Complex organic sewage step purification process

A technology of organic sewage and purification process, applied in water/sewage multi-stage treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of low cost, non-biological toxicity of wastewater, high process cost, and achieve anti-heavy metal Strong ion impact, efficient destruction of stability, and the effect of increasing dissolved oxygen value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

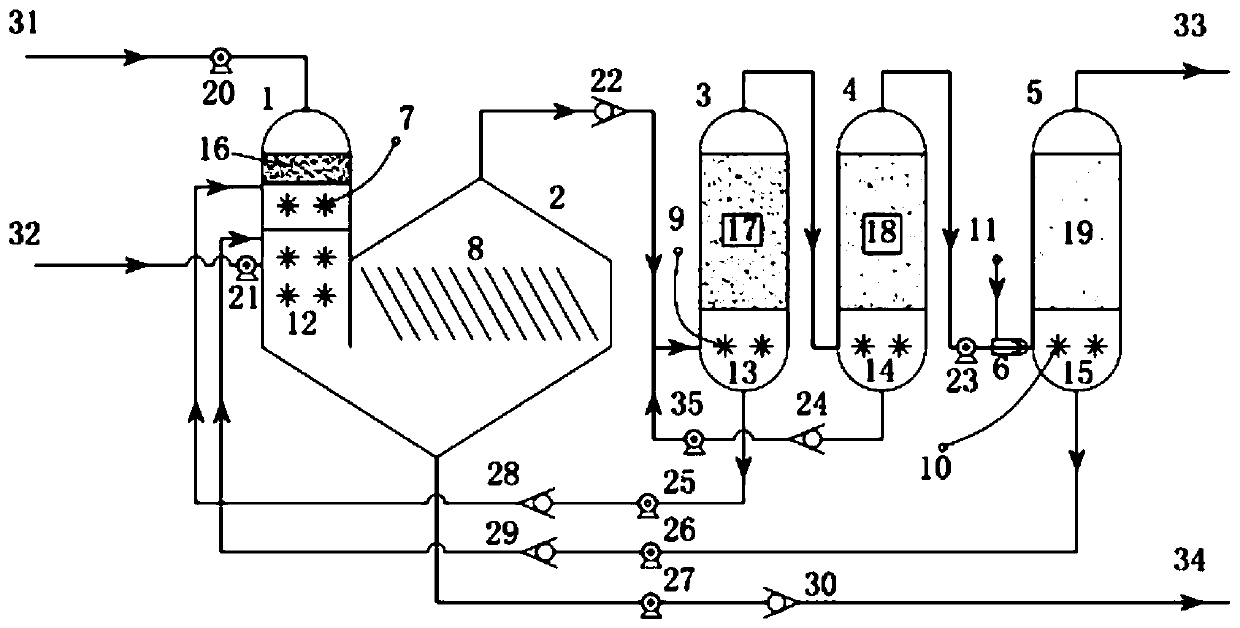

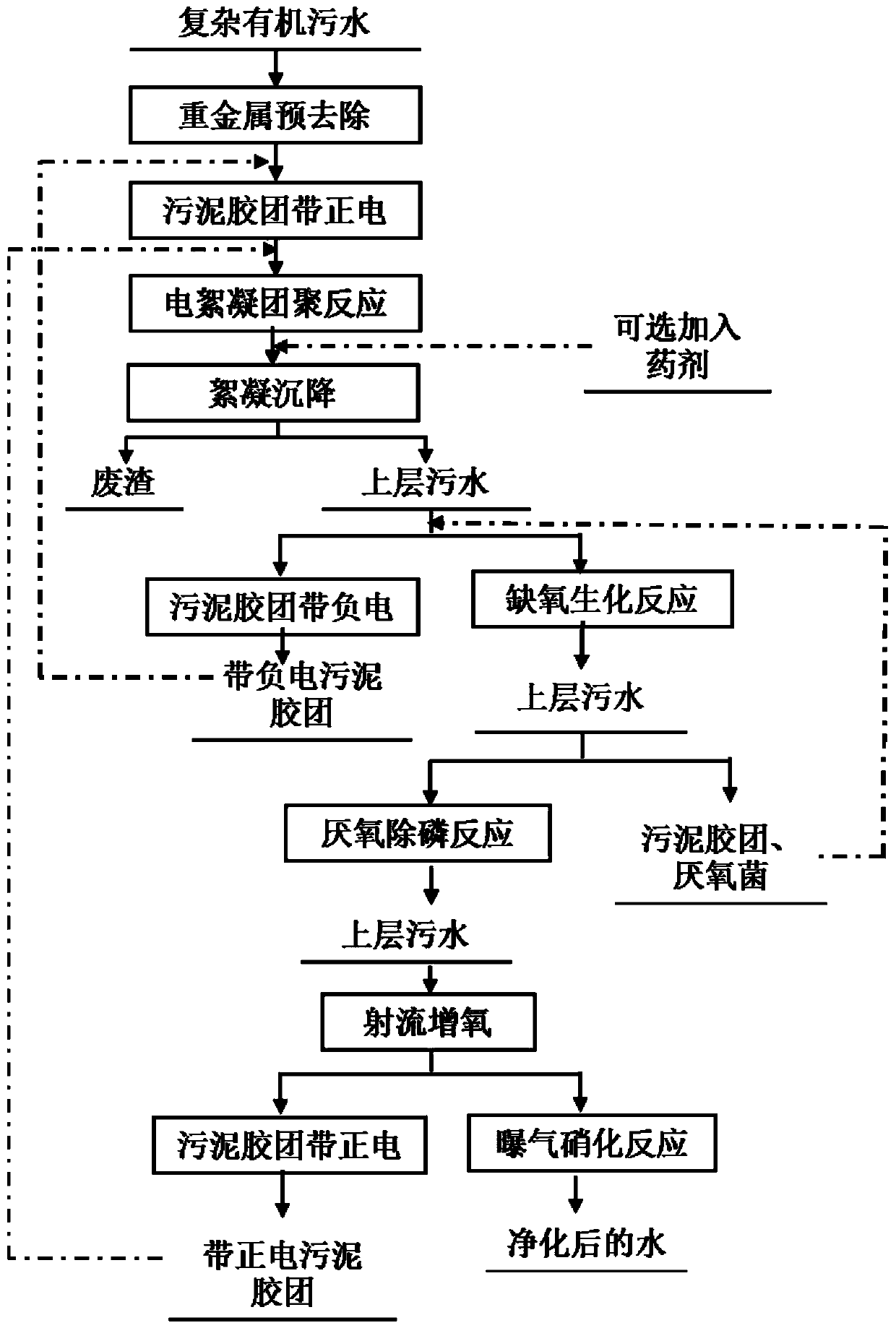

[0028]A cascade purification process for complex organic sewage. This process is suitable for the treatment of complex organic sewage such as suspended solids (SS), ammonia nitrogen organic matter, and phosphorus-containing organic matter in wastewater. It can be applied to the treatment and improvement of black and odorous water bodies, and the treatment of livestock and poultry breeding wastewater. , Domestic sewage treatment, rural lake and pond water restoration and other scenarios, it has the advantages of effectively improving the agglomeration performance of sludge flocculation particles, reducing microbial poisoning in biochemical areas and preventing suspended particles from blocking the packing layer, so as to achieve low reliability with high efficiency, energy saving and low cost. The complex organic wastewater with high biochemical rate and impurities can be discharged up to the standard, which is an economically feasible, stable performance and high water purificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com