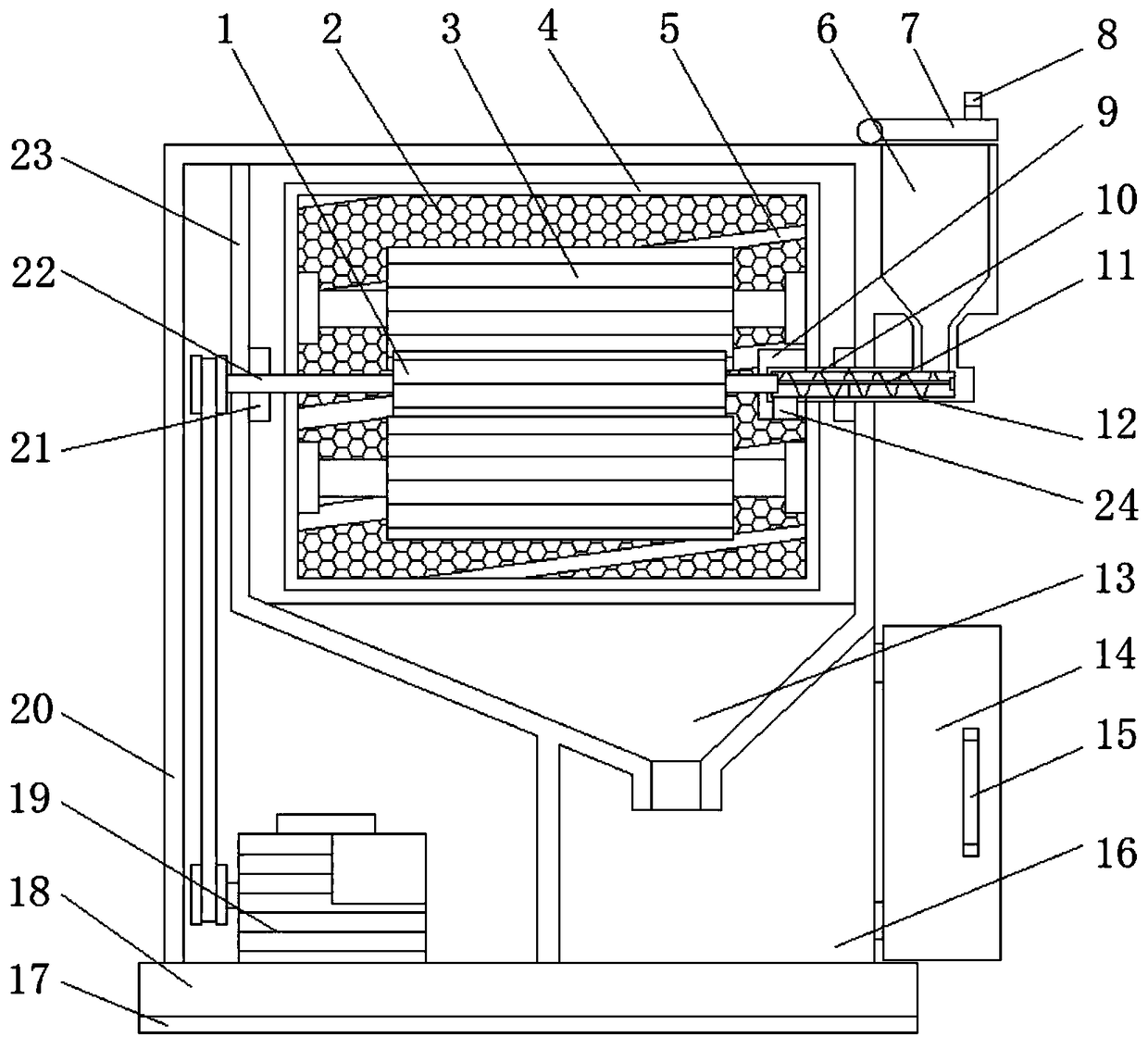

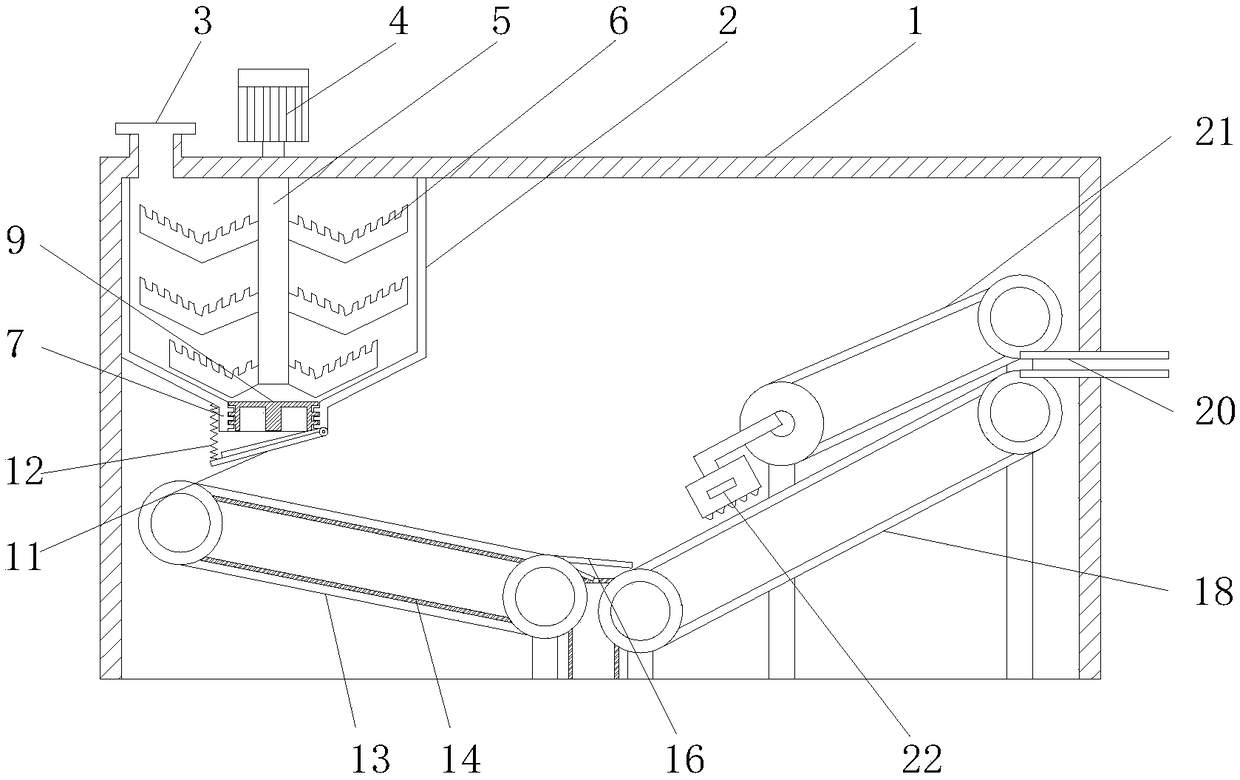

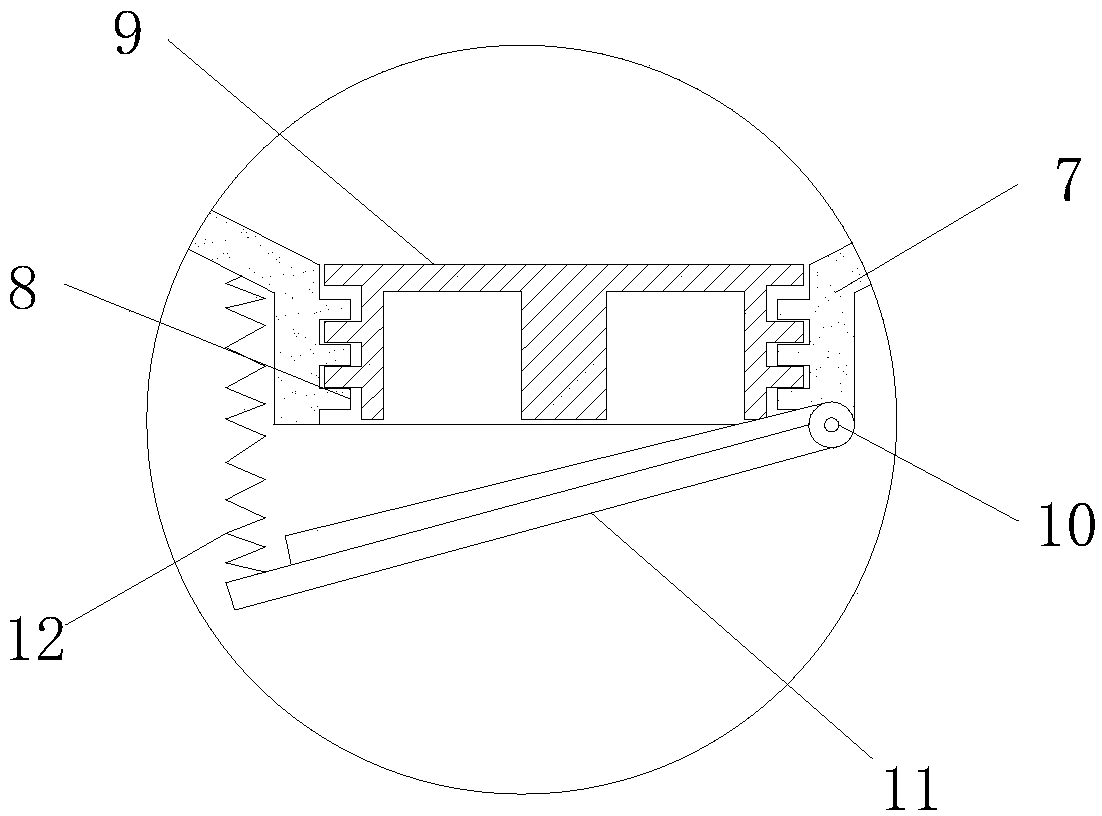

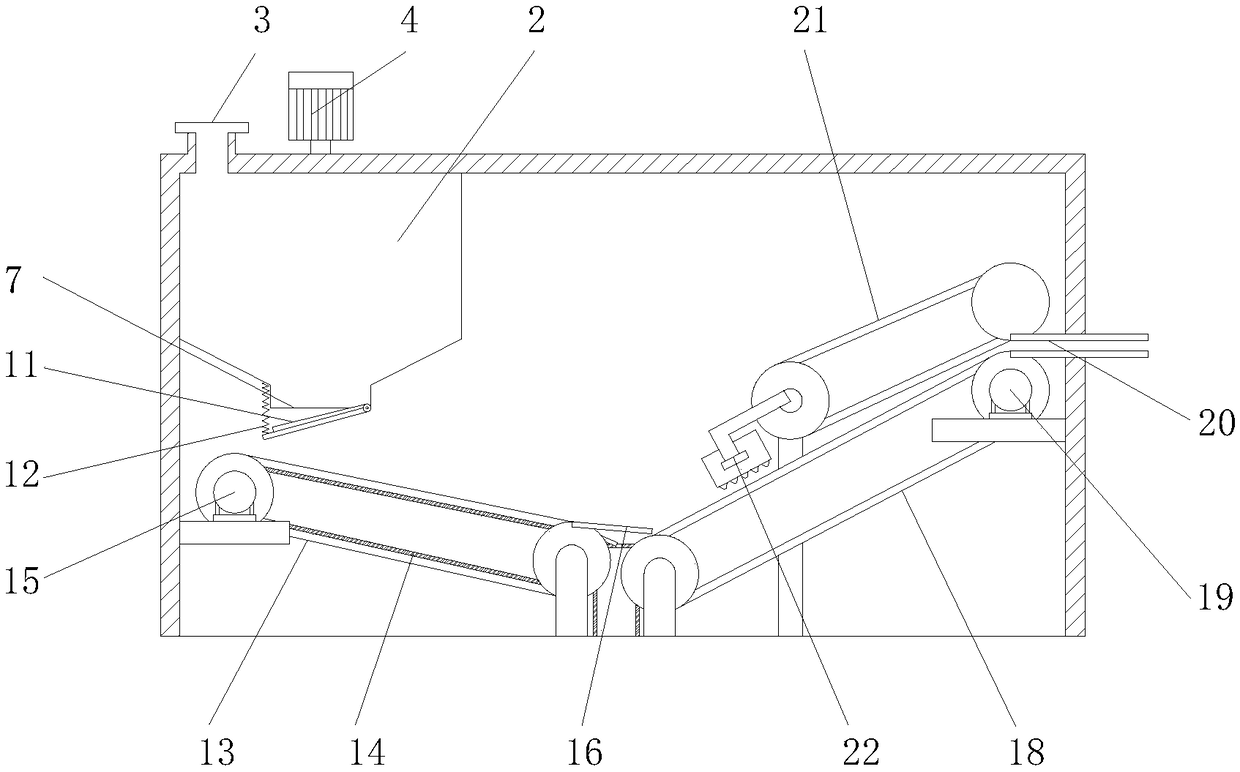

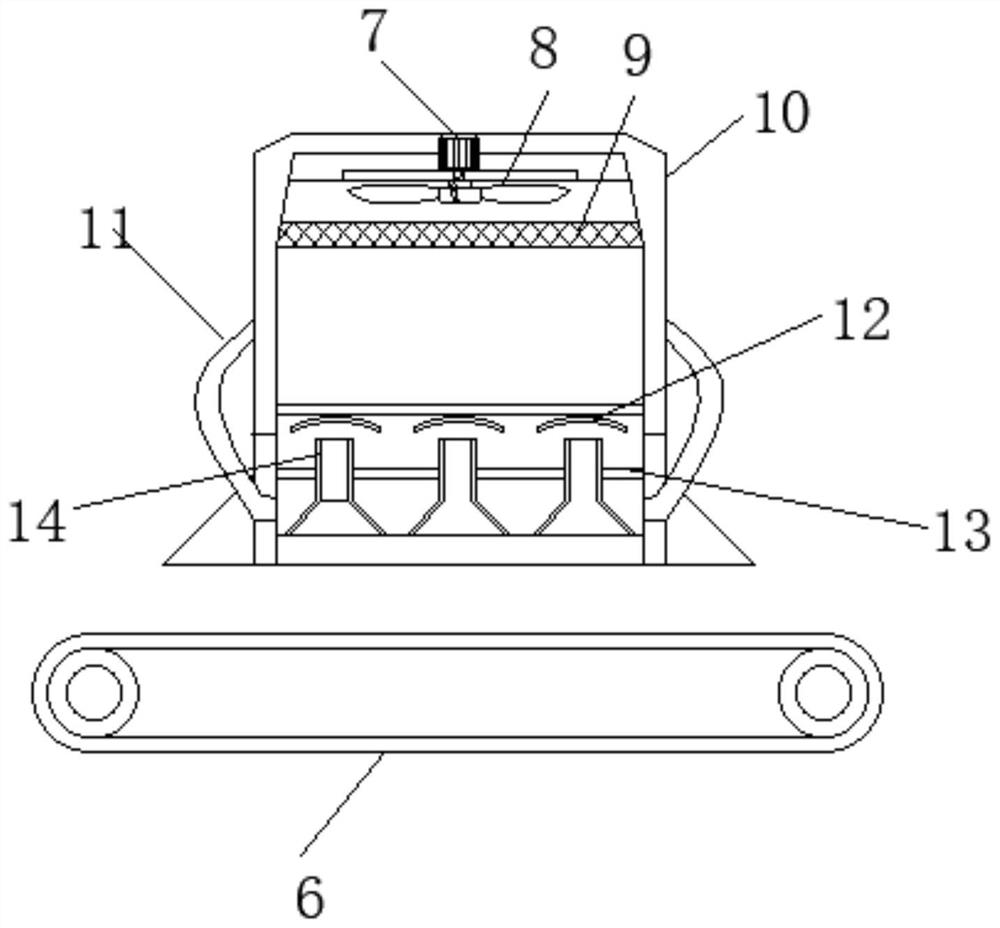

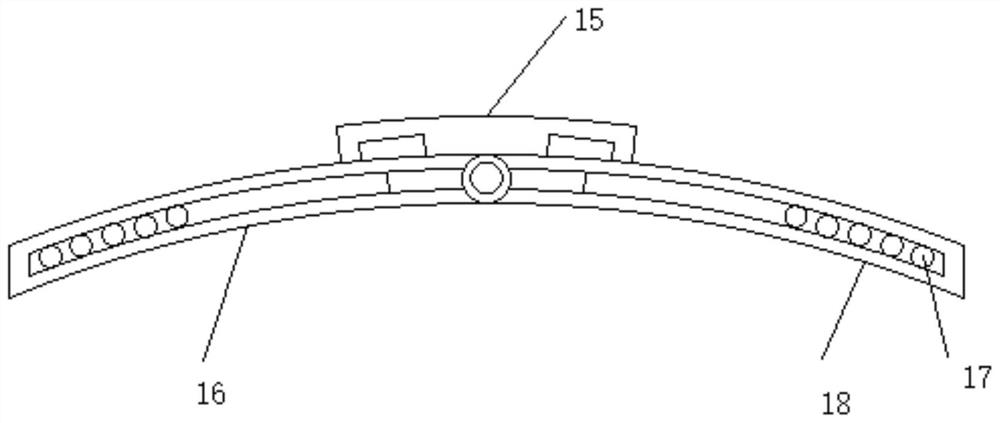

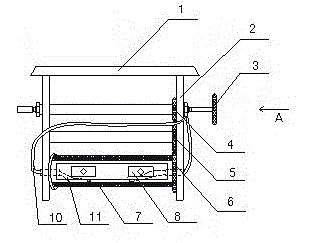

Magnetic separating method and magnetic separator

The invention discloses a magnetic separating method for improving the recovering effect of the fine-grained magnetic materials, which is characterized in that the materials rotate along with a separating drum in the separating drum and are separated under the common action of rinse water, wash water and the gradient of the separating drum. A magnetic separator for realizing the method is characterized in that a rack [2] is provided with a magnetic system [9] and the separating drum [8] driven by power [1], the included angle between the separating drum [8] and the horizontal plane is 6-20 degrees, a feeding device [11] is arranged on the upper part of the front end of the separating drum [8] and a discharging device [4] is arranged on the lower part of the tail end of the separating drum[8], a rinsing water pipe [5] and a washing water pipe [10] are arranged in the separating drum [8], a material receiving chute [7] is arranged below the washing water pipe [10] and is connected withthe discharging device of the magnetic materials. The method of the invention is feasible, the equipment is simple, the purity of the magnetic materials is improved by 10-20% and the yield is improvedby over 10%.

Owner:HUNAN KEYUAN MAGNETIC EQUIP CO LTD

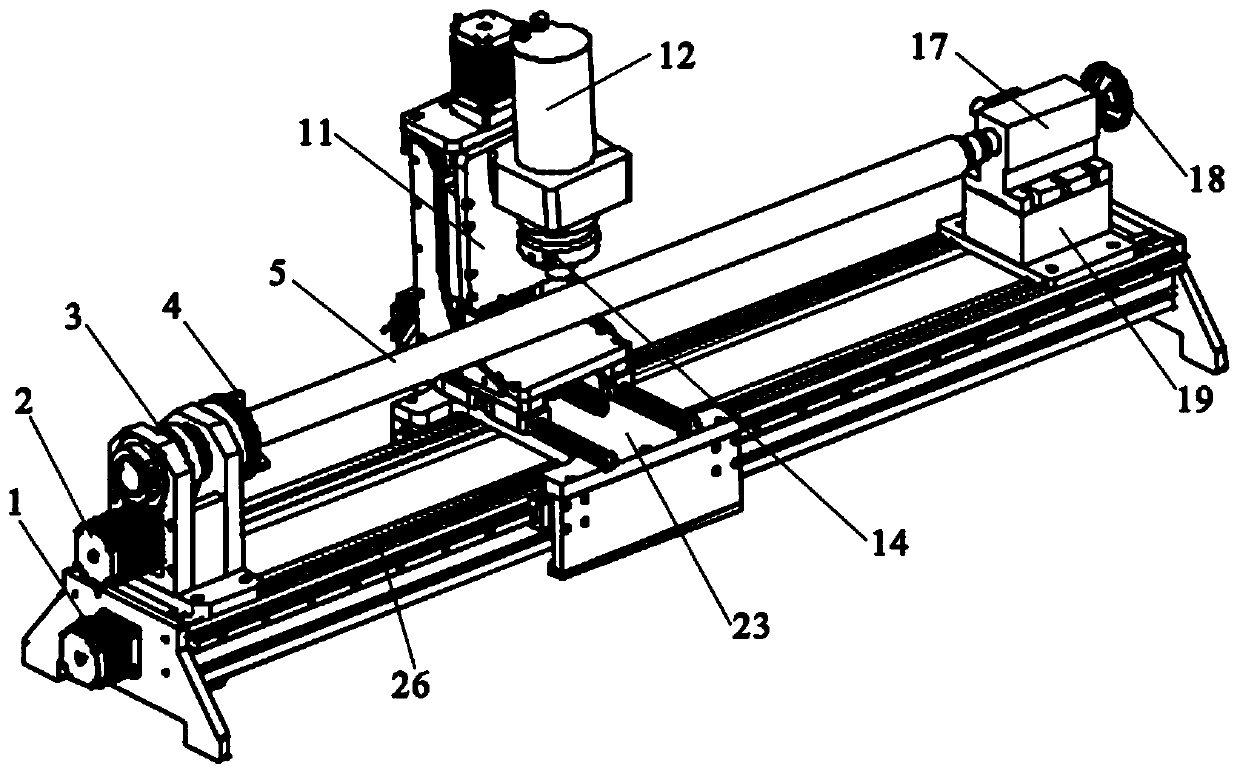

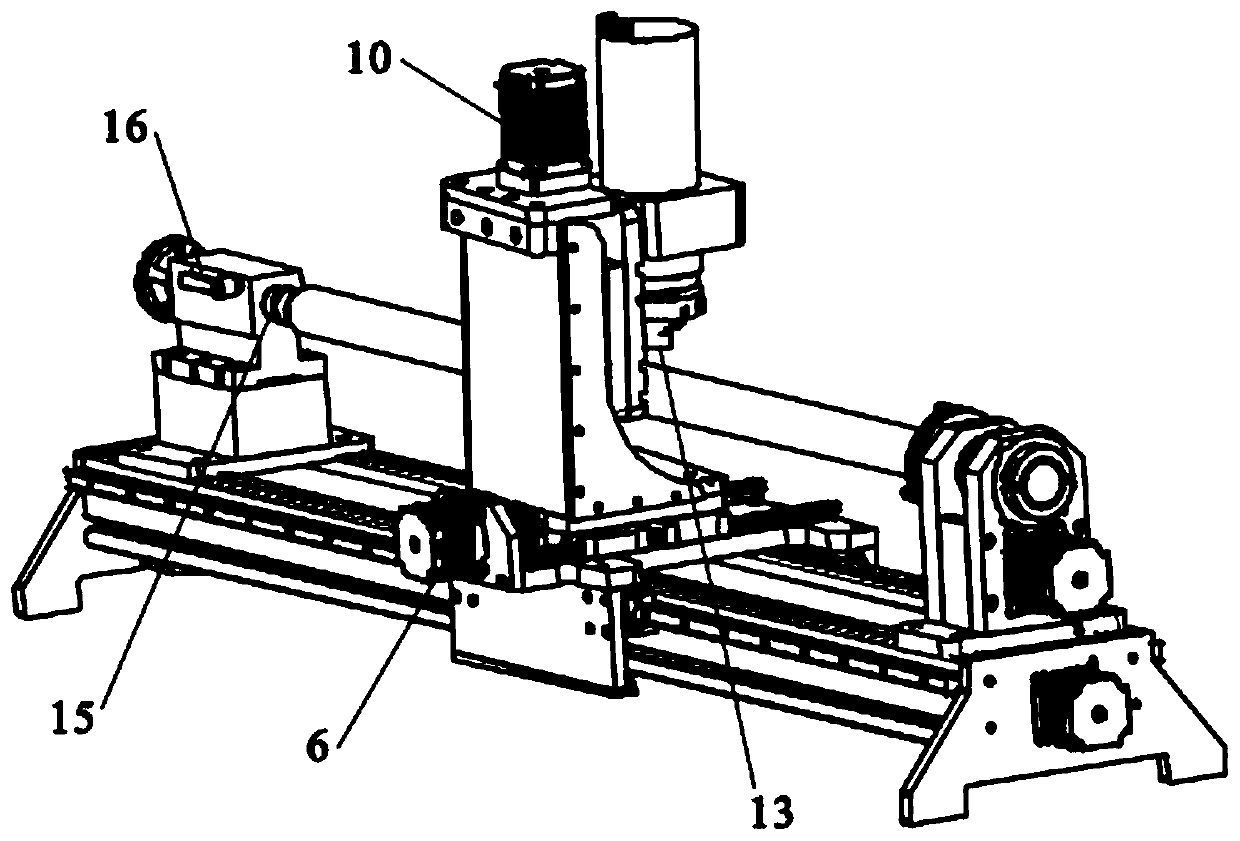

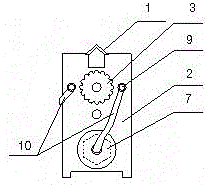

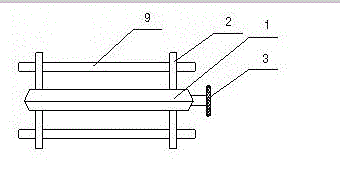

Device and method of rotating slotting magnetic pole polishing of inner surface of pipe fitting

PendingCN110253346AImprove surface roughnessComplicated trajectoryEdge grinding machinesPolishing machinesMotor drivePipe fitting

The invention relates to a device and method of rotating slotting magnetic pole polishing of the inner surface of a pipe fitting. The device comprises a horizontal driving mechanism, a vertical driving mechanism, a rotating motor, a rotating motor supporting plate, a slotting magnetic pole, a magnetic pole chuck, a main motor, a triangular chuck and a base. The horizontal driving mechanism is connected with the vertical driving mechanism and drives the vertical driving mechanism to move in the horizontal direction, and the vertical driving mechanism is connected with the rotating motor through the rotating motor supporting plate. The rotating motor drives the magnetic pole chuck to rotate, and the slotting magnetic pole is clamped on the magnetic pole chuck. The base is fixed to the horizontal driving mechanism, and the main motor drives the triangular chuck. One end of a workpiece is clamped on the triangular chuck, and the other end of the workpiece is limited by a tail base. The workpiece is arranged below the slotting magnetic pole. The device and method have the advantages that the inner surface of the pipe fitting can be processed, the rotating magnetic pole drives magnetic abrasive particles, the movement trail is more complex, the impact scratch caused by the magnetic abrasive particles on the pipe fitting which needs to be processed is more complex, and therefore the surface roughness of the pipe fitting which needs to be processed can be improved.

Owner:UNIV OF SCI & TECH LIAONING

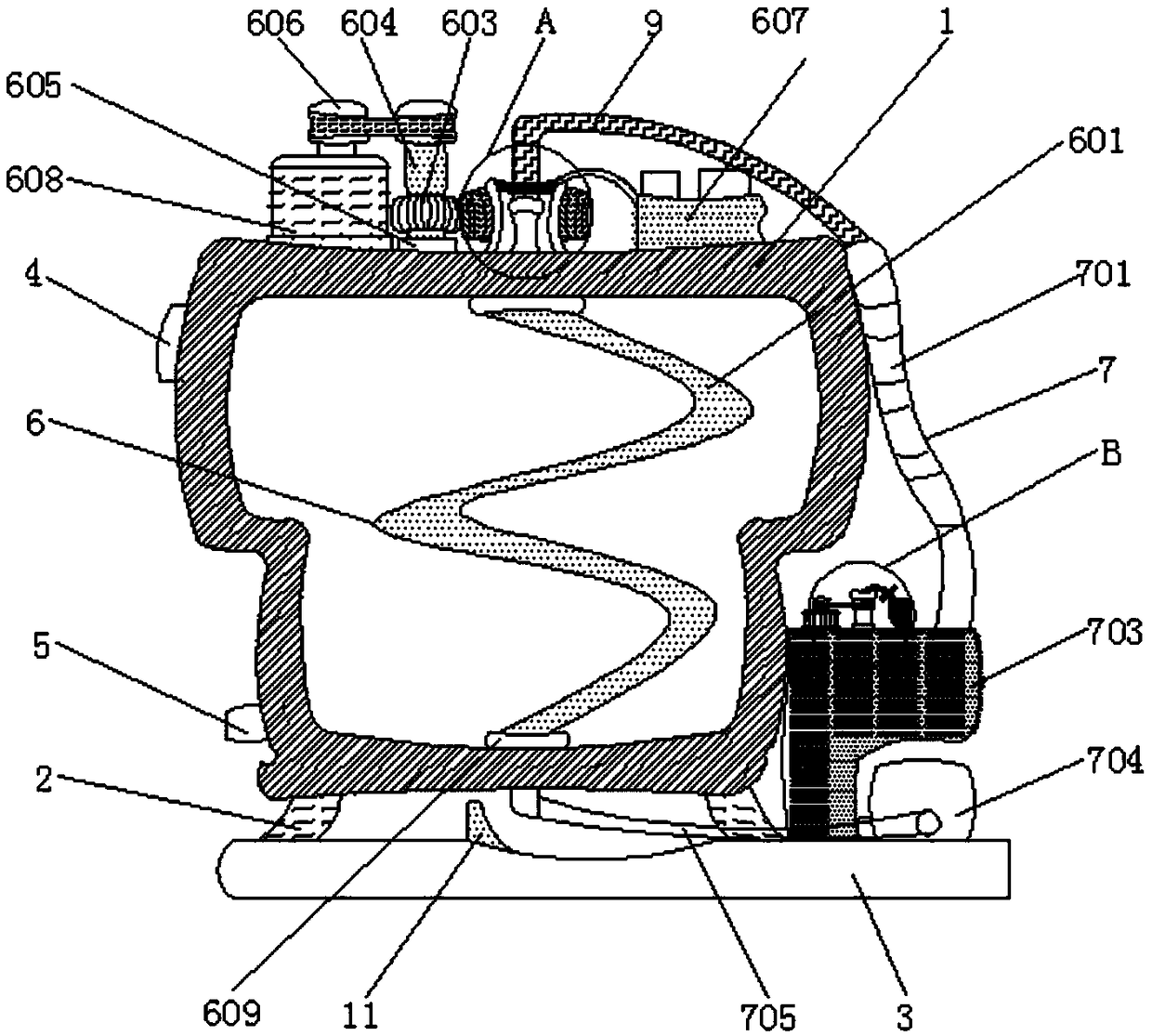

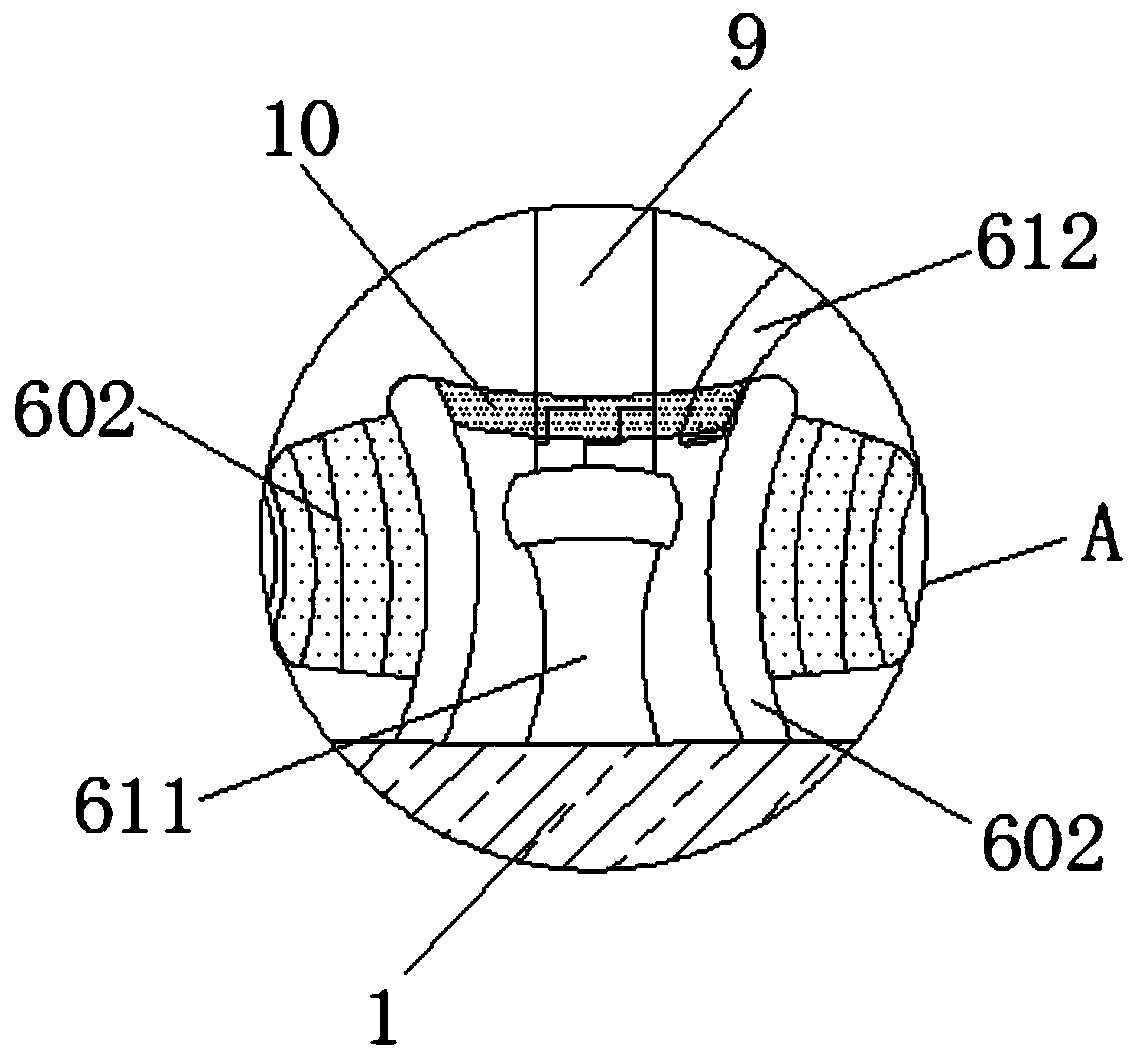

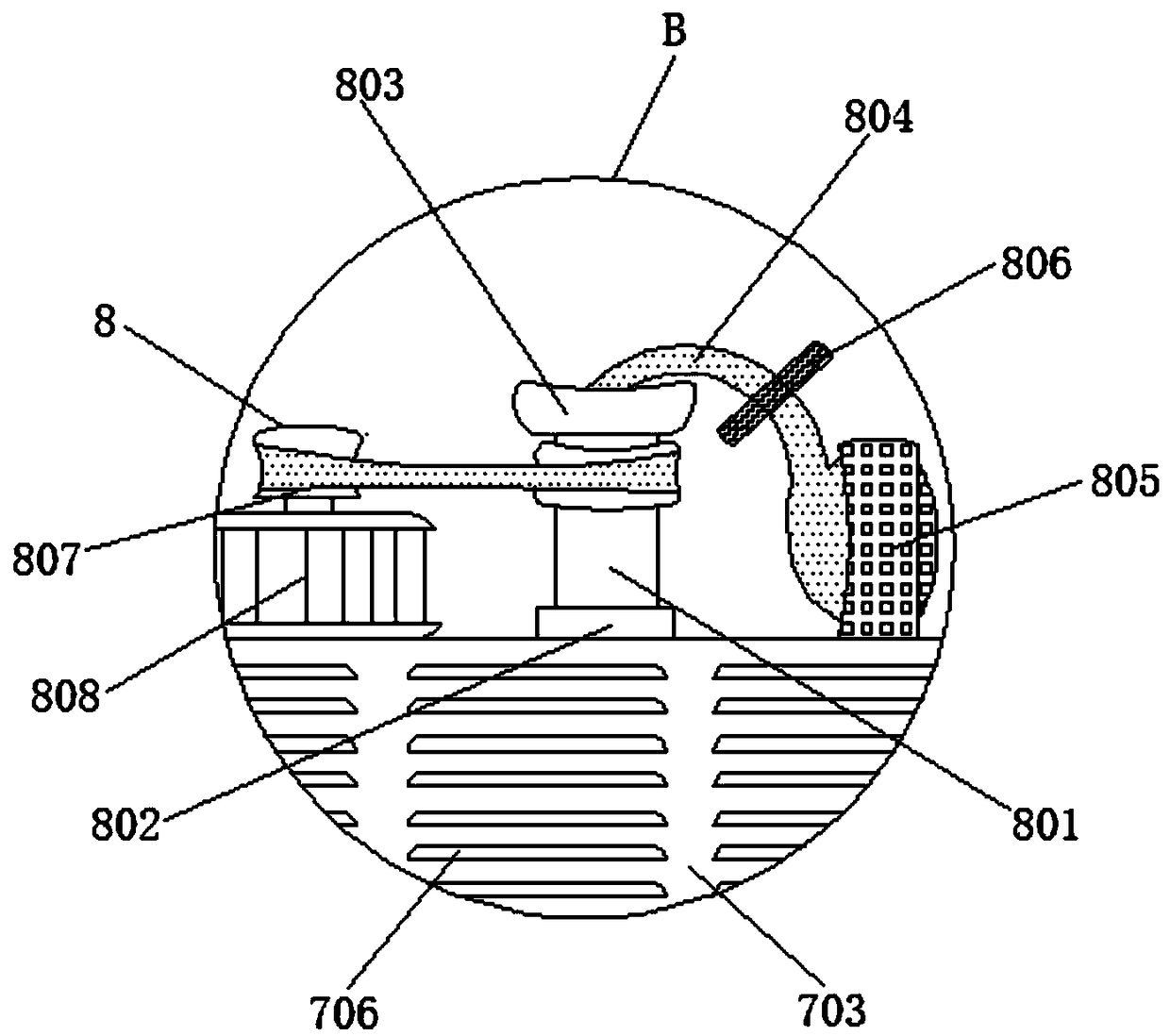

Heavy metal contaminated soil remediation device

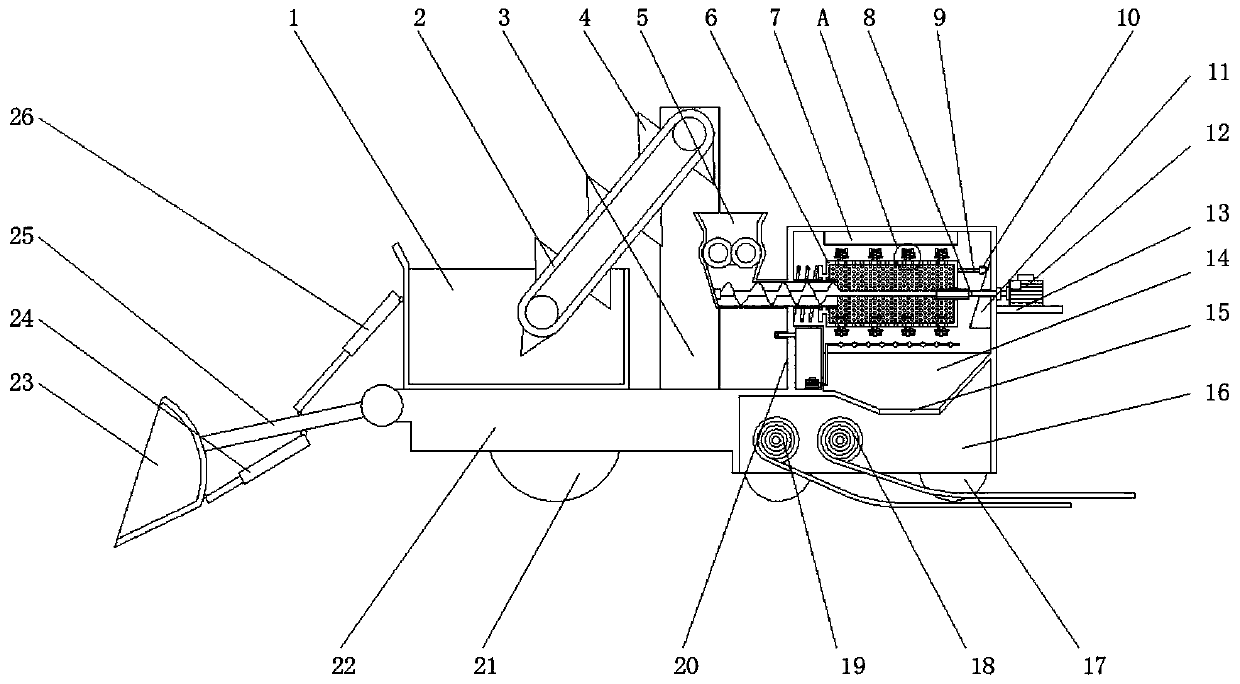

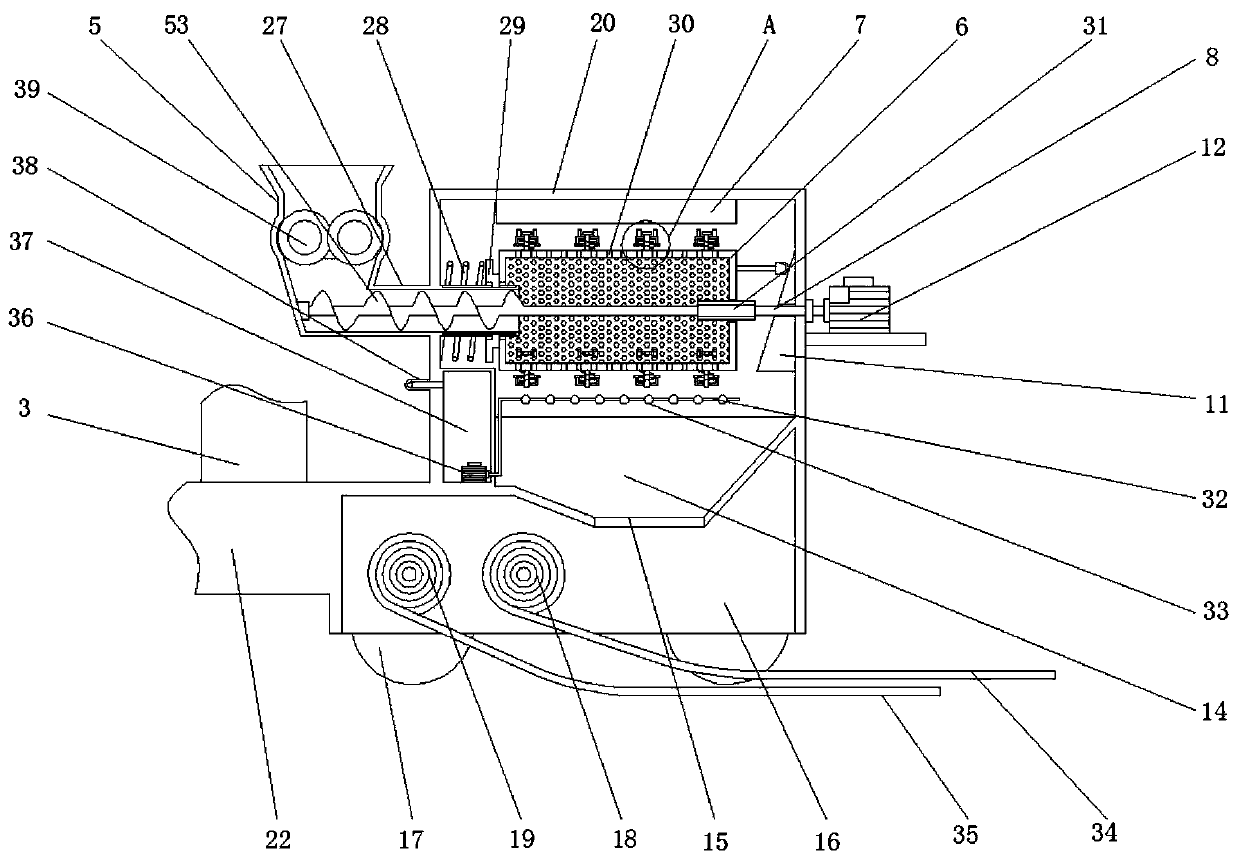

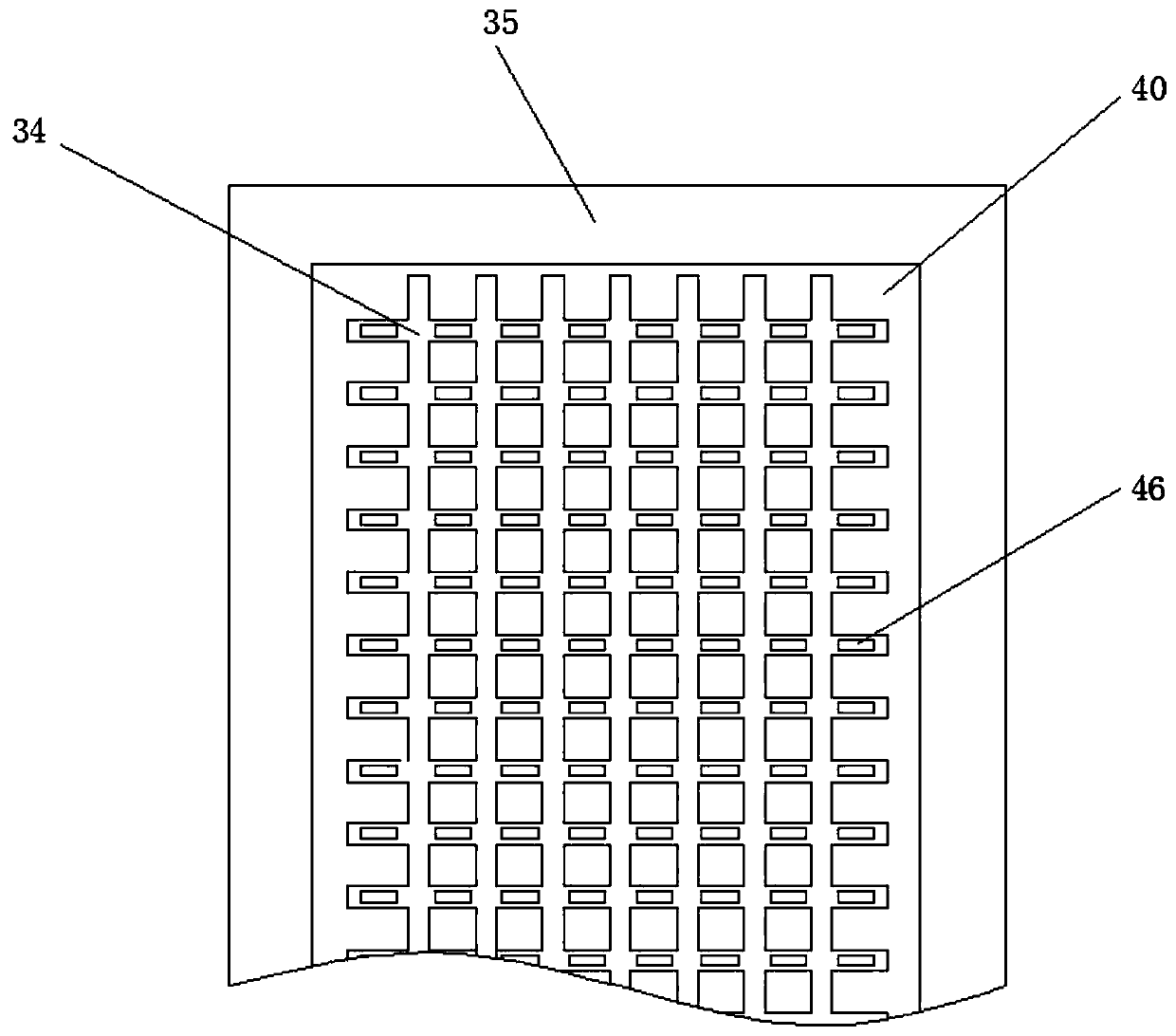

ActiveCN110153164AAvoid repairsPromote repairSoil lifting machinesContaminated soil reclamationSoil remediationEngineering

The invention discloses a heavy metal contaminated soil remediation device which comprises a storage barrel, a conveyor belt, a treatment seat, a connecting plate and a bucket, wherein two pairs of first traveling wheels are symmetrically arranged on two sides of the bottom end of an outer side wall of the treatment seat; and the connecting plate is welded on one side of the bottom end of the outer side wall of the treatment seat. A pulley matched with a guide seat is arranged on a connecting rod at one end of the screening bucket, and a movable sleeve is arranged on the outer side of a guiderod in a sleeving manner on the outer side wall of the screening bucket. On one hand, by utilizing guide of a bevel end of the guide seat, the screening bucket is matched with a reset spring at the other end of the screening bucket in a process of driving the screening bucket to rotate by a motor, so that the screening bucket can sway from side to side in the rotating and screening process, and the screening efficiency and the screening effect are improved; on the other hand, a second magnetic block having the same magnetism as a first magnetic block is arranged on the top of the movable sleeve, so that the movable sleeve enabling the screening bucket to rotate to a position just under the first magnetic block has a vibratory cleaning effect on the screening bucket, and blockage of sieve pores is avoided.

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

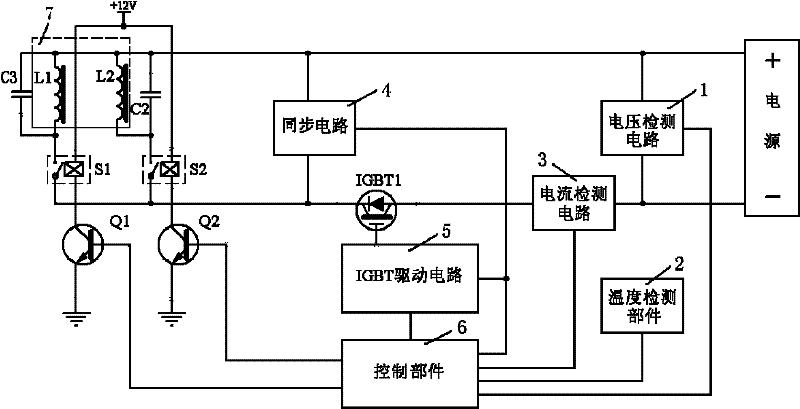

Convection heating control method of electromagnetic oven and heating control device

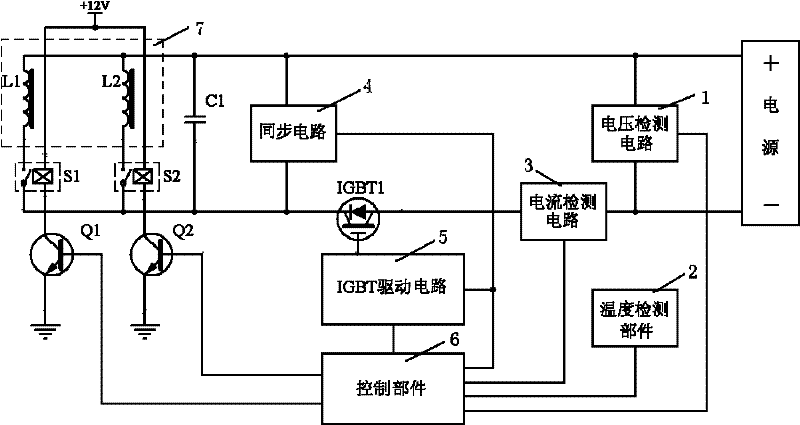

ActiveCN102200301AHeating evenlyPromote tumblingDomestic stoves or rangesLighting and heating apparatusHeat controlEngineering

Owner:JOYOUNG CO LTD

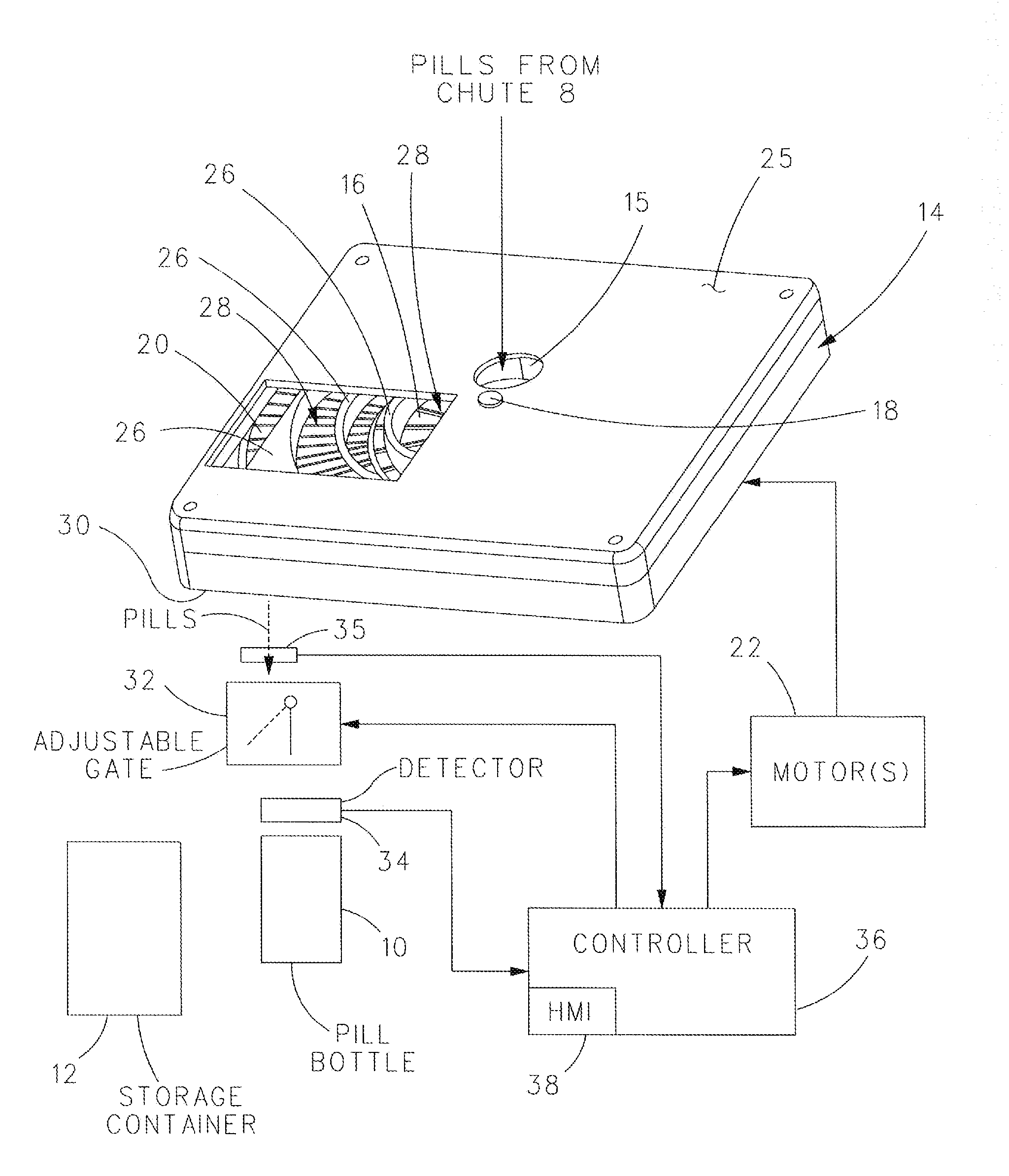

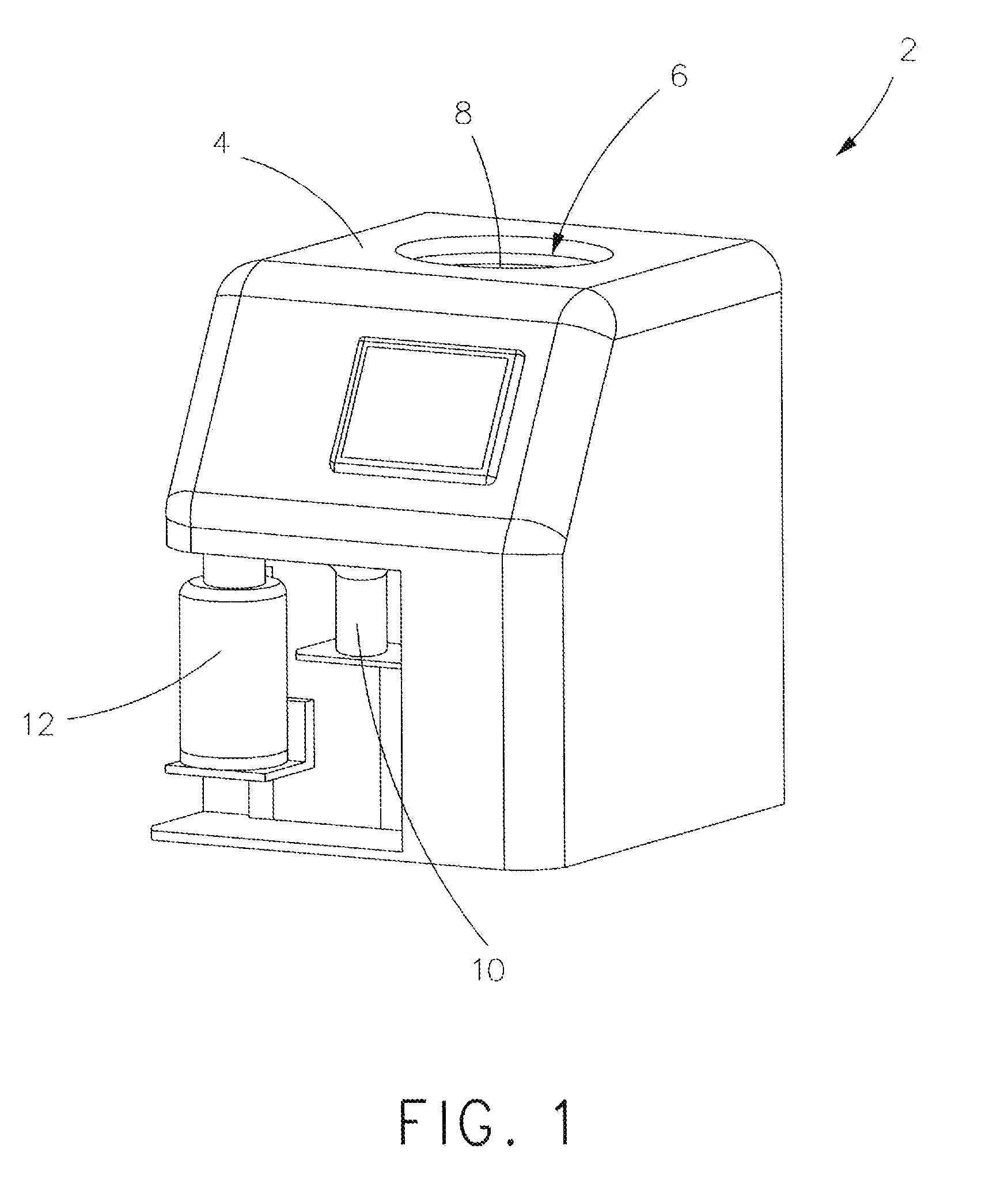

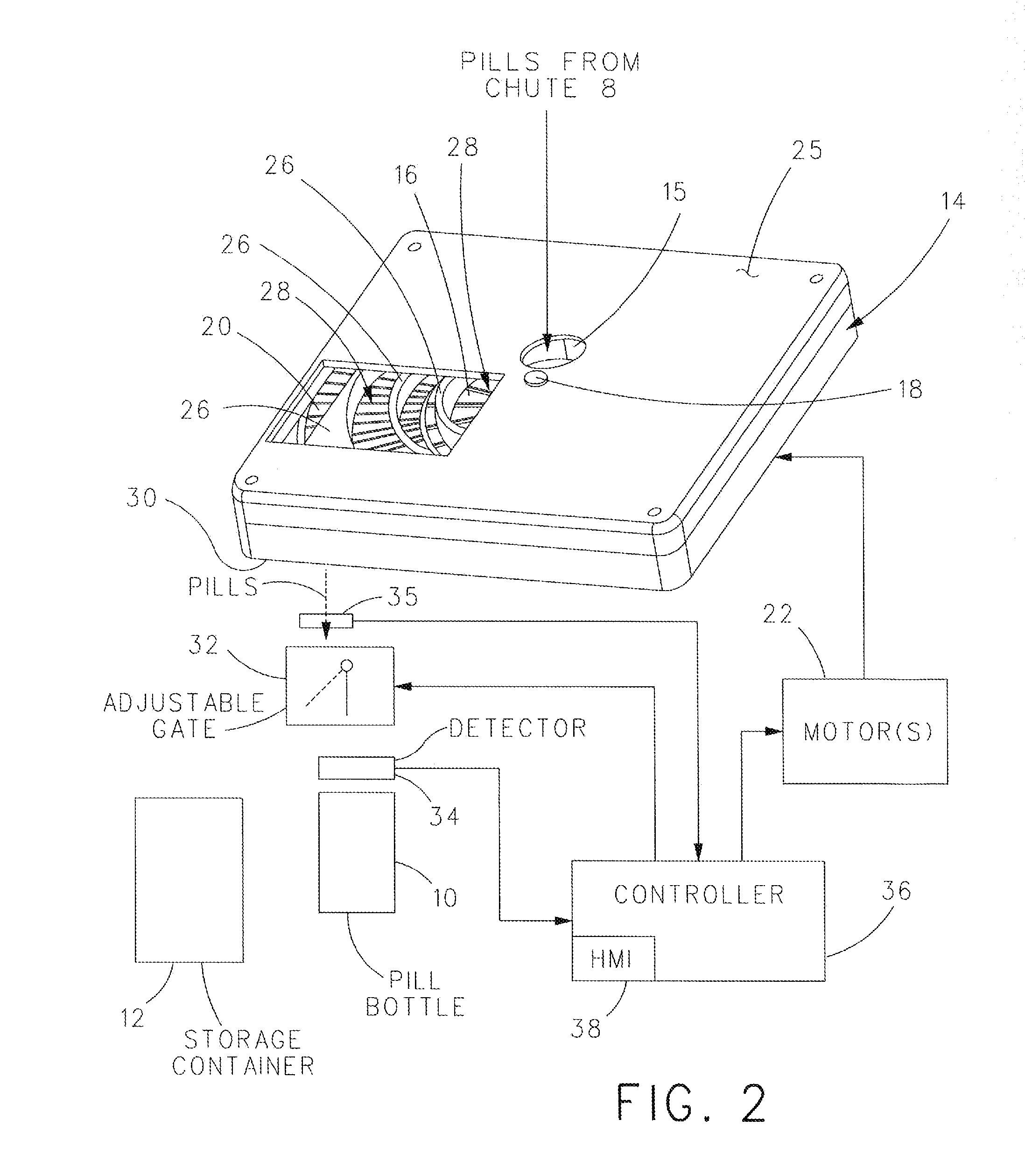

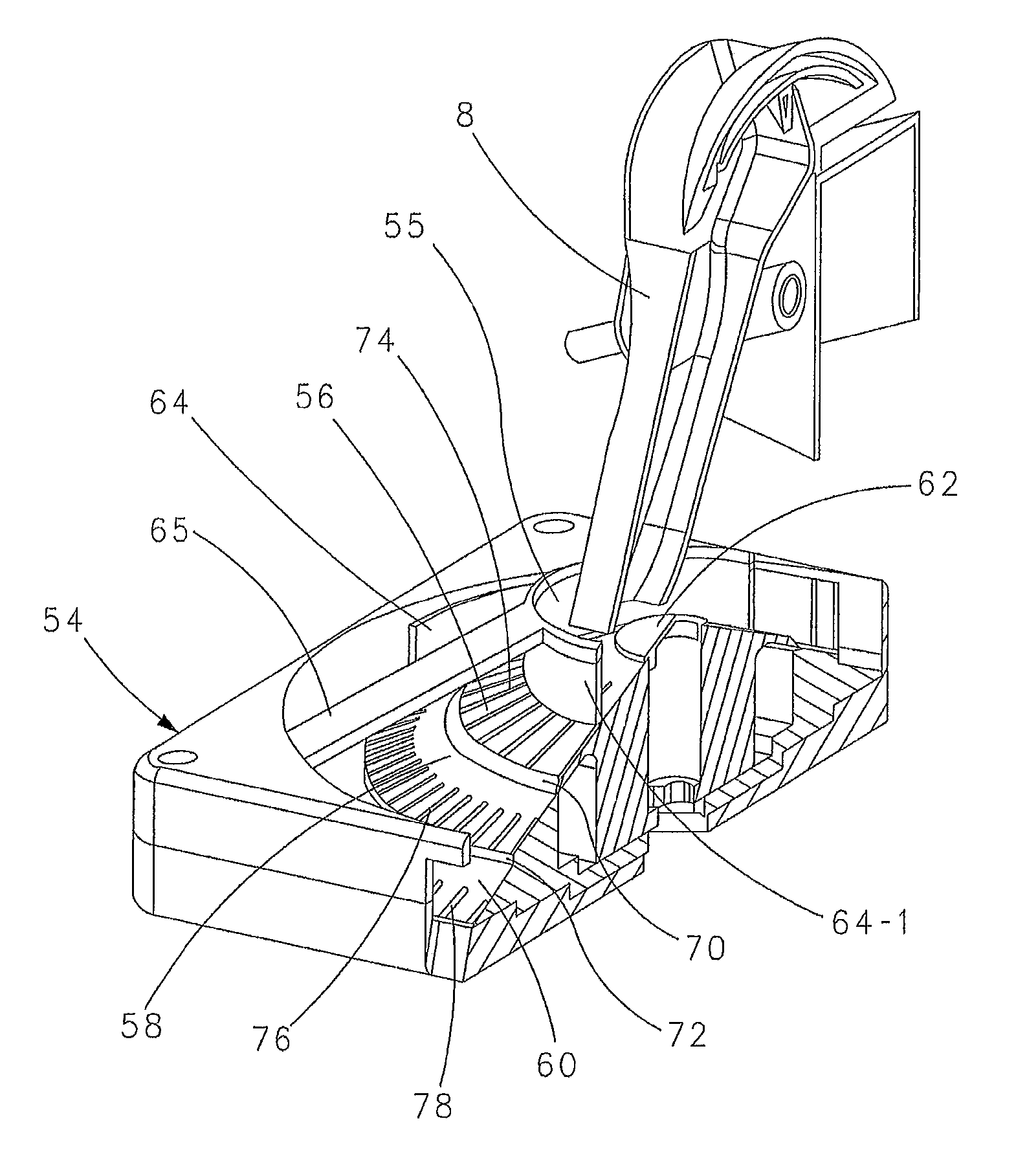

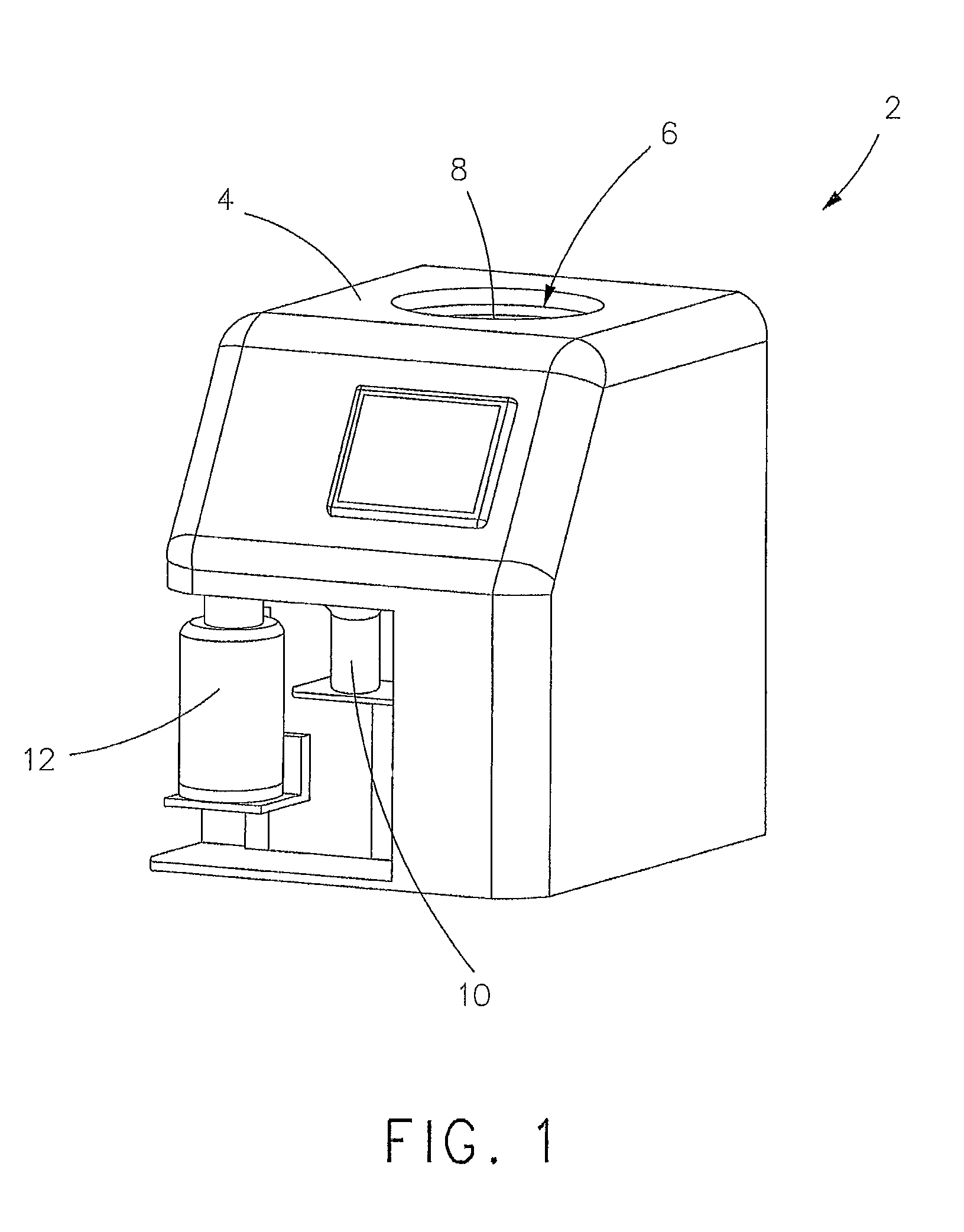

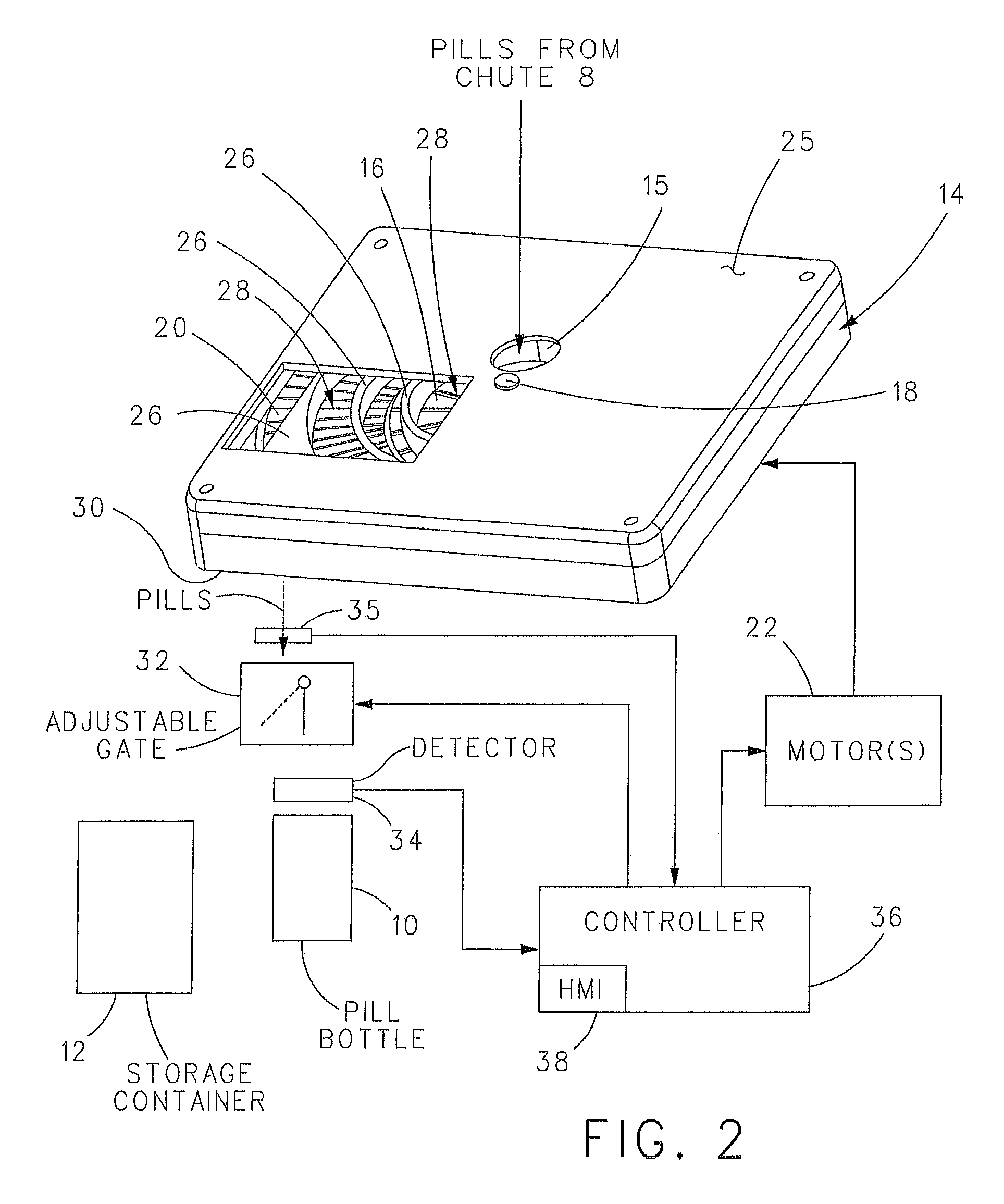

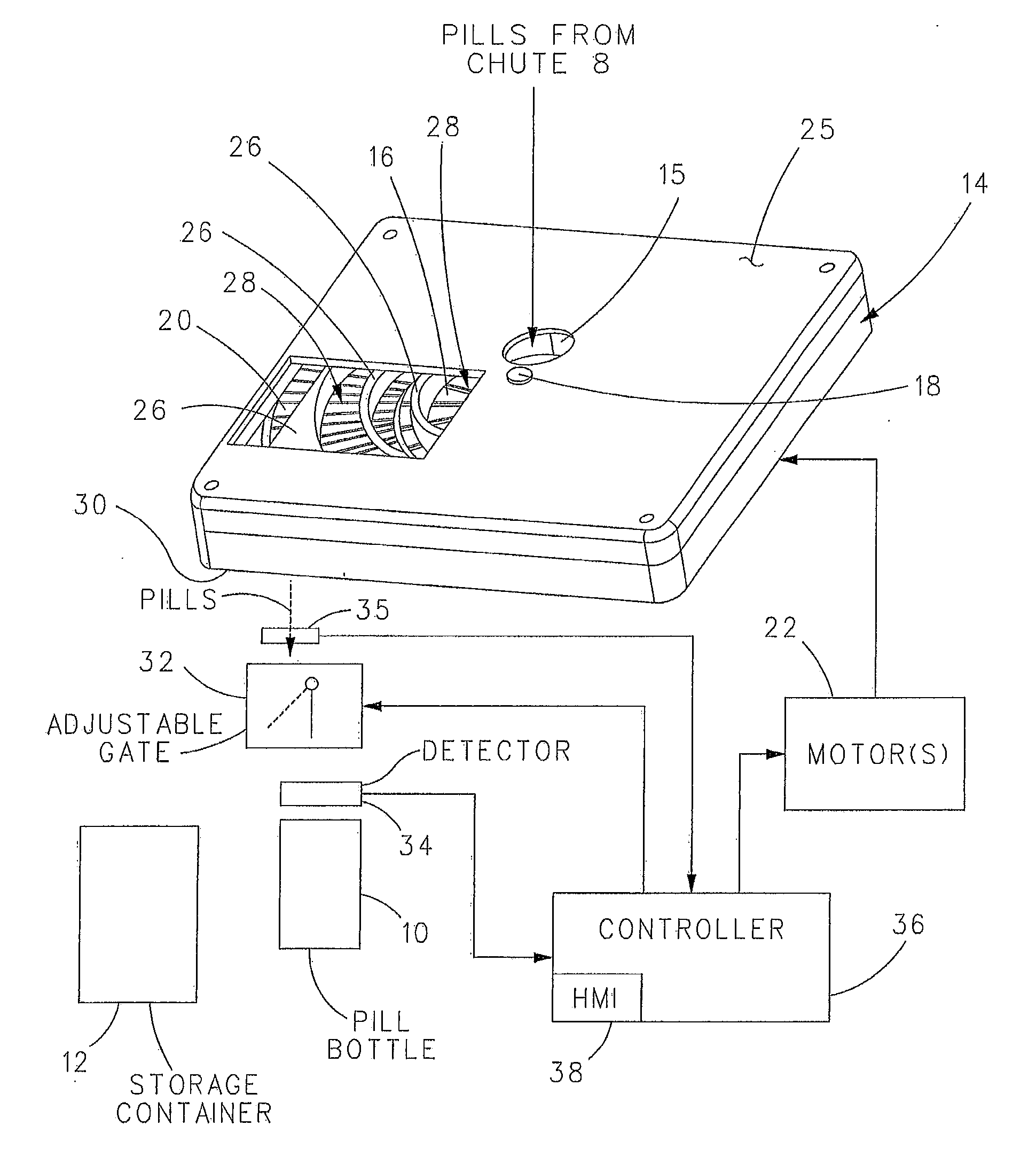

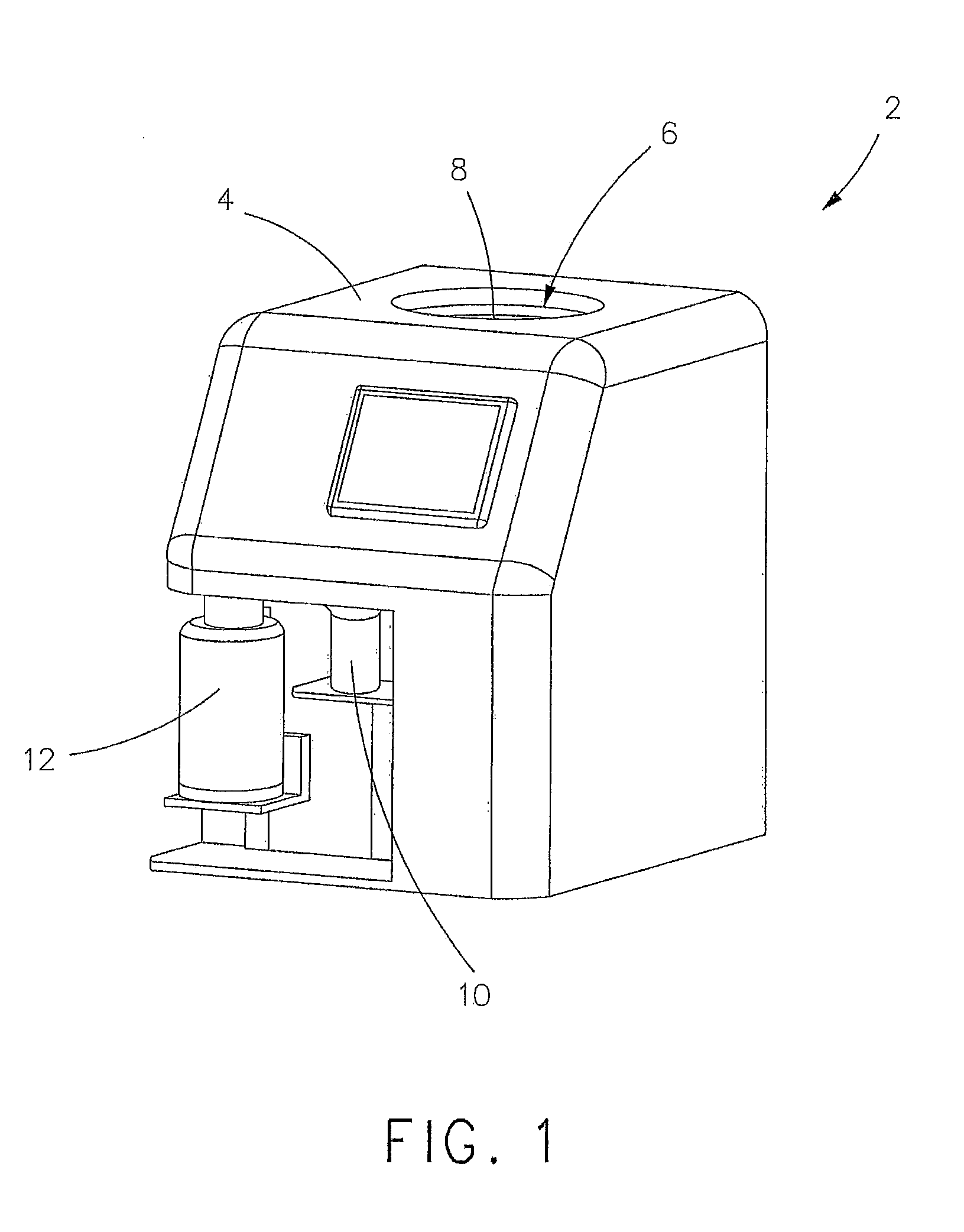

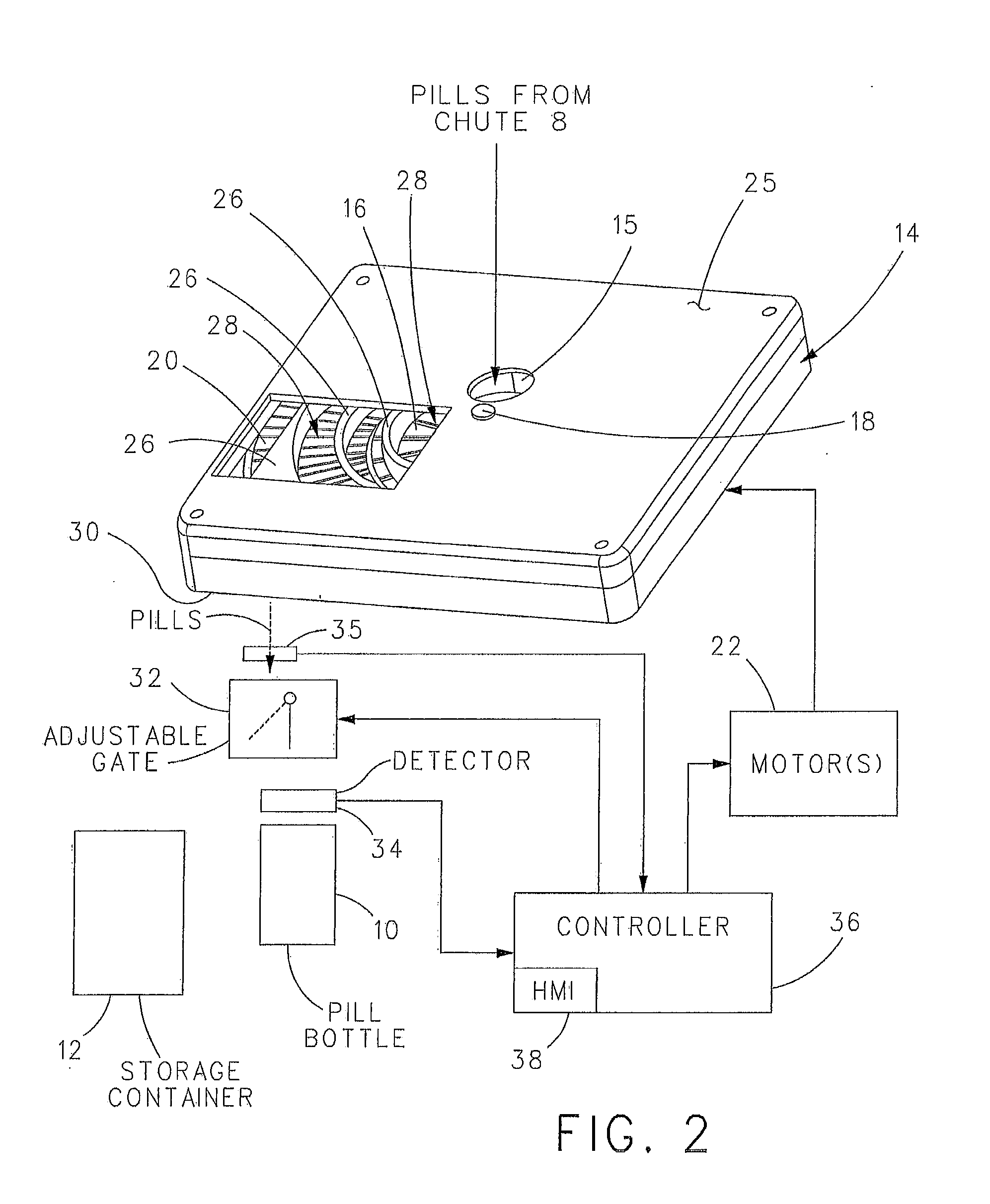

Pill Dispensing Method and Apparatus

ActiveUS20140361032A1Fast and well controlled movementAvoid miscalculationsSmall article dispensingCoin-freed apparatus detailsEngineeringBottle

The present invention is a pill dispensing method and apparatus wherein a first rotor rotates pills about a rotation axis along a first part of a spiral path at a first rotational speed whereupon the pills move spirally away from the rotation axis. A second rotor receives the pills from the first rotor and rotates the pills about the rotation axis along a second part of the spiral path at a second, greater rotational speed whereupon the pills move spirally away from the rotation axis toward a discharge chute which dispenses the pills into a pill bottle or a storage container. A counter can be provided for counting pills that exit the discharge chute or opening.

Owner:CZARNEK & ORKIN LAB

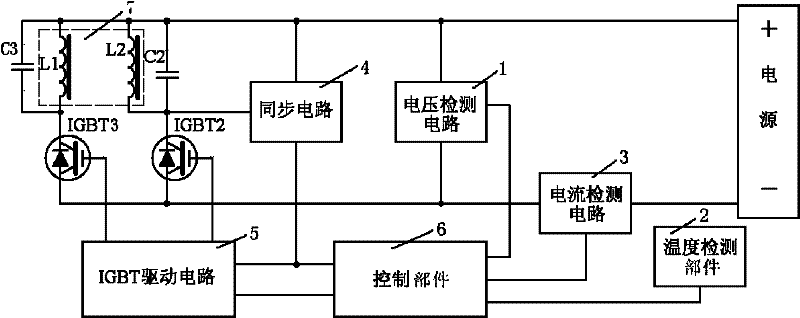

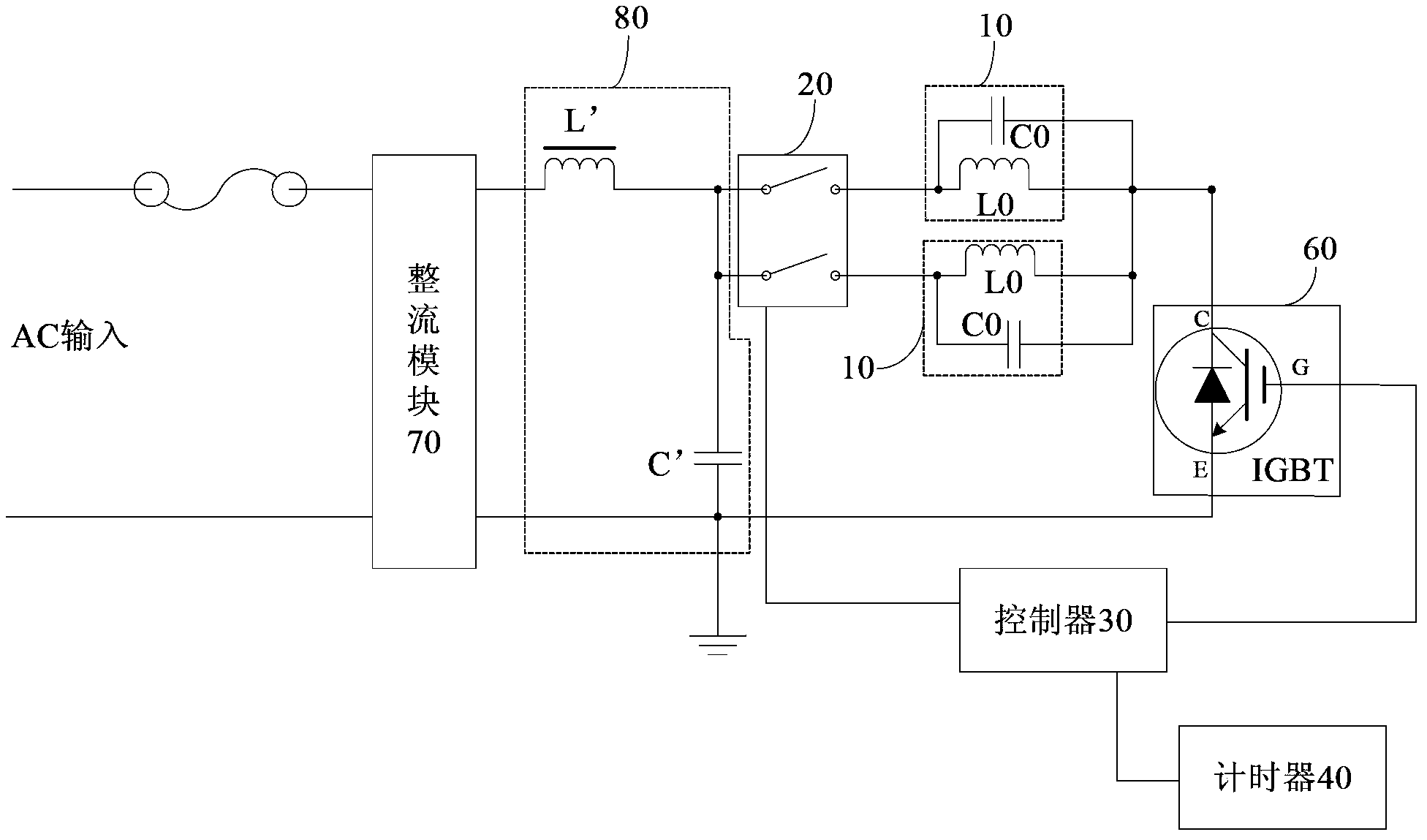

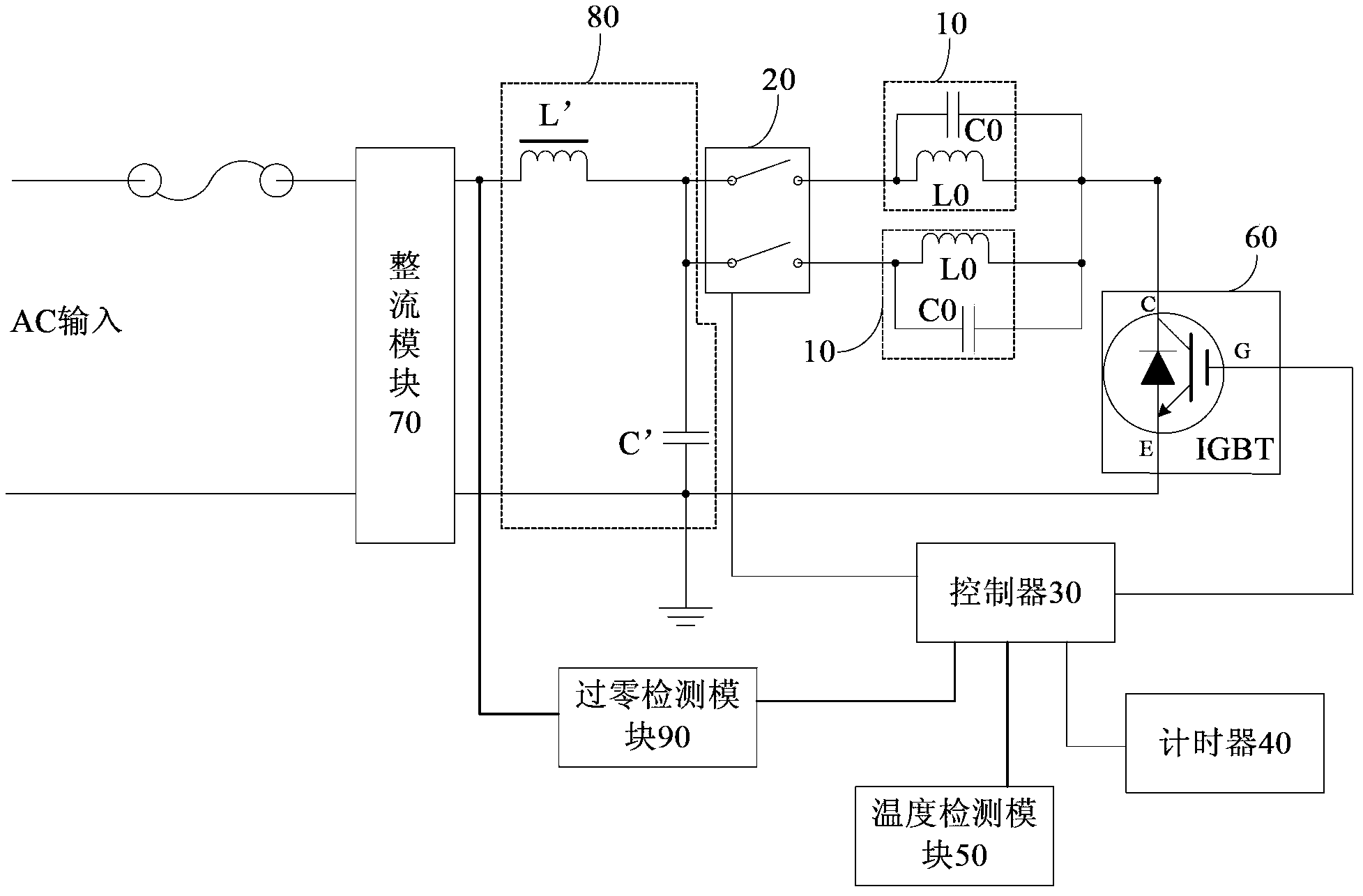

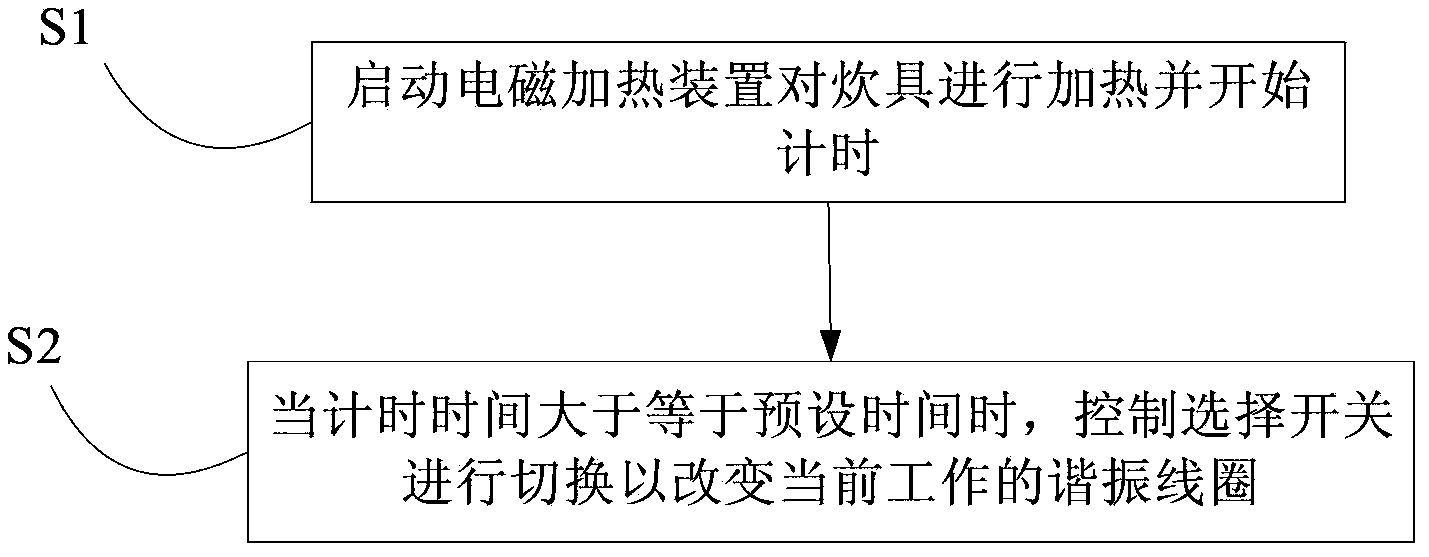

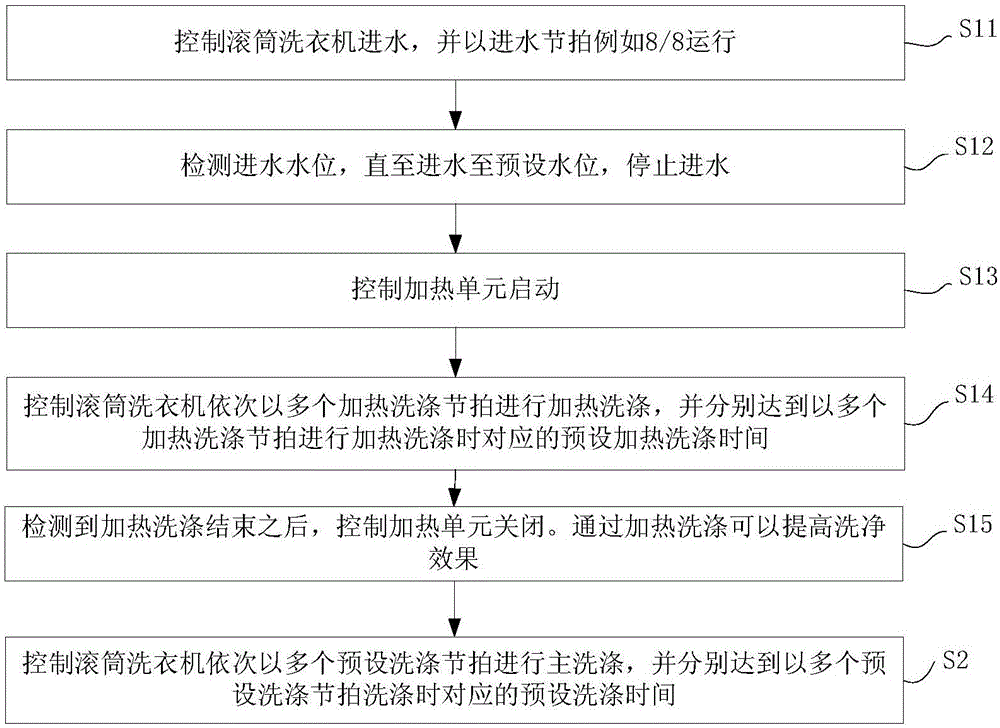

Intelligent control method of convection heating of multiple electromagnetic heating units and electromagnetic heating device

ActiveCN104284465AImprove cooking resultsMeet different cooking needsCoil arrangementsInduction heating controlHeating timeResonance

The invention relates to an intelligent control method of convection heating of multiple electromagnetic heating units and an electromagnetic heating device, and discloses a control method of the electromagnetic heating device. The electromagnetic heating device comprises two or more resonance coils and an option switch. The method comprises the steps that S1, the electromagnetic heating device is started to heat a cooker, and timekeeping begins; S2, when the kept time is longer than or equal to the preset time, the option switch is controlled to carry out switching to change the resonance coil working currently. According to the control method, the heating time is judged to control coil switching so as to achieve alternate heating, so that the effect of convection heating is achieved, the turning amplitude of food is improved in the food heating process, the heating uniformity is improved, and the food is effectively prevented from being burnt. In addition, the control method is simple and easy to implement. The invention further discloses the electromagnetic heating device.

Owner:MIDEA GRP CO LTD +1

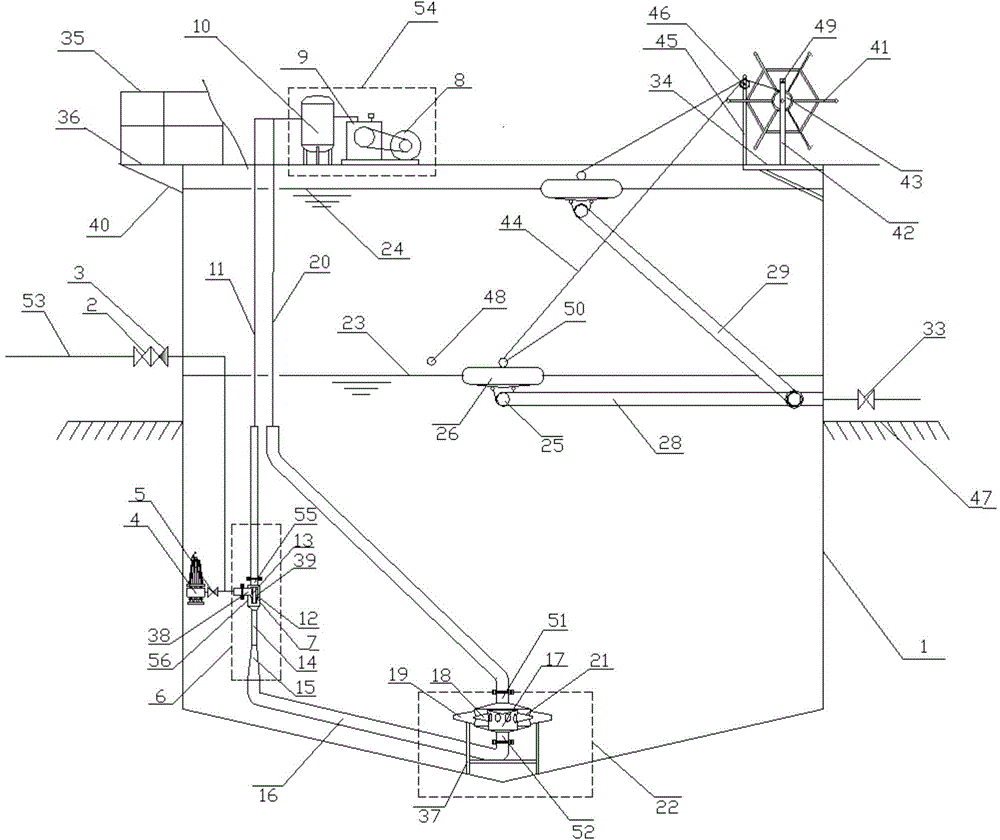

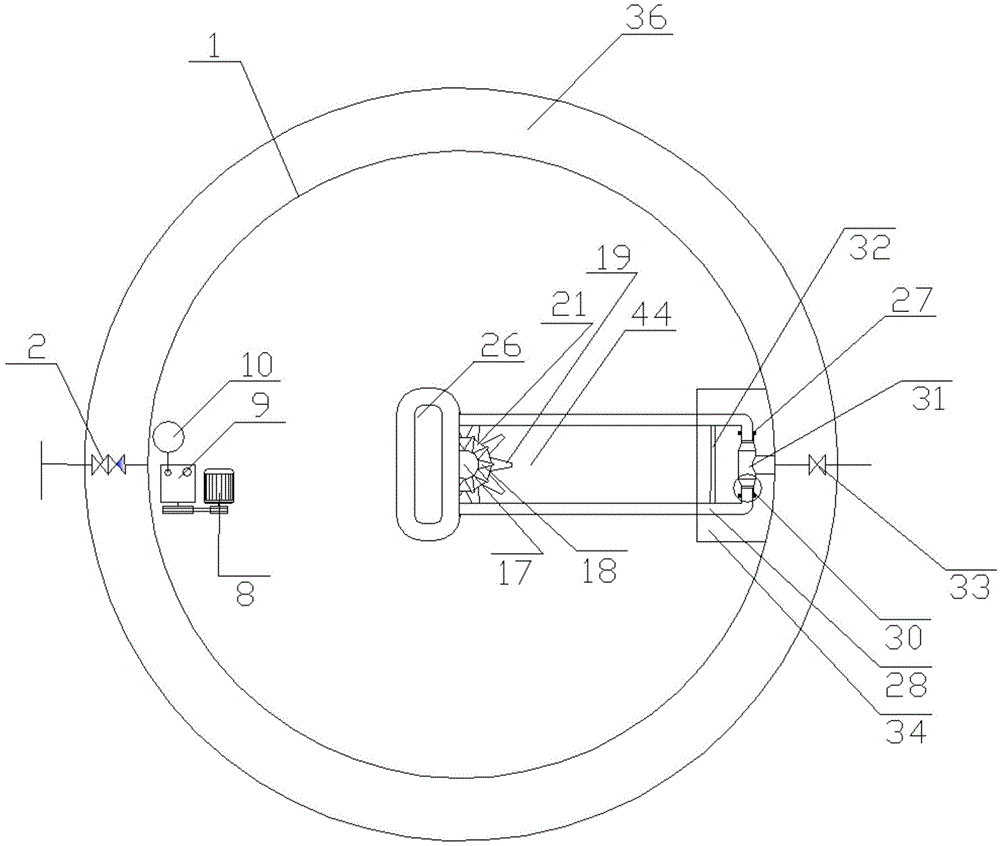

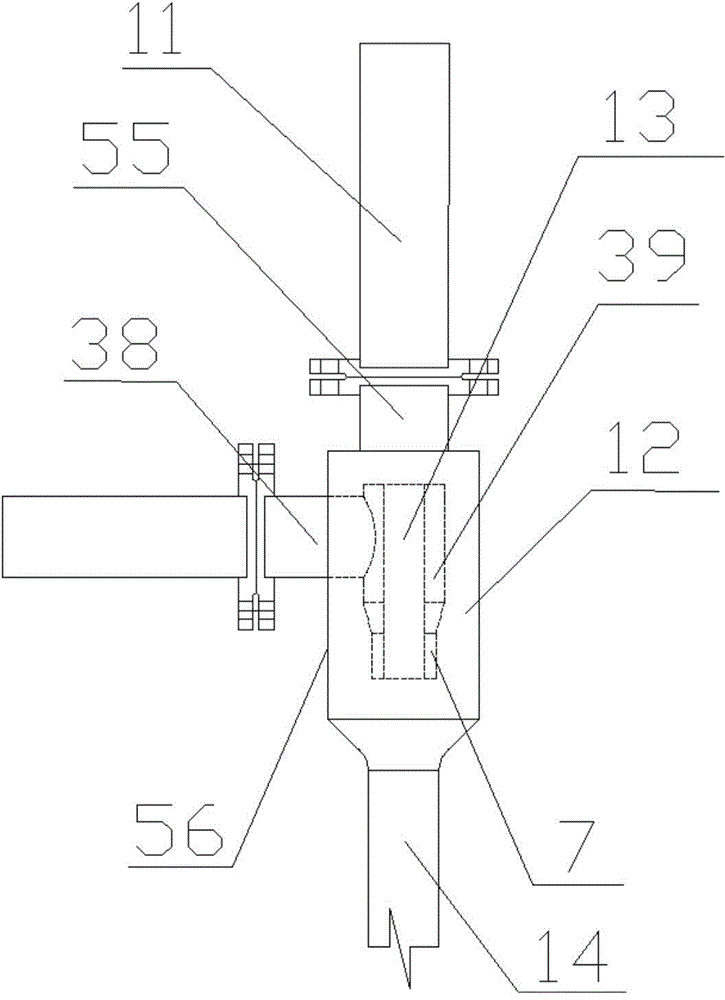

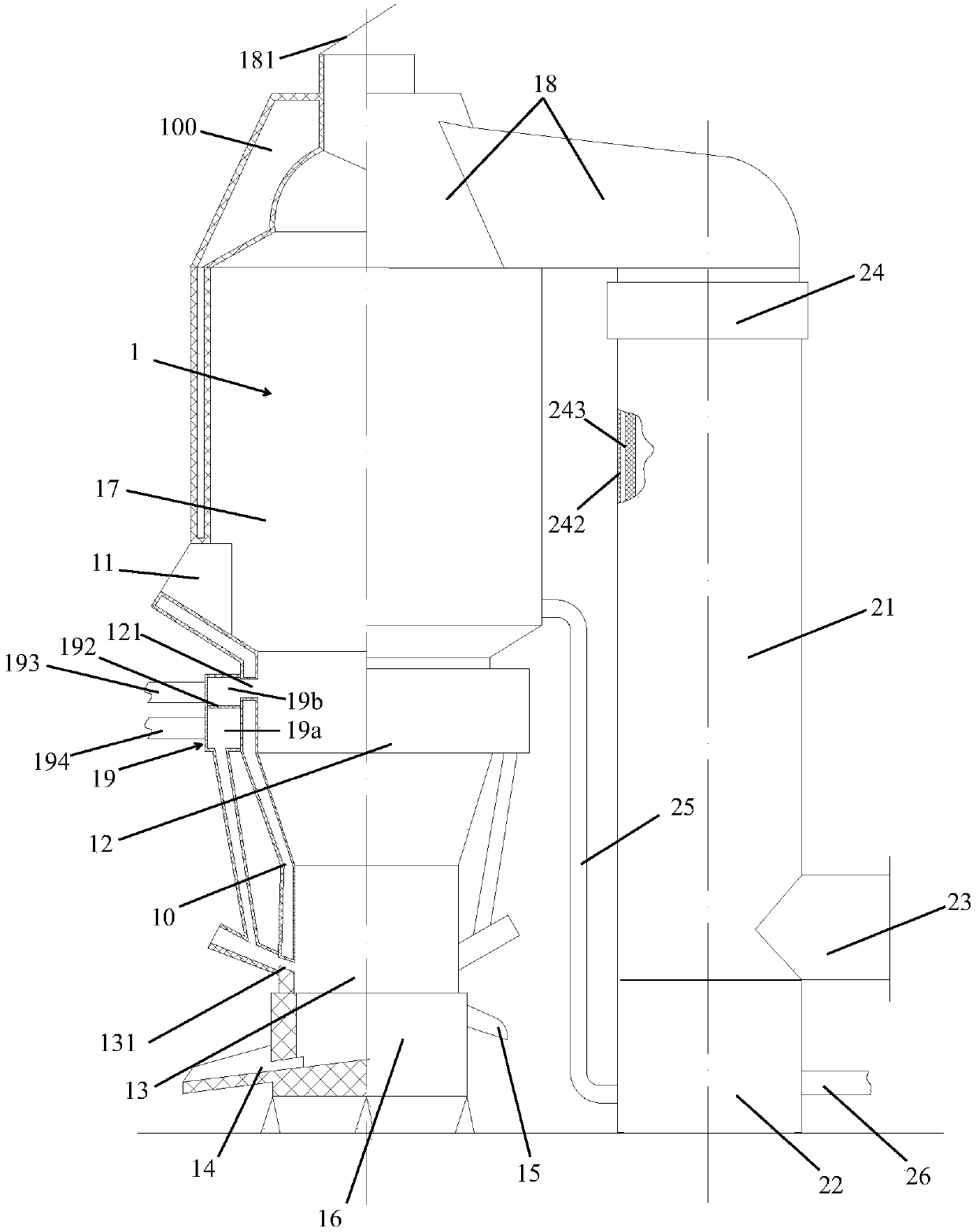

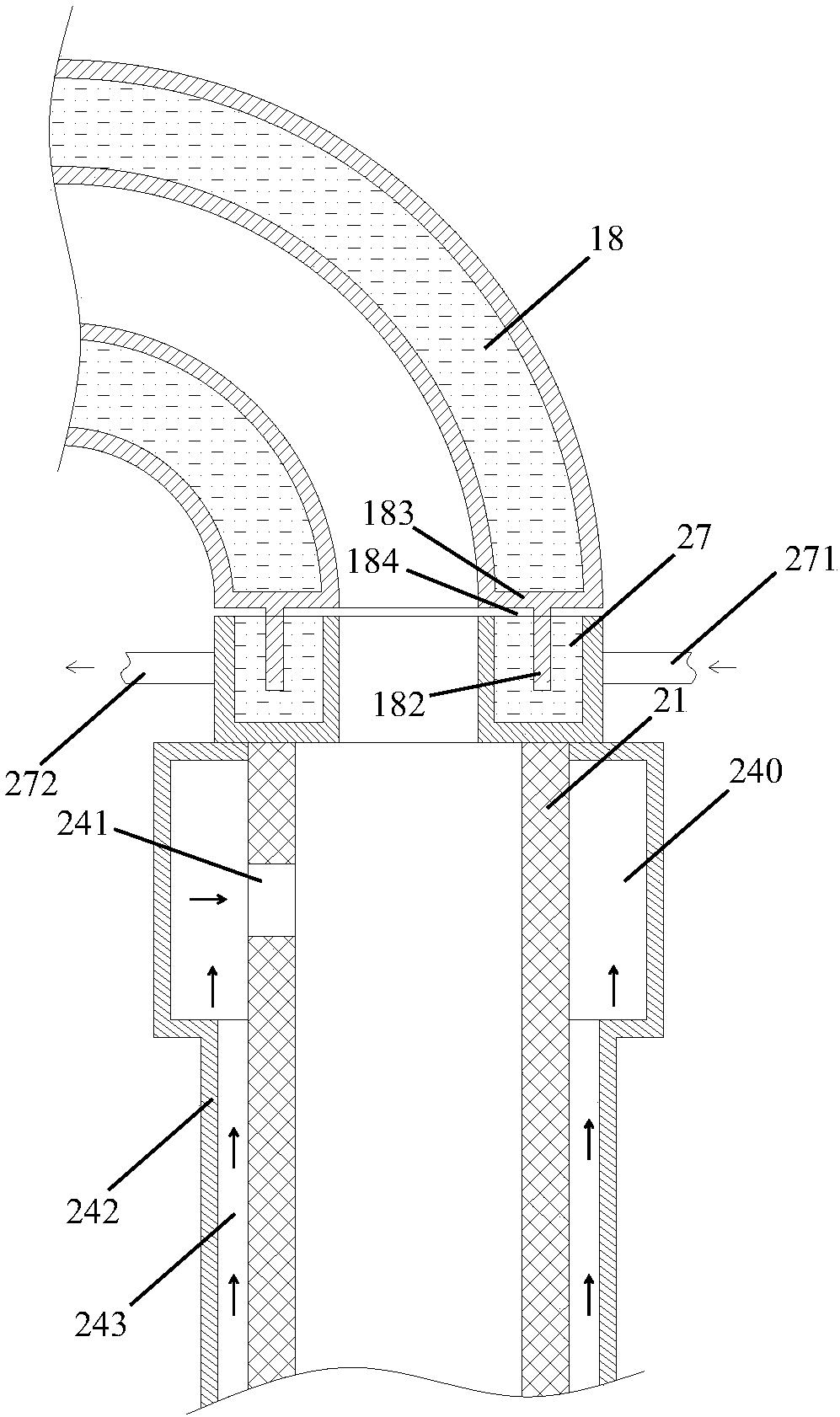

Sequencing batch jet-flow driven biochemical reactor

ActiveCN104386807AIncrease profitIncrease mass transfer rateSustainable biological treatmentBiological water/sewage treatmentWinchHorizon line

The invention relates to a sequencing batch jet-flow driven biochemical reactor, which comprises a reaction tank, a water inlet pipe, an immersible pump, a first-grade suction jet device with a double-gas-channel annular nozzle, a mixed solution guide pipe, a second-grade multi-nozzle radial jet-flow aerator, a gas supply device, a buoyancy driven water decanter and a driving winch of the water decanter; the first-grade suction jet device with the double-gas-channel annular nozzle is provided with an annular nozzle and inner and outer gas channels; the second-grade multi-nozzle radial jet-flow aerator is installed in the centre of the bottom of the reactor; the buoyancy driven water decanter is installed on the wall of the reaction tank over the horizon line of the reactor; and the driving winch of the water decanter is used for packing up or down the buoyancy driven water decanter through a driving rope. The sequencing batch jet-flow driven biochemical reactor disclosed by the invention can be used for increasing the aeration efficiency, accelerating the dynamic circulation of dynamic water and greatly increasing the mass transfer rate in the biochemical reaction process, so that the biochemical reaction efficiency is increased; and furthermore, the sequencing batch jet-flow driven biochemical reactor disclosed by the invention can also be used for treating various types of sewage, and can be flexibly combined with other sewage treatment processes.

Owner:ENVIRONMENTAL PROTECTION ENERGY SAVING TECHDEV CENT OF NANNING GUI HE SILK IND

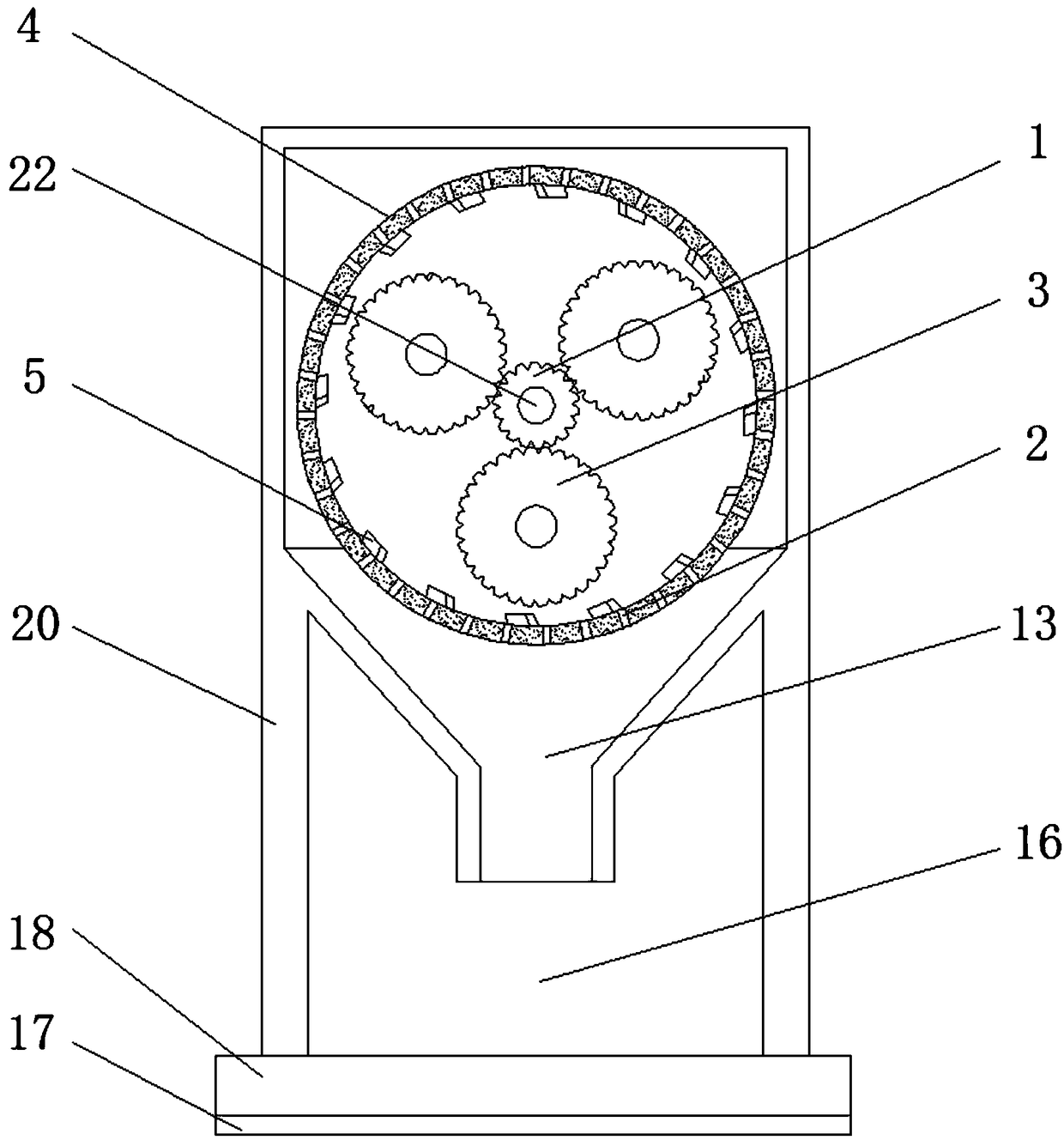

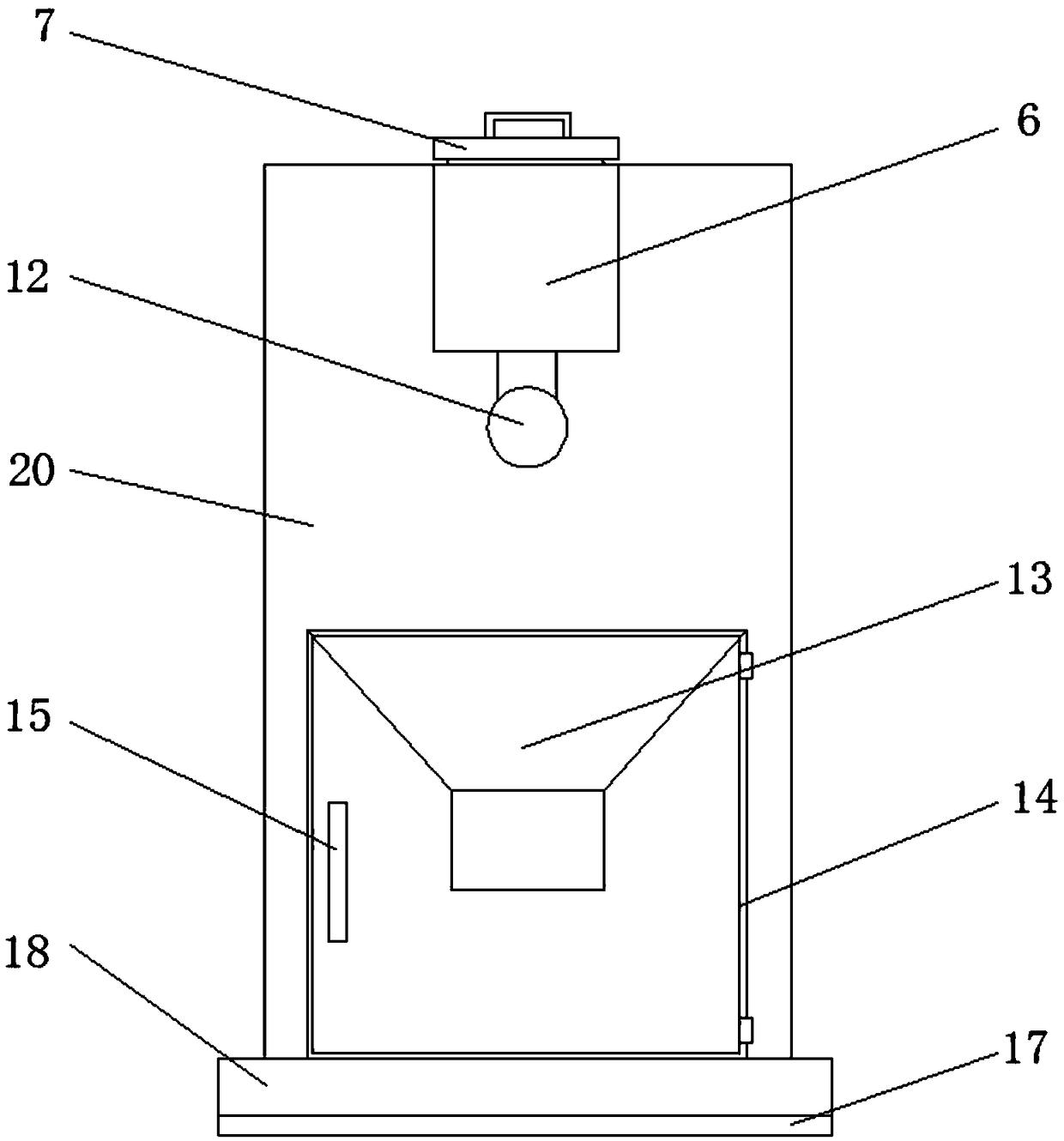

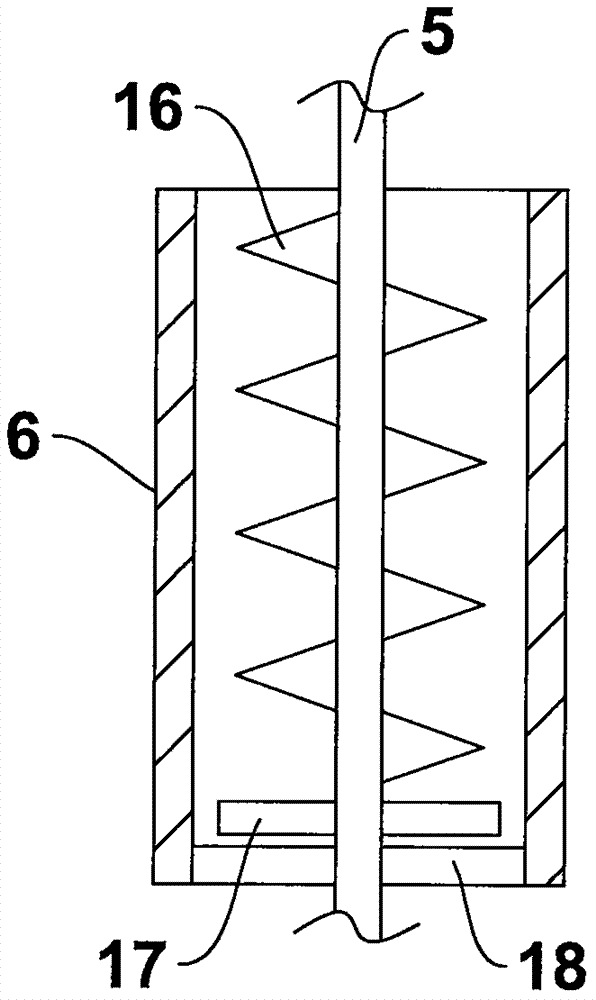

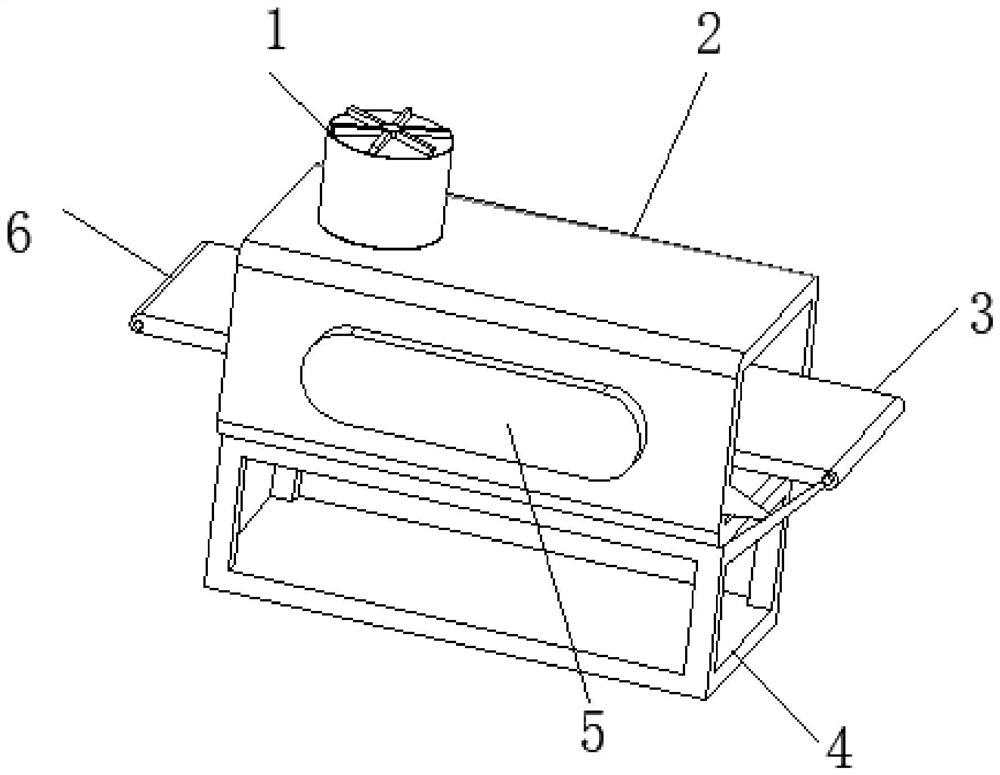

Efficient traditional Chinese medicine grinder capable of timely separating medicine powder

InactiveCN109261266AImprove work efficiencyImprove uniformityGrain treatmentsElectric machineryChinese herbology

The invention discloses an efficient traditional Chinese medicine grinder capable of timely separating medicine powder. The efficient traditional Chinese medicine grinder comprises a first grinding gear, a second grinding gear, a screen drum, a feeding hopper, a discharging groove, a base plate and a shell; the shell is welded to the top of the base plate; a motor is arranged at the top, on the inner side of the shell, of the base plate; a fixing plate is fixed to one side of the top end of the inner part of the shell; the screen drum is arranged between the fixing plate and the inner side wall of the shell; bearings are arranged between the two ends of the screen drum and the fixing plate and the inner side wall of the shell; and a fixing rod is fixed between the screen drum and the bearing close to one end of the fixing plate. According to the efficient traditional Chinese medicine grinder, the feeding hopper is arranged on one side of the top end of the outer side wall of the shell,a spiral stirring shaft extending to the lower part of the feeding hopper is fixed at one end of the fixing rod, so that medicinal materials are conveniently added, the spiral stirring shaft is driven to rotate in the grinding process of the medicinal materials, so that the medicinal materials are more uniformly added, in addition, the medicinal materials can be conveniently cut and crushed in the conveying process, a material conveying pipe is prevented from being blocked, and the grinding efficiency is improved.

Owner:侯红星

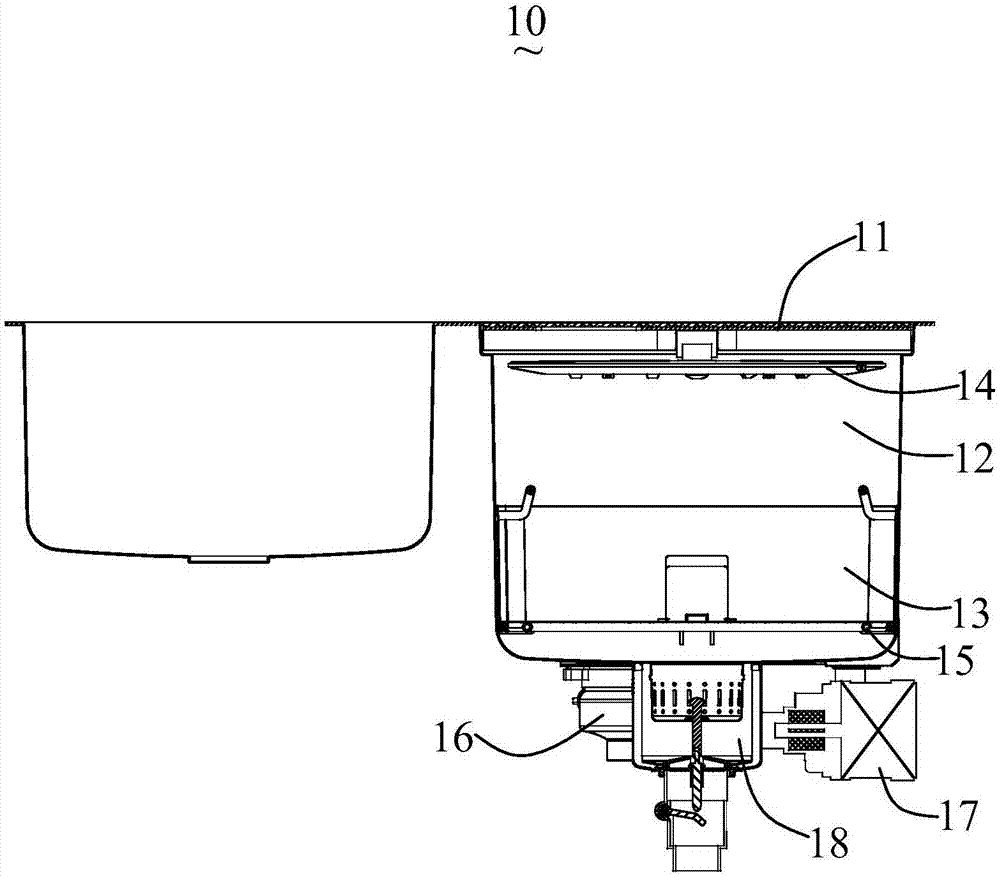

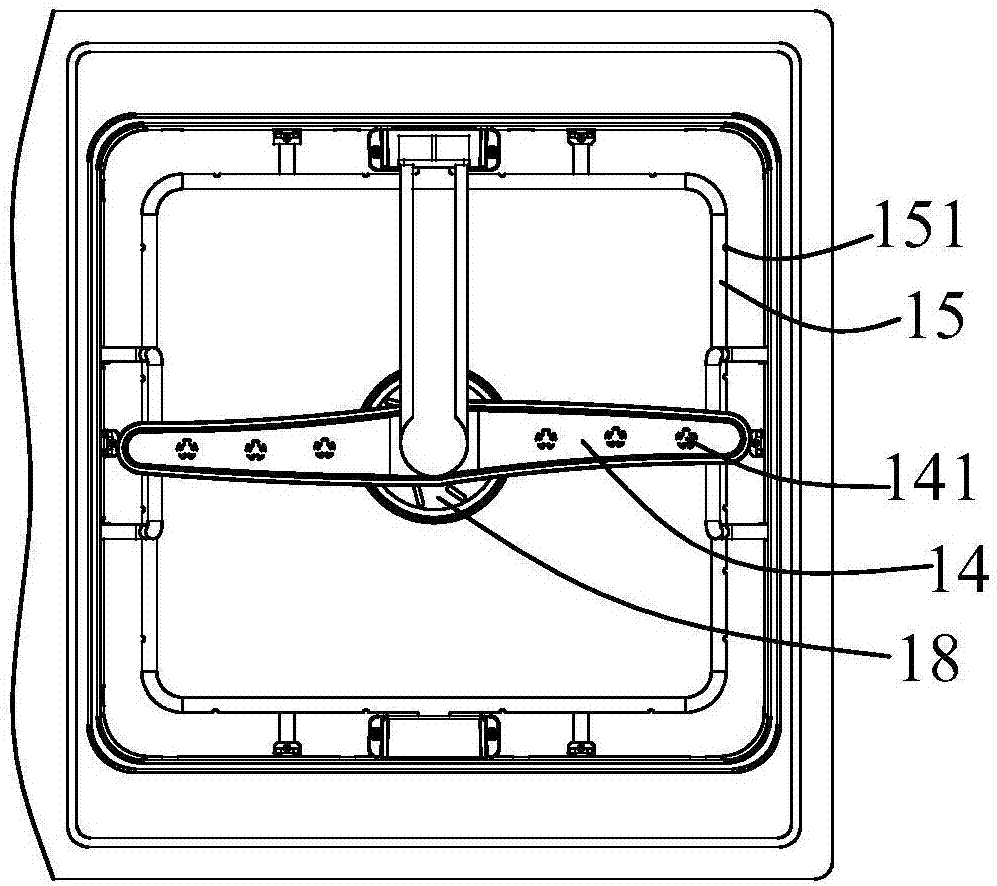

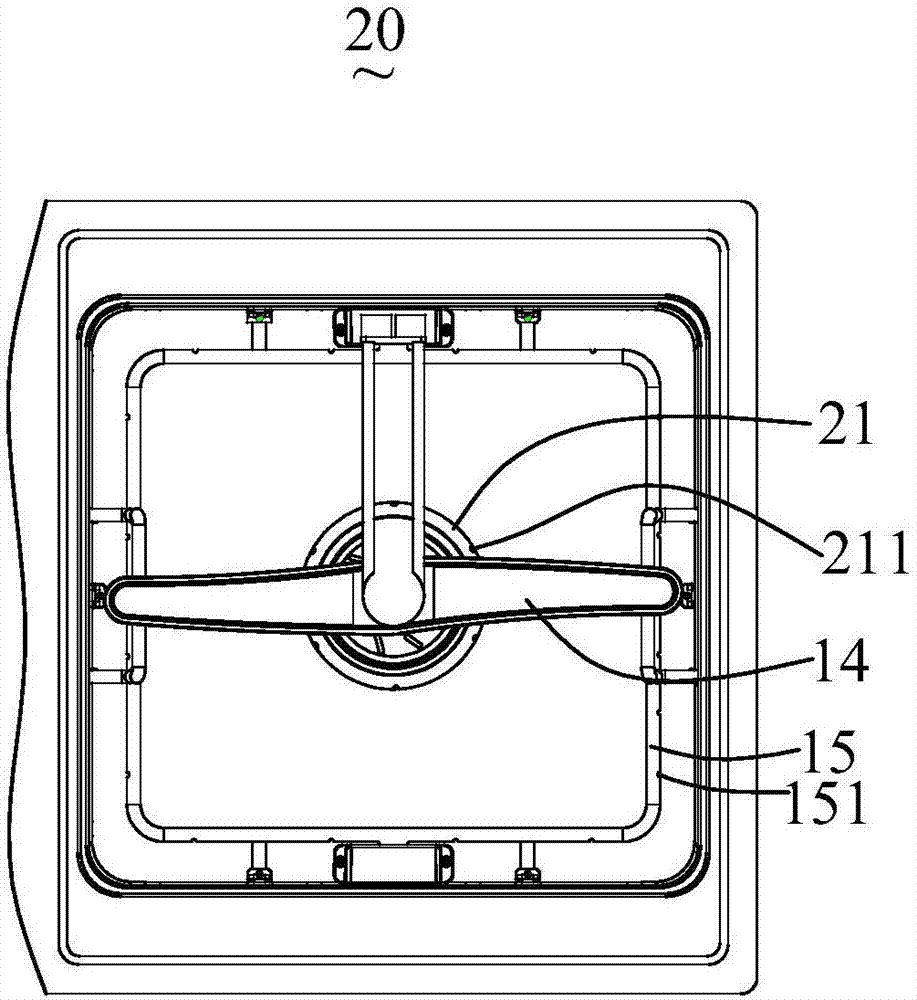

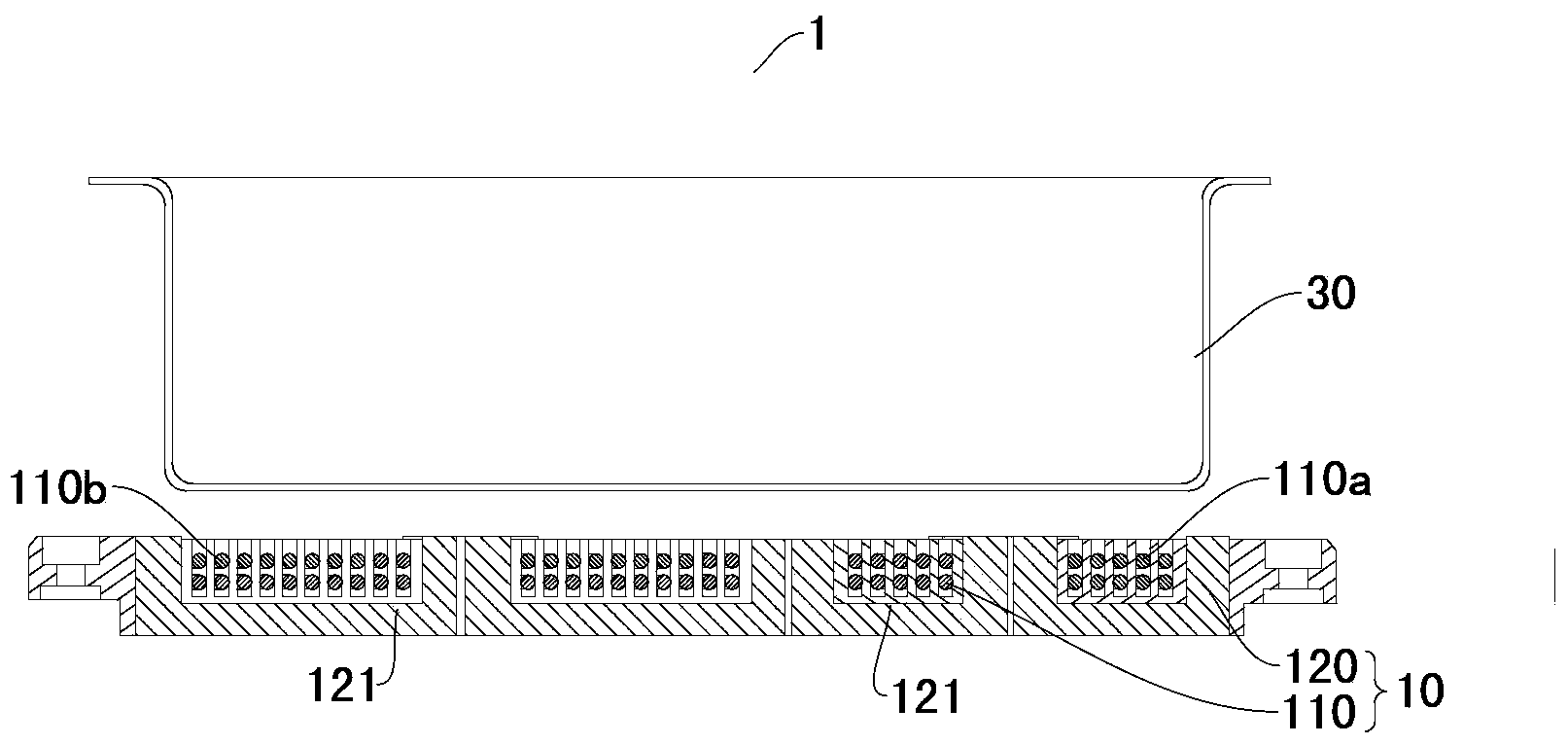

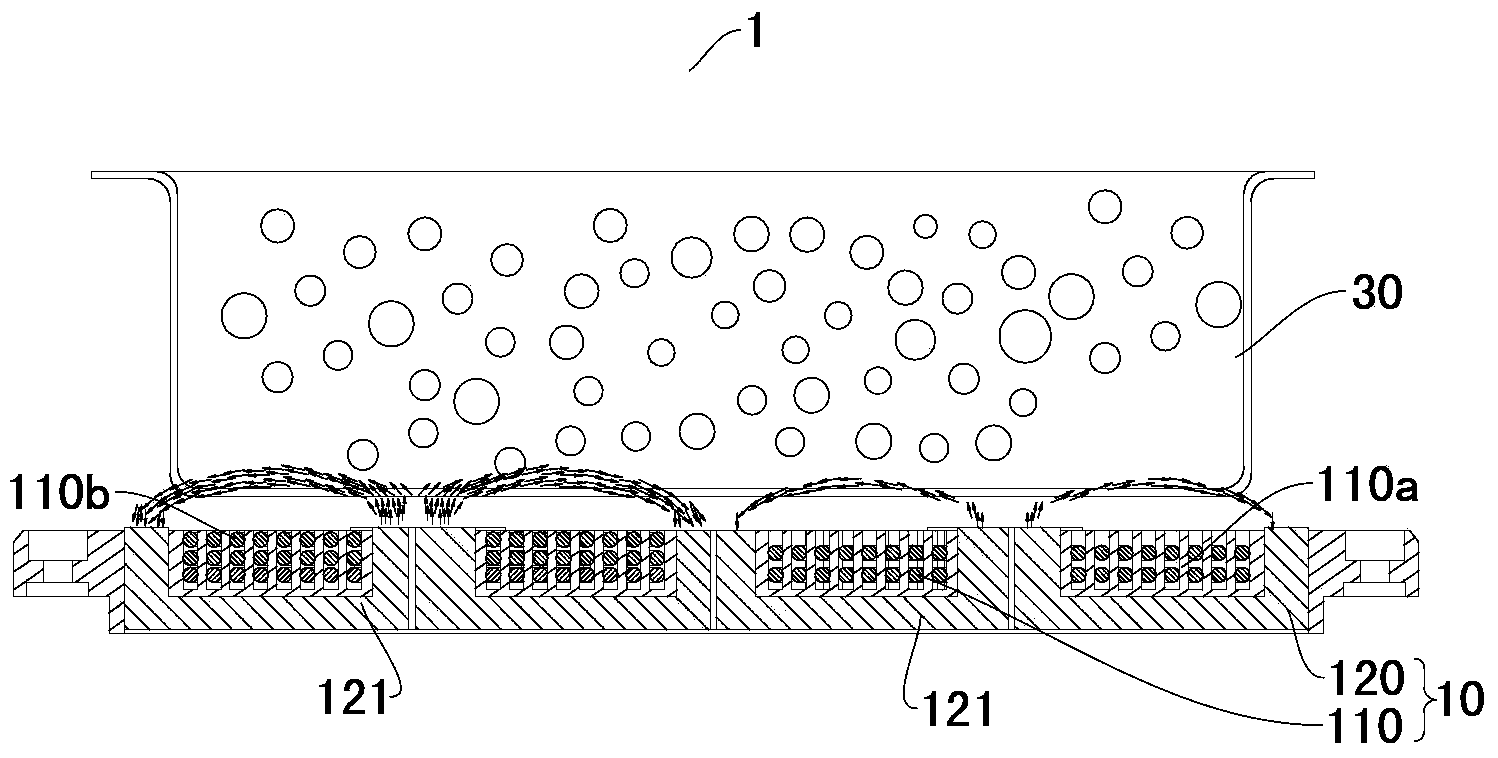

Water-tank-type cleaning machine with bubble cleaning basket

The invention relates to a water-tank-type cleaning machine with a bubble cleaning basket. The machine comprises a cover body, a water tank, the cleaning basket which is contained in the water tank and a rotation spraying arm. The cover body seals an opening of the water tank, a first air guide channel is formed in the bottom of the cleaning basket, and air outlets are formed in the first air guide channel; an air pump is arranged on the outer portion of the water tank and communicated with the first air guide channel, and the rotation spraying arm rotates relative to the water tank. The water-tank-type cleaning machine is characterized in that spraying holes in the rotation spraying arm are formed in the projection range of the first air guide channel. Compared with the prior art, the water-tank-type cleaning machine with the bubble cleaning basket has the advantages that bubbles from the air outlets of the first air guide channel exert application force to fruits and vegetables whichare gathered close to the side wall of the water tank in the rising or blasting process, the fruits and vegetables roll to the center of the water tank or upward, and 360-degree cleaning in all directions in the rolling process is achieved, so that the fruits and vegetables are cleaned more completely.

Owner:JOYOUNG CO LTD

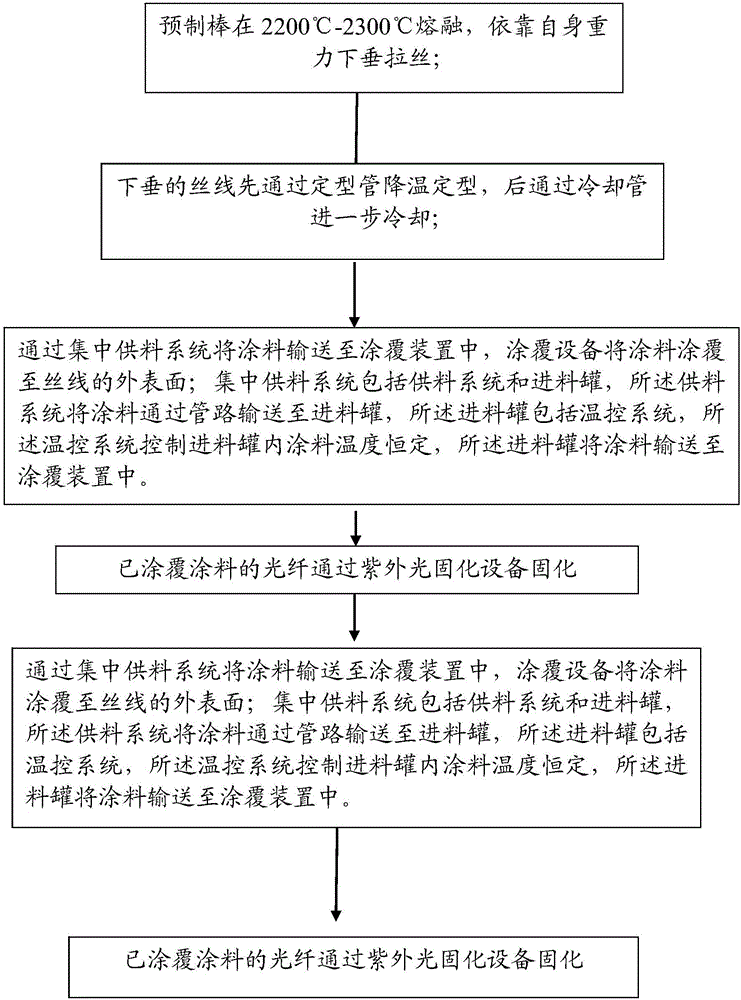

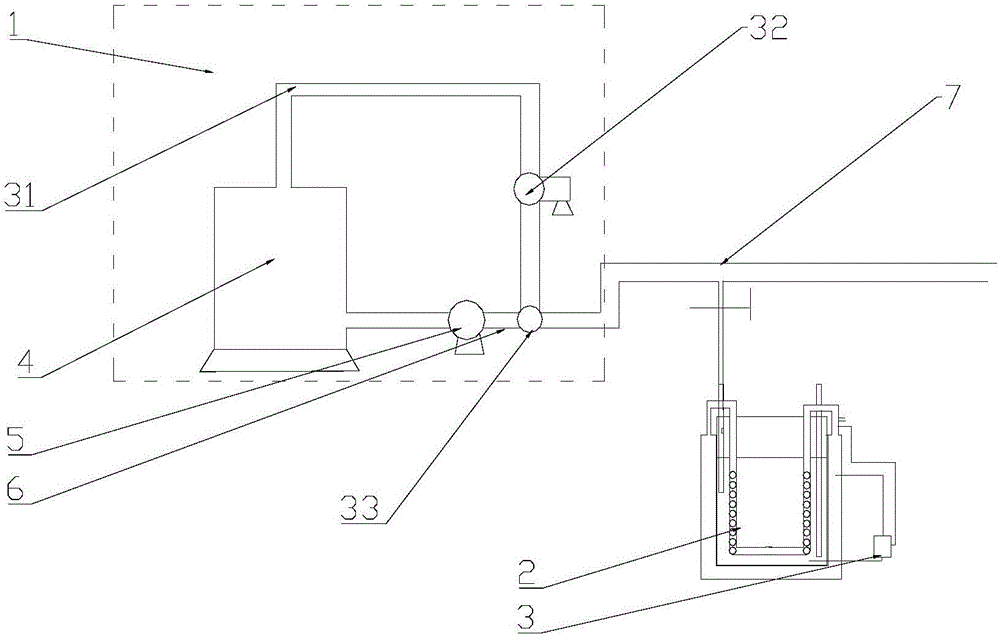

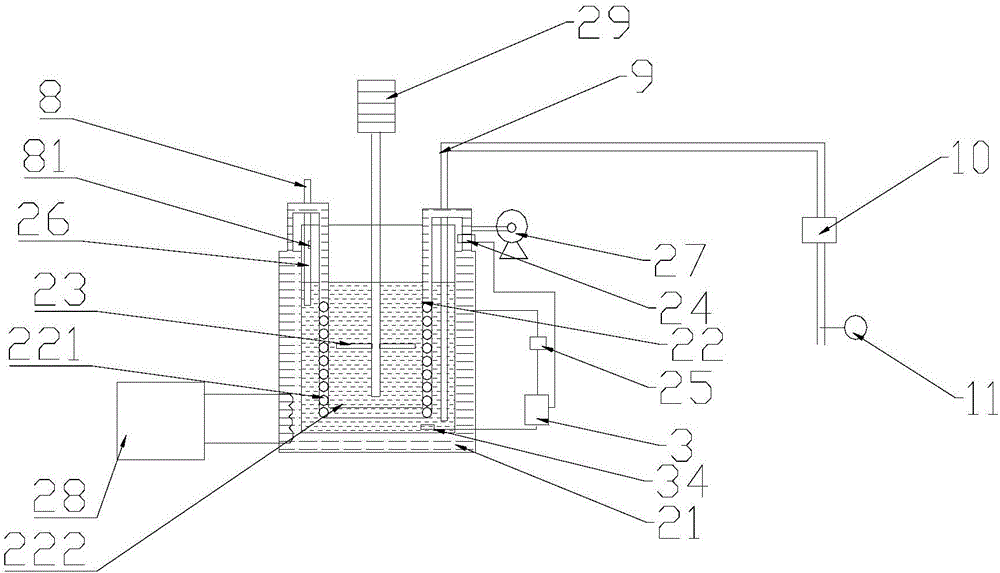

An optical fiber wire-drawing process

ActiveCN105859121AReduce labor intensityGuaranteed continuityGlass making apparatusGlass productionEngineeringMaterial supply

An optical fiber wire-drawing process is disclosed. The process includes 1) a melting and wire drawing step, 2) a sizing and cooling step, 3) a first coating step, 4) a first curing step, 5) a second coating step, and 6) a second curing step. The step 3) and the step 5) adopt a same central material supplying system. The central material supplying system comprises a material supplying system and a feeding tank. The material supplying system conveys coating to the feeding tank through a pipeline. The feeding tank comprises a temperature control system. The temperature control system controls the temperature of the coating in the feeding tank to be constant. The feeding tank conveys the coating to a coating device. The central material supplying system is adopted to supply and convey the coating in a unified manner, thus reducing labor intensity of workers and ensuring continuity of production. In addition, the temperature control system is utilized to ensure that the temperature of the coating in the feeding tank is constant, thus ensuring that viscosity of the coating fed into the coating device is proper.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

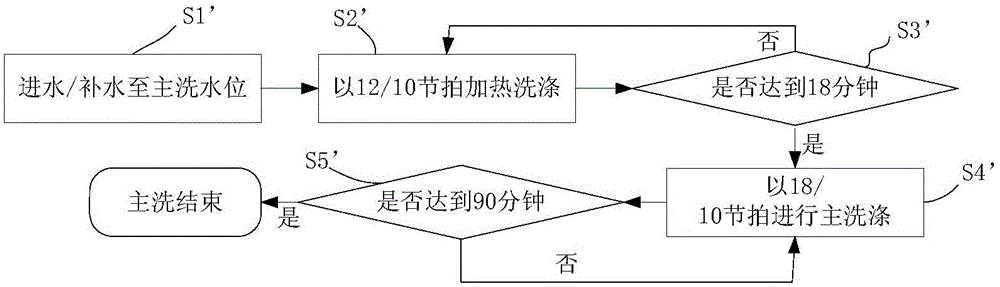

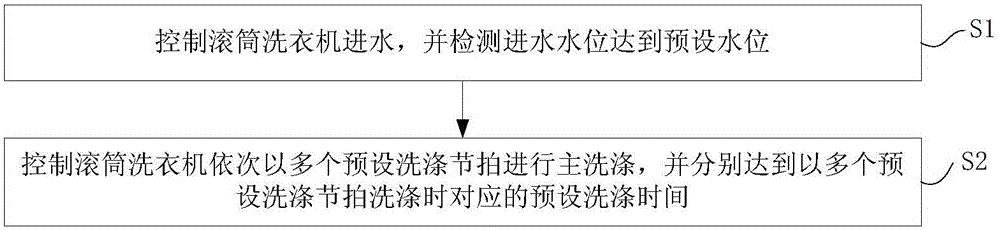

Drum type washing machine washing control method

InactiveCN105155200APromote tumblingUniform water absorptionOther washing machinesControl devices for washing apparatusProcess engineering

The invention discloses a drum type washing machine washing control method comprising the following steps: 1, controlling the drum type washing machine to inflow, and detecting an inflow water level reaches a preset water level; 2, controlling the drum type washing machine to do main washing according to a plurality of preset washing tempos in sequence, and preset washing time corresponding to the plurality of preset washing tempos is respectively reached. The washing control method enables clothes to be more uniformly washed, thus improving washing effect, and improving cleaning ratio.

Owner:WUXI LITTLE SWAN CO LTD

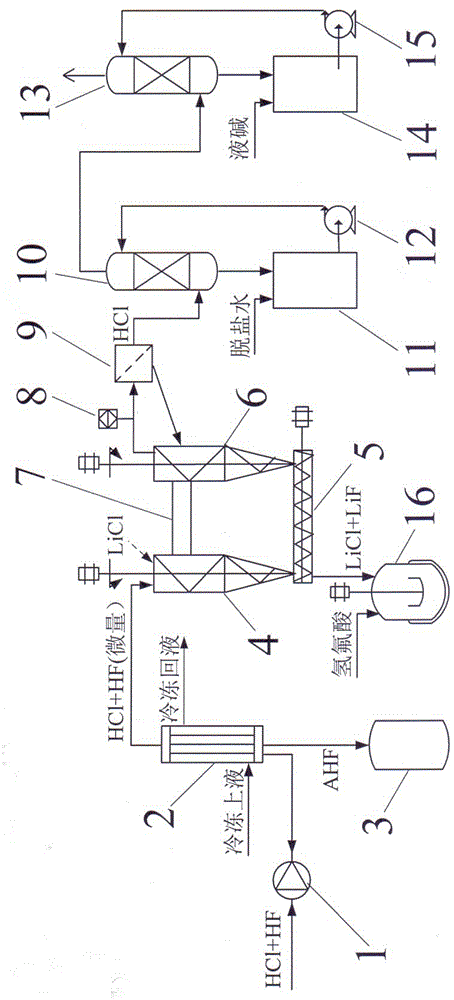

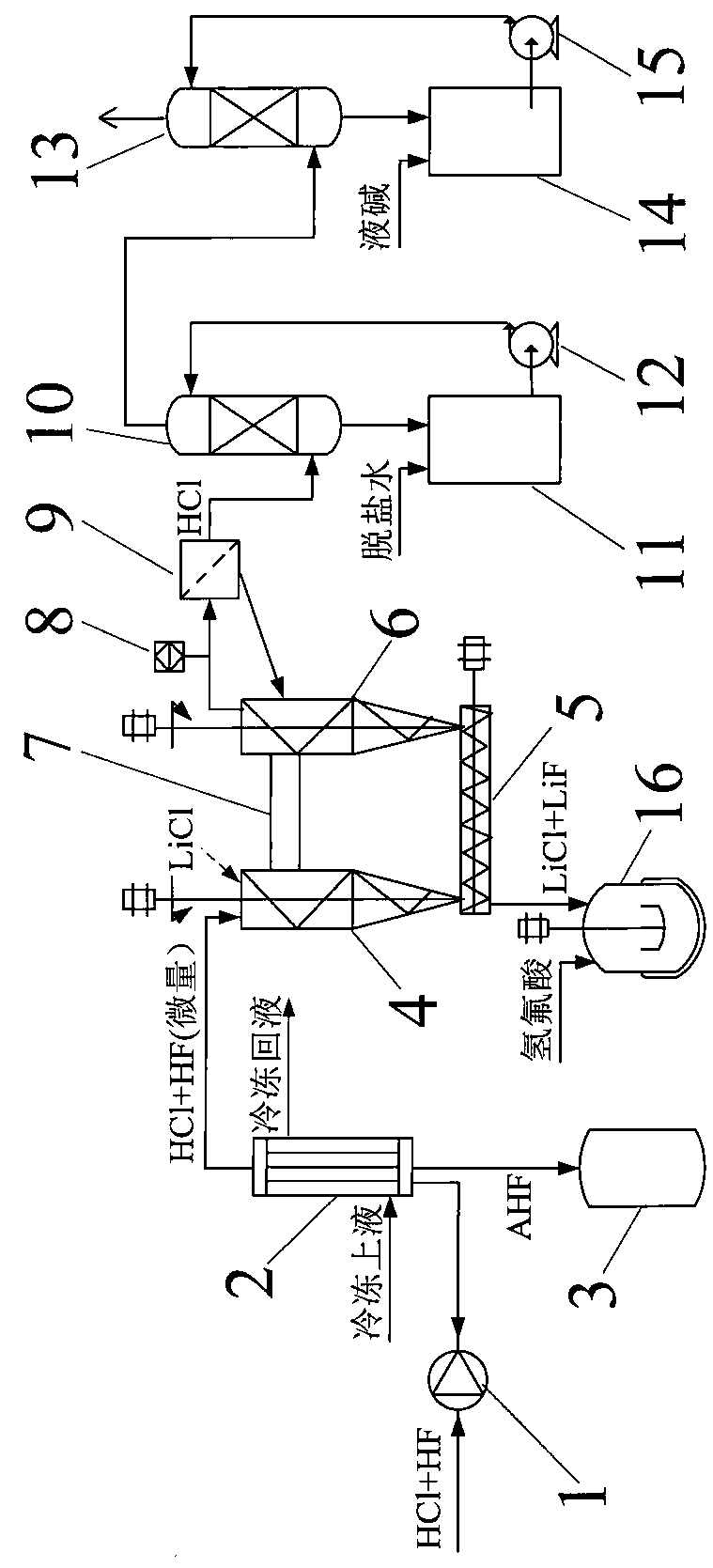

Method and dedicated device for lithium hexafluorophosphate synthesis tail gas treatment

ActiveCN105460893AEfficient removalImprove qualityChlorine/hydrogen-chlorideHydrogen fluorideHydrogen fluorideMaterial balance

The invention discloses a method and dedicated device for lithium hexafluorophosphate synthesis tail gas treatment. Tail gas is pressurized through a booster fan and then sent to a condenser, condensate is recycled to an anhydrous hydrogen fluoride reception tank, mixed gas discharged from the condenser passes through an airtight first-stage agitation reactor, a horizontal auger delivery reactor and a second-stage agitation reactor in sequence in the material stirring and guiding direction, a trace of HF in the mixed gas reacts with LiCl powder added into an agitation reaction combined device in advance, and LiCl powder in the second-stage agitation reactor returns into the first-stage agitation reactor through a material balance pipe to be forced to be stirred and circulated inside an agitation reaction system; tail gas discharged from the second-stage agitation reactor enters a water scrubber to generate hydrochloric acid after passing through a dust remover for gas trapping so that a small amount of powder can be taken away, and gas discharged from the water scrubber passes through an alkaline tower for alkaline washing and then is discharged. By the adoption of the method and dedicated device, HF in the mixed tail gas can be effectively removed, the quality of by-product hydrochloric acid is improved, and the application field is broadened.

Owner:JIANGSU JIUJIUJIU TECH

Pill dispensing method and apparatus

ActiveUS8794483B2Fast and well controlled movementAvoid miscalculationsSmall article dispensingRegistering devicesBottleHelix

The present invention is a pill dispensing method and apparatus wherein a first rotor rotates pills about a rotation axis along a first part of a spiral path at a first rotational speed whereupon the pills move spirally away from the rotation axis. A second rotor receives the pills from the first rotor and rotates the pills about the rotation axis along a second part of the spiral path at a second, greater rotational speed whereupon the pills move spirally away from the rotation axis toward a discharge chute which dispenses the pills into a pill bottle or a storage container.

Owner:CZARNEK & ORKIN LAB

Circuit board incineration smelting furnace and circuit board incineration smelting method

ActiveCN107726331AEmission reductionIncrease profitEmission preventionIncinerator apparatusThermal energyBrick

The invention discloses a circuit board incineration smelting furnace and a circuit board incineration smelting method adopting the circuit board incineration smelting furnace. The circuit board incineration smelting furnace comprises a main furnace body arranged vertically and a reversal combustion tower. The main furnace body is provided with a charging port, a waste material combustion chambercommunicating with the charging port, a smelting chamber located below the waste material combustion chamber, a boiling combustion chamber located above the waste material combustion chamber and a smoke collection hood located above the boiling combustion chamber. The reversal combustion tower communicates with the smoke collection hood. A smoke dust settling chamber is arranged below the reversalcombustion tower. A pneumatic carrier pipe communicates between the boiling combustion chamber and the smoke dust settling chamber. The lower side of the smoke dust settling chamber is further provided with a Venturi feed pipe. By means of the technical scheme, the utilization rate of thermal energy is increased, emissions of poisonous and harmful gas are reduced, and the combustion efficiency ishigh; the early-period treatment cost is reduced, energy is saved by 50%, consumption of refractory materials such as refractory bricks is reduced, and the service cycle of the furnace is prolonged.

Owner:邹资生

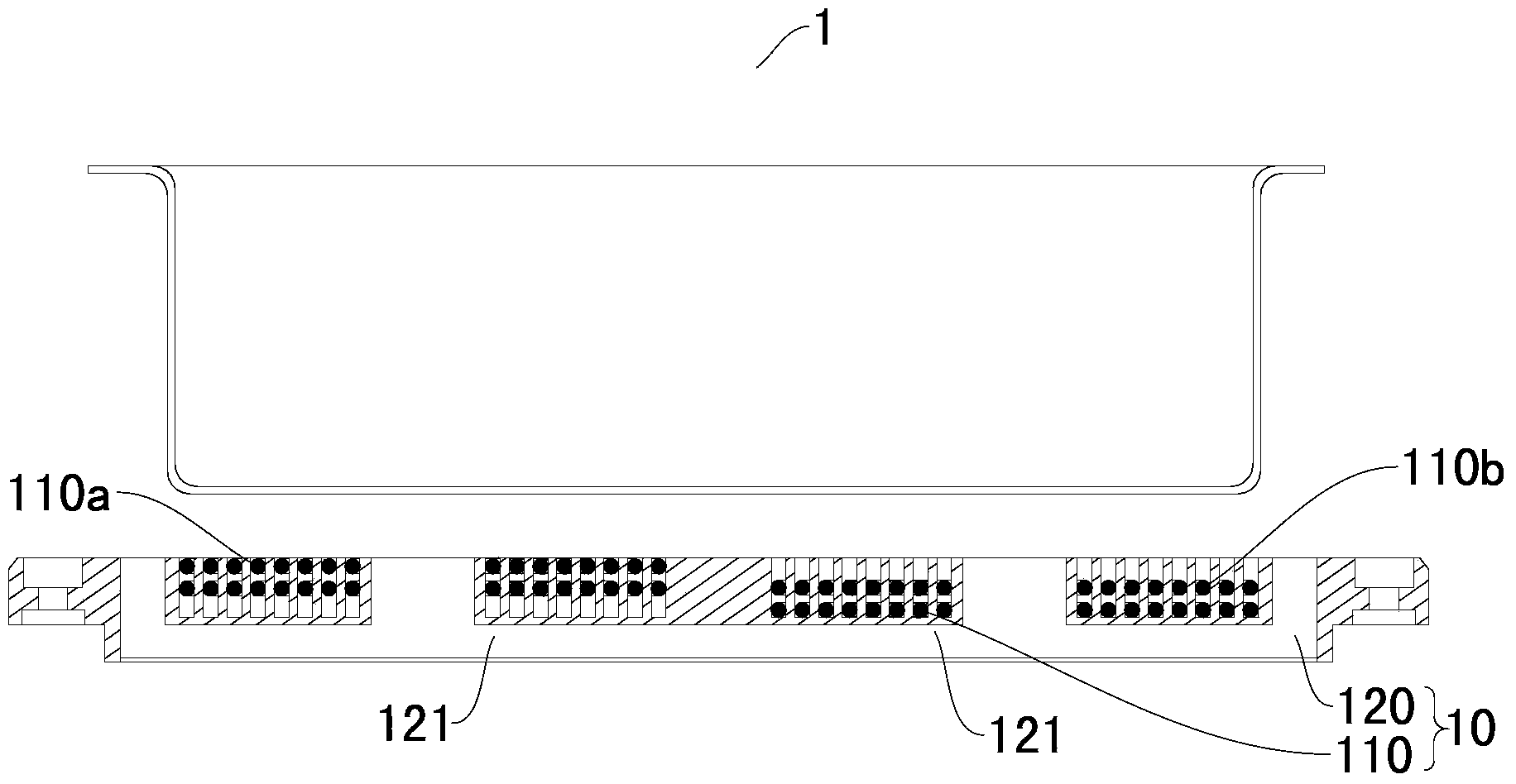

Coil panel for heating a cooker and induction cooker with coil panel

ActiveCN104349522AHeating evenlyEvenly heatedDomestic stoves or rangesCoil arrangementsCouplingInduction motor

The invention discloses a coil panel for heating a cooker, and also discloses an induction cooker with the coil panel for heating the cooker. The coil panel for heating the cooker comprises supports and more than two coils, wherein the more than two coils are respectively and correspondently arranged on more than two supports, at least one coil is different from a coupling resistor and / or coupling inductance of the cooker, and the other coil is different from the coupling resistor and / or the coupling inductance of the cooker. The coil panel for heating the cooker according to the invention has the advantages that different heated positions of the cooker can be heated in different heating levels, food in the cooker can be tumbled and is unlikely to stick on the cooker, the food is more uniformly heated, and the cooking effect is better.

Owner:MIDEA GRP CO LTD +1

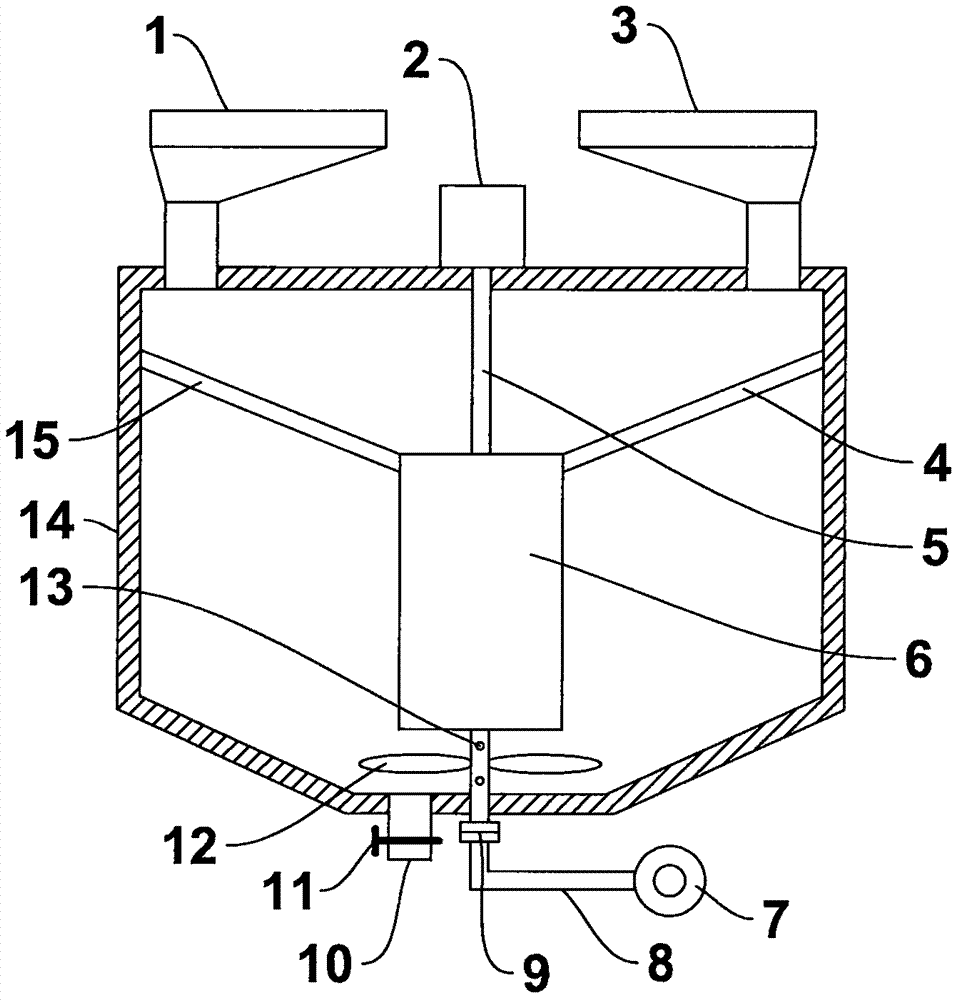

Production and modified treatment device for rapidly fermented organic fertilizer

InactiveCN107029593AGood for rollingAvoid cakingRotary stirring mixersTransportation and packagingDrive motorTreatment effect

The invention discloses a production and modified treatment device for a rapidly fermented organic fertilizer. The production and modified treatment device for a rapidly fermented organic fertilizer comprises a body, wherein a pulverizing barrel is arranged in the middle of the inner side of the body; a rotating shaft is arranged on the inner side of the pulverizing barrel; a driving motor which is connected with the rotating shaft is further arranged on the top of the body; the bottom of the body is connected with an air inlet tube through a rotating joint at the lower end of the rotating shaft; the other end of the air inlet tube is connected with a warm air machine; a plurality of pulverizing knives are arranged on the inner side of the pulverizing barrel and positioned on the rotating shaft; a scraper plate is arranged on the lower part of the pulverizing barrel and positioned on the rotating shaft; a sieve is arranged on the lower side of the scraper plate; a plurality of stirring blades are arranged on the lower side of the pulverizing barrel and positioned on the rotating shaft; a primary hopper and a secondary hopper are respectively arranged on the left side and the right side of the top of the body; and a primary vibrating sieve and a secondary vibrating sieve are respectively arranged on the left side and the right side of the upper end of the pulverizing barrel and are positioned on the inner side of the body. The production and modified treatment device for the rapidly fermented organic fertilizer is compact in structure; caking of media can be prevented effectively; and the modified treatment effect of the system is improved.

Owner:刘海明

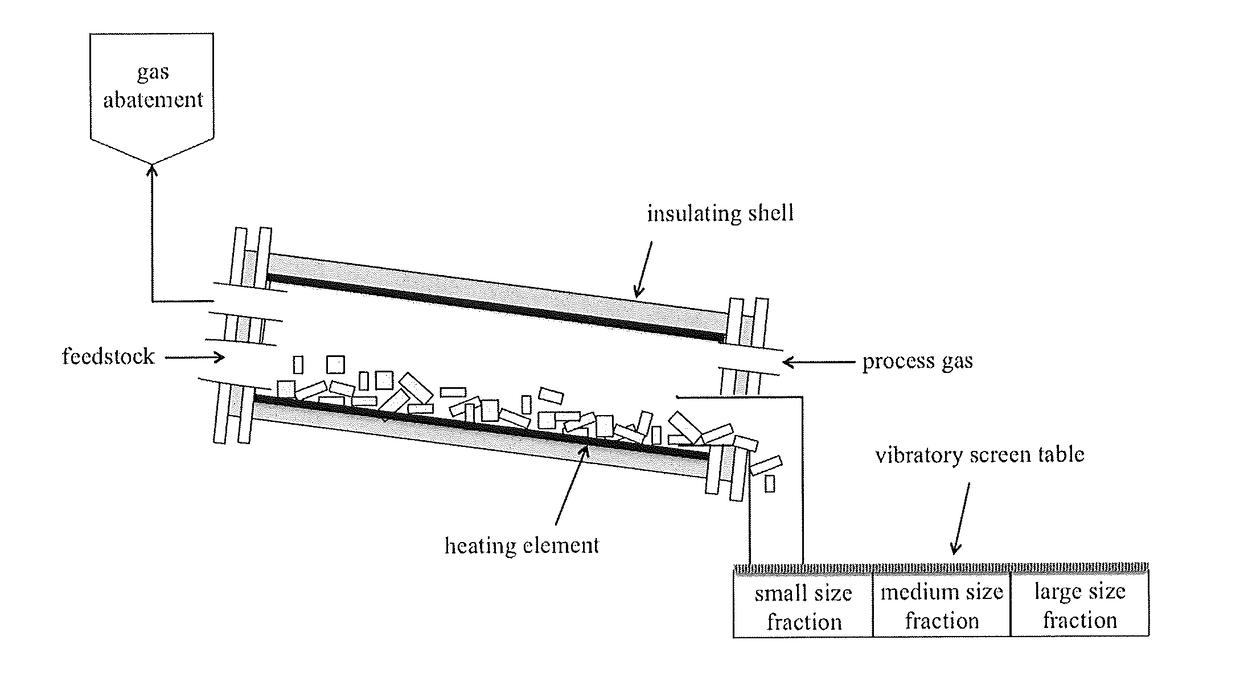

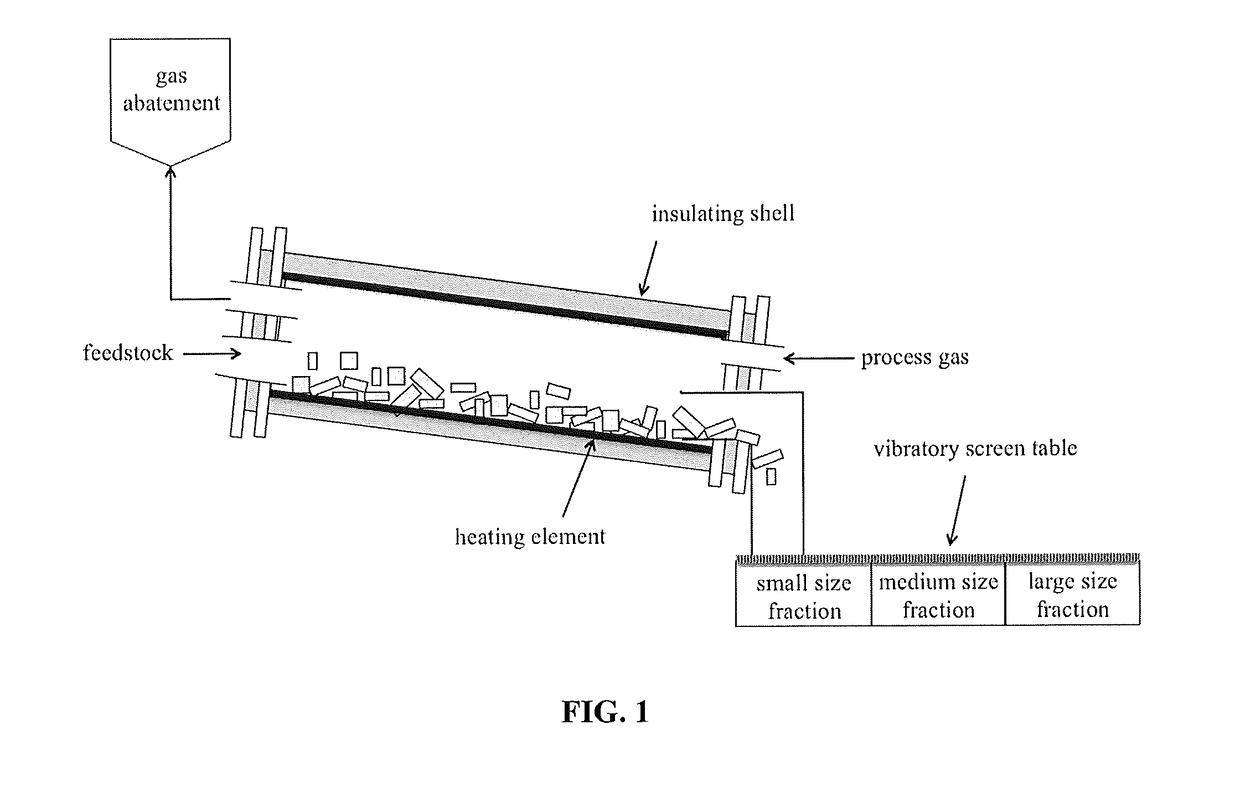

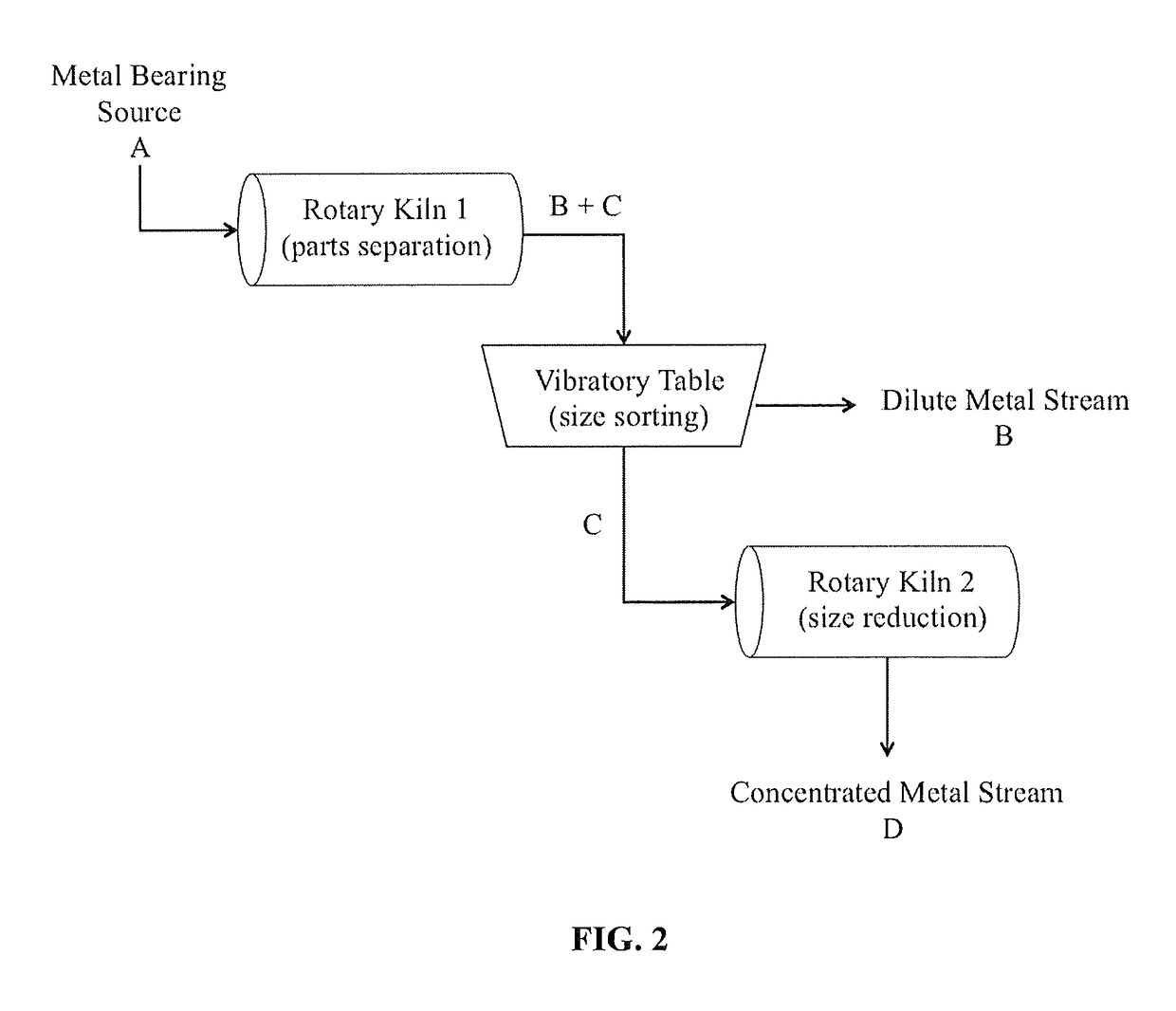

Method and apparatus for separation and size reduction of noble metal containing sources

InactiveUS20180318842A1Promote tumblingWell mixedSolid waste disposalTransportation and packagingEpoxyAdhesive

The invention discloses improvements and additional uses of thermo-mechanical processes using a rotary kiln for the separation of parts from a device that are held together by various means such as solder, epoxies, glues, and / or any other thermally degradable adhesives or underfills, and which is suitable for material size reduction via thermal decomposition of encapsulant materials such as integrated circuit casings or thermally degradable materials such as carbon-based hydro processing catalysts. The invention includes further sorting the materials according to predetermined size either in-situ or in series using a meshed vibrating table downstream of the rotary kiln. These devices can include, but not limited to, printed circuit boards, catalysts, solar panels, and the like.

Owner:EAUTERRE CONSULTING LLC

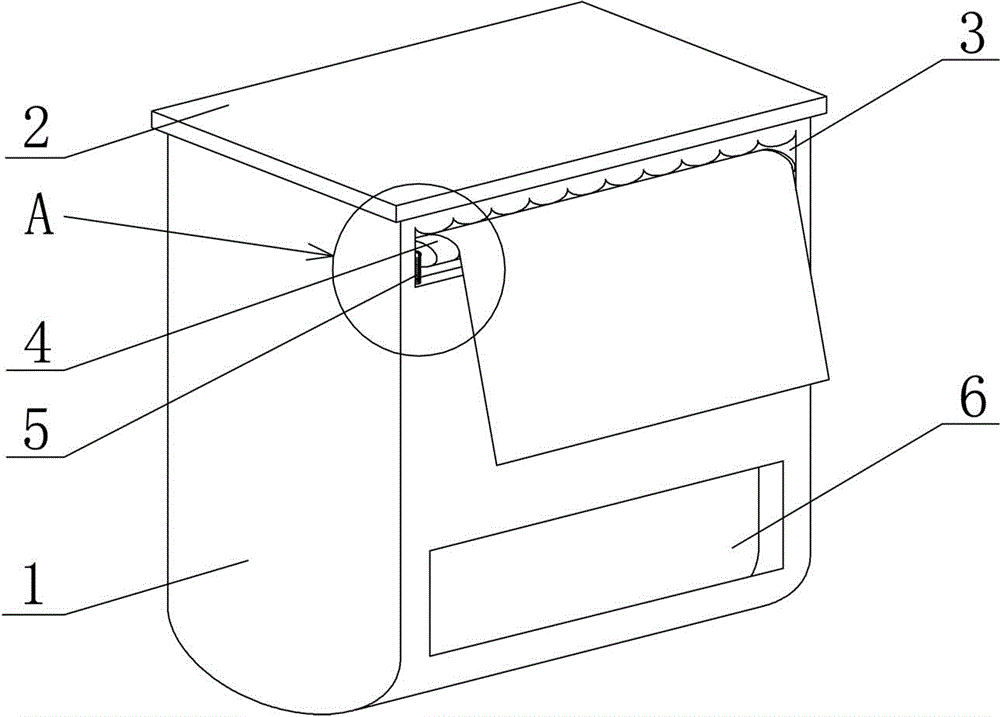

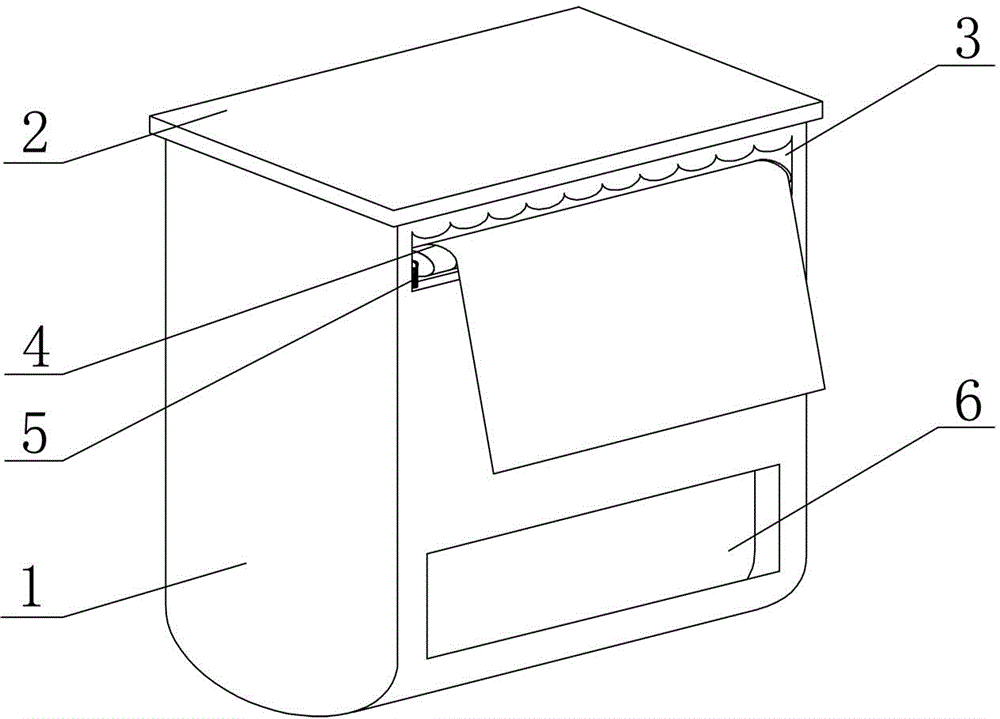

Toilet paper access device

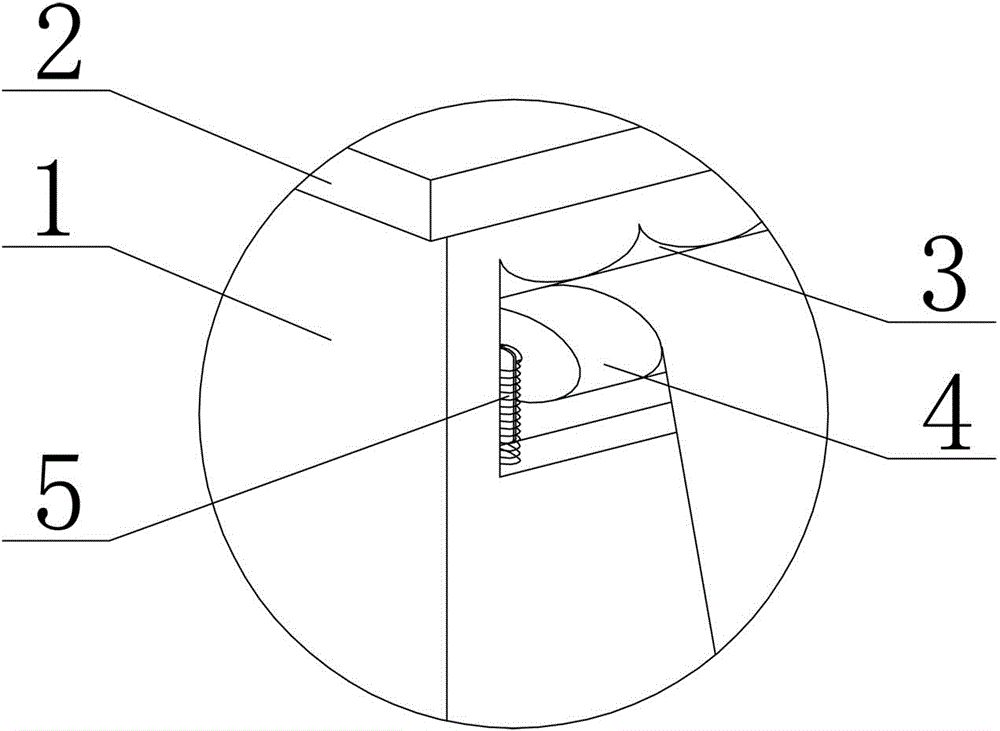

InactiveCN103330529APromote tumblingSimple structureDomestic applicationsToilet paperPulp and paper industry

The invention discloses a toilet paper access device, which comprises a box body and a box cover, wherein the box cover covers the top end of the box body, a paper outlet is formed in the box body, the bottom of the box body is made into the circular arc shape, the paper outlet is formed in a position near the top end part of the box body, and a rolling shaft is arranged on the paper outlet. The toilet paper access device has the advantages that the bottom of the box body is made into the circular arc shape, the paper outlet is formed in the position near the top end of the box body, the toilet paper extends out and falls down from a position between the upper edge of the paper outlet and the rolling shaft, during the pulling, the toilet paper is downwards pulled, the upward lifting acting force is finally exerted on pipe-core-free toilet paper in the box body, the rolling of the pipe-core-free toilet paper can be more favorably realized, the structure of the whole device is simple, and the use is convenient.

Owner:常熟市联合金属制品有限责任公司

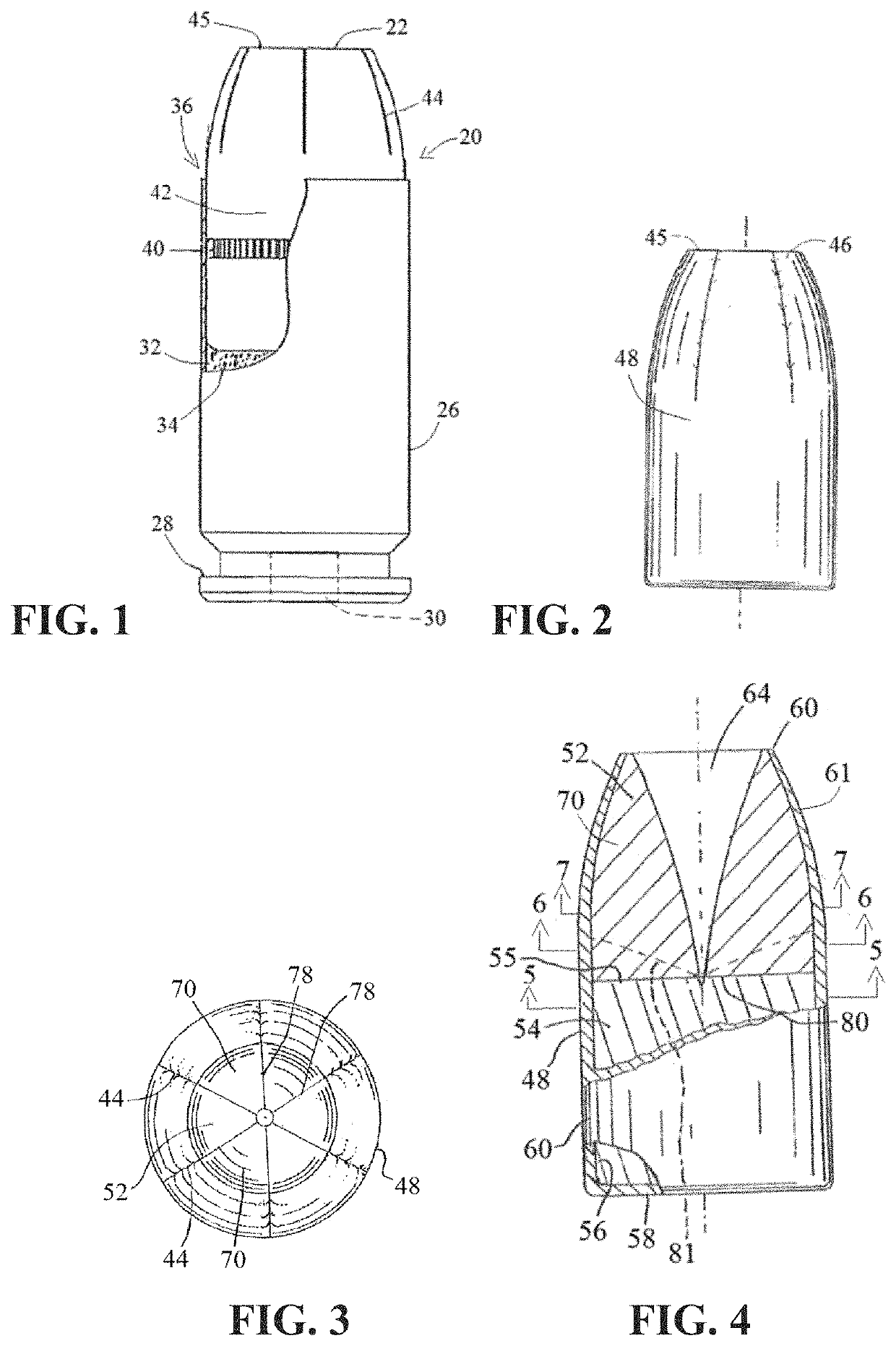

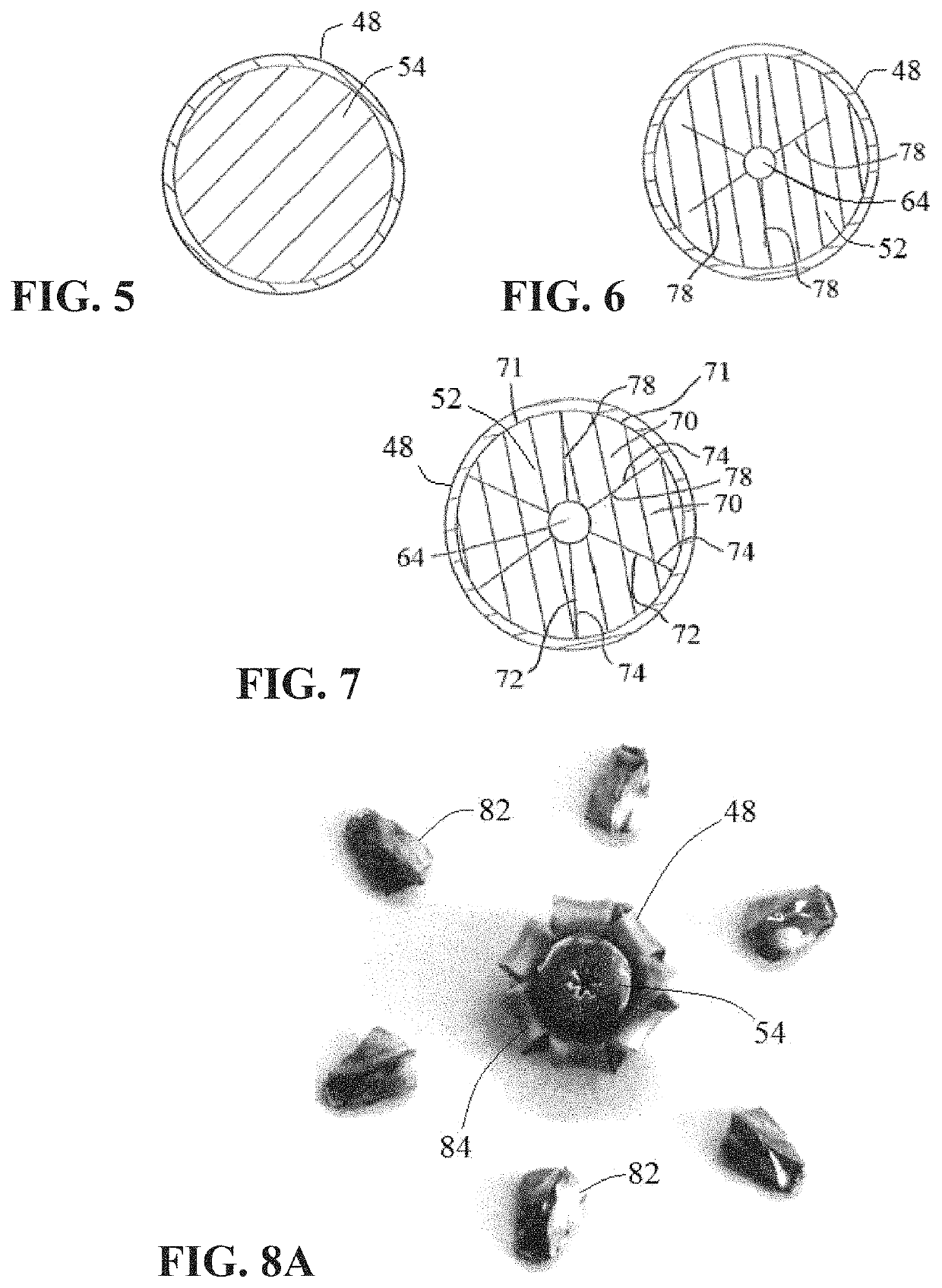

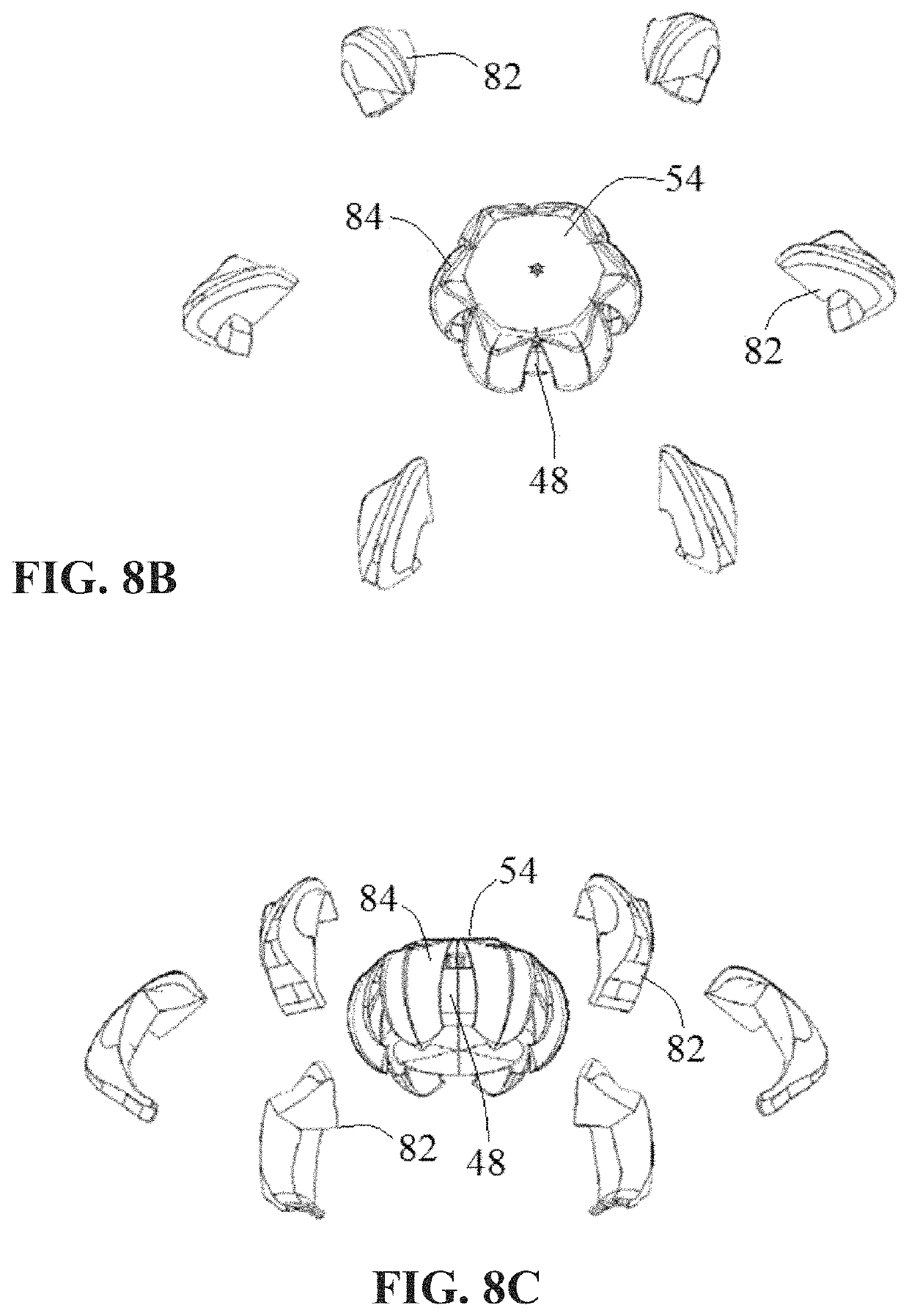

Cartridge with combined effects projectile

ActiveUS10690464B2Easy pedalPromote tumblingAmmunition projectilesSelf-propelled projectilesClassical mechanicsStructural engineering

A cartridge comprising a bullet, the bullet providing a radially expanding array of bullet fragments upon entering a target and also providing an increase in effective surface area of the bullet within the target by structural features that facilitate tumbling or mushrooming in the target. In an embodiment a pair of axial core members are aligned in a bullet jacket with the forward core member being segmented with separation junctures formed by engaged faces of adjacent segments. Impact causing fracturing of the segments from a base portion.

Owner:FEDERAL CARTRIDGE

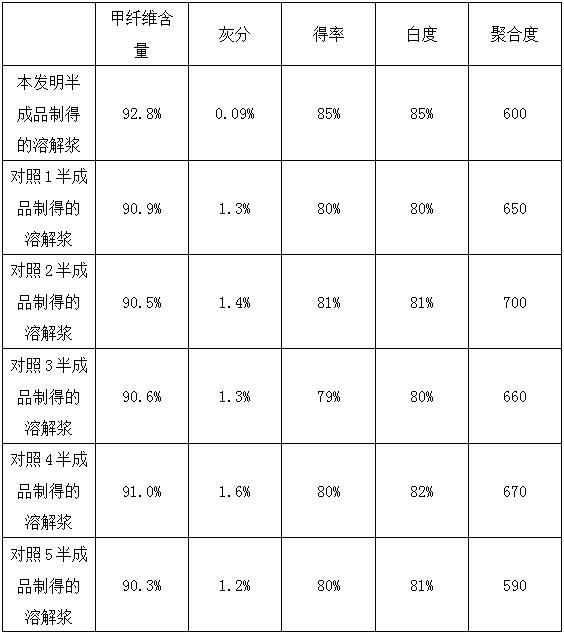

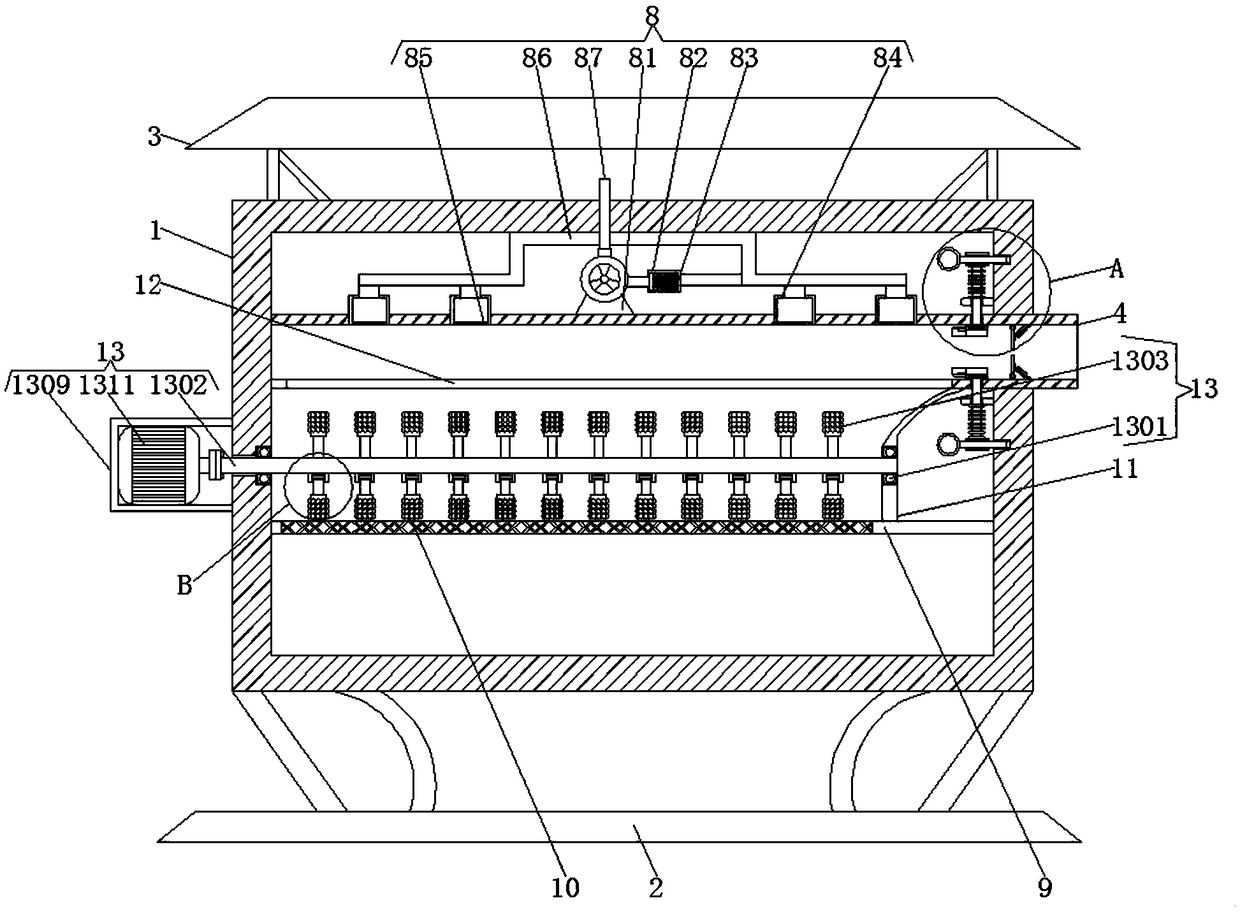

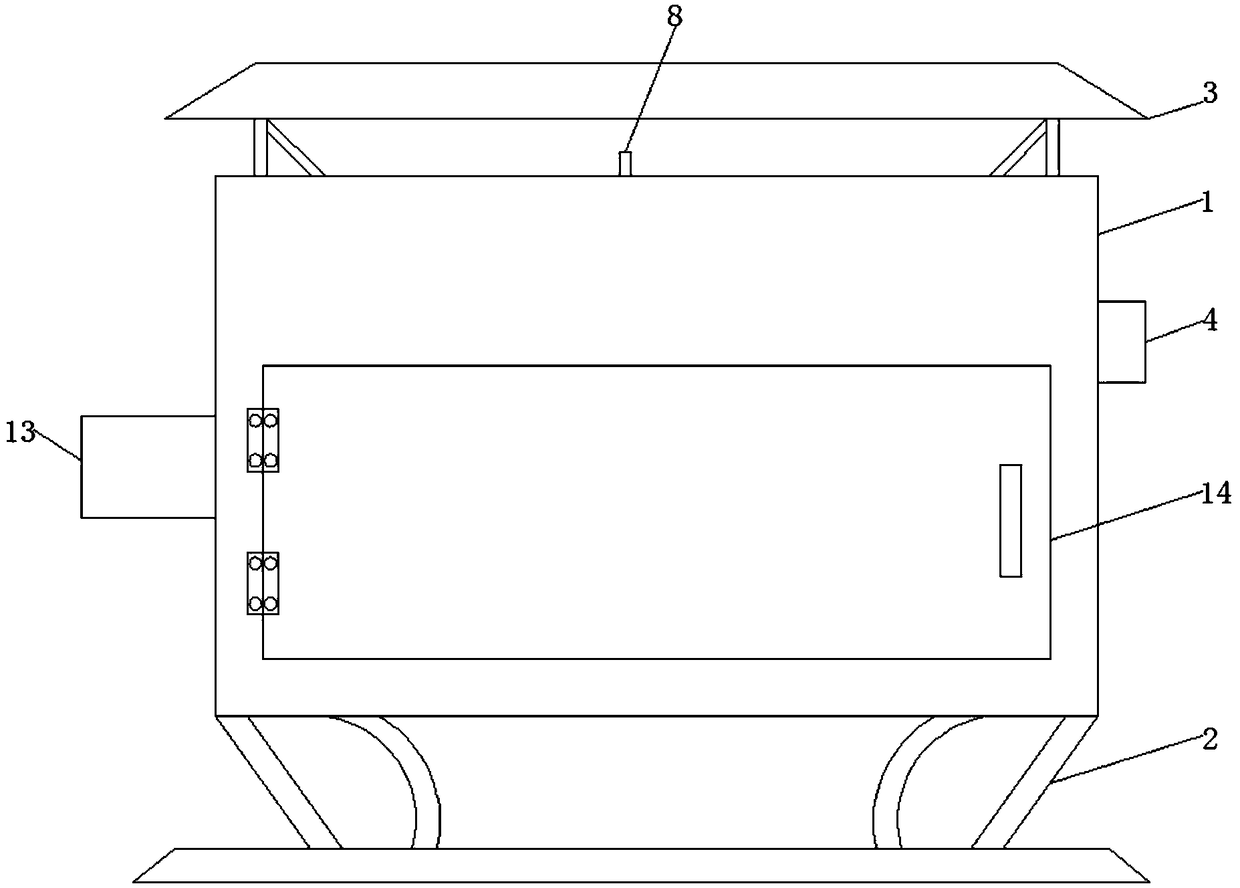

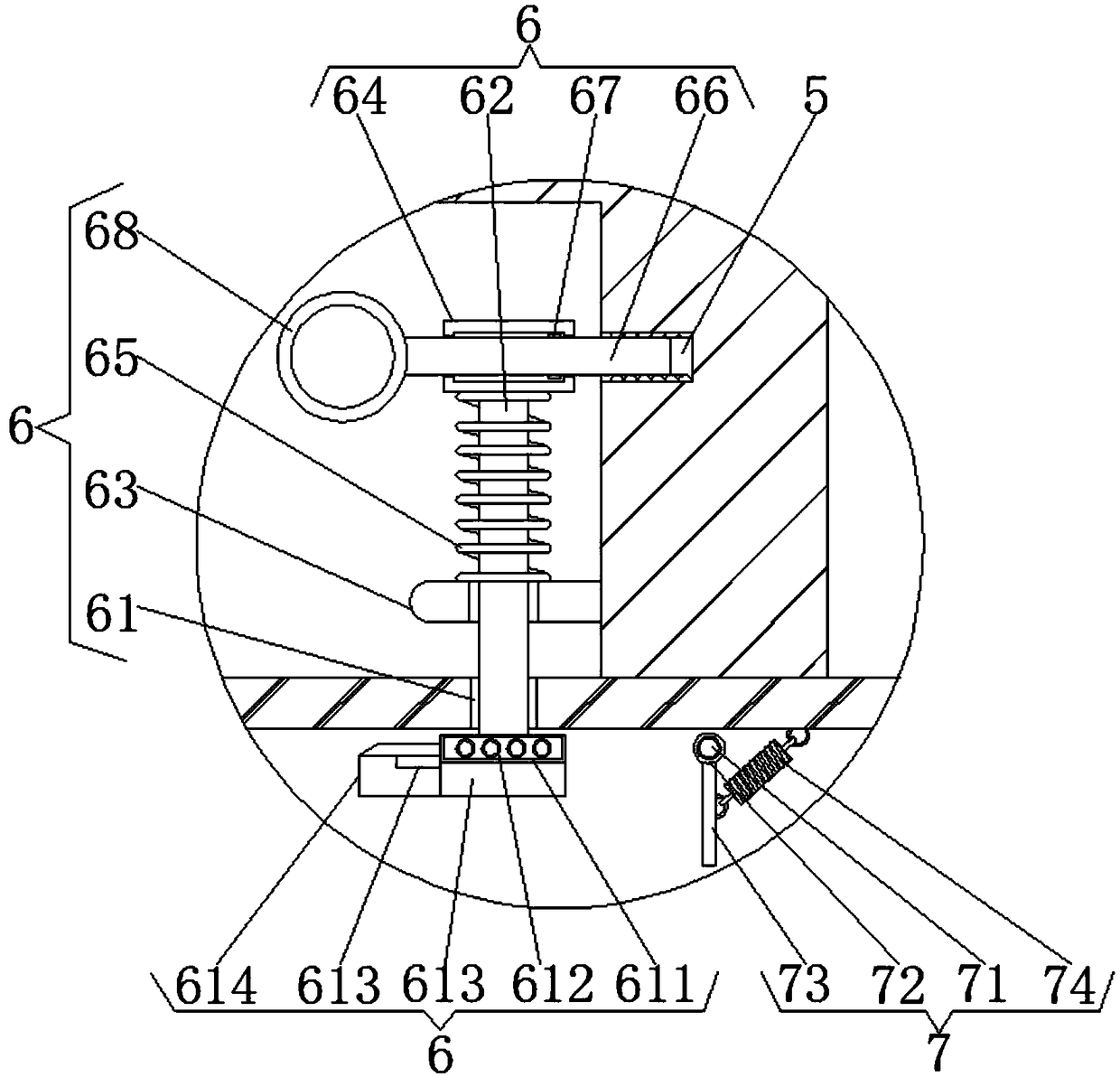

Material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in modified mode

InactiveCN102677500AMonotonous performanceUniform shapePretreatment with alkaline reacting compoundsRaw material divisionFiberMaterials preparation

The invention discloses a material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in a modified mode. The process comprises procedures of raw material preparation, dispersion, slicing, impregnation and the like. Specific to unbleached wood pulp raw materials, special process steps and process control parameters are utilized so that the purposes of improving quality of end products, energy saving and emission reduction can be achieved, armour fiber content, yield and whiteness of the end products can be improved, ash content of the end products is reduced, cost control of chemical liquid drug is facilitated, the curve of temperature rising in the follow-up cooking process is stable, poly reduction is even, prepared semi-finished products are suitable for various cooking modes, and the material preparation process has a wide application range.

Owner:YIBIN GRACE GROUP CO LTD

Sesame seed collection device for sesame oil processing

The invention discloses a sesame seed collection device for sesame oil processing and relates to the technical field of sesame processing. The sesame seed collection device comprises a box, a supporting seat is fixedly mounted on the undersurface of the box, a rainproof is fixedly mounted on the top face of the box, a pod removing pipe is fixedly mounted at the top of the left-side inner wall of the box, the right end of the pod removing pipe penetrates the right side face of the box and extends to the outside of the box, and two positioning grooves are formed in the right-side inner wall of the box and positioned above and below the right end of the pod removing pipe. By improving the sesame seed collection device, de-seeding of sesame can be completed thoroughly, and a filter net can bepromoted to realize anti-blocking effect; through matched use of a pod removing device and the de-seeding device, more convenience can be brought to collecting sesame seeds, so that usability of the sesame seed collection device is improved.

Owner:山东煜华建设工程集团有限公司

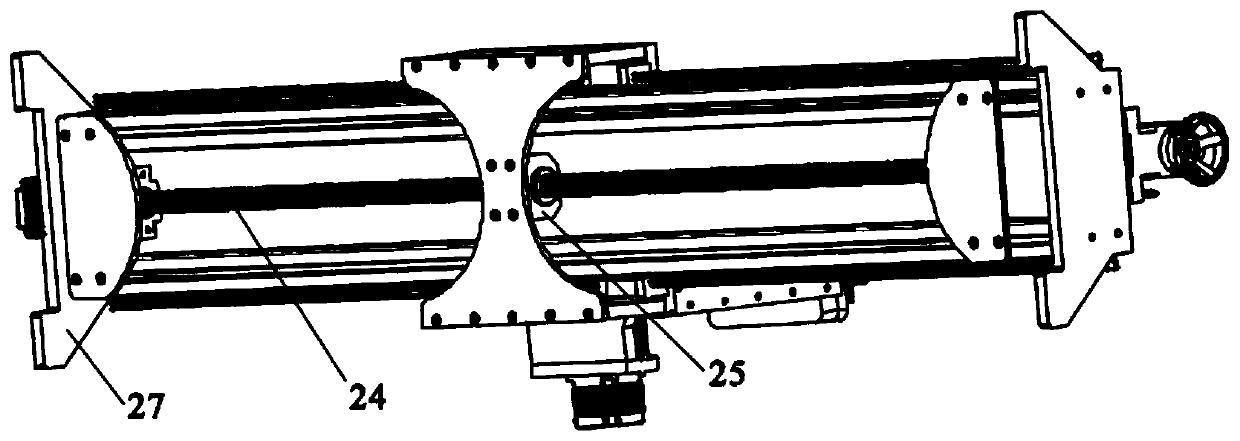

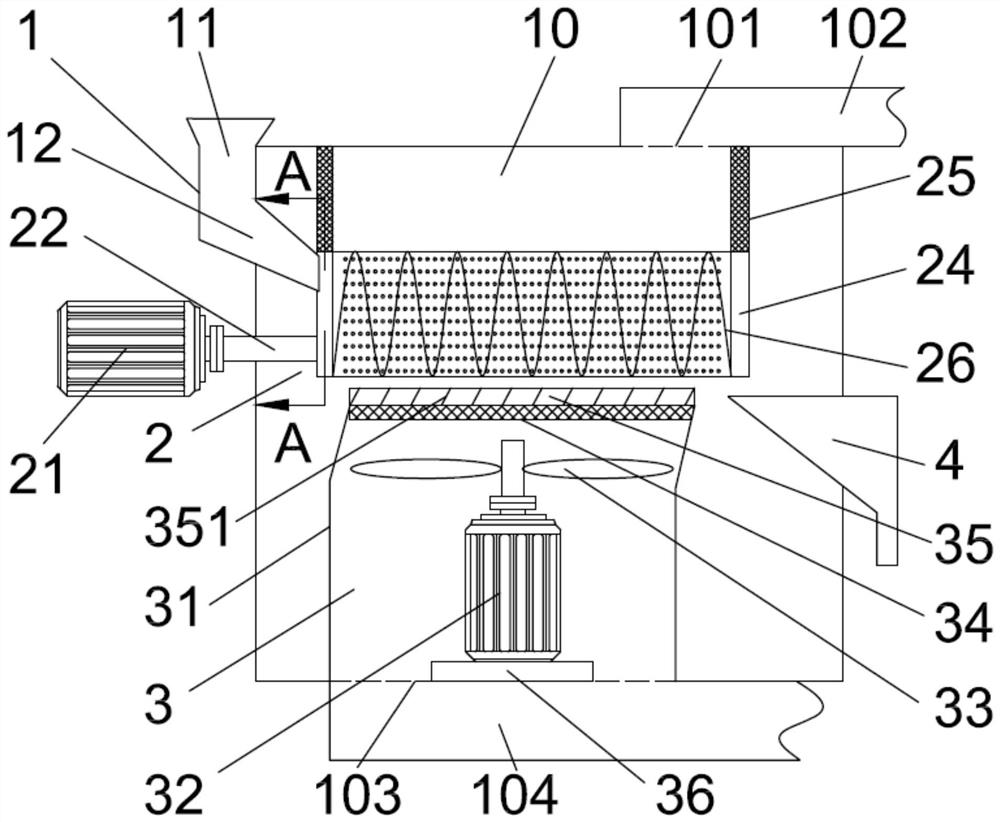

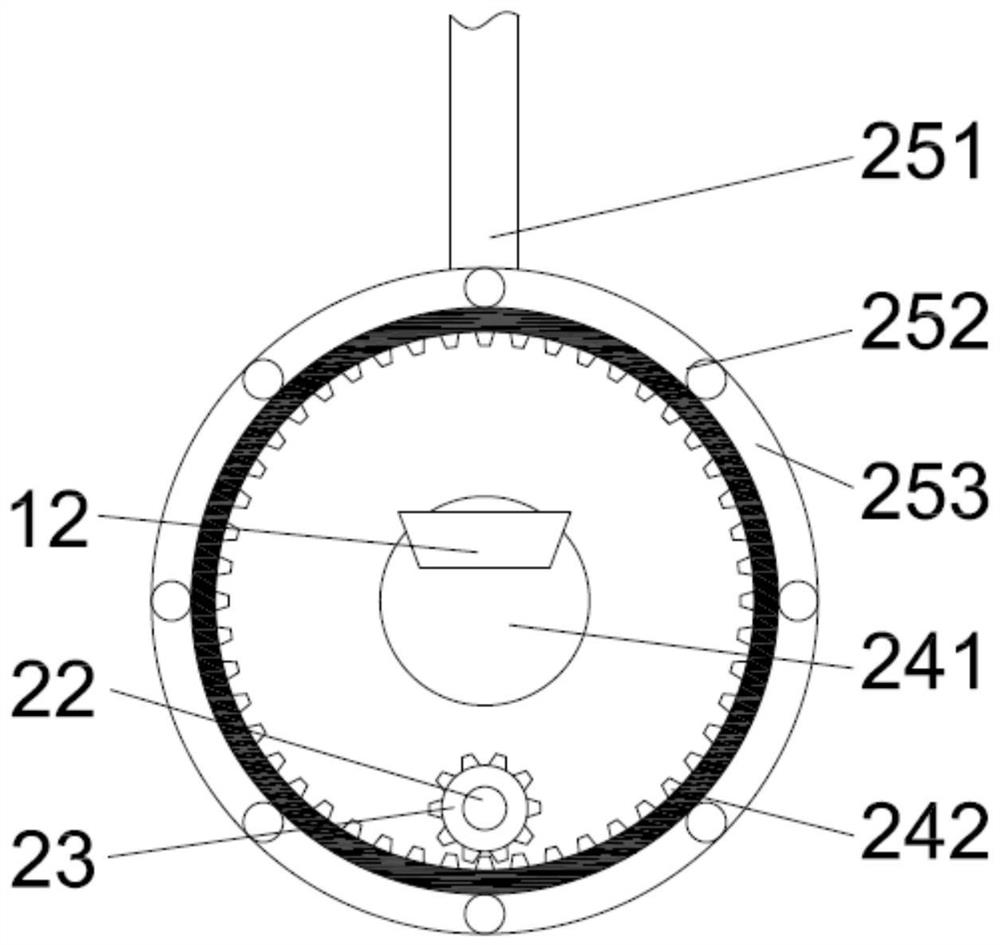

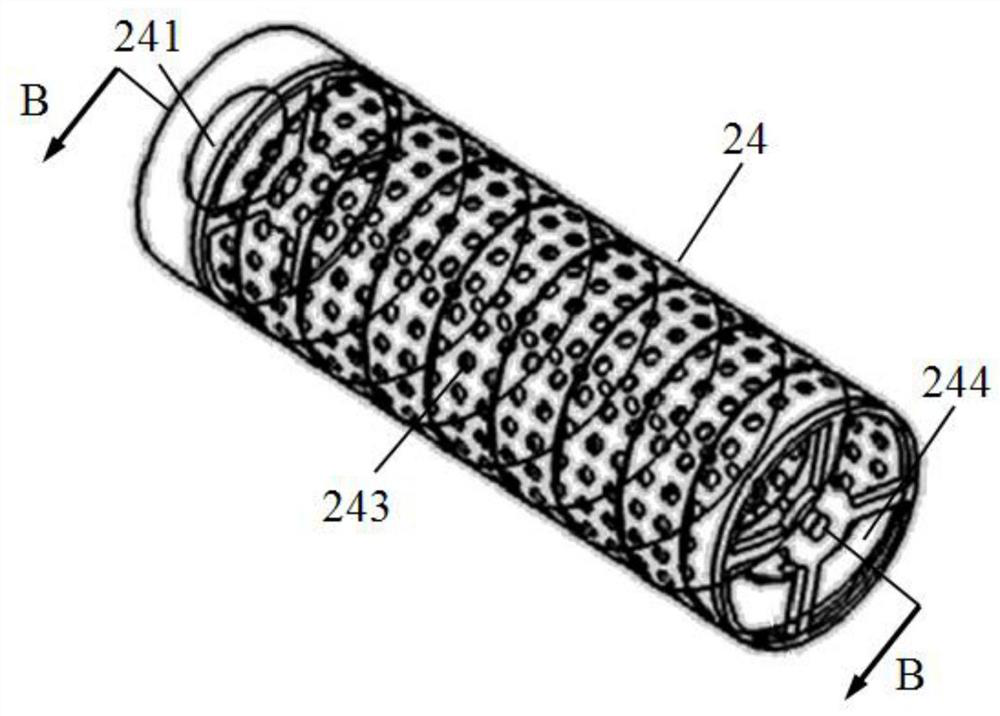

High-wind-speed auxiliary agitation drying apparatus

InactiveCN112284120APromote tumblingGood dispersionDrying gas arrangementsDrying solid materialsElectric machineSpiral blade

The invention provides a high-wind-speed auxiliary agitation drying apparatus, which comprises an apparatus body (10). The apparatus body (10) comprises a feeding device (1), an agitating device (2),a drying device (3) and a discharged material collecting device (4), wherein the agitating device (2) comprises an agitating motor (21), an output shaft (22), a driving gear (23), an overturning drum(24), a connecting device (25) and a spiral blade (26); and the drying device (3) comprises a device shell (31), a heating motor (32), heating blades (33), a heating device (34) and a wind guide plate(35). By using the apparatus, heated air can go deep into a material, and meanwhile, the overturning of the material is guaranteed, so that the heated air is in sufficient and uniform contact with the material, and then the drying effect is improved; meanwhile, the apparatus can screen the dried material preferentially and discharge the dried material from the overturning drum (24) quickly, so that the dried material is prevented from being continuously dried, and the drying efficiency is improved.

Owner:何申明

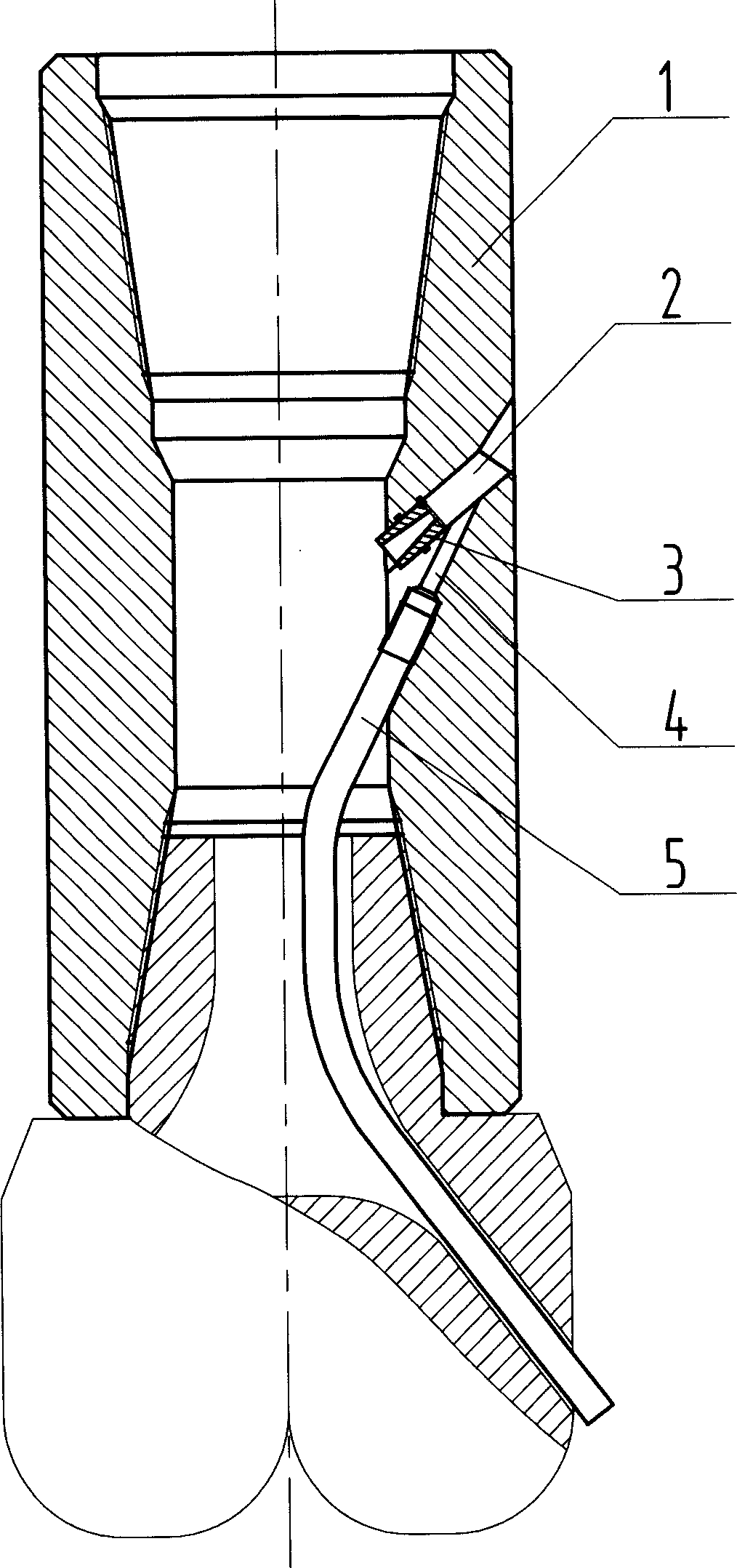

Well bottom hydraulic suction pressure lowering drilling tool

A well drilling tool able to decrease the pressure at well bottom by hydraulic sucking for increasing the drilling efficiency is composed of drill bit and its short joint segment, low-pressure cavity, jet nozzle, jet cavity and sucking tube. A high-speed jet from said nozzle is generated by the difference between the pressures in drilling column and annular space to form a local low pressure near the nozzle outlet. A sucking tube is used to deliver the low pressure to well bottom.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Method and special device for treating lithium hexafluorophosphate synthetic tail gas with simple process flow

ActiveCN107758620AEfficient removalImprove qualityChlorine/hydrogen-chlorideHydrogen fluorideHydrogen fluorideMaterial balance

The invention discloses a method and a special device for treating lithium hexafluorophosphate synthetic tail gas with a simple process flow. The tail gas is pressurized by a booster fan and then sentto a condenser, a condensate is recovered to an anhydrous hydrogen fluoride receiving tank, the mixed gas out of the condenser sequentially passes through a closed first-stage stirring reactor, a horizontal spiral conveying reactor and a second-stage stirring reactor in a material stirring diversion direction, trace HF in the mixed gas reacts with LiCl powder pre-added in a stirring reaction combination device, and the LiCl powder in the second-stage stirring reactor is returned to the first-stage stirring reactor through a material balance pipe; the tail gas out of the second-stage stirringreactor is collected by a dust collector to take away a small amount of powder and then enters a water washing tower to prepare hydrochloric acid, and the gas out of the water washing tower is discharged after alkali washing by an alkali washing tower. The method and the special device provided by the invention effectively remove HF in the mixed tail gas, improve the quality of a by-product namelyhydrochloric acid and broaden the application field.

Owner:JIANGSU JIUJIUJIU TECH

Dairy product cooling device based on water cooling mode

ActiveCN108827030AImprove cooling effectFaster coolingStationary tubular conduit assembliesCold airMotor drive

The invention provides a dairy product cooling device based on a water cooling mode, and relates to the field of dairy product cooling. The cooling device solves the problem that the existing diary product cooling is large in water consumption and poor in cooling effect. The cooling device comprises a cooling box, and the bottom of the cooling box is welded to the top of a base through overhead legs, and the side wall of the cooling box close to the top is provided with a feeding port, and the side wall of the cooling box close to the bottom is provided with a discharging pipe in communication, and a water and air integrated cooling mechanism is arranged inside the cooling box. The cooling device introduces water to a water cooling pipe inside a cooling elbow to promote cooling, and an airpump introduces outside cold air into the cooling elbow through an air guide pipe. A gear motor drives the cooling elbow through a pulley to rotate inside a dairy product to promote uniform temperature reduction of the dairy product and also drive stirring of the dairy product to expose the portion with higher temperature to promote cooling.

Owner:青海雪峰牦牛乳业有限责任公司

Dyeing sludge drying treatment device

PendingCN109231789AImprove efficiencyRapid responseSludge treatment by de-watering/drying/thickeningWaste water treatment from textile industryEngineeringSludge

The invention discloses a dyeing sludge drying treatment device. The device comprises a shell body, wherein a tank body is fixed to the upper end of the left side of the interior of the shell body, the left side of the upper end of the tank body is provided with a feeding port, stirring blades are installed on the surface of a shaft rod, the lower end of the tank body is provided with a dischargehole, a boss is welded to the surface of the interior of the discharge hole, a flow guiding plate is fixed to the other end of a rotary shaft, a spring is fixed to the upper end of the left side of the flow guiding plate; a first conveyor belt is fixed to the left side of the lower end of the interior of the shell body, a heating plate is installed in the first conveyor belt; the left side of theupper end of a connection plate is provided with a groove, a second conveyor belt is installed on the right side of the connection plate, a squeezing roller is fixed to the upper end of the second conveyor belt, and a squeezing plate is installed on the left side of the squeezing roller. The dyeing sludge drying treatment device improves the stirring efficiency, accelerates reaction of sludge anda coagulant, is convenient for guiding the discharging direction of the sludge, can discharge and distribute uniformly, and is convenient for achieving evenness and high efficiency of squeezing.

Owner:嘉兴市乔兰服饰有限公司

Pill Dispensing Method and Apparatus

ActiveUS20120085775A1Fast and well controlled movementAvoid miscalculationsSmall article dispensingCoin-freed apparatus detailsEngineeringBottle

The present invention is a pill dispensing method and apparatus wherein a first rotor rotates pills about a rotation axis along a first part of a spiral path at a first rotational speed whereupon the pills move spirally away from the rotation axis. A second rotor receives the pills from the first rotor and rotates the pills about the rotation axis along a second part of the spiral path at a second, greater rotational speed whereupon the pills move spirally away from the rotation axis toward a discharge chute which dispenses the pills into a pill bottle or a storage container.

Owner:CZARNEK & ORKIN LAB

Automobile waste cutting machine

The invention provides an automobile waste cutting machine, and relates to the field of automobile waste recycling. The automobile waste cutting machine comprises a negative-pressure mechanism, an installation plate, a feeding conveyor belt, an installation frame, a cutting mechanism and a discharging conveyor belt. The automobile waste cutting machine is characterized in that the installation frame is welded to the outer wall of the bottom of the installation plate; an installation groove is formed in the outer wall of the bottom of the installation plate; the negative-pressure mechanism is arranged on the inner wall of the installation groove; the feeding conveyor belt is fixedly connected with the inner walls of the two sides of the installation plate; a cutting mechanism is arranged on the inner wall, close to the feeding conveyor belt, of the installation plate; the discharging conveyor belt is arranged below the discharging part of the cutting mechanism; and the negative-pressure mechanism is located above the discharging conveyor belt. According to the automobile waste cutting machine, part of light plastic blocks are prevented from being pressed under metal scraps and cannot be sufficiently adsorbed, the effect of separating the light plastic blocks is further improved, the metal recycling rate is increased, and subsequent processing is facilitated.

Owner:江苏加德仕汽车科技有限公司

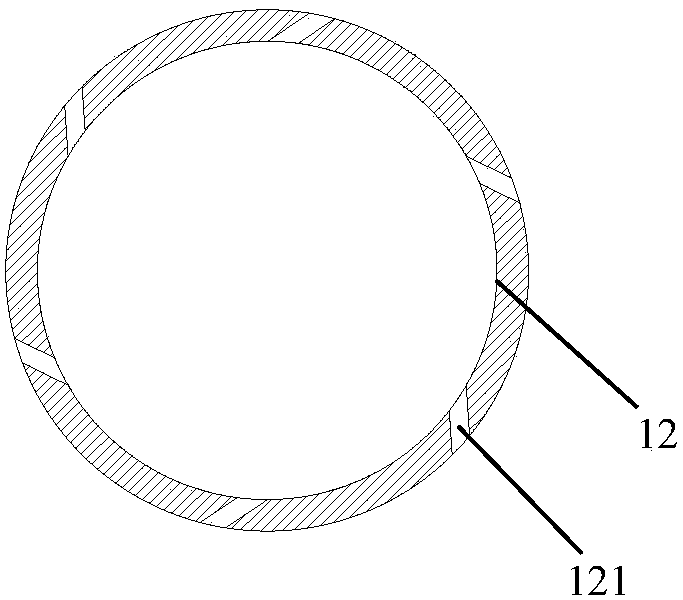

Electroplating roller

InactiveCN104695000ASimple structureIncrease loading capacityElectrolysis componentsElectroplatingProduction line

The invention relates to a roller used for an electroplating production line and discloses an electroplating roller. The electroplating roller comprises a suspension rod with a triangular cross section, two support bars and two side plates, wherein the suspension rod is arranged at the tops of the side plates, a roller is arranged between the two side plates, one end of the roller is provided with a roller gear, the roller gear is successively connected with a pinion and a main gear and is then connected with a power gear located out of one of the side plates, the two support bars are separately connected with a cathode wire, and the two cathode wires enter the roller from two ends of the roller and are respectively provided with mutually uncontactable conductive heads in the roller. The electroplating roller has the beneficial effects of simple structure, great loading capacity, good rolling performance and high production efficiency; moreover, rotation of the roller enables components to be uniformly turned over and full electroplating of products to be realized.

Owner:天津滨海新区增辉电镀有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com