Patents

Literature

182results about How to "Large mass transfer area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

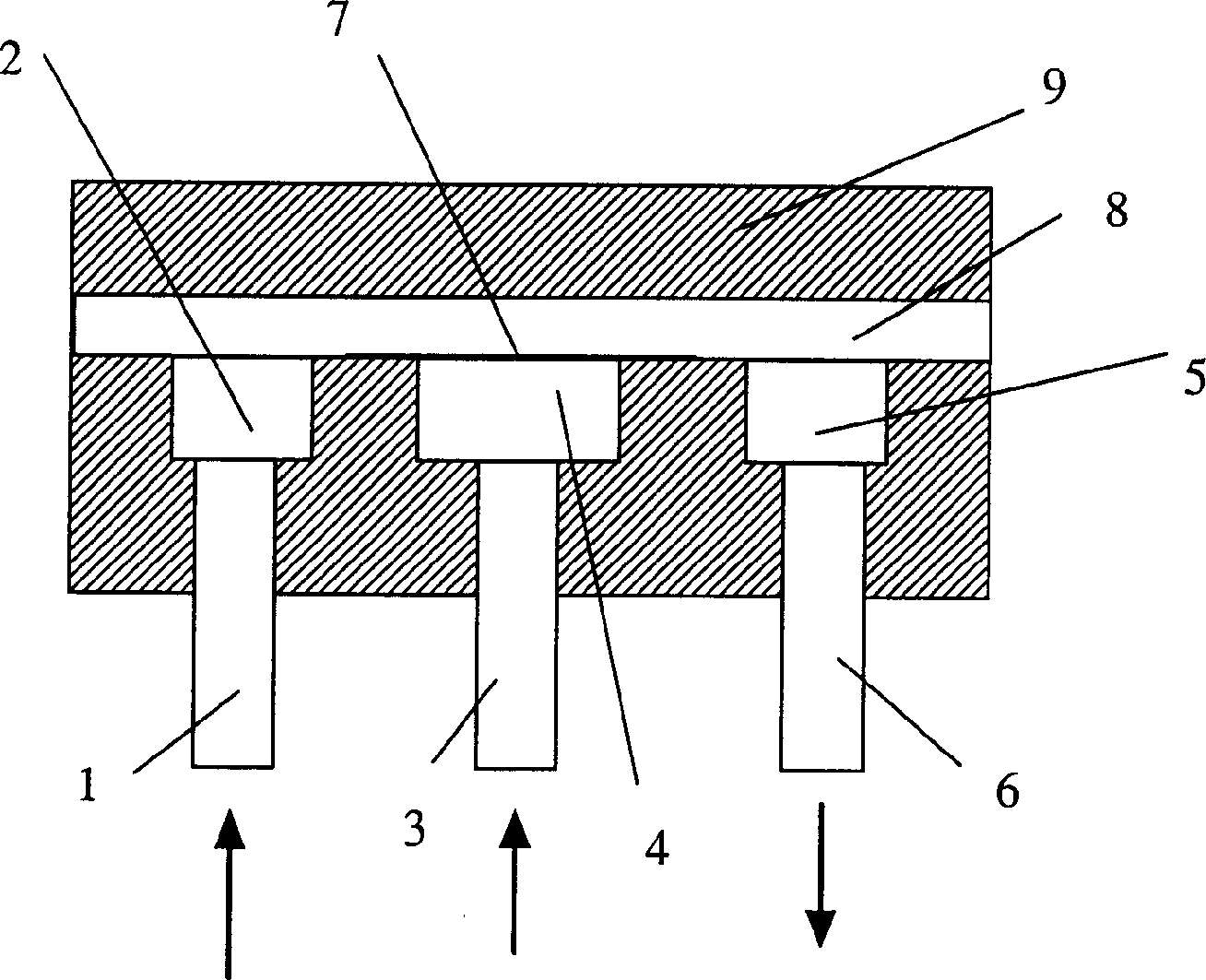

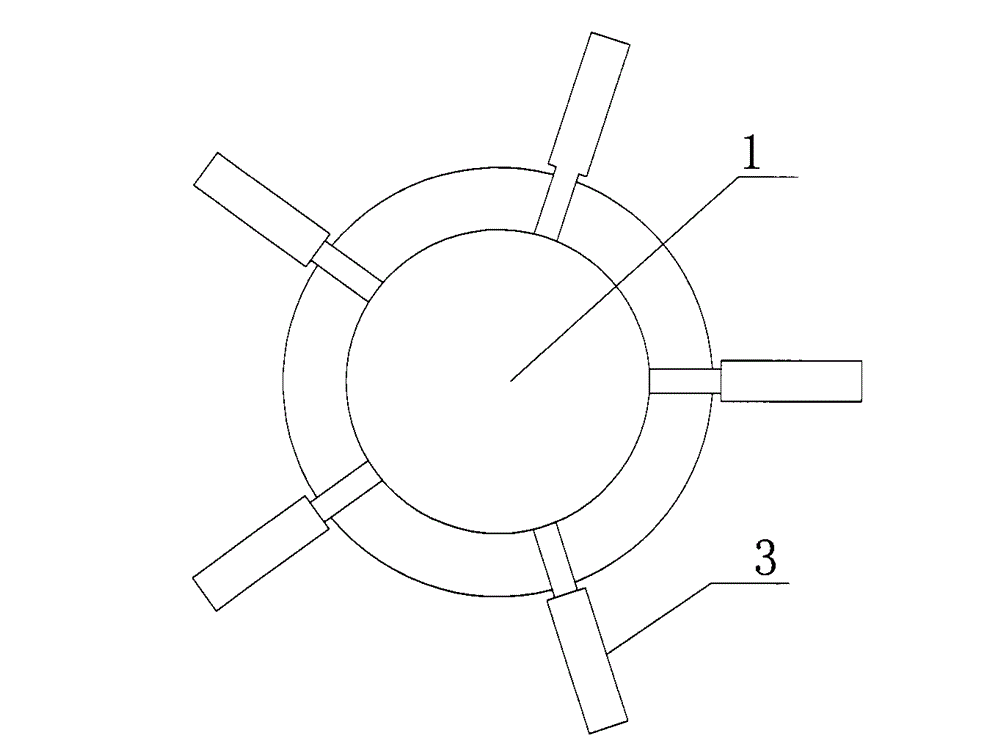

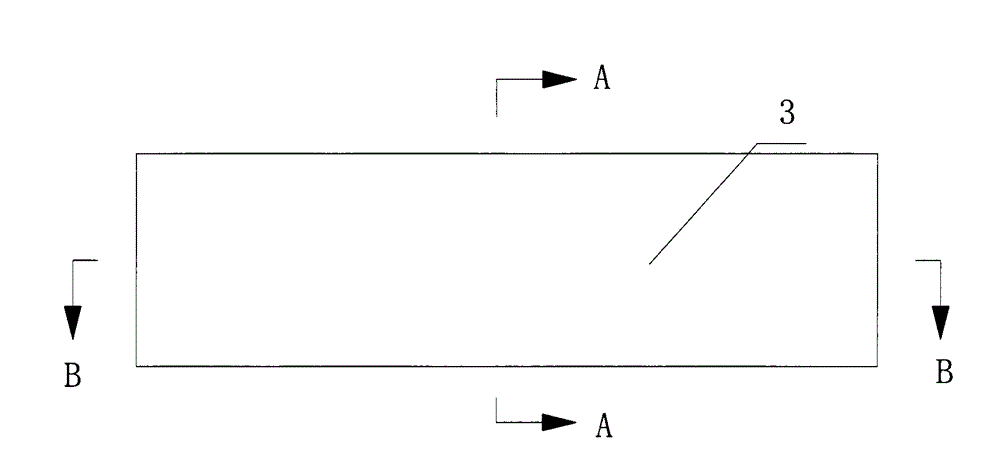

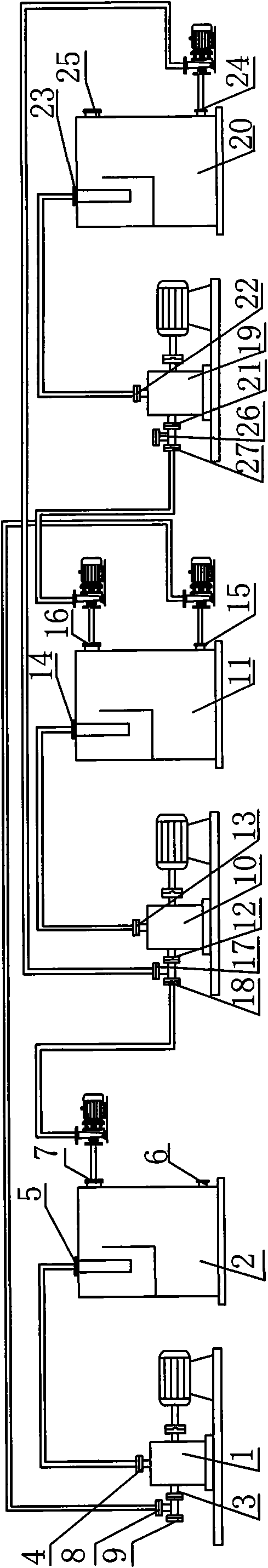

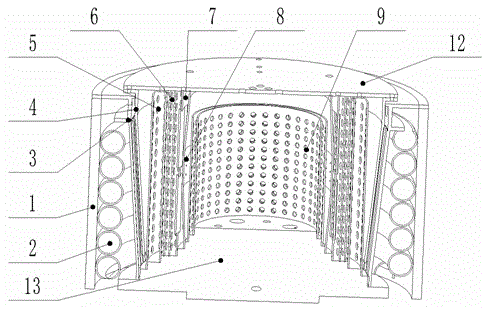

Multi-channeled micro-structured reactor

ActiveCN1736577AHigh selectivityIncrease throughputChemical/physical/physico-chemical processesLiquid-gas reaction processesEngineeringParallel channel

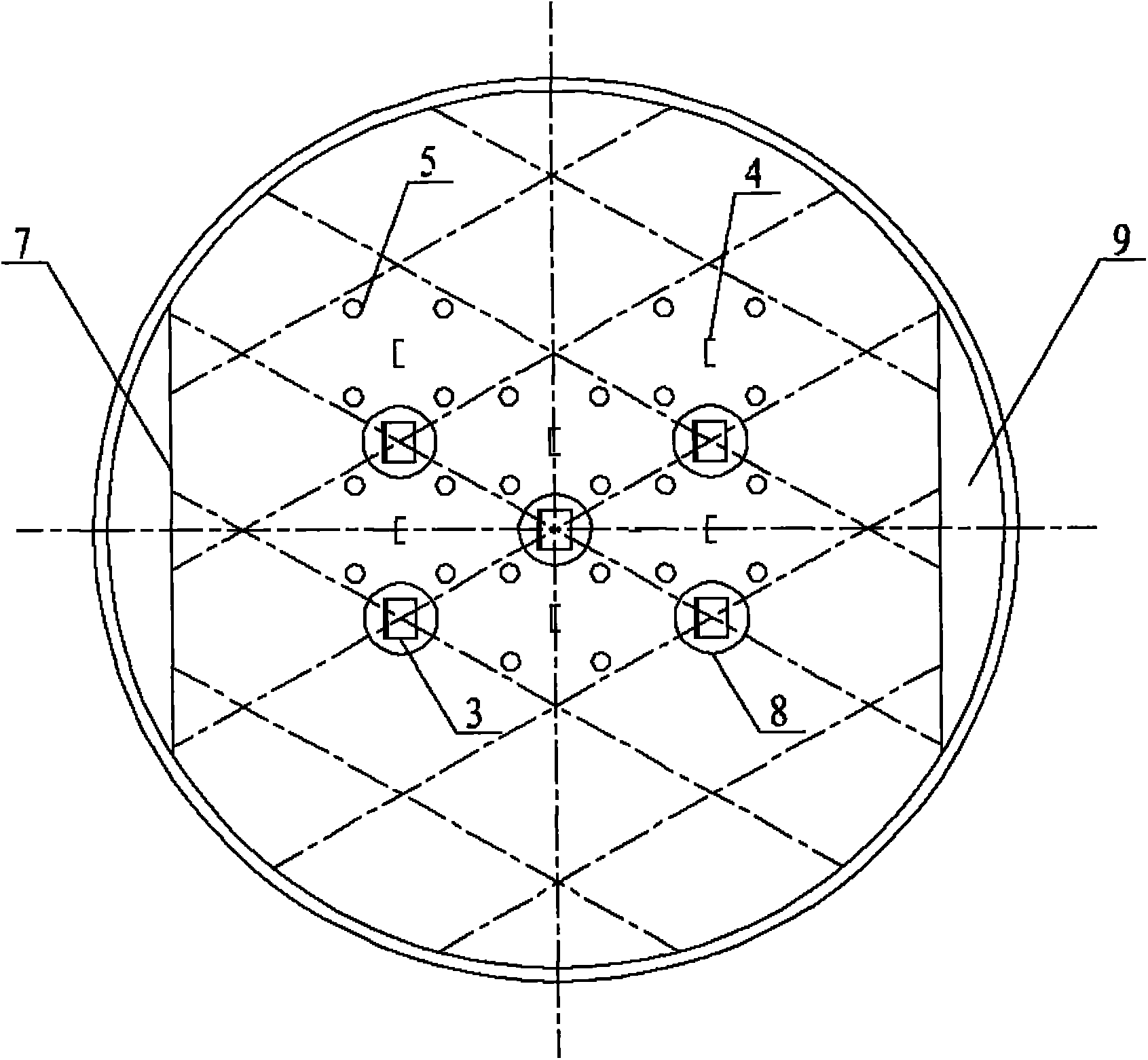

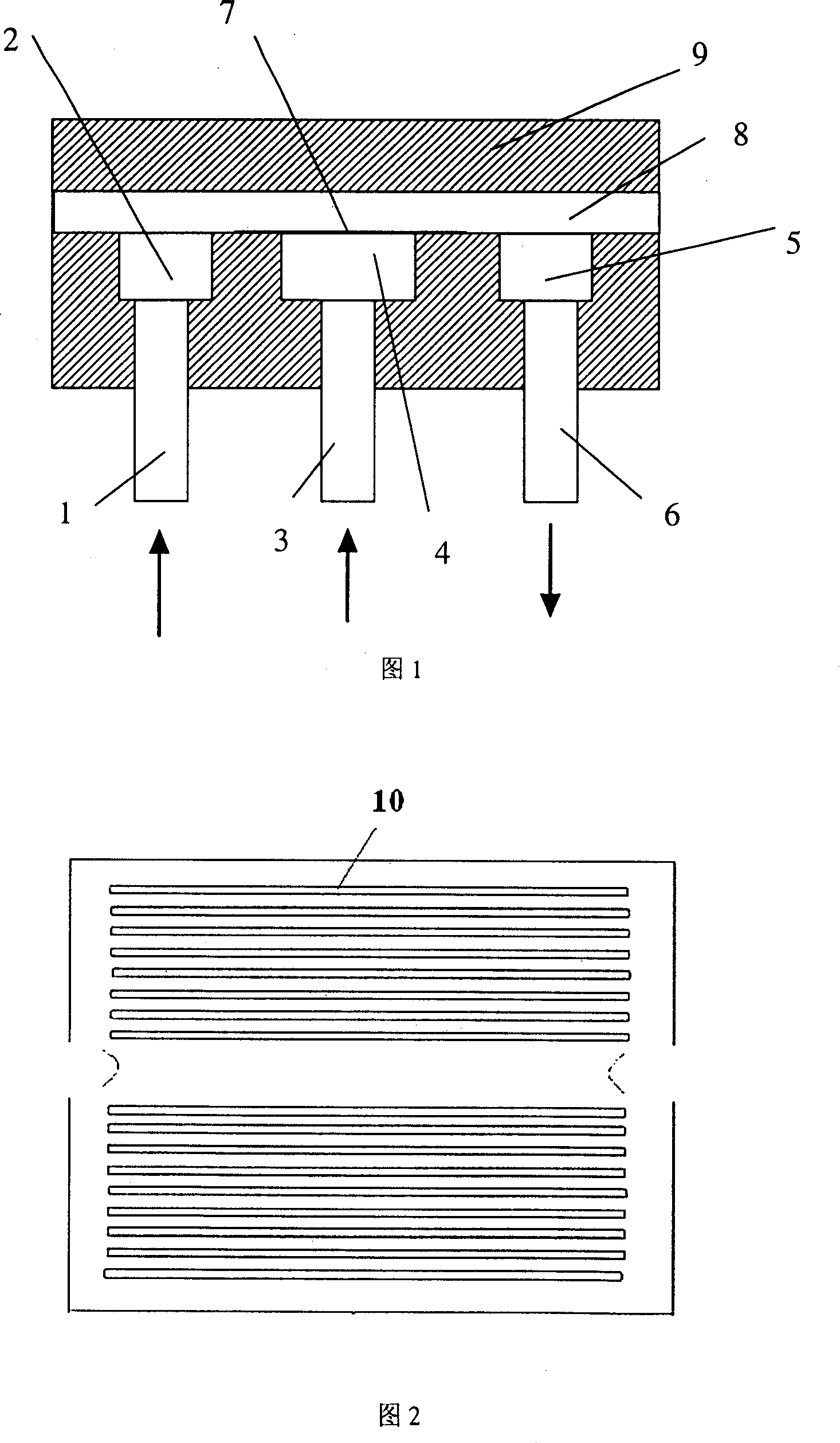

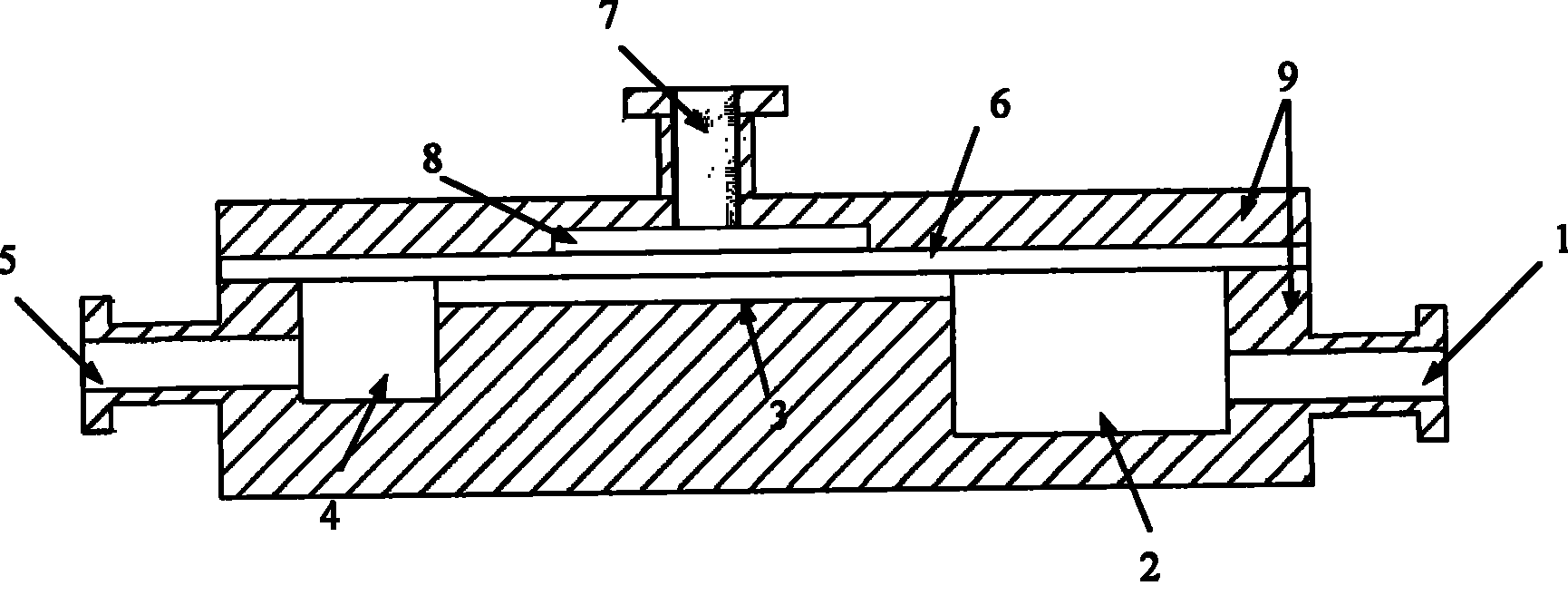

Disclosed is amultichannel reactor with microstructure. Continuous phase inlet pipe and distribution chamber, discontinuous phase inlet pipe and distribution chamber, mixture phase buffer chamber and fluid outlet pipe connects separately, and they compose the lower cavity. Porous distribution medium is sealed in the upper distribution chamber of discontinuous phase. A parallel channel plate of continuous phase is located above the lower cavity and the upper is sealed. The continuous phase liquid flows into the reactor from the distribution chamber of inlet pipe; the discontinuous liquid flows into the parallel channel of continuous phase following through the distribution medium, distributes into minute drop or air bubble with the floating shearing force of continuous phase liquid, and then connects with the continuous phase liquid to realize the rapid mixture and reaction of the two- phase liquid; then the liquid flows out of the reactor. With the invention, the area of mass transfer is big, the reaction conversion rate is high, and large scale production can be realized.

Owner:TSINGHUA UNIV

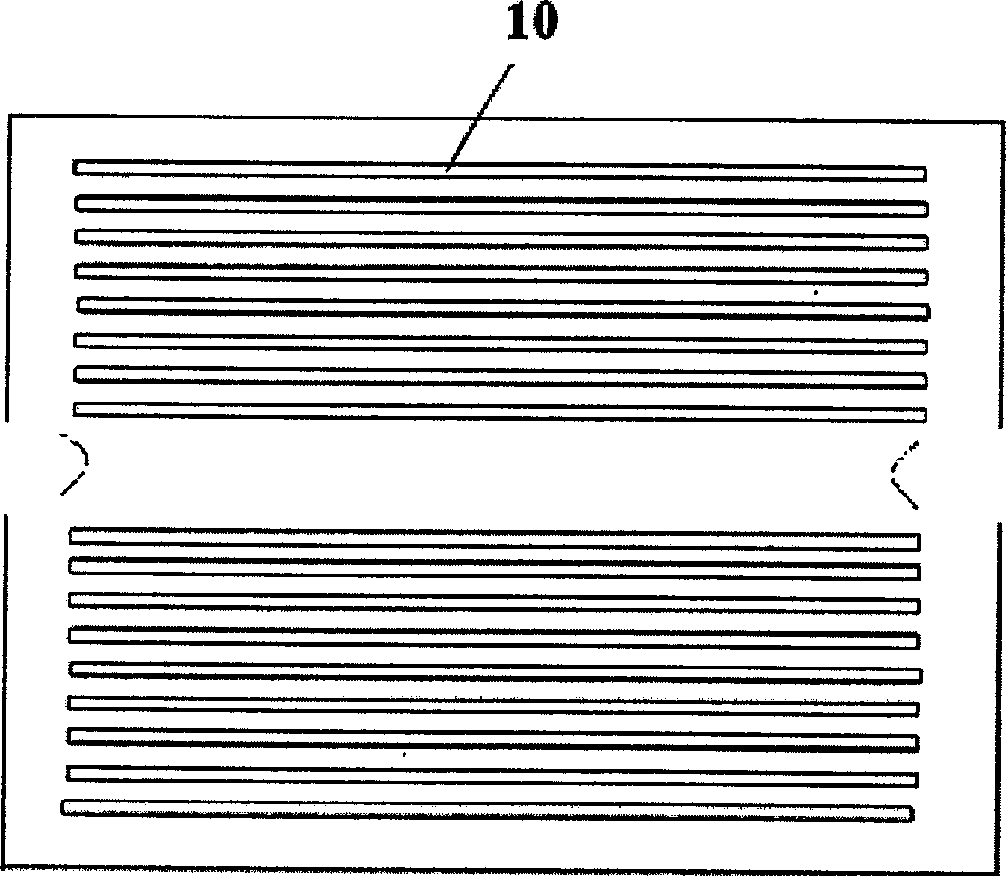

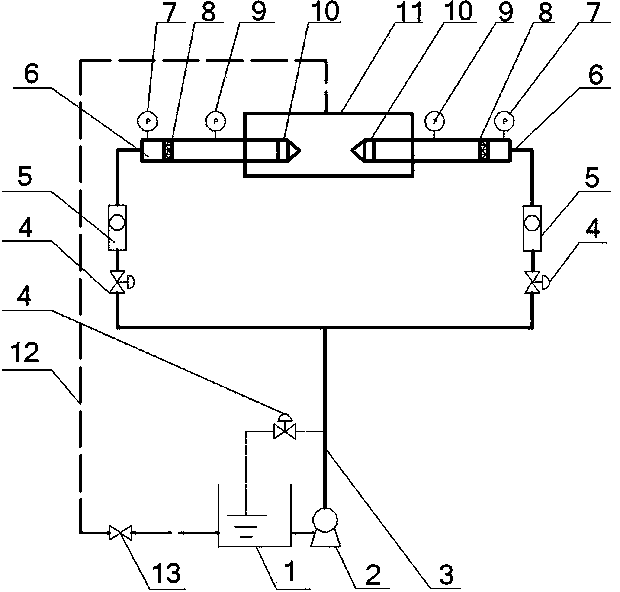

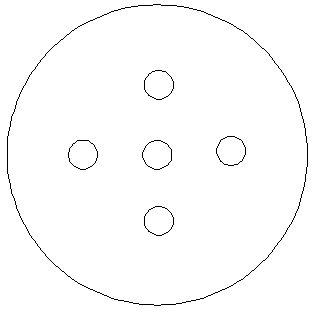

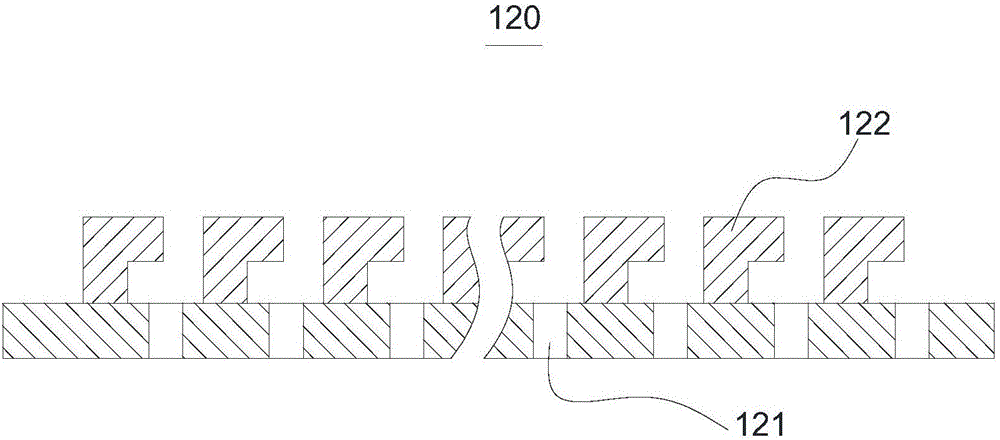

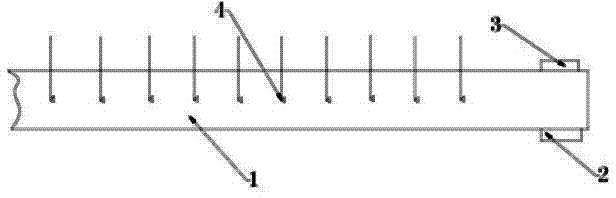

Reactor or mixer with micromesh structure

ActiveCN101224405AShort mass transfer distanceLarge mass transfer areaFlow mixersChemical/physical/physico-chemical processesEngineeringPetrochemistry

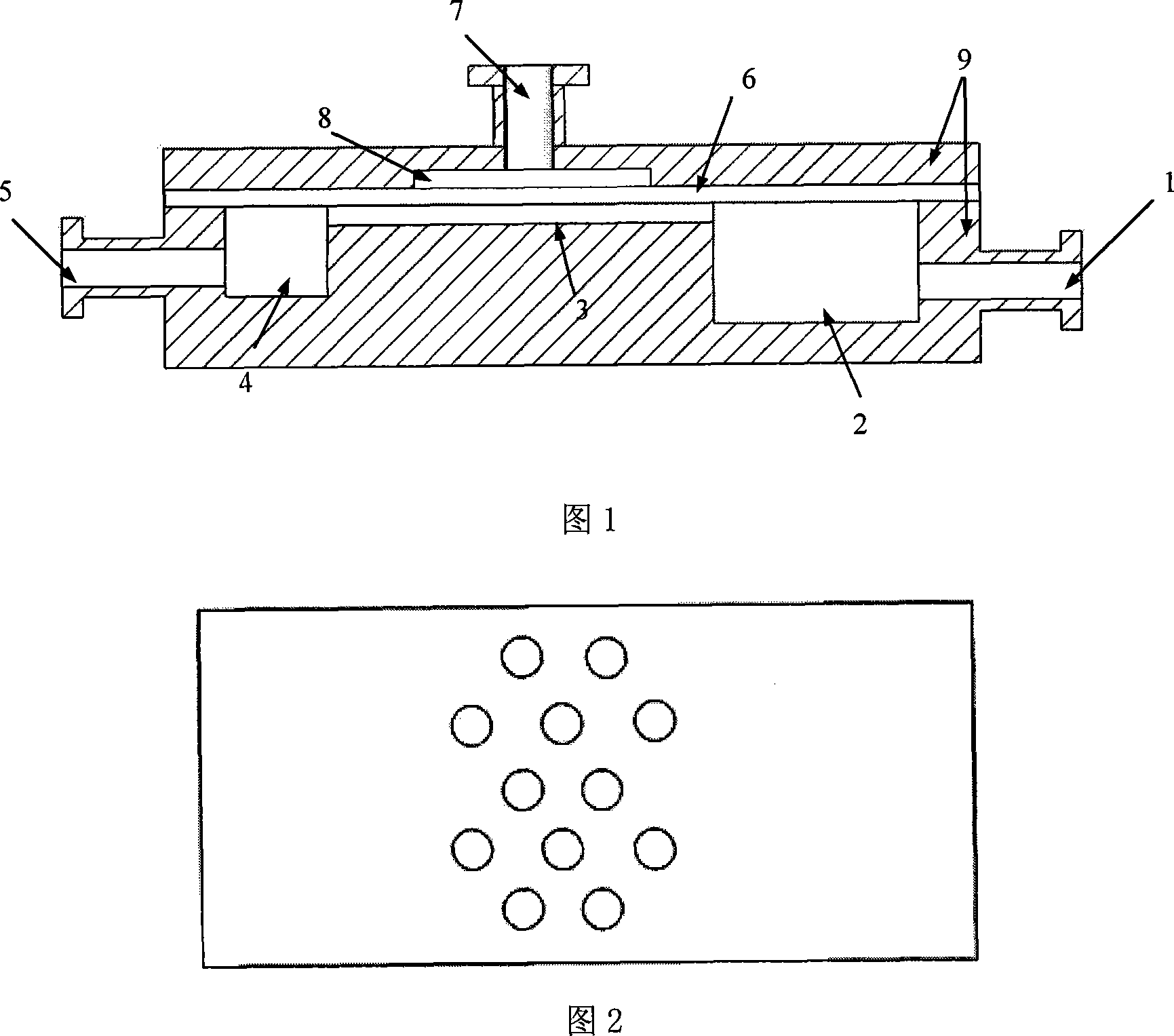

The invention provides a reactor or a blender with micro sieve mesh structure, which relates to the fluid micro dispersion technology and equipment. The invention contains micro sieve mesh structure, a hybrid channel and a fluid distribution chamber, and utilizes the micro sieve mesh to disperse one fluid to another fluid in a form of micron-sized drop or bubble, the blending and reaction process of the drop and the bubble which have high dispersion and high specific surface are rapidly finished in the hybrid channel, so the invention is a novel microstructure reaction vessel or blender which utilizes the micro sieve mesh structure to realize the reaction or blending of homogeneous phase or non homogeneous phase fluid. The invention is characterized by simple processing, convenient operation, large treating capacity for unit volume and so on and can be widely applied to a number of fields like the chemistry, chemical engineering, petrochemistry, medicine, foodstuff, etc.

Owner:TSINGHUA UNIV

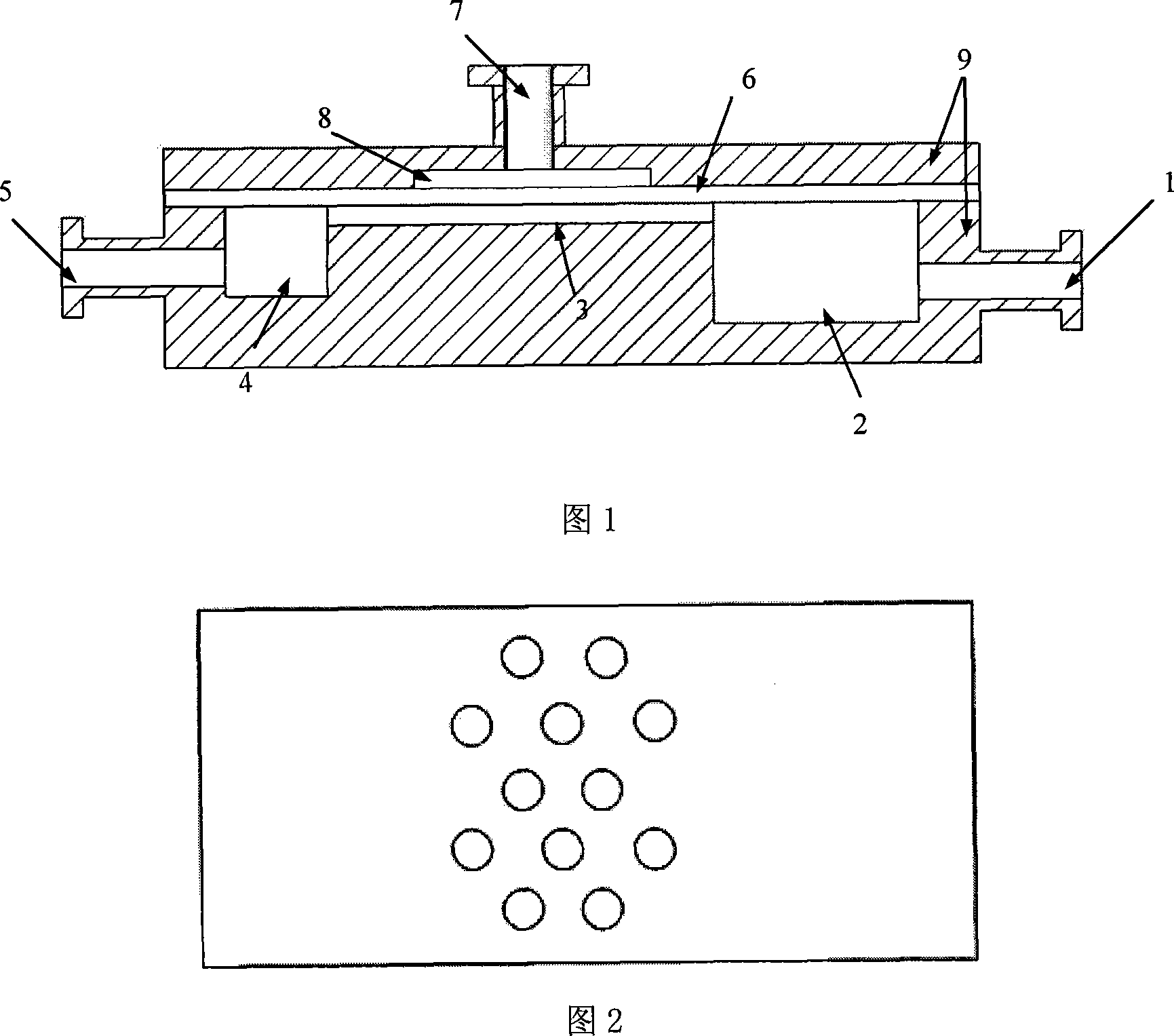

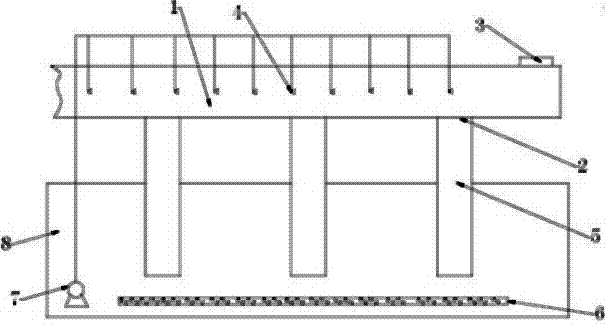

Micro-contact mixer

ActiveCN101234324AShort mass transfer distanceLarge mass transfer areaMixing methodsChemical/physical/physico-chemical processesChemical industryChemical process

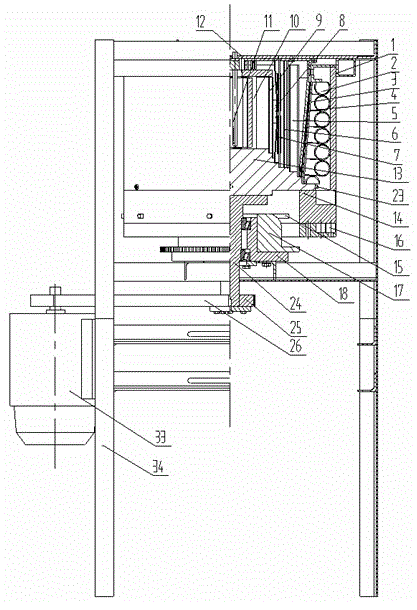

The invention relates to a high performance double multiple thin layer micro-contact mixer used for rapid mix, mass transfer and reaction of fluids in the chemical process, which belongs to the field of reaction and separation devices of chemistry and chemical engineering. The micro-contact mixer is formed by inserting an upper cavity chamber and a lower cavity chamber into an integral shell or by lapping closely connected shell components; a fluid inlet pipe of material A and a distribution chamber are communicated with a fluid parallel channel of material A; a fluid inlet pipe of material B and a distribution chamber are communicated with a fluid parallel channel of material B, thus forming the lower cavity chamber; a fluid mixing chamber and a mixed fluid outlet pipe are communicated to form the upper cavity chamber; two fluids enter the mixer from the inlet pipe through the distribution chamber respectively to make multiple thin layer contact in the fluid mixing chamber to realize rapid mix, mass transfer and reaction. The micro-contact mixer has the advantages of high mass transfer efficiency, high operational elasticity, uneasy blocking, easy processing and manufacturing and has good prospects in mixing and reaction fields such as the chemistry, chemical engineering, petrol-chemical industry, medicine and food.

Owner:TSINGHUA UNIV

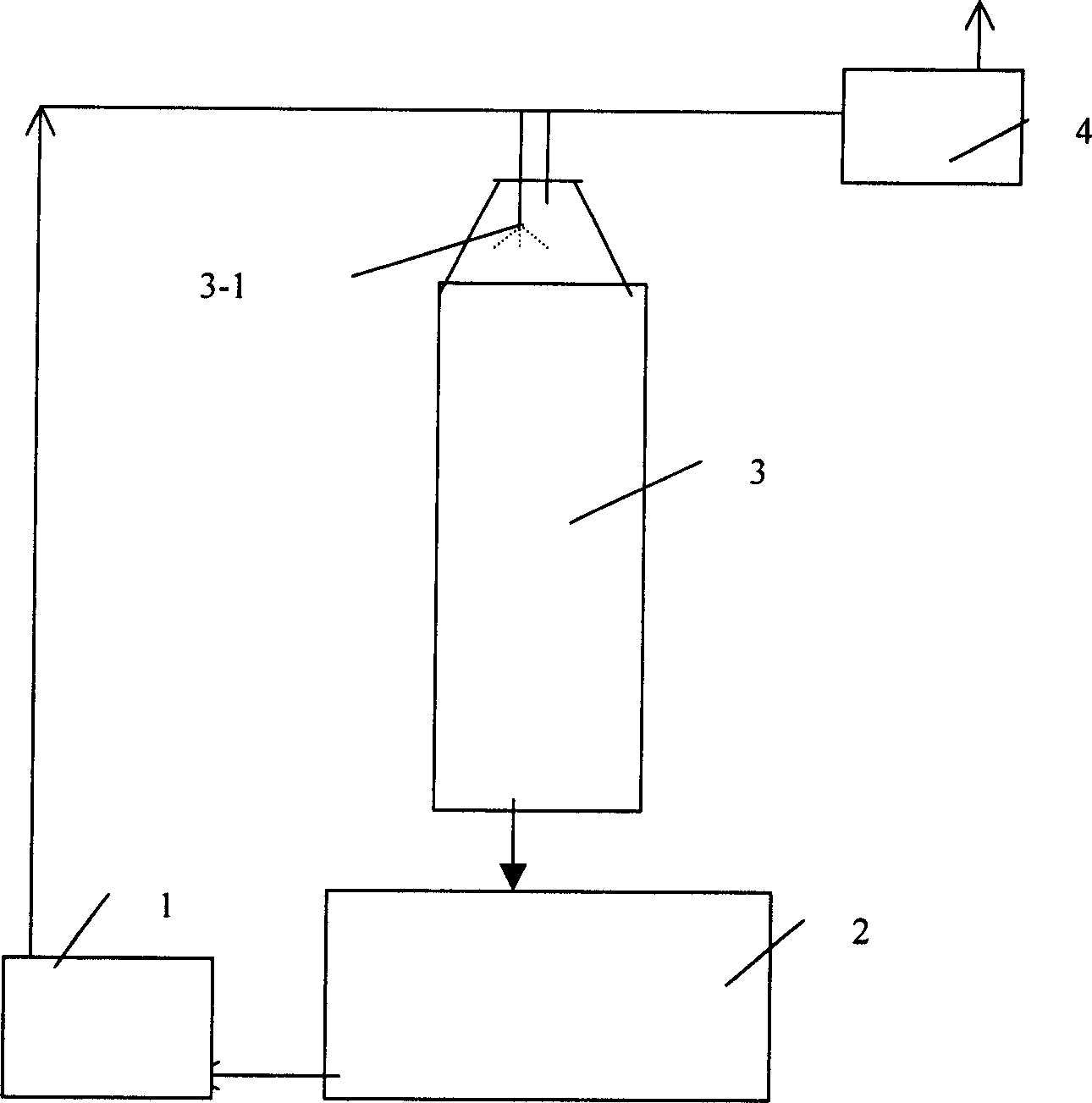

Atomization flash-evaporation ammonia-removing process for ammonia and nitrogen-containing wastewater

InactiveCN1884105ALarge mass transfer areaImprove efficiencyWater/sewage treatment by degassingNitrogenTower

The invention discloses an atomizing flashing deaminasing method with ammonia nitrogen waste water, which comprises the following steps: adjusting pH value of ammonia nitrogen waste water over 11; transmitting waste water to the atomizer on the top of atomizing tower; forming drip or fog drip; connecting atomizing tower and vacuum pump or fan through pipe; flashing ammonia and nitrogen in the negative pressure environment; extracting the flashed material; moving non-evaporated water from upwards to downwards; falling to bottom of atomizing tower to reserving groove; repeating those courses until reaching technological need.

Owner:重庆工学院

Enzymatic pretreatment assisted curcumin extraction technology

InactiveCN105061168ALarge mass transfer areaHigh extraction rateCarbonyl compound separation/purificationChromatographic columnActivated carbon

The invention provides an enzymatic pretreatment assisted curcumin extraction technology. The enzymatic pretreatment assisted curcumin extraction technology comprises steps as follows: after 1 part of curcuma powder is taken, ground, sieved, added with water and stirred uniformly, the mixture is subjected to water bath for 60 min and is cooled to the constant temperature of 52-58 DEG C, and curcuma pulp is obtained; compound enzyme comprising cellulase, amylase and papain is added to the curcuma pulp and reacts for 2-4 h, and enzymatic hydrolysate is obtained; the enzymatic hydrolysate is taken, added with an ethanol solution and homogenized for 1-2 min under the condition of 8,000-9,000 r / min, and a curcumin extracting solution is obtained; finally, a flocculant is added to the extracting solution, the mixture is stirred and filtered, a clear liquid flows through an activated carbon chromatographic column and is eluted with an alkaline solution, and a curcumin desorbed solution is obtained. The technology has the advantages of high extraction speed, low temperature, low energy consumption, high yield of the effective component curcumin, stable product quality and controllable reaction conditions, and is applicable to industrial large-scale production.

Owner:BAOTOU MEDICAL COLLEGE OF INNER MONGOLIA UNIV OF SCI & TECH

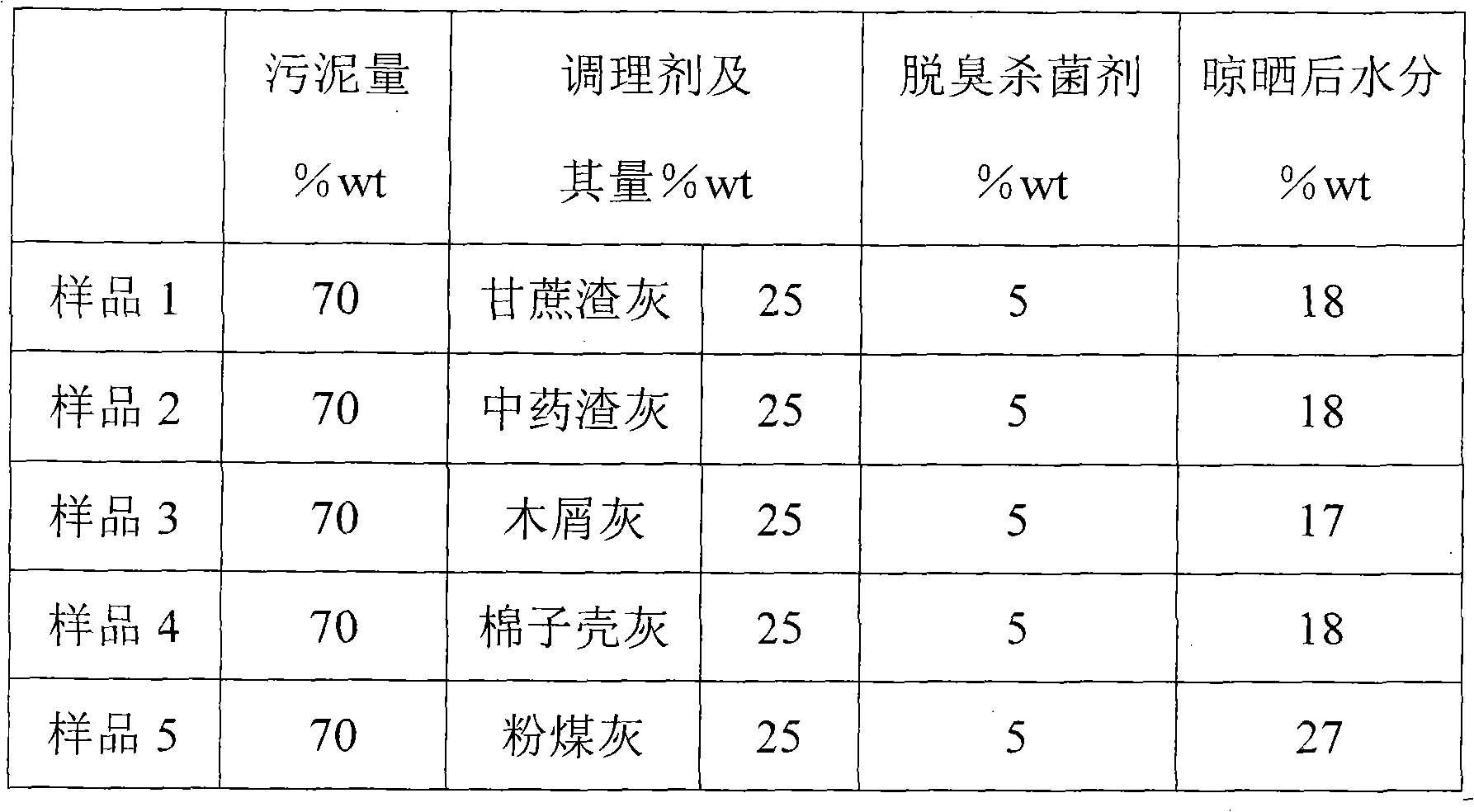

Sludge dry powder and preparation method thereof

InactiveCN101618934ADrying and dehydration is easyIncrease contact areaSludge treatment by de-watering/drying/thickeningBrickSolid fuel

The invention discloses a method for preparing dry powder by sludge, which comprises the following steps: uniformly mixing the following components in percentage by weight: 50-85 percent of sludge containing 40-98 percent of water, 14-40 percent of conditioner and 1-10 percent of deodorizing bactericide at room temperature; and then, drying the mixture through airing or afterheat and the like to acquire the sludge dry powder. The invention solves the problem of difficult municipal sludge treatment, greatly reduces the cost for sludge dehydration and drying, and prepares the sludge into dry powder. The sludge dry powder can be used for land utilization, used as solid fuel with a low combustion value, used as the raw material for producing clay or bricks or concrete and also used for direct sanitary landfills.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

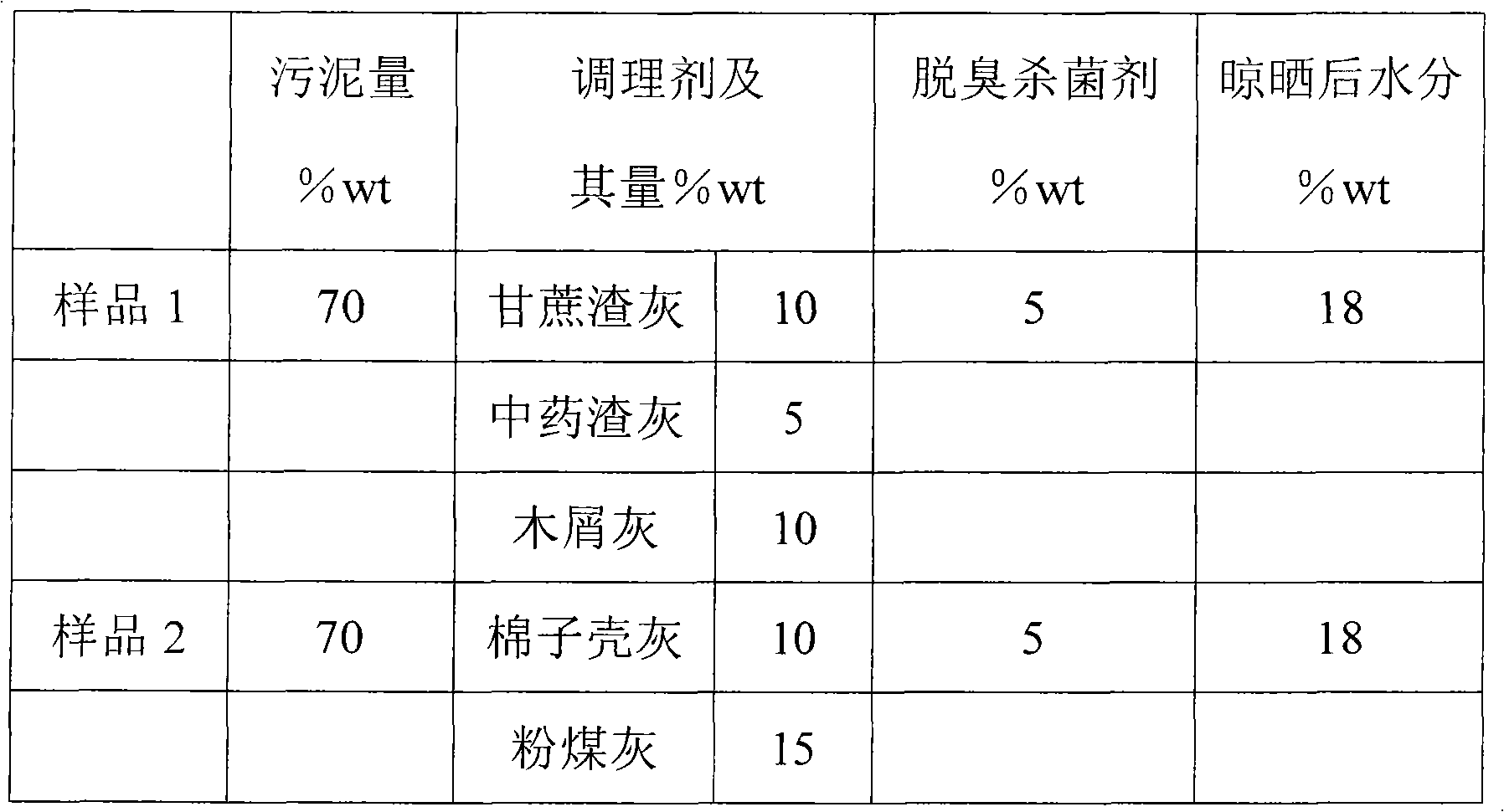

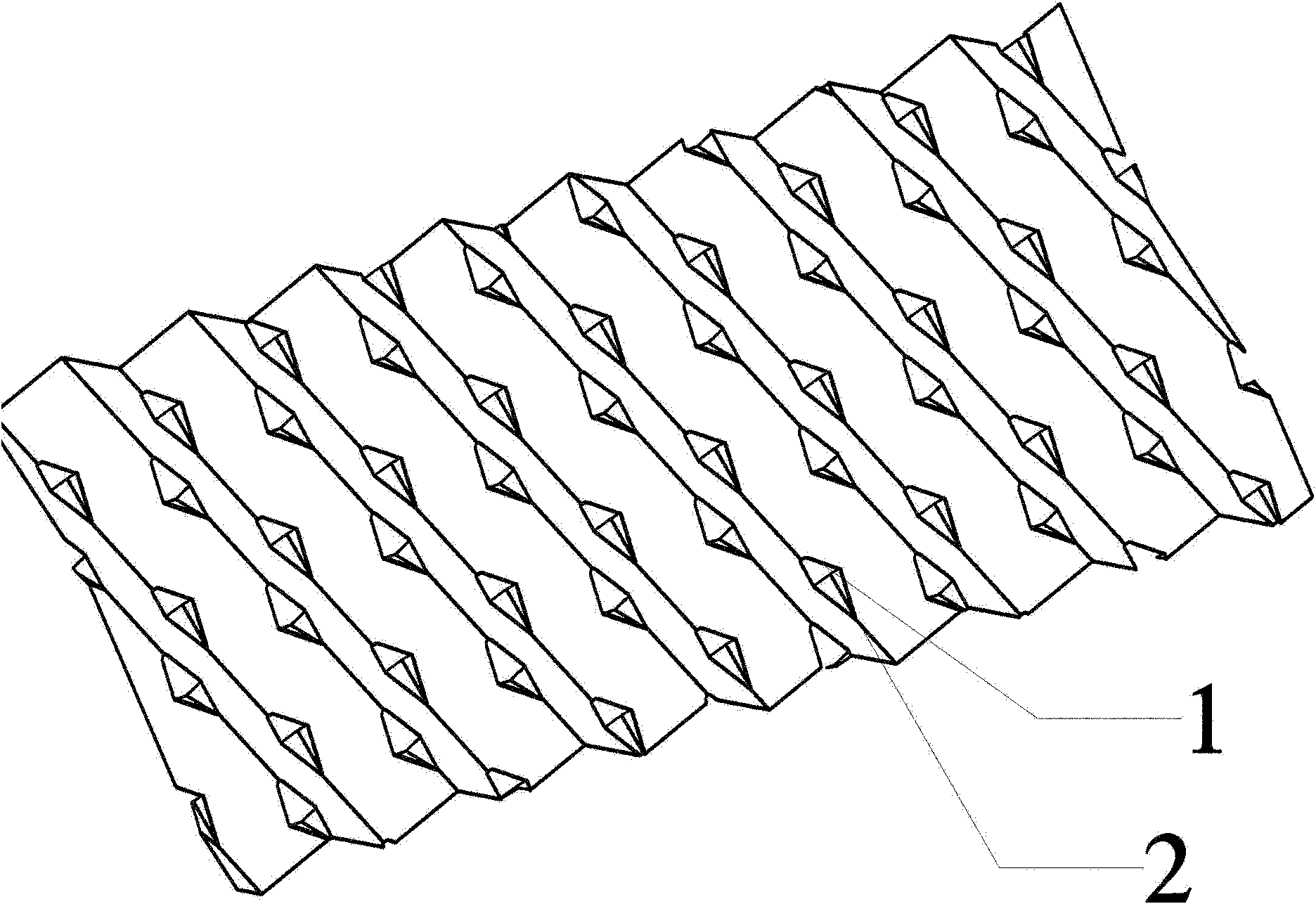

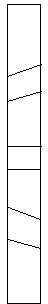

Window and hole combined flow guide regular filler sheet and filler

ActiveCN101979134AEffective aggregationIncreased turbulenceChemical/physical/physico-chemical processesEngineeringTower

The invention relates to a window and hole combined flow guide regular filler sheet and a filler. The crest and trough of a corrugated filler sheet are provided with a hole and a window which are communicated to form a window and hole combined structure; an inclination angle is formed between the ripple direction of the corrugated filler sheet and the vertical direction; a regular filler consists of the window and hole combined flow guide regular filler sheets which are parallel to one another and of which the ripple directions are arranged in a staggered mode; and when the tower diameter is larger, a plurality of regular fillers are arranged, and corrugated sheets of the fillers on an upper tray and a lower tray rotate by 15 to 90 degrees. Under the action of fluid velocity and gravity, flowing liquid can be more effectively aggregated due to a hole structure; and a window structure connected with the hole structure is just positioned below the hole structure, so that the liquid flowing down is guided to the crest position on the other side of the filler sheet, the turbulent degree of a gas-liquid phase liquid film between adjacent window bodies is increased, pressure drop is reduced, gas-liquid flux is increased, and the updating of the liquid film and the increase of gas-liquid mass transfer area are more effectively realized.

Owner:TIANJIN UNIV

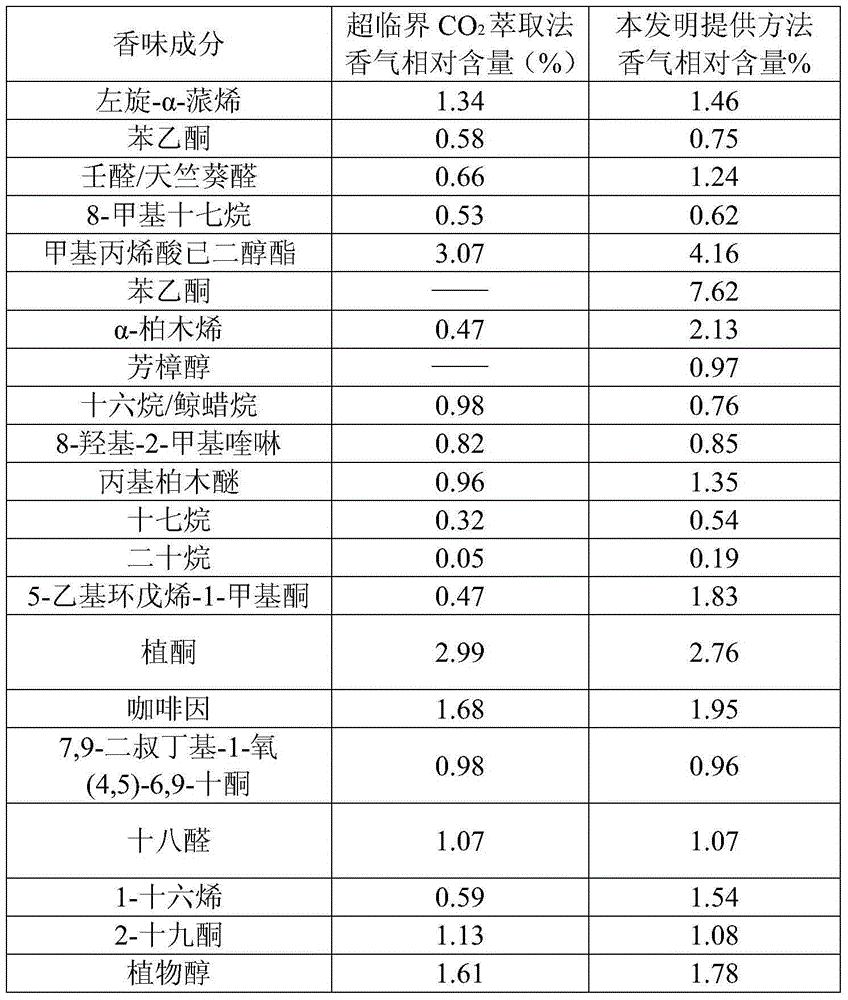

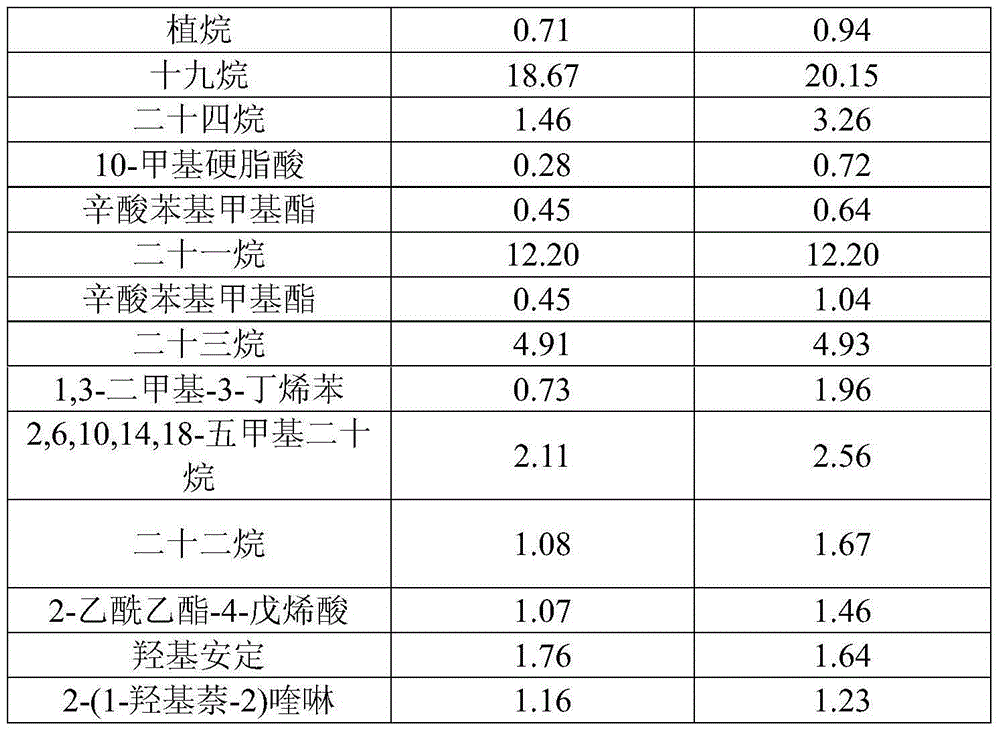

Method for preparing tea tree flower essential oil

The invention discloses a method for preparing tea tree flower essential oil. The method comprises the following steps: firstly, preparing a tea tree flower raw material into an sizing agent, adding a composite enzyme system for enzymolysis on the sizing agent so as to obtain first slurry; secondly, adding a defoaming agent into the first slurry so as to obtain second slurry; finally conveying the second slurry to a rotational conical distillation column for enhancing the fragrance, collecting a tea tree flower fragrance extract, and further separating by using an oil-water separator, thereby obtaining the tea tree flower essential oil. The composite enzyme system is adopted to treat tea tree flowers, so that the content of the effective fragrance component in the tea tree flowers is remarkably increased, release of precursor substances of the tea tree flower fragrance is promoted, the tea tree flower aromatic substances can be efficiently and comprehensively recycled by using SCC equipment, the yield of tea tree flower essential oil is greatly increased, and the natural flavor of the tea tree flower essential oil is effectively maintained.

Owner:ANJI E SWEET CANDY FOOD

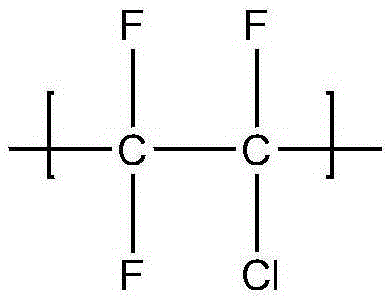

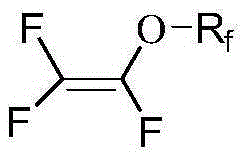

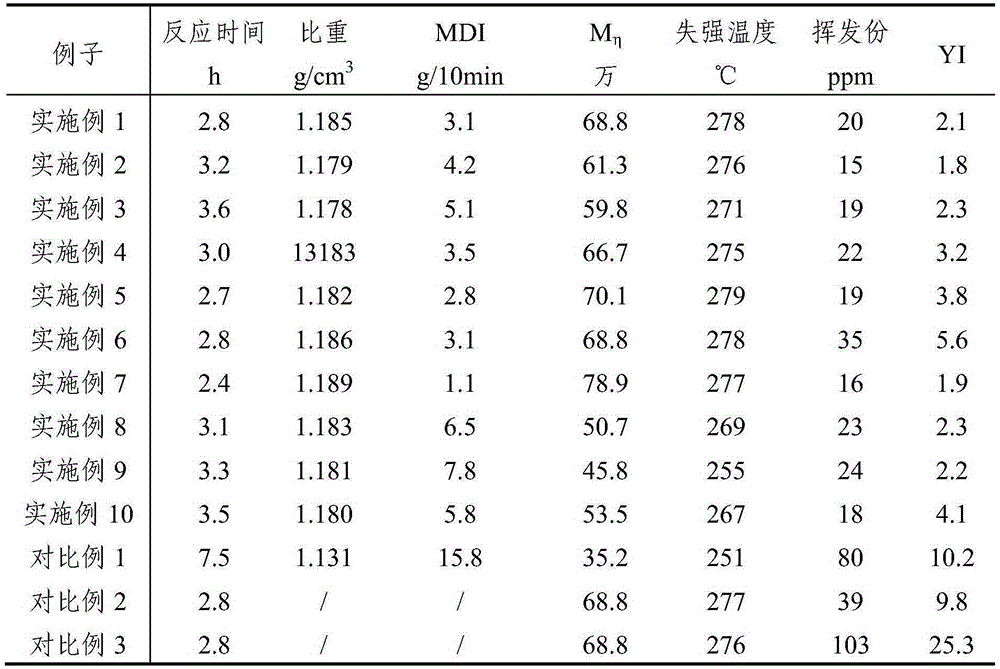

Polychlorotrifluoroethylene resin and preparation method thereof

ActiveCN106832072ALarge mass transfer areaQuick responseAnti-corrosive paintsPolymer scienceEmulsion

The invention relates to a preparation method of polychlorotrifluoroethylene resin, which adopts a horizontal reactor with an aspect ratio ≥ 1.0 as polymerization equipment; uses chlorotrifluoroethylene monomer or chlorotrifluoroethylene monomer and other comonomers The polymerization reaction occurs under constant pressure conditions, which improves the reaction speed and polymerization efficiency; the semi-mechanical and semi-chemical coagulation method is used to effectively separate the impurities in the emulsion, and the residual unstable groups are removed through wet heat treatment, effectively reducing the volatilization of the product parts, greatly improving the appearance of the product. M can be obtained by the method of the present invention η PCTFE and its copolymerization products exceeding 500,000, volatile matter less than 0.01%, strength loss temperature higher than 260°C, yellowness index (YI) less than 10.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Multi-nozzle jet-flow micro-nano bubble aerator

ActiveCN102942251AExtended stayLarge mass transfer areaTreatment using aerobic processesSustainable biological treatmentMicro nanoSpray nozzle

The invention discloses a multi-nozzle jet-flow micro-nano bubble aerator, which comprises a plurality of nozzle-type water pumps and air bubble aeration nozzles which are respectively communicated with the nozzle of the water pump, wherein each air bubble aeration nozzle comprises an aeration nozzle main body, a water pipeline and an air distribution pipeline. The air distribution pipeline and the water pipeline are vertical to each other and respectively provided with a leaf, so that the air flowing into the water pipeline from the air distribution pipeline can be cut by the high-speed flowing water into a great amount of micro-nano bubbles with ultra-small diameter by utilizing a cavity principle, the stop time of the bubbles in the water and the transferring area of the bubbles and the water can be greatly increased, the oxygen dissolving efficiency can be improved, and the biochemical reaction efficiency of aerobic bacteria in the water can be improved.

Owner:苏州香山红叶环境技术有限公司

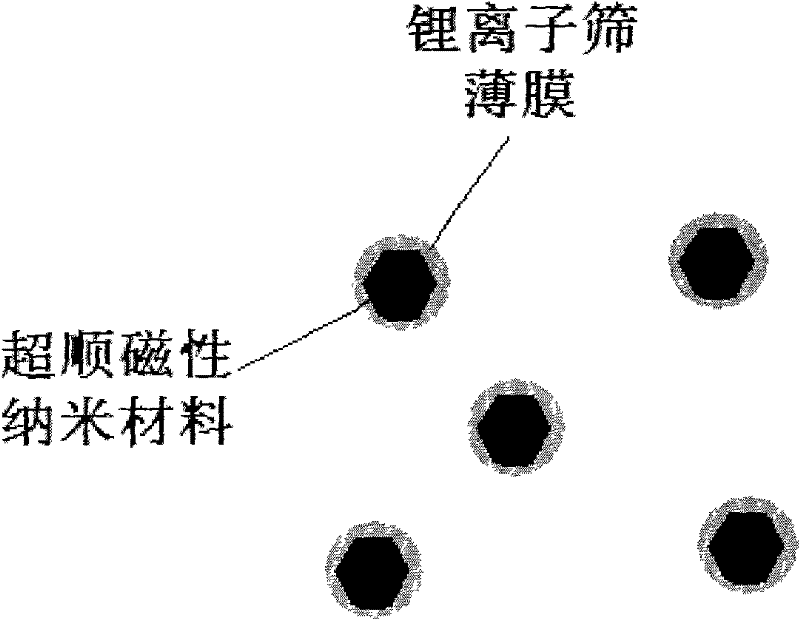

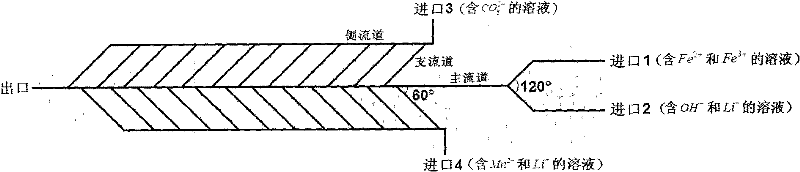

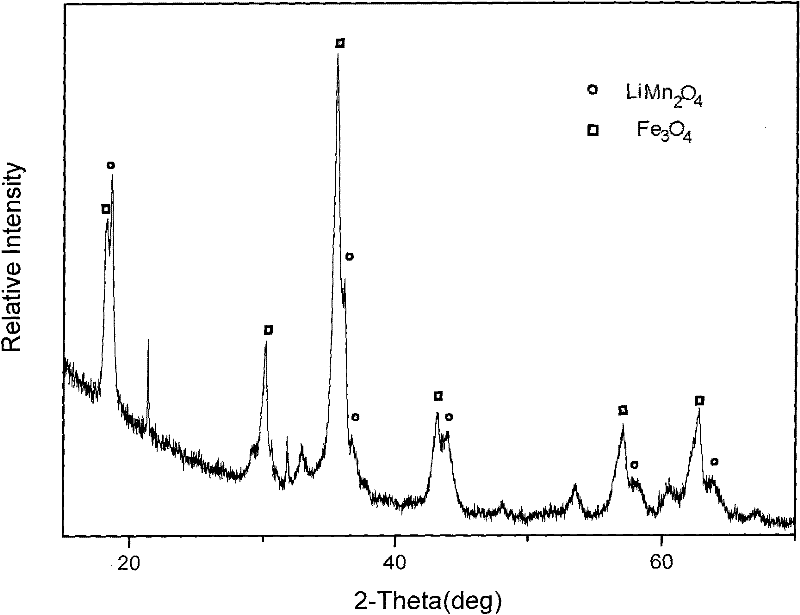

Magnetic nano lithium ion sieve adsorbent and preparation method thereof

ActiveCN102527320AImprove adsorption and desorption performanceQuick Recovery DispersionOther chemical processesAlkali metal oxides/hydroxidesDispersityCooking & baking

The invention discloses a magnetic nano lithium ion sieve adsorbent and a preparation method thereof. The magnetic nano lithium ion sieve is a Fe3O4 / LixMnyO4 shell structure in which nano Fe3O4 superparamagnetic material is used as a kernel and nano lithium-manganese oxide lithium ion sieve film is used as a shell, wherein the ratio x / y is between 0.5 and 1.5. The preparation method comprises the following steps of: synthesizing Fe3O4 / MnCO3+Li2CO3 gel particles at a time by use of a self-developed narrow-channel impact flow reactor; and performing water heating, leaching, drying, baking and acid leaching to obtain the product of magnetic nano lithium ion sieve adsorbent. According to the invention, the synthesized magnetic nano lithium ion sieve has the advantages of high specific surface area, high dispersity, high absorption / desorption rate, quick recovery and the like, and is particularly suitable for the process of large-scale lithium extraction from a dilute lithium solution; the absorption / desorption performance of the lithium ion sieve can be remarkably improved, and the dissolution loss rate of the lithium ion sieve is reduced; and moreover, the preparation method of the magnetic nano lithium ion sieve has simple technology, large yield and low cost, and can be magnified to a large scale easily.

Owner:ZHEJIANG OCEAN UNIV

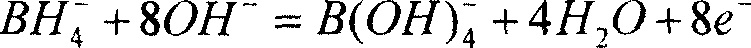

Method for using three-dimensional electrode as direct anode of hydroboron fuel cell

InactiveCN101013752ALarge mass transfer areaImprove mass transfer conditionsElectrolyte holding meansCell electrodesIon-exchange membranesAlkali hydroxide

The invention relates to one 3D electrode for direct borane fuel battery anode method, which is characterized by the following steps: processing filling bed electrode or multi-hole electrode as three dimensional anode and alkalinity liquid fuel, wherein, the cathode contacts oxygen, air and auricome agent and the middle ion exchange isolation film forms direct borane fuel battery system; borane fuel materials touching three dimensional electrode and alkalinity compound with materials feeding type as through or back entering type.

Owner:TAIYUAN UNIV OF TECH

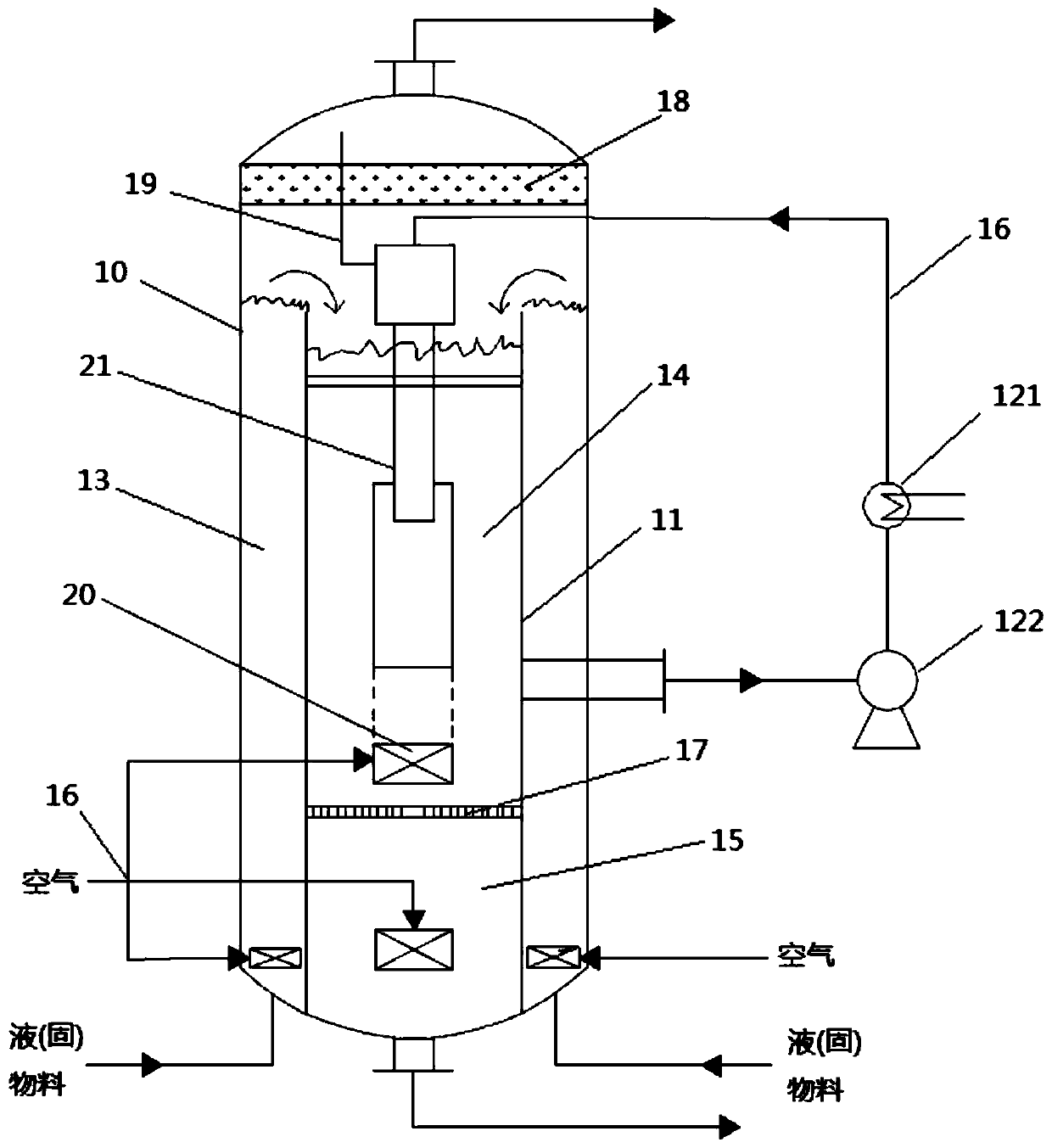

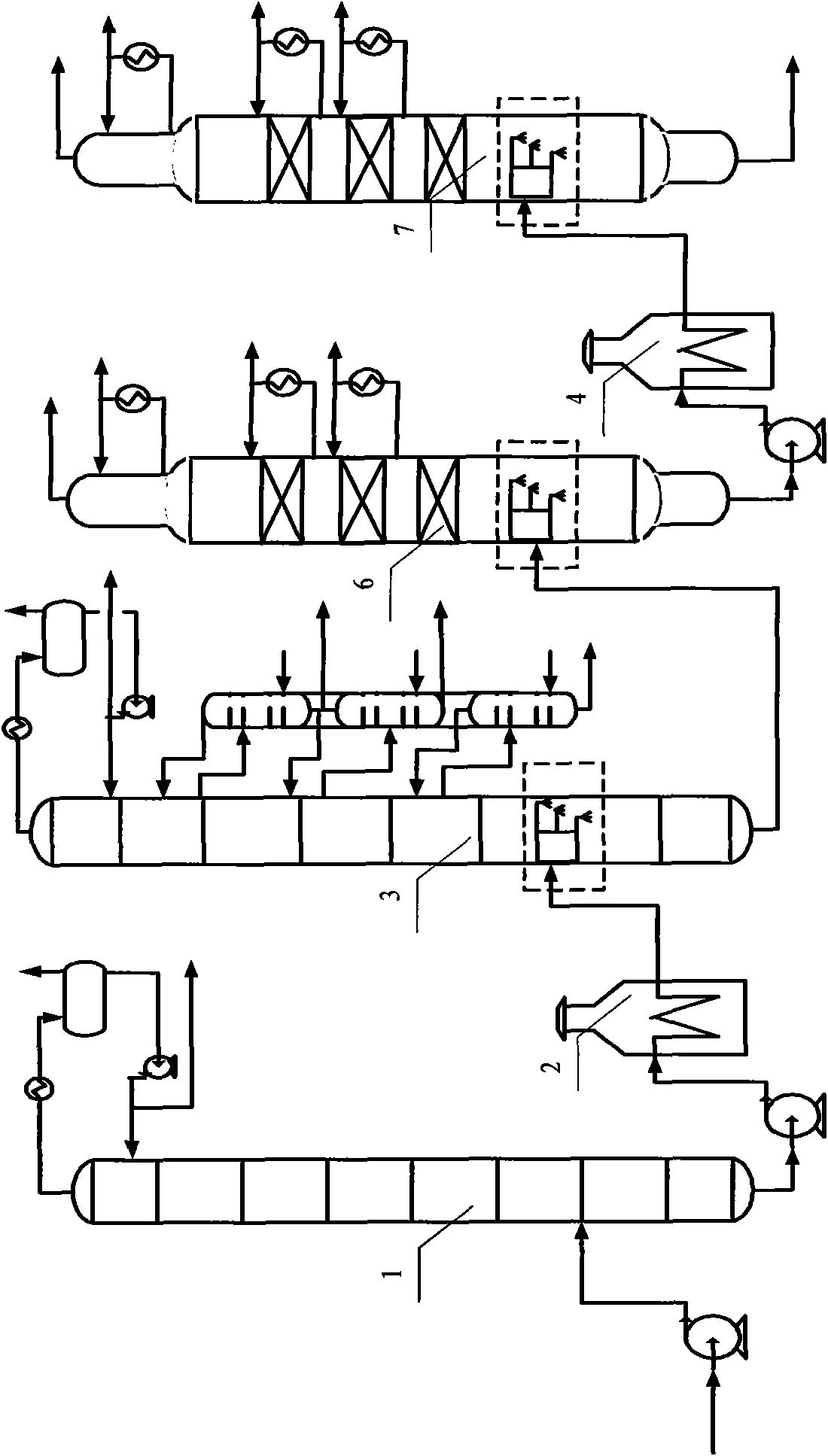

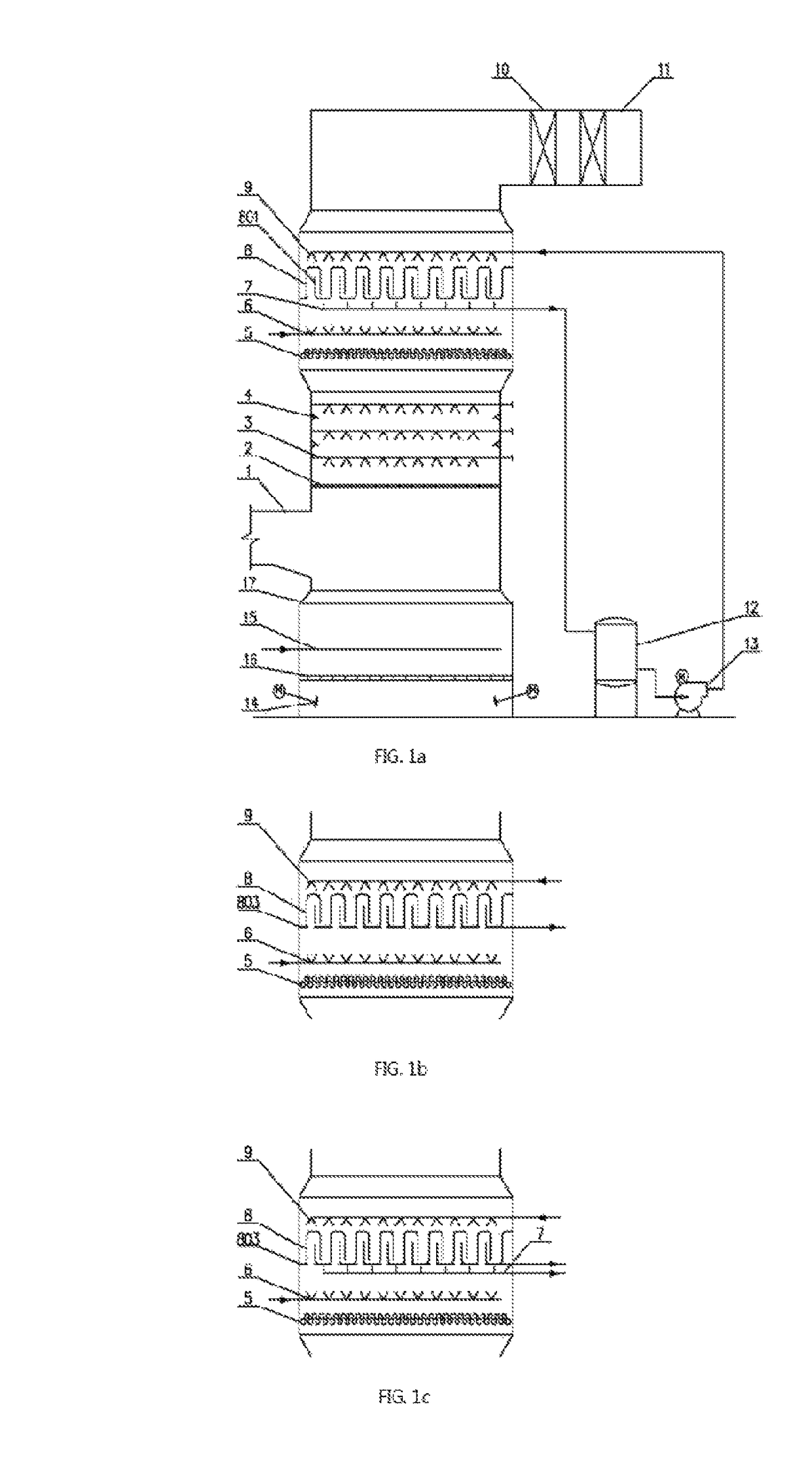

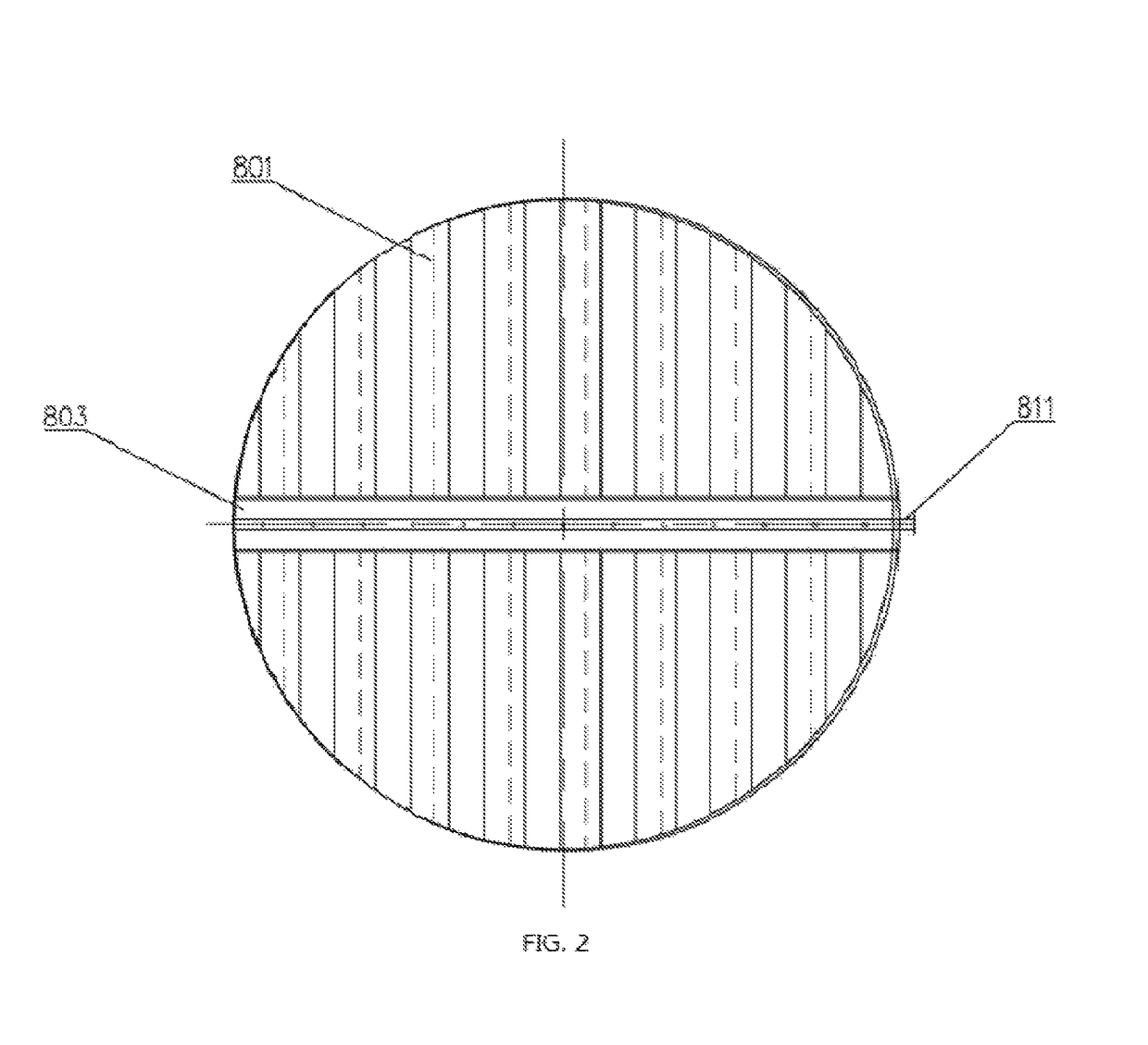

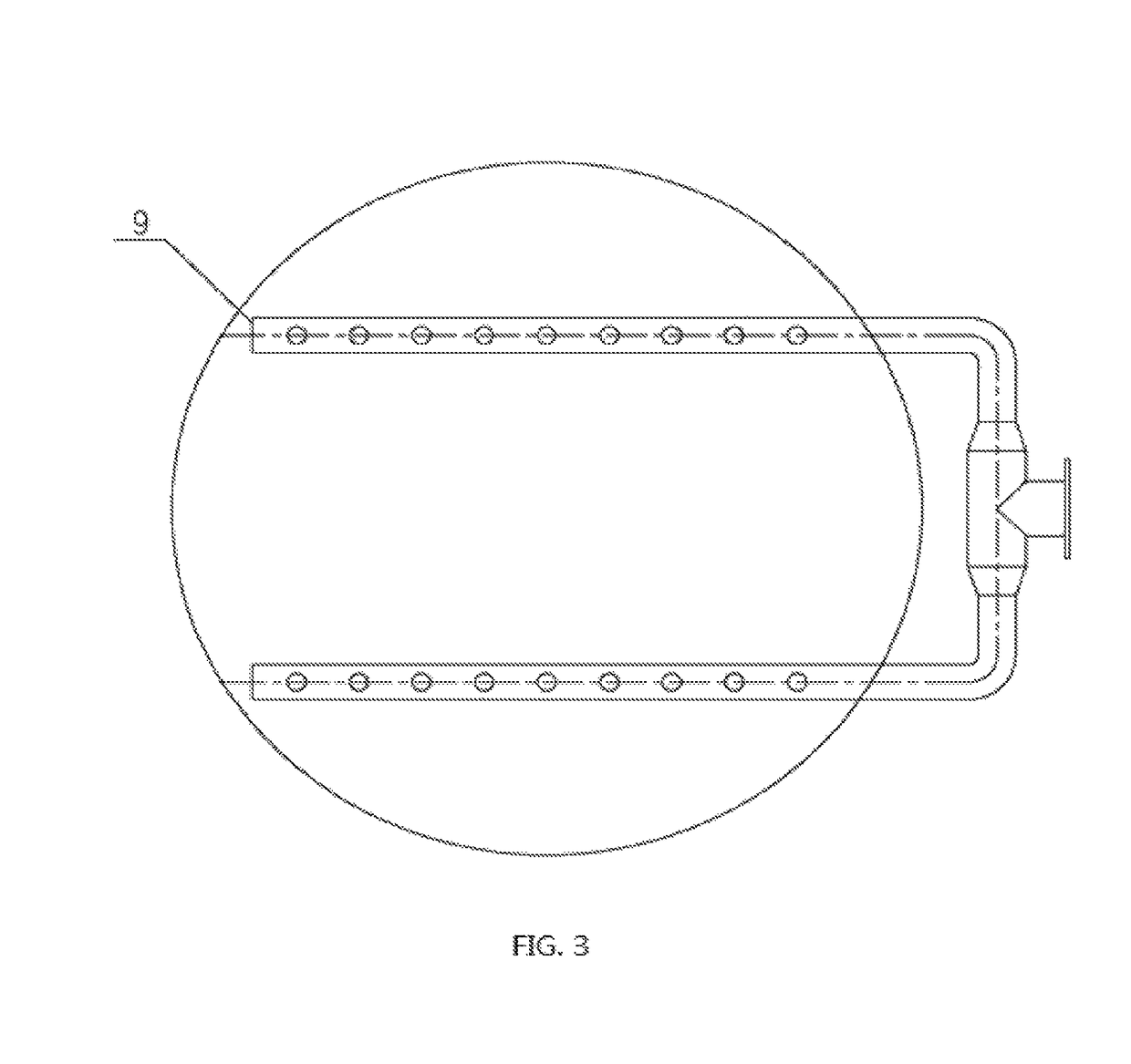

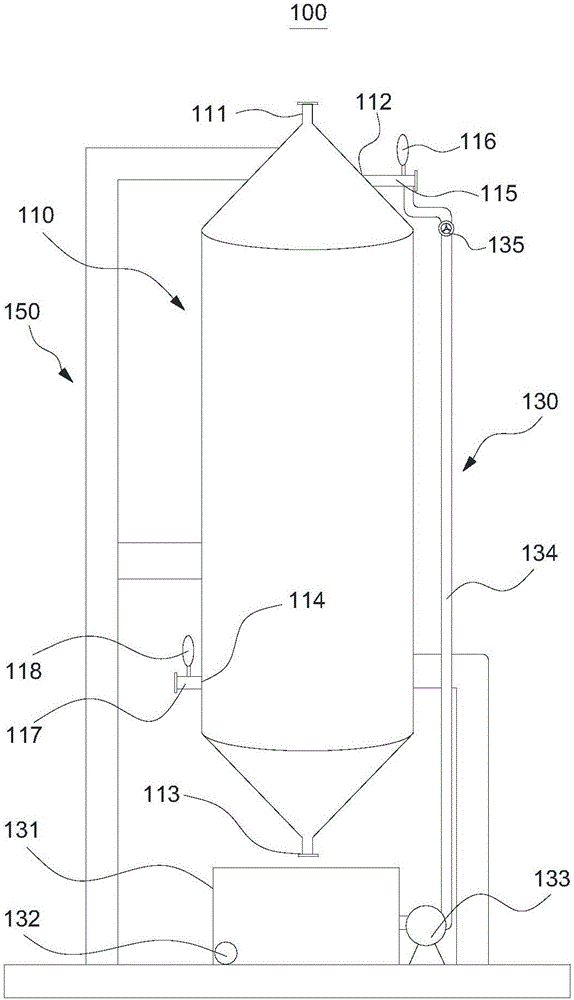

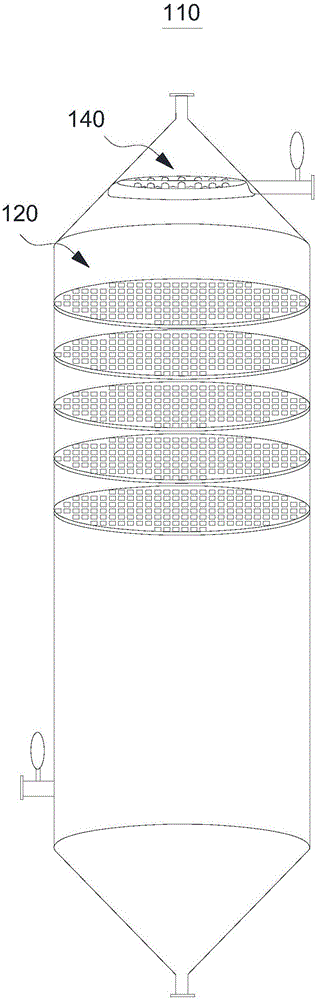

Built-in micro-interface unit enhanced reaction system for producing PTA through PX and process thereof

ActiveCN111389314ASolve the contradiction of not being able to withstand high temperature oxidation conditionsReduce energy consumptionLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationAcetic acidEthylic acid

The invention provides a built-in micro-interface unit enhanced reaction system for producing PTA through PX and a process thereof. The system comprises a reactor and a micro-interface unit arranged in the reactor. The reactor comprises a shell, an inner barrel concentrically arranged in the shell, and a circulating heat exchange device partially arranged outside the shell; wherein the bottom endof the inner cylinder is connected to the inner bottom surface of the shell in a closed manner, the top end of the inner cylinder is open, an area between the shell and the inner cylinder is a first reaction area, a second reaction area and a third reaction area are sequentially arranged in the inner cylinder from top to bottom, and the circulating heat exchange device is respectively connected with the inner cylinder and the micro-interface unit. According to the method, the problems that a large amount of reaction solvent acetic acid is wasted at high temperature and high pressure and a product TA cannot be taken out in time in the existing process of producing PTA through PX are effectively solved, so that the energy consumption is greatly reduced, an acetic acid solvent is saved, and the reaction efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

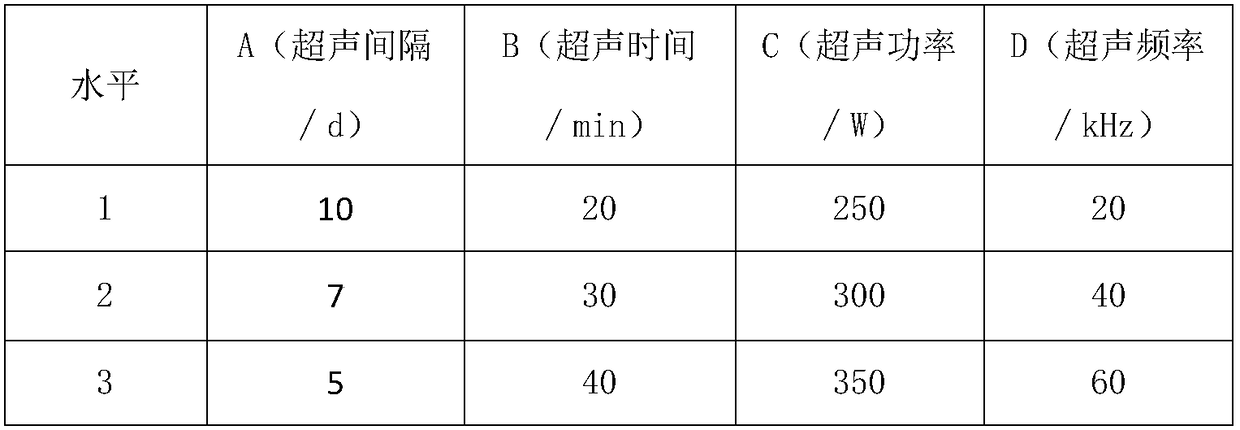

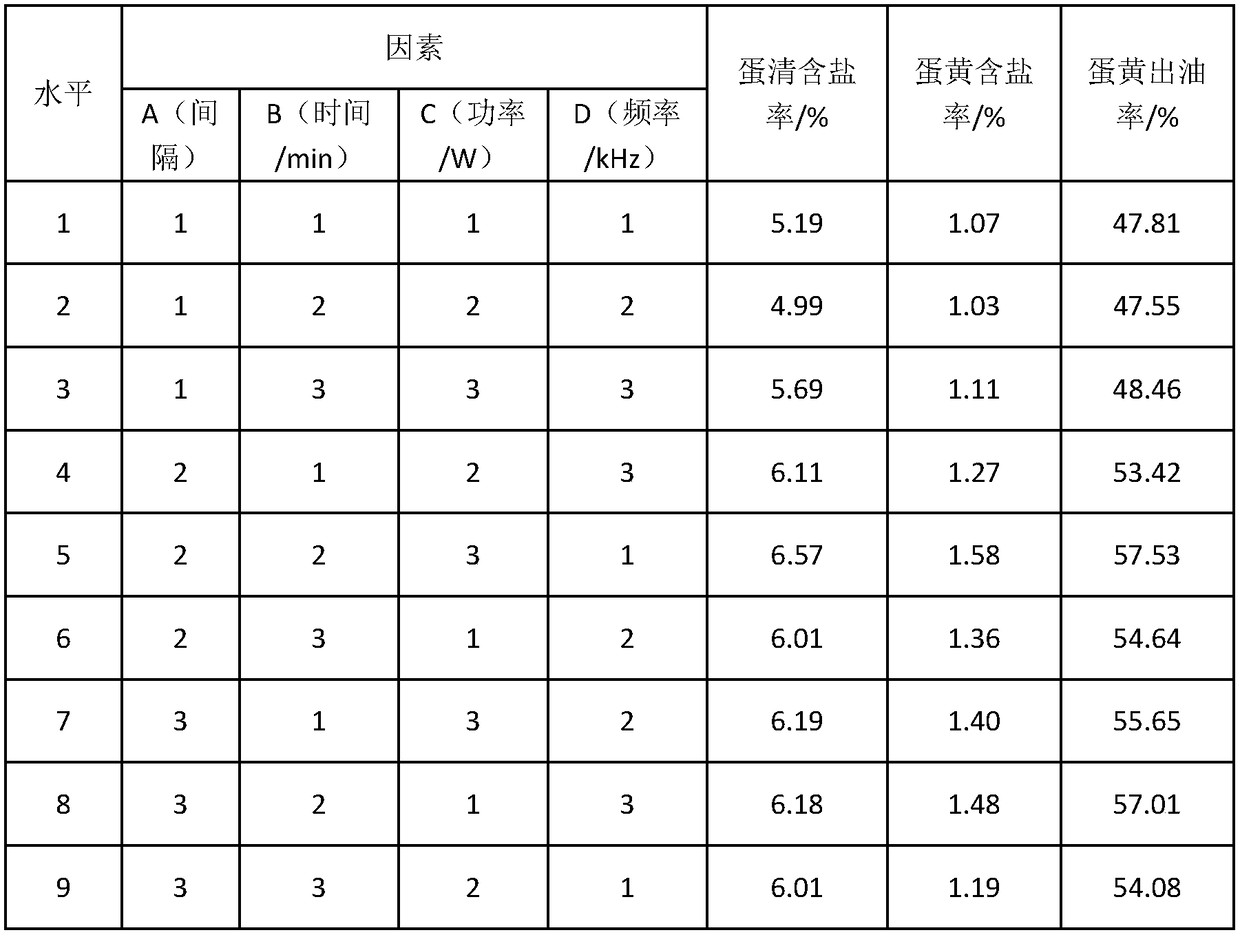

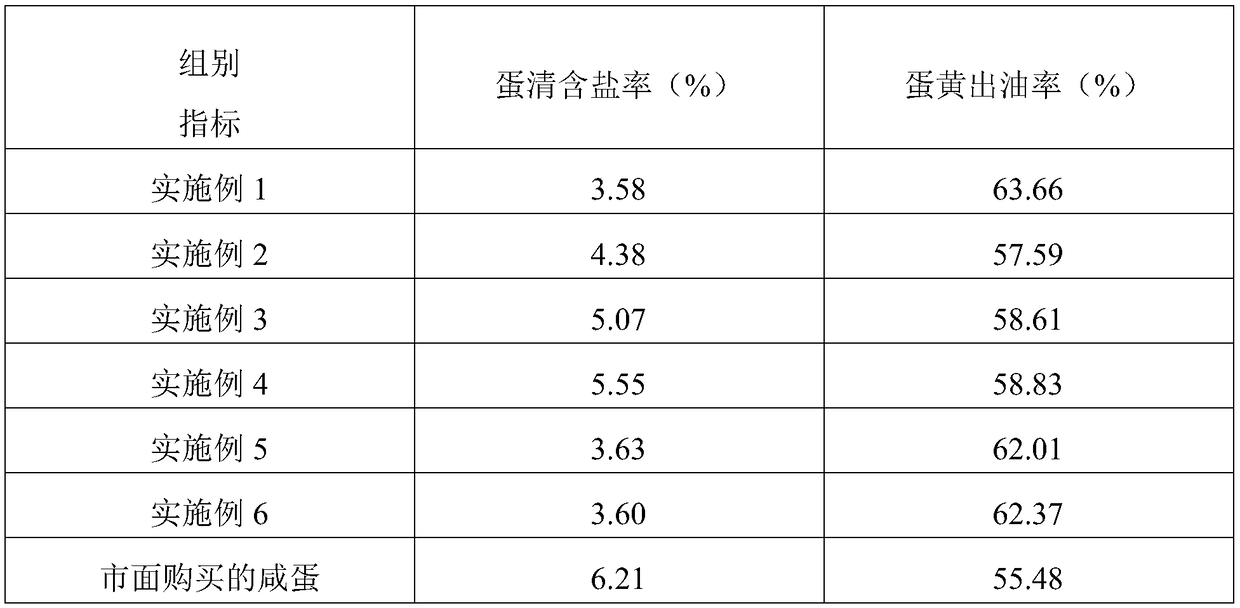

Intermittent ultrasonic assisted low-salt salted egg pickling technology

InactiveCN108634228AIncrease pickling ratePickling rate shortenedFood scienceUltrasonic assistedSalt content

The invention discloses an intermittent ultrasonic assisted low-salt salted egg pickling technology. Low-salt salted eggs can be obtained with the technology through pretreatment of duck eggs, pickling of duck eggs, desalting and cleaning. An ultrasonic technology is creatively used in assisting the salted egg pickling process, the table salt permeation rate is increased, the pickling period is shortened, the salted eggs can be well pickled within 15 days with the technology, and the pickling period is 20 days shorter than that in a traditional method. The well pickled salted eggs are placed in a 1% table salt solution to be desalted, the salt content of salted egg white can be decreased to 3.58% within 6 days, and the salinity is proper. In general, salted eggs with high oil yield and lowsalt can be pickled within 21 days.

Owner:HUAZHONG AGRI UNIV

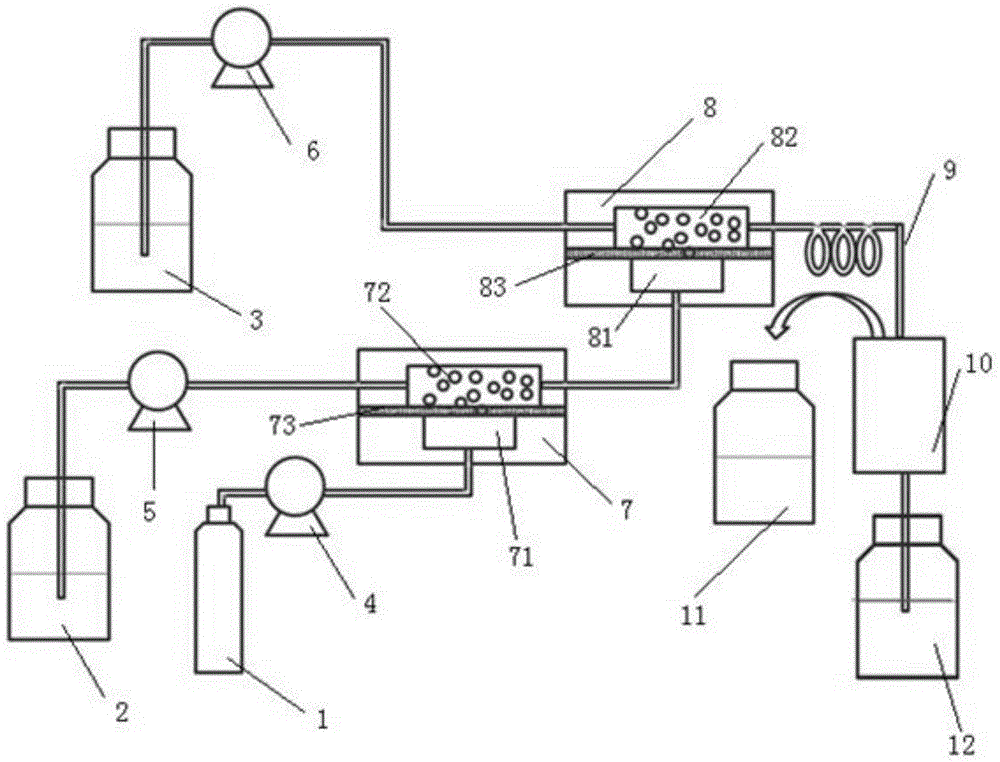

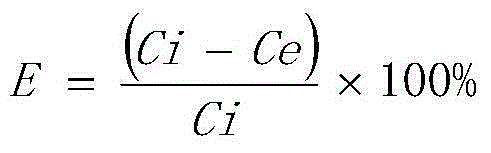

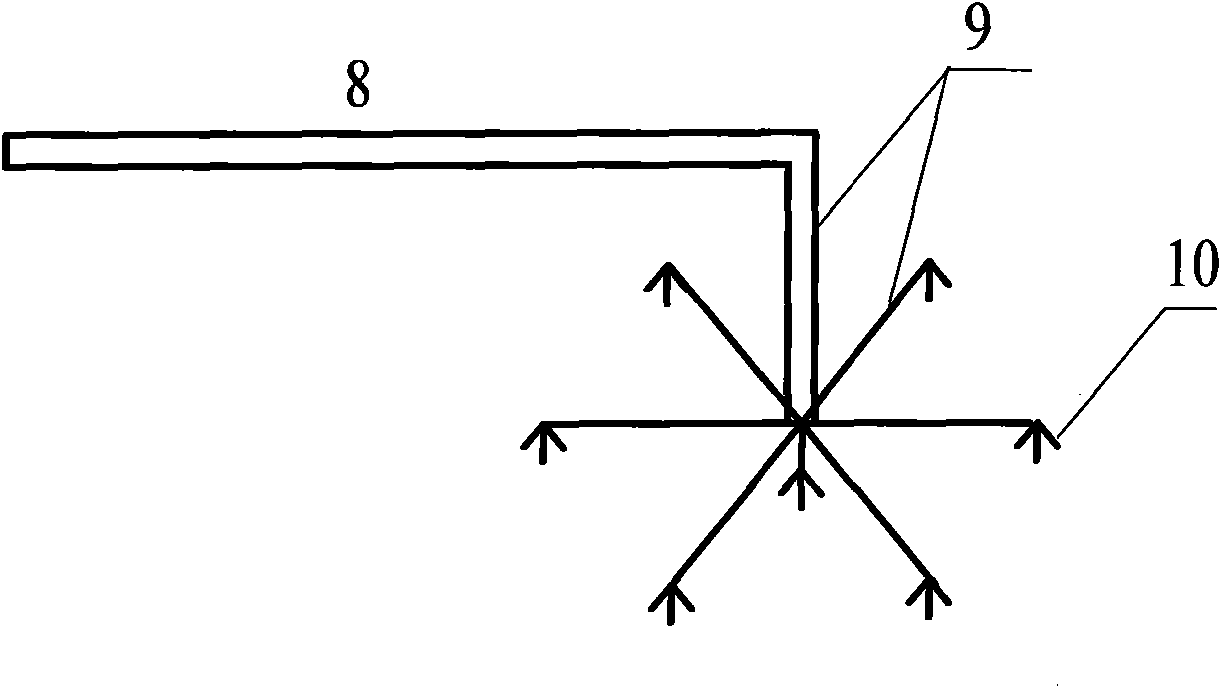

Membrane dispersion extraction device and method for extracting and separating rear-earth elements by using device

ActiveCN104313316AReduce adhesionExtended stayProcess efficiency improvementRare-earth elementMicrometer scale

The invention relates to a membrane dispersion extraction device. The membrane dispersion extraction device comprises an air bubble disperse phase device and an gas-in-oil disperse phase device which is connected with the air bubble disperse device in series; the air bubble disperse phase with air bubbles having uniform sizes are formed in the air bubble disperse phase device; the air bubble disperse phase enters the gas-in-oil disperse phase device to mix with a flowing water phase to complete an extraction separation process. In the extraction separation process, the mass transfer area and the mass transfer velocity are effectively increased by a micrometer scale structure of the gas-in-oil and turbulent flow and vortex produced by the water phase near the gas-in-oil, so that the extraction effect is improved. The device is simple in structure and relatively easy to industrialize. Meanwhile, the invention further discloses a method of extracting and separating rear-earth elements by virtue of the device, wherein the method is high in extracting efficiency for rear-earth elements, great in separating coefficient and relatively easy to realize industrialization.

Owner:TSINGHUA UNIV

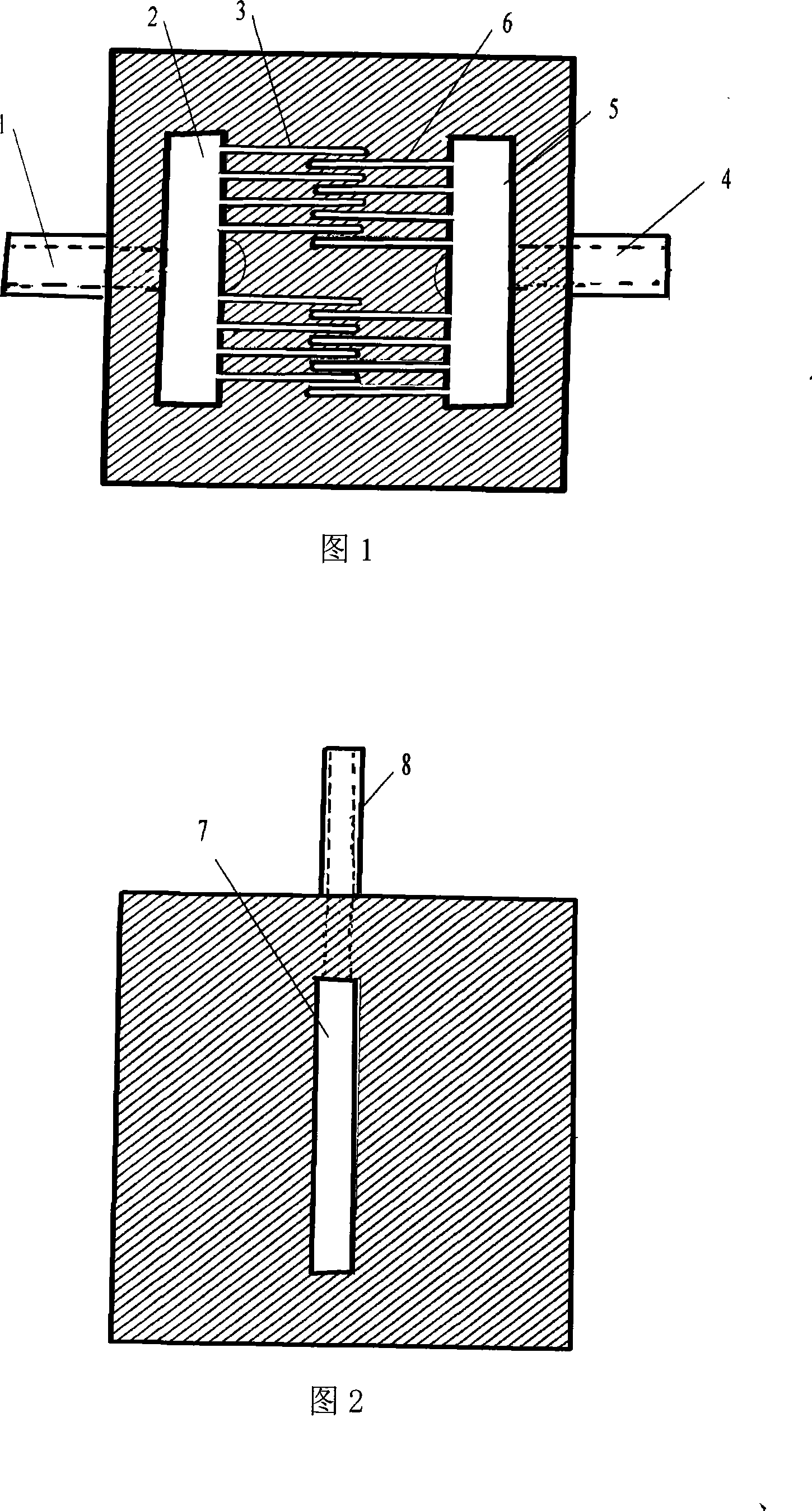

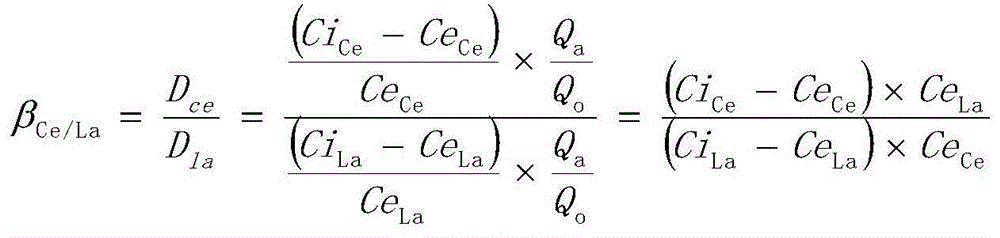

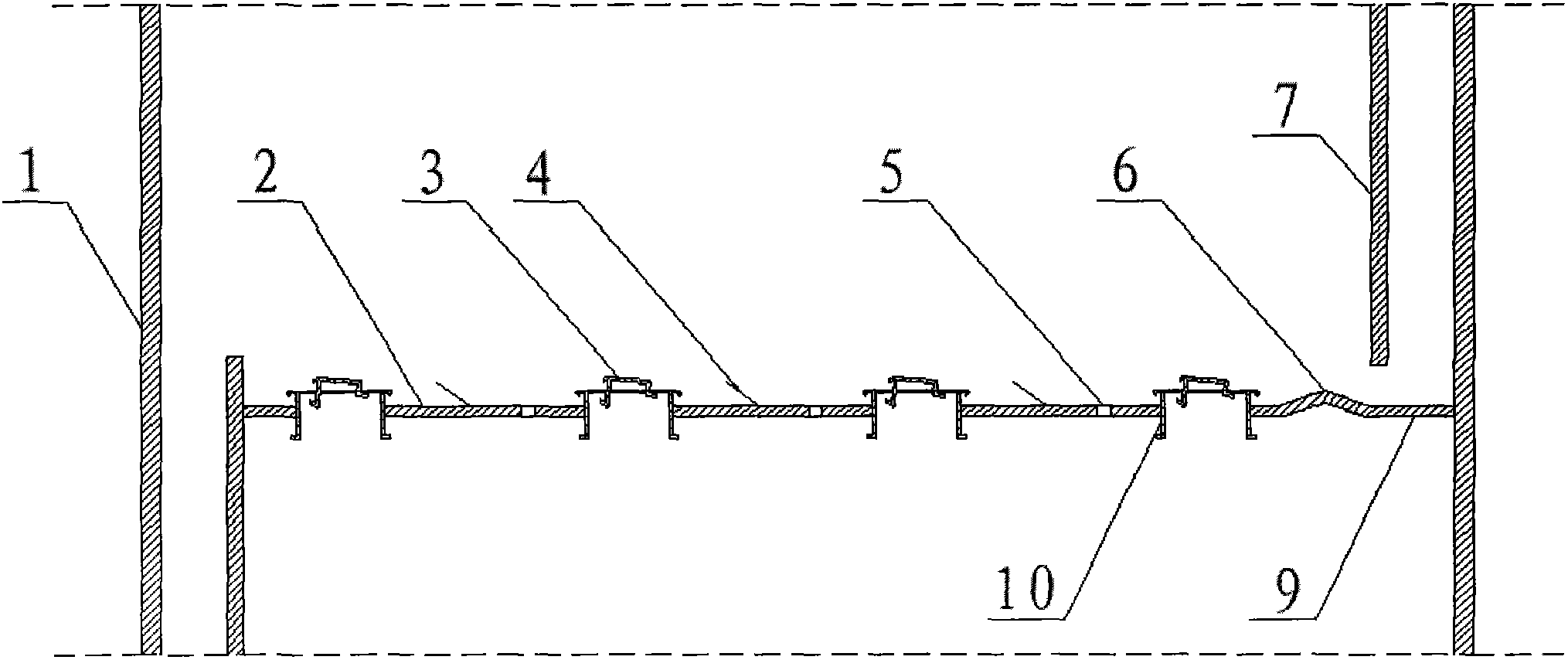

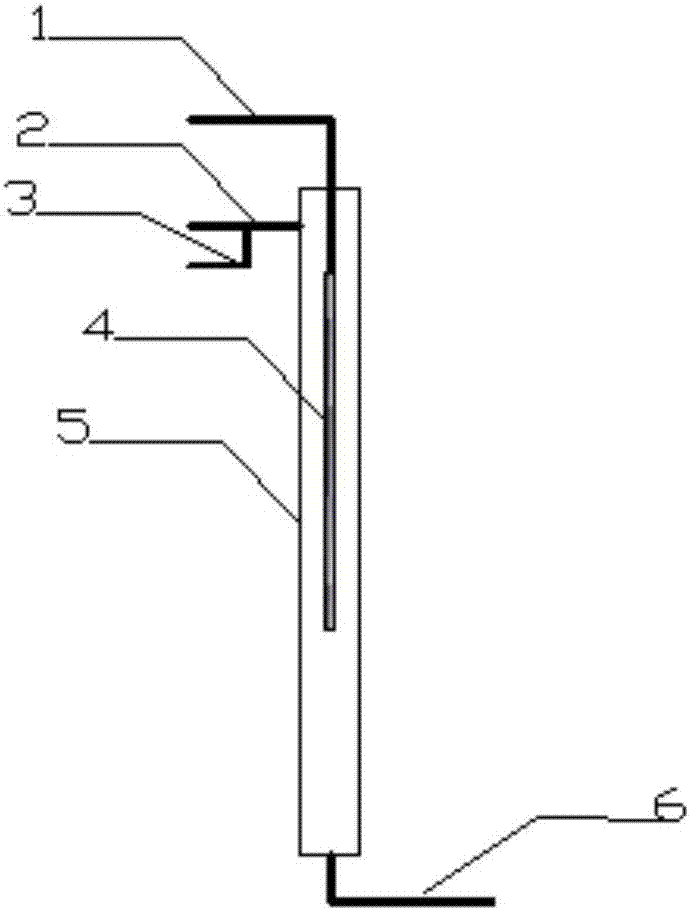

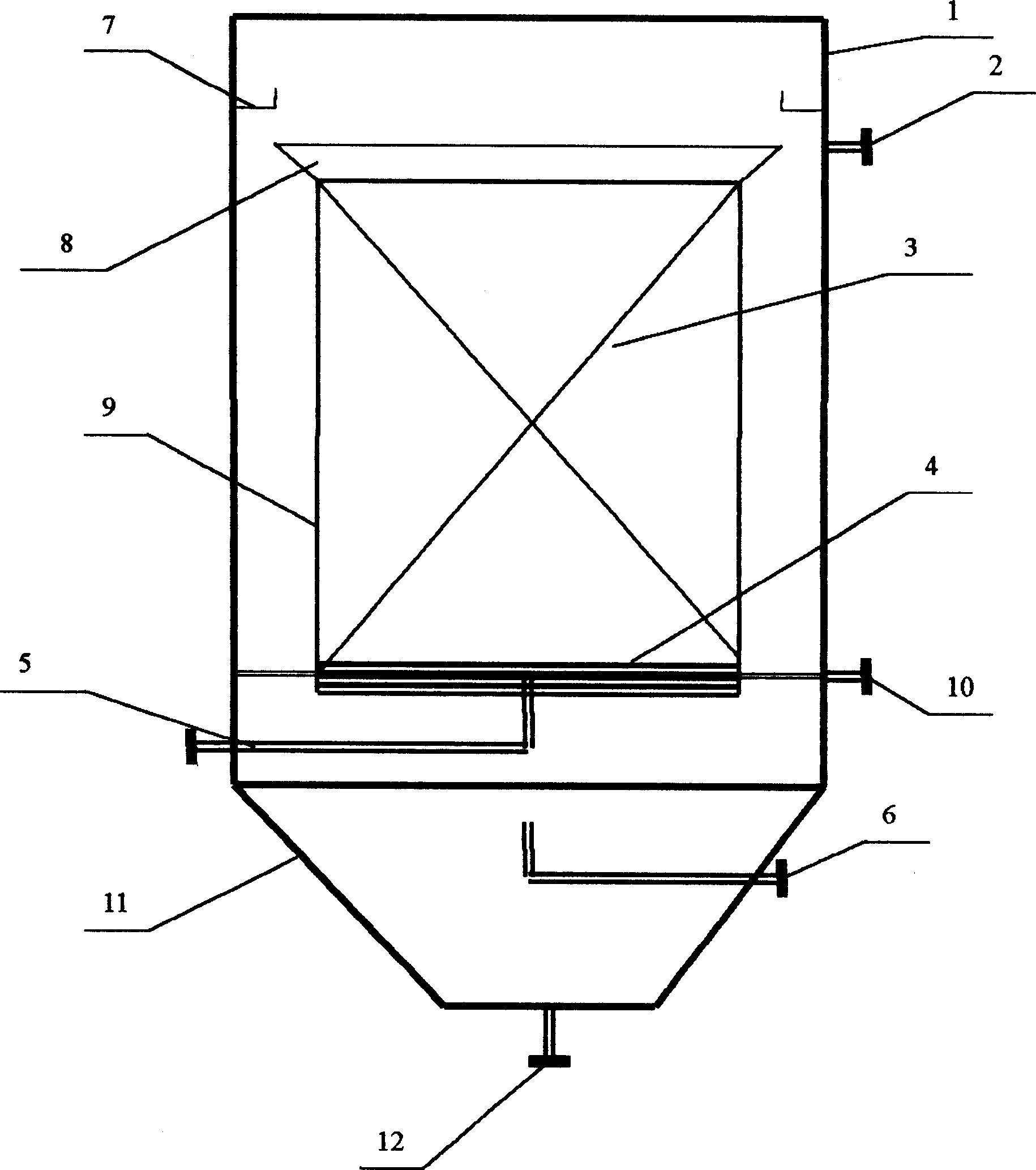

Guiding sieve plate float valve tower

The invention relates to a guiding sieve plate float valve tower, belonging to a gas-liquid mass-transfer separation plant in chemical process. The guiding sieve plate float valve tower disclosed herein mainly comprises a tower body (1), a tower plate (2), a down-flow plate (7), a seal pan (9), etc., wherein the liquid inlet of the tower plate (2) is provided with a bubbling promoter (6), the plate surface of the tower plate is provided with a floating tongue (3), a guiding pore (4), a sieve pore (5) and a float valve. According to the invention, when the gas velocity is low, the float valve on the tower plate is not open, gas only passes through the guiding pore (4), the sieve pore (5) and the floating tongue (3); when the gas velocity increases to a certain level, the float valve is open, and the opening height of the float valve increases gradually with the increase of the gas velocity. The guiding sieve plate float valve tower disclosed herein has the advantages of simple structure, low cost, and greatly raised operation flexibility and separation efficiency.

Owner:河北化大科技有限公司

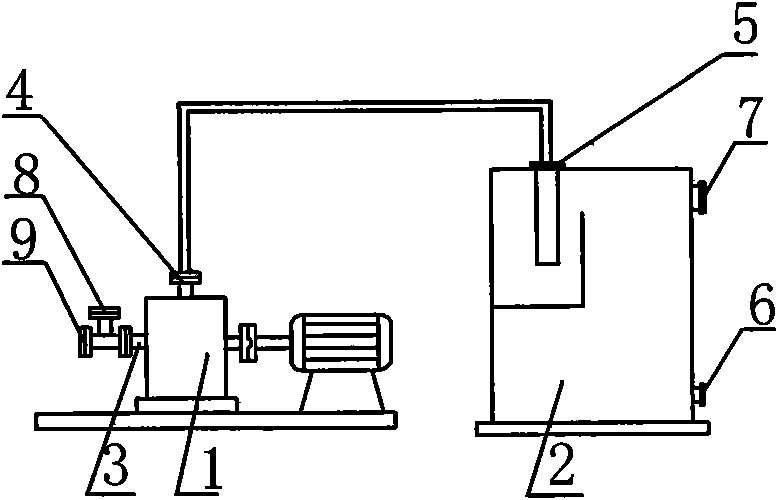

Extraction device

InactiveCN101898048ALarge mass transfer areaEasy to phaseLiquid solutions solvent extractionPhase splittingEngineering

The invention discloses an extraction device comprising an emulsifying machine (1) and a phase-splitting apparatus (2). The emulsifying machine (1) is provided with an emulsifying machine inlet (3) and an emulsifying machine outlet (4), the phase-splitting apparatus (2) is provided with a mixed phase inlet (5), a heavy phase outlet (6) and a light phase outlet (7), the emulsifying machine inlet (3) is connected with an extracted object inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed phase inlet (5) of the phase-splitting apparatus. When multistage extraction devices are combined, the light phase outlet of the phase-splitting apparatus in the extraction device at the current level is connected with the solvent inlet of the extraction device at the next level through a pipeline provided with a pump, and the heavy phase outlet of the phase-splitting apparatus in the extraction device at the next level is connected with the extracted object inlet of the extraction device at the current level through the pipeline provided with the pump. The invention has high extraction efficiency, small size, less occupied area, simple operation and capability of saving apparatus investment and running cost.

Owner:WENGFU (GRP) CO LTD

Method for extracting curcumin from fresh ginger

InactiveCN108147955ALarge mass transfer areaHigh extraction rateCarbonyl compound separation/purificationImpurityHigh-performance liquid chromatography

The invention relates to a method for extracting curcumin from fresh ginger. According to the method, fresh ginger raw materials are directly used without drying, an extraction process adopts wall breaking of a flash extraction device, compound enzyme enzymolysis and an ultrasonic-assisted sodium salicylate ethanol solution extraction method, a technique combined wall breaking of a flash extraction device with compound enzyme enzymolysis greatly improves extraction efficiency, most of impurities in solution can be remained in mother solution through crystallization, high-purity crystals can beacquired through filtering and washing, a HPLC (high performance liquid chromatography) detects that purity can reach 90% or more after crystallization, and the HPLC detects that the purity can reach97% or more after recrystallization.

Owner:温州瑞思生物科技有限公司

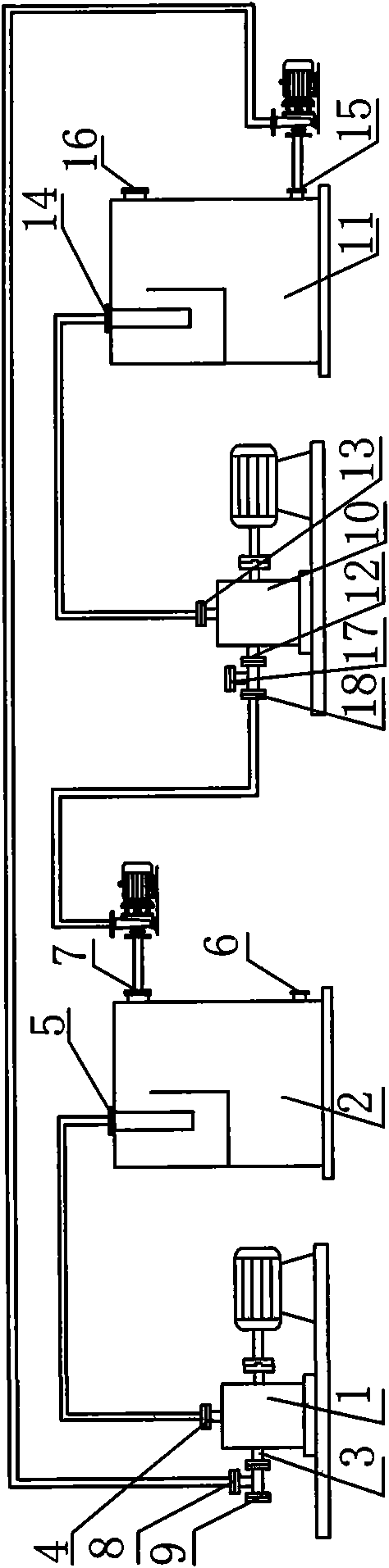

Device and method for preparing biodiesel

InactiveCN103881828ALarge mass transfer areaImprove exchange conversion rate effectFatty acid esterificationBiofuelsMotor driveBiodiesel

The invention discloses a device and a method for preparing biodiesel. The device comprises a pipeline system, a reaction system and a measurement system, wherein the pipeline system comprises a raw material circulating storage box, a material circulating pump, an inflow pipeline, a return pipeline, an adjustable butterfly valve, and an unadjustable butterfly valve, the reaction system comprises a hydrodynamic cavitation reactor, a hydrodynamic cavitation porous plate, a striking room, and a motor driving rotating nozzle, and the measurement system comprises an upstream pressure gage and a downstream pressure gage as well as a flowmeter. Based on the coupling hydrodynamic cavitation and rotating impinging stream technologies, the device realizes efficient preparation of biodiesel. Circulating fluid flows through throttling holes in the porous plate inside the cavitation reactor, so that the cavitation phenomenon increases the turbulence intensity of the fluid, and the mass transfer area of an alcohol phase and an ester phase is greatly increased; the rotating impinging stream technology strengthens the tangential force in collision and enhances the cavitation effect on the collision surface; the device runs safely, has low running cost, can greatly improve the preparation efficiency of biodiesel, and shortens the preparation time of the biodiesel.

Owner:JIANGSU UNIV

Multi-channeled micro-structured reactor

ActiveCN1326605CHigh selectivityLarge mass transfer areaChemical/physical/physico-chemical processesLiquid-gas reaction processesEngineeringParallel channel

Disclosed is amultichannel reactor with microstructure. Continuous phase inlet pipe and distribution chamber, discontinuous phase inlet pipe and distribution chamber, mixture phase buffer chamber and fluid outlet pipe connects separately, and they compose the lower cavity. Porous distribution medium is sealed in the upper distribution chamber of discontinuous phase. A parallel channel plate of continuous phase is located above the lower cavity and the upper is sealed. The continuous phase liquid flows into the reactor from the distribution chamber of inlet pipe; the discontinuous liquid flows into the parallel channel of continuous phase following through the distribution medium, distributes into minute drop or air bubble with the floating shearing force of continuous phase liquid, and then connects with the continuous phase liquid to realize the rapid mixture and reaction of the two- phase liquid; then the liquid flows out of the reactor. With the invention, the area of mass transfer is big, the reaction conversion rate is high, and large scale production can be realized.

Owner:TSINGHUA UNIV

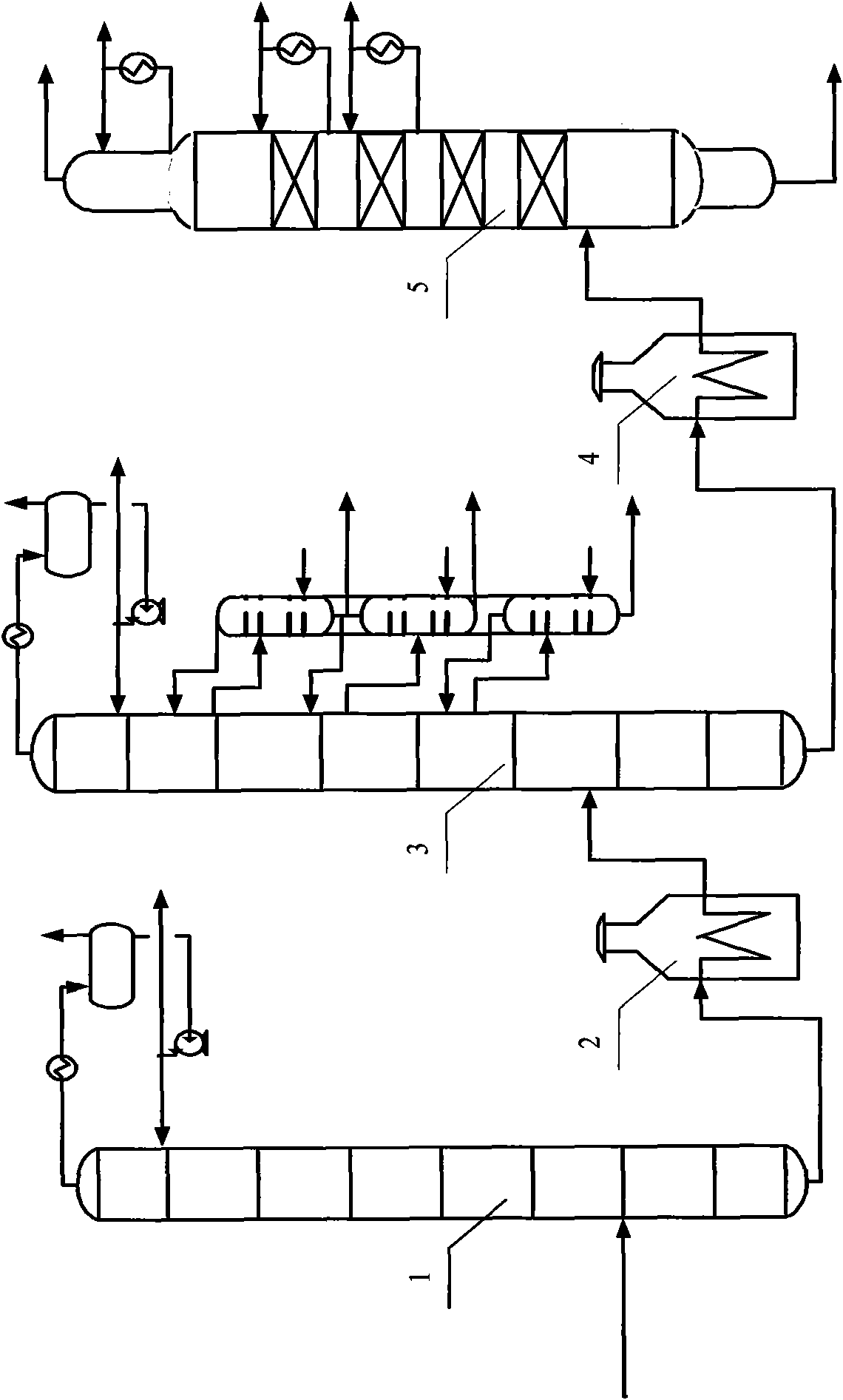

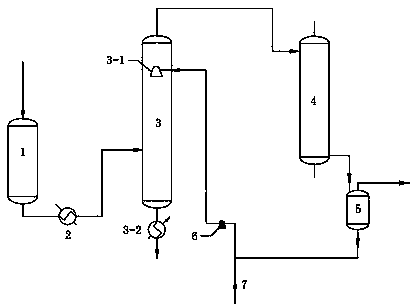

Crude oil distilling method and device for pressure type feeding

ActiveCN102559251ALarge mass transfer areaIncrease vaporization rateTreatment with plural serial refining stagesVacuum furnaceProcess engineering

Provided is a crude oil distilling method and a device for pressure type feeding. The device comprises an atmospheric distillation portion and a reduced pressure distillation portion. A primary vacuum tower is arranged in front of a vacuum furnace, and tower bottom oil of the primary vacuum tower is heated and wormed by the vacuum furnace and then led into a secondary vacuum distillation tower to be distilled, wherein all of an atmospheric tower, the primary vacuum tower and the secondary vacuum tower adopt a pressure type feeding system to atomize raw materials into liquid droplets to be sprayed into the distillation towers. By means of the method, the raw materials are atomized into the liquid droplets to be sprayed into the distillation towers, thereby increasing vapor-liquid interphase mass transfer area and improving vaporization ratio of a fractionating tower vaporized section. The primary vacuum tower is arranged in front of the vacuum furnace, an extracted portion comprises light components, and the heat load of a heating furnace and the device loss can be reduced under the condition that processing amounts at the reduced pressure distillation portion are the same.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficiency gradient hierarchy complex desulfurizing tower

ActiveUS10143957B2Improve efficiencyImprove performanceGas treatmentUsing liquid separation agentSlurryProcess engineering

Owner:HUANENG POWER INT INC +1

Efficient absorption method for 2-cyanopyridine

The invention relates to an efficient absorption method for 2-cyanopyridine. The method comprises the following concrete steps: in a process of preparing 2-cyanopyridine by ammoxidation of 2-methylpyridine, cooling and absorbing mixed gas with the temperature of 200-230 DEG C, obtained through primary cooling after ammoxidation reaction by taking high-pressure fine water mist as an absorbent, wherein the particle size of the high-pressure fine water mist is not more than 100 microns (preferably less than 50 microns). According to the method, the mixed gas generated by ammoxidation during production of 2-methylpyridine is quickly cooled and absorbed by the high-pressure fine water mist with the particle size of not more than 100 microns, so that the hydrolysis of 2-cyanopyridine is inhibited and the absorption efficiency is improved.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Production method for glyoxalate

ActiveCN107445831ALow yieldHigh yieldMolecular sieve catalystsOrganic compound preparationGas phaseDiluent

The invention relates to a production method for glyoxylate. The invention mainly aims to overcome the problem of low yield of glyoxylate in the prior art. The method comprises a step of contacting oxygen-containing gas, glycollate, a diluent and carrying gas with a catalyst in a reactor under gas-phase oxidation conditions. With the technical scheme that the oxygen-containing gas is allowed to pass through a ceramic membrane distributor and then enter a reactor, the above problem is overcome, and the production method is applicable to industrial production of glyoxalate from glycollate through oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

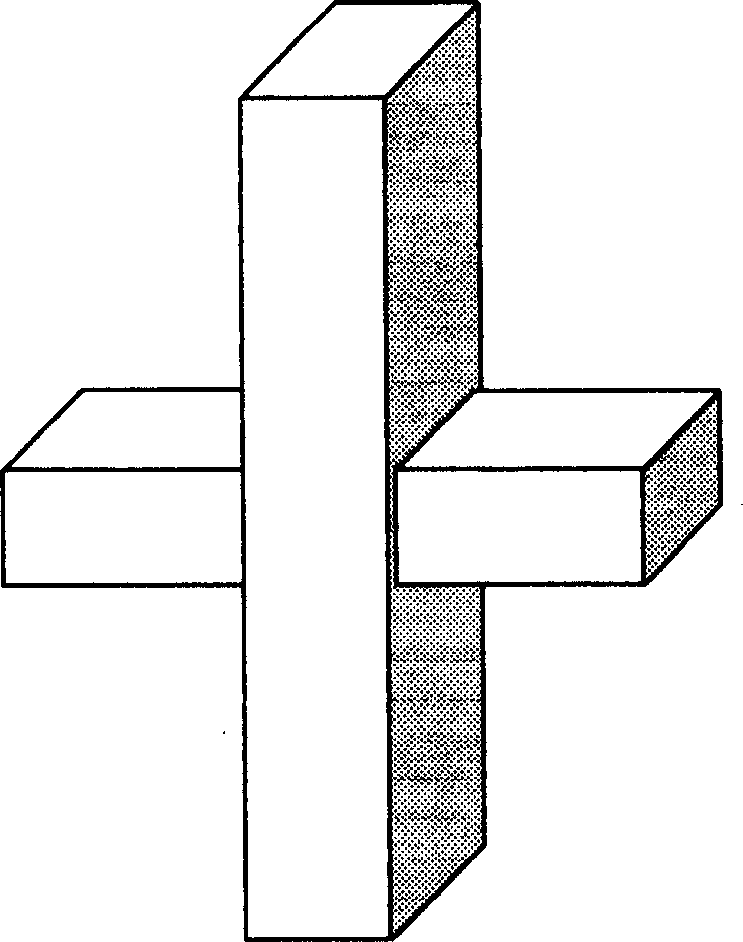

Oil-water rheological device and traditional Chinese medicine essential oil extraction system

PendingCN106753792AHigh extraction rateLarge mass transfer areaEssential-oils/perfumesSolid solvent extractionOil and greaseEngineering

The invention relates to the field of mechanical equipment and provides an oil-water rheological device. The oil-water rheological device comprises a tank body, wherein a steam outlet and an aromatic water inlet are arranged at the top of the tank body; a cooling liquid outlet is arranged at the bottom of the tank body; a steam inlet is arranged at the lower part of the tank body; a sieve plate is arranged in the tank body; a plurality of through holes are formed in the sieve plate; the edge of the sieve plate is connected with an inner wall of the tank body; the sieve plate is arranged above the steam inlet. The oil-water rheological device provided by the invention can be used for extracting aromatic water, which is remained after essential oil is extracted, again; the extraction rate of volatile oil is increased and wastes are avoided. The invention further provides a traditional Chinese medicine essential oil extraction system; the traditional Chinese medicine essential oil extraction system comprises the oil-water rheological device. The traditional Chinese medicine essential oil extraction system has relatively high essential oil extraction rate.

Owner:四川九渊医药科技有限公司

Reactor or mixer with micromesh structure

ActiveCN101224405BShort mass transfer distanceLarge mass transfer areaFlow mixersChemical/physical/physico-chemical processesEngineeringPetrochemistry

Owner:TSINGHUA UNIV

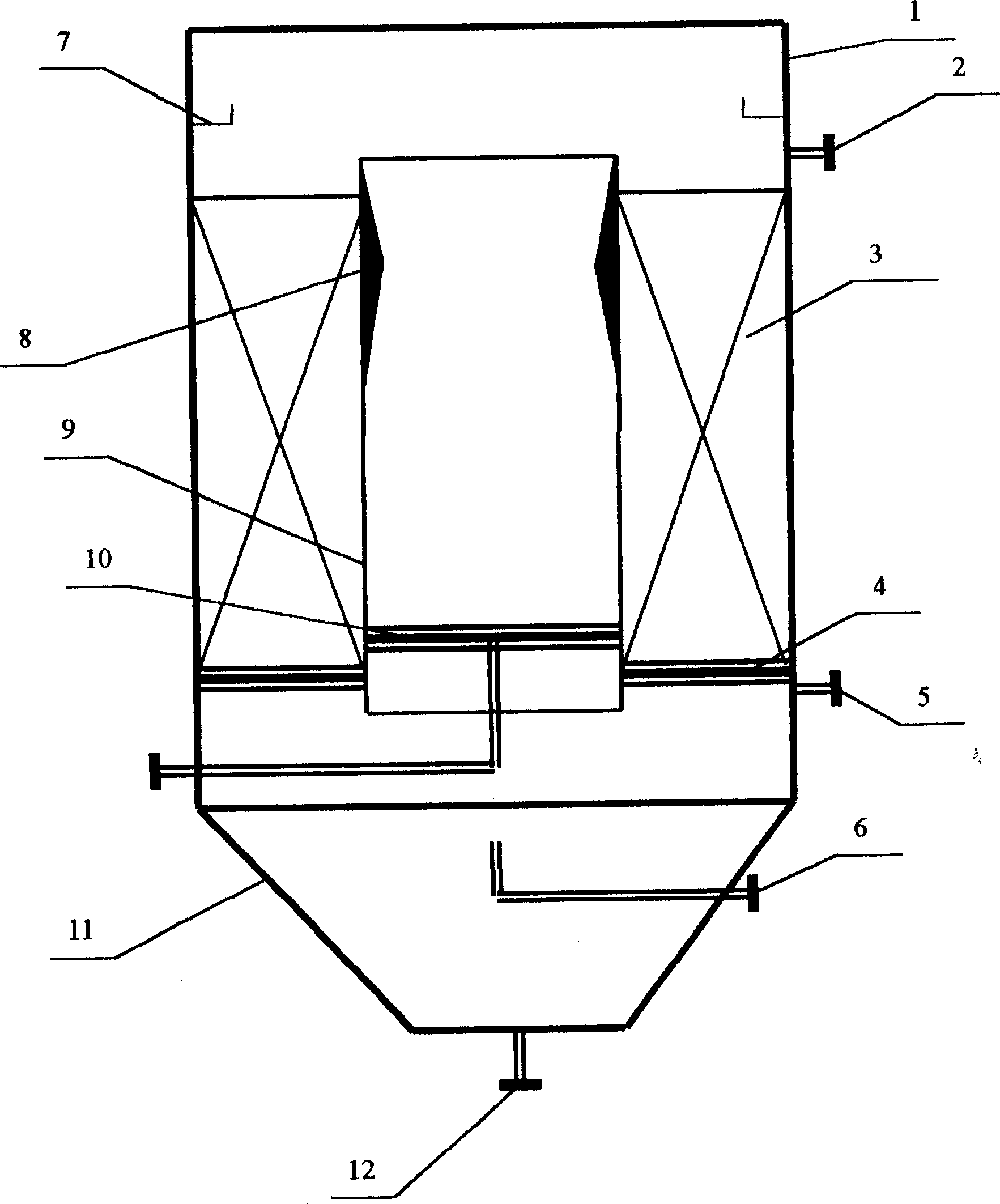

Labyrinth type hypergravity liquid-liquid extraction separator

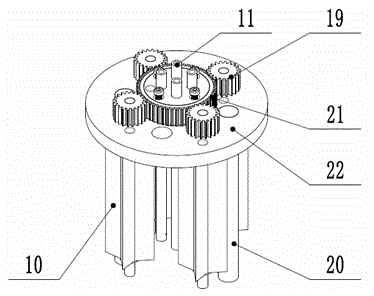

InactiveCN104815459ALarge mass transfer areaWell mixedLiquid solutions solvent extractionImpellerElectric machinery

The invention discloses a labyrinth type hypergravity liquid-liquid extraction separator which comprises a housing, a filler helix tube, a mixed mass transfer mechanism, a separation collection mechanism, a top cover plate, a pedestal, a bearing sleeve, a shaft and a motor. The mixed mass transfer mechanism comprises a feed planet impeller mixing device, a mass transfer device and conical milling fluid wheels. The mass transfer device is arranged between the feed planet impeller mixing device and the conical milling fluid wheels. The separation and collection mechanism comprises a phase-splitting trough, a spring switch and a collecting tank. By the extraction separator provided by the invention, high-efficiency extraction is realized, and two-phase separation is also considered. A multi-layer packing structure increases mass transfer area of a two-phase fluid. Due to the complex packing layer structure, mixing is more uniform. Reaction time is prolonged, and extraction rate is enhanced. The separation and collection mechanism, used as an important part of the extraction process, realizes integration of extraction and separation.

Owner:KUNMING UNIV OF SCI & TECH

Device for removing hydrogen sulfide in gas by using gas delivery pipeline

ActiveCN102886198AIncrease flow rateSmall pressure dropDispersed particle separationAtomizer nozzleProcess engineering

The invention relates to a device for removing hydrogen sulfide in gas by using a gas delivery pipeline, which comprises a gas delivery pipeline, wherein the gas delivery pipeline is basically horizontal, the diameter of the gas delivery pipeline is greater than or equal to 0.3m, the length-to-diameter ratio is greater than or equal to 10, and the gas flow rate in the gas delivery pipeline is 3-10 m / s; a liquid outlet is arranged on the gas delivery pipeline; in the gas delivery direction, the tail end of the gas delivery pipeline is provided with a gas outlet; and in the gas delivery direction, a plurality of atomizing nozzles for jetting a desulfurization liquid or desulfurization slurry are sequentially arranged in the gas delivery pipeline. In the device provided by the invention, the gas delivery pipeline is used as the location for desulfurizing H2S. Compared with the desulfurization tower or other desulfurization reactors in the prior art, the invention does not need to additionally construct any desulfurizing unit, thereby effectively lowering the construction cost of the equipment.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Improved internal electrolytic iron bed apparatus for treating water

InactiveCN1390789ALarge mass transfer areaEasy to handleWater/sewage treatmentElectrolysisDistributor

An improved internal electrolytic iron bed as water treating apparatus is composed of a water-treating cylinder, an axially arranged internal short cylinder, silt collecting hopper under said water-treating cylinder, the cubic iron filler between said internal and external cylinders or in internal one, and air distributor under the space between said internal and external cylinders. Its advantages are high activity, large mass transfer area and high treating effect.

Owner:宜兴市天立环保有限公司

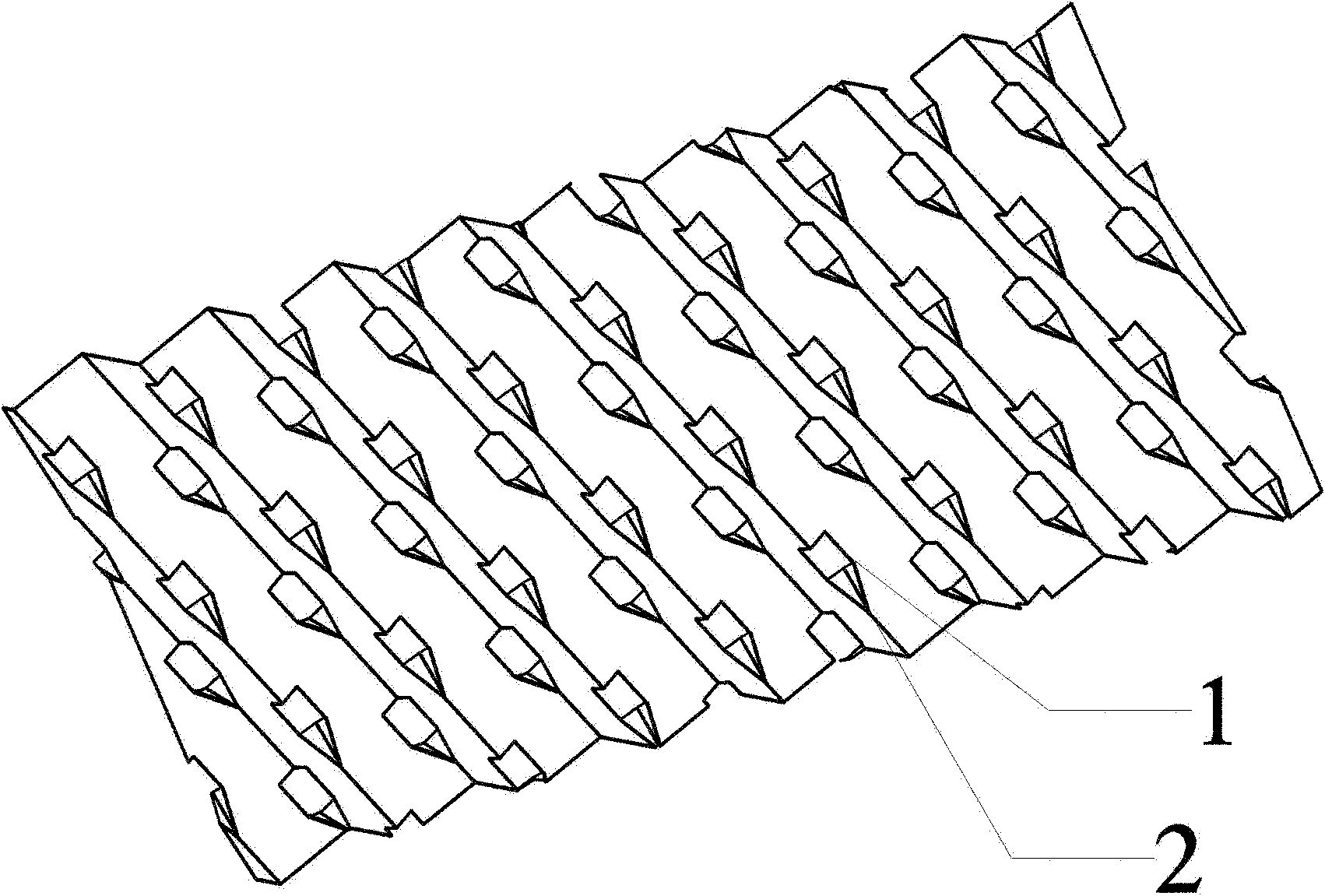

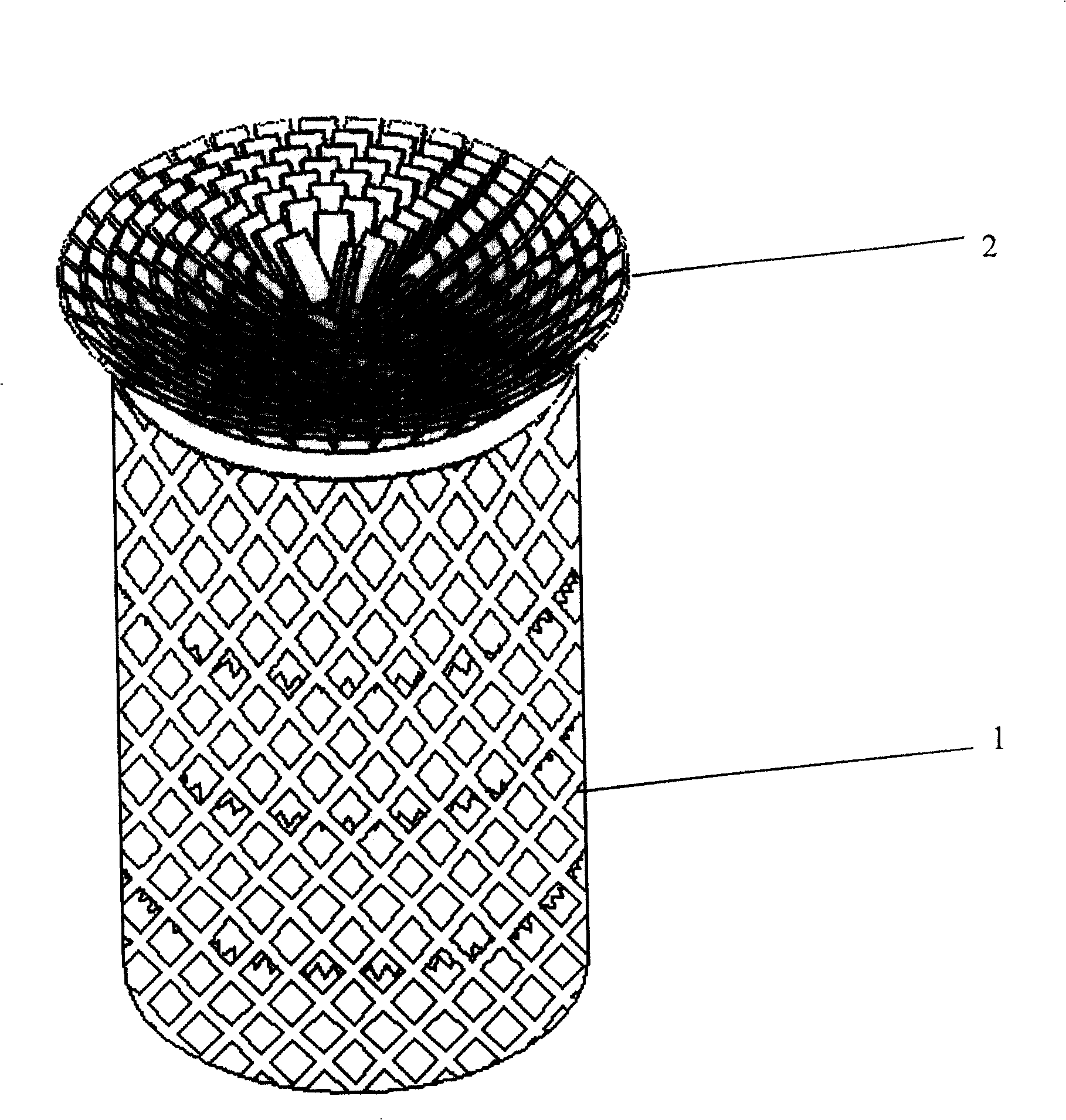

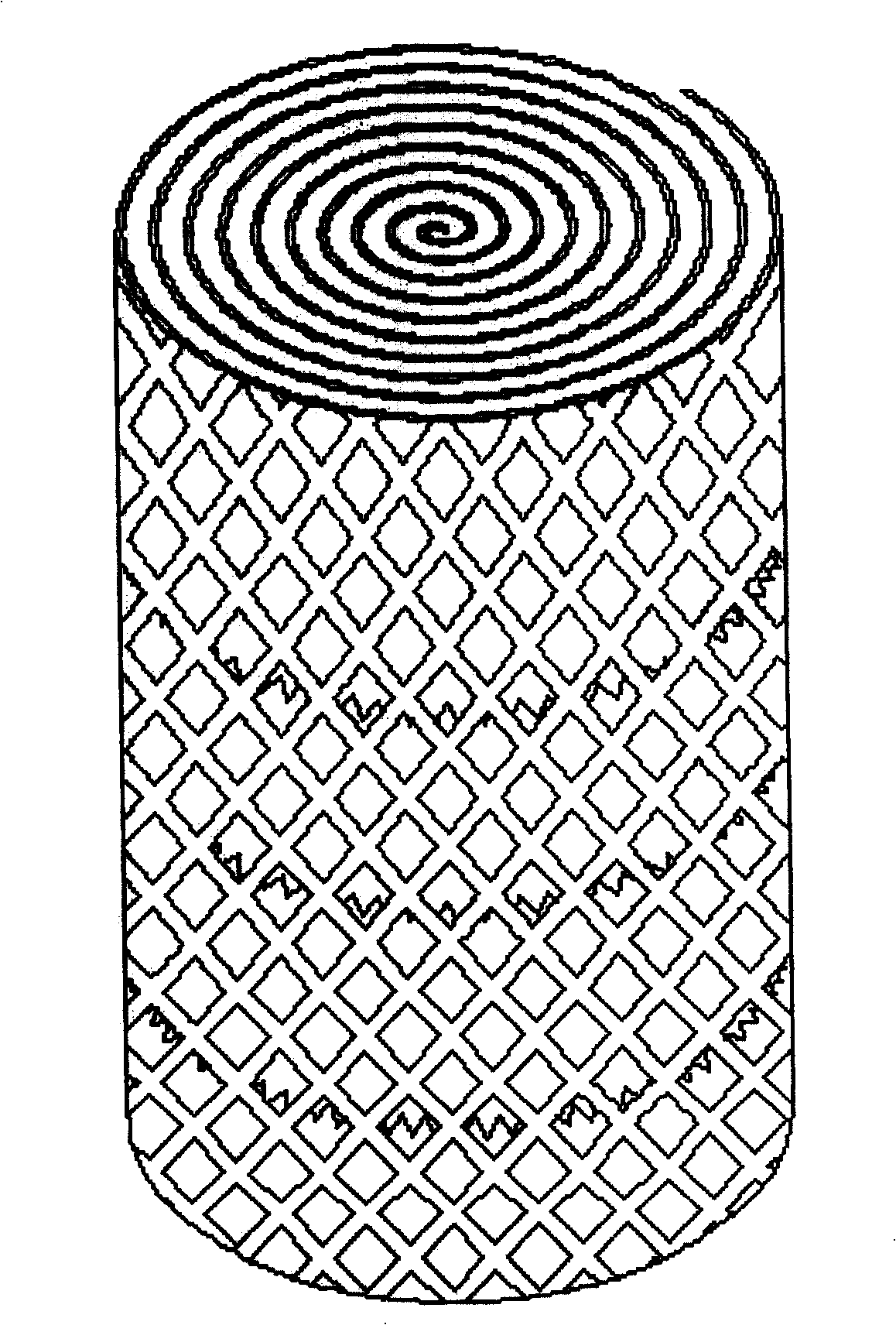

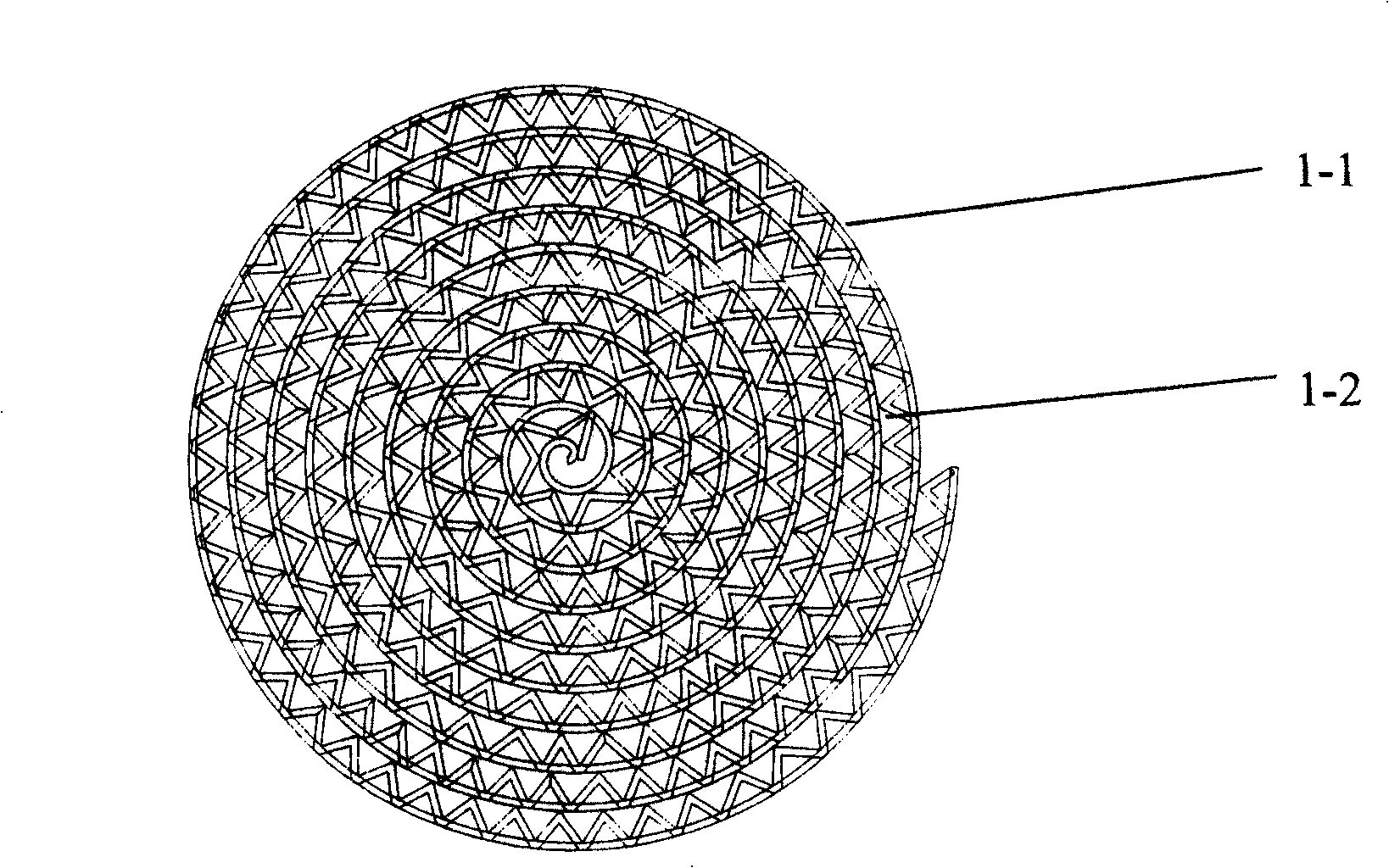

Regular packing of helical cylindrical net

ActiveCN100431687CIncreased turbulenceAvoid pressure dropChemical/physical/physico-chemical processesGas phaseMechanical engineering

The present invention discloses one kind of regular helical cylindrical net packing, and belongs to the field of gas-liquid mass transfer separator packing technology. The regular helical cylindrical net packing unit includes a cylindrical helical net and a conic disc on the upper end of the cylindrical helical net. The cylindrical helical net is one multilayer one made of plate net and springs and has several supporting spring rings between helical net layers. The conic disc includes a short helical plate cylinder in the same diameter, layer number and interval between layers and a helical cone disc connected to the short helical plate cylinder. The packing of the present invention is used in gas-liquid mass transfer process, and has the advantages of parallel gas and liquid channels, plunger type flow with low gas phase resistance and high mass transfer efficiency, easy processing of the packing and low cost.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com