Low-dissolved-oxygen biochemical reaction system and process thereof

A biochemical reaction, low-dissolution technology, applied in the field of water treatment, can solve the problem of high energy consumption of return pumps, reduce energy consumption and equipment use, improve biochemical reaction efficiency, and reduce the use of pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

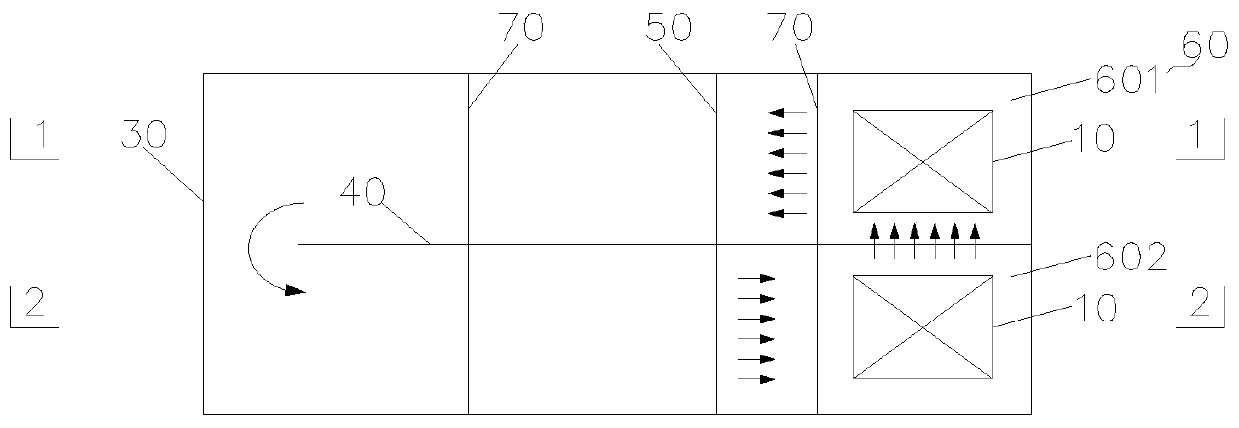

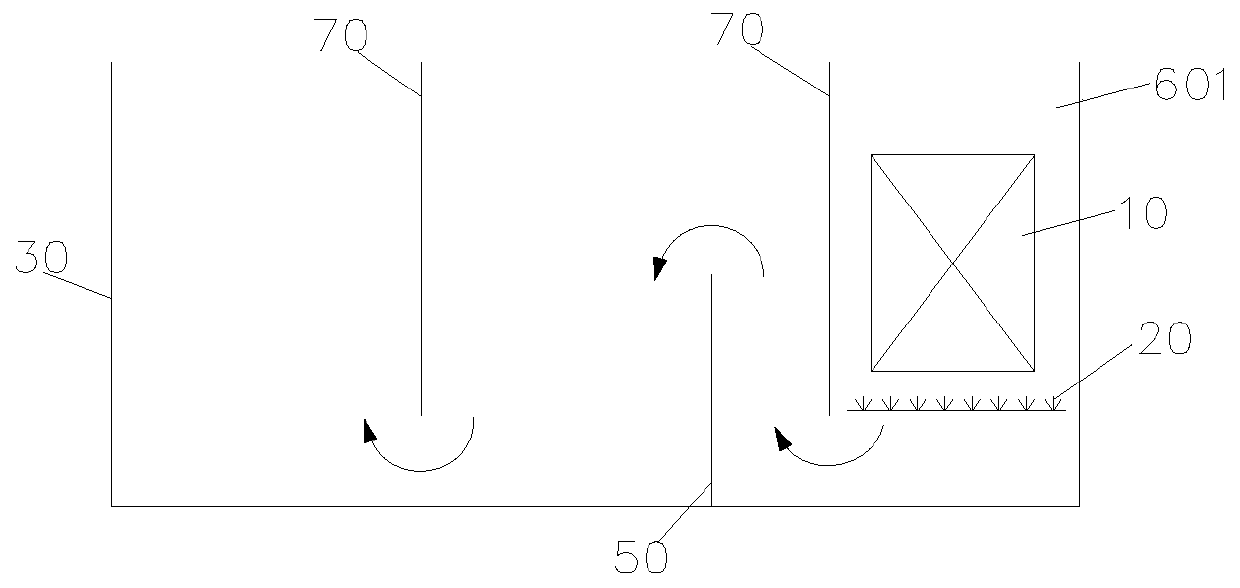

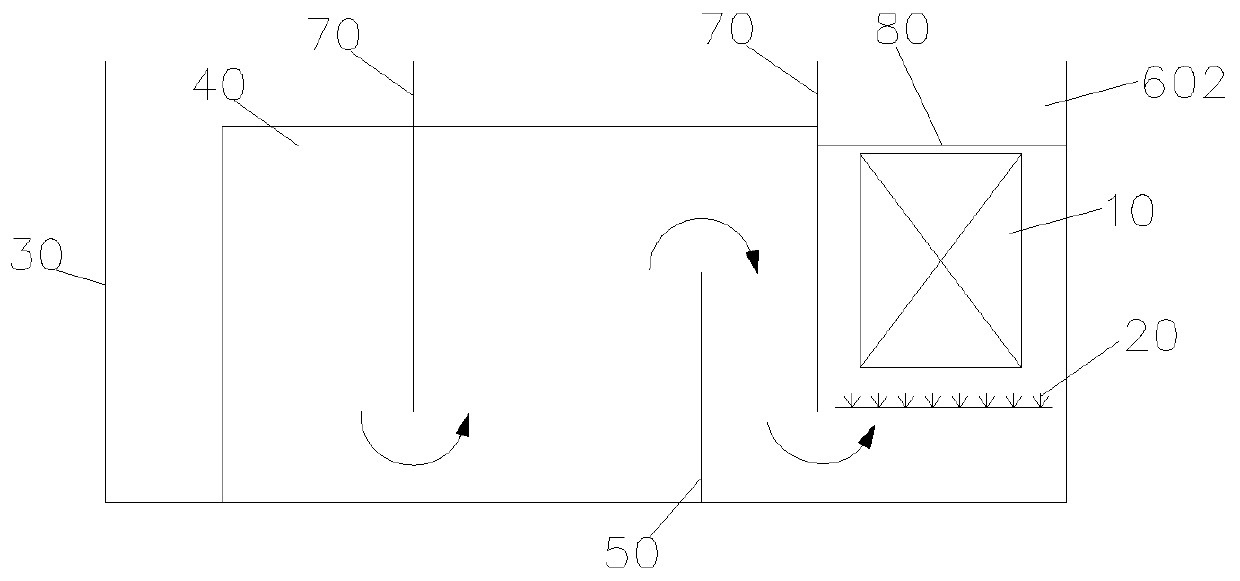

[0041] Such as Figure 1-3 As shown, a low dissolved oxygen biochemical reaction system includes two membrane tanks 60, each membrane tank 60 is provided with a membrane module 10, and the bottom of each membrane module 10 is provided with an aeration device 20, The aeration device 20 is used to flush and aerate the membrane module 10, and the two membrane pools 60 are arranged adjacent to each other, and the operation mode of intermittent aeration is adopted between the two membrane pools 60, and It includes a reaction channel 30 communicating with the two membrane pools, a partition wall 40, at least one upper opening deflector group 50 and at least one lower opening deflector group 70;

[0042] The reaction channel 30 communicates with the two membrane pools 60 through one of the lower opening guide plate groups 70 to form a reaction zone, and the reaction channel 30 is used to pass the solution containing dissolved oxygen when one of the membrane pools 60 is aerated. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com