Sewage treatment system and sewage treatment process based on super-effect separation

A technology of sewage treatment system and separation system, which is applied in the field of sewage treatment system and process based on ultra-efficient separation, high-concentration organic wastewater pretreatment process, and can solve high one-time investment costs, high management and maintenance costs, and large economic burdens and other issues, to achieve the effect of saving one-time investment costs, good economy, and reducing the burden on enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

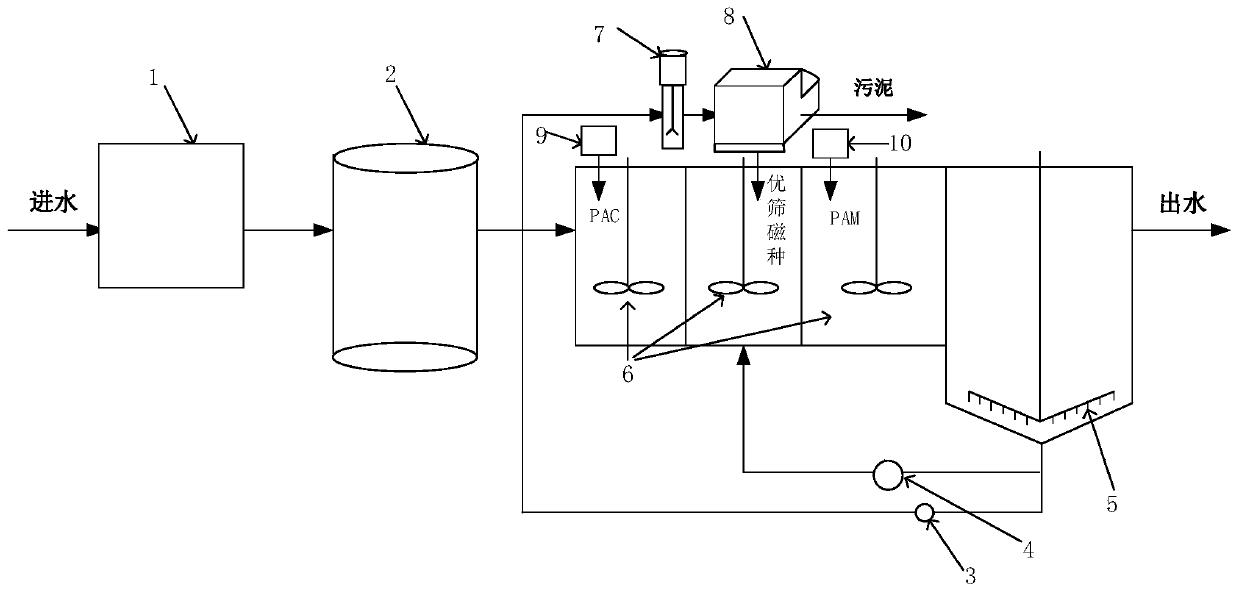

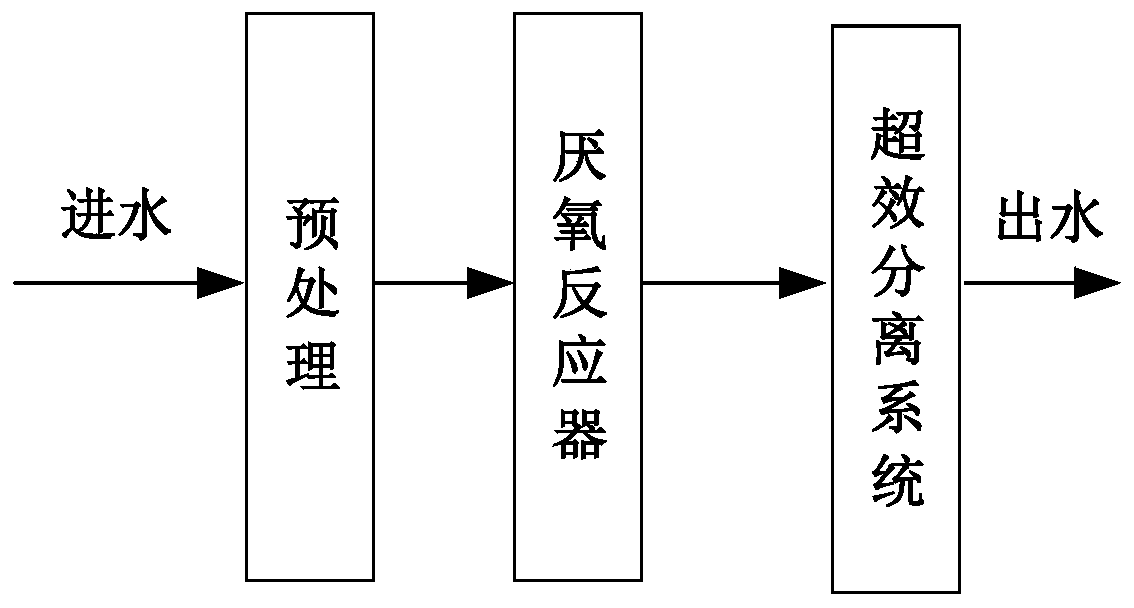

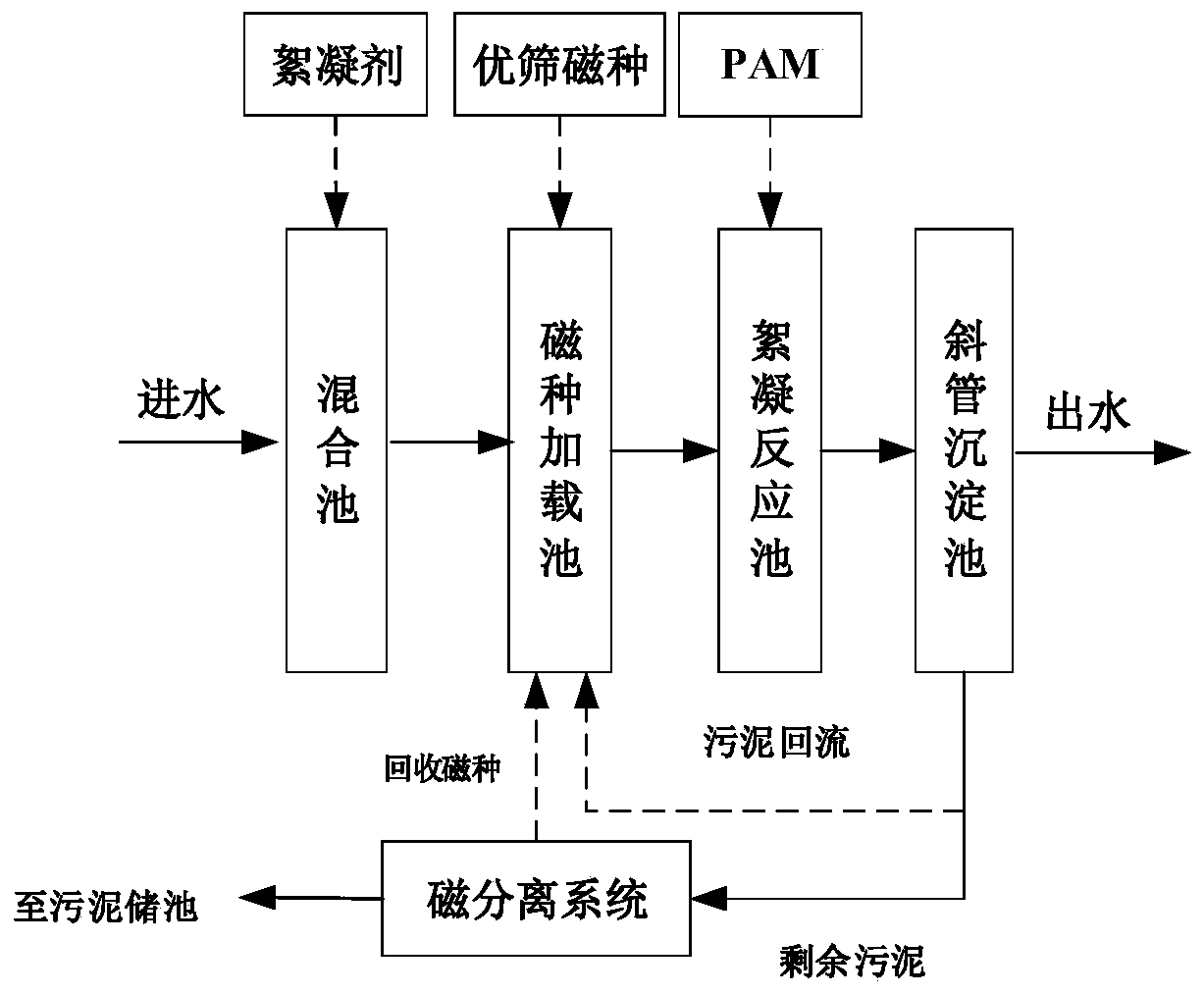

Method used

Image

Examples

Embodiment 1

[0041] The present invention is applied to a certain brewery wastewater treatment plant.

[0042] The treatment plant is designed to handle 7000m 3 / d, its water quality characteristics are: high COD, TN, TP.

[0043] See Table 1 for influent and effluent water quality:

[0044] Table 1

[0045] index COD (mg / L) TN (mg / L) TP (mg / L) SS(mg / L) Influent water quality 1500-2000 50-90 8-12 260-700 Water quality <350 <40 <1.2 <10

[0046] It can be known from Table 1 that the wastewater index of the enterprise can be stably reached the sewer discharge standard by adopting the present invention to treat the waste water of the enterprise. COD removal rate> 82.5%, TN removal rate> 55.6%, TP removal rate> 90%, SS removal rate> 98.6%. The invention greatly saves the production cost of the enterprise, and at the same time plays a positive role in energy saving and consumption reduction of the enterprise. The stable pre-treatment effluent is then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com