Magnetic separating method and magnetic separator

A technology of magnetic separation and magnetic separator, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of large volume of ore pulp, poor recovery effect of fine-grained magnetic materials, and large impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

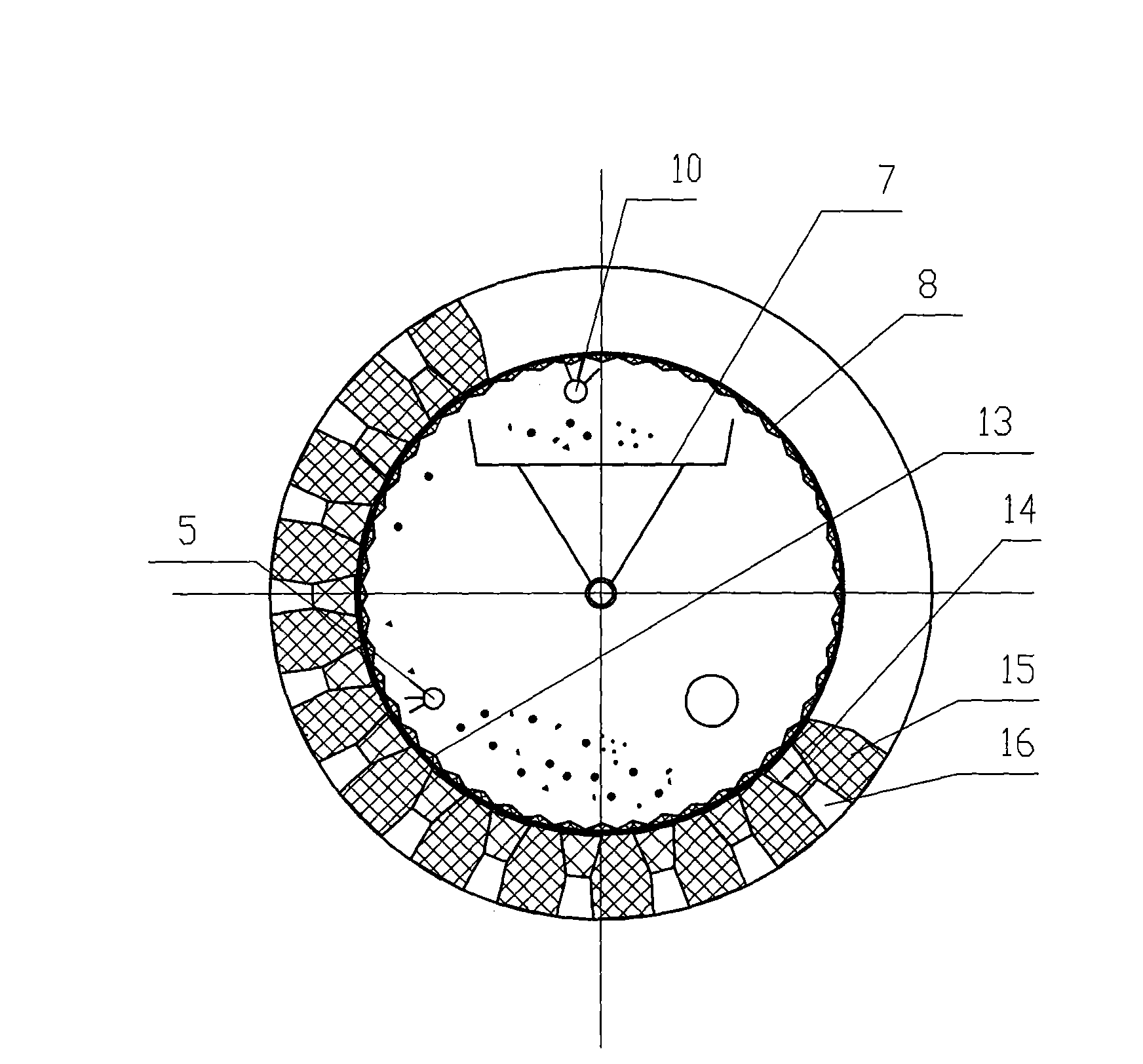

[0017] Depend on figure 1 , figure 2 It can be seen that in a magnetic separation method, the material rotates in the magnetic field with the sorting drum in the sorting drum, and the material is subjected to the combined action of magnetic force, gravity and centrifugal force, and the magnetic material and non-magnetic material are layered and adsorbed on the sorting drum. The inner wall realizes the separation of magnetic materials and non-magnetic materials under the joint action of rinsing water, flushing water and the slope of the sorting drum.

[0018] The gradient of the sorting drum of the present invention is 6°-20° (8° in this embodiment).

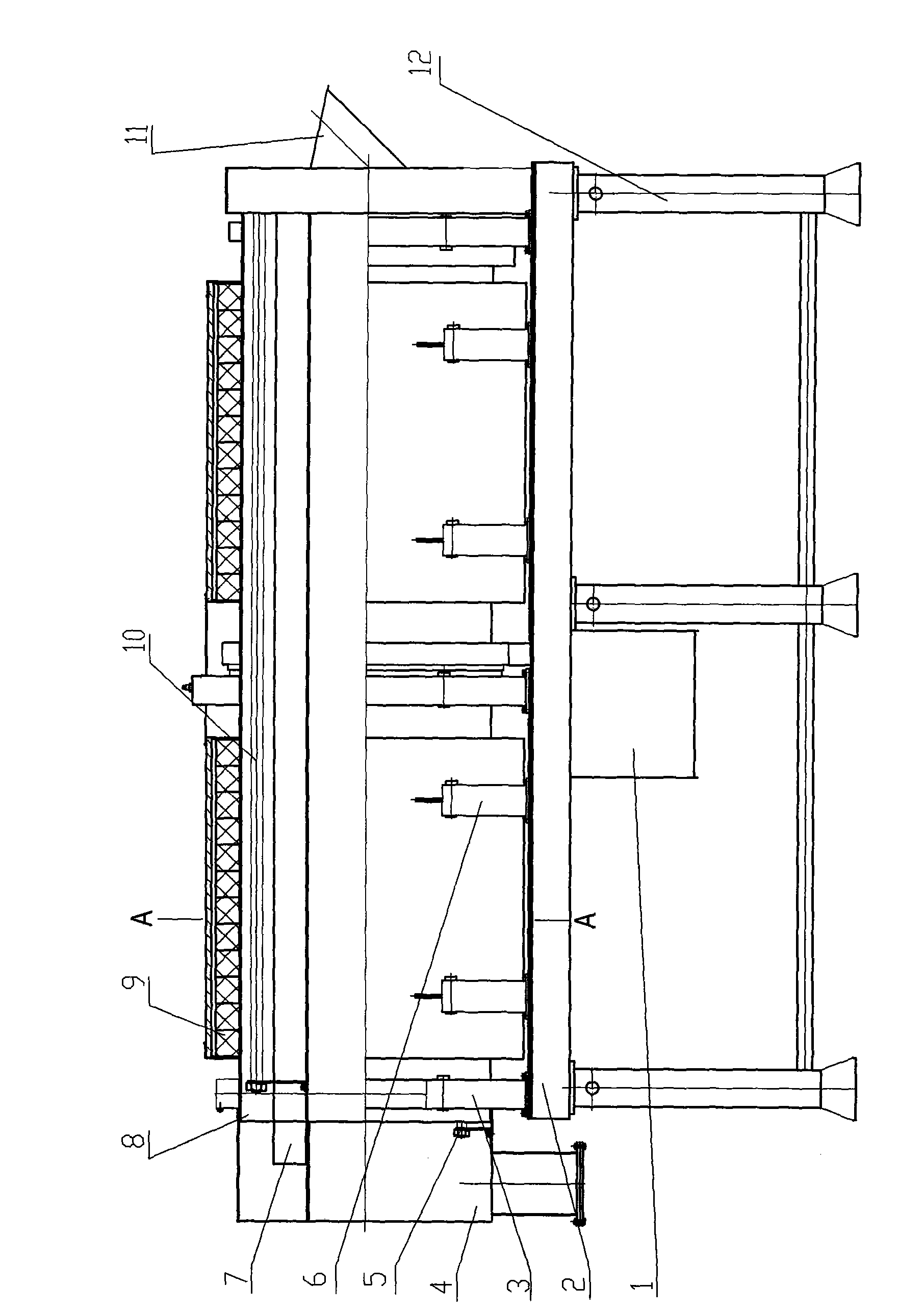

[0019] A kind of magnetic separator that realizes above-mentioned magnetic separation separation method, it comprises frame 2, power 1, feeding device 11, unloading device 4, magnetic system 9, on frame 2 is provided with b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com