Patents

Literature

52results about How to "Improve the efficiency of biochemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for produced water for ultra-low permeable oil field reinjection

InactiveCN101671091AImprove the efficiency of biochemical reactionsExtended service lifeTreatment with anaerobic digestion processesMultistage water/sewage treatmentActivated sludgeWater quality

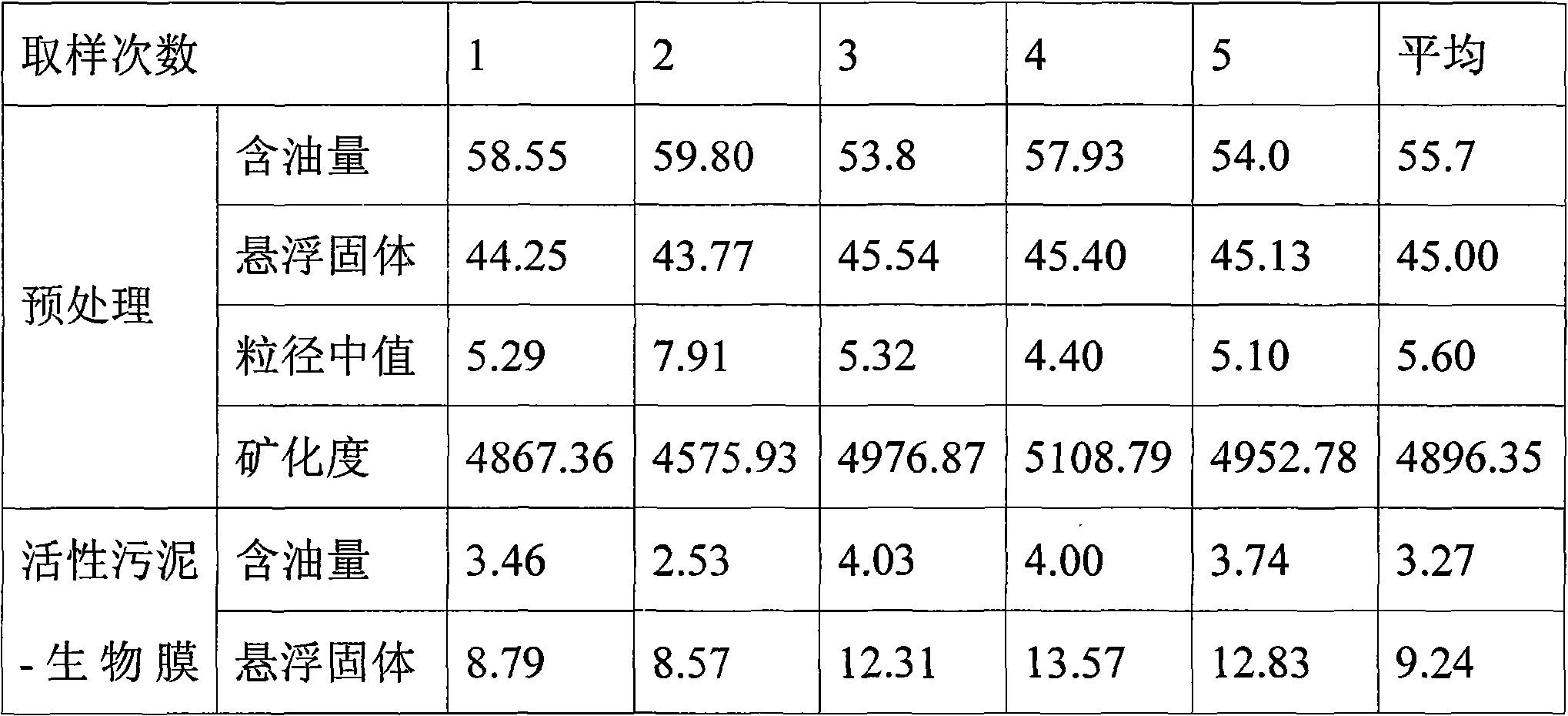

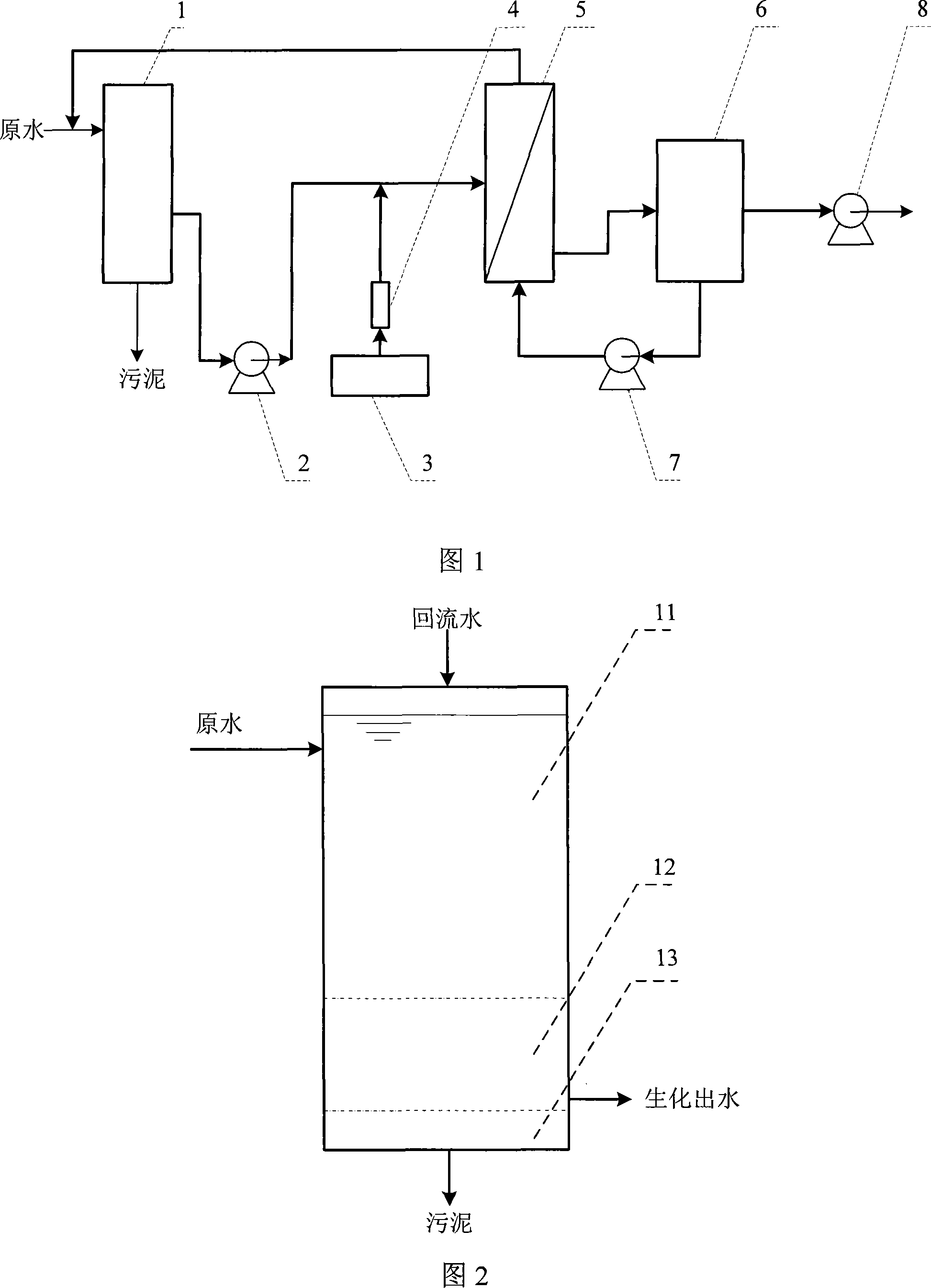

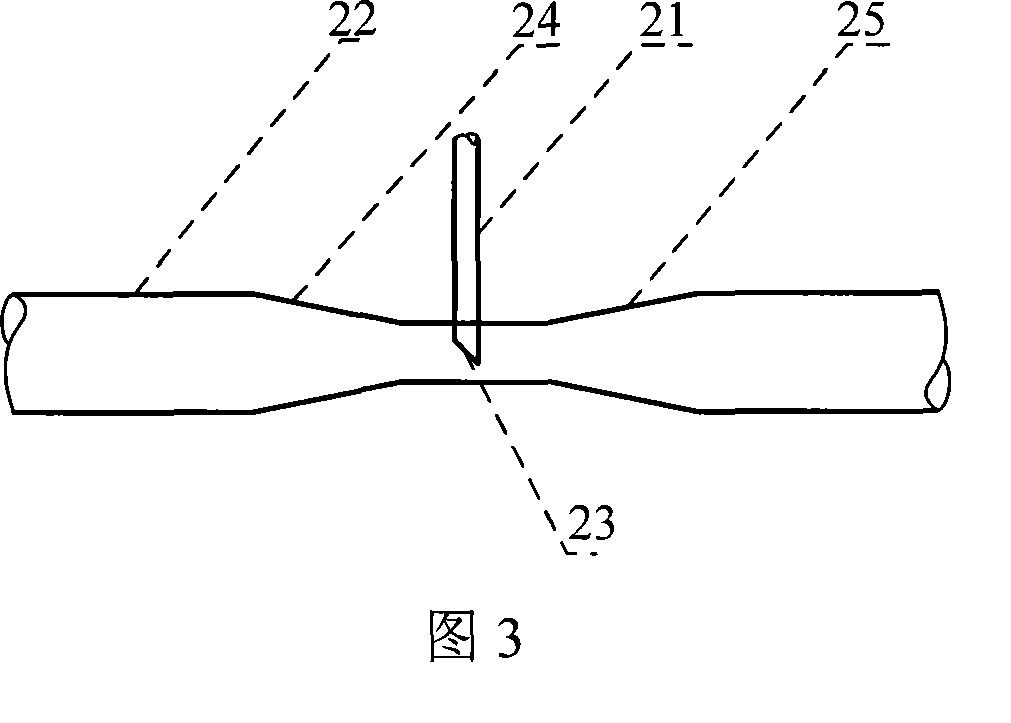

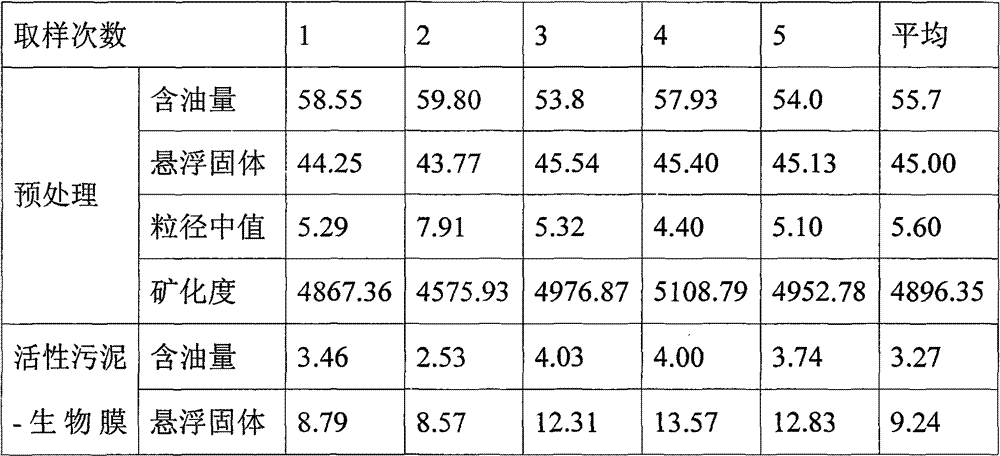

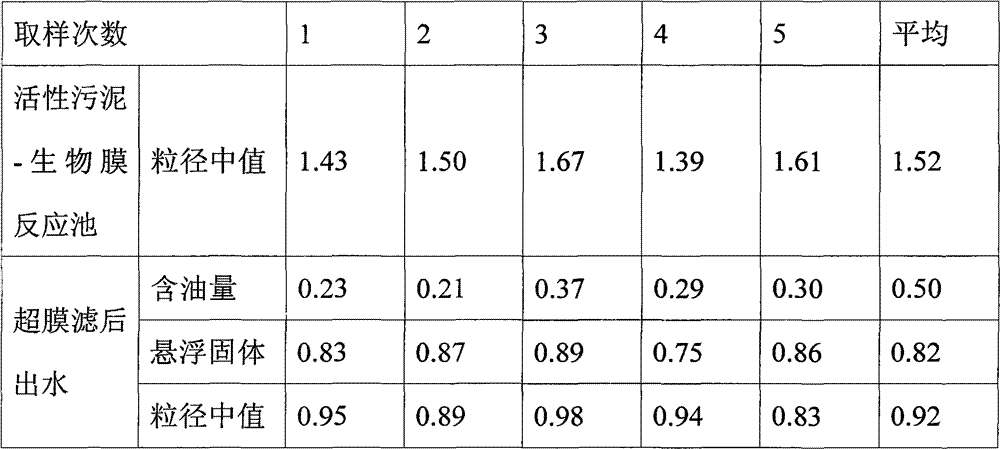

A processing method for produced water for ultra-low permeable oil field reinjection relates to a waste water processing method which solves the problems of complex operation, high cost, solid content suspended in effluent quality and incapability of medium particle size for achieving the 5, 1, 1 standard of produced water of the ultra-low permeable oil field existing in the existing method for processing oil field produced water. The processing method comprises the following steps: 1. preparing a supernatant; 2. carrying out acclimatization treatment in an activated sludge-biomembrane reaction tank, and then introducing the supernatant; and 3. after precipitation, carrying out hyperfiltration. The processing method adopts an activated sludge-biomembrane compound technology as a reactive agent, can give consideration to long-and-short sludge age, aerobic / anaerobic / anoxic environments, simultaneously removes nutritive materials and hard-degradable organic material in water and has highbiochemical reaction efficiency; the processing method has simple operation and low cost; after the processing method of the invention is adopted, effluence can stably achieve the water quality standard-the 5, 1, 1 standard of produced water of the ultra-low permeable oil field.

Owner:HARBIN INST OF TECH

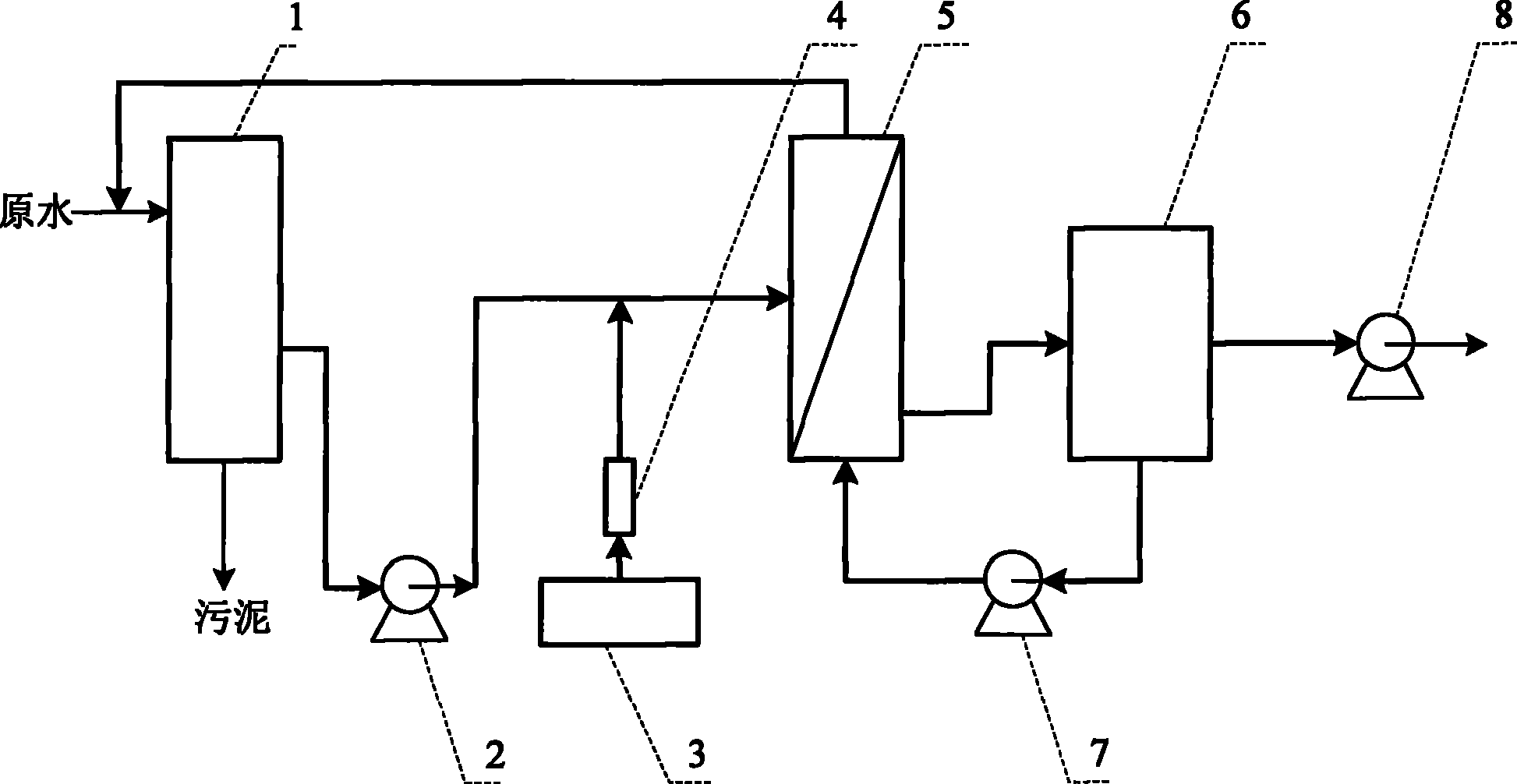

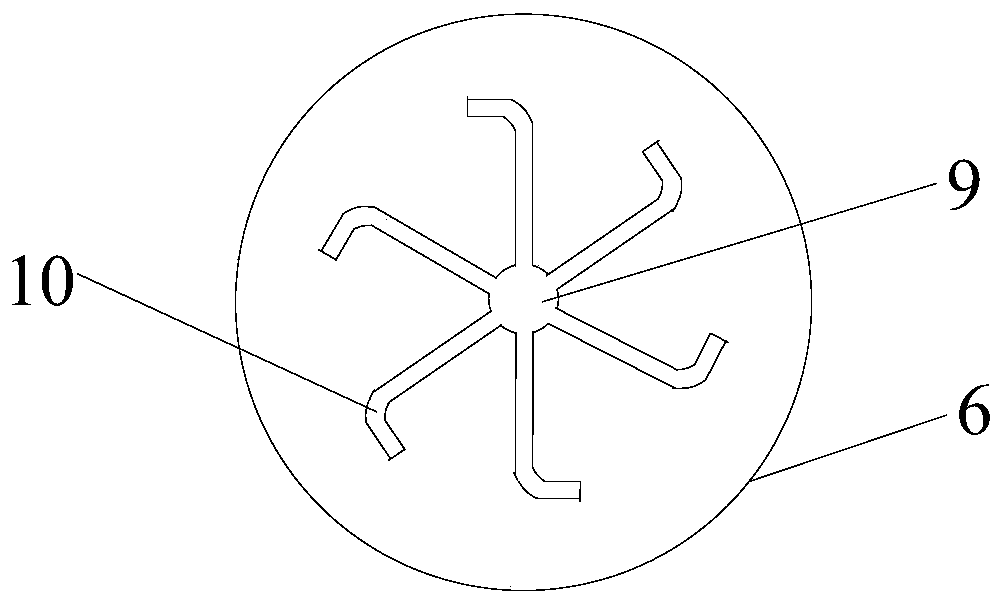

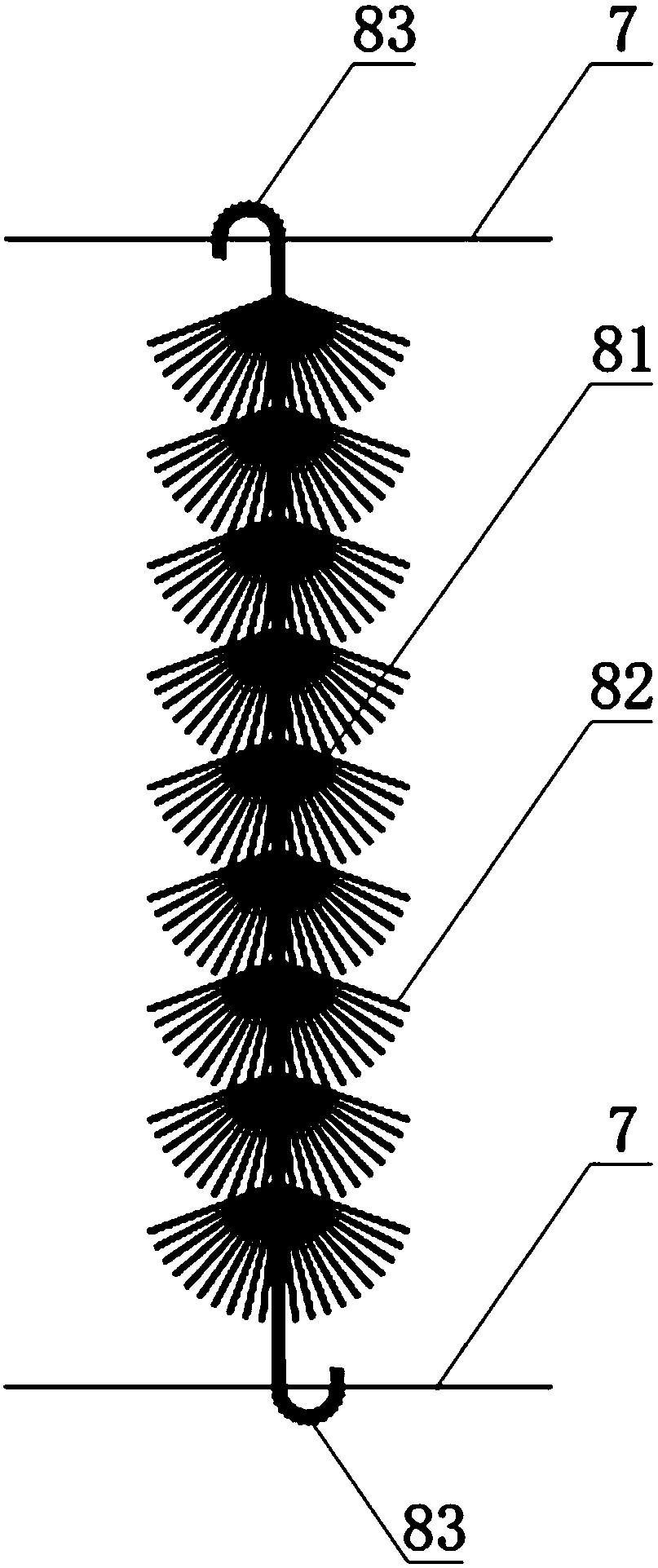

Multi-nozzle jet-flow micro-nano bubble aerator

ActiveCN102942251AExtended stayLarge mass transfer areaTreatment using aerobic processesSustainable biological treatmentMicro nanoSpray nozzle

The invention discloses a multi-nozzle jet-flow micro-nano bubble aerator, which comprises a plurality of nozzle-type water pumps and air bubble aeration nozzles which are respectively communicated with the nozzle of the water pump, wherein each air bubble aeration nozzle comprises an aeration nozzle main body, a water pipeline and an air distribution pipeline. The air distribution pipeline and the water pipeline are vertical to each other and respectively provided with a leaf, so that the air flowing into the water pipeline from the air distribution pipeline can be cut by the high-speed flowing water into a great amount of micro-nano bubbles with ultra-small diameter by utilizing a cavity principle, the stop time of the bubbles in the water and the transferring area of the bubbles and the water can be greatly increased, the oxygen dissolving efficiency can be improved, and the biochemical reaction efficiency of aerobic bacteria in the water can be improved.

Owner:苏州香山红叶环境技术有限公司

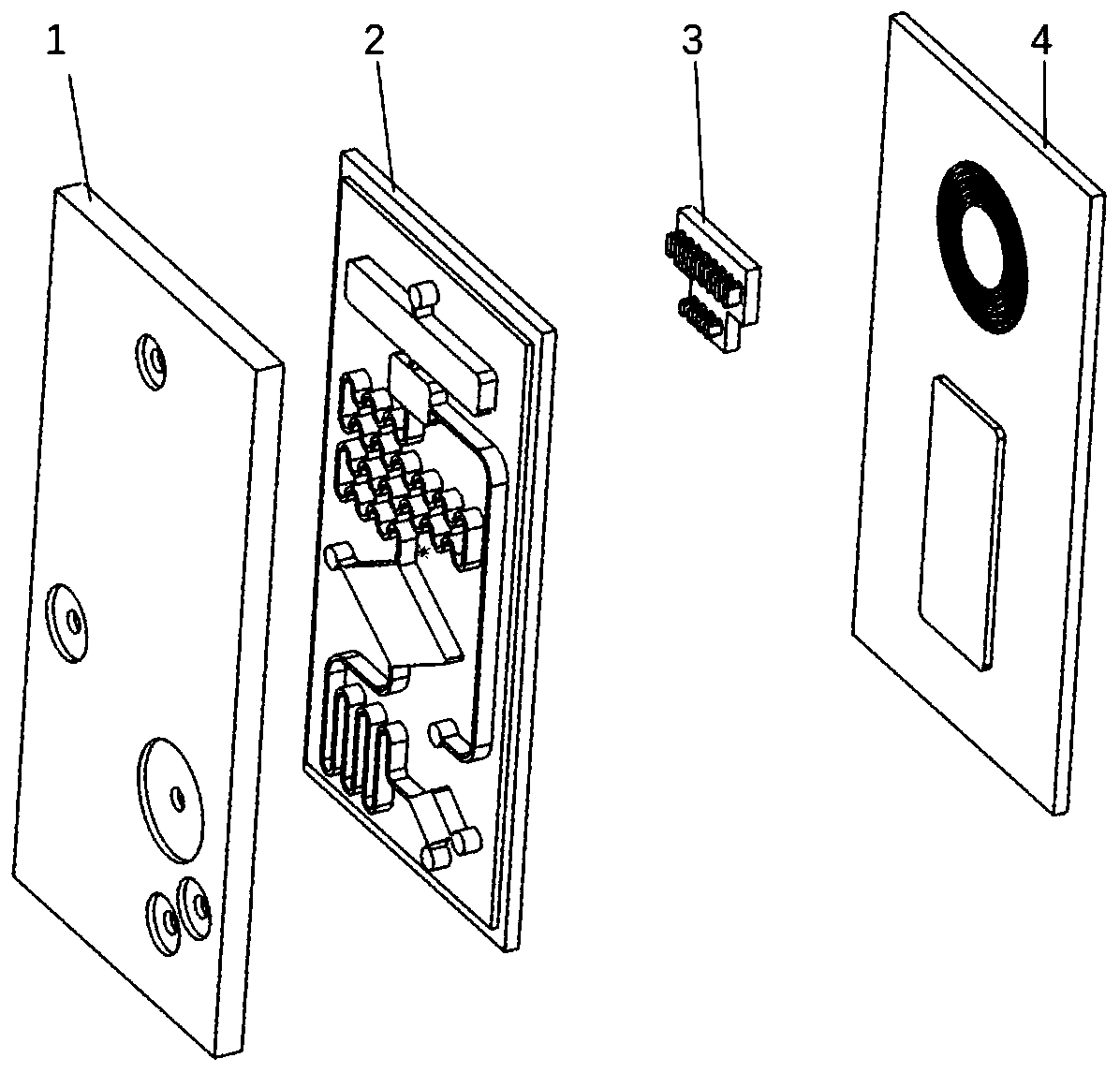

Micro-fluidic magneto-sensitive immune device based on magnetoresistive biosensor and using method thereof

ActiveCN110632168AEasy to operateHighly integratedBiological testingMaterial resistanceSensor arraySuperparamagnetic beads

The invention discloses a micro-fluidic magneto-sensitive immune device based on a magnetoresistive biosensor and a using method thereof. In the micro-fluidic magneto-sensitive immune device, a superparamagnetic bead storage area and an antibody storage area are arranged on an upper cover; a micro-fluidic chip is provided with a first biochemical reaction cavity and a first micro-fluidic channel;in use, the biotinylated superparamagnetic beads and the biotinylated antibodies are sequentially subjected to mixed reaction in the first biochemical reaction cavity and the first microfluidic channel, the reacted superparamagnetic beads marked with the antibodies react with a to-be-detected sample to generate immune protein marked with the superparamagnetic beads, and then the immune protein isreacted and combined with capture antibodies in the magnetic sensor array, so that the superparamagnetic beads are fixed on sensors in the magnetic sensor array for a subsequent detection process. Thecombination of the superparamagnetic beads and the biotinylated antibody in the magneto-sensitive immunoassay is completed in the chip, so that the integration level is improved, the operation stepsof biochemical reaction are simplified, and the biochemical reaction efficiency is improved.

Owner:XI AN JIAOTONG UNIV

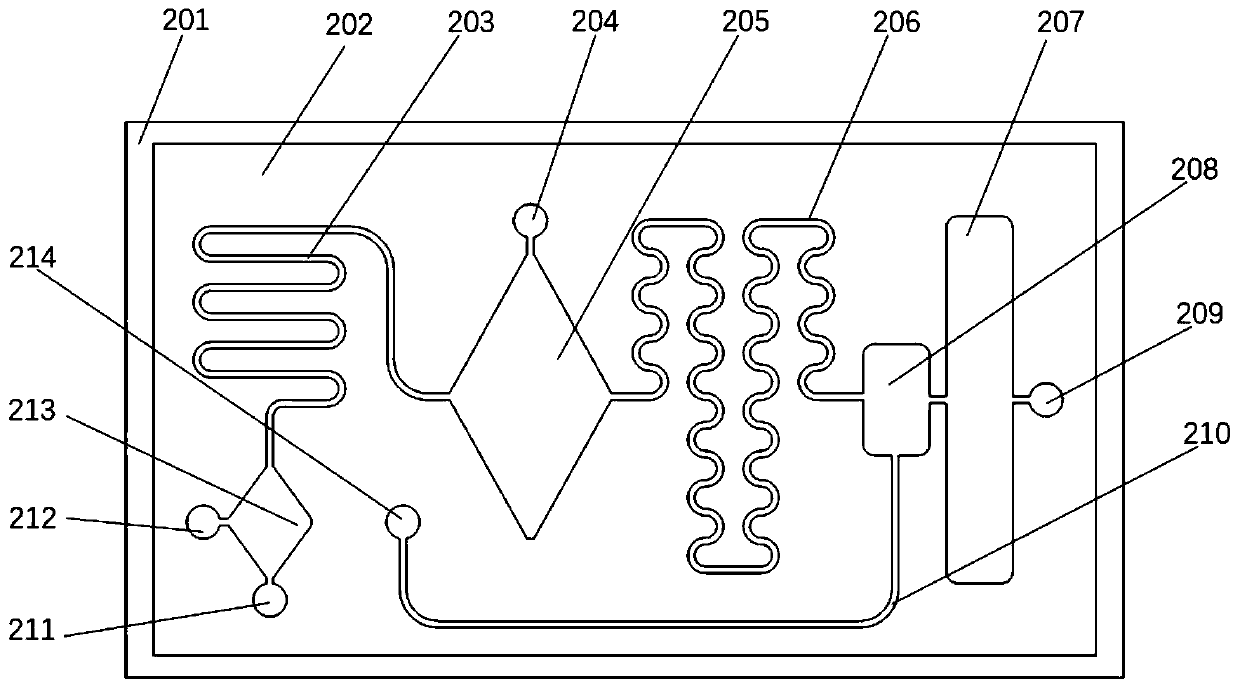

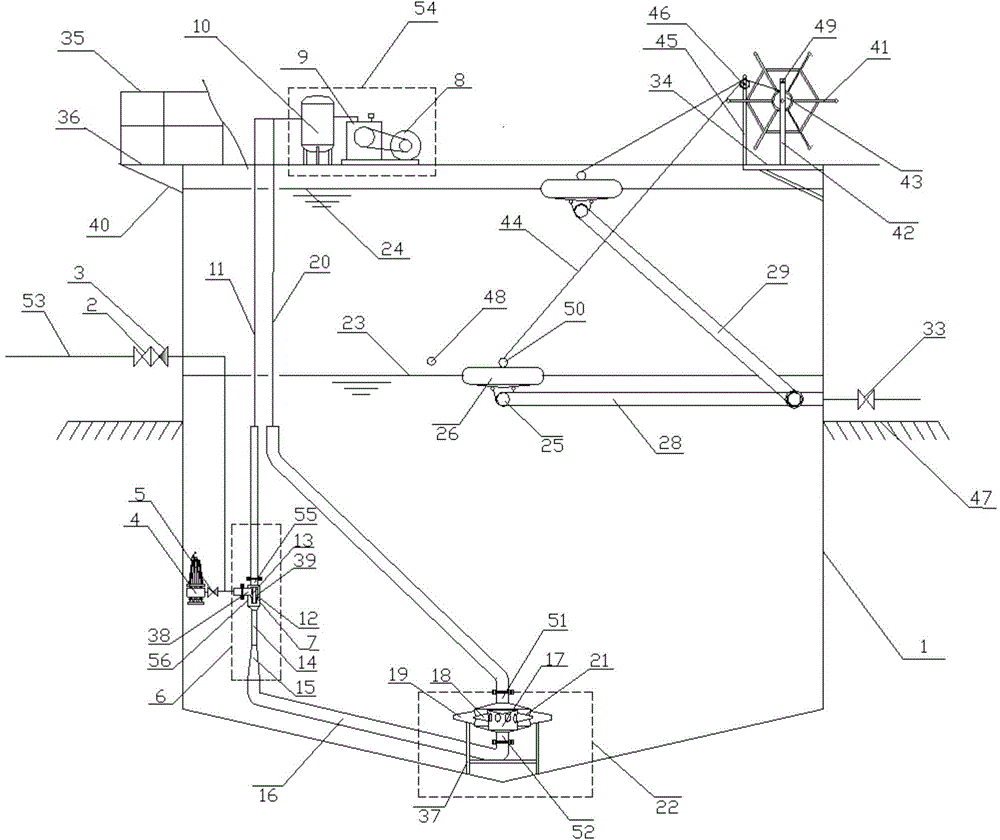

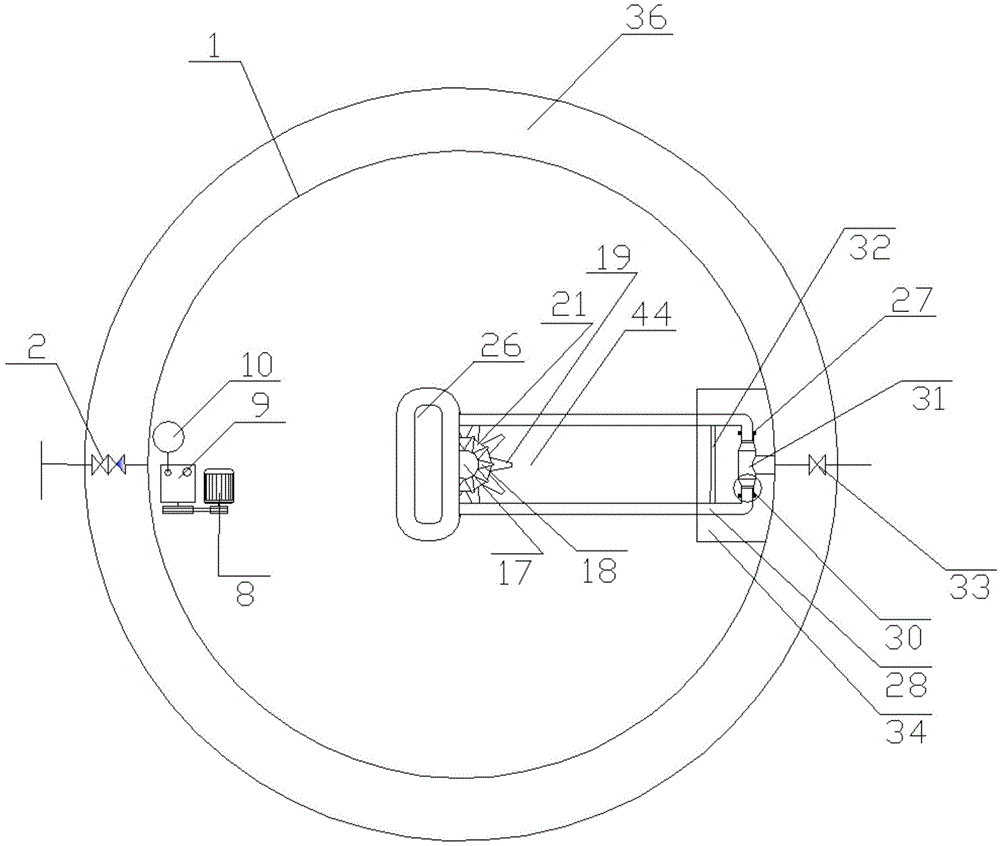

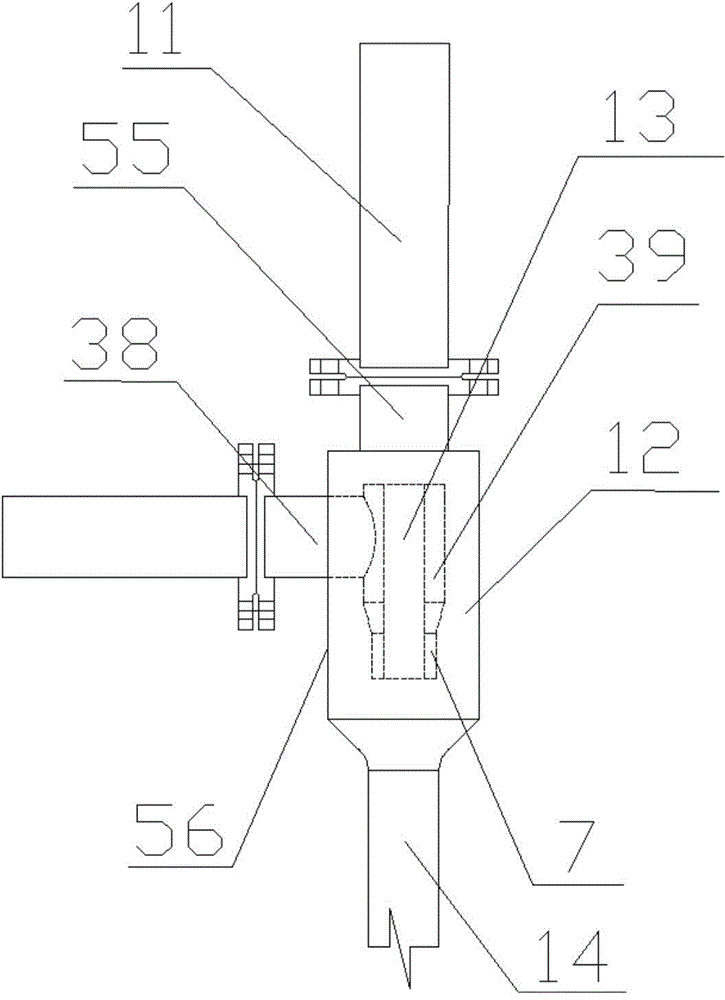

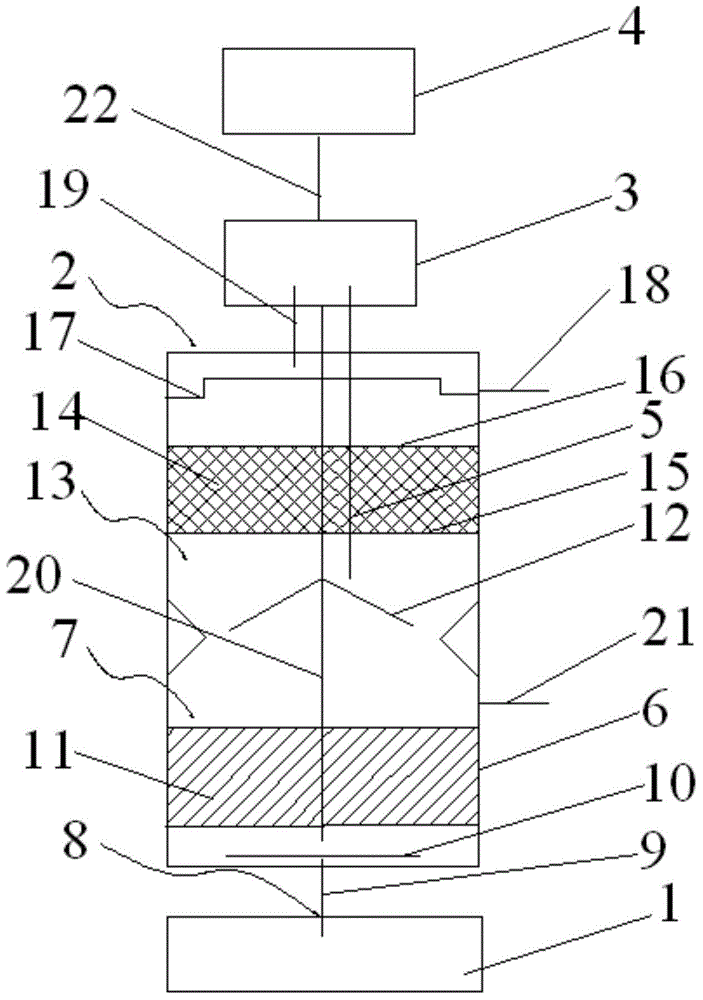

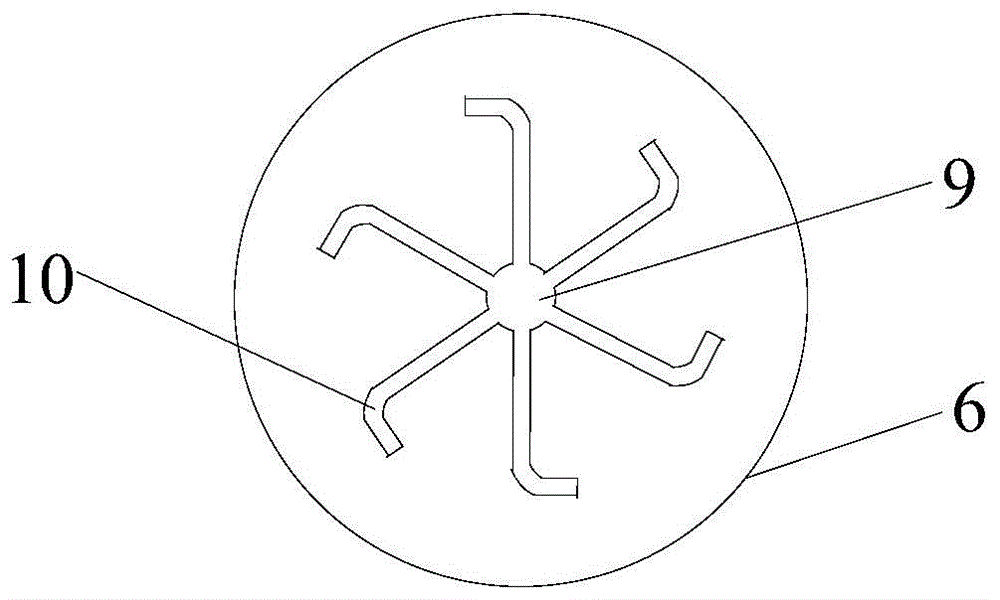

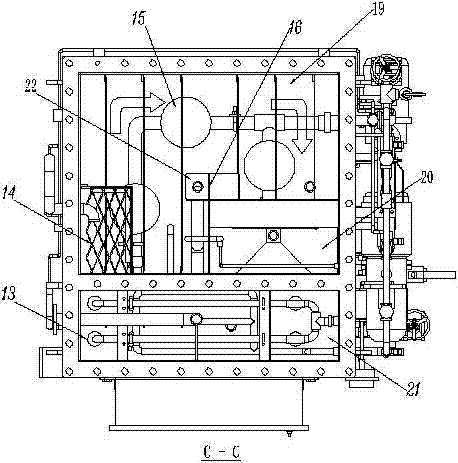

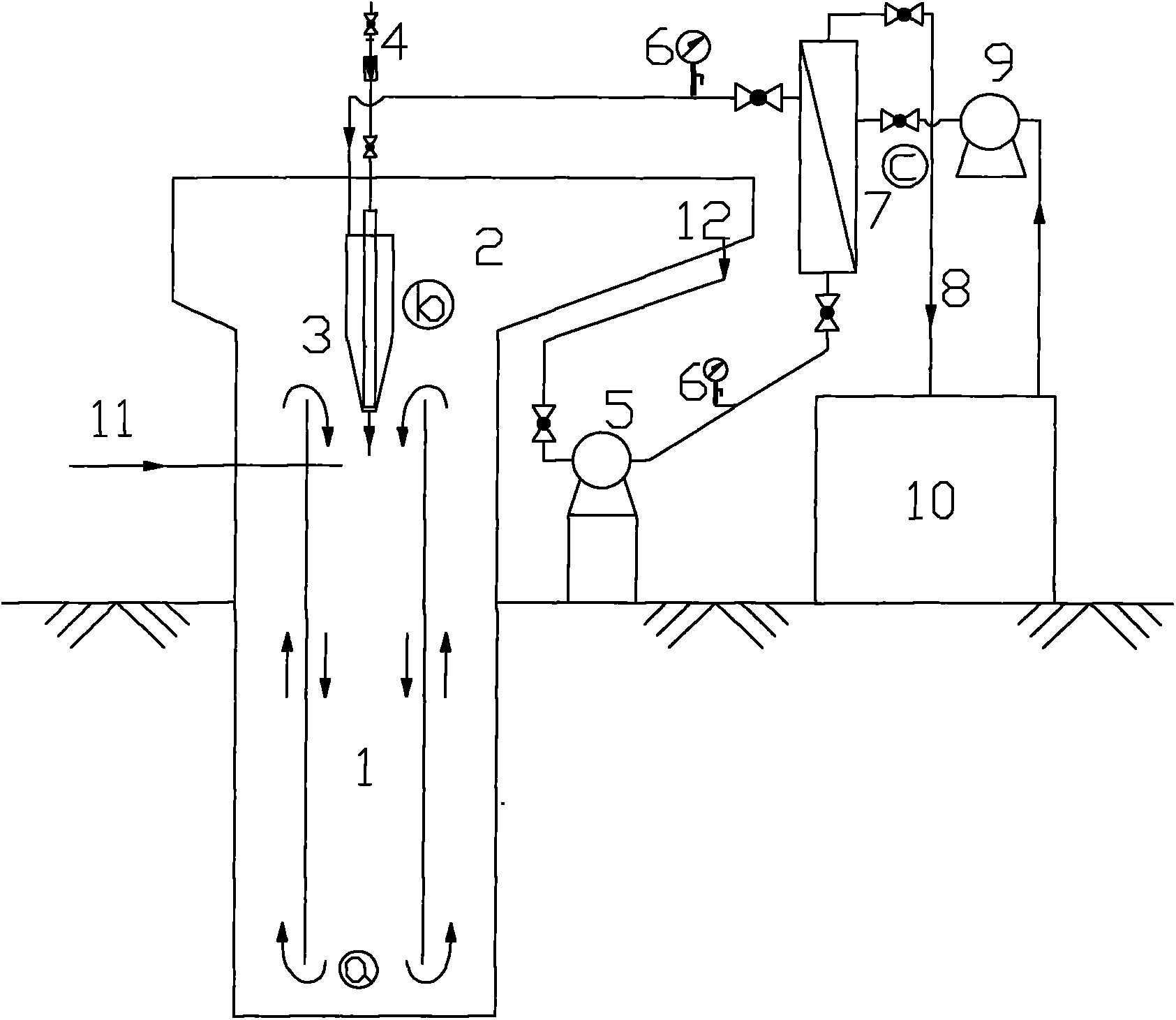

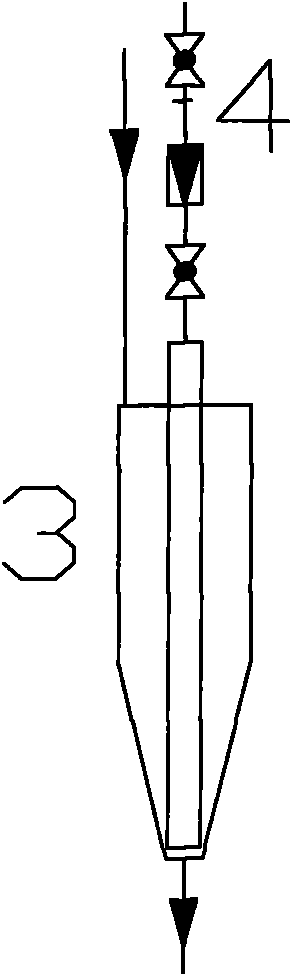

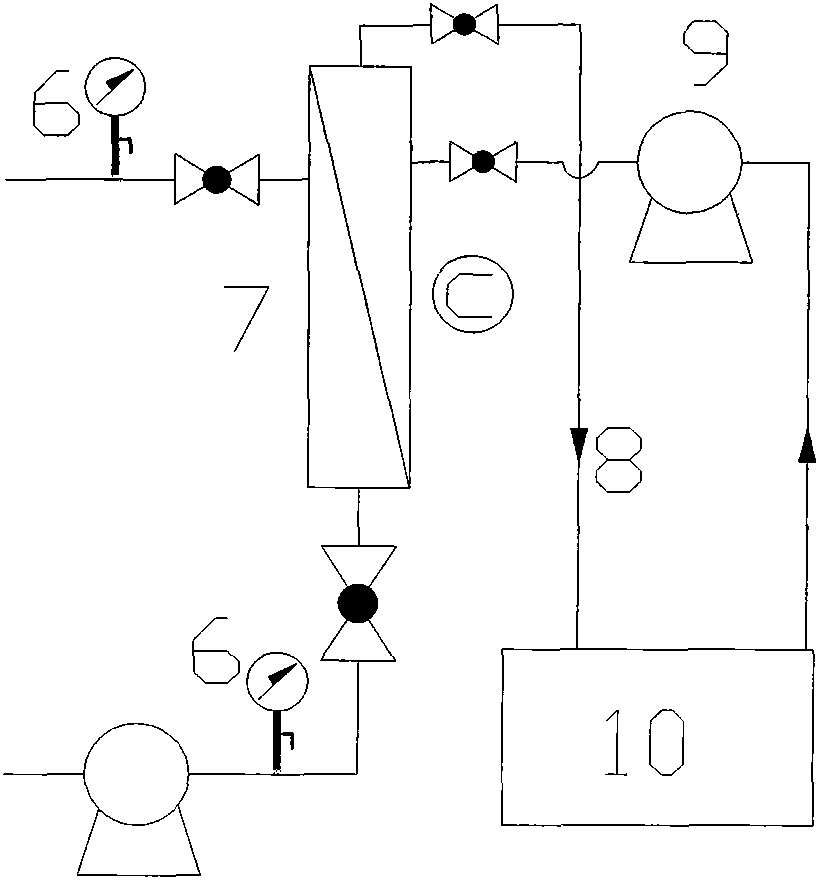

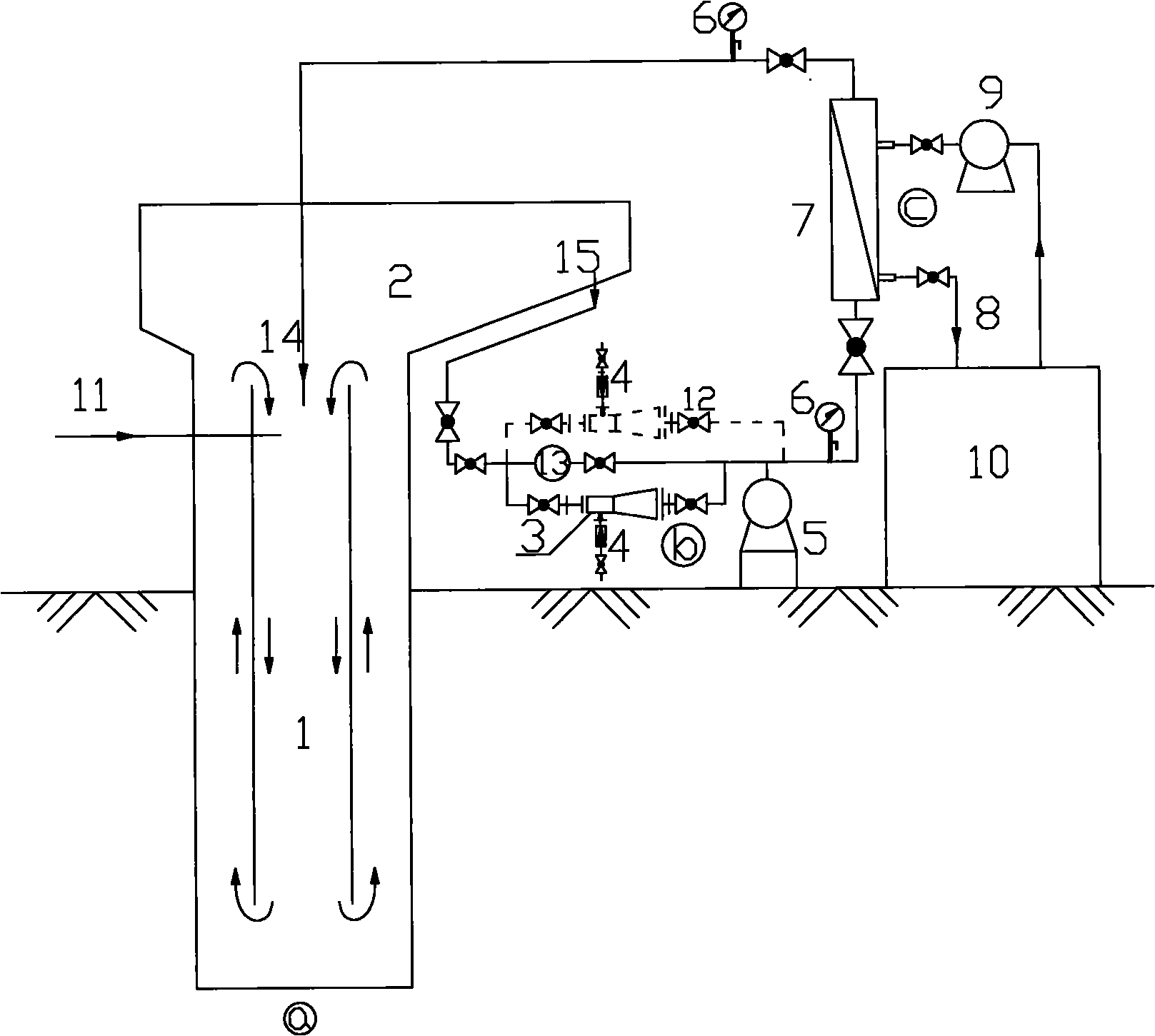

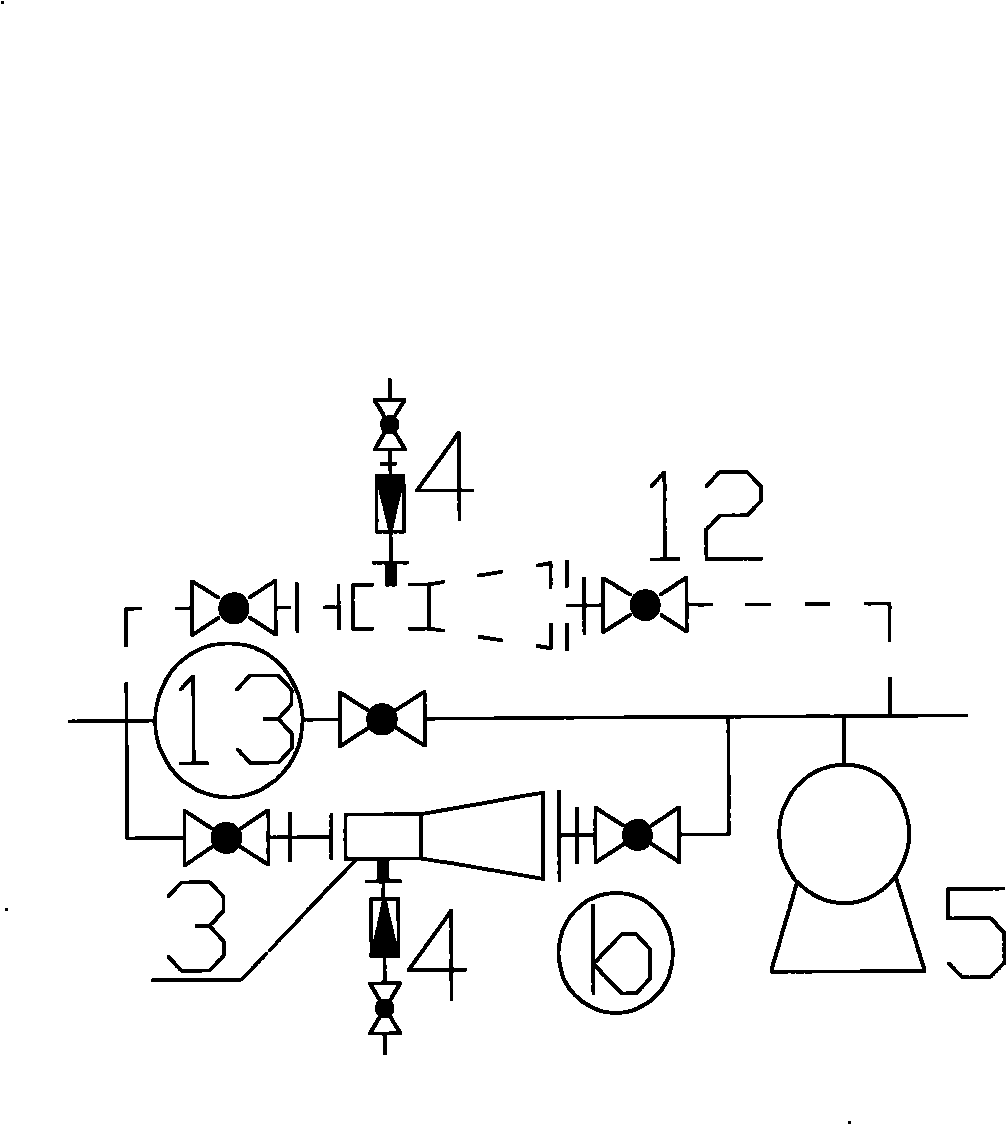

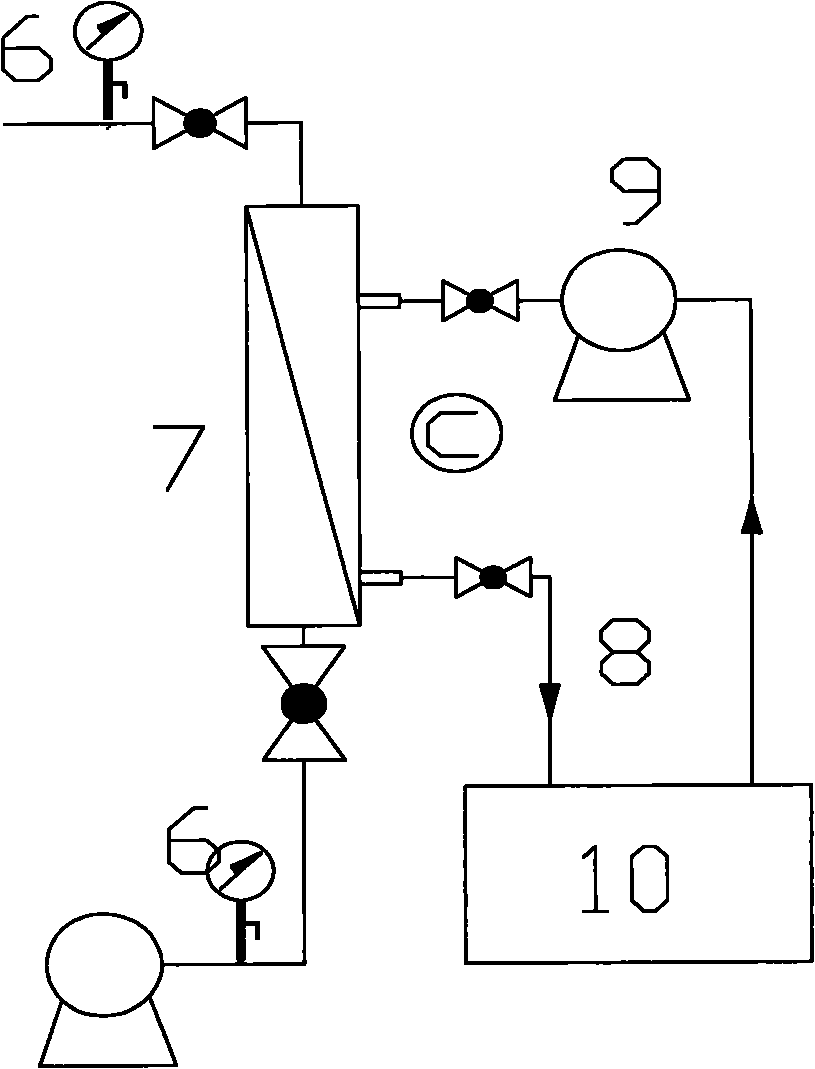

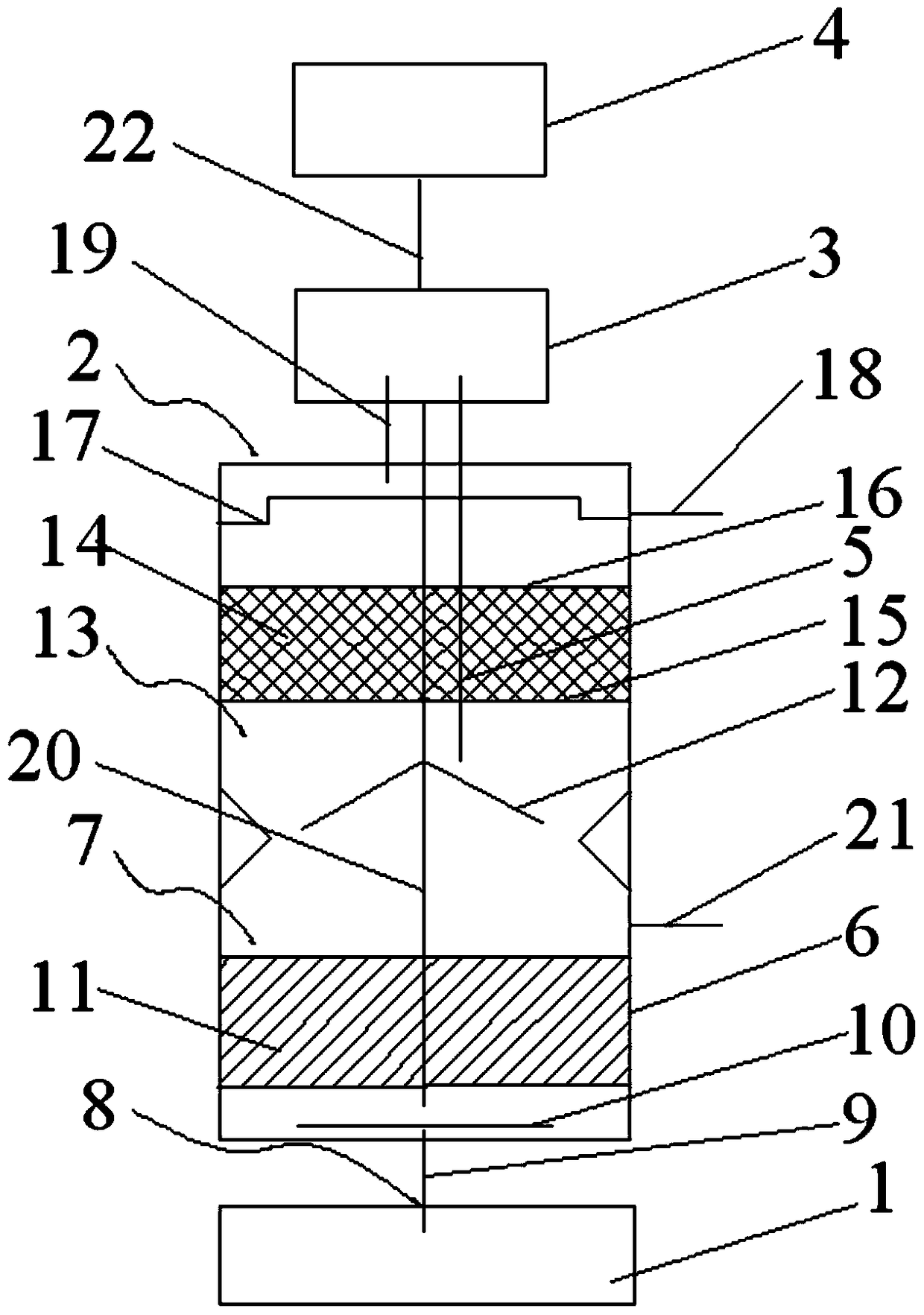

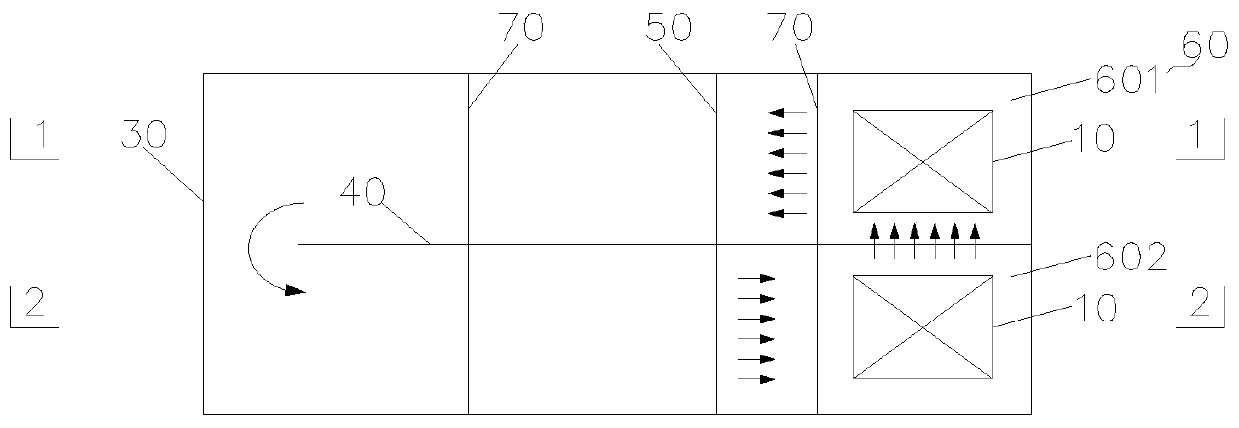

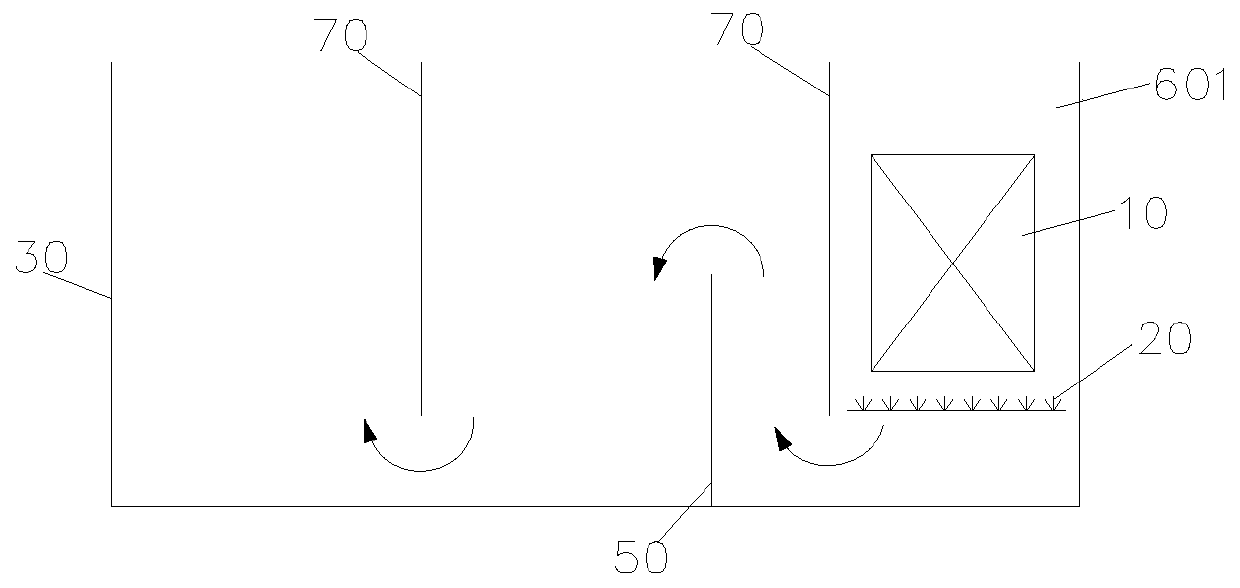

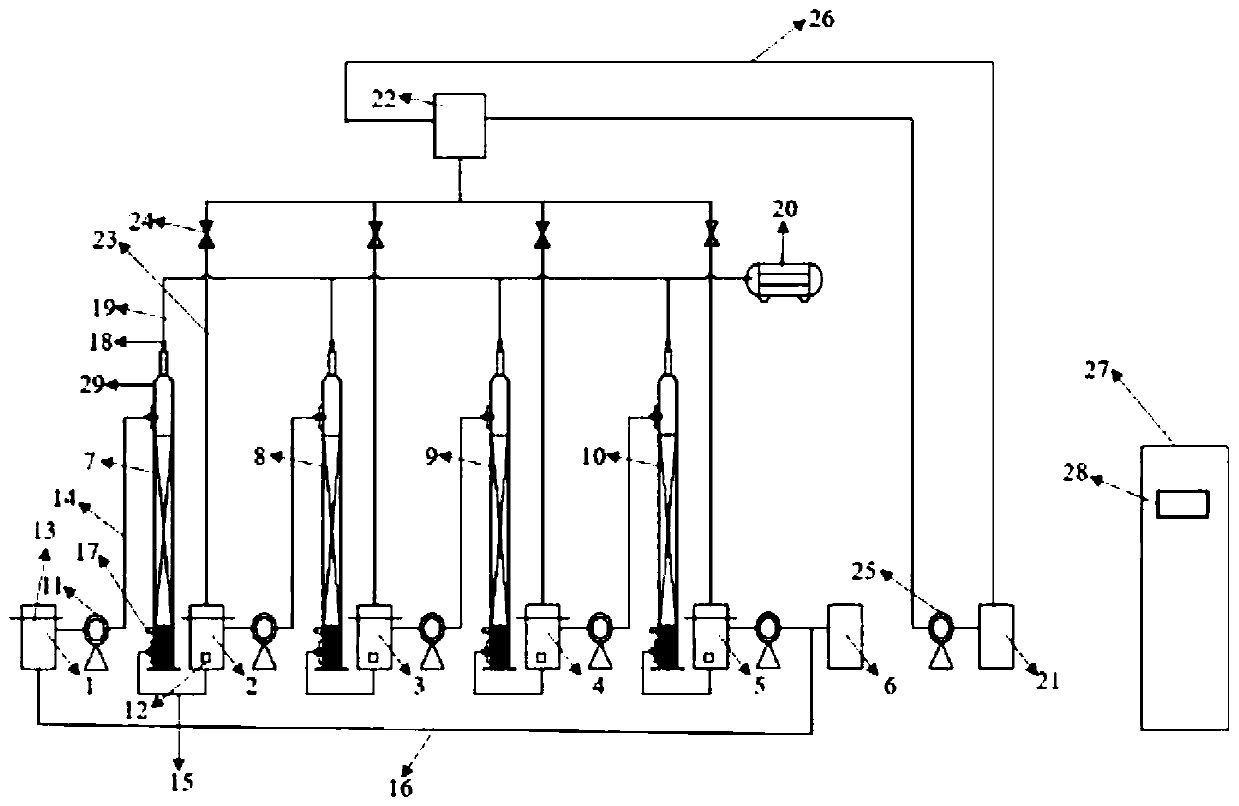

Sequencing batch jet-flow driven biochemical reactor

ActiveCN104386807AIncrease profitIncrease mass transfer rateSustainable biological treatmentBiological water/sewage treatmentWinchHorizon line

The invention relates to a sequencing batch jet-flow driven biochemical reactor, which comprises a reaction tank, a water inlet pipe, an immersible pump, a first-grade suction jet device with a double-gas-channel annular nozzle, a mixed solution guide pipe, a second-grade multi-nozzle radial jet-flow aerator, a gas supply device, a buoyancy driven water decanter and a driving winch of the water decanter; the first-grade suction jet device with the double-gas-channel annular nozzle is provided with an annular nozzle and inner and outer gas channels; the second-grade multi-nozzle radial jet-flow aerator is installed in the centre of the bottom of the reactor; the buoyancy driven water decanter is installed on the wall of the reaction tank over the horizon line of the reactor; and the driving winch of the water decanter is used for packing up or down the buoyancy driven water decanter through a driving rope. The sequencing batch jet-flow driven biochemical reactor disclosed by the invention can be used for increasing the aeration efficiency, accelerating the dynamic circulation of dynamic water and greatly increasing the mass transfer rate in the biochemical reaction process, so that the biochemical reaction efficiency is increased; and furthermore, the sequencing batch jet-flow driven biochemical reactor disclosed by the invention can also be used for treating various types of sewage, and can be flexibly combined with other sewage treatment processes.

Owner:ENVIRONMENTAL PROTECTION ENERGY SAVING TECHDEV CENT OF NANNING GUI HE SILK IND

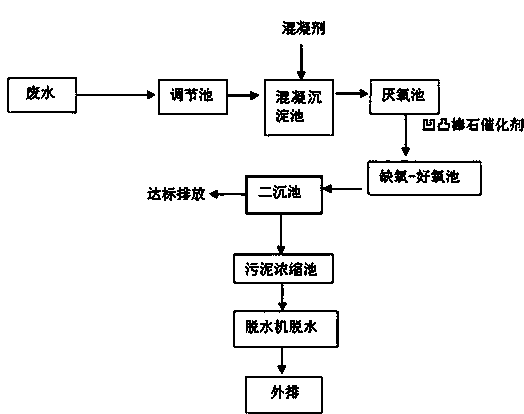

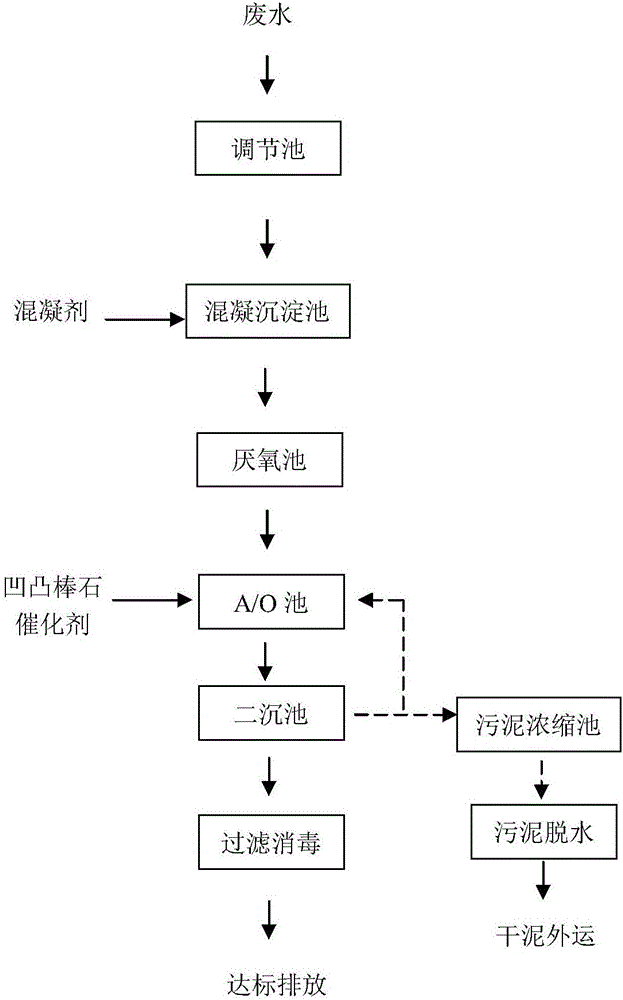

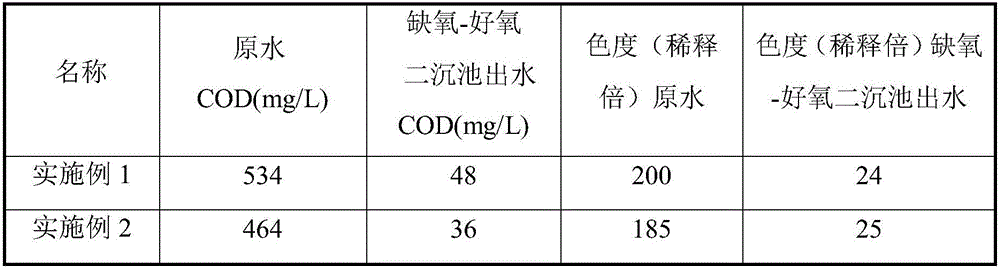

Process for deeply treating printing and dyeing wastewater in presence of attapulgite catalyst

InactiveCN104193119AEasy to handleGood effectMultistage water/sewage treatmentChemical oxygen demandWater quality

The invention discloses a process for deeply treating printing and dyeing wastewater in the presence of an attapulgite catalyst. The process comprises the following steps: collecting the printing and dyeing wastewater subjected to biochemical treatment for the first time into an adjusting tank, adjusting the water quantity and the water quality, feeding into a coagulative precipitation tank for coagulative sedimentation treatment, feeding outlet water of the coagulative precipitation tank into an anaerobic tank for acidification and hydrolysis, performing biochemical treatment on outlet water of the anaerobic tank by adopting an anoxic-aerobic tank with the attapulgite catalyst, removing organic matters, chromaticity and ammonia nitrogen, and discharging by standard. According to the process, the attapulgite catalyst is added during the biochemical treatment of the anoxic-aerobic tank, so that the aerobic biochemical treatment capability and effect are improved, the biochemical treatment effect on difficultly treated printing and dyeing wastewater is enhanced, COD (chemical oxygen demand), chromaticity and ammonia nitrogen in the printing and dyeing wastewater are efficiently removed, and the printing and dyeing wastewater is discharged by standard; the treatment cost of the printing and dyeing wastewater is reduced, the process is convenient to perform, and the practical application of engineering and the technical improvement of existing printing and dyeing wastewater treatment engineering are facilitated.

Owner:ANHUI JIANGHAI ENVIRONMENT ENG

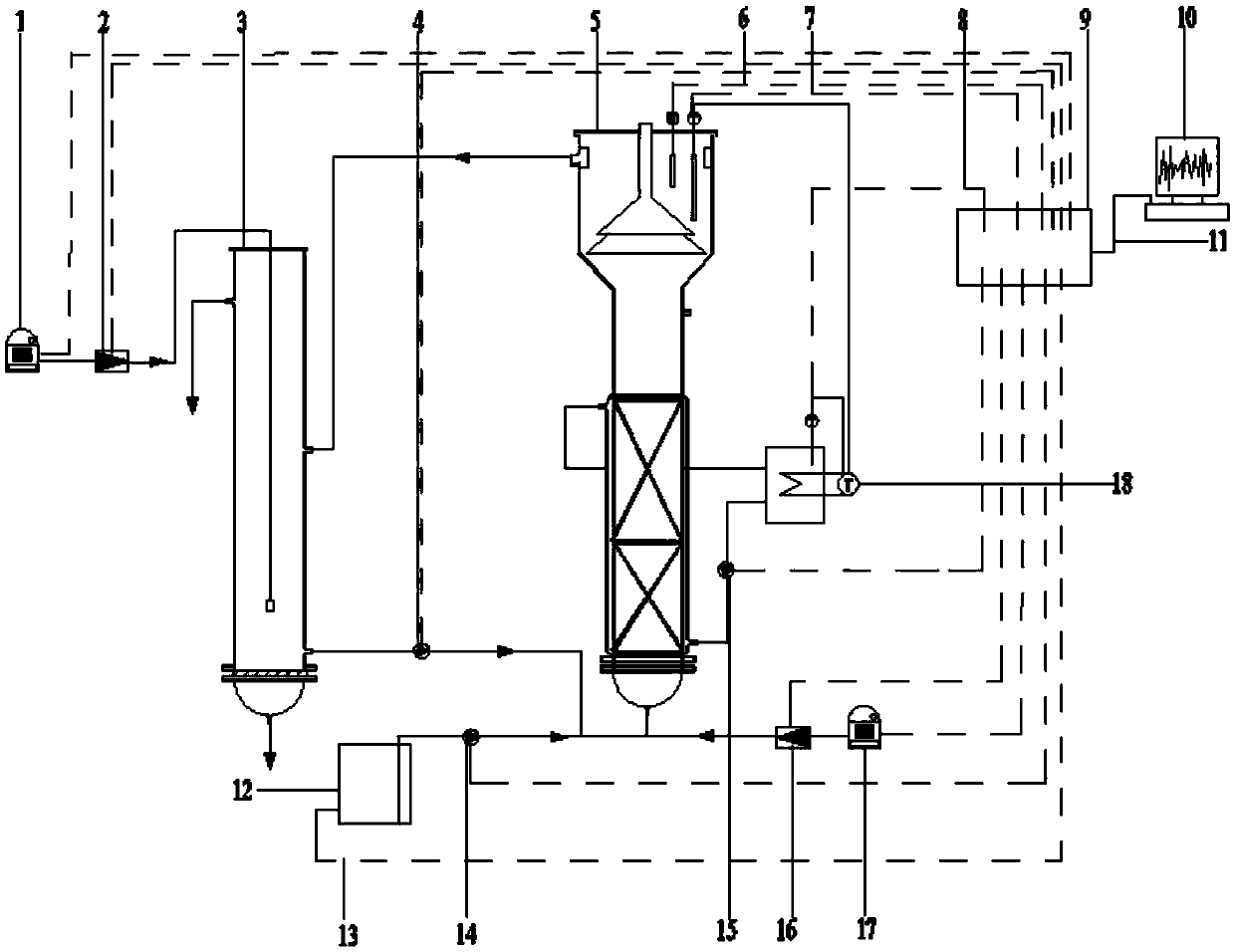

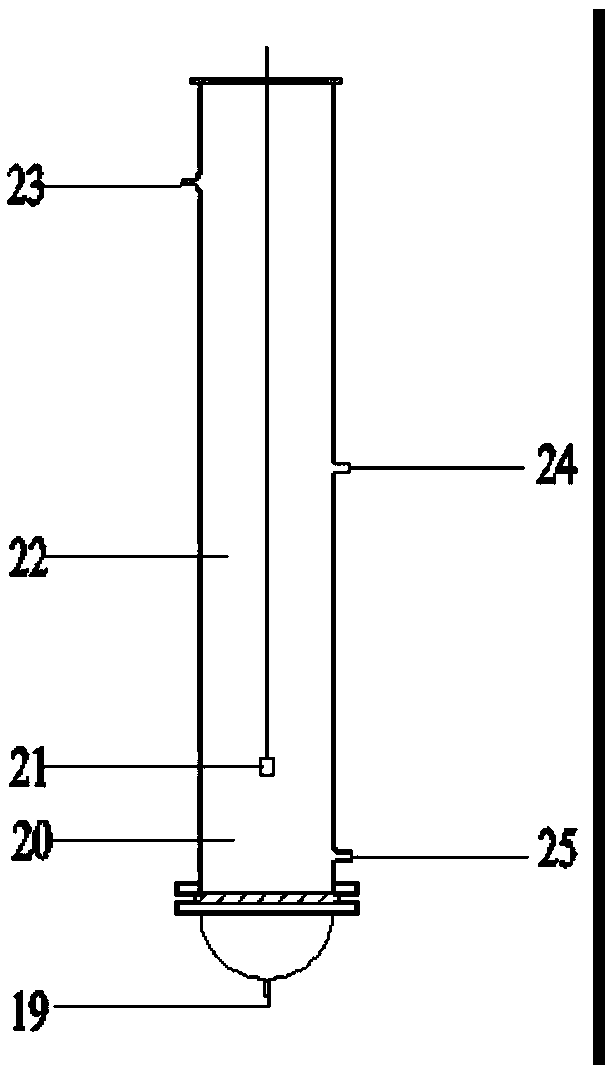

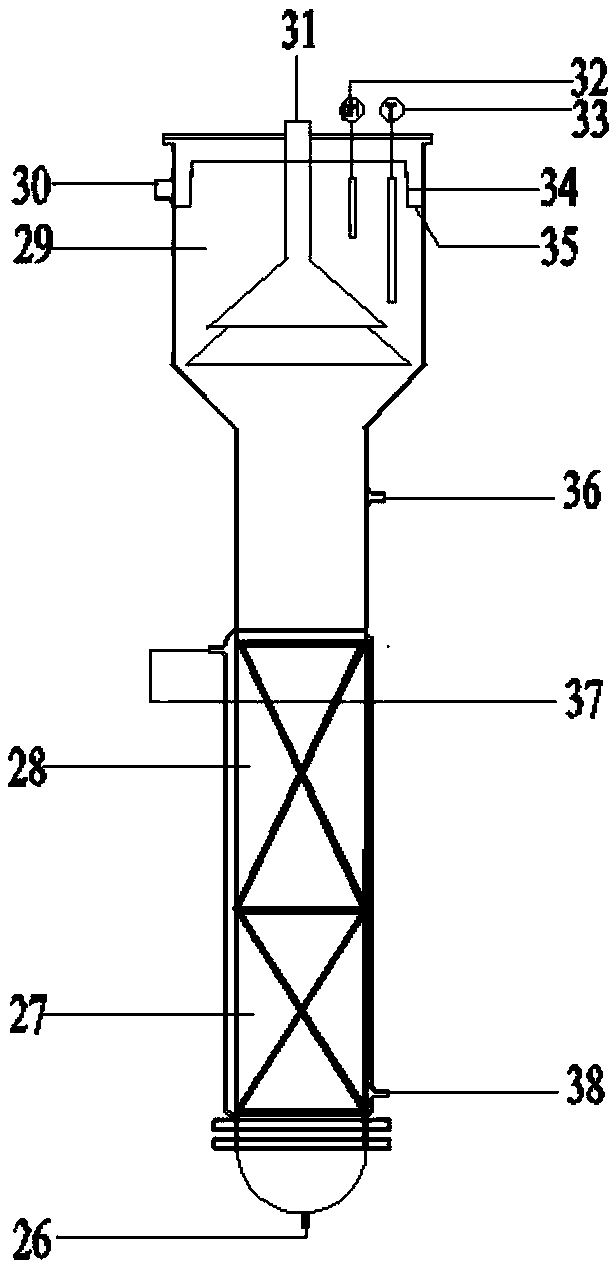

Method and equipment for treating antibiotic mycelium residues

ActiveCN104593433AImprove processing efficiencyImprove processing speedGas production bioreactorsWaste based fuelBiogasChemistry

The invention provides a method and equipment for treating antibiotic mycelium residues. According to the method, the antibiotic mycelium residues and water are prepared into a mycelium residue suspension which is subjected to anaerobic fermentation treatment. The invention also provides the equipment for treating the antibiotic mycelium residues, and the equipment comprises a residue water generating device, an anaerobic fermentation device, a gas-liquid separation device positioned above the anaerobic fermentation device, a biogas collection device positioned above the gas-liquid separation device and a riser pipe for communicating the gas-liquid separation device and the anaerobic fermentation device. By using the method and equipment for treating the antibiotic mycelium residues, the mycelium residue suspension obtained after the mixing of the antibiotic mycelium residues and the water is subjected to anaerobic fermentation treatment, so that the inhibition of harmful substances of anaerobic fermentation antibiotics and the like in the conventional antibiotic mycelium residues is overcome, the amount of preponderant bacteria is kept to the utmost extent, the efficiency of anaerobic fermentation is improved, and the method and the equipment have the advantages of small floor area, simple operation, low cost and the like.

Owner:ZHENGZHOU UNIV +1

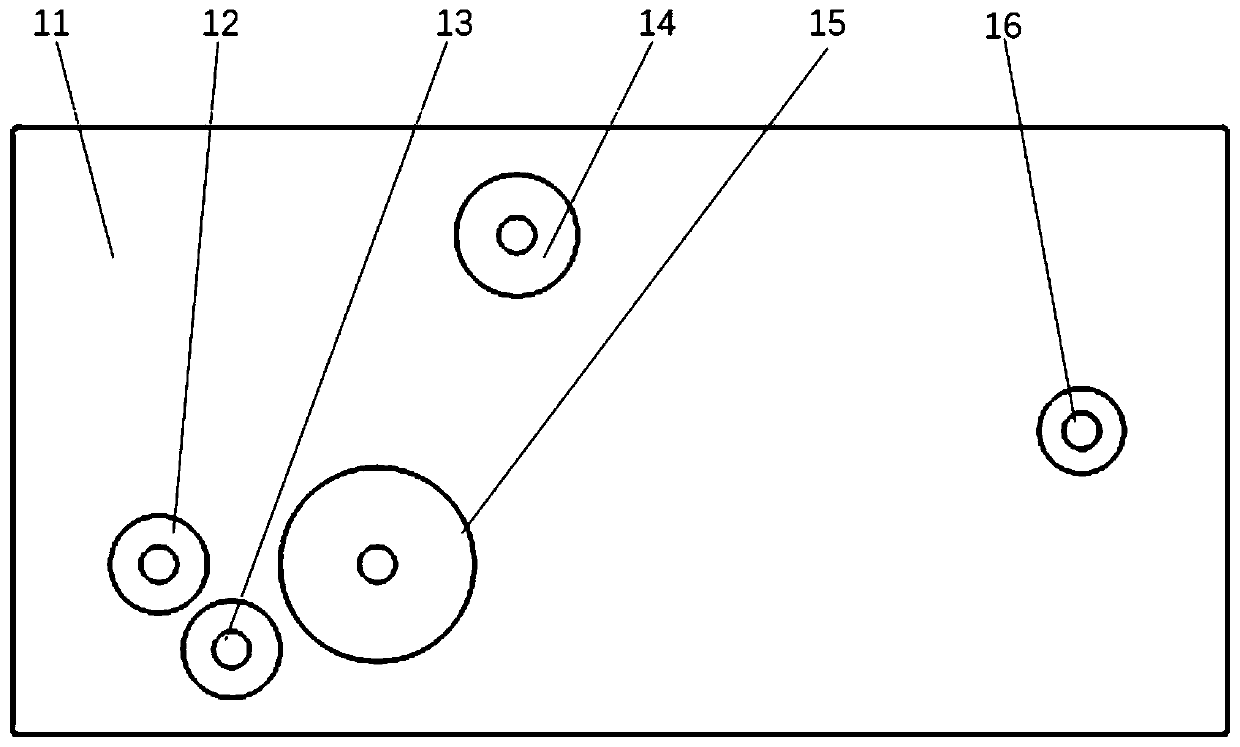

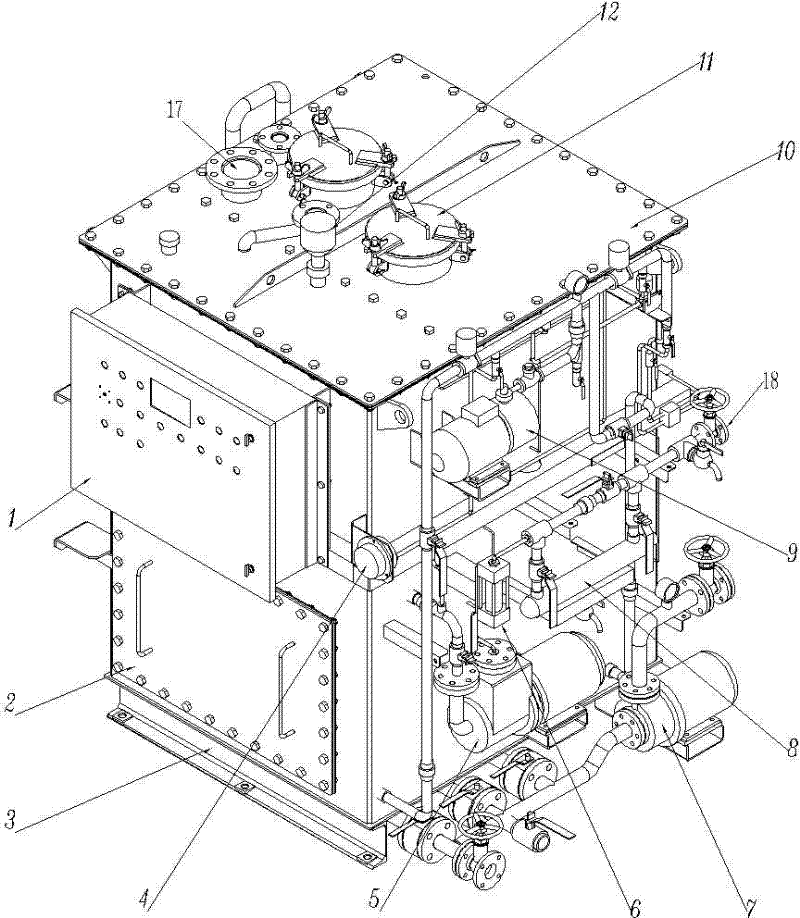

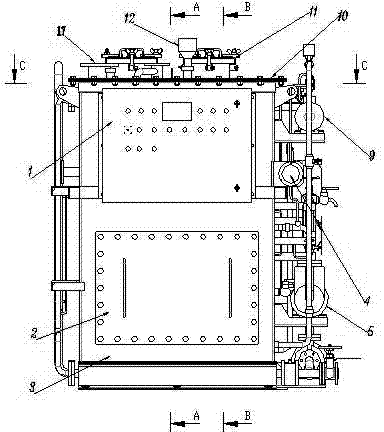

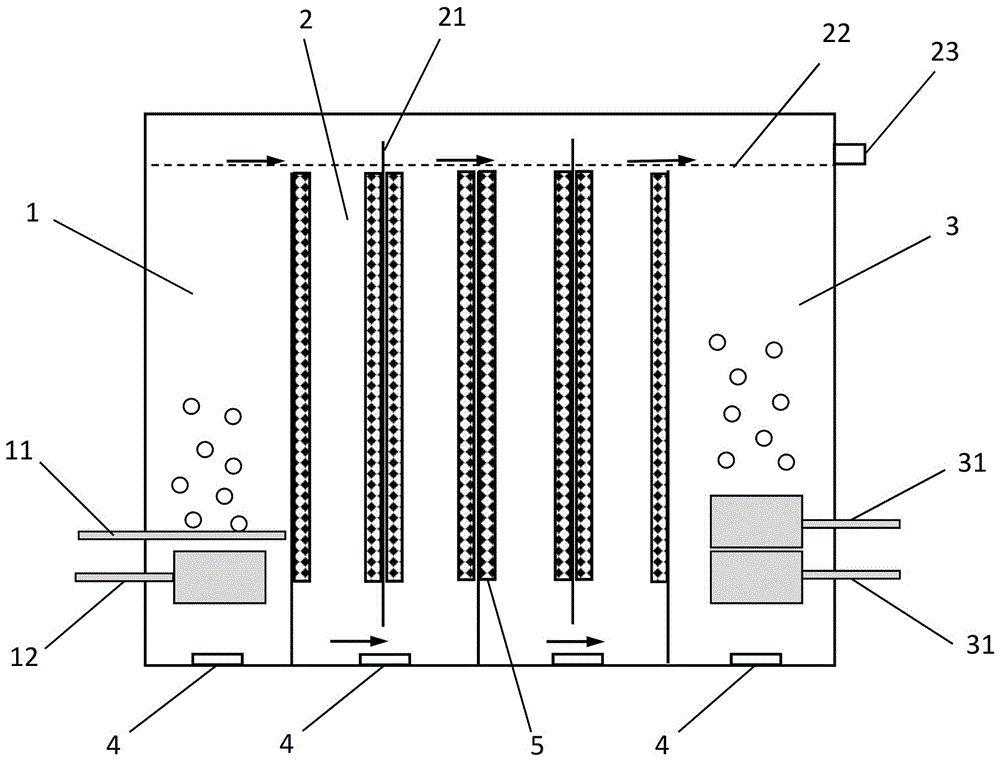

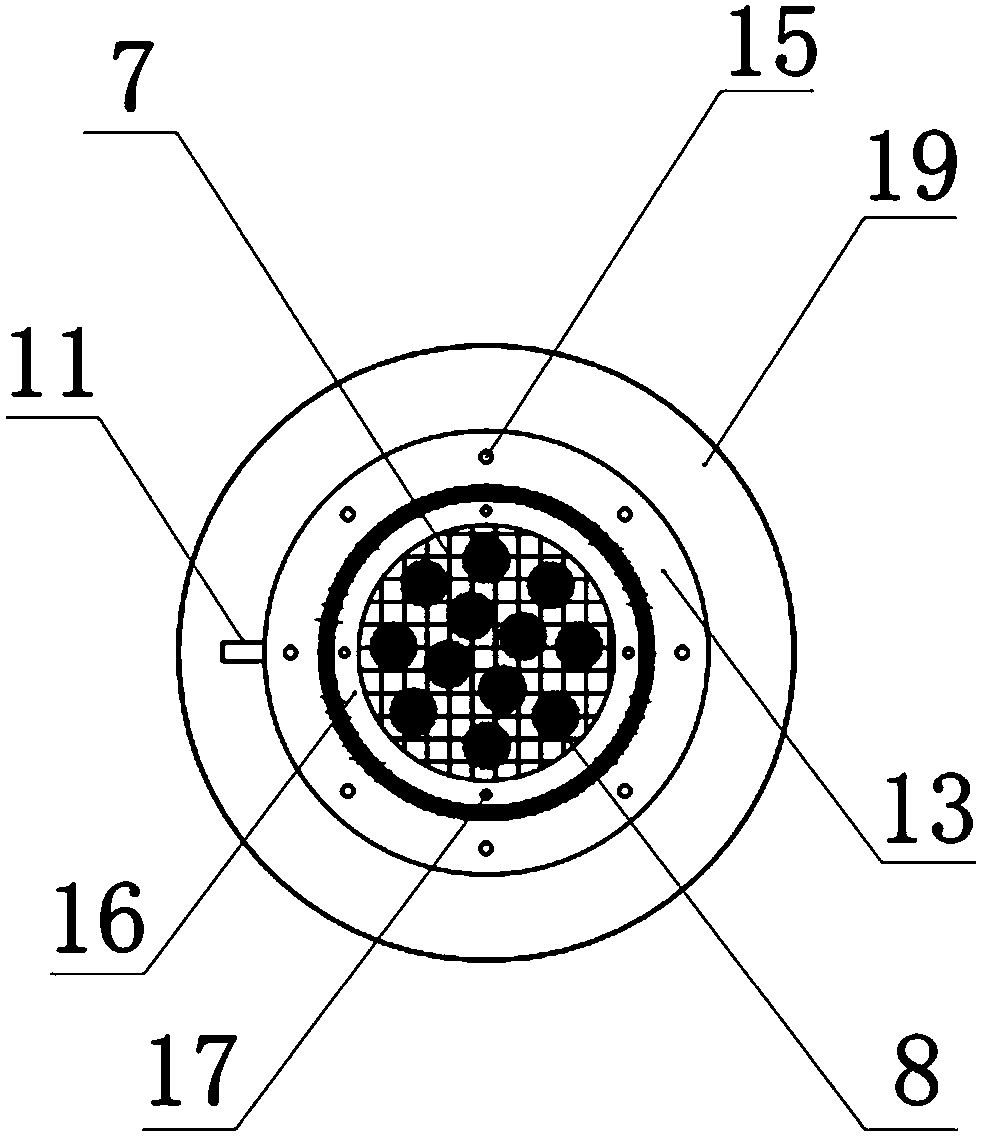

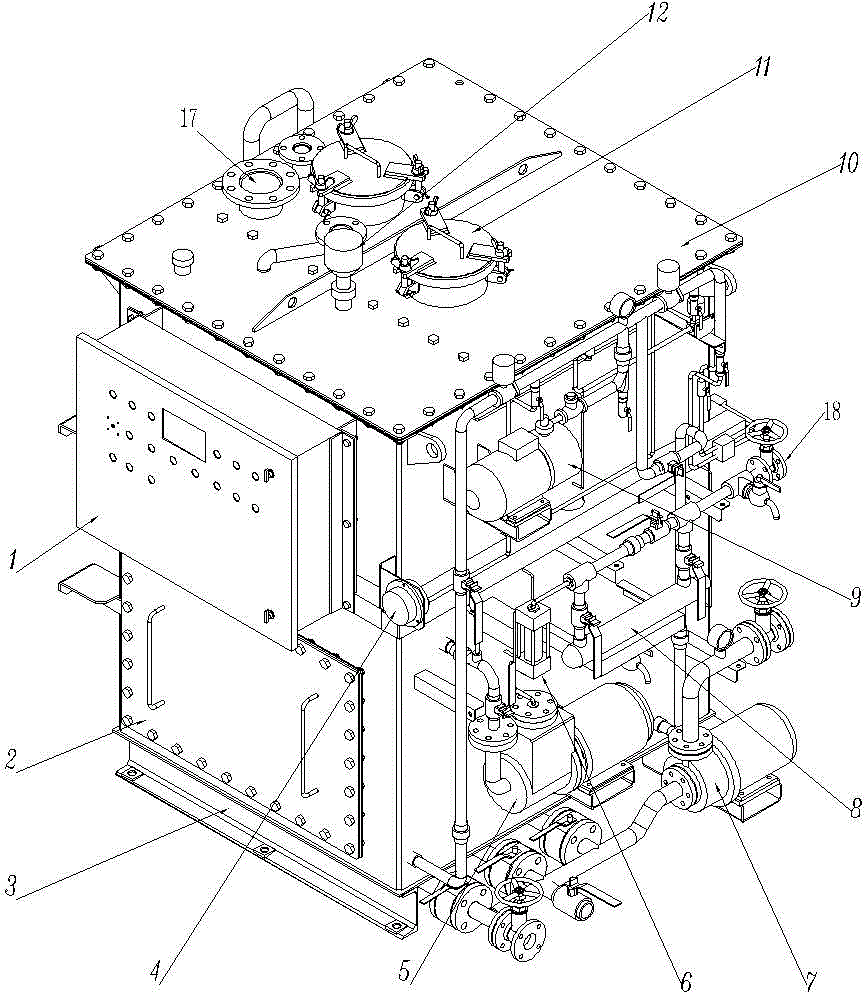

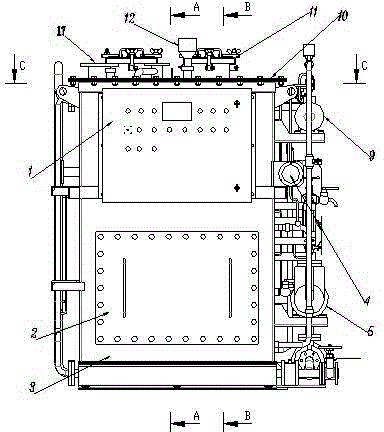

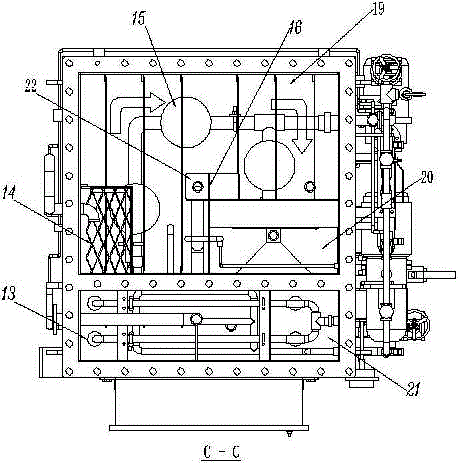

Domestic sewage treatment device for ship

ActiveCN102417280ASufficient and uniform biological oxidation reactionImprove the efficiency of biochemical reactionsWater/sewage treatment by irradiationMultistage water/sewage treatmentStable stateSewage

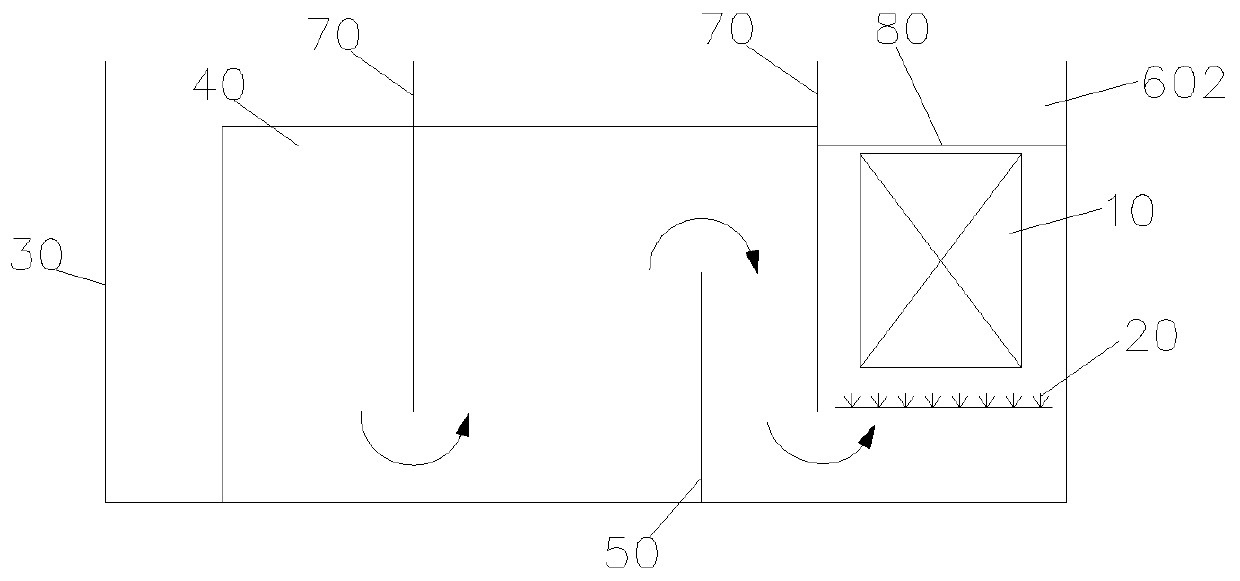

The invention relates to a domestic sewage treatment device for a ship. An aeration chamber, a precipitation chamber and a membrane chamber are formed in the body of the device respectively; the membrane chamber is a flat cube and is positioned on one side of the body; the aeration chamber and the precipitation chamber form a box type cube which is positioned on the other side of the body; a clapboard of which a half is isolated is arranged in the aeration chamber; the bottom of the precipitation chamber is funnel-shaped, and the top of the precipitation chamber is trumpet-shaped; and a wateroutlet cavity on the upper part of the precipitation chamber is positioned at the central position of the box type cube. Due to the design of the clapboard in the aeration chamber, a plug flow movement locus is formed while sewage is aerated by using an aerator at the bottom of the aeration chamber, so that higher biochemical reaction efficiency is realized for sewage; and by improving the structure of the precipitation chamber, the chemical oxygen demand (COD), biochemical oxygen demand after 5 days (BOD5) and total suspension solid (TSS) value can be lowered effectively. By improving the water outlet cavity of the precipitation chamber, a liquid in the precipitation chamber can keep in stable state no matter which direction the device is inclined in, and the stability of the device is further enhanced.

Owner:安庆泰邦船舶科技有限公司

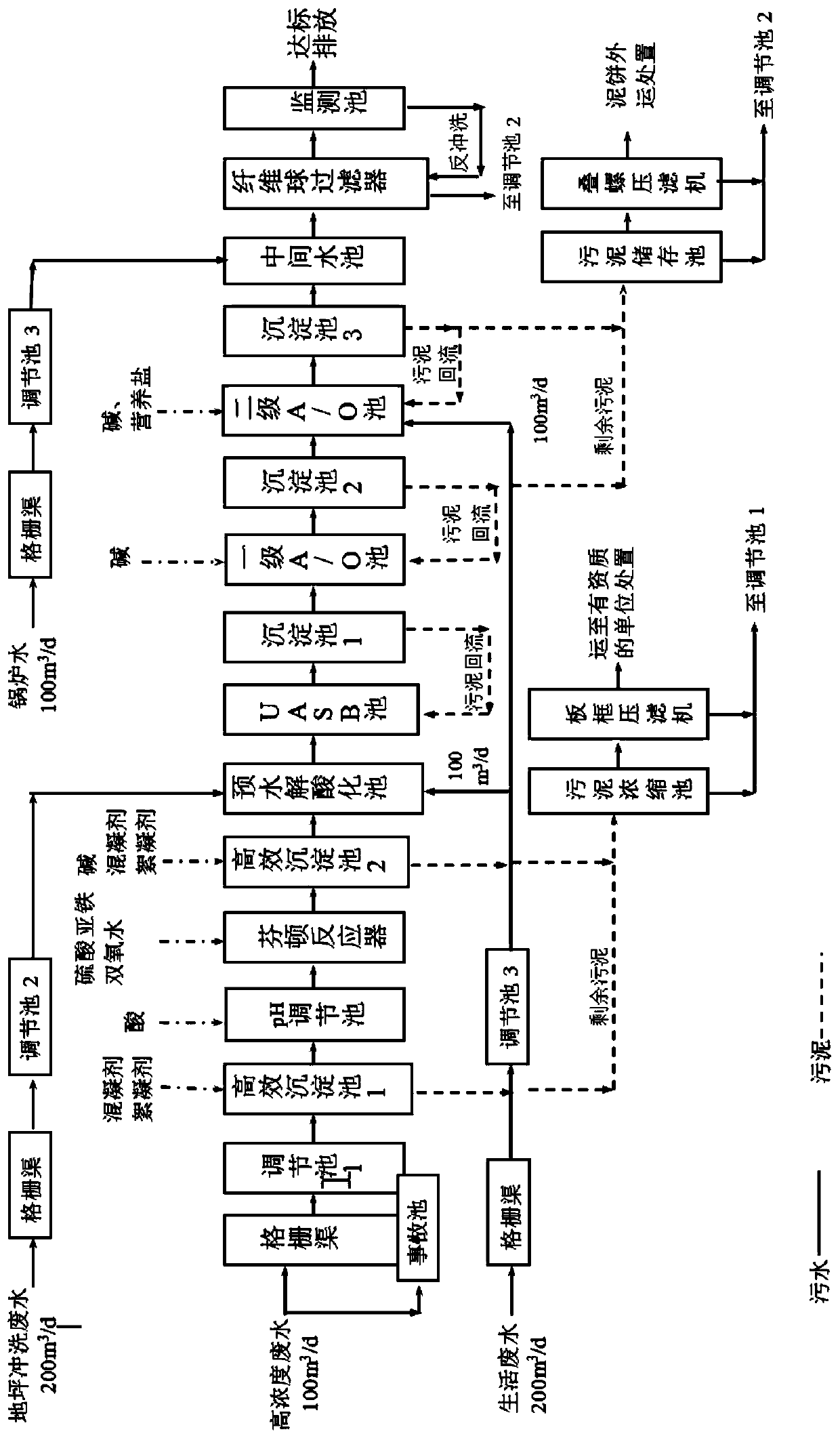

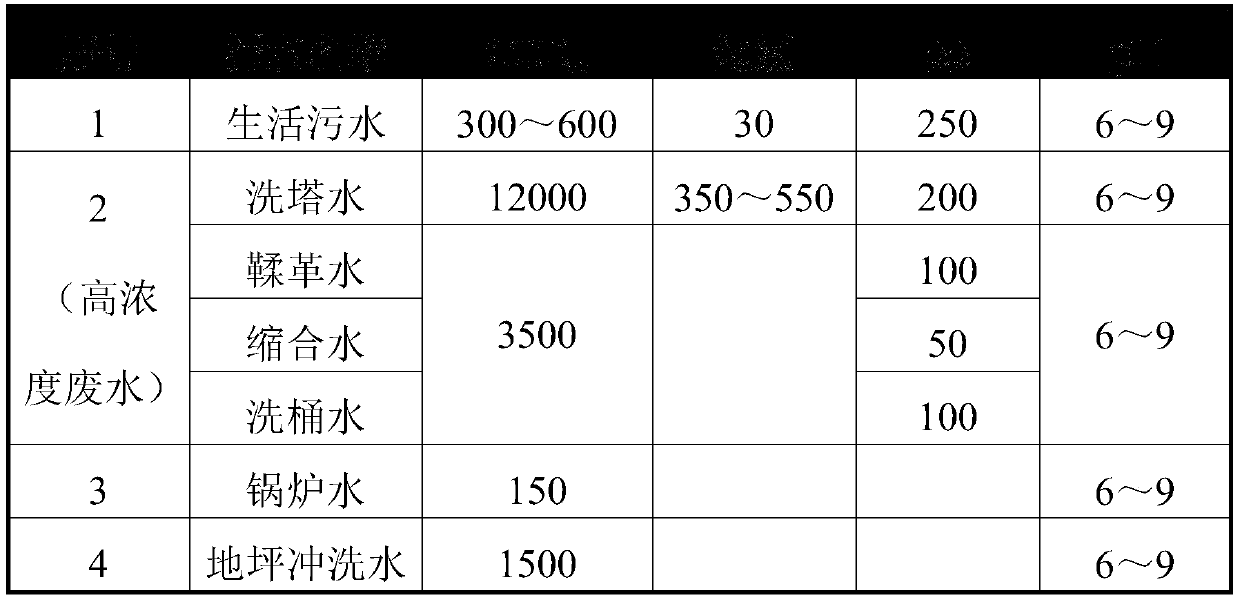

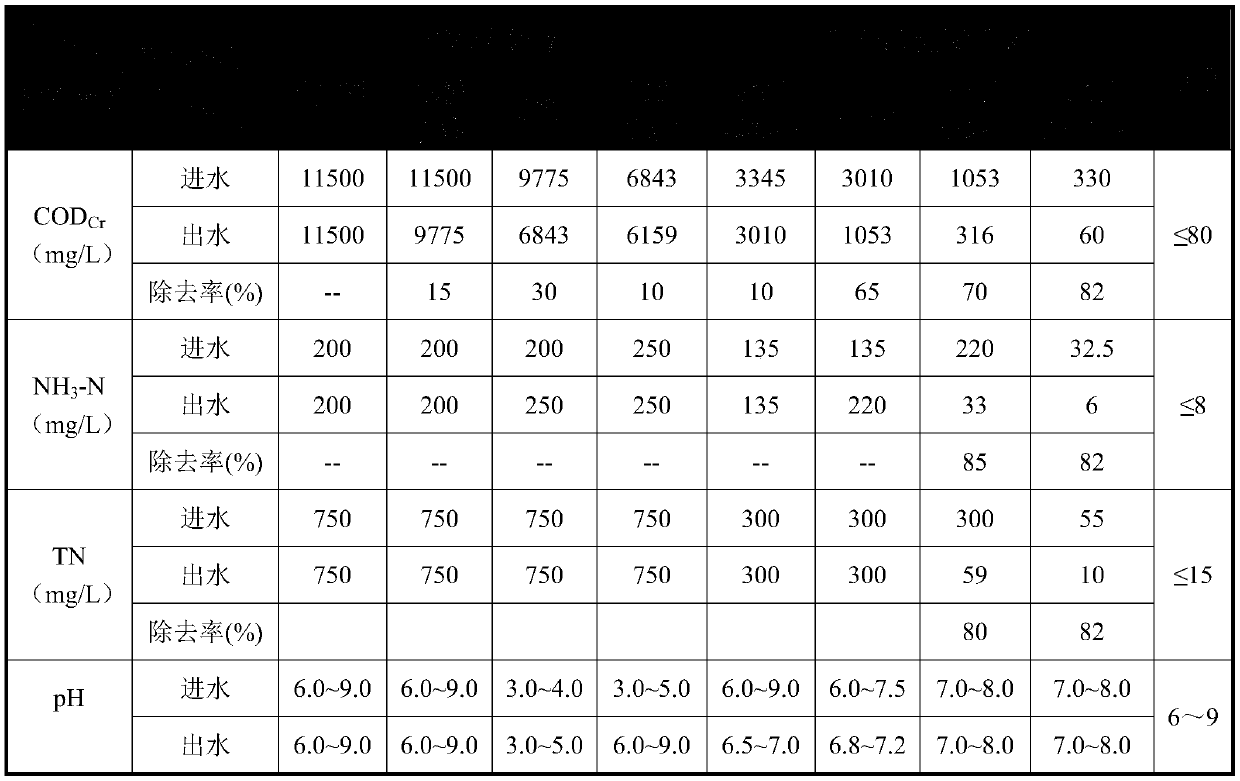

Treatment process for tannery wastewater

InactiveCN110451733AImprove biodegradabilityFacilitate subsequent biochemical treatmentWater treatment compoundsWater contaminantsHigh concentrationChemical oxygen demand

The invention discloses a treatment process for tannery wastewater and relates to the technical field of sewage treatment. The treatment process comprises the following steps: enabling high-concentration wastewater to flow into a grid canal and an adjusting tank 1, performing pretreatment through coagulating sedimentation, Fenton oxidation and coagulating sedimentation, and feeding the effluent into a pre-hydrolysis acidification tank; enabling floor washing water to flow into the grid canal and an adjusting tank 2, enabling the effluent to flow into the pre-hydrolysis acidification tank, mixing the effluent with the high-concentration wastewater, and performing hydrolysis and acidification; pumping the effluent into a UASB (upflow anaerobic sludge blanket) reactor, enabling the effluent to flow into a settling pond 1, enabling upper clear water of the settling pond 1 to flow into an air stripping tank, further feeding the effluent into a primary A / O (anoxic / oxic) tank, enabling the effluent to flow into a settling pond 2, enabling upper clear water to flow into a secondary A / O tank, feeding the effluent into a settling pond 3, and feeding upper clear water into a middle water tank; enabling boiler water to flow into the grid canal and an adjusting tank 3, performing coagulating sedimentation, and enabling upper clear water into the middle water tank; and filtering the effluentby using a fiber sphere filter, and feeding the effluent into a monitoring tank. By adopting the treatment process, a good treatment effect on pollutants such as SSs (suspended solids), CODs (chemical oxygen demands), ammonia nitrogen and organic matters in tannery wastewater can be achieved, and the effluent can meet the emission standard of GB 21902-2008.

Owner:安徽环境科技集团股份有限公司

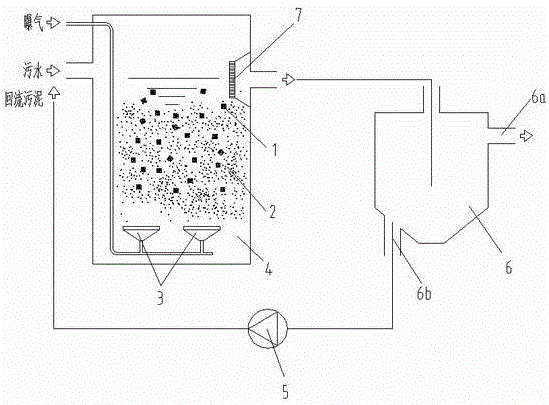

Dynamic composite sludge membrane treatment process

InactiveCN106630182AExtended stayIncrease sludge volumeWater contaminantsBiological treatment apparatusActivated sludgeEnvironmental resistance

The invention provides a dynamic composite sludge membrane treatment process and belongs to the technical field of environmental protection and water treatment. A dynamic composite sludge membrane reaction tank is filled with a multiphase flow-dynamic membrane microbial carrier filler, and meanwhile reflux is conducted on a part of active sludge in a follow-up settling pond, so that co-existence of activated sludge suspending in water and a biological membrane attached to the filler is formed in the dynamic composite sludge membrane reaction tank, aerobic microbes can grow on the activated sludge and also grow on the filler, the activated sludge and the filler perform fluidization motion under an aeration effect to fully perform contact reaction with organic matter in the water of the dynamic composite sludge membrane reaction tank, so that the utilization rate of the dynamic composite sludge membrane reaction tank is greatly improved, the sewage treatment amount under the same scale is doubled, the sludge discharging amount is small, and the sludge yield is only 30% of the yield of a transitional process. By adopting the dynamic composite sludge membrane treatment process, the size, only one half of the size required by the conventional process, of the dynamic composite sludge membrane reaction tank can completely meet the demand in the whole wastewater treatment process.

Owner:丁杰

External membrane bioreactor with self-suction jet nozzle aerating function

InactiveCN102863075ASimple structureLow costSustainable biological treatmentBiological water/sewage treatmentSequencing batch reactorAutomatic control

The invention discloses equipment for processing the wastewater through a biochemical technology and a membrane separating technology, and particularly relates to external membrane bioreactor wastewater processing equipment with a self-suction jet nozzle aerating function. The equipment comprises an integrated bioreactor, a self-suction jet nozzle aerating unit and an external membrane separating unit. The wastewater processing equipment, which integrates advantages of deep aeration, a biological fluidized bed, jet aeration, membrane separation, a sequencing batch reactor (SBR) nitrogen and phosphorus removal technology and other water treatment technologies, and is high in oxygen transfer utilizing efficiency, free from air-blowing aerating equipment, low in residual sludge, and capable of realizing a long-term stable operation with low energy consumption. The equipment is good in quality of discharged water, compact in process, small in occupied area, low in investment, convenient in maintenance and easy to realize the automatic control. The equipment has a good application prospect in the field of wastewater processing and recycling.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

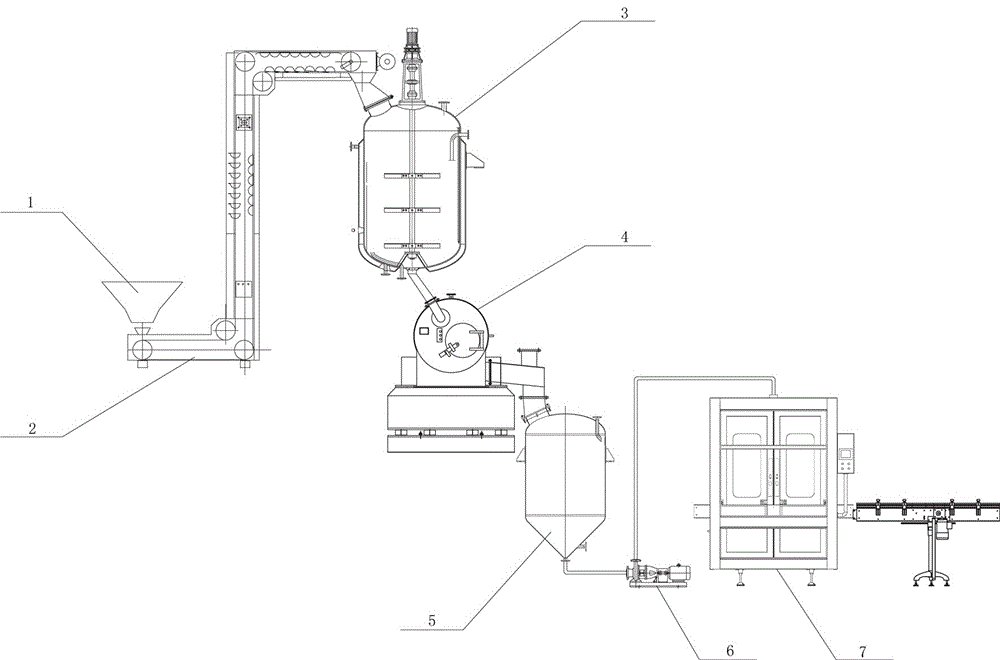

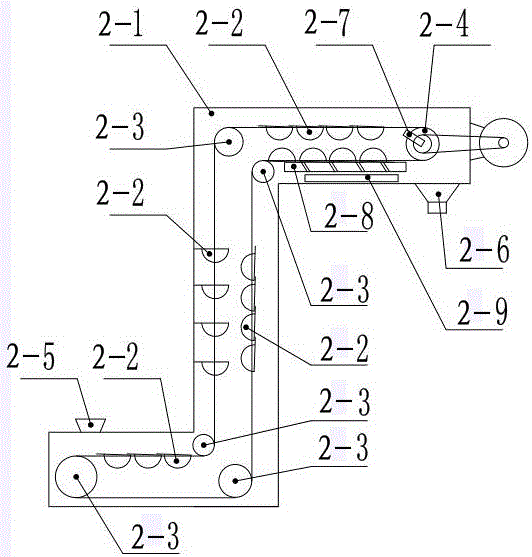

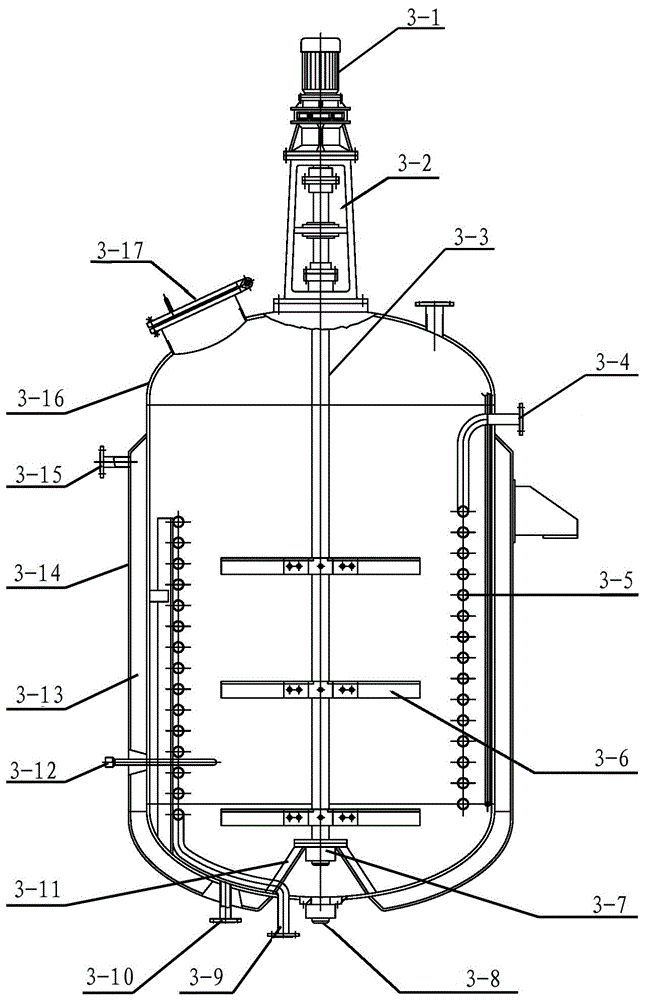

Microbial fermentation fertilizer production system

InactiveCN106316487ANot easy to deflectGuaranteed blankingChemical industryOrganic fertiliser preparationTemperature controlSolenoid valve

The invention provides a microbial fermentation fertilizer production system. A discharging opening of a mixture charging hopper (1) is located over a feeding opening (2-5) of a Z-shaped elevator (2), a discharging opening (2-6) of the Z-shaped elevator (2) is connected with a feeding opening (3-17) of a fermentation tank (3), a discharge solenoid valve (3-8) of the fermentation tank (3) is connected with the feeding end of a centrifuge (4), the liquid phase discharging end of the centrifuge (4) is connected with the feeding end of a finished product tank (5), and the discharging end of the finished product tank (5) is connected with a filling machine (7) through a centrifugal delivery pump (6). The microbial fermentation fertilizer production system has the advantages that overturning, caused by disturbance, of the Z-shaped elevator hopper is avoided, and the utilization rate of the Z-shaped elevator is increased; fermentation tank temperature control is more convenient, and a better energy-saving effect is achieved.

Owner:WUZHOUFENG AGRI SCI & TECH

Technology for deep-treating printing and dyeing wastewater by attapulgite catalyst

InactiveCN106630481AStrong purification functionImprove coagulation and sedimentation effectSludge treatmentTreatment with aerobic and anaerobic processesWater qualityHydrolysis

The invention discloses a technology for deep-treating printing and dyeing wastewater by an attapulgite catalyst. The technology comprises the following steps: collecting the wastewater after the first biochemical treatment to a regulating tank, sending to a coagulative precipitation tank after the water volume and water quality regulation, performing the coagulating sedimentation treatment to remove suspended matter and partial organic matter, sending the printing and dyeing wastewater to an anaerobic tank for acidized hydrolysis, hydrolyzing the macromolecular organic matter to the micromolecular organic matter so as to improve the biodegradability, treating the effluent by an anoxic-oxic method under the existence of the attapulgite, reaching the standard and discharging after removing the organic matter, the chromaticity and the ammonia nitrogen. The technology is capable of effectively improving the biochemical reaction efficiency and organic matter degradation ability, and reducing the wastewater treatment cost. The process operation is convenient.

Owner:安徽政涛环保科技有限公司

Self-priming jet aeration external membrane bioreactor

InactiveCN101941778AEliminate construction fixed investmentLess investmentMultistage water/sewage treatmentAutomatic controlFluidized bed

The invention provides equipment for treating waste water by a biochemical technique and a membrane separation technique and in particular relates to self-priming jet aeration external membrane bioreactor waste water treatment equipment. The equipment consists of an integrated bioreactor, a self-priming jet aeration unit and an external membrane separation unit. The equipment has the advantages of integration of the advantages of various water treatment techniques such as deep aeration, a biological fluidized bed, jet aeration, membrane separation, an SBR nitrogen phosphorus removal process and the like, no need of blast aeration equipment, high oxygen transfer utilization efficiency, little residual sludge, long-time stable operation under low energy consumption, readily realized function of removing nitrogen from waste water, good quality of output water, simple process, low fixed investment, small volume and occupied area, convenient operation and management, difficult damage, convenient maintenance, easily realized automatic control and good application prospect in the fields of waste water treatment and recycling.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Membrane bioreactor and use thereof in wastewater treatment

ActiveCN101434444BEasy loadingIncrease concentrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentMembrane surfaceMembrane bioreactor

The invention discloses a membrane bioreactor and an application method thereof in wastewater treatment. The membrane bioreactor comprises a biochemical reaction unit which adopts a particle biofilm medium, a pulse type air supply unit and a membrane filtering unit, wherein, a pulse airflow transforms wastewater entering the membrane filtering unit into pulse aerated flow, the particle biofilm medium in the wastewater is fluidized and rubbed and scraped with a membrane component, and fouling sedimentary on the membrane surface is removed. The membrane bioreactor and the application method have the advantages that the biochemical treatment of the particle biofilm medium has good effect, and the effect of rubbing and cleaning the membrane component is good; combined with the disturbing strengthening cleaning effect of the pulse aerated flow, synergistic effect is played, thus improving the membrane pollution preventing effect of an MBR unit, reducing the running cost of the unit, and being applicable to various wastewater treatment occasions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wastewater treatment device and wastewater treatment method thereof

InactiveCN106698643AAvoid mutual interferenceImprove responseTreatment using aerobic processesSustainable biological treatmentTreatment effectDissolution

The invention relates to a wastewater treatment device and a wastewater treatment method thereof. The wastewater treatment device mainly comprises an aerobic expanded bed, an oxygenator, a circulating pump, a feeding pump, a feeding tank, a heating pump, an air pump, a heater and a data control cabinet. According to the invention, by controlling of the rate of circulating water flow, operation of the aerobic expanded bed in an expansion state is realized, so short circuiting water flow is avoided, and organic matter removal loading is improved; a biochemical reaction and oxygen dissolution of the wastewater treatment device are separately completed and independently controlled, so mutual interference of oxygen dissolution and biochemistry performed in a same space in a traditional biochemical process is avoided, and optimization of processes of the biochemical reaction and the oxygen dissolution can be synchronously realized; the aerobic expanded bed and the oxygenator can adopt a high equipment height, and the thickness of a material filling area of the aerobic expanded bed is improved, so the occupied area of a land is reduced, and the efficiency of oxygen dissolution is improved; and the wastewater treatment device has the advantages of less investment, saved occupied land area, high benefits, simple and convenient operation, stable treatment effect, capability of greatly reducing manual labor intensity, and high economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

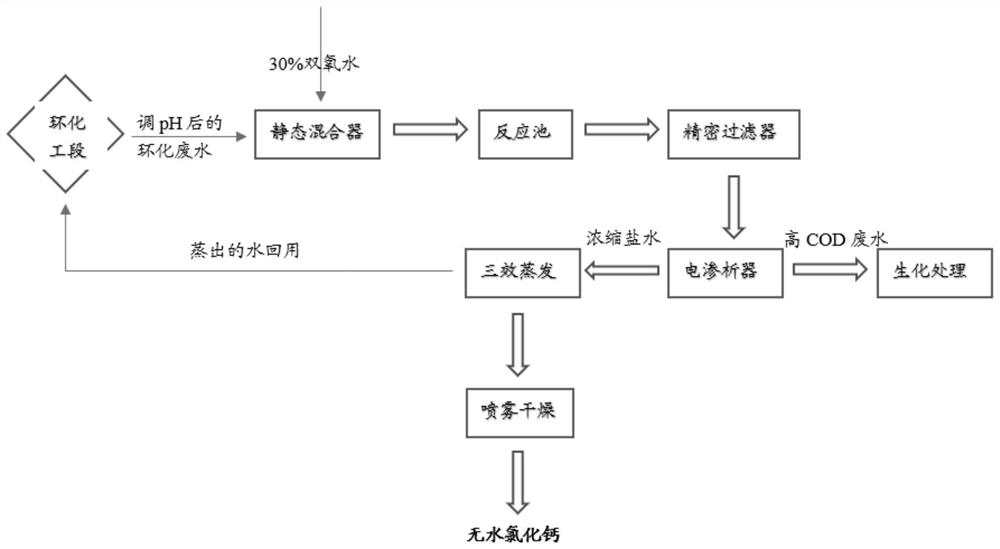

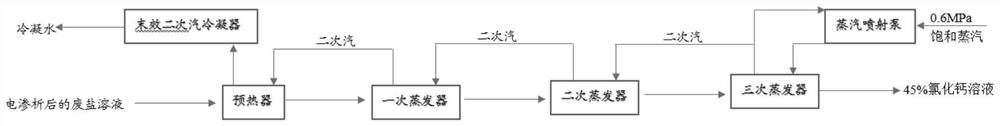

Method for treating cyclization wastewater generated in production process of epoxy chloropropane

InactiveCN111875153AReduce dosageReduced footprintWater contaminantsTreatment involving filtrationEpoxyPtru catalyst

The invention belongs to the technical field of high-salt and high-organic matter wastewater treatment, and relates to a method for treating cyclization wastewater generated in the production processof epoxy chloropropane. The treatment method comprises the steps of (1) pretreatment, (2) catalytic oxidation, (3) electrodialysis and (4) aftertreatment. The method adopts a hydrogen peroxide-catalyst combination mode, and is characterized in that the use amount of hydrogen peroxide is reduced; through contact with the catalyst, the degradation speed of organic matters is increased, the reactiontime is shortened, the residence time of cyclized wastewater in the reaction tank is shortened, and the occupied area and equipment investment of the reaction tank are reduced. Salt and organic matterare separated through electrodialysis, and meanwhile, saline water is concentrated, the load of multiple-effect evaporation is reduced, and the steam consumption is reduced. In biochemical treatment,due to reduction of salt, the activity of strains is improved, and the efficiency of biochemical reaction is greatly improved; In addition, the concentration of salt is improved through electrodialysis concentration, so that the amount of treated water is reduced, and the sewage treatment difficulty is reduced.

Owner:HUIZHI ENG SCI & TECH CO LTD

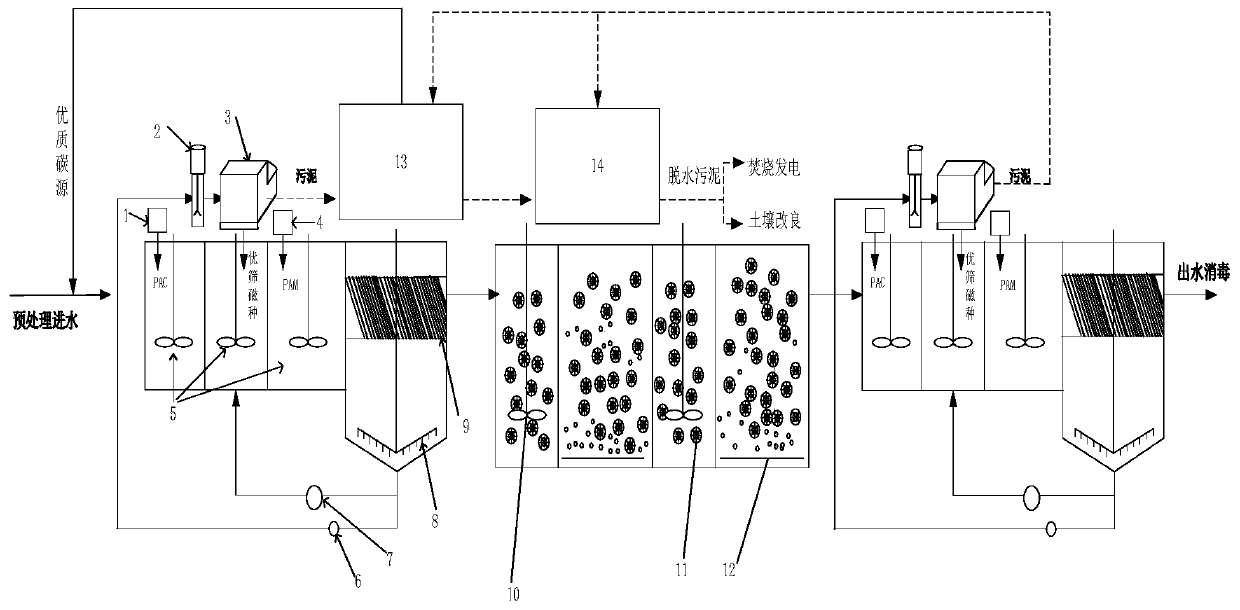

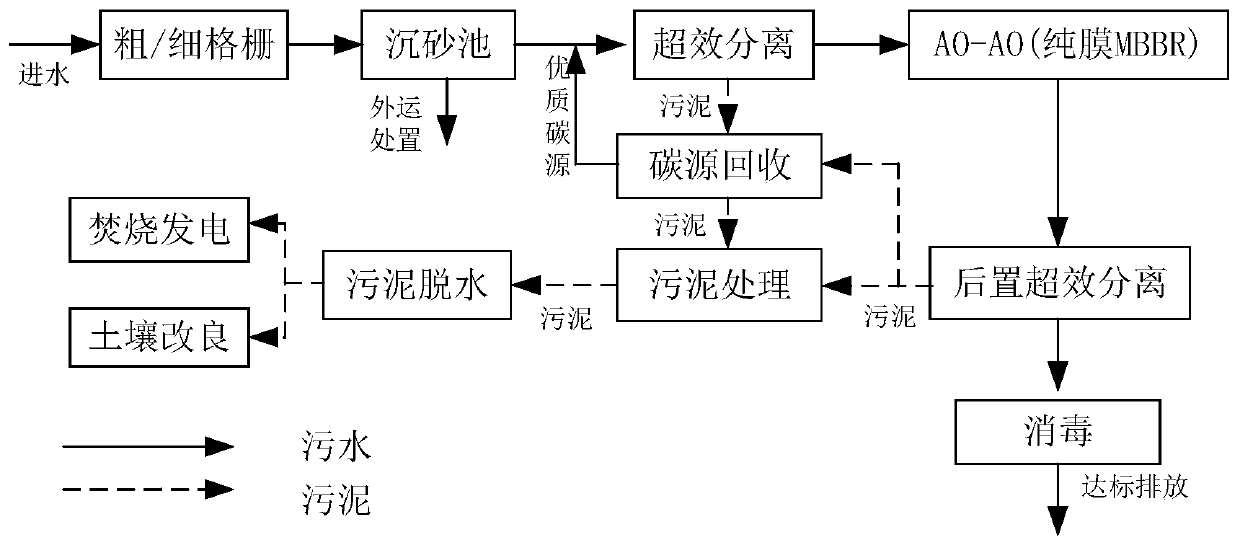

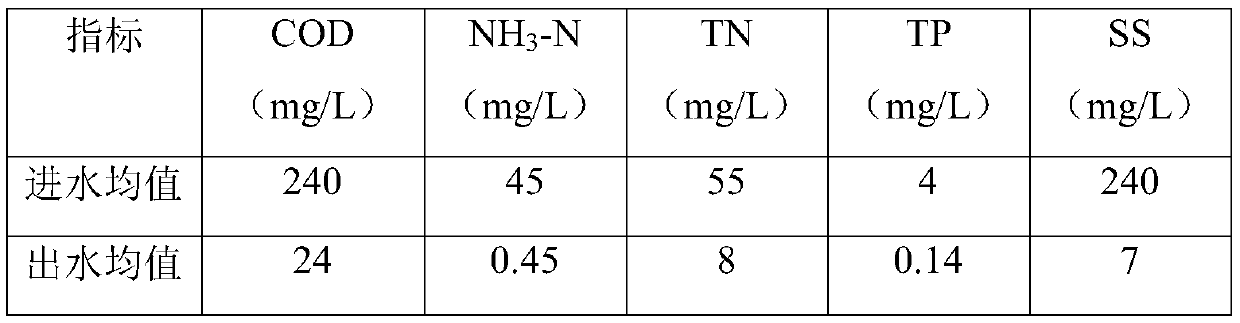

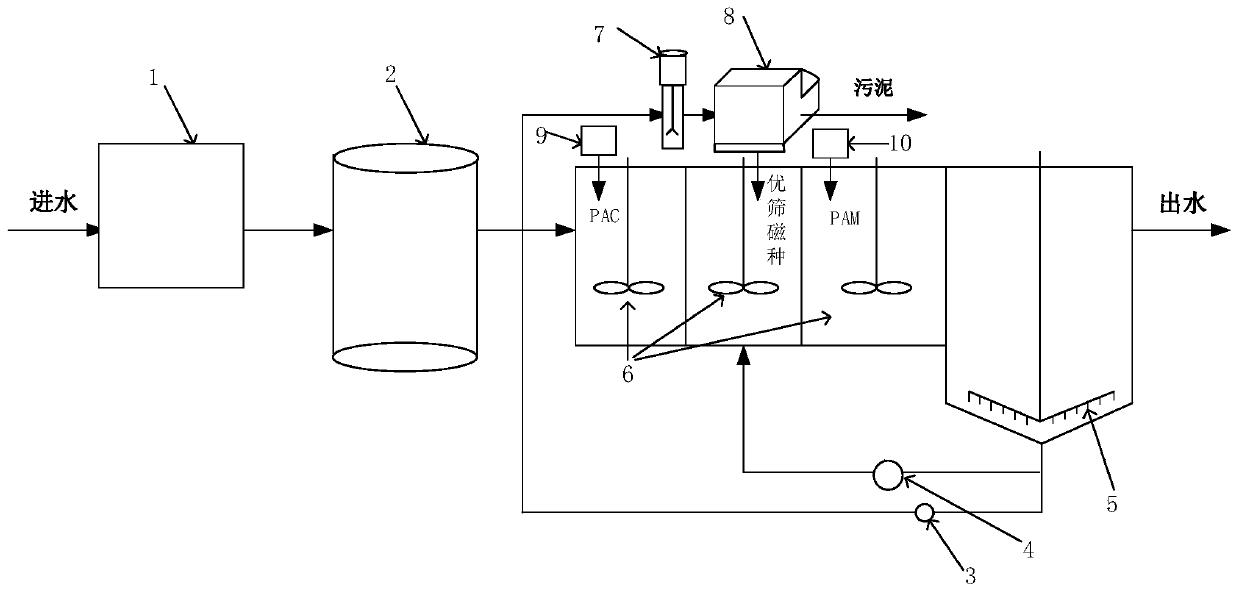

Sewage treatment system and sewage treatment process for strengthening efficient utilization of raw water carbon source

PendingCN111233282AReduce loadImprove the efficiency of biochemical reactionsTreatment using aerobic processesWater treatment compoundsCarbon sourceSewage treatment

The invention discloses a sewage treatment system and a sewage treatment process for strengthening efficient utilization of a raw water carbon source, and belongs to the technical field of water treatment. The system comprises a pretreatment system, a front super-effect separation system, a carbon source recovery system, a pure membrane MBBR biochemical system, a rear super-effect separation system and a sludge treatment system. The sewage treatment process includes: firstly, waste residues and sand in sewage are removed through a pretreatment system, then the pretreated sewage enters a frontsuper-effect separation system, and most of insoluble COD, TP, TN, SS and other pollutants are subjected to enhanced removal; then the sludge generated by the front super-effect separation process ishydrolyzed and fermented through a carbon source recovery system, and the dissolved-state high-quality carbon source is extracted from the sludge for denitrification of a subsequent biochemical system; and soluble COD, NH3-N and TN are subjected to biochemical treatment through a pure membrane MBBR biochemical system and then enter a rear super-effect separation system. According to the system andthe process, the effluent can stably reach the standard of quasi-surface IV or quasi-surface III type water.

Owner:QINGDAO SPRING WATER TREATMENT

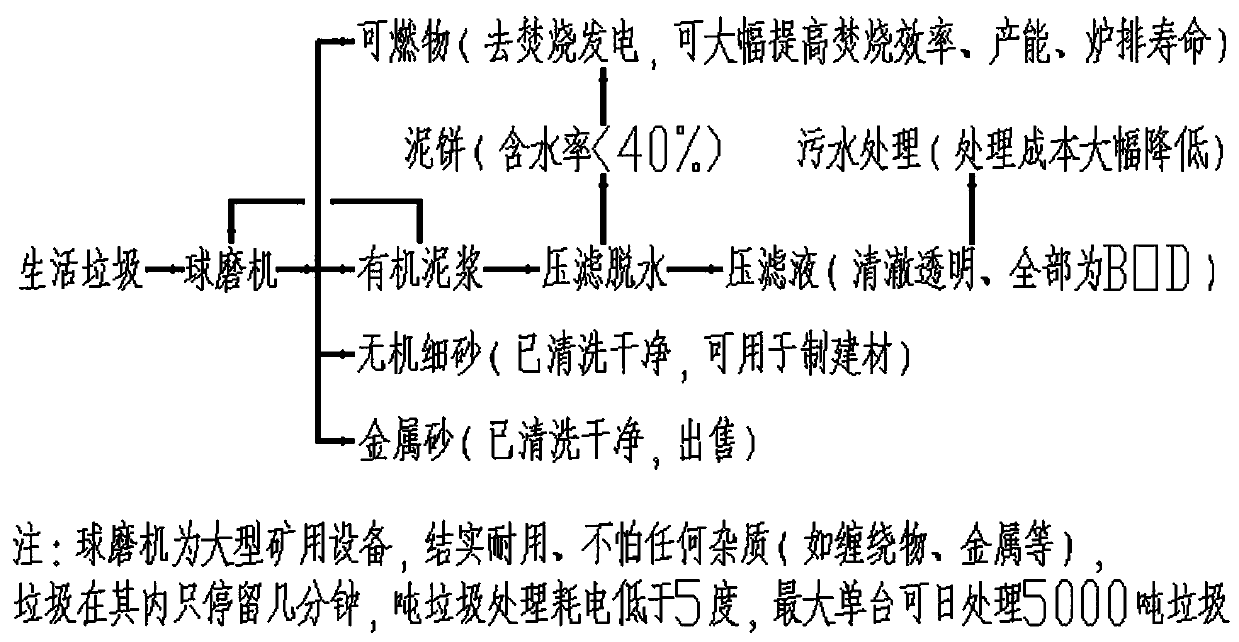

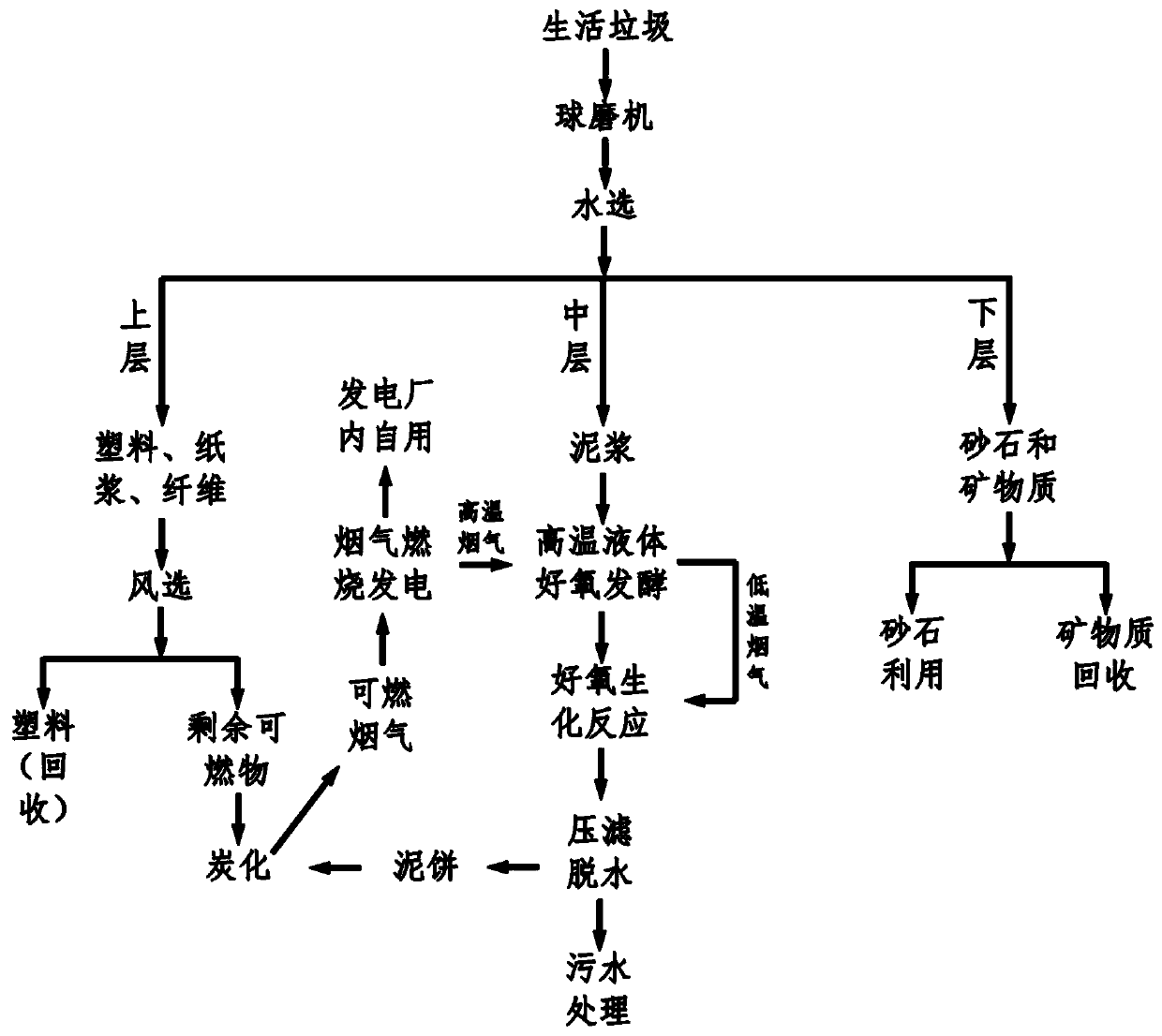

Garbage three-phase separation treatment process

InactiveCN110252781ARealize green processingImprove utilization efficiencyTransportation and packagingSolid waste disposalChemical industryClassification treatment

The invention relates to a garbage three-phase separation treatment process. The process effectively realizes the purpose of garbage separation, classification treatment and recycling facilitation. According to the technical scheme, the process comprises the following steps of 1 garbage crushing, 2 garbage sorting, 3 garbage slurry treating, 4 solid-liquid separation, and 5 waste gas treatment. Compared with an existing solid, liquid and gas three-phase separate treatment method, the process adopts a solid, liquid and gas synchronous treatment technology, a product after garbage treatment can be reused or recycled, the utilization efficiency of resources is improved, the green treatment of the garbage is realized, meanwhile, adopted equipment is commonly used equipment in the industry, the chemical industry and the like, the equipment is regular in operation and convenient to use, so that the method does not involve high-threshold technologies, so that the process does not involve excessively-high labor training cost, and the practicability is strong.

Owner:郑州同济环保工程有限公司

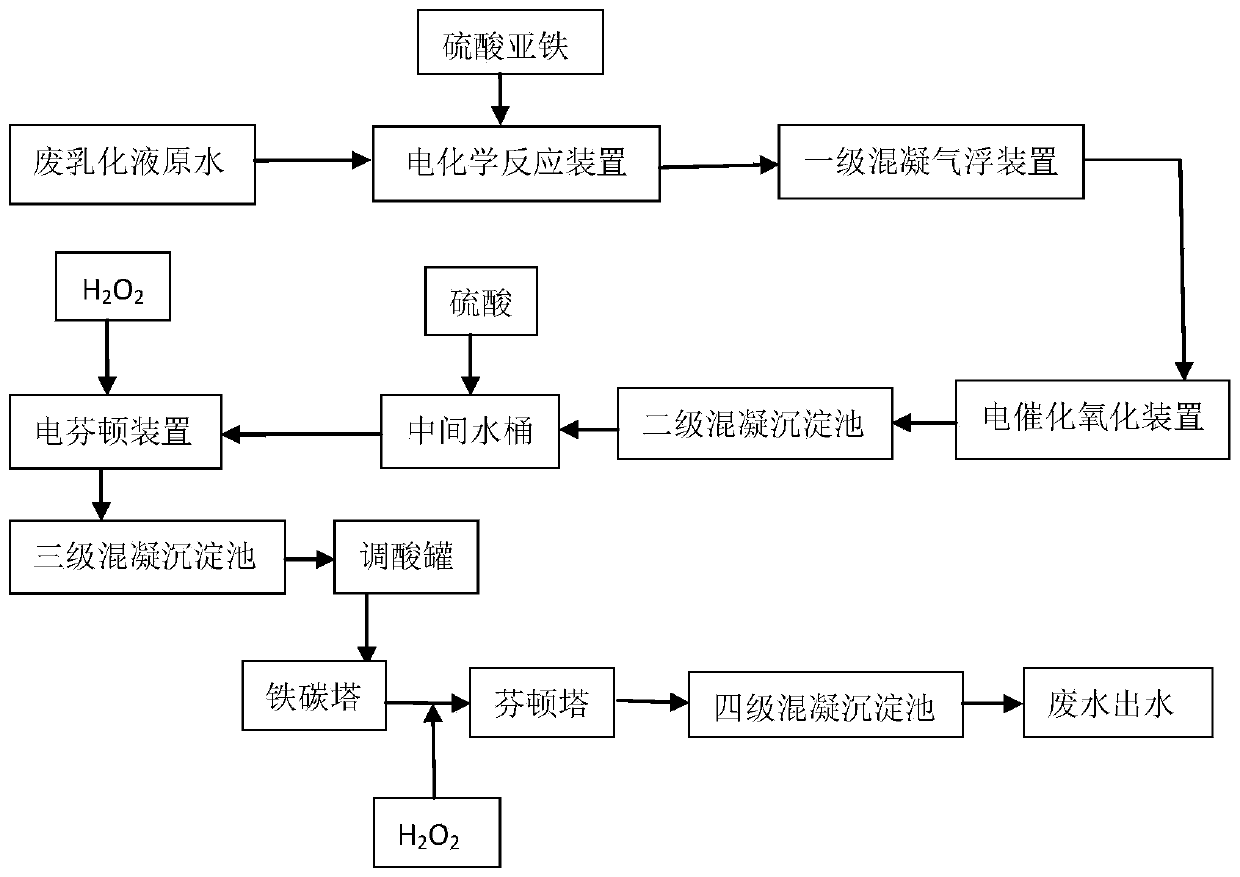

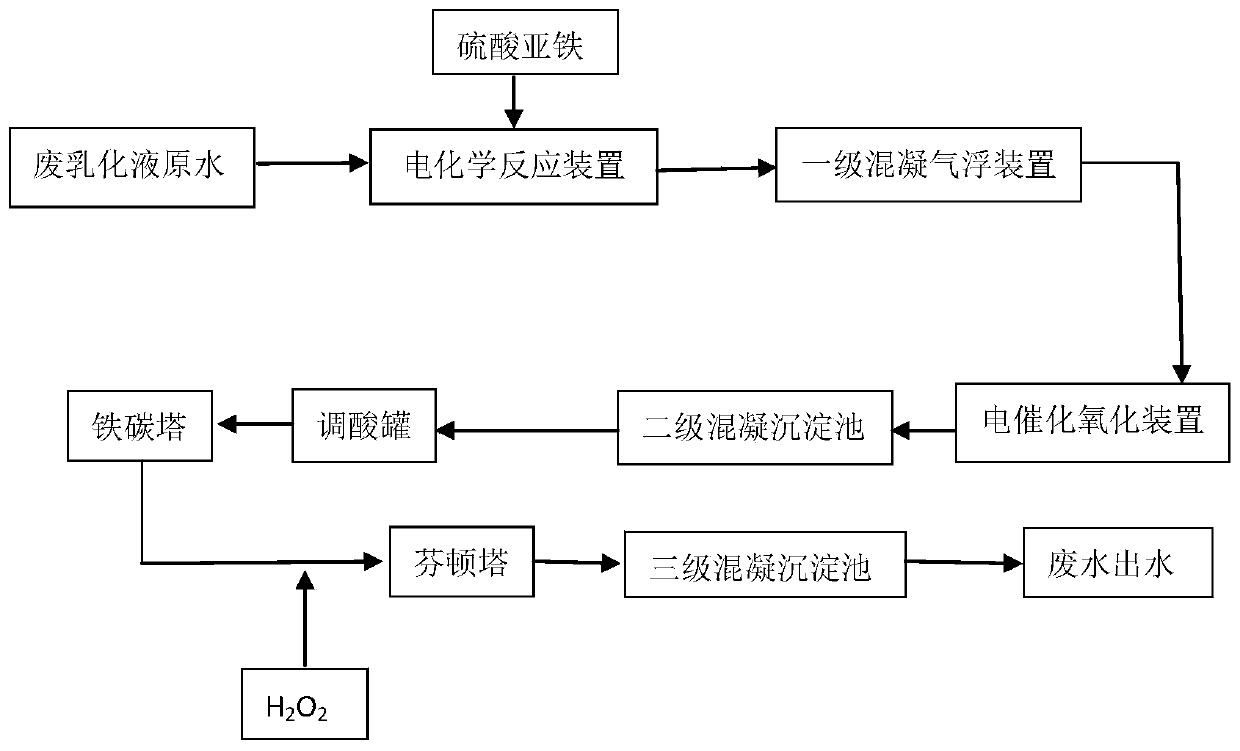

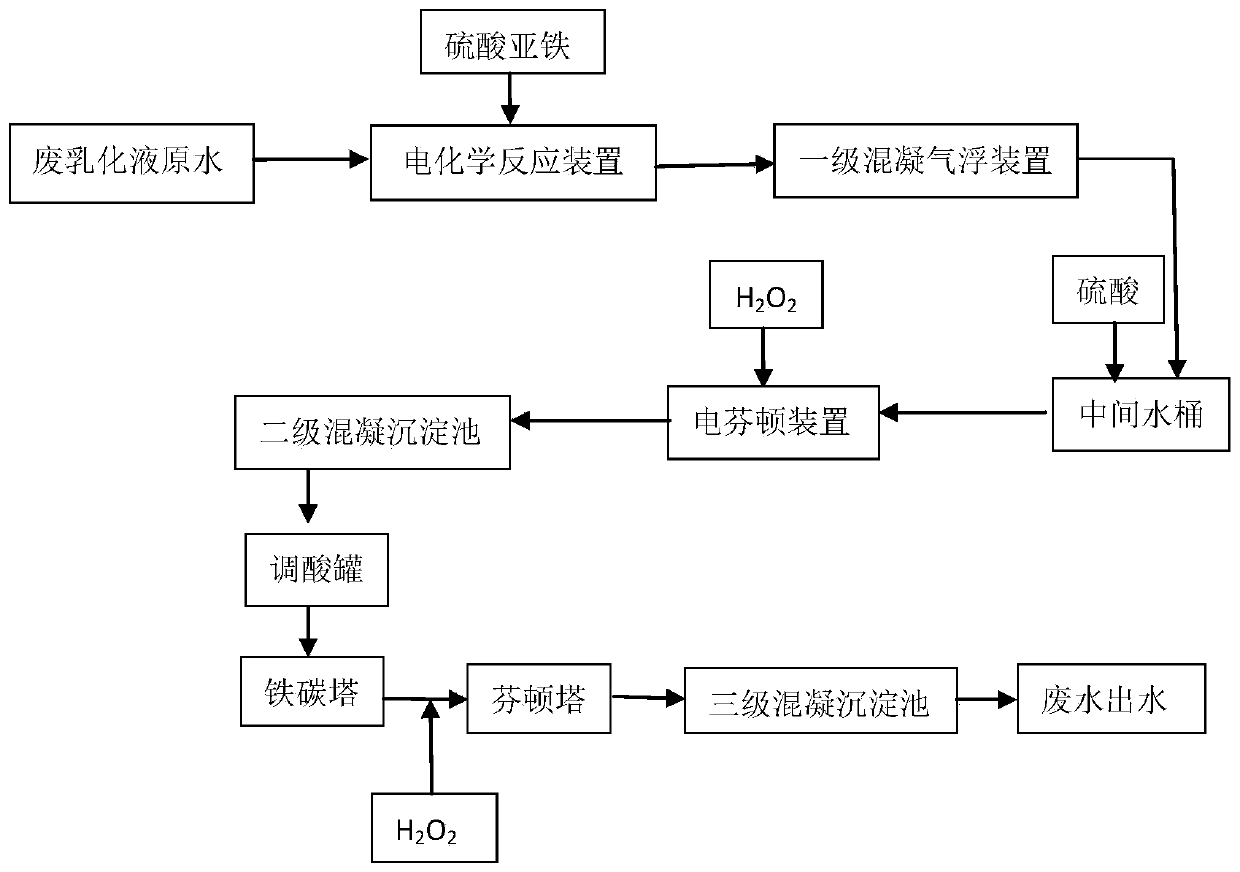

Pretreatment method of waste emulsion

InactiveCN111470679AHigh degree of mineralizationEfficient removalWater treatment parameter controlWater contaminantsPretreatment methodElectrolysis

The invention discloses a pretreatment method of waste emulsion, and belongs to the technical field of sewage treatment. The pretreatment method of the waste emulsion comprises the following steps: sequentially carrying out primary electrochemical demulsification reaction, primary sludge-water separation, electro-catalytic oxidation reaction, sludge-water separation, and / or electro-Fenton reaction, and sludge-water separation, or carrying out electro-Fenton reaction and then electro-catalytic oxidation reaction, iron-carbon micro-electrolysis reaction, Fenton reaction and sludge-water separation on waste emulsion stock solution, and enabling obtained wastewater to enter a biochemical reaction system for up-to-standard sewage discharge treatment. The pretreatment method of the waste emulsion is moderate in one-time investment, low in operation cost, high in automation degree and clear in effluent, and gives consideration to wastewater of other processes of enterprises; one-time treatment of the wastewater is achieved, concentrated liquid and secondary pollution are avoided, and the wastewater treated through the wastewater emulsion pretreatment method can directly enter a subsequentbiochemical system to be subjected to up-to-standard sewage discharge treatment.

Owner:浙江美纳环保科技有限公司

Processing method for produced water for ultra-low permeable oil field reinjection

InactiveCN101671091BImprove the efficiency of biochemical reactionsEasy to operate and maintainTreatment with anaerobic digestion processesMultistage water/sewage treatmentActivated sludgeWater quality

A processing method for produced water for ultra-low permeable oil field reinjection relates to a waste water processing method which solves the problems of complex operation, high cost, solid contentsuspended in effluent quality and incapability of medium particle size for achieving the 5, 1, 1 standard of produced water of the ultra-low permeable oil field existing in the existing method for processing oil field produced water. The processing method comprises the following steps: 1. preparing a supernatant; 2. carrying out acclimatization treatment in an activated sludge-biomembrane reaction tank, and then introducing the supernatant; and 3. after precipitation, carrying out hyperfiltration. The processing method adopts an activated sludge-biomembrane compound technology as a reactive agent, can give consideration to long-and-short sludge age, aerobic / anaerobic / anoxic environments, simultaneously removes nutritive materials and hard-degradable organic material in water and has highbiochemical reaction efficiency; the processing method has simple operation and low cost; after the processing method of the invention is adopted, effluence can stably achieve the water quality standard-the 5, 1, 1 standard of produced water of the ultra-low permeable oil field.

Owner:HARBIN INST OF TECH

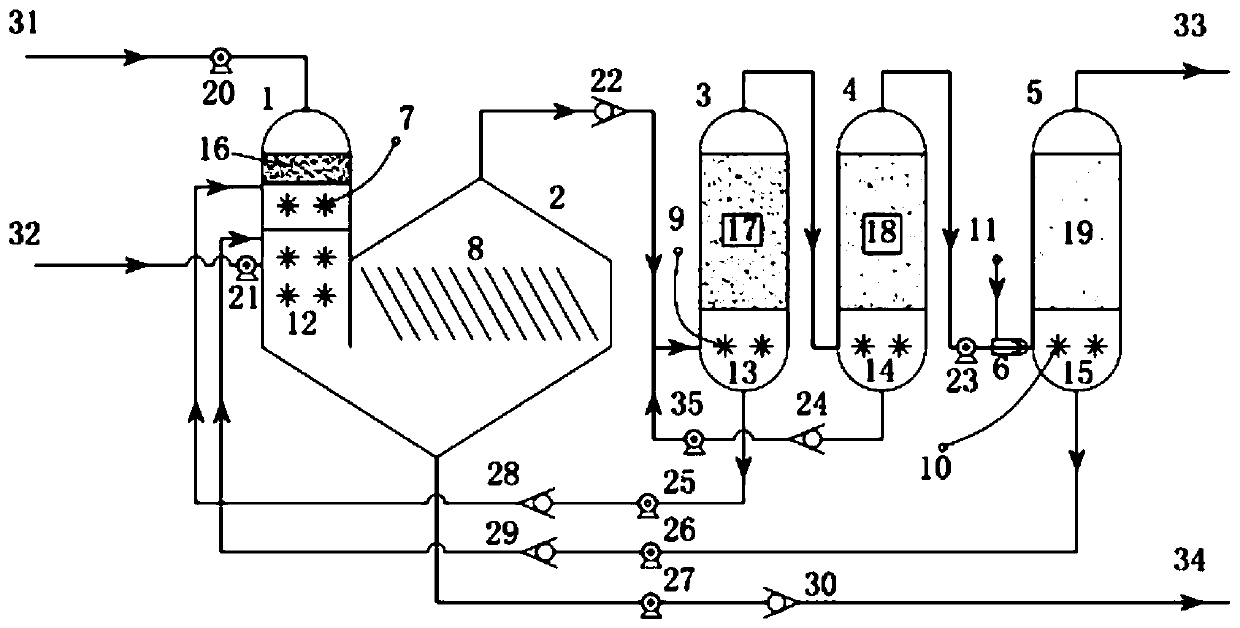

Complex organic sewage step purification process

InactiveCN111499102APromote growthLess quantityTreatment by combined electrochemical biological processesWater contaminantsSuspended particlesSludge

The invention provides a complex organic sewage step purification process, and belongs to the field of wastewater treatment. The process comprises the following steps: pre-removing heavy metals in sewage, electrically driving and inducing sludge micelle particles to settle, carrying out medicament enhanced regulation treatment, carrying out anoxic-anaerobic-aerobic gradient purification, and carrying out related reflux processes. The process has the following advantages: the agglomeration performance of sludge flocculation particles in sewage can be effectively improved, microbial poisoning ina biochemical region is reduced, suspended particles are prevented from blocking a filler layer, and the like. Therefore, up-to-standard discharge of low-biodegradability multi-impurity complex organic sewage is realized efficiently in an energy-saving and low-cost manner, and the process has relatively high application and popularization values.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +2

Fixed bed MBR (membrane bioreactor) device

InactiveCN106517500AEasy to set upImprove processing efficiencySustainable biological treatmentBiological water/sewage treatmentFixed bedMembrane bioreactor

The invention discloses a fixed bed MBR (membrane bioreactor) device which is applicable to the fields of sewage treatment, sewage recycling and the like. The MBR device is composed of an aeration tank, a transition tank, a membrane separation tank, and other assemblies and facilities required by the operation of the device. A fixed porous material used as a microbial carrier is installed in at least one of the aeration tank, transition tank and membrane separation tank (three biochemical reaction tanks), thereby forming the biological fixed bed. The MBR device disclosed by the invention has the characteristics of compact structure, flexible technique, high biochemical reaction efficiency, low operation energy consumption and the like, can obviously accelerate biodegradability of nondegradable organic pollutants, and is suitable for manufacturing minitype integrated sewage treatment devices and also suitable for application in large-scale sewage treatment.

Owner:邵俊轩

A method and equipment for treating antibiotic residue

ActiveCN104593433BImprove processing efficiencyImprove processing speedGas production bioreactorsWaste based fuelMyceliumHazardous substance

The invention provides a method and equipment for treating antibiotic mycelium residues. According to the method, the antibiotic mycelium residues and water are prepared into a mycelium residue suspension which is subjected to anaerobic fermentation treatment. The invention also provides the equipment for treating the antibiotic mycelium residues, and the equipment comprises a residue water generating device, an anaerobic fermentation device, a gas-liquid separation device positioned above the anaerobic fermentation device, a biogas collection device positioned above the gas-liquid separation device and a riser pipe for communicating the gas-liquid separation device and the anaerobic fermentation device. By using the method and equipment for treating the antibiotic mycelium residues, the mycelium residue suspension obtained after the mixing of the antibiotic mycelium residues and the water is subjected to anaerobic fermentation treatment, so that the inhibition of harmful substances of anaerobic fermentation antibiotics and the like in the conventional antibiotic mycelium residues is overcome, the amount of preponderant bacteria is kept to the utmost extent, the efficiency of anaerobic fermentation is improved, and the method and the equipment have the advantages of small floor area, simple operation, low cost and the like.

Owner:ZHENGZHOU UNIV +1

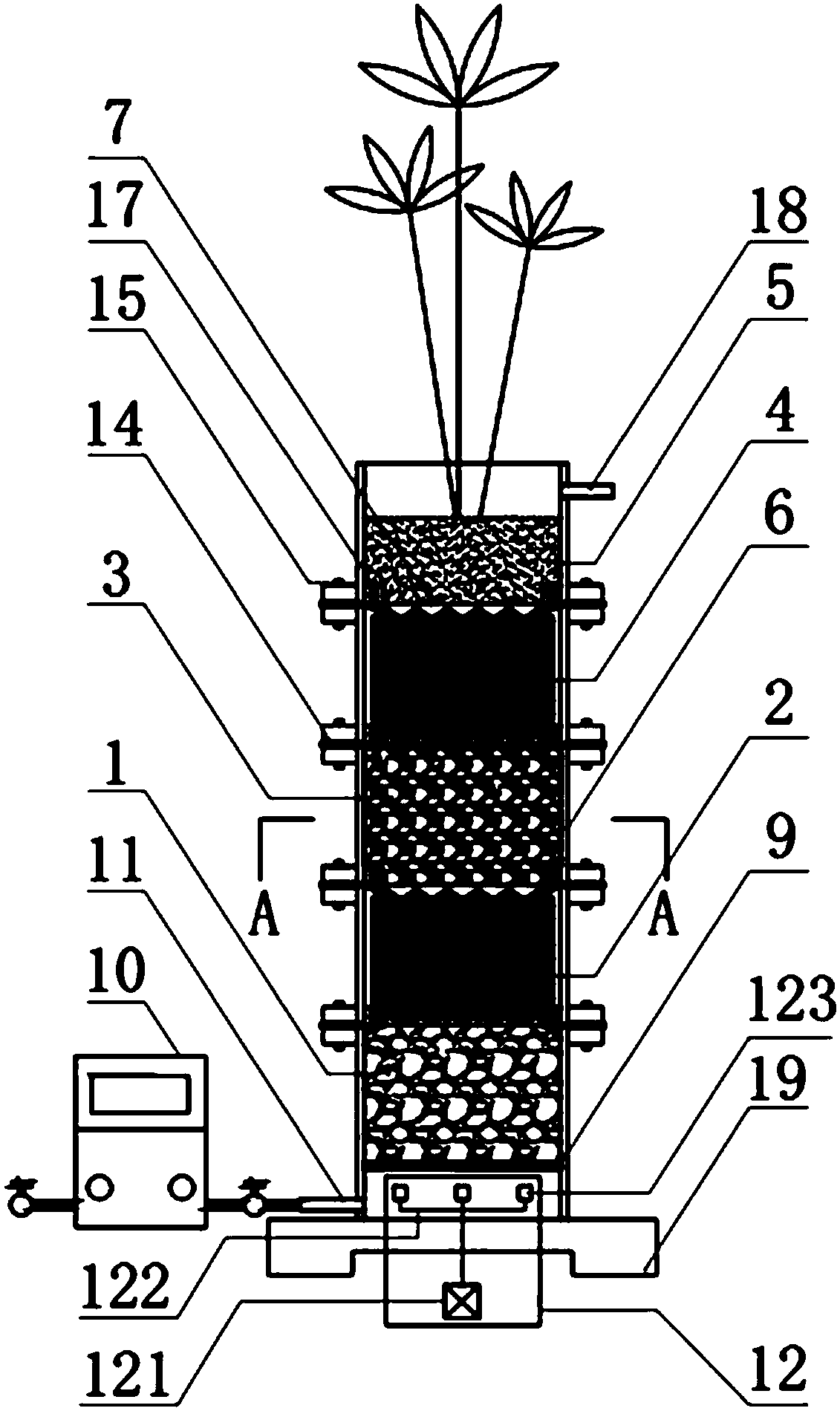

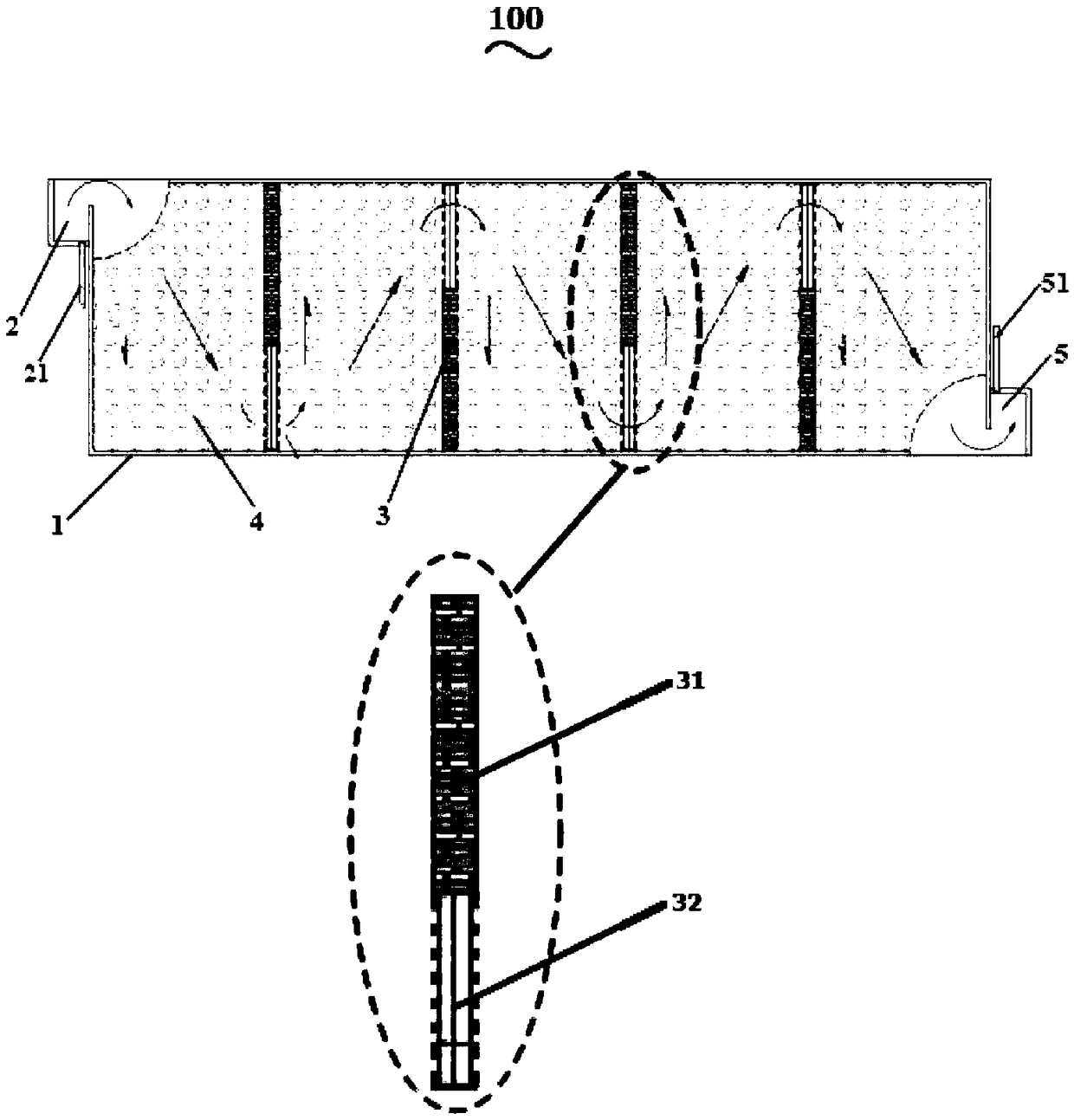

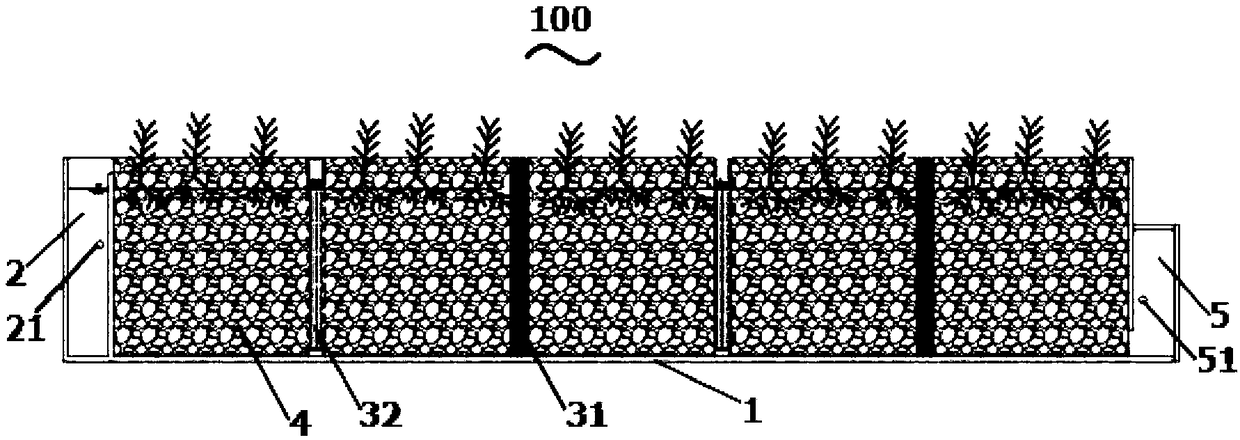

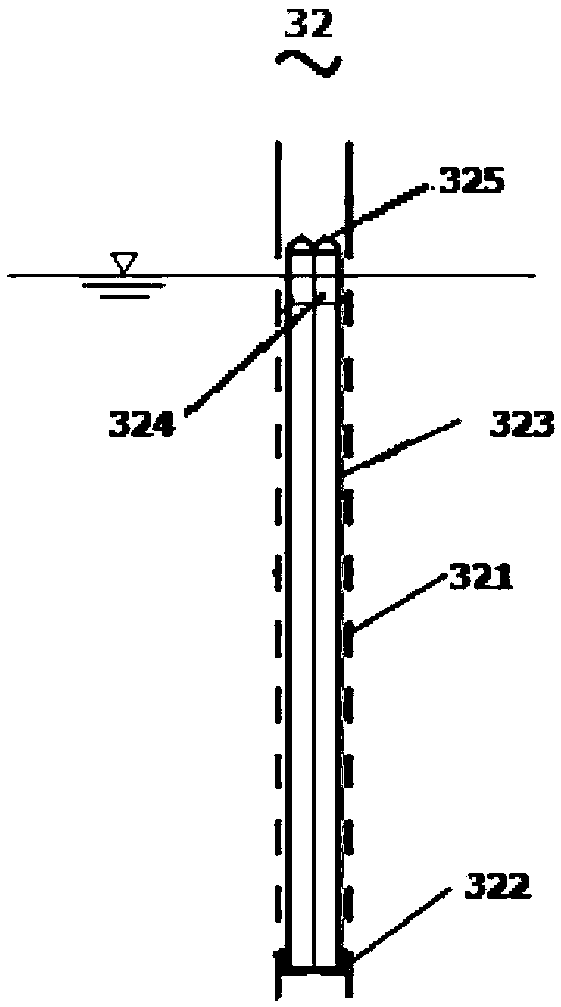

Multi-section basalt fiber bundle combined packing artificial wetland

InactiveCN108249594ALarge specific surface areaEasy for microorganisms to attachSpecific water treatment objectivesWater contaminantsTreatment effectBasalt fiber

The invention discloses a multi-section basalt fiber bundle combined packing artificial wetland which comprises a filtering zone, wherein the filtering zone is filled with multi-layer packing; the multi-layer packing comprises a granular packing layer, a basalt fiber bundle layer and a soil or sand layer; wastewater flows in from the bottom of the filtering zone and flows out from the upper part of the filtering zone. By adopting the wetland, a basalt fiber is creatively combined with conventional granular packing, novel packing can be molded, a synergetic treatment effect of three components,namely a matrix, microorganisms and plants, is brought into play to the maximum extent, the multi-section basalt fiber bundle combined packing artificial wetland is made of basalt fiber bundles as abiological carrier, is beneficial to growth and propagation of microorganisms, is capable of sufficiently bringing a microorganism degradation function into play, meanwhile has multiple advantages ofa conventional artificial wetland, and is an efficient and feasible sewage treatment device.

Owner:SOUTHEAST UNIV

Low-dissolved-oxygen biochemical reaction system and process thereof

InactiveCN111498992AImprove the efficiency of biochemical reactionsReduce usageTreatment with aerobic and anaerobic processesWater flowLow dissolved oxygen

The invention belongs to the technical field of water treatment, and particularly relates to a low-dissolved-oxygen biochemical reaction system and a process thereof. The low-dissolved-oxygen biochemical reaction system comprises two membrane pools, each membrane pool is internally provided with a membrane assembly, the bottom of each membrane assembly is provided with an aeration device, and theaeration devices are used for flushing and aerating the membrane assemblies; the system further comprises a reaction channel with an opening in the top, a partition wall and at least one upper-openingand lower-opening flow guide plate set. The reaction channel is communicated with the membrane pool through a lower opening flow guide plate set; the partition wall is vertically arranged at the bottom end in the reaction channel; at least one upper opening flow guide plate set and at least one lower opening flow guide plate set are fixedly arranged in the reaction channel at intervals; at the moment, a dissolved oxygen-containing solution generated by membrane scouring aeration is pushed to flow in the reaction channel by taking gas stripping as power, dissolved oxygen is gradually consumedand reduced in the process that water flow flows through the reaction channel, synchronous nitrification and denitrification are further realized under the required anoxic condition, and the use of aliquid circulating pump is reduced.

Owner:BEIJING HUIHENG ENVIRONMENTAL PROTECTION ENG CO LTD

Net-like basalt fiber combined-type baffling artificial wetland system

ActiveCN108862604ALarge specific surface areaImprove purification effectBiological water/sewage treatmentConstructed wetlandSewage

The invention provides a net-like basalt fiber combined-type baffling artificial wetland system. The net-like basalt fiber combined-type baffling artificial wetland system comprises a pool body, an artificial wetland sewage distributing area, an artificial wetland effluent collecting area, and separating sections, wherein the separating sections are arranged at interval so that the pool body is separated into conventional filler sections, the pool body comprises a bottom wall, long side walls and short side walls, the artificial wetland sewage distributing area and the artificial wetland effluent collecting area are respectively positioned at the outer sides of the two short side walls, the separating sections are installed parallel to the short side walls and butted with the bottom wall,the separating sections are extended in a direction from one long side wall to the other long side wall, the separating section comprises a separating plate and a net-like basalt fiber filler base groove, two neighboring separating sections are reversely installed, two neighboring conventional filler sections are communicated by the net-like basalt fiber filler base groove. Compared with the priorart, the net-like basalt fiber combined-type baffling artificial wetland system is capable of adopting a basalt fiber base material, and efficiently defouling, and good in effluent quality.

Owner:SOUTHEAST UNIV

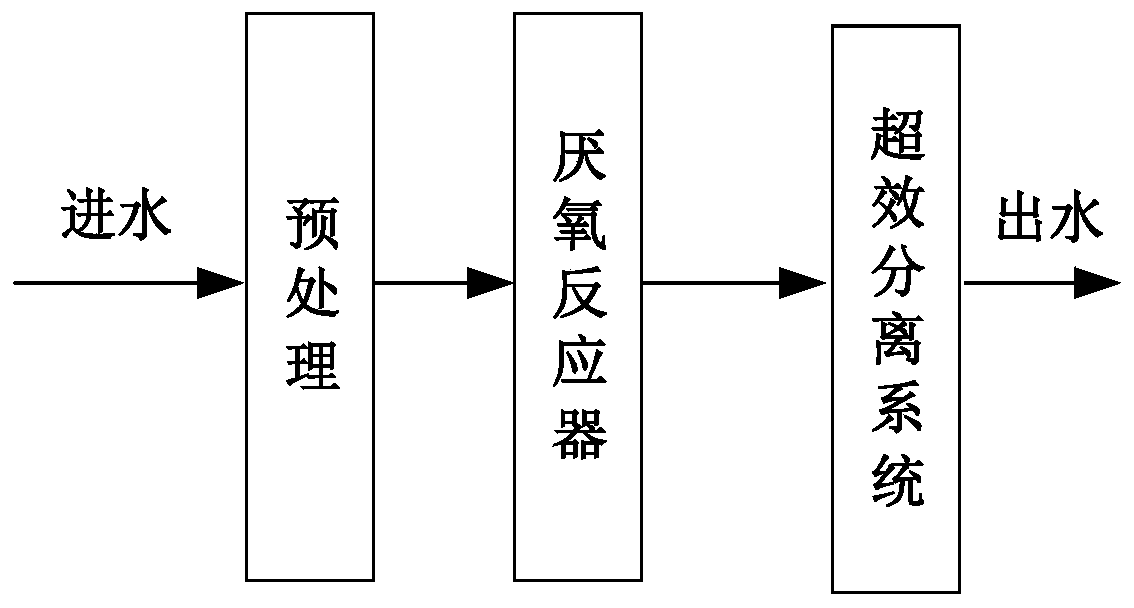

Sewage treatment system and sewage treatment process based on super-effect separation

PendingCN110395849AGood removal effectStably meet emission standardsWater treatment parameter controlWater contaminantsHigh concentrationTherapeutic effect

The invention discloses a sewage treatment system and a sewage treatment process based on super-effect separation, and relates to the technical field of water treatment. The technical problems that inthe prior art, the high-concentration organic wastewater treatment process is complex, and the treatment cost is high are solved. The system comprises a pretreatment system, an anaerobic reactor anda super-effect separation system, which are connected in sequence; the super-effect separation system comprises a mixing tank, a magnetic seed loading tank, a flocculation reaction tank and an inclined tube sedimentation tank; a mud scraper is arranged in the inclined tube sedimentation tank; the bottom of the inclined tube sedimentation tank is connected with a sludge return pipe, and the other end of the sludge return pipe is connected with the magnetic seed loading tank; the sludge return pipe is used for feeding the coagulated flocs containing the magnetic seeds into the magnetic seed loading tank; the bottom of the inclined tube sedimentation tank is also connected with a residual sludge return pipe, and the other end of the residual sludge return pipe is sequentially connected with ahigh-speed shearing machine and a magnetic separator. The sewage treatment system disclosed by the invention is good in treatment effect, can reach the sewer discharge standard, and is more energy-saving and environment-friendly.

Owner:QINGDAO SPRING WATER TREATMENT

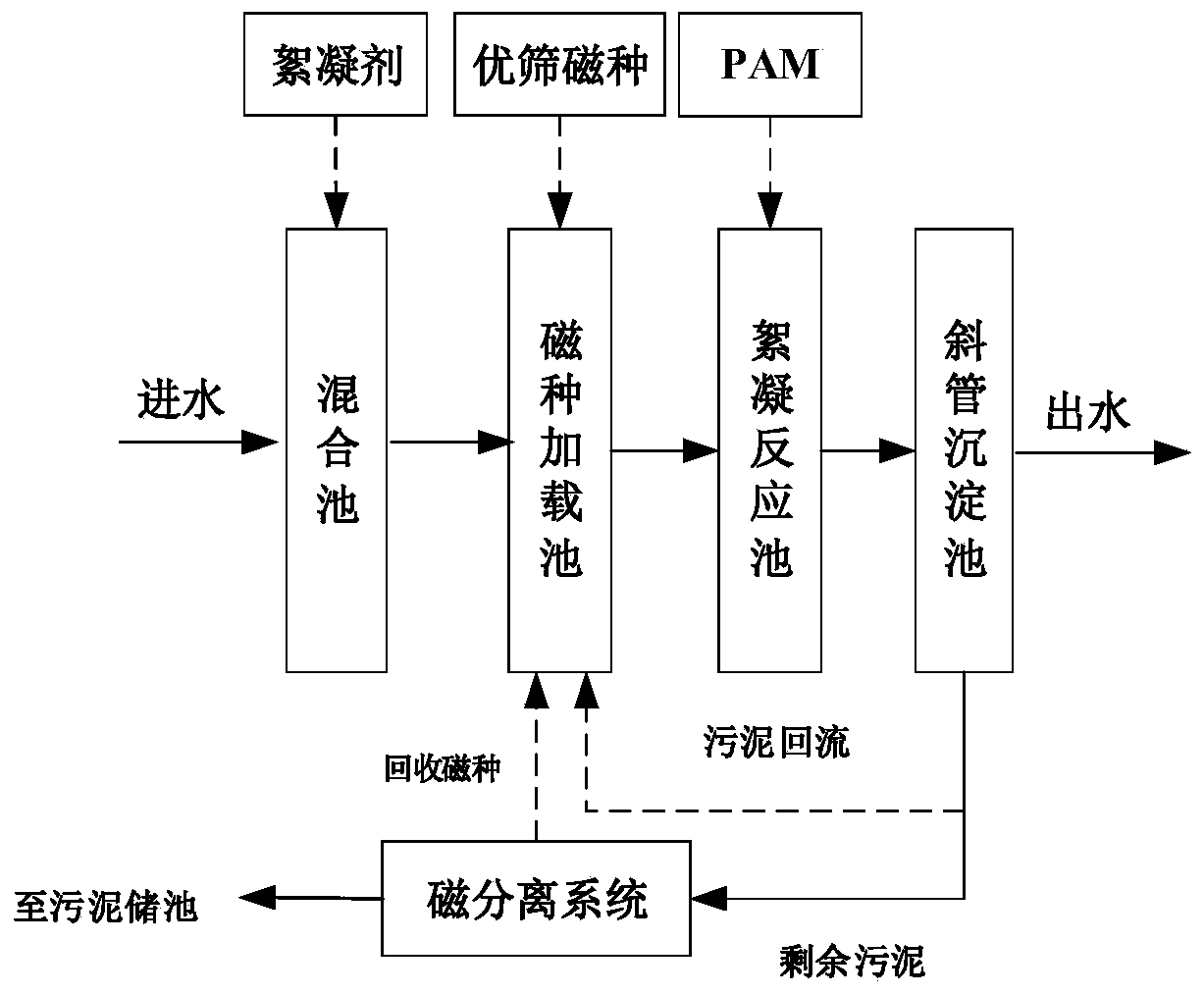

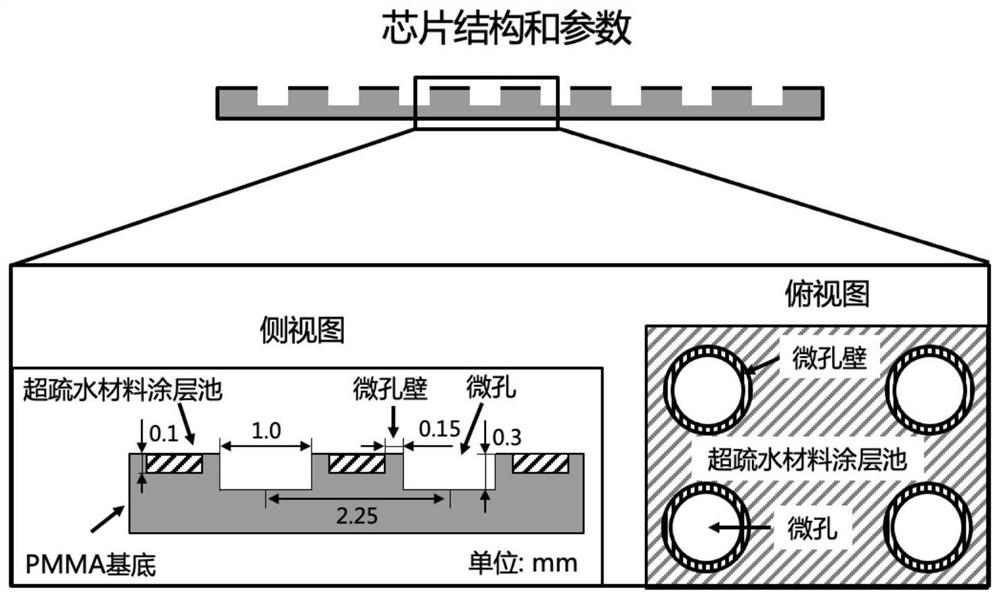

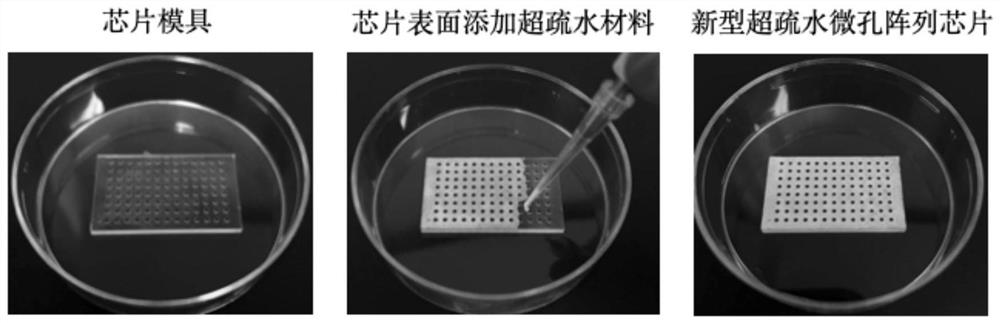

Method for preparing small-amount sample high-throughput chromatin co-immunoprecipitation sequencing sample

ActiveCN113462752AImprove throughputRealize the constructionMicrobiological testing/measurementLysisSpecific immunity

The invention discloses a method for preparing a small-amount sample high-throughput chromatin co-immunoprecipitation sequencing sample. The method comprises on-chip steps of conducting cell inoculation, cross-linking, cell lysis, chromatin fragmentation, specific co-immunoprecipitation reaction, in-situ DNA library construction and high-throughput sample coding; and off-chip steps of recovering an encoded sample from a chip, and then carrying out non-specific cleaning, de-crosslinking, purification, pre-amplification and on-chip sequencing. The chip is a novel super-hydrophobic micropore array chip. A high-throughput chromatin co-immunoprecipitation-sequencing (ChIP-seq) technical platform established on the basis of the novel super-hydrophobic microporous array chip provided by the invention can provide a convenient and feasible solution for realizing a ChIP-seq technology of a small number of cells.

Owner:TSINGHUA UNIV

Domestic sewage treatment device for ship

ActiveCN102417280BSufficient and uniform biological oxidation reactionImprove the efficiency of biochemical reactionsWater/sewage treatment by irradiationMultistage water/sewage treatmentStable stateSewage

Owner:安庆泰邦船舶科技有限公司

Efficient denitrification system and method for treating aged landfill leachate through combination of humic filler aerobic fixed bed and anoxic MBR

ActiveCN111470630AFull nitrificationEfficient and low consumption removalTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesMicroorganismNitrate salts

The invention belongs to the field of wastewater treatment, and discloses an efficient denitrification system and method for treating aged landfill leachate through combination of a humic filler aerobic fixed bed and an anoxic MBR. The method includes 1) introducing aged landfill leachate into the humic filler aerobic fixed bed for aerobic nitrification reaction treatment to obtain treated effluent; (2) enabling the effluent treated in the step (1) to automatically flow into the anoxic MBR for anoxic denitrification treatment. Firstly, sufficient aerobic nitrification is performed by utilizingthe strong nitrification capacity of microorganisms existing in a humic filler of the humic filler aerobic fixed bed to realize sufficient nitrification of ammonia, and sufficient denitrification isachieved through combination with the anoxic MBR. Sufficient nitrate is generated by utilizing the sufficient aerobic nitrification reaction in the previous step, so that the sufficient nitrate in thedenitrification of the anoxic MBR is ensured, a good denitrification condition is provided for the anoxic MBR, and finally, the high-efficiency and low-consumption removal of total nitrogen is realized.

Owner:NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com