Sequencing batch jet-flow driven biochemical reactor

A biochemical reactor, sequencing batch technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. The effect of increased mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific implementation plan

[0026] The technical solutions of the present invention will be further described below through the drawings and embodiments.

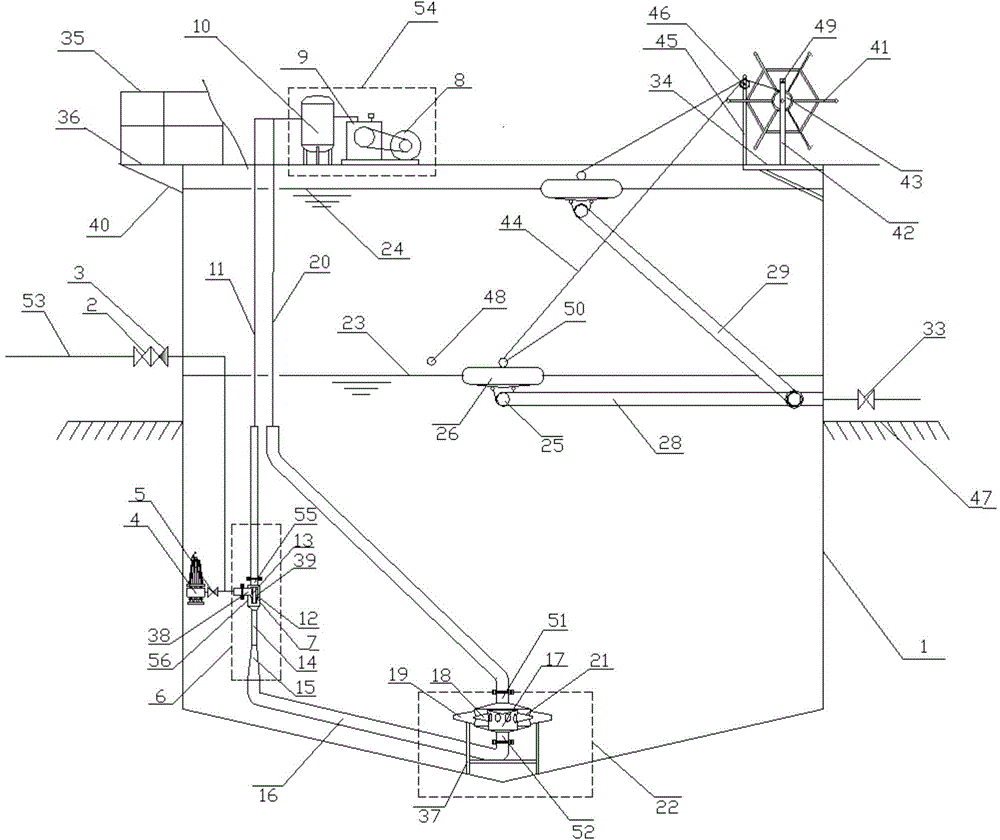

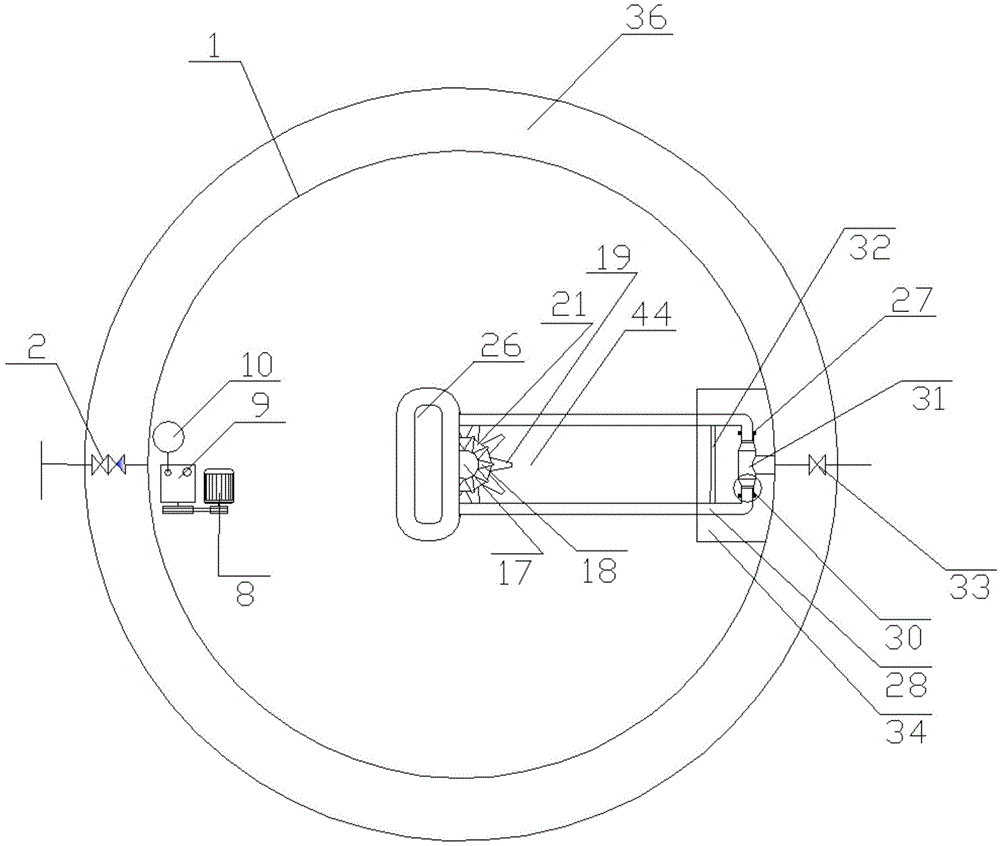

[0027] Such as Figure 1 to Figure 6 As shown, a jet-driven sequencing batch biochemical reactor includes a reaction tank 1, a water inlet pipe 53, a submersible pump 4, a dual gas path annular nozzle one-stage suction jet 6, a mixed liquid conduit 16, and a multi-nozzle radial two Stage jet aerator 22, air supply device 54, buoyancy drive decanter 25 and decanter drive winch 41;

[0028] The dual-air path annular nozzle first-stage suction jet 6 and the submersible pump 4 are installed in the reaction tank 1, and the multi-nozzle radial second-stage jet aerator 22 is installed at the bottom center of the reaction tank 1;

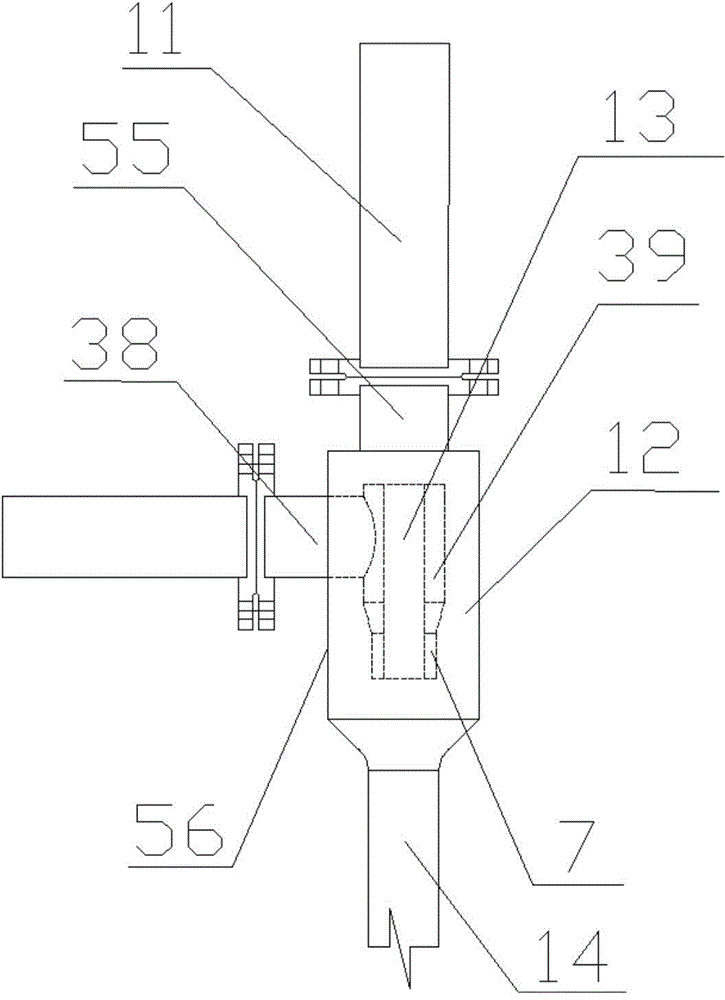

[0029] The dual gas path annular nozzle one-stage suction jet 6 includes a jet liquid inlet 38, a jet gas inlet 55, a suction chamber 56, a throat tube 14, a diffuser tube 15, an annular nozzle 7, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com