Dynamic composite sludge membrane treatment process

A treatment process and technology of composite mud, which are applied in water/sludge/sewage treatment, return water treatment, biological treatment devices, etc., can solve the problems of low treatment efficiency, large area and low utilization rate of aeration, etc. Achieve the effect of increasing sludge volume and treatment efficiency, increasing sludge residence time, and simple and convenient operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

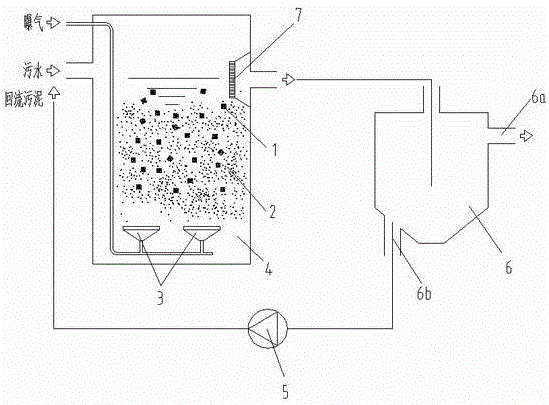

[0012] figure 1 A flow chart of a dynamic composite mud film process is shown. In the figure, in the actual construction, the dynamic composite mud film reaction tank 4 and the sedimentation tank 6 are built, and then the aeration device 3 and the sludge return pump 5 are configured. Prevent packing loss. The volume of the dynamic compound mud film reaction tank can be reduced to half of the volume of the conventional aerobic tank, and 30-40% of multiphase flow-dynamic film microbial carrier filler is added to the dynamic compound mud film reaction tank, which increases after the dynamic compound mud film reaction tank The bottom of the settling tank pumps 100-150% of the sewage flow back to the reaction tank as activated sludge backflow. The MLSS index in the dynamic composite mud membrane reaction tank can reach 15-20g / L; the indicators of the dynamic composite mud membrane sewage treatment process are: nitrification rate (max): >1500 gNH3-N g / m3.d, BOD treatment rate (ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com