Device for removing hydrogen sulfide in gas by using gas delivery pipeline

A technology for conveying pipelines and removing gases, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of high construction costs and high energy consumption in operation, and achieve low construction costs, high desulfurization efficiency, and low construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

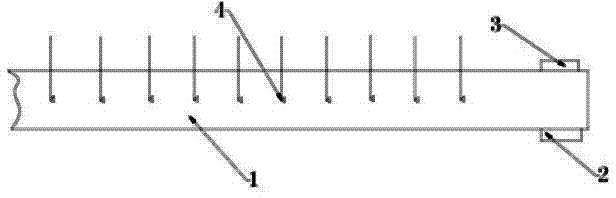

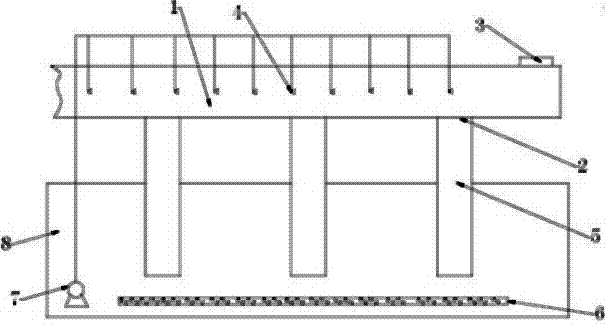

[0037] The device for removing hydrogen sulfide in gas using gas delivery pipeline 1 described in this embodiment, such as figure 1 shown, including:

[0038] A gas delivery pipeline 1 for transporting coke oven gas, the gas delivery pipeline 1 is arranged horizontally, the diameter of the gas delivery pipeline 1 is 0.3m, the length is 20m, and the gas flow rate in the gas delivery pipeline 1 is 10m / s ; Along the gas delivery direction, a liquid outlet 2 and a gas outlet 3 are provided at the end of the gas delivery pipeline 1;

[0039] In the gas delivery pipeline 1, 30 atomizing nozzles 4 for spraying desulfurization liquid are sequentially arranged along the gas delivery direction, and the distance between every two adjacent atomizing nozzles 4 is 0.2m, as In a preferred embodiment, the atomizing nozzle 4 described in this embodiment is arranged along the axis of the gas delivery pipeline 1, and the injection direction of the atomization nozzle 4 is in line with the delive...

Embodiment 2

[0043] The device for removing hydrogen sulfide in gas using gas delivery pipeline 1 described in this embodiment, such as figure 1 shown, including:

[0044] A gas delivery pipeline 1 for transporting coke oven gas, the gas delivery pipeline 1 is arranged horizontally, the diameter of the gas delivery pipeline 1 is 2.5m, the length is 25m, and the gas flow rate in the gas delivery pipeline 1 is 3m / s ; Along the gas delivery direction, a liquid outlet 2 and a gas outlet 3 are provided at the end of the gas delivery pipeline 1;

[0045] In the gas delivery pipeline 1, 25 atomizing nozzles 4 for spraying desulfurization liquid are sequentially arranged along the gas delivery direction, and the distance between every two adjacent atomizing nozzles 4 is 0.8m, as In a preferred embodiment, the atomizing nozzle 4 described in this embodiment is arranged along the axis of the gas delivery pipeline 1, and the injection direction of the atomization nozzle 4 is in line with the deliver...

Embodiment 3

[0049] The device for removing hydrogen sulfide in the gas by using the gas delivery pipeline 1 described in this embodiment is as follows: figure 1 shown, including:

[0050] A gas delivery pipeline 1 for transporting coke oven gas, the gas delivery pipeline 1 is arranged horizontally, the diameter of the gas delivery pipeline 1 is 0.5m, the length is 35m, and the gas flow rate in the gas delivery pipeline 1 is 10m / s ; Along the gas delivery direction, a liquid outlet 2 and a gas outlet 3 are provided at the end of the gas delivery pipeline 1;

[0051] In the gas delivery pipeline 1, 30 atomizing nozzles 4 for spraying desulfurization liquid are sequentially arranged along the gas delivery direction, and the distance between every two adjacent atomizing nozzles 4 is 1 m. The distance between the last atomizing nozzle 4 in the delivery direction and the gas outlet 3 is 6m, the atomizing nozzle 4 described in this embodiment is arranged along the axis of the gas delivery pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com