Method for treating cyclization wastewater generated in production process of epoxy chloropropane

A technology for the production process of epichlorohydrin, which is applied in the field of cyclization wastewater treatment, can solve the problems of reducing the competitiveness of epichlorohydrin products, strong corrosion of salt wastewater, and no clear instructions, so as to shorten the residence time, The effect of increasing the concentration of salt and accelerating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

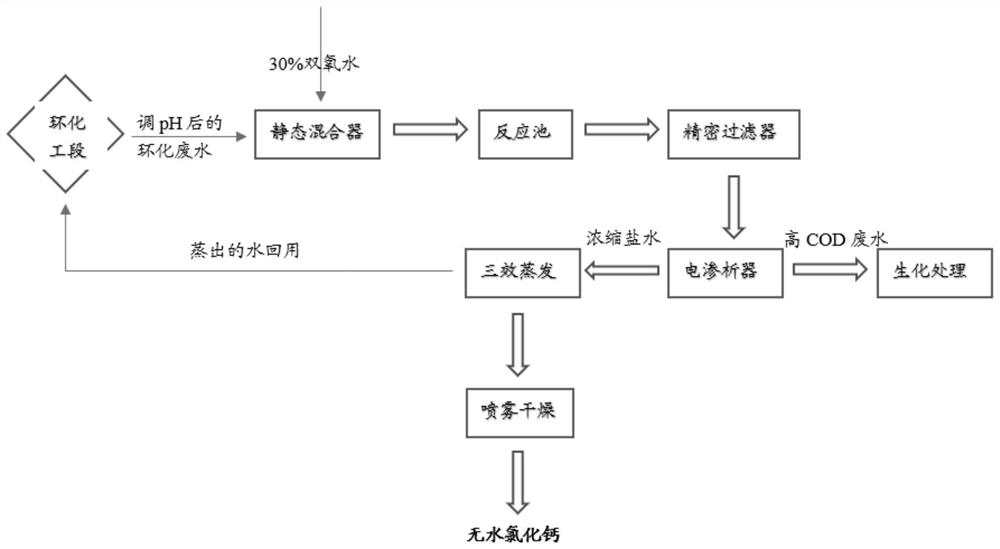

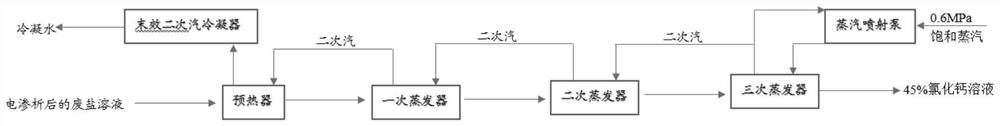

Image

Examples

Embodiment 1

[0036] In this example, the composition of the wastewater produced by the cyclization of calcium hydroxide to epichlorohydrin is shown in Table 1.

[0037] Table 1. The composition table of the wastewater produced by the cyclization of calcium hydroxide to epichlorohydrin

[0038] serial number name Specification 1 water (H 2 O)

0.828 2 Calcium Hydroxide (Ca(OH) 2 ),wt%

0.006 3 Magnesium Hydroxide (Mg(OH) 2 ),wt%

0.009 4 Calcium Chloride (CaCl 2 ),wt%

0.134 5 Glycerin (C 3 h 8 o 3 ),wt%

0.012 6 Monochloropropanediol (C 3 h 7 ClO 2 ),wt%

0.0006 7 Calcium Carbonate (CaCO 3 ),wt%

0.010 8 Calculation of chemical oxygen demand COD, mg / L 10688

[0039] (1) Pretreatment

[0040] The cyclized calcium chloride wastewater from the bottom of the cyclization tower of the epichlorohydrin unit enters the wastewater buffer tank, adds 30% hydrochloric acid to adjust the pH to 5-6, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com