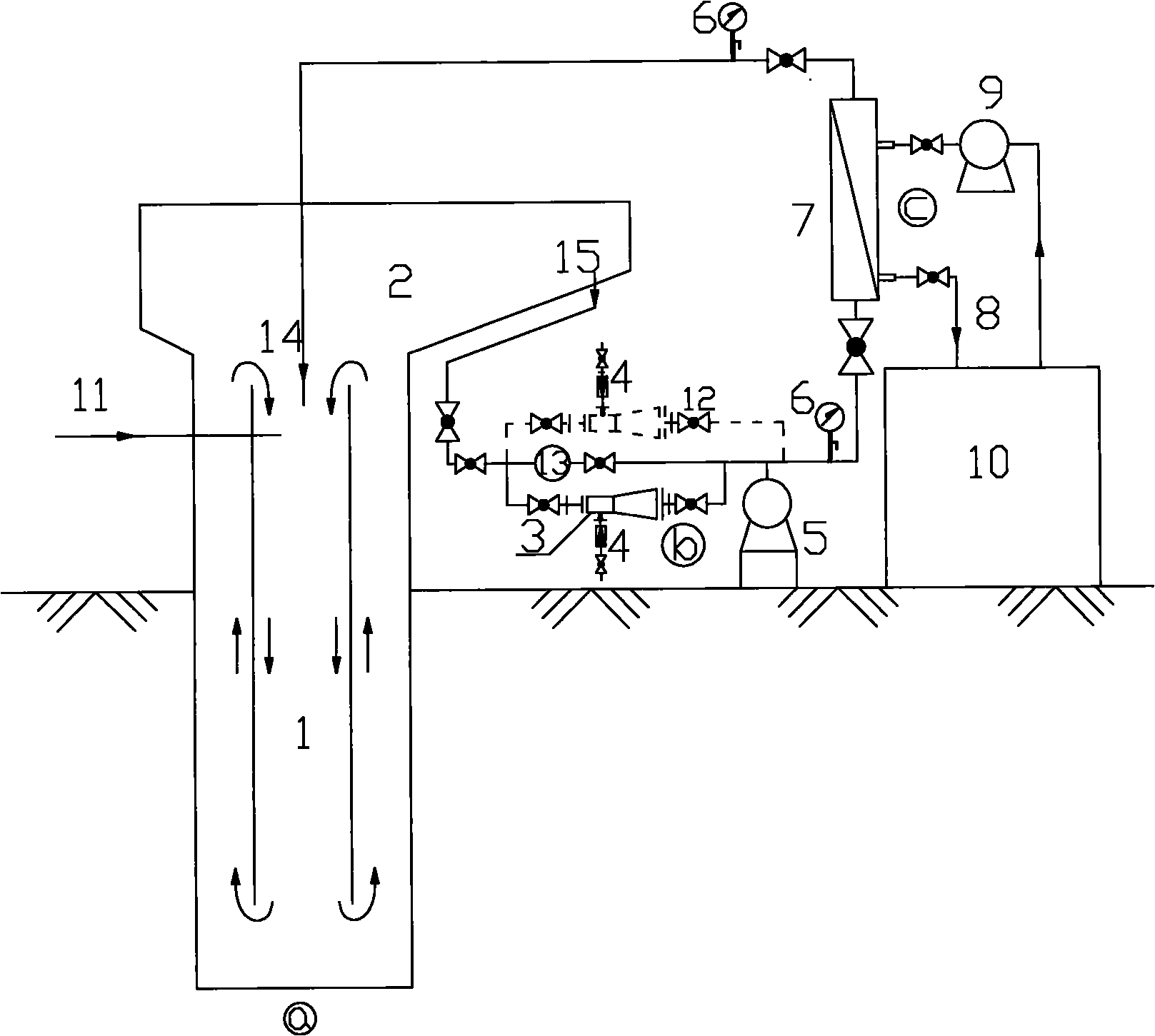

Self-priming jet aeration external membrane bioreactor

A membrane bioreactor, bioreactor technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high operating costs and investment in external membrane bioreactors High problems, to achieve the effect of reducing operating costs, prolonging membrane cleaning cycle and service life, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

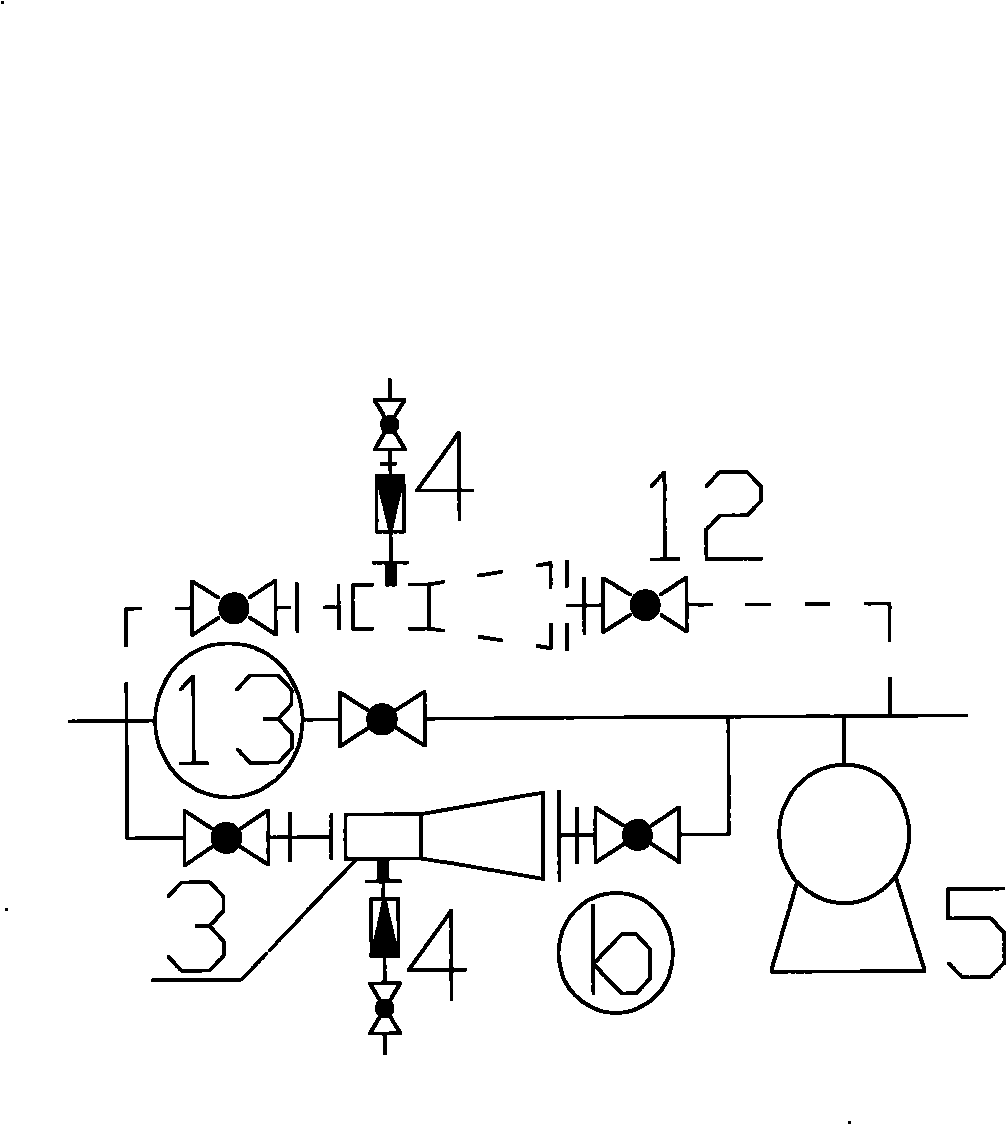

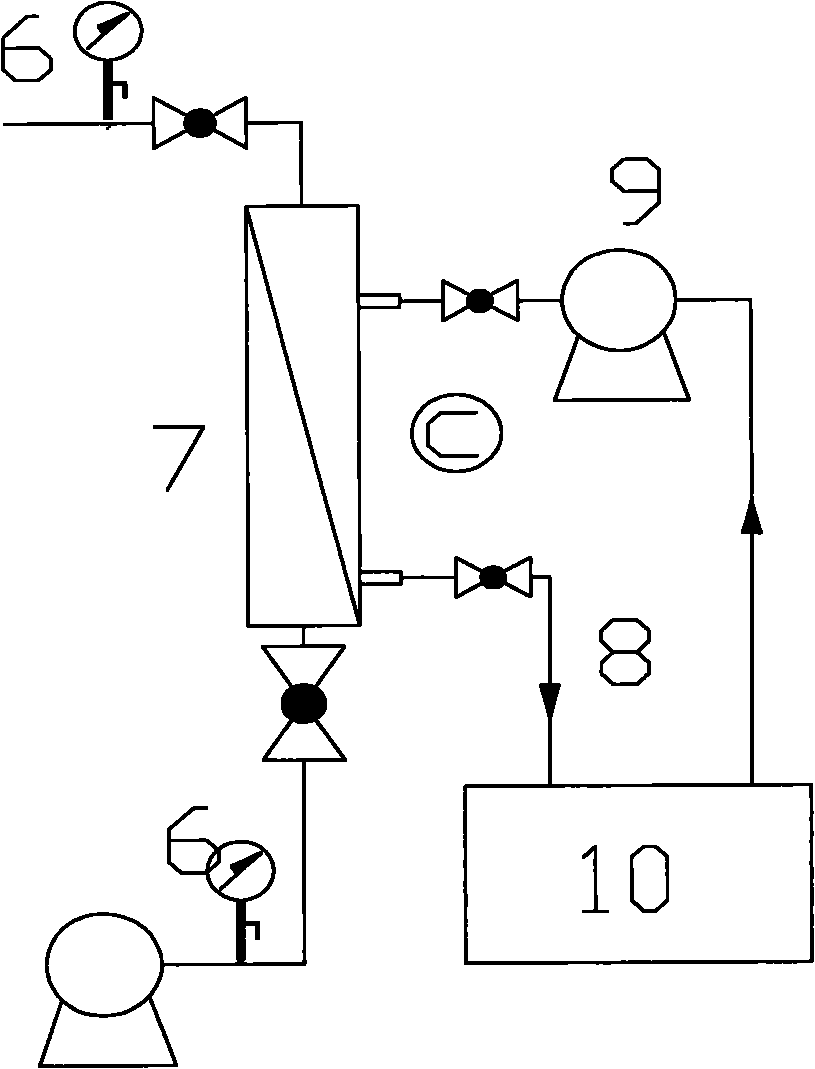

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, utilize the device of the present invention to process a municipal sewage plant waste water, the index of inlet and outlet water is:

[0028] project

[0029] The treatment effect is higher than the first grade A standard of GB18918-2002, and the water output is stable.

Embodiment 2

[0030] Embodiment 2, using the device of the present invention to process simulated domestic sewage, the water inlet index of the reaction device is:

[0031] The treatment effect is better than the GB18918-2002 Grade A standard, and the water output is stable.

[0032] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com